Brazed diamond dressing tool

a diamond dressing and diamond dressing technology, applied in the direction of grinding devices, manufacturing tools, grinding devices, etc., can solve the problems of loss of exposed cutting edge, small geometric irregularities, dulling of abrasive tools as they are used,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

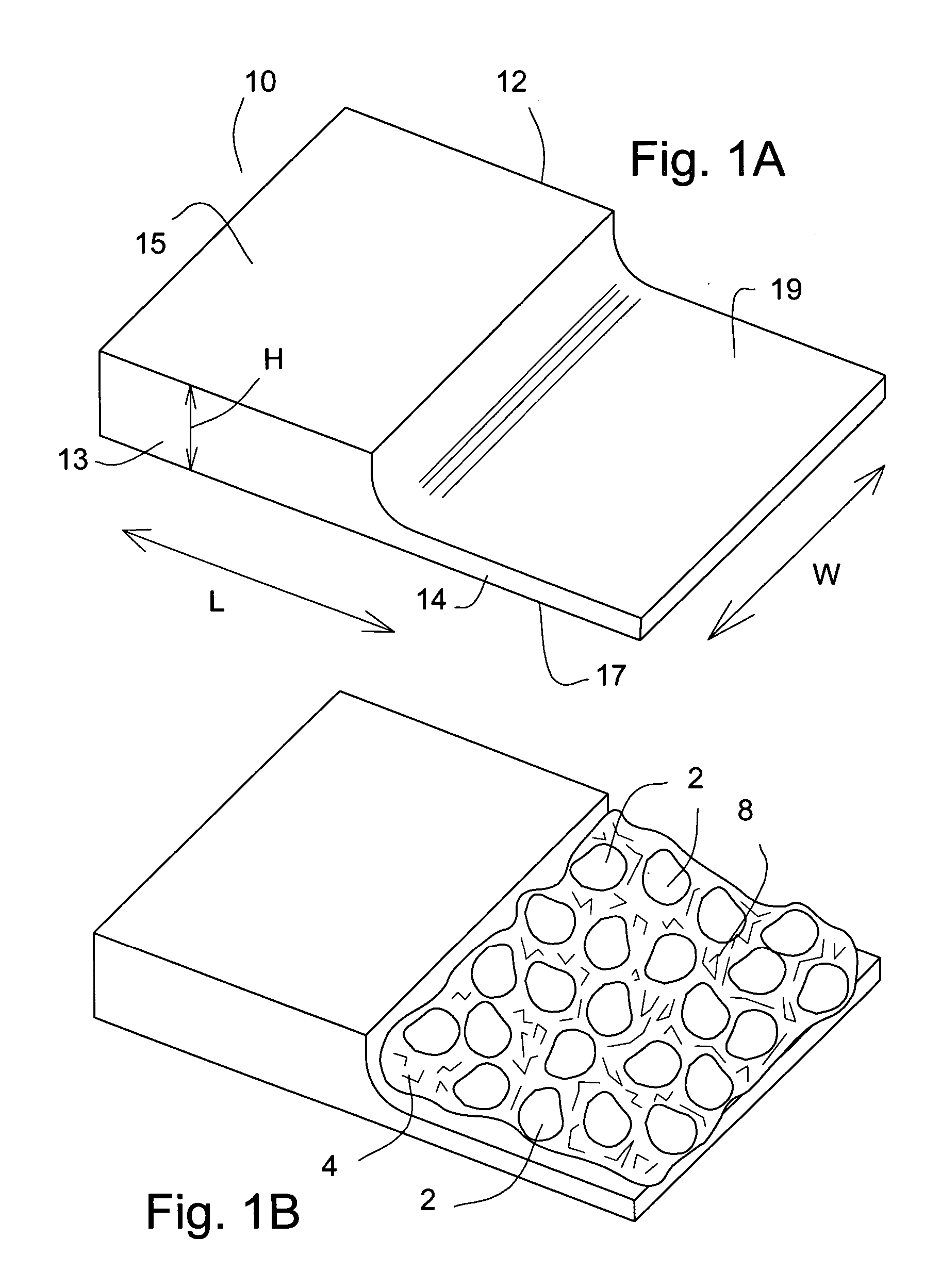

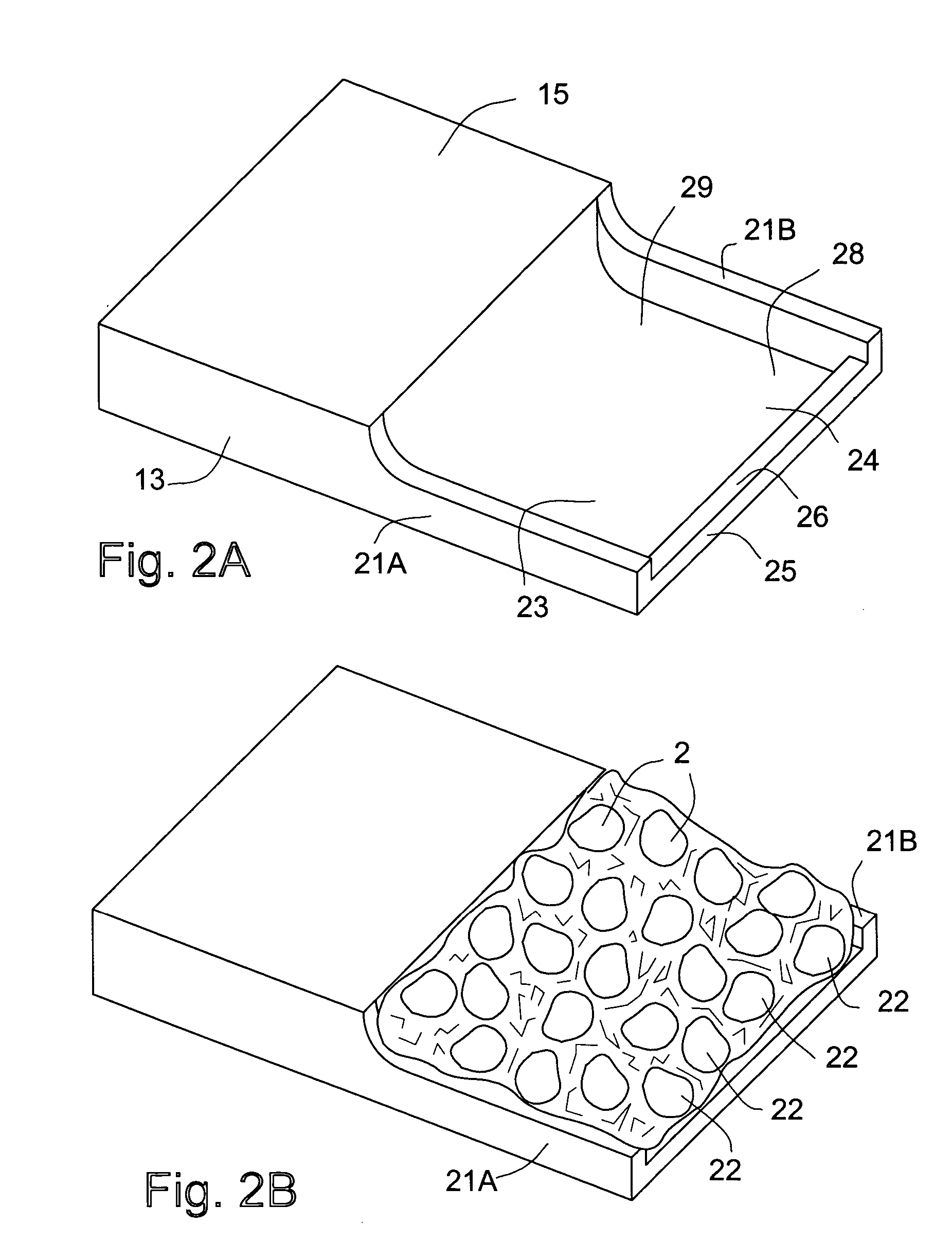

[0055] This example describes a tool having a single pocket, illustrating the format described in FIGS. 2A and 2B. The tool was made by first machining a 10 mm square, 1 mm deep milled pocket in a steel bar measuring 2 mm×12.5 mm×38 mm. The pocket was filled with braze paste consisting of 15% by volume of an organic water based binder (Vitta Corp) and 70% by volume of powdered braze components. The braze components consisted of 70% by weight copper, 21% by weight tin and 9% by weight of titanium hydride, TiH2. The pocket was then filled with 20 / 25 mesh SDA 100+ diamond (DeBeers) by displacing the braze paste. The excess braze paste was removed by wiping, and then the resulting tool was dried in air at room temperature. The tool was then heated for 0.5 hours at 880° C. in a vacuum furnace at a pressure of 0.01-1 μm Hg, followed by cooling to room temperature. It was finished by grinding flat the exposed surface of the abrasive and removing the residual steel at the tool front.

example 2

[0056] The tool prepared in Example 1 was tested in dressing a K grade 80 grit 5SG grinding wheel. Its performance was compared with that of a commercially available dressing tool manufactured by the conventional method of placing diamonds in a powdered metal matrix in a mold and pressing and sintering or hot pressing the assembly to obtain a dense compact. The compaction movement inherent in a powder metal pressing operation often leads to the diamonds moving out of their plane. Two samples of the commercially available blade were utilized. The results of the comparative tests are presented in Table 1. In all cases the traverse rate was 11 in / min. “Wear Ratio” is the ratio of wheel volume removed per unit of tool length.

TABLE 1WheelBladeDepthVolumeHeightWearofChangeChangeRatioCut(cu. in.)(in.)(cu. in. / in.)(in.)Ex. 14630.06670360.002Comparative Tool B1Sample 11800.09718590.001Sample 21980.09920000.001

1Cincinnati CM336

[0057] These data in Table 1 illustrate that despite doubling t...

example 3

[0058] This example describes preparation and testing of a dressing tool having the format illustrated in FIG. 5B.

[0059] The tool preform was prepared with a structure of the type seen in FIG. 5A, however, in this example the tool had 9 rows of abrasive brazed into alleys machined into the steel preform (5 alleys exposed on one surface, 4 on the other). The alleys were filled with braze paste consisting of 15% by volume of an organic water based binder (Vitta Corp) and 70% by volume of powdered braze components. The braze powder consisted of 70% by weight copper, 21% by weight tin and 9% by weight of titanium hydride. The alleys were then filled with 20 / 25 mesh SDA 100+ diamond (DeBeers) by displacing the braze paste. The excess braze paste was removed by wiping, and then the tool was dried in air at room temperature. The tool was then heated for 0.5 hours at 880° C. in a vacuum furnace at a pressure of 0.01-1 μm Hg, followed by cooling to room temperature. The tool was finished by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Knoop hardness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com