Method for preparing reactive fluid rubber-epoxide resin polymer

A technology of epoxy resin and liquid rubber, applied in the field of modified epoxy resin, can solve the problems of insignificant modification effect of epoxy resin, affecting electrical properties, chemical resistance, easy precipitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: the preparation of liquid rubber-epoxy resin polymer

[0015] Mix 100 parts of liquid bisphenol A epoxy resin (E-52 provided by Wuxi Resin Factory), 0-20 parts of hydroxyl-terminated polybutadiene rubber (HTPB) and 0.1-1.0 parts of catalyst N, N-dimethyl Bian amine, 100 parts of methyl endomethylene tetrahydrophthalic anhydride, added to a three-necked flask with a thermometer, heated and mechanically stirred, reacted at 100-150 ° C for 2-6 hours, degassed for 5-10 minutes, and prepared the product reaction Resistant liquid rubber-epoxy polymer.

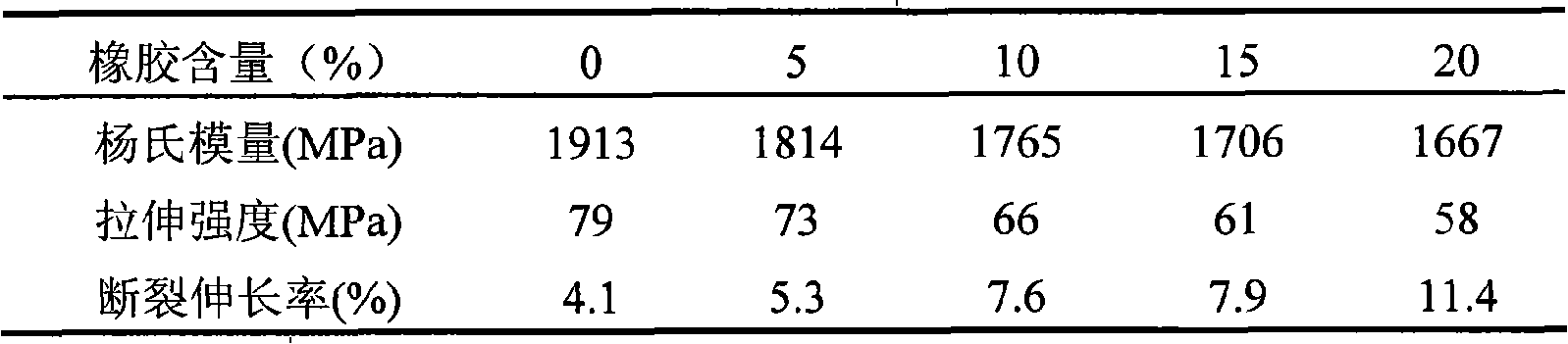

[0016] When in use, inject the product into the mold and cure at 100-180°C for 1-1.5 hours. The mechanical properties of the cured modified epoxy resin are shown in Table 1.

[0017] Table 1 Mechanical properties

[0018]

Embodiment 2

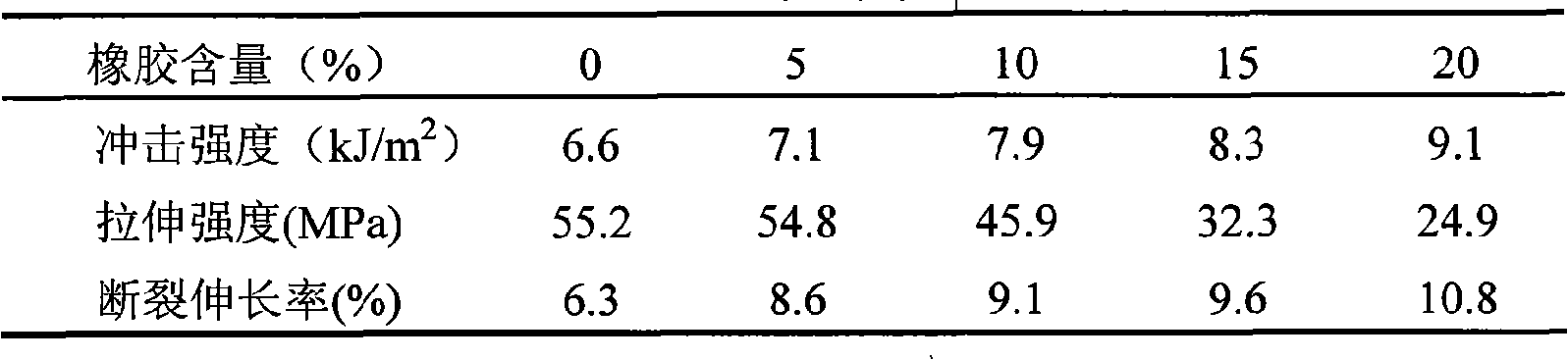

[0020] Mix 400 parts of liquid bisphenol A type epoxy resin (E-54 provided by Wuxi Resin Factory), 0-80 parts of liquid carboxyl-terminated nitrile rubber (CTBN) and 0.2-4.0 parts of catalyst (tripropyl benzyl phosphorus) Add it into a three-necked flask with a thermometer, heat and mechanically stir, react at 100-120°C for 2-6h, precipitate with excess deionized water, wash the product, and obtain a prepolymer of CTBN modified epoxy resin after vacuum drying, and The resulting modified product is marked as C according to the CTBN content (%) 0 、C 5 、C 10 、C 15 and C 20 (The subscript is the content of CTBN), obtains the reactive liquid rubber-epoxy resin polymer with good toughness. The mechanical properties after curing are shown in Table 2. Scanning electron microscope picture as figure 1 shown.

[0021] Table 2 Mechanical properties

[0022]

[0023] figure 1 It is the SEM image of the sample section, the liquid rubber content (mass fraction) is 0%, 10%, 20% fr...

Embodiment 3

[0025] Mix 800 parts of solid bisphenol A epoxy resin (DER671 provided by Dow Chemical), 0-160 parts of carboxy-terminated nitrile rubber CTBN and 0.4-8.0 parts of catalyst (ethyltriphenylphosphine iodide fluorene) Evenly, heat and stir mechanically, and react at 120-170°C for about 2-6h. The resulting modified product is marked as C according to the CTBN content (%) 0 、C 5 、C 10 、C 15 , and C 20 (The subscript is the content of CTBN). The synthesized liquid carboxyl-terminated nitrile rubber (CTBN)-epoxy resin polymer is pulverized into powder on a pulverizer, and packed in bags for subsequent use. A series of reactive liquid rubber-epoxy polymers with good toughness were obtained. The mechanical properties after curing are shown in Table 3.

[0026] Table 3 mechanical properties

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com