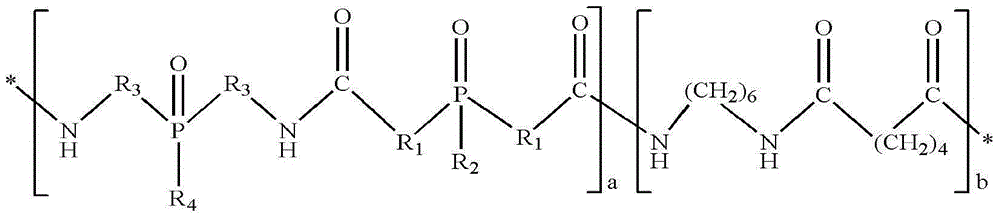

Bi-phosphorous flame-retardant copolymer nylon and preparation method thereof

A technology of copolymerizing nylon and linear alkyl, which is applied in the field of polyamide and its preparation, can solve the problems of unsolved flame retardant decomposition, affecting the flame retardant performance and mechanical properties of flame retardant nylon 66, and achieves droplet-free mechanics Performance, high flame retardancy, high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

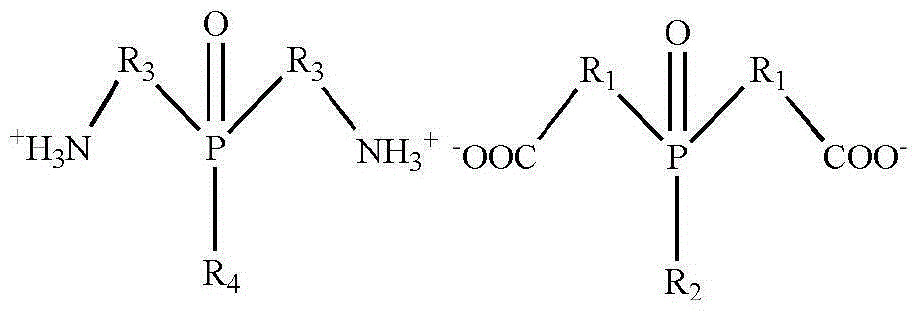

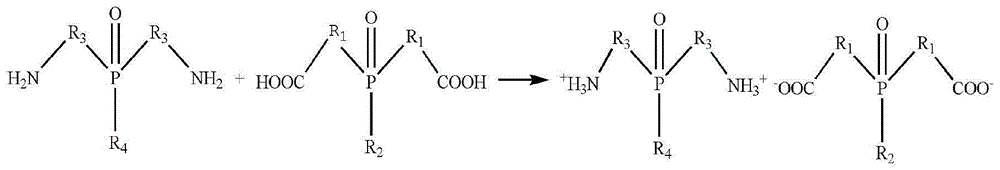

Method used

Image

Examples

Embodiment 1-1

[0042] The phosphine oxide-based dibasic acid BCPPO and the phosphine oxide-based diamine BNPPO were selected as reactants, and the temperature in the heating interval was set at 80°C to prepare 700 moles of bisphosphorus organic phosphine ammonium salt (1#) for future use.

Embodiment 1-2

[0044] The phosphine oxide-based dibasic acid BBPPO and the phosphine oxide-based diamine MDHPO were selected as reactants, and the temperature in the heating interval was set at 80°C to prepare 850 moles of bisphosphorus organic phosphine ammonium salt (2#) for future use.

Embodiment 1-3

[0046] The phosphine oxide-based dibasic acid CEMPO and the phosphine oxide-based diamine CNMPO were selected as reactants, and the temperature in the heating interval was set at 80°C to prepare 900 moles of bisphosphorus organic phosphine ammonium salt (3#) for future use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com