Roof drilling robot

A technology of robots and drilling mechanisms, applied in the field of robots, can solve the problems of deviation of punched holes, difficulty of punching, and inaccuracy of punching holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

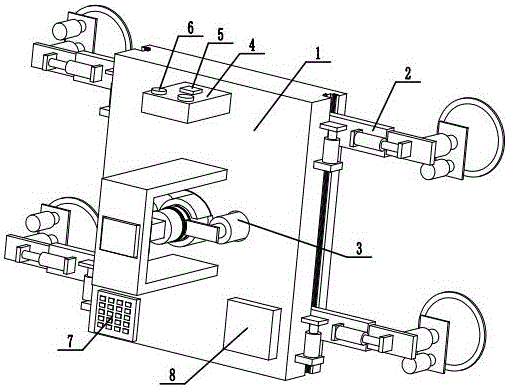

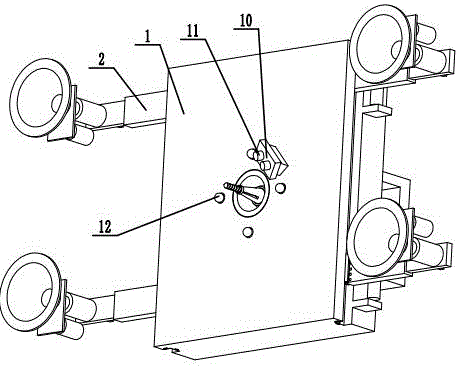

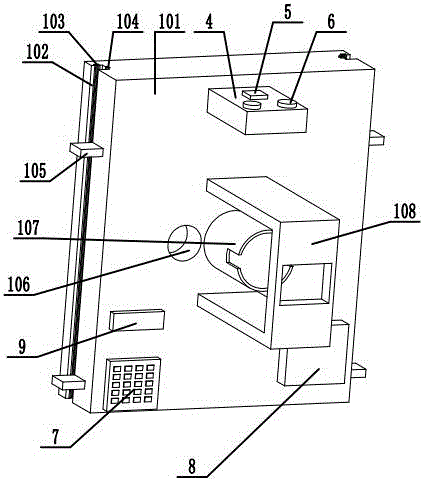

[0016] Example figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 As shown, a roof drilling robot includes a base 1, four fixed mechanical arms 2 and a drilling mechanism 3, and is characterized in that: the four fixed mechanical arms 2 are separated in pairs and installed on the left and right sides of the base 1 On the side, the stepping motor 302 of the drilling mechanism 3 is fixedly installed in the hole of the stepping motor fixing frame 108 on the base 1, and the drilling mechanism 3 is integrally installed in the drilling mechanism fixing seat 107 on the base 1;

[0017] The base includes a bottom plate 101, two first grooves 102, two first slots 103, two second slots 104, four first hydraulic cylinder fixing seats 105, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com