Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

27030results about "Grinding drives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

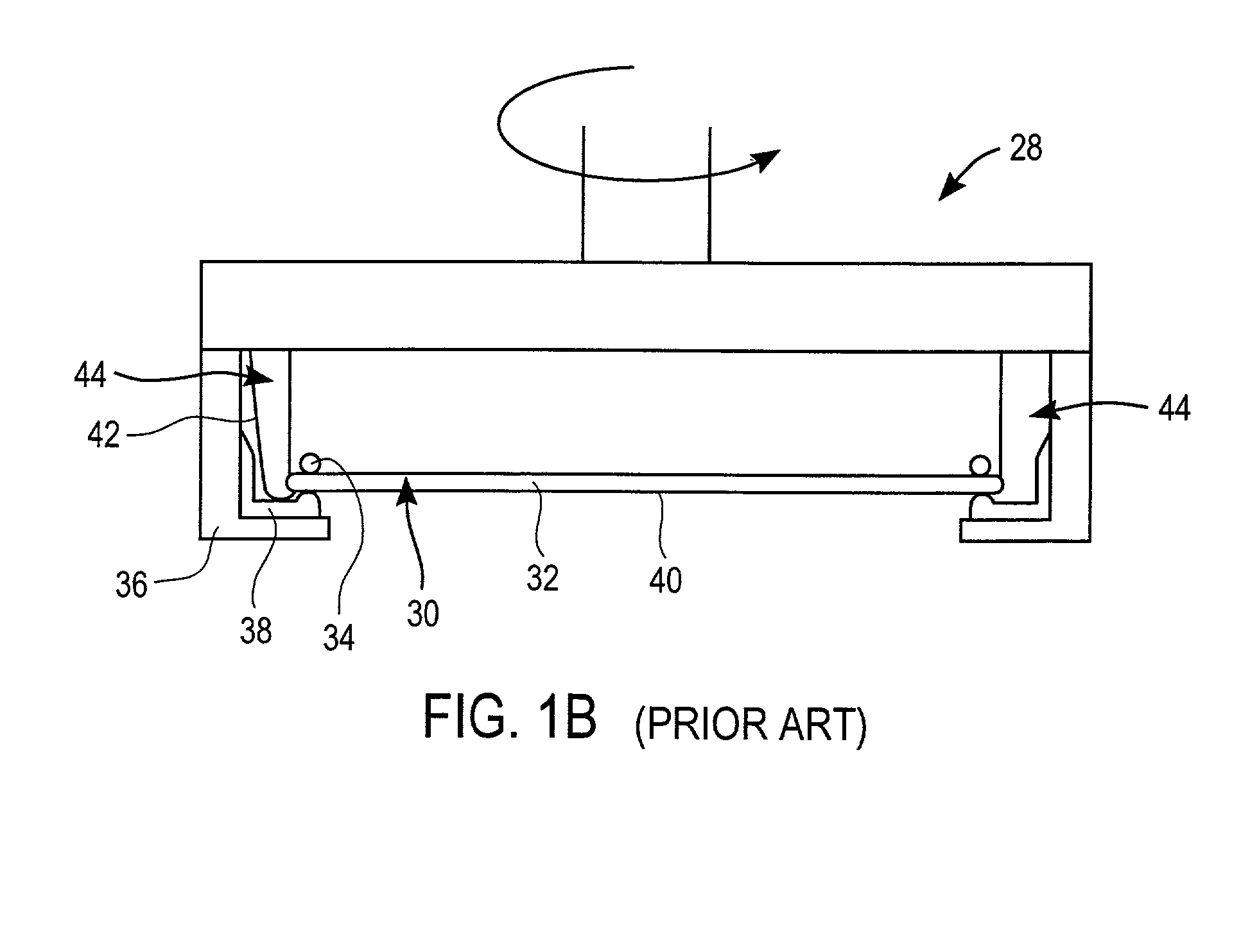

Wafer carrier checker and method of using same

ActiveUS20060252351A1Grinding drivesBelt grinding machinesSemiconductorElectrical and Electronics engineering

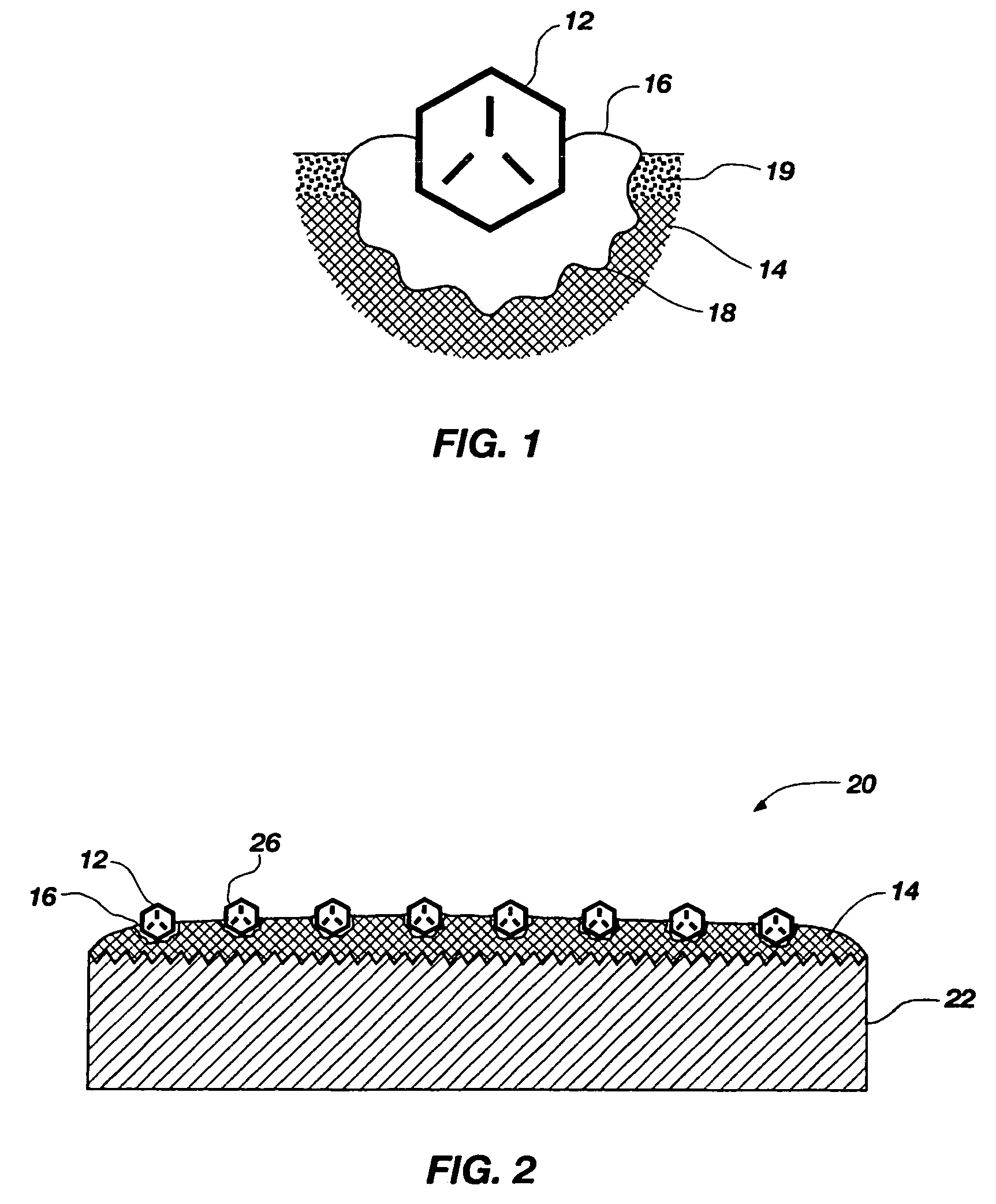

A tool and method for assessing whether a disk carrier, and especially a carrier for holding semiconductor disks, is properly dimensioned. The tool has a body that includes a socket in which a portion of the disk carrier will seat fully if the disk carrier is properly dimensioned. Alignment structures may be provided in the socket to align with features of the carrier to assist in determining whether the disk carrier is properly dimensioned. The socket may include two spaced apart cavities that correspond with end portions of walls of the disk carrier.

Owner:MICREL

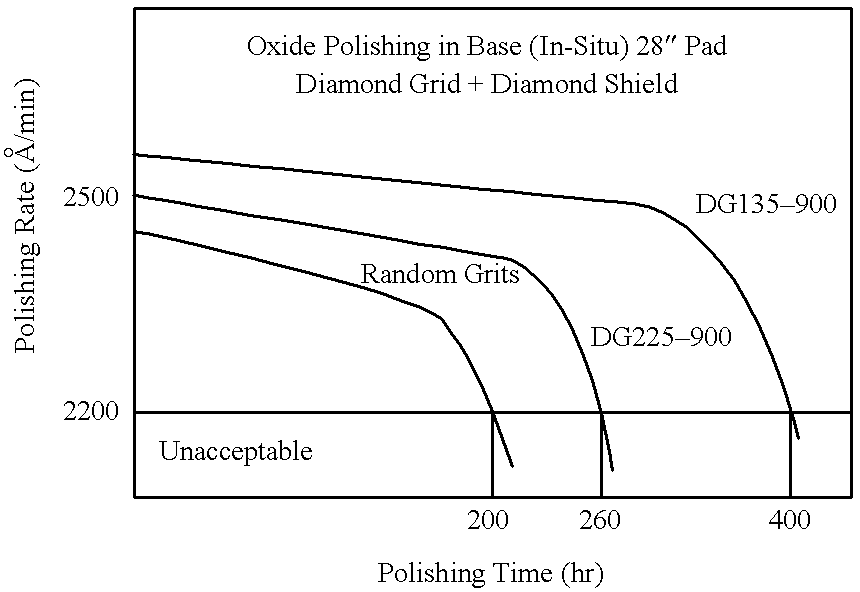

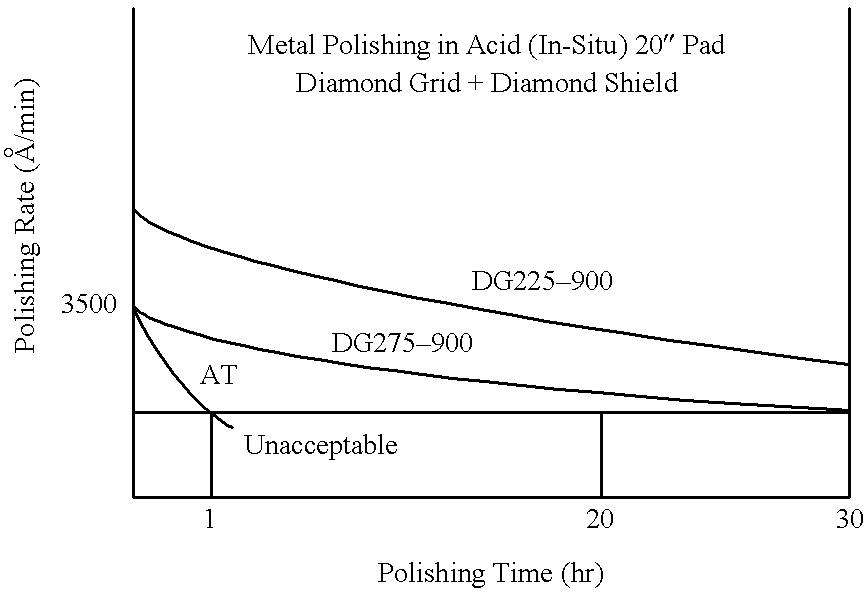

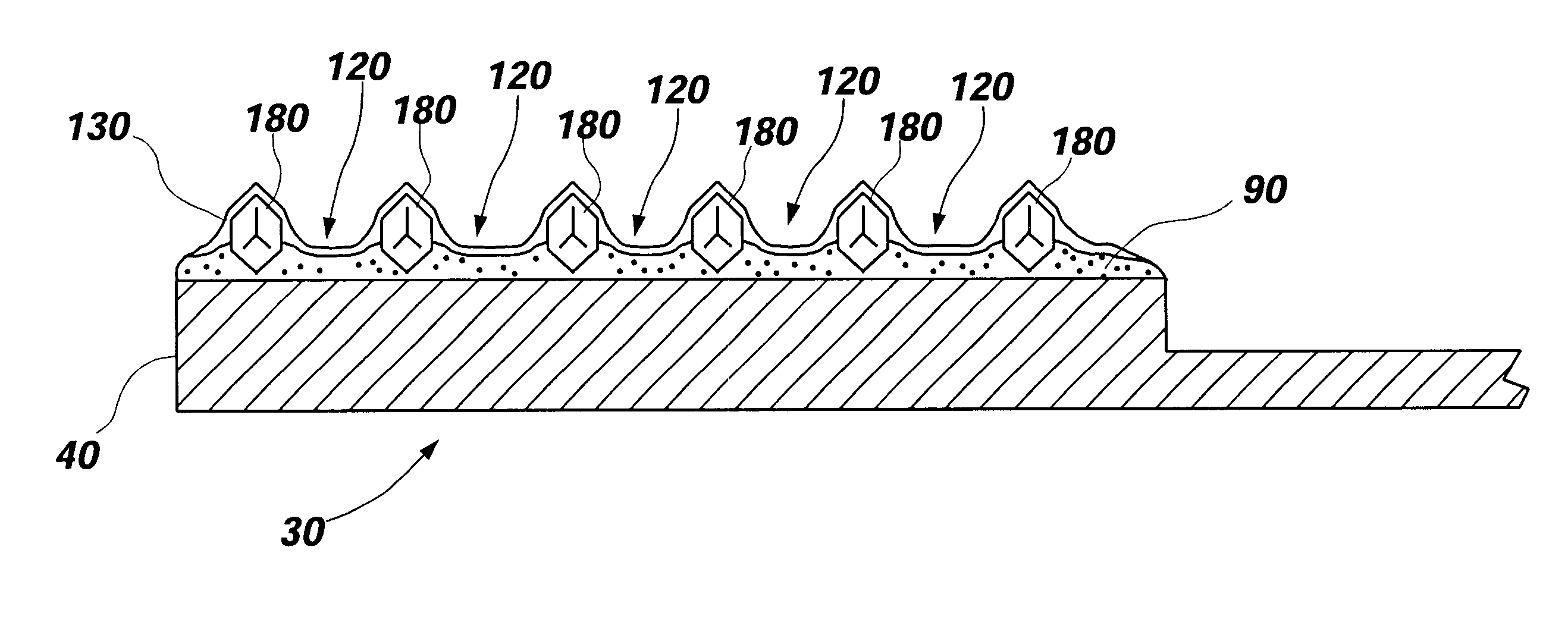

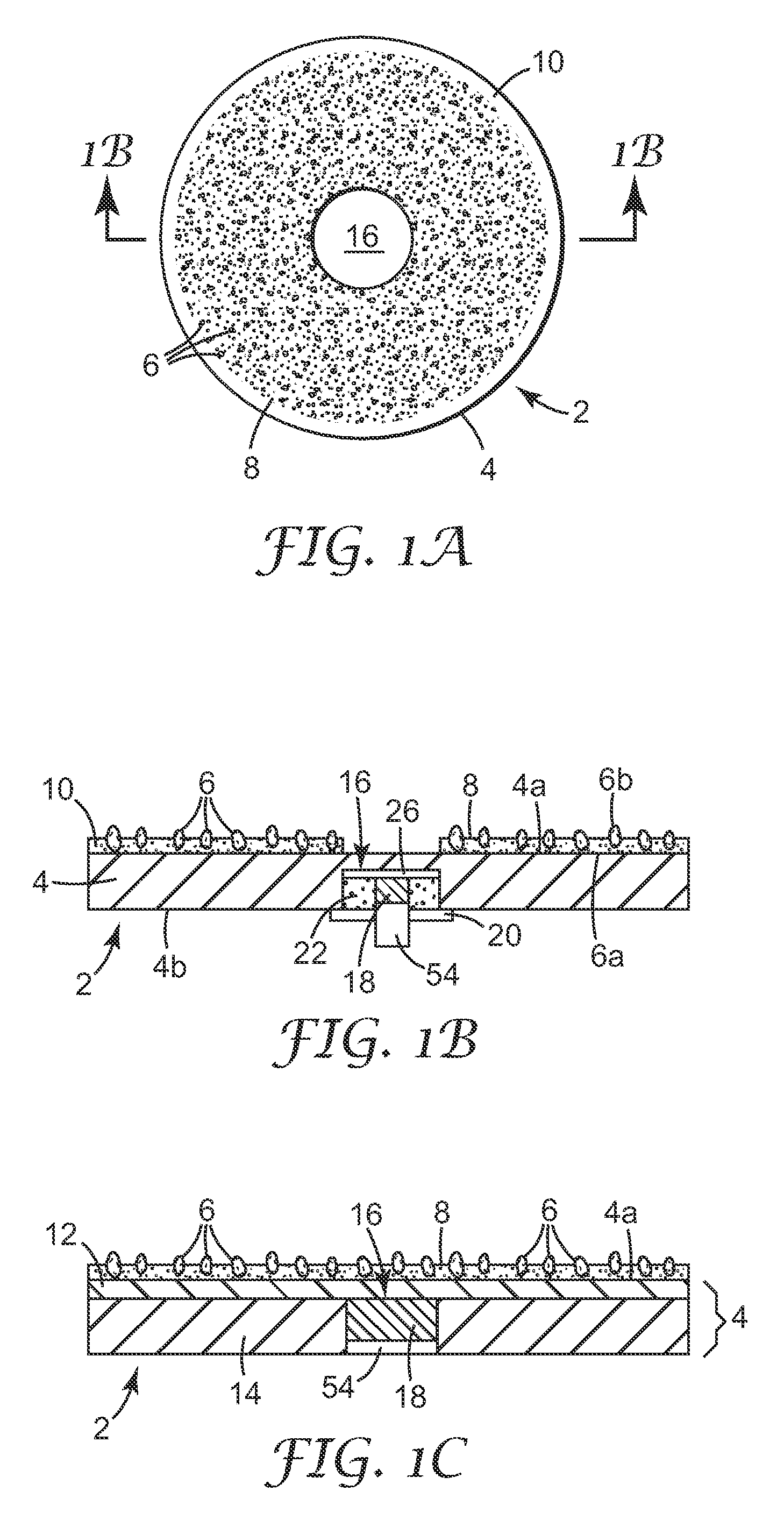

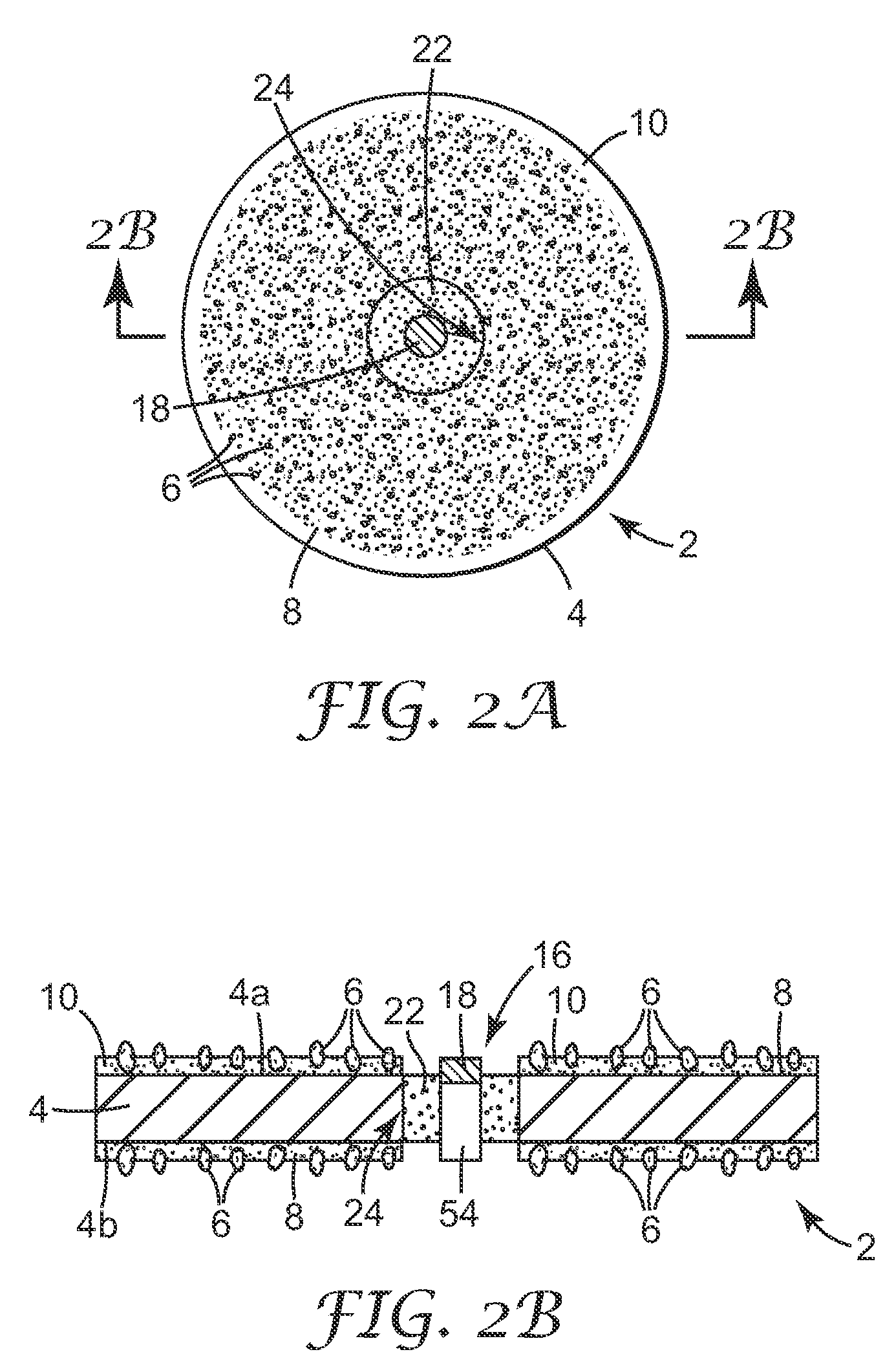

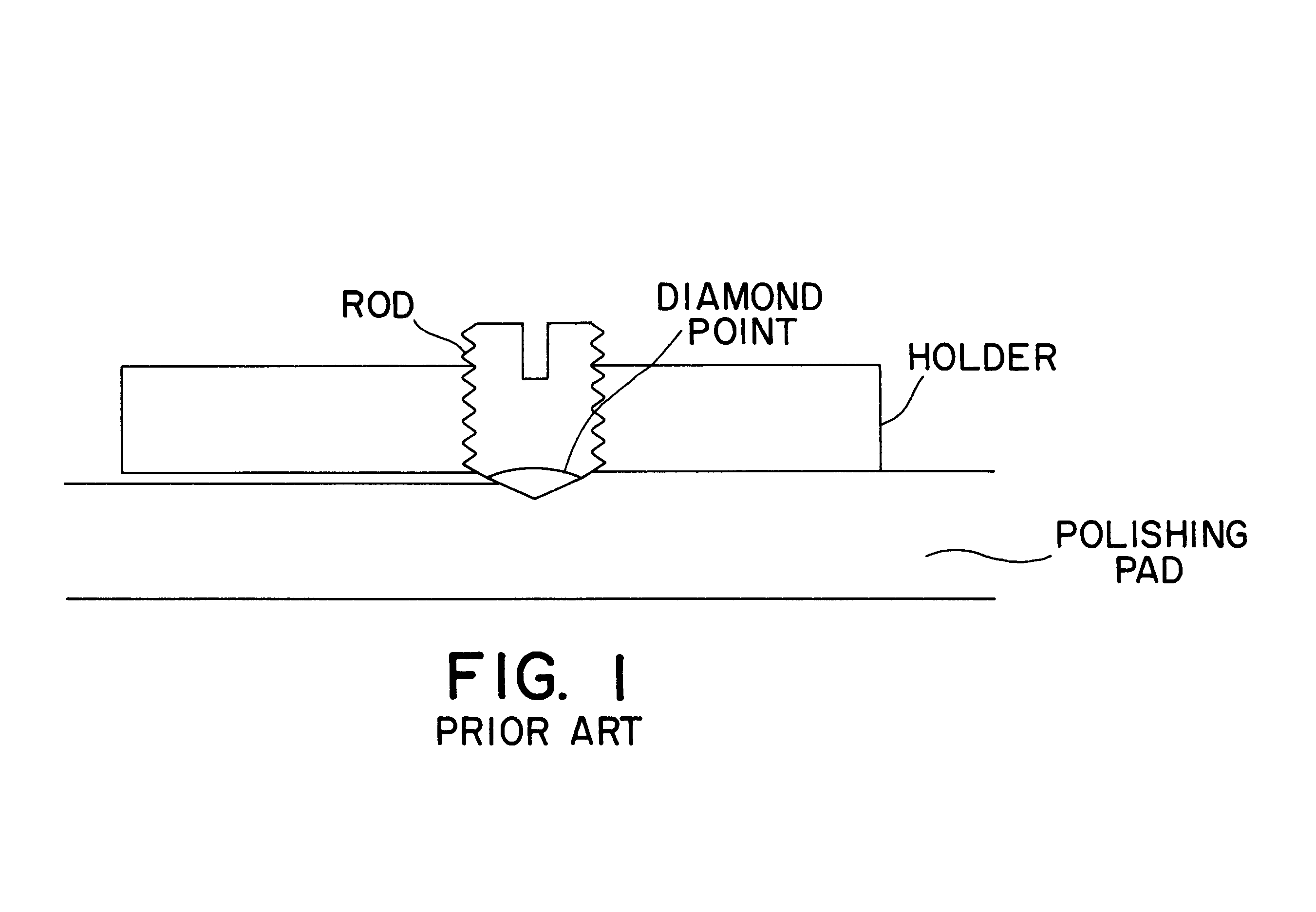

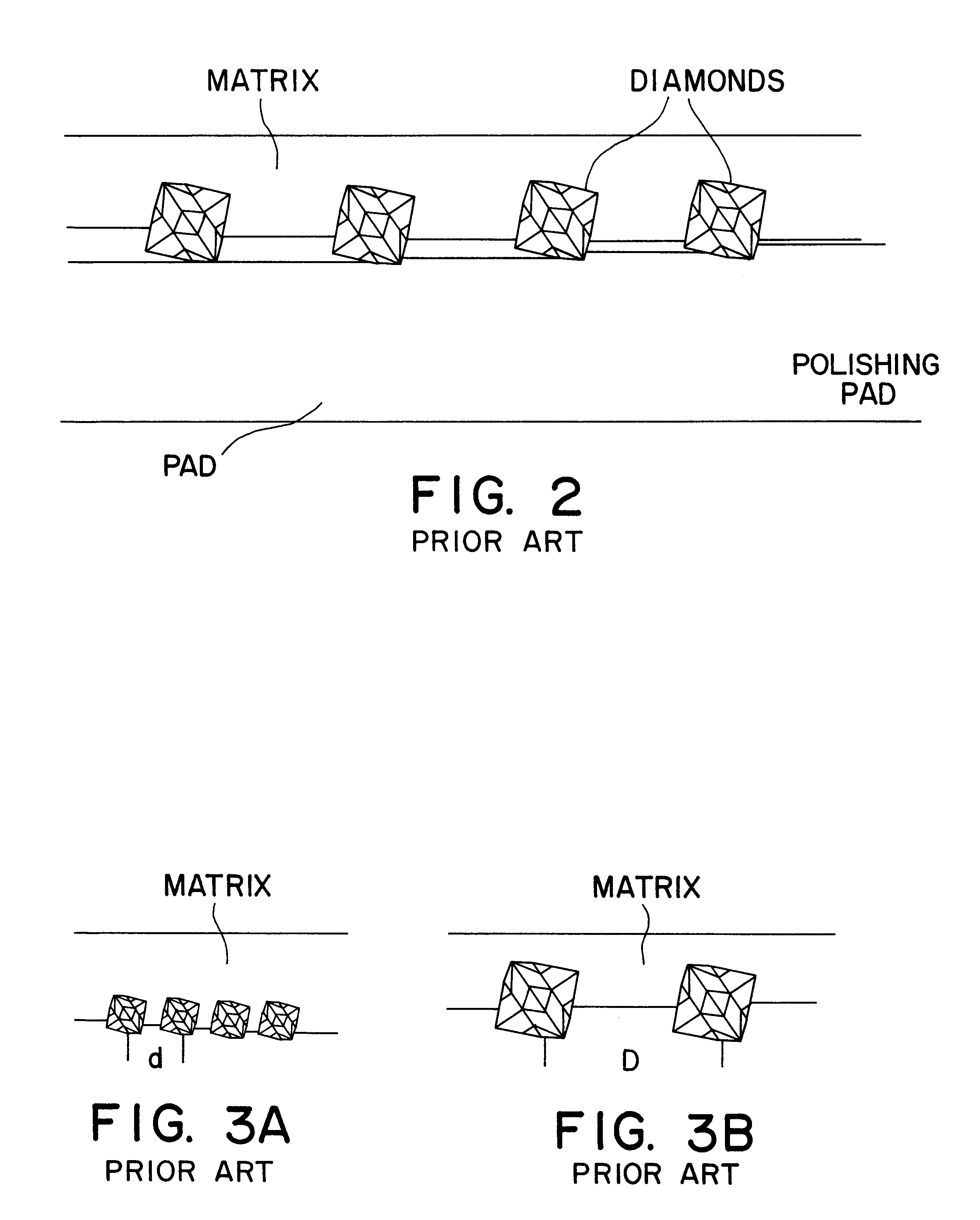

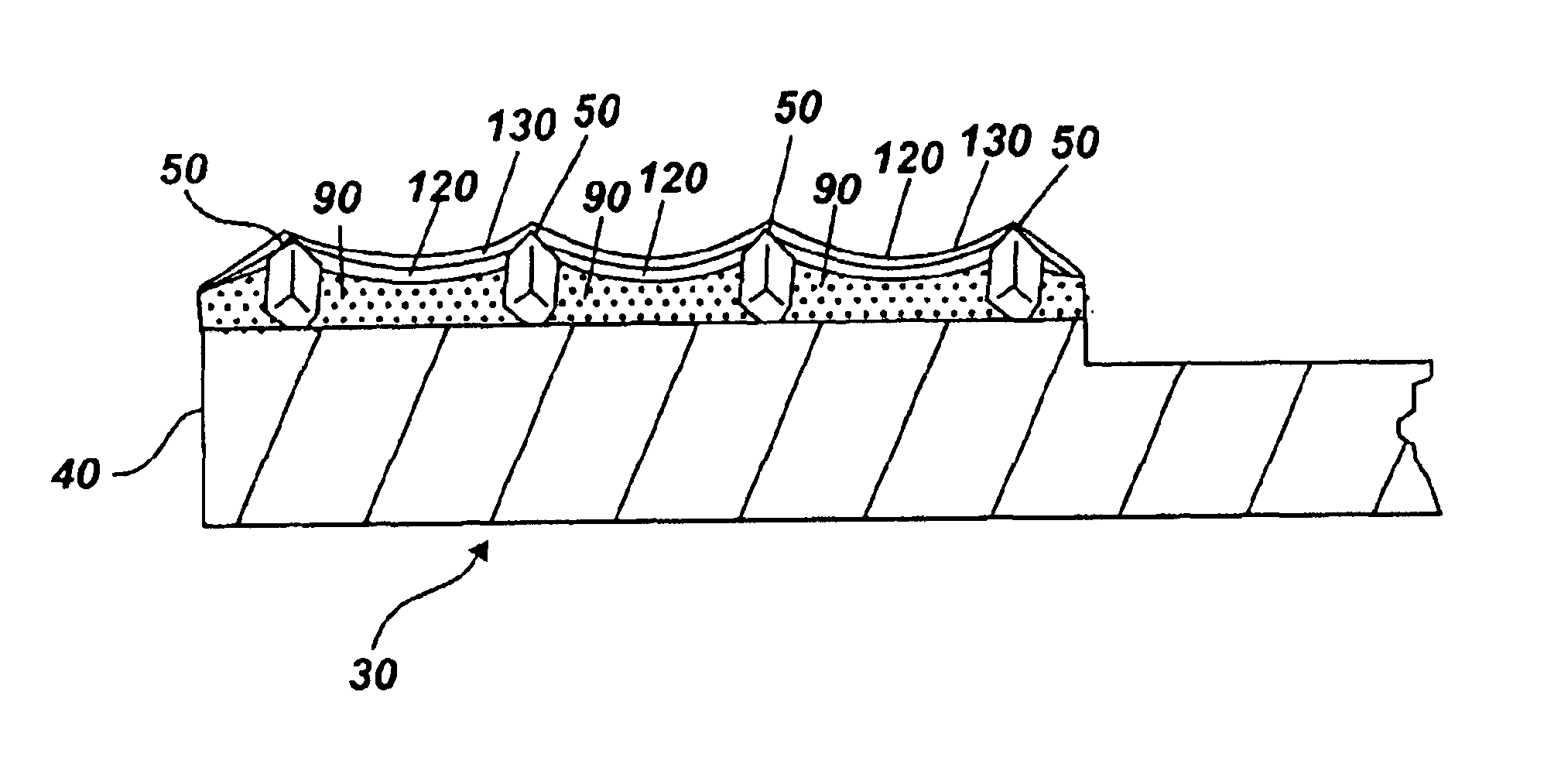

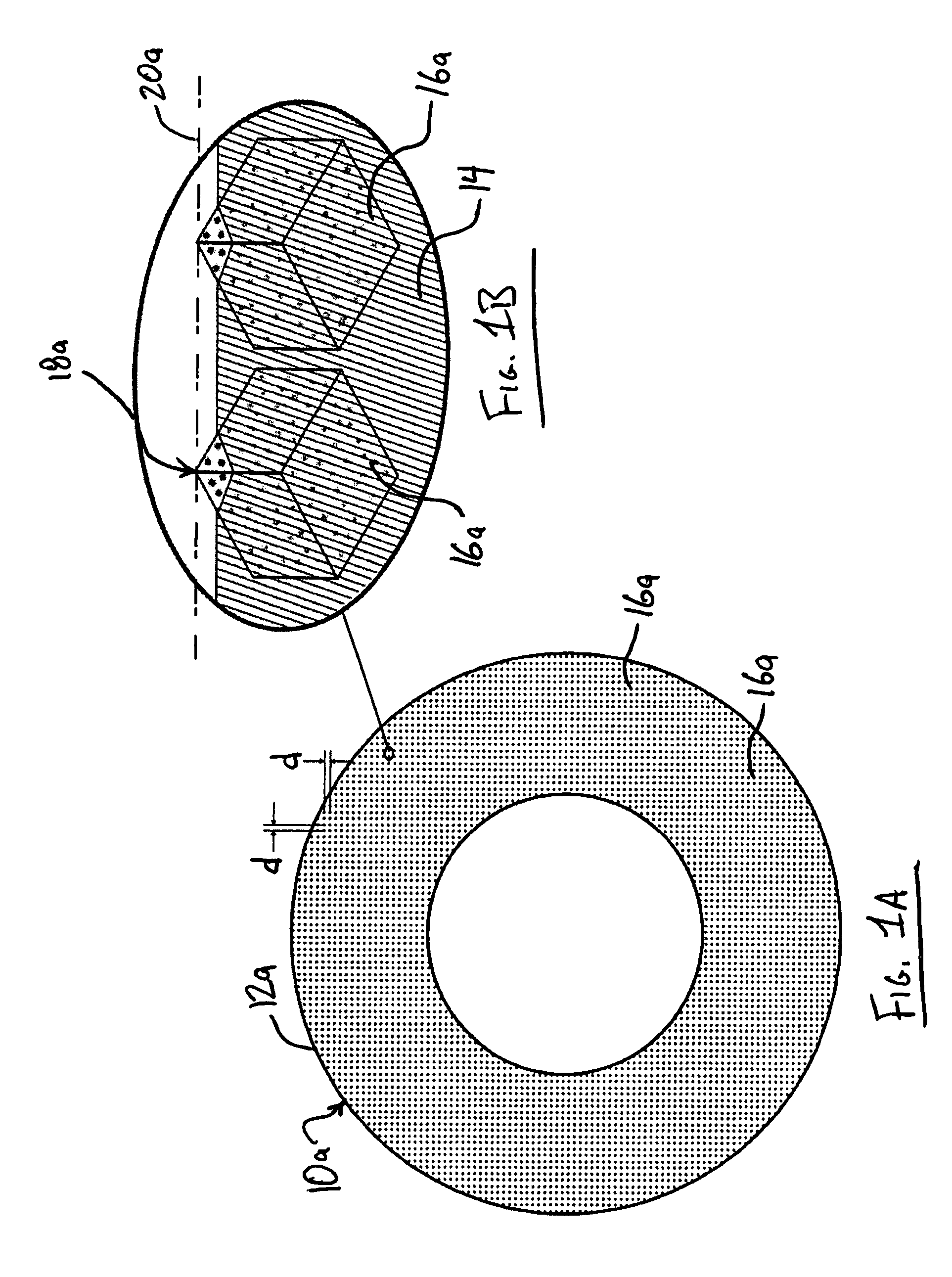

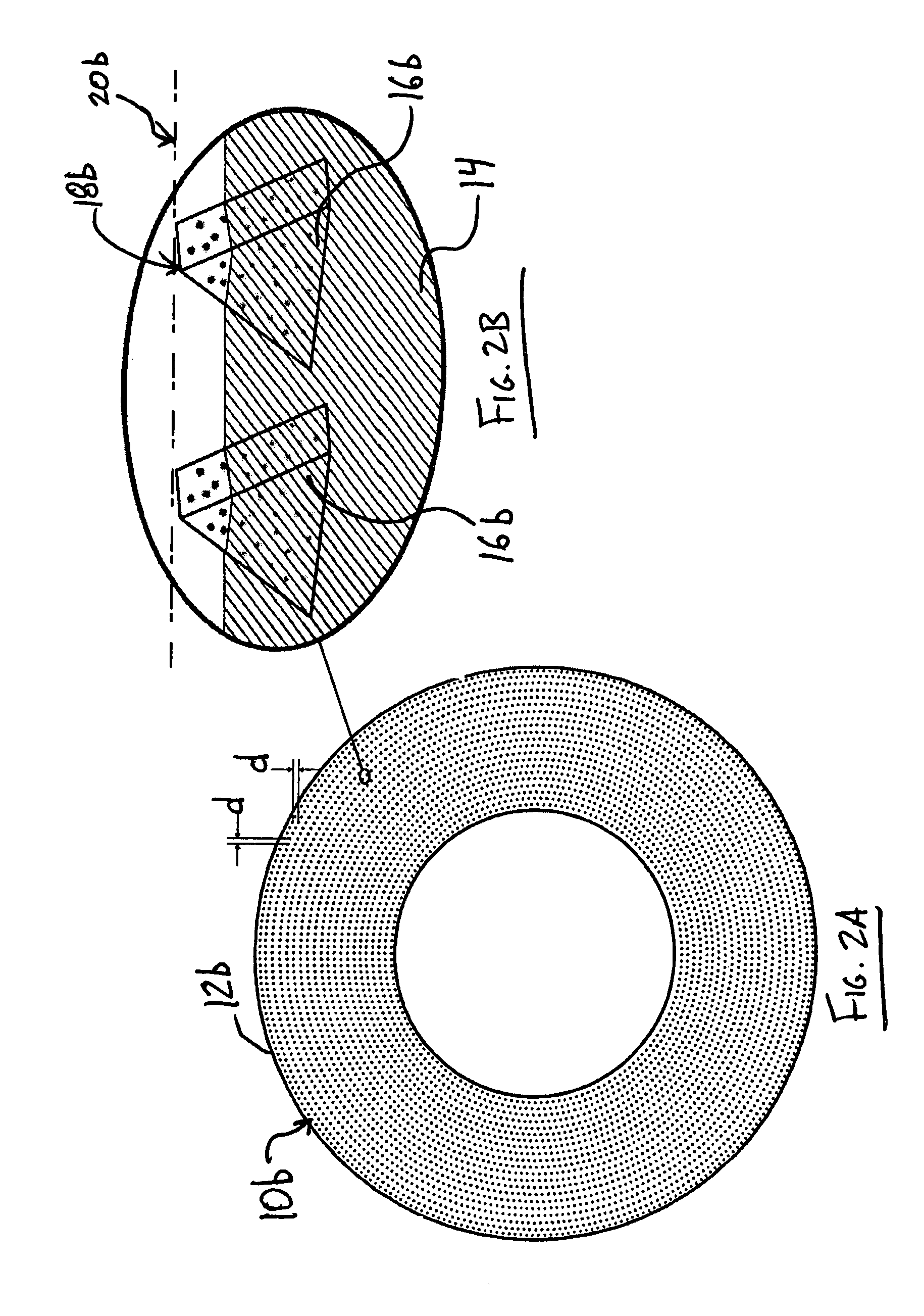

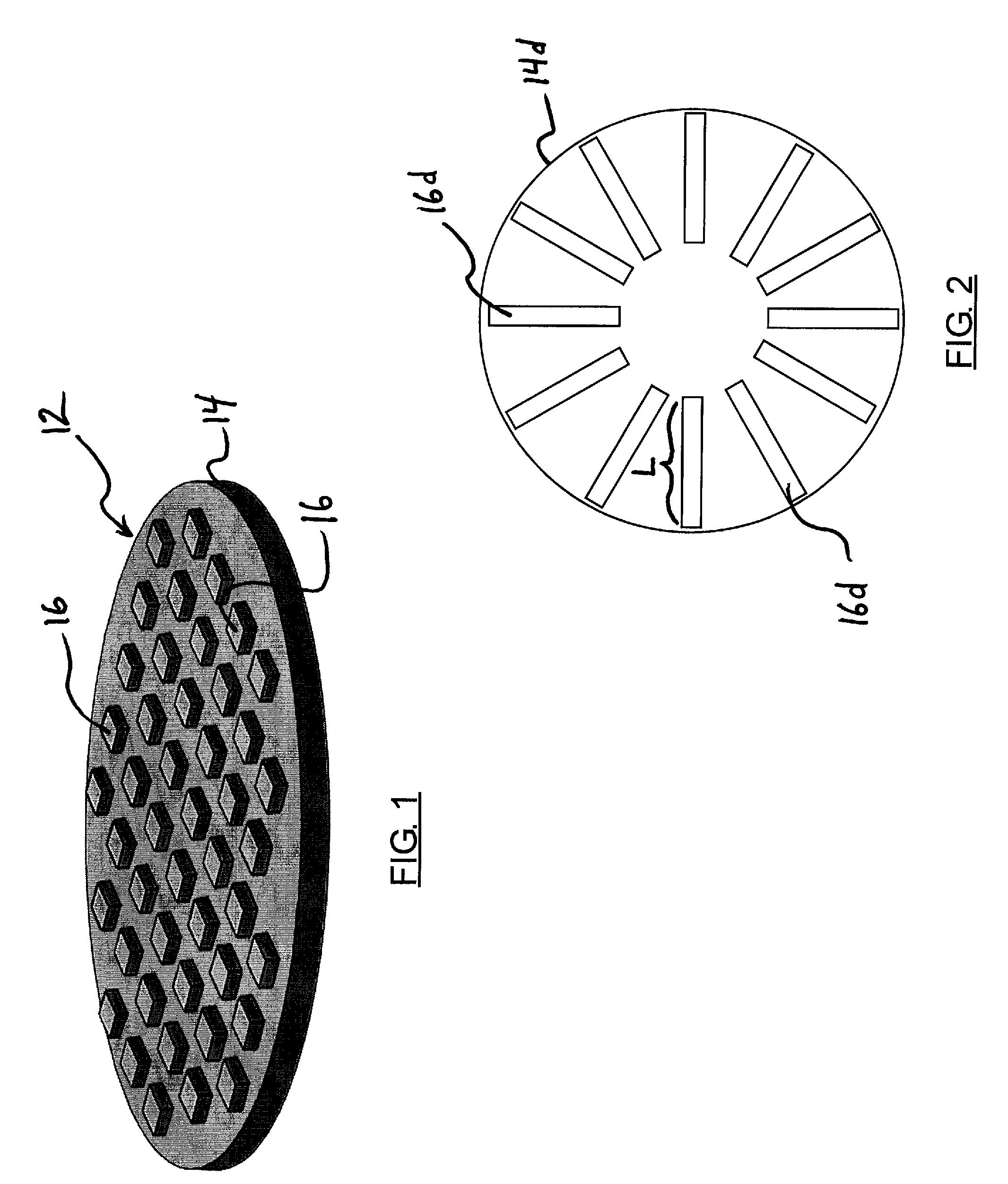

Diamond grid CMP pad dresser

InactiveUS6368198B1Improve polishing efficiencyExtended service lifePolishing machinesRevolution surface grinding machinesSuperhard materialDiamond-like carbon

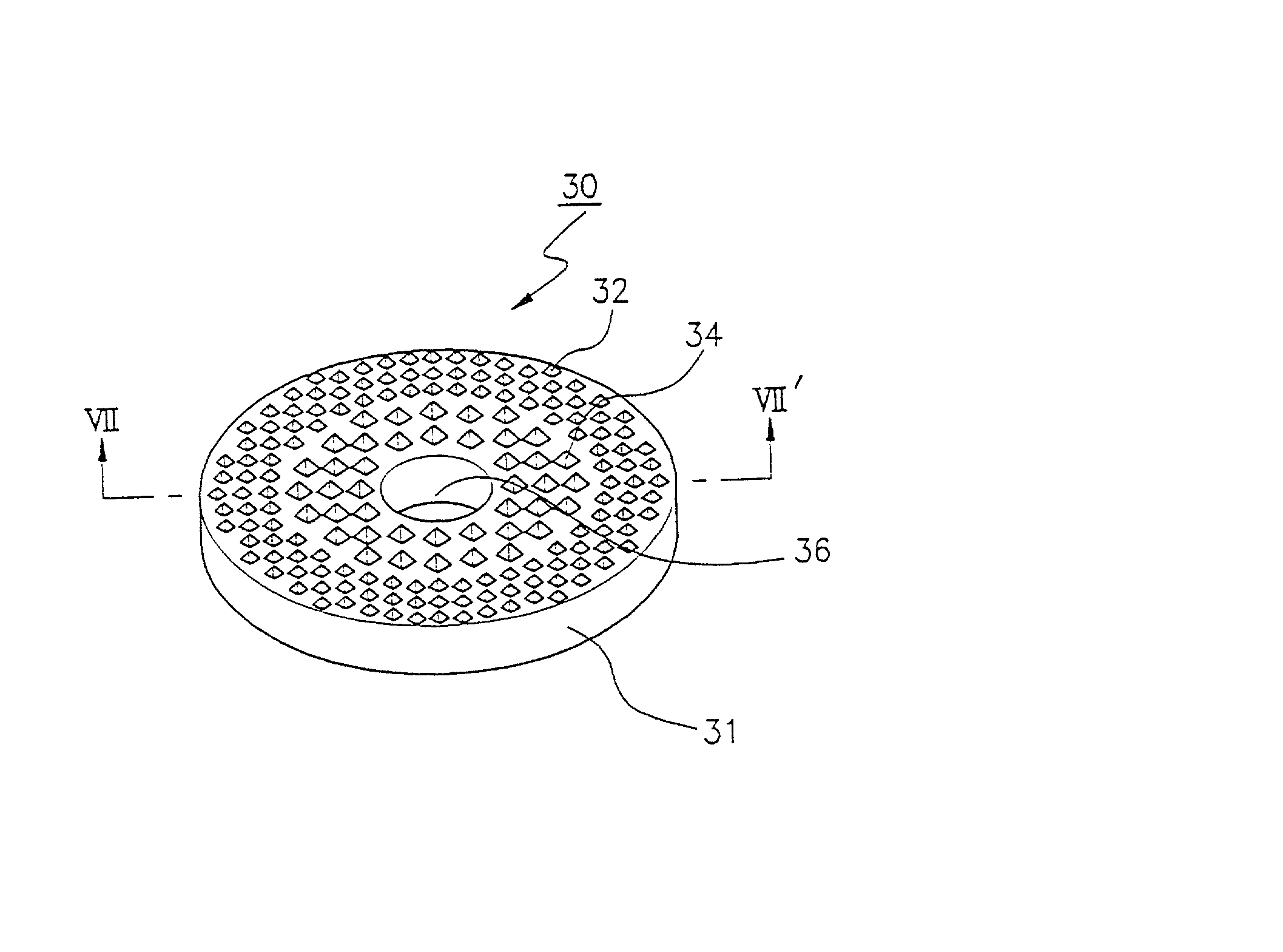

The present invention discloses a CMP pad dresser which has a plurality of uniformly spaced abrasive particles protruding therefrom. The abrasive particles are super hard materials, and are typically diamond, polycrystalline diamond (PCD), cubic boron nitride (cBN), or polycrystalline cubic boron nitride(PcBN). The abrasive particles are brazed to a substrate which may be then coated with an additional anti-corrosive layer. The anti-corrosive layer is usually a diamond or diamond-like carbon which is coated over the surface of the disk to prevent erosion of the brazing alloy by the chemical slurry used in conjunction with the CMP pad. This immunity to chemical attack allows the CMP pad dresser to dress the pad while it is polishing a workpiece. In addition to even spacing on the substrate, the abrasive particles extend for a uniform distance away from the substrate, allowing for even grooming or dressing of a CMP pad both in vertical and horizontal directions. A method of producing such a CMP pad dresser is also disclosed.

Owner:KINIK

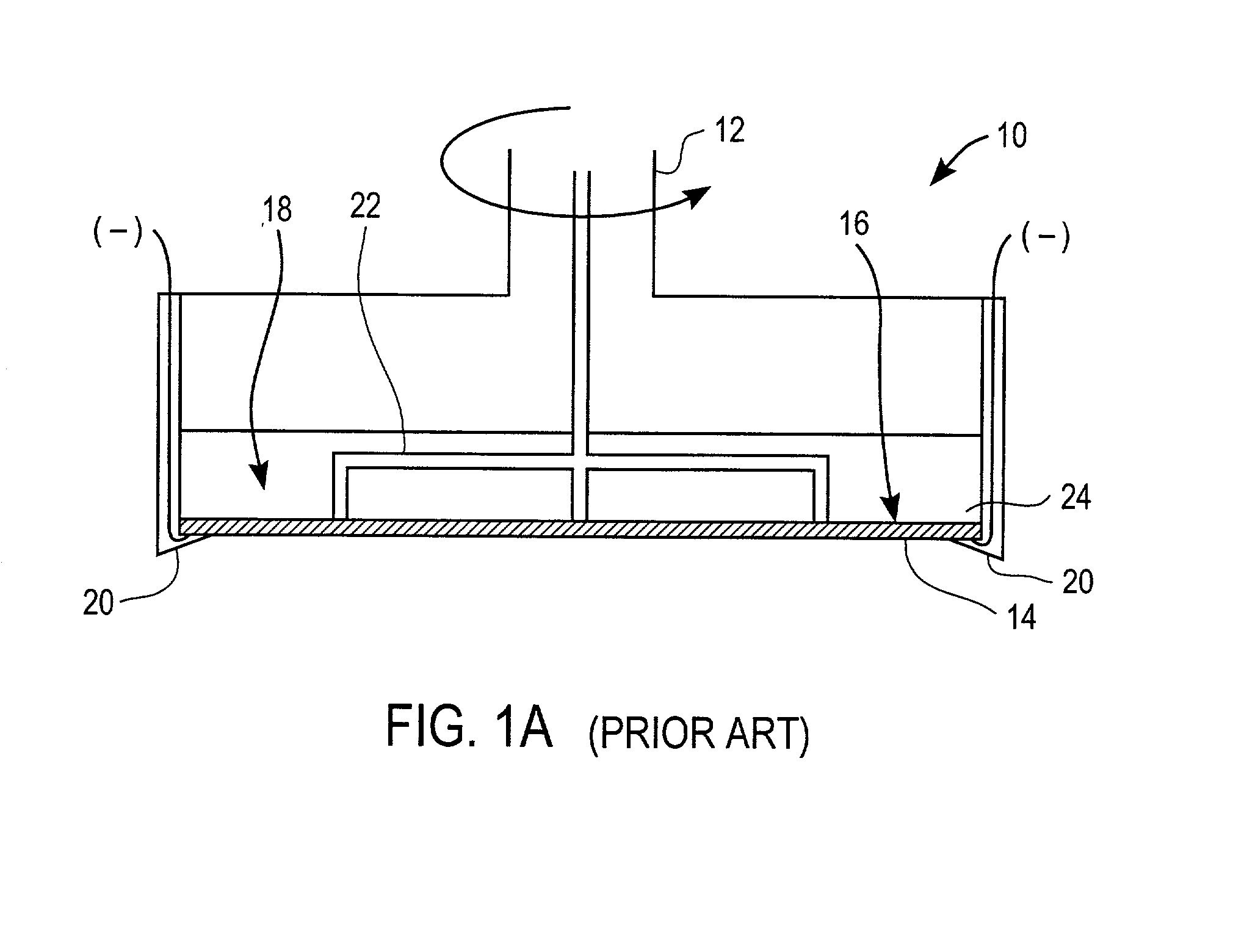

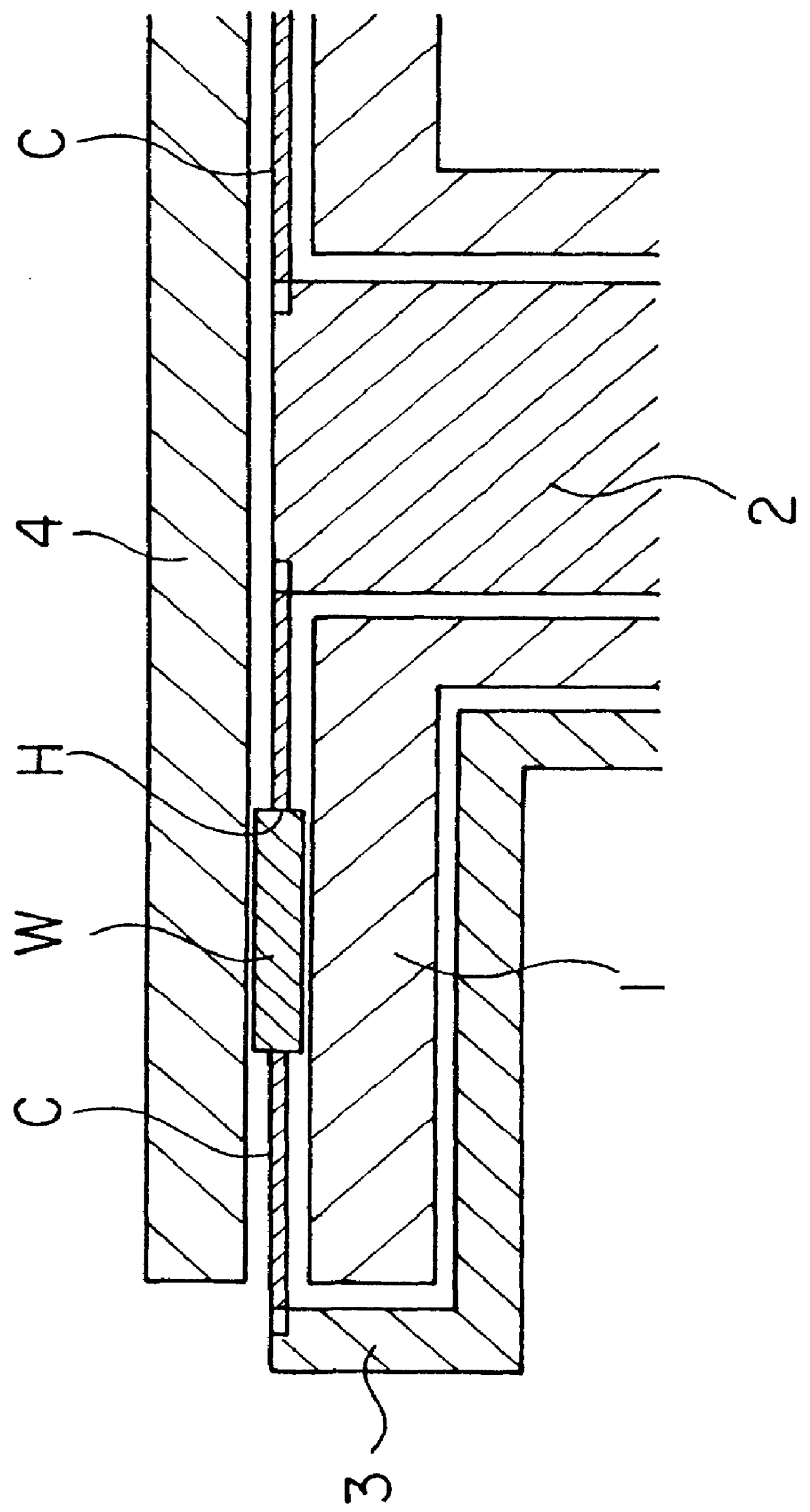

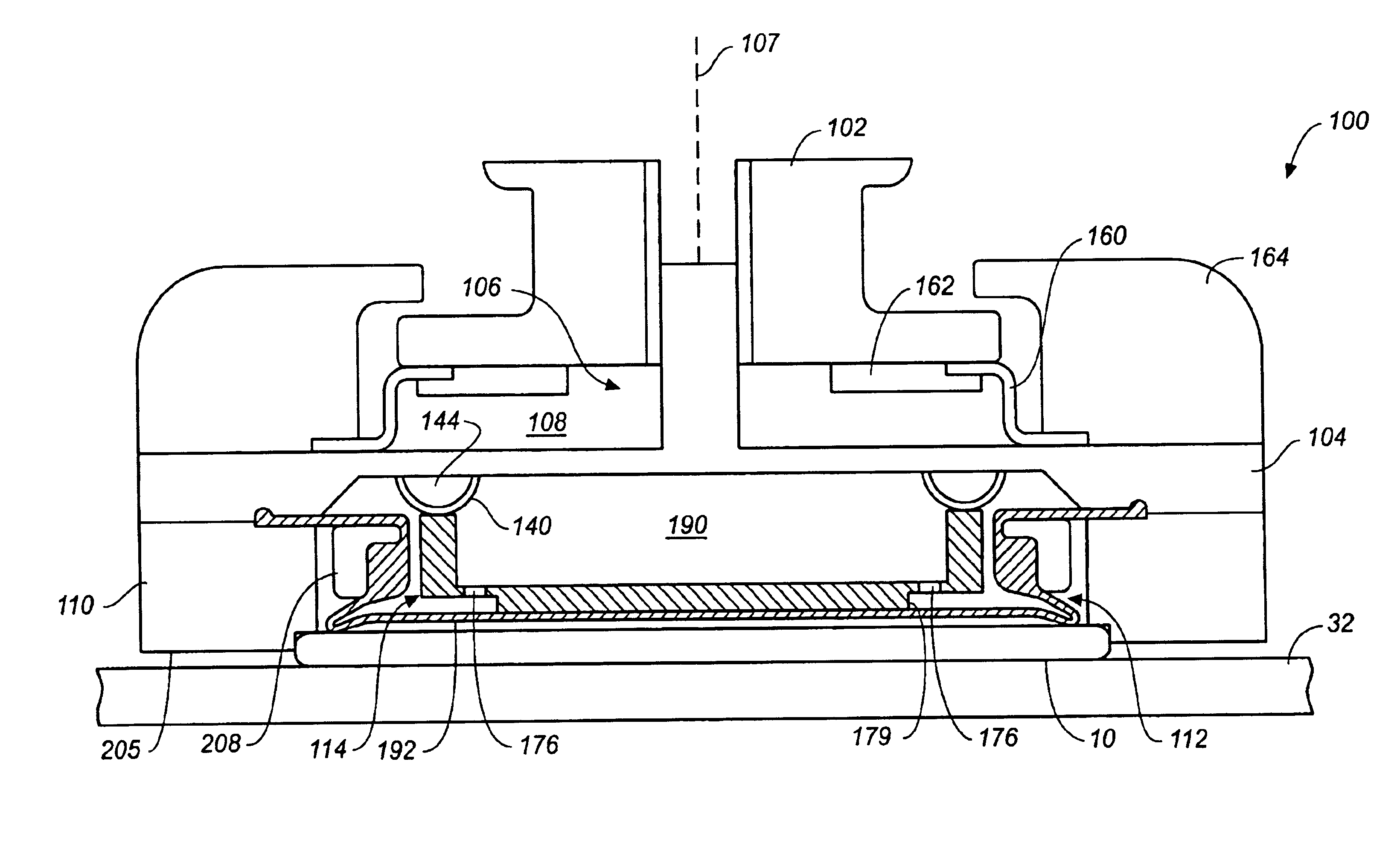

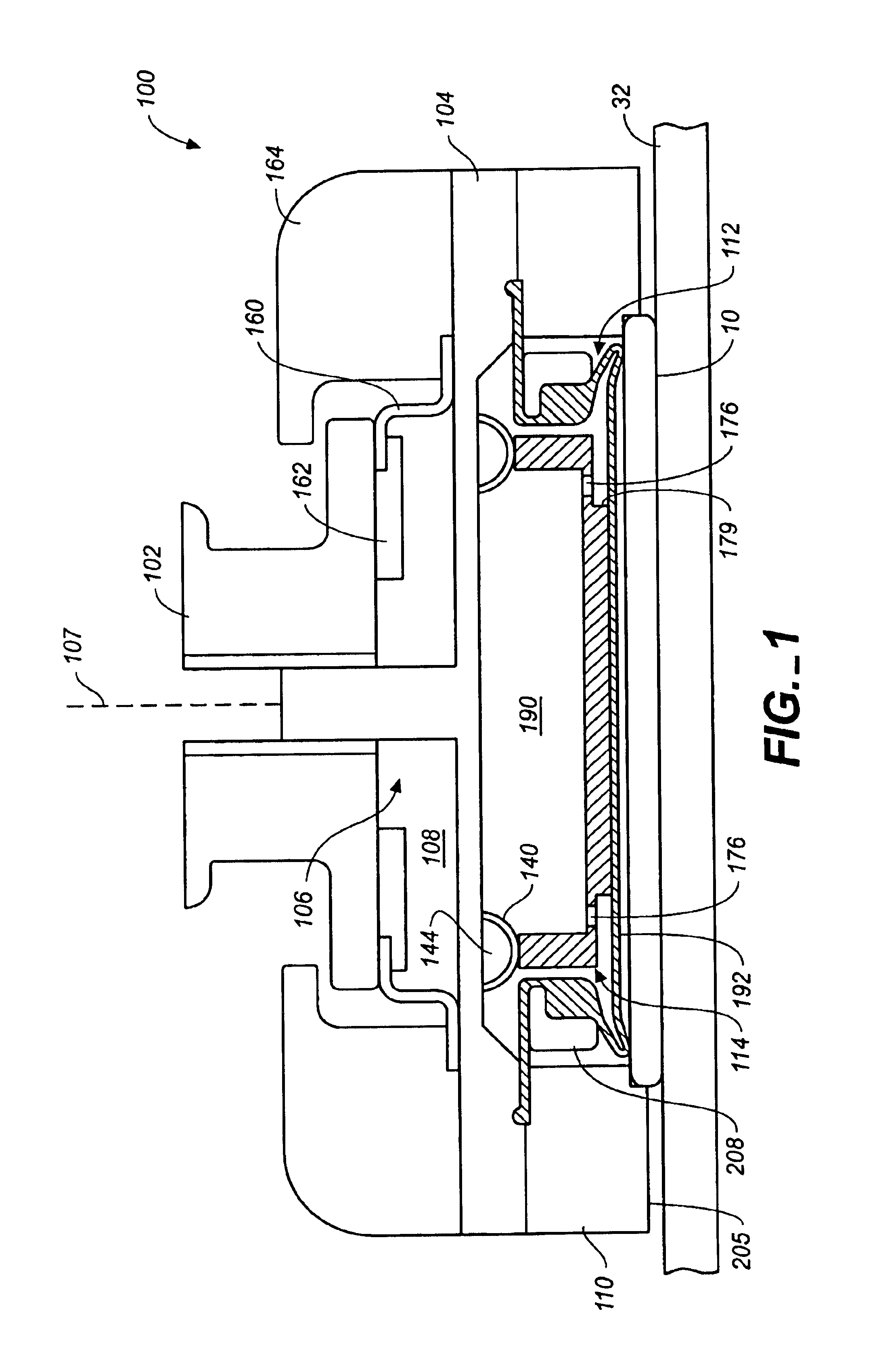

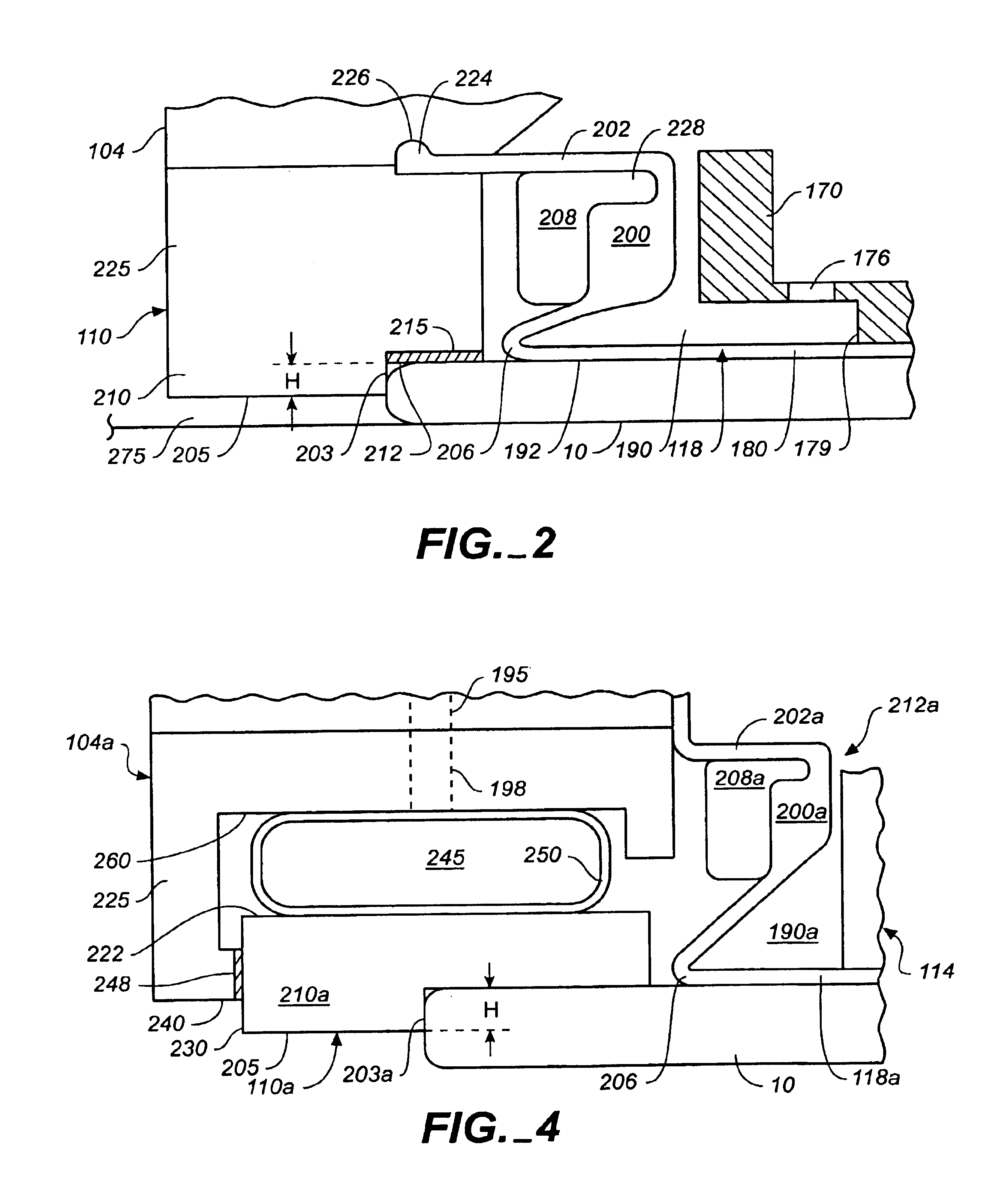

Method and apparatus of sealing wafer backside for full-face electrochemical plating

InactiveUS20030008602A1Efficient configurationMinimize irregularityEdge grinding machinesPolishing machinesMechanical engineeringElectroplating

The present invention provides a wafer carrier that includes a plurality of concentric sealing members that provide a seal, with the outer seal independently movable to allow cleaning of a peripheral backside of the wafer to occur while the wafer is still attached to the wafer carrier, and a plurality of vacuum openings that a re disposed only adjacent to an inner side of the inner seal at a location corresponding to the backside periphery of the wafer.

Owner:NOVELLUS SYSTEMS

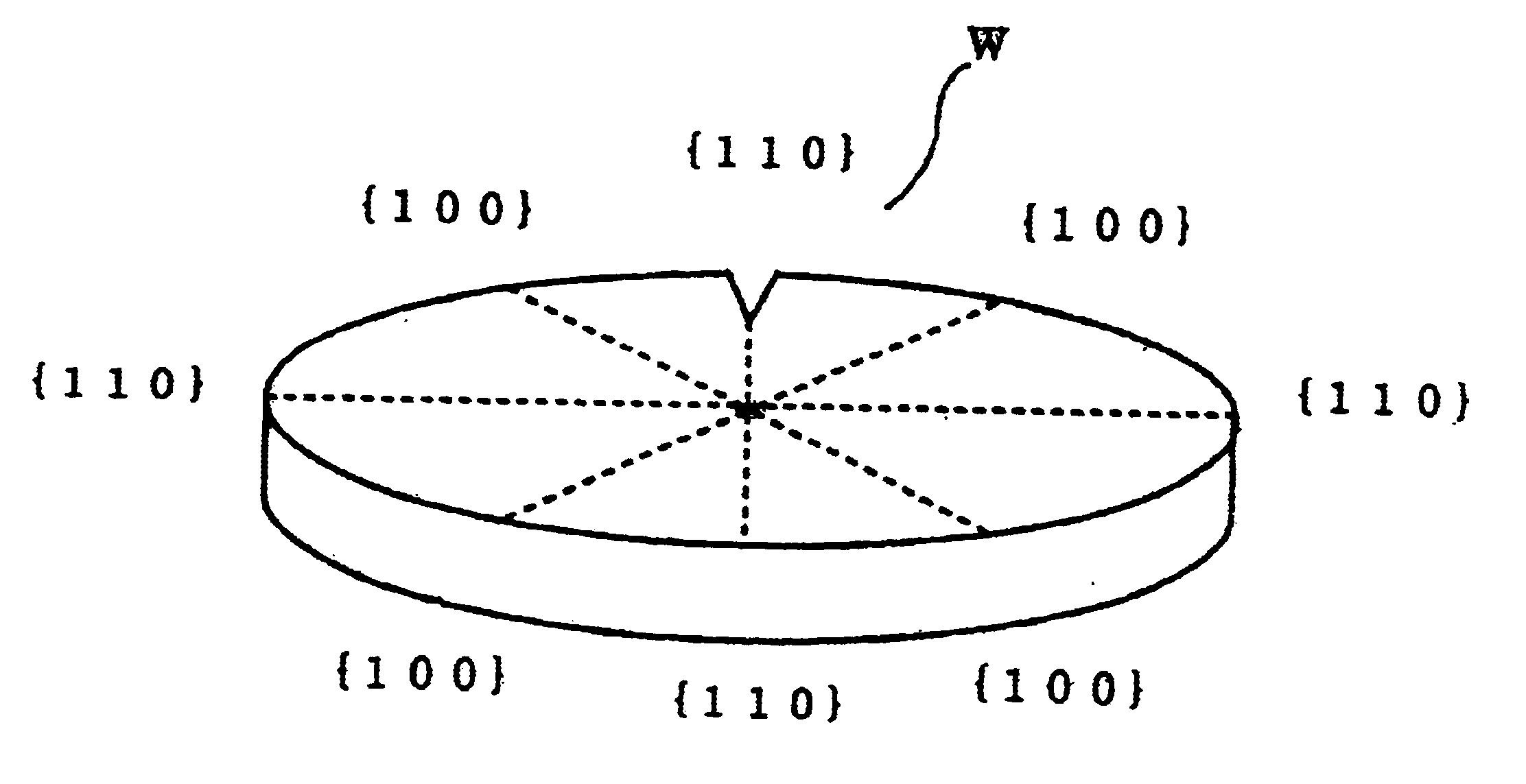

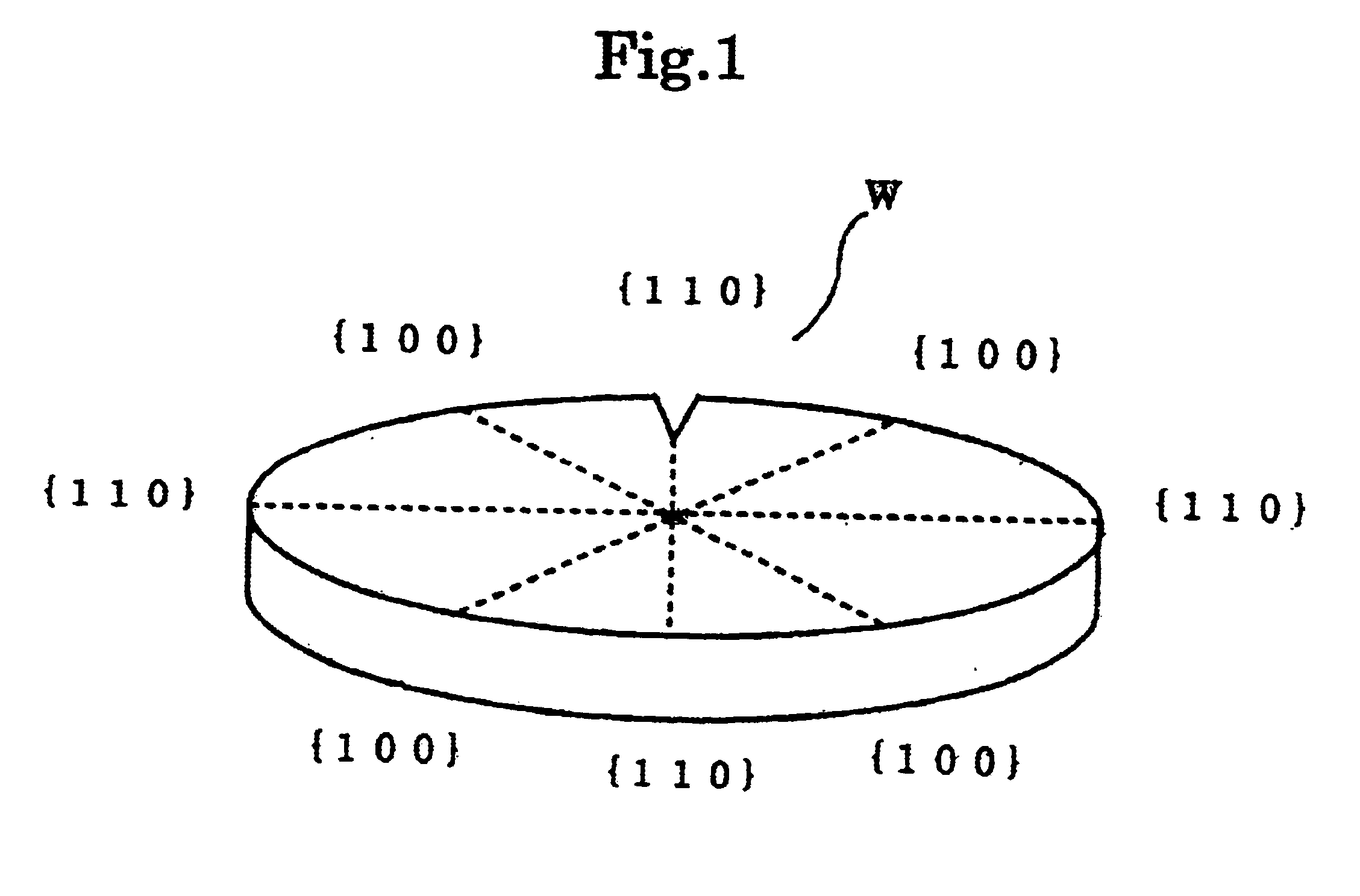

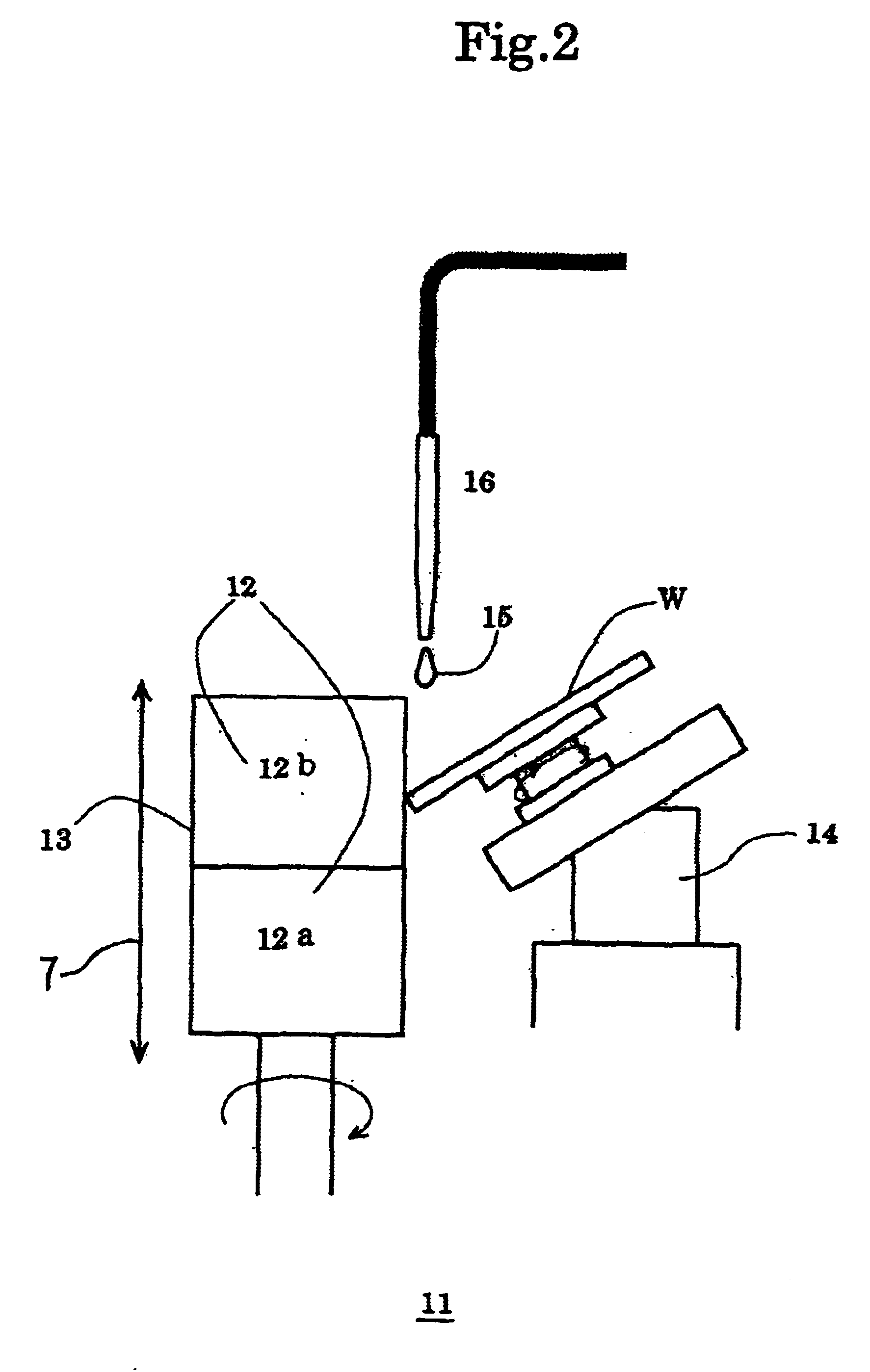

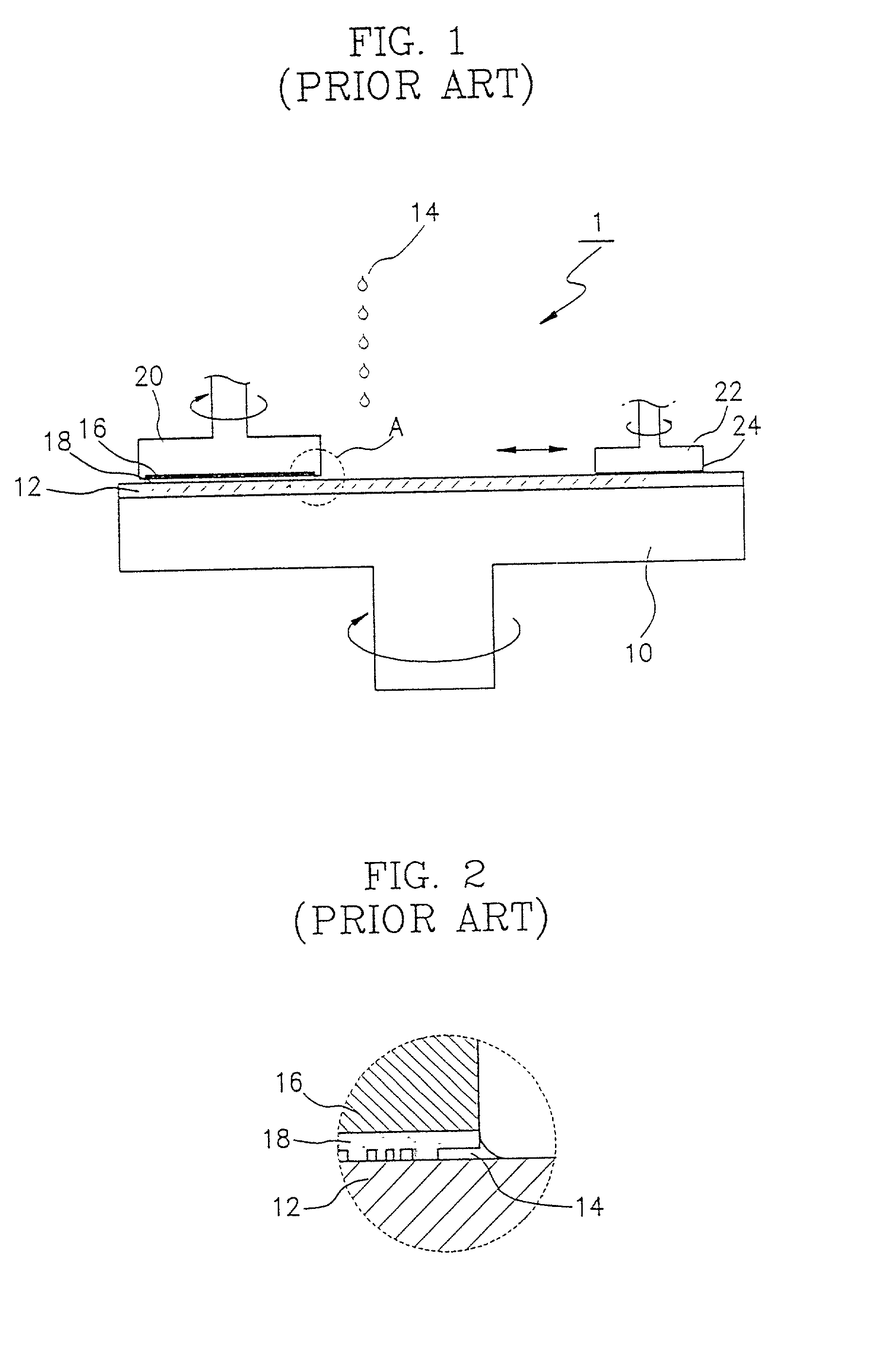

Method for apparatus for polishing outer peripheral chamfered part of wafer

InactiveUS6884154B2Improve productivityShorten polishing timeEdge grinding machinesPolishing machinesProduction rateHardness

In a process for polishing the chamfered peripheral part of a wafer using a polishing cloth while supplying a polishing slurry in order to improve productivity of the process by reducing a polishing time, at least two steps of polishing processes are performed in sequence. The process comprises a first polishing process to polish a particular part, e.g. the part corresponding to the {110} plane of a peripheral part of the wafer and a second polishing process in which the whole part of a peripheral part of the wafer is polished for finishing by means of varying a hardness of the polishing clothes and / or a particle size of abrasives in the slurry such as the hardness of the polishing cloth in the second polishing process being softer than that of in the first polishing process and a particle size of abrasives in the slurry in the second polishing process being finer than that of in the first polishing process.

Owner:SHIN-ETSU HANDOTAI CO LTD

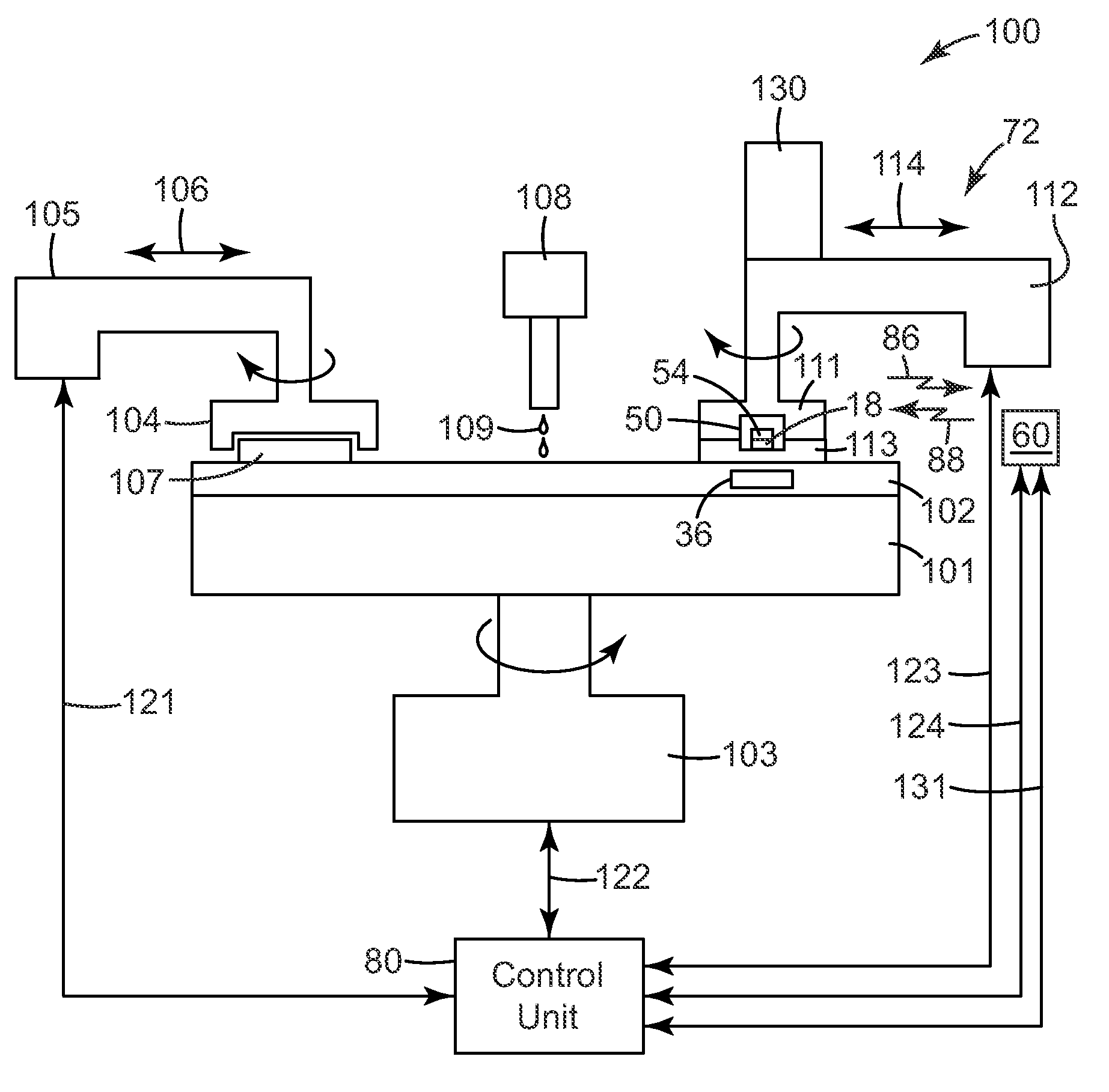

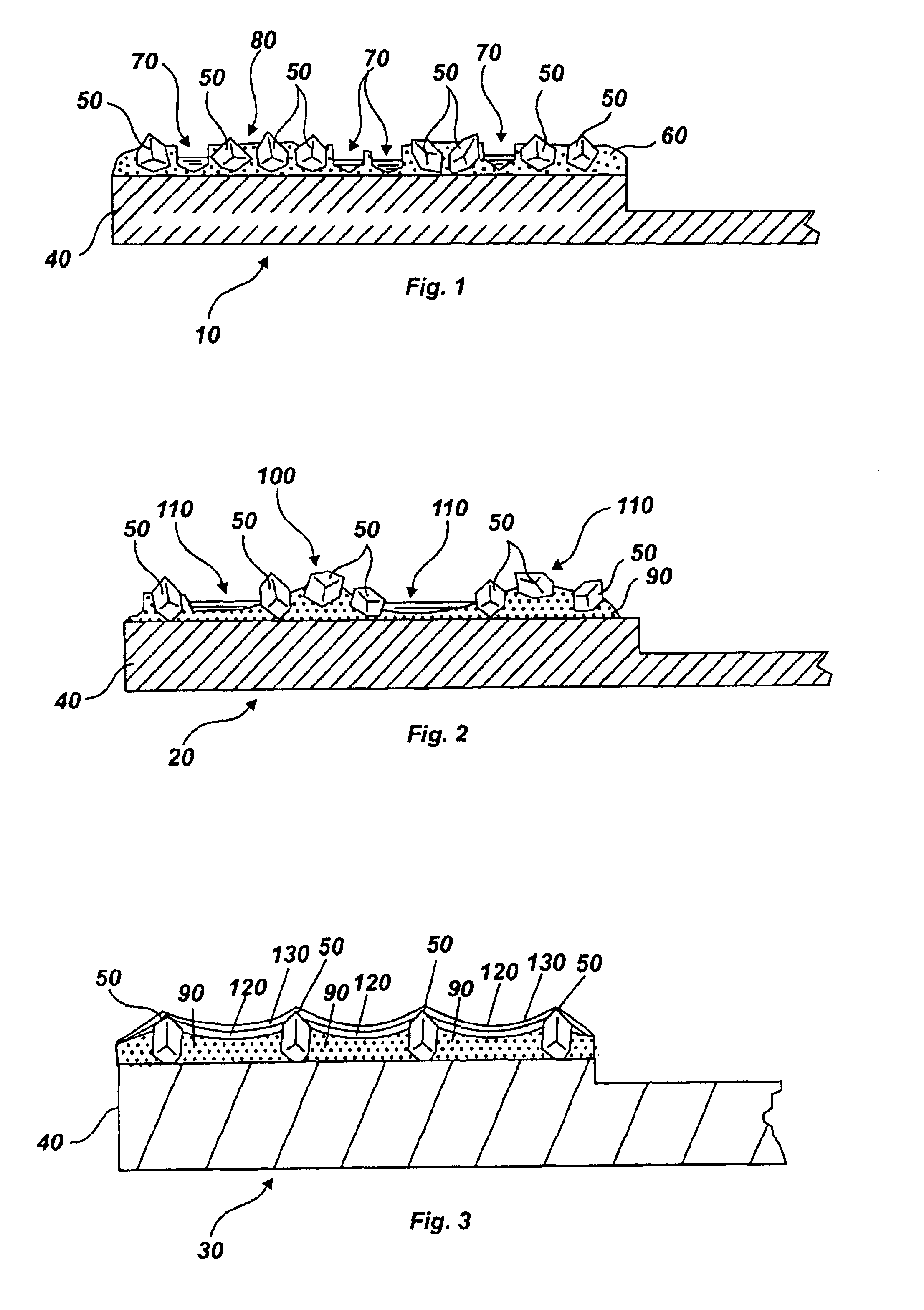

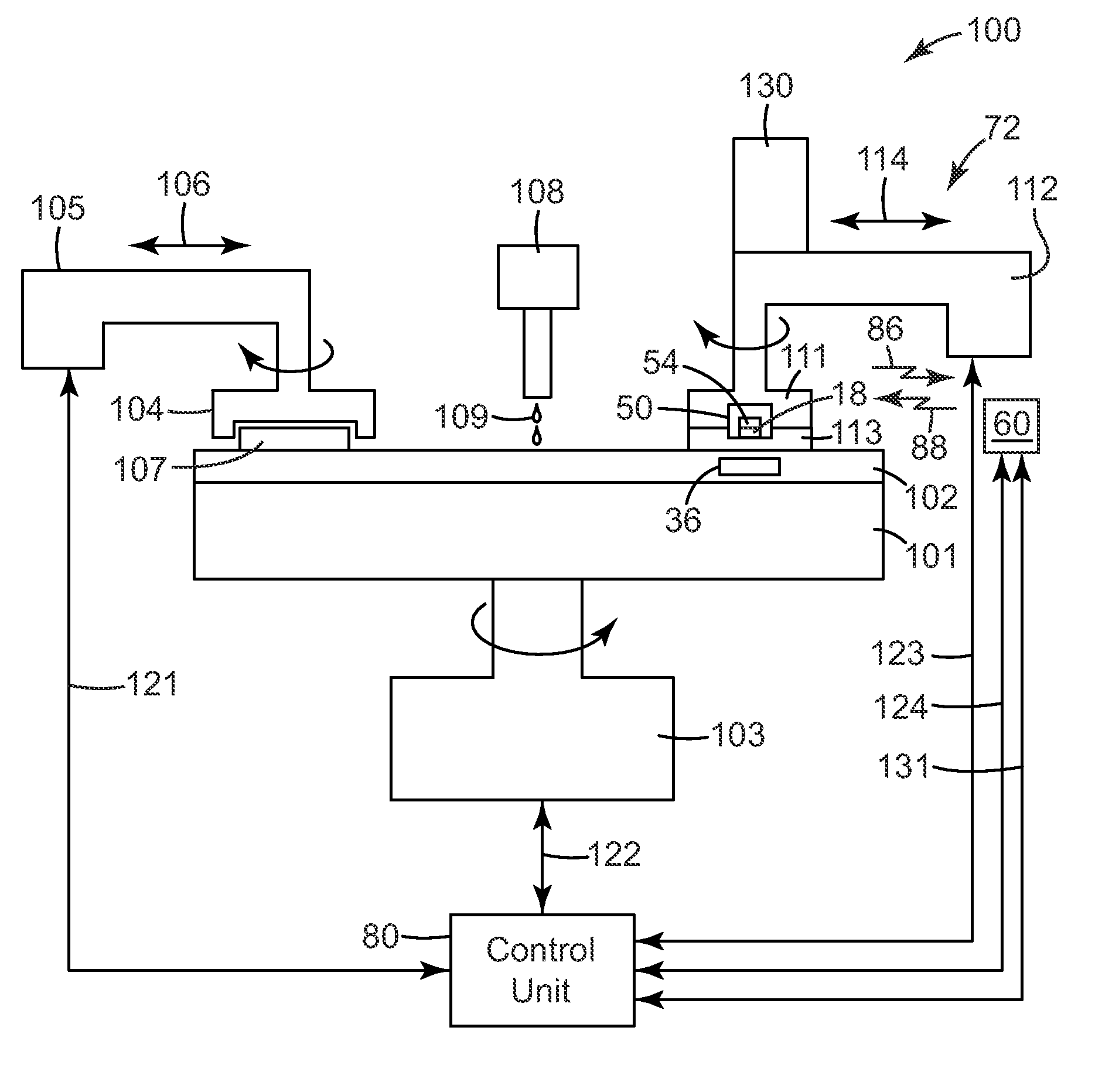

Abrasive Articles, CMP Monitoring System and Method

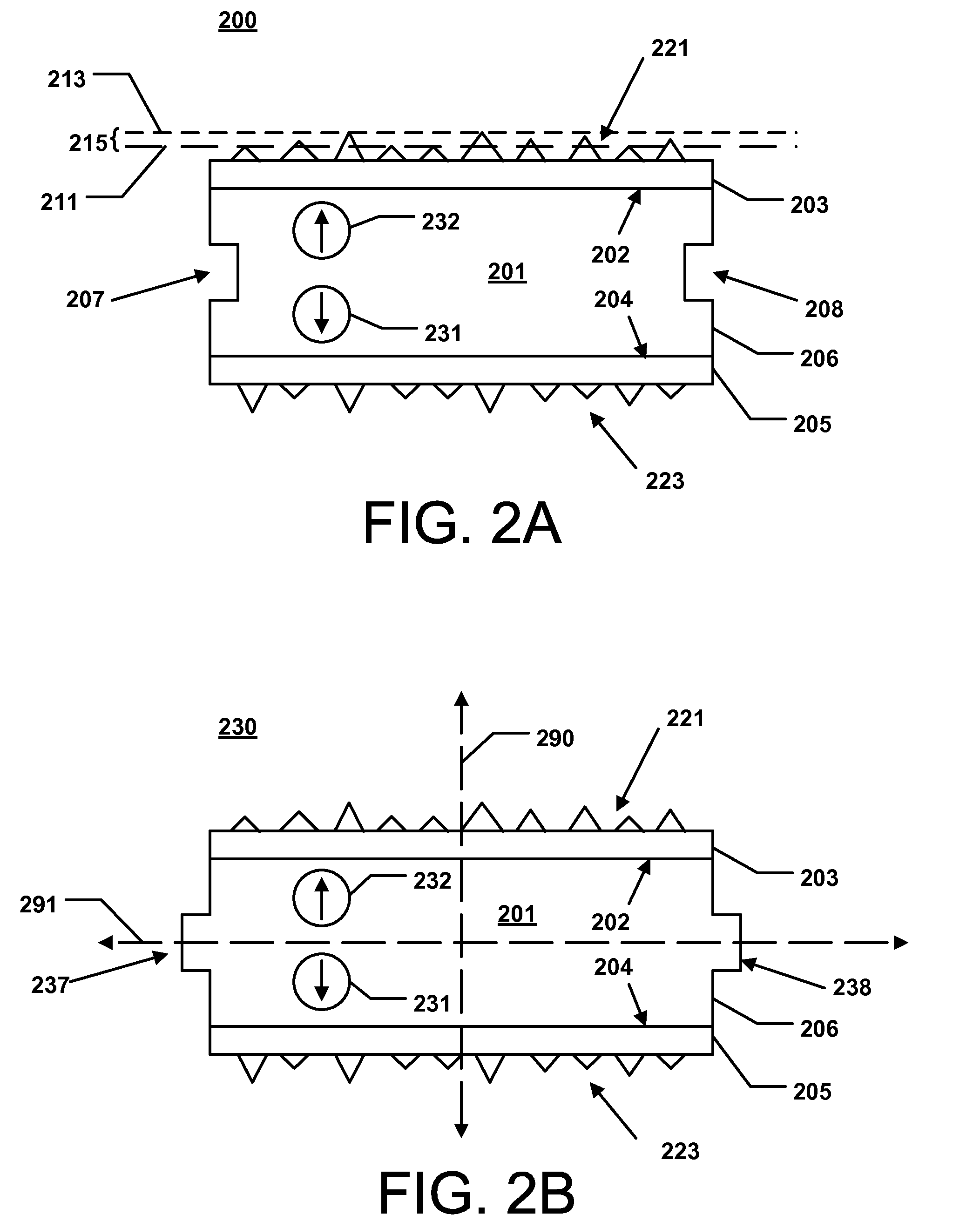

ActiveUS20080004743A1Easy to operate the machineAvoid damageGrinding drivesBelt grinding machinesMonitoring systemEngineering

The disclosure relates to abrasive articles useful in chemical-mechanical polishing (CMP), the articles including a substrate with opposite major surfaces, an abrasive material overlaying at least a portion of at least one of the major surfaces, a means for providing CMP information positioned near the substrate, and a transmitter positioned near the substrate and adapted to transmit the CMP information to a remote receiver. The disclosure also relates to a CMP pad conditioner having a means for communicating CMP information, a CMP process monitoring system, and a method for conditioning a CMP pad.

Owner:3M INNOVATIVE PROPERTIES CO

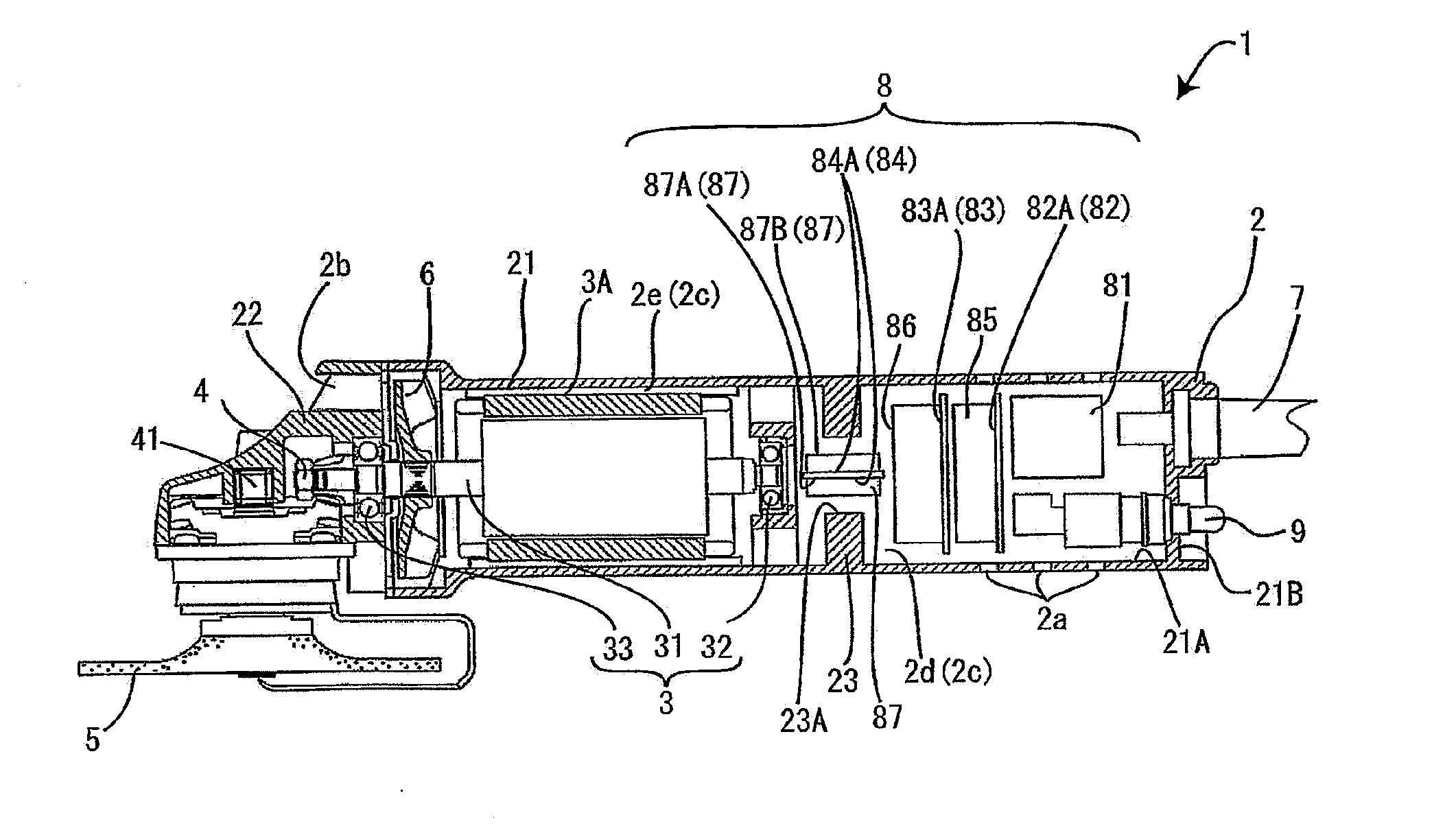

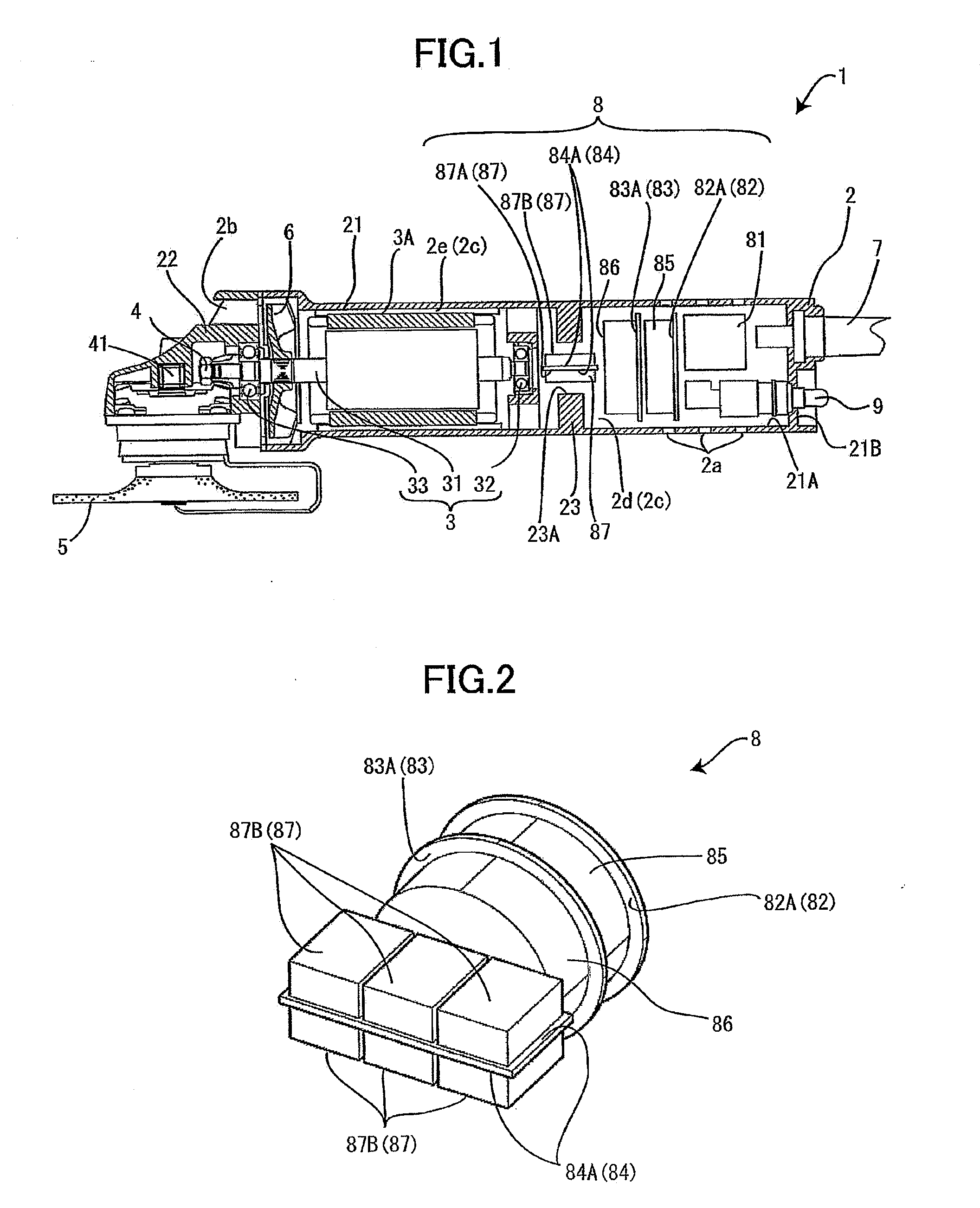

Power Tool

ActiveUS20110171887A1Easy to assembleIncrease productionAssociation with control/drive circuitsMagnetic circuitBrushless motorsDriver circuit

An electric power tool includes a housing, a brushless motor, an output shaft, and a motor driver circuit. The housing defines an axial direction. The brushless motor is accommodated in the housing and having a drive shaft. The output shaft extends in a direction generally perpendicular to the drive shaft. The motor driver circuit is accommodated in the housing for driving the brushless motor. The housing has a cylindrical shape and has a part functioning as a grip portion.

Owner:HITACHI KOKI CO LTD

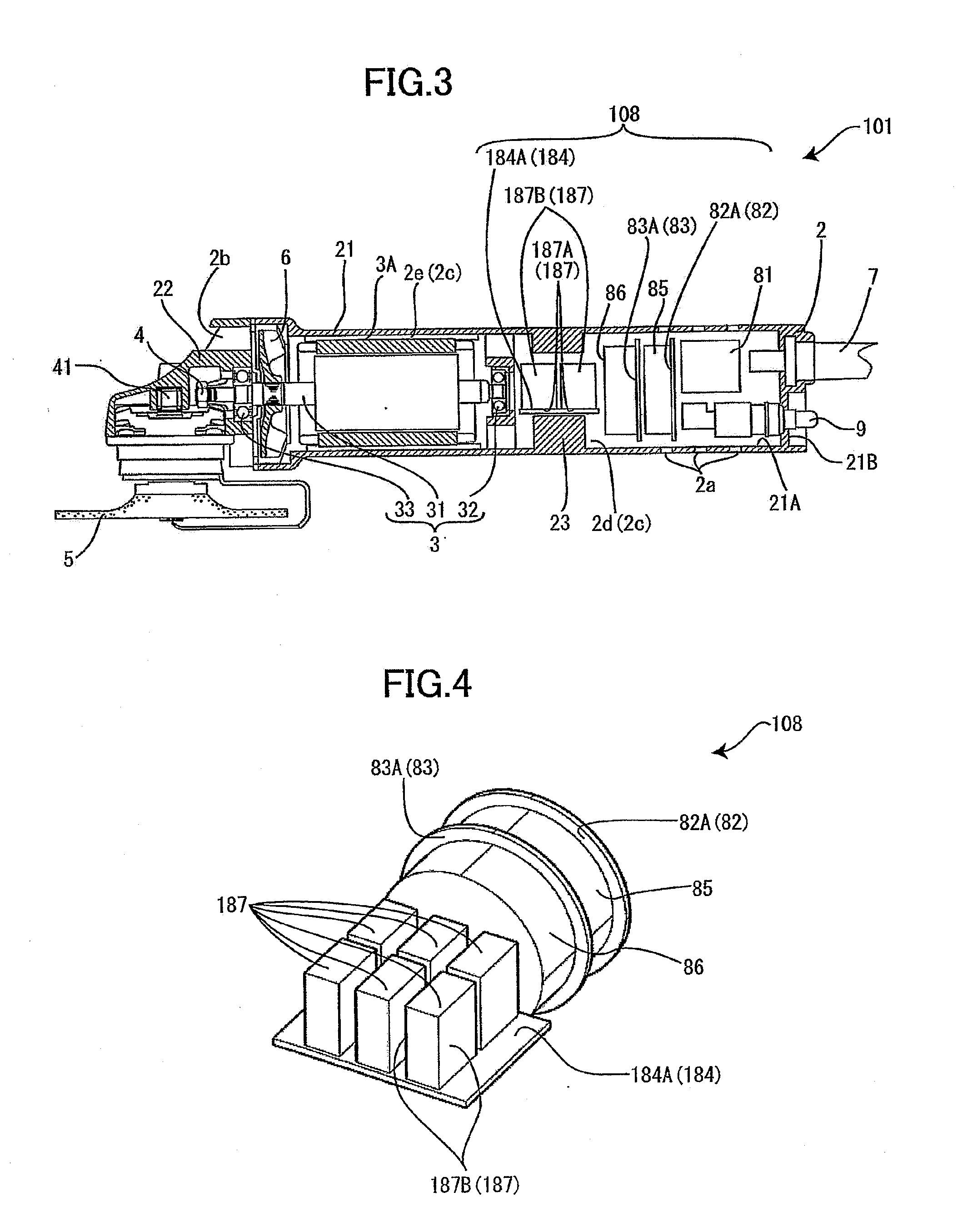

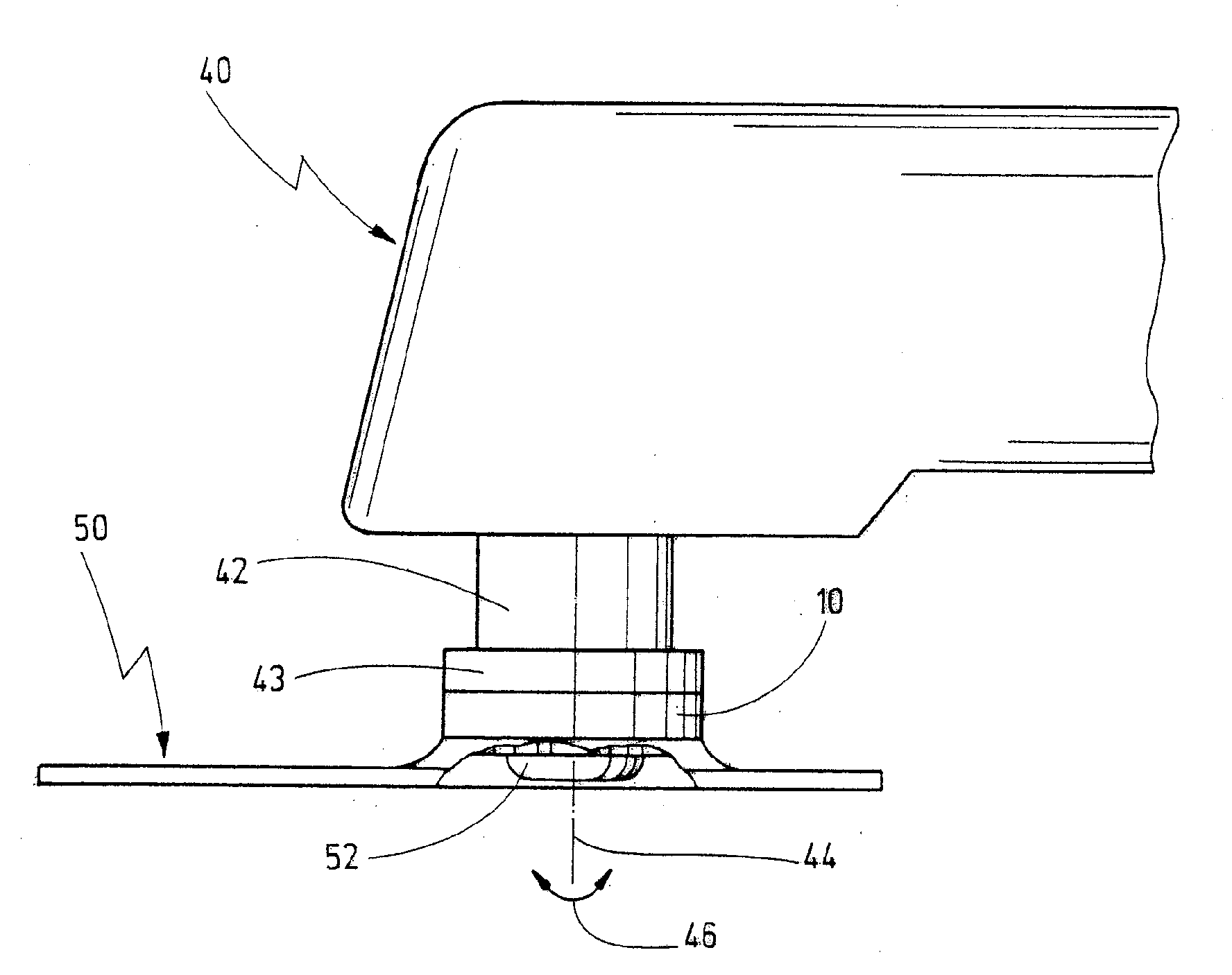

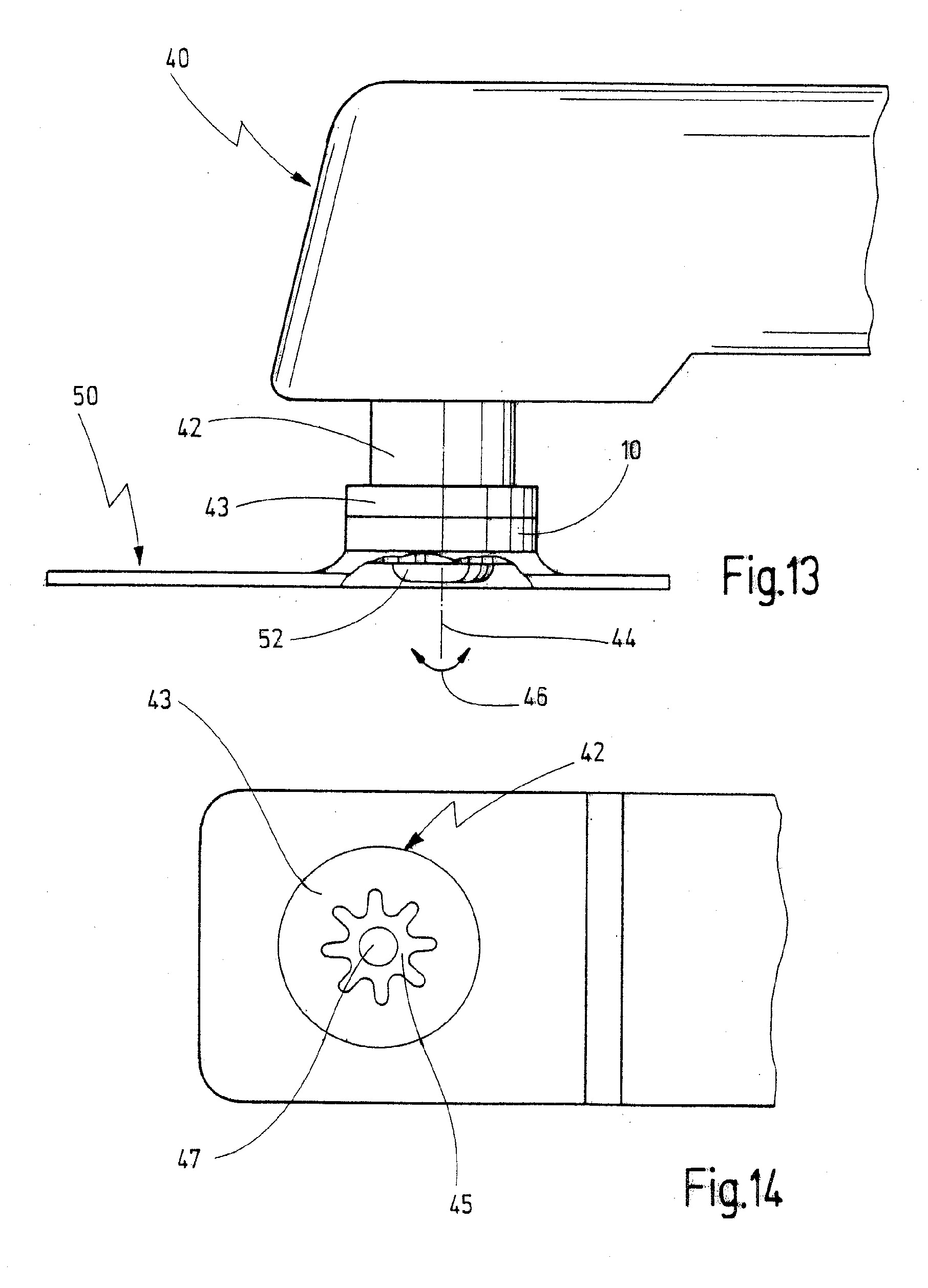

Adapter For Mounting A Tool On An Oscillating Drive

ActiveUS20100056029A1Reduce tool typesLow costGrinding wheel securing apparatusGrinding drivesMating connectionDrive shaft

An adapter is disclosed for mounting a tool on an oscillating drive having a drive shaft that can be driven to oscillate about its longitudinal axis, wherein the adapter is passed by a central opening, and has at its drive end at least one positive-locking element for positive connection with the tool, the positive-locking element having the shape of a regular polygon, or a plurality of positive-locking elements arranged on a circle concentric to the center axis, or a plurality of outwardly extending convex projections having rounded tips and being connected with neighboring projections via rounded concave lateral flanks, wherein the positive-locking elements on the drive end are configured for positive-locking connection with a matching positive-locking counter-element on the drive shaft, and wherein the adapter has a second receptacle on its tool end for effecting connection with a tool having a shape different from the first receptacle and being configured as a circle, or as a plurality of positive-locking elements arranged along a circle concentric to the center axis, or as plurality of outwardly extending convex projections with rounded tips and being connected with neighboring projections via rounded concave lateral flanks.

Owner:C & E FEIN GMBH & CO KG

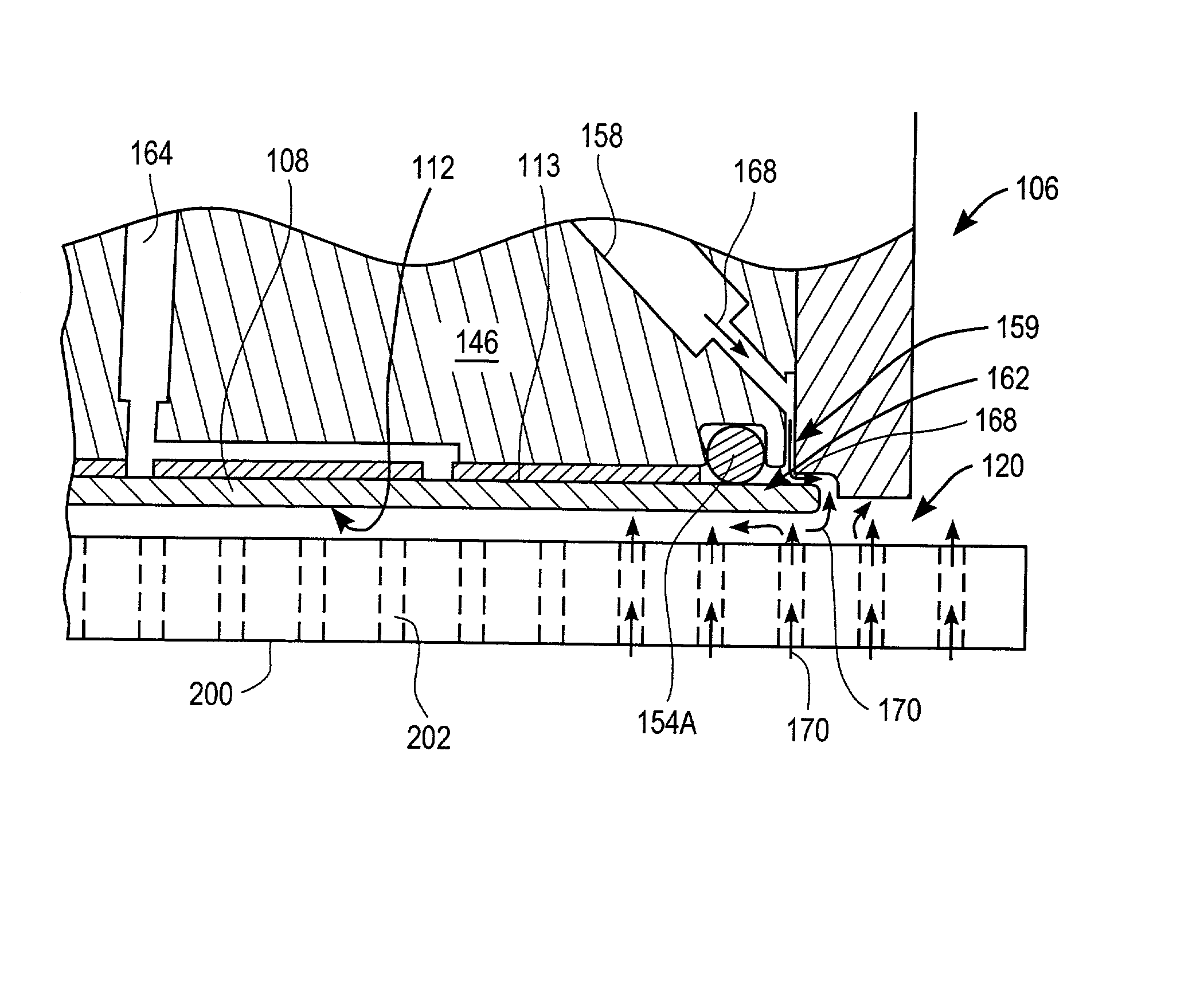

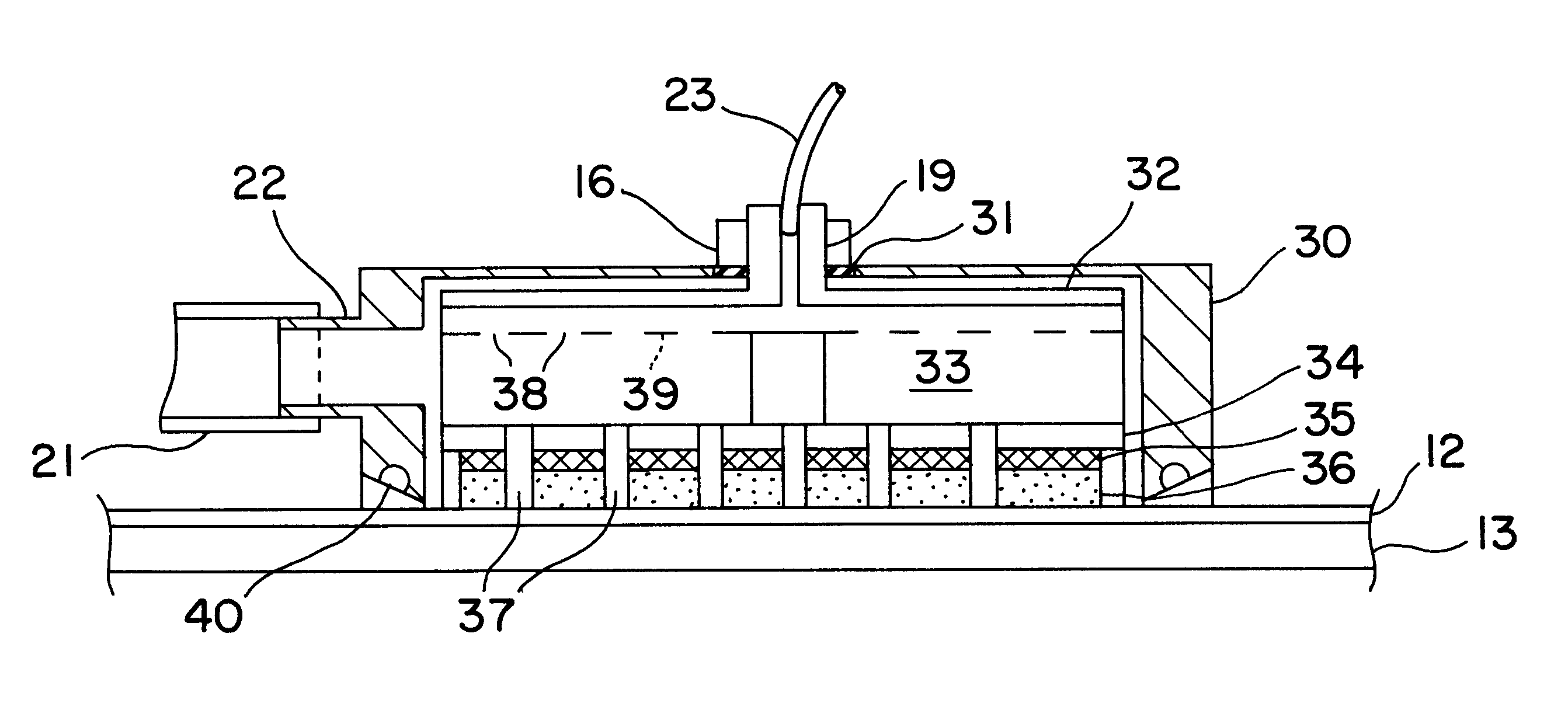

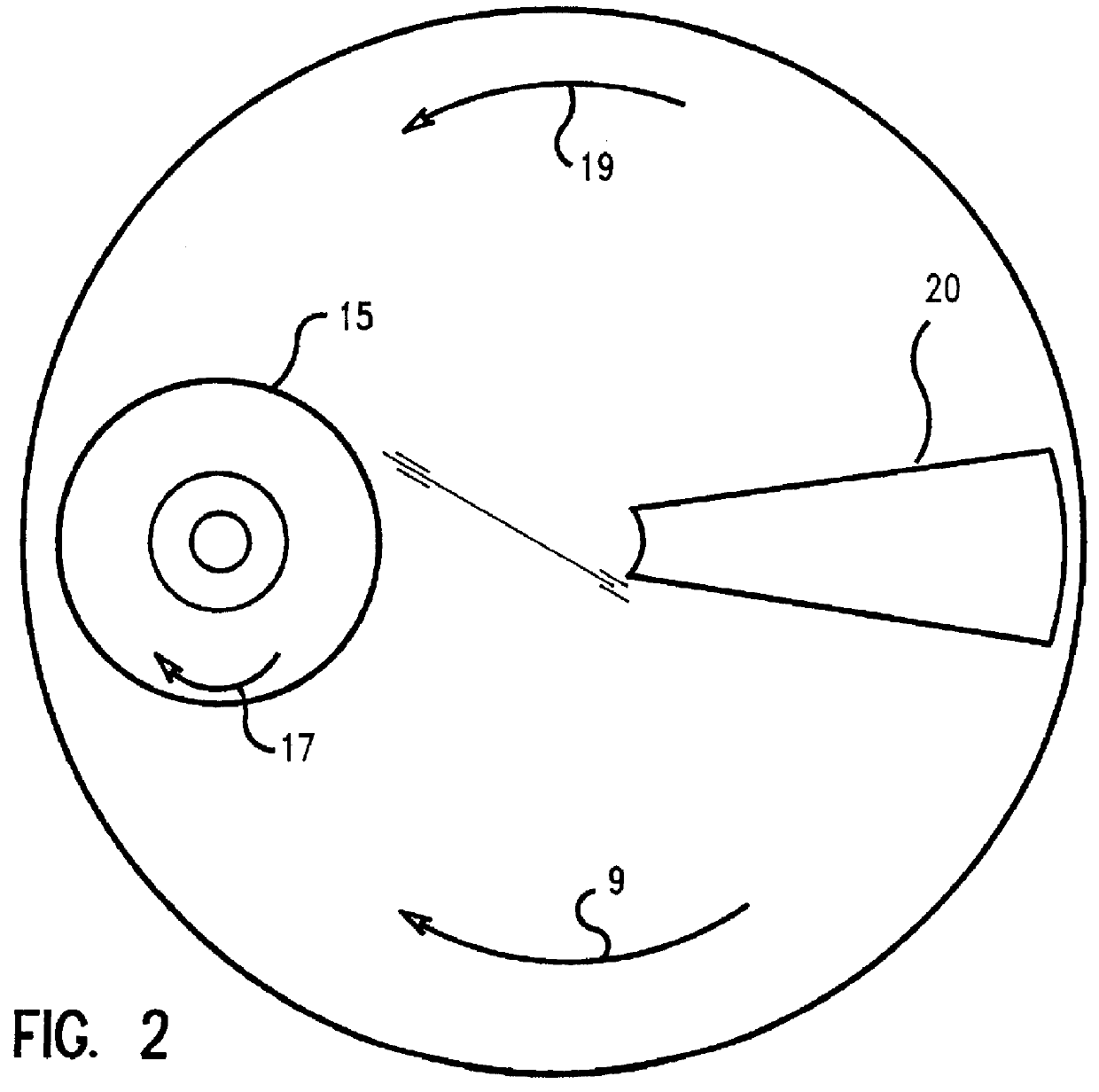

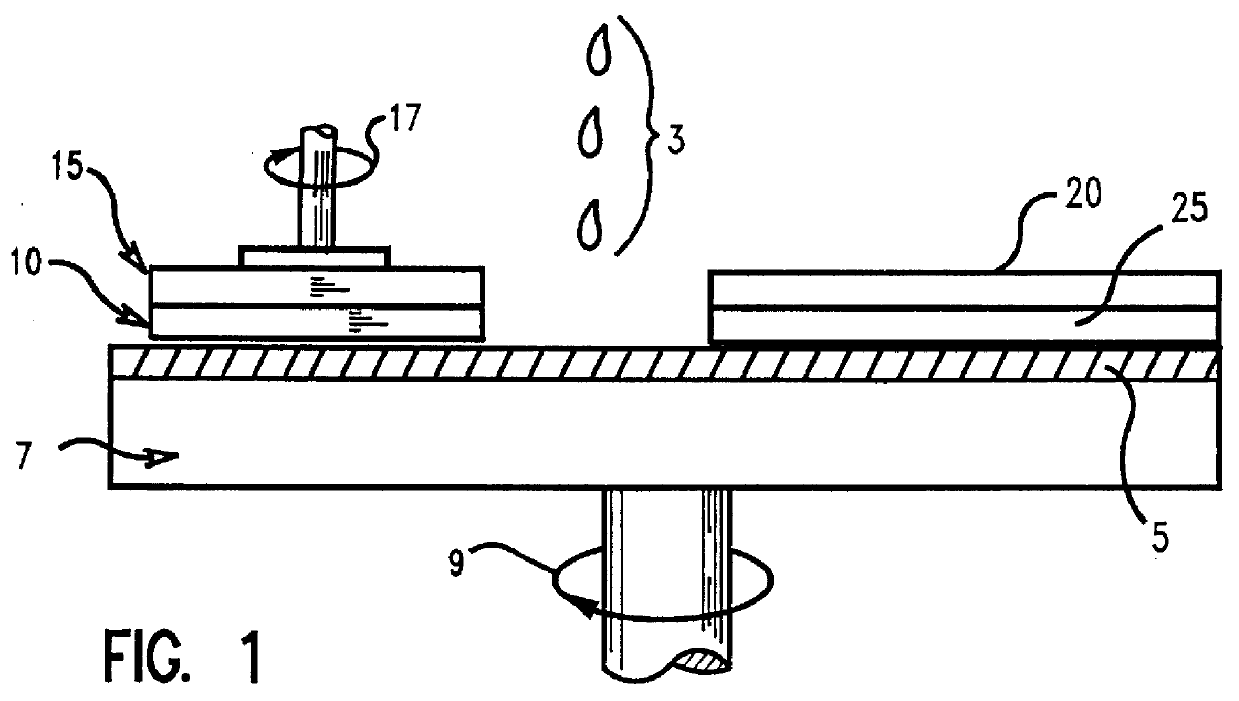

Polishing pad conditioning system

InactiveUS6508697B1Polishing machinesRevolution surface grinding machinesPiezo electricWaste material

A system for conditioning rotatable polishing pads used to planarize and polish surfaces of thin film integrated circuits deposited on semiconductor wafer substrates, microelectronic, and optical system. The system has a pad conditioning apparatus, process fluids, a vacuum capability to pull waste material out of the conditioning pad, self-contained flushing means, and a piezo-electric device for vibrating the pad conditioning apparatus.

Owner:BENNER ROBERT LYLE +2

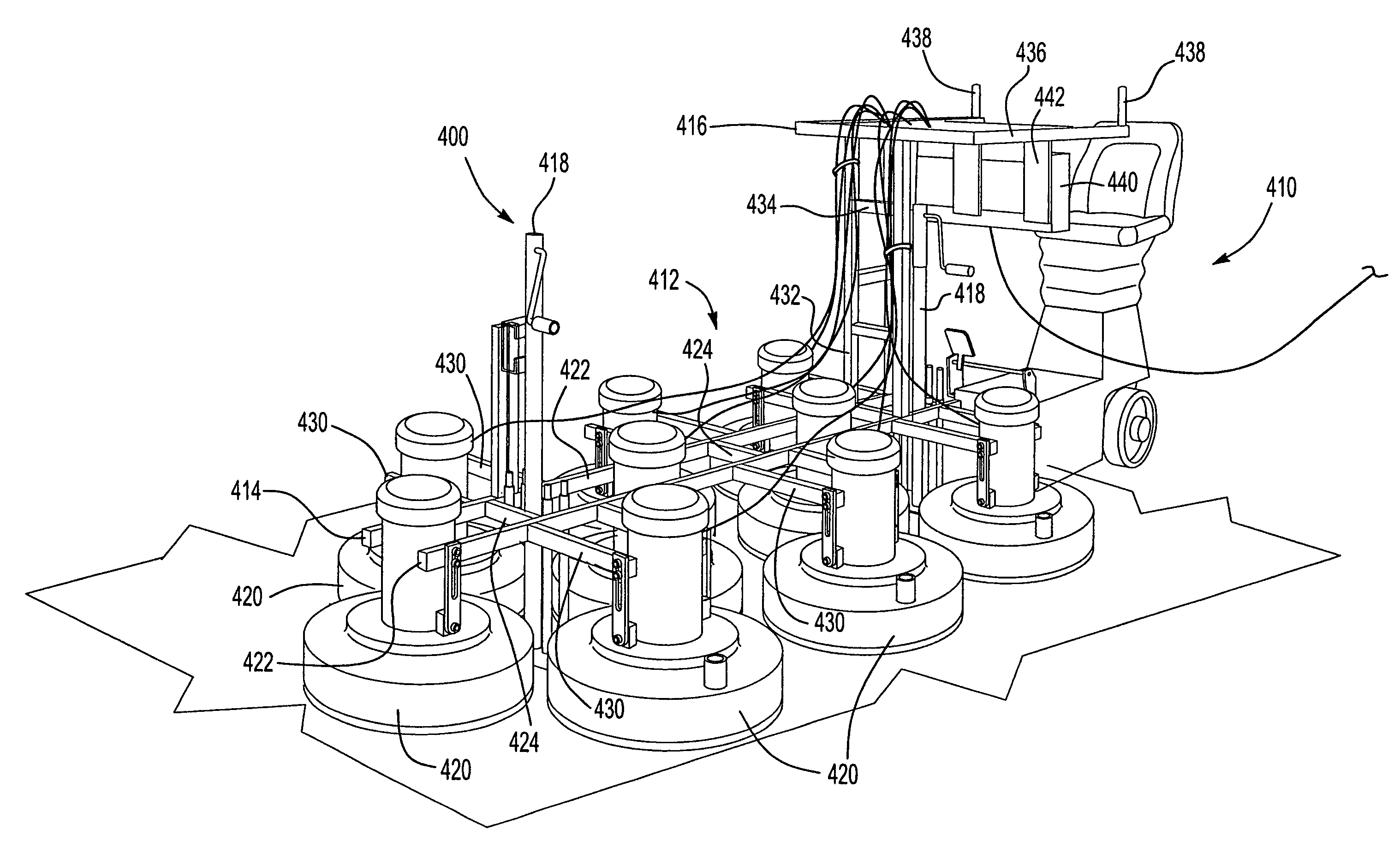

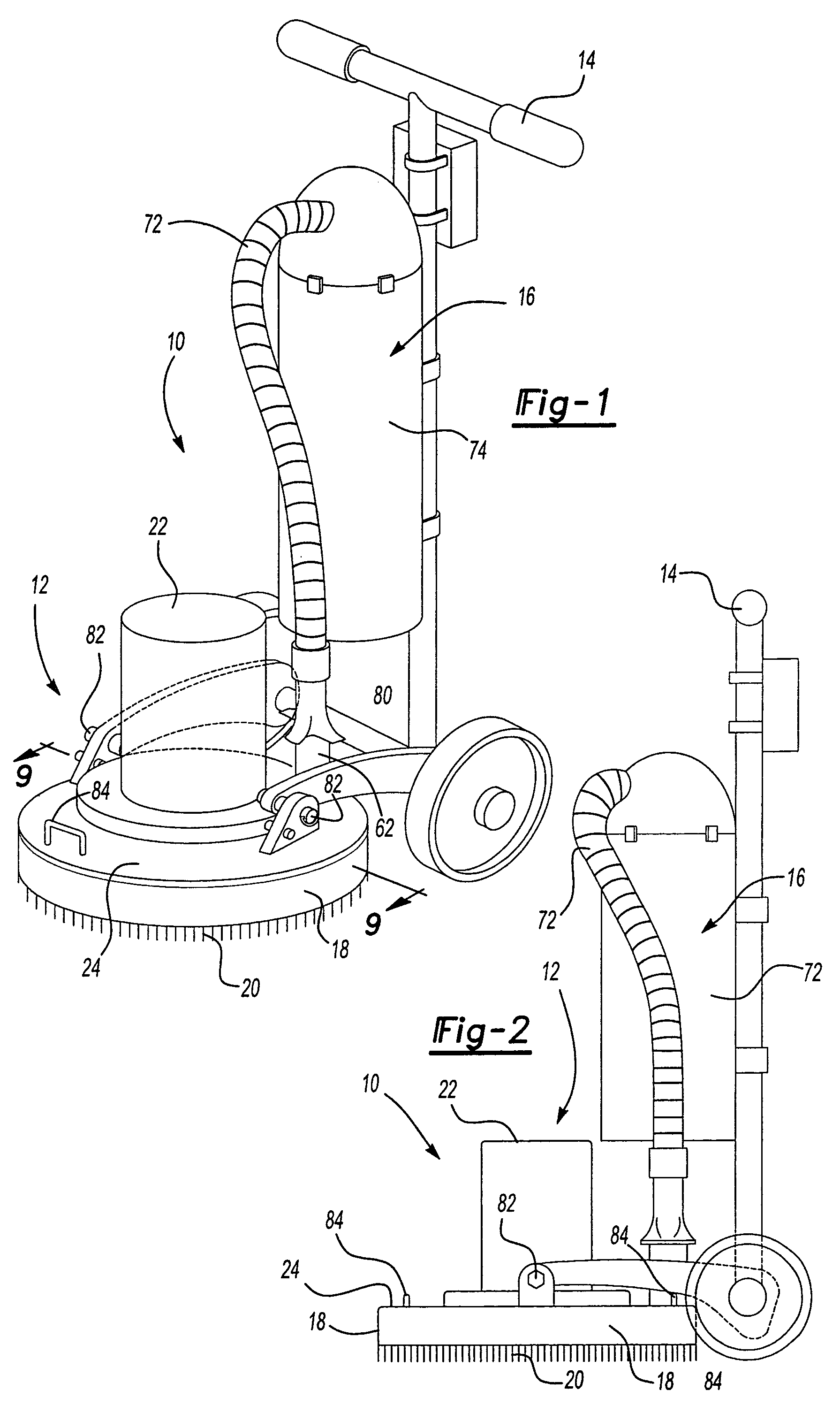

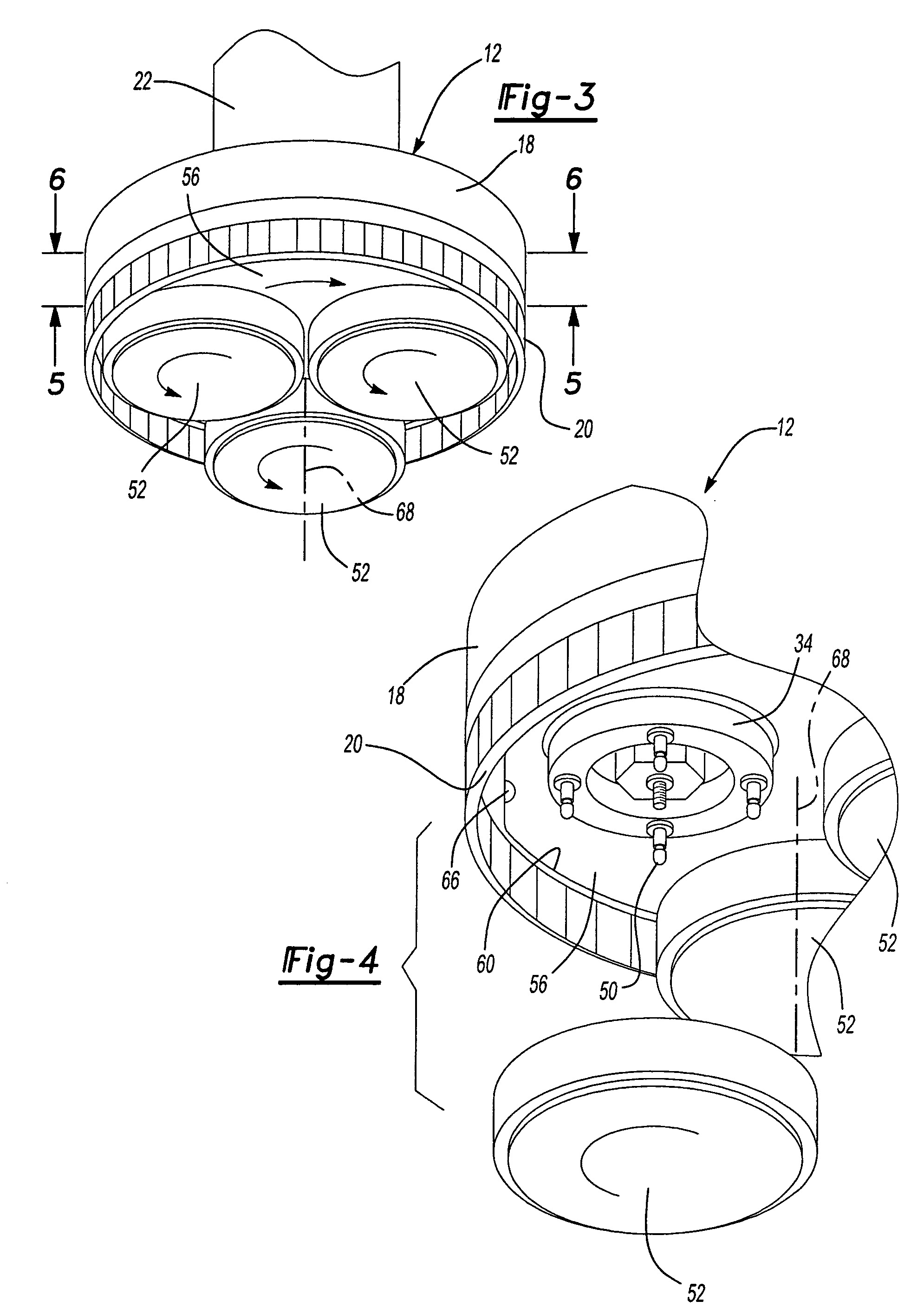

Wood floor sanding machine

A power sanding machine (10) has three circumferentially spaced cogged belts (40) to drive three discs (52) rotatably mounted to an inner bowl (30) which is rotatably mounted to a housing (12), which in turn is connected to an operating handle (14). Mechanical lock can rotationally affix the inner bowl (30) to the housing to circumferentially position a pulley at the left or right edge (326, 322) of the sanding machine or at the front end (330) of the sanding machine. Power cleaning and sanding machines (412, 500, 600) incorporate the three disc (52) arrangement or a direct-drive one disc arrangement (572, 672). The machines (412, 500, 600) include multiple floor finishing units (420, 514, 614) ganged together in unique arrangements.

Owner:ONFLOOR TECH

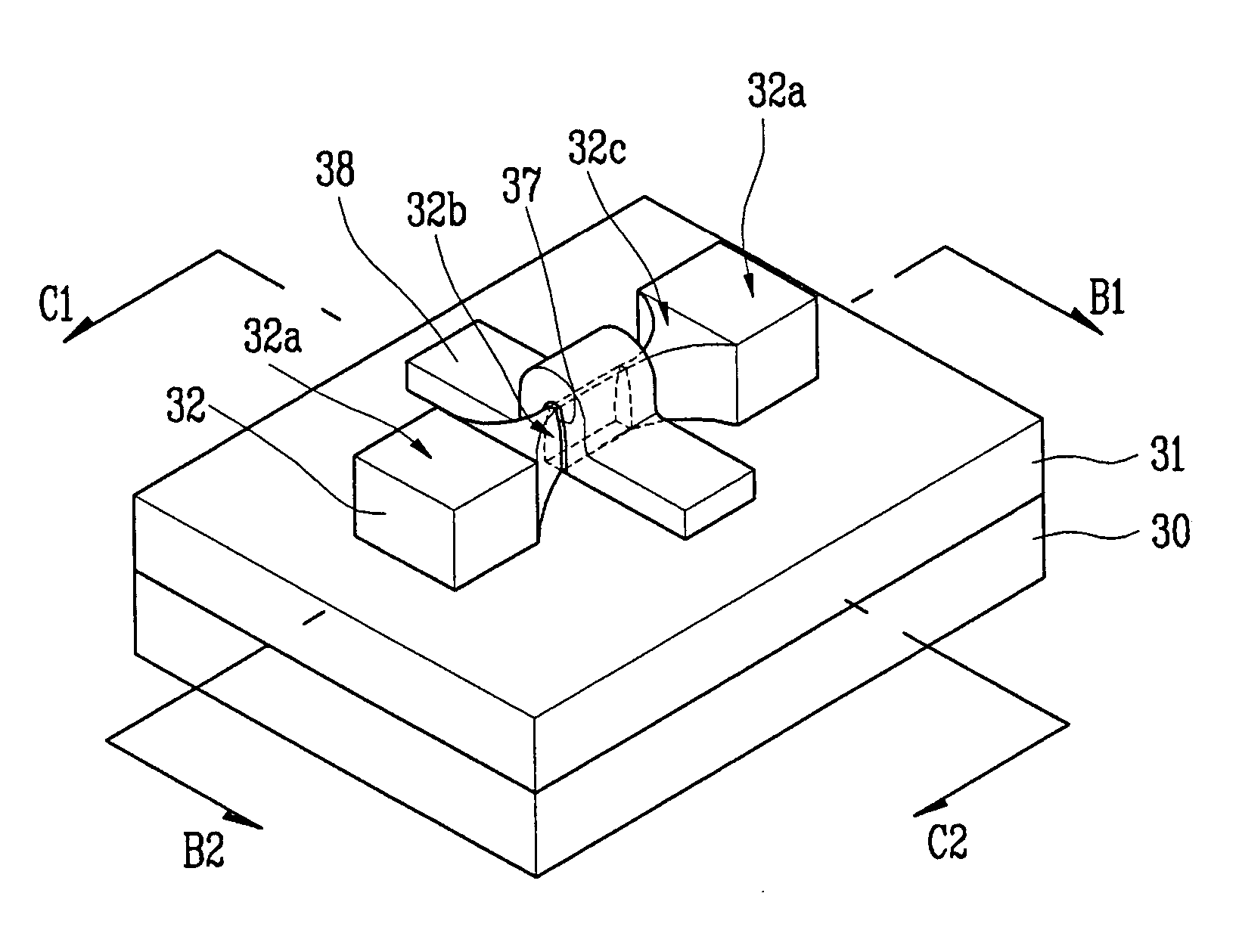

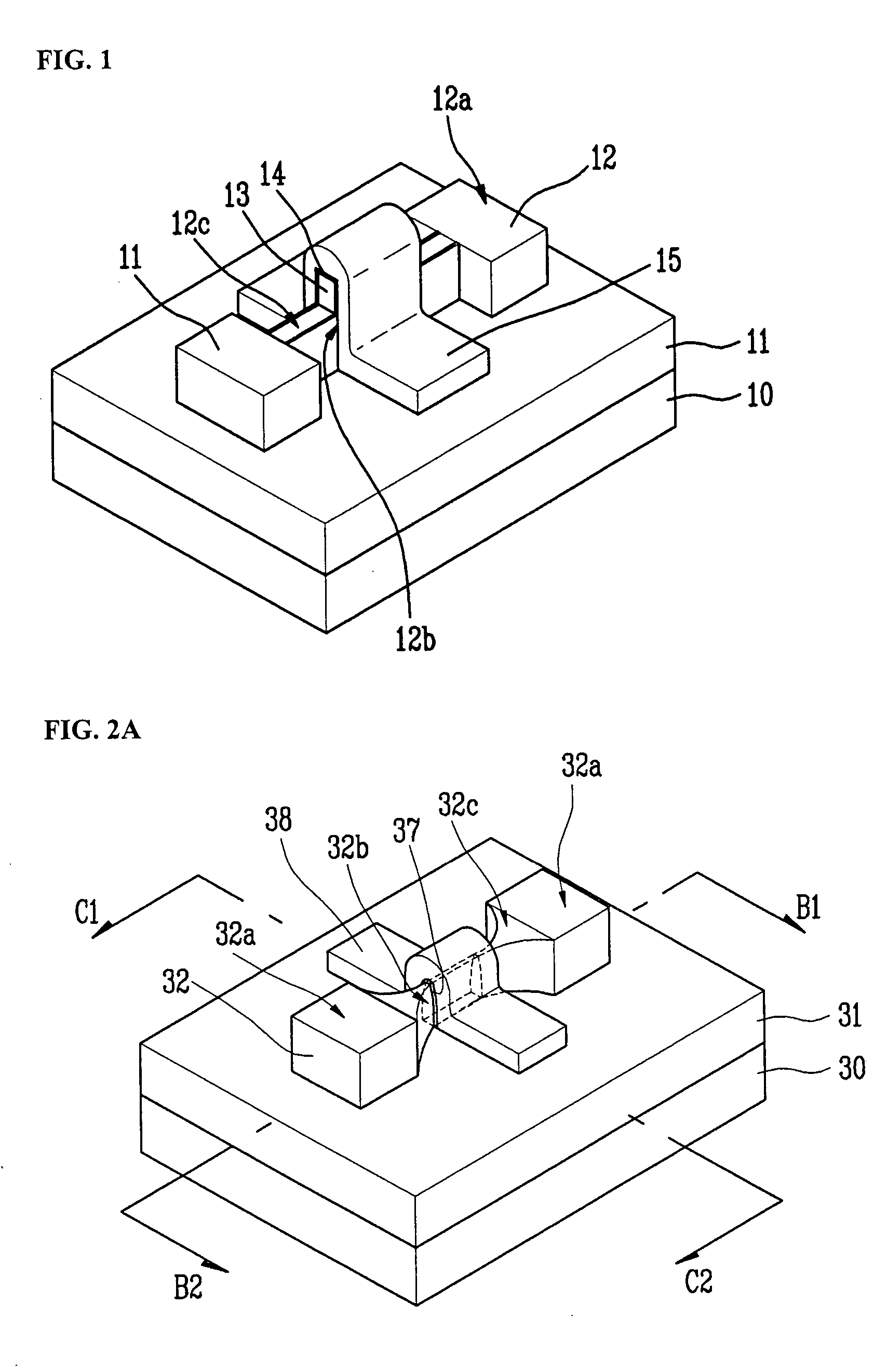

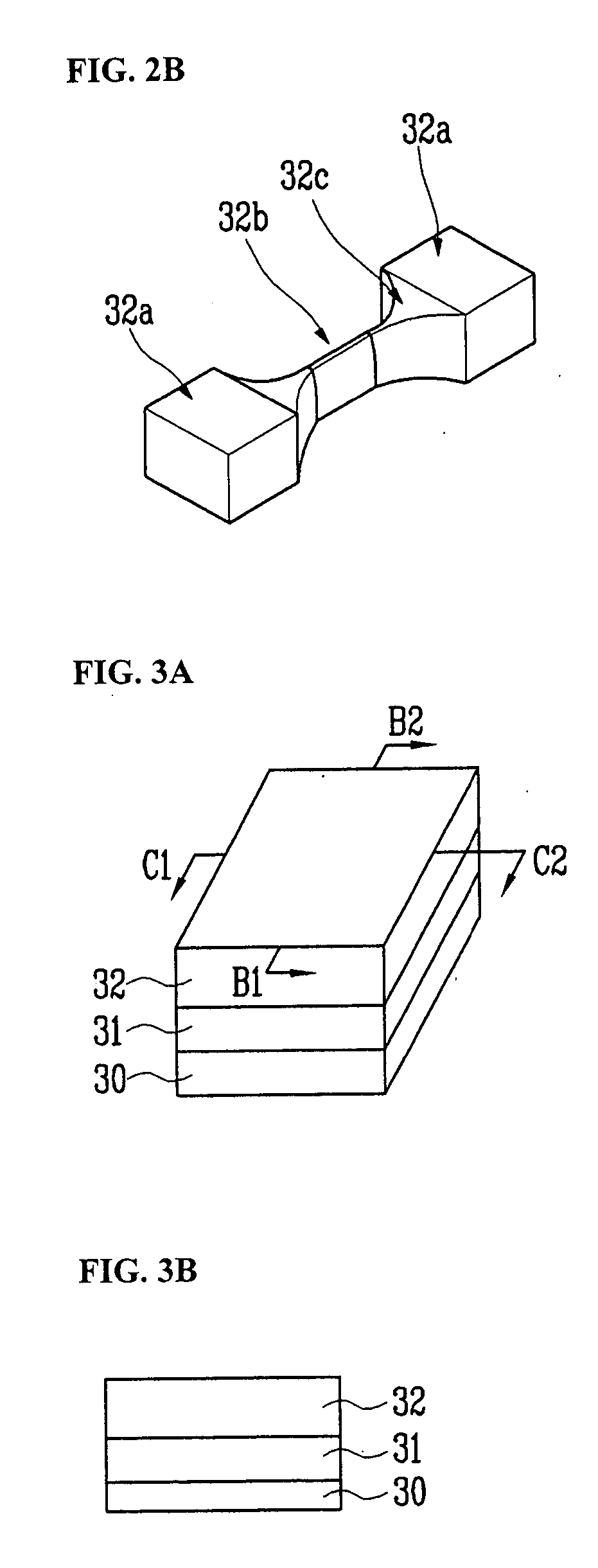

Multiple-gate MOS transistor and a method of manufacturing the same

InactiveUS20050263821A1Improve reliabilityImprove rendering capabilitiesTransistorGrinding drivesCrystal orientationGate voltage

Provided is a multiple-gate metal oxide semiconductor (MOS) transistor and a method for manufacturing the same, in which a channel is implemented in a streamline shape, an expansion region is implemented in a gradually increased form, and source and drain regions is implemented in an elevated structure by using a difference of a thermal oxidation rate depending on a crystal orientation of silicon and a geographical shape of the single-crystal silicon pattern. As the channel is formed in a streamline shape, it is possible to prevent the degradation of reliability due to concentration of an electric field and current driving capability by the gate voltage is improved because the upper portion and both sides of the channel are surrounded by the gate electrodes. In addition, a current crowding effect is prevented due to the expansion region increased in size and source and drain series resistance is reduced by elevated source and drain structures, thereby increasing the current driving capability.

Owner:III HLDG 2

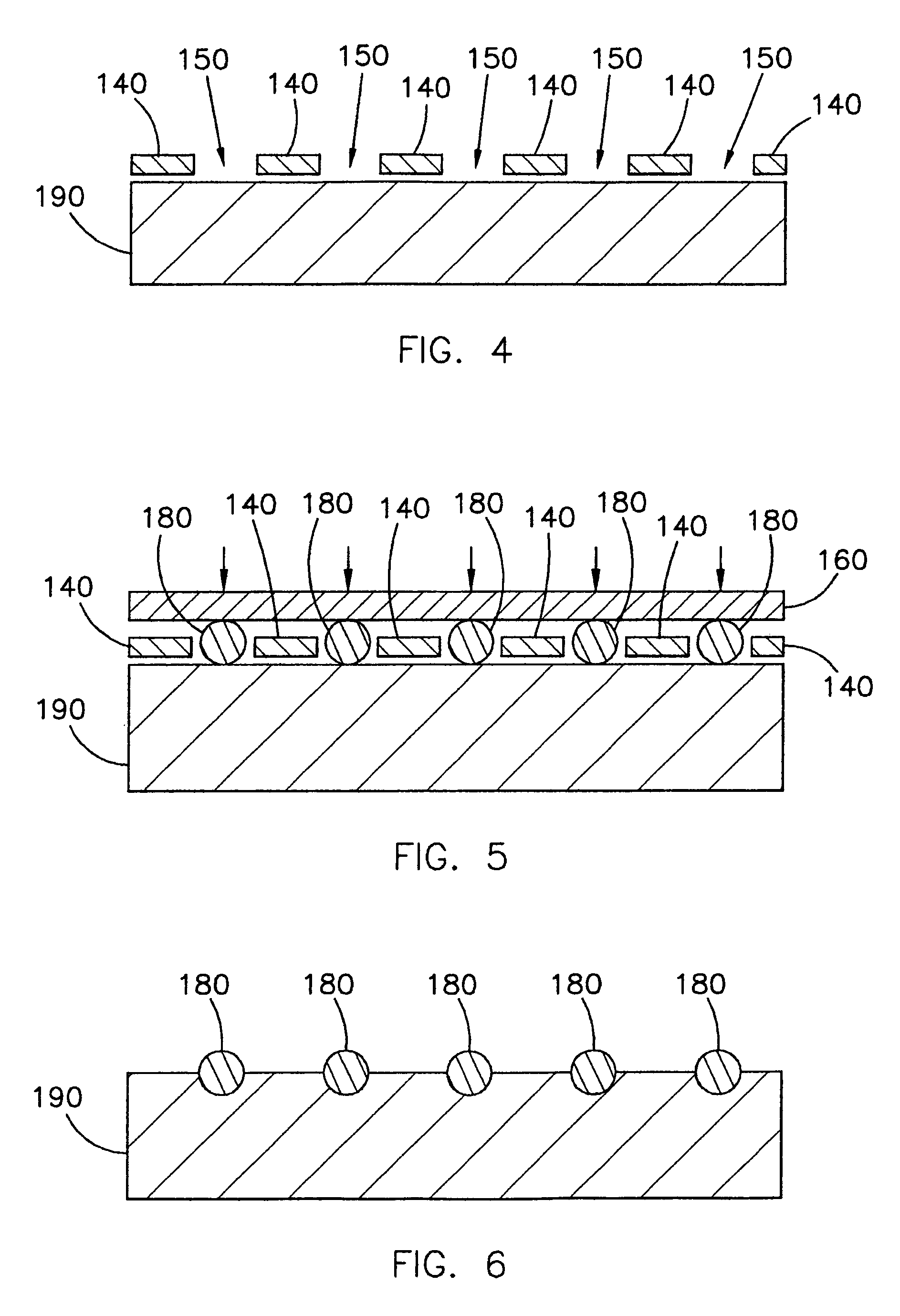

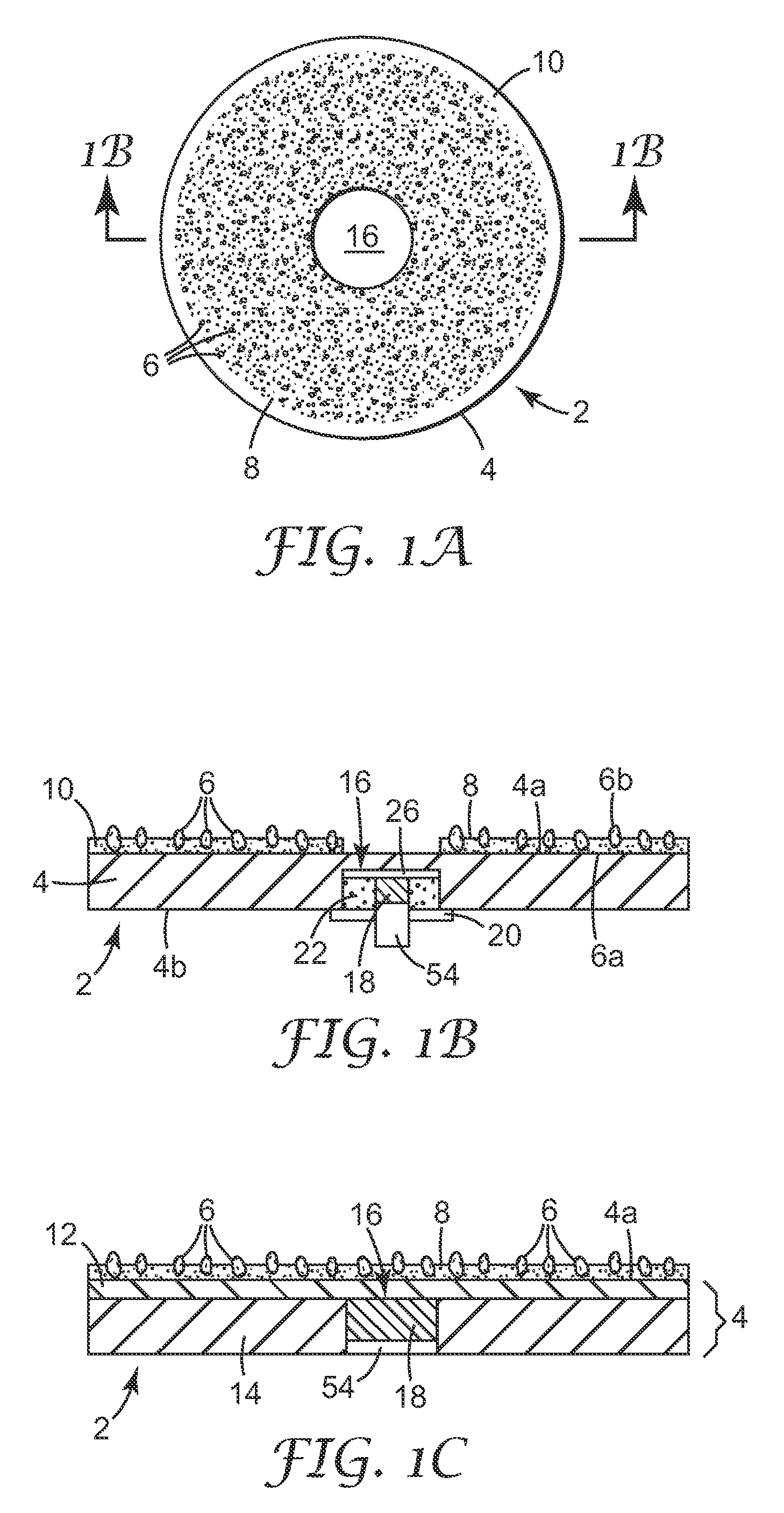

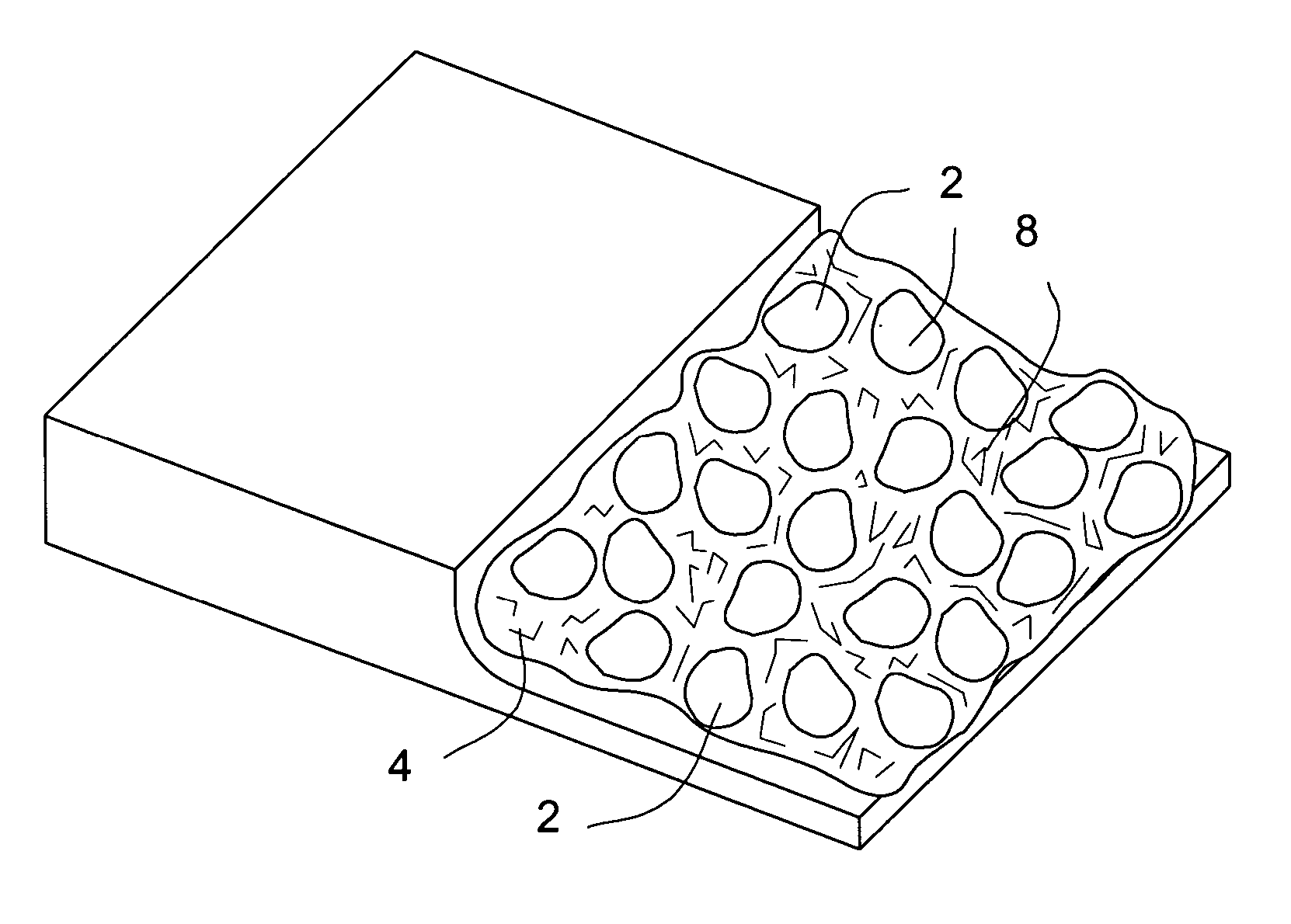

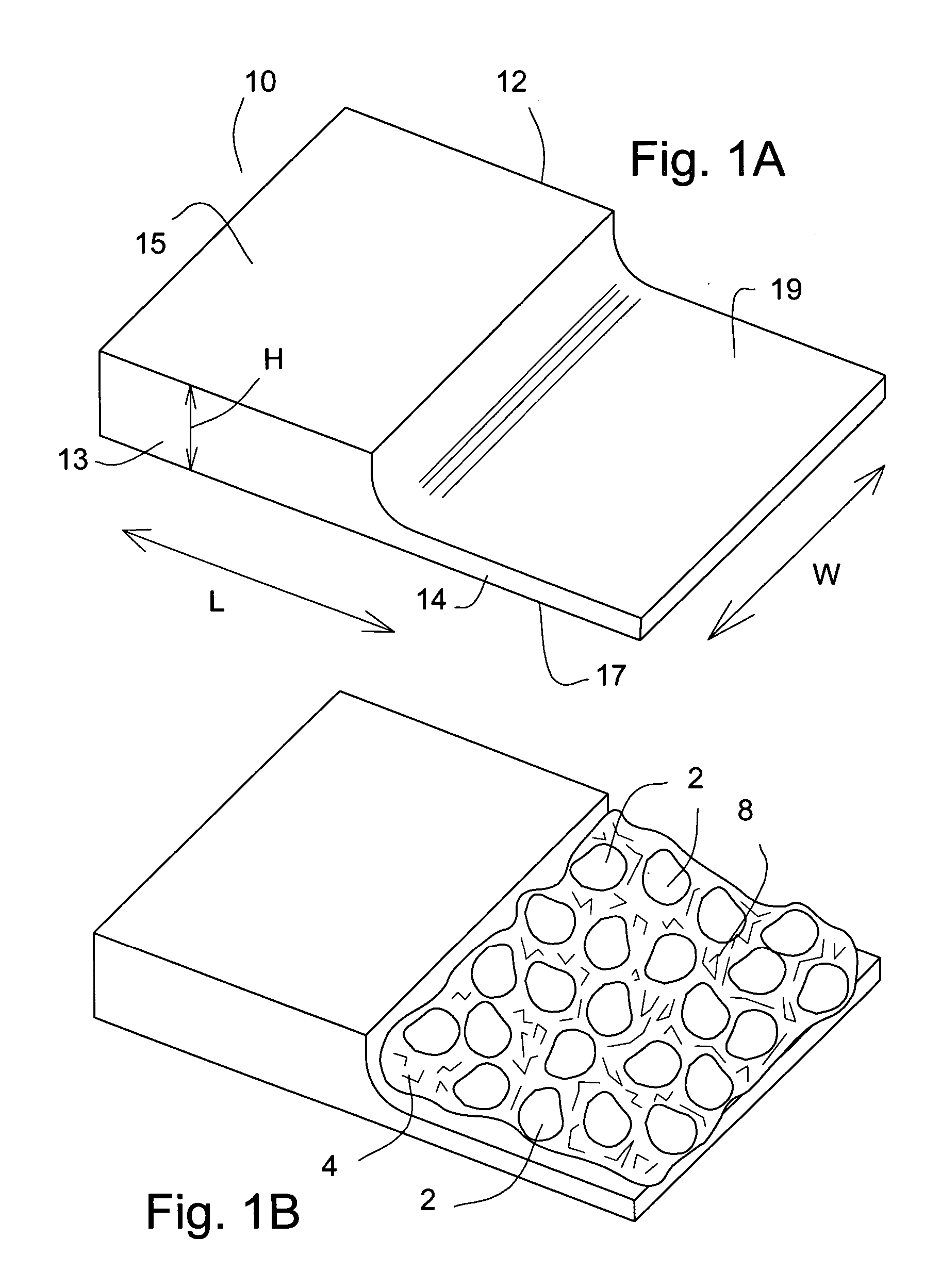

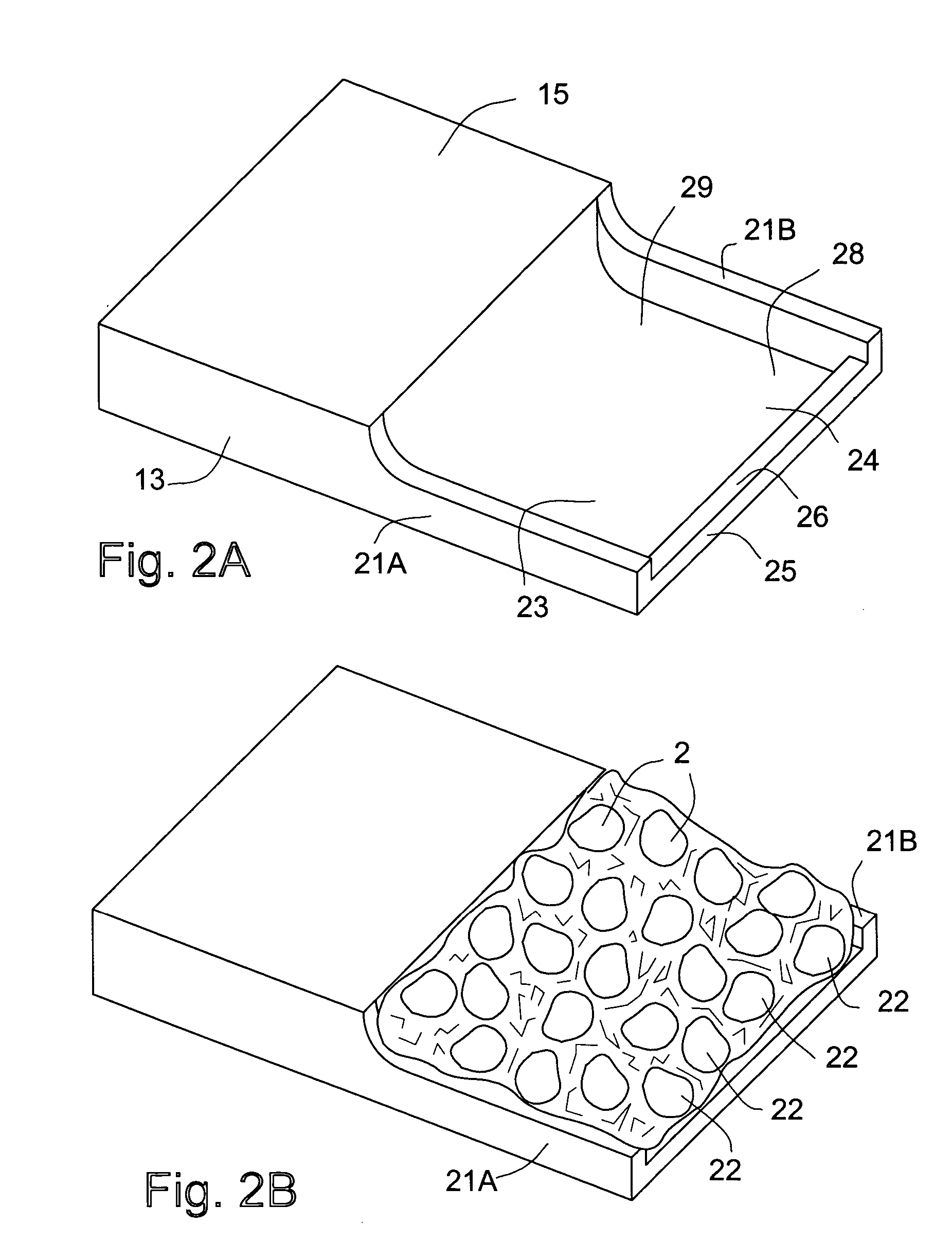

Contoured CMP pad dresser and associated methods

InactiveUS7201645B2Increase loadImprove permeabilityPolishing machinesRevolution surface grinding machinesEngineeringMechanical engineering

Owner:KINIK

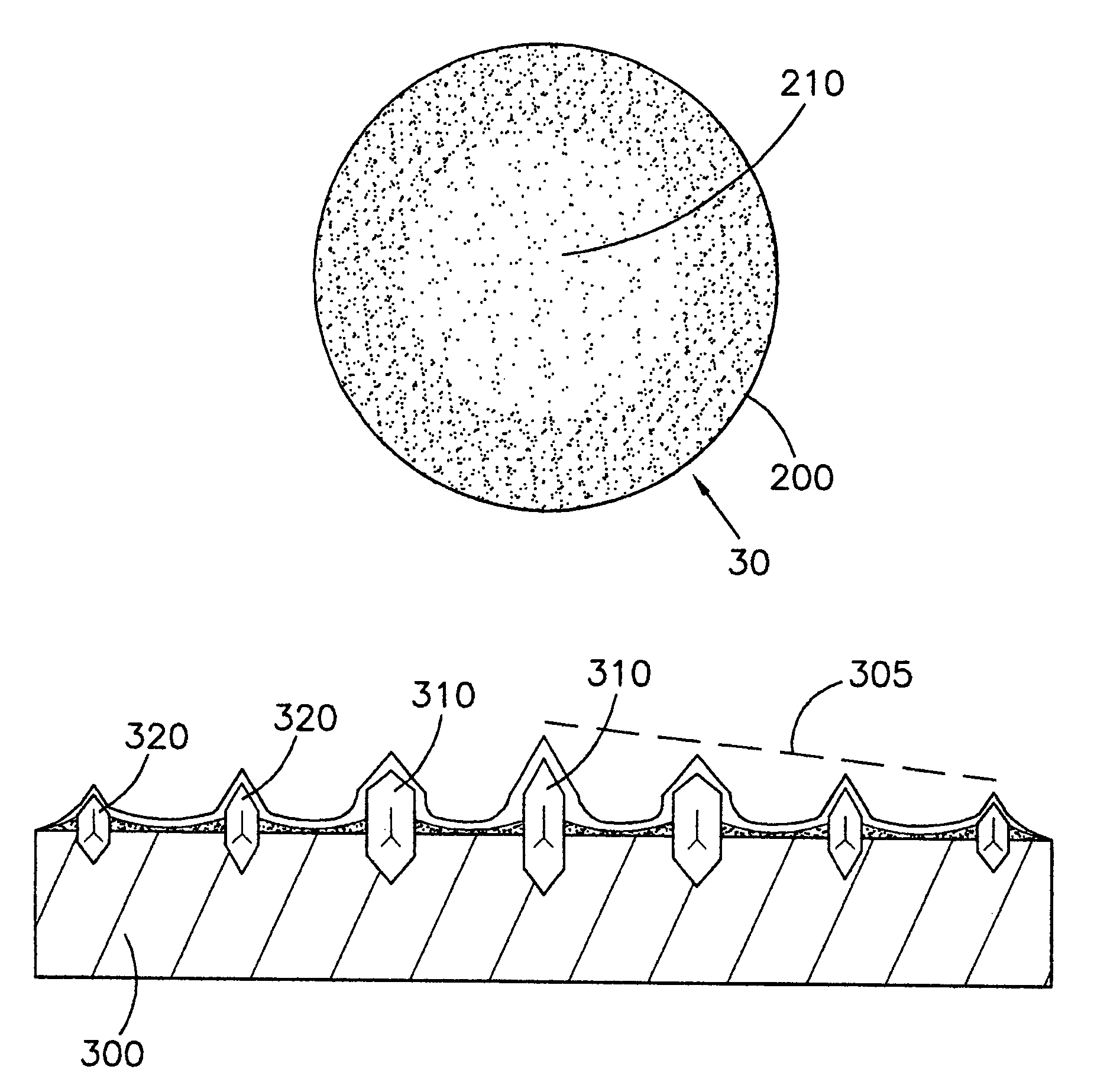

Diamond grid CMP pad dresser

InactiveUS6884155B2Easy to monitorUniform sizePolishing machinesRevolution surface grinding machinesSuperhard materialDiamond-like carbon

The present invention discloses a CMP pad dresser which has a plurality of uniformly spaced abrasive particles protruding therefrom. The abrasive particles are super hard materials, and are typically diamond, polycrystalline diamond (PCD), cubic boron nitride (cBN), or polycrystalline cubic boron nitride(PcBN). The abrasive particles are brazed to a substrate which may be then coated with an additional anti-corrosive layer. The anti-corrosive layer is usually a diamond or diamond-like carbon which is coated over the surface of the disk to prevent erosion of the brazing alloy by the chemical slurry used in conjunction with the CMP pad. This immunity to chemical attack allows the CMP pad dresser to dress the pad while it is polishing a workpiece. In addition to even spacing on the substrate, the abrasive particles extend for a uniform distance away from the substrate, allowing for even grooming or dressing of a CMP pad both in vertical and horizontal directions. A method of producing such a CMP pad dresser is also disclosed.

Owner:KINIK

In-situ pad conditioning process for CMP

InactiveUS6022266AGood conditioning effectGrinding drivesBelt grinding machinesSlurryImproved method

Owner:GOOGLE LLC

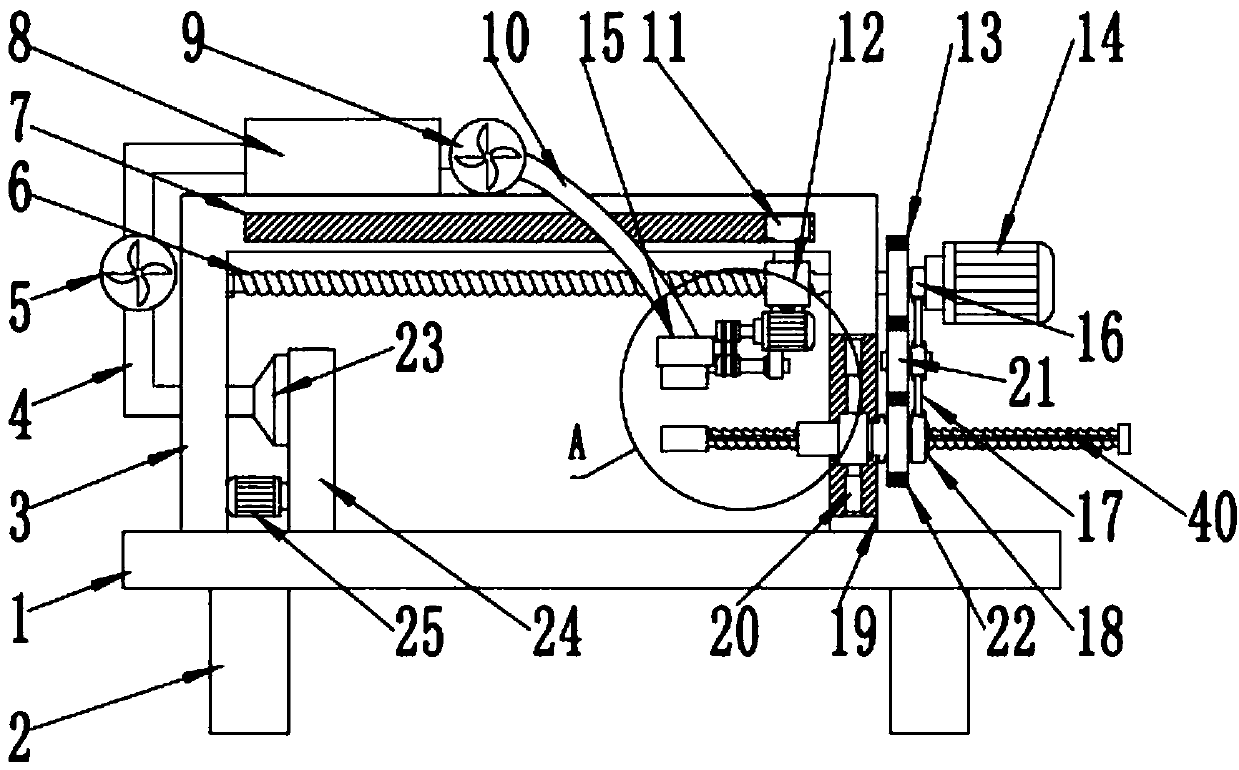

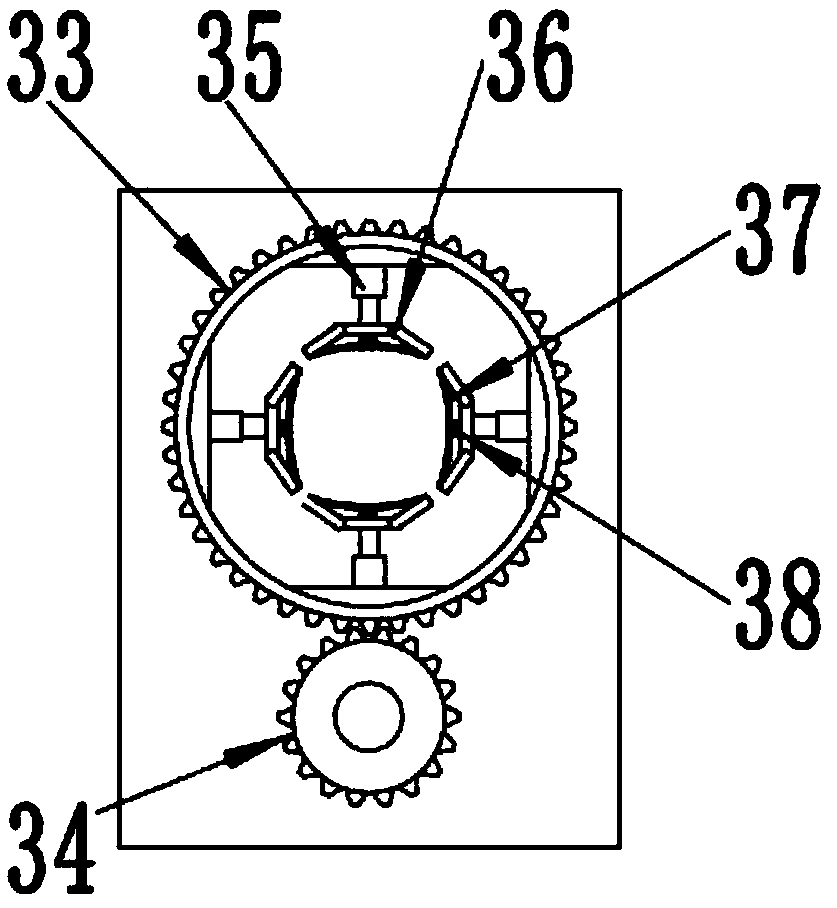

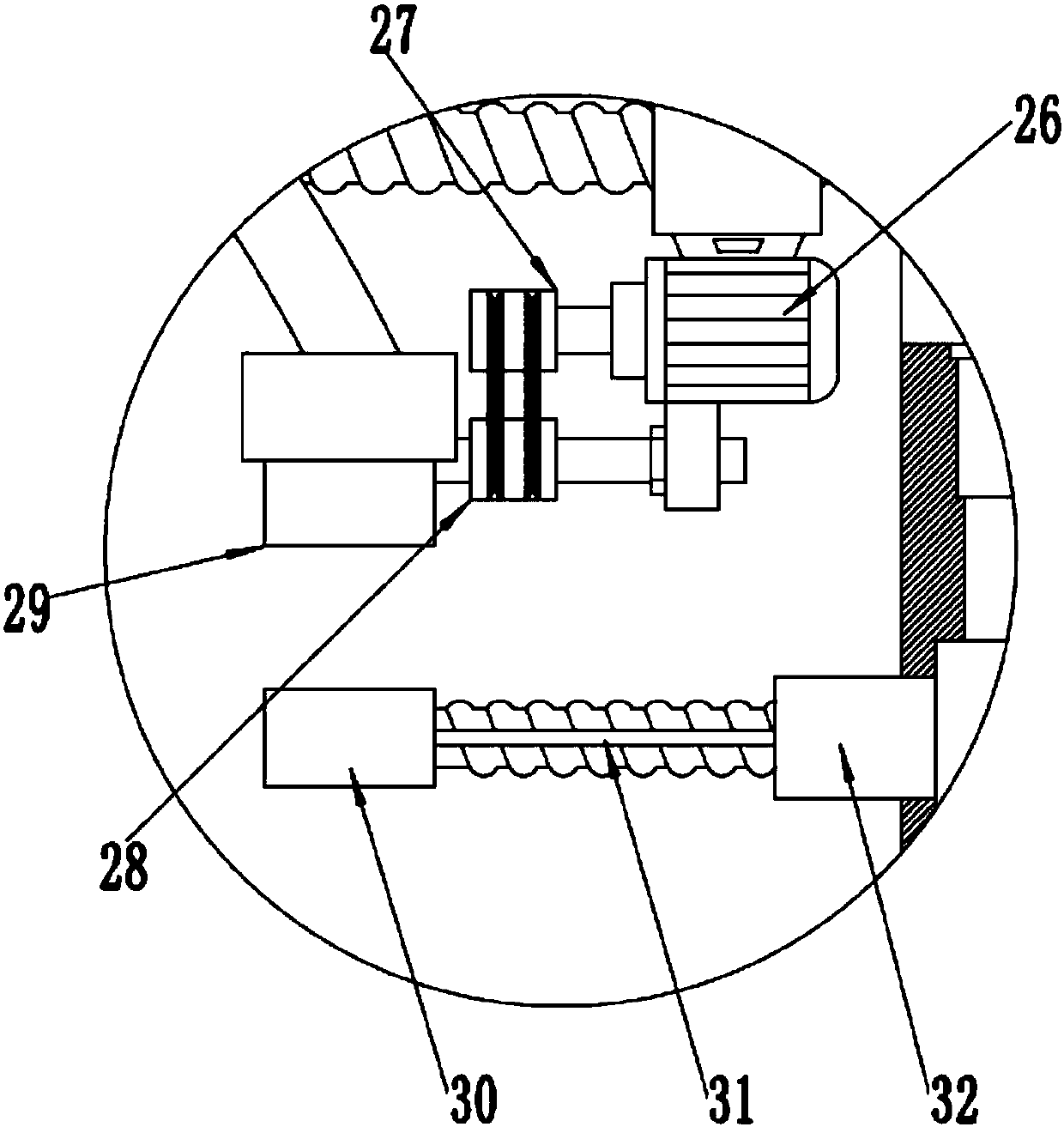

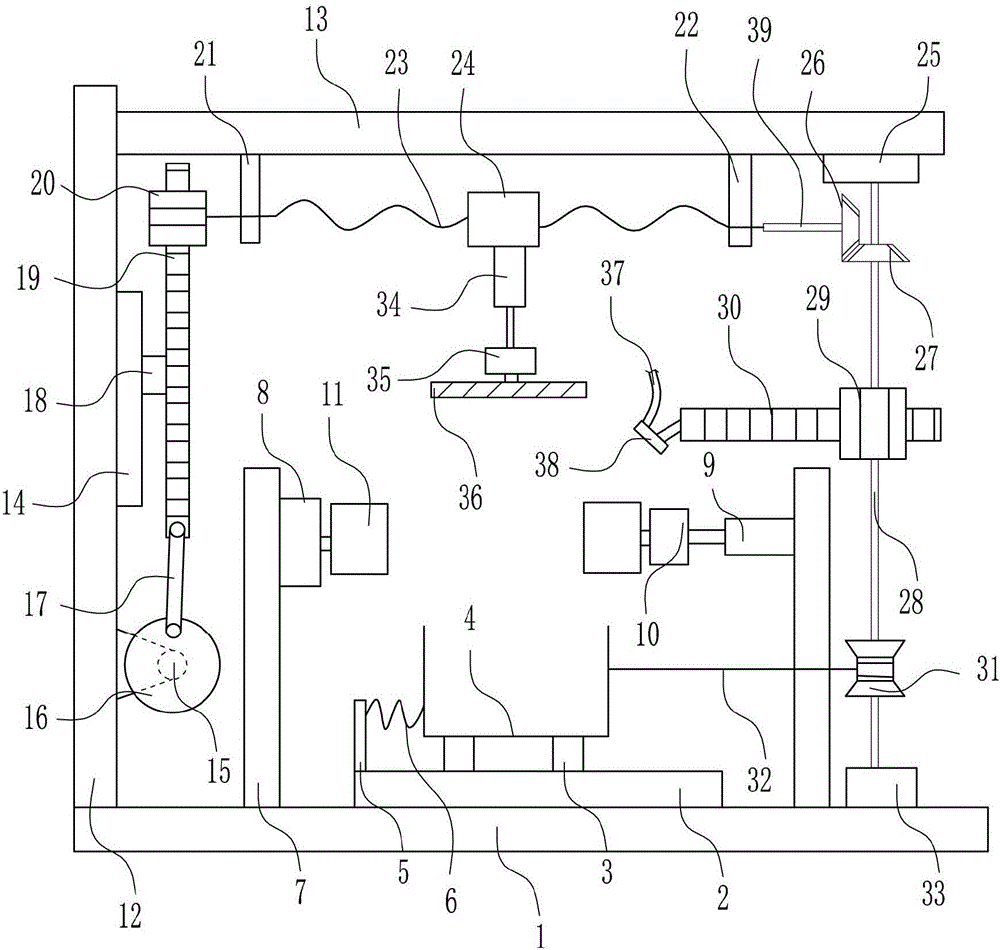

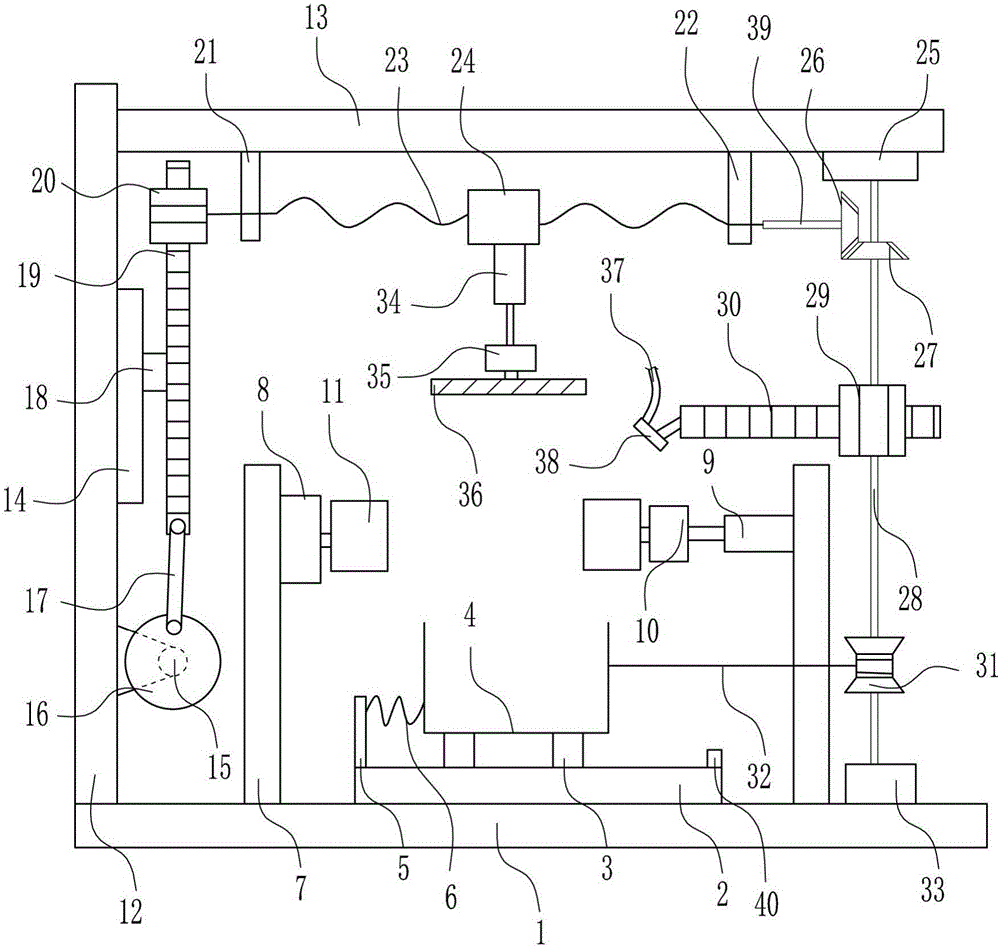

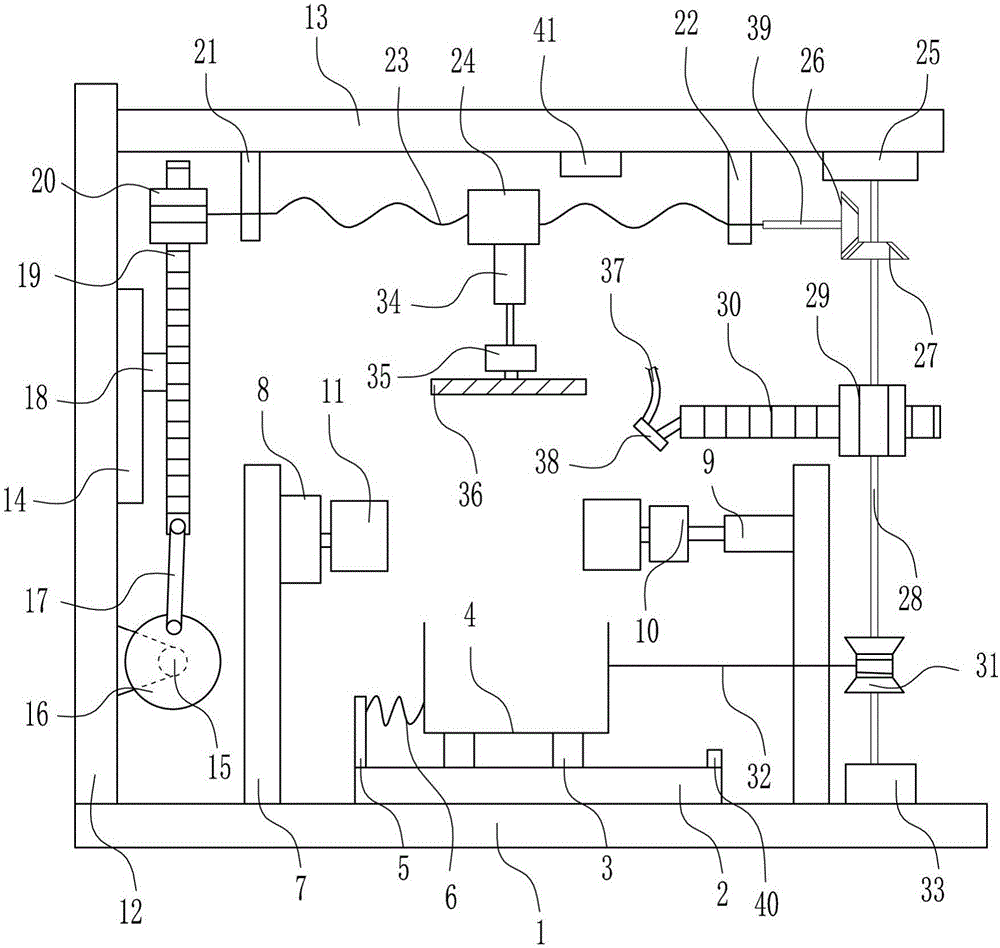

Device for simultaneously grinding inner walls and outer walls of steel pipes

InactiveCN107738167AAvoid pollutionShorten the timeGrinding carriagesRevolution surface grinding machinesHydraulic cylinderEngineering

The invention discloses a device for simultaneously grinding the inner walls and the outer walls of steel pipes. The device comprises a workbench, a support, a collecting tank, a clamping mechanism, an outer grinding mechanism and an inner grinding mechanism; the support is arranged at the upper end of the workbench, and the clamping mechanism is arranged at the left end of the inner side of the support and comprises a clamping plate, a rotating motor, an annular gear, a gear, electric telescopic rods, supporting plates, rubber pads and springs; the outer grinding mechanism is installed at thelower end of a moving block; and the inner grinding mechanism is arranged under the outer grinding mechanism and comprises an inner grinding wheel, a threaded rod B, a fixing sleeve, a threaded sleeve, a second sliding groove, an electric hydraulic cylinder, a drive gear, a driven gear A, a driven gear B, a rectangular block and a connecting rod. The device is novel in design, simple in structure, capable of simultaneously grinding the inner walls and the outer walls of steel pipes with different thicknesses, high in grinding efficiency, wide in application range, capable of effectively preventing impurities such as scrap iron from polluting the environment, high in practicality and worthy of popularization.

Owner:宁波高新区峰林化工科技有限公司

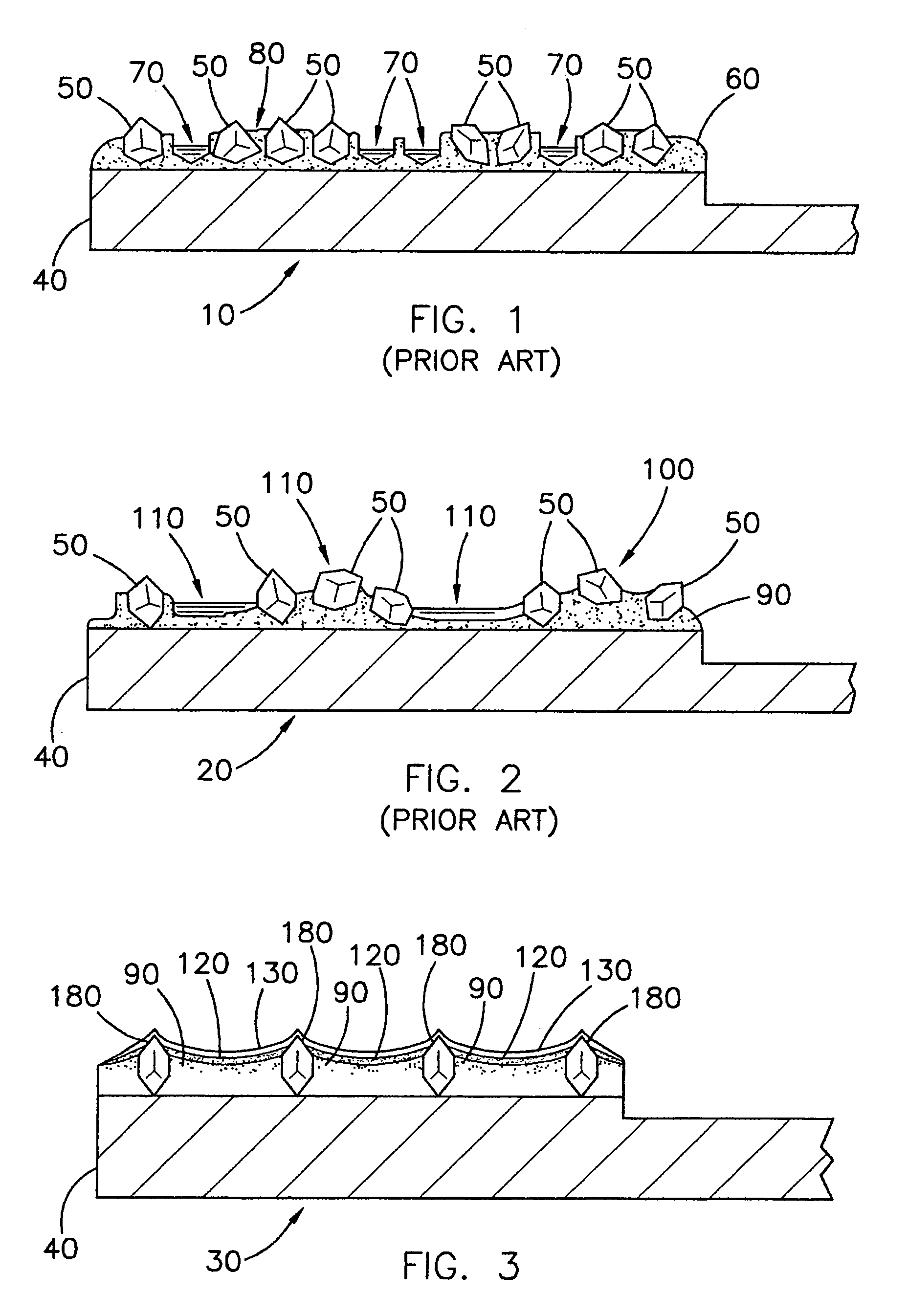

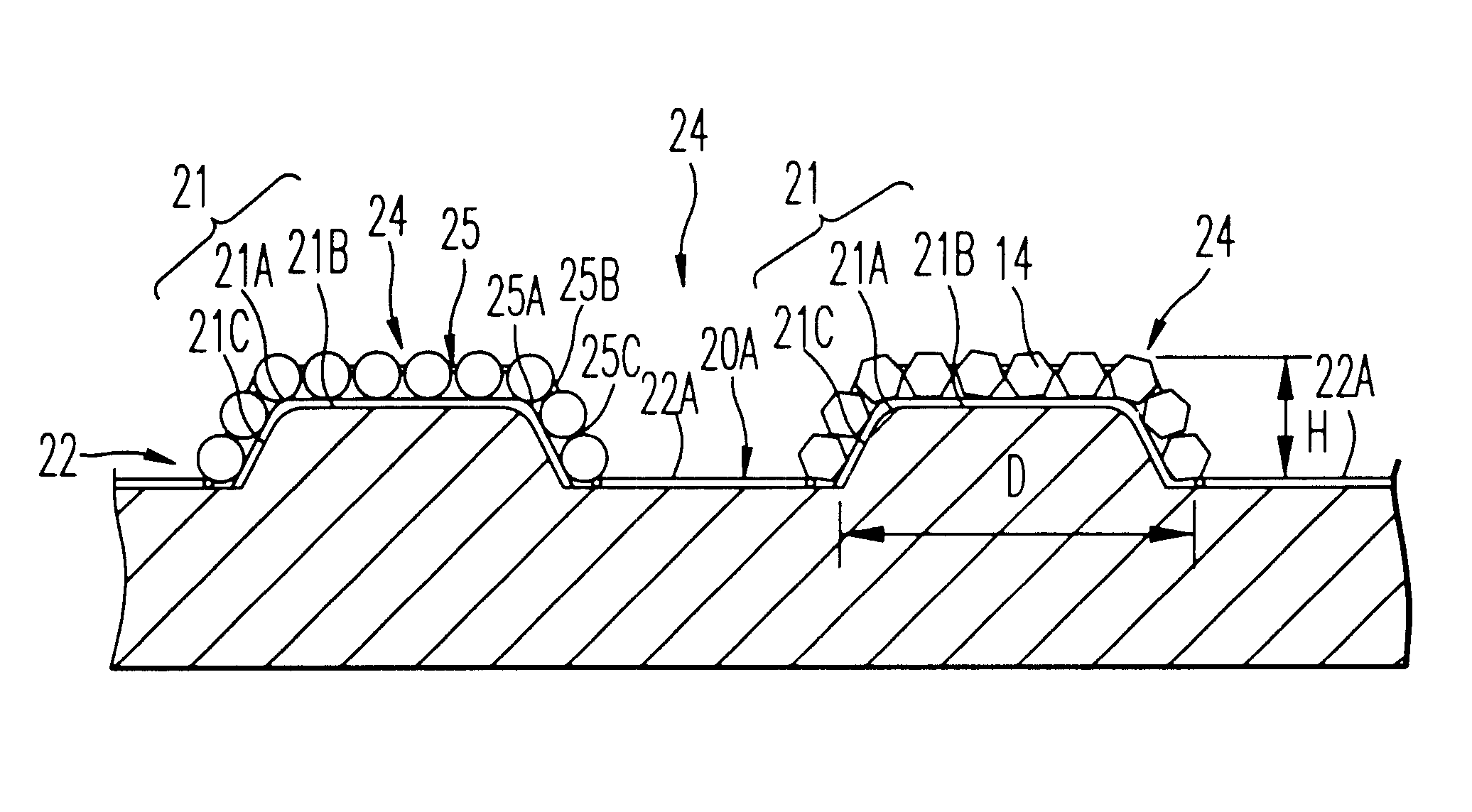

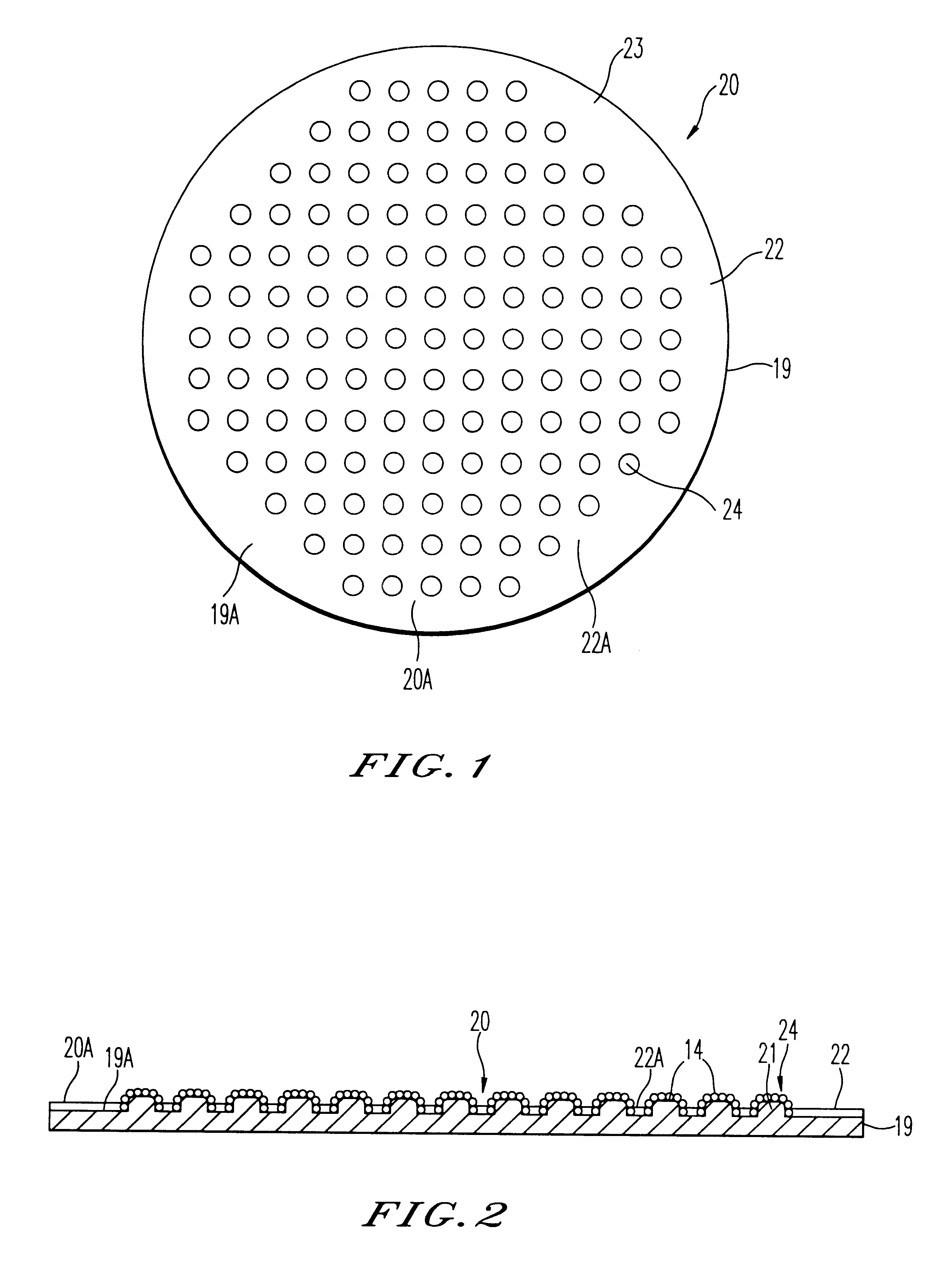

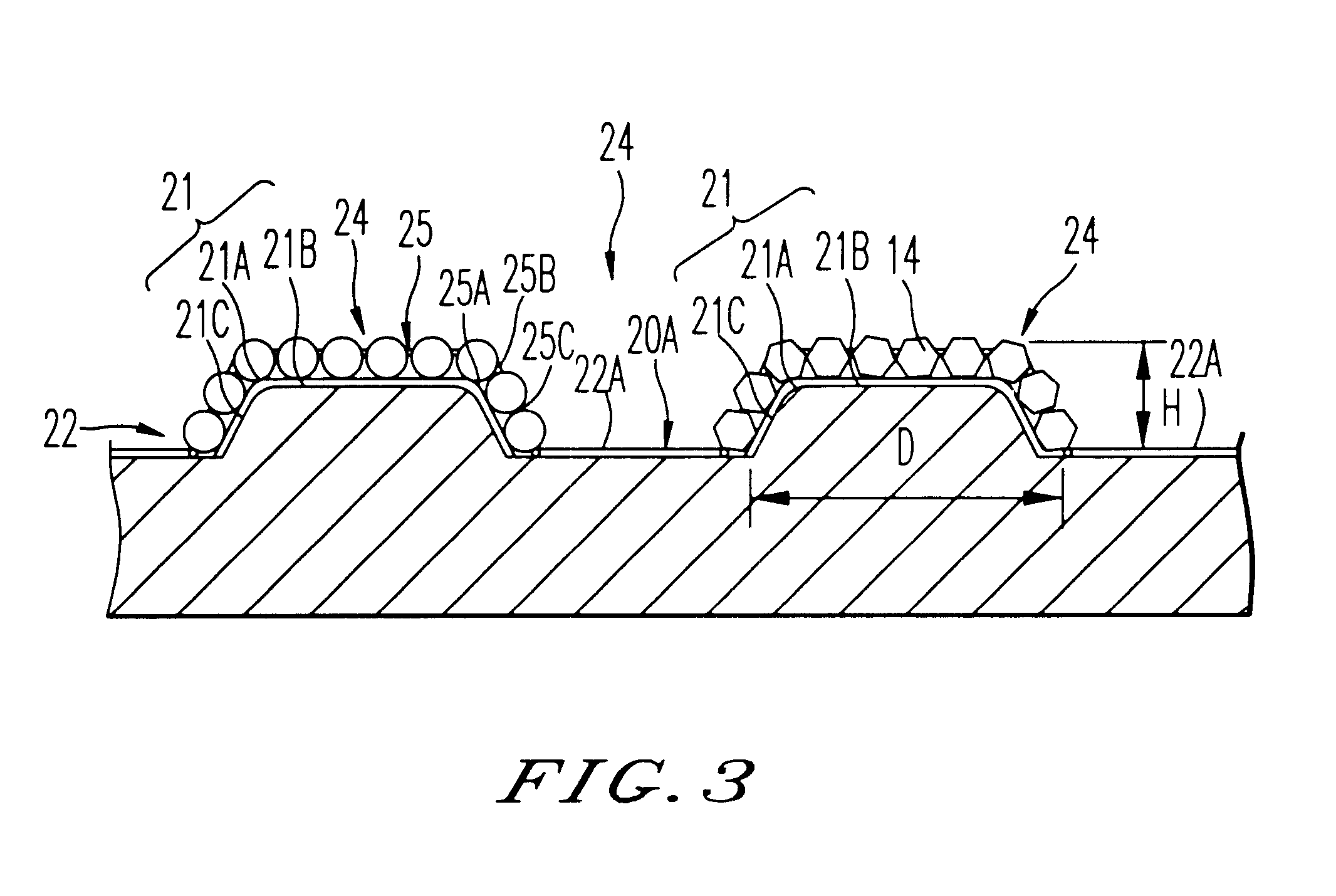

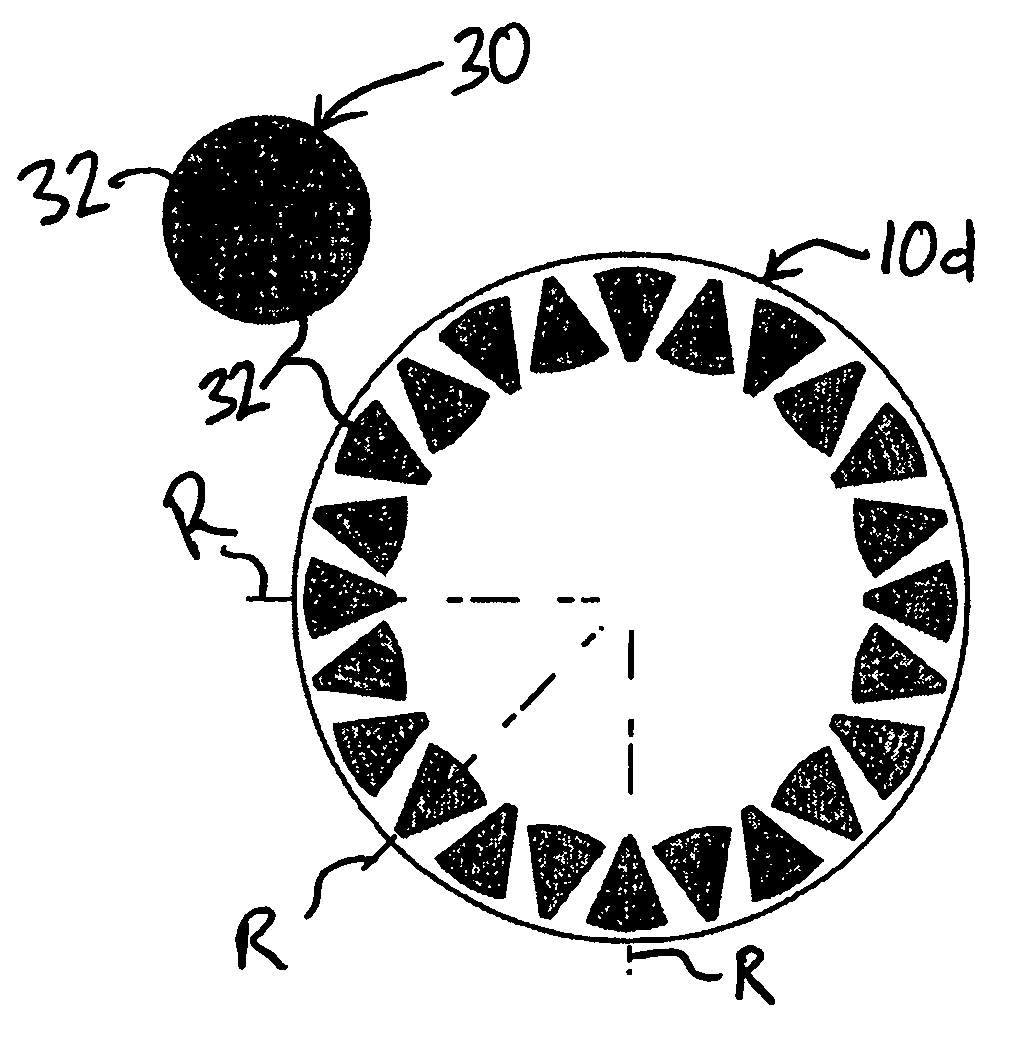

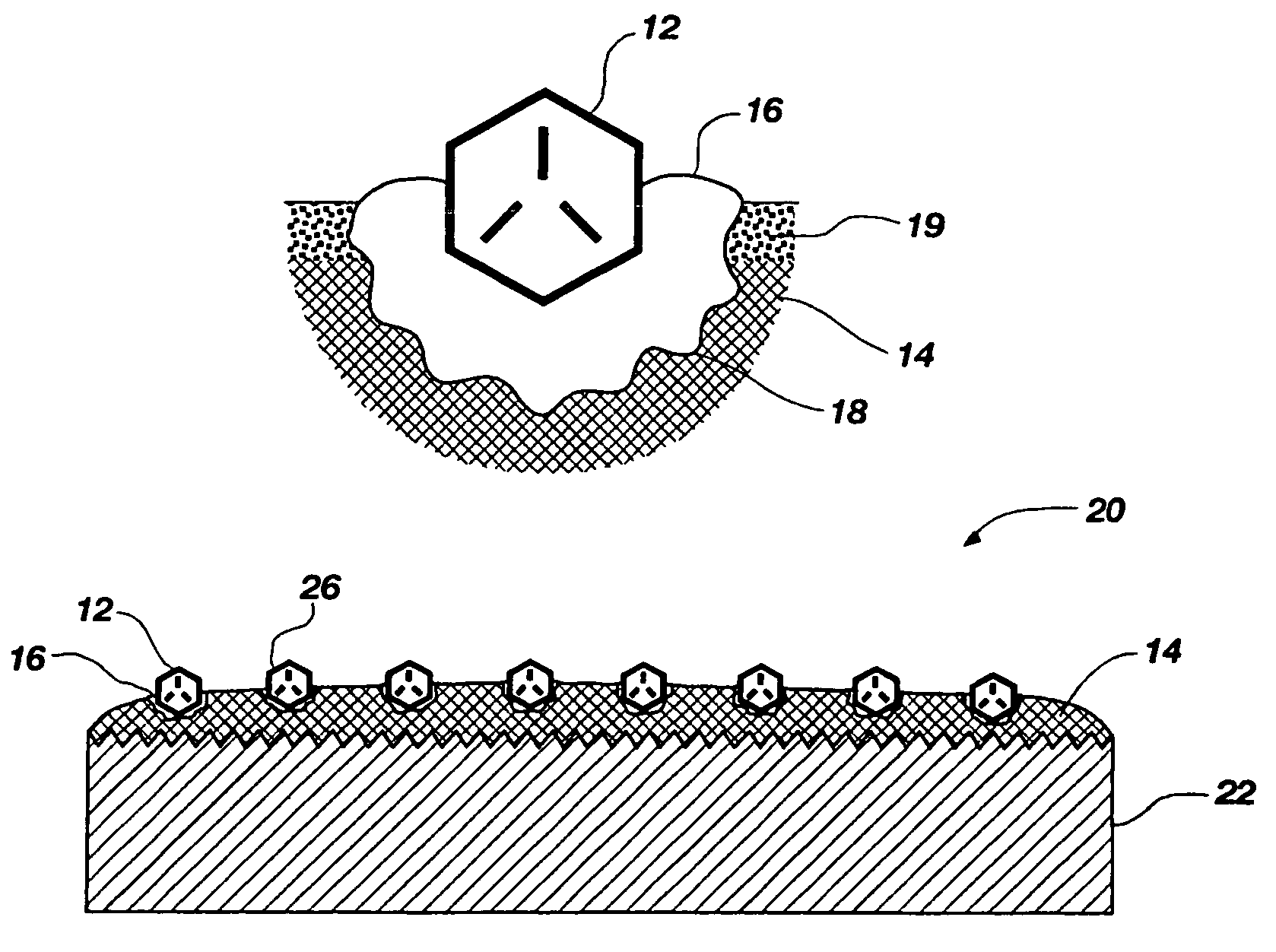

Abrasive tool with metal binder phase

InactiveUS6419574B1Sufficient sharpnessImprove discharge performanceRevolution surface grinding machinesGrinding drivesWear particleMetal

In the electrodeposited abrasive wheel 20 of the abrasive tool according to the present invention, plural mound parts 21, which are upheaved at the central domain of base metal 19 in almost columnar shape, are arranged mostly in the shape of lattice. An abrasive grain layer 22 is formed on a base metal 19, and plural ultra abrasive grains 14 are adhered only to each mound parts 21 by electrodeposited metal phase 25, and referred as the small abrasive-grain-layer parts 24, respectively. Ultra abrasive grains are laid out at corner R part 21a and top 21b of the mound parts 21 at the small abrasive-grain-layer parts 24. Ultra abrasive grains at each small abrasive-grain-layer parts are set as 11-500 pieces, and the rate which ultra abrasive grains occupy to the whole area of abrasive grain layer accounted by plane projection is set as 20%-80% of the range. At the time of grinding, only ultra abrasive grains contact to grinding work piece, then high abutment pressure is maintained, and sharpness and the discharge performance of ground wastes are good.

Owner:MITSUBISHI MATERIALS CORP

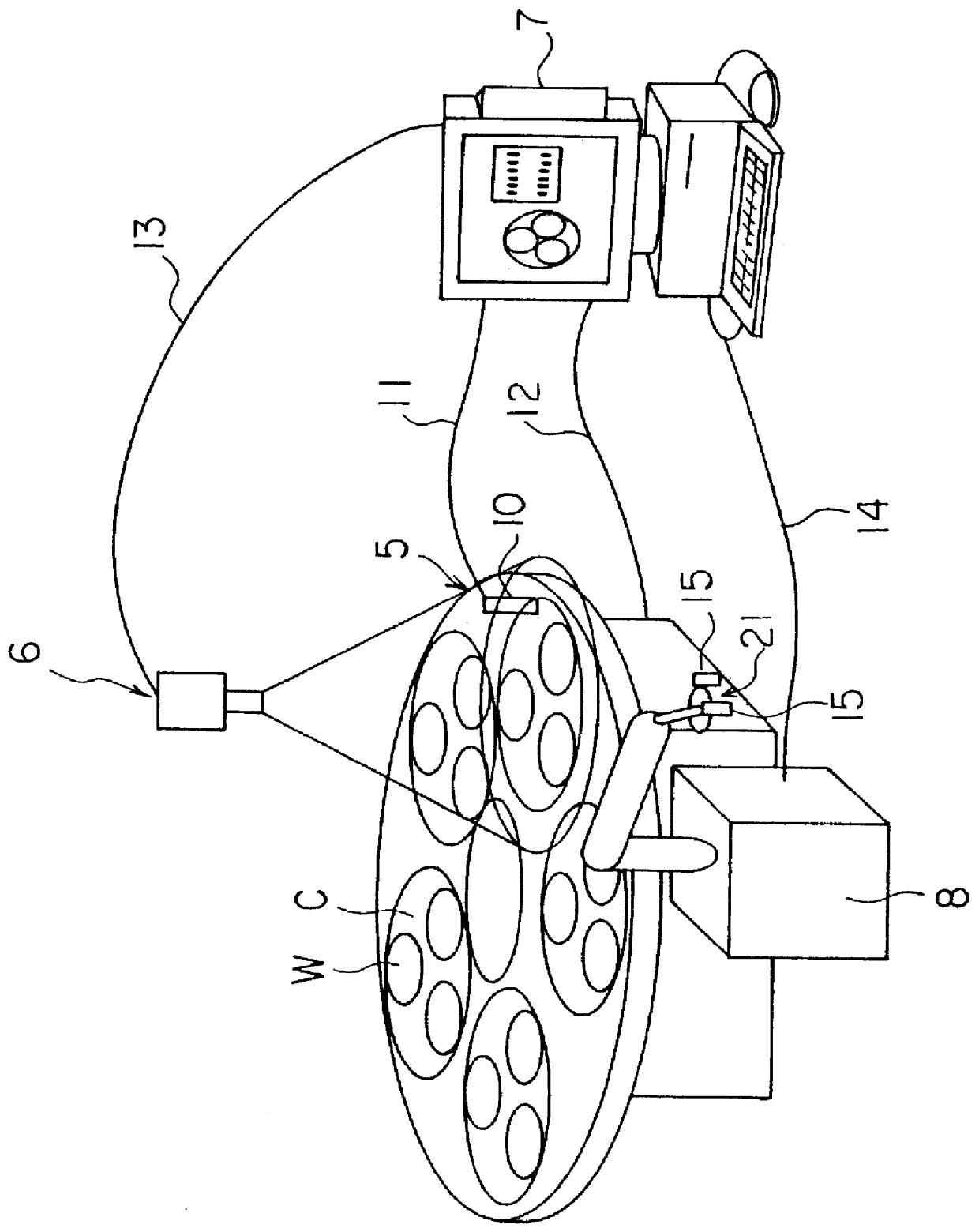

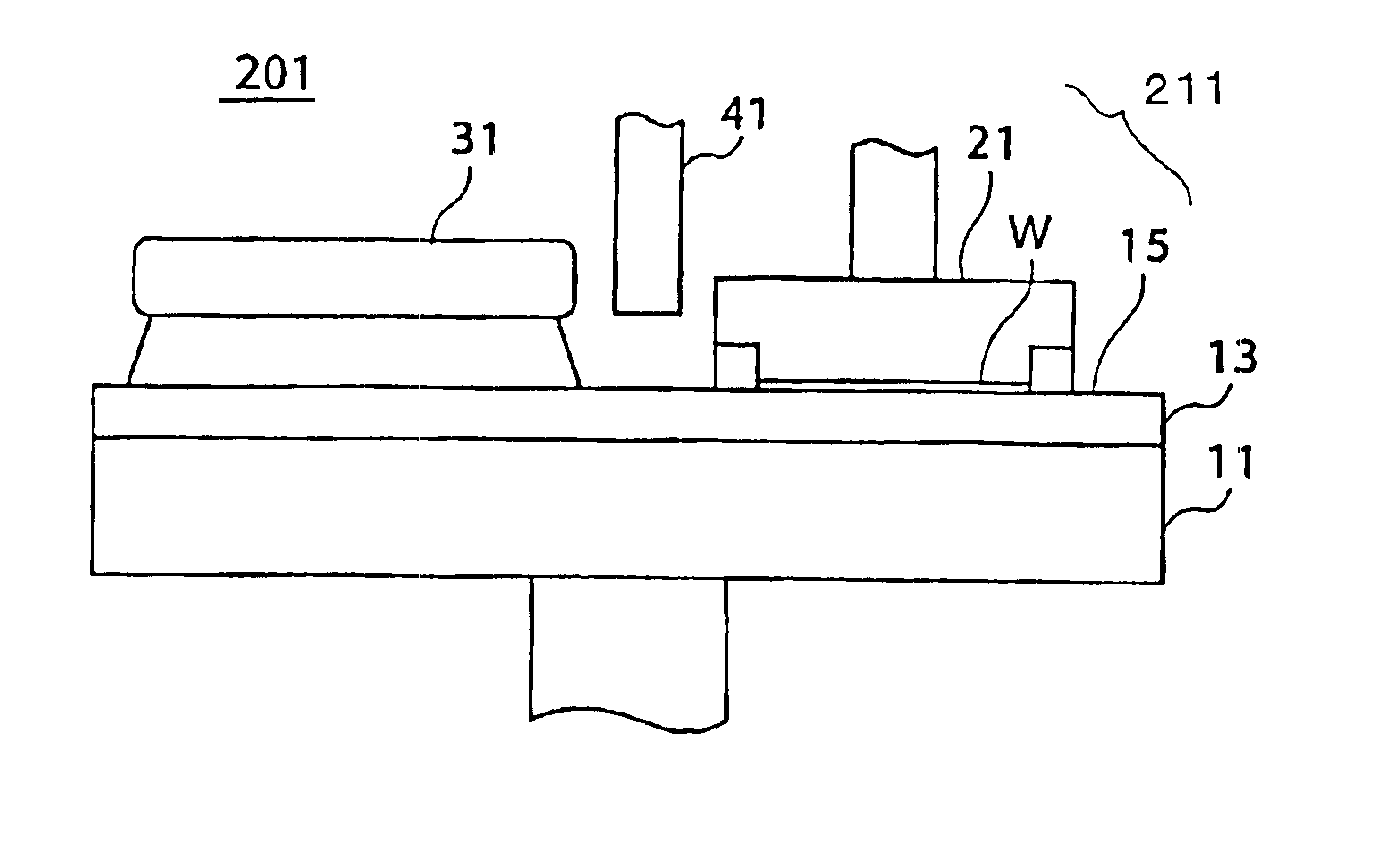

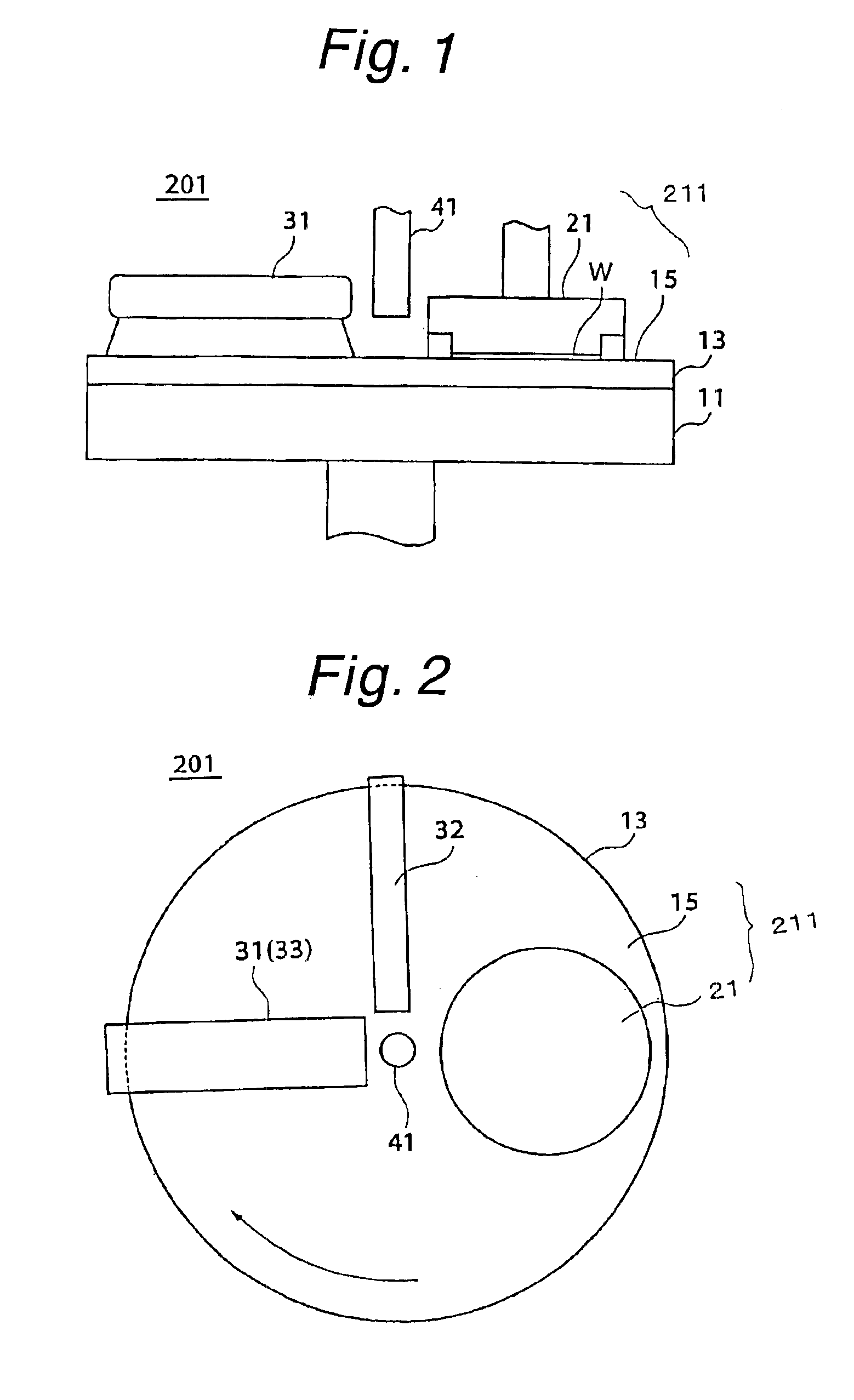

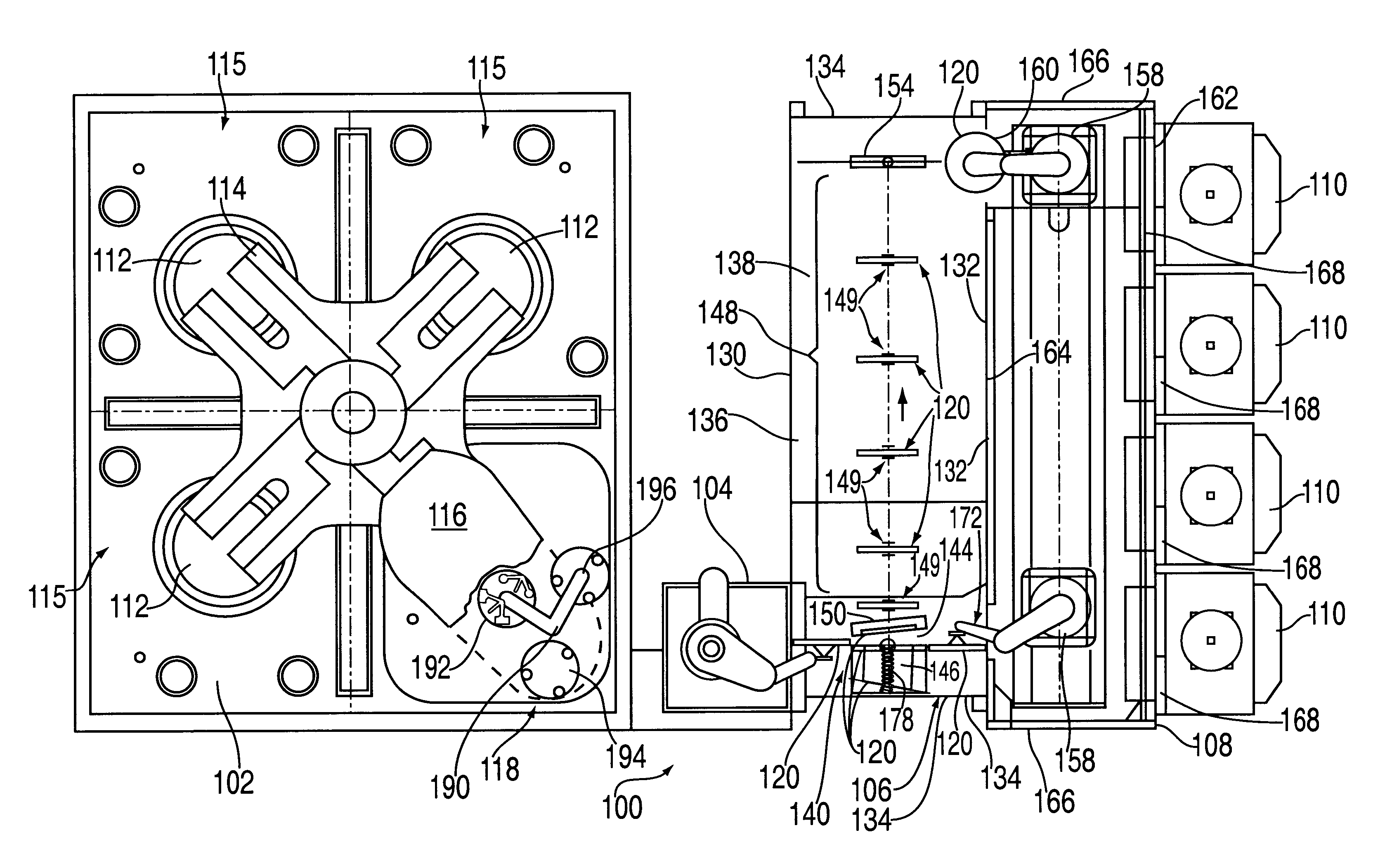

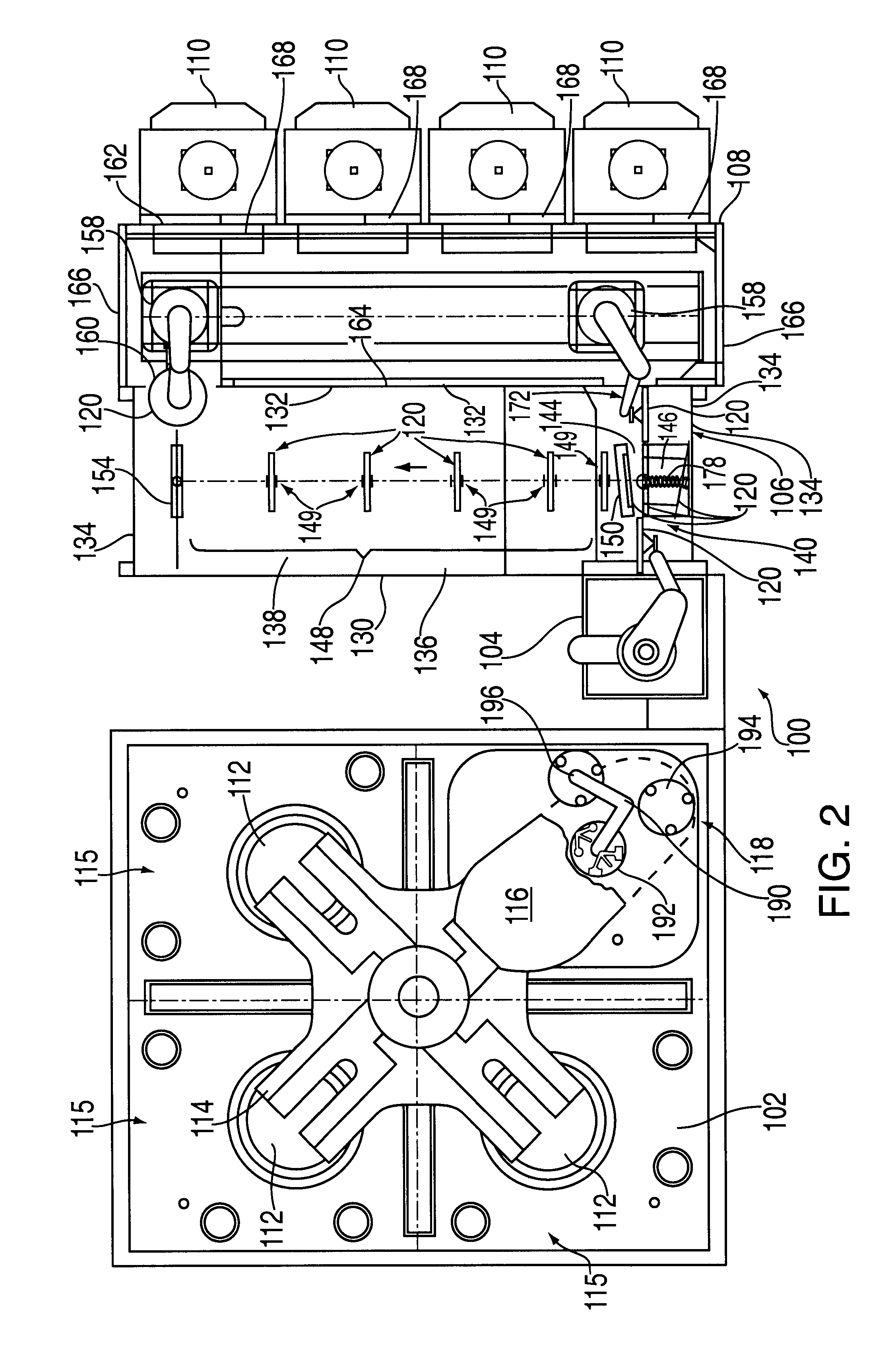

Automatic workpiece transport apparatus for double-side polishing machine

InactiveUS6135854AReliable loadingAccurate detectionRevolution surface grinding machinesGrinding drivesImaging processingEngineering

An automatic workpiece transport apparatus for a double-side polishing machine is disclosed. A carrier is positioned at a predetermined position by a positioning unit, and an image of the top surface of the carrier is captured by use of a visual sensor. A computer performs image processing to obtain the center coordinates of the wafers or the workpiece holders while reference marks or the like provided on the carrier are used as references. The transport robot is moved and controlled based on the thus-detected coordinate data in order to load the wafers into the workpiece holders or to unload the wafers from the workpiece holders. Further, two visual sensors are provided at the tip end of the arm of the transport robot. These visual sensors send to the computer an image of the peripheral portion of the held wafer. Thus, the computer performs fine adjustment in positioning the wafer and the workpiece. The automatic workpiece transport apparatus can reliably load and unload semiconductor wafers to and from the carrier that holds semiconductor substrates.

Owner:SHIN-ETSU HANDOTAI CO LTD

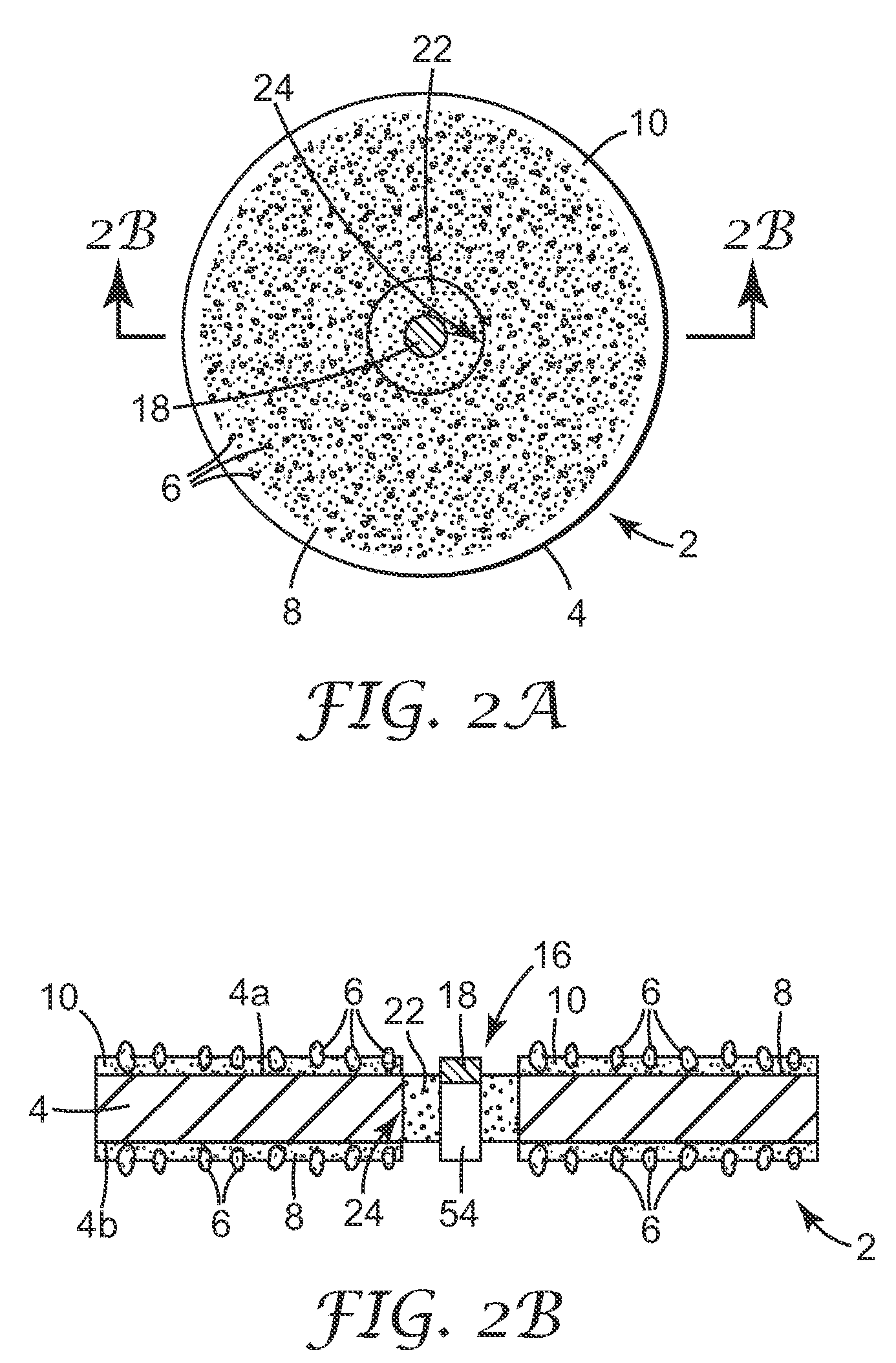

Abrasive articles, CMP monitoring system and method

ActiveUS7840305B2Easy to operate the machineAvoid damageGrinding drivesBelt grinding machinesMonitoring systemEngineering

The disclosure relates to abrasive articles useful in chemical-mechanical polishing (CMP), the articles including a substrate with opposite major surfaces, an abrasive material overlaying at least a portion of at least one of the major surfaces, and at least one of a radio frequency identification (RFID) tag, a RFID tag reader, or a sensor for providing CMP information to a transmitter positioned near the substrate, the transmitter positioned near the substrate and adapted to wirelessly receive CMP information and wirelessly transmit the CMP information to a remote receiver. The disclosure also relates to a CMP pad conditioner for wirelessly communicating CMP information to a remote receiver, a CMP process monitoring system for wirelessly communicating CMP information to a remote receiver, and a method for conditioning a CMP pad using a CMP process monitoring system for wireless communicating CMP information to a remote receiver.

Owner:3M INNOVATIVE PROPERTIES CO

CMP diamond conditioning disk

A method of making and the resulting non-metallic CMP conditioning pad comprising a non-metallic substrate and a single layer of abrasive particles bonded to the substrate by a non-metallic bonding medium. Preferred substrates include aluminum oxide and graphite. A bonding system employing finely powdered aluminum oxide particles mixed with a suitable adhesive is employed to bond the abrasive layer to the aluminum oxide substrate. Silicon carbide particles mixed into a compatible adhesive carrier including a polymer composition is preferred for bonding the abrasive particle layer to a graphite or carbide substrate.

Owner:ABRASIVE TECH

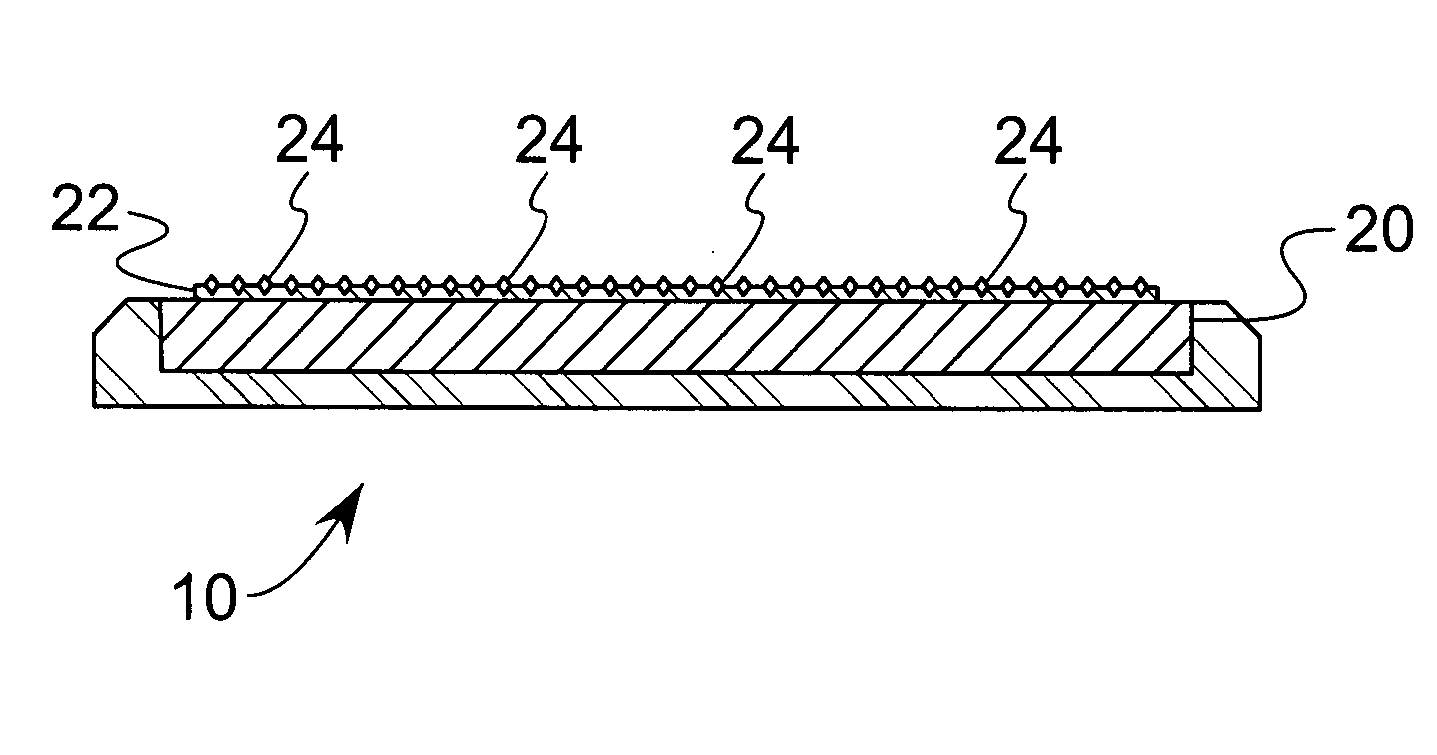

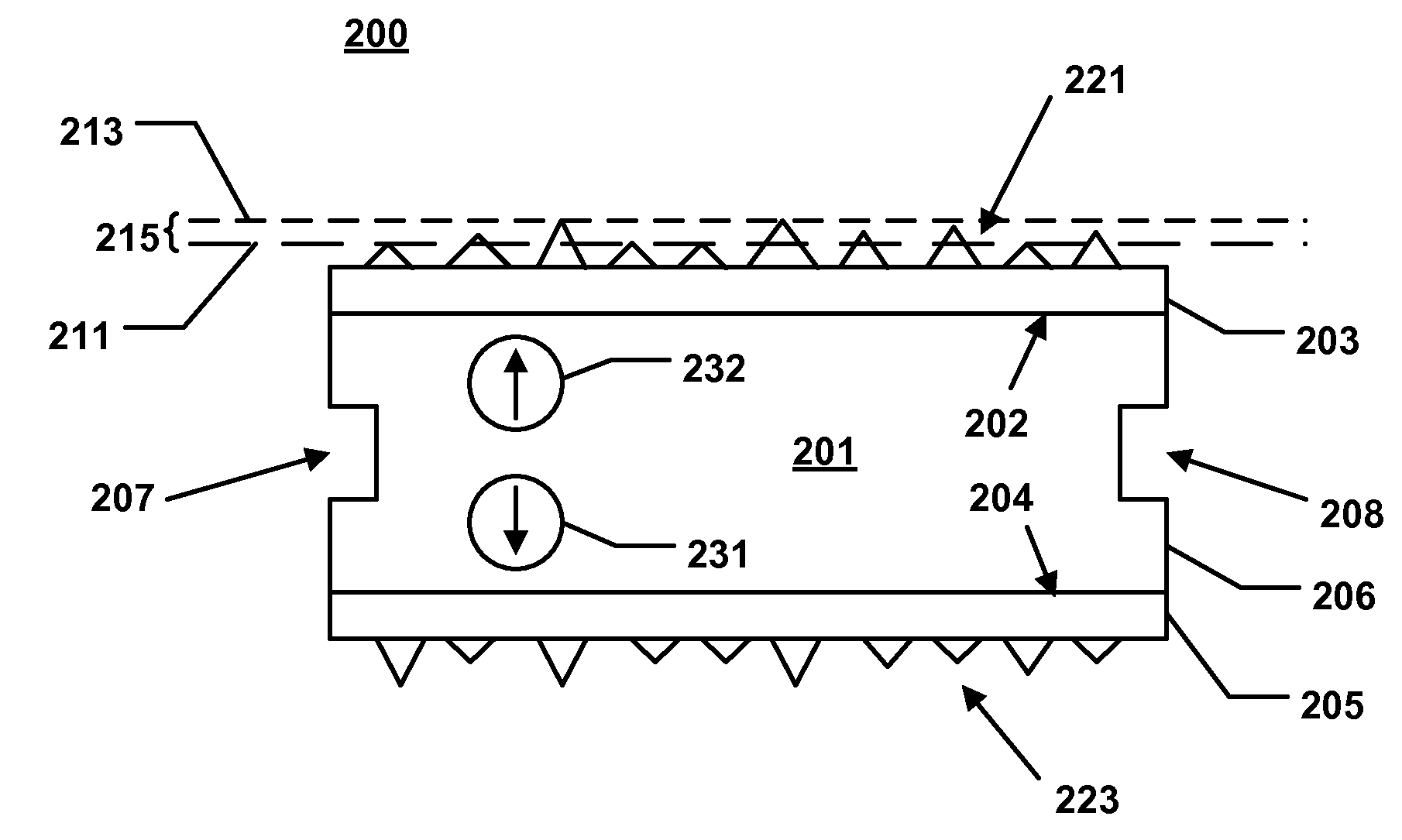

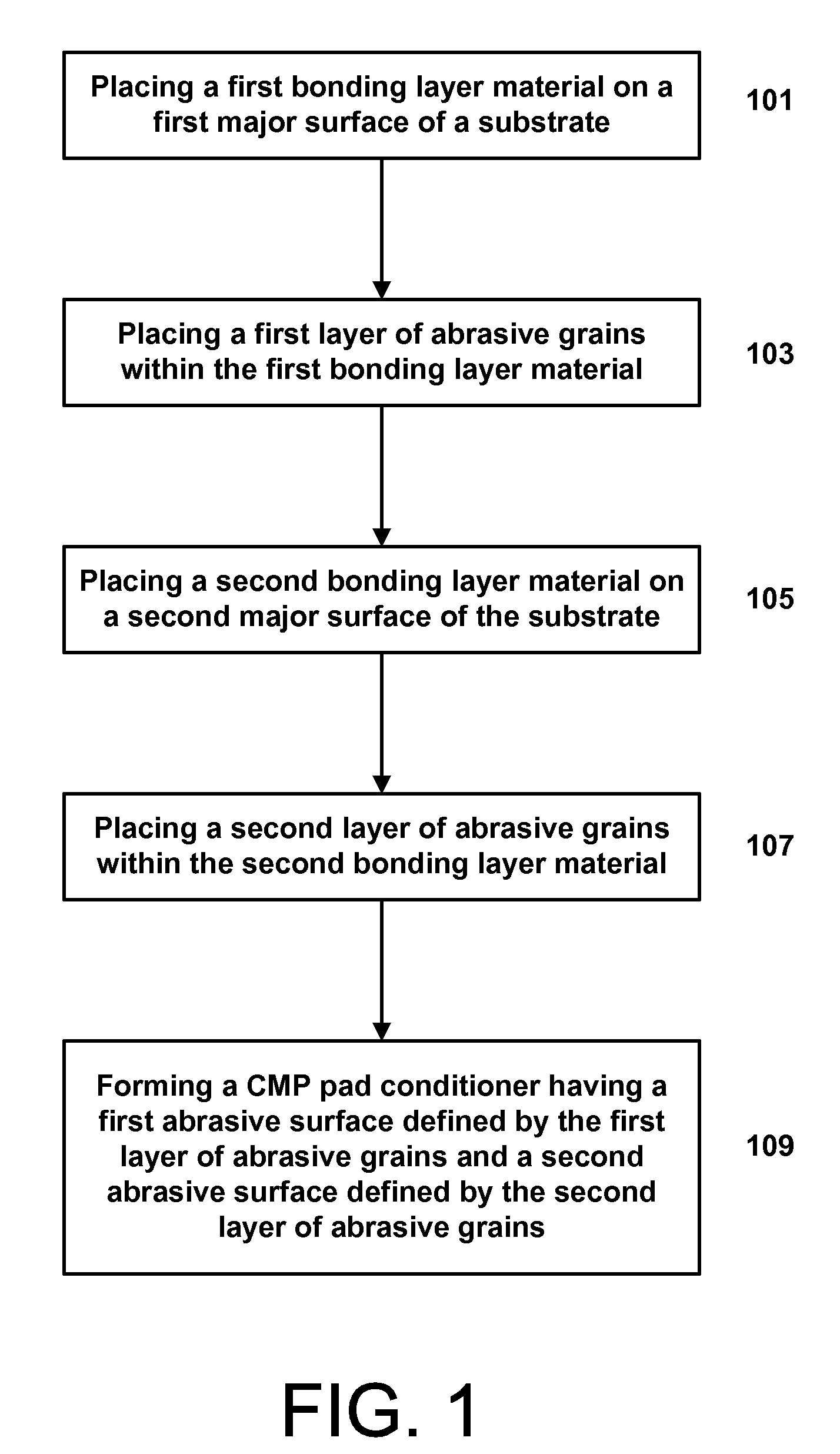

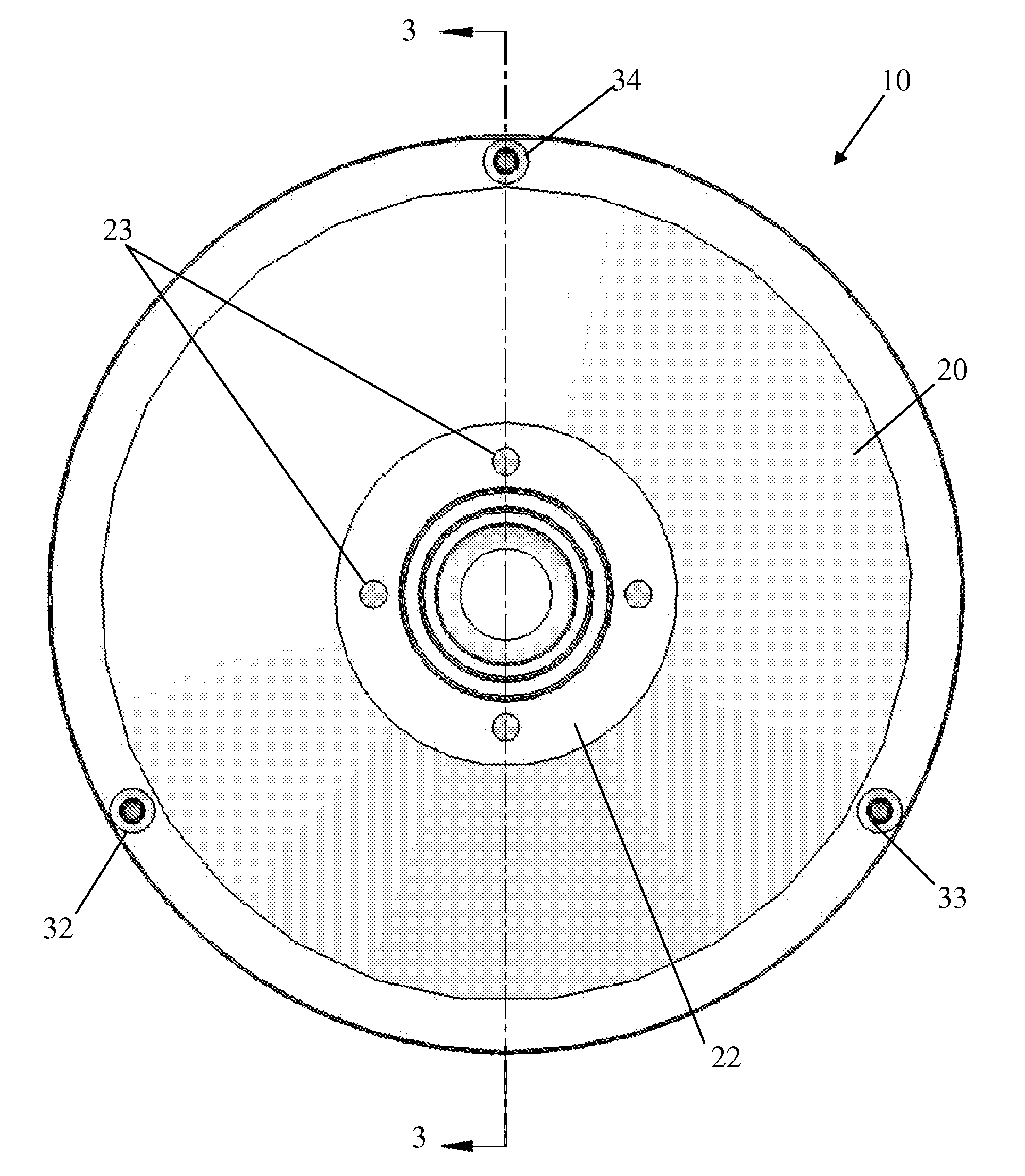

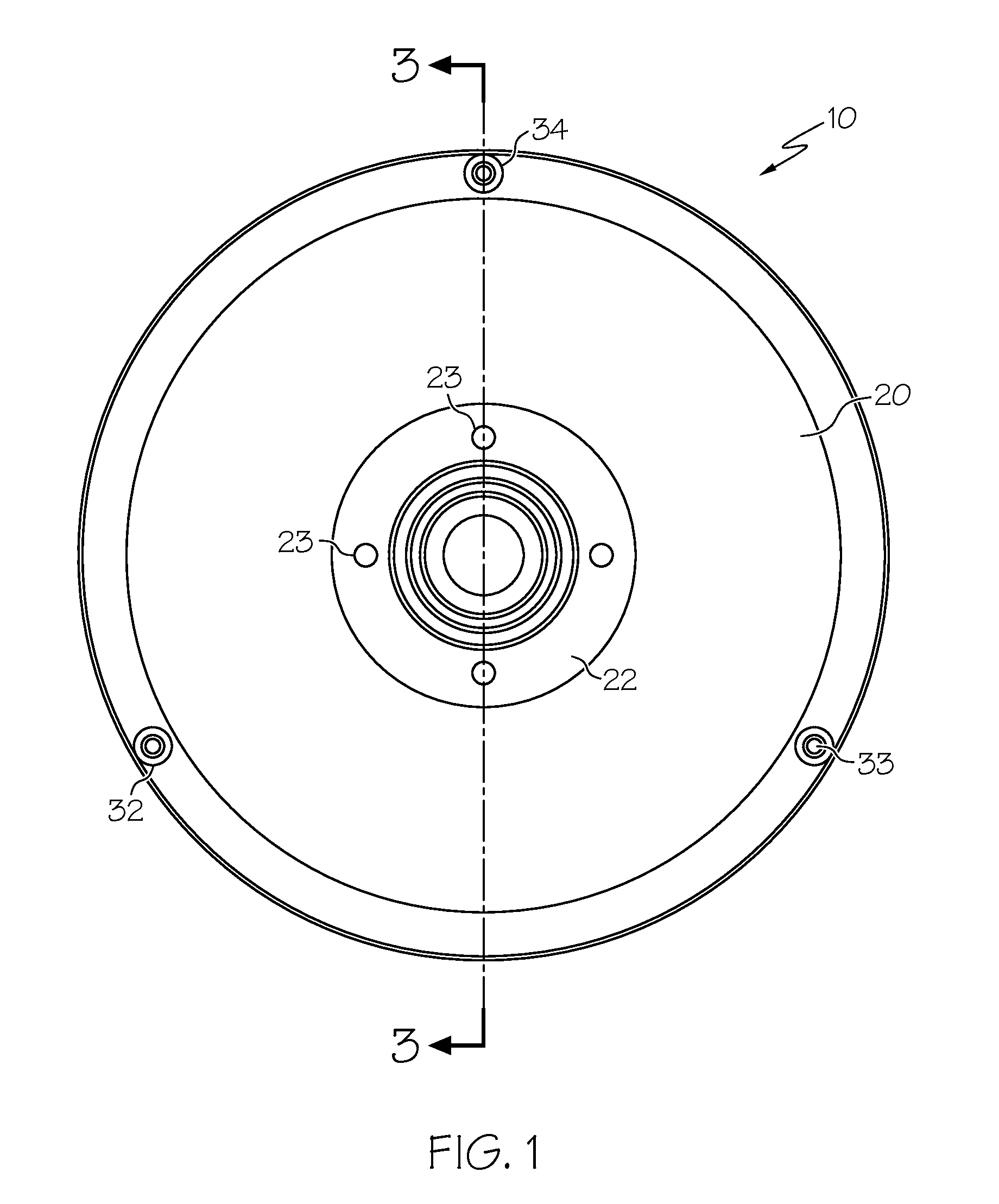

Abrasive tool for use as a chemical mechanical planarization pad conditioner

An abrasive tool including a CMP pad conditioner having a substrate including a first major surface, a second major surface opposite the first major surface, and a side surface extending between the first major surface and the second major, wherein a first layer of abrasive grains is attached to the first major surface and a second layer of abrasive grains is attached to the second major surface. The conditioner further includes a first sealing member extending in a peripheral direction along a portion of the side surface of the substrate.

Owner:SAINT GOBAIN ABRASIVES INC +1

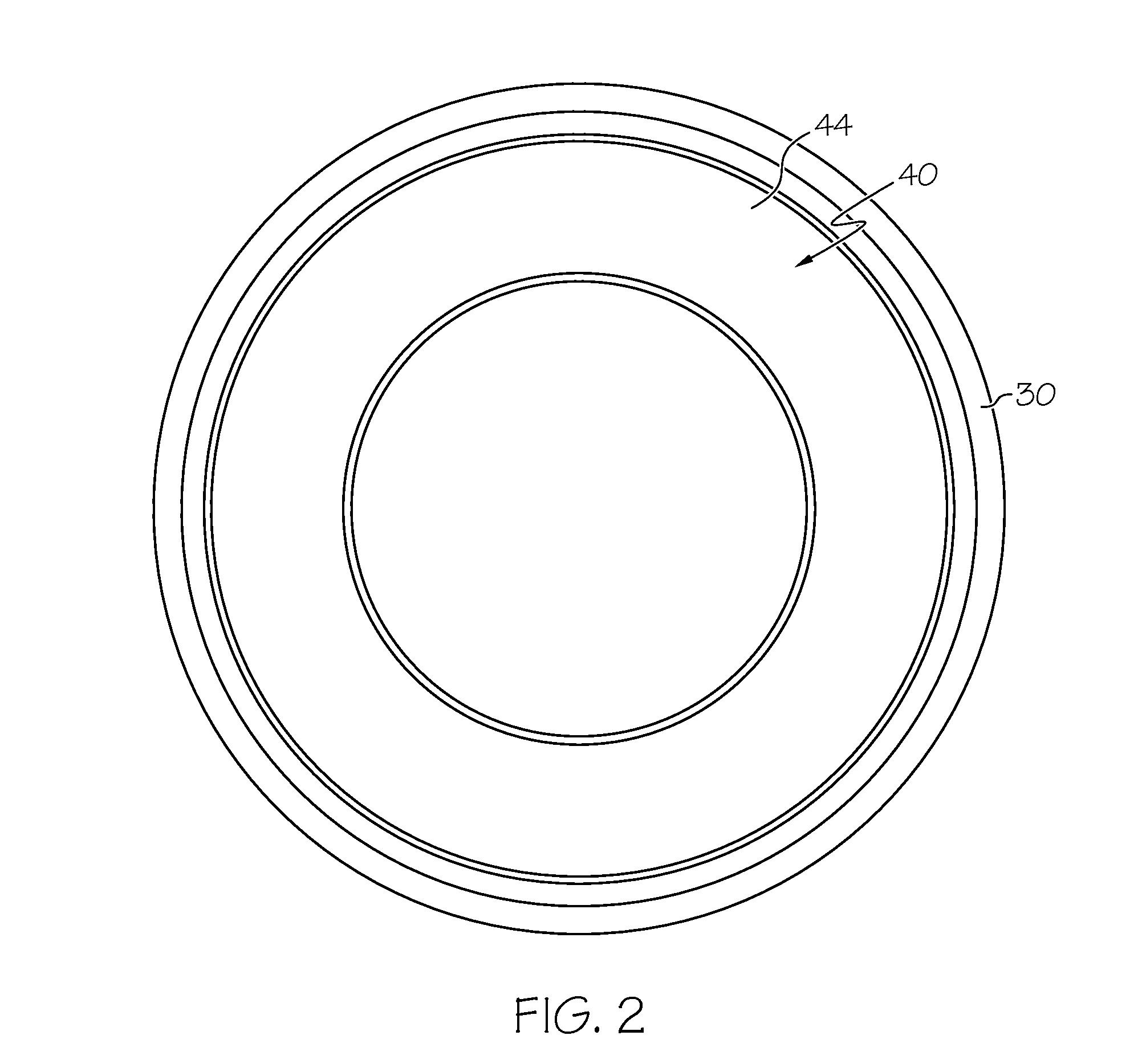

Multiple-sided cmp pad conditioning disk

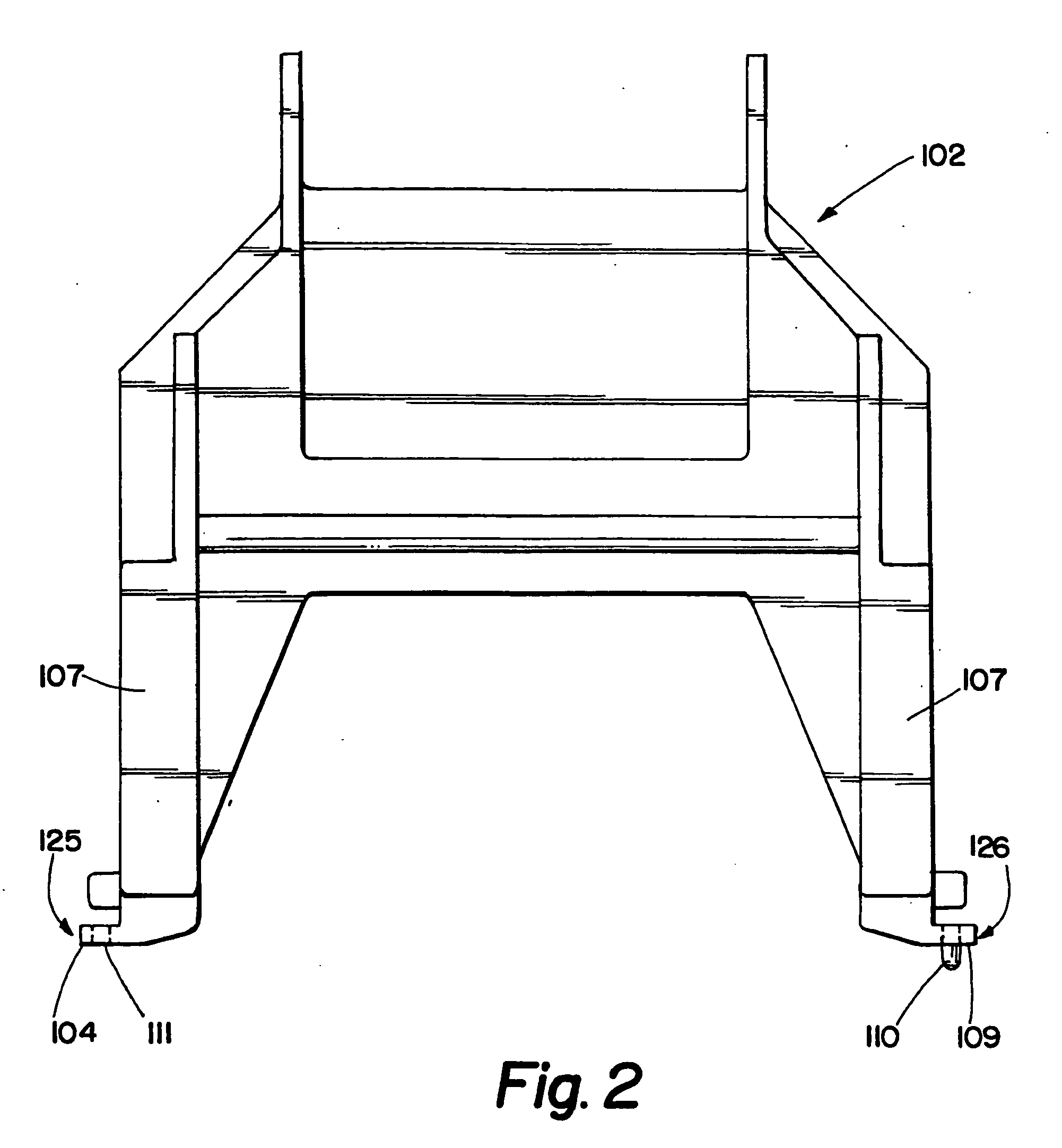

InactiveUS20110097977A1Efficiently provideGrinding drivesBelt grinding machinesEngineeringMechanical engineering

A conditioning tool for restoring a used CMP polishing pad to an operable condition. The tool includes a base that attaches to a driven machine and has a surface from which a shoulder protrudes that receives a peripheral edge of a disk. The disk has two opposing surfaces, each of which is substantially planar and has abrasive mounted thereon. The disk's peripheral edge is held in place between the base shoulder and a ring that has a shoulder that is complementary to the disk's peripheral edge. The ring is fastened to the base with the abrasive of the first disk surface protruding through an aperture in the ring, and the opposing disk surface spaced from the base's surface. After the disk's first surface is worn, the disk can be turned around to expose the opposite surface's abrasive to a CMP pad.

Owner:ABRASIVE TECH

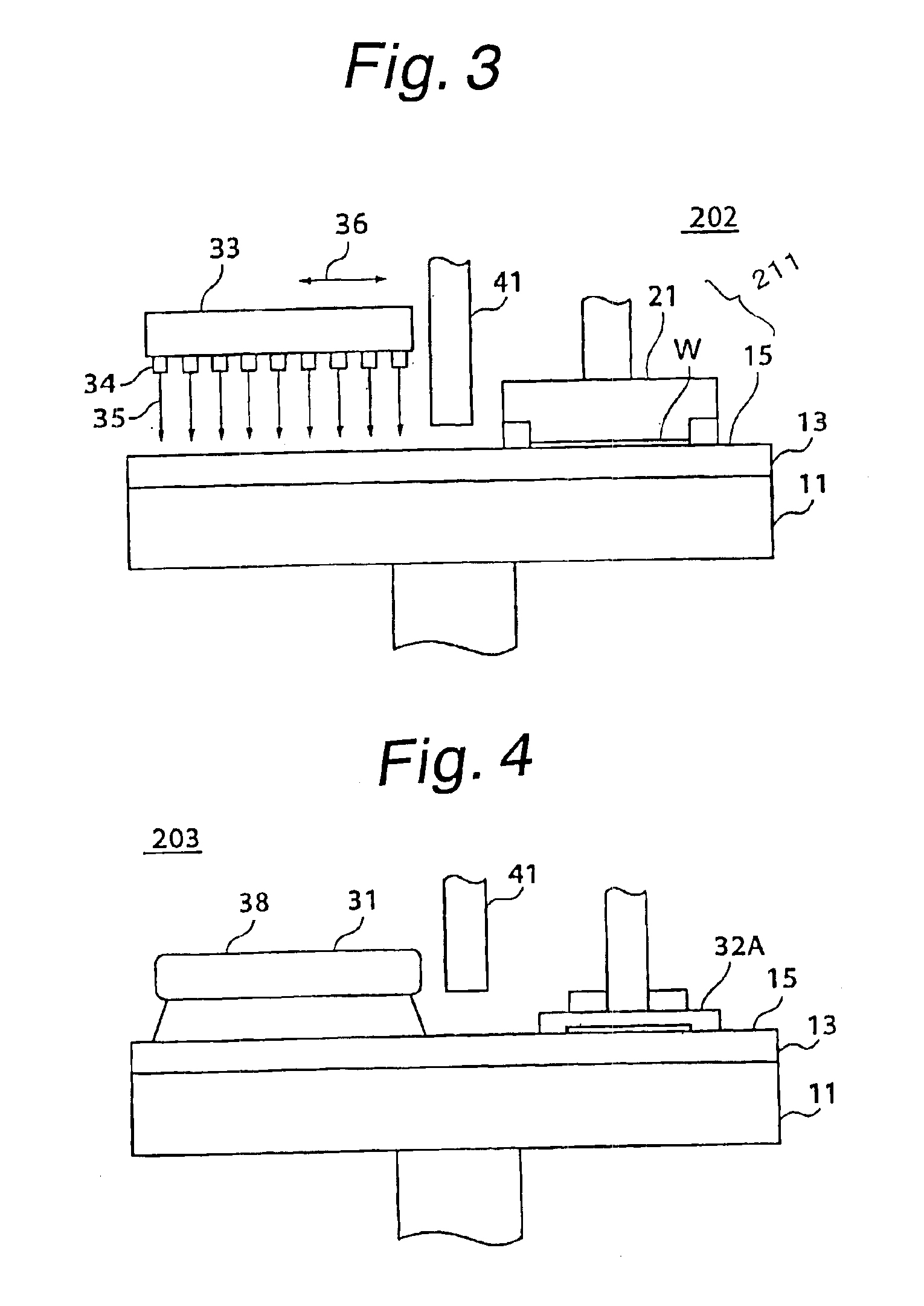

Polishing apparatus and dressing method for polishing tool

InactiveUS6899592B1Easy to dressReduce the binding forceGrinding drivesAbrasive surface conditioning devicesIrradiationBond Force

In a polishing apparatus, a polishing tool including abrasive particles and a binder for bonding together the abrasive particles is pressed against a substrate to polish the substrate. The polishing apparatus has a light source for irradiating a polishing surface with light rays for weakening a bond force of the binder for bonding together the abrasive particles, and a waste matter removing mechanism for forcefully removing waste matter produced by polishing or waste matter produced by irradiation. By irradiating the polishing surface with the light rays, dressing of the polishing surface is performed, and products resulting from dressing and the like are removed. The polishing apparatus supplies abrasive particles to the polishing surface stably by dressing and allows high-speed polishing of the substrate.

Owner:EBARA CORP

Superhard cutters and associated methods

A cutting device comprises a plurality of individual polycrystalline cutting elements secured in a solidified organic material layer. Each of the plurality of individual polycrystalline cutting elements has a substantially matching geometric configuration.

Owner:KINIK

Steel plate surface polishing device for hardware machining

ActiveCN106141875AImprove corrosion resistanceHigh strengthGrinding carriagesPolishing machinesSheet steelMachining

The invention relates to a steel plate surface polishing device, in particular to a steel plate surface polishing device for hardware machining. The steel plate surface polishing device for hardware machining aims to achieve the technical purposes that manual labor is not needed, the requirement for professional operation skills is not high, operation is easy, the price-performance ratio is high, the safety coefficient is high, and harm of the operation environment to health of operators is small. In order to achieve the technical purposes, the steel plate surface polishing device for hardware machining comprises a bottom plate, a first sliding rail, a first sliding block, a collection tank, a fixing stop block, a spring, a supporting rod, a first bearing pedestal, a first air cylinder, a disc and the like, wherein the first sliding rail is arranged in the middle of the top of the bottom plate. Through ingenious cooperation of the components, the effects that manual labor is not needed, the requirement for professional operation skills is not high, operation is easy, the price-performance ratio is high, the safety coefficient is high, and harm of the operation environment to health of the operators is small are achieved.

Owner:如皋市通城冲压机械制造有限公司

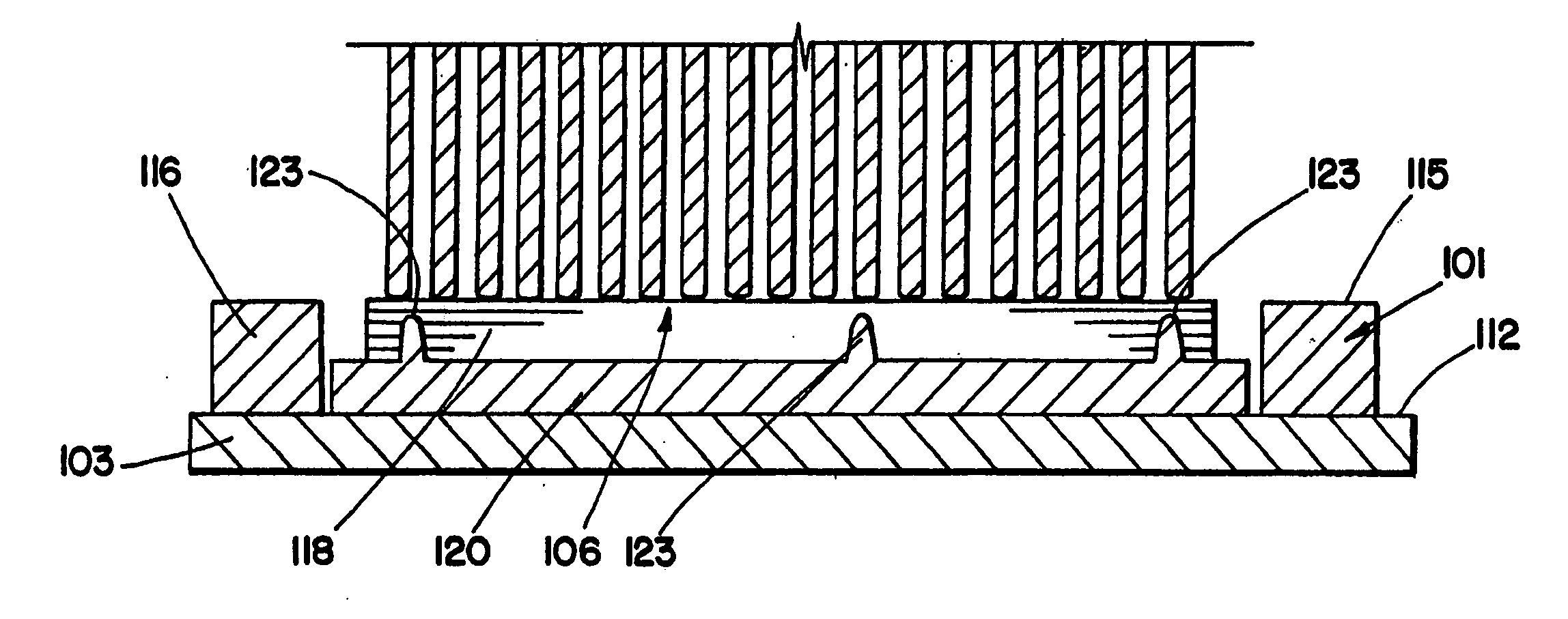

Carrier head with non-contact retainer

A carrier head for chemical mechanical polishing of a substrate has a base and a retaining ring positioned beneath the base. The retaining ring includes a main portion with a first surface to apply a load to a perimeter portion of the back surface of the substrate and an annular projection with a second surface to retain the substrate. A bottom surface of the projection is separated from a top surface of a polishing pad by a gap.

Owner:APPLIED MATERIALS INC

Brazed diamond dressing tool

A dressing blade for finishing and reconditioning new and used abrasive grinding and cutting tools has a slab-shaped shank with an extension protruding longitudinally from the shank. Superabrasive grains are disposed on the surface of the extension and held in place by a brazed metal composition. This composition is formed by brazing a powdered mixture of brazing metal components and active metal components. Specific extension configurations are provided which allow aligning the superabrasive grains in single layer arrangement for precise dressing and simple fabrication of the tool. The novel dressing tool exhibits excellent wear characteristics.

Owner:SAINT GOBAIN ABRASIVES INC

Chemical mechanical polishing pad dresser

ActiveUS7258708B2Enhance layeringHigh retention ratePigmenting treatmentOther chemical processesMetal coatingMetallic coating

CMP pad dressers and their methods of manufacture are disclosed. One aspect of the present invention provides a CMP pad dresser having improved superabrasive grit retention in a resin layer. The CMP pad includes a resin layer, superabrasive grit held in the resin layer such that an exposed portion of each superabrasive grit protrudes from the resin layer, and a metal coating layer disposed between each superabrasive grit and the resin layer, where the exposed portions are substantially free of the metal coating layer. The metal coating layer acts to increase the retention of the superabrasive grit in the resin layer as compared to superabrasive grit absent the metal coating layer.

Owner:KINIK

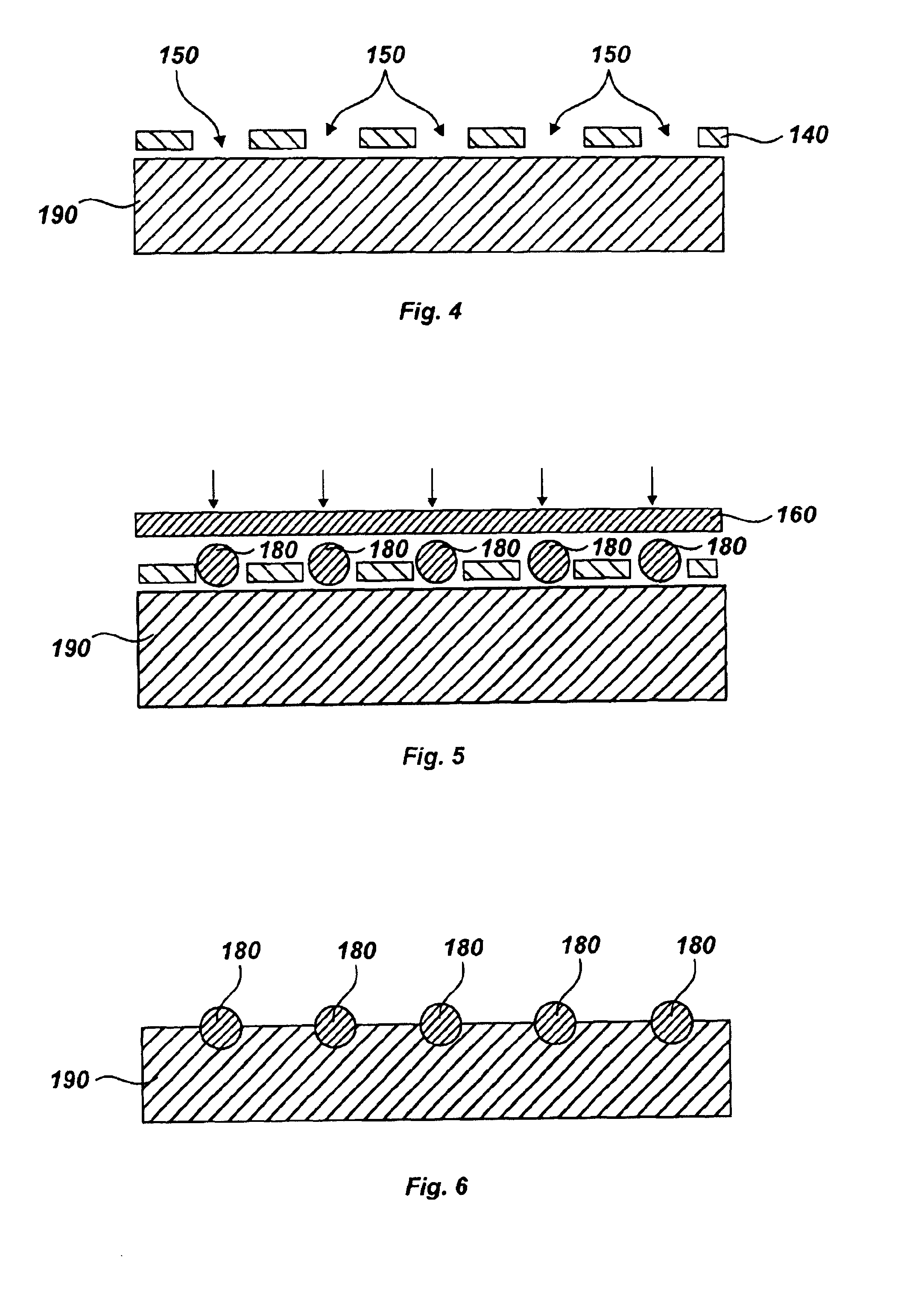

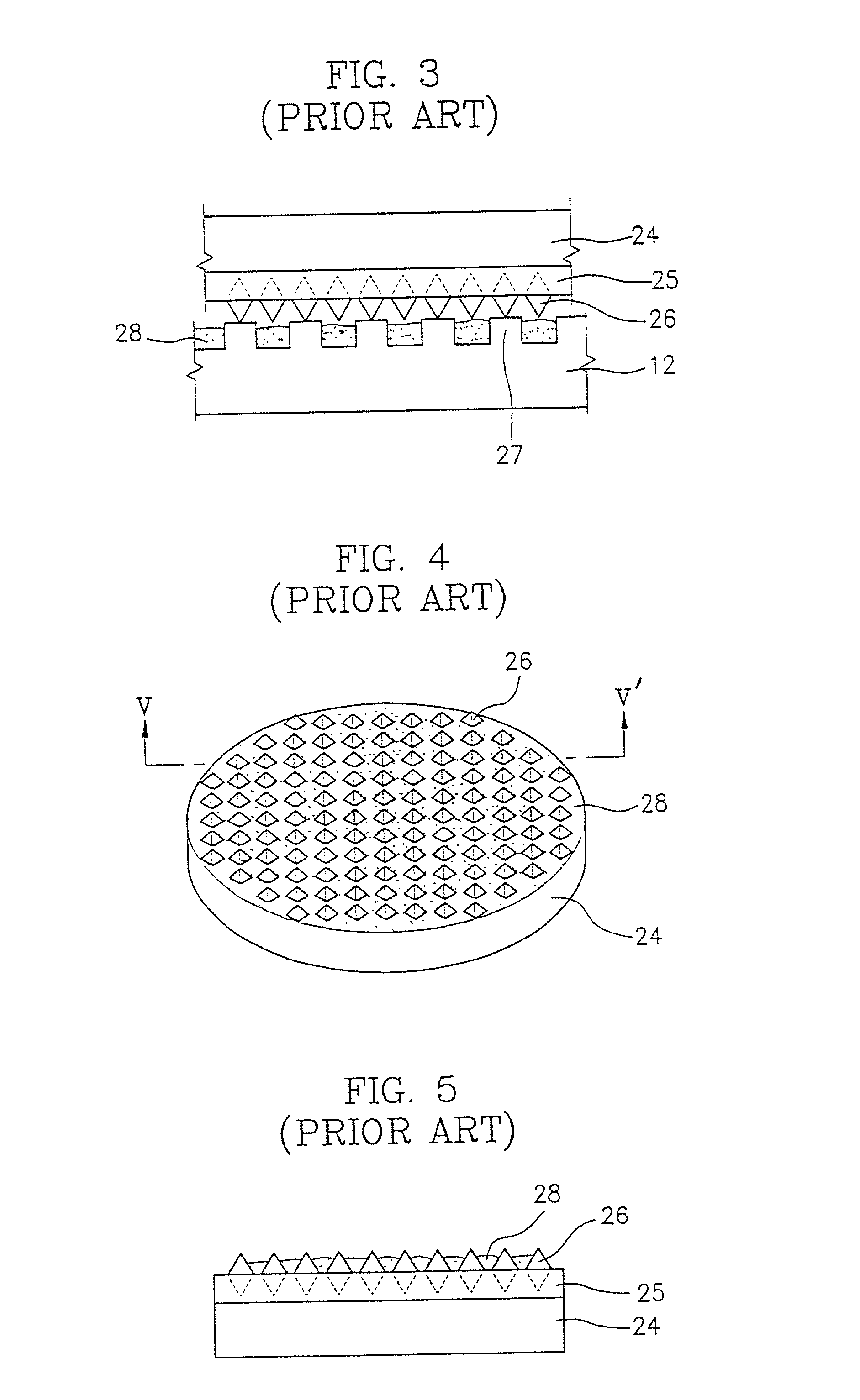

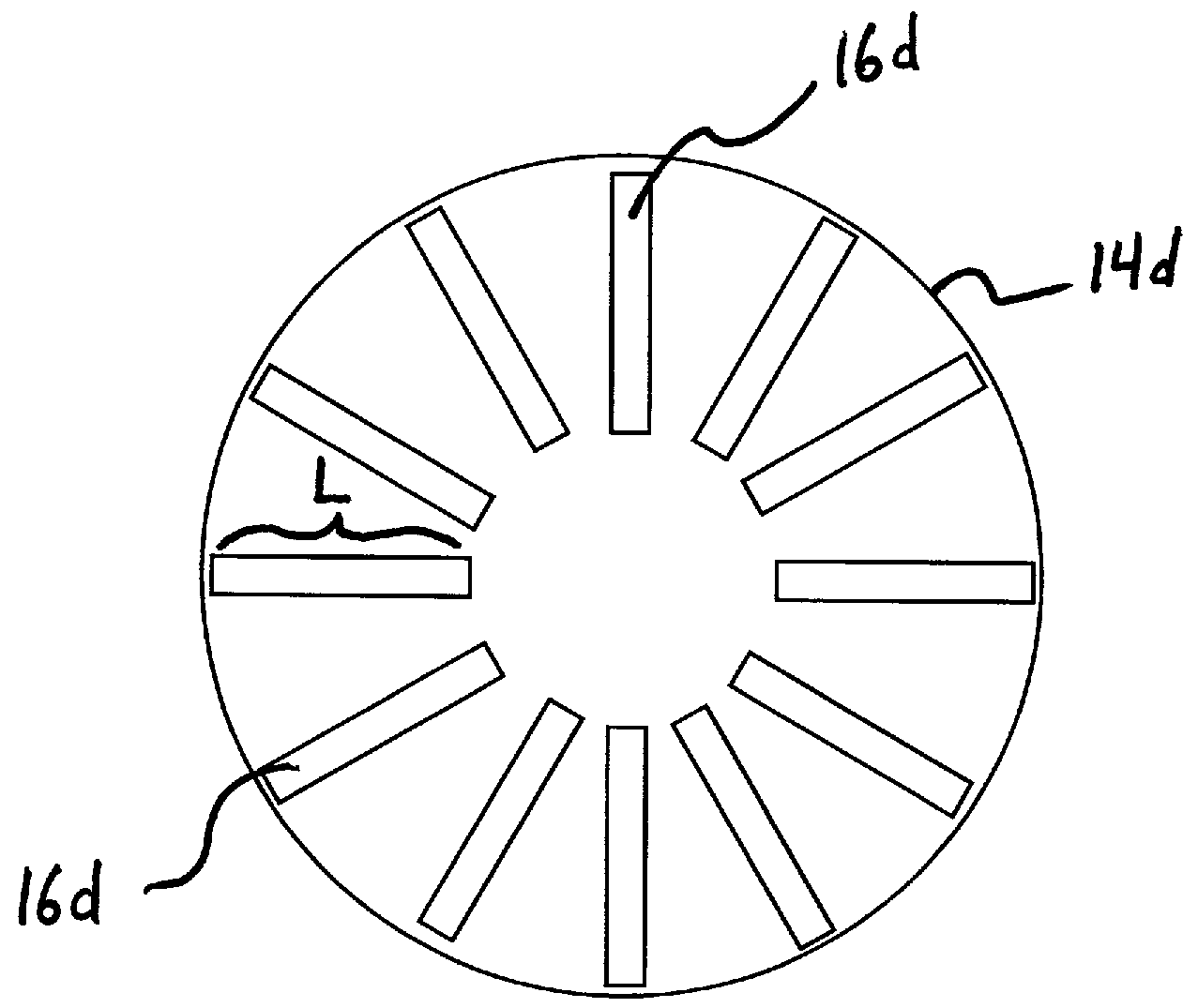

Conditioner and conditioning disk for a CMP pad, and method of fabricating, reworking, and cleaning conditioning disk

InactiveUS20020127962A1Effective conditioningProlong lifeGrinding drivesBelt grinding machinesSize differenceCleaning methods

A conditioning disk and a conditioner for a chemical mechanical polishing (CMP) pad, and a method of fabricating, reworking, and cleaning the conditioning disk, are utilized to improve conditioning efficiency, and to reduce production expenses. The conditioning disk for a CMP pad is divided into regions defined by a size difference of abrasive grains formed on the body surface in each region of the conditioning disk. The method of fabricating the conditioning disk is performed by forming adhesive films for attaching the abrasive grains onto the body surface multiple times. In addition, a used conditioning disk may be reworked by detaching the abrasive grains from the body, and attaching new abrasive grains. A used conditioning disk can also be cleaned of by-products of the conditioning process by a cleaning method using a HF solution or BOE (buffered oxide etch) solution.

Owner:SAMSUNG ELECTRONICS CO LTD

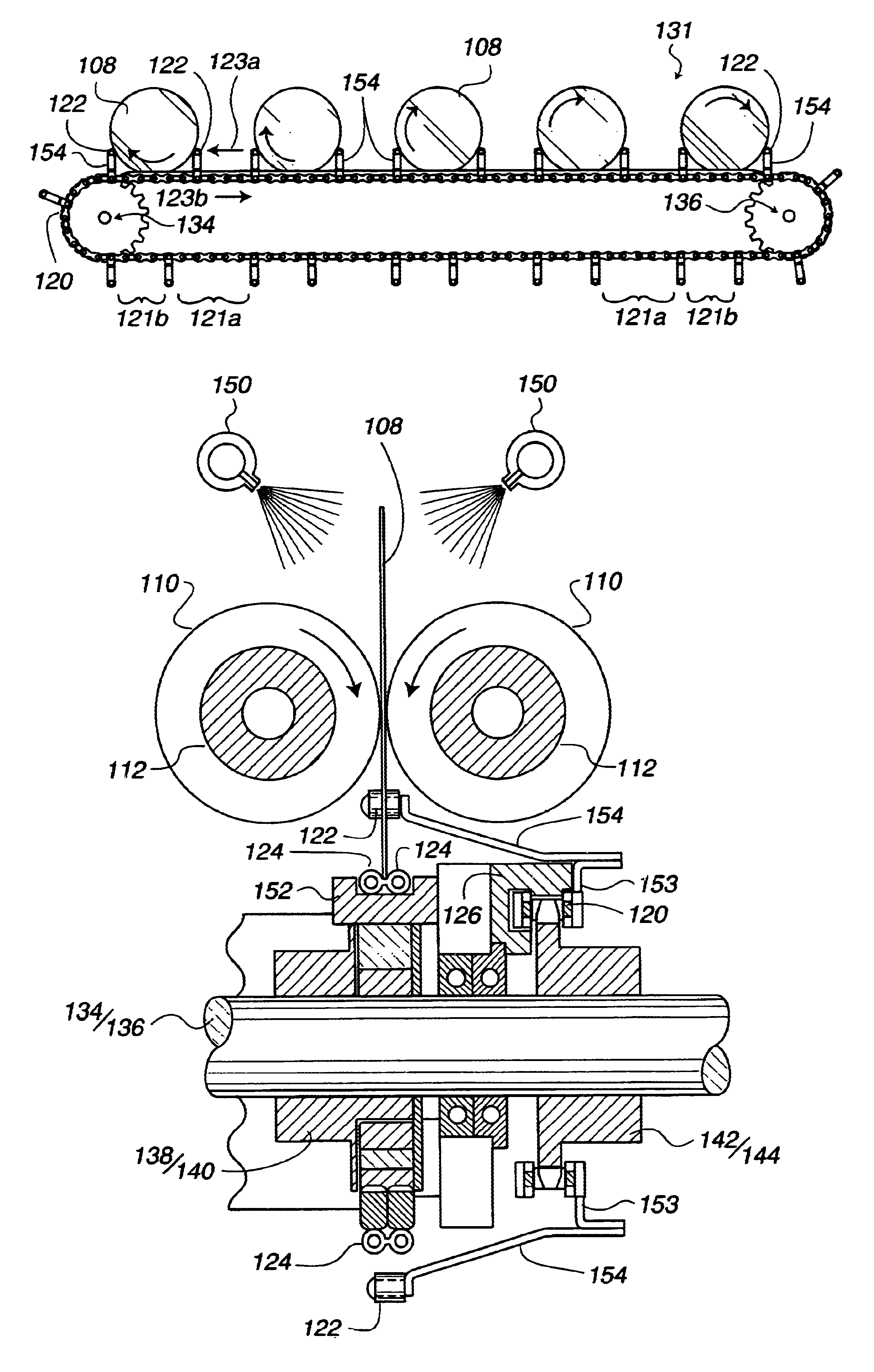

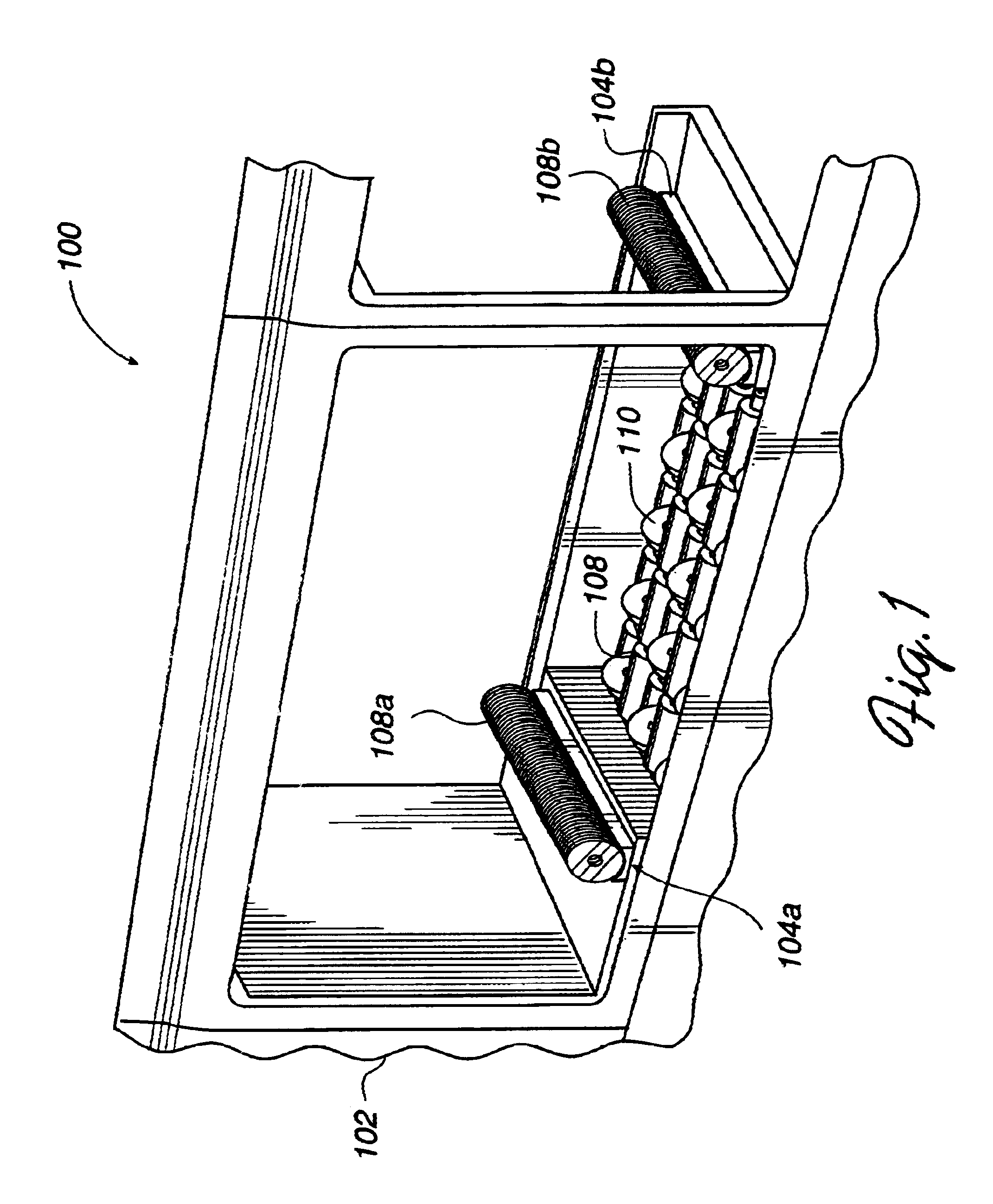

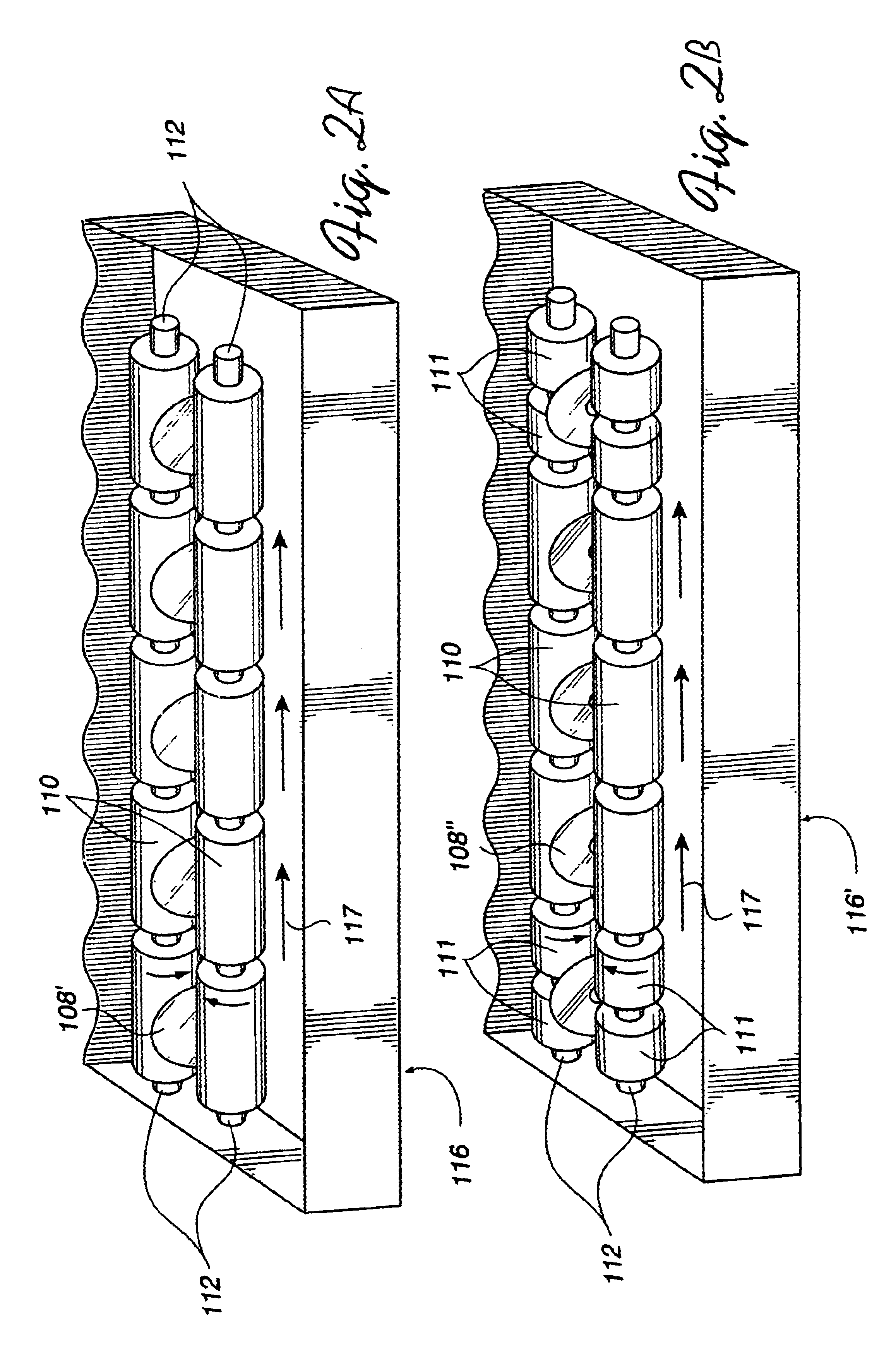

Disk cascade scrubber

A cascaded disk scrubbing system and method are provided. The cascaded disk scrubbing system includes an array of rows of brush pairs. Each row includes a plurality of counter-rotating brush pairs that are arranged horizontally and longitudinally, and configured to receive and process a disk in a vertical orientation through disk preparation zones defined by each pair of brushes. Below and between the pairs of brushes is a track that is configured to apply a rotation to the disk and to transition the disk in a vertical orientation through the brush pairs. Nozzles dispense fluids on and over the brush pairs, and the brush pairs are configured such that fluids are dispensed through the brush pairs. Nozzles dispense a curtain of fluid between each disk preparation zone, and the cascaded disk scrubbing system is configured to progress from dirtiest to cleanest as the disk transitions through each disk preparation zone.

Owner:LAM RES CORP +1

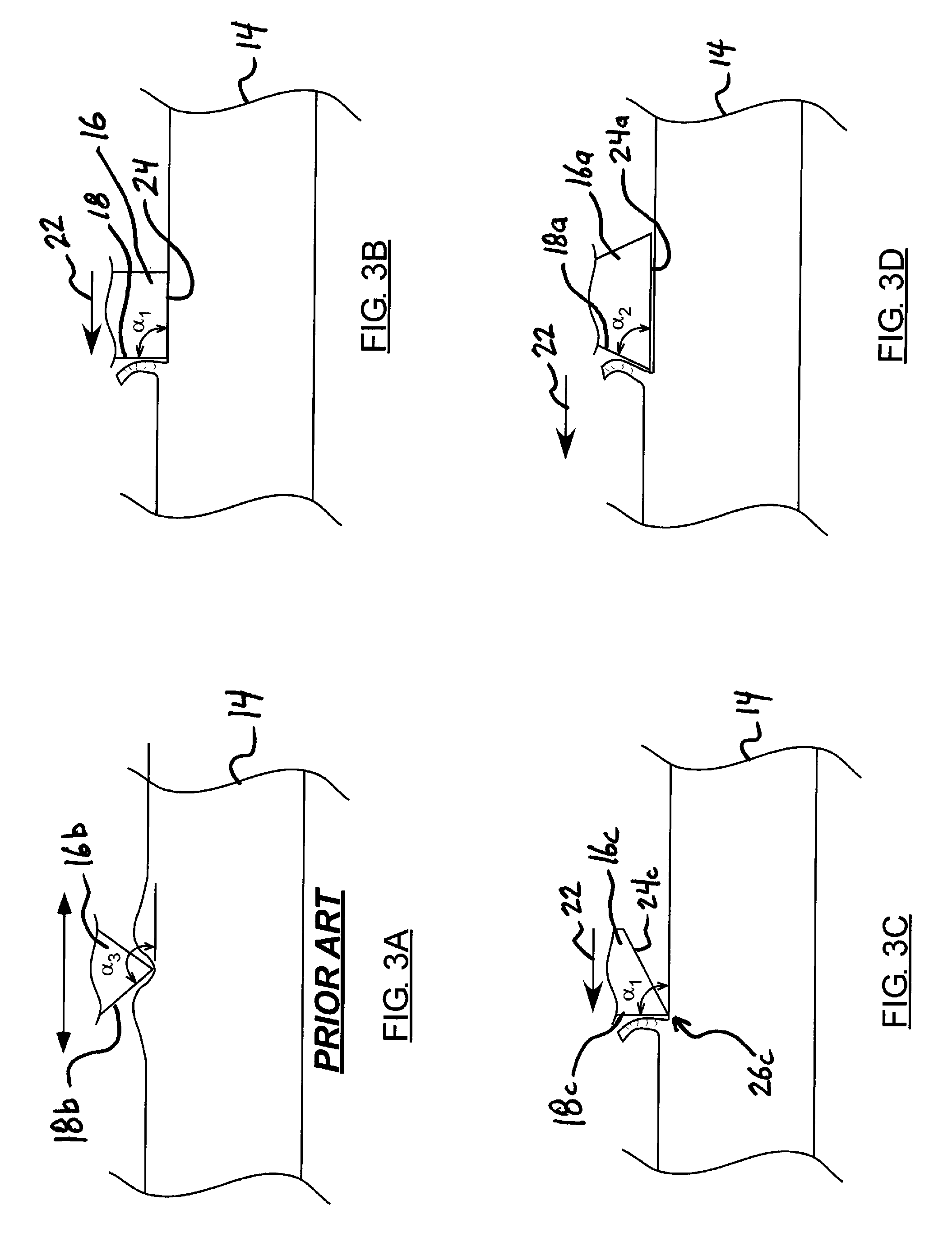

Cmp pad conditioners and associated methods

InactiveUS20080153398A1Reduce degree of compressionMinimize compressionGrinding drivesBelt grinding machinesBiomedical engineering

A method of reducing a degree of compression of a CMP pad during conditioning of the CMP pad comprises engaging the CMP pad with at least one superhard cutting element, the cutting element including a cutting face, the cutting face being angled at 90 degrees or less relative to a finished surface of the CMP pad; and moving the CMP pad and the cutting element relative to one another in a direction resulting in removal of material from the CMP pad with the cutting face to thereby condition the CMP pad.

Owner:SUNG CHIEN MIN

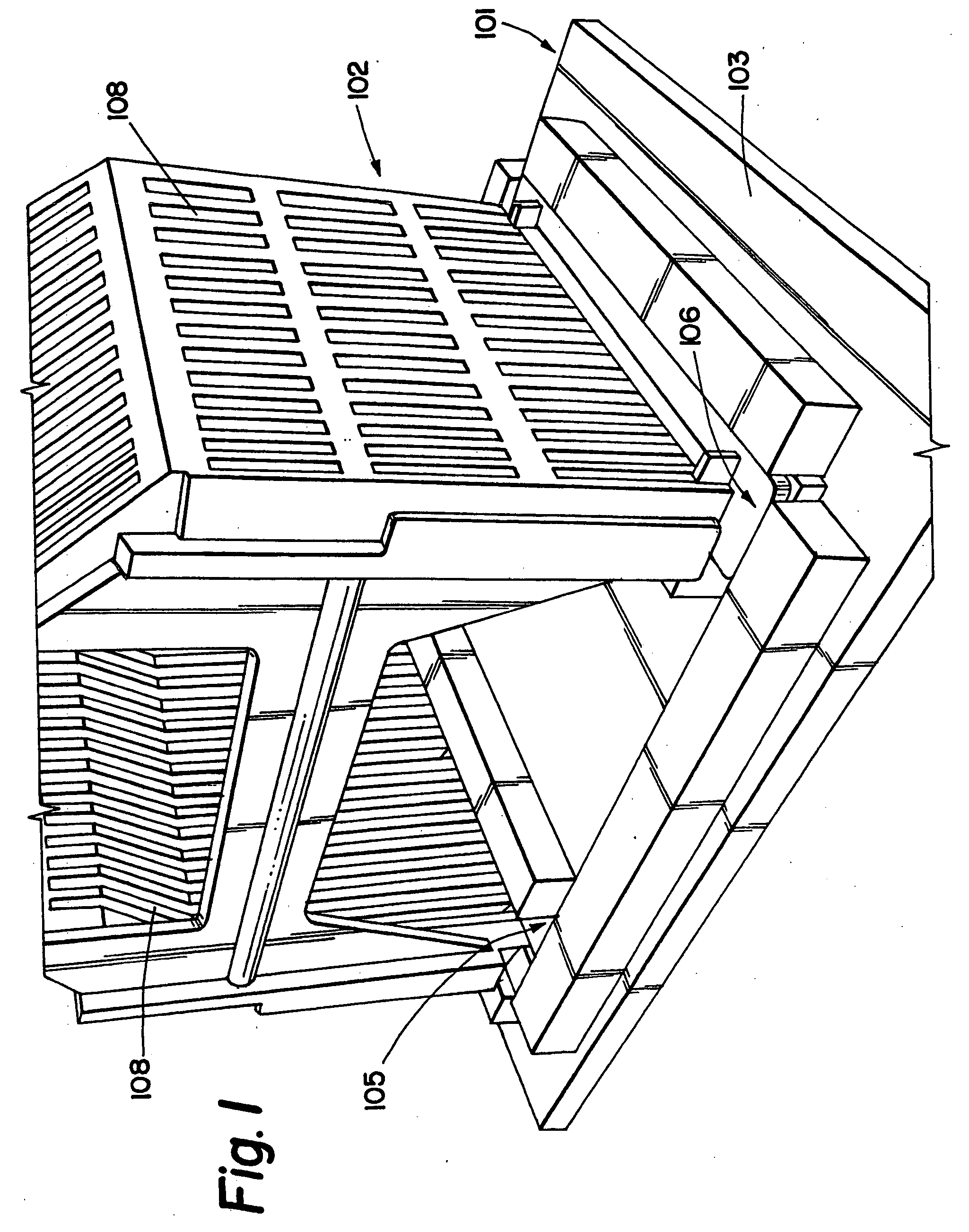

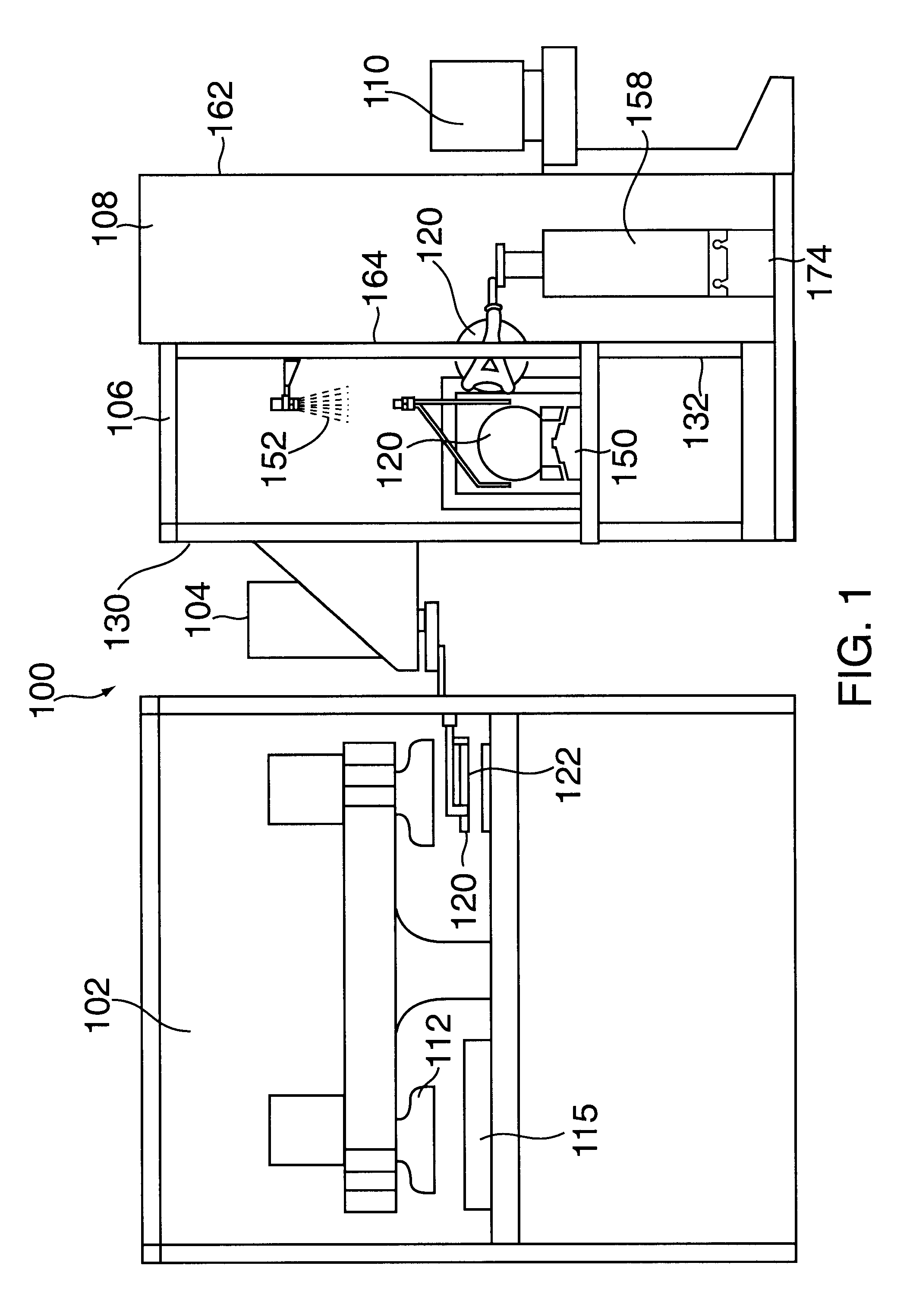

Method and apparatus for transferring semiconductor substrates using an input module

InactiveUS6361422B1Easy to understandPolishing machinesRevolution surface grinding machinesComputer moduleEngineering

A semiconductor substrate processing method and apparatus, more specifically, a method and apparatus for polishing a substrate or semiconductor wafer in a polishing system. In one embodiment, the system includes one or more polishing modules, an input module, a first robot and a second robot that provides a compact polishing system that has a minimal tool footprint. The first robot is adapted to transfer the substrate to the input module, while the second robot is adapted to transfer the substrate between the input module and the one or more polishing modules. In another embodiment, the first and second robots have rotary actuators coupled to their grippers that enable the substrate to be orientated between a horizontal and vertical position. The input module is adapted to maintain the substrate in a vertical orientation. The vertical orientation of the substrates facilitates integration of a cleaning system that cleans the substrates while in the vertical orientation.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com