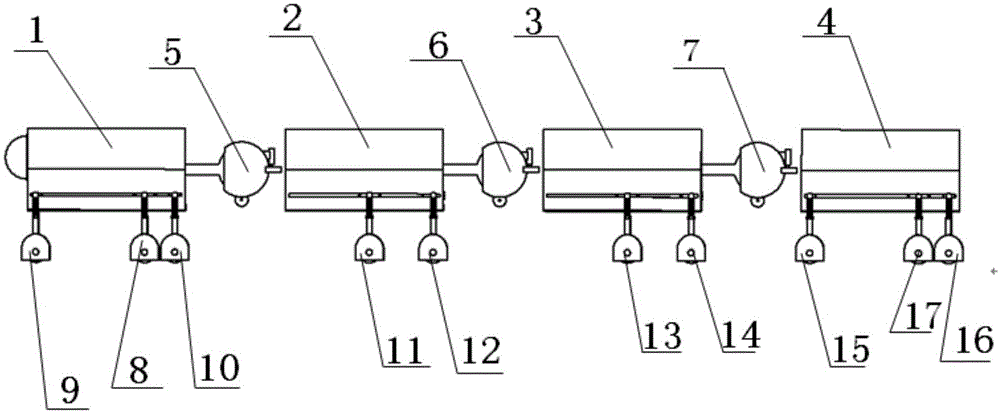

Nondestructive testing robot for pipes

A non-destructive testing and robotic technology, applied in the direction of pipe components, special pipes, mechanical equipment, etc., can solve the problem of undetectable pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

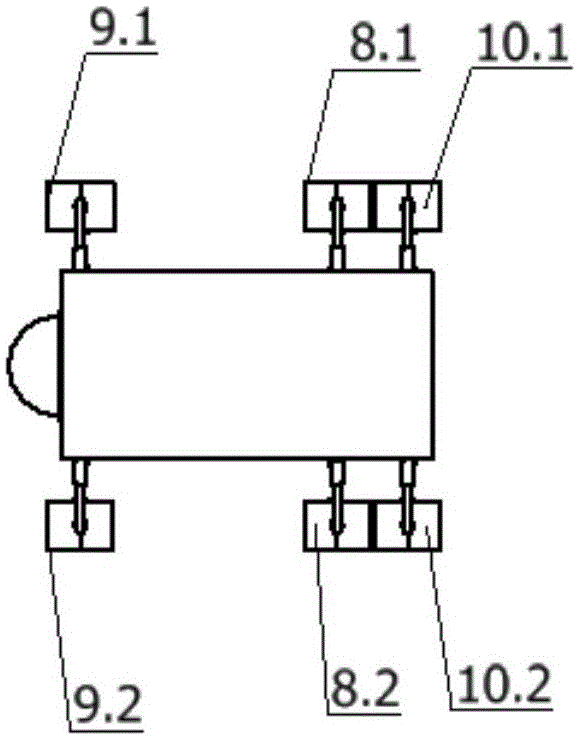

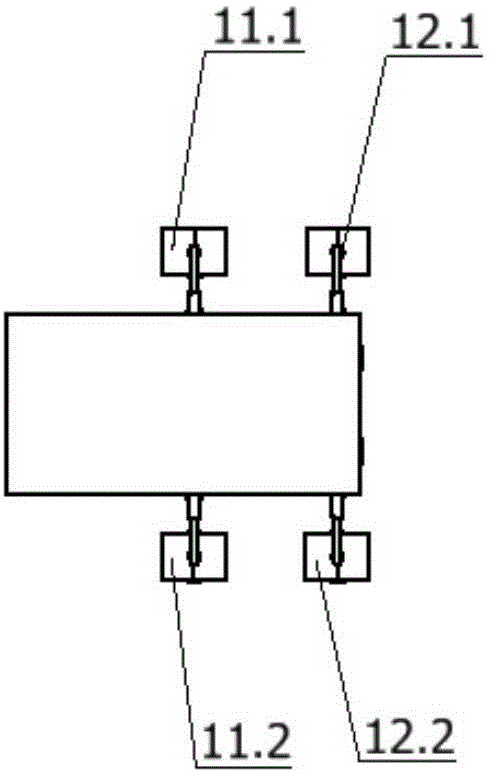

[0032]When the robot advances, the third foot 9.1, the fourth foot 9.2, the fifth foot 10.1, the sixth foot 10.2, the fifteenth foot 15.1, the sixteenth foot 15.2, the seventeenth foot 16.1, and the eighteenth foot 16.2 are electrified. The electromagnet generates magnetic force and adsorbs to the inner wall of the pipeline, then the first leg 8.1, the second leg 8.2, the seventh leg 11.1, the eighth leg 11.2, the ninth leg 12.1, the tenth leg 12.2, the eleventh leg 13.1, and the twelfth leg 13.2, the thirteenth foot 14.1, the fourteenth foot 14.2, the nineteenth foot 17.1, and the twentieth foot 17.2 move forward under the drive of the motor, and when they reach the designated position, energize the electromagnet to absorb with the pipe wall. Three feet 9.1, fourth feet 9.2, fifth feet 10.1, sixth feet 10.2, fifteenth feet 15.1, sixteenth feet 15.2, seventeenth feet 16.1, and eighteenth feet 16.2. The spring is pulled back into the foot, and after completion, the motor revers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com