Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10570results about "Revolution surface grinding machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

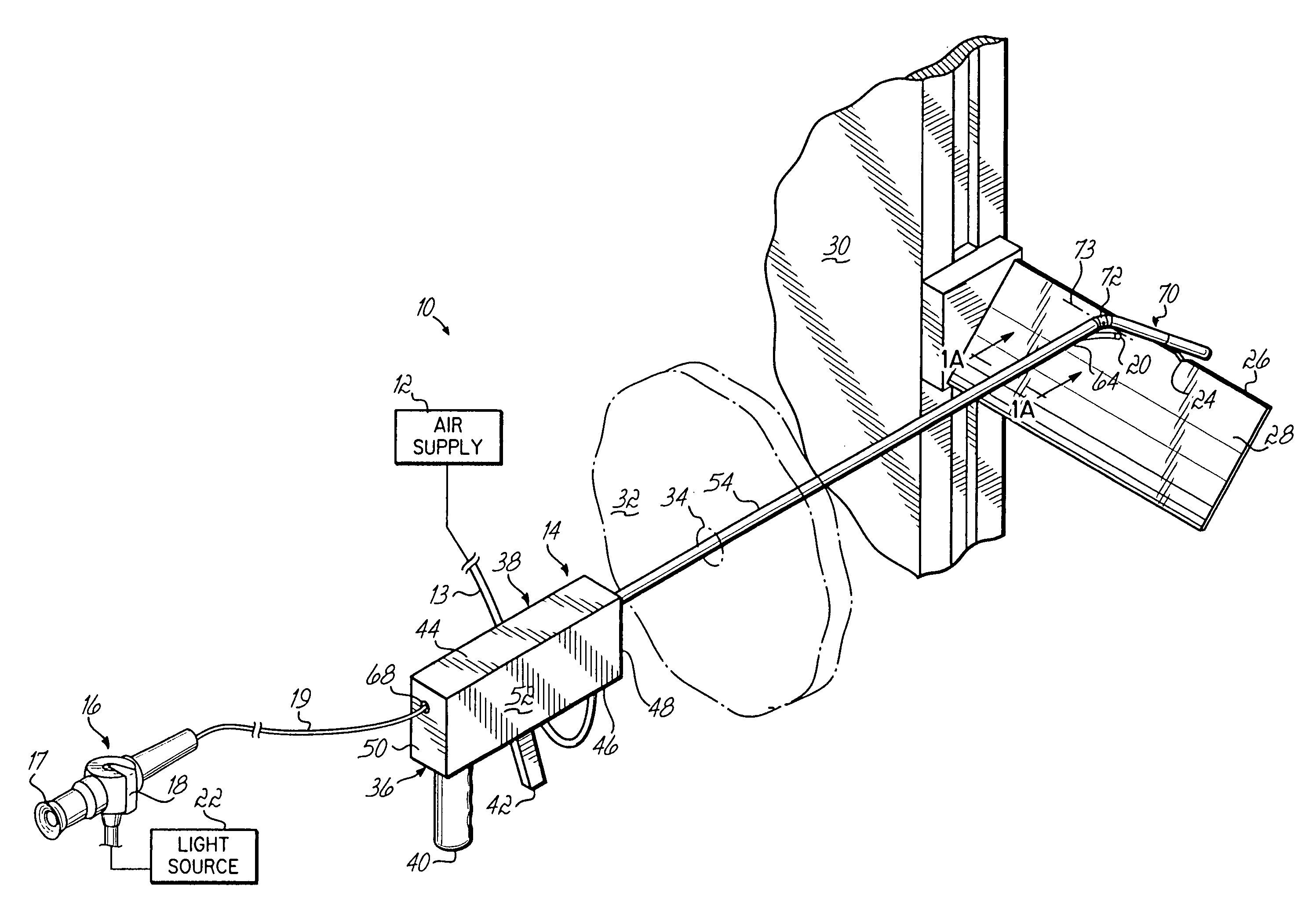

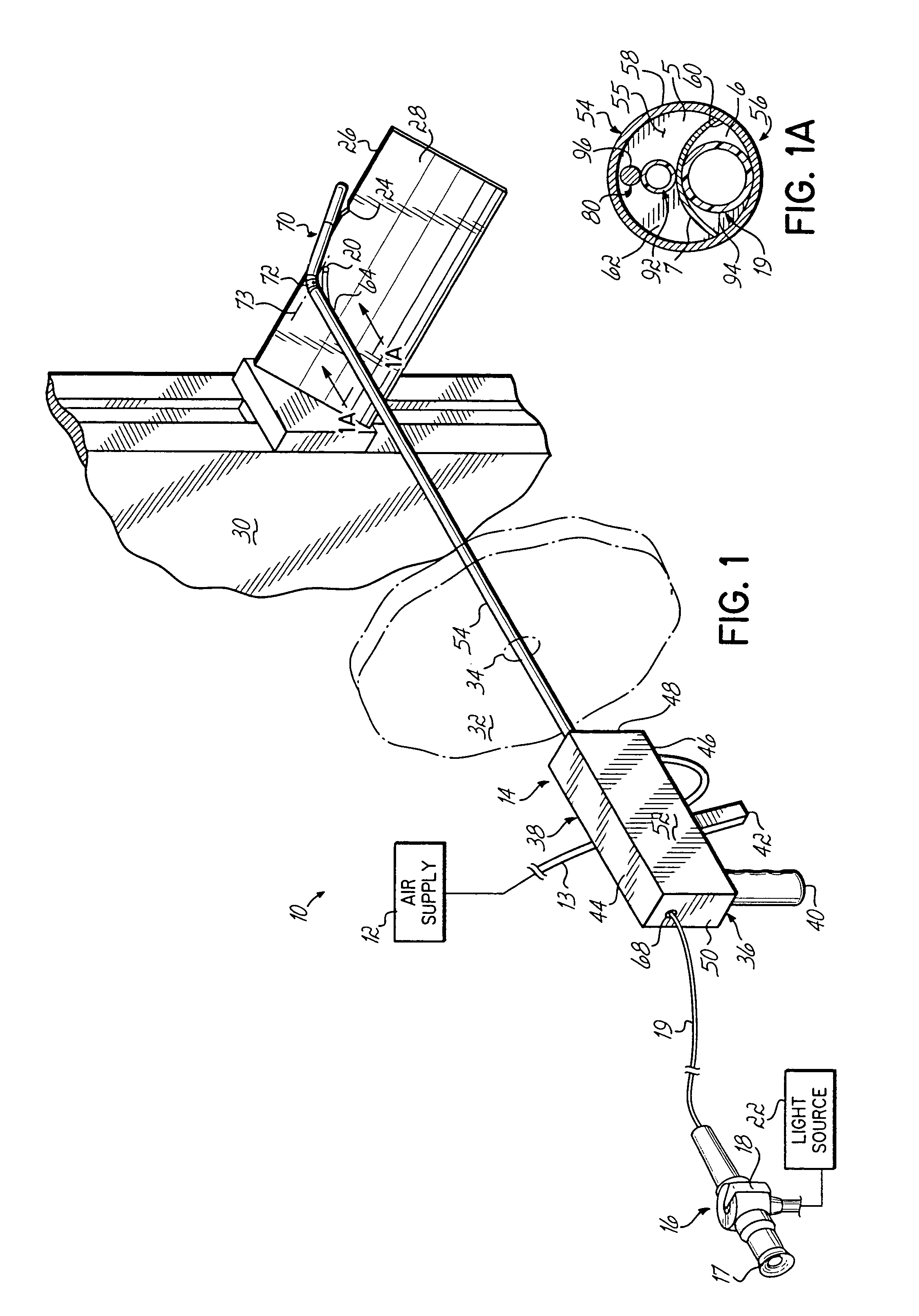

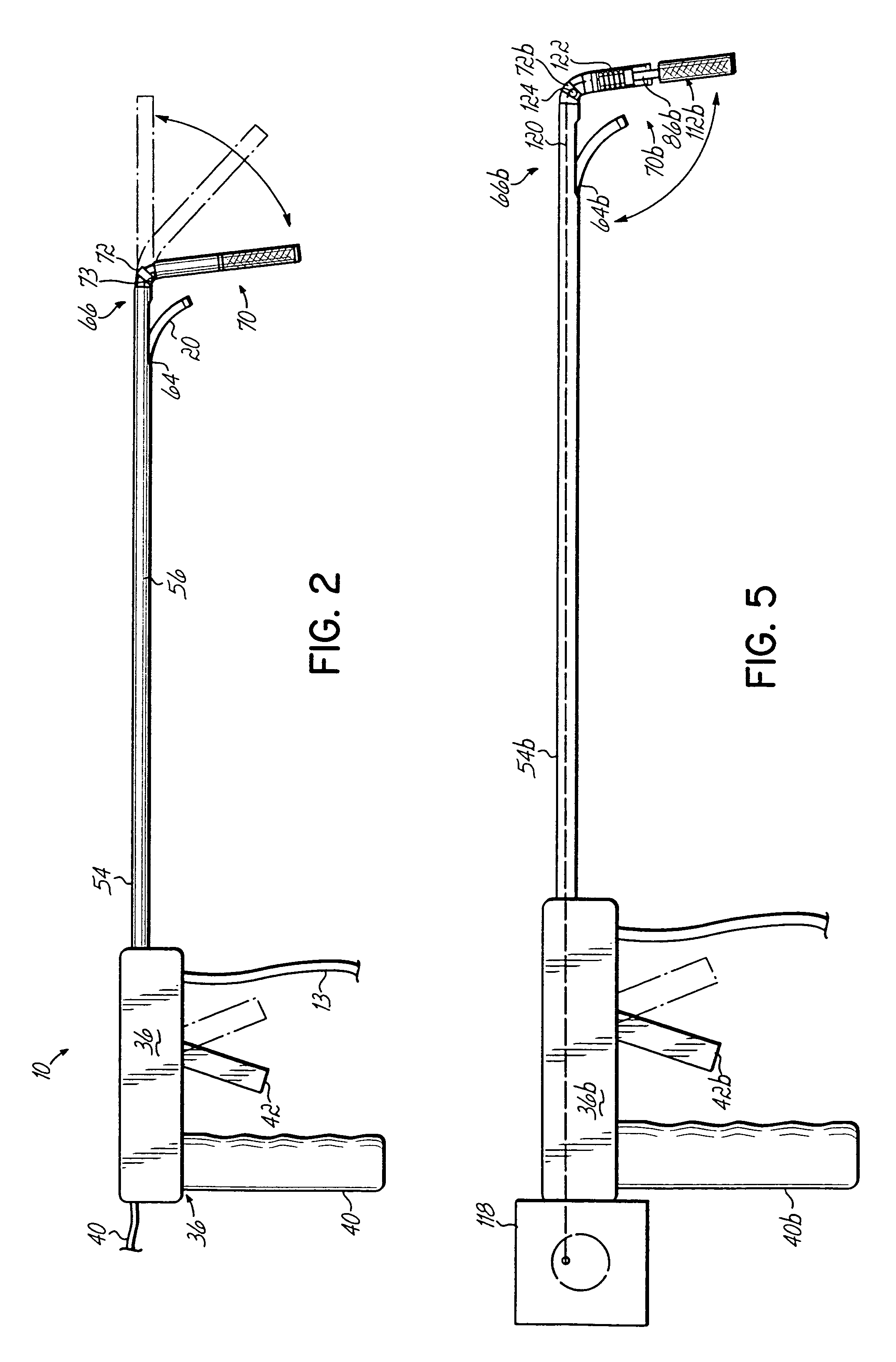

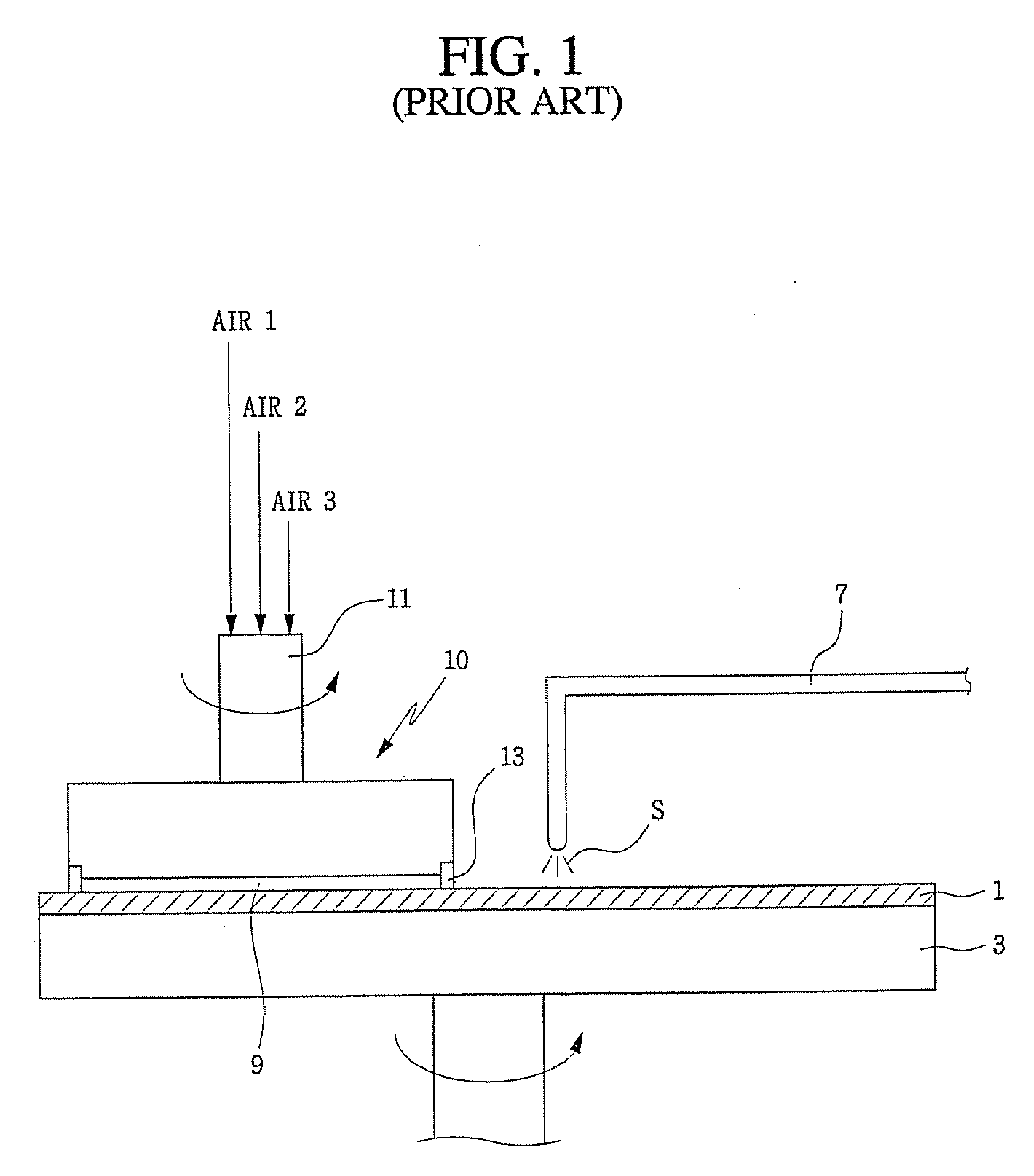

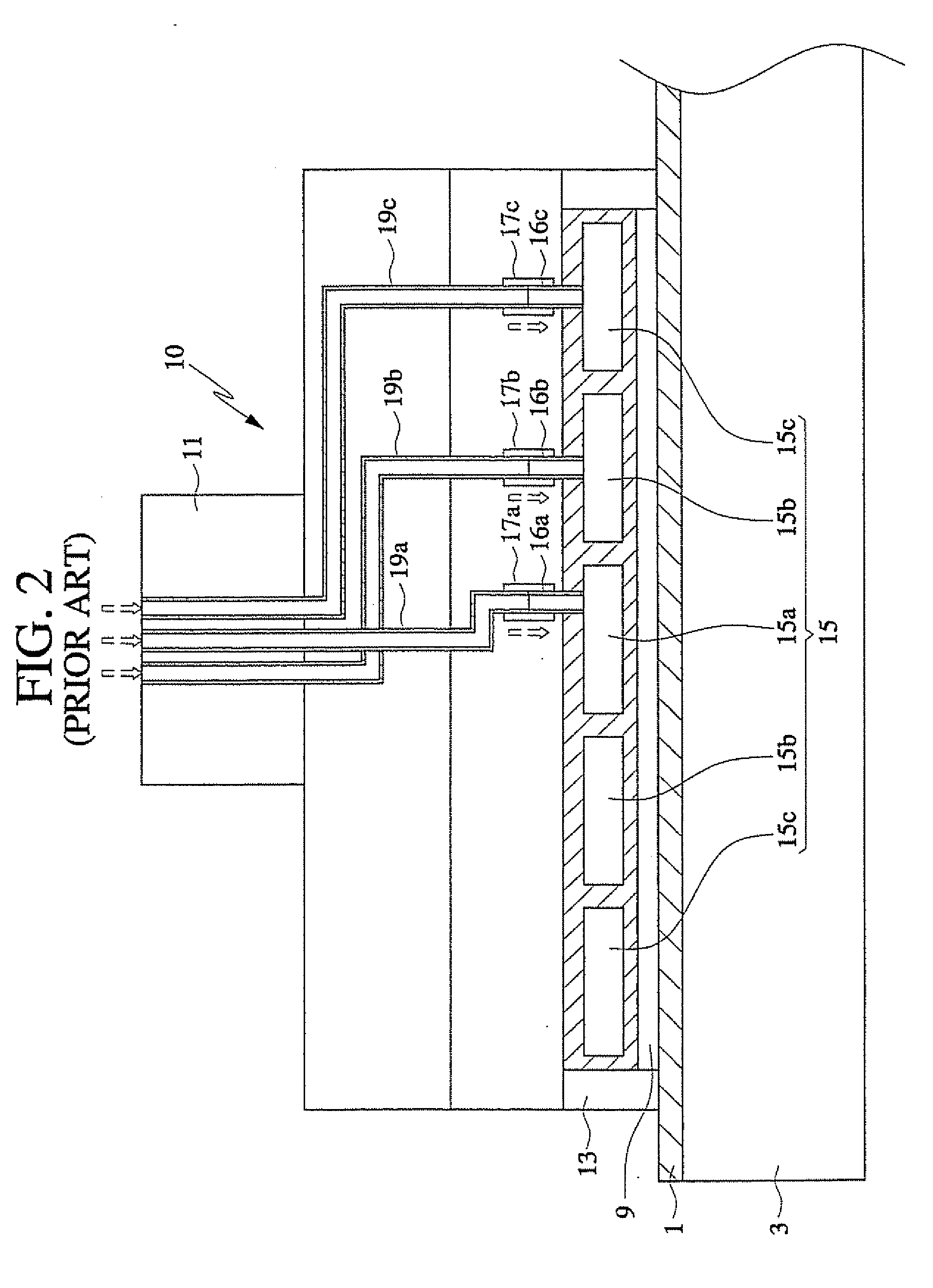

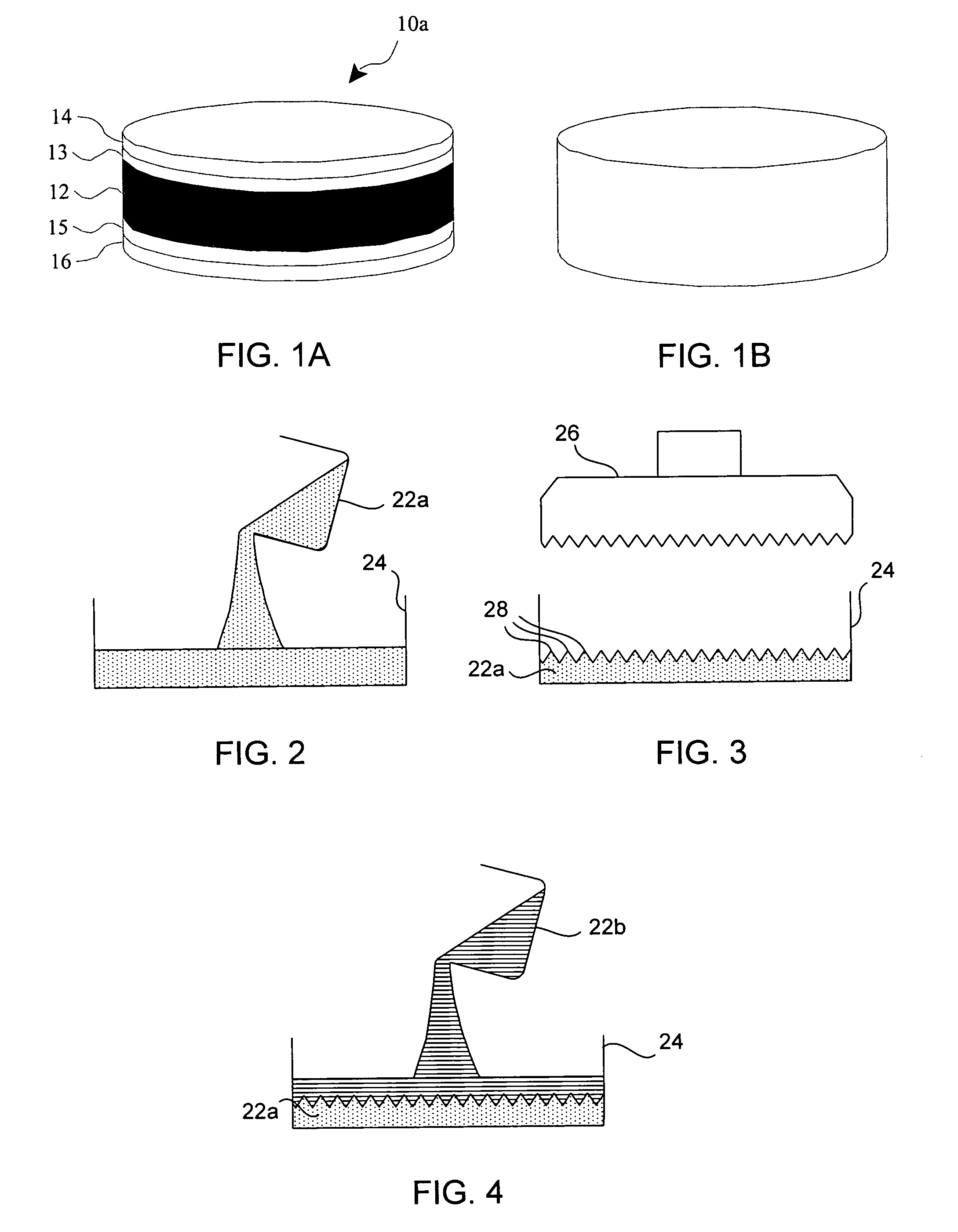

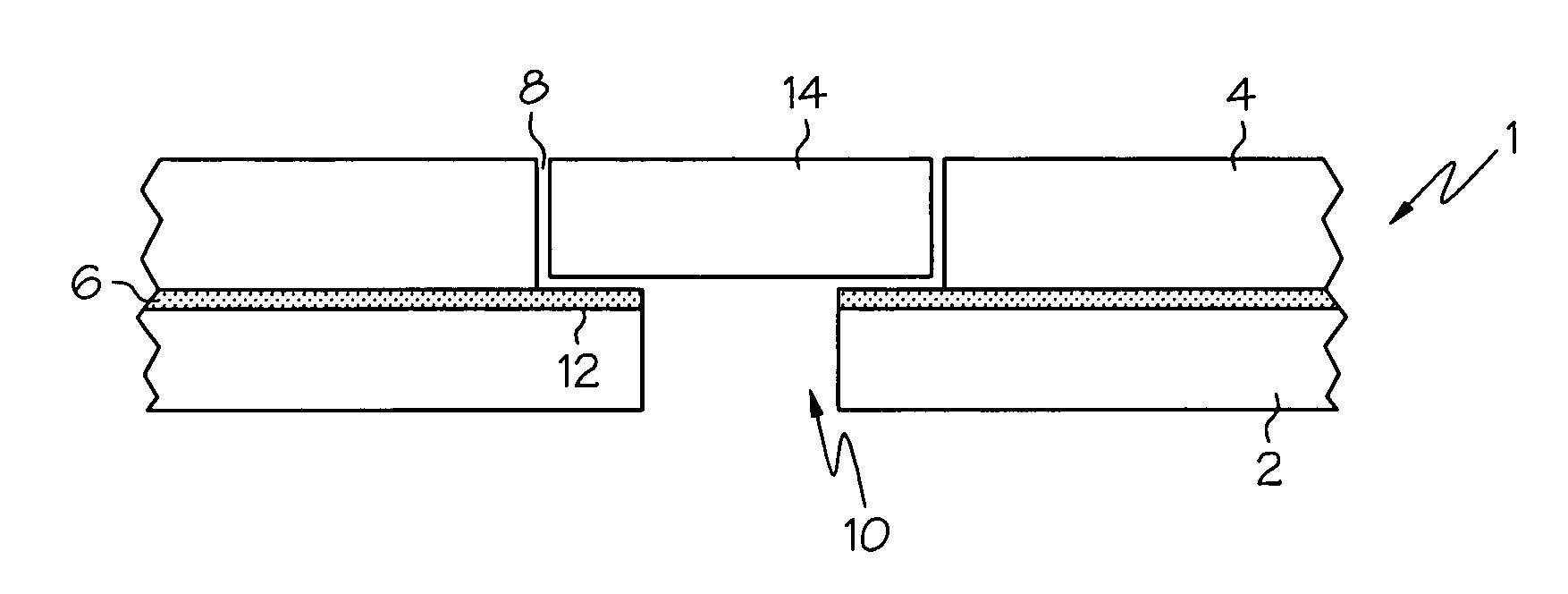

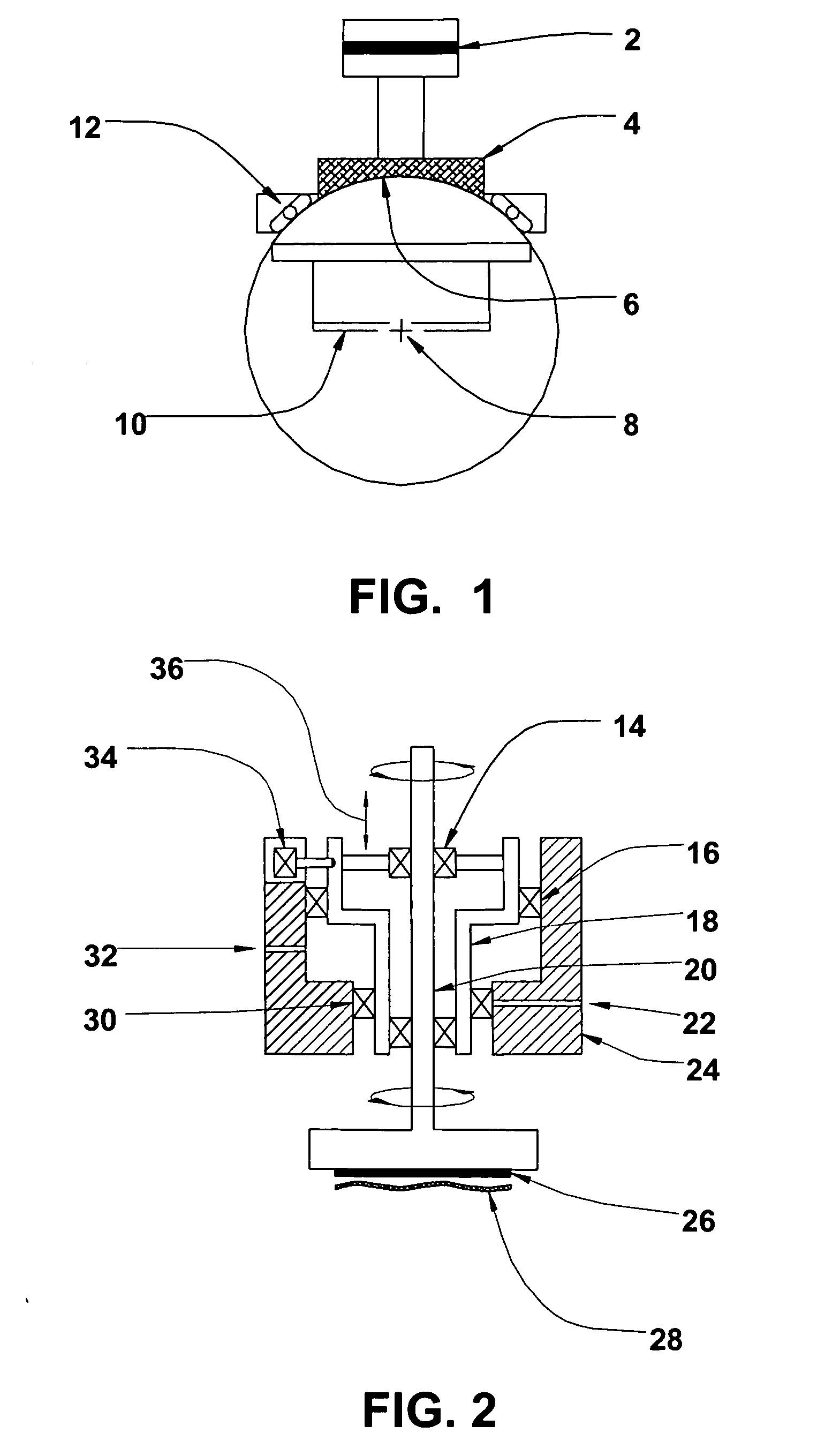

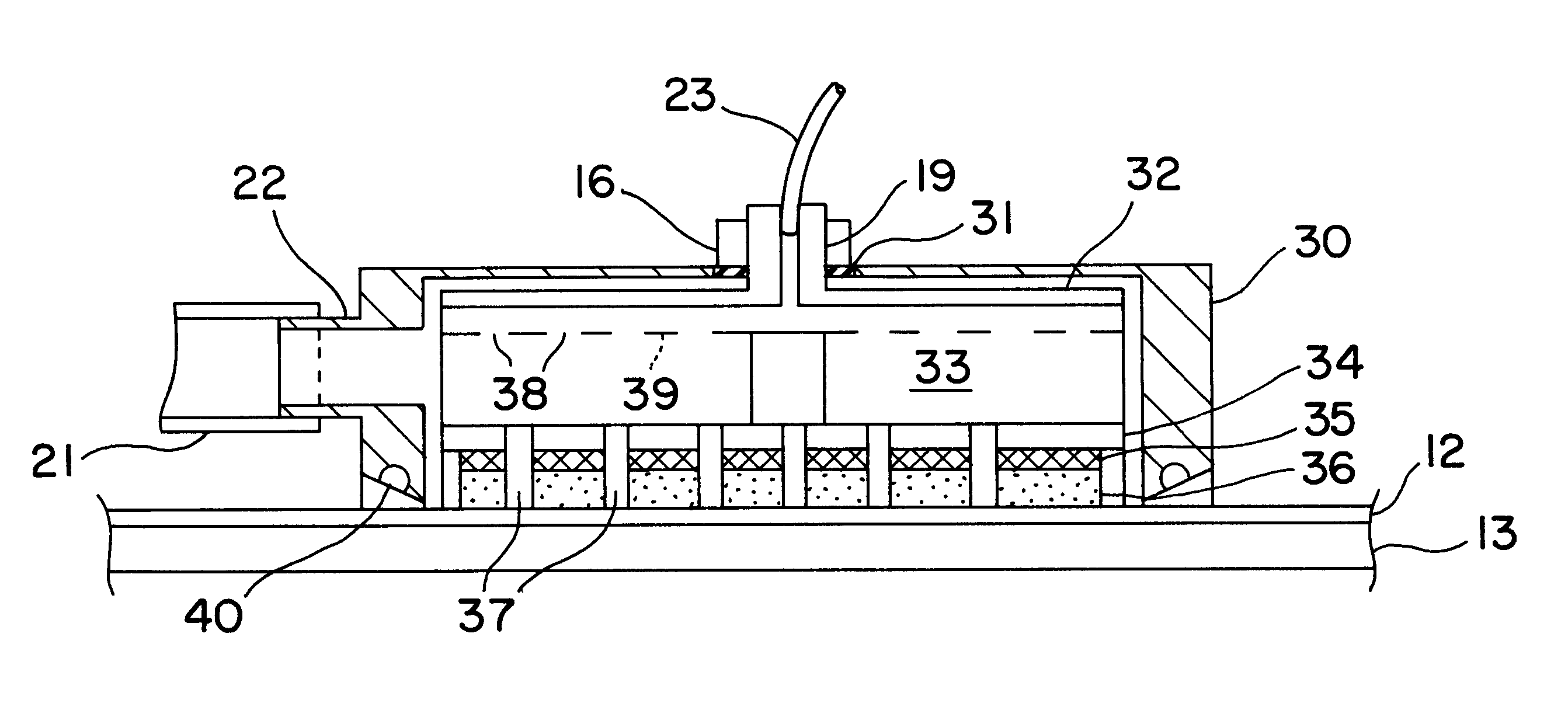

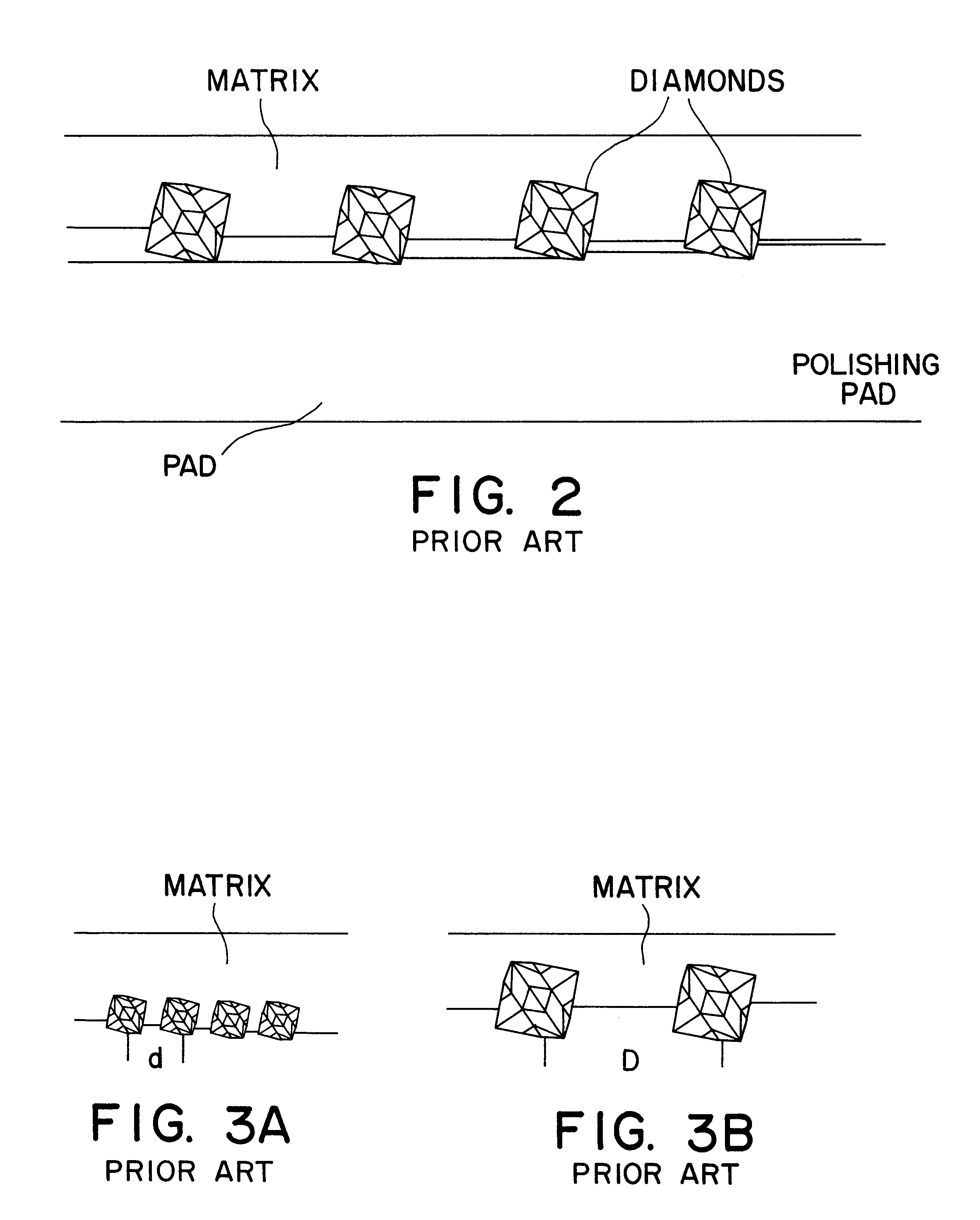

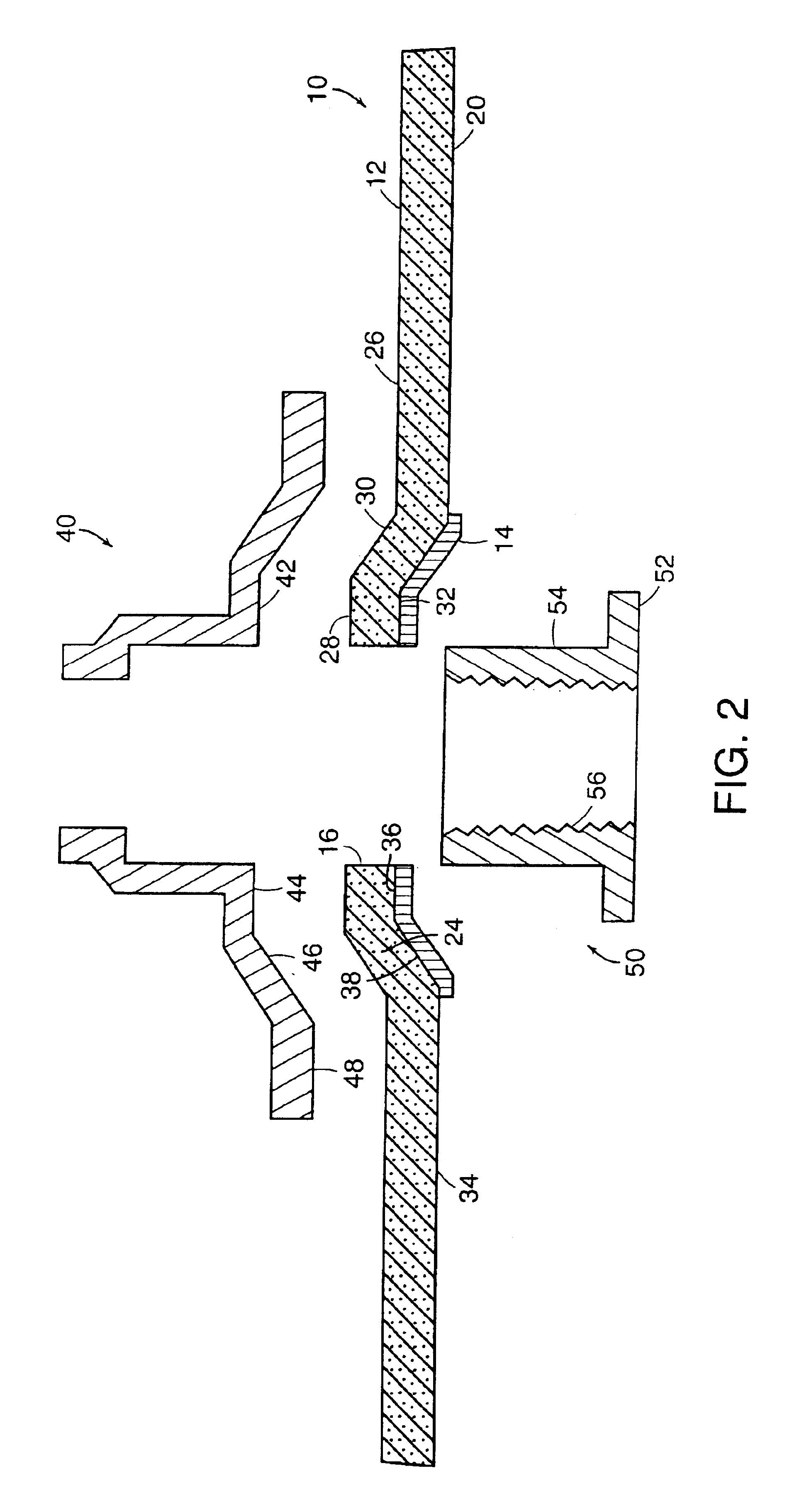

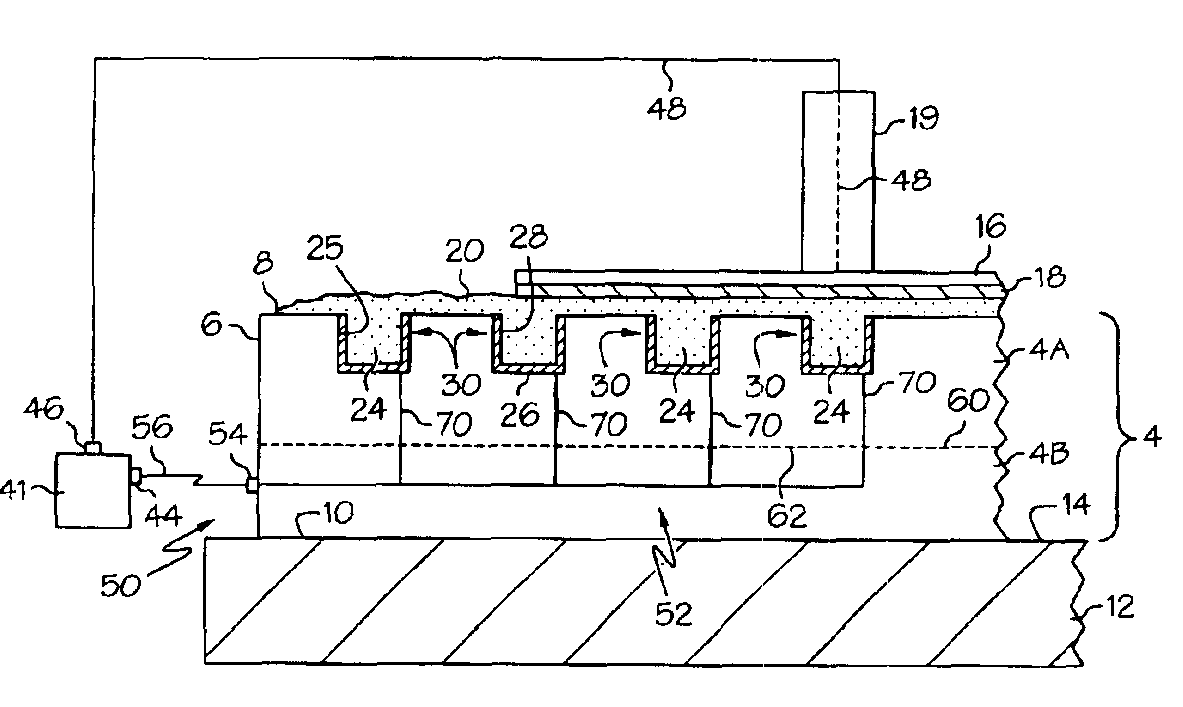

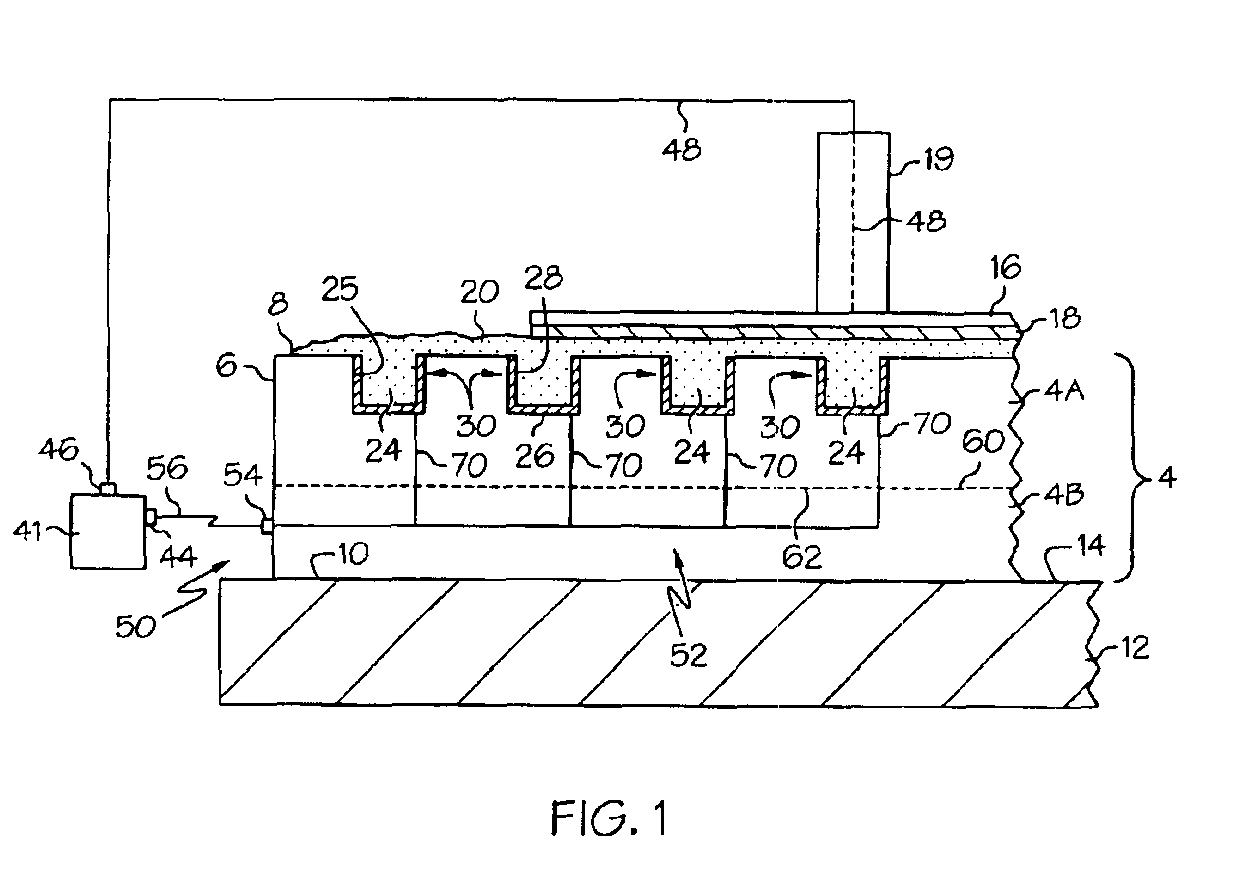

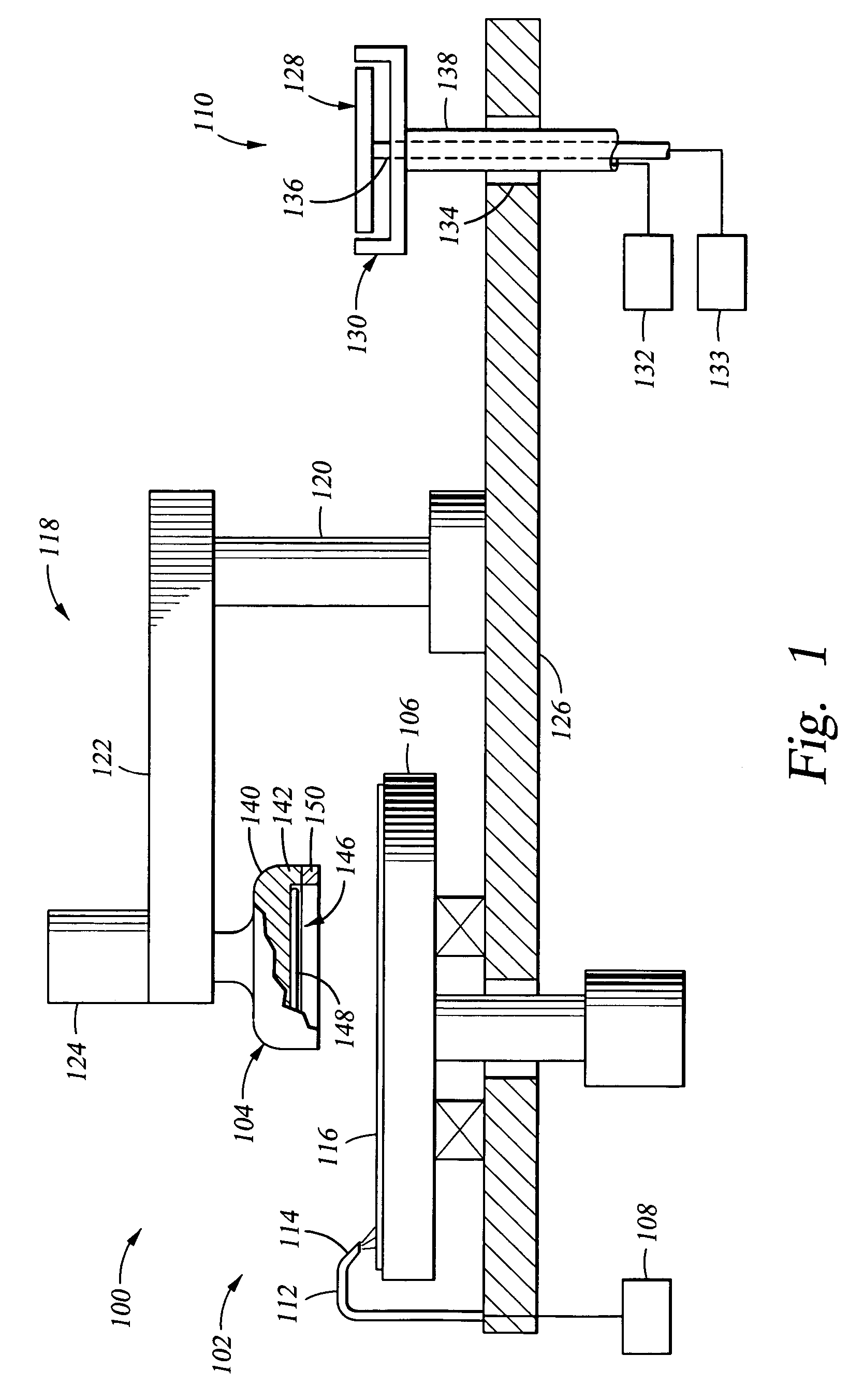

Grinding apparatus for blending defects on turbine blades and associated method of use

InactiveUS6899593B1Revolution surface grinding machinesBlade accessoriesReciprocating motionTurbine blade

A grinding apparatus for use with an endoscope for viewing and blending defects on a turbine engine blade is provided. In one preferred embodiment air pulses from an air supply cause a grinding head on the end of a grinding tool to reciprocate at a predetermined speed. The position of the grinding head is fixed via the operator via a trigger on the grinding tool which articulates an outer portion of a support tube of the grinding tool. In another preferred embodiment, fluid is used to reciprocate the grinding head.

Owner:MOELLER DIETER +2

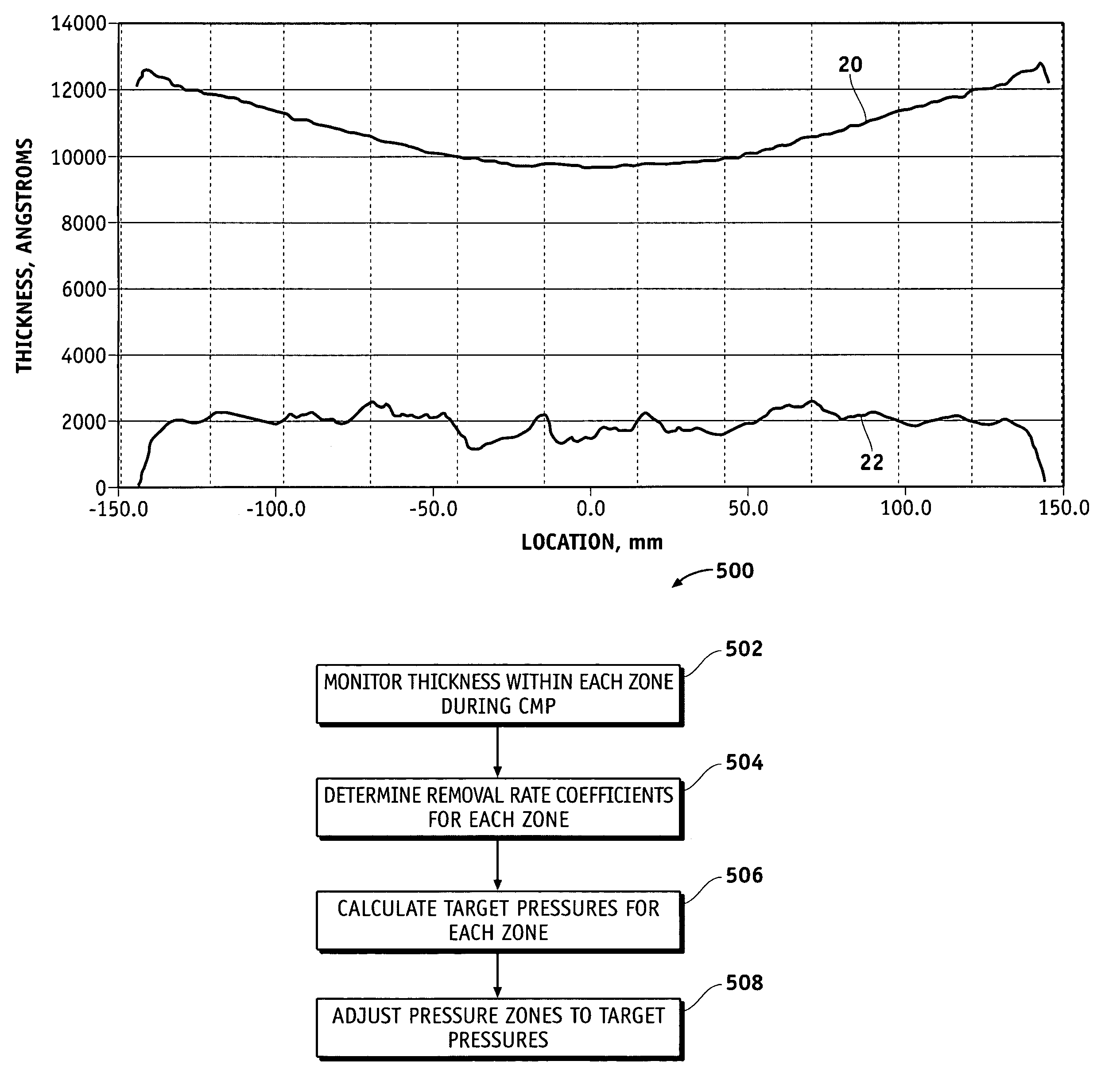

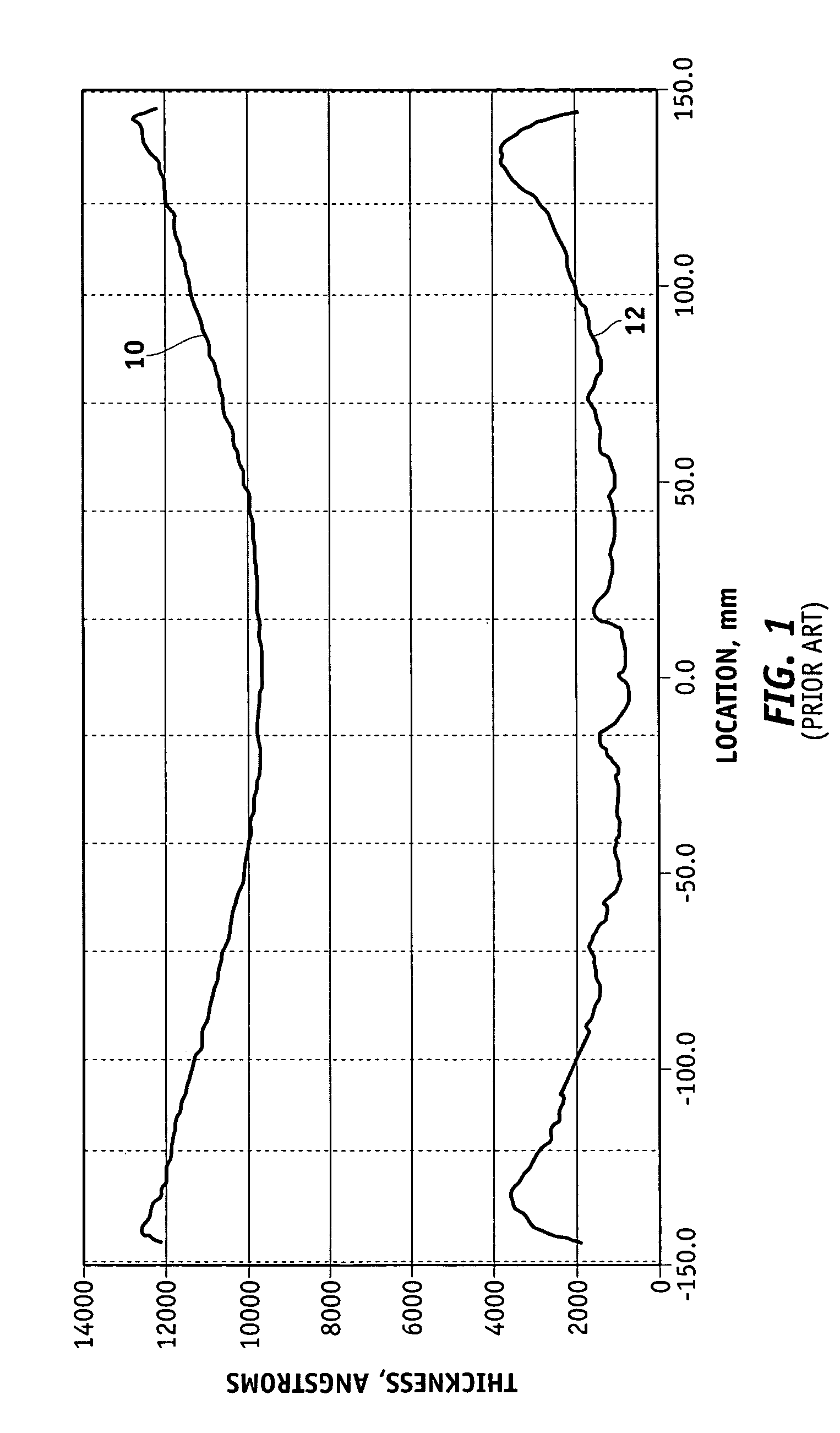

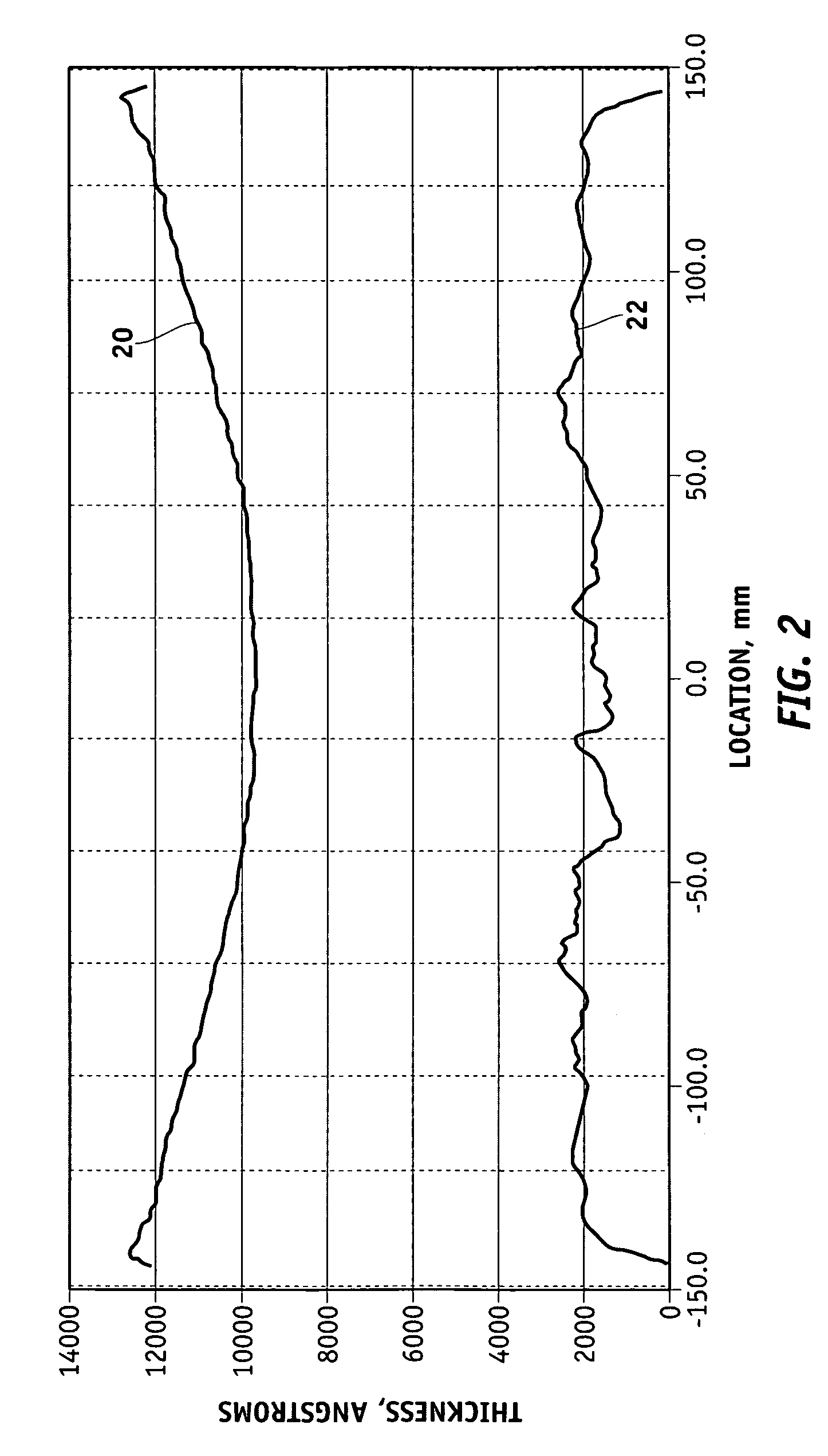

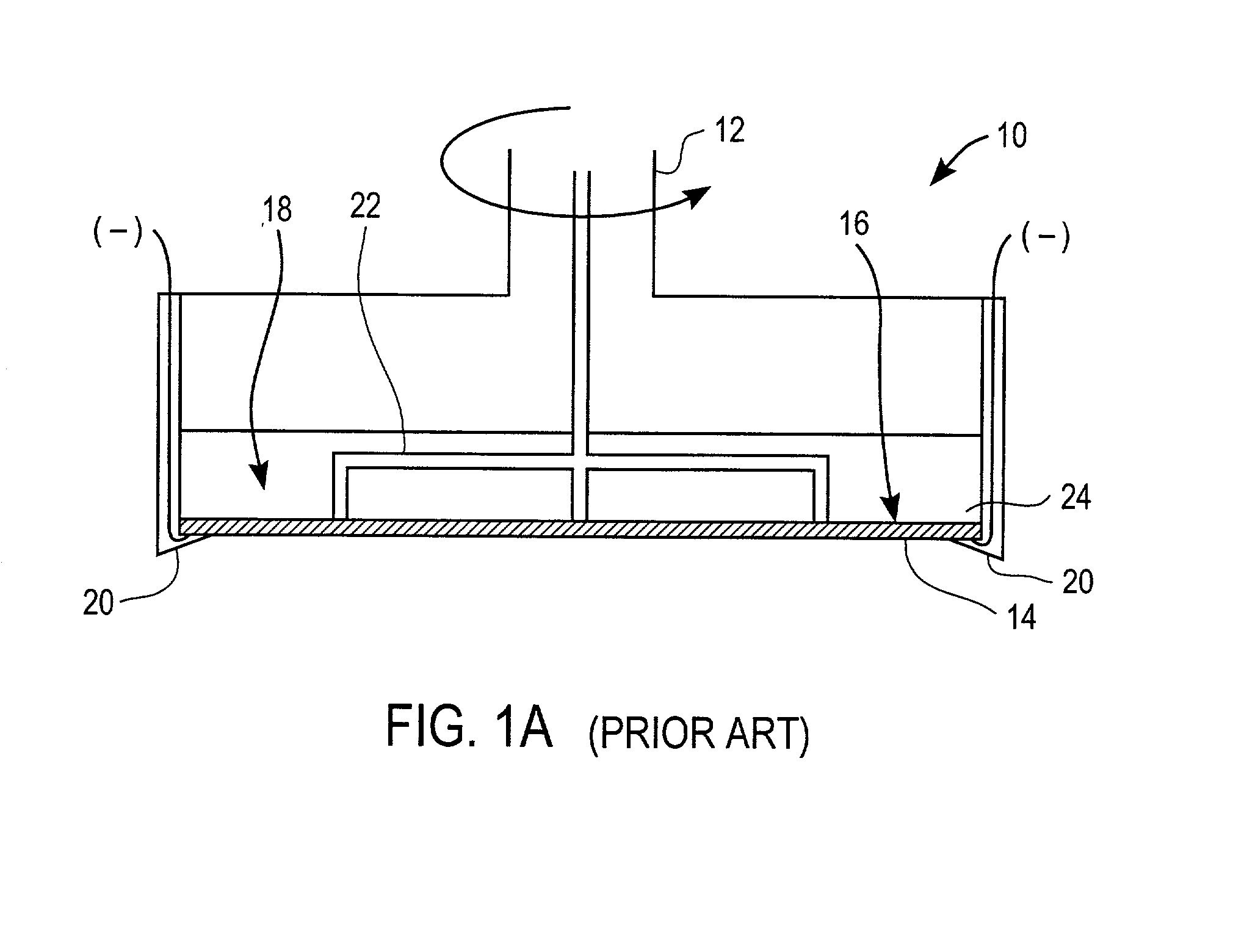

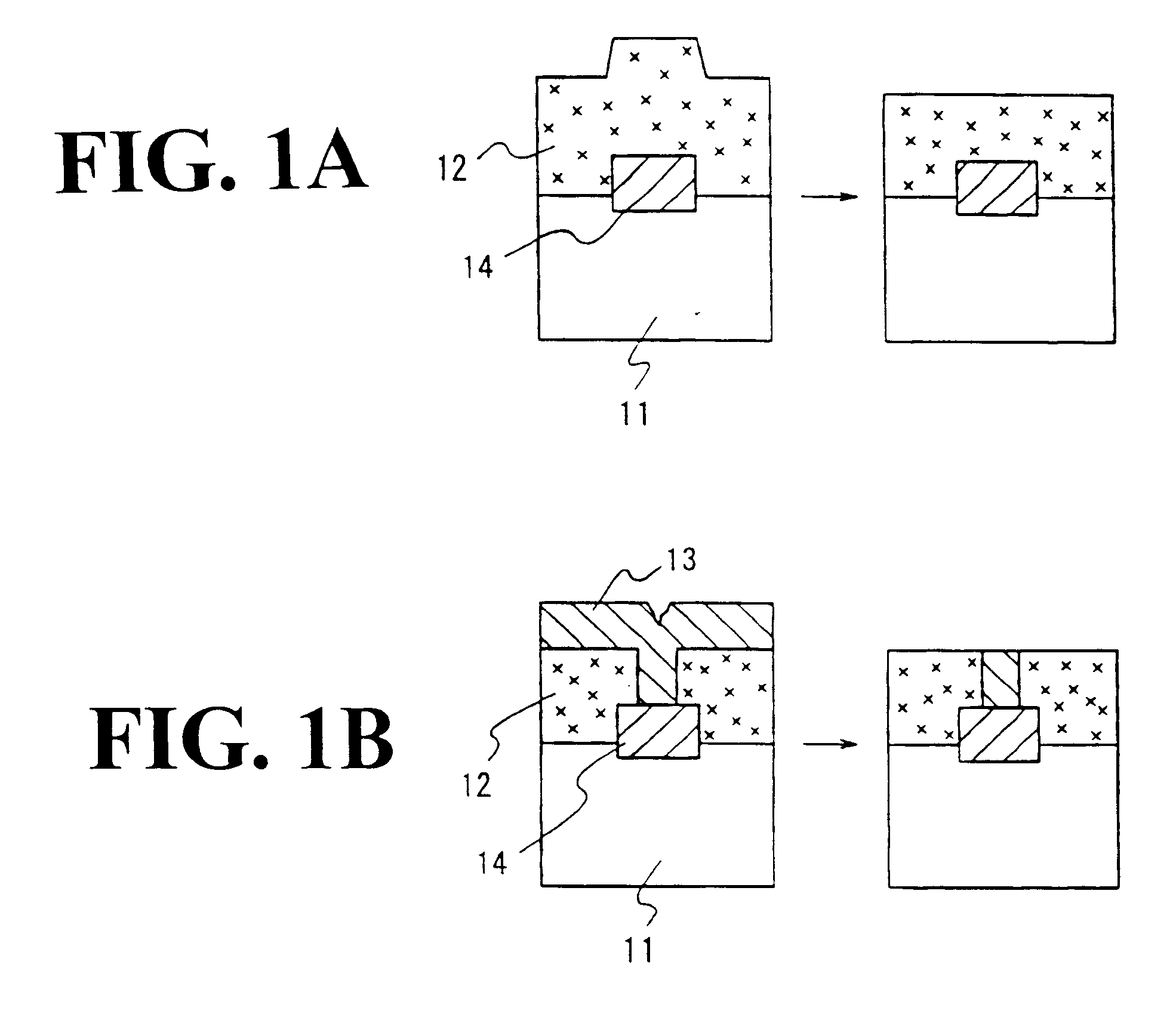

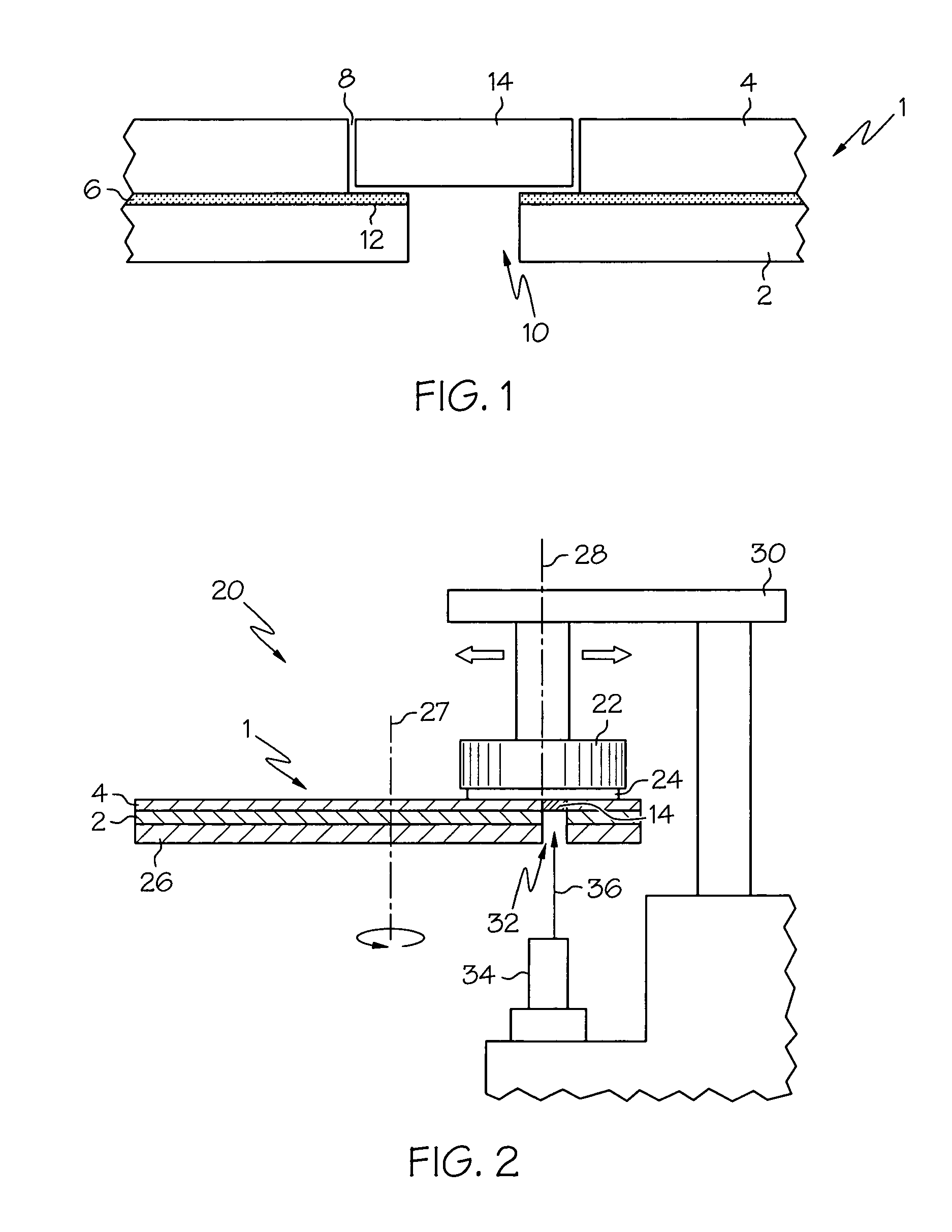

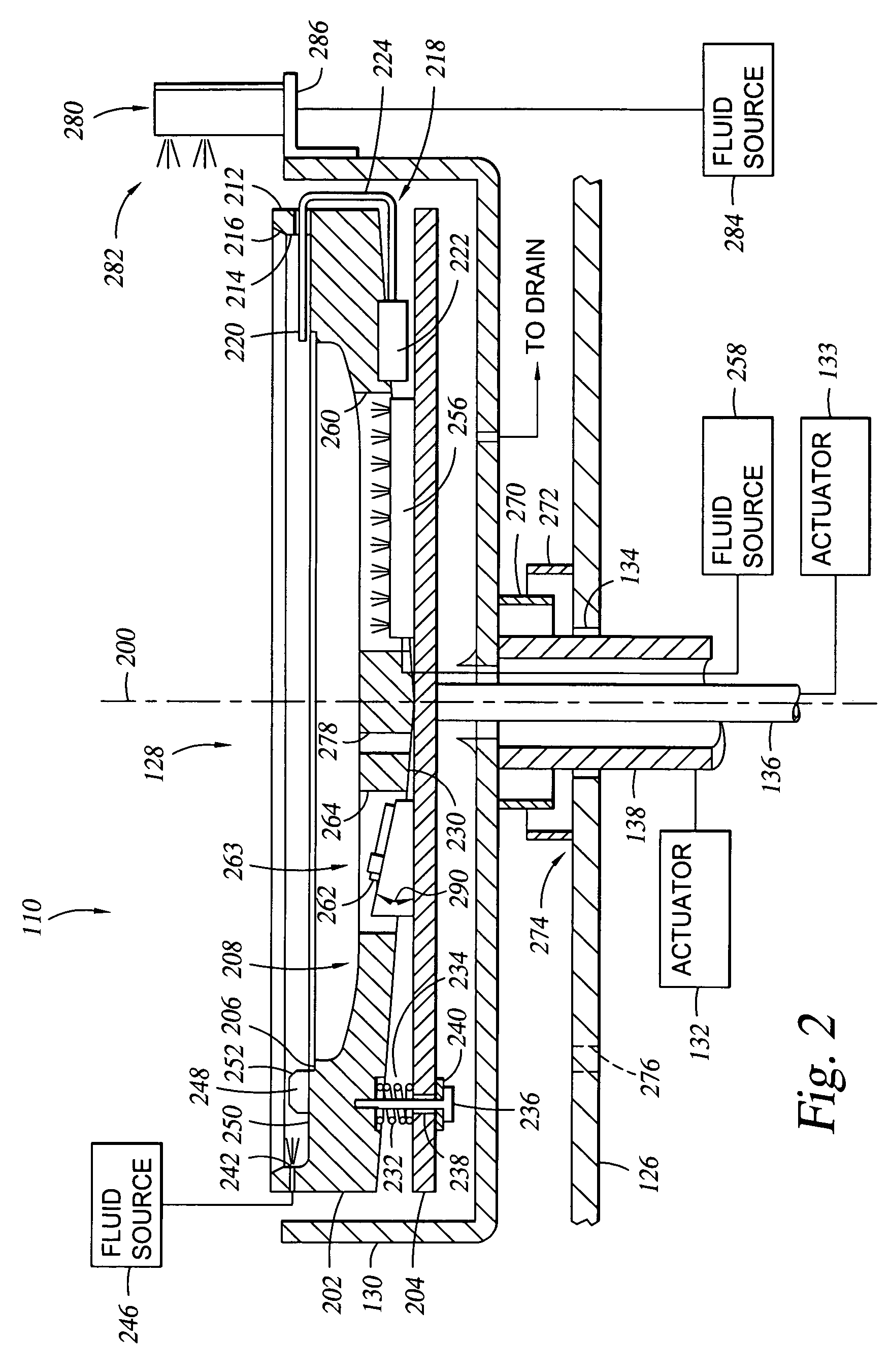

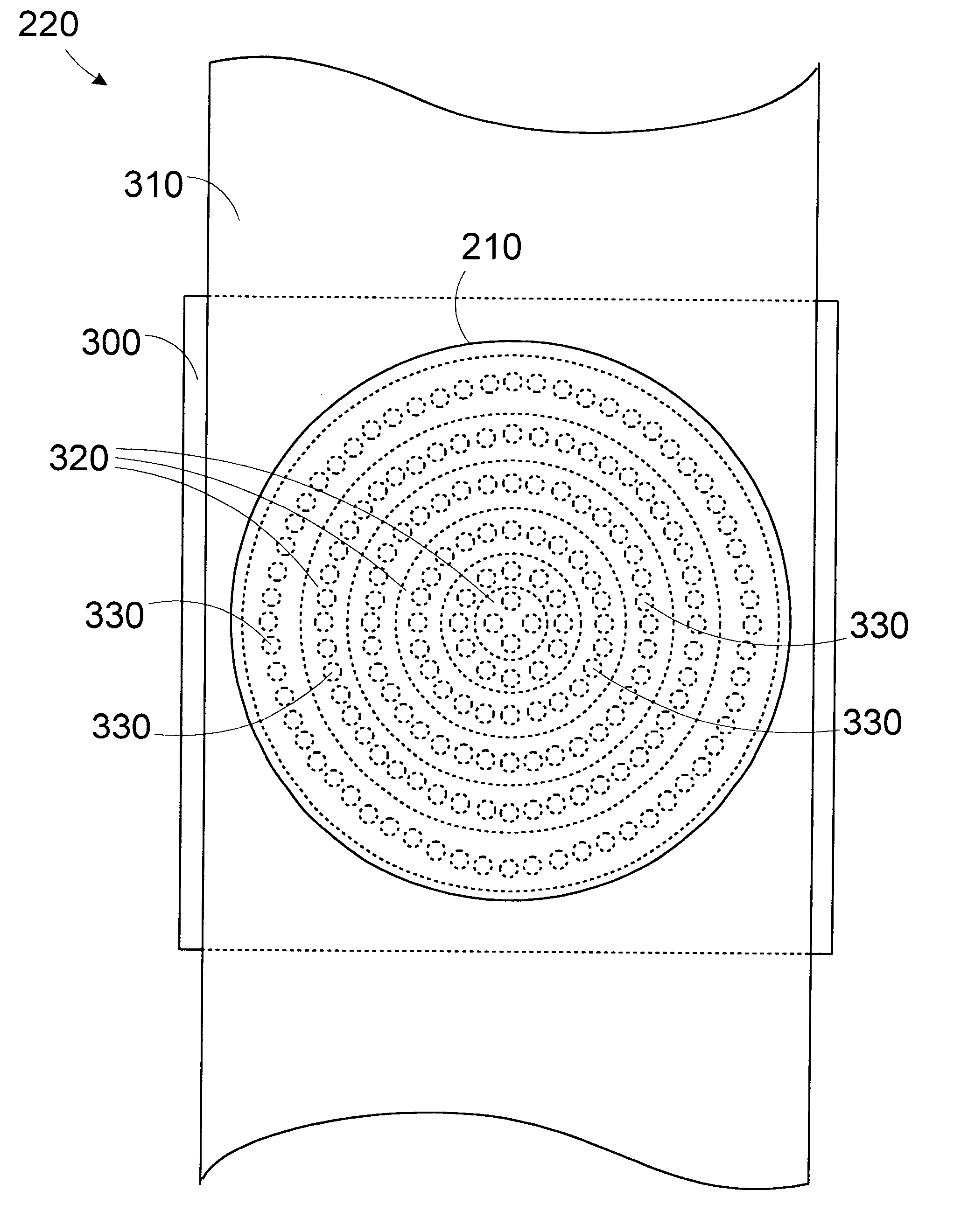

Methods for controlling the pressures of adjustable pressure zones of a work piece carrier during chemical mechanical planarization

ActiveUS7115017B1Polishing machinesRevolution surface grinding machinesEngineeringChemical-mechanical planarization

Methods are provided for controlling adjustable pressure zones of a CMP carrier. A method comprises determining a first thickness of a layer on a wafer underlying a first zone of the carrier. A first portion of the layer underlying the first zone is removed. The first zone is configured to exert a first pressure against the second surface of the wafer. A second thickness of the layer underlying the first zone is determined and a target thickness corresponding to a predetermined thickness profile is selected. A second pressure for the first zone is calculated using the first thickness, the second thickness, the first pressure, and the target thickness. The pressure exerted by the first zone against the second surface of the wafer is adjusted to the second pressure and the steps are repeated for a second zone.

Owner:NOVELLUS SYSTEMS

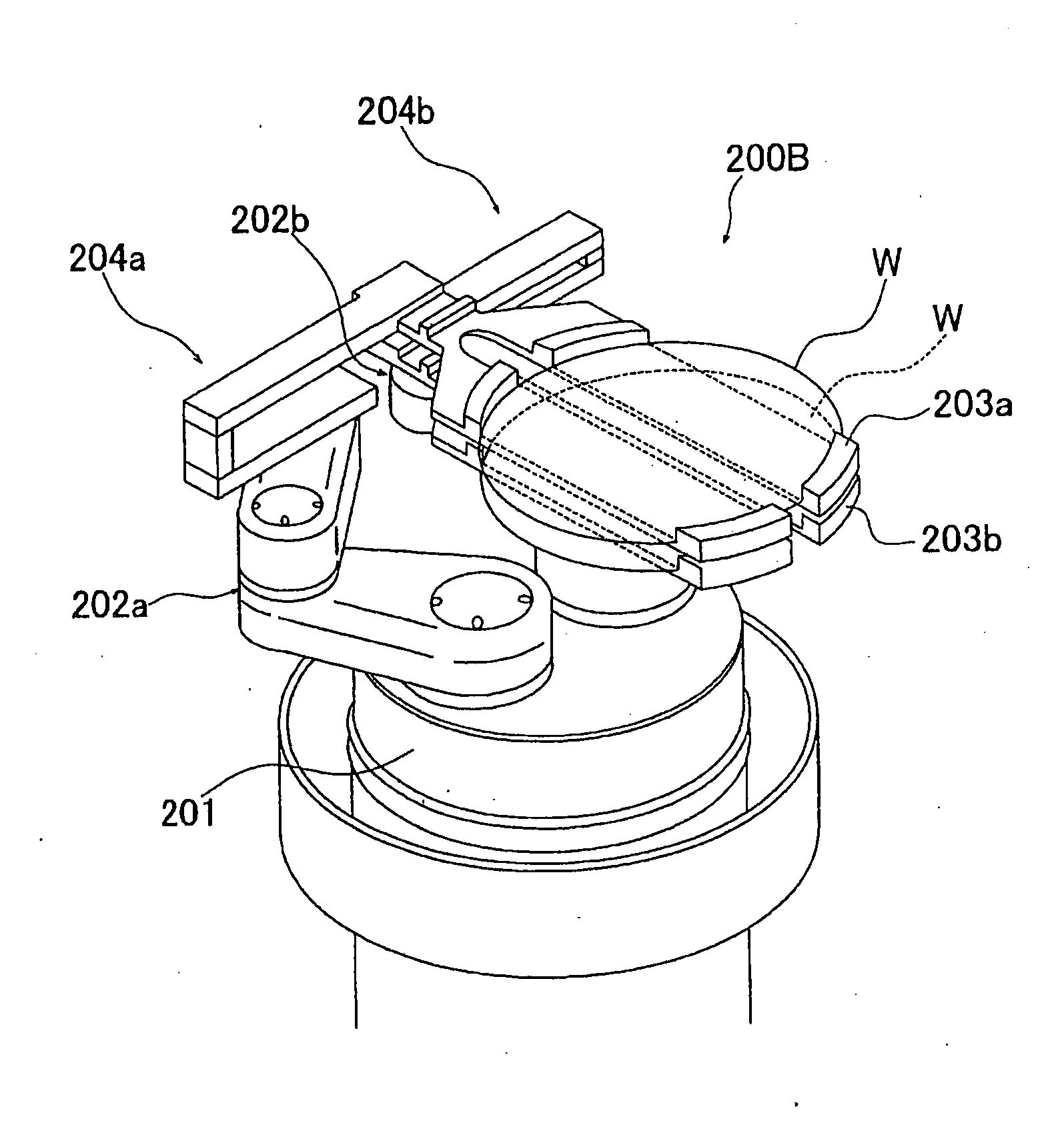

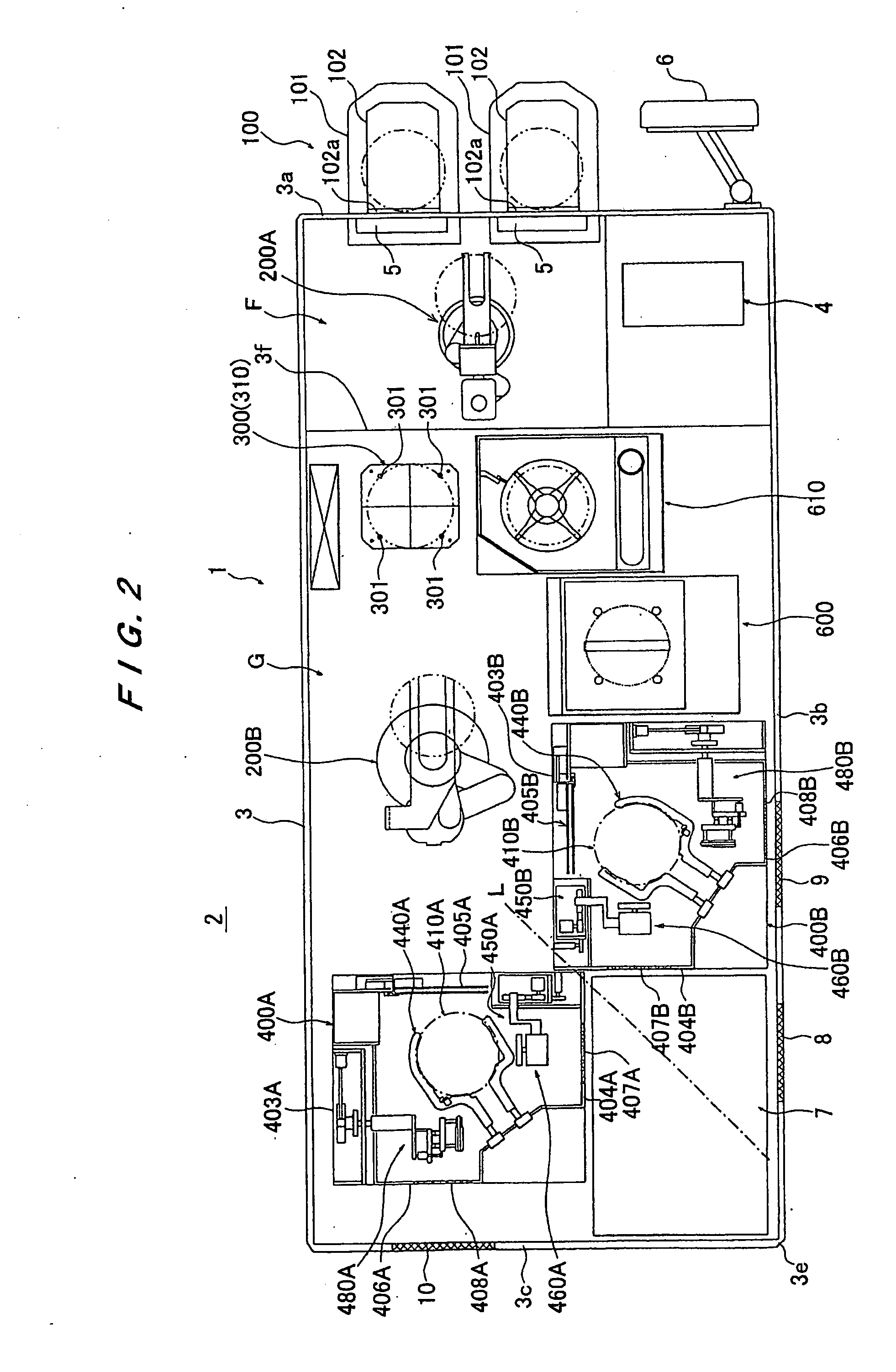

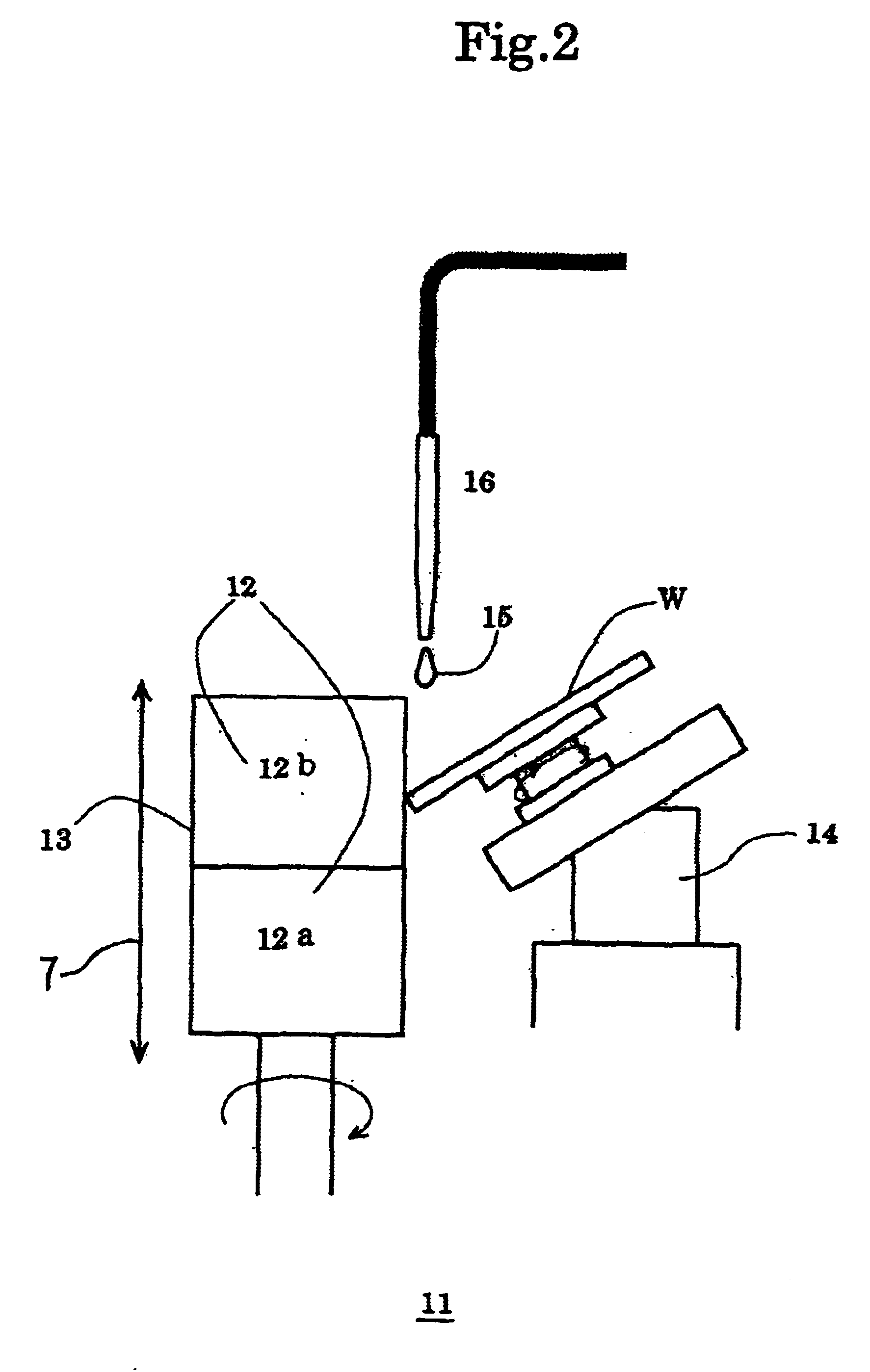

Substrate processing apparatus

InactiveUS20090017733A1Improve processing efficiencyEfficiently conductedEdge grinding machinesPolishing machinesEngineering

A substrate processing apparatus (1) has a first polishing unit (400A) and a second polishing unit (400B) for polishing a peripheral portion of a substrate. Each of the two polishing units (400A, 400B) includes a bevel polishing device (450A, 450B) for polishing a peripheral portion of a substrate and a notch polishing device (480A, 480B) for polishing a notch of a substrate. The substrate processing apparatus (1) has a maintenance space (7) formed between the two polishing units (400A, 400B). The bevel polishing devices (450A, 450B) in the two polishing units (400A, 400B) face the maintenance space (7) so as to be accessible from the maintenance space (7).

Owner:EBARA CORP

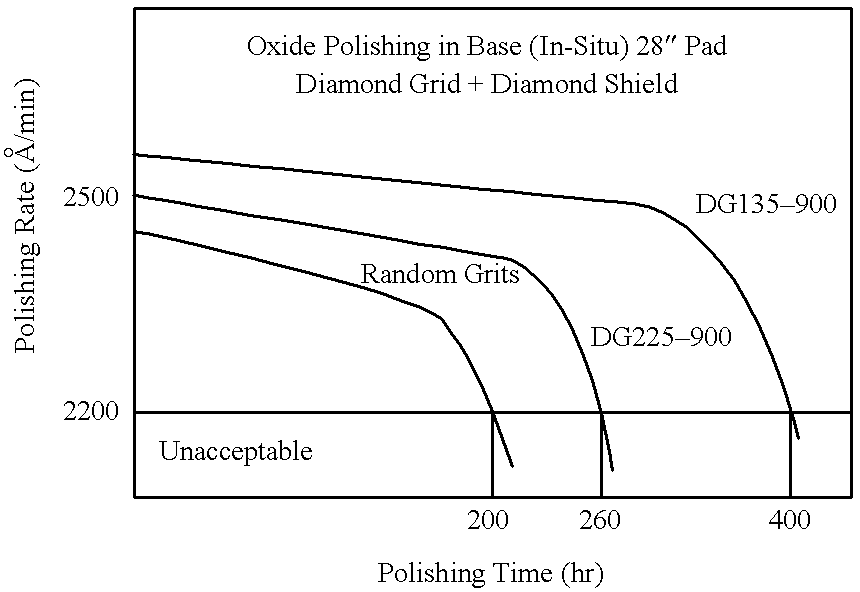

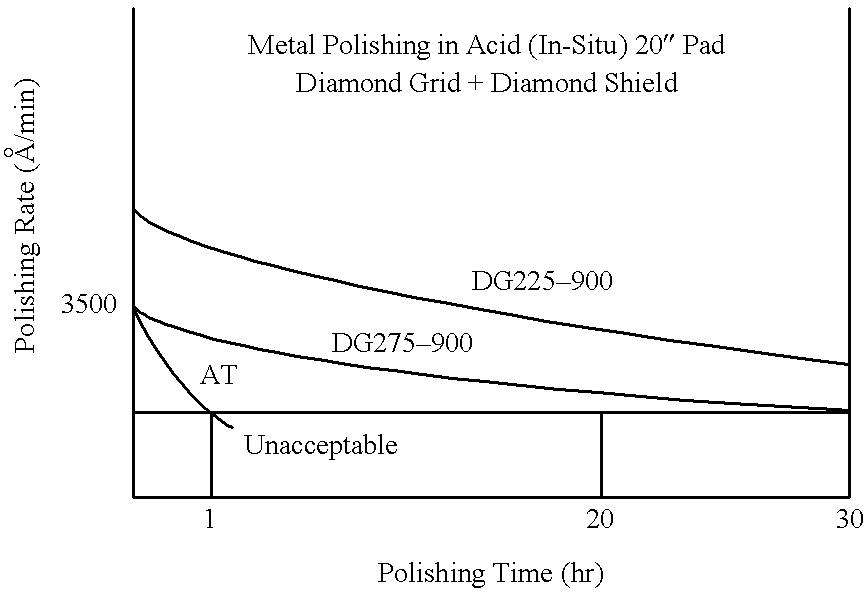

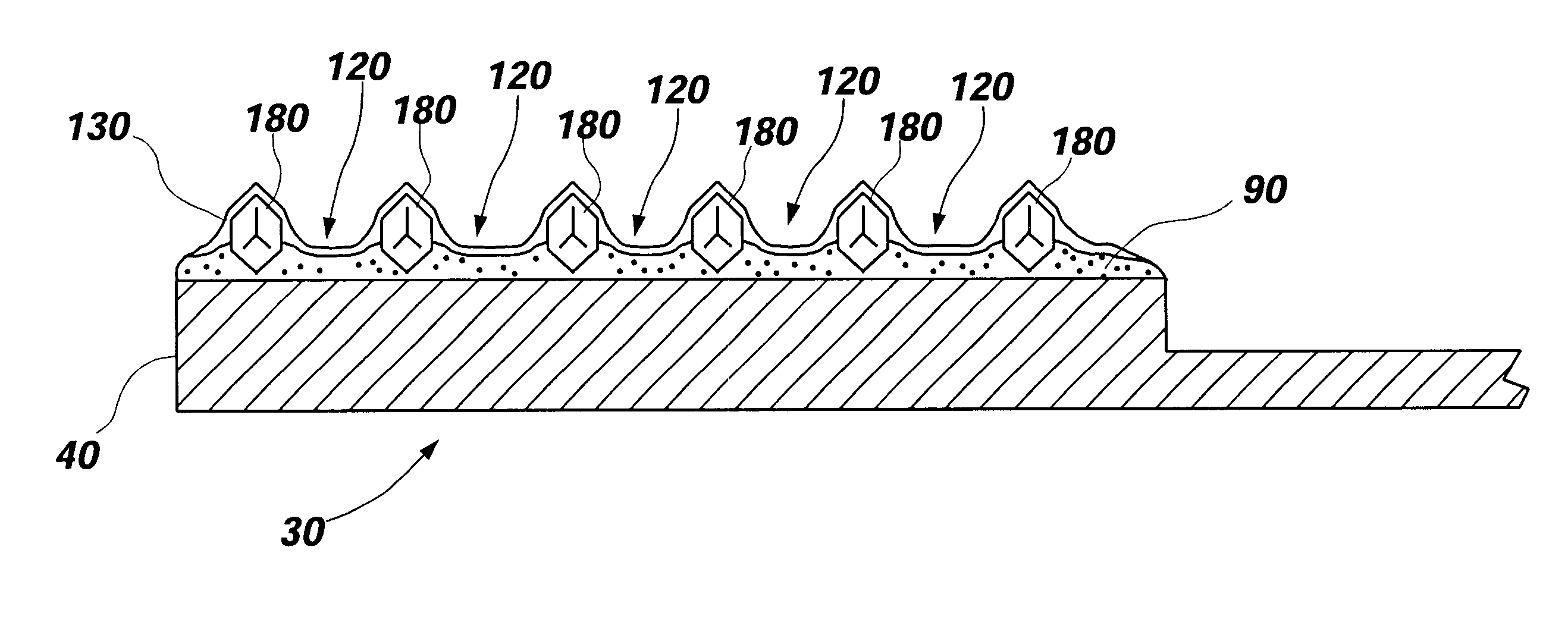

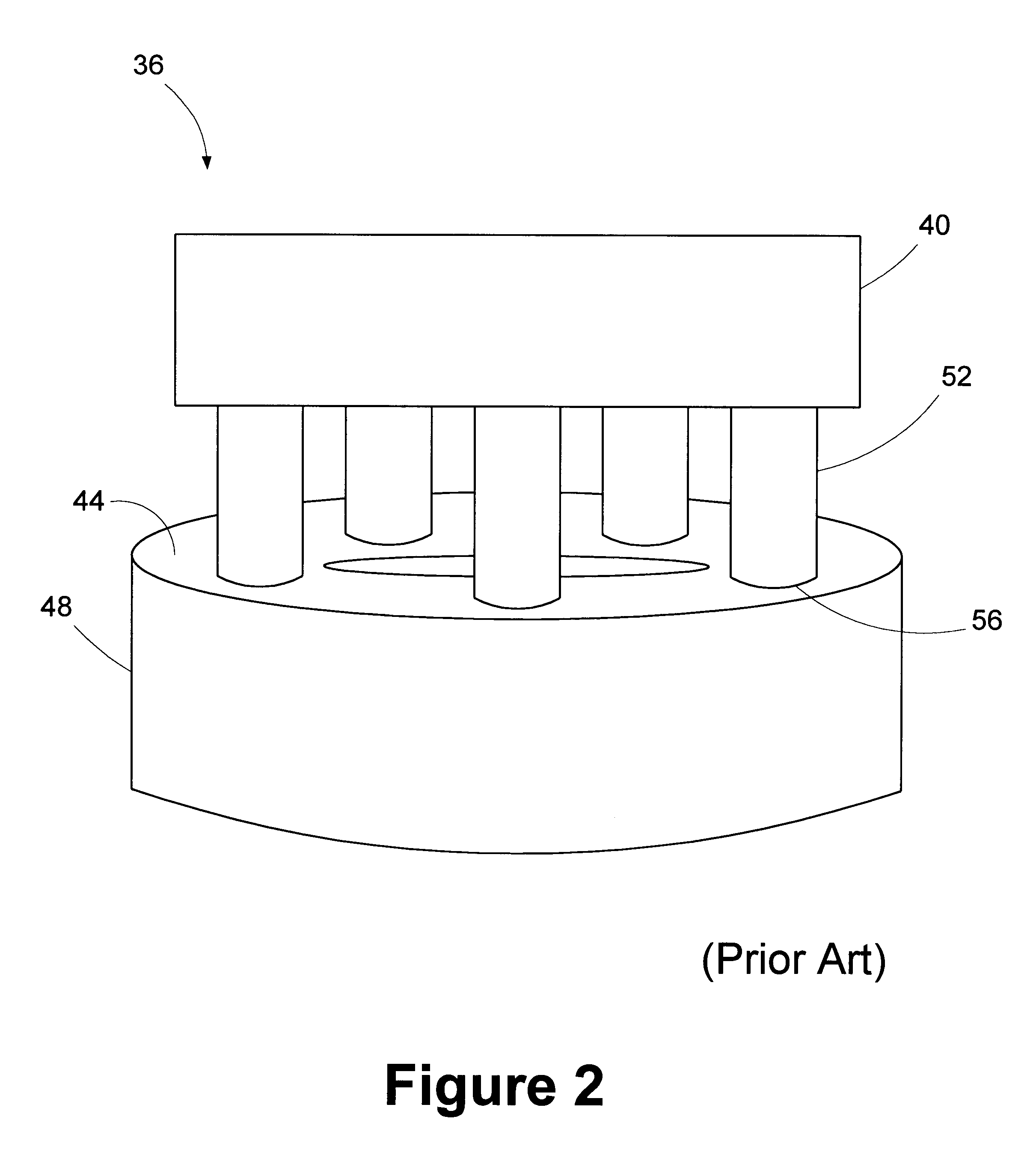

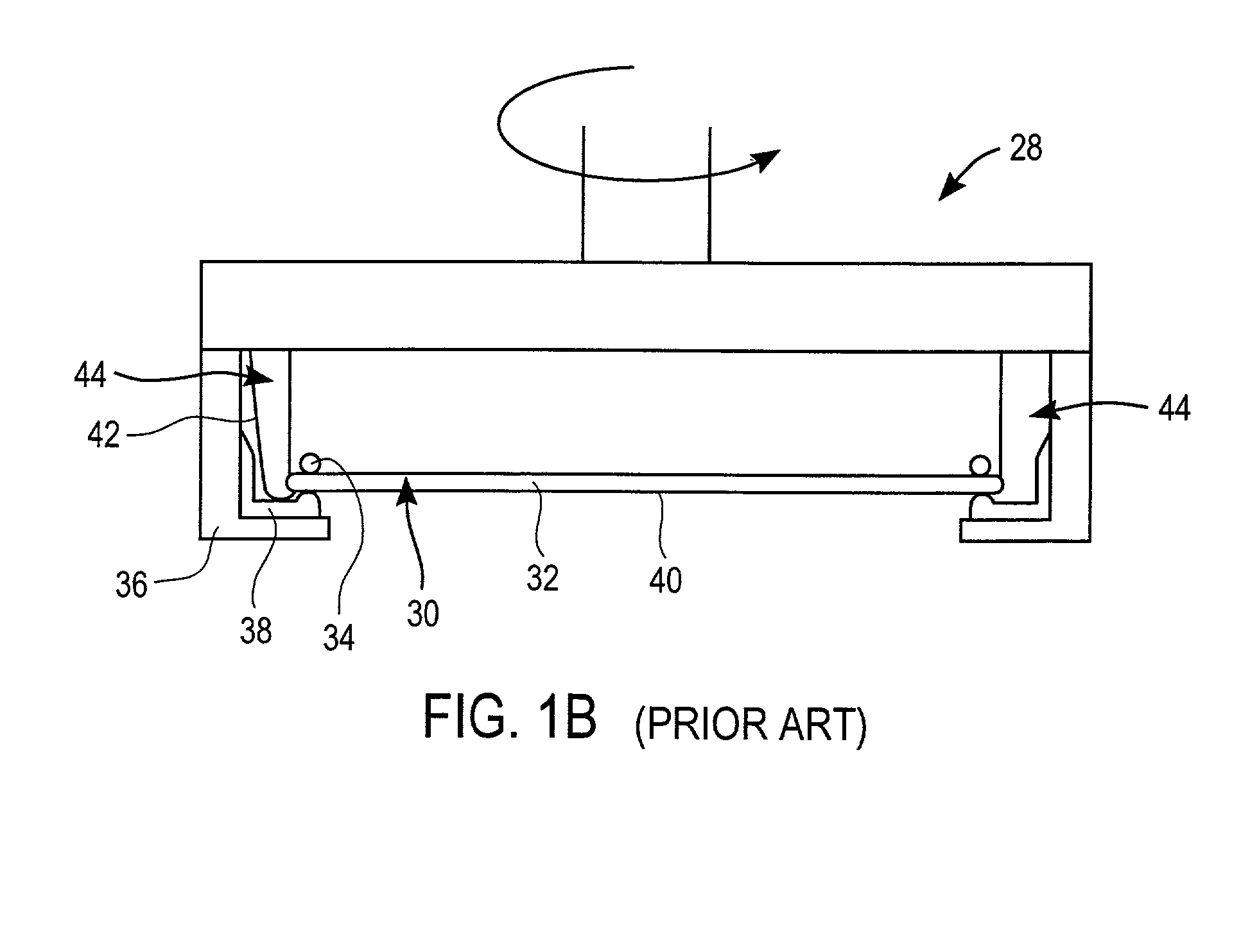

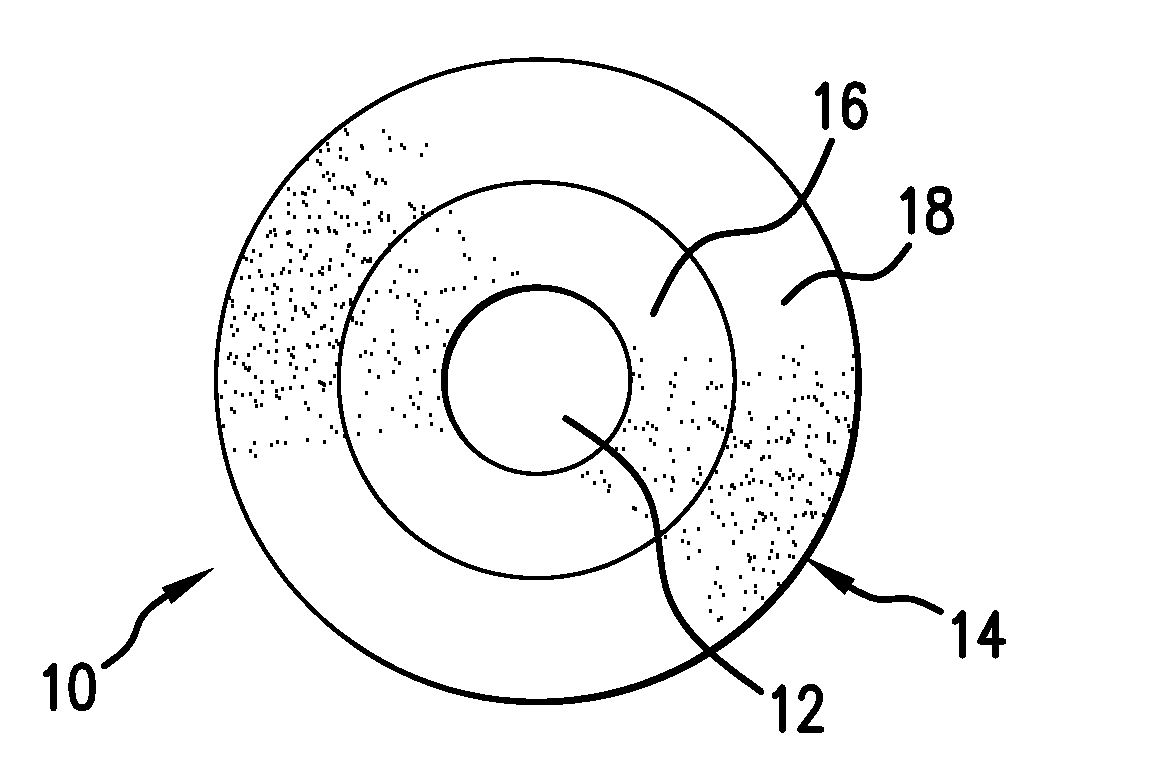

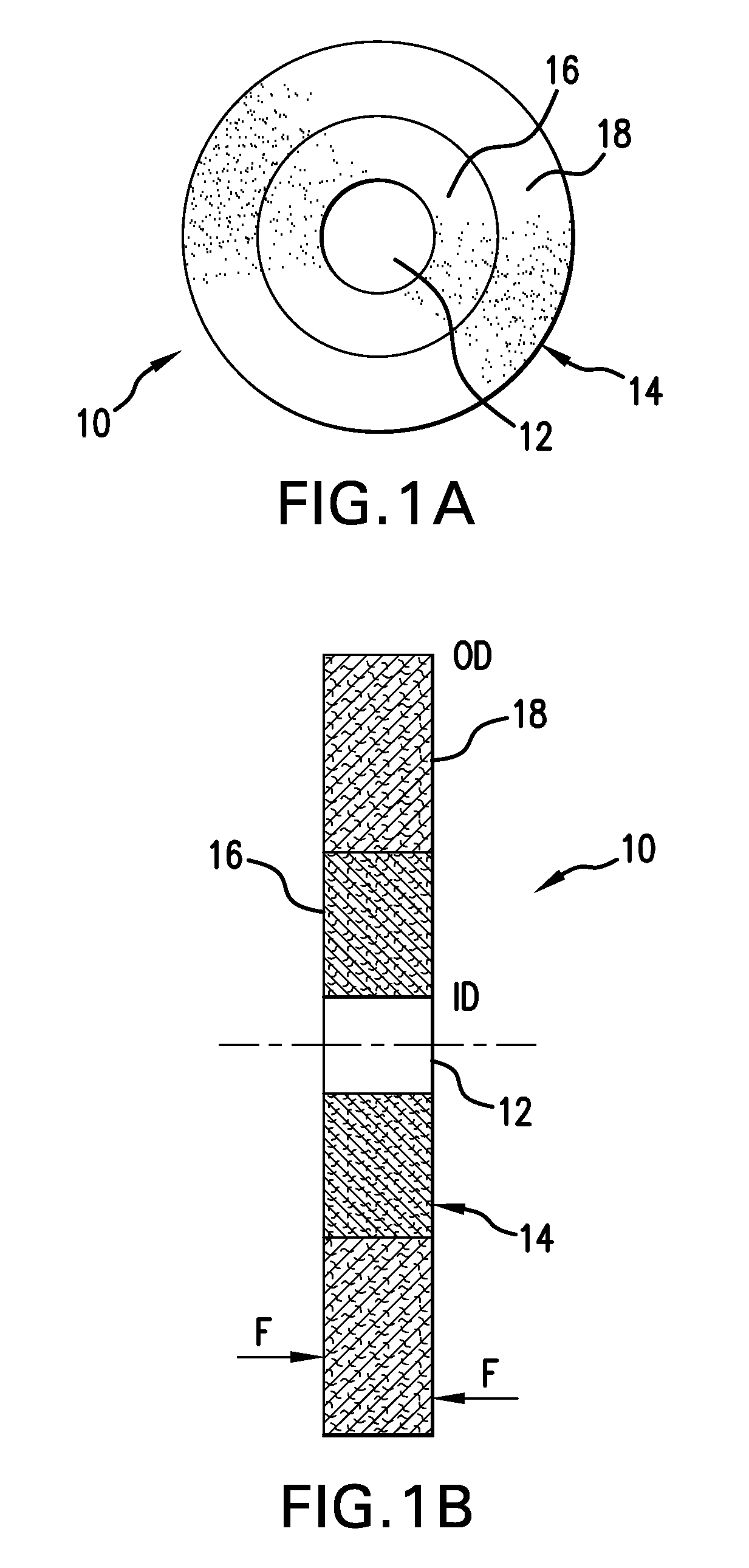

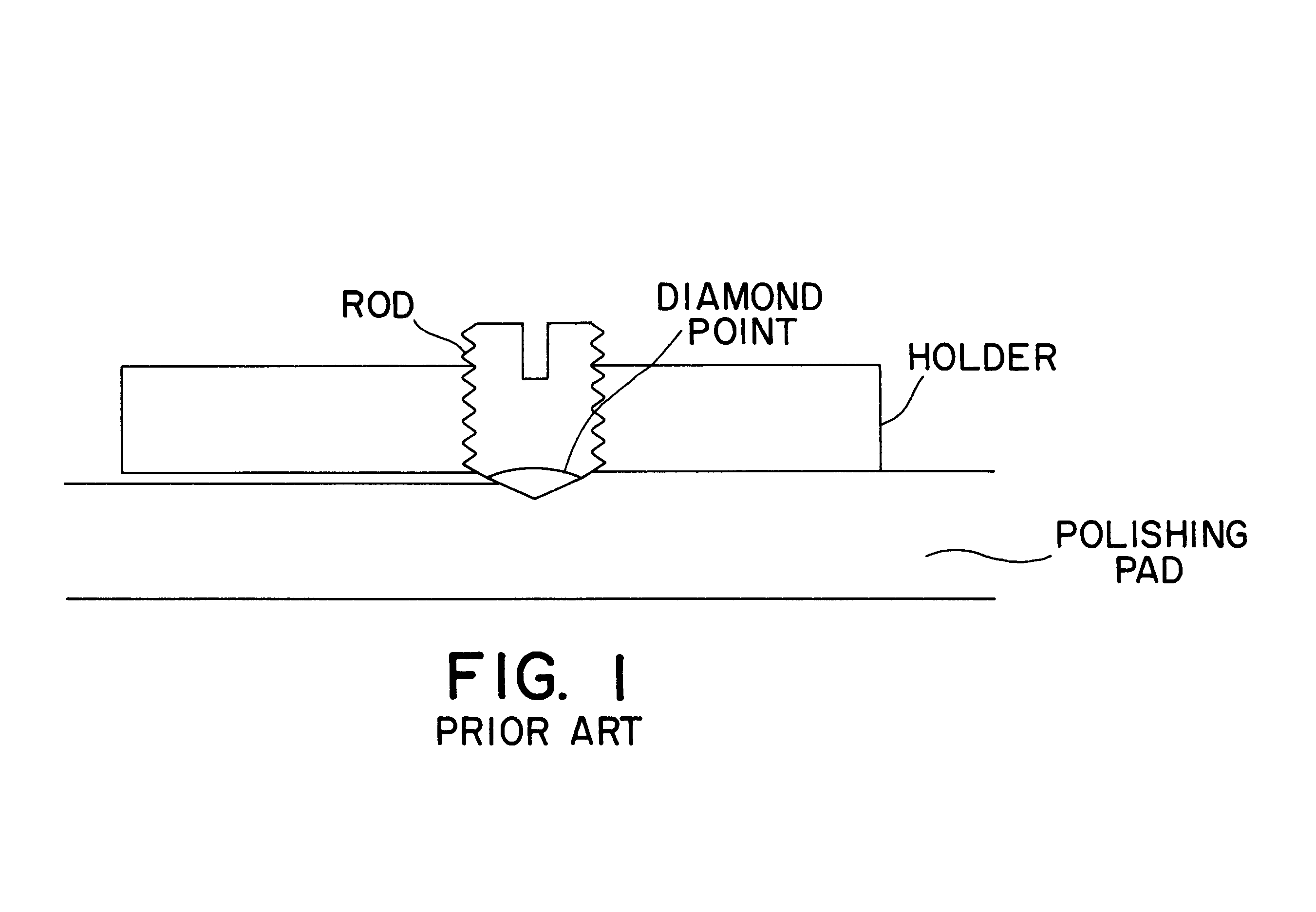

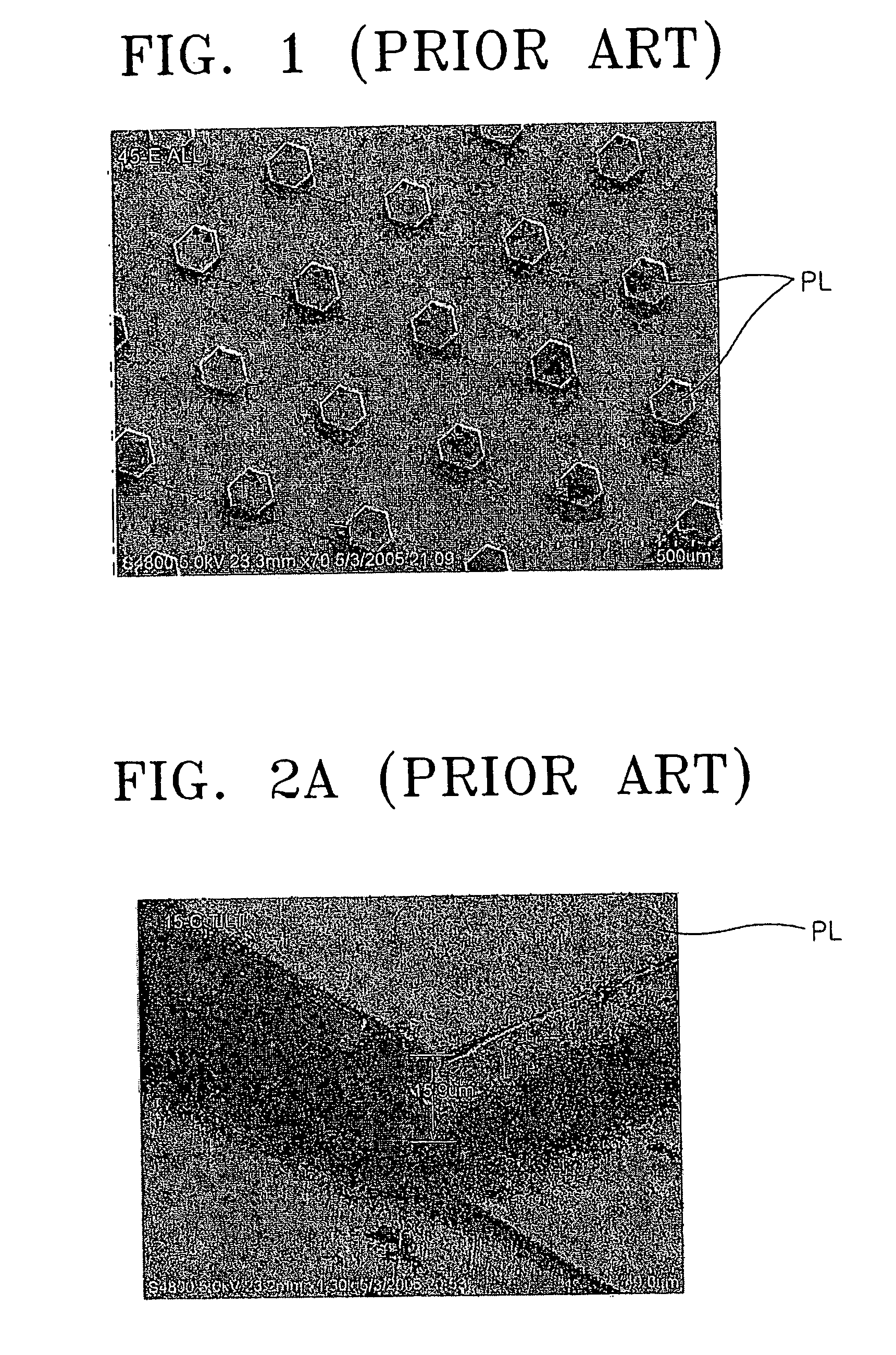

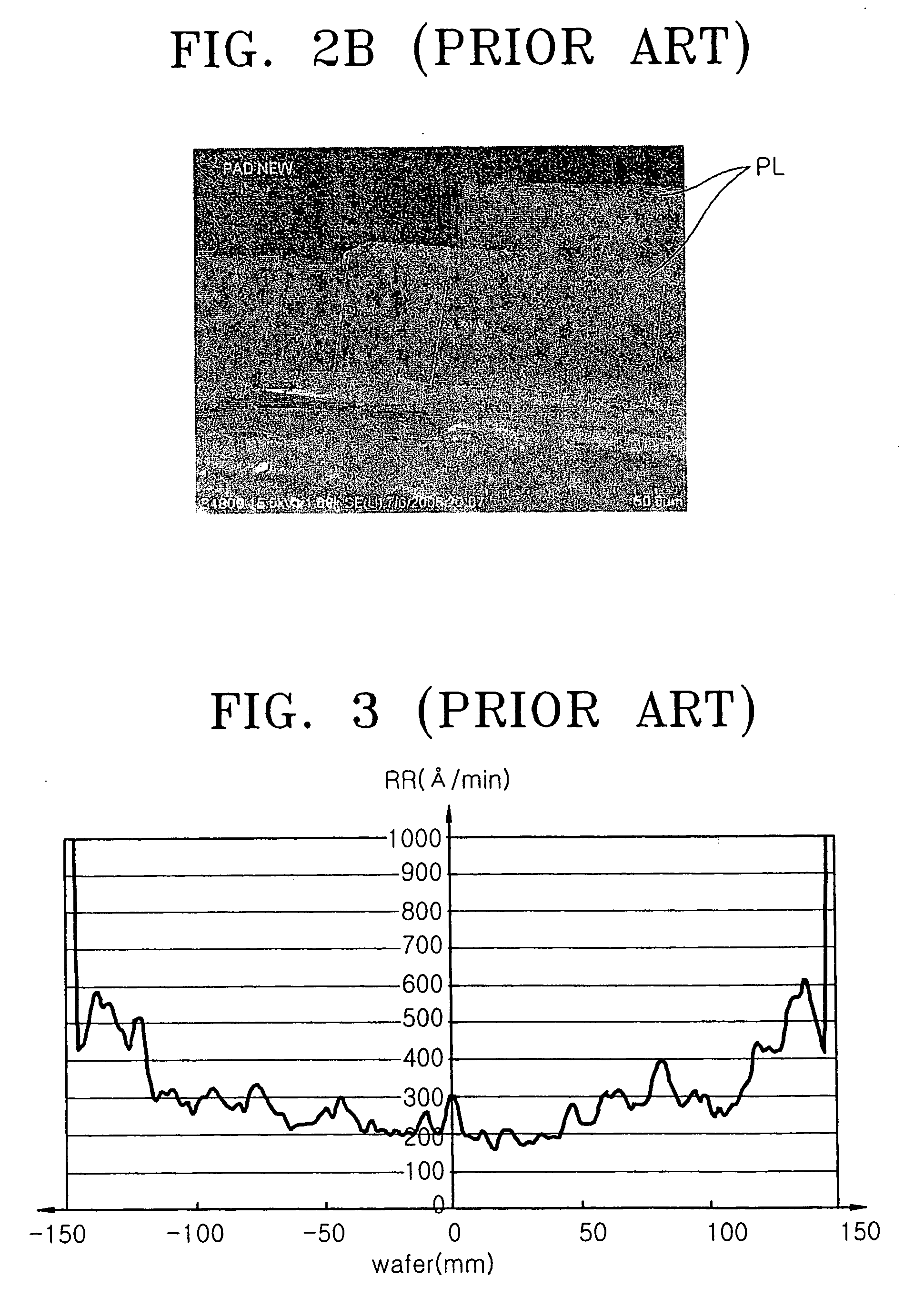

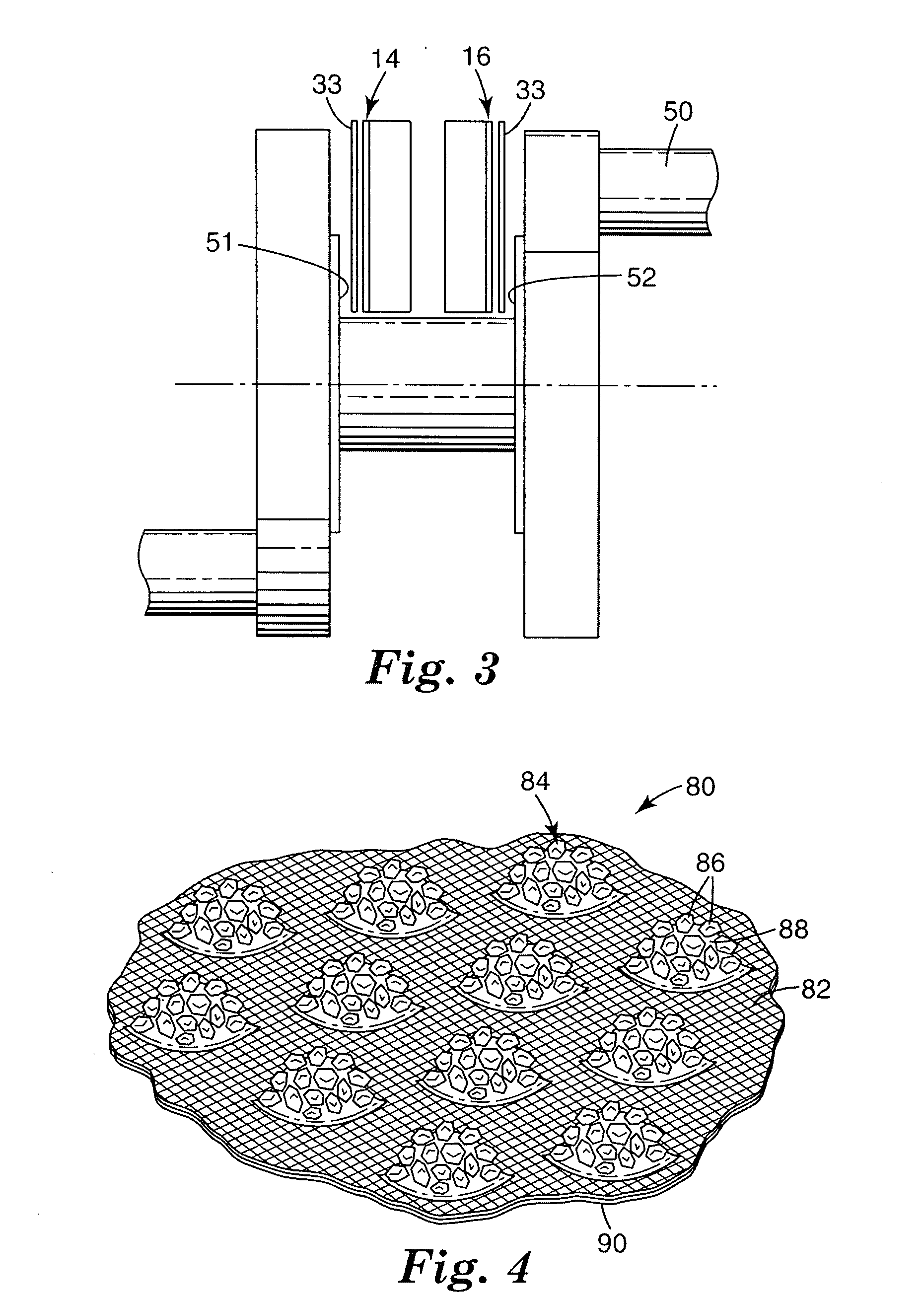

Diamond grid CMP pad dresser

InactiveUS6368198B1Improve polishing efficiencyExtended service lifePolishing machinesRevolution surface grinding machinesSuperhard materialDiamond-like carbon

The present invention discloses a CMP pad dresser which has a plurality of uniformly spaced abrasive particles protruding therefrom. The abrasive particles are super hard materials, and are typically diamond, polycrystalline diamond (PCD), cubic boron nitride (cBN), or polycrystalline cubic boron nitride(PcBN). The abrasive particles are brazed to a substrate which may be then coated with an additional anti-corrosive layer. The anti-corrosive layer is usually a diamond or diamond-like carbon which is coated over the surface of the disk to prevent erosion of the brazing alloy by the chemical slurry used in conjunction with the CMP pad. This immunity to chemical attack allows the CMP pad dresser to dress the pad while it is polishing a workpiece. In addition to even spacing on the substrate, the abrasive particles extend for a uniform distance away from the substrate, allowing for even grooming or dressing of a CMP pad both in vertical and horizontal directions. A method of producing such a CMP pad dresser is also disclosed.

Owner:KINIK

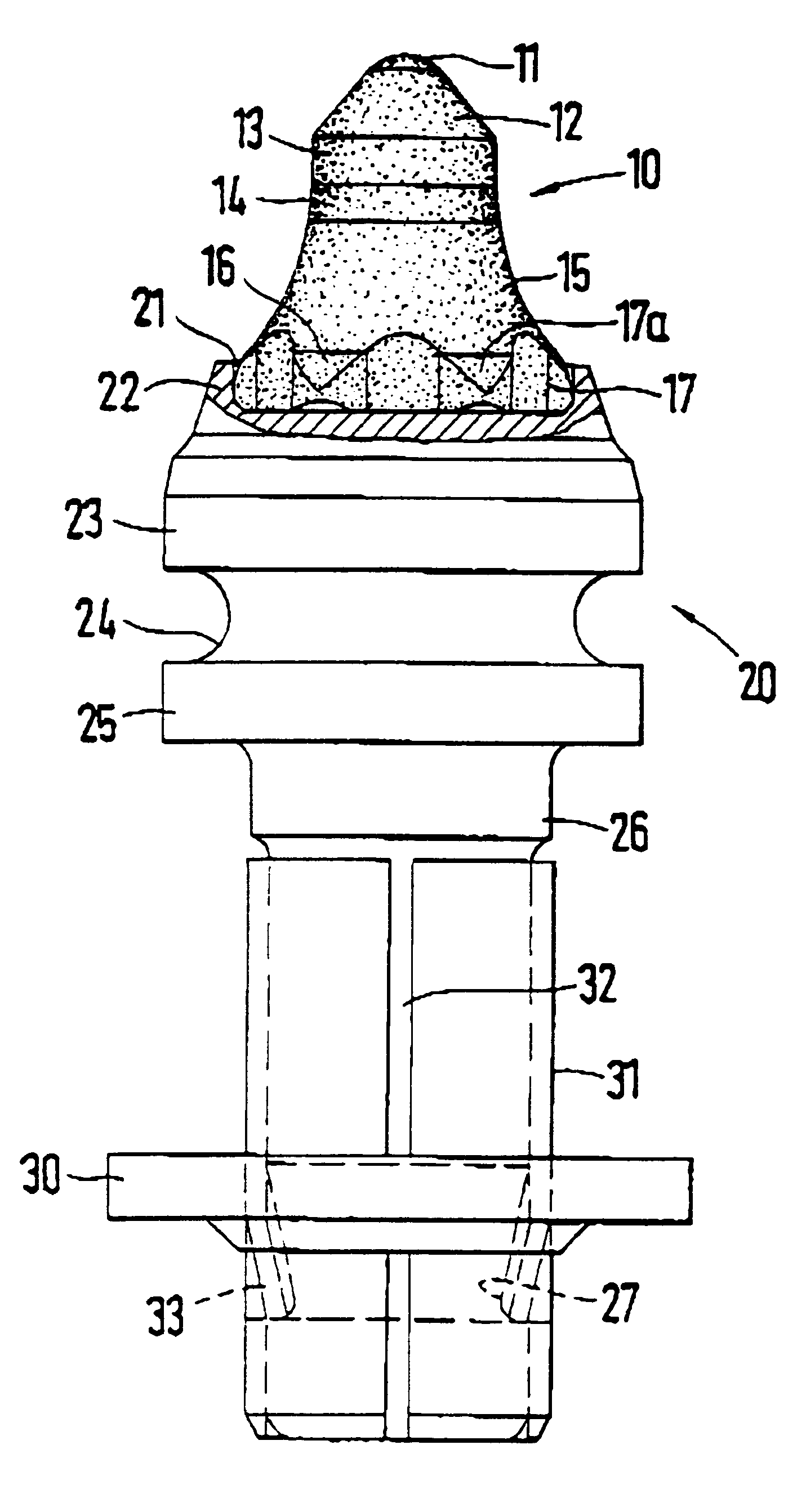

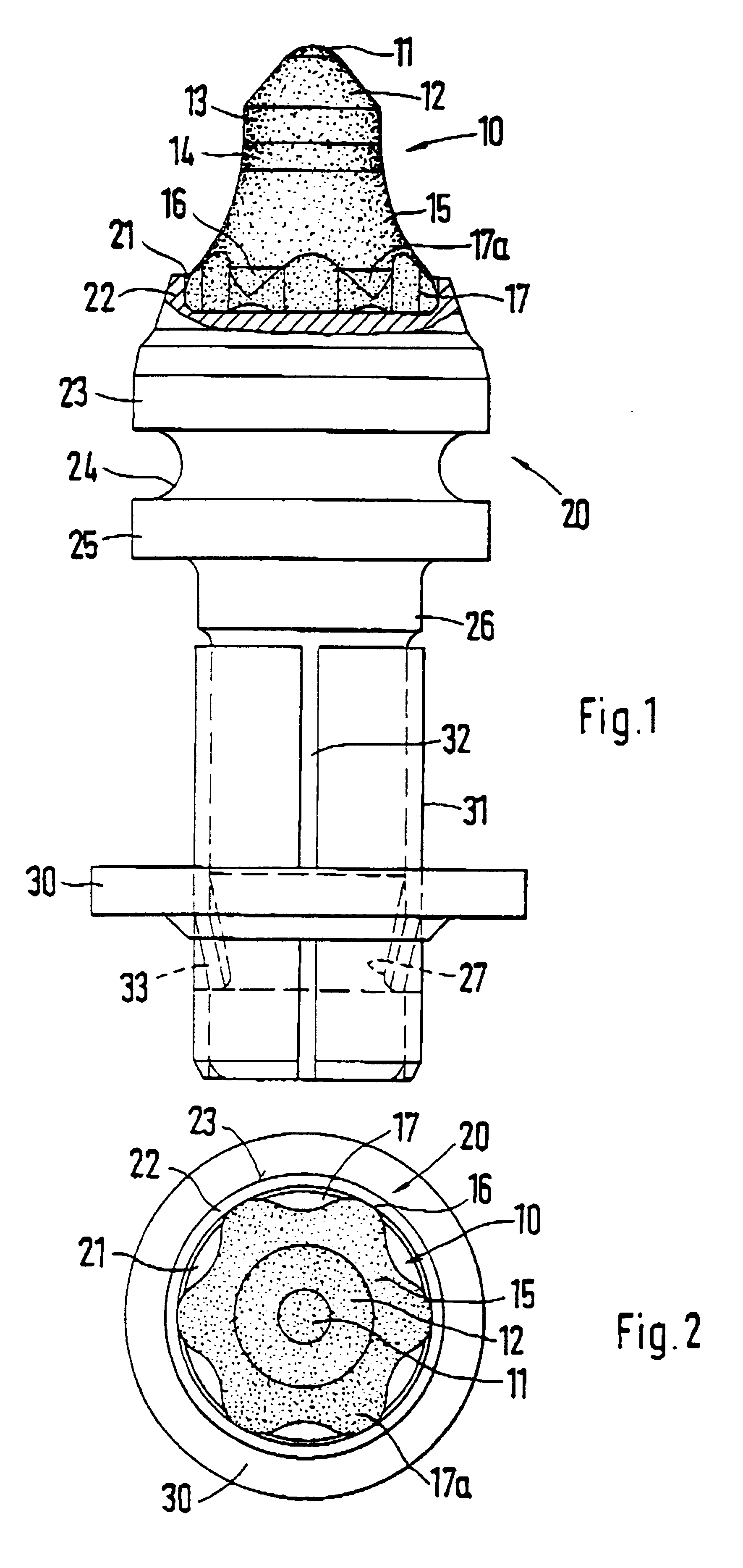

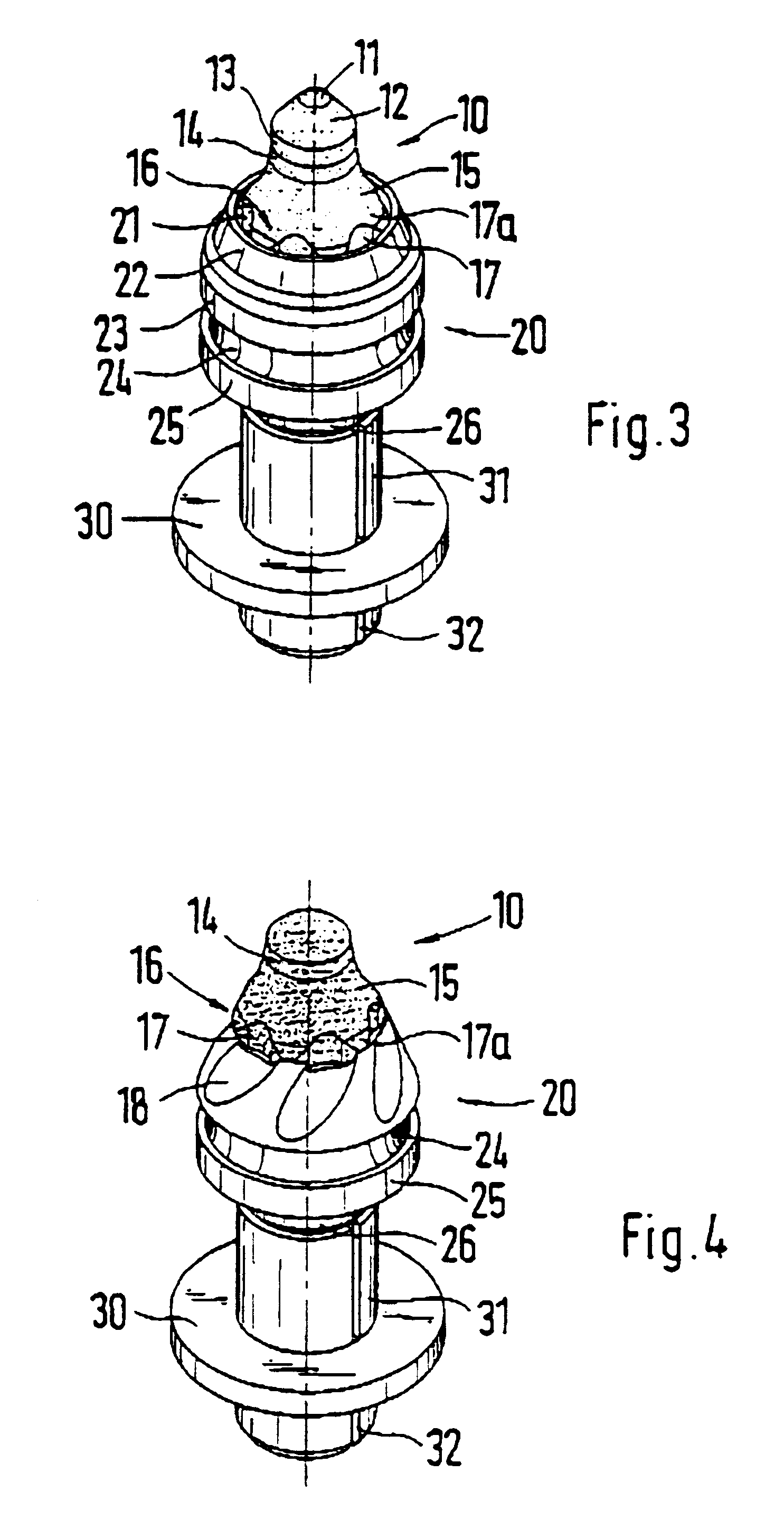

Round-shank bit for a coal cutting machine

InactiveUS6199956B1Sufficient supportLess stressPolishing machinesRevolution surface grinding machinesMaximum diameterEngineering

A round-shank bit for a coal cutting machine or the like, having a bit head and a bit shank, wherein the bit head has a bit tip, maintained by a base element in a receptacle of the bit head. Starting at the base element, the bit tip tapers in a direction toward the free end of the bit tip, wherein the base element forms a maximum diameter of the bit tip, and wherein the bit tip has recesses on its outer contour. In order to assure good rotational behavior over the entire length of the operating time, the base element has the recesses on an outer circumference forming the maximum diameter.

Owner:BETEK BERGBAU UND HARTMETALLTECHN KARL HEINZ SIMON

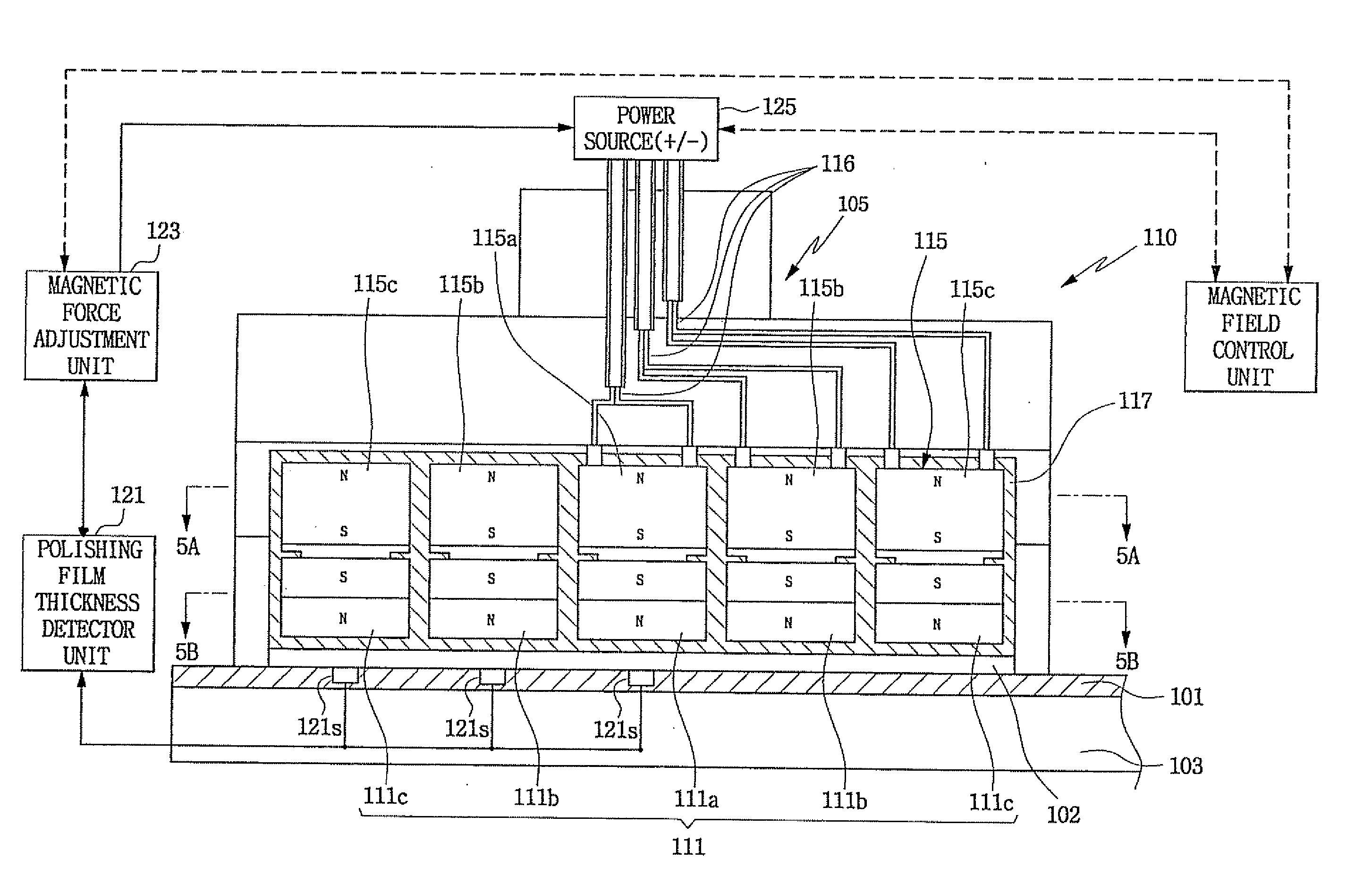

Polishing apparatus and related polishing methods

InactiveUS20060189259A1Uniform thicknessPolishing machinesRevolution surface grinding machinesEngineeringMagnetic field

Polishing apparatus and related methods employ aligned first and second magnetic field sources to adjust the compressive force and / or pressure applied by a carrier head against a target workpiece (such as a wafer) by selectively and controllably generating a repellant or attractive force between the two magnetic field sources.

Owner:SAMSUNG ELECTRONICS CO LTD

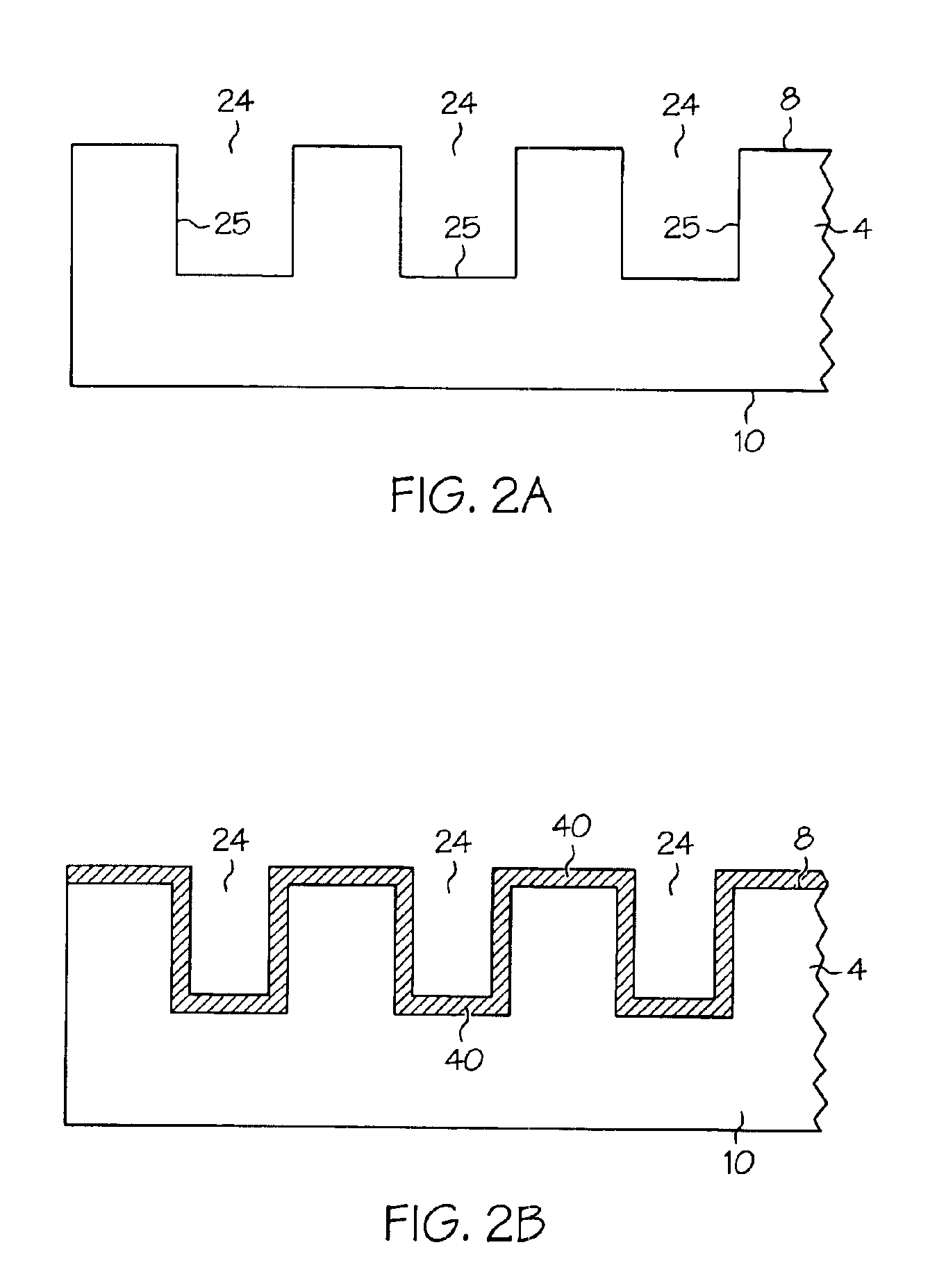

Polishing pads and methods relating thereto

InactiveUS6022268AEnhanced interactionLess-proneRevolution surface grinding machinesOther chemical processesEngineeringTopography

This invention describes improved polishing pads useful in the manufacture of semiconductor devices or the like. The pads of the present invention have an advantageous hydrophilic polishing material and have an innovative surface topography and texture which generally improves predictability and polishing performance.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

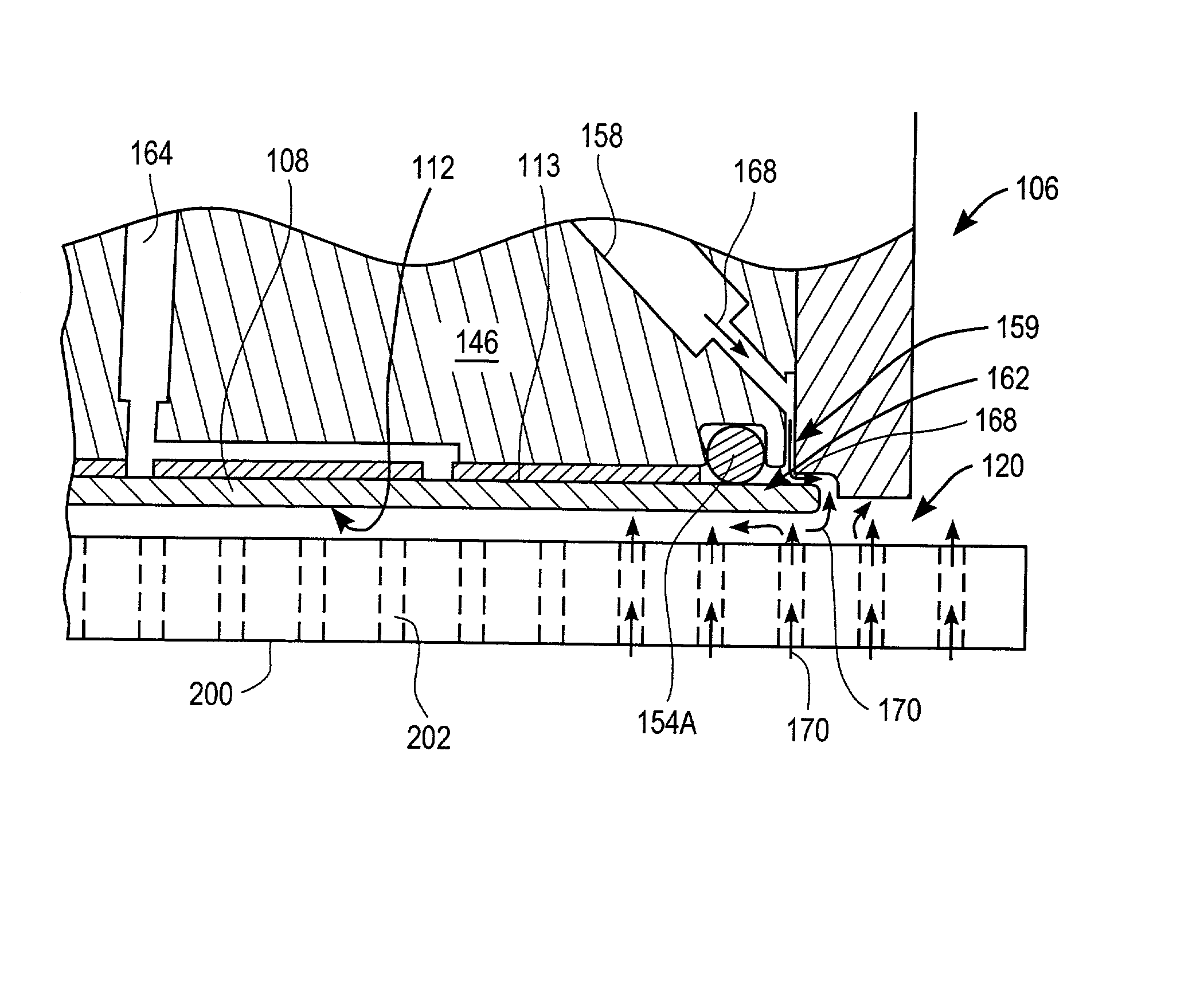

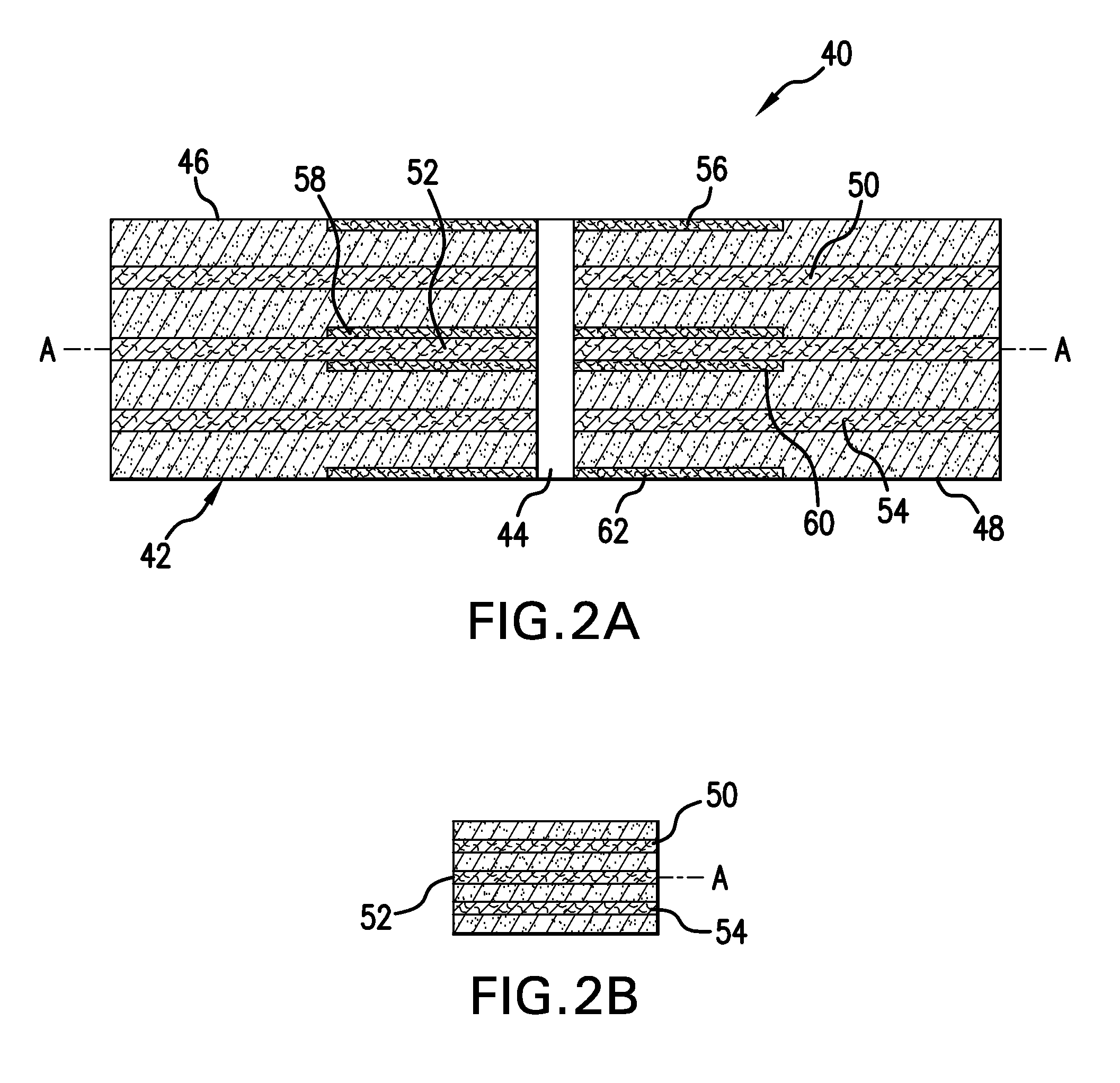

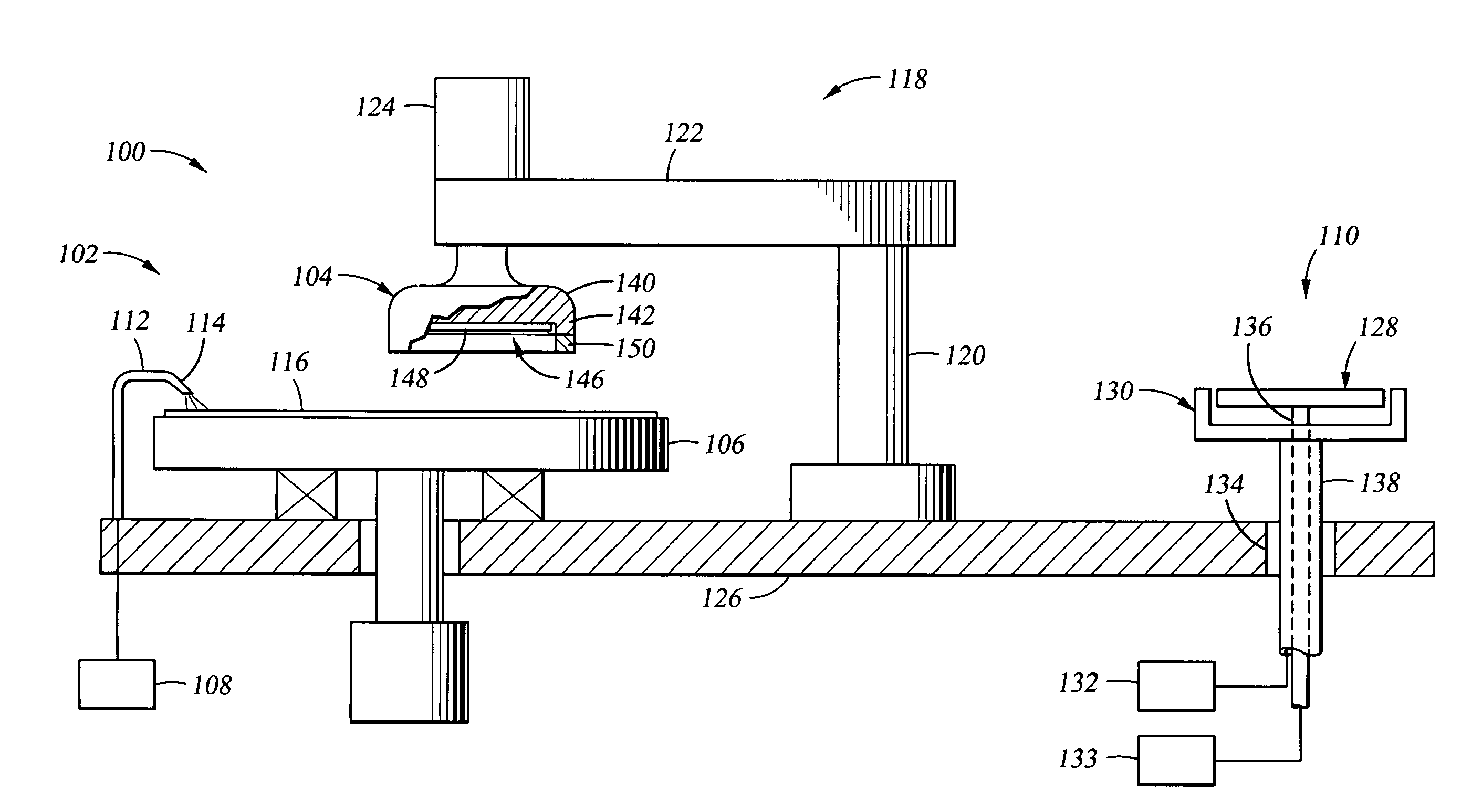

Apparatus for determining metal CMP endpoint using integrated polishing pad electrodes

A polishing system includes a polishing tool having a platen, a polishing pad, and a controller. The platen is adapted to have the polishing pad attached thereto. The polishing pad includes a polishing surface and a back surface that is opposite the polishing surface. At least one sender electrode and at least one response electrode is disposed in the polishing pad. The controller is coupled to the polishing tool. A method includes polishing a conductive process layer of a wafer using a polishing pad of a polishing tool having at least one sender electrode and at least one response electrode disposed therein. A signal is provided to the at least one sender electrode. The signal provided to the at least one sender electrode is monitored with at least one of a group of the at least one response electrode, the at least one response electrode communicating with the at least one sender electrode through the conductive process layer of the wafer. Endpoint of the polishing process is determined based on the signal received by the at least one response electrode.

Owner:ADVANCED MICRO DEVICES INC

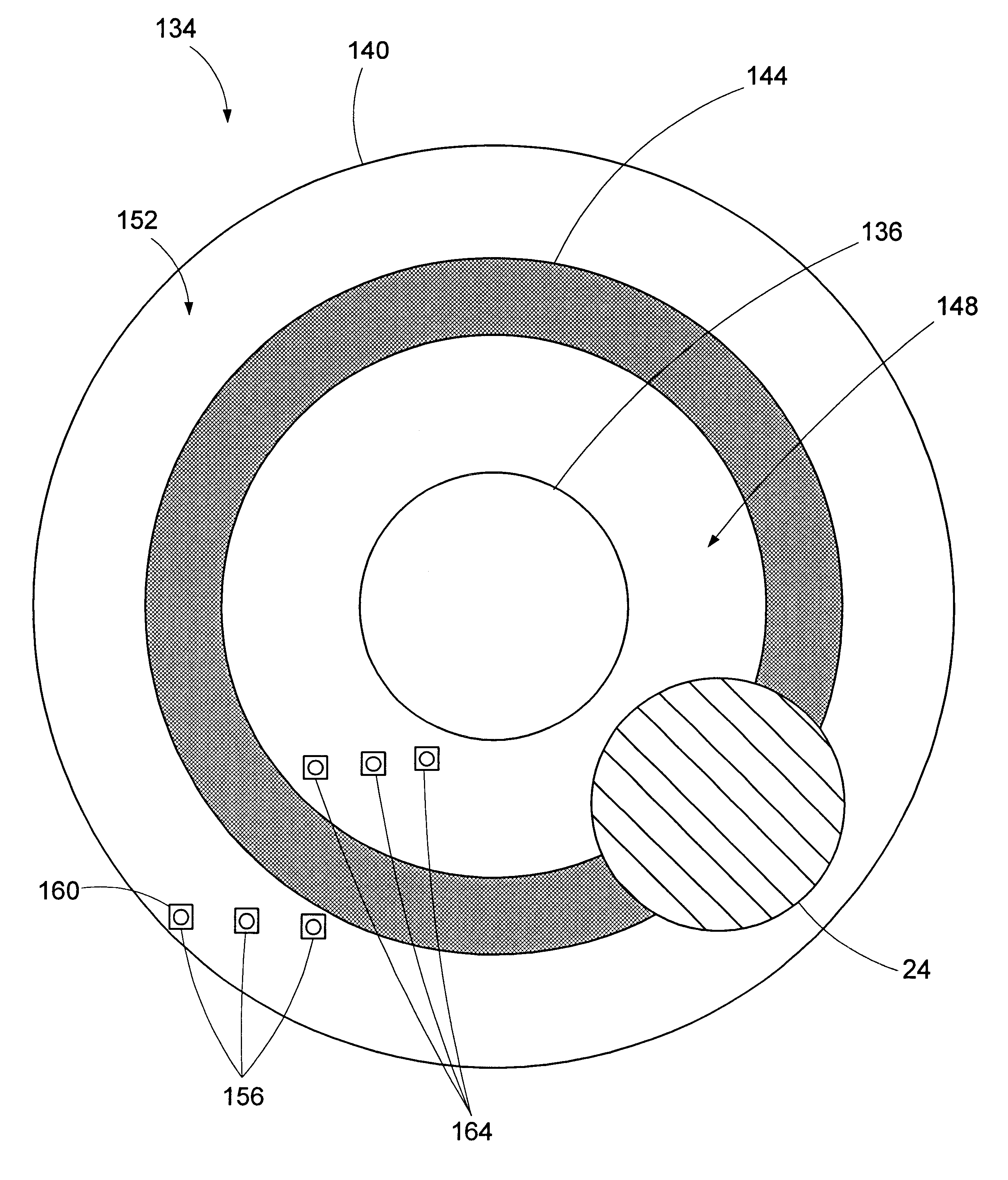

Method and apparatus of sealing wafer backside for full-face electrochemical plating

InactiveUS20030008602A1Efficient configurationMinimize irregularityEdge grinding machinesPolishing machinesMechanical engineeringElectroplating

The present invention provides a wafer carrier that includes a plurality of concentric sealing members that provide a seal, with the outer seal independently movable to allow cleaning of a peripheral backside of the wafer to occur while the wafer is still attached to the wafer carrier, and a plurality of vacuum openings that a re disposed only adjacent to an inner side of the inner seal at a location corresponding to the backside periphery of the wafer.

Owner:NOVELLUS SYSTEMS

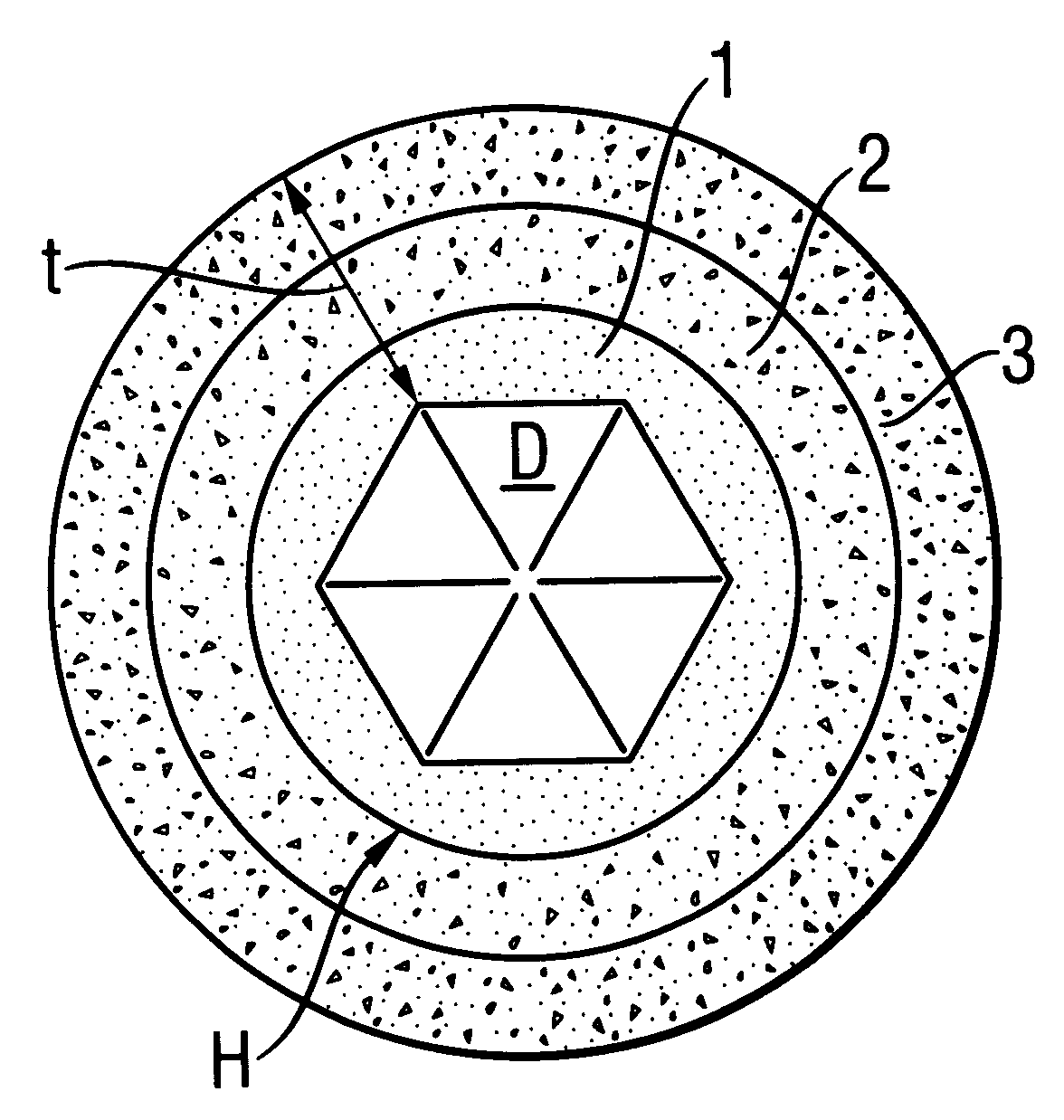

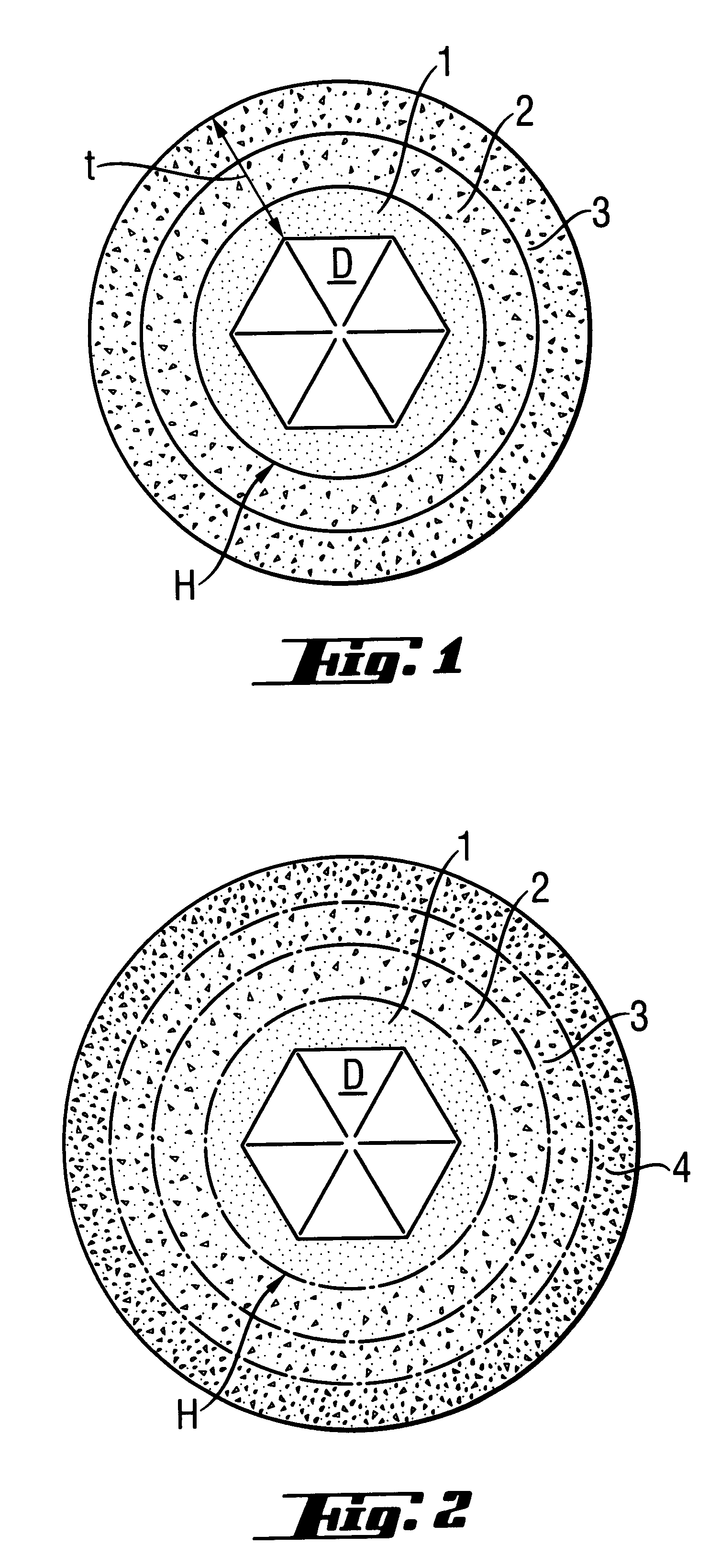

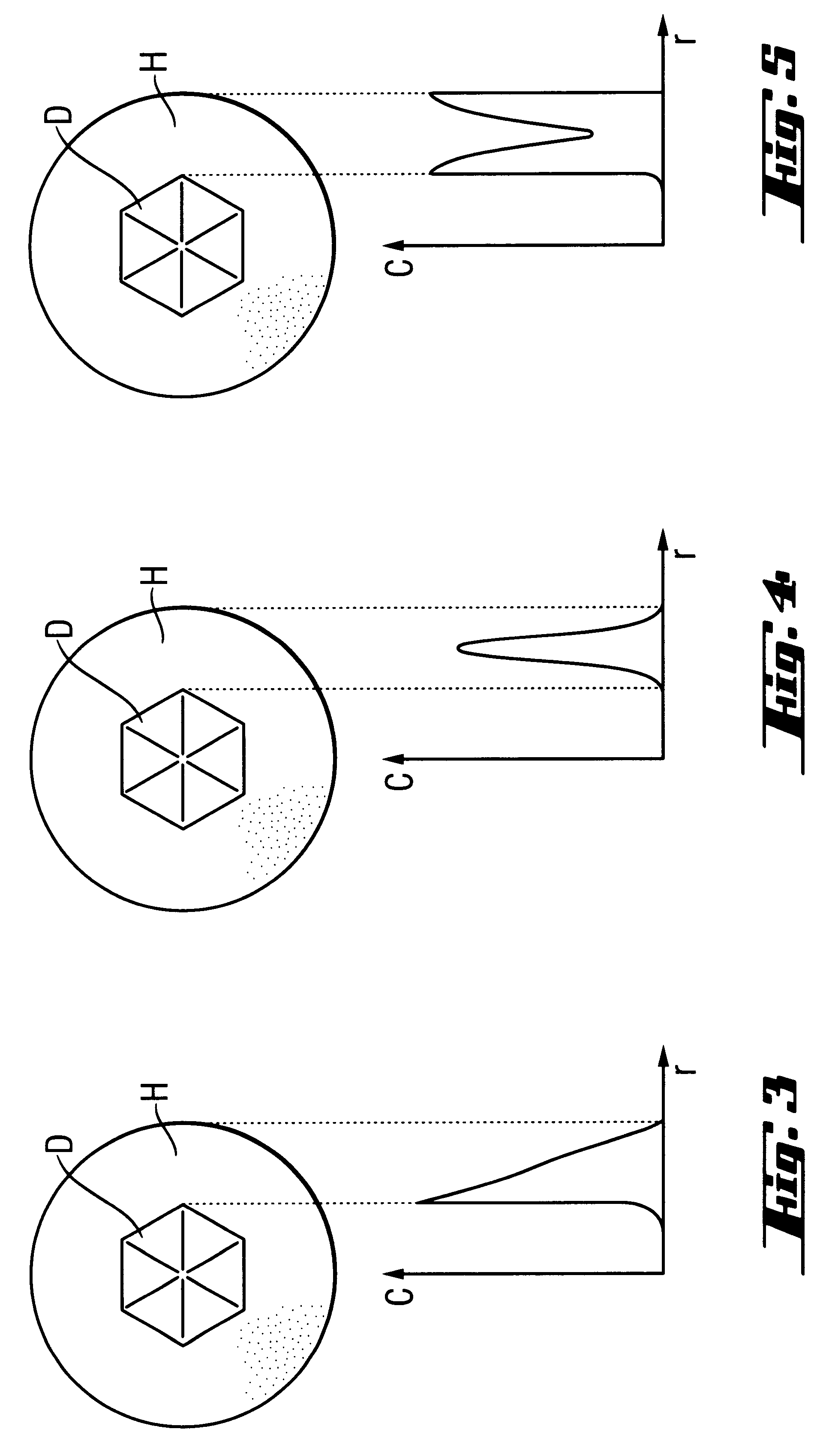

Abrasive cutter containing diamond particles and a method for producing the cutter

InactiveUS6238280B1Eliminate disadvantagesAvoid attenuationRevolution surface grinding machinesBonded abrasive wheelsMetal coatingDiamond crystal

An abrasive cutter formed of at least one diamond particle, preferably at least one mono-diamond crystal and metallic binder material distinguished by the fact that the diamond particle (D) has a size of about 50 mum to about 500 mum and each diamond particle (D) is enclosed by a coating (H) produced in a fluidized bed with the coating having a wall thickness of about 10 mum to about 200 mum. The volume of the coating (H) constitutes at least 30% of the volume of the diamond particles (D) in the fully consolidated state following individual sintering of the coated diamond particles (D, H). The abrasive cutters can be applied directly onto an abrasive tool. Further they can be processed to form composite cutters or cutting segments. In the method of forming the abrasive cutter, the diamond particle (D) is brought into a fluidized bed reactor and enclosed in a metallic coating (H). Coated diamond particle (D, H) can be processed into larger cutters or segments in each case individually sintered and fixed directly on an abrasive tool.

Owner:HILTI AG

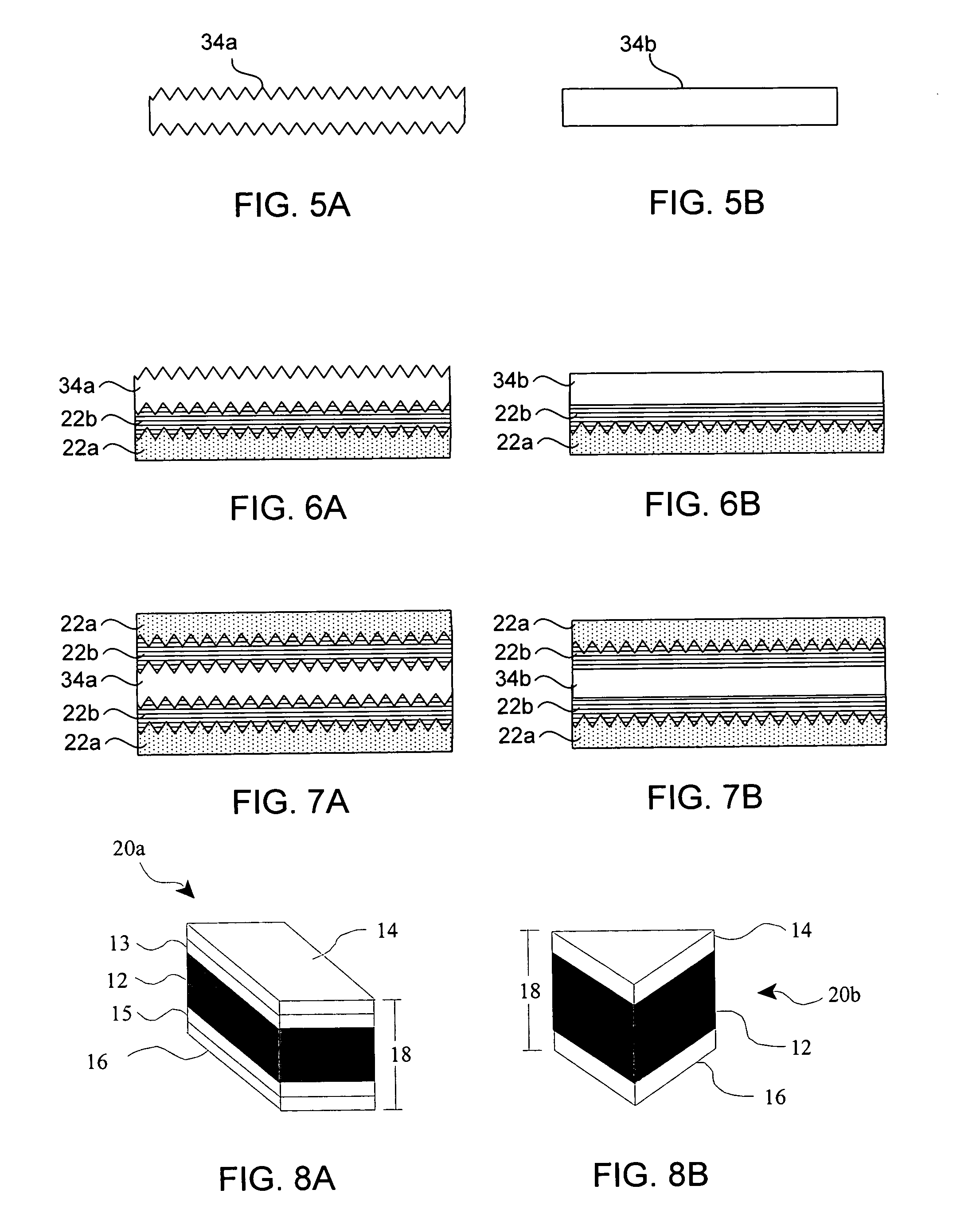

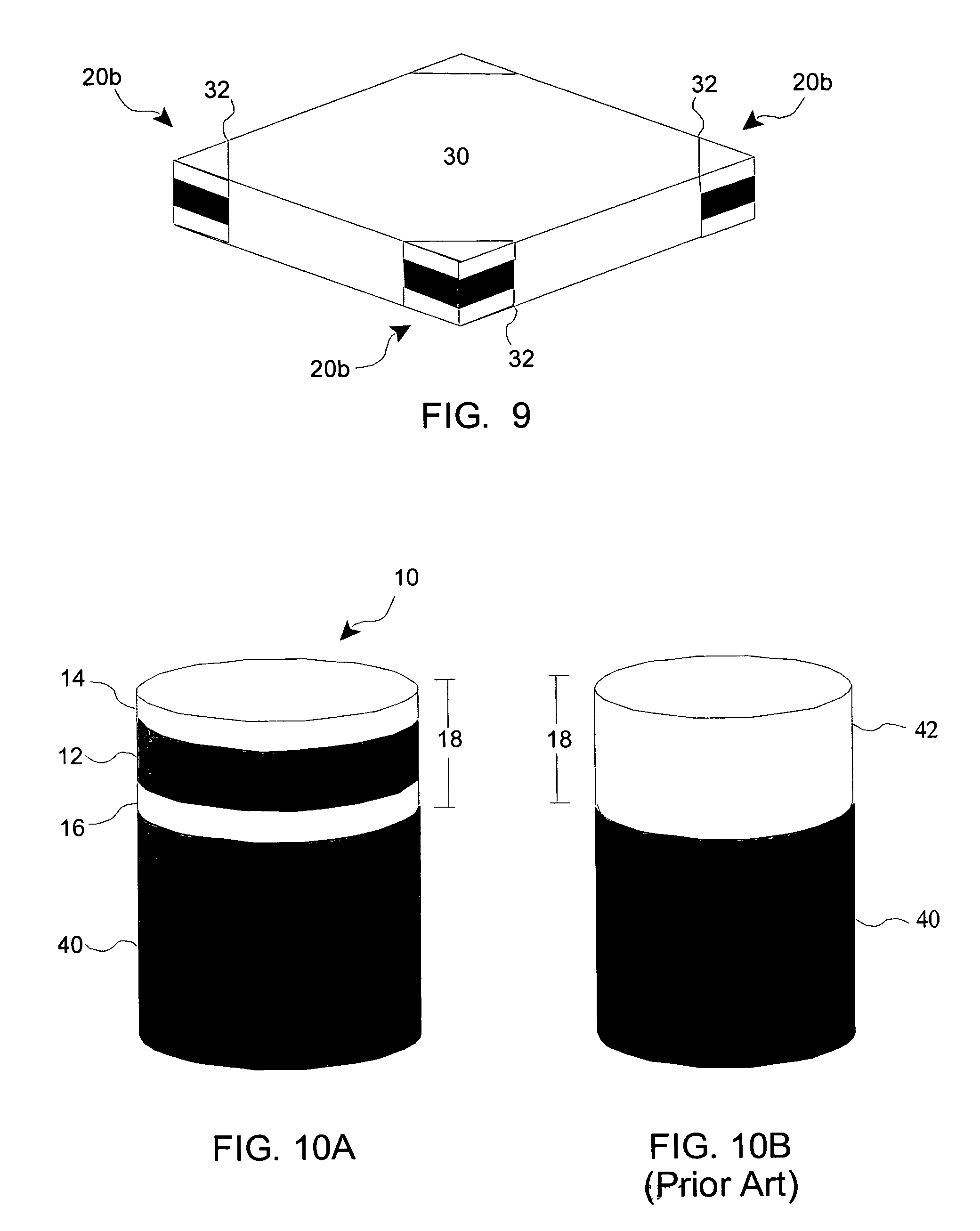

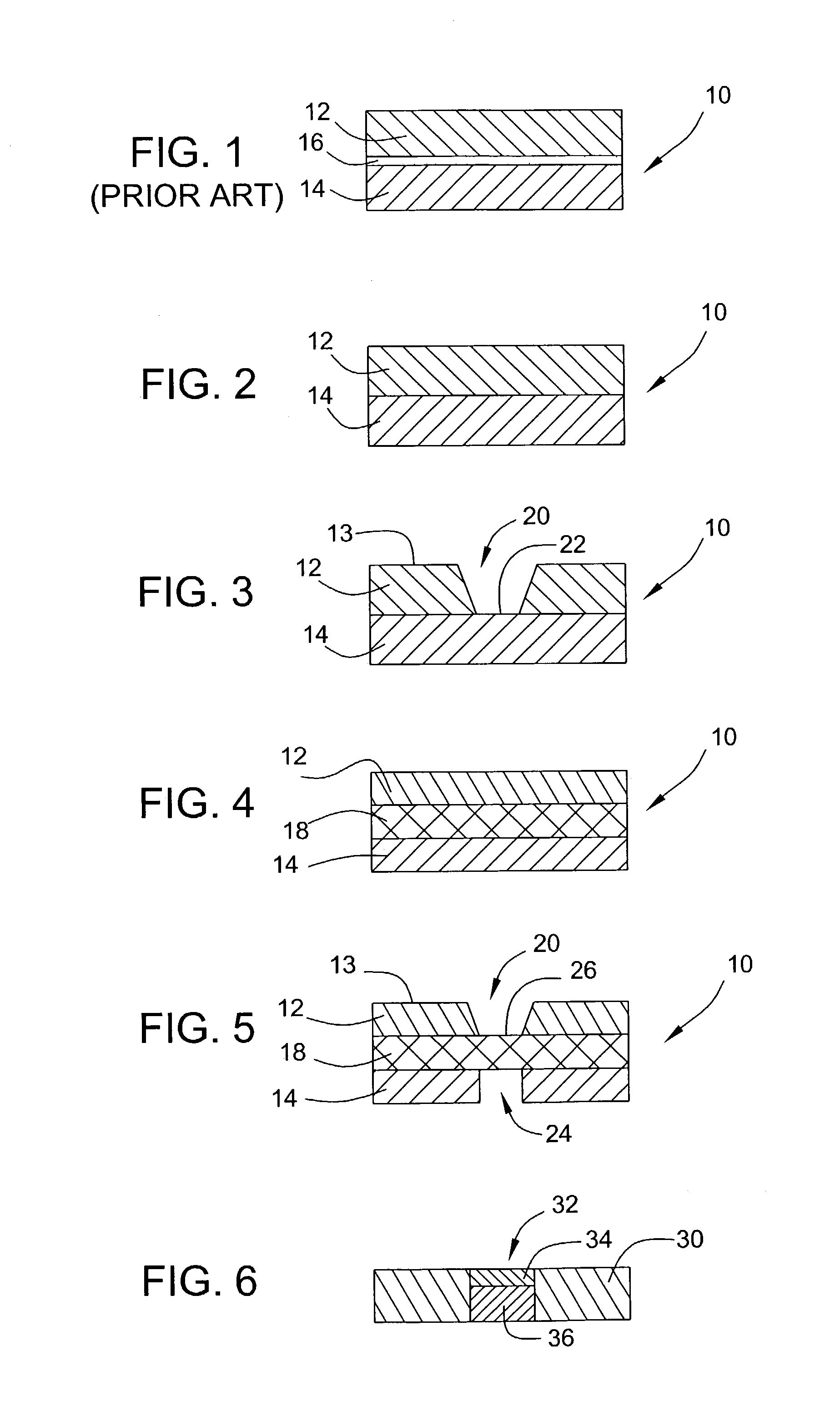

Doubled-sided and multi-layered PCBN and PCD abrasive articles

InactiveUS20050210755A1Improve propertiesIncreasing the thicknessPigmenting treatmentTool workpiece connectionWear particleHigh pressure

A doubled-sided PCBN and / or PCD compact can be produced using high pressure high temperature processes allowing for increased effective thickness of abrasive tools, decreased delamination, and increased useful service life. A polycrystalline compact can include a substrate having a first surface and a second surface which are non-contiguous. Additionally, a first polycrystalline layer can be attached to the first surface of the substrate and a second polycrystalline layer attached to the second surface of the substrate. The first and second polycrystalline layers can be attached to the substrate via an intermediate layer containing superabrasive particles. Such double-sided PCBN and PCD compacts allow for increased effective thickness of a tool without suffering from non-homogenous results typical of standard PCD and PCBN compacts, regardless of superabrasive particle size. Each polycrystalline layer can include superabrasive particles of varying particle sizes such that the final tool is tailored for specific abrading characteristics. Such doubled-sided PCBN and PCD compacts can be incorporated into a wide variety of abrasive tools for use in cutting, milling, grinding, polishing, drilling and other similar abrasive applications.

Owner:ADICO ASIA POLYDIAMOND

Polishing pads for chemical mechanical planarization

An improved pad and process for polishing metal damascene structures on a semiconductor wafer. The process includes the steps of pressing the wafer against the surface of a polymer sheet in combination with an aqueous-based liquid that optionally contains sub-micron particles and providing a means for relative motion of wafer and polishing pad under pressure so that the moving pressurized contact results in planar removal of the surface of said wafer, wherein the polishing pad has a low elastic recovery when said load is removed, so that the mechanical response of the sheet is largely anelastic. The improved pad is characterized by a high energy dissipation coupled with a high pad stiffness. The pad exhibits a stable morphology that can be reproduced easily and consistently. The pad surface resists glazing, thereby requiring less frequent and less aggressive conditioning. The benefits of such a polishing pad are low dishing of metal features, low oxide erosion, reduced pad conditioning, longer pad life, high metal removal rates, good planarization, and lower defectivity (scratches and Light Point Defects).

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

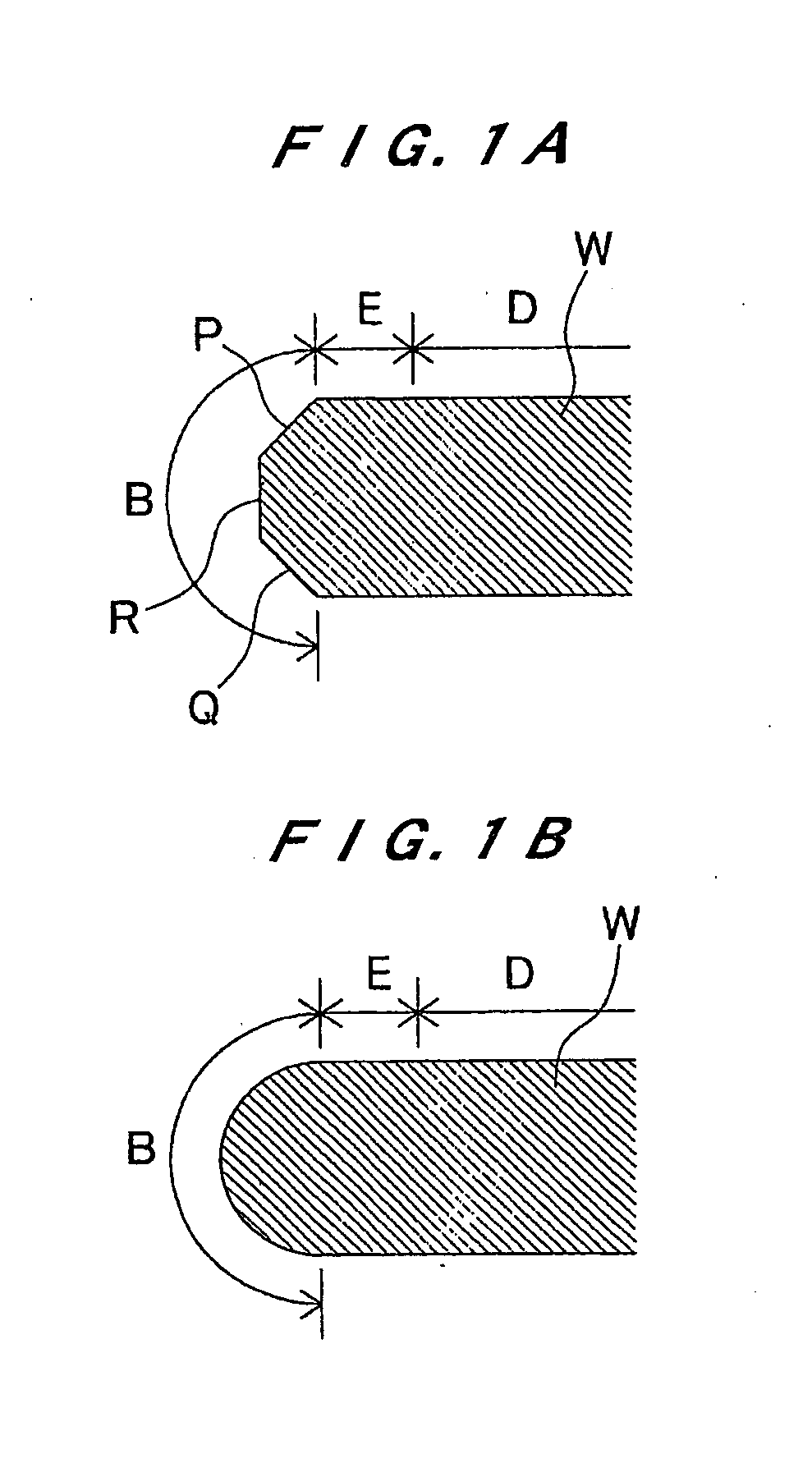

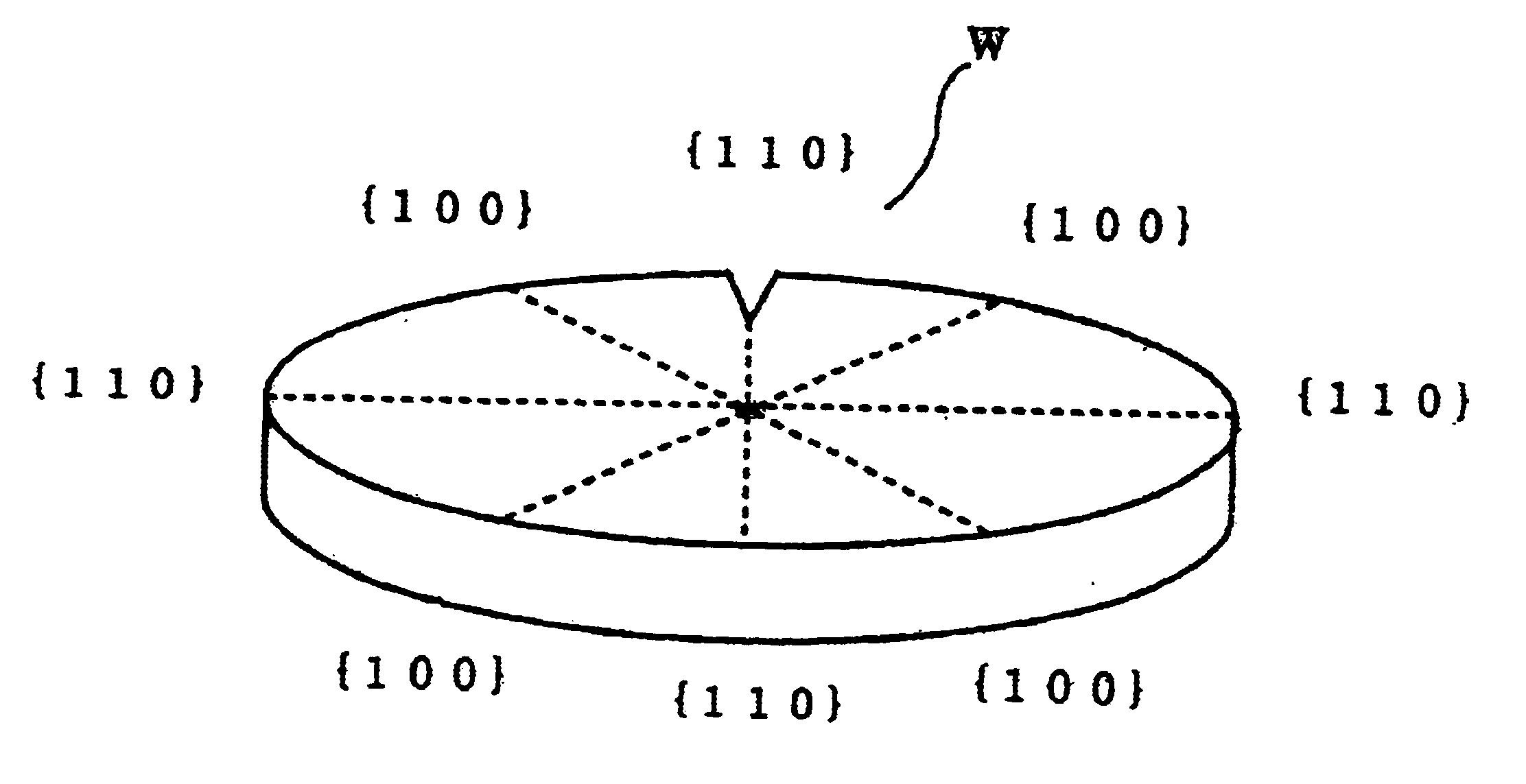

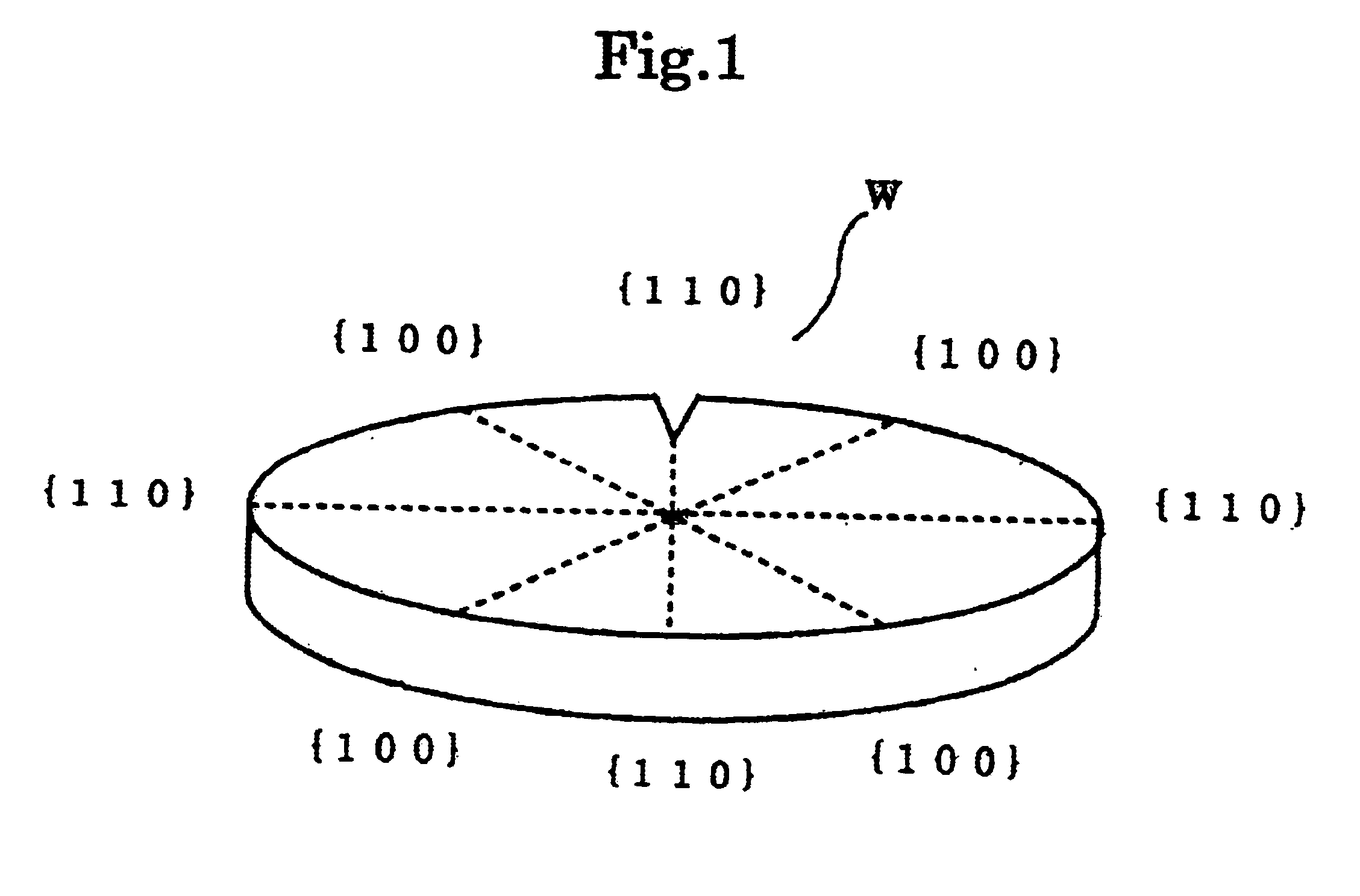

Method for apparatus for polishing outer peripheral chamfered part of wafer

InactiveUS6884154B2Improve productivityShorten polishing timeEdge grinding machinesPolishing machinesProduction rateHardness

In a process for polishing the chamfered peripheral part of a wafer using a polishing cloth while supplying a polishing slurry in order to improve productivity of the process by reducing a polishing time, at least two steps of polishing processes are performed in sequence. The process comprises a first polishing process to polish a particular part, e.g. the part corresponding to the {110} plane of a peripheral part of the wafer and a second polishing process in which the whole part of a peripheral part of the wafer is polished for finishing by means of varying a hardness of the polishing clothes and / or a particle size of abrasives in the slurry such as the hardness of the polishing cloth in the second polishing process being softer than that of in the first polishing process and a particle size of abrasives in the slurry in the second polishing process being finer than that of in the first polishing process.

Owner:SHIN-ETSU HANDOTAI CO LTD

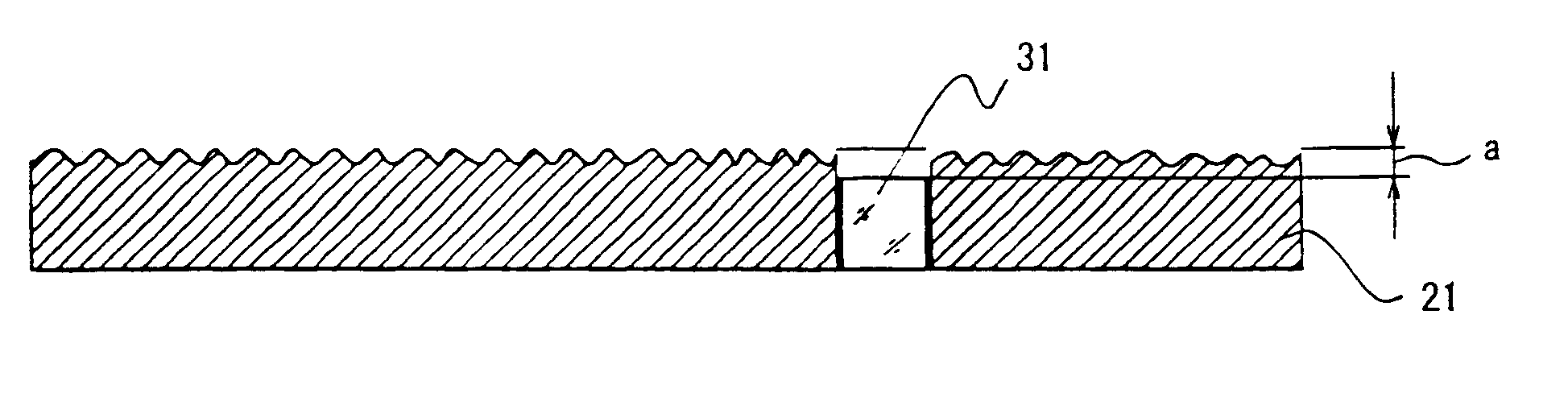

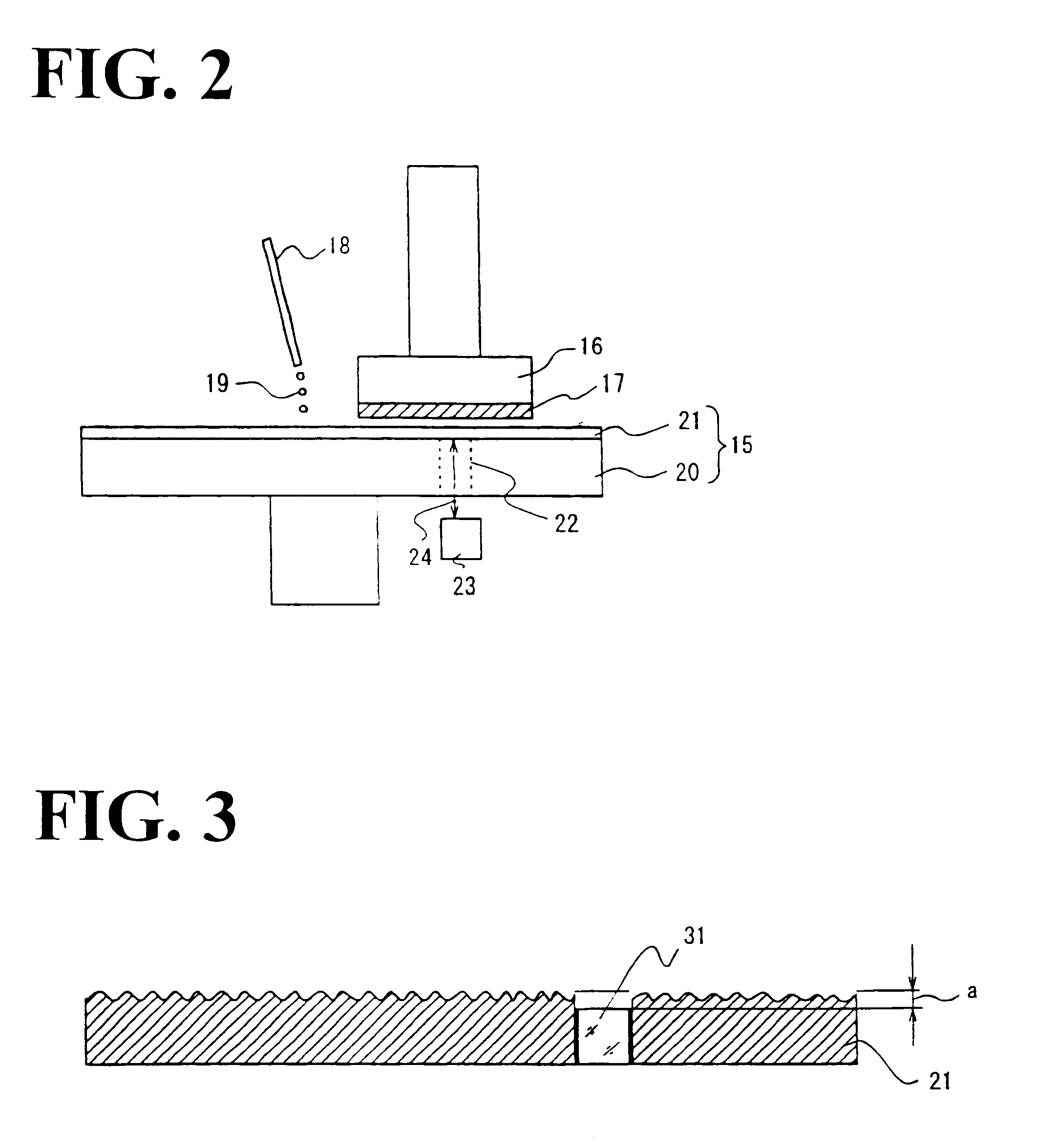

Polishing body, polishing apparatus, polishing apparatus adjustment method, polished film thickness or polishing endpoint measurement method, and semiconductor device manufacturing method

After a hole is formed in a polishing pad, a transparent window plate is inserted into the hole. Here, a gap is left between the upper surface of the transparent window plate and the outermost surface constituting the working surface of the polishing pad. During polishing, the polishing head holding the wafer applies a load to the polishing pad by means of a load-applying mechanism, so that the polishing pad and transparent window plate are compressed. In this case, the system is arranged so that the gap remains constant, and so that a dimension equal to or greater than a standard value is maintained. Since the upper surface of the transparent window plate is recessed from the upper surface of the polishing pad, there is no scratching of the surface of the transparent window plate during dressing. Accordingly, the polishing pad has a long useful life.

Owner:NIKON CORP

Polishing pad with high optical transmission window

ActiveUS6984163B2Spread the wordPolishing machinesRevolution surface grinding machinesEngineeringIsocyanate

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

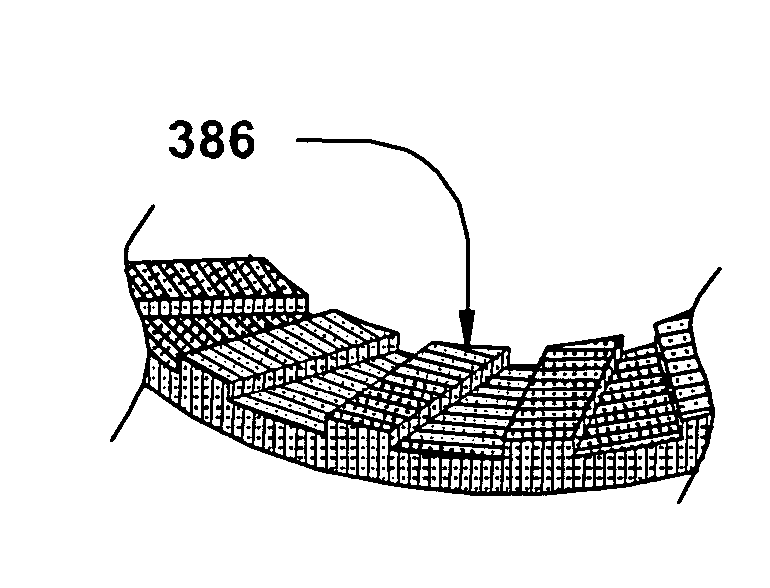

Reinforced Bonded Abrasive Tools

InactiveUS20100190424A1Improve performanceReduce the amount requiredPigmenting treatmentRevolution surface grinding machinesFiberFiberglass mesh

Bonded abrasive tools, e.g., grinding wheels, can be reinforced using, for instance, one or more fibreglass web(s) having a surface of glass per unit of at least 0.2. Alternatively or in addition, the fibreglass web has a thickness of 2 mm or less. The web can be designed to provide improved adhesion between the fibreglass reinforcement and the mixture employed to form the bonded abrasive tool. In some examples, the middle reinforcement at the neutral zone of the wheel can be eliminated or minimized.

Owner:SAINT GOBAIN ABRASIVES INC +1

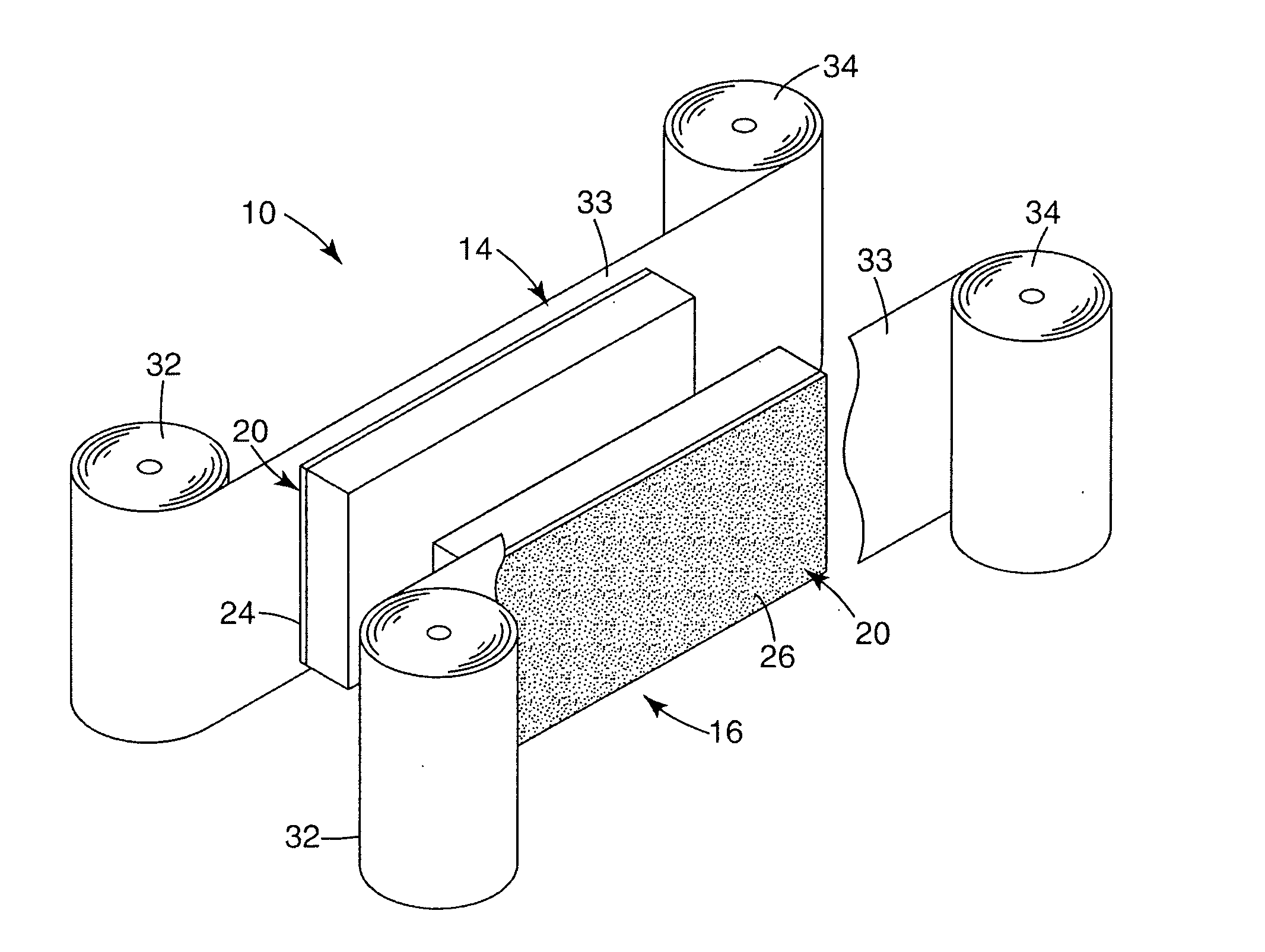

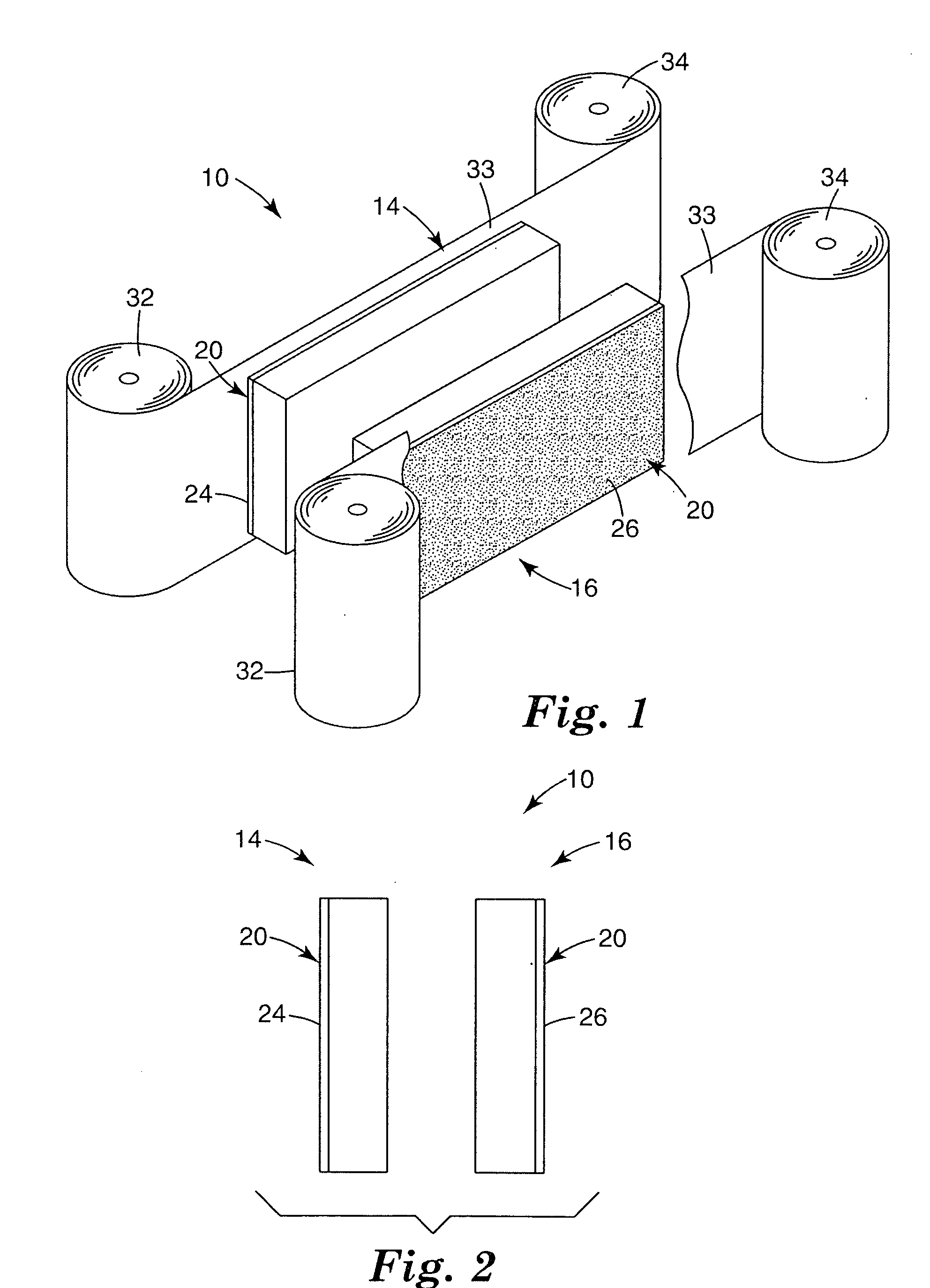

Raised island abrasive, lapping apparatus and method of use

InactiveUS20050032469A1Provide supportReduce workpiece tiltingRevolution surface grinding machinesOther chemical processesMono layerAgglomerate

Flexible abrasive sheet materials having annular bands of precise height flat-topped raised island structures that are coated with a mono layer of abrasive particles or abrasive agglomerates, processes for manufacture of the abrasive sheet materials, processes for using the abrasive sheeting in high speed lapping / abrading processes, and apparatus for using the abrasive sheeting are described. The process for manufacturing the abrasive sheeting provides an economical method for providing an improved configuration of abrasive sheeting that can provide precisely flat workpiece surfaces that are also highly polished.

Owner:DUESCHER WAYNE O

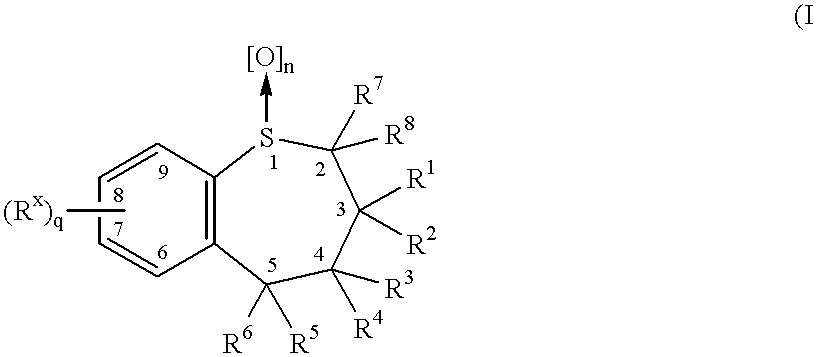

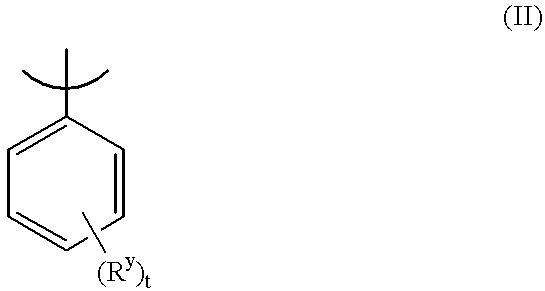

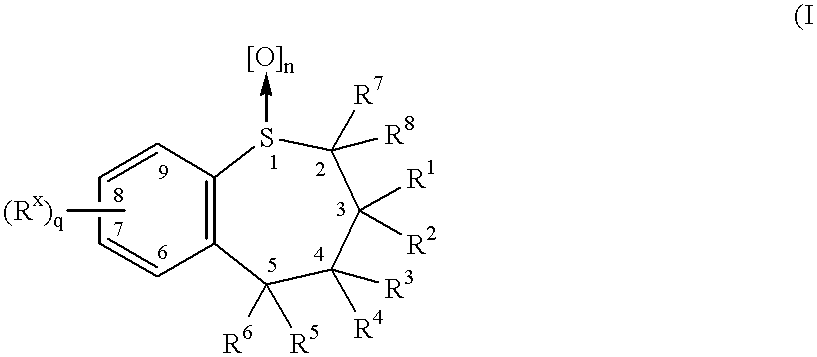

Benzothiepines having activity as inhibitors of ileal bile acid transport and taurocholate uptake

Provided are novel benzothiepines, derivatives, and analogs thereof; pharmaceutical compositions containing them; and methods of using these compounds and compositions in medicine, particularly in the prophylaxis and treatment of hyperlipidemic conditions such as those associated with atherosclerosis or hypercholesterolemia, in mammals.

Owner:GD SEARLE & CO

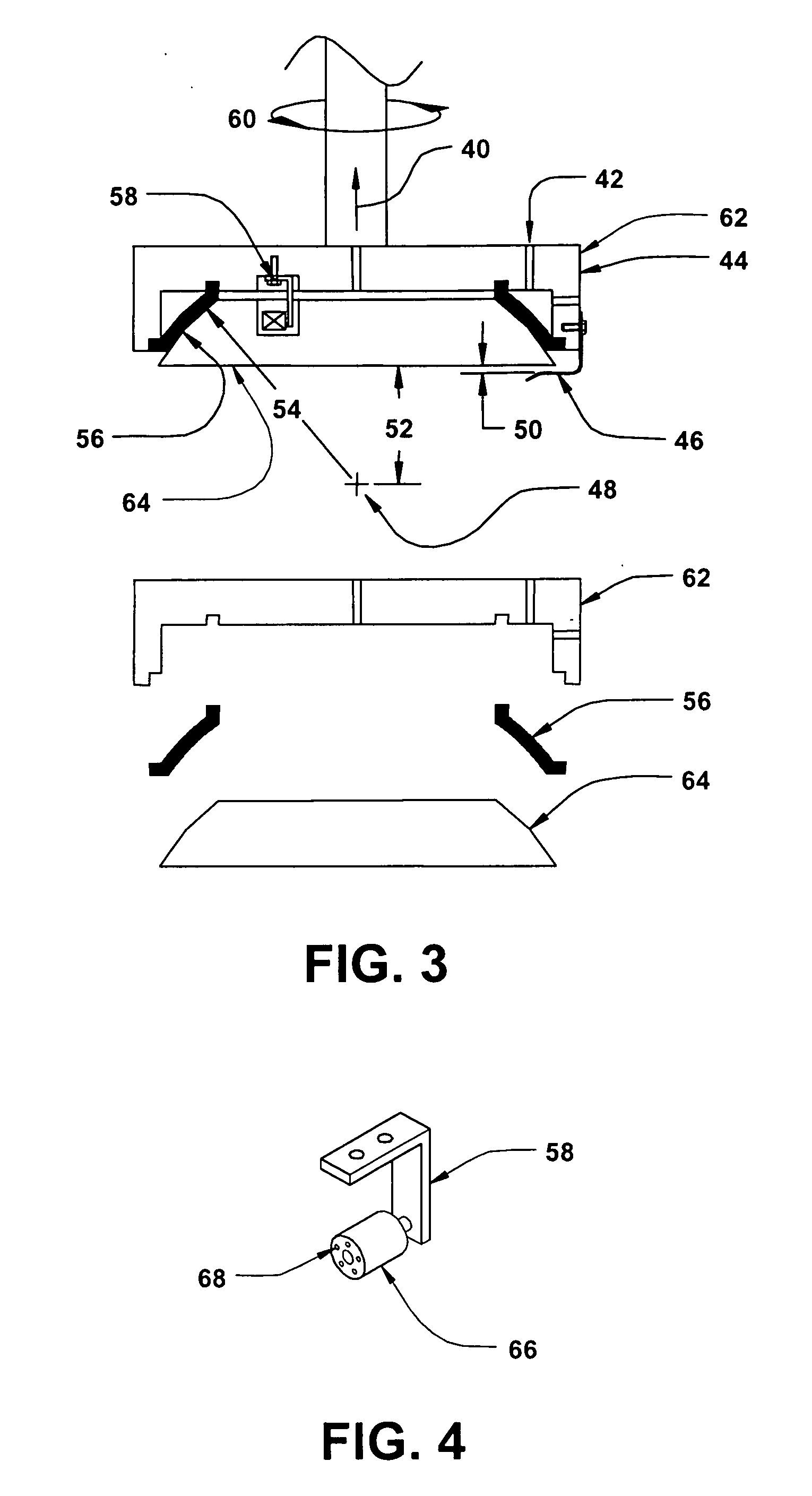

Polishing pad conditioning system

InactiveUS6508697B1Polishing machinesRevolution surface grinding machinesPiezo electricWaste material

A system for conditioning rotatable polishing pads used to planarize and polish surfaces of thin film integrated circuits deposited on semiconductor wafer substrates, microelectronic, and optical system. The system has a pad conditioning apparatus, process fluids, a vacuum capability to pull waste material out of the conditioning pad, self-contained flushing means, and a piezo-electric device for vibrating the pad conditioning apparatus.

Owner:BENNER ROBERT LYLE +2

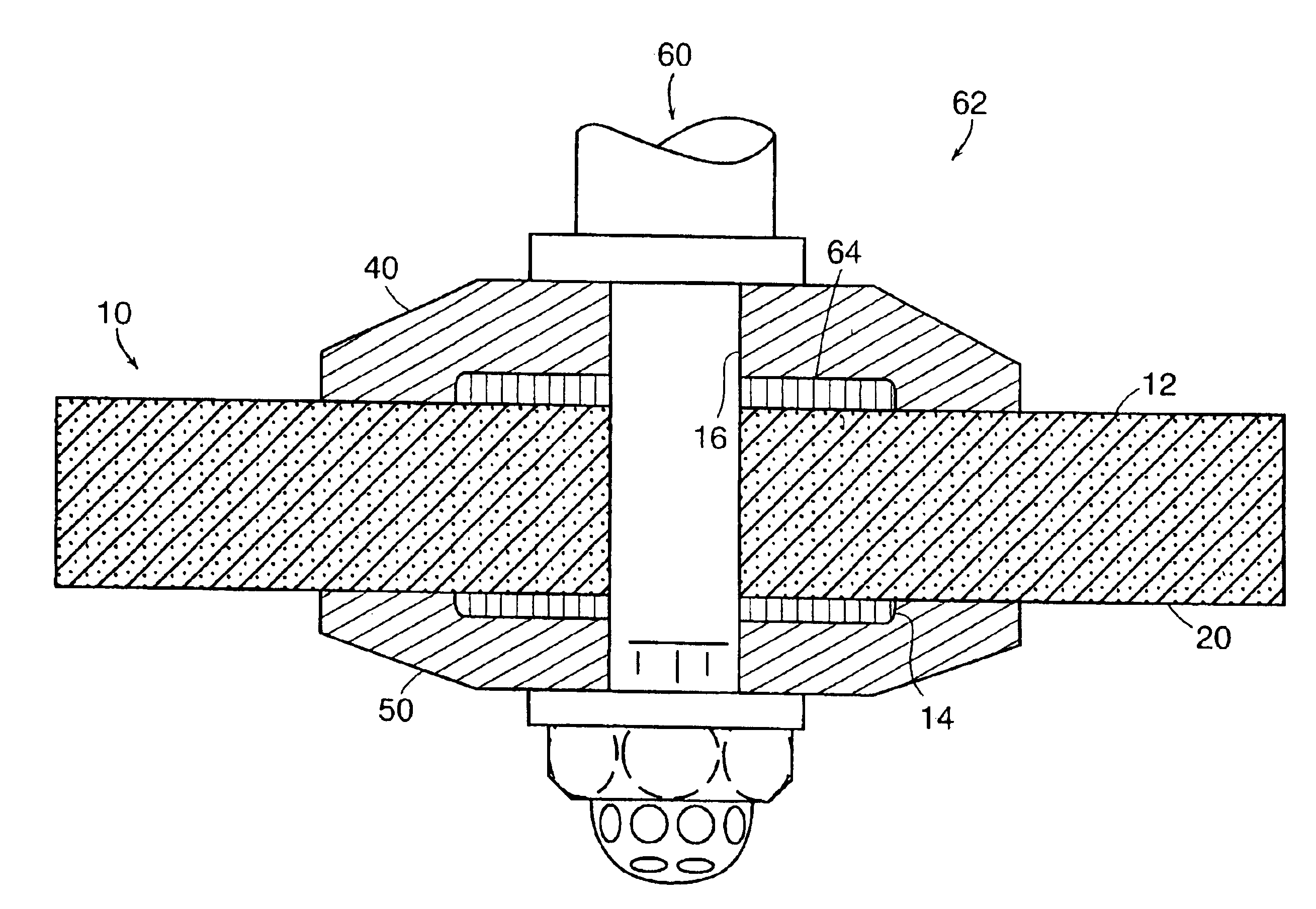

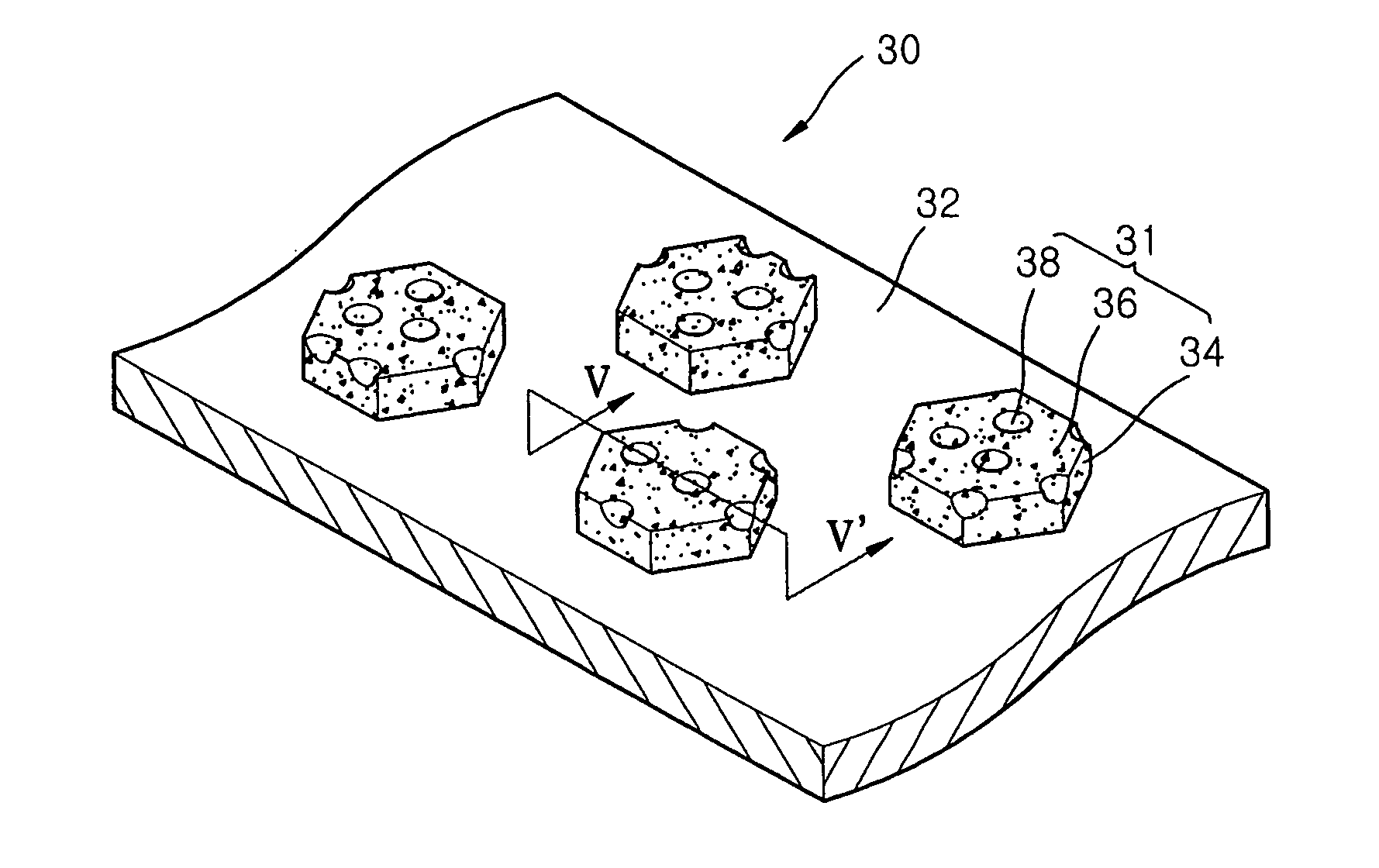

Reinforced abrasive wheels

InactiveUS6942561B2Minimize empty spaceSaving in layer materialGrinding machine componentsRevolution surface grinding machinesGlass fiberEngineering

In a depressed-center abrasive wheel assembly a reinforcement layer of polygonal shape is located between a front face of the abrasive wheel and a front flange. The reinforcement layer is dimensioned to entirely cover the depressed center portion of the wheel. An example of polygonal reinforcement layer has a hexagonal shape and is made of fiberglass cloth. A polygonal shape reinforcement layer can also be employed between the front flange and the front face in an abrasive flat wheel assembly that employs a wheel without internal reinforcement.

Owner:SAINT GOBAIN ABRASIVES INC

Polishing pad for electrochemical mechanical polishing

InactiveUS6848977B1Easy to moveElectrolysis componentsPolishing machinesEngineeringElectrical and Electronics engineering

The present invention provides a polishing pad for electrochemical mechanical polishing of conductive substrate. The pad comprises a plurality of grooves formed in a polishing surface of the polishing pad, the grooves being adapted to facilitate the flow of polishing fluid over the polishing pad. The conductive layers are respectively formed in the grooves and are in electrical communication with each other.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Sanding disks

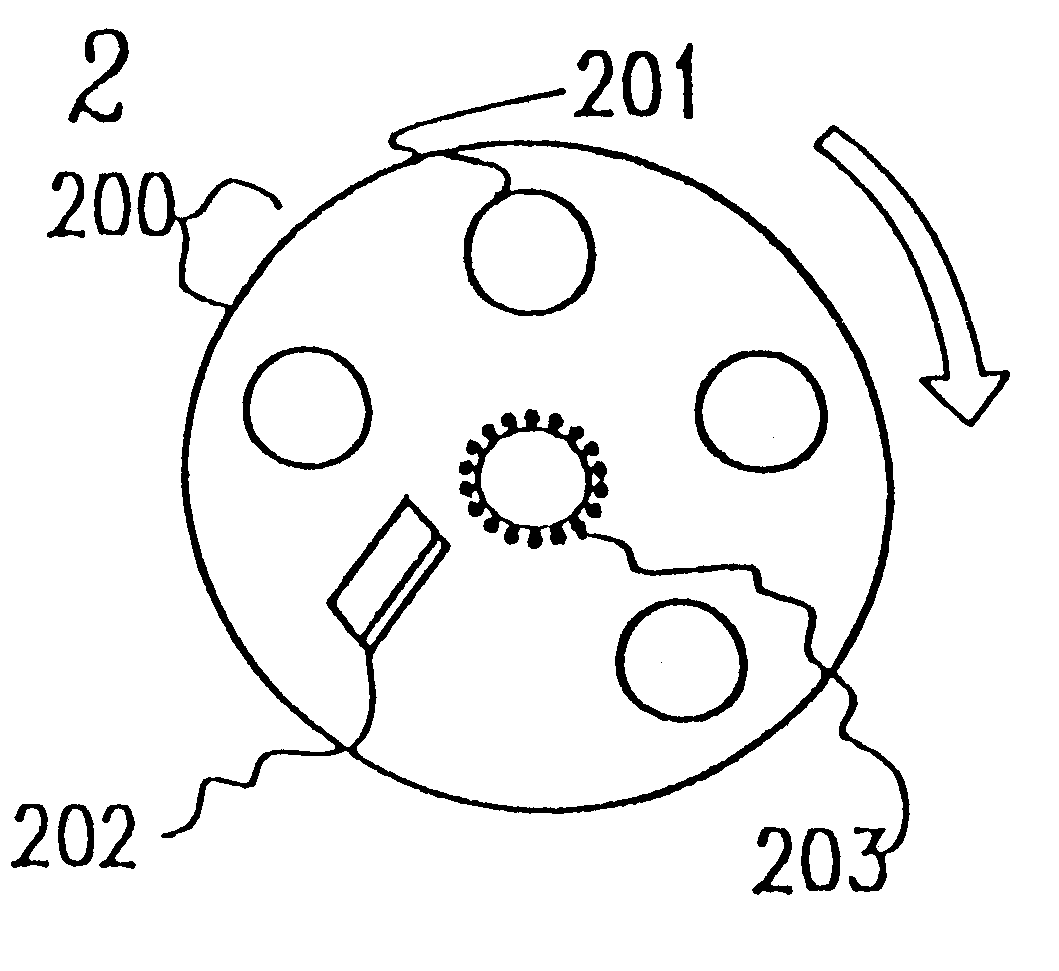

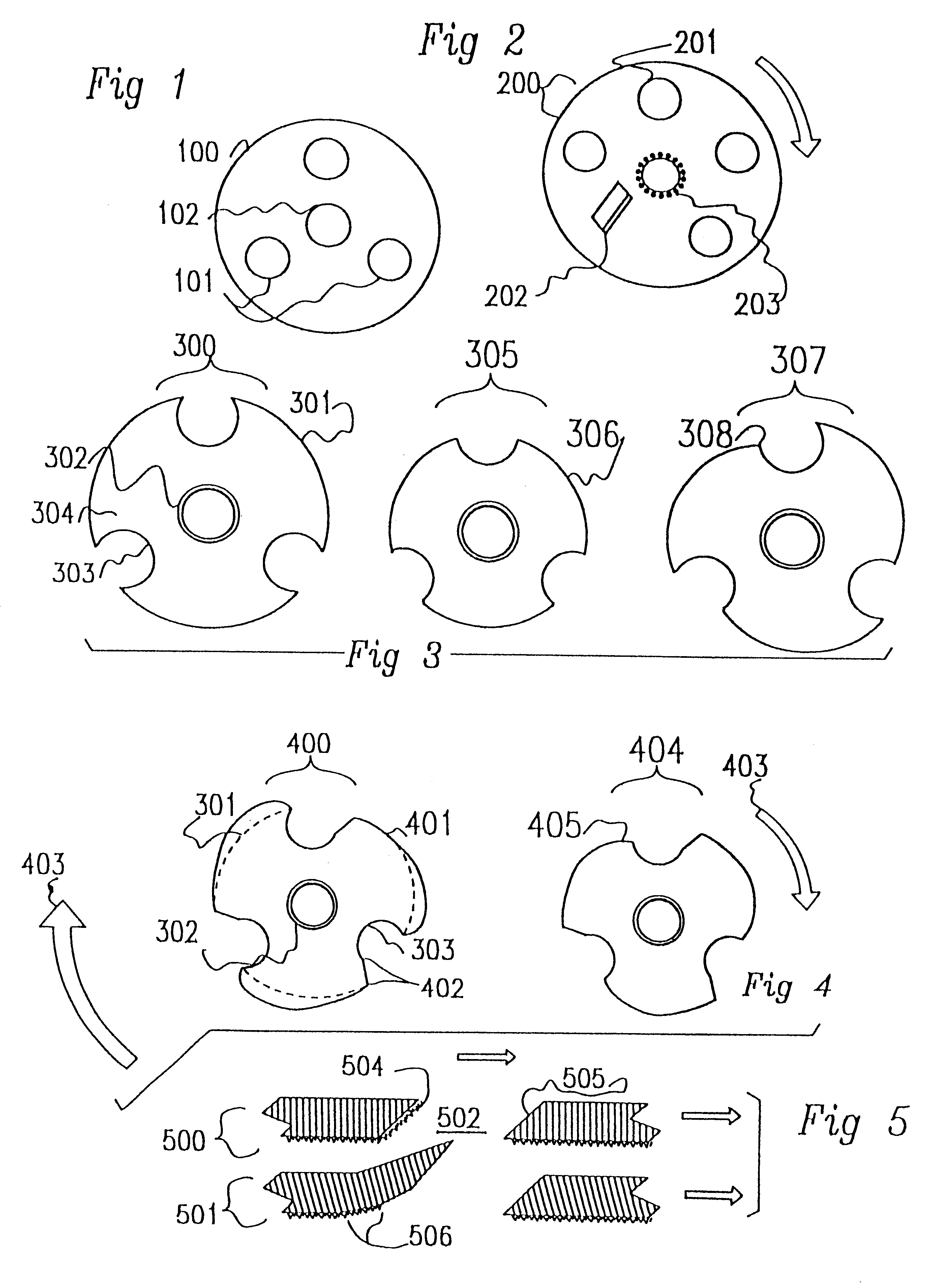

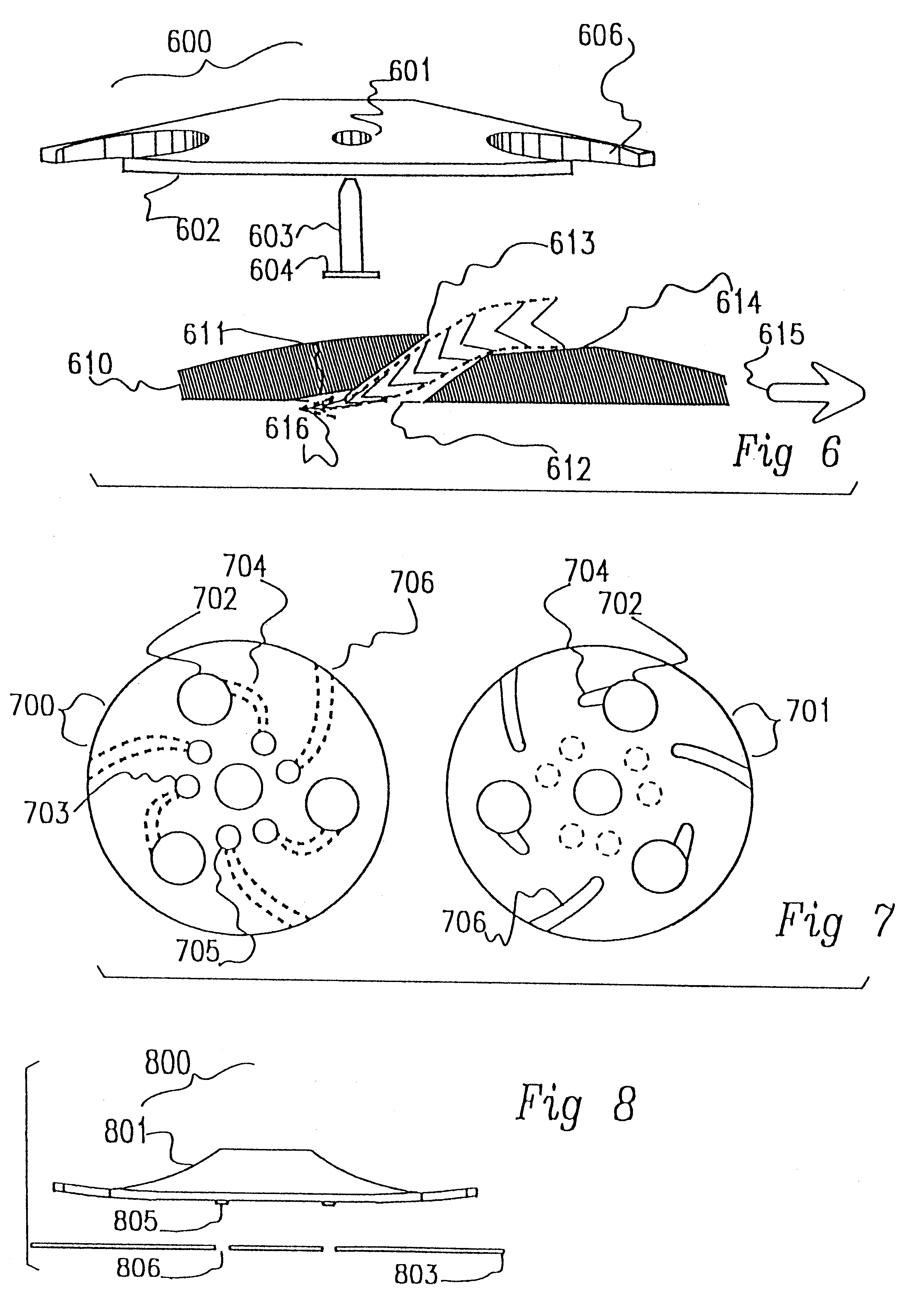

InactiveUS6312325B1Risk minimizationProtect from harmRevolution surface grinding machinesSupport wheelsAngle grinderEngineering

Accessories for an angle grinder include a disposable rotary sanding disk having quite large shaped ventilating / viewing apertures, for use with a resilient backing plate also having shaped ventilating apertures. The apertures of one or both parts are shaped so that snagging of the apertures on projections from the work surface is minimized and to facilitate air flow across the work surface during use. This air flow helps in cooling the work and ejecting detritus, so minimising clogging effects. The ventilating apertures also facilitate viewing the work to be sanded through the spinning disk during the abrasion process, so that operator feedback is immediate. The holes also give the sanding disk more resilience so that a greater area comes in contact with the work and the disk wears more evenly over its abrasive surface.

Owner:MORTON CO

Polishing pad with microporous regions

The invention provides a polishing pad for chemical-mechanical polishing comprising a polymeric material comprising two or more adjacent regions, wherein the regions have the same polymer formulation and the transition between the regions does not include a structurally distinct boundary. In a first embodiment, a first region and a second adjacent region have a first and second non-zero void volume, respectively, wherein the first void volume is less than the second void volume. In a second embodiment, a first non-porous region is adjacent to a second adjacent porous region, wherein the second region has an average pore size of about 50 μm or less. In a third embodiment, at least two of an optically transmissive region, a first porous region, and an optional second porous region, are adjacent. The invention further provides methods of polishing a substrate comprising the use of the polishing pads and a method of producing the polishing pads.

Owner:CMC MATERIALS INC

Fixed abrasive polishing pad, method of preparing the same, and chemical mechanical polishing apparatus including the same

InactiveUS20070128991A1Improve abilitiesPolishing machinesRevolution surface grinding machinesCompound (substance)Abrasive

Owner:SAMSUNG ELECTRONICS CO LTD

Method and apparatus of monitoring polishing pad wear during processing

InactiveUS6045434AMinimize degradationPolishing machinesRevolution surface grinding machinesClosed loopEngineering

A method and apparatus for monitoring polishing pad wear during processing is developed to extend the pad's useful life, and maintain pad uniformity. This is accomplished in the present invention by measuring and monitoring the diminished pad thickness using a non-intrusive measurement system, and creating a closed-loop system for adjusting the chemical-mechanical polishing tool process parameters. The non-intrusive measurement system consists of an interferometer measurement technique utilizing ultrasound or electromagnetic radiation transmitters and receivers aligned to cover any portion of the radial length of a polishing pad surface. The measurement system is sensitive to relative changes in pad thickness for uniformity, and to abrupt changes such as detecting wafer detachment from the CMP wafer carrier.

Owner:IBM CORP

Multi-layer polishing pad material for CMP

InactiveUS6884156B2Polishing machinesRevolution surface grinding machinesAdhesiveBiomedical engineering

The invention is directed to a multi-layer polishing pad for chemical-mechanical polishing comprising a polishing layer and a bottom layer, wherein the polishing layer and bottom layer are joined together without the use of an adhesive. The invention is also directed to a polishing pad comprising an optically transmissive multi-layer polishing pad material, wherein the layers of the polishing pad material are joined together without the use of an adhesive.

Owner:CMC MATERIALS INC

Load cup for chemical mechanical polishing

ActiveUS7044832B2Polishing machinesRevolution surface grinding machinesEngineeringMechanical engineering

Embodiments of a load cup for transferring a substrate are provided. The load cup includes a pedestal assembly having a substrate support and a de-chucking nozzle. The de-chucking nozzle is positioned to flow a fluid between the polishing head and the back side of a substrate during transfer of the substrate from the polishing head to the substrate support.

Owner:APPLIED MATERIALS INC

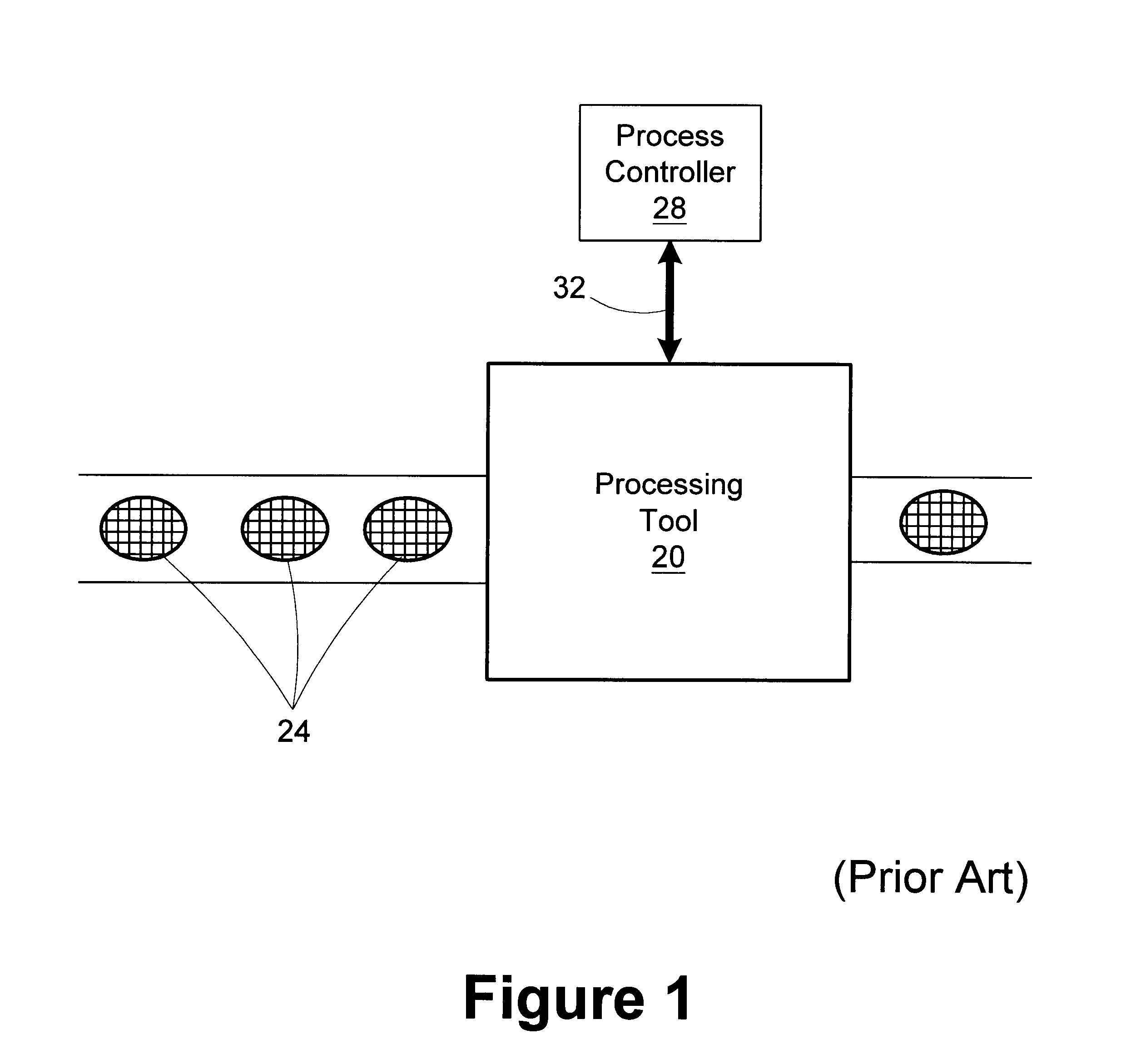

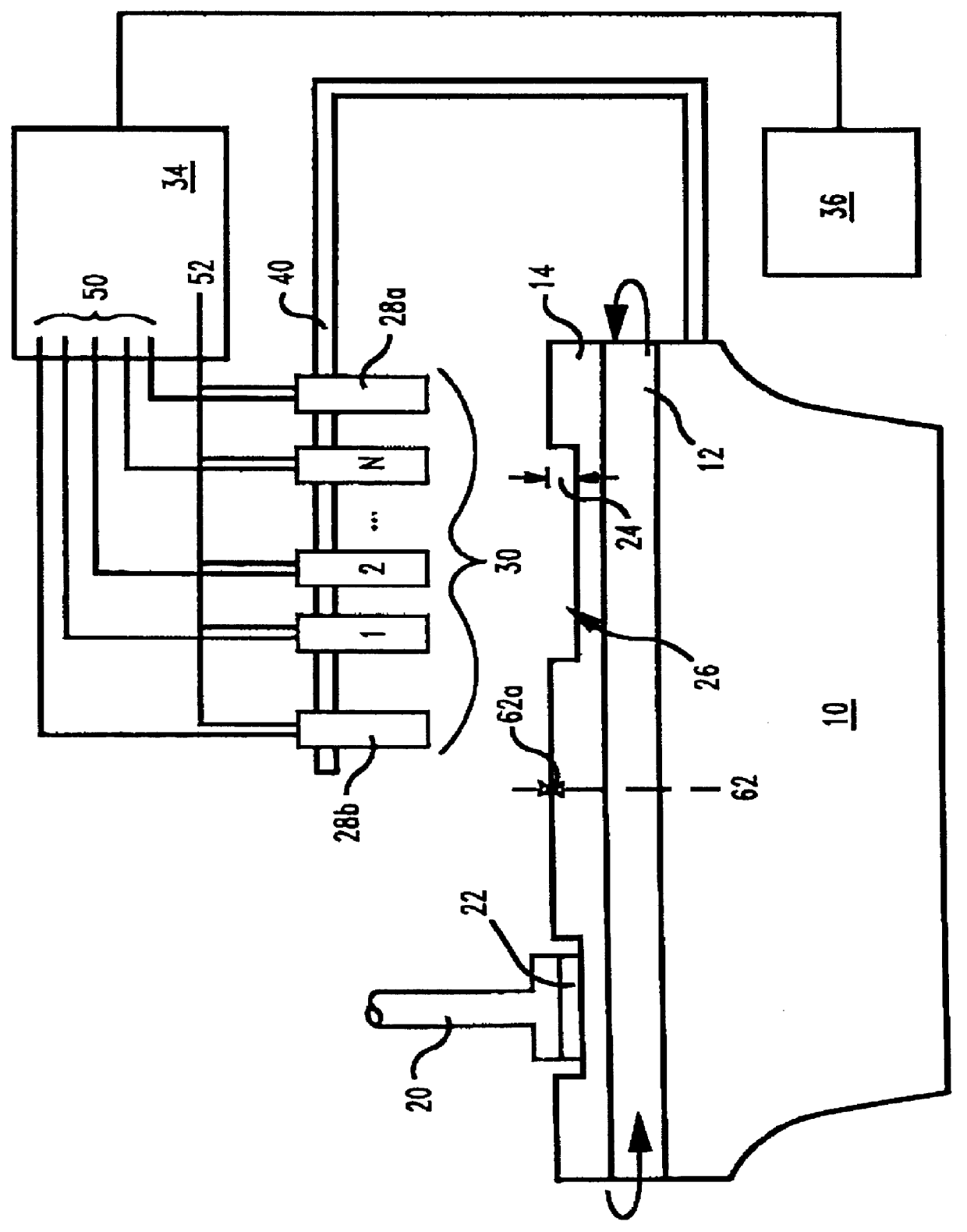

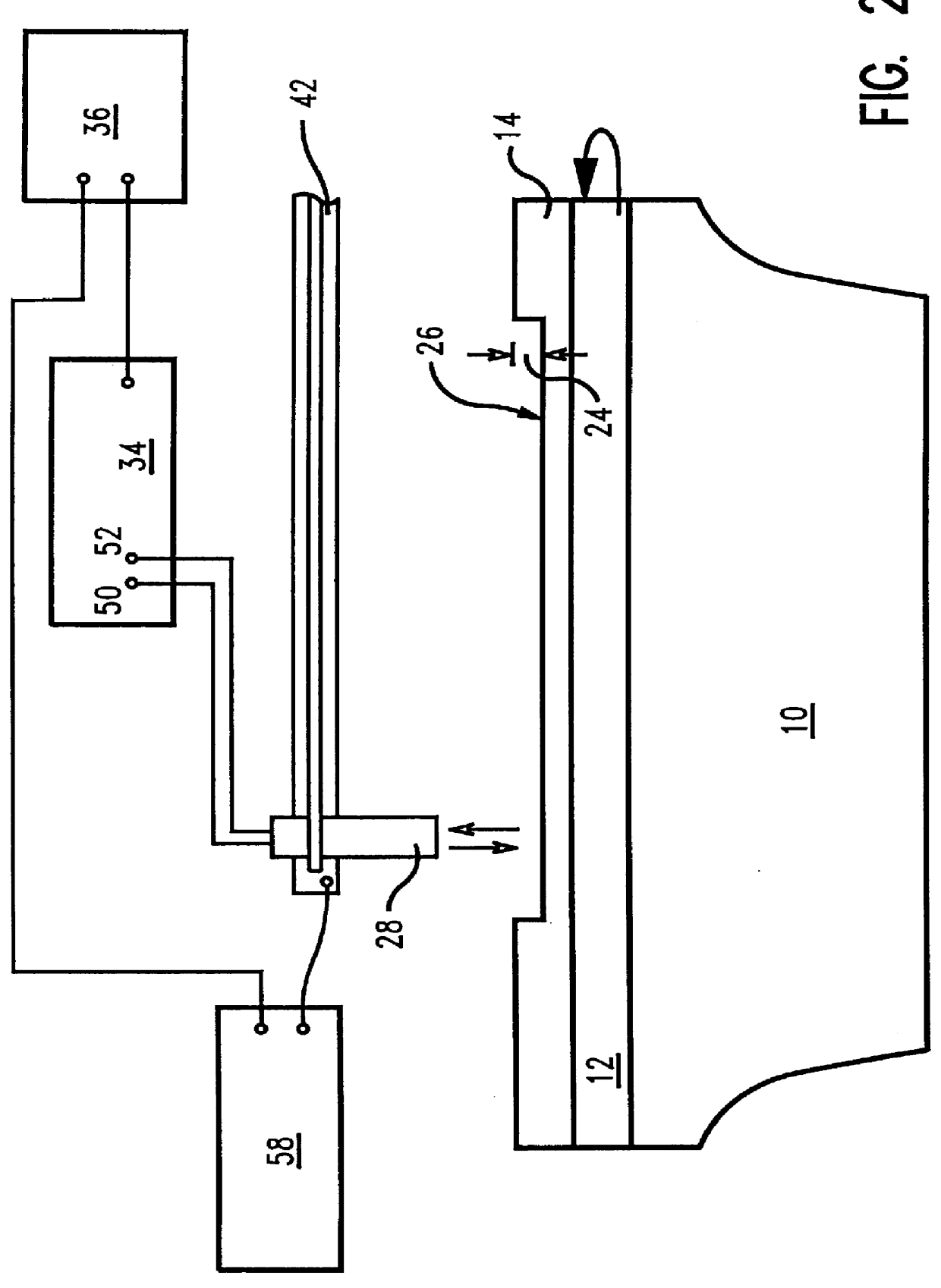

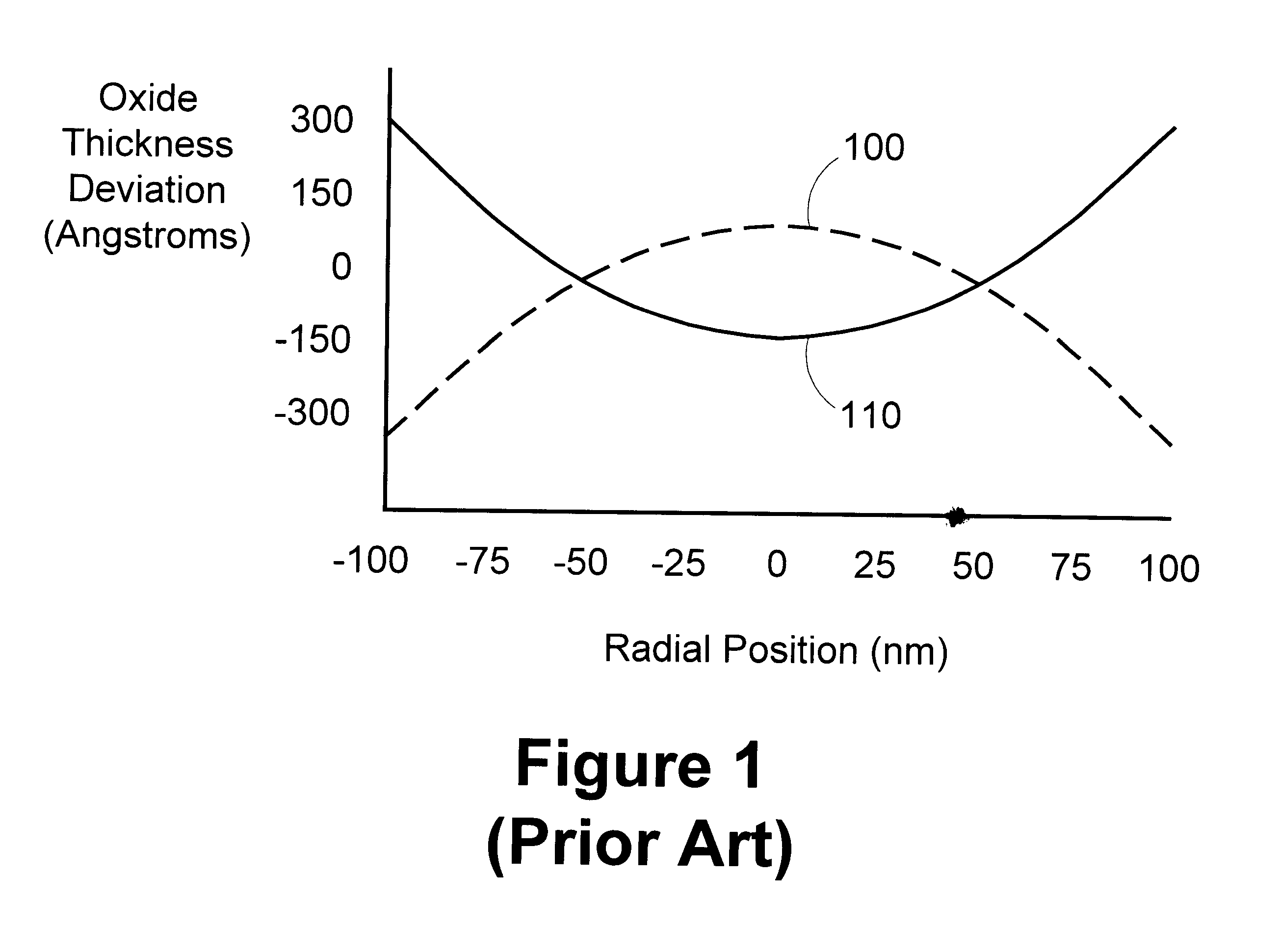

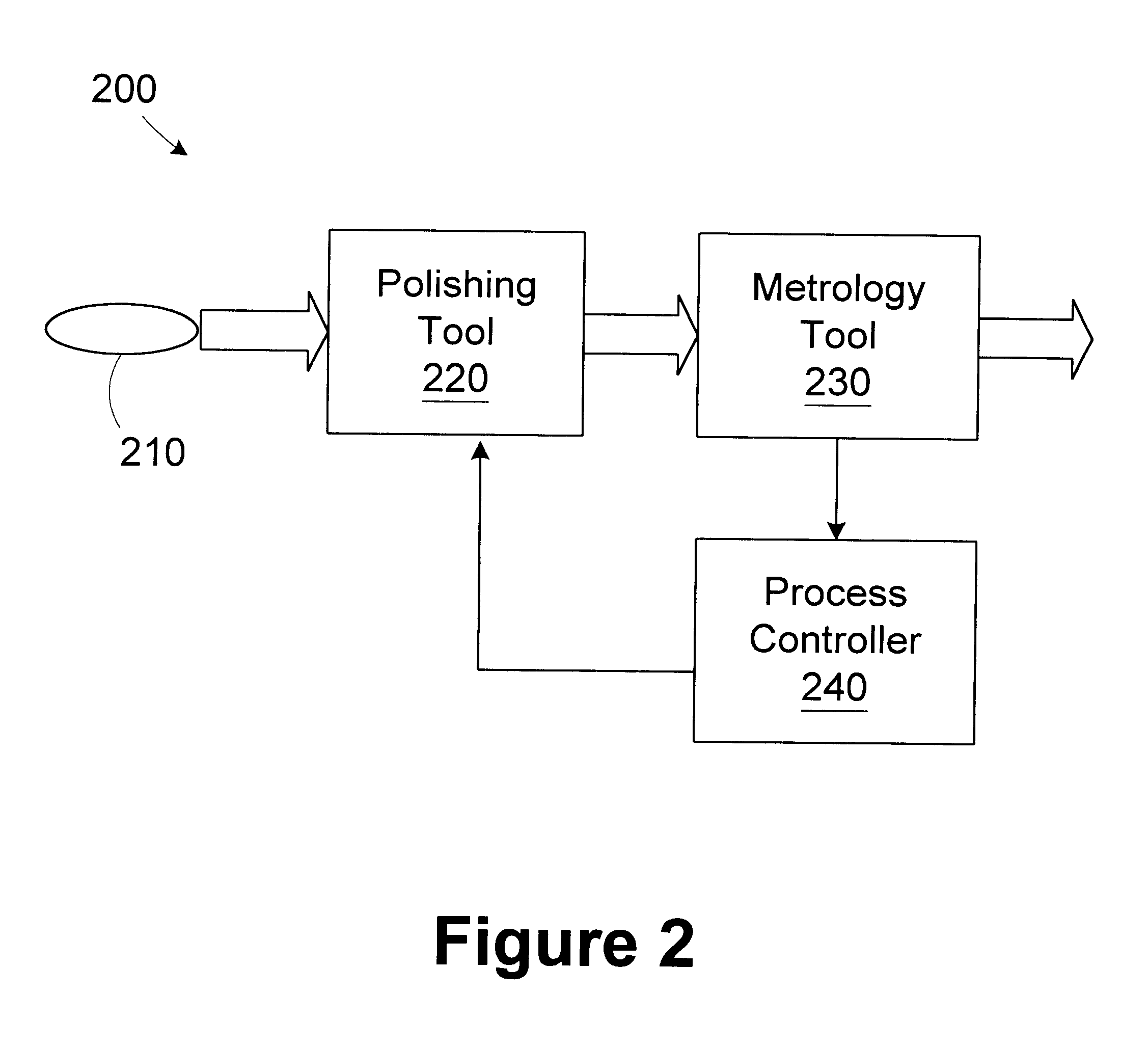

Method and apparatus for post-polish thickness and uniformity control

A method for polishing wafers includes providing a wafer having a process layer formed thereon; providing a polishing tool having a plurality of control zones and being adapted to polish the process layer based on an operating recipe, the operating recipe having a control variable corresponding to each of the control zones; measuring a pre-polish thickness profile of the process layer; comparing the pre-polish thickness profile to a target thickness profile to determine a desired removal profile; determining values for the control variables associated with the control zones based on the desired removal profile; and modifying the operating recipe of the polishing tool based on the values determined for the control variables. A processing line includes a polishing tool, a metrology tool, and a process controller. The polishing tool is adapted to polish a wafer having a process layer formed thereon based on an operating recipe. The polishing tool includes a plurality of control zones and the operating recipe includes a control variable corresponding to each of the control zones. The metrology tool is adapted to measure a pre-polish thickness profile of the process layer. The process controller is adapted to compare the pre-polish thickness profile to a target thickness profile to determine a desired removal profile, determine values for the control variables associated with the control zones based on the desired removal profile, and modify the operating recipe of the polishing tool based on the values determined for the control variables.

Owner:GLOBALFOUNDRIES INC

Polishing pads for chemical mechanical planarization

InactiveUS6860802B1Revolution surface grinding machinesFlexible-parts wheelsHigh energyRelative motion

An improved pad and process for polishing metal damascene structures on a semiconductor wafer. The process includes the steps of pressing the wafer against the surface of a polymer sheet in combination with an aqueous-based liquid that optionally contains sub-micron particles and providing a means for relative motion of wafer and polishing pad under pressure so that the moving pressurized contact results in planar removal of the surface of said wafer, wherein the polishing pad has a low elastic recovery when said load is removed, so that the mechanical response of the sheet is largely anelastic. The improved pad is characterized by a high energy dissipation coupled with a high pad stiffness. The pad exhibits a stable morphology that can be reproduced easily and consistently. The pad surface resists glazing, thereby requiring less frequent and less aggressive conditioning. The benefits of such a polishing pad are low dishing of metal features, low oxide erosion, reduced pad conditioning, longer pad life, high metal removal rates, good planarization, and lower defectivity (scratches and Light Point Defects).

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Backup shoe for microfinishing and methods

InactiveUS20050245179A1Revolution surface grinding machinesBelt grinding machinesSupport surfaceMetallic Nickel

A shoe for supporting an abrasive tape having an abrasive face and an opposed back face, wherein the shoe comprises a support surface including a frictional engagement material for frictionally engaging the back face of the abrasive tape. The frictional engagement material comprises a plurality of individual frictional engagement areas on a flexible substrate, each frictional engagement area having a plurality of abrasive particles. In an exemplary embodiment, the frictional engagement material comprises diamond abrasive particles retained in a nickel matrix supported on a flexible mesh substrate. The support surface of the shoe may be curvilinear, arcuate, convex, or concave.

Owner:3M INNOVATIVE PROPERTIES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com