Comprehensive plant production management system and method

A production management and comprehensive system technology, applied in the field of plant production management, can solve the problems of inability to realize production supervision, inability to guarantee product quality, inability to face the impact of agricultural products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

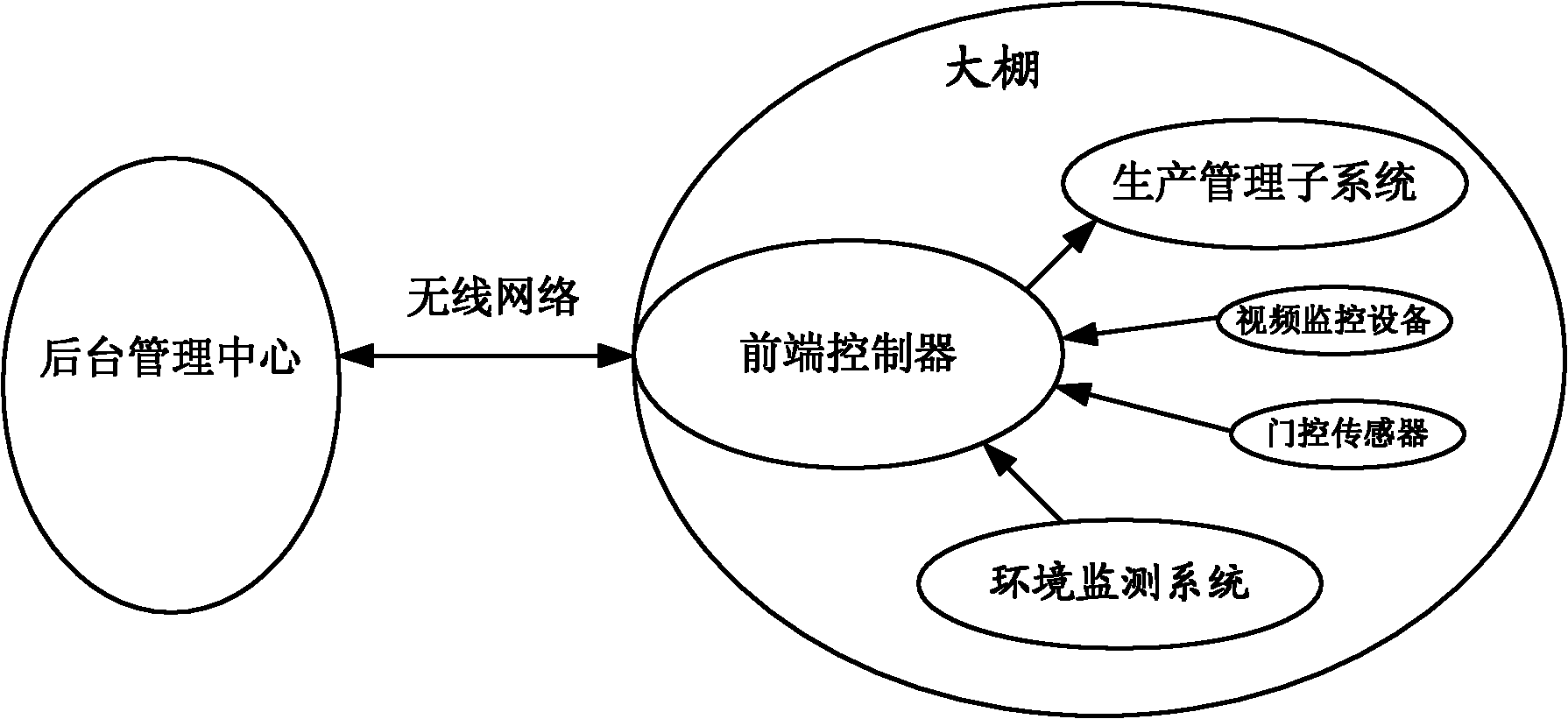

[0061] Such as figure 1 As shown, the integrated plant production management system includes:

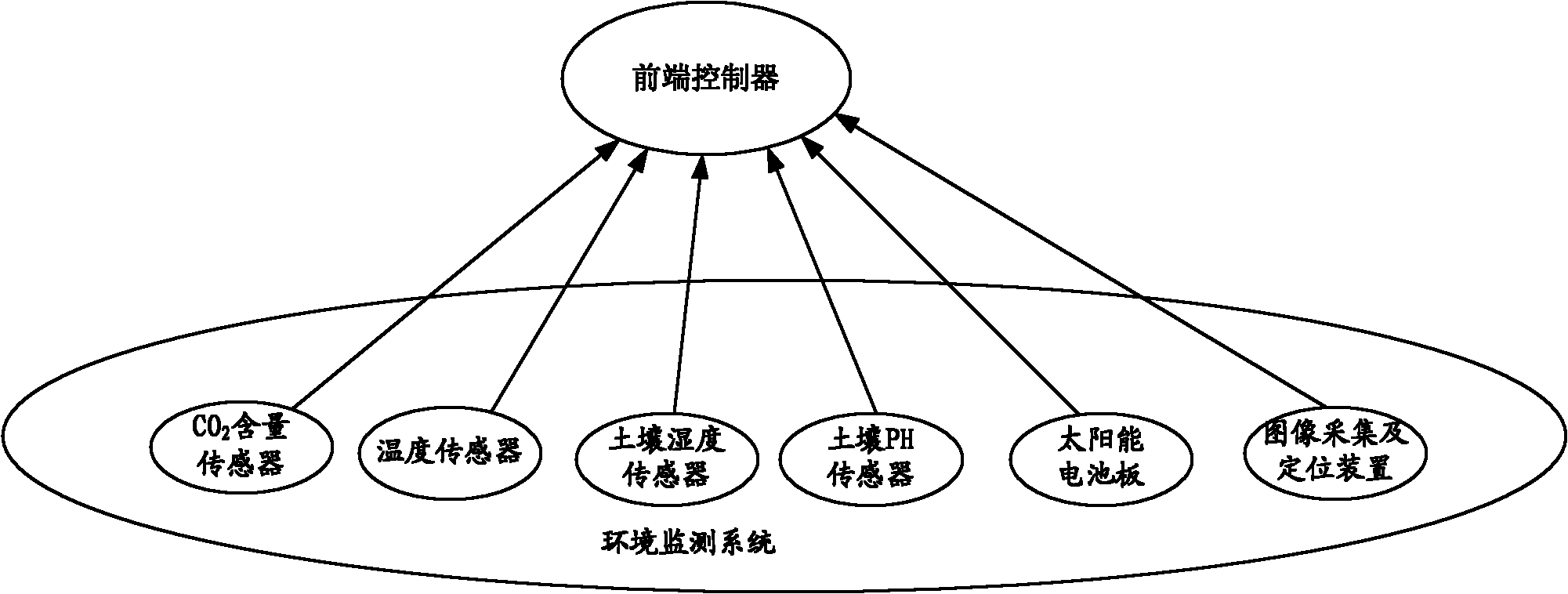

[0062] The environmental monitoring system is used to collect the growth environment parameters and growth status parameters of plants in the production site;

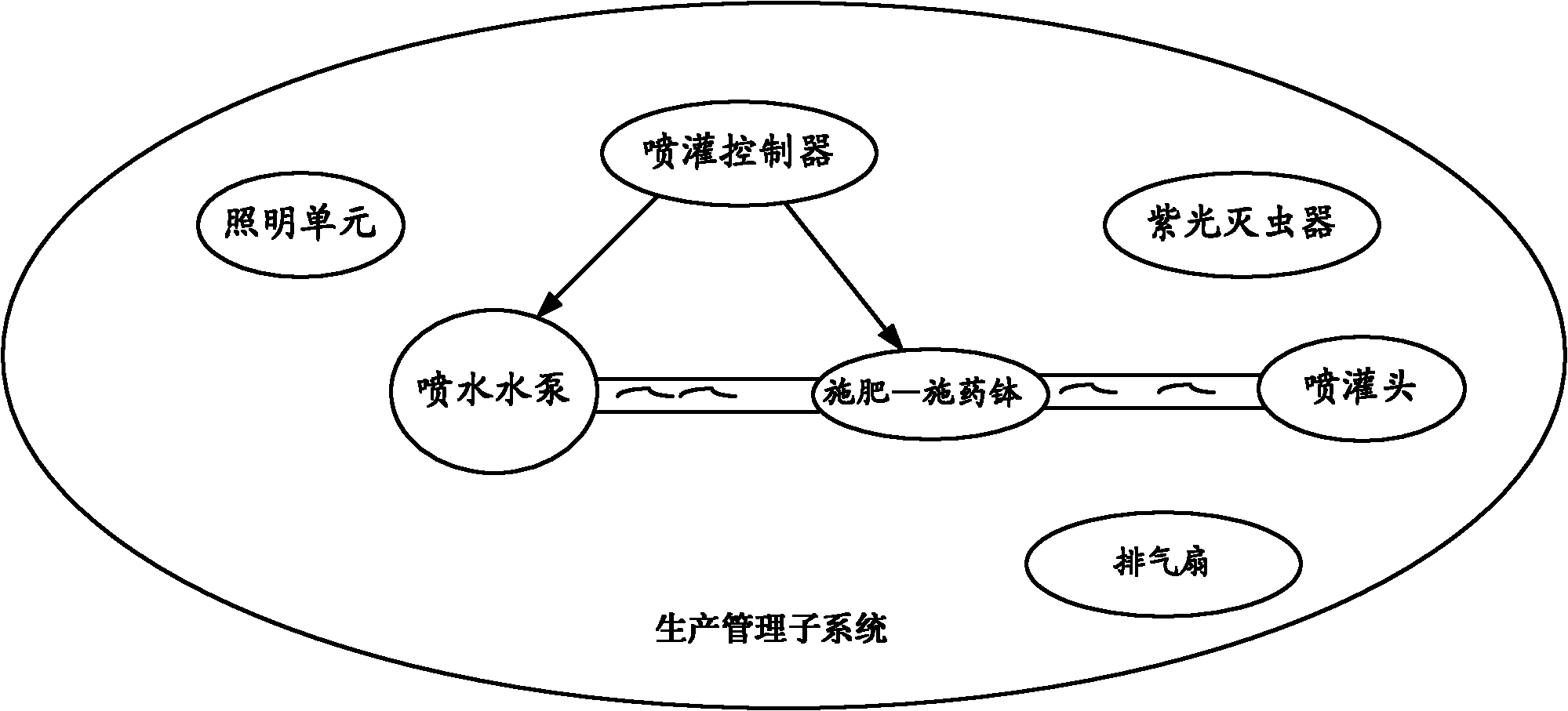

[0063] The front-end controller is used to upload the growth environment parameters and growth status parameters to the background management center, and control the production management subsystem to perform corresponding production management operations according to the control instructions issued by the background management center;

[0064] The background management center is used to receive the growth environment parameters and growth status parameters uploaded by the front-end controller, and issue control instructions to the front-end controller;

[0065] Video monitoring equipment is used to collect video data in the greenhouse and transmit it to the background management center, and display it through the human-com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com