Seedling raising matrix and production method thereof

A technology for raising seedling substrate and production method, which is applied in the treatment, application, organic fertilizer and other directions of bio-organic parts, can solve the problems of high purchase cost of rice husk or straw, impact on economic benefits of agricultural production, unfavorable industrial production, etc. ways, improving the use value, and increasing the effect of the economic benefits of the enterprise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A production method for seedling raising substrate, comprising the following steps:

[0040] (1) Pre-treatment stage: remove non-composting materials such as stones, wood blocks, and metal objects in fresh manure. The wood chips and rice husks in the auxiliary materials can be used directly. The waste mushroom culture substrate should remove impurities and be crushed into a powder that passes through a mesh sieve below 8 mm for use. Mix livestock and poultry manure and auxiliary materials according to the volume ratio of 1-2:0-1, adjust the water to 50-60% and C / N to 25-30, add organic fertilizer fermentation bacteria with 0.1% of the weight of livestock and poultry manure and stir to form mixture;

[0041] (2) Main fermentation stage: stack the mixture into strip-type fermentation stacks, with a height of 1-1.5 meters, keep the temperature of the mixture at 55-75°C, and turn it once a day for 5-7 days;

[0042] (3) Post-ripening fermentation stage: transfer the main ...

Embodiment 2

[0047] A production method for seedling raising substrate, comprising the following steps:

[0048] (1) Pre-treatment stage: remove non-composting materials such as stones, wood blocks, and metal objects in fresh manure. The wood chips and rice husks in the auxiliary materials can be used directly. The waste mushroom culture substrate should remove impurities and be crushed into a powder that passes through a mesh sieve below 8 mm for use. Mix livestock and poultry manure and auxiliary materials according to the volume ratio of 1-2:0-1, adjust the water to 50-60% and C / N to 25-30, add organic fertilizer fermentation bacteria with 0.5% of the weight of livestock and poultry manure and stir to form mixture;

[0049](2) Main fermentation stage: stack the mixture into strip-type fermentation stacks, with a height of 1-1.5 meters, keep the temperature of the mixture at 55-75°C, and turn it once a day for 5-7 days;

[0050] (3) Post-ripening fermentation stage: transfer the main f...

experiment example

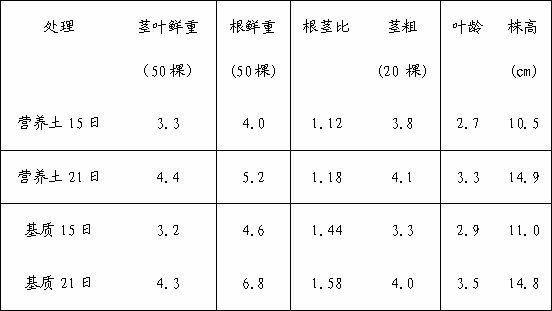

[0054] Experimental example: Seedling-raising matrix seedling-raising seedling quality test of the present invention

[0055] This substrate has been used for rice seedling raising and has been tested many times, and compared with the conventional nutrient soil seedling raising method in production, the test area is 16 square meters, and the transplanting area reaches 4 mu. The quality of the seedlings raised in this substrate is better, and the quality of the seedlings is better than that of the pair group, and the packing is well developed.

[0056] The advantage of matrix seedling raising is that the matrix can increase temperature quickly, and it can raise seedlings early and transplant seedlings early; it can avoid weeding and sealing chemicals. In order to verify the seedling quality of the substrate, carry out this test, test method and result are as follows:

[0057] 1 Materials and methods

[0058] 1.1 Test materials

[0059] 1.1.1 Test materials

[0060] Substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com