Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

156results about How to "Uniform rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

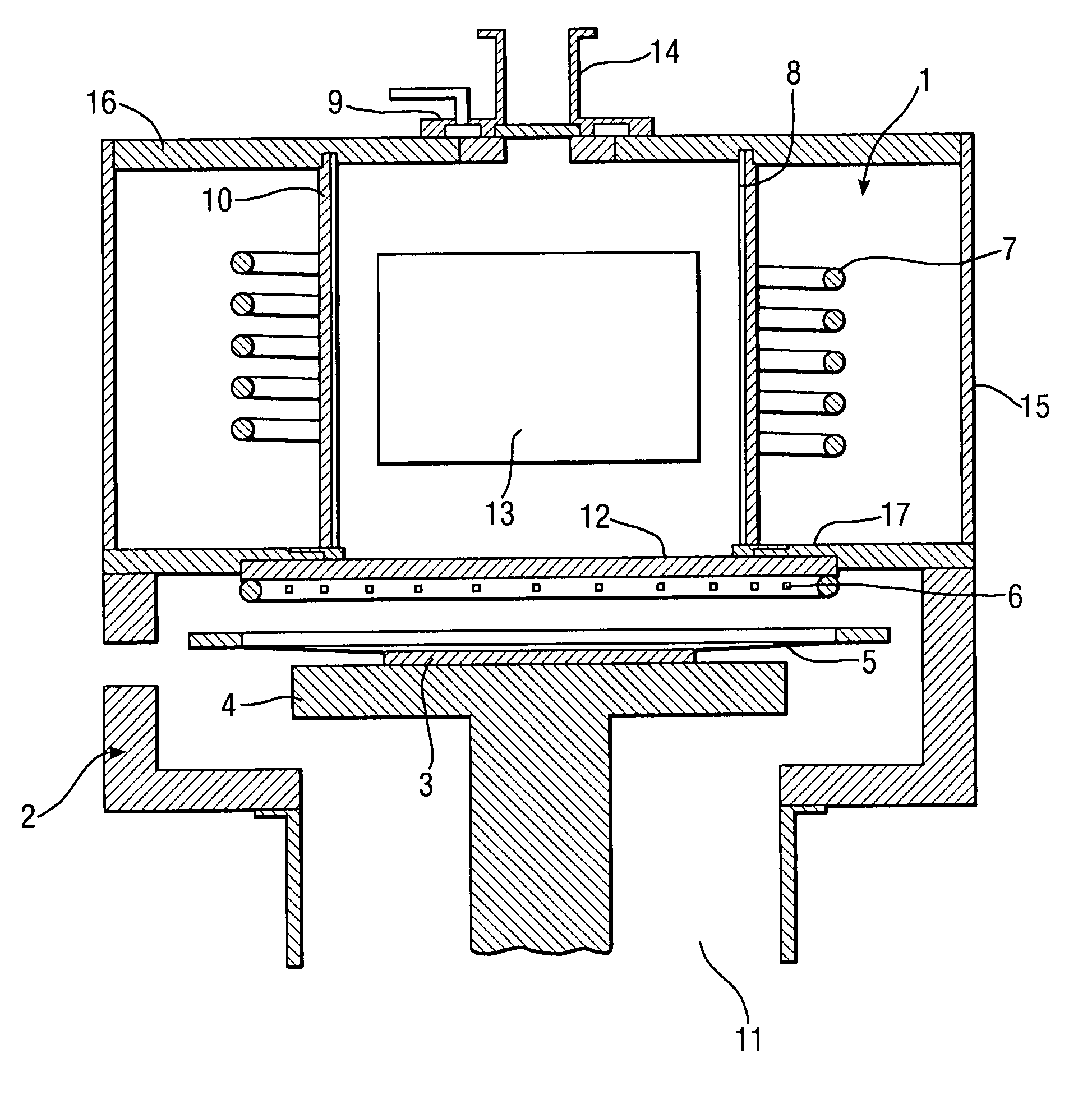

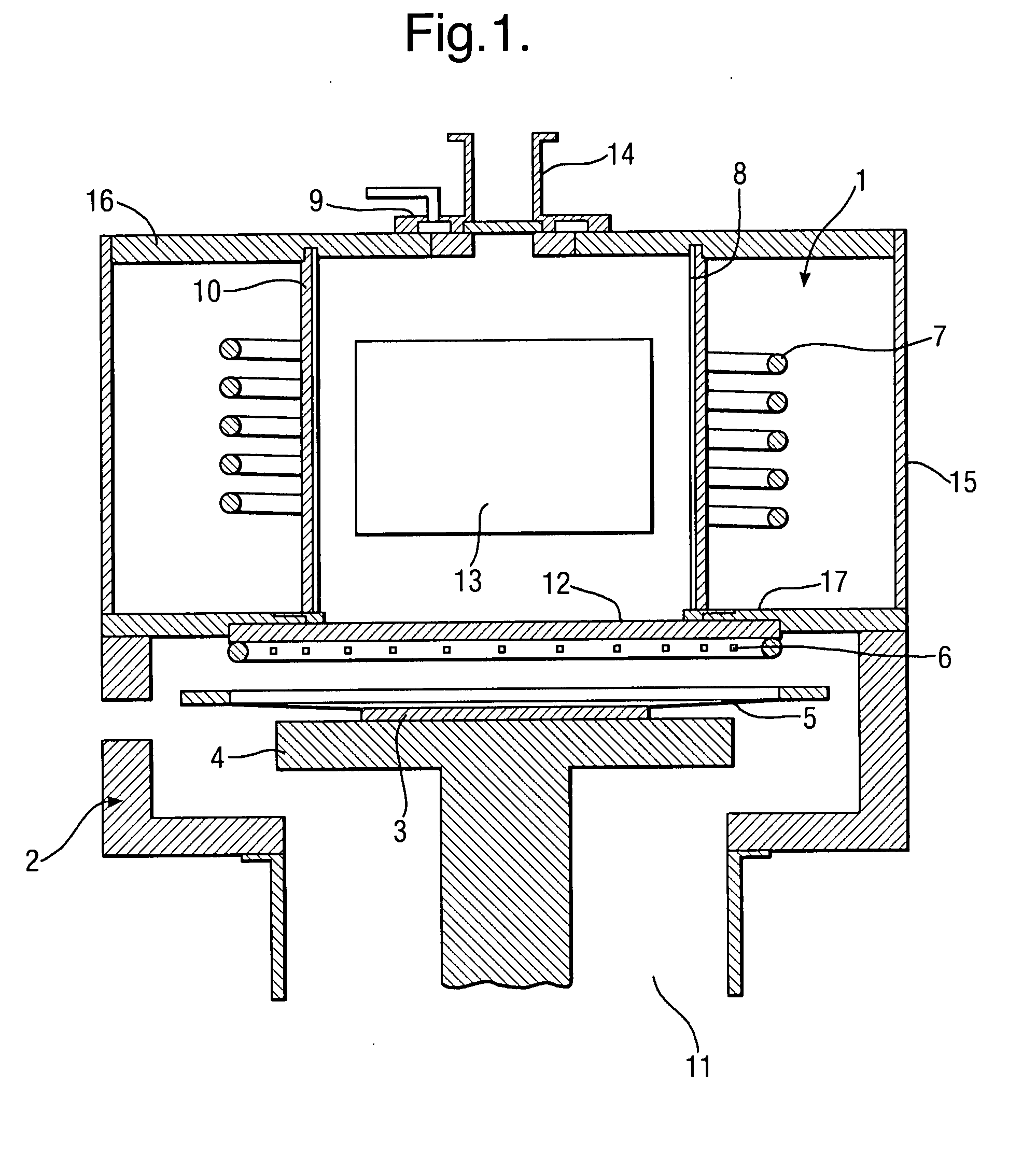

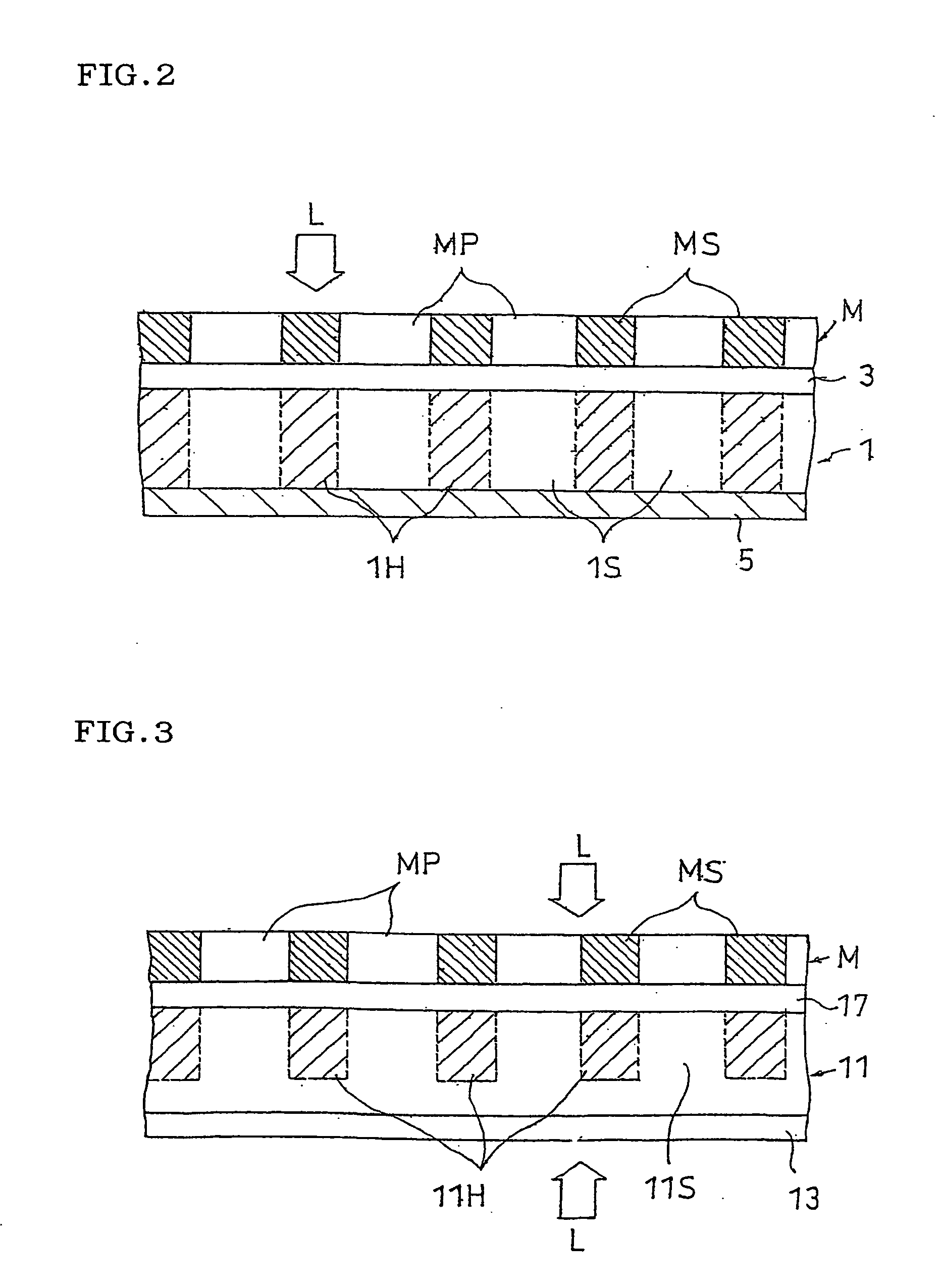

Surface processing apparatus

InactiveUS20080035608A1Uniform deposition and material removal ratePrevent thermal degradationElectric discharge tubesDecorative surface effectsEngineeringSurface processing

A surface processing apparatus is provided for use in the surface processing of a substrate. The surface processing apparatus comprises a plasma source and processing chamber in which a substrate is mounted in use. The processing chamber is operatively connected to the plasma source and the surface processing apparatus is characterised by a transmission plate for the transmission of plasma in use between the plasma source and processing chamber. The transmission plate comprises one or more apertures wherein the physical form of the one or more apertures and / or the distribution of the one or more apertures is adapted to provide a predetermined processing pattern upon the surface of the substrate. Typically the design of the apertures is adapted to provide a substantially uniform deposition rate across a wafer substrate.

Owner:OXFORD INSTR NANOTECH TOOLS

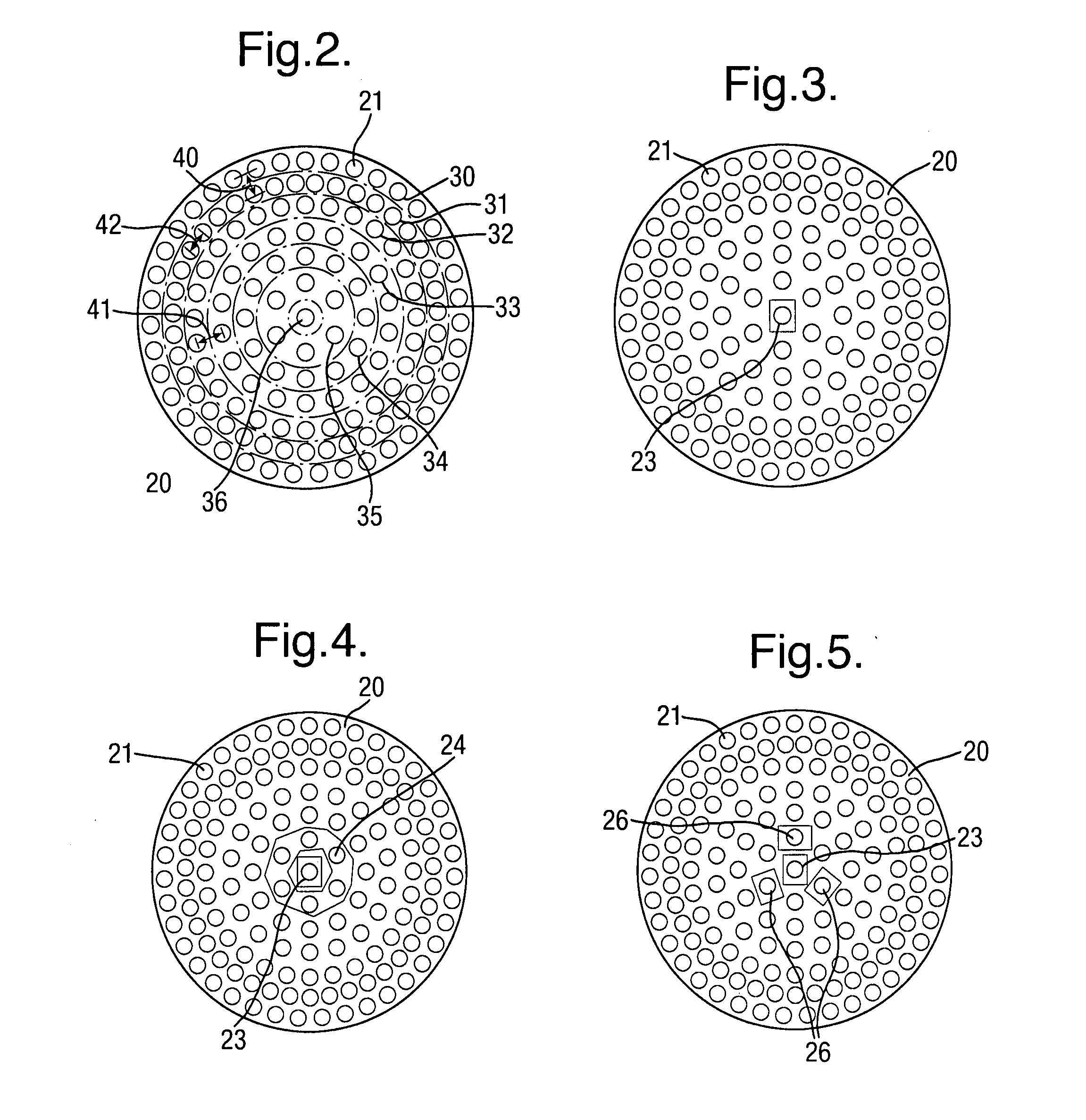

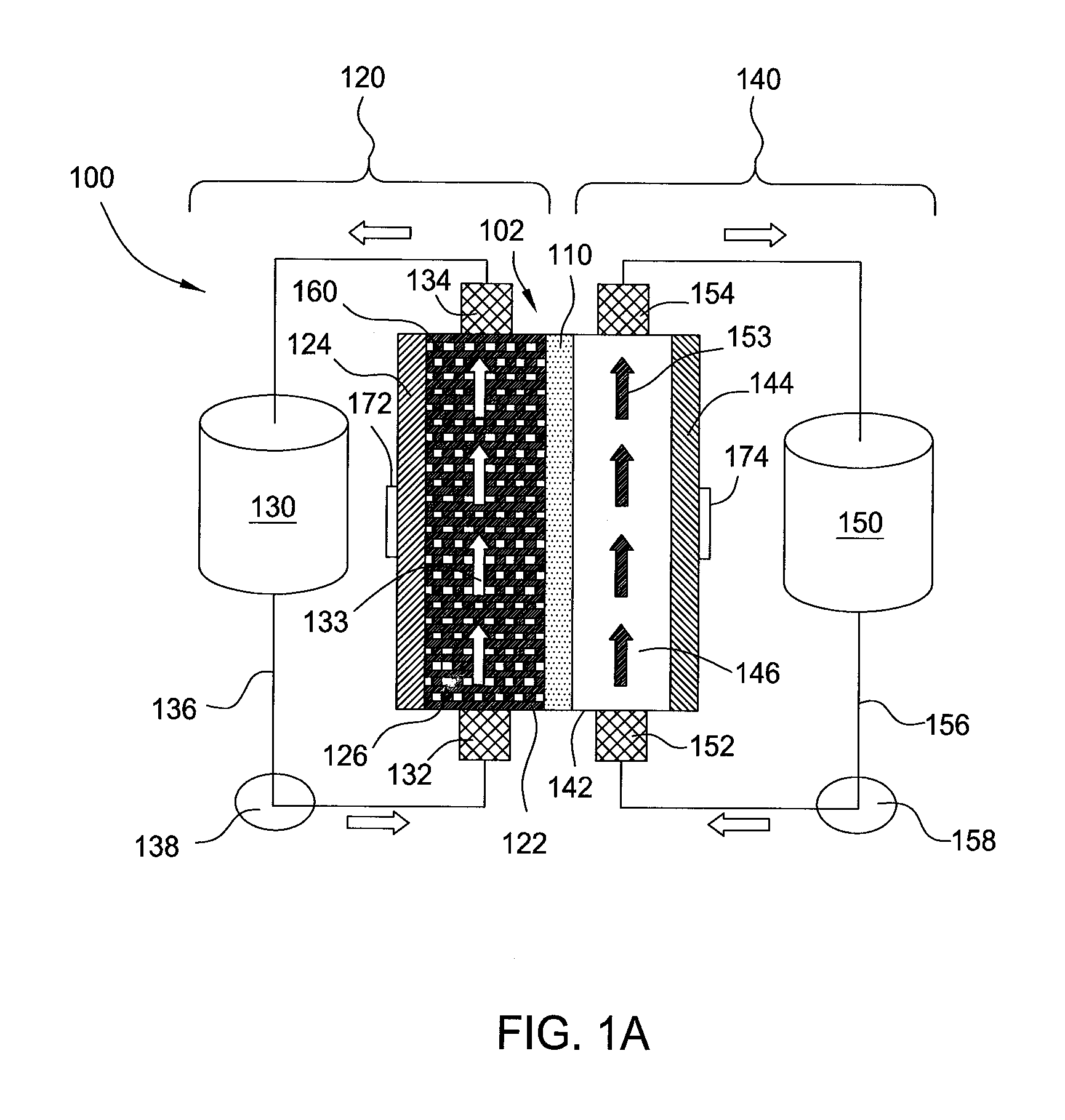

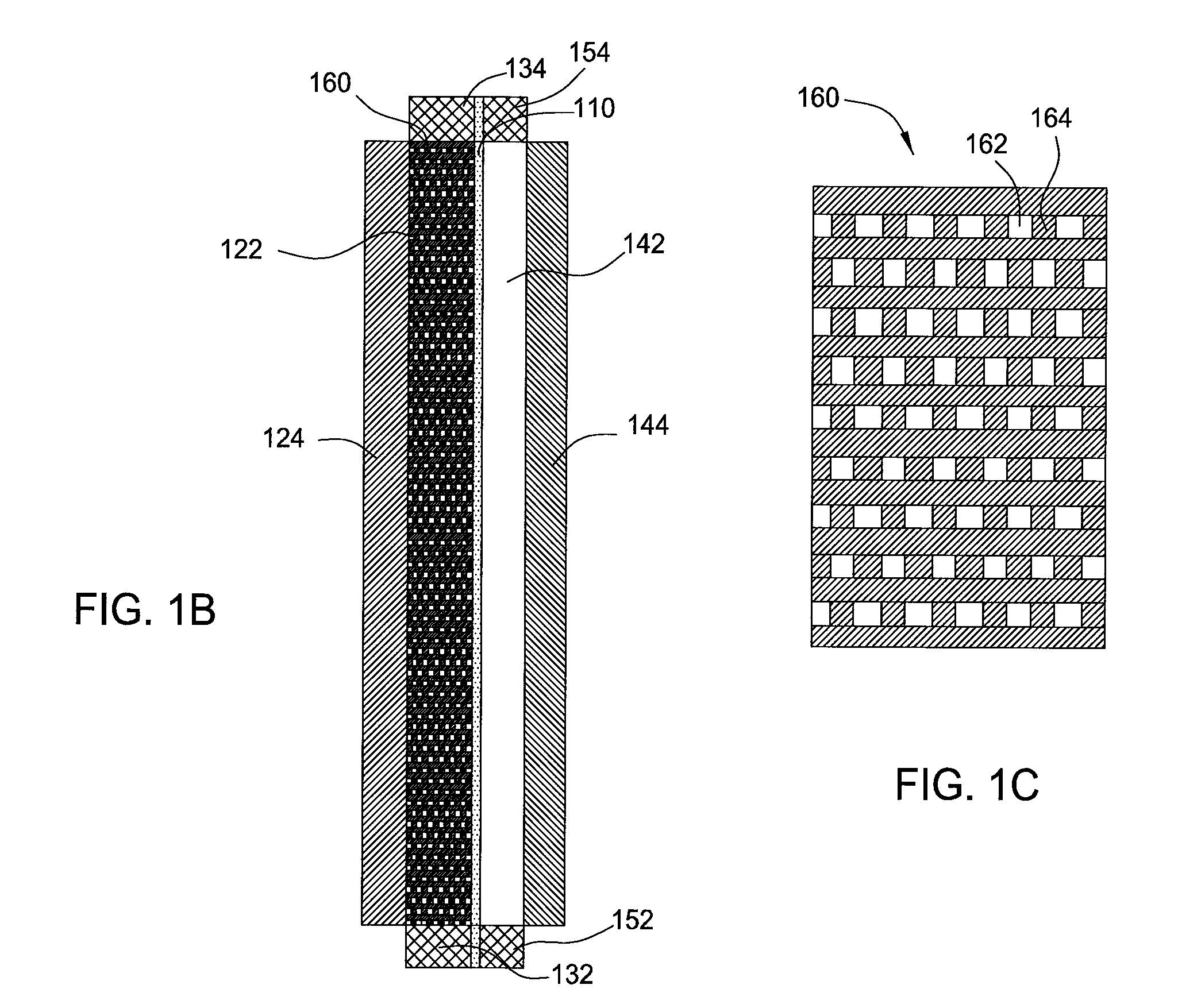

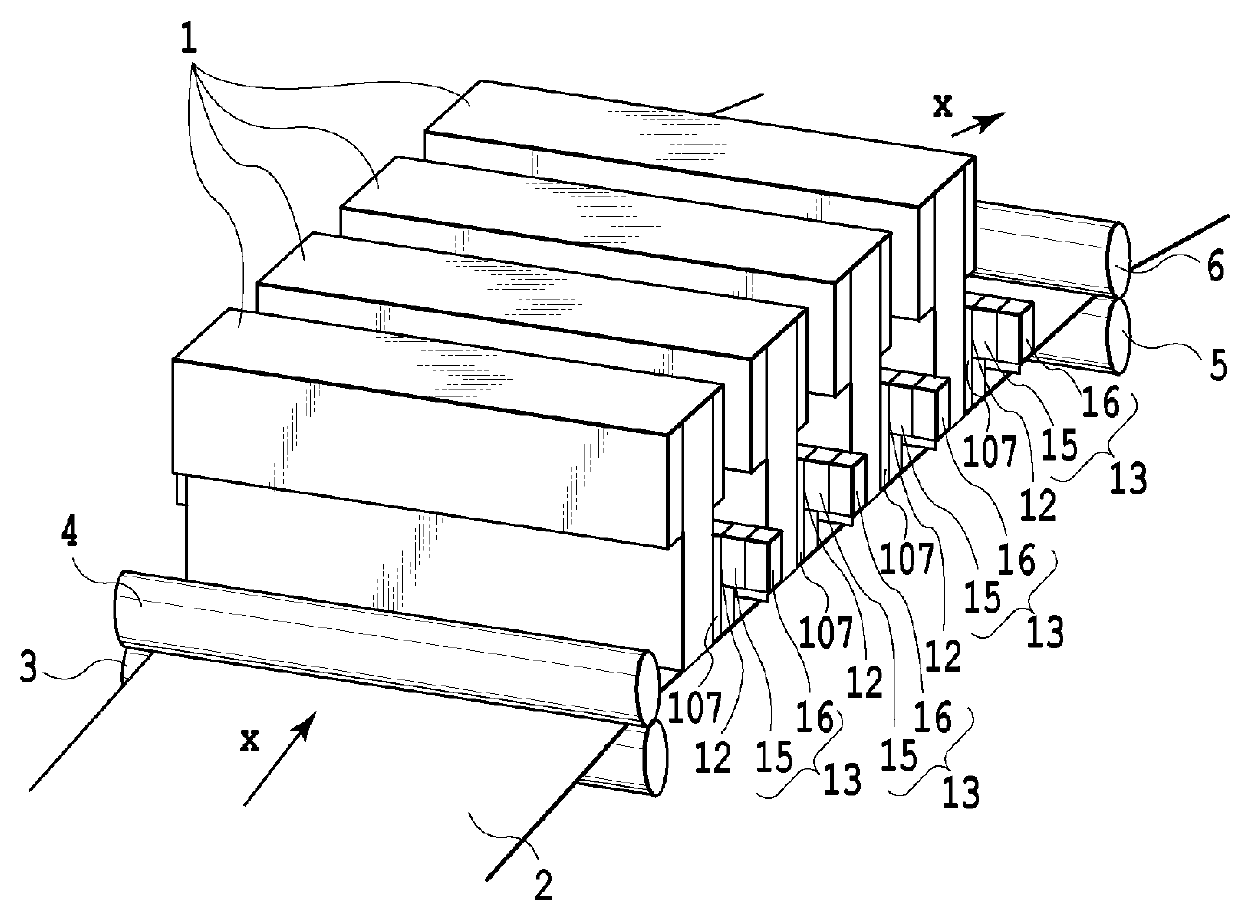

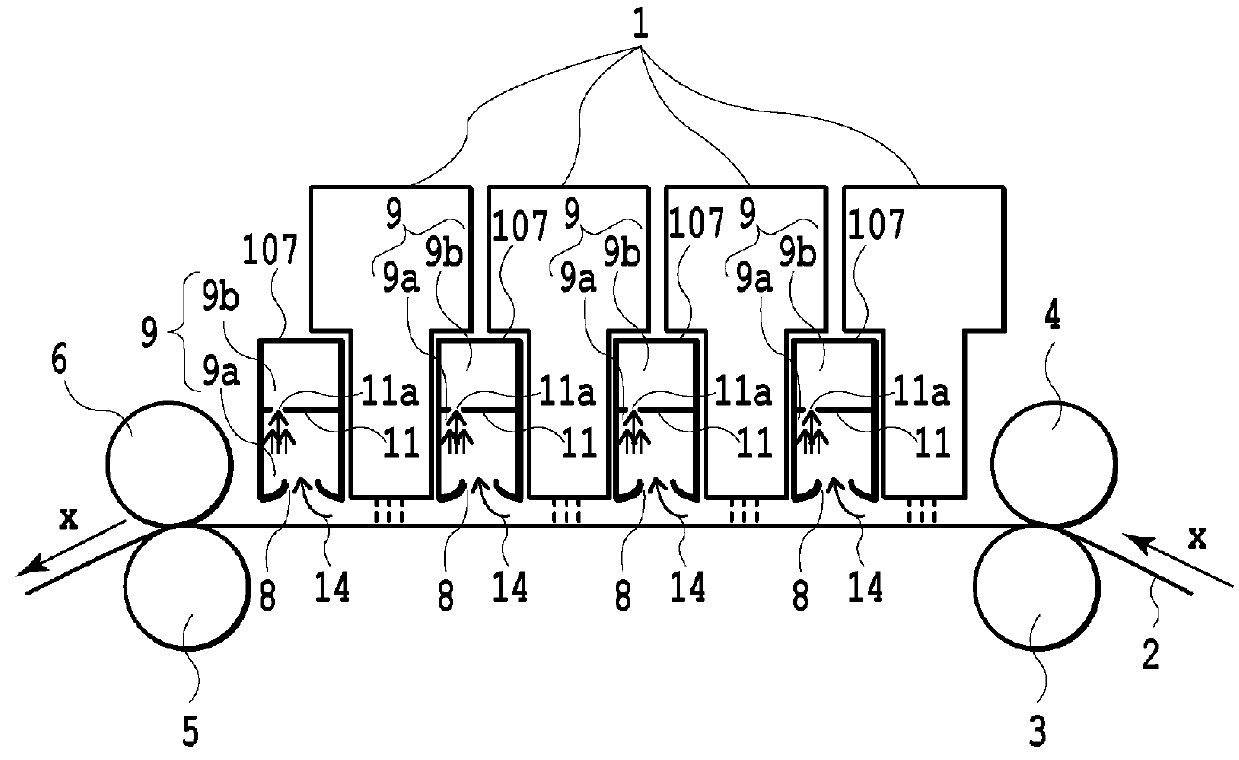

Flow battery systems

ActiveUS20120052347A1Uniform metal platingHigh cell current densityFuel and secondary cellsCell electrodesEngineeringMetal

Embodiments of the invention generally provide for flow battery cells and systems containing a plurality of flow battery cells, and methods for improving metal plating within the flow battery cell, such as by flowing and exposing the catholyte to various types of cathodes. In one embodiment, a flow battery cell is provided which includes a cathodic half cell and an anodic half cell separated by an electrolyte membrane, wherein the cathodic half cell contains a plurality of cathodic wires extending perpendicular or substantially perpendicular to and within the catholyte pathway and in contact with the catholyte, and each of the cathodic wires extends parallel or substantially parallel to each other. In some examples, the plurality of cathodic wires may have at least two arrays of cathodic wires, each array contains at least one row of cathodic wires, and each row extends along the catholyte pathway.

Owner:APPLIED MATERIALS INC

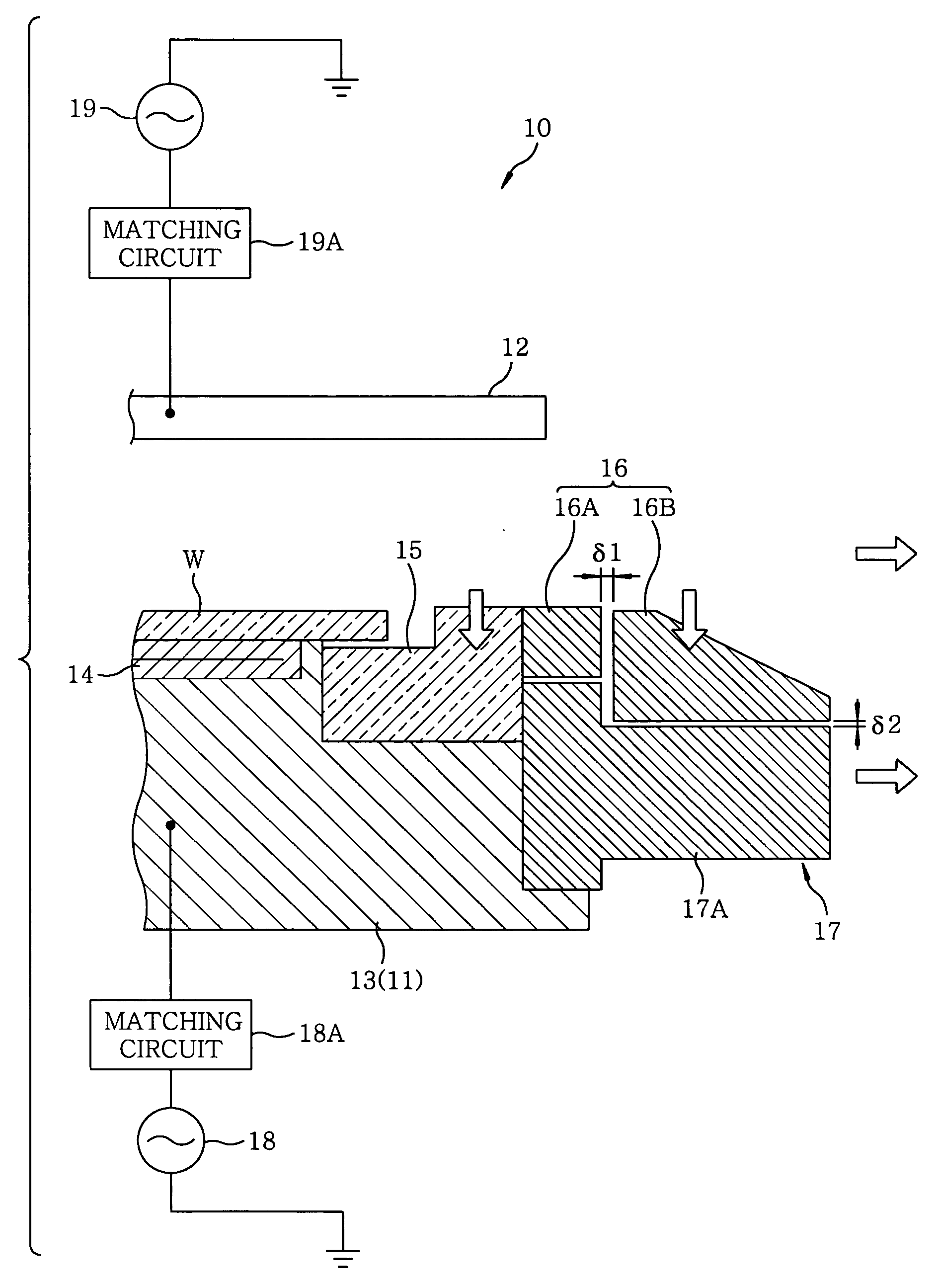

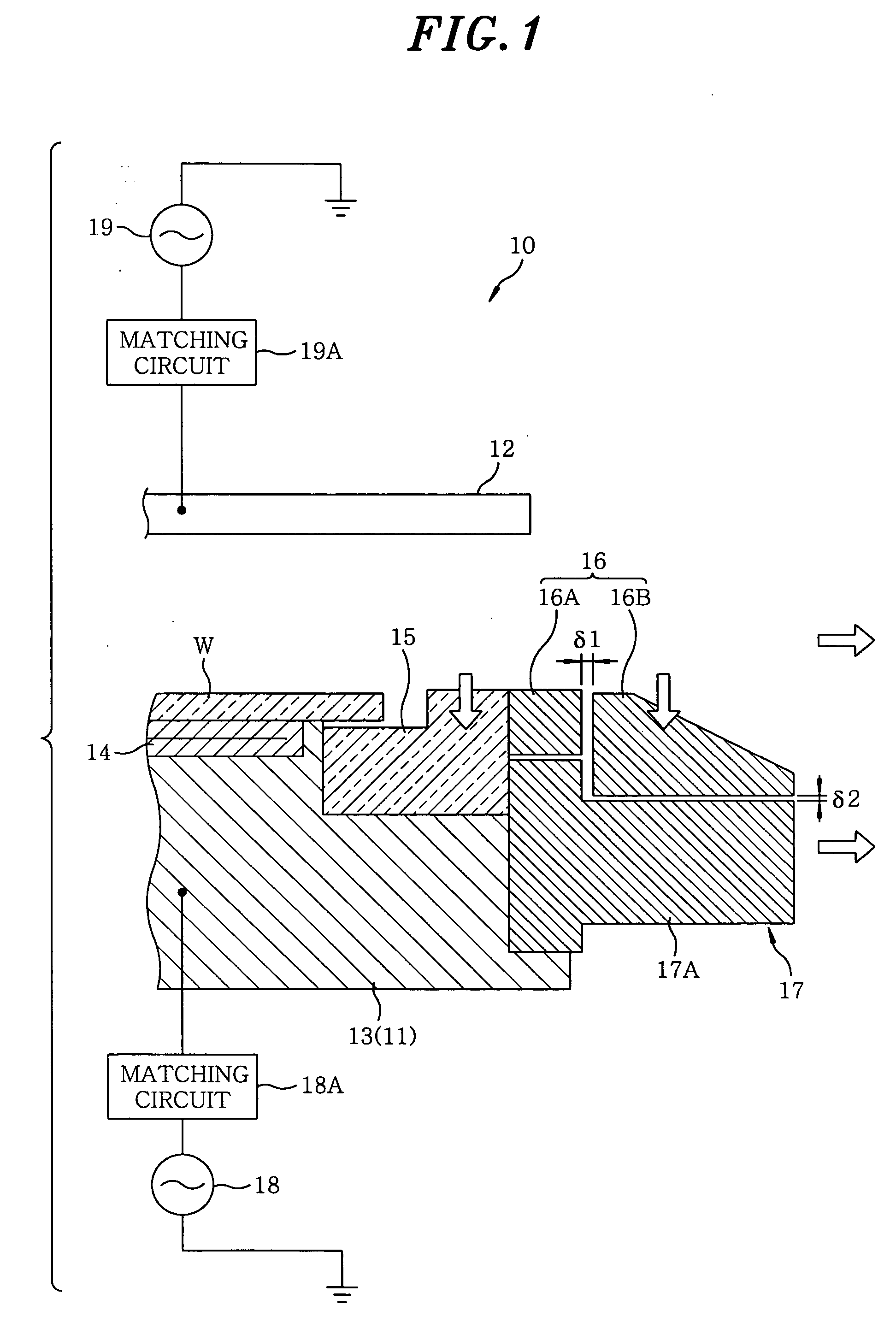

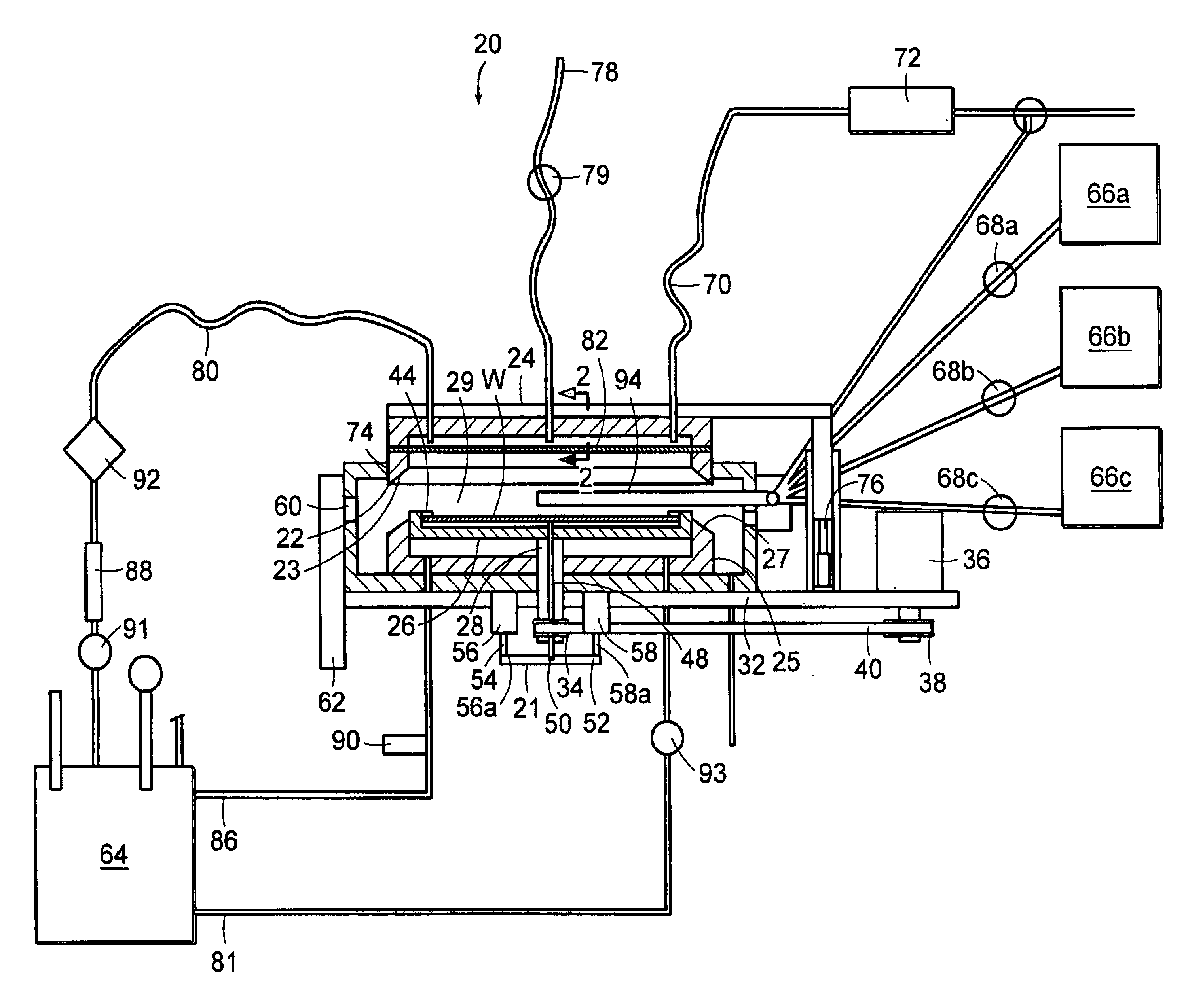

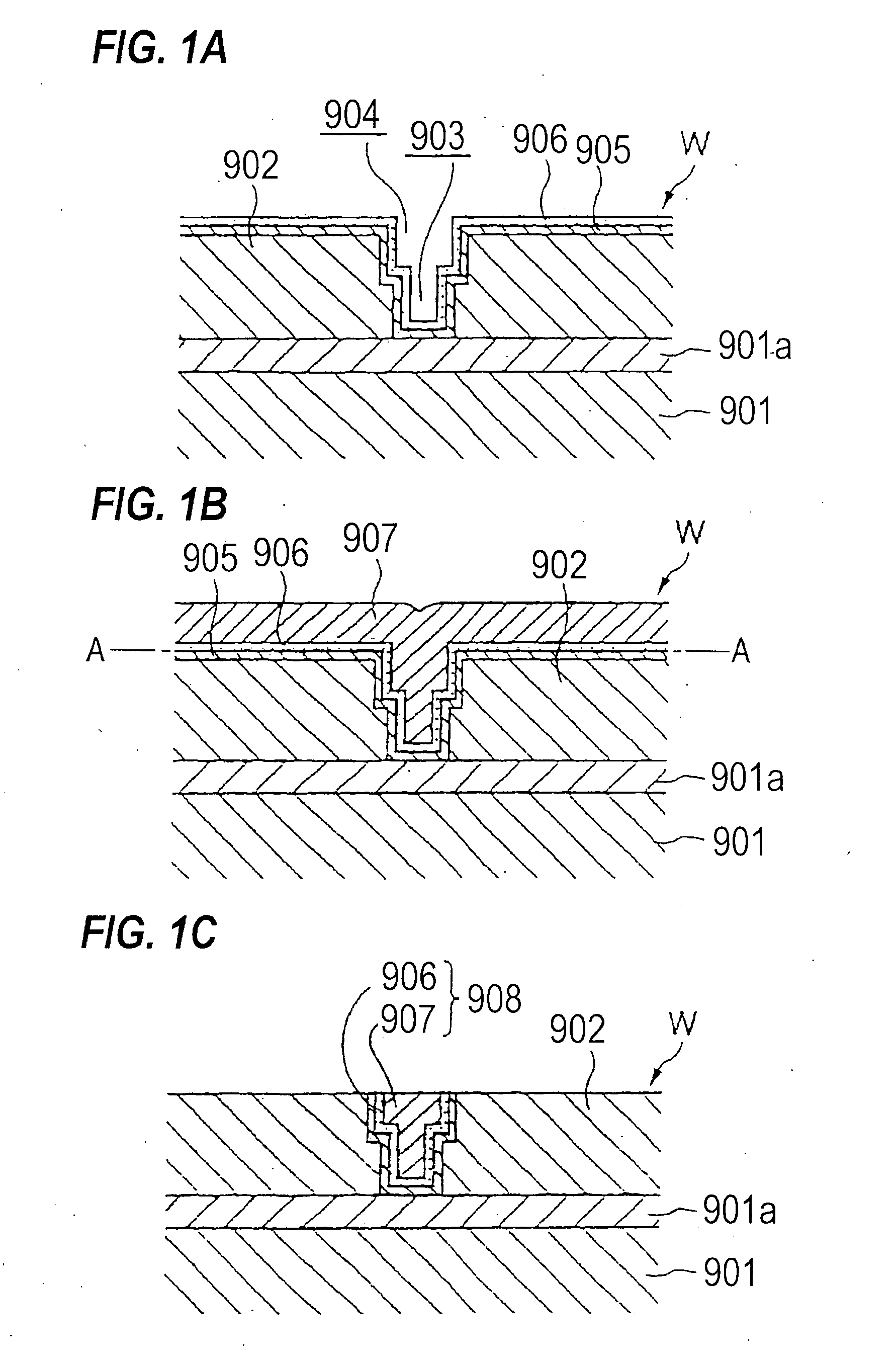

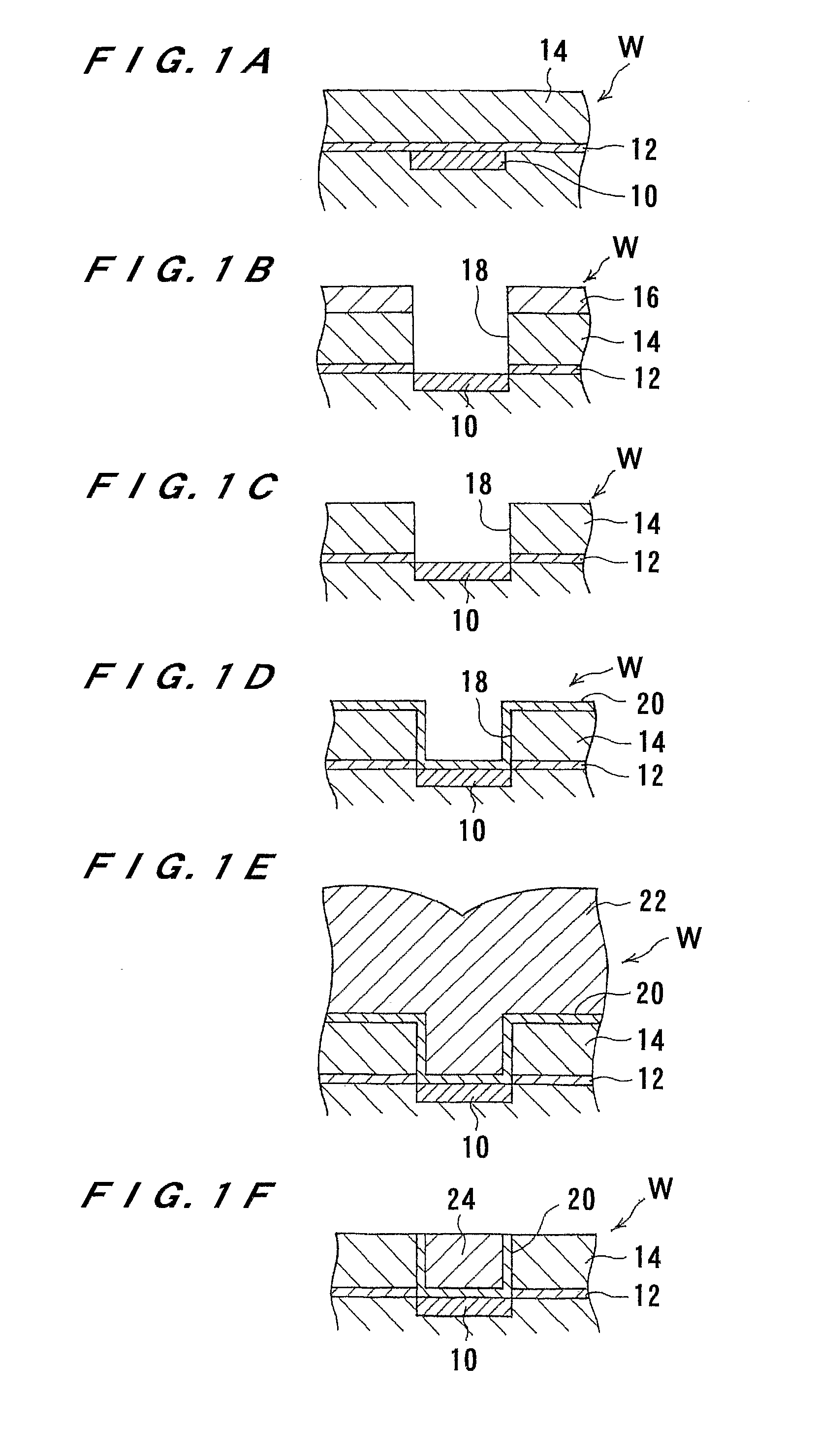

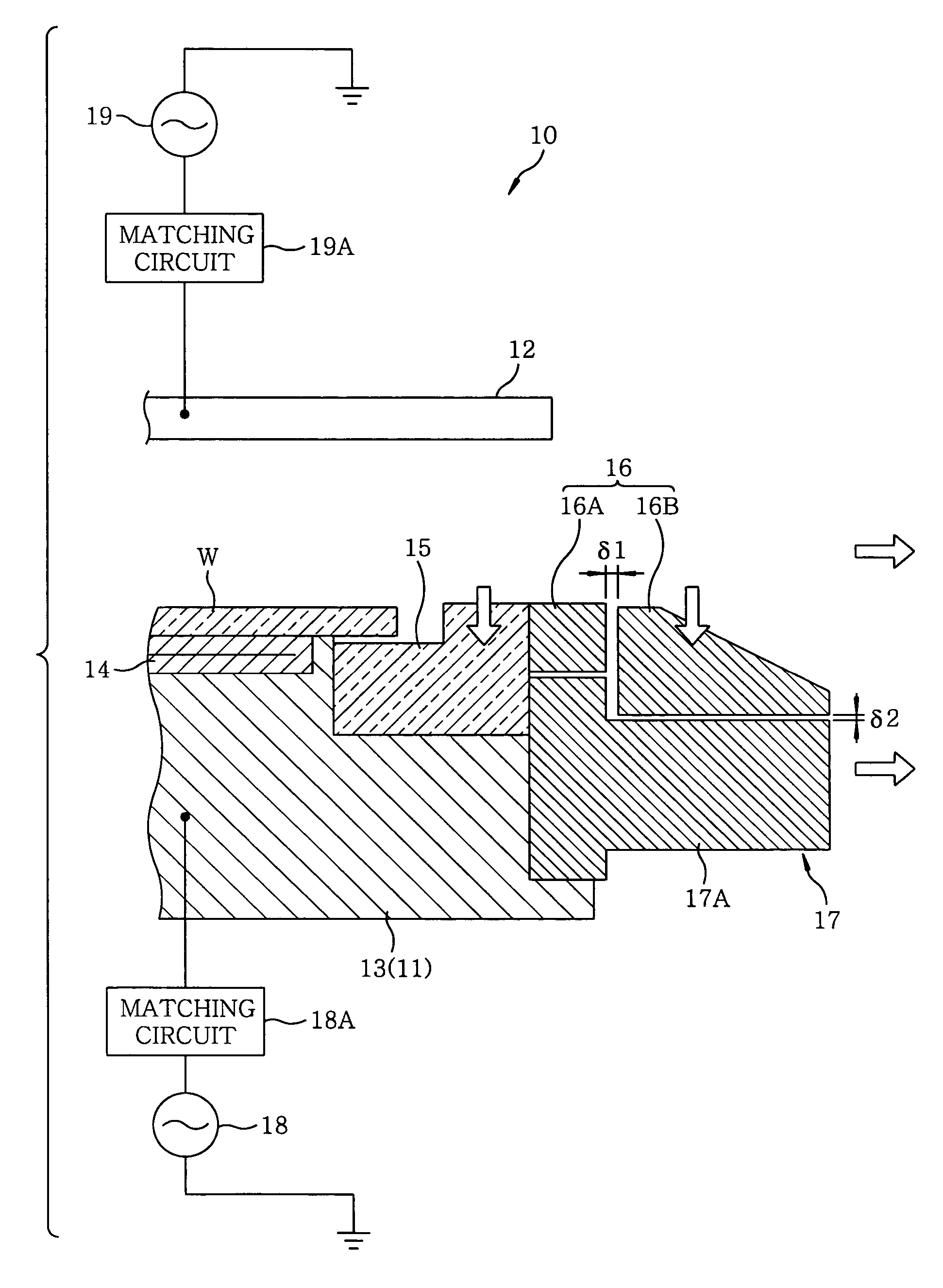

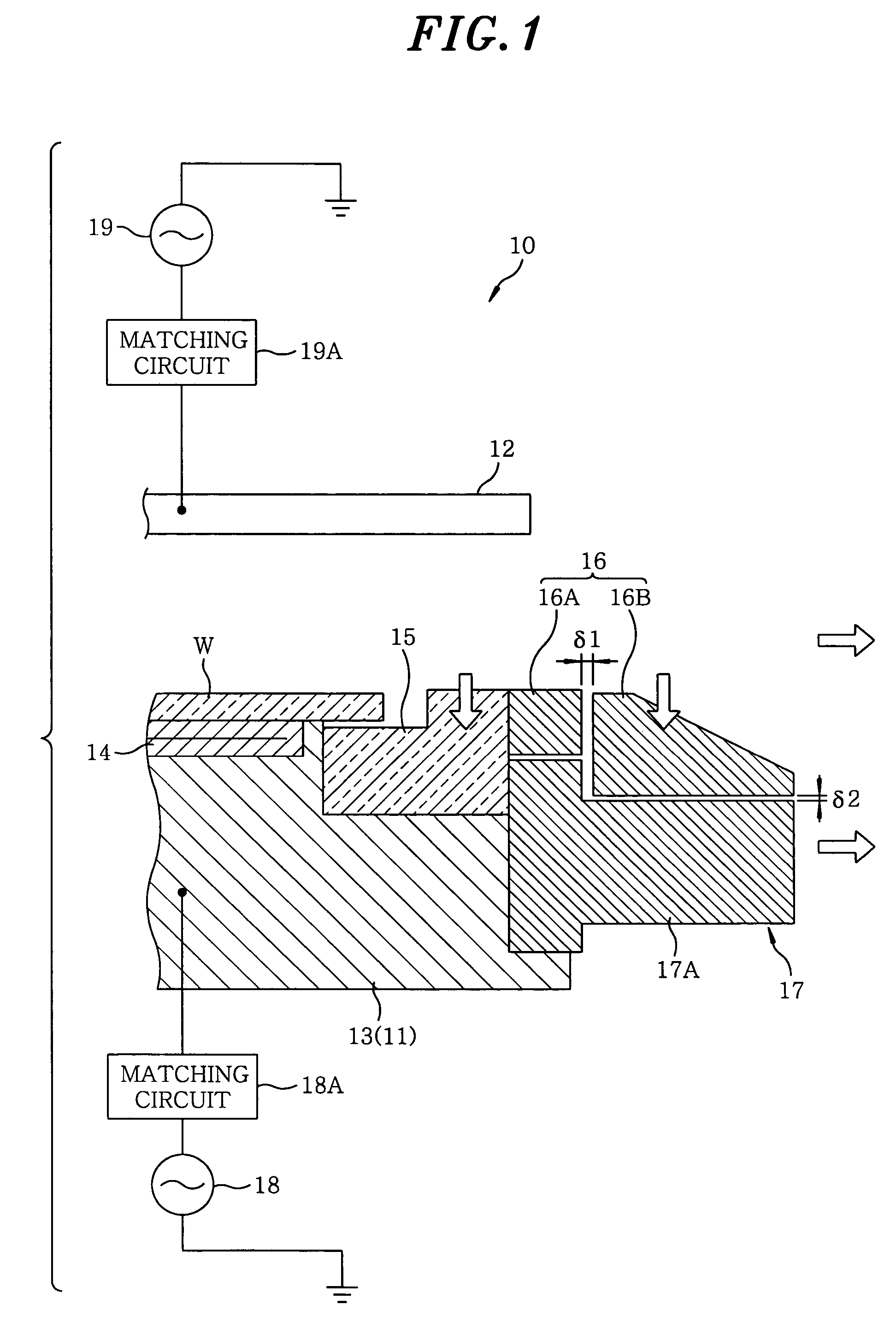

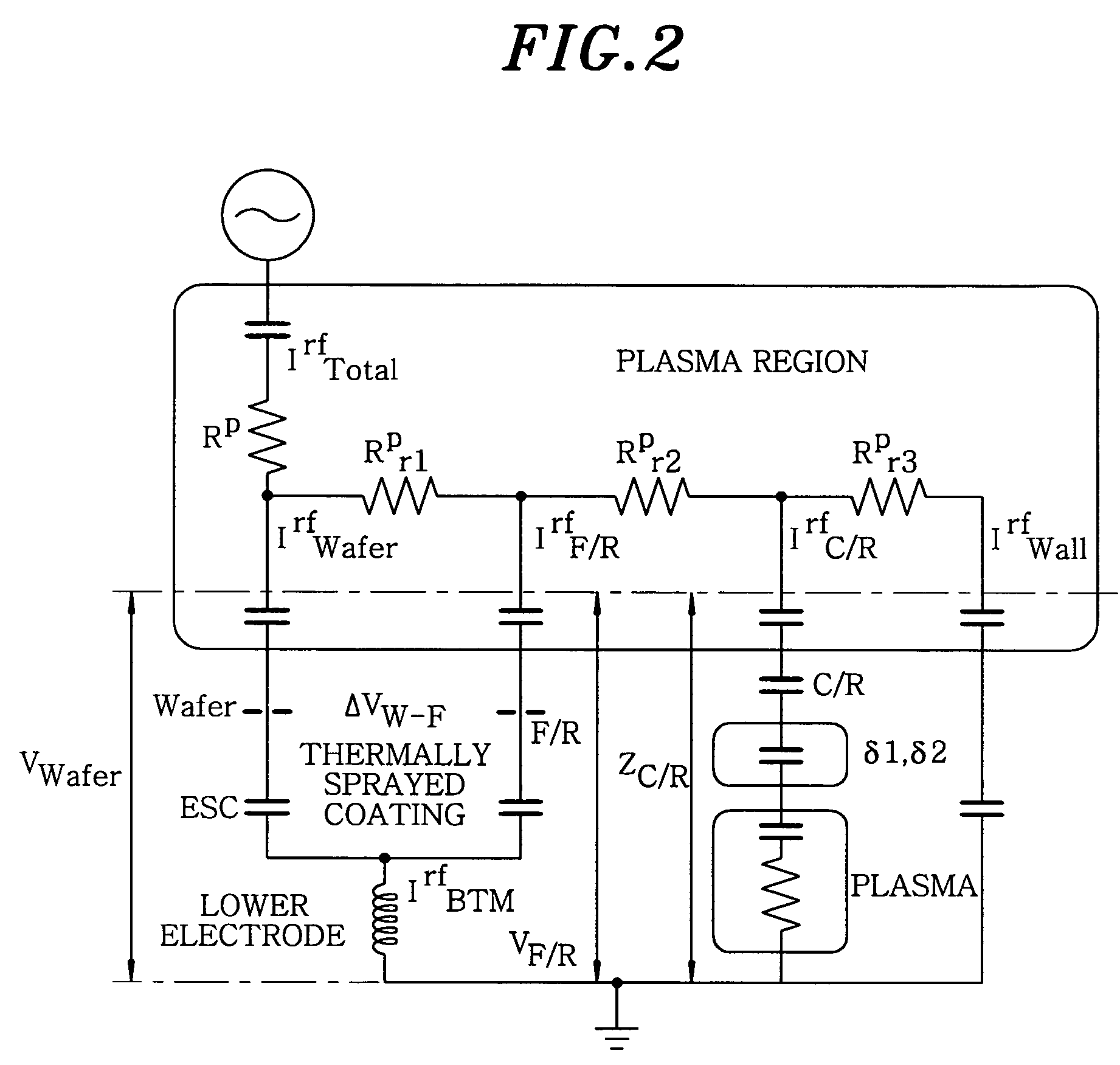

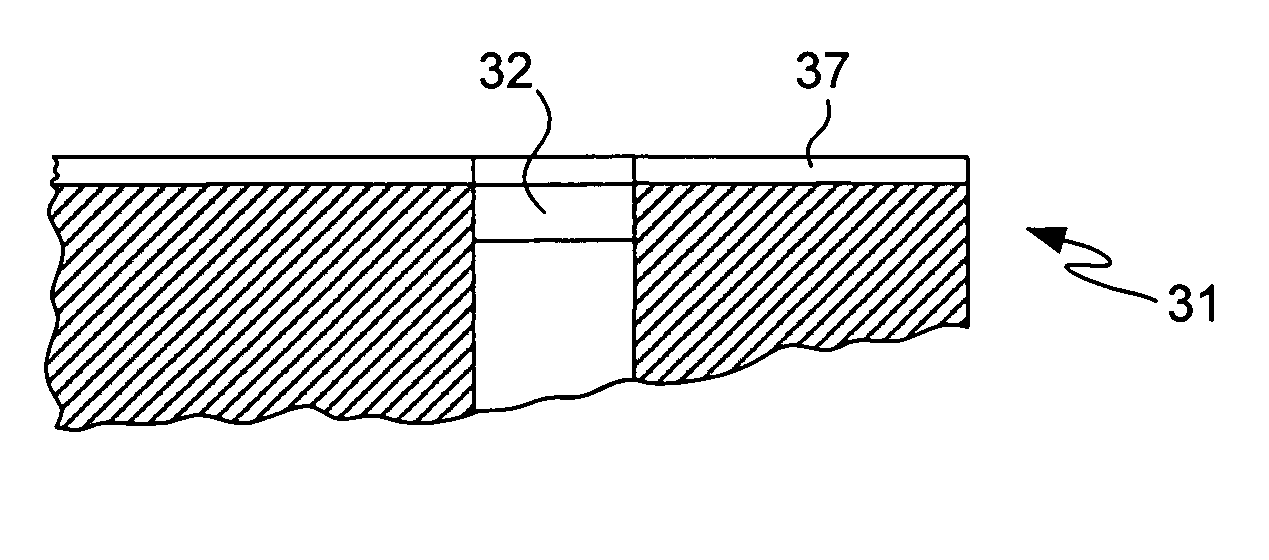

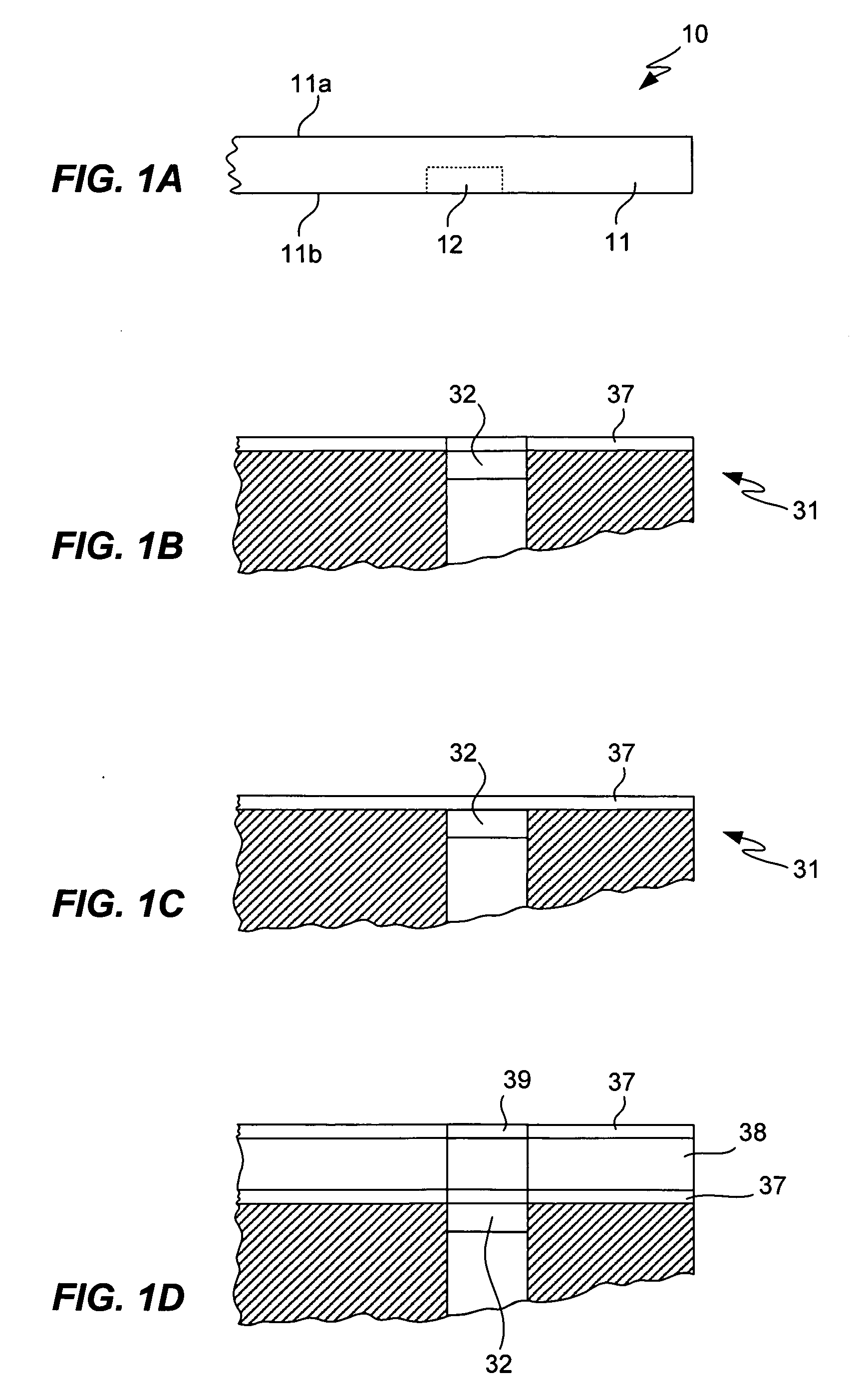

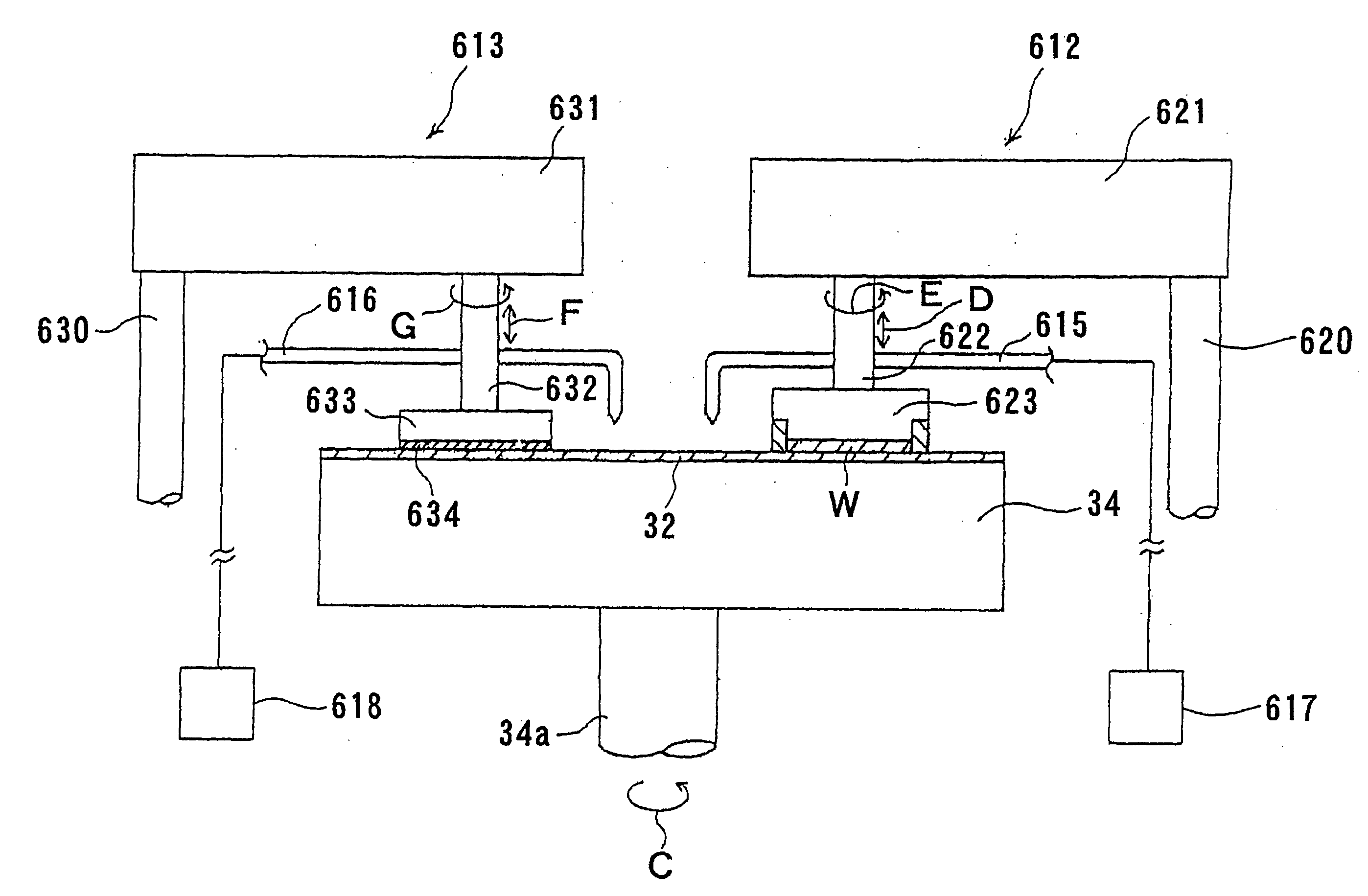

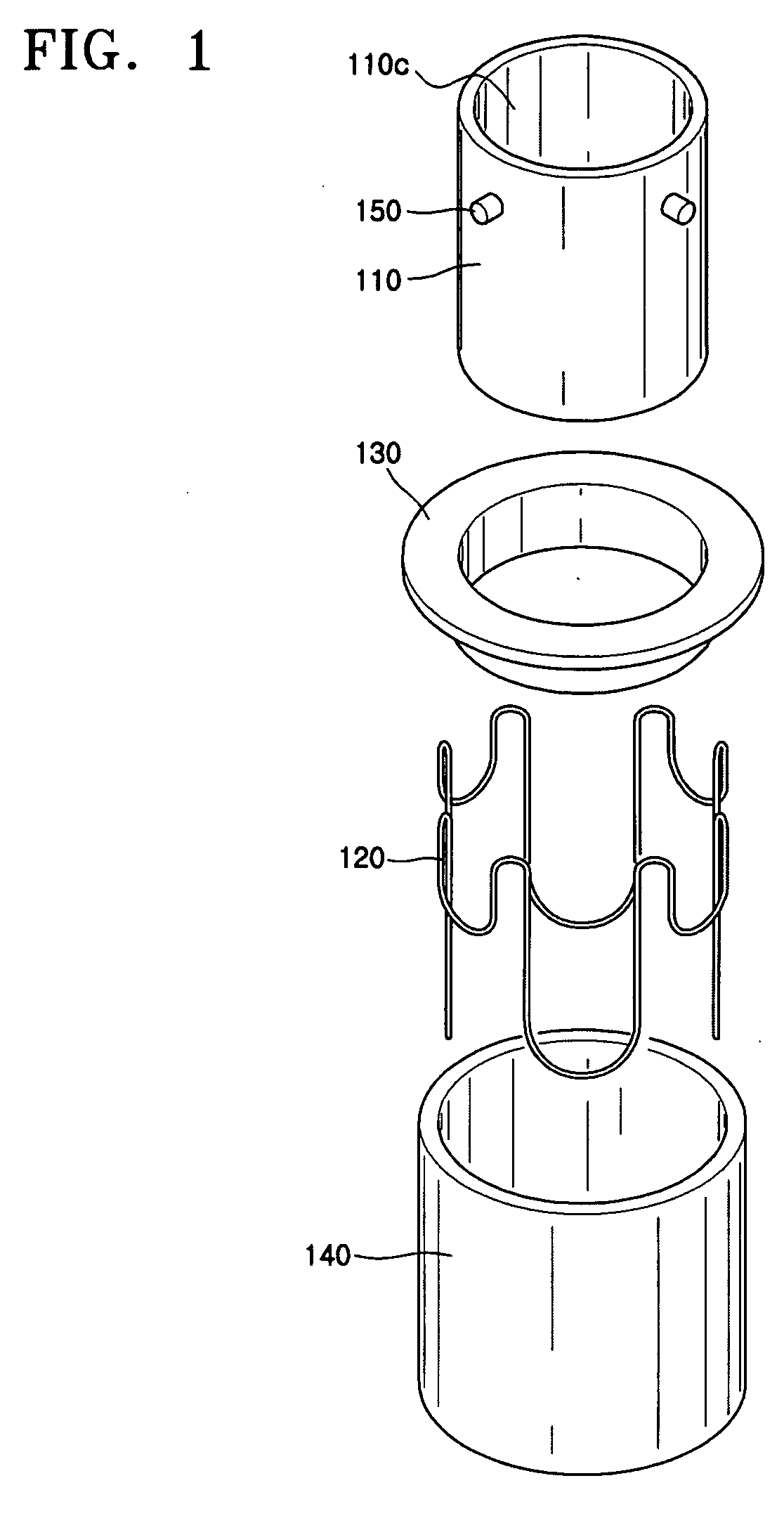

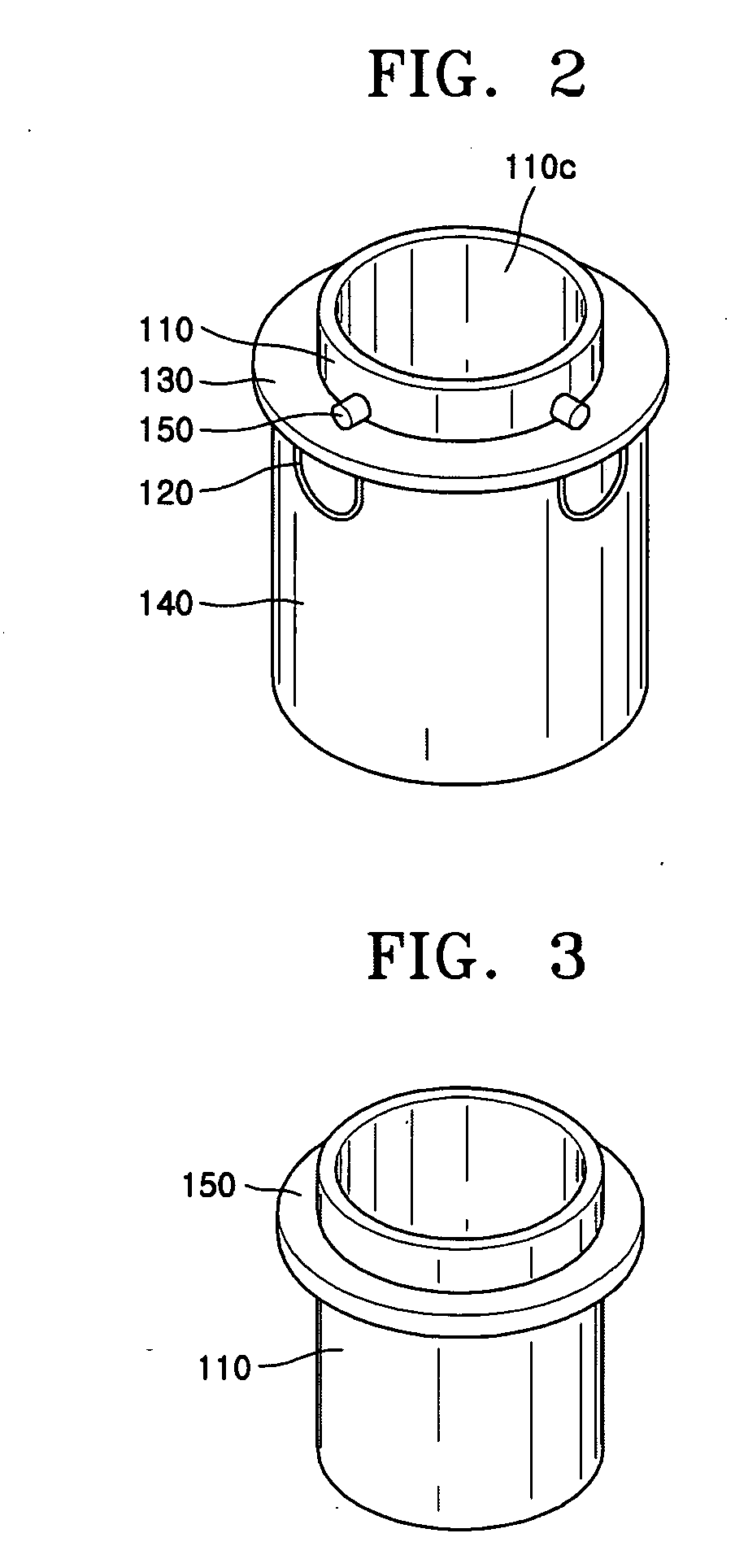

Ring mechanism, and plasma processing device using the ring mechanism

InactiveUS20050005859A1Avoid influenceUniform rateElectric discharge tubesSemiconductor/solid-state device manufacturingPotential differenceEngineering

A ring mechanism, comprising a focus ring and divided cover rings surrounding a wafer W placed on a loading table (lower electrode) mounted in a processing chamber, wherein a ring-shaped clearance δ1 is provided between the divided rings to spread plasma to the radial outside of the focus ring to allow plasma to get therein, whereby a potential difference between the wafer W and the focus ring can be eliminated to prevent arc discharge by plasma from occurring between the wafer W and the focus ring.

Owner:TOKYO ELECTRON LTD

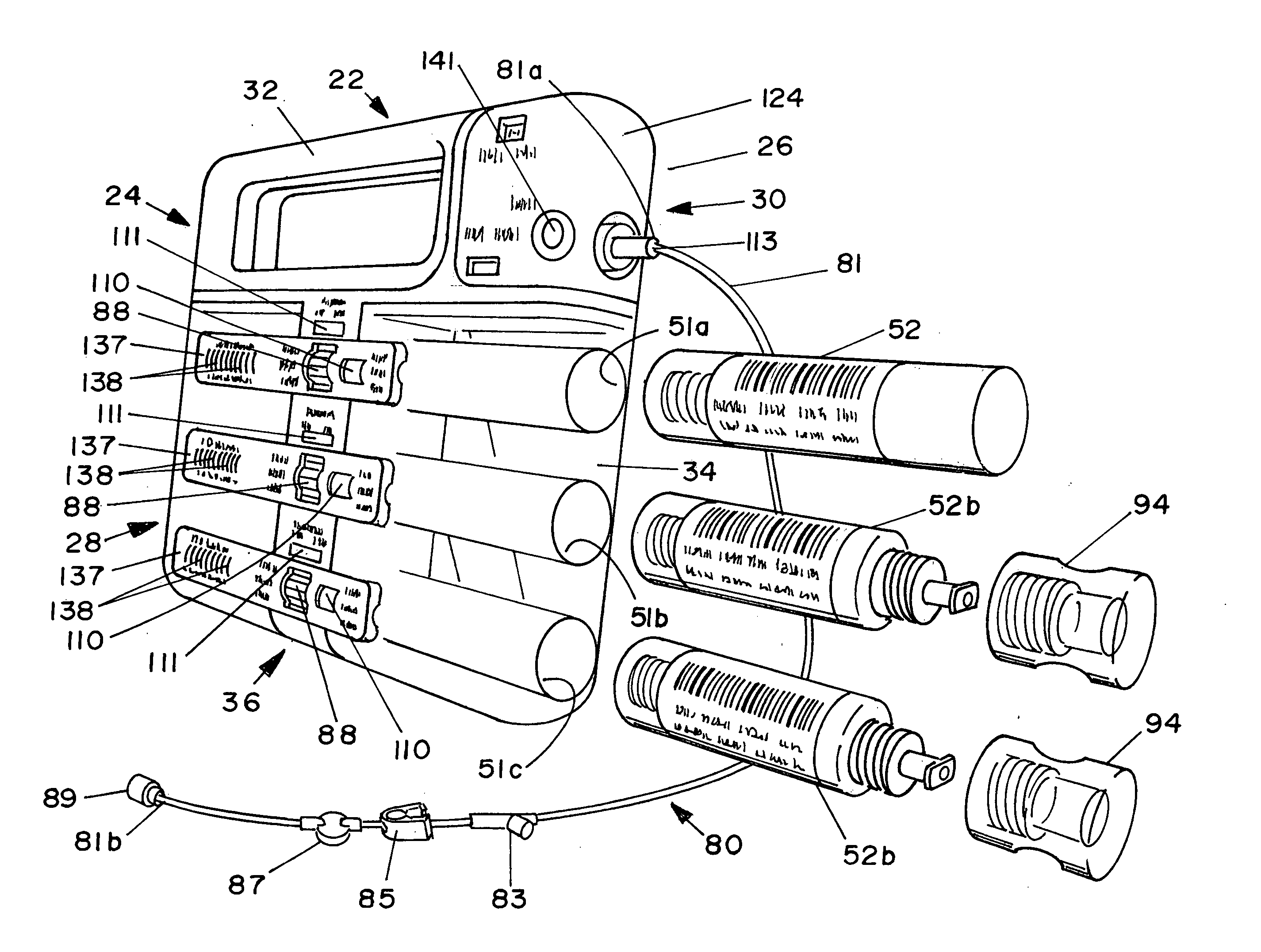

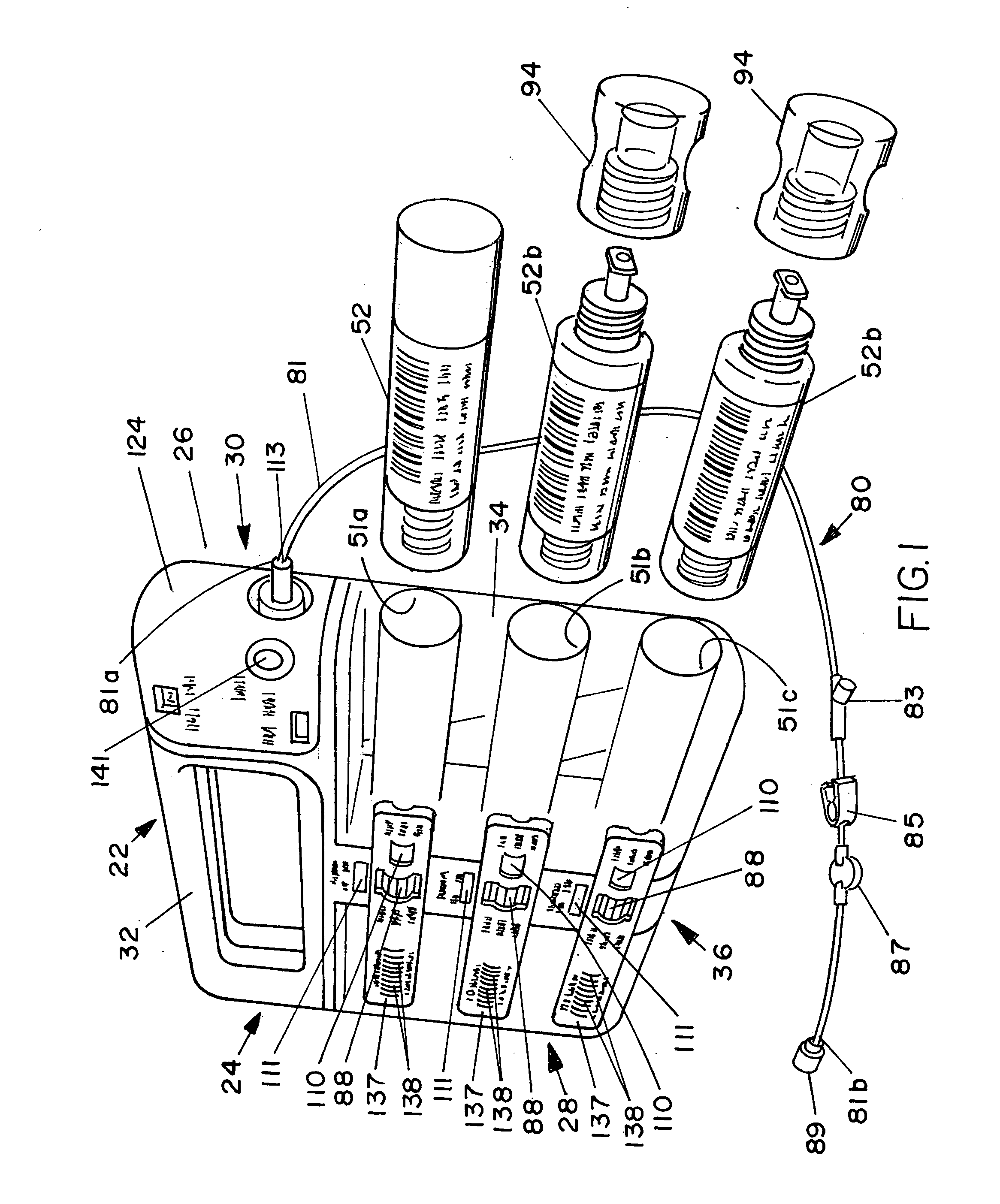

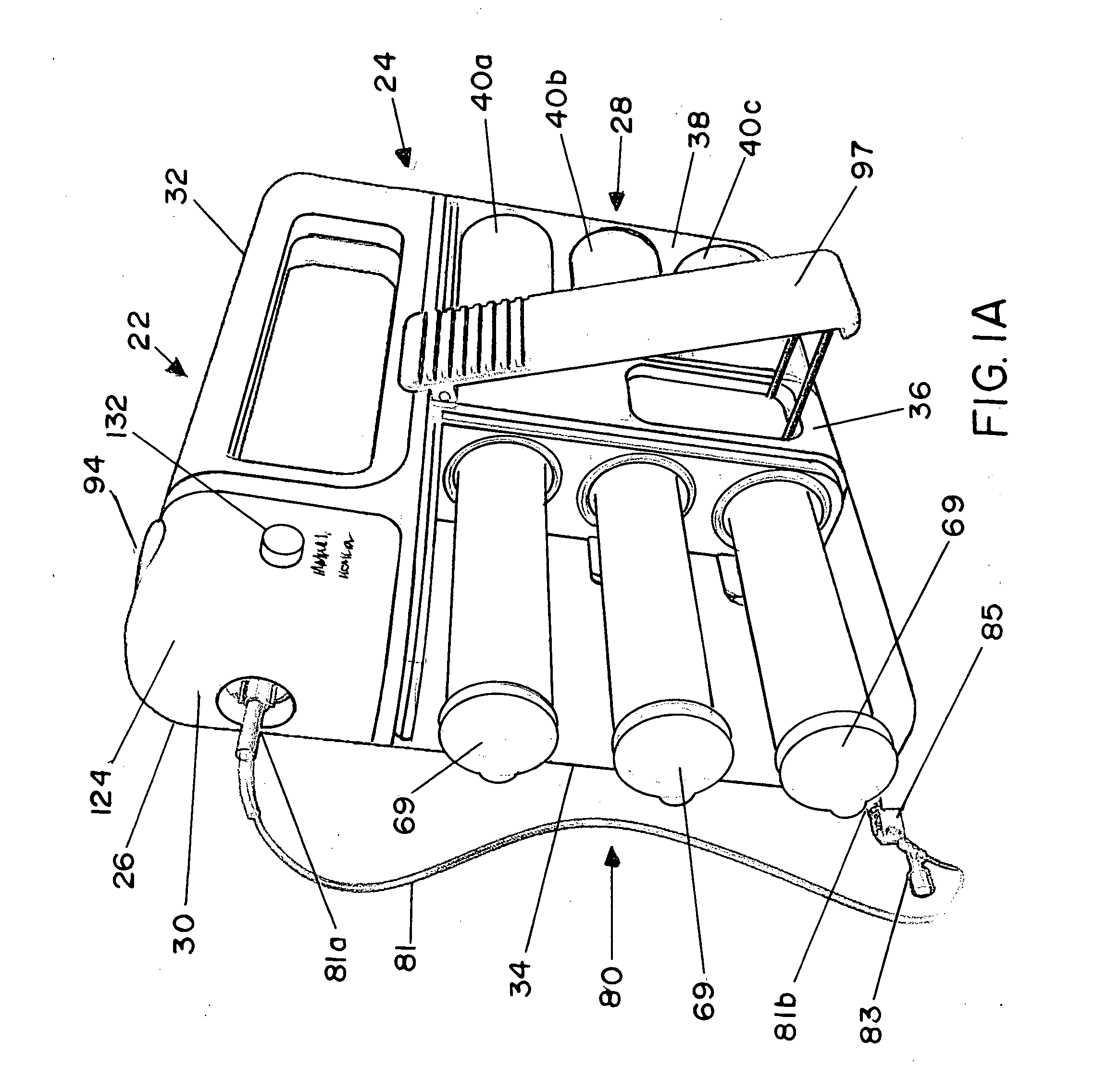

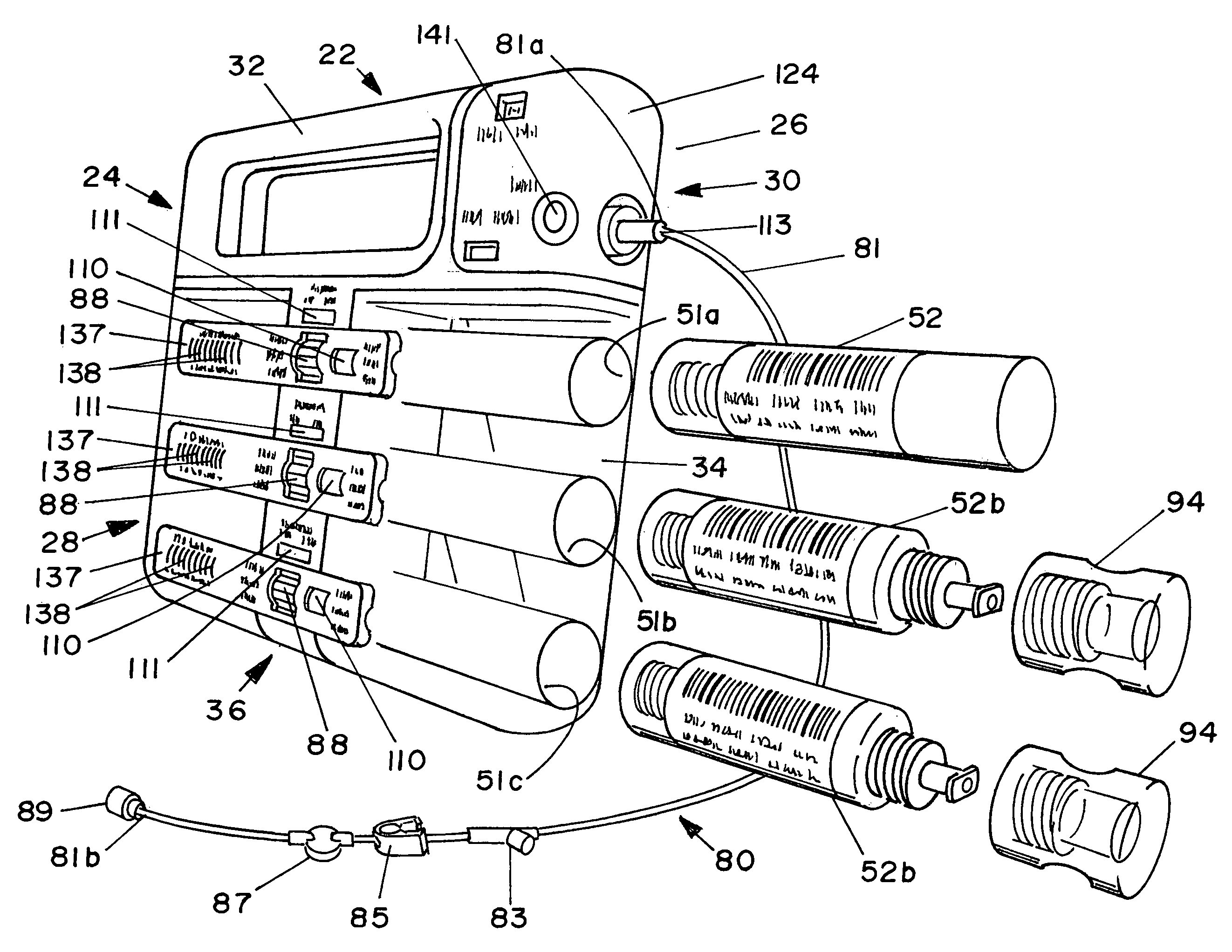

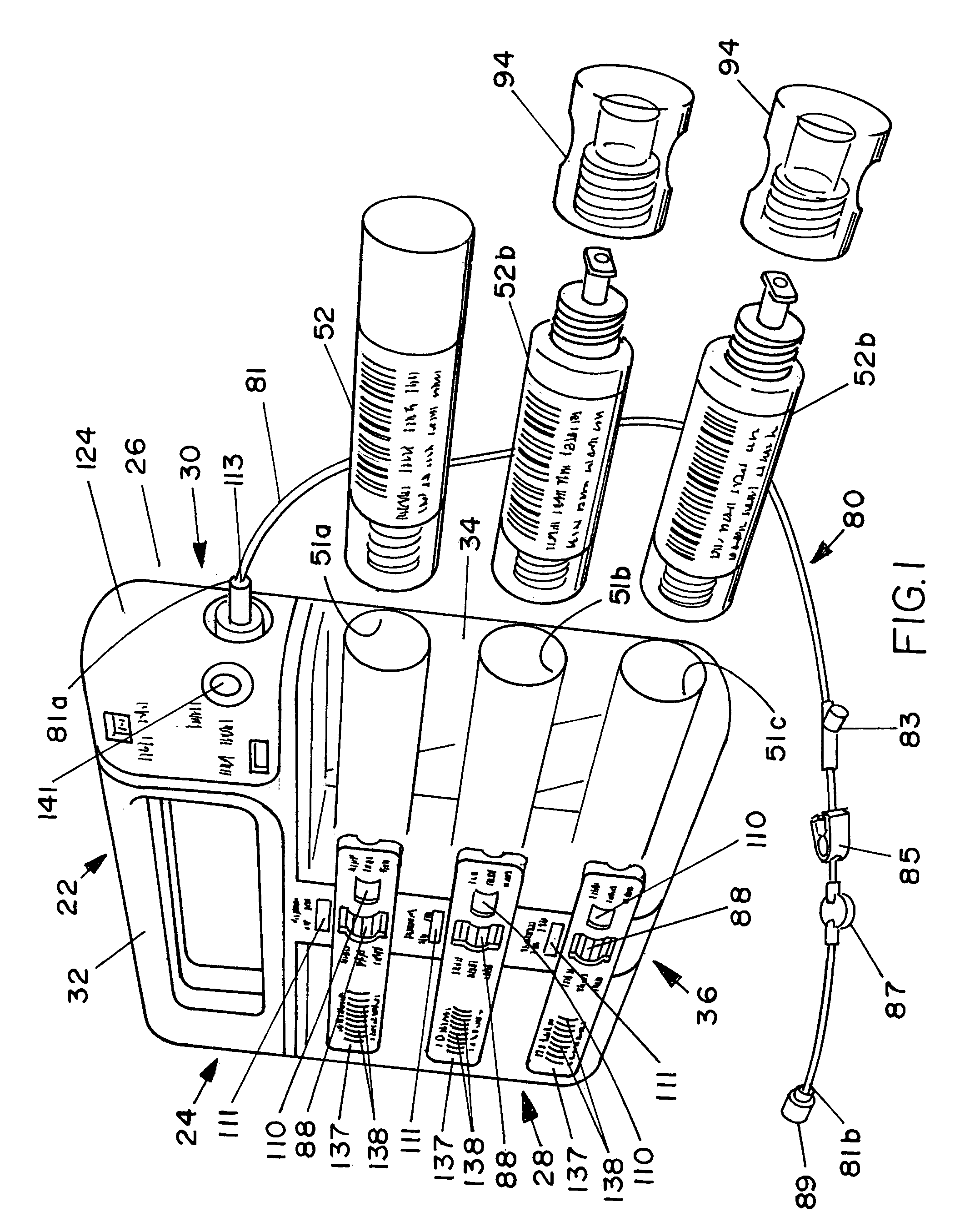

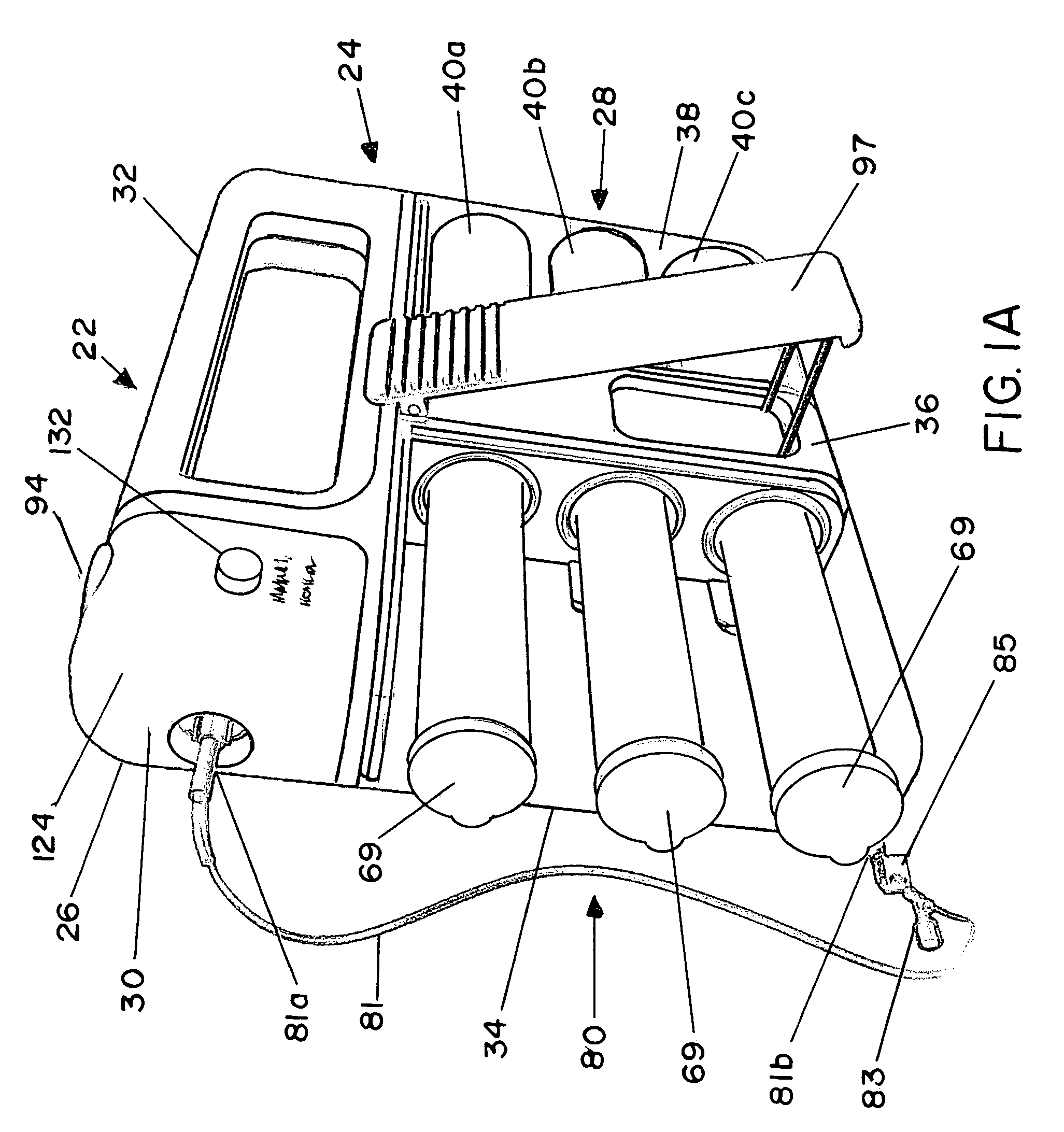

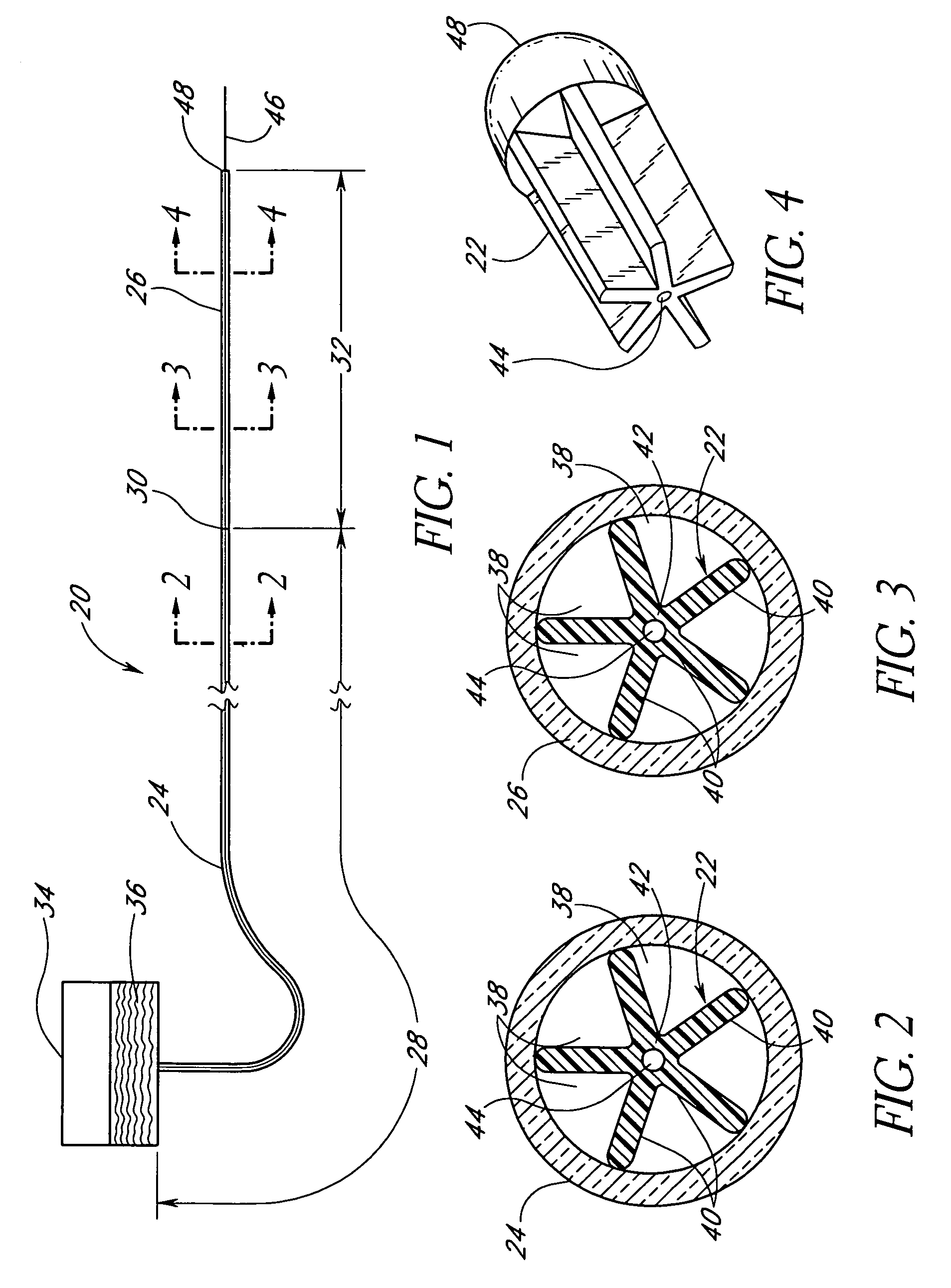

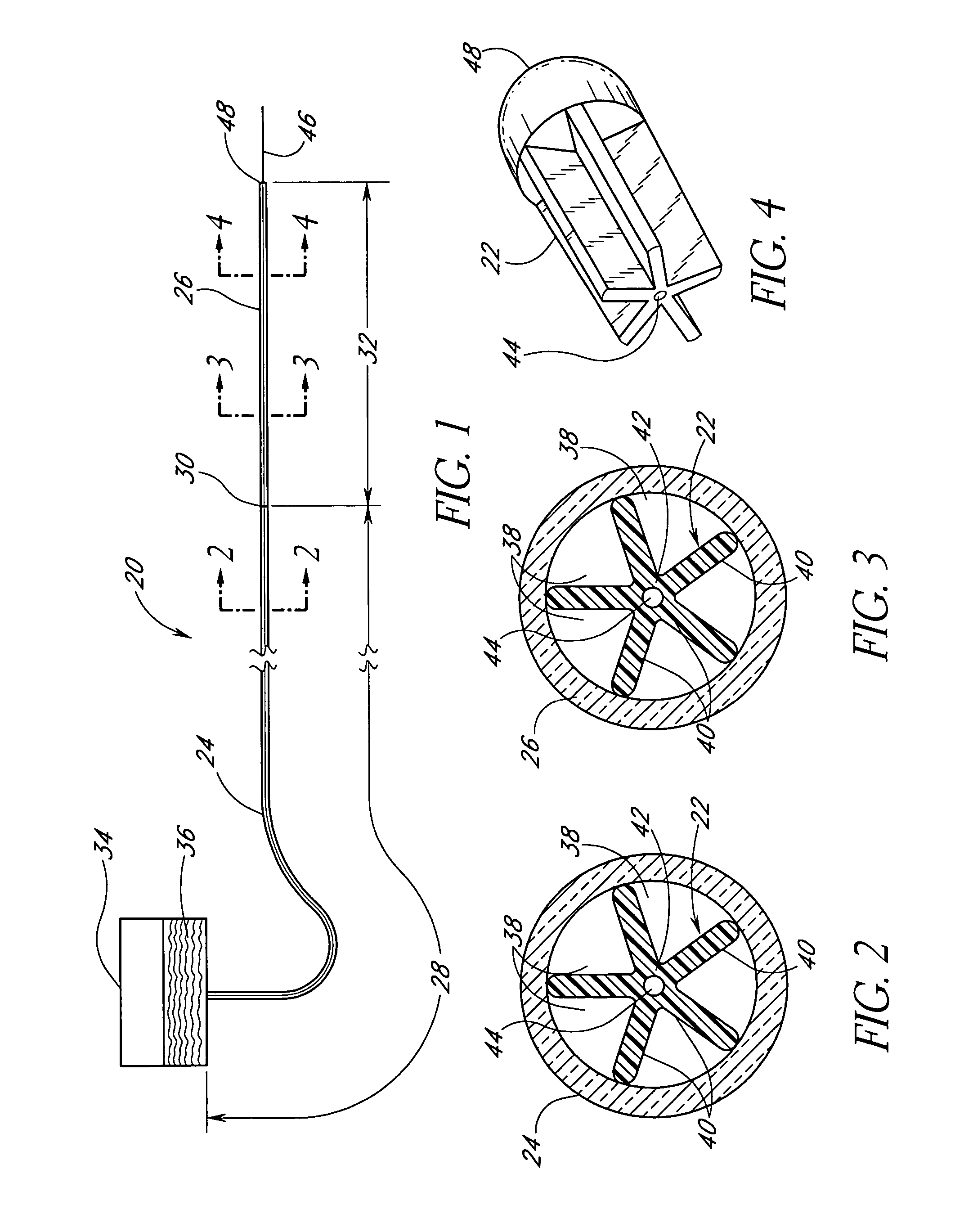

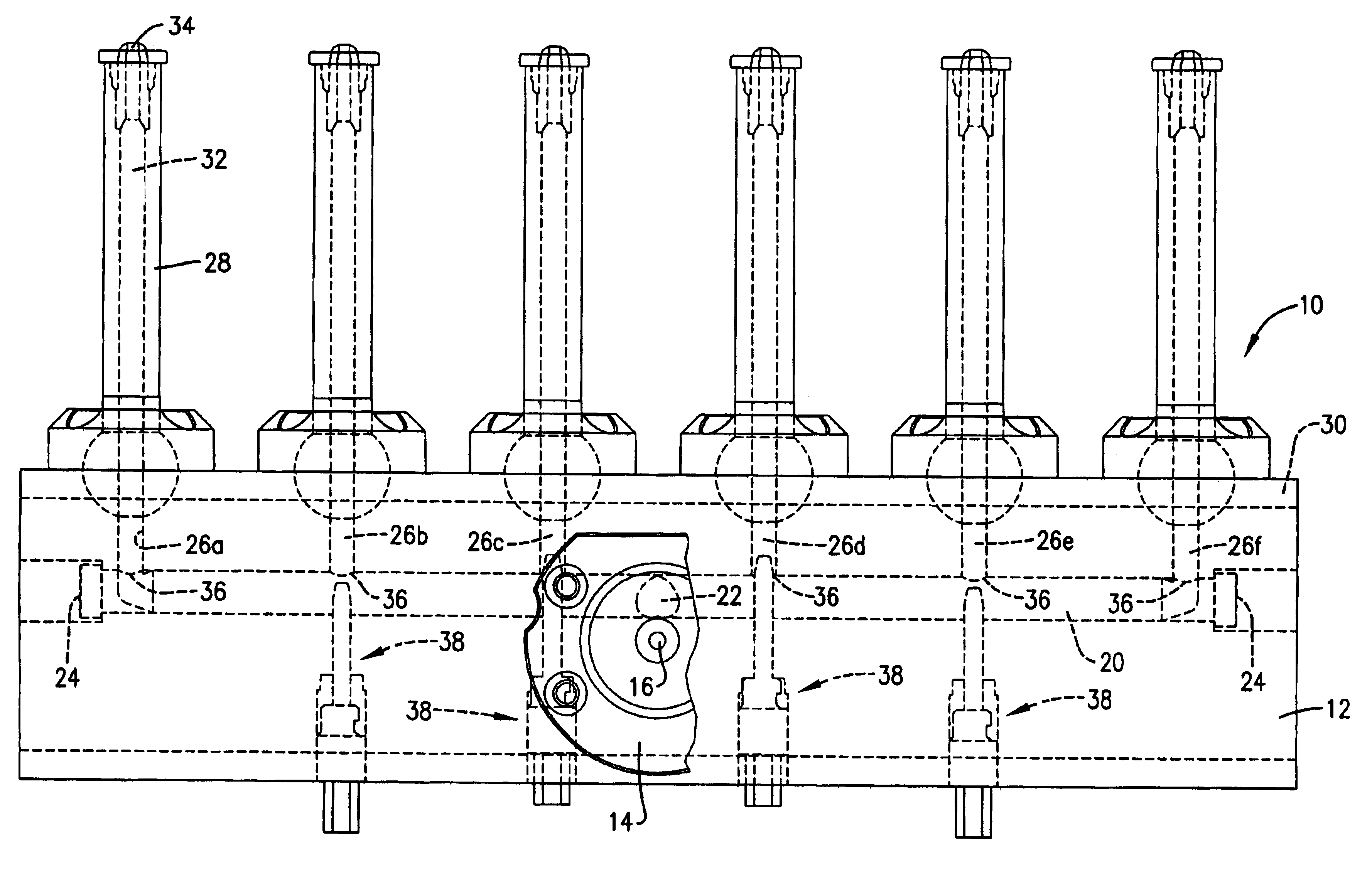

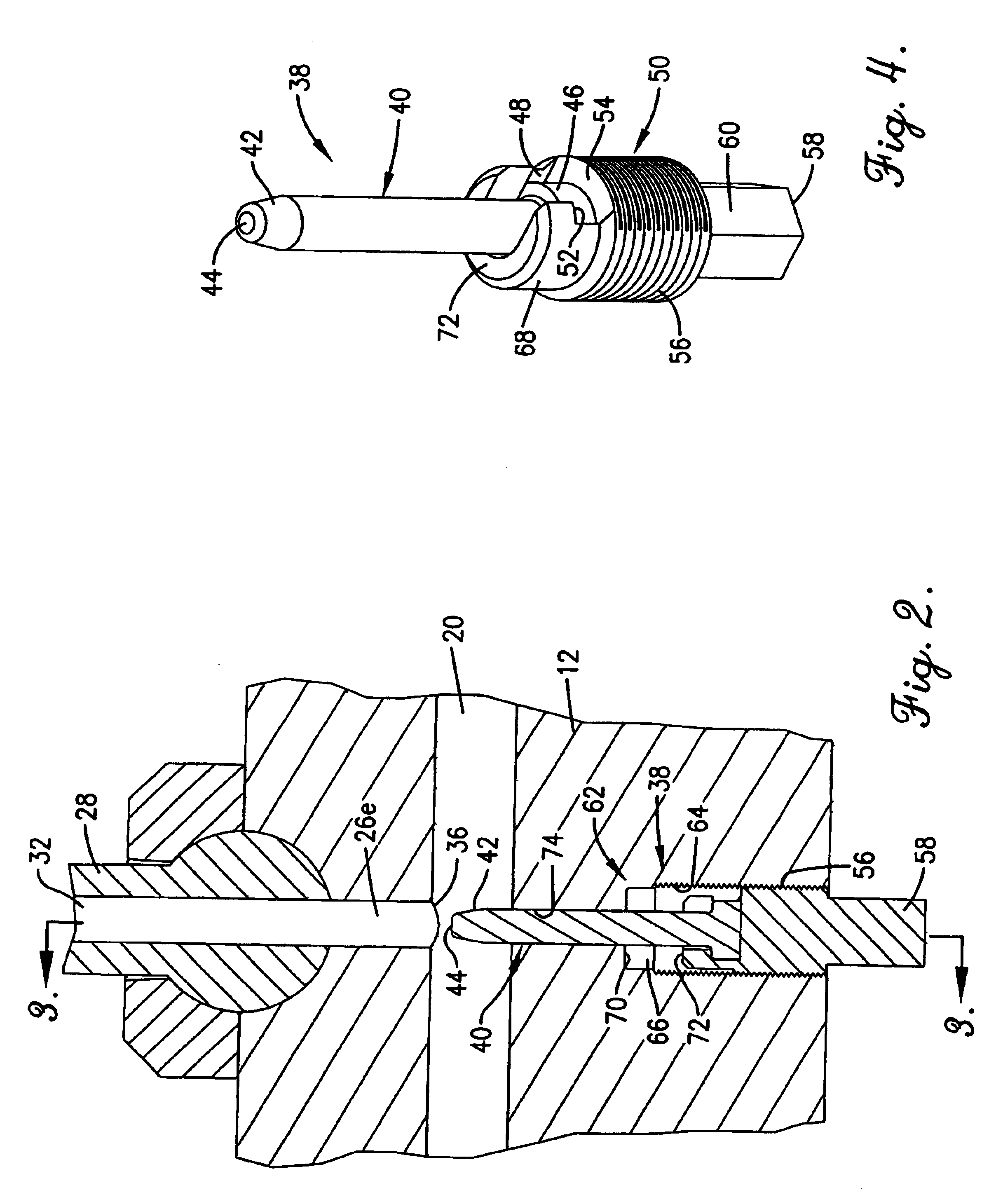

Multichannel fluid delivery device

ActiveUS20050038387A1Easy and inexpensive to manufactureUniform rateMedical devicesPharmaceutical delivery mechanismStored energyAntibiotic Y

A compact fluid dispenser for use in controllably dispensing fluid medicaments, such as antibiotics, oncolytics, hormones, steroids, blood clotting agents, analgesics, and like medicinal agents from a plurality of prefilled containers at a uniform rate. The dispenser uniquely includes a plurality of stored energy source that are provided in the form of compressible-expandable members of novel construction that provide the force necessary to continuously and uniformly expel fluid from a plurality of device reservoirs. The apparatus further includes a plurality of fluid flow control assemblies that precisely control the flow of the medicament solutions from the plurality of device reservoirs to the patient.

Owner:BIOQ PHARMA

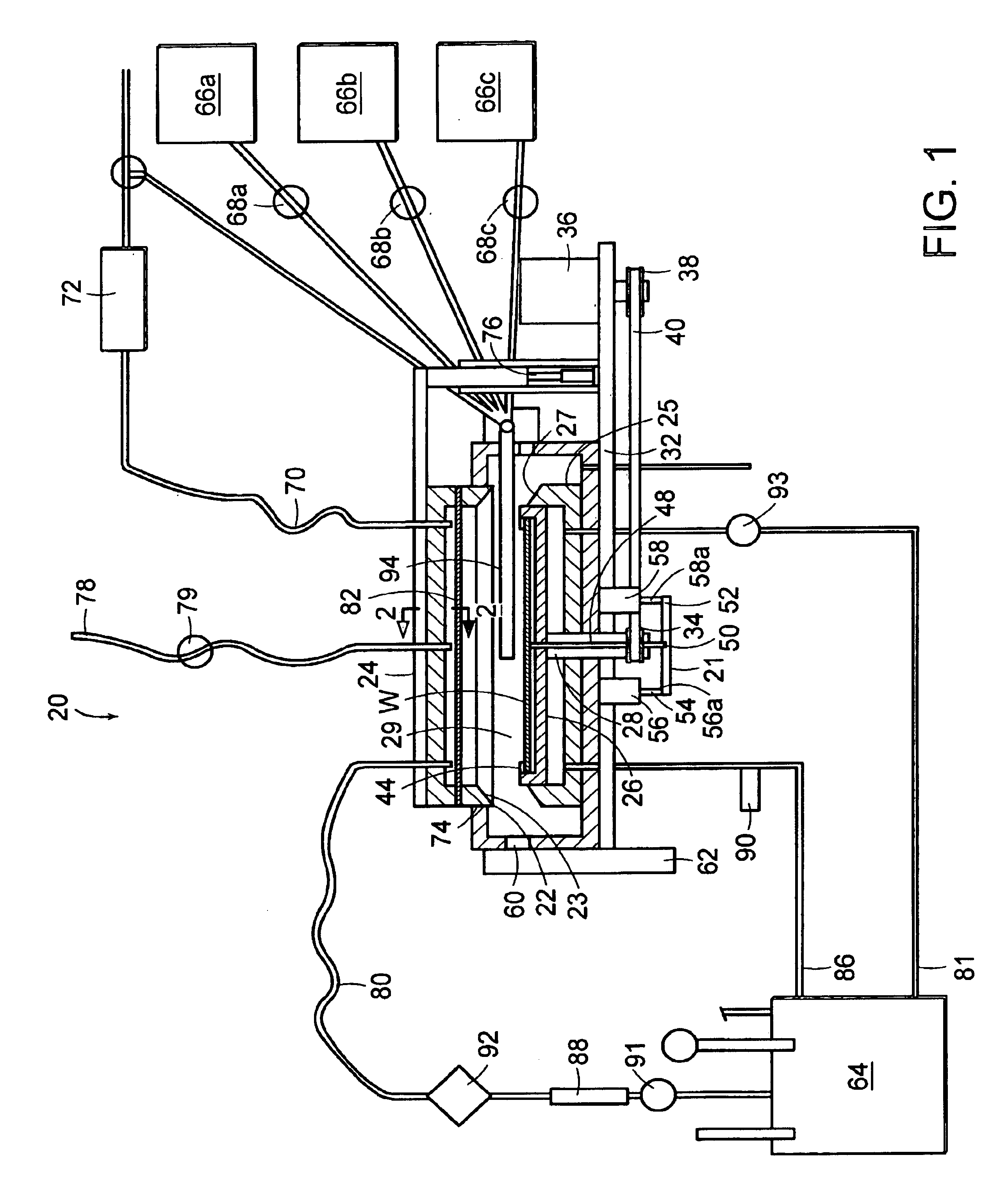

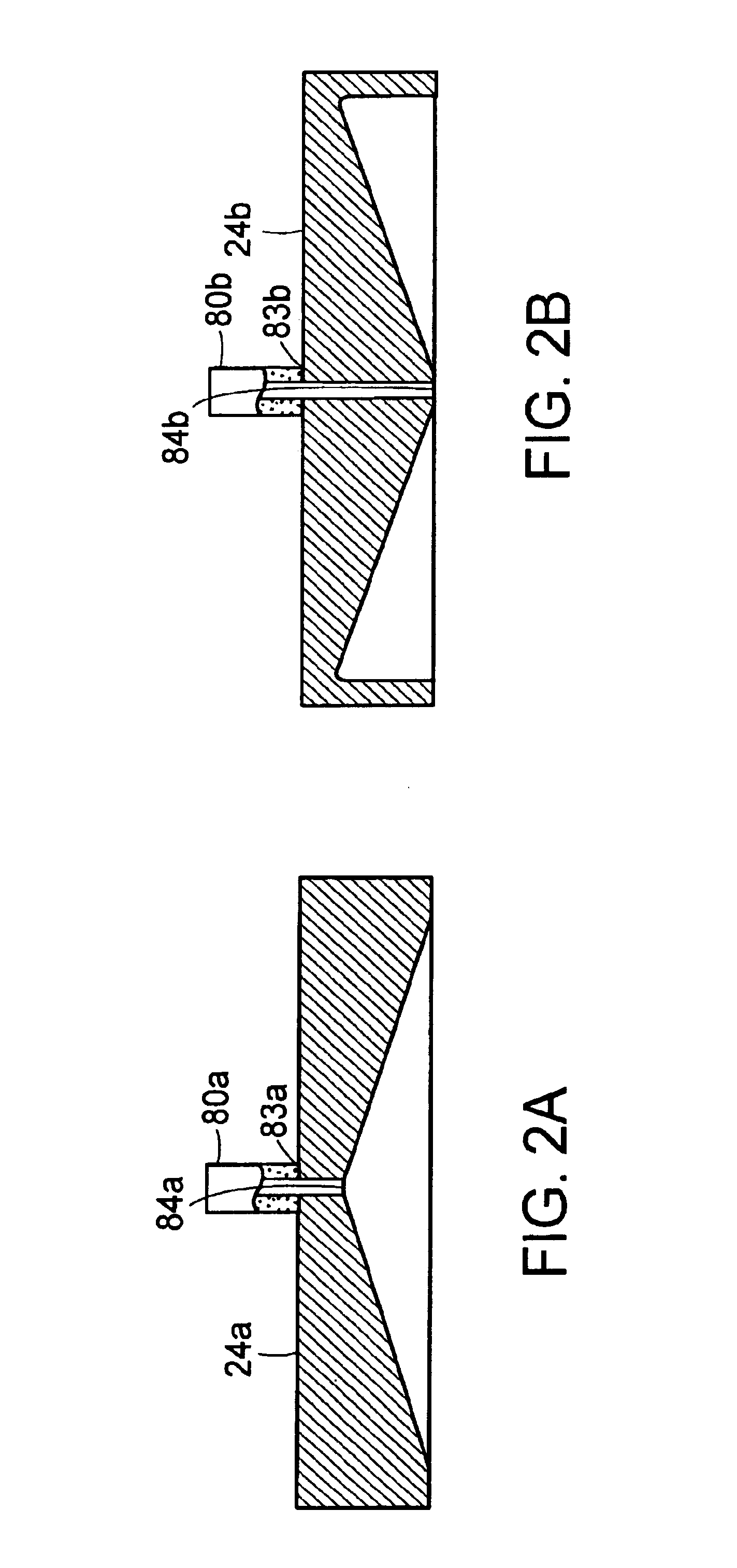

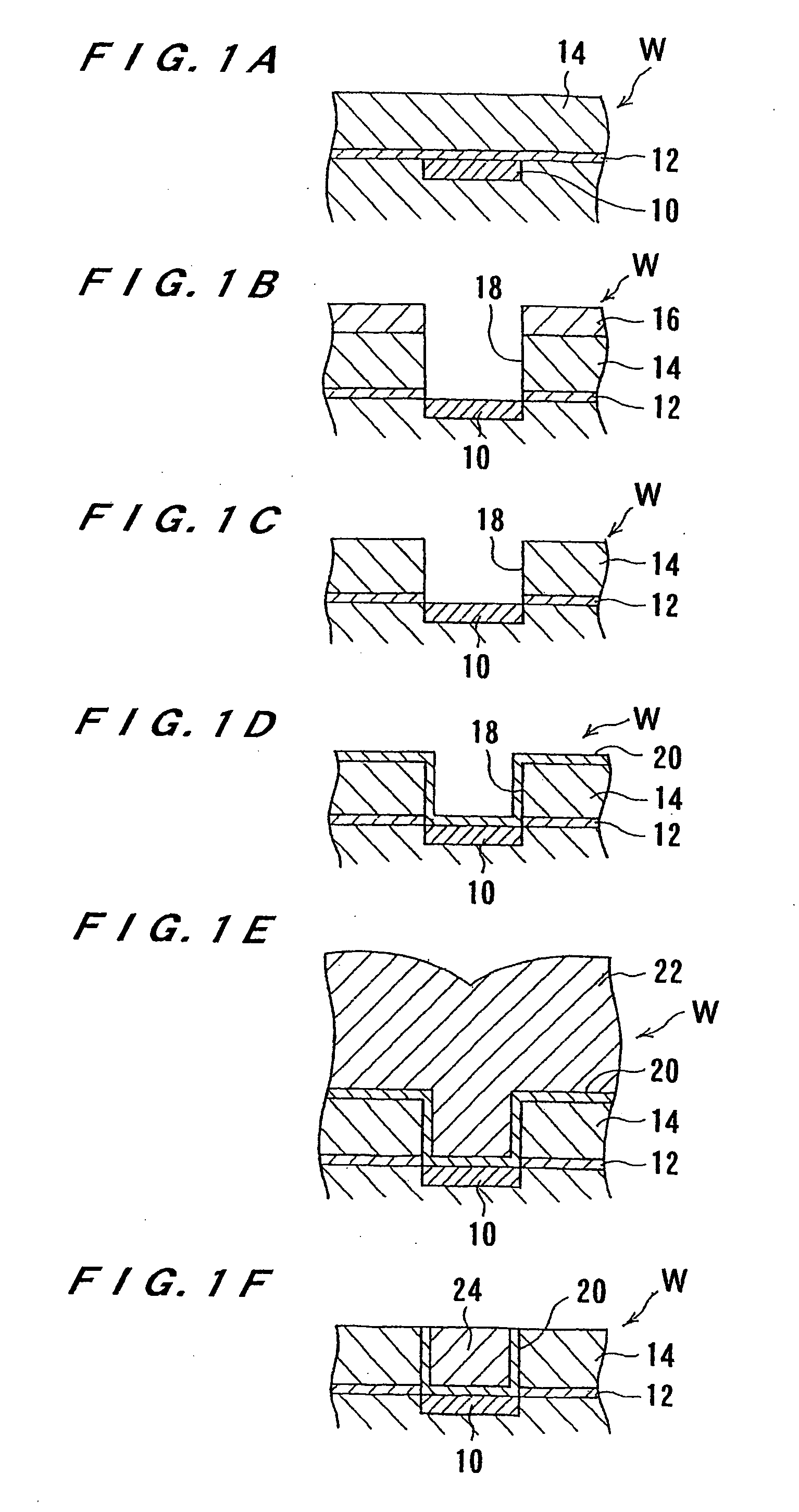

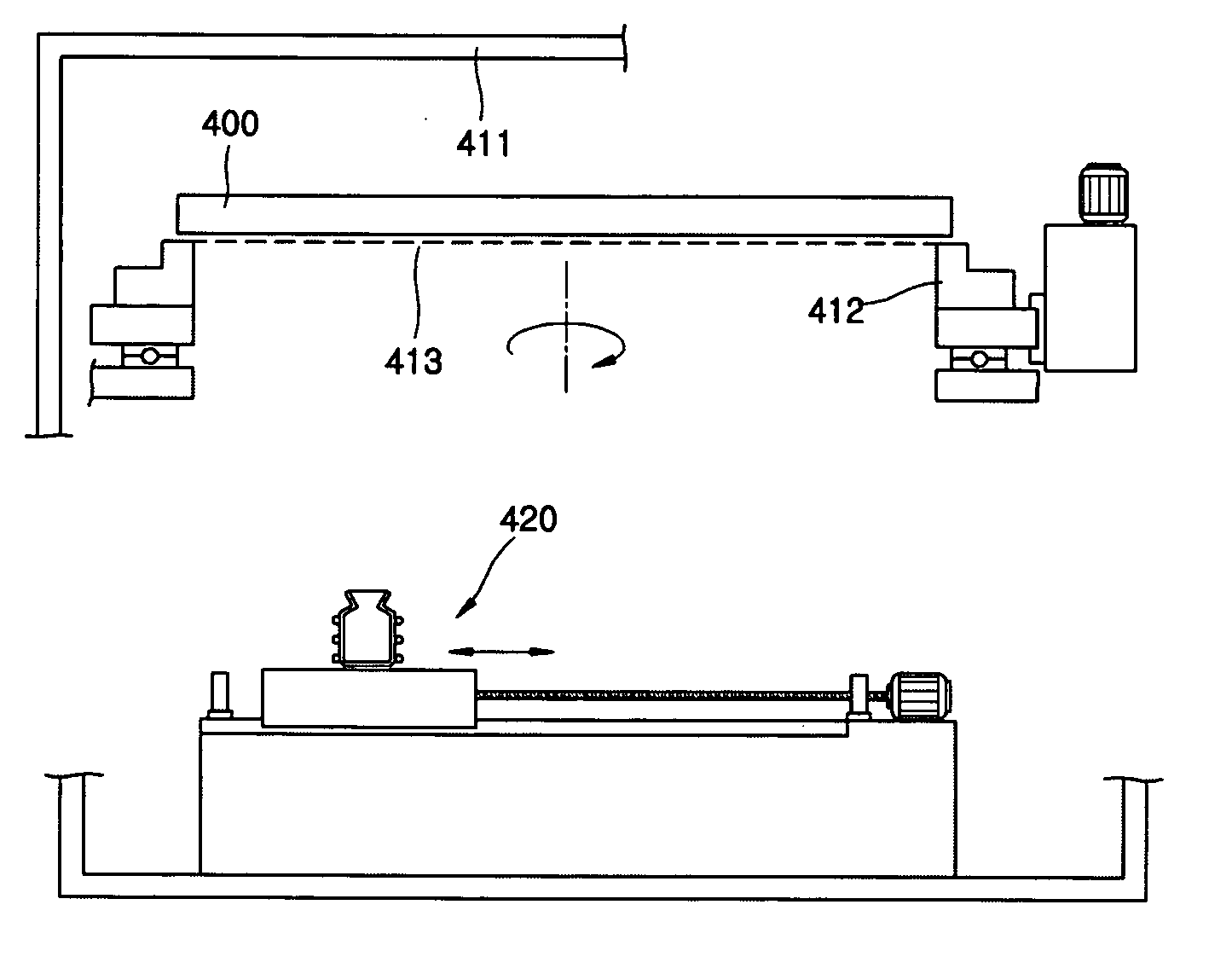

Apparatus and method for electroless deposition of materials on semiconductor substrates

InactiveUS6913651B2Simple and compact structureReduce manufacturing costLiquid surface applicatorsSpraying apparatusEngineeringElectroless deposition

An apparatus of the invention has a closable chamber that can be sealed and is capable of withstanding an increased pressure and high temperature. The chamber contains a substrate holder that can be rotated around a vertical axis, and an edge-grip mechanism inside the substrate holder. The deposition chamber has several inlet ports for the supply of various process liquids, such as deposition solutions, DI water for rinsing, etc., and a port for the supply of a gas under pressure. The apparatus is also provided with reservoirs and tanks for processing liquids and gases, as well as with a solution heater and a control system for controlling temperature and pressure in the chamber. The heater can be located outside the working chamber or built into the substrate holder, or both heaters can be used simultaneously. Uniform deposition is achieved by carrying out the deposition process under pressure and under temperature slightly below the boiling point of the solution. The solution can be supplied from above via a shower head formed in the cover, or through the bottom of the chamber. Rinsing or other auxiliary solutions are supplied via a radially moveable chemical dispensing arm that can be arranged above the substrate parallel thereto.

Owner:LAM RES CORP

Multichannel fluid delivery device

ActiveUS7169128B2Uniform ratePharmaceutical delivery mechanismMedical devicesStored energyAntibiotic Y

A compact fluid dispenser for use in controllably dispensing fluid medicaments, such as antibiotics, oncolytics, hormones, steroids, blood clotting agents, analgesics, and like medicinal agents from a plurality of prefilled containers at a uniform rate. The dispenser uniquely includes a plurality of stored energy source that are provided in the form of compressible-expandable members of novel construction that provide the force necessary to continuously and uniformly expel fluid from a plurality of device reservoirs. The apparatus further includes a plurality of fluid flow control assemblies that precisely control the flow of the medicament solutions from the plurality of device reservoirs to the patient.

Owner:BIOQ PHARMA

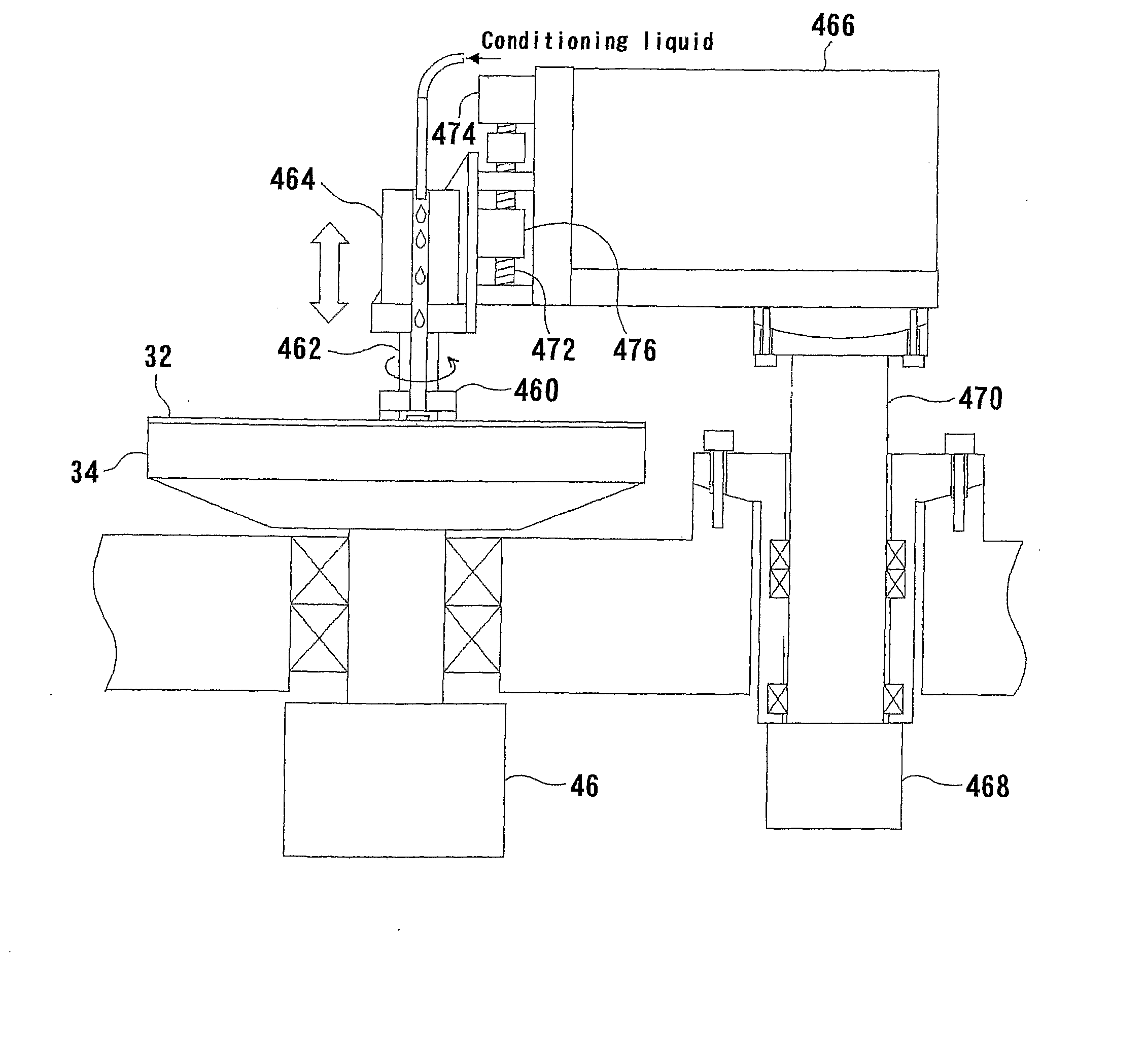

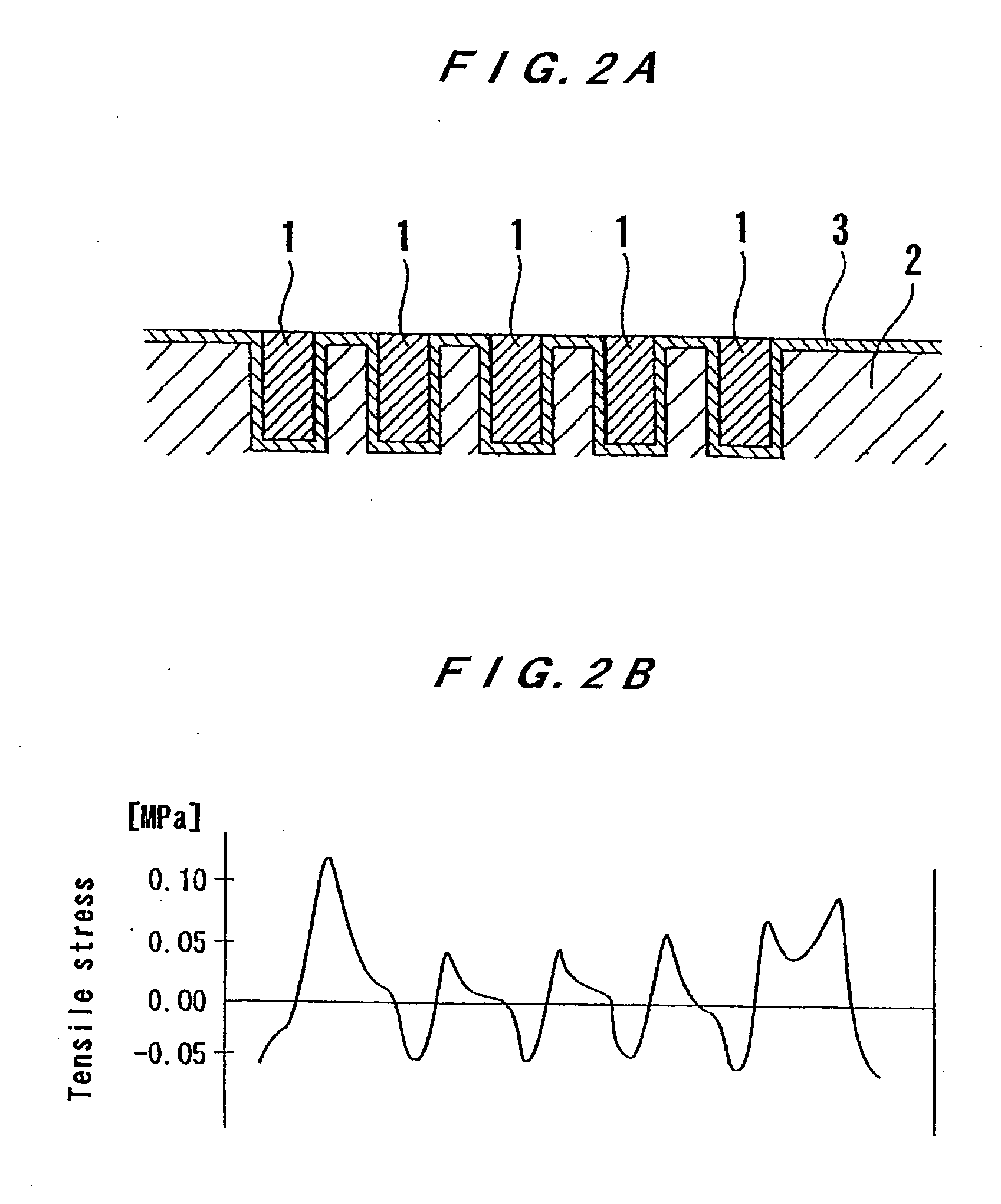

Electrochemical mechanical polishing apparatus conditioning method, and conditioning solution

InactiveUS20080188162A1Low costEasy to implementSemiconductor/solid-state device manufacturingLapping machinesElectrical resistance and conductancePower flow

An electrochemical mechanical polishing apparatus is for use in polishing of a conductive material (e.g., metal) on a surface of a substrate by combination of electrochemical action and mechanical action. This apparatus includes a polishing table having divided electrodes and adapted to hold a polishing pad having a polishing surface, a polishing head adapted to hold a workpiece having a conductive film and to press the workpiece against the polishing surface, a second electrode for supplying an electric current to the conductive film, an electrolytic-solution supply section for supplying an electrolytic solution to the polishing surface, a detecting section adapted to detect a signal corresponding to a thickness of the conductive film, a variable resistance unit having the same number of variable resistors as the number of divided electrodes, a moving mechanism for providing relative movement between the workpiece and the polishing surface, and a control section adapted to control each of the variable resistors based on the signal from the detecting section.

Owner:EBARA CORP

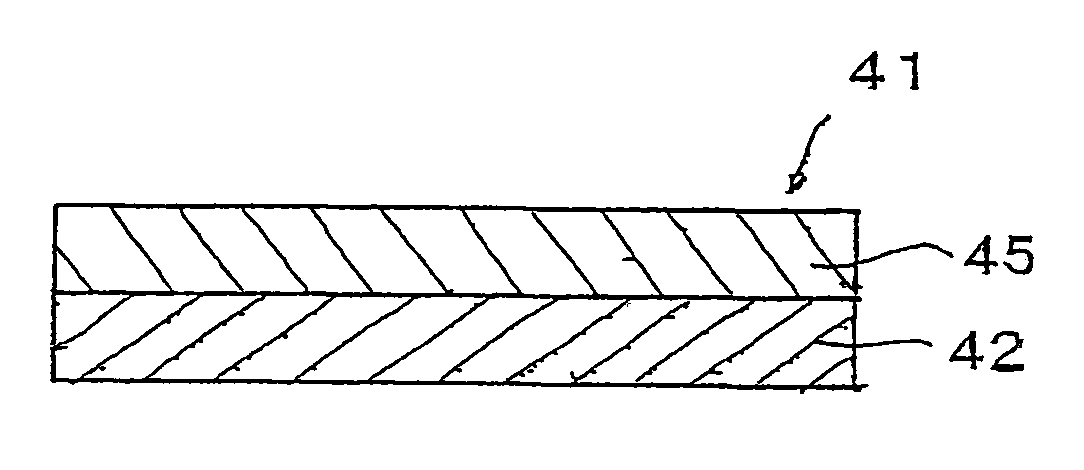

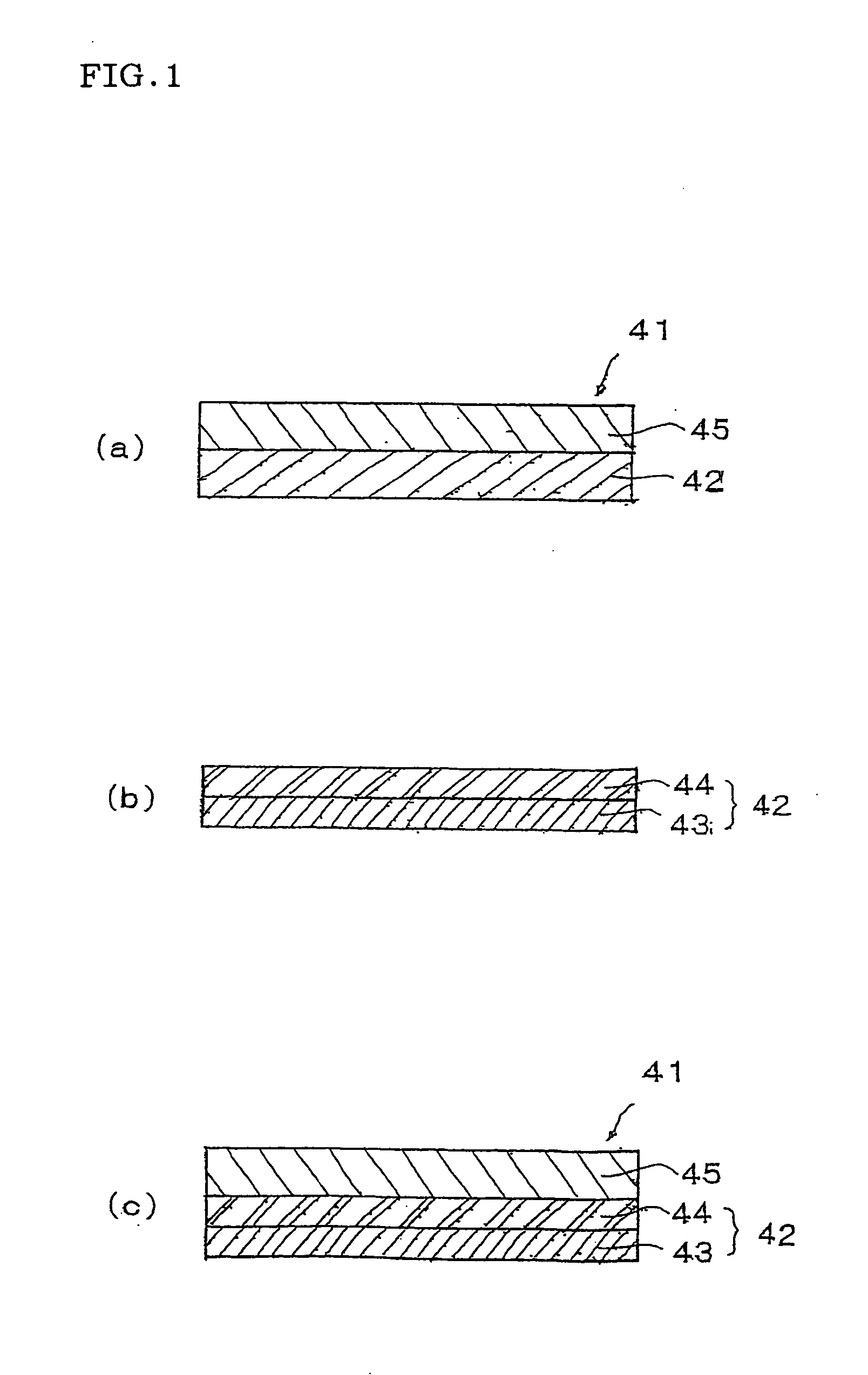

Polishing pad and cushion layer for polishing pad

InactiveUS20060148391A1Easy to processHigh thickness accuracyBelt grinding machinesAbrasion apparatusEngineeringHardness

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

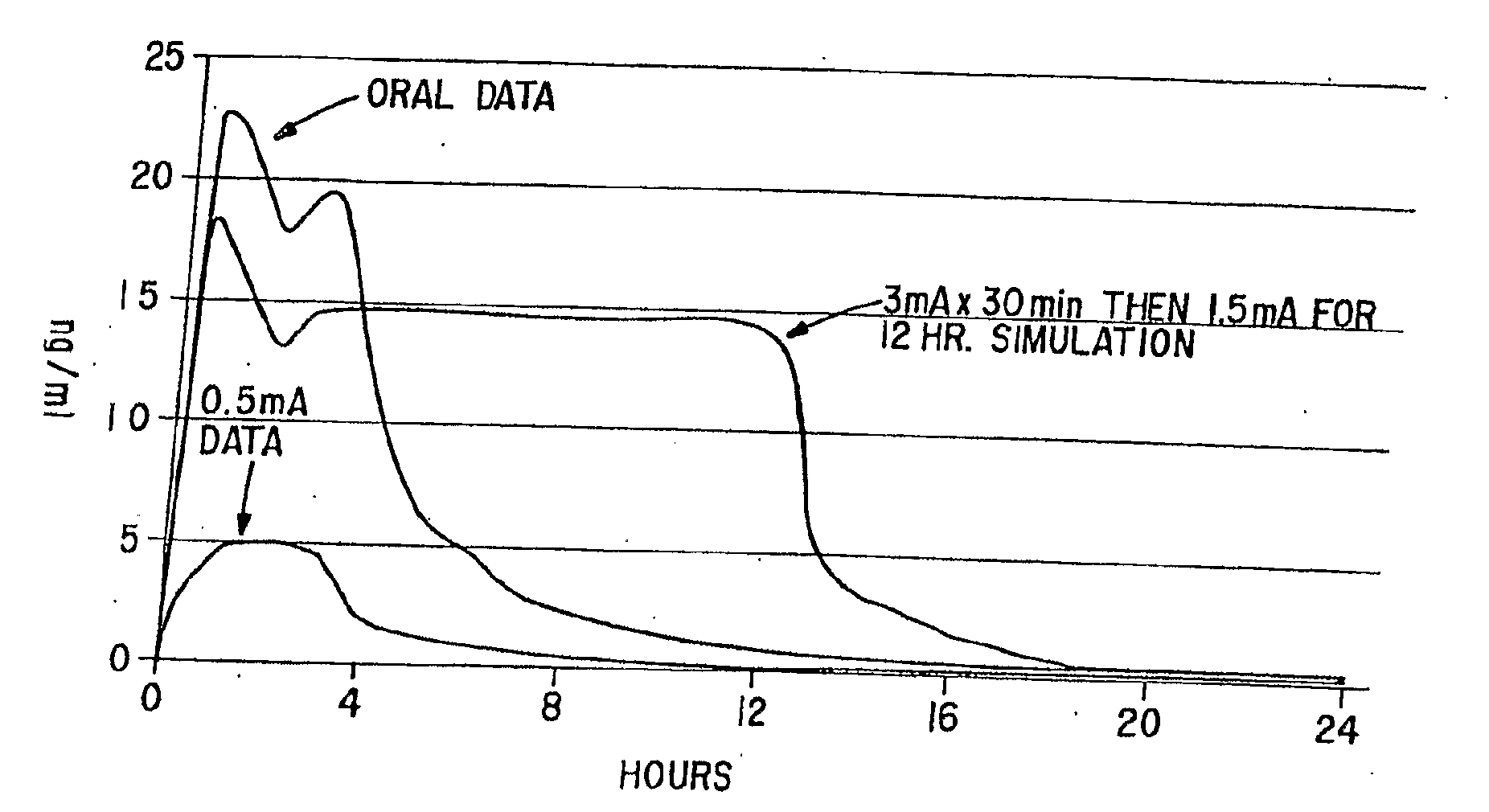

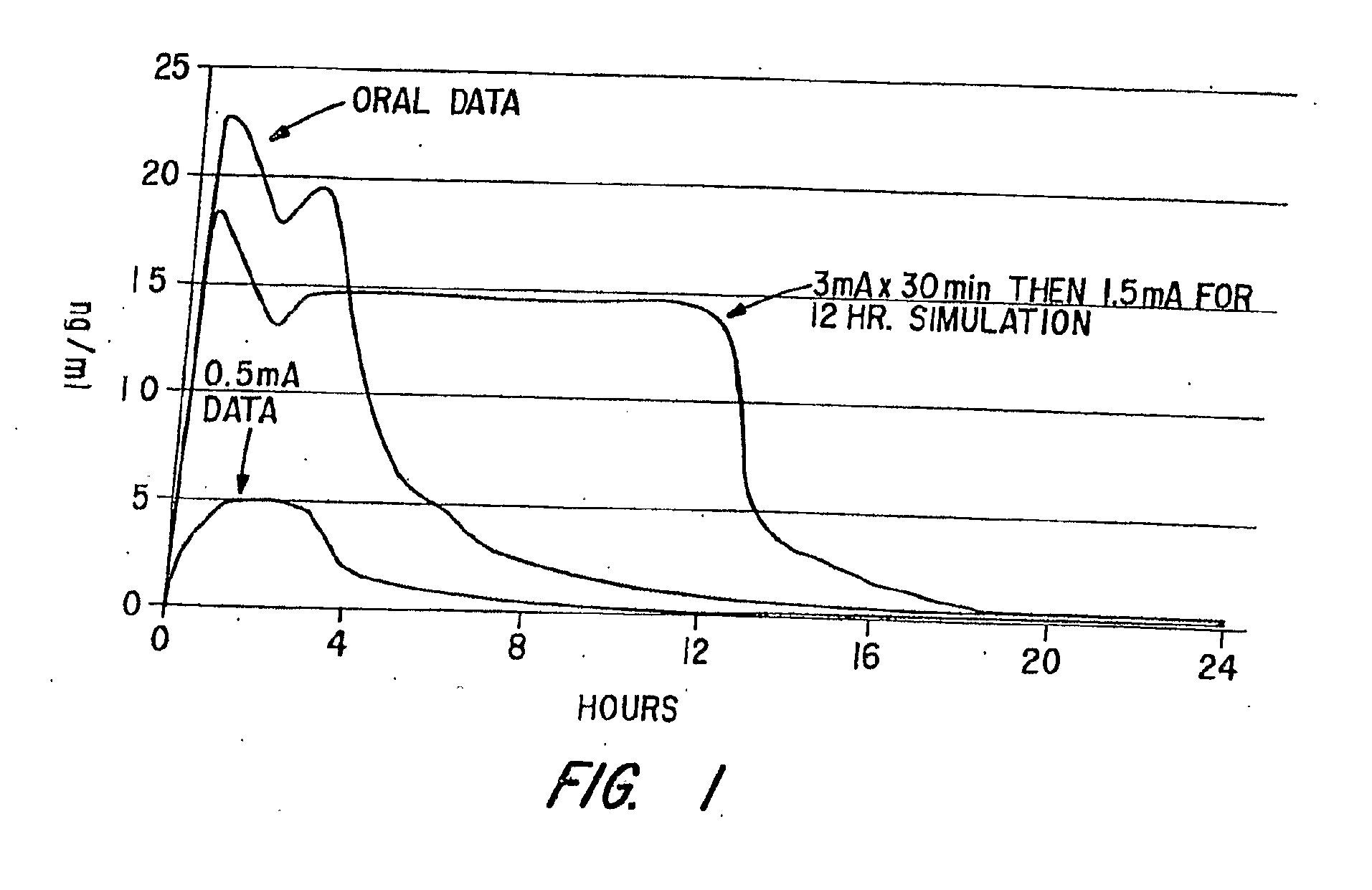

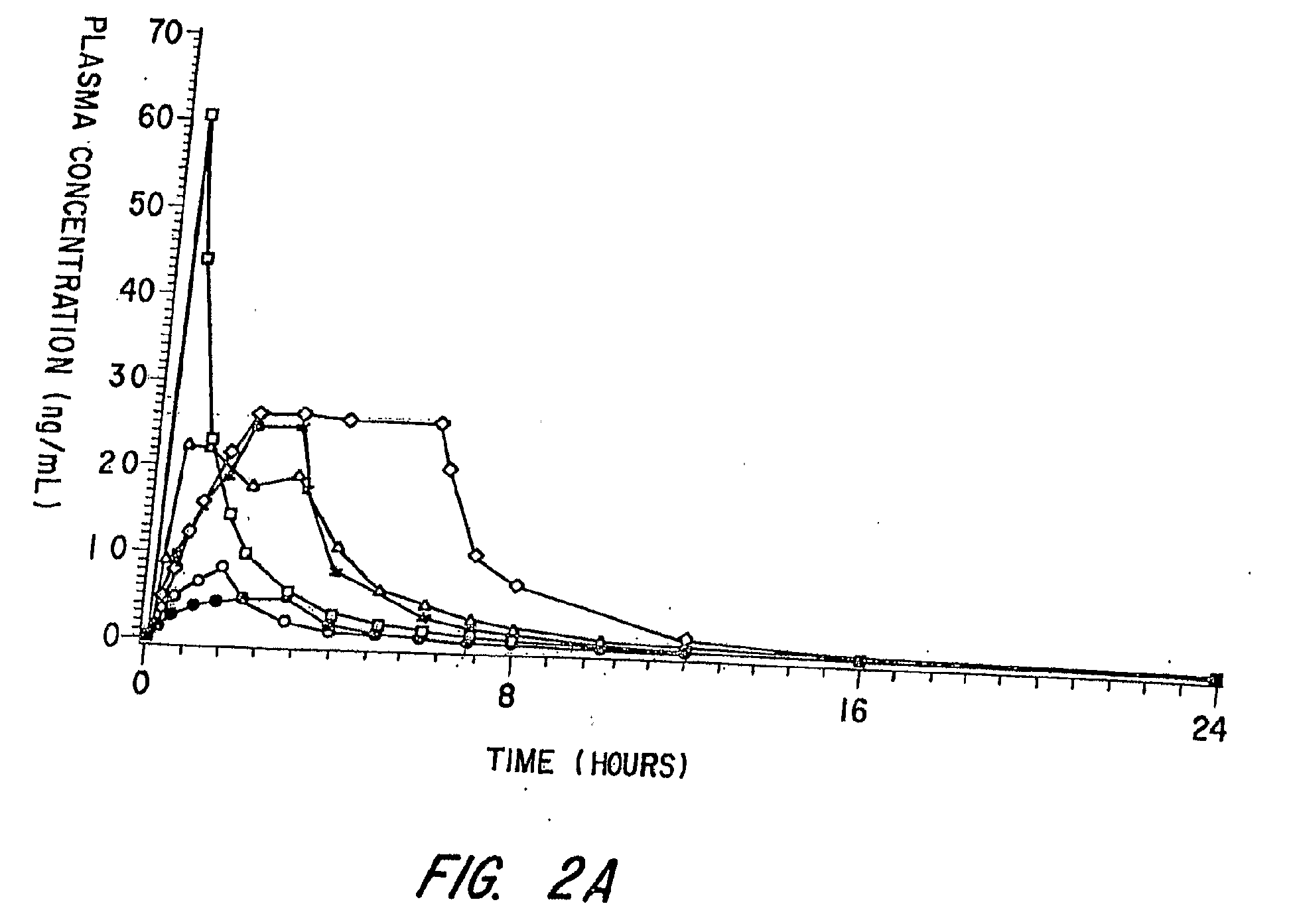

Transdermal methods and systems for the delivery of Anti-migraine compounds

Iontophoretic patches for the delivery of anti-migraine compounds and methods of using the patches are described.

Owner:TEVA PHARMACEUTICALS INTERNATIONAL GMBH

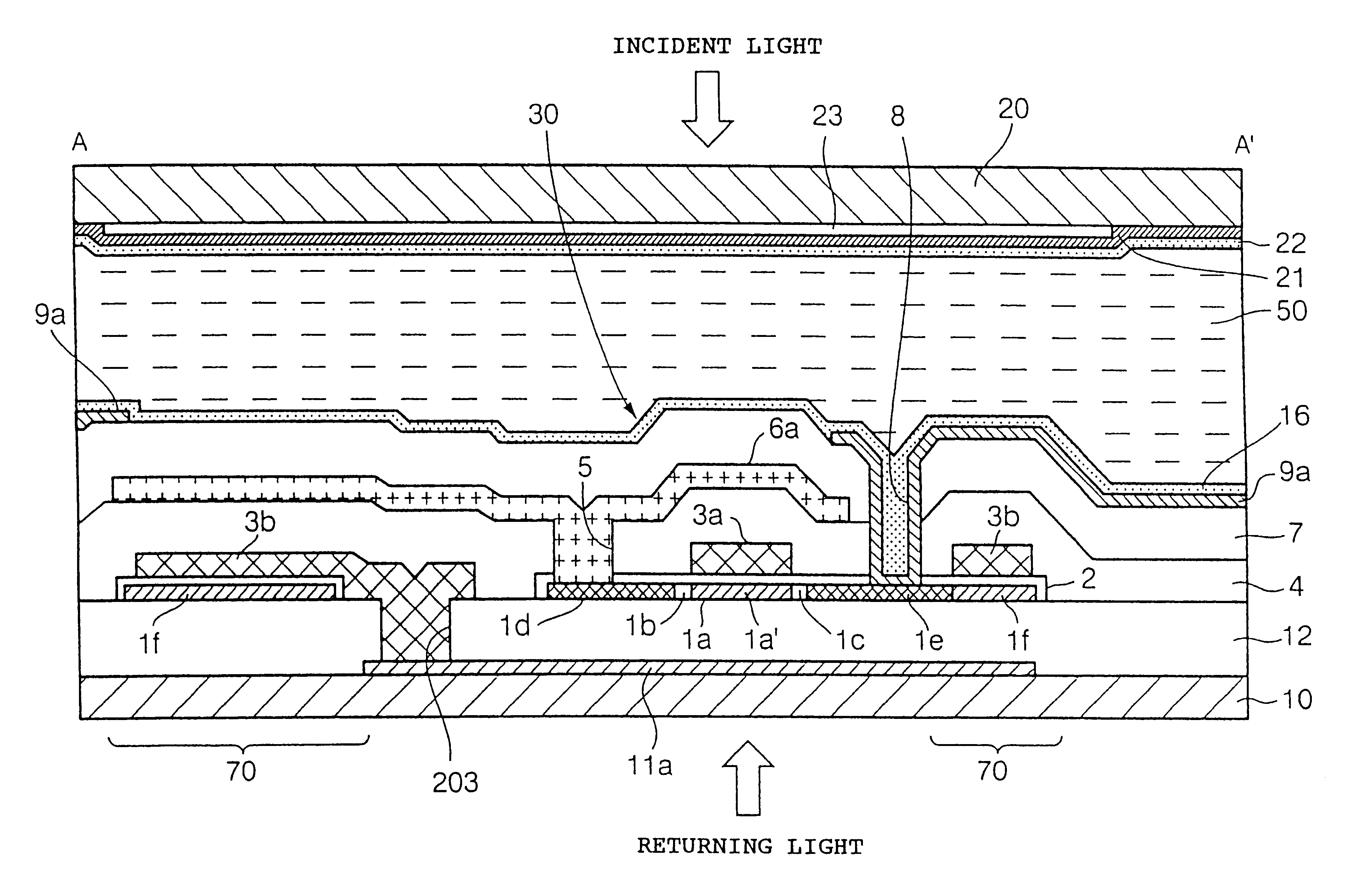

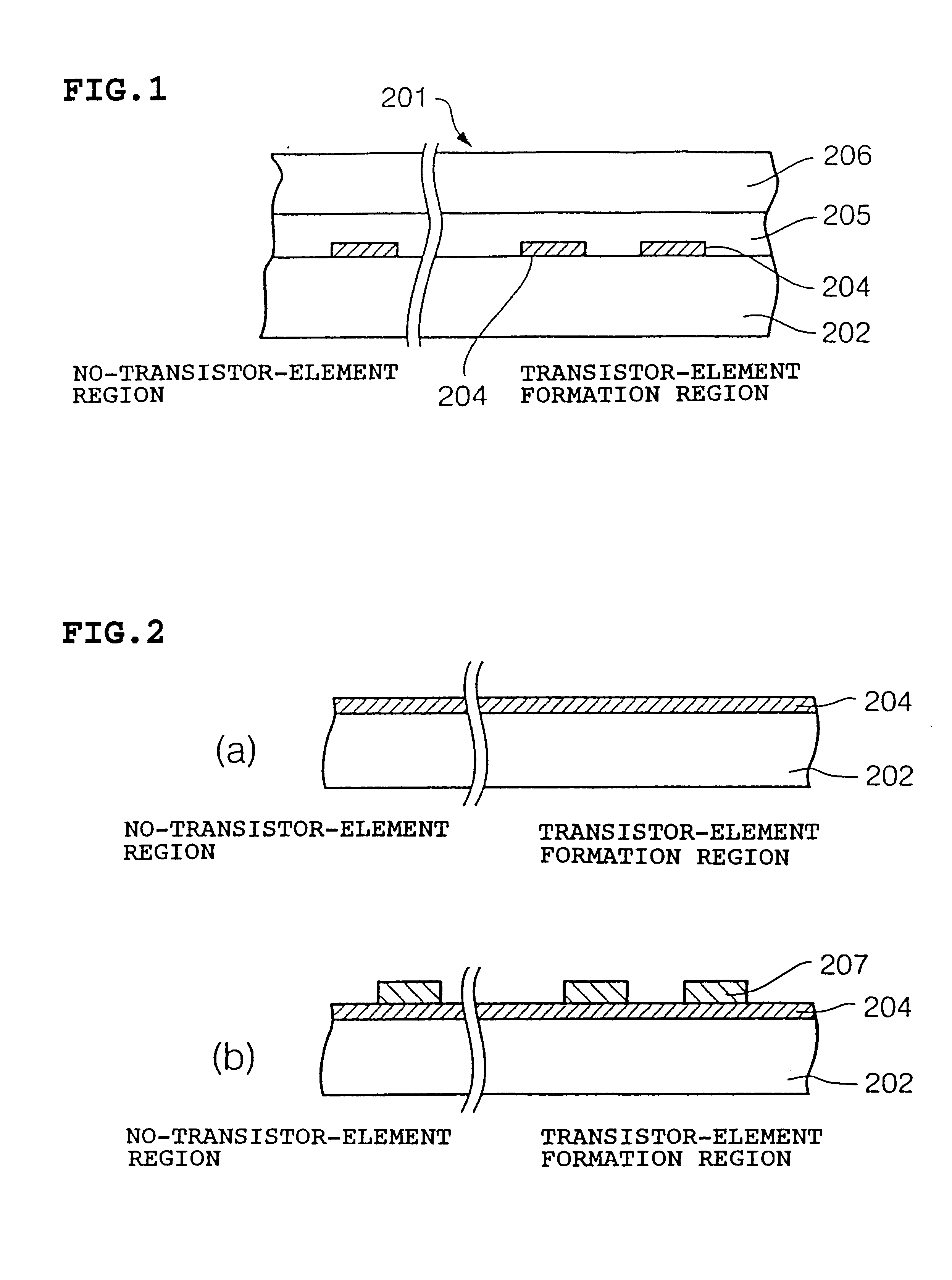

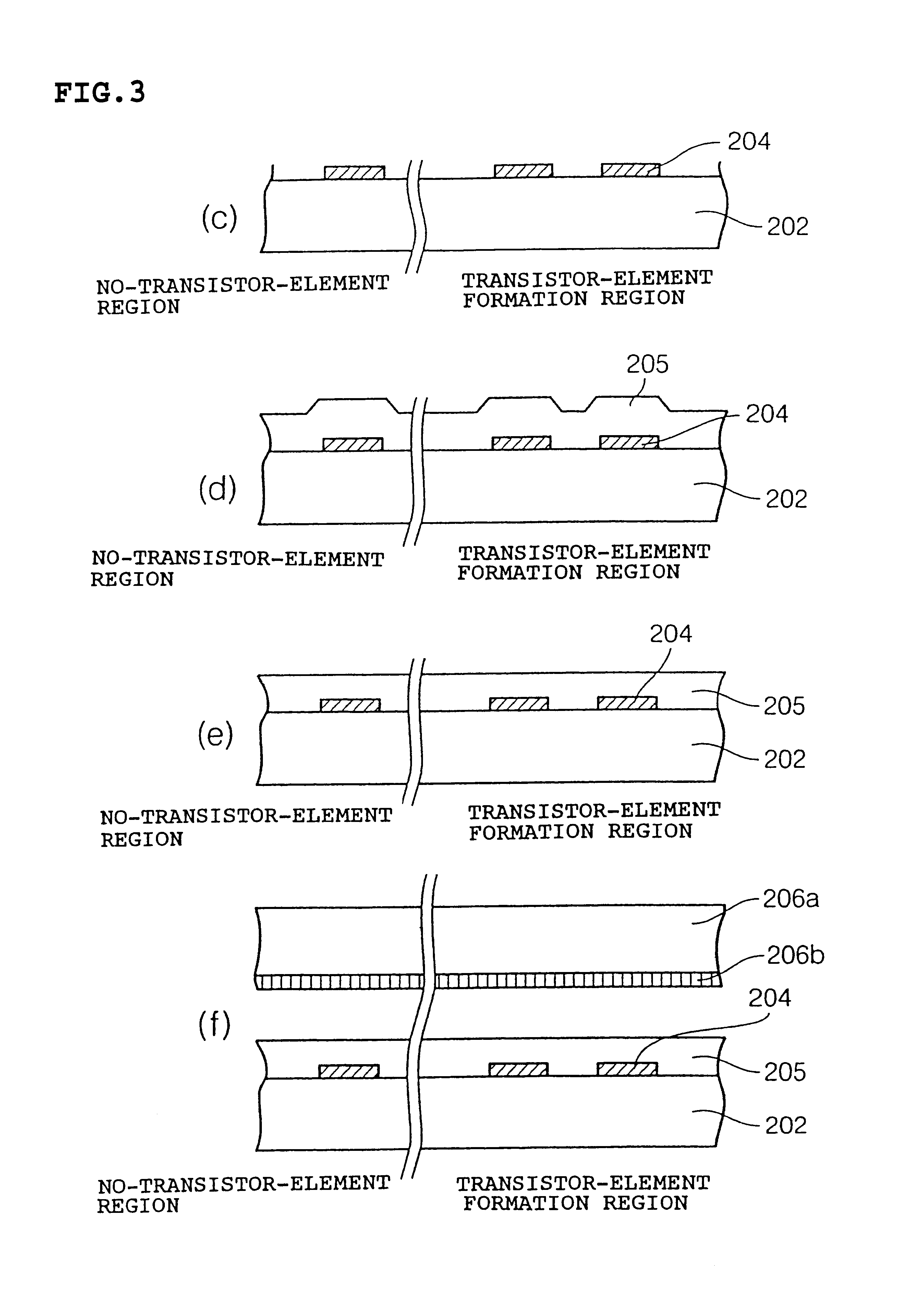

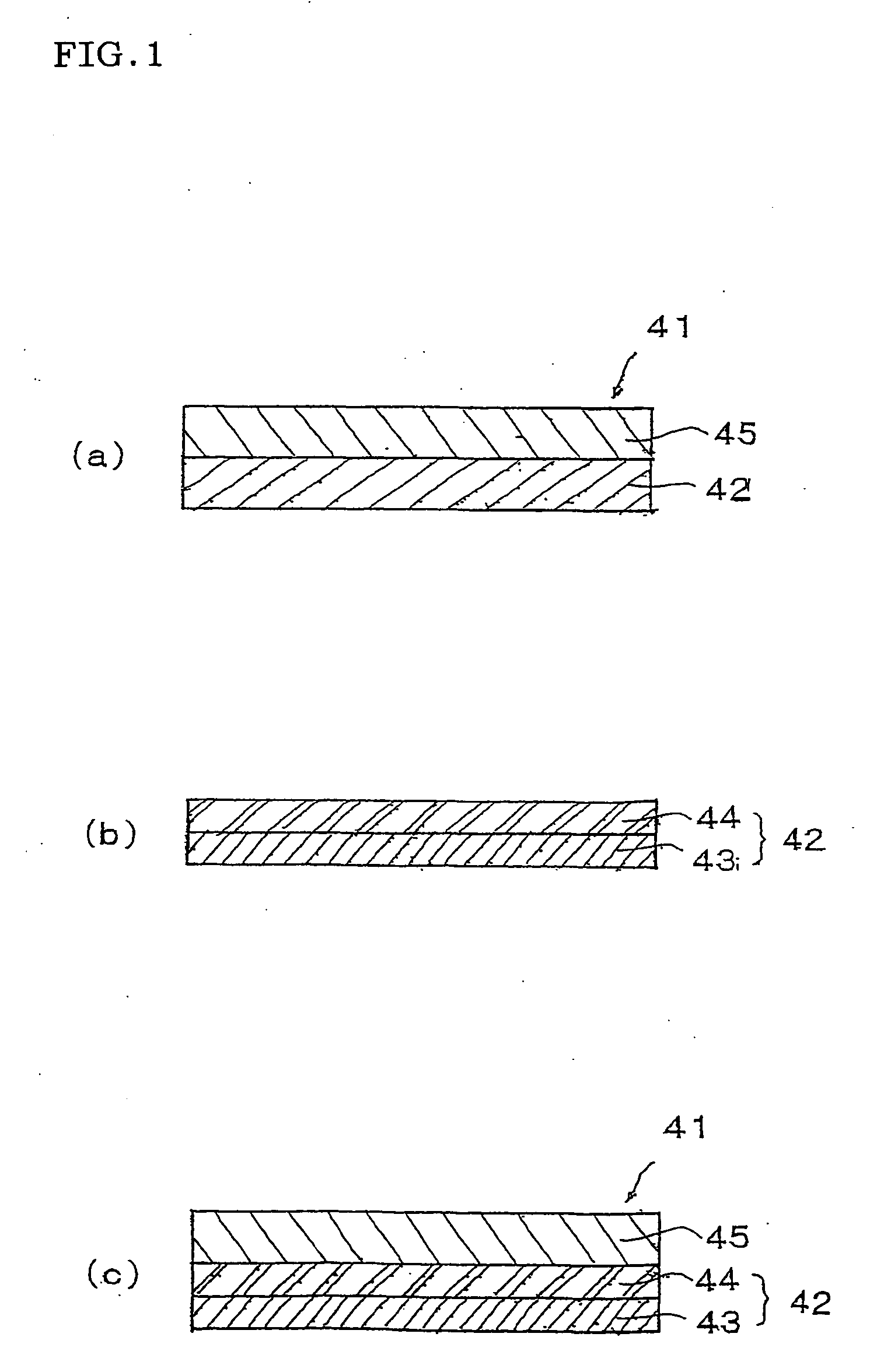

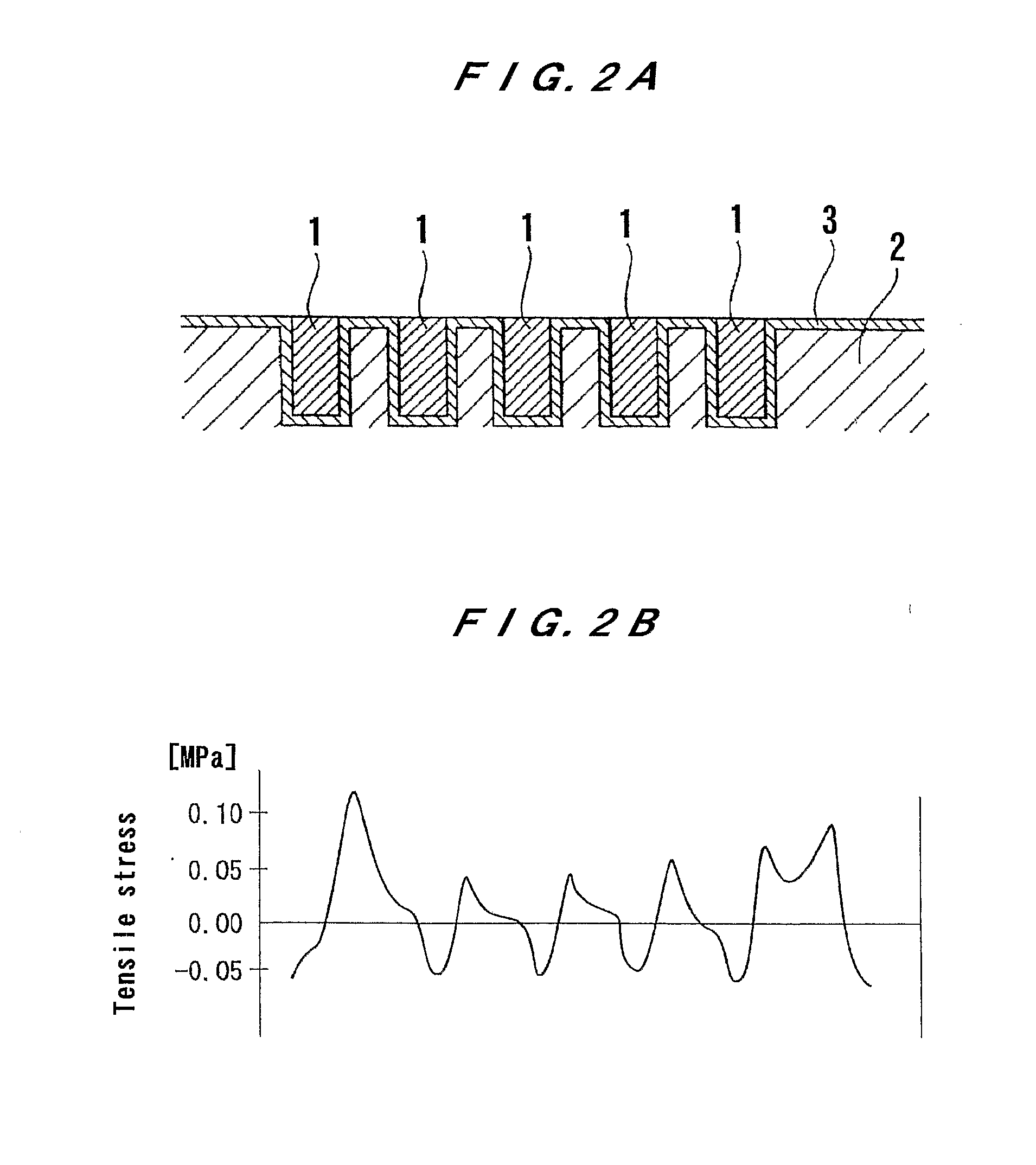

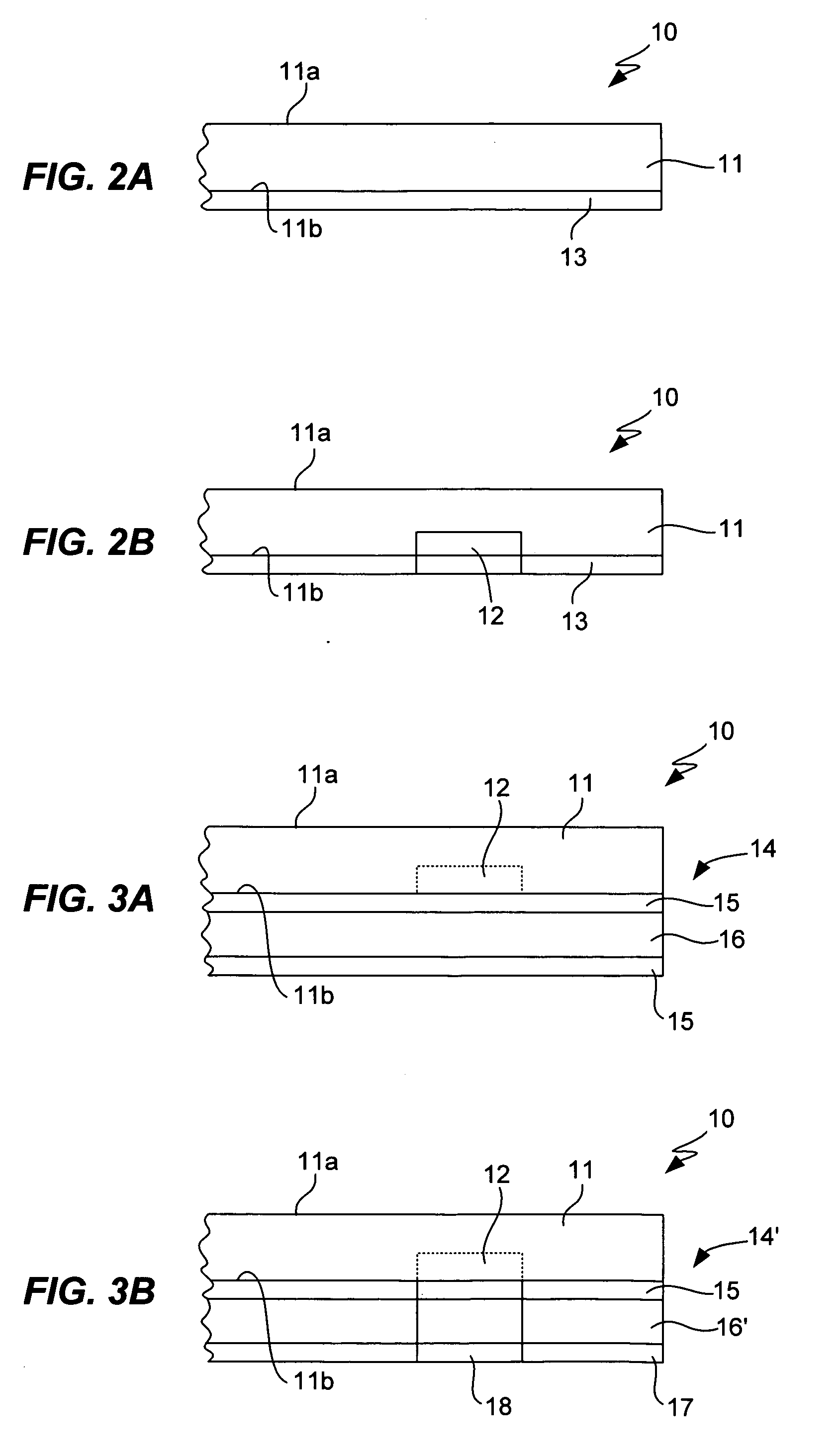

Method for manufacturing electro-optical device, electro-optical device, and electronic equipment

InactiveUS6358759B1Uniform rateReduce variationTransistorSolid-state devicesOptoelectronicsCrystalline silicon

A electro-optical device and manufacturing method are provided for an electro-optical device that has the step of forming a light shielding layer on one side of a light transmissive substrate, patterning the light shielding layer, forming an insulating layer on the patterned light shielding layer, planarizing the insulating layer, bonding a model crystalline silicon layer on the surface of the planarized insulating layer, and forming a transistor element from the monocrystalline silicon layer, wherein the patterned light shielding layer is arranged in an area facing the transistor element and in a peripheral area surrounding the transistor element.

Owner:138 EAST LCD ADVANCEMENTS LTD

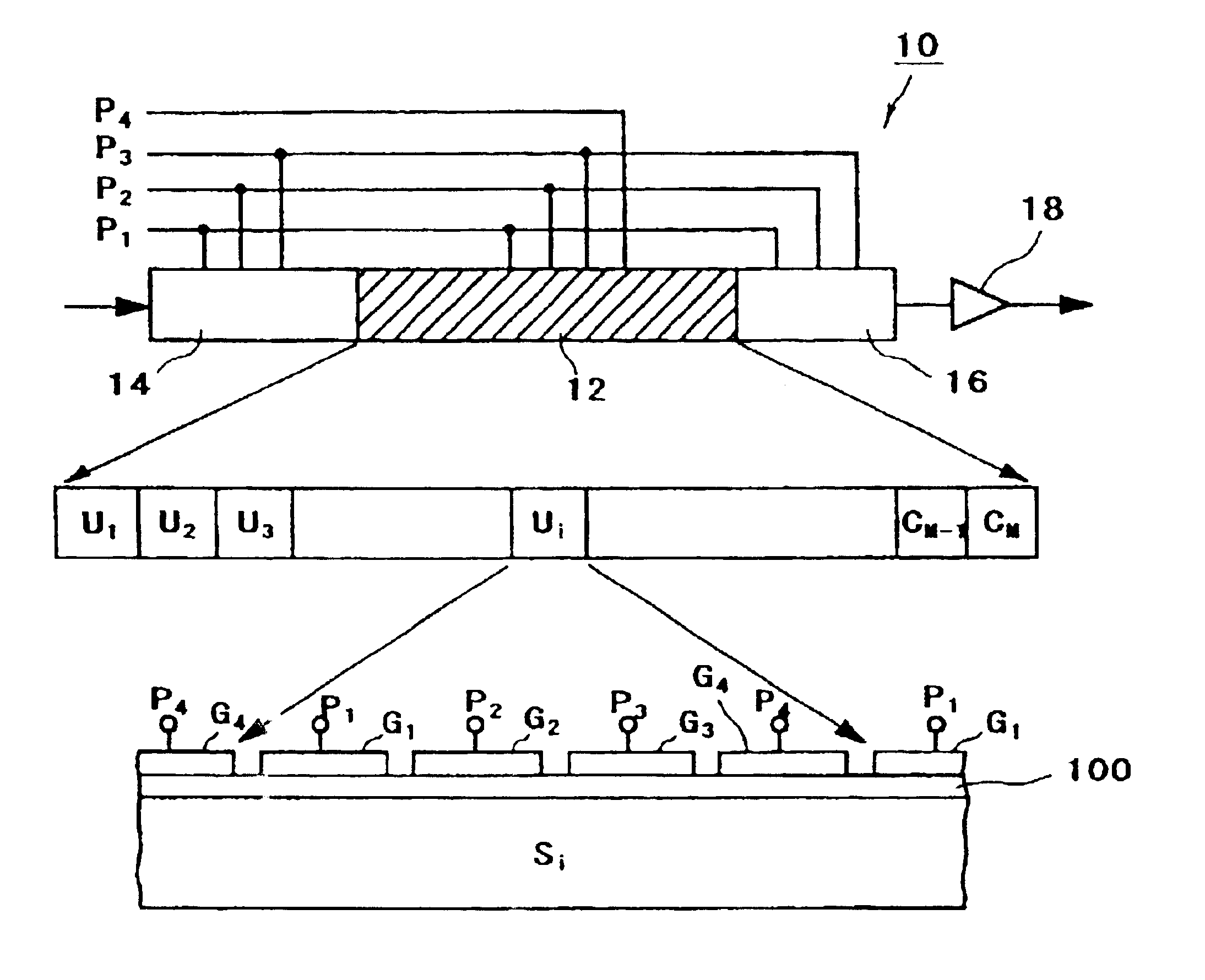

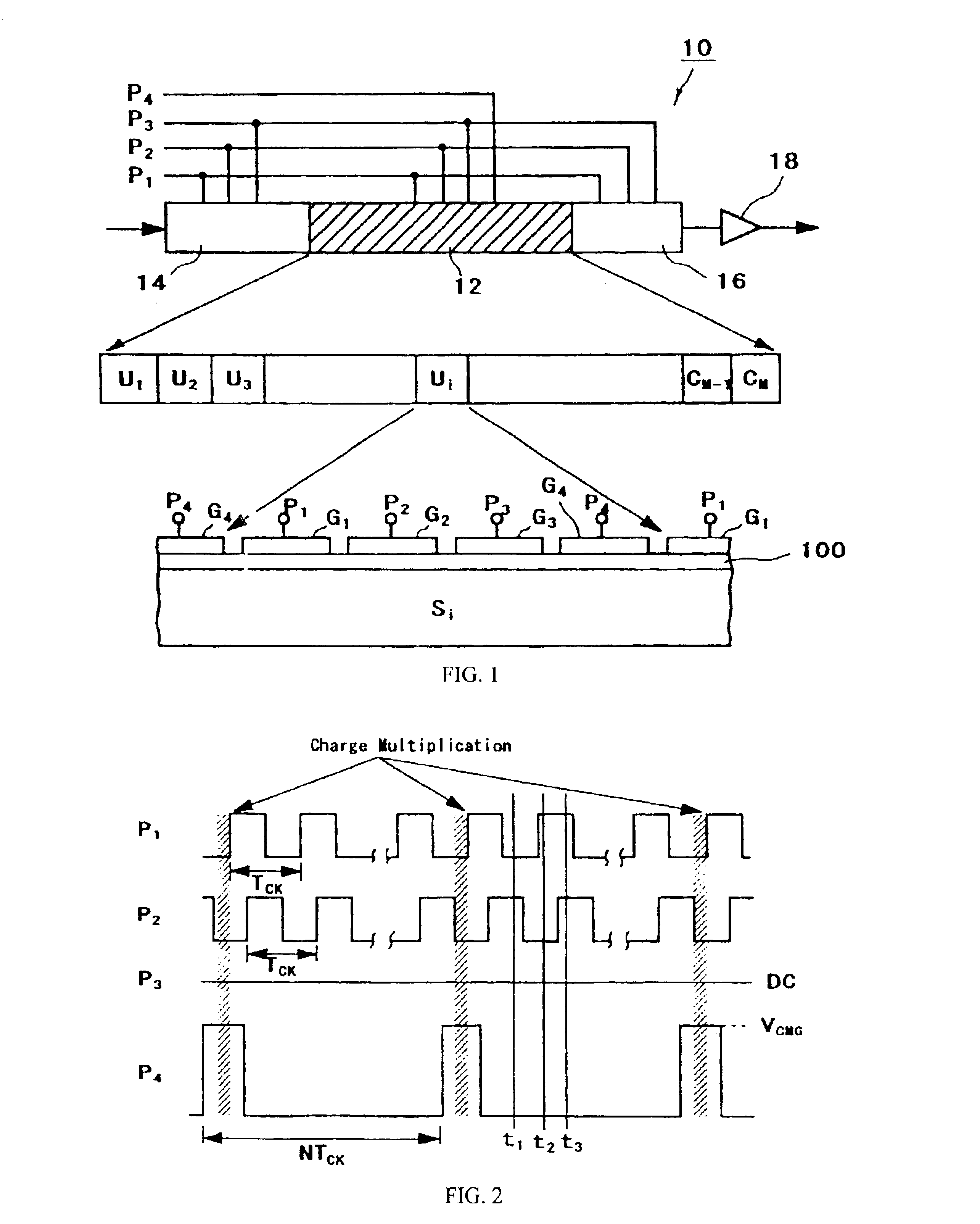

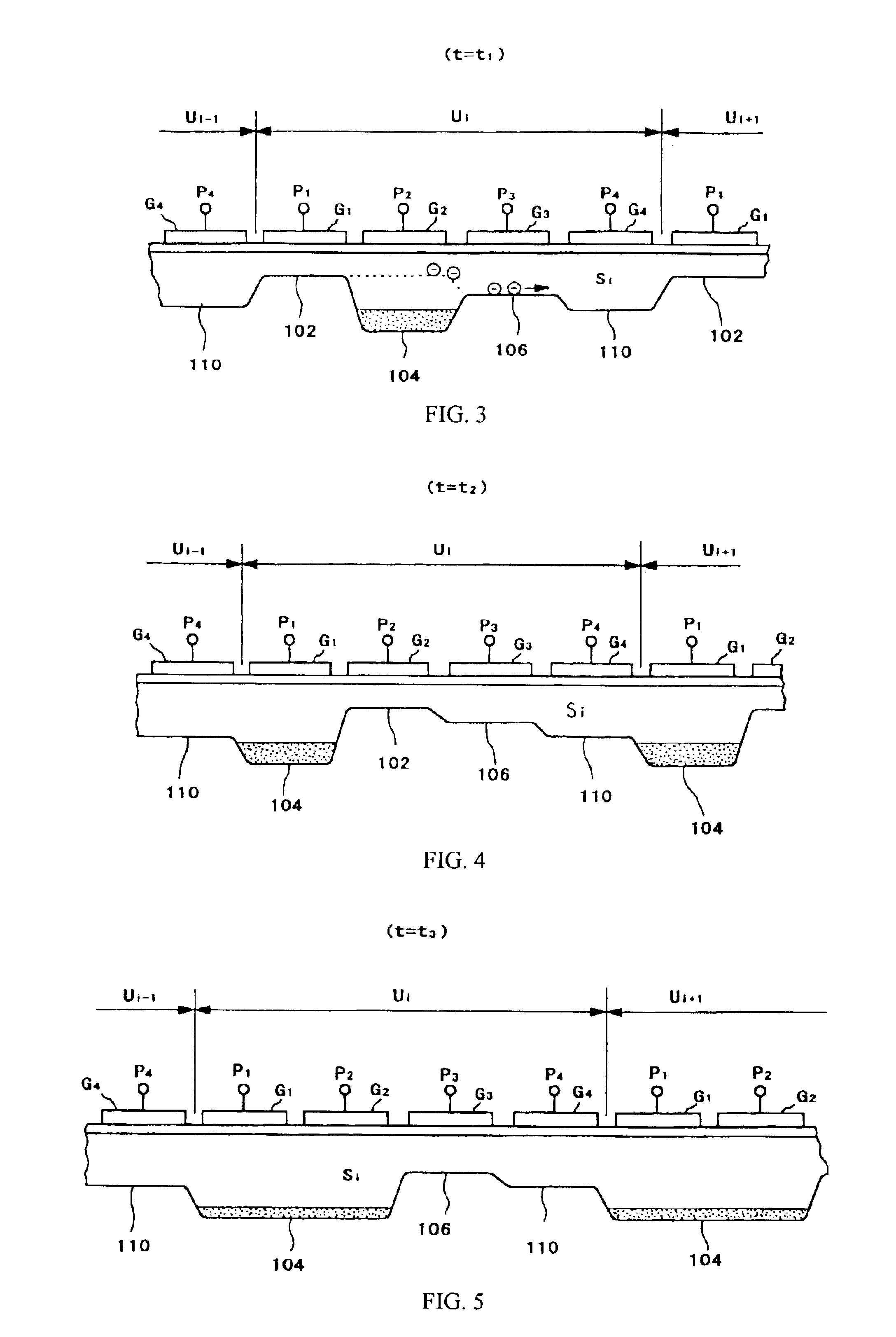

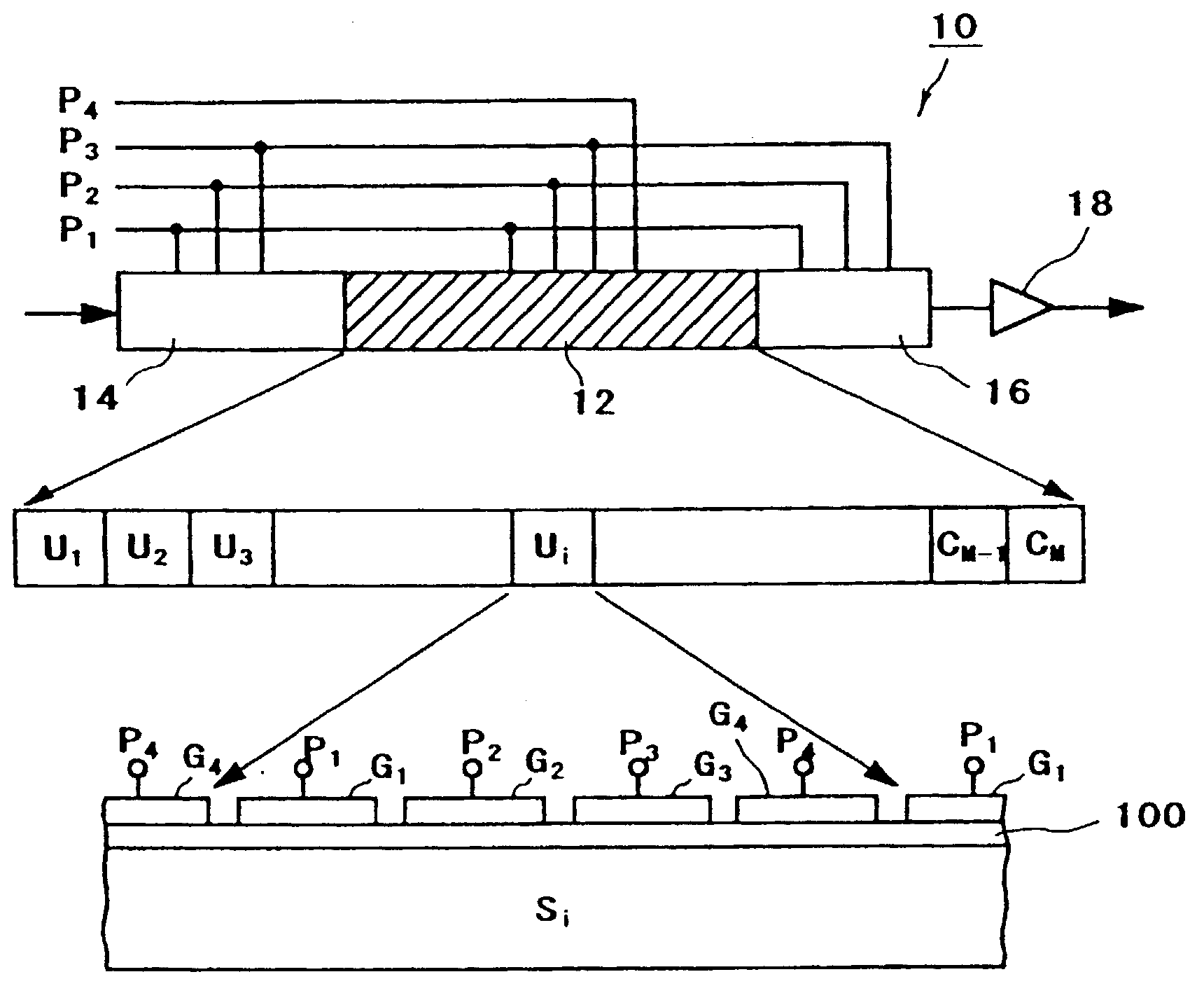

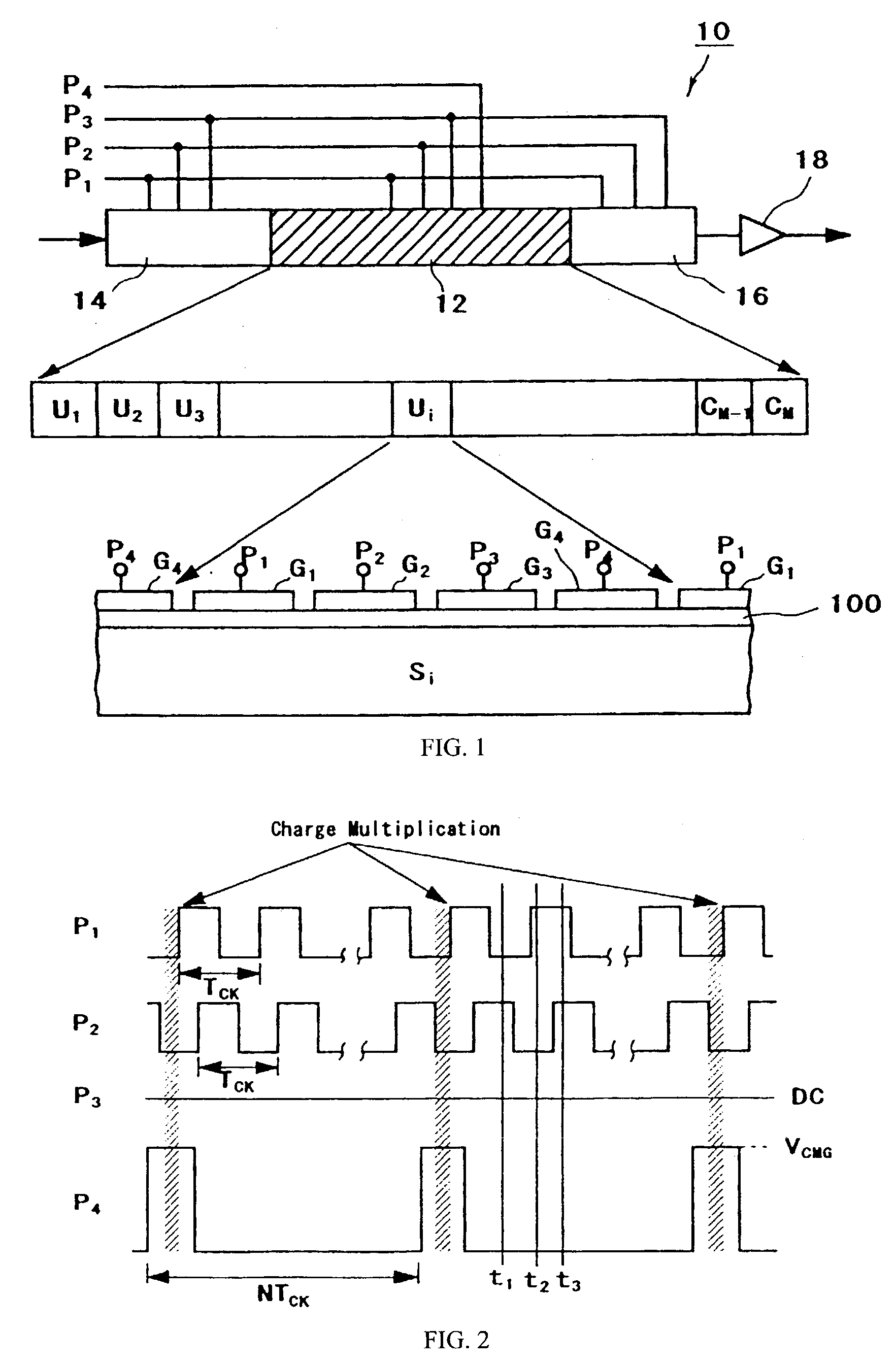

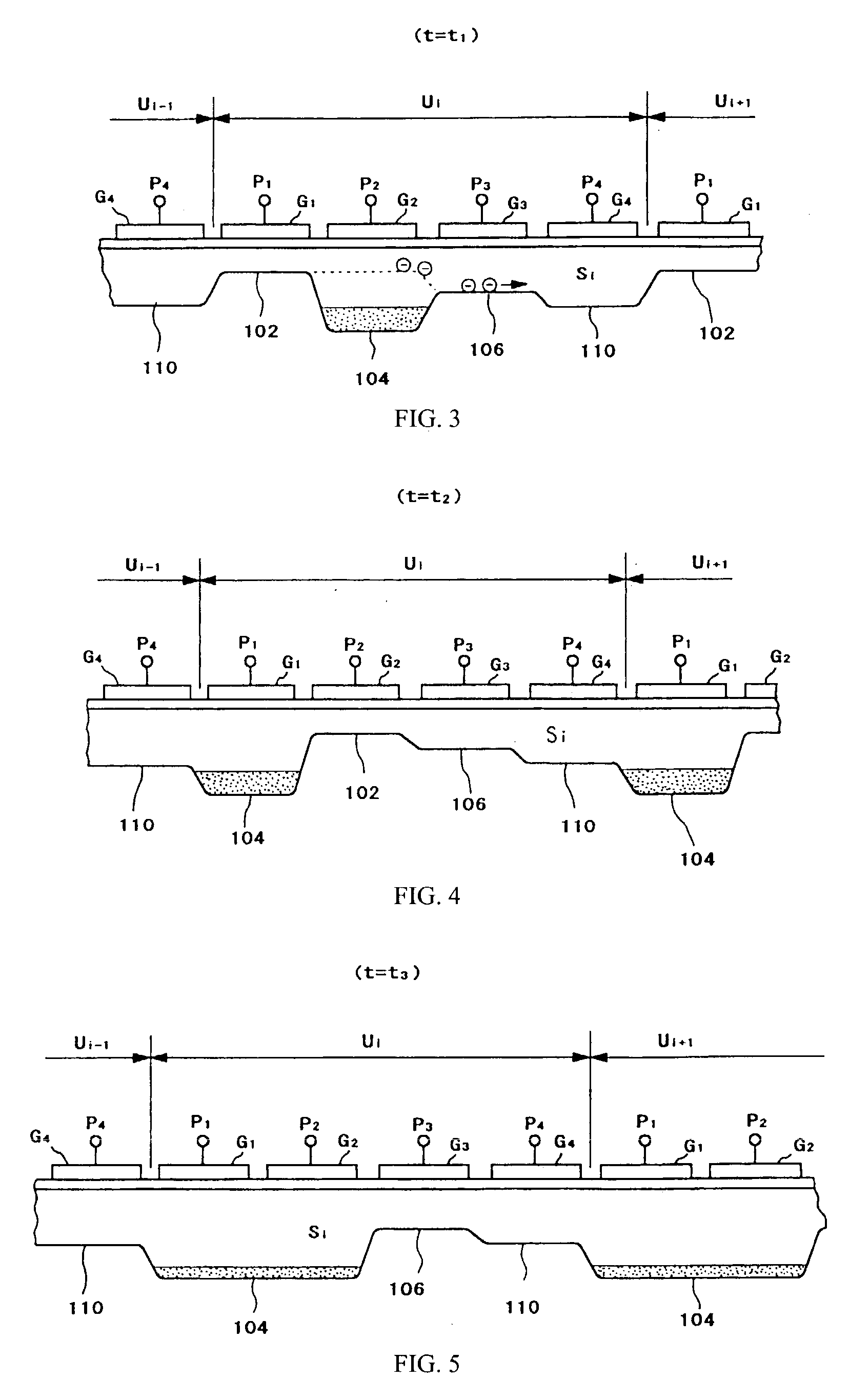

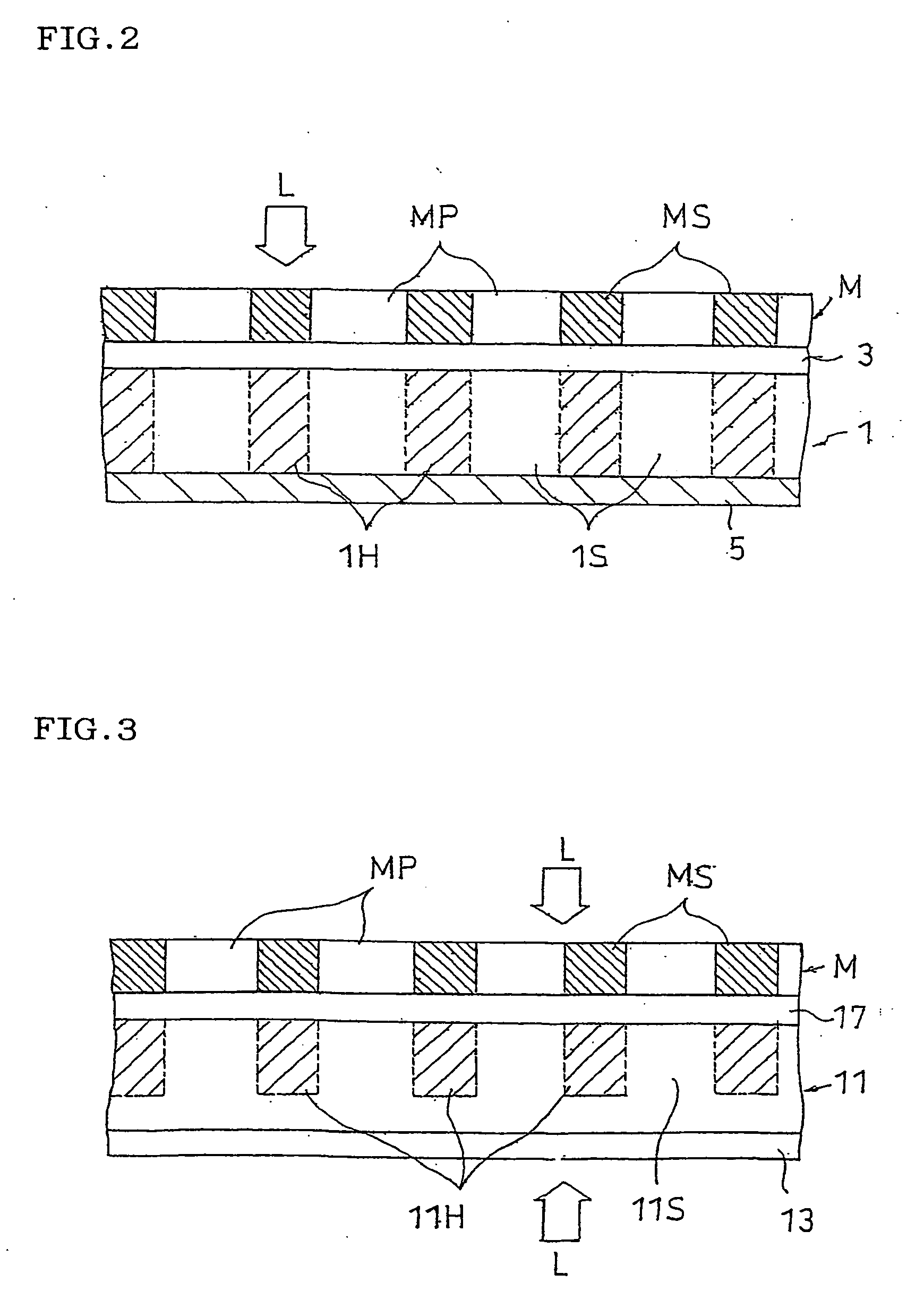

CMD and CMD-carrying CCD device

InactiveUS6862333B2Uniform rateTelevision system detailsCounting chain synchronous pulse countersControl signalSilicon oxide

This invention controls the signal amplification rate in a simple way with high precision in a CMD or CMD-carrying CCD device. CMD 12 has plural sections, such as M sections (U1-UM), each of which is a CMD unit U that can perform a charge multiplication operation, set in series. Each section of CMD unit Ui has plural (such as 4) electrodes G1, G2, G3, G4 set in a row via an insulating film, such as silicon oxide film 100, on a silicon insulating film. Among driving voltages P1, P2, P3, P4 applied on the electrodes G1, G2, G3 and G4, P1 and P2 are applied in the same cycle as the transfer clock, P4 for impact ionization is applied in intermittent cycles with respect to P1 and P2, and P3 is applied as a DC voltage at a prescribed level.

Owner:TEXAS INSTR INC

CMD and CMD-carrying CCD device

InactiveUS20030223531A1Uniform rateTelevision system detailsCounting chain synchronous pulse countersControl signalSilicon oxide

This invention controls the signal amplification rate in a simple way with high precision in a CMD or CMD-carrying CCD device. CMD 12 has plural sections, such as M sections (U1-UM), each of which is a CMD unit U that can perform a charge multiplication operation, set in series. Each section of CMD unit Ui has plural (such as 4) electrodes G1, G2, G3, G4 set in a row via an insulating film, such as silicon oxide film 100, on a silicon insulating film. Among driving voltages P1, P2, P3, P4 applied on the electrodes G1, G2, G3 and G4, P1 and P2 are applied in the same cycle as the transfer clock, P4 for impact ionization is applied in intermittent cycles with respect to P1 and P2, and P3 is applied as a DC voltage at a prescribed level.

Owner:TEXAS INSTR INC

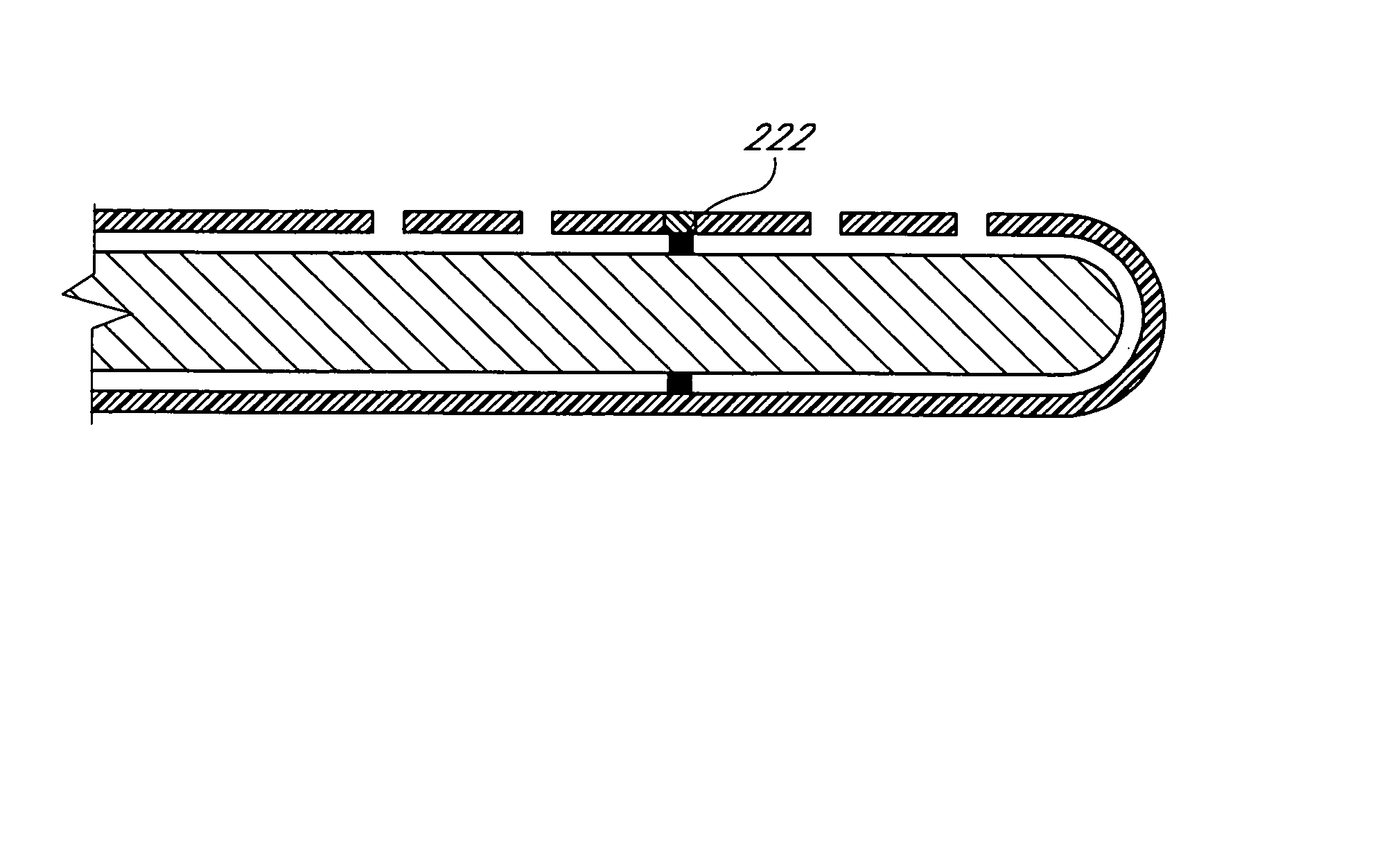

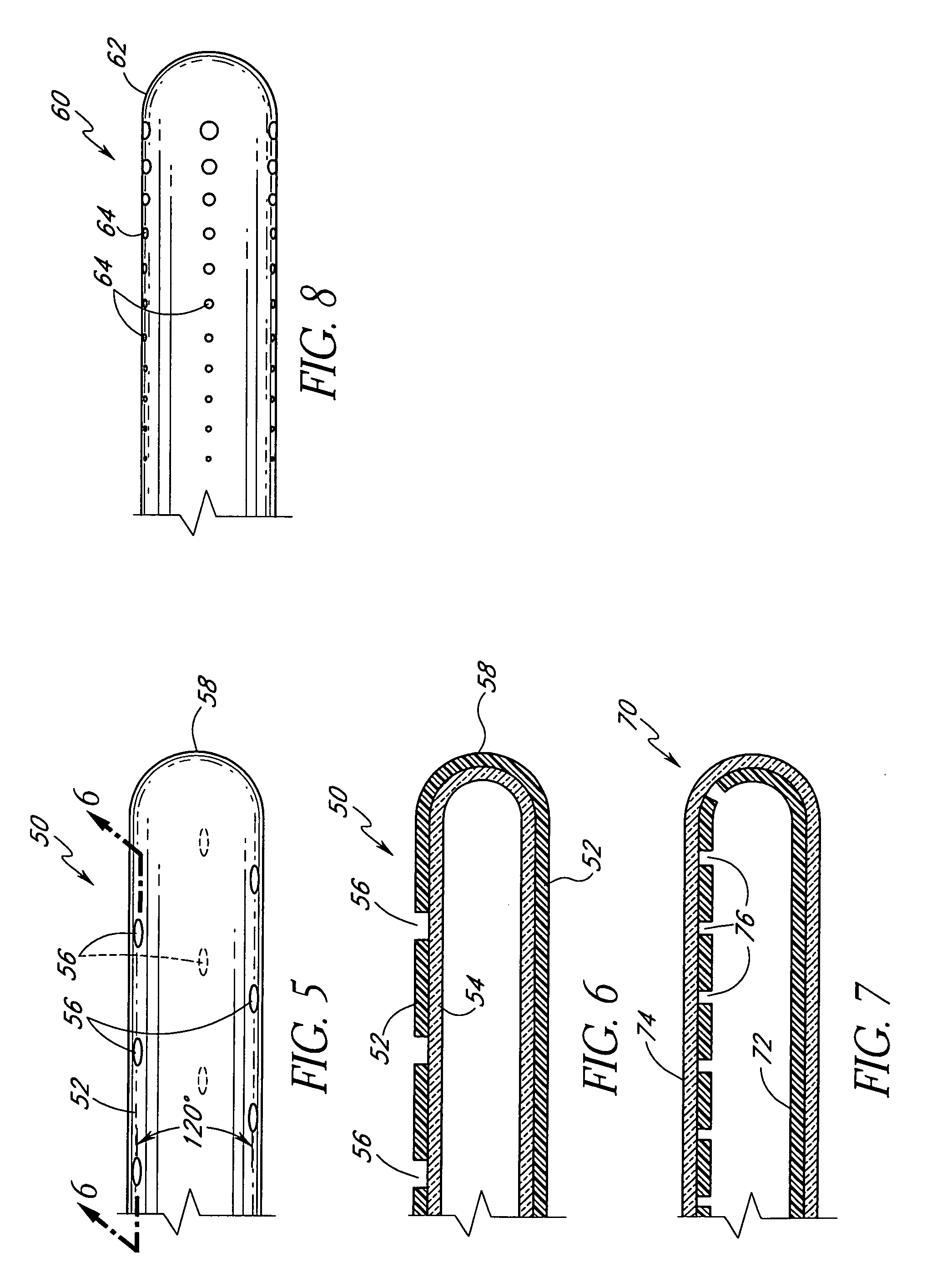

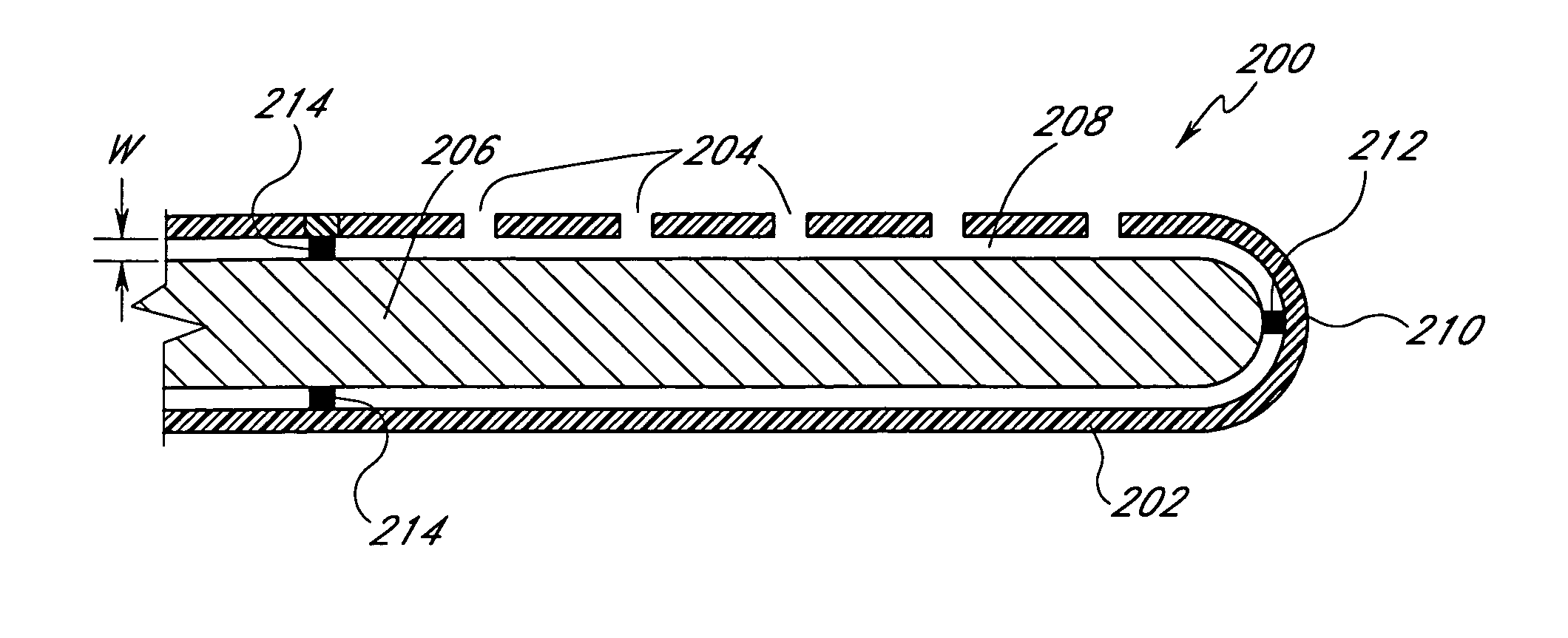

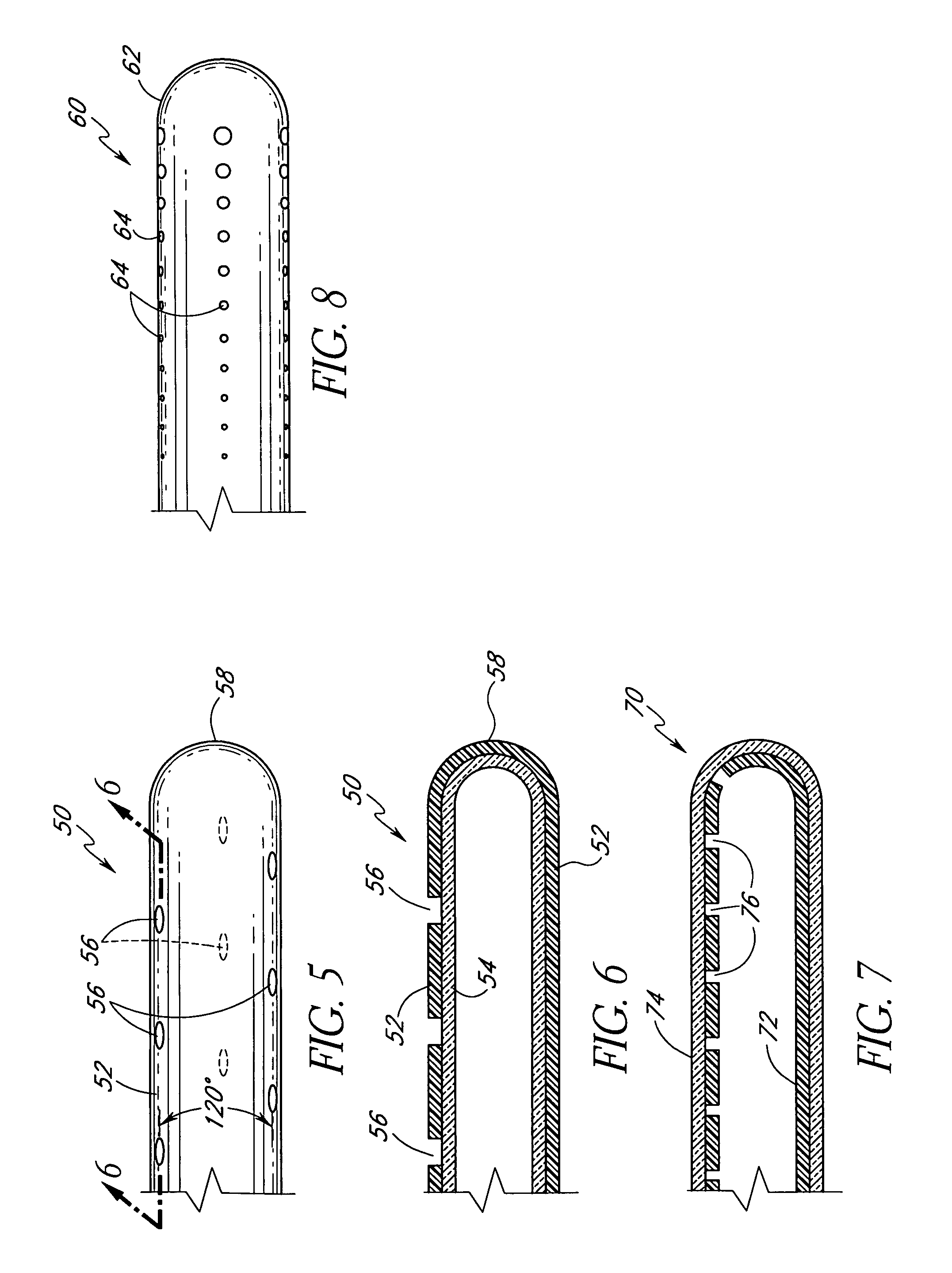

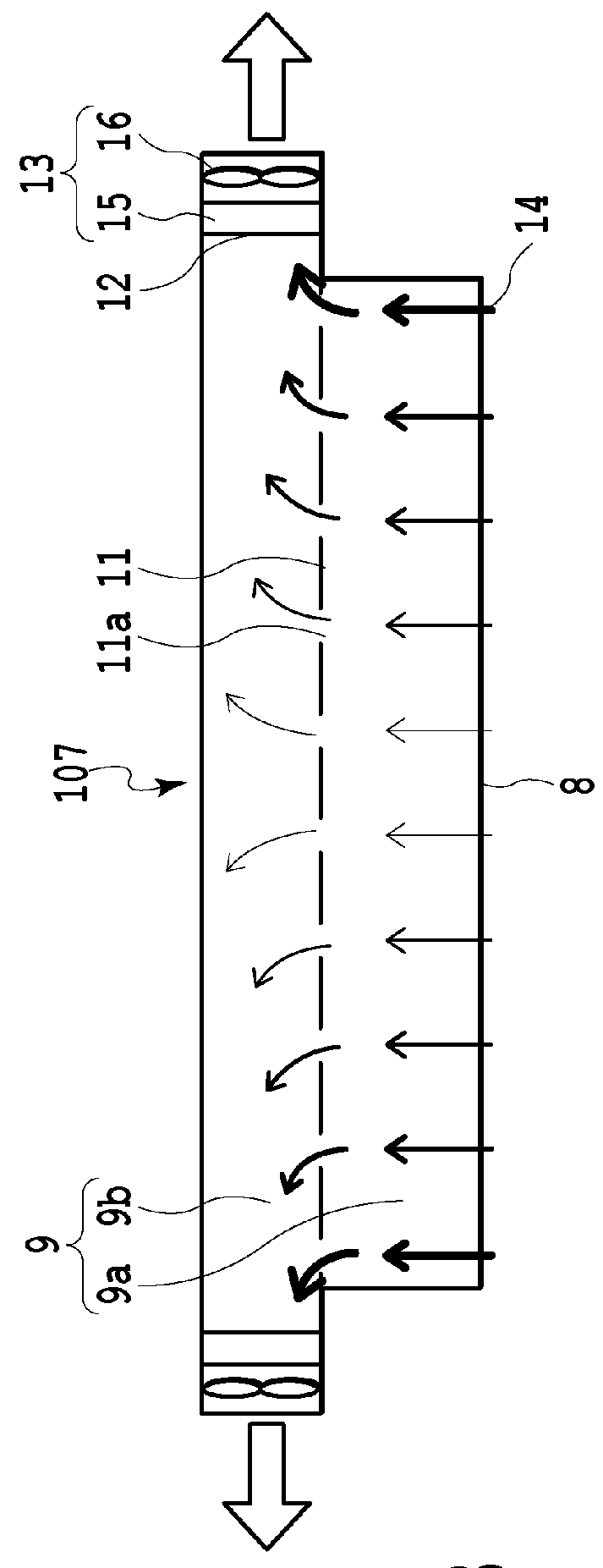

Catheter for uniform delivery of medication

The present invention provides a catheter for the delivery of fluid medication across an anatomical region. In accordance with one embodiment, the catheter comprises an elongated tube with a plurality of exit holes along an infusion section of the catheter, and an elongated flexible porous member residing within the tube and forming an annular space between the tube and the member. In accordance with other embodiments, the catheter includes a tube having a plurality of exit holes in a side wall of the tube. The exit holes may combine to form a flow-restricting orifice of the catheter. In one particular embodiment, the catheter comprises a tube having elongated exit slots therein. In accordance with other embodiments, the catheter includes an elongated tubular member made of a porous membrane. In accordance with other embodiments, the catheter includes an elongated “weeping” tubular coil spring attached to an end of, or enclosed within, a tube.

Owner:AVENT INC

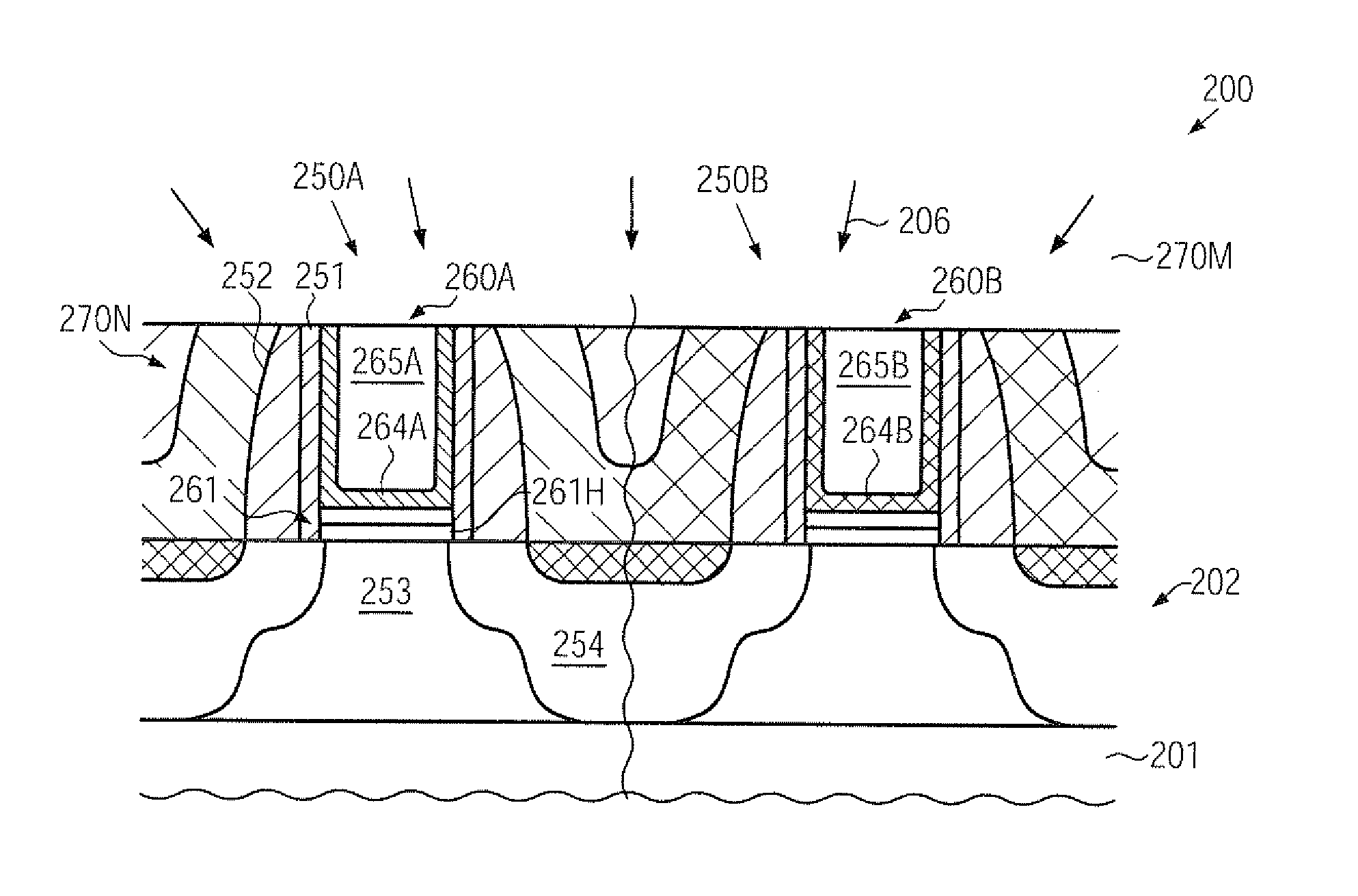

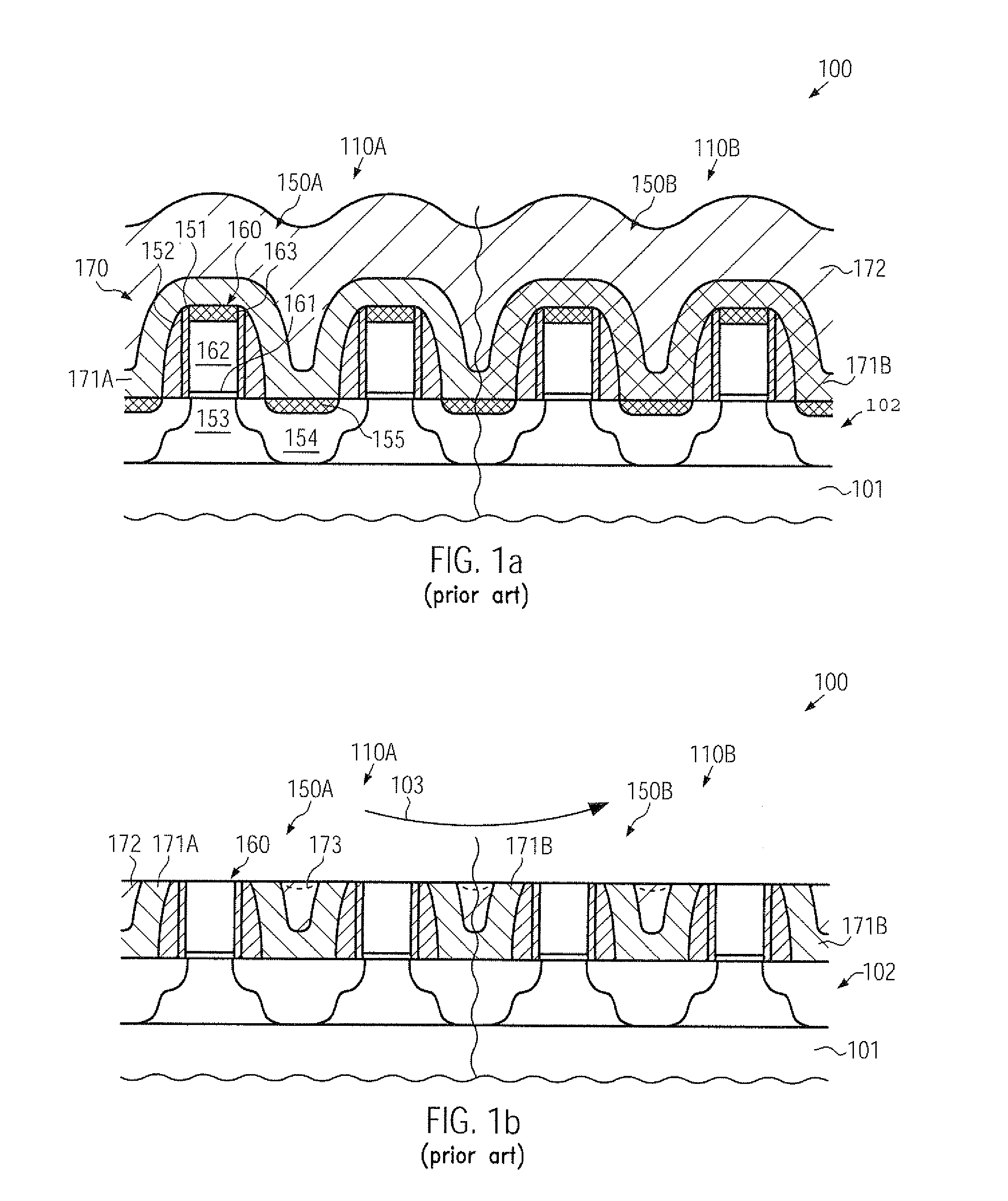

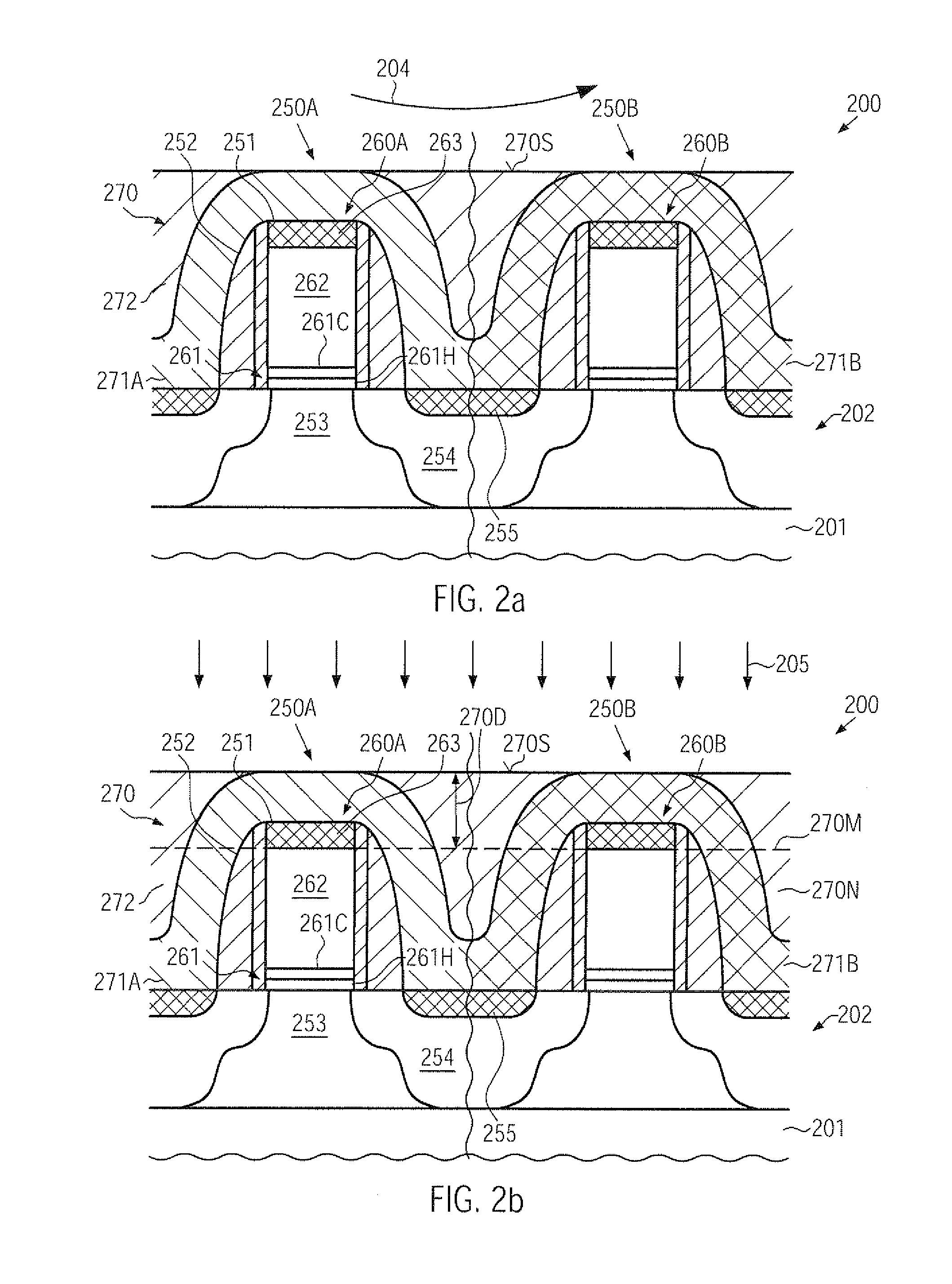

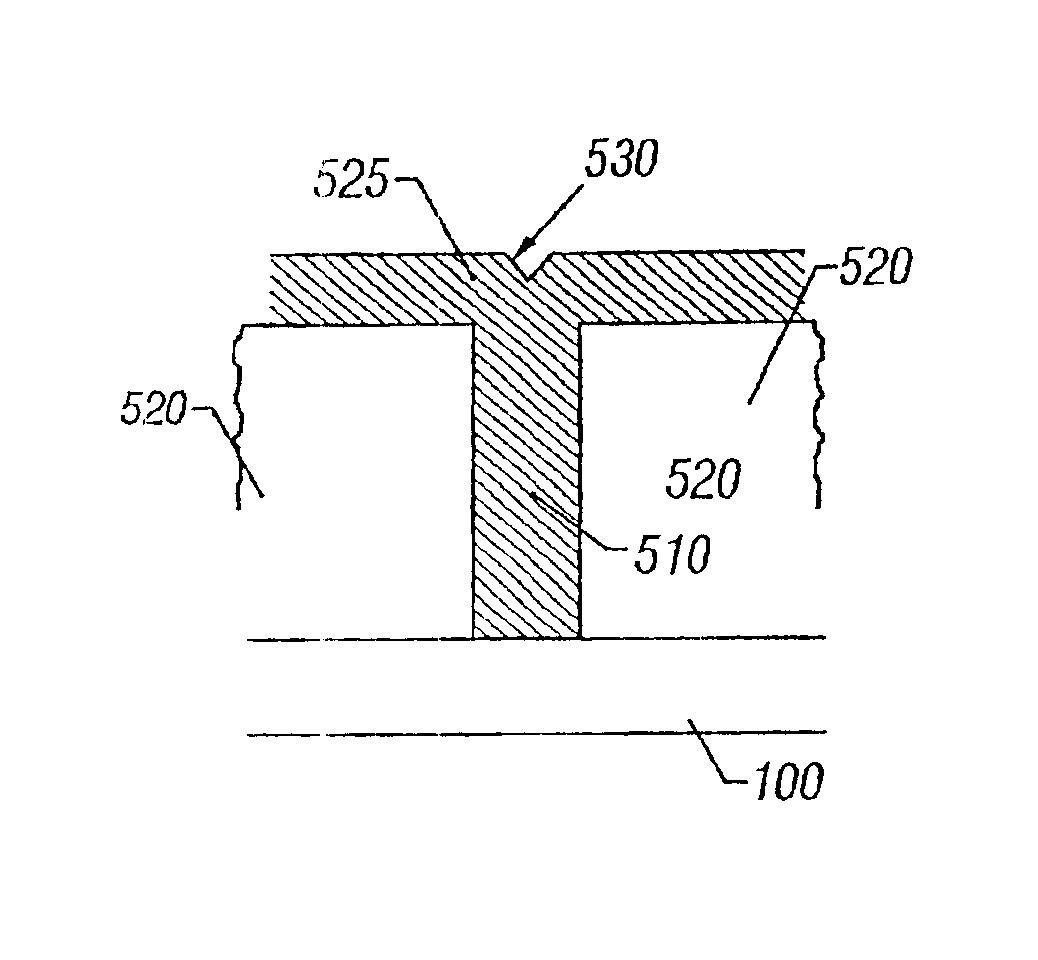

Technique for exposing a placeholder material in a replacement gate approach by modifying a removal rate of stressed dielectric overlayers

ActiveUS20100330790A1Increase flexibilityUniform removal rateSemiconductor/solid-state device manufacturingSemiconductor devicesDielectricEngineering

In a replacement gate approach, the sacrificial gate material is exposed on the basis of enhanced process uniformity, for instance during a wet chemical etch step or a CMP process, by forming a modified portion in the interlayer dielectric material by ion implantation. Consequently, the damaged portion may be removed with an increased removal rate while avoiding the creation of polymer contaminants when applying an etch process or avoiding over-polish time when applying a CMP process.

Owner:GLOBALFOUNDRIES US INC

Polishing pad and cushion layer for polishing pad

InactiveUS20060148393A1Easy to processHigh thickness accuracyAbrasion apparatusSemiconductor/solid-state device manufacturingCushionChemistry

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Catheter for uniform delivery of medication

The present invention provides a catheter for the delivery of fluid medication across an anatomical region. In accordance with one embodiment, the catheter comprises an elongated tube with a plurality of exit holes along an infusion section of the catheter, and an elongated flexible porous member residing within the tube and forming an annular space between the tube and the member. In accordance with other embodiments, the catheter includes a tube having a plurality of exit holes in a side wall of the tube. The exit holes may combine to form a flow-restricting orifice of the catheter. Advantageously, fluid within the catheter flows through all of the exit holes, resulting in uniform distribution of fluid within an anatomical region. In one particular embodiment, the catheter comprises a tube having elongated exit slots therein. In accordance with other embodiments, the catheter includes an elongated tubular member made of a porous membrane. The porous membrane is configured so that a fluid introduced into an open end of the tubular member will flow through side walls of the tubular member at a substantially uniform rate along a length of the tubular member. In accordance with other embodiments, the catheter includes an elongated “weeping” tubular coil spring attached to an end of, or enclosed within, a tube. Fluid within the spring and greater than or equal to a threshold pressure advantageously flows radially outward between the spring coils. Advantageously, the fluid is dispensed substantially uniformly throughout a length of the spring.

Owner:AVENT INC

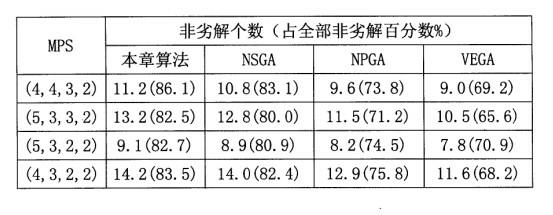

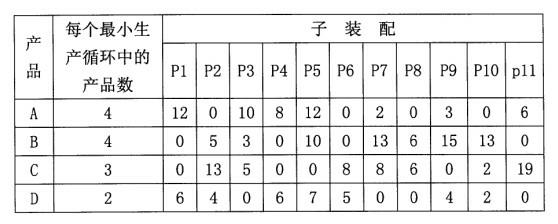

Reconfigurable assembly line sequencing method based on improved genetic algorithm

InactiveCN102323952AUniform rateEquilibrium costGenetic modelsSpecial data processing applicationsGenetics algorithmsAssembly line

The invention discloses a reconfigurable assembly line sequencing method based on an improved genetic algorithm. The method comprises the following steps of: determining a population size according to a minimum production cycle of a reconfigurable assembly production line, and executing genetic encoding according to a standard of taking a chromosome as a full array of all tasks; calculating the idleness of the minimum reconfigurable assembly line, the quantity of unfinished work, the uniform parts use rate and the minimum production adjustment cost of the individual; executing a grading operation, executing a Pareto solution set optimization filtering operation, calculating the fitness of each grade, executing genetic operations according to the fitness, executing an elite reservation strategy, and obtaining a Pareto optimal solution set and a corresponding objective function value by judging whether convergence is realized or the pre-set maximum number of iteration is achieved. In the method, three major factors influencing the optimized sequencing of the reconfigurable assembly line are comprehensively considered, a plurality of technologies are used in the genetic operation, population diversity is ensured, algorithm prematurity is avoided, and global optimal search ability of the algorithm is enhanced.

Owner:HOHAI UNIV CHANGZHOU

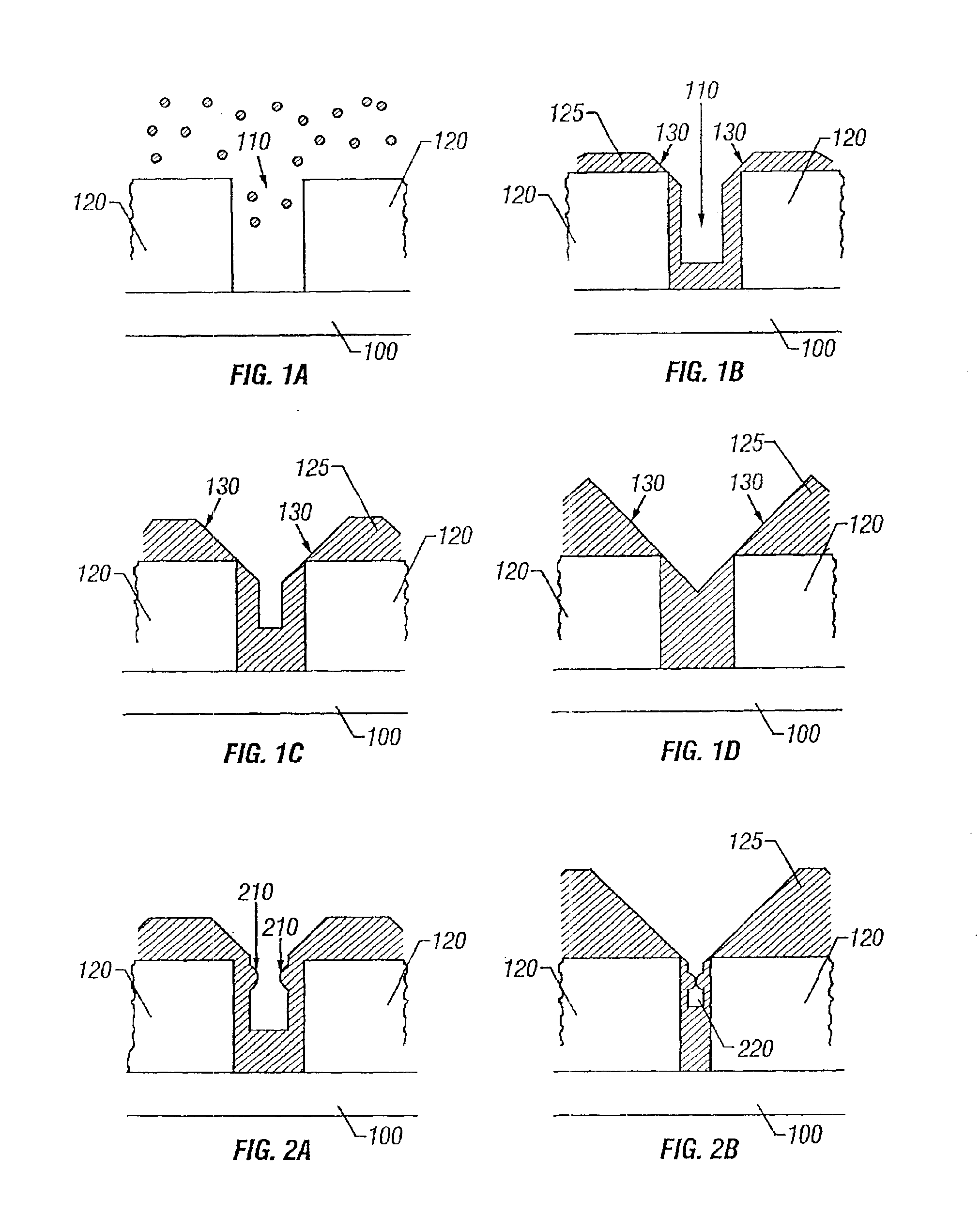

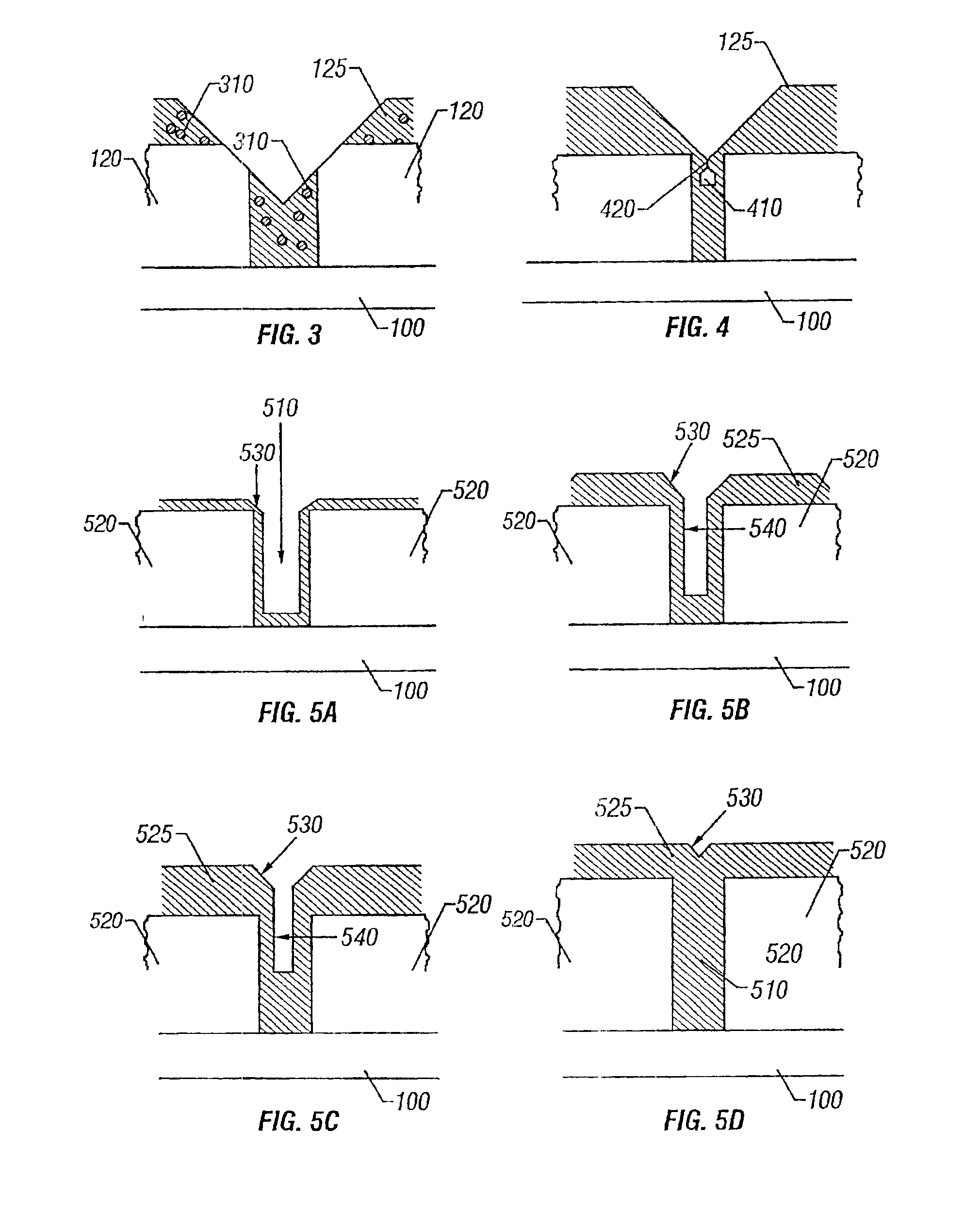

Process for depositing F-doped silica glass in high aspect ratio structures

InactiveUS6846391B1Reduce effect of sputteringHigh aspect ratio gapDecorative surface effectsVacuum evaporation coatingHigh densityHydrogen

A process for filling high aspect ratio gaps on substrates uses conventional high density plasma deposition processes to deposit fluorine-doped films, with an efficient sputtering inert gas, such as Ar, replaced or reduced with an inefficient sputtering inert gas such as He and / or hydrogen. By reducing the sputtering component, sidewall deposition from the sputtered material is reduced. Consequently, gaps with aspect ratios greater than 3.0:1 and spacings between lines less than 0.13 microns can be filled with low dielectric constant films without the formation of voids and without damaging circuit elements.

Owner:NOVELLUS SYSTEMS

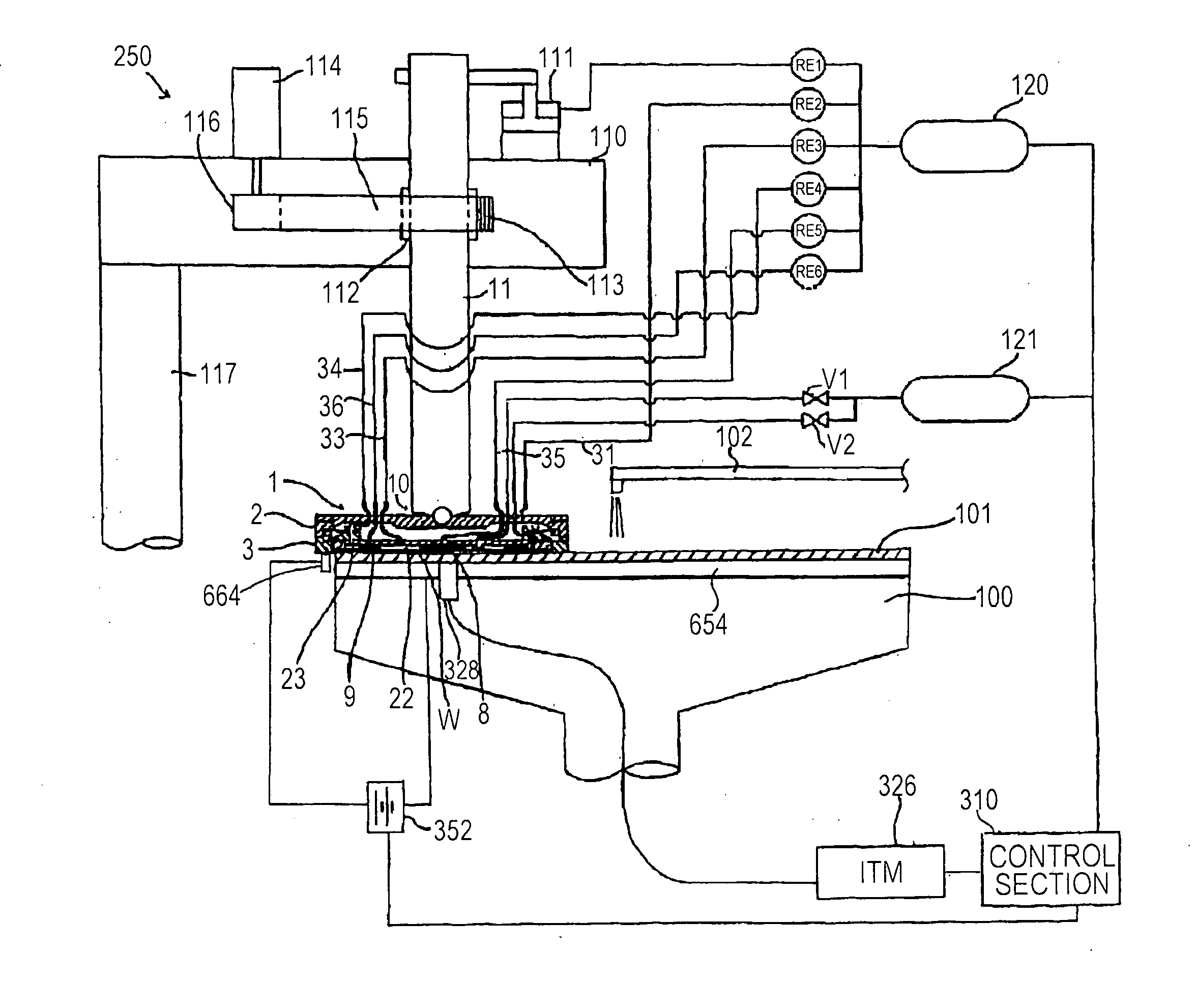

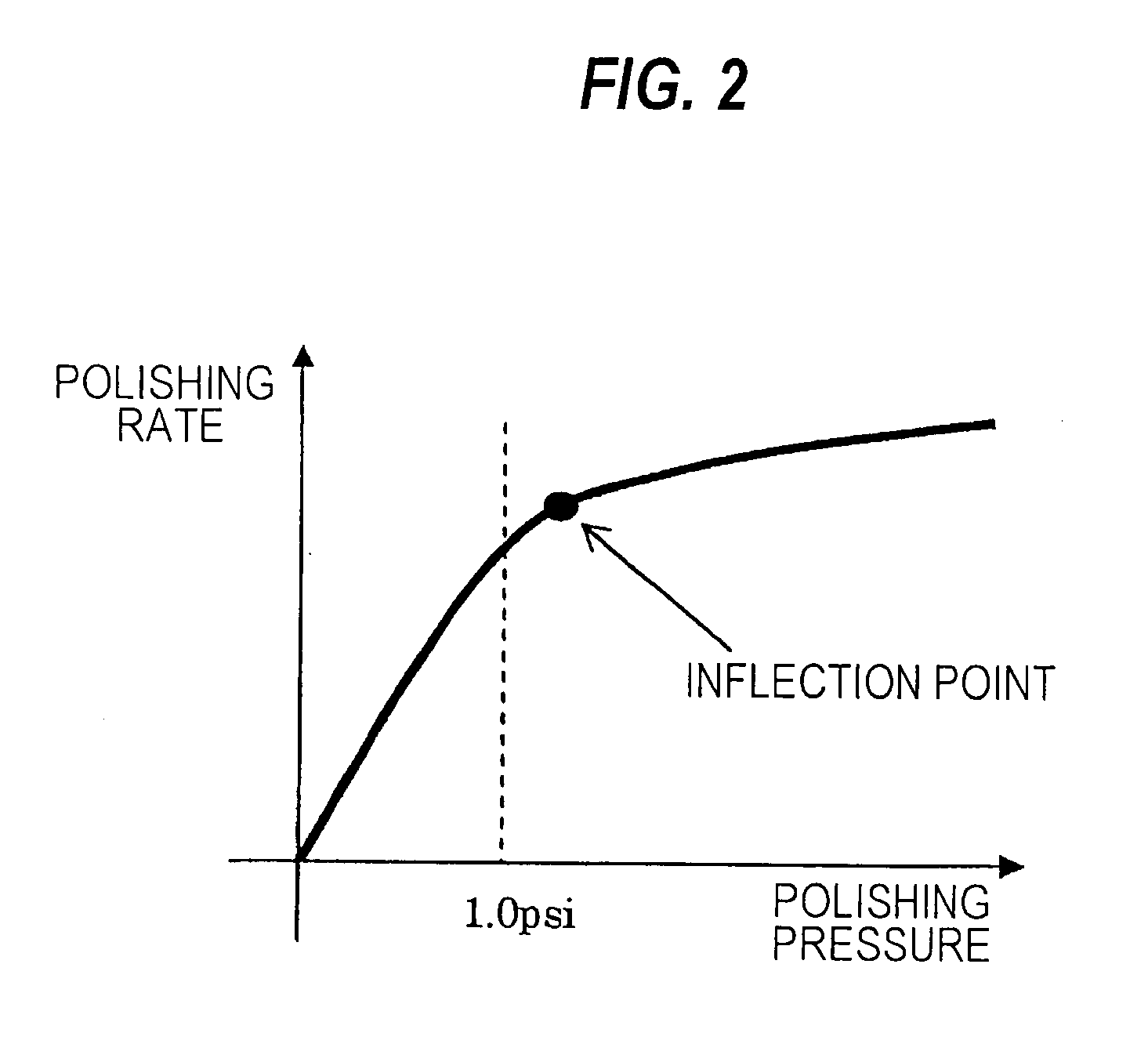

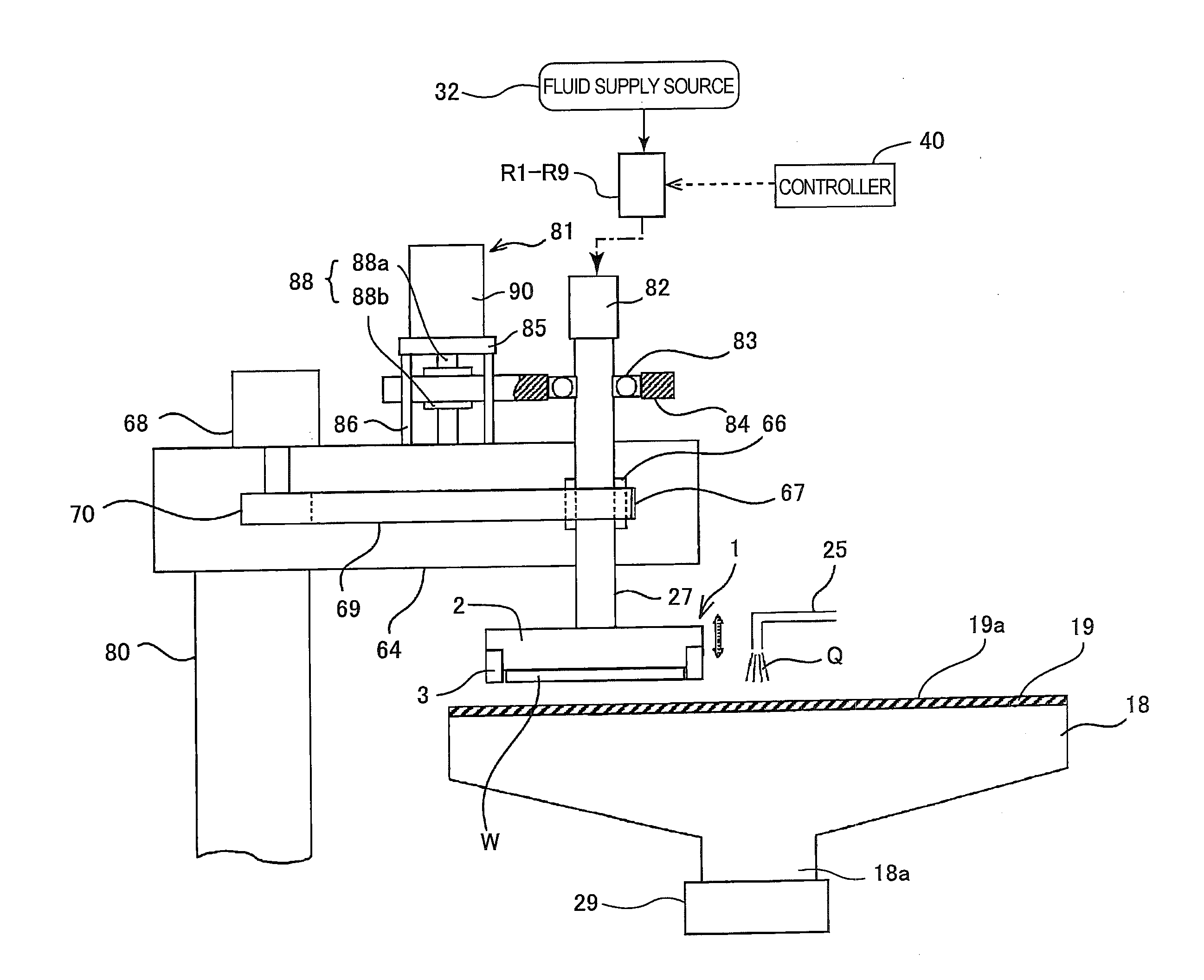

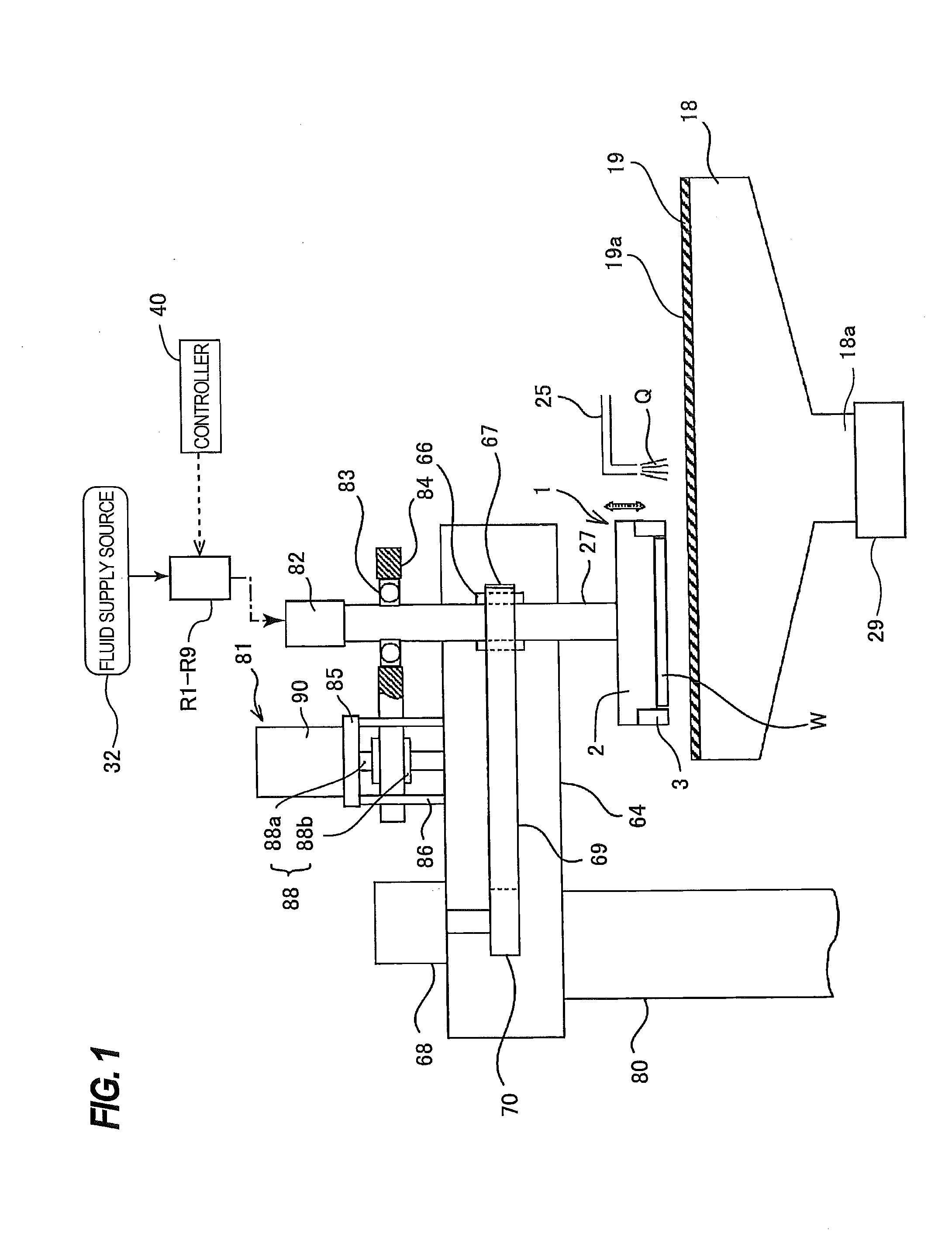

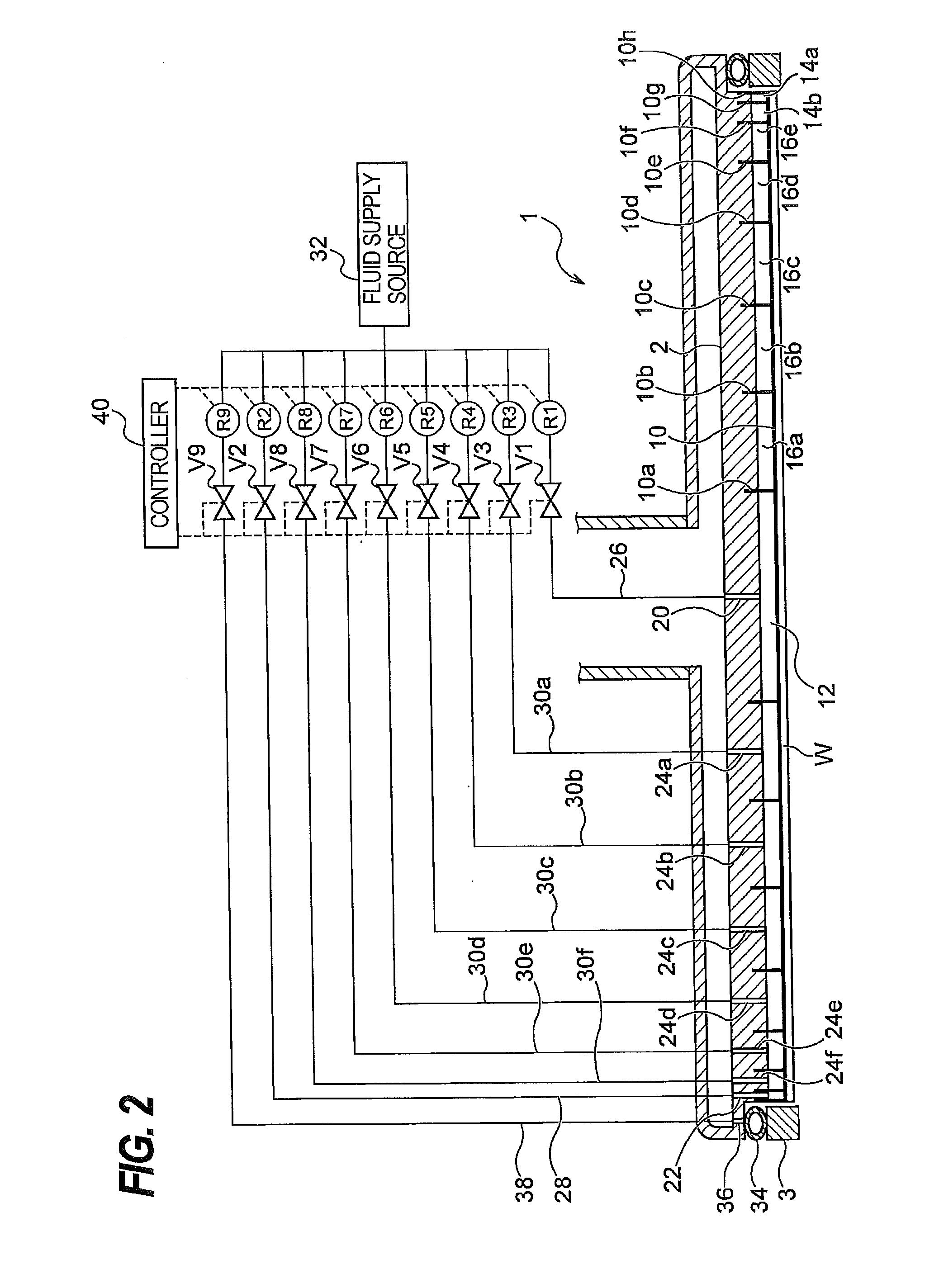

Polishing Apparatus and Polishing Method

InactiveUS20070254558A1Uniform supplyUniform polishing rateEdge grinding machinesSemiconductor/solid-state device manufacturingMechanical engineeringEngineering

A polishing apparatus (30) has a polishing surface (32), a top ring (36) for holding a wafer (W), motors (46, 56) to move the polishing surface (32) and the wafer (W) relative to each other at a relative speed, and a vertical movement mechanism (54) to press the wafer (W) against the polishing surface (32) under a pressing pressure. The polishing apparatus (30) also has a controller (44) to adjust a polishing condition in a non-Preston range in which a polishing rate is not proportional to a product of the pressing pressure and the relative speed. The polishing apparatus (30) can simultaneously achieve uniform supply of a chemical liquid to a surface of the wafer (W) and a uniform polishing rate within the surface of the wafer (W).

Owner:EBARA CORP

Ring mechanism, and plasma processing device using the ring mechanism

InactiveUS7882800B2Uniform rateAvoid it happening againElectric discharge tubesSemiconductor/solid-state device manufacturingPotential differenceEngineering

Owner:TOKYO ELECTRON LTD

Polishing pad and method of producing same

InactiveUS20050142996A1Stably polishing the surface of a target object evenly and smoothlyHigh transparencySemiconductor/solid-state device manufacturingFlexible-parts wheelsSurface roughnessLength wave

A transparent pad having a polishing surface with an average surface roughness of 5 μm or less is used as a polishing pad. An indentation is formed on the back surface of the transparent pad such that its rate of light transmission is locally changed. The transparent pad has a rate of light transmission equal to or greater than 10% or preferably 30% for light of at least one wavelength in the range of 350 nm-900 nm.

Owner:NIHON MICRO COATING

Polishing apparatus and polishing method

InactiveUS20070205112A1Uniform supplyUniform polishing rateElectrolysis componentsMachining electric circuitsCompound (substance)Engineering

A polishing apparatus (30) has a polishing surface (32), a top ring (36) for holding a wafer (W), motors (46, 56) to move the polishing surface (32) and the wafer (W) relative to each other at a relative speed, and a vertical movement mechanism (54) to press the wafer (W) against the polishing surface (32) under a pressing pressure. The polishing apparatus (30) also has a controller (44) to adjust a polishing condition in a non-Preston range in which a polishing rate is not proportional to a product of the pressing pressure and the relative speed. The polishing apparatus (30) can simultaneously achieve uniform supply of a chemical liquid to a surface of the wafer (W) and a uniform polishing rate within the surface of the wafer (W).

Owner:KODERA MASAKO +7

Elastic membrane, substrate holding apparatus, and polishing apparatus

ActiveUS20150273657A1Uniform polishing rateImprove production yieldPolishing machinesRevolution surface grinding machinesBiomedical engineering

An elastic membrane capable of precisely controlling a polishing profile in a narrow area of a wafer edge portion is disclosed. The elastic membrane includes a contact portion to be brought into contact with a substrate; a first edge circumferential wall extending upwardly from a peripheral edge of the contact portion; and a second edge circumferential wall having a horizontal portion connected to an inner circumferential surface of the first edge circumferential wall. The inner circumferential surface of the first edge circumferential wall includes an upper inner circumferential surface and a lower inner circumferential surface, both of which are perpendicular to the contact portion. The upper inner circumferential surface extends upwardly from the horizontal portion of the second edge circumferential wall, and the lower inner circumferential surface extends downwardly from the horizontal portion.

Owner:EBARA CORP

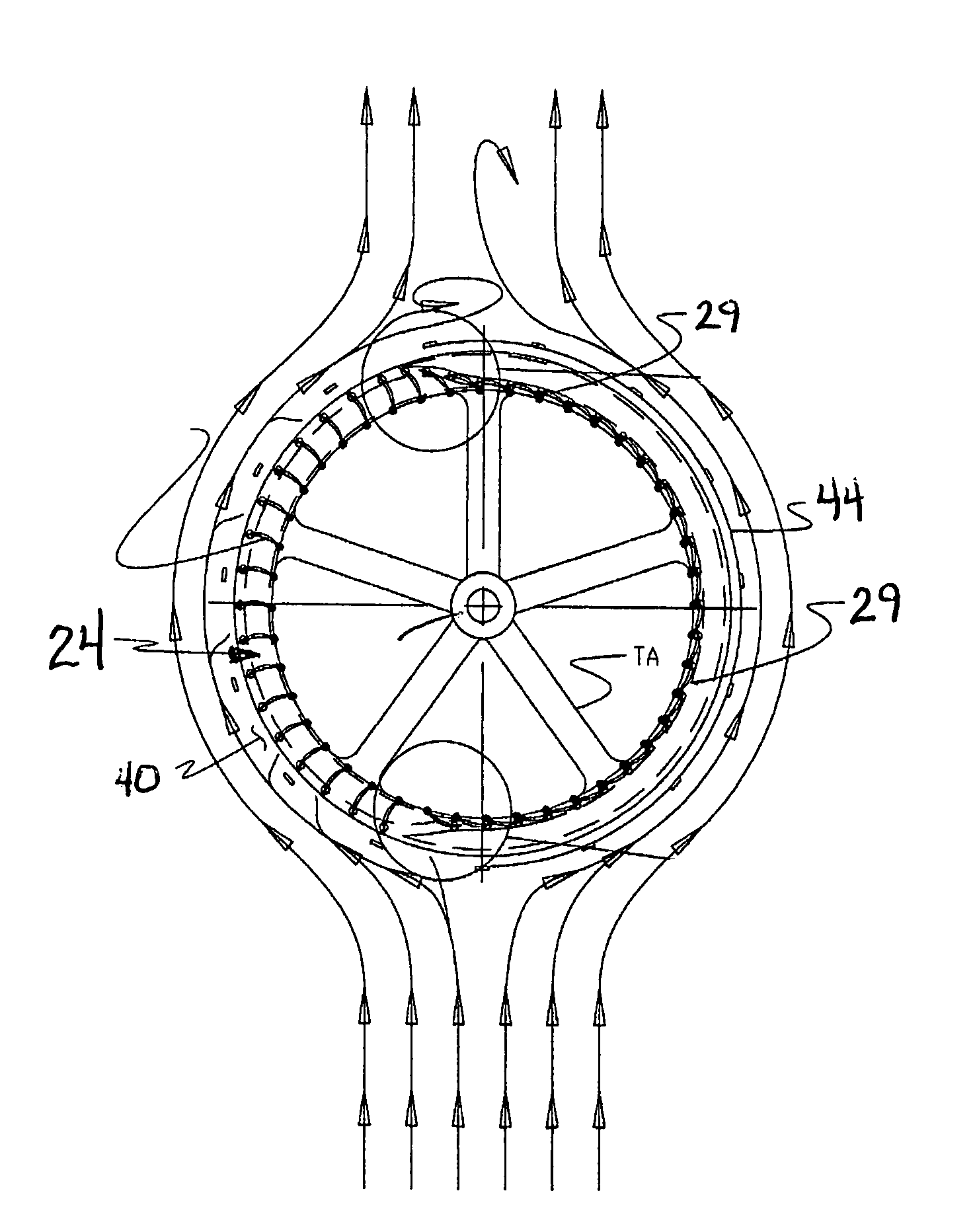

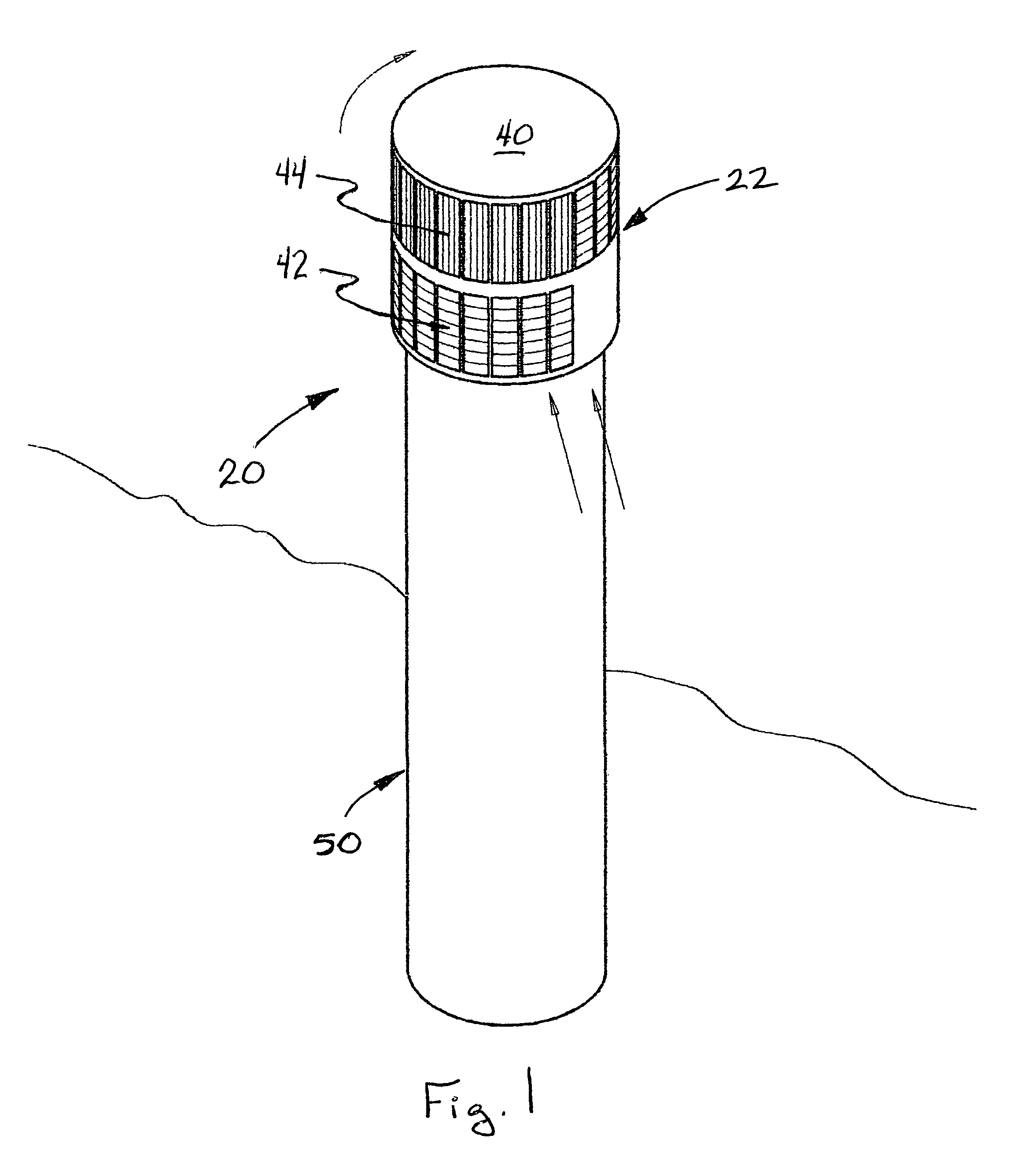

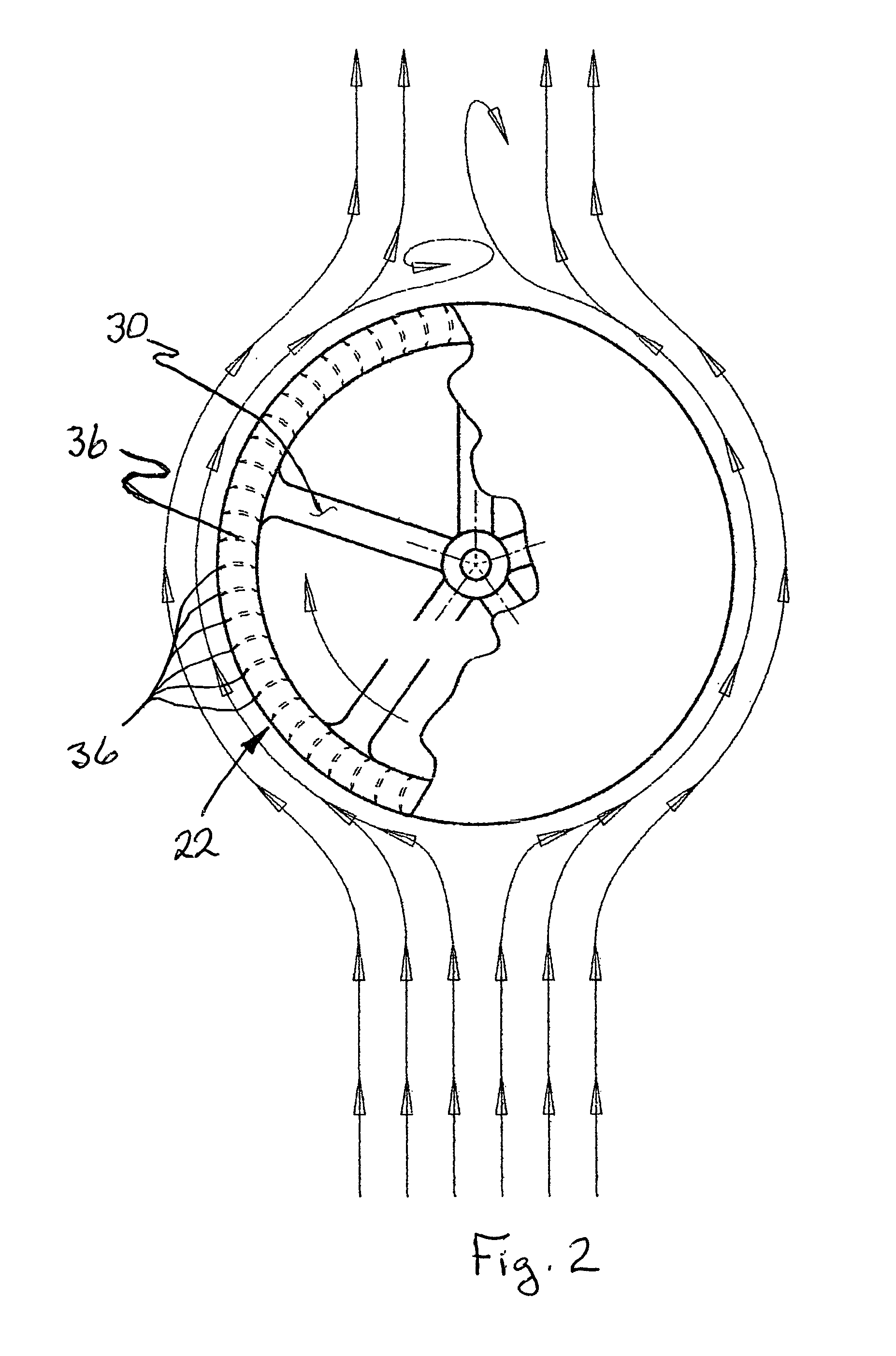

Wind turbine assembly

InactiveUS7758299B1Reduce turbine blade exposureUniform rateCircumferential flow pumpsWind motor controlElectricityAir volume

A wind turbine for generating electricity is configured as a drum with a housing that has adjustable shutters to control the amount of wind reaching the turbine blades. Alternatively, the turbine blades can be pivotably mounted and opened and closed using a cam follower, cam track system to minimize wind exposure to downstream turbine blades.

Owner:JARECKI FR

Printing device

A printing device includes: a head that ejects an ink on a medium to perform printing; and a mist collection mechanism having: a suction port facing the medium and sucking air near the head; an exhaust port discharging the sucked air; and an airflow path between the suction port and the exhaust port, wherein the airflow path includes a first spatial region located on a side of the suction port, and a second spatial region located on a side of the exhaust port and adjacent to the first spatial region through a communicating port having an opening area smaller than that of the suction port.

Owner:CANON KK

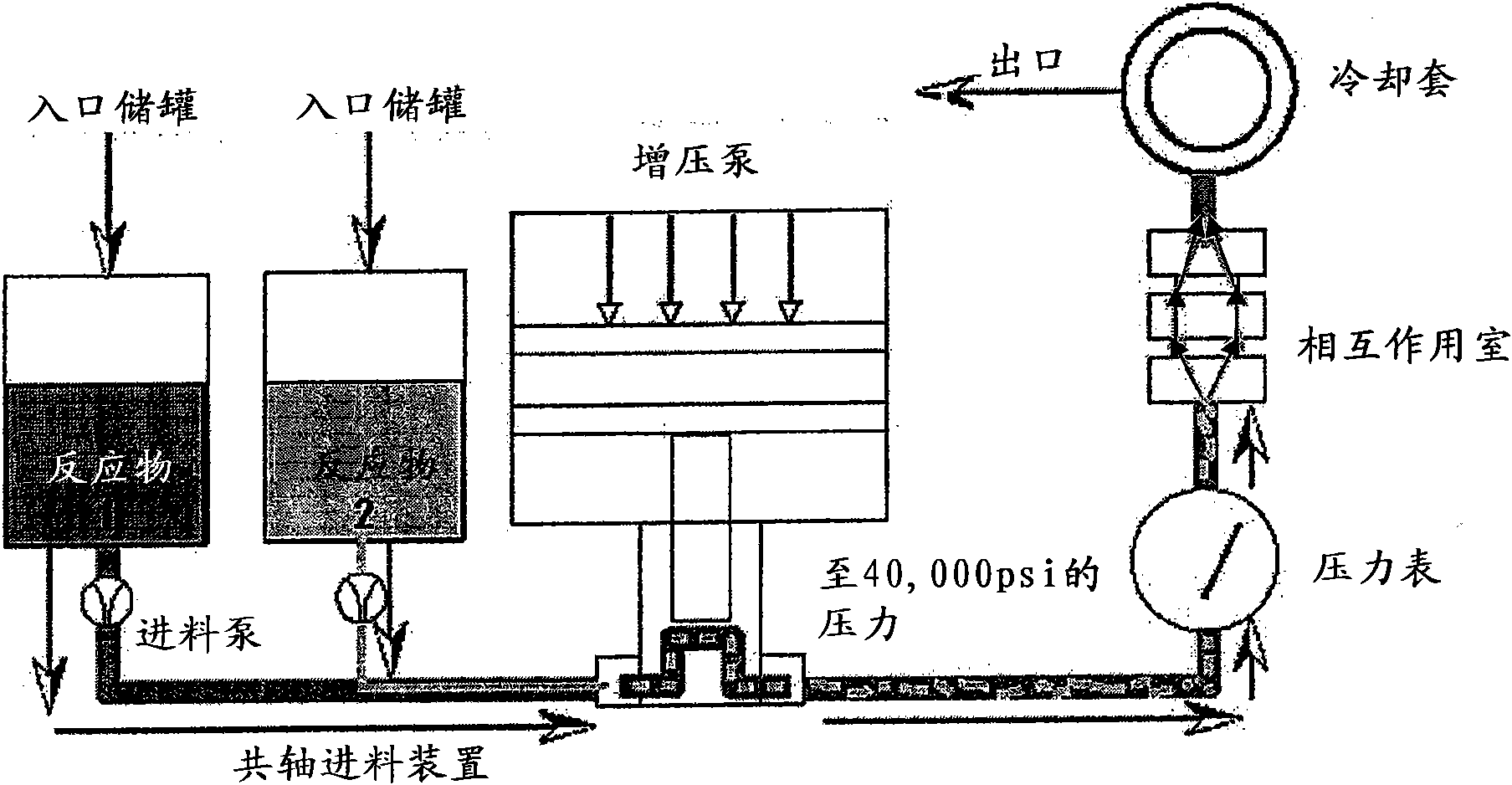

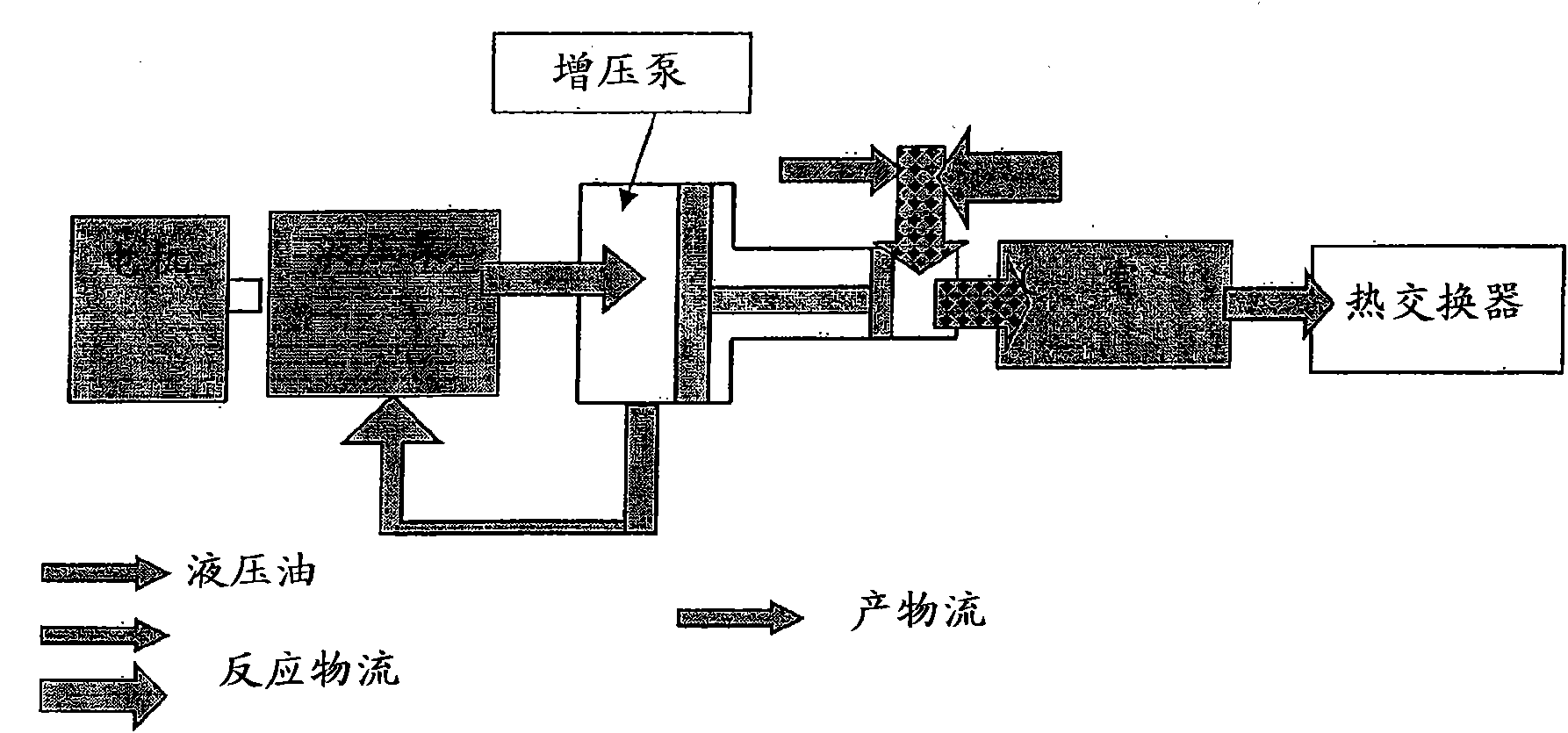

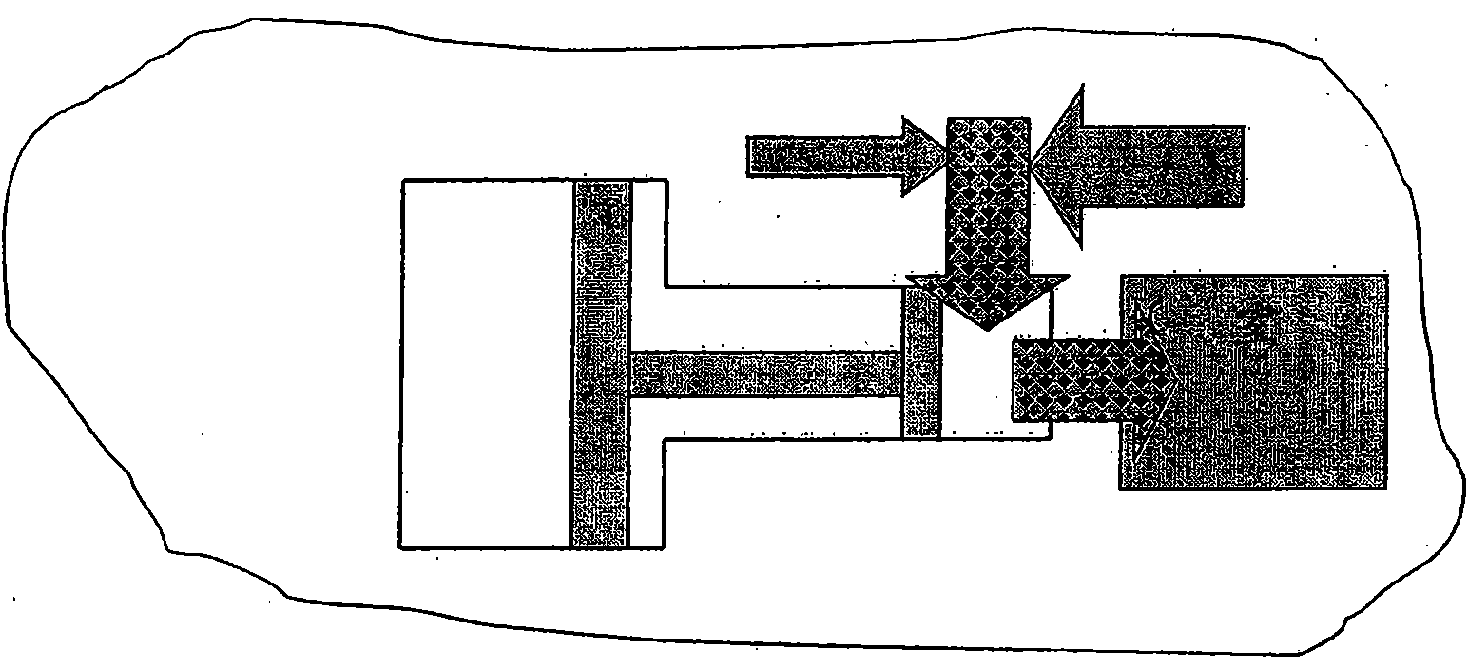

Apparatus and methods for nanoparticle generation and process intensification of transport and reaction systems

InactiveCN102046518AAvoid damageReduce system entropyNanostructure manufactureFlow mixersMicroreactorEmulsion

Apparatus, systems and methods are provided that utilize microreactor technology to achieve desired mixing and interaction at a micro and / or molecular level between and among feed stream constituents. Feed streams are fed to an intensifier pump at individually controlled rates, e.g., based on operation of individually controlled feed pumps. The time during which first and second feed streams are combined / mixed prior to introduction to the microreactor is generally minimized, thereby avoiding potential reactions and other constituent interactions prior to micro- and / or nano-scale interactions within the microreactor. Various microreactor designs / geometries may be employed, e.g., ''Z'' type single or multi-slot geometries and ''Y'' type single or multi-slot geometries. Various applications benefit from the disclosure, including emulsion, crystallization, encapsulation and reaction processes.

Owner:MICROFLUIDICS INT

Apparatus for obtaining balanced flow of hot melt in a distribution manifold

An injection manifold has a main runner provided with a supply inlet intermediate opposite ends of the runner. A number of branches intersect with the runner along its length so as to be disposed at unequal distances from the inlet. In order to achieve more simultaneous delivery, uniform fill rate, and identity of temperature of hot melt across all cavities of a multi-cavity set to achieve more uniform cooling of the preforms, restrictor pin assemblies are provided in association with certain of the branches to adjustably constrict the space available for melt flow from the runner into the branch. In a preferred form each restrictor pin assembly includes a pin aligned axially with the branch and passing transversely through the runner, the pin being adjustable between a fully extended, maximum constriction position in which the tip of the pin is located within the branch and a fully retracted, open position in which the tip is withdrawn out of the branch and is spaced below the opening of the branch.

Owner:R & D TOOL & ENG

Textile-elastomer composite preferable for transfer or film coating and method of making said composite

InactiveUS6475562B1Easy to produceControl more effectively the amount of coating appliedSynthetic resin layered productsPretreated surfacesProduct gasFilm coating

The present invention relates to a process-for producing a fabric-elastomer composite that, when transfer or film coated, is preferable for use as an artificial leather substrate. The inventive procedure involves (a) producing an elastomer composition of at least four ingredients (an anionically-stabilized waterborne polymer dispersion, an acid-generating chemical, a cloud-point surfactant, and a foam-stabilizing surfactant); (b) incorporating sufficient gas into the liquid mixture to generate a spreadable foam; (c) applying the foam onto a porous textile substrate; (d) heating said foamed fabric until the elastomer coagulates over the fabric substrate; and (e) drying the resultant composite without destroying the coagulated structure. The resultant composite obtains a suppleness that is similar to that of leather and a surface that is suitable for transfer coating to produce artificial leather. The composite may be utilized as upholstery fabric in furniture or in automobiles, apparel, and the like. The particular composites produced are also contemplated within this invention.

Owner:SAGE AUTOMOTIVE INTERIORS INC

Heating crucible and deposition apparatus including the same

InactiveUS20060096542A1Uniform overall deposition rateGood deposition reproducibilityElectrical apparatusElectroluminescent light sourcesCrucibleTitanium

A heating crucible and a deposition apparatus are provided that have a uniform deposition rate and good reproducibility. The heating crucible of the deposition apparatus includes a titanium body with an internal cavity to contain a material to be deposited and an opening to emit the material to be deposited, a wire to heat the body, and an insulator to insulate the body from the wire.

Owner:SAMSUNG DISPLAY CO LTD

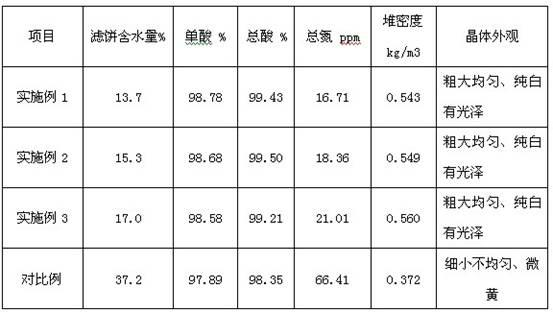

Refining method for long-chain binary acid

ActiveCN102329212AAchieve reuseAvoid hidingCarboxylic compound separation/purificationSingle crystalPre treatment

The invention discloses a refining method for long-chain binary acid. The refining method comprises the steps of: performing pretreatments including demulsifying, filtering and decoloring on fermentation liquor, then, reacting the pretreated fermentation liquor with dilute sulphuric acid through a microchannel reactor, heating an obtained mixture by using a sleeve to remove fine crystals, introducing crystal mush into a crystallization kettle for curing, controlling the growing speed and the size of crystals by means of gradient temperature to form crystals with uniform particle size, filtering, washing and drying to obtain long-chain binary acid crystals. The long-chain binary acid crystals have the advantages of uniform particles, low content of protein and impurities, high product purity, good color, and capability of meeting requirements on quality of polymerization-level products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com