Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

620 results about "Reactive material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In the U.S. military, reactive materials (RM) are a new class of materials currently being investigated by the Office of Naval Research and others as a means to increase the lethality of direct-hit or fragmentation warheads. Reactive materials are similar to insensitive high explosives, but are usually thermite-like pyrotechnic compositions of two or more nonexplosive solid materials, which stay inert and do not react with each other until subjected to a sufficiently strong mechanical, electrical or laser stimulus, after which they undergo fast burning or explosion with release of high amount of chemical energy in addition to their kinetic energy. Fragments or projectiles made of such materials have therefore greater damaging effect than inert ones, with expected lethality increase up to 500%.

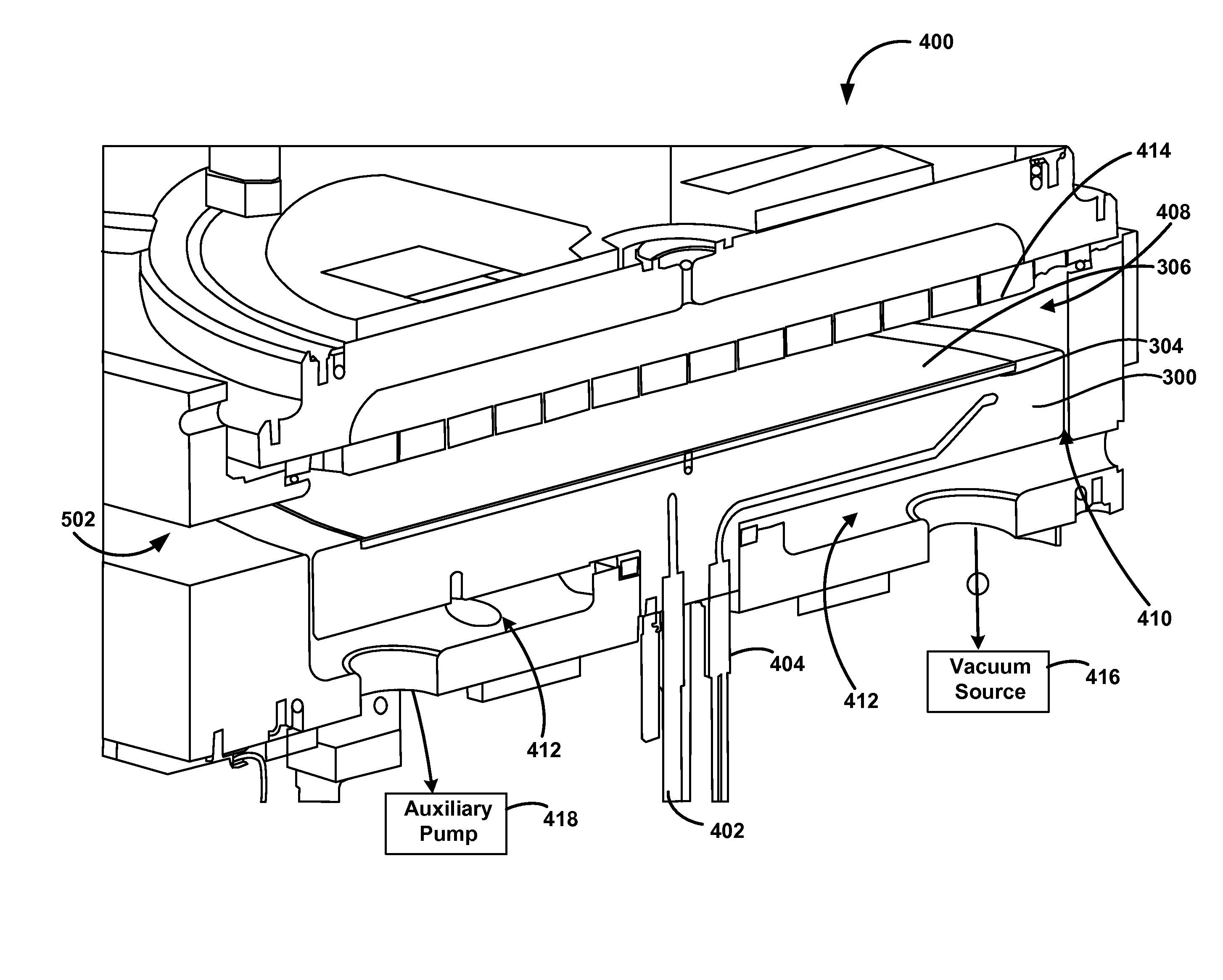

Removable substrate tray and assembly and reactor including same

InactiveUS20150267295A1Easy to replaceReduce manufacturing costFurnaces without endless coreSemiconductor/solid-state device manufacturingReactive materialBiomedical engineering

A substrate tray, a susceptor assembly including a substrate tray, and a reactor including a substrate tray and / or susceptor assembly are disclosed. The substrate tray is configured to retain a substrate during processing and can be formed of a substantially non-reactive material. The substrate tray can be received by a susceptor, formed of another material, to form the susceptor assembly.

Owner:ASM IP HLDG BV

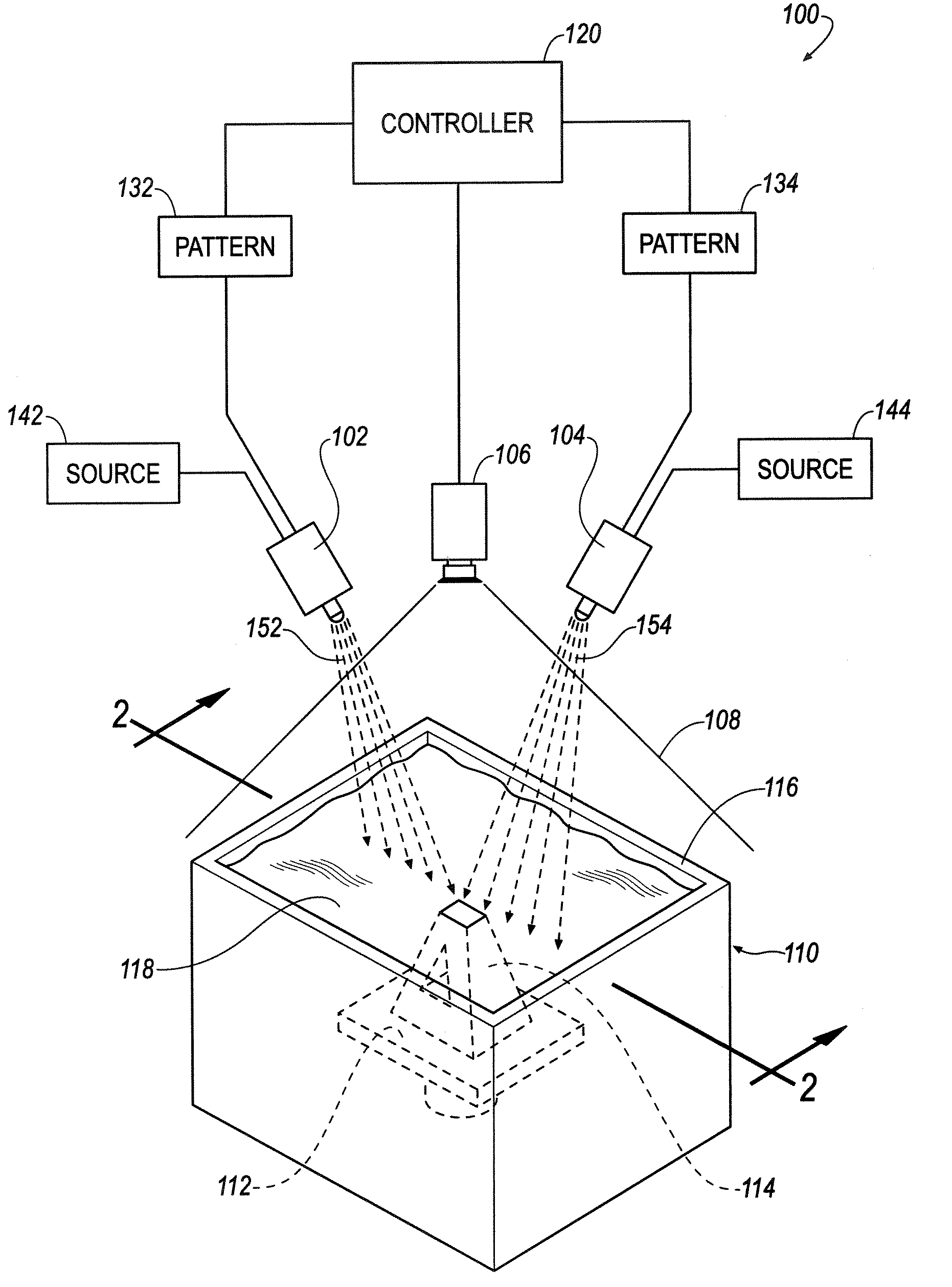

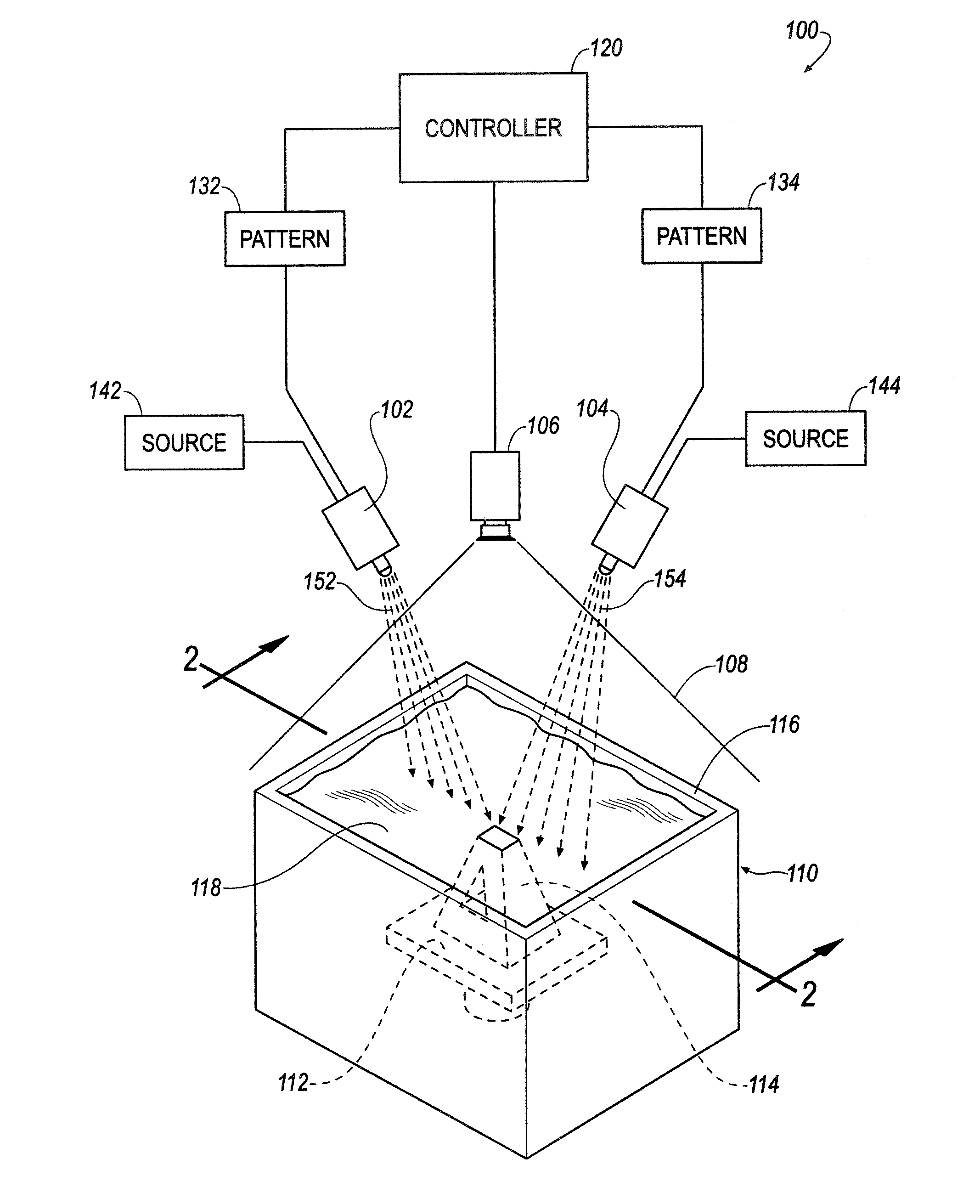

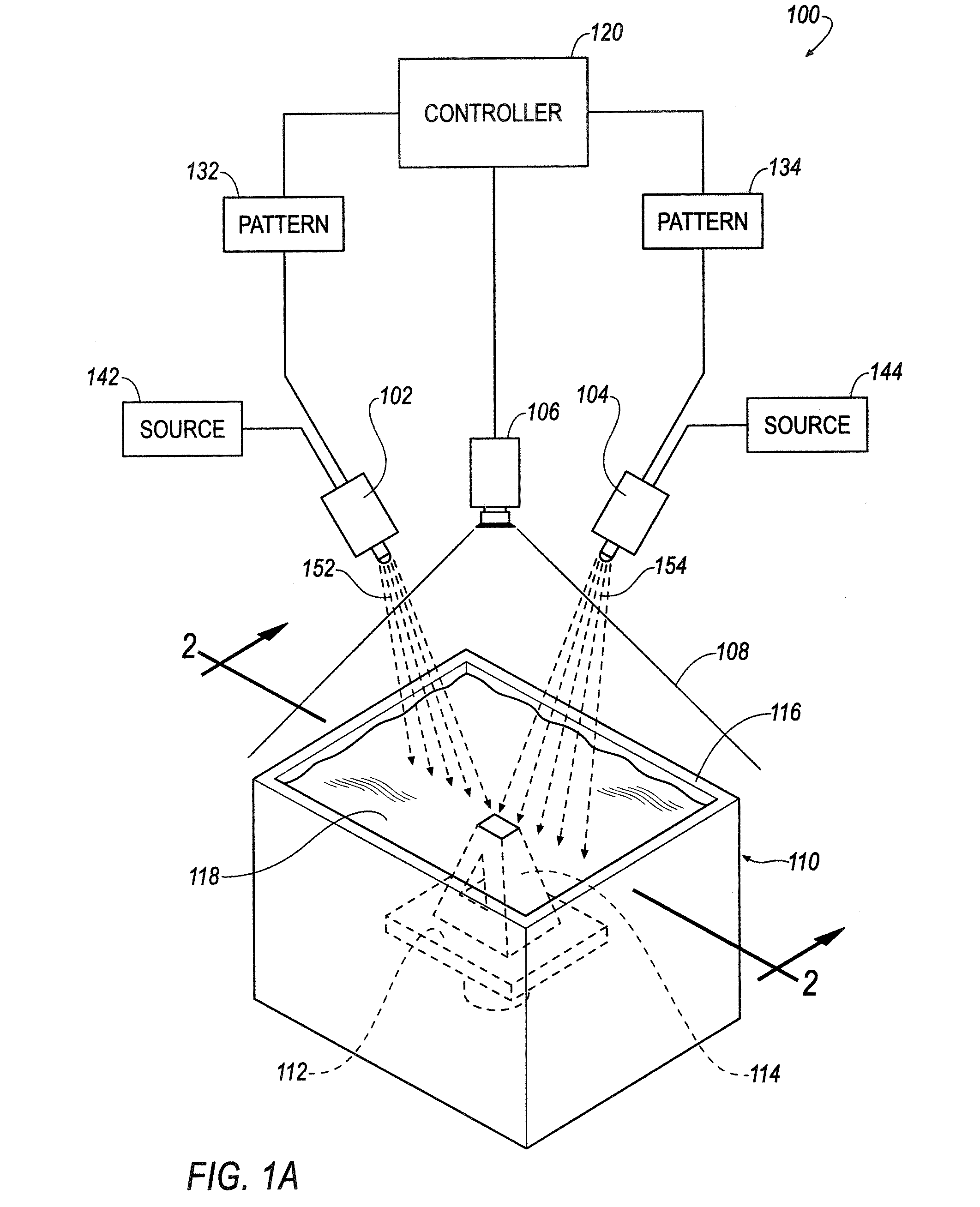

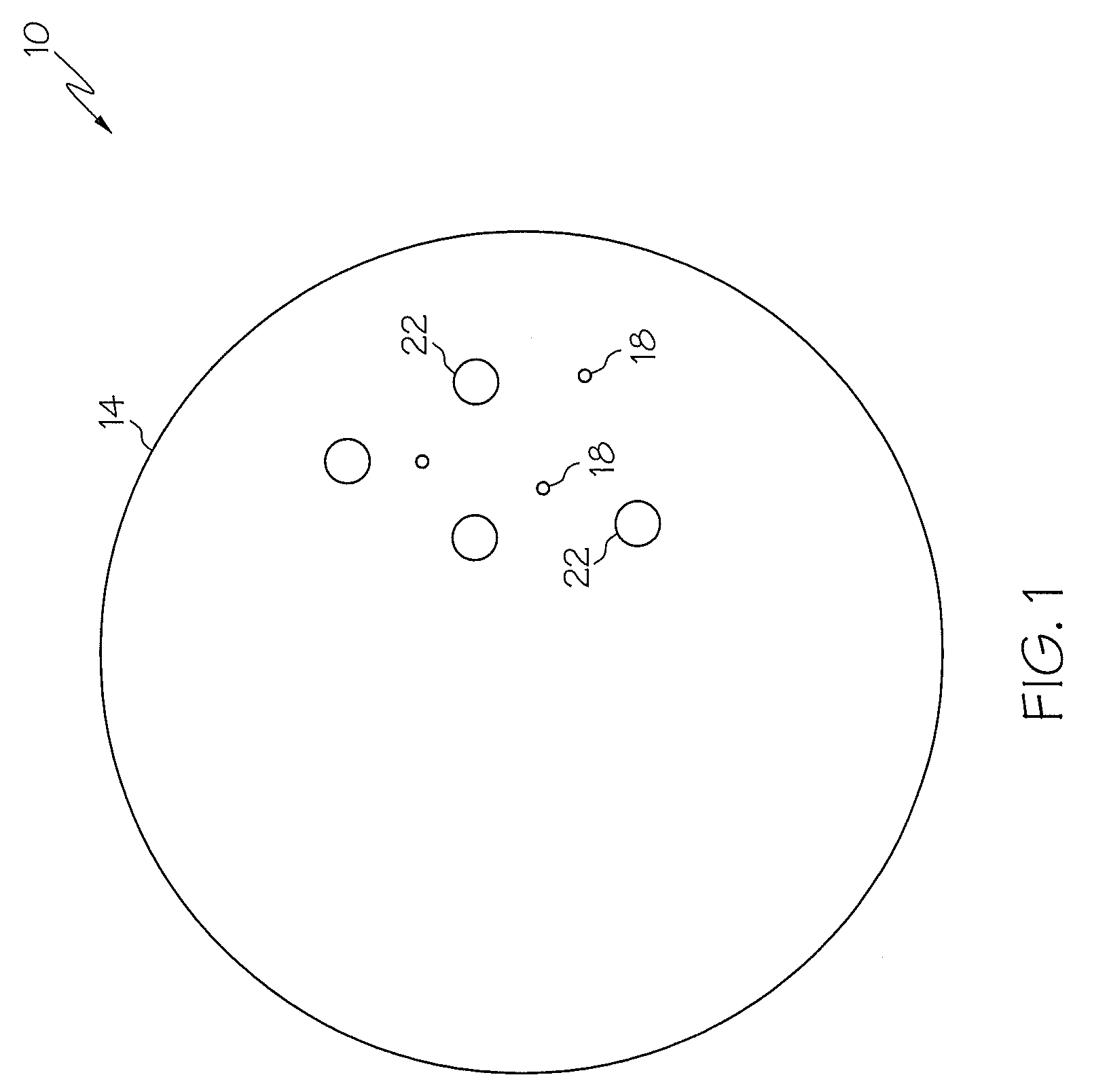

System and Method for Manufacturing

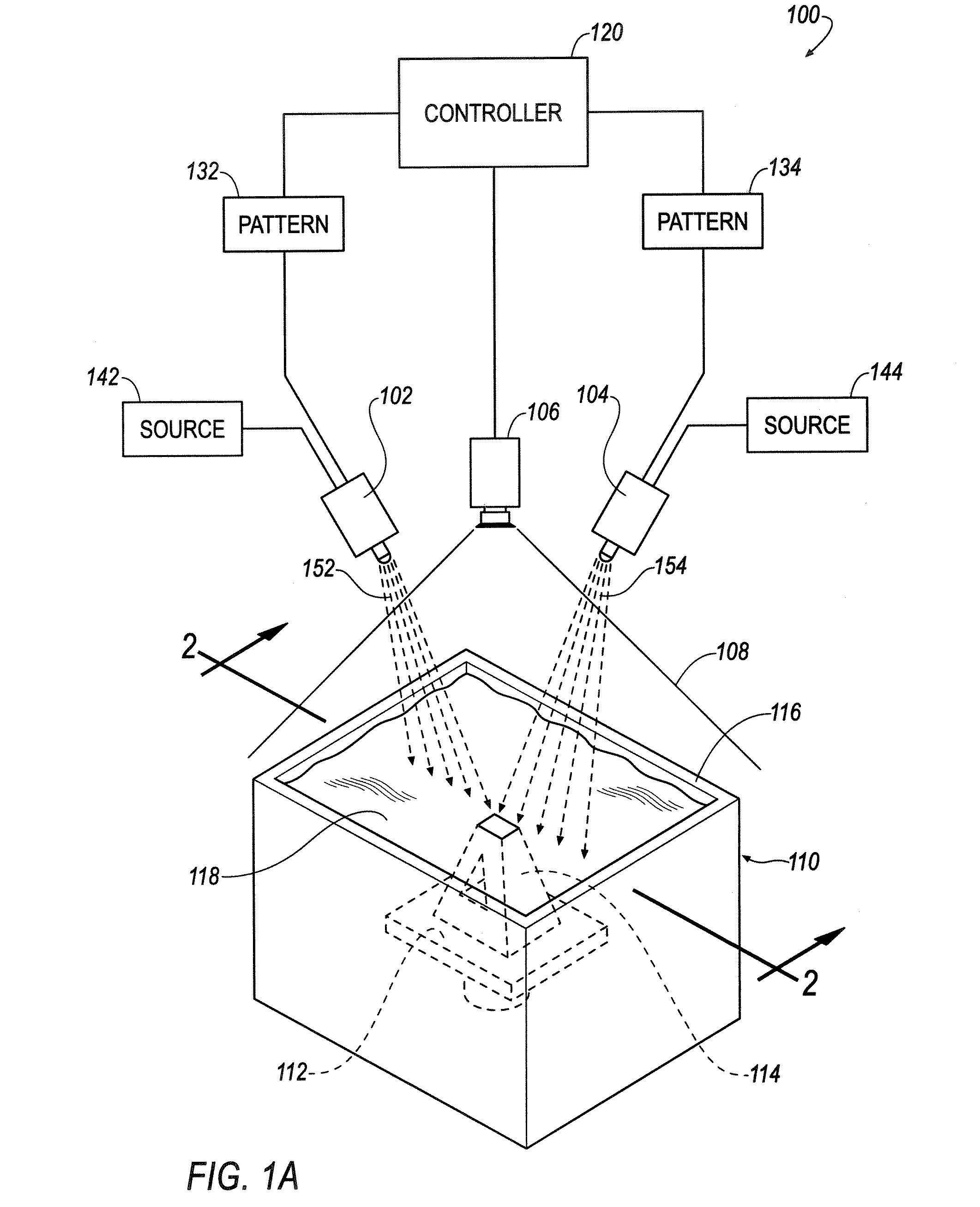

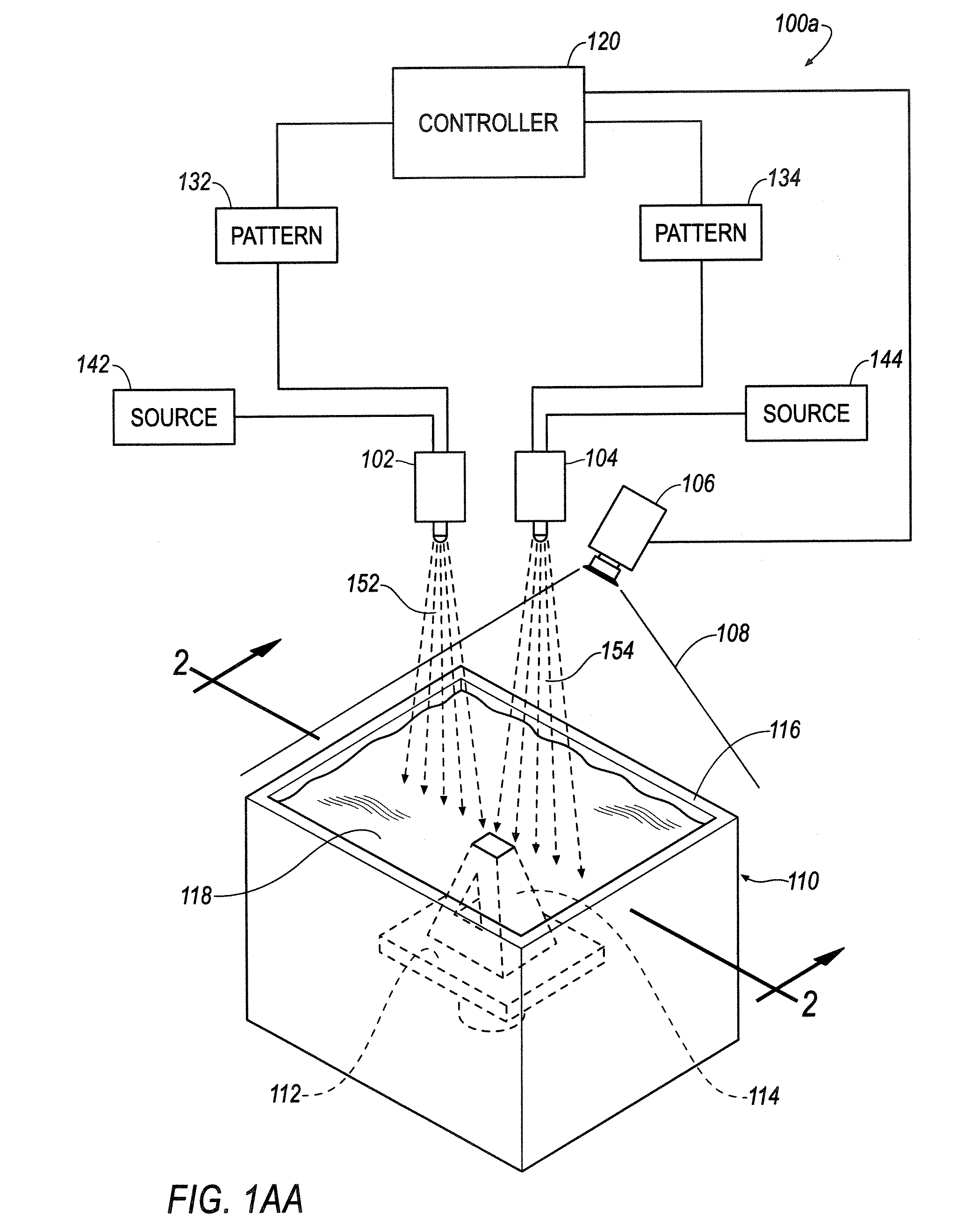

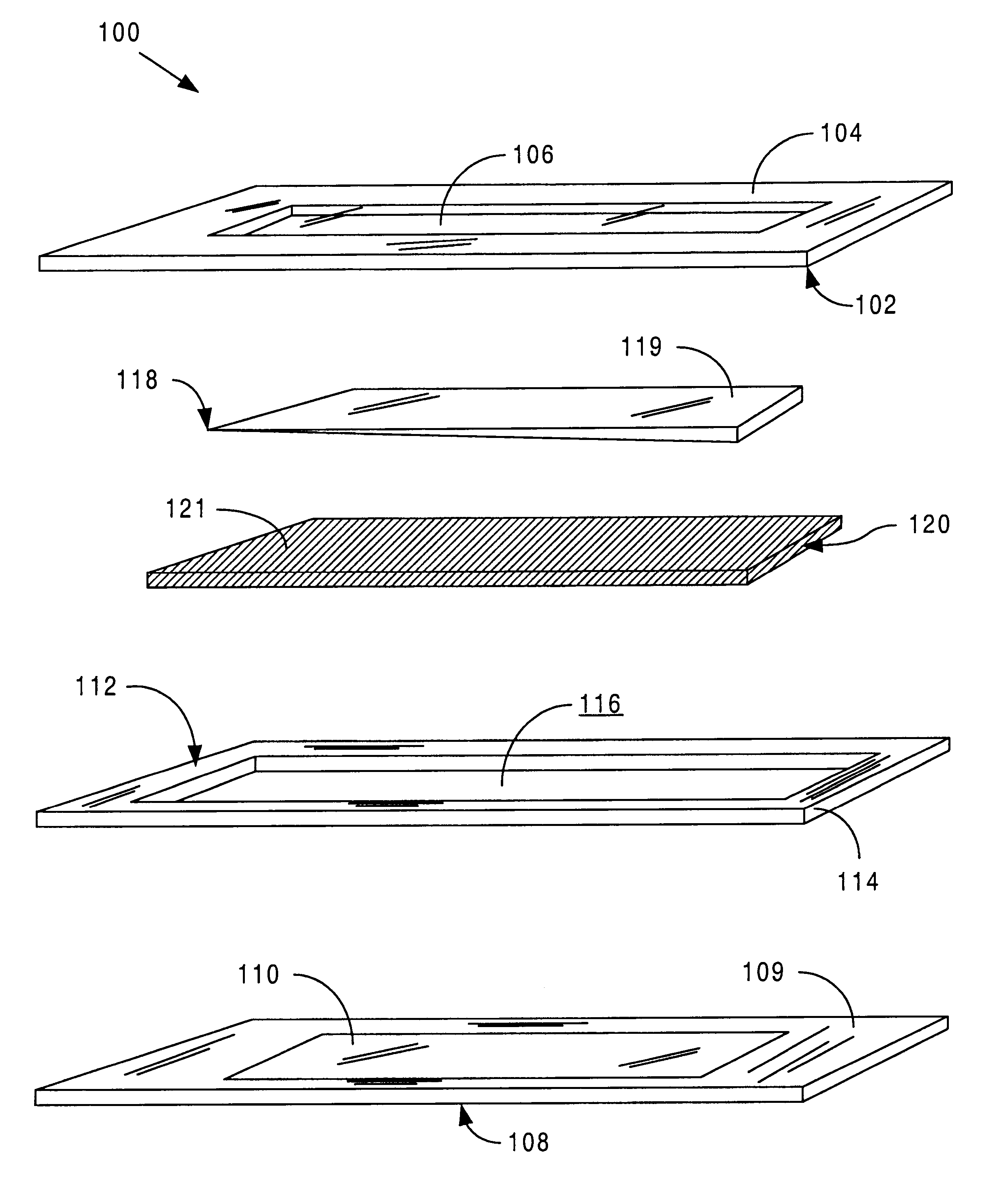

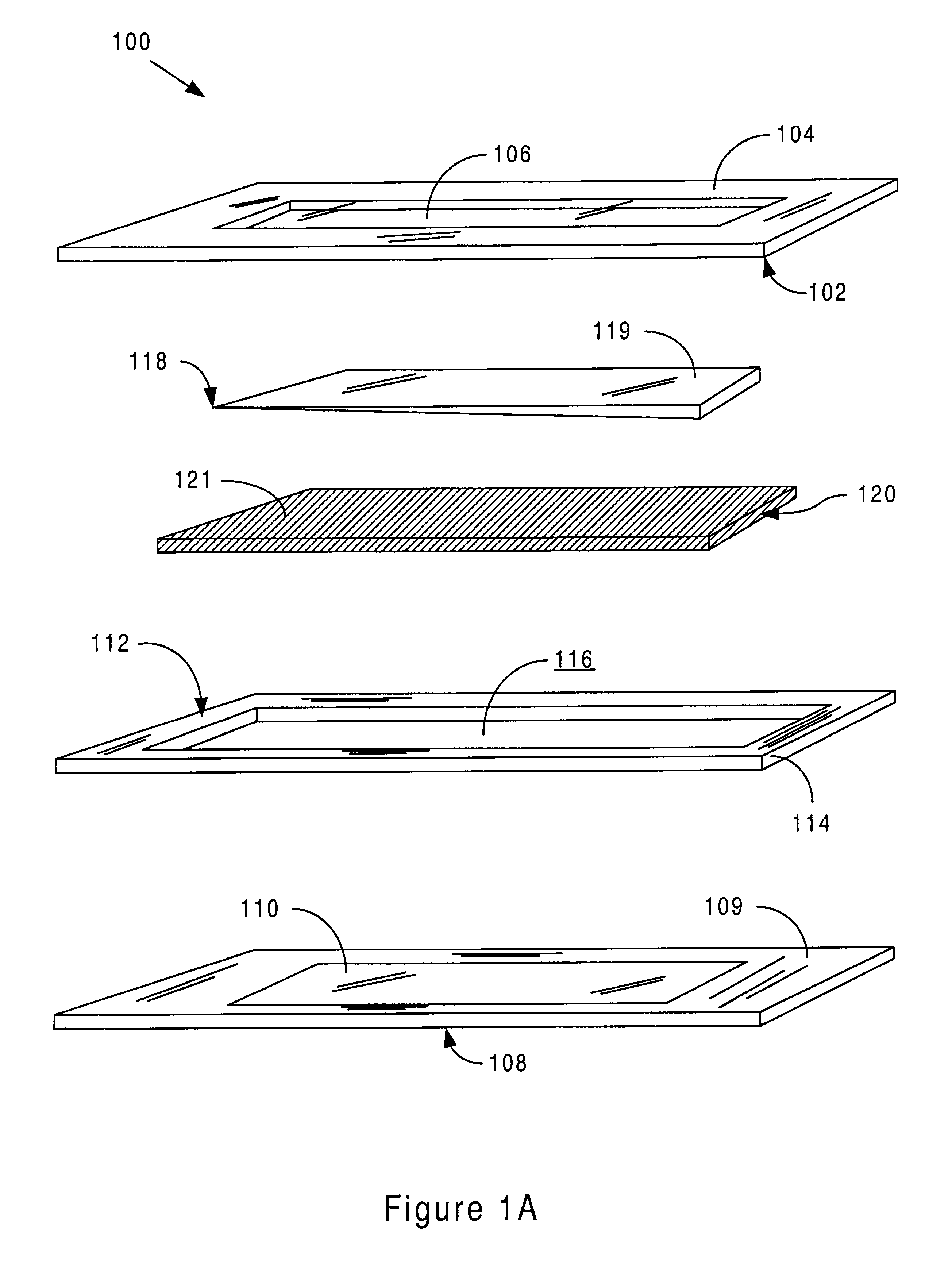

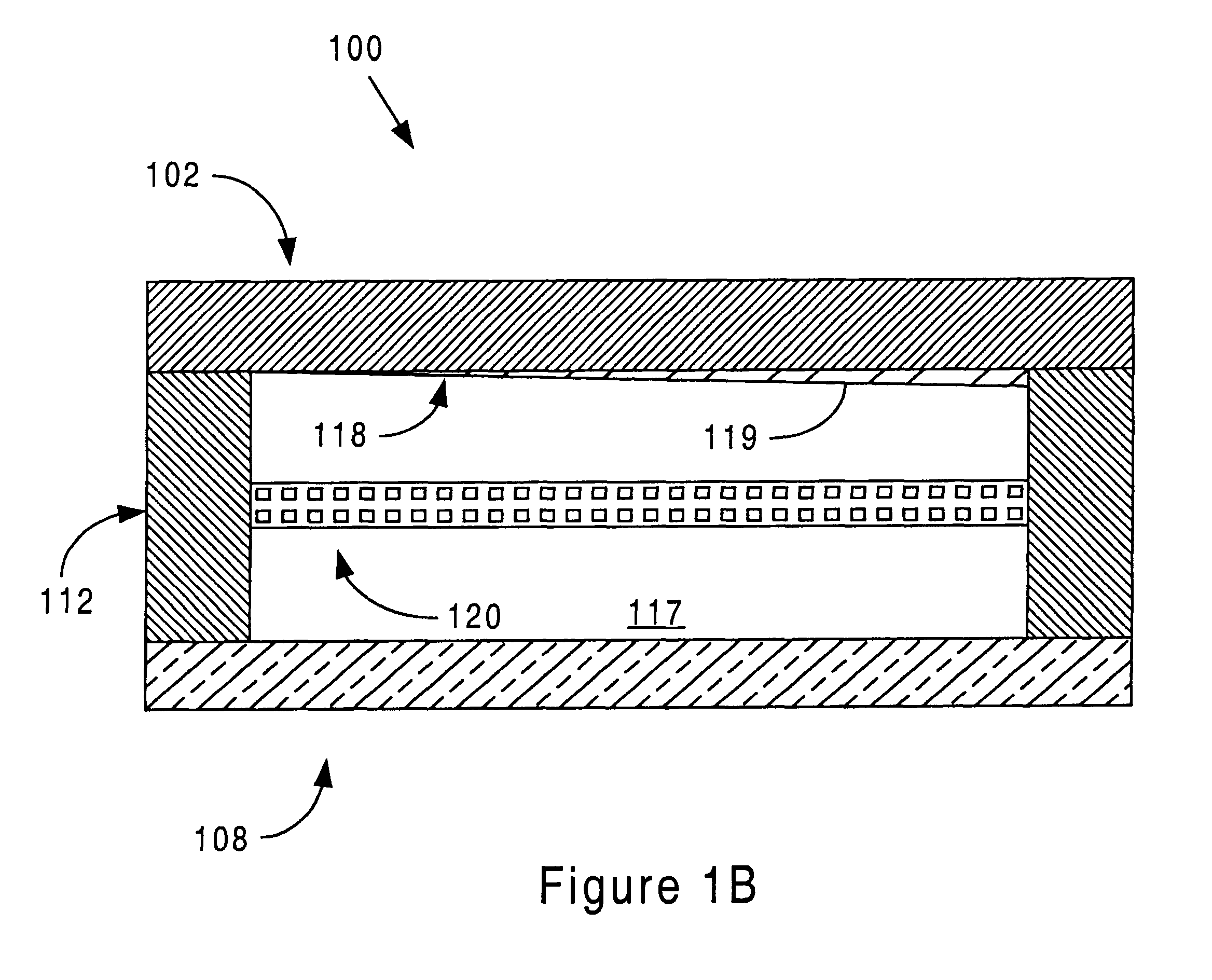

ActiveUS20100125356A1Image enhancementAdditive manufacturing apparatusComputer graphics (images)Reactive material

A method includes receiving a predetermined object pattern representing a portion of a three-dimensional object, modifying the predetermined object pattern to correct for geometric distortion of a pattern generator, and generating the modified pattern using the pattern generator. The generated pattern interacts with a reactive material to form the portion of the three-dimensional object defined by the predetermined object pattern.

Owner:GLOBAL FILTRATION SYST

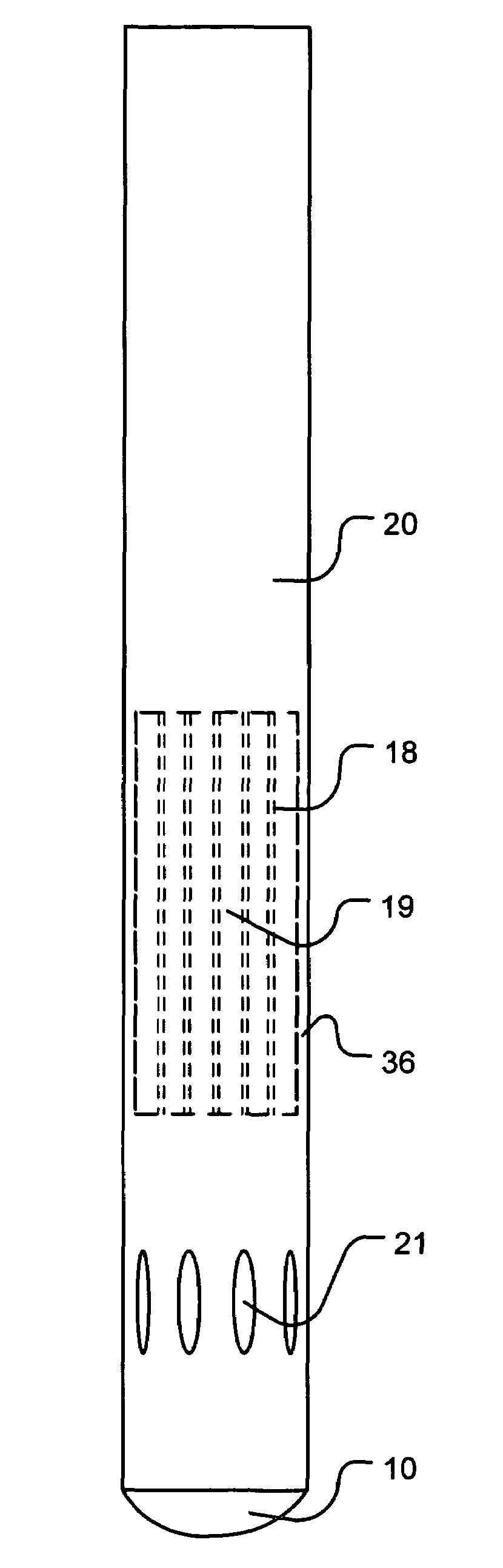

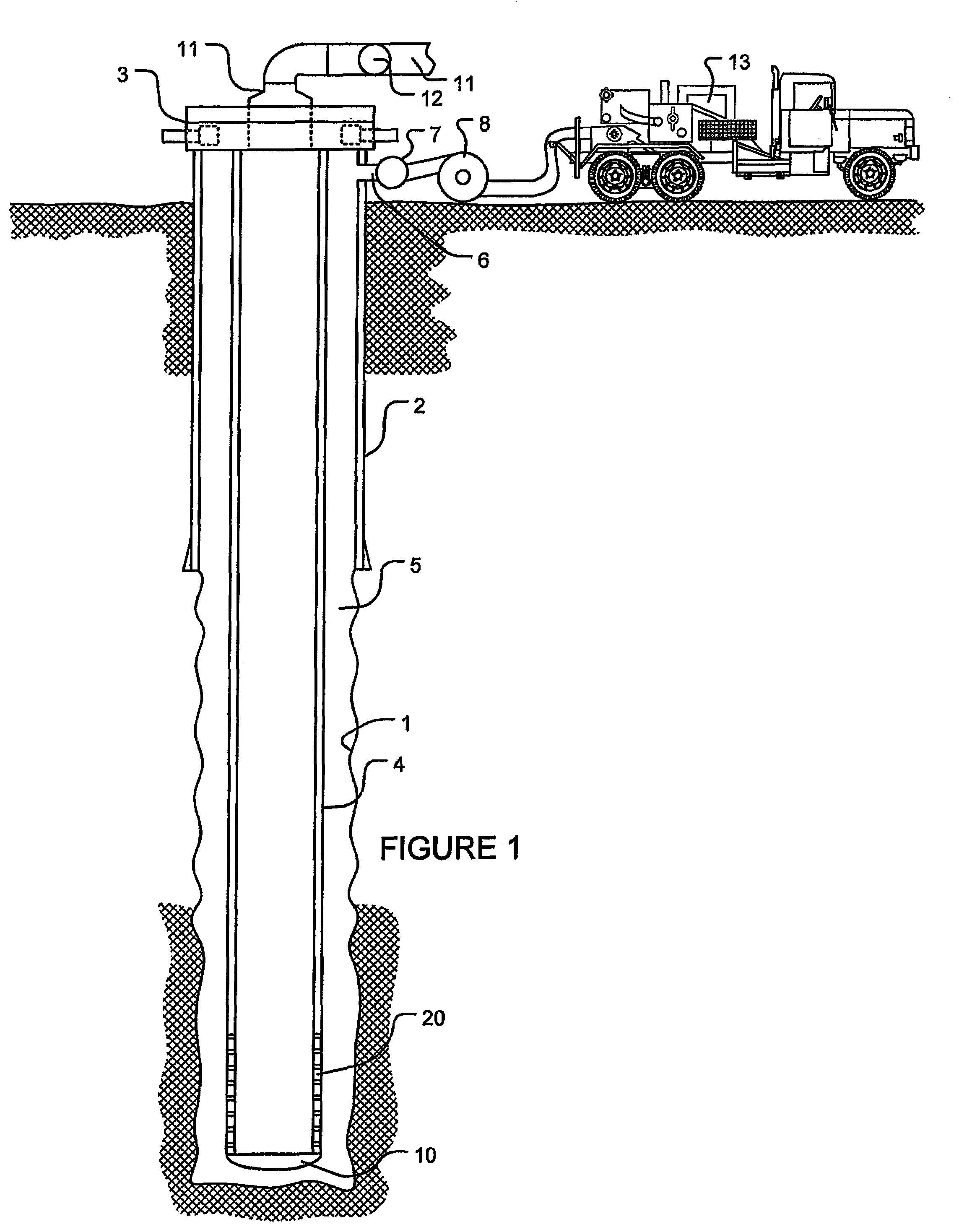

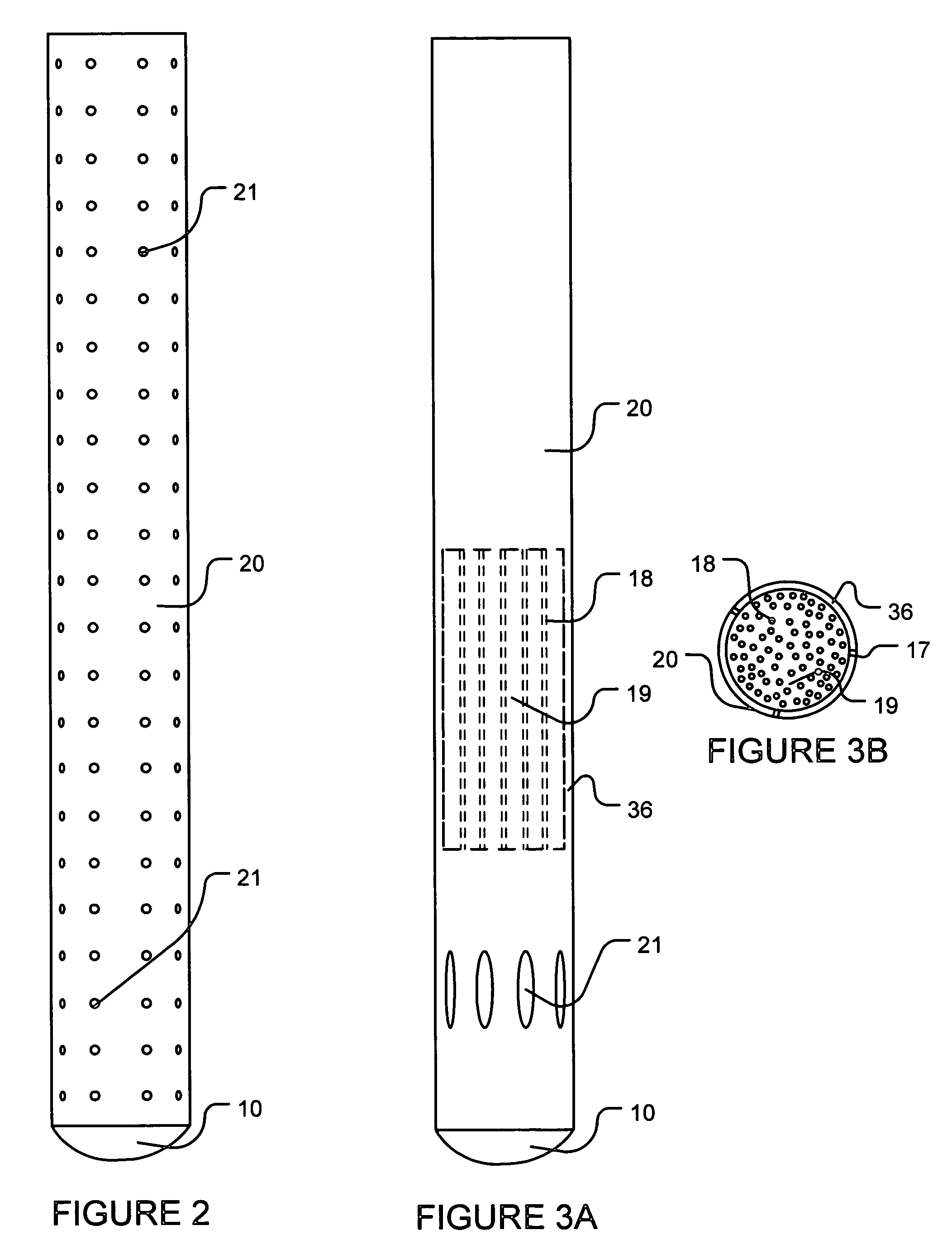

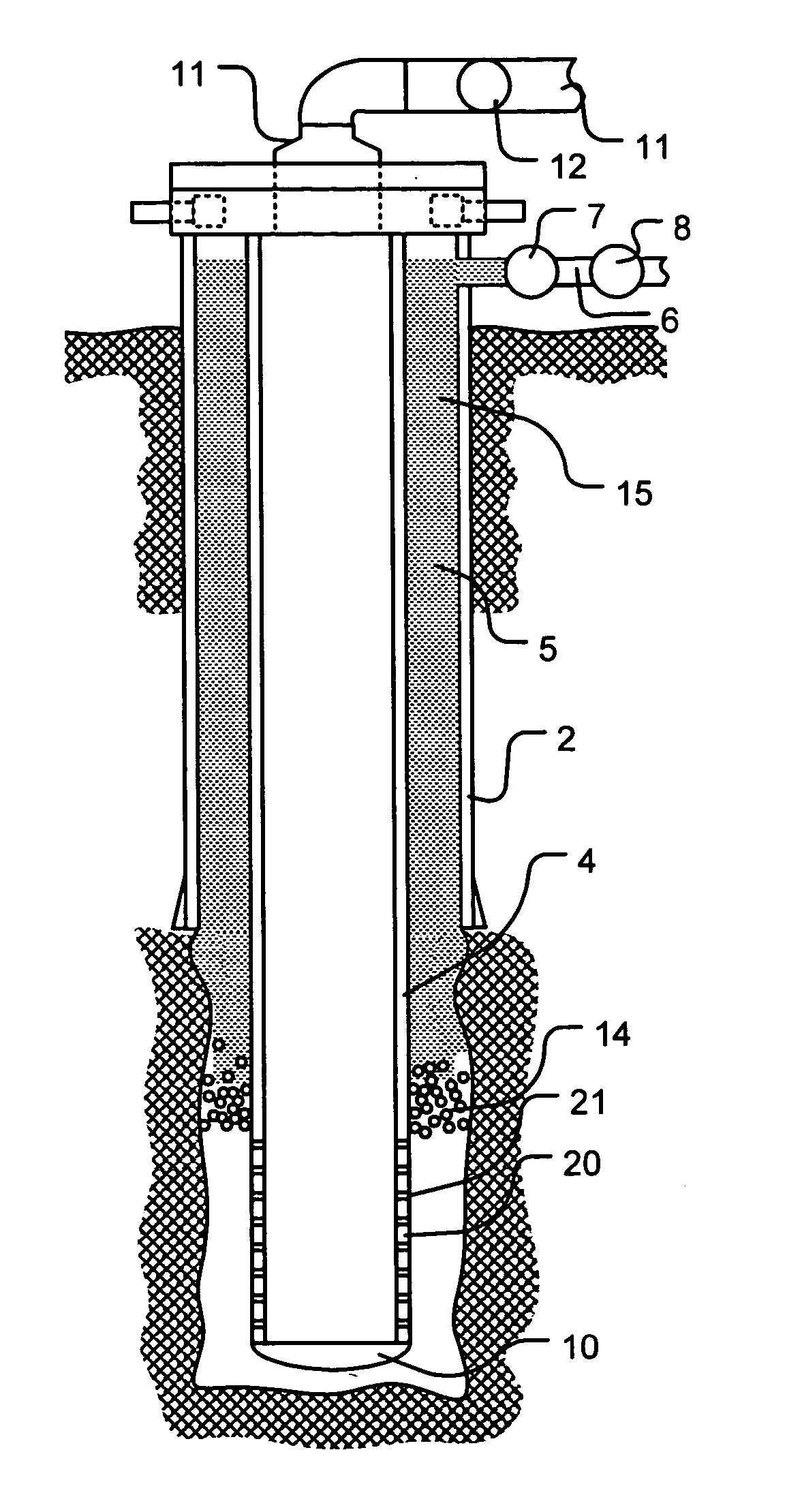

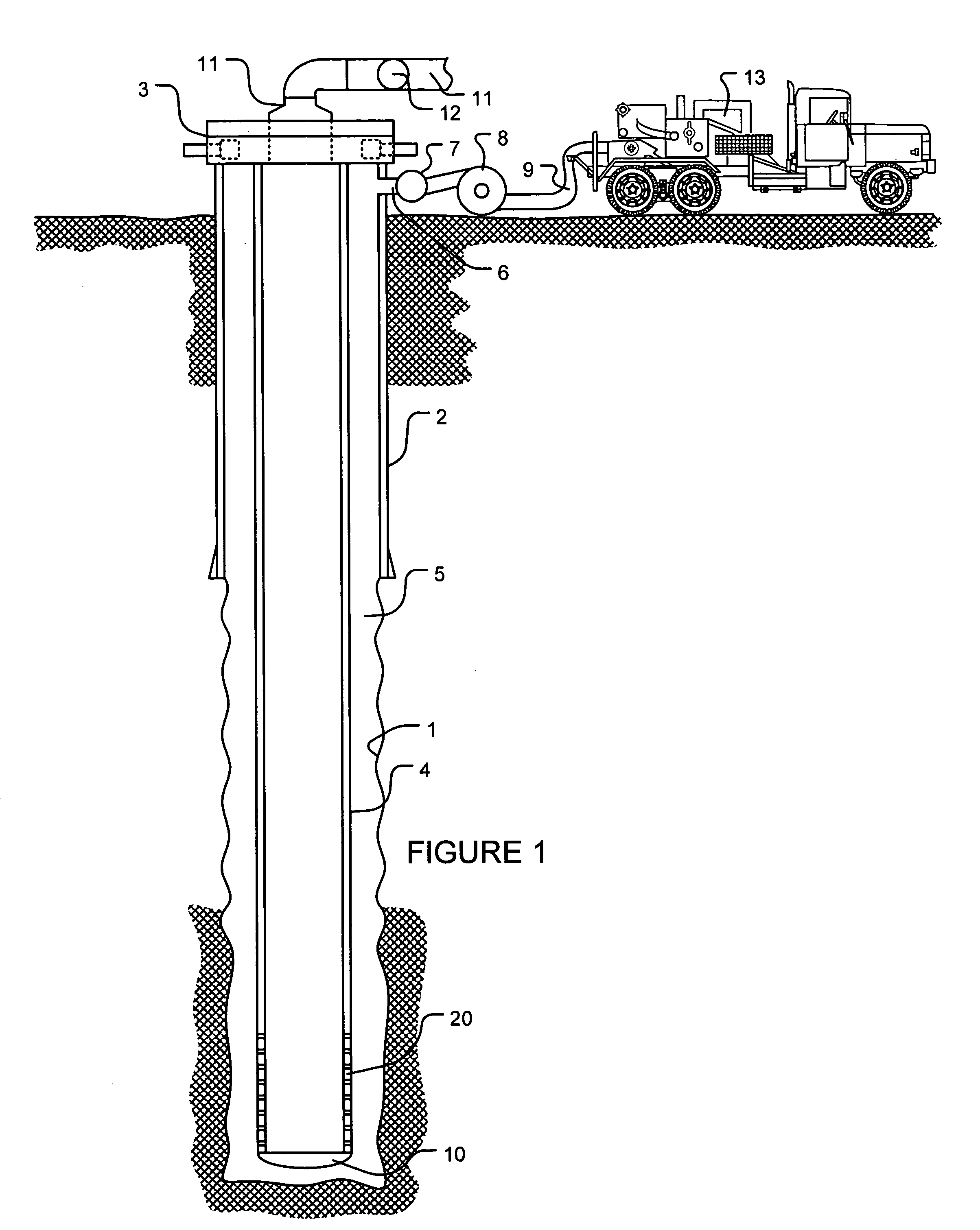

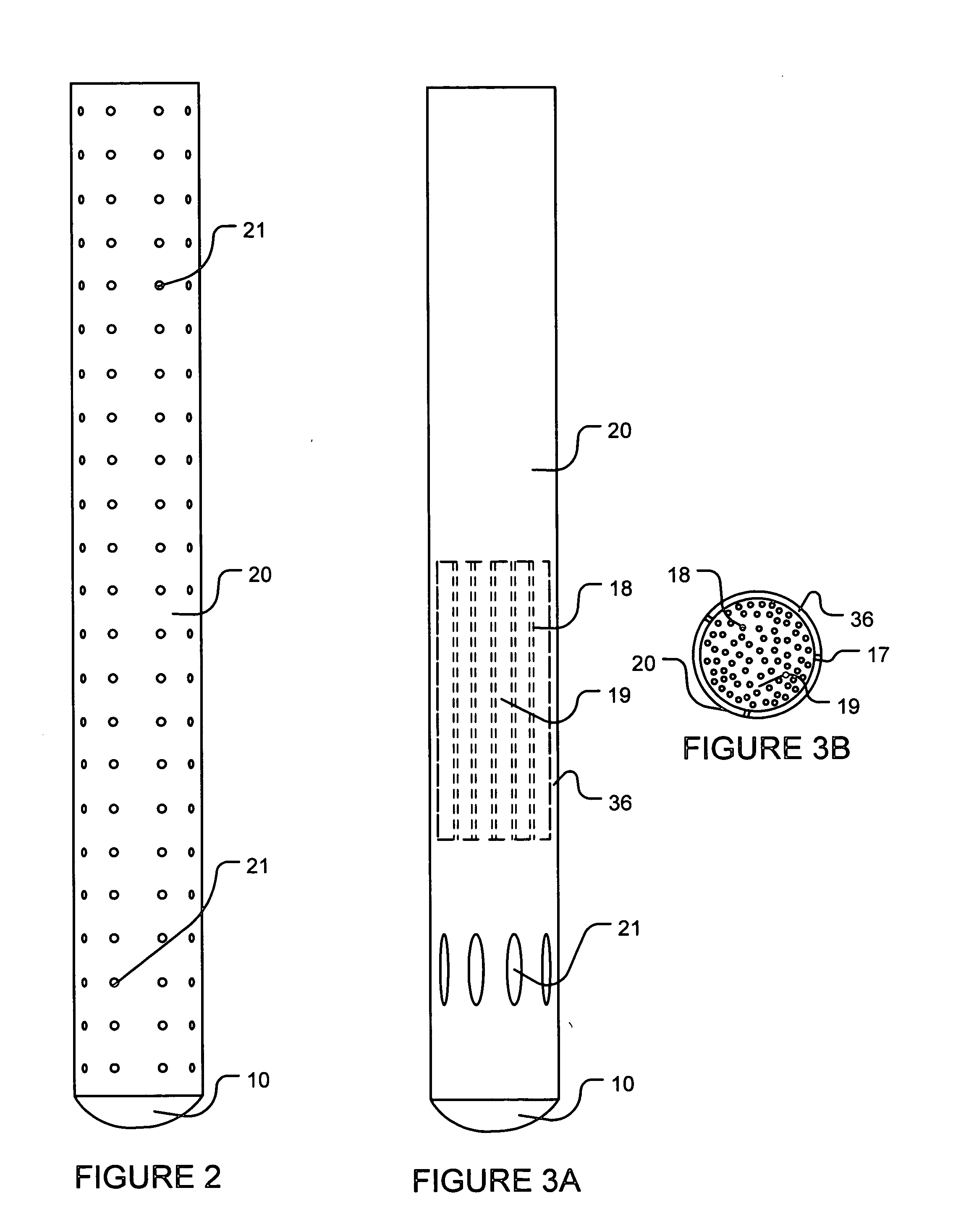

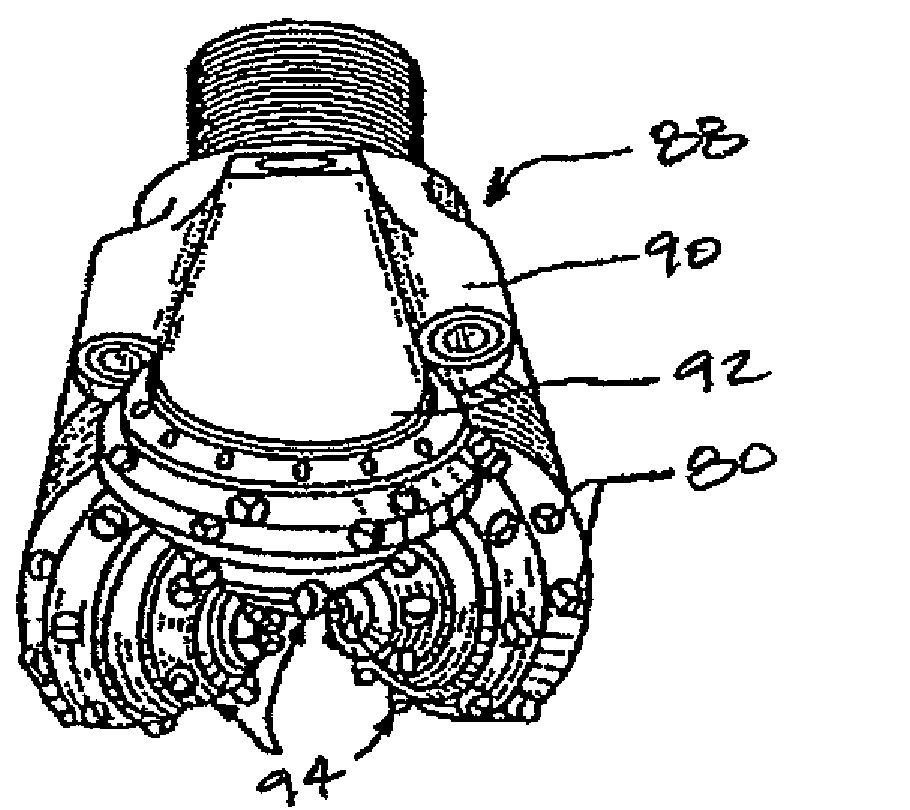

Casing shoes and methods of reverse-circulation cementing of casing

A method having the following steps: running a circulation valve comprising a reactive material into the well bore on the casing; reverse-circulating an activator material in the well bore until the activator material contacts the reactive material of the circulation valve; reconfiguring the circulation valve by contact of the activator material with the reactive material; and reverse-circulating a cement composition in the well bore until the reconfigured circulation valve decreases flow of the cement composition. A circulation valve for cementing casing in a well bore, the valve having: a valve housing connected to the casing and comprising a reactive material; a plurality of holes in the housing, wherein the plurality of holes allow fluid communication between an inner diameter of the housing and an exterior of the housing, wherein the reactive material is expandable to close the plurality of holes.

Owner:HALLIBURTON ENERGY SERVICES INC

Casing shoes and methods of reverse-circulation cementing of casing

A method having the following steps: running a circulation valve comprising a reactive material into the well bore on the casing; reverse-circulating an activator material in the well bore until the activator material contacts the reactive material of the circulation valve; reconfiguring the circulation valve by contact of the activator material with the reactive material; and reverse-circulating a cement composition in the well bore until the reconfigured circulation valve decreases flow of the cement composition. A circulation valve for cementing casing in a well bore, the valve having: a valve housing connected to the casing and comprising a reactive material; a plurality of holes in the housing, wherein the plurality of holes allow fluid communication between an inner diameter of the housing and an exterior of the housing, wherein the reactive material is expandable to close the plurality of holes.

Owner:HALLIBURTON ENERGY SERVICES INC

Dissolvable downhole tool, method of making and using

Disclosed herein is a dissolvable downhole tool. The tool includes, a dissolvable body constructed of at least two materials and at least one of the at least two materials is a reactive material, and a first material of the at least two materials being configured to substantially dissolve the dissolvable body and a second material configured to control reaction timing of the first material.

Owner:BAKER HUGHES INC

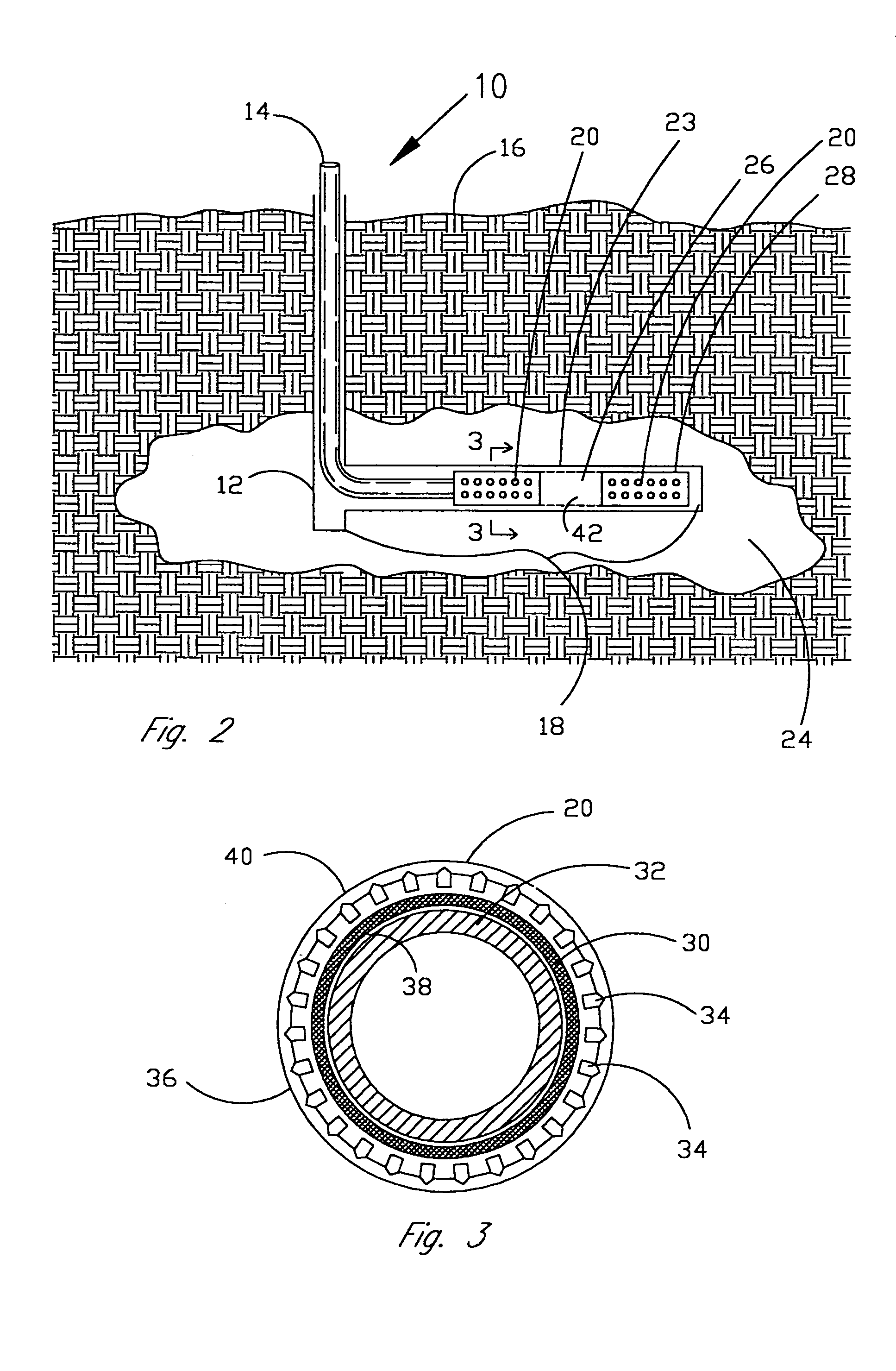

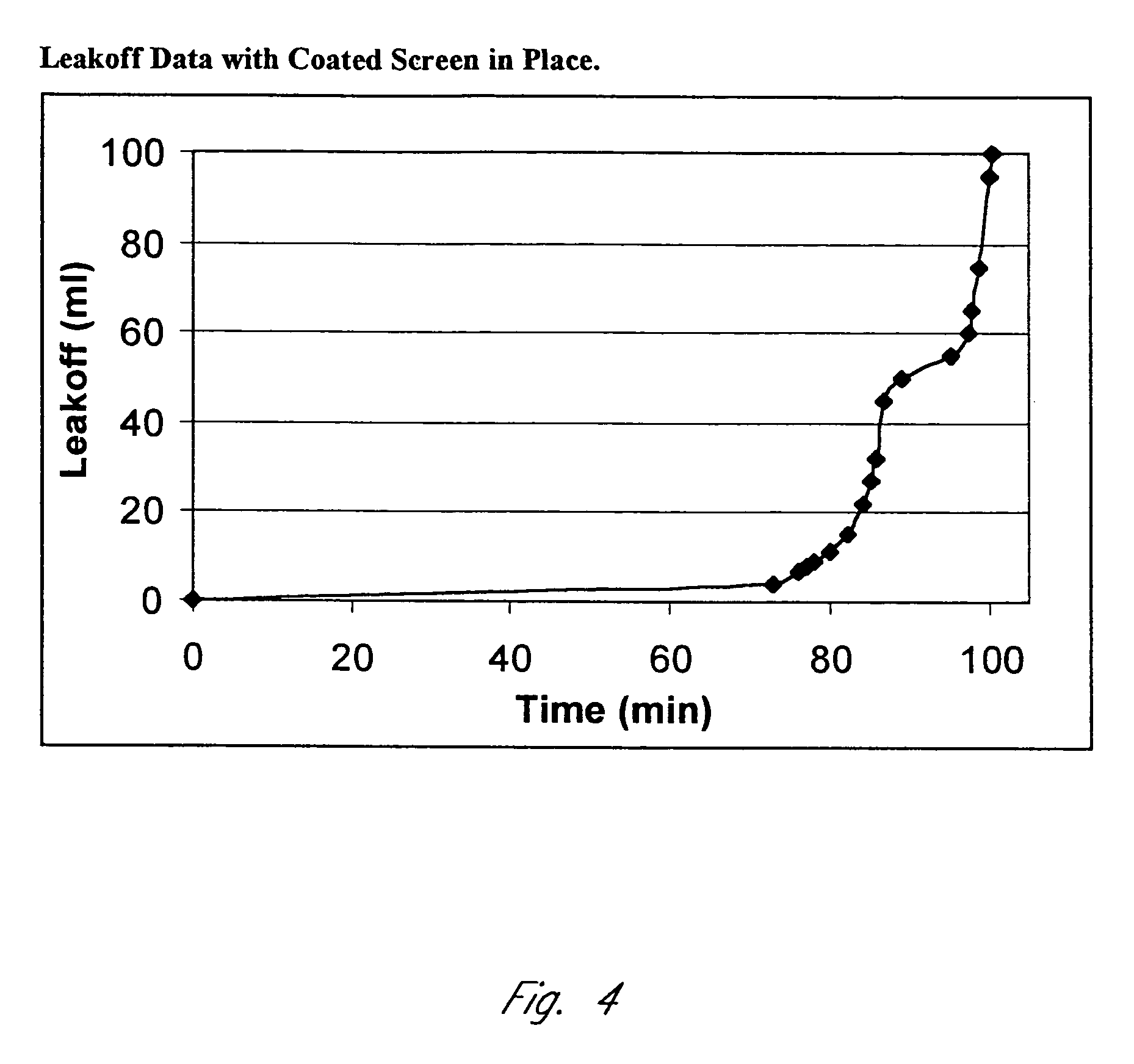

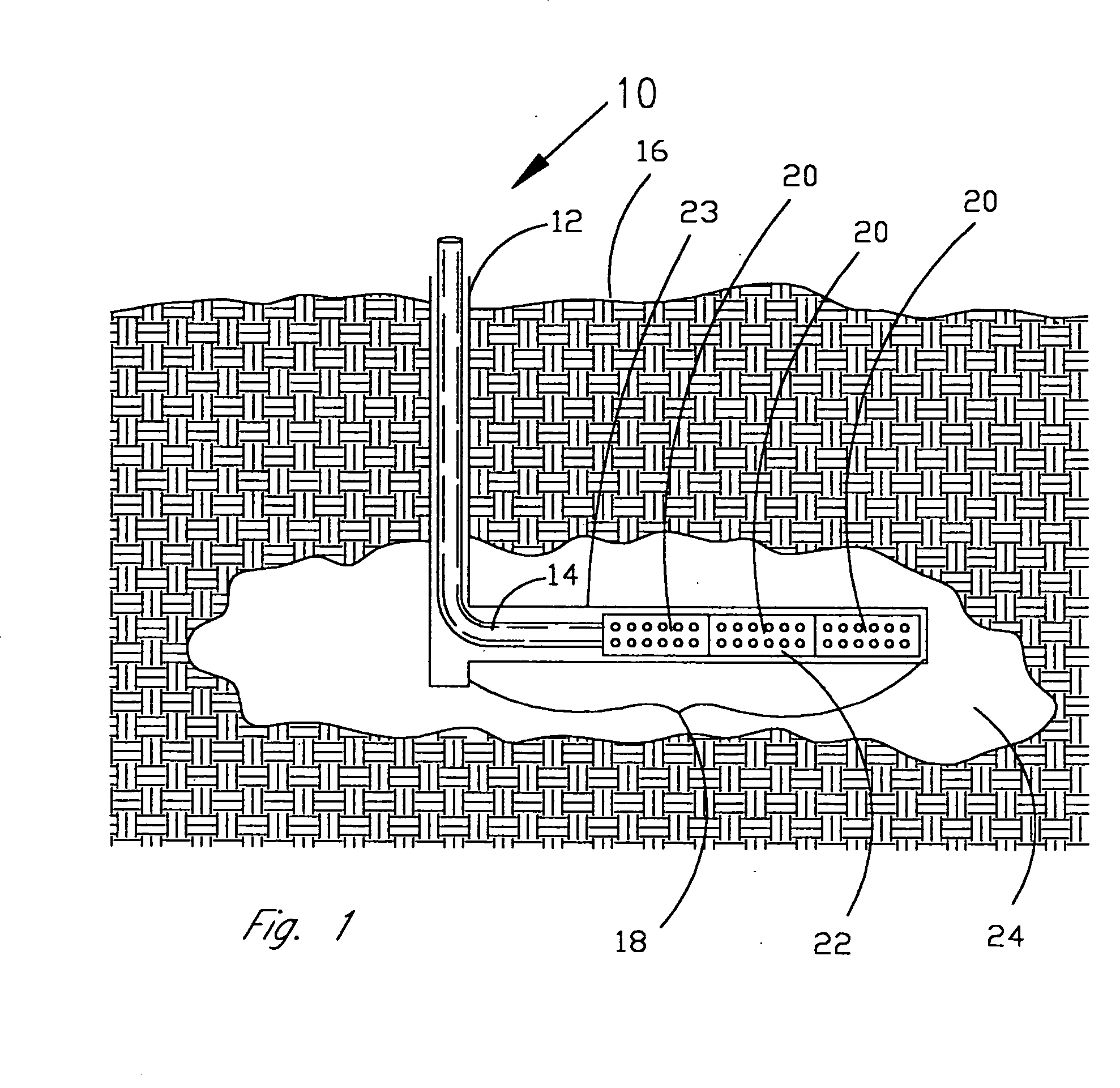

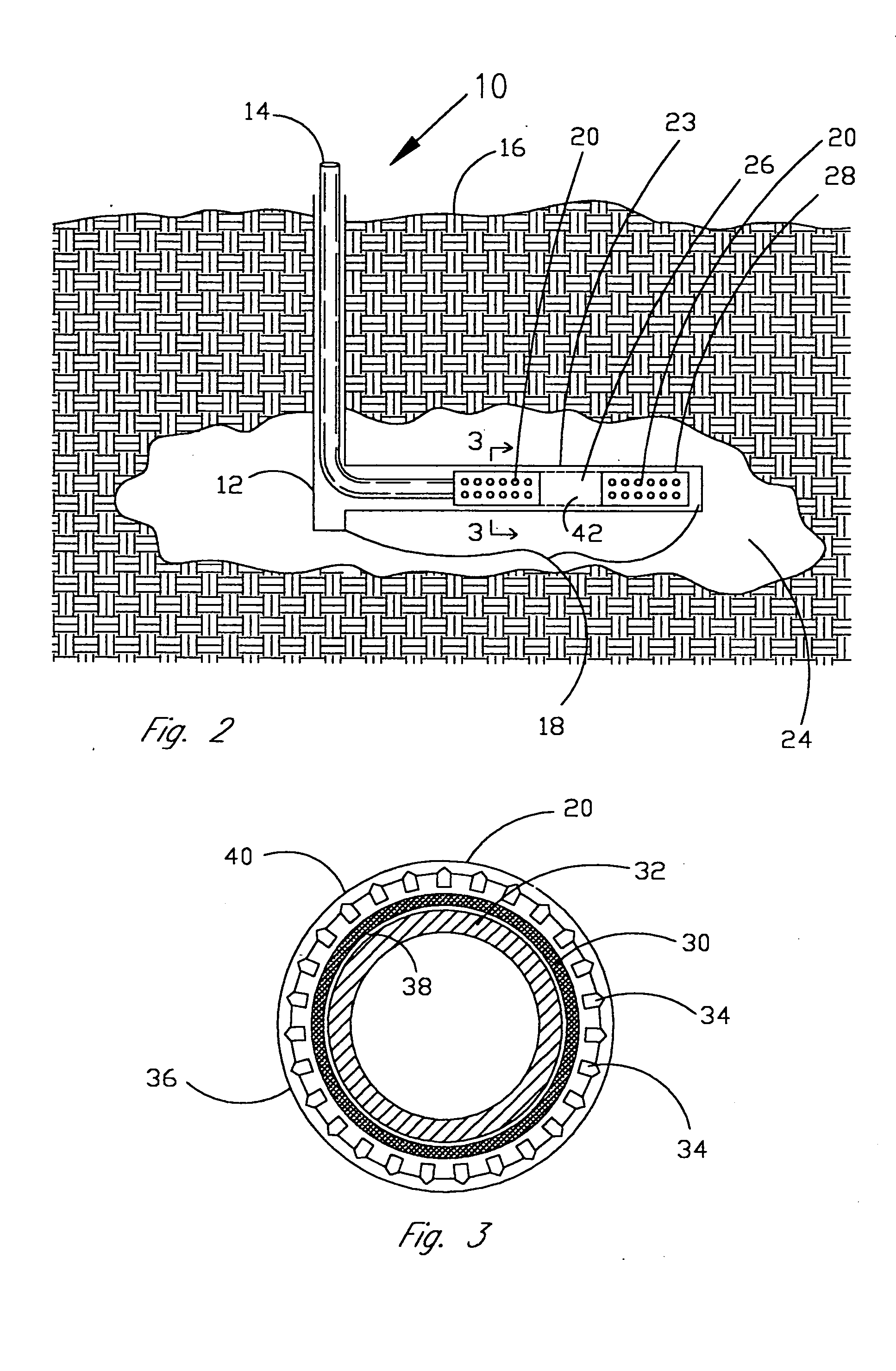

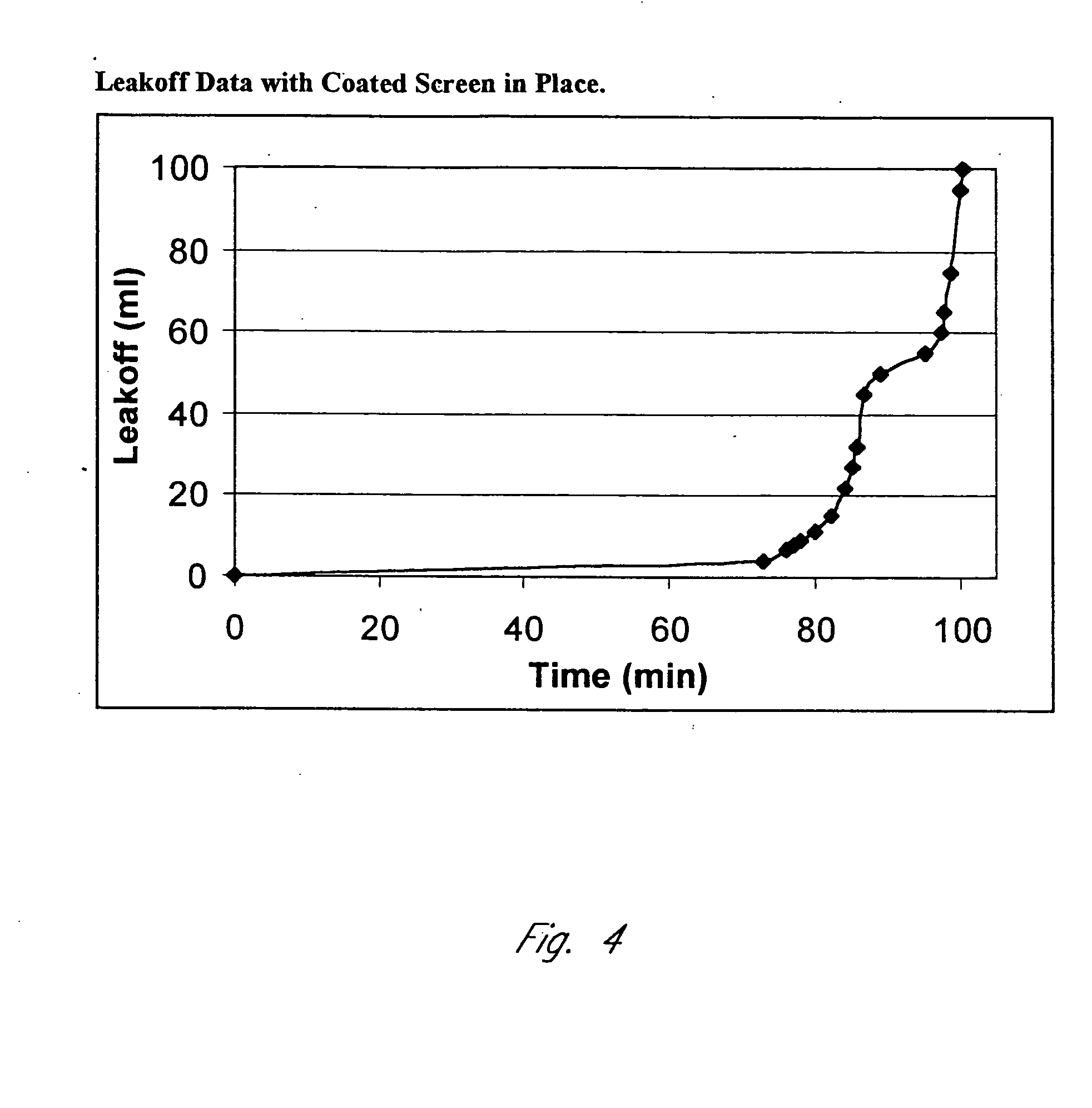

Product for coating wellbore screens

InactiveUS7360593B2Prevent flow capacity damageMinimizes flow capacity damageFluid removalFlushingReactive materialSURFACTANT BLEND

Coatings for well screens that protect the screens from damage as they are inserted into the wellbore and once in the well, release reactive materials to react with and degrade potentially plugging materials such as drill solids, fluid filtercakes, fluid loss additives, and drilling fluids. The coatings can be specifically designed for individual well conditions and are comprised of a binder that either melts or dissolves within the wellbore and one or more reactive materials such as acids, enzymes, surfactants, chelants, oxidizers or free radical generators and the like which are released into the screen and the near wellbore area and which are effective in degrading or dissolving materials which could potentially plug the screen.

Owner:CONSTIEN VERNON GEORGE

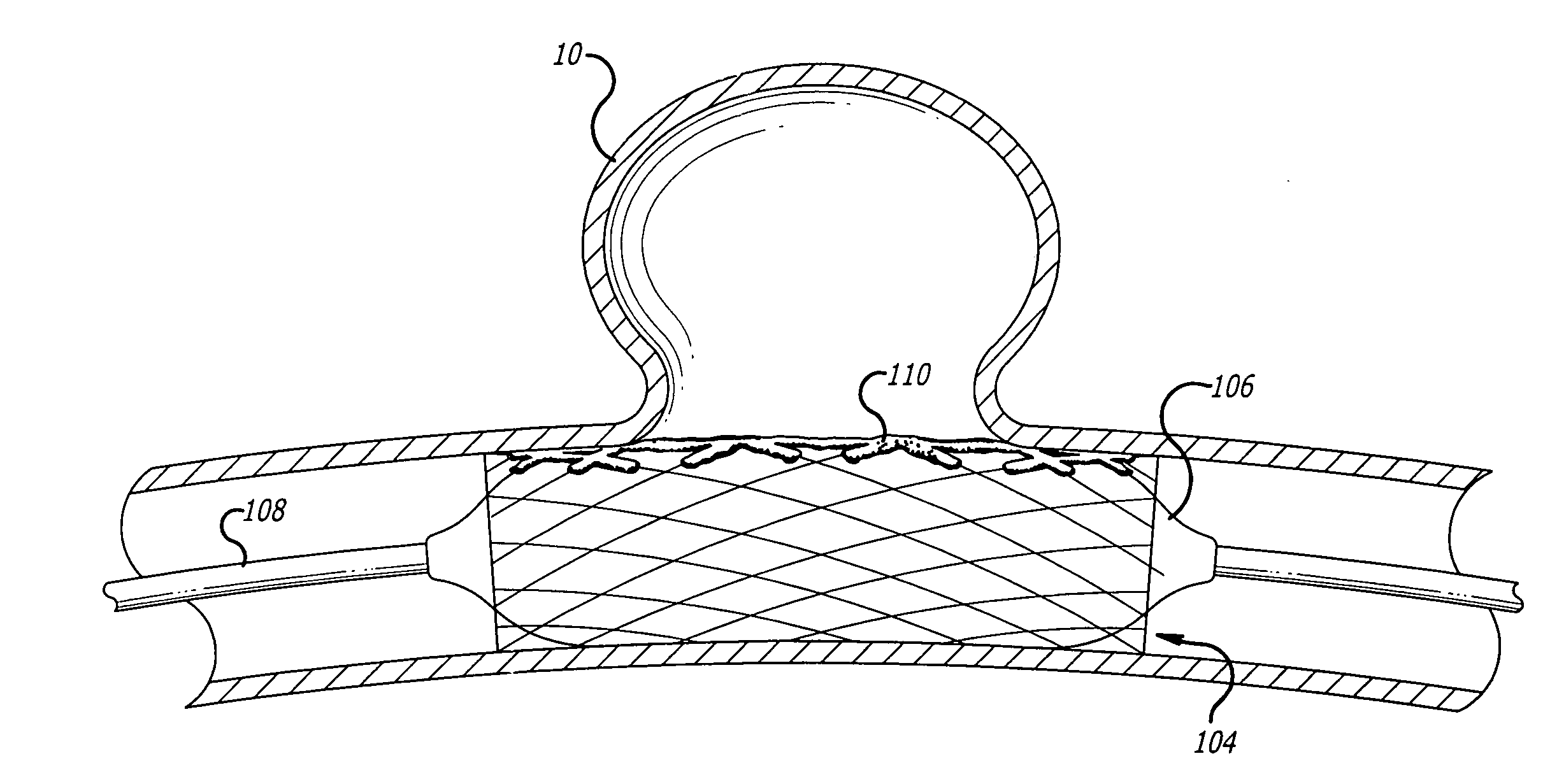

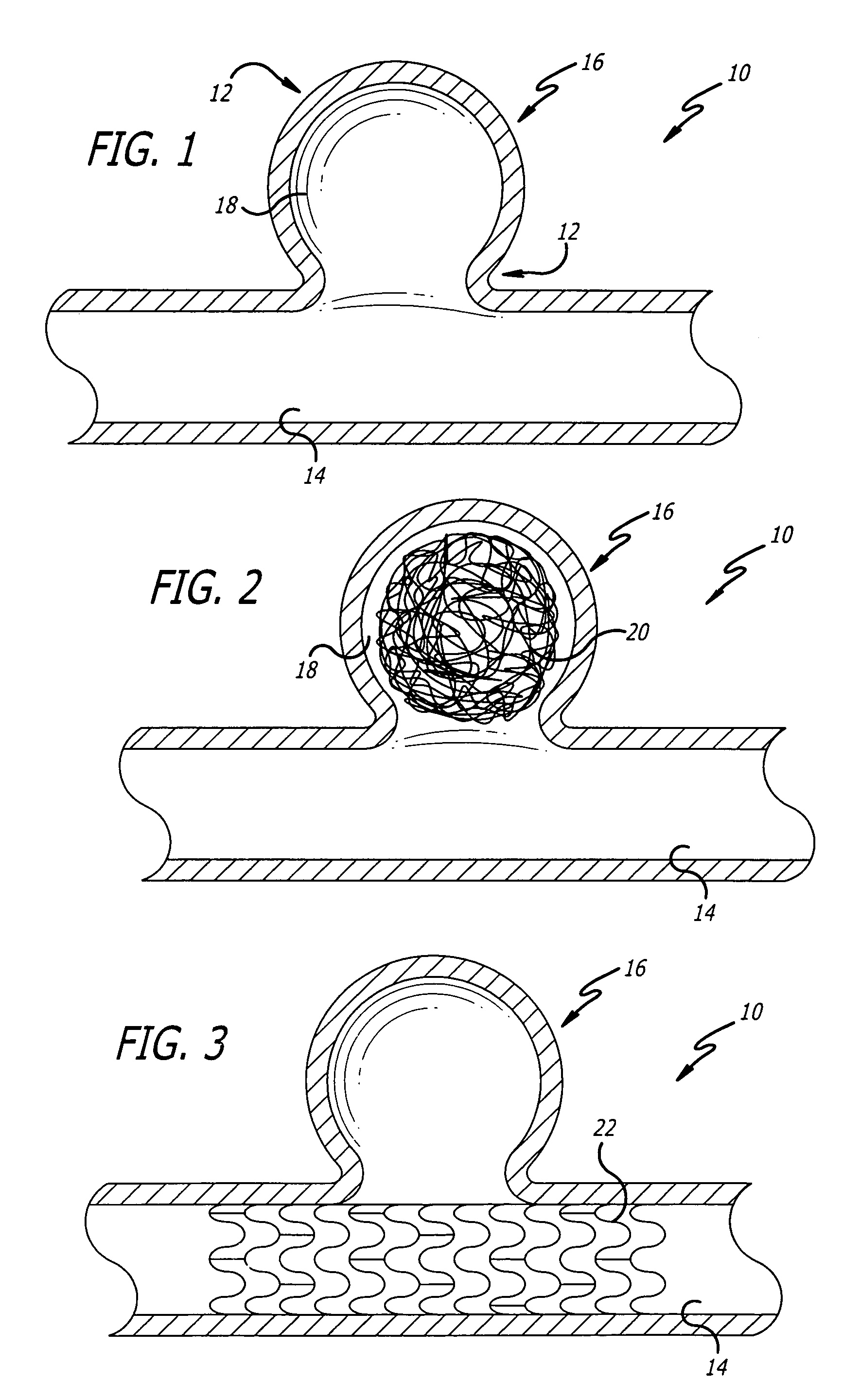

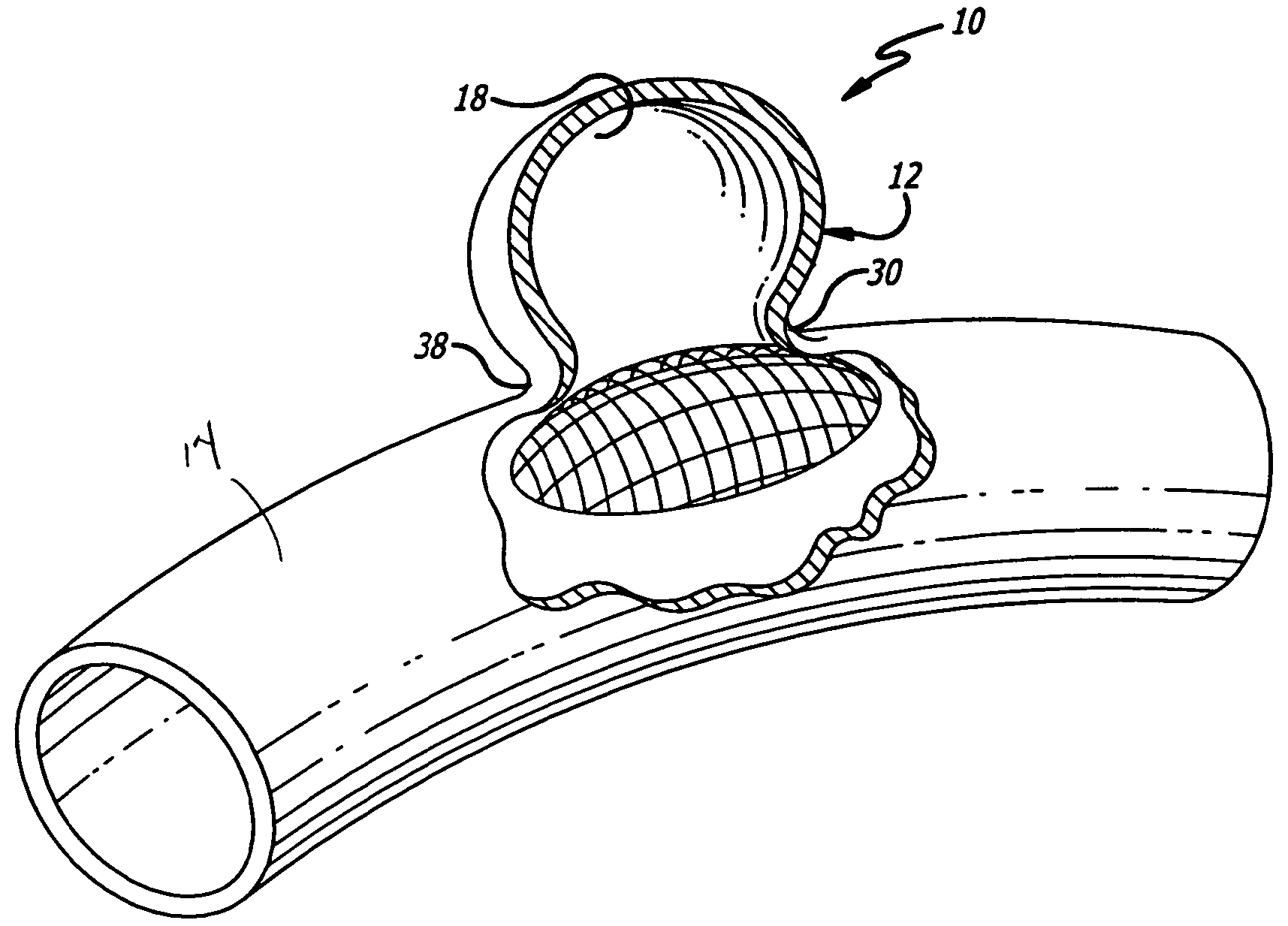

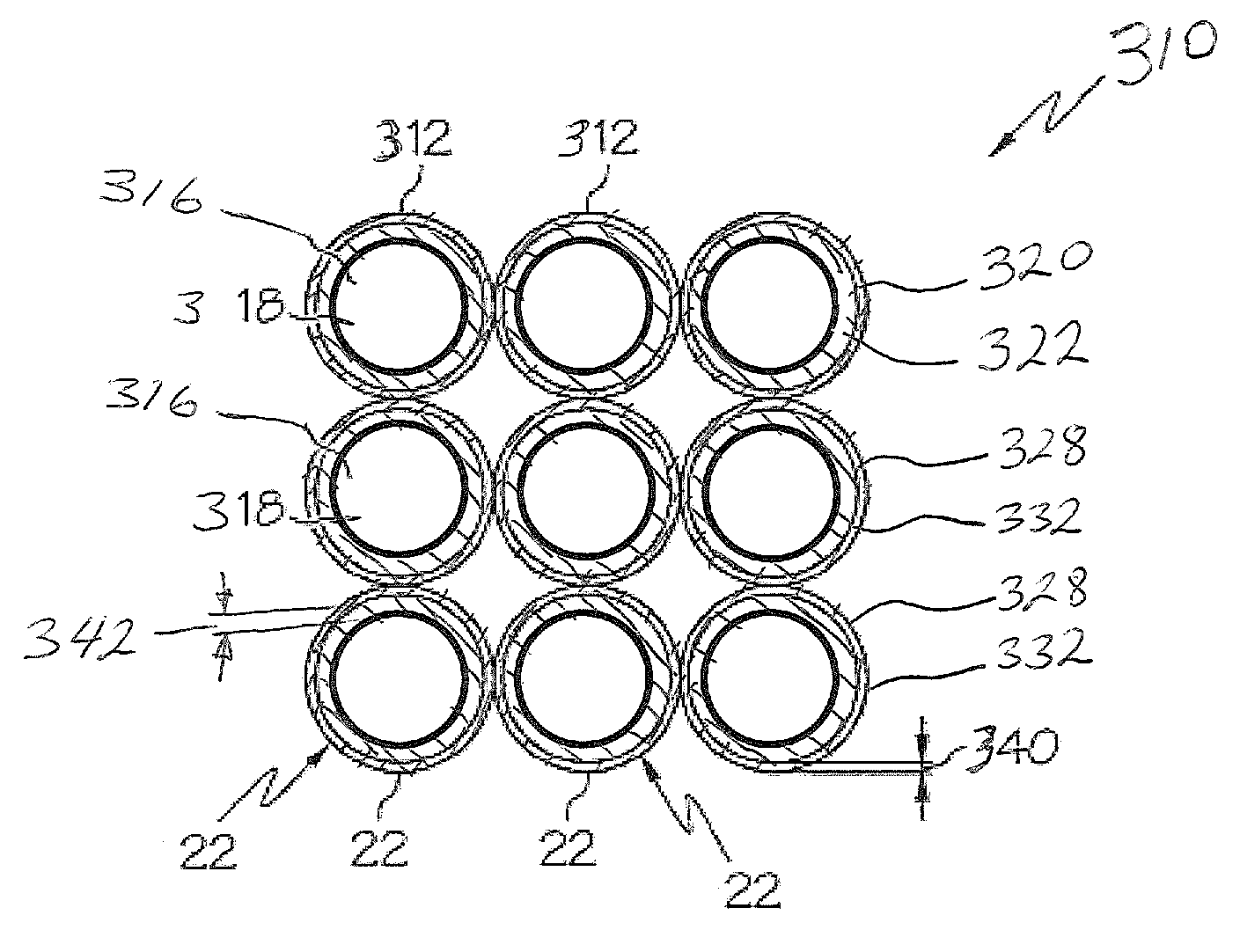

Aneurysm treatment device and method of use

InactiveUS7572288B2Impaired blood flowEasy to manufactureStentsElectrotherapyMedicineAneurysm treatment

The present invention is directed to aneurysm treatment devices which are capable of being delivered to the situs of a vascular aneurysm through a catheter. The treatment devices comprise, in general, an expandable stent having fenestrations and a reactive material selectively applied to not all of the fenestrations. The reactive material has a non-reacted state and a reacted state and the reactive material in the reacted state is capable of increasing the resistance to blood flow through said fenestrations.

Owner:MICROVENTION INC

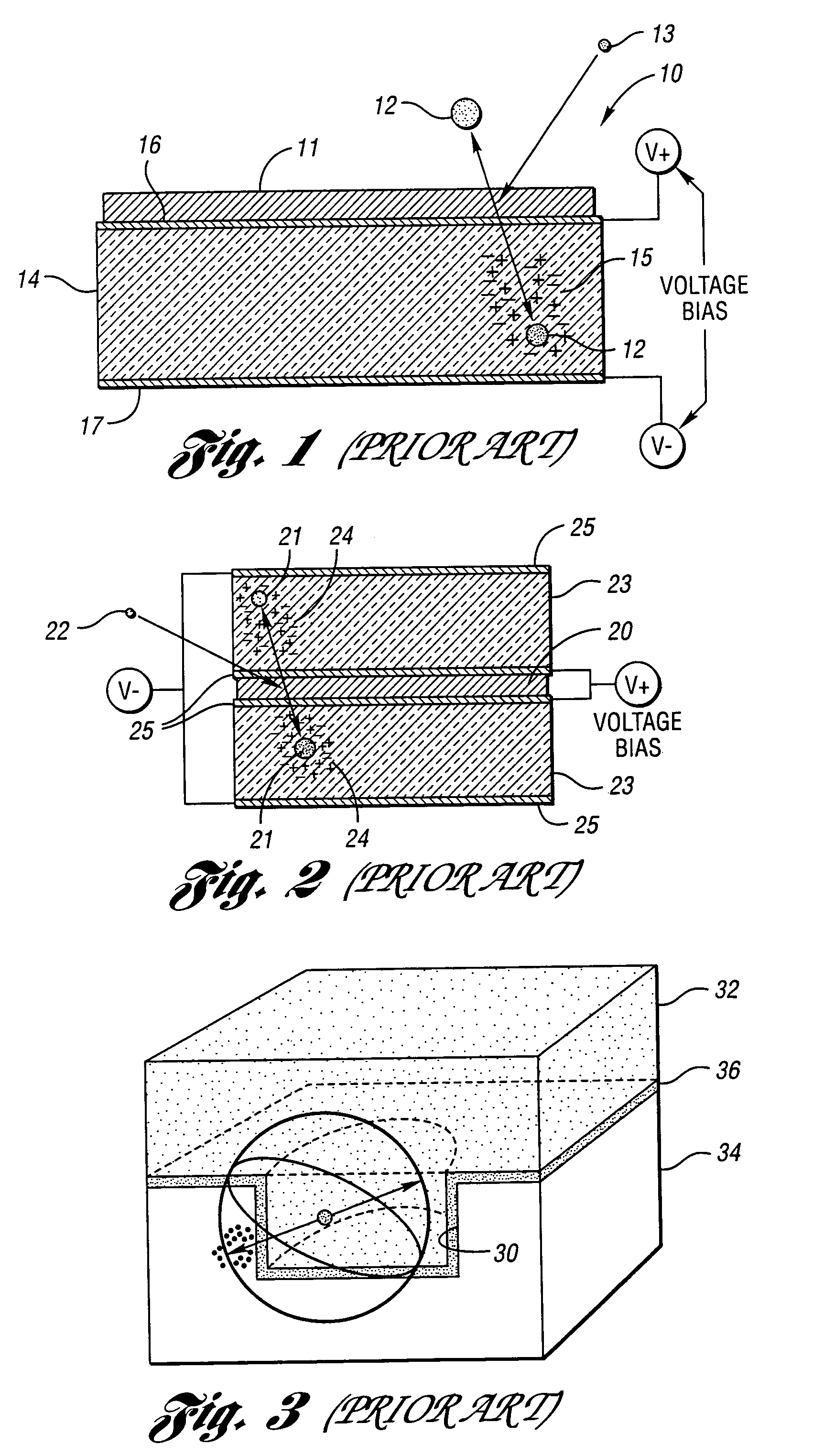

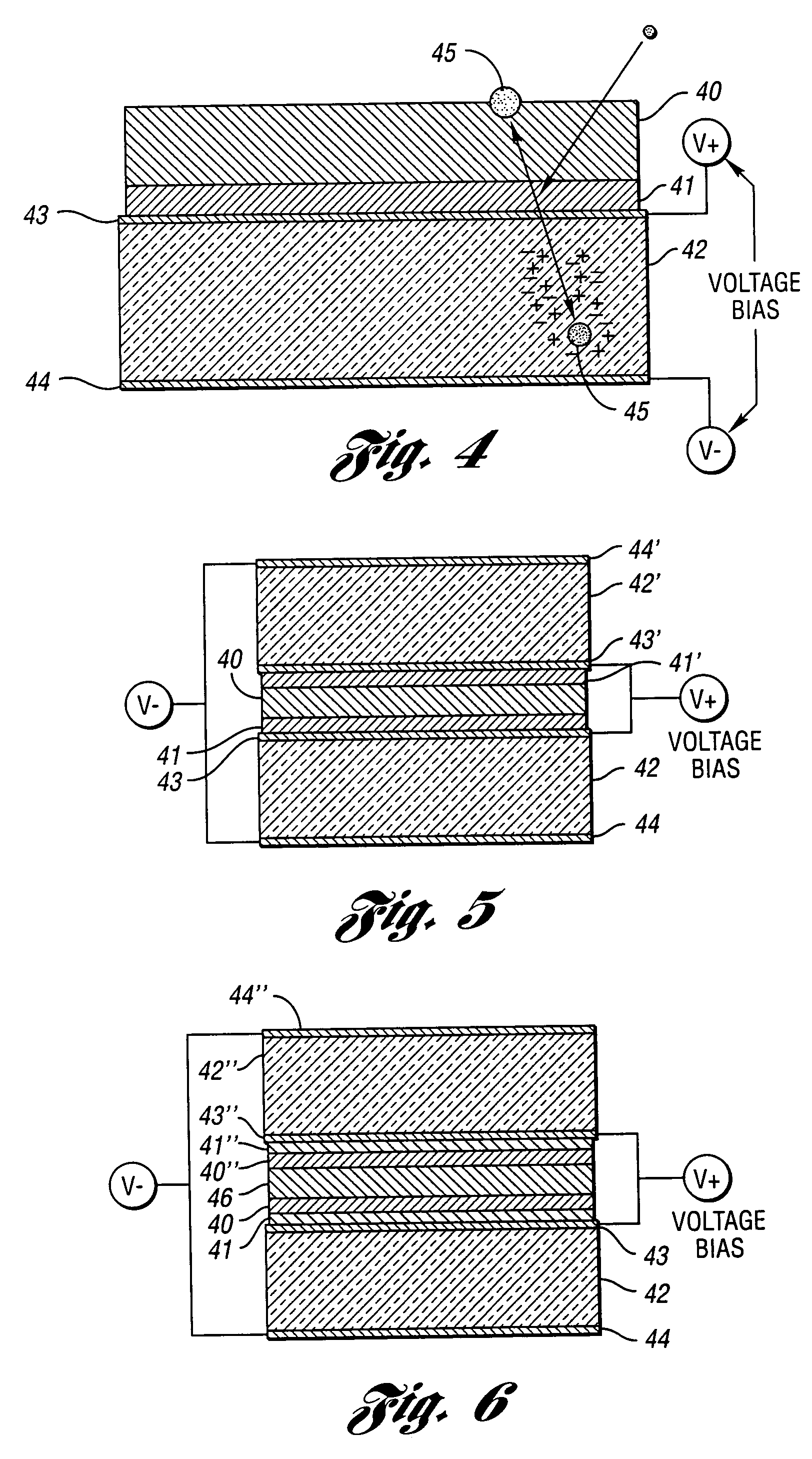

Electrochemical timer

InactiveUS6198701B1Easy to useReduce manufacturing costMeasurement devicesTime interval measurement without driving mechanismElectrochemical responseReactive material

An electrochemical timer is described that is compact, lightweight, inexpensive to manufacture, and simple to use in which the consumption of reactive materials in an electrochemical reaction provides a visual indication of the passage of time. In one embodiment, the electrochemical timer includes a first electrode, an electrolyte, and a second electrode. The electrodes and electrolyte are chosen such that the first electrode is consumed at a predetermined rate upon electrochemical contact of the electrodes and electrolyte. The electrodes and electrolyte are further configured such that the consumption of the first electrode can be monitored to provide an indication of the passage of time. In one embodiment, the electrochemical timers provided herein are used to monitor the shelf-life of perishables.

Owner:POLYPLUS BATTERY CO INC

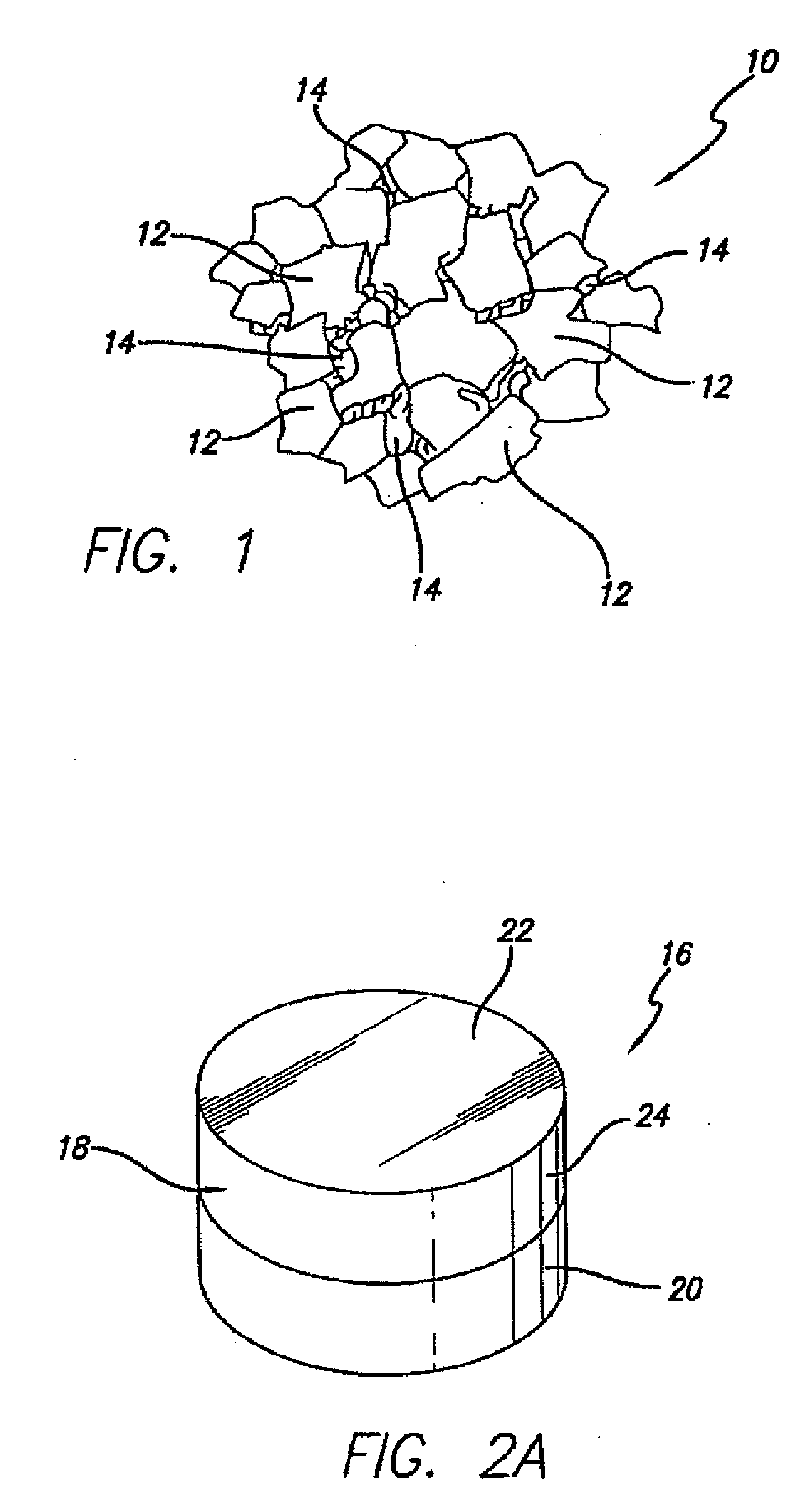

Diamond-bonded constrcutions with improved thermal and mechanical properties

InactiveUS20090090563A1Excellent characteristicsImprove thermal stabilityDrill bitsConstructionsDiamond crystalCarbide

Diamond-bonded constructions include a diamond-bonded body having a thermally stable region extending a distance below a diamond-bonded body surface. The thermally stable region comprises a matrix phase of bonded-together diamond crystals, and interstitial regions comprising a reaction product. The reaction product is formed by reaction between the diamond crystals and a reactive material. The reactant is a carbide former and the reaction product is a carbide. The diamond-bonded body includes a further diamond region extending from the thermally stable region that comprises the matrix phase and a Group VIII metal disposed within interstitial regions of the matrix phase. The thermally stable region is substantially free of a catalyst material used to initially form the diamond-bonded body. The diamond-bonded body may include a material layer formed from the reaction product that is disposed on a surface of the diamond-bonded body thermally stable region.

Owner:SMITH INT INC

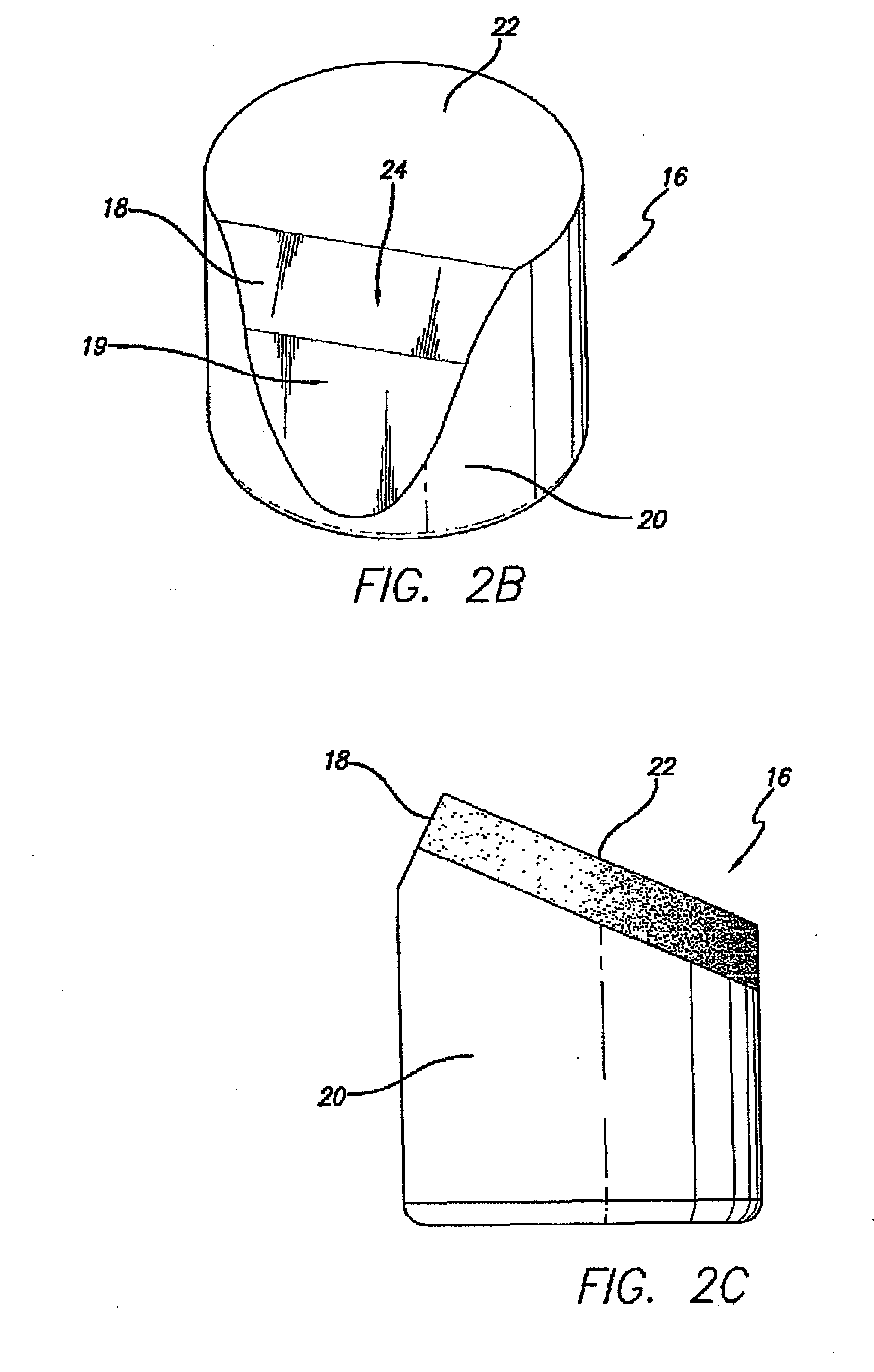

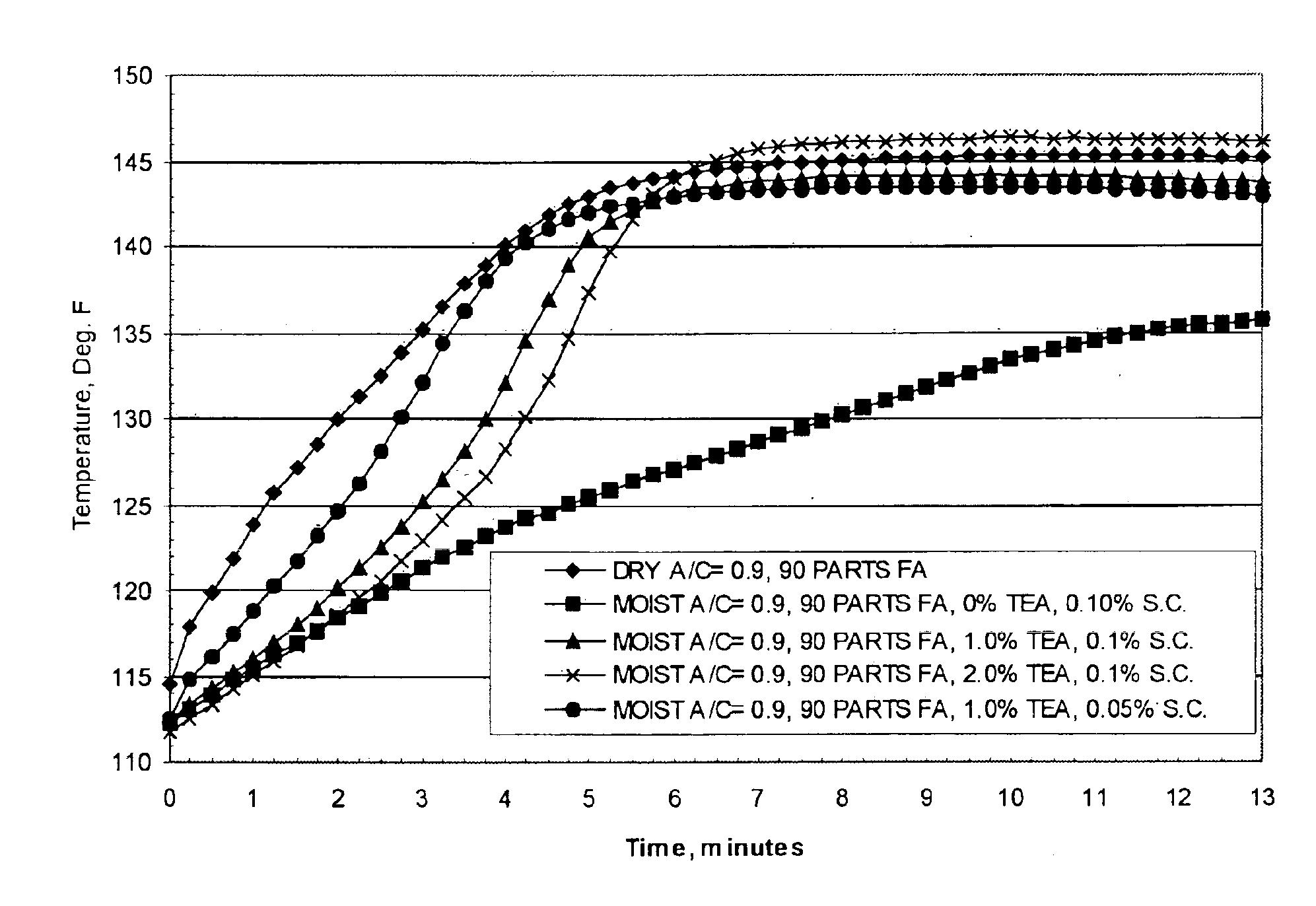

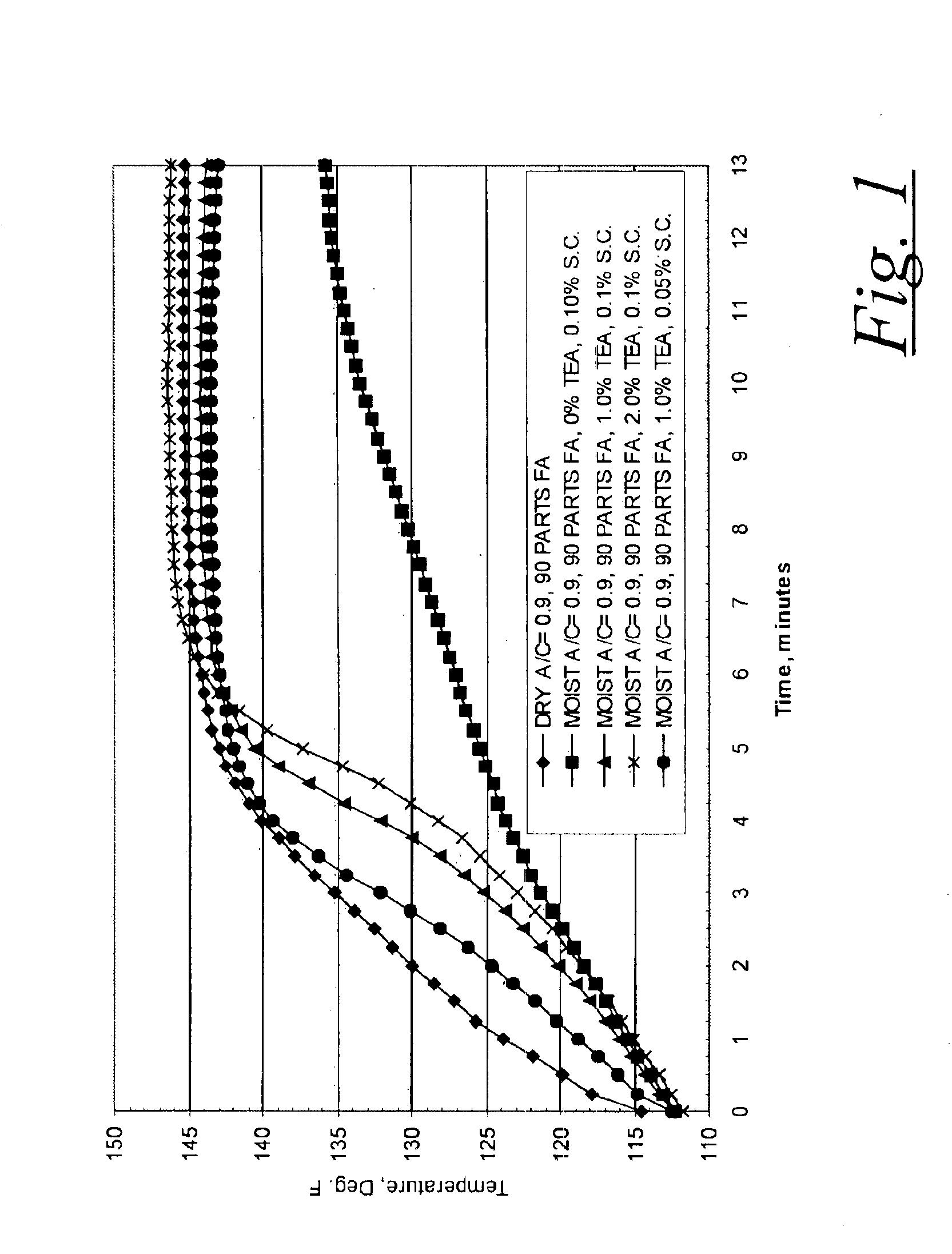

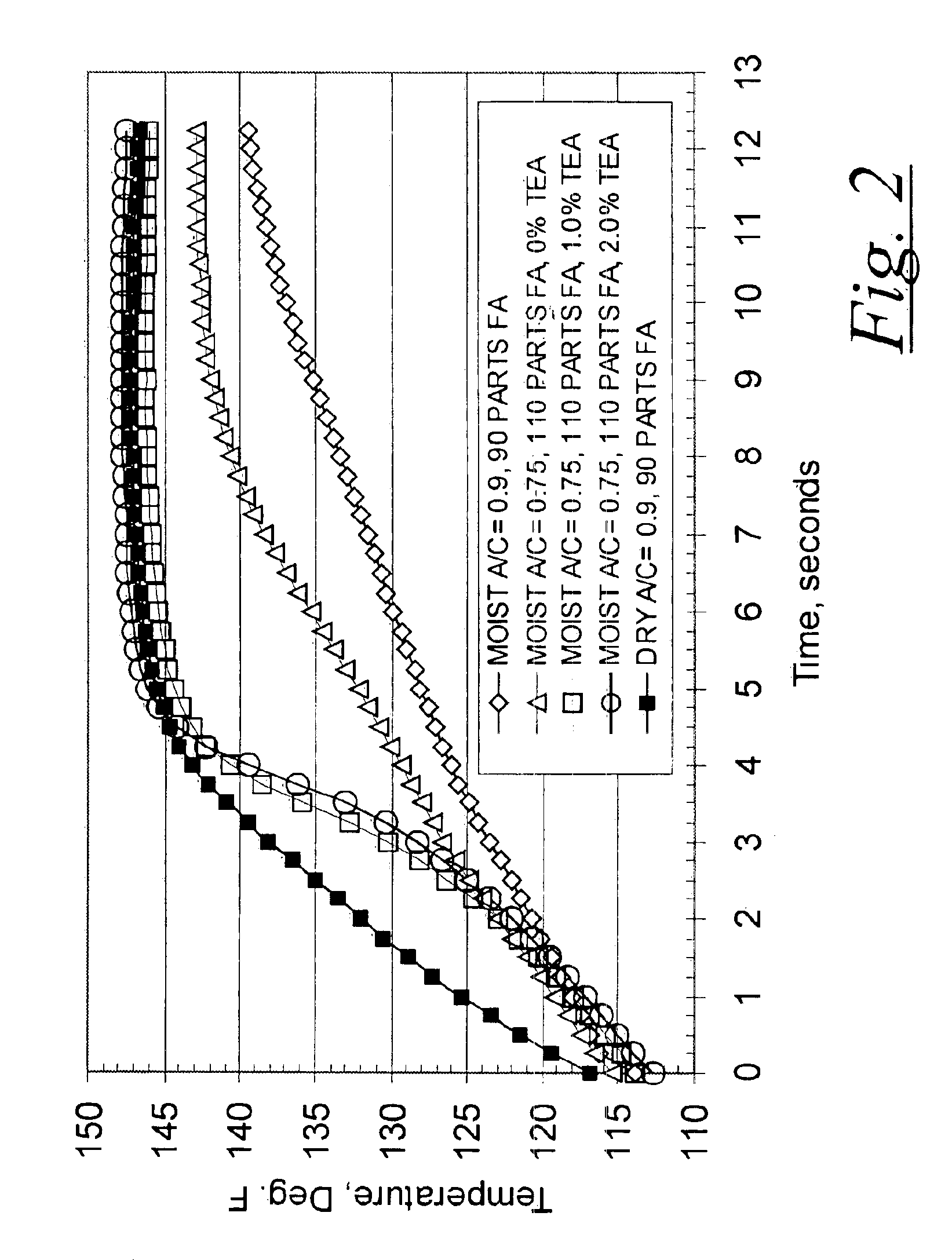

Very fast setting cementitious composition

Extremely fast setting of cementitious compositions for producing cement-based products such as cement boards is made possible by adding an alkanolamine to a hydraulic cement such as portland cement, and forming a slurry with water under conditions that provide an initial slurry temperature of at least 90° F. Use of alkanolamine under conditions disclosed herein allows an extremely rapid setting of the cementitious composition. Additional reactive materials may be included such as high alumina cement, calcium sulfate and a pozzolanic material such as fly ash. The extremely fast rapid set permits rapid production of cementitious products.

Owner:UNITED STATES GYPSUM CO

Compartmentalized resin pellets for oxygen scavenging

Owner:M&G POLIMERI ITALIA SPA +1

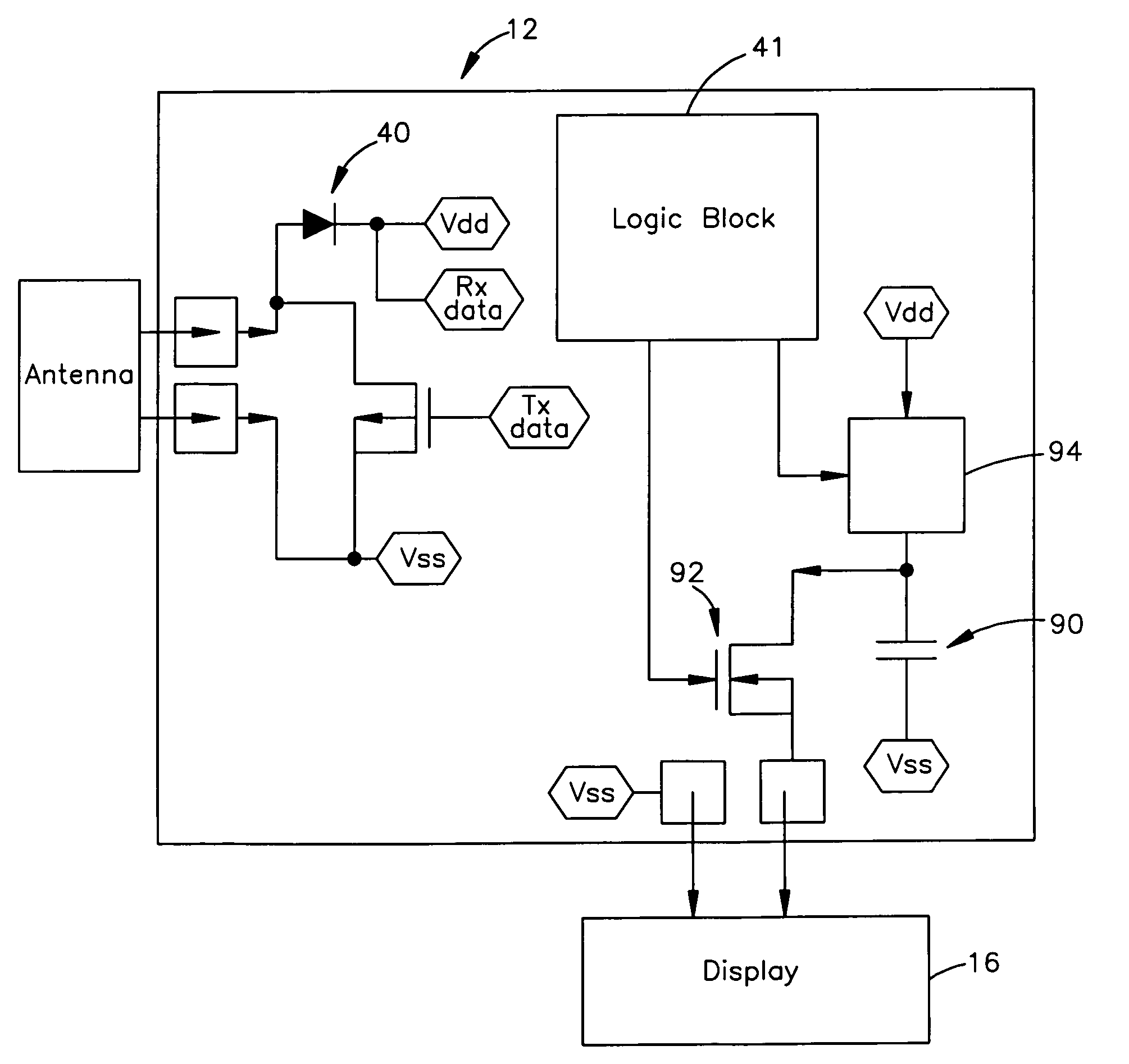

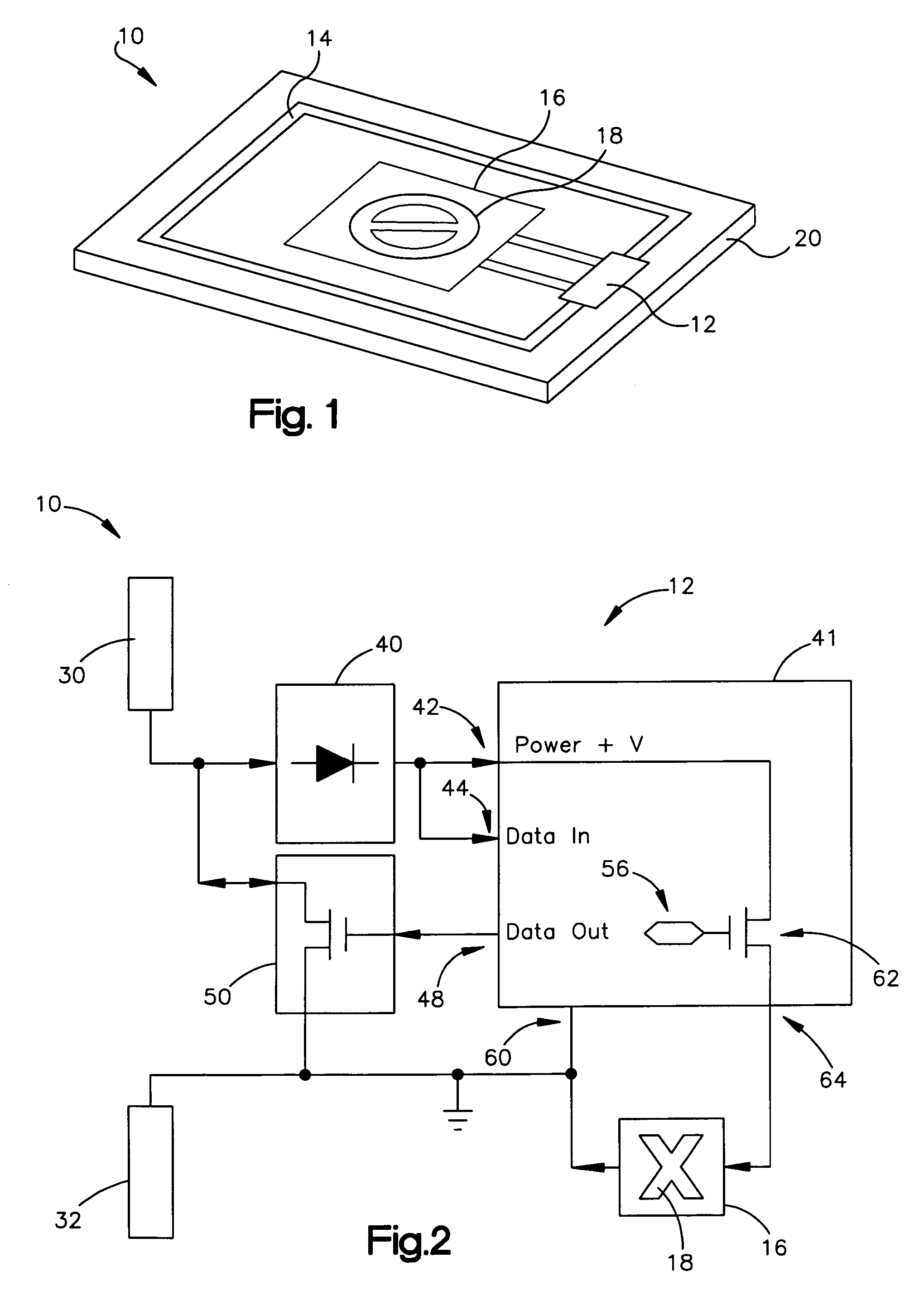

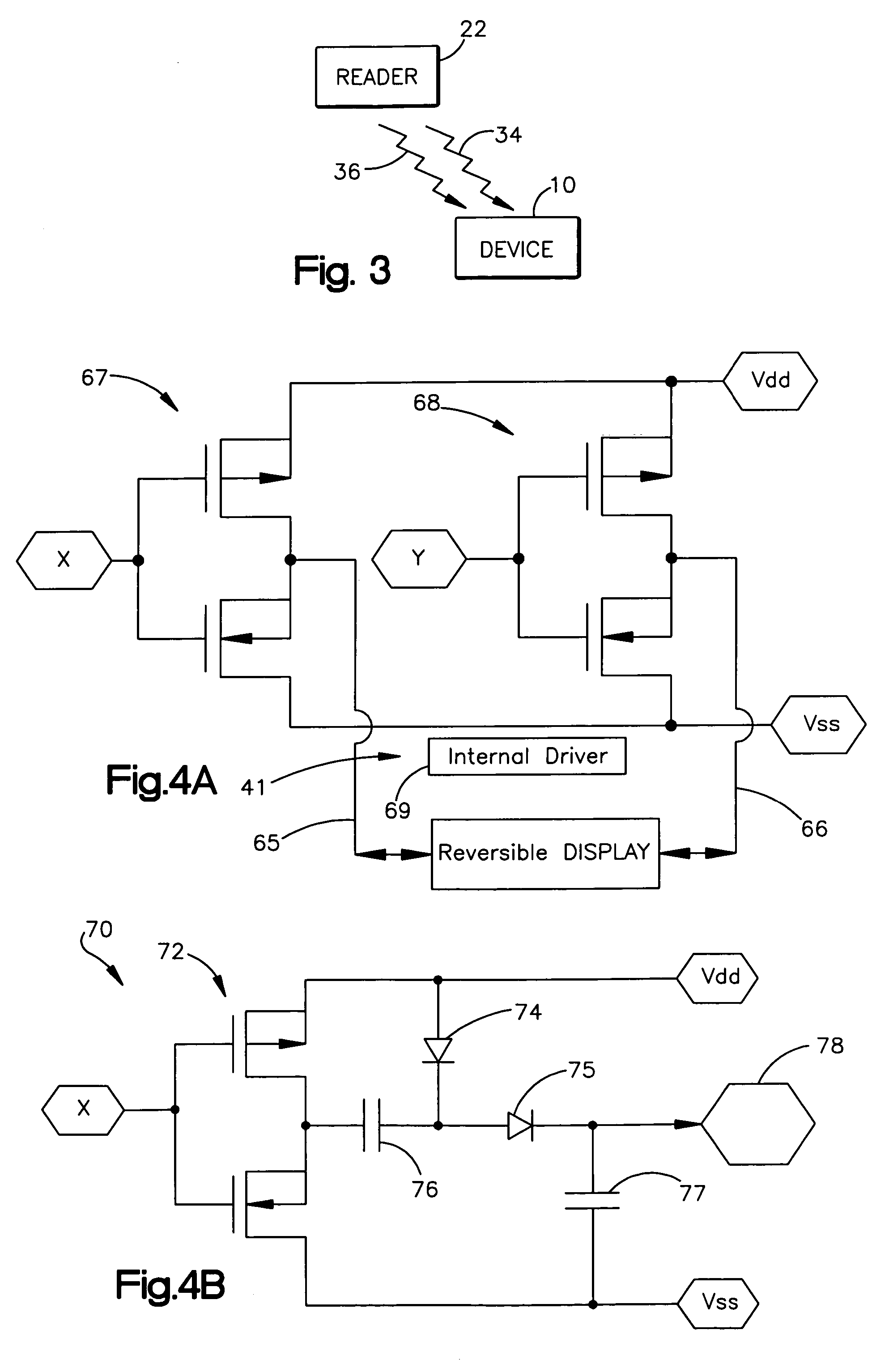

Radio frequency identification device with visual indicator

An RFID device includes a chip, an antenna operatively coupled to the chip, and a visual indicator operatively coupled to the chip. The visual indicator provides a visual indication of an operative state of the device. The visual indication may be human readable and / or machine readable, and may provide visual indication that is dependent on a change in an operative state of the device. The operative state that triggers the visual indication may include a state in which the chip has temporarily or permanently been rendered inoperative or disabled, that is, in which the chip no longer responds to, or otherwise interacts with, ordinary incoming RF signals such as from a device reader. The visual indicator may be included in a display that functions by any of a variety of suitable mechanisms, such as by use of electrochromic materials, thermochromic materials, liquid crystals, or chemically-reactive materials.

Owner:AVERY DENNISON CORP

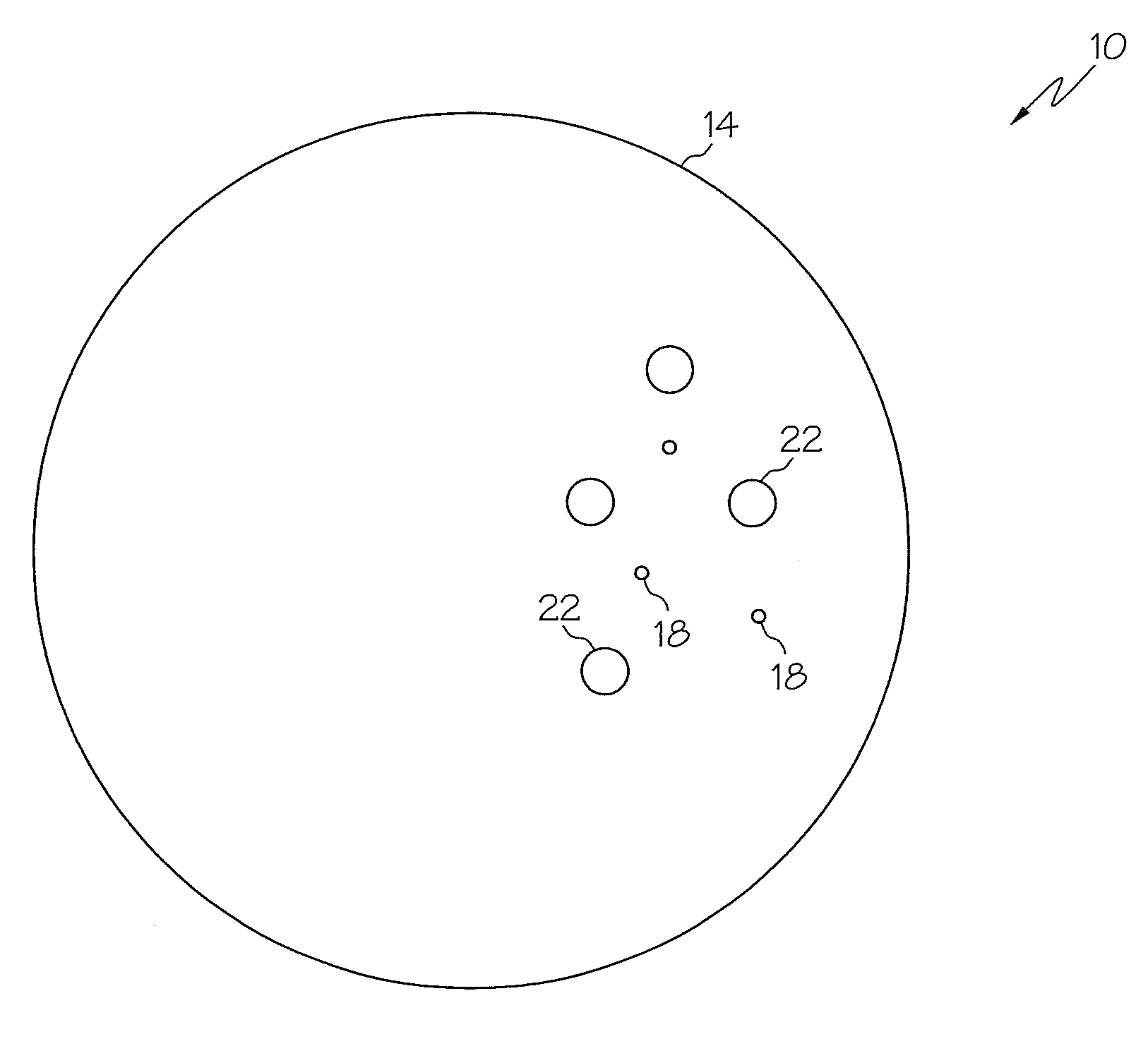

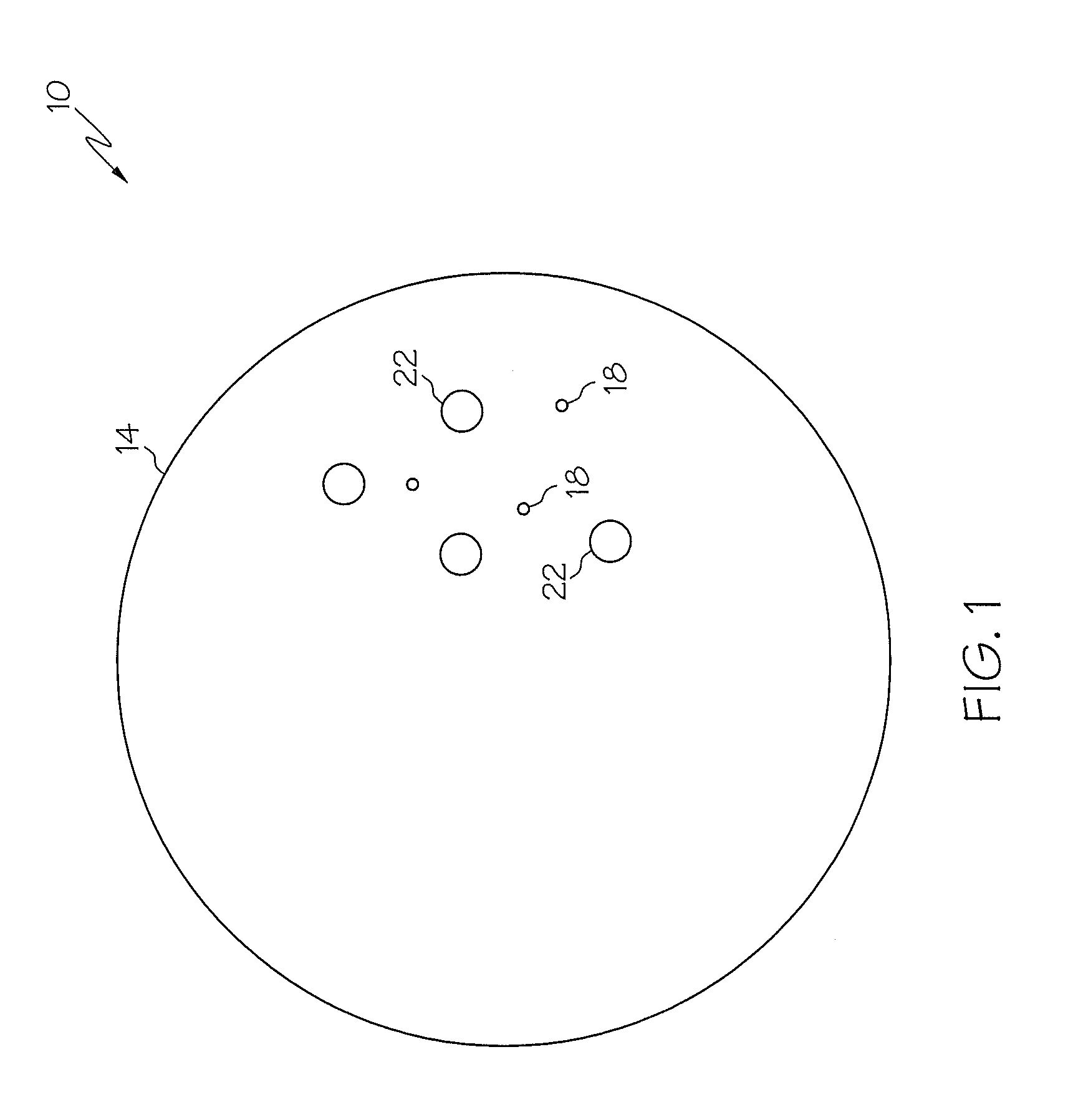

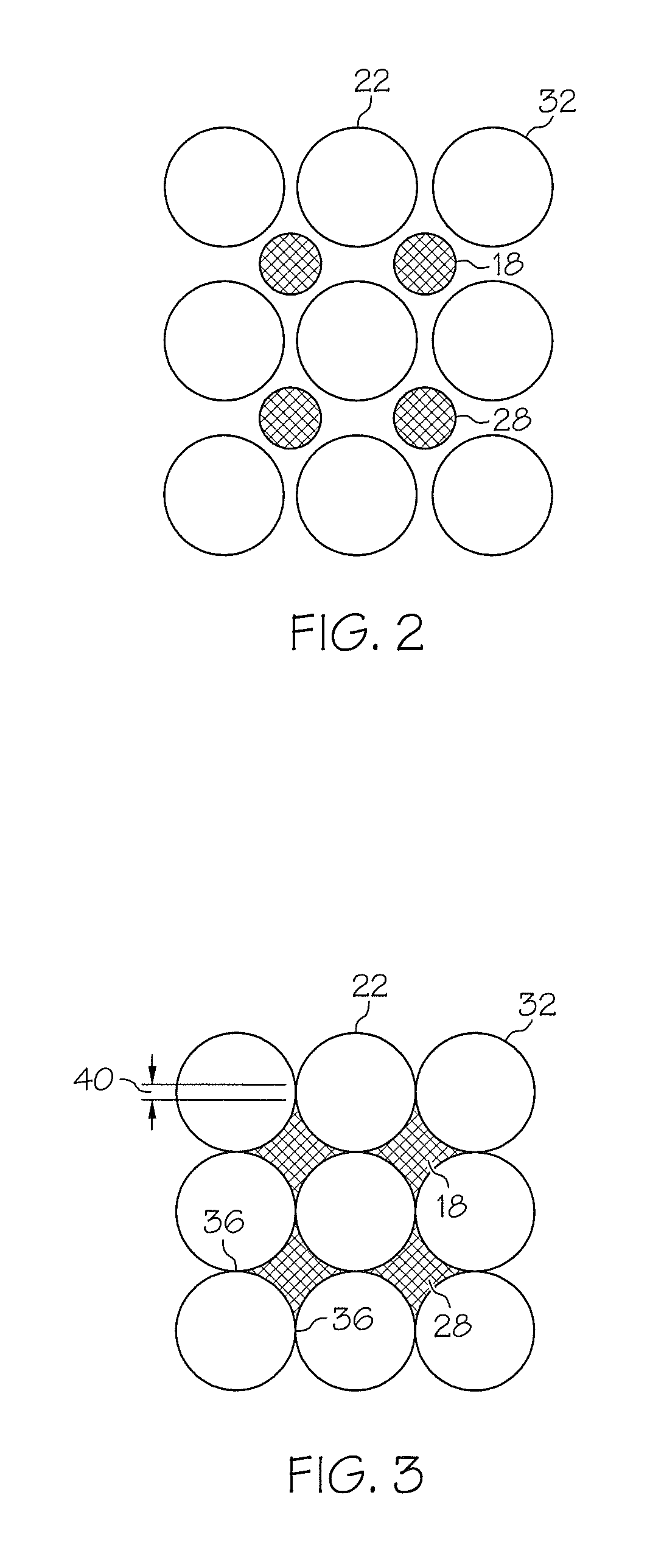

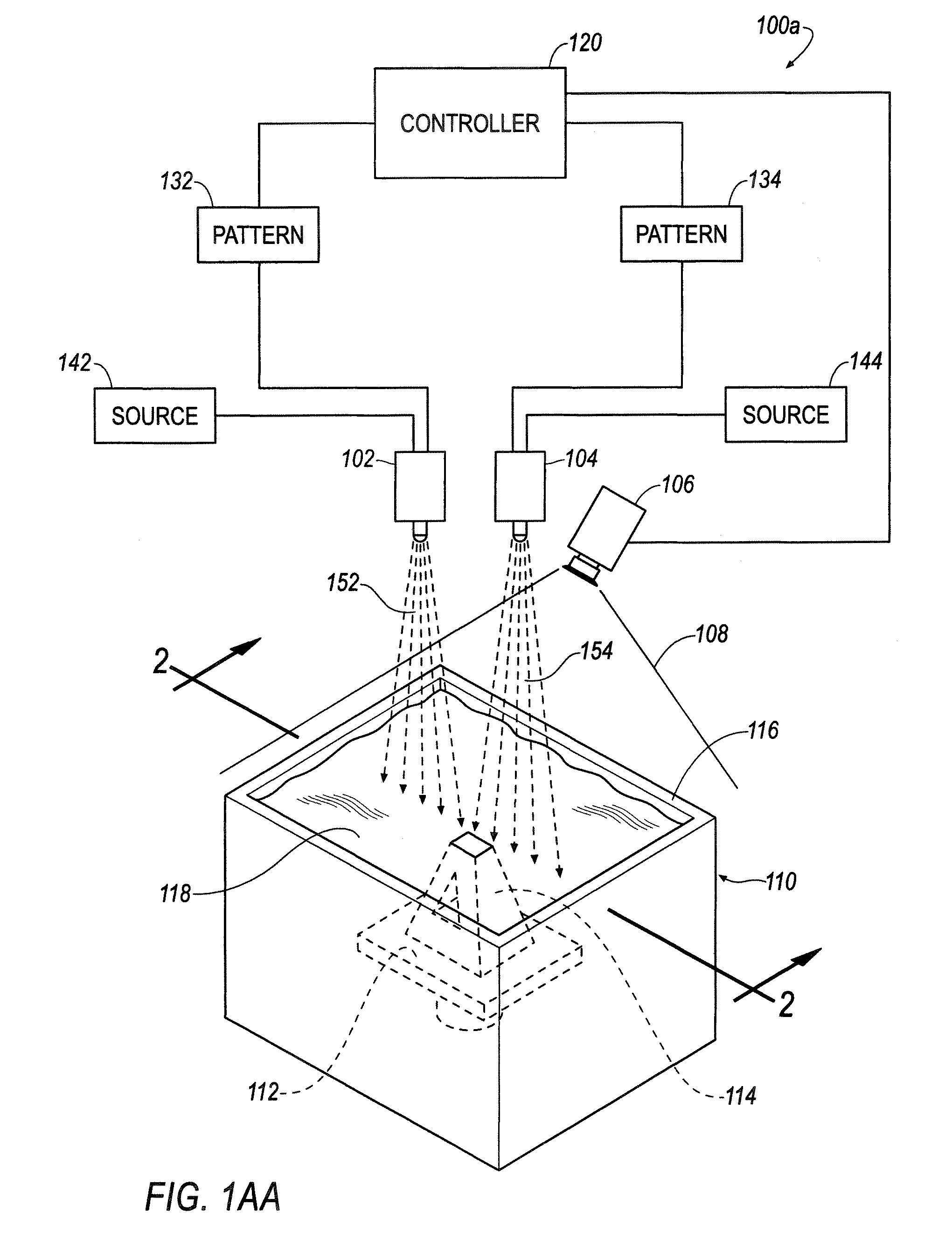

High-efficiency neutron detectors and methods of making same

ActiveUS20050258372A1Efficient detectionThin and compactMeasurement with semiconductor devicesMaterial analysis by optical meansRoom temperatureReactive material

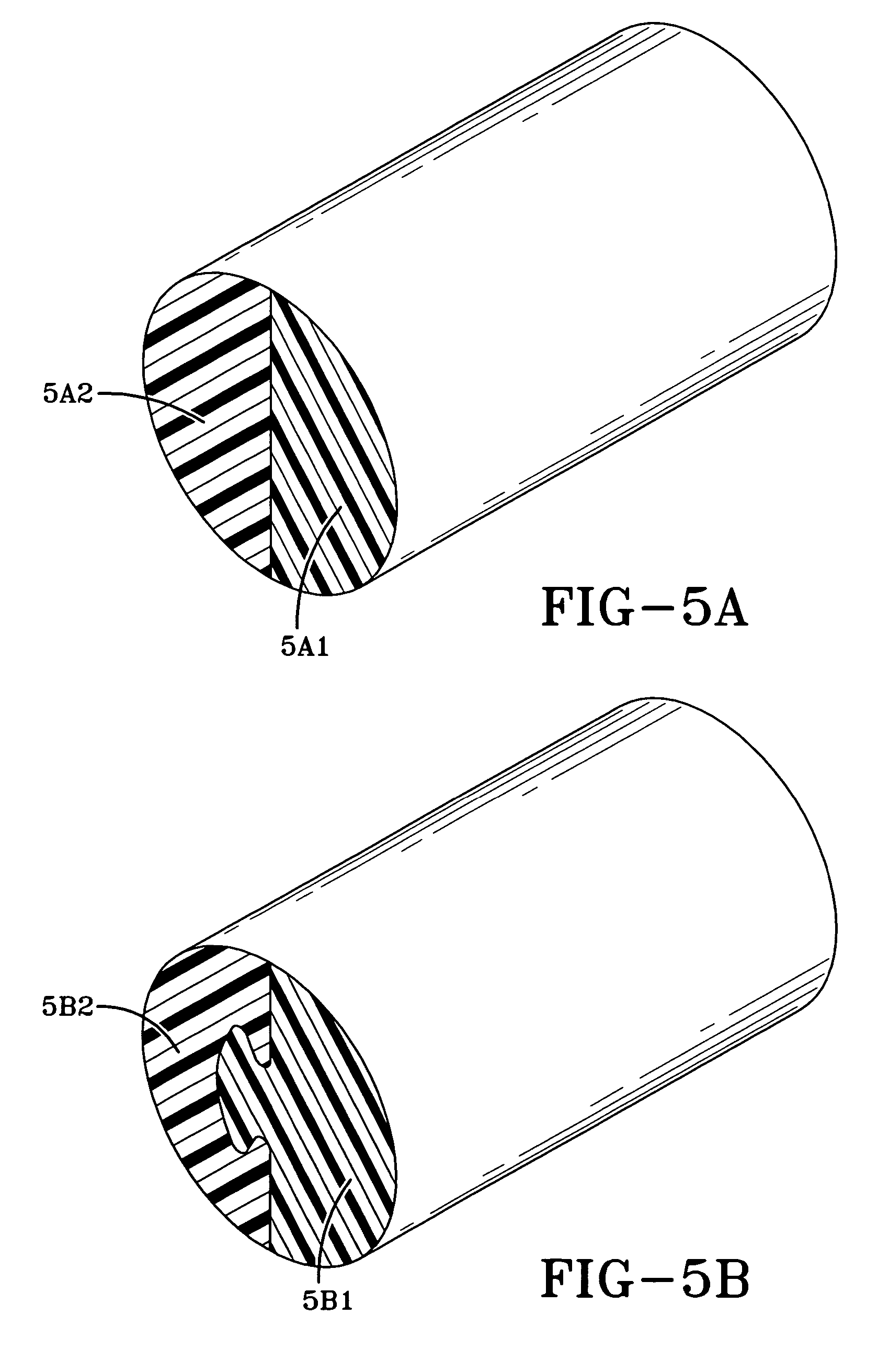

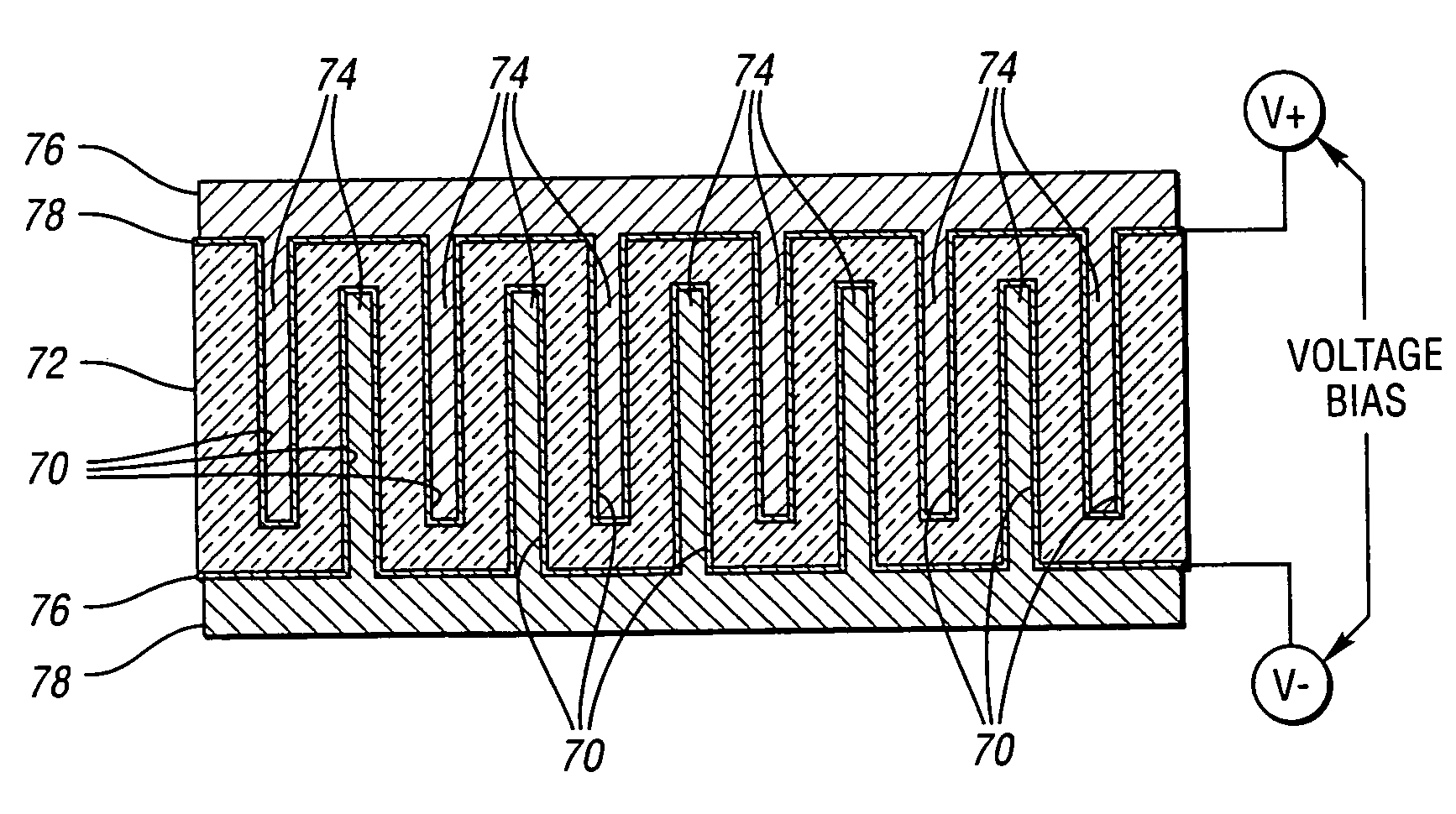

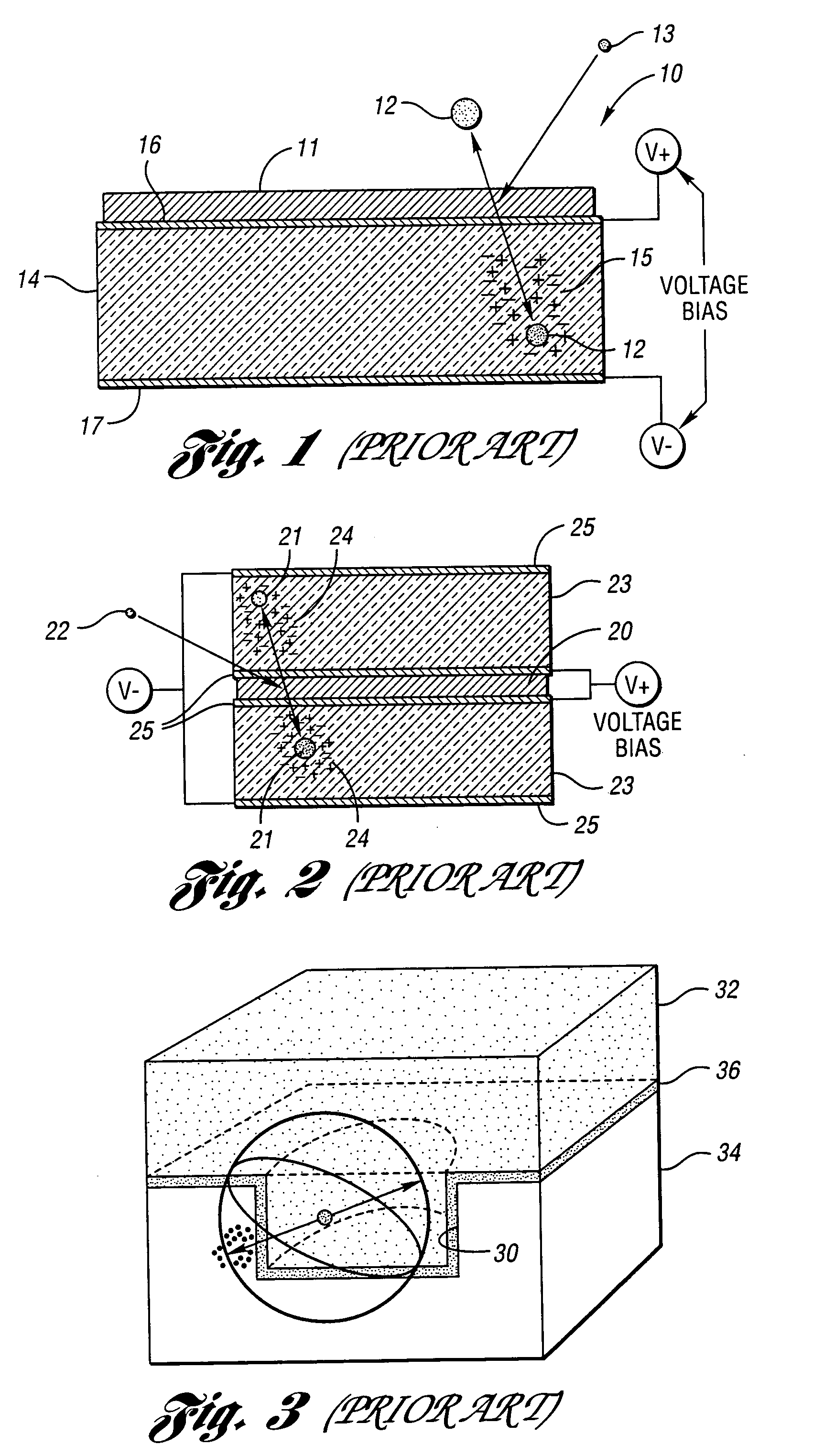

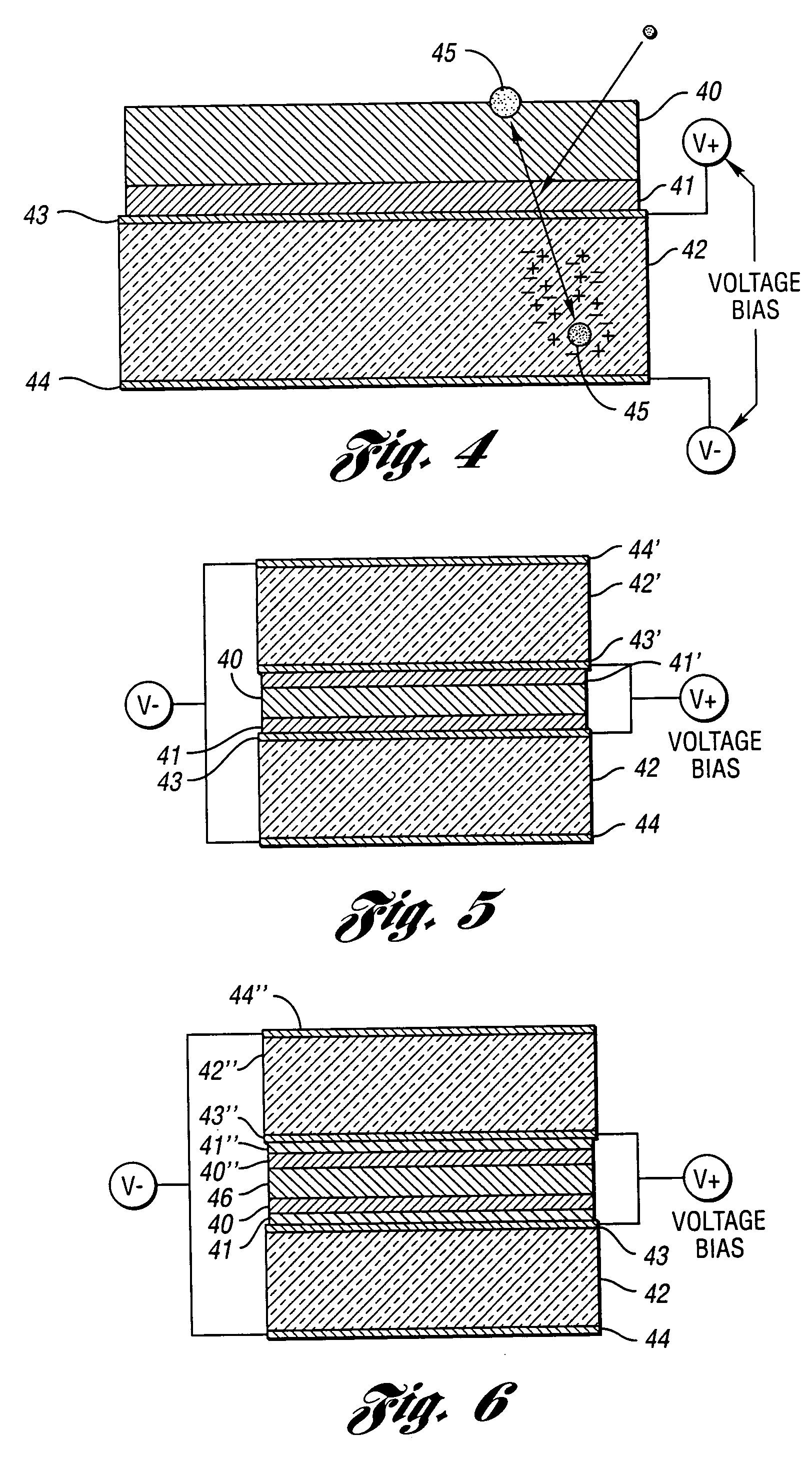

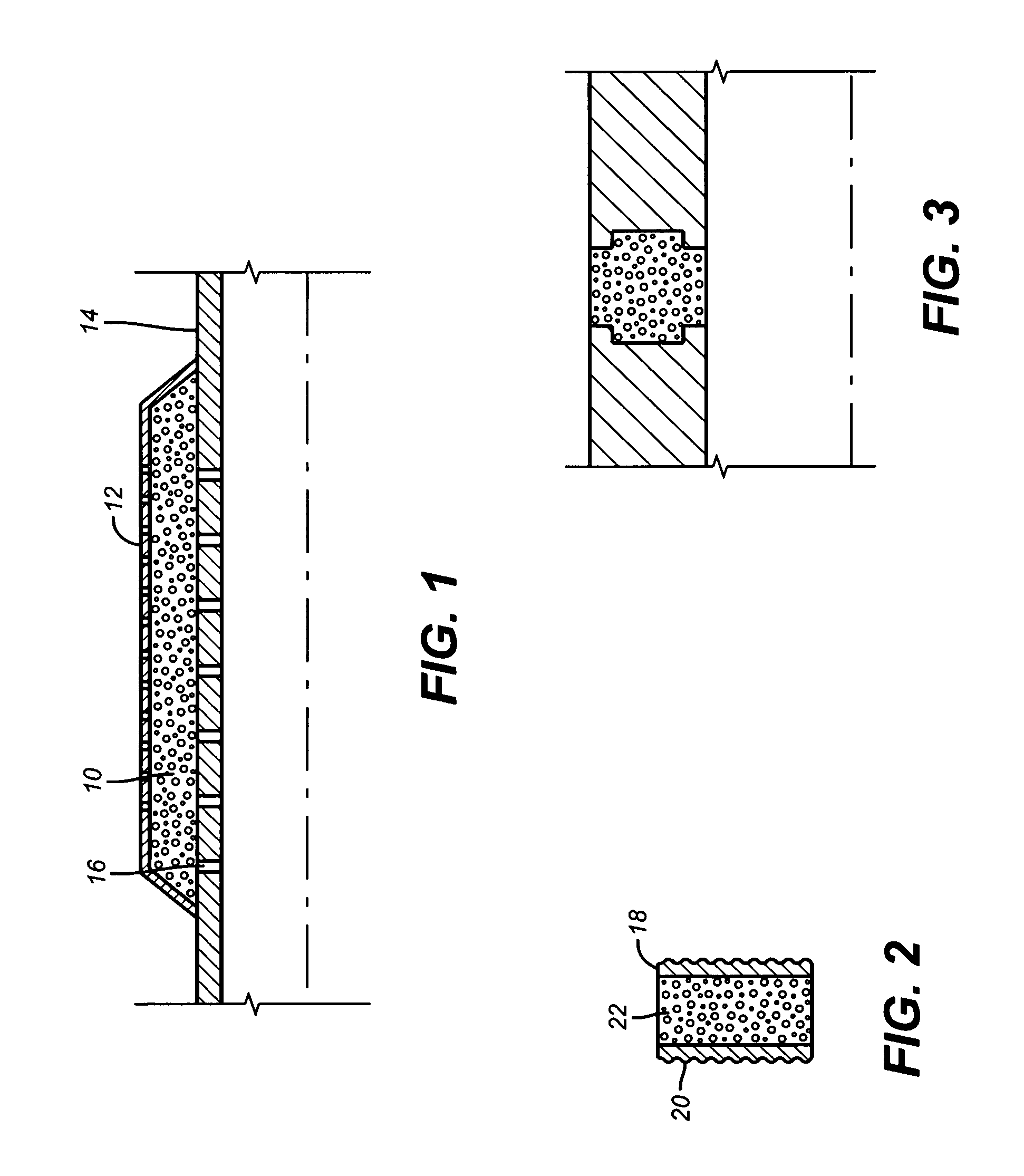

Neutron detectors, advanced detector process techniques and advanced compound film designs have greatly increased neutron-detection efficiency. One embodiment of the detectors utilizes a semiconductor wafer with a matrix of spaced cavities filled with one or more types of neutron reactive material such as 10B or 6LiF. The cavities are etched into both the front and back surfaces of the device such that the cavities from one side surround the cavities from the other side. The cavities may be etched via holes or etched slots or trenches. In another embodiment, the cavities are different-sized and the smaller cavities extend into the wafer from the lower surfaces of the larger cavities. In a third embodiment, multiple layers of different neutron-responsive material are formed on one or more sides of the wafer. The new devices operate at room temperature, are compact, rugged, and reliable in design.

Owner:RGT UNIV OF MICHIGAN

Aneurysm Treatment Device And Method Of Use

InactiveUS20090287297A1Effective occlusionInhibition is effectiveStentsOcculdersAneurysm treatmentReactive material

The present invention is directed to aneurysm treatment devices which are capable of being delivered to the situs of a vascular aneurysm through a catheter. The treatment devices comprise, in general, a body member formed by at least one support member and a reactive material selectively applied to the at least one support member. The body member provide support mechanical support to a weakened or otherwise incompetent blood vessel. The reactive material is capable of restricting or occluding blood flow to the aneurysm, without substantially affecting blood flow through the blood vessel.

Owner:MICROVENTION INC

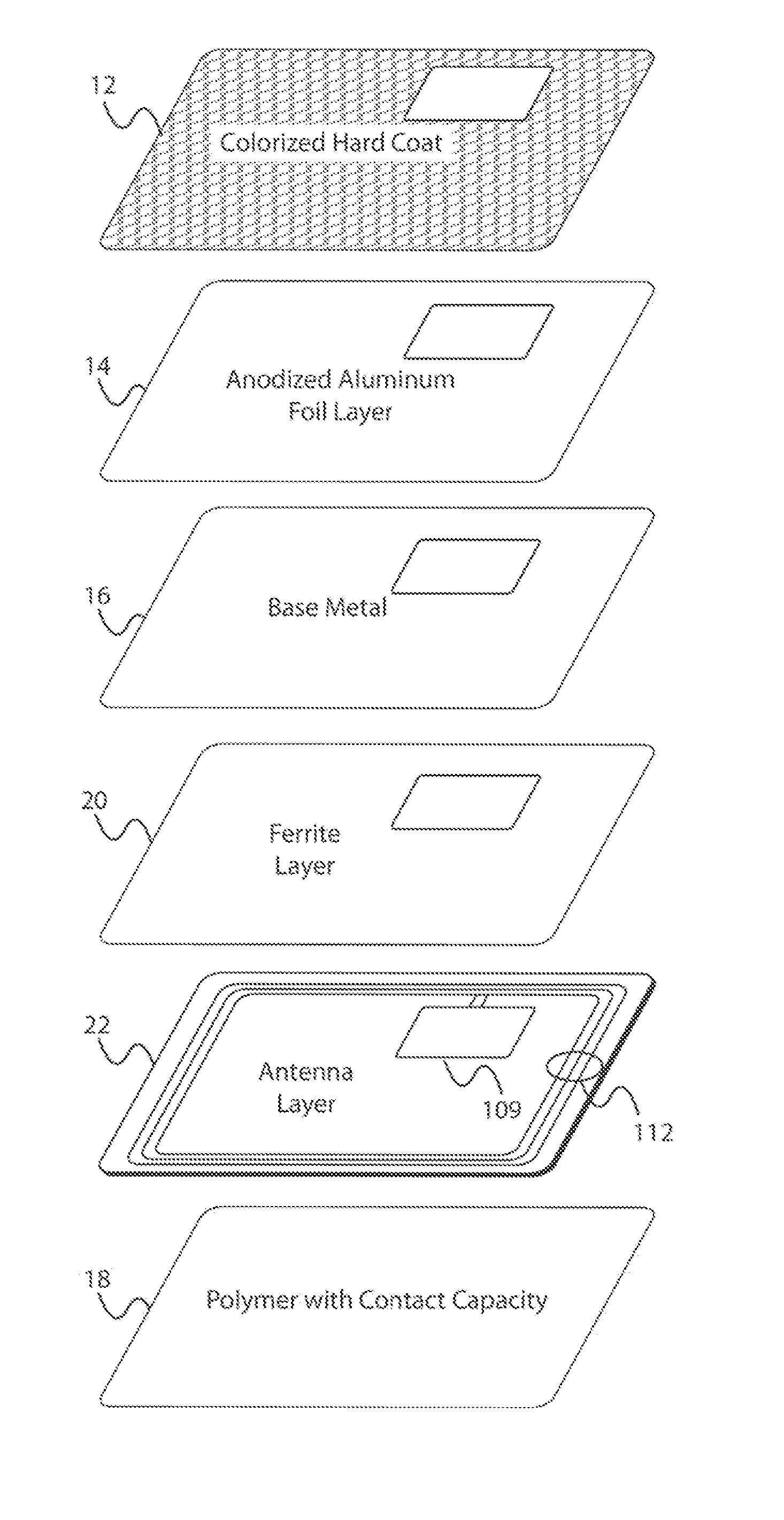

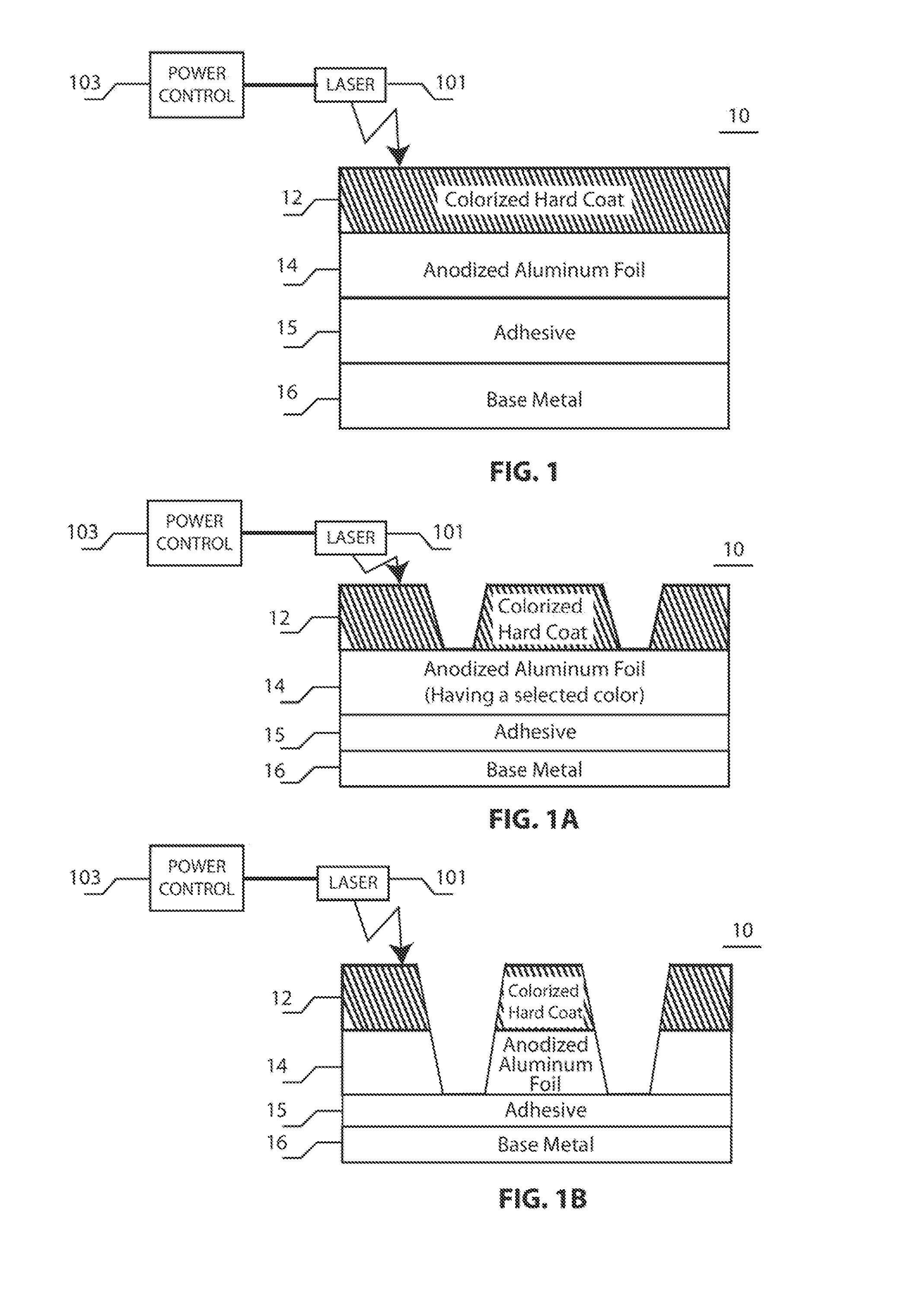

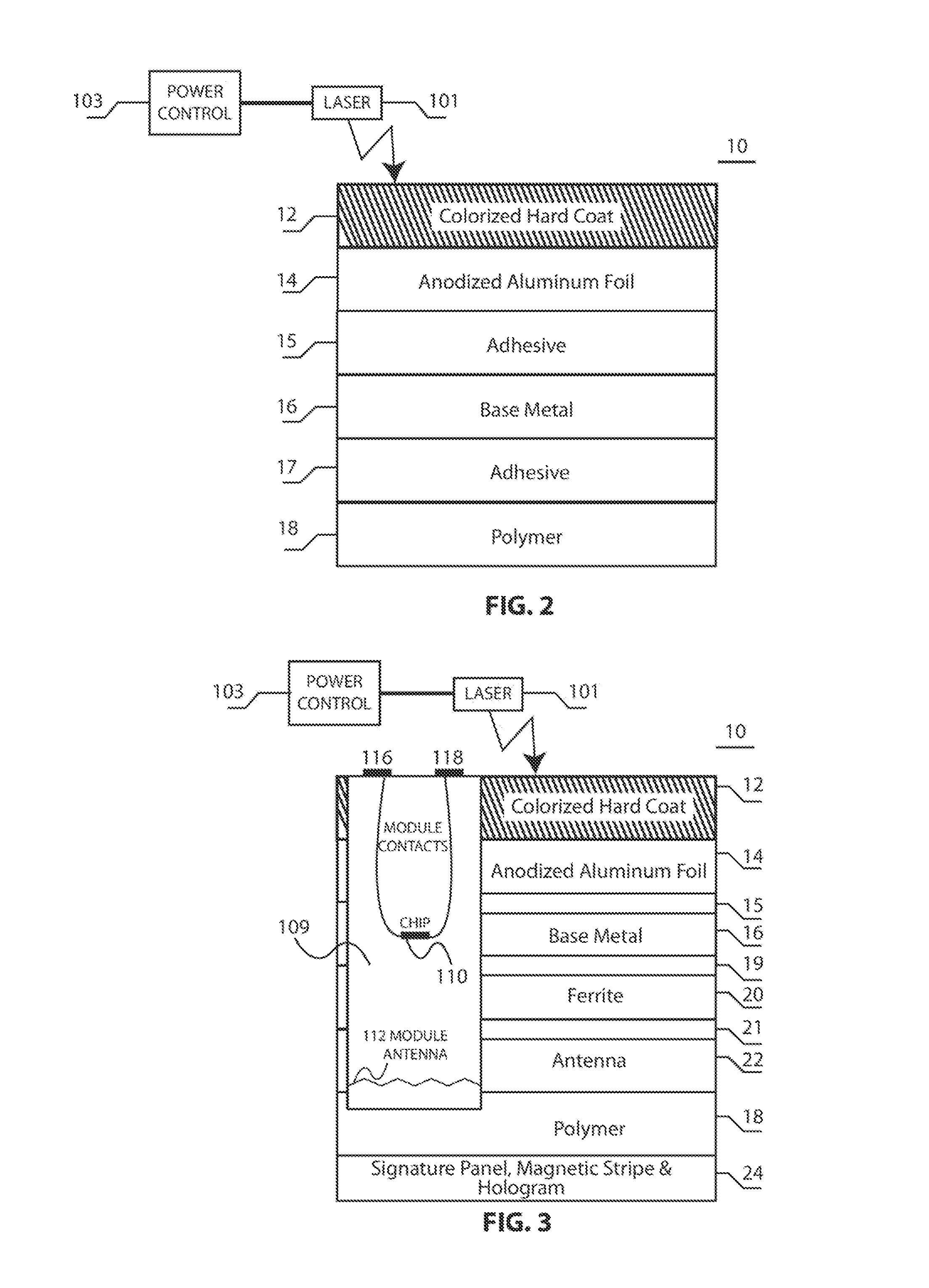

Transaction and id cards having selected texture and coloring

ActiveUS20150339564A1More costAvoid less flexibilityAnodisationWave amplification devicesEpoxyFinancial transaction

Cards made in accordance with the invention include a specially treated thin decorative layer attached to a thick core layer of metal or ceramic material, where the thin decorative layer is designed to provide selected color(s) and / or selected texture(s) to a surface of the metal cards. Decorative layers for use in practicing the invention include: (a) an anodized metal layer; or (b) a layer of material derived from plant or animal matter (e.g., wood, leather); or (c) an assortment of aggregate binder material (e.g., cement, mortar, epoxies) mixed with laser reactive materials (e.g., finely divided carbon); or (d) a ceramic layer; and (e) a layer of crystal fabric material. The cards may be dual interface smart cards which can be read in a contactless manner and / or via contacts.

Owner:COMPOSECURE LLC

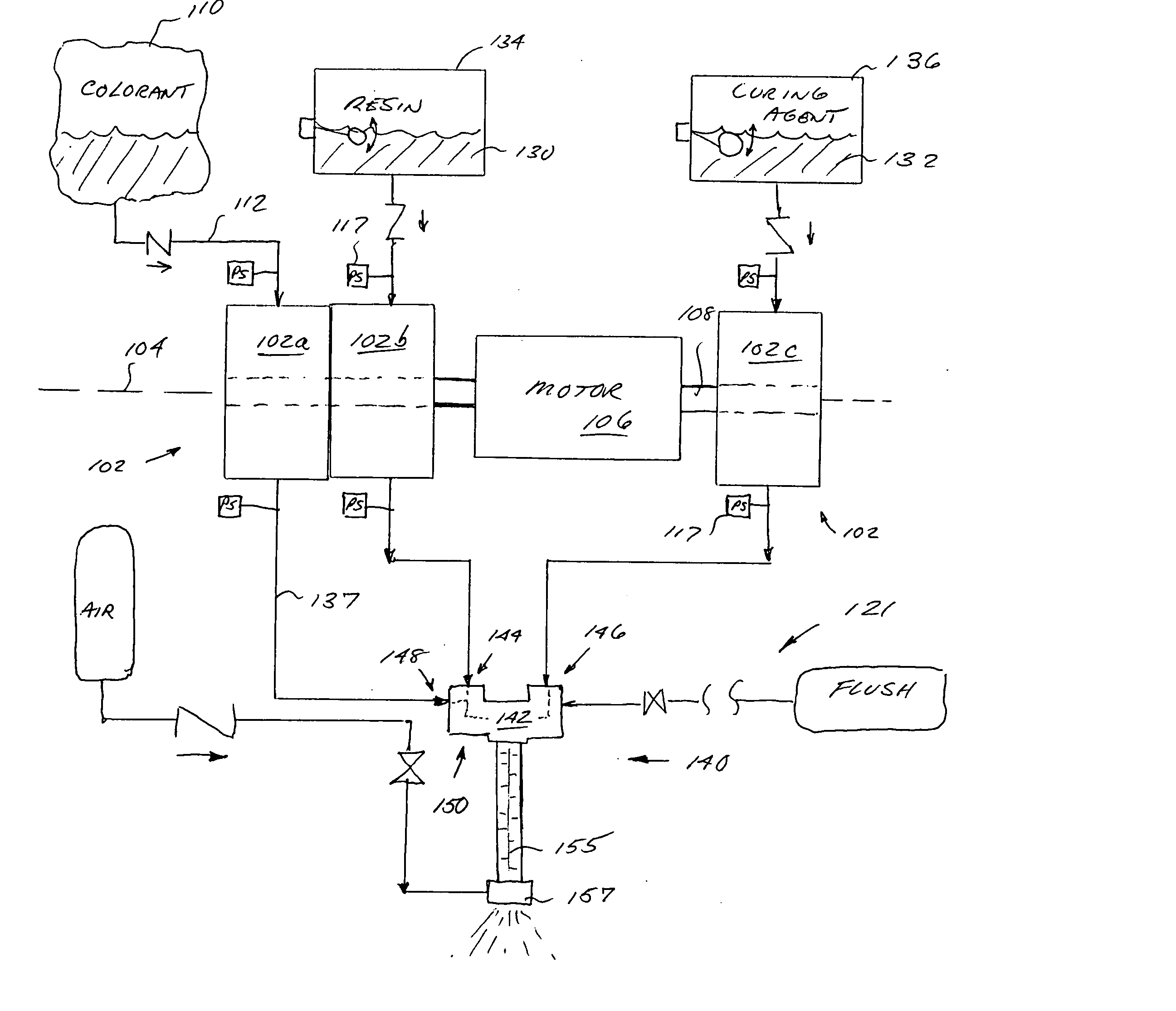

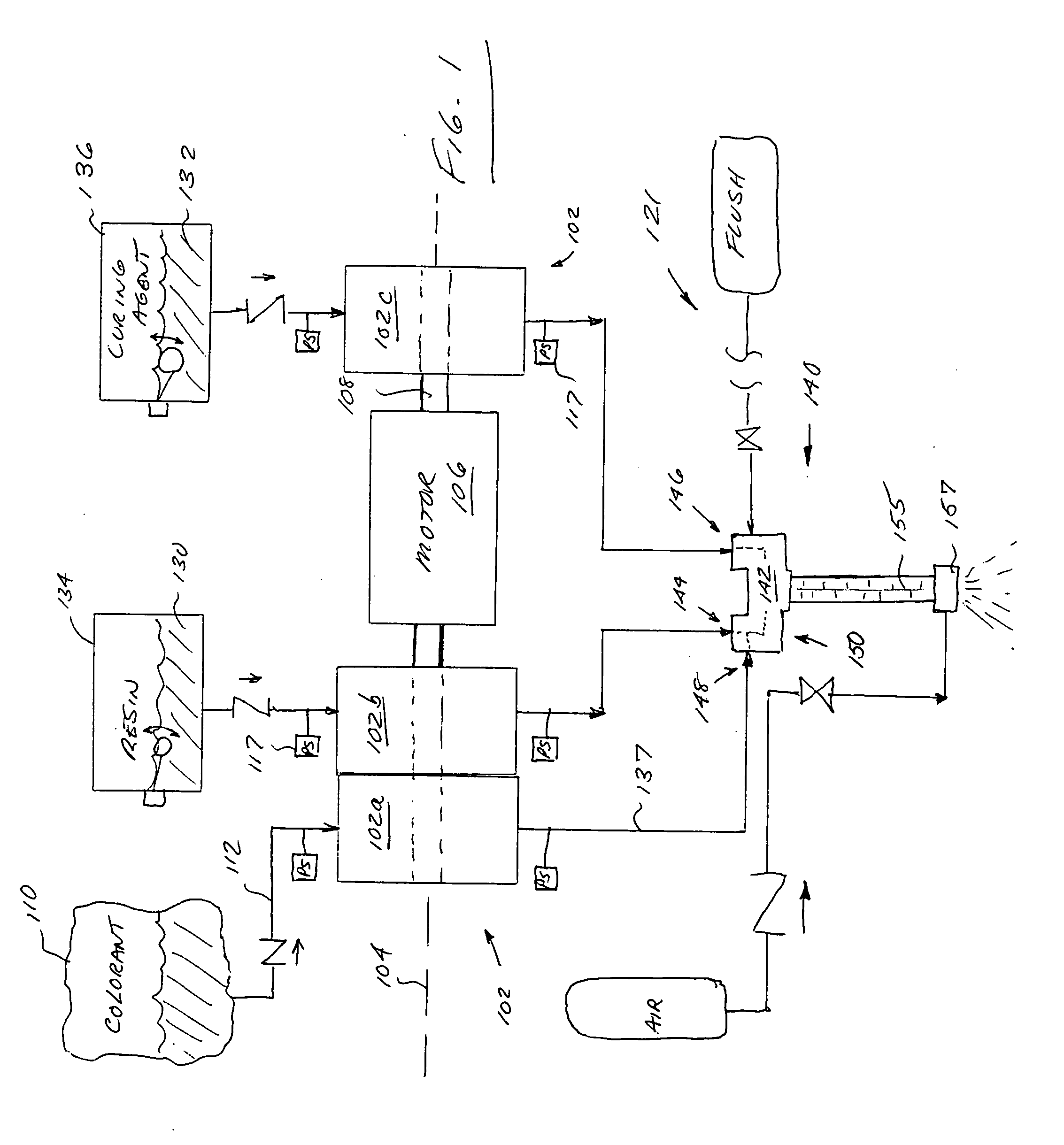

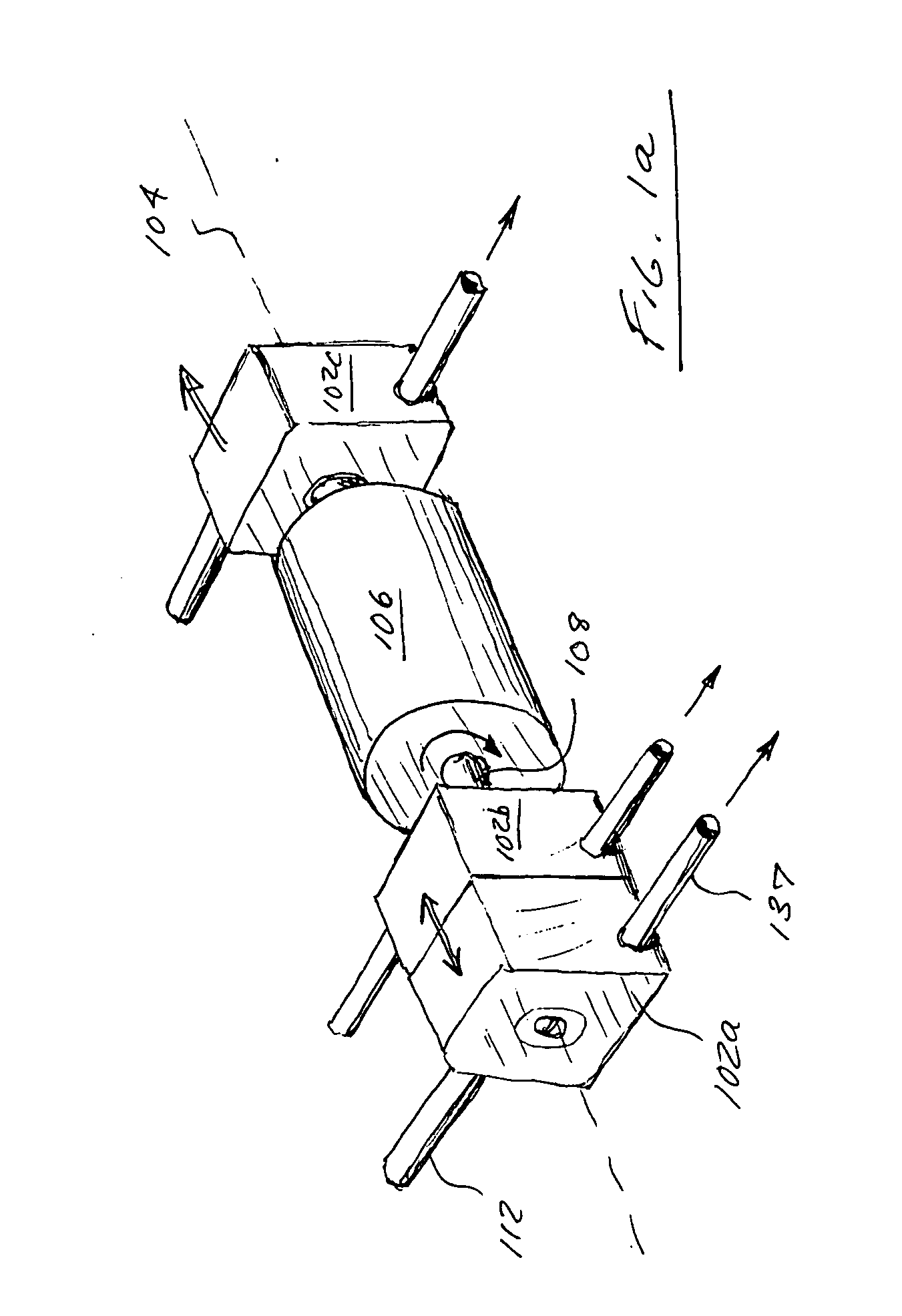

Apparatus and methods for dispensing fluidic or viscous materials

InactiveUS20070000947A1Satisfies needReduce the burden onMixer accessoriesLiquid transferring devicesProduction rateReservoir bag

Mixing and dispensing apparatus and methods for use with, e.g., a multi-component reactive material process is disclosed. In one embodiment, the apparatus comprises a series of positive displacement pumps adapted for stacked or “piggy-back” mating to a common motive source. At least one of the pumps is supplied by a sealed and collapsible reservoir bag and flexible tubing, thereby allowing removal (and optionally disposal) of one or more complete material pathways within the system. Such a configuration allows for, inter alia, rapid colorant changing with minimal material waste, obviates the use of hazardous solvents, and increases process efficiency and worker productivity. This arrangement also obviates complex metering apparatus common to prior art systems, thereby allowing it to be as small and power / cost efficient as possible.

Owner:RHINO LININGS CORP

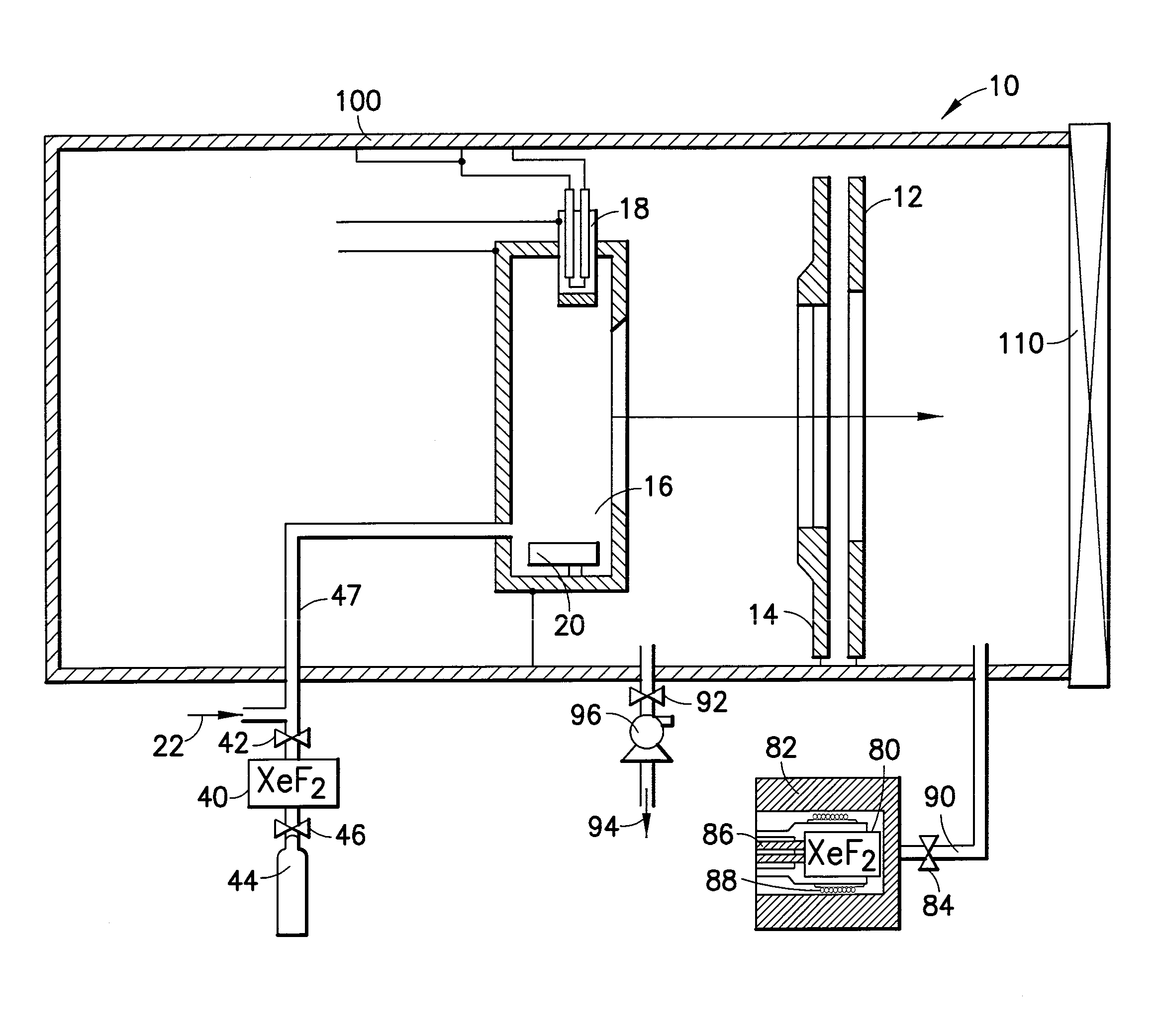

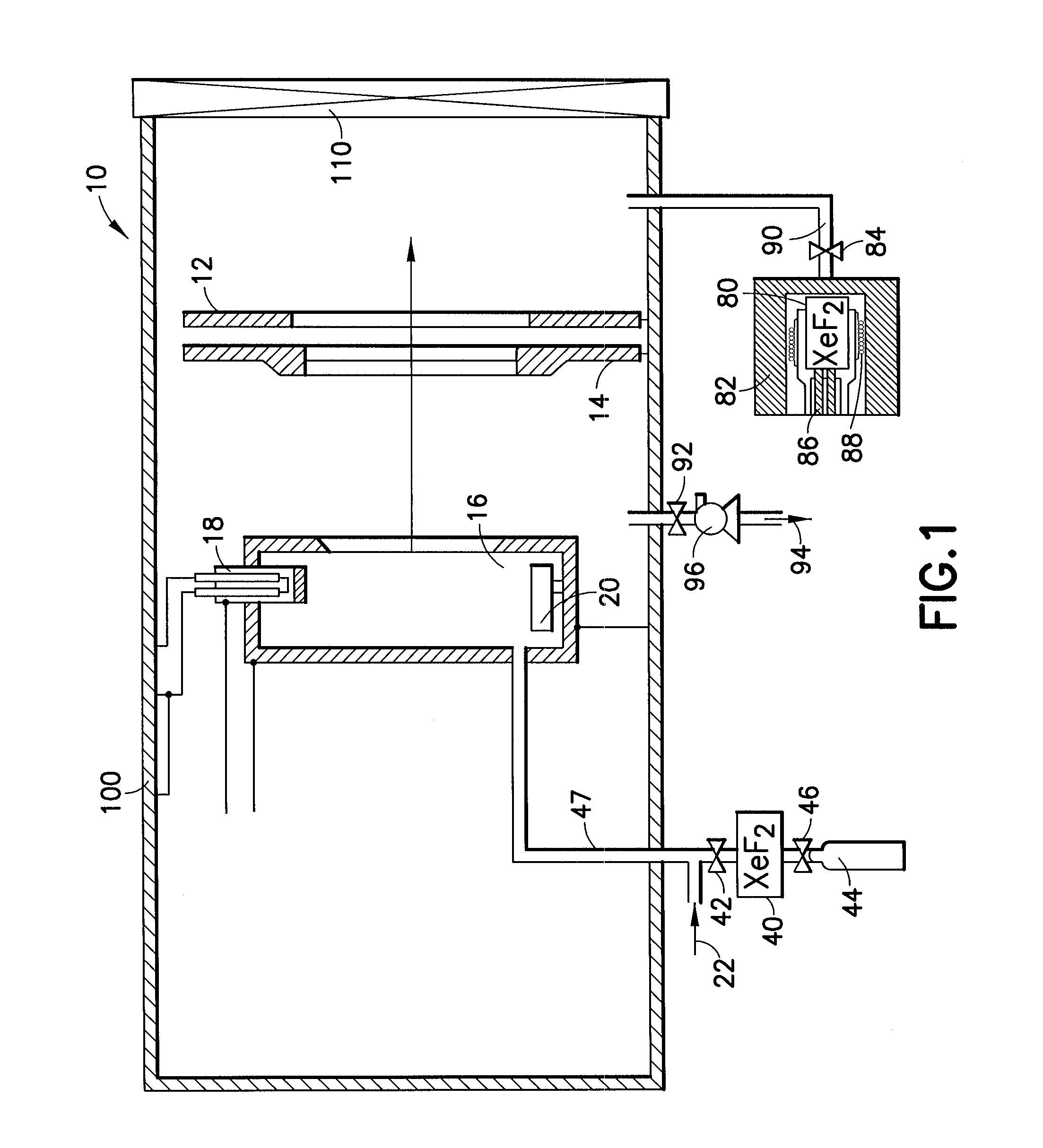

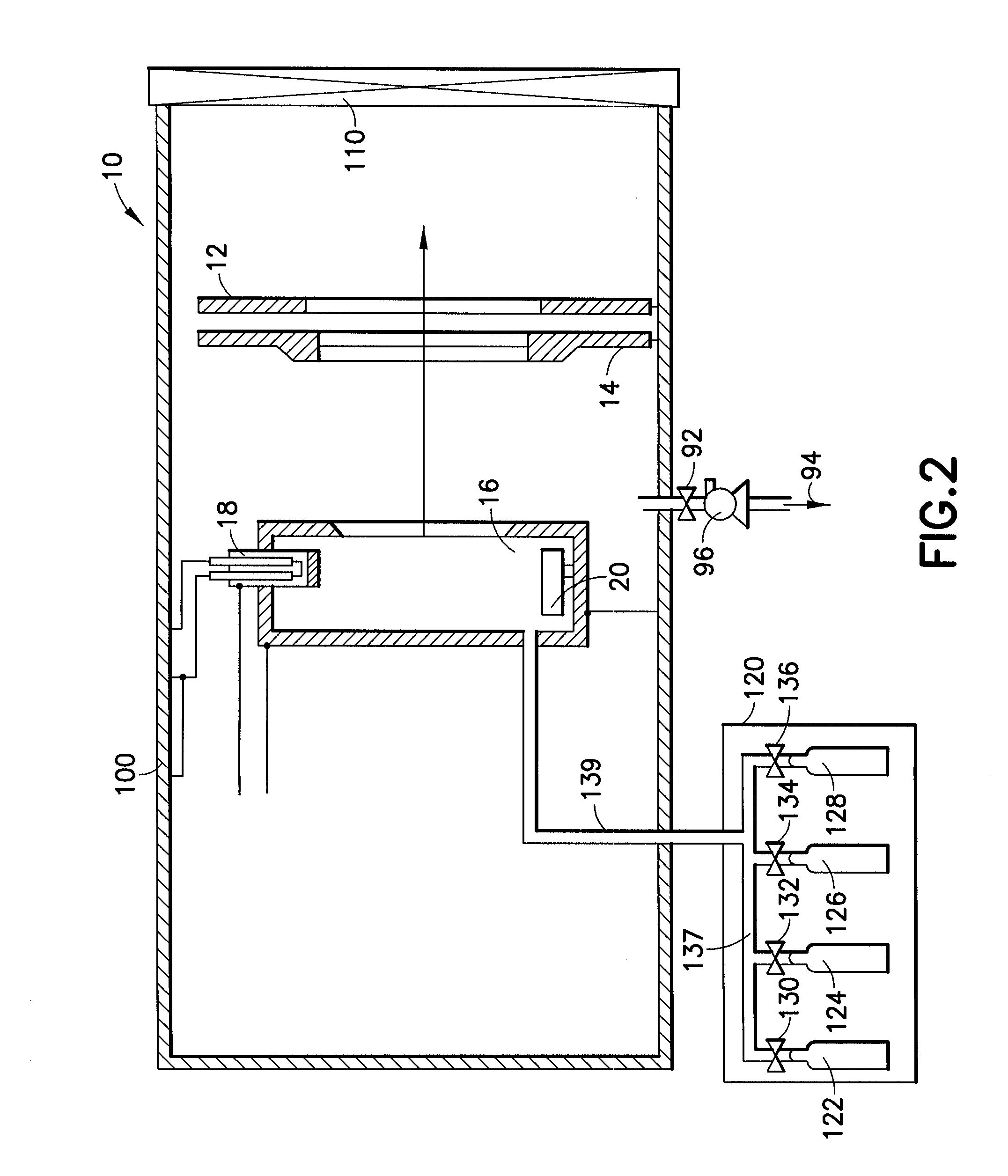

Cleaning of semiconductor processing systems

ActiveUS20100154835A1Improve stabilityElectric discharge tubesHollow article cleaningOrganic chloride compoundSufficient time

A method and apparatus for cleaning residue from components of semiconductor processing systems used in the fabrication of microelectronic devices. To effectively remove residue, the components are contacted with a gas-phase reactive material for sufficient time and under sufficient conditions to at least partially remove the residue. When the residue and the material from which the components are constructed are different, the gas-phase reactive material is selectively reactive with the residue and minimally reactive with the materials from which the components of the ion implanter are constructed. When the residue and the material from which the components are constructed is the same, then the gas-phase reactive material may be reactive with both the residue and the component part. Particularly preferred gas-phase reactive materials utilized comprise gaseous compounds such as XeF2, XeF4, XeF6, NF3, IF5, IF7, SF6, C2F6, F2, CF4, KrF2, Cl2, HCl, ClF3, ClO2, N2F4, N2F2, N3F, NFH2, NH2F, HOBr, Br2, C3F8, C4F8, C5F8, CHF3, CH2F2, CH3F, COF2, HF, C2HF5, C2H2F4, C2H3F3, C2H4F2, C2H5F, C3F6, and organochlorides such as COCl2, CCl4, CHCl3, CH2Cl2 and CH3Cl.

Owner:ENTEGRIS INC

System and method for manufacturing

ActiveUS8666142B2Image enhancementAdditive manufacturing apparatusComputer graphics (images)Reactive material

Owner:GLOBAL FILTRATION SYST

Dissolvable downhole tool, method of making and using

Disclosed herein is a dissolvable downhole tool. The tool includes, a dissolvable body constructed of at least two materials and at least one of the at least two materials is a reactive material, and a first material of the at least two materials being configured to substantially dissolve the dissolvable body and a second material configured to control reaction timing of the first material.

Owner:BAKER HUGHES INC

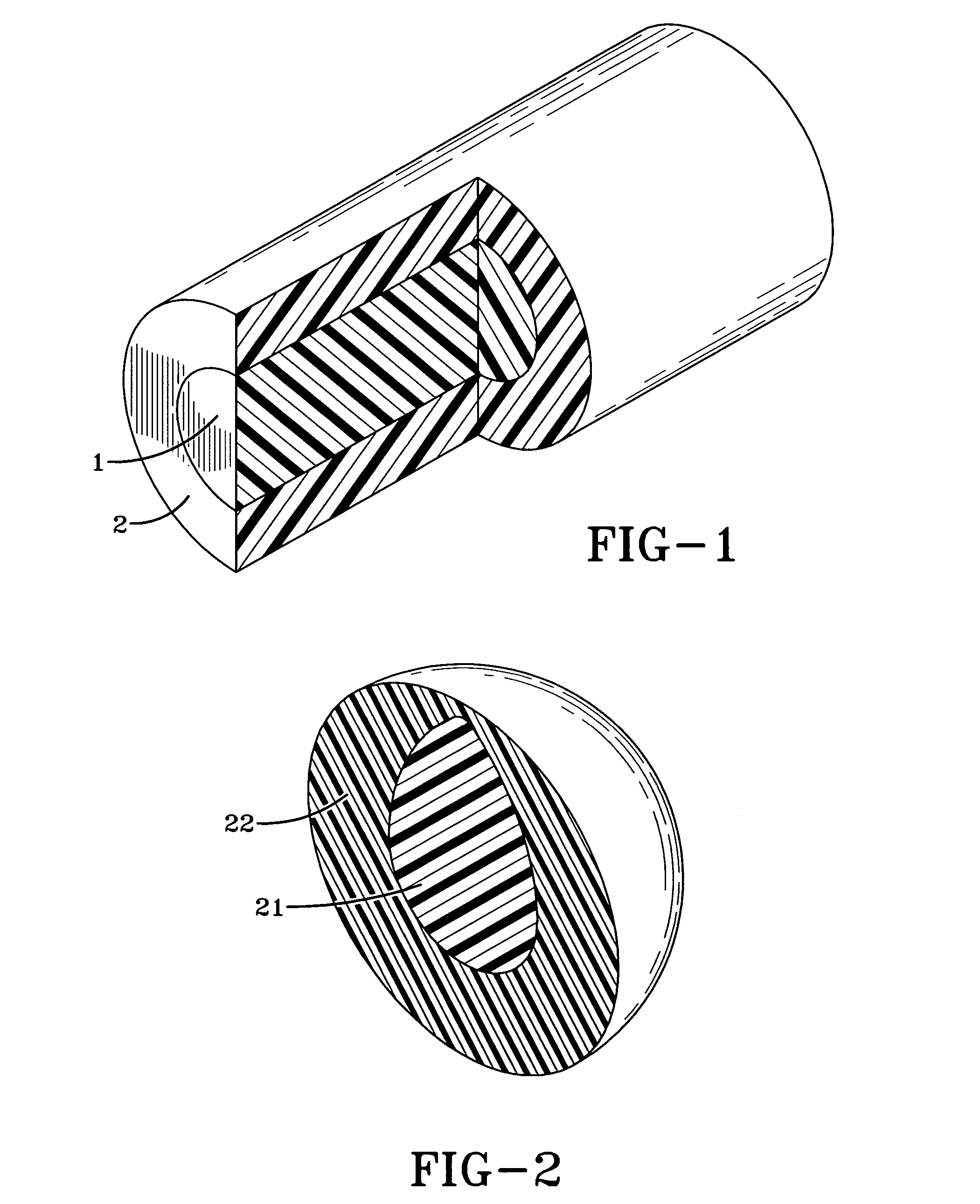

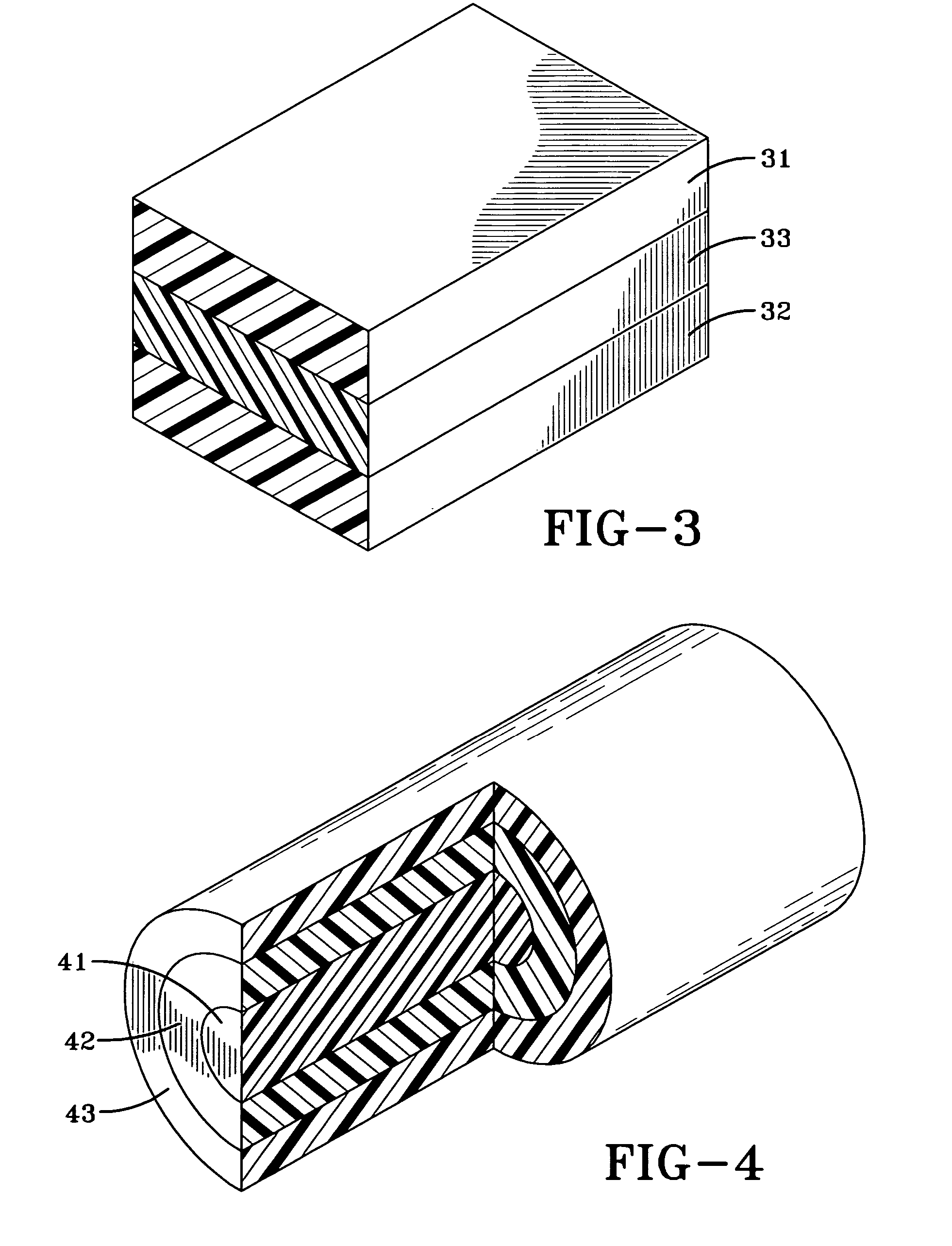

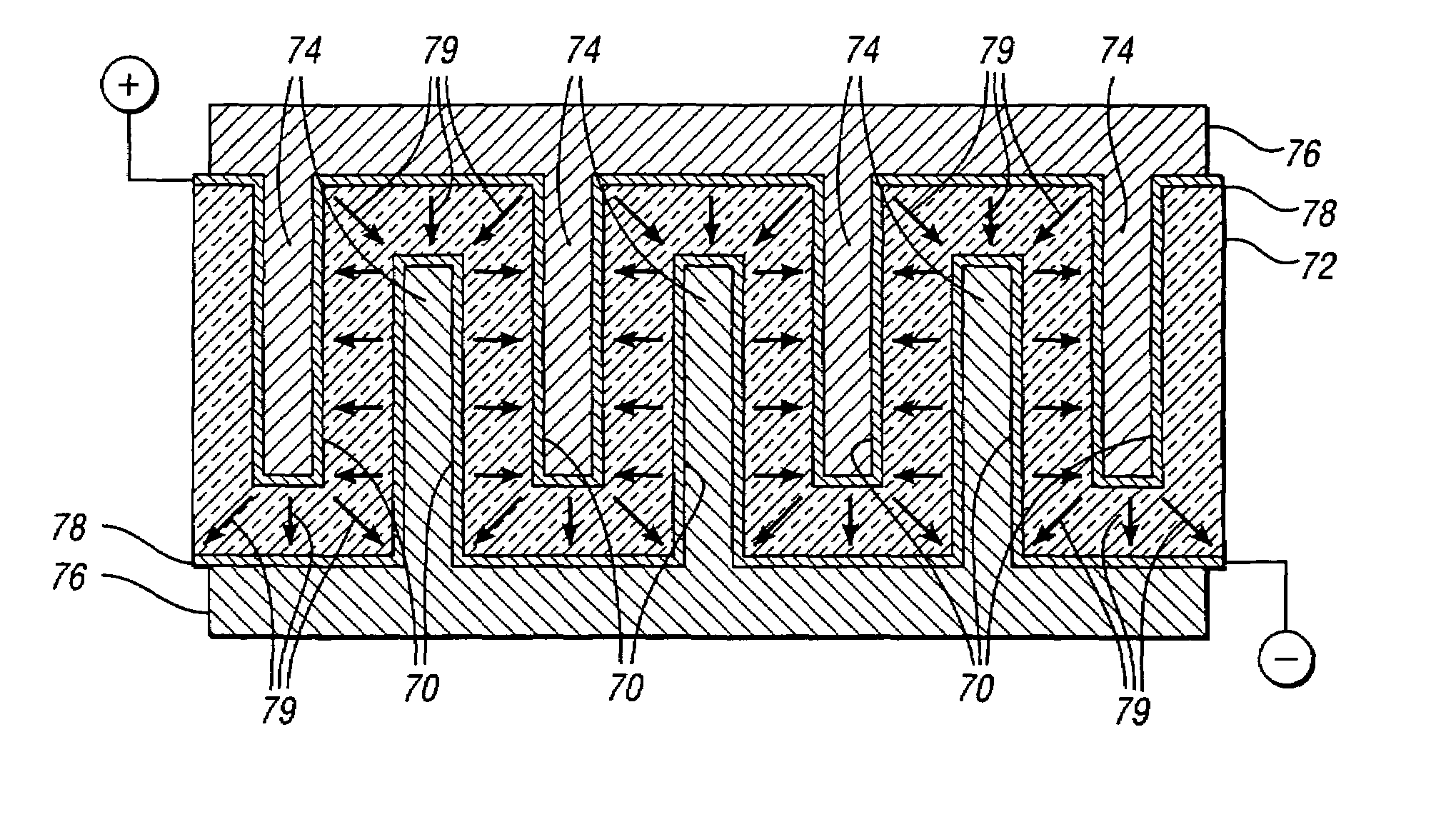

High-efficiency neutron detectors and methods of making same

ActiveUS7164138B2Many timesThin and compactMeasurement with semiconductor devicesMaterial analysis by optical meansRoom temperatureReactive material

Neutron detectors, advanced detector process techniques and advanced compound film designs have greatly increased neutron-detection efficiency. One embodiment of the detectors utilizes a semiconductor wafer with a matrix of spaced cavities filled with one or more types of neutron reactive material such as 10B or 6LiF. The cavities are etched into both the front and back surfaces of the device such that the cavities from one side surround the cavities from the other side. The cavities may be etched via holes or etched slots or trenches. In another embodiment, the cavities are different-sized and the smaller cavities extend into the wafer from the lower surfaces of the larger cavities. In a third embodiment, multiple layers of different neutron-responsive material are formed on one or more sides of the wafer. The new devices operate at room temperature, are compact, rugged, and reliable in design.

Owner:RGT UNIV OF MICHIGAN

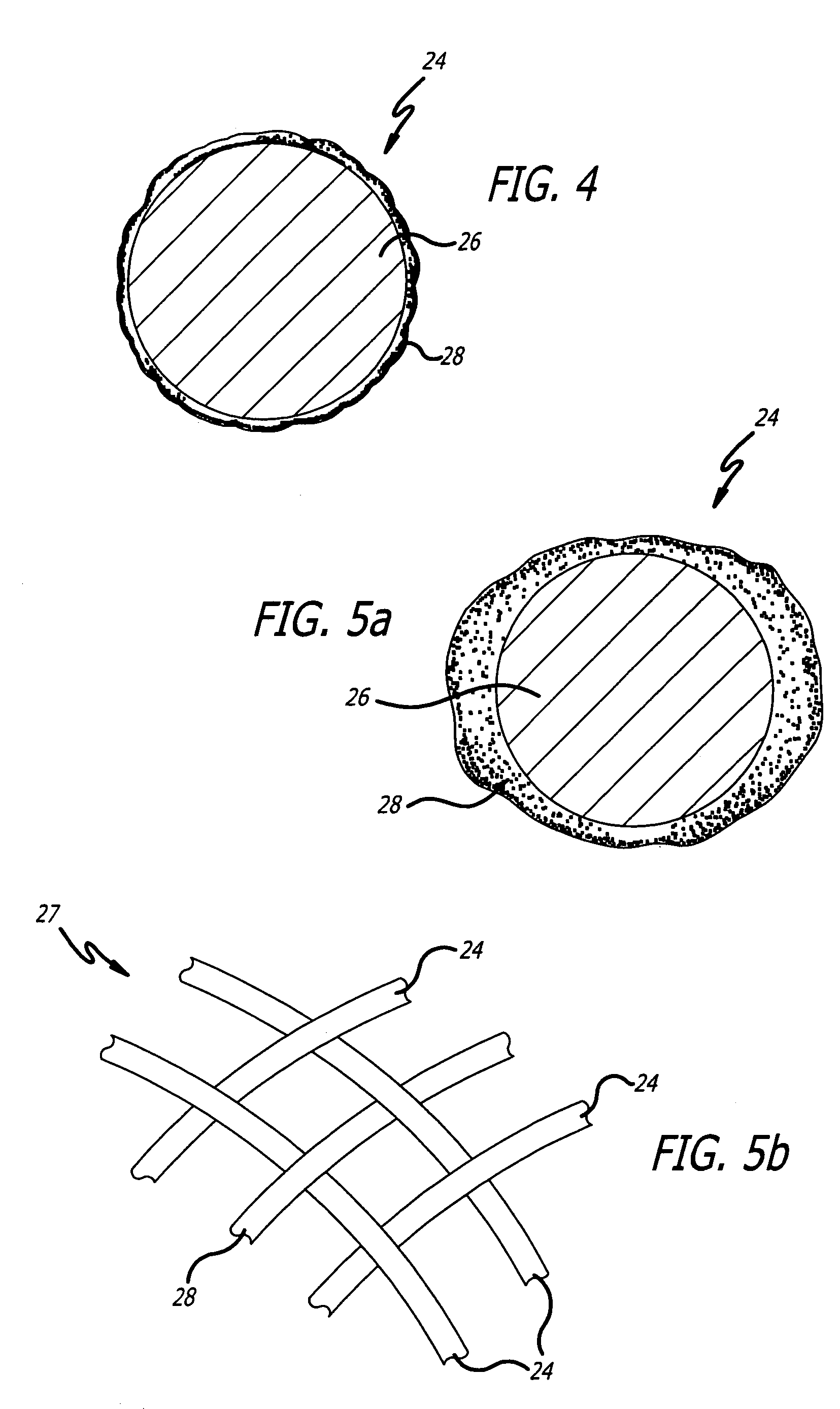

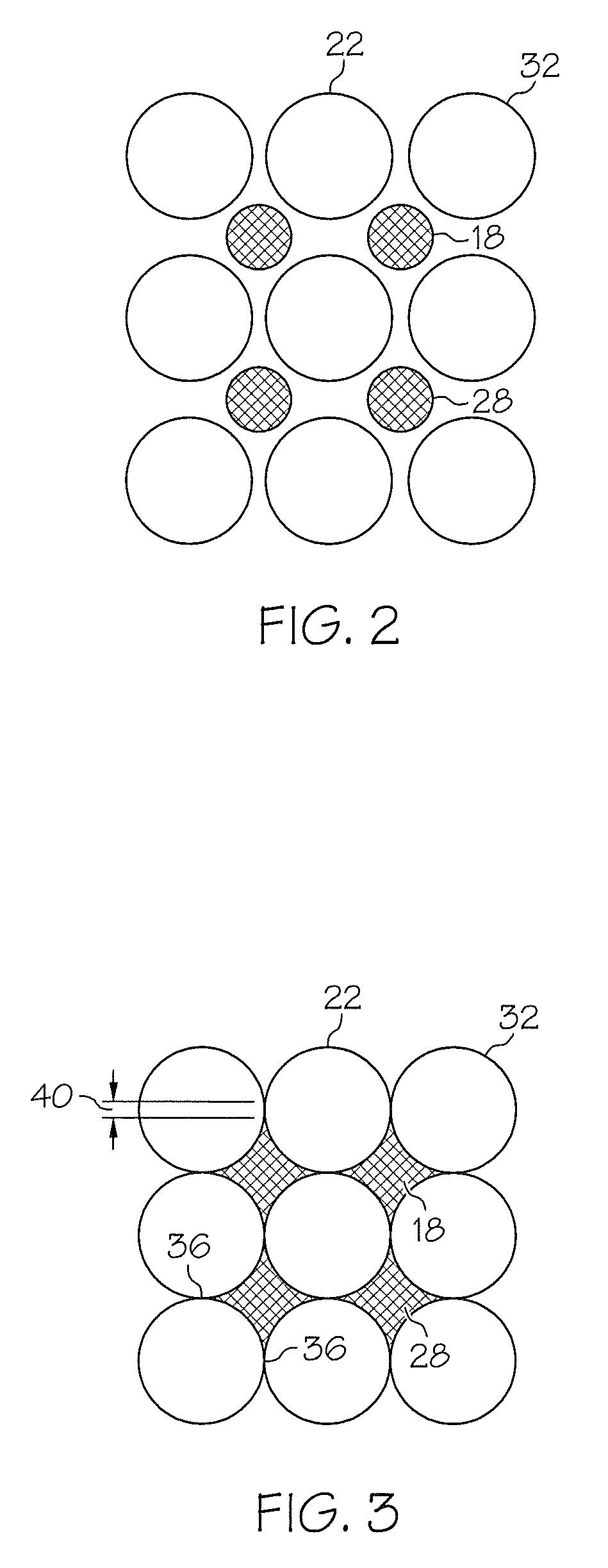

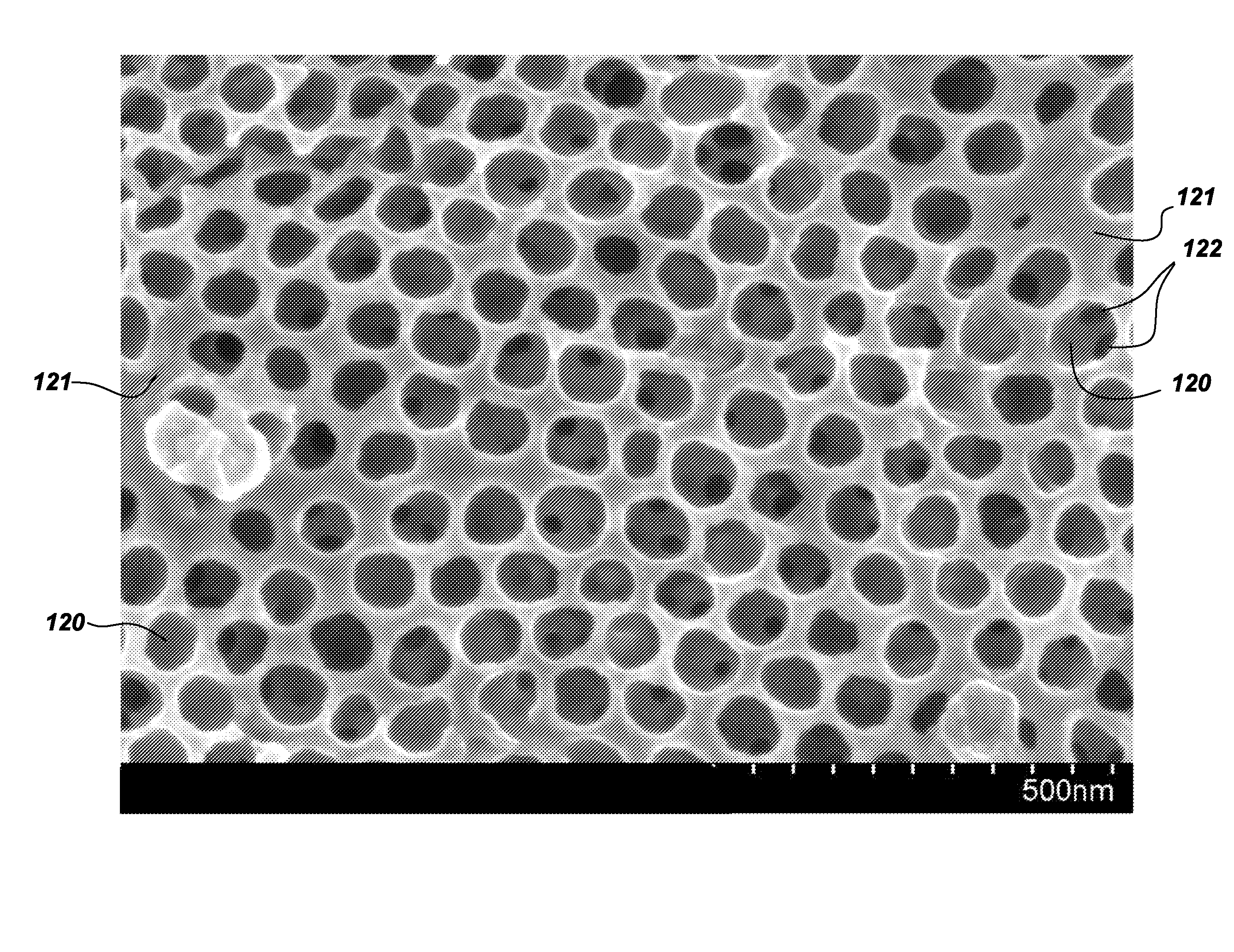

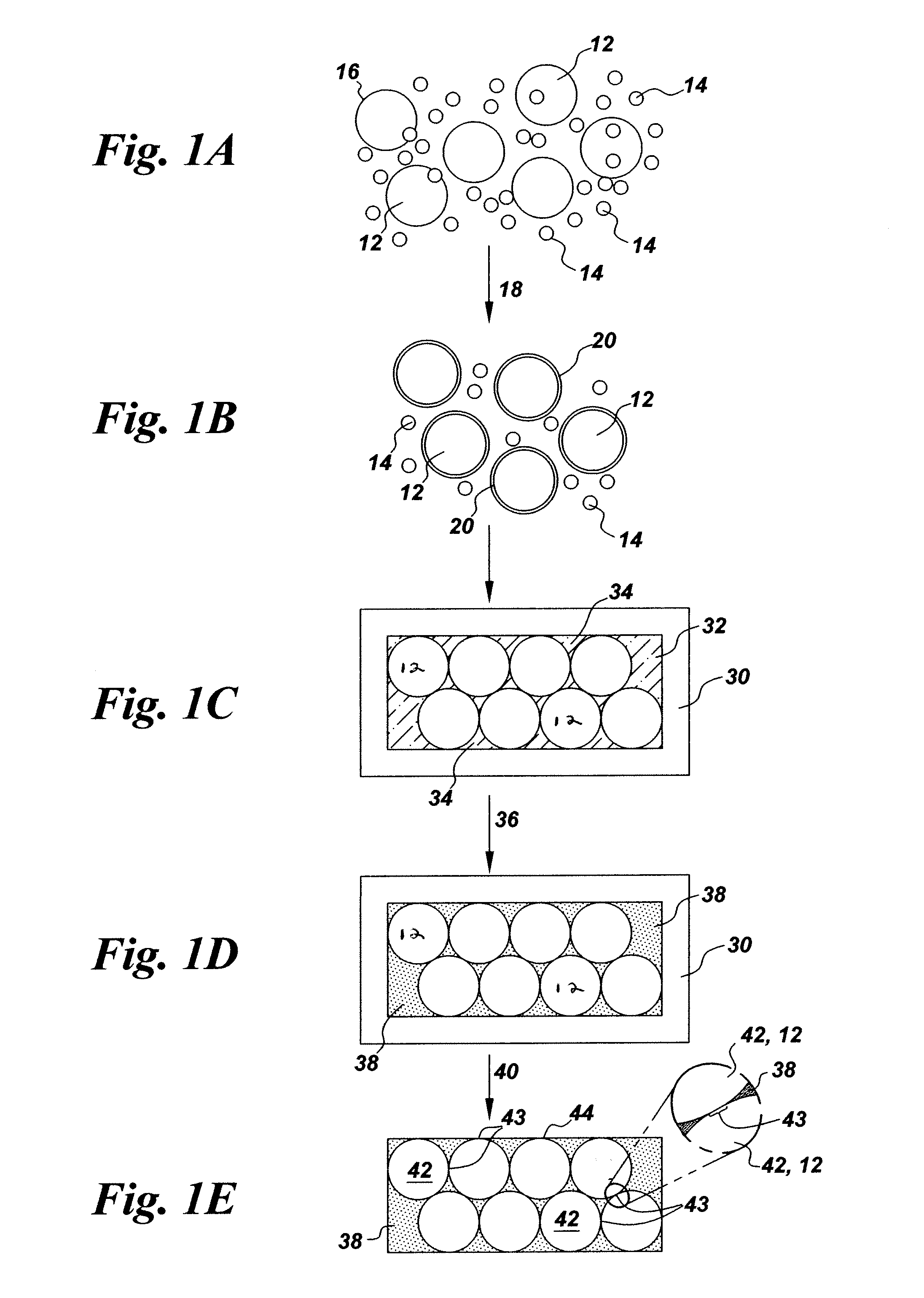

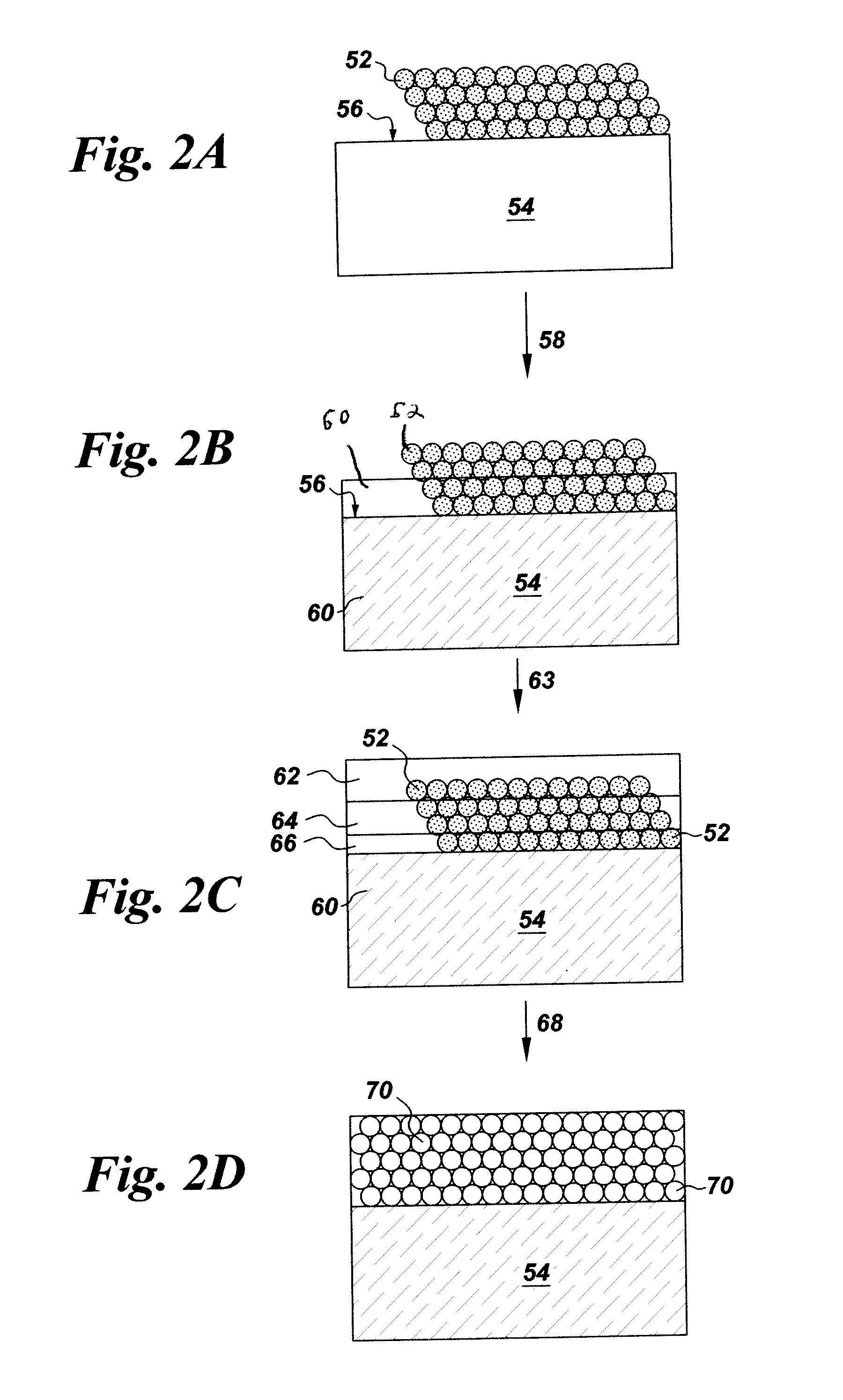

Particle-templated membranes, and related processes for their preparation

InactiveUS20100155325A1Small sizeSemi-permeable membranesMembranesInterfacial reactionFiltration membrane

A method for the formation of a membrane is described. A collection of substantially spherical particles formed from a selected material is contacted with at least one reactive material. The reactive material is cured or otherwise polymerized by various techniques, so that it forms a matrix that substantially surrounds and contains the particles. A portion of the particle material is then removed, so that the matrix contains a pattern of pores that are permeable to selected substances in solution. In some instances, the matrix is formed by an interfacial reaction between at least two reactive materials. Related filtration membranes are also described.

Owner:GENERAL ELECTRIC CO

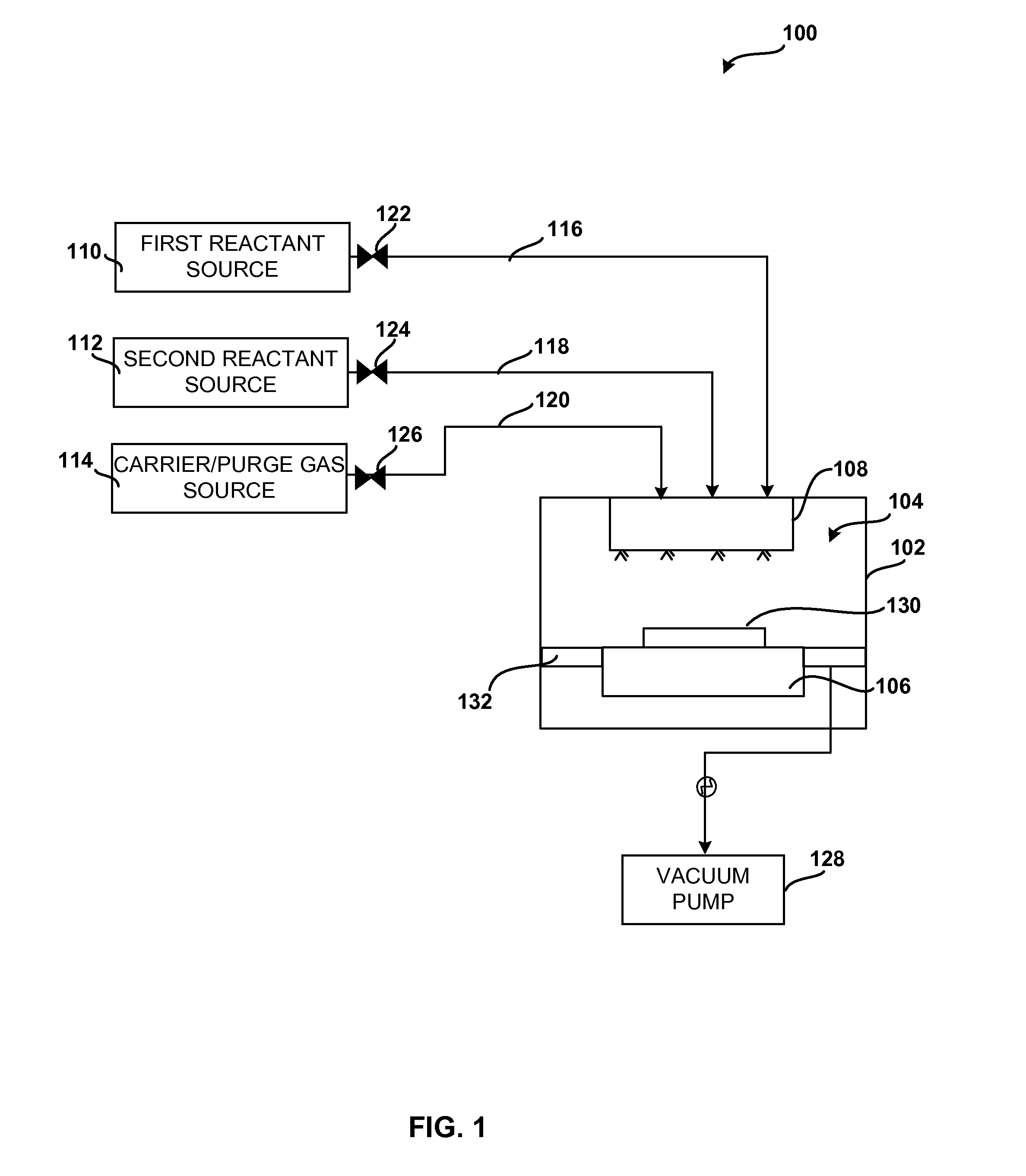

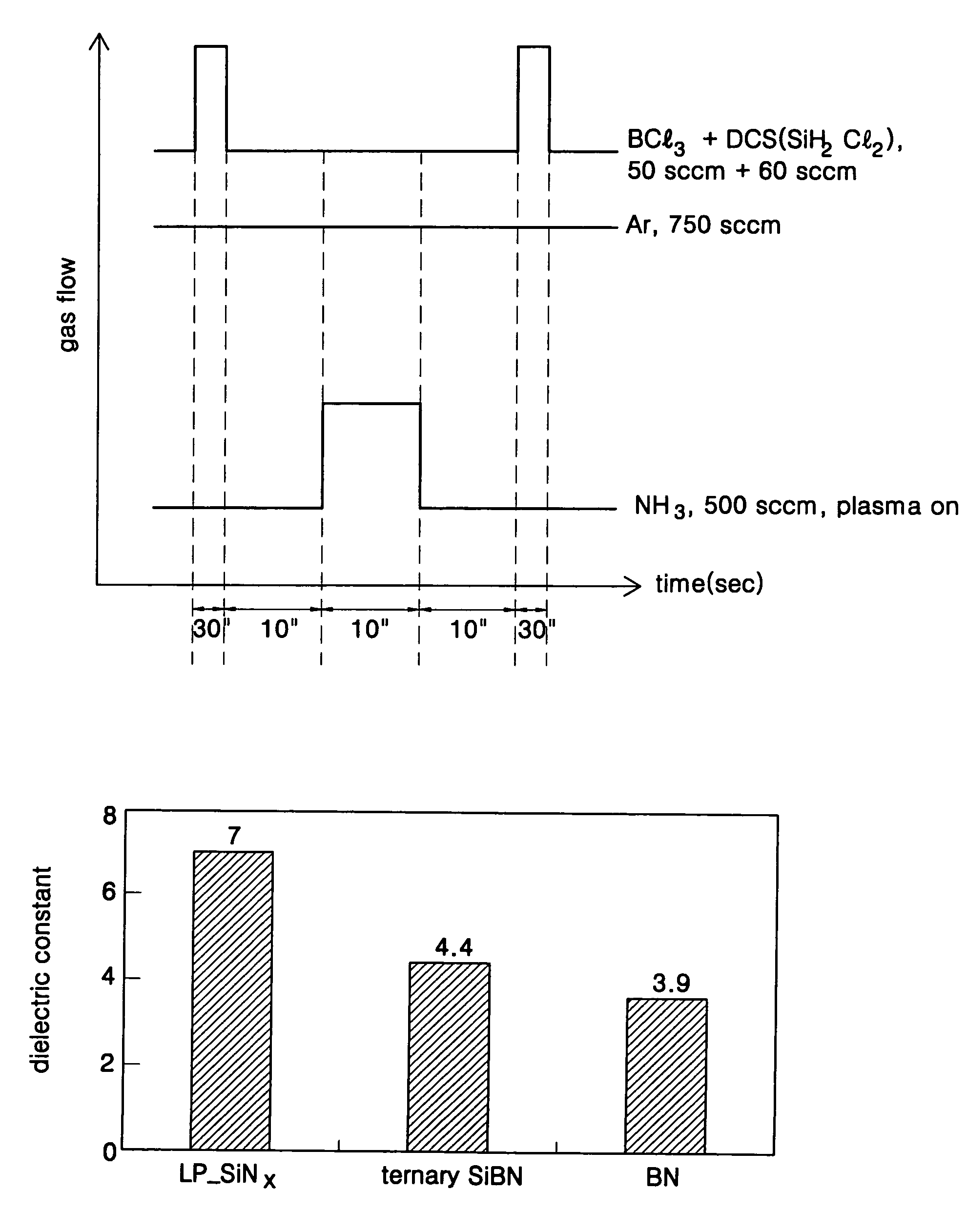

Method for forming a low-k dielectric layer for a semiconductor device

InactiveUS6962876B2Excellent step coverage and uniformity in thicknessUniform thicknessSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDevice materialEngineering

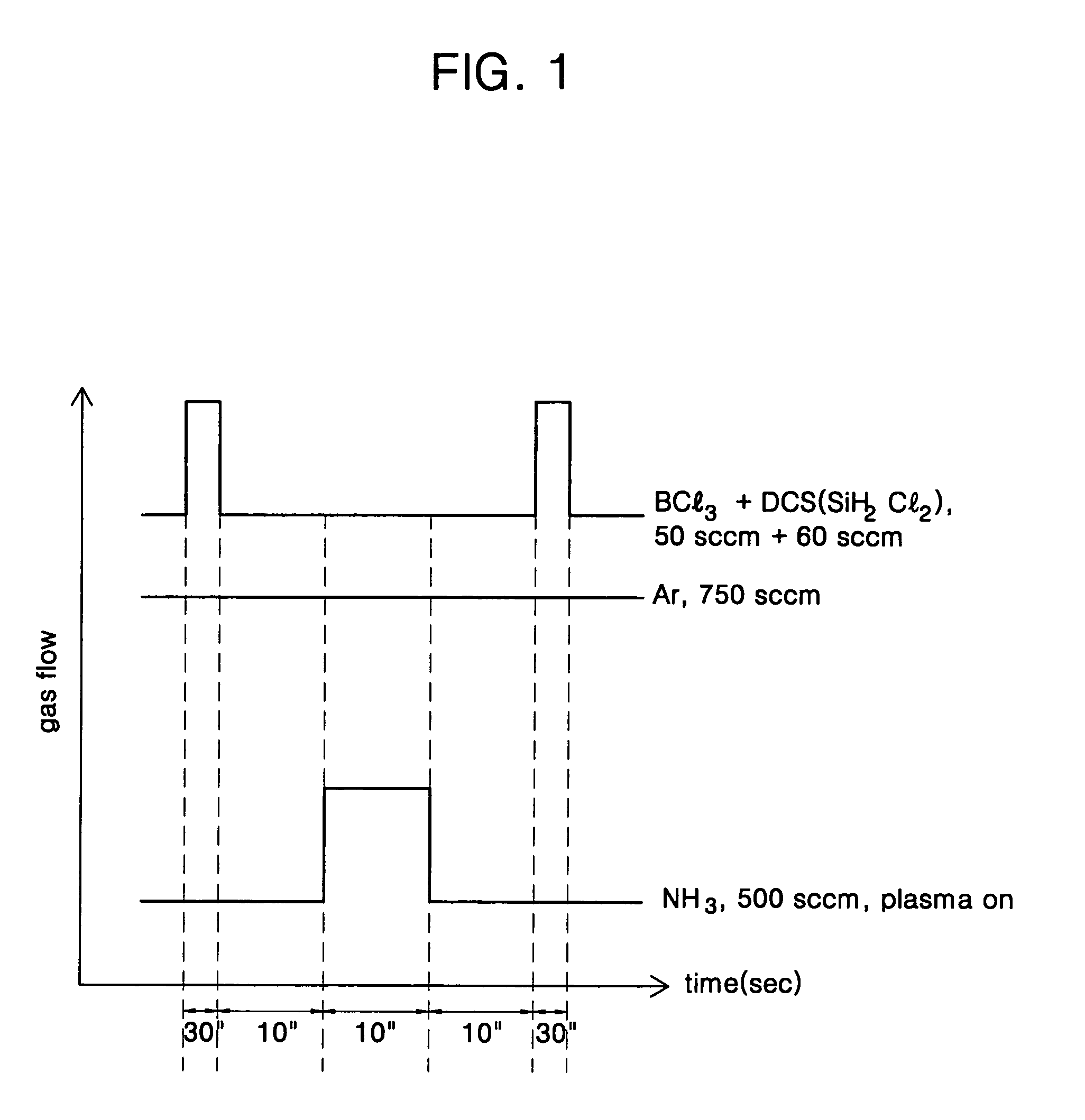

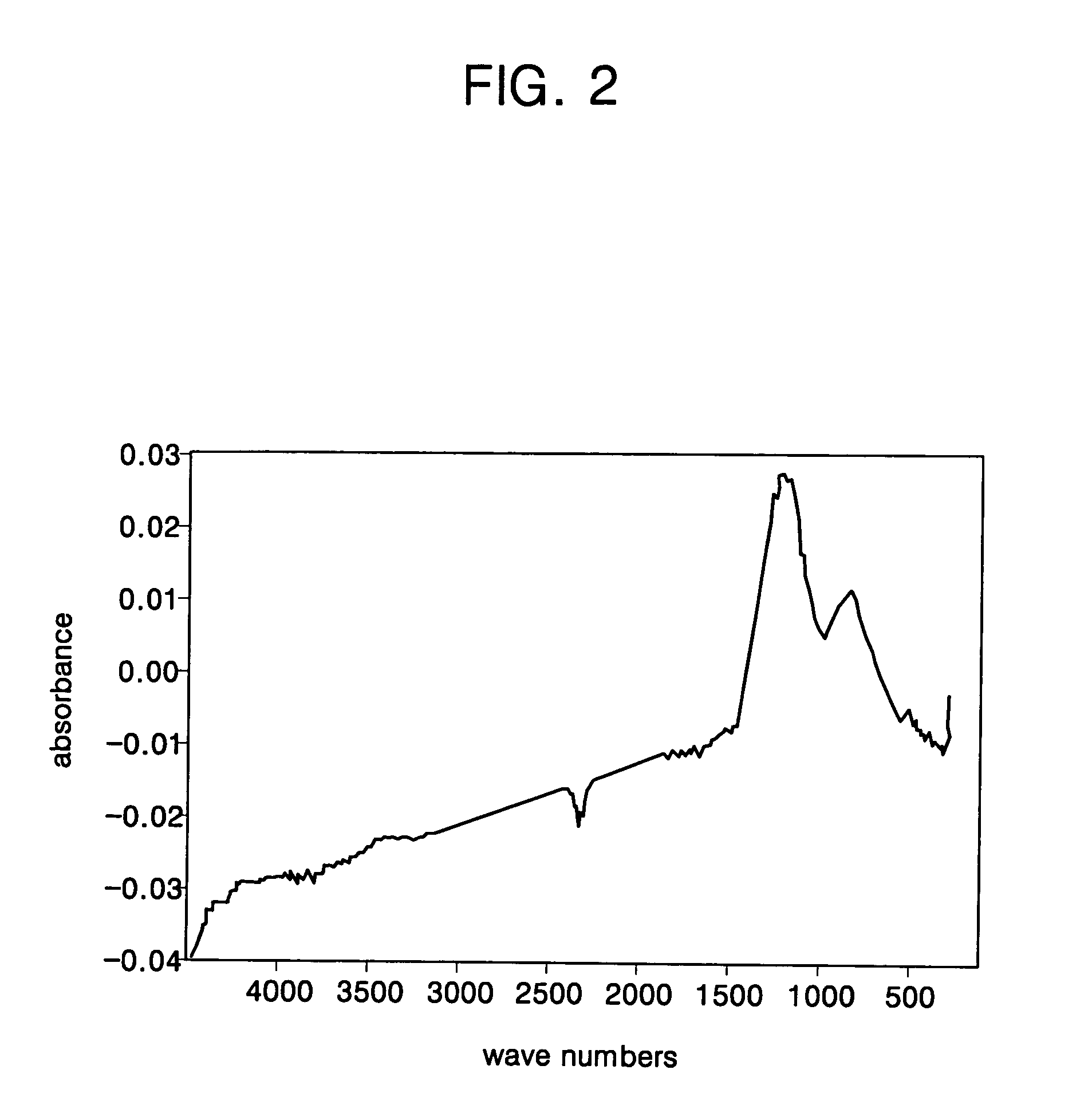

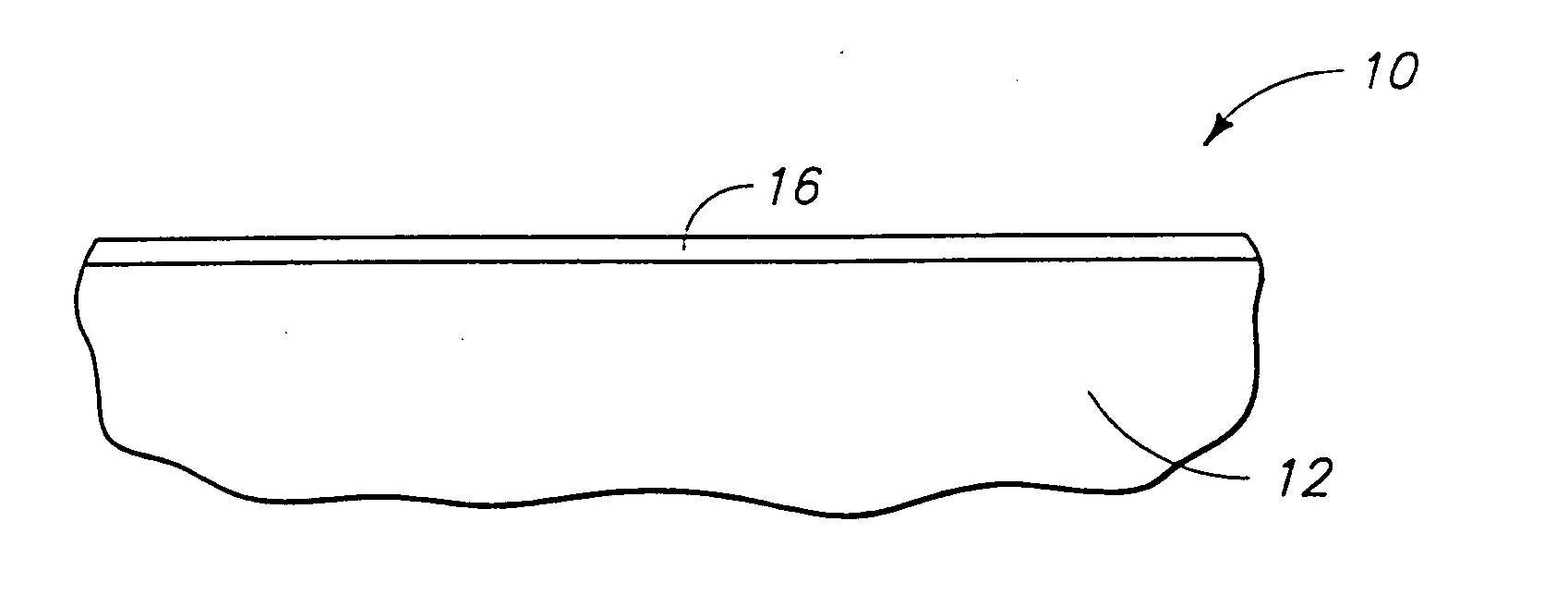

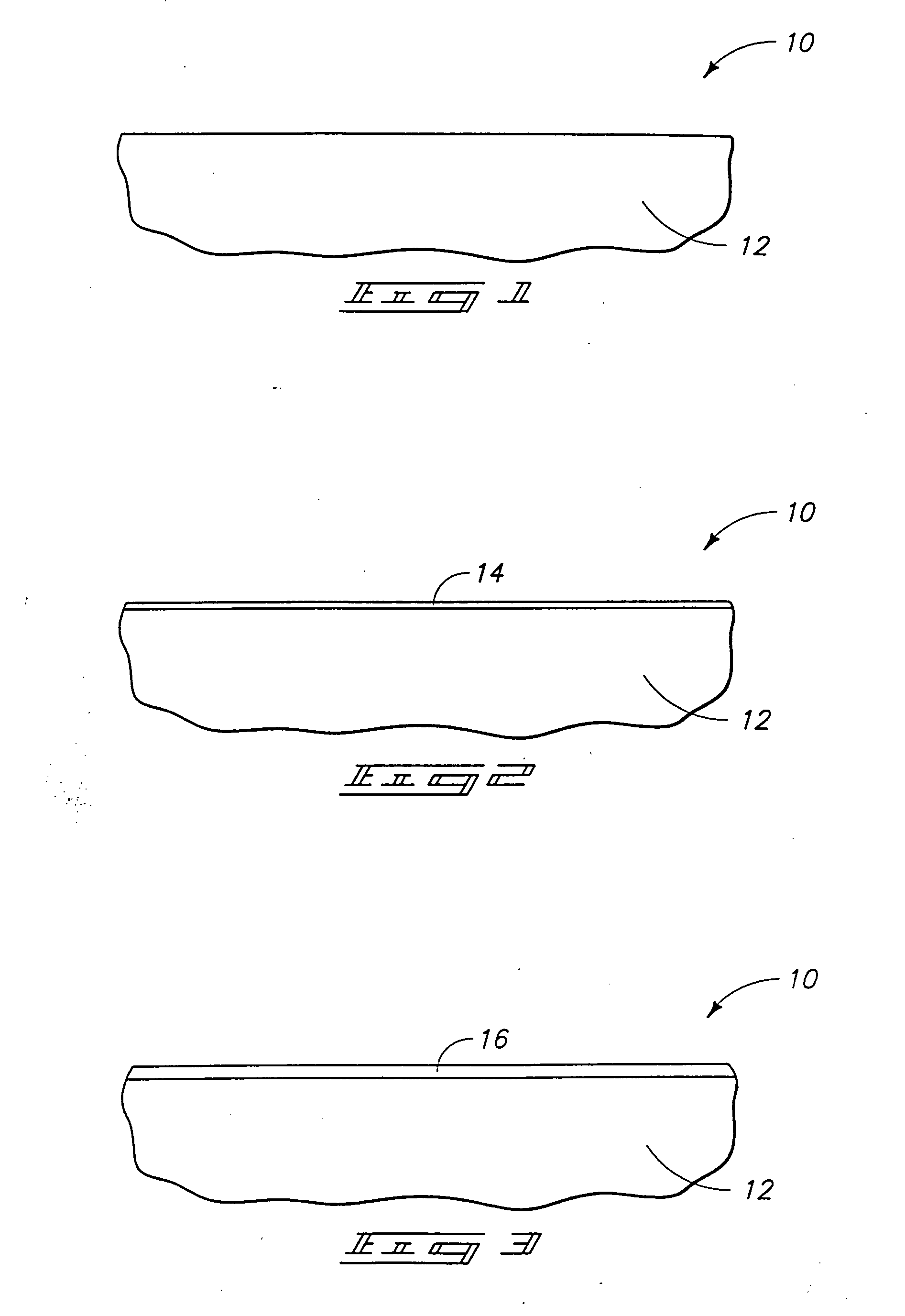

A method for forming a low-k dielectric layer for a semiconductor device using an ALD process including (a) forming predetermined interconnection patterns on a semiconductor substrate, (b) supplying a first and a second reactive material to a chamber having the substrate therein, thereby adsorbing the first and second reactive materials on a surface of the substrate, (c) supplying a first gas to the chamber to purge the first and second reactive materials that remain unreacted, (d) supplying a third reactive material to the chamber, thereby causing a reaction between the first and second materials and the third reactive material to form a monolayer, (e) supplying a second gas to the chamber to purge the third reactive material that remains unreacted in the chamber and a byproduct; and (f) repeating (b) through (e) a predetermined number of times to form a SiBN ternary layer having a predetermined thickness on the substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

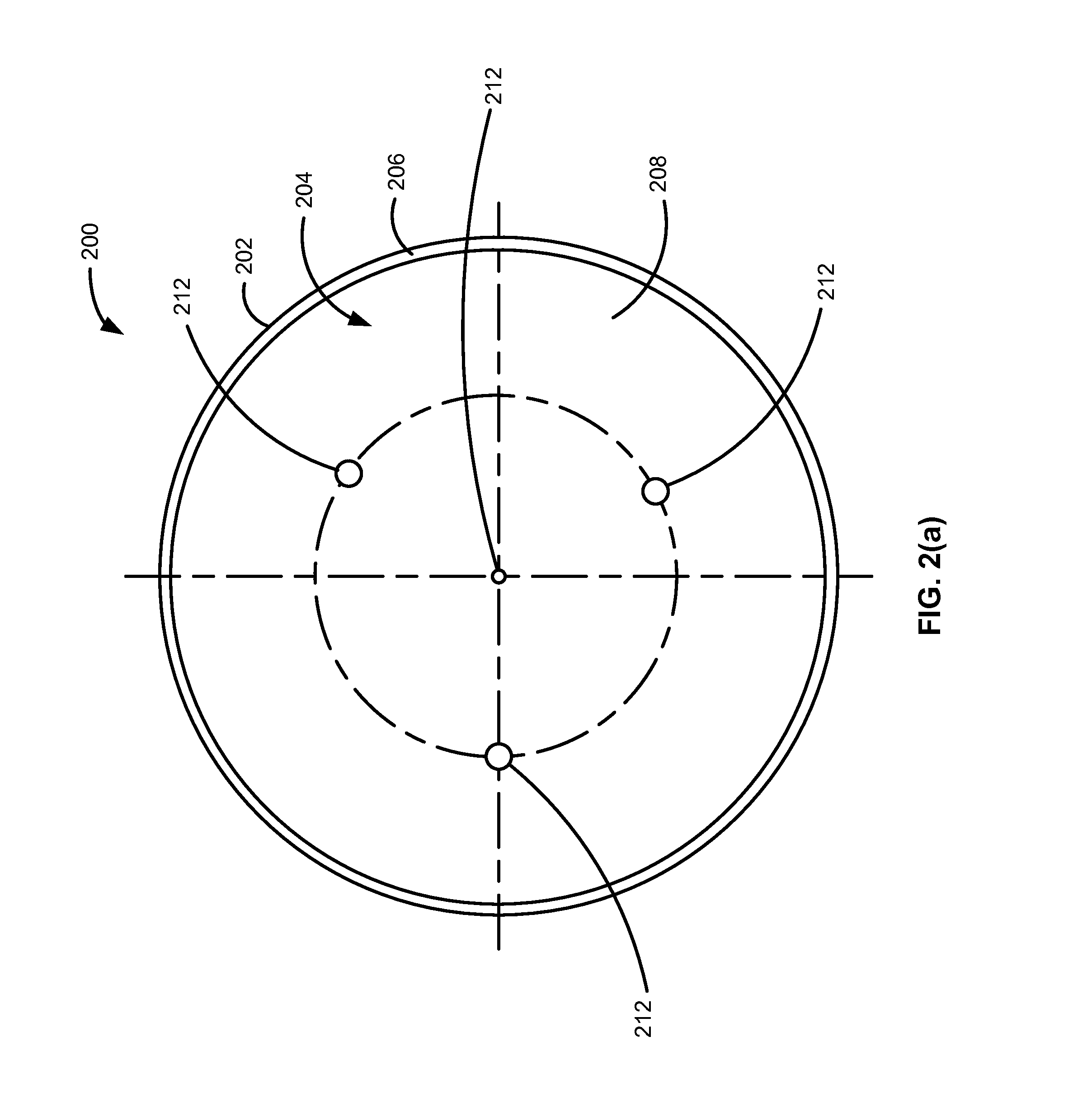

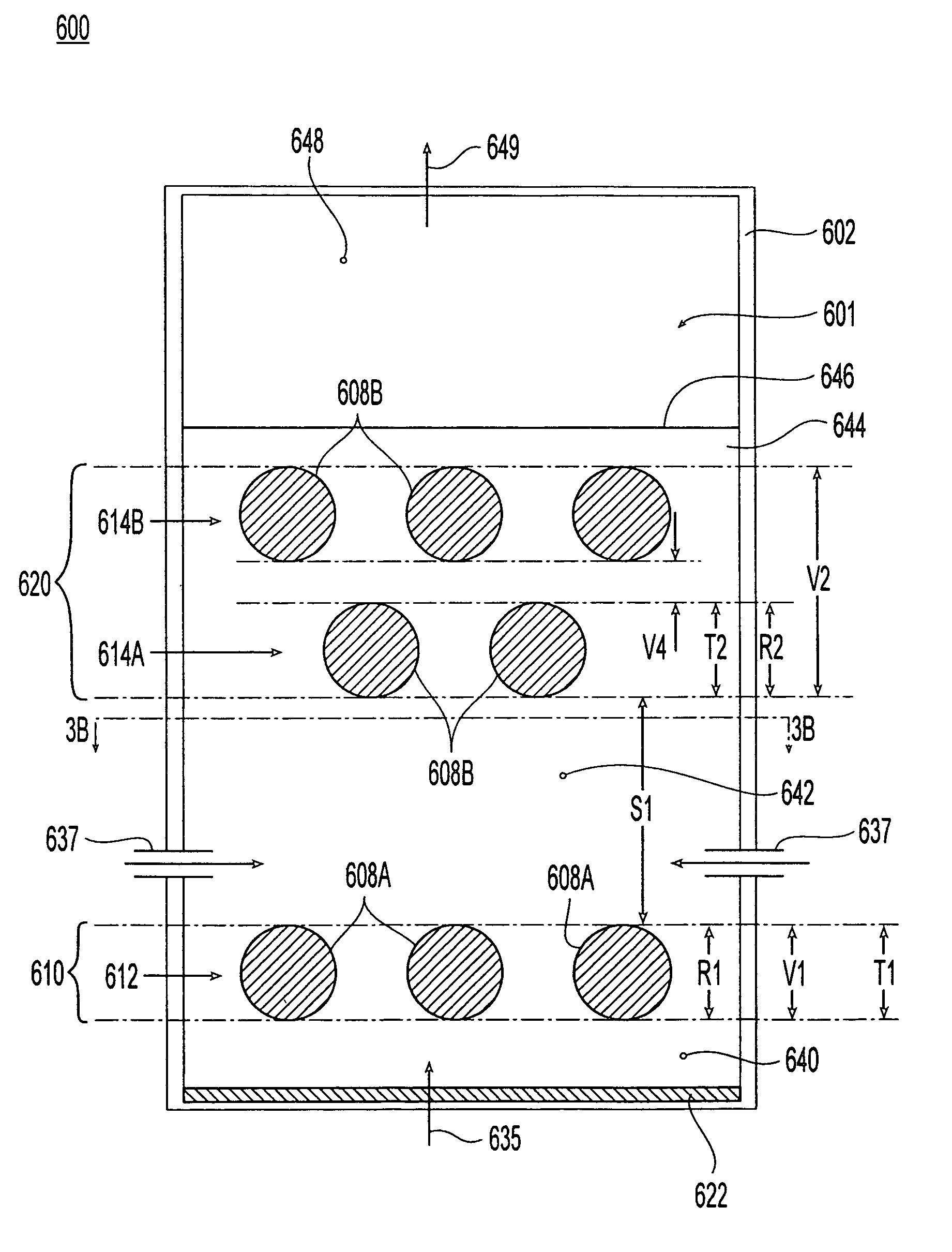

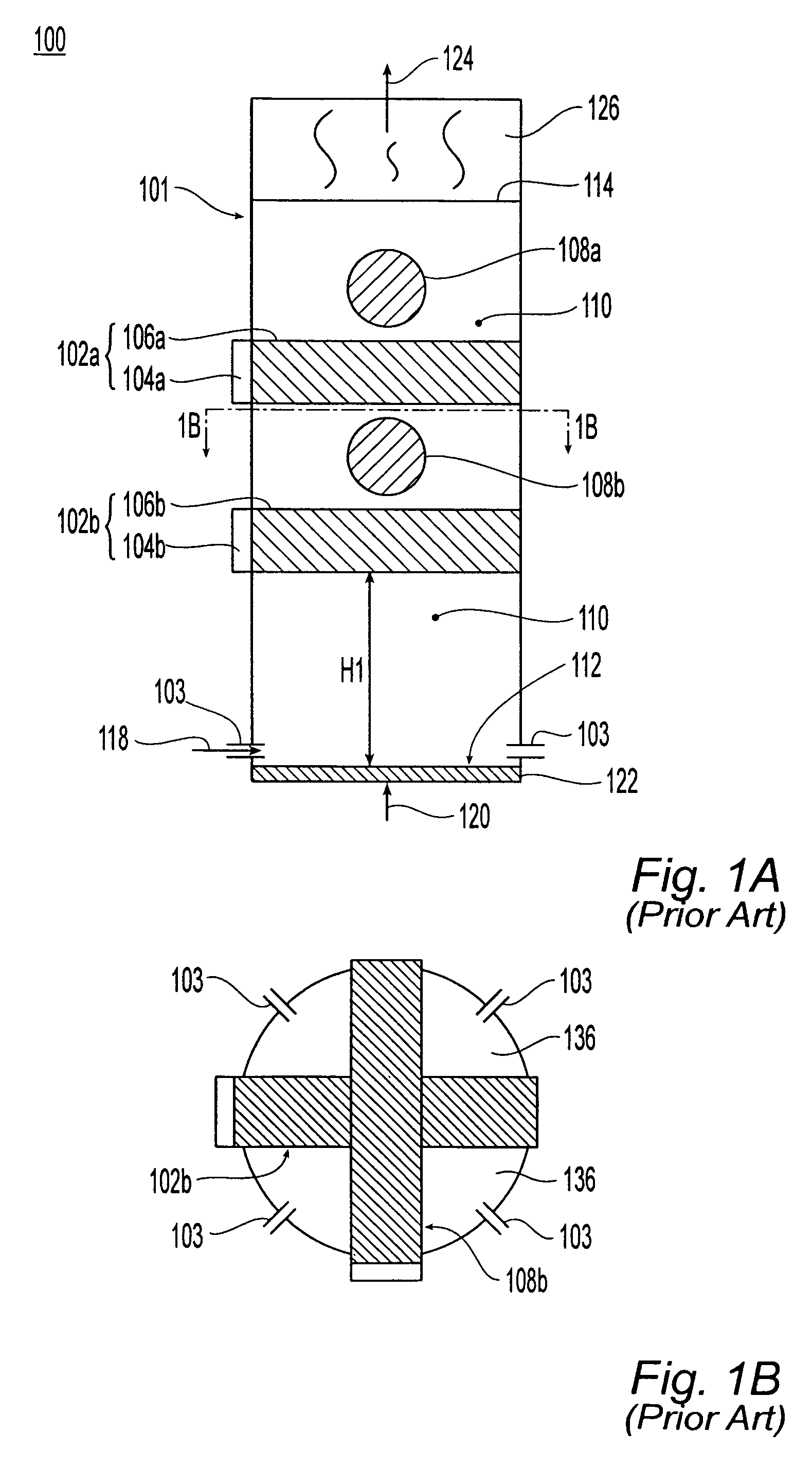

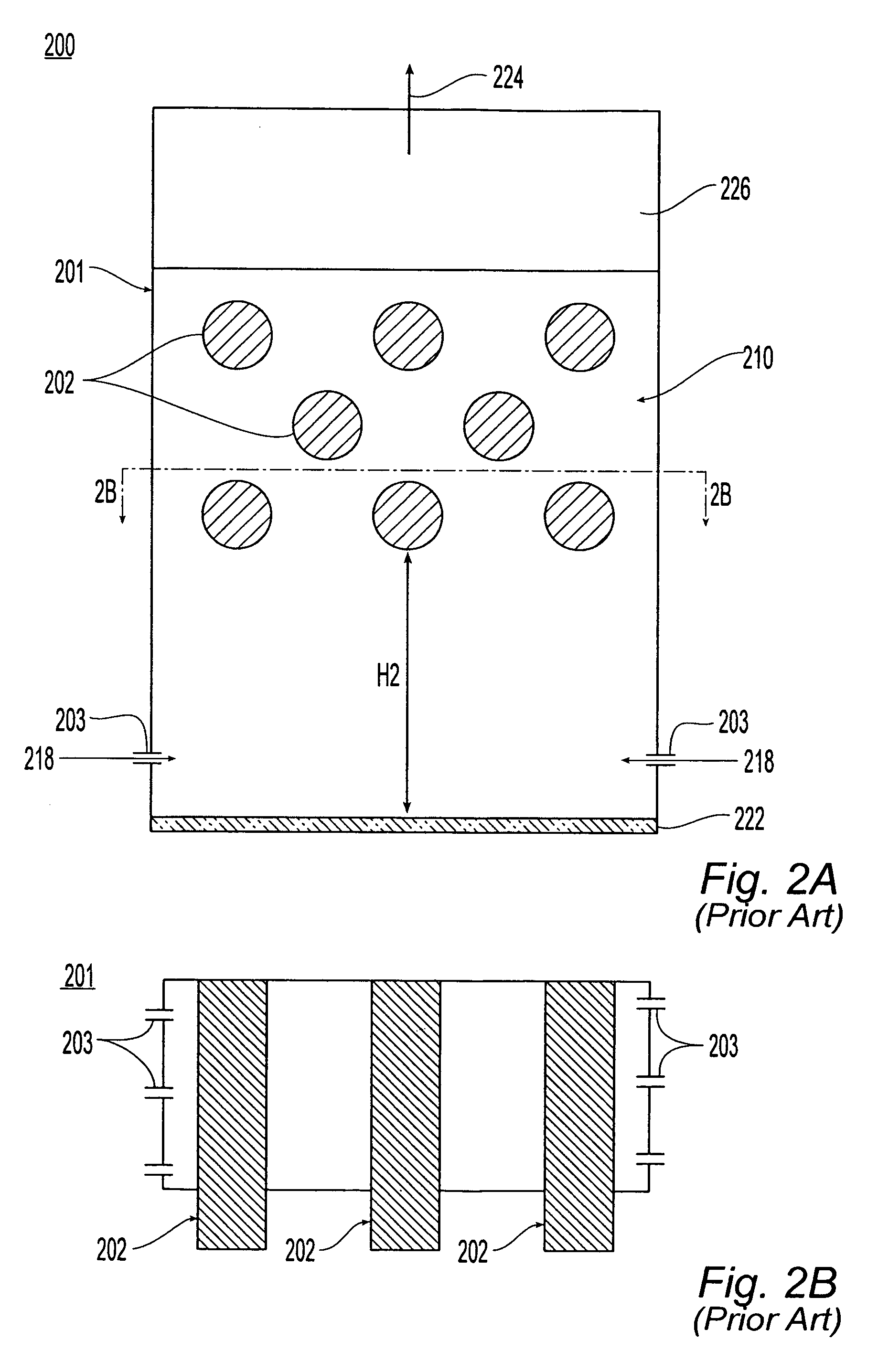

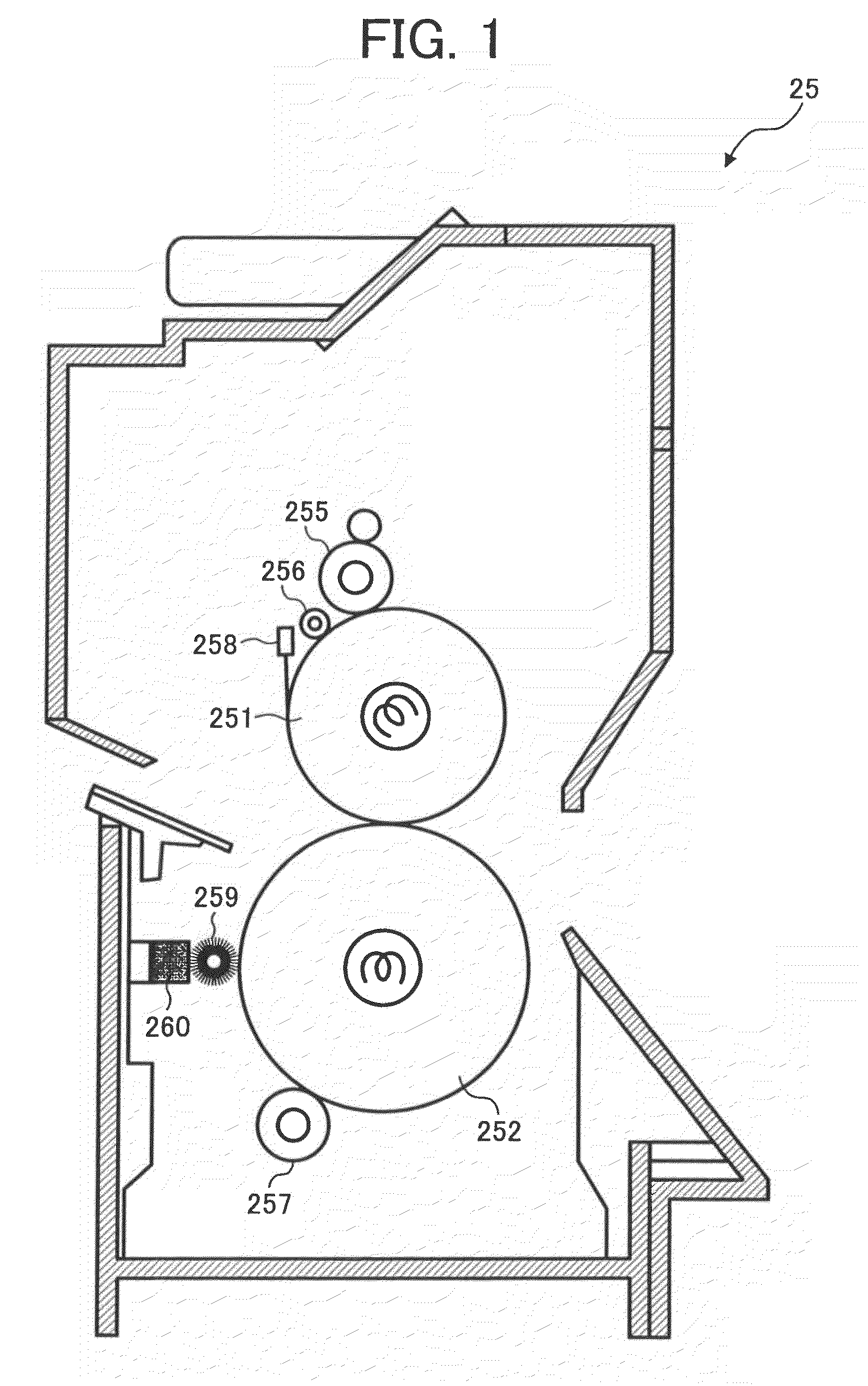

Apparatuses for treating pluralities of discrete semiconductor substrates; and methods for treating pluralities of discrete semiconductor substrates

InactiveUS20050009335A1Enhance layeringPhotosensitive materialsSemiconductor/solid-state device manufacturingReactive materialSemiconductor

The invention includes a method for treating a plurality of discrete semiconductor substrates. The discrete semiconductor substrates are placed within a reactor chamber. While the substrates are within the chamber, they are simultaneously exposed to one or more of H, F and Cl to remove native oxide. After removing the native oxide, the substrates are simultaneously exposed to a first reactive material to form a first mass across at least some exposed surfaces of the substrates. The first reactive material is removed from the reaction chamber, and subsequently the substrates are exposed to a second reactive material to convert the first mass to a second mass. The invention also includes apparatuses which can be utilized for simultaneous ALD treatment of a plurality of discrete semiconductor substrates.

Owner:DEAN TRUNG TRI +3

Product for coating wellbore screens

InactiveUS20050065037A1Prevent flow capacity damageMinimizes flow capacity damageFluid removalFlushingSURFACTANT BLENDReactive material

Coatings for well screens that protect the screens from damage as they are inserted into the wellbore and once in the well, release reactive materials to react with and degrade potentially plugging materials such as drill solids, fluid filtercakes, fluid loss additives, and drilling fluids. The coatings can be specifically designed for individual well conditions and are comprised of a binder that either melts or dissolves within the wellbore and one or more reactive materials such as acids, enzymes, surfactants, chelants, oxidizers or free radical generators and the like which are released into the screen and the near wellbore area and which are effective in degrading or dissolving materials which could potentially plug the screen.

Owner:CONSTIEN VERNON GEORGE

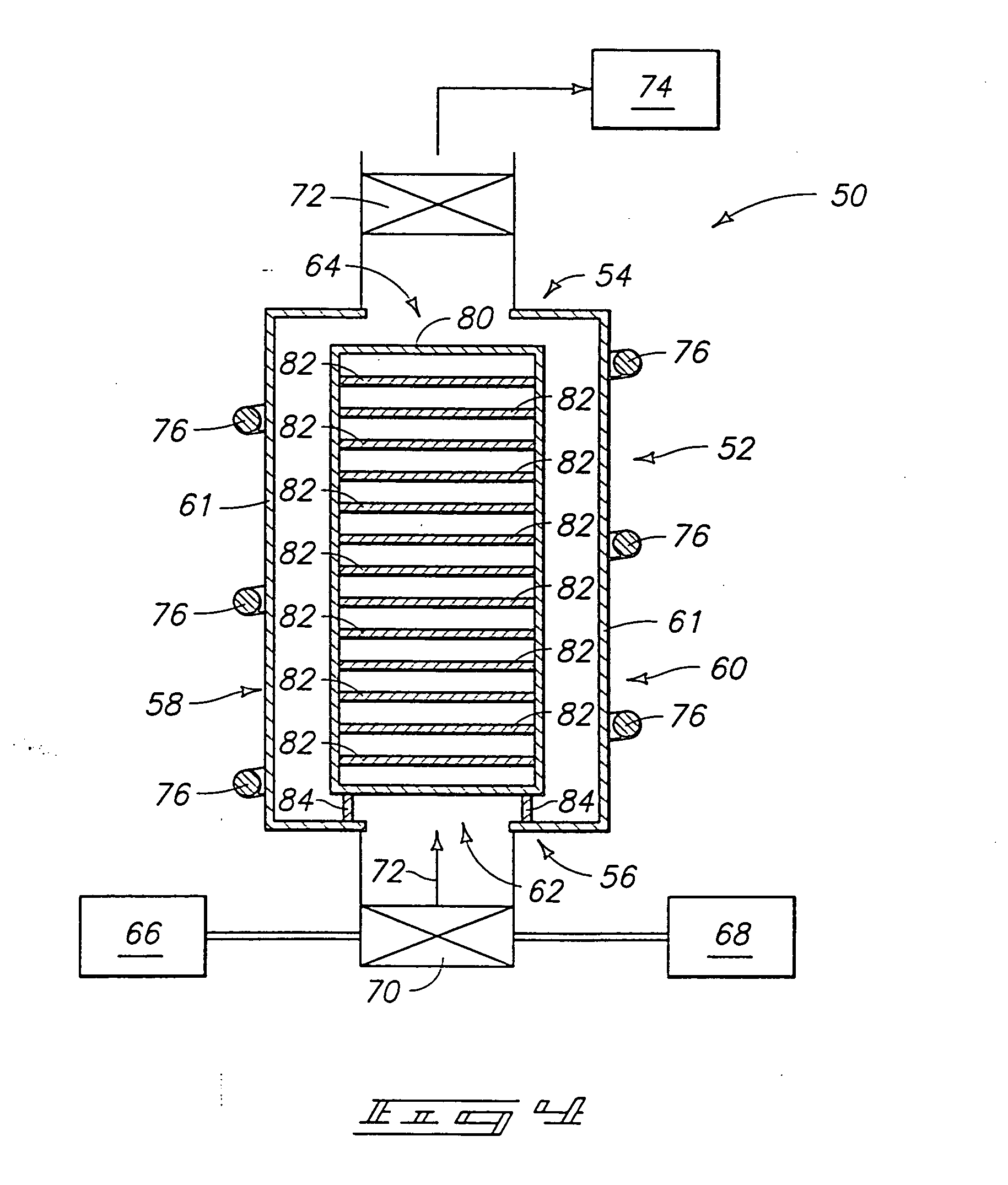

Fluid bed reactor having vertically spaced apart clusters of heating conduits

A fluid bed reactor is configured to process a reactive material to form one or more products. The reactor includes a reaction vessel defining a compartment configured to receive the reactive material. A first cluster of heating conduits at least partially occupies the compartment and extends over a first vertical extent within the compartment. A second cluster of heating conduits partially occupies the compartment and extends over a second vertical extent within the compartment. The first cluster of heating conduits is vertically below the second cluster of heating conduits and spaced apart therefrom by a first separation distance. Feedstock inlets are configured to introduce the reactive material into a region that is vertically between the first and second clusters of heating conduits. The heating conduits in the first cluster have a first thickness while the heating conduits in the second cluster have a second thickness. The first separation distance is at least as great as the smaller of the first and second thicknesses.

Owner:THERMOCHEM RECOVERY INT

Polyurethane-based pressure sensitive adhesives and methods of manufacture

Polyurethane-based pressure sensitive adhesives comprising the reaction product of: an isocyanate-reactive component comprising at least two isocyanate-reactive materials, an isocyanate-functional component; a reactive emulsifying compound; a chain capping agent and an optional chain extending agent. The adhesives, which are preferably pressure sensitive adhesives, can be prepared from 100% solids, waterborne or solventborne systems.

Owner:3M INNOVATIVE PROPERTIES CO

Fixing device, and image forming apparatus using the fixing device

InactiveUS7702271B2High imagingHigh quality tonerElectrographic process apparatusImage formationEngineering

Owner:RICOH KK

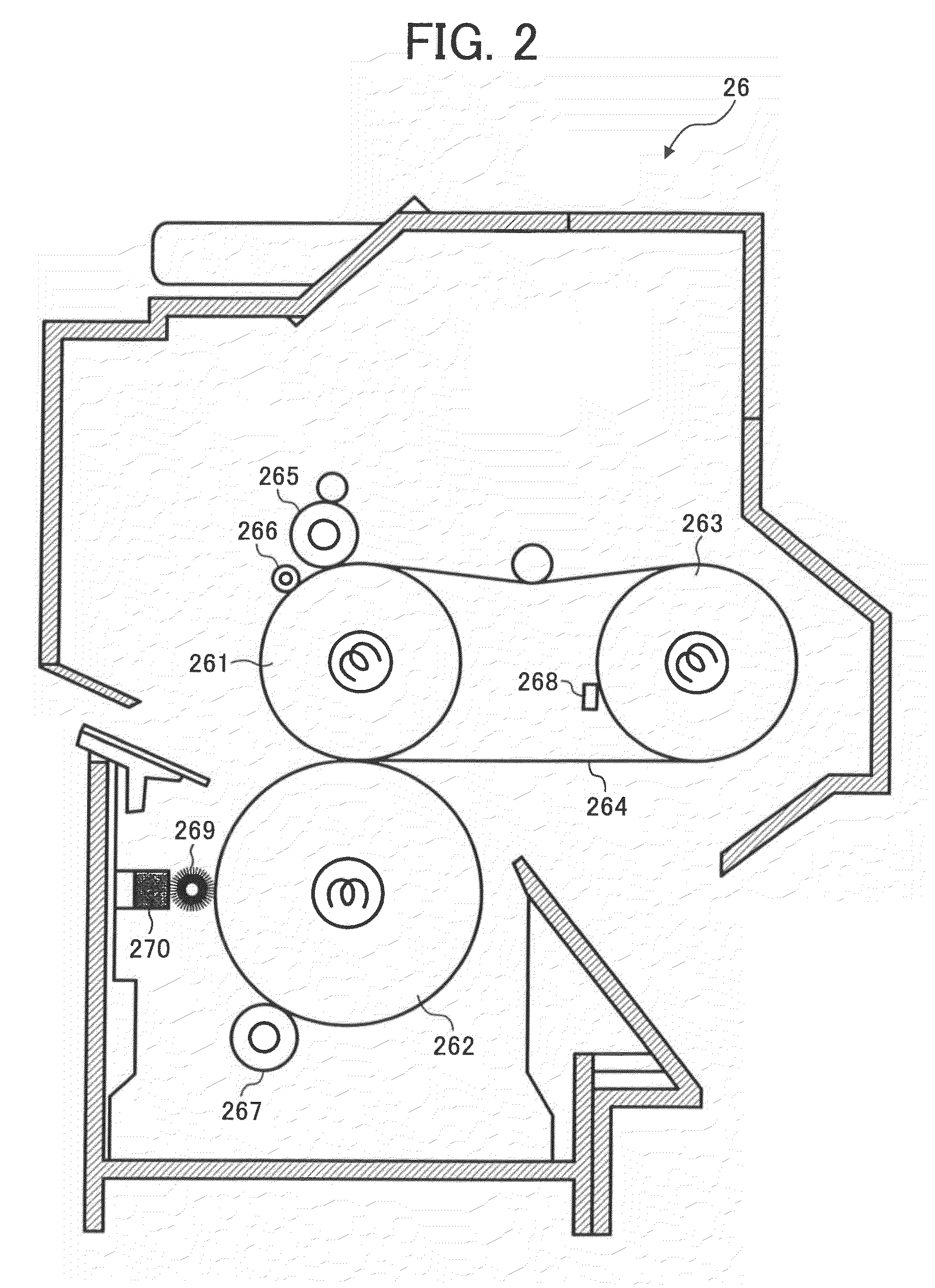

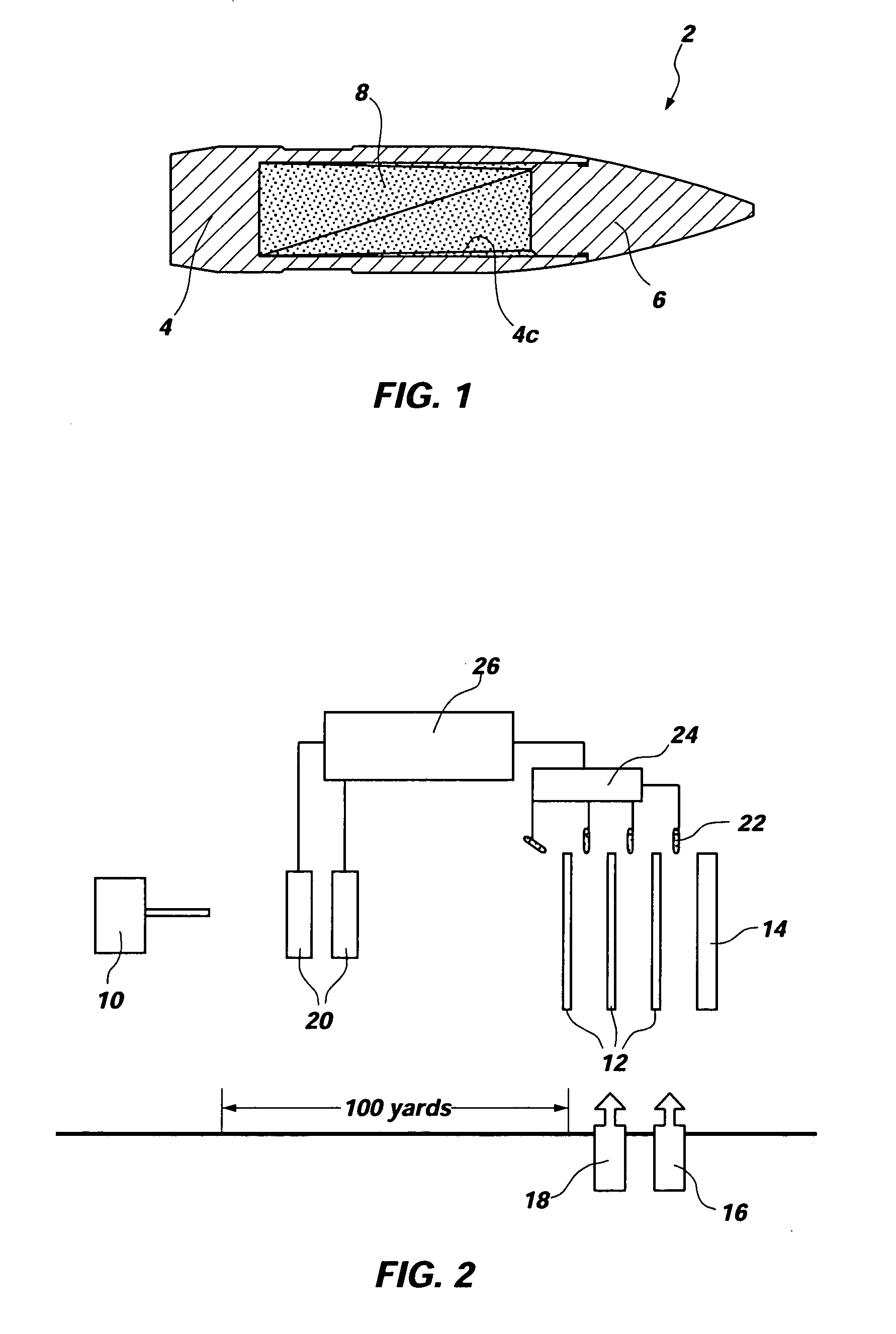

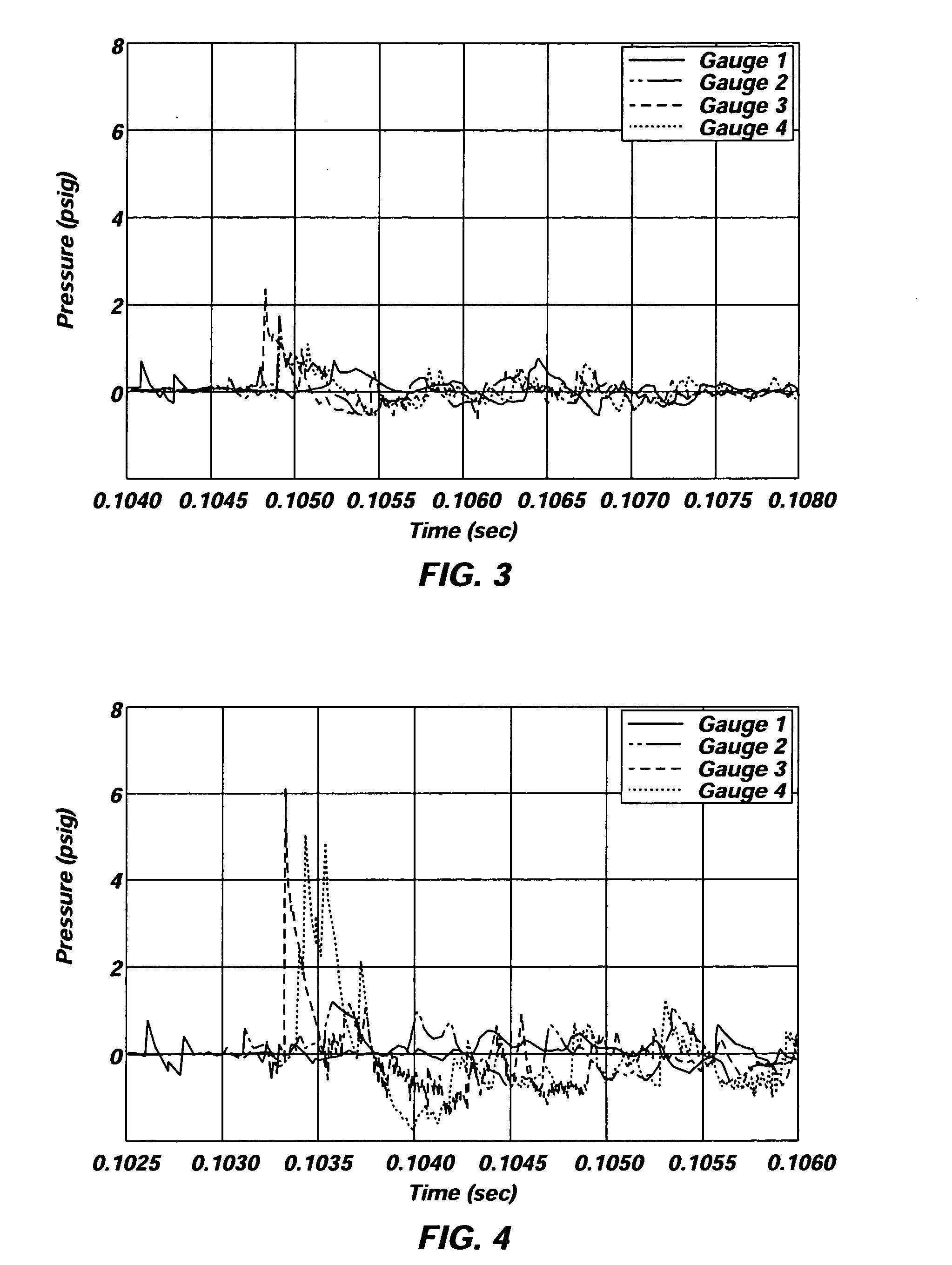

Reactive material enhanced munition compositions and projectiles containing same

A reactive material that includes at least one of a fuel, an oxidizer, and a class 1.1 explosive and is formulated for use in a reactive material projectile. The reactive material is formulated to provide at least one of an overpressure of greater than approximately 9 pounds per square inch at a radial measurement of 12 inches from a point of impact on a target, a hole greater than approximately 2 square inches at an optimum penetration level in a target, and pressure, damage, and a flame when the reactive material bullet impacts a target. The fuel may be a metal, a fusible metal alloy, an organic fuel, or mixtures thereof. The oxidizer may be an inorganic oxidizer, sulfur, a fluoropolymer, or mixtures thereof. A reactive material projectile having the reactive material disposed therein is also disclosed.

Owner:ORBITAL ATK INC

Fluid Activated Disintegrating Metal System

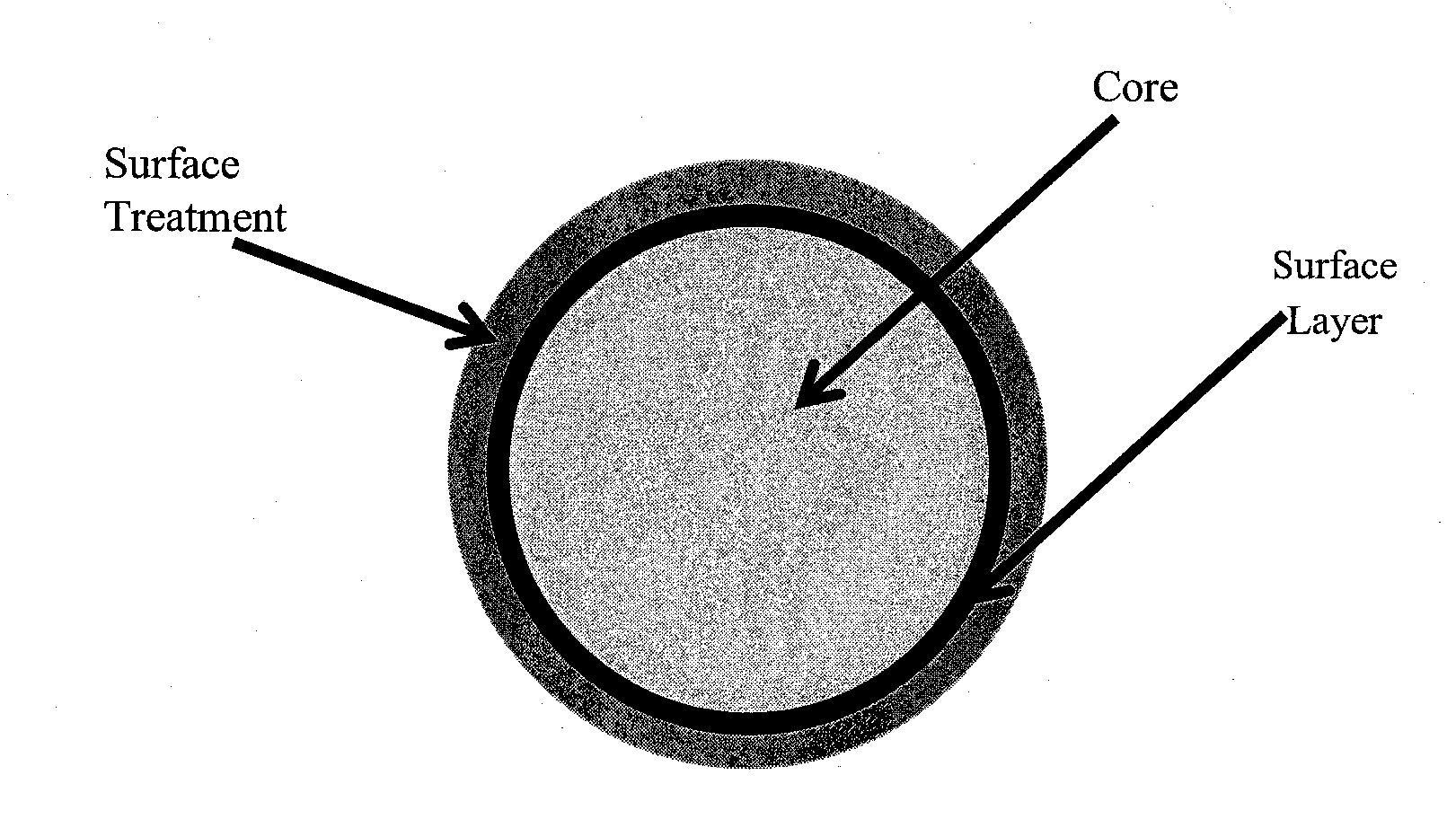

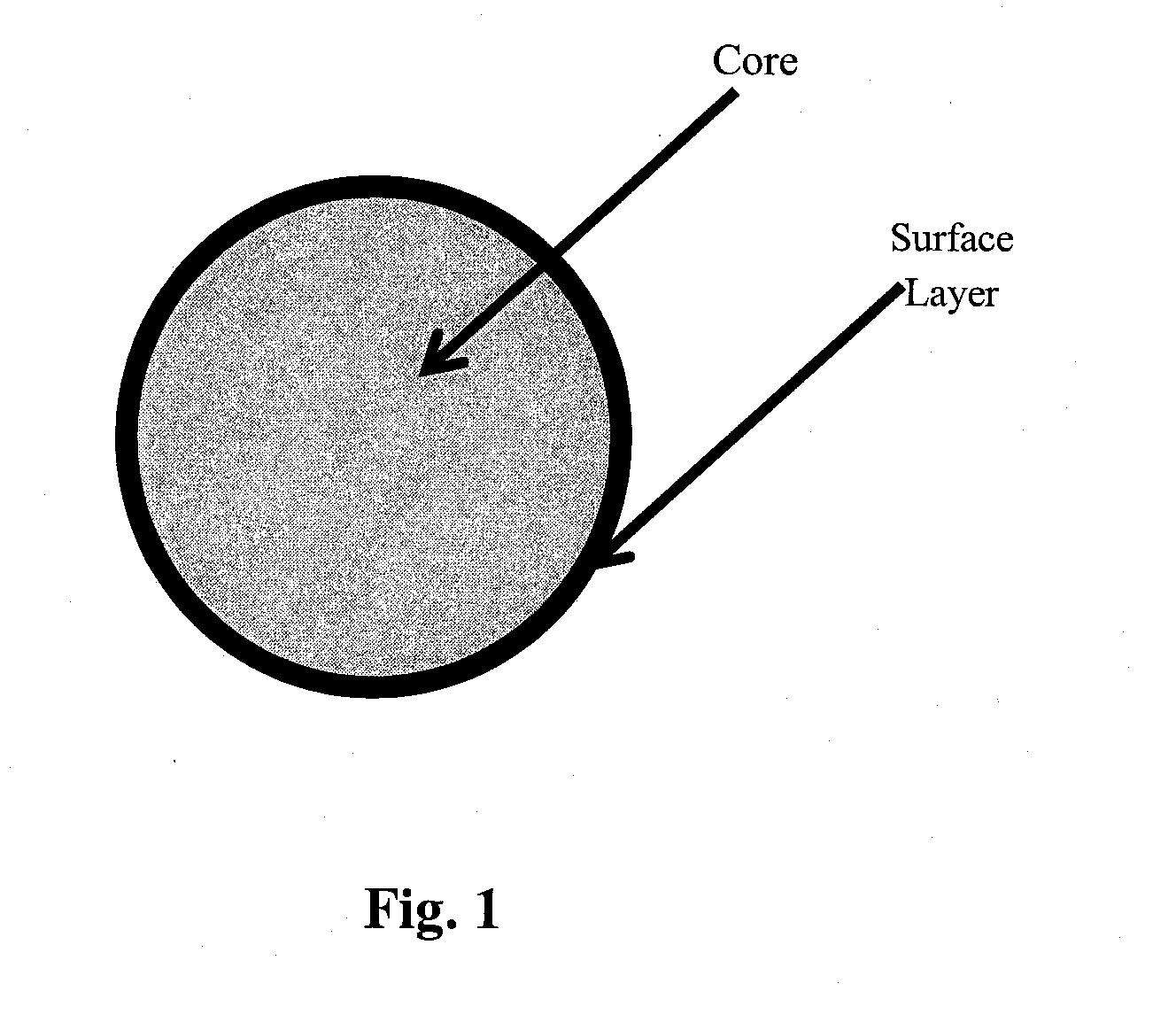

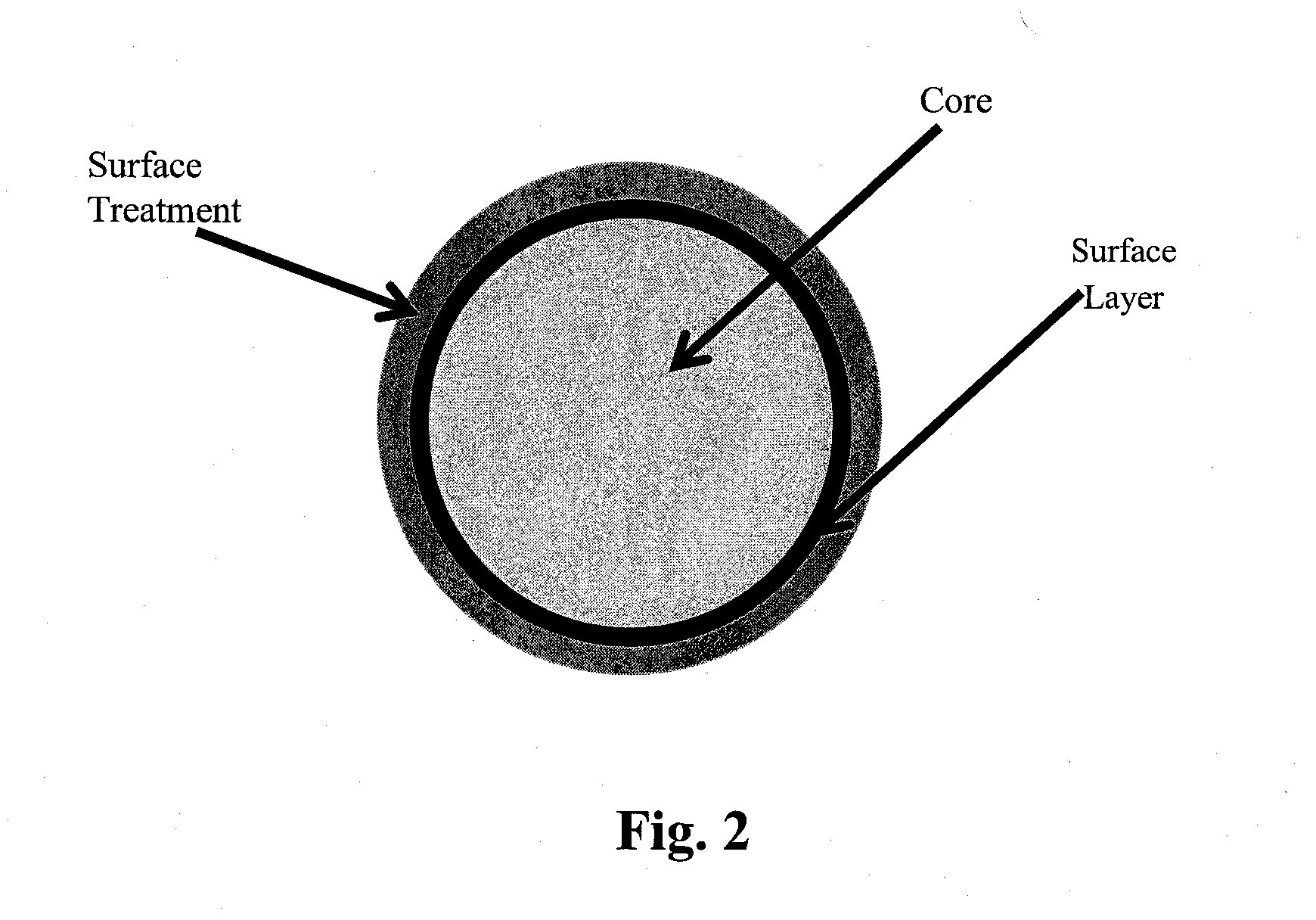

ActiveUS20150239795A1Keep for a long timeSynthetic resin layered productsExplosivesSystems designHigh energy

An engineered composite system designed to be passive or inert under one set of conditions, but becomes active when exposed to a second set of conditions. This system can include a dissolving or disintegrating core, and a surface coating that has higher strength or which only dissolves under certain temperature and pH conditions, or in selected fluids. These reactive materials are useful for oil and gas completions and well stimulation processes, enhanced oil and gas recovery operations, as well as in defensive and mining applications requiring high energy density and good mechanical properties, but which can be stored and used for long periods of time without degradation.

Owner:TERVES

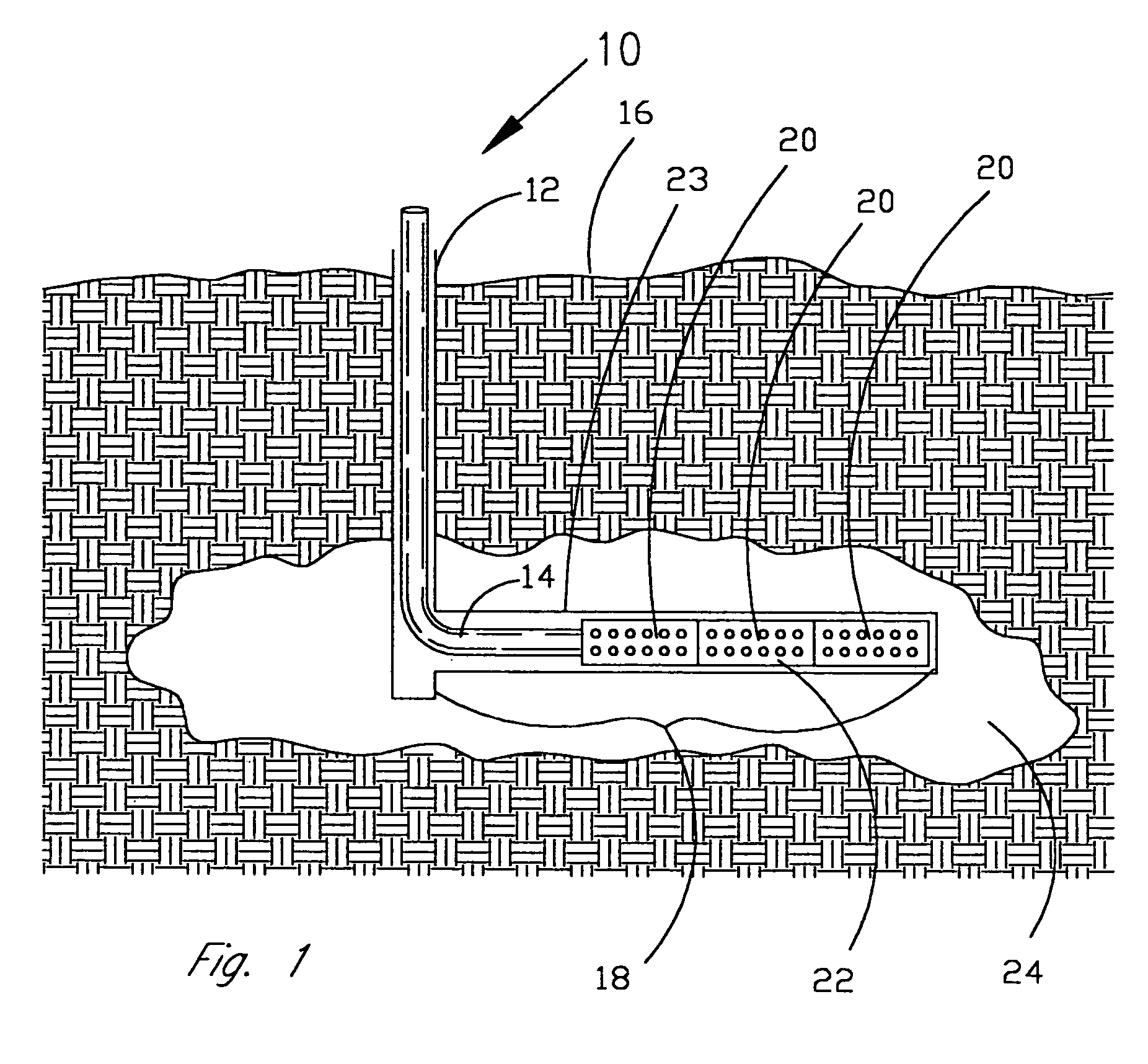

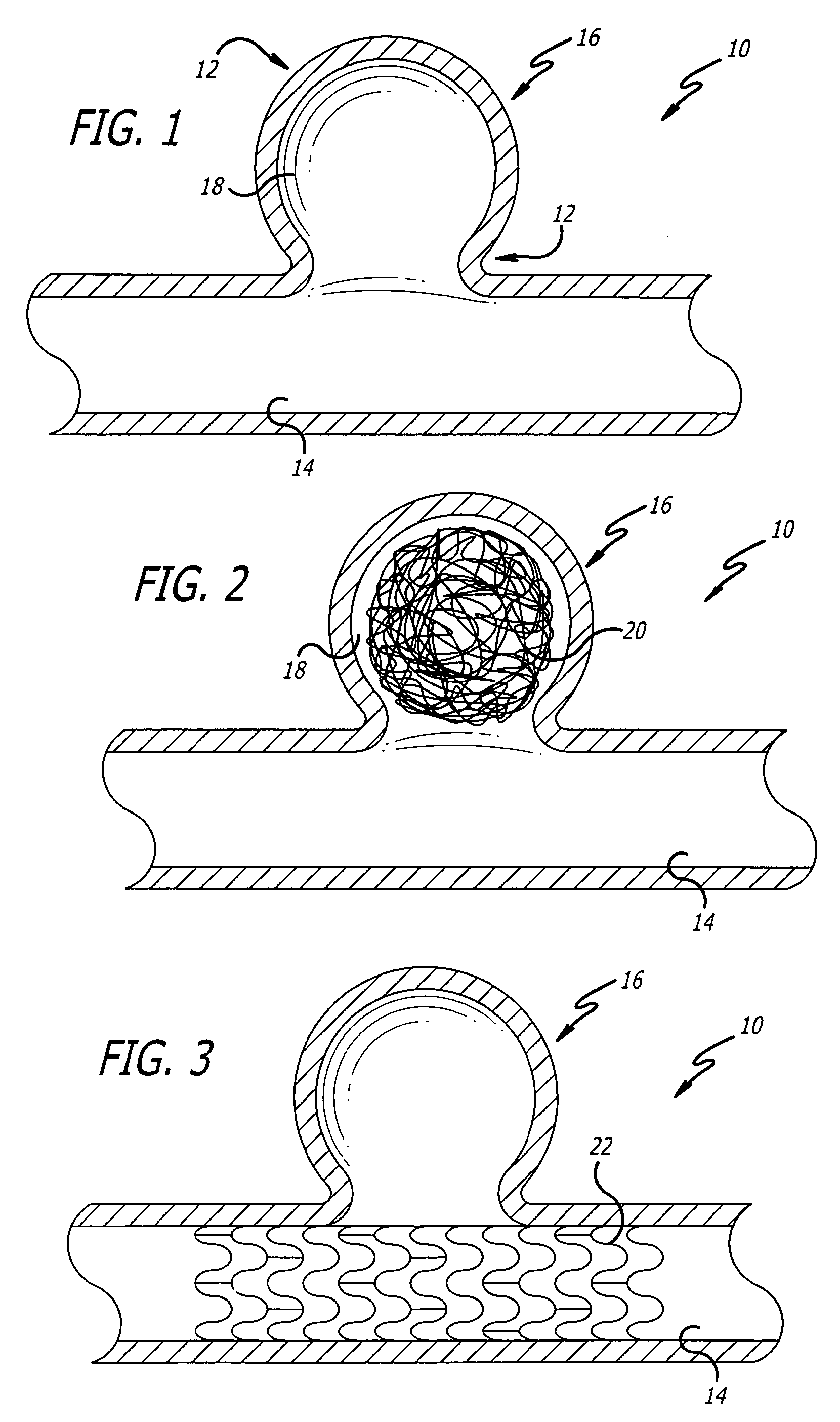

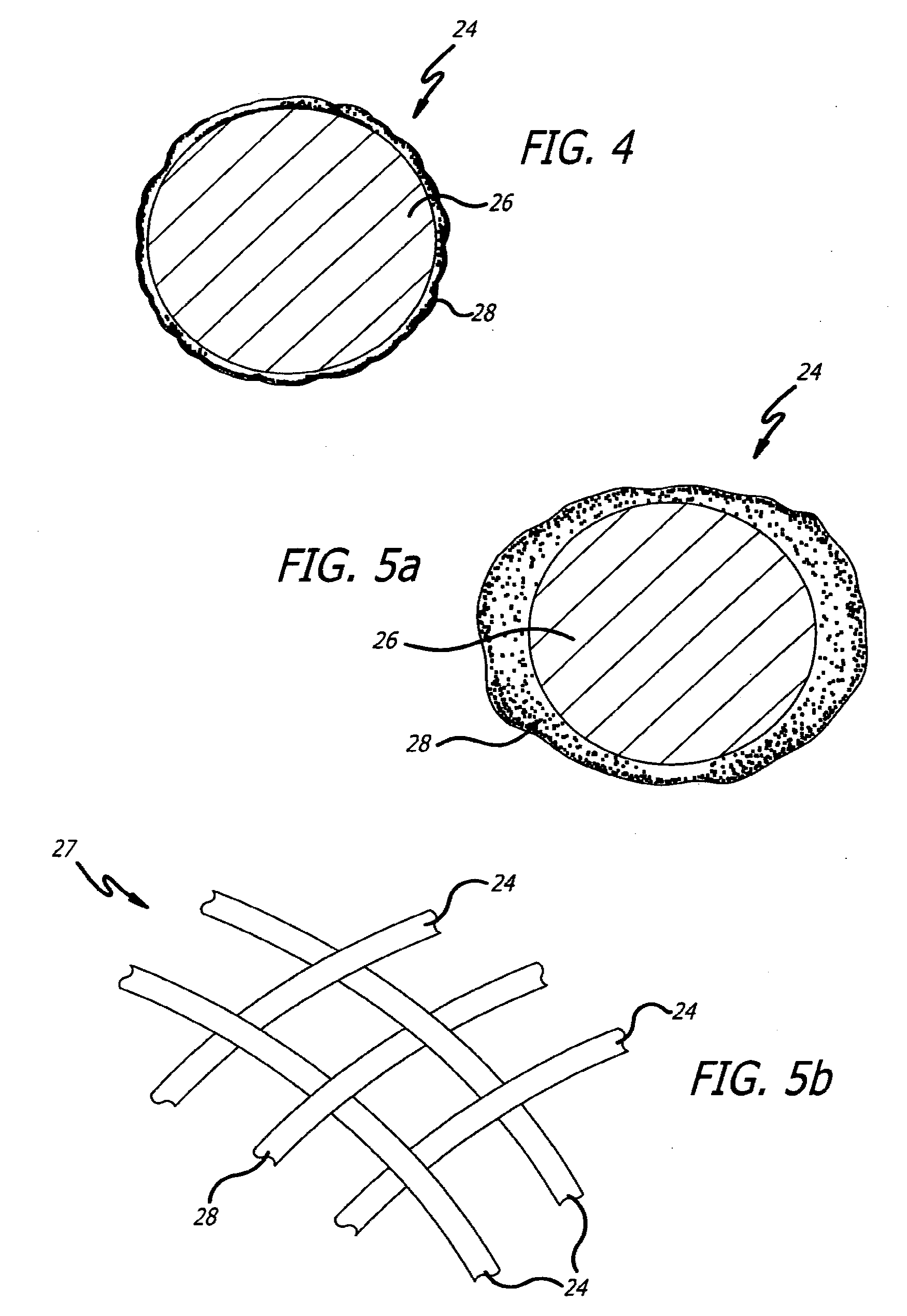

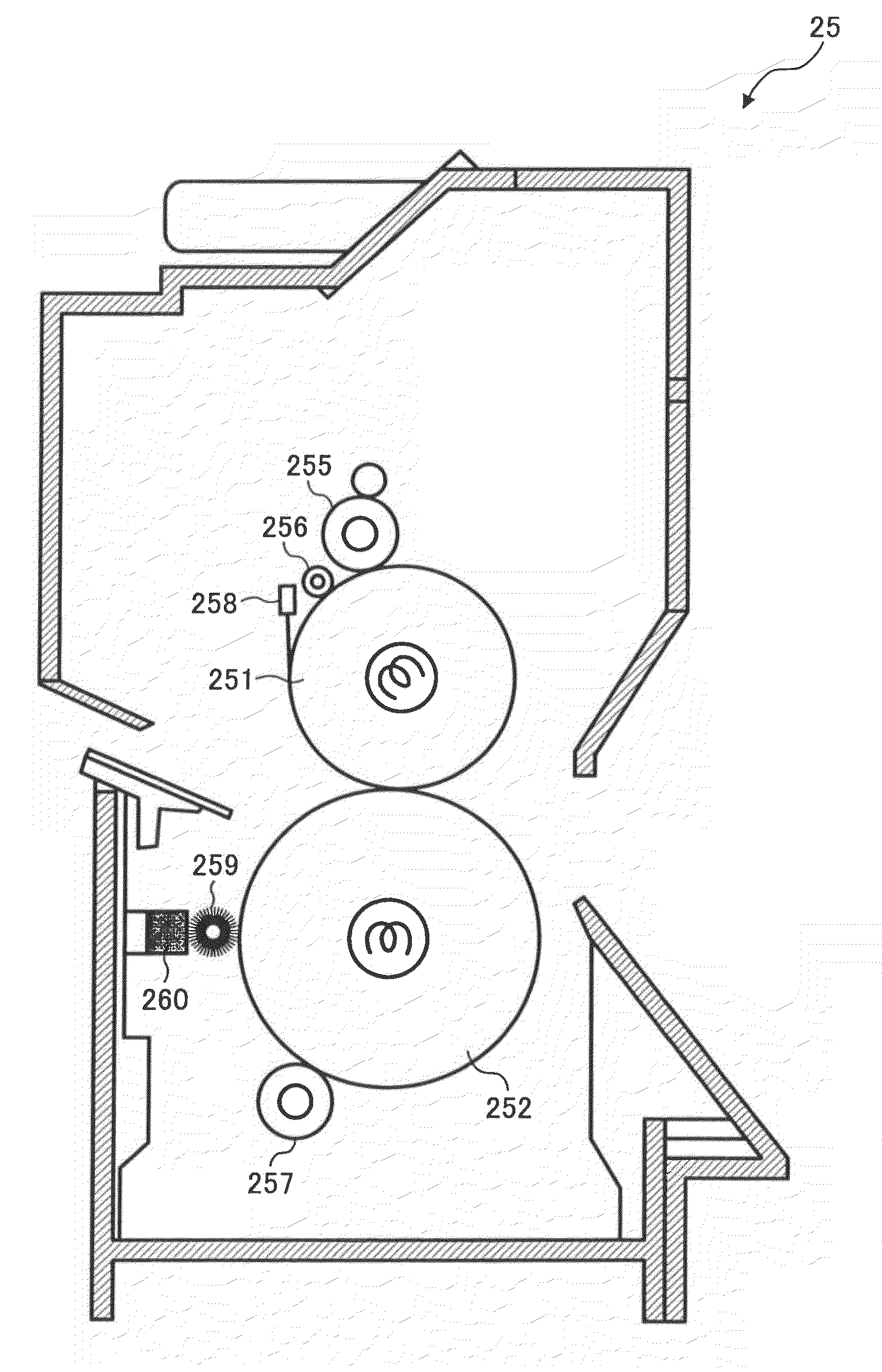

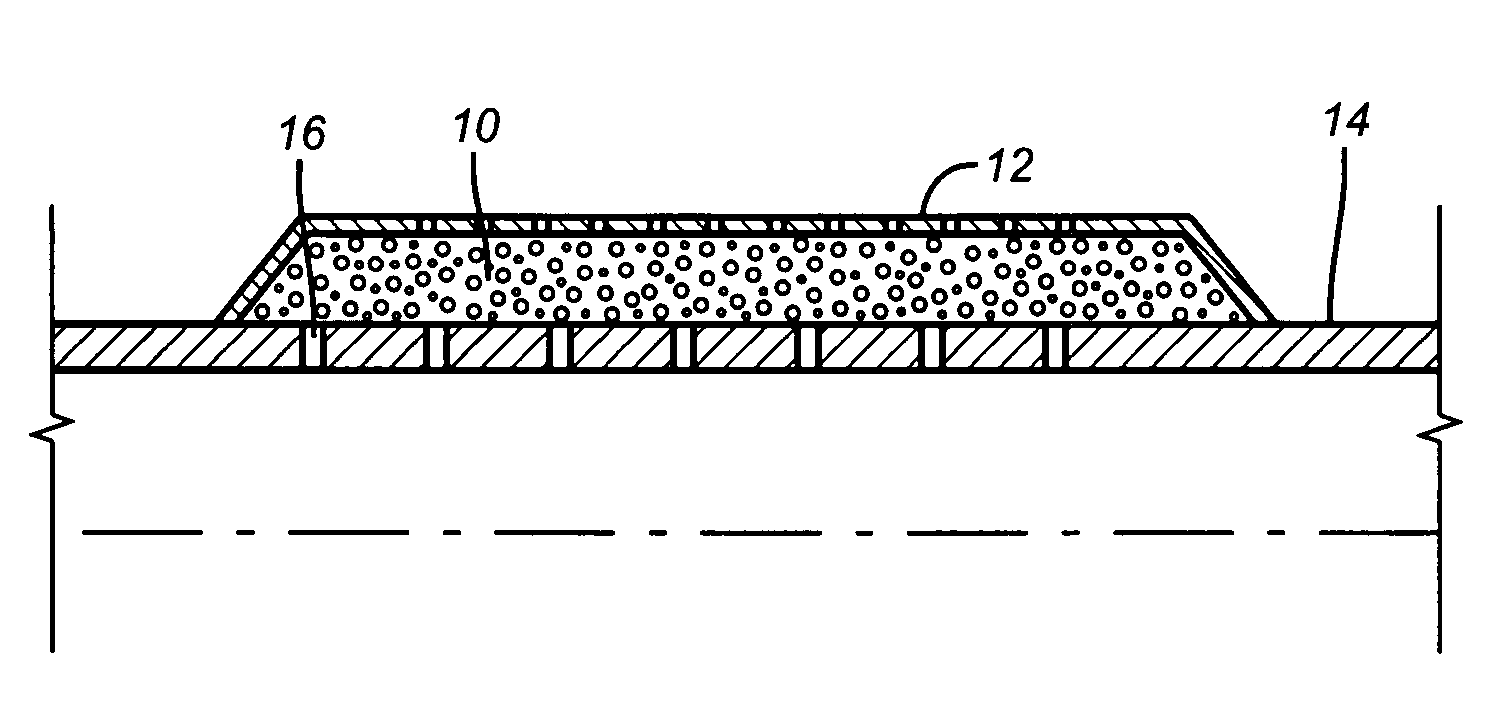

Bead pack brazing with energetics

InactiveUS7644854B1Reduce energy consumptionPrevent movementFluid removalWelding/cutting media/materialsEnergeticsUnit structure

A method of making porous shapes from unit structures such as beads involves coating the beads with two or more layers of material deposited such that it forms an energetic material. These bi-layer energetic materials are formed from a variety of materials including, but not limited to: Ti & B, Zr & B, Hf & B, Ti & C, Zr & C, Hf & C, Ti & Si, Zr & Si, Nb & Si, Ni & Al, Zr & Al, or Pd & Al, all of which can be deposited from vapor. Pressure is applied to prevent the components from moving and the solid-state reaction between the alternating layers produces exothermic heat. Heat from the reaction alone or in conjunction of an applied brazing compound joins the beads forming a porous shape that is desired. The reaction in the materials may be activated with a small pulse of local energy that can be applied using optical, electrical, or thermal sources. Common examples include an electrical pulse, spark, hot filament, a laser beam, etc. The method reduces energy consumption and the need for specialized equipment. The reactive materials and optional brazing material are preferably applied in a fluidized CVD furnace.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com