Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

116results about "Non-explosive desensitisers/phlegmatisers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

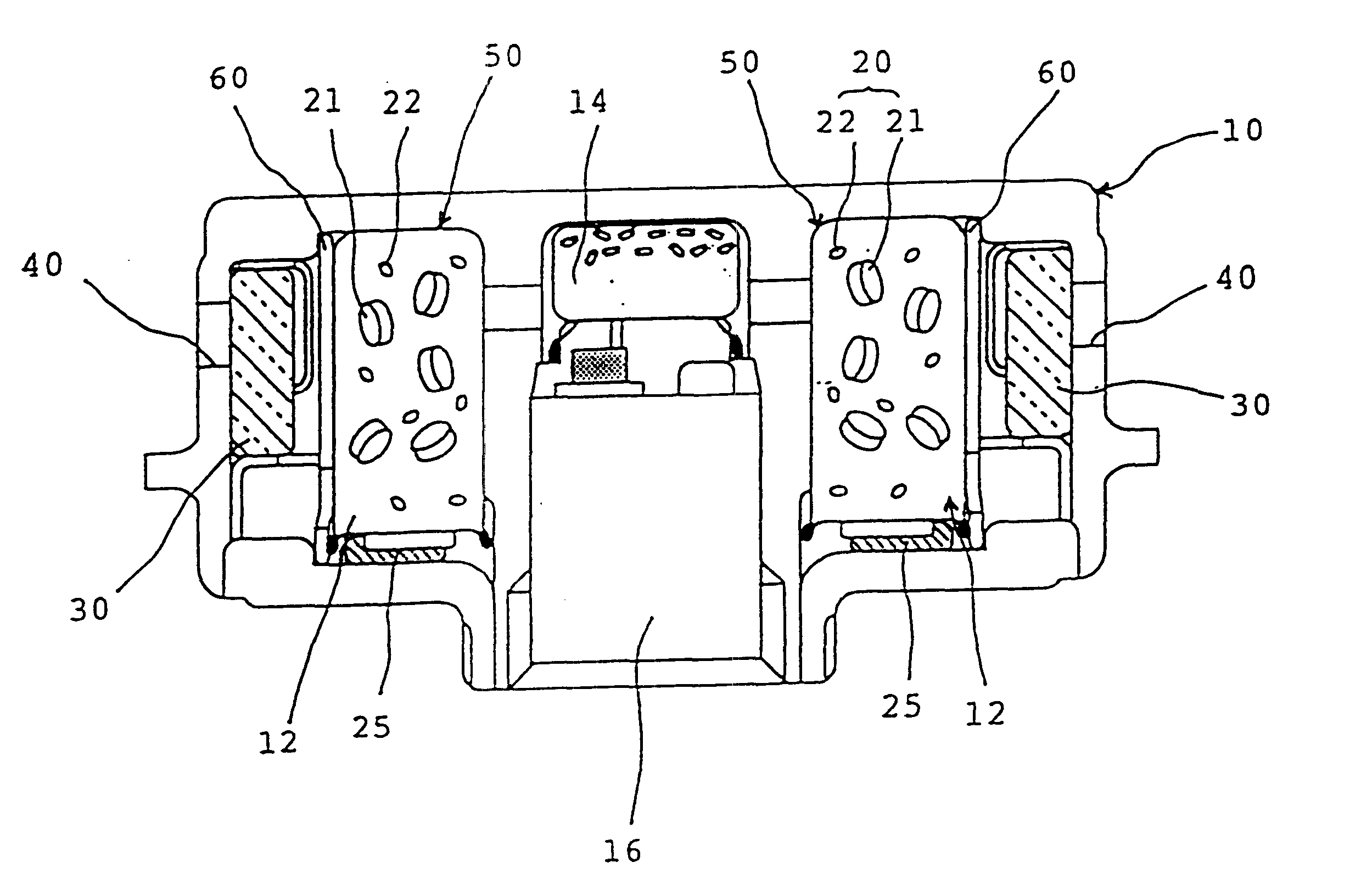

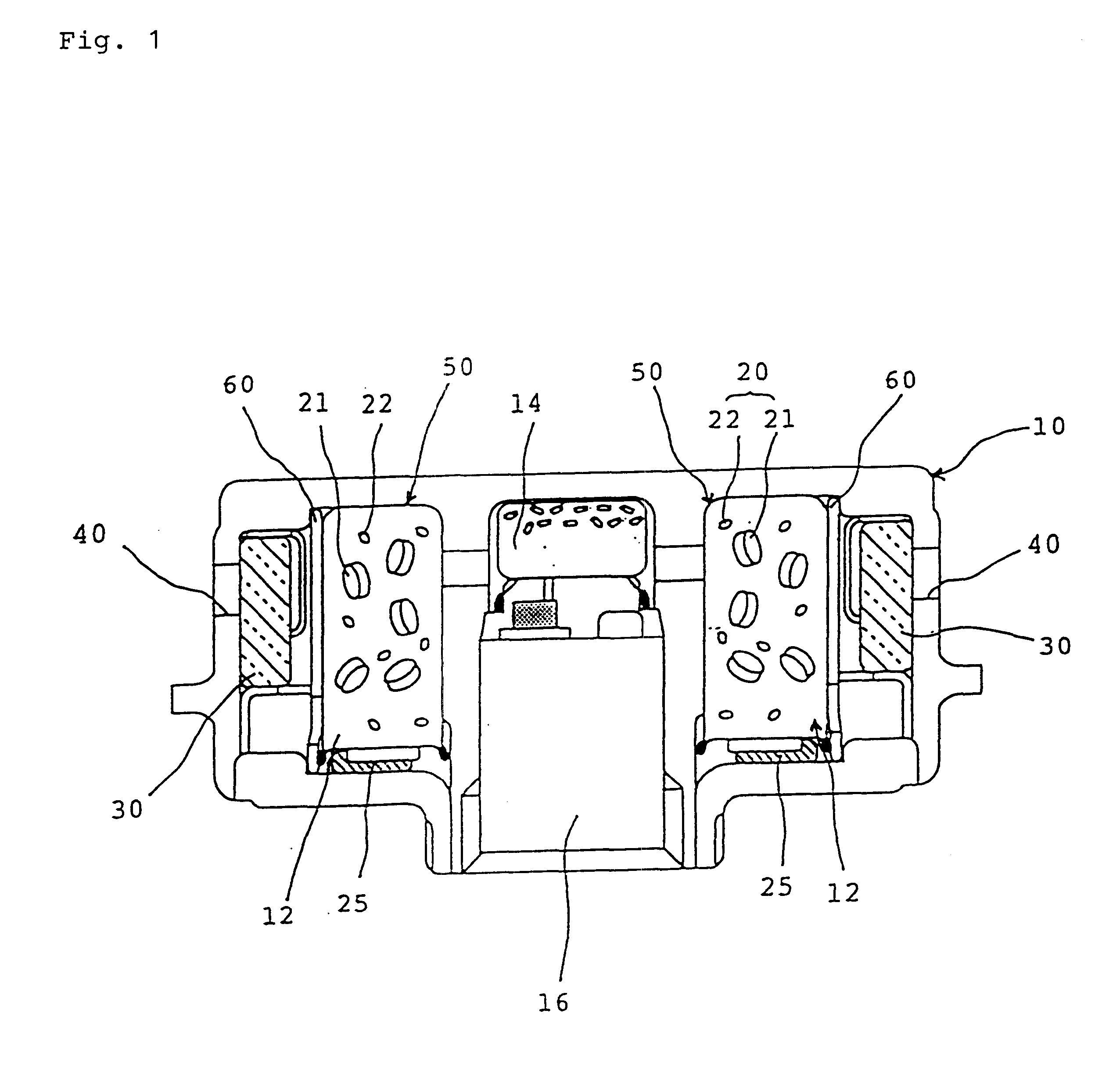

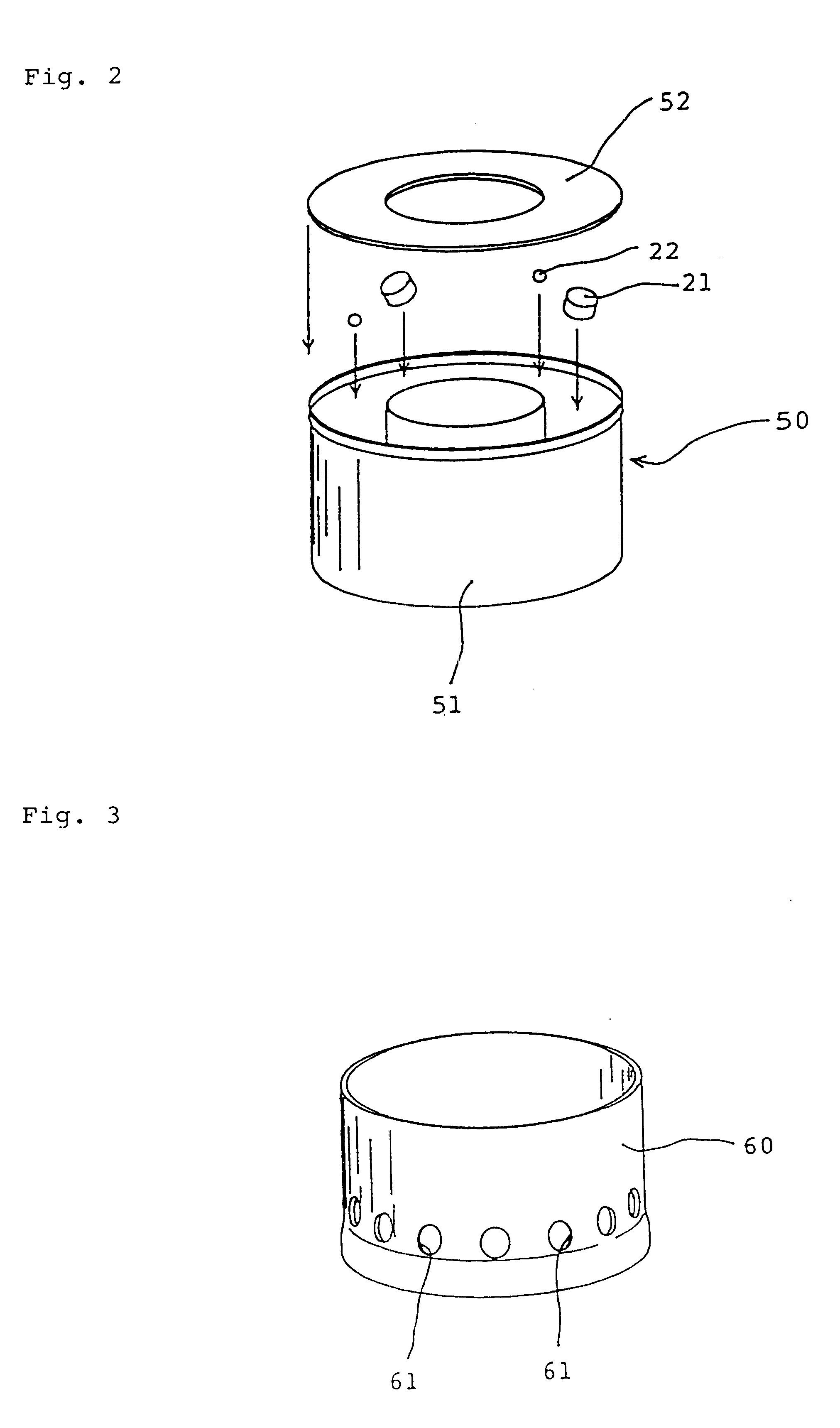

Gas generating agent composition and gas generator

InactiveUS6517647B1Improve thermal stabilityImprove reliabilityNon-explosive desensitisers/phlegmatisersPressure gas generationSorbentDecomposition

A gas generating composition having an improved thermal stability of a fuel is obtained.A gas generating compostion comprising a gas generating agent containing a non-sodium azide compound fuel and an oxidizing agent, and an adsorbent. Since substances accelerating decomposition of a fuel, such as radicals generating by decomposition of the fuel are adsorbed and kept on the adsorbent, further decomposition of the fuel is inhabited, so that the thermal stability is increased.

Owner:DAICEL CHEM IND LTD

Methods of reducing ignition sensitivity of energetic materials, methods of forming energetic materials having reduced ignition sensitivity, and related energetic materials

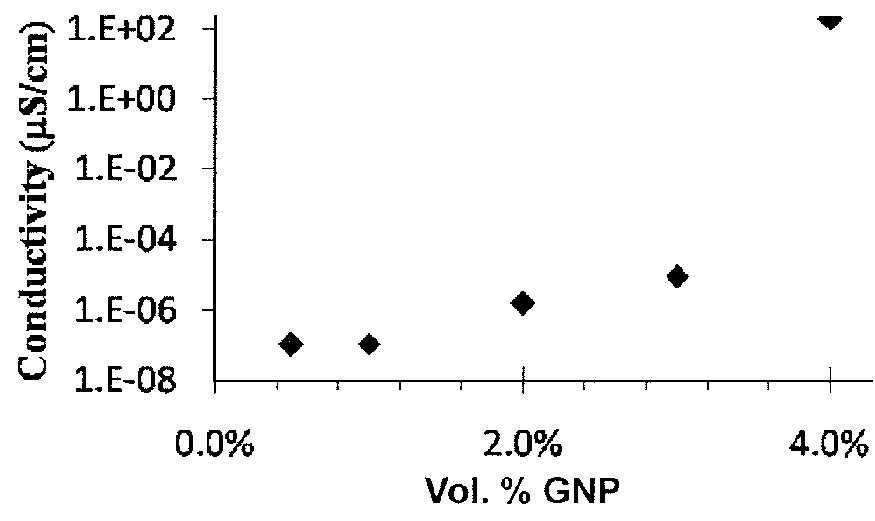

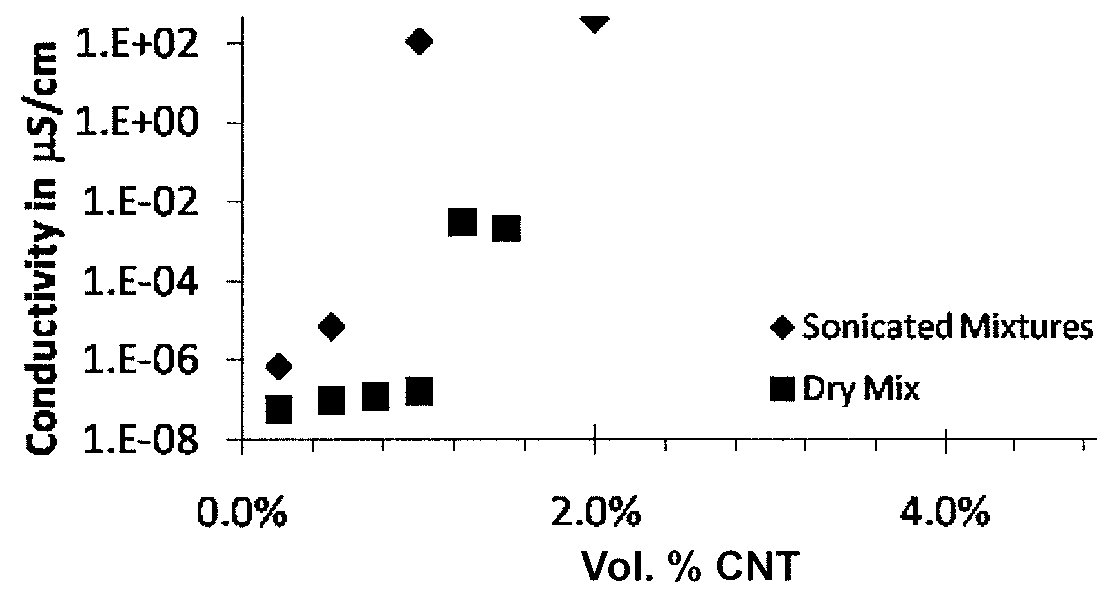

InactiveUS20160031769A1Reducing ignition sensitivityReduce sensitivityNon-explosive desensitisers/phlegmatisersExplosive working-up apparatusFiberMaterials science

An energetic material comprising an elemental fuel, an oxidizer or other element, and a carbon nanofiller or carbon fiber rods, where the carbon nanofiller or carbon fiber rods are substantially homogeneously dispersed in the energetic material. Methods of tailoring the electrostatic discharge sensitivity of an energetic material are also disclosed. Energetic materials including the elemental fuel, the oxidizer or other element, and an additive are also disclosed, as are methods of reducing ignition sensitivity of the energetic material including the additive. The additive is combined with the elemental fuel and a metal oxide to form the energetic material. The energetic material is heated at a slow rate to render inert the energetic material to ignition while the energetic material remains ignitable when heated at a fast rate.

Owner:BATTELLE ENERGY ALLIANCE LLC +1

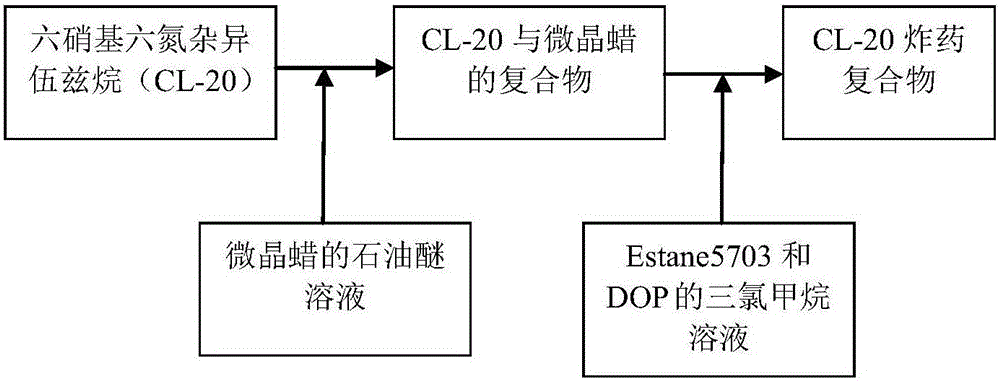

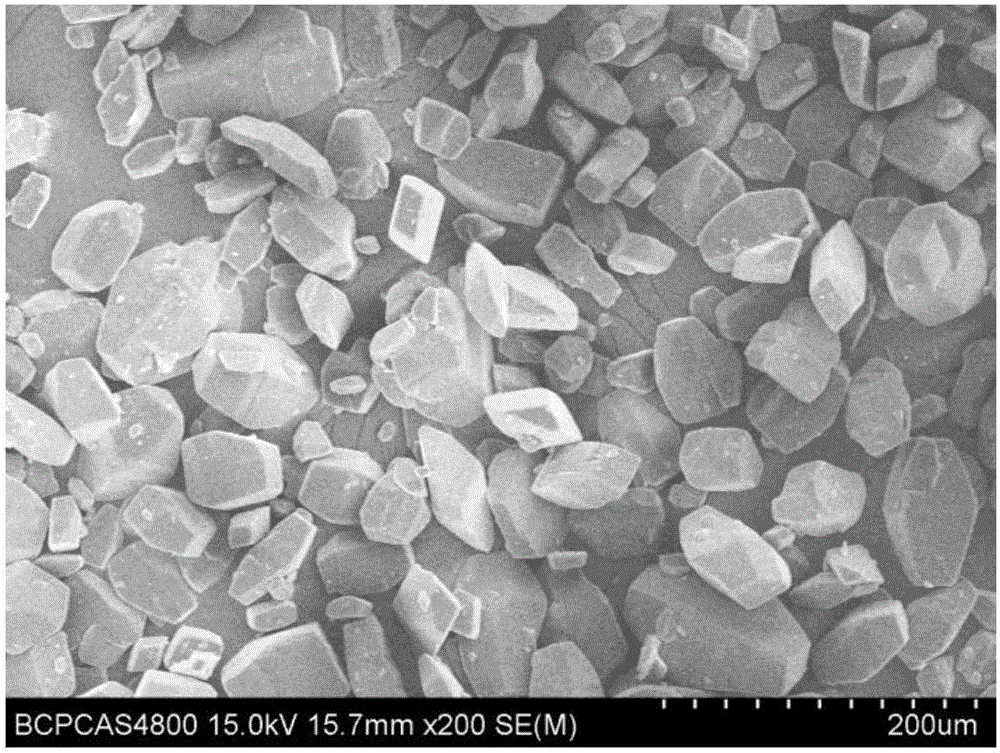

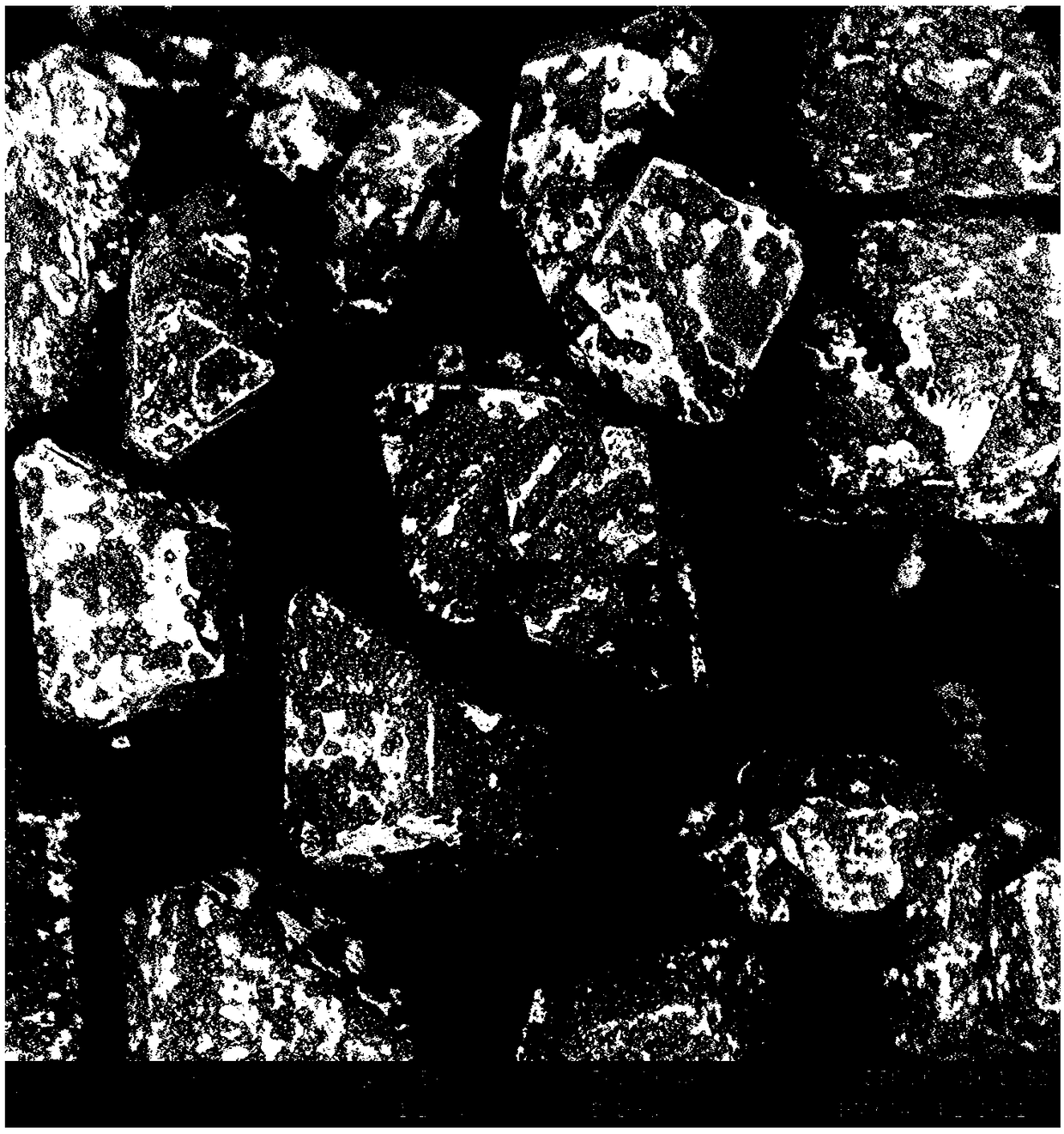

Method for coating CL-20 explosive with plasticized Estane5703

InactiveCN106083494AUniform particle sizeLow impact sensitivityNon-explosive desensitisers/phlegmatisersExplosive working-up apparatusFriction sensitivityMicrocrystalline wax

The invention relates to a method for coating a CL-20 (hexanitrohexaazaisowurtzitane) explosive with plasticized Estane5703. The method comprises the following steps: coating the surface of CL-20 with a desensitizer microcrystalline wax to prepare a CL-20 and microcrystalline wax compound, and coating the surface of the CL-20 and microcrystalline wax compound with Estane5703 to prepare a CL-20 explosive compound. The method allows a uniform and compact film to be formed on the surface of the CL-20 explosive, so the mechanical sensitivity of the CL-20 explosive is substantially reduced. The CL-20 explosive compound prepared in the invention and the coating film thereof are controlled to be in a nanometer range, account for 2-4% of the total system, and have small influences on the energy of the CL-20 explosive. The bump sensitivity of the coated CL-20 explosive is reduced to 52-72% from 100%, and the friction sensitivity of the coated CL-20 explosive is reduced to 40-80% from 100%.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

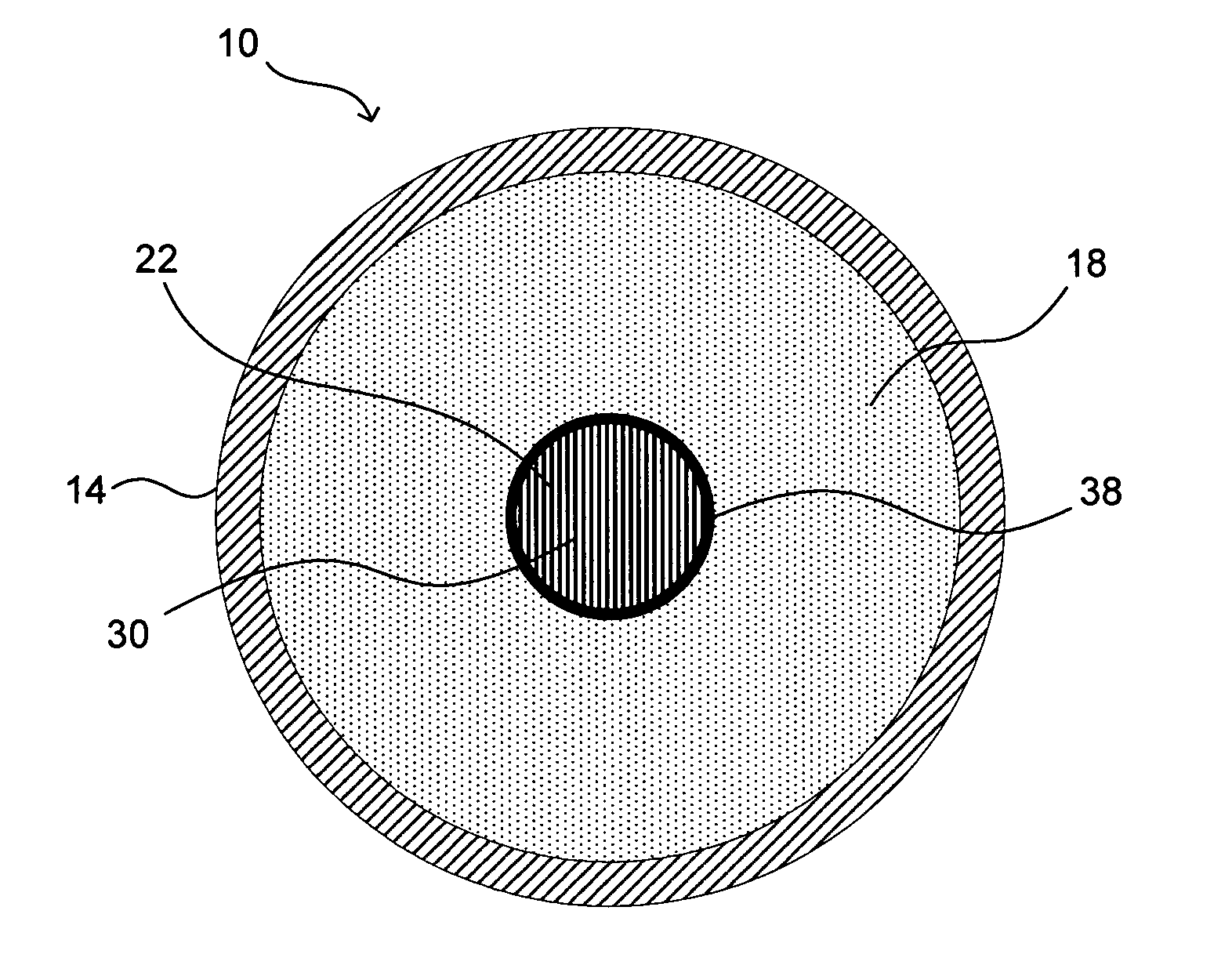

Method for reducing violence of accidental explosions in solid fuel rocket motors and other energetic devices

InactiveUS20060032562A1Reduce violencePrevent crashExplosive chargesNuclear energy generationEngineeringEnergetic material

A method and system for reducing the violence of an accidental explosive reaction of an energetic material, the method comprising: (a) obtaining a solid energetic material configured for use within an energetic device, the energetic material comprising at least one void formed therein; and (b) filling at least a portion of the at least one void with an inert, incompressible material configured to mechanically stabilize the energetic material to prevent the void from collapsing and the surface area of the energetic material from increasing in the event of an insult tending to damage the energetic the material. In one exemplary embodiment, the inert, incompressible material is configured to temporarily modify the energetic device, meaning that the inert, incompressible material is configured to be removably inserted or otherwise applied to the energetic device.

Owner:UNIV OF UTAH RES FOUND

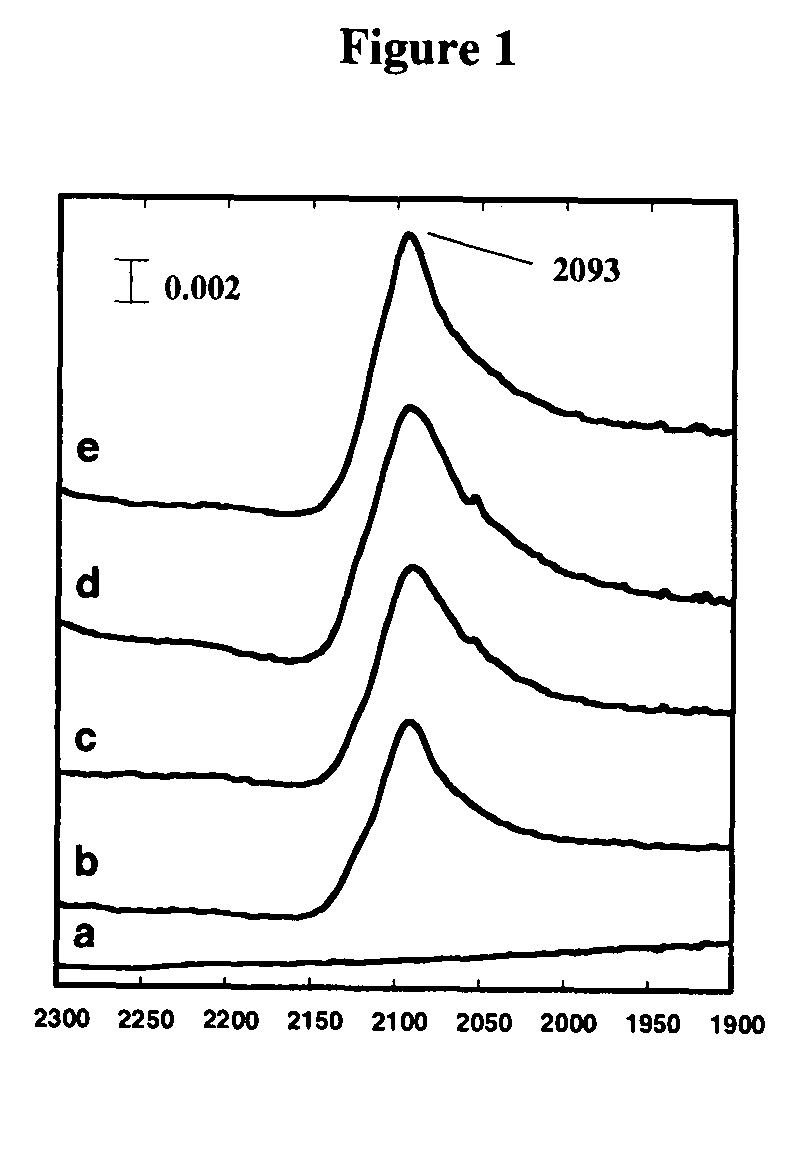

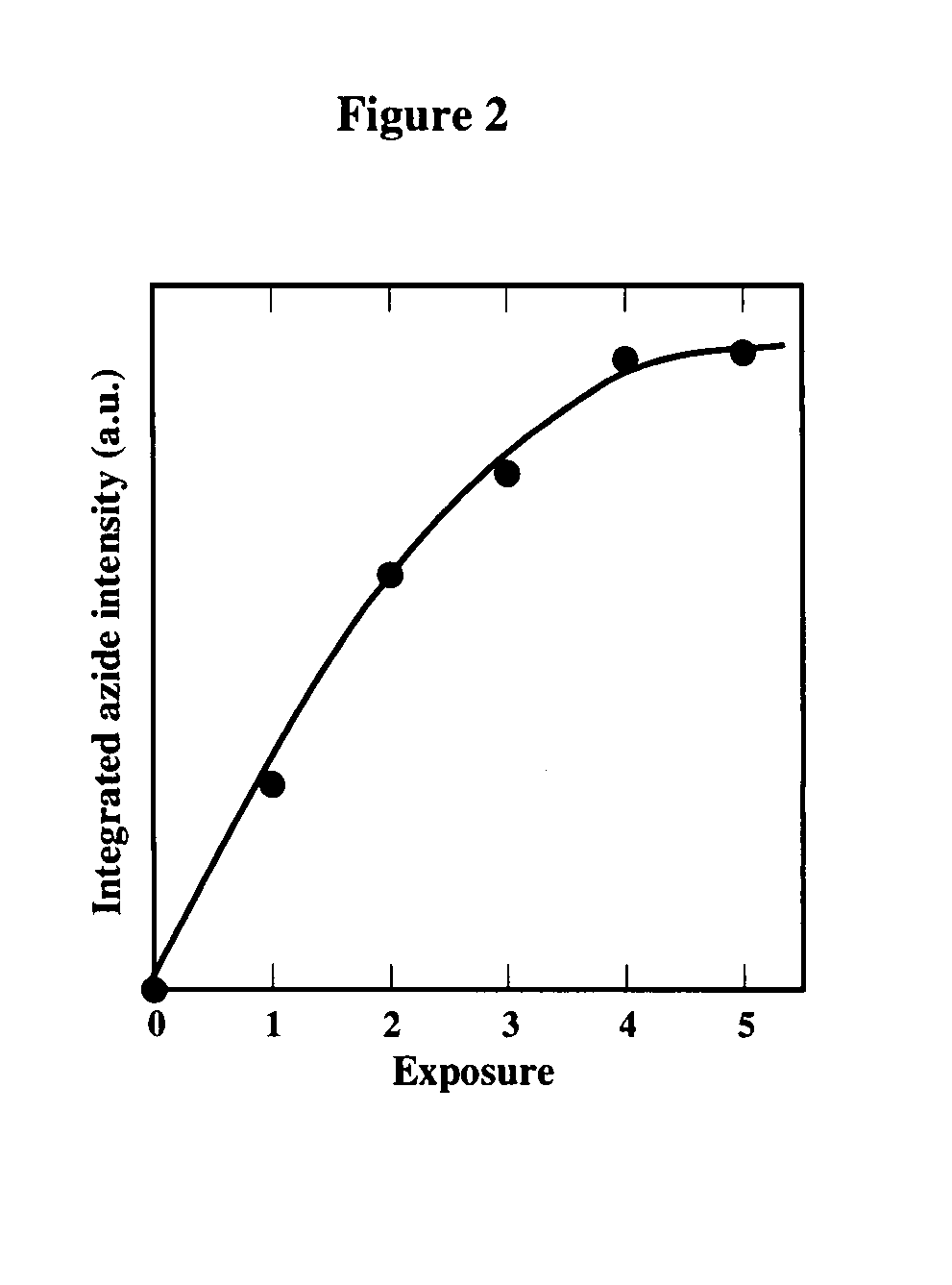

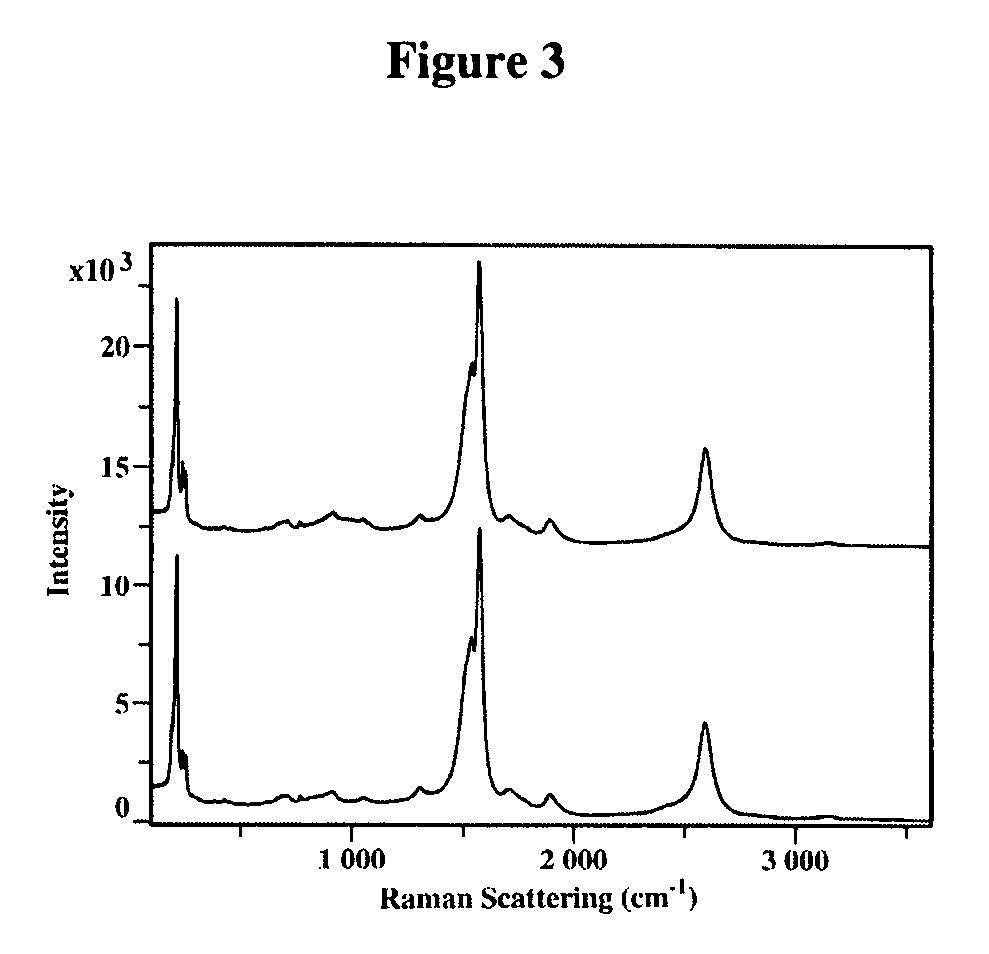

Single walled carbon nanotubes activated with hydrazoic acid

InactiveUS7879166B1Metal azide explosive compositionsMaterial nanotechnologyActivated carbonHydrazoic acid

The present invention relates generally to carbon nanotubes, and more particularly to the interaction of single wall carbon nanotubes with hydrazoic acid to introduce energetic azide groups into the nanotubes to form activated carbon nanotubes.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Method for reducing sensitivity by elastomer and graphene double coating of HMX

InactiveCN108383673AEvenly dispersedImprove conductivityNon-explosive desensitisers/phlegmatisersNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsElastomerDouble coating

The invention discloses a method for reducing sensitivity by elastomer and graphene double coating of HMX. The method comprises the following steps: (1) soaking the HMX in absolute ethyl alcohol, cleaning, then filtering and drying; (2) putting the dried HMX in a beaker, then adding an elastomer polymer solution to mix and stir and obtaining first mixed liquid; (3) adding a grapheme solution in the first mixed liquid to mix and stir till a solvent is completely volatilized and obtaining a residual solid; (4) drying the residual solid, coating an elastomer and grapheme onto the surface of the HMX by means of the adhesion force of an elastomer polymer and obtaining the double-coated HMX after the elastomer polymer is cured. When an explosive is under the loading action of force, an elastomerpolymer material can play a role in elastic energy absorption, the grapheme can play a role in reducing the friction, and the coupling effect of two sensitivity reducing mechanisms can play a role indeeply reducing the sensitivity of the HMX.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

HMX (octogen) surface coating sensitivity decreasing method

InactiveCN108329185AHigh mechanical sensitivityLow mechanical sensitivityNon-explosive desensitisers/phlegmatisersNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsChlorideAqueous solution

The invention discloses an HMX surface coating sensitivity decreasing method. The HMX surface coating sensitivity decreasing method comprises (1) preparing a polyphenol phenolic compound aqueous solution; (2) preparing a ferric chloride aqueous solution; (3) performing coating treatment, specifically, weighing out and rapidly stirring HMX particles into the polyphenol phenolic compound aqueous solution of the step (1), then adding in the ferric chloride aqueous solution, and continuing to stirring the mixture, or, rapidly stirring the HMX particles into the ferric chloride aqueous solution, then adding in the polyphenol phenolic compound aqueous solution and continuing to stir the mixture; (4) regulating the pH of the mixture; (5) performing separating treatment, specifically, water-washing, filtering, separating out and drying the HMX particles to obtain surface coating sensitivity-decreased HMX particles. The HMX surface coating sensitivity decreasing method is characterized by processing HMX, which is high in mechanical sensitivity. By means of the HMX surface coating sensitivity decreasing method, the surface-coated HMX can significantly reduce the mechanical sensitivity.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

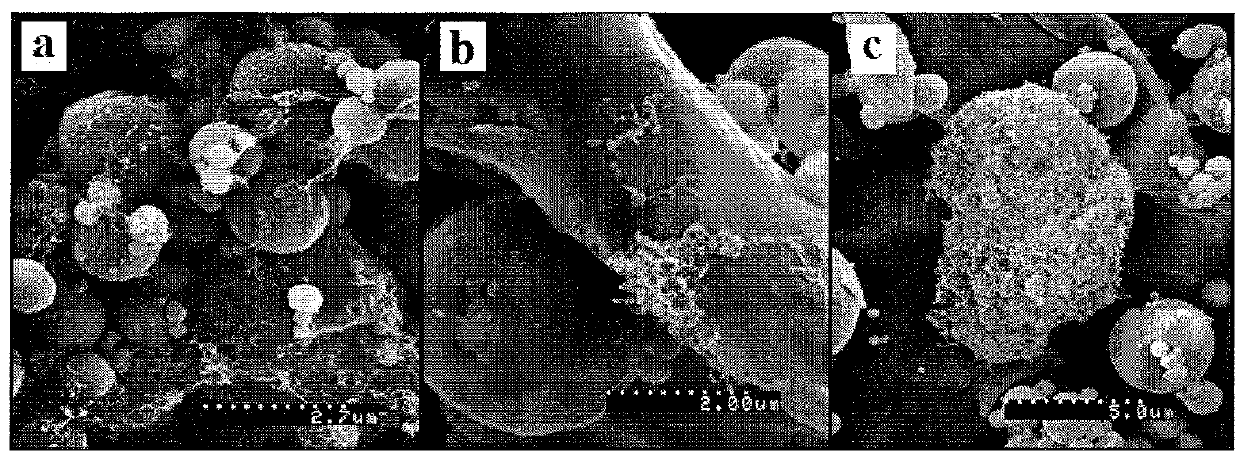

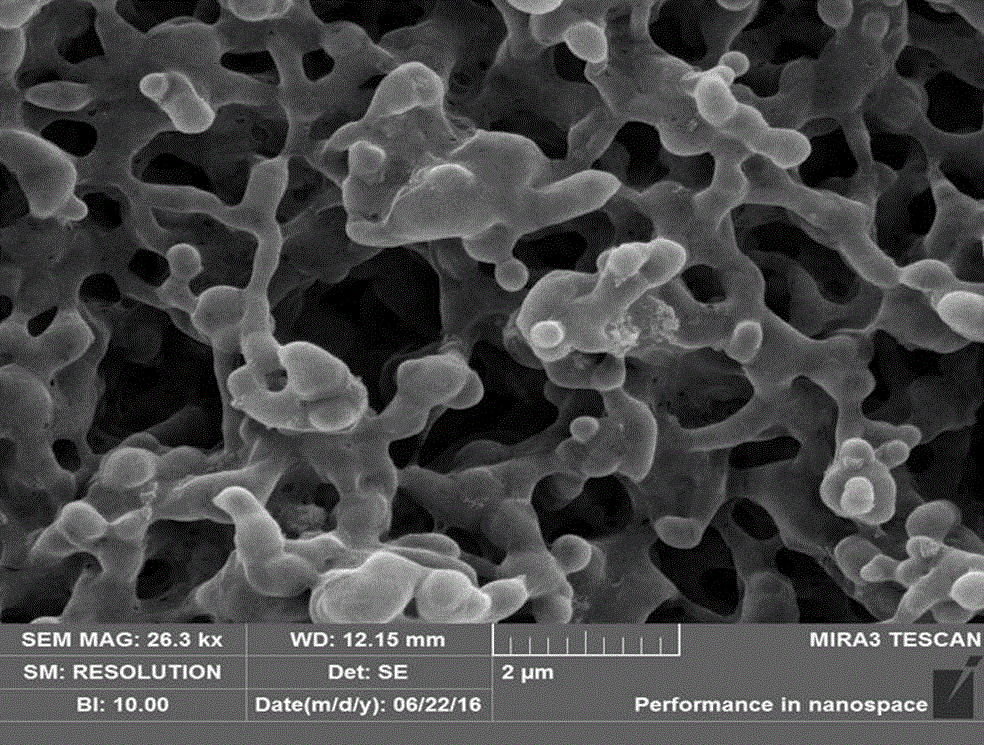

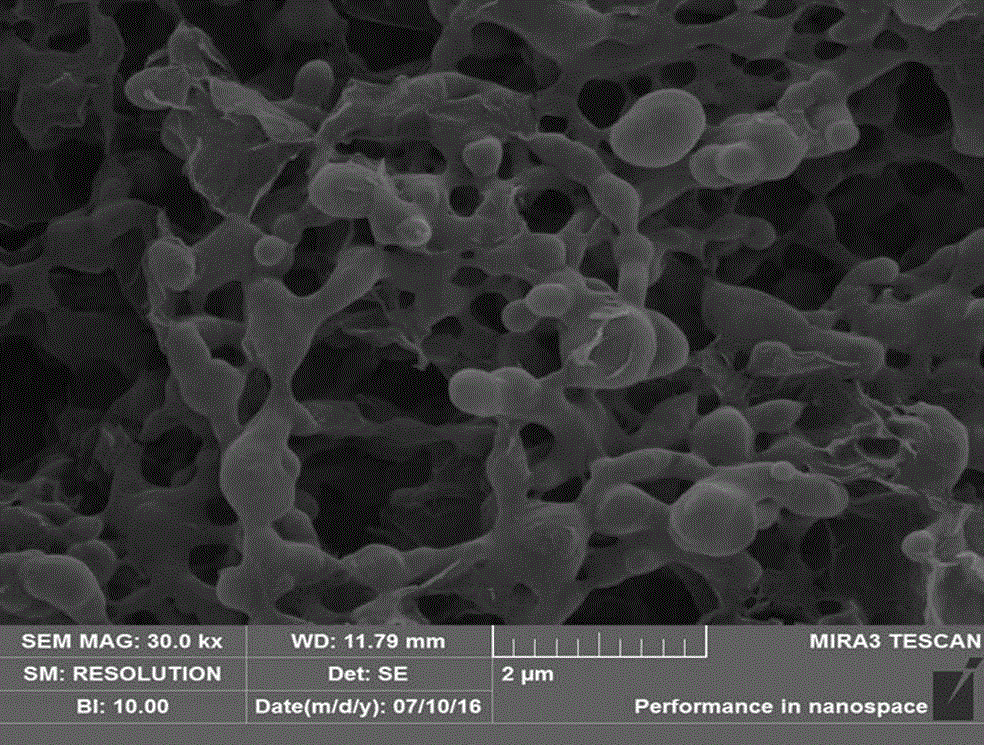

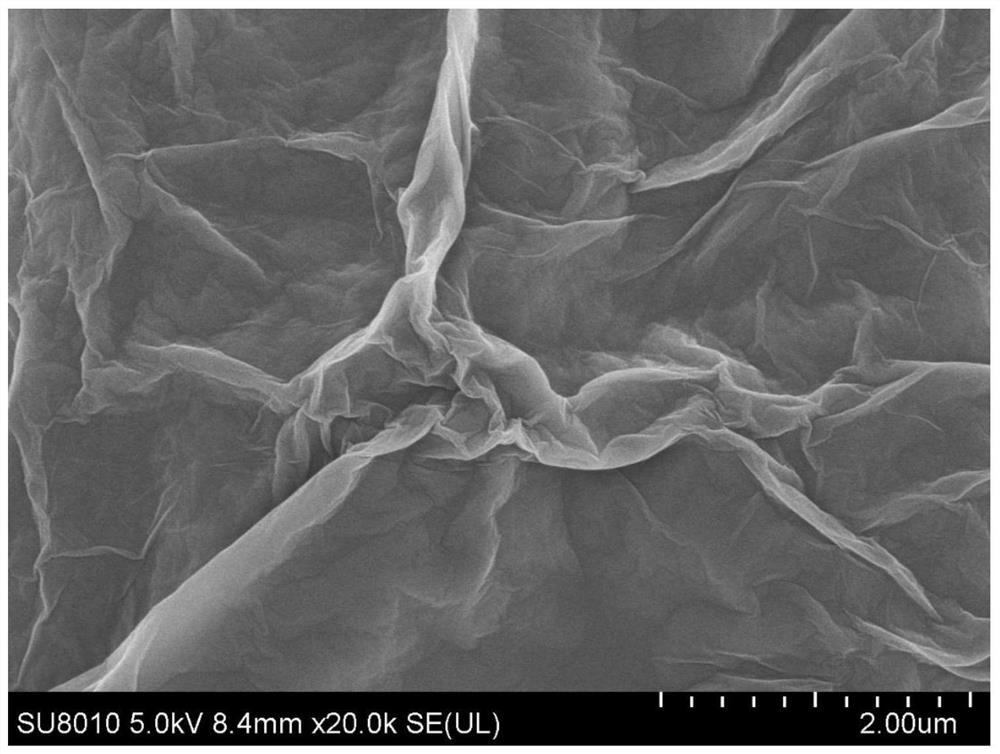

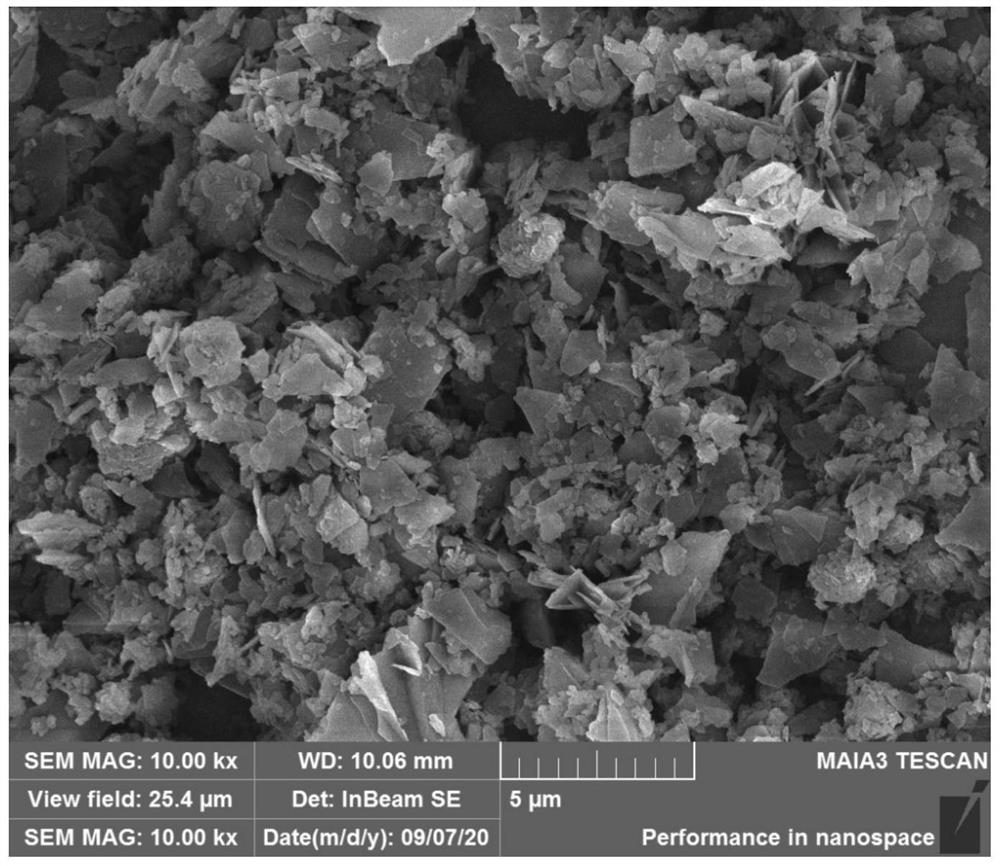

Preparation method of graphene-based composite energetic material

ActiveCN106220460ASmall particlesEvenly dispersedNon-explosive desensitisers/phlegmatisersNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsHigh energyFreeze-drying

The invention belongs to the technical field of preparation of high-energy insensitive energetic materials and in particular relates to a preparation method of a graphene / explosive composite energetic material. The preparation method comprises the following steps: mixing graphene materials with explosive in mass ratio of 1:99-5:95, putting the mixture, solution and grinding balls into a ball grinding tank, fixing on a ball milling machine, grinding for 3-10 hours at a rotating speed of 200-400r / min, then screening out the grinding balls from the obtained solution, filtering, washing, and carrying out freeze drying, so that the graphene-based composite energetic material is obtained. The method adopted by the invention realizes integration of refining and coating technology, particles of the prepared product are small and uniformly distributed, and insensitivity of graphene and graphene oxide is utilized for preparing a high-energy insensitive composite energetic material.

Owner:ZHONGBEI UNIV

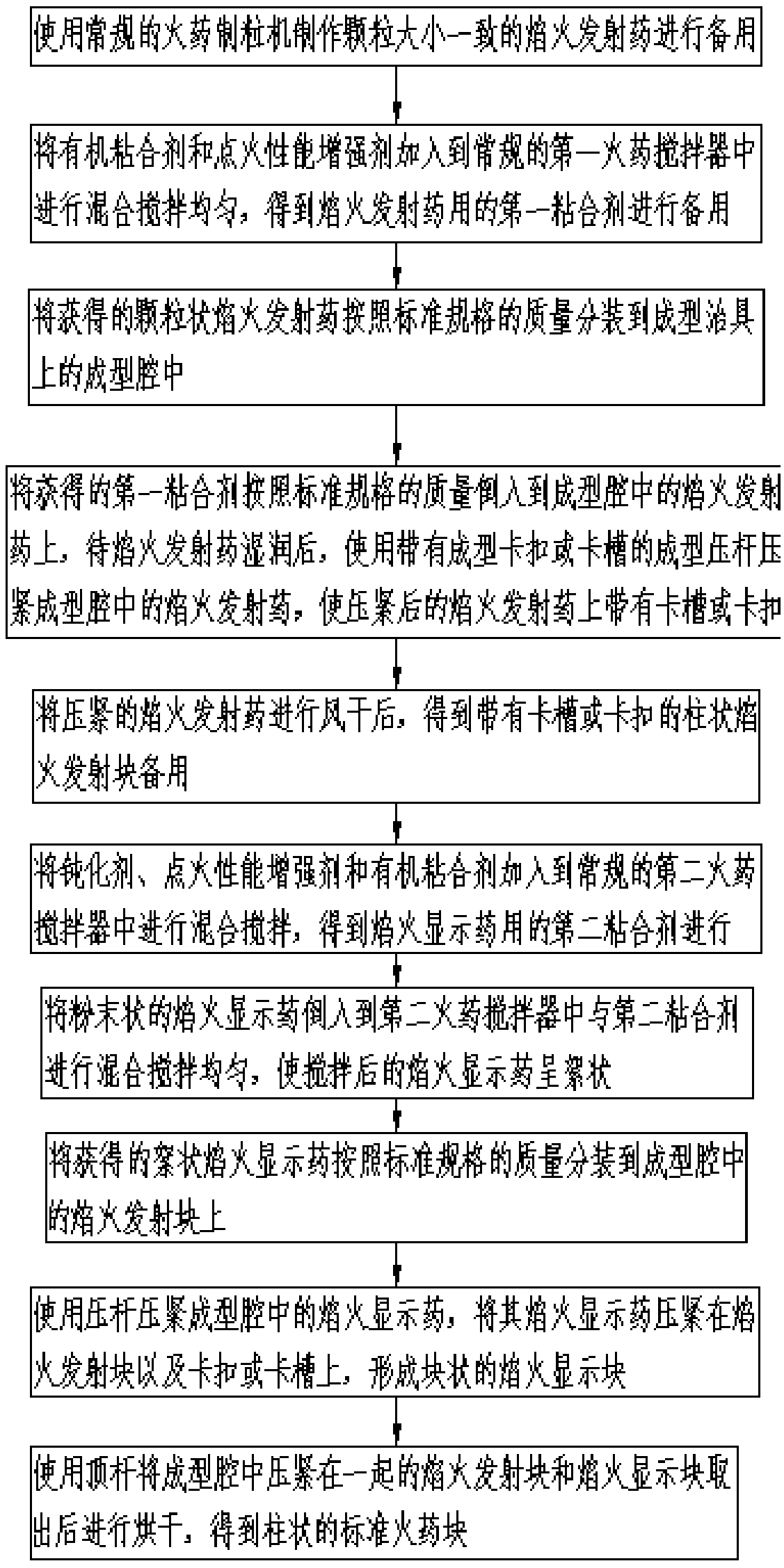

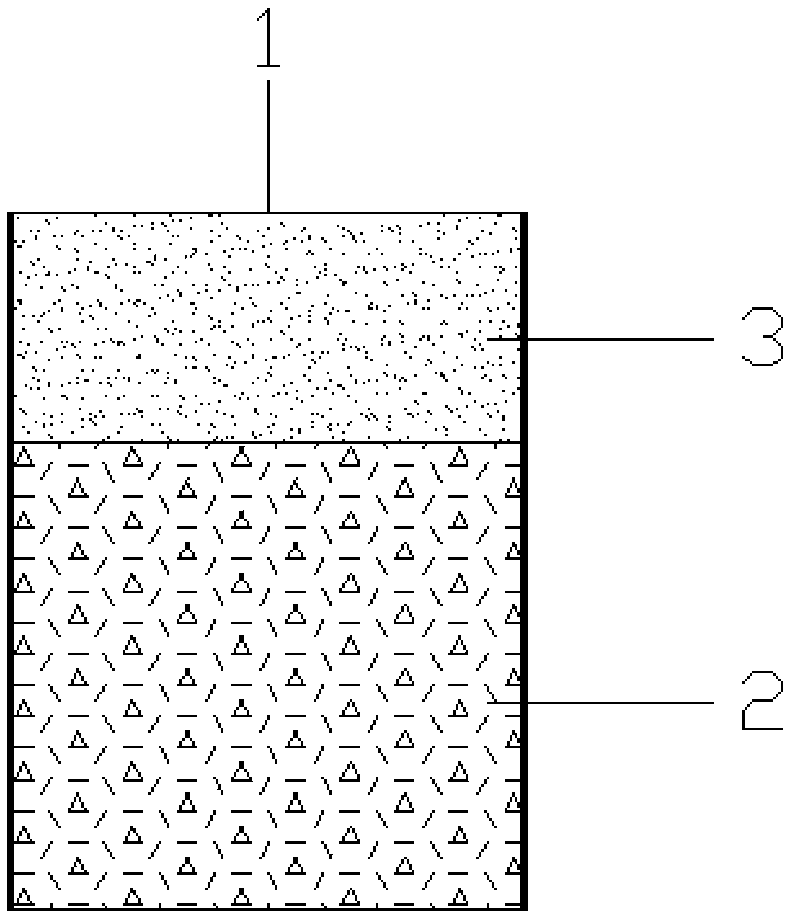

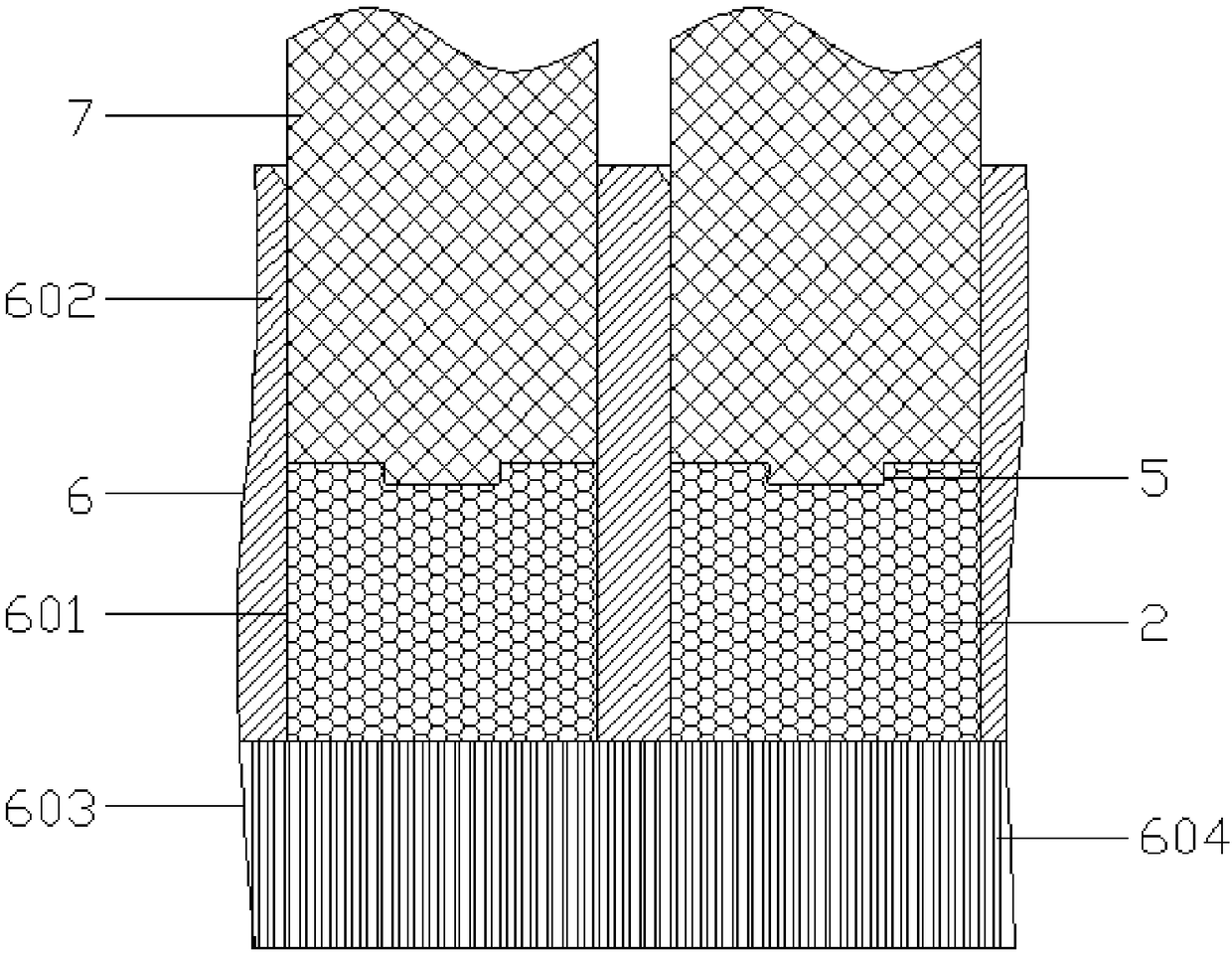

Standard gunpowder block special for fireworks lattice structural body and preparation method of standard gunpowder block

InactiveCN109443105AImprove the safety of useDot matrix helpsNon-explosive desensitisers/phlegmatisersExplosive working-up apparatusFireworksEngineering

The invention discloses a standard gunpowder block special for a fireworks lattice structural body and a preparation method of the standard gunpowder block. A standard gunpowder block body is included, the standard gunpowder block body is arranged as a columnar gunpowder block, the columnar gunpowder block is formed by connecting a flame launching block and a flame display block through a connecting piece, the connecting piece includes a buckle arranged on the flame launching block or the flame display block and a clamping groove formed in the flame display block or the flame launching block,and the buckle is connected with the clamping groove. According to the gunpowder block, the production efficiency is high, the cost is low, the production process is simple and convenient, standardized design is facilitated, the cost of graphic fireworks is reduced, the gunpowder block is suitable for wide application and promotion, and thus the graphic fireworks can meet public use; and since quantity production manufacturing is conducted though a jig, not only can the consistent proportion of drugs be ensured, but also the needs of mechanized integrated production are met, and in addition, consistent display of the fireworks lattice structural body is facilitated.

Owner:SUZHOU TIANWEIMU FIREWORKS TECH CO LTD

Low mechanical sensitiveness high-energy composite explosive and preparation method

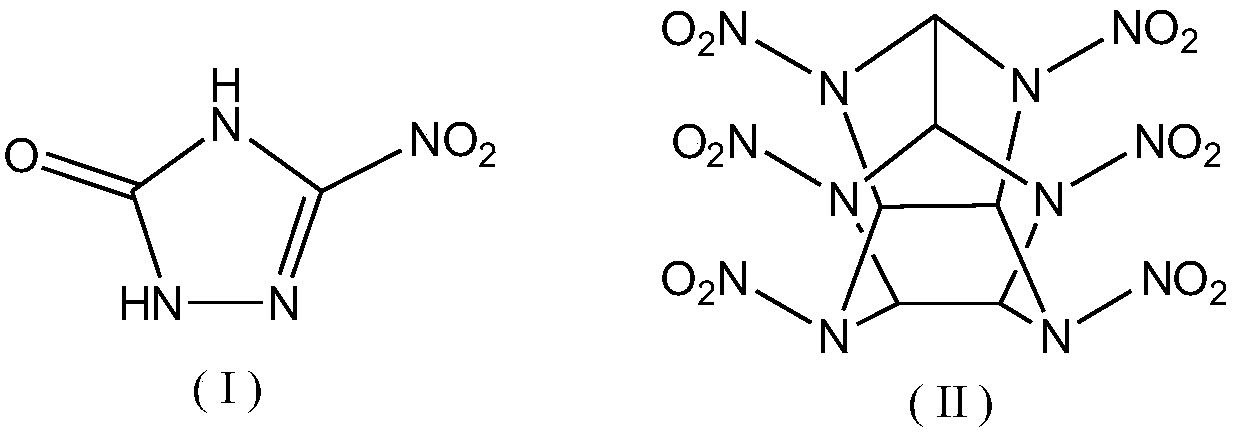

InactiveCN109053341ALow mechanical sensitivityReduced friction sensitivityNon-explosive desensitisers/phlegmatisersNitroparaffin explosive compositionsChemistryHigh energy

The invention discloses a low mechanical sensitiveness high-energy composite explosive which consists of NTO (Nitrogen Tetroxide) and CL-20, wherein the mass ratio of CL-20 to NTO is 1:(0.5-1.5). Thepreparation method comprises the following steps: putting an NTO explosive solid into water, stirring, and increasing the temperature till NTO is completely dissolved so as to obtain an NTO solution;putting the CL-20 explosive solid and a surfactant into water, controlling the temperature to be less than 20 DEG C, stirring so as to obtain a CL-20 water suspension, slowly putting the NTO solutioninto the water suspension of CL-20, filtering, washing, and drying, thereby obtaining the NTO / CL-20 composite explosive. The composite explosive disclosed by the invention has the advantages of beinghigh in density, high in explosion speed, low in mechanical sensitiveness, and the like, the mechanical sensitiveness of CL-20 is effectively degraded, and the security of CL-20 is improved.

Owner:XIAN MODERN CHEM RES INST

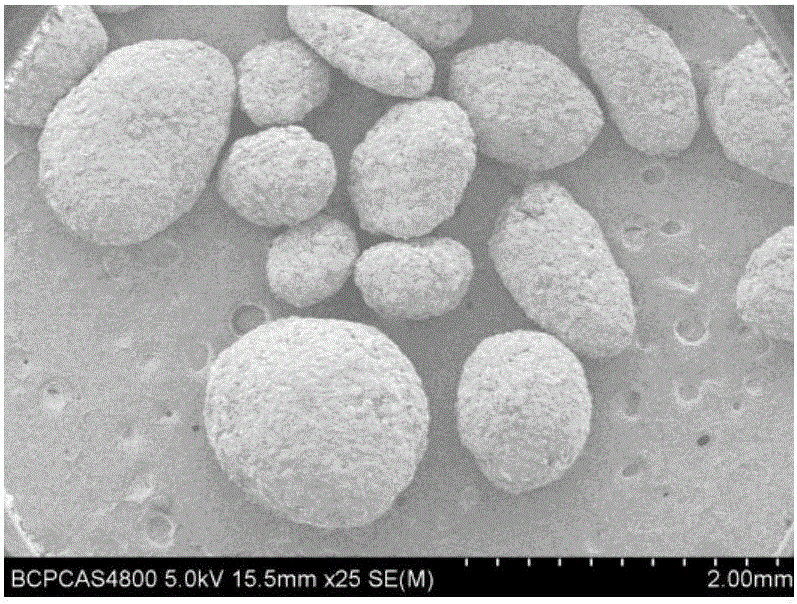

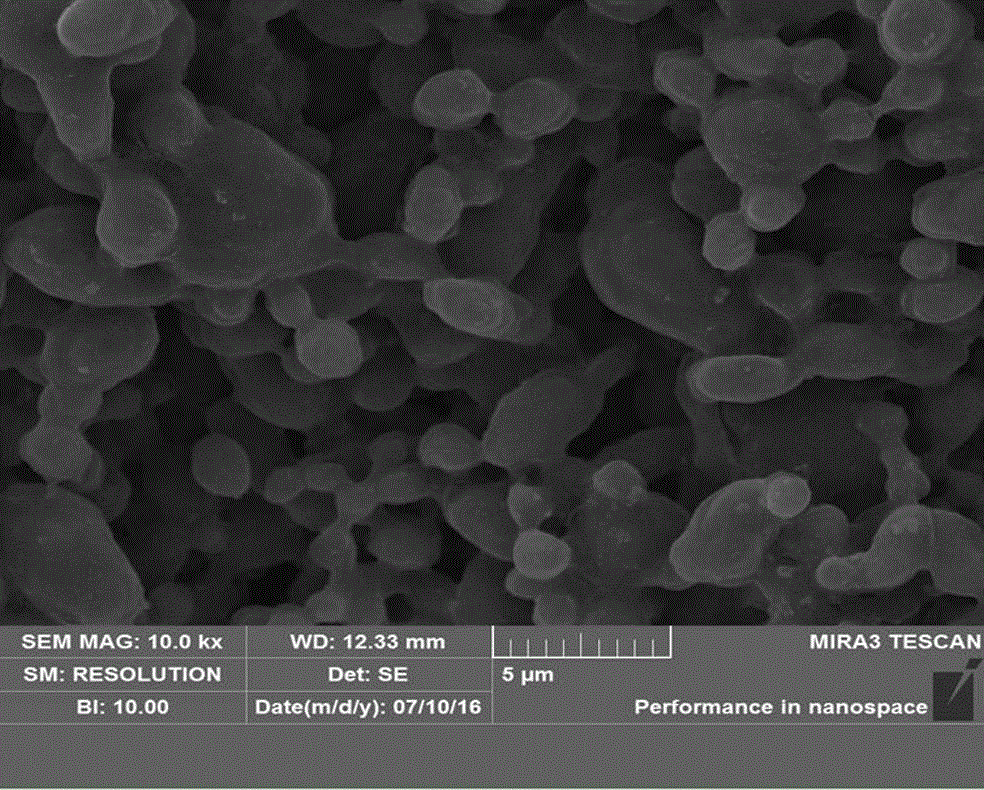

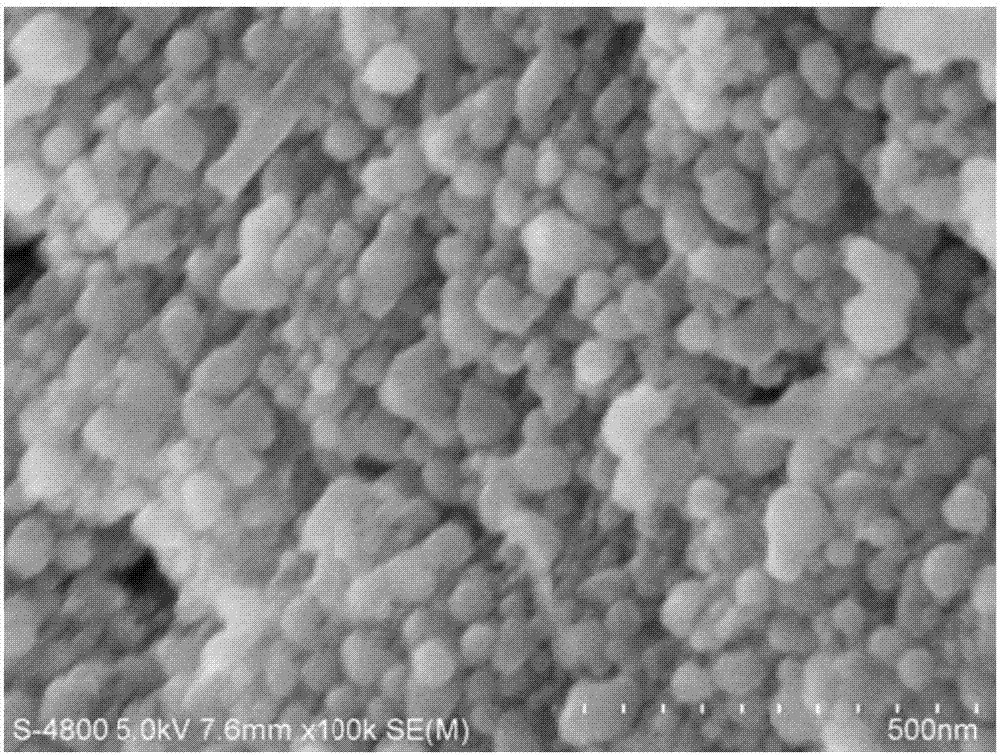

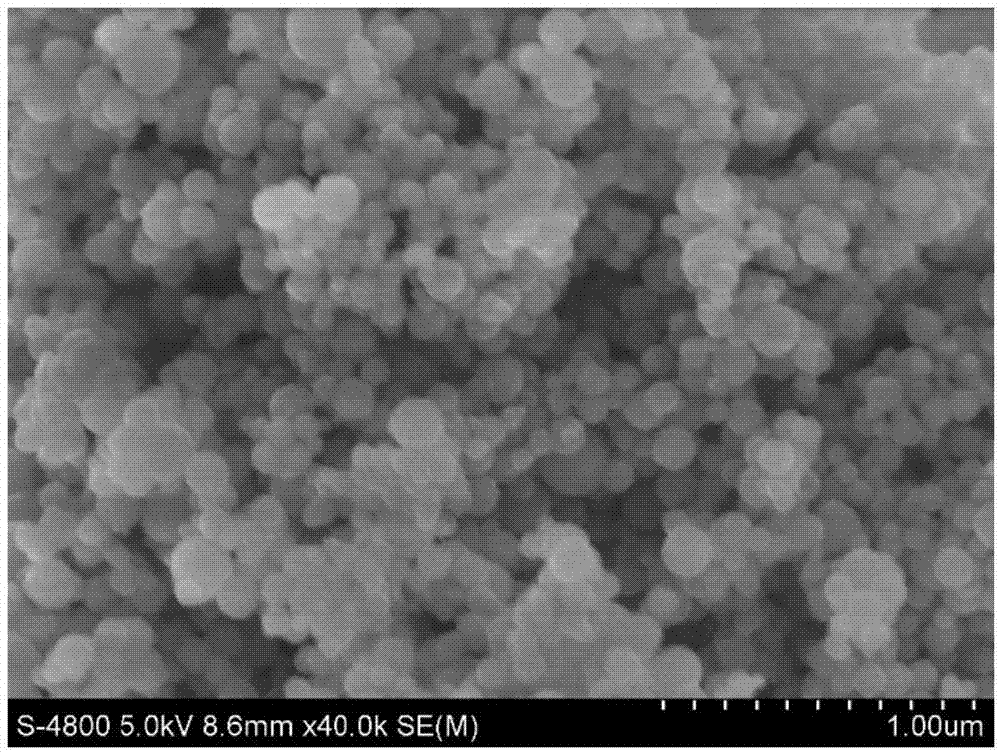

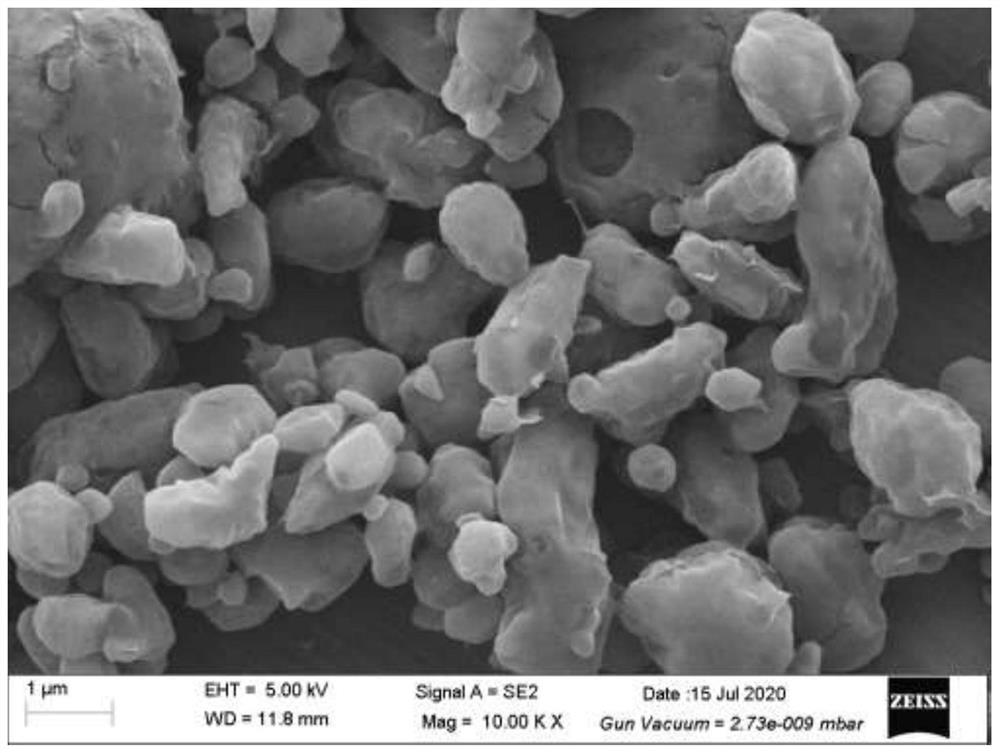

Nano-aluminum powder/paraffin energy-containing composite particle and preparation method and application thereof

InactiveCN107282919AKeep alivePrevent oxidationMaterial nanotechnologyTransportation and packagingParaffin oilsPropellant

The invention discloses a nano-aluminum powder / paraffin energy-containing composite particle, a preparation method and application of the nano-aluminum powder / paraffin energy-containing composite particle as a solid propellant. According to the energy-containing composite particle, in-situ coating is directly performed on nano-aluminum with paraffin, a dense paraffin layer is formed on the surface of the nano-aluminum, and finally the formed spherical or approximately-spherical particle is the energy-containing composite particle. The nano-aluminum powder / paraffin energy-containing composite particle and the preparation method and application thereof have the advantages that the prepared energy-containing composite particle is adjustable in particle size, high in activated aluminum content and good in stability and can be served as an incendiary agent to be widely applied to the propellant.

Owner:NANJING NORMAL UNIVERSITY

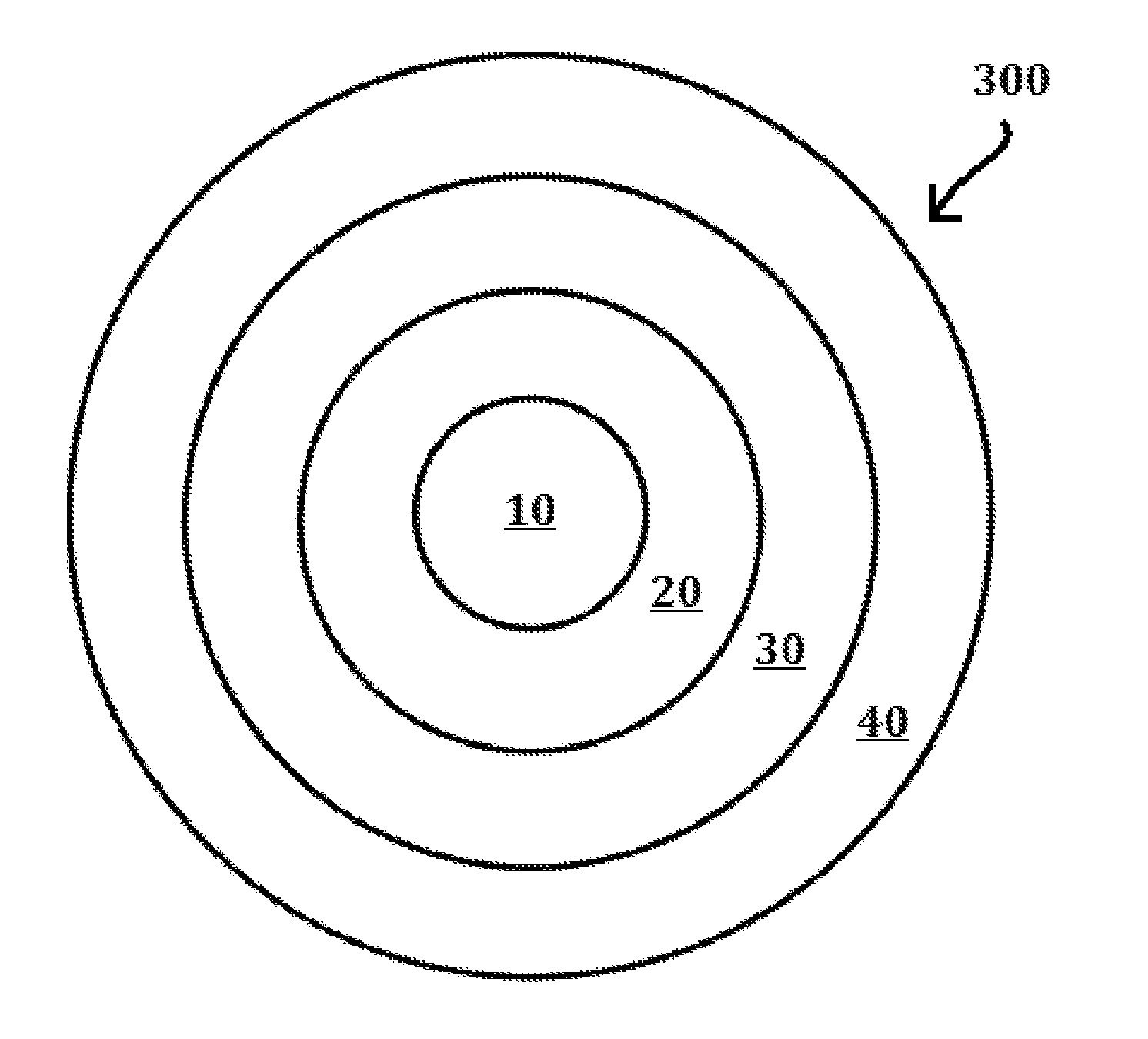

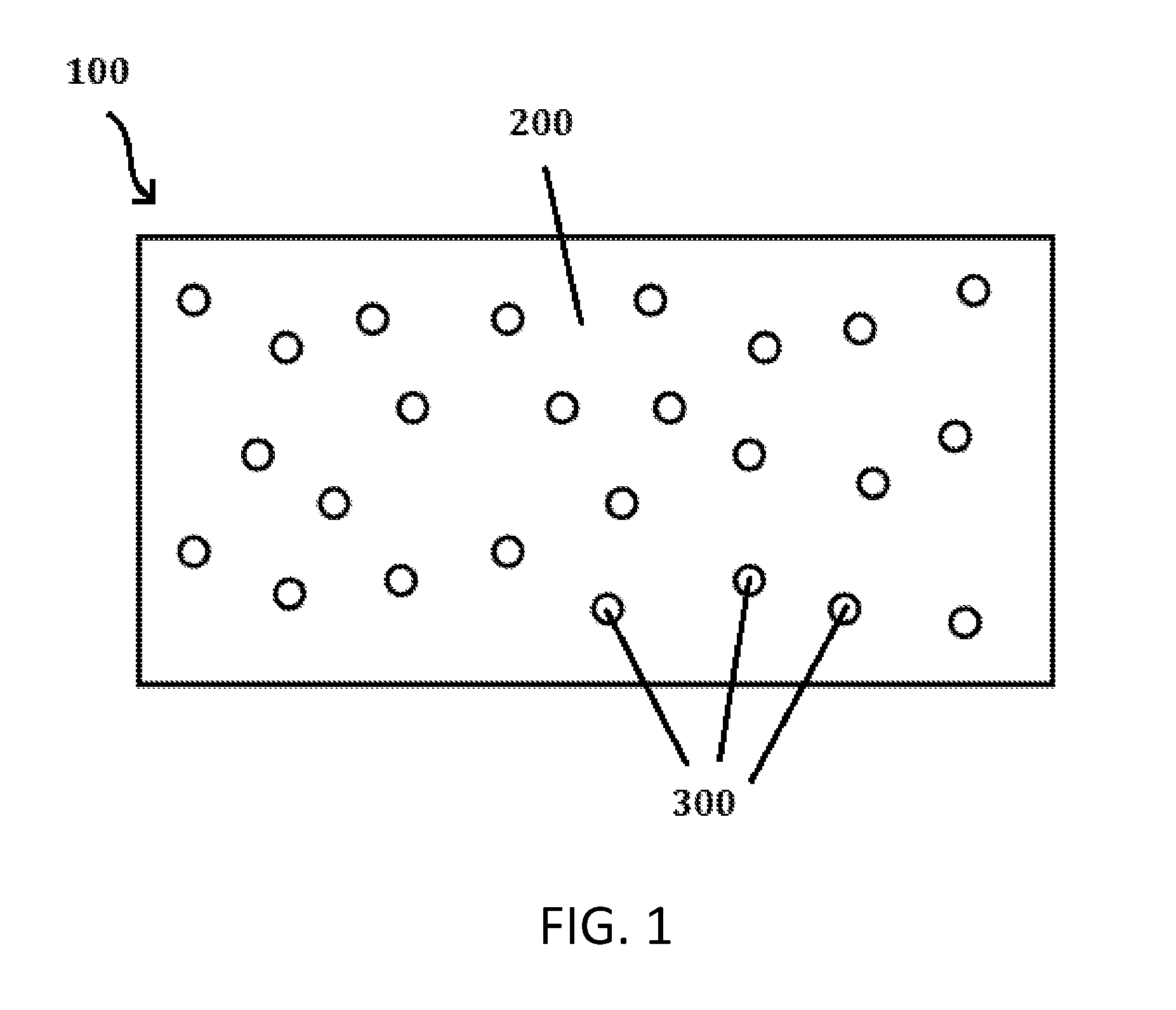

Polymer composite comprising metal based nanoparticles in a polymer matrix

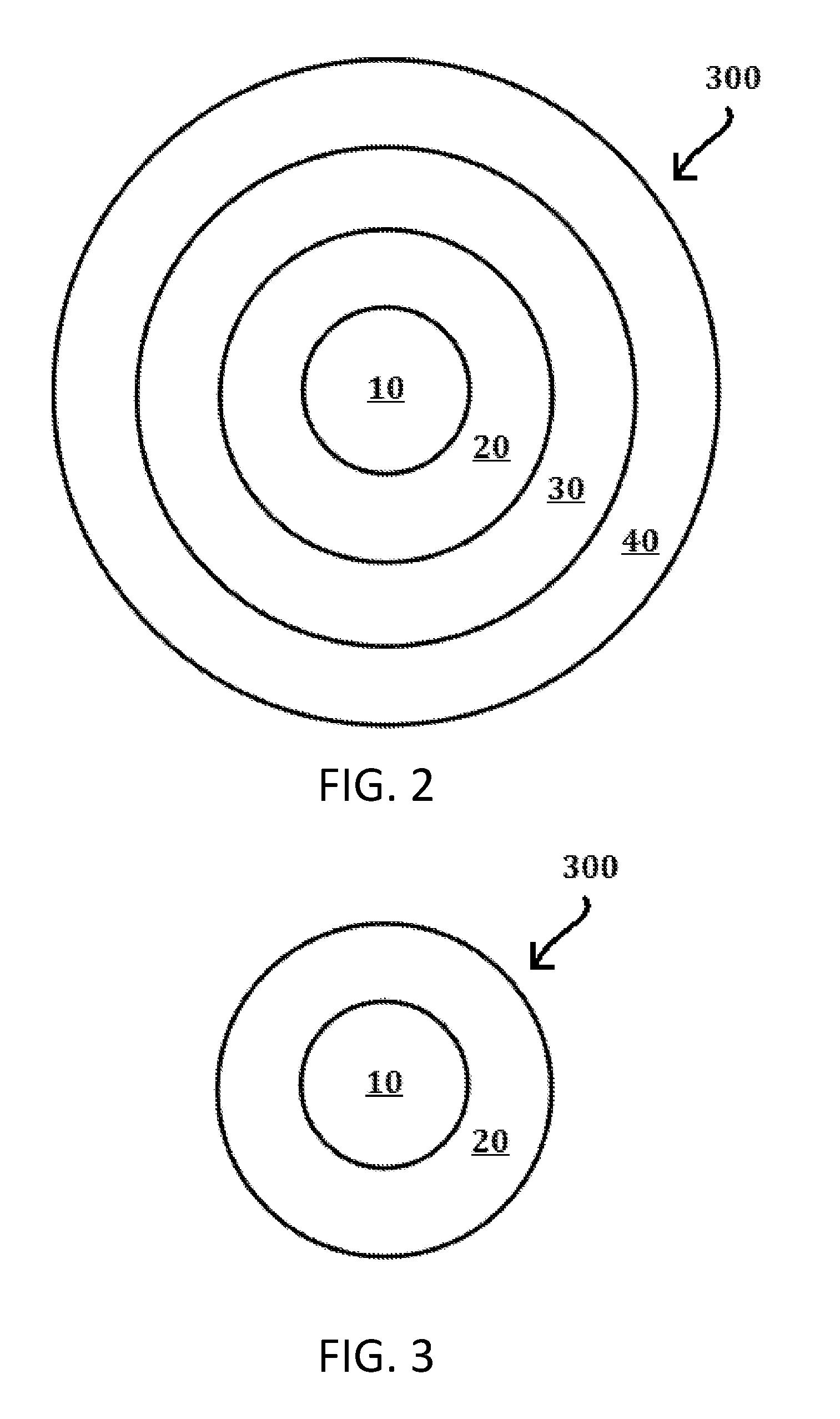

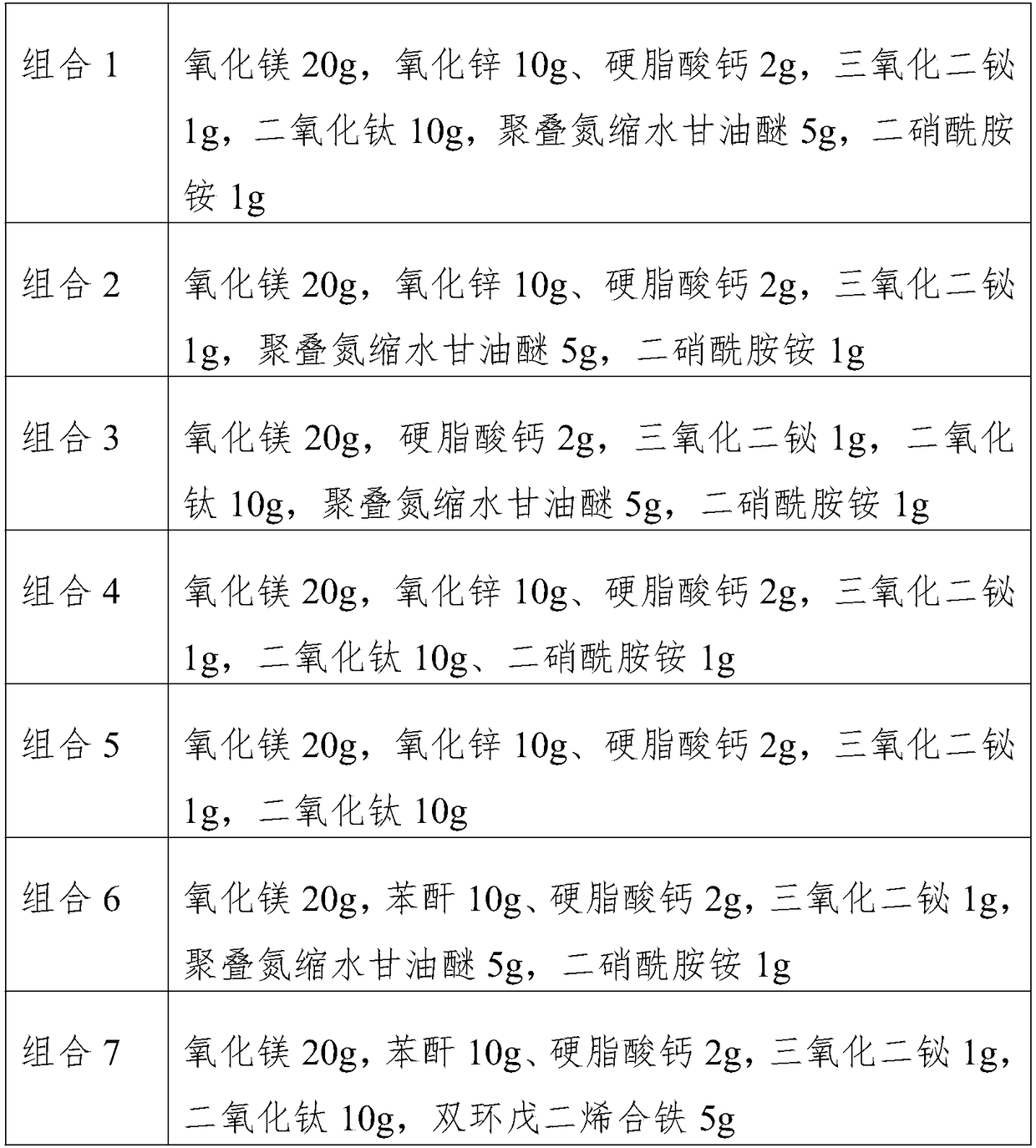

ActiveUS9446994B1LoomsNon-explosive desensitisers/phlegmatisersPolymer scienceCore shell nanoparticles

A composite having a substrate and a plurality of core-shell nanoparticles. The substrate has microporosity, nanoporosity, or free volume and is a polymer matrix, a metal-organic framework, a micro-porous structure, or a nano-porous structure. The plurality of core-shell nanoparticles each has a core and at least one shell layer. The core is made from a decomposed product of a first precursor disposed in the microporosity, nanoporosity, or free volume of the substrate. The at least one shell layer is made from a decomposed product of a second precursor and is disposed on the core.

Owner:CORNERSTONE RES GROUP

Wax composite insensitive agent with adjustable friction coefficient and preparation method thereof

PendingCN108456124ALow mechanical sensitivityImprove securityNon-explosive desensitisers/phlegmatisersNitroparaffin explosive compositionsWaxEnergetics

The invention belongs to the field of energetics, and particularly provides a wax composite insensitive agent with an adjustable friction coefficient and a preparation method thereof. The wax composite insensitive agent comprises wax materials and functional agents; the functional agents are selected from at least one of graphene, graphene oxide, nitrified graphene, fluoridized graphene, molybdenum disulfide, tungsten disulfide, graphene and carbon nanotube. The adjustable range of the friction coefficient of the wax composite insensitive agent is 0.03-0.25, the content of the composite insensitive agent only covers 1.5%-3% of the mass of energetic compounds such as RDX, HMX, CL-20, AP and the like, mechanical sensitivity of the energetic compounds can be significantly reduced, the safetyperformance of the energetic compounds can be greatly improved to further improve the content application safety performance of the energetic compounds in the energetic materials such as composite explosive, propellent and the like, and the preparation method is simple in process, economic and effective.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Metal hydride in situ polymerization and cladding passivation method

ActiveCN107021864AEnergy traits are not affectedImprove stabilityNon-explosive desensitisers/phlegmatisersAcetic acidIn situ polymerization

The invention discloses a metal hydride in situ polymerization and cladding passivation method, and is characterized by comprising the following steps: (1) dissolving 3,3-diazido methyloxetane and tetrahydrofuran (BAMO-THF) copolyether and a curing agent into anhydrous ethyl acetate, and preparing into a dilute solution; (2) putting metal hydride into the dilute solution and performing ultrasonic dispersion to form suspension liquid; (3) stirring and warming to the temperature of 40 to 60 DEG C, stirring for reaction, and recycling the solvent ethyl acetate by evaporation after the reaction is ended; (4) a product obtained after the solvent is removed completely by evaporation is dried and cured in a drying oven, so as to obtain the clad passivated metal hydride. According to the metal hydride in situ polymerization and cladding passivation method provided by the invention, the BAMO-THF copolyether is used for in situ polymerization and cladding of the metal hydride, and the treated and obtained metal hydride is insensitive to water in air. The own energy performance of the metal hydride is not affected while passivating the metal hydride.

Owner:河南纳宇新材料有限公司

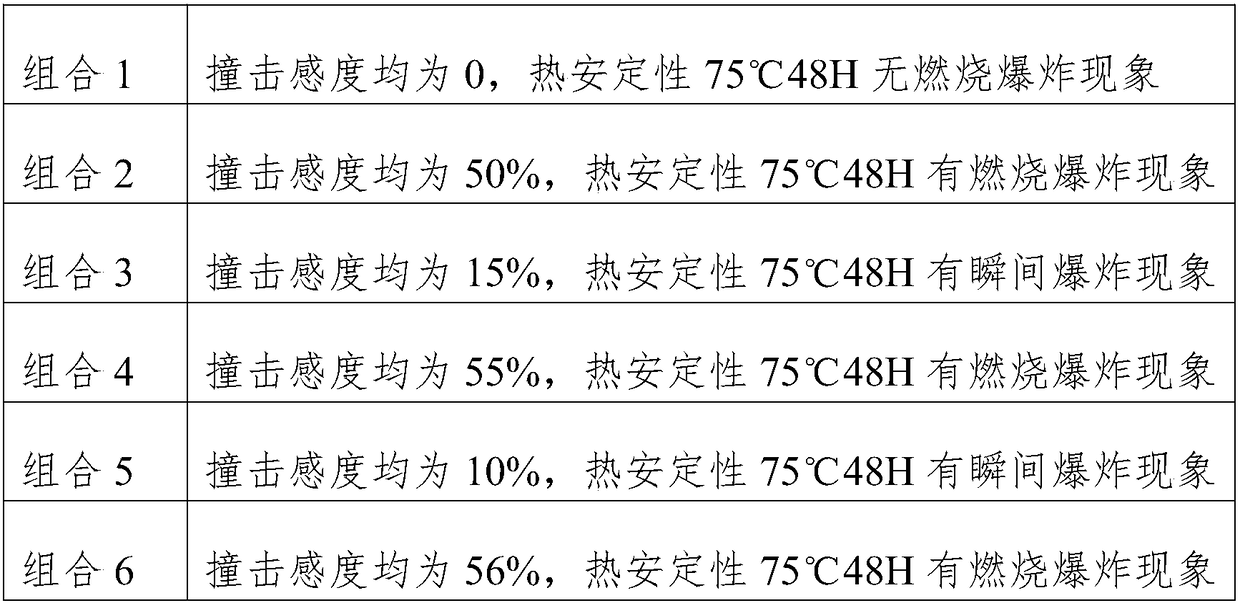

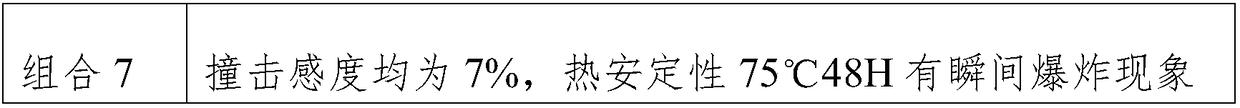

Desensitizer for pyrotechnic composition and preparation method

InactiveCN108440225AImprove diffusivityImprove moisture resistanceNon-explosive desensitisers/phlegmatisersFireworksMoisture resistance

The invention relates to the technical field of fireworks and firecrackers, in particular to a desensitizer for pyrotechnic composition and preparation method. According to the parts by weight, the desensitizer for pyrotechnic composition comprises 20-30 parts of magnesium oxide, 10-15 parts of zinc oxide, 2-4 parts of calcium stearate, 1-5 parts of antimony trioxide, and 10-15 parts of titanium dioxide, 5-10 parts of polyazide glycidyl ether, 1-3 parts of ammonium dinitramide. The desensitizer for pyrotechnic composition has good diffusion performance, moisture resistance, stability and invariability, which can be stored for a long time without deterioration and can better mix the other components of pyrotechnics.

Owner:余庆县东瑞烟花爆竹有限责任公司

Induced crystallization method of ammonium salt

InactiveCN108409513ARegular shape structureLow impact sensitivityNon-explosive desensitisers/phlegmatisersNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsPhysical chemistryGraphite

The invention relates to an induced crystallization method of an ammonium salt and belongs to the field of processing and preparation of materials. The method comprises the following steps: taking graphene and an energy-containing inorganic ammonium salt as raw materials, carrying out induced crystallization and compounding the energy-containing organic ammonium salt on graphene to prepare a graphene / energy-containing inorganic ammonium salt composite material; the morphology of the inorganic ammonium salt can be effectively improved; and the safety of the energy-containing inorganic ammoniumsalt can be improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Impact resistant explosive compositions

ActiveUS7744710B2Non-explosive fillers/gelling/thickening agentsNon-explosive desensitisers/phlegmatisersExplosive AgentsSucrose

An explosive composition comprising a high density hydrocarbon compound selected from the group consisting of xylitol, sucrose, mannitol, and mixtures thereof and at least one energetic material. The high density hydrocarbon compound and the at least one energetic material form a substantially homogeneous explosive composition. A method of producing an explosive composition that is insensitive to impact is also disclosed.

Owner:NORTHROP GRUMMAN SYST CORP

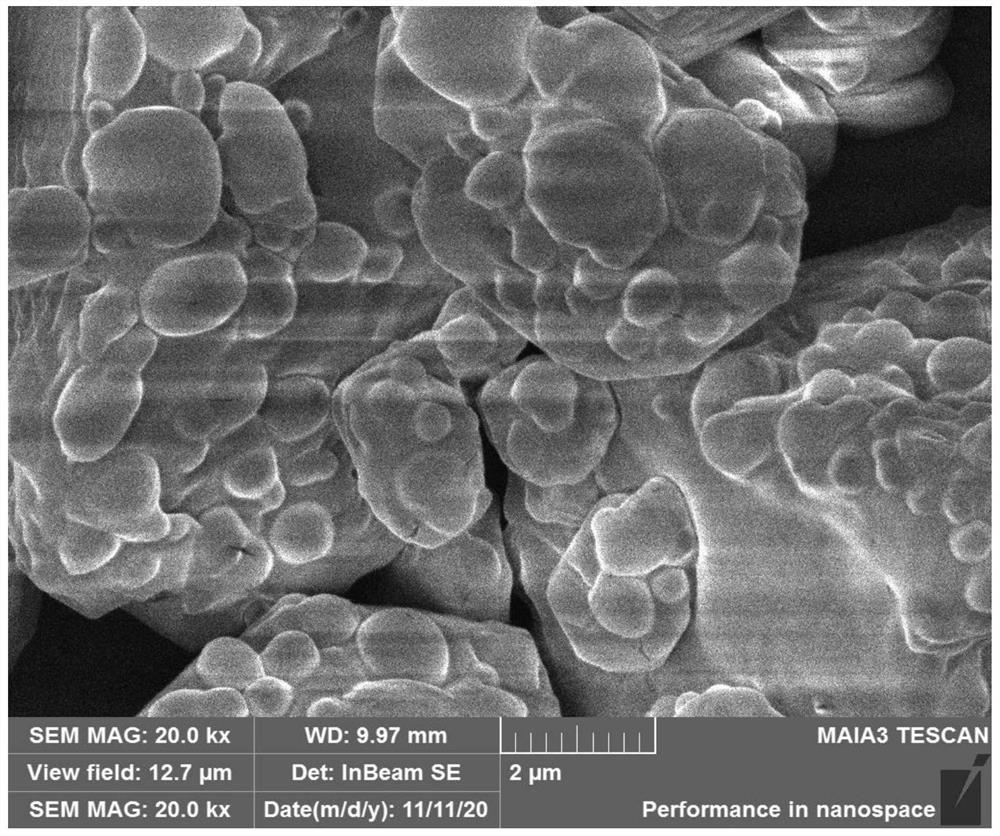

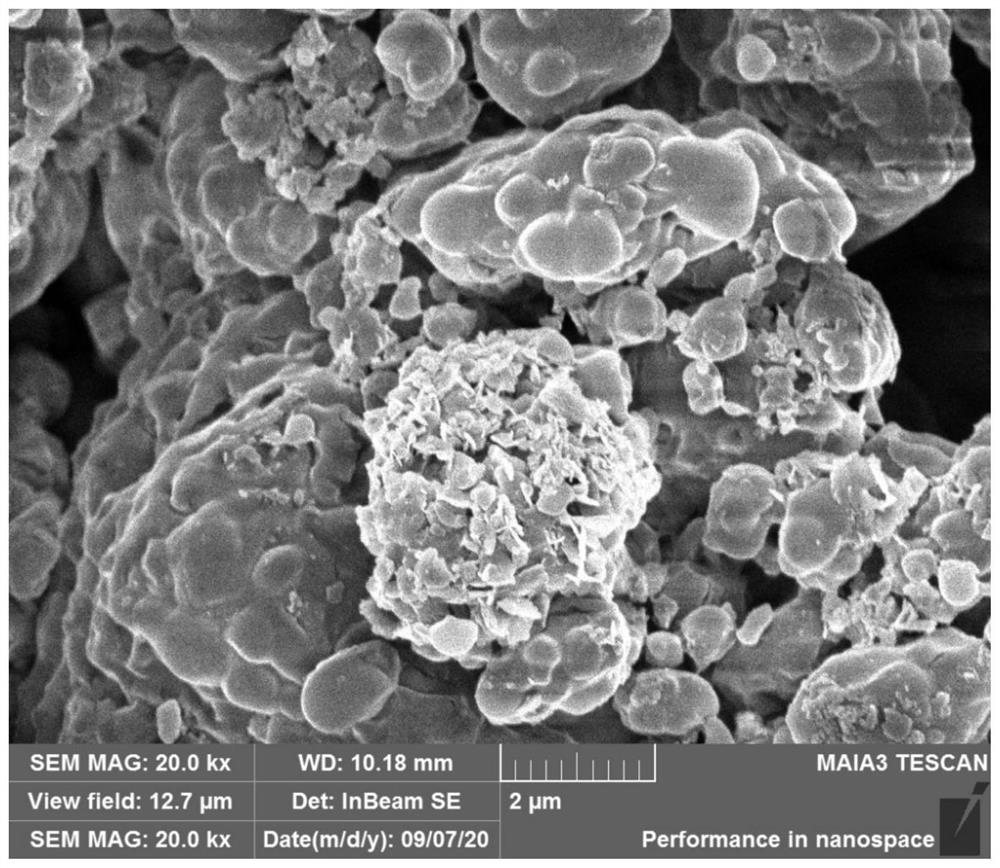

Polyethyleneimine reinforced graphene insensitive energetic material and preparation method thereof

InactiveCN111925261AImprove the wrapping effectImprove the desensitization effectNon-explosive desensitisers/phlegmatisersExplosive ingredient compoundingGrapheneAqueous solution

The invention discloses a polyethyleneimine reinforced graphene insensitive energetic material and a preparation method thereof. The preparation method includes the following steps that the energeticmaterial is dispersed in a water phase, a polyethyleneimine aqueous solution is slowly added under the stirring condition to obtain a first mixed solution, and the mass ratio of the energetic materialto polyethyleneimine is 98: (0.05-1.95); under the stirring condition, a graphene dispersion aqueous solution is added into the first mixed solution, a second mixed solution is obtained, and the massratio of polyethyleneimine to graphene is 1.95: 0.05-0.05: 1.95; the second mixed solution is continuously stirred for 2-10 hours to obtain a suspension; and the suspension is filtered, washed and dried to obtain the polyethyleneimine reinforced graphene insensitive energetic material. According to the method, the interaction between the insensitive agent and the energetic material can be enhanced, and the mechanical sensitivity of the energetic material is reduced.

Owner:SOUTHWEAT UNIV OF SCI & TECH

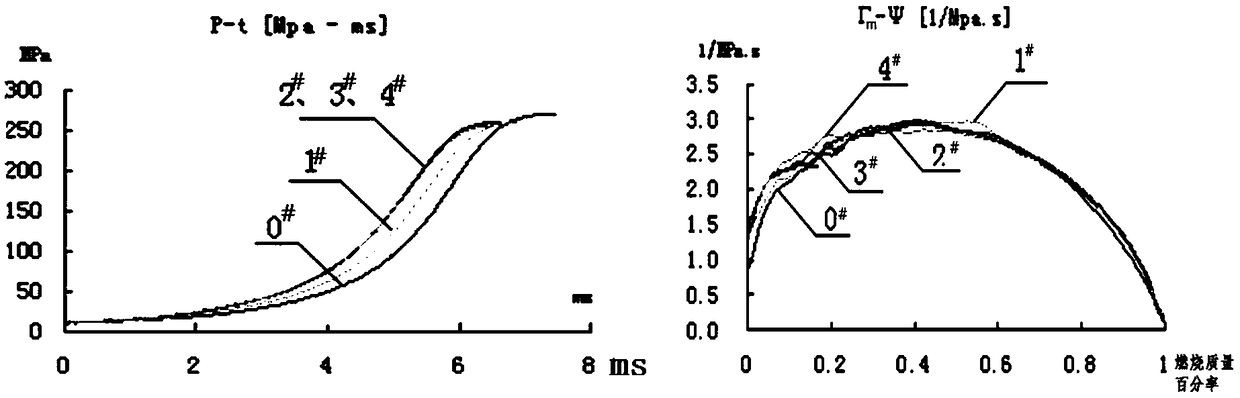

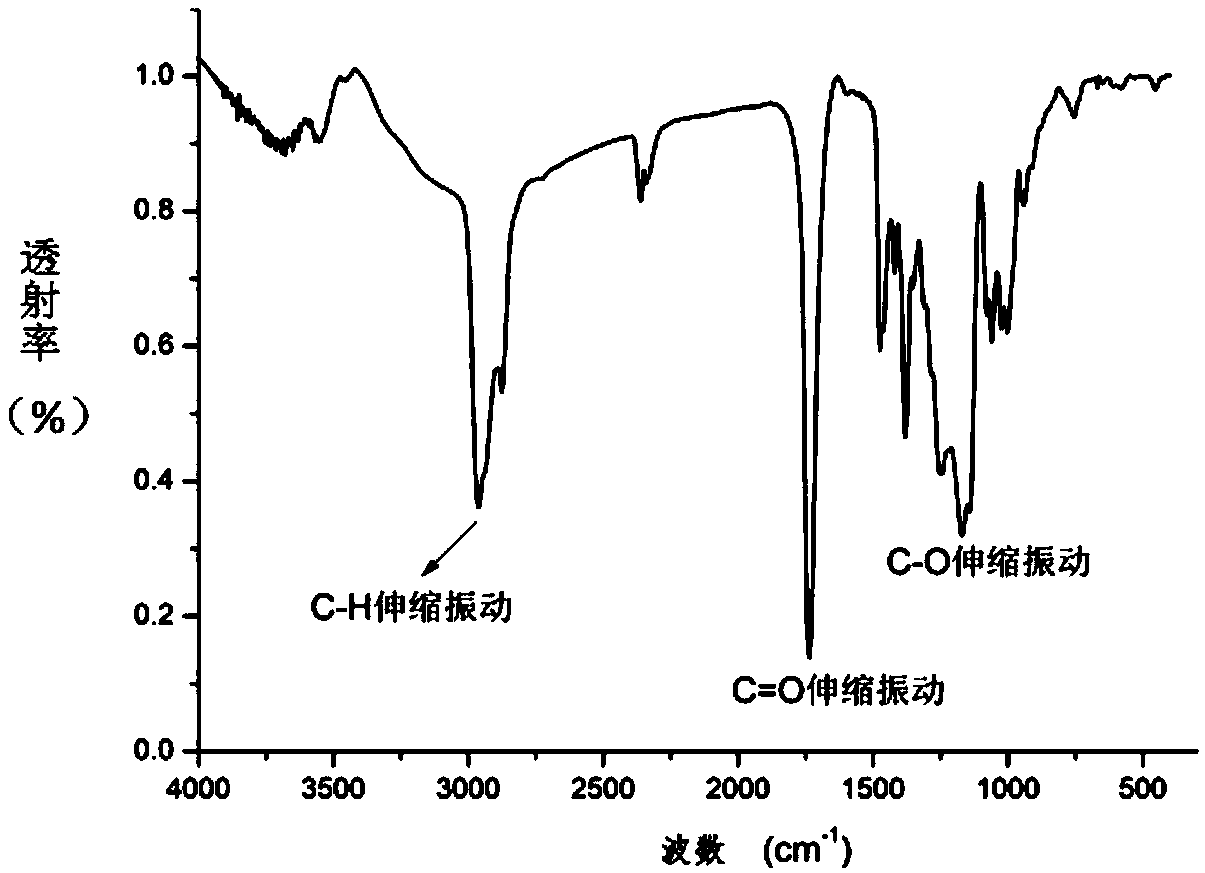

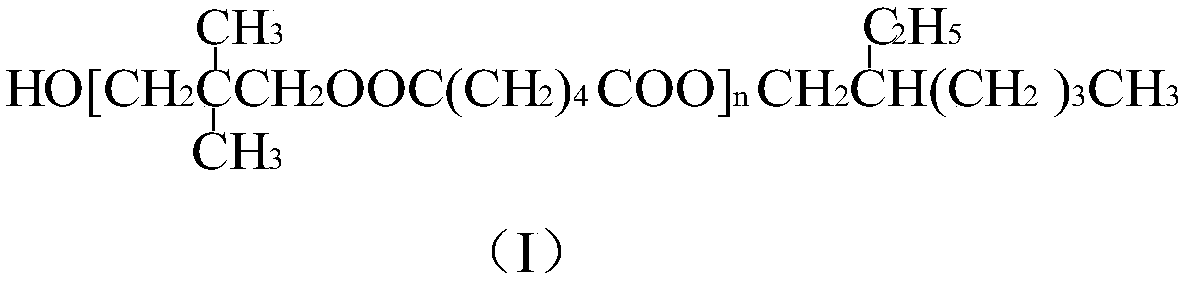

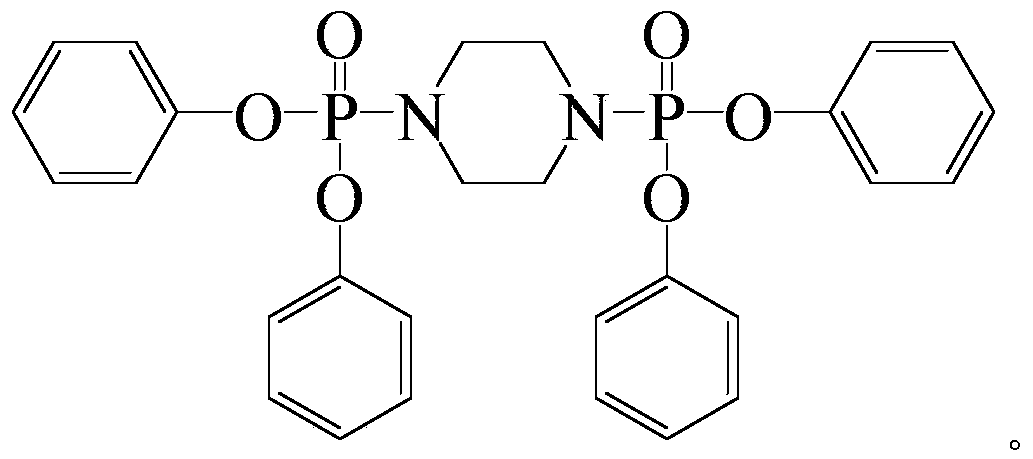

Deterrent for double-base propellant, and preparation method and application of deterrent

InactiveCN109320384AGuaranteed service lifeKeep healthyNon-explosive desensitisers/phlegmatisersSteam pressurePhysical well being

The invention provides a deterrent for a double-base propellant, and a preparation method and application of the deterrent. The deterrent for the double-base propellant belongs to a macromolecular polymer deterrent, compared with a small-molecule deterrent, the macromolecular deterrent is small in volatility and quite slow in diffusion due to the large molecular weight and low steam pressure of the macromolecular deterrent, and thus the deterrent has the good anti-mobility under the long storage condition; the propellant desensitized by the deterrent can significantly relieve the mobility problem of long-term storage, thus the normal service life of the propellant can be ensured, the efficient deterrent propellant with long storage performance being capable of meeting the using requirements can be obtained, and the ballistic performance of ammunition is not affected; and in addition, the macromolecular polymer deterrent adopted by the double-base propellant has no toxicity to the humanbody, and the health of a user can be ensured.

Owner:LUZHOU NORTH CHEM IND

Method for producing explosive insensitive wax

ActiveCN107523351AEasy dischargeNo pollution in the processWax physical treatmentNon-explosive desensitisers/phlegmatisersWaxProduct gas

The invention discloses a method for producing an explosive insensitive wax. According to the method, on the basis of a common sweating technology, air flow is utilized to carry liquid oil by a wax layer so as to forcefully separate the wax from the oil in a sweating process, and meanwhile, optimally, the raw material wax and aqueous solutions of more than two matters capable of reacting and generating gas are respectively emulsified and then sweated and the quick emission of the oil is benefited, so that an explosive insensitive wax product with low oil content can be produced according to a sweating de-oiling method. The method disclosed by the invention has the advantages of low equipment investment, simple preparation process, low operation cost, safety, energy-saving effect, no solvent pollution, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oil penetration-preventing polymer-bonded explosive containing paraffin microcapsules and preparation method of explosive

ActiveCN106365931APrevent seepageImprove mechanical propertiesNon-explosive desensitisers/phlegmatisersAmmonium perchlorate explosive compositionsShock waveParaffin wax

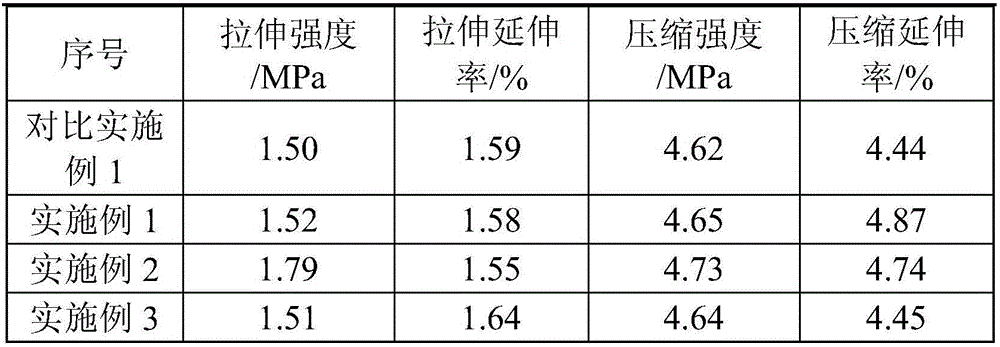

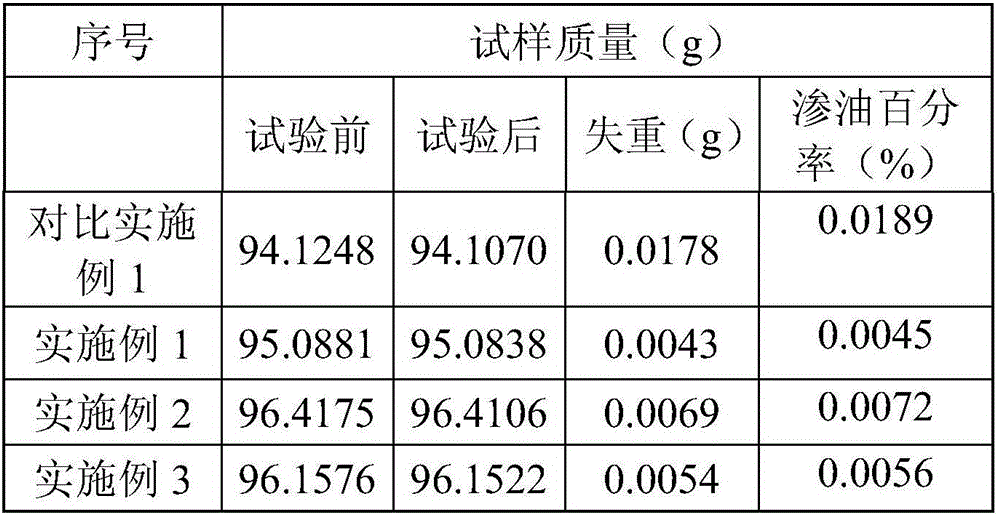

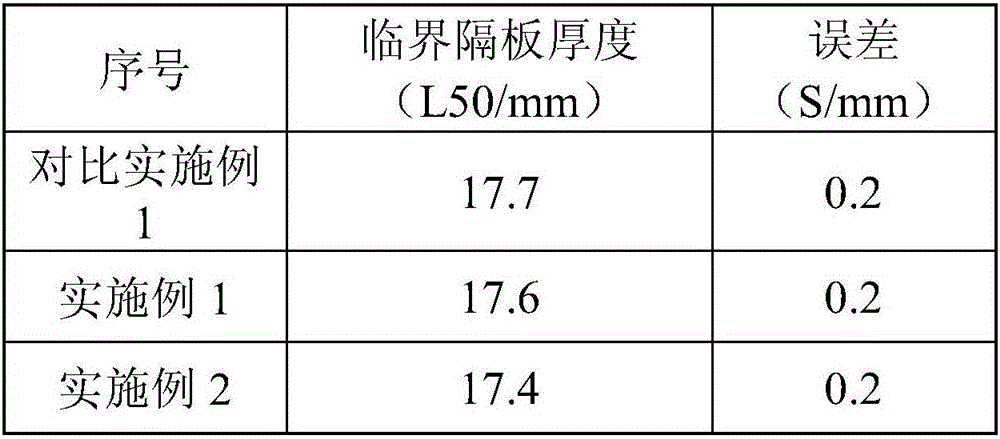

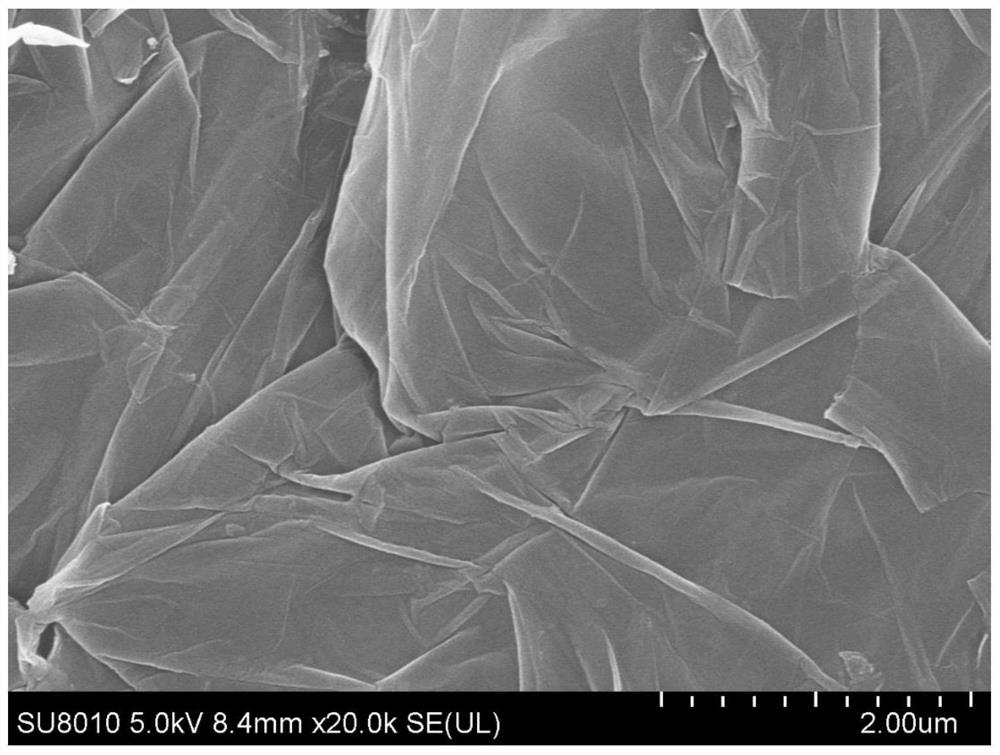

The invention discloses an oil penetration-preventing polymer-bonded explosive containing paraffin microcapsules and a preparation method of the explosive. The explosive is prepared from, by mass, 30-90 parts of an explosive, 0-45 parts of metal, 0-35 parts of ammonium perchlorate, 8-20 parts of a bonding agent, 0-5 parts of paraffin, 0.1-5 parts of the paraffin microcapsules and 0-1 part of a curing agent. The method comprises the following steps that batching is conducted; the materials are put in a kneader to be mixed; the mixed materials are poured into a mold, and the mold is put in an oven for curing the materials. According to the oil penetration-preventing PBX explosive containing the paraffin microcapsules, the oil penetration performance is reduced by 60%-70%, the mechanical properties such as the tensile and compressive strength, the strain rate and the elasticity modulus are all improved, and the shock wave sensitivity is reduced.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS +1

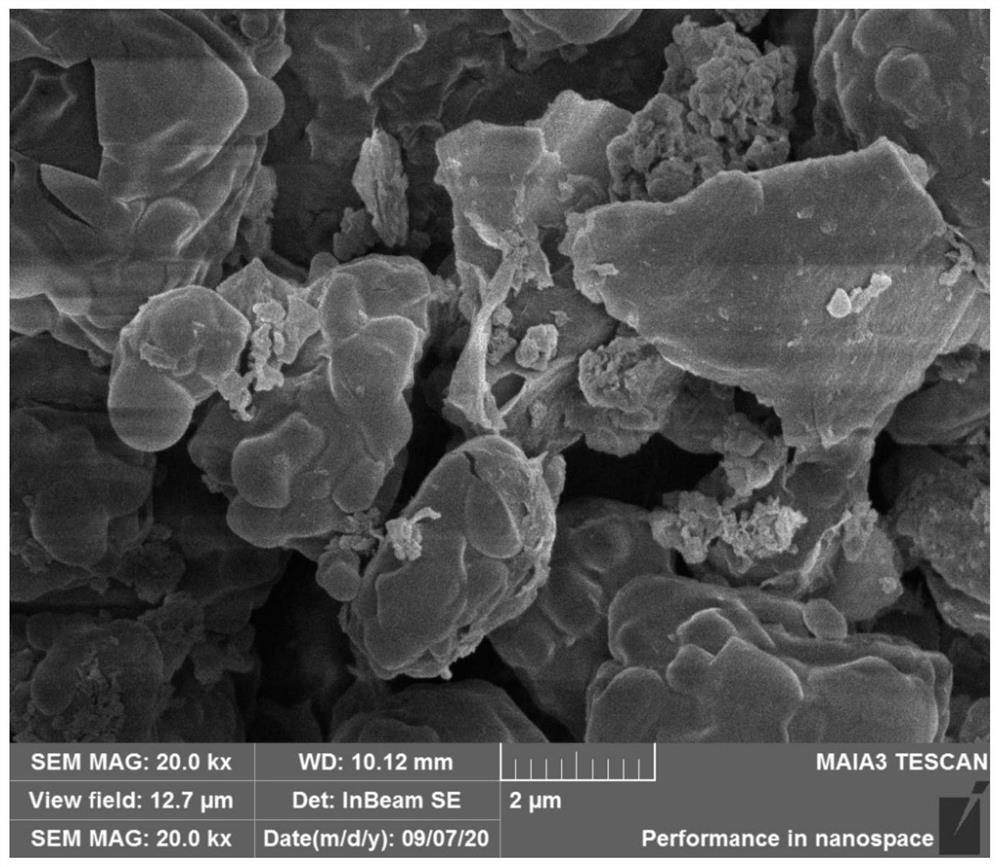

Preparation method of ammonia water functionalized graphene insensitive coated energetic material

InactiveCN112898099AEnhanced interactionImprove the wrapping effectNon-explosive desensitisers/phlegmatisersPhysical chemistryGraphite

The invention discloses a preparation method of an ammonia water functionalized graphene insensitive coated energetic material, which comprises the steps of (1) dispersing graphene in a water phase to obtain a graphene dispersion liquid, and adding an energetic material into the graphene dispersion liquid to be continuously dispersed to obtain a first mixed solution, wherein the mass ratio of the energetic material to the graphene is 98: (0.05-1.95); (2) in a stirring state, adding ammonia water into the first mixed solution to obtain a second mixed solution; (3) heating the second mixed solution to the temperature of 60-100 DEG C, and continuously stirring to obtain a suspension; and (4) filtering, washing and drying the suspension to obtain the ammonia water functionalized graphene insensitive energetic material. The method can improve the coating effect and reduce the mechanical sensitivity of the energetic material.

Owner:SOUTHWEAT UNIV OF SCI & TECH

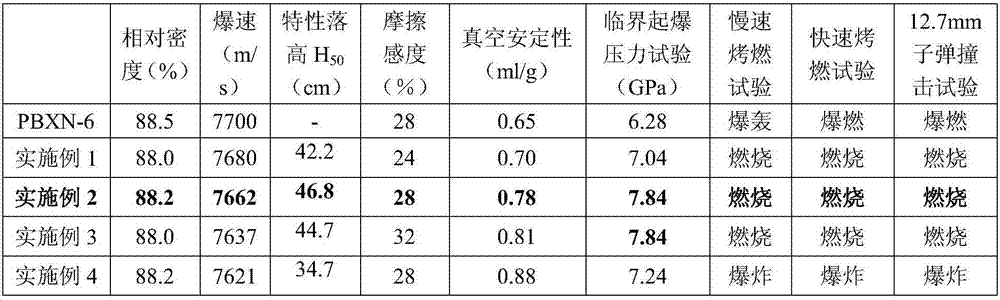

High-energy pressure-loaded and insensitive booster explosive and preparation method

InactiveCN107473914AHigh energyImprove securityNon-explosive desensitisers/phlegmatisersNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsDetonationHigh density

The invention discloses a high-energy pressure-loaded and insensitive booster explosive and a preparation method, and aims to solve the problems that the urgent application demand of current insensitive ammunition has to be met and the existing cyclonite booster explosives cannot meet the insensitive technical requirement. The booster explosive is prepared from, a mixed-crystalline composite material (comprising 1, 1-diamino-2, 2-dinitroethylene and cyclonite) and a binder, and the booster explosive is prepared from moulding powder through an emulsion method. The high-energy pressure-loaded and insensitive booster explosive has the advantages of high-density, high detonation speed, high safety and low cost (simple process, and easy amplification), the insensitive requirement is also met, and the comprehensive performance is excellent. The booster explosive is mainly used for safety detonation of all kinds of explosive charges.

Owner:XIAN MODERN CHEM RES INST

Al-Na compound fuel and preparation method and application thereof

InactiveCN109081766AImprove low temperature oxidation performanceImprove combustion efficiencyNon-explosive desensitisers/phlegmatisersExplosive working-up apparatusMicro nanoAl powder

The invention relates to Al-Na compound fuel and a preparation method and application thereof and belongs to the technical field of propellant preparation. The preparation method includes: micron-sized Al powder and NaF are added into the ball milling tank of a planetary ball mill according to a certain proportion, the weight of stainless steel grinding balls is determined according to ratio of grinding media to material, certain rotation speed is kept to perform ball milling under inert gas protection, the ball milling tank is opened in a glove box to add an inert stabilizing solvent after the ball milling is completed, the solvent is allowed to slowly volatilize in room-temperature air to complete the natural passivation of fuel, drying in a drying oven is performed after the solvent isvolatilized and dried to obtain solid, namely the Al-Na compound fuel. The micro-nano-structure Al-NaF compound fuel is used to replace aluminum powder to perform a propellant forming test to obtain apropellant containing the micro-nano-structure Al-NaF compound fuel.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

An insensitive composite material used for triggering explosion of fireworks and crackers

ActiveCN106905087AExcellent safety indexReduce sensitivityNon-explosive desensitisers/phlegmatisersFirecrackerTitanium dioxide

An insensitive composite material used for triggering explosion of fireworks and crackers is disclosed. The composite material includes, by weight, 57-62 parts of aluminum powder, 8-12 parts of zinc oxide, 7-11 parts of chlorinated rubber, 3-6 parts of graphite, 4-7 parts of an aluminum magnesium alloy, 5-6 parts of potassium carbonate and 3-5 parts of titanium dioxide. Safety performance indexes of an explosion triggering agent prepared by adopting the composite material as a reductant are lower than those of traditional agents, sensitivity is low and the safety coefficient of the explosion triggering agent is greatly higher than those of the traditional agents.

Owner:LIUYANG YIHELONG FIREWORKS GRP

Amorphous energetics

ActiveUS10703687B1Readily detonableImprove responseNon-explosive stabilisersNon-explosive desensitisers/phlegmatisersHigh Blast ExplosiveMaterials science

Stabilized, amorphous high energetic compositions having crystallization inhibiting polymers dispersed throughout the solid composition. The compositions disclosed herein are an improvement over crystalline high energetic compositions in that such disclosed compositions are stable and possess physical properties desirable in propellant and high explosive applications.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

A metal hydride in-situ polymerization coating passivation method

ActiveCN107021864BEnergy traits are not affectedImprove stabilityNon-explosive desensitisers/phlegmatisersAcetic acidIn situ polymerization

The invention discloses a metal hydride in situ polymerization and cladding passivation method, and is characterized by comprising the following steps: (1) dissolving 3,3-diazido methyloxetane and tetrahydrofuran (BAMO-THF) copolyether and a curing agent into anhydrous ethyl acetate, and preparing into a dilute solution; (2) putting metal hydride into the dilute solution and performing ultrasonic dispersion to form suspension liquid; (3) stirring and warming to the temperature of 40 to 60 DEG C, stirring for reaction, and recycling the solvent ethyl acetate by evaporation after the reaction is ended; (4) a product obtained after the solvent is removed completely by evaporation is dried and cured in a drying oven, so as to obtain the clad passivated metal hydride. According to the metal hydride in situ polymerization and cladding passivation method provided by the invention, the BAMO-THF copolyether is used for in situ polymerization and cladding of the metal hydride, and the treated and obtained metal hydride is insensitive to water in air. The own energy performance of the metal hydride is not affected while passivating the metal hydride.

Owner:河南纳宇新材料有限公司

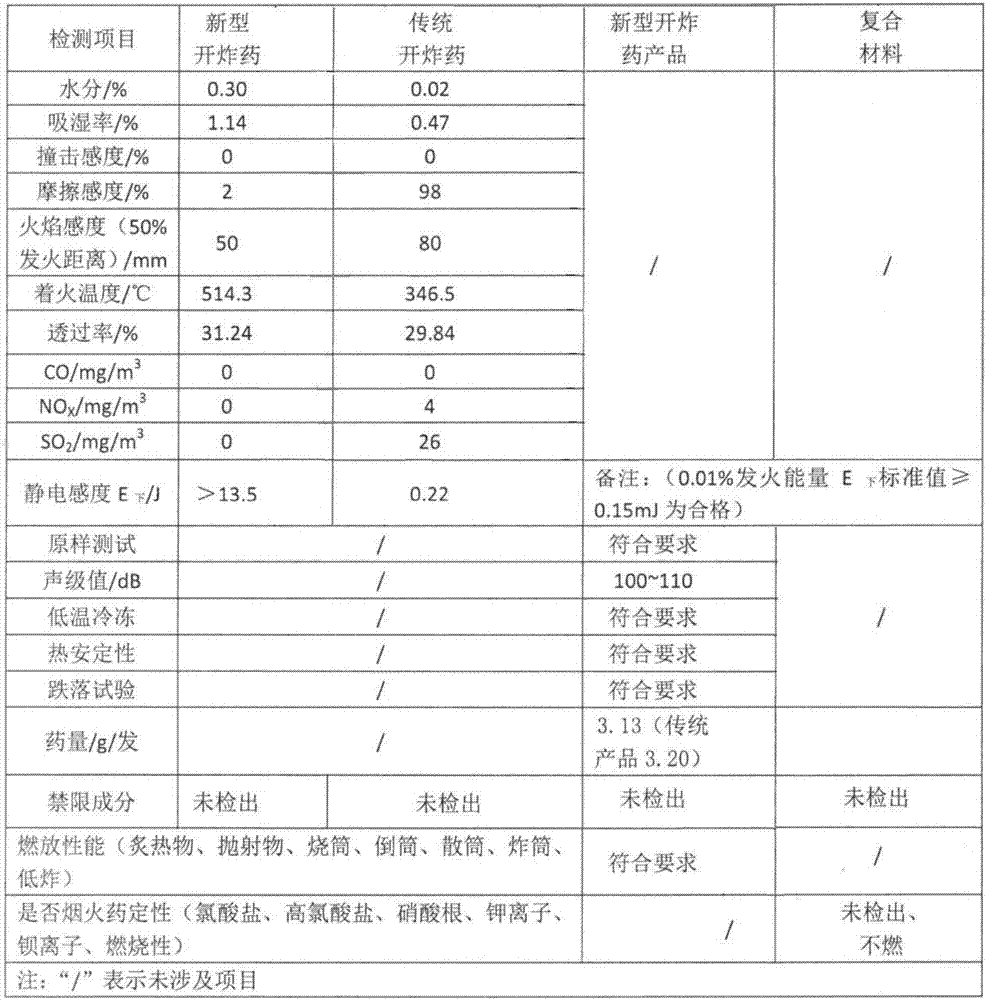

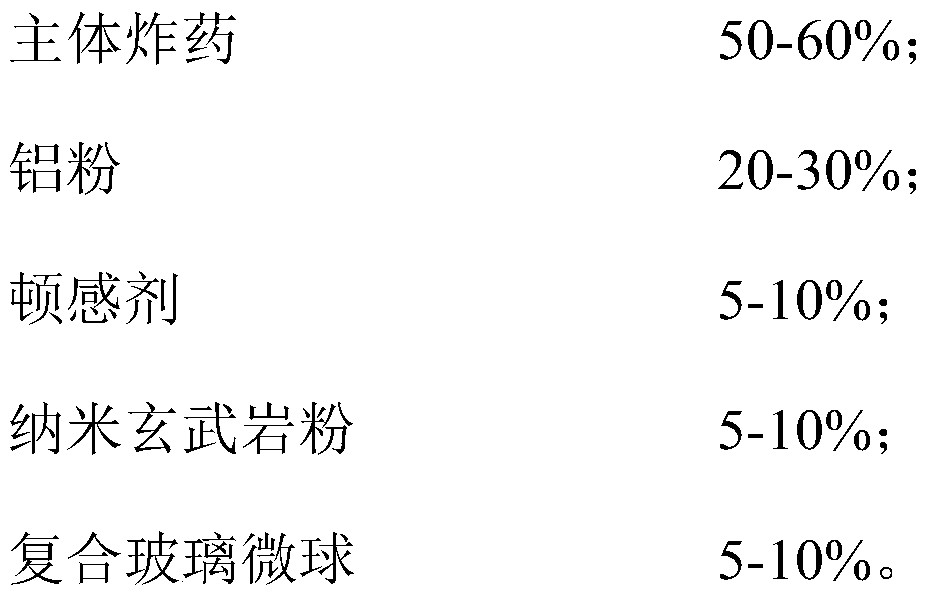

Explosive, and preparation method and application thereof

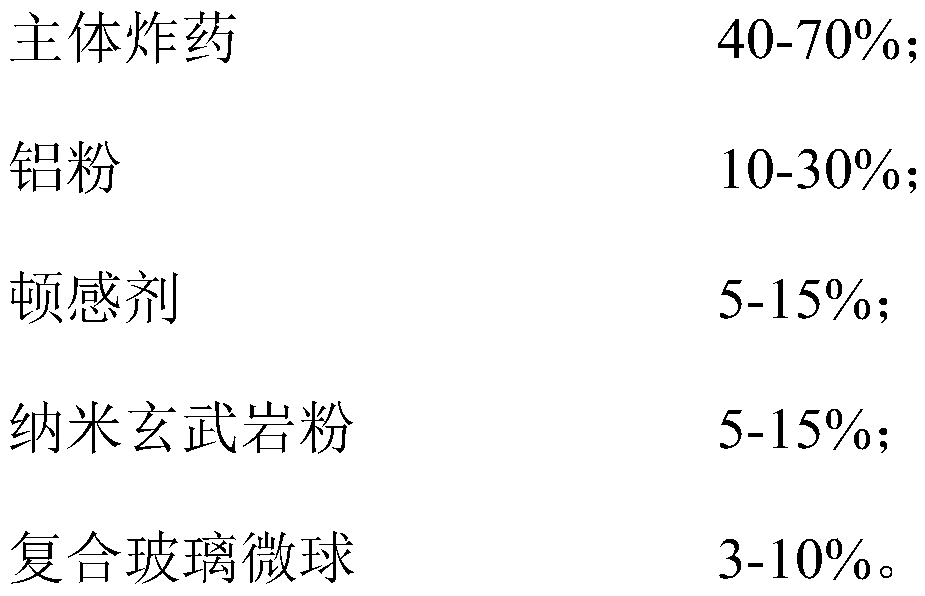

ActiveCN110218133AReduced explosion rateLow detonation velocityNon-explosive desensitisers/phlegmatisersPressure gas generationFiberExternal energy

The invention discloses an explosive, and a preparation method and an application thereof. The explosive comprises the following components in percentages by weight: 40 to 70% of a main explosive, 10to 30% of aluminum powder, 5 to 15% of a desensitizing agent, 5 to 15% of nanometer basalt powder and 3 to 10% of a composite glass microsphere. According to the invention, through addition of the composite glass microsphere, the explosion rate of the explosive can be reduced through the combined action of silicon dioxide on the surface of the composite glass microsphere and the nanometer basalt powder; meanwhile, under the action of external energy or explosive energy, the silicon dioxide on the surface of the composite microsphere is broken, and a flame retardant located in hollow aluminum fiber can be gradually released; thus, by combination of substances and through combined action, an obtained explosive has low explosion rate and high insensitiveness and flame-retardant performance, can achieve high safety performance and is applicable to the fields of stone mining, etc. The preparation method for the explosive has the advantages of simplicity, easily-available and cheap raw materials, convenient implementation, and applicability to industrial large-scale production application.

Owner:US DIAMOND OIL DRILLING SYST ENG (SHANGHAI) CO LTD

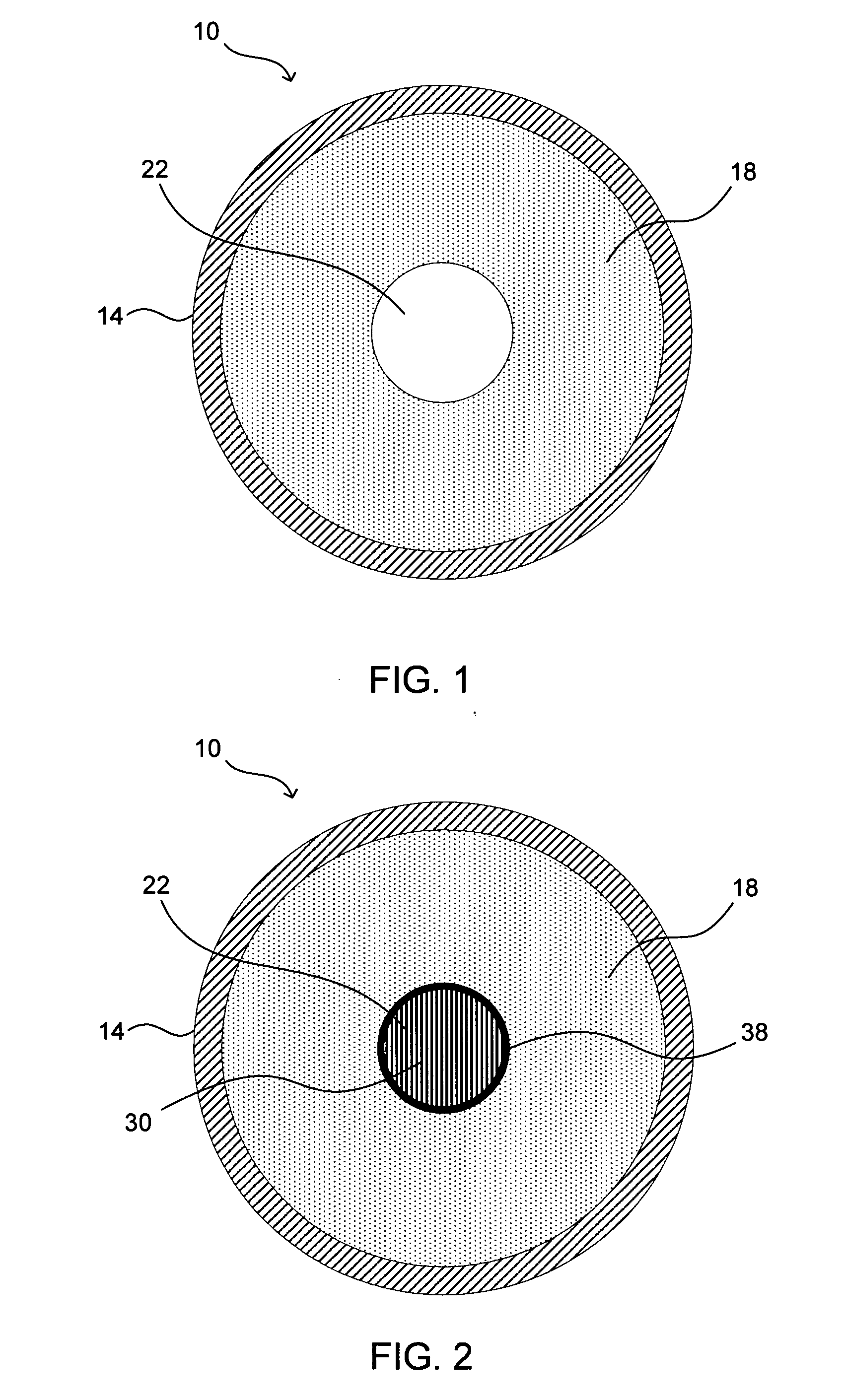

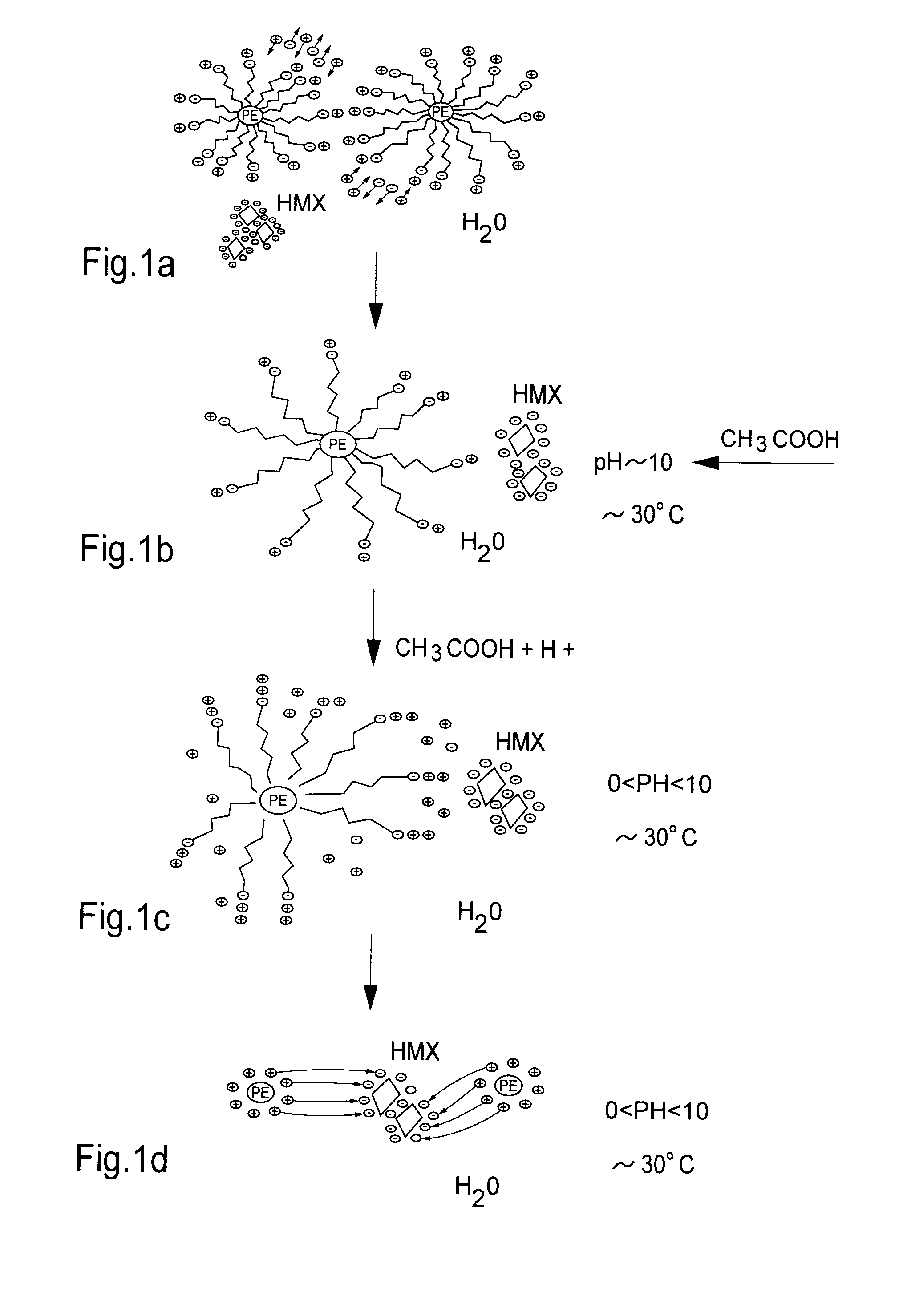

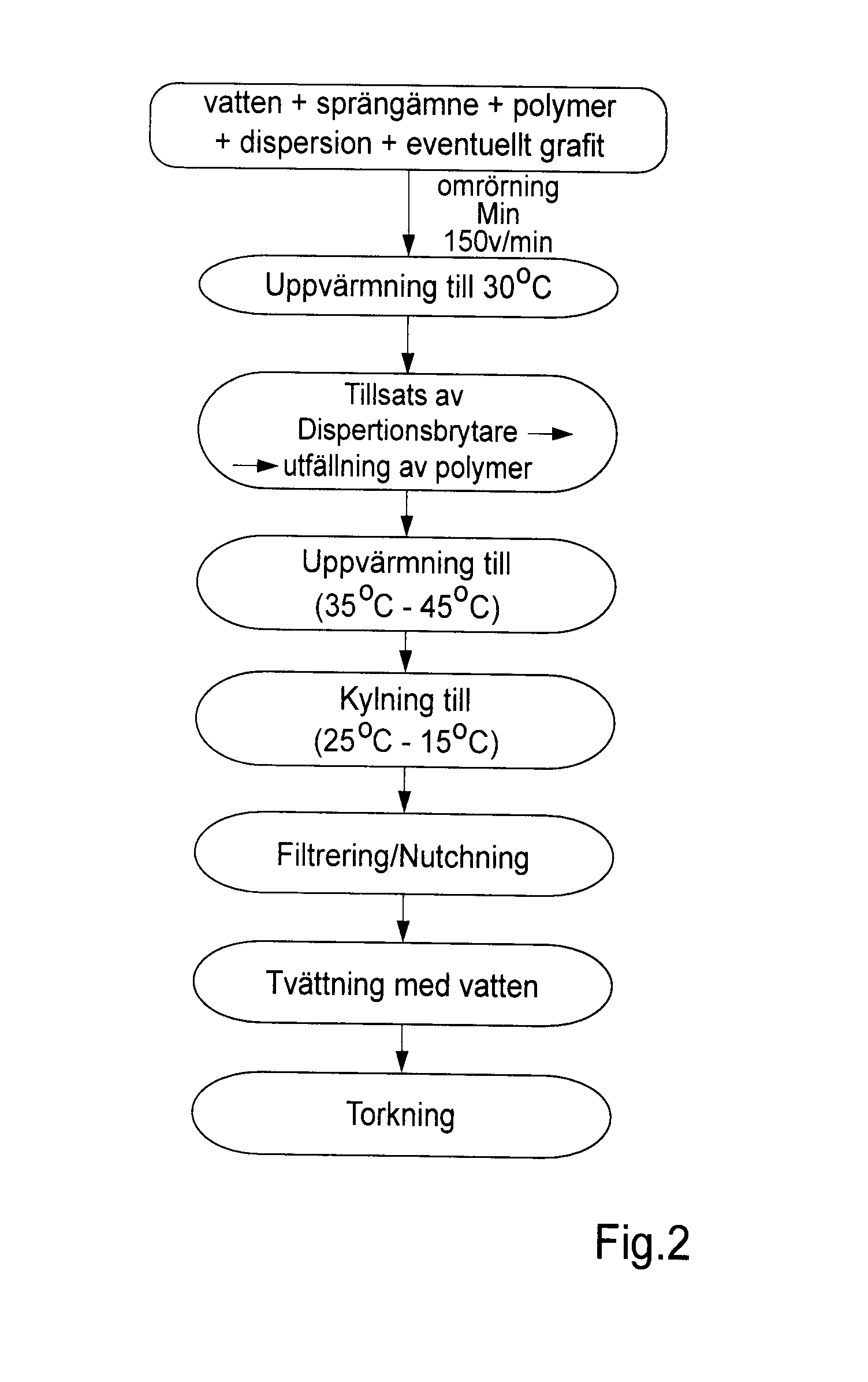

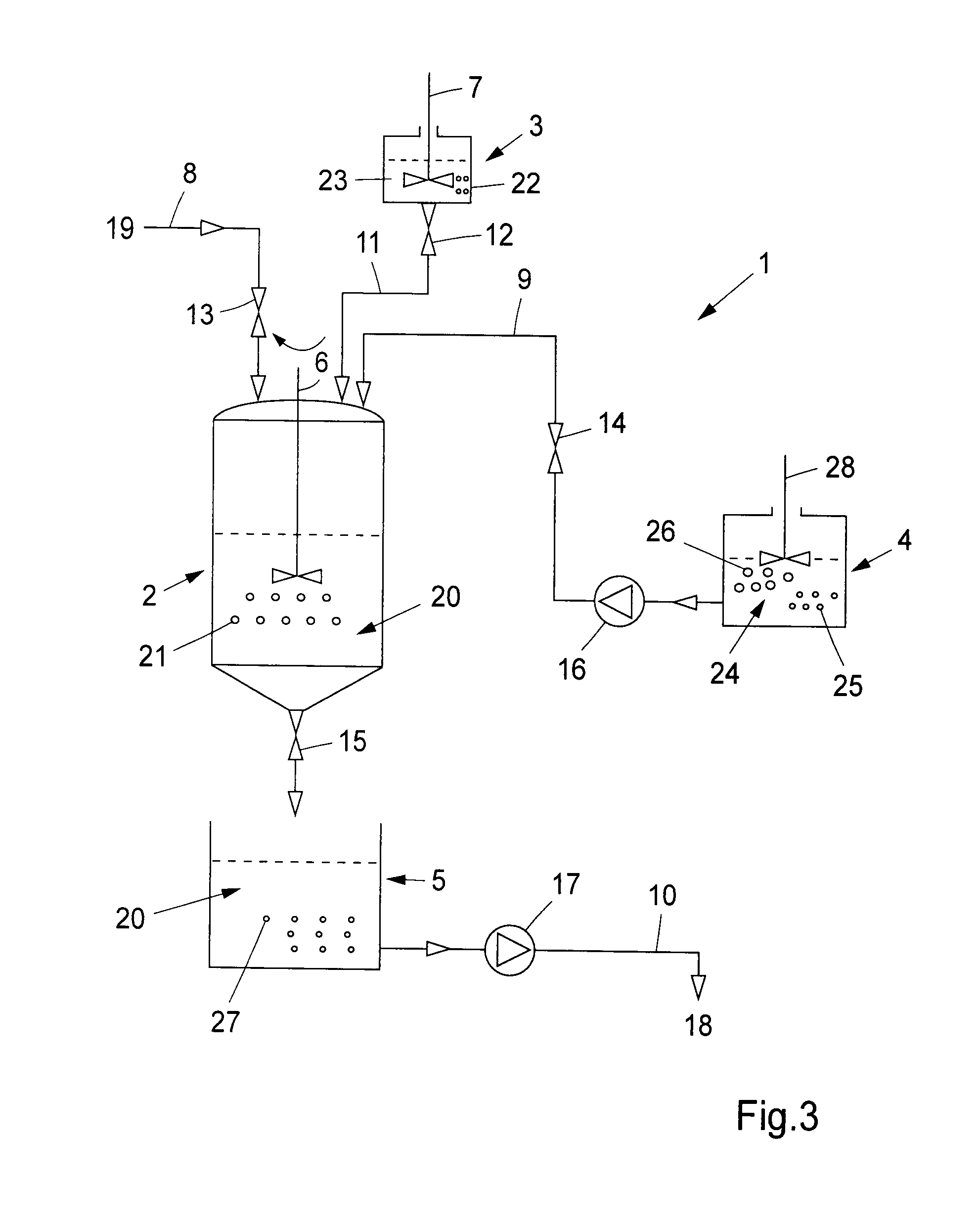

Phlegmatisation of an explosive in an aqueous suspension

ActiveUS20160137566A1High compression densityLow impact sensitivityLiquid surface applicatorsElectric shock equipmentsExplosive materialChemistry

A method for phlegmatising an explosive in an aqueous suspension including a dispersed phlegmatising agent. The phlegmatising agent is deposited on a surface of the explosive at low temperature utilizing opposite electric charges of the phlegmatising agent and the explosive. Also a device and a phlegmatised explosive.

Owner:EURENCO BOFORS

Preparation method of g-C3N4-based composite energetic material

PendingCN112898103AImprove thermal stabilityImprove securityNon-explosive desensitisers/phlegmatisersExplosive AgentsAmmonium nitrate

The invention discloses a preparation method of a g-C3N4-based composite energetic material, which comprises the following steps: physically grinding g-C3N4 and an explosive according to a certain mass ratio by respectively adopting simple physical grinding, in-situ reduction and electrostatic self-assembly methods to obtain a composite material 1, coating the surfaces of explosive crystals with g-C3N4 and GO subjected to ultrasonic treatment through in-situ reduction to obtain a composite material 2, modifying the surface of the ammonium nitrate explosive by utilizing the high cation characteristic of polyethyleneimine, and then obtaining a composite material 3 by an electrostatic self-assembly method. According to the invention, g-C3N4 and GO are combined to jointly reduce sensitivity of ammonium nitrate explosive crystals, the ammonium nitrate explosive composite material with sensitivity reduction effect and high energy performance is obtained, and high stability, high thermal conductivity and lubricity of g-C3N4 and GO are utilized to passivate the mechanical sensitivity of an energetic material.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com