Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

345results about How to "Low elongation at break" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing reactive fluid rubber-epoxide resin polymer

The invention provides a method for preparing reactive fluid rubber-epoxide resin polymer, and belongs to the technical field of modified epoxide resin. The method comprises the following steps: 5 to 50 portions of reactive fluid rubber containing carboxyl or hydroxyl as a modifier, and 0.1 to 2.0 portions of catalyst are added into 100 to 200 portions of epoxide resin by weight; when the reactive fluid rubber containing the hydroxyl is used as the modifier, isocyanate or estolide with the same weight portion as the epoxide resin is required to be added; and an active group in the reactive fluid rubber reacts with an epoxide group in the epoxide resin for 2 to 6 hours at a temperature of between 100 and 180 DEG C to prepare the reactive fluid rubber-epoxide resin polymer with excellent toughness. The modified epoxide resin has improved toughness, non organic solvent is used in the whole synthesizing process, non environmental pollution is caused, the synthesizing process is simple and easily controlled, and the problem is not found in amplification experiments carried out for small amount, medium amount and large amount respectively, so that the method is applicable to industrial production.

Owner:JIANGNAN UNIV

A method for manufacturing high-strength, high-modulus, low-shrinkage polyester industrial yarn

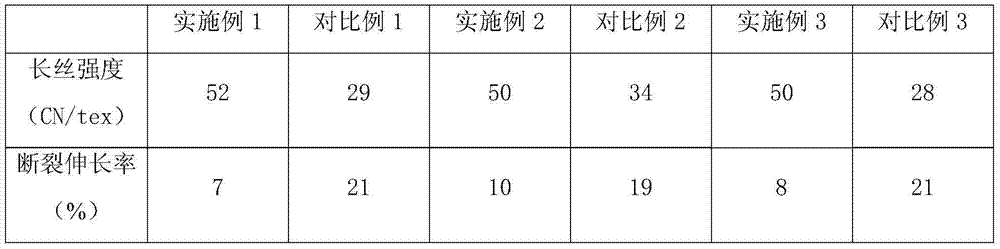

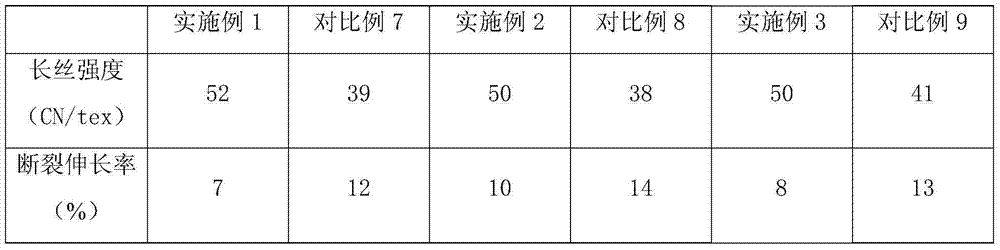

ActiveCN102797054BReduce disturbanceReduce the temperatureFilament/thread formingMonocomponent polyesters artificial filamentYarnFiber

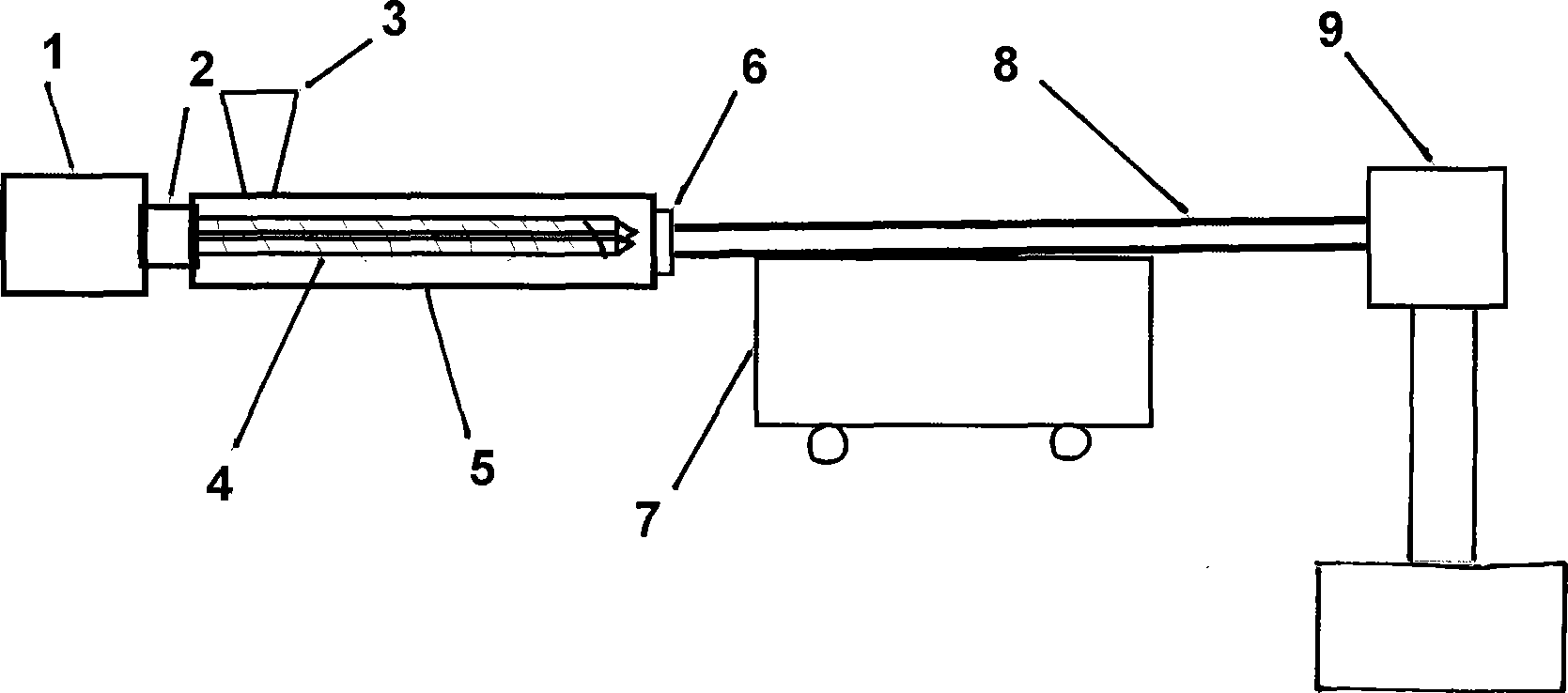

The invention discloses a manufacturing method of a high-strength, high-modulus and low-shrinkage polyester industrial yarn. The manufacturing method comprises the processes of preparation of a highly viscous melt polyester raw material, metering, spinning, cooling, oil applying, drawing, heat shaping and winding formation; the cooling comprises slow cooling, precooling, cooling in an air free zone and air blast cooling in sequence; the precooling part uses a driven hollow-out successive annular strip. Through the introduction of a precooling device, irregularity caused by tow shaking due to move-down of a curing point of a fiber is reduced, the linear density deviation is controlled within a lower range, and orientation and crystallization of an as-spun fiber are reduced, so that the high-strength, high-modulus and low-shrinkage polyester industrial yarn is obtained; and the high-strength, high-modulus and low-shrinkage polyester industrial yarn has the advantages of high breaking tenacity, high initial modulus, low linear density deviation, low breaking elongation and lower dry-heat shrinkage rate and can be used for preferably satisfying requirements on application.

Owner:JIANGSU HENGLI CHEM FIBER

Nonporous moisture permeable and water-repellent modified polyether ester functional film material and preparation method thereof

The invention discloses a non-porous moisture permeable waterproof modified polyether ester functional film material and a preparation method thereof. The non-porous moisture permeable waterproof modified polyether ester functional film material of the invention contains components with the following weight percent: 50 to 70 percent of polyether ester, 10 to 30 percent of daiamid 6, 5 to 10 percent of hydrophilic polymer, 5 to 10 percent of ethylene-vinyl acetate copolymer, 2 to 4 percent of antibacterial masterbatch, 0.4 to 1 percent of novolac epoxy, 0.2 to 0.5 percent of antioxidant, 0.2 to 0.6 percent of processing additive. The modified polyether ester material of the invention has the advantages of polyester, polyether and daiamid, and has the advantages of good heat resistance, low cost and environmental protection. The film prepared in the process of melting casting has the functions of non-porous moisture permeation and watertightness, etc, and is mainly applicable to the production of clothing, waterproof breathable tape, and roof or wall film in the construction industry, etc.

Owner:SOUTH CHINA UNIV OF TECH

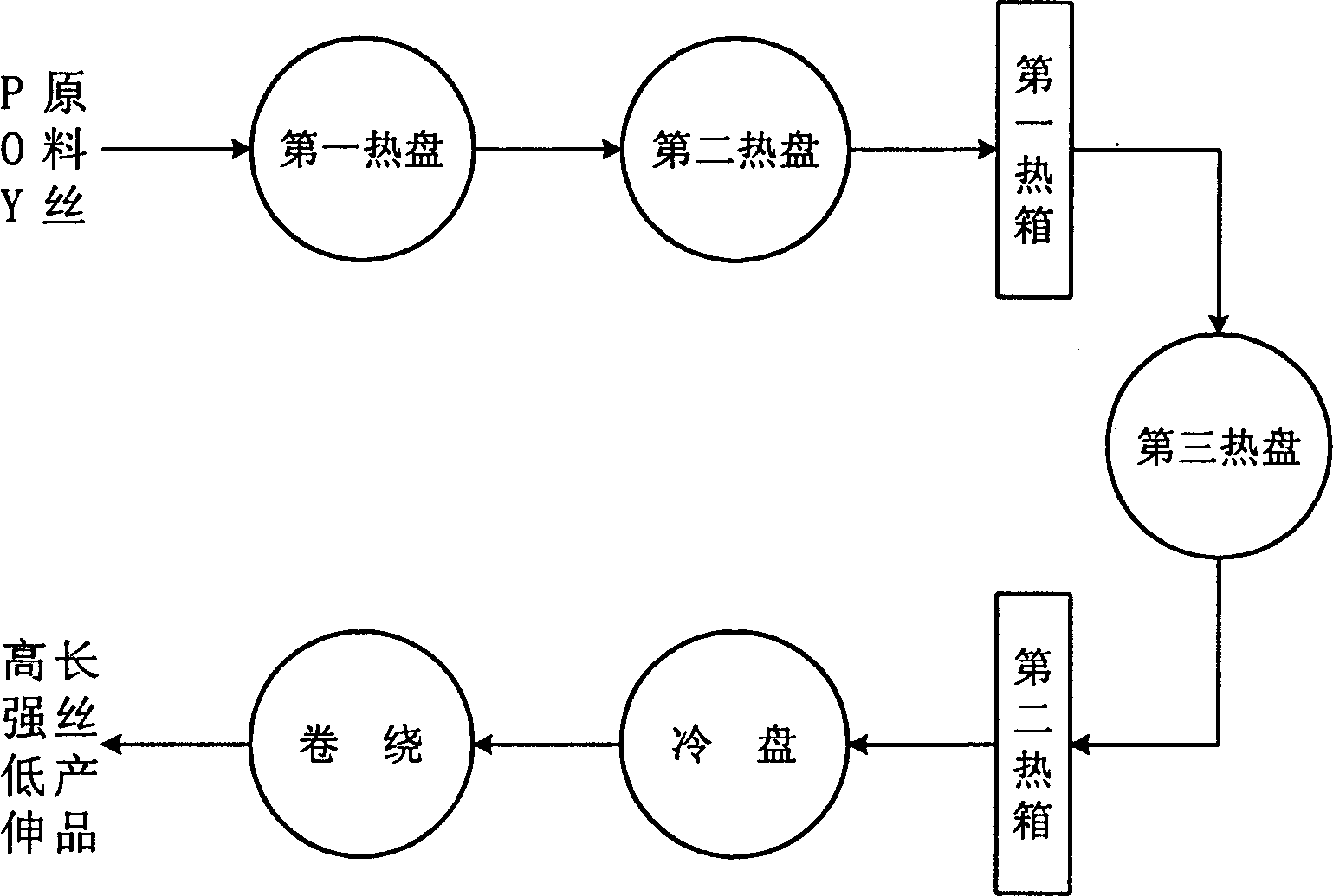

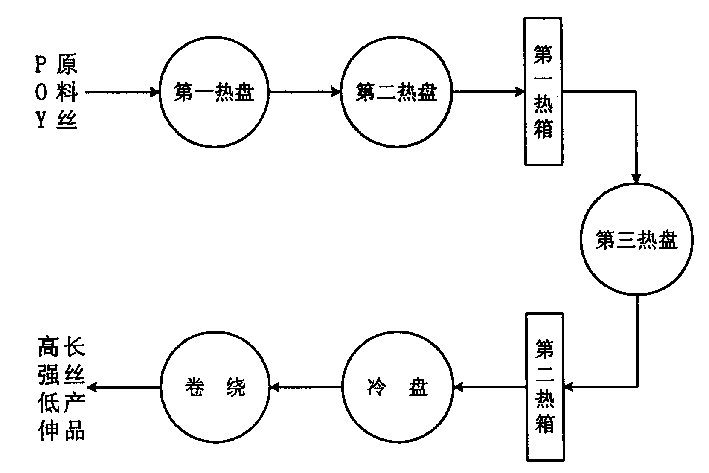

Manufacture of high tenacity low-stretch polyester filaments

InactiveCN1448547AWide variety of sourcesIncrease production capacityMelt spinning methodsYarnHigh intensityUltimate tensile strength

The present invention relates to Dacron producing process, and is especially preparation process of high-strength and low-elongation Dacron filament for sewing thread. The preparation process with routine pre-oriented POY filament includes successive first high-power drafting in the first and the second heating discs, high temperature tensed heat setting in the first heating box and the third heating box, the second drafting and the high temperature relax heat setting in the second heating box. In the process, POY filament has good drafting performance, no teasing and breaking, and the final product has high strength, low elongation and less heat shrinkage.

Owner:SINOPEC YIZHENG CHEM FIBER

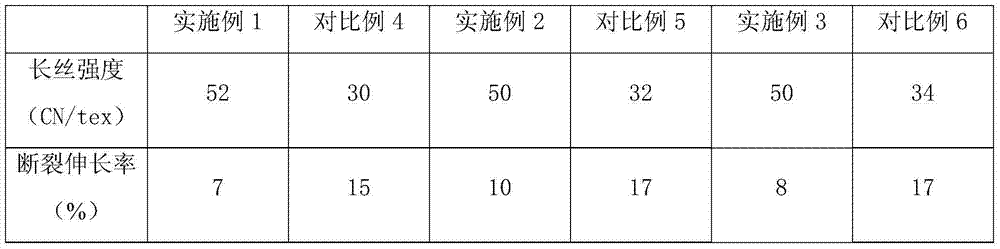

Manufacturing method for high-modulus low-shrinkage PET industrial yarn

ActiveCN102797057AReduce disturbanceReduce the temperatureFilament/thread formingMonocomponent polyesters artificial filamentYarnFiber

The invention discloses a manufacturing method for high-modulus low-shrinkage PET industrial yarn, and the technological process of the method is as follows: hyperviscous melting to polyester fiber raw materials, metering, spinning, cooling, oil applying, stretching, hot shaping and reeled forming, wherein the cooling process sequentially comprises four parts including slow-cooling, pre-cooling, calm zone cooling and blow cooling, and the pre-cooling part adopts a passive hollow ring-shaped belt device. Through the introduction of the pre-cooling device, the irregularity caused by tows quivering produced under the down moving of a solidification point of fiber can be reduced, the deviation ratio of linear density can be controlled within a lower range, the purpose of reducing orientation and crystallization of embryo fiber is achieved, finally high-modulus low-shrinkage PET industrial yarn can be obtained, the high-modulus low-shrinkage PET industrial yarn has the advantages of high modulus, low dry heat shrinkage percentage, low breaking elongation and low linear density deviation ratio, and practical application can be well met.

Owner:JIANGSU HENGLI CHEM FIBER

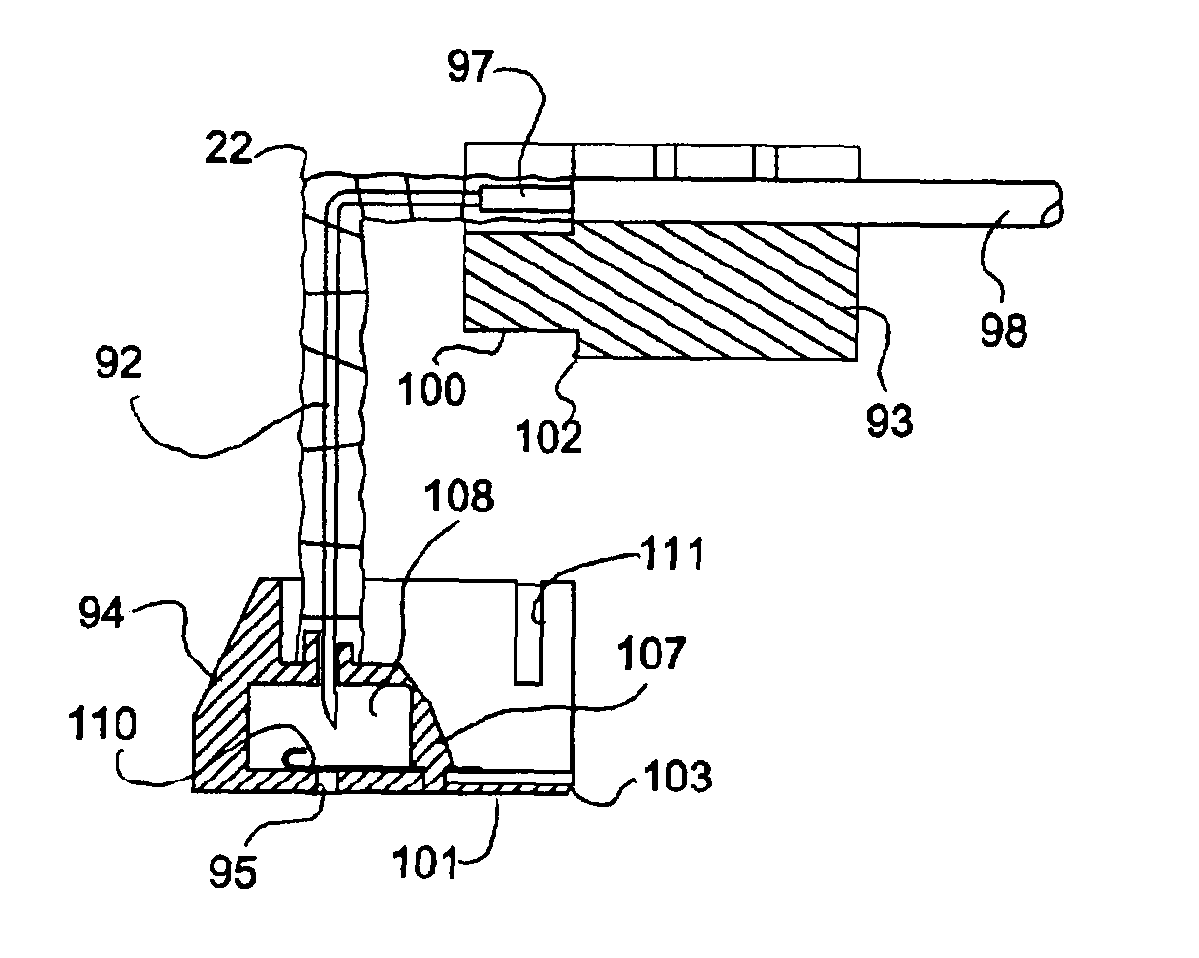

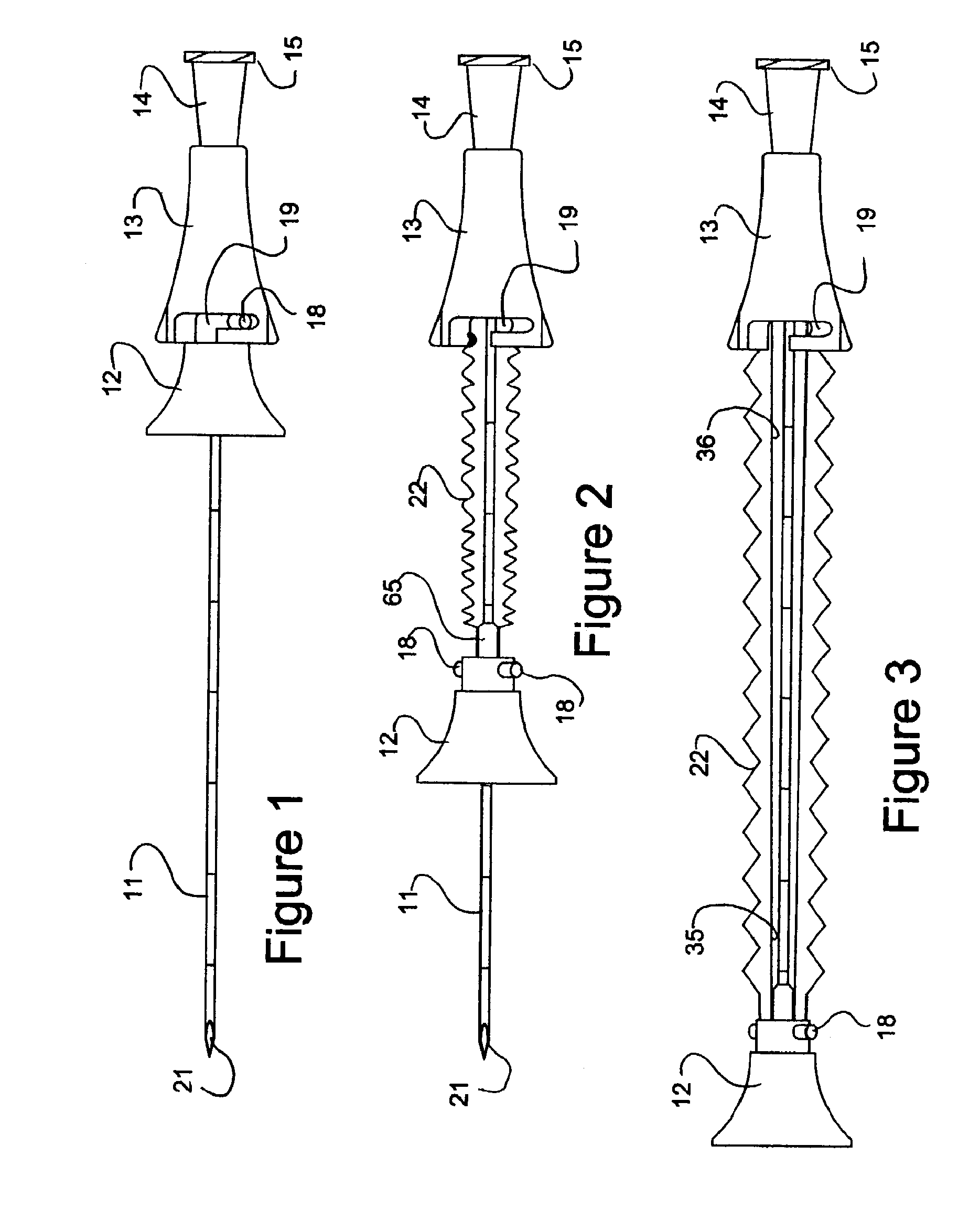

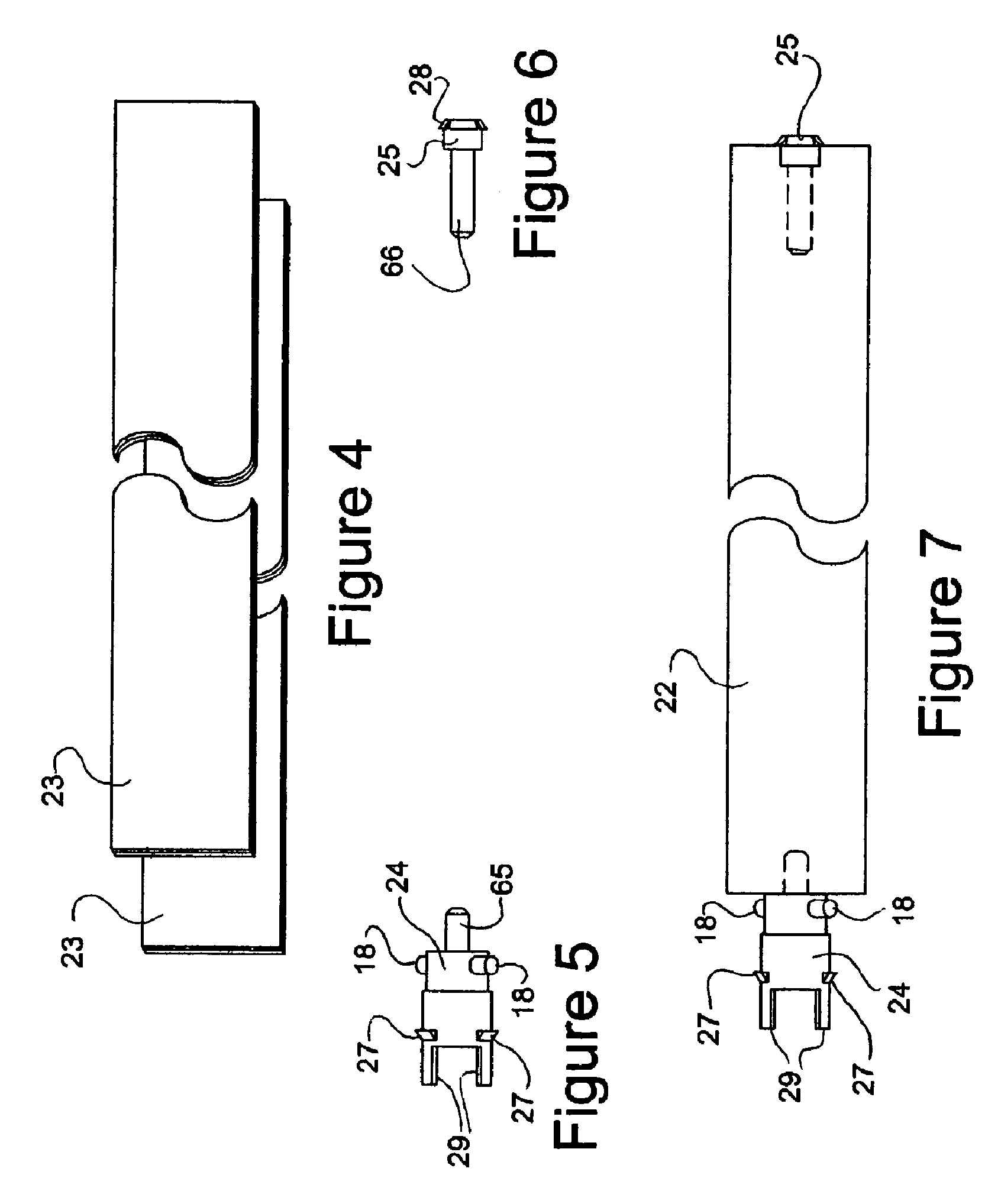

Safety needle with collapsible sheath

InactiveUS8728029B2Easy to handleEasy to break awayDiagnostic recording/measuringSensorsBiomedical engineeringSafety needles

Owner:BARD ACCESS SYST

Low-smoke halogen-free flame retardant high-elongation-rate polyolefin cable material for bullet train and preparation method of polyolefin cable material

ActiveCN104231394ASmall mechanical propertiesLow elongation at breakPlastic/resin/waxes insulatorsLow-density polyethyleneElastomer

The invention discloses a low-smoke halogen-free flame retardant high-elongation-rate polyolefin cable material for a bullet train. The polyolefin cable material is prepared from the following raw materials in parts by weight: high-density polyethylene, linear low-density polyethylene, a flame retardant, silicon dioxide, ethylene-vinyl acetate graft maleic anhydride copolymer, an elastomer, an antioxidant and a lubricant. The invention further discloses a preparation method of the polyolefin cable material. The preparation method comprises the following steps: adding prepared polyolefin and an assistant into a high-speed mixer, mixing at the speed of 1,000-1,500r / min for 5-10 minutes, and mixing and granulating by virtue of a double-screw extruder at 150-170 DEG C to obtain the polyolefin cable material. The polyolefin cable material has the advantages of high elongation rate, low smoke, no halogen, flame retardancy, no toxics and the like, and specifically can be used for manufacturing wires and cables for the bullet train with the speed of 350km / h.

Owner:ANHUI HUALING CABLE GRP

Technique for producing medium strong polyester filament yarn by melt direct spinning

InactiveCN101205632AReduced breaking strengthBreaking strength ≥ 6.0g/d, low elongation at breakFilament manufactureMelt spinning methodsMaterials scienceFilament yarn

The invention aims to provide a processing technology for utilizing a melt direct spinning production mode to produce medium strength polyester fiber filaments (FDY). Technical routes adopted by the invention are the same with conventional varieties, but first hot-roller temperature and second hot-roller temperature which are higher than universal-energy domestic filaments and higher drafting multiple are adopted, and simultaneously winding devices are improved in a certain degree, thereby the medium strength polyester fiber FDY filaments meeting requirements can be produced on the premise that large equipment investment is not increased. The FDY filaments have the characteristics of high strength and low elongation at break. The invention is mainly applied in the polyester fiber sewing thread and paper package rib reinforcement weaving field.

Owner:SHENGHONG GRP CO LTD

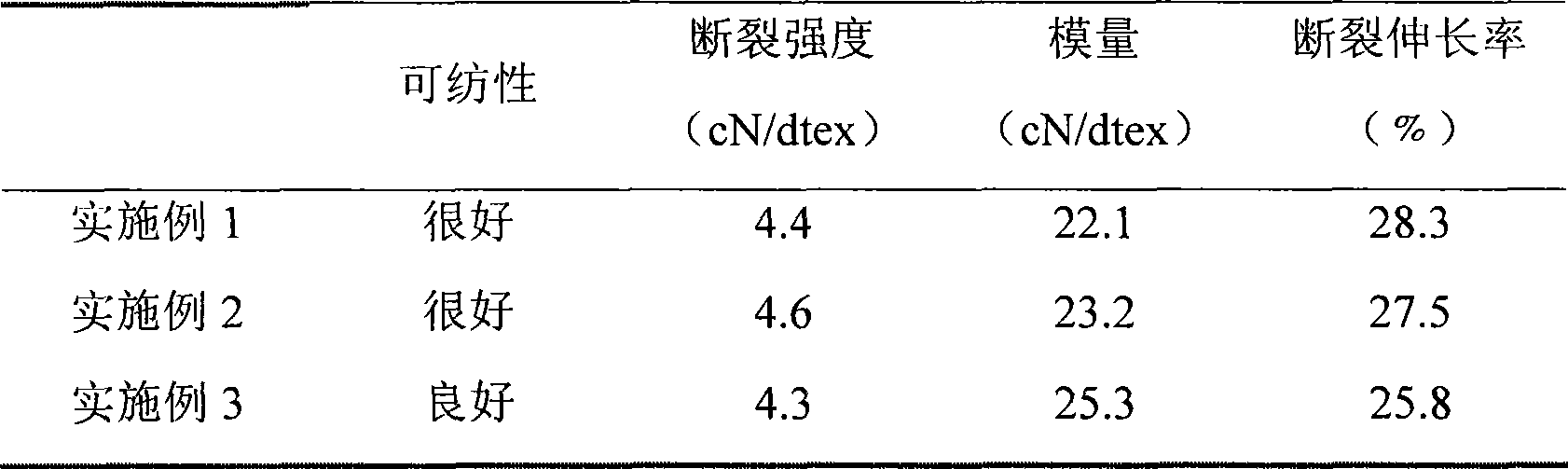

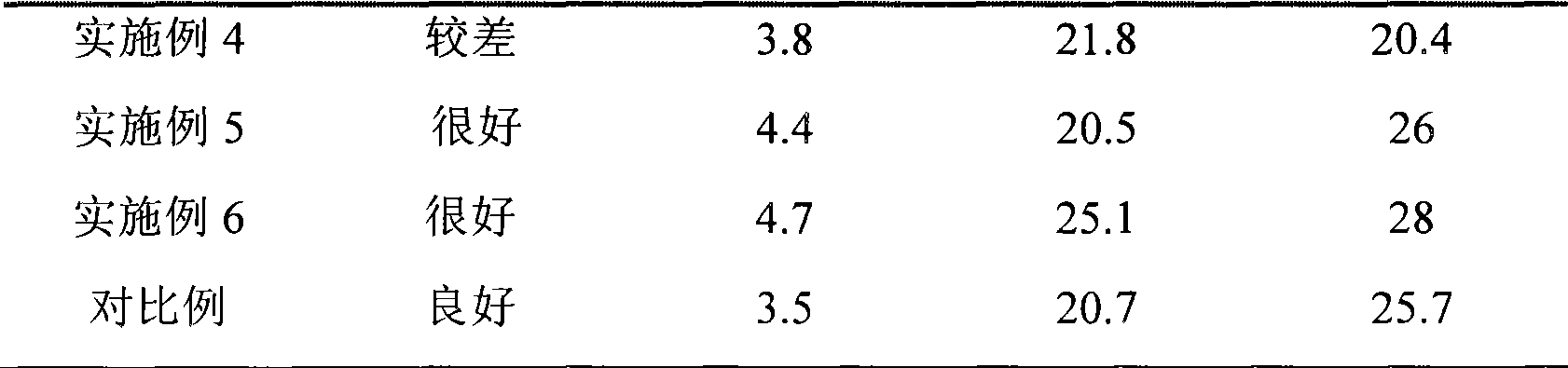

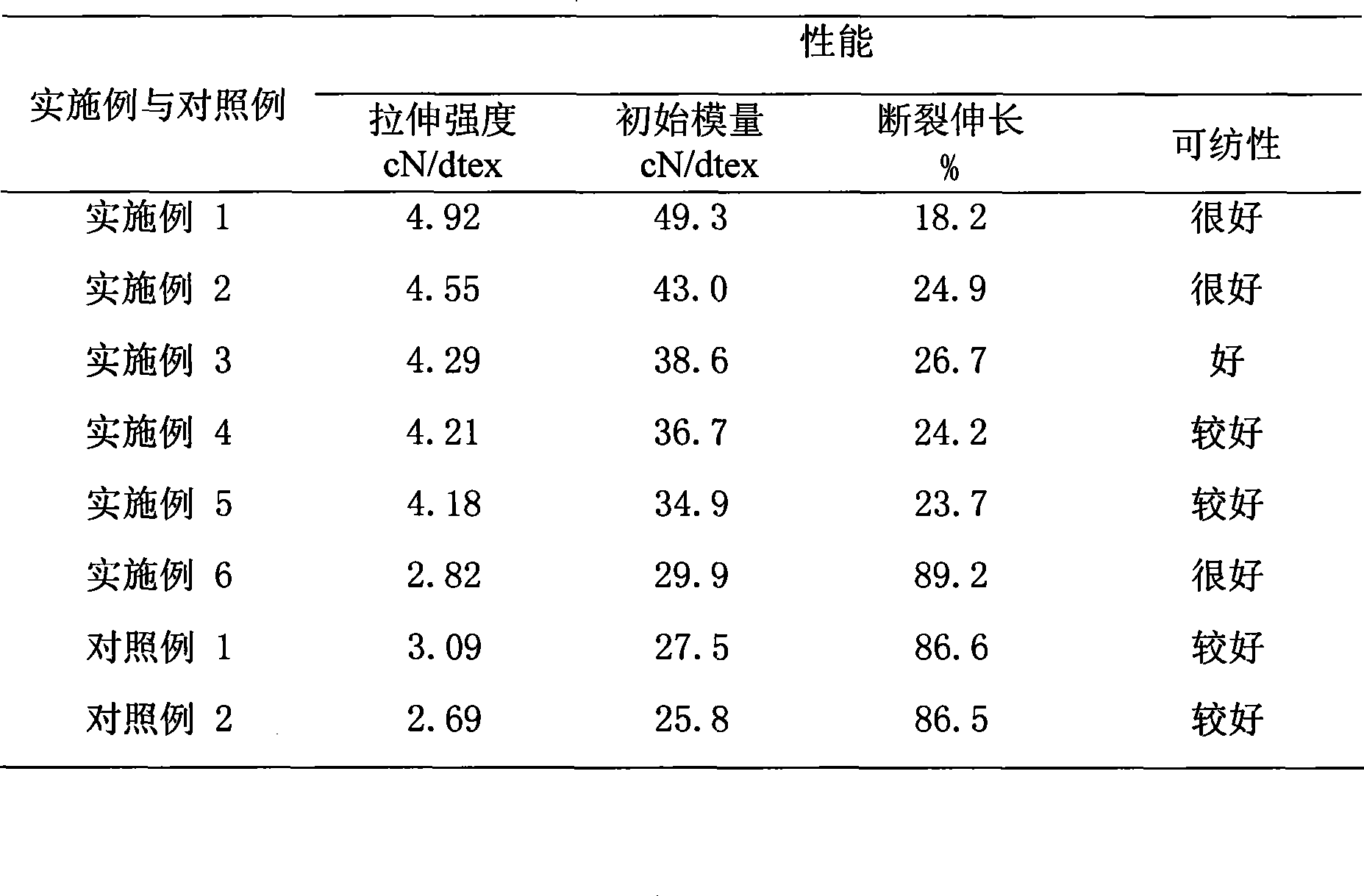

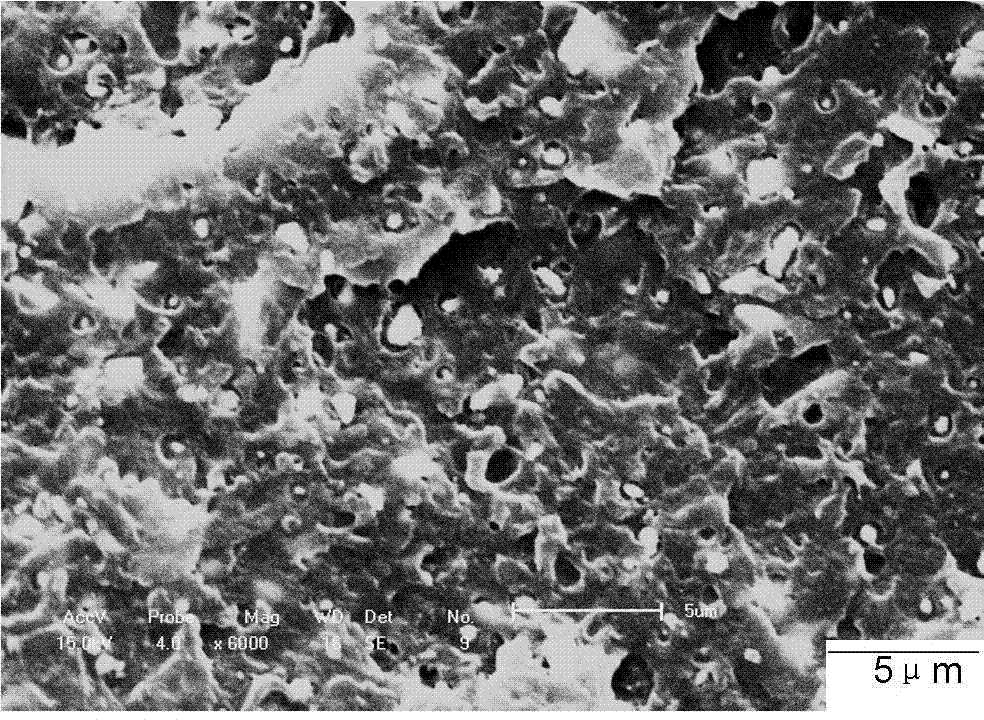

Polyphenyl thioether/ultra-fine calcium carbonate particulate composite fiber and preparation method thereof

InactiveCN101368300ANo severe adhesionsAvoid energy consumptionMonocomponent synthetic polymer artificial filamentMelt spinning methodsTextile fiberChemical industry

The invention relates to polyphenylene sulfide (PPS) / nano-calcium carbonate mixture and a preparation method for the fiber thereof. The method includes the steps of mixing polyester slices, nano-calcium carbonate particulates, reactive monomer and other additives in a high speed mixer while rising the temperature to approximately 205 DEG C so as to enable the polyphenylene sulfide slices to intenerate and the nano-calcium carbonate and other additives to be evenly adhibitted onto the polyphenylene sulfide slices, without heavy conglutination between the particles on the polyphenylene sulfide slices. The polyphenylene sulfide (PPS) / nano-calcium carbonate mixture prepared through the method has excellent processability and can be made into textile fiber, thin film or reinforcement plastics by means of melt blown or melt spinning process. The invention can greatly reduce the production cost and bring good economic benefits. The polyphenylene sulfide(PPS) / nano-calcium carbonate mixture has good thermal stability, flame retardancy, chemical corrosion resistance and good mechanical property and spinning property; therefore the polyphenylene sulfide(PPS) / nano-calcium carbonate mixture is widely applicable to the industrial sectors like chemical industry, light industry and mechanical industry, and is particularly good for accelerating the popularization and application of high-temperature house-bag dust removal. The preparation method has the advantages of simple process, easy control, low cost, short production period, environment friendly and particularly being applicable to the industrial production.

Owner:DONGHUA UNIV

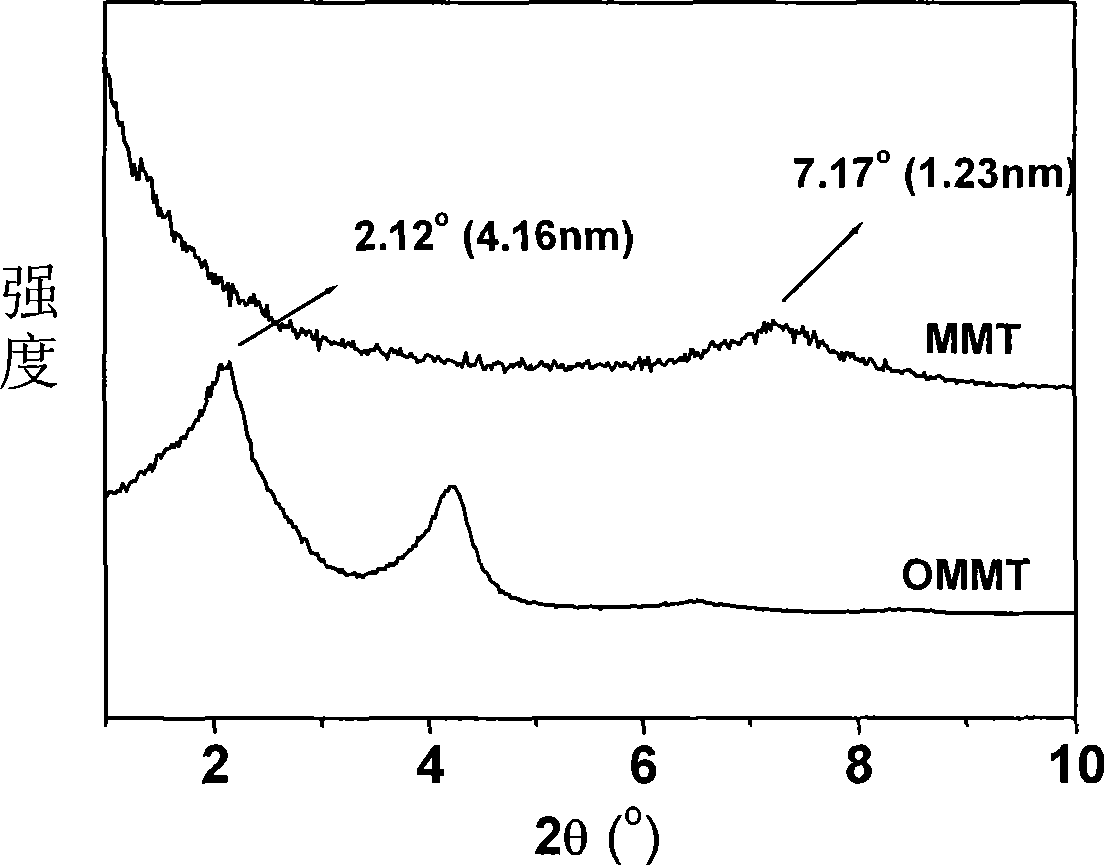

Organic montmorillonite-aqueous polyurethane compound leather finishing agent and method for preparing same

InactiveCN101544820ARestricted free movementImprove mechanical propertiesEthylene diaminePolymer science

The invention discloses an organic montmorillonite-aqueous polyurethane compound leather finishing agent and a method for preparing the same. The method comprises the following steps: firstly using quaternary ammonium salt such as cetyl trimethyl ammonium chloride, octadecyl dihydroxyethyl methyl ammonium bromide and the like, organic amine such as ethylene diamine, octadecylamine and the like, or a silane coupler, polyisocyanate and the like to organically modify montmorillonite to prepare organic montmorillonite; and secondly, performing intercalation reaction of emulsion of a polyurethane resin finishing agent and the organic montmorillonite to obtain the finished product of the organic montmorillonite-aqueous polyurethane compound leather finishing agent. In the method, the quaternary ammonium salt, the organic amine, the silane coupler or the polyisocyanate are used for organically modifying the montmorillonite, so that the interlamellar spacing of the montmorillonite is increased, the micro environment among the lamellas is improved, the compatibility of the montmorillonite and the organic phase is improved, and the intercalation reaction of the polyurethane molecules and the montmorillonite is easily performed; moreover, due to the interlamellar compound of the organic montmorillonite on the polyurethane resin finishing agent, the mechanical property, the thermal resistant stability, the water resistance and the water vapor permeability of the finishing material are improved. When the leather finishing material is applied to leather finishing, the leather finishing material has the advantages of greatly improving the mechanical strength and thermal resistant stability of the coating and having active effects on water resistance, sanitary property and the like of the coating.

Owner:SICHUAN UNIV

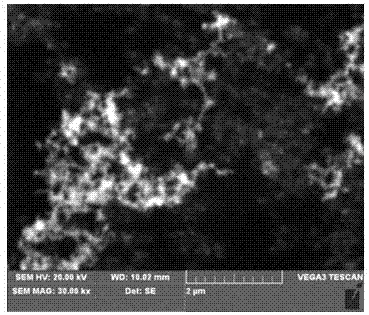

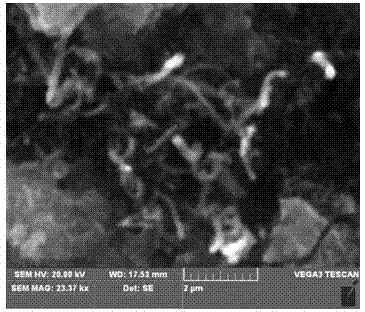

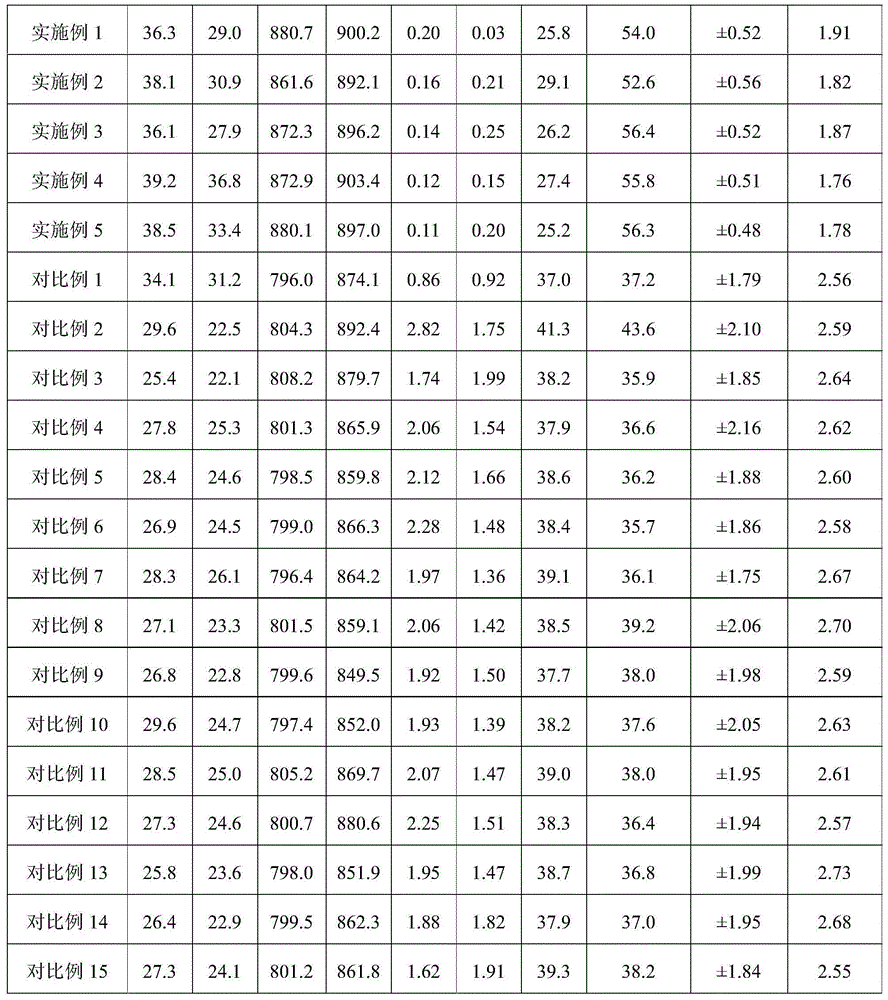

Application and preparation method of helical carbon nano tube

InactiveCN102766286ASimple processLow costMaterial nanotechnologyCarbon compoundsCarbon nanotubeSolid matter

The invention discloses application and a preparation method of a helical carbon nano tube. The helical carbon nano tube serving as a reinforcing material is used for reinforcing rubber. The preparation method includes: placing nickel oxide of the nanometer size into a quartz tube through a carrier; leading nitrogen, then hydrogen and finally acetylene, and conducting reduction to obtain primary products of the helical carbon nano tube; ultrasonic separating the primary product to obtain a deionized solution of the primary product; centrifugal separating the deionized solution to obtain a solid matter and drying; preparing mixed acid of concentrated nitric acid and concentrated sulfuric acid, adding the dried solid matter into the mixed acid, then heating to 90 DEG C and keeping the temperature for 6 hours; and separating the solid matter, washing to neutral and drying to obtain the helical carbon nano tube. The helical carbon nano tube is simple in process, low in cost and easy to achieve and is used for reinforcing the rubber. The rubber reinforced by using the helical carbon nano tube is improved on the aspects of 300% and 500% stress at definite elongation, elongation at break, hardness and abrasion compared with standard rubber reinforced by using carbon black.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

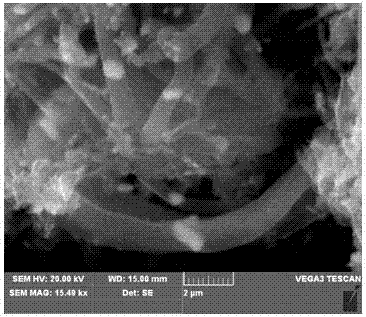

SiC fiber reinforced polyurethane series skid-resistant coating and preparation method thereof

InactiveCN104710926AUniform appearanceGood adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsDefoaming AgentsTitanium dioxide

The invention discloses a SiC fiber reinforced polyurethane series skid-resistant coating and a preparation method thereof. The skid-resistant coating is prepared from a component A, a component B, a component C, and other components through mixing, wherein the component A comprises polytetramethylene ether glycol, liquidated MDI, and E44 type epoxy resin; the B component comprises SiC short fiber, Al2O3 and a surface modifier; the component C comprises liquidated MDI, a chain extender, BaSO4, titanium dioxide and talcum powder; other components comprise a diluent, a defoaming agent and a levelling agent. The preparation method comprises the following steps: all components in the component A are mixed, so that the component A is prepared; all components in the component B are mixed, so that the component B is prepared; the component B, which accounts for 3-8% of the component C is mixed with the component C, and other components are added into the mixture so as to obtain a component D; finally, the component A and the component D are mixed according to the mass ratio of 1: (1-1.1), so that the skid-resistant coating is prepared. The skid-resistant coating disclosed by the invention is high in friction coefficient and adhesive force, excellent in comprehensive performance at low temperature and simple in preparation method.

Owner:NAT UNIV OF DEFENSE TECH

Method for preparing polyester/nano calcium carbonate mixture

The invention relates to a preparation method for a mixed material of polyester / nanometer calcium carbonate, which includes the steps as follows: when polyester chips, nanometer calcium carbonate particles, a reactive monomer and other additives are mixed at a high speed in a high-speed mixing machine simultaneously, the temperature of a mixed system is raised to the temperature of 145 DEG C by utilizing a method of mixed heating or added heating to soften the polyester chips and to lead the nanometer calcium carbonate as well as the other additives to be uniformly stuck on the polyester chips; while no serious conglutination exists between the particles of the polyester chips. The mixed material of polyester / nanometer calcium carbonate prepared by the invention has excellent processing properties and can be used for manufacturing fibers, films or reinforced plastics used for weaving by melt blowing or melt spinning.

Owner:DONGHUA UNIV +1

Preparation method and application method of graphene-based leather finishing agent with high physical properties

ActiveCN109651945AMeet the needs of environmental protection leatherNot easy to fall offWax coatingsPolyurea/polyurethane coatingsPolymer scienceAcrylate ester

The invention relates to the technical field of leather making chemistry and engineering, and provides a preparation method and an application method of a graphene-based leather finishing agent with high physical properties. Graphene oxide is used as a modifying material, and the oxygen-containing groups in the graphene oxide make the graphene oxide have a good water solubility and a good reactionactivity, so the graphene oxide can react with hydroxyl groups, carboxyl groups or amino groups in polyacrylate, polyurethane resin or polysiloxane, or can be combined with the hydroxyl groups, carboxyl groups or amino groups of leather collagen fibers to achieve a low shedding possibility. The polyacrylate, polyurethane resin and polysiloxane are used as carriers to prepare the graphene-based leather finishing agent with a stable homogeneous system, so the dispersion stability of graphene oxide in the polyacrylate, polyurethane resin and polysiloxane is effectively improved, and the advantages of the polyacrylate, polyurethane resin, polysiloxane and graphene are complementary; and the obtained leather finishing agent is applied to the surface of leather to form a uniform graphene-containing film on the surface of the leather, so the performances of the leather coating layer are improved.

Owner:XINGYE LEATHER TECH CO LTD

Polyurethane waterproof coating material

The invention discloses a polyurethane waterproof coating material, which comprises a component A and a component B, wherein the component A comprises: isocyanate, hydroxyl-terminated polyether diol having a molecular weight of 2000-5000, hydroxyl-terminated polyether diol having a molecular weight of 200-1000, a plasticizer and a silane coupling agent, and the component B comprises: hydroxyl-terminated polyether polyol, a plasticizer, an organic solvent, a pigment filler, a catalyst, a curing agent, a high performance auxiliary agent and an acidic aid. According to the present invention, thepolyurethane waterproof material has advantages of high tensile strength, high elongation at break, high right angle tear strength, high bond strength, moisture heat resistance, aging resistance, chemical corrosion resistance, low cost, dense film sheet, high brightness, reliable construction and the like, has all the performances higher than the standards of TB / T 2965-2011 Technical specificationfor waterproof layer of railway concrete bridge, and is especially suitable for railway bridges.

Owner:TANGSHAN DONGFANG YUHONG WATERPROOF TECH CO LTD

Polylactic acid anti-bacterial-activity packaging material and preparation method thereof

InactiveCN104212136AEasy to processAvoid the effects of antimicrobial activityAdditive ingredientAntibacterial activity

The invention discloses a polylactic acid anti-bacterial-activity packaging material and a preparation method thereof and belongs to the technical field of macromolecule. The anti-bacterial-activity packaging material includes, in a blending manner, a matrix resin and natural anti-bacterial plant essential oil, wherein the matrix resin accounts 100 parts by weight and the natural anti-bacterial plant essential oil accounts 2-10 parts by weight. The matrix resin is blended by polylactic acid and polytrimethylenecarbonate with a weight ratio of the polylactic acid to the polytrimethylenecarbonate being (60-90):(40-10). The natural anti-bacterial plant essential oil includes clove essential oil, cinnamon essential oil, fennel essential oil and lemongrass essential oil, thyme essential oil or origanum vulgare essential oil. The ingredients are blended in a double-screw extruder and are prepared into the novel polylactic acid anti-bacterial-activity packaging material through a film blowing machine. The material has a certain tensile strength and a certain elongation at break, can be biologically degraded completely, has an excellent anti-bacterial activity and can be widely applied in the field of packaging.

Owner:KUNMING UNIV OF SCI & TECH

Online double-layer composite plastic blow-molding film sheet and manufacturing method thereof

ActiveCN104527189AImproved material designReduce the temperatureSynthetic resin layered productsBoxesHot pressingMelting point

The invention discloses an online double-layer composite plastic blow-molding film sheet which is formed by softening inner layers of a plurality of layers membrane bubbles which are co-extruded and blow-molded, wherein the inner layers of the membrane bubbles consist of EVA, COC and SEBS; a melting point of materials of the outer layers of the membrane bubbles is higher than a Vica softening point of the materials of the inner layer of the membrane bubbles. By optimizing the materials of the inner layers of the membrane bubbles, sticking is inhibited when the hot-pressing effect is improved, the thickness uniformity, the transparency, the heat-sealing uniformity, and the like of the membrane sheet are improved, the prepared membrane sheet has extensive re-processing capacity; after being heat-sealed and thickened, the membrane sheet is stretched and thinned, so that the film sheet has the performances of a blow-molding material and a flow casting material, and can be used as a packaging box back seal strip on a high-speed packaging body production line. Besides, the invention further discloses a manufacturing method for the online double-layer composite plastic blow-molding film sheet.

Owner:JIANGYIN BAOBO PACKING

Process for manufacturing high-strength low-elongation polytetrafluoroethylene filaments

ActiveCN104294382AHigh strengthFilament quality improvement and breakthroughStretch-spinning methodsCompression moldingPolymer science

The invention belongs to the field of polytetrafluoroethylene functional material manufacturing, and particularly relates to a process for manufacturing high-strength low-elongation polytetrafluoroethylene filaments. The process comprises the steps that disperse polytetrafluoroethylene granules are processed in a low-temperature oil supply mode, cured and subjected to vacuum compression molding, material strips are extruded in a pushing and pressing mode, a thin film is obtained through compression, longitudinal heating stretching is conducted twice, the thin film is slit into flat filaments, the flat filaments are twisted into round filaments, heating stretching and forming are conducted on the round filaments, and the PTFE filaments of different specifications are manufactured. The filaments manufactured through the process meet the ideal indexes of high strength and low elongation, thereby being an improvement and breakthrough in the quality of polytetrafluoroethylene filaments.

Owner:常州华福环境科技股份有限公司

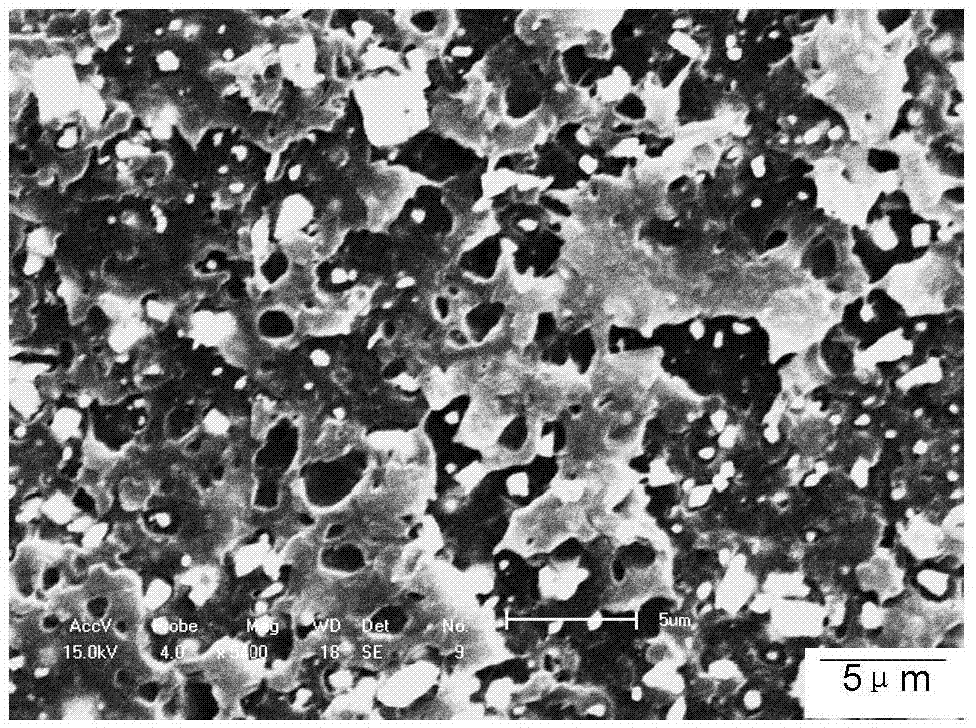

Composite material of polyetheretherketone/organizing montmorillonite and method of producing the same

The invention belongs to the field of special engineering plastics, in particular to a polyether-ether-ketone / organic montmorillonite composite material and a preparation method thereof. Calculated by the mass, the polyether-ether-ketone / organic montmorillonite composite material is prepared by controlling the temperature in all sections of the charging barrel of a double-screw extruder after changing the addition (1 portion to 20 portions) of the organic montmorillonite with 100 portions of polyether-ether-ketone as reference. The polyether-ether-ketone / organic montmorillonite composite material can have properties, such as higher strength, modulus, the same processing window with polyether-ether-ketone, size stability and the like by adding a small amount of organic montmorillonite (1 portion to 10 portions); in addition, because montmorillonite is natural, the resource is rich and the price is low, a large amount of montmorillonite (15 portions to 20 portions) can be added, so as to reduce the cost of the polyether-ether-ketone composite material and not to affect the use properties.

Owner:JILIN UNIV

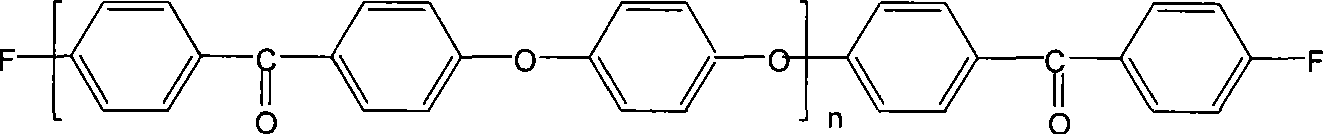

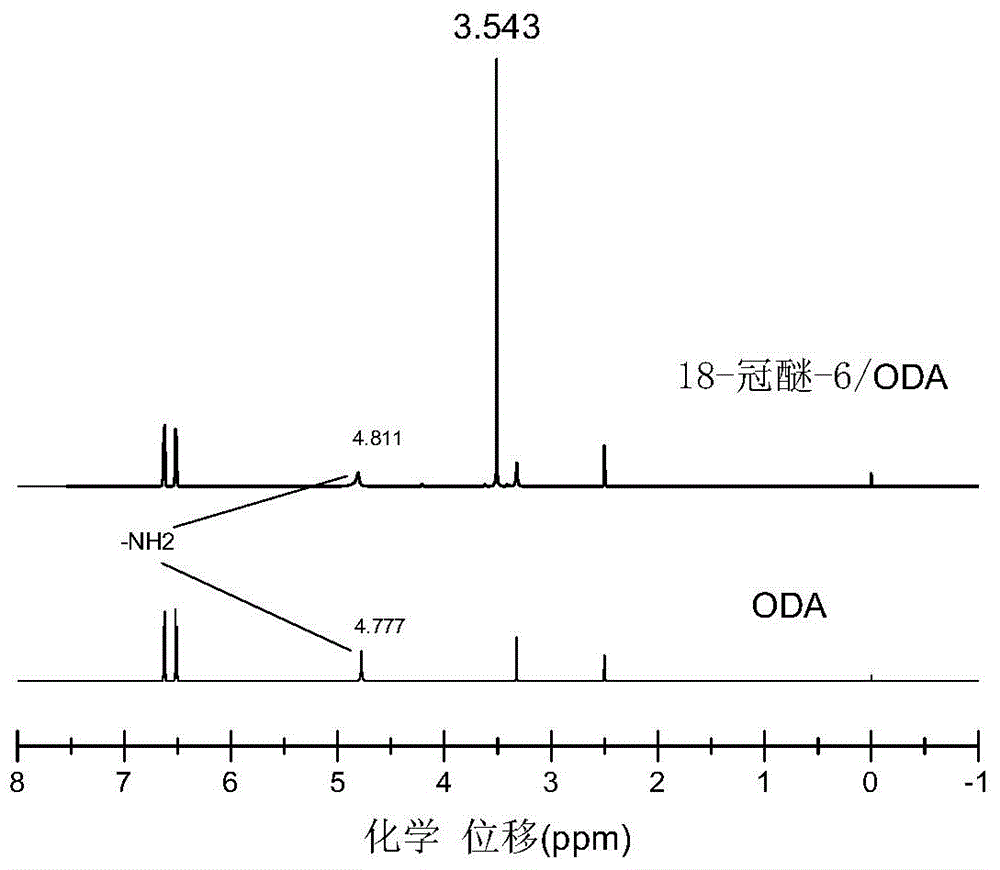

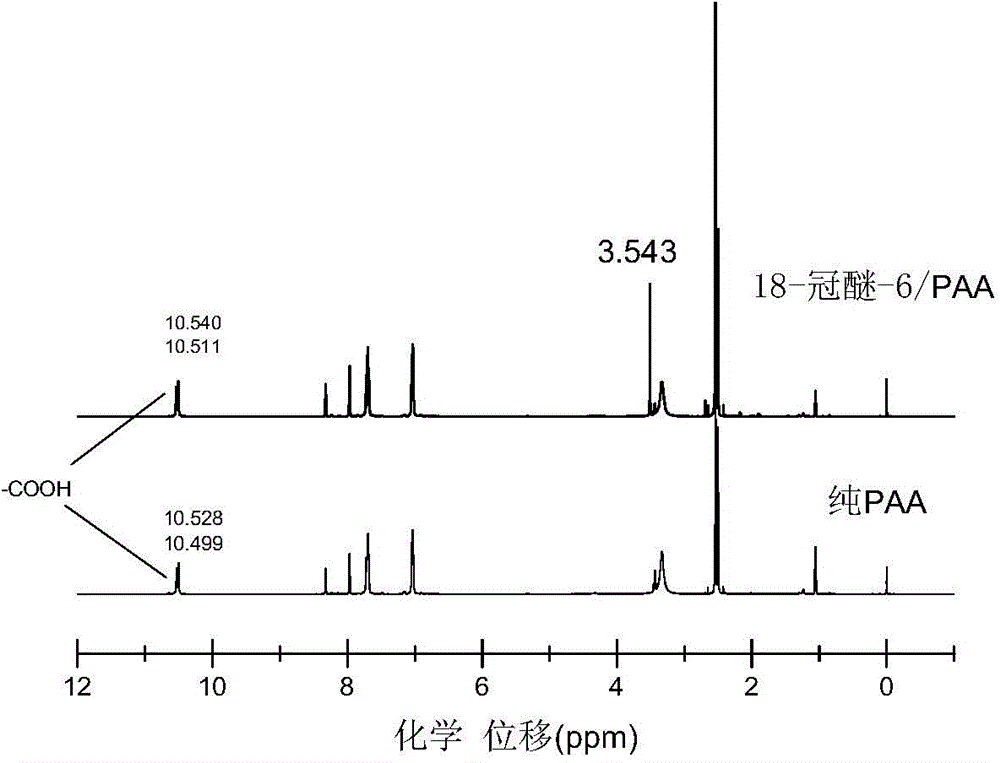

Crown ether modified polyimide hybrid membrane and preparation method thereof

The invention discloses a crown ether modified polyimide hybrid membrane and a preparation method thereof. The preparation method comprises the following steps: under the conditions of the humidity lower than 50%, room temperature and mechanical stirring, in an atmosphere of nitrogen, dissolving crown ether and aromatic diamine into a polarity organic solvent until the crown ether and the aromatic diamine are completely dissolved, continuing to stir to obtain a crown ether / diamine inclusion compound solution, adding aromatic dianhydride to the crown ether / diamine inclusion compound solution, after adding the aromatic dianhydride, continuing stirring to obtain a crown ether modified polyamide acid solution, uniformly smearing the crown ether modified polyamide acid solution on a clean glass sheet, eliminating bubbles, raising the temperature according to the setup program, after treatment, cooling the glass sheet to the room temperature, stripping off the membrane, drying and obtaining the crown ether modified polyimide hybrid membrane. In the invention, the crown ether molecules sleeve the polyamide acid chains to form necklace type supramolecular structures; the polyimide molecular chains are extended to be three-dimensional from two-dimensional type, so that the flexibility of the molecular chains is reduced, and the rigidity is promoted.

Owner:SOUTH CHINA UNIV OF TECH

Manufacturing method of non-woven needling adhesive tape substrate

ActiveCN103451854ATo achieve the effect of tearingLittle strengthNon-woven fabricsPolyesterVolumetric Mass Density

The invention discloses a manufacturing method for a non-woven needling adhesive tape substrate. The method comprises the following steps: mixing 80-95 percent by weight of regenerated polyester fiber and 5-20 percent by weight of low-melting-point chopped fiber serving as raw materials; mixing, opening, feeding, carding into a net, lapping and needling to form a non-woven cloth layer; and performing hot rolling treatment and calendaring treatment on the non-woven fabric layer to obtain the non-woven needling adhesive tape substrate, wherein the liner density of the regenerated polyester fiber is 0.9-2.0D, and the fiber length is 36-51 millimeters; and the linear density of the low-melting-point chopped fiber is 1.0-3D, the fiber length is 38-51 millimeters, and the gram weight of the adhesive tape substrate is 50-80 g / m<2>. According to the method, the tearing property of the entire adhesive substrate can be realized, and the non-woven needling adhesive tape substrate has the characteristics of freeness from burrs and high surface flatness.

Owner:福建鑫华股份有限公司

Nylon 6/superfine calcium carbonate microparticle complex fiber and preparation method thereof

InactiveCN101363143AReduce manufacturing costEase of industrial productionMelt spinning methodsArtifical filament manufactureYarnMicroparticle

The invention relates to a composite fiber of nylon 6 / ultra-fine calcium carbonate particles and a preparation method thereof. The temperature is raised to 140 DEG C so that nanometer calcium carbonate and other additives are evenly wrapped and stuck on the nylon resin, whereas the inter-particles of the nylon resin do not have severe conglutination. The composite fiber comprises the following component with the weight parts: 85-100 parts of nylon slices, 0.5-15 parts of ultra-fine calcium carbonate particles and 0.01-0.5 parts of surface treatment agent; the preparation method is as follows: (1) raw materials are weighed according to the weight parts; (2) calcium carbonate particles and the surface treatment agent are blended and mixed in a high-speed mixer, and added with the nylon slices to be well blended; after the mixture reaches 180 DEG C to 230 DEGC, the heating is ceased; the mixture is stirred and cooled, and then is discharged at a room temperature; (3) after being dried, the mixture is put into a screw extruder for melt spinning, and the winding wires are obtained; (4) drafting and heat setting treatments are applied to the the winding wires, and then drawn yarns are obtained; (5) the follow-up treatment of the drawn yarns is as usual. The fiber has the advantages of good mechanical properties and wear-resistance property and can be widely applied to clothing and technical textiles fields. The invention has the advantages of simple process, easy control, low cost, and short cycle; besides, the invention is environment-friendly and suitable for industrial production.

Owner:DONGHUA UNIV +1

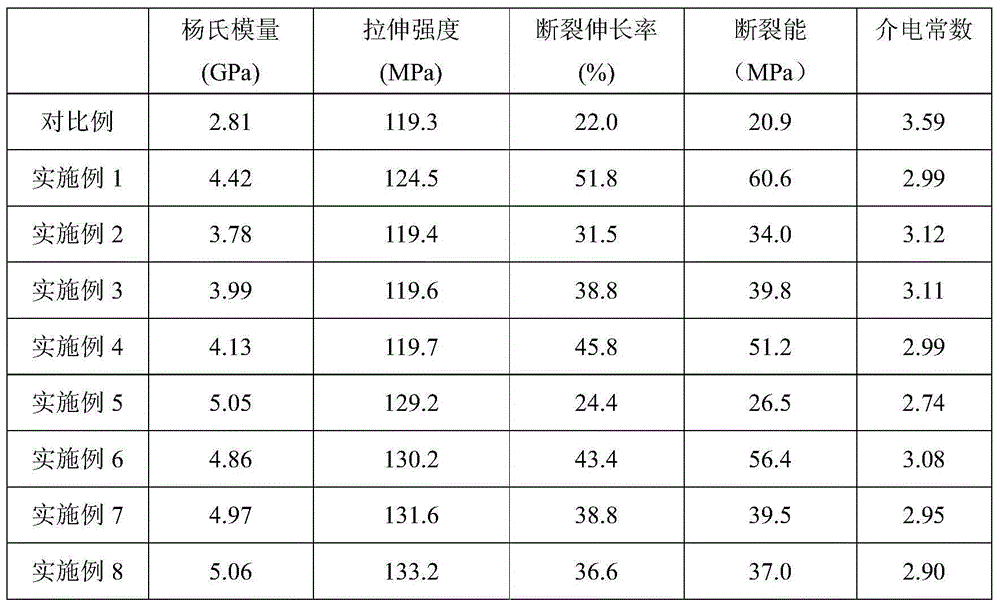

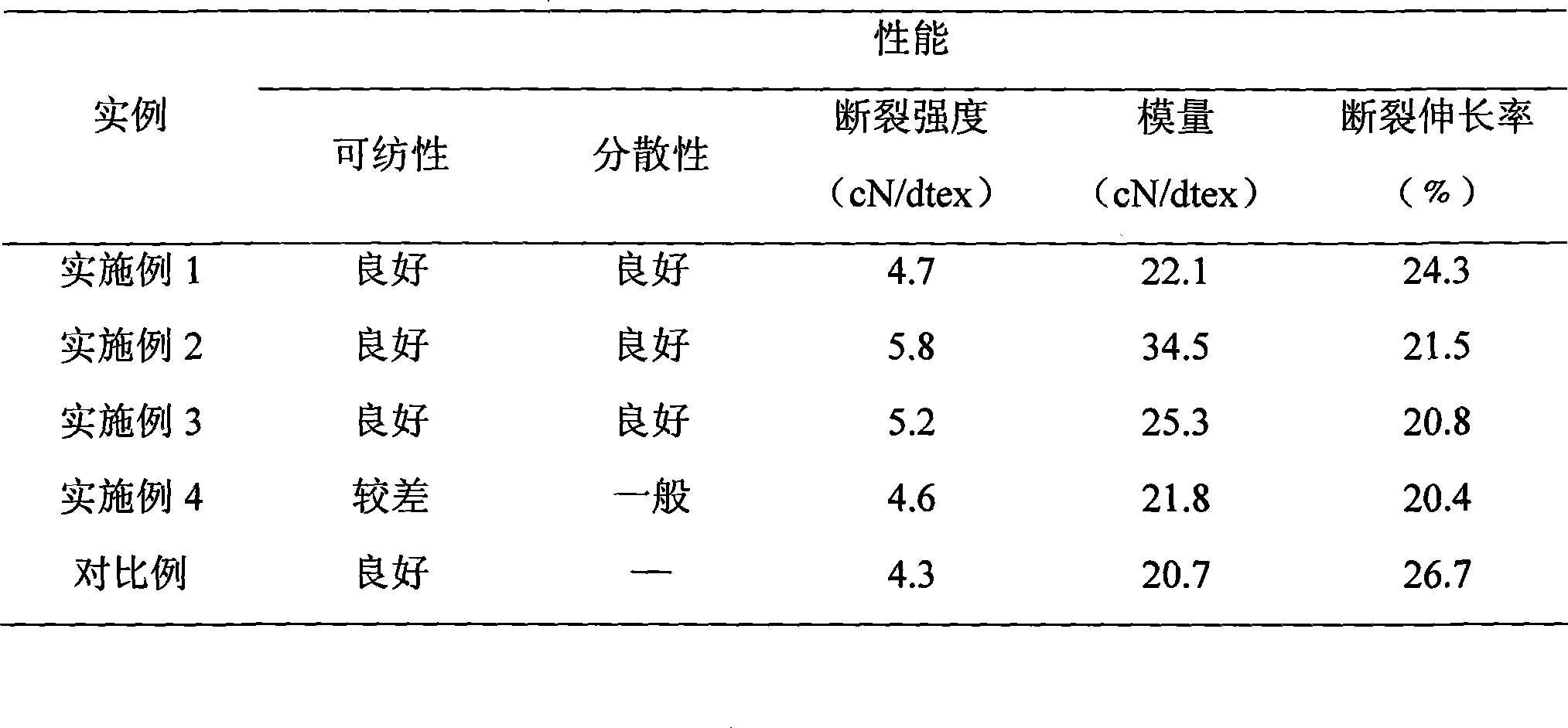

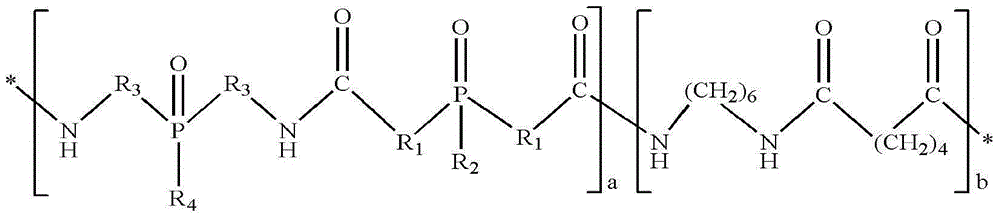

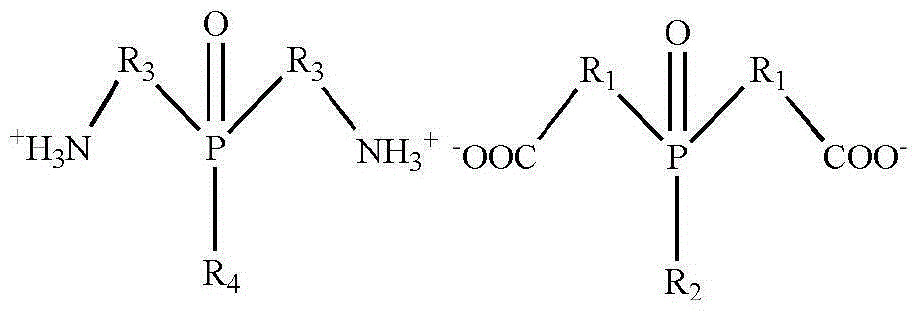

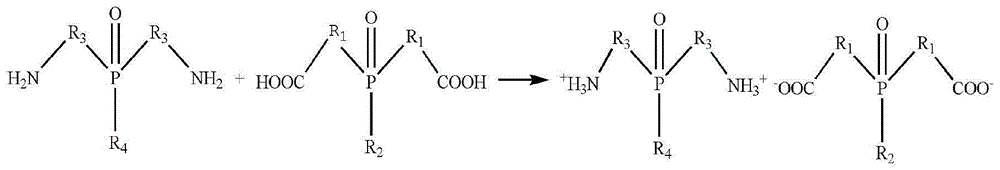

Bi-phosphorous flame-retardant copolymer nylon and preparation method thereof

InactiveCN105153416AHigh viscosityImprove mechanical propertiesMonocomponent polyamides artificial filamentFiberPolymer science

The invention discloses bi-phosphorous flame-retardant copolymer nylon and a preparation method thereof. The nylon is characterized in that a midbody which is synthesized by diamine of phosphine oxide category and dibasic alcohol of phosphine oxide category, namely bi-phosphorous organophosphoryl ammonium salt, is adopted, and the bi-phosphorous flame-retardant copolymer nylon is prepared through copolymerization between the bi-phosphorous organophosphoryl ammonium salt and polyamide 66 salt. The bi-phosphorous flame-retardant copolymer nylon is an amorphous glass form polymer in milk white, the melting range is between 255 DEG C to 275 DEG C, and the relative viscosity is 2.60-2.90; the total phosphorus content of the bi-phosphorous flame-retardant copolymer nylon ranges from 0.6% to 0.8%, the flame retardation level is grade UL-94V-0, the tensile strength is not lower than 75.0 Mpa, and the elongation at break ranges from 54.5% to 60.0%. The bi-phosphorous flame-retardant copolymer nylon has the advantages being halogen-free flame retardant, high in viscosity, free of molten drops and high in mechanical strength, and the nylon can be widely applied to the fields of fibers and textile.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

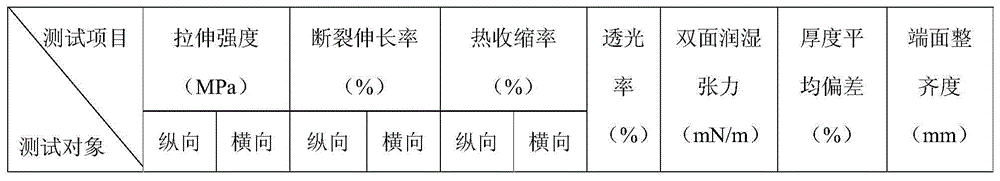

Polypropylene synthetic paper and production method thereof

ActiveCN104943308AReduce light transmittanceIncrease wetting tensionLamination ancillary operationsSynthetic resin layered productsFiberPolymer science

The invention relates to polypropylene synthetic paper and a production method thereof. The polypropylene synthetic paper comprises an outer surface layer, a middle layer and an inner surface layer, and the outer surface layer is obtained by preparing titanium dioxide, calcium carbonate and modified polypropylene copolymer; the middle layer is obtained by preparing polypropylene; the inner surface layer is obtained by preparing the titanium dioxide, the calcium carbonate and the modified polypropylene copolymer. The production method comprises the following steps: 1 extruding the outer surface layer raw materials, the middle layer raw materials and the inner surface layer raw materials through an extruder respectively; 2 extruding the melt of the raw materials which are extruded through the extruder of each layer through a T-shaped die head through a three-layer co-extruding tape casting method, after film is formed, conducting sizing and curing, and obtaining the polypropylene synthetic paper. According to the polypropylene synthetic paper, the surface is flat and smooth, the uniformity of the film thickness is good, and the neatness of end faces is good; the appearance expressive force is good, the light transmittance of the synthetic paper is low, and the wetting tension is high; the thickness control range is wide, traditional fiber paper can be replaced, and the polypropylene synthetic paper is used for presswork, commodity package materials and manufacturing adhesive tapes and tags.

Owner:安徽双津实业有限公司

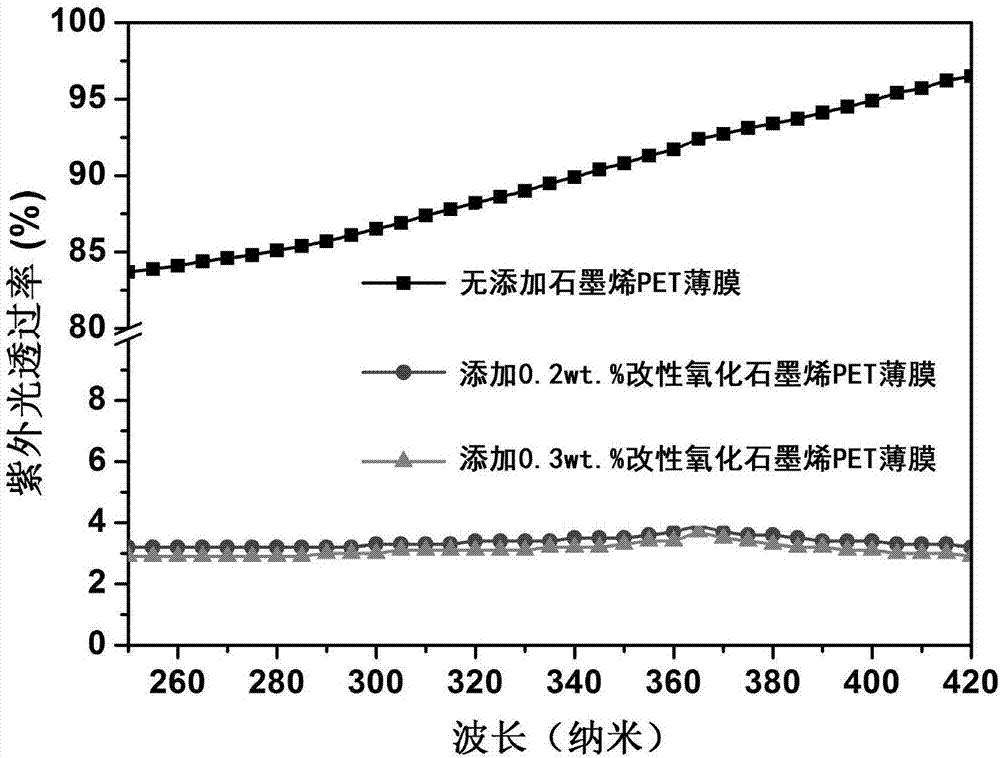

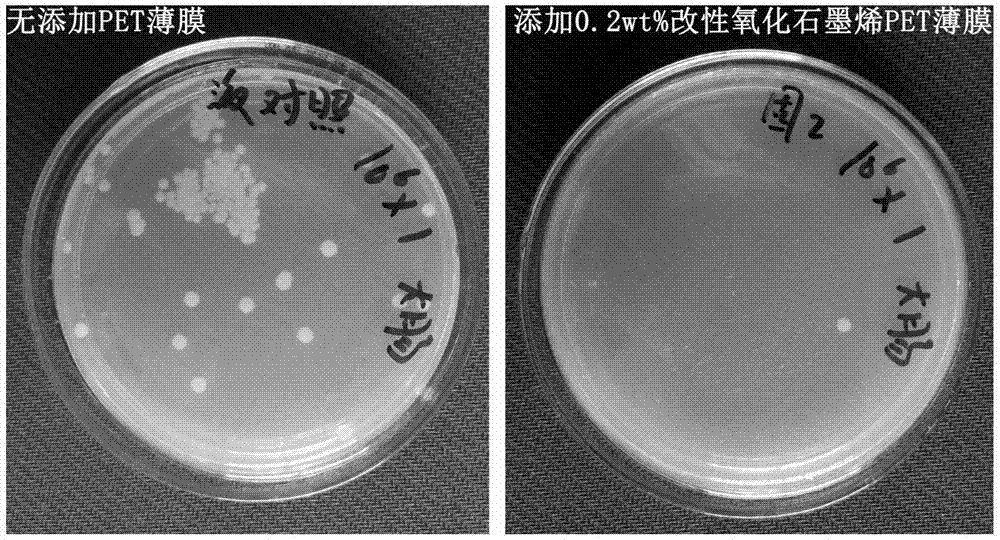

Preparation method of solar cell back plate

InactiveCN107230732AThermally stableSelf-cleaningPhotovoltaic energy generationSemiconductor devicesEngineeringSolar cell

The invention provides a preparation method of a solar cell back plate. The method comprises the following steps of uniformly mixing a graphene filler and resin sections, performing mixing, extrusion, drum sizing and bidirectional stretching in sequence to obtain a solar cell back plate, carrying out the low-temperature plasma treatment on the surface of the solar cell back plate, coating the surface of the back plate of the solar cell by using a coating, and drying and solidifying to obtain the product. Compared with the same type of patents, through the grapheme modification of the PET slice, the invention can realize thermal stability, self-cleaning performance, anti-aging performance, gas / water resistance, and ultraviolet resistance of the PET substrate of the back plate of the solar cell.

Owner:NANTONG QIANGSHENG PHOTOVOLATIC TECH

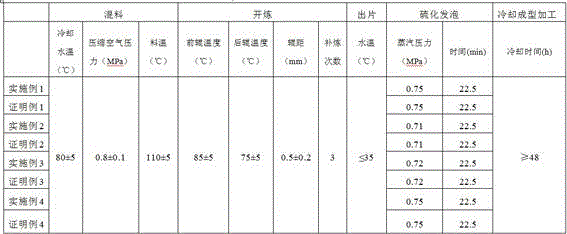

Recyclable foaming material and preparation method thereof

InactiveCN106147036APromote sustainable developmentHigh inorganic filling capacityElastomerChemical composition

The invention provides a recyclable foaming material and a preparation method thereof. The recyclable foaming material is prepared from chemical components including, by weight, 70-80 Phr of PP elastomers, 20-30 Phr of anti-shrinking masterbatch, 1.0-4.0 Phr of a foaming agent, 3.0-5.0 Phr of zinc oxide, 1.0-1.5 Phr of stearic acid, 1.5-2.0 Phr of a peroxide cross-linking agent, 1-1.5 Phr of a crosslinking coagent, 1.0-3.0 Phr of pigments and 10-100 Phr of heavy calcium carbonate. Research finds that the foaming material has the 100% recycling property, the very good flexibility, the excellent handfeel and the very good slip resistance, elasticity and compression performance and provides a good direction for preparation of many foaming products such as shoe materials, packaging materials, yoga mats, bath mats, floor mats and outdoor mats.

Owner:SANSD JIANGSU ENVIRONMENTAL PROTECTION TECH

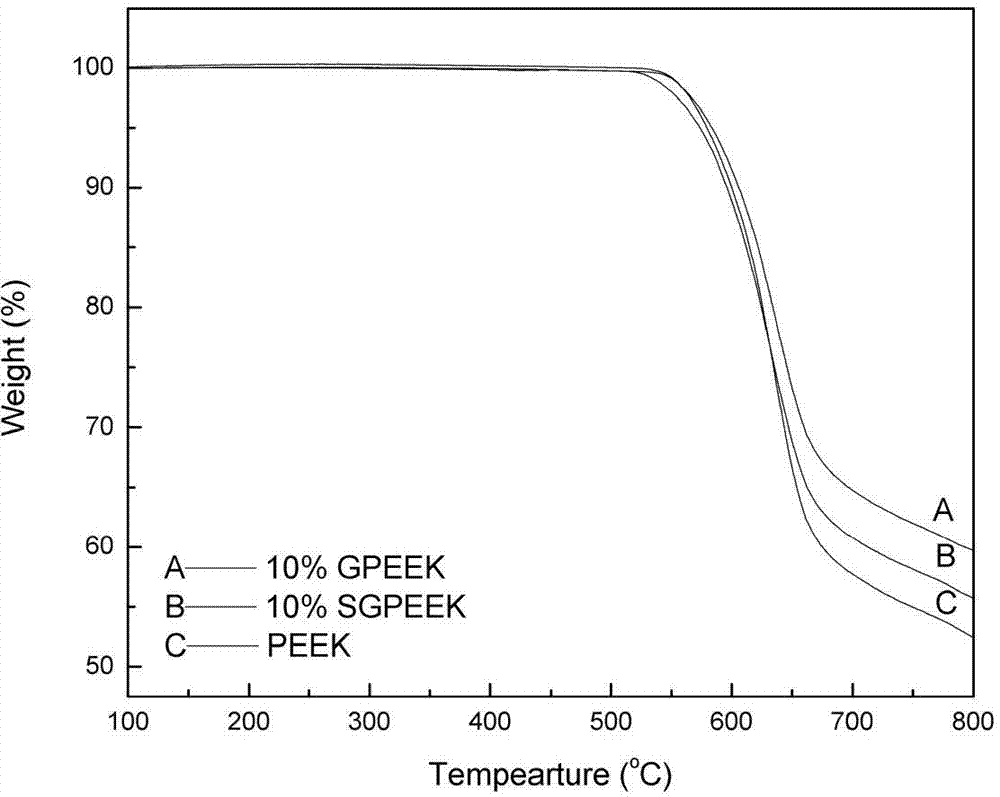

Polyether-ether-ketone composite material containing gadolinium oxide and preparation method of composite material

The invention relates to a polyether-ether-ketone composite material containing gadolinium oxide and a preparation method of the composite material, which belong to the technical field of special engineering plastics. The polyether-ether-ketone composite material comprises the following raw materials in parts by weight: 5-35 parts (X) of the gadolinium oxide, 0-0.08X of sulfonated polyether-ether-ketone and the balance of polyether-ether-ketone. The preparation method of the composite material comprises the following steps of: modified treatment of the gadolinium oxide and melt blending of the raw materials, wherein the modified gadolinium oxide and the polyether-ether-ketone are mixed together, and a double-screw extruding machine is used for carrying out the melting blending on the mixture to obtain the composite material. In order to improve interaction between two phases of the polyether-ether-ketone and the gadolinium oxide in the composite material, the sulfonated polyether-ether-ketone is firstly added into the gadolinium oxide to modify the gadolinium oxide, and then the melt blending is carried out on the mixture, so that the gadolinium oxide can be dispersed well in the polyether-ether-ketone matrix. The composite material has higher strength and modulus, excellent heat stability and a favorable X-ray shielding property.

Owner:JILIN UNIV

Colored special-shaped size-stabilized type polyester monofilament and preparation method thereof

InactiveCN104532388AImprove heat resistanceGood dimensional stabilityArtificial thread manufacturing machinesFilament/thread formingPolyesterPolyethylene terephthalate glycol

The invention relates to a colored special-shaped size-stabilized type polyester monofilament and a preparation method thereof. The colored special-shaped size-stabilized type polyester monofilament is composed of, by weight, 84.5 parts to 99.75 parts of polyethylene terephthalate (PET), 0.2 part to 5 parts of color master batches, 0.1 part to 10 parts of poly(ethylene 2,6-naphthalate) (PEN) and 0.05 part to 1 part of barium sulfate powder. By adding the PEN, the thermal resistance of fiber is improved, and no roller sticking phenomenon can occur even when the heat setting temperature is above 245 DEG C; nanometer barium sulfate plays a role of plasticizer, the slippage among high polymers is improved, the drawing ratio is increased, the fiber contraction rate is decreased, and meanwhile the colored fiber can be more uniform and brighter in color and luster; the high drawing ratio is achieved in the fiber drawing process, induced crystallization produced in the fiber drawing process is improved, and the boiling water shrinkage is decreased; the fiber preparing process is simple, dry strands are uniform, fiber is uniform in thickness, woven fabric is smooth, grids are exquisite and uniform, and a colored special-shaped filament is softer and richer in color so that stylized reflection can be facilitated.

Owner:ZHEJIANG JINXIA NEW MATERIAL TECH CO LTD +1

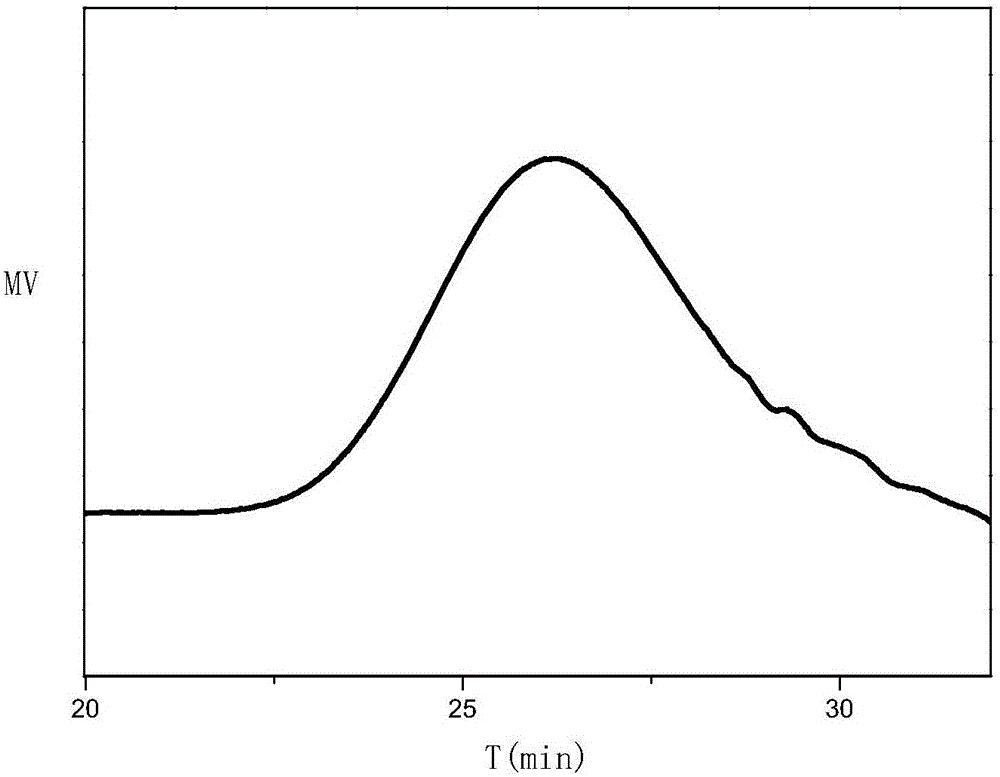

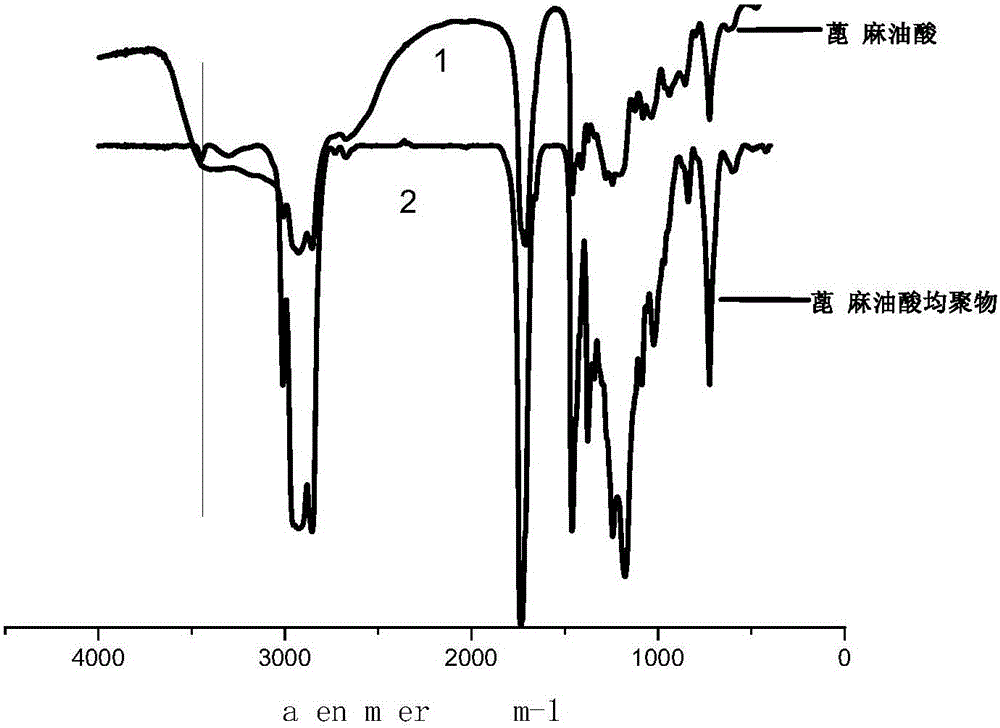

Preparation method of non-migratory rubber plasticizer based on ricinoleic acid homopolymerisation

The invention discloses a preparation method of a non-migratory rubber plasticizer based on ricinoleic acid homopolymerisation and belongs to the technical field of preparation of bio-based materials. Synthesized bio-based polyester can be used for plasticization of common rubber. With the adoption of a ricinoleic acid homopolymerisation method, specific synthesis comprises two steps of pre-polymerization and condensation polymerization, wherein the pre-polymerization stage is completed at the temperature of 160-180 DEG C, the condensation polymerization is completed at the temperature of 200-220 DEG C, the preparation method is simple and convenient to operate, the plasticizer meets the characteristics of a bio-based environment-friendly plasticizer, the processing performance, the mechanical performance, the hardness, the abrasion performance and the like of the rubber can be effectively improved, and the preparation method has better popularization and application values while bio-based environment-friendly plasticizers are vigorously developed at present.

Owner:BEIJING UNIV OF CHEM TECH

Long fiberglass-reinforced polypropylene composite material and preparation method thereof

The invention discloses a long fiberglass-reinforced polypropylene composite material, which is prepared from the raw materials of polypropylene, a compatilizer, a filler, cooling masterbatch, an antioxidant, a coupling agent and a flow modifier at a ratio of 52.4:4:40:1:0.1:0.5:2. The preparation method comprises the steps of: (1) mixing and stirring the raw materials according to the ratio; (2) adding the mixture obtained in the step (1) to a double-screw extruder, extruding melt by a double-screw extrusion mouth mold, and conveying to an immersing device; (3) preheating and drying continuous long fiberglass, conveying to an immersing mold from the mold head, and entering a coating device for coating; and (4) finally cooling, solidifying and pelleting. The composite material has the advantages of high rigidity, high toughness, low elongation at break, high elasticity modulus, resistance to fire, mild, heat and corrosion, good dimensional stability and the like.

Owner:江苏雅泰新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com