Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51 results about "Energetics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Energetics (also called energy economics) is the study of energy under transformation. Because energy flows at all scales, from the quantum level to the biosphere and cosmos, energetics is a very broad discipline, encompassing for example thermodynamics, chemistry, biological energetics, biochemistry and ecological energetics. Where each branch of energetics begins and ends is a topic of constant debate. For example, Lehninger (1973, p. 21) contended that when the science of thermodynamics deals with energy exchanges of all types, it can be called energetics.

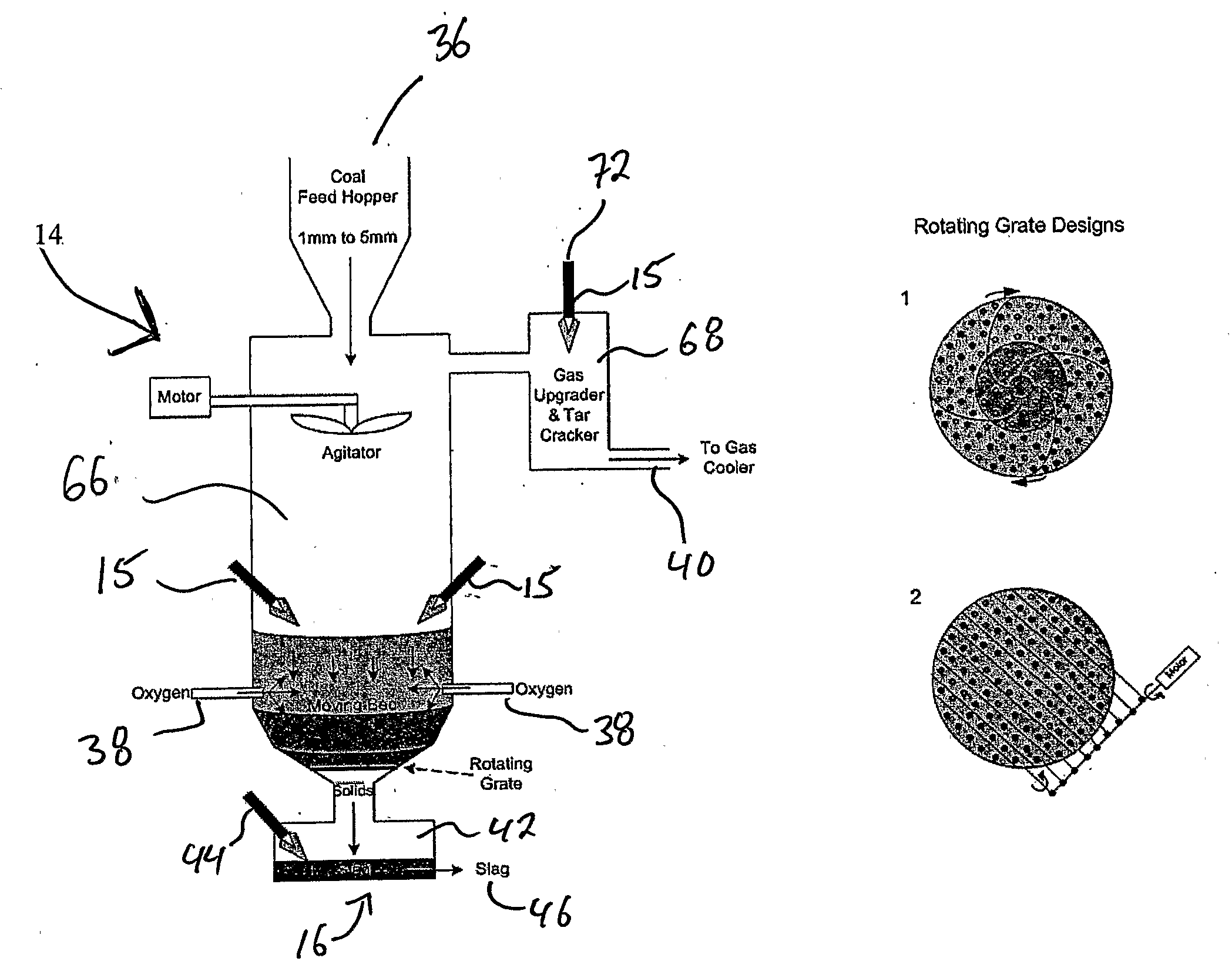

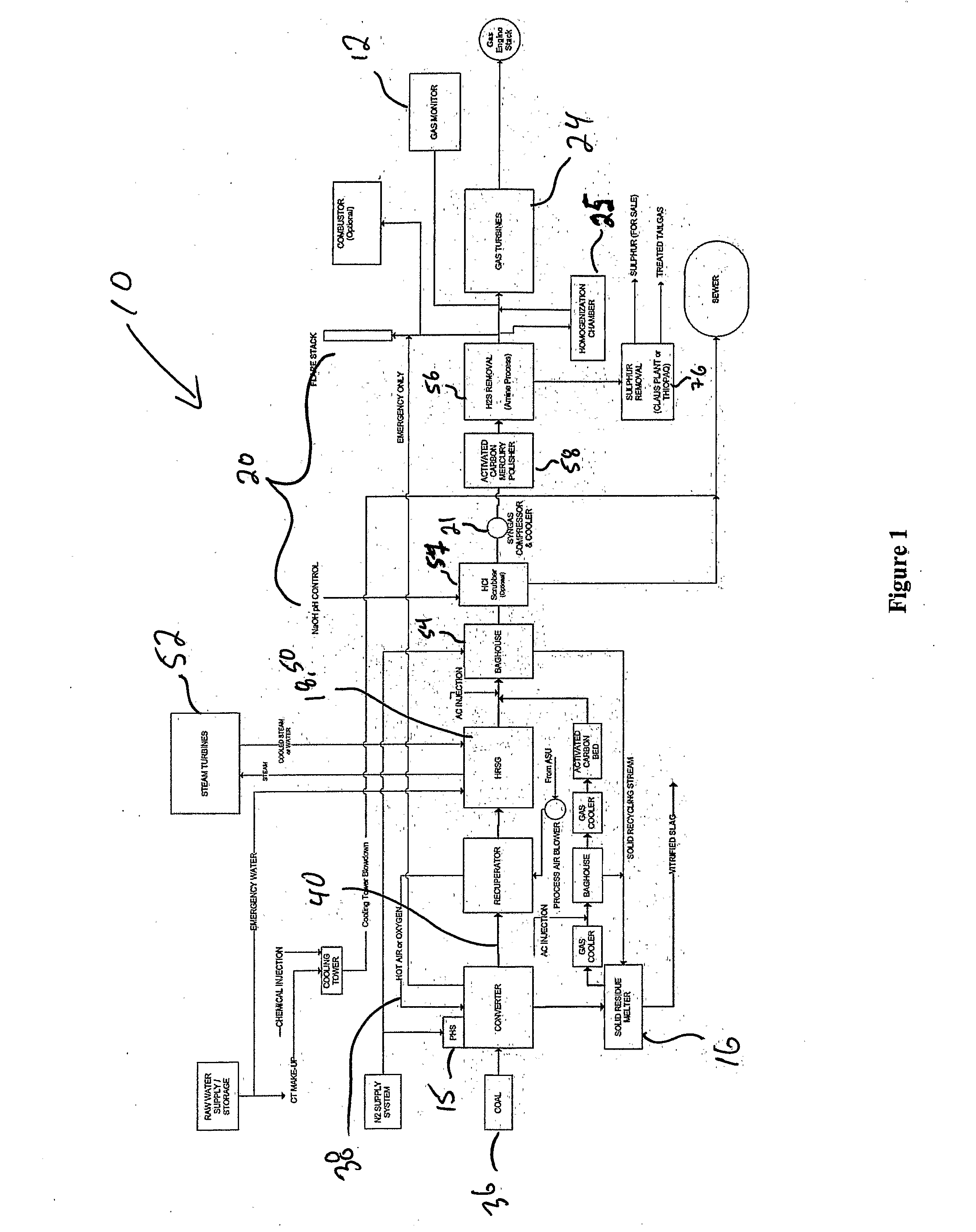

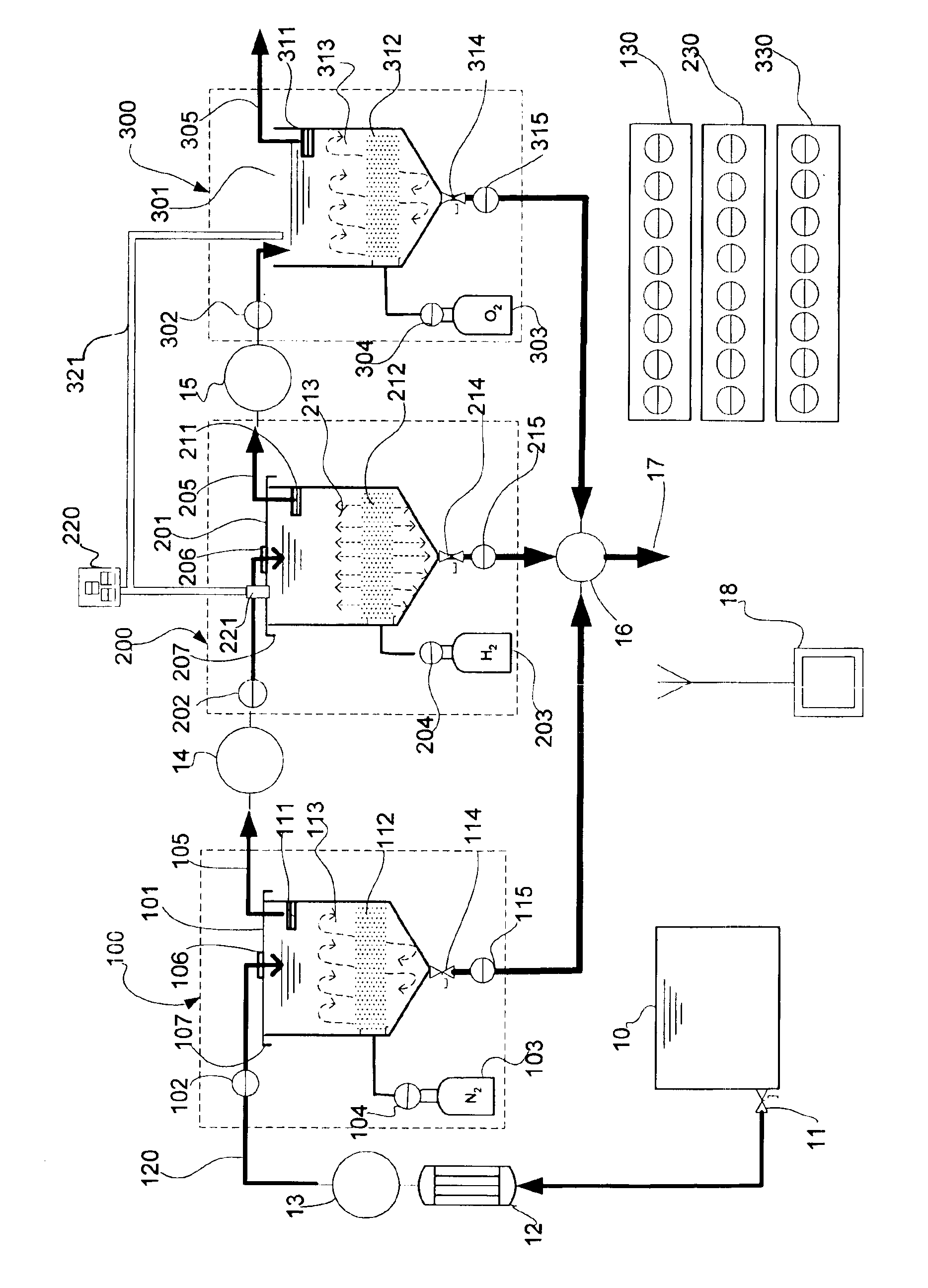

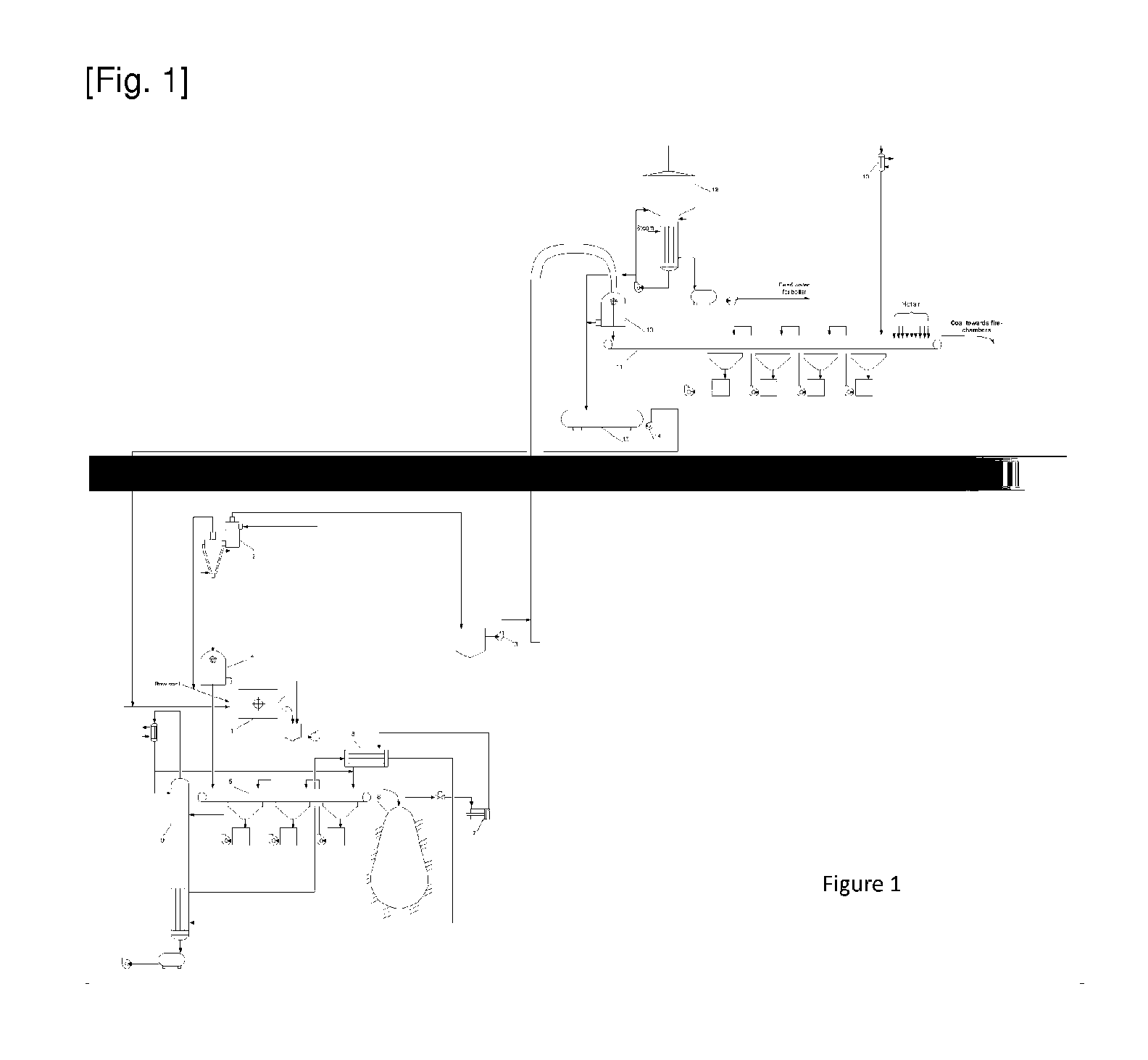

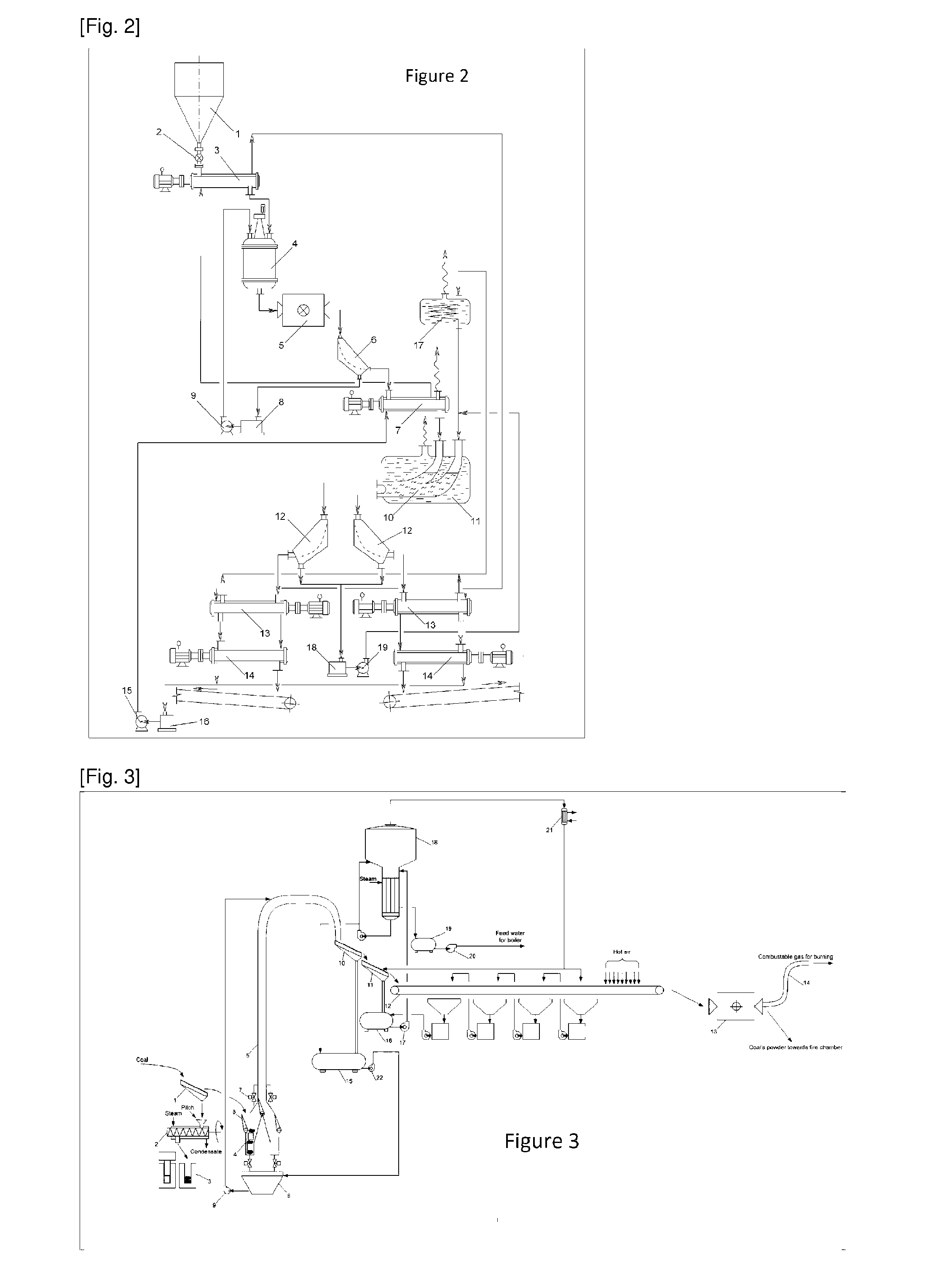

System for the Conversion of Coal to a Gas of Specified Composition

InactiveUS20080222956A1Energy inputCarburetting by solid carbonaceous material pyrolysisEnergeticsProduct gas

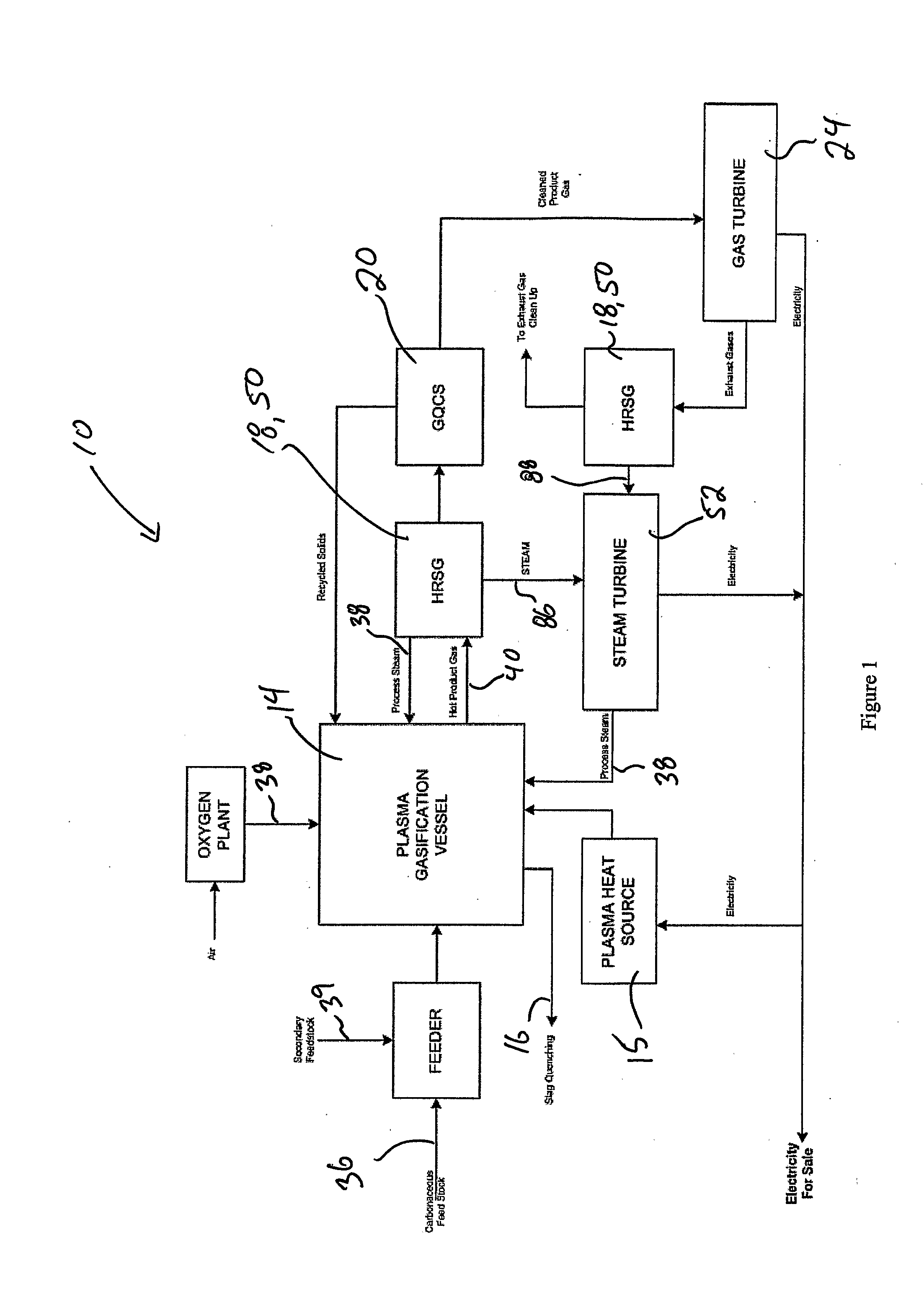

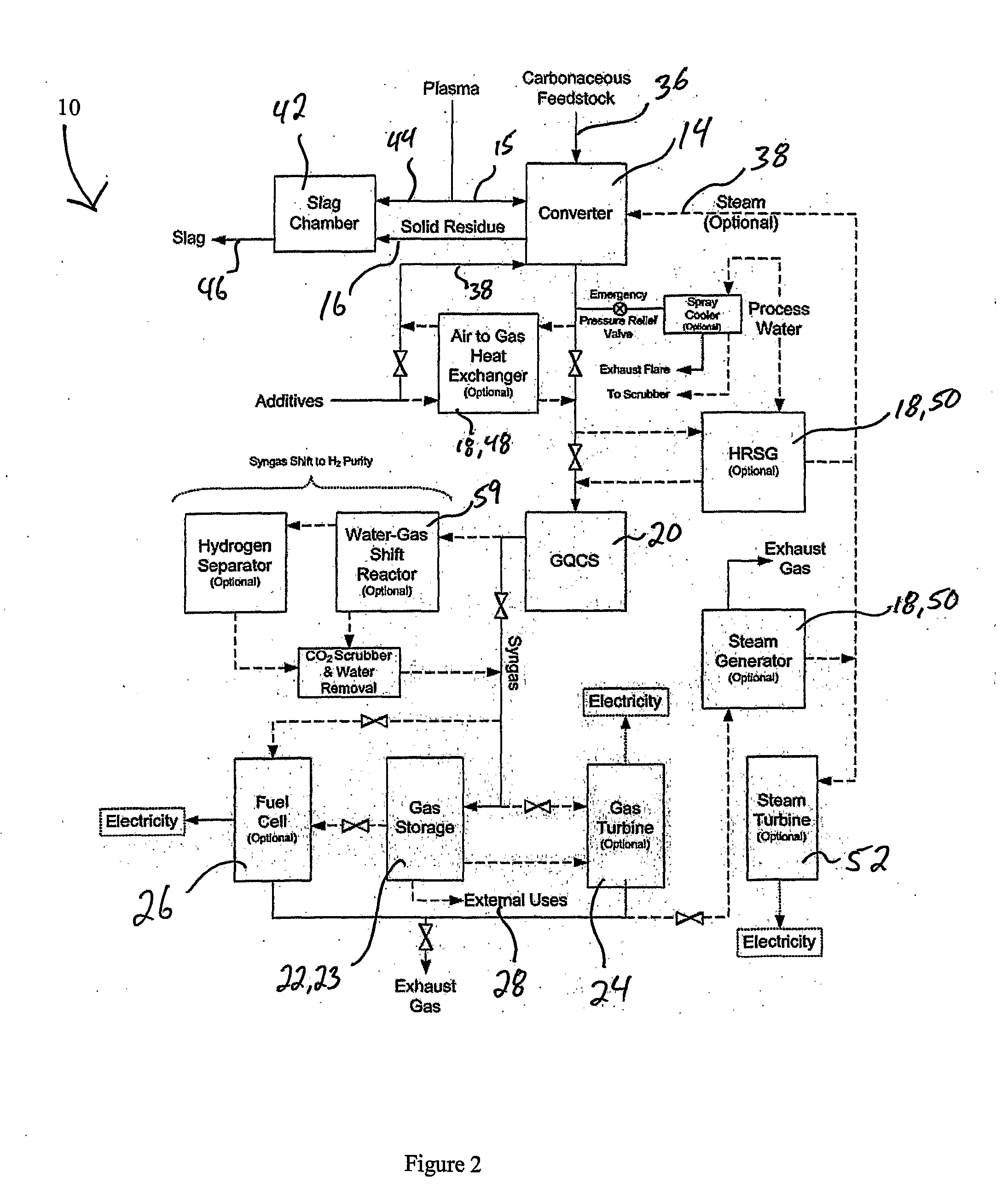

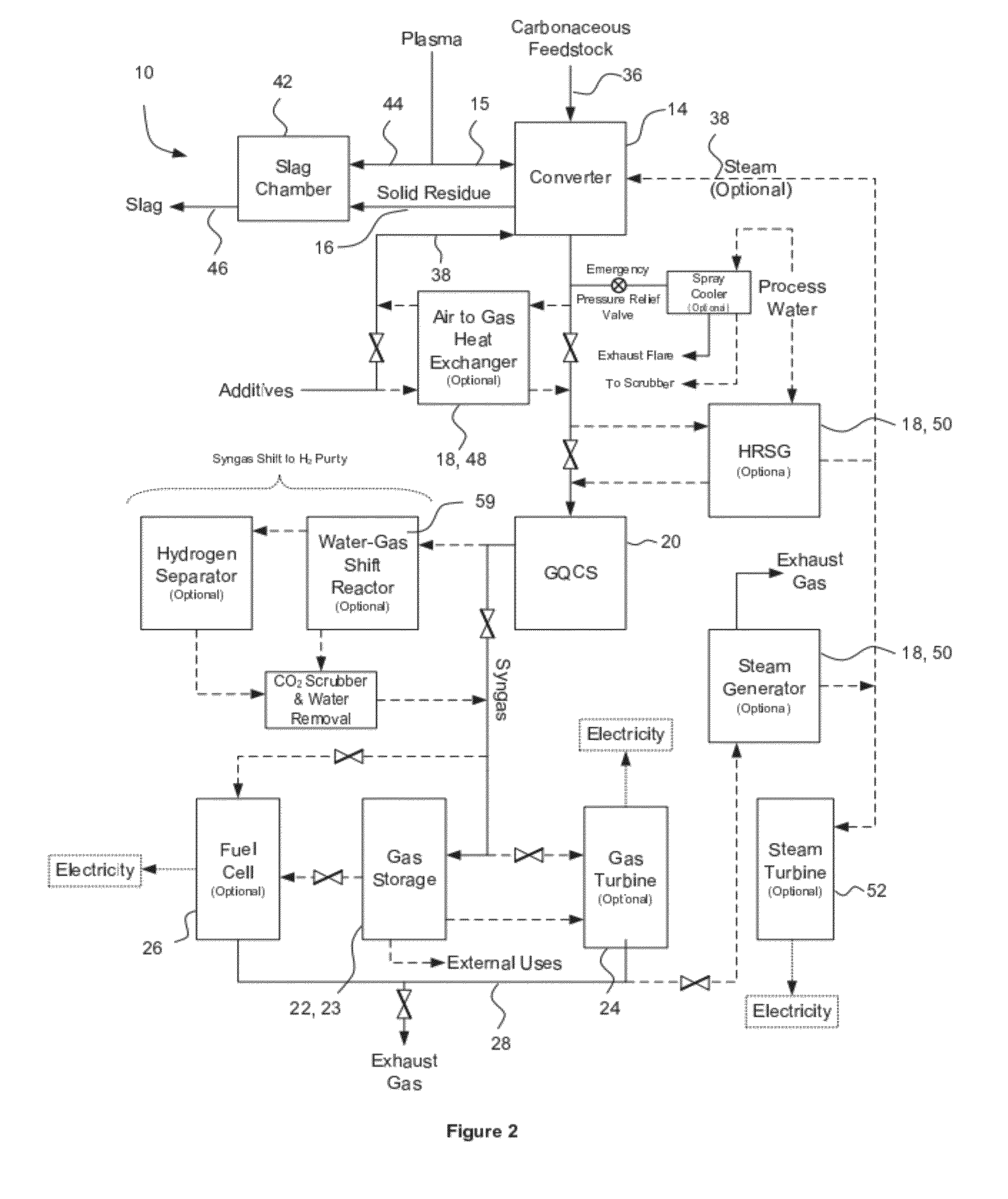

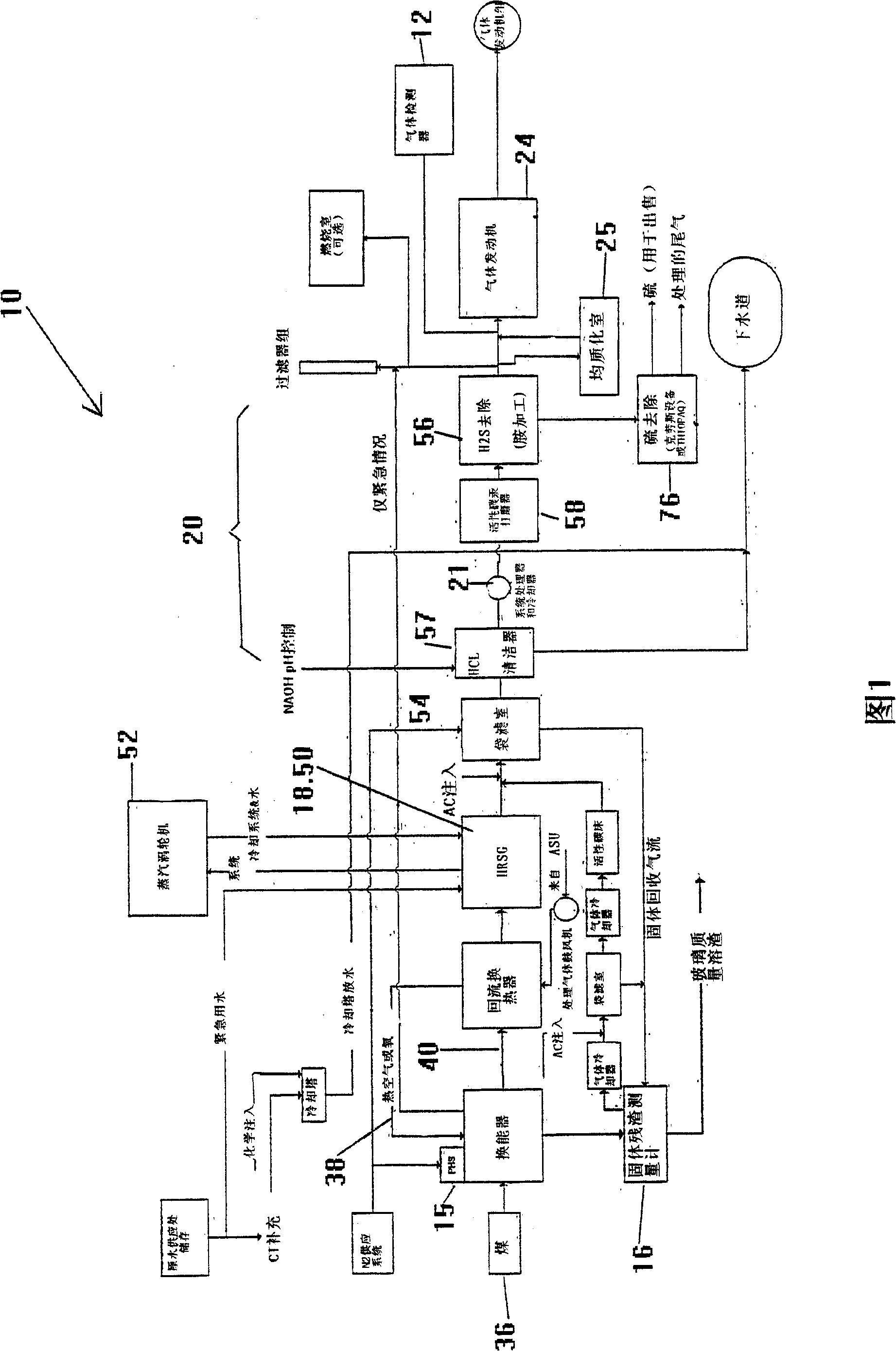

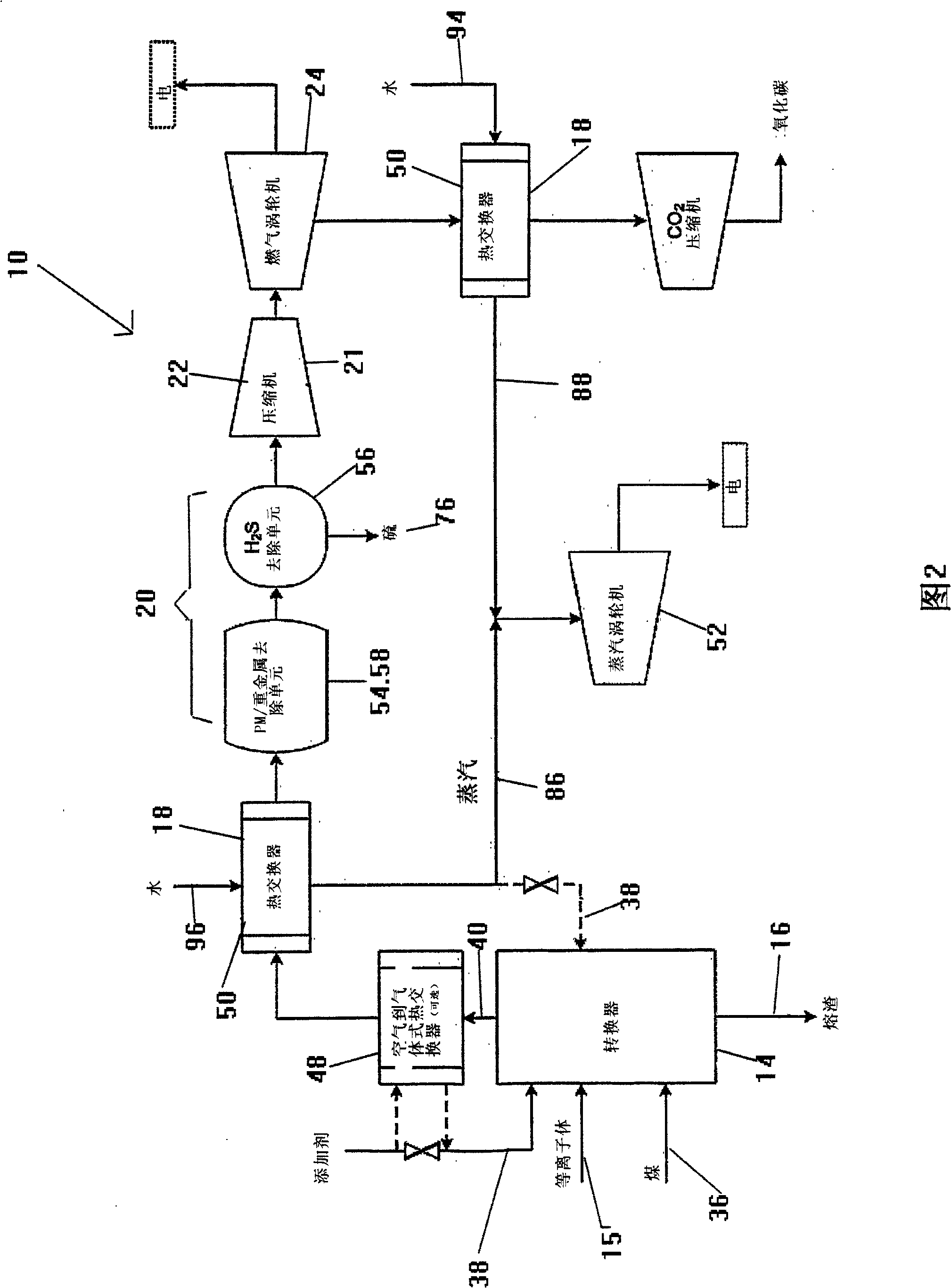

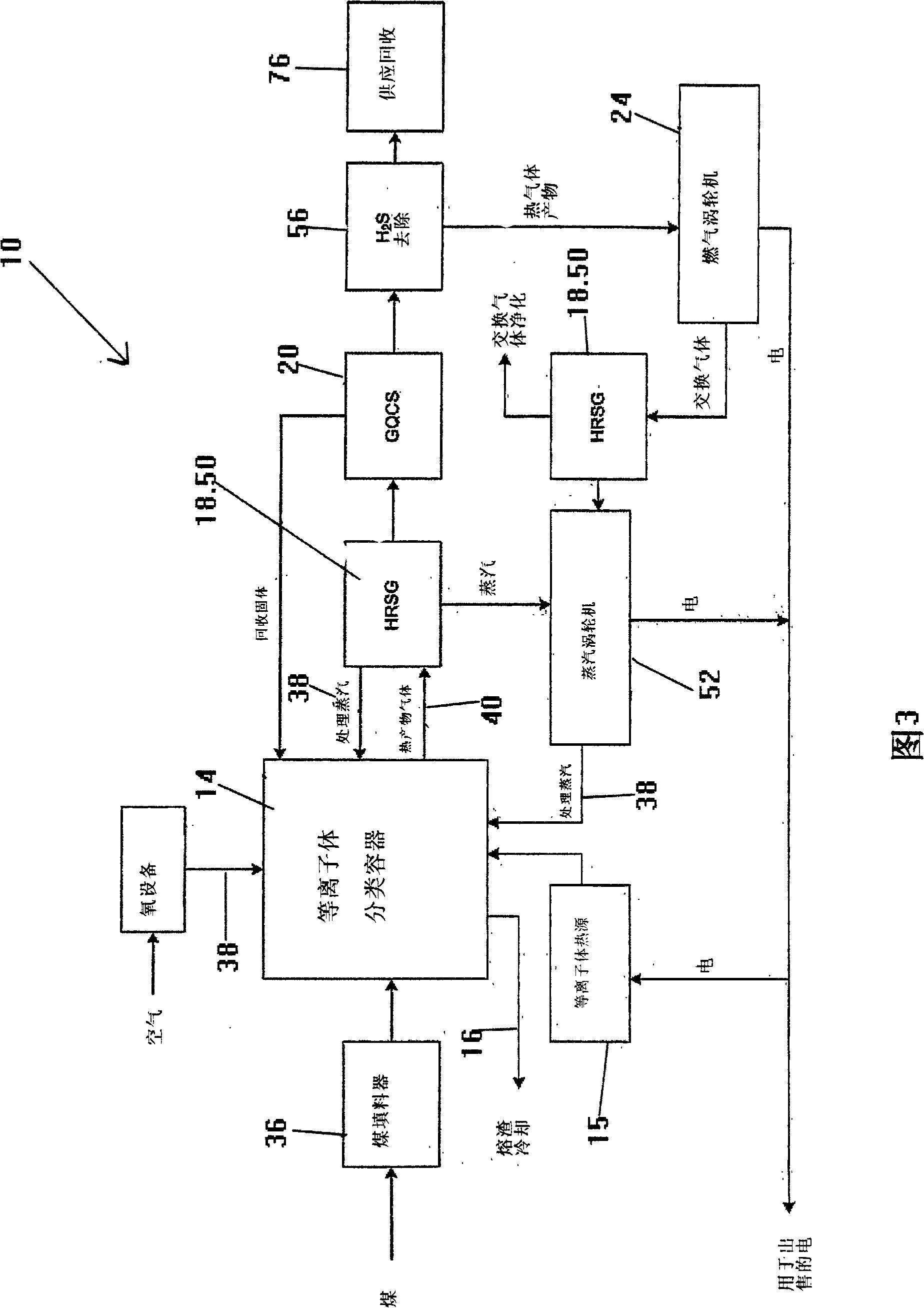

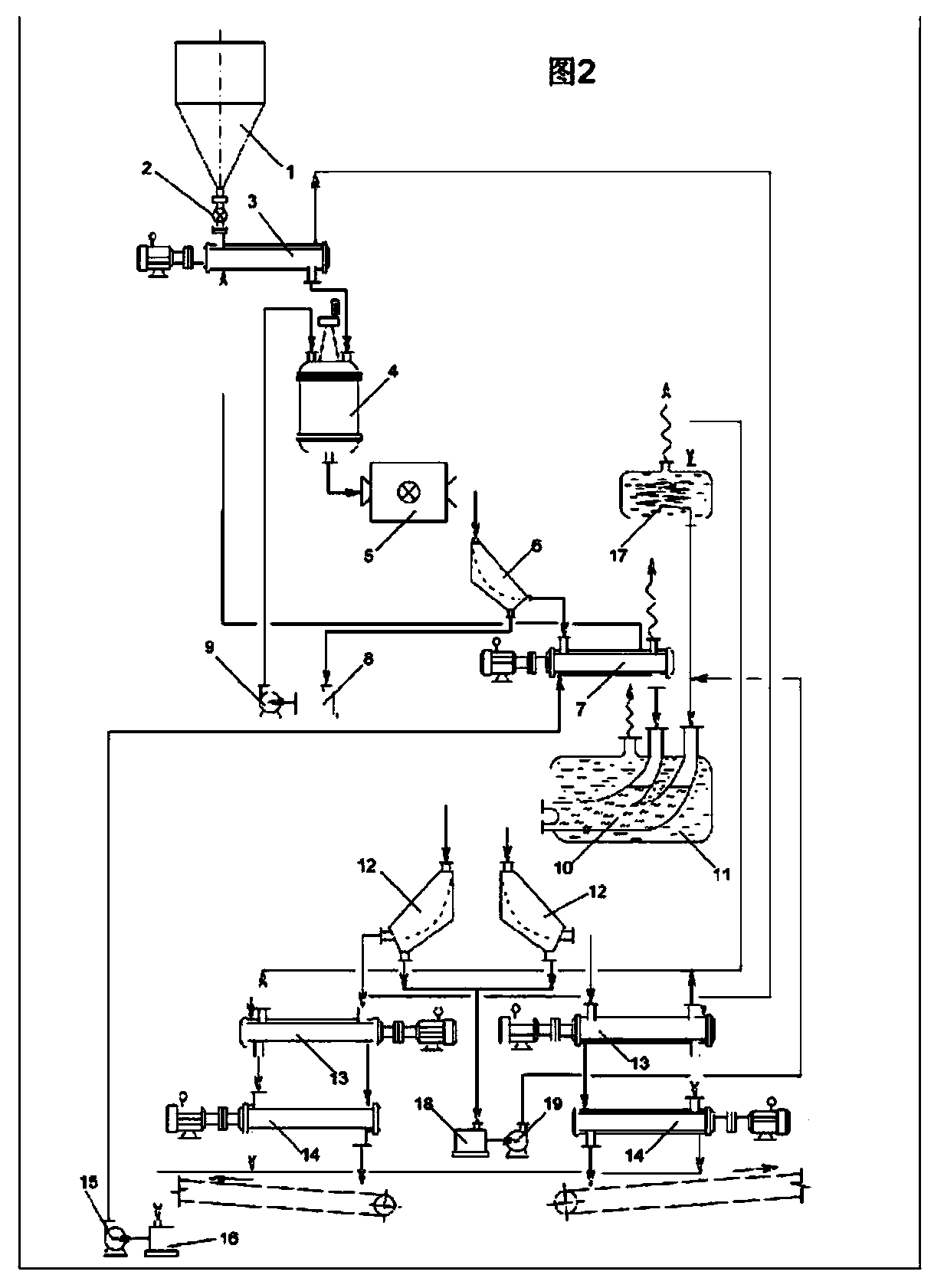

The present invention provides a coal gasification system with an integrated control subsystem. The system generally comprises, in various combinations, a gasification reactor vessel (or converter) having one or more processing zones and one or more plasma heat sources, a solid residue handling subsystem, a gas quality conditioning subsystem, as well as an integrated control subsystem for managing the overall energetics of the conversion of coal to energy and maintaining all aspects of the gasification processes at an optimal set point The gasification system may also optionally comprise a heat recovery subsystem and / or a product gas regulating subsystem.

Owner:PLASCO ENERGY GROUP INC

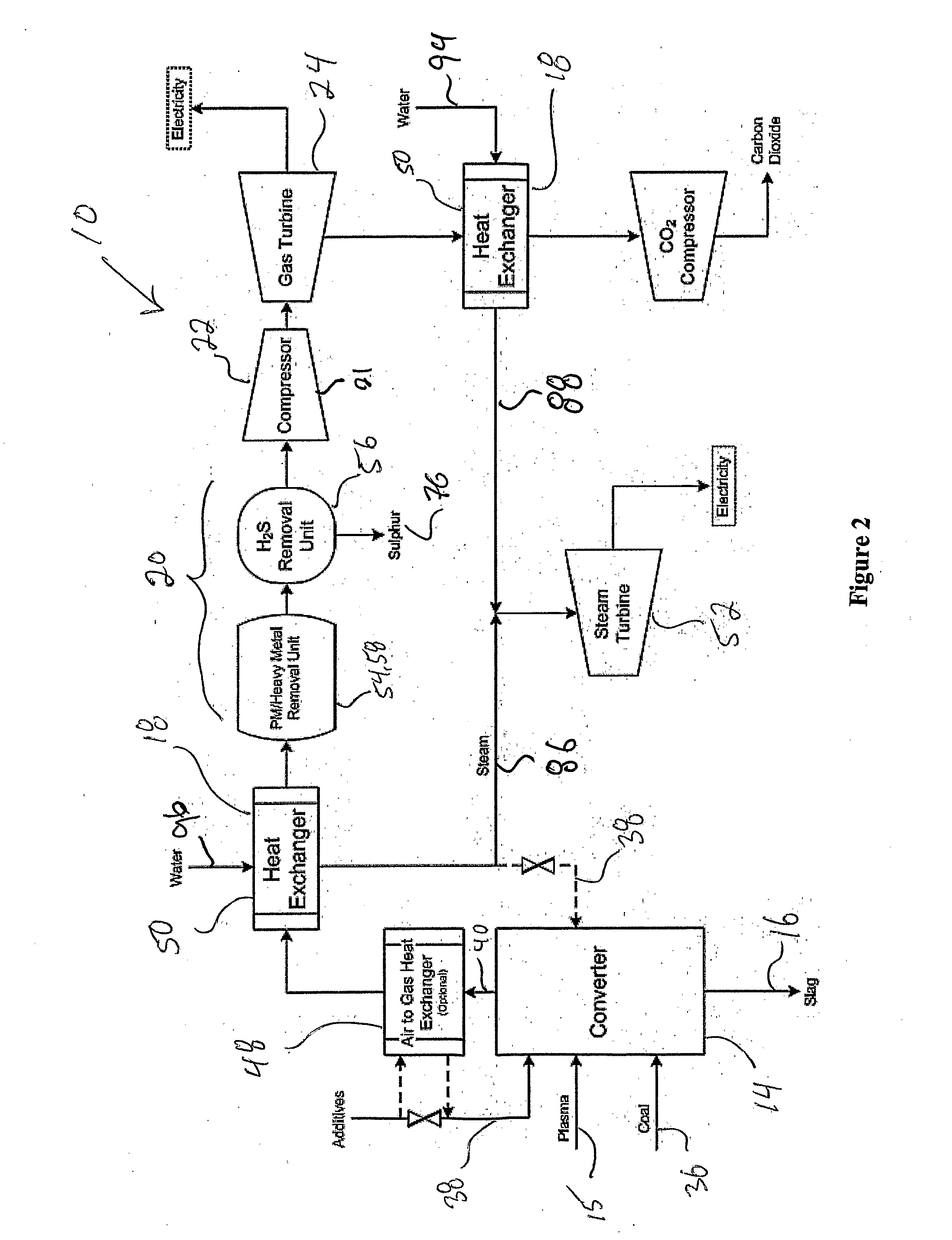

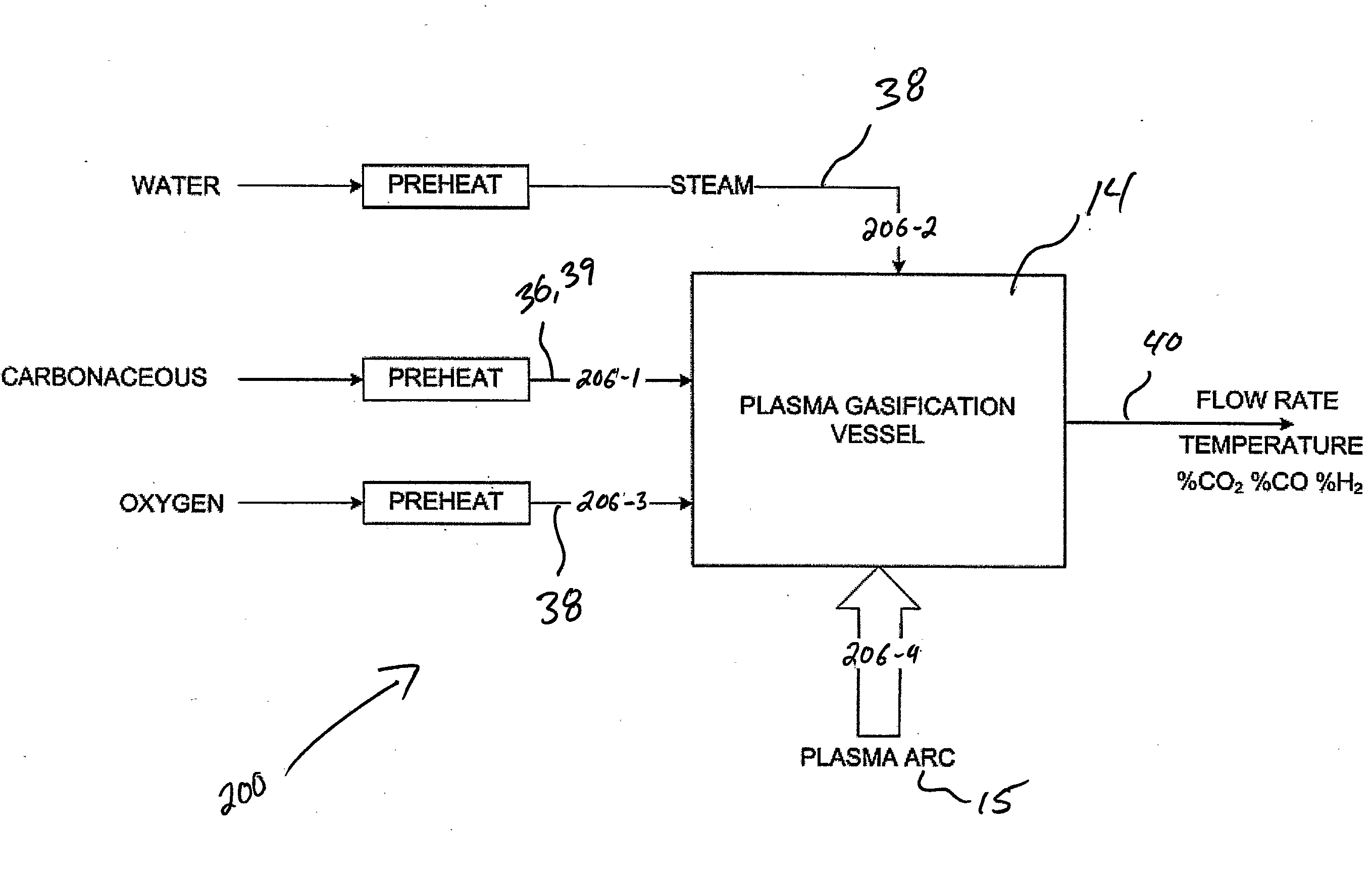

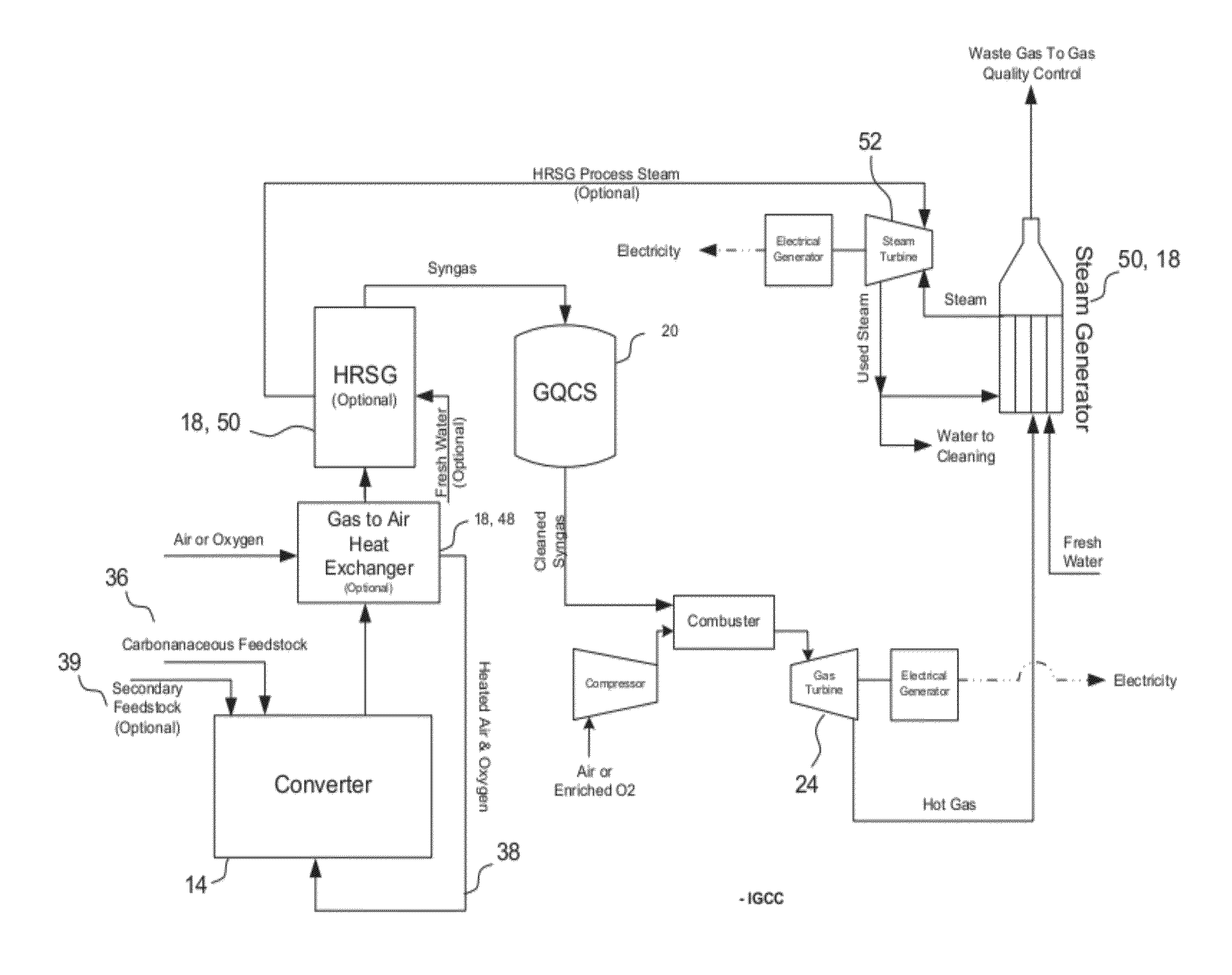

System For the Conversion of Carbonaceous Fbedstocks to a Gas of a Specified Composition

The present invention provides a carbonaceous feedstock gasification system with integrated control subsystem. The system generally comprises, in various combinations, a gasification reactor vessel (or converter) having one or more processing zones and one or more plasma heat sources, a solid residue handling subsystem, a gas quality conditioning subsystem, as well as an integrated control subsystem for managing the overall energetics of the conversion of the carbonaceous feedstock to energy, as well as maintaining all aspects of the gasification processes at an optimal set point. The gasification system may also optionally comprise a heat recovery subsystem and / or a product gas regulating subsystem.

Owner:PLASCO ENERGY GROUP INC

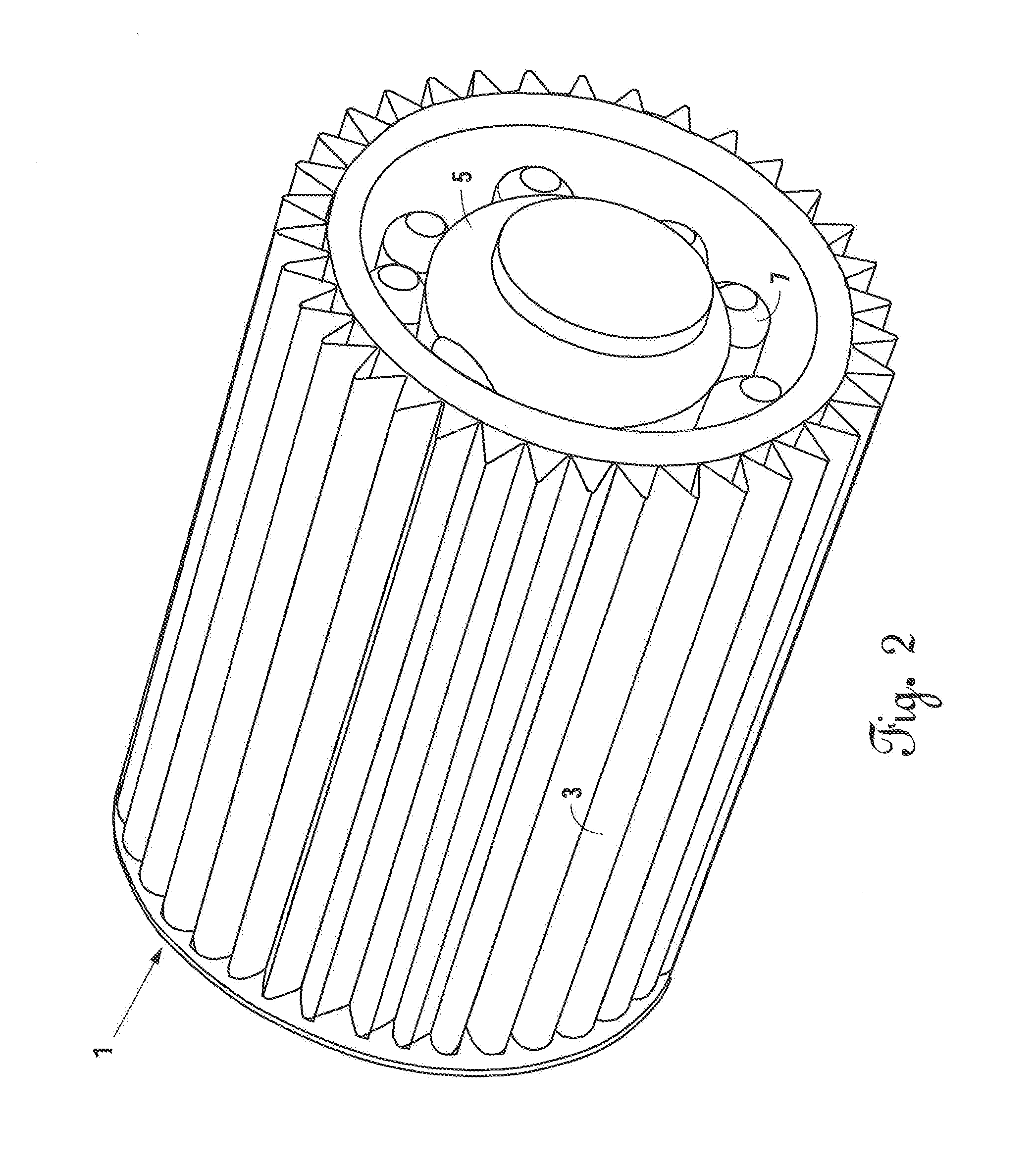

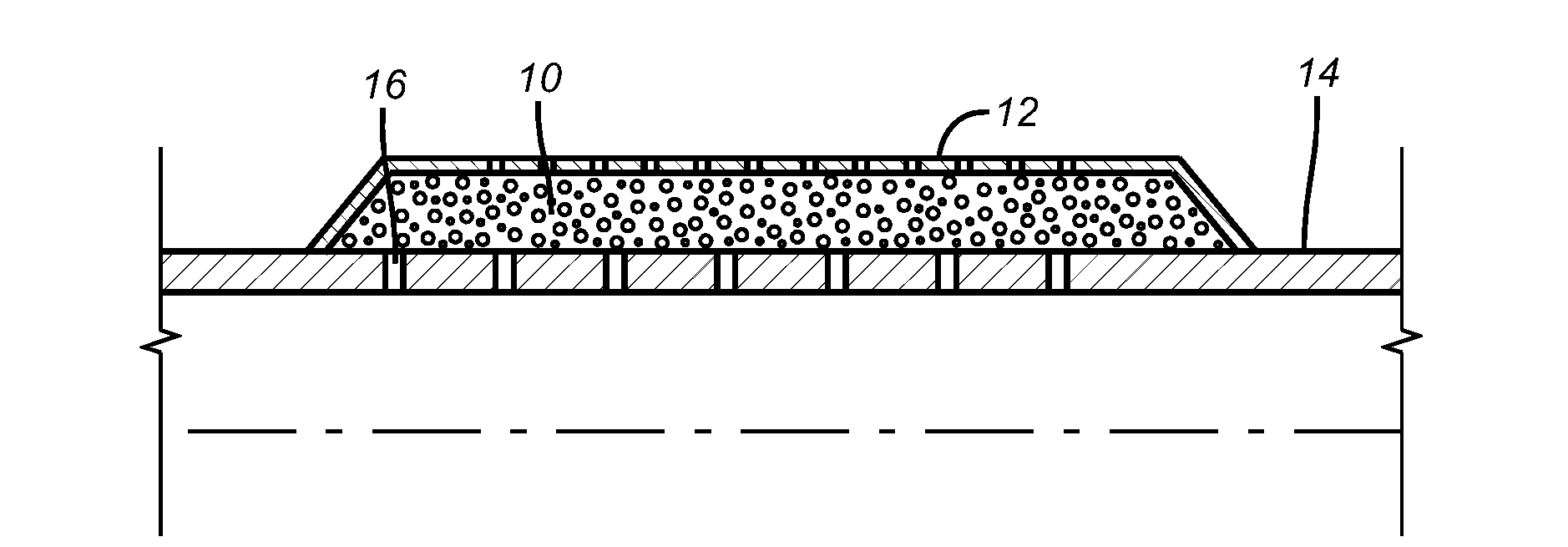

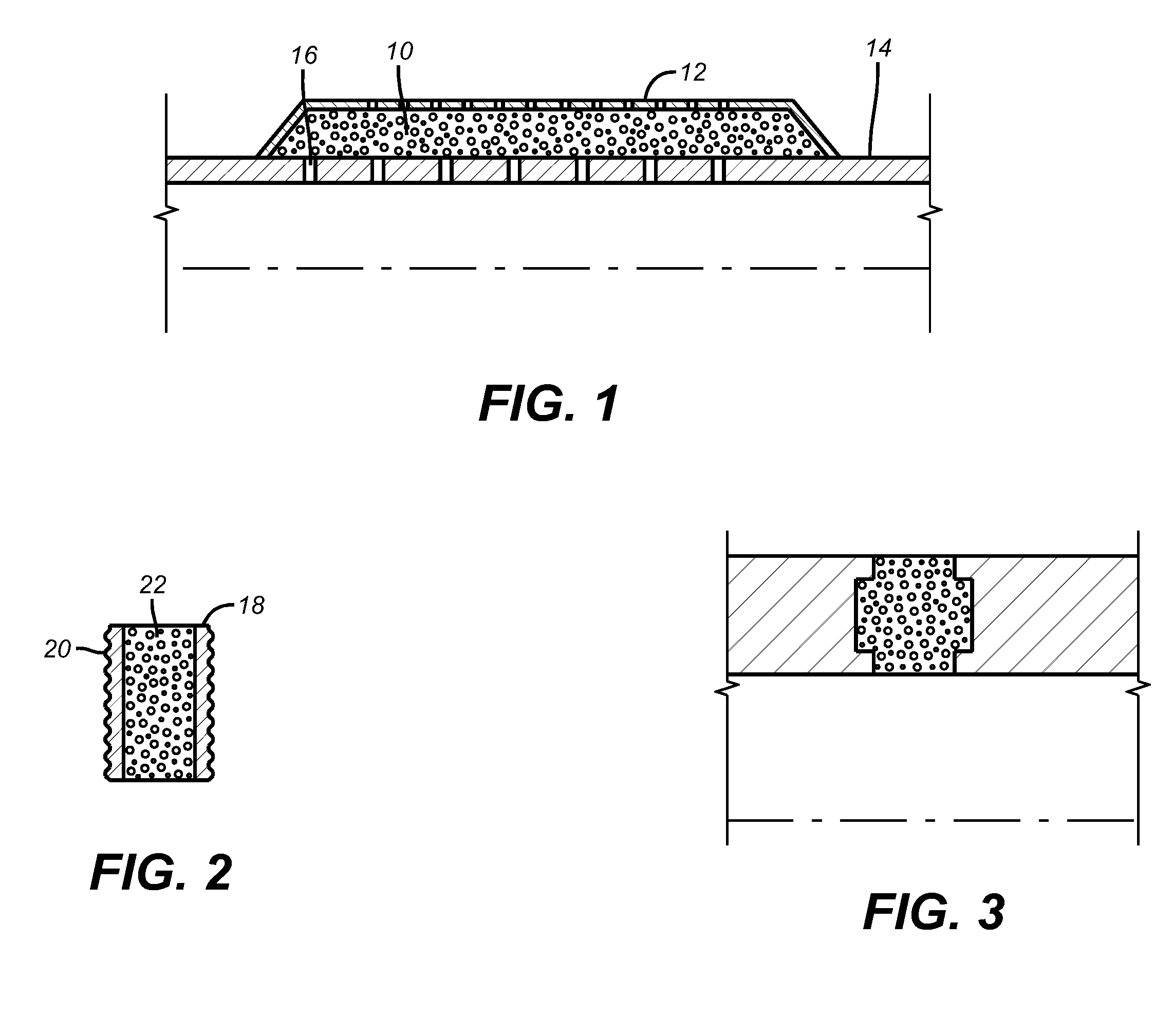

Bead pack brazing with energetics

InactiveUS7644854B1Reduce energy consumptionPrevent movementFluid removalWelding/cutting media/materialsEnergeticsUnit structure

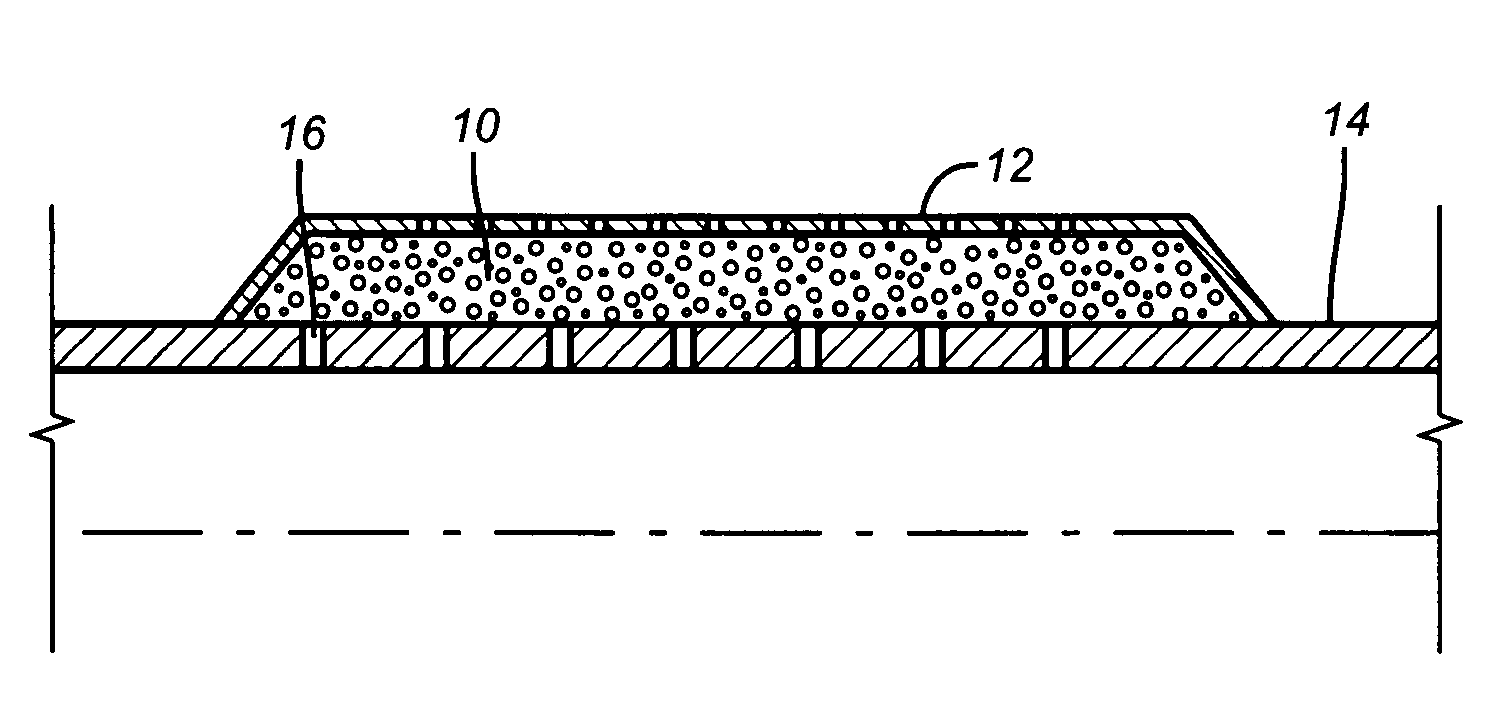

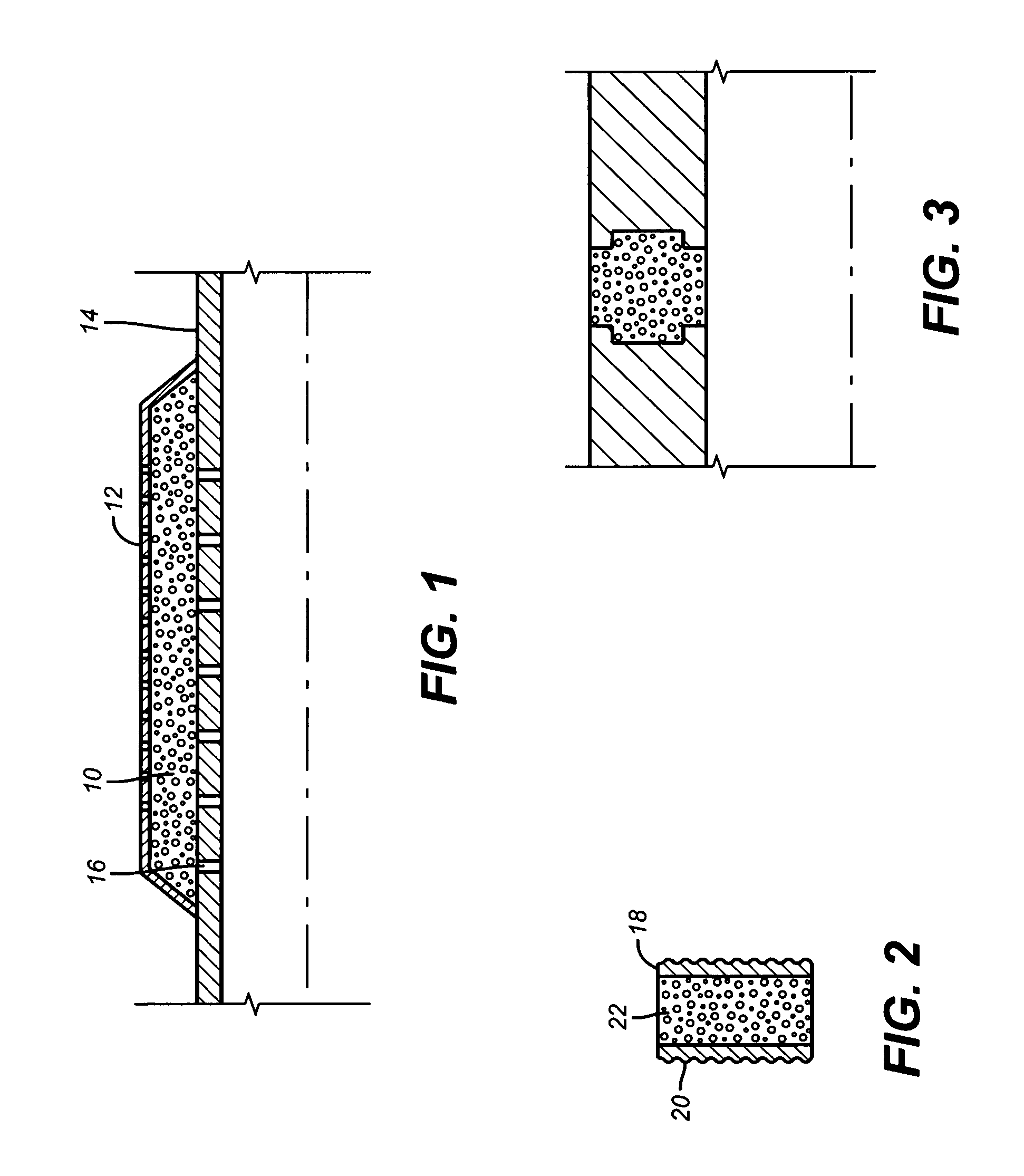

A method of making porous shapes from unit structures such as beads involves coating the beads with two or more layers of material deposited such that it forms an energetic material. These bi-layer energetic materials are formed from a variety of materials including, but not limited to: Ti & B, Zr & B, Hf & B, Ti & C, Zr & C, Hf & C, Ti & Si, Zr & Si, Nb & Si, Ni & Al, Zr & Al, or Pd & Al, all of which can be deposited from vapor. Pressure is applied to prevent the components from moving and the solid-state reaction between the alternating layers produces exothermic heat. Heat from the reaction alone or in conjunction of an applied brazing compound joins the beads forming a porous shape that is desired. The reaction in the materials may be activated with a small pulse of local energy that can be applied using optical, electrical, or thermal sources. Common examples include an electrical pulse, spark, hot filament, a laser beam, etc. The method reduces energy consumption and the need for specialized equipment. The reactive materials and optional brazing material are preferably applied in a fluidized CVD furnace.

Owner:BAKER HUGHES INC

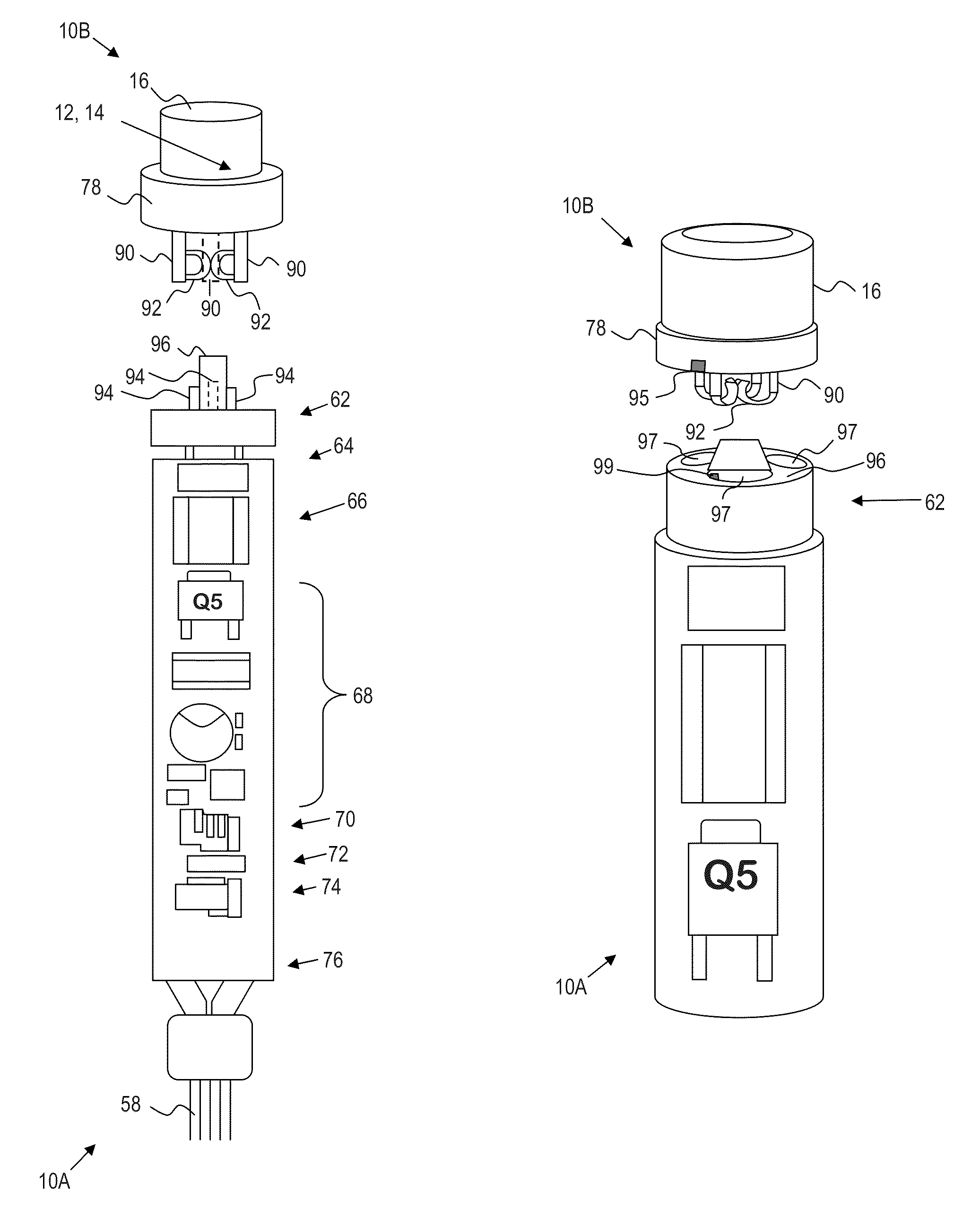

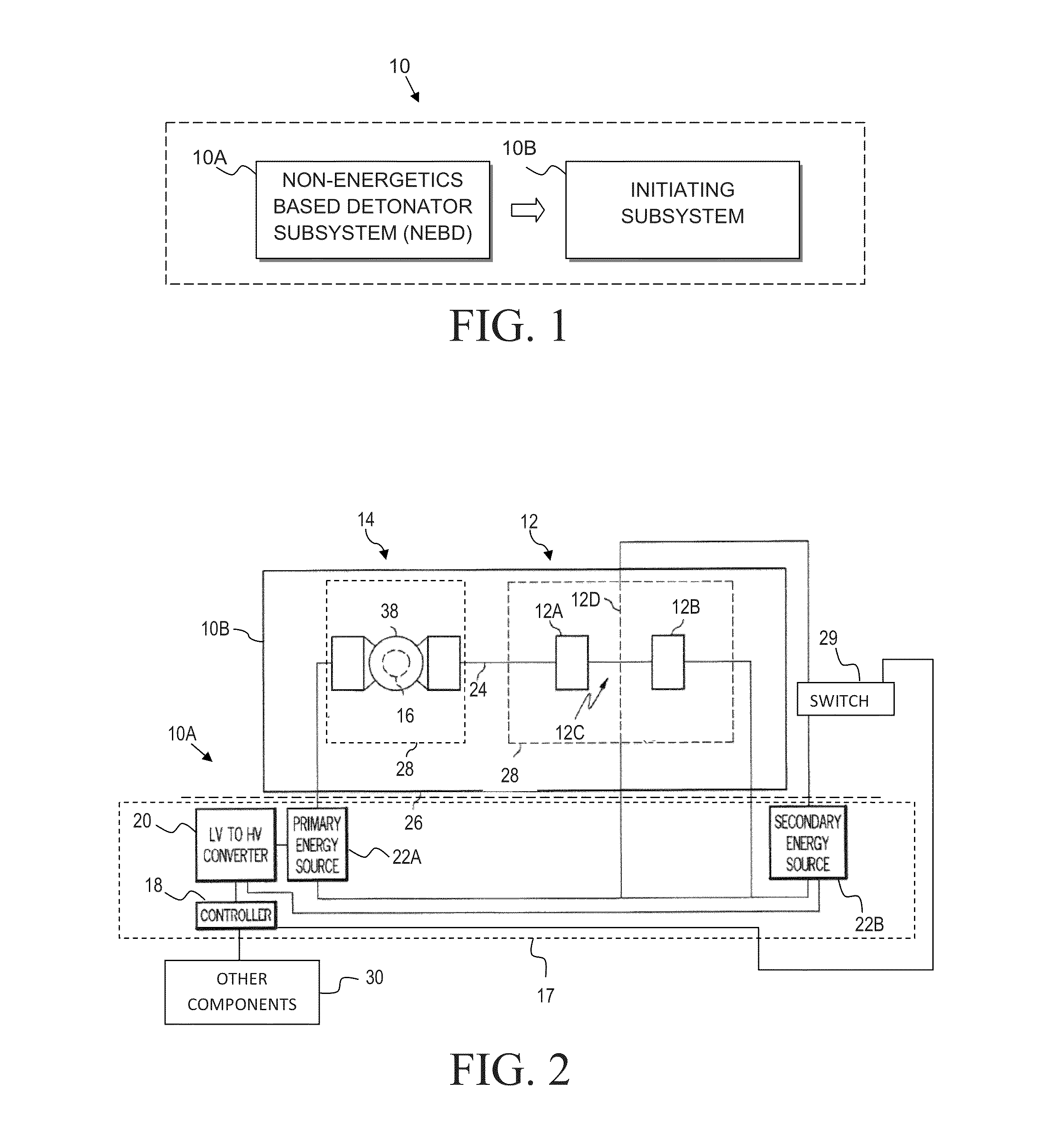

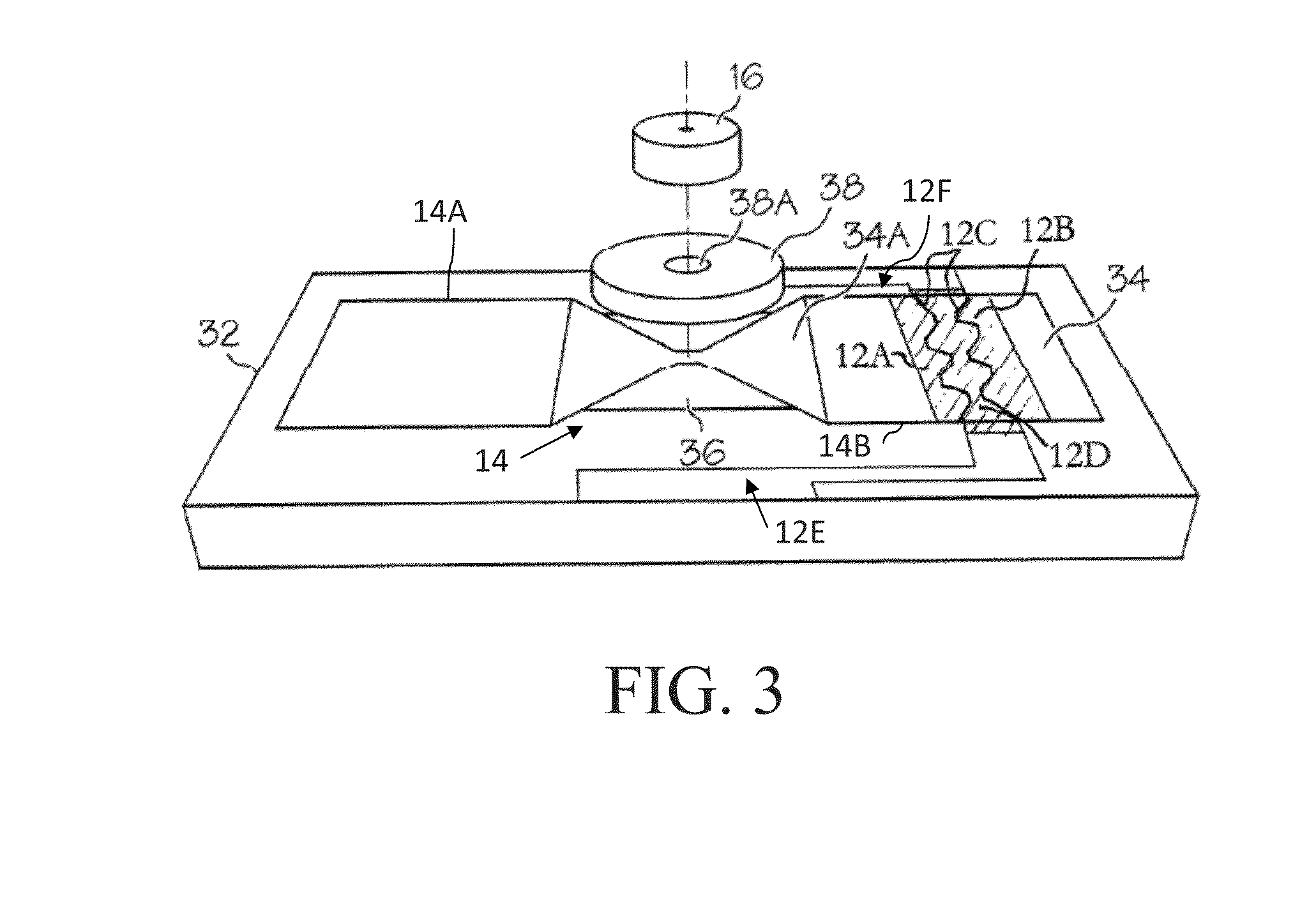

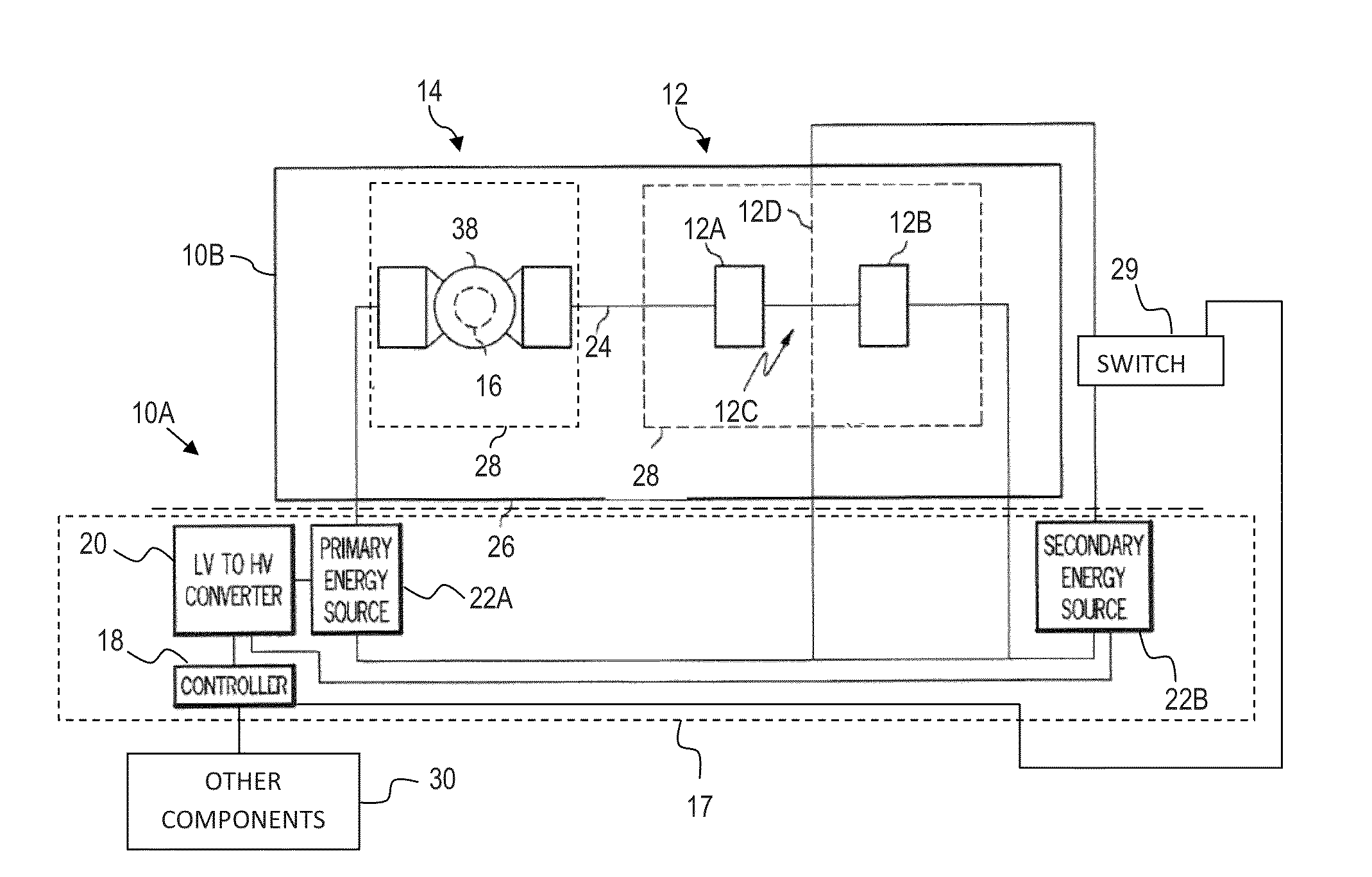

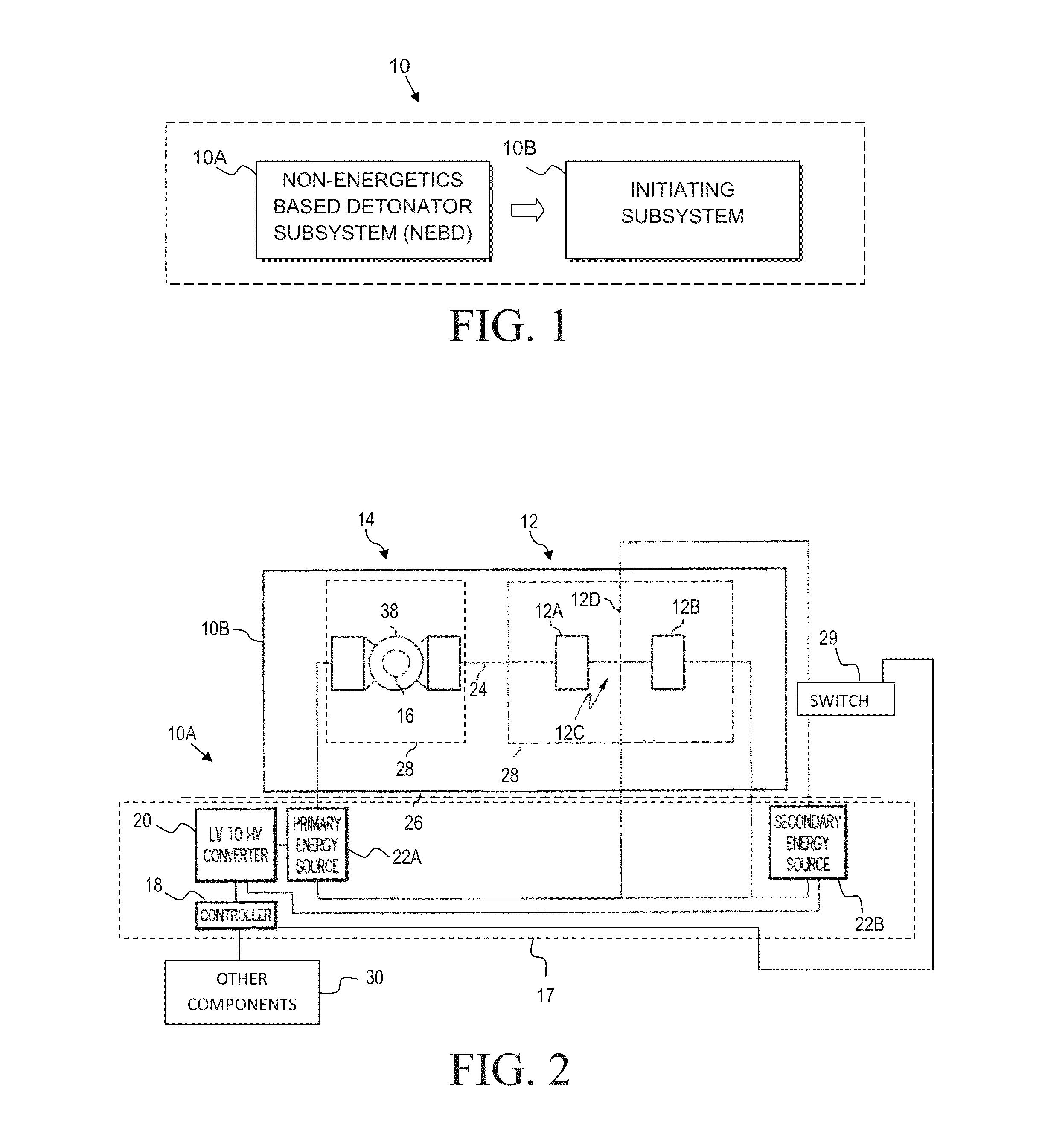

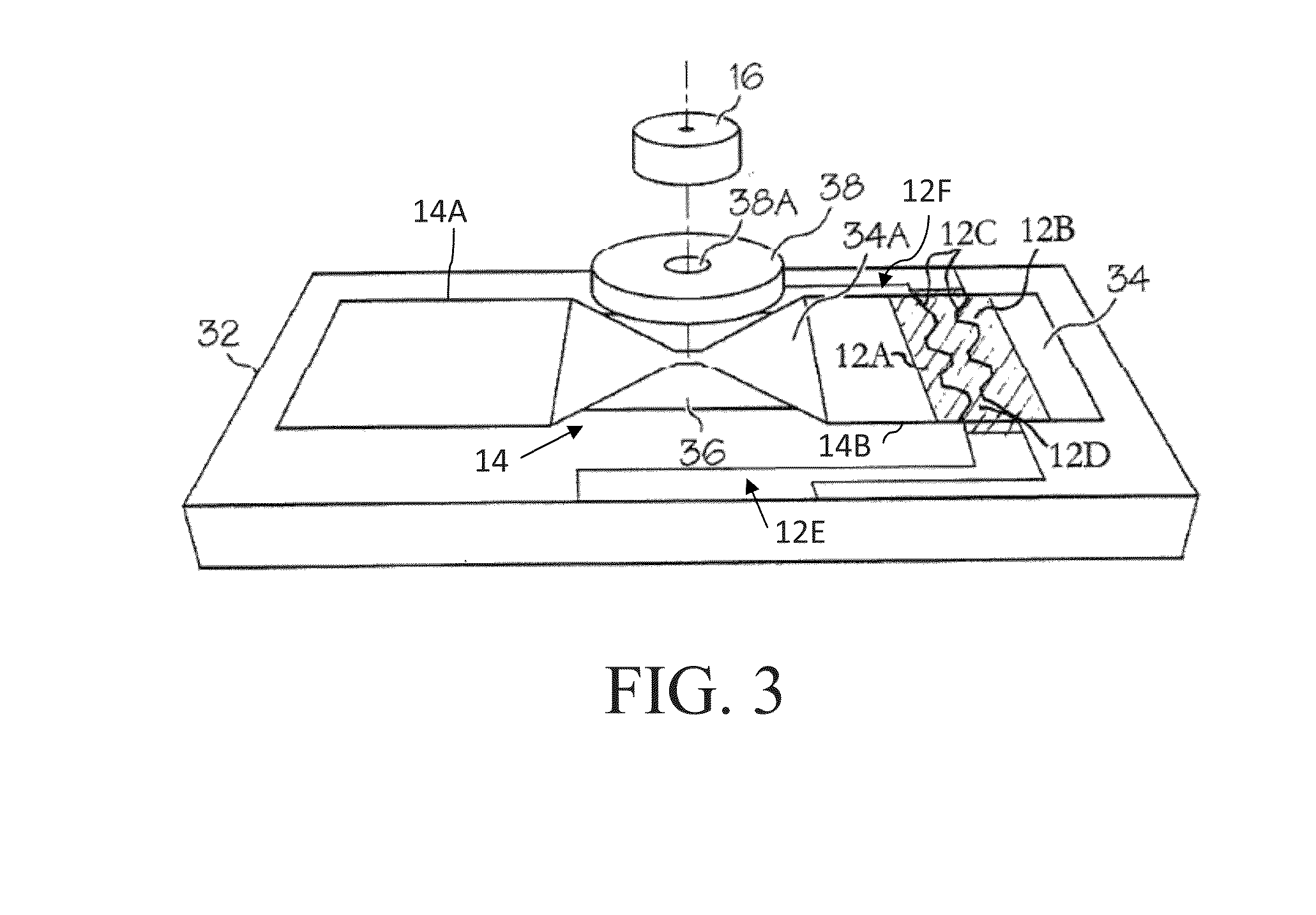

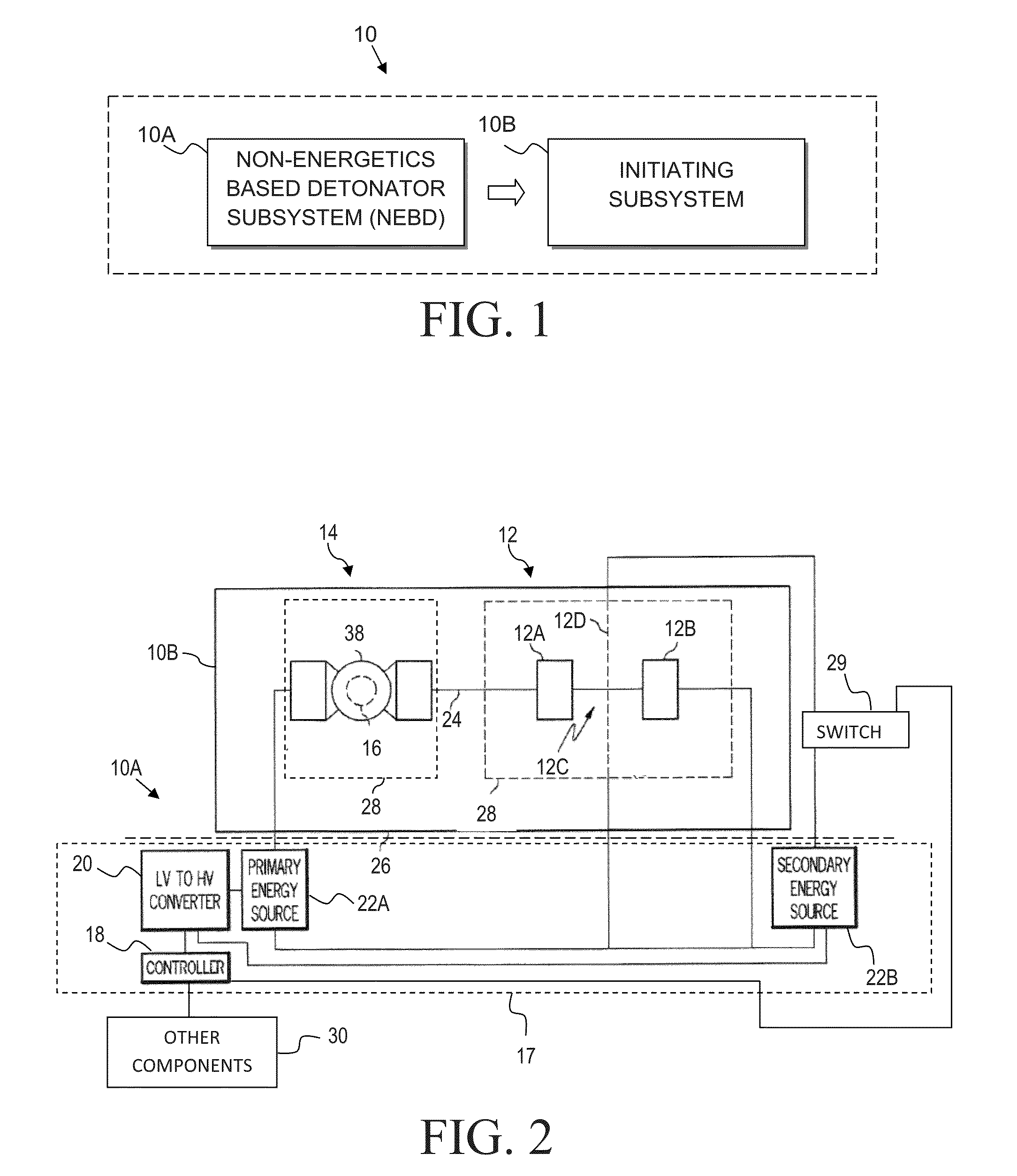

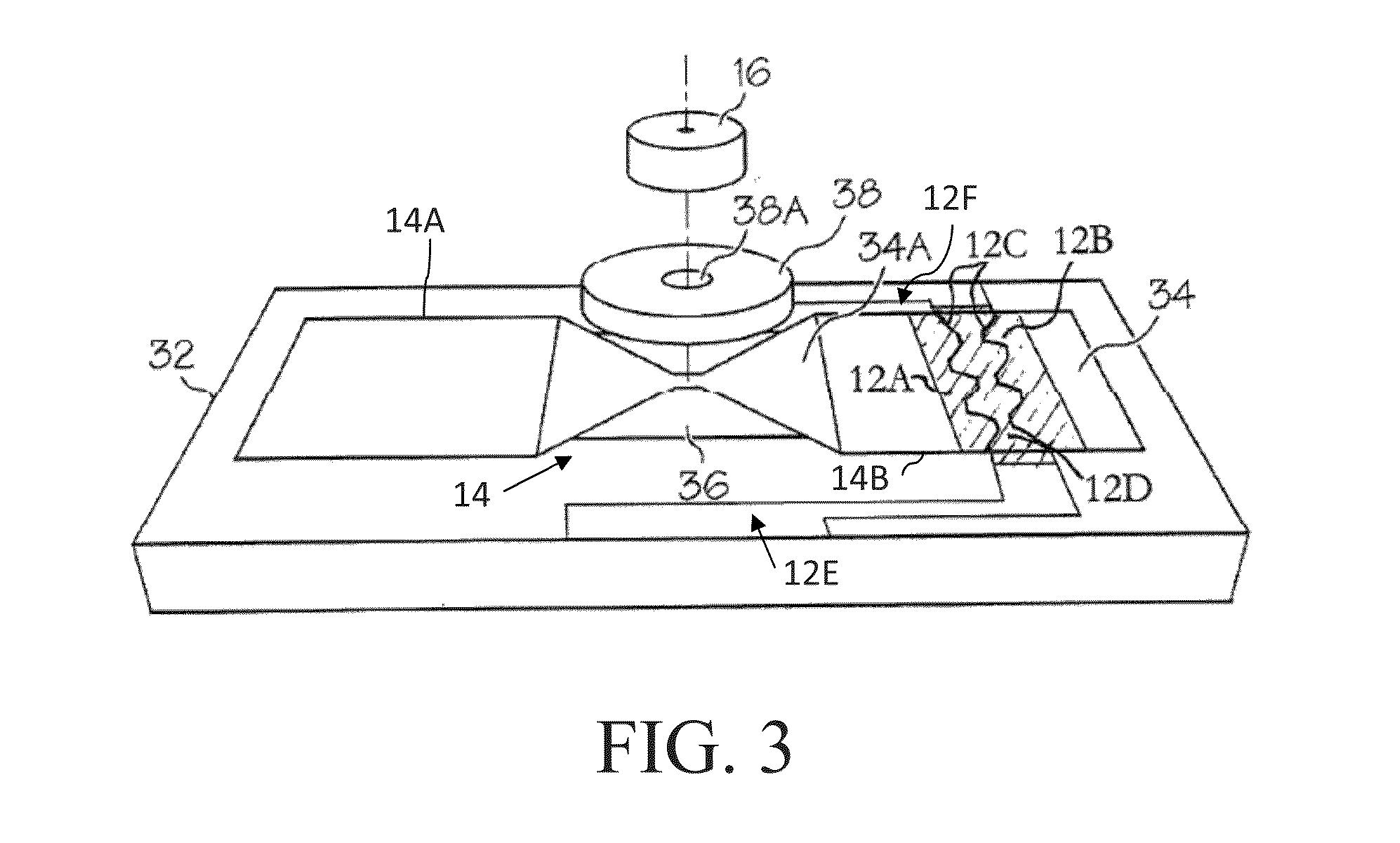

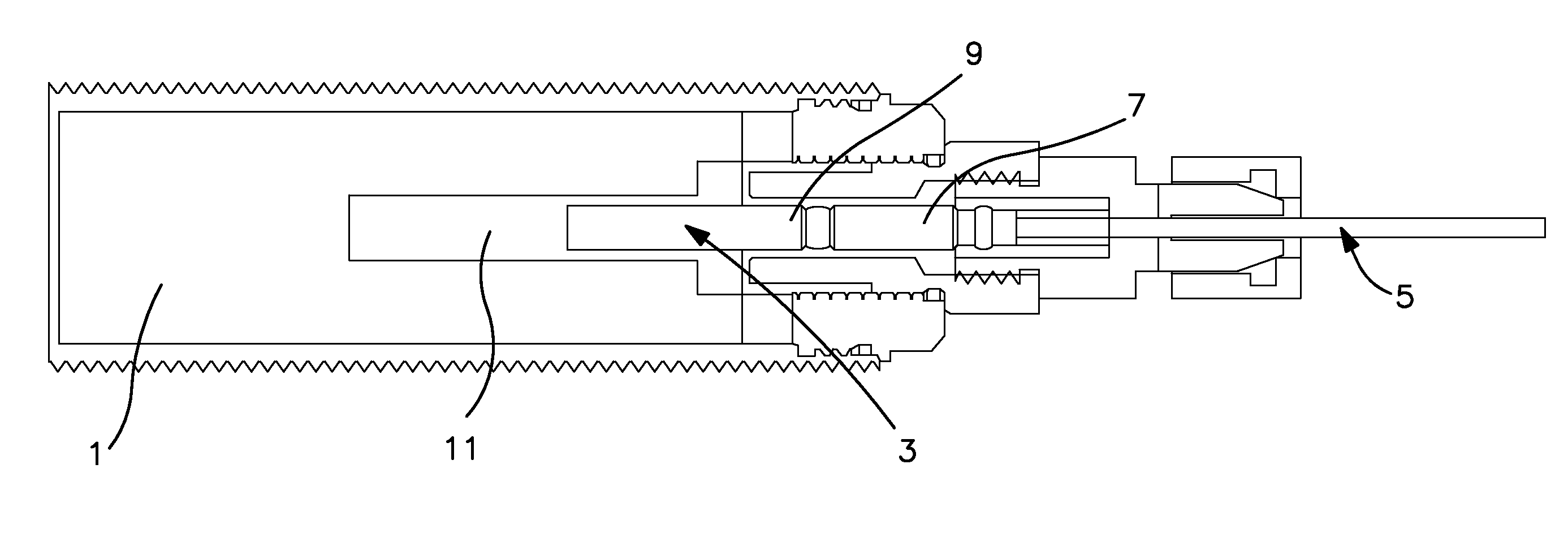

Non-energetics based detonator

A detonator system is provided for use with explosives that utilizes two subsystems. A first subsystem functions as a non-explosives based detonator, which does not contain any explosives. The second subsystem is an initiating subsystem, which includes an initiating pellet. To set off an explosive event, the non-energetics based detonator is coupled to the initiating subsystem and the non-energetics based detonator is commanded to provide a suitable signal to the initiating subsystem that is sufficient to function the initiating pellet. Further, the initiating subsystem can be integrated directly into an associated explosive such as a booster that has been configured to receive the initiator subsystem without changing the hazard class of the booster.

Owner:BATTELLE MEMORIAL INST

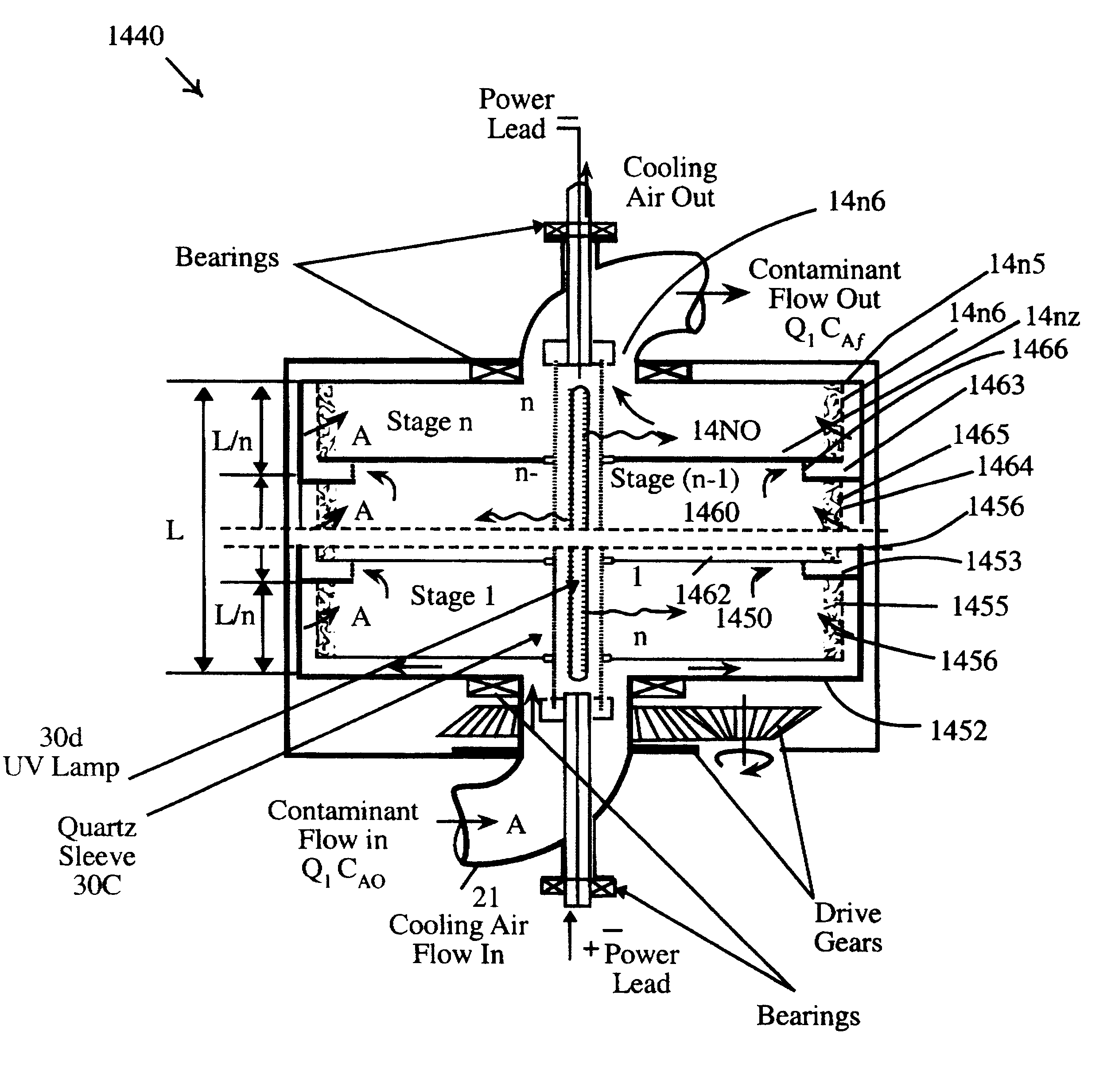

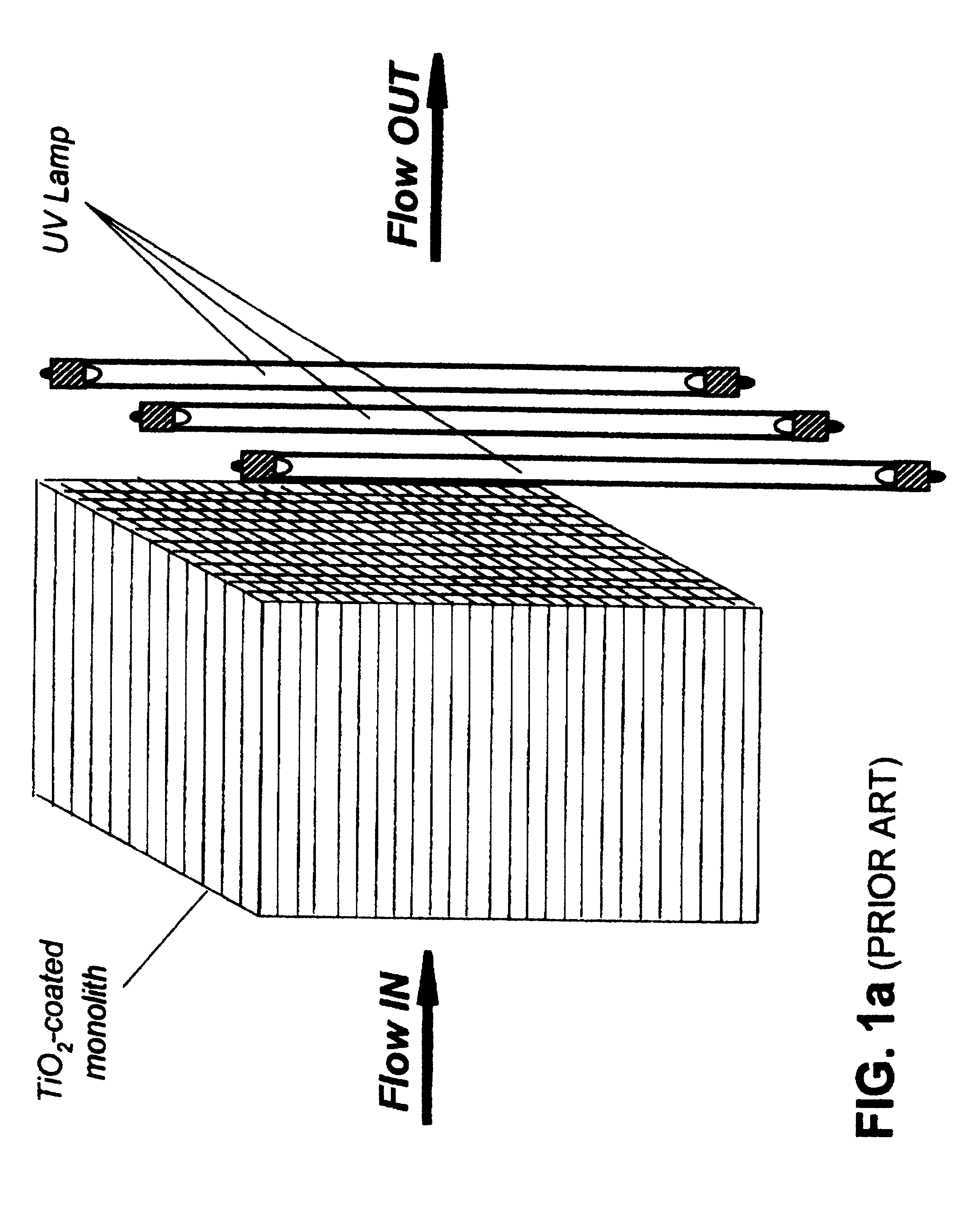

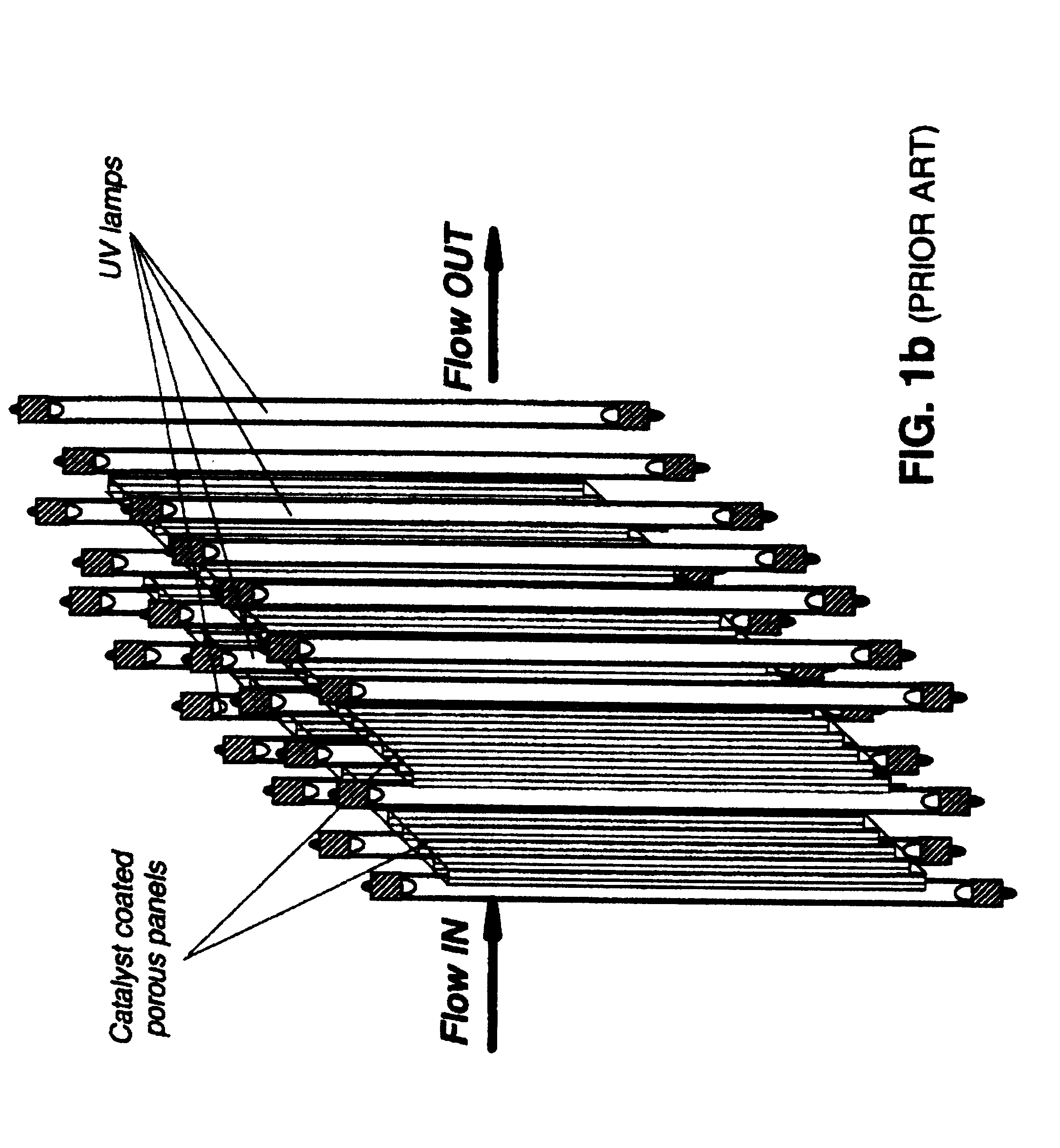

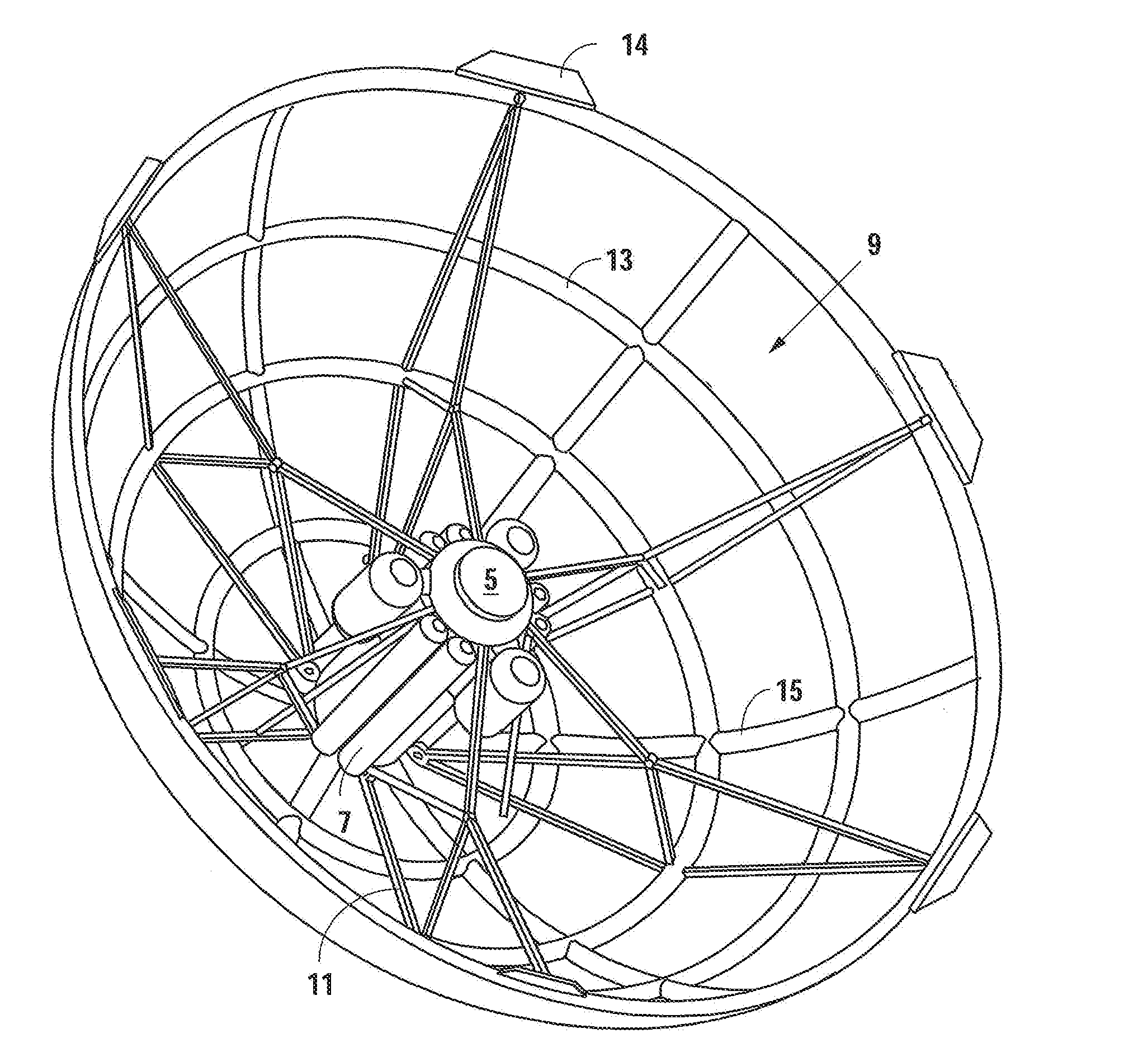

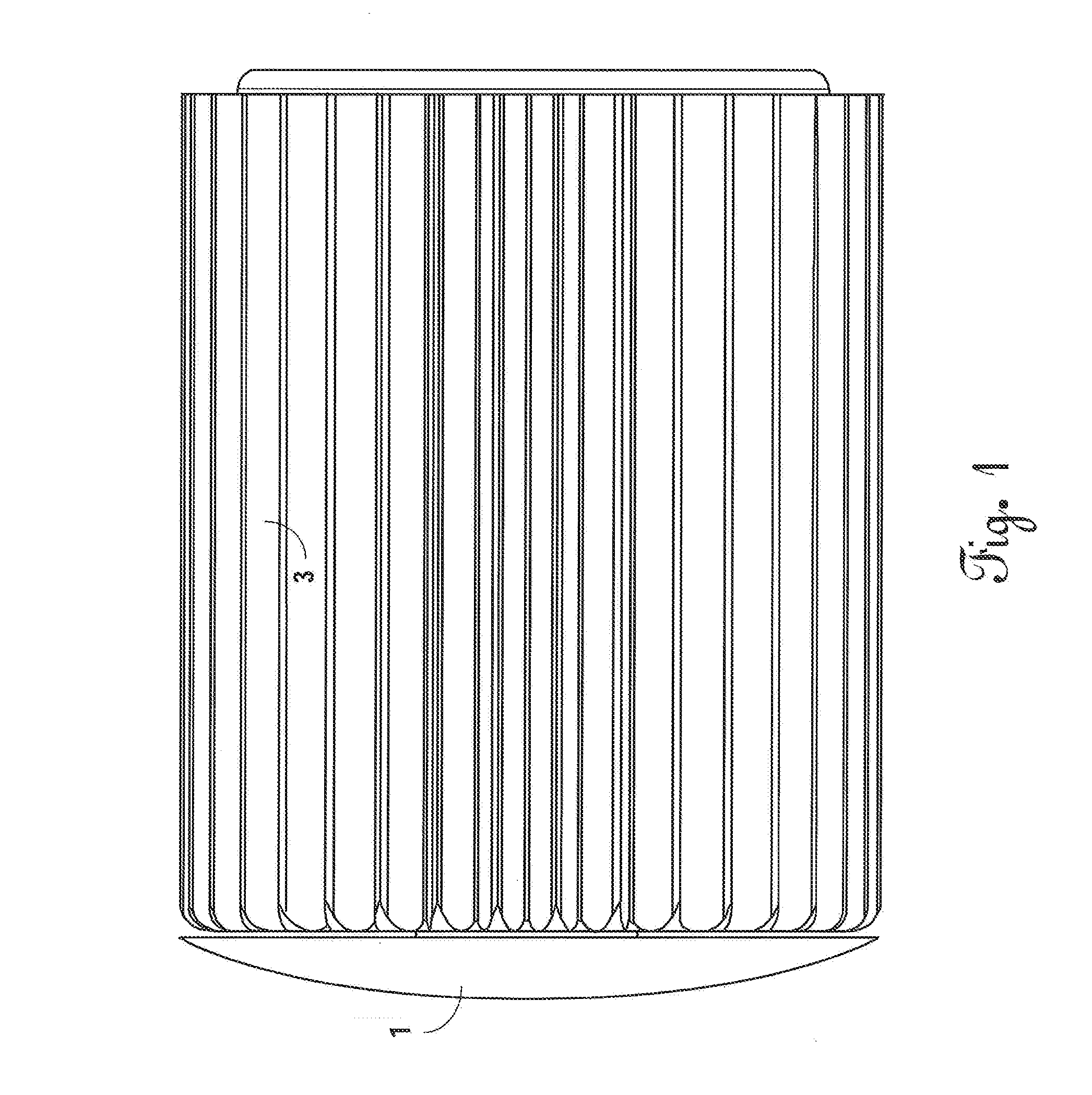

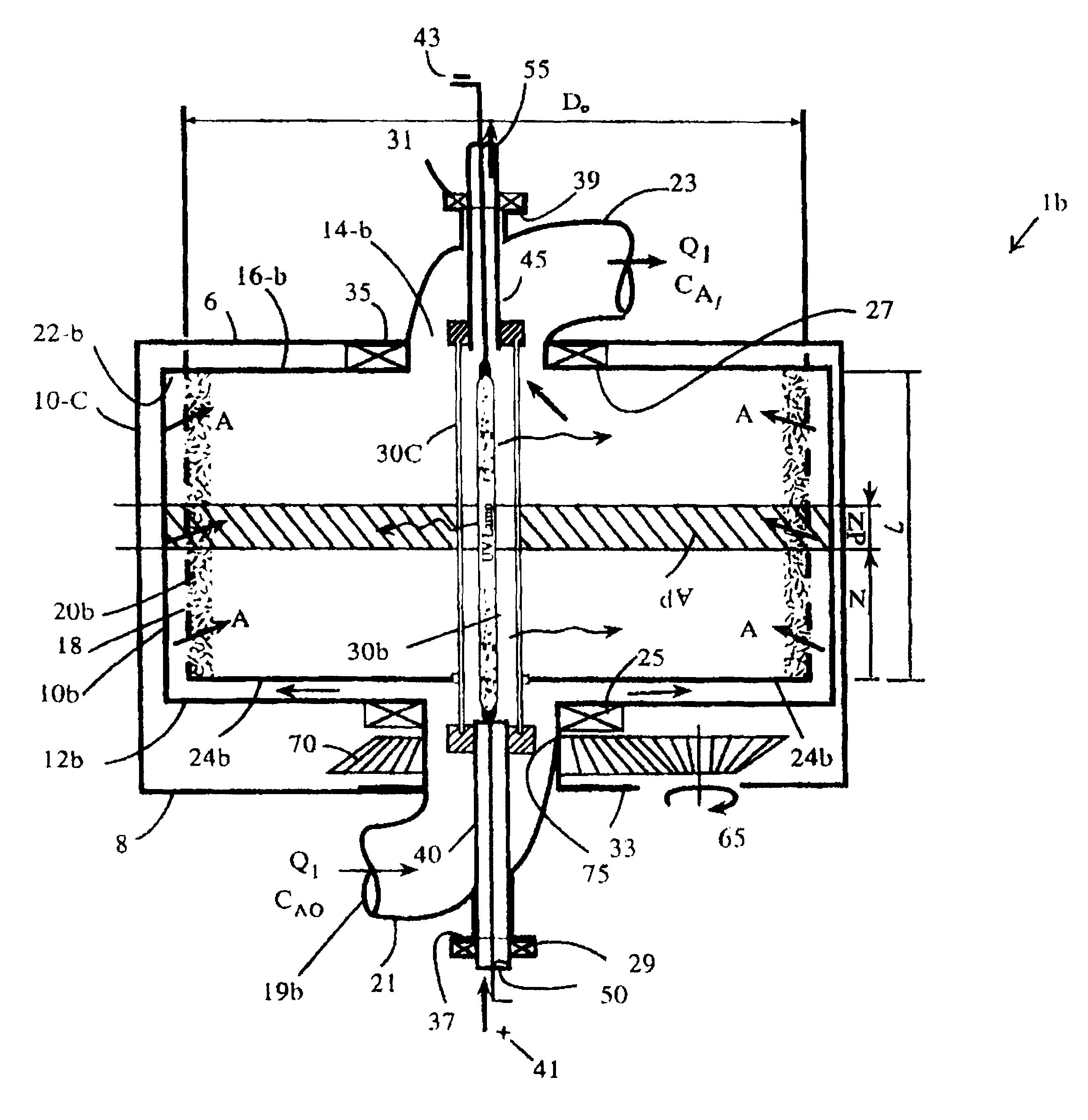

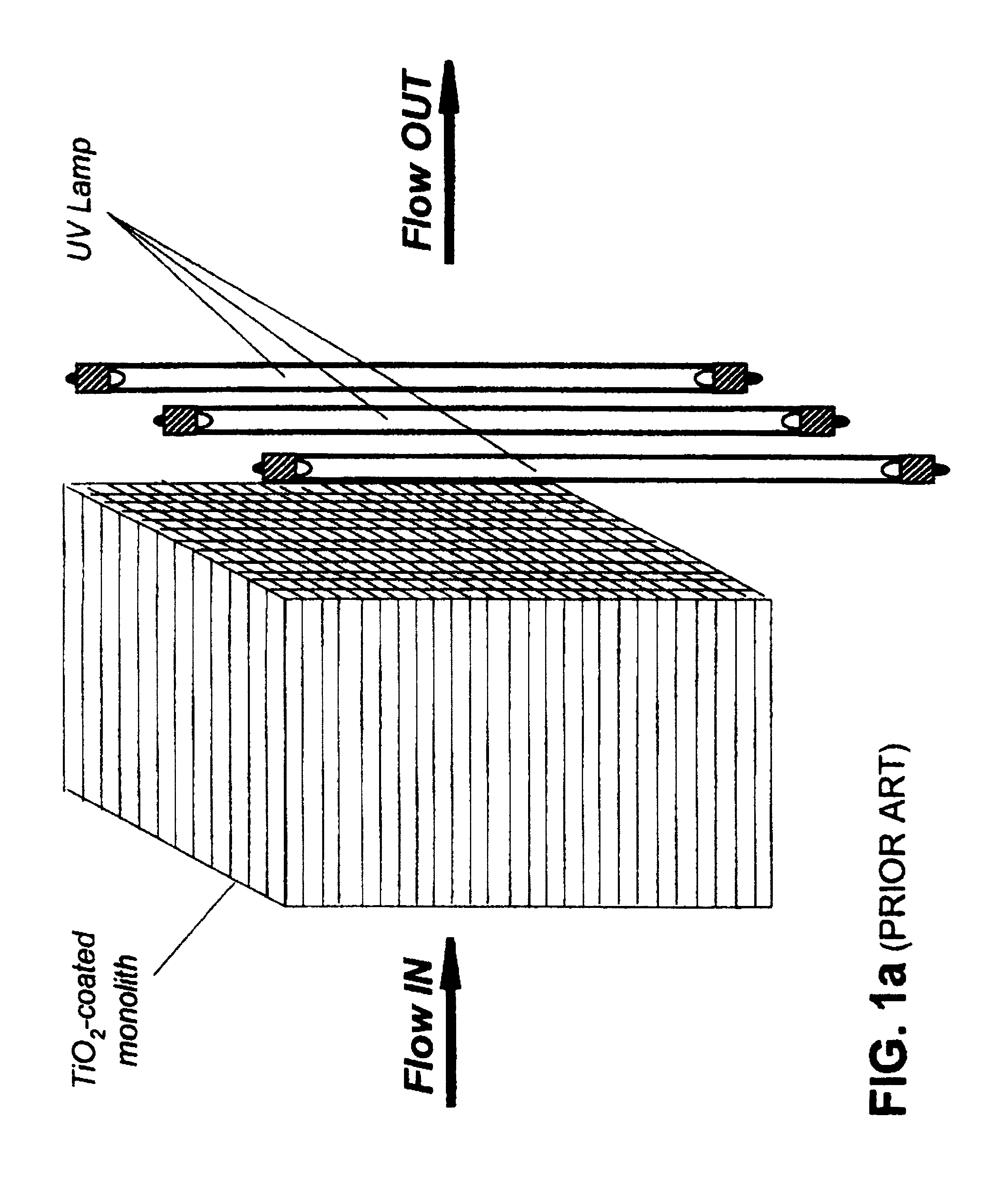

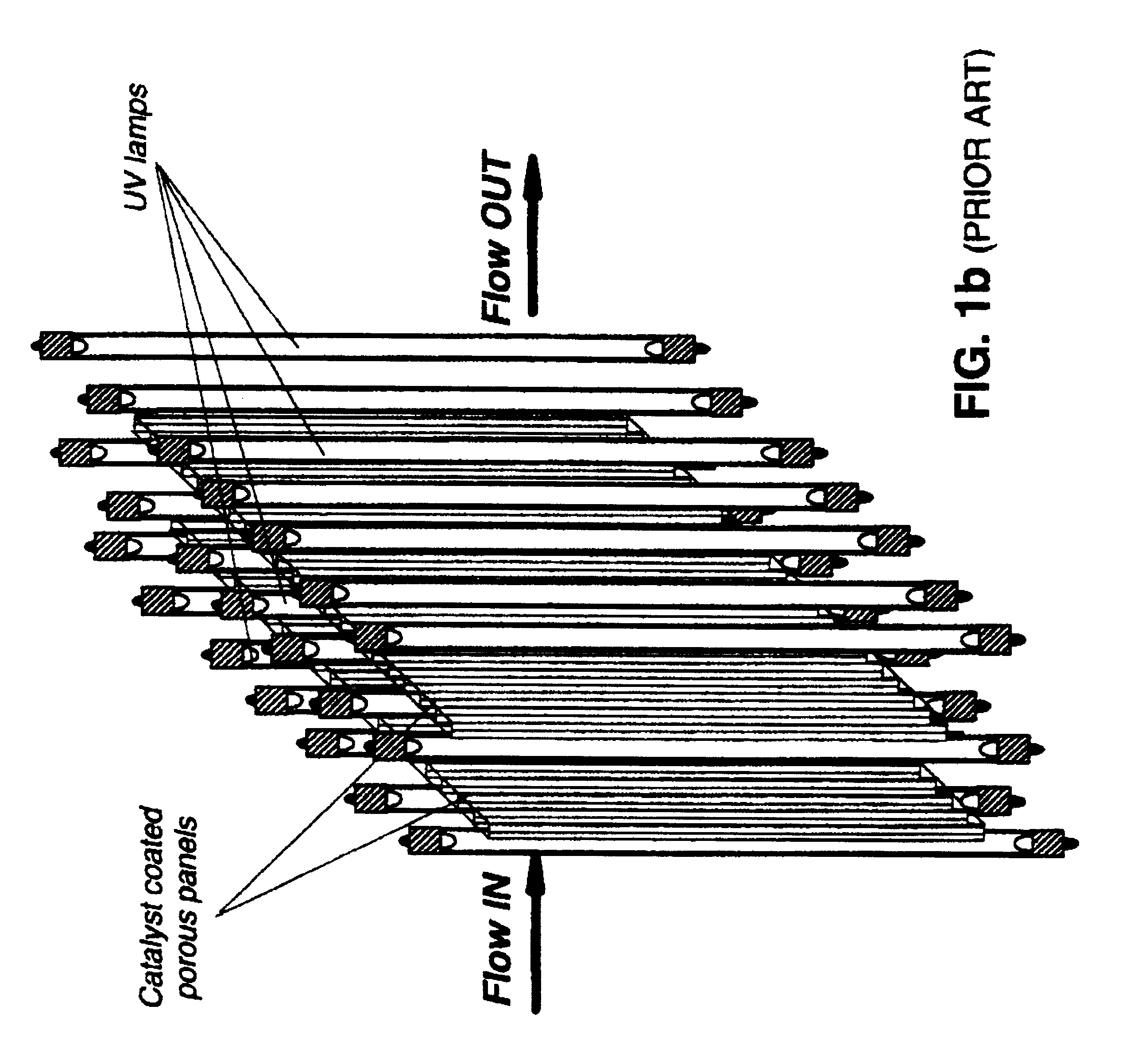

Apparatus for low flux photocatalytic pollution control

InactiveUS6309611B1Minimizes mass transfer intrusionOptimizationWater/sewage treatment by centrifugal separationPhysical/chemical process catalystsEnergeticsNuclear engineering

A new apparatus for design and scale-up of photocatalytic and thermocatalytic processes is disclosed. The apparatus is based on optimizing photoprocess energetics by decoupling of the process energy efficiency from the DRE for target contaminants and is applicable to both low- and high-flux photoreactor design and scale-up. The low-flux apparatus is based on the implementation of natural biopolymeric and other low-pressure drop media support for titanium dioxide and other band-gap photocatalysts and is further based on the implementation of multifunctional metal oxide aerogels and other media in conjunction with a novel rotating fluidized particle bed reactor.

Owner:CENT FLORIDA UNIV OF

System for Emergency Crew Return and Down-Mass from Orbit

ActiveUS20160264266A1High level of operation safetyEconomy of scaleCosmonautic thermal protectionArtificial satellites3d shapesHuman use

A system for emergency crew return and down-mass orbit comprising a stowable, self-contained, deployable maneuvering reentry vehicle for automated, on-demand reentry to ground for cargo of 1-10 kilograms or up to single or multiple human use for evacuation of orbital facilities. The system includes a deployable “aeroshell” that is contiguous (a single geometric object—surface or hollow shape—that can morph in 3D shape), modular (a collection of modular components externally acting as a contiguous shape, but morphed in 3D via actuators contained in each modular member to create a general asymmetric geometry), or discontiguous (a collection of independently controlled surfaces or bodies that morph to form desirable asymmetric drag configurations). The system contains traditional spacecraft guidance, navigation and control, propulsion, and attitude control elements, in addition to communications, power, and actuator energetics systems for controlling the vehicle aeroshell shape during reentry, thus, minimizing the landing footprint of the vehicle.

Owner:STONE WILLIAM C

Non-energetics based detonator

A detonator system is provided for use with explosives that utilizes two subsystems. A first subsystem functions as a non-explosives based detonator, which does not contain any explosives. The second subsystem is an initiating subsystem, which includes an initiating pellet. To set off an explosive event, the non-energetics based detonator is coupled to the initiating subsystem and the non-energetics based detonator is commanded to provide a suitable signal to the initiating subsystem that is sufficient to function the initiating pellet. Further, the initiating subsystem can be integrated directly into an associated explosive such as a booster that has been configured to receive the initiator subsystem without changing the hazard class of the booster.

Owner:BATTELLE MEMORIAL INST

Method for high flux photocatalytic pollution control

InactiveUS6315870B1Efficient retentionMinimizes mass transfer intrusionNitrogen compoundsEnergy based wastewater treatmentEnergeticsPollution

A new method for design and scale-up of photocatalytic and thermocatalytic processes is disclosed. The method is based on optimizing photoprocess energetics by decoupling of the process energy efficiency from the DRE for target contaminants. The technique is applicable to both low- and high-flux photoreactor design and scale-up. The low-flux method is based on the implementation of natural biopolymeric and other low-pressure drop media support for titanium dioxide and other band-gap photocatalysts. The high-flux method is based on the implementation of multifunctional metal oxide aerogels and other media in conjunction with a novel rotating fluidized particle bed reactor.

Owner:CENT FLORIDA UNIV OF

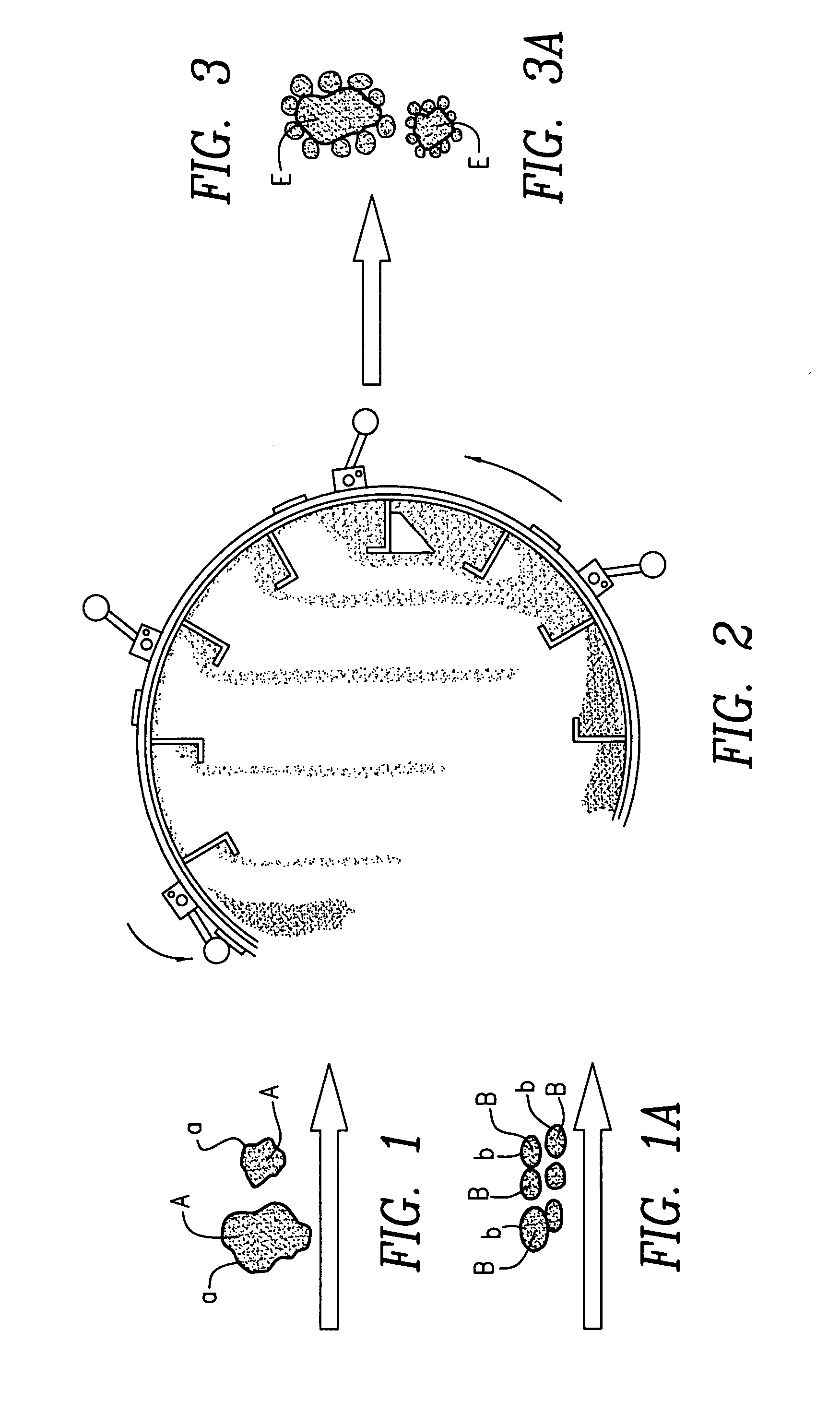

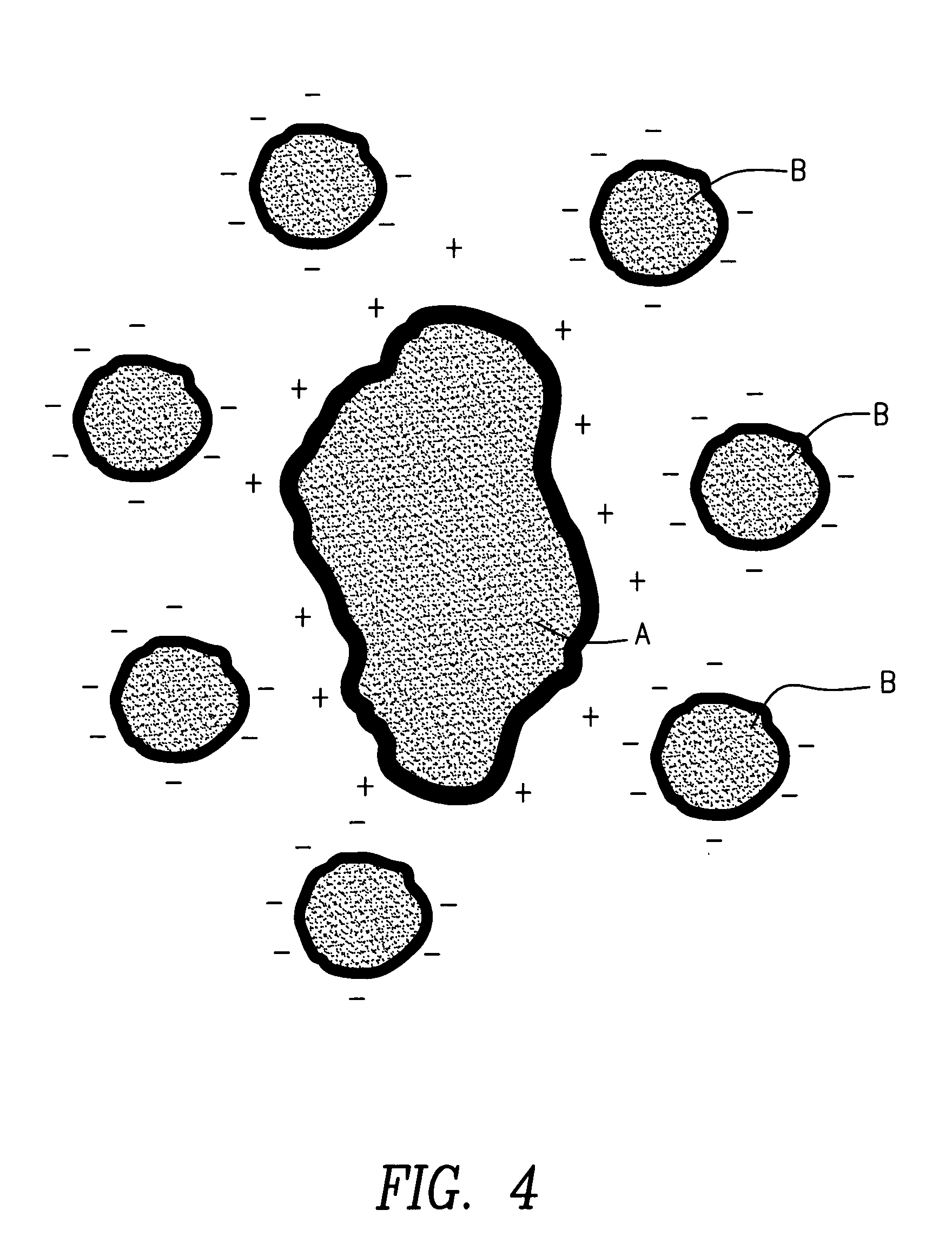

Ordered particle structures and methods of making same

InactiveUS20050228075A1Increase loadCost effectiveSolid fuelsExplosive working-up apparatusOral suspensionsEnergetics

Techniques and methods of formation of ordered mixtures of particles by “clustering”. Clustering comprises local “structuring” consisting of a large “host” and smaller “guest” particles by various techniques. Small amounts of polymer are coated onto solid particles by various means. In one embodiment, an ordered mixture is created wherein the material that is of lesser quantity is of small particle size (the “B” particles) and the “A” particles are of larger size. The “B” particles are then coated onto a single A particle. By creating this ordered structure, each composite particle has the proper or stoichiometric amount of all ingredients. This dry composite material produced is appropriately used in various applications such as pharmaceutical formulations in the form of tablets, capsules, oral suspensions, inhalant, parenteral formulations and the like; energetics manufacture such as but not limited to explosives, propellants and pyrotechnics; agricultural products including but not limited to fertilizers, herbicides and pesticides; nutritional supplements and the like.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

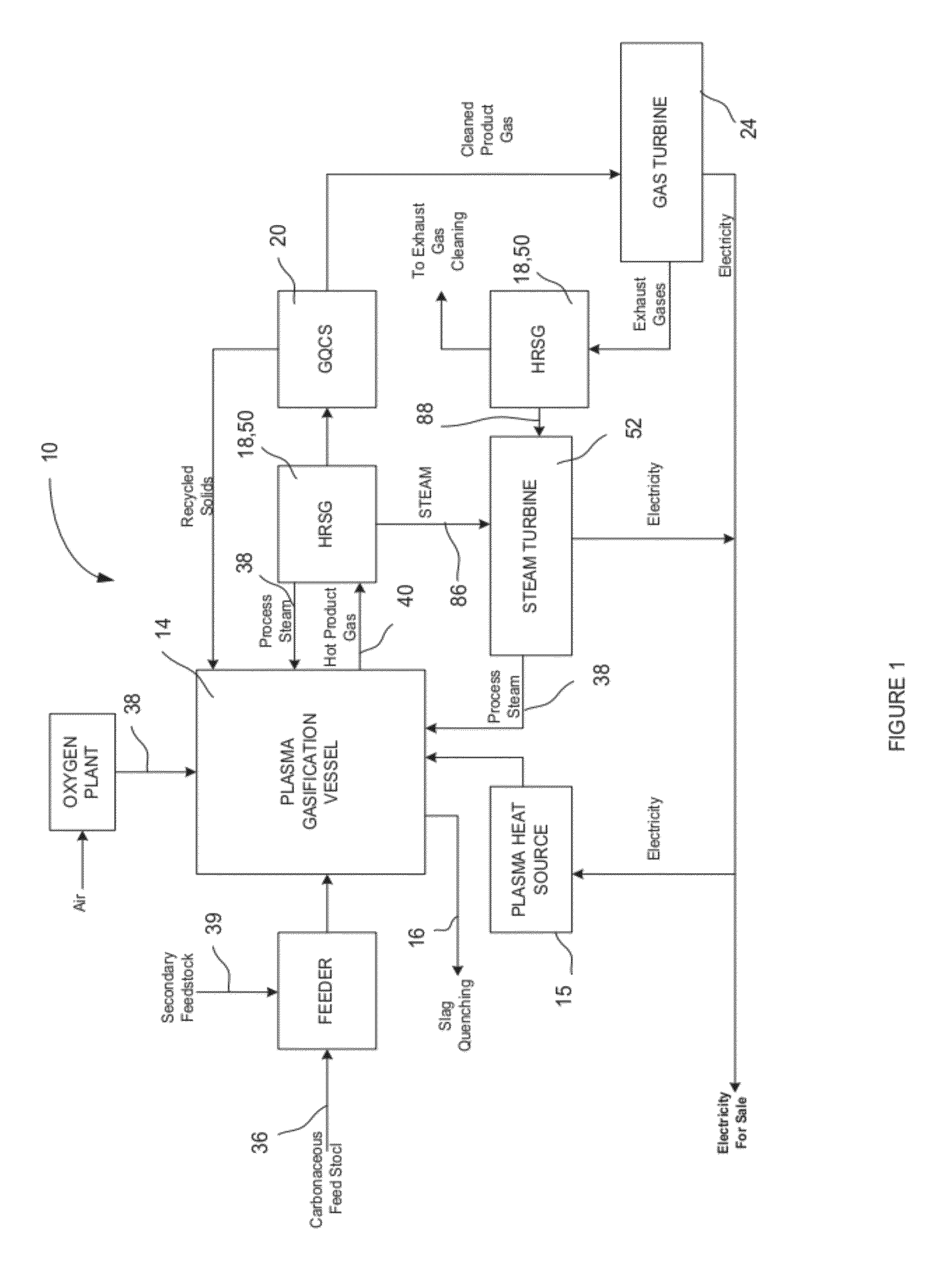

System For The Conversion Of Carbonaceous Feedstocks To A Gas Of A Specified Composition

The present invention provides a carbonaceous feedstock gasification system with integrated control subsystem. The system generally comprises, in various combinations, a gasification reactor vessel (or converter) having one or more processing zones and one or more plasma heat sources, a solid residue handling subsystem, a gas quality conditioning subsystem, as well as an integrated control subsystem for managing the overall energetics of the conversion of the carbonaceous feedstock to energy, as well as maintaining all aspects of the gasification processes at an optimal set point. The gasification system may also optionally comprise a heat recovery subsystem and / or a product gas regulating subsystem.

Owner:PLASCO ENERGY GROUP INC

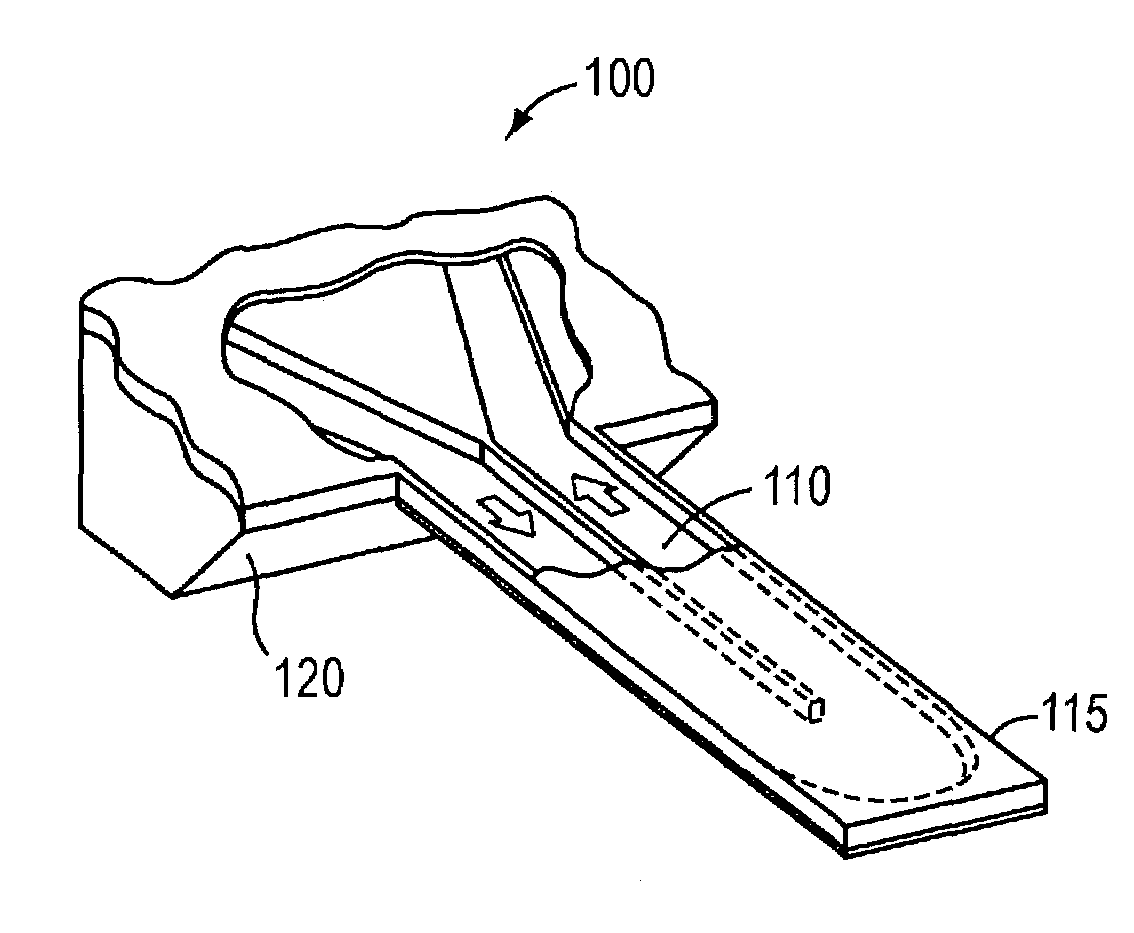

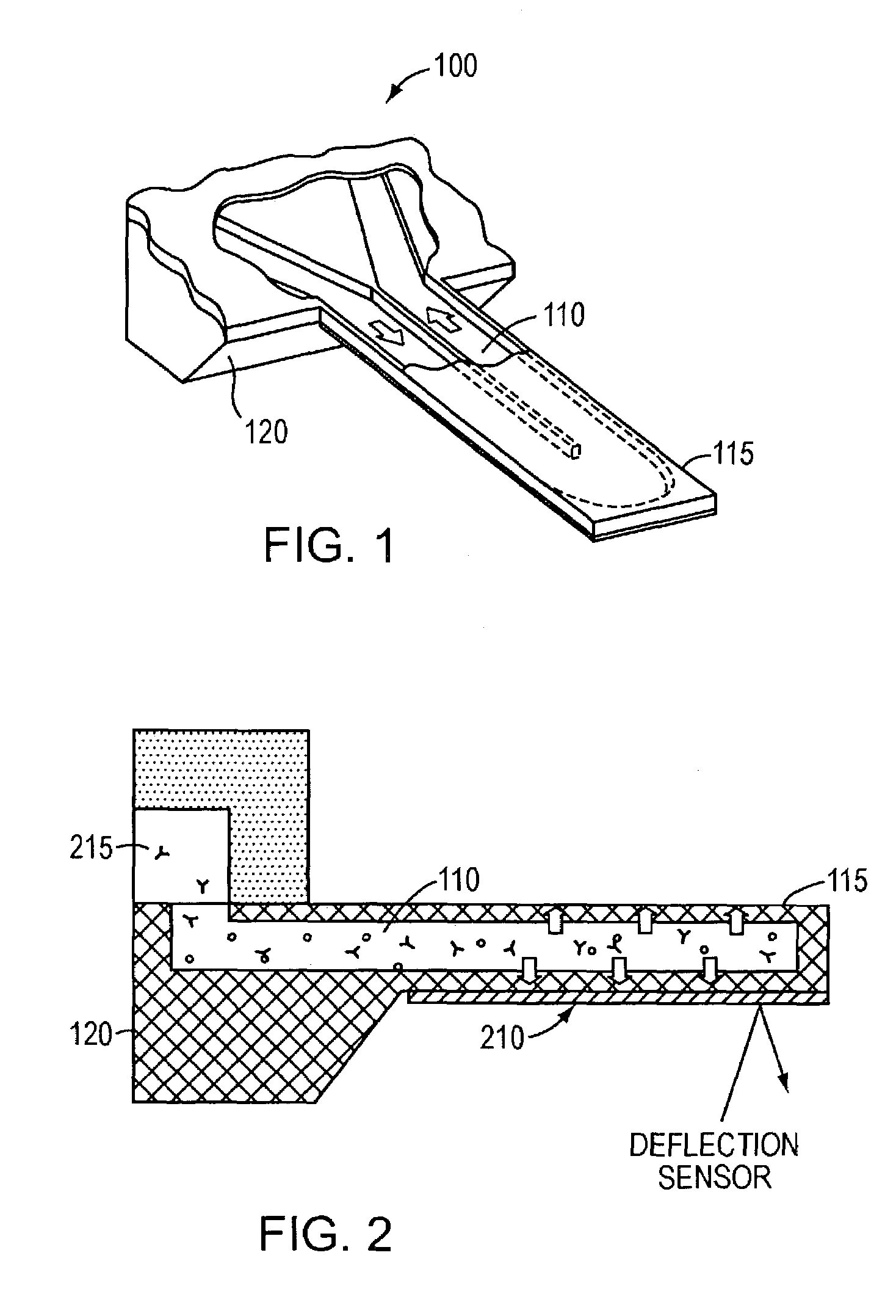

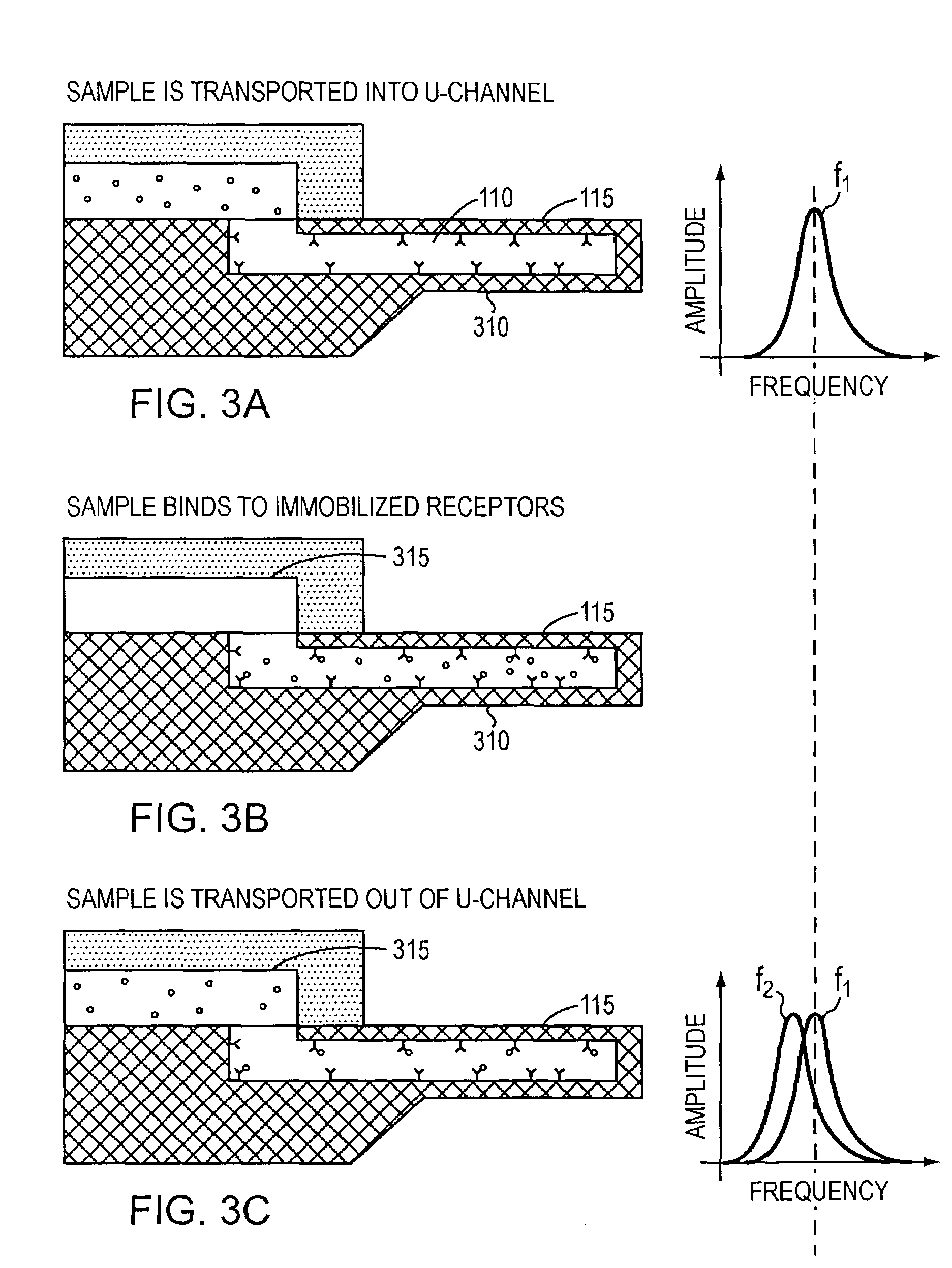

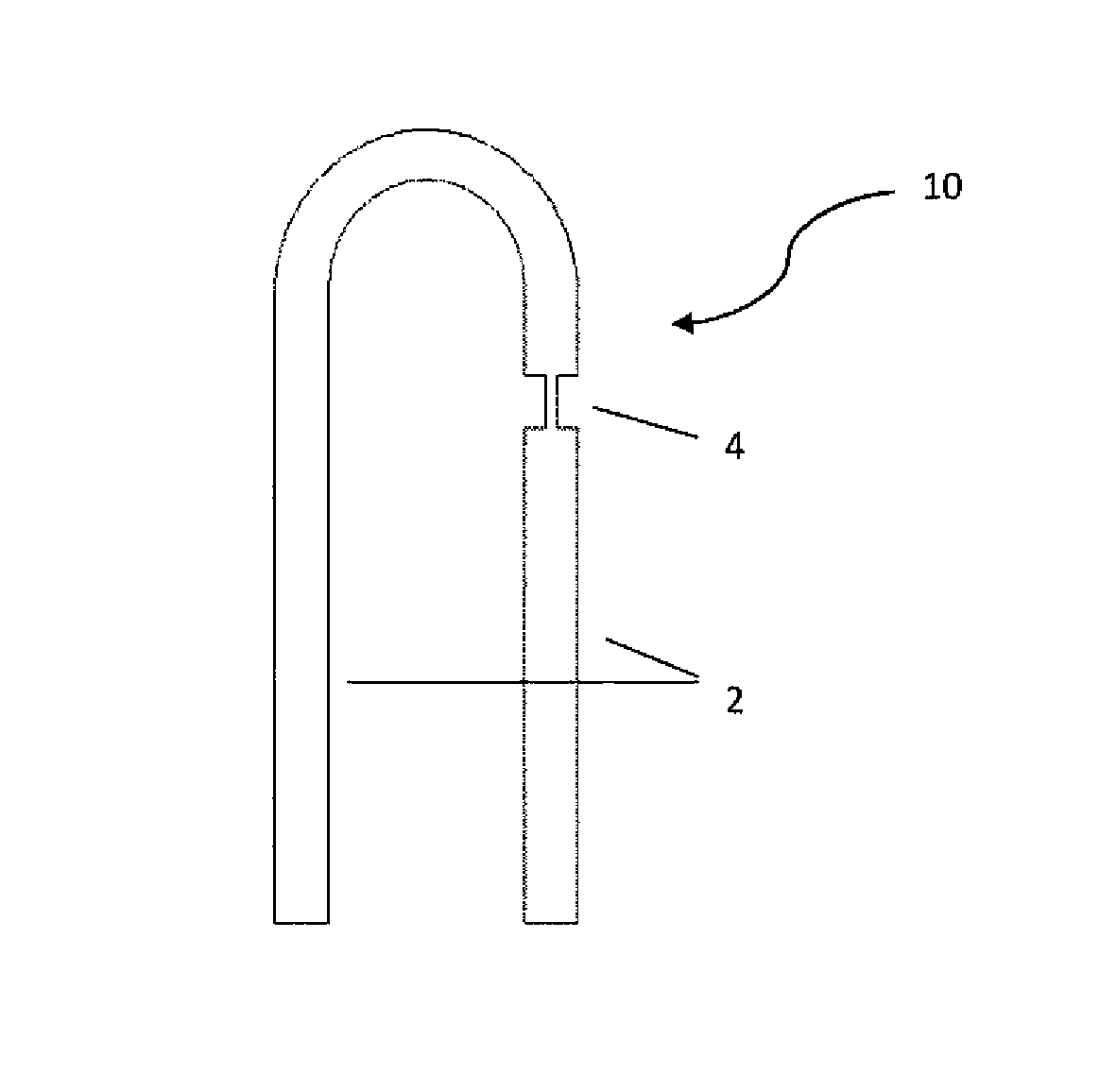

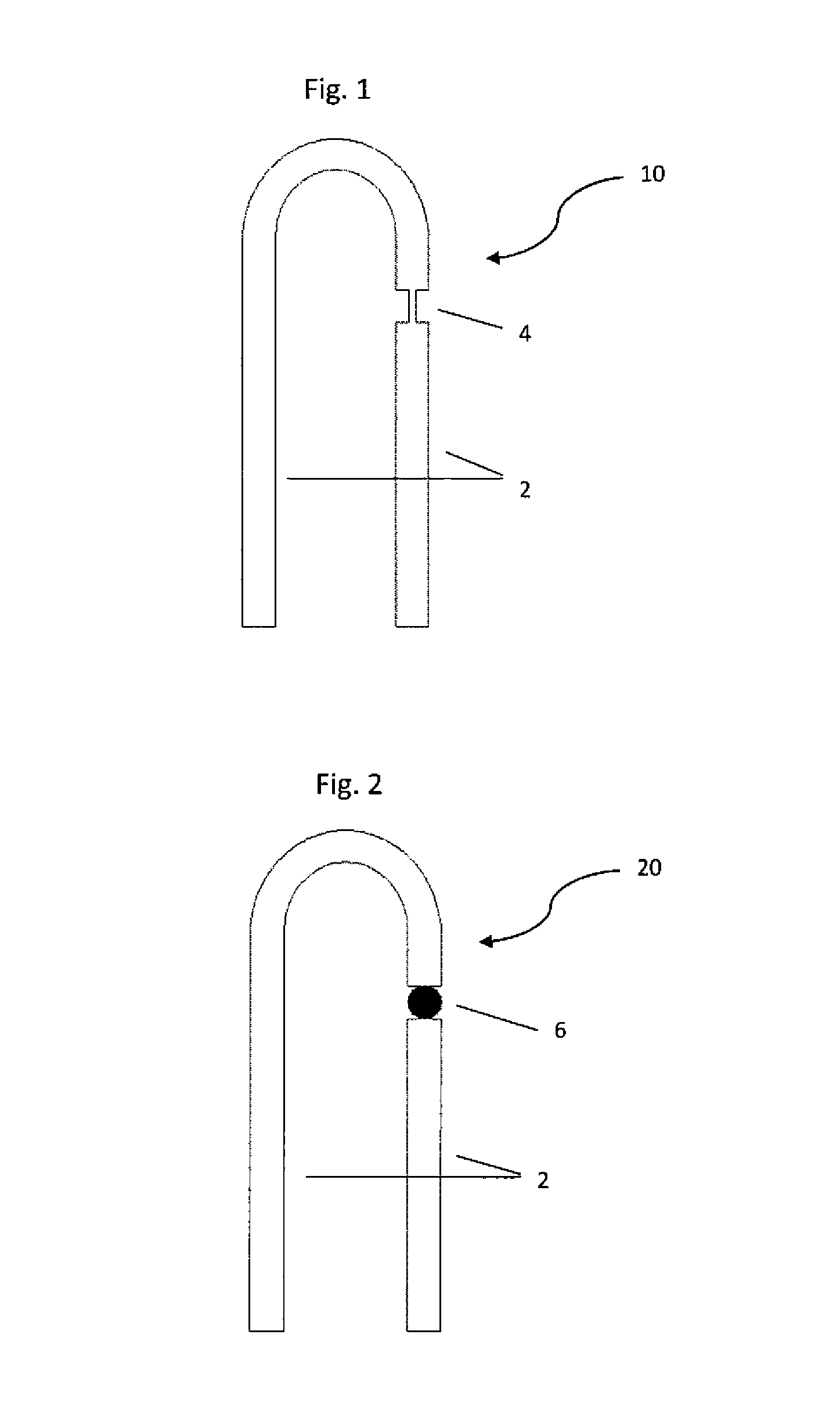

Measurement of concentrations and binding energetics

ActiveUS7387889B2Eliminate needBioreactor/fermenter combinationsBiological substance pretreatmentsEnergeticsEquilibrium constant

Free-standing microfluidic channels are used to both transport and analyze molecules of interest. In a biochemical context, such molecules may be polypeptides, nucleic acids, or other biomolecules. The free-standing channels provide a real-time readout of concentration without the need for labeling with reporter molecules. The channels can also measure enthalpy values and equilibrium constants by detecting heat released from or absorbed by the sample.

Owner:MASSACHUSETTS INST OF TECH

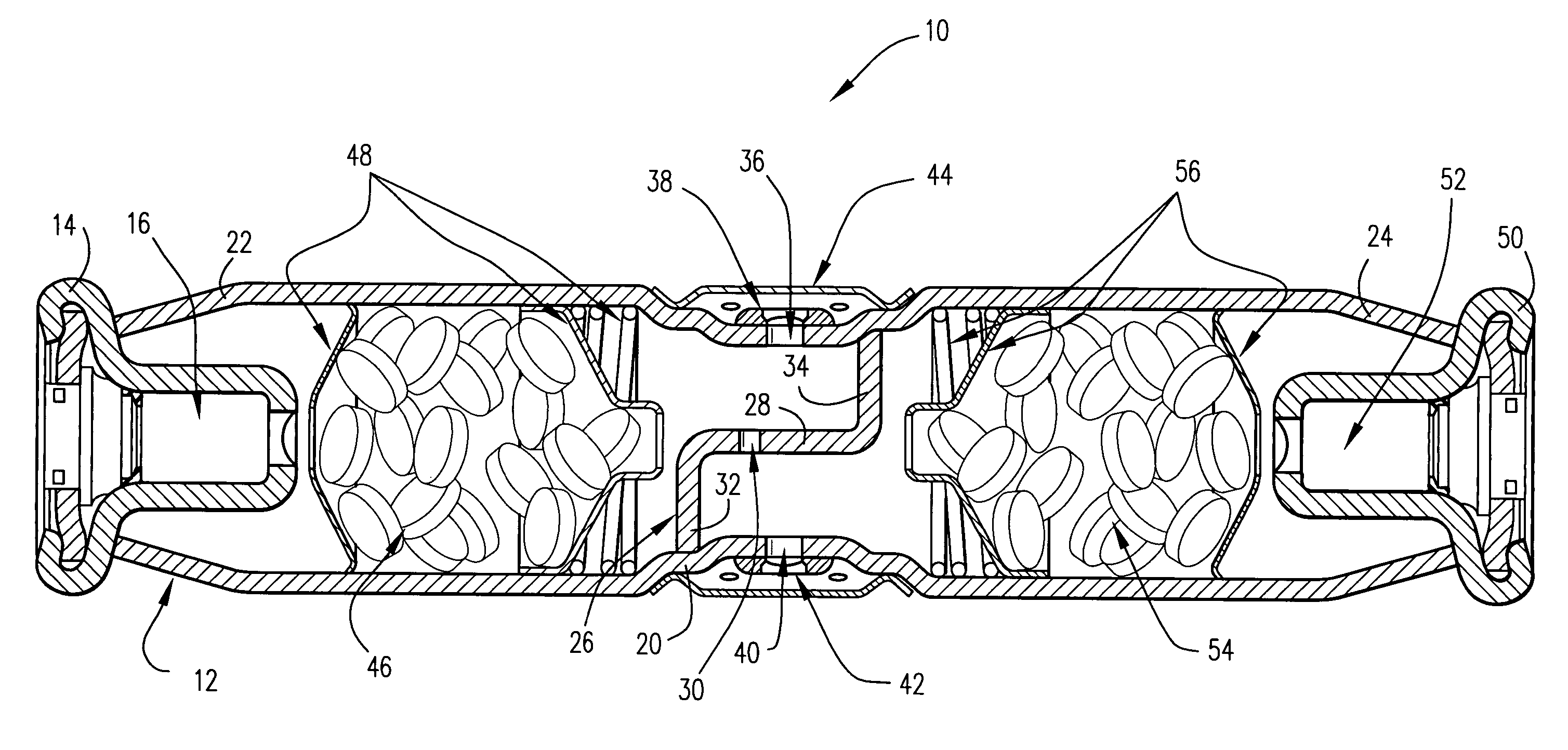

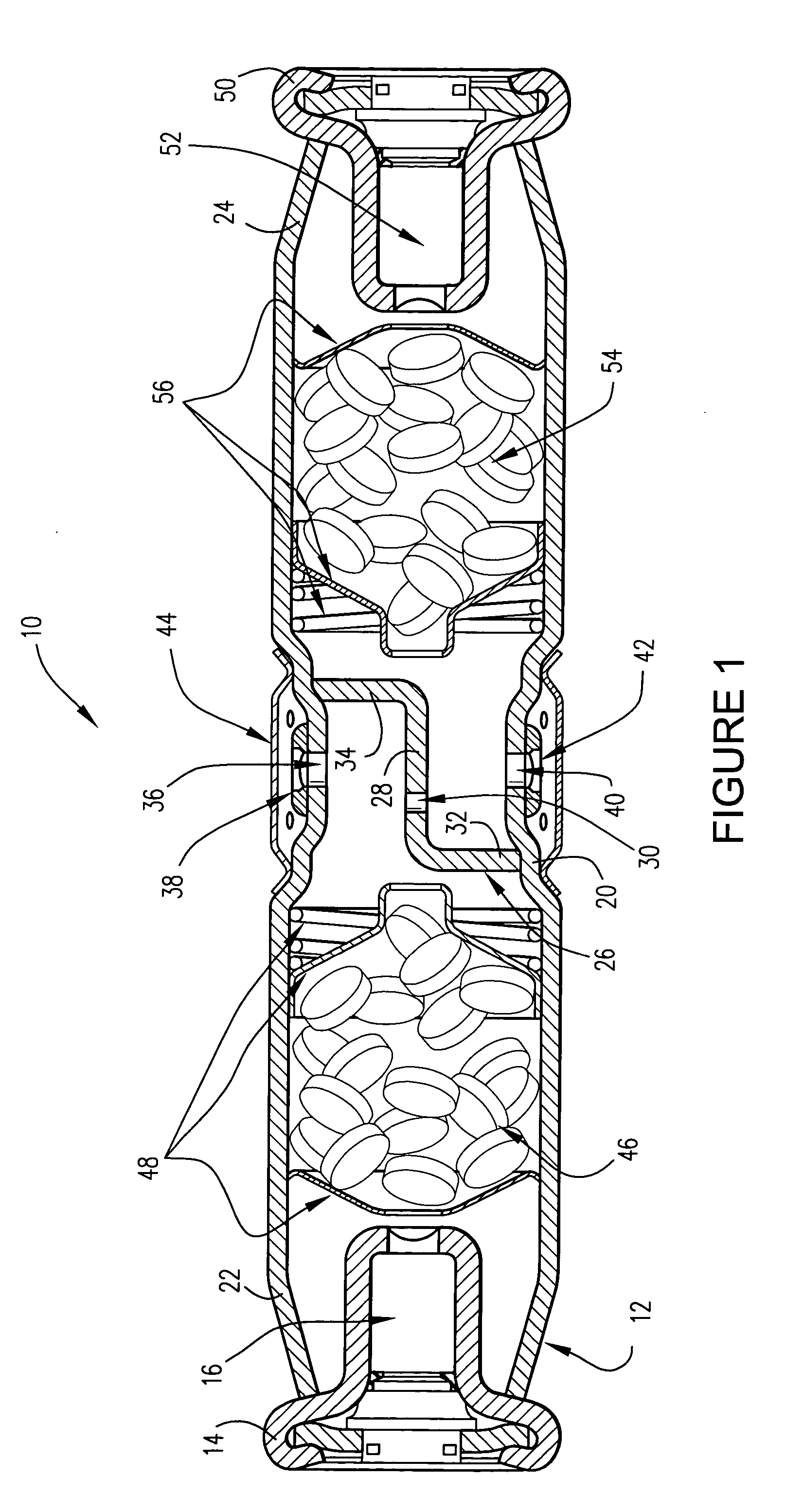

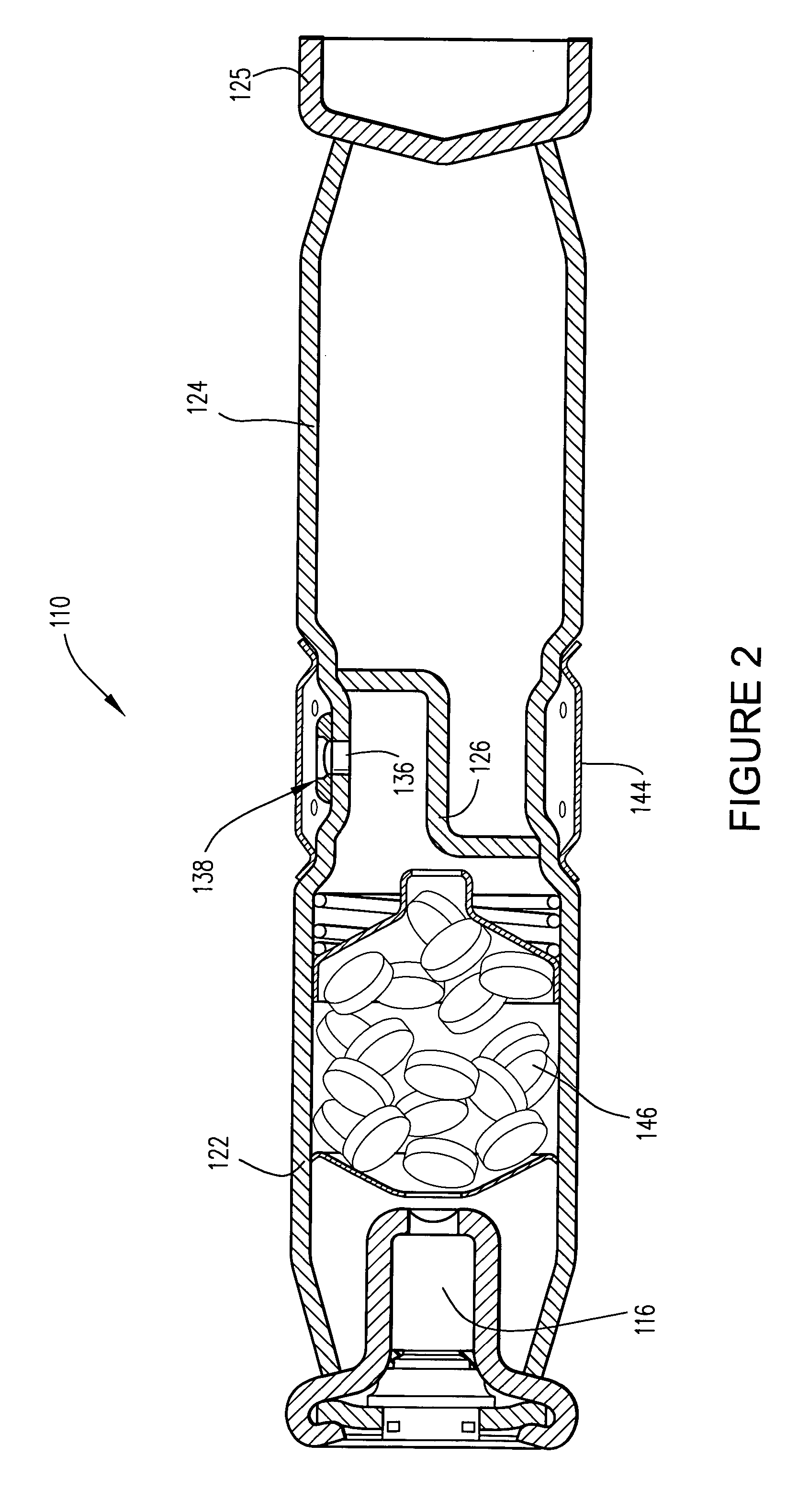

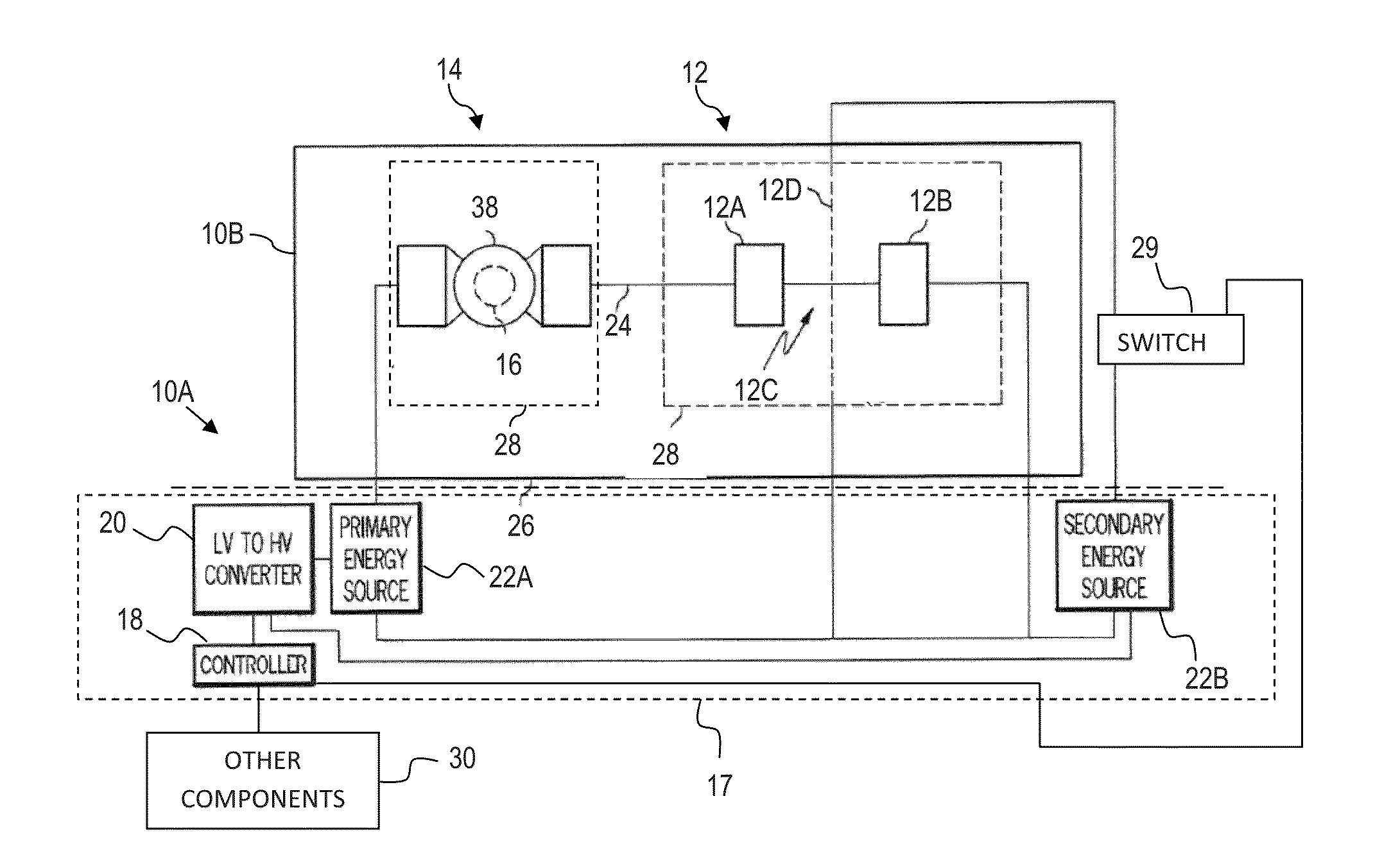

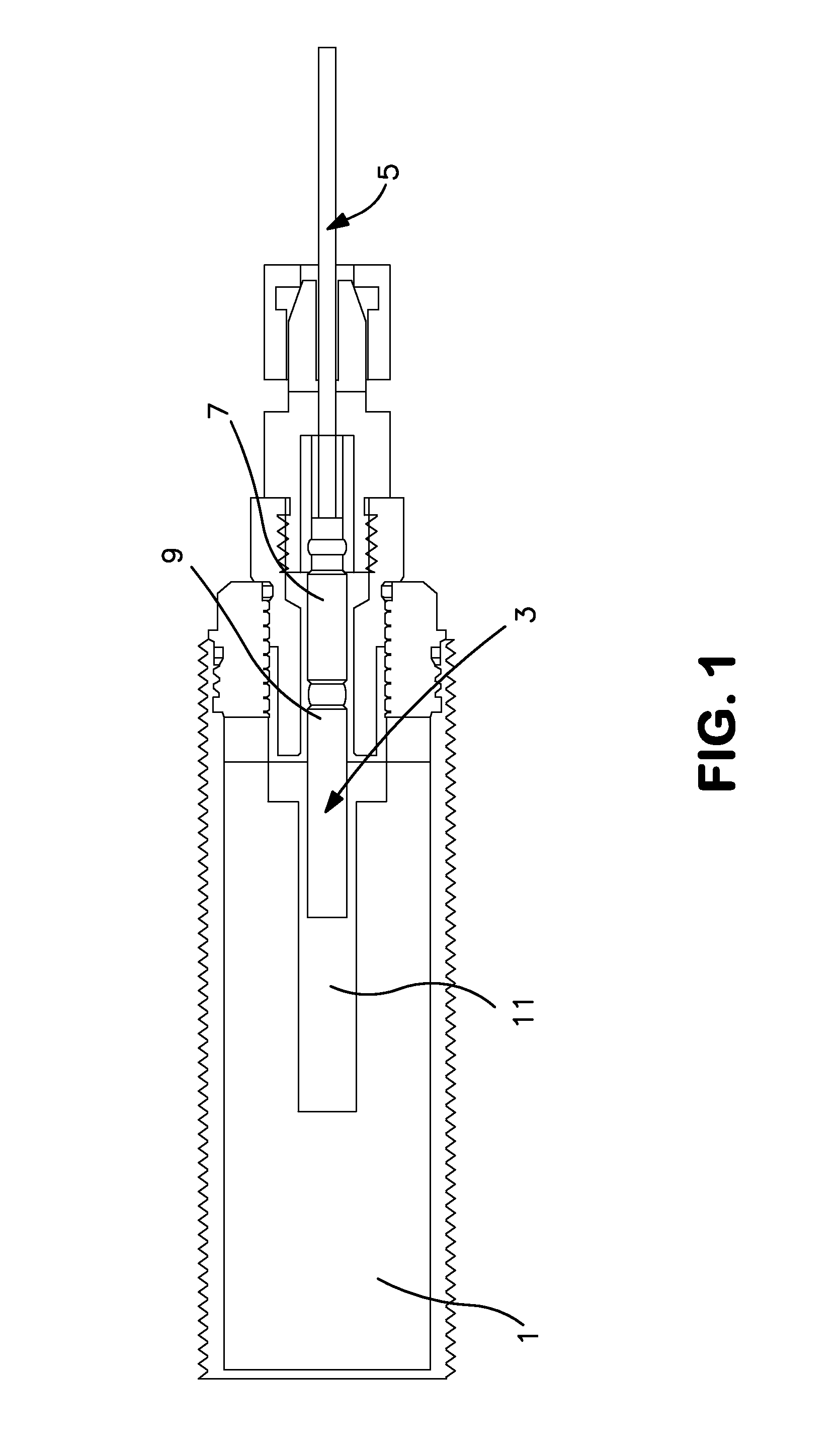

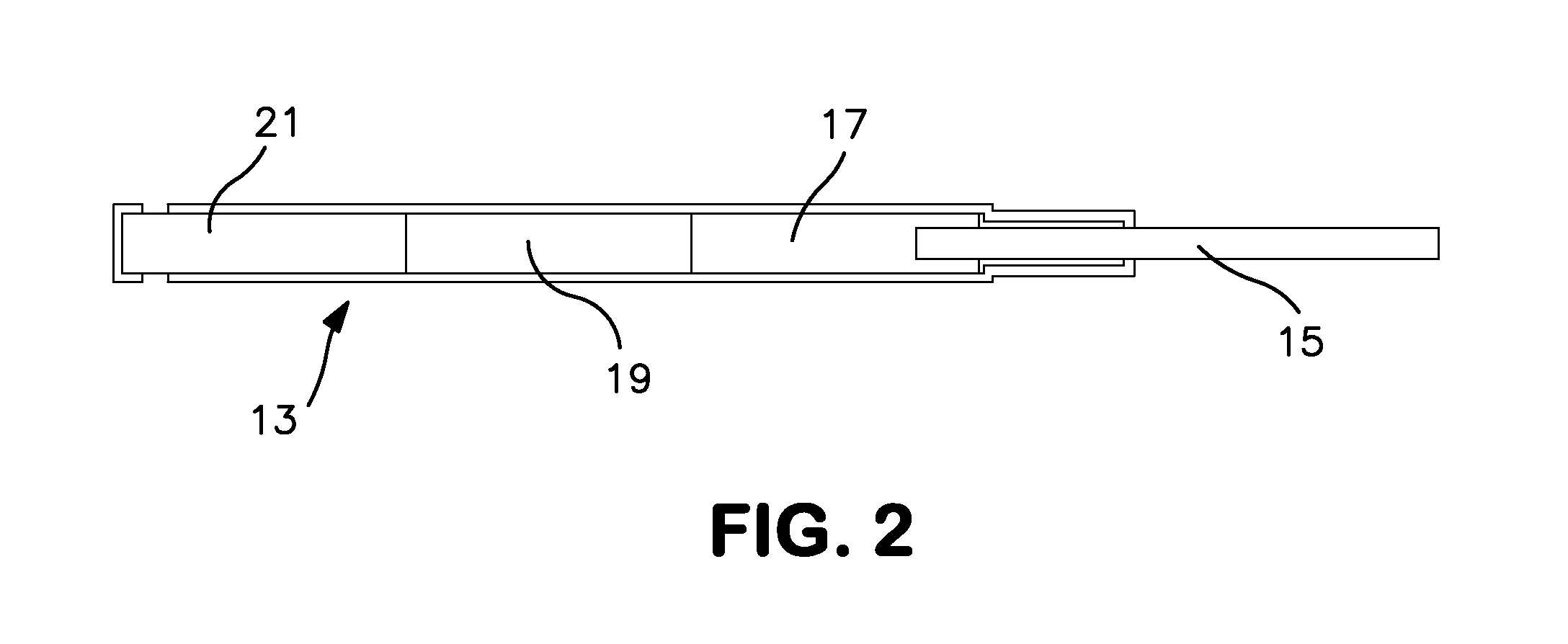

Compact multi-level output hybrid gas generator

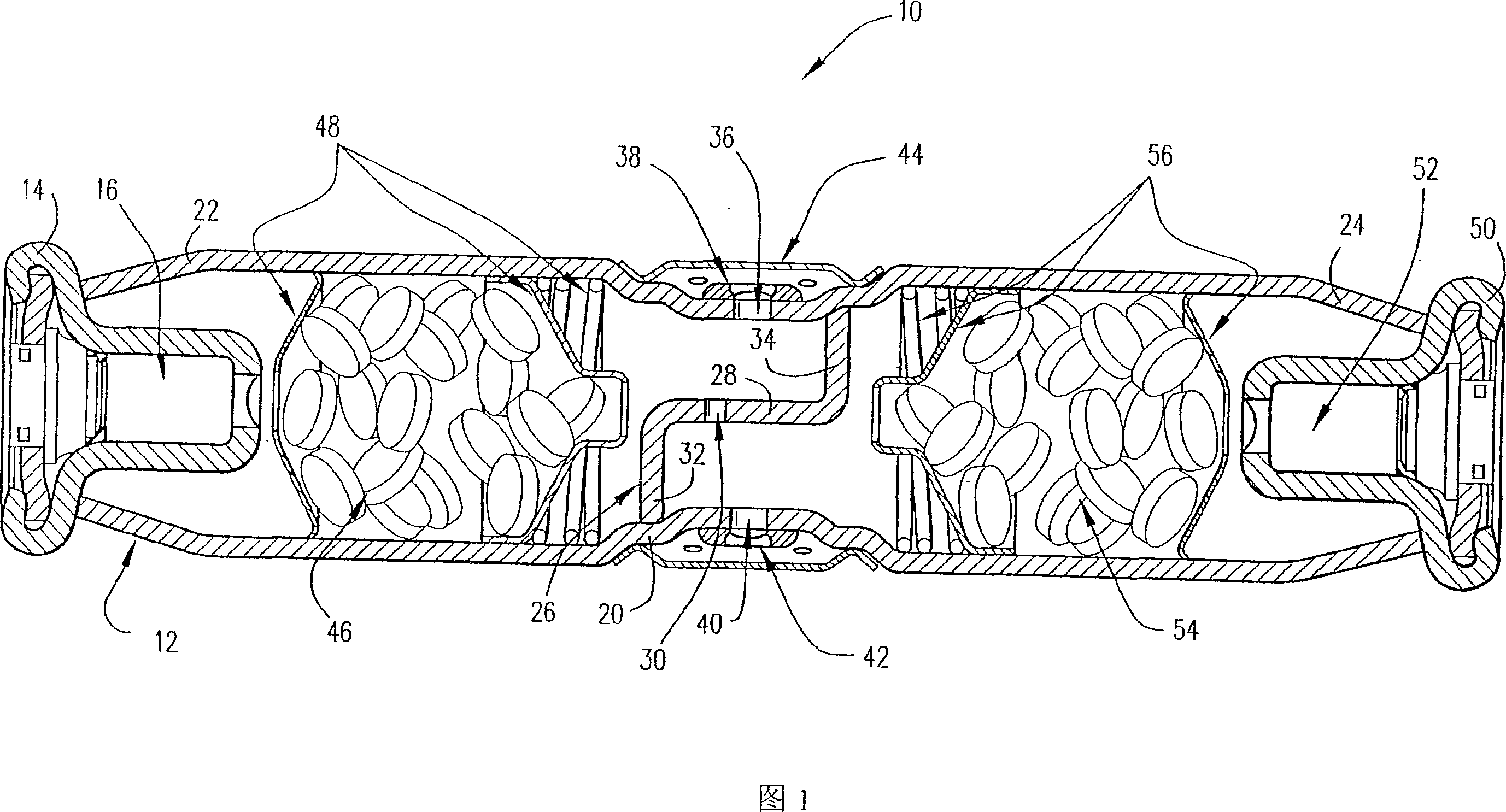

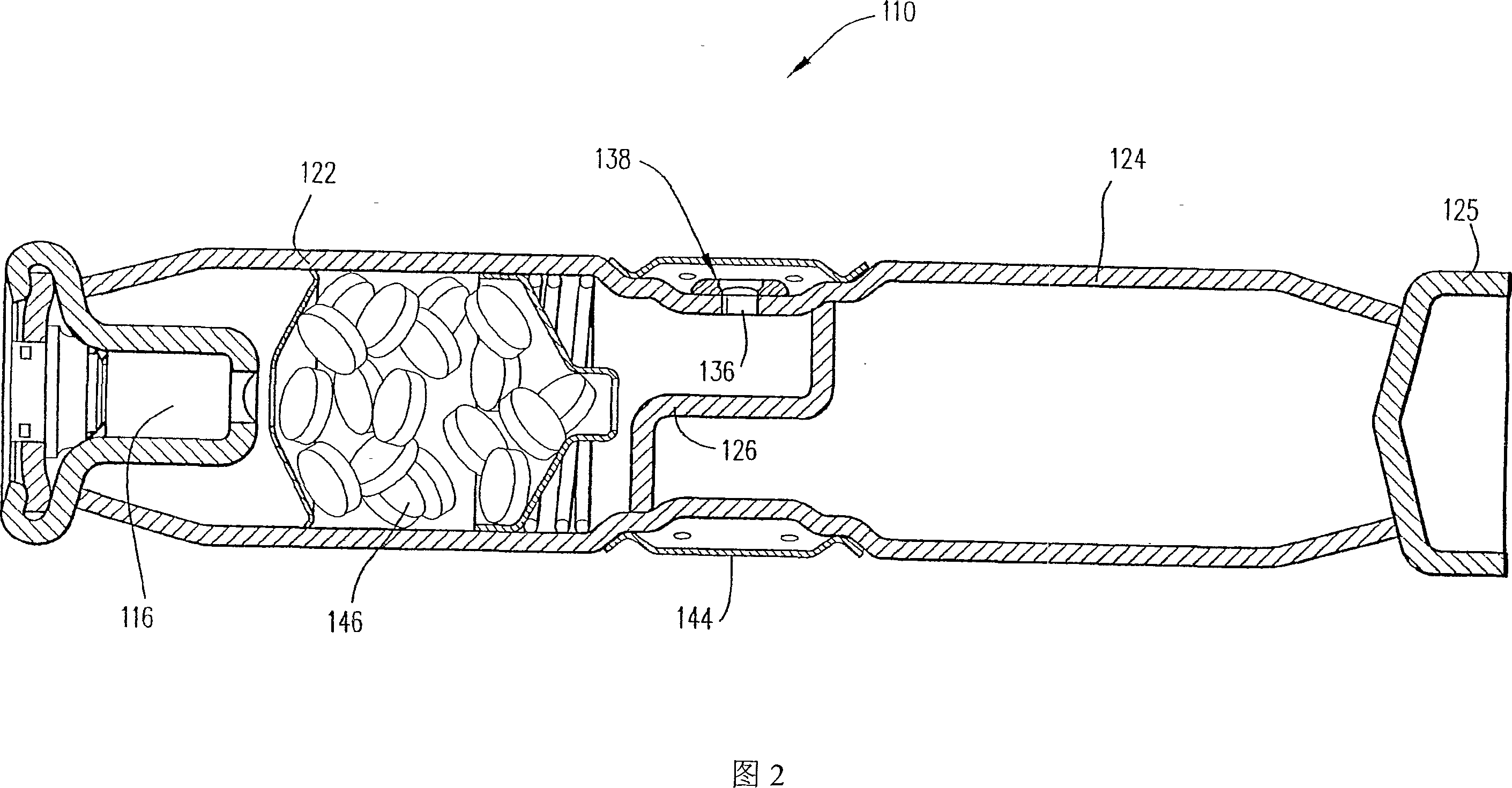

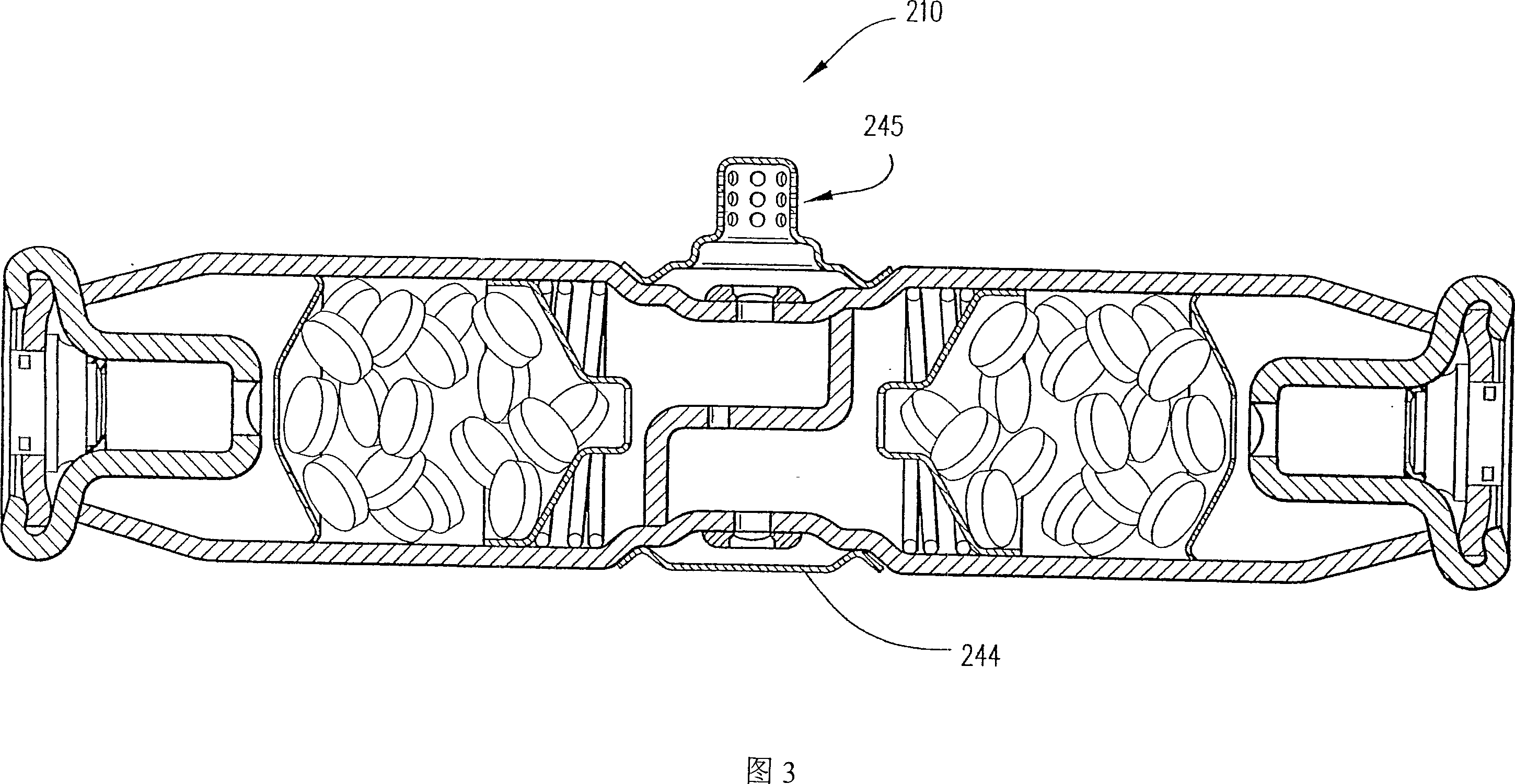

InactiveUS20050029785A1Cost-effectiveGuaranteed uptimePedestrian/occupant safety arrangementVehicle design optimisationEnergeticsSingle level

A multi-level gas inflator for an air bag or other safety device, comprising an elongated pressure vessel having a primary gas generant portion with a first open end and a secondary gas generant portion with a second open end. The primary gas generant portion has a primary ignition device and primary gas generating energetics disposed therein. The primary ignition device is mounted on and closes the pressure vessel at the first open end thereof. The secondary gas generant portion has a secondary ignition device and secondary gas generating energetics disposed therein. The secondary ignition device is mounted on and closes the pressure vessel at the second open end thereof. A suitable gas under a predetermined pressure is present in the primary and secondary gas generant portions. One or more dividers or divider walls are disposed within the midportion of the pressure vessel to separate the primary and secondary gas generant portions. The pressure vessel has a primary exit orifice in the midportion thereof that is in communication with the primary gas generant portion, and a secondary exit orifice in the midportion thereof that is in communication with the secondary gas generant portion. A primary rupture disk is disposed over the primary exit orifice, and a secondary rupture disk is disposed over the secondary exit orifice. A diffuser is mounted on and surrounds the pressure vessel midportion and the primary and secondary exit orifices. The diffuser is in communication with the air bag for the inflation thereof. The inflator can be easily converted to a single level output inflator by omitting the secondary ignition device and the secondary gas generating energetics.

Owner:ARC AUTOMOTIVE

Bead pack brazing with energetics

InactiveUS20100012323A1Reduce energy consumptionPrevent movementFluid removalWelding/cutting media/materialsEnergeticsEnergy expenditure

A method of making porous shapes from unit structures such as beads involves coating the beads with two or more layers of material deposited such that it forms an energetic material. These bi-layer energetic materials are formed from a variety of materials including, but not limited to: Ti & B, Zr & B, Hf & B, Ti & C, Zr & C, Hf & C, Ti & Si, Zr & Si, Nb & Si, Ni & Al, Zr & Al, or Pd & Al, all of which can be deposited from vapor. Pressure is applied to prevent the components from moving and the solid-state reaction between the alternating layers produces exothermic heat. Heat from the reaction alone or in conjunction of an applied brazing compound joins the beads forming a porous shape that is desired. The reaction in the materials may be activated with a small pulse of local energy that can be applied using optical, electrical, or thermal sources. Common examples include an electrical pulse, spark, hot filament, a laser beam, etc. The method reduces energy consumption and the need for specialized equipment. The reactive materials and optional brazing material are preferably applied in a fluidized CVD furnace.

Owner:BAKER HUGHES INC

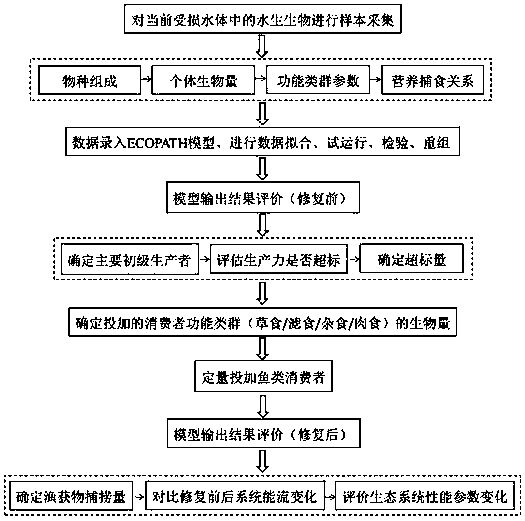

Ecosystem model and biomanipulation technology based eutrophic water body remediation method

InactiveCN108793410AEasy to operateIncrease the number of cyclesBiological water/sewage treatmentEnergeticsCommunity structure

The invention discloses an ecosystem model and biomanipulation technology based eutrophic water body remediation method. Firstly, an ECOPATH model is used to fit the energy flowing mode of the currentecosystem, when the annual production of phytoplankton or aquatic macrophyte in a water body is too high, the minimum primary production requiring for maintaining the operation of the system is takenas the baseline according to the output result of the model, the consumption of the extra primary production in the system is increased through the predation action of fish by using a method of quantitatively adding a fish consumer, and meanwhile, the top-down effect is produced to control the biomass and the community structure of a primary producer. After finishing remediation, the ECOPATH model is used to access the fish catch, the commercial fish species added in the same year are harvested according to the assessment result, so that the balance of energy of the ecosystem is maintained, the fishing catch directly takes away a large quantity of nutritive salts in the water body, and certain economic value is produced. The novel thinking for reference and the technical support are provided for the remediation method taking the scientific experiment as the method from the perspectives of ecology, quantity and energetics, and the method has a very important application value for the ecological remediation of the damaged water body.

Owner:JINAN UNIVERSITY

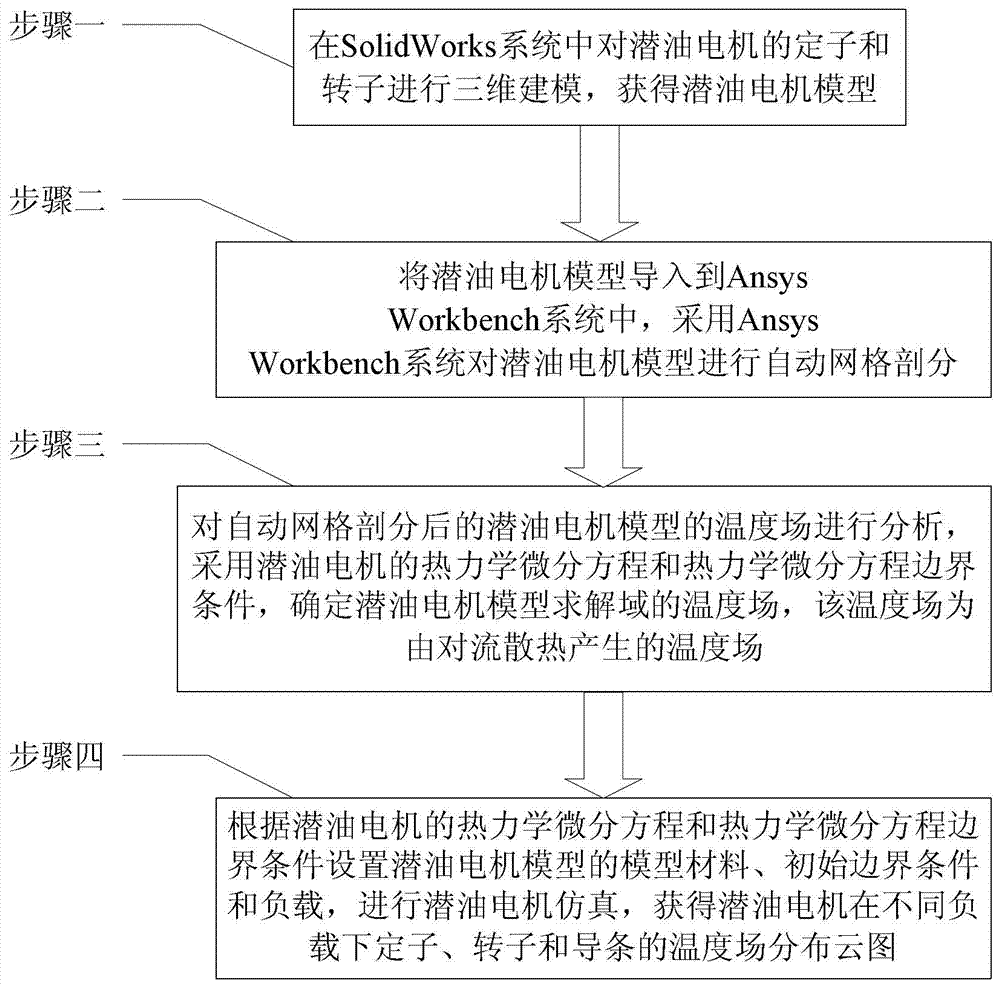

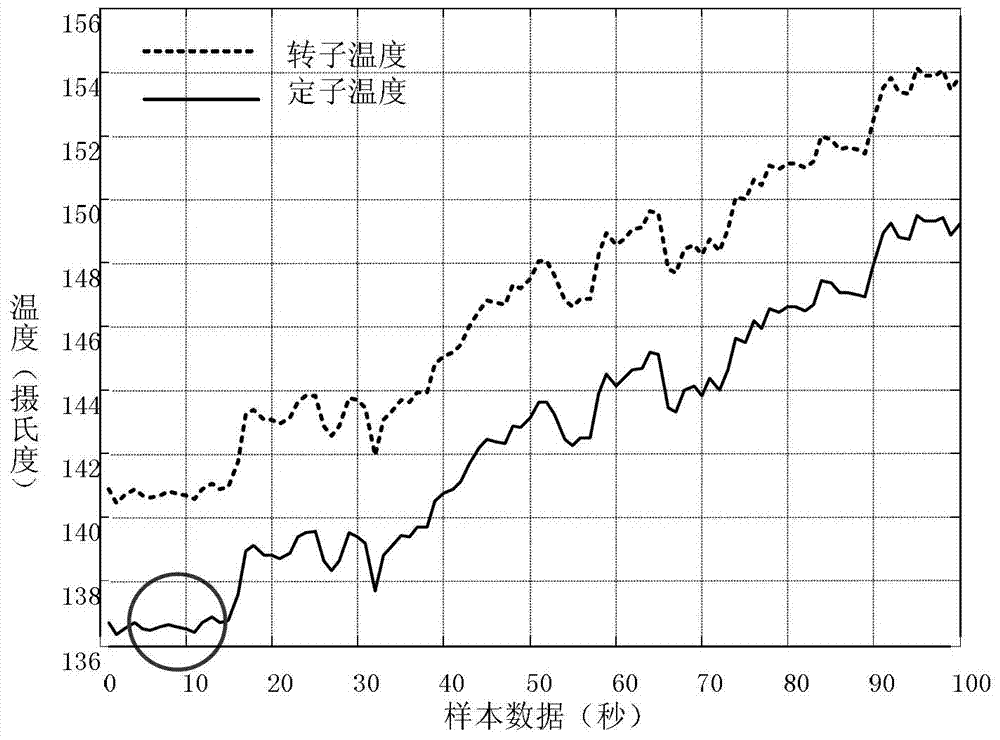

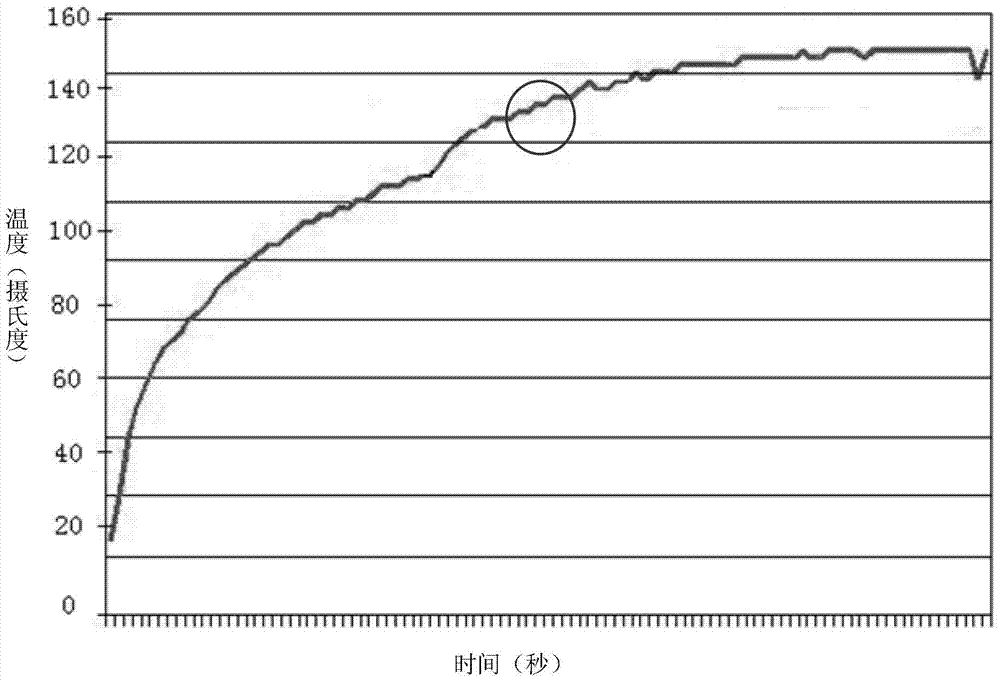

Submersible electric machine with oil temperature field simulation method based on ansys workbench

InactiveCN103246764AWorking temperature real-time monitoringSafe and stable operationAerodynamics improvementSpecial data processing applicationsEnergeticsElectric machine

The invention discloses a submersible electric machine with oil temperature field simulation method based on ansys workbench, belongs to the technical field of a submersible electric machine with oil temperature field simulation, and aims to solve problems that the submersible electric machine with oil cannot be monitored in real time in the existing submersible electric machine with oil temperature field analyzing method so as to perform overheating protection. With the submersible electric machine with oil temperature field simulation method, three dimensional models of stators and rotors of the submersible electric machine with oil can be built in a solidworks system to acquire submersible electric machine with oil models, the submersible electric machine with oil models are loaded into the ansys workbench system to automatically perform mesh generation, energetics differential equation and energetics differential equation boundary conditions of the submersible electric machine with oil are adopted to confirm a temperature field of a submersible electric machine with oil models solution method area, the submersible electric machine with oil simulation is performed to acquire a temperature field distribution cloud chart of stators, rotors and conducting bar of the submersible electric machine with oil under different loads. The submersible electric machine with oil temperature field simulation method is used for simulating the submersible electric machine with oil temperature field.

Owner:HARBIN INST OF TECH

Non-energetics based detonator

A detonator system is provided for use with explosives that utilizes two subsystems. A first subsystem functions as a non-explosives based detonator, which does not contain any explosives. The second subsystem is an initiating subsystem, which includes an initiating pellet. To set off an explosive event, the non-energetics based detonator is coupled to the initiating subsystem and the non-energetics based detonator is commanded to provide a suitable signal to the initiating subsystem that is sufficient to function the initiating pellet. Further, the initiating subsystem can be integrated directly into an associated explosive such as a booster that has been configured to receive the initiator subsystem without changing the hazard class of the booster.

Owner:BATTELLE MEMORIAL INST

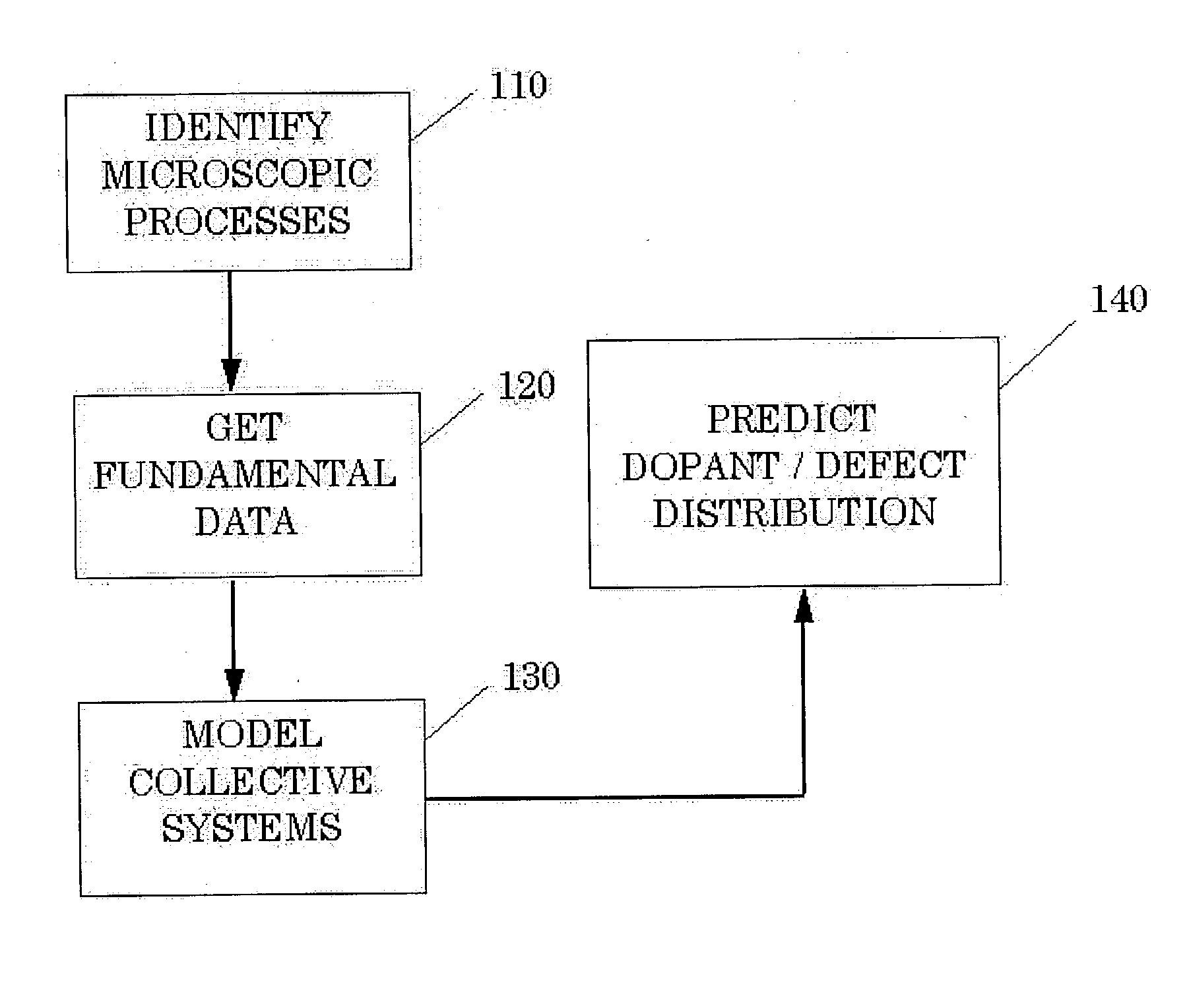

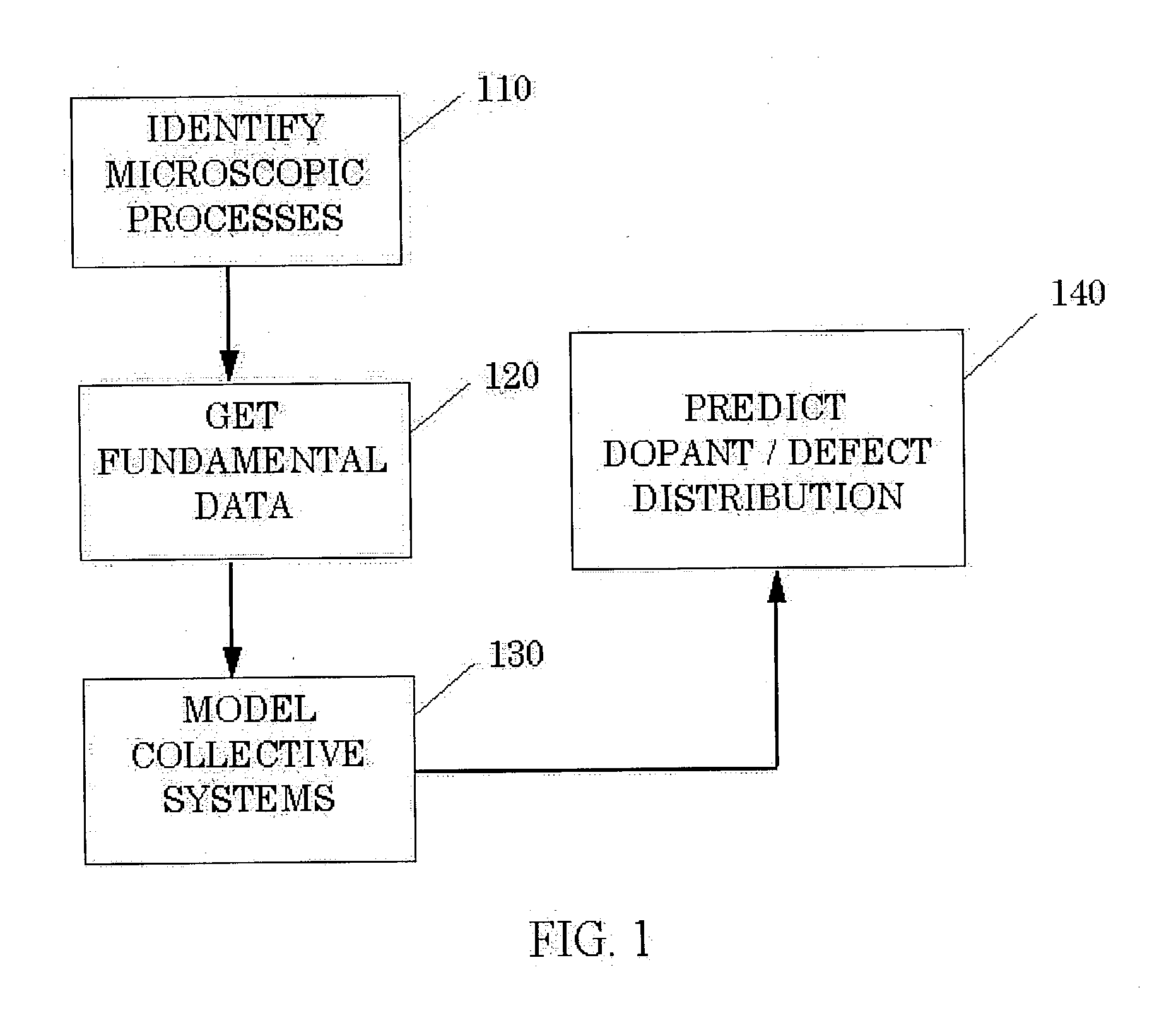

Method for predicting the behavior of dopant and defect components

Owner:SEIKO EPSON CORP +1

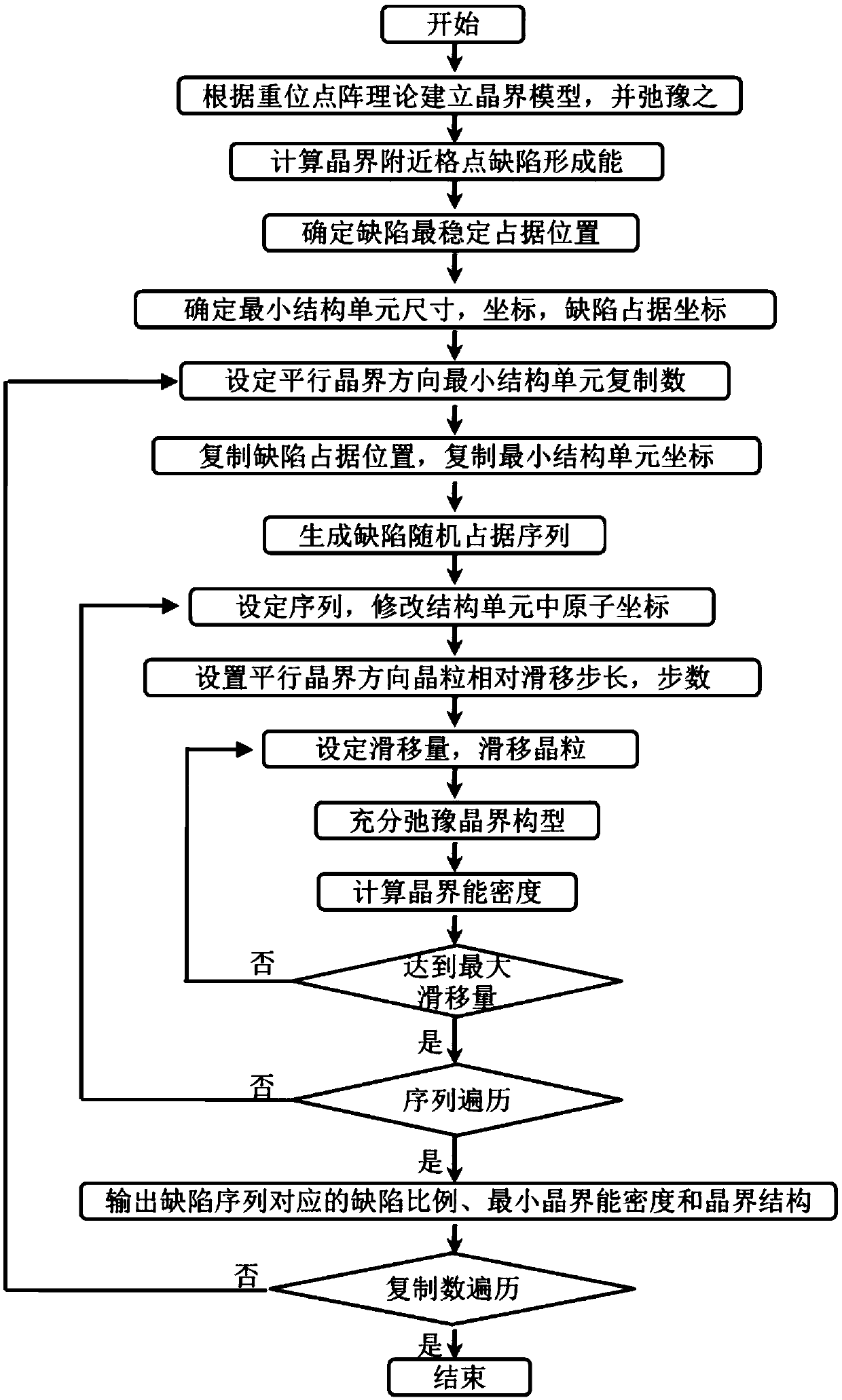

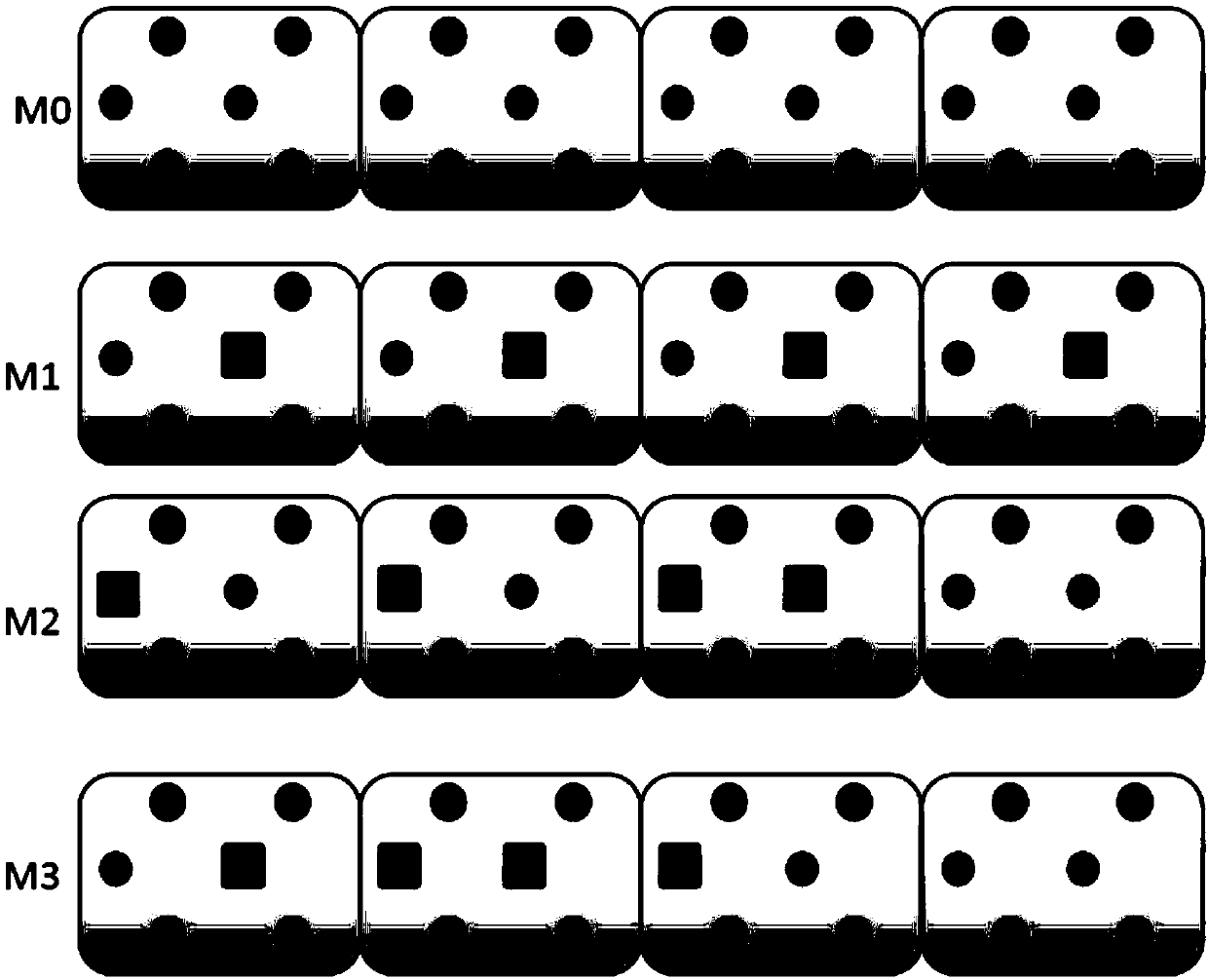

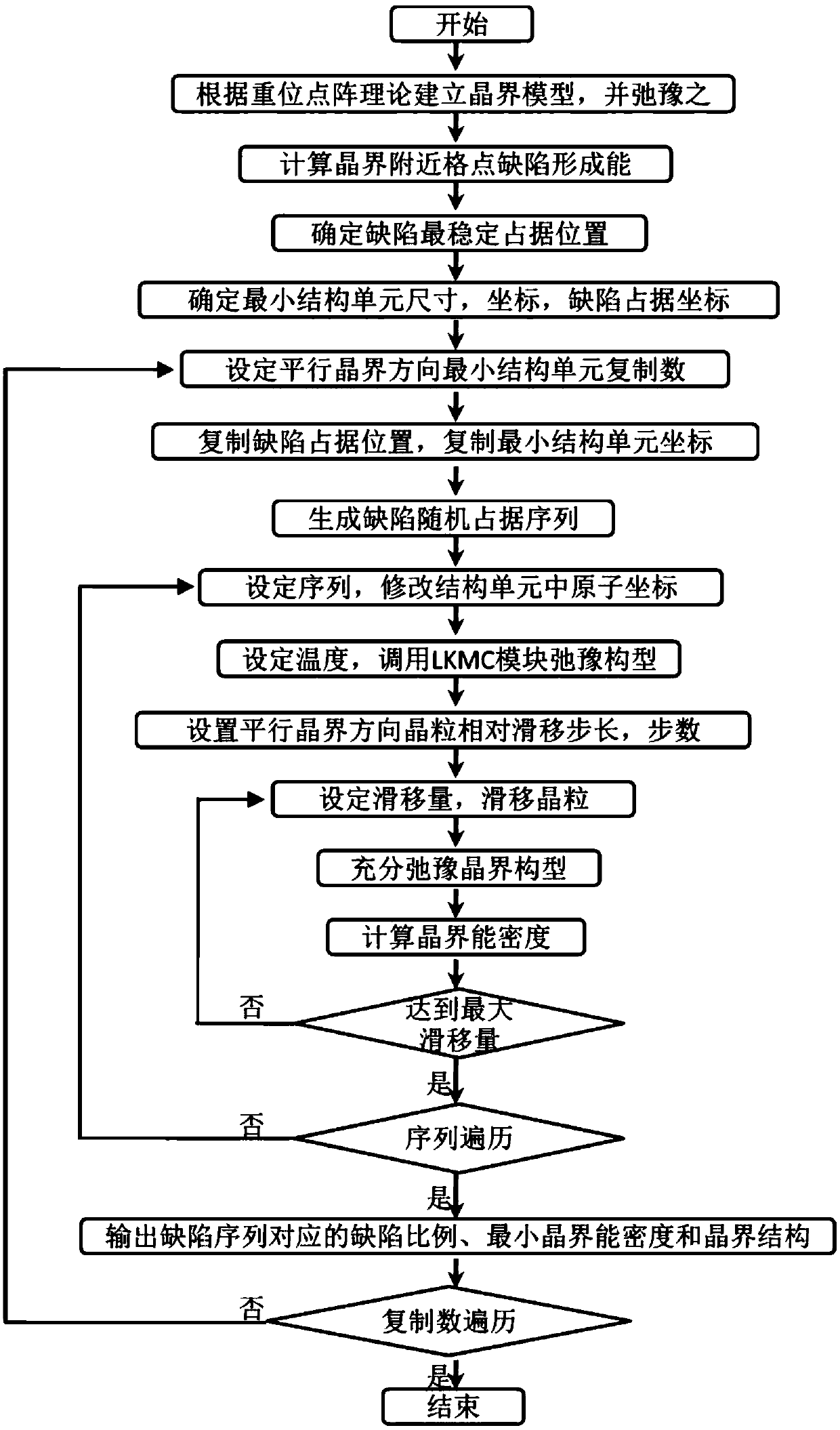

Grain boundary structure searching method based on defect properties and multiscale simulation

ActiveCN108959709ADesign optimisation/simulationSpecial data processing applicationsEnergeticsIrradiation

The invention discloses a grain boundary structure searching method based on defect properties and multiscale simulation, and belongs to the technical field of nuclear material irradiation damage simulation. The method combines defect energetics properties with the multiscale simulation, a concentration relationship between a grain boundary structure and energy as well as defects is investigated,and a grain boundary structure change process induced by radiation defects can be given. Compared with an existing simulation method, the method considers a defect occupation and evolution process, and has a better physical meaning.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Energetics Train Reaction And Method Of Making An Intensive Munitions Detonator

ActiveUS20120240806A1Facilitate initiationEliminate needFuse ignition meansFuse connectorsDetonatorEnergetics

A detonator formed entirely from a plurality of discrete segments of an insensitive energetic composition, each of the segments employed in the detonator being compacted at different pressures from powder and / or granules of insensitive energetic composition so as to form an energetic train which sequences detonation of the individual segments. Initiation of a main charge can only be effected when a last segment in the detonation train is initiated. Detonation starts with a first segment in the detonation train which is produced under the lowest compaction pressure, and then detonation progresses to a last segment compacted under a higher compaction pressure. The first segment can be detonated by a safety fuse or detonating cord, and the last segment can only be detonated by the next to the last segment in the detonation train.

Owner:GONSALVES VINCENT +4

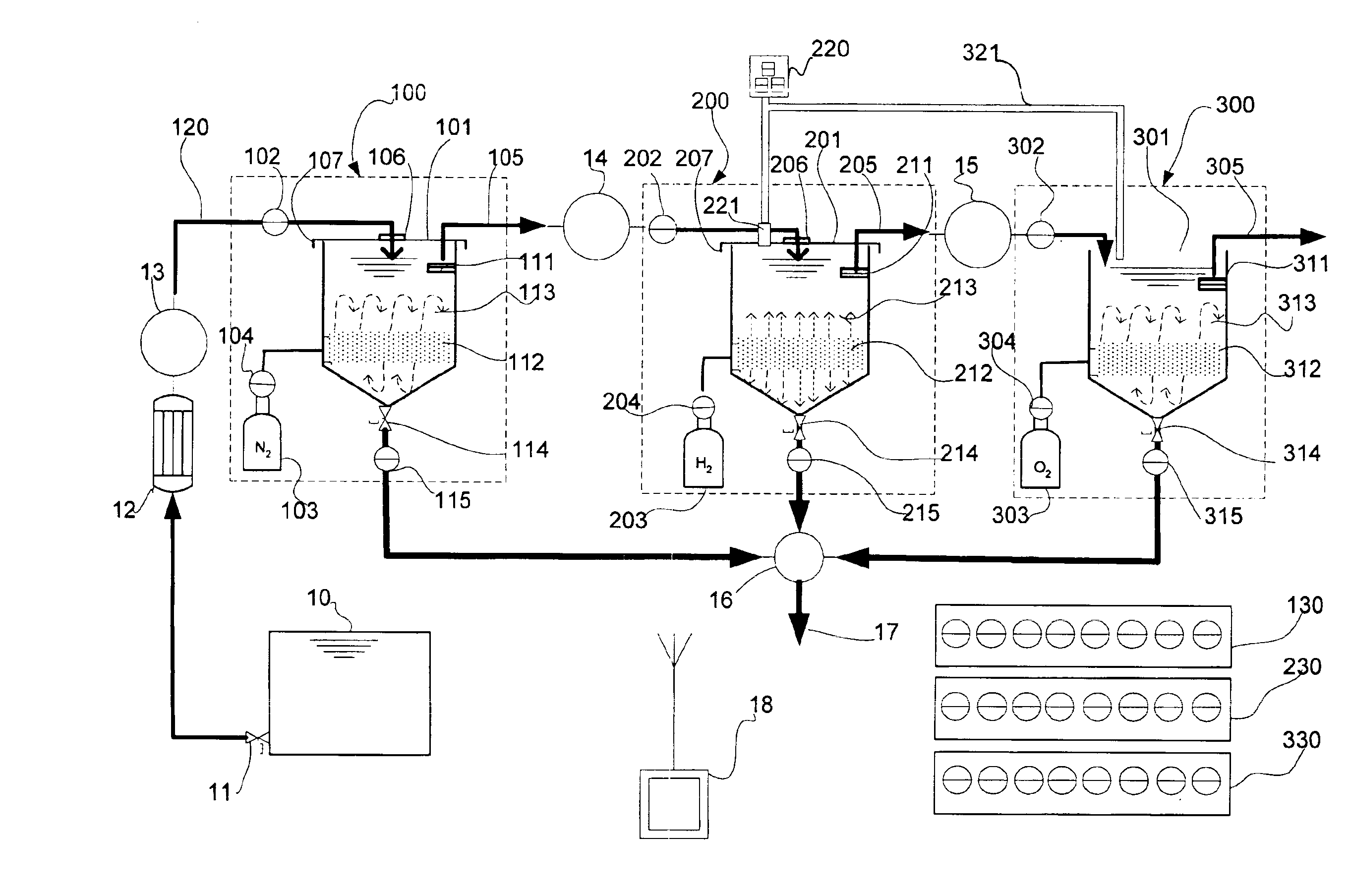

System and method for bioremediating wastestreams containing energetics

InactiveUS6878856B2Easy to integrateEase of controlBioreactor/fermenter combinationsBiological substance pretreatmentsSequencing batch reactorEnergetics

A bioremediation system converts a waste stream, at least part of which is a fluid containing energetics, to carbon dioxide (CO2), water, and environmentally benign end products. It uses gas-enhanced sequencing-batch-reactors (SBRs), treating the waste stream in three SBRs seriatim. The first SBR uses a nitrogen purge, the second a hydrogen gas supplement, and the third an oxygen gas or forced air supplement. Each reactor may be supplemented with additives to optimize conditions such as pH, dissolved oxygen, and nutrient level. The system may be implemented under manual control, semi-automated, or fully automated, as needed. A waste stream of consideration is the pink water resultant from munitions fabrication and handling.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Flexible detonator integrated with directly written energetics

InactiveUS8573123B1Easily withstand very high-G forceBlasting cartridgesElectric fuzesElectricityDetonator

A method of forming a conductive ink bridge wire EED on either a flat or curved substrate, wherein a finely detailed bridge wire EED is printed on the substrate using a nano-particle conductive material applied with a commercially available piezoelectric drop-on-demand ink jet printer—which bridge wire is subsequently coated with a first primary explosive layer, an optional second transition explosive layer, and a third secondary explosive layer—such that upon creating a current through the bridge wire EED, the bridge wire is heated and the explosive layers detonate in turn, and in turn initiate the detonation of the device to which the detonator is attached.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

System for the conversion of coal to a gas of specified composition

The present invention provides a coal gasification system with an integrated control subsystem. The system generally comprises, in various combinations, a gasification reactor vessel (or converter) having one or more processing zones and one or more plasma heat sources, a solid residue handling subsystem, a gas quality conditioning subsystem, as well as an integrated control subsystem for managing the overall energetics of the conversion of coal to energy and maintaining all aspects of the gasification processes at an optimal set point The gasification system may also optionally comprise a heat recovery subsystem and / or a product gas regulating subsystem.

Owner:PLASCOENERGY IP HLDG SL

Method of mineral fuel beneficiation with subsequent delivery to the consumer by pipeline transportation

InactiveUS20130099552A1Improve reliabilityReduce power intensityUnderground miningSolid separationEnergeticsPipeline transport

A method of mineral fuel beneficiation with subsequent delivery to the consumer by pipeline transportation relates fuel and energy complex and can find application in coal and slate energetics. Invention main objective is security of solid fuel delivery from mine (or an open cut coal mine) in already enriched form, with its subsequent through delivery to the consumer by pipeline on any distances in stream mode, without any intermediate transshipment operations. For this purpose use liquid with set complex physical, sanitary-and-hygienic and ecological properties, simultaneously, in 4 qualities: As environment for grinding material that needed further reduction of size; As separation environment for the subsequent, after reduction of size, deep underground gravitational enrichment of combustible mineral, As motionless filler of the vertical pipeline, for buoyancy in it ready product from mine on terrestrial surface: As carrying medium for final drift of end-product to the consumer by main pipeline. Depending on consumer type of solid fuel, a time of year, and weather conditions in which such, non-polluting, mining-energetic complex functions, there are used various technological approaches as to the general principles of construction of such, non-polluting, beneficiating transport technological process as well as within the limits of separate links of such technological chain, various methods of the regeneration, used many functional liquids which are in the closed contour of circulation between producer of solid fuel and its consumer.

Owner:ENKHBOLD CHULUUN

Method for manufacture of amorphous energetics

ActiveUS9850180B1Improve responseReduce sensitivityExplosive working-up apparatusEnergeticsExplosive material

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

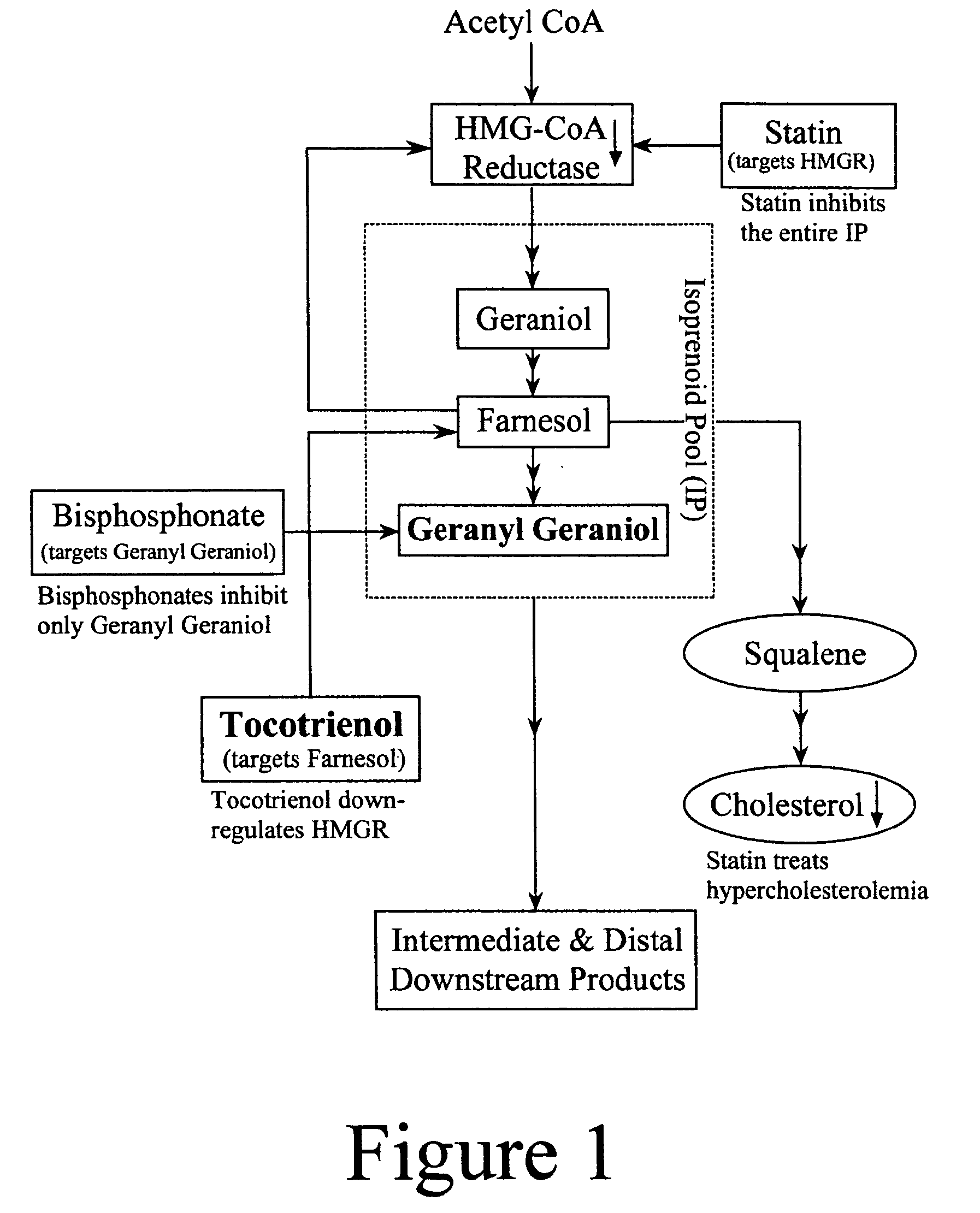

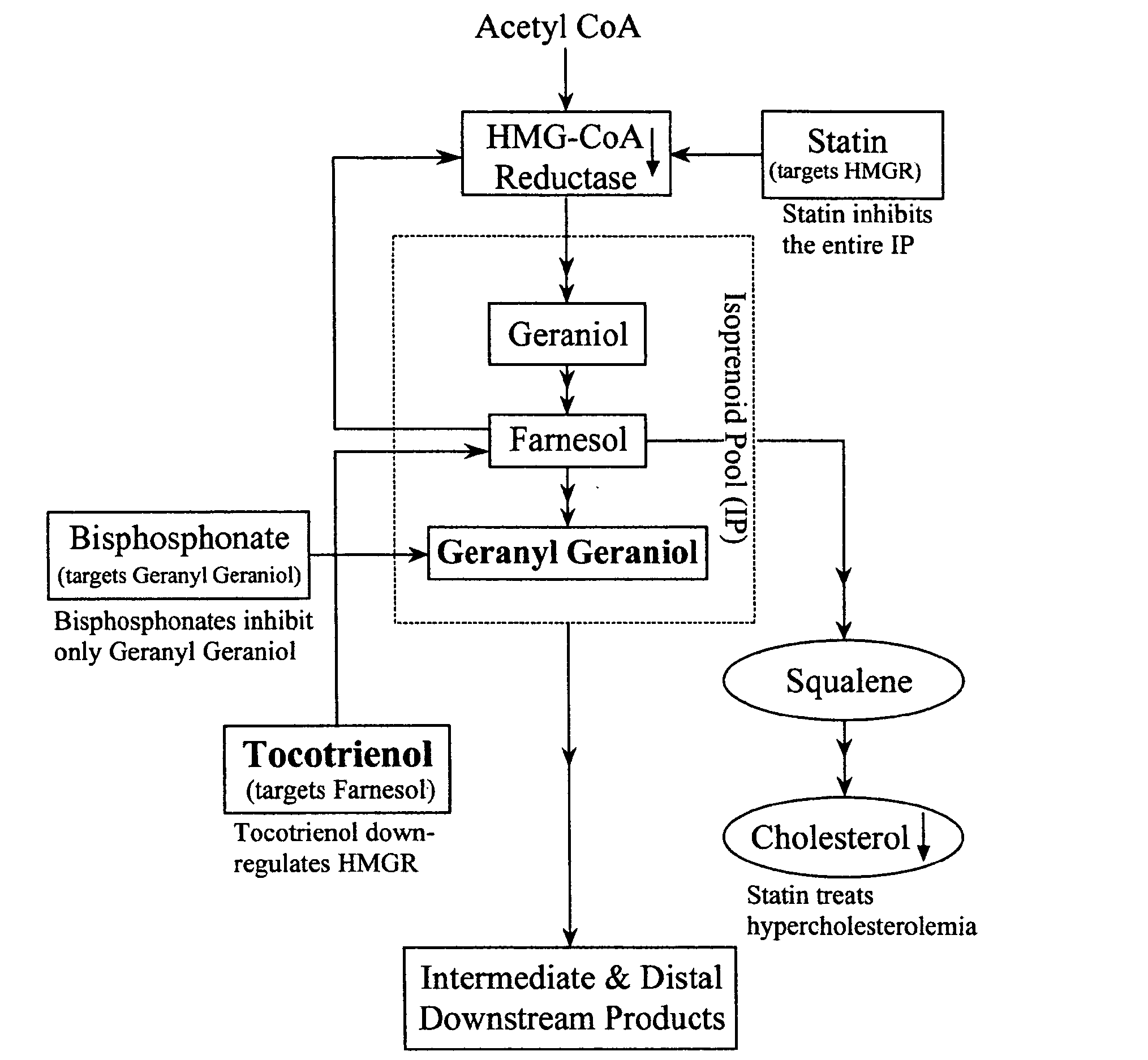

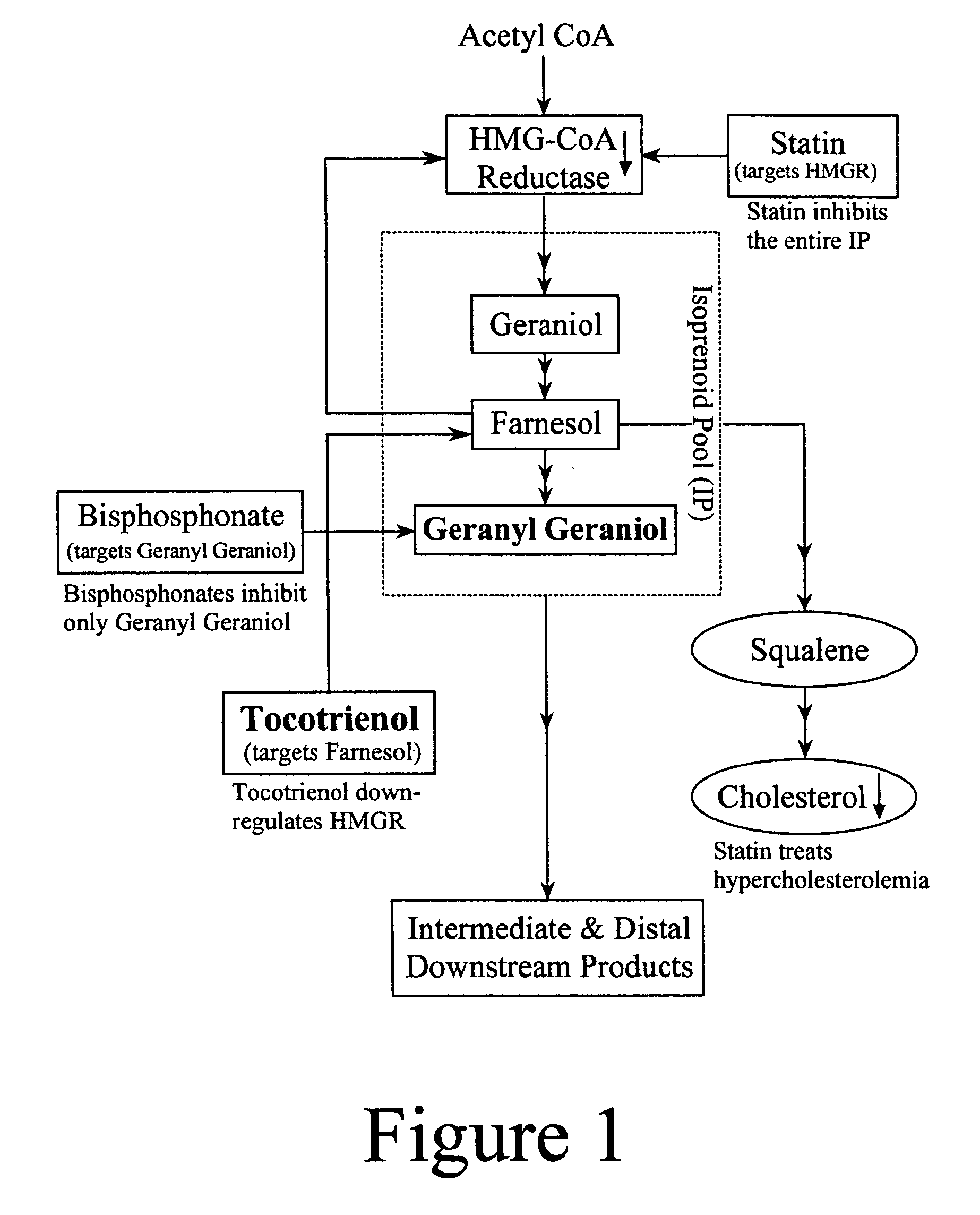

Annatto extract compositions, including geranyl geraniols and methods of use

ActiveUS7989006B2Reduce disease riskIncreasing cellular uptakeBiocideSenses disorderEnergeticsPhysiology

Owner:AMERICAN RIVER NUTRITION LLC

Compact multi-level output hybrid gas generator

InactiveCN101137525ASmall sizeSimple structurePedestrian/occupant safety arrangementVehicle design optimisationHybrid typeEnergetics

A multi-level gas inflator for an air bag or other safety device, comprising an elongated pressure vessel having a primary gas generant portion with a first open end and a secondary gas generant portion with a second open end. The primary gas generant portion has a primary ignition device and primary gas generating energetics disposed therein. The primary ignition device is mounted on and closes the pressure vessel at the first open end thereof. The secondary gas generant portion has a secondary ignition device and secondary gas generating energetics disposed therein. The secondary ignition device is mounted on and closes the pressure vessel at the second open end thereof. A suitable gas under a predetermined pressure is present in the primary and secondary gas generant portions. One or more dividers or divider walls are disposed within the midportion of the pressure vessel to separate the primary and secondary gas generant portions. The pressure vessel has a primary exit orifice in the midportion thereof that is in communication with the primary gas generant portion, and a secondary exit orifice in the midportion thereof that is in communication with the secondary gas generant portion. A primary rupture disk is disposed over the primary exit orifice, and a secondary rupture disk is disposed over the secondary exit orifice. A diffuser is mounted on and surrounds the pressure vessel midportion and the primary and secondary exit orifices. The diffuser is in communication with the air bag for the inflation thereof. The inflator can be easily converted to a single level output inflator by omitting the secondary ignition device and the secondary gas generating energetics.

Owner:ARC AUTOMOTIVE

Wax composite insensitive agent with adjustable friction coefficient and preparation method thereof

PendingCN108456124ALow mechanical sensitivityImprove securityNon-explosive desensitisers/phlegmatisersNitroparaffin explosive compositionsWaxEnergetics

The invention belongs to the field of energetics, and particularly provides a wax composite insensitive agent with an adjustable friction coefficient and a preparation method thereof. The wax composite insensitive agent comprises wax materials and functional agents; the functional agents are selected from at least one of graphene, graphene oxide, nitrified graphene, fluoridized graphene, molybdenum disulfide, tungsten disulfide, graphene and carbon nanotube. The adjustable range of the friction coefficient of the wax composite insensitive agent is 0.03-0.25, the content of the composite insensitive agent only covers 1.5%-3% of the mass of energetic compounds such as RDX, HMX, CL-20, AP and the like, mechanical sensitivity of the energetic compounds can be significantly reduced, the safetyperformance of the energetic compounds can be greatly improved to further improve the content application safety performance of the energetic compounds in the energetic materials such as composite explosive, propellent and the like, and the preparation method is simple in process, economic and effective.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A method of mineral fuel beneficiation with subsequent delivery to the consumer by pipeline transportation?

InactiveCN103797136AReduce power consumptionReduce adverse effectsUnderground miningSolid separationEnergeticsOpen-pit mining

A method of mineral fuel beneficiation with subsequent delivery to the consumer by pipeline transportation relates fuel and energy complex and can find application in coal and slate energetics. Invention main objective is security of solid fuel delivery from mine (or an open cut coal mine) in already enriched form, with its subsequent through delivery to the consumer by pipeline on any distances in stream mode, without any intermediate transshipment operations. For this purpose use liquid with set complex physical, sanitary-and-hygienic and ecological properties, simultaneously, in 4 qualities: - As environment for grinding material that needed further reduction of size; - As separation environment for the subsequent, after reduction of size, deep underground gravitational enrichment of combustible mineral, - As motionless filler of the vertical pipeline, for buoyancy in it ready product from mine on terrestrial surface: - As carrying medium for final drift of end-product to the consumer by main pipeline. Depending on consumer type of solid fuel, a time of year, and weather conditions in which such, non-polluting, mining-energetic complex functions, there are used various technological approaches as to the general principles of construction of such, non-polluting, beneficiating- transport technological process as well as within the limits of separate links of such technological chain, various methods of the regeneration, used many functional liquids which are in the closed contour of circulation between producer of solid fuel and its consumer.

Owner:C·恩克博德

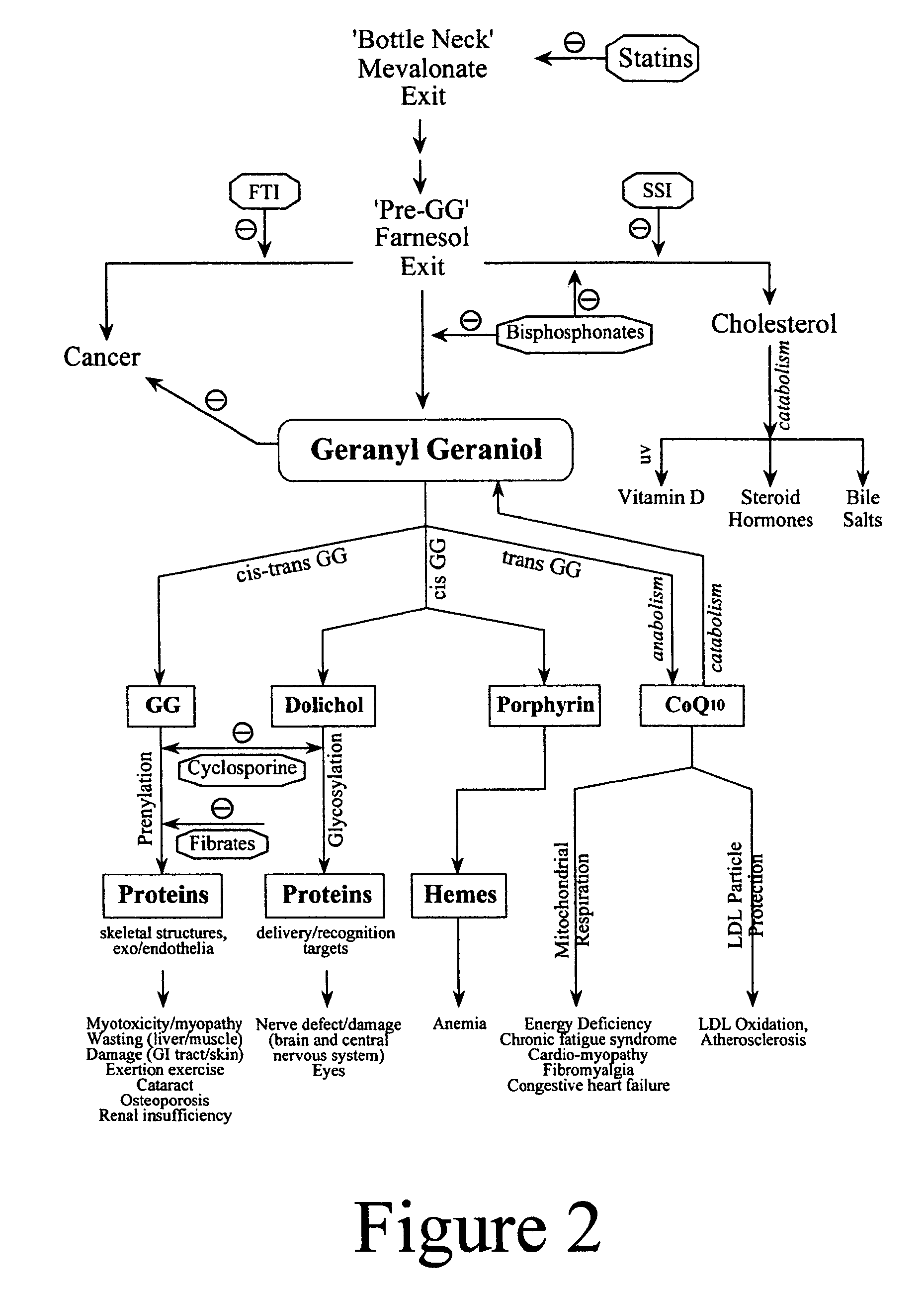

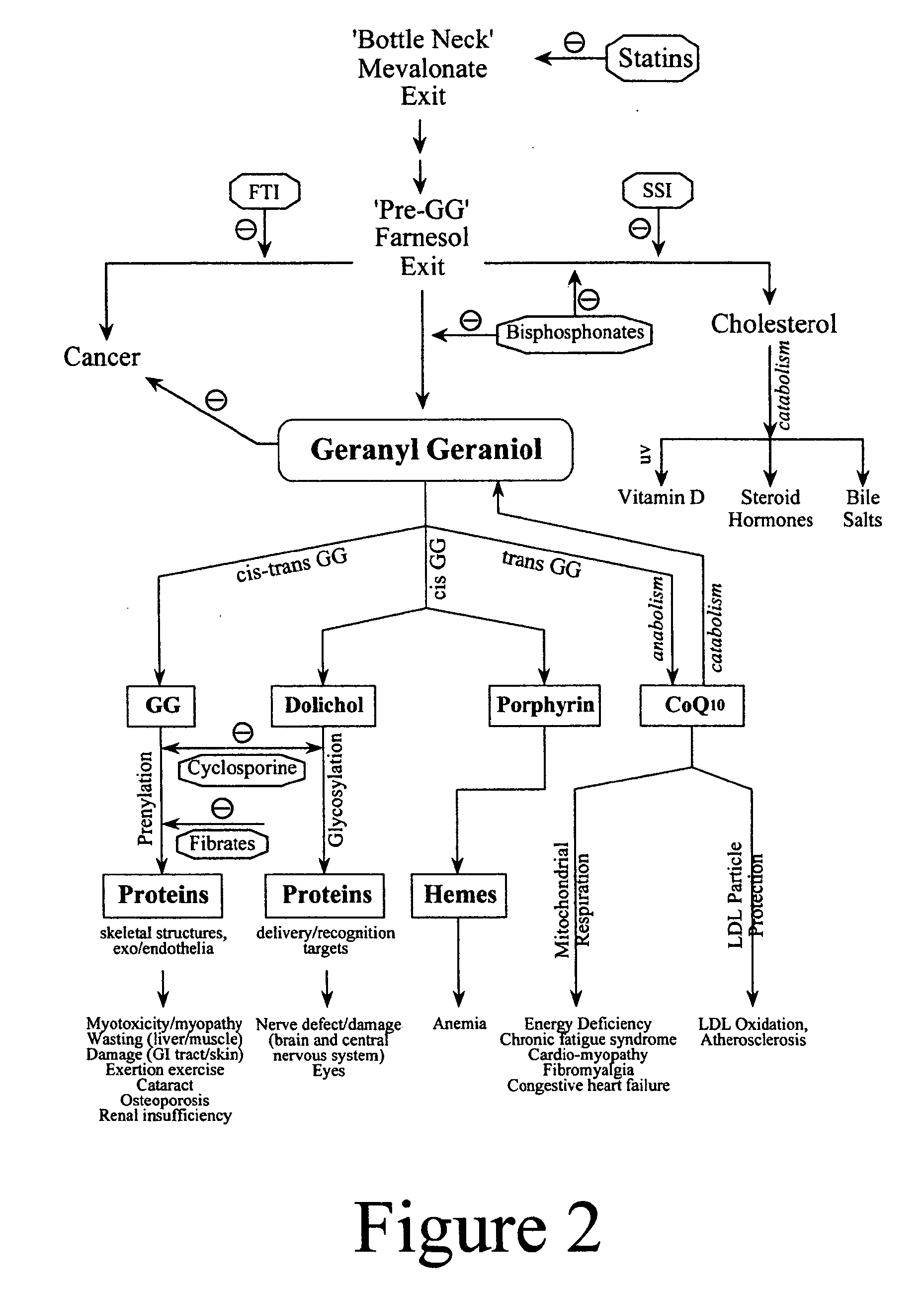

Annatto Extract Compositions, Including Geranyl Geraniols And Methods Of Use

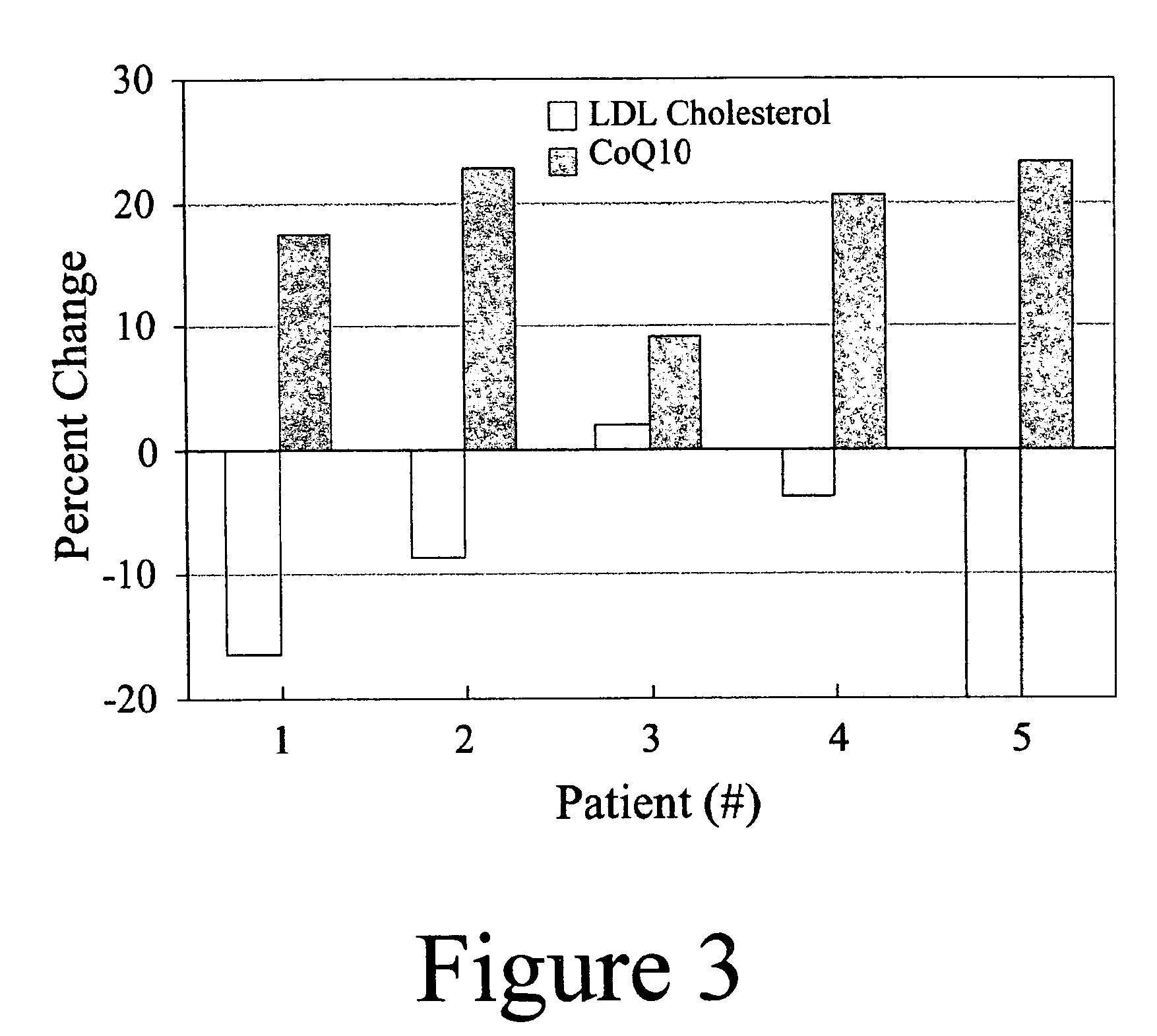

ActiveUS20080031985A1Preventing statin toxicityIncreasing CoQBiocideSenses disorderEnergeticsSide chain

Annatto extract composition (AEC), including cis and trans geranyl geraniols (GG) and tocopherol-free C-5 unsubstituted tocotrienols (T3), increases the de novo synthesis of intermediate isoprenoid and distal protein products, including endogenous coenzyme Q10 (CoQ10), dolichols (DL) and all subsequent GG-prenylated and DL-glycosylated proteins, including GG-porphyrinated hemes. This intermediate and distal product replenishment by AEC reverses maladies of myotoxicity (of both drug and non-drug origins), including maladies that affect the muscle, kidney, eye, GI tract and skin, nerve, blood, and CoQ10-related syndromes of energetics and LDL protection. AEC anabolically increases the endogenous de novo CoQ10 synthesis via GG elongation / prenylation of side-chain and conversely CoQ10 catabolically increases the endogenous de novo GG synthesis via beta-oxidation of CoQ10. Also, such AEC decreases de novo synthesis and increases disposal of triglycerides (TG) in humans via PPAR activation and SREBP deactivation. Such drop in TG by AEC reverses maladies of insulin resistance (IR) and metabolic syndrome (MS), prediabetes, diabetes and diabetes-related cardiovascular diseases (CVD). GG activates PPAR and down regulates SREBP transcription factors. This AEC, containing GG, inhibits cancer growth whether or not GG involvement in protein prenylation is required.

Owner:AMERICAN RIVER NUTRITION LLC

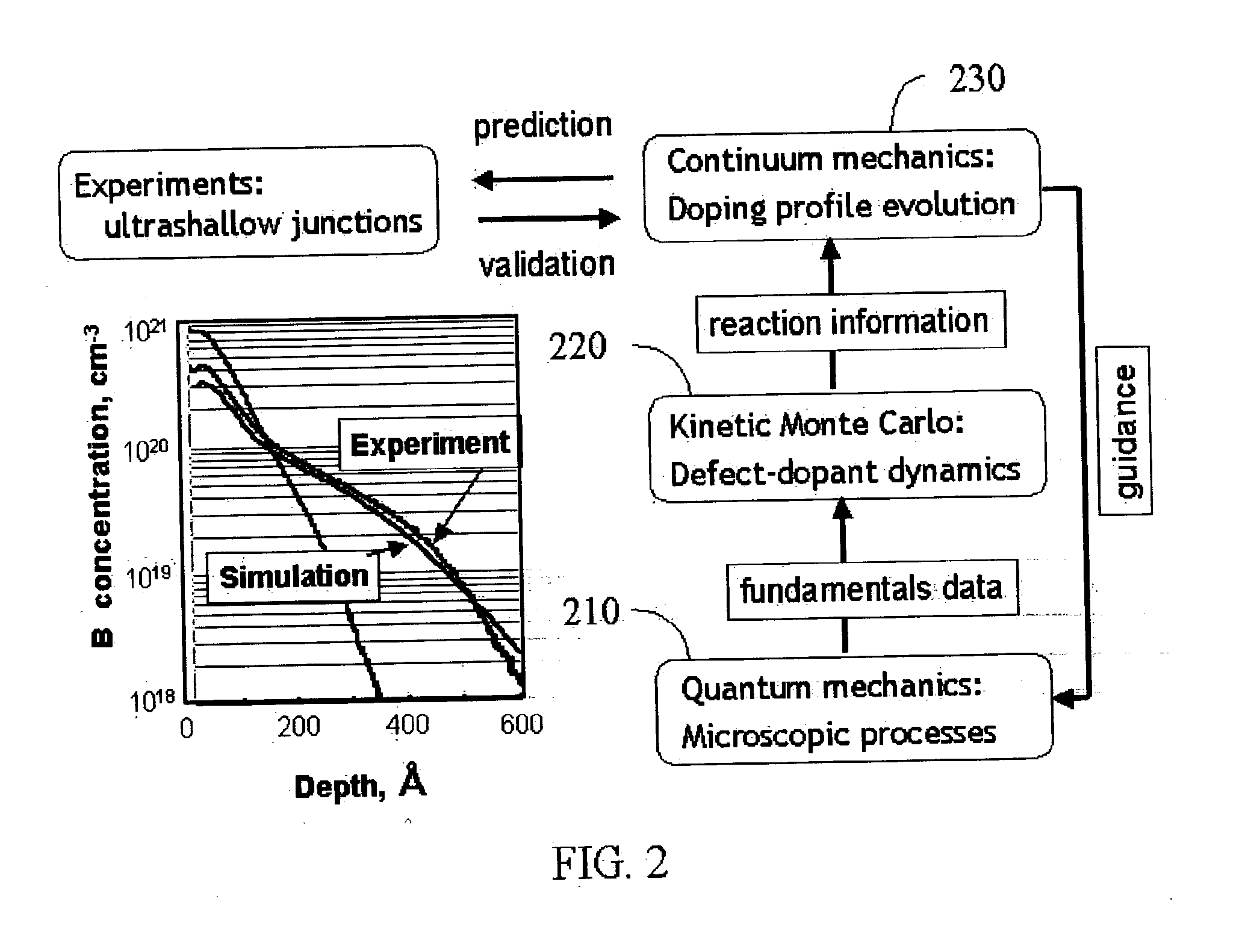

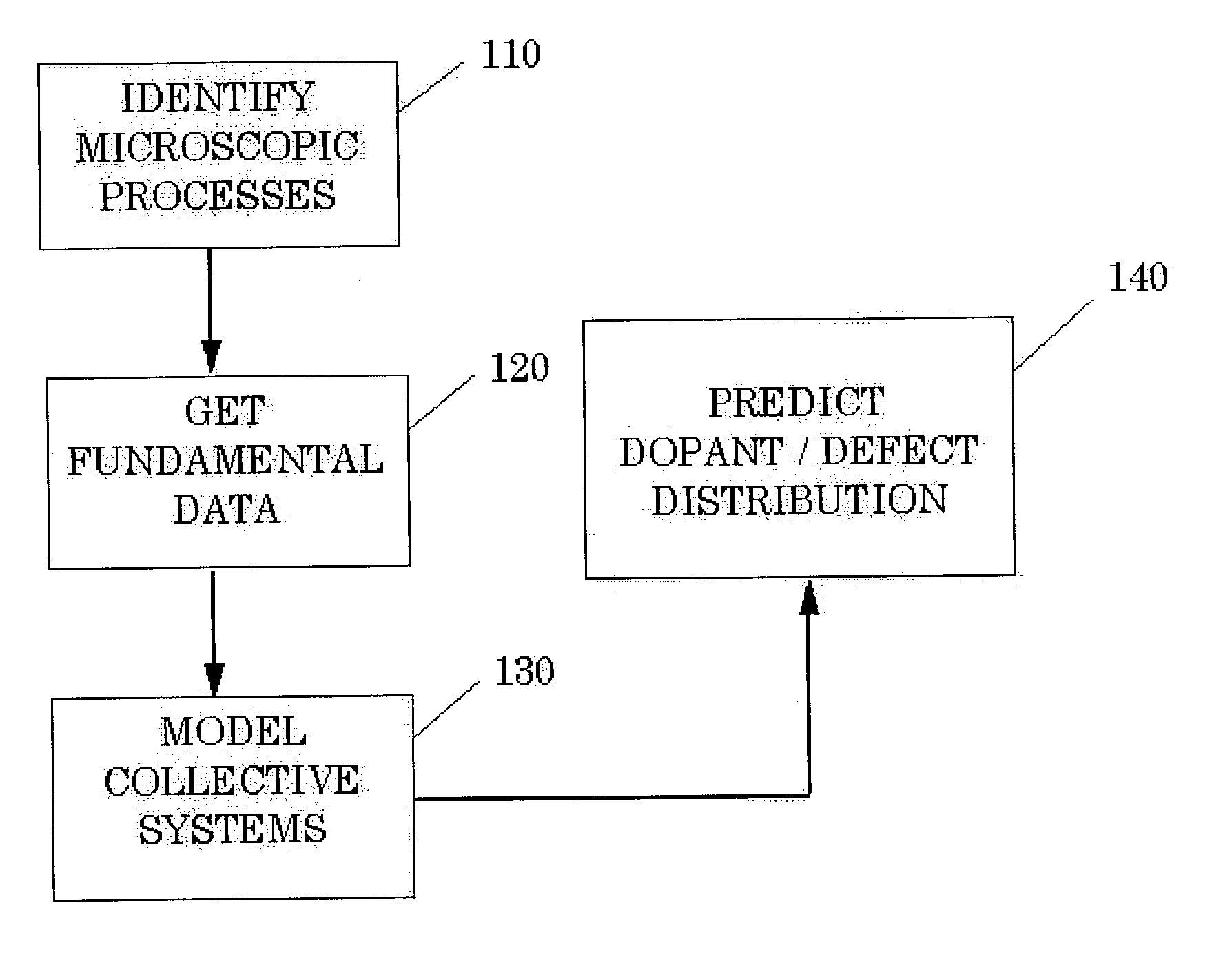

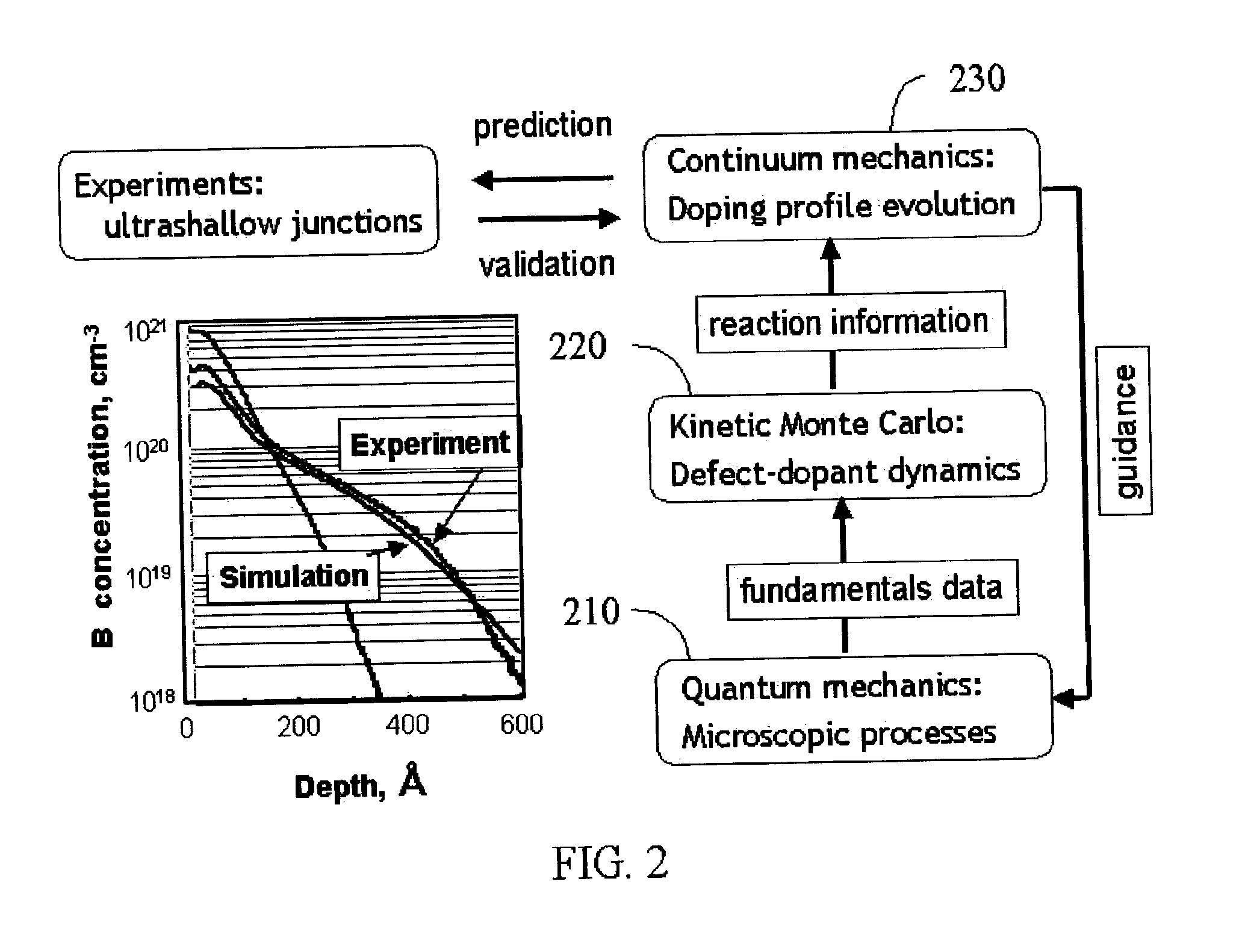

Method for predicting the behavior of dopant and defect components

Techniques for predicting the behavior of dopant and defect components in a substrate lattice formed from a substrate material can be implemented in hardware or software. Fundamental data for a set of microscopic processes that can occur during one or more material processing operations is obtained. Such data can include data representing the kinetics of processes in the set of microscopic processes and the energetics and structure of possible states in the material processing operations. From the fundamental data and a set of external conditions, distributions of dopant and defect components in the substrate lattice are predicted. The distributions of one or more fast components are each predicted by calculating the concentration of the particular fast component for a time period before that fast component reaches its pseudo steady state by solving a first relationship and calculating the concentration of that fast component after the time period by solving a second relationship based on other components, the pseudo steady state of a fast component being a state in which the concentration of that fast component is determined by concentrations of other components. The distribution of Bs3Bi, in addition to the distributions of Bs, BsI, BsI2, BsI3, BsBi, BsBi2, BsBi3, BsBiI, BsBiI2, Bs2Bi, Bs2Bi2, I and In, are calculated by solving the first relationship to predict the distribution of boron after annealing, where Bs and Bi represent substitutional boron and interstitial boron, respectively, and I and In represent interstitial silicon and a cluster of n I's, respectively.

Owner:SEIKO EPSON CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com