Preparation method of oxidized graphene modified PET (polyethylene terephthalate) material

A graphene modification and graphene technology, which is applied in the field of polyethylene terephthalate material preparation, can solve the problems of flat wire unevenness, poor toughness, brittleness, etc., and achieve broad application surface and elongation at break The effect of rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

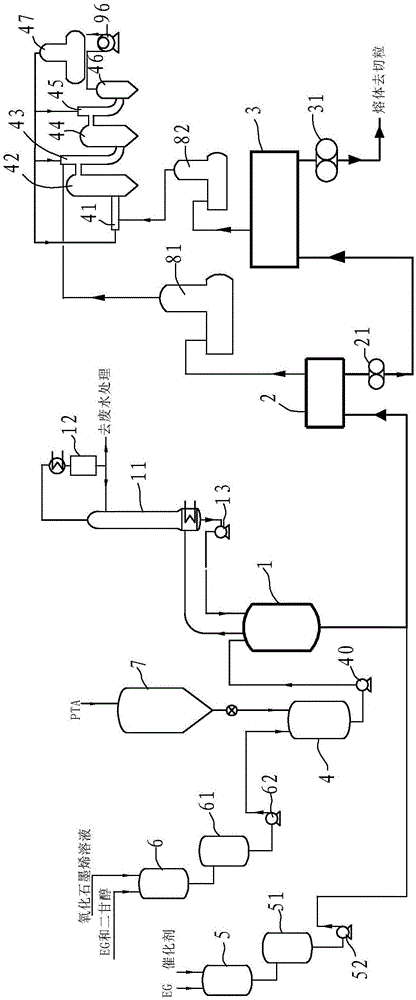

Method used

Image

Examples

Embodiment 1

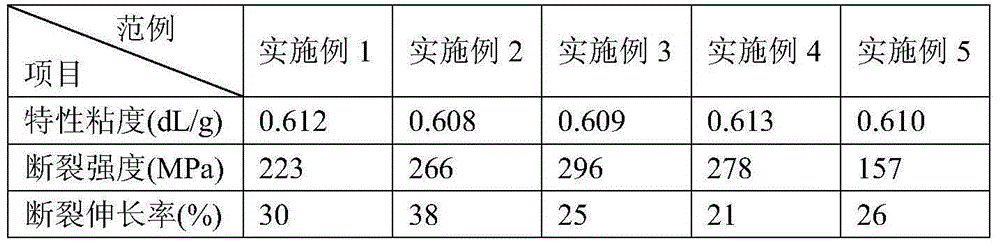

[0019] Example 1, weigh 15KG of purified terephthalic acid (PTA), 6.655KG of ethylene glycol (EG), 0.599Kg of diethylene glycol (addition amount 5% mol), 4.03g of graphene oxide / water / ethylene glycol solution (graphene addition 5ppm), stabilizer phosphoric acid 42g (phosphorus addition 9ppm). Prepare the slurry first, and then use the pump to continuously transport the slurry to the esterification reaction tank for the first-stage esterification reaction. Use nitrogen to replace the air in the esterification reaction tank, and the replacement is completed. The rotation speed of the agitator is 60rpm, the frequency is 50HZ, and the esterification reaction is carried out by heating to above 190°C. The esterification reaction temperature is 250-255°C, and the esterification pressure is medium At 0.2-0.25MPa (relative pressure), the esterification reaction time is 3 hours, the material temperature when the esterification reaction is completed is about 258°C, and the esterification...

Embodiment 2

[0027] As in Example 1, but purified terephthalic acid (PTA) 14.7KG, isophthalic acid (IPA) 0.3KG (addition amount 2% mol), ethylene glycol (EG) 6.795KG, diethylene glycol 0.359Kg (addition amount 3% mol), graphene oxide / water / ethylene glycol solution 80.64g (graphene oxide addition amount 100ppm). The prepared basic slices were dried, pulled and stretched on a PET wire drawing machine, and various tests were carried out. The results are shown in Table 1.

Embodiment 3

[0029] As in Example 1, but graphene oxide / water / ethylene glycol solution 806.4g (graphene oxide addition 1000ppm). The prepared basic slices were dried, pulled and stretched on a PET wire drawing machine, and various tests were carried out. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com