Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1106 results about "Binary acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Binary acids or Hydracids are certain molecular compounds in which hydrogen is combined with a second nonmetallic element.

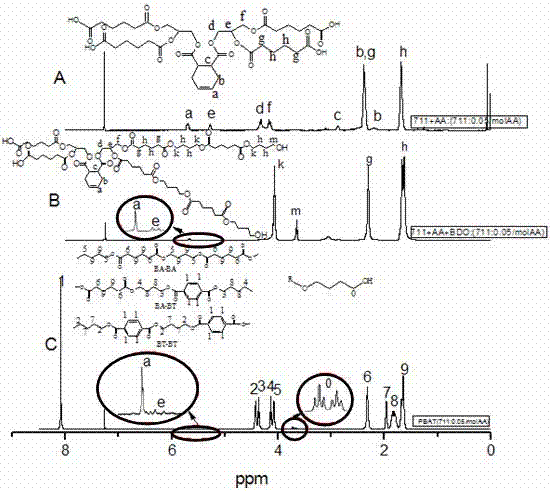

Copolyester as well as preparation method and application thereof

InactiveCN102030893AImprove dyeing effectLow investment costMonocomponent copolyesters artificial filamentDisperse dyeSide chain

The invention discloses copolyester and a preparation method and application thereof. The copolyester comprises binary acid components and binary alcohol components, wherein in the binary acid components, the content of the terephthalic acid structural unit is more than 90mol%; and in the binary alcohol components, the content of the ethylene glycol structural unit is 70-99mol%, and the content of the aliphatic dihydric alcohol structural unit which contains side chains and less than 6 carbon atoms is 1-30mol%. The copolyester also comprises a polyethylene glycol structural unit. Because the aliphatic dihydric alcohol structural unit which contains side chains and less than 6 carbon atoms and the polyethylene glycol structural unit are added to the copolyester, the copolyester can be made into fiber with the known method, and the fiber can be made into fabric. The prepared finished product has good dyeing property on disperse dye at normal temperature and pressure, thus the high equipment investment and operation cost resulted from high-temperature and high-pressure dying can be reduced.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

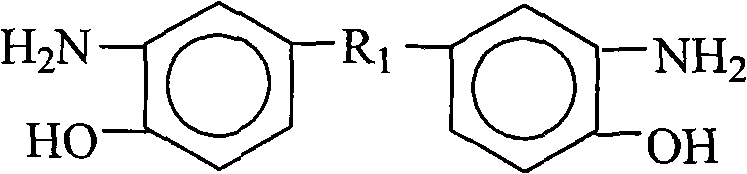

Preparation method of high temperature resistant single-component solventless epoxy adhesive

InactiveCN101649174AConvenient sourceSimple preparation processEpoxy resin adhesivesSolventThermoplastic polyimide

The invention relates to a preparation method of high temperature resistant single-component solventless epoxy adhesive. The method comprises the following steps: adding aromatic binary primary amine and strongly polar non-proton organic solvent in a reaction tank, stirring at room temperature to dissolve, adding aromatic binary acid anhydride to perform refluxing and water-segregating reaction at 120-150 DEG C for 6-12h, cooling, adding the reaction solution in a stamp tank with precipitant to precipitate solid powder, namely white thermoplastic polyimide powder, adding white thermoplastic polyimide powder and tertiary amine compound or imidazole compound in epoxy resin to react for 1-2h, adding active diluent and latent curing agent to stir evenly and obtaining the product. The production process is easy and the cost is low so as to realize industrialized production; the tensile shear intensions of the epoxy adhesive at room temperature and 120 DEG C are respectively up to 28Mpa and26Mpa and the epoxy adhesive has broad application prospect in fields such as electronics and microelectronics, electrical motors, aviation and aerospace and the like.

Owner:DONGHUA UNIV

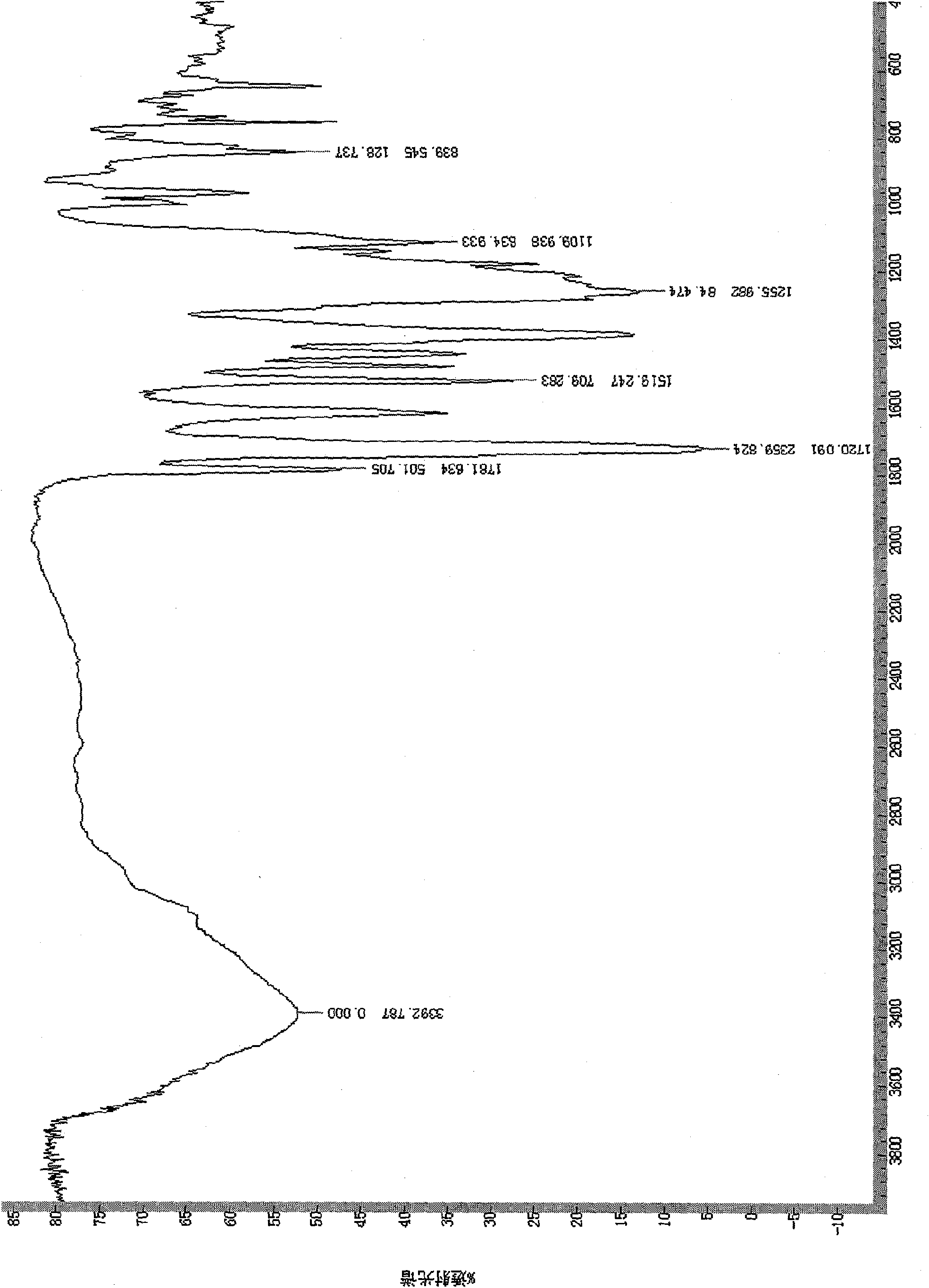

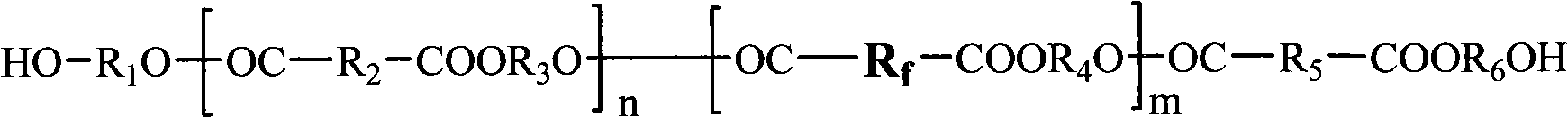

Weather-proof self-cleaning transparent material and preparation method thereof

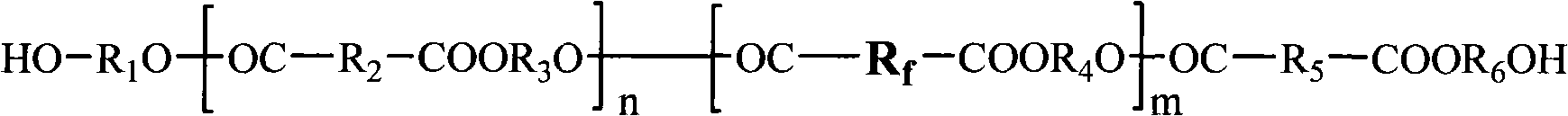

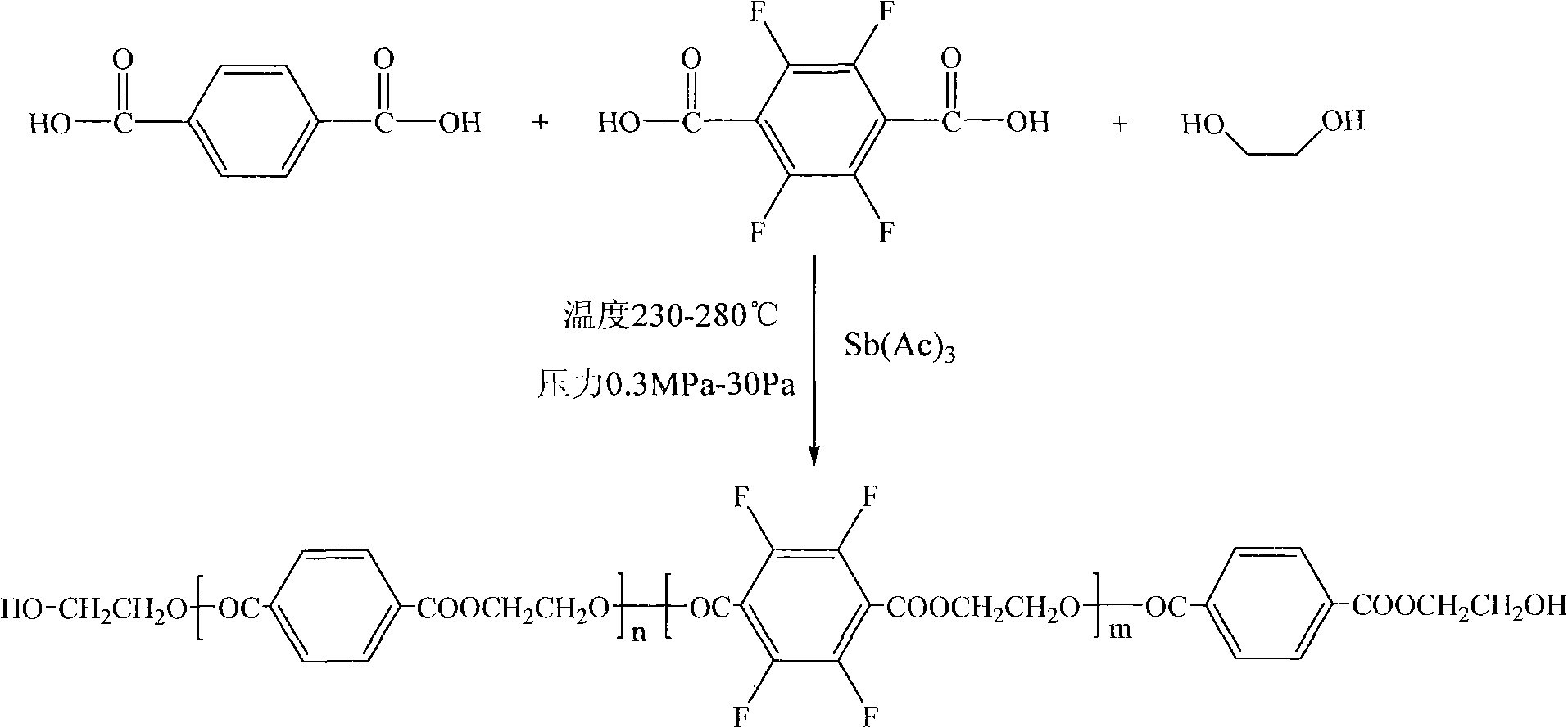

The invention relates to a weather-proof self-cleaning transparent material and a preparation method thereof. A novel polymer with polyester and fluorinated block by adopting the way of introducing fluorine atom or fluorine-containing group monomer to a benzene ring and carrying out direct esterification and then copolycondensation on binary acid and dibastic alcohol, and controlling the ratio, temperature, pressure and catalyst of the system reactant. The preparation line has cheap and available raw materials, mild reactive condition, simple and convenient operation, and the novel material has outstanding weather-proof performance and excellent self-cleaning and photopermeability, and can be widely used in fields of photology, thermal electricity generation and the like.

Owner:WUHAN UNIV OF TECH

Graphene oxide/unsaturated polyester composite material and preparation method thereof

The invention discloses a graphene oxide / unsaturated polyester composite material and a preparation method of the composite material. The composite material comprises the raw materials: dihydric alcohol, graphene oxide, saturated binary acid or acid anhydride, unsaturated binary acid or acid anhydride, vinyl monomer, and normal polymerization inhibitor, initiator and accelerant, wherein the content of the graphene oxide is 0.06-0.5wt%. The preparation method of the graphene oxide / unsaturated polyester composite material comprises the following steps of: adding the graphene oxide into the dihydric alcohol to directly and ultrasonically disperse, or adding the dihydric alcohol into graphene oxide water solution to ultrasonically disperse and remove water in a fractional distillation way so as to obtain graphene oxide / dihydric alcohol solution which is evenly dispersed; performing polycondensation between the obtained graphene oxide / dihydric alcohol solution and the saturated binary acidor acid anhydride, unsaturated binary acid or acid anhydride and polymerization inhibitor with metering ratio, and diluting by adding the vinyl monomer after the polymerization so as to prepare graphene oxide / unsaturated polyester resin; and adding the initiator and the accelerant, and curing and crosslinking to prepare the graphene oxide / unsaturated polyester composite material.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Bearing lubricating grease and preparation method thereof

ActiveCN102977978AHigh dropping point temperatureNot collapseLubricant compositionLithium hydroxideAntioxidant

The invention relates to bearing lubricating grease comprising the following components of: (a) a compound thickening agent formed by lithium 12-hydroxystearate soap, lithium binary acid soap and lithium borate, (b) an additive, and (c) base oil, wherein the compound thickening agent is formed by soapnifying 12-hydroxystearic acid, binary acid and boric acid with lithium hydroxide; and the additive amount of the boric acid is 1-5 parts by weight while the weight of the base oil is 100 parts by weight, wherein the additive is one or combination of at least two of an antioxidant, an antirusting agent, an anti-wear reagent at extreme pressure and a metal passivator. The dropping point temperature of the bearing lubricating grease provided by the invention is more than or equal to 300 DEG C, and the bearing lubricating grease provided by the invention does not collapse or fade and has the characteristics of long service life, silence and high temperature resistance.

Owner:安徽意博润滑科技有限公司

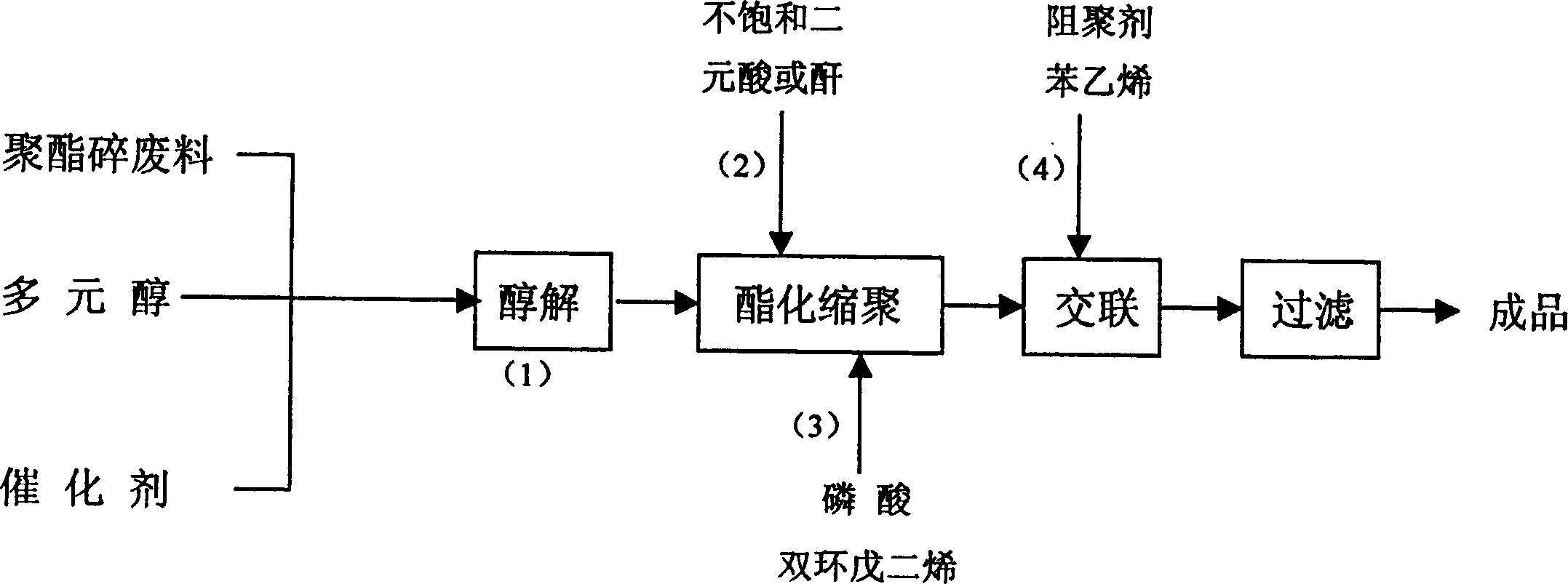

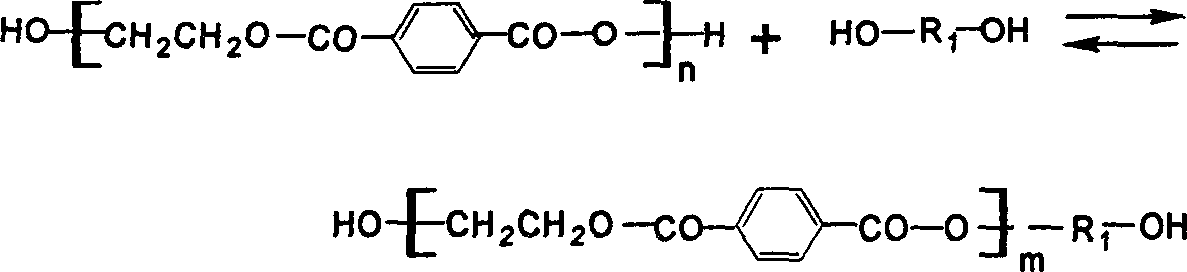

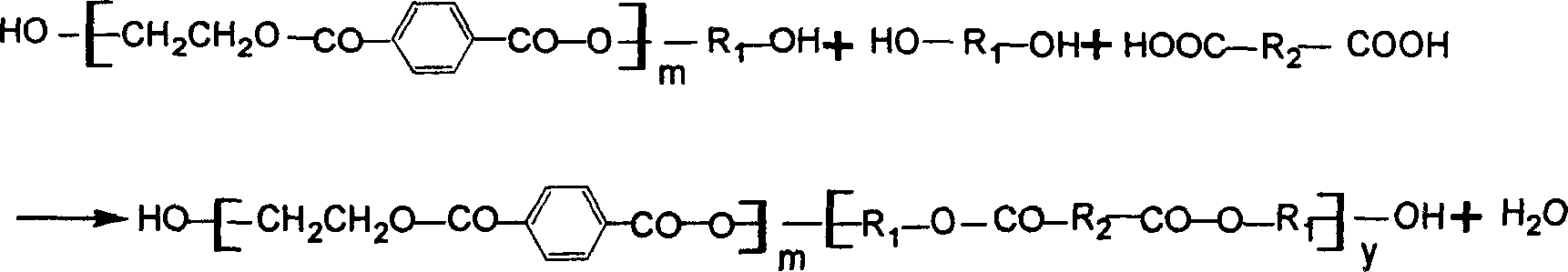

Synthesis of p-phenyl unsaturated polyester resin by using waste polyester material

The invention relates to a method for synthesizing unsaturated phenolic resin with various etherification waste, which includes the four steps: (1) etherification waste and polyhydric alcohol have alcohol sis and ester interchange with catalyst existing; (2)alcohol zed product and unsaturated binary acid or have etherification polycondensation; (3) use dicyclopentadiene (DCPD) to blocking modify in the later period of etherification polycondensation; (4) add into styrene solution for cross linking. The invention has plentiful sources of raw material, low price, decreased pollution and productive cost and energy saving, as well as eliminates the disadvantage of bad dissolubility in styrene .

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

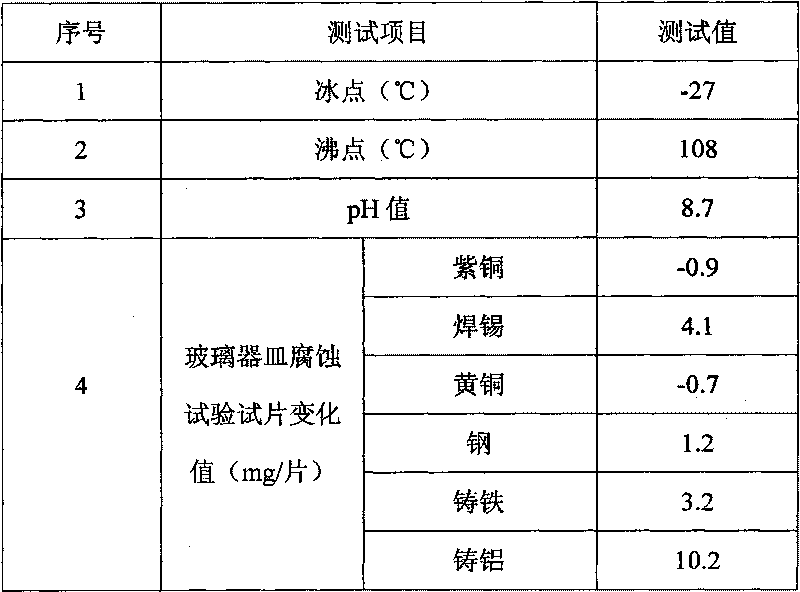

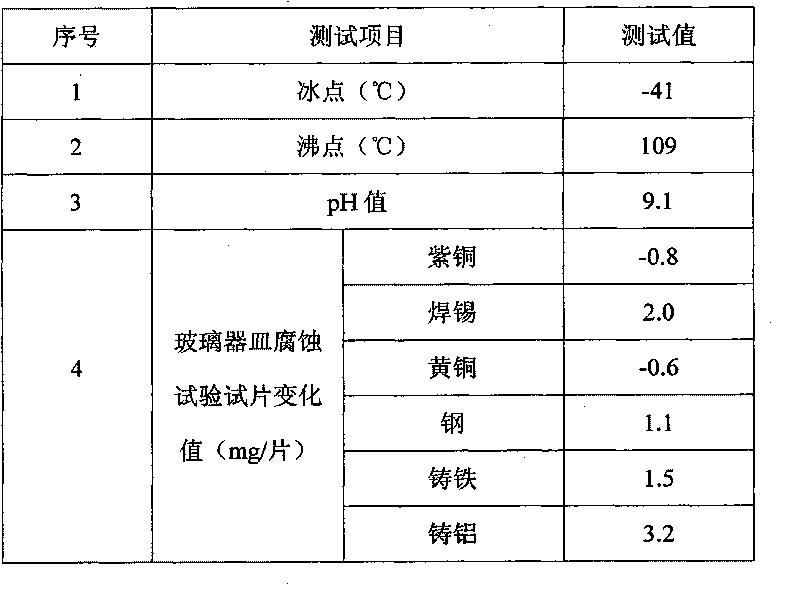

Engine antifreezing solution

ActiveCN101691484AAvoid the disadvantages of instabilityWith boiling suppressionHeat-exchange elementsCooperative interactionSebacic acid

The invention relates to an engine antifreezing solution which is prepared by mixing the following components to react: glycol, sodium molybdate, sodium hydroxide, isooctanoic acid, sebacic acid, sodium benzoate, benzotriazole, sodium 2-mercaptobenzothiazole, dye and deionized water. The invention adopts a new formula which uses organic matter as main component and inorganic matter as auxiliary component to reach the aim of controlled release on the basis of conventional inorganic and all-organic engine antifreezing solution technologies, wherein the organic acid uses the combination of monoacid and binary acid. The invention does not contain sodium borate and silicate so as to avoid the defect that precipitate is easy to generate due to the existence of sodium borate and silicate in glycol series antifreezing solution and the antifreezing solution is unstable; and the engine antifreezing solution of the invention does not contain amine, nitrate, phosphate and other substances which are harmful to the environment and human body. The researched antifreezing solution has good performances of stability, freeze-proofing, boil-proofing, corrosion-proofing and scale prevention through the cooperative interaction of components so as to perform multi-level anticorrosion protection for the cooling system of the vehicle.

Owner:SHAANXI DADI IND CO LTD OF CHINA NAT NUCLEAR

Long chain branched polyester and preparation method thereof

The invention discloses long-chain branched polyester and a preparation method thereof. The long-chain branched polyester is obtained by carrying out esterification and polycondensation on a diacid component A, a diacid component B and a bifunctional branching agent component C such as biglycidyl ester, diglycidyl ether or glycidol and the like. According to the invention, a non-toxic bifunctional branching agent is directly adopted to in situ generate branching points; the preparation method is unique, preparation process is simple and environmentally-friendly, branching reaction is uniform,branching degree is easy to regulate and control, and the high molecular weight long-chain branched polyester can be prepared; and the preparation method can be used for preparation of non-degradablepolyester and preparation of biodegradable polyester, thereby being beneficial to the realization of commercialization. The long-chain branched polyester has the characteristics of long-chain branching and large molecular weight in structure and is beneficial to increase of melt strength and improvements of blow molding and foaming processing performance.

Owner:ZHEJIANG UNIV

Environment-friendly flame-retarded unsaturated polyester resin and preparation method thereof

The invention relates to a novel environment-friendly flame-retarded unsaturated polyester resin and a preparation method thereof. The resin can be used in vehicles, constructions, electrical appliances and other glass fiber reinforced plastic parts requiring flame retardancy. In the environment-friendly flame-retarded unsaturated polyester resin, bibasic alcohol and dibasic acid or estolide are condensed into unsaturated polyester; the unsaturated polyester resin contains solid reactive phosphorus flame retardant and liquid phosphonium flame retardant, and the content of phosphorus element in the resin is not less than 4 percent of gross mass, wherein the reactive phosphorus flame retardant can be one or two of hydroxyphenylphosphinyl-propanoic acid and hydroxyphenylphosphinyl-ethanoic acid; and the liquid phosphonium flame retardant can be one or more of triethyl phosphate, triphenyl phosphate and dimethyl methyl phosphonate. Each substance in the resin can be directly melted and polymerized without a catalyst; the product does not require separating solvent, does not have the problem of environmental pollution, and reduces the production cost; and the flame retardant can be easily obtained without adding new equipment.

Owner:上海新天和树脂有限公司 +1

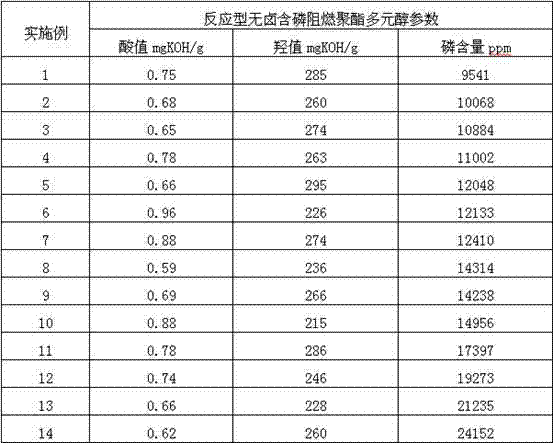

Preparation method of reaction type halogen-free phosphorous flame retardant polyester polyol

The invention discloses a preparation method of reaction type halogen-free phosphorous flame retardant polyester polyol. The preparation method is characterized by comprising following steps: taking binary acid, dihydric alcohol, halogen-free phosphorous copolymer fire retardant and catalyst to be put into a reaction kettle, stirring and warming up, filling nitrogen to empty, reacting for 2 to 8h when the temperature reaches 125 to 155 DEG C, then warming up to 180 DEG C, vacuumizing to ensure the air pressure to be 100 to 5000 Pa, controlling reaction temperature to be 180 to 245 DEG C, after reacting for 2 to 4h, sampling at an interval of 10 to 40 min to test acid value, stopping heating when the acid value is reduced below 2 mgKOH / g, and stirring for cooling so as to obtain the reaction type halogen-free phosphorous flame retardant polyester polyol. The reaction type halogen-free phosphorous flame retardant polyester polyol is applied to synthesis of rigid or soft polyurethane foamed plastic, and the prepared polyurethane foamed plastic has excellent flame retardant property, and the limit oxygen index can be up to more than 32%.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

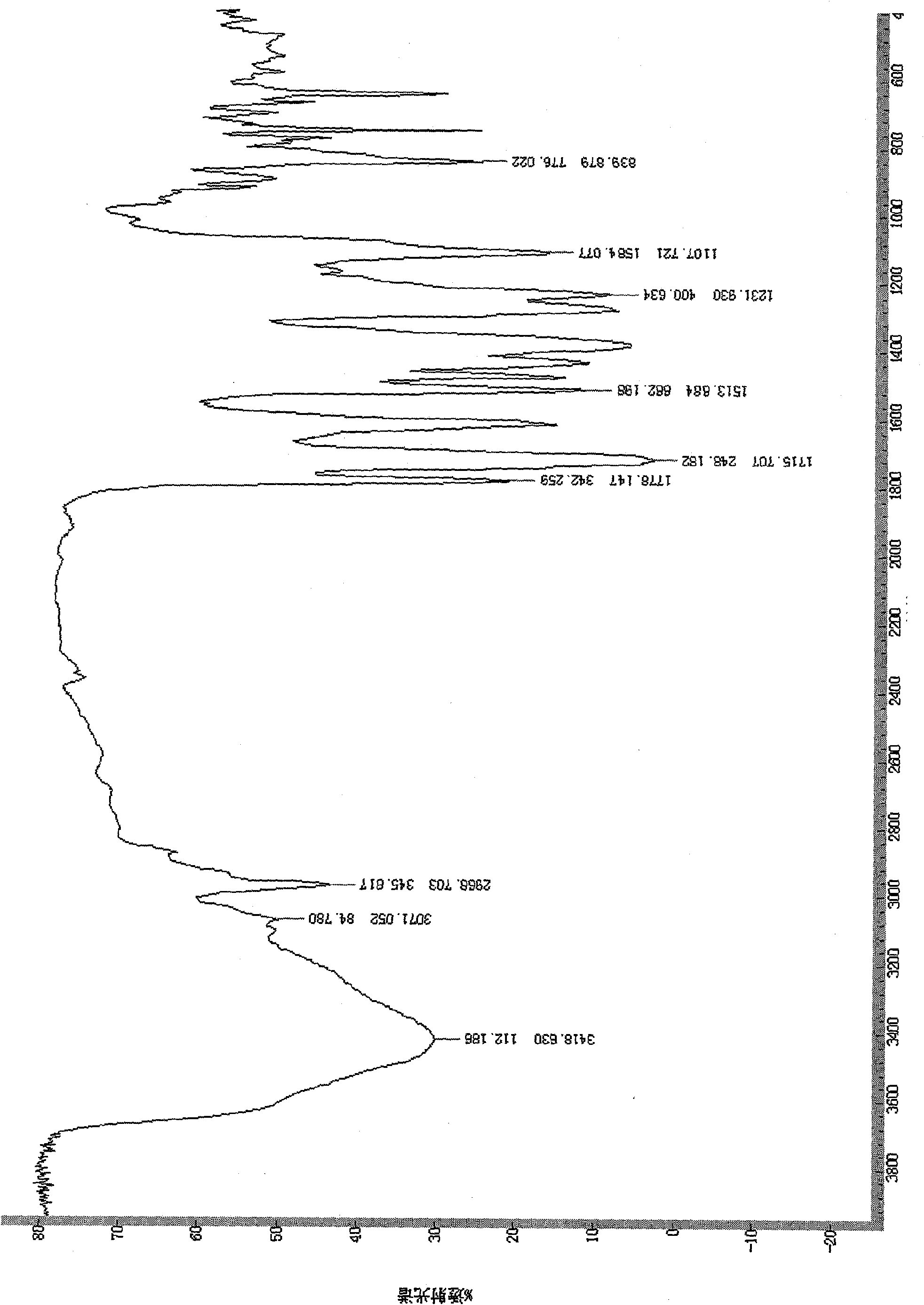

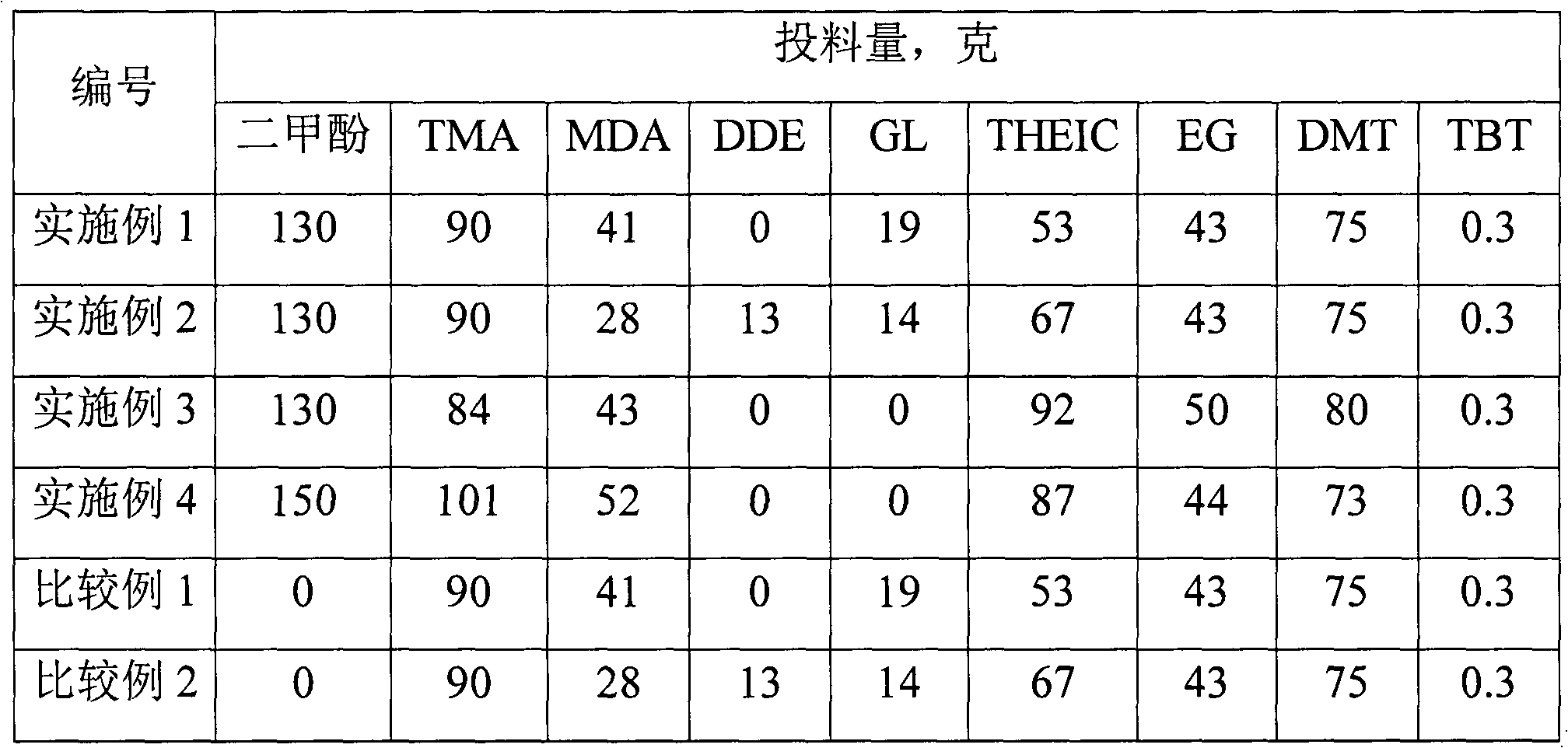

Polyester-imide wire coating enamel and preparation method thereof

InactiveCN101613572ALow costHigh imine contentPlastic/resin/waxes insulatorsCoatingsSolid componentCross-link

The invention discloses polyester-imide wire coating enamel and a preparation method thereof. The polyester-imide wire coating enamel is prepared from binary acid, triacid anhydride, aromatic diamine, dihydric alcohol, trihydric alcohol, phenol solvents, aromatic hydrocarbon solvents, a cross-linking agent and an additive, wherein the molar ratio of the binary acid to the binary acid+ the triacid anhydride is 0.3-0.5: 1; the molar ratio of the trihydric alcohol to the dihydric alcohol+ the triacid anhydride is 0.3-0.5: 1; the molar ratio of the dihydric alcohol to the binary acid+ the triacid anhydride is 0.6-1.0:1; the molar ratio of the triacid anhydride to the aromatic diamine is 2:1; the molar ratio of the phenol solvents to the triacid anhydride+ the aromatic diamine is 1-1.5: 1; and the molar ratio of the phenol solvents to the aromatic hydrocarbon solvents is 1.5-4: 1; the consumption of the cross-linking agent is calculated by the weight of effective metal components contained in the cross-linking agent and solid components in the polyester-imide wire coating enamel, and is between 0.3 and 1.3 percent; and the consumption of the additive is calculated by the weight of solid components contained in the additive and the weight of the solid components in the polyester-imide wire coating enamel, and is between 1 and 4 percent. The polyester-imide wire coating enamel can save the cost, and has high imine content as well as good heat resistance, solvent resistance and refrigerant resistance.

Owner:南通远景电工器材有限公司

Biodegradable polyester and preparation method thereof

InactiveCN103570925AReduce dependenceReduce usageSynthetic resin layered productsPolyester coatingsPolymer scienceCarboxylic acid

The present invention provides a biodegradable copolyester containing 2,5-furandicarboxylate, a product thereof, a preparation method therefor and a use thereof. The polyester has irregularly repeating structural units. The aromatic-aliphatic copolyester of the present invention integrates high crystallinity and high melting point of terephthalate copolyester, biomass sources of 2,5-furandicarboxylate, and biodegradability of aliphatic polyester.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Method for preparing polyester film for solar cell backsheet film

ActiveCN101967272AHigh crystallinityImproved crystal configurationPhotovoltaic energy generationSemiconductor devicesSolar cellFatty acid

The invention discloses a method for preparing a polyester film for a solar cell backsheet film, which is characterized by comprising the following steps of: mixing 200 to 400 mass parts of binary acid, 80 to 160 mass parts of dihydric alcohol, 0.01 to 0.5 mass part of highly-branched polyatomic alcohol, an esterification catalyst for synthesis of polyester, a polycondensation catalyst and a stabilizing agent and carrying out an esterification reaction; adding 0. 1 to 1.0 mass part of high-grade polyenoic fatty acid or alcohol, continuously esterifying, filtering materials and pressing into a polycondensation kettle for a pre-polycondensation reaction so as to prepare modified polyester resin slices; mixing the modified polyester resin slices and master batch polyester slices according to a mass ratio of 100:5-30; and drying, melting, filtering, extruding, cooling a cast piece, biaxially drawing, performing molding treatment and the like so as to prepare the polyester film for the solar cell backsheet film. The film product has excellent mechanical and electrical performances, heat and humidity resistance, dimensional stability, flame retardant property and water vapor permeability resistance.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

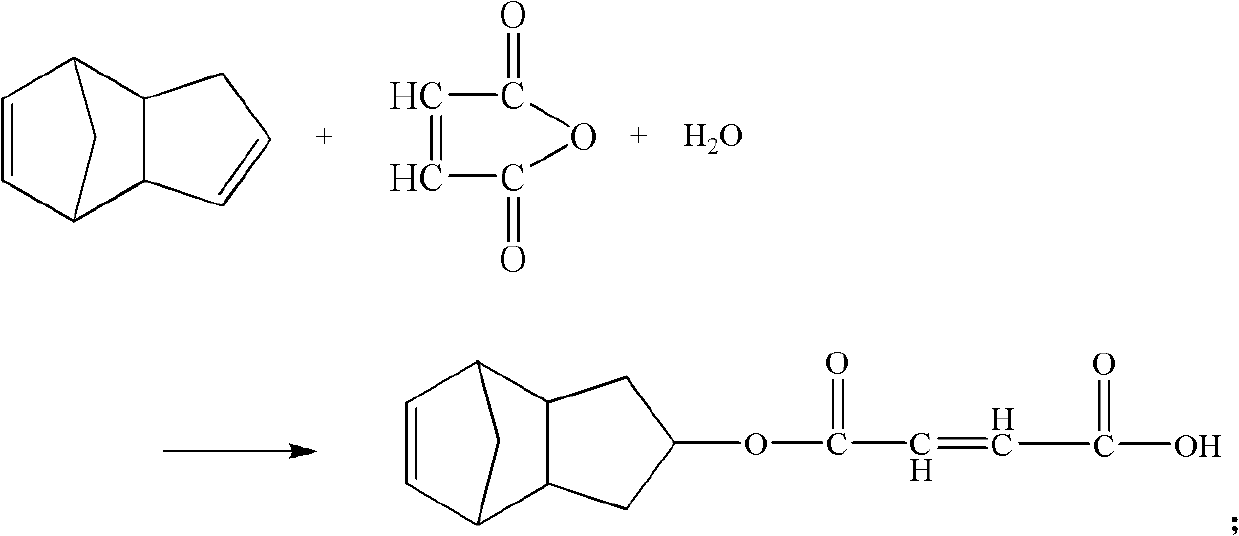

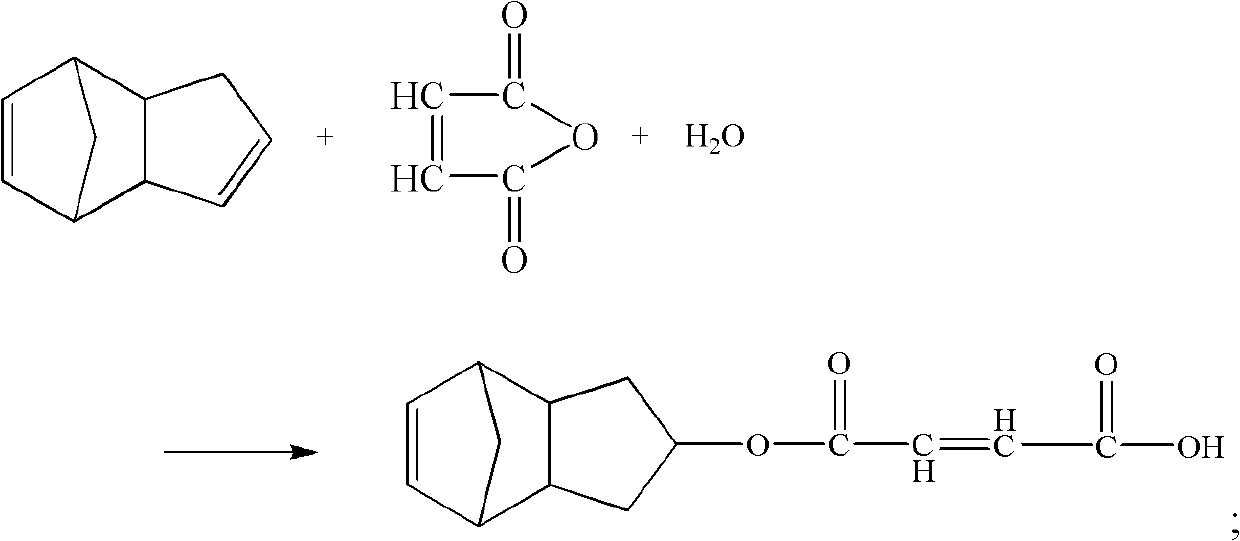

Dicyclopentadiene type unsaturated polyester modified by tung oil, and preparation method and application thereof

InactiveCN102115534AEasy to operateImprove product qualityPlastic/resin/waxes insulatorsOther chemical processesAlcoholAcid value

The invention discloses a dicyclopentadiene type unsaturated polyester modified by tung oil, and a preparation method and application thereof. The method comprises the following steps: reacting raw materials maleic anhydride and dicyclopentadiene under the action of a catalyst to obtain dicyclopentadiene semi-maleate; adding dihydric alcohol, dibasic acid and polymerization inhibitor, and heatingto 190-210 DEG C for dehydration and esterification; when the acid value reaches 50-120 mg KOH / g, cooling to 120-180 DEG C, adding a certain amount of tung oil, and heating to 200-210 DEG C to continue the reaction; and after the acid value reaches 20-35 mg KOH / g under the action of esterification, cooling to 100-120 DEG C, diluting with styrene dissolved with a small amount of polymerization inhibitor, and uniformly dispersing to obtain the product. The dicyclopentadiene type unsaturated polyester modified by tung oil according to the method has the advantages of favorable air-drying property, aging resistance, biodegradability and the like. The product is suitable to be used as an unsaturated polyester paint for corrosion protection, insulation and binding.

Owner:山东中洋新创复合材料有限公司

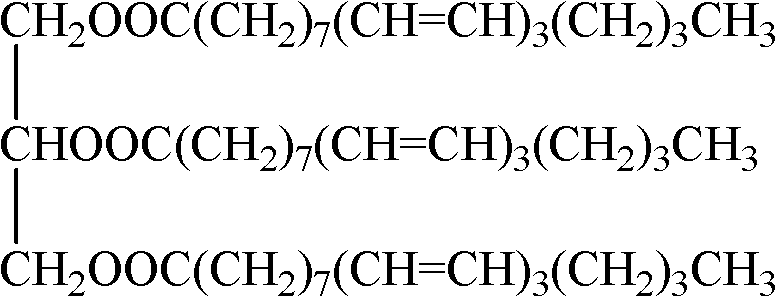

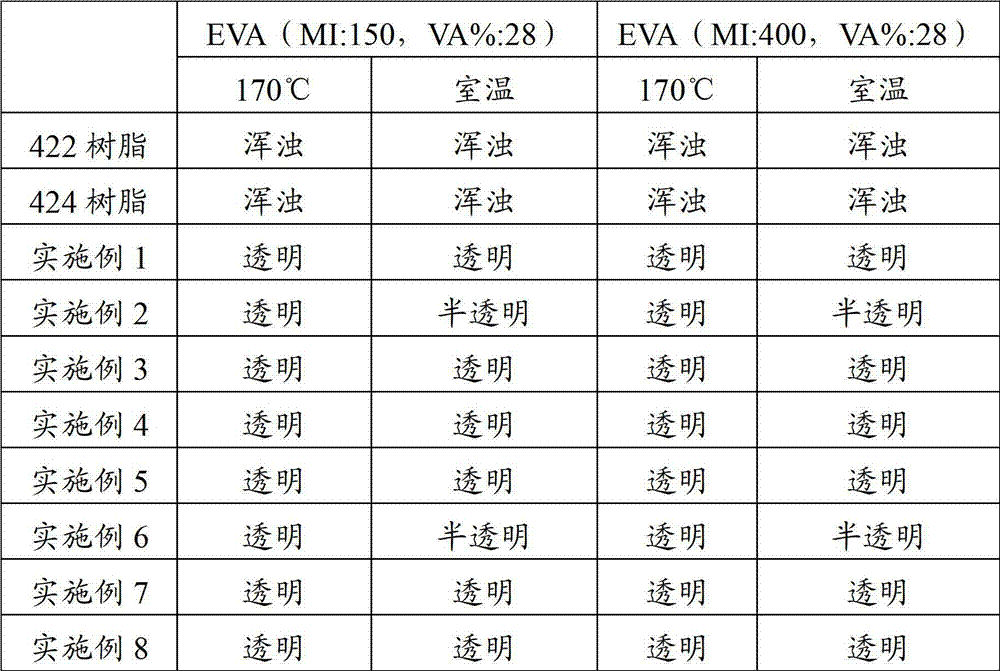

Rosin viscosified resin as well as preparation method and application thereof

ActiveCN102965024AImprove molecular structureHigh softening pointNatural resin chemical modificationRosin adhesivesElastomerDistillation

The invention discloses a preparation method of rosin viscosified resin, and the preparation method comprises the following steps of: (1) adding rosin into a distillation flask, vacuumizing, heating and distilling at the temperature of 240-280 DEG C, so that part of rosin is distilled; and (2) adding the rest rosin in the distillation flask into a reaction flask, adding a catalyst and polyalcohol into the reaction flask under the inert gas protection condition, and reacting for 4-24 hours at the temperature of 240-290 DEG C, so that the rosin viscosified resin is obtained, wherein the rosin contains pinus latteri acid. According to the preparation method disclosed by the invention, the pinus latteri acid contained in the rosin component is utilized, and the pinus latteri acid is rosin binary acid, so that the molecular structure of the resin is increased and the aim of increasing the softening point of the rosin viscosified resin is achieved. Meanwhile, the invention also provides rosin viscosified resin prepared by adopting the preparation method disclosed by the invention, and the rosin viscosified resin has higher softening point and good compatibility with EVA (ethylene vinyl acetate) elastomer and can be better used for preparing hot melt glue.

Owner:普洱科茂林化有限公司

Polyester biodegradation agricultural mulching film as well as preparation and application of polyester biodegradation agricultural mulching film

ActiveCN102702694ADoes not affect normal plantingDegradation precisionClimate change adaptationPlant protective coveringsPolymer scienceCopolyester

The invention discloses a polyester biodegradation agricultural mulching film, which is prepared from A-J ingredients. Meanwhile, the invention discloses a preparation method and an application of the polyester biodegradation agricultural mulching film. The polyester biodegradation agricultural mulching film provided by the invention belongs to the polyester biodegradation agricultural mulching film which is prepared by a preparation method of aromatic dibasic acid introduction and dibasic alcohol copolyester chain extension modification and is used in Sinkiang regions. The polyester biodegradation agricultural mulching film has the advantages that the degradation period is controllable, the performance is excellent, the molecular weight is high, the branching degree is high, the crystallinity degree is high, few impurities are contained, and nontoxicity and biodegradability are realized.

Owner:新疆康润洁环保科技股份有限公司

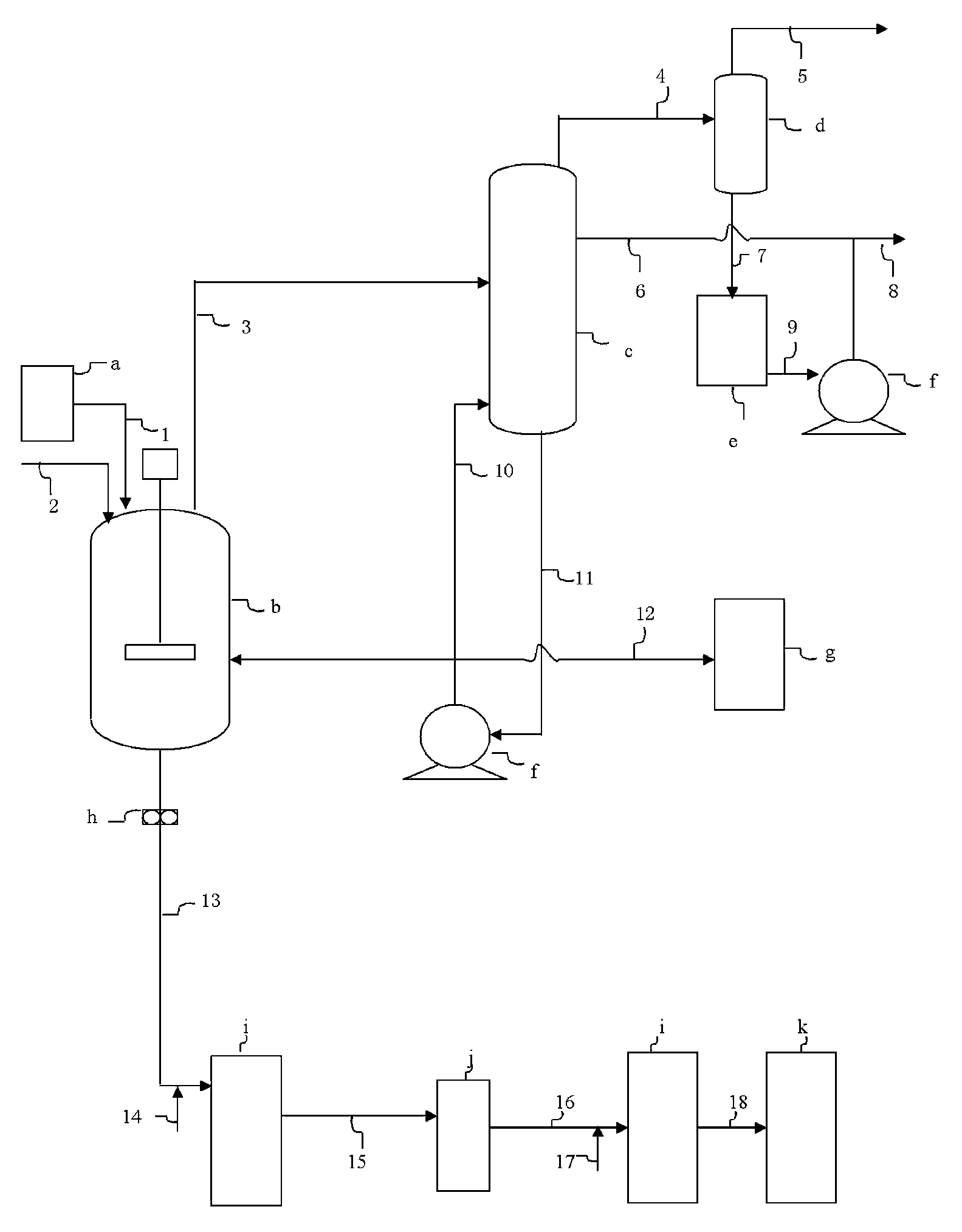

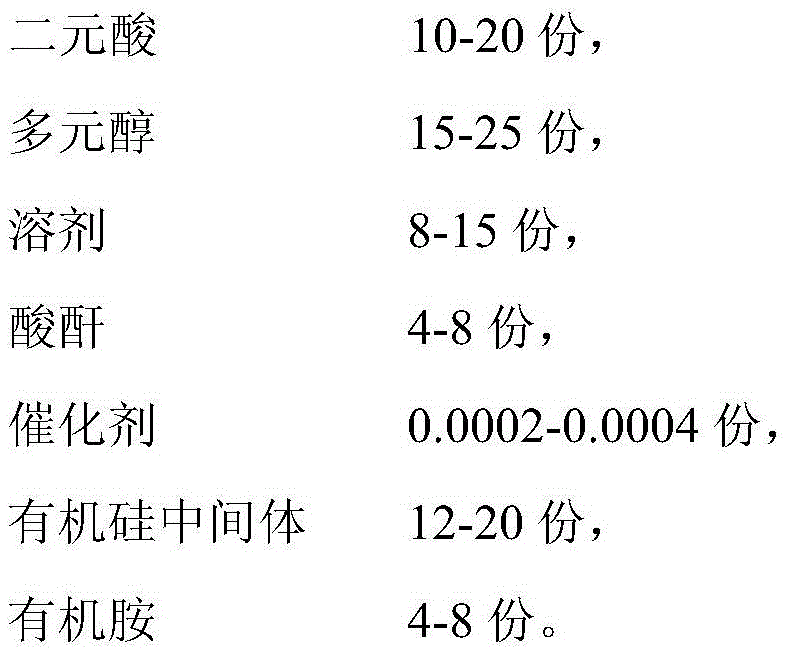

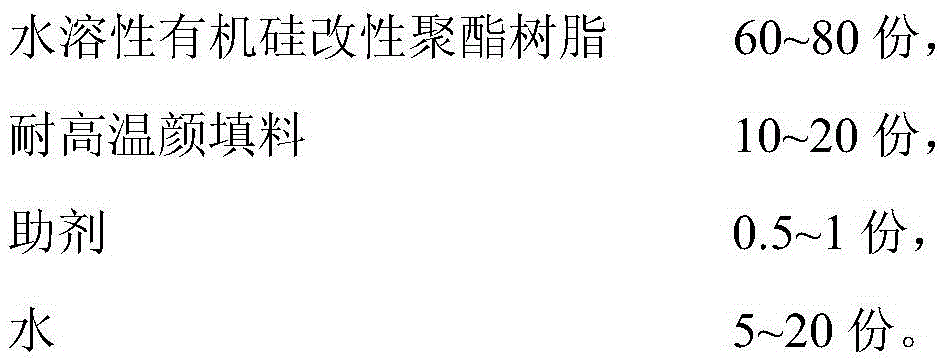

Water-soluble organic silicone modified polyester resin as well as preparation method and application thereof

The invention relates to the field of organic polymer compounds and provides water-soluble organic silicone modified polyester resin and a preparation method thereof to solve the technical problems that almost all the organic silicone modified polyester coatings on the market at present are solvent-based coatings and solvents contained in the coatings have great impacts on the environment and constructors. The water-soluble carboxylate organic silicone modified polyester resin is obtained by adopting polyols and binary acids to prepare hydroxyl-terminated polyester resin, then blocking the polyester resin with a monomer containing a carboxyl functional group, modifying the polyester resin with organic silicone intermediates containing silicone hydroxyl, silicone methoxyl or silicone ethoxyl and neutralizing the polyester resin with an amine to form salt after modification is completed. The organic silicone modified polyester resin prepared by the method can be uniformly dissolved in water. Films prepared from water-based coatings containing the resin have excellent heat, water and solvent resistance.

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

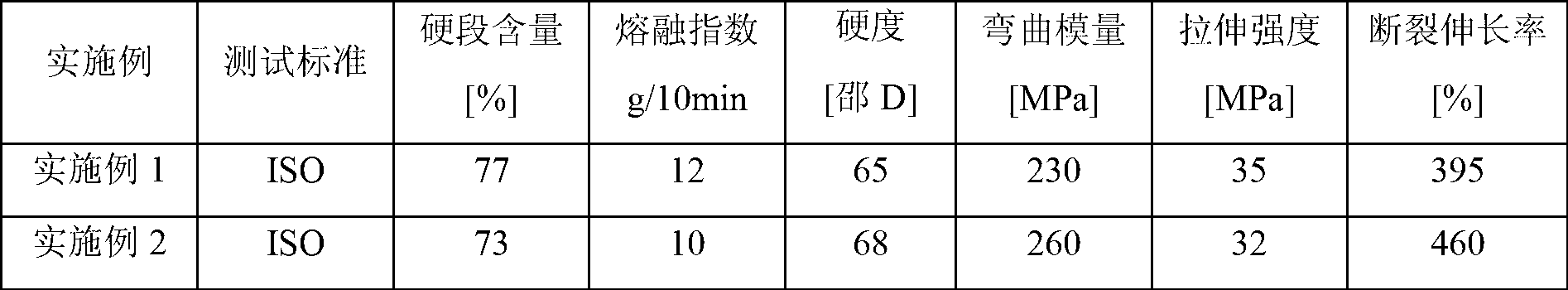

Method for preparing copolyether ester elastomer

The invention discloses a method for preparing copolyether ester elastomer. The method comprises the following steps of mixing aromatic binary acid, polyether glycol and micromolecule glycol to carry out an esterification reaction, removing by-products of tetrahydrofuran and water to obtain carboxylate after the reaction is finished; transferring the obtained carboxylate into a pre-polycondensation reactor, adding an antioxidant and a catalyst to react for 1-2 hours, so as to obtain a prepolymer; transferring the prepolymer to a polycondensation kettle, wherein the polymerization time is 1.5-3 hours and the pressure is 100-200Pa; and obtaining the copolyether ester elastomer after the reaction is finished. By adopting the method disclosed by the invention, the copolyether ester elastomer is prepared from terephthalic acid as a raw material; the cost is low; and the by-product tetrahydrofuran generated by reaction is rectified and purified to obtain the high-purity tetrahydrofuran. The method has no negative effect on the cost of synthetizing TPEE (thermoplastic polyeher ester elastomer); the performance of the synthetized copolyether ester elastomer is consistent with that of the product prepared from dimethyl terephthalate.

Owner:KINGFA SCI & TECH CO LTD +1

Preparation method of oxidized graphene modified PET (polyethylene terephthalate) material

InactiveCN105017511AHigh intrinsic viscosityHigh breaking strengthPolyethylene terephthalate glycolSlurry

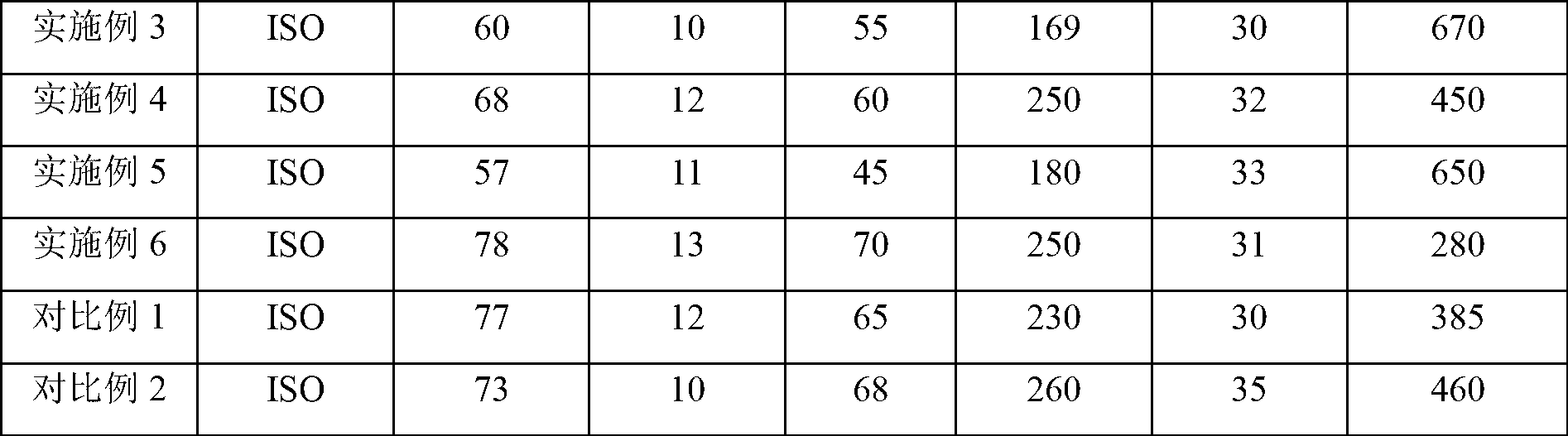

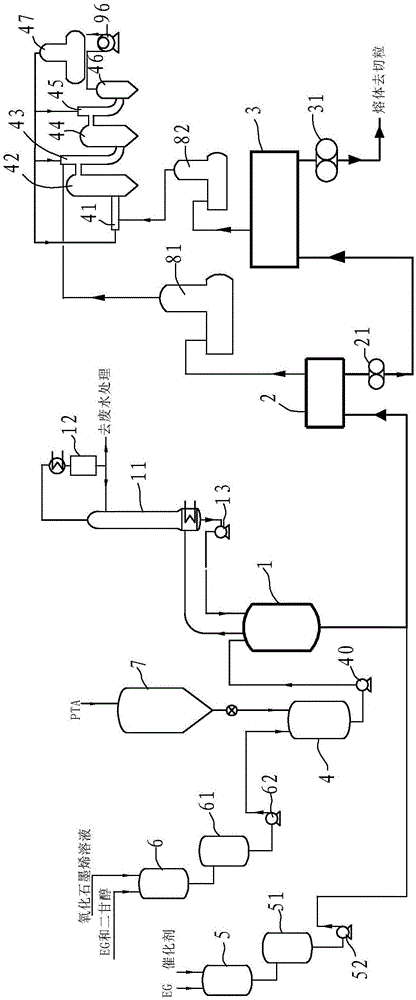

A preparation method of an oxidized graphene modified PET (polyethylene terephthalate) material is characterized by comprising steps as follows: purified terephthalic acid, binary acid, ethylene glycol, dihydric alcohol and a solution of an oxidized graphene liquid and ethylene glycol are firstly mixed to form slurry, and the esterification rate of an esterification reaction kettle outlet is larger than or equal to 92%; a catalyst is added after an esterification reaction ends; a monomer prepared through the esterification reaction is subjected to a second-stage condensation polymerization reaction in a pre-condensation kettle; the temperature of the material subjected to pre-condensation ranges from 265 DEG C to 275 DEG C; the absolute pressure ranges from 1 KPa to 30 KPa, and the time ranges from 1 hour to 1.5 hours; low-grade polymer obtained after the pre-condensation reaction is conveyed to a final condensation polymerization tank for a further condensation polymerization reaction, and the intrinsic viscosity is increased to be at least 0.60 dl / g. Compared with the prior art, the preparation method has the advantages as follows: the oxidized graphene in an appropriate proportion is added to the material, the intrinsic viscosity, the breaking strength and the elongation at break are remarkably improved, and the application range of PET is greatly widened.

Owner:ZHEJIANG WANKAI NEW MATERIAL

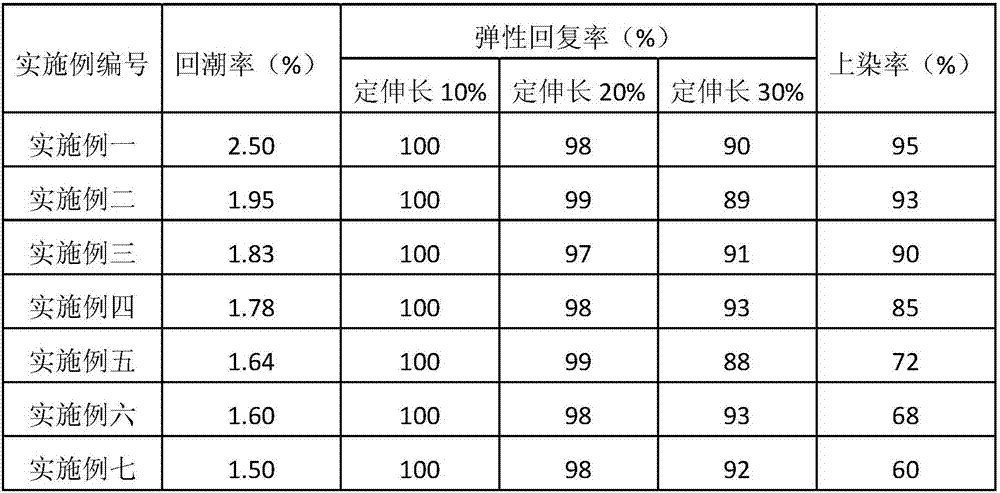

High-temperature-resistant nylon PA66T material and preparation method thereof

The invention belongs to the field of polymer synthesis, and relates to a high-temperature-resistant nylon PA66T material and a preparation method thereof. The nylon PA66T material is prepared from the following components in mole number: 11.00-12.32 moles of aromatic binary acid, 9.00-9.90 moles of hexane diacid, 19.20-21.34 moles of hexamethylenediamine, 0.035-0.05 mole of a nucleating agent, 0.015-0.03 mole of a catalyst and 250-300 mole of deionized water. The high-temperature-resistant nylon PA66T material provided by the invention has the advantages of light weight, high temperature resistance, high mechanical strength, superior size stability and the like, and is suitable to be applied in a high-temperature environment; and meanwhile, the high-temperature-resistant nylon PA66T material is simple in the synthesis process, is moderate in viscosity, and is suitable for industrial popularization and subsequent machine shaping.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Preparation method for organically-modified nano-silica/nylon 66 composite material

InactiveCN101570590AGood dispersionReduce clumpingPigment treatment with non-polymer organic compoundsIn situ polymerizationHigh pressure

The invention discloses an organically-modified nano-silica / nylon 66 composite material and a preparation method thereof. The method has the following advantages that: 1) the surface of nano-silica subjected to chemical modification has an epoxy group, an amino-group and other groups, the nano-silica can react with binary acid to form a chemical bond which is subjected to ultrasonic dispersion so as to reduce the agglomeration phenomenon of nano-silica particles, improve the dispersibility of the nano-silica and further obtain the composite material with good dispersibility; and 2) in the preparation process, a GSH-2 type high-pressure autoclave is adopted to prepare the composite material by in-situ polymerization, and the method has certain directive significance on industrialized production of the composite material.

Owner:XIANGTAN UNIV

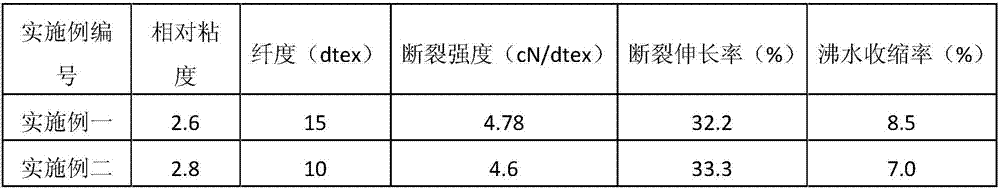

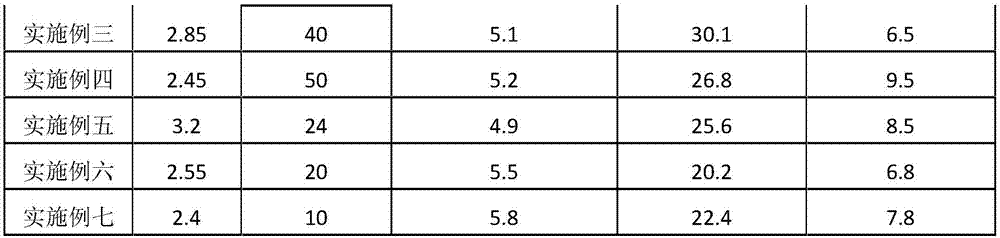

Bio-base high-elastic moisture-absorbing easily-dyed long carbon chain polyamide 5X fiber and preparation method thereof

InactiveCN106868623AEmission reductionReduce the greenhouse effectMelt spinning methodsMonocomponent polyamides artificial filamentMolten stateFiber

The invention provides a bio-base high-elastic moisture-absorbing easily-dyed long carbon chain polyamide 5X fiber and a preparation method thereof. The production raw material of the polyamide 5X fiber at least contains 1,5-pentamethylene diamine and long carbon chain binary acid, or 1,5-pentamethylene diamine and long carbon chain binary acid are taken as monomers and polymerized into the polyamide 5X. The preparation method comprises the following steps: (1) polymerizing 1,5-pentamethylene diamine and long carbon chain binary acid, thereby forming the polyamide 5X flux, or heating the polyamide 5X resin till being molten, thereby forming the polyamide 5X flux; (2) spinning the polyamide 5X flux, thereby obtaining a primary raw silk; and (3) treating the primary raw silk, thereby obtaining the polyamide 5X fiber. The polyamide 5X fiber has excellent mechanical properties, such as, breaking strength and elongation at break, has the characteristics of high elasticity, lower water absorption, easiness in dyeing, and the like, is suitable for civil and industrial silk preparation and has an extensive application.

Owner:CATHAY R&D CENT CO LTD +1

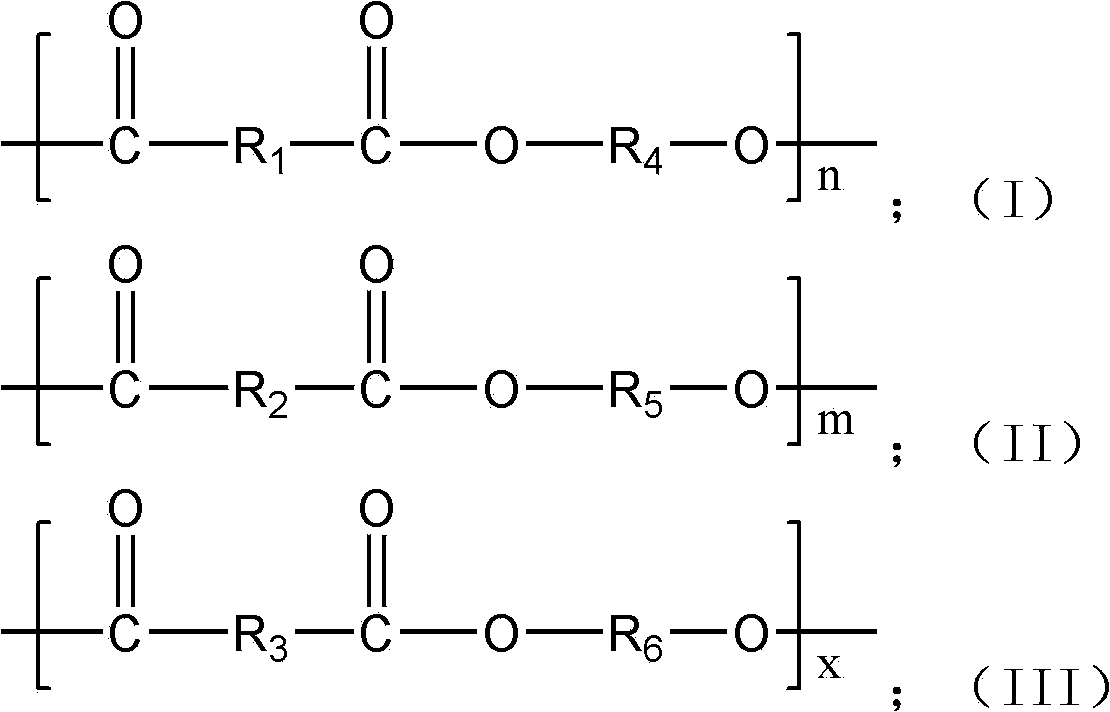

Polyester polyol as well as preparation method and application thereof

The invention belongs to the technical field of novel chemical material synthesis and application and relates to polyester polyol as well as a preparation method and an application thereof. The preparation method comprises the steps: adopting binary acid and polyol, in the presence of a catalyst, and carrying out polycondensation on the binary component and the polyol component to produce the polyester polyol, wherein the mass ratio of the binary, the catalyst and micromolecule polyol is 100:(0.003-0.015):(50-100); and carrying out synthesis on the polyester polyol and isocyanate to obtain a prepolymer, and carrying out reaction on the isocyanate and a chain extender to obtain a polyurethane elastomer, wherein the weight content of isocyanato in the prepolymer is 2.1-28 percent. The polyester polyol is strong in the polyurethane elastomer rigidity, good in the rebound force, good in the abrasive resistance, strong in the bearing capacity, strong in the tear strength, and long in the service life. With the adoption of the polyurethane elastomer, as the crystallinity is strong and the high temperature resistance is good, the freeness of diisocyanate is reduced, the working environment is improved, the environmental pollution is alleviated, and the cost is saved.

Owner:SHANDONG INOV POLYURETHANE

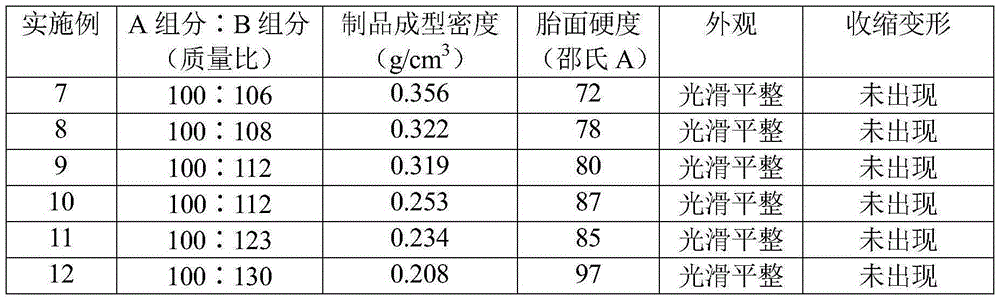

Polyurethane solid tire material and preparation method thereof

The invention relates to a polyurethane solid tire material. The polyurethane solid tire material comprises a component A and a component B, wherein the component A is a mixture prepared by mixing polyester polyol, a chain extender, a foaming agent, a catalyst A and a foam stabilizer according to a mass ratio of 100:(5 to 30):(0.3 to 3.0):(0.3 to 3.0):(0.3 to 2.5), the component B is prepared by prepolymerizing isocyanate, polyester polyol and polyether polyol under the existence of a side reaction inhibitor according to a mass ratio of 100:(20 to 50):(0 to 30), and the polyester polyol in the component A and the component B is prepared by prepolymerizing binary acid and polyhydric alcohols under the action of a catalyst B. The component A and the component B are fully mixed, and are then injected into a mold for reaction to form, and demolding and aging are performed, so as to prepare a tire product. The prepared tire product has the advantages of low density, stable size, high tread hardness, good abrasion resistance and good bonding capability with other accessories of the tire.

Owner:JIAXING HEXIN CHEM IND

Halogen-free fire-retardant unsaturated polyester resin, preparation method and use thereof

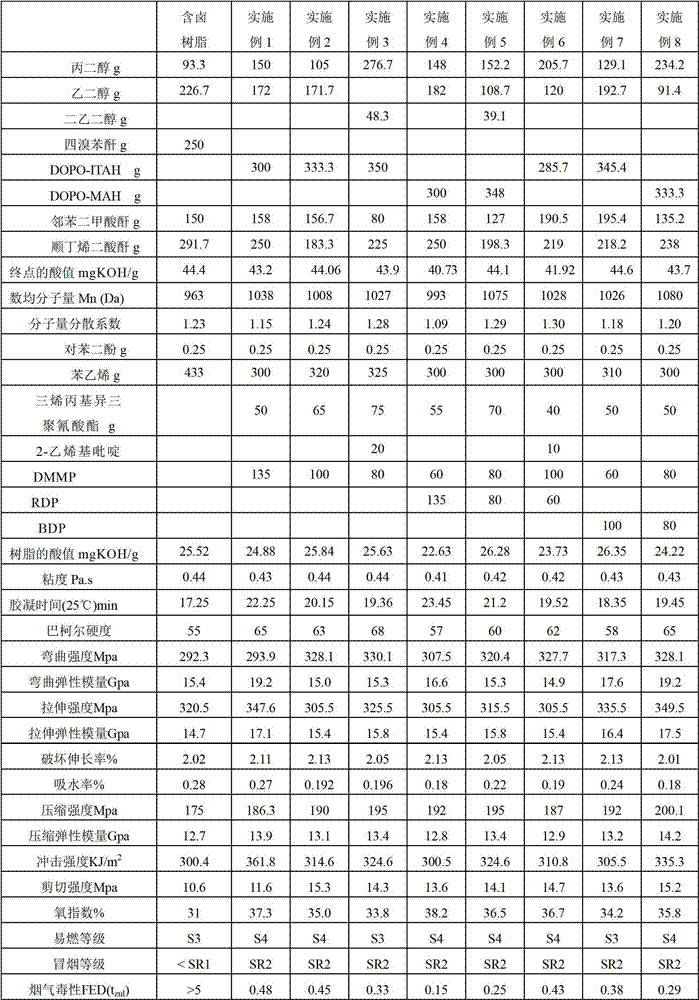

The invention relates to a halogen-free fire-retardant unsaturated polyester resin, which mainly comprises, 63-69wt% of a halogen-free fire-retardant unsaturated polyester, 19-22 wt% of styrene, 3-7wt% of a nitrogen-containing cross-linking monomer and 5-14wt% of a phosphorus-containing additive-type fire-retardant agent, wherein the halogen-free fire-retardant unsaturated polyester is prepared by carrying out blending polymerization on 26-36 parts by weight of a diacid grafted DOPO derivative, 30-44 parts by weight of a phosphorus-free diacid or an anhydride, and 28-34 parts by weight of a diol (the number average molecular weight Mn of the resulting polyester is 970-1120 Daltons, and the molecular weight dispersion coefficient is 1.05-1.4). According to the present invention, benzoyl peroxide and a nitrogen-containing promoter tertiary arylamine curing system are adopted to achieve normal temperature curing of the resin; flammability level of the product of the present invention achieves the S3 standard and above, the smoking level achieves SR2, the toxicity achieves the requirement of FED (tzul) less than 0.5, and the fire-retardant property of the product meets fire safety standards in Germany DIN 5510-2:2009-05.

Owner:CHANGZHOU HUARUN COMPOSITE MATERIALS +1

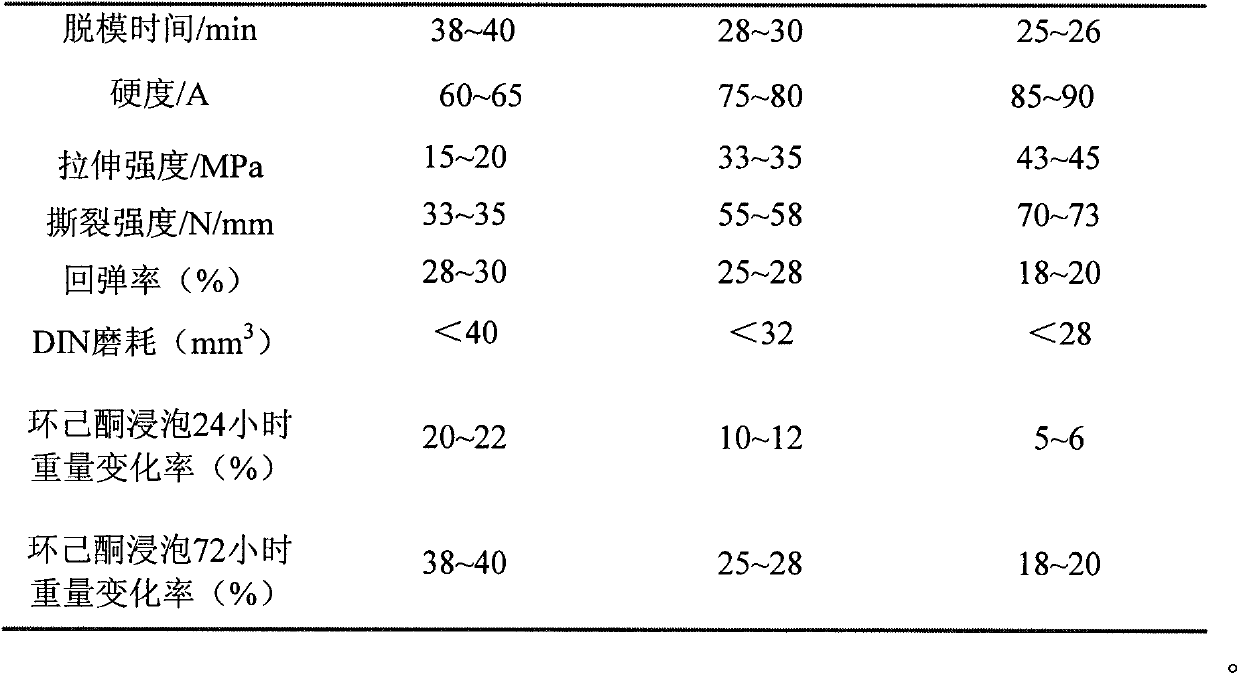

Polyurethane elastic body material for silk-screen printing squeegee and preparation method thereof

The invention discloses a polyurethane elastic body material for silk-screen printing squeegee and a preparation method thereof. The raw material of the elastic body material comprises three components: component A which comprises 100 parts of polyester polyatomic alcohol PSE 1 and 110-120 parts of isocyanate, component B which comprises polyester polyatomic alcohol PSE 2, and component C which comprises 100 parts of chain extendor, 3.3-8.3 parts of catalyst, wherein the mass ratio of the A:B:C is 100 / 85-160 / 10.5-13.5; the polyester polyatomic alcohol PSE 1 is obtained through polycondensation reaction of the mixed dibasic acid and mixed polyatomic alcohol; the polyester polyatomic alcohol PSE 2 is obtained through polycondensation reaction of the dibasic acid and mixed polyatomic alcohol. Through adjusting the ratio of the three components, the polyurethane elastic body material, which has the Shore hardness of 60-90 A, the material has the advantages of excellent solvent resistance, good resilience performance, wearing resistance, bending resistance, and good mechanical property and cutting processing behavior.

Owner:LIMING RES INST OF CHEM IND

Polyurethane plastic runway adhesive and preparation method thereof

The invention discloses a polyurethane plastic runway adhesive and a preparation method thereof. The adhesive is characterized in that it includes a component A and a component B, the component A is an -NCO functional group containing polyurethane prepolymer obtained by subjecting diol and binary acid to esterification reaction to obtain specific polyester diol, and then polymerizing the specific polyester diol with polyether polyol, a chain extender and MDI; the component B is obtained by taking polyether polyol, small molecule diol, small molecule amine, a plasticizer, an antioxidant, a catalyst, and white carbon black as raw materials, conducting stirring and vacuum dehydration; the component A and component B are stirred evenly according to certain ratio, the mole ratio of -NCO in the component A to -OH in the component B is 0.97-0.99. The polyurethane plastic runway adhesive provided by the invention has high strength and excellent performance, and does not contain solvent.

Owner:GOOD CHEM SCI & TECH

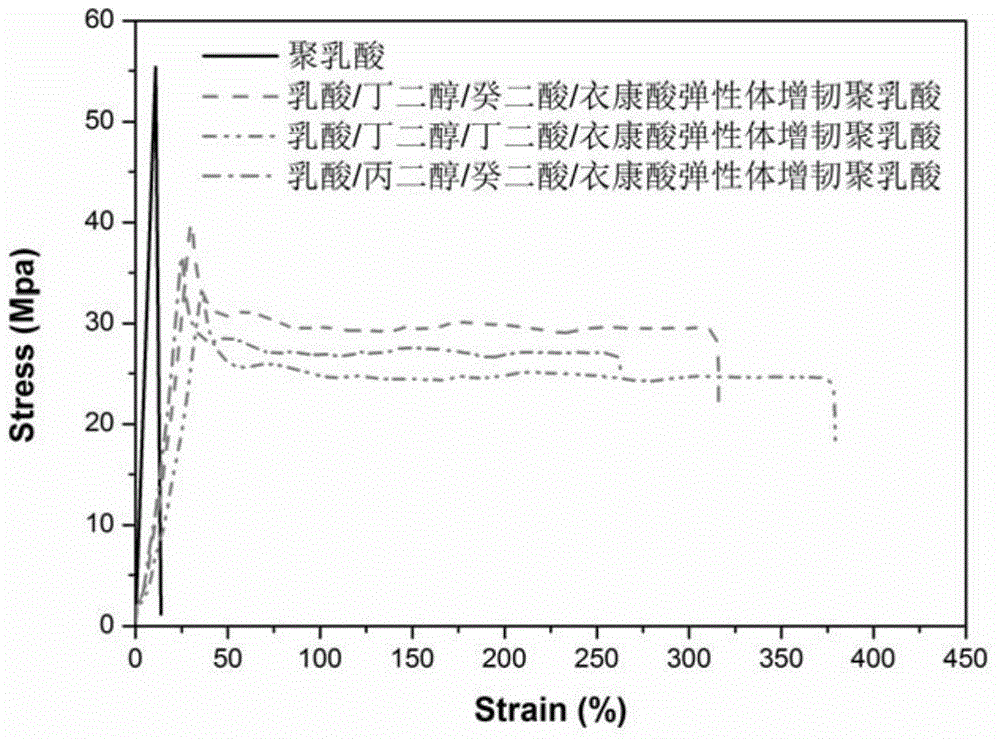

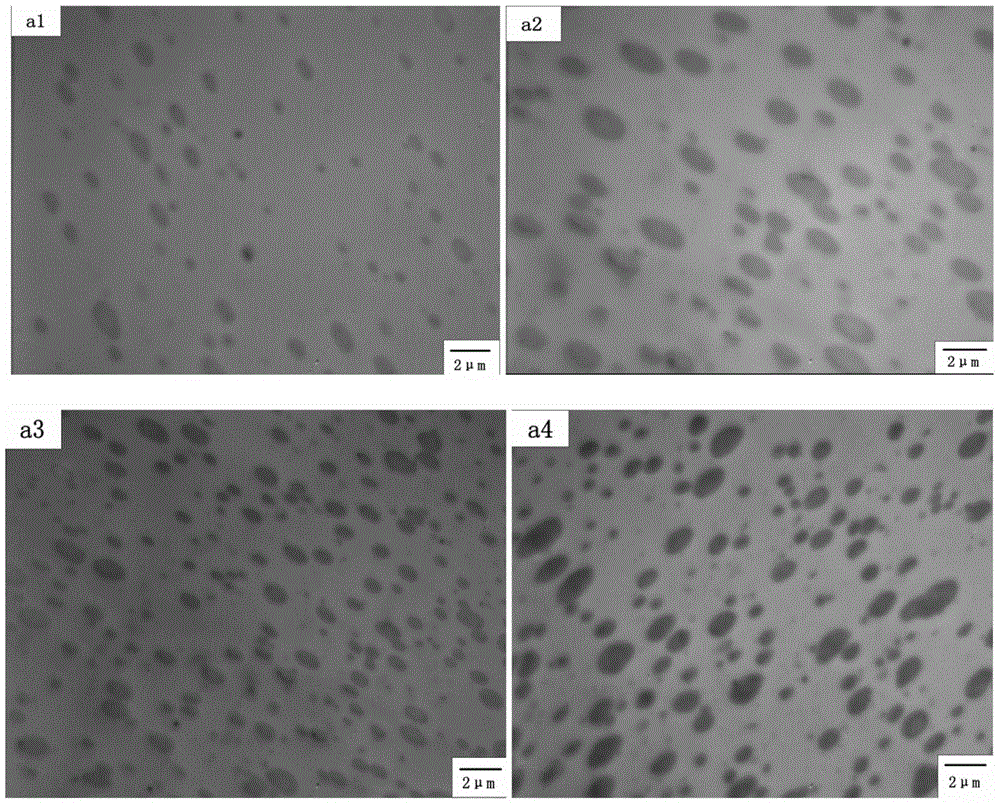

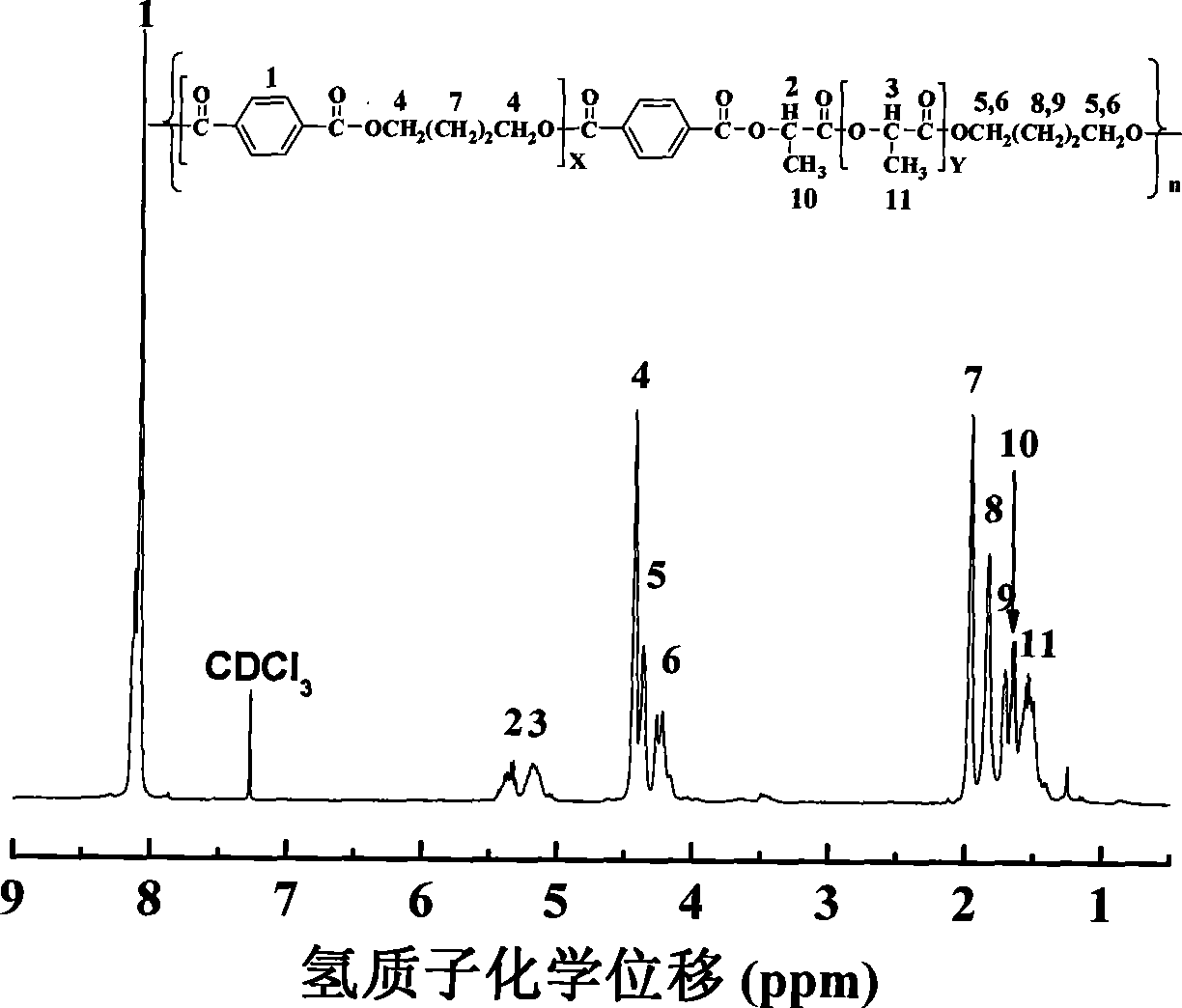

Toughened polylactic acid and preparation method thereof

ActiveCN104559097ASolve the problem of migration and detachment to the surfaceLong-lastingPolyesterElastomer

The invention provides toughened polylactic acid and a preparation method thereof. The toughened polylactic acid is prepared by carrying out melt blending on a polyester elastomer and polylactic acid at the temperature of 180-220 DEG C, wherein the adopted polyester elastomer is synthesized by taking biomass binary acid and dihydric alcohol like lactic acid as raw materials; a lactic acid chain segment contained in the elastomer has good compatibility with polylactic acid and can be crushed and dispersed in polylactic acid matrix in a blending process, so that the toughening effect is realized; meanwhile, due to double bonds in the elastomer, a crosslinking agent is added, crosslinking reaction is carried out on the elastomer in a melt blending process, polylactic acid can be grafted onto the elastomer after crosslinking, and compatibility of a system is further improved; compared with the common plasticizer like polyethylene glycol, the polyester elastomer can not migrate from the matrix due to high molecular weight, so that the polyester elastomer can be used for effectively toughening polylactic acid and also can be used for maintaining a long-acting stable toughening effect; and elongation at break of the toughened polylactic acid is increased to 100-350%, and impact strength is increased to 6.1-35.3KJ / M<2>.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing aromatic-aliphatic copolyester

The invention relates to a method for preparing aromatic-aliphatic copolyester. In the method, aromatic binary acid, dihydric alcohol and aliphatic hydroxy acid are used as a copolymerization system to prepare the aromatic-aliphatic copolyester by direct melt polycondensation under the action of a catalyst, wherein the dihydric alcohol is one or both of aliphatic dihydric alcohol and cyclized aliphatic dihydric alcohol. The method overcomes the defect of the generation of poisonous methanol in the prior ester exchange process. By the random copolymerization, a polylactic acid chain segment can be introduced to an aromatic polyester chain segment, and the sequence length of an aromatic component is reduced, thereby improving the degradation property of the copolyester and keeping better mechanical behavior; moreover, the method also has the advantages of simple synthesis process, easy reaction operation and low-priced and easily obtained materials, and the obtained copolyester has certain degradation property.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

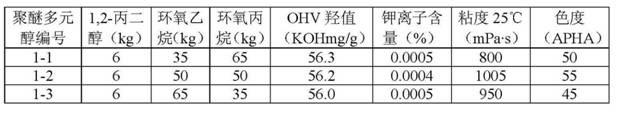

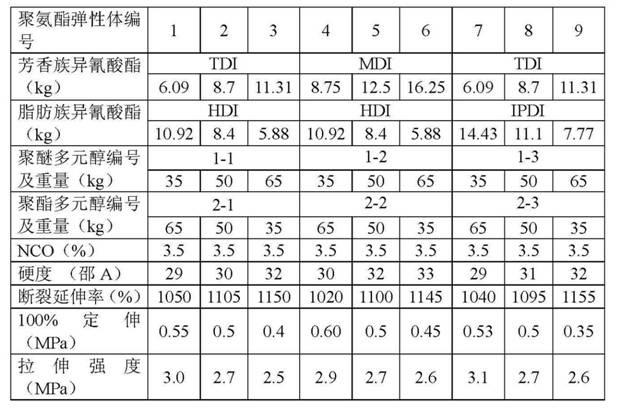

Polyurethane elastomer

The invention belongs to the organic polymer compound field, and relates to a polyurethane elastomer, which is prepared by performing chain extension on isocyanic acid prepolymer prepared by the reaction of pluronic polyol and organic isocyanate; the pluronic polyol is composed of polyester polyol and polyether polyol; the polyester polyol is prepared by polycondensation of binary acid, dipropylene glycol and diethylene glycol; the polyether polyol is polymerized by ethylene oxide and / or propylene epoxide; the organic isocyanate is composed of aromatic isocyanate and aliphatic isocyanate; and the chain extender used for extending chains is amine chain extender. The polyurethane elastomer of the invention starts out from the theory of structure and performance of polyurethane, adopts well-known prepolymer synthesis, and performs casting and moulding; the body is synthesized into an environment protected polyurethane elastomer without solvent; the polyurethane elastomer has super-high-limit elongation at break more than 1000%, and satisfies the applications in special fields of bonding, damping and sealing and the like.

Owner:WENZHOU HONGDELI RESIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com