Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

114results about How to "Evenly punched" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

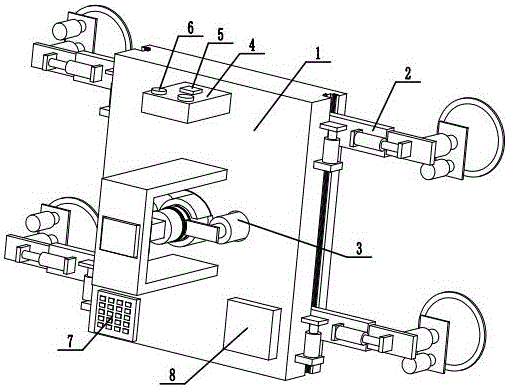

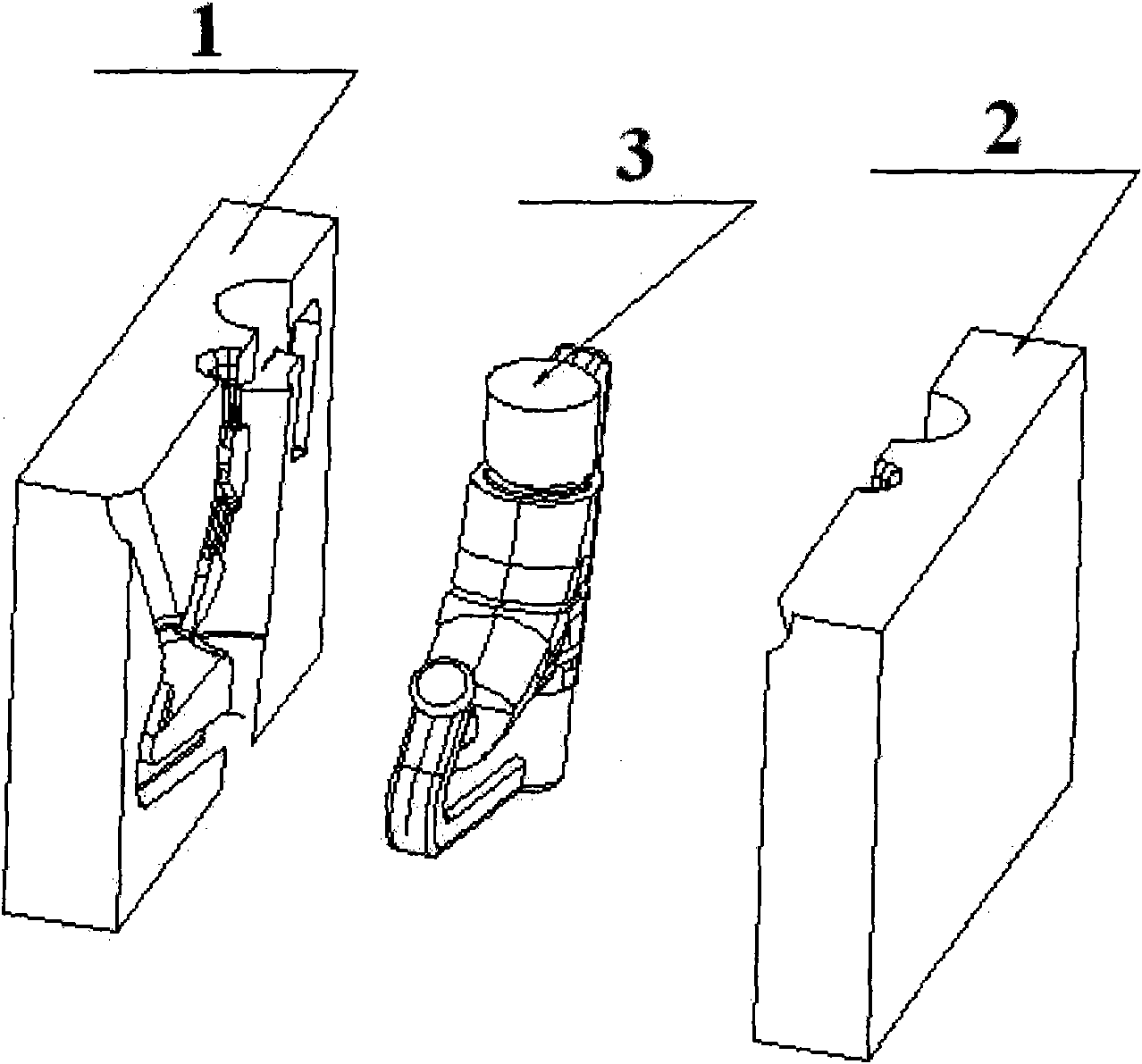

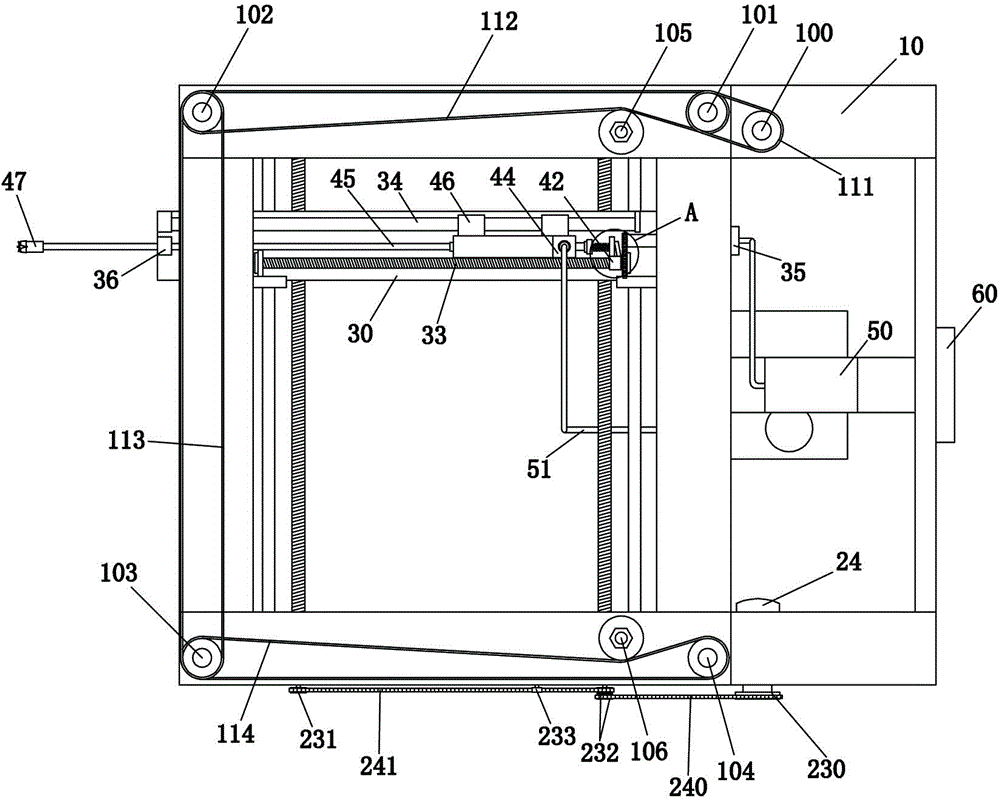

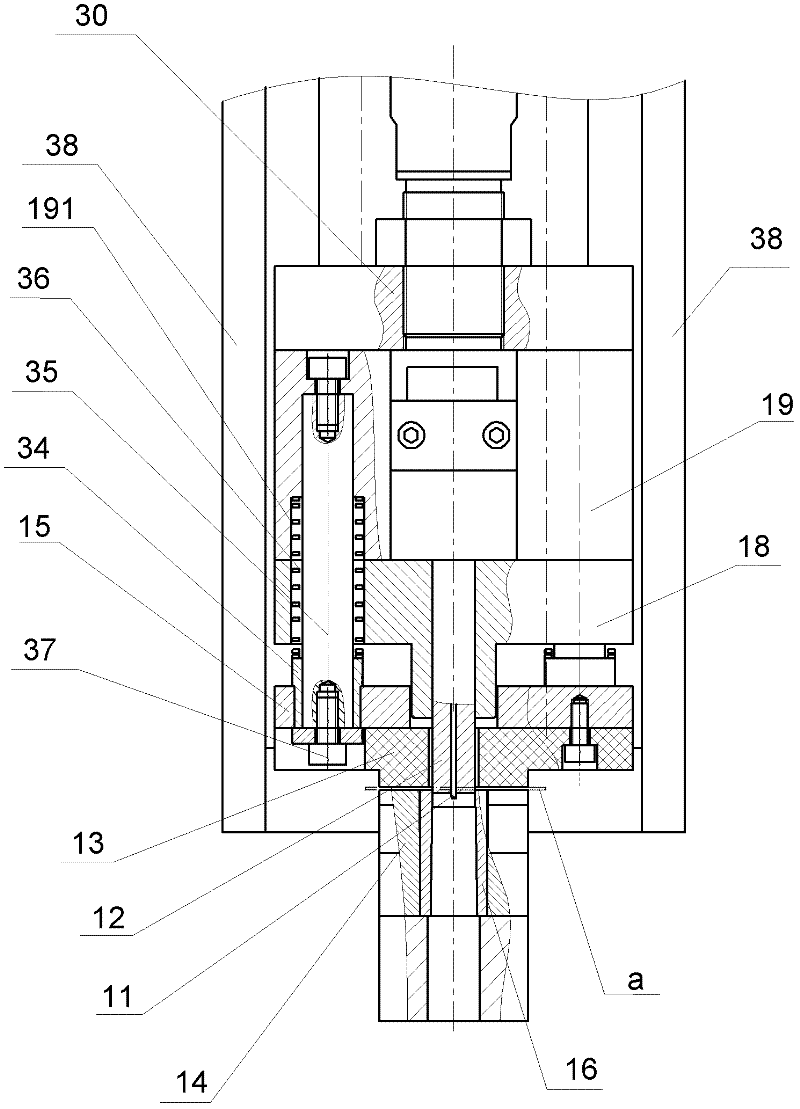

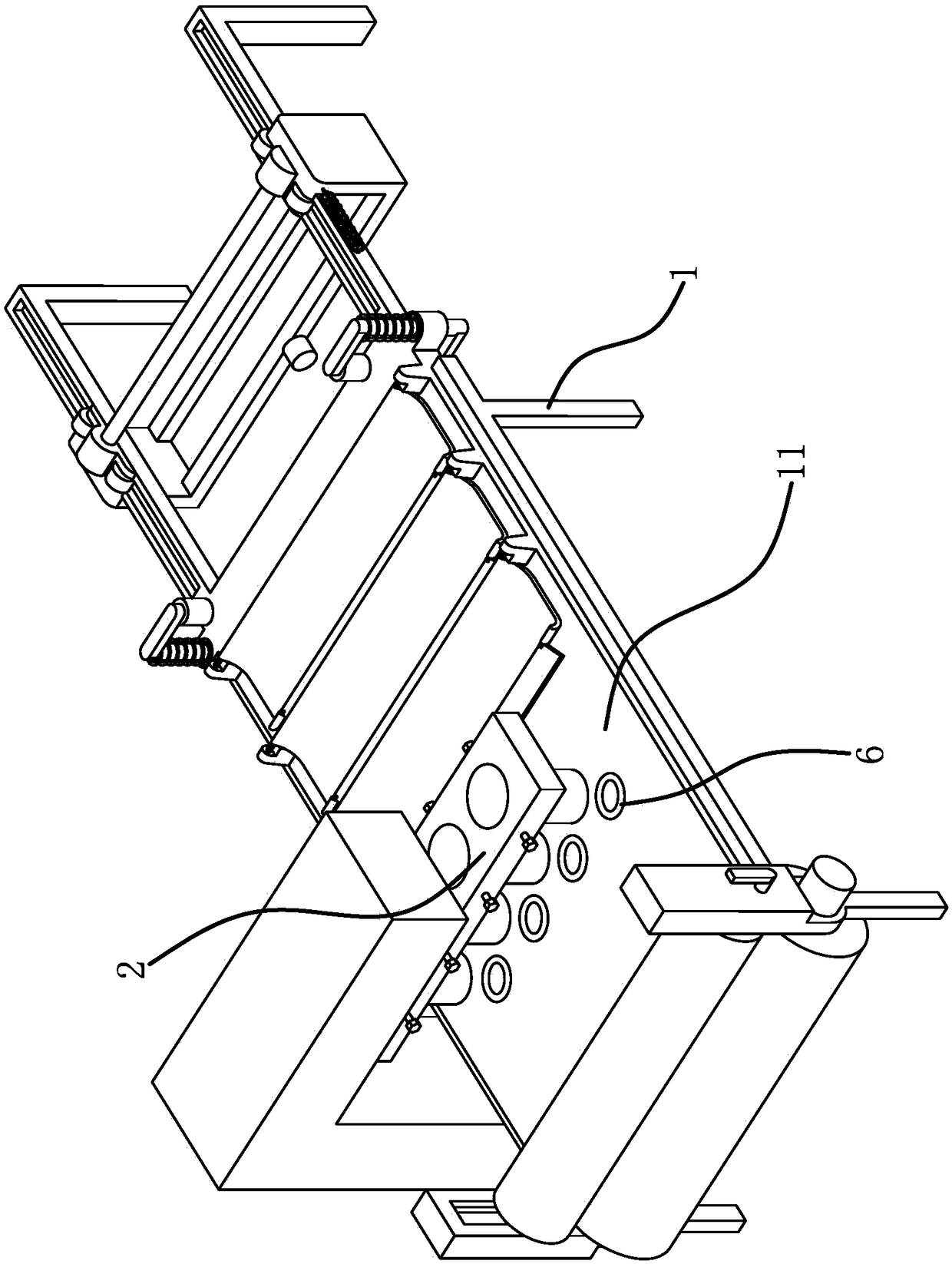

Roof drilling robot

A roof drilling robot comprises a base, four fixed mechanical arms and a drilling mechanism. The roof drilling robot is characterized in that the four fixed mechanical arms are separated in pairs and are mounted on the left and right sides of the base respectively, a stepping motor of the drilling mechanism is fixed in a hole in a stepping motor fixing frame on the base, and the overall drilling mechanism is mounted in a drilling mechanism fixing seat on the base 1; the rear end of a cylinder body of a first hydraulic cylinder is fixed on a first hydraulic cylinder fixing seat, and the end of a piston rod of the first hydraulic cylinder is fixedly connected with one side of a first hydraulic cylinder fixing plate; the rear end of a cylinder body of a second hydraulic cylinder is fixed on the left side of a second hydraulic cylinder fixing plate, and the end of a piston rod of the second hydraulic cylinder is fixedly connected with a support plate on a telescopic rod. According to the robot, the stepping motor is used for driving a square transmission shaft sleeve to rotate, and a rotating head is further driven to rotate and pressurized by two fourth hydraulic cylinders and smoothly drills the roof accordingly.

Owner:中机城市建设有限公司

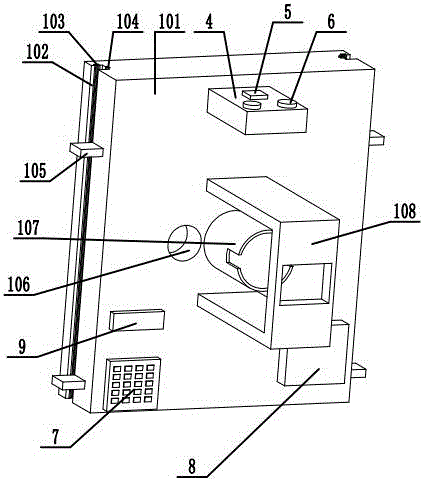

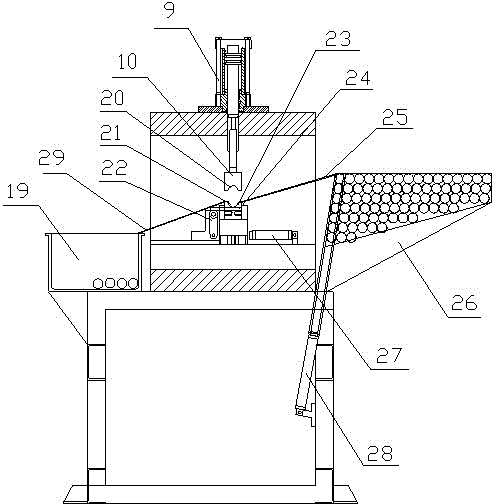

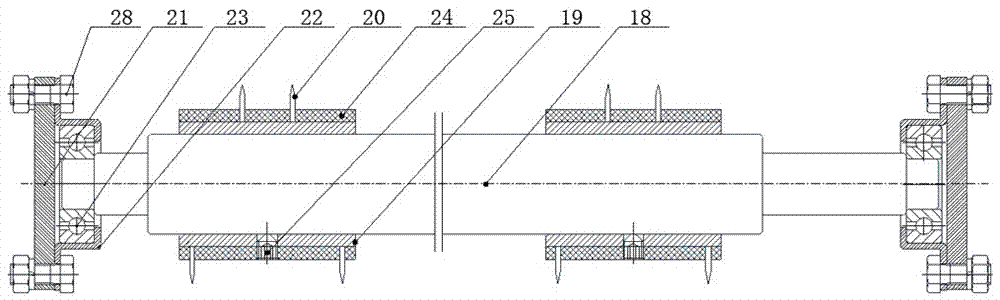

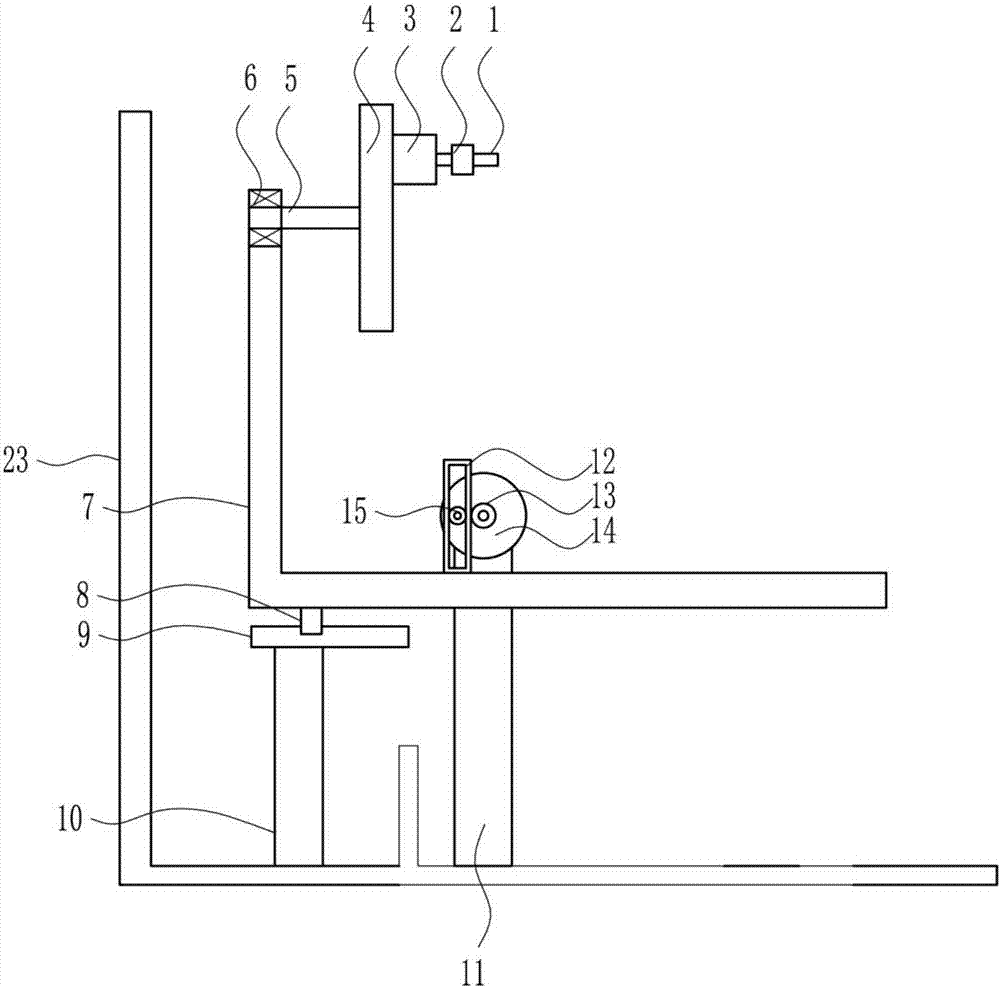

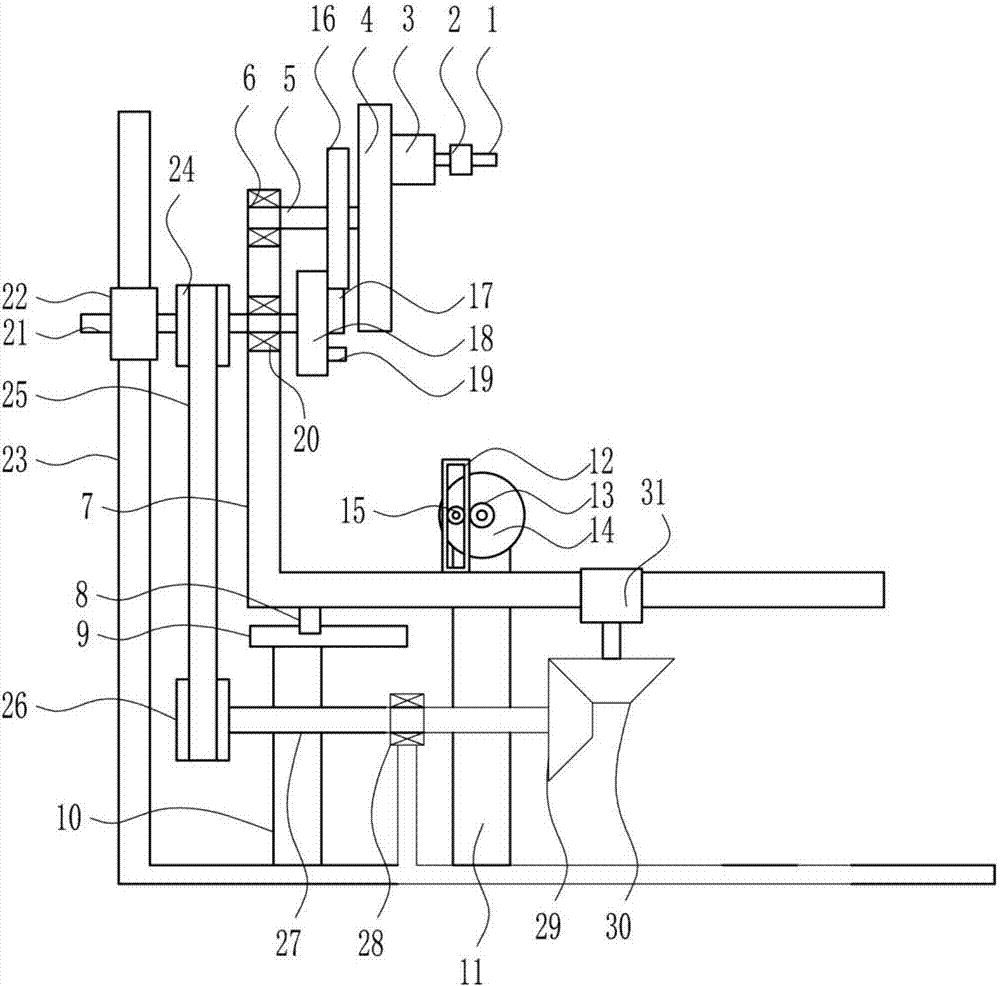

Automatic continuous horizontal-type punching machine for steel tube

ActiveCN103056210ARealize automatic feedingRealize dischargeShaping toolsMetal-working feeding devicesPunchingEngineering

An automatic continuous horizontal-type punching machine for a steel tube comprises a frame and a working platform on the upper portion of the frame. A hydraulic device and an electric control device are further arranged on the frame, and a stamping device, a fixing device and a sample conveying device are arranged on the working platform. The stamping device comprises a stamping oil cylinder, a stamping die and a discharge ejecting rod located between the stamping oil cylinder and the stamping die, a discharge oil cylinder is arranged at the front end of the stamping oil cylinder, and the stamping oil cylinder is connected with the discharge ejecting rod. The fixing device comprises an upper swaging die and a lower swaging die, and a swaging oil cylinder is arranged above the upper swaging die. The sample conveying device comprises a feeding hopper, a receiving hopper and a connecting plate located between the feeding hopper and the receiving hopper. The upper swaging die and the lower swaging die are respectively located on the upper side and the lower side of the connecting plate, and the stamping die is located on the front side of the connecting plate. The sample conveying device directing at shapes of the steel tube is arranged, one-time stamping of the steel tube is completed, and automatic feeding and discharging of the steel tube are achieved.

Owner:QINGDAO ZHANGSHI MACHINERY

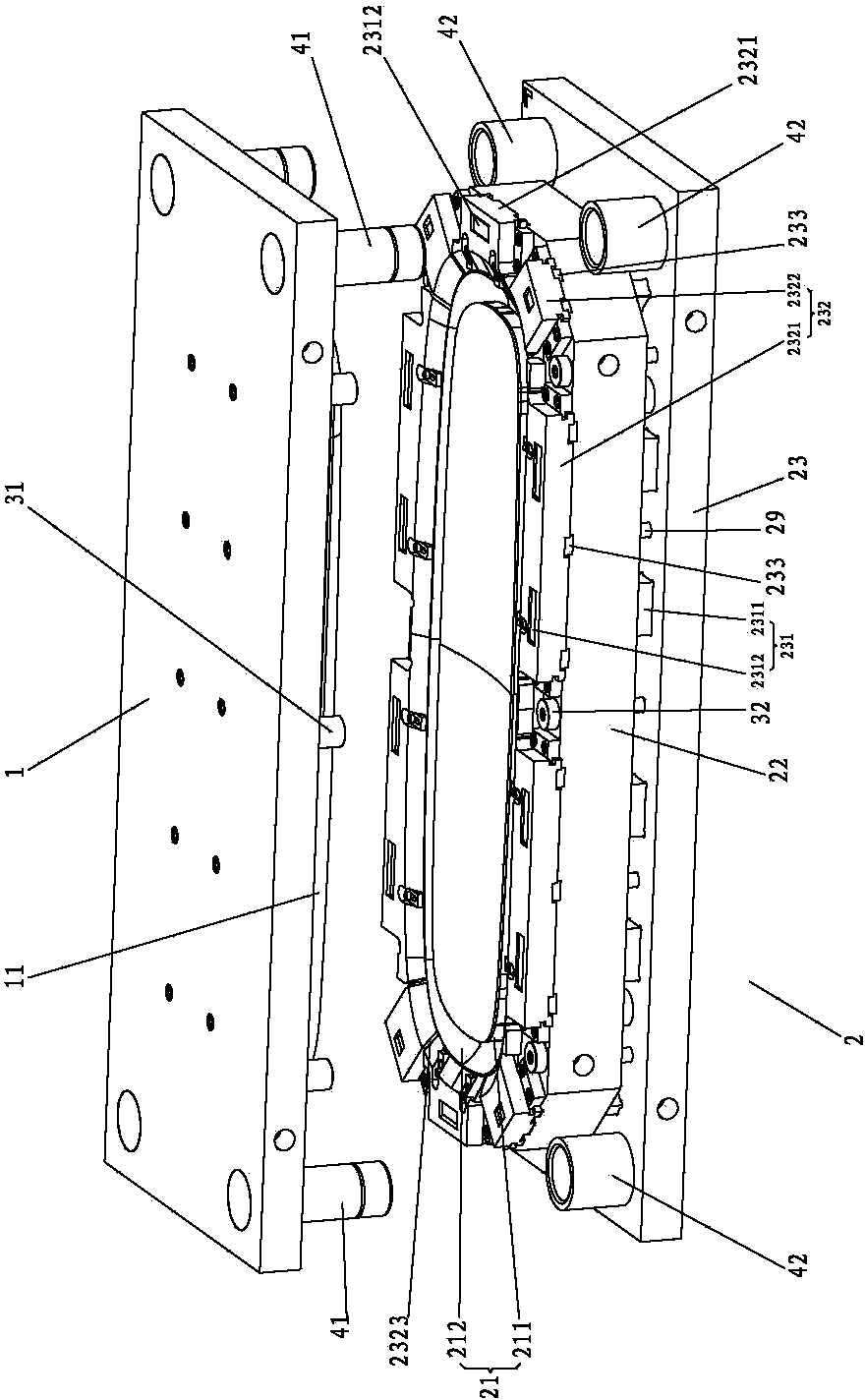

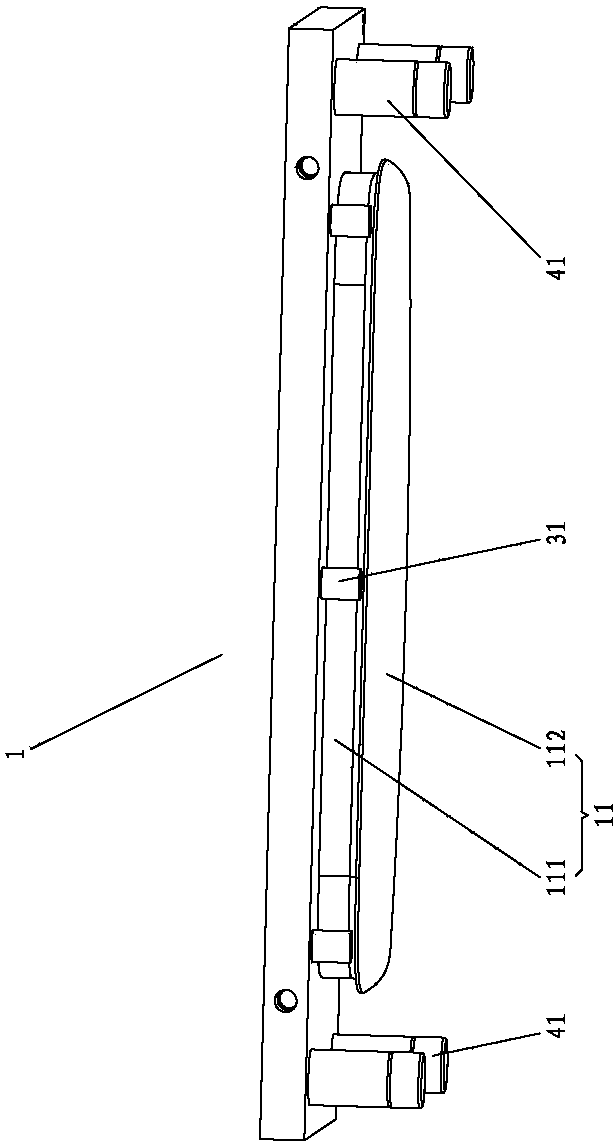

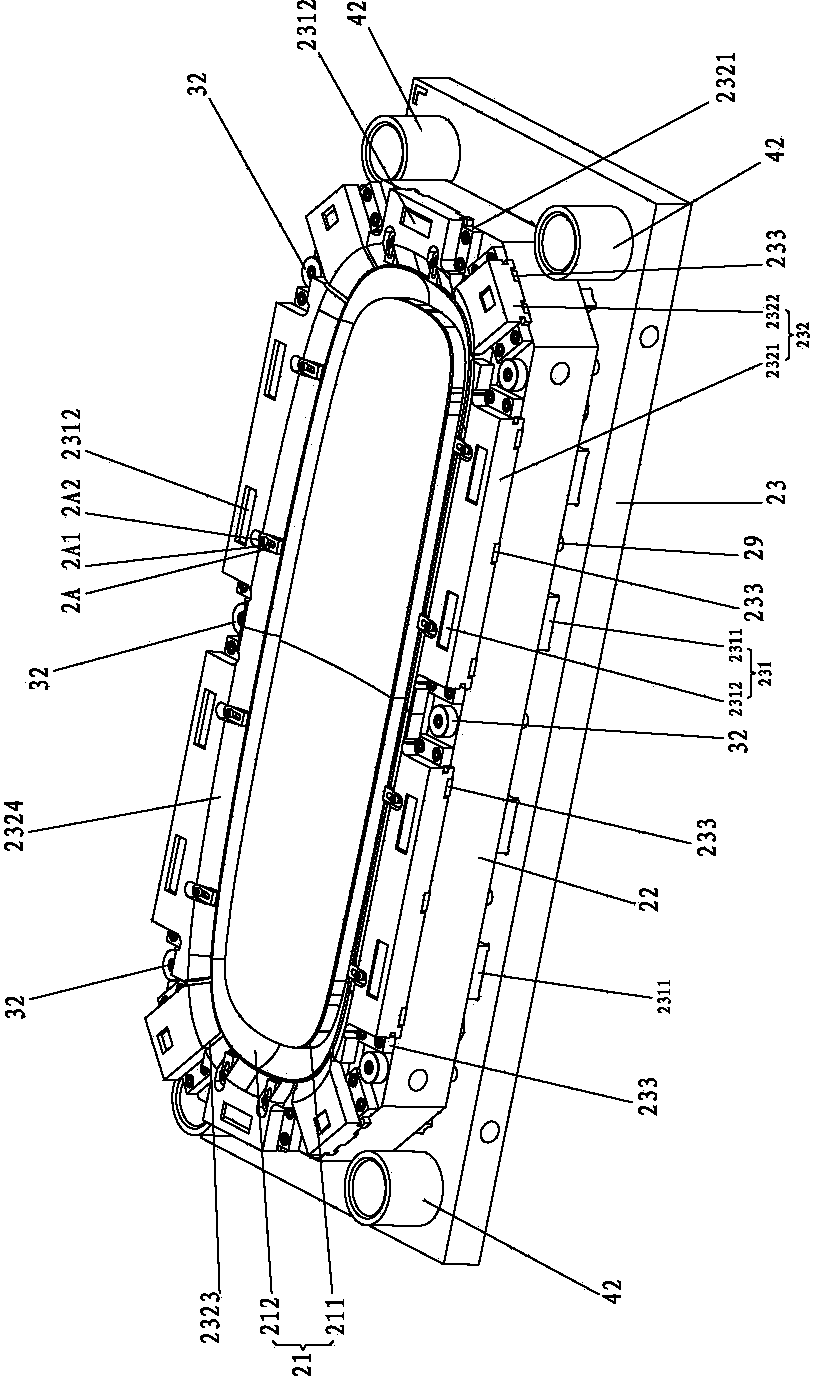

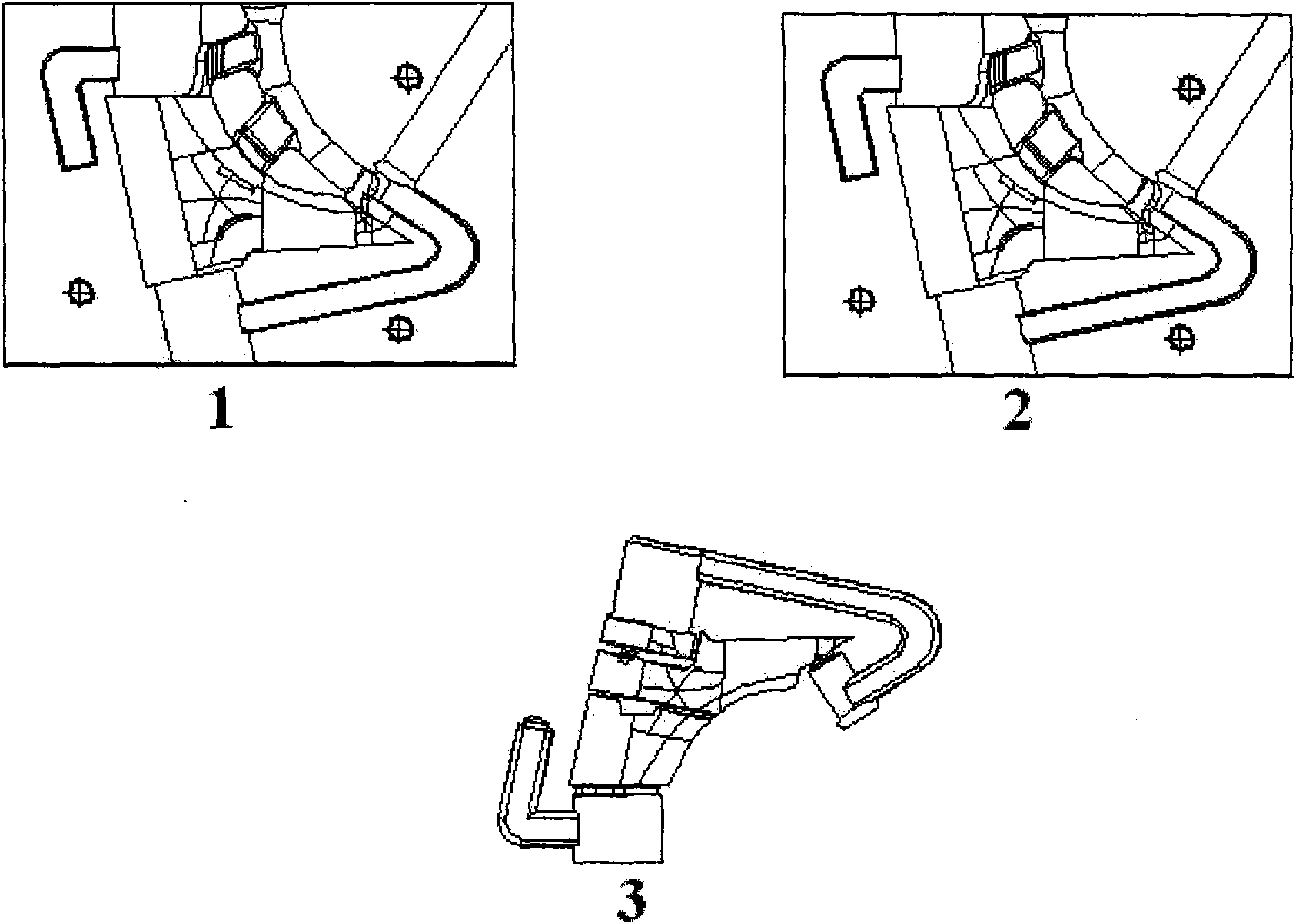

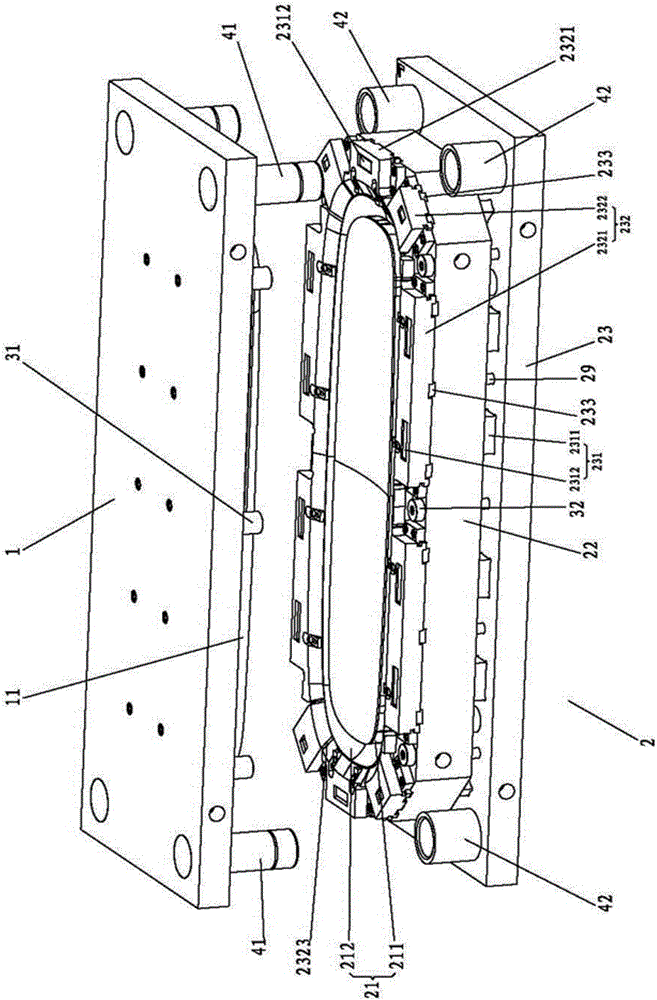

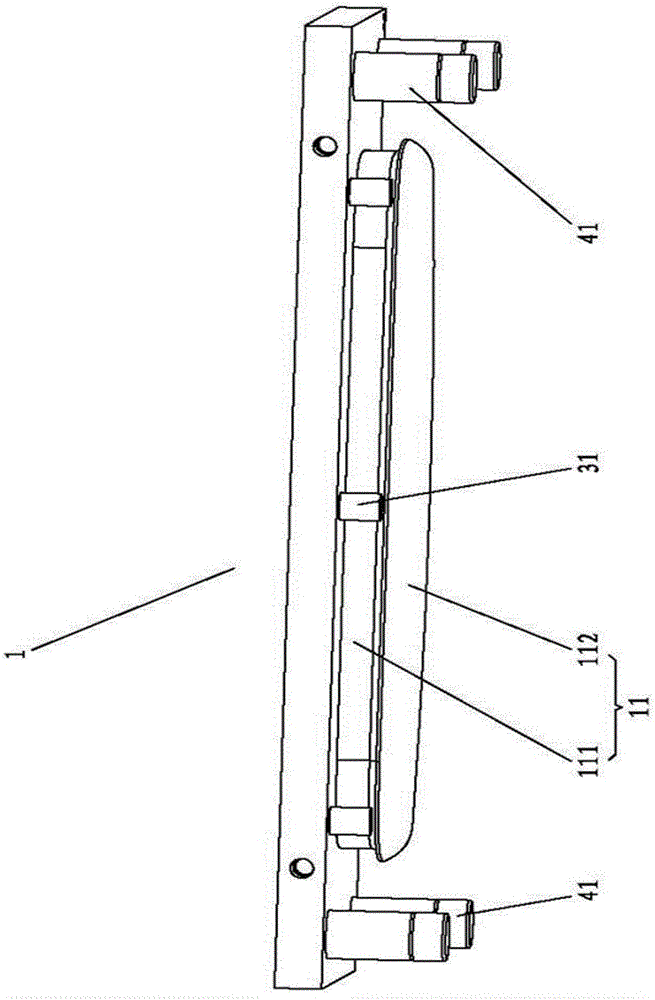

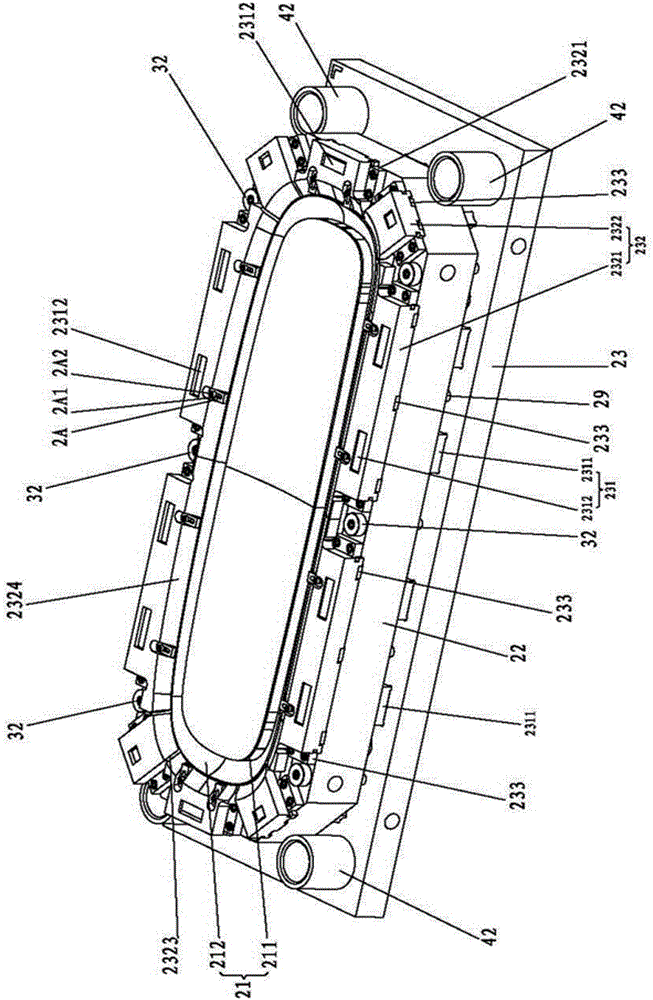

Stamping die of shell

The invention discloses a stamping die of a shell. A shell blank is horizontally put on the upper surface of a die bottom block, is positioned and heated to be softened, an upper die stamps downwards, a stamping head drives the die bottom block to move downwards firstly, when the die bottom block is in contact with a die wall bottom plate, the die bottom block is just fitted and spliced with a die wall block so as to form a complete concave die, the stamping head is propped against a first layer and a second layer to move downwards continuously, then a first spring and a second spring are compressed, a turnup edge is formed on the shell blank, when the first layer and the second layer descend to a certain extent, the die wall bottom plate pushes a die frame bottom plate to drive a die frame block to move downwards along a vertical block, the die frame block drives a sliding block to move downwards relying on an inclined block, at the same time the sliding block moves inwards through a sliding track based on the horizontal inward thrust of the inclined block, when a small neck part corresponds to the sliding block, the sliding block props the turnup edge of the shell blank into the small neck part against a step part between the end and the small neck part, thereby forming an inverted cover edge. The stamping die can smoothly and efficiently form inverted cover edges of shells, and is novel and reasonable in structure and high in practicability.

Owner:FUJIAN HUAKE MOLD TECH

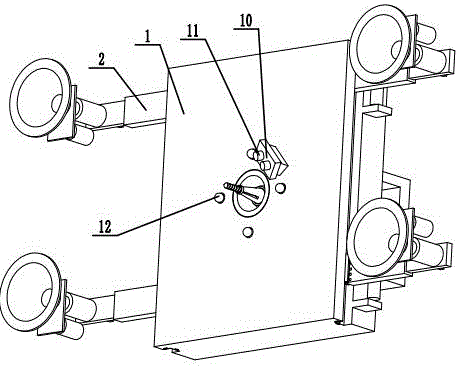

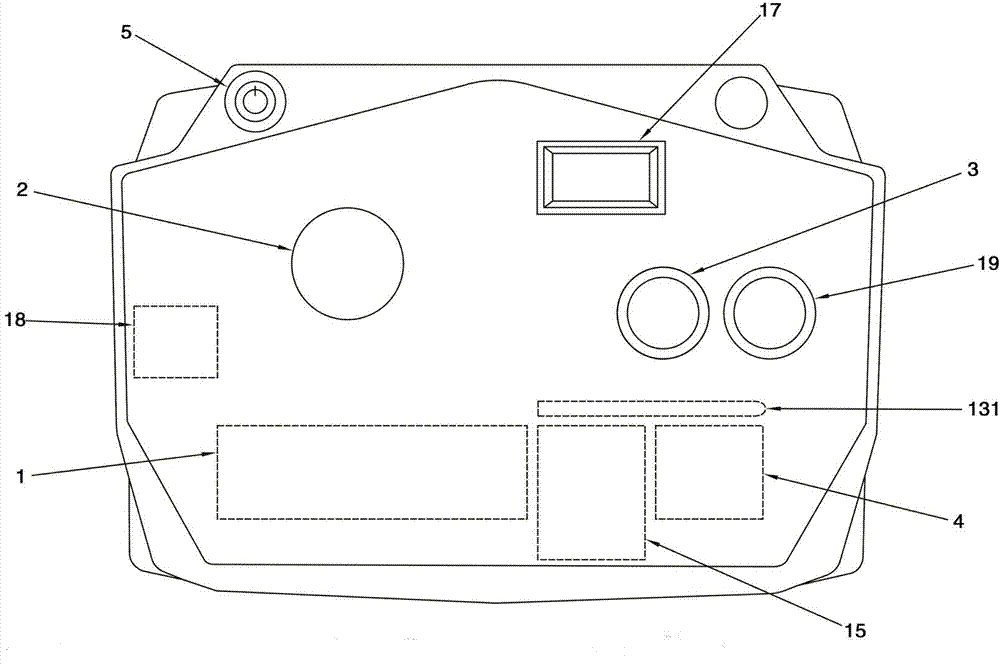

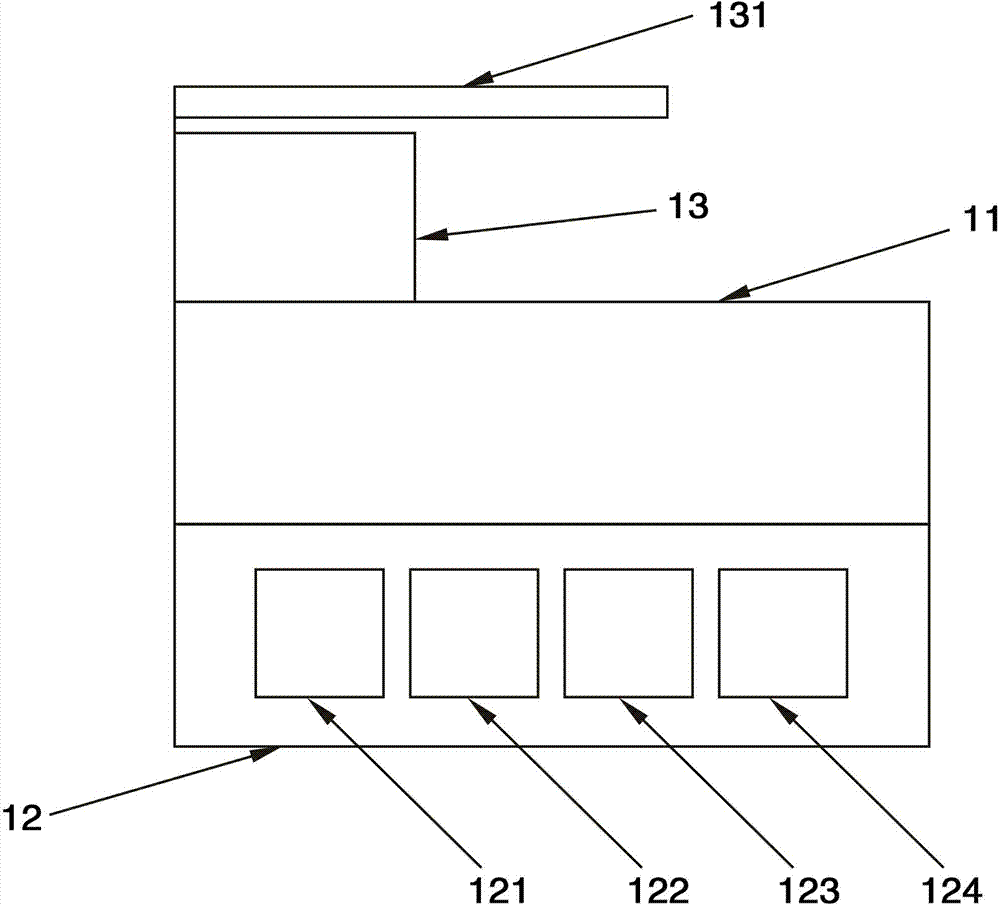

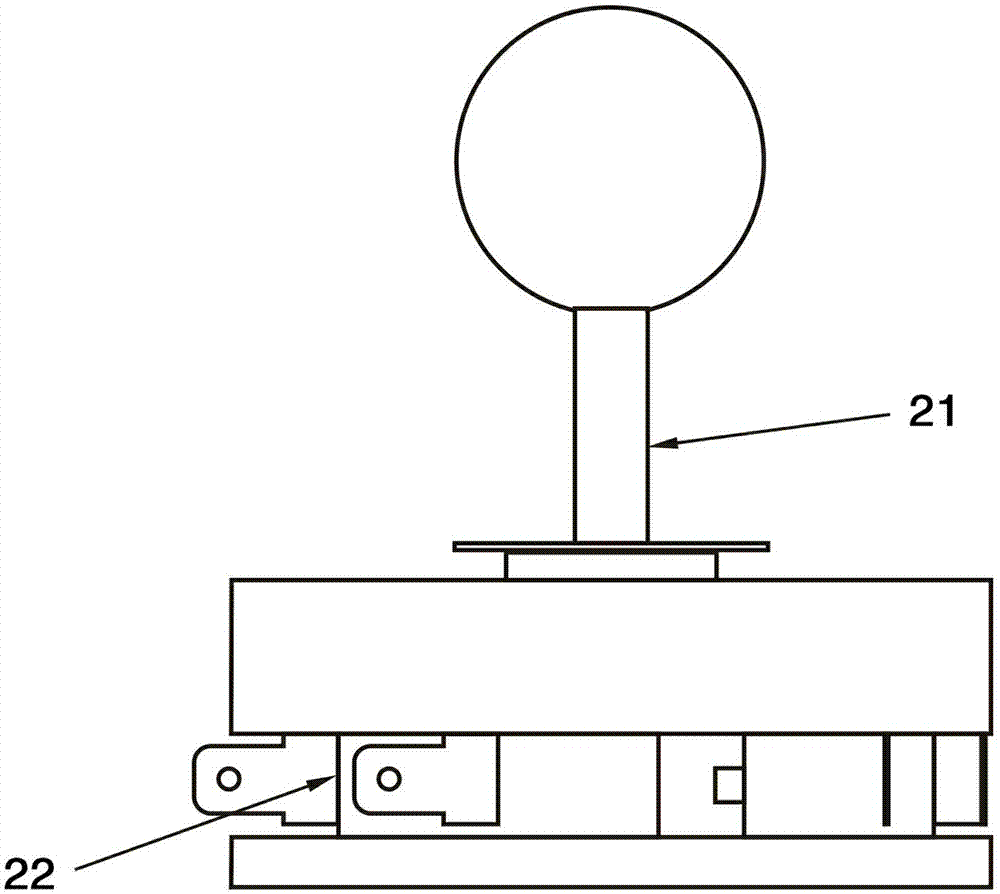

Rocking handle touch-tone wireless remote control device and boxing robot toy controlled by the device remotely

InactiveCN104771914ASolid workmanshipEasy to manageSelf-moving toy figuresRemote-control toysElectricityRemote control

The invention discloses a rocking handle touch-tone wireless remote control device, comprising a digital remote control emitting plate (1); the digital remote control emitting plate is electrically connected with a rocking handle unit (2), a left fist control button (3) and a right fist control button (19); the rocking handle touch-tone wireless remote control device has the advantages of being simple and flexible to operate, firm, durable, and convenient in business management. The invention further discloses a boxing robot toy controlled by the rocking handle touch-tone wireless remote control device remotely, which comprises a housing (6); the housing comprises a head part, an arm part (61), a trunk part and a left part (62); a digital remote control receiving plate (7) is installed in the housing (6); the digital remote control receiving plate (7) is connected with a battery (59) by a voltage stabilizing circuit board (57); a signal output and power input-output interface (72) of the digital remote control receiving plate (7) is electrically connected with a left steering engine (8) and a right steering engine (9); the boxing robot toy has the advantages of throwing a punch smoothly, preventing toppling, replacing the battery in time, having interaction and dynamic voice music in fighting and improving the playing effect and the playing smoothness.

Owner:蔡迪

Sand mold rotary gravity mould and casting method thereof

InactiveCN101602089AHigh thermal conductivityWon't drain quicklyFoundry mouldsFoundry coresMaterial consumptionMaterials science

The invention relates to a sand mold rotary gravity mould and a casting method thereof. The mould comprises an inner structure sand core and an exterior sand mold gravity mould, wherein the exterior sand mold gravity mould comprises resin, curing agent and crude sand. The casting method includes the following steps: (1) a sand core mould comprising the inner structure sand core and the exterior sand mold gravity mould is well installed on a sand core machine; (2) the sand is mixed: resin, curing agent and crude sand; (3) the mould is heated: according to the structural sizes of the sand core and the sand mold, the mould is warmed to a proper curing temperature to manufacture the core and the mold, and residual parts on the sand core are scraped; (4) the inner structure sand core is arranged in the exterior sand mold gravity mould according to a positioning head, and rotary casting is carried out in the mode of front casting or lateral casting after mould closing; (5) after casting, the cast is taken out from the exterior sand mold gravity mould, and the time of taking the cast is determined according to the curing states of the dead head of the cast and a thicker part; and (6) the cast is processed by slinging and shot blasting. The invention can avoid the disadvantages of the traditional casting method, and has the advantages of low material consumption and lower cost.

Owner:付政权

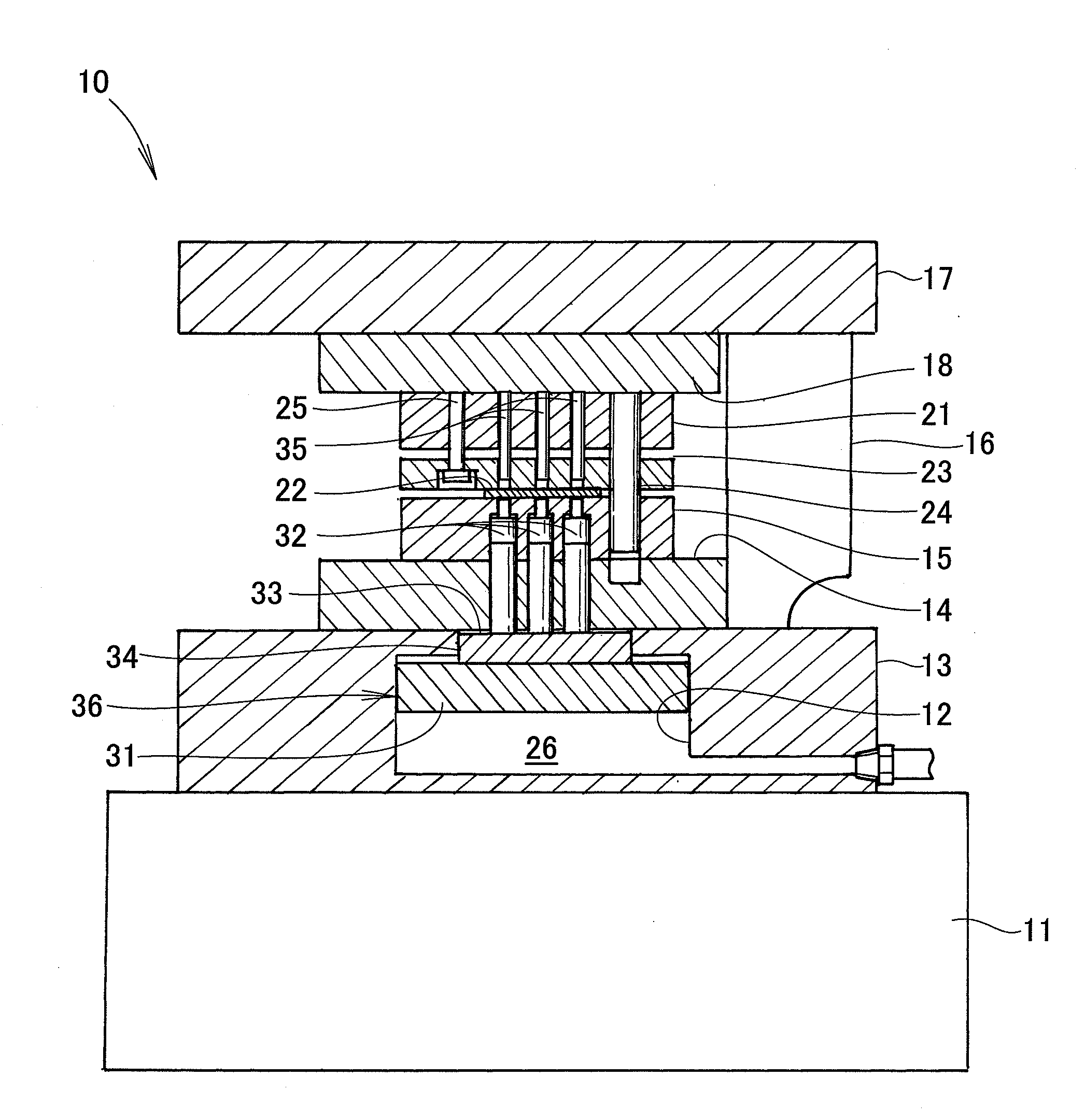

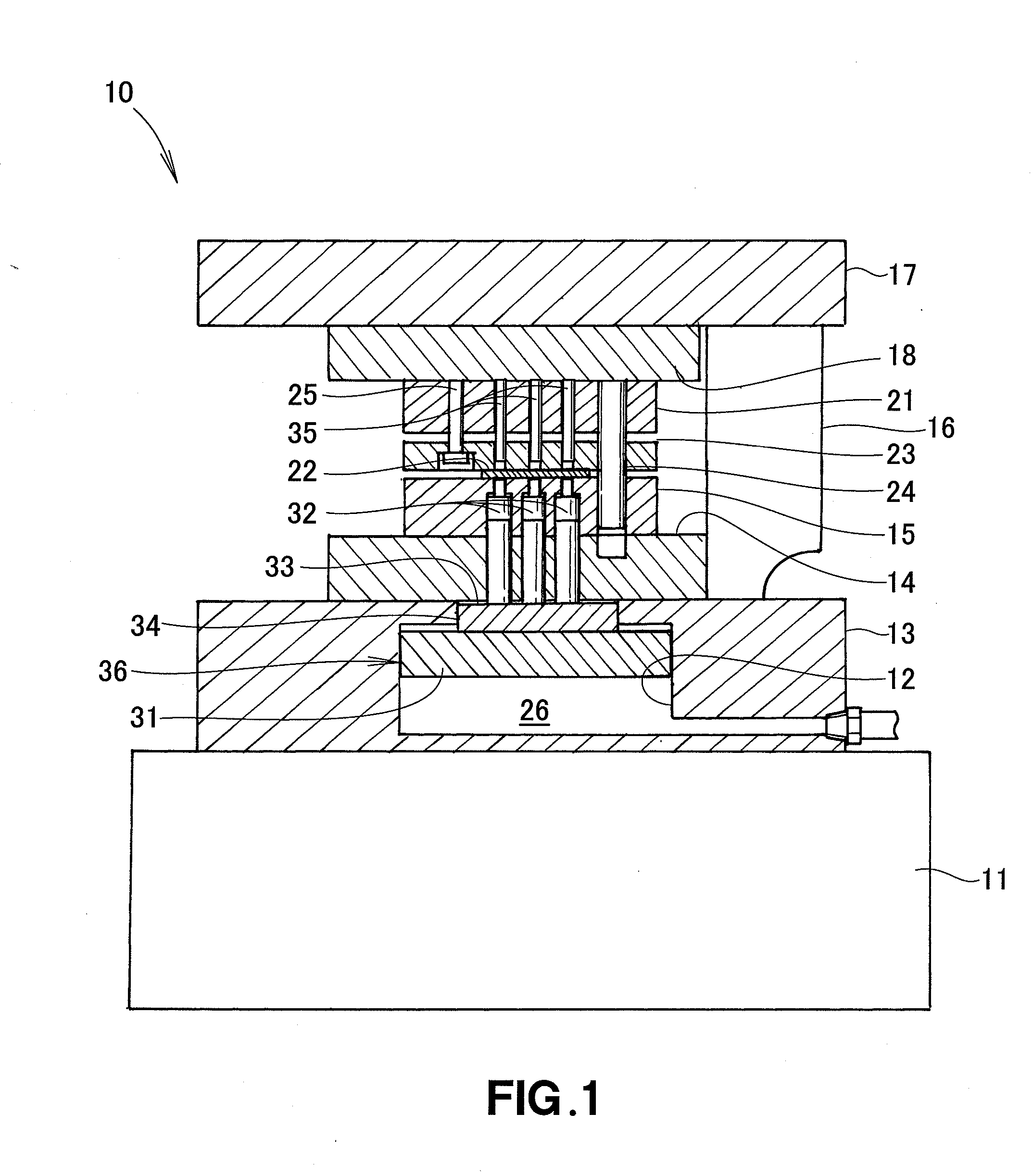

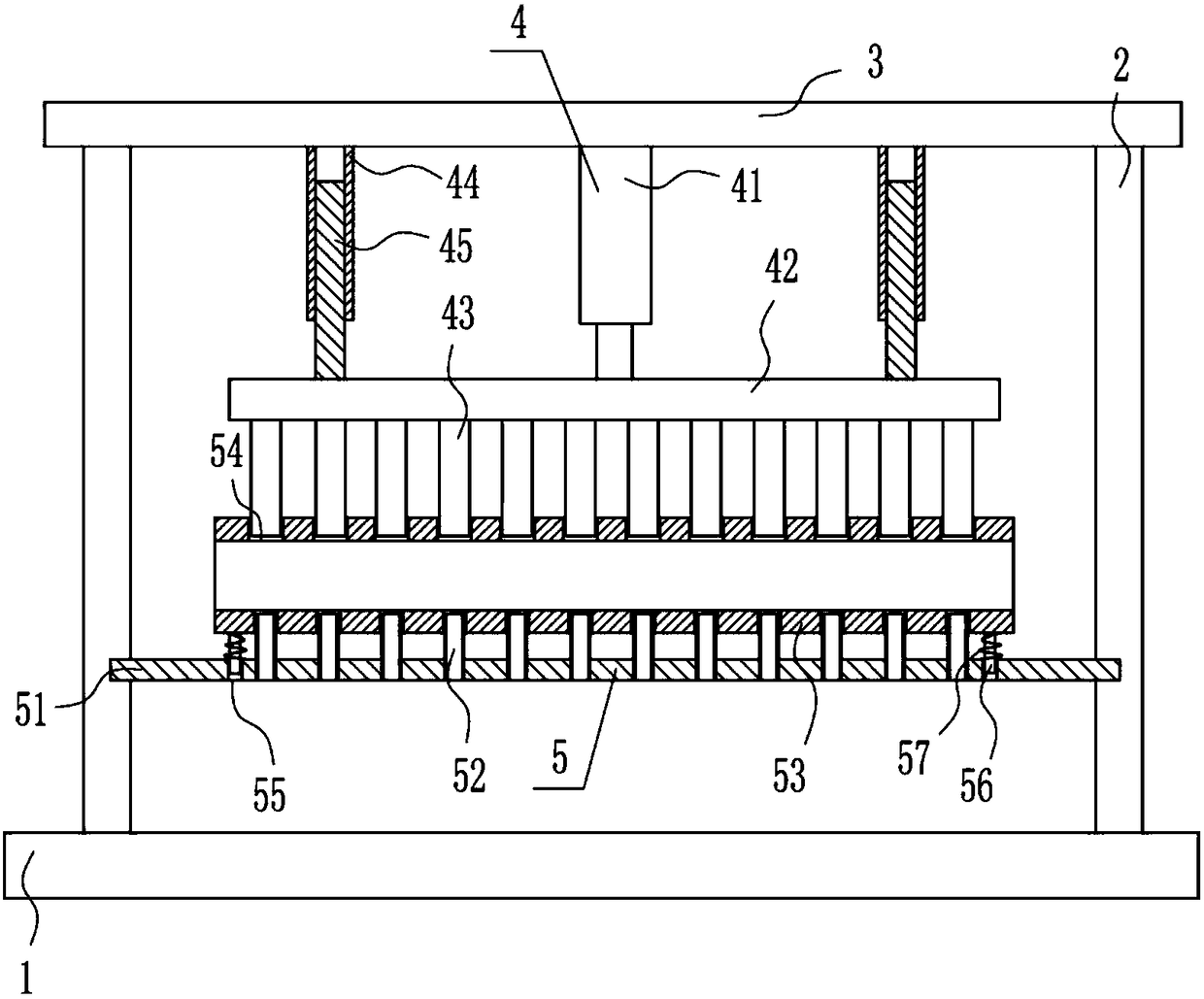

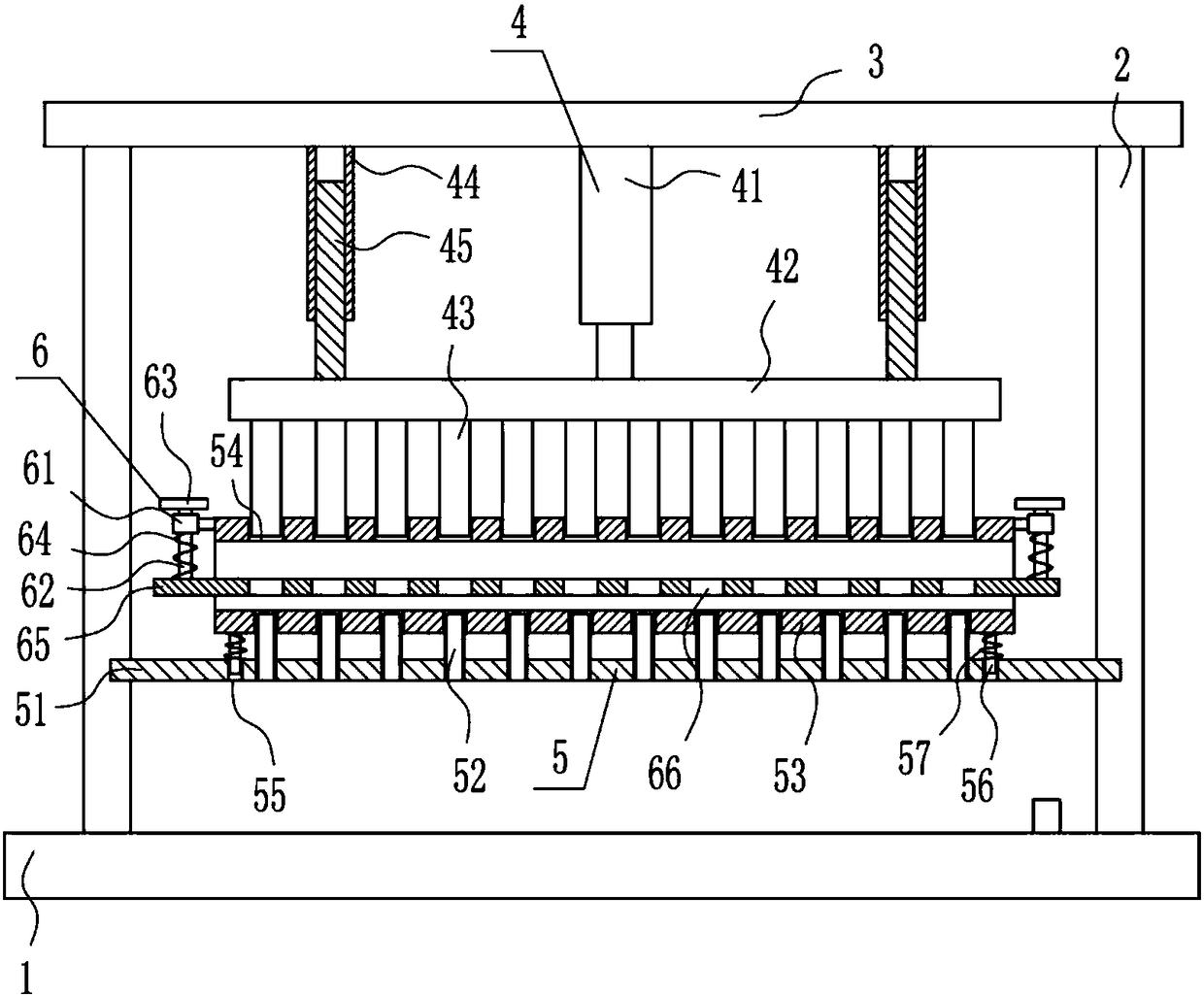

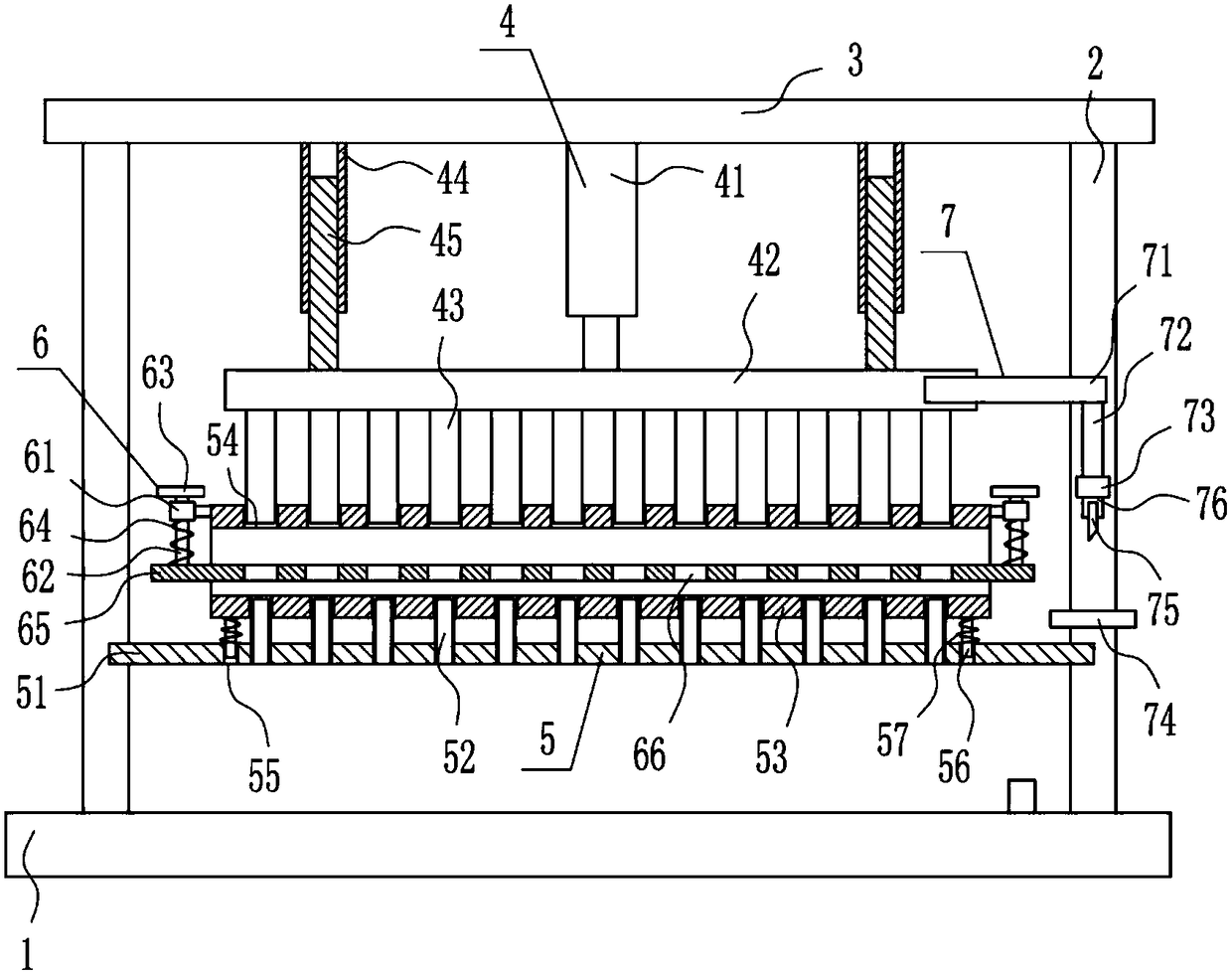

Punching apparatus and method

InactiveUS20130186245A1Improve productivityHigh thickness accuracyBeltsMetal working apparatusPunchingPiston

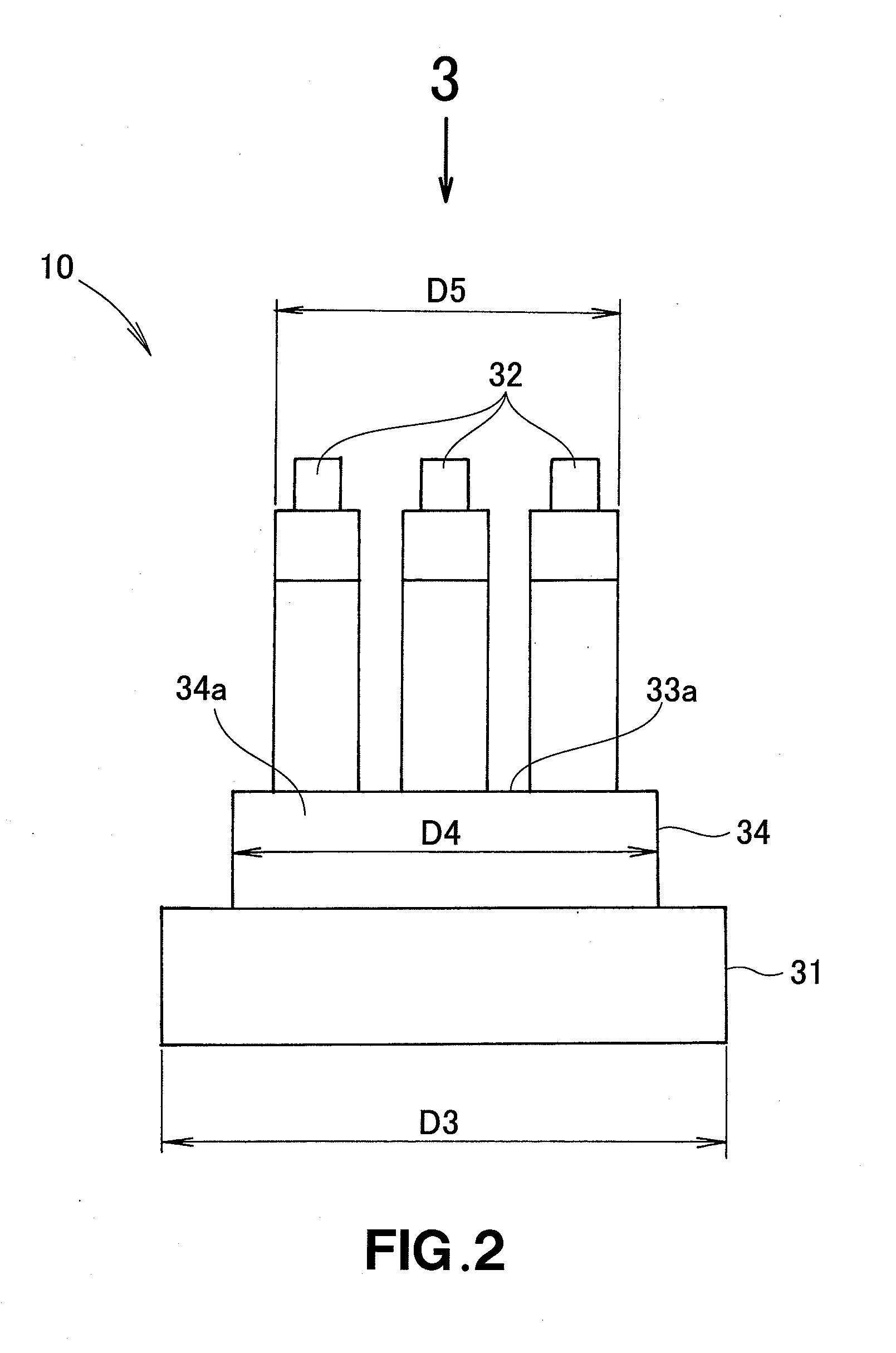

A punching apparatus includes a plurality of punches for punching a workpiece, a pad, and a single piston supporting the pad. The punches are disposed on a top surface of a portion of the pad. The top surface has a circumference circumscribing circumferences of outermost ones of the punches. A diameter of the piston is larger than a diameter of the portion of the pad.

Owner:HONDA MOTOR CO LTD

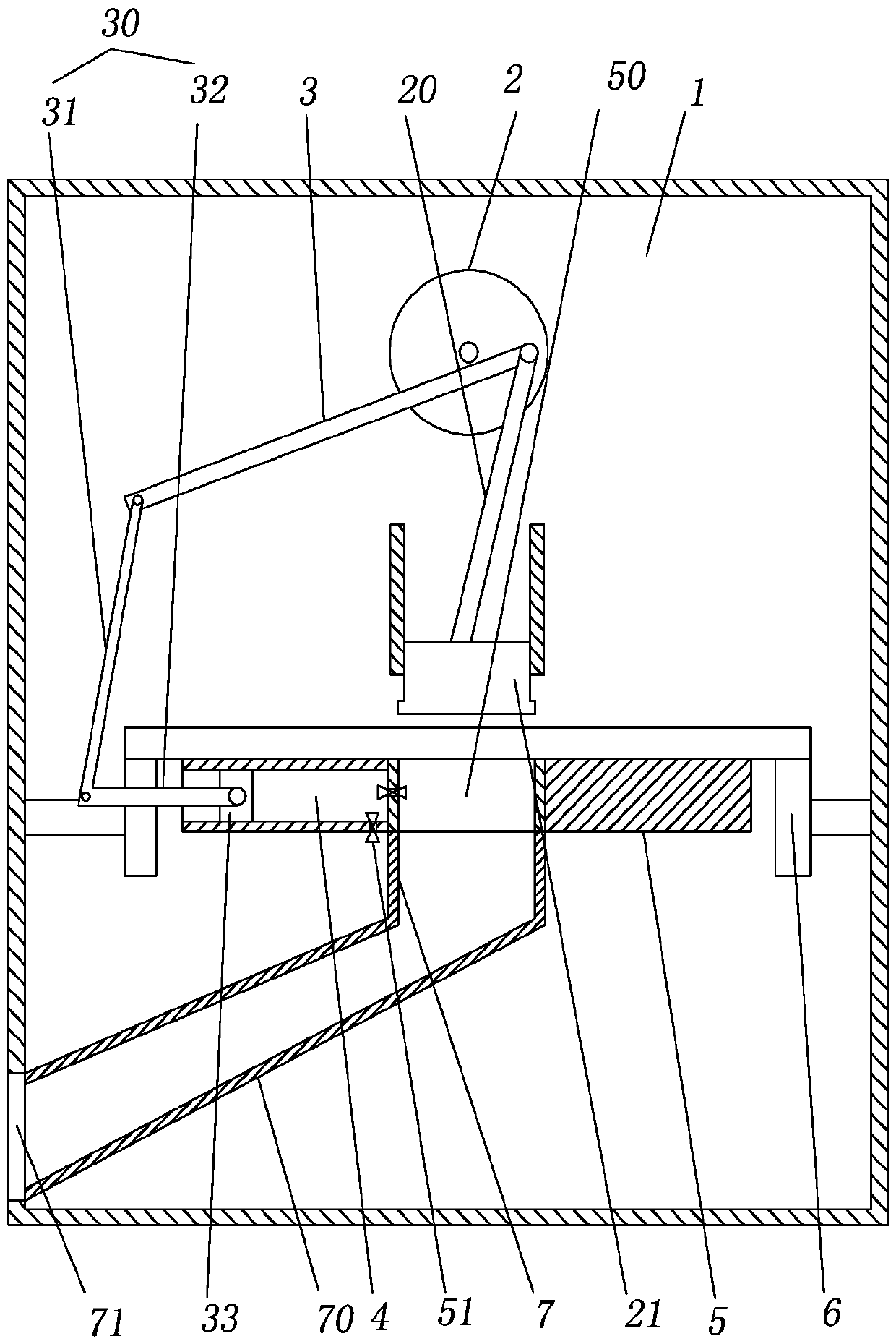

Punching device

InactiveCN107597951AAvoid depositionEvenly punchedPerforating toolsMetal-working feeding devicesPunchingEngineering

The invention relates to the technical field of rigidity piece punching, in particular to a punching device. The punching device comprises a motor, a punching die, a punching box and a punching head.A punching hole is formed in the punching die. The punching device further comprises a power mechanism, an air blowing mechanism and a conveying mechanism for conveying steel plates. The power mechanism comprises a crank and a punching rod. An output shaft of the motor is connected with the crank, one end of the punching rod is hinged to the crank, the other end of the punching rod is hinged to the punching head, and the punching head is in sliding connection into the punching box. The air blowing mechanism comprises a swinging rod, an air blowing rod and a piston, a sliding cavity is formed in the punching die, the sliding cavity is provided with an air inlet pipe for air inflow and an air outlet pipe for air outflow, each of the air inlet pipe and the air outlet pipe is provided with a one-way valve, and the air outlet pipe is aligned with the punching hole. By adoption of the technical scheme, scraps at the position of the punching hole can be cleaned away, and it is guaranteed thatpunching is smoothly conducted.

Owner:象山信基机械厂

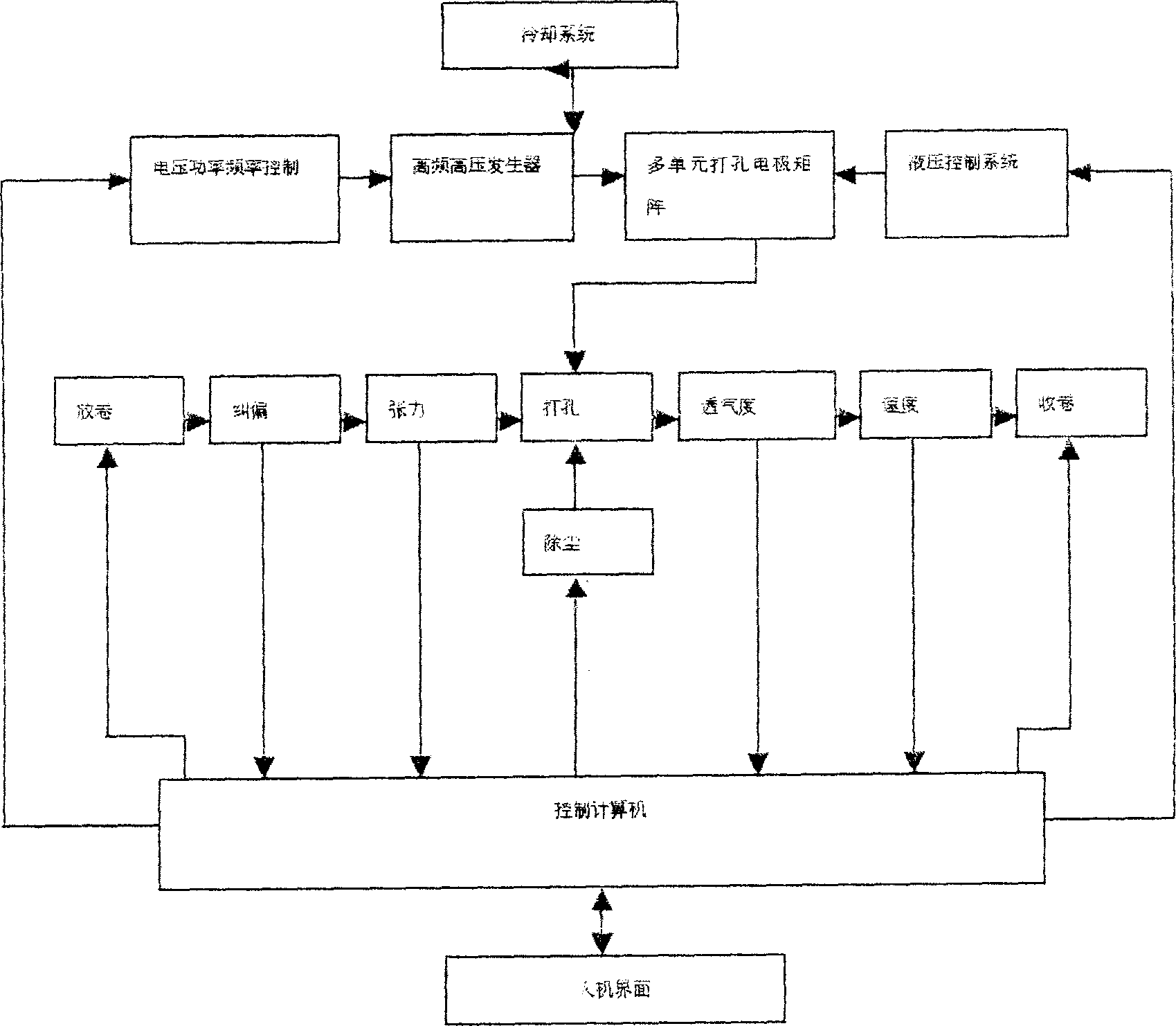

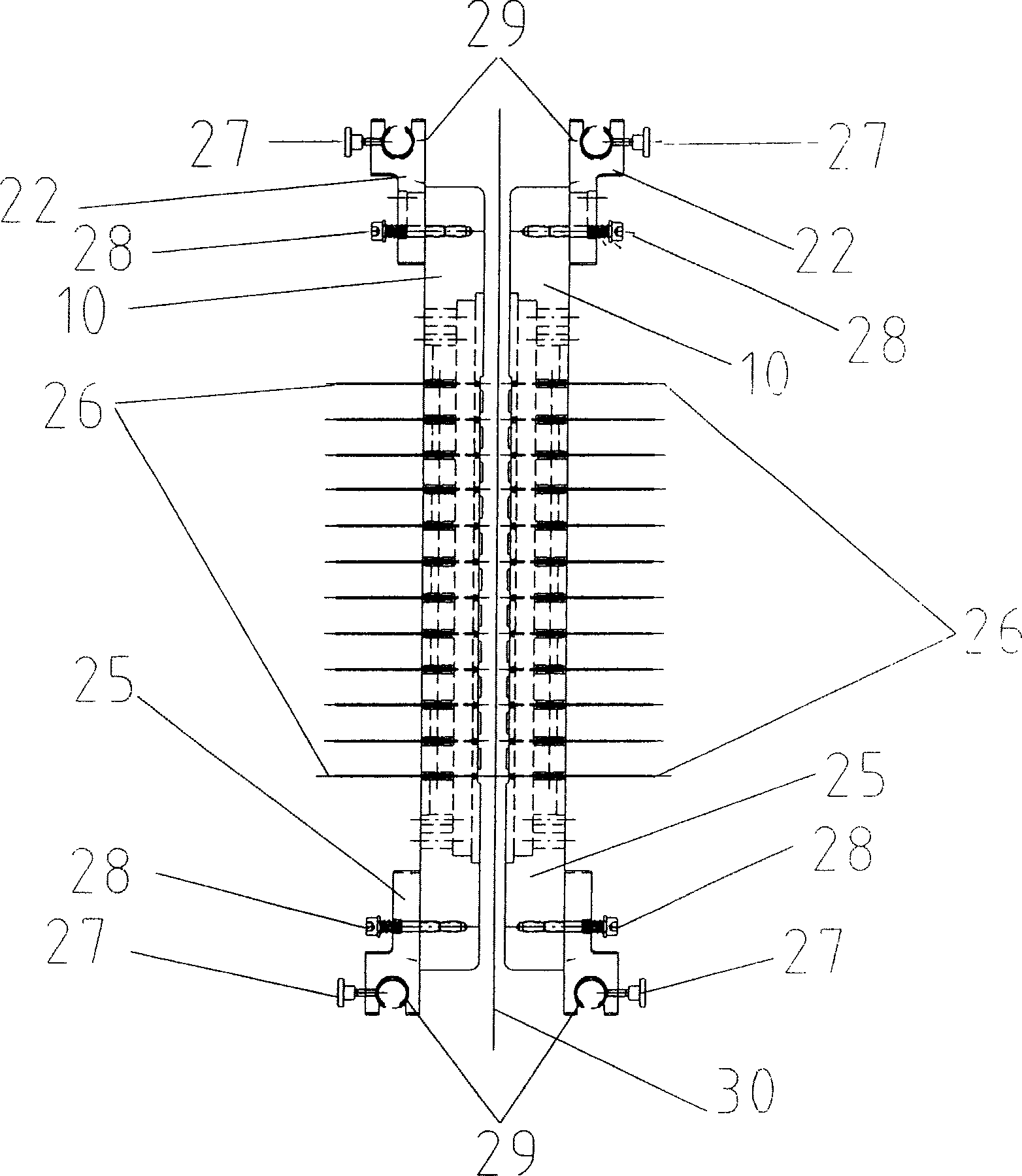

Multiple-unit drilling apparatus for wide breadth thin type base material

InactiveCN1520973AMeet the needs of large-scale mass productionEvenly punchedMetal working apparatusElectricityMan machine

The present invention relates to electrically perforating, and is especially one wide coverage perforating apparatus for thin base material. The perforating apparatus consists of unwinding mechanism, winding mechanism, correction controller, tension controller, hydraulic mechanism, perforating mechanism, HF high voltage generator, detection mechanism, speed, frequency and pulse width controller, and man-machine interface. It features the perforating mechanism comprising at least two electrode matrixes, each of which consists of two, including one positive and one negative, electrodes set on two sides of the base material separately, in some angle to the base material motion direction and with M electrode pins. The present invention has the advantages of multiple perforating, capacity of perforating in millimeter level narrow strip and capacity of perforating in meter level broad width.

Owner:ENDIAN SCI & TECH DEV OF YUNNAN

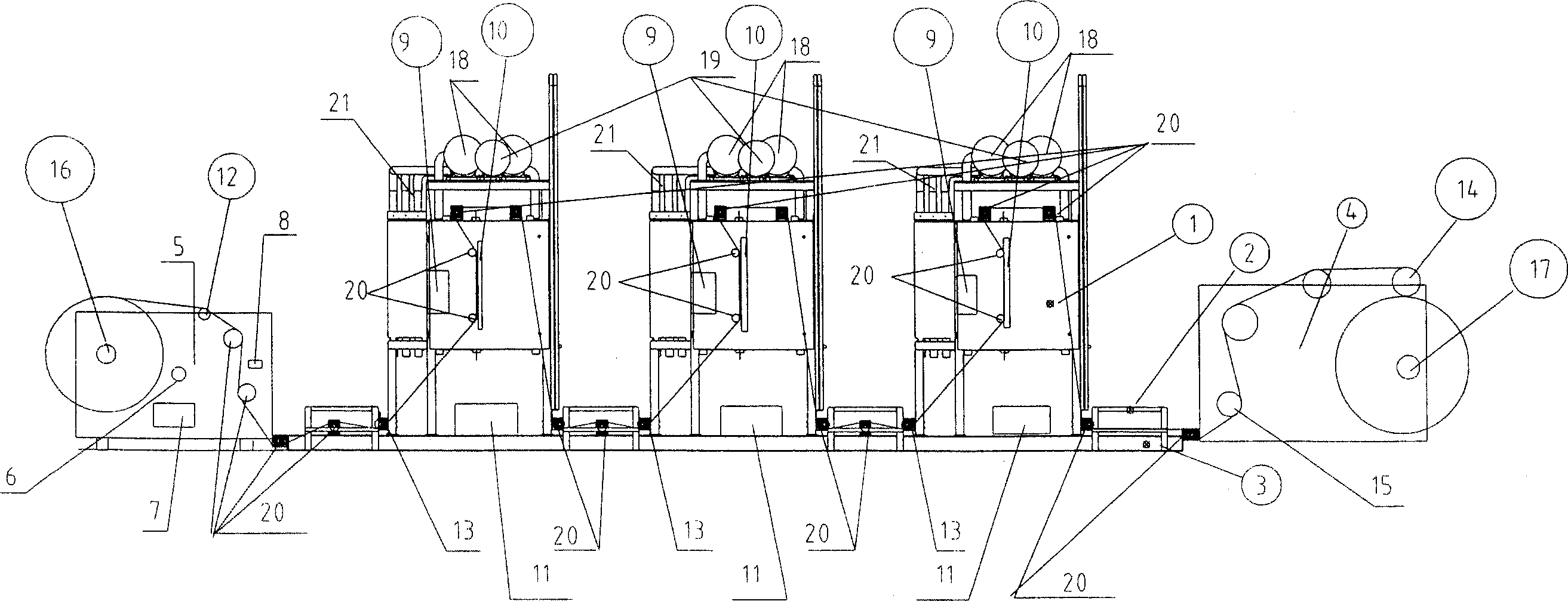

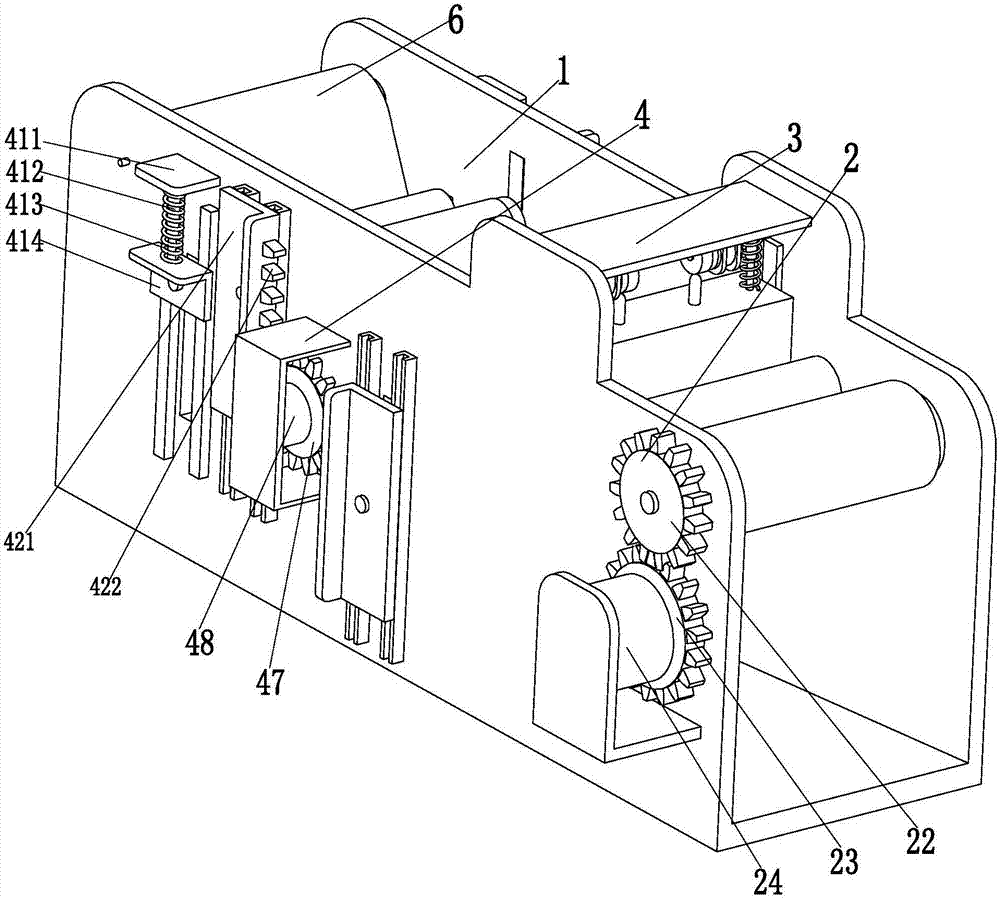

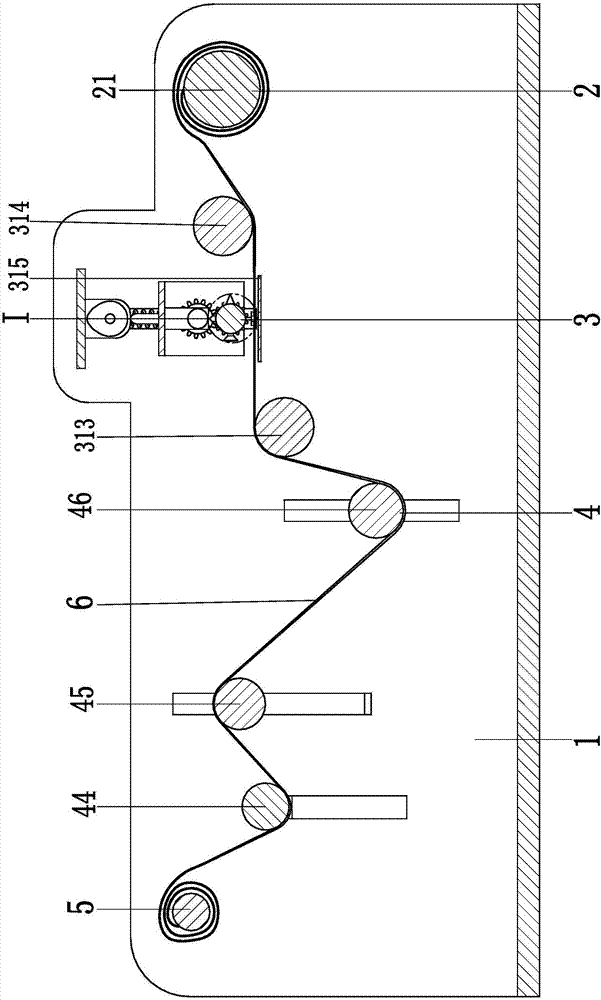

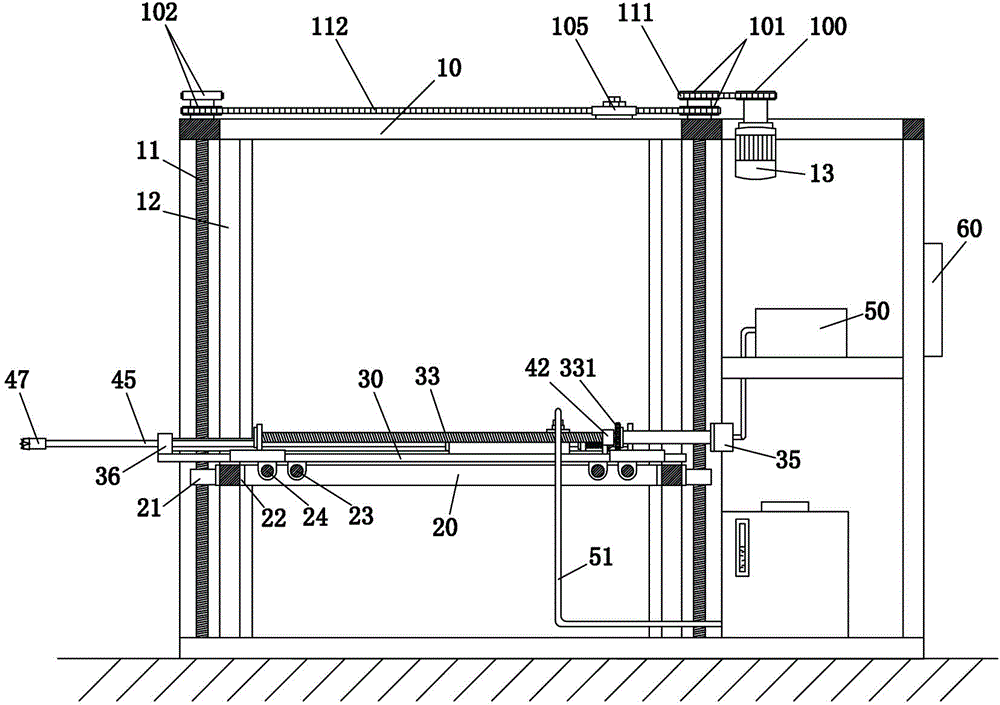

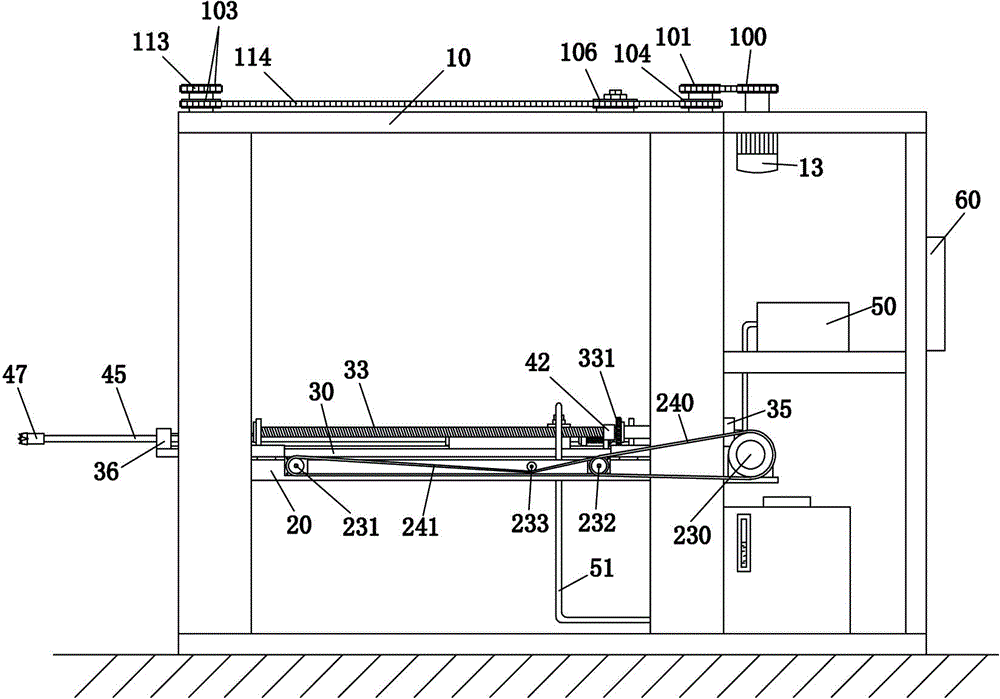

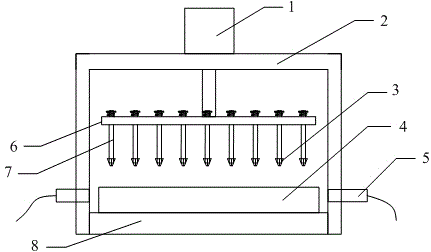

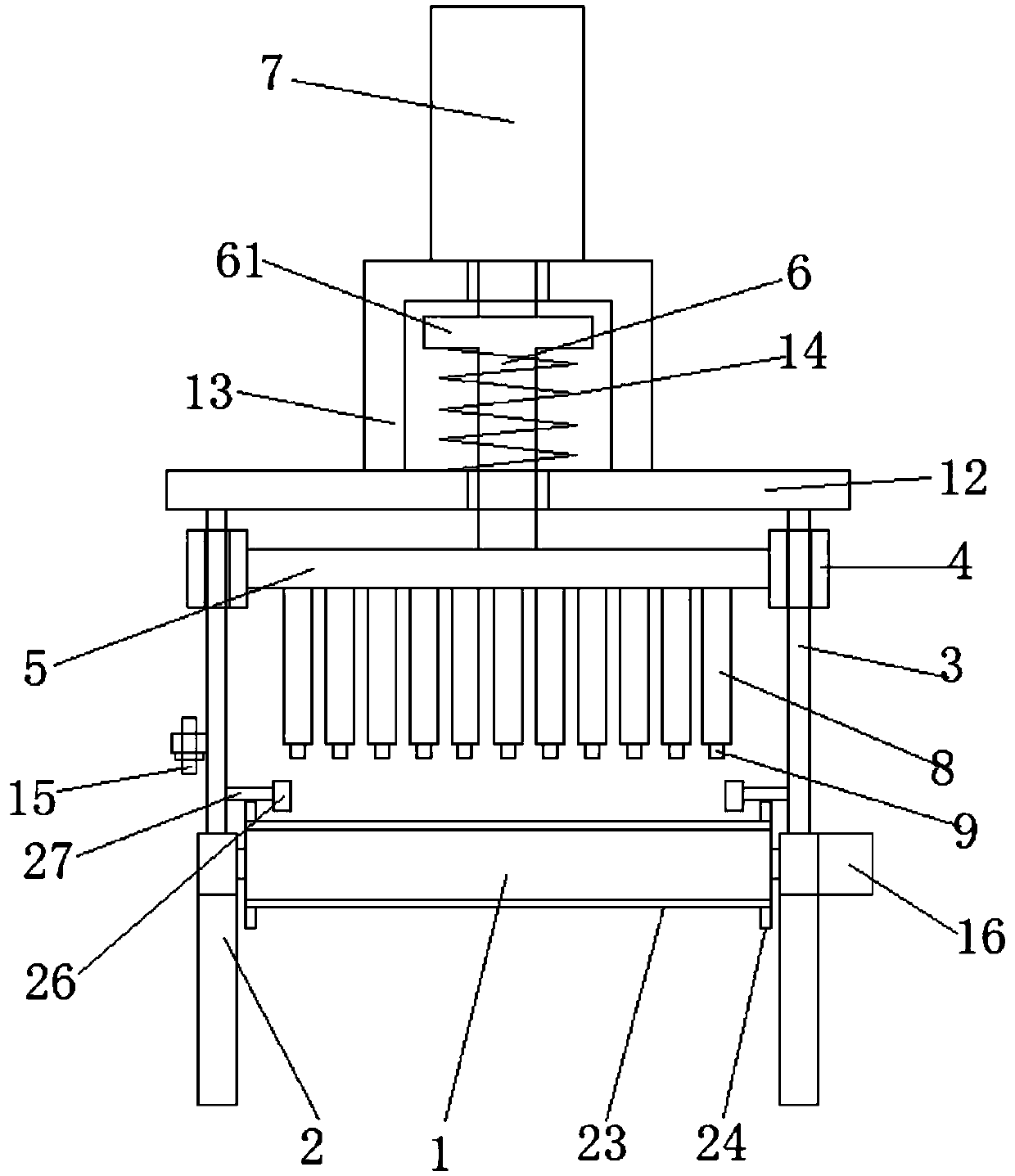

Precise punching equipment special for medical sterilizing dialyzing paper

InactiveCN106956320AWill not affect efficiencyEvenly punchedMetal working apparatusPunchingEngineering

The invention relates to precise punching equipment special for medical sterilizing dialyzing paper. The precise punching equipment comprises a working rack, and a winding device, a punching device, a tensioning device and a winding roller are sequentially arranged on the working rack from front to back; and the winding roller is wound with a dialyzing paper body, the dialyzing paper body sequentially passes through the winding roller, the tensioning device, the punching device and the winding device in a winding manner from back to front, and the winding device, the punching device and the tensioning device are mutually matched for use to complete a punching process of the medical dialyzing paper. According to the precise punching equipment special for the medical sterilizing dialyzing paper, the problems that in the existing medical dialyzing paper punching process, for an existing punching device, punching cutter heads are single, cutter heads need to be manually replaced when the punching device is used for processing dialyzing paper with different uses, punching is nonuniform, the punching position is inaccurate, and the punching efficiency is low can be solved, the function of precisely punching the medical dialyzing paper can be achieved, the using efficiency of the dialyzing paper cannot be affected, and the precise punching equipment has the advantages that punching is uniform, the punching position is accurate, and the punching efficiency is high.

Owner:FIRST HOSPITAL OF QINHUANGDAO

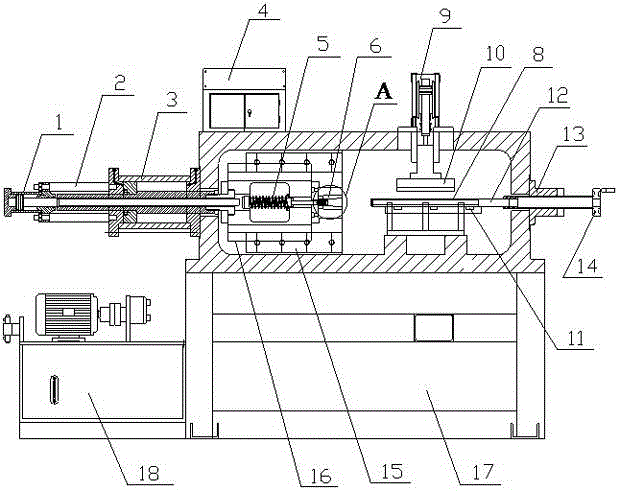

Motorcycle assembling system

ActiveCN108480695AImprove drilling accuracyNo movementOther manufacturing equipments/toolsLarge fixed membersEngineeringBevel gear

The invention belongs to the technical field of part assembly treatment, in particular to a motorcycle assembling system. The system comprises a machine frame, wherein a motor is fixedly arranged on the machine frame, the machine frame is rotationally connected with a workbench, and the machine frame is further rotationally connected with a bevel gear set for driving the workbench to rotate; firstair cylinders are fixedly arranged on the two sides of the workbench, a second air cylinder is further fixedly arranged on the machine frame, and a sleeve is connected to the machine frame in a sliding mode; the output shaft of the second air cylinder is fixedly connected with the sleeve, and a drilling rod and a grinding rod are rotationally connected in the sleeve; a motor is fixedly arranged on the sleeve, the output end of the motor is fixedly connected with the drilling rod, and the drilling rod is connected with the grinding rod through a transmission mechanism; a pawl is fixedly arranged on the sleeve, and a ratchet wheel matched with the pawl is rotationally connected to the machine frame; and the ratchet wheel is used for driving the bevel gear set to rotate. By adopting the scheme of the motorcycle assembling system, after an initial position hole is formed in the workpiece, circumferential punching and polishing treatment is carried out on the workpiece, the machining stepsare simplified, and the motorcycle assembling system is mostly used for treatment of motorcycle assembly parts.

Owner:重庆荣爵摩托车有限公司

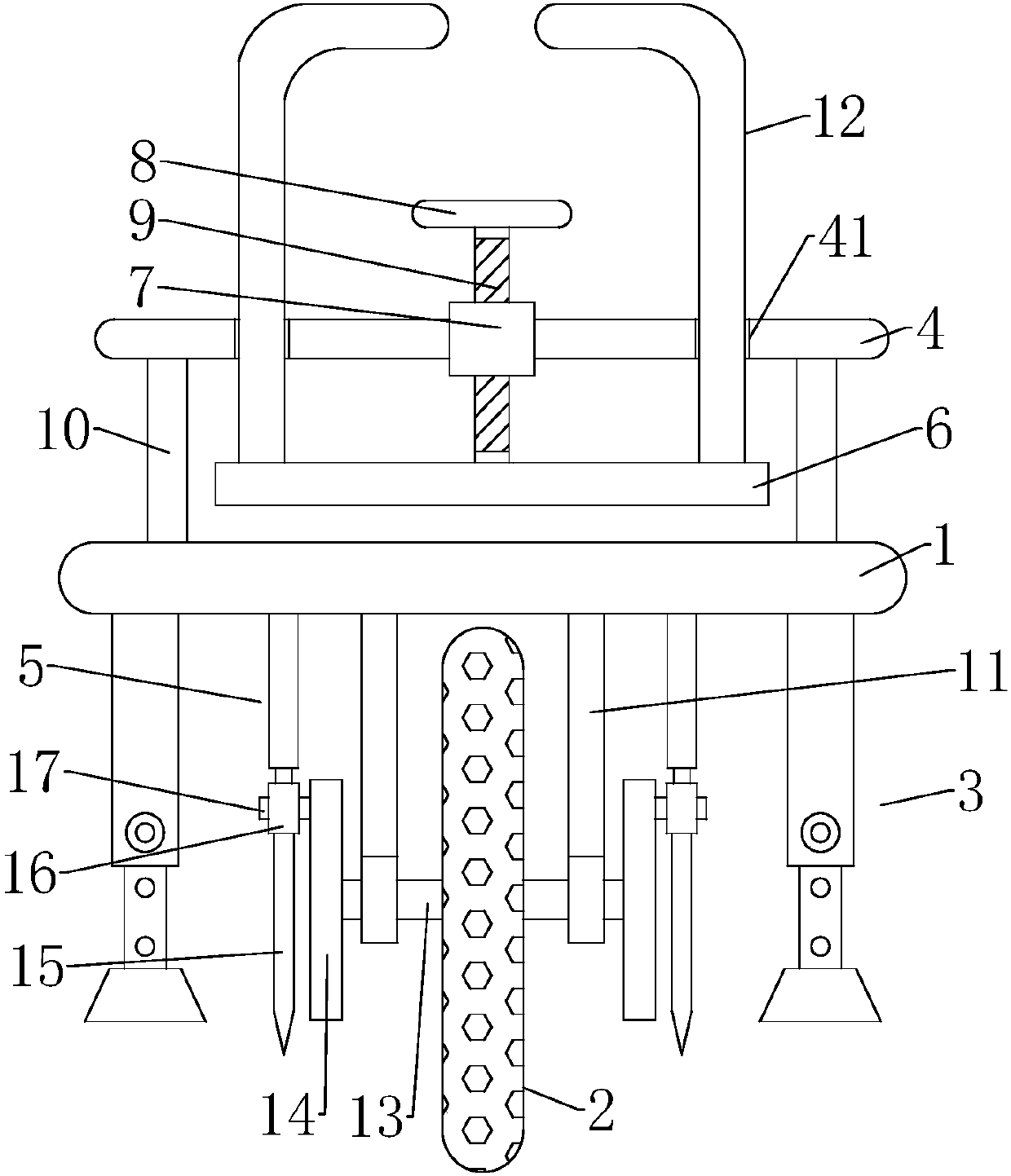

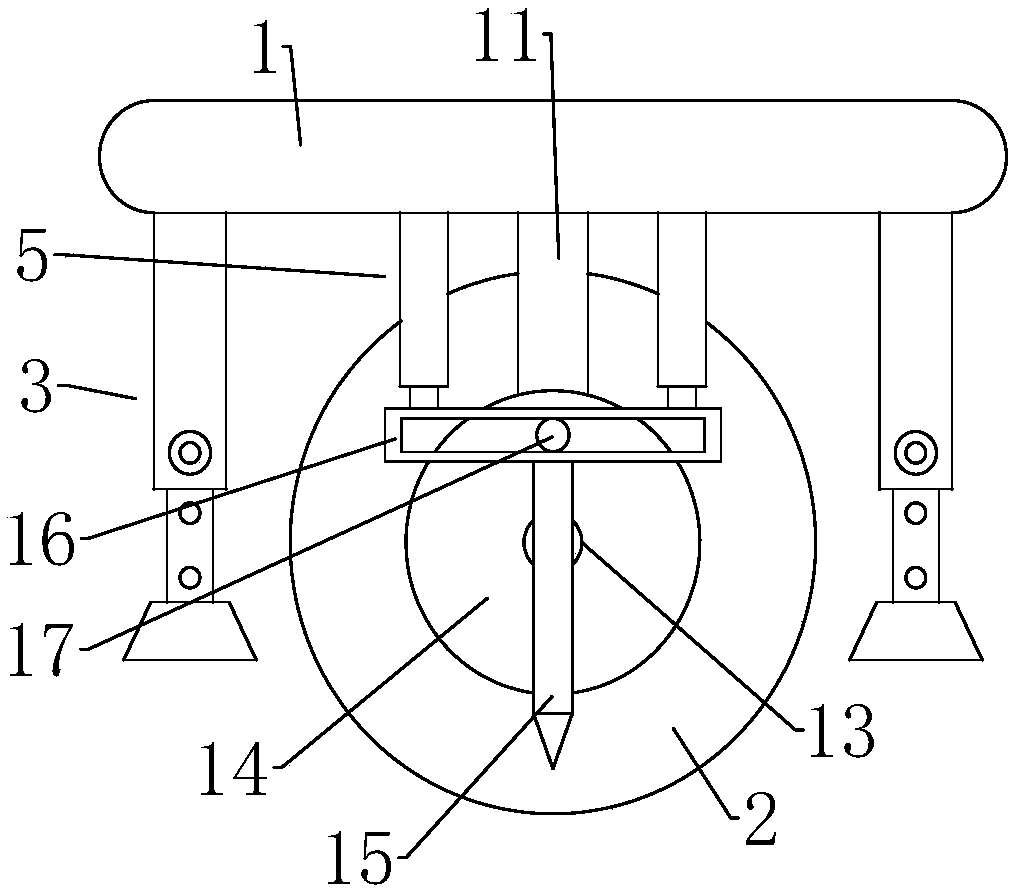

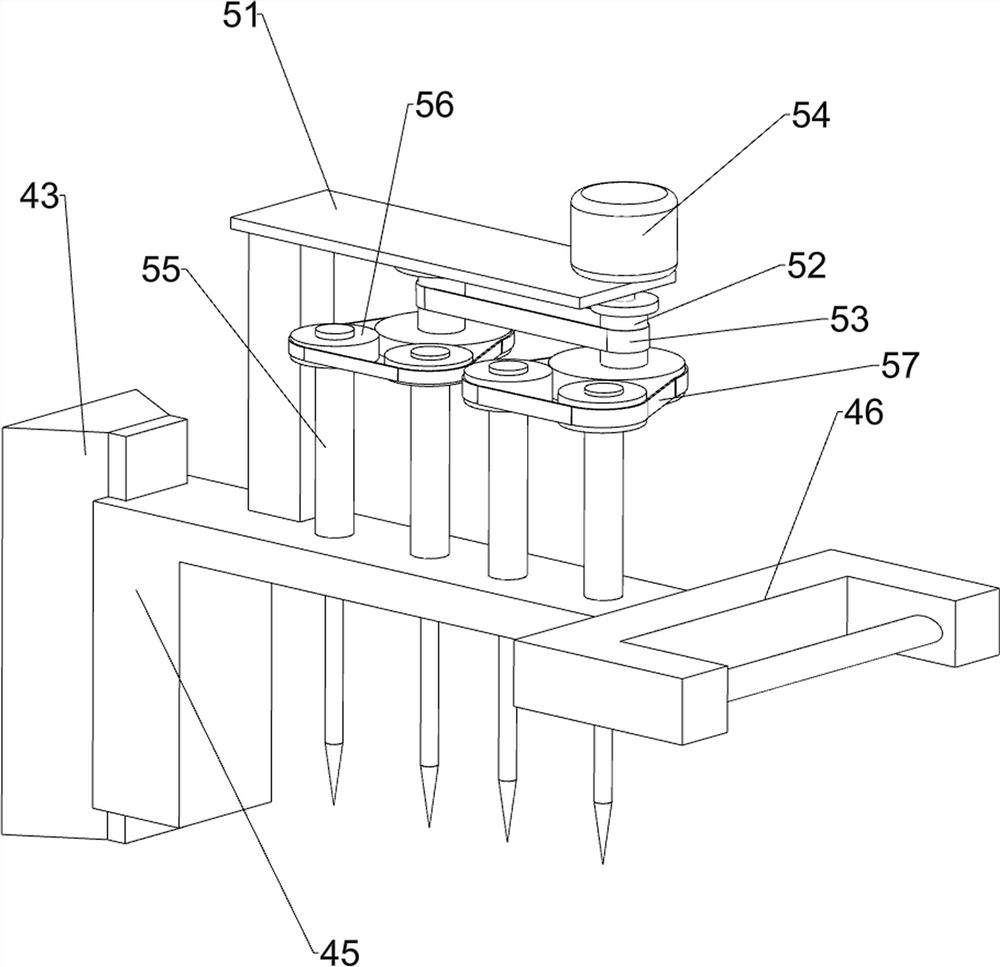

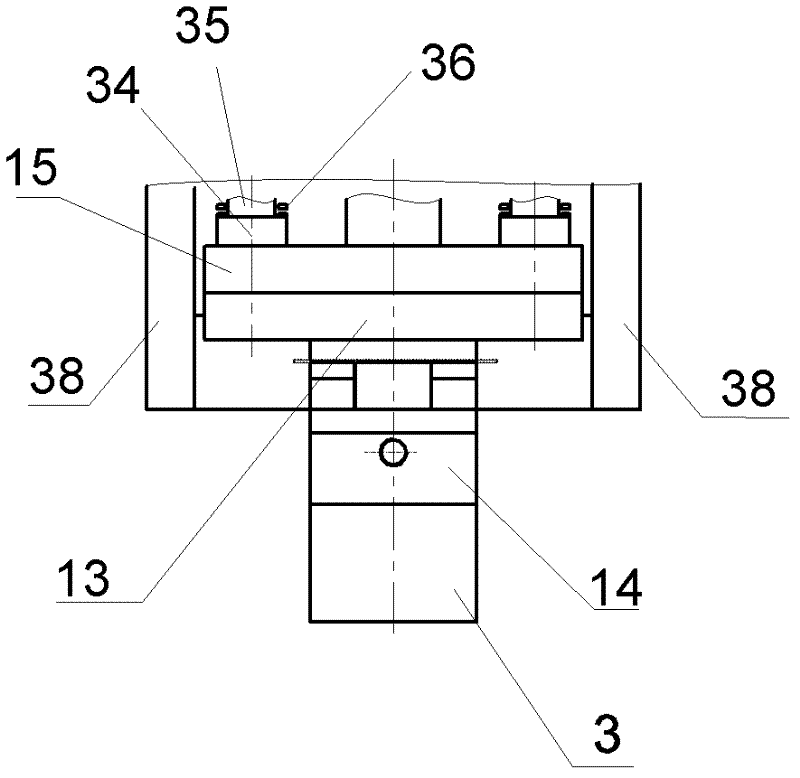

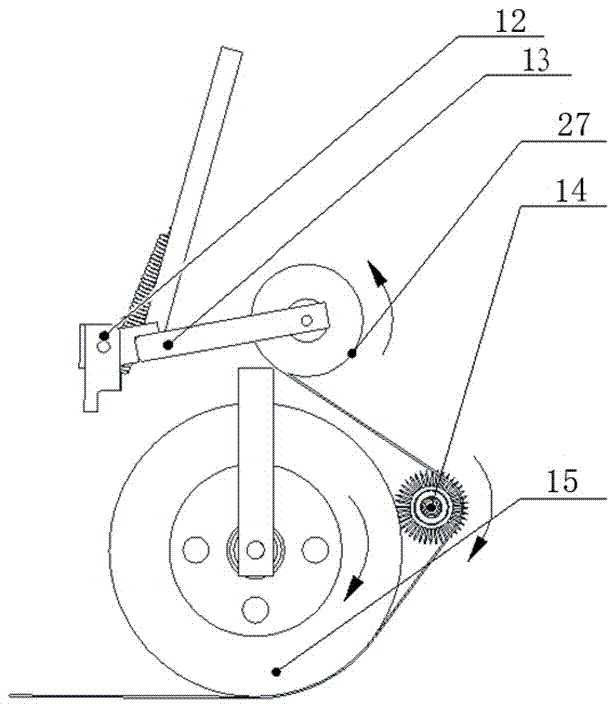

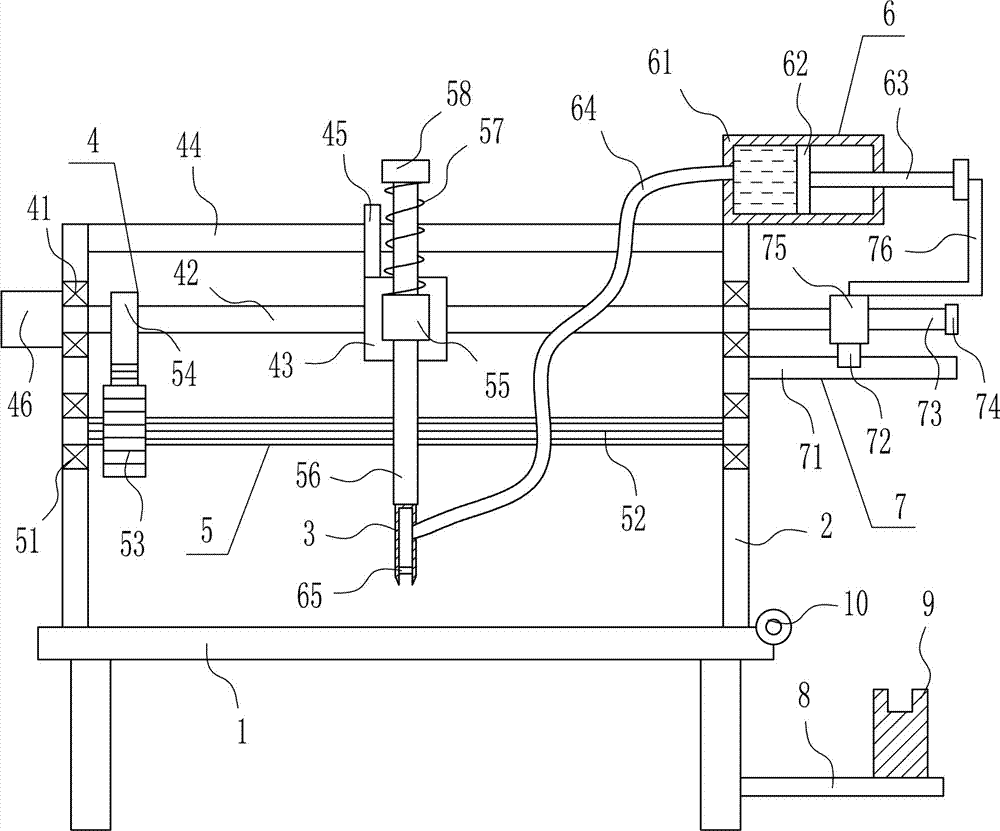

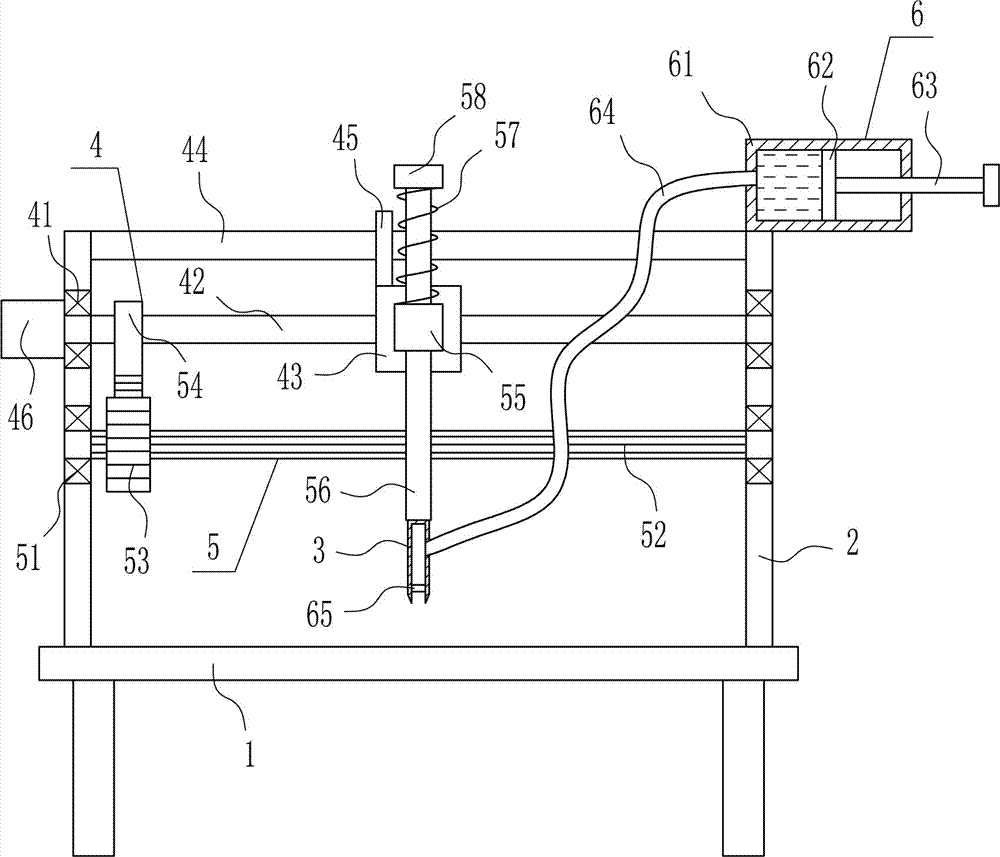

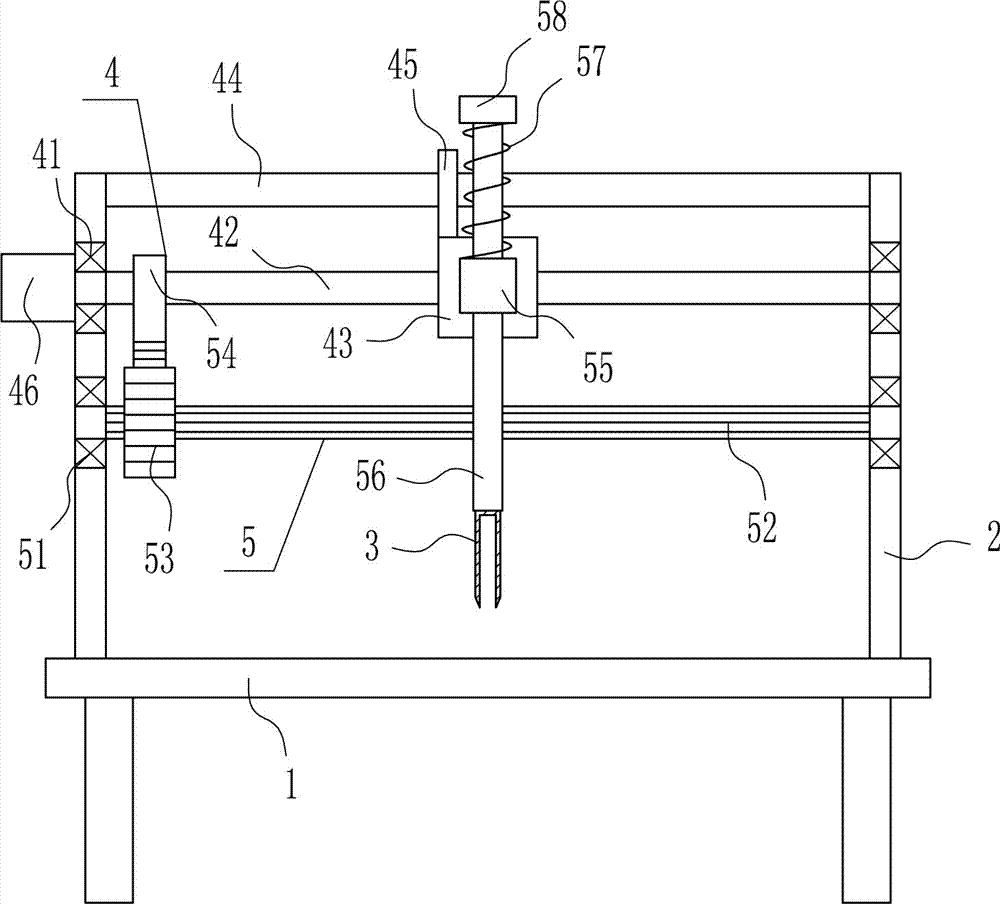

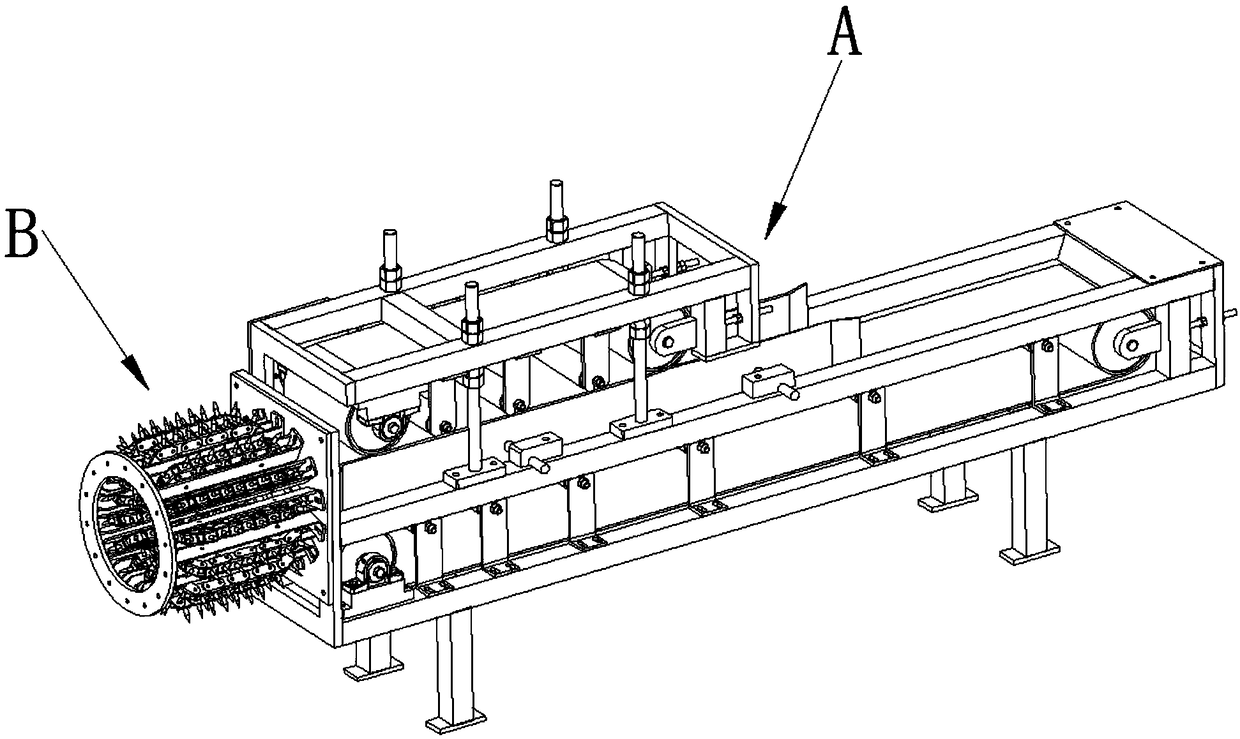

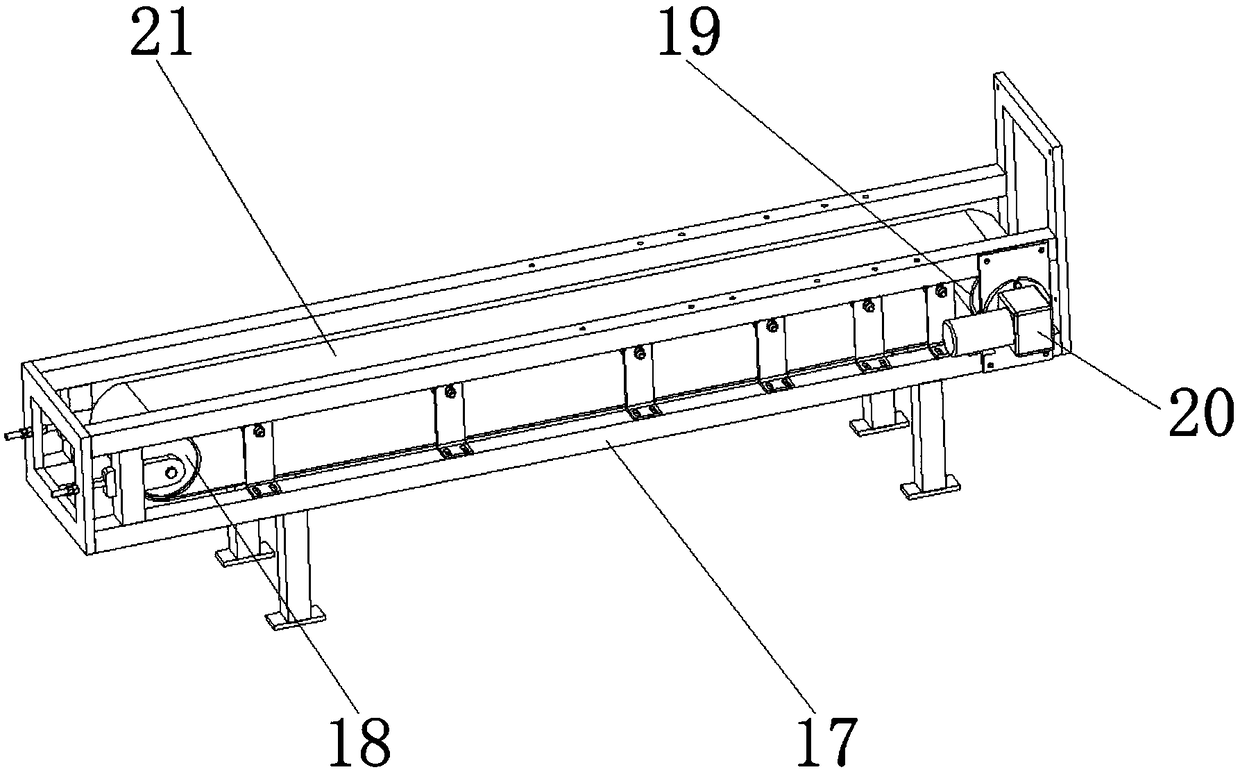

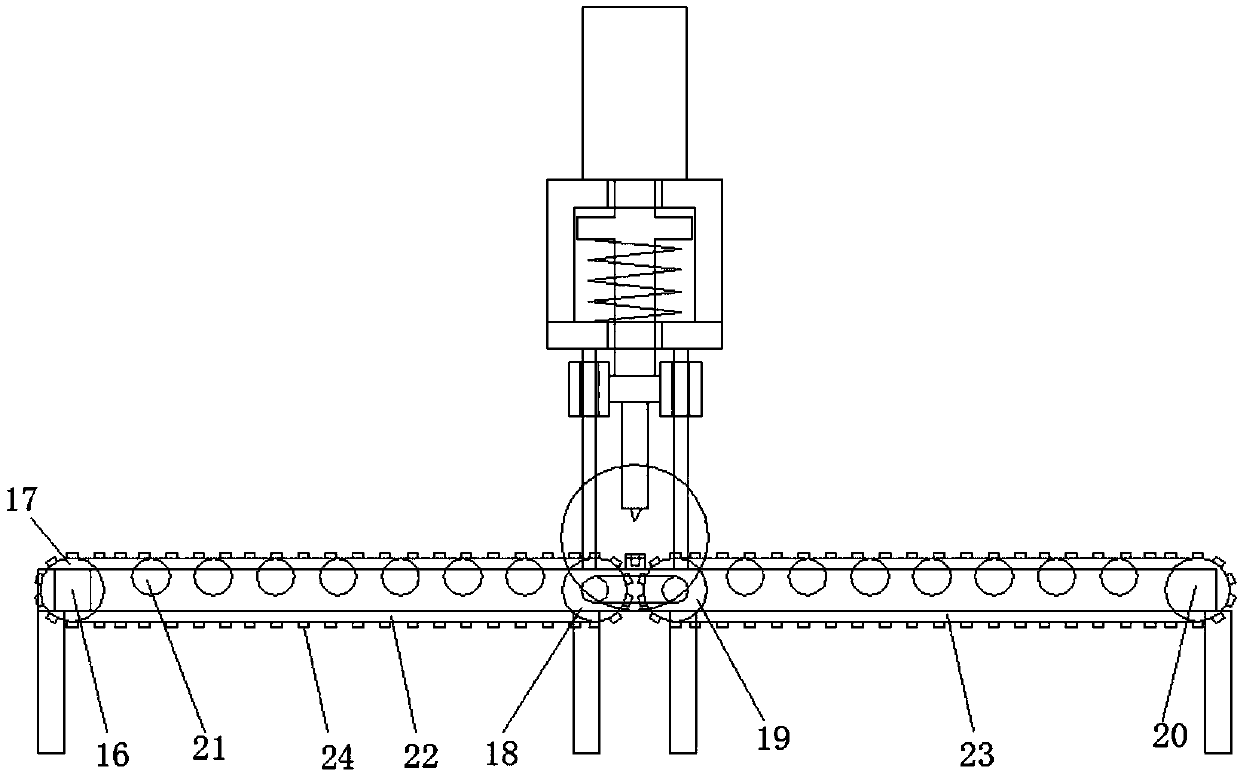

Crop planting cart-type continuous perforation apparatus

InactiveCN107736105AEvenly punchedUniform hole punchingPlantingFurrow making/coveringEngineeringUltimate tensile strength

The invention discloses a crop planting cart-type continuous perforating apparatus. The crop planting continuous perforation apparatus comprises a stander, traveling wheels, a supporting leg apparatus, a guiding sleeve rod, a handrail, rotary discs, a perforation roller and a lifting sleeve plate, wherein the lower surface of the middle part of the stander is symmetrically and fixedly provided with supporting rods, the bottom end of each supporting rod is provided with a rotary rod by virtue of a rotary frame of a bearing connection way, the traveling wheels are fixedly installed in the middlepart of the rotary rods, the two rotary discs are separately and fixedly installed on two ends of the rotary rod, an outer circle of each rotary disc is respectively and fixedly provided with a guidecolumn, the guide column is sleeved with the lifting sleeve plate in a sliding manner, and the bottom end of the lifting sleeve plate is fixedly provided with the perforation roller. The crop planting cart-type continuous perforation apparatus is simple in structure, convenient to use, wide in application range, energy-saving, environmentally friendly, uniform and continuous in perforation, low in labor intensity, high in working efficiency and suitable for popularization and application.

Owner:守农(山东)企业信息咨询有限公司

Cave mining device of finishing-use granite

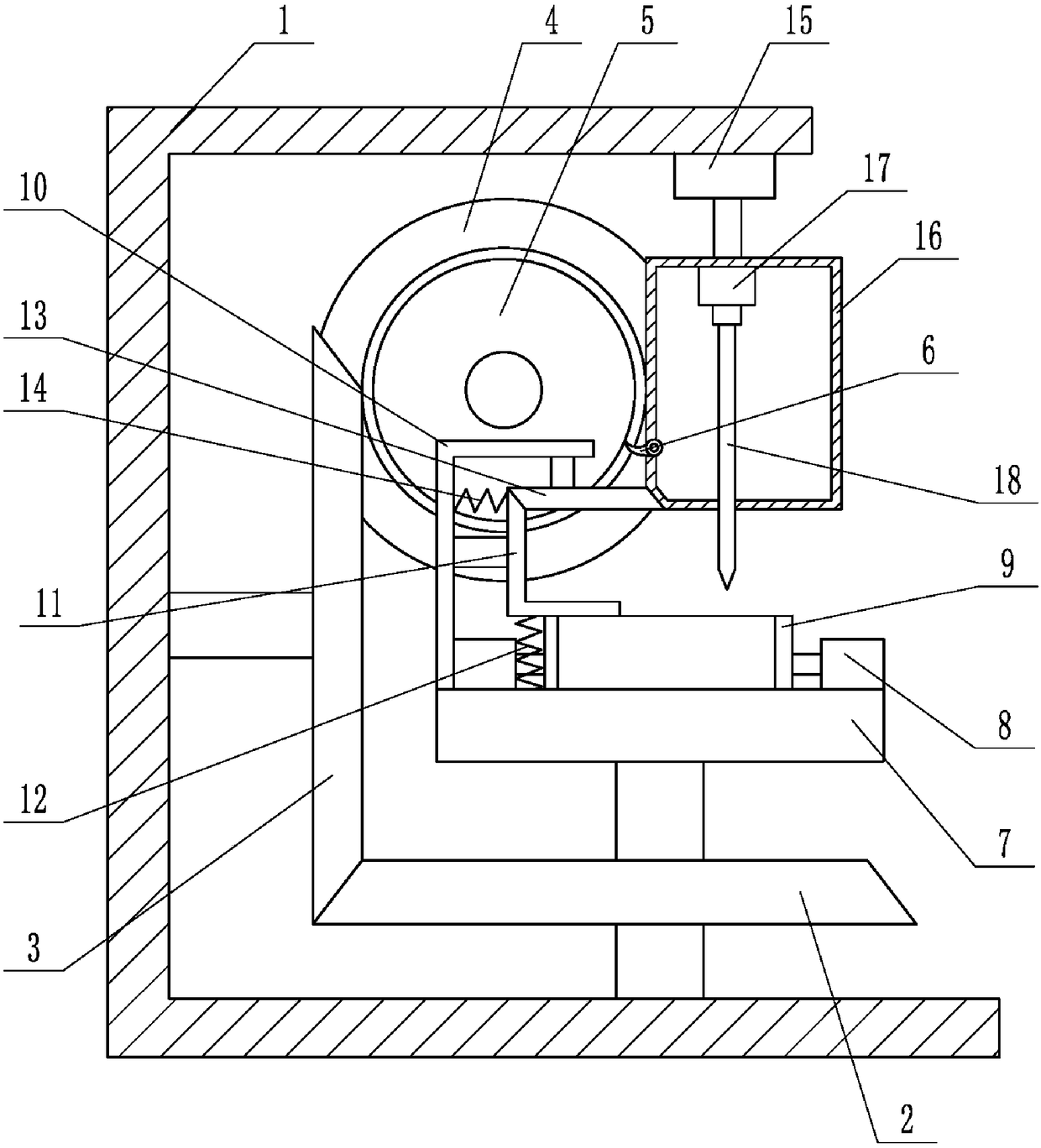

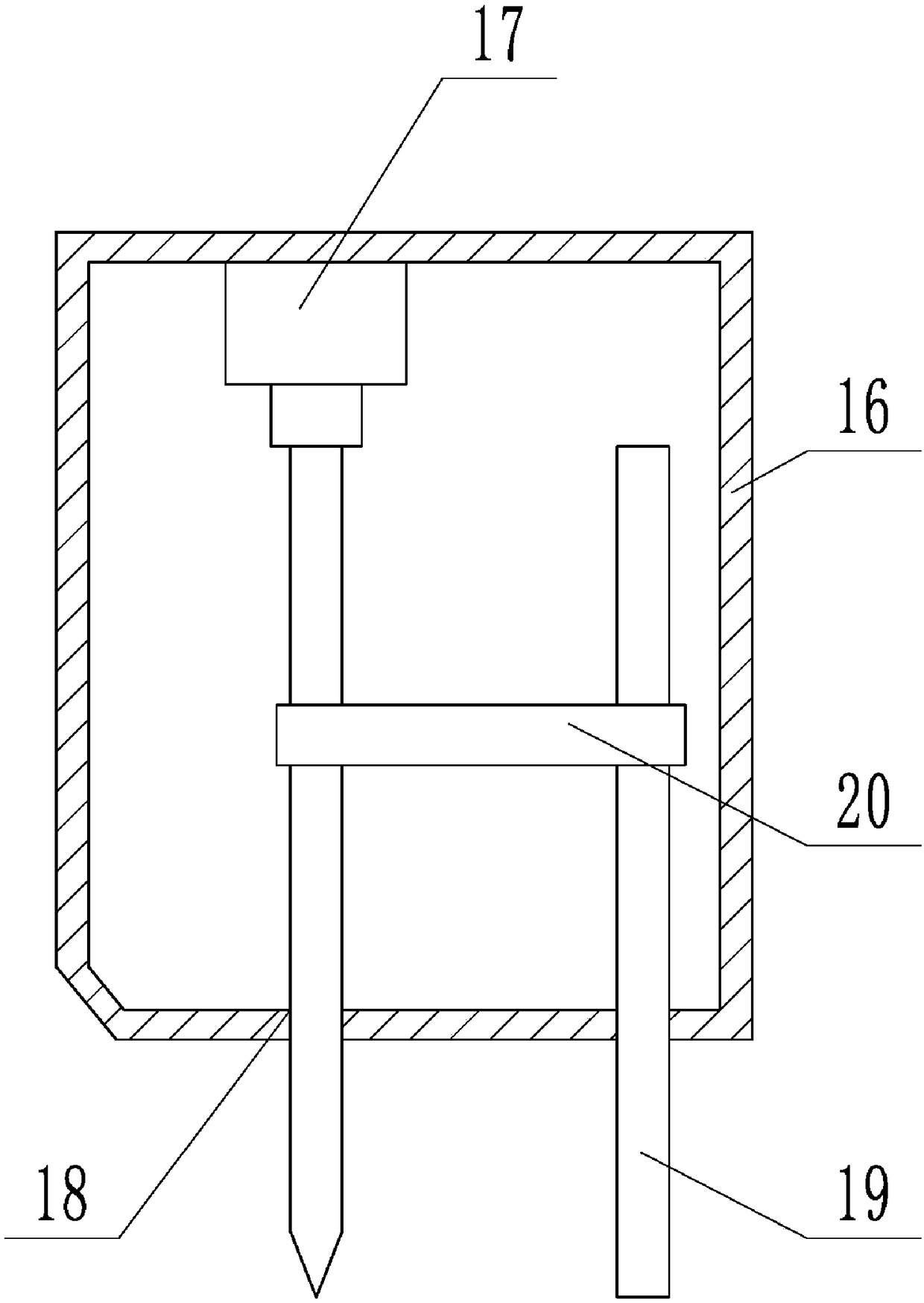

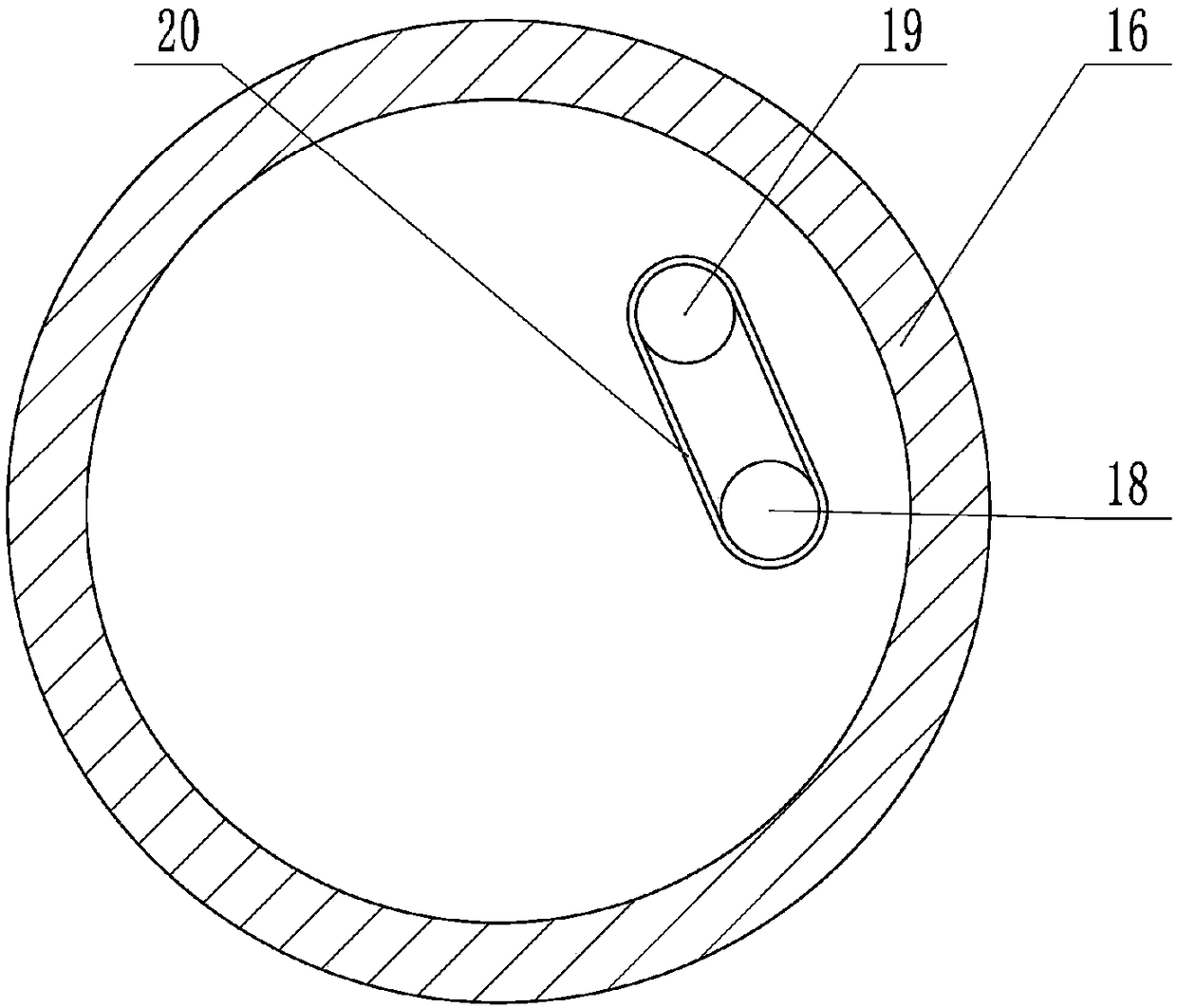

InactiveCN104818990AAvoid destructionHigh degree of automationConstructionsReciprocating drilling machinesEngineeringCave

The invention discloses a cave mining device of finishing-use granite, wherein the cave mining device includes a machine body and a rock drilling mechanism thereon. The machine body includes an outer rack, a movable frame which can move vertically in the outer rack, and a moving bench which is arranged on the movable frame and can move left-and-right. The rock drilling mechanism can move front-and-back along the moving bench. The movements of the movable frame, the moving bench and the rock drilling mechanism are all controlled by a controller. The device is designed for cave mining of rock material, can achieve horizontal mining of rock materials, can avoid damage on vegetation and protect environment, is high in automation degree, and is stable and is accurate in positioning.

Owner:林永强

Punching equipment for belt production

ActiveCN108588299APrevent affecting the punching effectEasy to useLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusArchitectural engineeringPunching

The invention relates to punching equipment, in particular to the punching equipment for belt production. The technical effect of the invention is that the punching equipment for belt production whichsaves time and labor, performs punching evenly, has good punching effect and does not affect the quality of belts is provided. The technical scheme of the punching equipment for belt production is that the punching equipment for belt production comprises a bottom plate and the like, the left side and the right side of the top of the bottom plate are symmetrically provided with support rods, a topplate is installed between the top ends of the left side support rod and the right side support rod, the middle of the bottom of the top plate is provided with a pushing device, a punching device isarranged between the lower portions of the front sides of the left side support rod and the right side support rod, and the punching device is located below the pushing device and is matched with thepushing device. According to the punching equipment for belt production, the belt can be compressed and fixed through fixing devices to prevent the belt from moving in punching to affect the punchingeffect, the right end of the belt can be cut through a cutting device, the belt is made to be more attractive and have better use effect, and the effect of saving time and labor, performing punching evenly, having good punching effect and not affecting the quality of the belts is achieved.

Owner:炳铄联华金属(山东)有限公司

Perforating device of hardware block

InactiveCN108127139AImprove work efficiencyEvenly punchedFeeding apparatusOther manufacturing equipments/toolsEngineeringCam

The invention relates to a perforating device, in particular to a perforating device of a hardware block, and aims at achieving the technical purpose of providing the perforating device of the hardware block high in work efficiency and uniform in perforating and makes holes smooth. To achieve the technical purpose, the perforating device of the hardware block comprises an L-shaped plate, a first spring, a slide block, a slide rail, a first guide wheel, a stay wire, a second guide wheel, an electric push rod, a T-shaped plate, a wire winding cylinder, a cam, a fourth belt pulley, a contact plate, a lifting rod, a movable plate, a first motor, a first rotary shaft, a first connecting belt, a perforating drill, a first bearing base, a second rotary shaft, a first belt pulley, a sand blastingcylinder body and the like, and the slide block and the first guide wheels are arranged at the top in the L-shaped plate. The perforating device has the advantages that the work efficiency is high, perforating is uniform, and the holes are smooth; meanwhile, the perforated holes can be polished and are convenient to use, and scraps on the surface of the hardware block can also be swept.

Owner:ANHUI ZHONG XIN MOLD IND DEV CO LTD

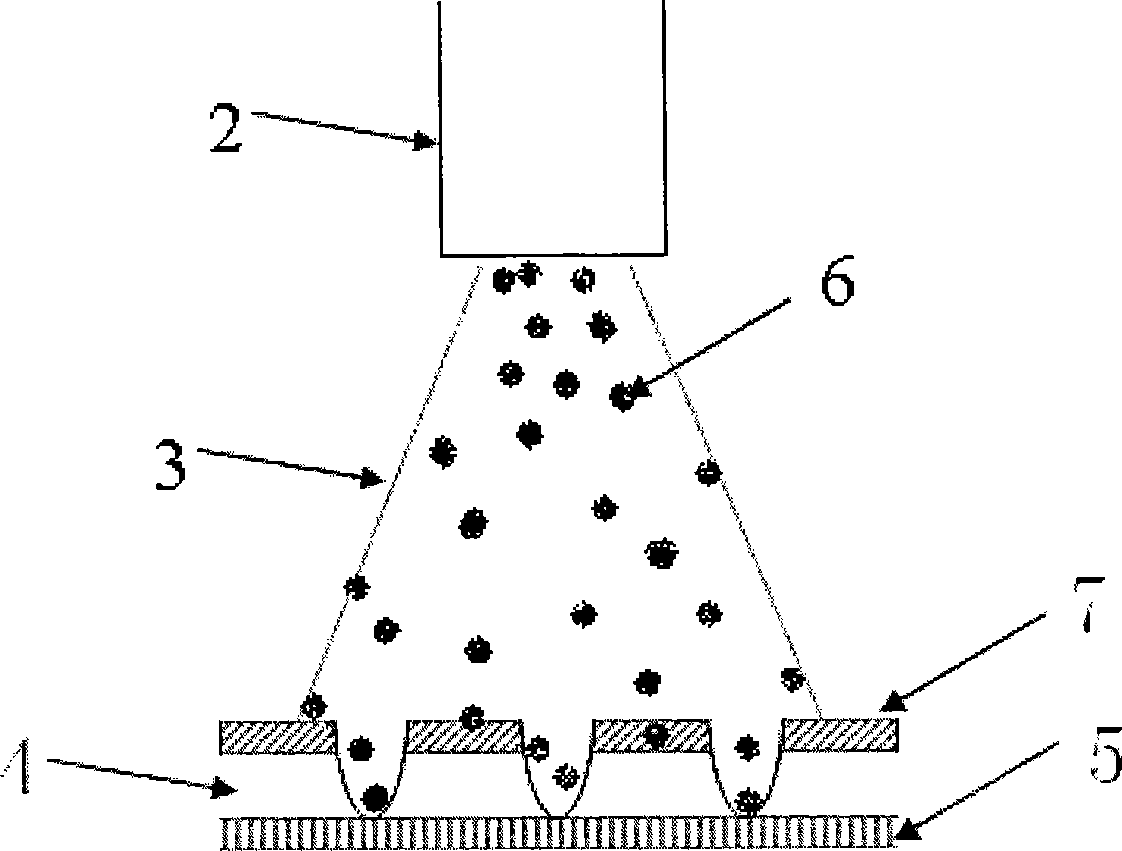

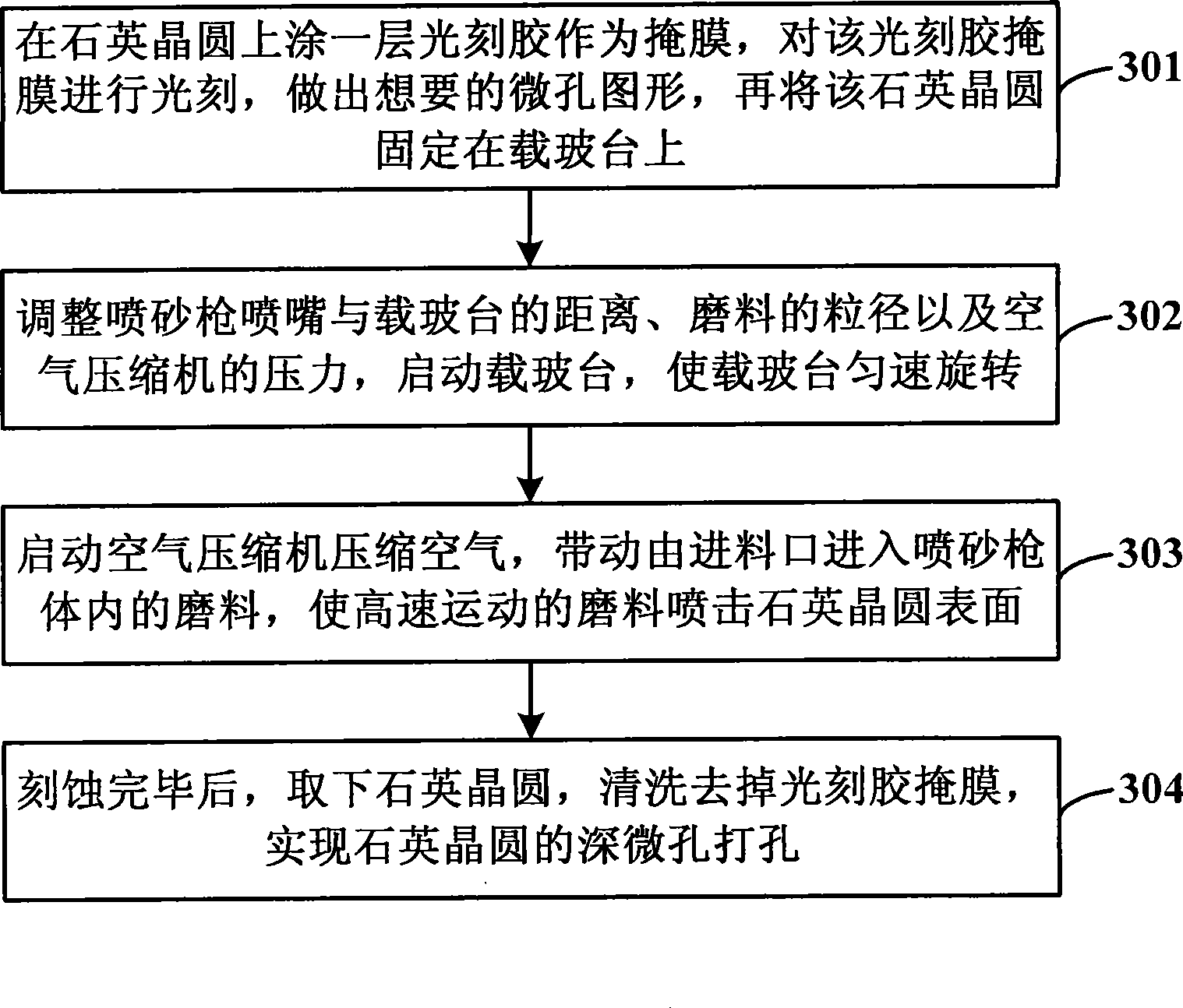

Quartz wafer deep micropore processing equipment and method

InactiveCN101450788ASolve unsolvable problemsImplementation problemsSemi-permeable membranesPhotomechanical exposure apparatusSand blastingEngineering

The invention discloses a device for machining quartz-wafer round deep micropores. The device comprises an air compressor, a sand blasting gun and a glass loading table, wherein the compressor is connected with the sand blasting gun, and the compressor conveys high-compression air to the sand blasting gun, so that abrasive in the sand blasting gun is spouted onto a quartz wafer placed on the glass loading table at a high speed; and a deep micropore is machined on the quartz wafer by utilizing the abrasive in high-speed movement to impact quartz material. The invention simultaneously discloses a deep-micropore machining method for the quartz wafer. By utilizing the invention, the disadvantage that laser can not perforate transparent materials, as well as a series of problems of ion perforation charge, incapability of machining deep micropores and the like, is solved, and deep micropore manufacture on quartz is realized. The device has the advantages of simplicity, implementation easiness, low cost, high etching speed and capability of batch production.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

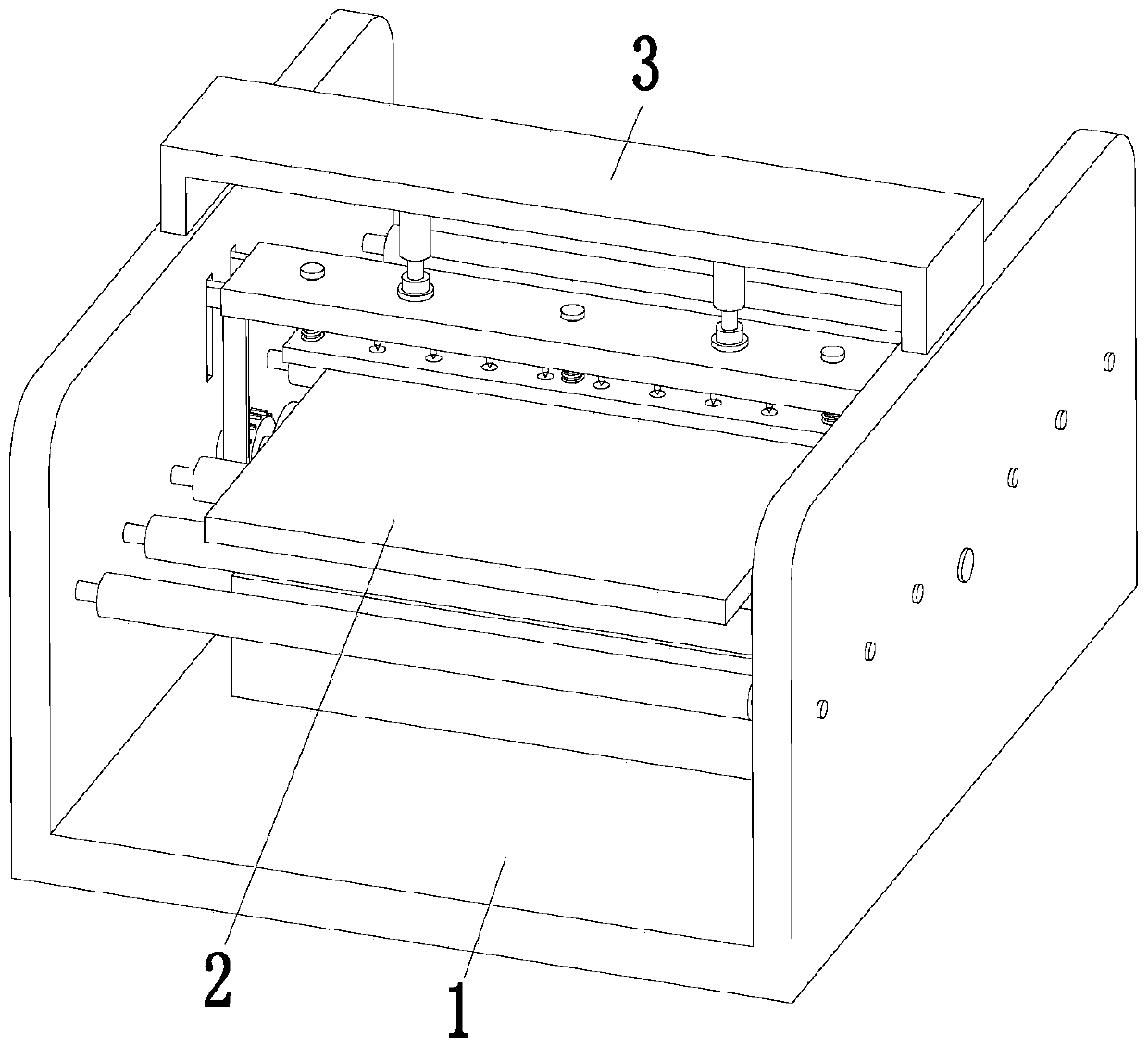

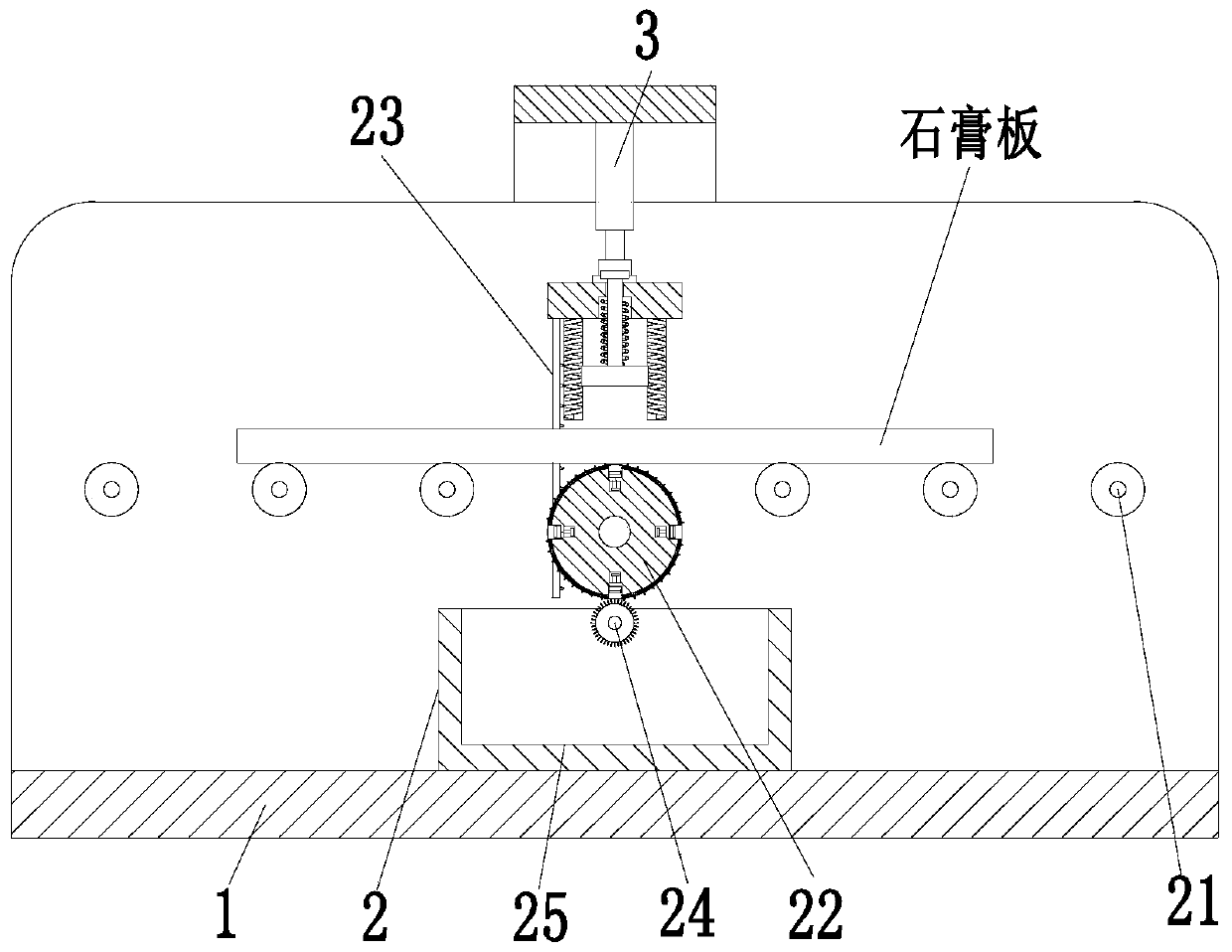

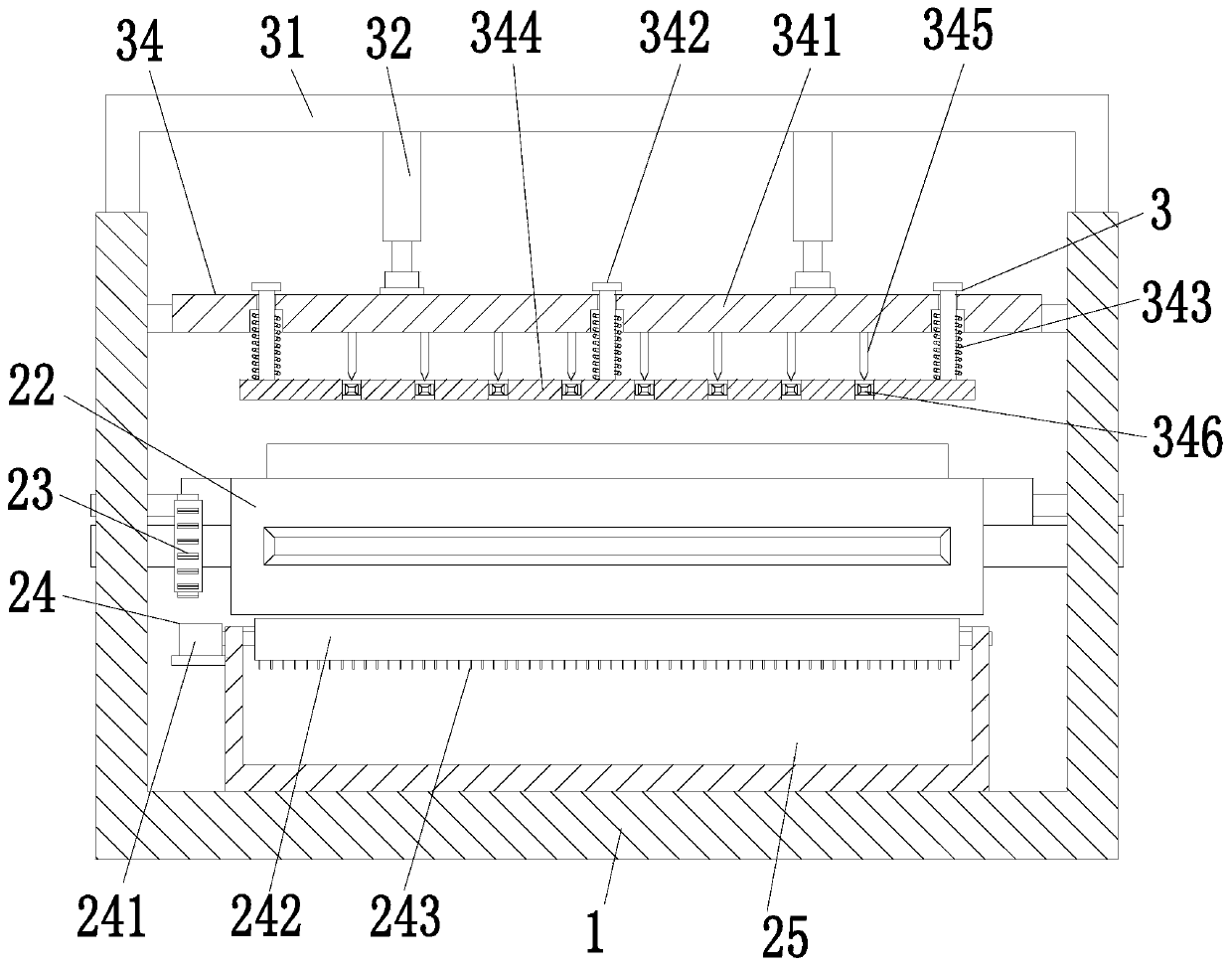

Sound absorption gypsum board positional punching machining machine and machining method

ActiveCN110861223AAffect processing efficiencyAvoid pollutionWorking accessoriesStone-like material working toolsThermodynamicsPunching

The invention relates to a sound absorption gypsum board positional punching machining machine and a machining method. The sound absorption gypsum board positional punching machining machine comprisesa supporting frame, a collecting device and a punching device. The supporting frame is of a U-shaped structure, and the collecting device is mounted at the lower end in the supporting frame. The punching device is arranged above the collecting device and mounted on the supporting frame. According to the sound absorption gypsum board positional punching machining machine and the machining method,the problems that when a gypsum board is punched through existing equipment, a large amount of gypsum dust is usually attached to the outer surface of a punching needle, the gypsum dust cannot be fastremoved, and consequently the punching precision of the gypsum board is influenced by the gypsum dust, and environmental pollution is likely to be caused; and meanwhile when the gypsum board is punched, punching materials generated during punching cannot be fast discharged, the gypsum dust is inconvenient to collect, and the machining efficiency of the gypsum board is influenced can be solved.

Owner:深圳市光济建设工程有限公司

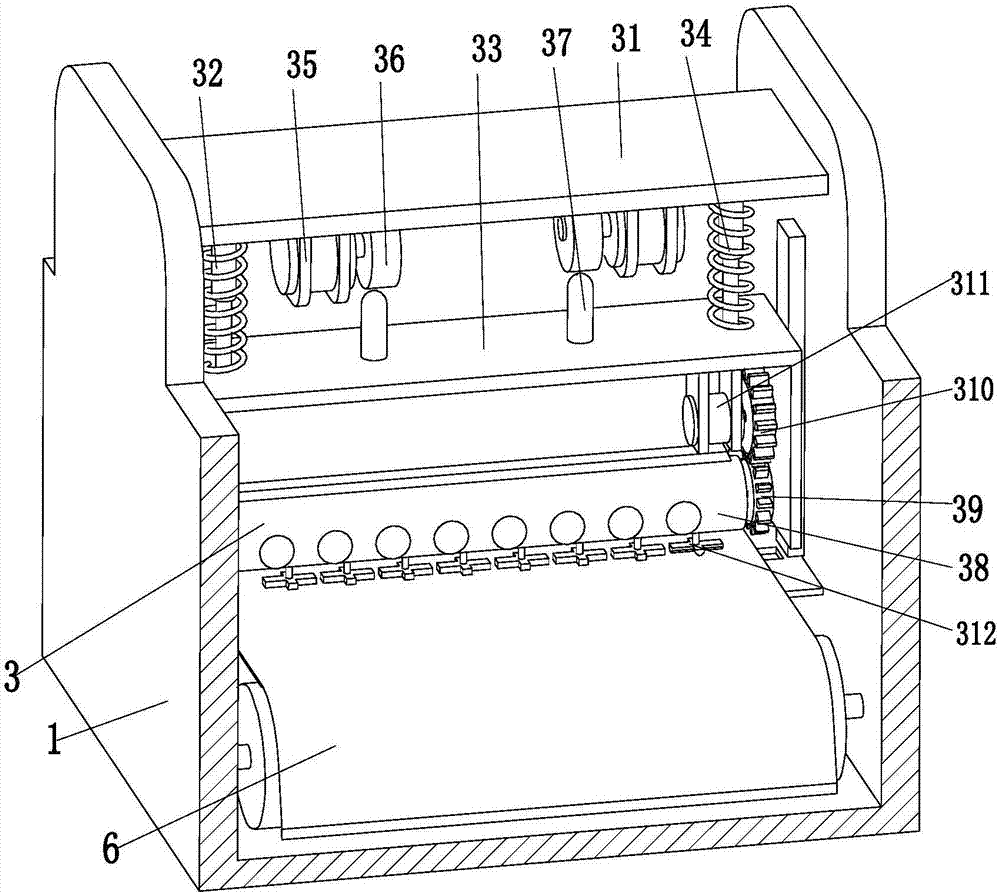

Automatic magnetic powder punching device

InactiveCN104400826AReduce labor costsEvenly punchedMetal working apparatusFiber optic sensorMagnetic powder

The invention relates to the field of electronic element material preparation, in particular to an automatic magnetic powder punching device. The automatic magnetic powder punching device comprises a transmission belt, a fixing frame, a power air cylinder and a punching disc; the fixing frame which is a door-shaped frame is arranged on the conveying belt; the power air cylinder is fixed on a cross beam of the fixing frame; the punching disc is fixedly connected with an extensible rod of the power air cylinder; the punching disc comprises a disc surface and a punching rod; the disc surface is provided with a plurality of isometric array installation holes; the punching rod penetrate the installation holes and can relatively slide; the punching rod and the disc surface are fixedly connected through a spring; the end portion of the punching rod is provided with a cross punching head; a vertical pile of the fixing frame is provided with an optical fiber sensor which is used for detecting a mineral powder box. The automatic magnetic powder punching device has the advantages of achieving automatic loosening of mineral powder, saving manual costs, being uniform in punching and not easy to collapse, enabling the mineral powder to be fully oxidized during roasting and achieving the product percent of pass.

Owner:CHONGQING KUGEER ELECTRONICS

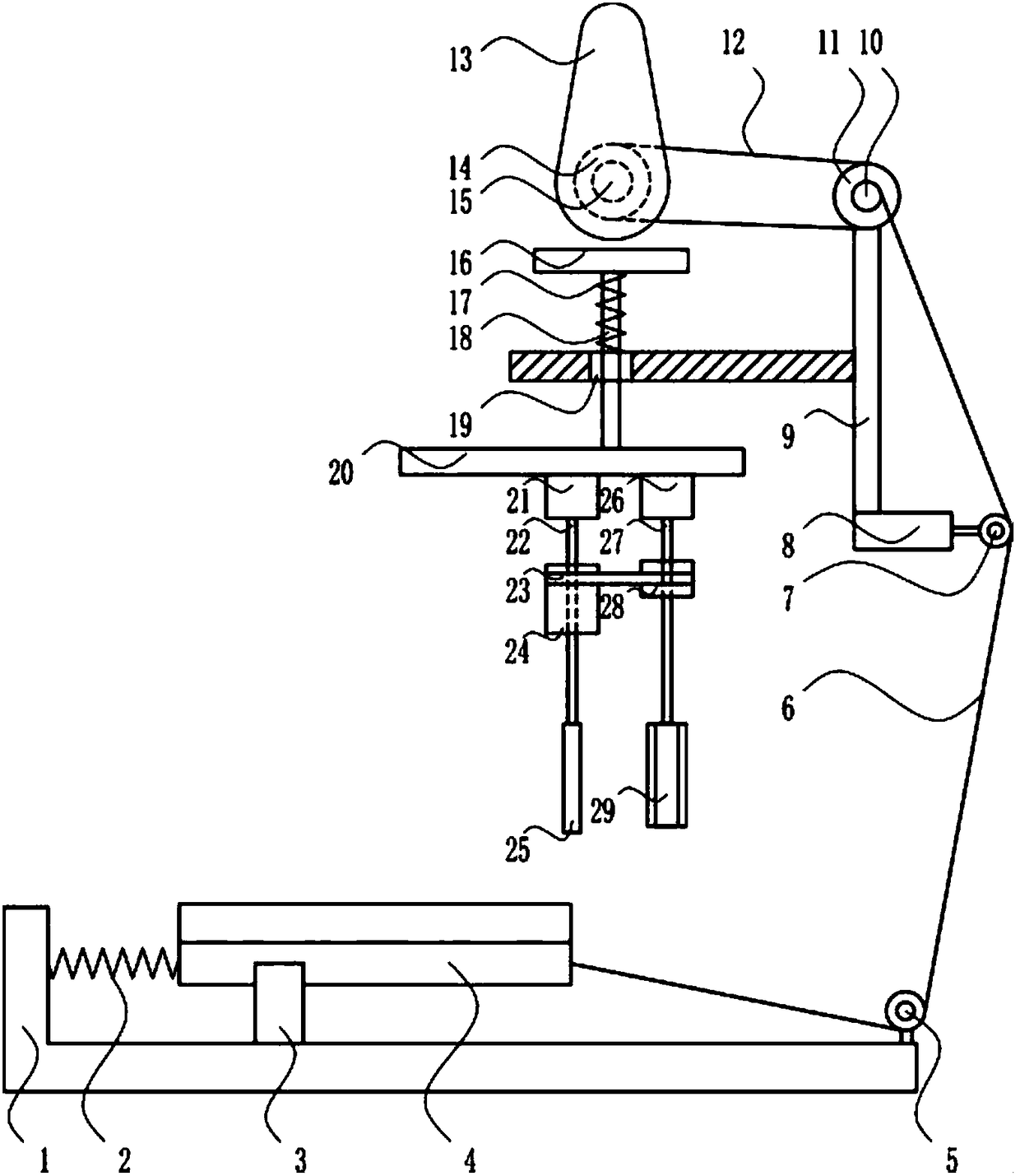

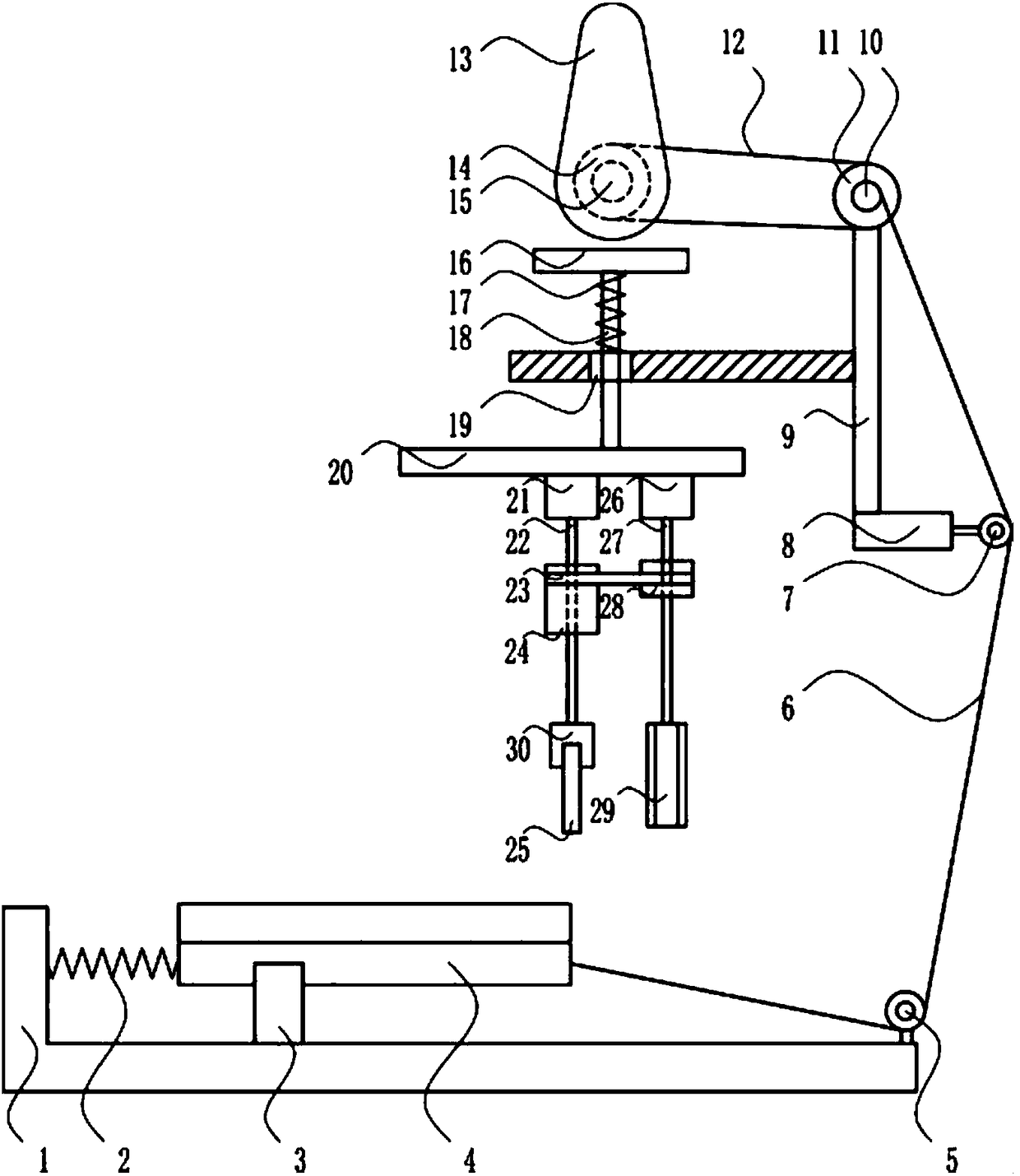

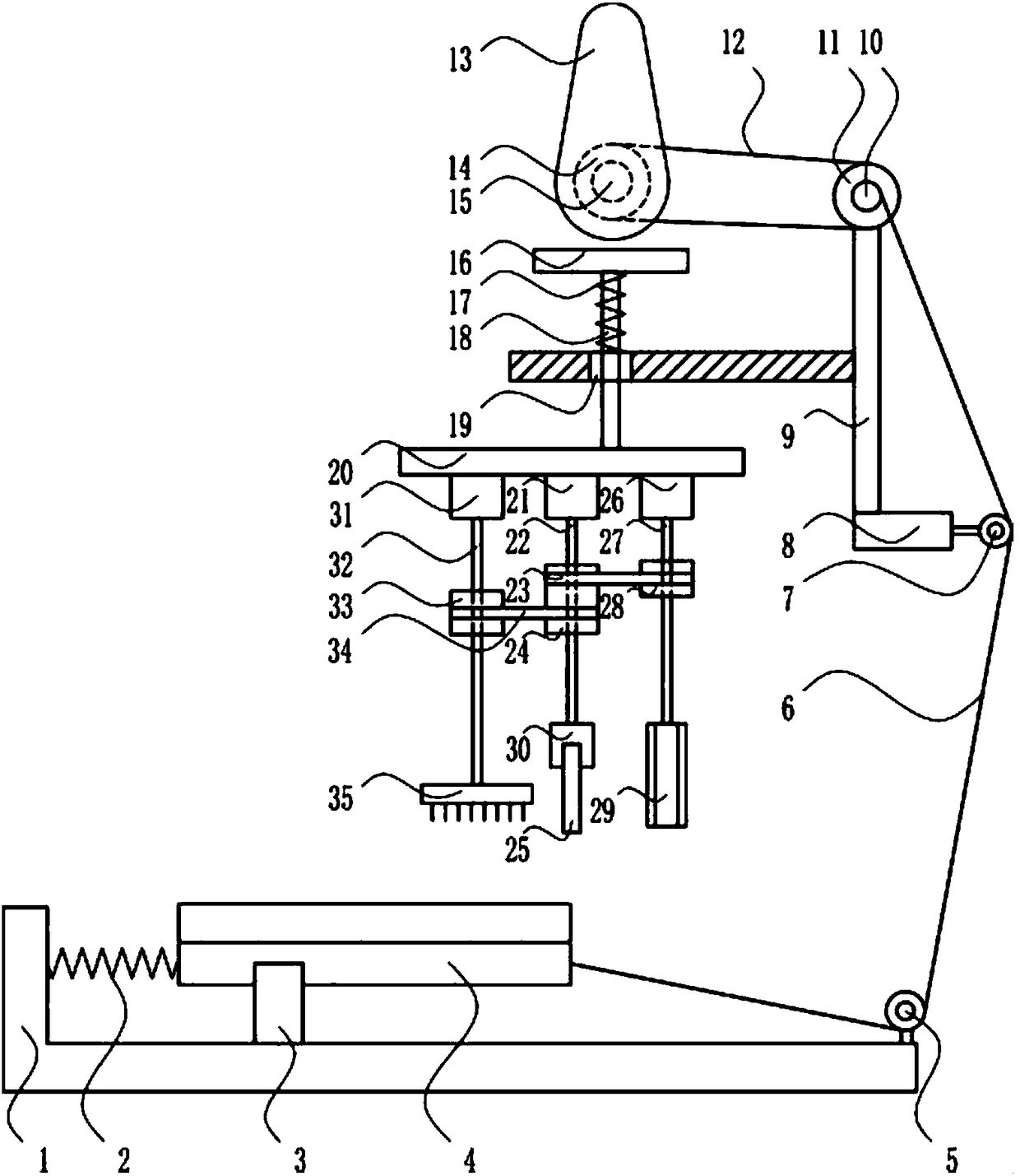

Wood stick punching equipment for furniture production

InactiveCN112192669AAchieve fixationEvenly punchedStationary drilling machinesPunchingIndustrial engineering

The invention relates to wood stick punching equipment, and in particular relates to wood stick punching equipment for furniture production. The technical problem to be solved by the invention is to provide the wooden stick punching equipment for furniture production, which is safer to operate by people and more uniform in punching of wooden sticks. In order to solve the technical problem, the invention provides the wood stick punching equipment for furniture production that comprises at least two placing frames, connected to a base plate; at least two baffles, connected to the placing frames;a sliding mechanism, connected to one side of the bottom plate in a sliding manner; and a punching mechanism, connected to the sliding mechanism. Under the action of the sliding mechanism and the punching mechanism, a wood stick can be rapidly and uniformly punched, and the people are prevented from being scalded by high-temperature wood chips.

Owner:吴小冬

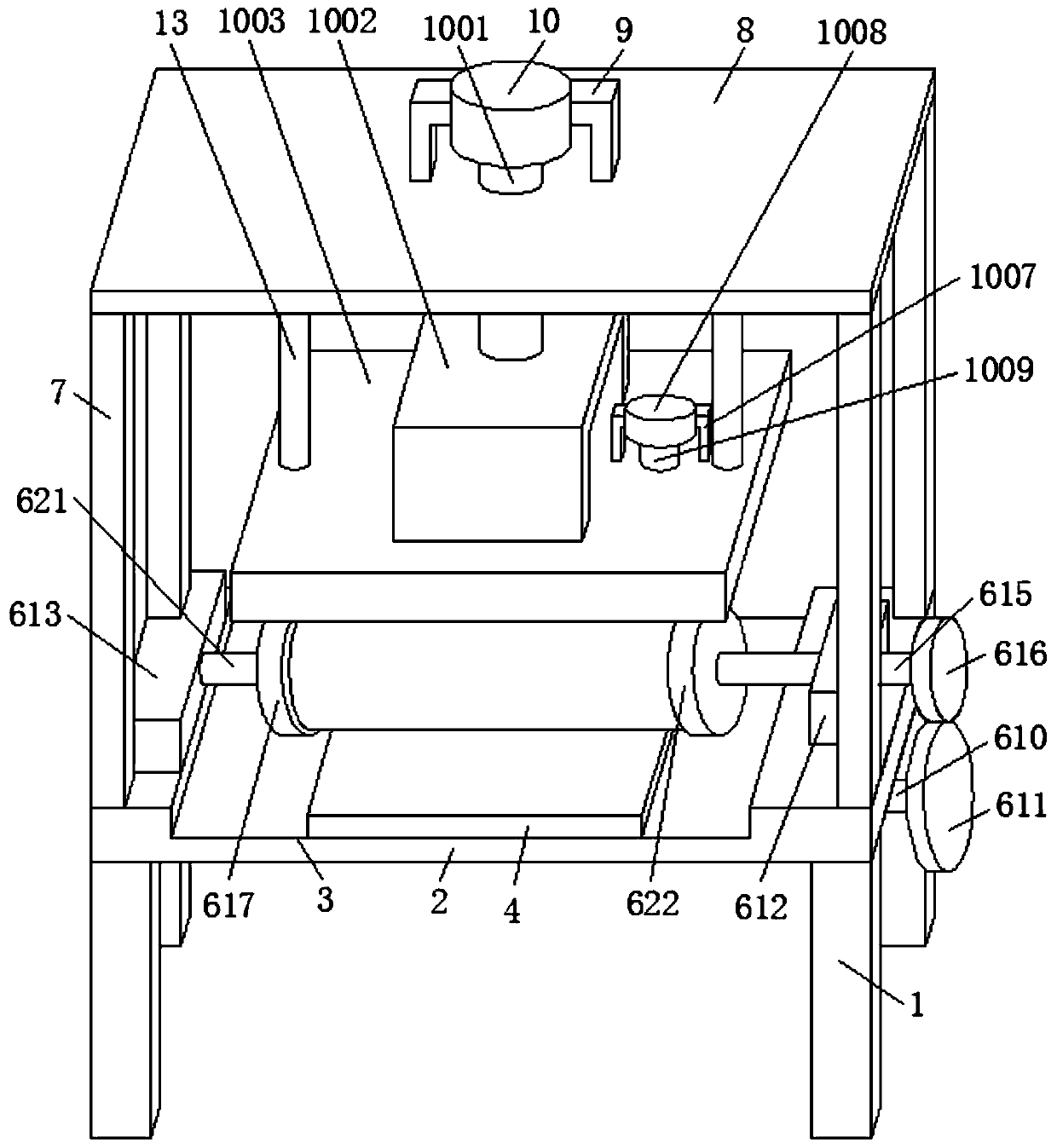

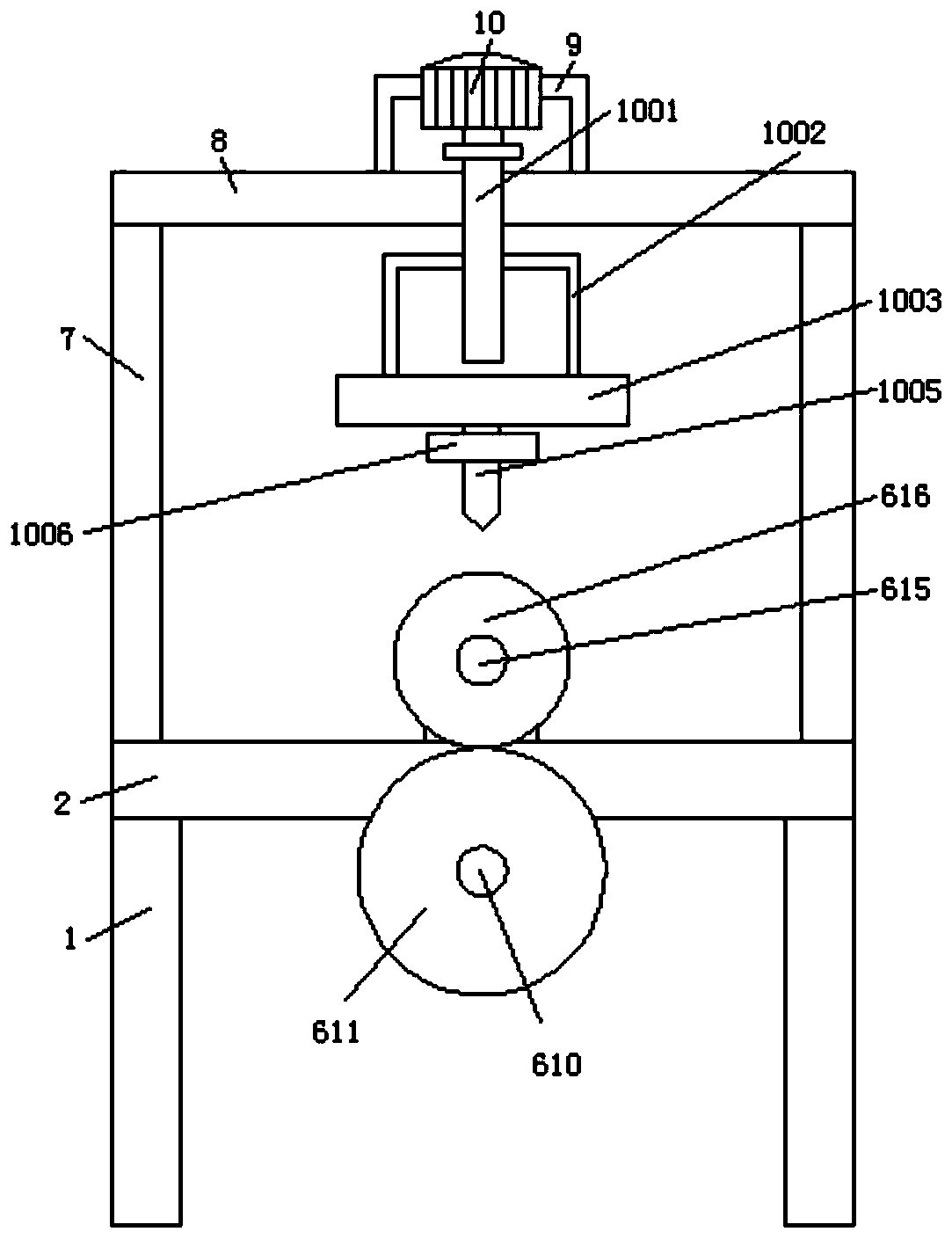

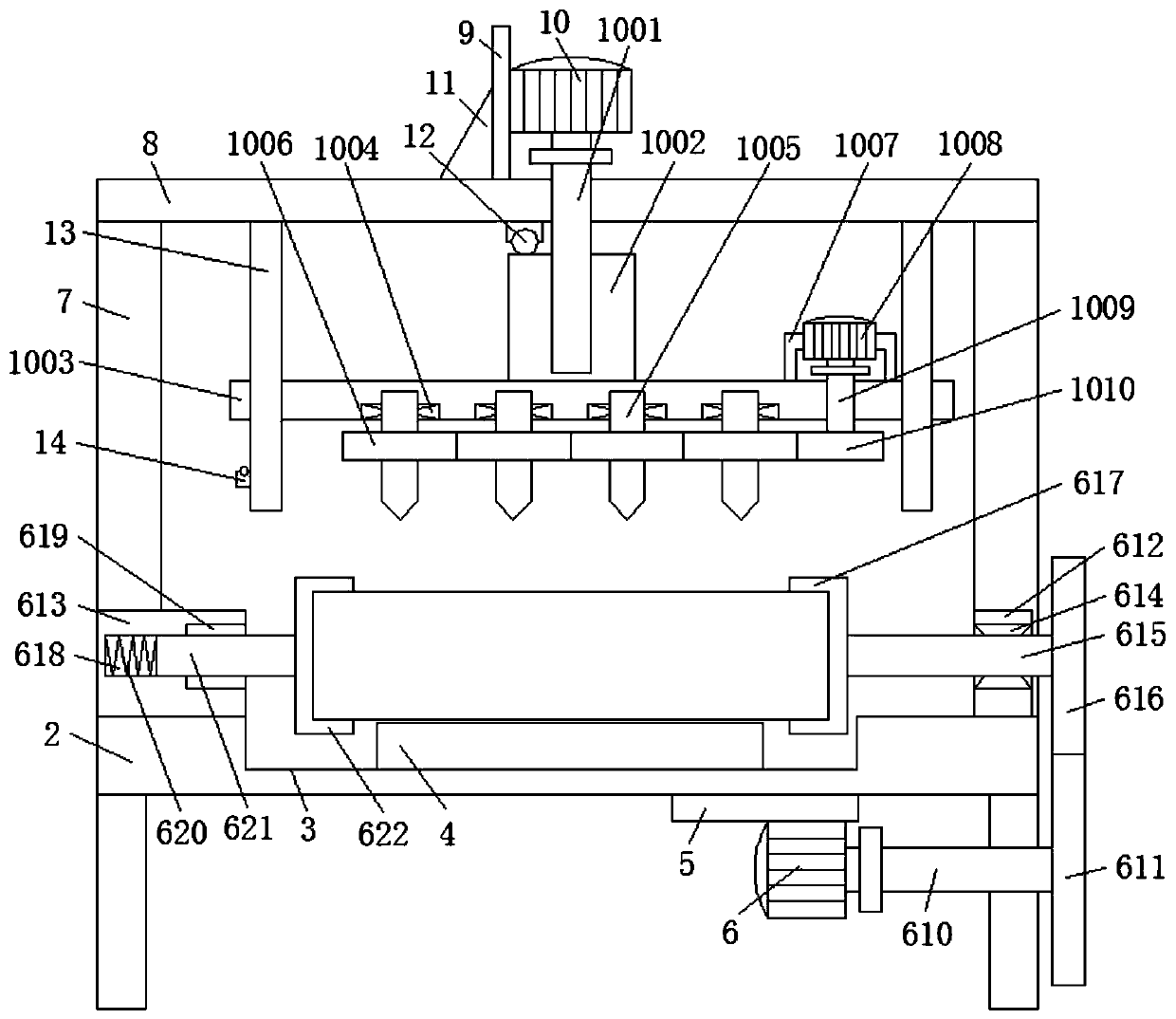

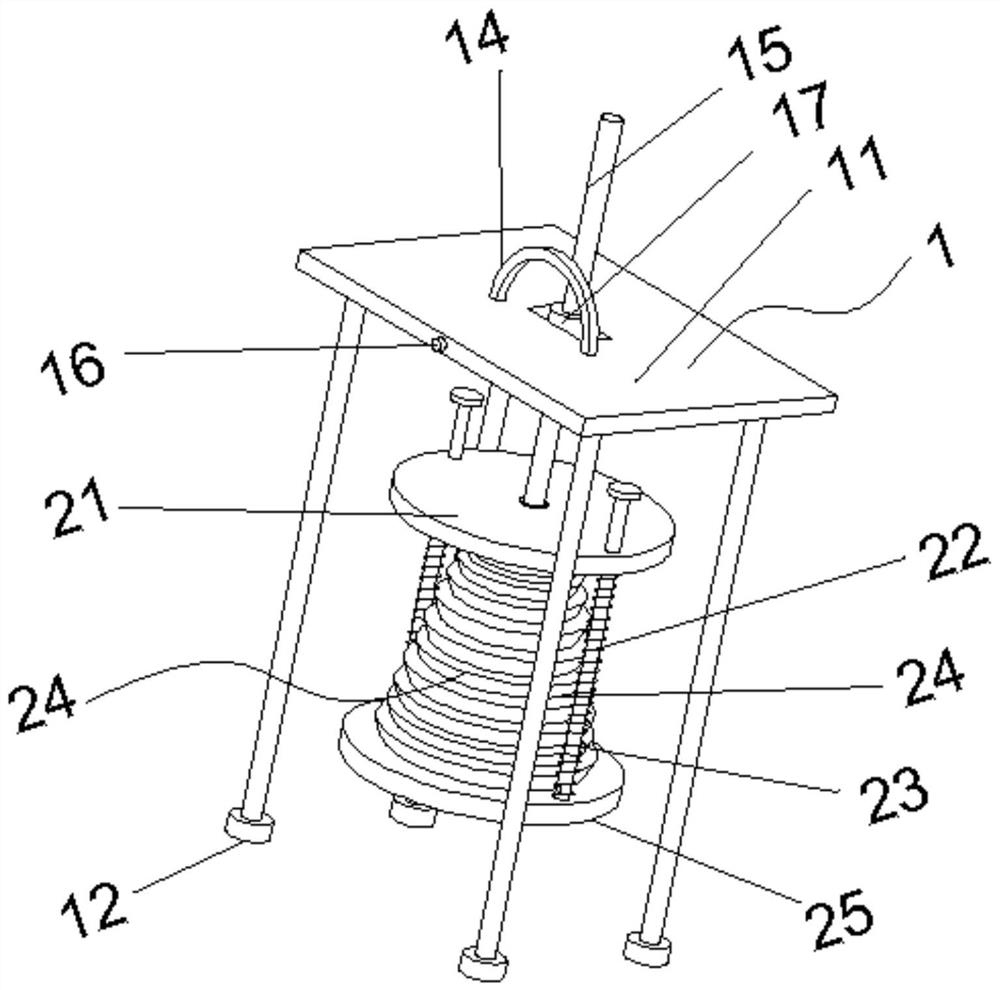

Strain cultivation auto-perforating device for mushroom stick molds

InactiveCN110720351AEvenly punchedAvoid pollutionCultivating equipmentsMushroom cultivationElectric machineryEngineering

The invention belongs to the technical field of mushroom equipment and particularly relates to a strain cultivation auto-perforating device for mushroom stick molds, comprising four support legs. Theupper surfaces of the four support legs are fixedly connected with a bottom plate; the upper surface of the bottom plate is provided with a fixing cavity; the inner bottom wall of the fixing cavity isfixedly connected with a carrier plate; the upper surface of the bottom plate is provided with a rotating device that comprises a first motor base plate; the upper surface of the first motor base plate is fixedly connected with the lower surface of the bottom plate; a first motor is fixedly connected to the lower surface of the first motor base plate; fixing posts are fixedly connected to the surfaces of four corner of the bottom plate; and the top ends of the four fixing posts are fixedly connected with a top plate. The rotating device is arranged on the upper surface of the bottom plate inthe strain cultivation auto-perforating device for mushroom stick molds, the rotating device comprises the first motor base plate, the upper surface of the first motor base plate is fixedly connectedwith the lower surface of the bottom plate, and therefore, the circumference of a whole fungus stick is uniformly and fully perforated.

Owner:屈年宝

Modified shell punching die

The invention provides a modified shell punching die. A shell blank is laid on the upper surface of a die bottom block, positioned and heated to be softened, an upper die body punches downwards, a puncher pin drives the die bottom block to move downwards at first, when the die bottom block makes contact with a die wall bottom plate, the die bottom block exactly fits with die wall blocks, and the die bottom block and the die wall blocks are spliced into a complete female die. The puncher pin abuts against a first layer and a second layer to continue to move downwards so as to compress first springs and second springs, and turnup edges of the shell blank are formed; when the puncher pin decreases to a certain degree, the die wall bottom plate pushes a die frame bottom plate to drive a die frame block to move downwards along a vertical block, the die frame block drives a sliding block to move downwards by the aid of an inclined block, and meanwhile, the sliding block moves inwards through a guide rail by the aid of inward horizontal thrust of the inclined block; and when a slender neck part corresponds to the sliding block, the turnup edges of the shell blank are ejected into the slender neck part through the sliding block by means of a step between an end socket and the slender neck part, and reverse coating edges are formed. The modified shell punching die can smoothly and efficiently form the reverse coating edges of a shell, and is novel and reasonable in structure and high in practicability.

Owner:FUJIAN HUAKE MOLD TECH

Punching component

The invention discloses a punching component which comprises a mounting bracket, and a punching bracket fixed on the mounting bracket. A guide rod is vertically arranged on the punching bracket; a connecting plate which is conducted to a driving source and can move longitudinally along the guide rod and a male die seat fixed below the connecting plate are horizontally sleeved on the guide rod; a male die is arranged in the male die seat; a hold down block which moves longitudinally relative to the male die seat is arranged below the male die seat; the male die extends out the lower part of the hold down block; and a female die seat is positioned below the male die and matched with the male die. The punching component can adopt the hold down block to hold down a work piece to be machined before punching, ensures that the elongate and elastic work piece to be machined can be properly jointed with a positioning surface of an operating platform, so as to ensure that a product can be smoothly punched, guarantees the punching quality and punching stability, reduces the labor intensity, simultaneously adopts detection measures, such as a detection pin, a switch and the like, can effectively prevent stagnancy, avoids omission caused by manual detection, and can further improve the production efficiency and reduce the production cost.

Owner:NINGBO XINTAI MACHINERY

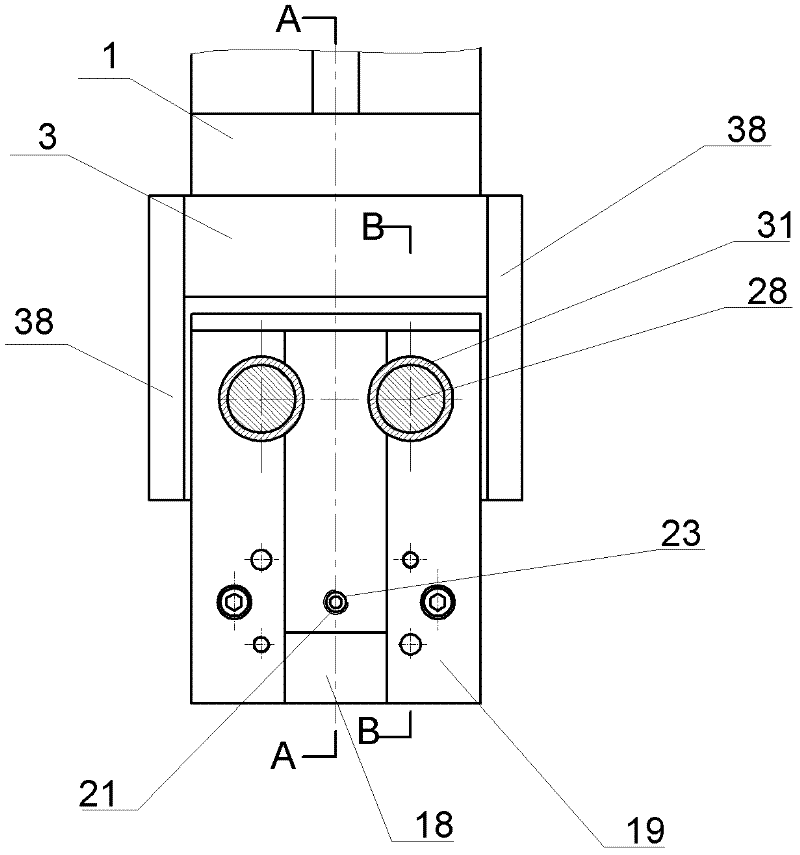

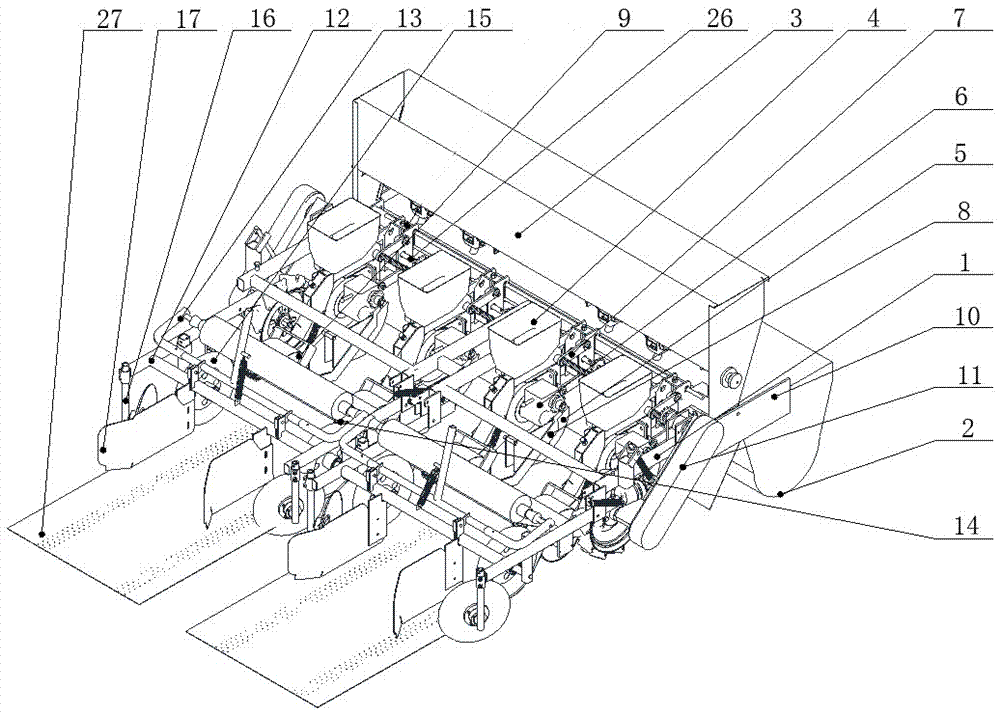

Corn rotary tillage film mulching precision seeder of planting under film and free putting seedling

InactiveCN107493707AAchieving membrane ruptureEvenly punchedSpadesPlantingPunchingAgricultural engineering

The invention relates a corn rotary tillage film mulching precision seeder of planting under film and free putting seedling, a film mulching device rack is hinged on the rear of the seeder rack, a film hanging device is hinged with a film mulching device, and a punching device, a film pressing wheel, a second soil coverer and a clean-up scraper are respectively connected with the film mulching device rack; the punching device includes a shaft, a steel tube, nails and a connecting plate which is connected to both sides of the film mulching device rack, wherein the steel tube is fixed on a circumferential surface of the shaft, a rubber layer is arranged on the outer surface of the steel tube, and nail roots are fixed to the steel tube and run through the rubber layer so that nail tips are higher than a surface of the rubber layer; the nail tips of the punching device contact with the film. In the planting method of achieving corn rotary tillage precision planting under film with free putting seedlings, evenly punching is performed on the seedbed area of the film through a punching mechanism, so that the film is permeable to air and water and seeds can achieve their own rupture of the film and emergence with free putting seedling. Planting requirements of film mulching or non-mulching is satisfied, and duplex operation can be carried out in both cultivated land and uncultivated land.

Owner:山西省农业机械化科学研究院

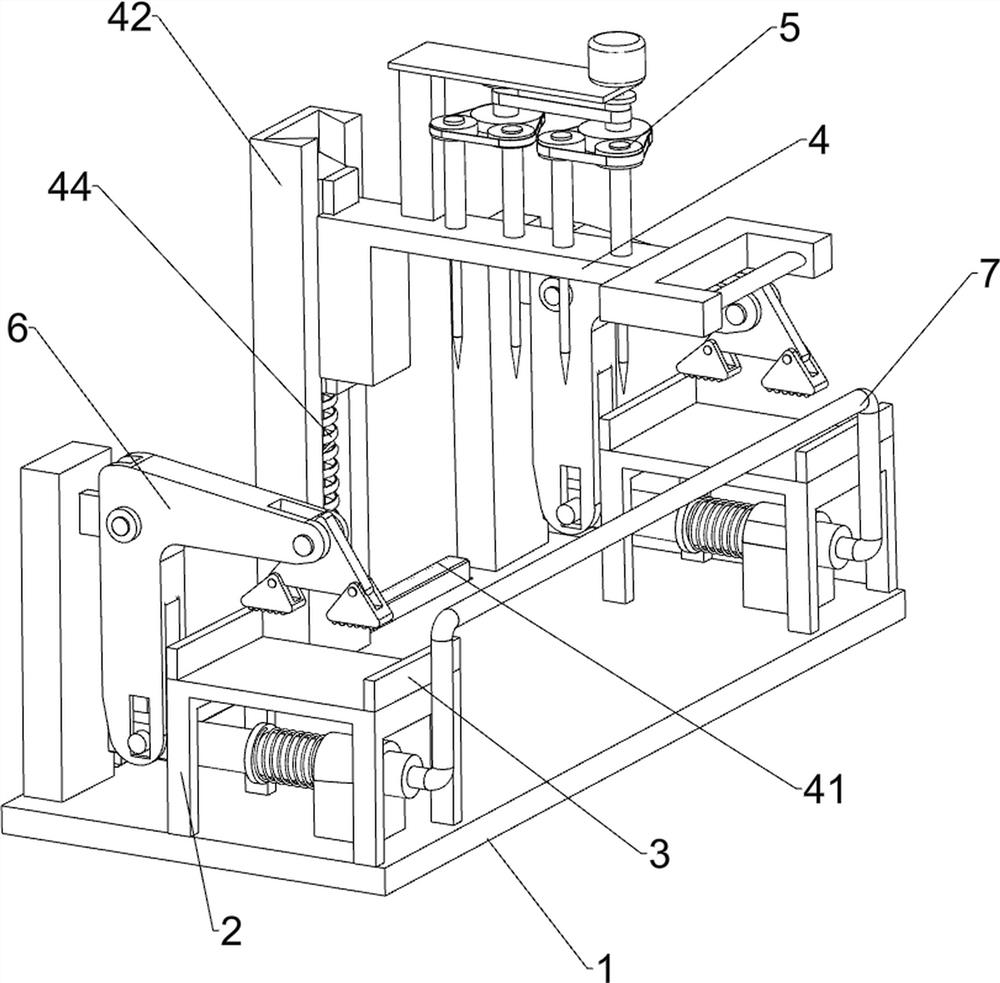

Leather perforating equipment for producing leather shoes

ActiveCN108004353APrevent fallingDoes not affect the effect of subsequent useLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusEngineeringOperating table

The invention relates to perforating equipment, in particular to leather perforating equipment for producing leather shoes. The leather perforating equipment for producing the leather shoes aims at achieving the technical effects that the perforating speed is high, perforating is conducted uniformly, and subsequent use of leather is not affected. The leather perforating equipment for producing theleather shoes comprises an operating table and the like. Vertical plates are symmetrically mounted at the left side and the right side of the top of the operating table. A moving device is arranged between the upper portion of the vertical plate at the left side and the upper portion of the vertical plate at the right side. An ascending-and-descending device is arranged between the middle of thevertical plate at the left side and the middle of the vertical plate at the right side. The ascending-and-descending device is connected with the moving device. A perforating head is connected to an ascending-and-descending component of the ascending-and-descending device and located above the operating table. According to the leather perforating equipment, by means of a clearing-away device, theresidual leather in the perforating head can be cleared away, and leather perforating conducted through the perforating head is not affected; by means of a storage base, an operator can place the leather on the operating table better; and the effects that the perforating speed is high, perforating is conducted uniformly, and subsequent use of the leather is not affected are achieved.

Owner:广东辛迪丹顿鞋业有限公司

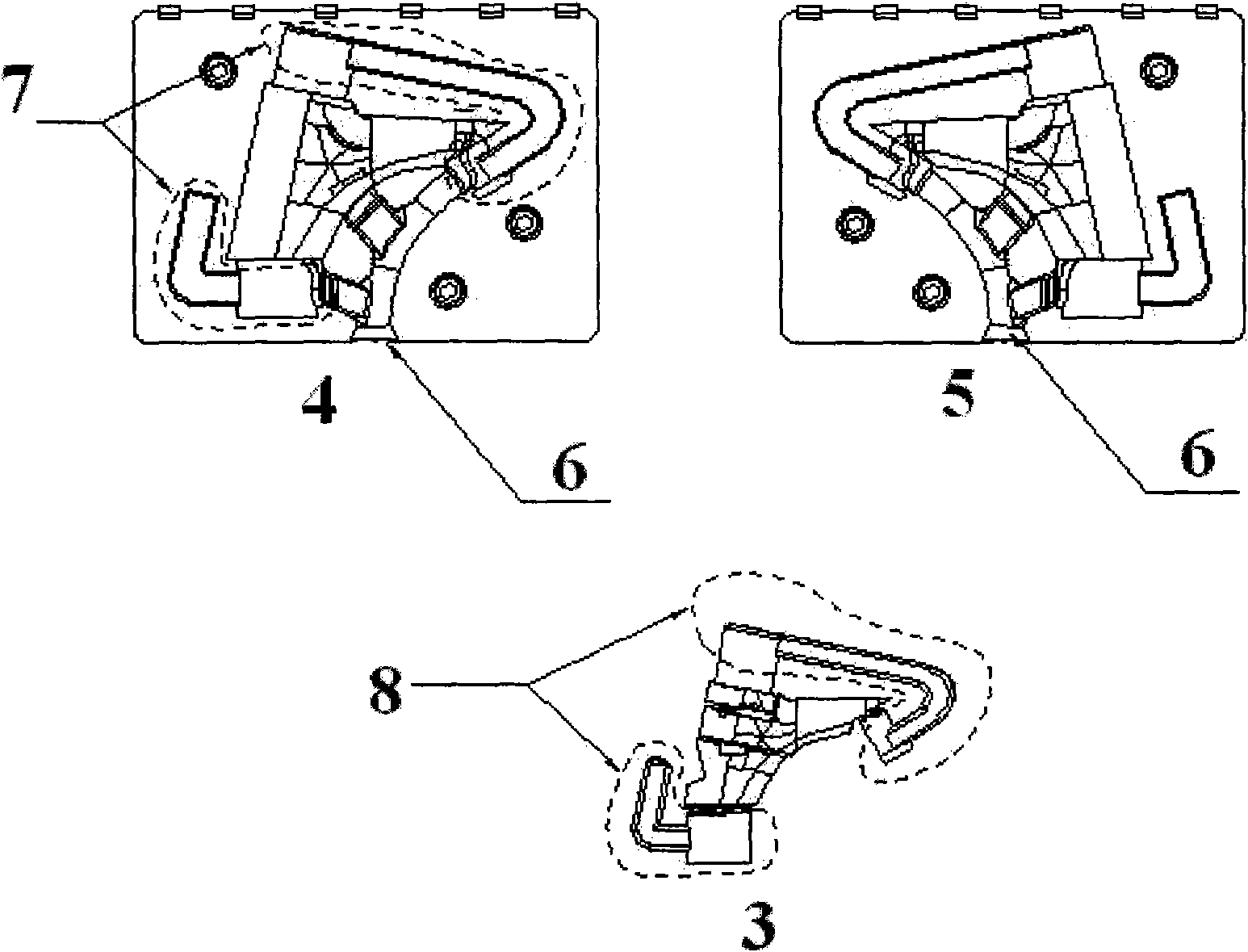

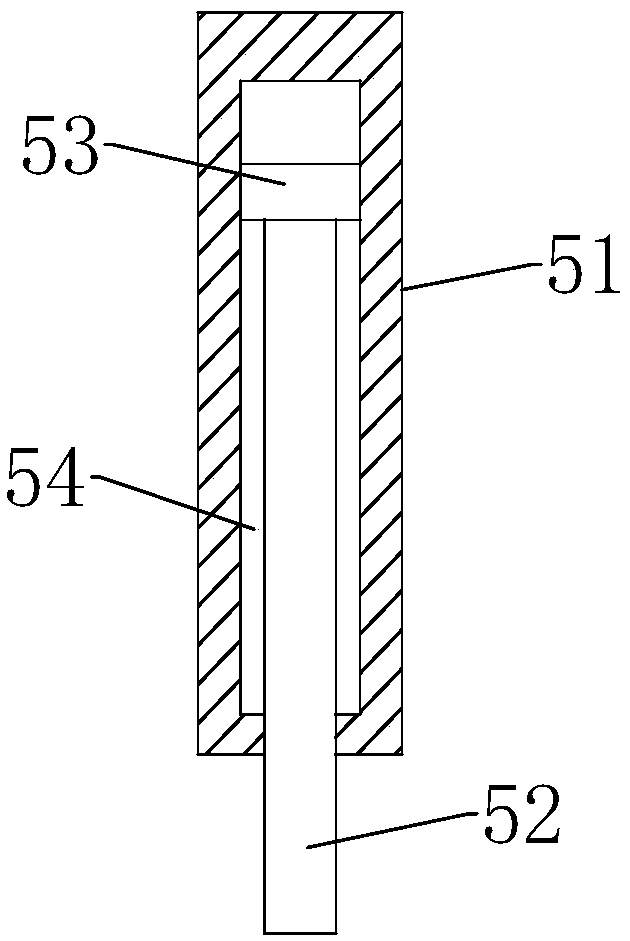

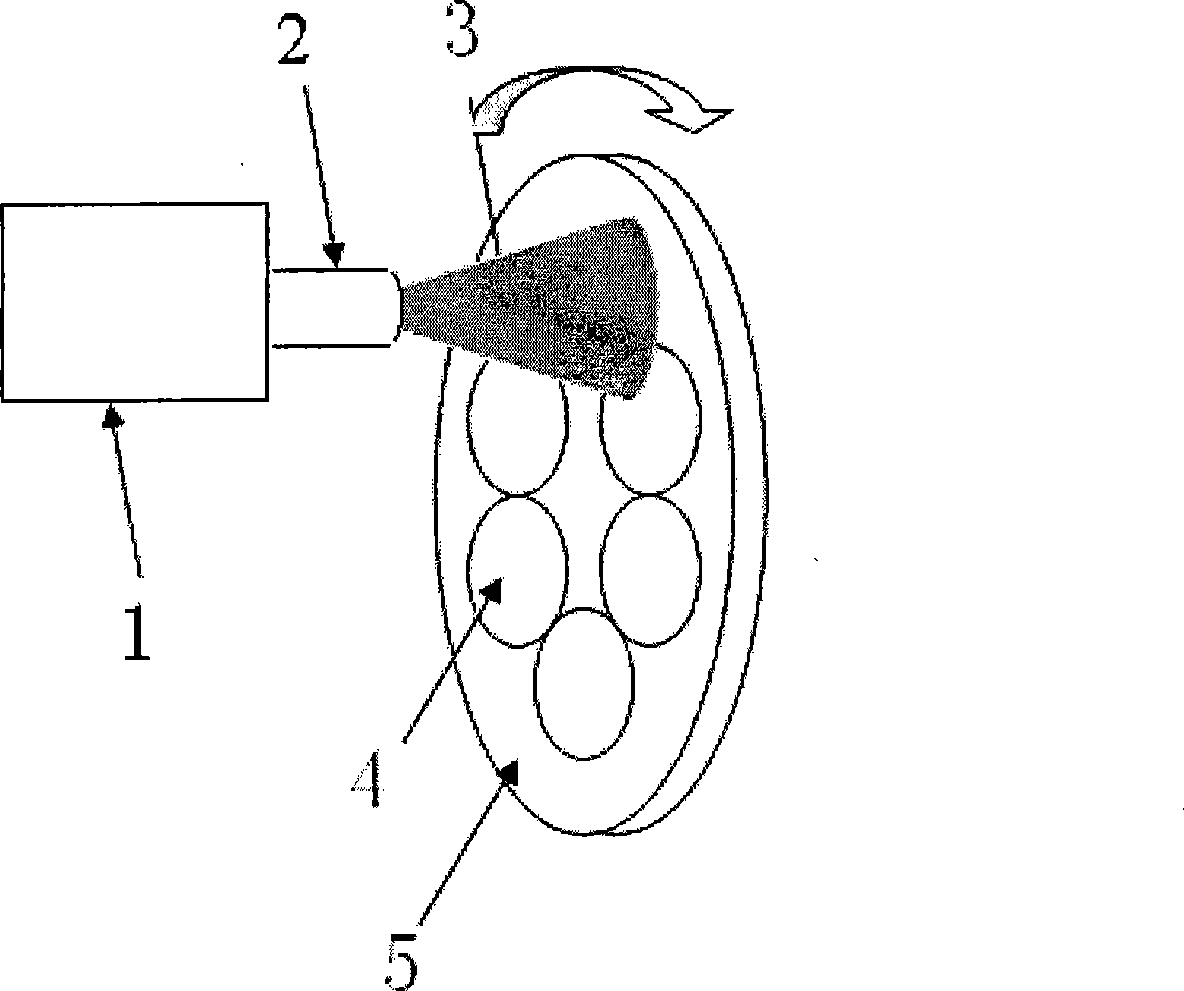

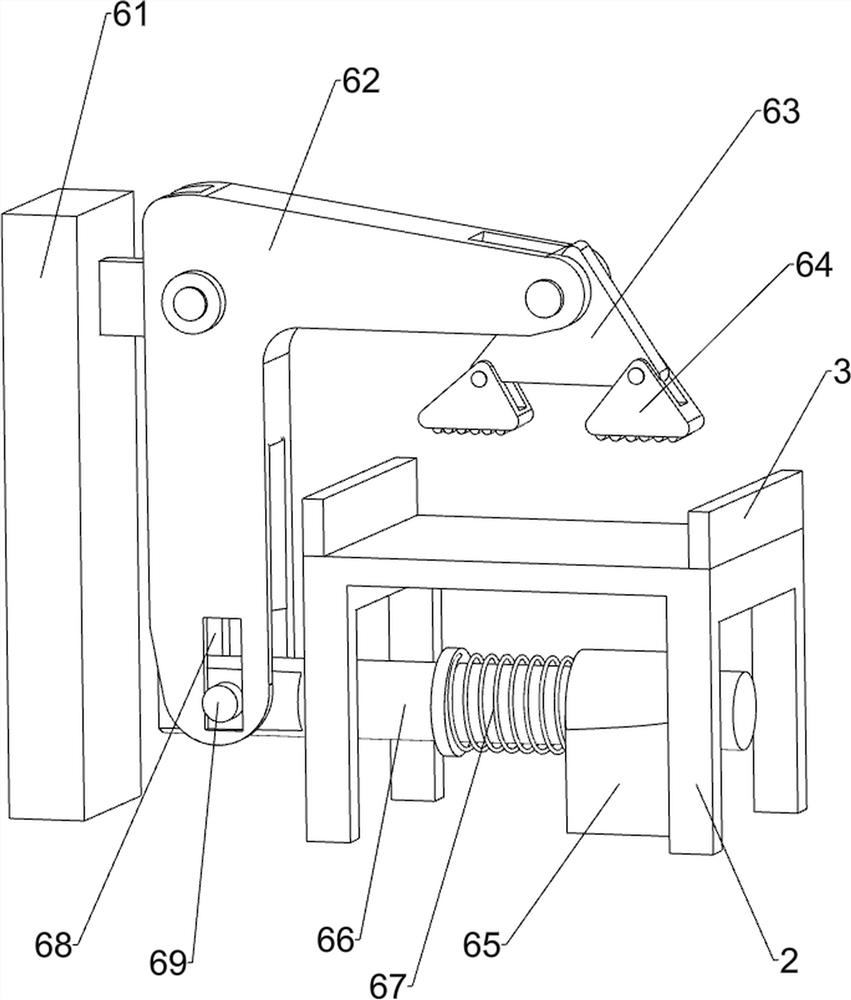

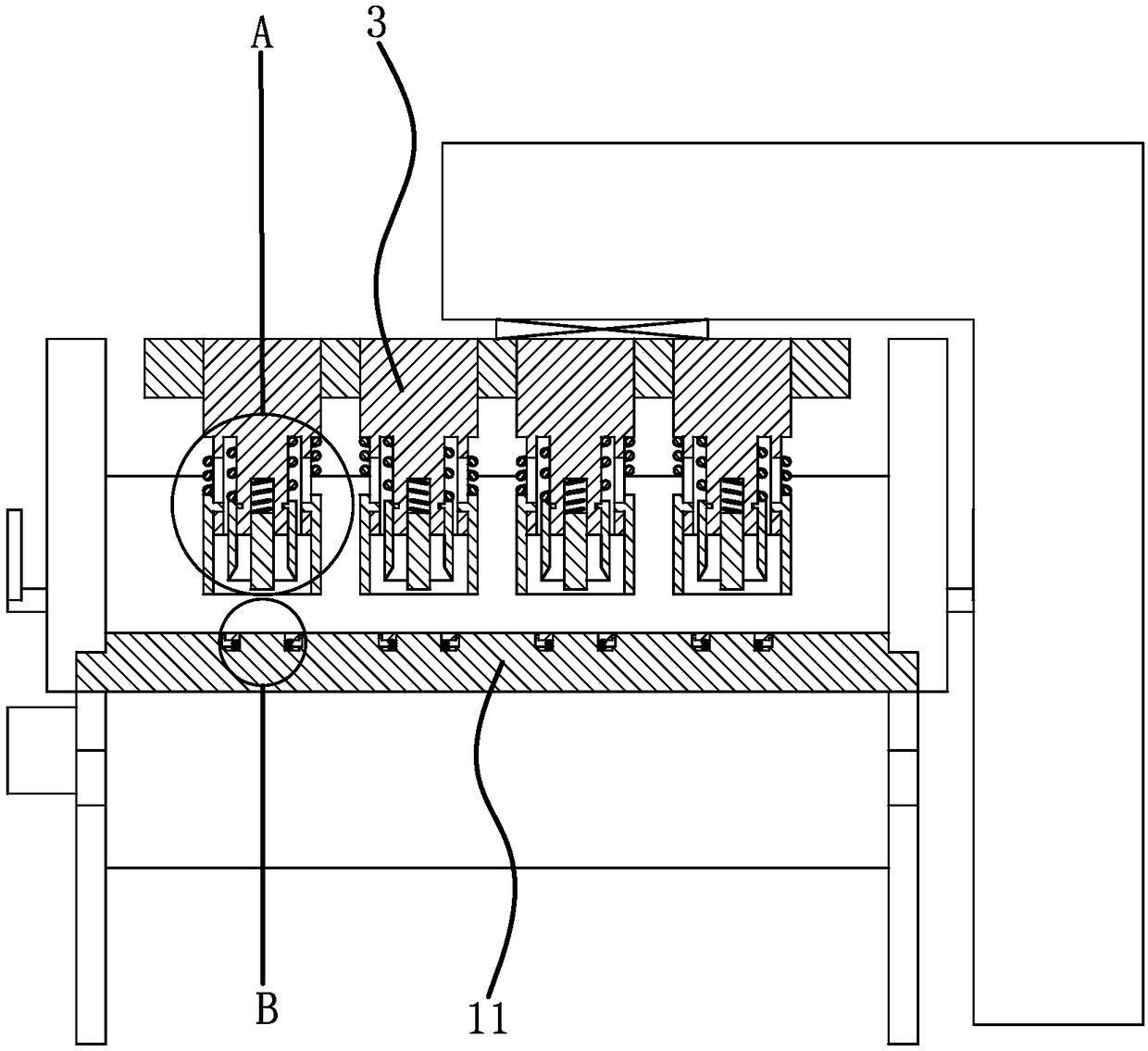

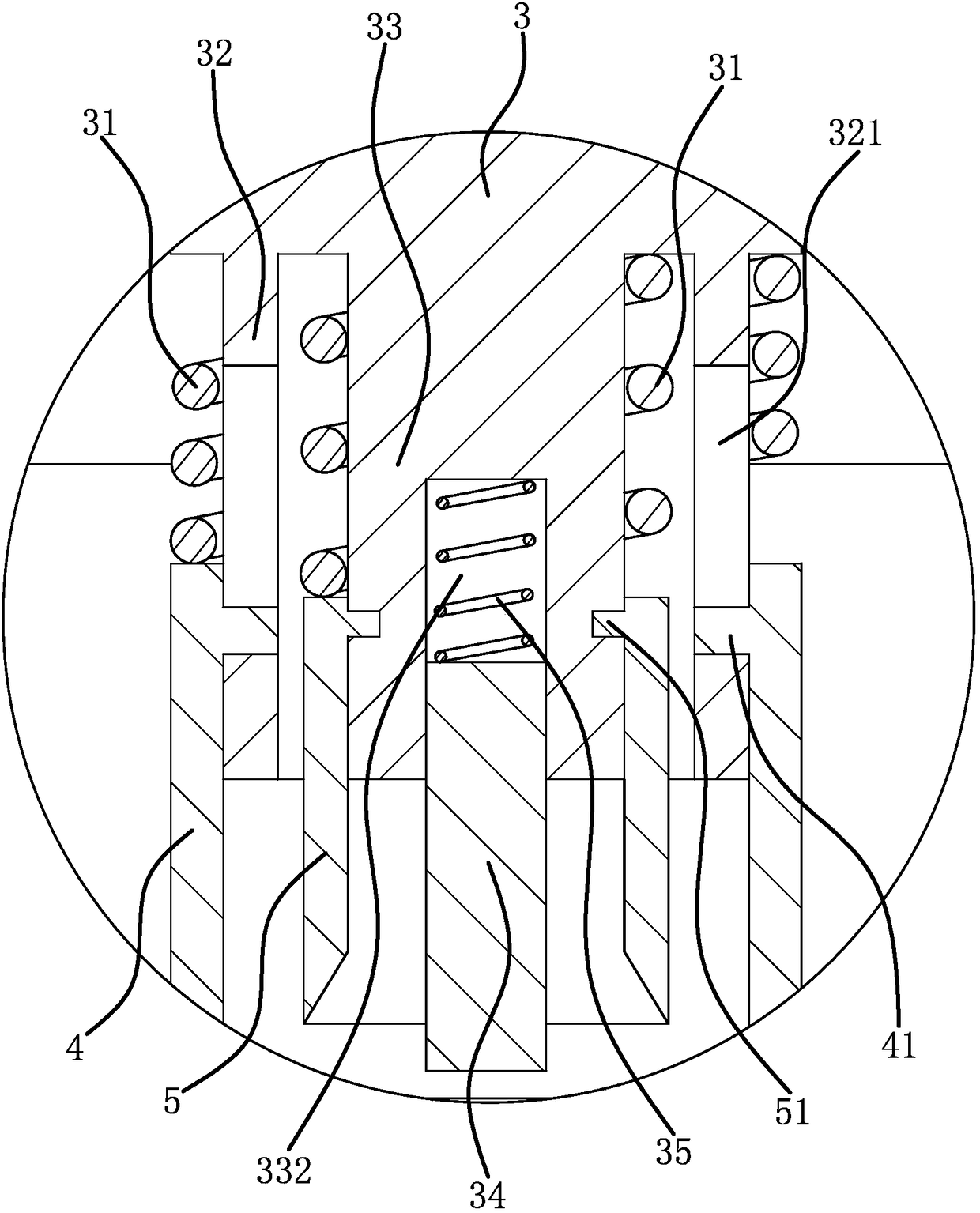

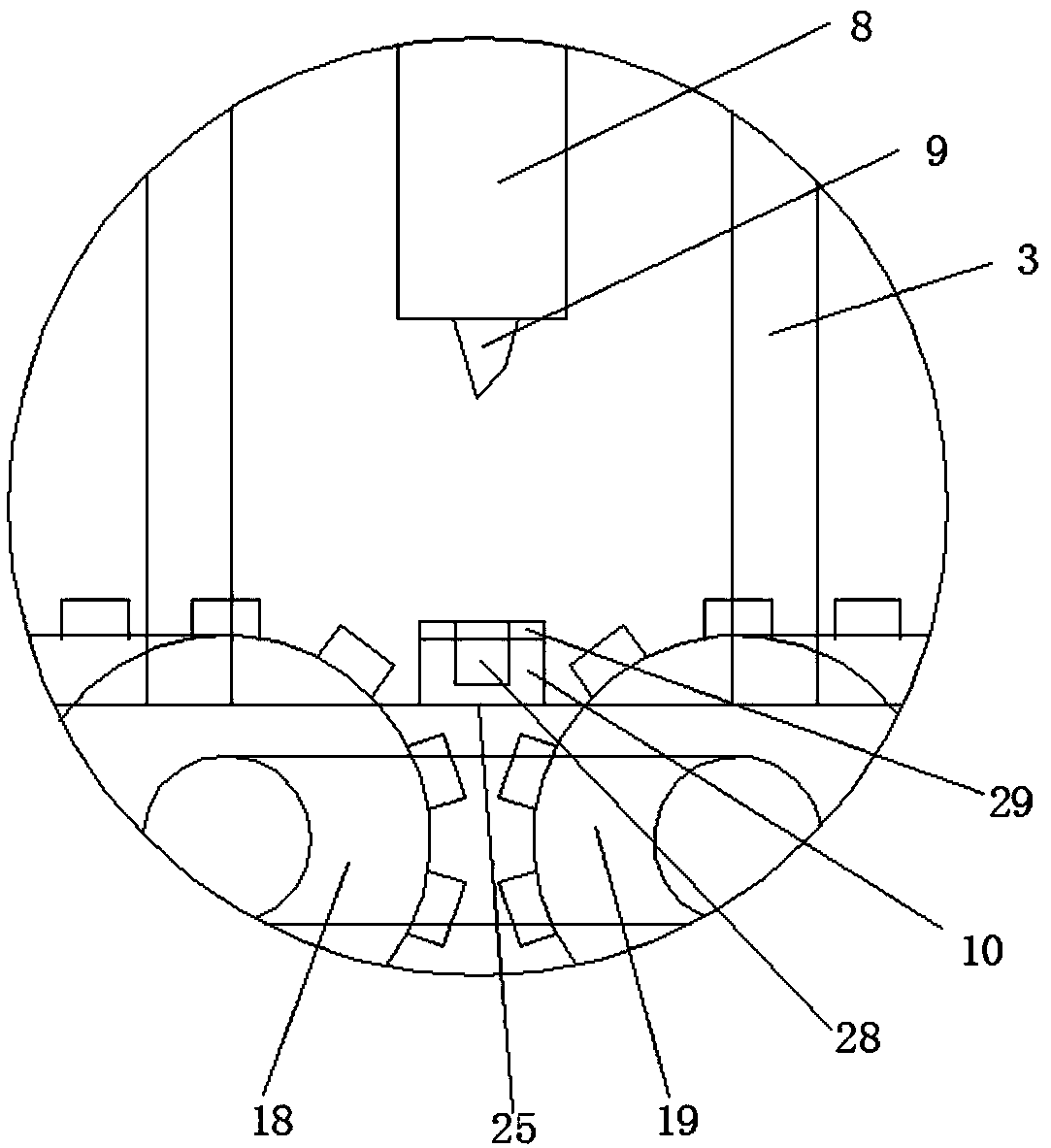

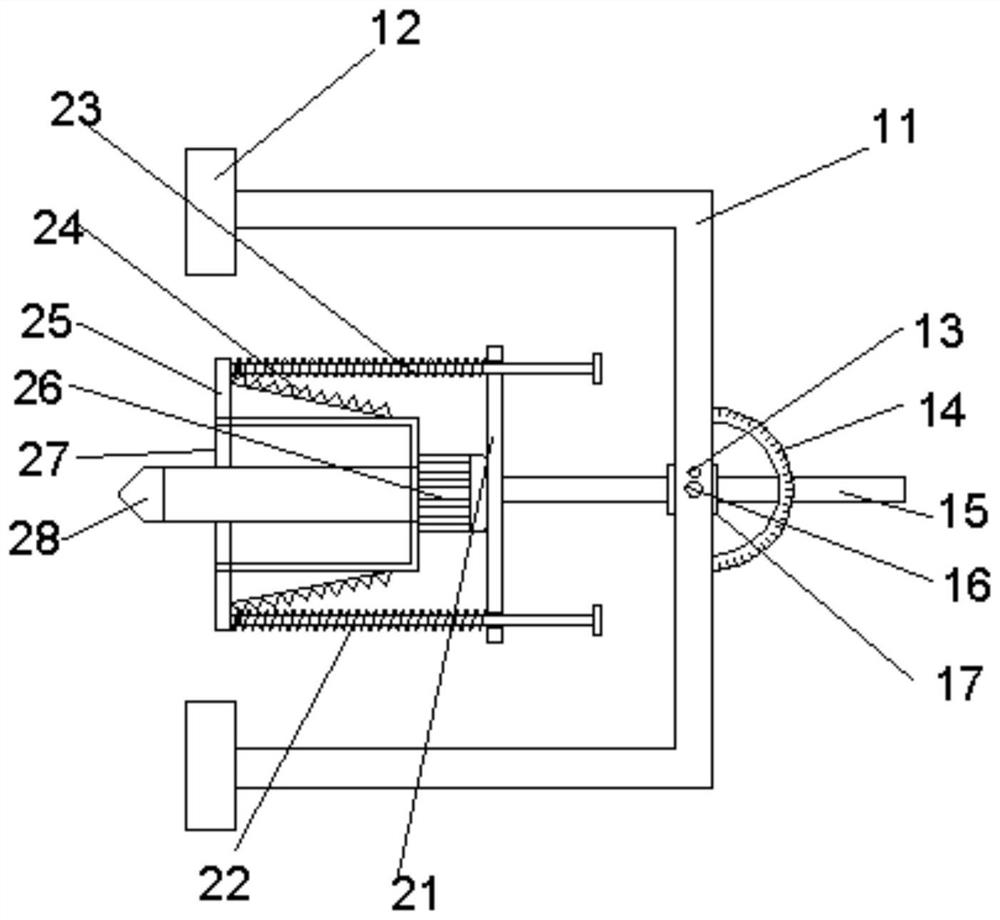

Fungus cultivating bag punching device

PendingCN108432558AEvenly punchedThe treatment effect is stableCultivating equipmentsMushroom cultivationMushroomTreatment effect

The invention provides a fungus cultivating bag punching device. The fungus cultivating bag punching device comprises a connecting plate 3 of which the middle is provided with a round hole structure,and several punching units 4 which are distributed around the circumference of the round hole structure are arranged on the connecting plate 4; the circumferential distribution center of the punchingunits 4 is coaxial to the axis of the round hole structure of the connecting plate 3; each punching unit 4 comprises a mounting support 5, guide wheels 6 which are movably connected with each mountingsupport are arranged at the two ends of each mounting support respectively, an annular connecting belt 7 is arranged to be connected with the corresponding guide wheels 6, and several conical barns 8perpendicular to the annular connecting belts 7 are arranged at the outer sides of the annular connecting belts 7. The fungus cultivating bag punching device is used for punching the peripheries of cultivating bags after inoculation of cultures like auricularia fuscosuccinea or some mushrooms, punching is uniform, the treatment effect is stable, and the bag bodies cannot be torn expect for punching. After the fungus cultivating bag punching device is properly applied, the labor intensity can be low, the high-quality processing effect and high-efficiency production efficiency are obtained, andthus the economic benefit of enterprises is increased.

Owner:贵州大秦农业科技有限公司

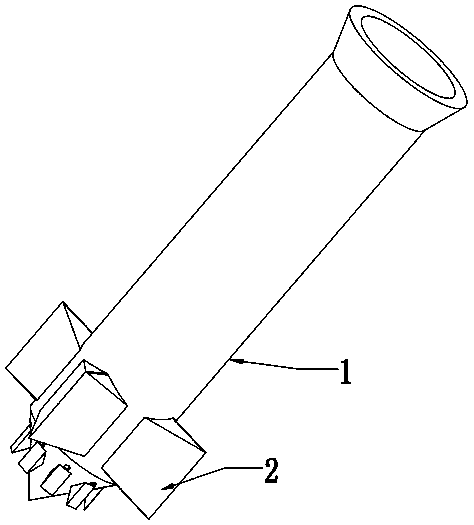

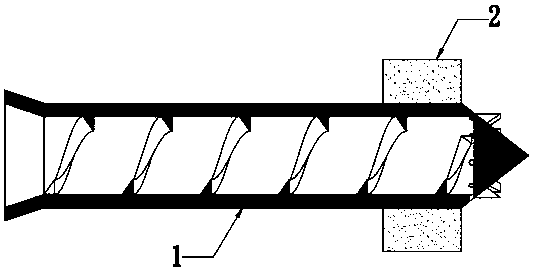

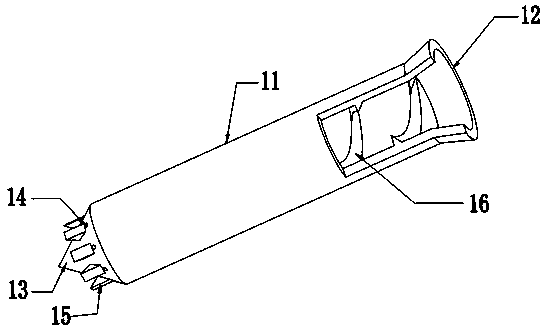

Braised meat punching nail

The invention discloses a braised meat punching nail. The braised meat punching nail comprises a feeding pipe and a slotting tool; the feeding pipe is cylindrical and the internal part of the feedingpipe is hollow; and the slotting tool is arranged at the front end of the feeding pipe. The problems that the traditional braised meat preparation needs manual making and early-period processing punching links, the punching efficiency is low and pigskin cannot be soft and tasty through punching can be effectively solved.

Owner:NANNING SHENGRUN TECH

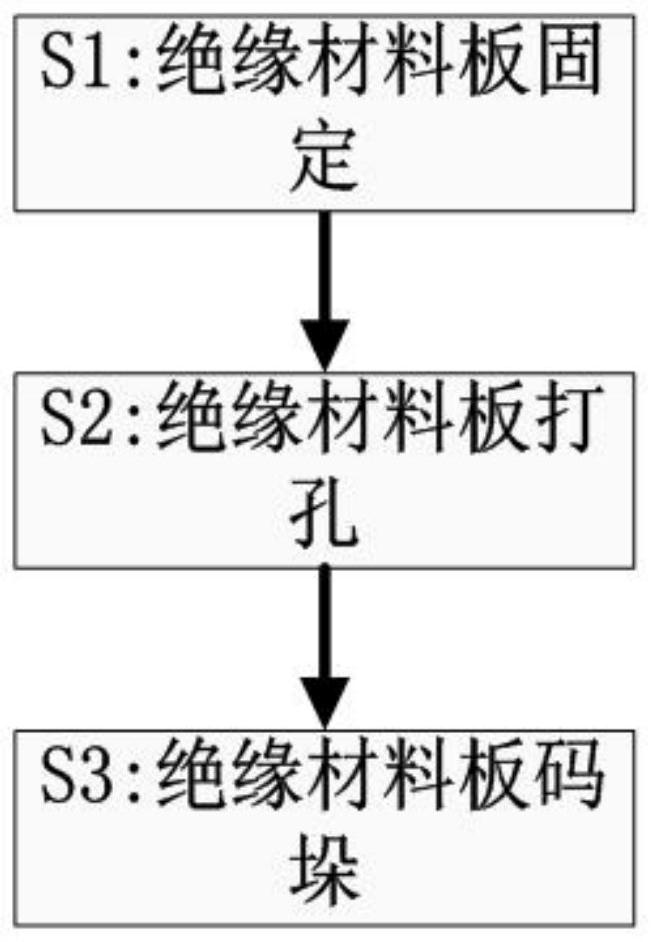

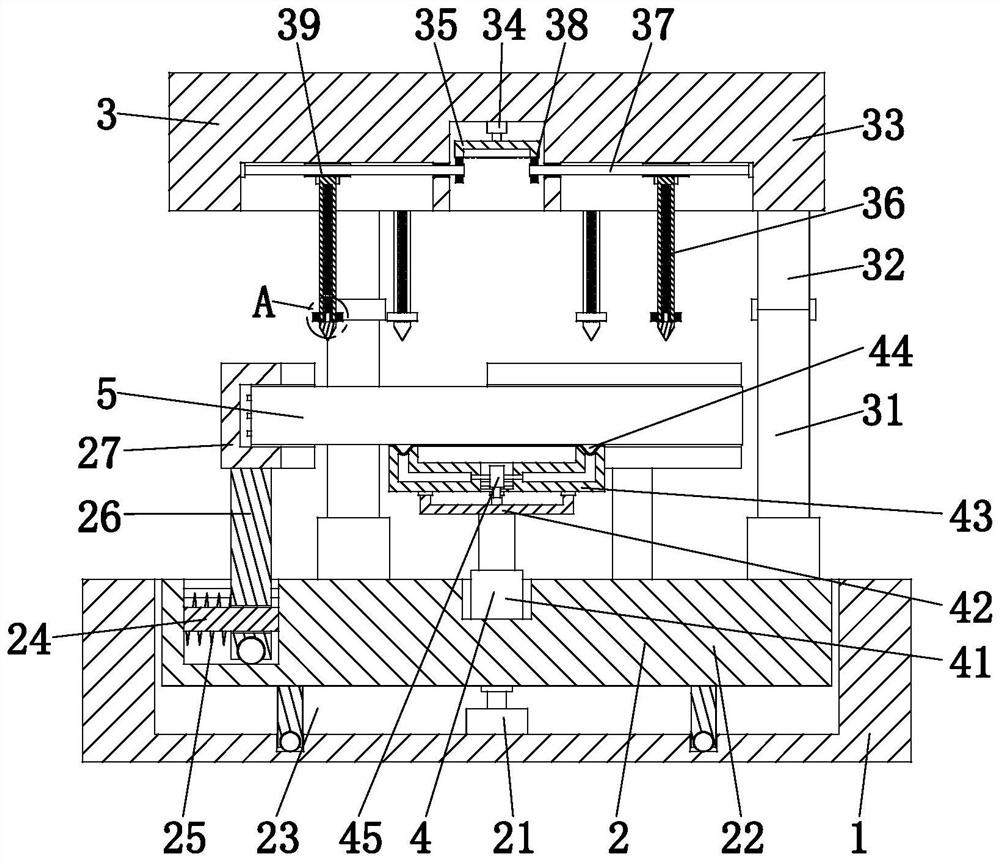

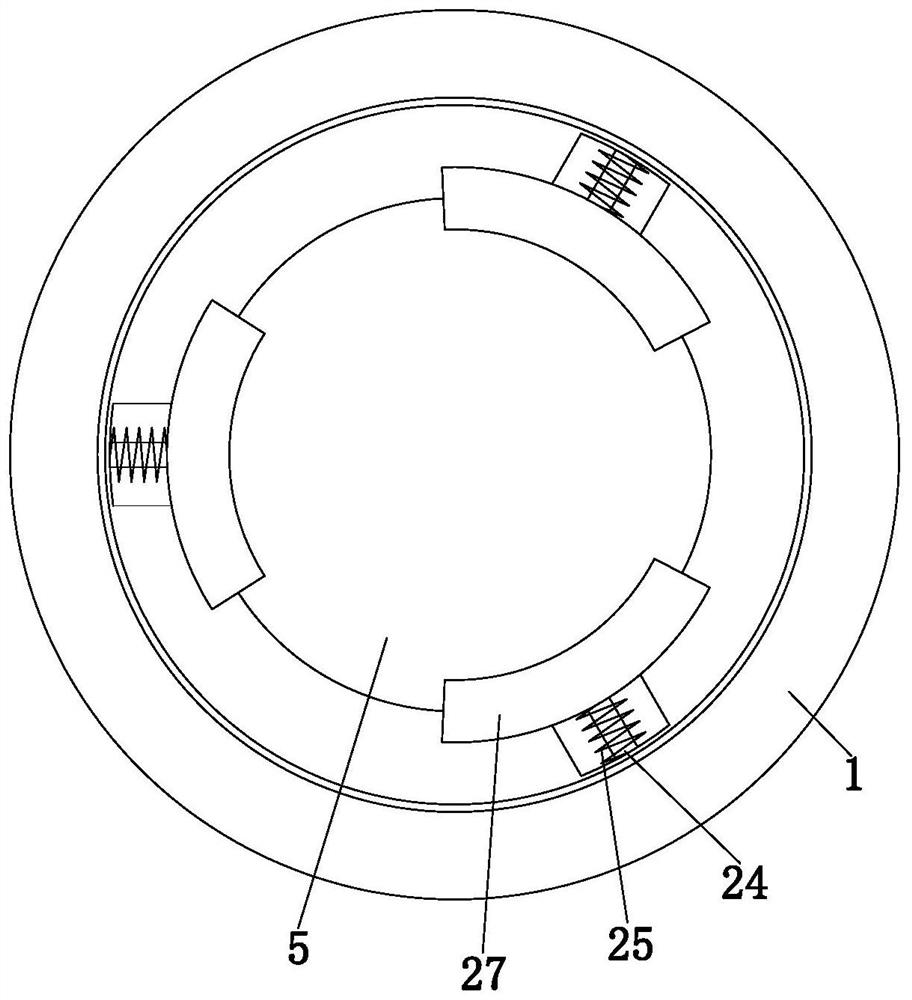

Manufacturing and processing process of electrical insulating material

InactiveCN111958680AAvoid shakingGuaranteed stabilityCleaning using toolsMetal working apparatusPunchingMachining process

The invention provides a manufacturing and processing process of an electrical insulating material. The manufacturing and processing of the electrical insulating material is completed by the cooperation of an annular sleeve, a fixing unit, a drilling unit, an adsorption unit and an insulating material plate to be processed. According to the manufacturing and processing process of the electrical insulating material provided by the invention, the problems that most of punching holes of a circular insulating material plate are radial, the current radial punching mode is difficult to maintain thestability of the circular insulating material plate, the circular insulating material plate shakes to affect the punching quality, an existing punching mode is easy to block with the insulating material plate, the penetration capability of a needle to the insulating material plate is further influenced, and the like can be solved.

Owner:尤之浩

A stamping mechanism of a stamping machine

The invention provides a punching mechanism of a punching machine and belongs to the technical field of mechanical equipment. The punching mechanism of the punching machine solves the problem that the punching quality of an existing punching machine is low. According to the punching mechanism of the punching machine, the punching machine comprises a rack, and a punching platform is fixedly connected to the rack; the punching mechanism comprises a lifting platform, and a plurality of punching heads are fixedly connected to the lifting platform; each punching head is slidably sleeved with a positioning drum and a tool bit, wherein punching springs enabling the positioning drum and the tool bit to have a downward moving tendency are arranged on the positioning drum; a transmission piece enabling the corresponding tool bit to circumferentially rotate when the corresponding tool bit moves downwards and abuts against felt is installed between each tool bit and the corresponding punching head; and a retainer is installed on the punching platform. The punching mechanism of the punching machine can achieve higher felt punching quality.

Owner:海宁英和金属制品有限公司

Packing bag tearing line punching apparatus

The invention discloses a packing bag tearing line punching apparatus, comprising a conveyor belt apparatus and a rack. A sliding rod and a knife rest are disposed on the rack upwards, a compression rod and a cylinder are sequentially connected to the tool knife upwards, a cutter bar and a cutter head are sequentially connected to a lower surface of the knife rest downwards; a knife seat for accommodating the cutter head is disposed directly below the cutter head, the upper surface of the knife seat is flush with the upper surface of the conveyor belt on the conveyor belt apparatus; a photoelectric detecting switch is disposed on both sides of the conveyor belt apparatus, the photoelectric detecting switch is located on the feeding direction side of the cutter head, pressure rollers are arranged on both sides of the conveyor belt apparatus, and the pressure rollers are fixed to the rack by a length-adjustable and height-adjustable connecting rod. According to the packing bag tearing line punching apparatus, the height-adjustable and spacing-adjustable pressure rollers are arranged to adapt to the width and thickness of the packing bag, the pressure rollers flattens the packing bag, prevents the packing bag from warping, the tearing lines are guaranteed to be uniform and parallel, and the tearing lines of the packing bags of various specifications can be punched.

Owner:句容市东山纸品厂

Quick drilling device for natural gas pipes

InactiveCN107962202AEasy to punchHeight adjustableFeeding apparatusDriving apparatusCouplingHuman power

The invention relates to a drilling device, in particular to a quick drilling device for natural gas pipes. The quick drilling device for the natural gas pipes comprises a drill bit, a coupling, a first motor, a first rotating wheel and the like; a first support rod is mounted on the left side of the lower part of a fixed frame; a second support rod is mounted on the right side of the lower part of the fixed frame; a first slide rail is mounted at the upper part of the first support rod; a first slide block is slidingly arranged at the upper part of the first slide rail; and an L-shaped frameis mounted at the upper part of the first slide block. The quick drilling device for the natural gas pipes achieves the effects of saving of the labor force, acceleration of the working efficiency anduniform drilling; the equipment can be used for quickly finishing the drilling work of a lot of natural gas pipes, so that a lot of manpower is saved; the machined natural gas pipes are fast in installation and long in service life; and the device is well structured and delicate in design.

Owner:文永林

Perforating device for building detection

InactiveCN112895160AImprove stabilityGuaranteed stabilityWorking accessoriesStone-like material working toolsSet screwElectric machinery

The invention discloses a perforating device for building detection. The perforating device comprises a directional holding mechanism and a drilling dustproof structure; the drilling dustproof structure is mounted in the directional holding mechanism; a motor is installed on a fixed plate of the drilling dustproof structure in a matched mode through bolts; a set of through holes are formed in the fixed plate in the circumferential direction; one end of each positioning rod is in sliding fit with the corresponding through hole, and the other end of each positioning rod is hinged to a movable compression plate through pin shafts; each positioning rod is sleeved with a compression spring; and the two ends of each compression spring abut against the fixed plate and the movable compression plate respectively. According to the scheme, the supporting frame of a table structure is supported on the wall, the drilling angle is determined by a positioning barrel and locked by a positioning screw, the compression plate presses the wall under the action of the compression springs, the compression springs and the pin shafts are matched with each other so that the compression plate can be tightly attached to the wall all the time during drilling, the contact area can be increased, and the drilling stability can be guaranteed.

Owner:先兴发

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com