Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

687 results about "Integrated production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Integrated production refers to a sustainable farming system that produces high quality food and other products by using natural resources and regulating mechanisms to replace polluting inputs. Emphasis is placed on a systems approach involving the entire farm as the basic unit, on the central role of agro-ecosystems, on balanced nutrient cycles, and on the welfare of all species in animal husbandry. The preservation and improvement of soil fertility and of a diversified environment are essential components. Biological, technical and chemical methods are tuned to take into account the protection of the environment, profitability and social requirements.

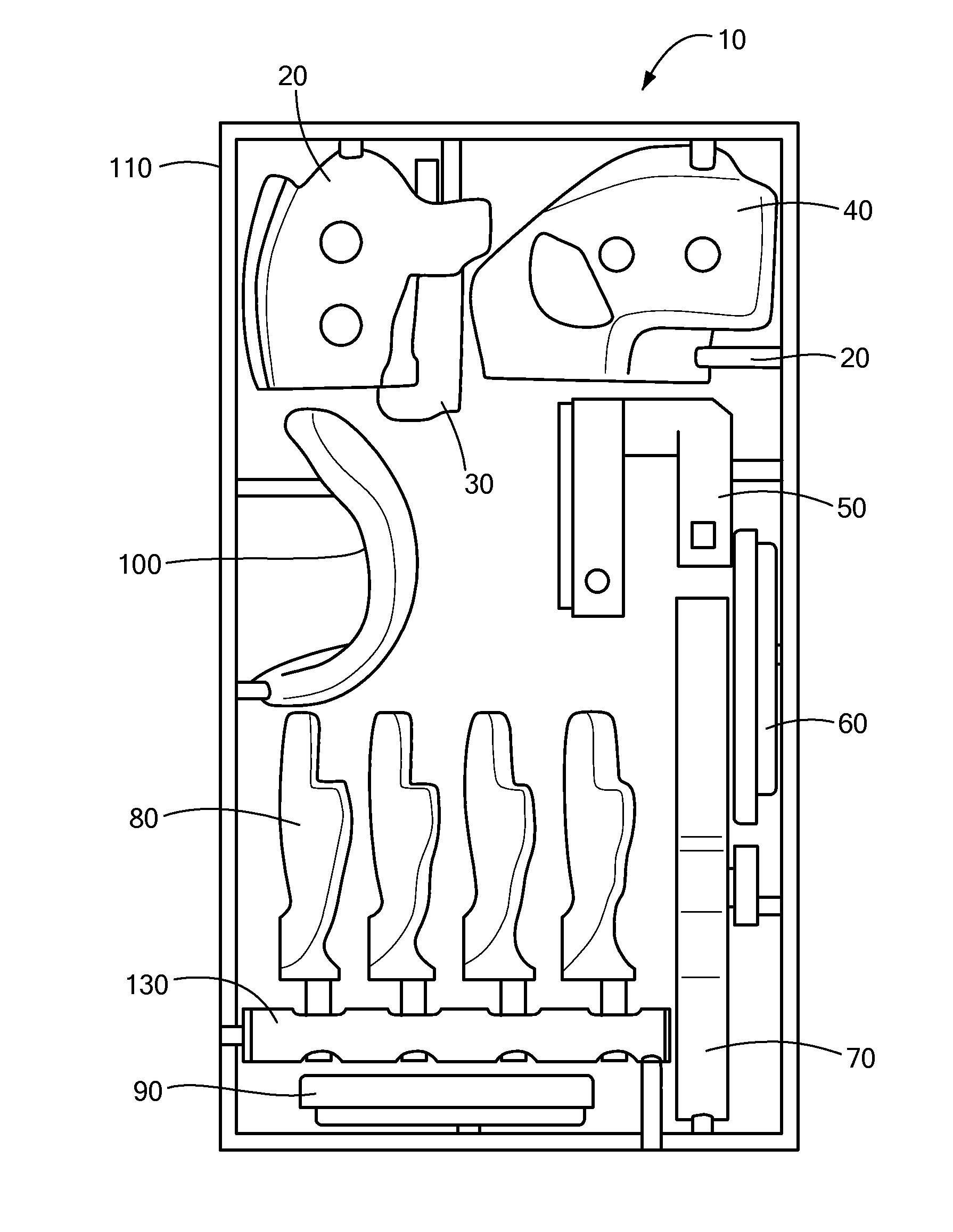

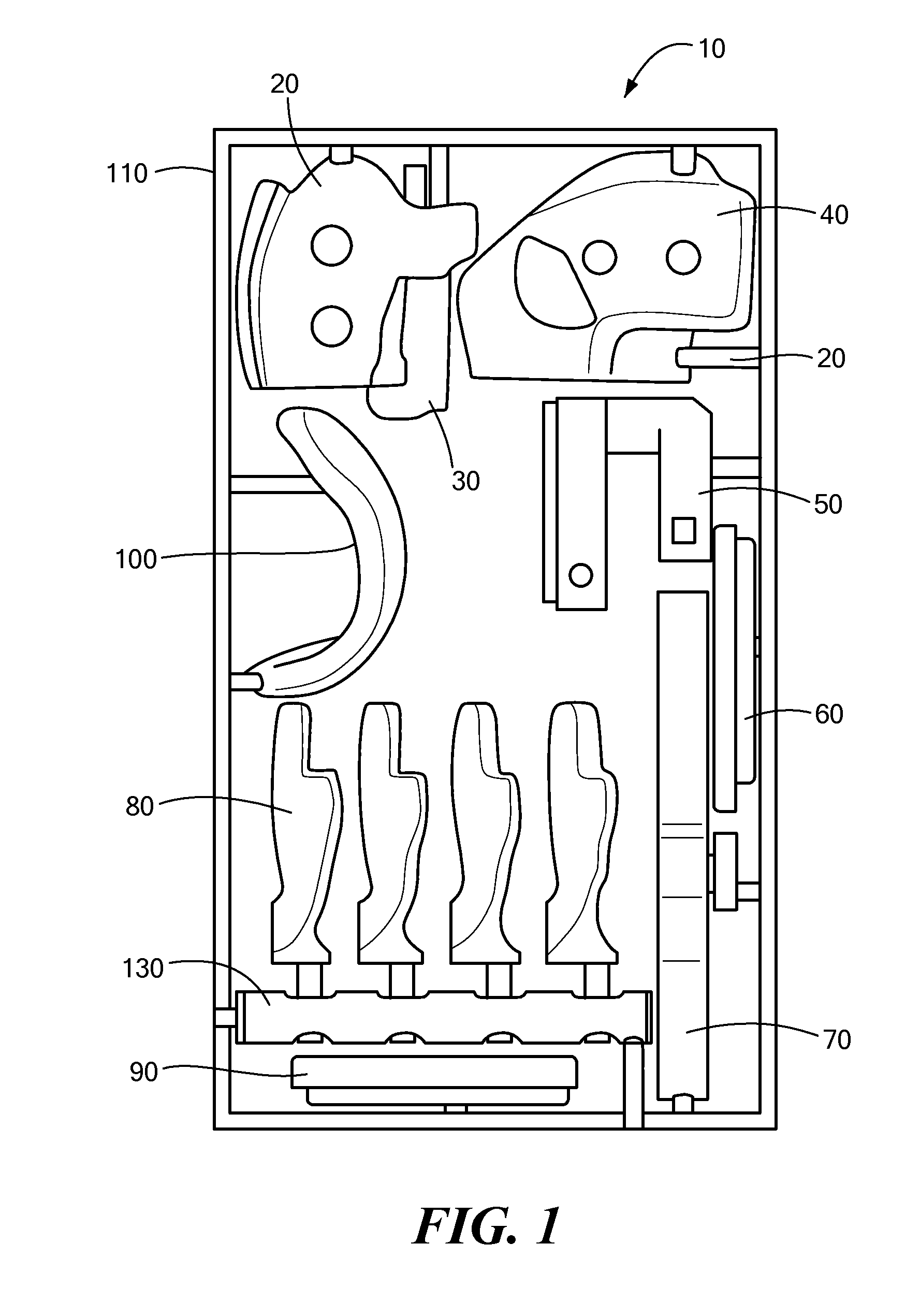

Integrated Production of Patient-Specific Implants and Instrumentation

InactiveUS20100217270A1Easy and efficient to manufactureManufactured efficiently and inexpensivelySurgical furnitureDiagnosticsPlastic surgeryTarsal Joint

Disclosed herein are devices, systems and methods for the automated design and manufacture of patient-specific / patient-matched orthopedic implants. While the embodiments described herein specifically pertain to unicompartmental resurfacing implants for the knee, the principles described are applicable to other types of knee implants (including, without limitation, other resurfacing implants and joint replacement implants) as well as implants for other joints and other patient-specific orthopedic applications.

Owner:CONFORMIS

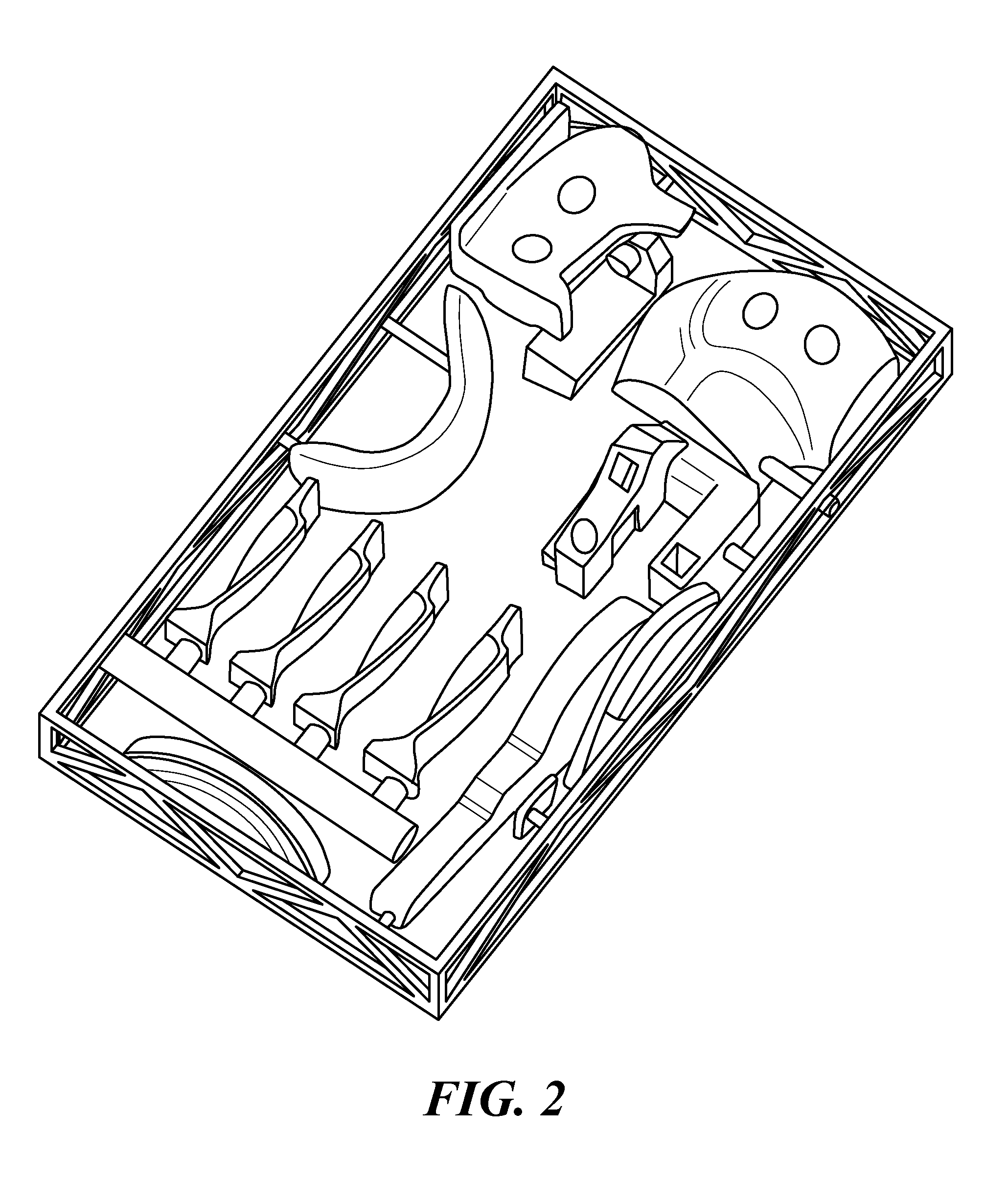

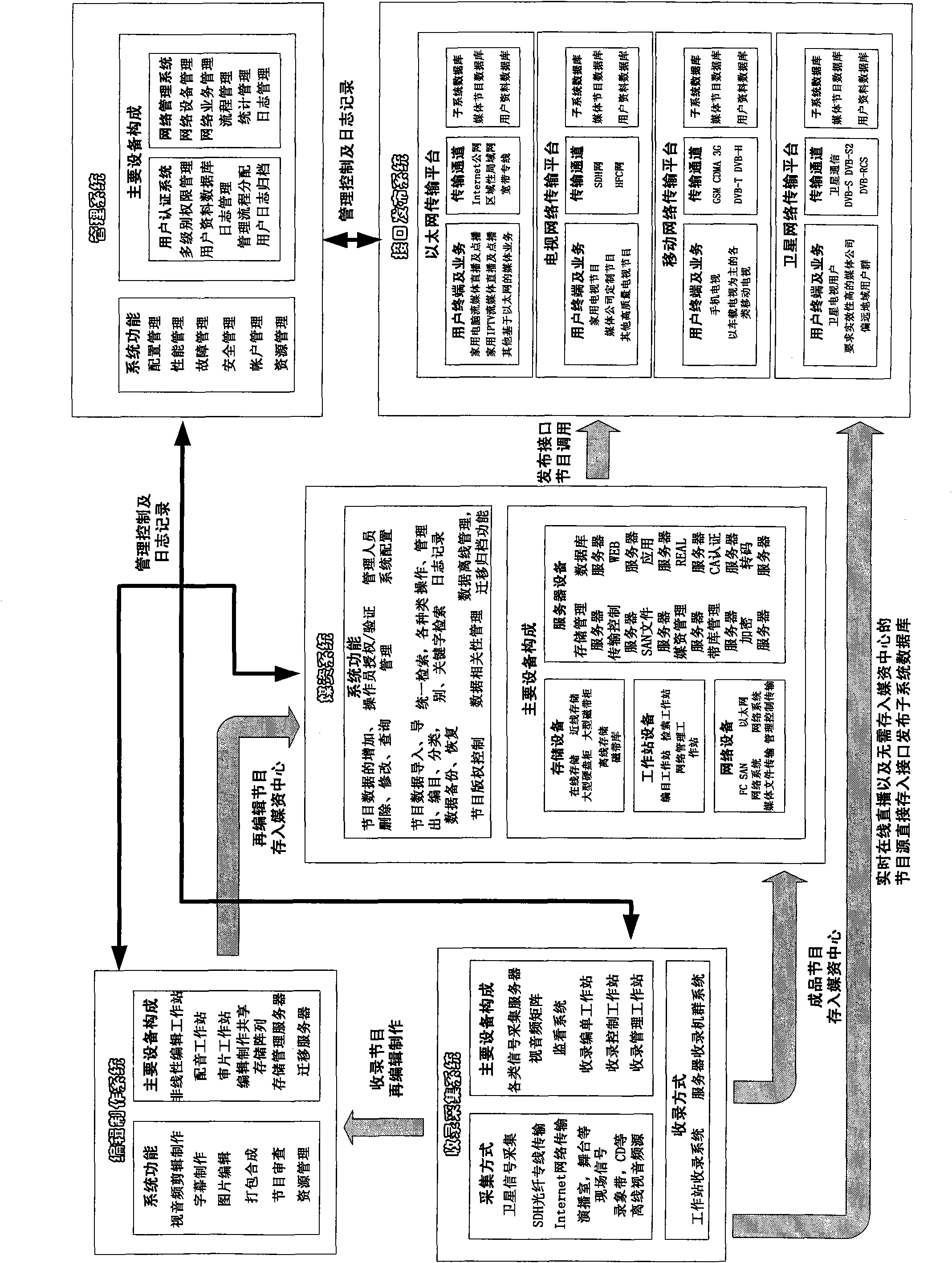

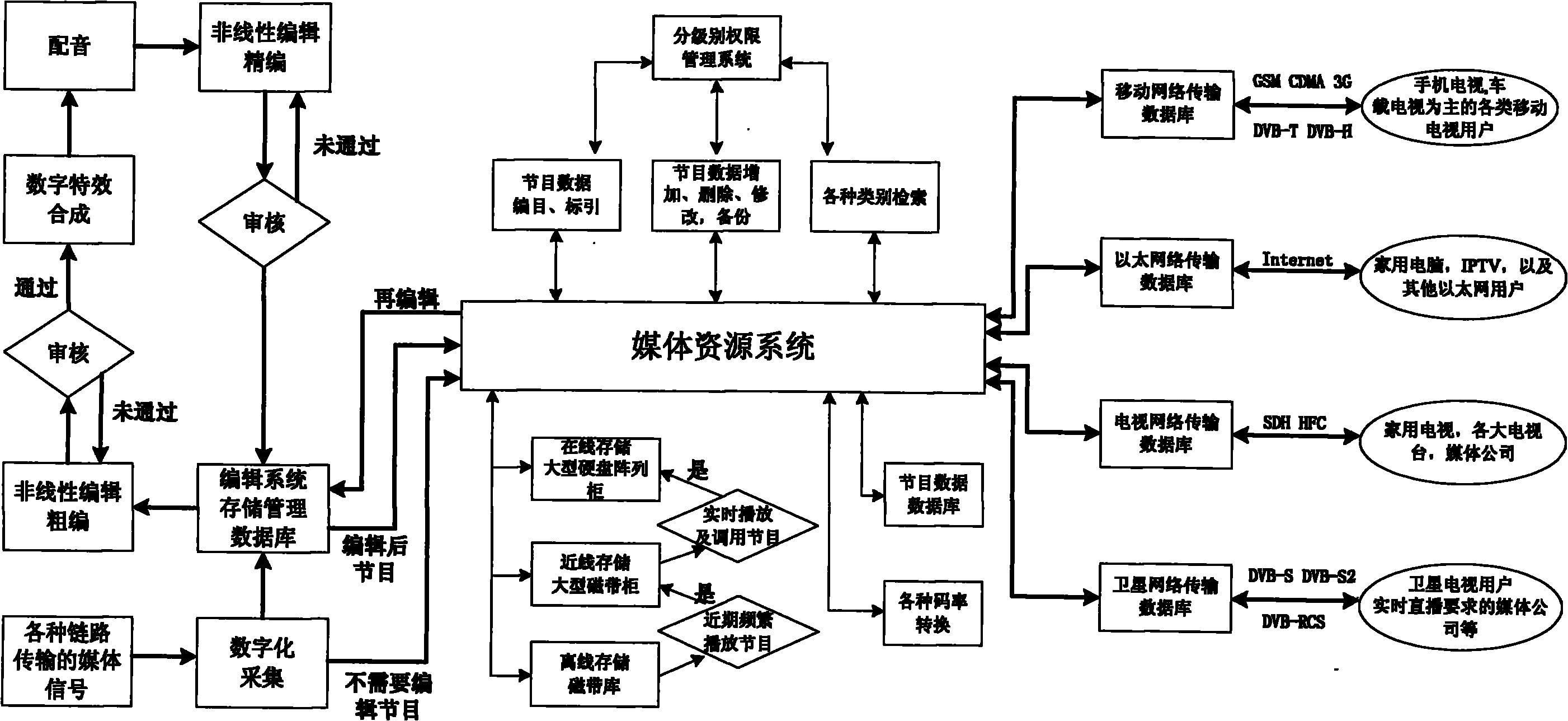

Digital multimedia information transmission platform

InactiveCN101783873ASupport automatic technical review functionImprove review efficiencyTelevision system detailsColor television detailsSystems managementCataloging

The invention discloses a digital multimedia information transmission platform, which comprises an acquisition system, a manufacturing system, a media resource system, a management system and a release system, wherein the acquisition system consists of control equipment, outside network material receiving server and an foreign signal, studio signal and magnet tape material acquisition and collection subsystem; the manufacturing system consists of a program editing system, a program examination system, a background packing and synthesizing system and a resource manager; the media resource system consists of a media resource cataloging and searching work station, a transcoding server, a database server, a storage management and migration server and a system management working station; the management system consists of a uniform user identification system and a network management system; the release system serving as an external interface module of a multimedia center encrypts finished products in multiple formats and executes related release according to outside service demands; and the platform is an integrated production line of digital media contents and also a digital media resource comprehensive service system platform and can realize overall media resource sharing.

Owner:BEIJING INFV MEDIA TECH

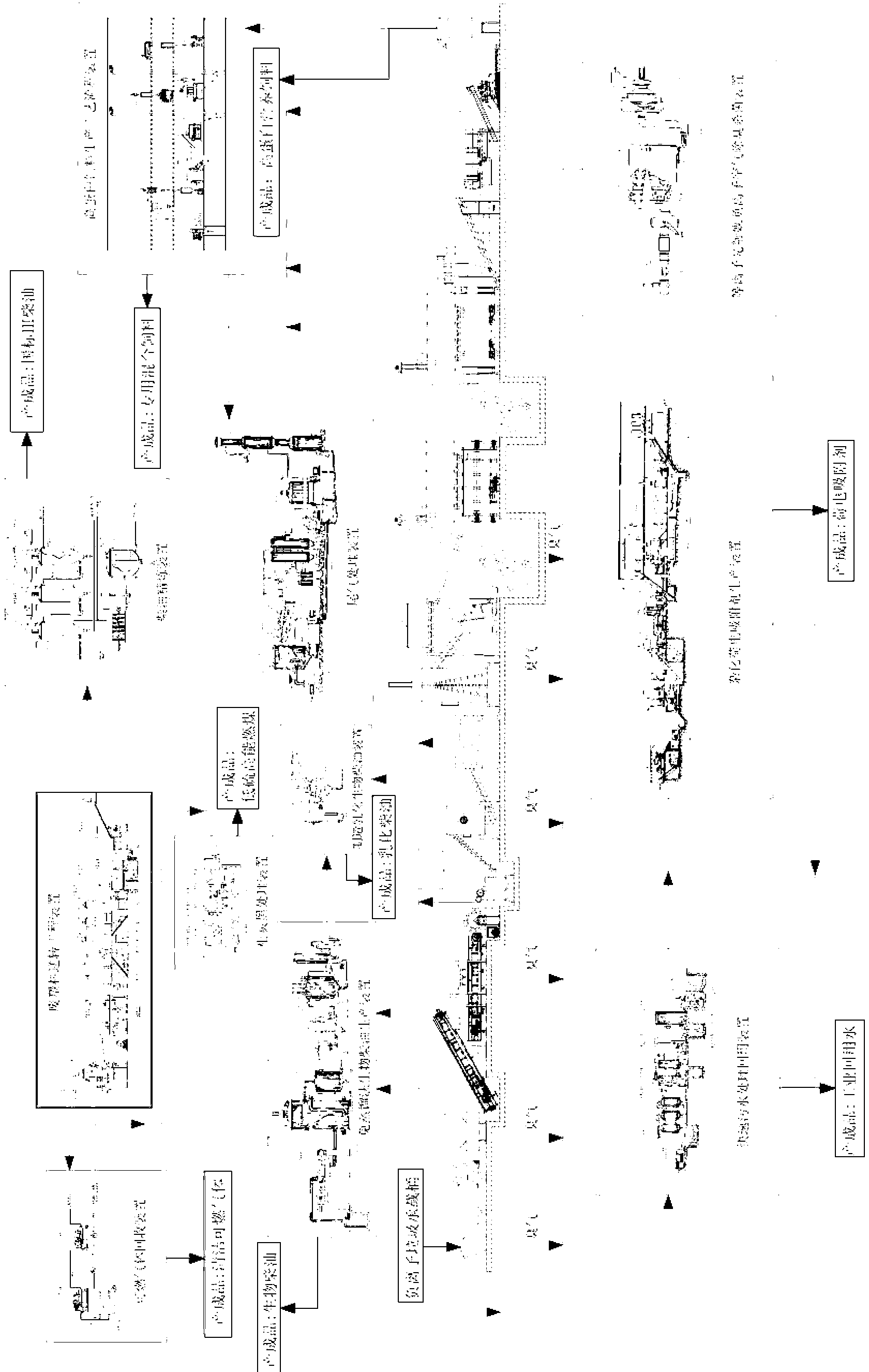

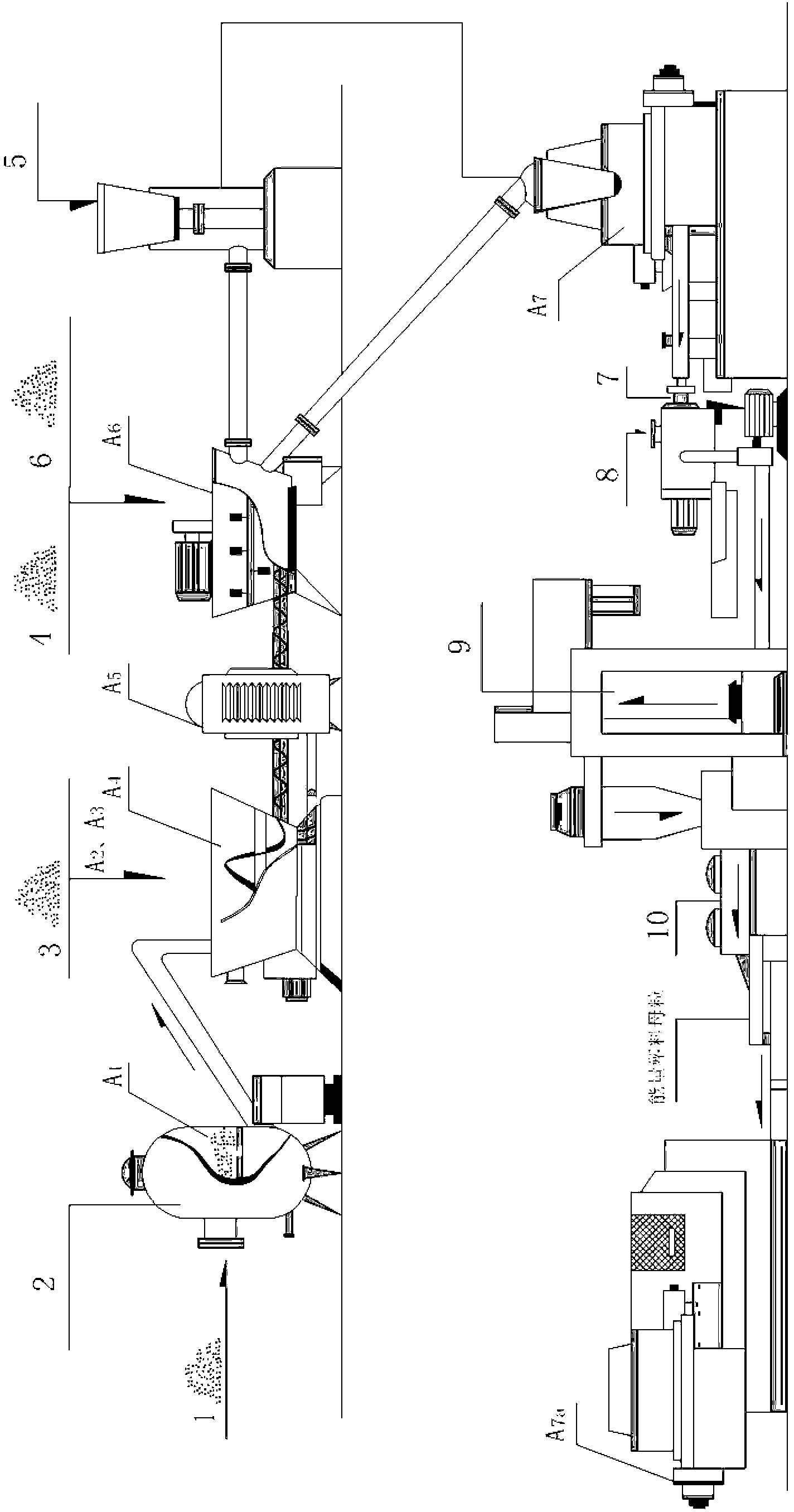

Integrated equipment for omnibearing treatment of kitchen garbage and production method of products

InactiveCN103071666ANo secondary pollutionIncrease added valueSolid waste disposalBiofuelsAutomatic controlBiodiesel

The invention discloses integrated equipment for omnibearing treatment of kitchen garbage and a production method of products. The equipment comprises a central intelligent automatic control system, an air treatment system, a straw biochemical system, an advanced oxidization artificial forced inactivation system, a combined screening and impurity removal system, a compound biochemical system, an automatic drying system, a combined conveying system, a waste plastic reversion engineering system, a sludge treatment system, a sewage treatment system, an oil treatment system and a hot smoke combined treatment system. Produced finished products comprise high-nutrition microbial protein feed, mineral state III diesel, biodiesel, emulsification diesel, low-sulfur clean fire coal, hybrid charge adsorbents and industrial recycle water. A recycling rate of the kitchen garbage reaches above 95%; basically no waste water is discharged, no sludge is transferred, no room temperature discharge exists, no peculiar smell or smoke is discharged and no residue is transferred during production; and the environment-friendly, safe and reliable highly-integrated production equipment and the production method are provided for the treatment of the kitchen garbage.

Owner:SOUTH CHINA REBORN RESOURCES ZHONGSHAN

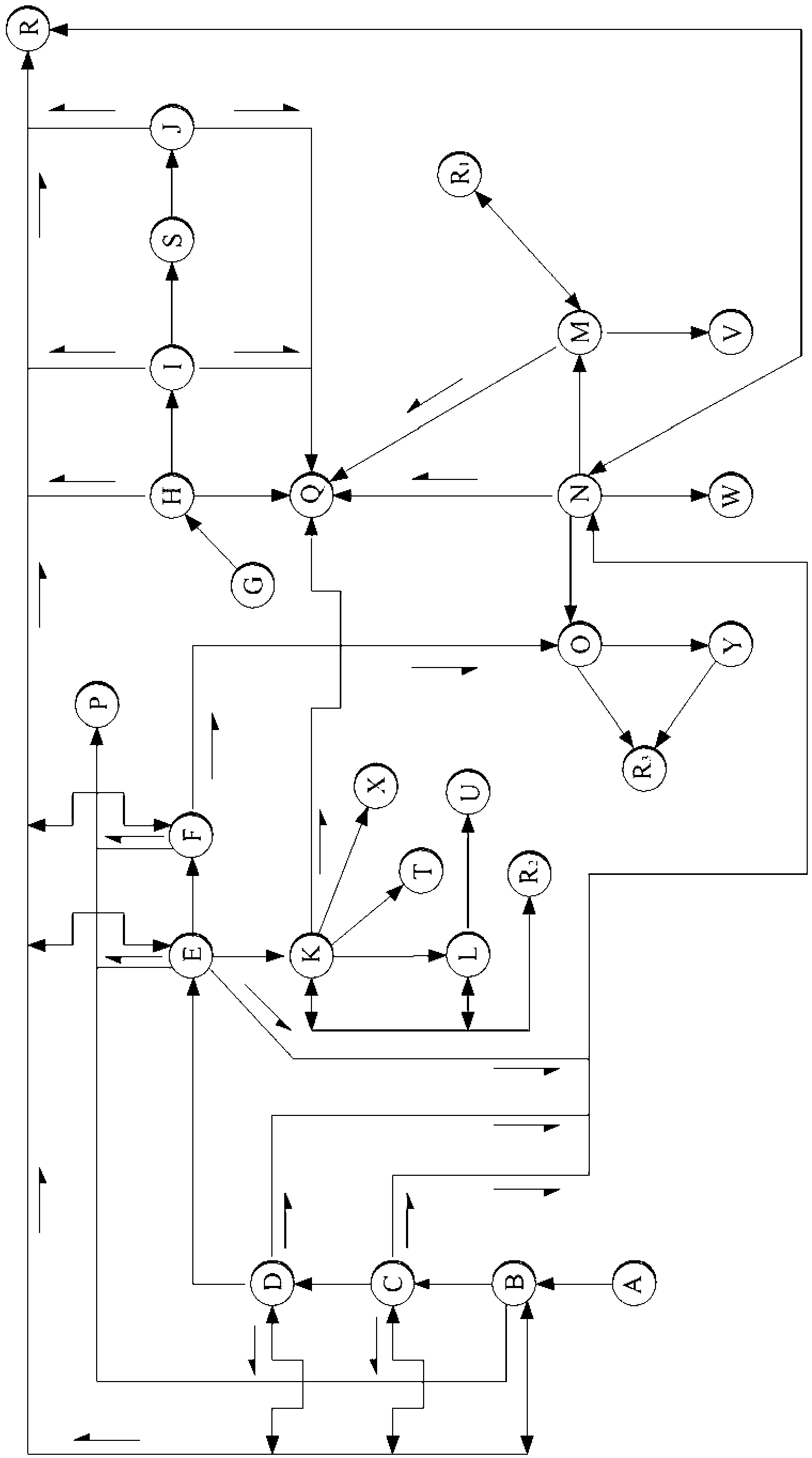

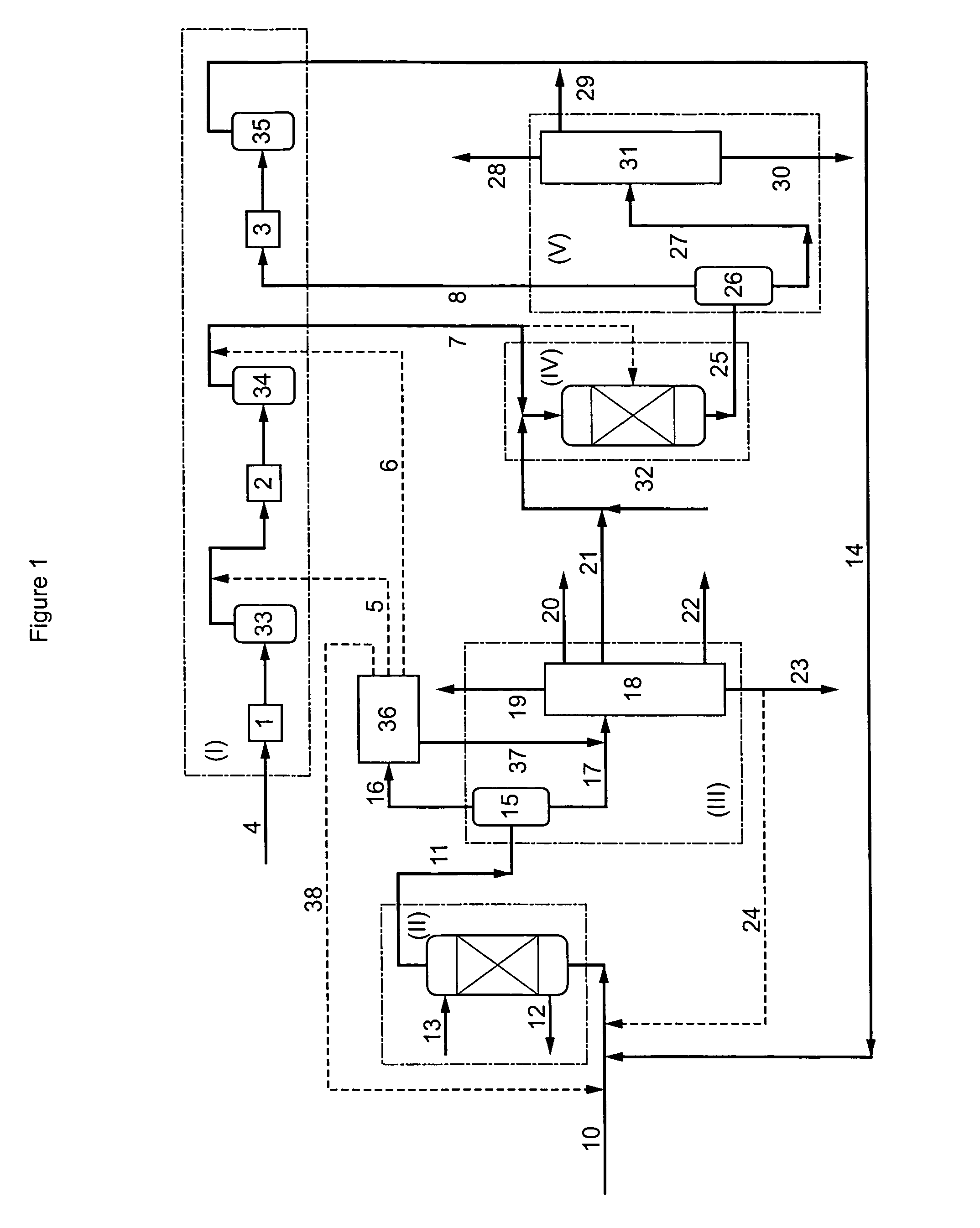

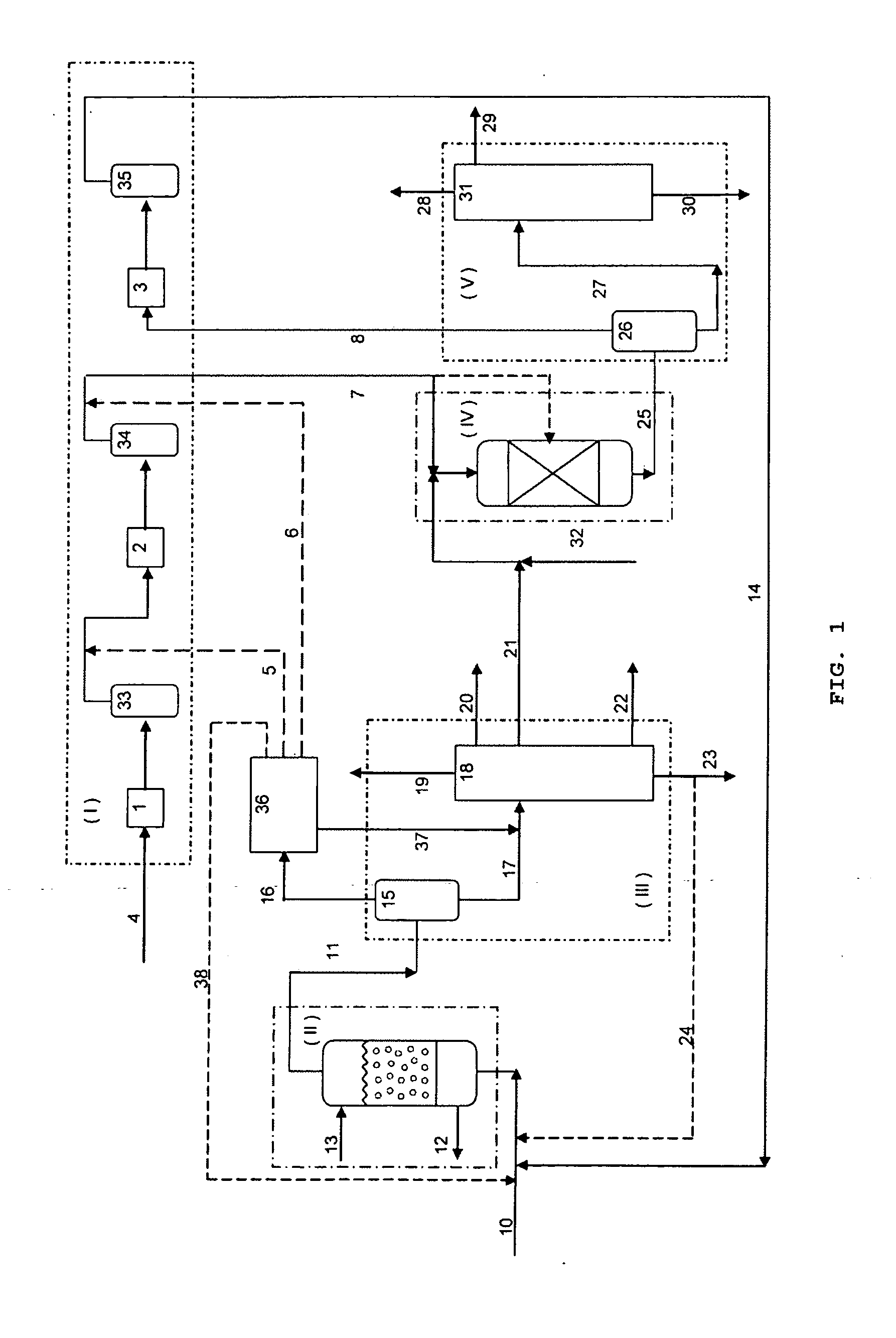

Process and installation for conversion of heavy petroleum fractions in a fixed bed with integrated production of middle distillates with a very low sulfur content

InactiveUS20080093262A1Low investment costEasy to useHydrocarbons from unsaturated hydrocarbon additionHydrocarbon oil crackingDistillates petroleumNaphtha

This invention relates to a process and an installation for treatment of a heavy petroleum feedstock, of which at least 80% by weight has a boiling point of greater than 340° C., whereby the process comprises the following stages:(a) Hydroconversion in a fixed-bed reactor operating with an upward flow of liquid and gas, whereby the net conversion in products boiling below 360° C. is from 10 to 99% by weight;(b) Separation of the effluent obtained from stage (a) into a gas containing hydrogen and H2S, a fraction comprising the gas oil, and optionally a fraction that is heavier than the gas oil and a naphtha fraction;c) Hydrotreatment by contact with at least one catalyst of at least the fraction comprising the gas oil obtained in stage (b);d) Separation of the effluent obtained at the end of stage (c) into a gas containing hydrogen and at least one gas oil fraction having a sulfur content of less than 50 ppm, preferably less than 20 ppm, and more preferably still less than 10 ppm,the hydroconversion stage (a) being conducted at a pressure P1 and the hydrotreatment stage (c) being conducted at a pressure P2, the difference ΔP=P1−P2 being at least 2 MPa, the hydrogen supply for the hydroconversion (a) and hydrotreatment (c) stages being ensured by a single compression system with n stages.

Owner:INST FR DU PETROLE

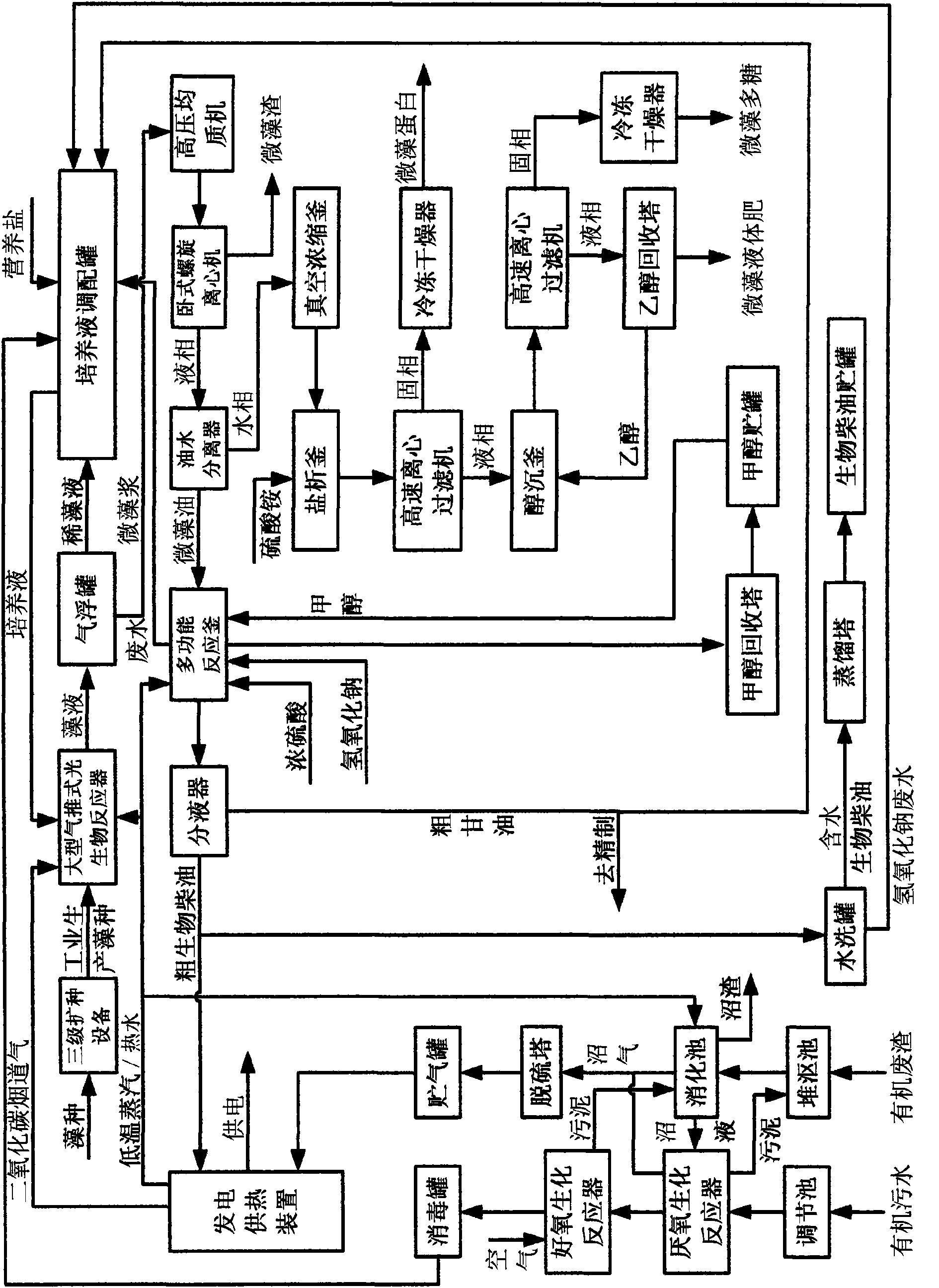

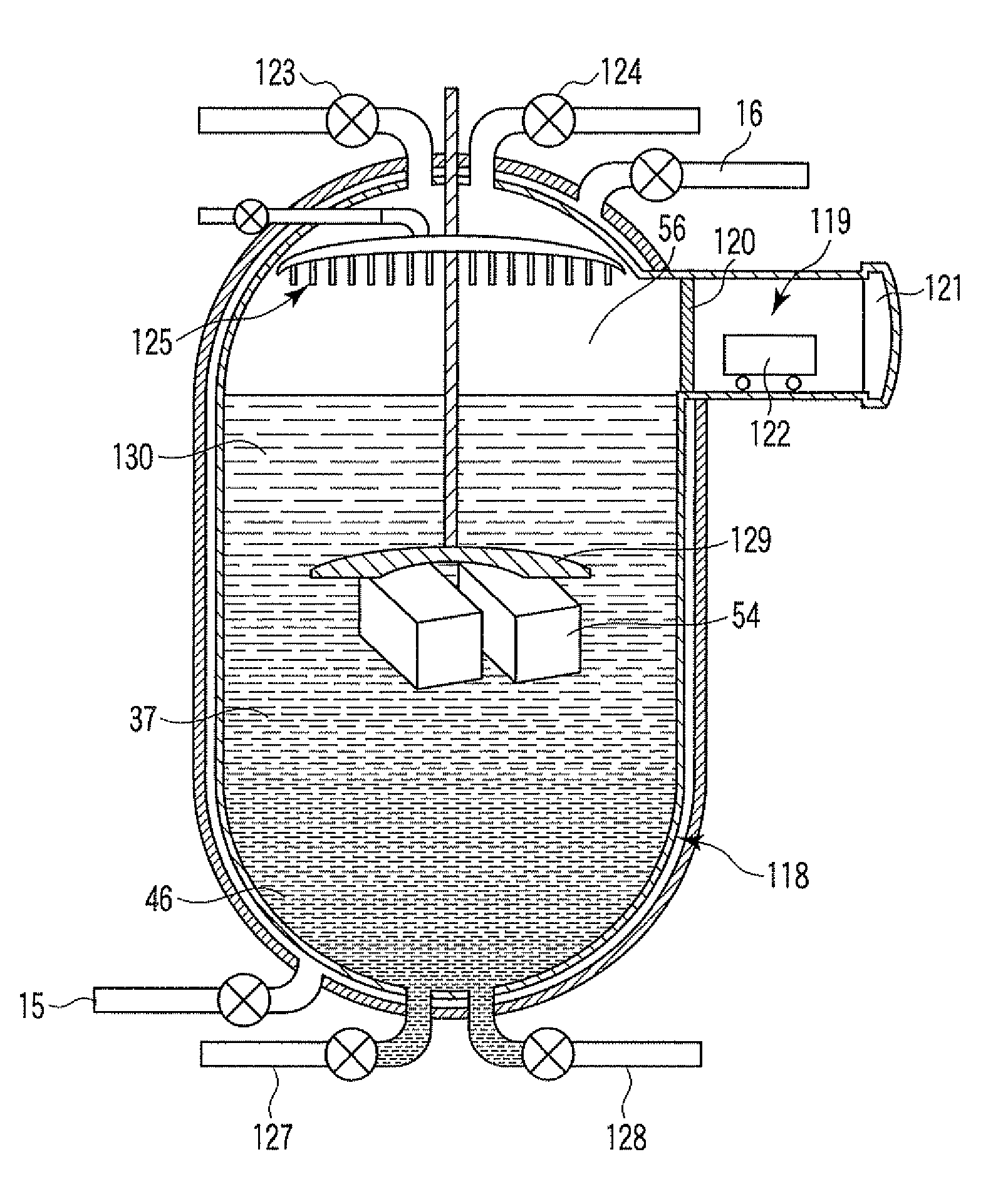

Integrated production method of organic sewage/waste residue treatment, microalgae culturing and oil refining

The invention relates to the environmental protection field, the microalgae cultivation engineering field and the biodiesel refining field, specifically an integrated production method of organic sewage / waste residue treatment, microalgae culturing and oil refining. The method comprises: treating the organic sewage and organic waste residue respectively by anaerobic biochemical technology to generate biogas for generating electricity and supplying heat; performing aerobic biochemical treatment to the sewage and biogas slurry; blending into nutrient solution, and adding into large-scale photobioreactor; passing into biogas, burning to generate carbon dioxide waste gas for culturing oil-containing microalgae; collecting the obtained microalgae by air floatation method and breaking the walls; separating the oil-containing microalgae into microalgae oil, microalgae protein, microalgae polysaccharide and microalgae residue; and refining biodiesel accorded with the national standard using the microalgae oil as raw oil. The invention integrates the organic sewage and waste residue treatment, microalgae culturing and processing, and biodiesel refining; reduces production cost; realizes biodiesel clean production; and treats the 'three wastes'.

Owner:启东市三江建筑机械有限公司

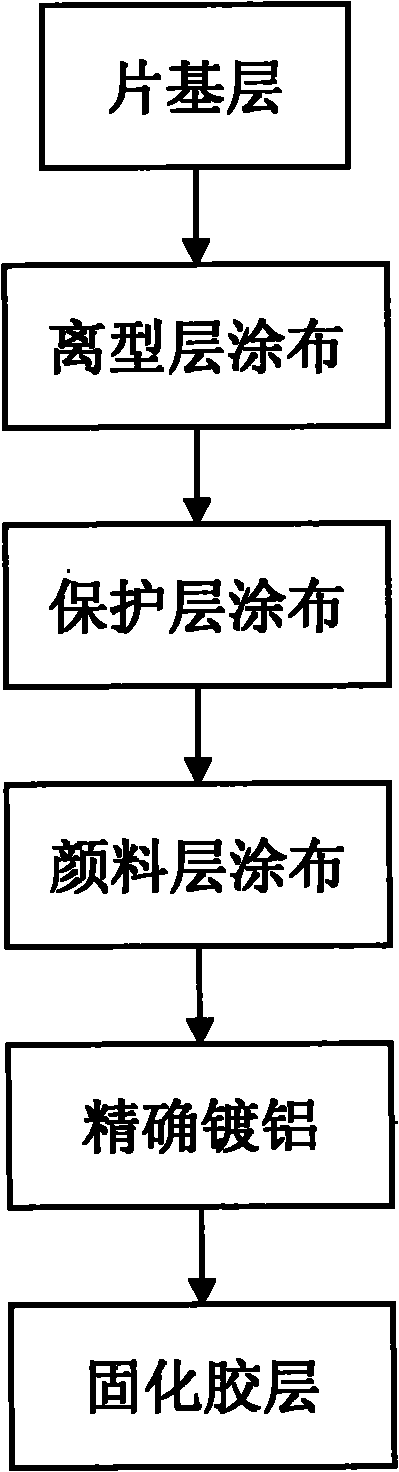

Production method of hot stamping foil

ActiveCN101879819ASolving Hot Stamping RequirementsEvenly paintedCoatingsThermographyPolyvinyl butyralHot stamping

The invention discloses a production method of hot stamping foil, which adopts six production process flows: release coating, protective layer coating, color layer coating, accurate aluminizing and curing glue layer coating. In the whole production process, water soluble glue, water soluble ink and water soluble gloss oil are used to realize the integrated production of the hot stamping foil, methacrylates and monomers which are emulsified and polymerized are mixed in a certain ratio, a dye leveler, thickener and the like are added in the mixture, the resulting product is coated and dried, polyvinyl butyral-based glue is coated, and the whole production of the hot stamping foil is finished. The hot stamping foil produced by the process has the characteristics of energy conservation, environmental protection and sanitation.

Owner:江苏卫星新材料股份有限公司

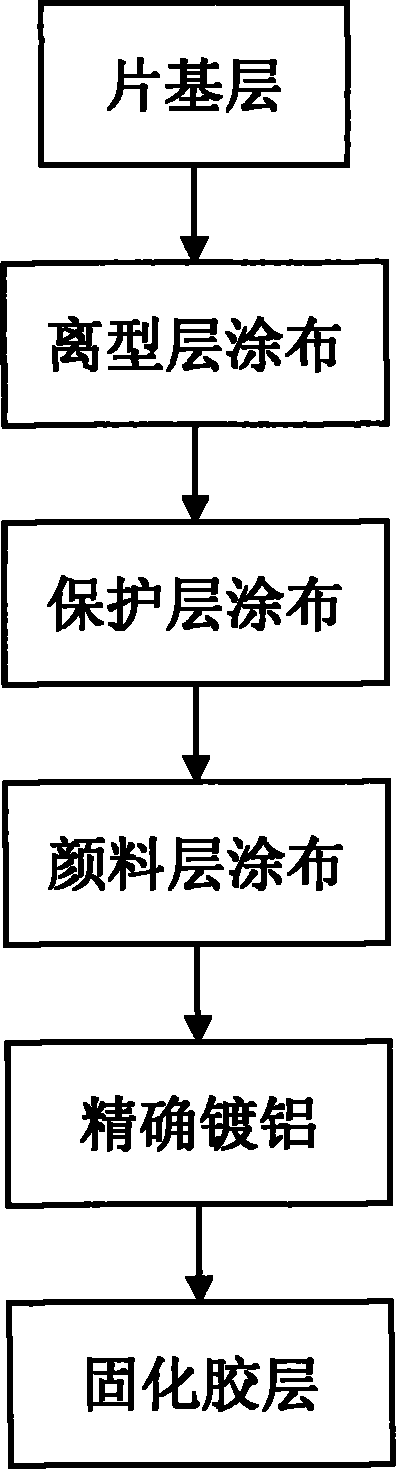

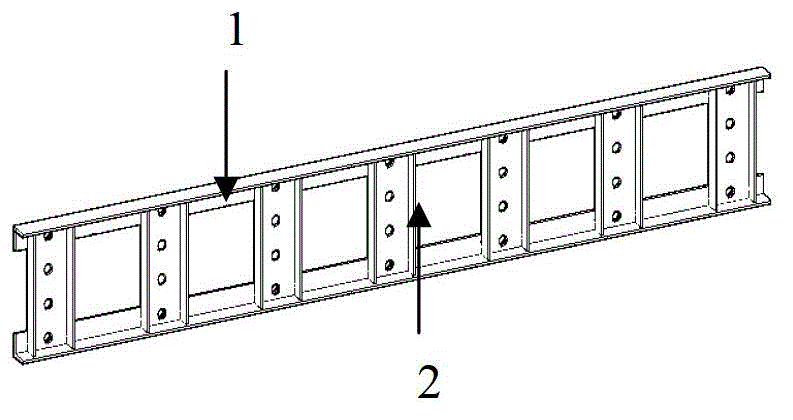

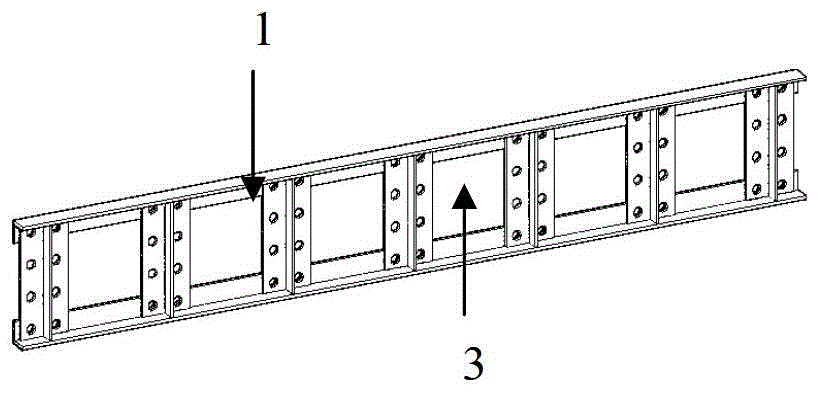

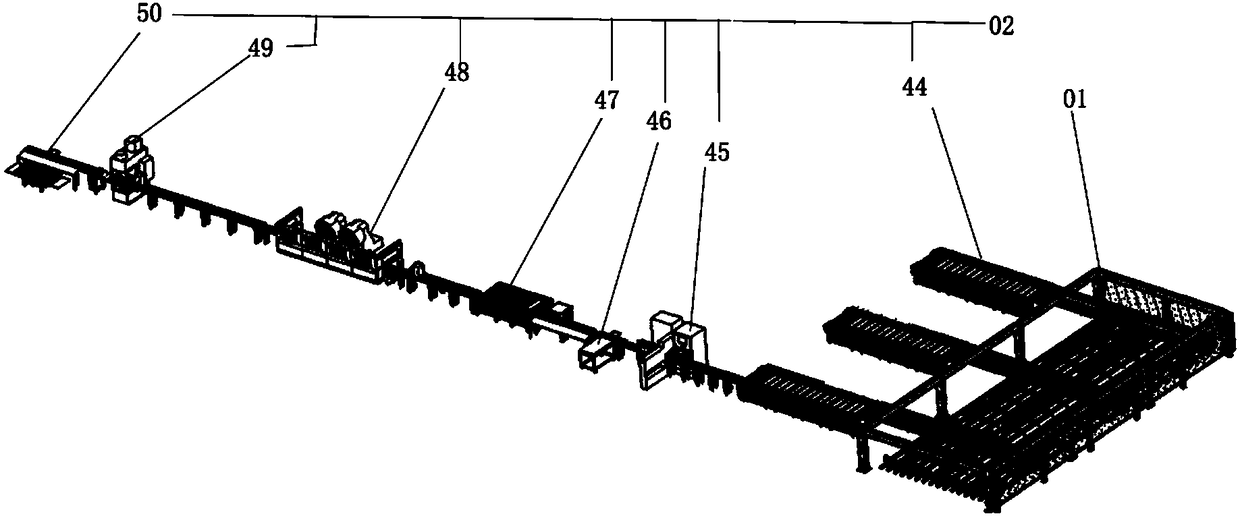

Digital control section steel sawing, drilling and welding integrated production line

ActiveCN102909563AIncrease productivityImprove machining accuracyOther manufacturing equipments/toolsMetal working apparatusProduction lineEngineering

The invention discloses a digital control section steel sawing, drilling and welding integrated production line. The digital control section steel sawing, drilling and welding integrated production line comprises a digital control sawing machine production line, a buffer storage device, a digital control drilling machine production line, a turnover welding forming production line, a hydraulic system and an electric control system, wherein the digital control sawing machine production line and the digital control drilling machine production line comprise a sawing host and a drilling host; a discharge channel is arranged at the rear part of the host; a charge channel is arranged at the front part of the host; roller shafts and side positioning rollers are arranged on the discharge channel and the charge channel; a side pushing device is also arranged on one side of the charge channel; and a digital control length calculating positioning device is mounted at one end of the charge channel close to the host. The buffer storage device is arranged to prevent workpieces from being overstocked due to different production rhythms of the sawing host and the drilling host, is used for bearing and conveying the finished sawed workpieces and can enable the workpieces to pass freely; a turnover charge device can turn the workpieces which cannot be drilled temporarily onto a buffer horizontal charge channel; and the turnover welding forming device can turn over freely by 360 DEG.

Owner:济南天辰智能装备股份有限公司

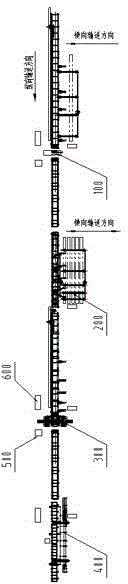

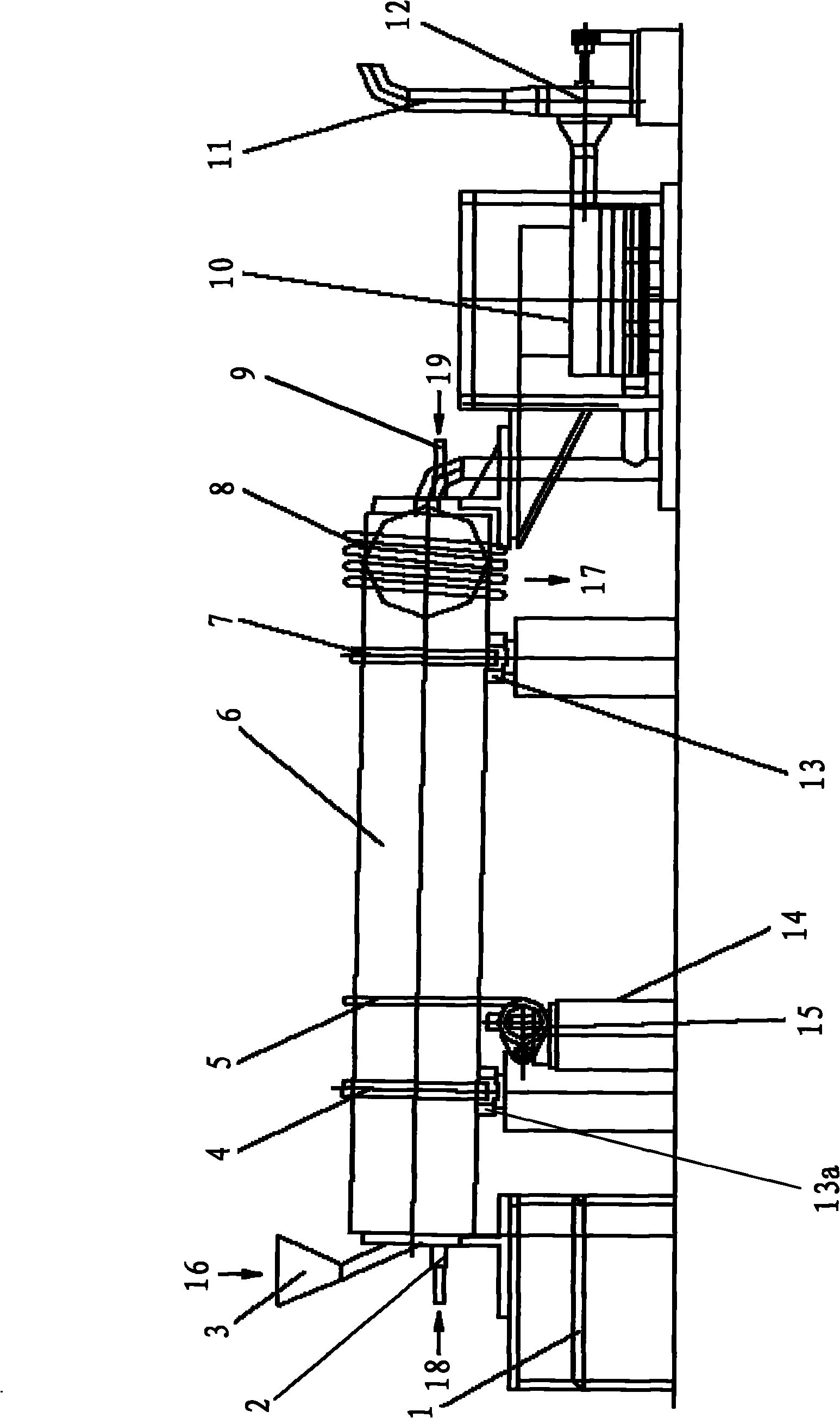

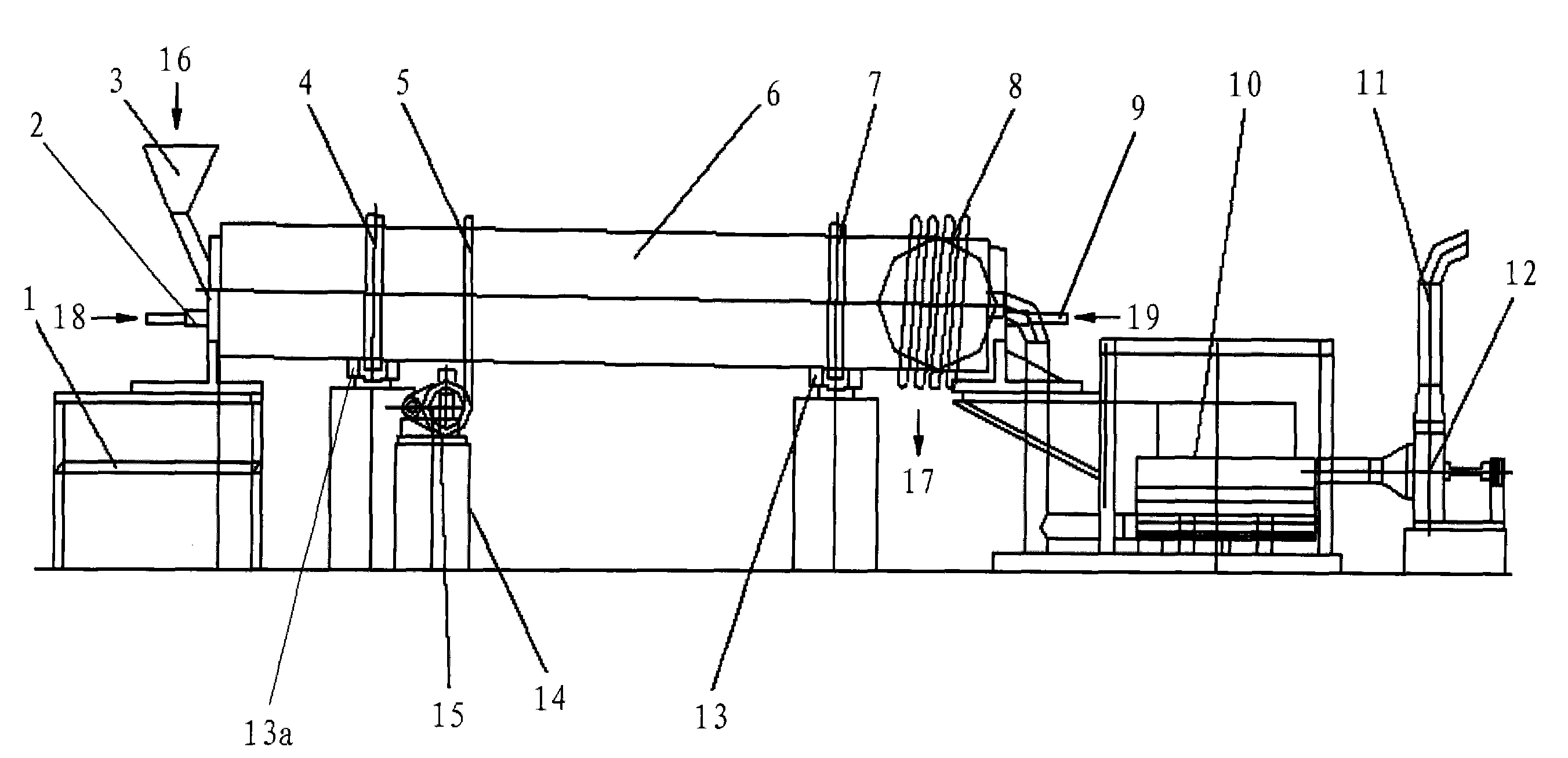

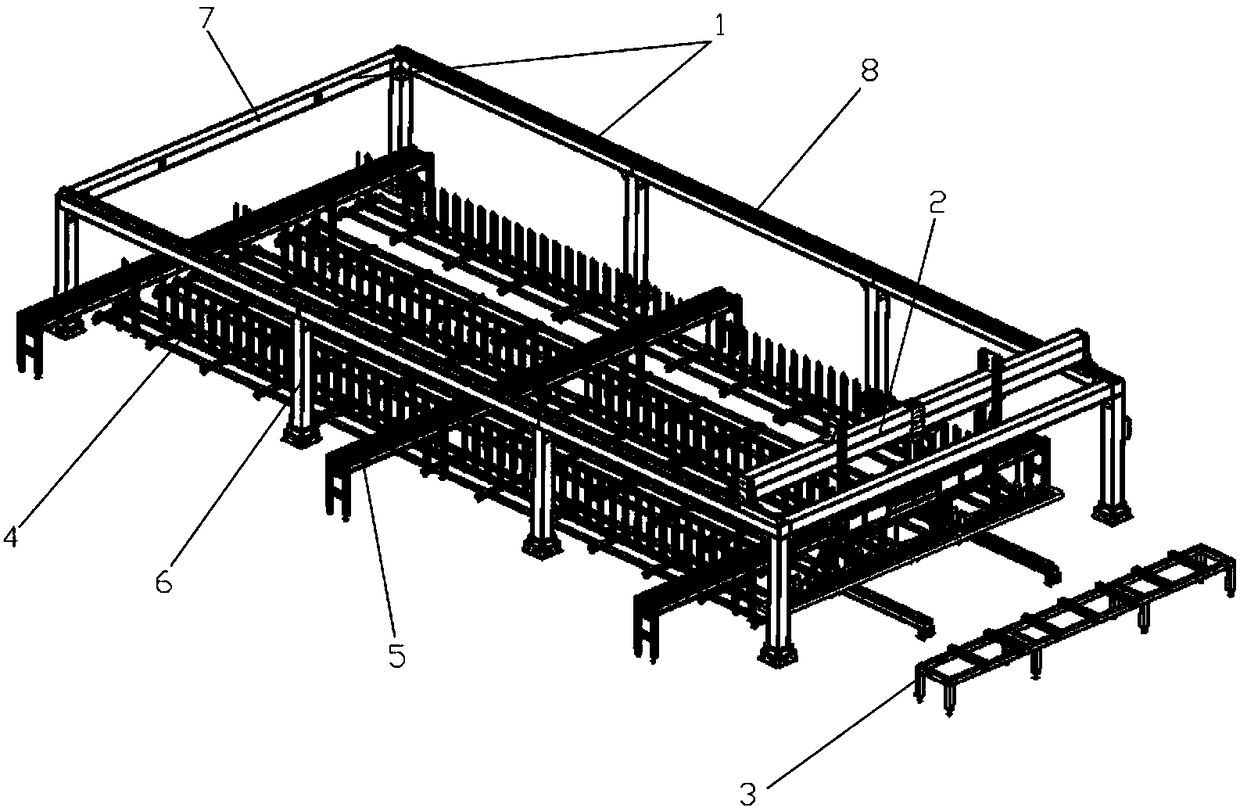

Robot automatic welding production line of middle groove and technological method thereof

ActiveCN101722373AImprove welding qualityEfficient automatic weldingWelding/cutting auxillary devicesArc welding apparatusProduction lineManufacturing technology

The invention relates to the technical field of production manufacturing of a cast middle groove by a heavy-duty scraper conveyor used on coal mines, and provides a robot automatic welding production line of a middle groove and a technological method thereof. The production line designs 8 stations according to the manufacturing process flow of the middle groove, comprises 6 parts of a primary assembly station, a middle plate preheating station, a backing welding station, a middle plate and bottom plate robot welding work station, a secondary assembly station and a bending rail rest robot welding work station, and forms an integrated production line layout of the middle groove. The invention integrates and uses multiple technologies of a welding robot, double-wire welding, digital double-pulse welding power source, computer control, high-efficiency flame preheating and the like, and establishes technical measures of preheating temperature, bevel form, welding sequence, welding parameters and the like; and the welding process is controlled by a computer, thereby realizing high-efficiency automatic robot welding of the middle groove in the overall process. Compared with the traditional manual gas shielded welding, the invention obviously improves the welding quality of the middle groove and increases the welding efficiency by 3-4 times.

Owner:CHINA COAL ZHANGJIAKOU COAL MINING MACHINERY

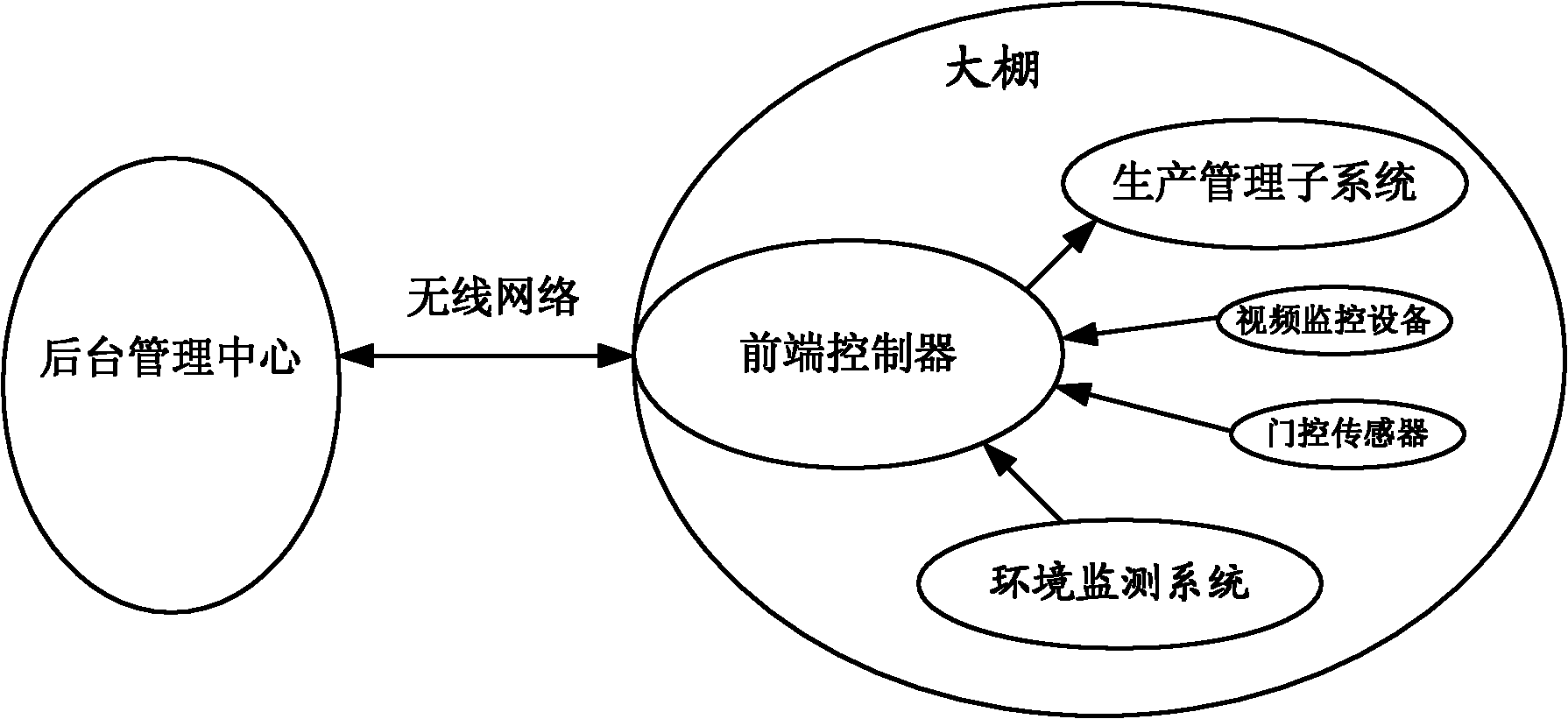

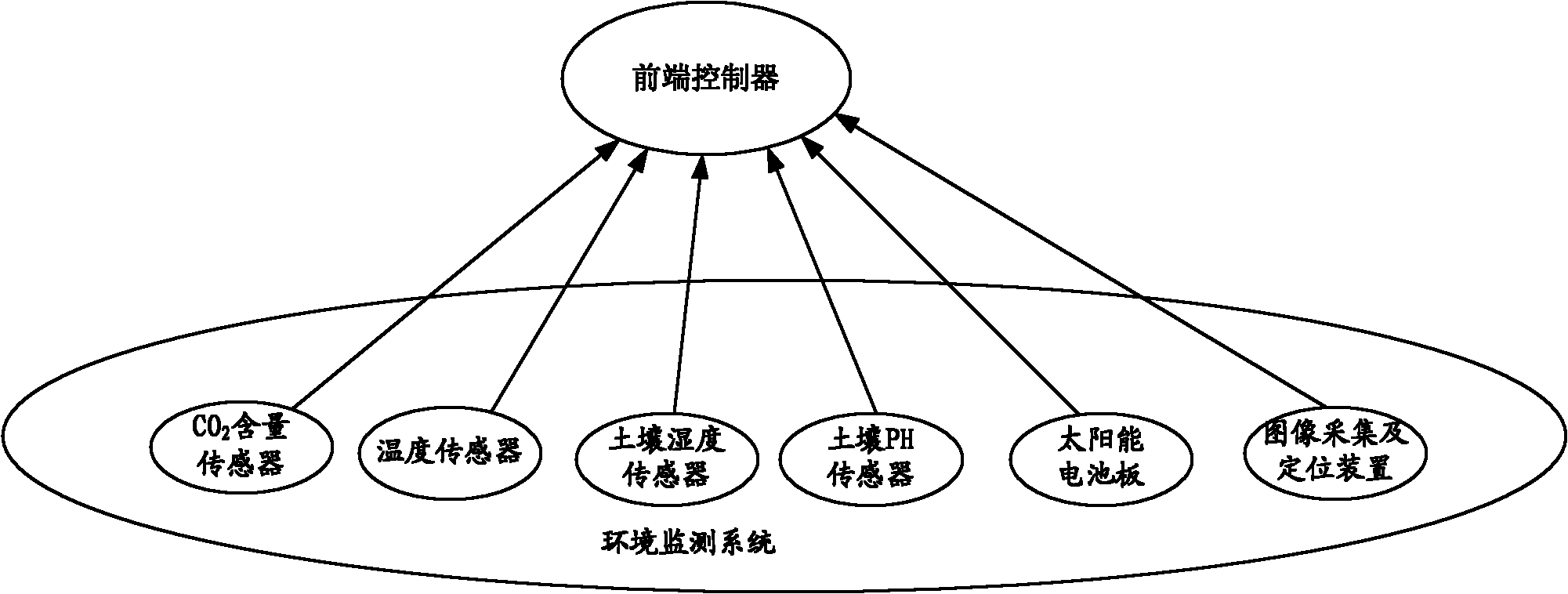

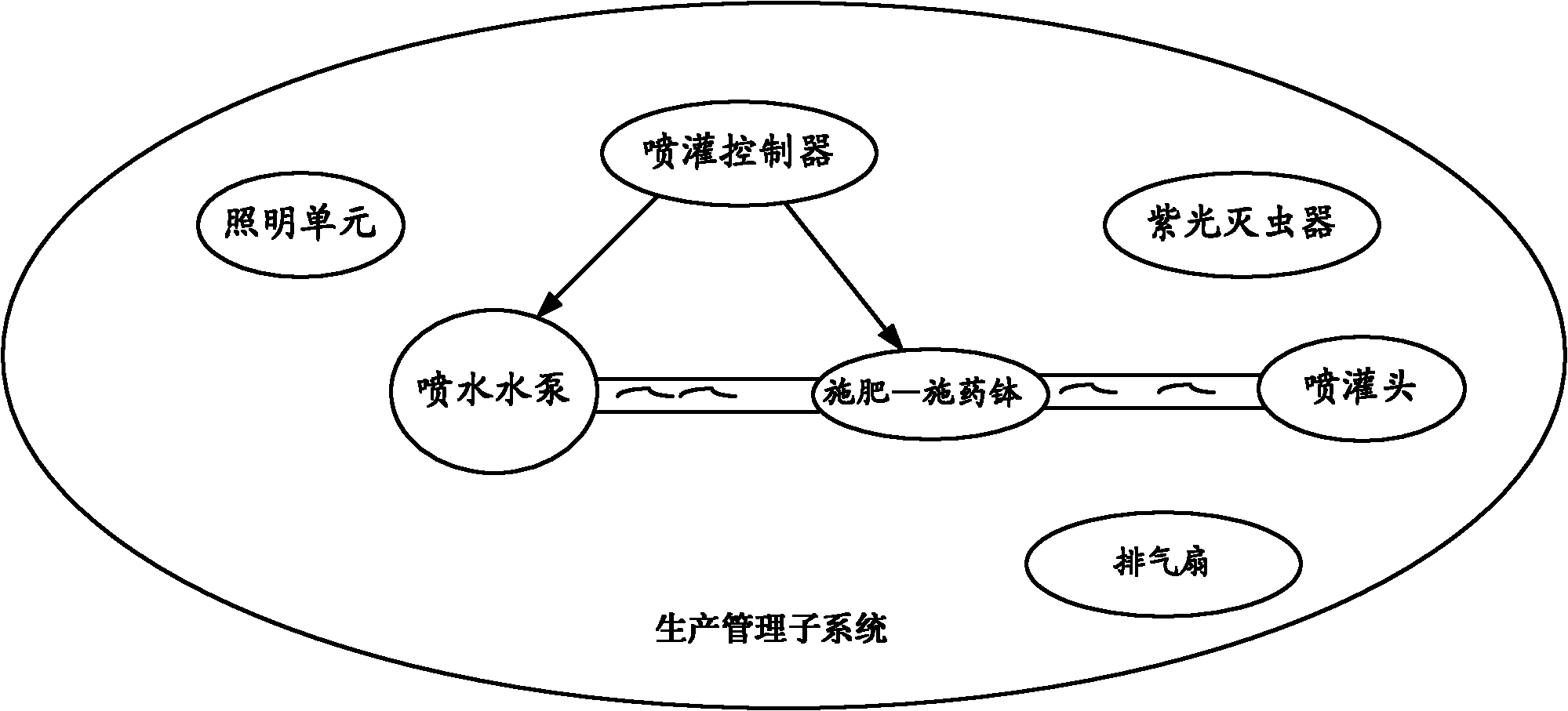

Comprehensive plant production management system and method

InactiveCN102156923ARealize fully automatic collection and monitoringThe growth environment is clearly understoodData processing applicationsWatering devicesMonitoring systemEngineering

The invention discloses a comprehensive plant production management system and an implementation method thereof. The comprehensive plant production management system comprises an environment monitoring system, a front controller and a background management center, wherein the environment monitoring system acquires growth environment parameters and growth status parameters of plants in a production field; the front controller uploads the growth environment parameters and the growth status parameters to the background management center, and controls a production management subsystem to execute corresponding production management operations according to control instructions sent by the background management center; and the background management center receives the growth environment parameters and the growth status parameters uploaded by the front controller, and sends the control instructions to the front controller. In the system, as the growth environment parameters and the growth status parameters of the plants in the field are acquired, and are uploaded to the background management center through a network, the background management center can automatically analyze the growth environment parameters and the growth status parameters, or sends the control instructions to the front controller through a human-machine interaction means to control the production management subsystem to perform corresponding production management operations on the plants according to the control instructions, therefore the probability of needing a person to visit the production field is reduced, and the production efficiency is improved.

Owner:华建武 +1

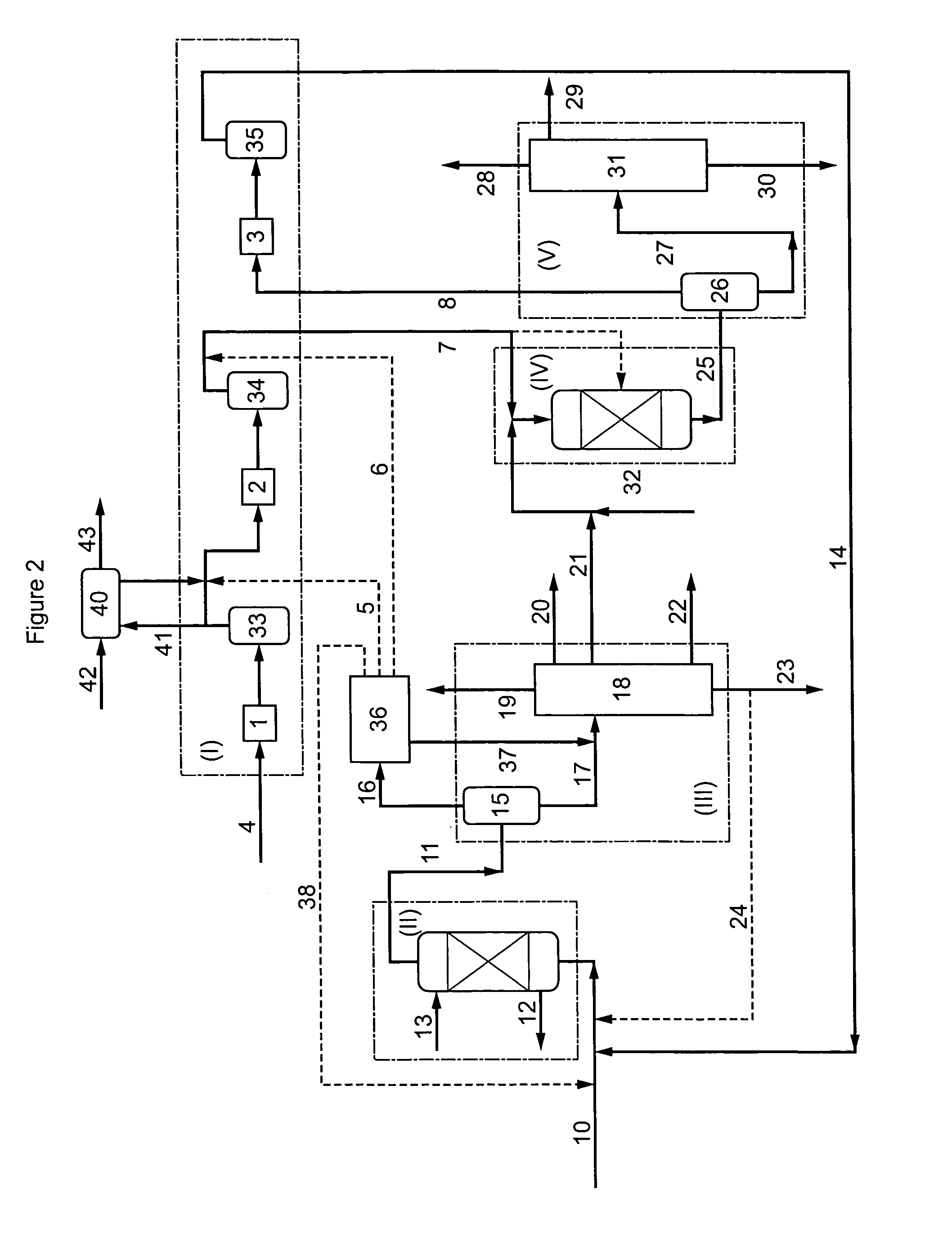

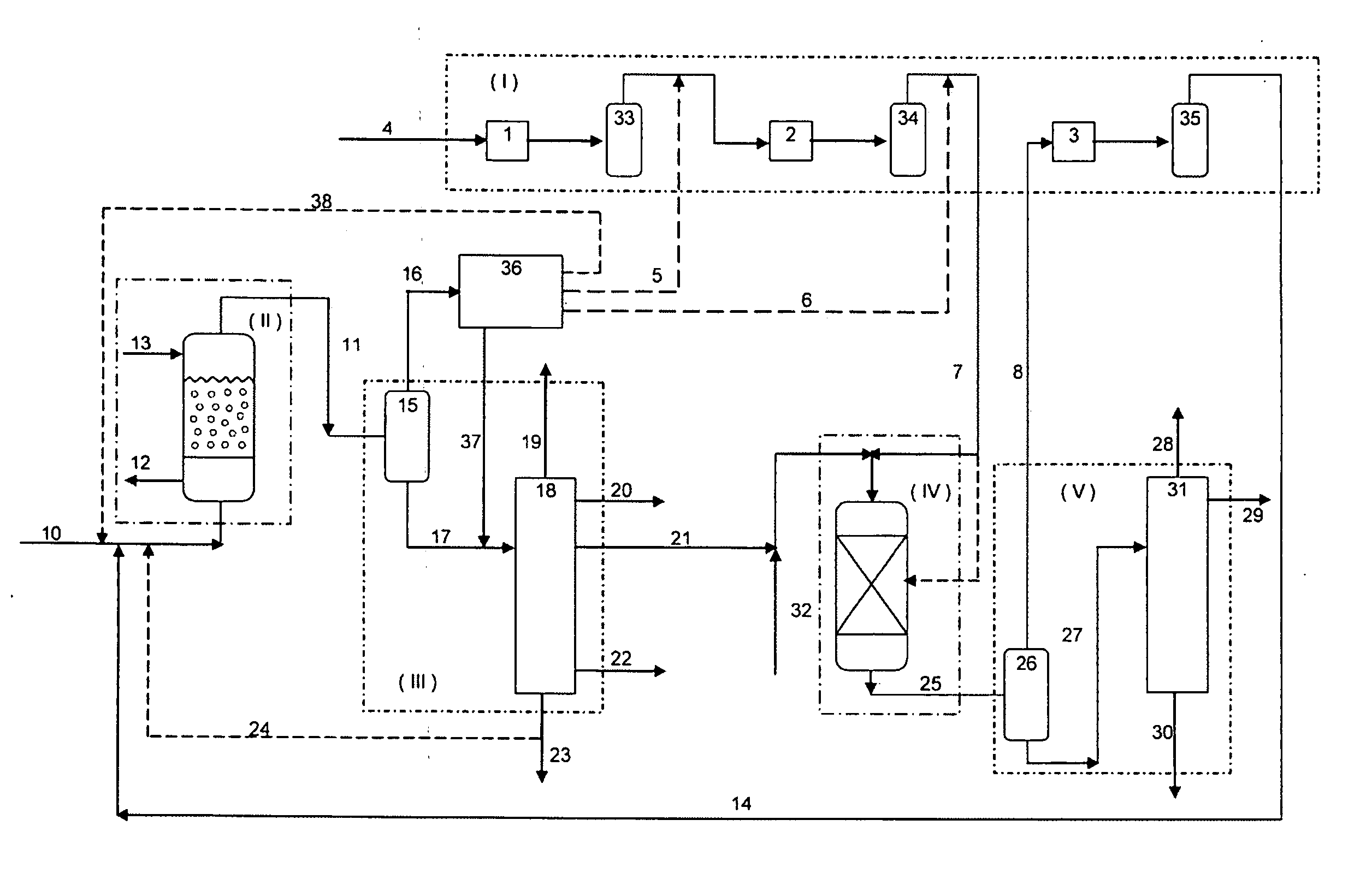

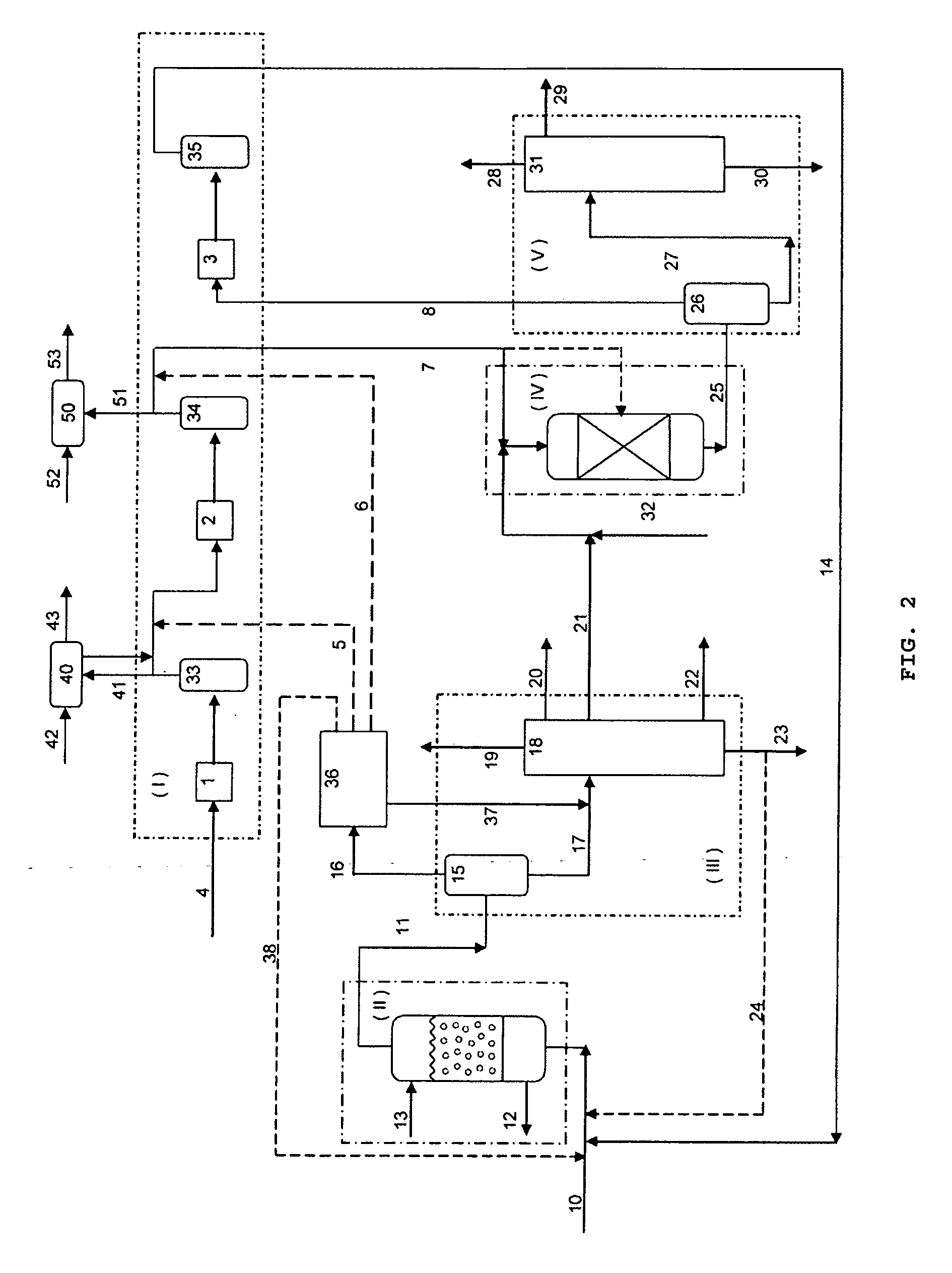

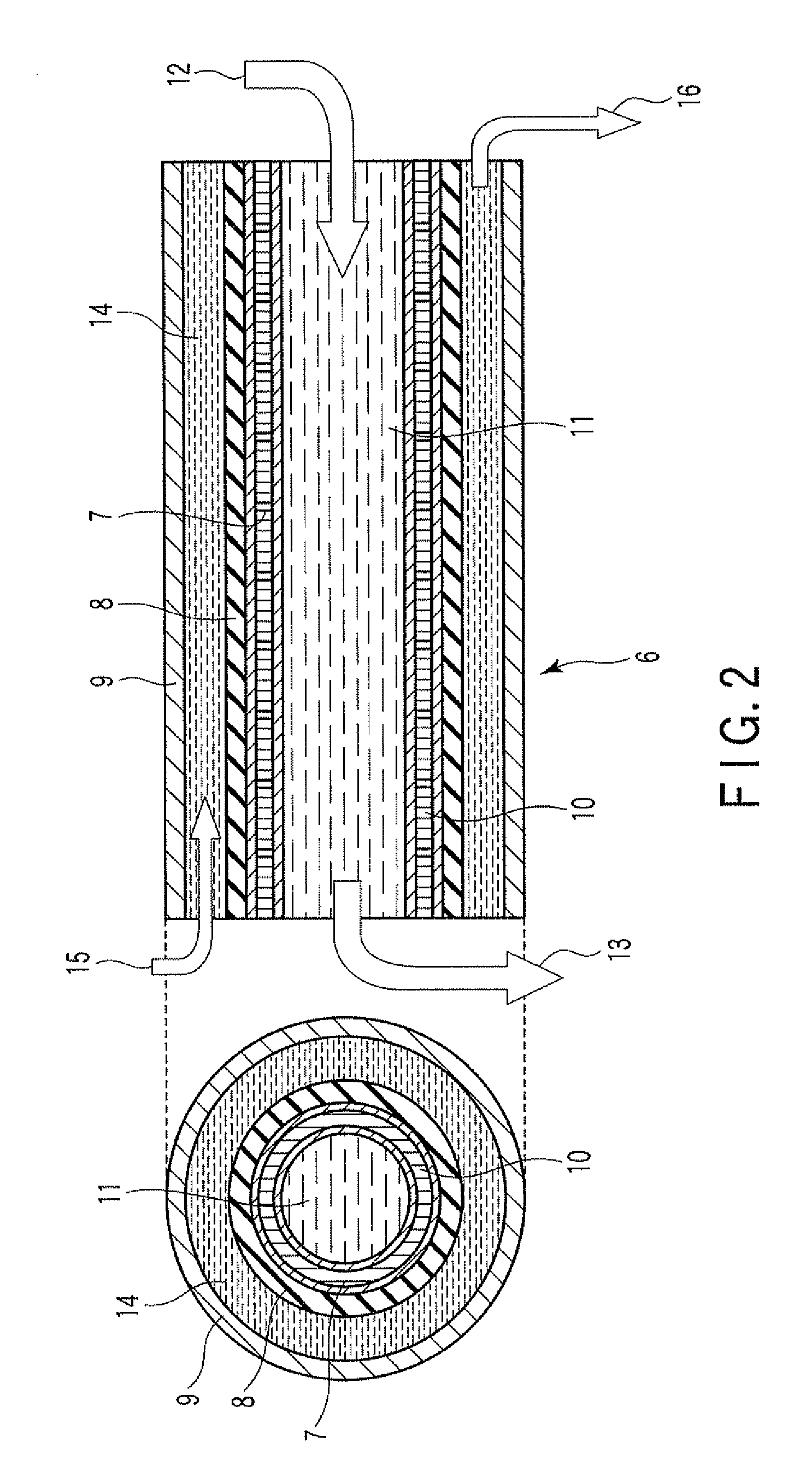

Process and installation for conversion of heavy petroleum fractions in a boiling bed with integrated production of middle distillates with a very low sulfur content

ActiveUS20070209965A1Low investment costOptimizing operating pressureTreatment with plural serial cracking stages onlyCoke ovensDistillates petroleumNaphtha

This invention relates to a process and an installation for treatment of a heavy petroleum feedstock, of which at least 80% by weight has a boiling point of greater than 340° C., whereby the process comprises the following stages: (a) hydroconversion in a boiling-bed reactor operating with a rising flow of liquid and gas, conversion in % by weight of the fraction having a boiling point of greater than 540° C. being from 10 to 98% by weight; (b) separation of the effluent obtained from stage (a) into a gas containing hydrogen and H2S, a fraction comprising the gas oil and optionally a fraction that is heavier than gas oil and a naphtha fraction; c) hydrotreatment by contact with at least one catalyst of at least the fraction comprising the gas oil obtained in stage (b); d) separation of the effluent obtained at the end of stage (c) into a gas containing hydrogen and at least one gas oil fraction having a sulfur content of less than 50 ppm, preferably less than 20 ppm, and more preferably less than 10 ppm, the hydroconversion stage (a) being conducted at a pressure P1 and the hydrotreatment stage (c) being conducted at a pressure P2, the difference ΔP=P1−P2 being at least 3 MPa, hydrogen supply for the hydroconversion (a) and hydrotreatment (c) stages being ensured by a single compression system with n stages.

Owner:INST FR DU PETROLE

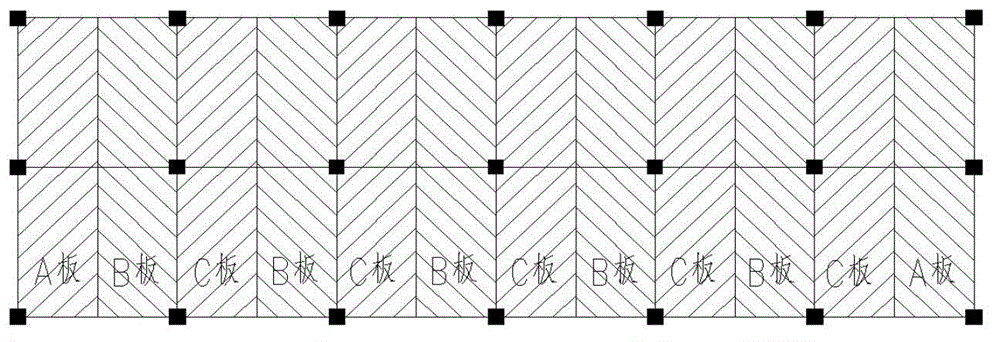

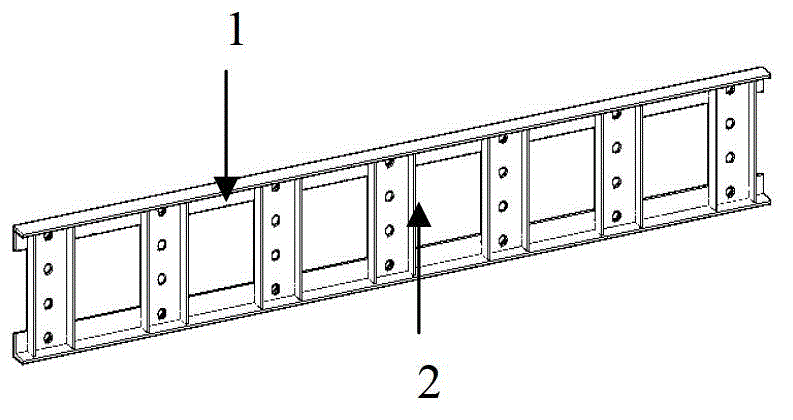

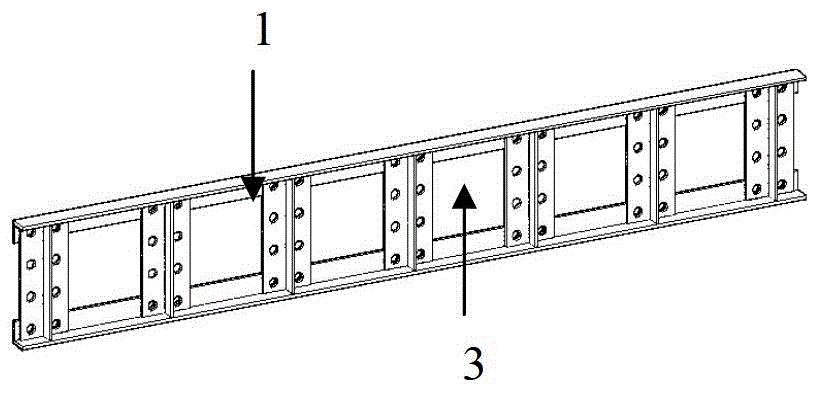

Multi-story high-rise assembled steel structure frame - prestressed centrally-braced system

The invention relates to a multi-story high-rise assembled steel structure frame - prestressed centrally-braced system, belonging to the technical field of structure engineering. The multi-story high-rise assembled steel structure frame - prestressed centrally-braced system comprises assembled beams and slabs, assembled stand columns and prestressed sway braces. The assembled beams and slabs in the system consist of slabs, column base joints and open-web steel beams with section steel web members. The open-web steel beams are connected with the column base joints. The slabs are supported on the open-web steel beams. The assembled stand columns consist of box columns and flanges. During construction, the assembled beams and slabs and the assembled stand columns can be spliced to form a frame structure, and the prestressed sway braces are arranged on the basis of the steel frame, so as to improve the lateral rigidness of the structure. All members of the structure system are prefabricated in factories and are rapidly assembled through bolts on the construction site to form the structure system. Concrete pouring and welding operation are avoided, the defects of long construction period, serious material wastage, great pollution during construction and the like existing the traditional buildings are overcome, and the factory integrated production of buildings can be realized.

Owner:CHINA RAILWAY CONSTR GROUP +1

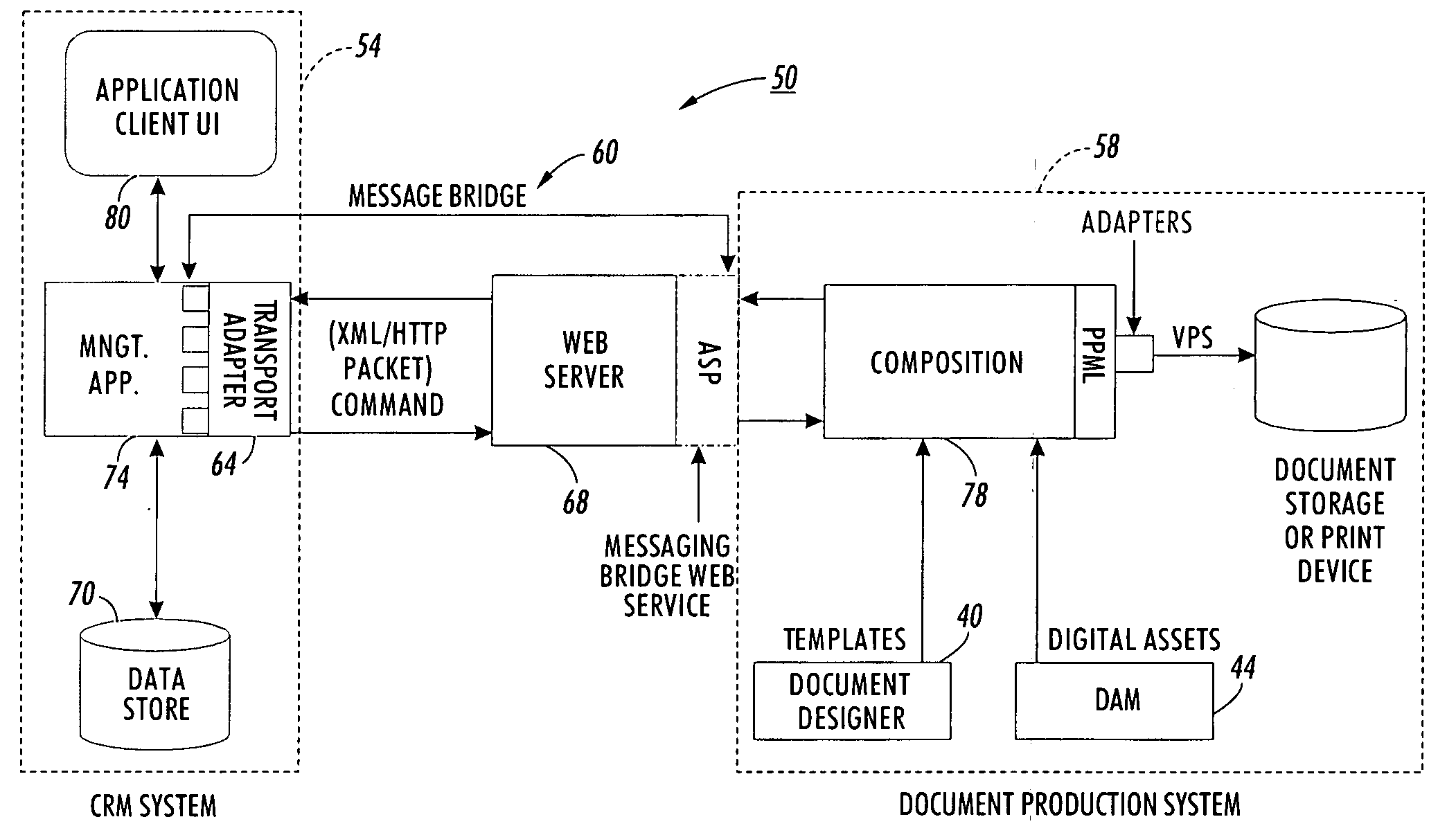

Method and system for integrated production of documents using variable data from a data management system

ActiveUS20050151999A1Promote generationEfficient productionDigital computer detailsVisual presentationData managementPaper document

A message bridge integrates a data management system with a document production system so that variable data may be provided to the document production system without off-line processing. The message bridge includes a transport adapter and a Web server. Preferably, a transport adapter resides at the data management system and a transport adapter resides at the Web server. The transport adapter at the data management system collects and converts variable data into data messages for communication with the document production system so a document composition engine may incorporate variable data in document layouts and printed documents. Soft documents generated by the document composition engine may be communicated to the data management system through the message bridge for proofing and approval.

Owner:XEROX CORP

Carbonization and activation integrated activated carbon production method and equipment

The invention relates to a carbonization and activation integrated activated carbon production method and carbonization and activation integrated activated carbon production equipment. The production method comprises the following steps of: preparing a raw material, namely dissociating a coal material at a high speed, pre-oxidizing in an oxygen-rich environment to ensure that the coal material has primary adsorption property, adding solid coal pitch in the coal mixing process, pressing a dissociated and pre-oxidized semi-finished product for forming, and crushing and granulating to form a carbonization and activation raw material; performing carbonization and activation integrated production, namely feeding the raw material into a carbonization and activation integrated furnace, preheating the raw material by using high-temperature flue gas returned to a furnace body, transferring the preheated raw material to a furnace tail from a furnace head with the rotation of the furnace body, and activating the raw material by using mixed gas sprayed from throat tubes of the furnace head and the furnace tail; and cooling the activated raw material by using a cooling system and discharging out of the furnace body. The activation rate is high, yield is high, cost is low, and autothermal equilibrium and product upgrading are realized; meanwhile, environmental pollution is reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Double-foaming cellular concrete and production method thereof

The invention discloses double-foaming cellular concrete and a site production construction method thereof. The volume weight of the double-foaming cellular concrete ranges from 100 KG / M<3> to 400 KG / M<3>; the heat conduction coefficient is as little as 0.020 W / M.DEG C, and the intensity is up to 5 MPa. The double-foaming cellular concrete can be widely applied to the production of light-weight heat preservation materials such as roof heat preservation materials and external wall heat preservation materials and hanging pieces such as light-weight building hanging beams, and has the purposes of the filling of light-weight hollow bricks and hollow building covers; more importantly, the double-foaming cellular concrete can be applied to the construction of underwater facilities. The site production construction method for the double-foaming cellular concrete is simple in technology and simple and convenient to operate; by special equipment, full-automatic integrated productions, such as automatic foaming, metering and proportioning, are effectively realized; upon automatic control, the production construction of the double-foaming cellular concrete is finished highly efficiently at low cost.

Owner:河南华泰新材科技股份有限公司

Automatic wire take-up reel rocking machine

ActiveCN105668316ARealize integrated productionIncrease productivityFilament handlingWrapping with article rotationEngineeringDriven element

The invention discloses an automatic wire take-up reel rocking machine. The automatic wire take-up reel rocking machine comprises a machine frame. A wire take-up mechanism for driving a wire reel to rotate is arranged on the machine frame and comprises a rotating disc arranged on the machine frame and a pressing head arranged above the rotating disc. During working, the wire reel is clamped between the rotating disc and the pressing head and driven by a driving element to rotate, so that a wire is wound on the wire reel. The automatic wire take-up reel rocking machine further comprises an automatic reel feeding mechanism and an automatic wire feeding mechanism, wherein the automatic reel feeding mechanism automatically conveys the wire reel onto the rotating disc, and the automatic wire feeding mechanism automatically conveys the wire onto the wire reel. The wire take-up mechanism further comprises a take-up wire pressing device used for pressing the end of the wire. According to the automatic wire take-up reel rocking machine, full automation in the take-up process is achieved, and the production efficiency of wire winding and packaging is improved; and meanwhile, integrated production of wire winding and film wrapping is realized, the production efficiency is further improved, the utilization rate of production space is increased, and economical benefits of enterprises are increased in the limited space.

Owner:DONGGUAN JINGTIE MACHINERY

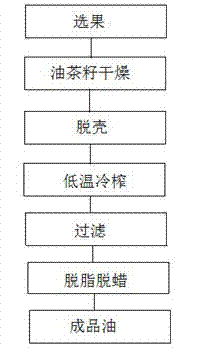

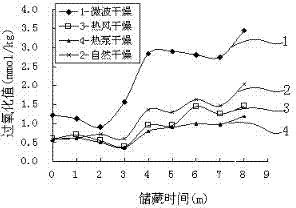

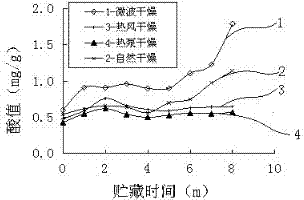

Method for producing edible camellia oleosa seed oil

InactiveCN103113979AEasy to processHigh yieldFatty-oils/fats refiningFatty-oils/fats productionAdditive ingredientEdible oil

The invention relates to the technical field of edible oil production and discloses a method for producing an edible camellia oleosa seed oil and the edible camellia oleosa seed oil. The method for producing the edible camellia oleosa seed oil provided by the invention comprises the steps of fruit selection, camellia oleosa seed drying, unshelling, low-temperature cold pressing, filtering, and degreasing and dewaxing, and abandons the complicated refining processes including degumming, deacidification, decoloration, deodorization and the like. The key process of the method for producing the edible camellia oleosa seed oil is optimized and improved creatively so that the integrated production process of the edible camellia oleosa seed oil which is obviously different from the prior art is obtained; the process is greatly simplified and the losses of the nutritional ingredients in the camellia oleosa seed oil and the finished product oil are also avoided; as a result, the nutritional and functional ingredients such as flavonoids, polyphenols, sterol and carotenoid in the camellia oleosa seed oil are guaranteed to an utmost extent; and the first-grade edible camellia oleosa seed oil is obtained simply and feasibly.

Owner:SOUTH CHINA AGRI UNIV

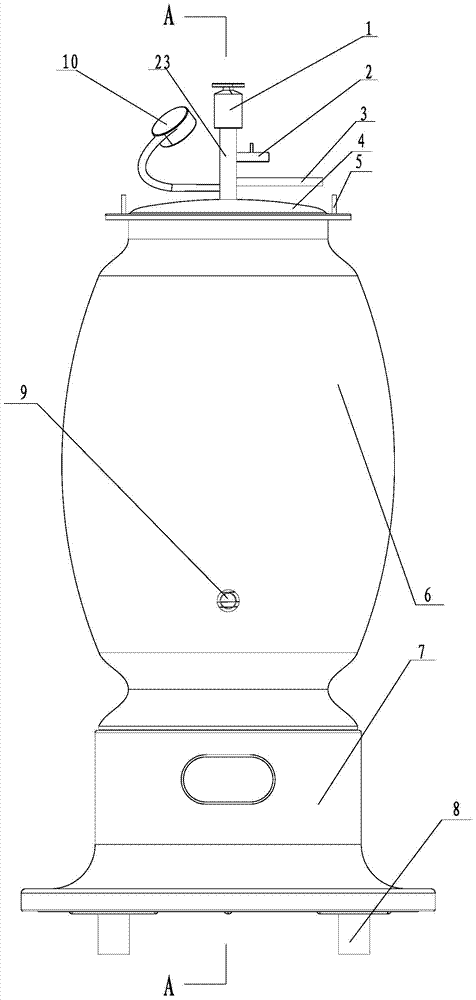

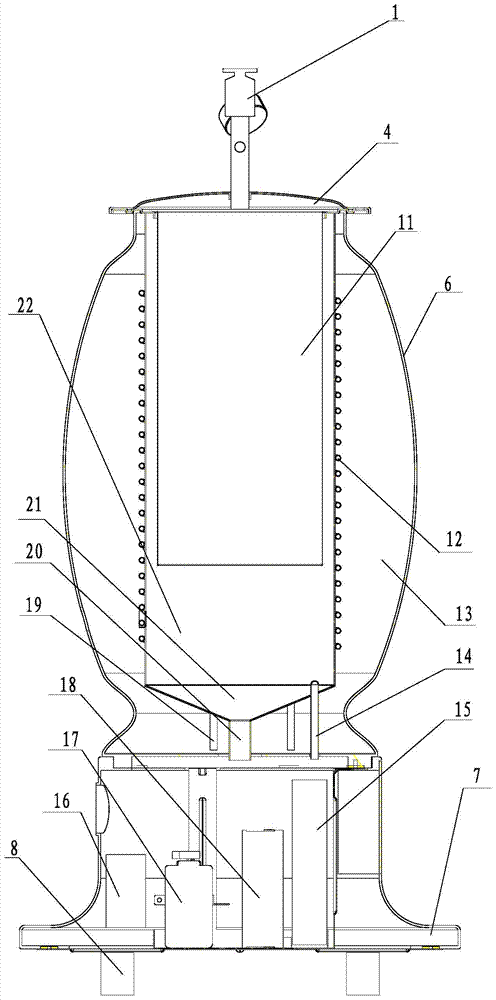

Household wine brewing machine and method for brewing wine by using household wine brewing machine

ActiveCN104498246ARealize integrated productionRich choiceWine preparationHops treatmentFruit wineIndustrial fermentation

The invention relates to a household wine brewing machine and a method for brewing wine by using the household wine brewing machine. The household wine brewing machine can be used for overcoming the defects that the existing industrial fermentation equipment is oversized and cannot achieve miniaturization and domestication. The household wine brewing machine is divided into four parts, namely a sealing cover, a fermentation tank, a control part and a power part, wherein the fermentation tank adopts a brand-new design. The household wine brewing machine not only can be used for producing grape wine, but also can be used for producing various fruit wines and beers, so that the integrated production of various wines is realized to provide more choices for consumers, the equipment cost is lowered and the product quality is guaranteed.

Owner:山东九道生物科技有限公司

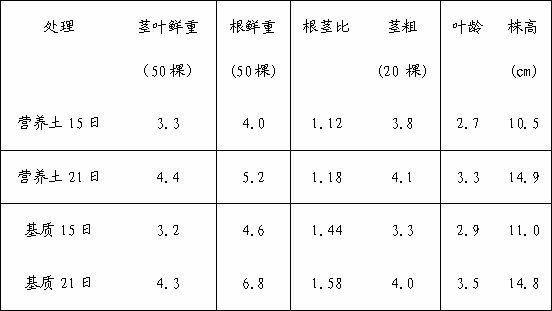

Seedling raising matrix and production method thereof

InactiveCN102584479ASolve the difficulty of fetching soilSolve the problem of destroying vegetationBio-organic fraction processingOrganic fertiliser preparationDiseaseDecomposition

The invention relates to a seedling raising matrix and a production method thereof. The seedling raising matrix comprises the following components in percentage by volume: 15 to 45 percent of decomposed organic fertilizer, 20 to 50 percent of light material and 5 to 35 percent of binder, wherein the decomposed organic fertilizer is prepared by fermenting livestock and poultry excrement and auxiliary materials. The method comprises the following steps of: pretreatment, primary fermentation, secondary fermentation, decomposition fermentation, aftertreatment, fine treatment, and mixed treatment. After the measures are adopted, the produced seedling raising matrix is developed in packing and light, seedlings are robust, and the growth period is short; the problems that soil is difficult to take and vegetations are damaged when nutritional soil is used for raising the seedlings can be solved; the transmission of soil-borne disease is reduced; the production process for the seedling raising is simplified, and production efficiency is improved; after an organic fertilizer matrix is moved to a large field, a soil structure can be improved, and soil fertility is increased; the livestock and poultry excrement is used for producing the matrix, so that environmental pollution is reduced; and by the seedling raising matrix, integrated production cost is reduced, and the farming income of farmers is improved.

Owner:江苏科力农业资源科技有限公司

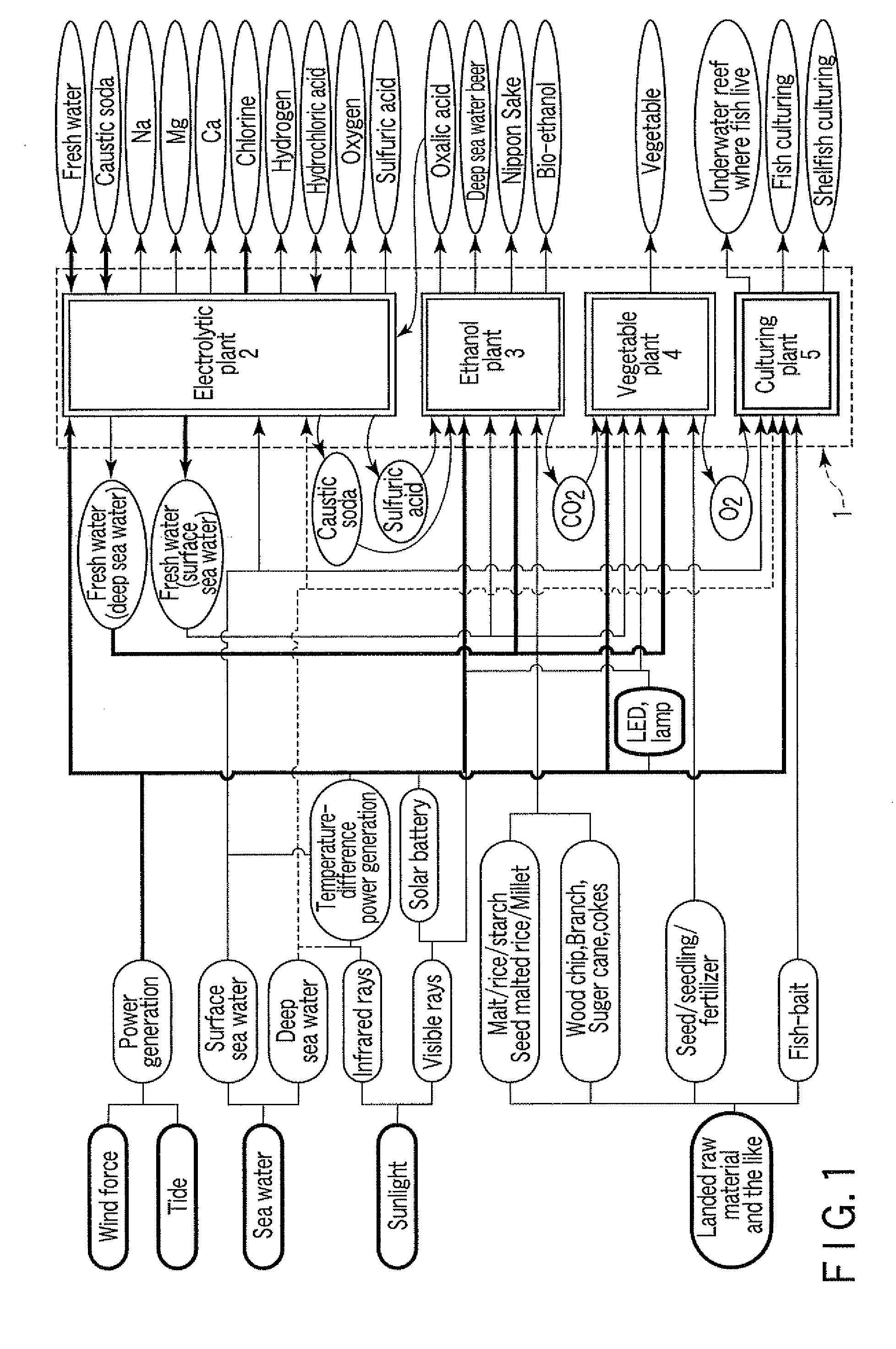

Onsite integrated production factory

ActiveUS20100051450A1Low costDemand is substantialSolar heating energyElectrolysis componentsFresh water organismPotassium

Using electric power obtained by marine wind force and a tide, sea water is electrolyzed to produce fresh water, sodium, magnesium, calcium, potassium, caustic soda, chlorine, hydrochloric acid, sulfuric acid, hydrogen, oxygen or the like, at the same time, unloaded malts, saw dust and the like are fermented to brew ethanol, carbon dioxide generated here is used for photosynthesis to culture vegetables and oxygen generated here is supplied to a fish preserve and an under reef where fish live to culture fishes and also returned to sea water dropped in the concentration of oxygen to suppress the generation of a red tide.

Owner:M HIKARI & ENERGY LAB

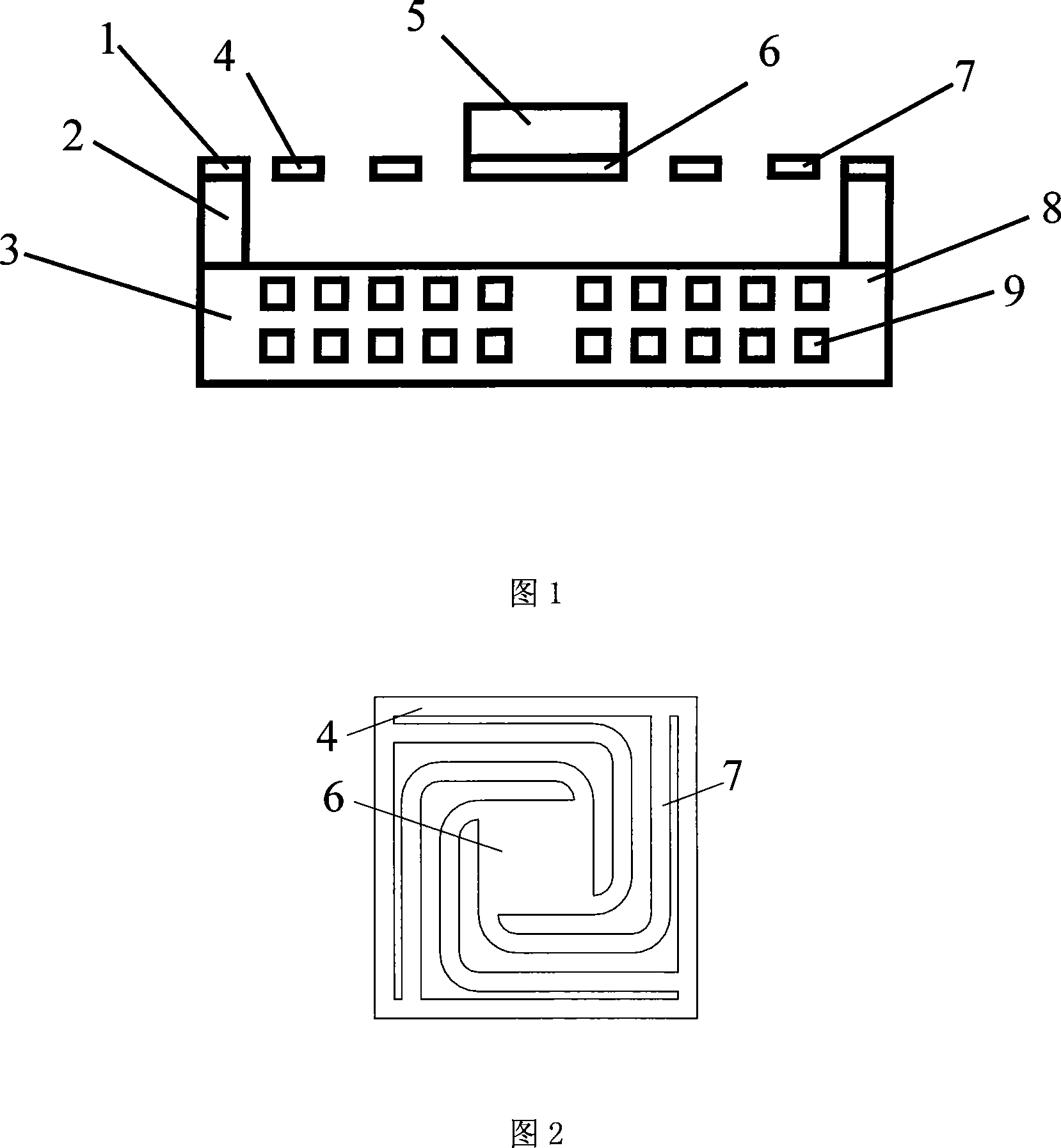

Minisize electromagnetic low-frequency vibration energy collecting device

The invention discloses a mini-type electromagnetism low frequency energy collector in the field of electronic component which comprises a libration pick up structure, a support structure and a micro-coil structure. The libration pick up structure comprises a metal plane spring and a permanent magnet. The metal plane spring comprises four square spirality elastic arms and a metal platform. The permanent magnet is arranged at the metal platform. The micro-coil comprises a micro-coil winding and an insulated underlay. The metal plane spring and the support structure are integrated as a whole. The libration pick up structure and the support structure are at the micro-coil. The libration pick up structure of the utility model has a natural frequency near to 100 HZ and is easy to satisfy the integrated requirements such as improvement of the low frequency energy collecting efficiency, low production cost and integrated production.

Owner:SHANGHAI JIAO TONG UNIV

Aluminum substrate cutting, pressing and trimming integrated production line

The invention relates to the technical field of aluminum substrate production and processing, in particular to an aluminum substrate cutting, pressing and trimming integrated production line. The aluminum substrate cutting, pressing and trimming integrated production line comprises a workbench, a cutting device, a pressing device and a trimming device; the cutting device, the pressing device and the trimming device are sequentially arranged on the workbench from left to right; the cutting device comprises a conveying assembly for driving the aluminum substrate to move forwards and a fixing assembly for fixing the aluminum substrate; the conveying assembly is arranged at the left end of the workbench; the fixing assembly is arranged at the side part of the conveying assembly; a first conveying rail is arranged at the end, far away from the conveying assembly, of the fixing assembly; a connecting rail perpendicular to the first conveying rail is arranged at the tail end of the first conveying rail; a second conveying rail parallel to the first conveying rail is arranged at the tail end of the connecting rail; the pressing device is arranged at the side part of the second conveying rail; and the trimming device is arranged on the side, far away from the cutting device, of the pressing device. The aluminum substrate cutting, pressing and trimming integrated production line has theadvantage that the aluminum substrate cutting, pressing and trimming efficiency is improved.

Owner:赣州逸豪新材料股份有限公司

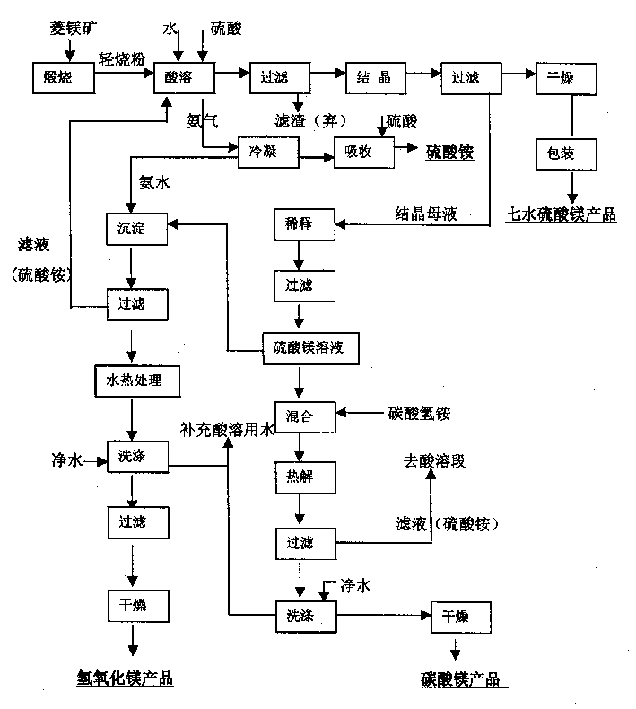

Method for integrated production of magnesium sulfate, magnesium carbonate and magnesium hydroxide from magnesite

InactiveCN1401573AImprove protectionReduce manufacturing costMagnesium carbonatesMagnesium sulfatesAmmonium Hydrogen CarbonateCarbonate

A process for preparing magnesium sulfate, magnesium carbonate and magnesium hydroxide from magnesite includes reaction of light-burned magnesium oxide powder obtained by calcining magnesite, the solution of ammonium sulfate as the by-product obtained by reaction with magnesium carbonate and magnesium hydroxide precipitate and industrial concentrated sulfuric acid, evaporating ammonia gas, dissolving in water, depositing to obtain magnesium hydroxide, controlling acidity and temp. filtering to remove impurities, cooling crystallizing to obtain magnesium sulfate heptahydrate, diluting the mother liquid, preparing alkaline magnetic carbonate by ammonium hydrogen carbonate method, and sulfuric acid absorption to residual ammonia water to obtain ammonium sulfate as by-product. Its advantage is no generation of gas and liquid pollutants.

Owner:TSINGHUA UNIV

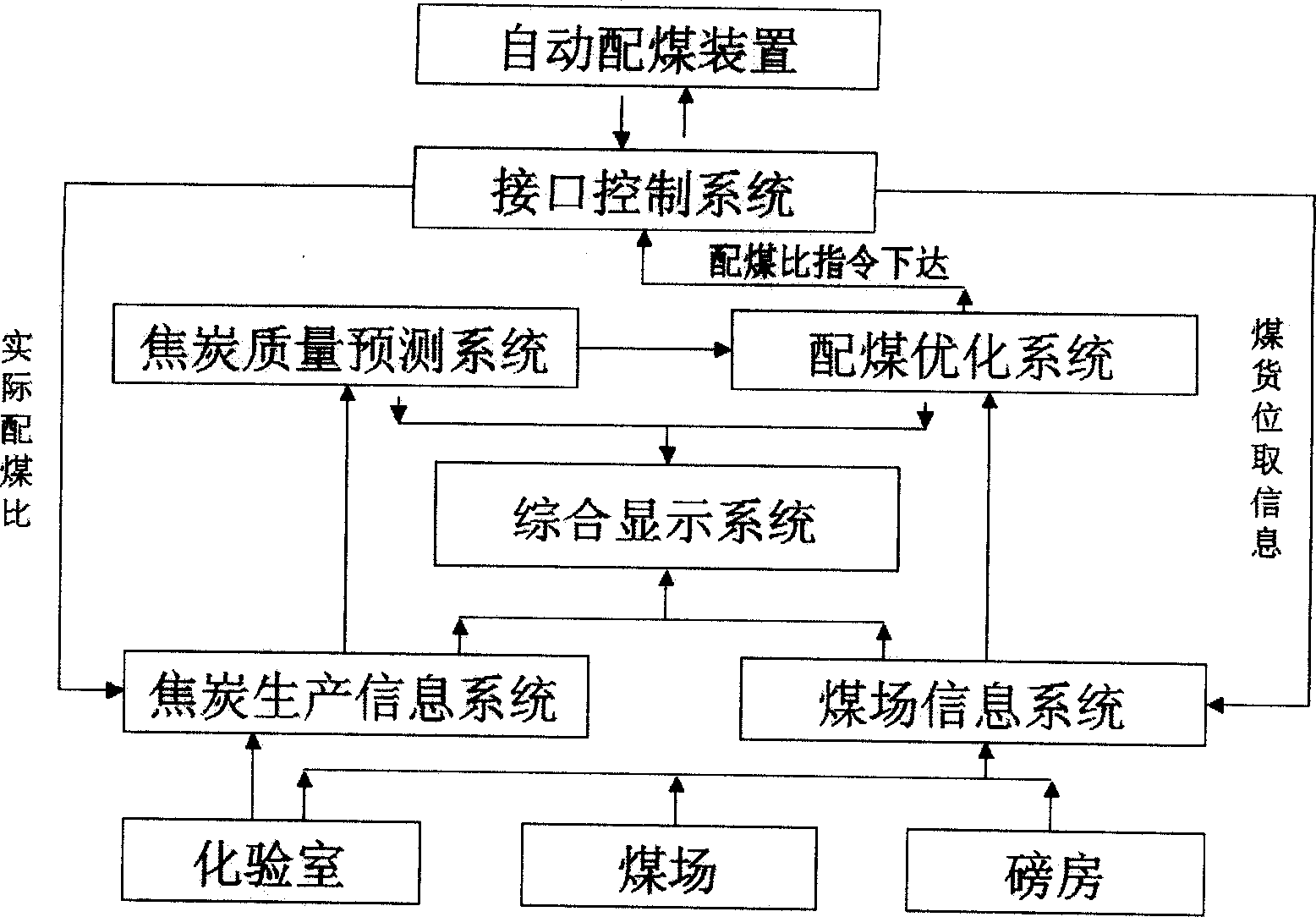

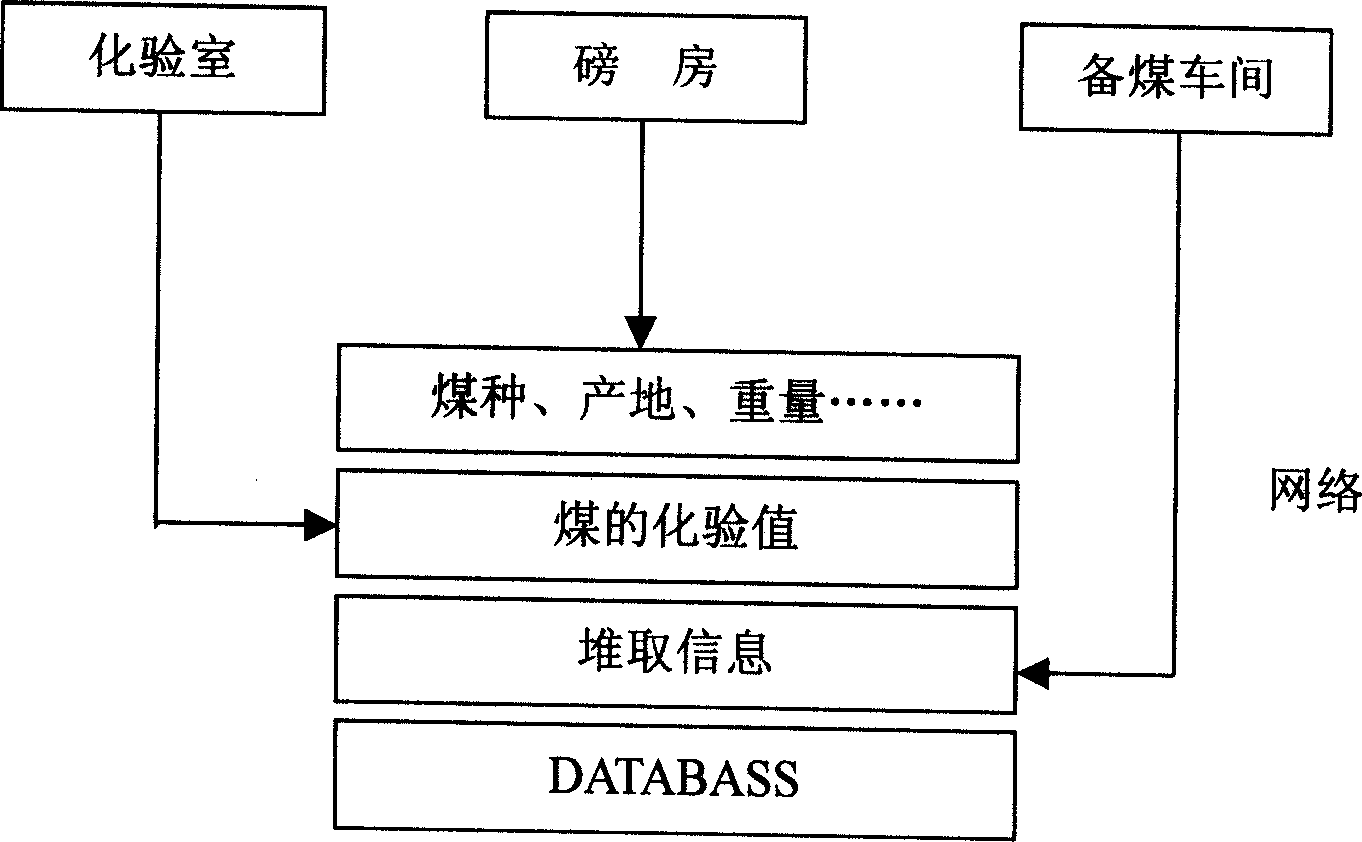

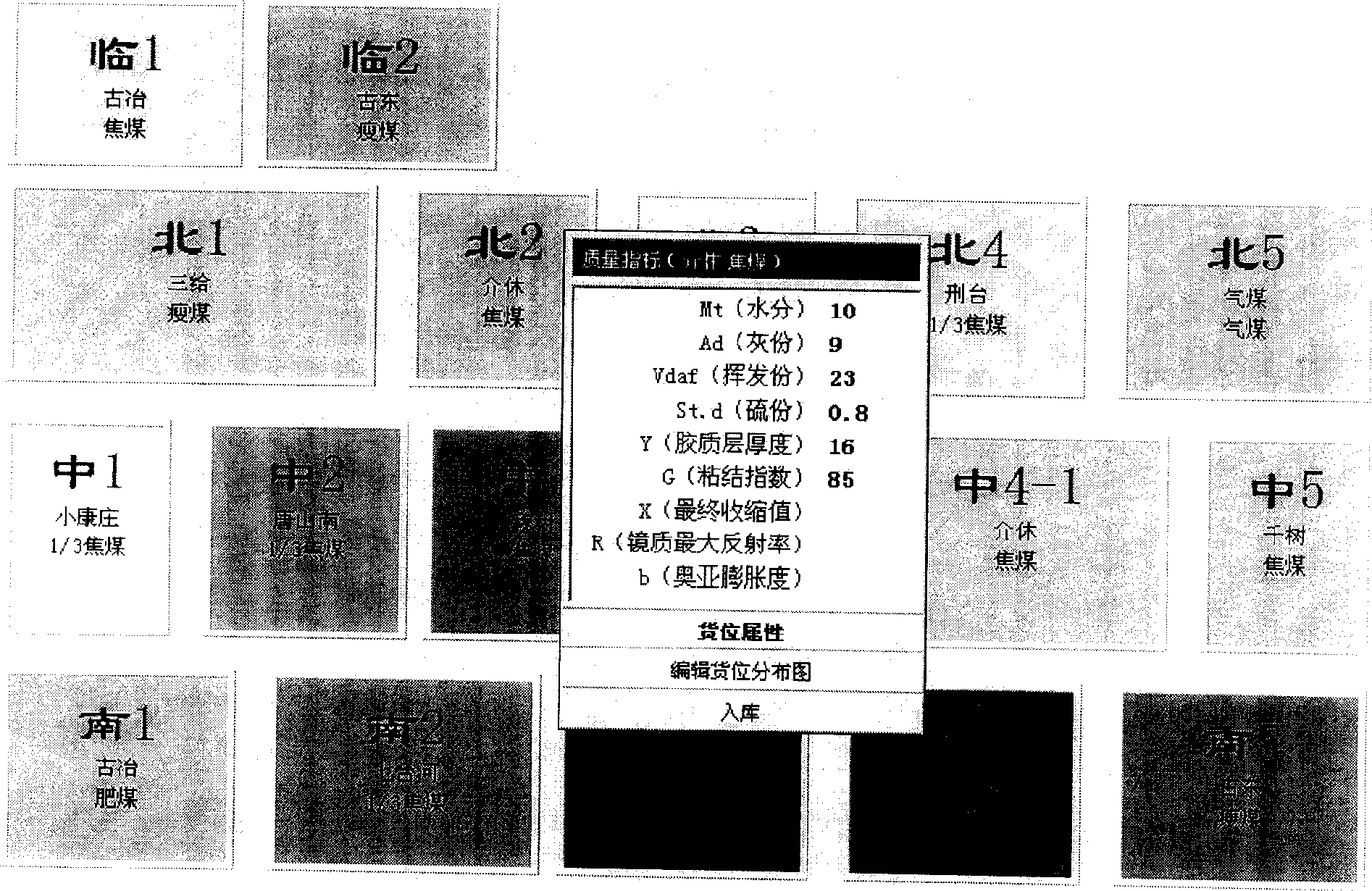

Optimum system for distributing coal of coking controlled by computer

ActiveCN1749358ALow costRealize scientificCoke oven safety devicesComputer controlInformation repositoryControl system

The computer controlled coking-coal distributing optimizing system has a coke producing information system integrating the coal compounding and coke information to form production information database; a coal yard information system integrating the coal information to form coal material database; a coal distribution optimizing system; a coke quality predicting system to ensure coke quality and an interface control system, integrated production control in coke plant. The computer controlled coking-coal distributing optimizing system can ensure the coke quality, and provide coal distributing scheme with minimized cost.

Owner:ACRE AUTOMATION CO LTD MCC

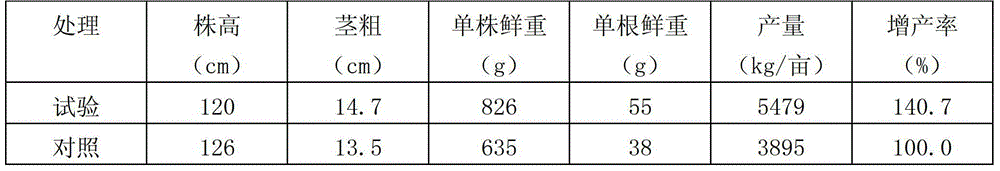

Microbial organic fertilizer and preparation method thereof

The invention provides a microbial organic fertilizer and a preparation method thereof. The preparation method comprises the steps of strain culture, compounding and liquid submerged fermentation, and belongs to an agricultural integrated production technique. 15-20% of Bacillus mucilaginosus, 15-18% of Bacillus megaterium, 15-18% of Azotobacter chroococcum, 10-13% of Saccharomyces cerevisiae, 10-13% of Candida utilis, 15-18% of Lactobacillus plantarum and 10-13% of actinomycete are respectively subjected to primary and secondary strain culture and tertiary liquid submerged fermentation until the bacterial count in the fermentation liquid reaches 10-15*10<8> / mL, thereby obtaining the microbial organic fertilizer (707(Y)). By adopting the advanced liquid submerged fermentation technique and using the strains with high stability and functionality, which are screened from the natural world over the years and have the advantages of many varieties and convenient application method, the invention can promote the plant growth, improve the fruit quality, promote prematurity, increase the yield, enhance the utilization ratio of the fertilizer, improve the ecological environment of soil, and have certain effects of disease prevention and disease resistance.

Owner:DALIAN SANKE BIO ENG

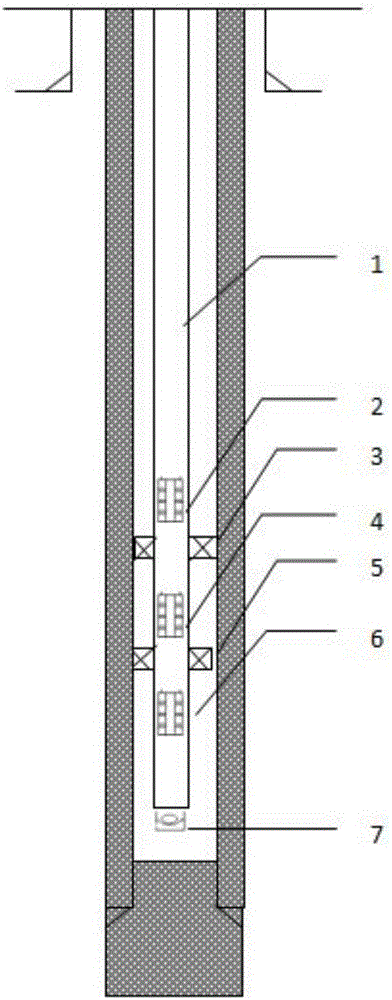

Coal bed gas well sand blasting perforation jet hole forming and fracturing integrated production increasing process method

The invention discloses a coal bed gas well sand blasting perforation jet hole forming and fracturing integrated production increasing process method. The coal bed gas well sand blasting perforation jet hole forming and fracturing integrated production increasing process method comprises the following steps that an integrated pipe column is descended into a well needing to be transformed; sand blasting perforation is conducted on the well, and a coal bed is opened; hole forming transforming is conducted on the well; a cylinder or spherical body with hole cavities uniformly distributed along a shaft, the gun length being the height and the spray gun operating distance being the radius is formed; and fracturing construction is conducted on the well. If multi-layer multi-stage construction is conducted, ball throwing is conducted after fracturing of the first layer on the lower portion is completed, a packer is subjected to seat sealing, a sliding sleeve on the packer is opened in a pressure rise mode, sand blasting perforation, jet hole forming, fracturing and the like are conducted on the second section, and the rest can be done in the same manner till all construction layers are constructed. According to the coal bed gas well sand blasting perforation jet hole forming and fracturing integrated production increasing process method, perforation, hole forming and fracturing integrated production increasing construction can be completed in the coal bed gas well at the same time; the problems that near wellbore areas are polluted and the crack radiating area is small are effectively solved; the flow conductivity of coal reservoirs of the near wellbore areas is improved; the seepage area is increased; and the gas yield of the coal bed is increased.

Owner:CNPC BOHAI DRILLING ENG

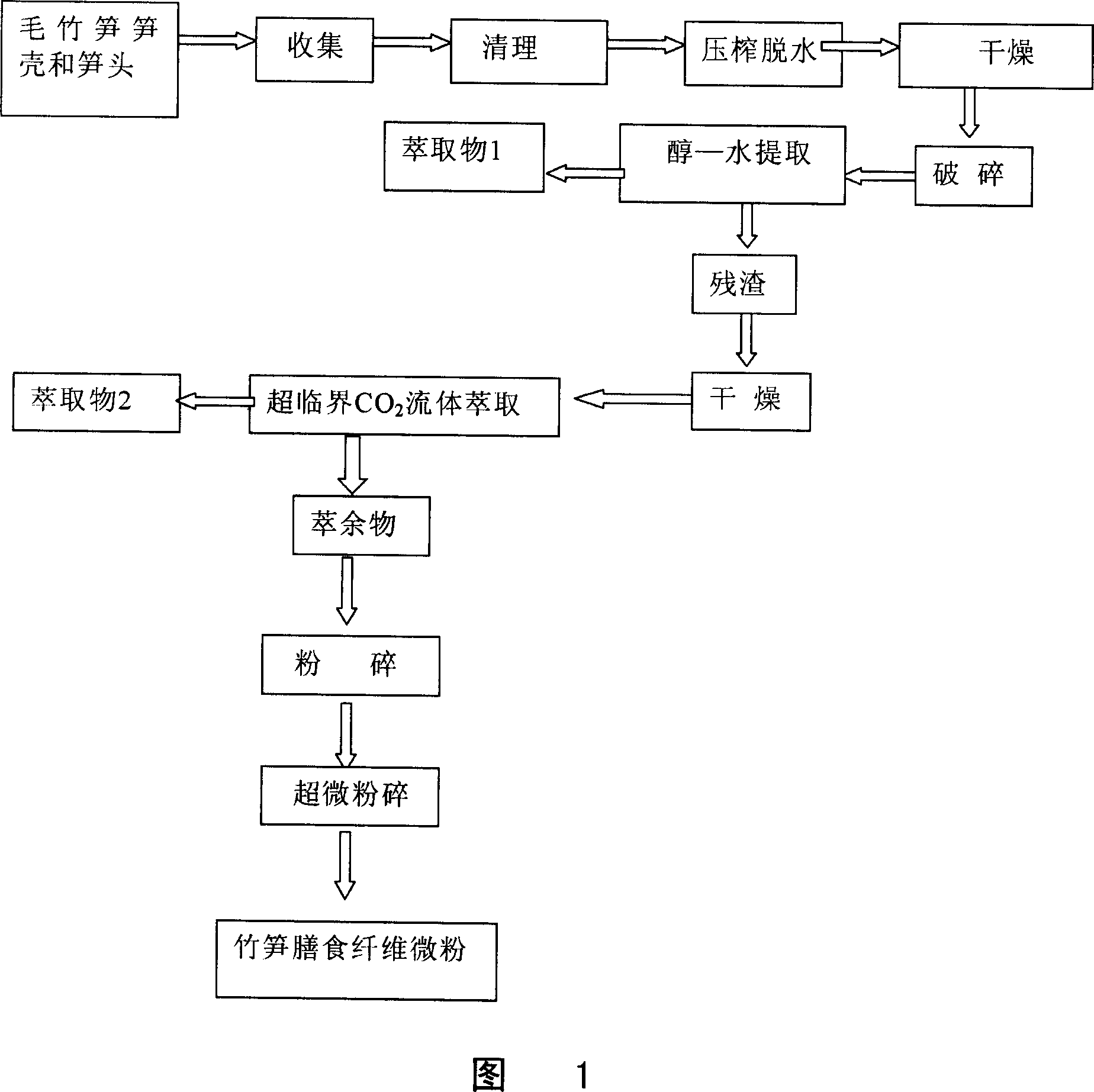

High-quality insoluble plant edible fiber micropowder and preparation method and application thereof

InactiveCN101142979ASmall particle sizeLarge specific surface areaFood preparationFiberDietary fiber

The invention discloses high-quality insoluble plant dietary fiber powder, and the particle size of more than 90 percent of dietary fiber powder is less than 30 mum and dietary fiber powder has the capacity of strong water binding, swelling, fat (oil) absorbency and chelating metal ion. The invention also discloses a preparation method for fine powder. Fine powder is widely used in health care (functional) food with the function of weight loss, purge, detoxification, etc., and is used for fiber reinforcing in the process of baking and expanding food, moreover, fine powder can also be used as fill material of drug. Fine fiber powder provided by the invention has low integrated production cost, high quality of product and long shelf life, and meanwhile, the powder is friendly to the environment in the production process and is suitable for large-scale industrial production.

Owner:城步锦龙农林科技开发有限责任公司

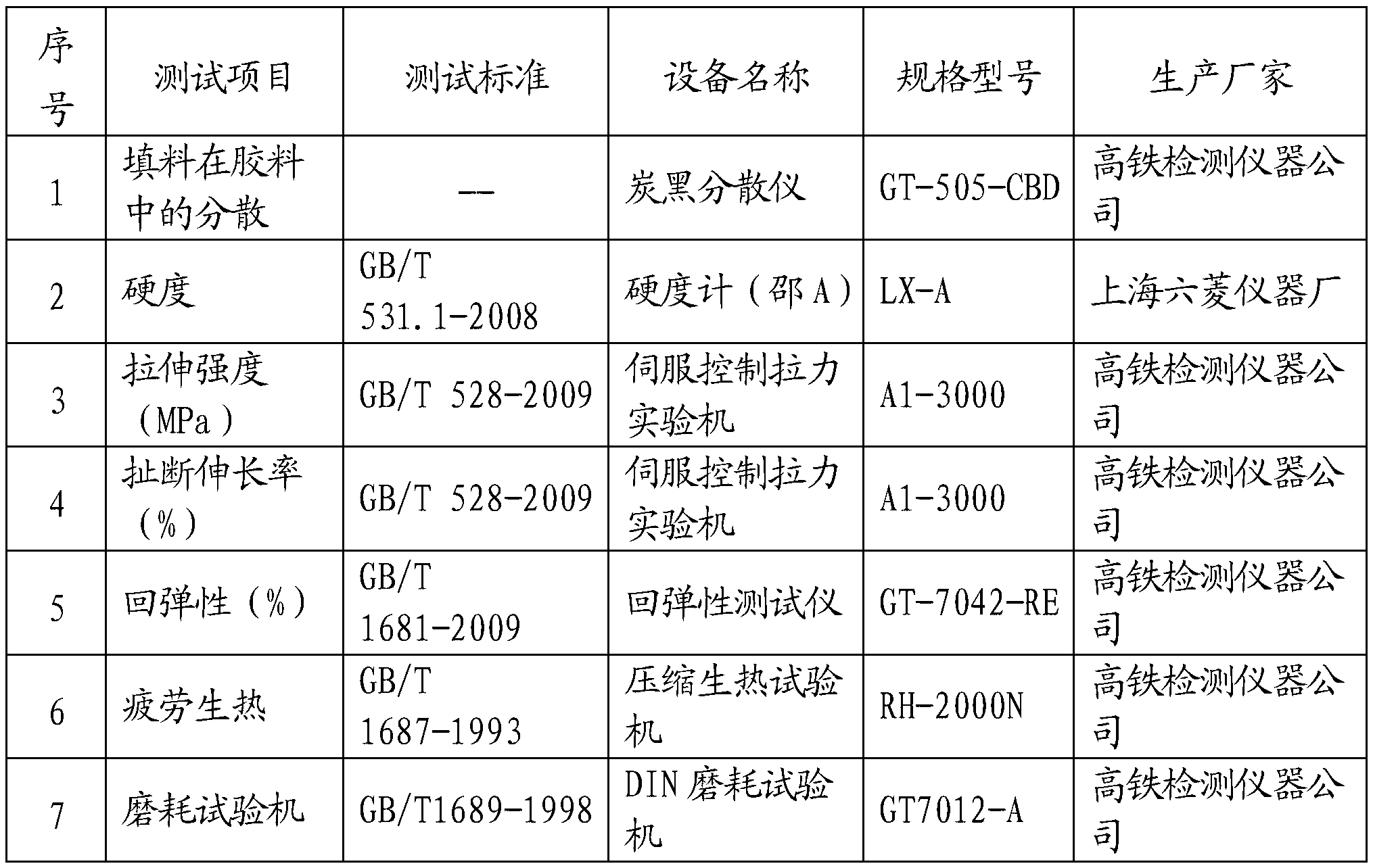

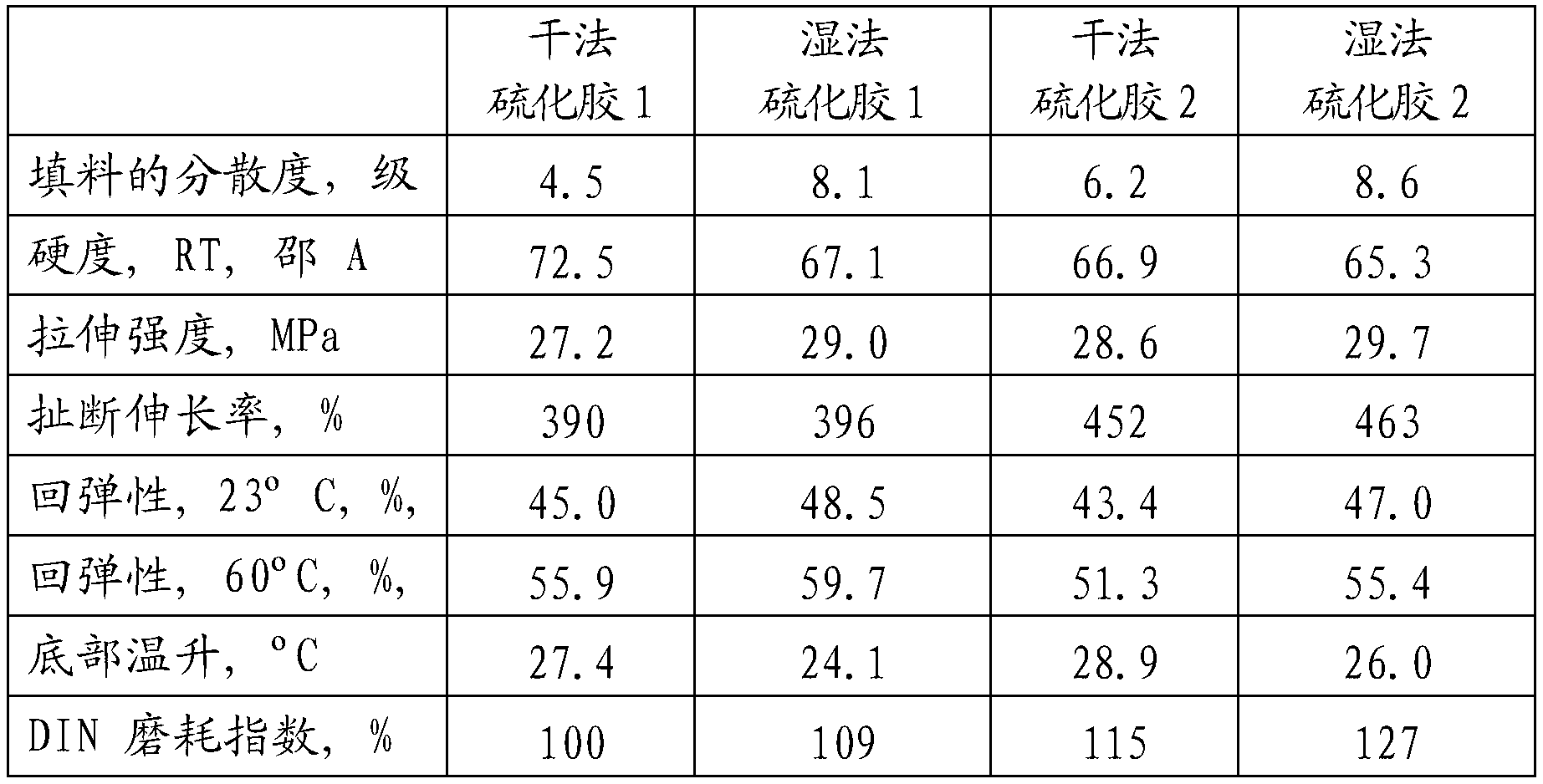

Filler, synthetic rubber and wet rubber compound integrated production method

ActiveCN103224659ABreakthrough applicabilityBreakthrough performancePigmenting treatmentSilicon oxidesSynthetic rubberIntegrated production

The invention discloses a filler, synthetic rubber and wet rubber compound integrated production method. A filler is selected from carbon black, white carbon black or a combination of the carbon black and the white carbon black. Compared with traditional and respective independent technologies, the method disclosed in the invention has the advantages of omitting of the post-treatment technologies of the filler and a synthetic rubber, realization of the cycle of sodium carbonate, and full utilization of carbon dioxide and heat generated in a traditional carbon black production technology. So the method can reduce production equipment and simultaneously realize the low carbon and low pollution discharge through the integrated optimization of the process flow in order to reach the recycle purpose.

Owner:EVE RUBBER RES INST

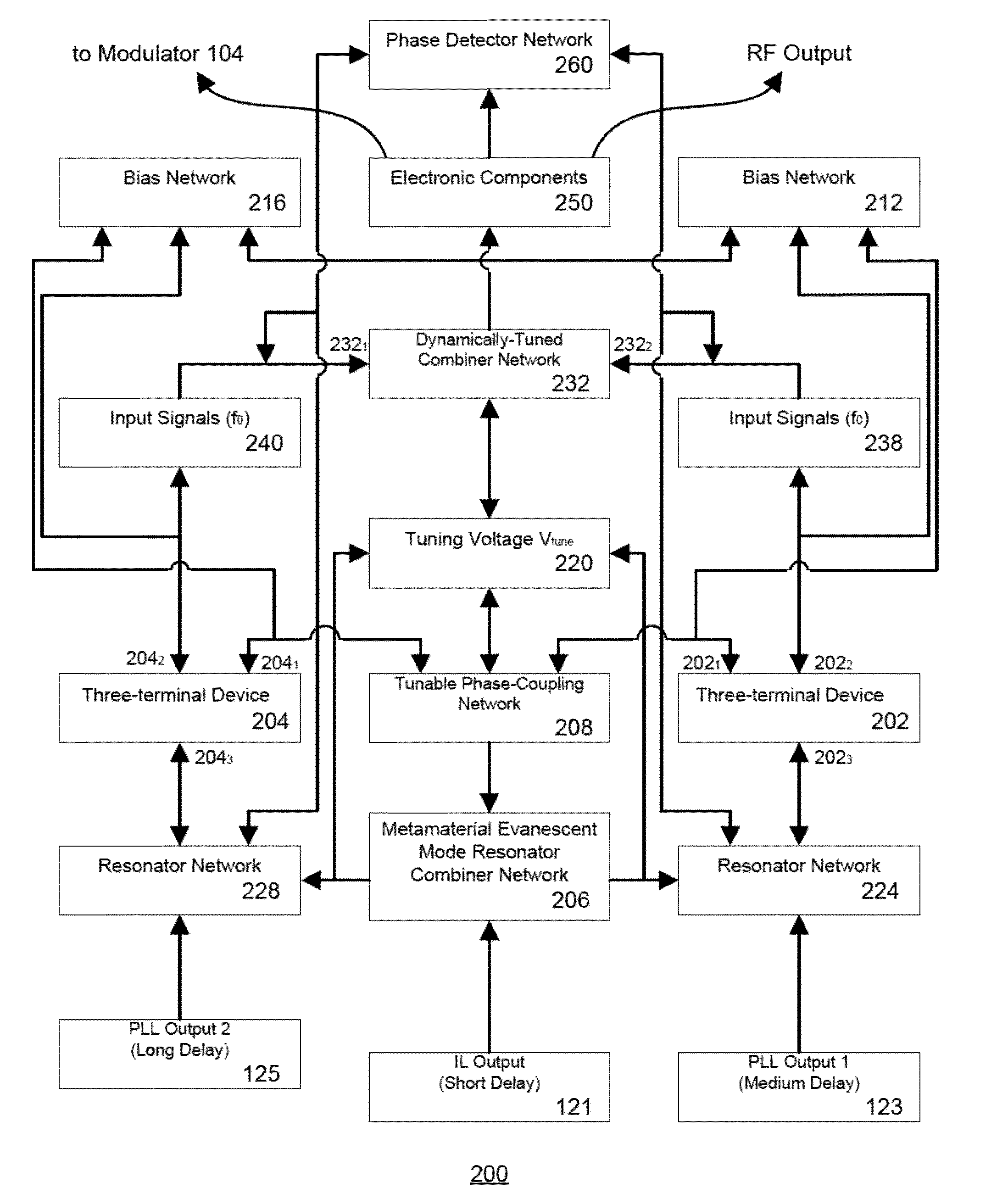

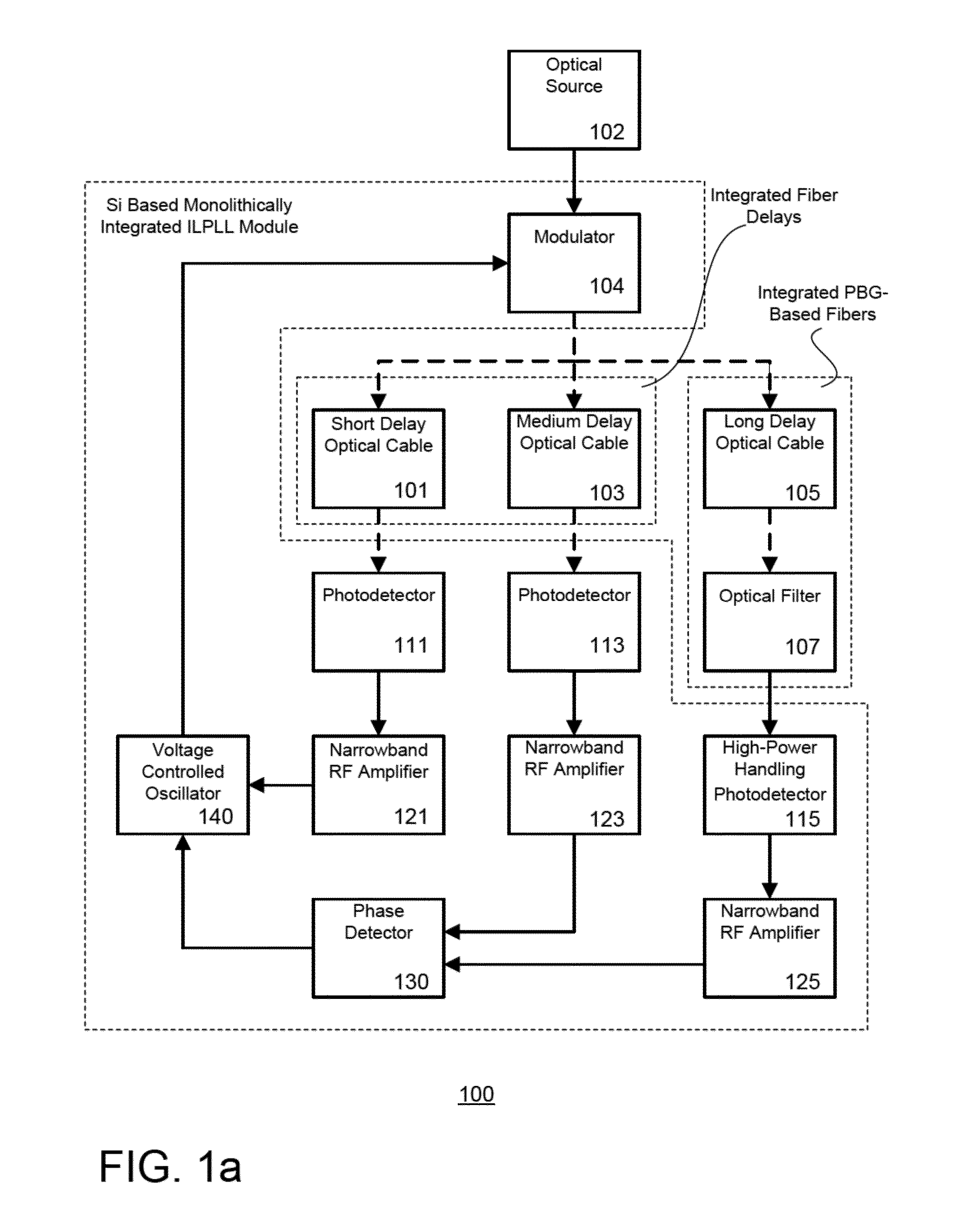

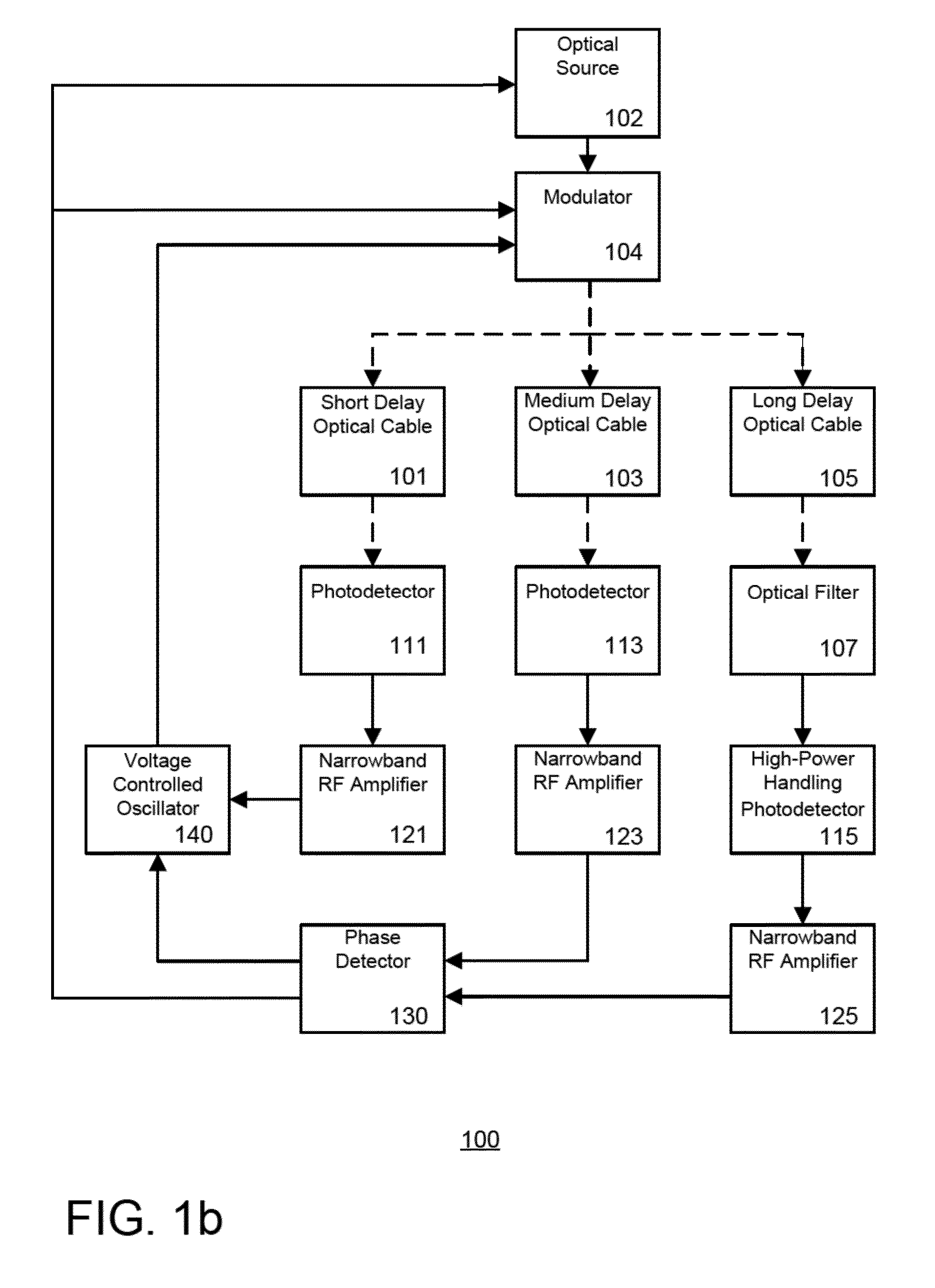

Integrated production of self injection locked self phase loop locked optoelectronic oscillator

ActiveUS20140270786A1Reduce power consumptionEliminate needElectromagnetic transmittersOscillations generatorsPhotonicsRf filters

The present invention details fabrication guidelines of integrated optoelectronic oscillators with frequency and phase stability, having higher frequency selectivity in a relatively small size (compared to the larger size of a higher order electrically realized RF filter), reduced temperature sensitivity, and minimized frequency drift. The integrated photonic components and RF oscillator may use Silicon photonics and microelectronic integration using CMOS and BiCMOS technology, eliminating the need for bulky and / or discrete optical and microwave components.

Owner:SYNERGY MICROWAVE CORP

Multi-story high-rise assembled steel structure frame - prestressed eccentrically-braced system

The invention relates to a multi-story high-rise assembled steel structure frame - prestressed eccentrically-braced system, belonging to the technical field of structure engineering. The multi-story high-rise assembled steel structure frame - prestressed eccentrically-braced system comprises assembled beams and slabs, assembled stand columns and prestressed sway braces. The assembled beams and slabs in the system consist of slabs, column base joints and open-web steel beams with section steel web members. The open-web steel beams are connected with the column base joints. The slabs are supported on the open-web steel beams. The assembled stand columns consist of box columns and flanges. During construction, the assembled beams and slabs and the assembled stand columns can be spliced to form a frame structure, and the prestressed eccentric sway braces are arranged on the basis of the steel frame to form energy-dissipating beam sections, so as to improve the lateral rigidness and the energy dissipation capacity of the structure. All members of the structure system are prefabricated in factories and are rapidly assembled through bolts on the construction site to form the structure system. Concrete pouring and welding operation are avoided, the defects of long construction period, serious material wastage, great pollution during construction and the like existing the traditional buildings are overcome, and the factory integrated production of buildings can be realized.

Owner:CHINA RAILWAY CONSTR GROUP +1

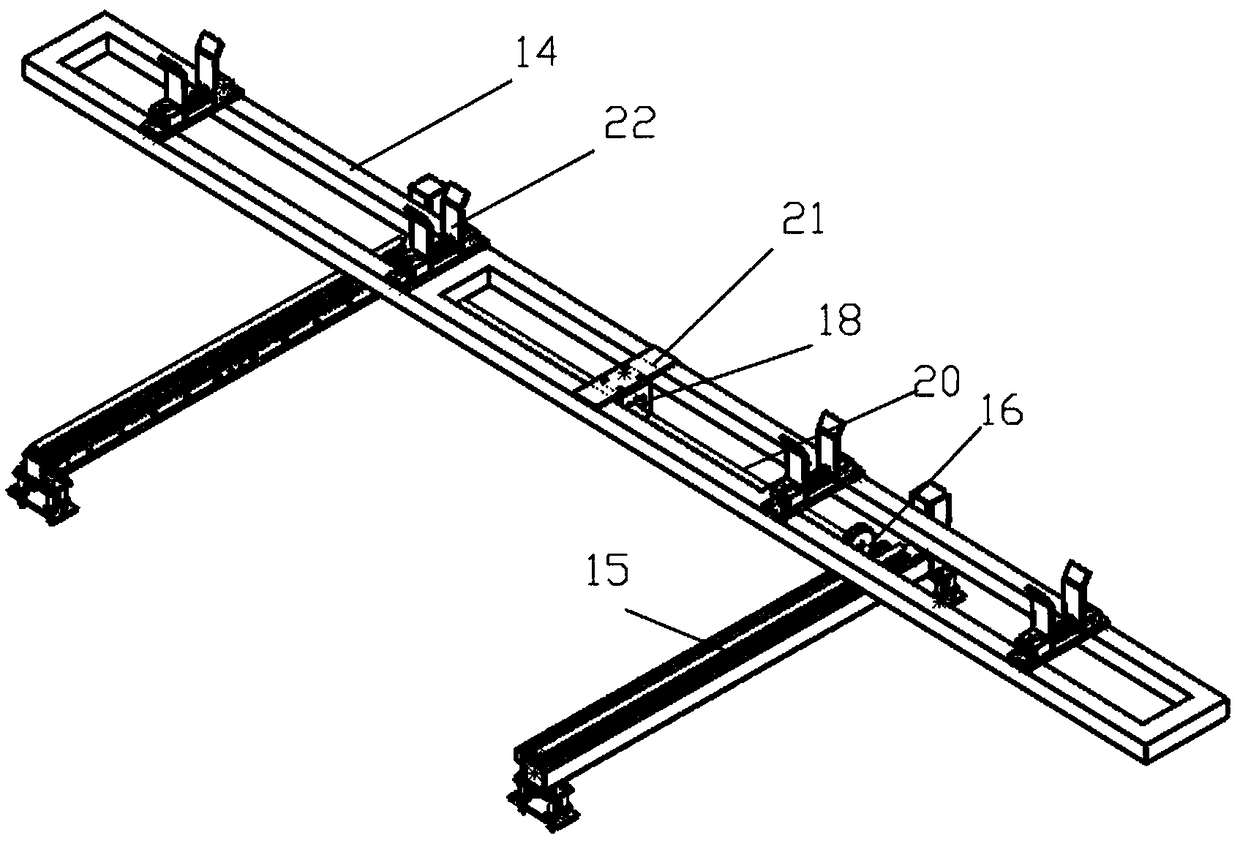

Copper bar automatic plane warehouse and copper bar integrated production line

PendingCN108249119ASmooth transferRealize automatic loading and unloading functionOther manufacturing equipments/toolsMechanical conveyorsProduction lineEngineering

The invention relates to a copper bar production technology, in particular to copper bar automatic plane warehouse and copper bar integrated production line which achieves automatic storage, automaticfeeding, automatic production and automatic discharge for copper bars. The production line comprises a copper bar automatic plane warehouse and a copper bar automatic production line. A copper bar warehouse outer frame comprises stand columns, a beam and a linear guide rail, the stand columns are installed on the ground, the beam is connected with the stand columns on the two sides, the linear guide rail is installed on the stand column, each copper bar warehouse location comprises a copper bar warehouse location frame and multiple limiting columns, the copper bar warehouse location is arranged inside the copper bar warehouse outer frame, the multiple limiting columns are installed on the copper bar warehouse location frame, a copper bar discharge conveying line is also arranged in the copper bar warehouse outer frame and penetrates through multiple copper bar warehouse locations, the copper bar discharge conveying line comprises a copper bar discharge conveying frame, a copper bar discharge motor and a conveying belt wheel, and the copper bar discharge motor is installed on the copper bar discharge conveying frame and is in linkage with the conveying belt wheel.

Owner:JIANGSU SENLAN INTELLIGENCE SYST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com