Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3595results about How to "Easy to polish" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

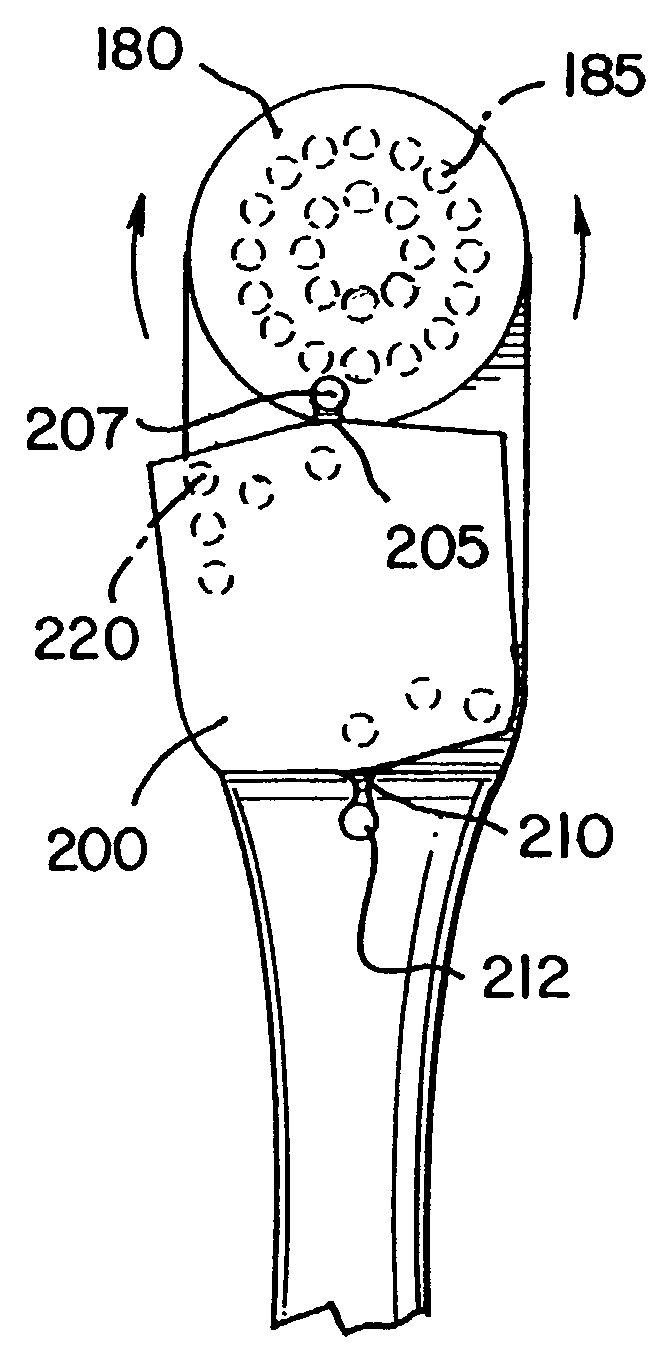

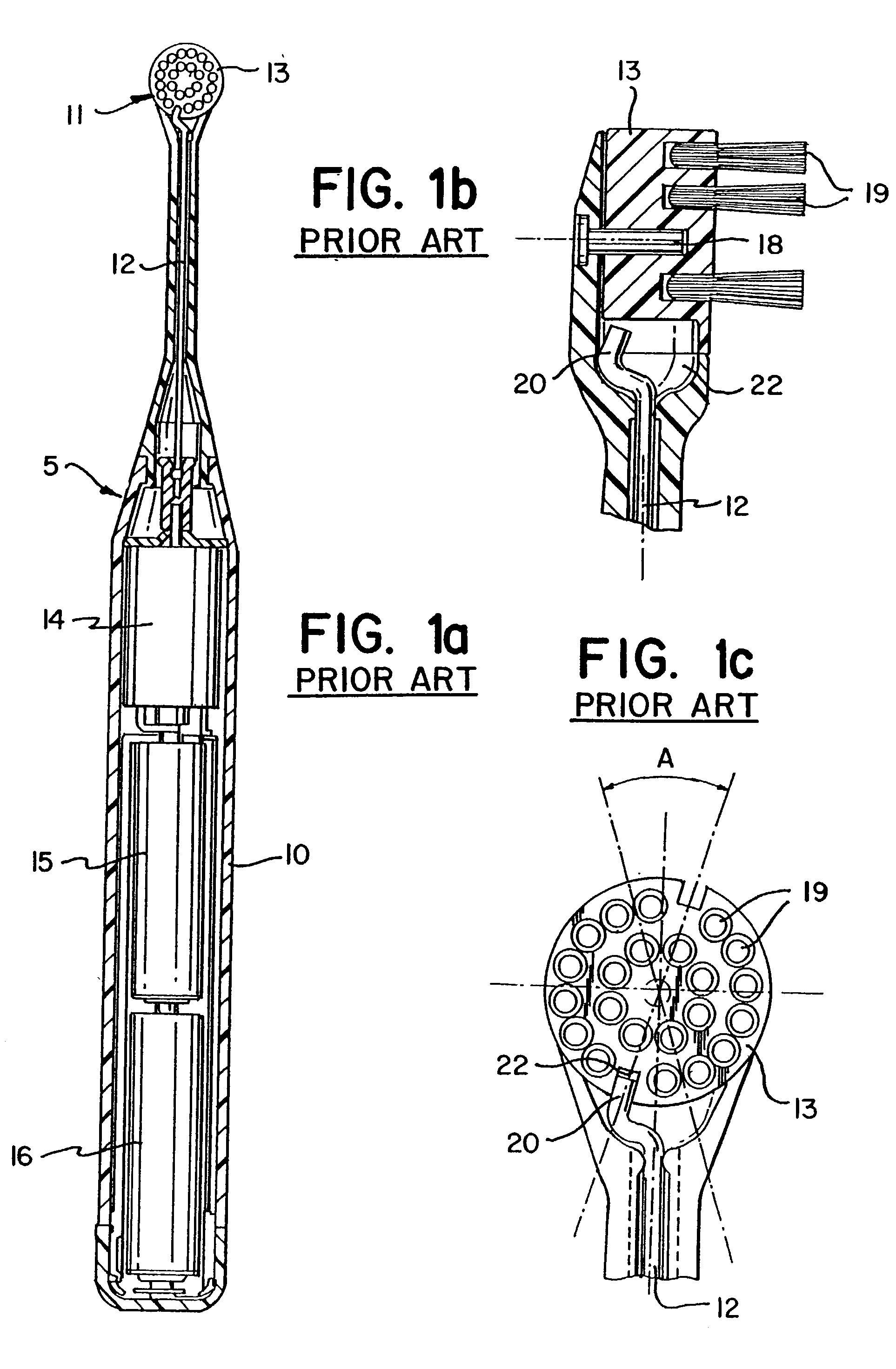

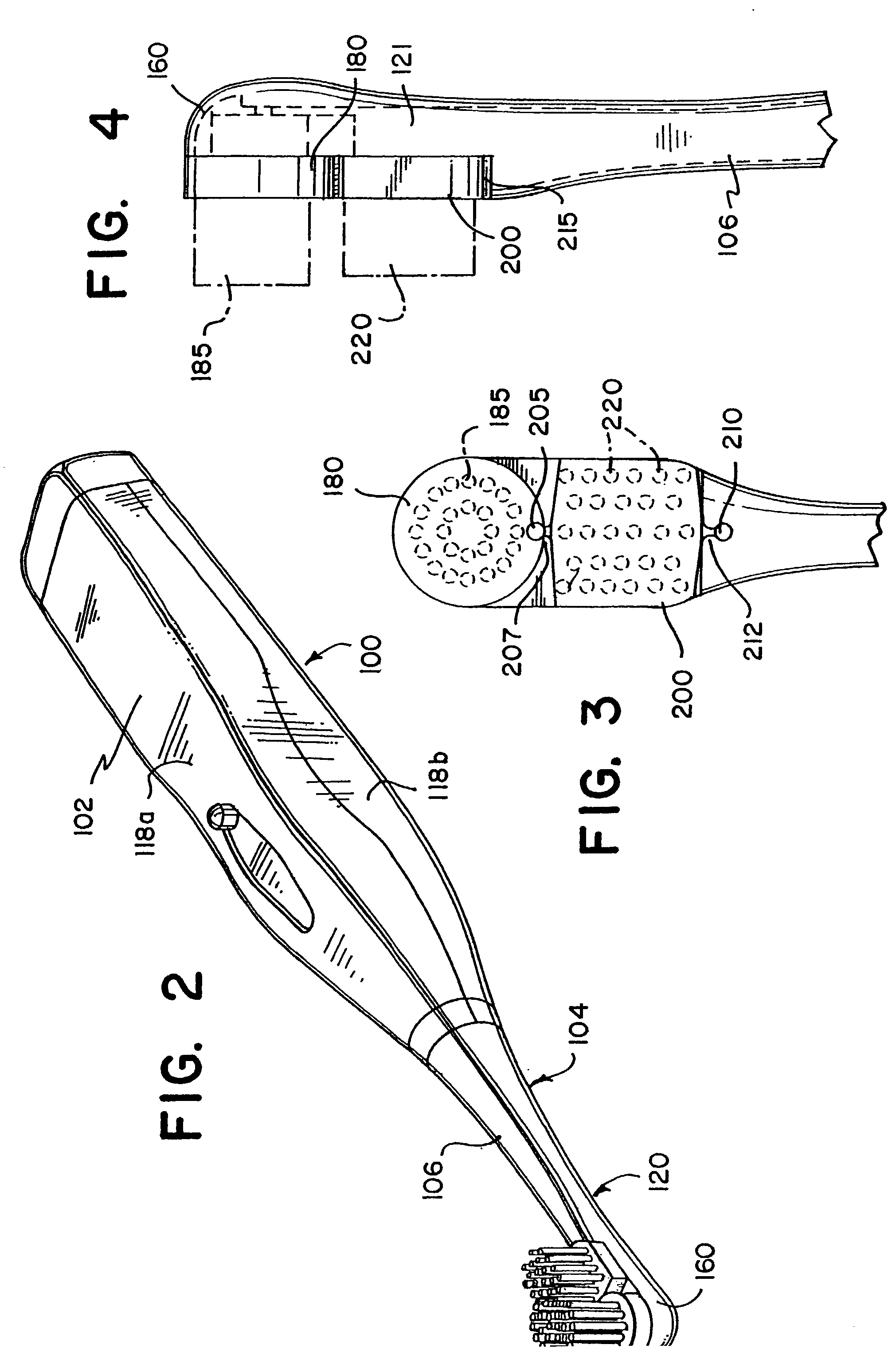

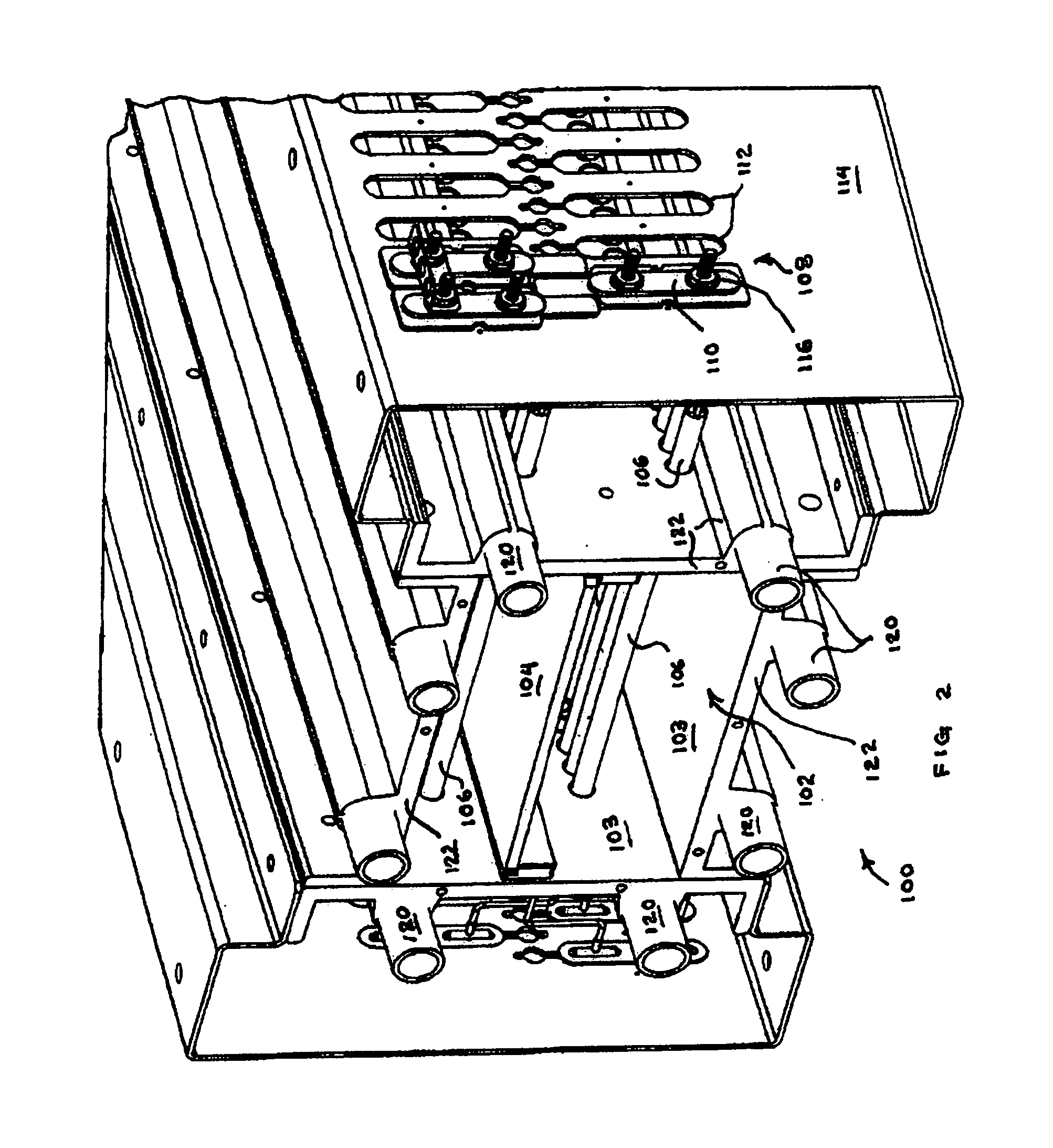

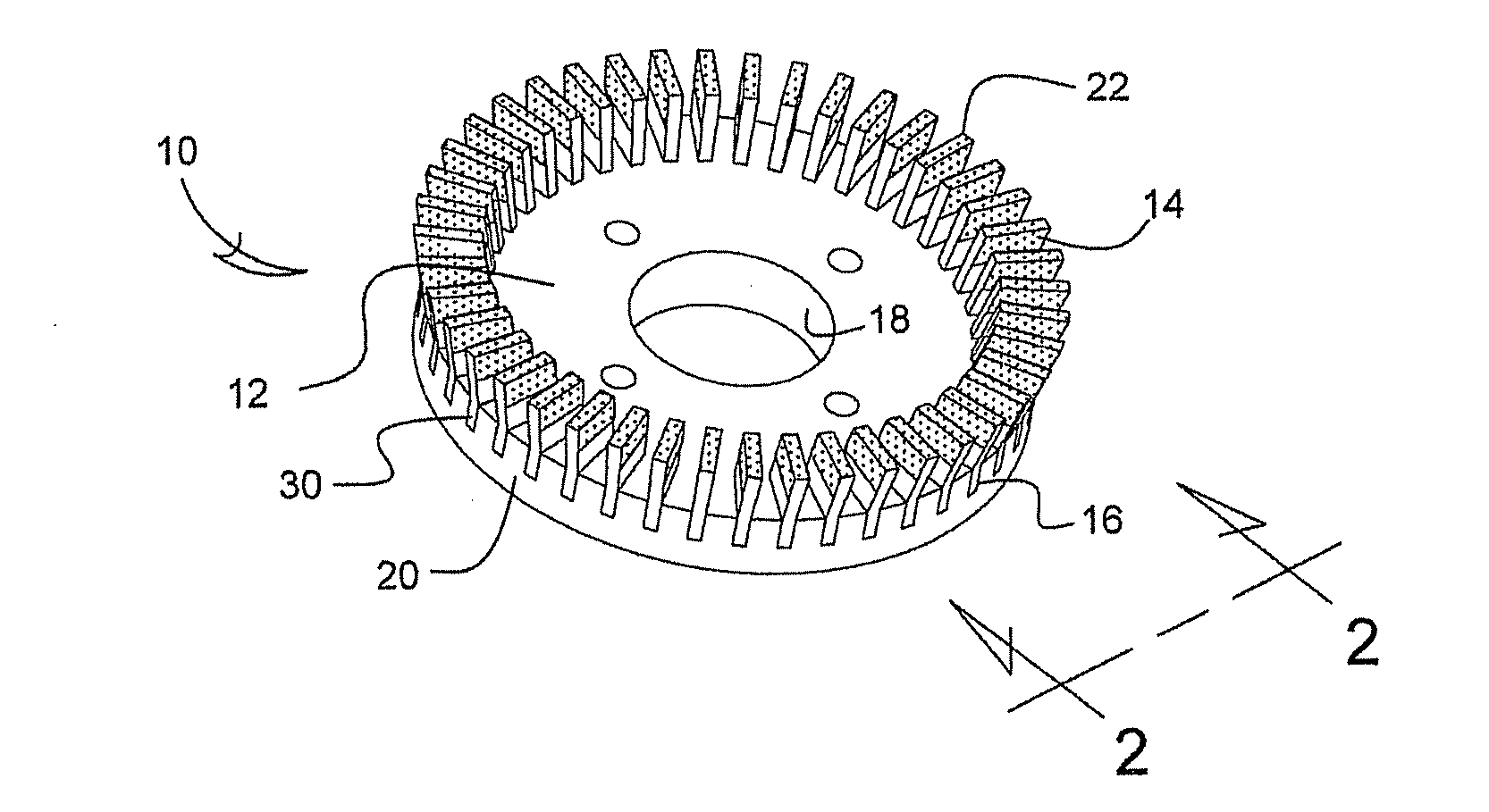

Toothbrush with sectorial motion

InactiveUS20040060137A1Increased moving bristle areaImprove cleanlinessCarpet cleanersKitchenware cleanersBristleEngineering

A powered toothbrush to provide oral hygiene having a brush section with a first bristle carrier that is powered and driven to rotate in an oscillating manner through a prescribed angle. A second bristle carrier is pivotally connected to the first bristle carrier and also pivotally connected to the brush section. The second bristle carrier oscillates in accordance with the oscillation of the first bristle carrier in a sectorial manner. The bristle carriers may include a variety of elastomeric and non-elastomeric bristles or combinations thereof to provide cleaning, polishing, whitening and stimulating to the teeth and gums.

Owner:COLGATE PALMOLIVE CO

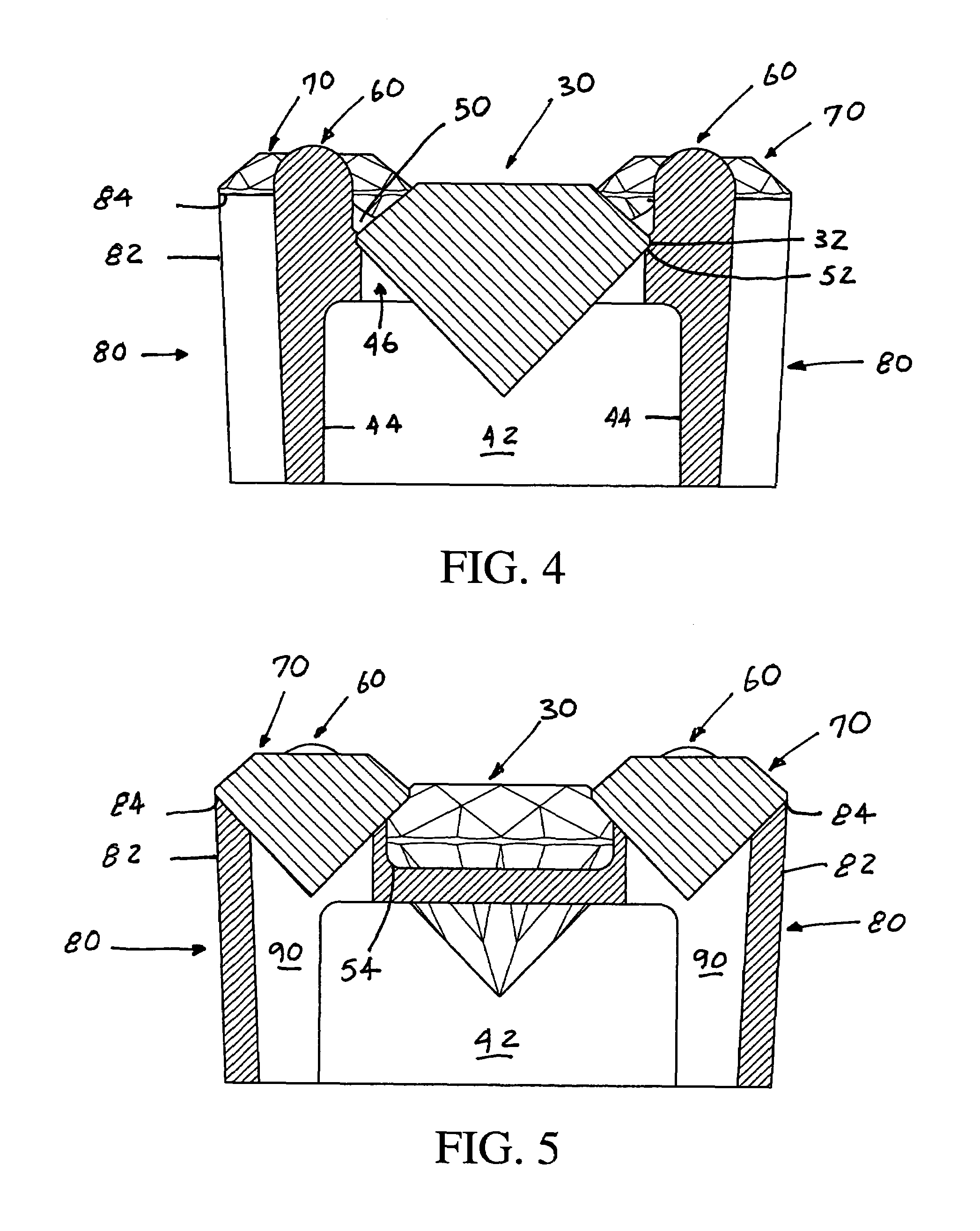

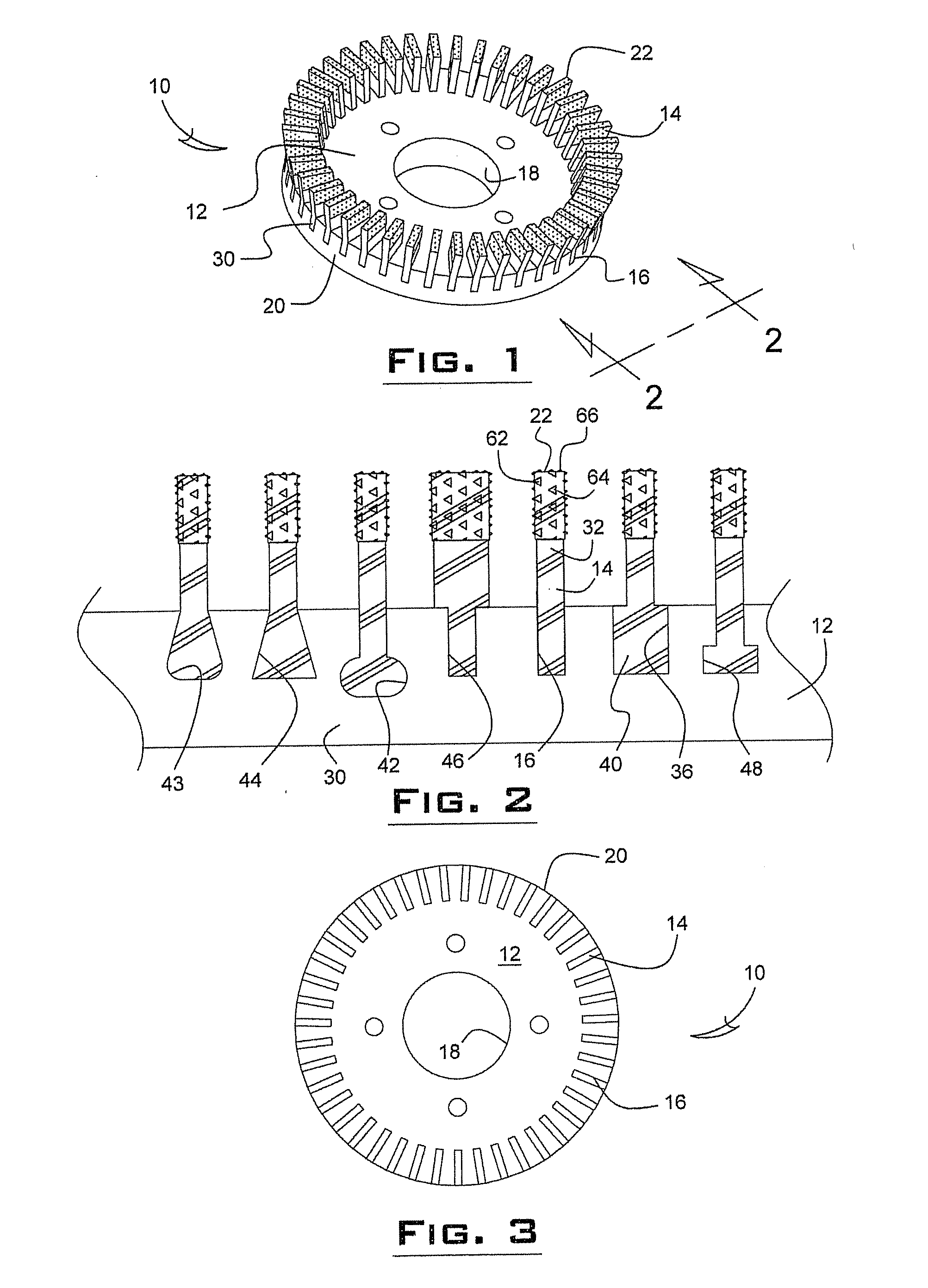

Methods for making bearings, races and components thereof having diamond and other superhard surfaces

InactiveUS20030019106A1Easy to polishReduce coefficient of frictionShaftsMetal-working apparatusPolycrystalline diamondHigh pressure

Method for making diamond bearings and diamond bearing components. Some methods include sintering diamond feedstock and a substrate under high pressure and high temperature to create a sintered polycrystalline diamond compact with a non-planar bearing and articulation surface. Various machining, grinding and polishing methods for finishing the compact are provided.

Owner:DIAMICRON

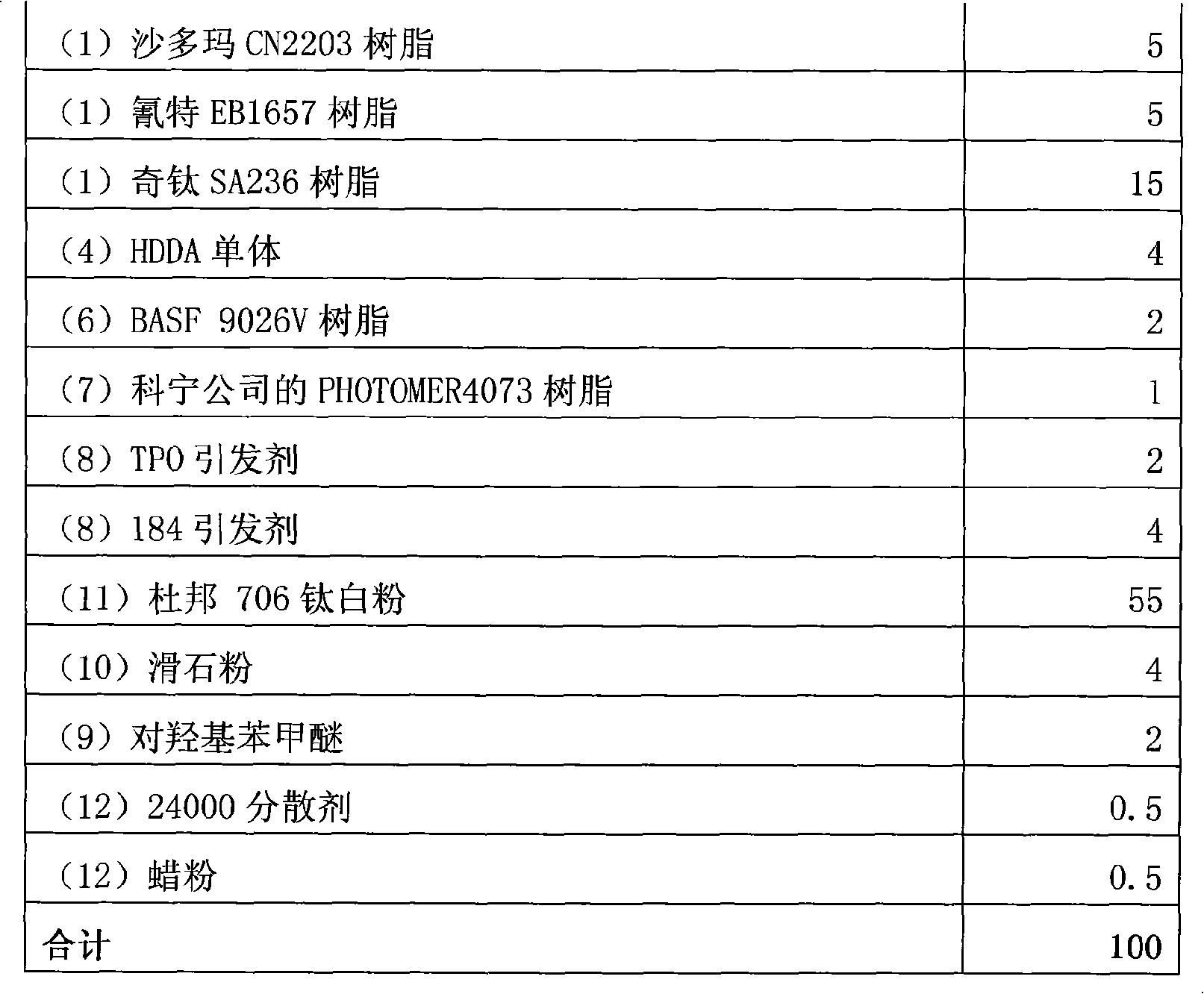

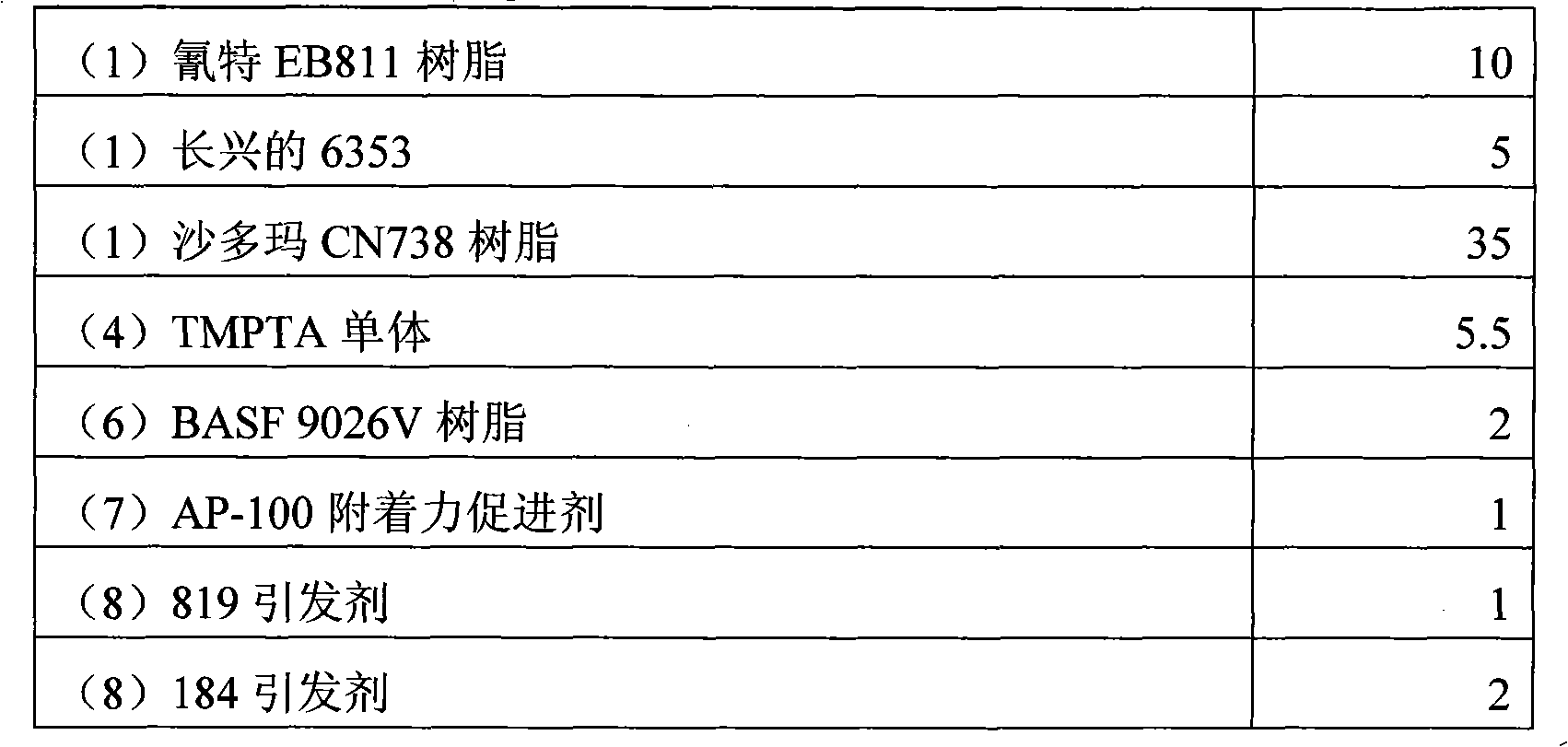

Ultraviolet light curing offset printing ink and preparation method thereof

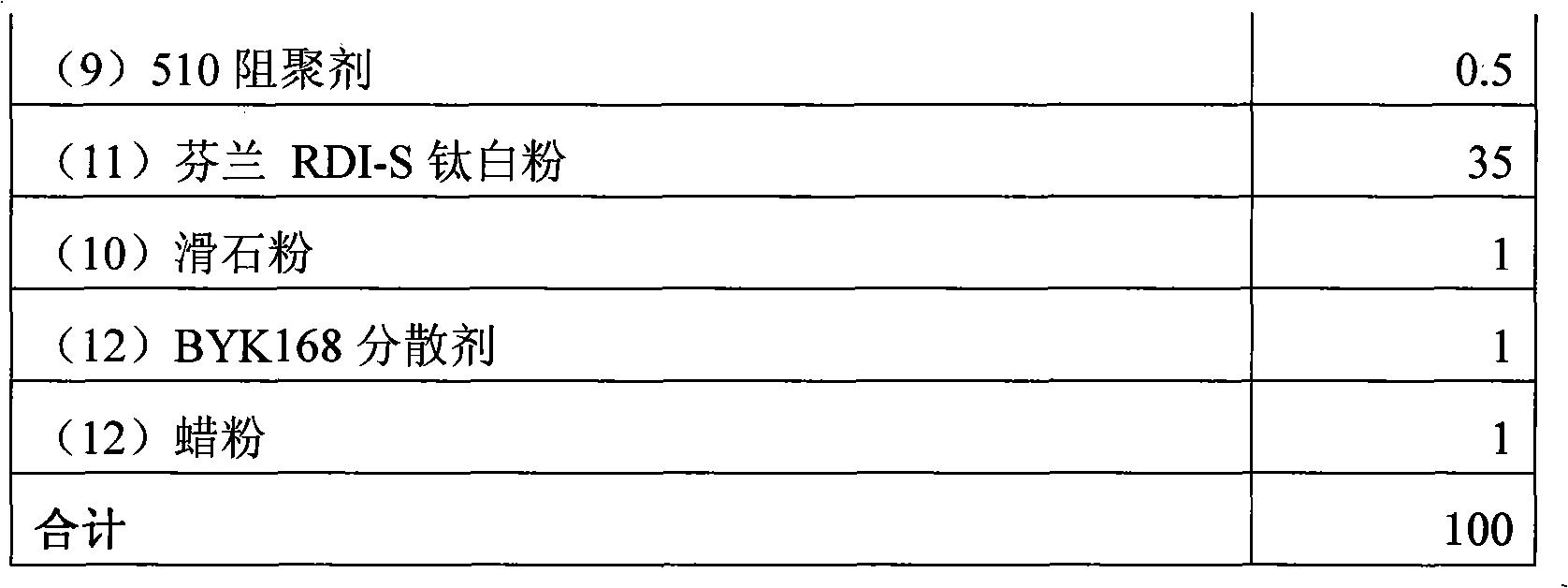

The invention relates to an ultraviolet light curing offset printing ink and a preparation method thereof. The ultraviolet light curing offset printing ink is made of 25.0-50.0% of polyfunctional polyester acrylic resin or polyfunctional chlorinated polyester acrylate, 0.0-15.0% of epoxy acrylate oligopolymer, 0.0-20.0% of polyfunctional urethane acrylate, 0.0-15.0% of difunctional or polyfunctional acrylic monomer, 0.0-20.0% of grinding-type resin, 2.0-10.0% of polyether acrylate modified by nano silicon dioxide, 0.0-5.0% of adhesion promoter, 3.0-5.0% of photoinitiator, 0.1-2.0% of polymerization inhibitor, 0.0-10.0% of filler, 16.0-55.0% of paint or dye and 0.2-5.0% of accessory ingredient. The prepared offset printing ink has high transparency as well as good adhesive attraction and flexility, and can be widely applied to packages printing industry and the printing of various transfer paper.

Owner:CHUZHOU JINQIAO TEXAS NEW MATERIALS CO LTD

Automobile gear end surface polishing device

InactiveCN107336096AQuality improvementEasy to polishGrinding carriagesGrinding work supportsGear wheelEngineering

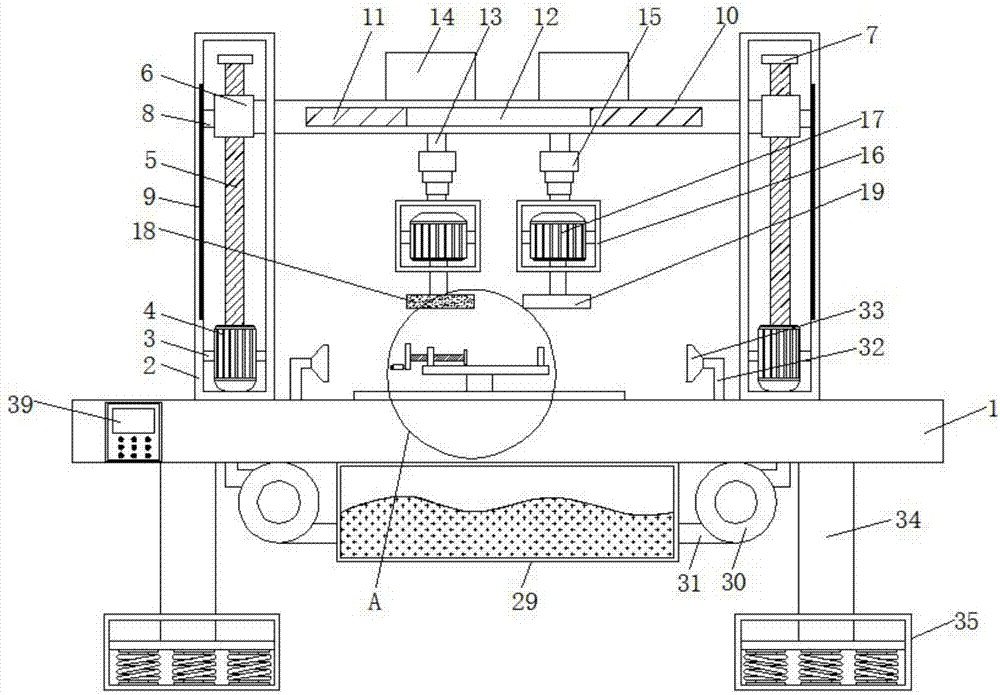

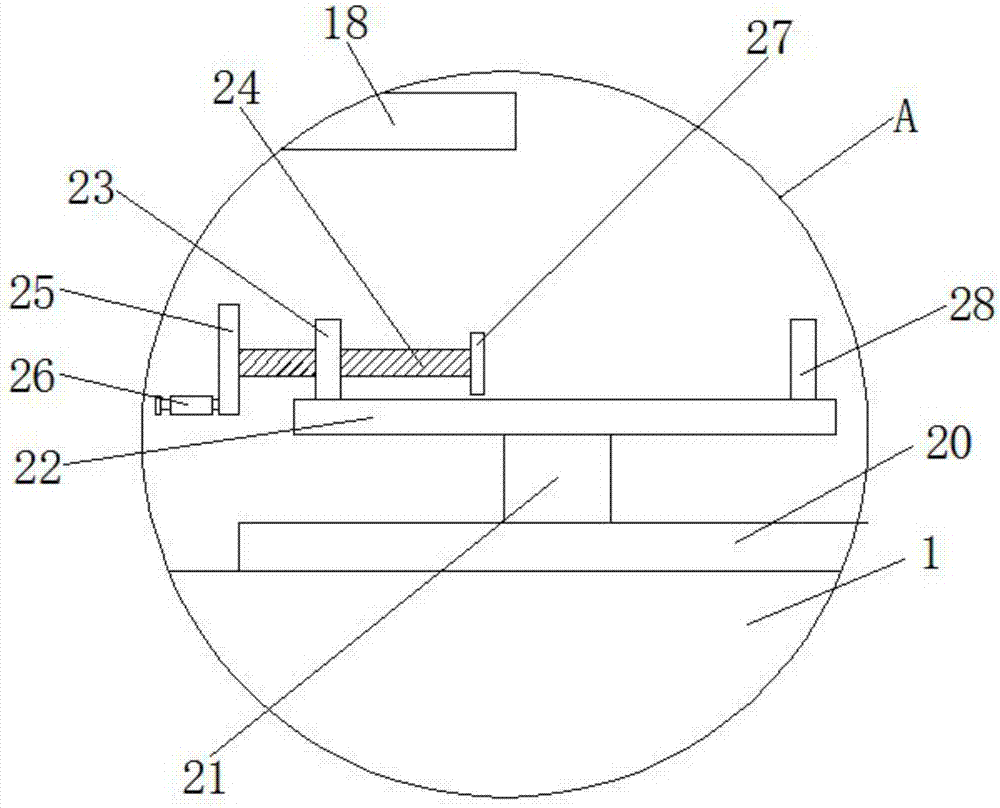

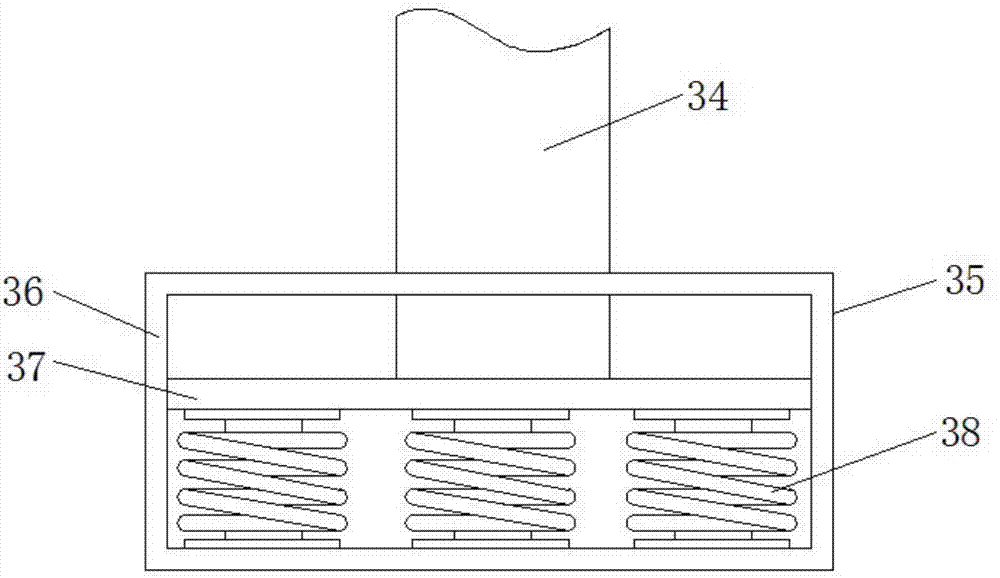

The invention provides an automobile gear end surface polishing device, and relates to the technical field of automobile gear polishing. The automobile gear end surface polishing device comprises a working table, standing columns are fixedly installed on both sides of the top of the working table, and motor mounting blocks are fixedly installed on both sides of the inner wall of each standing column. According to the automobile gear end surface polishing device, through arrangement of telescopic motors, threaded rods, telescopic blocks, sliding rods, a strip-shaped sliding groove and a cross plate, a polishing device body on the bottom of the cross plate can vertically move between the two standing columns under driving of the telescopic motors; through arrangement of the cross plate, the sliding groove and supports, the polishing device body on the bottom of the cross plate can transversely move on the bottom of the cross plate; through arrangement of a polishing table, a rotating rod and a clamping base, a gear to be polished which is fixed to the top of the clamping base in a clamped mode can conduct circular motion on the bottom of a polishing motor under driving of the rotating rod. In sum, by means of the automobile gear end surface polishing device, the effect that adjustment is convenient is achieved, it is convenient for people to polish the end surface of the gear from different angles, and the quality of the gear after polished is better.

Owner:姚飞

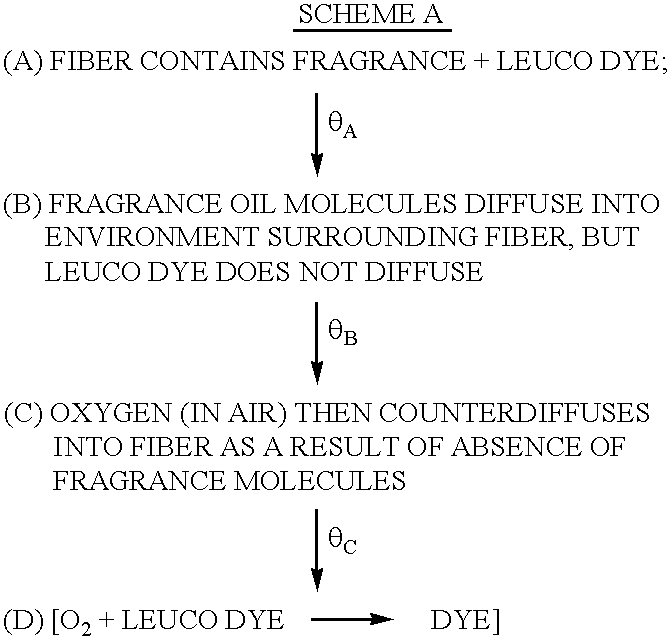

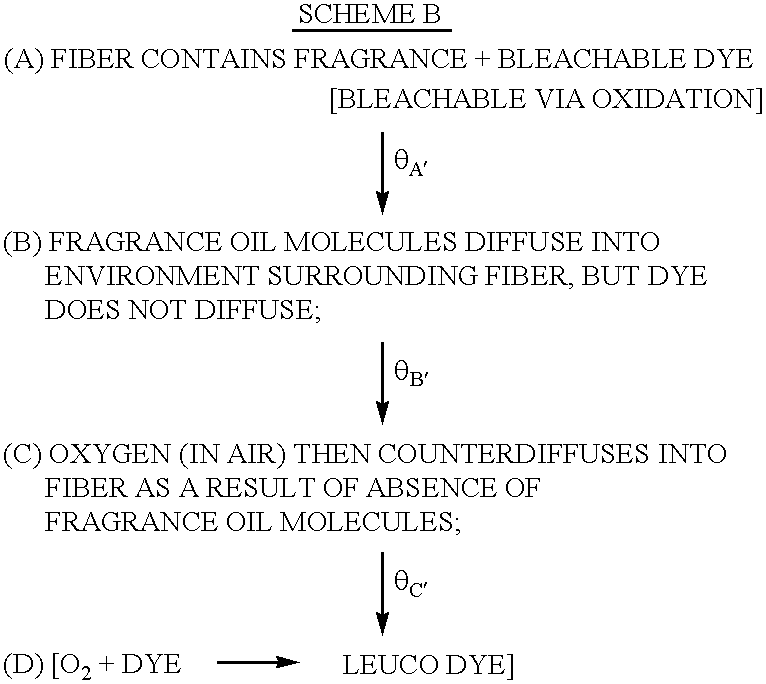

Fragrance containing fiber

InactiveUS6207274B1Easy to polishImprove sealingMonocomponent synthetic polymer artificial filamentYarnFiberPolymer chemistry

Described is a fragrance-containing and fragrance-emitting polymeric fiber which optionally contains (i) at least one antimicrobial agent; and (ii) at least one compatible coloring material or color-forming material which is useful in the ascertainment of the exhaustion or substantial reduction of fragrance, produced by either (i) a processing comprising the steps of:(a) co-extruding fragrance and optionally (i) antimicrobial agent and / or (ii) at least one compatible coloring material or color-forming material which is useful for ascertainment of the exhaustion or substantial reduction of fragrance with a thermoplastic polymer to form an extrudate;(b) forming fragrance and (optionally (i) antimicrobial agent and / or (ii) at least one compatible coloring material or color-forming material which is useful for ascertainment of the exhaustion or substantial reduction of fragrance agent)-emitting particles which may or may not be foamed from the extrudate; and(c) extruding a fiber of from about 3 denier up to about 60 denier from the thus-formed particles;or (ii) a process comprising the steps of:(a) forming fragrance-emitting particles, foamed or not foamed, from a mixture of fragrance and thermoplastic polymer; and then(b) extruding a fiber of from about 3 denier up to about 60 denier from the thus-formed particles.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

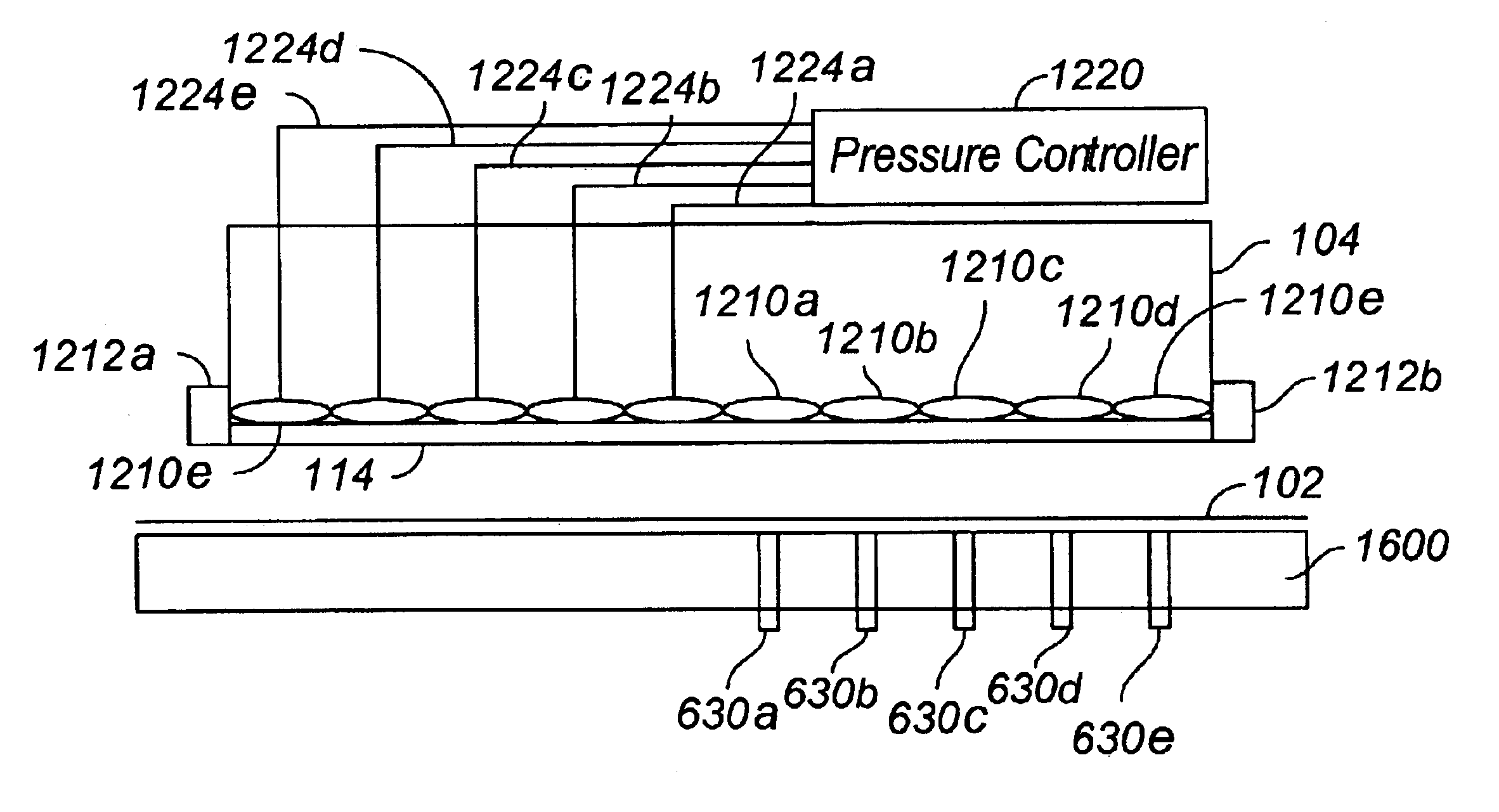

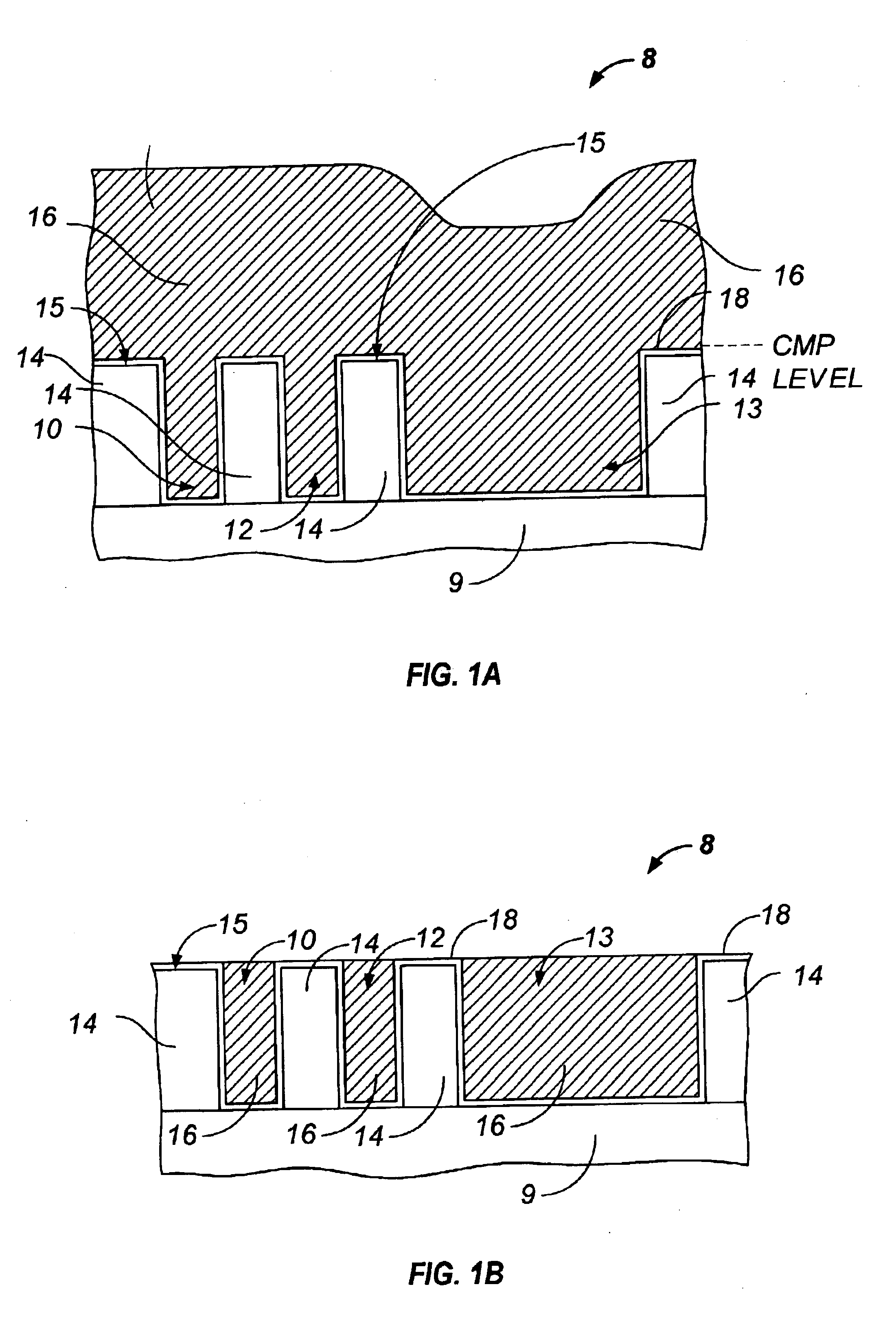

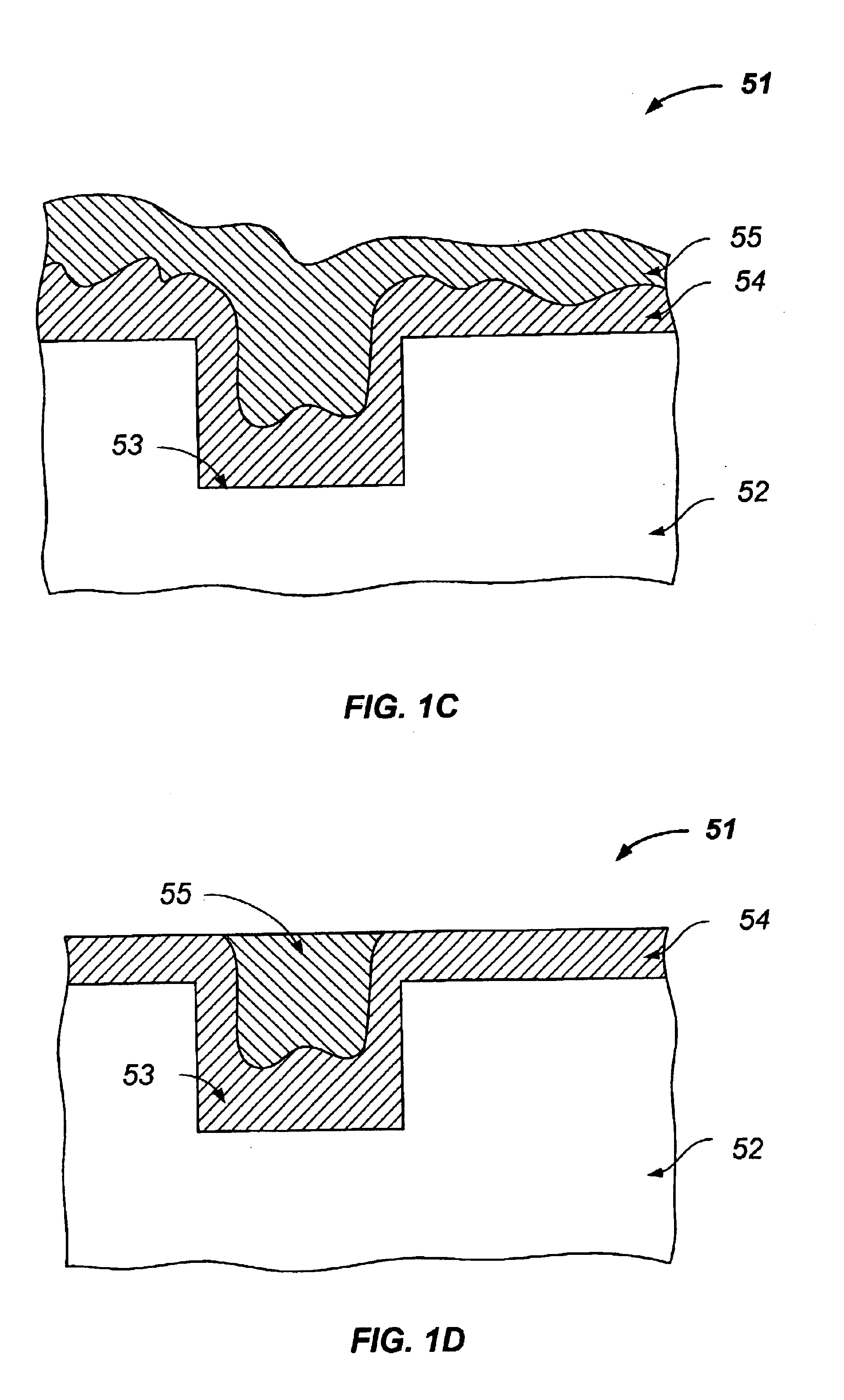

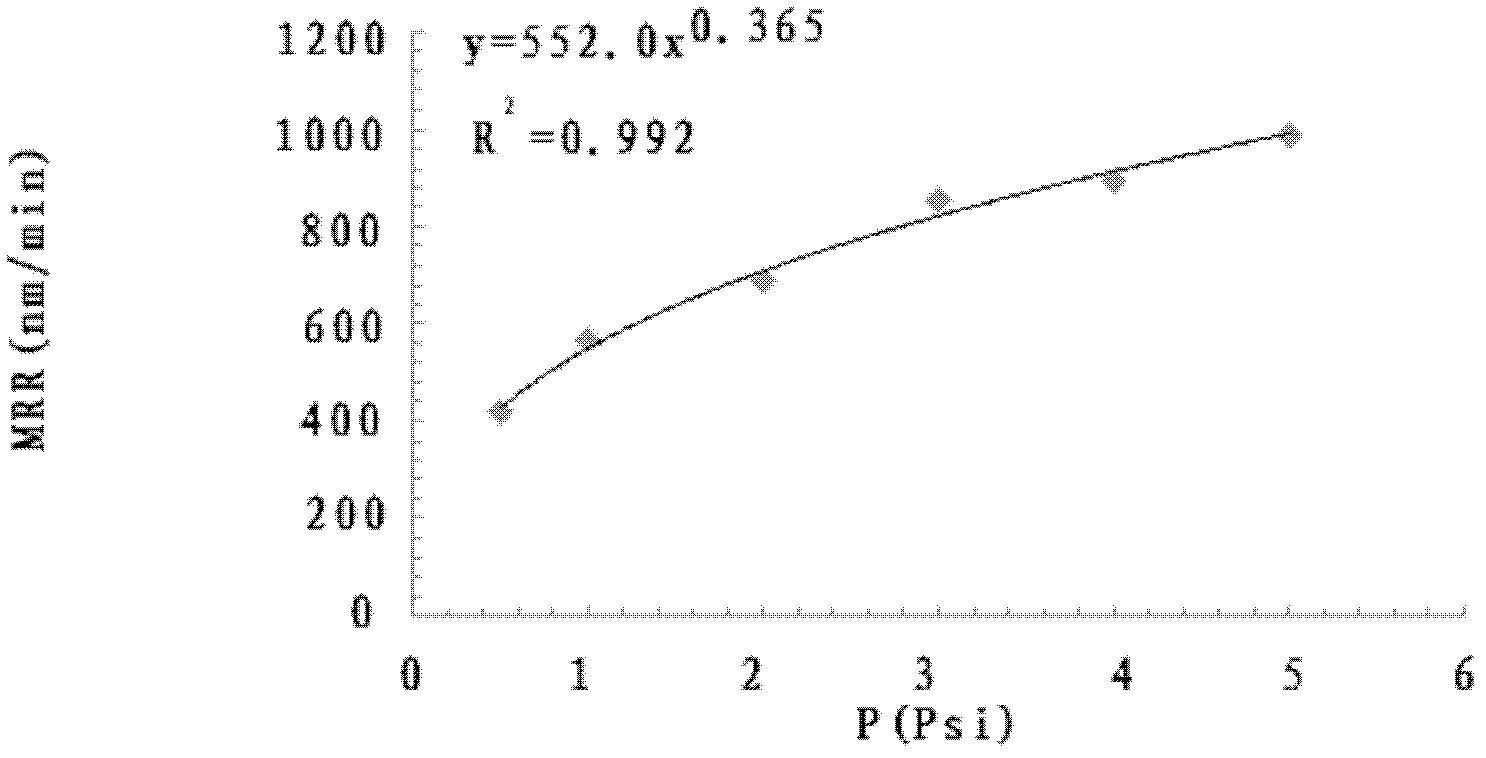

Composition for oxide CMP in CMOS device fabrication

InactiveUS20060216935A1Easy to polishSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingCMOSSilicon oxide

The present invention provides an oxide CMP slurry composition for use in planarizing silicon oxide-containing films via CMP during CMOS device fabrication, and a method of planarizing silicon oxide-containing films via CMP using the slurry composition. The oxide CMP slurry composition according to the invention includes: (i) proline, lysine and / or arginine; (ii) a pyrrolidone compound; and (iii) abrasive particles. Proline is presently most preferred for use in the invention. In the STI sub-process of the CMOS device fabrication process, the oxide CMP slurry composition according to the present invention acts to aggressively remove only the silicon dioxide overburden on the processed wafer that is in contact with a polishing pad, which results in the formation of a substantially planar, defect-free surface. The oxide CMP slurry composition according to the invention does not aggressively remove trench silicon dioxide thereby allowing for extended polishing beyond the end point without substantially increasing the minimum step height.

Owner:FERRO CORP

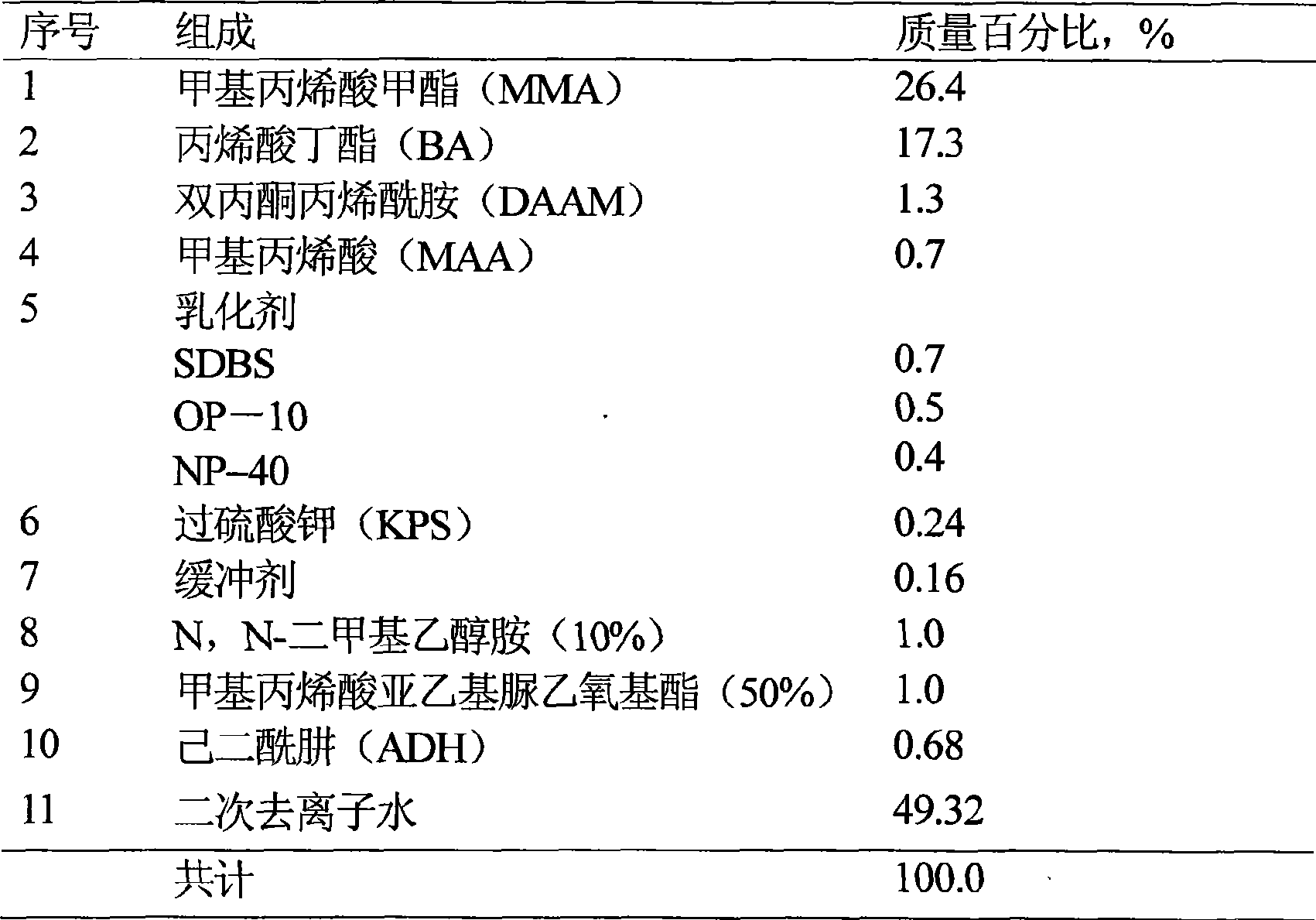

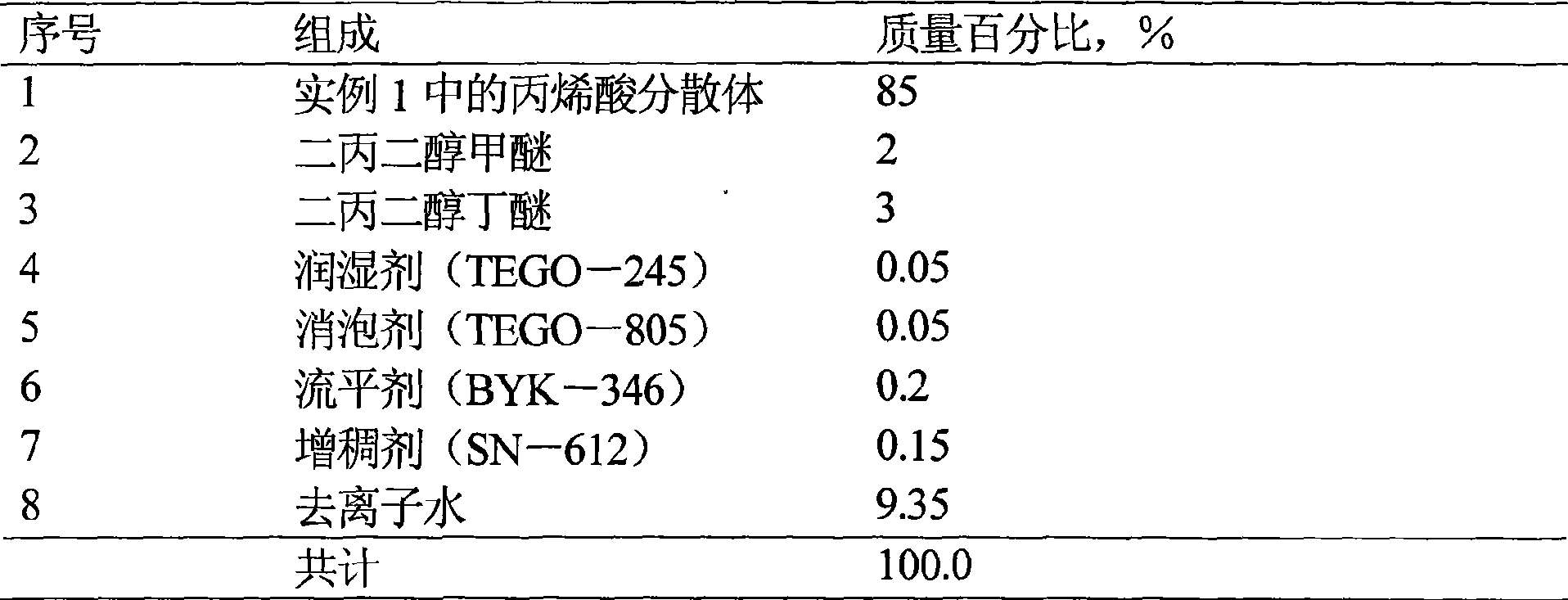

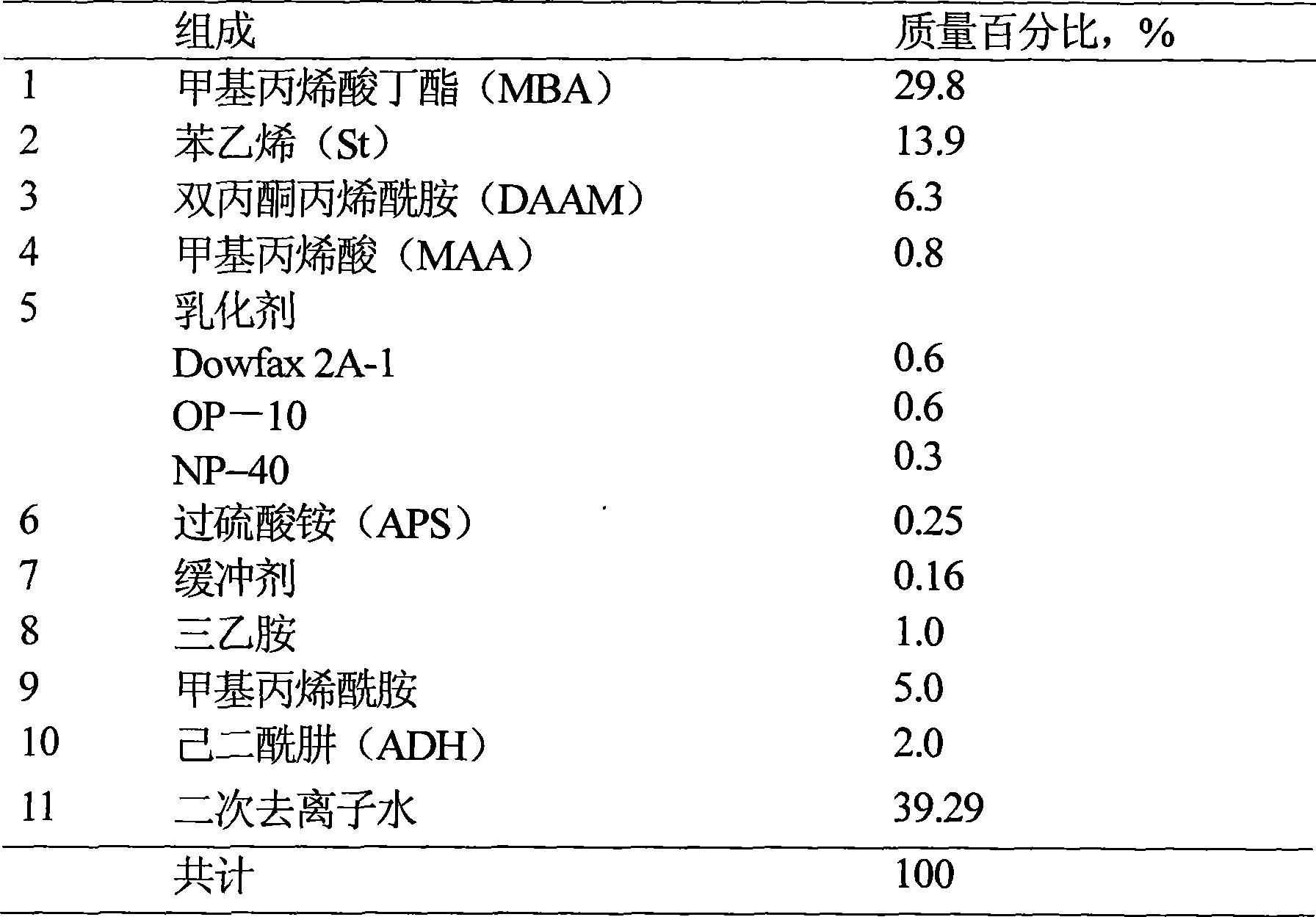

Preparation of high closeness polyacrylacid ester dispersion

The invention relates to a high-sealing polyacrylic ester dispersoid and a preparation method thereof; a multi-element emulsifier system which consists of an anionic emulsifier and a compound non-ionic emulsifier is adopted for controlling the charging process and components of the emulsifier in different polymerization periods, and the room-temperature self-crosslinking high-sealing polyacrylic ester dispersoid is prepared by a semi-continuous seeding emulsion polymerization process. The dispersoid has small particle size, good electrolyte-resistance (calcium ion) stability and high tolerance to various film forming accessory ingredients (various organic solvents with high boiling point). The dispersoid is used as seal coat of water-based wood coating and has good sealing performance to various woods; harmful volatile organic compounds (VOC) such as formaldehyde, and the like sealed against escaping from plates to pollute indoor environment, and the colored compounds such as turpentine, pine oil and tannin and the like are sealed against dissolving out of the plates to pollute pure top coating and white top coating of a water-based wooden ware; and in addition, the dispersoid can be used in water-based leather finishing agents.

Owner:SOUTH CHINA UNIV OF TECH

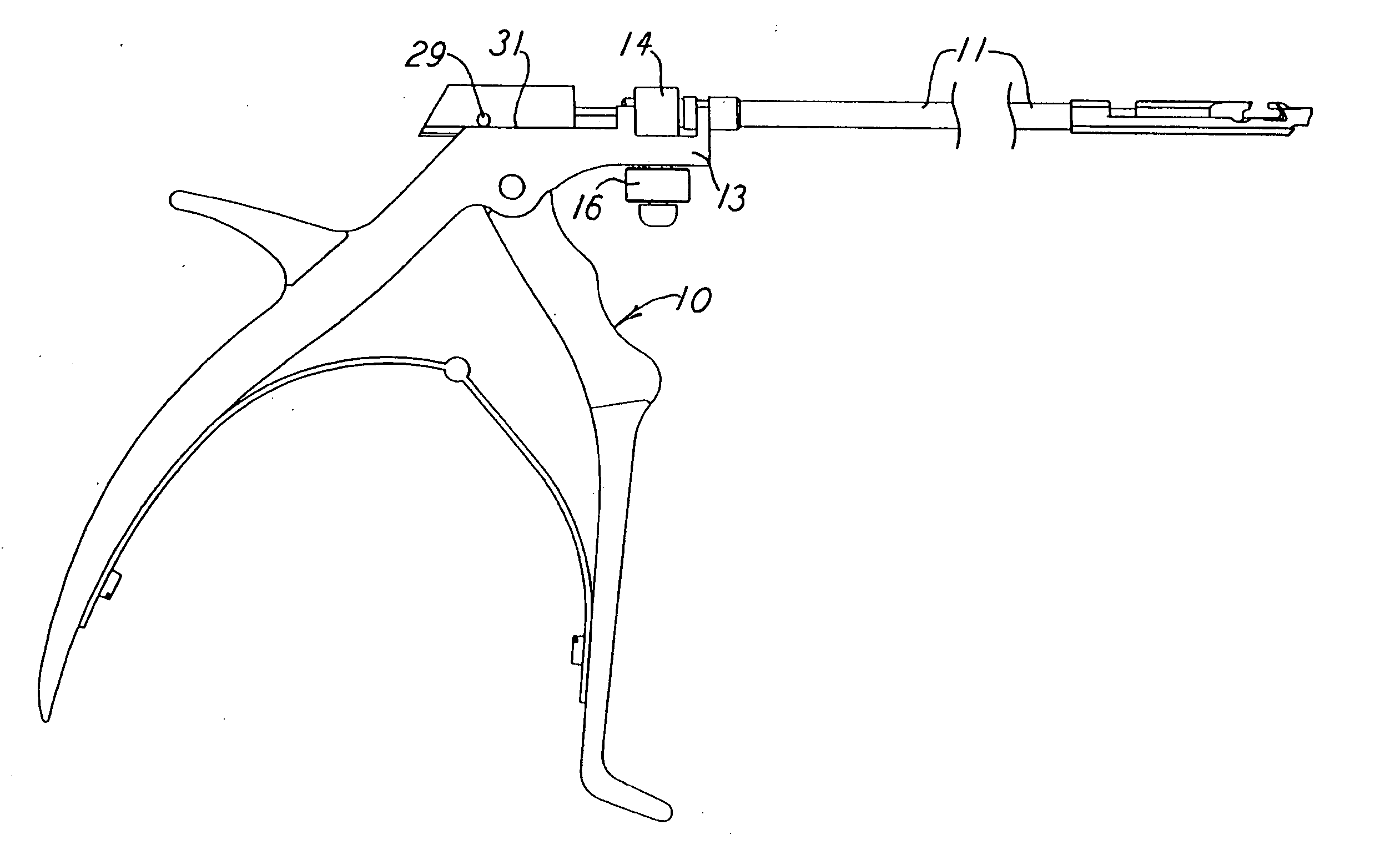

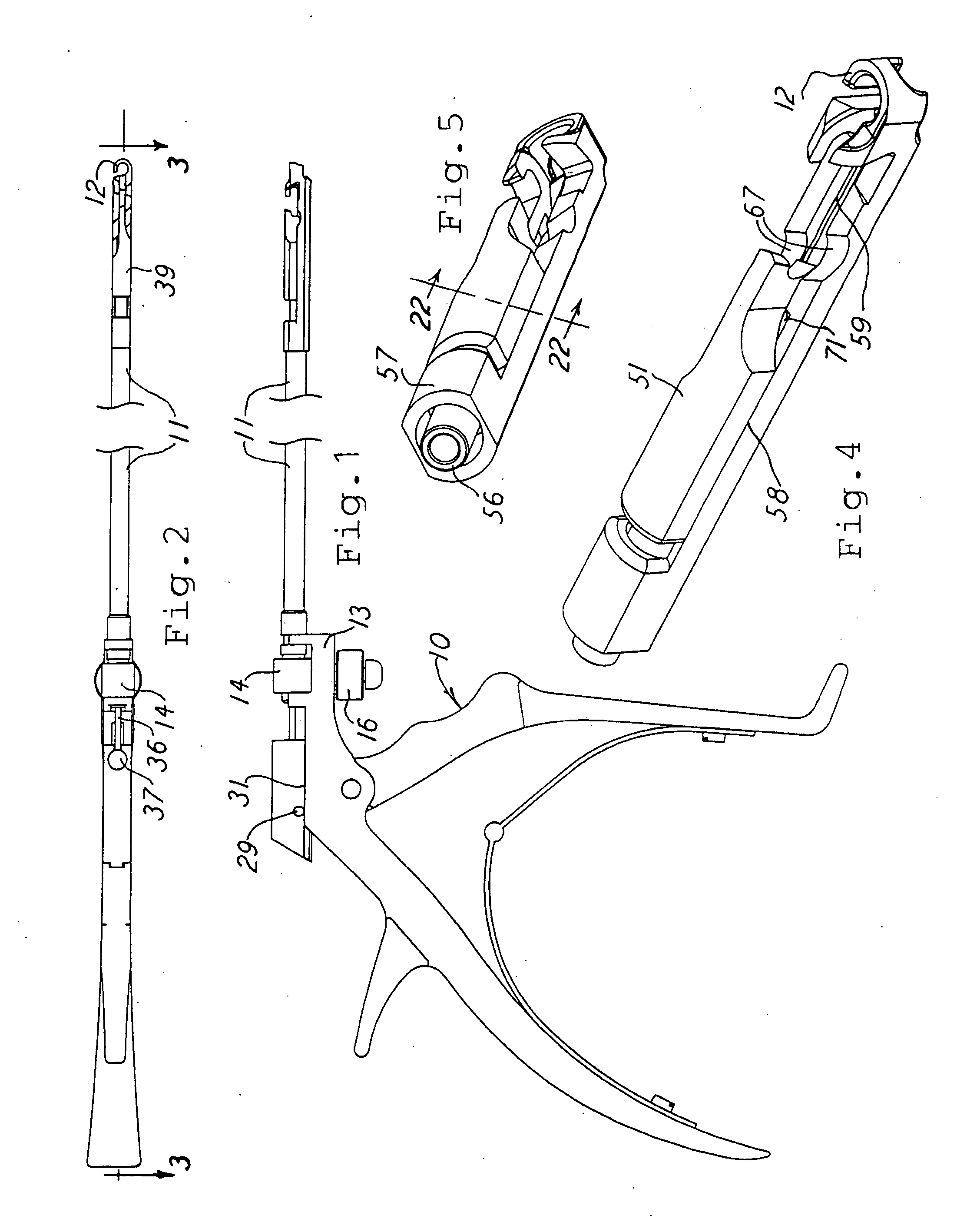

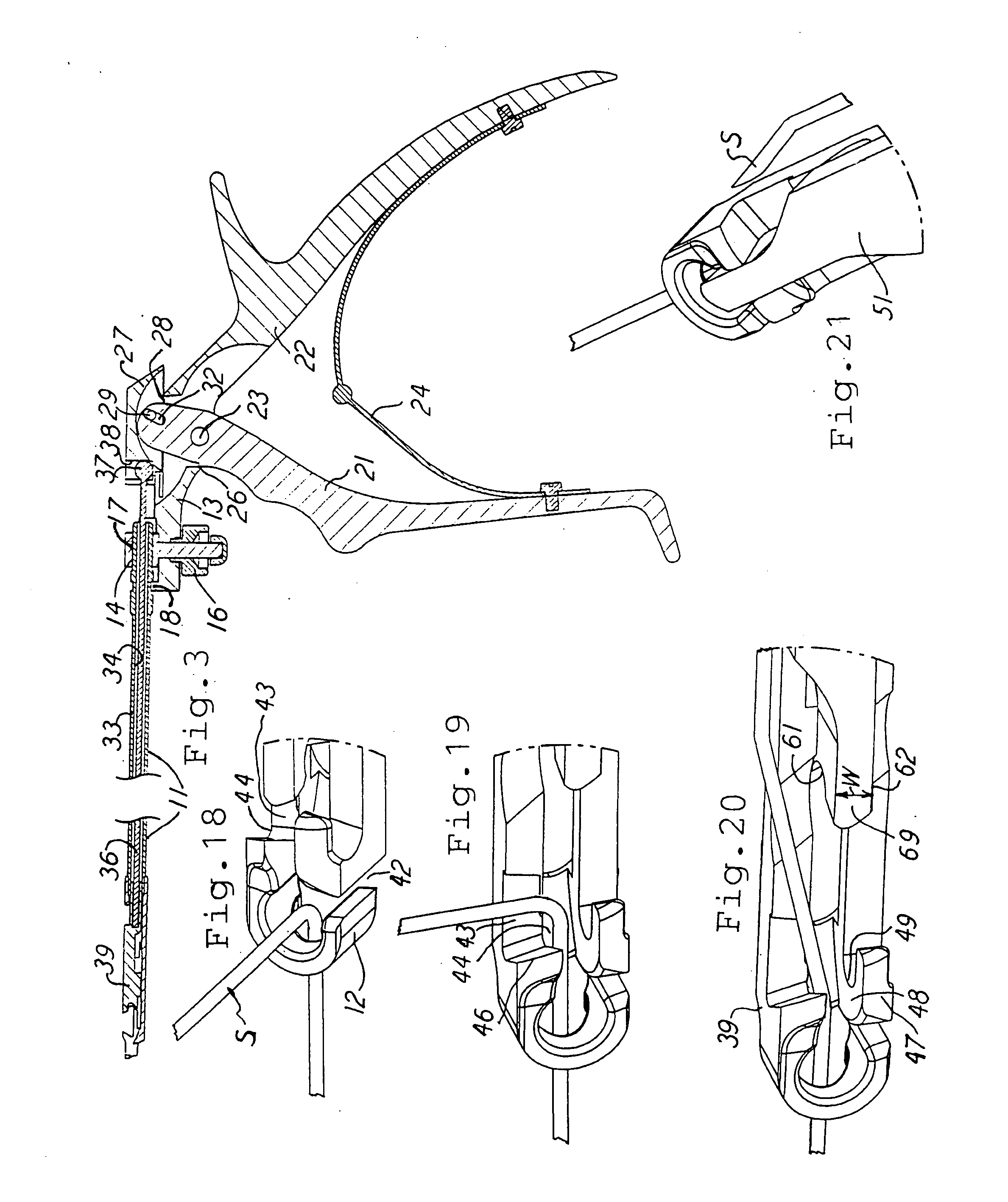

Surgical suture cutter

InactiveUS20060212045A1Enhanced accuracy of cutEnhance stabilitySuture equipmentsSurgical scissorsSurgical sutureSurgical stapling

A suture cutter having a handle and a barrel with a movable cutting head on the barrel, and the barrel supporting a stationary cutting edge and a movable cutting edge. A movable support carries the movable cutting edge and includes a surface spaced from the stationary cutting edge a selected distance. An abutment wall spaced from the stationary cutting edge at the selected distance provides for snugly restricting movement of the moving cutting edge away from cutting contact with the stationary cutting edge while cutting the suture. Recesses are defined on a guiding support surface along which the movable cutting edge slides when the handle is actuated, allowing for sharpening of the moveable cutting edge when said edge is retracted proximally.

Owner:TELEFLEX MEDICAL INC

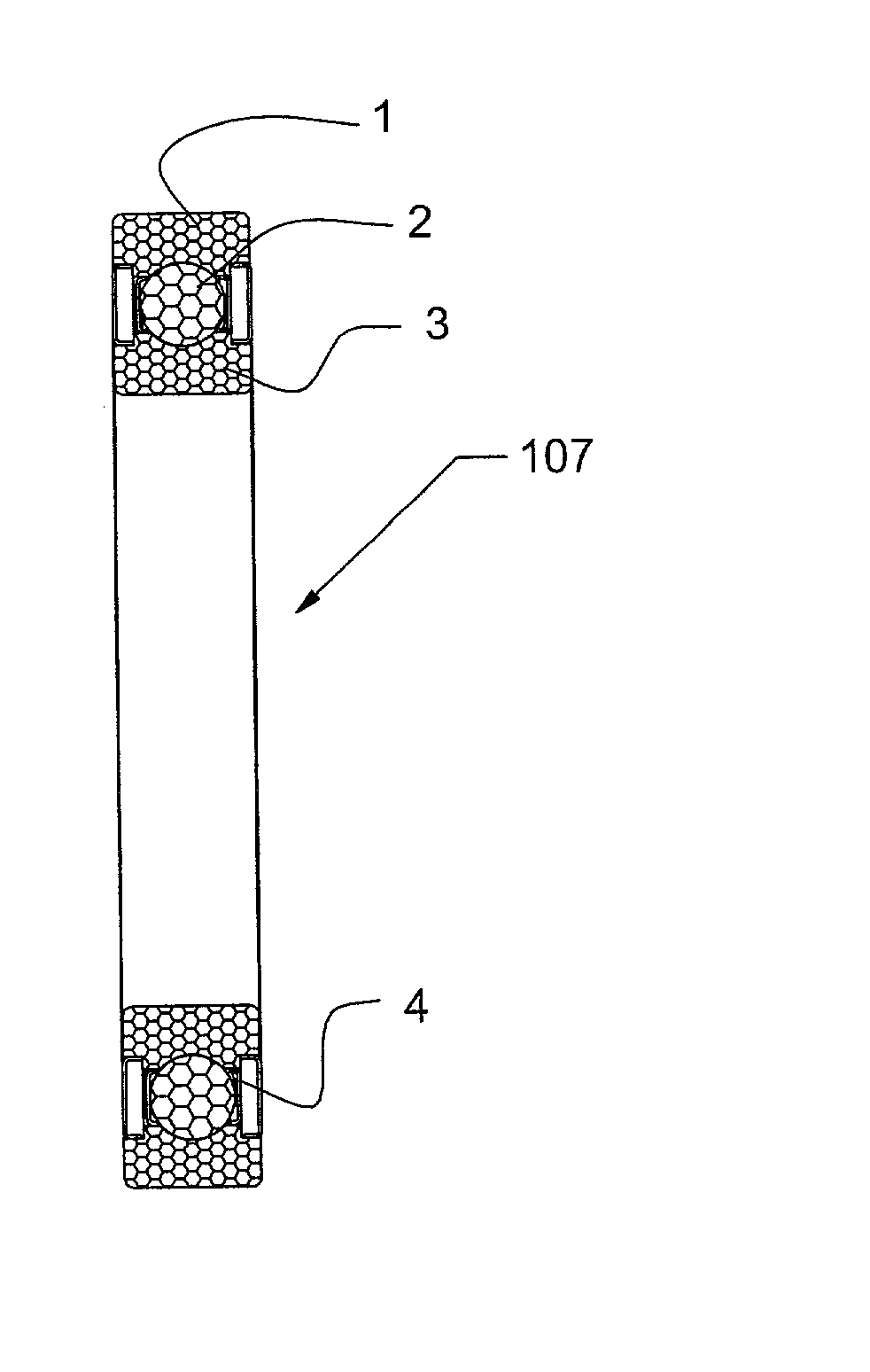

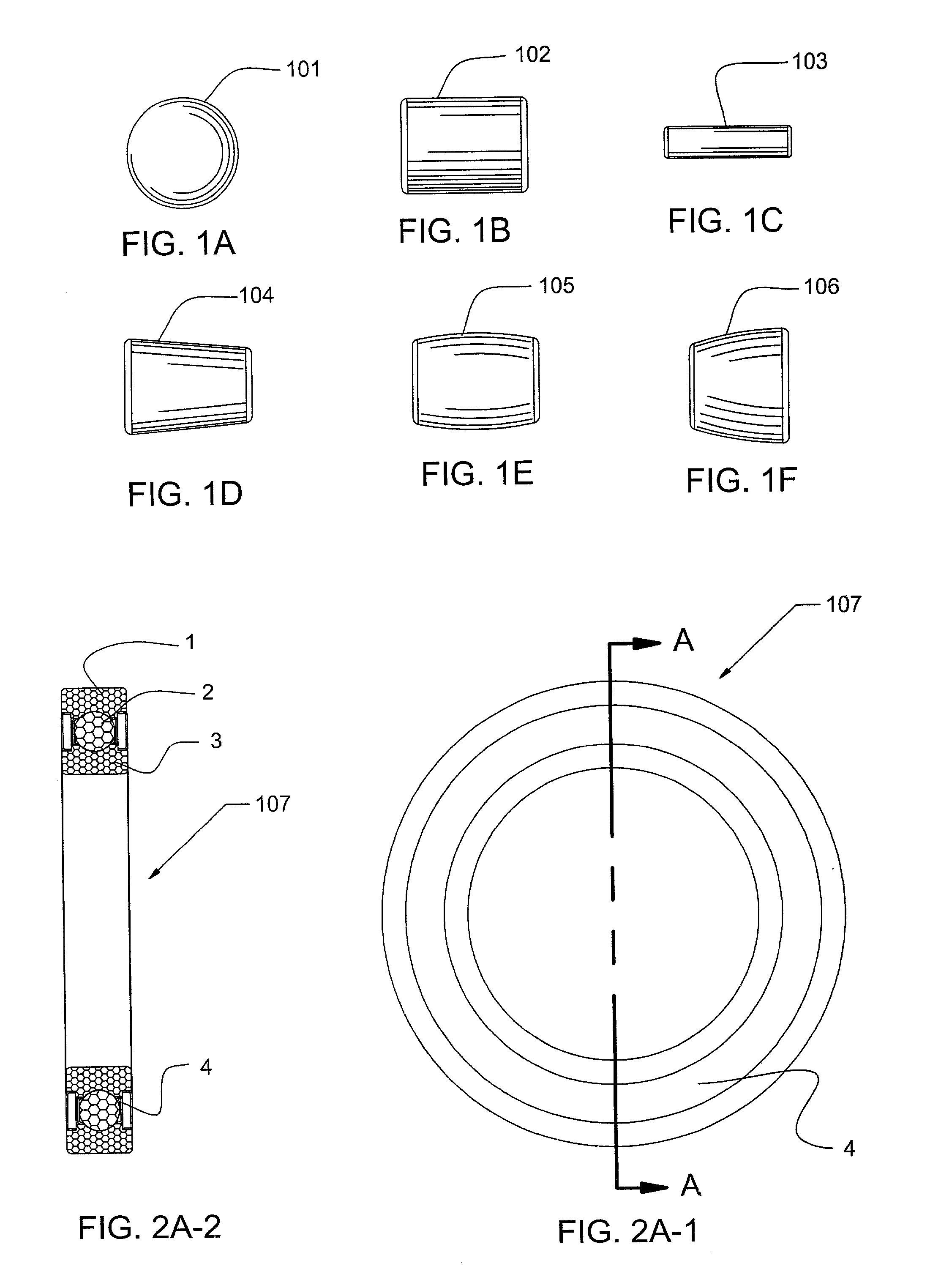

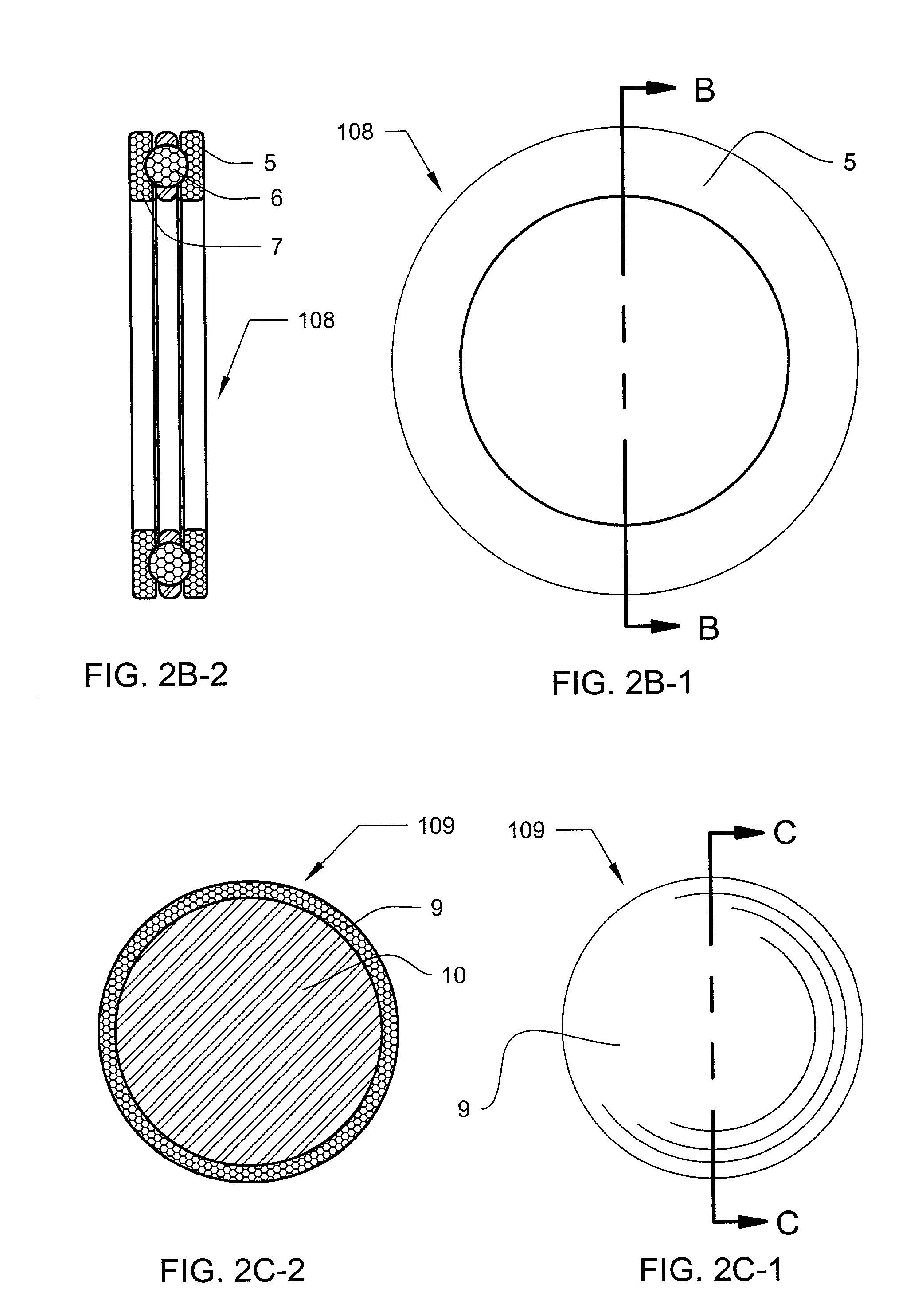

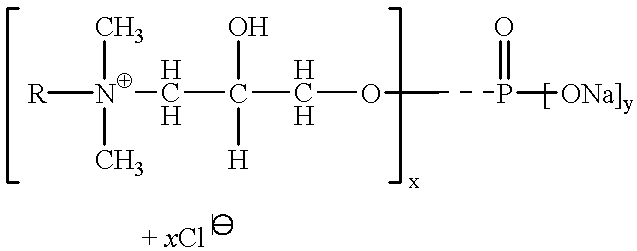

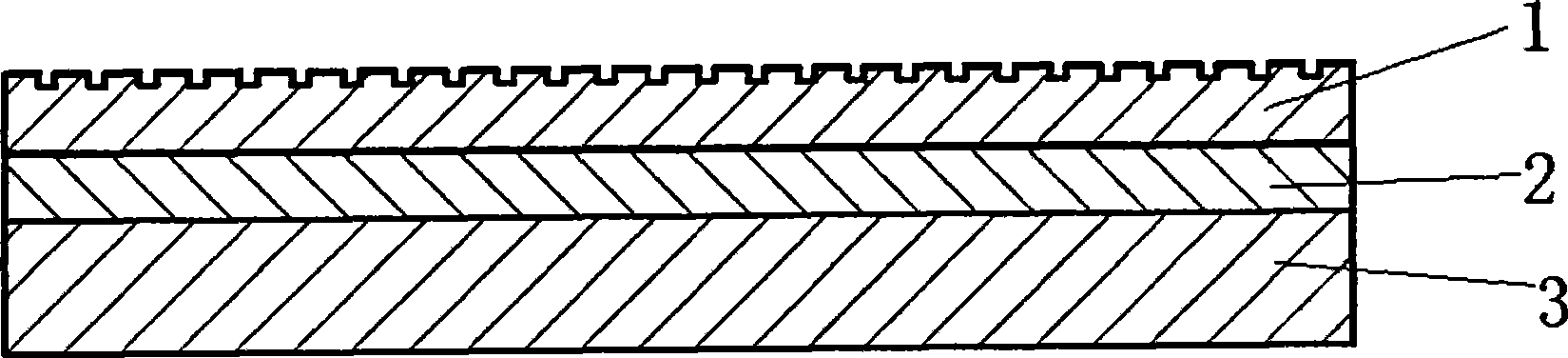

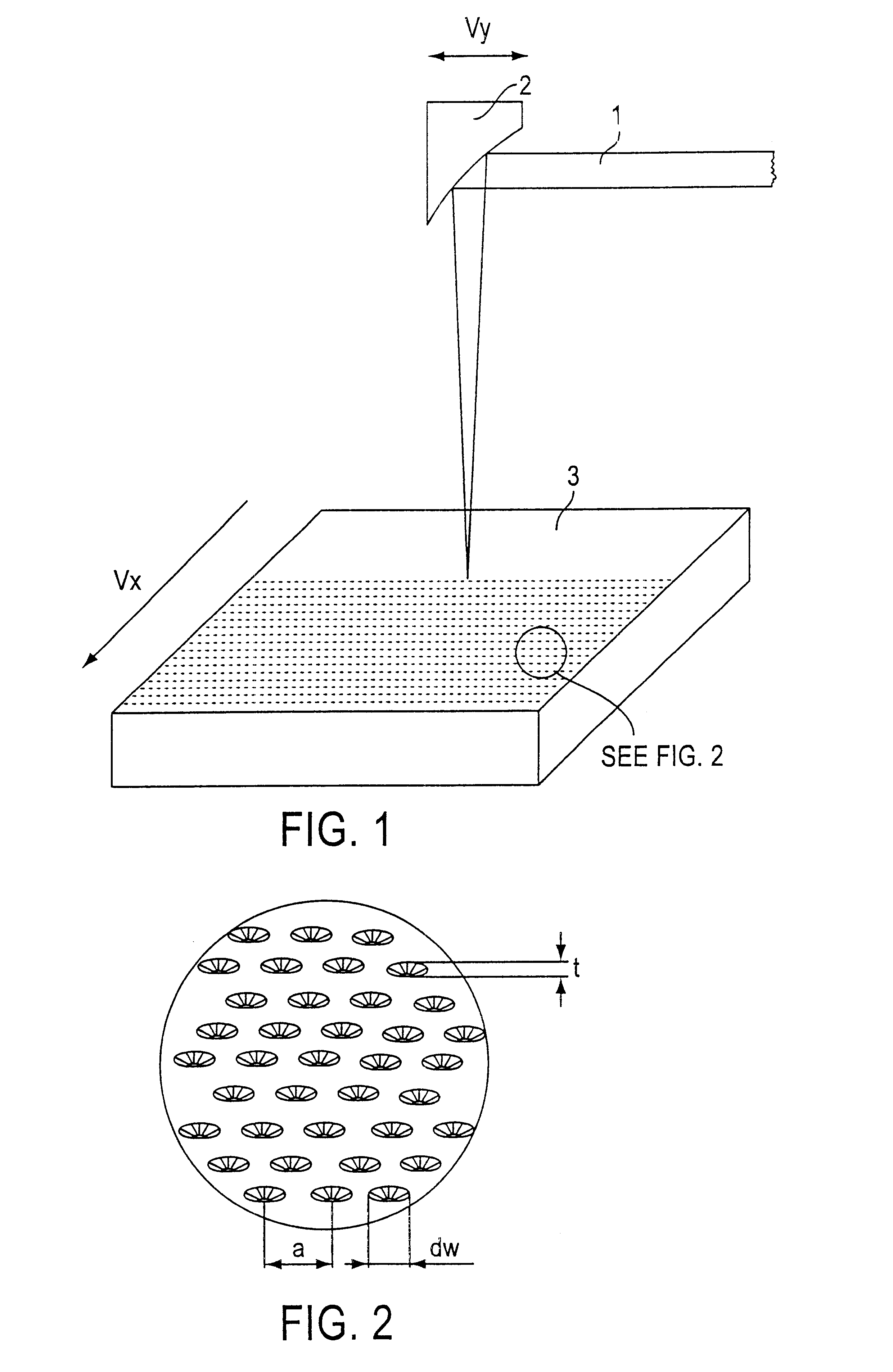

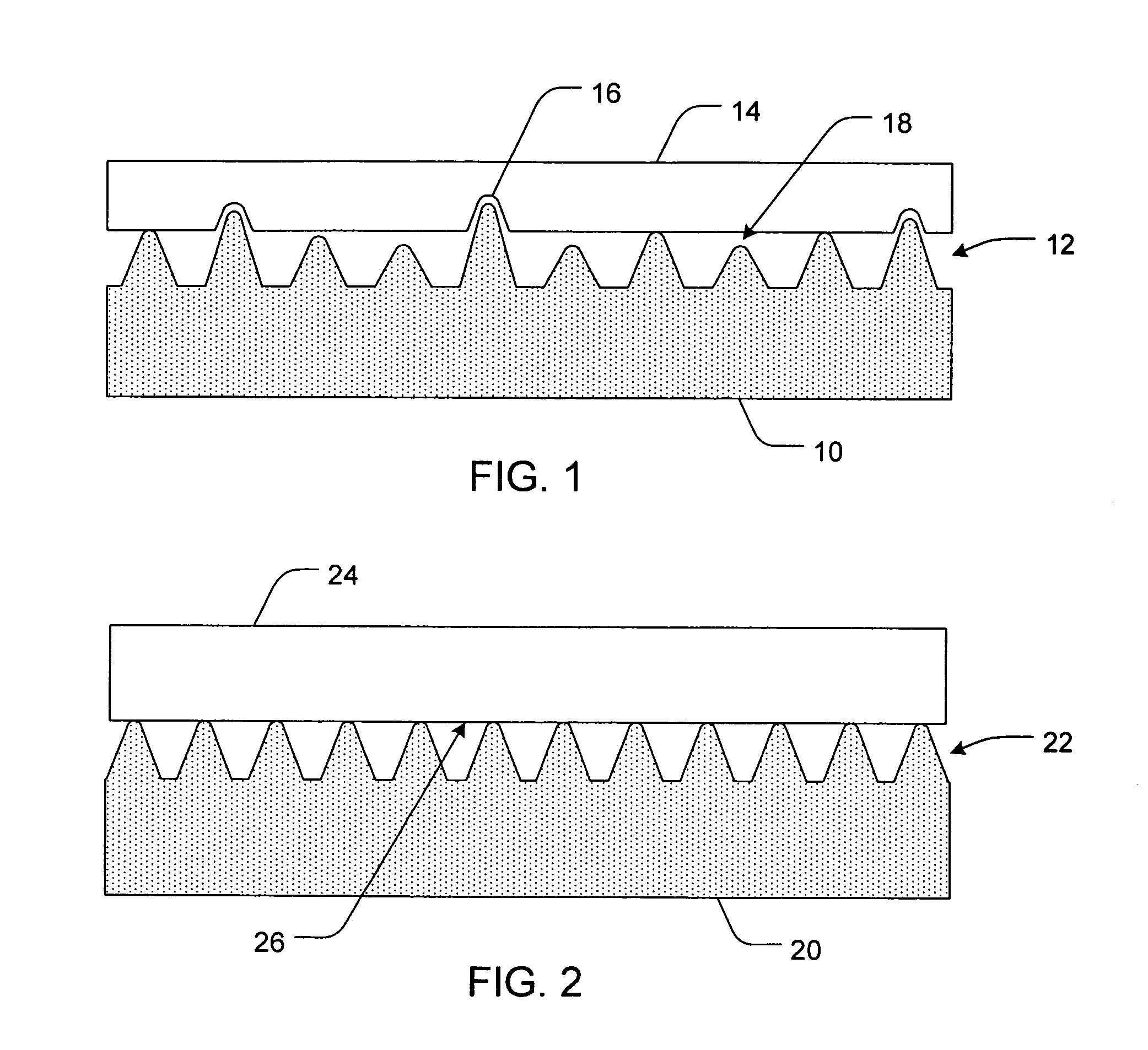

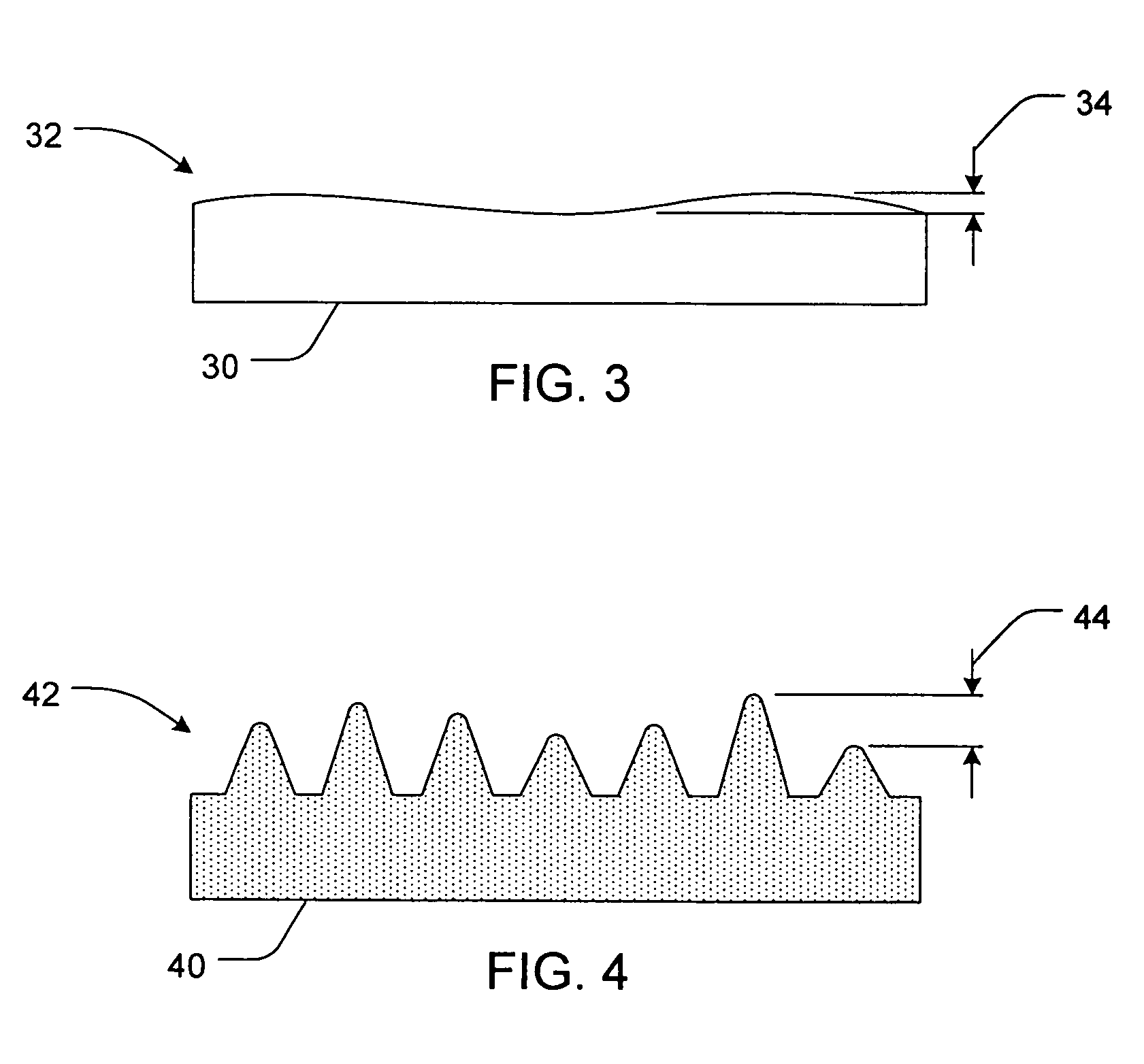

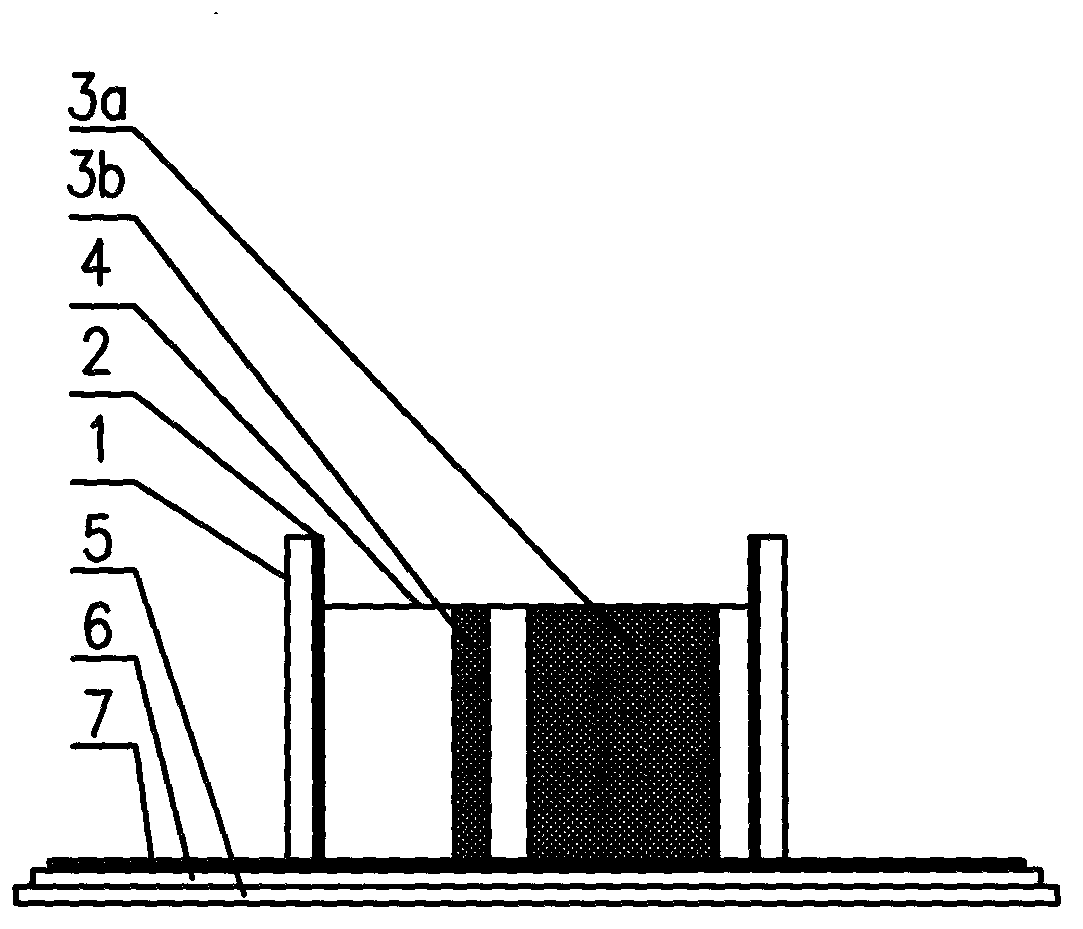

Fixed abrasive grinding polishing pad and method of manufacturing the same

InactiveCN101428404AImprove flatnessPlay a cutting roleAbrasion apparatusGrinding devicesReactive diluentEngineering

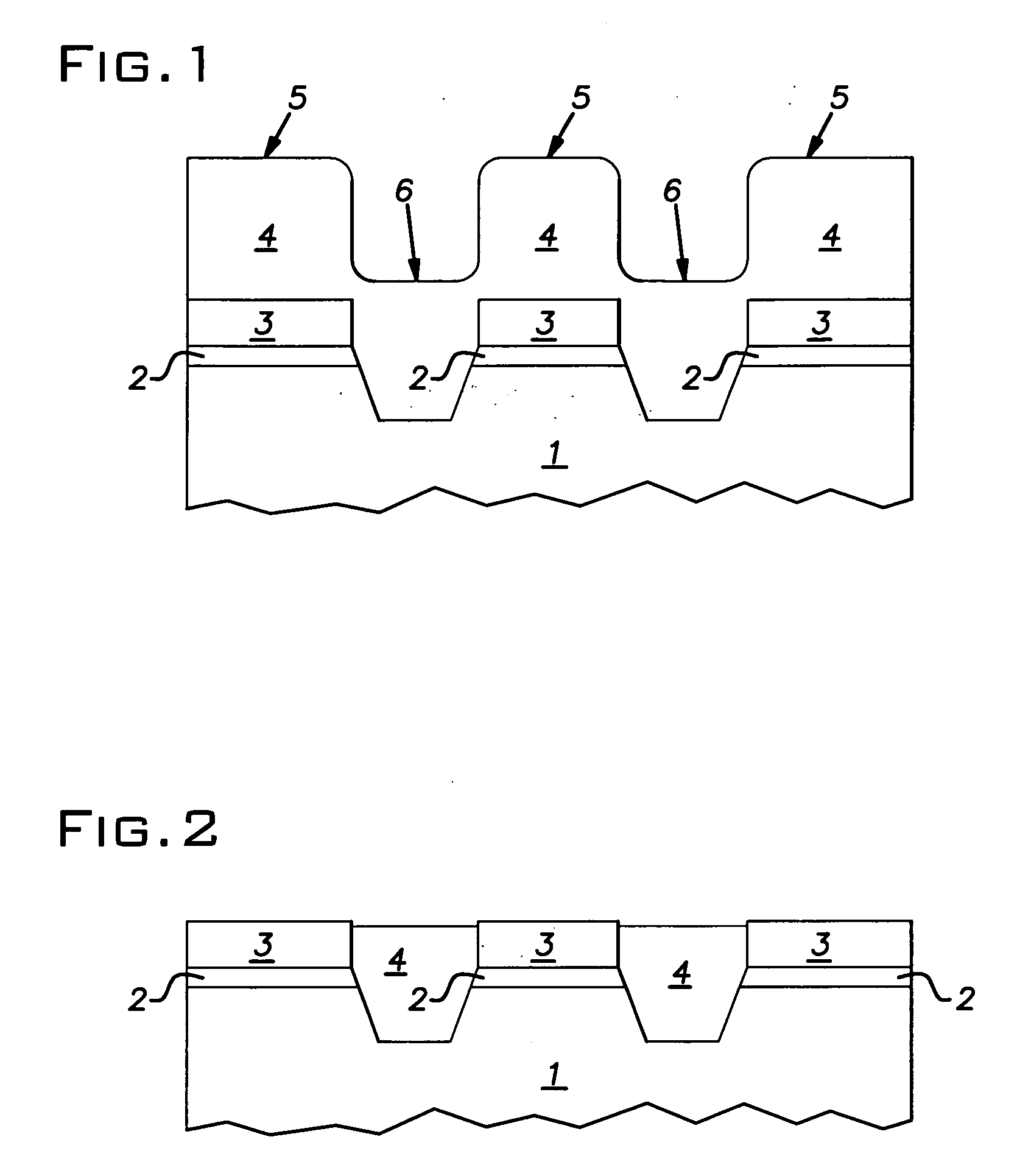

The invention provides a solidified abrading agent polishing pad and the preparation method thereof. The solidified abrading agent polishing pad comprises at least three layers, including an elastic layer (3), a rigid layer (2) and an abrading agent layer (1) sequentially arranged from the bottom layer to the top layer. The solidified abrading agent polishing pad is characterized in that the abrading agent layer (1) comprises the following components by the weight percentage: 1% to 40% of an abrading agent with the particle size being 1 nm to 40 Mum, 20% to 80% of polyacrylate prepolymer, 0.05% to 3% of free radical photoinitiator, 0% to 2% of poly-dimethylsiloxane / acrylic polymer, 0% to 20% of a performance adjusting addition agent, and 5% to 40% of esterified acrylic acid reactive diluent. The solidified abrading agent polishing pad which is prepared by the figure-transfer method has a series of advantages of stable grinding and polishing performance, high polishing efficiency, high surface texture of processed workpieces, and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Polishing pad and method for manufacturing the polishing pad

InactiveUS20110171890A1Increase stiffnessGood rate and flatnessOther chemical processesAbrasion apparatusFinenessElastomer

A polishing pad is disclosed which is less likely to cause scratches, and has an excellent planarization performance and polishing stability. In one aspect, the invention provides a polishing pad comprising an ultrafine fiber-entangled body formed of ultrafine fibers having an average fineness of 0.01 to 0.8 dtex, and a polymeric elastomer. The polymeric elastomer has a glass transition temperature of −10° C. or below, storage moduli at 23° C. and 50° C. of 90 to 900 MPa, and a water absorption ratio, when saturated with water at 50° C., of 0.2 to 5 mass %.

Owner:KURARAY CO LTD

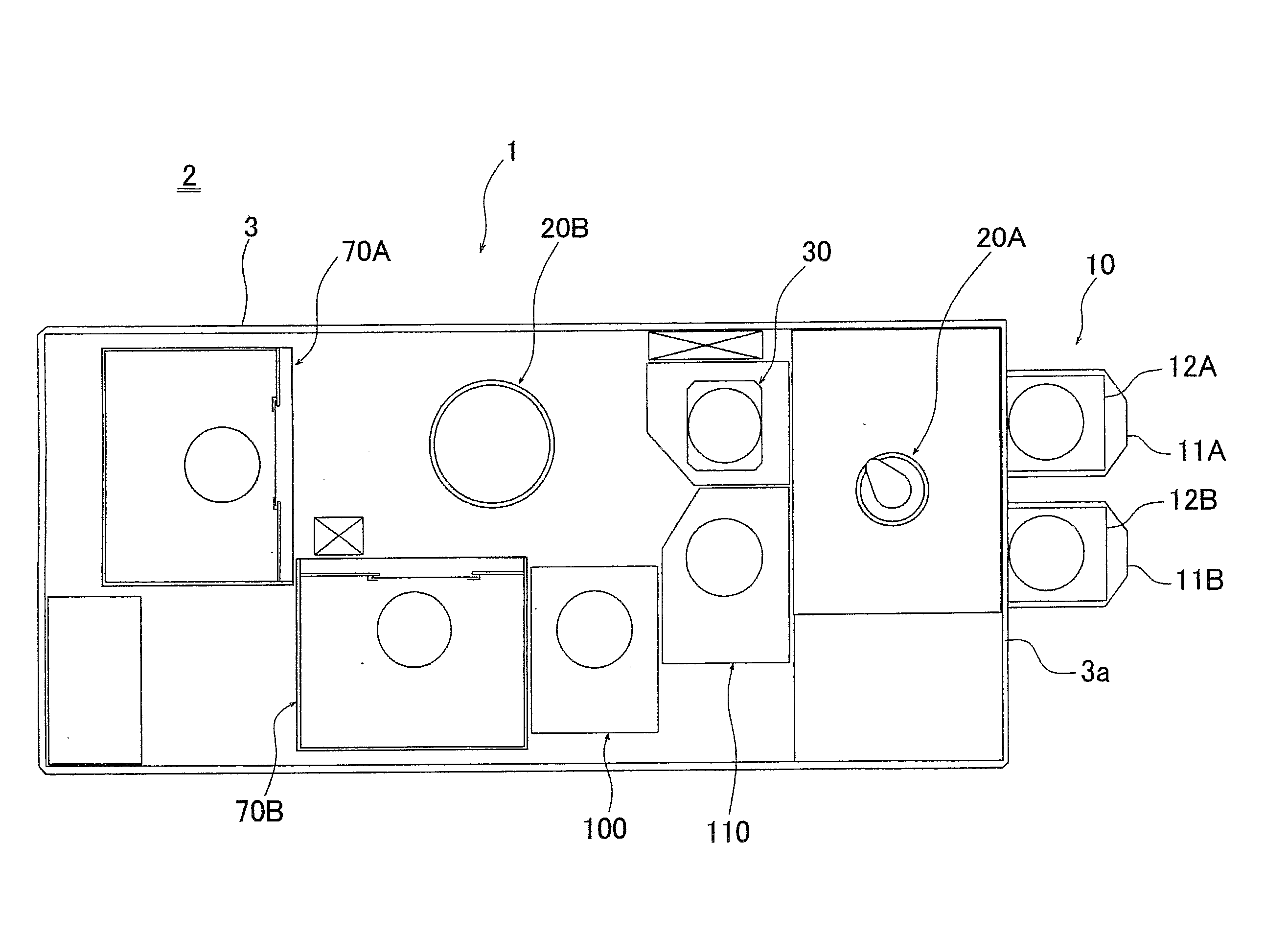

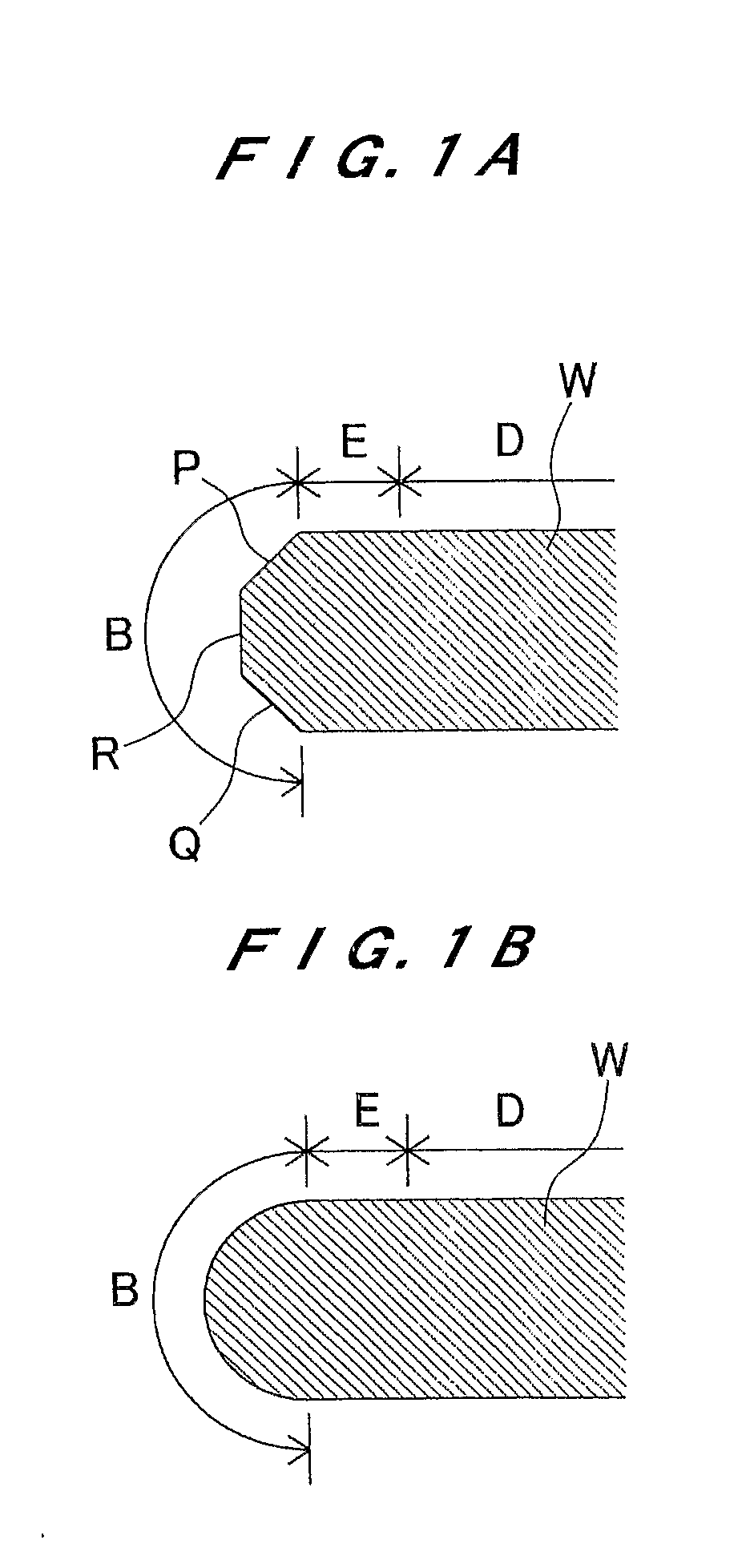

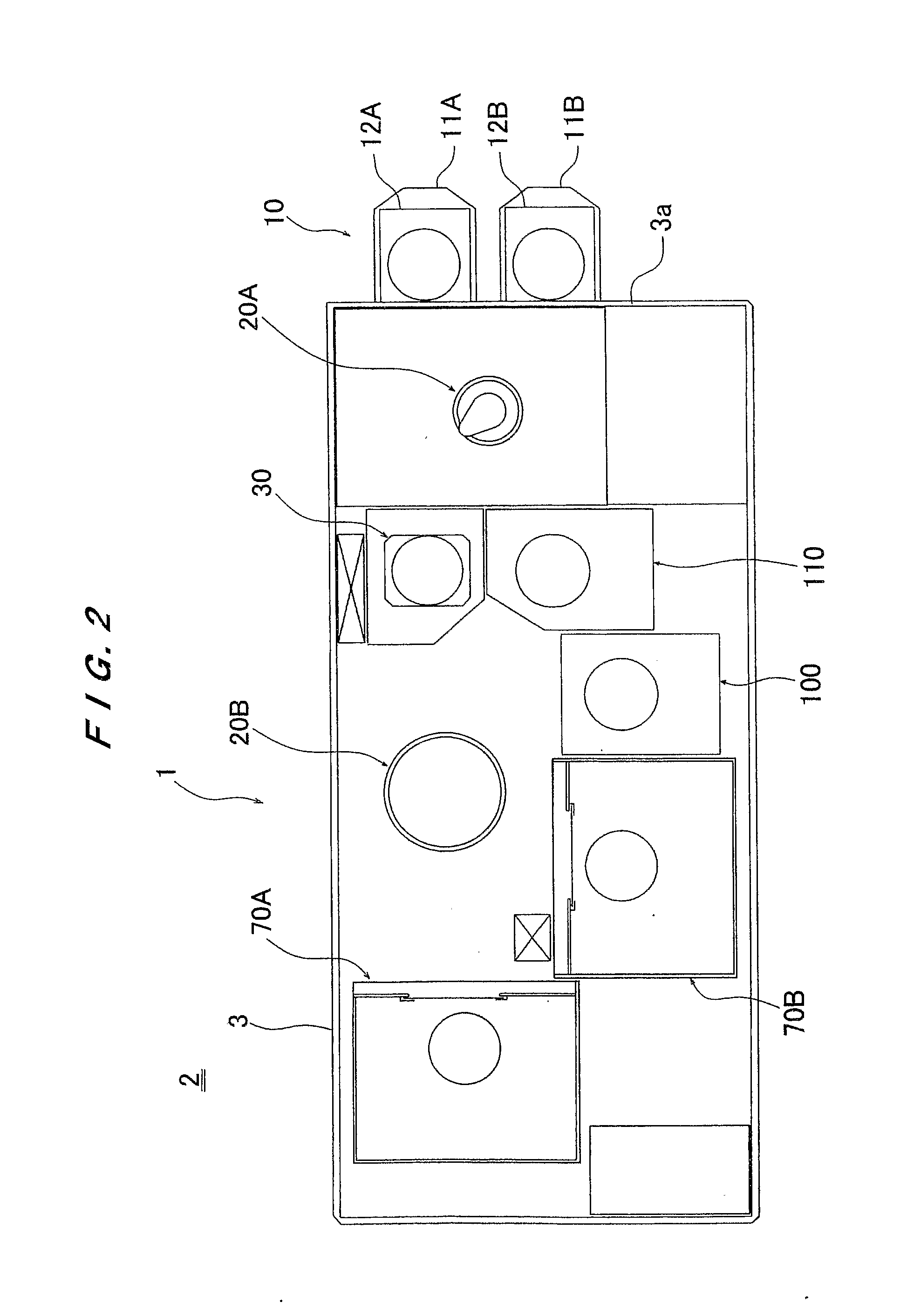

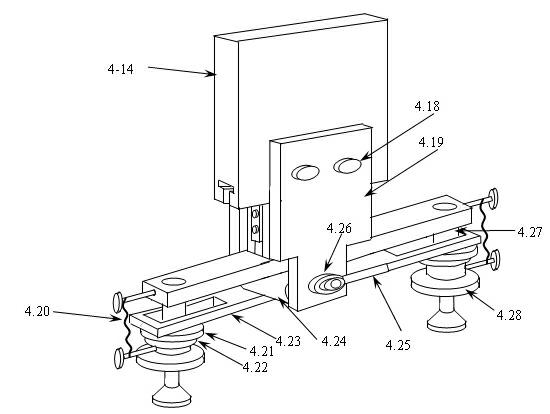

Substrate Processing Apparatus

ActiveUS20080200100A1Easy to polishEdge grinding machinesPolishing machinesSurface conditionsDiameter measurement

A substrate processing apparatus (1) includes first and second polishing units (70A, 70B) for polishing a peripheral portion of a substrate (W), a primary cleaning unit (100) for cleaning the substrate (W), a secondary cleaning and drying unit (110) for drying the substrate (W) cleaned in the primary cleaning unit (100), and a measurement unit (30) for measuring the peripheral portion of the substrate (W). The measurement unit (30) includes a mechanism for measurement required for polishing in the first and second polishing units (70A and 70B), such as a diameter measurement mechanism, a cross-sectional shape measurement mechanism, or a surface condition measurement mechanism.

Owner:EBARA CORP

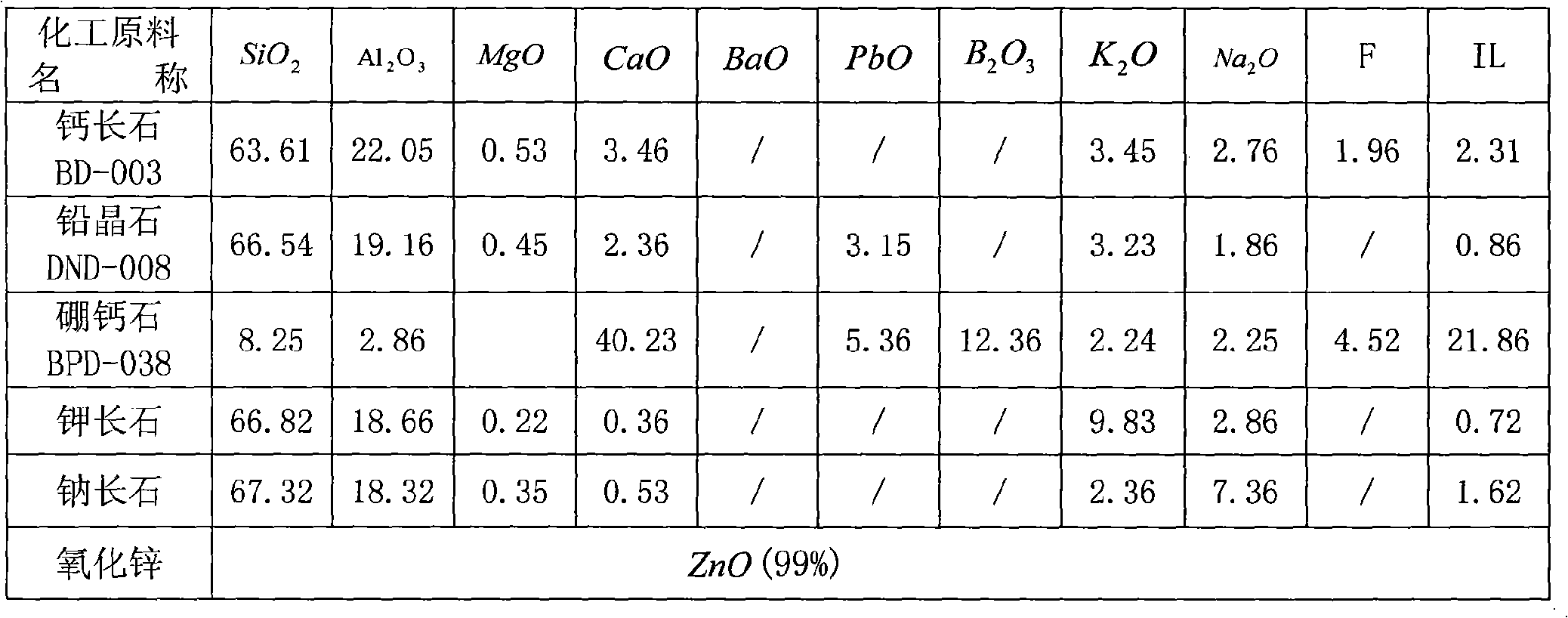

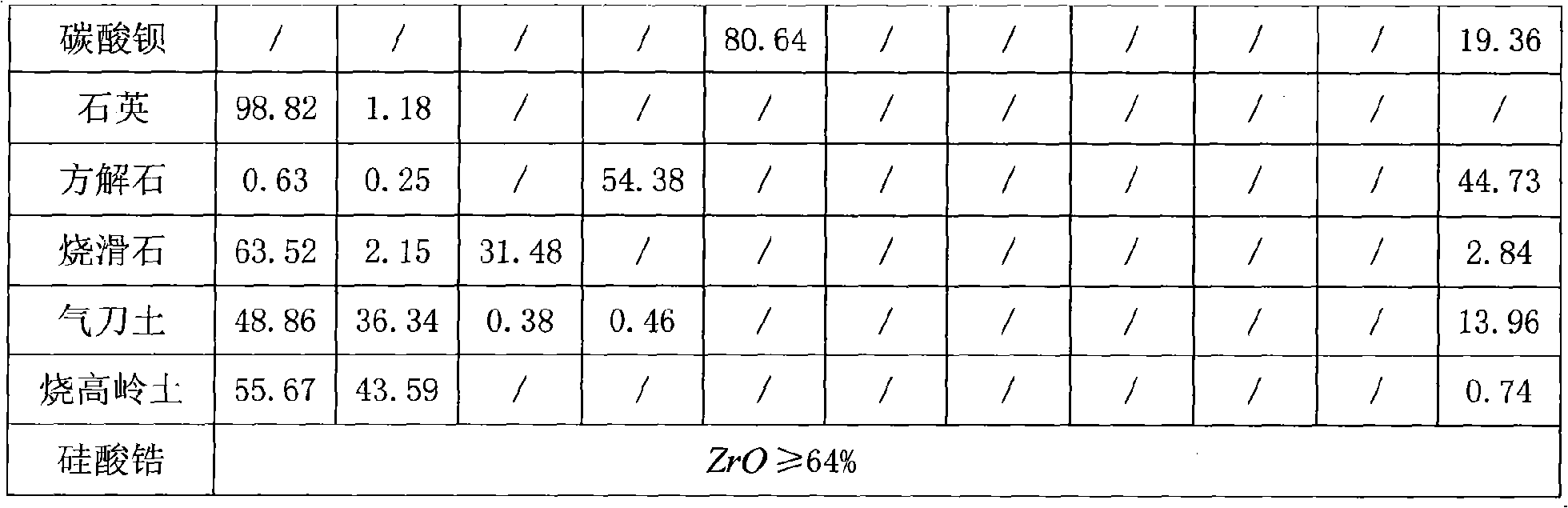

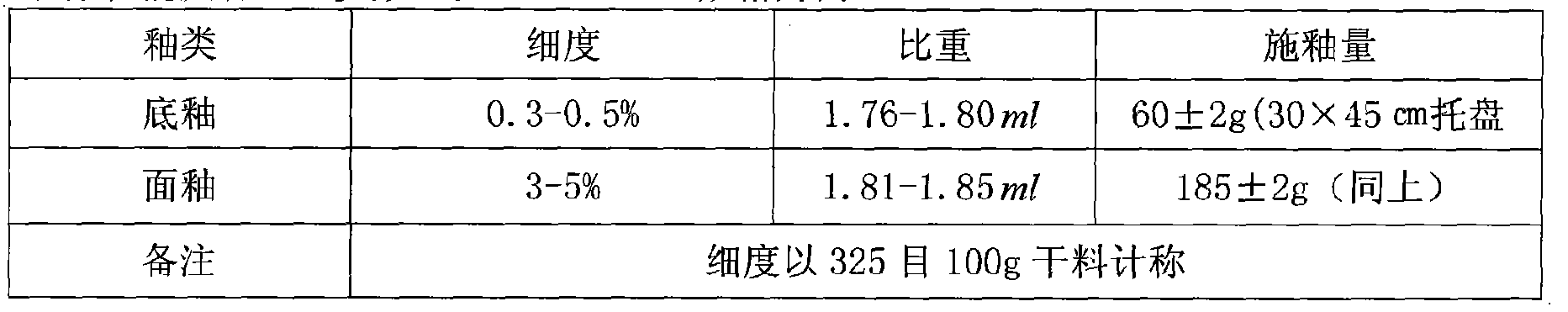

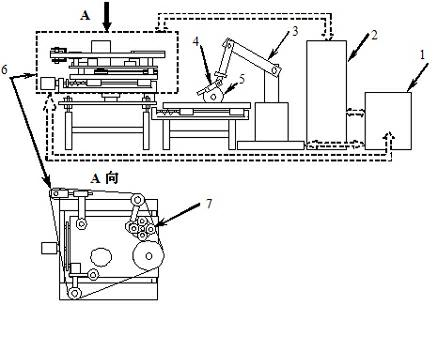

Ceramic glaze pattern-glazed brick and production method thereof

The invention discloses a ceramic glaze pattern-glazed brick and a production method thereof. The ceramic glaze pattern-glazed brick is prepared by performing decorations of printing, colors and patterns in a ceramic brick glaze, burning the ceramic brick glaze at a high temperature of between 1,220 and 1,260 DEG C, and adopting a soft surface polishing process. The production method comprises the following steps: preparing a formulation of a combined blank; performing press forming on the blank; drying the blank; spraying a ground glaze on the surface of the dried blank; using a fancy glaze to perform printing on the ground glaze; spraying a cover glaze on the surface of the blank after the printing; burning the blank sprayed with the cover glaze at a temperature of between 1,220 and 1,260 DEG C for 50 to 60 minutes; and finally edging and polishing the burnt blank to obtain the ceramic glaze pattern-glazed brick. The ceramic glaze pattern-glazed brick has the advantages of abrasion resistance, no dirt absorption, good texture, high glossiness and transparency, good decorative effect and wide decorative varieties.

Owner:郑水泉

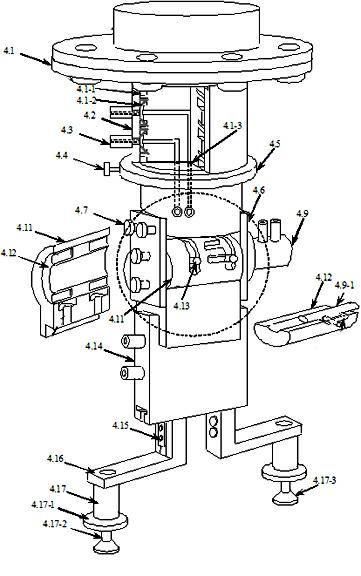

Automatic sanding and polishing device for industrial robot

InactiveCN102107384AGuaranteed positioning accuracyConsistent removalBelt grinding machinesContact forceAutomatic testing

The invention relates to an automatic sanding and polishing device for an industrial robot, wherein the industrial robot is served as the core of the device; the device comprises the industrial robot, an automatic shifting fixture, a polishing machine, and a force control program; and the device can be used for sanding and polishing the parts having complex exteriors, and is especially suitable for processing faucet, ironware, blade, and the like. A method for automatically sanding and polishing by using the device comprises the following steps: the automatic shifting fixture arranged on the tail end of the industrial robot is used for holding the parts; adjusting the position and posture of the industrial robot according to different areas for sanding or polishing of the parts; contacting the areas for sanding or polishing with a sanding belt of the polishing machine and keeping a certain contact force; controlling the size of the contact force by a force control mechanism; after finishing programming the whole surface of parts, using the industrial robot to perform the reprogramming operation; and sanding or polishing the parts having same exteriors in batch.

Owner:厦门煜雄智能机器人有限公司

High reflectivity atmospheric pressure furnace for preventing contamination of a work piece

InactiveUS20050166844A1High purityPerformance upgradeMuffle furnacesSemiconductor/solid-state device manufacturingElectrical resistance and conductanceActive cooling

A furnace incorporating a novel thermal design is disclosed. Heating element temperature is reduced compared to conventional designs while providing a precisely controllable process temperature in the range 1000-1400 degrees centigrade. A plurality of Kanthal heating elements are arranged in a planar array as close to the work as possible, thus approximating an isothermal condition with respect to the work. The process chamber is made of aluminum and its internal surfaces are highly polished to reflect heat. The chamber walls have built in active cooling to carry away non-reflected heat and preserve high reflectivity. The heating elements are modular to facilitate removal and replacement without disassembly of the furnace. The configuration of the heating elements is linear rather than coiled and the temperature is monitored directly by measuring the electrical resistance of the Kanthal wires.

Owner:SOLAICX

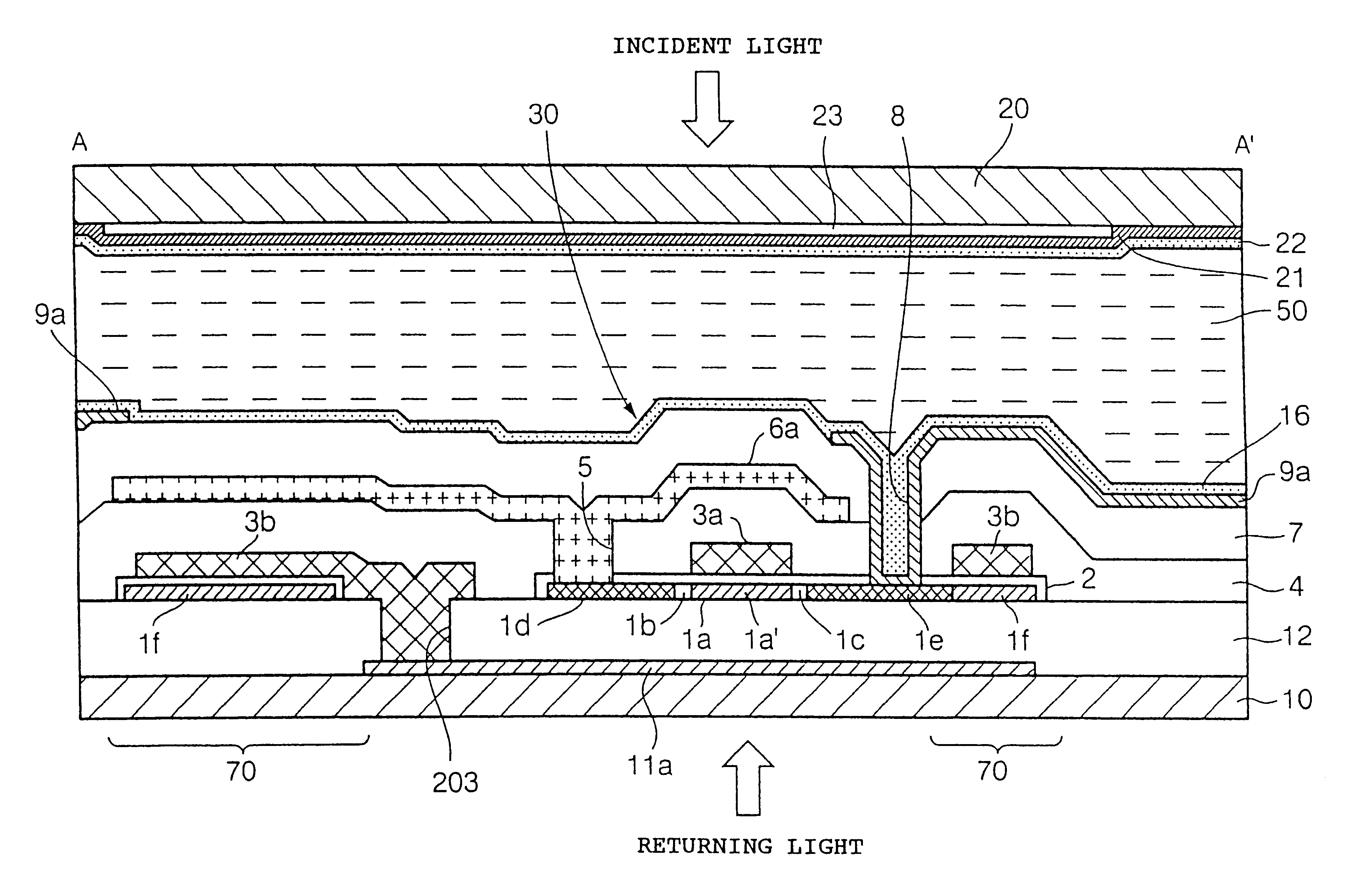

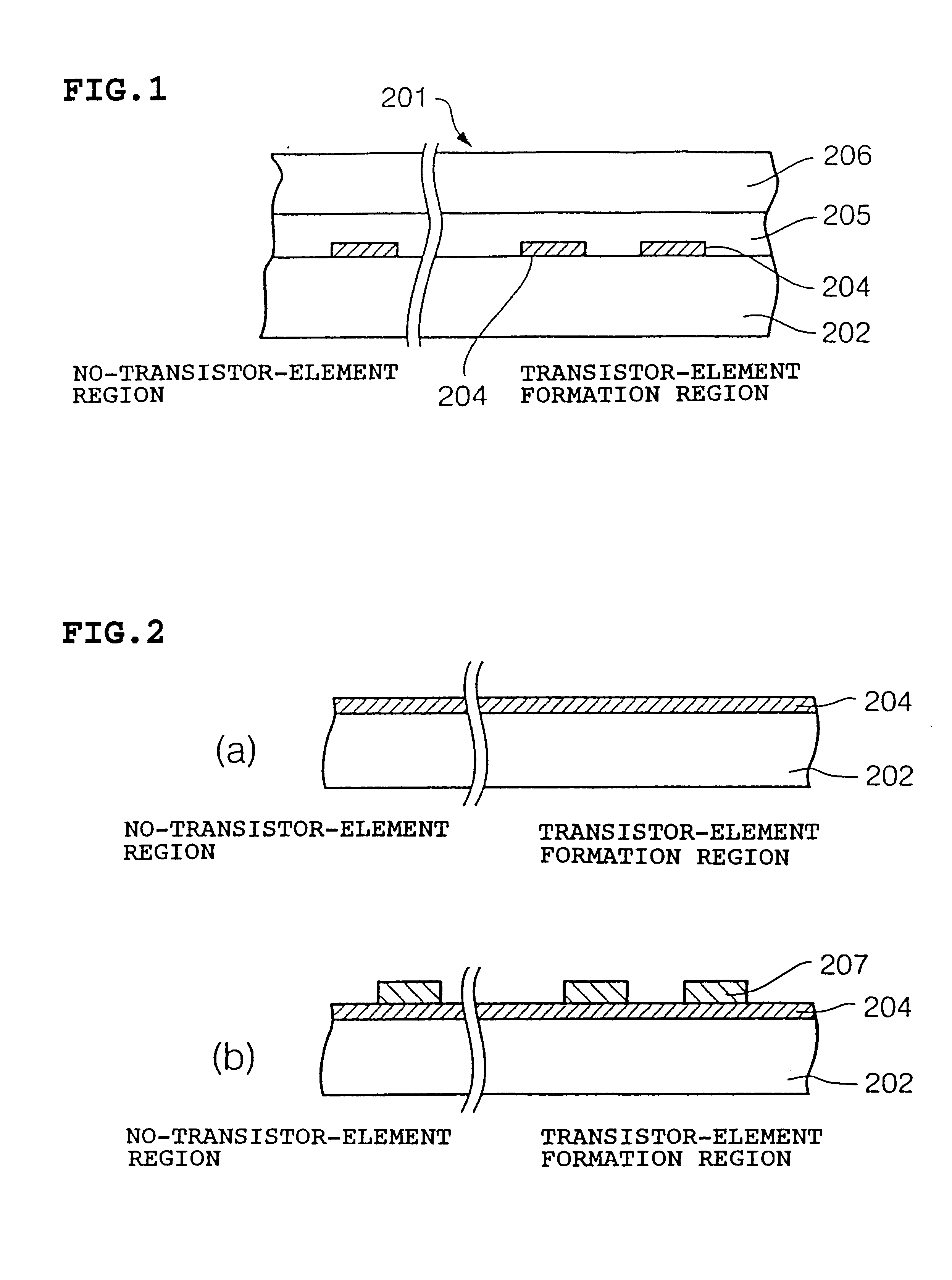

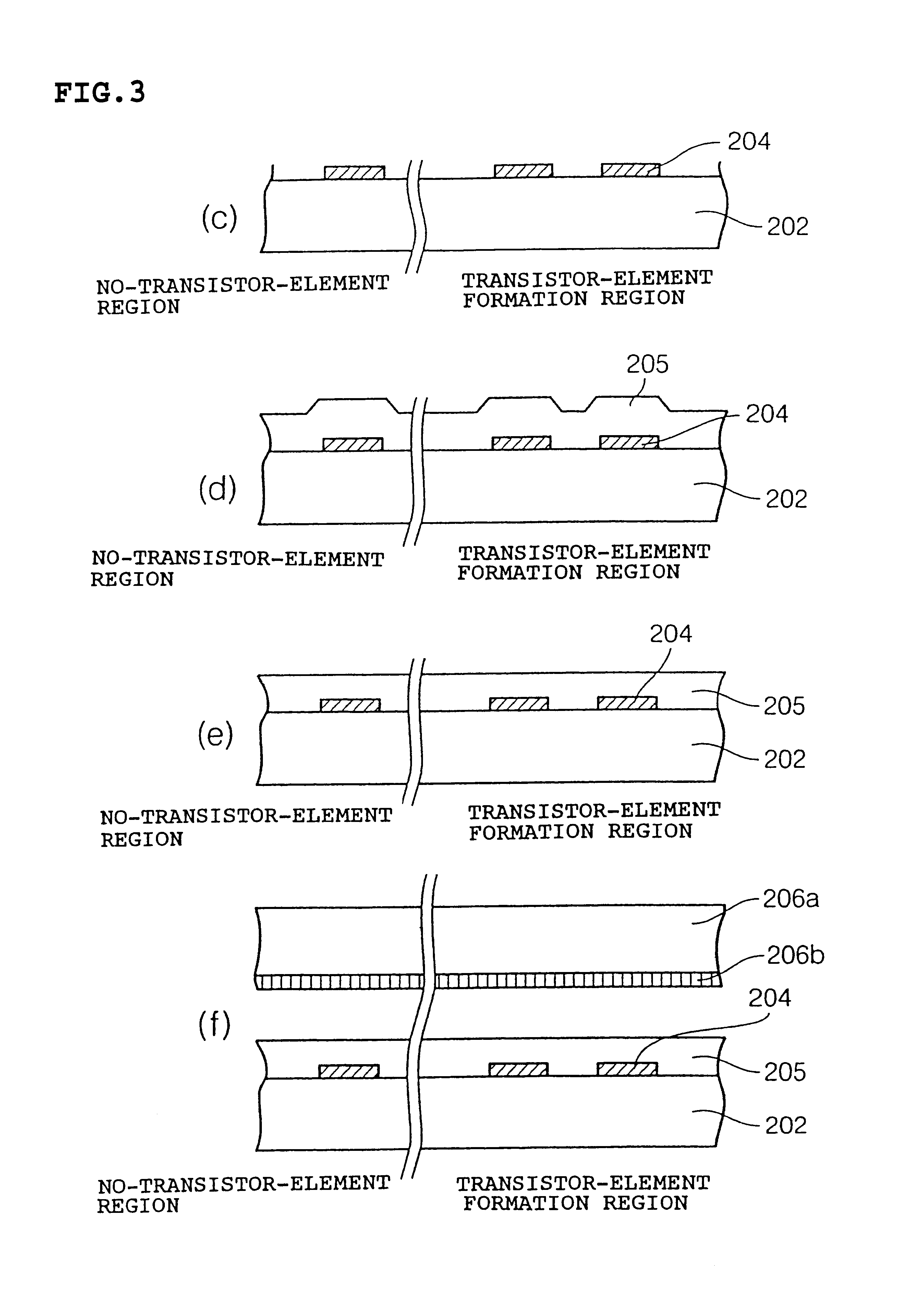

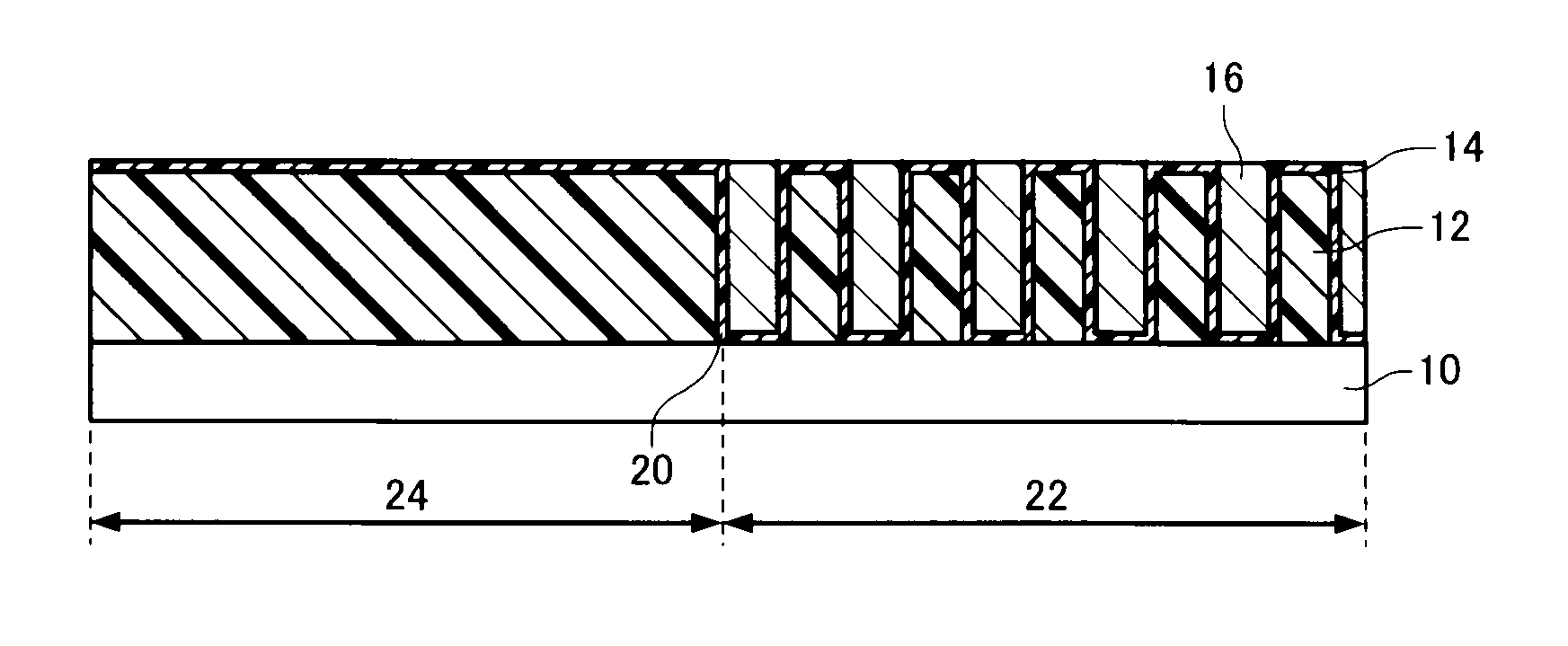

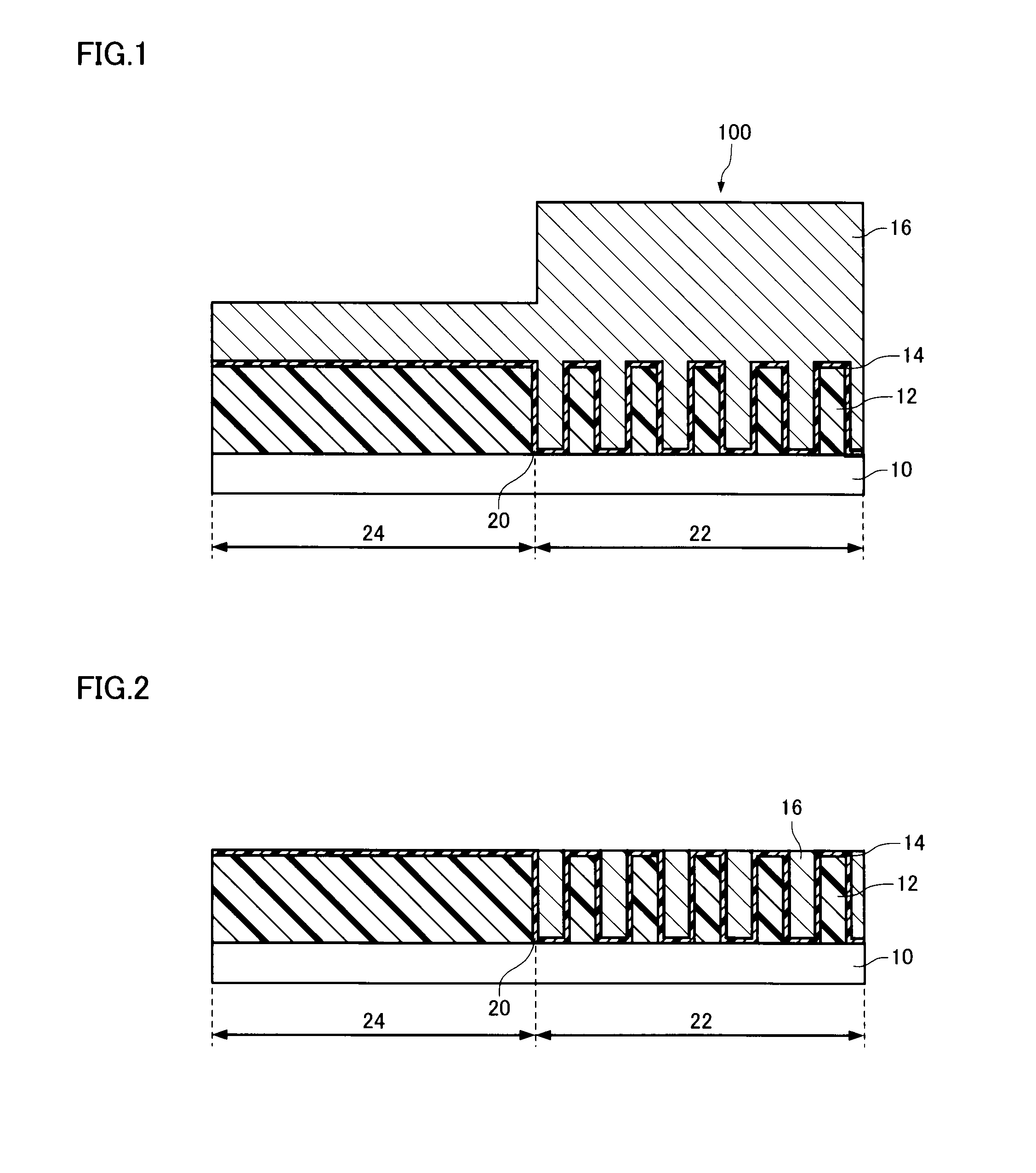

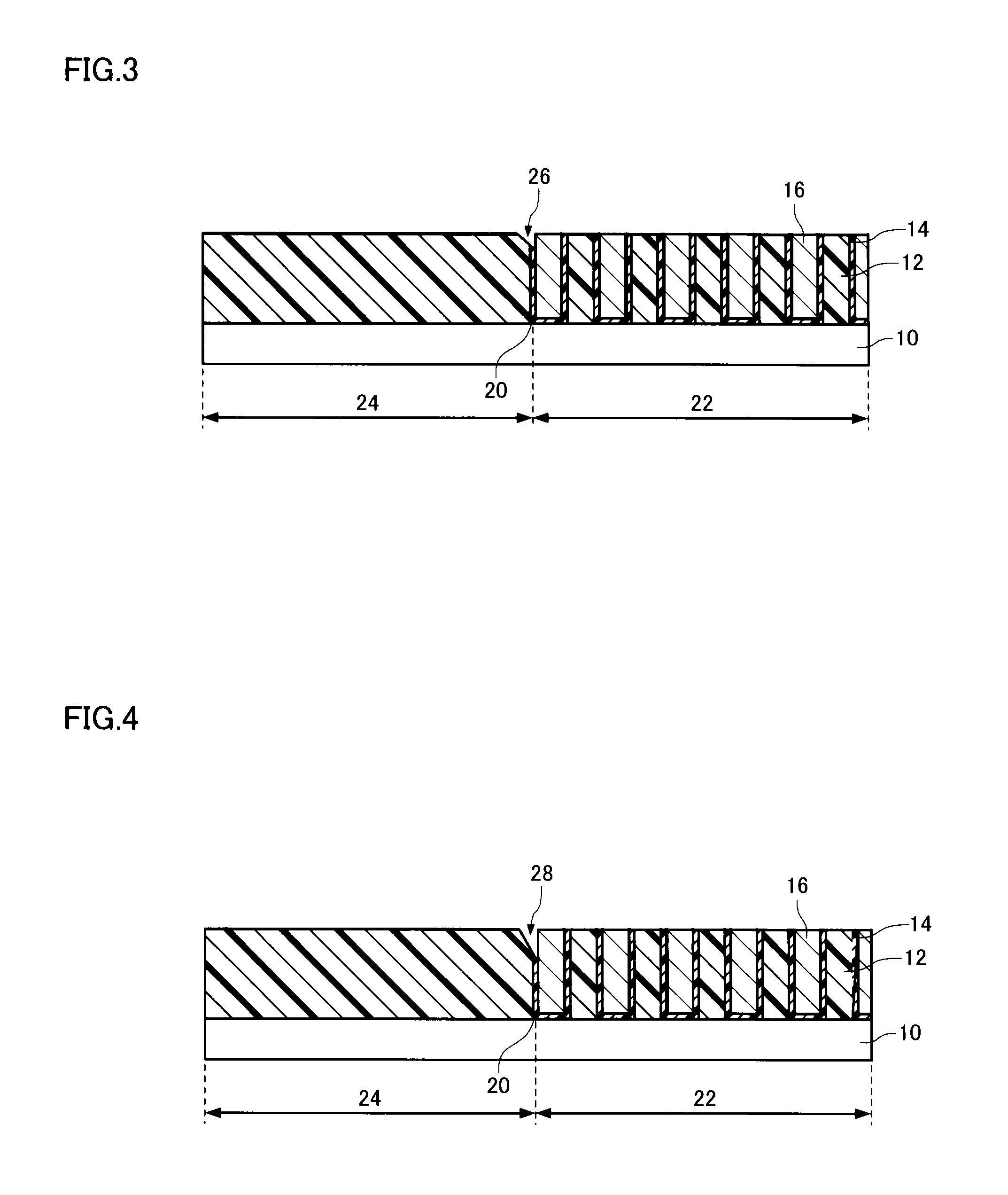

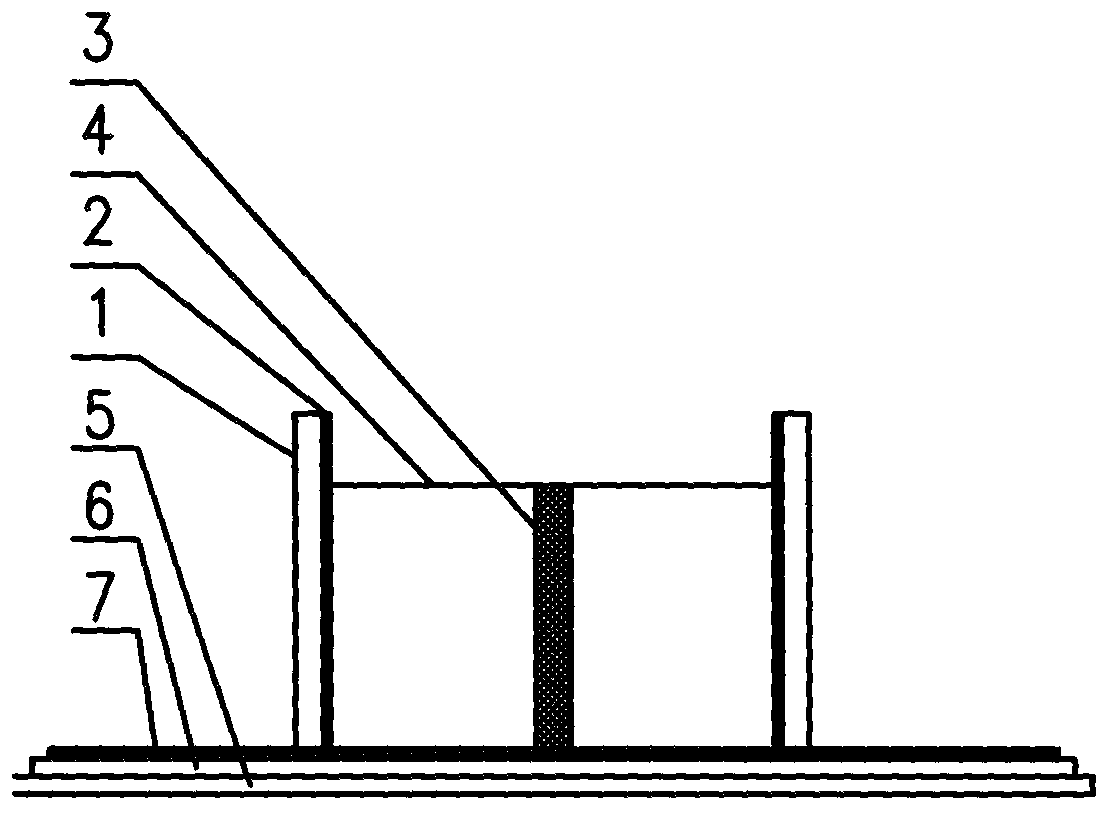

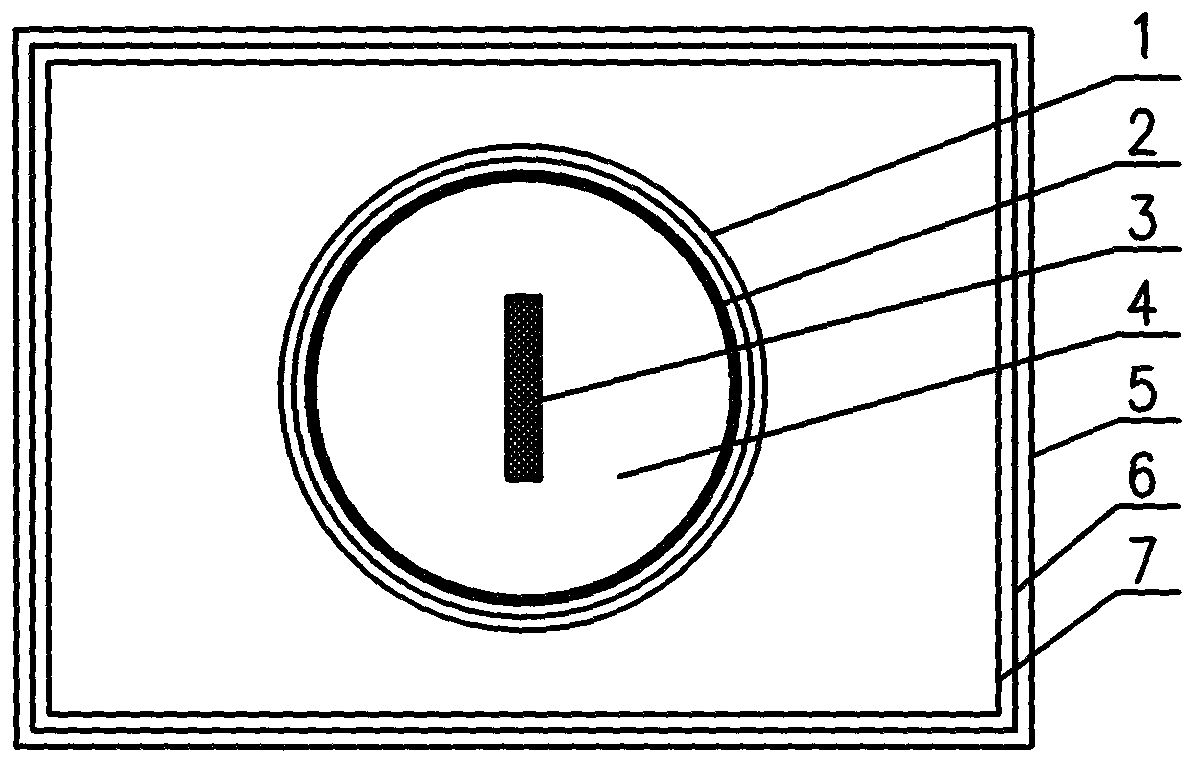

Method for manufacturing electro-optical device, electro-optical device, and electronic equipment

InactiveUS6358759B1Uniform rateReduce variationTransistorSolid-state devicesOptoelectronicsCrystalline silicon

A electro-optical device and manufacturing method are provided for an electro-optical device that has the step of forming a light shielding layer on one side of a light transmissive substrate, patterning the light shielding layer, forming an insulating layer on the patterned light shielding layer, planarizing the insulating layer, bonding a model crystalline silicon layer on the surface of the planarized insulating layer, and forming a transistor element from the monocrystalline silicon layer, wherein the patterned light shielding layer is arranged in an area facing the transistor element and in a peripheral area surrounding the transistor element.

Owner:138 EAST LCD ADVANCEMENTS LTD

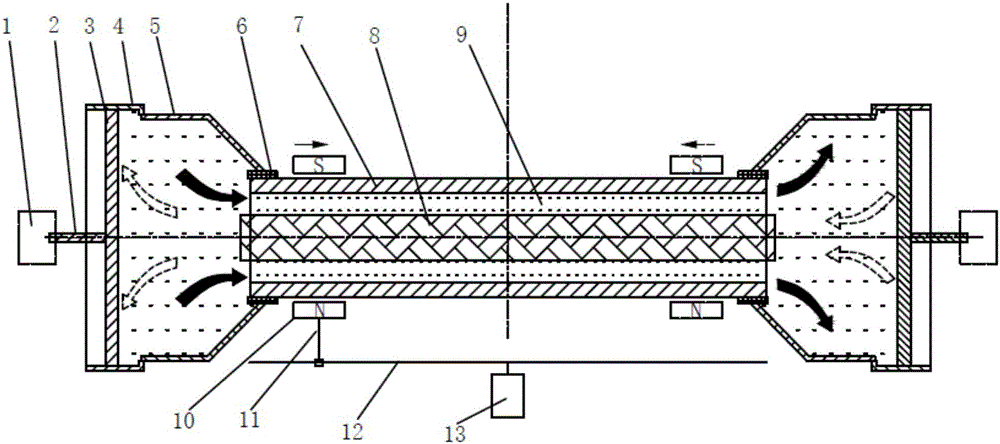

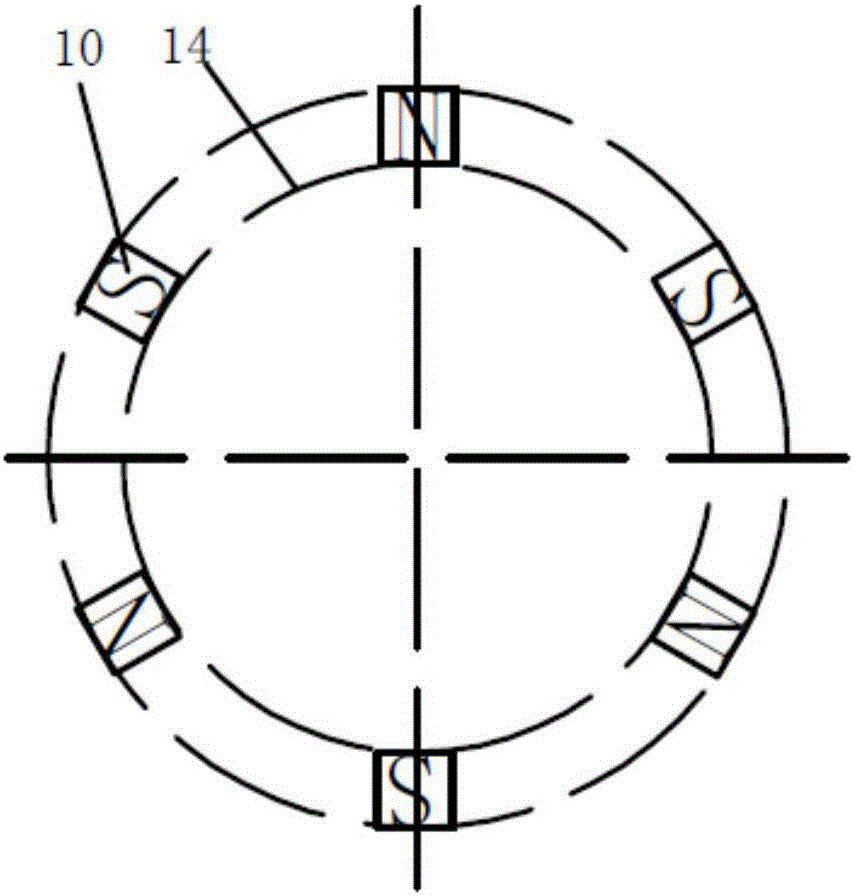

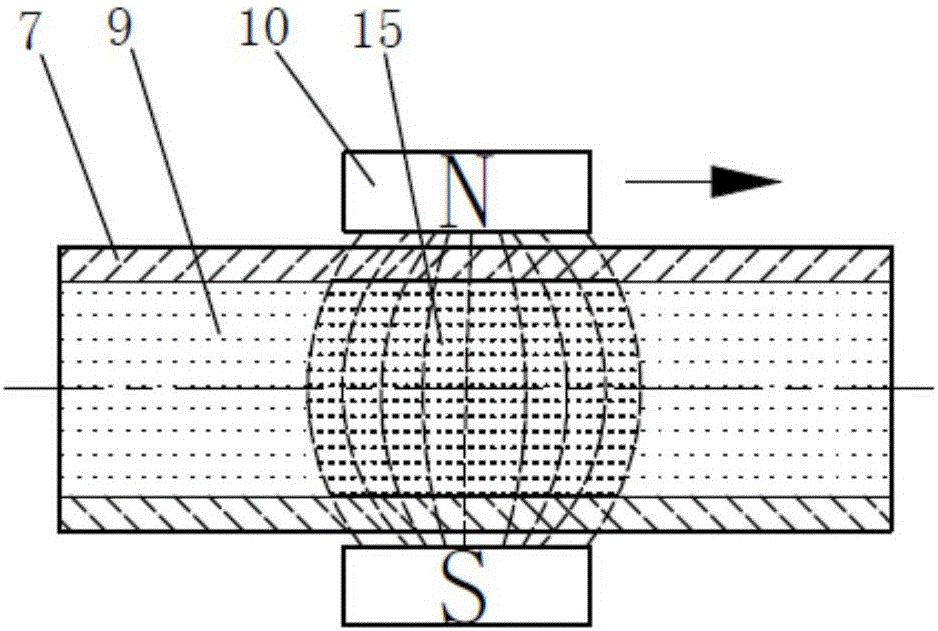

Self-pressurized high-speed polishing method and device for inner surface of hole by means of abrasive particles and magnetic flow

InactiveCN105881185AImprove machining accuracyImprove processing efficiencyEdge grinding machinesPolishing machinesMagnetic currentReciprocating motion

The invention provides a self-pressurized high-speed polishing method for the inner surface of a hole by means of abrasive particles and a magnetic flow. According to the method, the abrasive particles are coated with and restrained on the inner surface of the hole of a workpiece by the aid of ferromagnetic particles in a magnetorheological polishing fluid, which flows at a high speed, under the effect of a magnetic field produced by moving magnetic bodies, a flexible polishing abrasive brush flowing at a high speed is formed and reciprocates to rub against the inner surface of the hole of the machined workpiece to remove burrs and reduce the roughness of the inner surface of the hole, and burr removal and deterministic polishing are realized for various types of inner surfaces of holes. The invention further provides a self-pressurized high-speed polishing device for the inner surface of the hole by means of the abrasive particles and the magnetic flow. The device comprises a polishing mechanism, the magnetic bodies, a clamping mechanism, a sliding guide rail and a driving motor, wherein the driving motor drives the magnetic bodies to enable the polishing fluid to reciprocate in the hole at the high speed for polishing. The method and the device can solve problems that special holes are difficult to polish and the polishing efficiency is low, and have the advantages of high precision, high machining efficiency, low damage and low cost.

Owner:GUANGDONG UNIV OF TECH

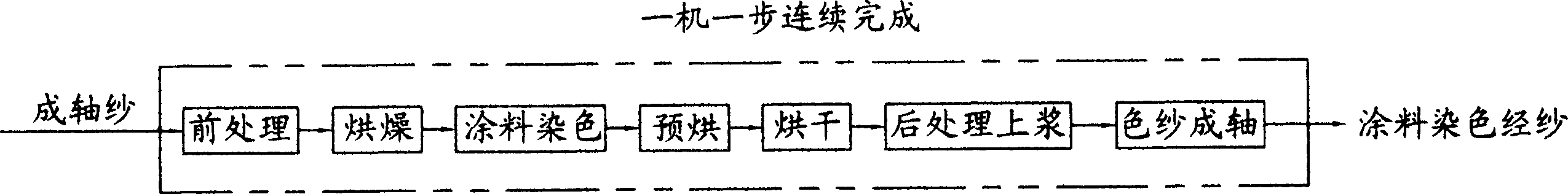

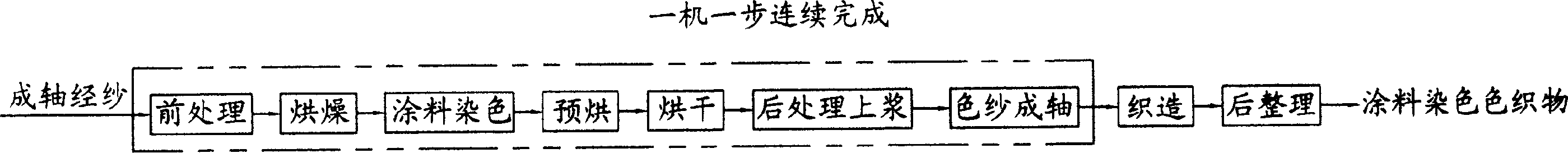

Pigment dyed colored cloth production method

InactiveCN1884659AQuality improvementGood processing depthSucessive textile treatmentsSingeingSewageEnergy consumption

The invention discloses a manufacturing method of paint dyeing weaver with oxford textile, chambray and denim, which comprises the following steps: predisposing warp; drying; dyeing; predrying; drying; after-treating; shafting warp; weaving; dressing; finishing one step by one machine continually. The invention satisfies large batch and scale manufacturing request, which is fit for producing original paint dyeing and other pain dyeing weaver product.

Owner:常州市森容纺织品有限公司

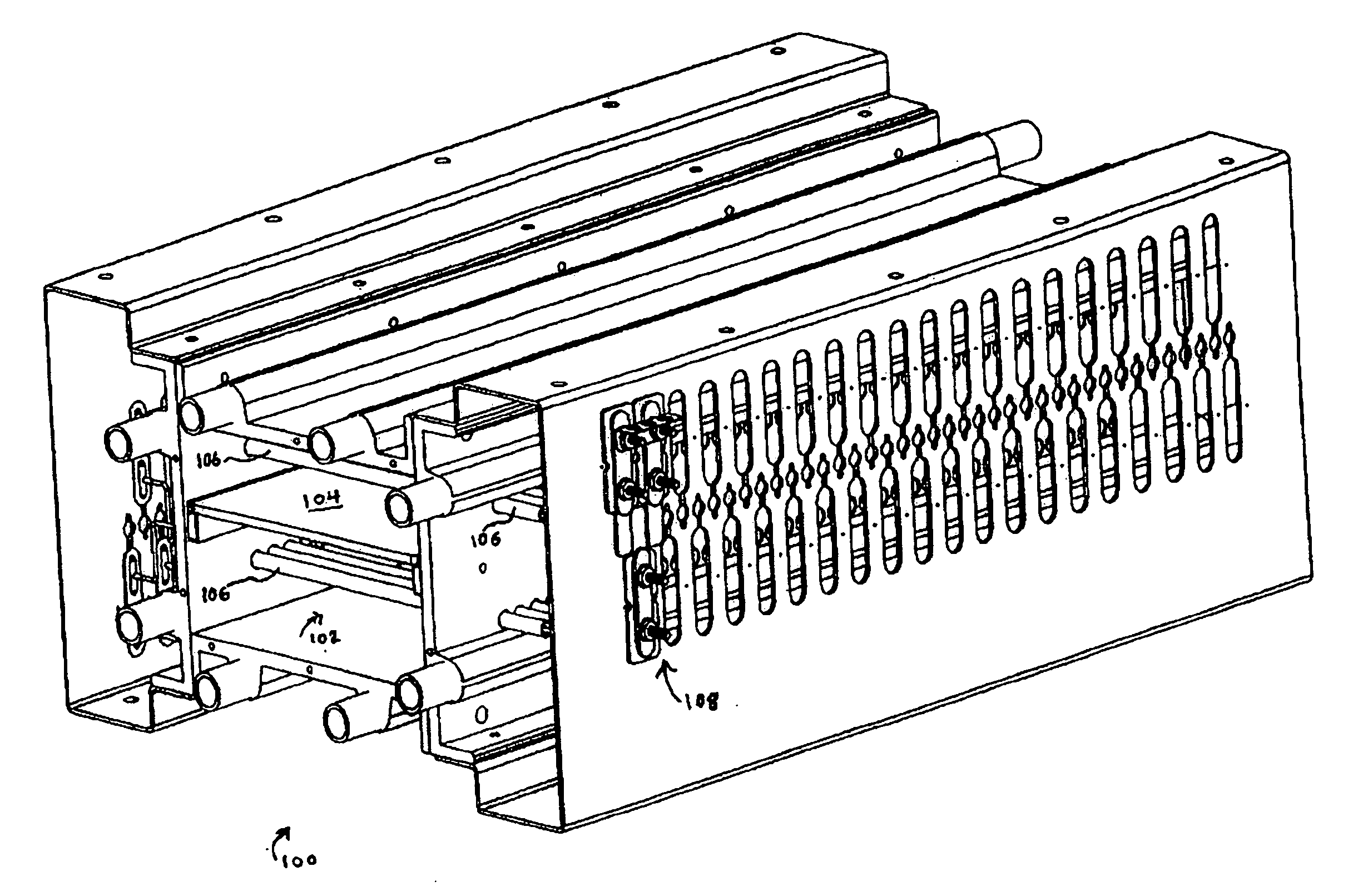

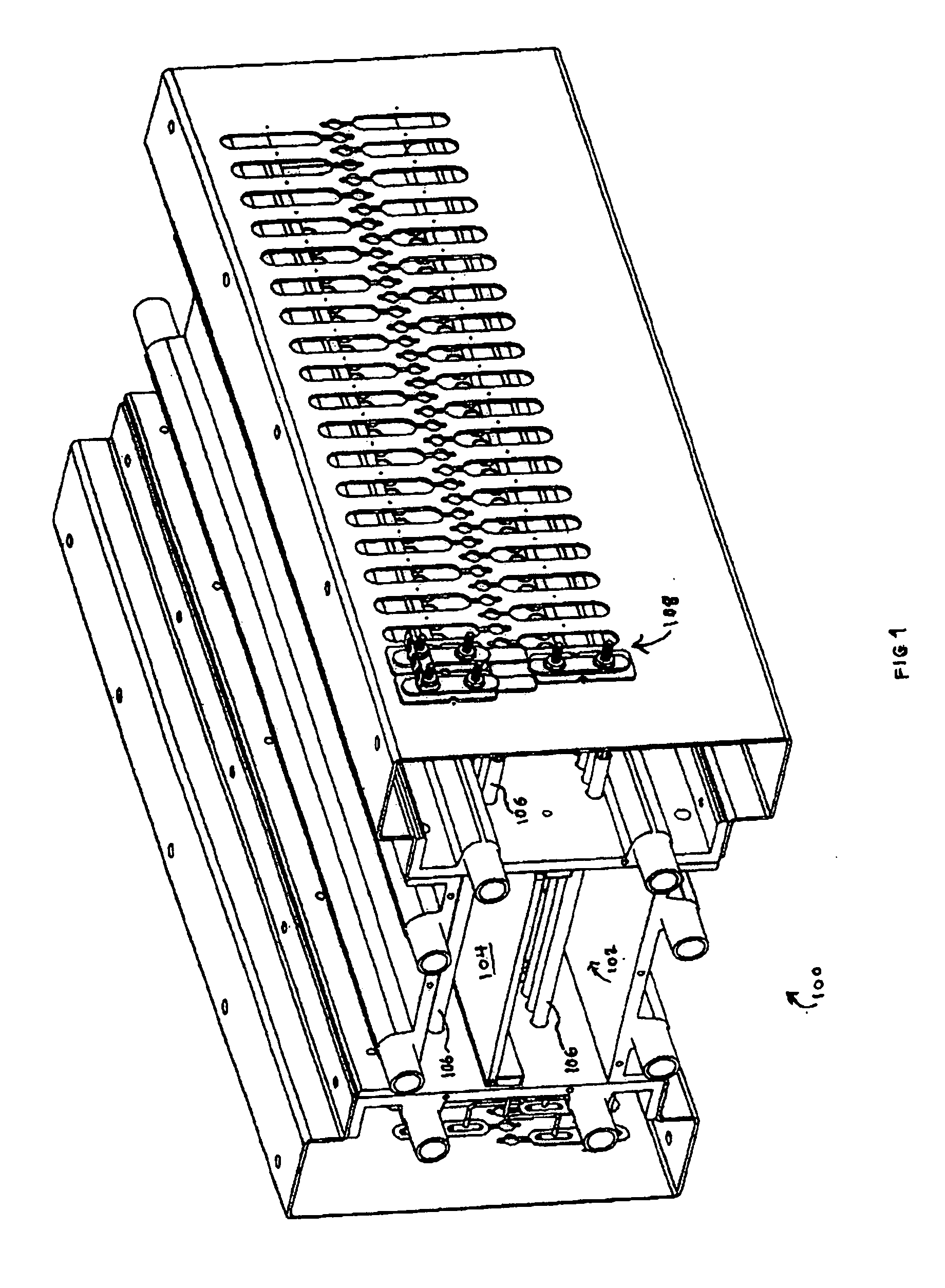

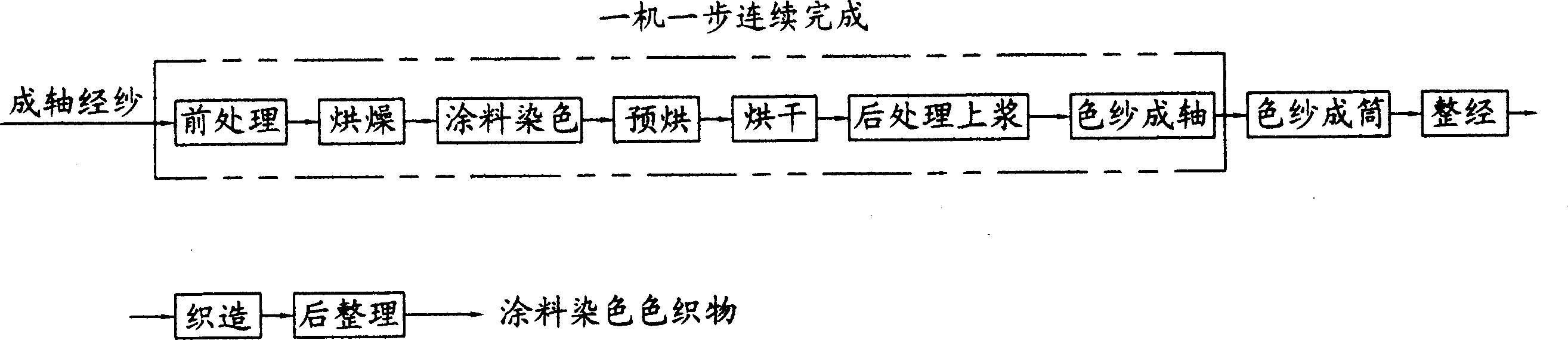

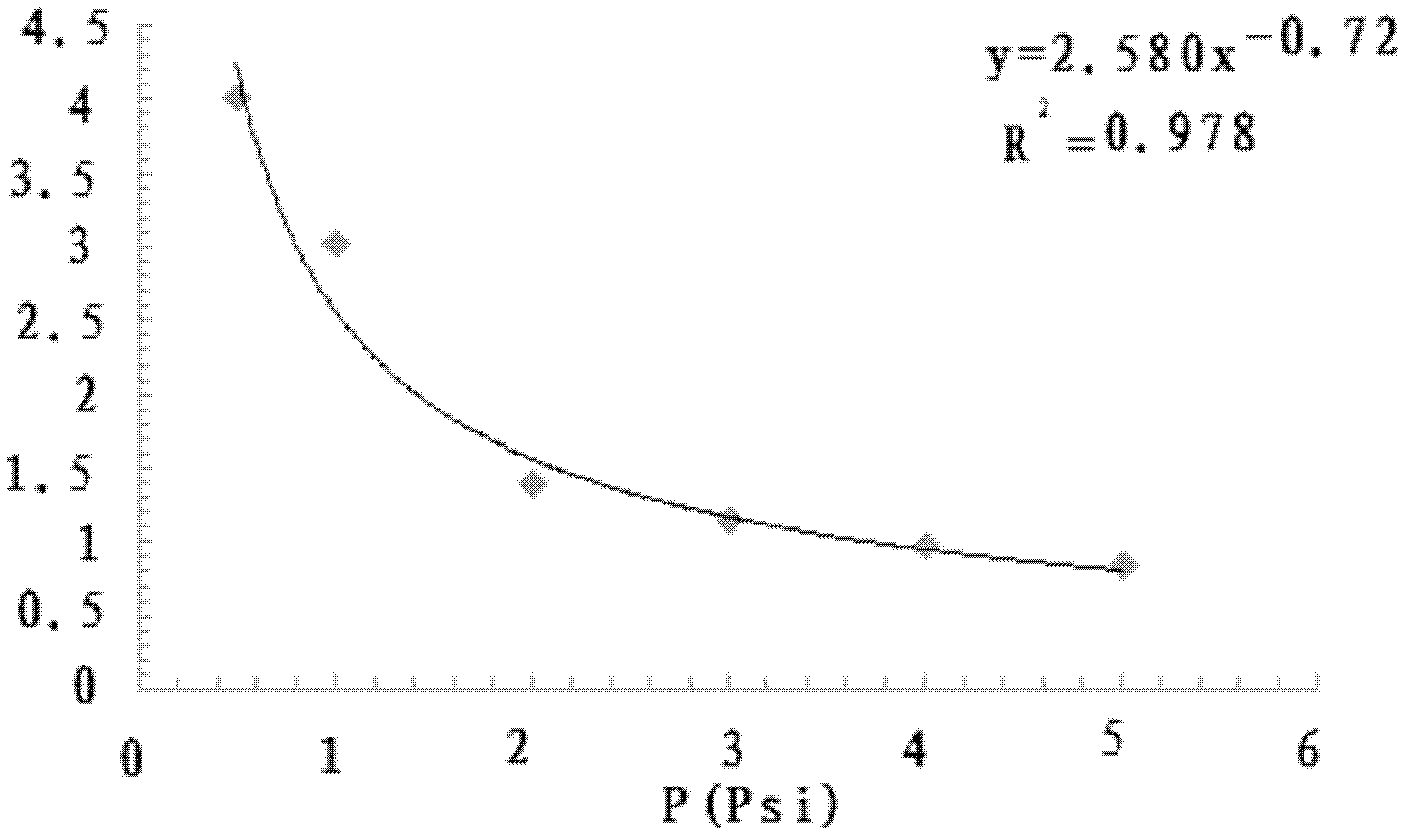

Advanced chemical mechanical polishing system with smart endpoint detection

InactiveUS6857947B2Save time and moneyReduce, andPolishing machinesRevolution surface grinding machinesPhysicsPolishing

An apparatus for polishing a workpiece includes a workpiece holder configured to hold the workpiece, a polishing member configured to be positioned adjacent to a face of the workpiece in order to polish the workpiece face with a front side of the polishing member, and a platen having a plurality of pressure zones configured to selectively apply pressure to the polishing member thereby causing the polishing member to contact the workpiece face with selective pressure. In another embodiment, the apparatus includes a pressure controller coupled to the platen and configured to selectively adjust the pressure zones.

Owner:NOVELLUS SYSTEMS

Tantalum barrier removal solution

InactiveUS20030181345A1Reduce erosionMaterial removalPigmenting treatmentSoap detergents with inorganic compounding agentsGuanidine derivativesTantalum nitride

A chemical mechanical planarization solution is useful for removing tantalum barrier materials. The solution includes by weight percent 0 to 25 oxidizer, 0 to 15 inhibitor for a nonferrous metal and 0 to 20 complexing agent for the nonferrous metal, 0.01 to 12 tantalum removal agent selected from the group consisting of formamidine, formamidine salts, formamidine derivatives, guanidine derivatives, guanidine salts and mixtures thereof, 0 to 5 abrasive, 0 to 15 total particles selected from the group consisting of polymeric particles and polymer-coated coated particles and balance water. The solution has a tantalum nitride to TEOS selectivity of at least 3 to 1 as measured with a microporous polyurethane polishing pad pressure measure normal to a wafer less than 20.7 kPa.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

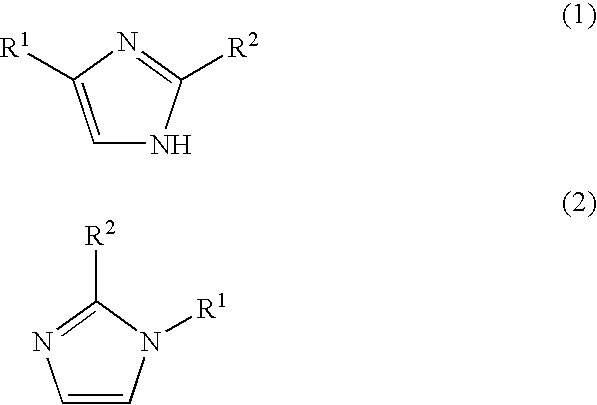

Compositions and methods for controlled polishing of copper

InactiveUS20050136670A1Good removal effectAvoid corrosionOther chemical processesAbrasion apparatusNonferrous metalCopper

The present invention provides an aqueous composition useful for polishing copper on a semiconductor wafer comprising by weight percent 0.001 to 6 inhibitor for a nonferrous metal, 0.05 to 10 complexing agent for the metal, 0.01 to 25 copper removal agent for accelerating the removal of the copper, 0.5 to 40 abrasive, 0 to 10 selected from the group comprising, polyvinylpyrrolidone, thermoplastic polymer and mixtures thereof, wherein the copper removal agent is imidazole.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Non-slip floor covering and process for producing it

InactiveUS6434897B1No optical disadvantagesEasy to polishTreadsPaving detailsBiomedical engineeringFloor covering

A non-slip floor covering which includes a plurality of depressions that are regularly or randomly distributed over a floor covering surface such that the depressions provide a suction effect.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

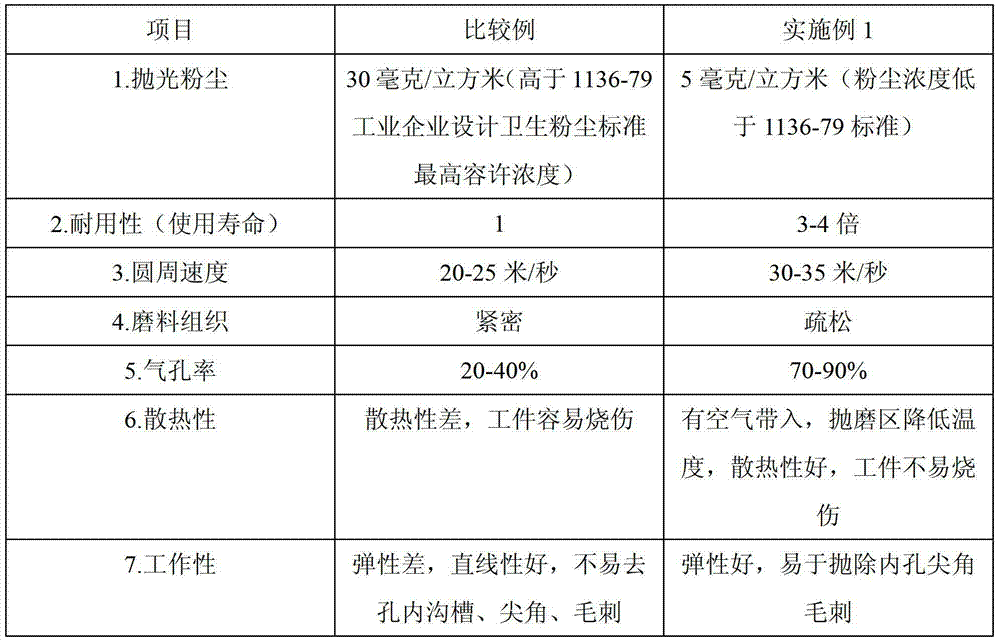

Polyvinyl alcohol-polyurethane elastic buffing wheel and preparation method thereof

InactiveCN103395011AUniform cellsNo stuffingAbrasion apparatusGrinding devicesWater bathsDistilled water

The invention discloses a polyvinyl alcohol-polyurethane elastic buffing wheel and a preparation method of the polyvinyl alcohol-polyurethane elastic buffing wheel. The preparation method comprises the steps that firstly, polyvinyl alcohol is mixed with distilled water, and the mixture is dissolved for 20-30 minutes under the condition of 50-95 DEG C water bath and at the rotation speed of 400-600r / min to obtain a polyvinyl alcohol aqueous solution; then, the polyvinyl alcohol aqueous solution is heated up to 30-100 DEG C, grinding materials are firstly added into the polyvinyl alcohol aqueous solution, after the mixture of the grinding materials and the polyvinyl alcohol aqueous solution is stirred and mixed evenly at the rotation speed of 400-600r / min, polyurethane pre-polymers, catalysts and air hole generating agents are added, and all the components are stirred and mixed evenly at the rotation speed of 400-600r / min and react for 5-10min; solidification is conducted for 2-4h under the condition of 30-100 DEG C, and then the buffing wheel which is good in elasticity, good in water resistance, good in heat-dissipating performance and high in mechanical strength is obtained. The elastic buffing wheel is even in foam hole, good in abrasion resistance and grinding force, not prone to deforming or curling in humid environment and applicable to long-time grinding work.

Owner:SOUTH CHINA UNIV OF TECH

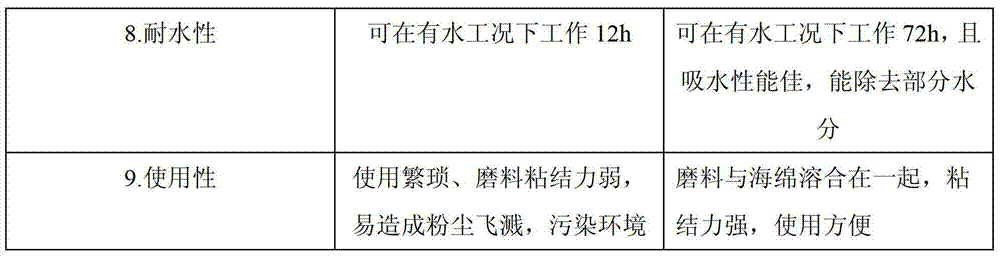

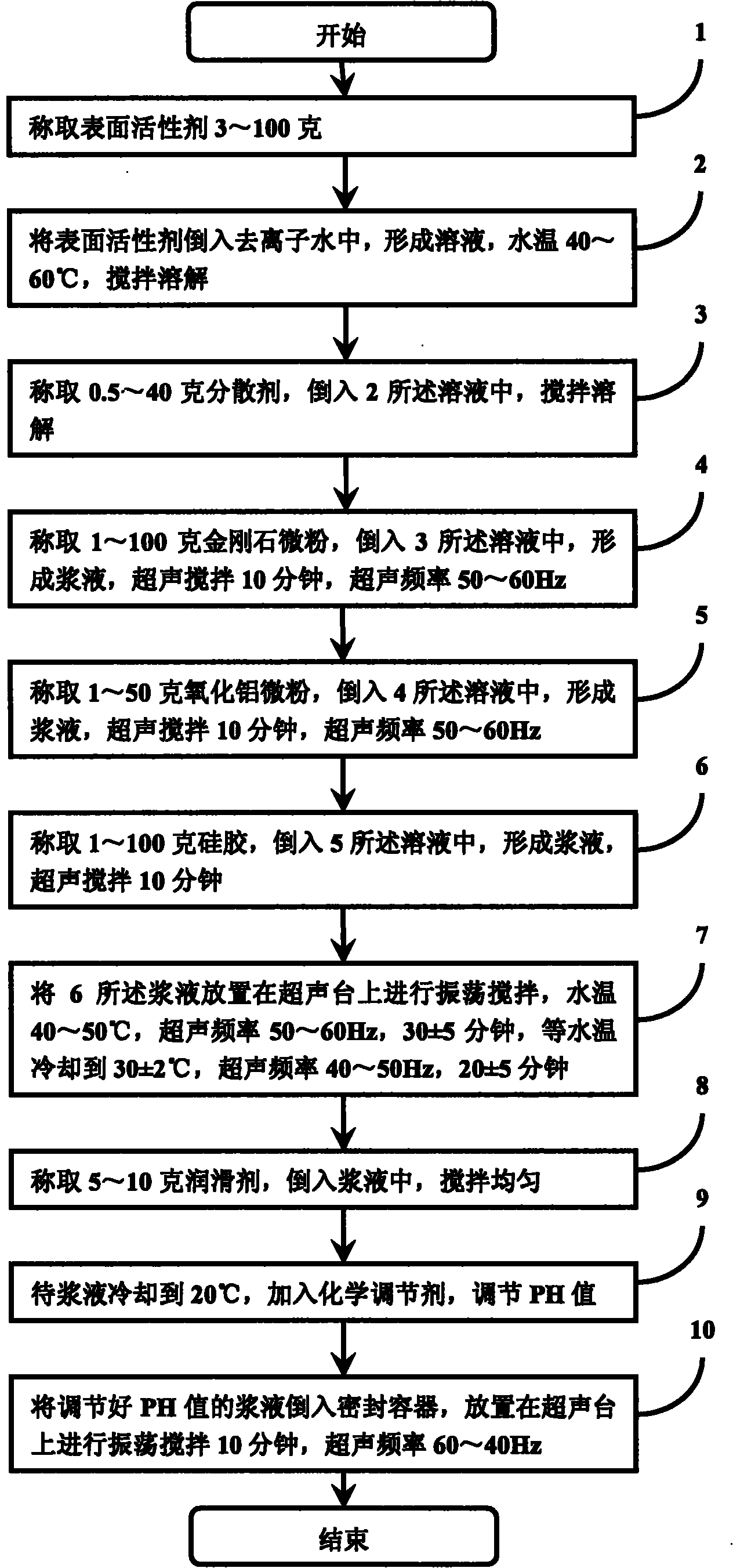

Nanometer level polishing solution and preparation method thereof

ActiveCN102311706AMeet the requirements of thinning grinding processEasy to polishPolishing compositions with abrasivesSilica gelSolvent

The invention discloses a nanometer level polishing solution and a preparation method thereof. The polishing solution is prepared from the following components in percentage by mass: 0.1 to 10 percent of monocrystal artificial diamond micro powder, 0.1 to 5 percent of aluminum oxide micro powder, 0.1 to 10 percent of silica gel, 0.3 to 10 percent of surfactant, 0.05 to 4 percent of dispersing agent, 0.5 to 1 percent of lubricant, 0.01 to 1 percent of chemical PH value regulator and 60 to 98.2 percent of solvent. The invention also discloses the preparation method for the nanometer level polishing solution. By the method, mixed serous fluid is prepared from the nanometer level diamond, the aluminum oxide and the silica gel, so an ideal polishing effect is achieved, the requirement of a process for thinning and grinding substrates (silicon carbide and sapphire) for GaN extension is met, and a technical means is provided for a polishing process for semiconductors.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

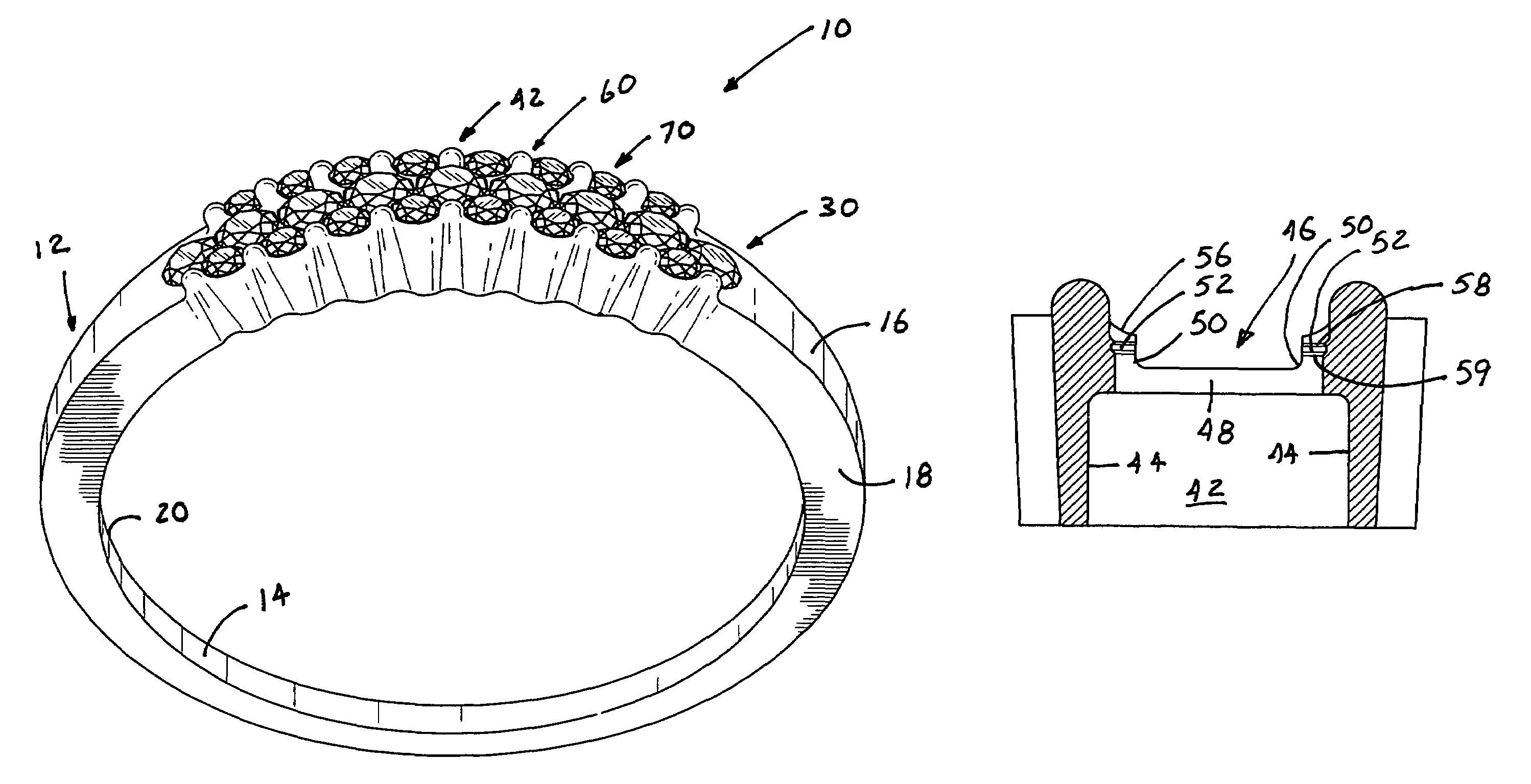

Jewelry article utilizing a linear stone setting

InactiveUS7546749B1Easy to polishEliminates appearanceBraceletsWrist-watch strapsEngineeringLost-wax casting

An article of jewelry supports a plurality of primary stones in a linear mounting array and which is bordered on both sides by accent stones. The girdles of the primary stones and of the accent stones are positioned close to each other with the accent stone girdles being above the primary stone girdles. A method of making the article of jewelry includes the use of a lost wax casting process followed by hand-setting of the accent stones and an application of a highly reflective coating, such as rhodium to surfaces that are adjacent the areas of congruence of the primary and accent stones. The resultant piece of jewelry presents the appearance of floating or unsupported primary stones.

Owner:B G A TRADING

Methods of polymeric stent surface smoothing and resurfacing to reduce biologically active sites

ActiveUS20090095715A1Reduces surface reactivityReduction and elimination of platelet adhesionDecorative surface effectsSurgeryChemical treatmentVitrification

The present invention provides methods for fabricating a stent using a chemical treatment to smooth, polish or strengthen the stent. One such treatment involves exposing the stent to acetone or a similar solvent. In certain embodiments, the additional step comprises placing the stent in a bath containing acetone, or a similar solvent, where the bath also contains the polymer the stent is composed of. The acetone bath step may be conducted at a temperature that is below the glass transition temperature. The present invention also provides for methods of fabricating a stent using an acetone bath that comprises poly (lactic) acid. Other embodiments provide for methods of fabricating a stent using an acetone bath that comprises poly (lactic) acid and polyethylene glycol.

Owner:SAHAJANAND TECHNOLOGIES PRIVATE LTD

Acidic chemical and mechanical polishing composition

ActiveCN102585706AEasy to polishBoost rateOther chemical processesPolishing compositions with abrasivesColloidal silicaOrganic film

The invention provides an acidic chemical and mechanical polishing composition. The pH value of the acidic chemical and mechanical polishing composition is 2-7, and the acidic chemical and mechanical polishing composition comprises 1-20% by weight of abrasive material, 0.5-10% by weight of oxidant, 0.1-10% by weight of complexing agent, 0.001-1% by weight of corrosion inhibitor, 0.001-5% by weight of organic film-forming auxiliaries and the balance of pH regulator and deionized or distilled water, wherein the abrasive material is of colloidal silica sol after modification in the special step, and the average particle size is of 10-200nm. According to the chemical and mechanical polishing composition provided by the invention, the abrasive material is refined and modified; by using the method, the stability of the abrasive material in polishing slurry can be effectively upgraded, and polishing removal rate and surface roughness degree are respectively optimized to a certain extent; and the unique adding effect of the organic film-forming auxiliaries can well balance the strength of chemical corrosion action and the strength of mechanical grinding action, and achieve the effects of improving polishing removal efficiency and performing global planarization.

Owner:TSINGHUA UNIV

Aqueous dispersion for chemical mechanical polishing and chemical mechanical polishing method

InactiveUS20110081780A1Reduce polishing rateHigh polishing rateOther chemical processesSemiconductor/solid-state device manufacturingOrganic acidSilica particle

A chemical mechanical polishing aqueous dispersion includes (A) silica particles, and (B1) an organic acid, the number of silanol groups included in the silica particles (A) calculated from a signal area of a 29Si-NMR spectrum being 2.0 to 3.0×1021 / g.

Owner:JSR CORPORATIOON

Low Pressure Polishing Method and Apparatus

ActiveUS20090221212A1Low pressure conditionHigh surface finishEdge grinding machinesBrush bodiesLow speedEngineering

An improved low pressure low speed concrete polishing apparatus and method of cleaning and polishing a floor is used with a conventional rotary flooring machine. A polishing pad has interchangeable polymer strips that are slideably received within the housing of the pad. The polymer strips have an abrasive material embedded therein which collectively work to polish the floor while cleaning the floor during normal low speed floor cleaning conditions.

Owner:DIAMABRUSH

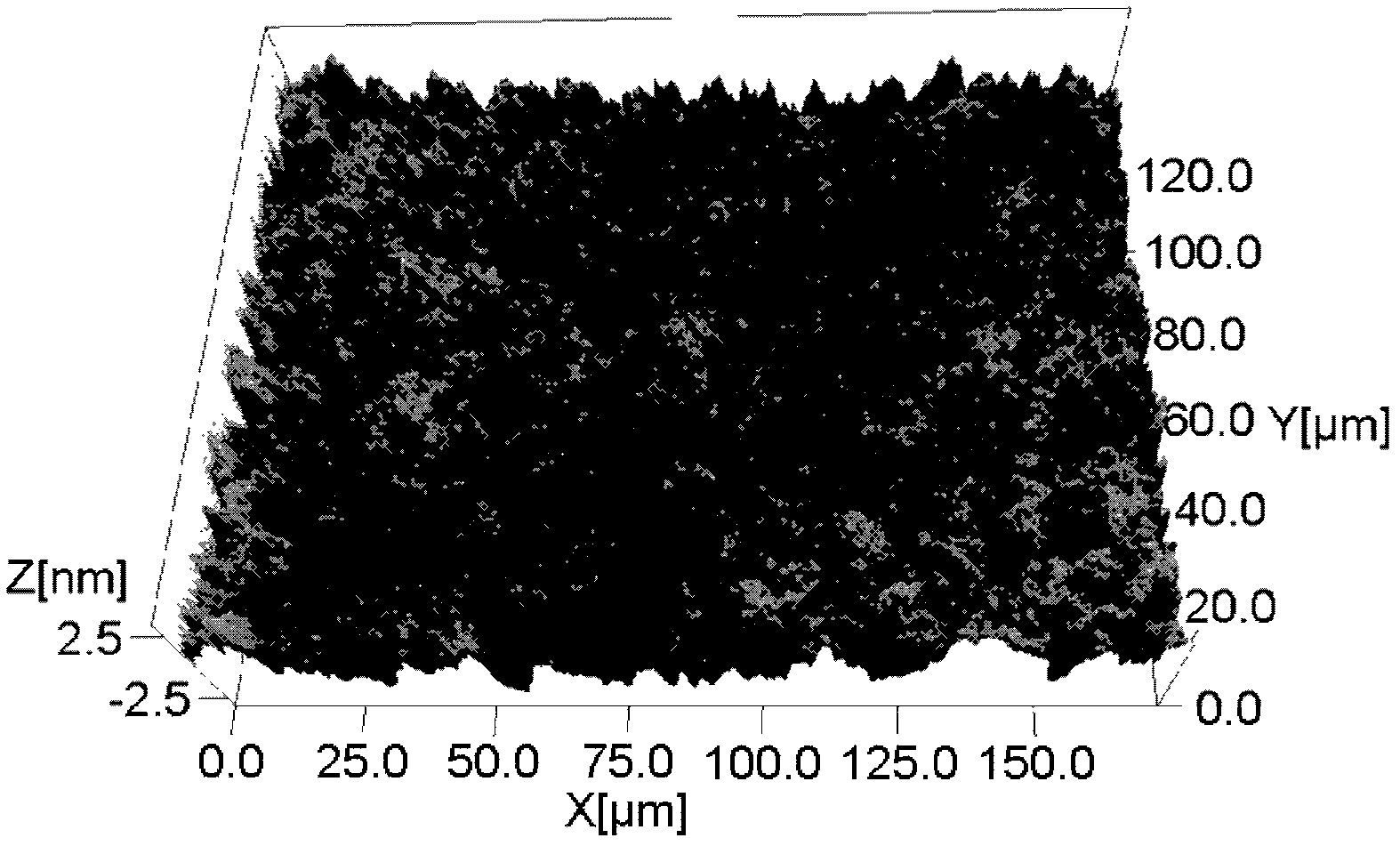

Tools for polishing and associated methods

ActiveUS7241206B1Easy to polishAbrasion apparatusAbrasive surface conditioning devicesSurface roughnessEngineering

Polishing tools and associated methods are disclosed. In one aspect, a method of polishing a work piece is provided. Such a method may include providing a polishing tool having asperities on a working surface, where the asperities have a tip-to-tip RA value of less than or equal to about 10 μm, and the working surface has a surface roughness RA value of less than or equal to about 50 μm. The method may further include contacting the tips of the asperities against an interface surface of the work piece and moving the tips of the asperities in a direction substantially parallel to the interface surface of the work piece such that the interface surface is polished.

Owner:KINIK

Corrosion sample inlaying method

InactiveCN103543060ATightly boundSample preparation is beautiful and generousPreparing sample for investigationEpoxyRoom temperature

The invention discloses a corrosion sample inlaying method. The method comprises the following steps of: based on an epoxy resin inlay, which is composed of 60-80% of matrix resin, 10-25% of conductive powder, 2-10% of dispersing agent and 7-15% of curing agent by weight, orderly arranging the sample to be inlaid, namely the corrosion sample, completely covering the sample with a die, and then, pouring the epoxy resin inlay into the die until submerging the corrosion sample; curing 3-12h at room temperature, uncovering flat surface paper, taking out the sample from the die, respectively sanding the sample with 120#, 240#, 400#, 600#, 800# and 1000# sand paper stage by stage, and then, polishing the sample. With the method disclosed by the invention, the processed corrosion sample can be used for metallomicroscopy observation or electron microscopy scanning observation, so that organization, structure and form of the cross section of the corrosion sample are shown integrally and really.

Owner:CHINA PETROCHEMICAL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com