Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5272results about How to "High elongation at break" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Interpenetrating Networks With Covalent and Ionic Crosslinks

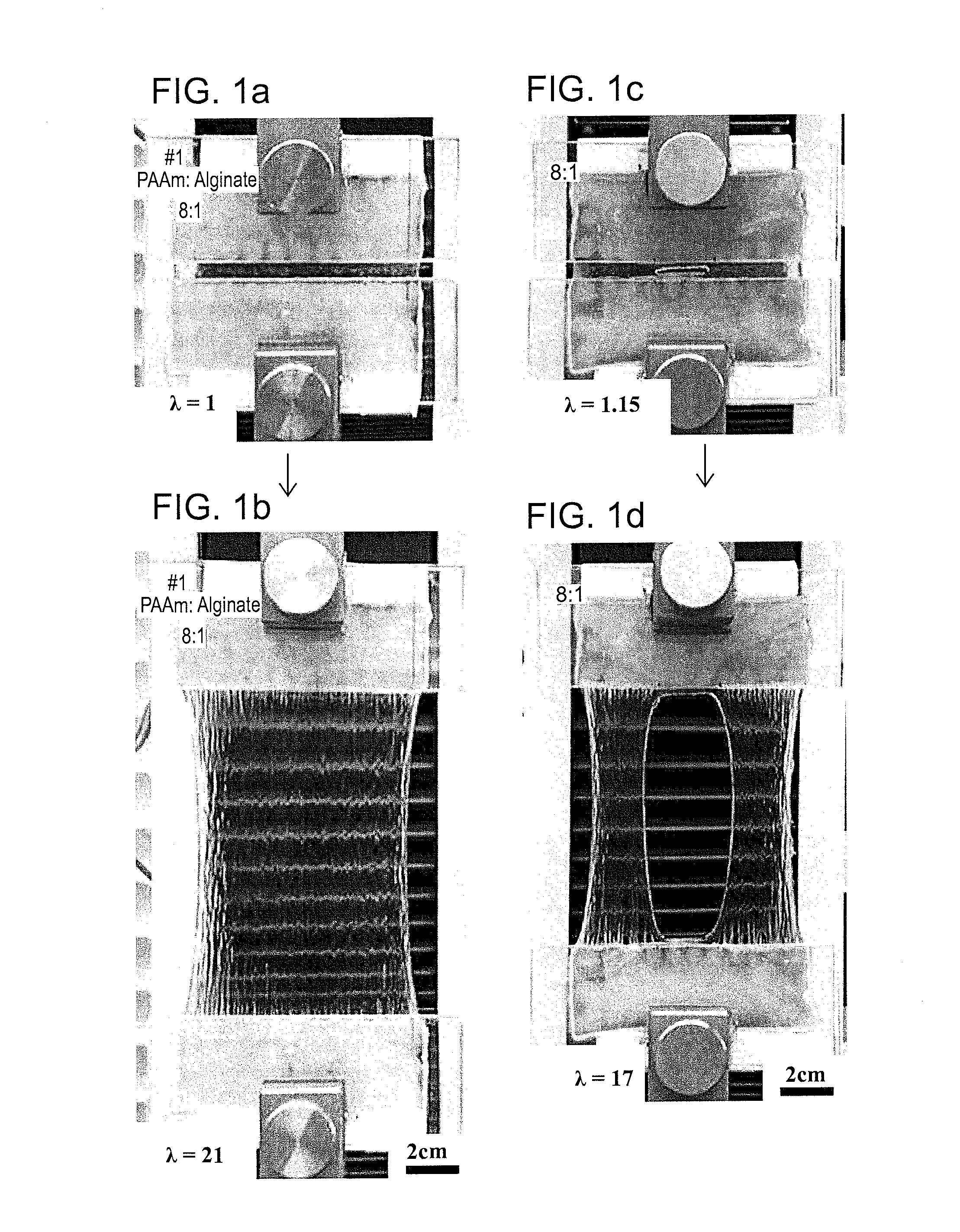

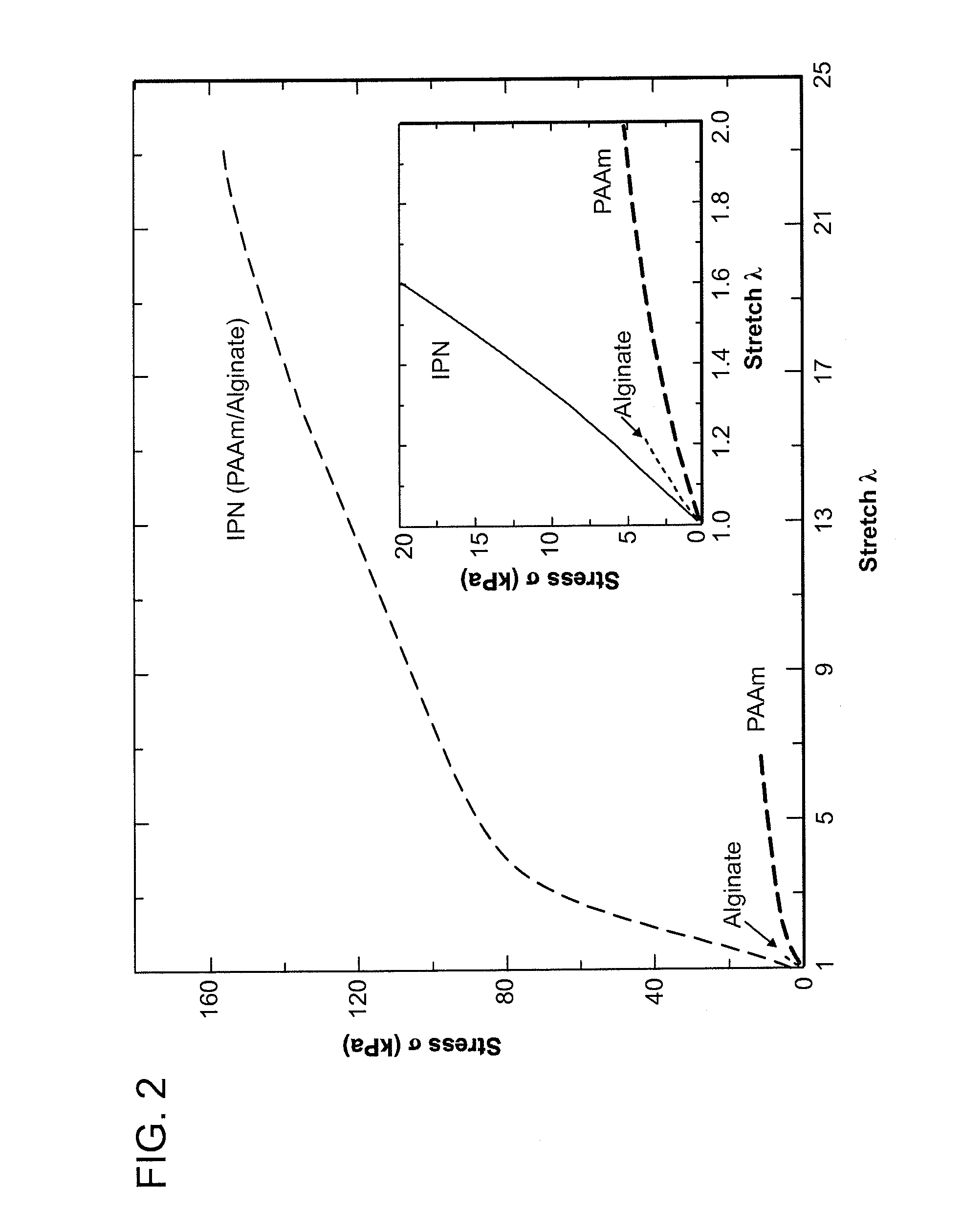

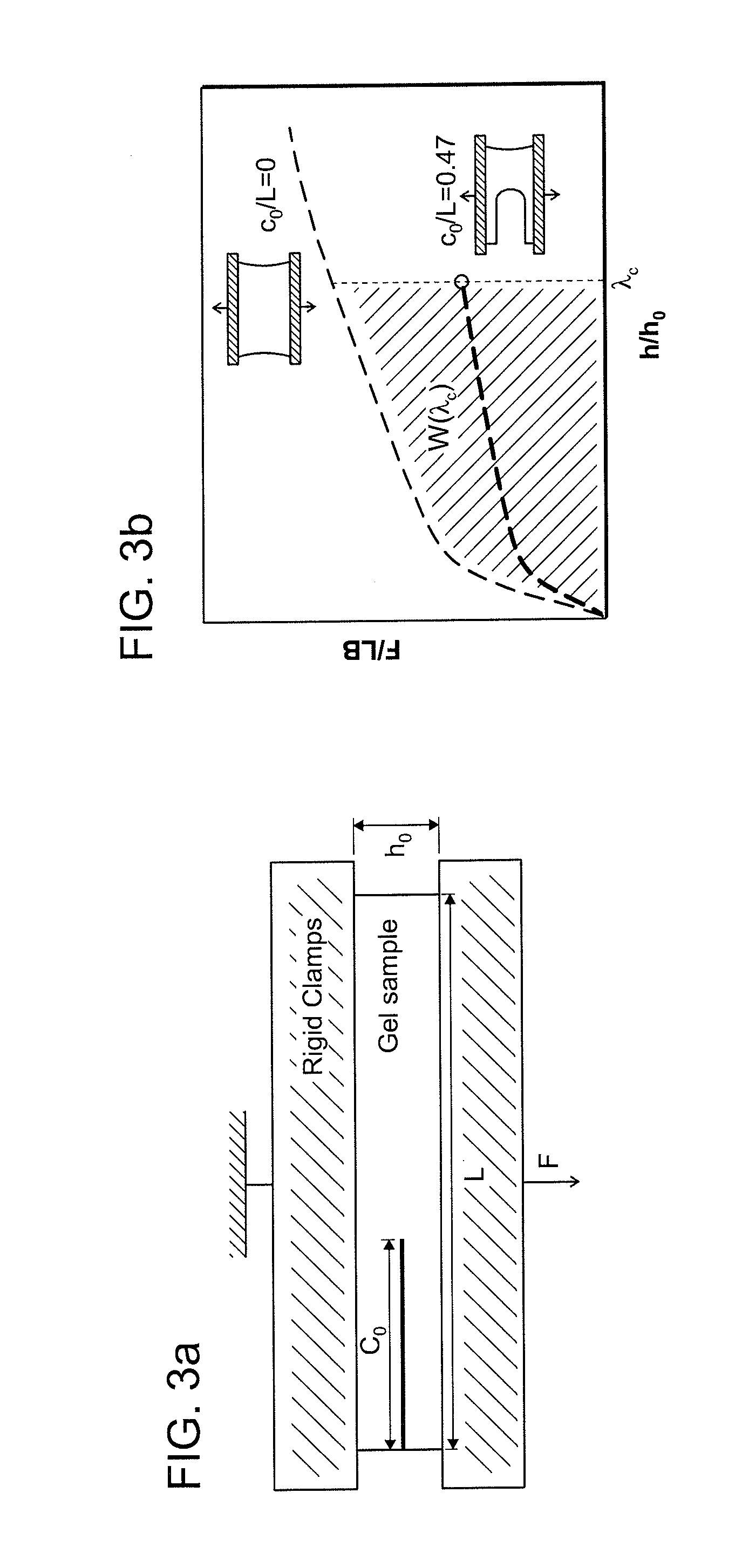

ActiveUS20150038613A1Stay resilientImprove mechanical propertiesSurgical adhesivesProsthesisSelf-healingEngineering

The invention features a composition comprising a self-healing interpenetrating network hydrogel comprising a first network and a second network. The first network comprises covalent crosslinks and the second network comprises ionic or physical crosslinks. For example, the first network comprises a polyacrylamide polymer and second network comprises an alginate polymer.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE +1

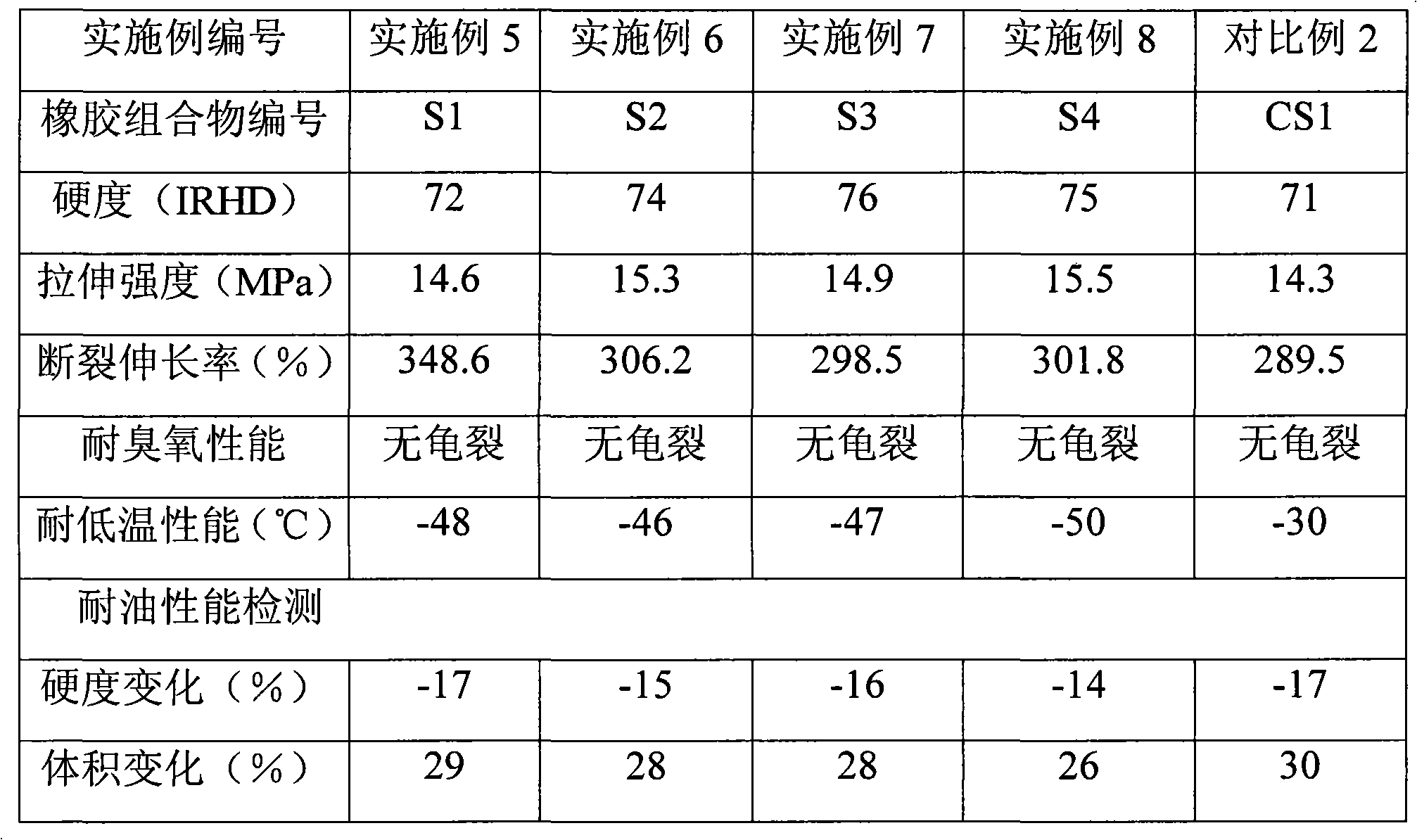

Oil resistant low temperature resistant rubber composition

InactiveCN101353451AGuaranteed oil resistanceGuaranteed ozone resistancePolymer scienceNitrile rubber

The invention relates to a rubber composite, comprising nitrile rubber, polyvinyl chloride, carbon soot, activator, vulcanizator, age inhibitor, antiscorcher, accelerant and plasticizer, wherein, the plasticizer is ethylhexyl sebacate and adipate. The rubber composite of the invention obviously improves the anti-low temperature performance of the rubber composite while ensuring the anti-oil performance, anti-ozone performance, tensile strength and elongation at break.

Owner:BYD CO LTD

Method for preparing aminosilane coupling agent modifying ammonium polyphosphate

InactiveCN101235221AHigh flame retardant efficiencyReduce solubilityFireproof paintsFibre treatmentSolubilityPolyolefin

The invention discloses a preparation process of modifying ammonium polyphosphate with amino silane coupling agent, relating to the flame-retardant technology in chemical field. The invention provides a surface organic modified technology which can significantly reduce the water-solubility of ammonium polyphosphate, increases the compatibility of ammonium polyphosphate expansion flame-proof macromolecule material and the flame-proof efficiency, aiming to the problems existing the current ammonium polyphosphate flame-retardant that the current ammonium polyphosphate flame-retardant has higher dissolvability in water, and serious mechanical loss after applied on flame-proof plastic. The invention is conducted through two steps that firstly mixing amino silane coupling agent with deionized water according to weight ratio to hydrolyze, and secondly conducting surface organic modifying processing for ammonium polyphosphate (II type) with hydrolyzed amino silane coupling agent, which makes the dissolvability of II type ammonium polyphosphate in water be reduced to 0.43g / 100mL H2O from 1.101g / 100mL H2O, and respectively increases elongation at break and tension strength by 39.4% and 8.0% through applying modified ammonium polyphosphate on expansion flame-proof polypropylene. The modified ammonium polyphosphate can be extensively applied on the expansion flame-proof of polyolefins plastic, textile, lumber, paper and painting.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

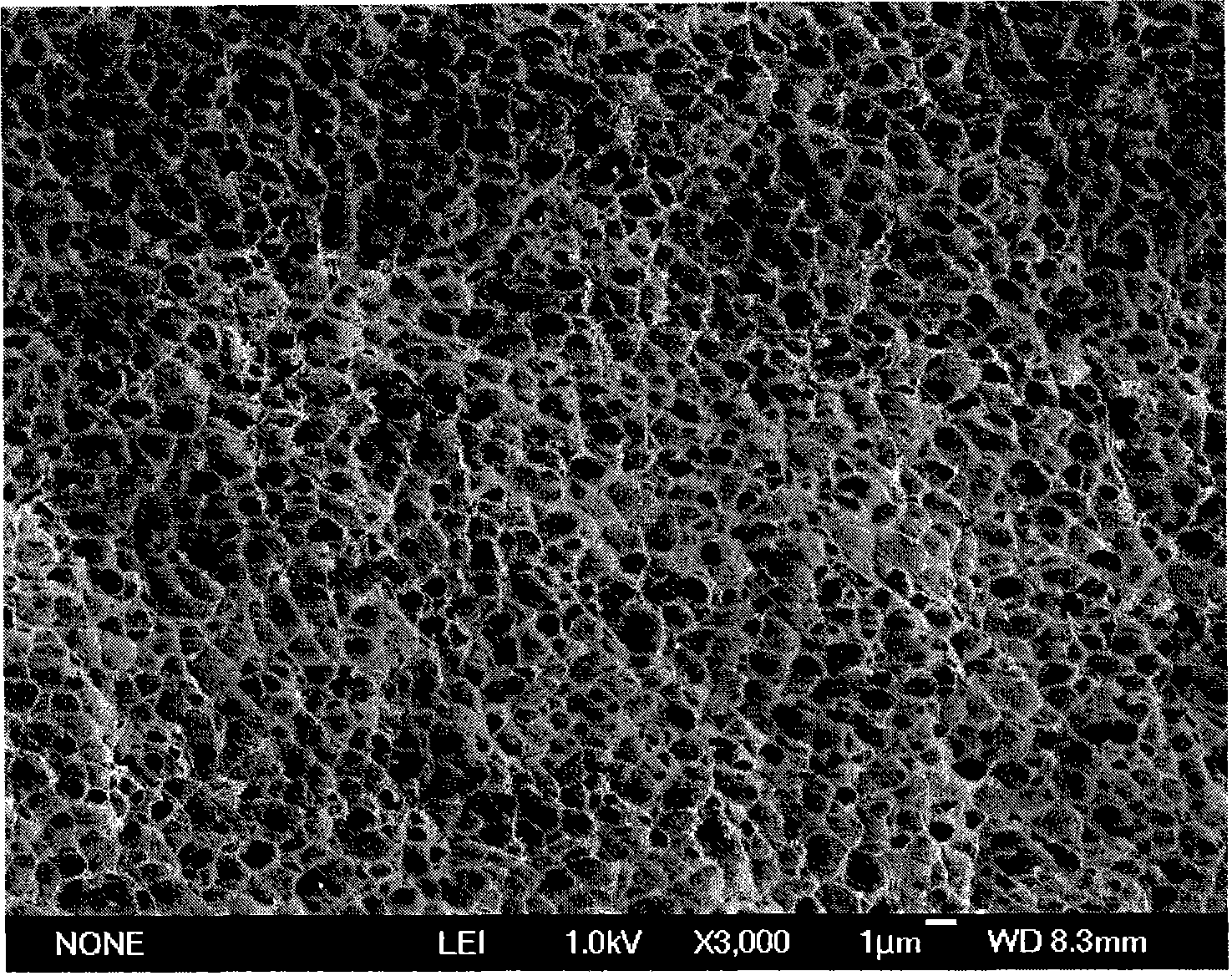

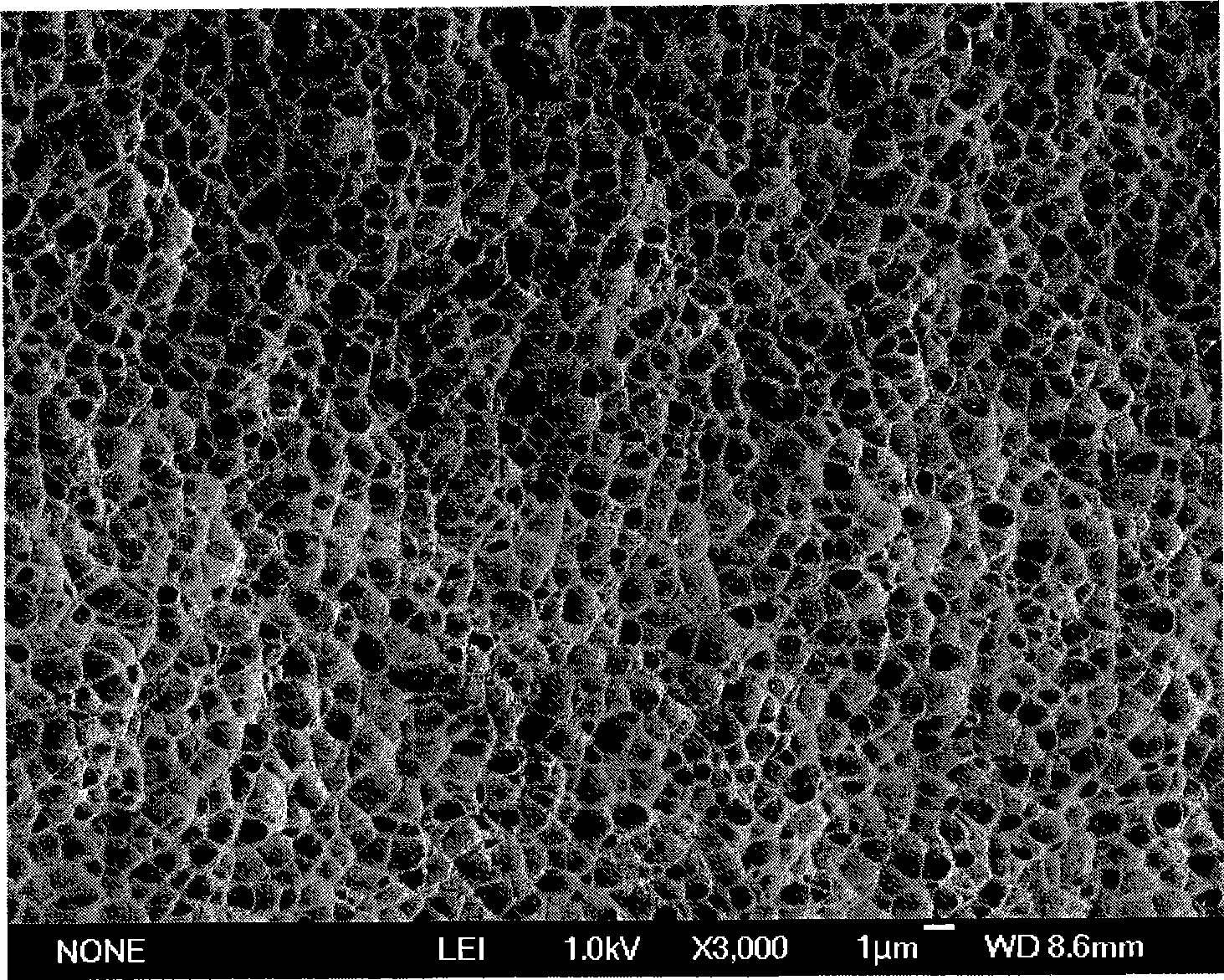

Method for preparing polyvinylidene fluoride porous membrane

ActiveCN101362057AGuaranteed StrengthGuaranteed high water fluxSemi-permeable membranesMembranesHollow fibreFiber

Owner:TSINGHUA UNIV

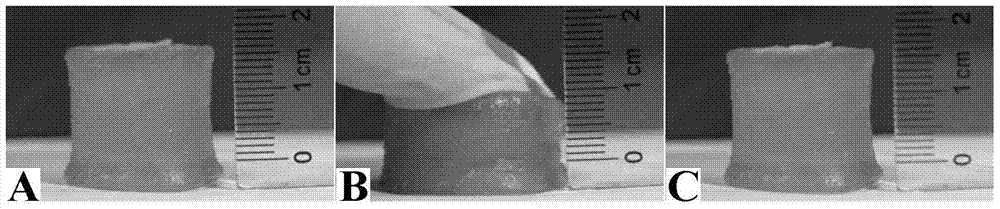

High-strength chemical-physical dual-network hydrogel with self-recovery capability, and preparation method and application of hydrogel

The invention discloses high-strength chemical-physical dual-network hydrogel with self-recovery capability, and a preparation method and application of the hydrogel. The high-strength chemical-physical dual-network hydrogel with the self-recovery capability is prepared from a first chemical network formed by the polymerization of hydrophilic monomers or by enabling hydrophilic macromolecules to be mixed and have a reaction, and a second physical network formed by carrying out physical crosslinking on polysaccharide and derivatives thereof, wherein the first chemical network and the second physical network are arranged in a way of being interspersed with each other. The dual-network hydrogel has high compressive strength and tensile strength, high toughness as well as good self-recovery property and fatigue resistance, and can maintain higher tensile strength and breakage elongation under the condition of having a notch. The prepared hydrogel has good mechanical property and biocompatibility, can be widely applied to the field of biological medicine, and can be used as a surface coating of a scaffold for tissue engineering, medical sponge or a medical implant.

Owner:INST OF CHEM CHINESE ACAD OF SCI

High-polymer modified pitch, its water-proof roll material and use thereof

ActiveCN101070434AImprove standardsHigh standard waterproof functionOther chemical processesRoof covering using flexible materialsPolymer modifiedCrack resistance

The invention provides a polymer modified asphalt, and the weight of the components comprising as follows :45-55% matrix asphalt, 4 - 8% blend oil, 12 - 14% of SBS ,5-9 % APAO, 2-7% of High-temperature improvement and 15-20% filler. It also offers polymer modified asphalt, which made of waterproof membrane and the railway bridge, highway bridge deck waterproofing project applications. The invention of these waterproofing membrane have a high standard of waterproof function, it can withstand high intensity of railway bridge and particularly high stress dynamic load .It also have excellent performance on water-resistance, high and low temperature resistance, adhesion, crack resistance, fatigue resistance and other aspects .it can be used for railway bridge and the road deck waterproofing works.

Owner:JINZHOU DONGFANG YUHONG BUILDING MATERIALS +1

Spray polyurea high-performance waterproof paint and preparation method thereof

InactiveCN101818019AFast curingHigh strengthPolyurea/polyurethane coatingsDiluentUltimate tensile strength

The invention relates to a spray polyurea high-performance waterproof paint which is characterized by comprising component A and component B, wherein the component A comprises semi-prepolymer formed by the reaction between 70-35 parts of polyisocyanate and 30-50 parts of polyether glycol, and 0-15 parts of diluent based on parts by weight; the component B comprises 50-70 parts of amine-terminated polyether, 20-40 parts of amine chain extender and 5-10 parts of filler; and the volume ratio between the component A and the component B is 1:1. Compared with the common spray polyurea high-performance waterproof paint, the spray polyurea high-performance waterproof paint has higher tensile strength, elongation at break, tearing strength and other physical properties, and not only is applicable to waterproof projects of common building projects, basic facilities and the like, but also is especially suitable for high-difficulty waterproof projects of large basic facility construction such as a high speed railway, a subway, a tunnel, water conservancy project and the like.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

Polylactic acid foaming material and preparation method thereof

The invention provides a polylactic acid foaming material and a preparation method thereof. The polylactic acid foaming material is prepared from the following ingredients according to parts by weight: 45-93 parts of polylactic acid, 5-28 parts of toughener, 1-5 parts of nucleating agent and 1-10 parts of foaming agent. The polylactic acid is one of poly-L-lactic acid, poly-D-lactic acid and poly-DL-lactic acid or a mixture or a polymer thereof, and has the weight average molar mass of 0.8-3.5 million, molecular weight distribution of 1.2-2.5, and degree of crystallinity of 15-60 percent. The toughener is one of poly succinic acid butyl ester and poly adipate / butylene terephthalate or a mixture of two with random ratio. Other accessory ingredients can also be added. The preparation method comprises the following steps: evenly mixing the polylactic acid, the toughener, the nucleating agent, the foaming agent, the accessory ingredients and the like in a high mixing machine according to a certain proportion, then milling for 5-25 minutes at the temperature of 100-170 DEG C, and carrying out die pressing foaming on obtained materials at the temperature of 120-210 DEG C on a vulcanizing machine for 2-10 minutes to prepare the polylactic acid foaming material. The polylactic acid foaming material prepared by using the preparation method has the advantages of high resistance to shock, high elongation at break, high tensile strength and complete biodegradation after used.

Owner:南京冠创生物科技有限公司

Stereolithographic resins with high temperature and high impact resistance

InactiveUS6989225B2High modulusHigh elongation at breakAdditive manufacturing apparatusImpression capsMeth-Cationic polymerization

A liquid radiation-curable composition that comprises(A) at least one polymerizing organic substance comprising a mixture of(1) at least one alicyclic epoxide having at least two epoxy groups; and(2) at least one difunctional or higher functional glycidylether of a polyhydric compound;(B) at least one free-radical polymerizing organic substance comprising a mixture of(1) optionally, at least one trifunctional or higher functional (meth)acrylate compound; and(2) at least one aromatic di(meth)acrylate compound;(C) at least one cationic polymerization initiator;(D) at least one free-radical polymerization initiator;(E) optionally, at least one hydroxyl-functional aliphatic compound; and(F) at least one hydroxyl-functional aromatic compound;wherein the concentration of hydroxyl groups in the radiation-curable composition is at least about 1.1 equivalent OH groups per kilogram;wherein the concentration of epoxy groups in the radiation-curable composition is at least about 5.5 equivalent epoxy groups per kilogram; andwherein the amount of trifunctional or higher functional (meth)acrylate compound (B)(1) is from 0% to about 3% of the composition and the amount of aromatic di(meth)acrylate compound (B)(2) is at least 10% of the composition.

Owner:3D SYST INC

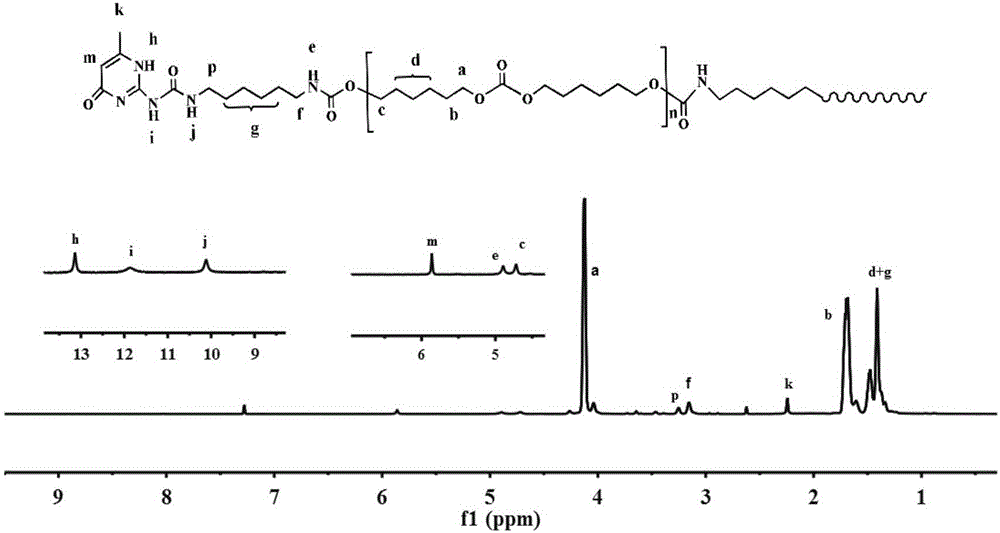

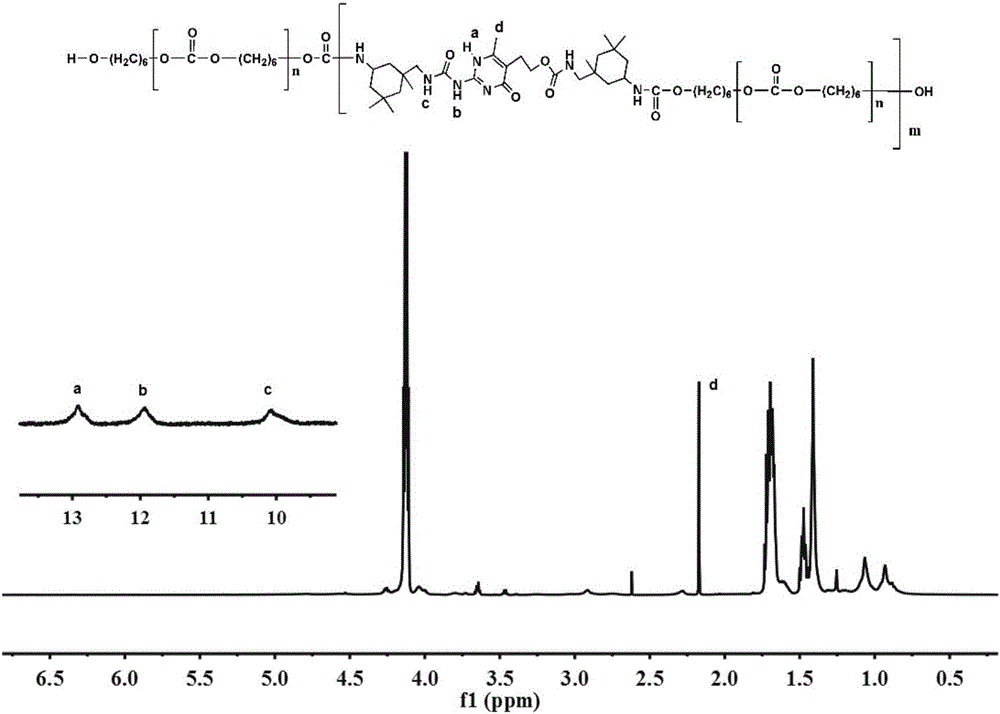

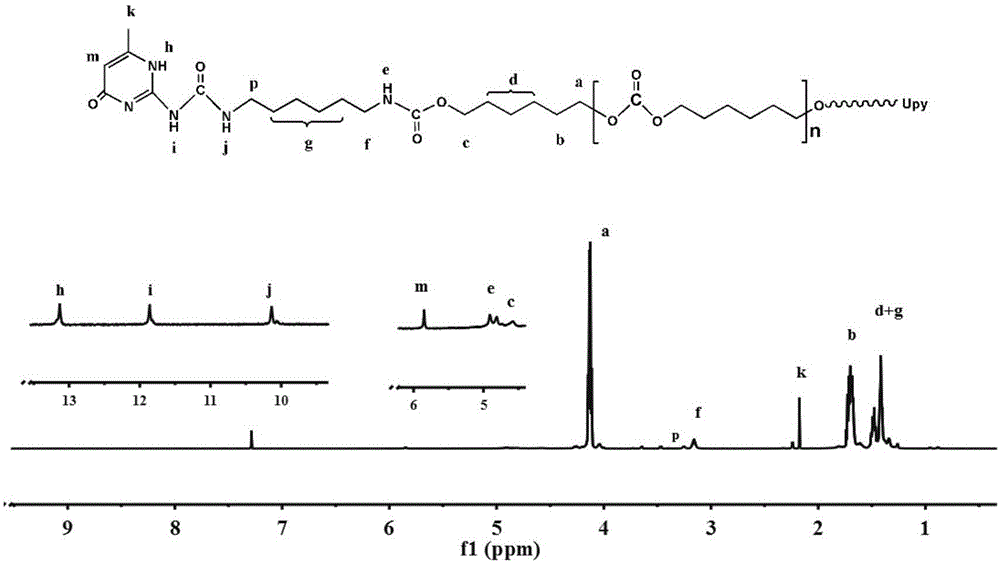

Preparing method of thermally-driven self-repairing elastomer based on hydrogen-bond interaction

The invention provides a preparing method of thermally-driven self-repairing elastomer based on hydrogen-bond interaction. The method comprises the steps that firstly, ureido pyrimidone type mono-isocyanate molecules are prepared, then diisocyanate is used for carrying out chain extension on low polymer glycol to prepare a hydroxyl-terminated polyurethane low polymer, and finally, Upy-terminated type thermally-driven self-repairing elastomer is prepared by terminating the hydroxyl-terminated polyurethane low polymer with UPY-NCO; secondly, ureido pyrimidone type diisocyanate is prepared, then ureido pyrimidone type diisocyanate and the low polymer glycol are subjected to addition polymerization, and the hydrogen bond network type thermally-driven self-repairing elastomer with Upy units in a main chain controllable is prepared. Compared with a traditional foreign-aid type self-preparing material (a micro capsule type, a micro vessel type and the like), the thermally-driven self-repairing material is a thermoplastic material and can be repeatedly processed and used, and theoretically multi-time repairing capability can be achieved at the same position.

Owner:SOUTH CHINA UNIV OF TECH

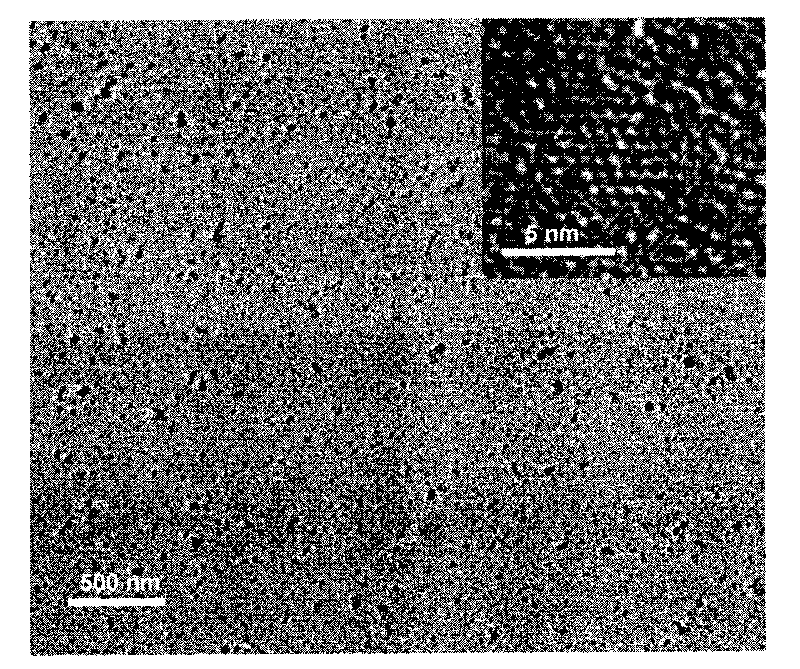

High-performance quantum dot-polymer fluorescent nano composite material and preparation method thereof

InactiveCN101759946AImprove luminous performanceImprove mechanical propertiesLuminescent compositionsMolten stateFluorescence

The invention discloses a high-performance quantum dot-polymer fluorescent nano composite material and a preparation method thereof. The high-performance quantum dot-polymer fluorescent nano composite material comprises polymer and quantum dot which has fluorescent property and is hybridized by silicon dioxide. The method comprises the following steps of: firstly, dissolving 1g of polymer by using a solvent or heating 1g of polymer into a molten state, then adding 0.0002-0.08g of quantum dot which has the particle diameter of 5-30 nanometers, is not modified or is modified by using silane coupling agent and is hybridized by the silicon dioxide and removing the solvent or cooling naturally after stirring for 2min-24hr to obtain the quantum dot-polymer nano composite material. The nano composite material has very strong photoinduced fluorescent property, and the mechanical property of the nano composite material is also enhanced greatly in comparison with that of a corresponding straight polymer. The high-performance quantum dot-polymer fluorescent nano composite material has simple preparation and is suitable for mass production. The invention has very good application prospect in the aspects of preparing an optical device and an optical material, replacing a traditional polymer material and the like.

Owner:ZHEJIANG UNIV

Preparation method of polylactic acid/nano-cellulose composite material

The invention provides a preparation method of a polylactic acid / nano cellulose composite material. The composite material comprises the following components in percentage by weight: 55 to 99.8% of polylactic acid, 0.1 to 15% of nano cellulose, and 0.1 to 30% of polyethylene glycol. The method comprises the following steps of: preparing a 5 to 15% an aqueous solution of microcrystalline cellulose, dripping concentrated sulfuric acid until the concentration of sulfuric acid reaches 40 to 60%, stirring and reacting for 1 to 2hours, carrying out centrifugation, ultrasound treatment and adjusting pH value to be neutral to obtain a nano cellulose suspension; dissolving polyethylene glycol, mixing with the nano cellulose suspension, stirring for 1 to 3hours at the temperature of 90 DEG C and carrying out vacuum drying to obtain a polyethylene glycol / nano cellulose comixture; and carrying out melt blending on the polyethylene glycol / nano cellulose comixture and polylactic acid for 5 to 8minutes at the temperature of 120 to 170 DEG C to obtain the composite material. The method is convenient and simple to operate, short in the time of the preparation process and solves the problem of uniform dispersion of nano-cellulose in the polylactic acid.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

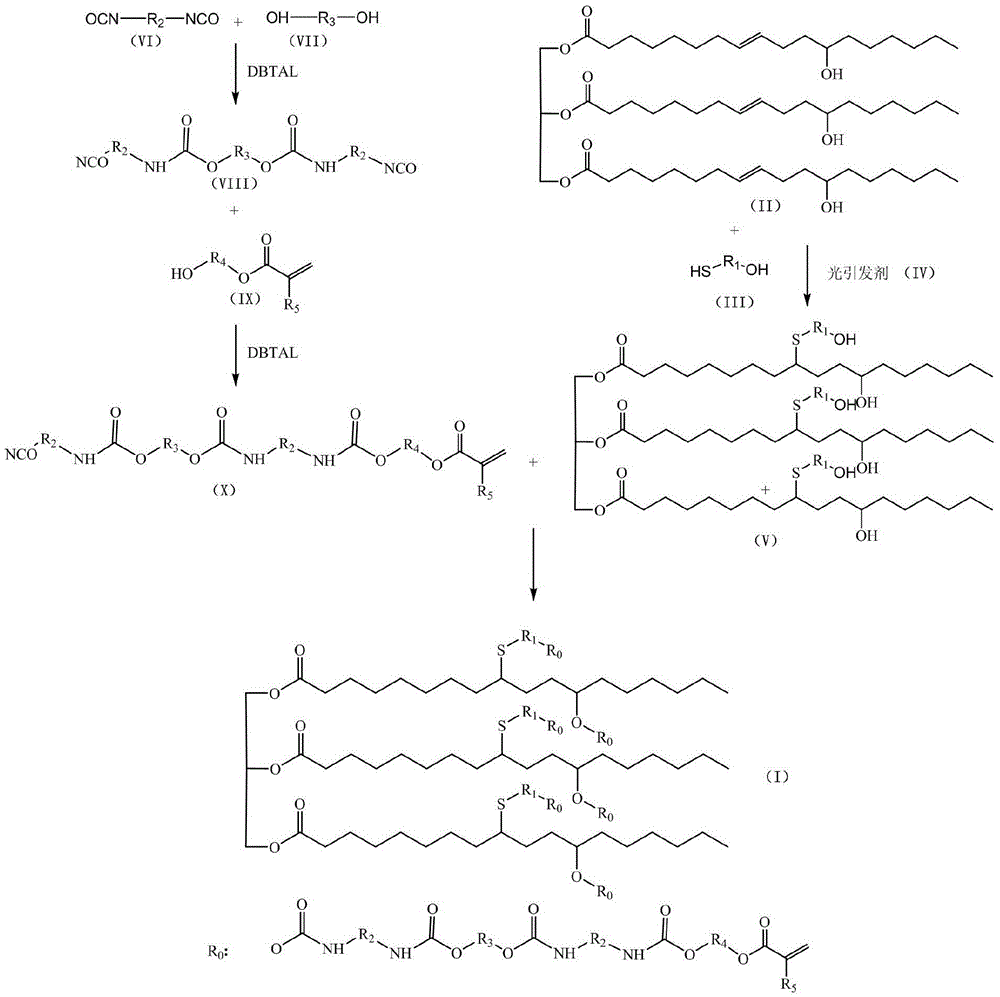

Castor oil-based polyurethane acrylate and preparation method as well as application thereof

ActiveCN105601880ALight curing speed is fastHigh tensile strengthPolyureas/polyurethane adhesivesInksCross-linkMethacrylate

The invention discloses castor oil-based polyurethane acrylate and a preparation method as well as application thereof. The castor oil-based polyurethane acrylate is hexa-functional or octa-functional castor oil-based polyurethane (methyl) acrylate resin. An acrylate radical comprises a methacrylate radical and an acrylate radical, and is suitable for carrying out free radical polymerization. Under the action of a photoinitiator, the resin is irradiated by ultraviolet light and can generate cross linking at a higher speed. A film formation product of the castor oil-based polyurethane acrylate has excellent flexibility and adhesive force; the hardness and the glossiness of a cured film are obviously improved; the castor oil-based polyurethane acrylate can be used as a formula ingredient of a photo-cured coating material, ink, and an adhesive.

Owner:广州纽楷美新材料科技有限公司

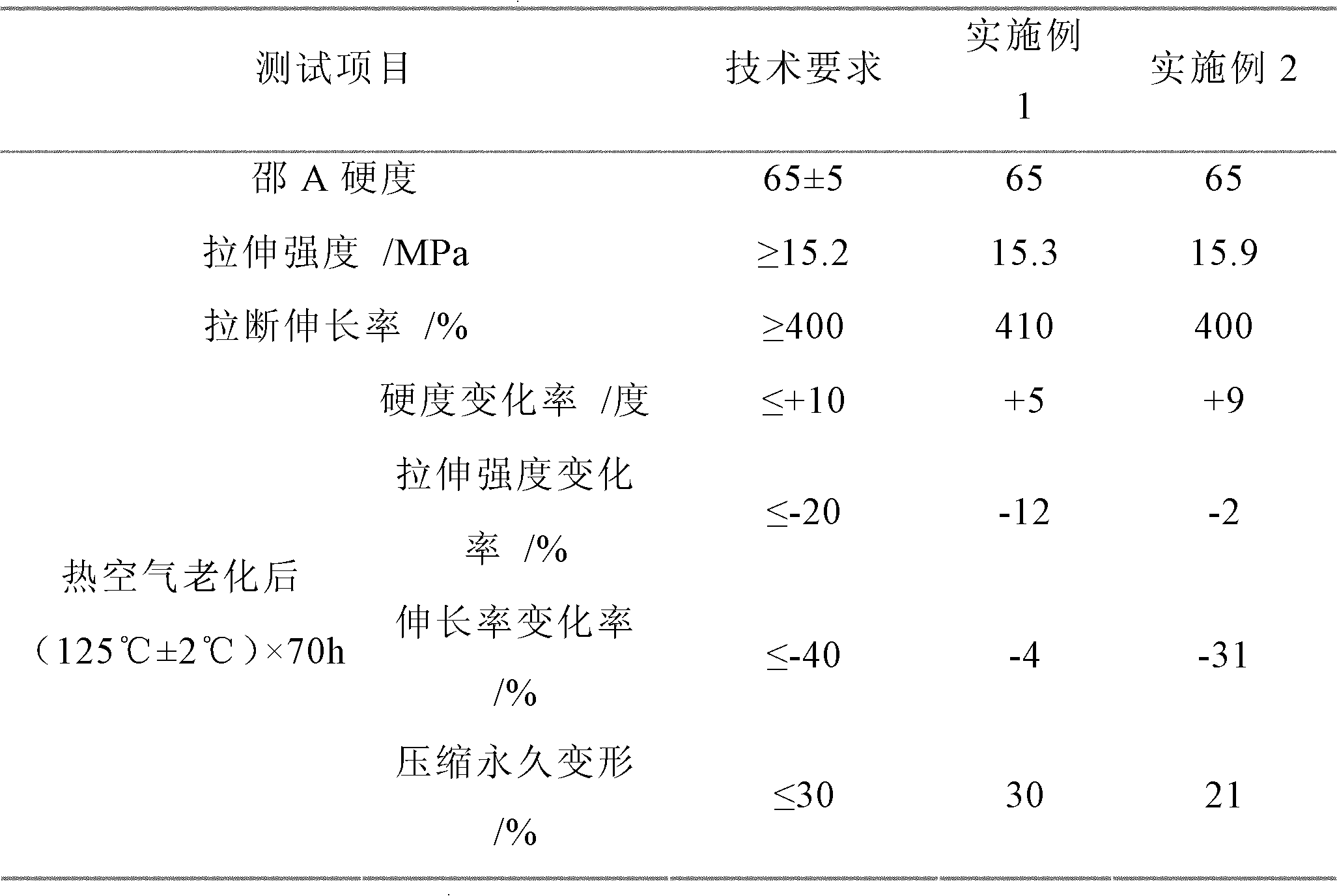

Ethylene propylene diene rubber composition and preparation method

The invention discloses an ethylene propylene diene rubber composition and a preparation method. The preparation method comprises the following steps of: firstly, performing after plastication on ethylene propylene diene rubber; then, adding zinc oxide, stearic acid, anti-aging agent, carbon black, plasticizers, accelerant, vulcanizer and the like in sequence; evenly mixing and then extruding a sheet; and preparing the sheet into the ethylene propylene diene rubber / carbon black nanometer composite material by adopting the after vulcanization process. Through adding various plasticizers and adopting special process treatment, the tensile strength of the ethylene propylene diene rubber composition disclosed by the invention is at least 15.2MPa, the elongation at break is at least 400 percent, and the compression set is lower than 30 percent under the condition of 125 DEG C*70h. The composite material can be used as a sealing article of rubber, especially a rubber sealing washer applied to a groove-type pipeline joint part of an automatic water spray fire extinguishing system, and thereby, a long-term sealing effect is ensured.

Owner:BEIJING RES & DESIGN INST OF RUBBER IND

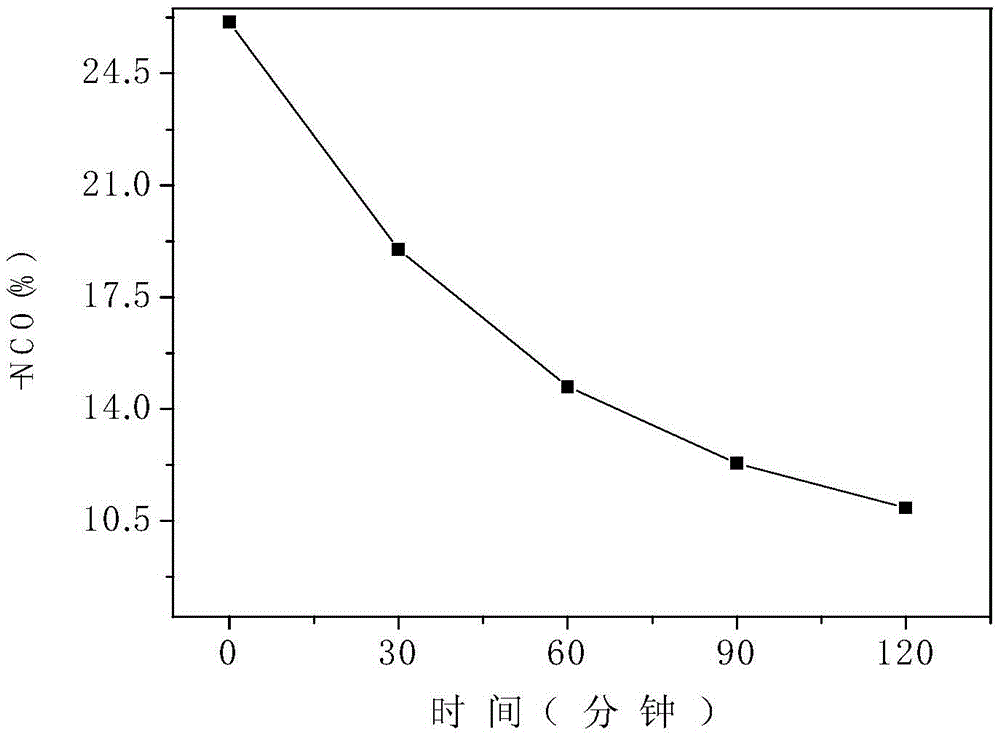

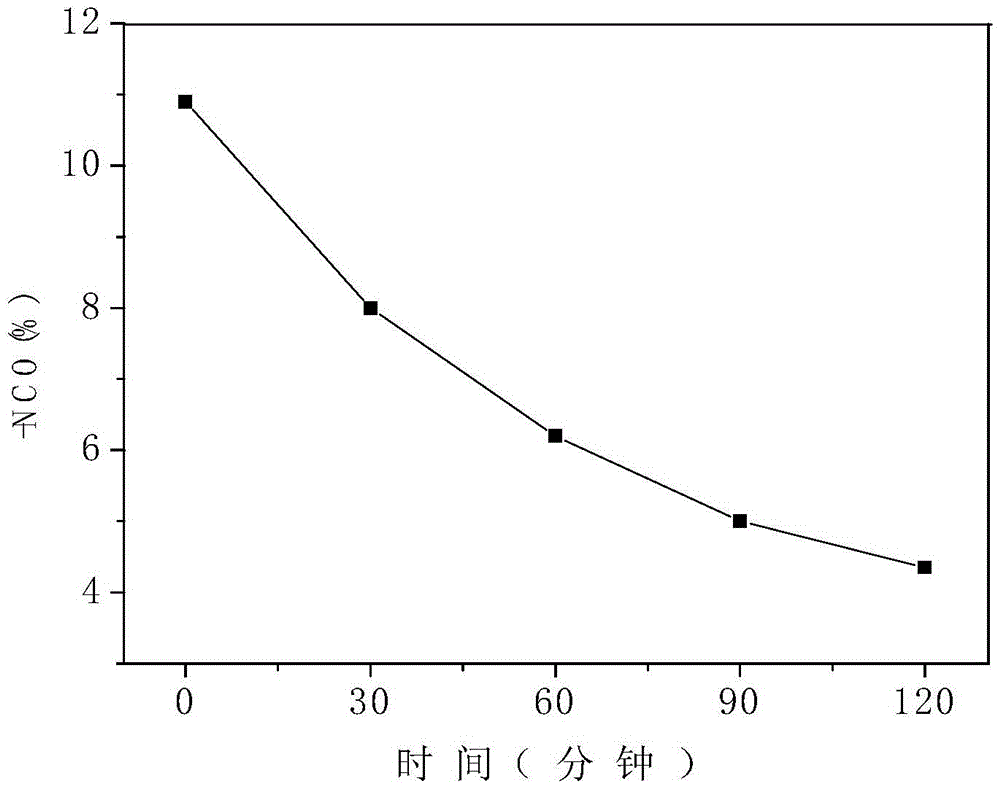

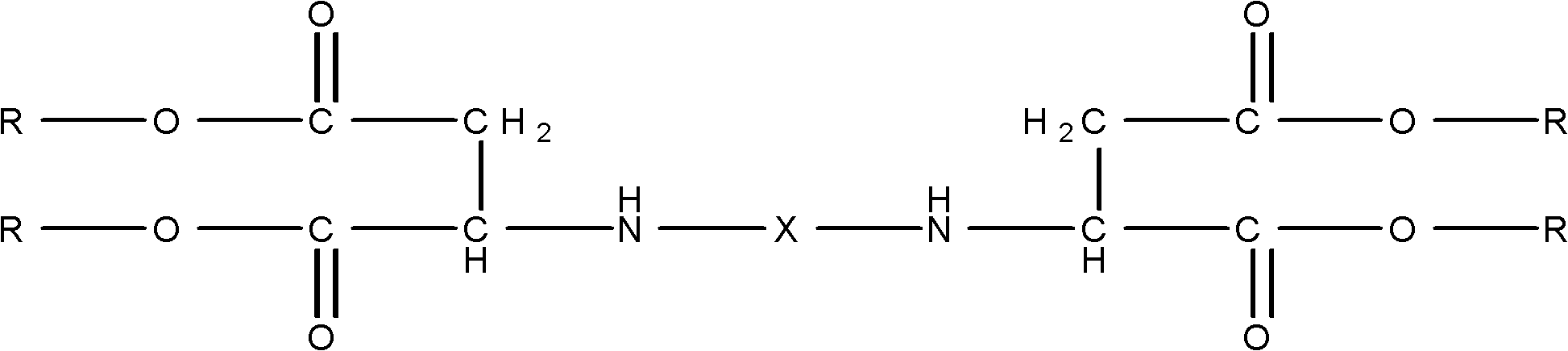

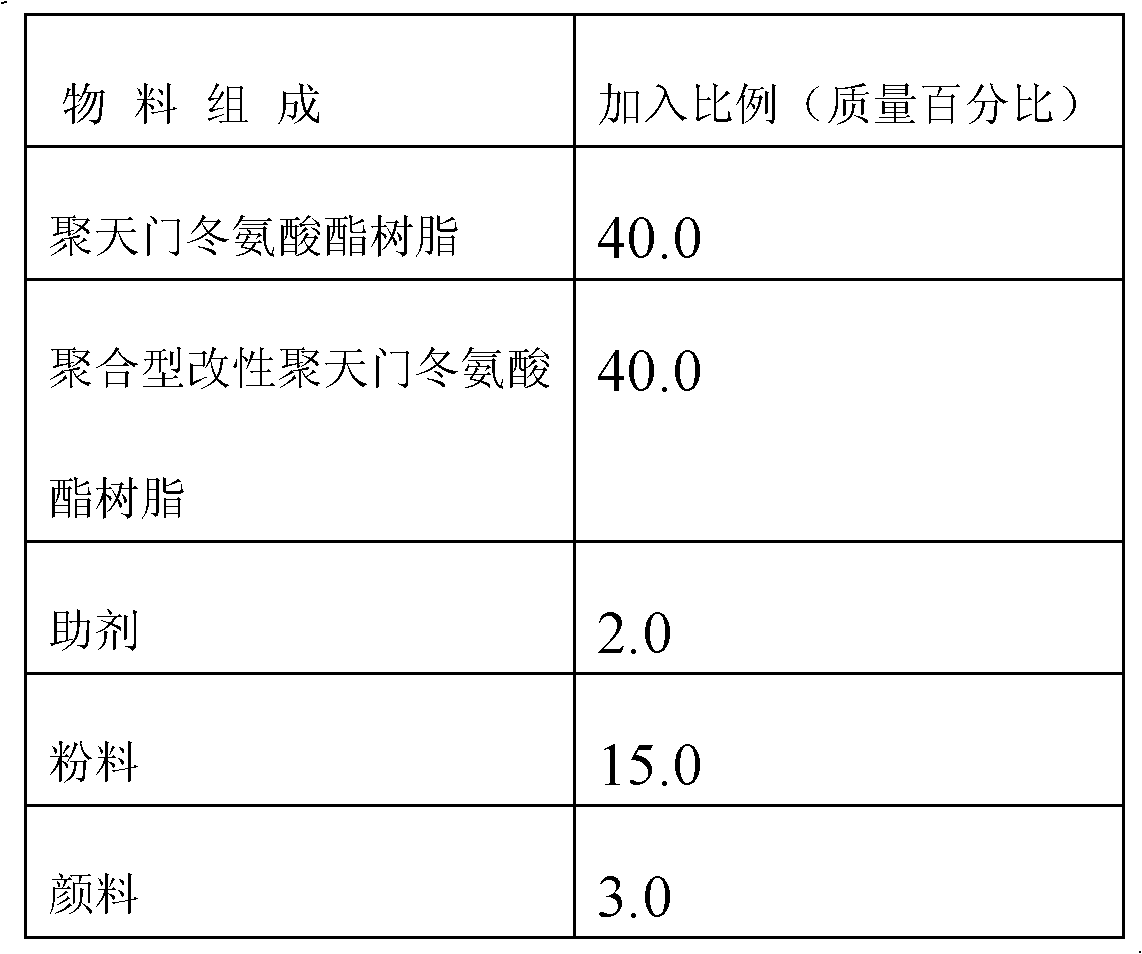

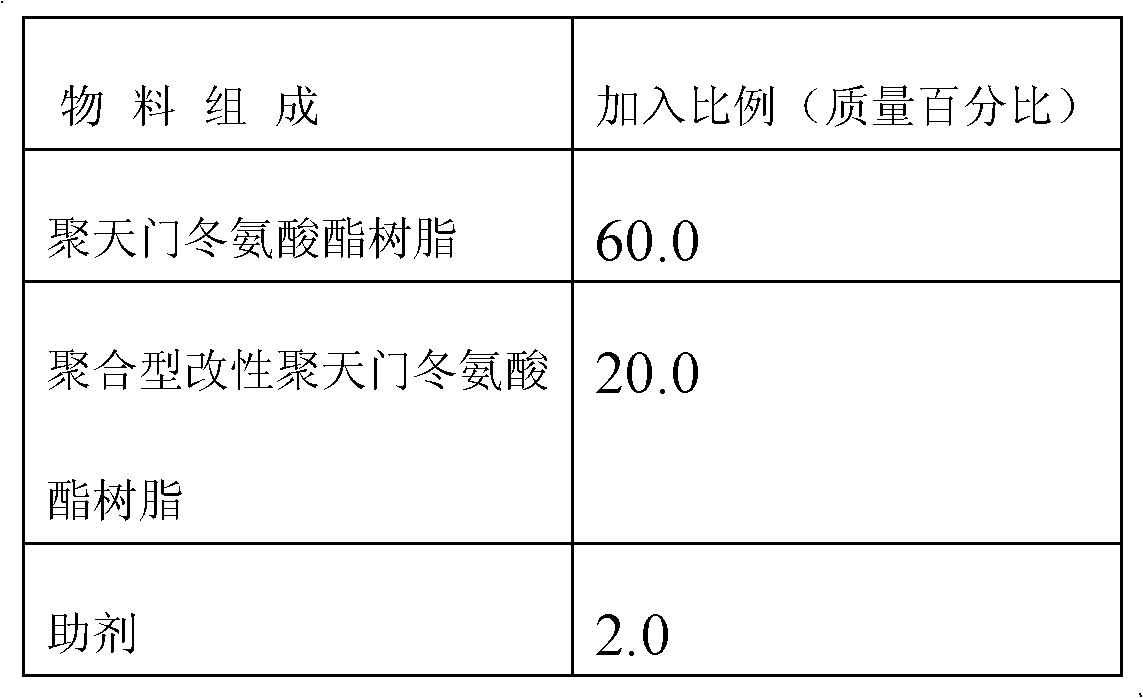

Solvent-free polyaspartic acid ester polyurea elastic waterproof paint

ActiveCN103031045AGood elongation at breakEasy constructionPolyurea/polyurethane coatingsSolventIsocyanate

The invention relates to paint and a preparation method thereof and discloses solvent-free polyaspartic acid ester polyurea elastic waterproof paint. The solvent-free polyaspartic acid ester polyurea elastic waterproof paint is composed of a component A and a component, wherein the component A comprises 2%-35% of polyisocyanate and 65%-98% of end seal isocyanate prepolymer by weight percent; and the component B comprises 20%-60% of polyaspartic acid ester, 10%-40% of polymeric modified poly aspartic acid ester, 5%-30% of stuffing and a small amount of additives by weight percent. Compared with the polyurea paint processed by the polyaspartic acid ester, the solvent-free polyaspartic acid ester polyurea elastic waterproof paint processed by raw materials has the advantages that the construction is convenient, a special large-scale spraying device is not needed, the gelation time is prolonged, the surface drying time is shortened, the tensile strength is enhanced, the elongation at break is increased, and the elastic coating film hardness is increased, does not have a solvent, is environment-friendly and harmless to a human body.

Owner:SHENZHEN FEIYANG JUNYAN TECH DEV

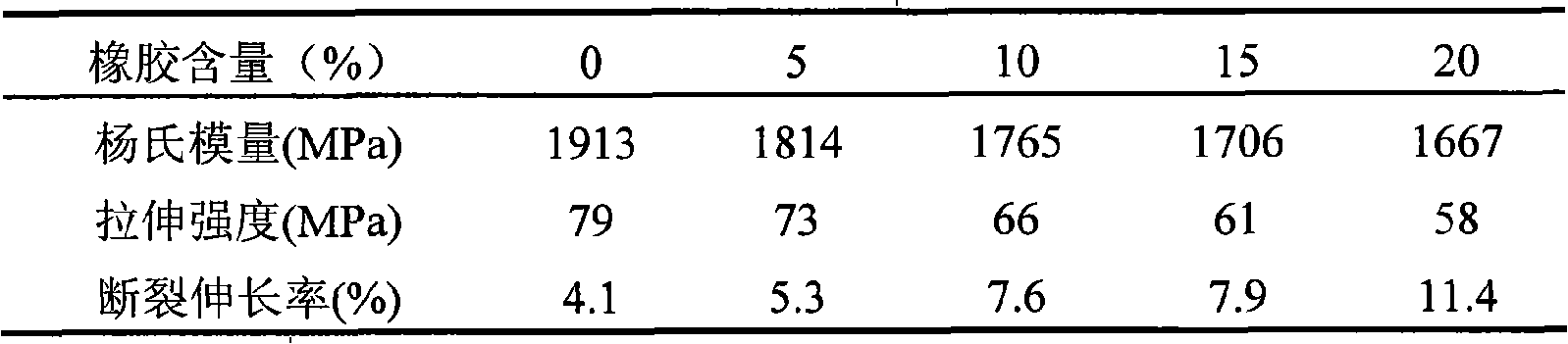

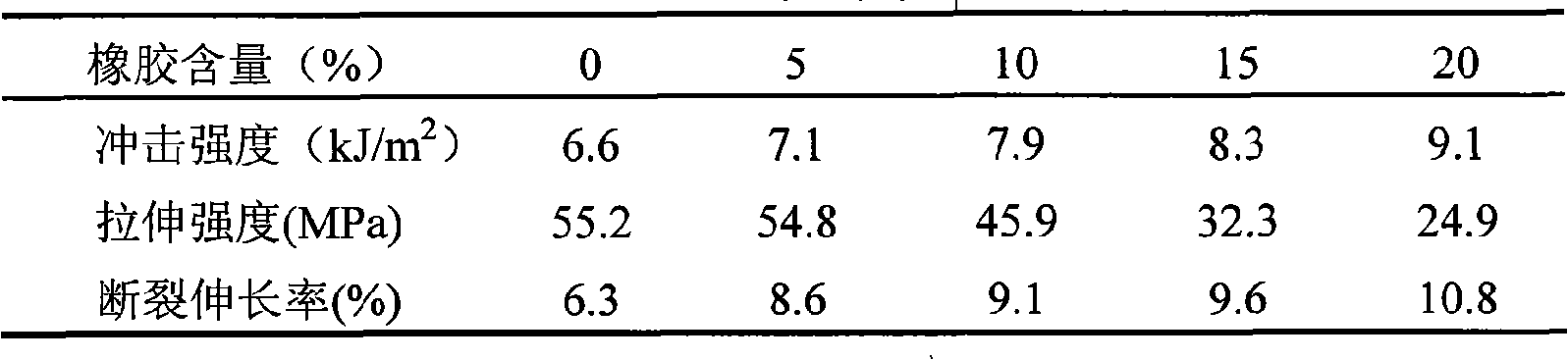

Method for preparing reactive fluid rubber-epoxide resin polymer

The invention provides a method for preparing reactive fluid rubber-epoxide resin polymer, and belongs to the technical field of modified epoxide resin. The method comprises the following steps: 5 to 50 portions of reactive fluid rubber containing carboxyl or hydroxyl as a modifier, and 0.1 to 2.0 portions of catalyst are added into 100 to 200 portions of epoxide resin by weight; when the reactive fluid rubber containing the hydroxyl is used as the modifier, isocyanate or estolide with the same weight portion as the epoxide resin is required to be added; and an active group in the reactive fluid rubber reacts with an epoxide group in the epoxide resin for 2 to 6 hours at a temperature of between 100 and 180 DEG C to prepare the reactive fluid rubber-epoxide resin polymer with excellent toughness. The modified epoxide resin has improved toughness, non organic solvent is used in the whole synthesizing process, non environmental pollution is caused, the synthesizing process is simple and easily controlled, and the problem is not found in amplification experiments carried out for small amount, medium amount and large amount respectively, so that the method is applicable to industrial production.

Owner:JIANGNAN UNIV

Emulsified acrylic acid modified asphalt cement group waterproof coating material and method for producing the same

InactiveCN101220233AGood alkali resistanceAvoid demulsificationAntifouling/underwater paintsPaints with biocidesEmulsionAsphalt

The invention relates to an acrylic acid modified asphalt cement-based and water-proof coating and a preparation method. The emulsified acrylic acid modified asphalt cement-based and water-proof coating consists of component A and component B; wherein, the mixture ratio of the component A to the component B is from 1 : 0.5 to 1.5 (in weight); wherein, the raw materials of component A and the weight percentage thereof are respectively as follows: acrylic emulsion or amphetamine emulsion accounting for 40 to 70 percent, emulsified asphalt accounting for 10 to 50 percent, filler accounting for 8 to 20 percent, accessory ingredient accounting for 0.1 to 3 percent and water accounting for 1 to 19.0 percent; the raw materials of component B and the weight percentage thereof are as follows respectively: cement accounting for 70 to 100 percent and filler accounting for 0 to 30 percent. The acrylic acid modified asphalt cement-based and water-proof coating has the advantages of strong binding power with the base, high tensile strength, large unit extension, low cost and environment protection.

Owner:WUHAN YANGGUANG CONSTR NEW MATERIAL

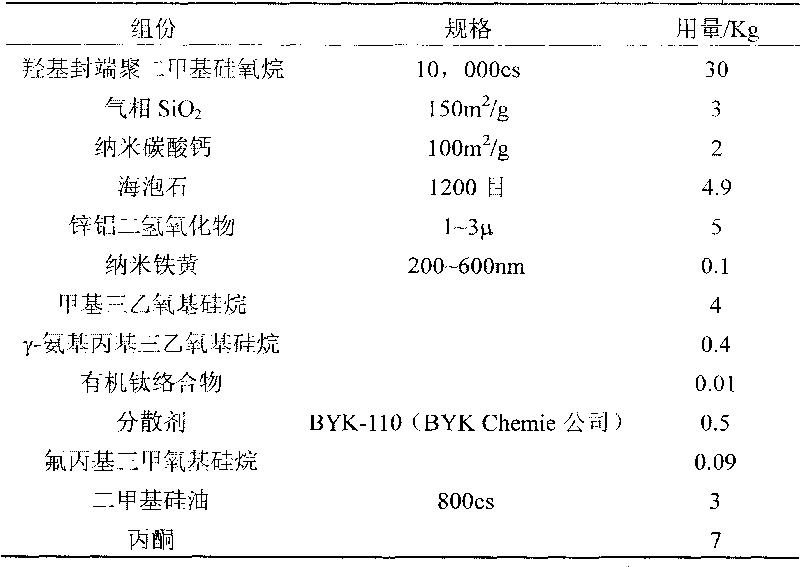

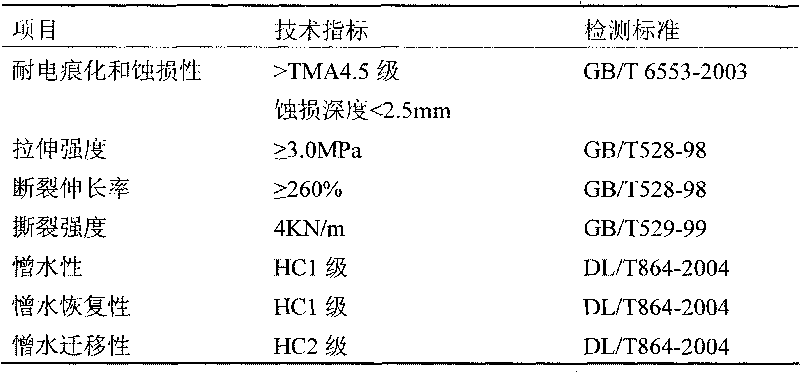

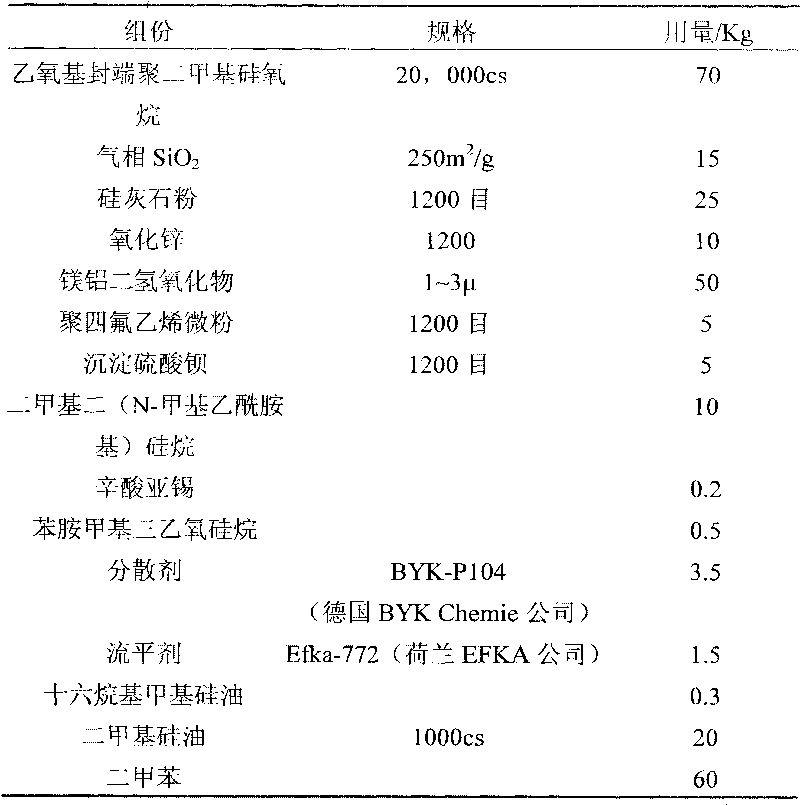

Tracking-proof corrosion-proof room temperature silicon disulfide rubber composite

ActiveCN101747630AHigh tensile strengthHigh elongation at breakPlastic/resin/waxes insulatorsCoatingsRoom temperatureDiluent

The invention relates to a tracking-proof corrosion-proof room temperature silicon disulfide rubber composite which has the following formula: 30-70 parts of polysiloxane by weight, 5-40 parts of reinforced filler by weight, 10-70 parts of electric corrosion resistance stabilizer by weight, 5-15 parts of auxiliary agent by weight and 10-80 parts of diluent by weight. The tracking-proof corrosion-proof room temperature silicon disulfide rubber composite provided by the invention has favourable tracking-proof corrosion-proof performance, has higher tensile strength, breaking elongation and tearing strength as well as favourable surface hydrophobicity, hydrophobicity transference and hydrophobicity restoration and is a functional composite capable of effectively preventing and curing pollution flashover.

Owner:CHINA ELECTRIC POWER RES INST +3

Method for preparing sofa leather with strong wear resistant property and flame retardant property

A high-wearing and fire-retardancy sofa leather is made by 1) wet condensing coating, molding in condensing groove, washing in water groove, drying and shaping and finally cooling and winding to become semi product wet process Bayes; 2) back spread coating with the semi product going through drawoff roller extraction shaping, dressing and spread coating, drying and baking and becoming fire-retardancy Bayes after cooling and winding; 3)nonaqueous shifting surface making, namely, separate paper shifting overlay; 4) kneading after treatment with pre-soaking of semi product sofa, squeezing out partial liquid, kneading and drying and finally batching on checking and final product packing. Apart from the major features of anti-friction and anti-retardancy, it can keep fine physical and mechanical performance and cosmetic styles with good quality and durable service.

Owner:HAININ JINDA COATING

Modified silicone rubber cable material with high flame retardance and high wear resistance

InactiveCN104403318AGood flame retardancyImprove wear resistanceRubber insulatorsPlastic/resin/waxes insulatorsCarboxylationDicumyl peroxide

The invention discloses a modified silicone rubber cable material with high flame retardance and high wear resistance. The modified silicone rubber cable material is prepared from the following raw materials: silicone rubber, ethylene-propylene-diene monomer rubber, butyl rubber, ethylene-vinyl acetate rubber, polyurethane, modified alumina, nylon 6, 2,2,6,6-tetramethylpiperidinooxy, nanometer calcium carbonate, a carboxylation carbon nanotube, a coupling agent, dicumyl peroxide, modified enzymatic hydrolysis lignin, zinc oxide, stearic acid, ultra-fine aluminum hydroxide, ethyl glycol tetraethyl diphosphate, diethylene glycol tetraethyl diphosphate, a red phosphorus microcapsule, triallyl isocyanurate, acrylic acid, an accelerant, an anti-ageing agent, and a softener. The modified silicone rubber cable material with high flame retardance and high wear resistance disclosed by the invention is good in flame retardance, high in wear resistance, high in mechanical strength, and long in service life.

Owner:ANHUI DUJIANG CABLE GROUP

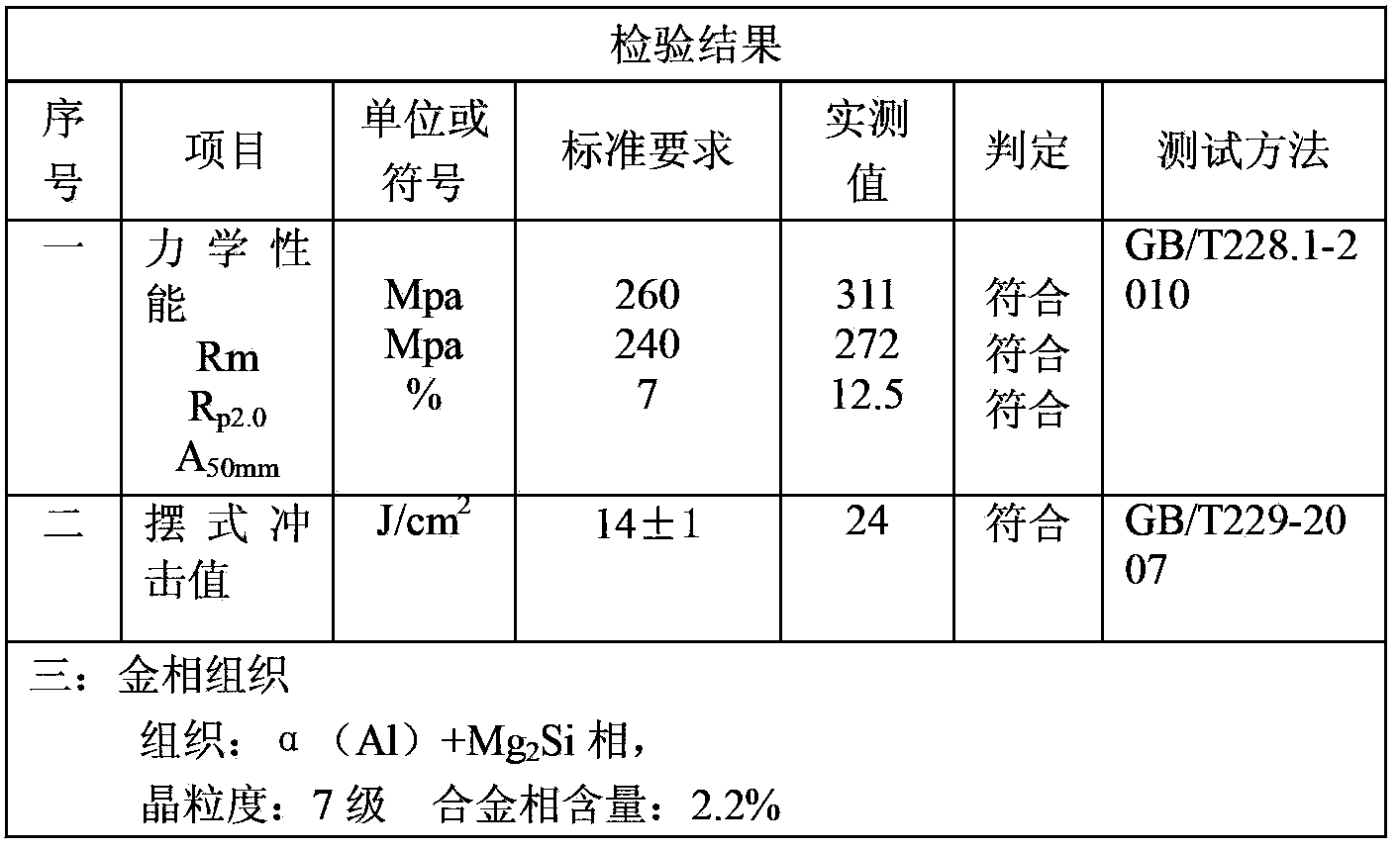

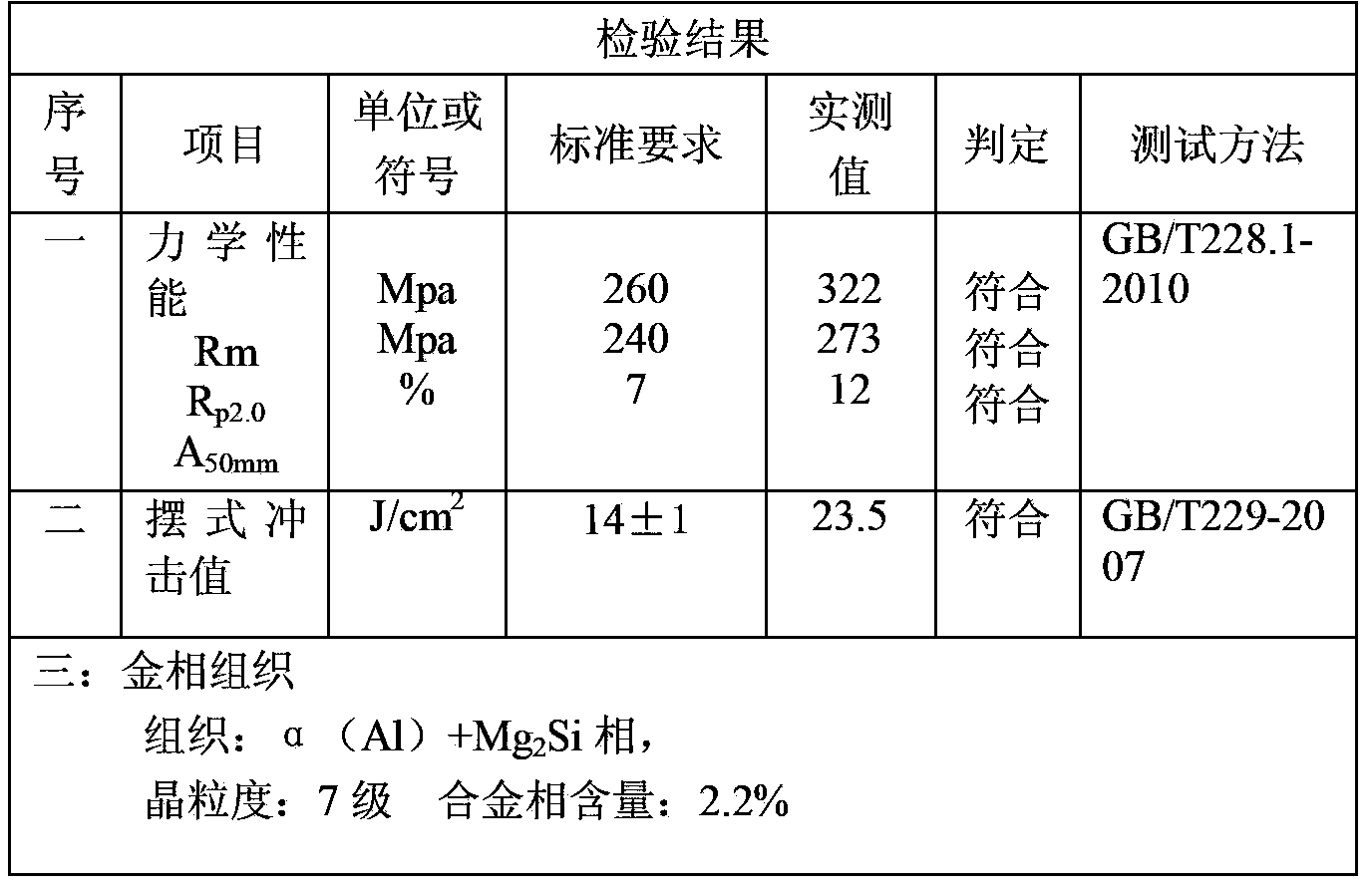

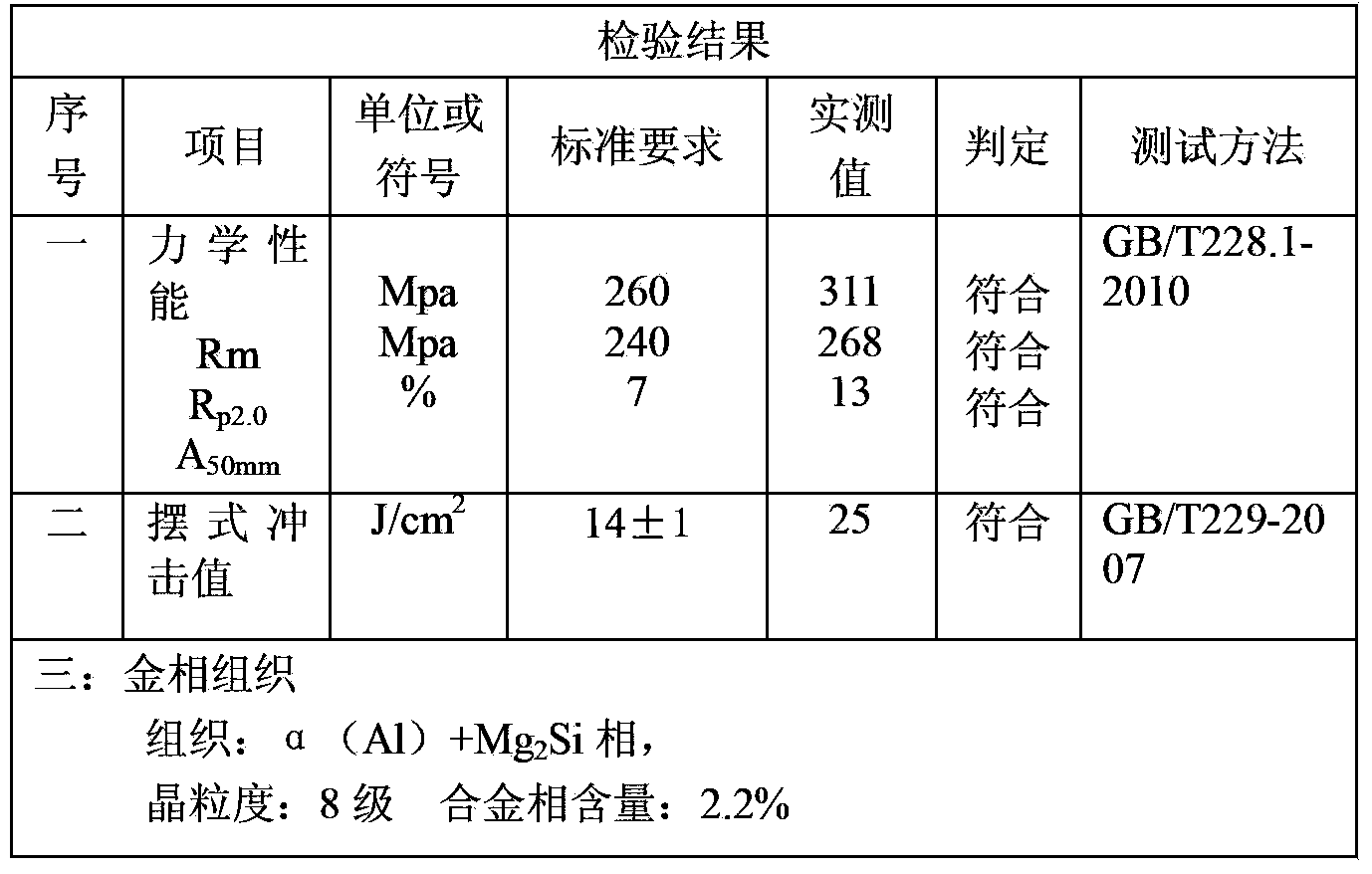

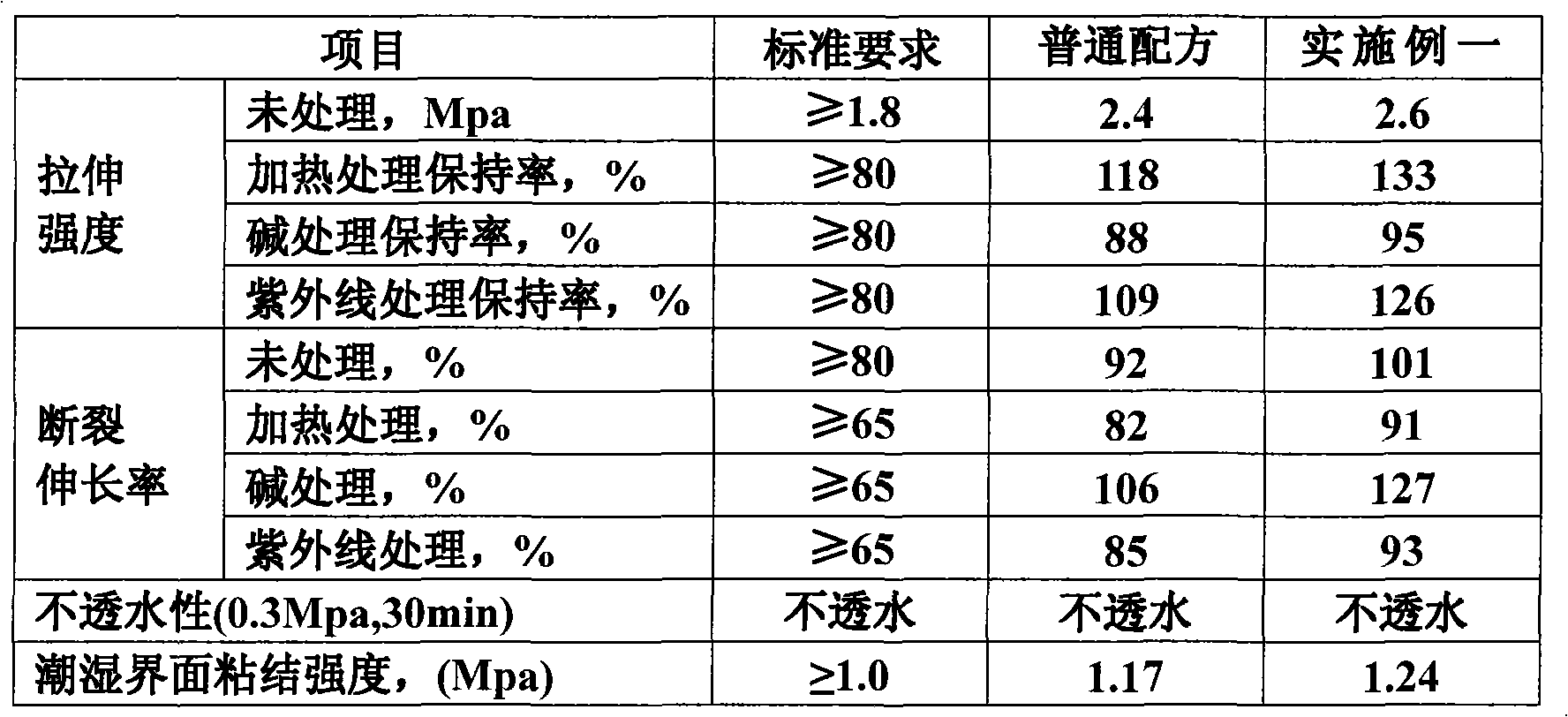

Aluminium alloy profile for building template, and preparation method thereof

The invention discloses an aluminium alloy profile for a building template, and a preparation method thereof. The aluminium alloy profile comprises the following components in percentage by weight: 0.85-0.95 percent of magnesium, 0.06-0.65 percent of silicone, 0.15-0.20 percent of copper, 0.05-0.08 percent of manganese, 0.03-0.05 percent of zirconium, 0.04-0.06 percent of chromium, 0.008-0.012 percent of titanium, 0-0.2 percent of iron, 0-0.10 percent of zinc and the balance of aluminium. The aluminium alloy profile provided by the invention has the advantages that the tensile strength is more than 300 MPa, the yield strength is more than 260 MPa, the breakage elongation percentage is more than 12 percent, the tenacity, the weldability and the corrosion resistance are obviously improved compared with that of an original 6061 alloy, the pendulum impact value is more than 20 J / cm<2>, the welding coefficient is not less than 0.6, smaller quench sensitivity is provided, and critical quenching speed is dropped from 10 DEG C / S of the original alloy to 7 DEG C / S; during the processing of the aluminium alloy profile, air cooling is adopted to process an extrusion outlet with the temperature of 450 DEG C in a high-temperature segment as well as an extrusion outlet with the temperature of being smaller than or equal to 25 DEG C in a low-temperature segment, while a moderate-temperature segment, namely a quench sensitive area with the temperature of 450-250 DEG C utilizes water mist to replace direct water-cooling, so that the difficulty for controlling cross section deformation of the profile in the production field is greatly reduced.

Owner:GUANGDONG WEIYE ALUMINUM FACTORY GRP

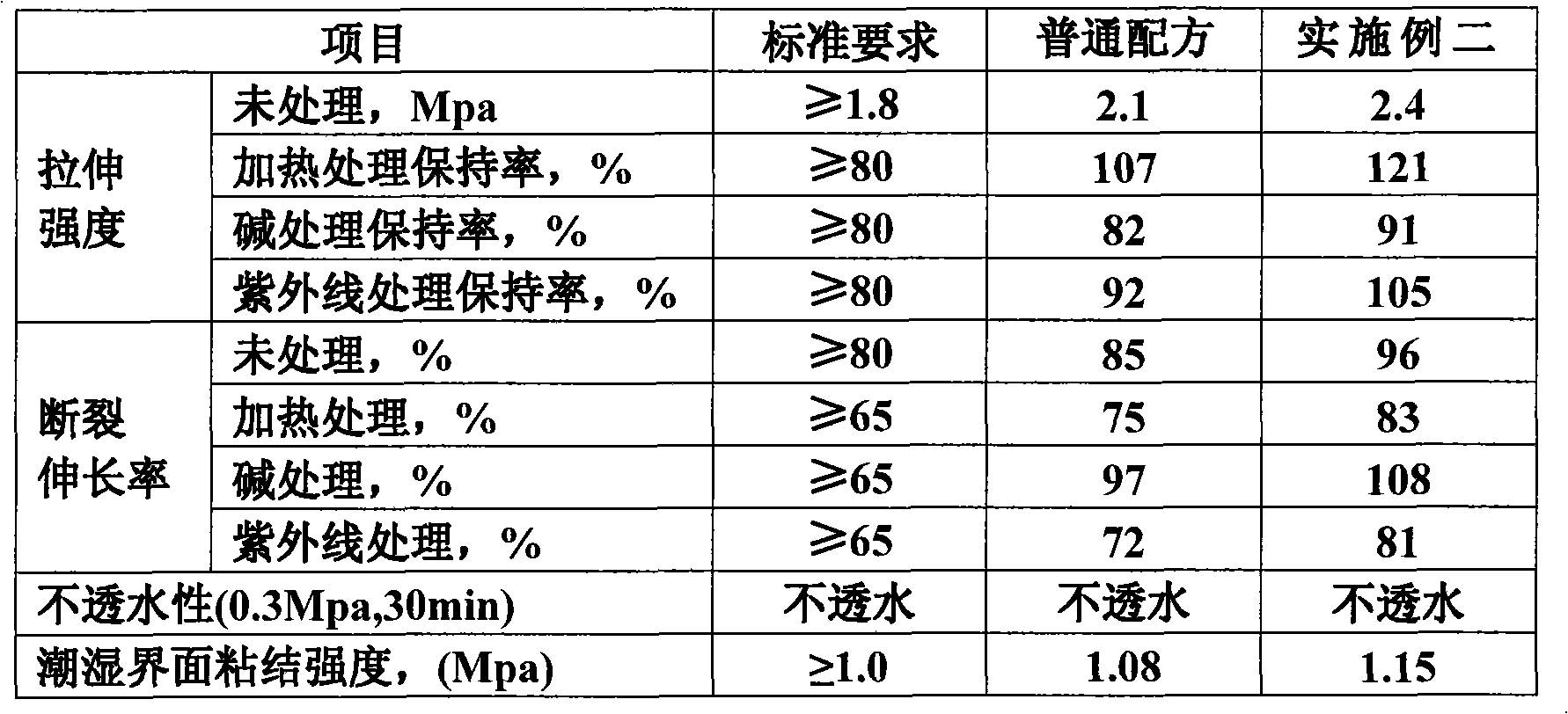

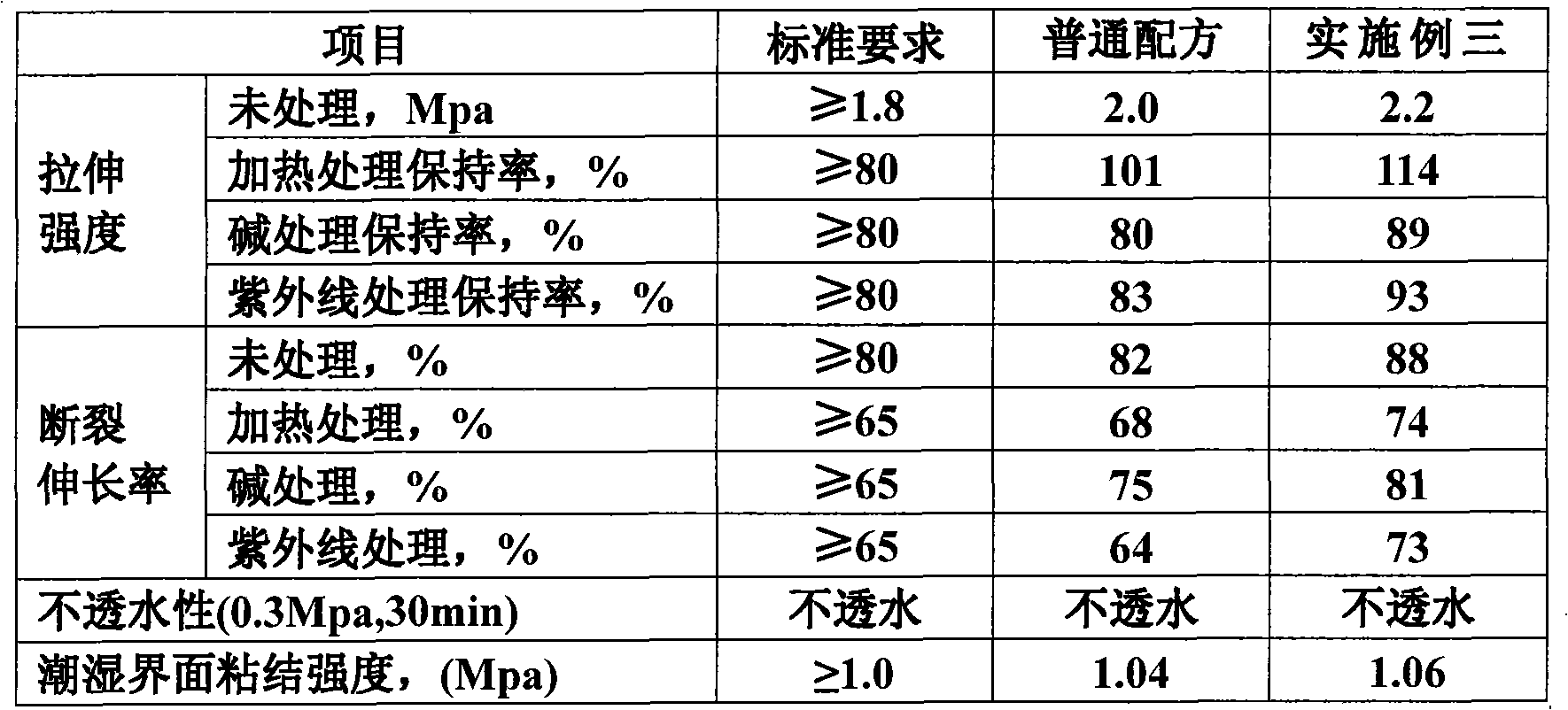

II-type polymer cement waterproofing coating modified by nano materials and preparation method thereof

ActiveCN101550309AImprove thixotropyPrevent saggingAntifouling/underwater paintsPaints with biocidesPlasticizerPolymer

The invention discloses a II-type polymer cement waterproofing coating modified by nano materials, which consists of a liquid material component and a powder material component, wherein the liquid material component comprises the following ingredients by weight: 85-95 percent of acrylic ester latex, 0.5-2 percent of plasticizer, 0.2-0.4 percent of dispersant, 0.2-0.5 percent of silicone antifoam agent, 0.1-0.3 percent of preservative, 0.3-0.6 percent of active ingredient content of pre-dispersed nano silicon dioxide solution, 0.02-0.06 percent of active ingredient content of pre-dispersed nano alumina solution, and the balance of water. The mixture ratio of the liquid material component to the powder material component is 10:14-20 according to proportions by weight. The invention greatly improves the thixotropy of the coating, prevents coating elevation construction from sagging, reduces loss in coating construction, simultaneously enhances all properties of the coating such as water resistance, alkaline resistance and the like, and obtains obvious effects.

Owner:苏州市姑苏新型建材有限公司

Cation water polyurethane/acrylic ester composite emulsion and preparation method thereof

The invention relates to cationic water-based polyurethane / acrylic ester composite emulsion and the preparation process, belonging to the chemical product and preparation technology field. Raw materials comprise diisocyanate mixture, polyhydric alcohol, organotin catalyst, chain extender, thinner, neutralizing agent and initiating agent. The preparation process comprises adding polyhydric alcohol into a reactor to dehydrate in vacuum, adding into diisocyanate mixture and organotin catalyst, conducting prepolymerization reaction to synthesize prepolymer with isocyanate-termi-nated, coldly adding thinner to dilute and to condense and reflow, adding chain extender to obtain mixture through chain extending reaction, cooling down, adding neutralizing agent to finish salt-forming reaction, regulating pH value, adding deionized water to conduct dispersed emulsification to obtain cationic water-based polyurethane elusion, and heating up and adding initiating agent to initiate free radical polymerization reaction to prepare composite elusion. The cationic water-based polyurethane / acrylic ester composite emulsion is synthesized through adopting non solvent process with low pollution and environment-friendly, increases solvent resistance, water resistance and tensile strength of glue film through introducing micro-cross-linked structure, increases hydrolytic stability of the glue film through introducing carbodiimide structure, and increases elongation at break and elasticity property through of glue film through introducing 2, 4-MDI.

Owner:WANHUA CHEM GRP CO LTD

Polyurethane foam compositions

A polyurethane foam assemblage contains an A component and a B component and the A component contains the polyether polyol, the polymer polyol, the crosslinking agent, the catalyst, the stabilizer and the foaming agent; the B component contains the isocyanate; wherein, the catalyst is the mixed catalyst containing the 2-dimethylamine ethanol, the triethylenediamine, the Bis(2-dimethylaminoethyl) ether and the organotin. Compared with the existing high elastic foam, the polyurethane foam assemblage of the invention has lower density, and thus has lower cost and stable formula and simple process on the premise of the same tensile and tear strength. The polyurethane foam assemblage provided by the invention has the advantages of low density, high resilence, cold curing, etc., is in particular suitable for automobile cushion, sofa, mattress, etc.

Owner:BYD CO LTD

Preparation method of silicon rubber foam material

The invention discloses a preparation method of a silicon rubber foam material, which is characterized by mixing 100 parts of silicon rubber, 12-85 parts of white carbon black, 2-15 parts of constitution controller, 3-15 parts of foaming agent, 0-5 parts of blowing promoter and 0-8 parts of cross-linking agent promoter and forming, radiating the silicon rubber by electron beams or gamma rays to generate cross-linking reaction, heating the foaming agent for decomposing and foaming, immediately utilizing the electron beams or the gamma rays to carry out secondary radiation crosslinking after foaming the silicon rubber to further improve the comprehensive properties of the silicon rubber foam material. The silicon rubber foam material can be used for sealing, damping, insulation, sound insulation and thermal insulation materials.

Owner:WUJIANG LANGKE CHEM FIBER

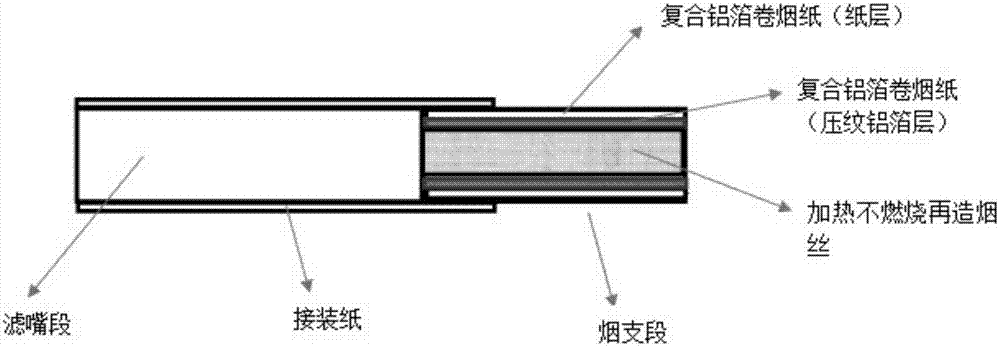

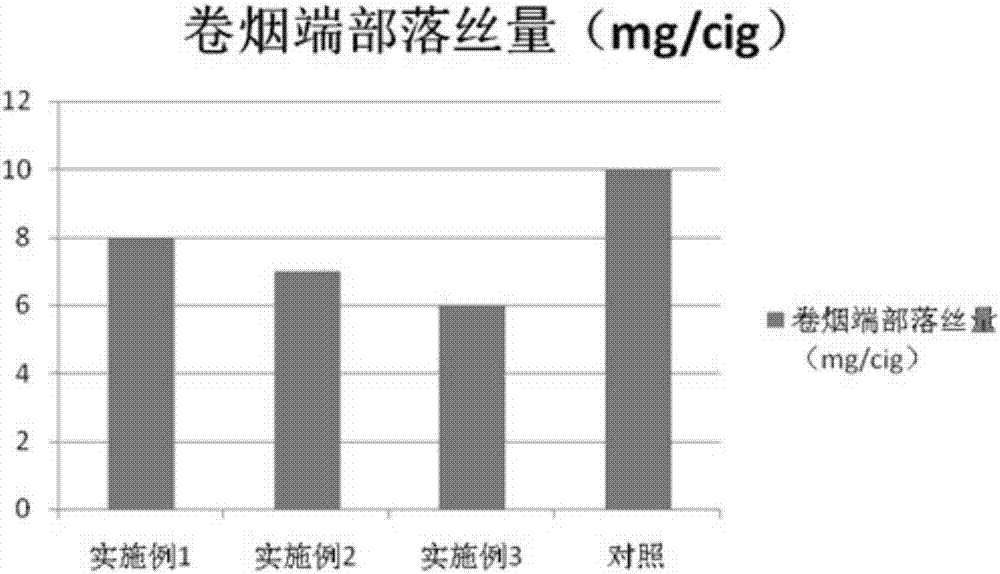

Method for preparing heating but incombustible cigarettes and application thereof

ActiveCN107981405AIncrease frictionLow costTobacco preparationCigarette manufactureKnurlingEngineering

The invention discloses a method for preparing heating but incombustible cigarettes and application thereof. The method and the application have the advantages that novel knurling rolling technologiesare adopted, accordingly, heating but incombustible reconstituted tobaccos with certain thicknesses have uneven surfaces, the surface areas can be enlarged, atomization effects can be enhanced, and surface frictional force can be enlarged; embossed composite aluminum-foil cigarette paper is adopted, accordingly, friction between the reconstituted tobaccos and aluminum-foil pattern surfaces of thecomposite aluminum-foil cigarette paper which is a cigarette making and plug assembling material can be greatly enhanced when the reconstituted tobaccos and the composite aluminum-foil cigarette paper are loaded in a cigarette making and plug assembling machine and cigarette making and plug assembling are powered on in later periods, the heating but incombustible cigarettes are easy to process, equipment shutdown frequencies can be reduced, the heating but incombustible cigarettes can be continuously produced, the production efficiency can be improved, and the material cost and the productioncost can be reduced; low-temperature cigarettes have short cut tobacco sections, accordingly, friction can be improved, the method is beneficial to reducing cut tobacco dropping, and the shortcomingsof low frictional force between smooth surfaces of existing heating but incombustible reconstituted tobaccos and non-embossed aluminum-foil paper which is a wrapping material, severe slipping, frequent equipment shutdown due to incapability of driving cigarette paper, influence on production efficiency, low frictional force due to short cut tobacco sections of existing low-temperature cigarettes,vulnerability to dropping of low-temperature cut tobaccos of the existing low-temperature cigarettes and the like can be overcome.

Owner:HUBEI CHINA TOBACCO IND

Aliphatic-aromatic copolyester, preparation method and application thereof

ActiveCN101717493AAvoid problems such as affecting performanceEvenly dispersedAdhesivesCarboxylic acid halidesMonomer

The invention provides aliphatic-aromatic copolyester, a preparation method and application thereof. Polymerization monomers comprise a compound selected from aliphatic dibasic acid, and naphthenic base dibasic acid or the ester, the anhydride and the acyl halide thereof, a compound selected from aromatic dibasic acid or the ester, the anhydride and the acyl halide thereof, a compound simultaneously with two functional groups selected from an amino-group, a mercapto group or a hydroxy or a compound of a derivative of the amino-group, the mercapto group or the hydroxyl with an epoxy group and an azepine ring, a compound selected from unsaturated acid with at least one C-C, C-O, C-N or C-S double bond and C-C or C-N triple bond or the ester, the anhydride and the acyl halide thereof and a compound of unsaturated alcohol with at least one C-C double bond or a C-C triple bond or an epoxide thereof. The aliphatic-aromatic copolyester is prepared by carrying out esterification and polycondensation after mixing the polymerization monomers, polymerizing the double bonds and / or the triple bonds on the polymerization monomers under the action of an initiator and then carrying out a graftingand / or coupling reaction.

Owner:HANGZHOU XINFU TECH CO LTD

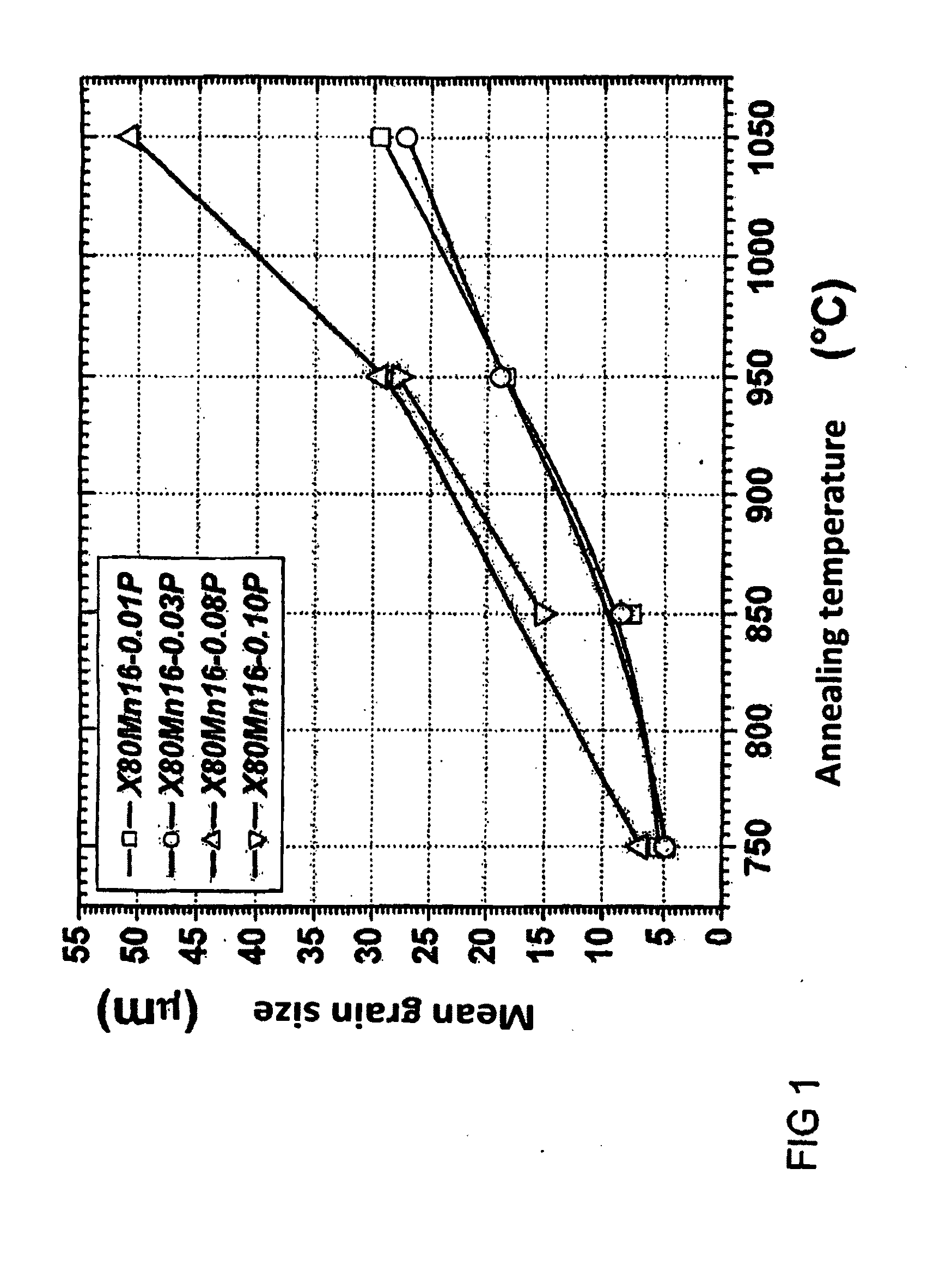

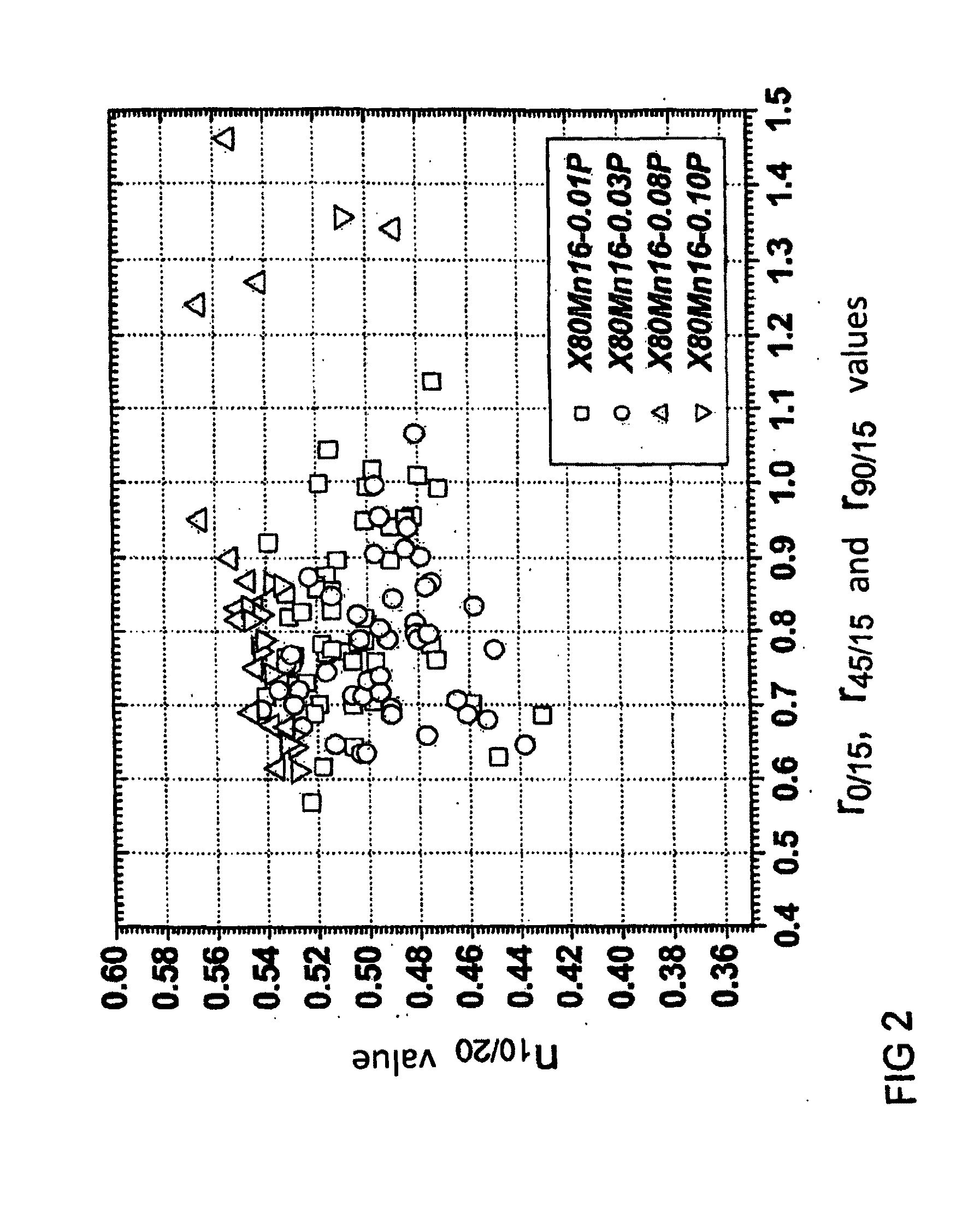

Manganese steel strip having an increased phosphorous content and process for producing the same

InactiveUS20110308673A1Improve solid solubilityImprove solubilityFurnace typesHeat treatment furnacesChemical compositionManganese

A hot-rolled austenitic manganese steel strip having a chemical composition in percent by weight of 0.4%≦C≦1.2%, 12.0%≦Mn≦25.0%, P≧0.01% and Al≦0.05% has a product of elongation at break in % and tensile strength in MPa of above 65,000 MPa %, in particular above 70,000 MPa %. A cold-rolled austenitic manganese steel strip having the same chemical composition achieves a product of elongation at break in % and tensile strength in MPa of above 75,000 MPa %, in particular above 80,000 MPa %.

Owner:VOESTALPINE STAHL GMBH

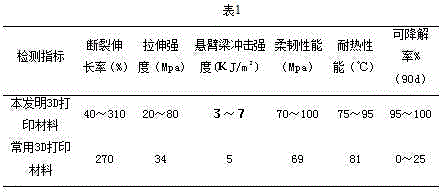

Bio-based 3D printing material and preparation method thereof

ActiveCN104448738AIncrease added valueLow costMicroorganism based processesFermentationPolymer scienceCross linker

The invention relates to a bio-based 3D printing material and a preparation method thereof, and aims to solve the problems that a conventional 3D printing material of polylactic acid is relatively small in crystallization degree, small in bond energy of ester bonds in molecule chains and has high probability of cracking. The bio-based 3D printing material is prepared from the following raw materials in percentage by weight: 20-40% of polyactic acid, 35-60% of thermoplastic starch, 3-10% of a toughening agent, 5-10% of a cross-linking agent, 5-13.4% of a filling agent, 0.5-2% of a thermal stabilizing agent, 1-3% of a lubricating agent and 0.1-5% of a preservative. The preparation method comprises the following steps: mixing polyactic acid with the thermoplastic starch, the toughening agent, the cross-linking agent, the filling agent, the thermal stabilizing agent, the lubricating agent and the preservative, pelleting and performing injection molding to obtain a modified polylactic acid. Due to adoption of the polyactic acid and the thermoplastic starch, the bio-based 3D printing material is good in compatibility, the elongation at break, the strength, the flexibility and the thermal resistance of the modified polyactic acid are all improved, and the additional value of a starch material is also increased.

Owner:甘肃圣大方舟马铃薯变性淀粉有限公司

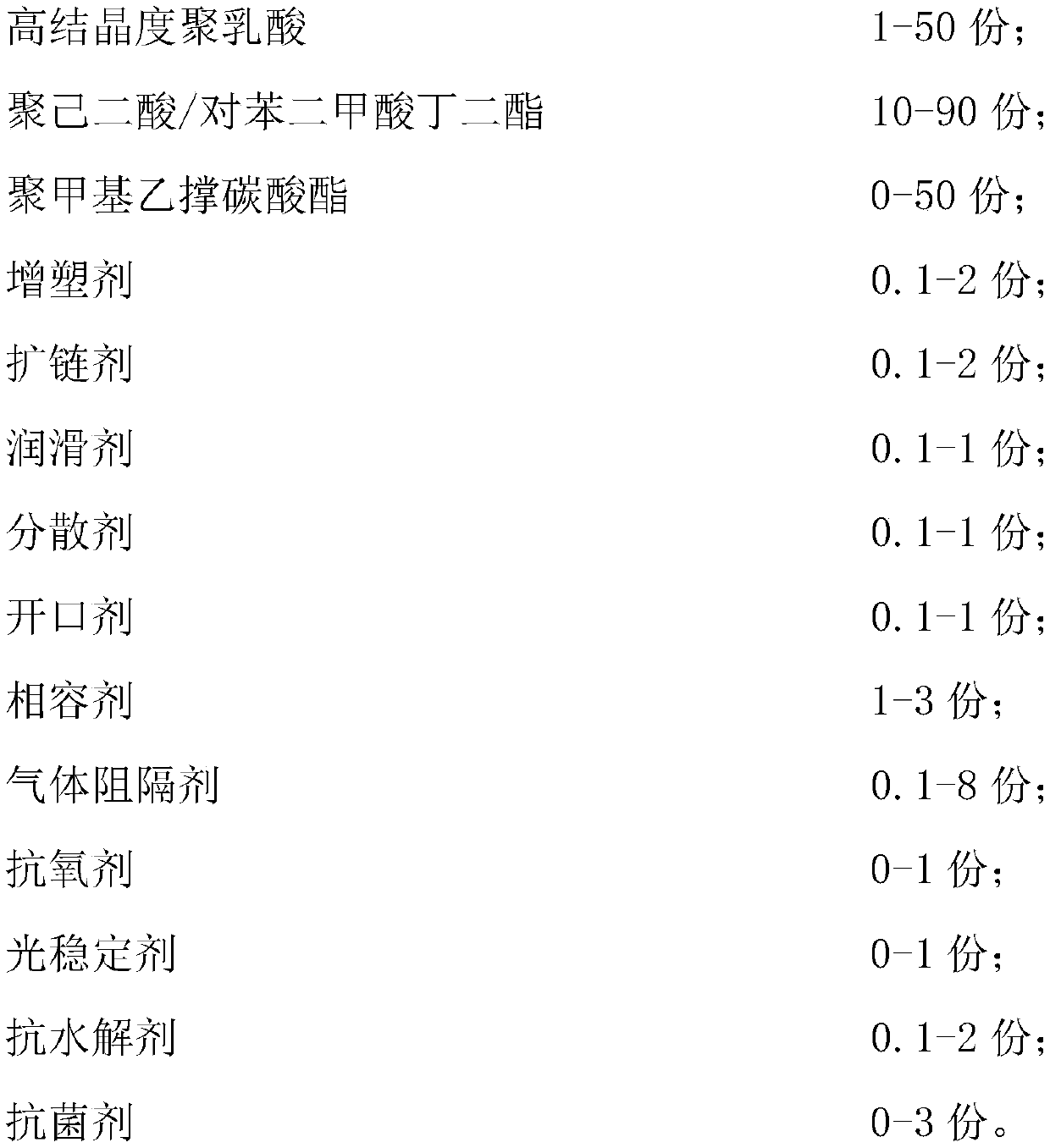

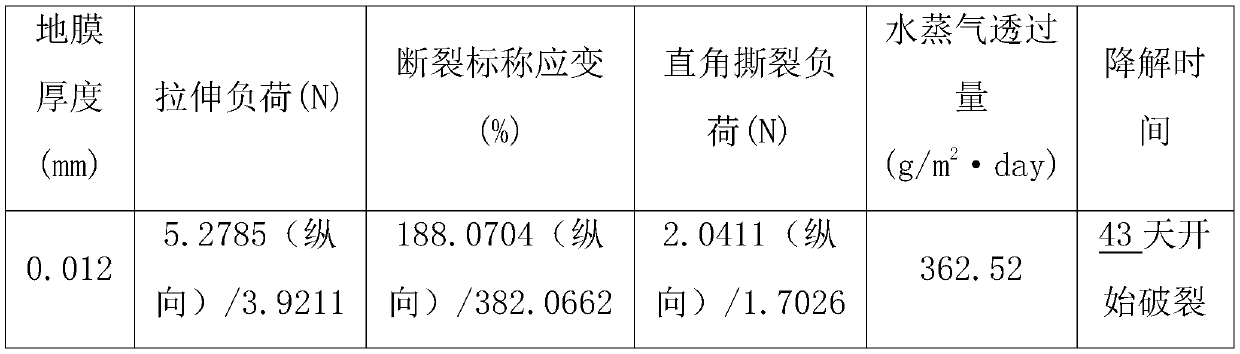

Controllable fully biodegradable mulching film and preparation method thereof

InactiveCN110330773AHigh water vapor barrierHigh tensile strengthClimate change adaptationPlant protective coveringsPolymer sciencePolybutylene

The invention belongs to the technical fields of biodegradable material modification and application, and relates to a controllable fully biodegradable mulching film and a preparation method thereof.The controllable fully biodegradable mulching film comprises the following raw materials in parts by weight: 1-50 parts of high-crystallinity polylactic acid, 10-90 parts of polybutylene adipate / butylene terephthalate, 0-50 parts of poly propylene carbonate, 0.1-2 parts of a plasticizer, 0.1-2 parts of a chain extender, 0.1-1 part of a lubricant, 0.1-1 part of a dispersant, 0.1-1 part of an opening agent, 1-3 parts of a compatibilizer, 0.1-8 parts of a gas barrier, 0-1 part of an antioxidant, 0-1 part of a light stabilizer, 0.1-2 parts of an anti-hydrolysis agent and 0-3 parts of an antibacterial agent. The raw materials are pretreated and uniformly mixed, the controllable fully biodegradable mulching film is obtained by extrusion and blow molding, and the thickness of the mulching film is0.005 to 0.020 mm. The fully biodegradable mulching film provided by the invention has good mechanical properties, excellent heat preservation and moisture retention performance, and can be completely degraded by itself; the mulching film degradation rate can be regulated according to the 'mulching film function period' of different crop mulching films in different regions to meet the needs of different crops in different regions.

Owner:深圳利峰达科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com