Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1696 results about "Increase temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

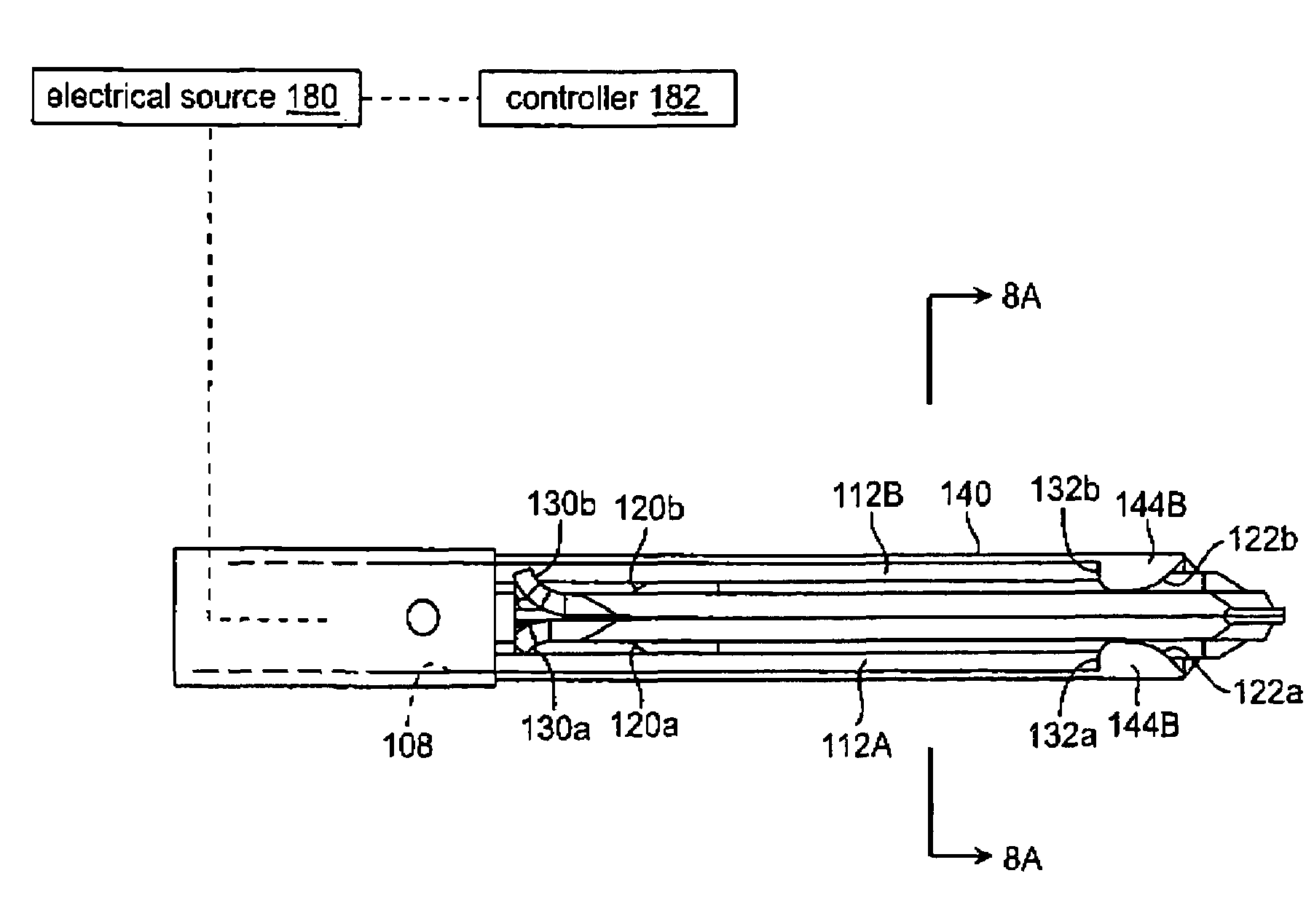

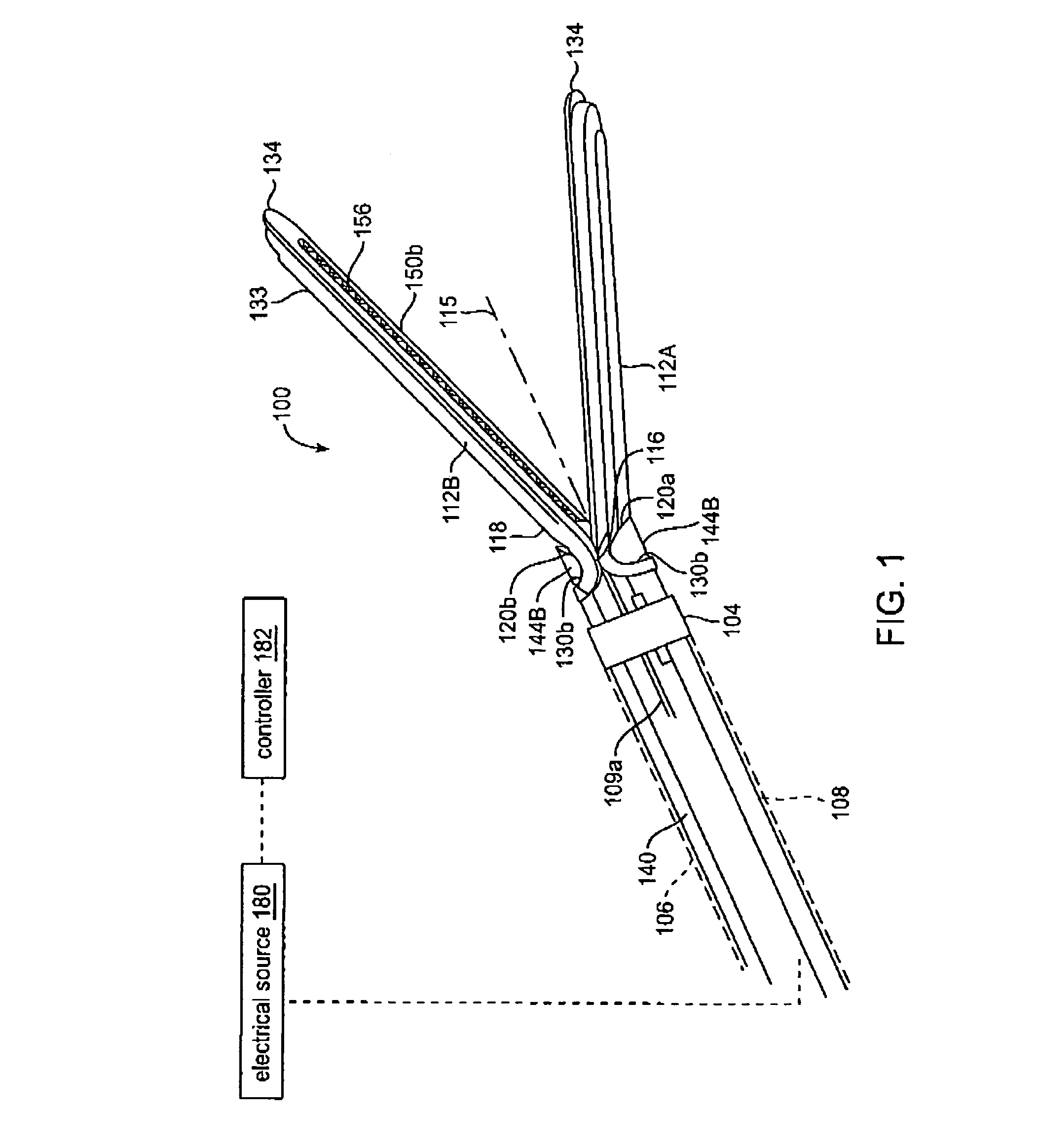

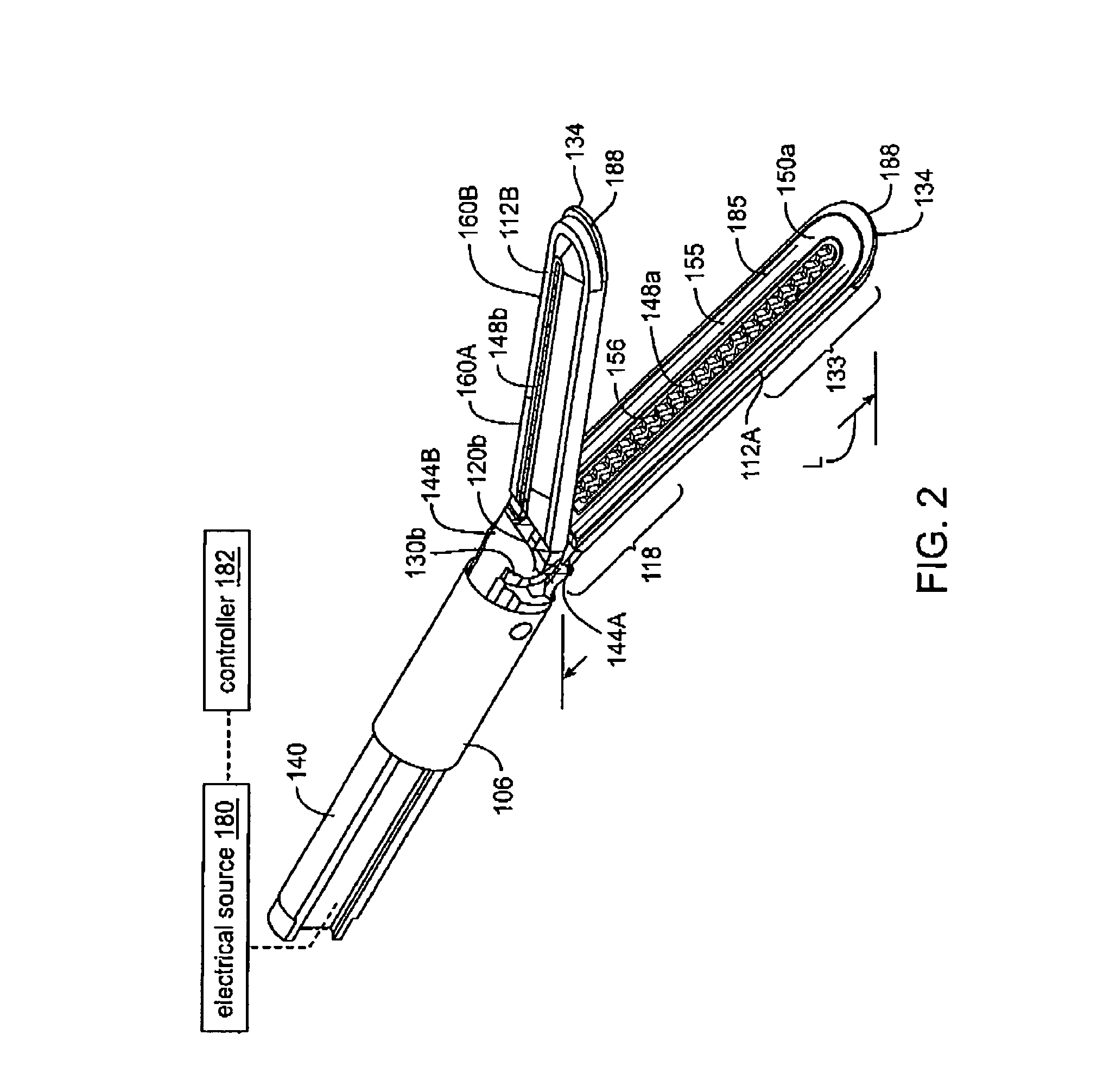

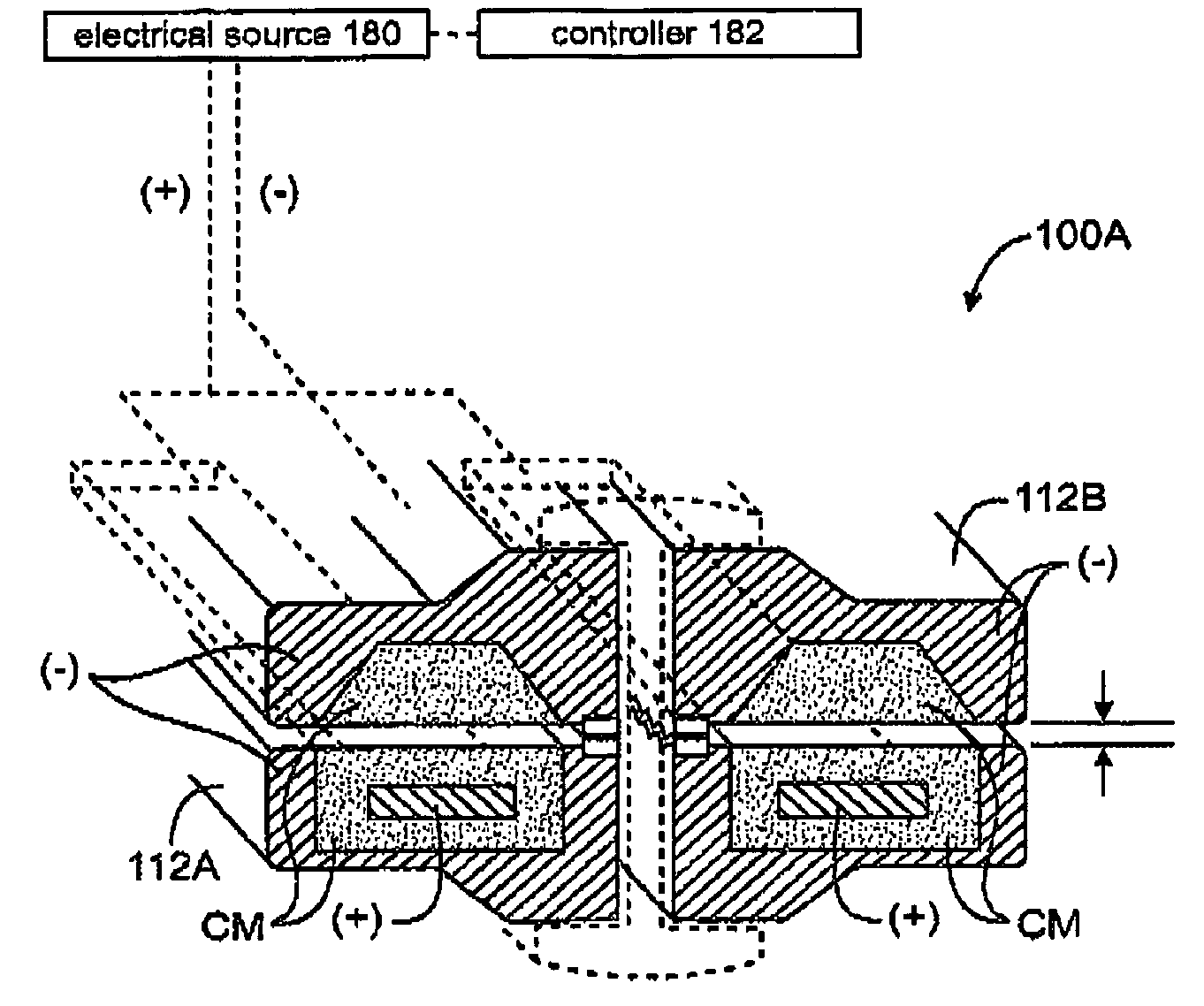

Jaw structure for electrosurgical instrument and method of use

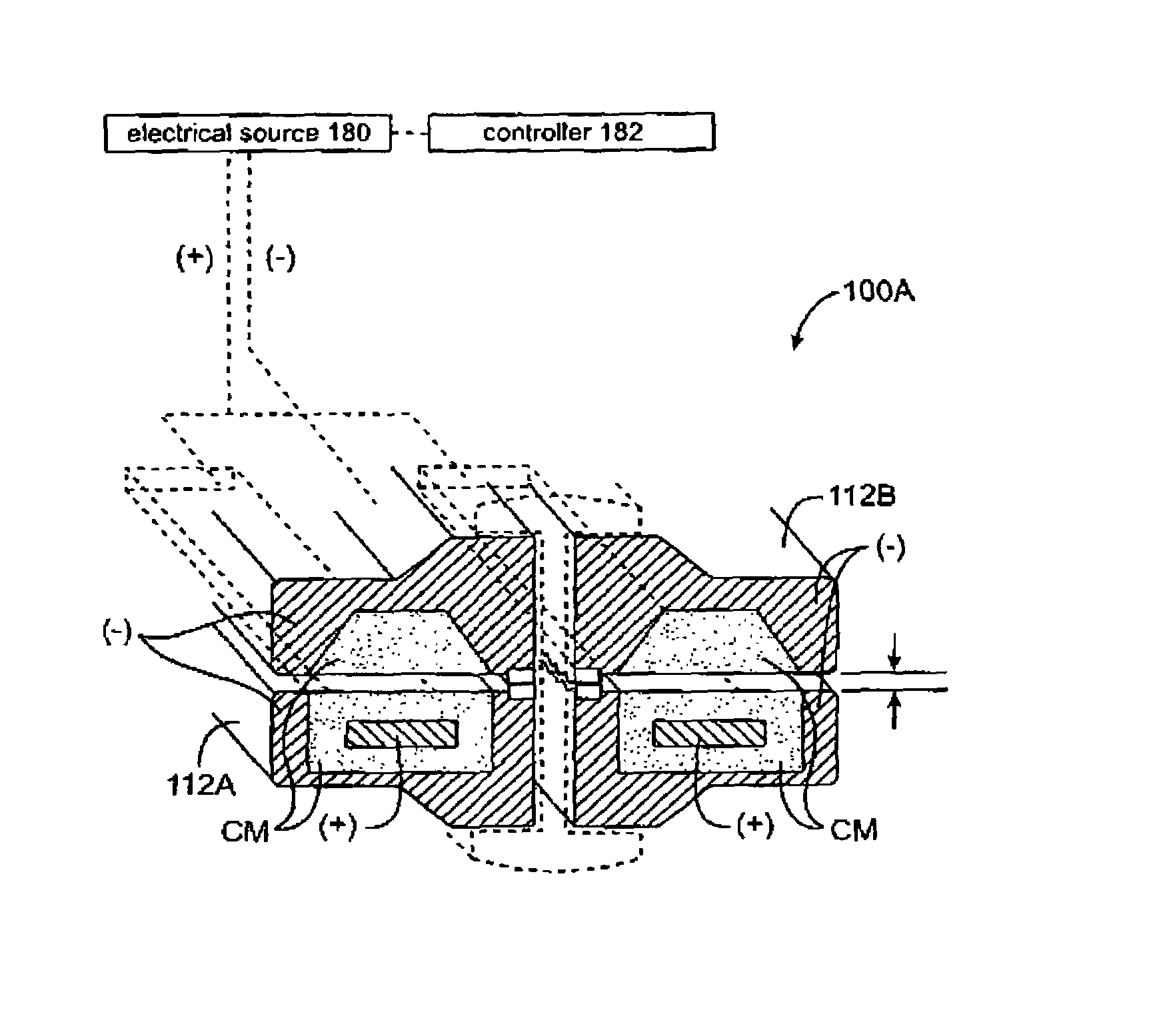

InactiveUS7011657B2Improve the immunityEfficient weldingElectrotherapySurgical instruments for heatingTissue heatingVolumetric Mass Density

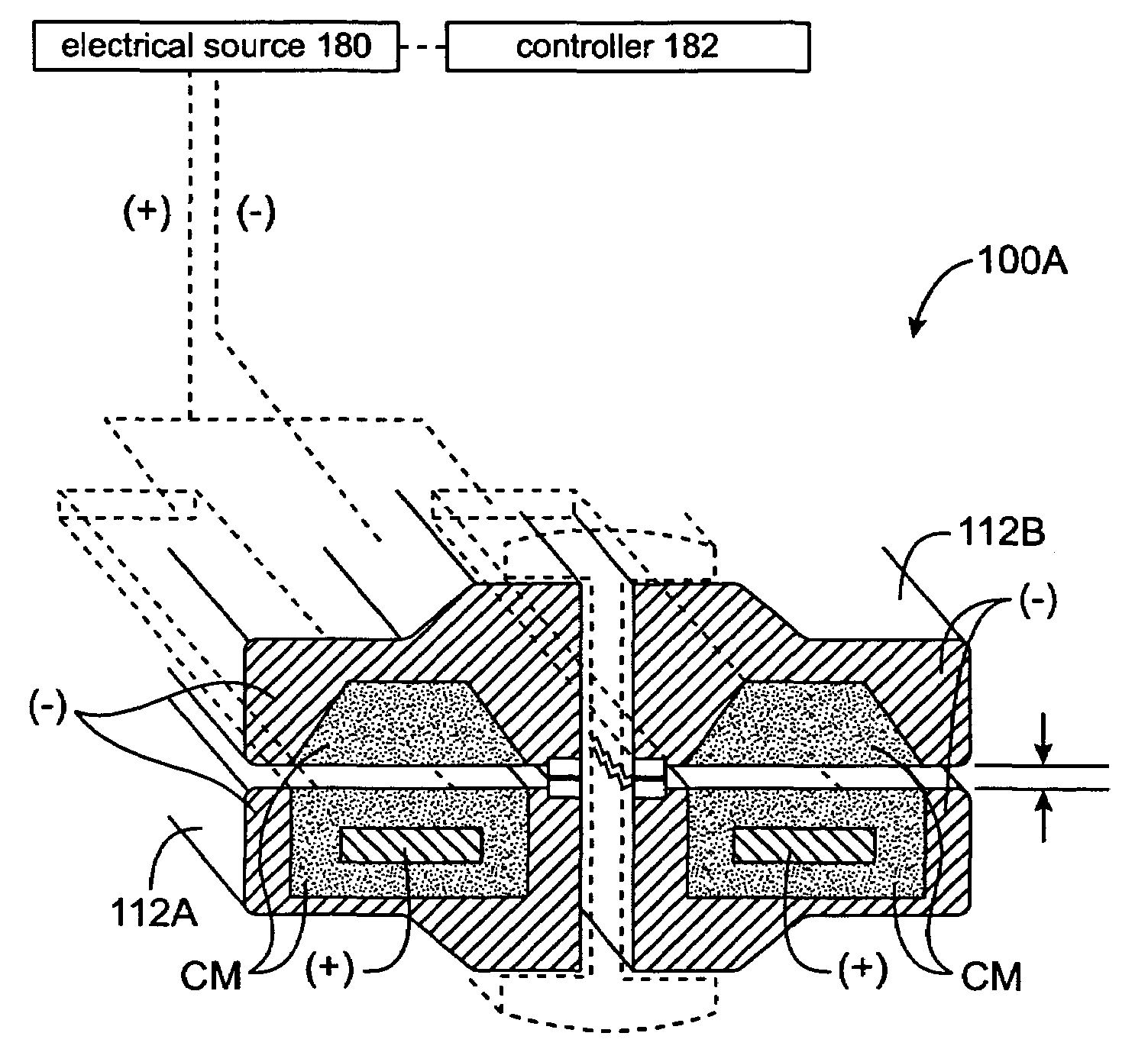

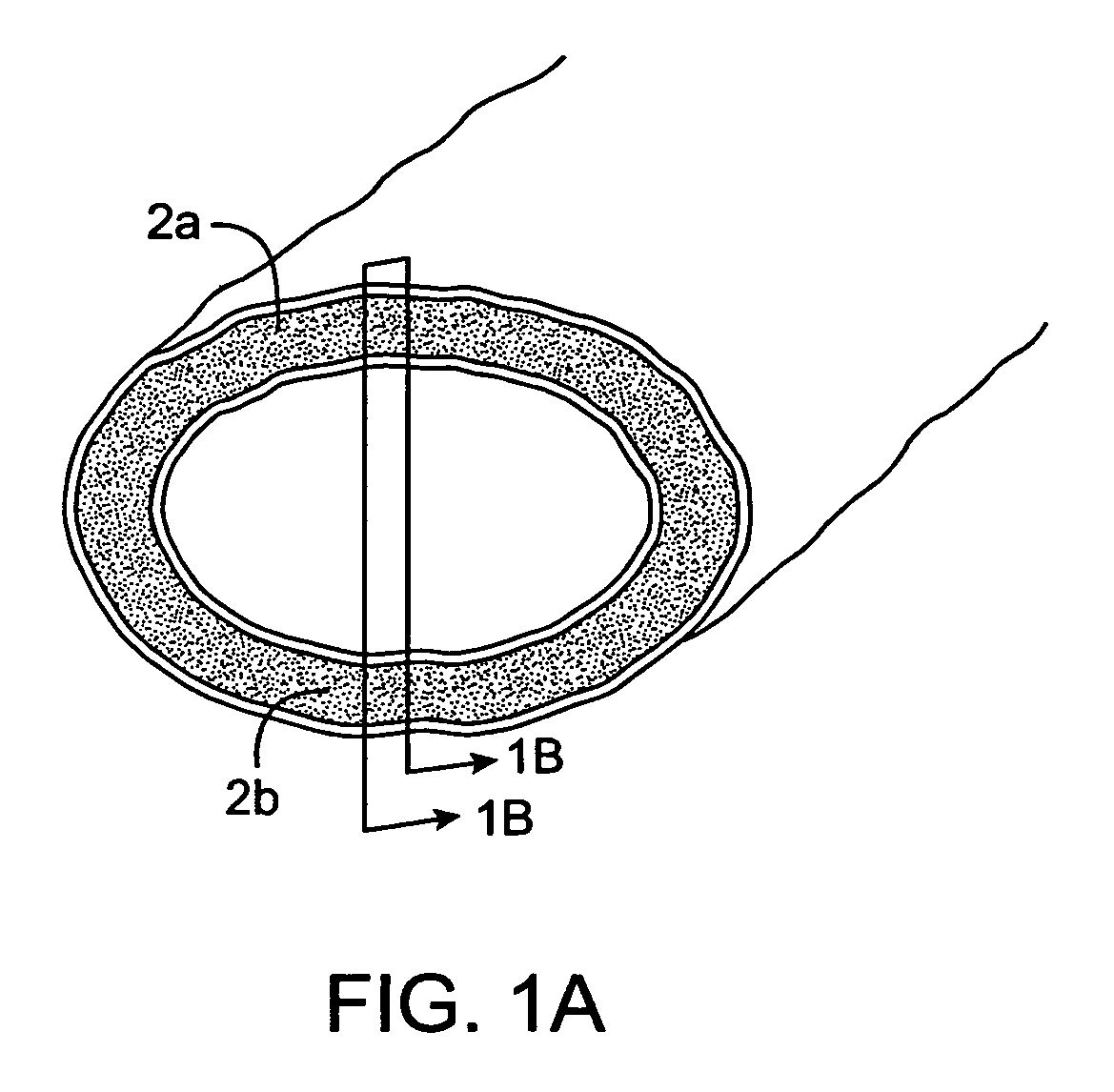

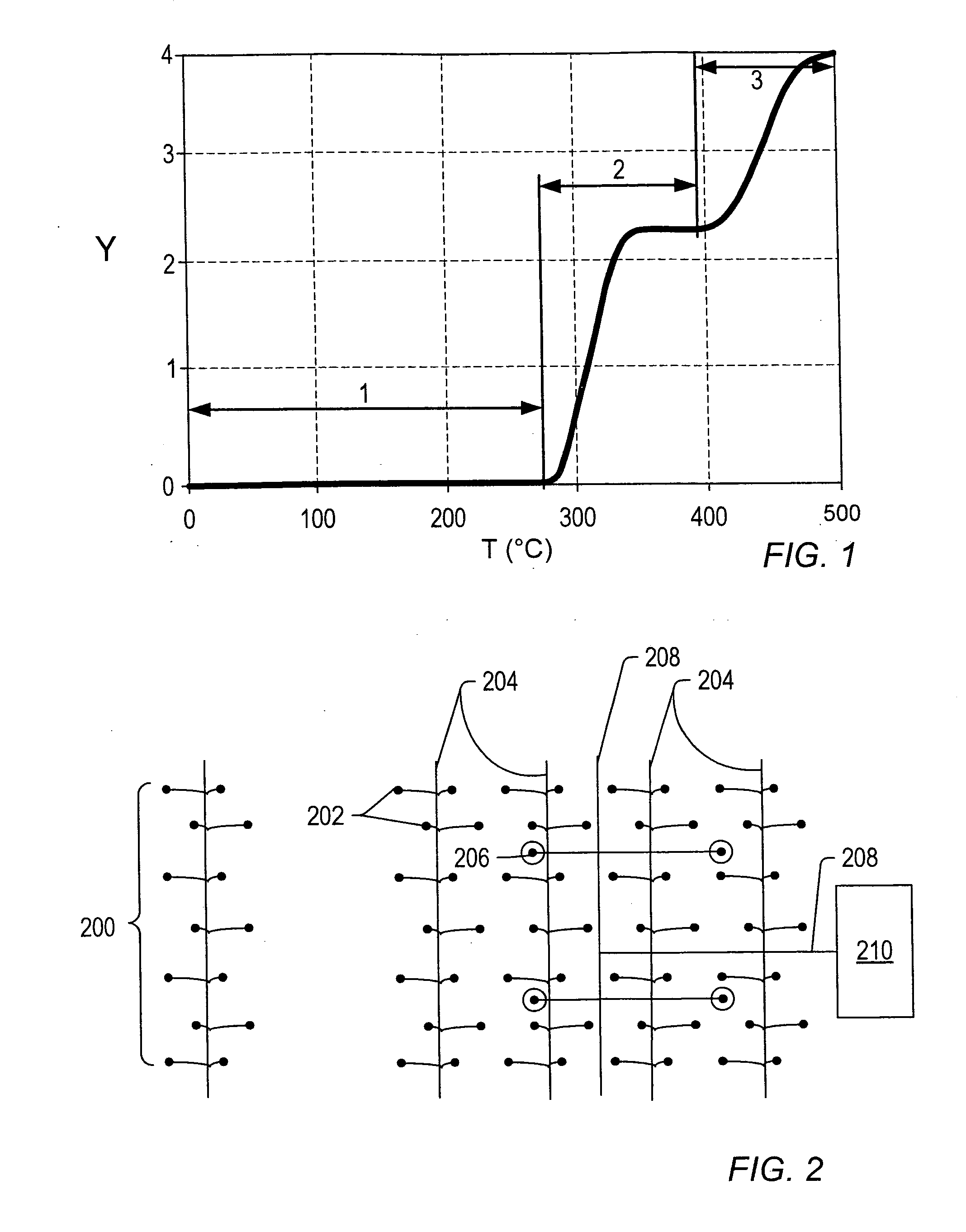

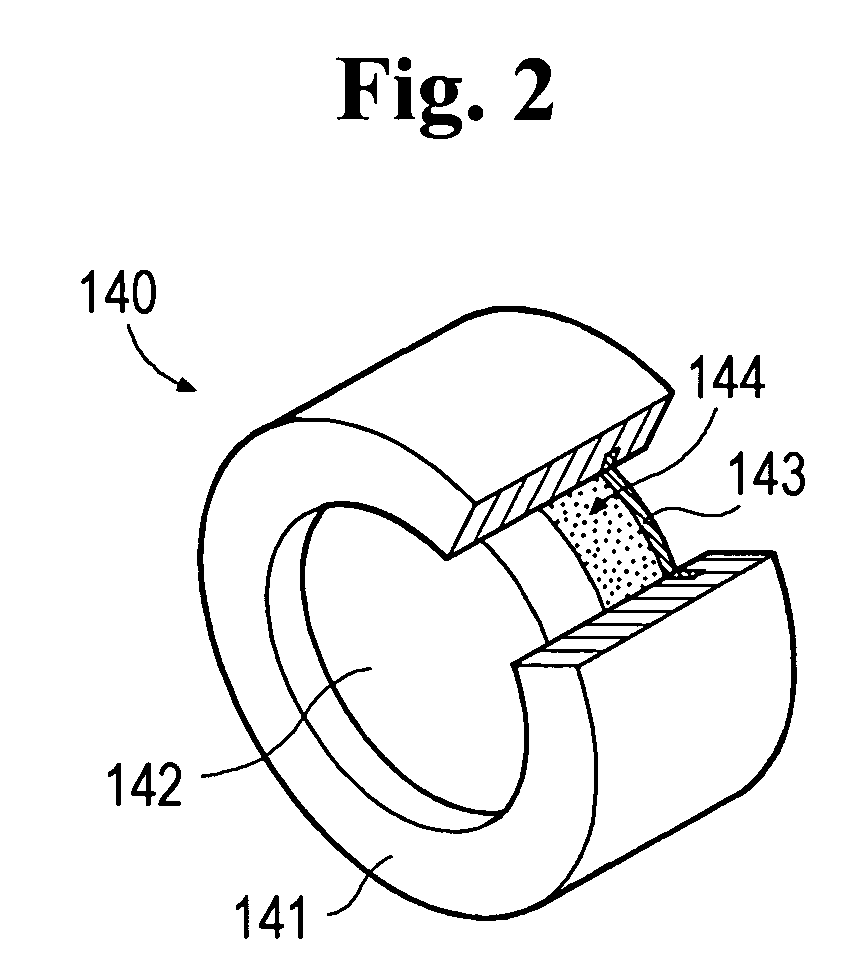

An electrosurgical medical device and technique for creating thermal welds in engaged tissue that provides very high compressive forces. In one exemplary embodiment, at least one jaw of the instrument defines a tissue engagement plane carrying first and second surface portions that comprise (i) an electrically conductive material and (ii) a positive temperature coefficient (PTC) material having a selected increased resistance that differs at each selected increased temperature over a targeted treatment range. One type of PTC material is a doped ceramic that can be engineered to exhibit a selected positively sloped temperature-resistance curve over about 37° C. to 100° C. The 70° C. to 100° C. range can bracket a targeted “thermal treatment range” at which tissue welded can be accomplished. The engineered resistance of the PTC matrix at the upper end of the temperature range will terminate current flow through the matrix. In one mode of operation, the engagement plane cause ohmic heating within tissue from Rf energy delivery tissue PTC matrix is heated to exceed the treatment range. Thereafter, energy density in the engaged tissue will be modulated as the conductivity of the second portion hovers within the targeted treatment range to thereby provide optical tissue heating for purposes of tissue welding.

Owner:ETHICON ENDO SURGERY INC

Electrosurgical instrument and method of use

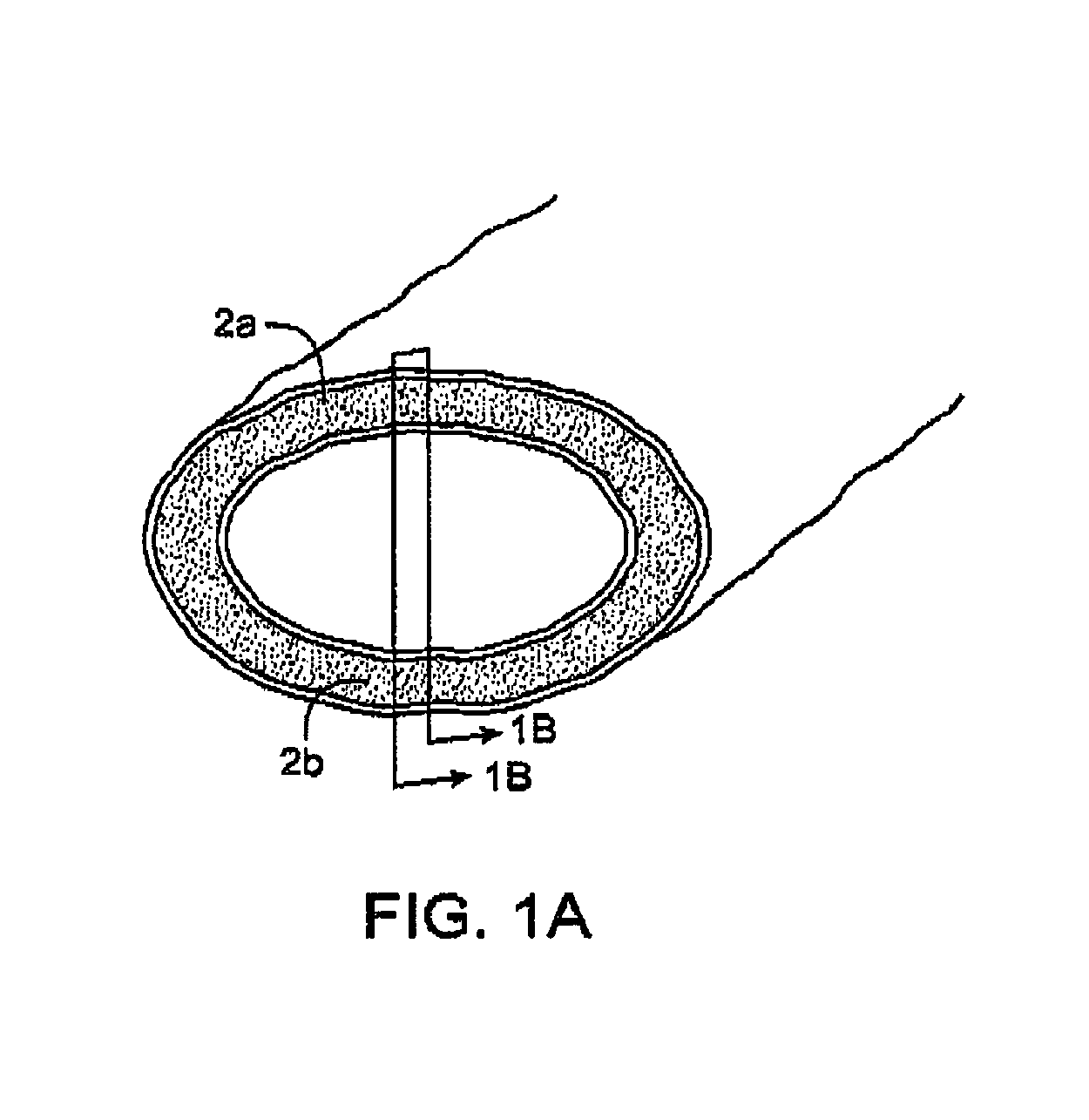

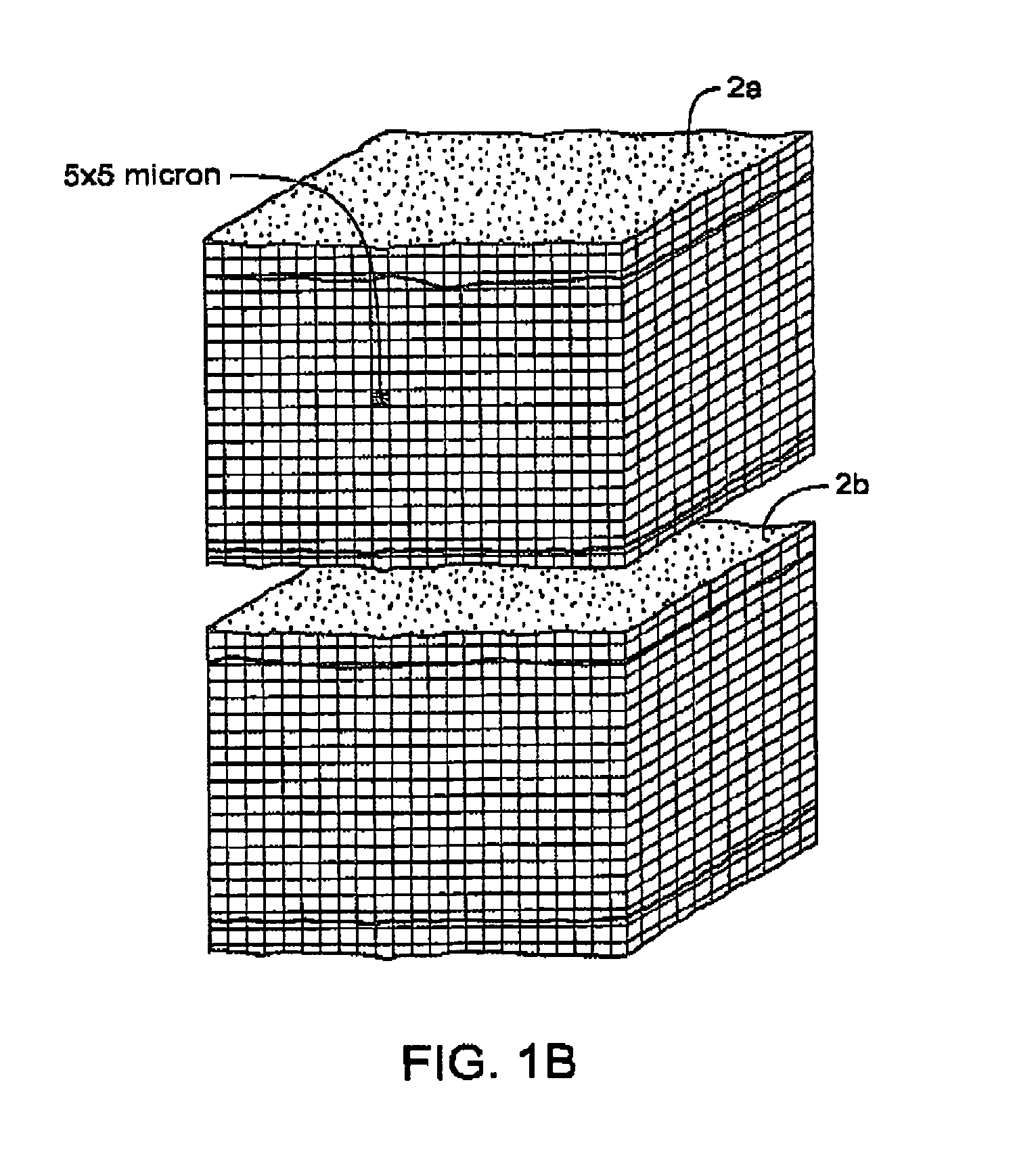

InactiveUS7083619B2Reduce conductancePrevent any substantial dehydrationSurgical instruments for heatingCoatingsMicron scaleElastomer

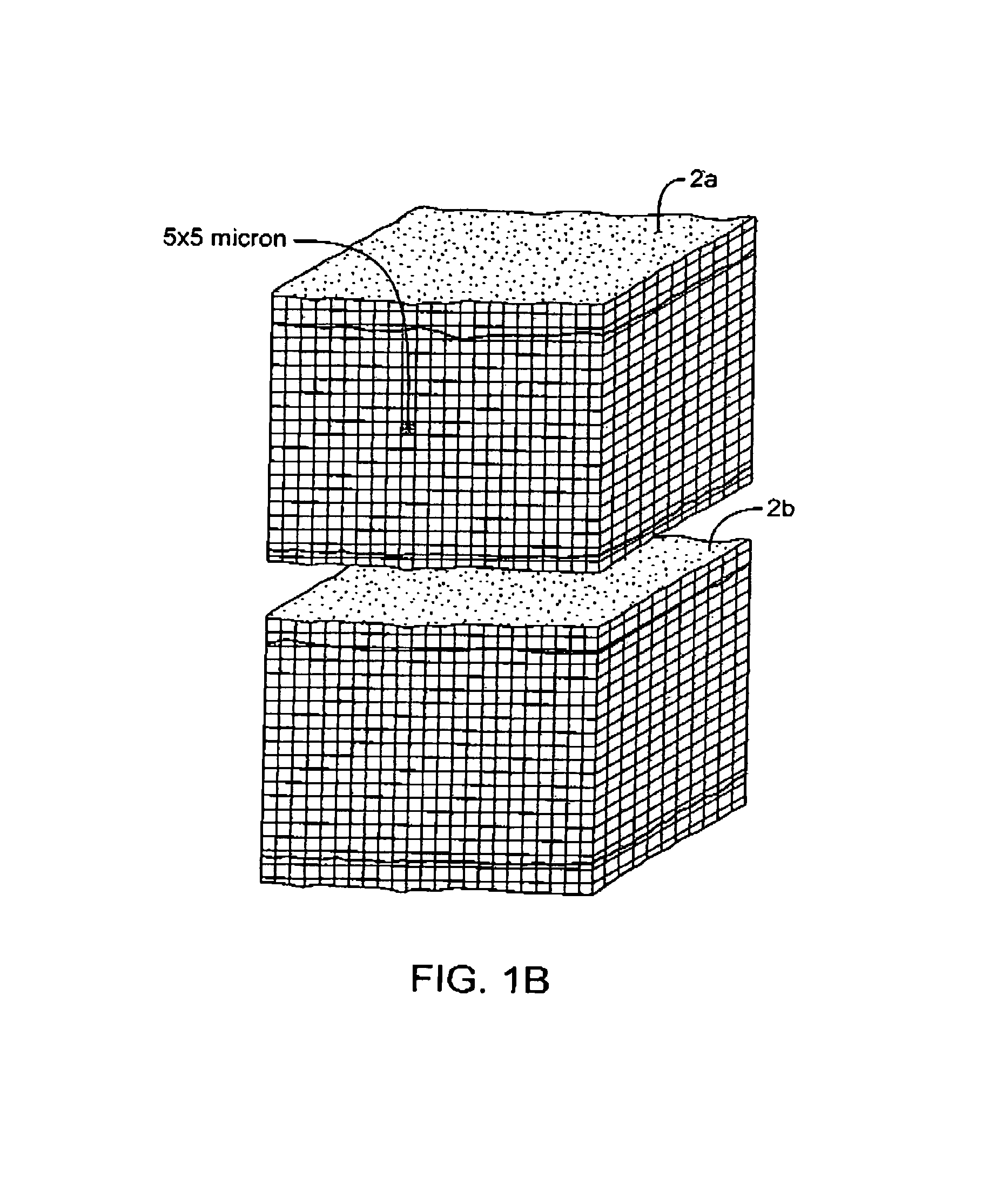

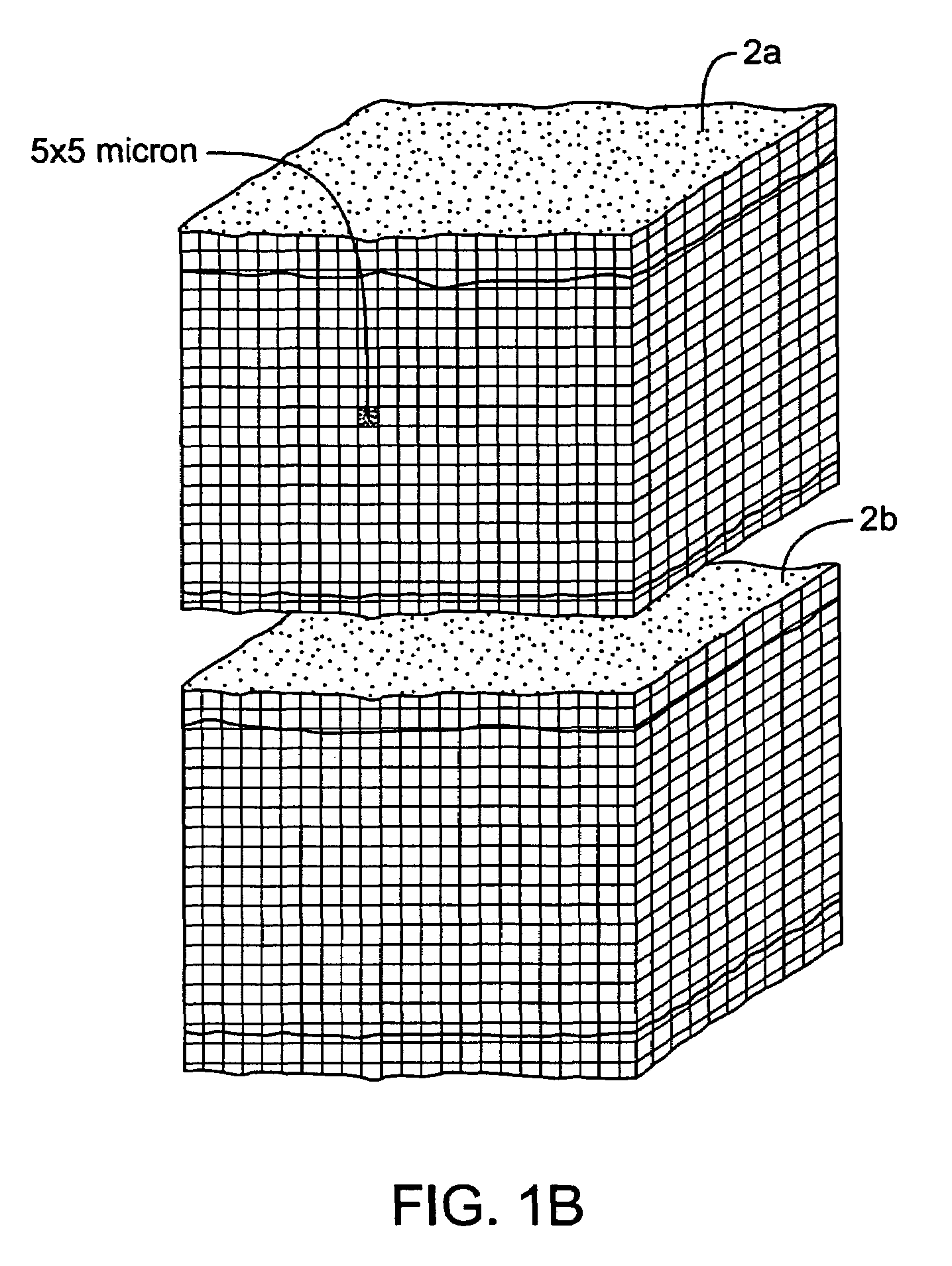

An electrosurgical medical device and method for creating thermal welds in engaged tissue. In one embodiment, at least one jaw of the instrument defines a tissue engagement plane carrying a conductive-resistive matrix of a conductively-doped non-conductive elastomer. The engagement surface portions thus can be described as a positive temperature coefficient material that has a unique selected decreased electrical conductance at each selected increased temperature thereof over a targeted treatment range. The conductive-resistive matrix can be engineered to bracket a targeted thermal treatment range, for example about 60° C. to 80° C., at which tissue welding can be accomplished. In one mode of operation, the engagement plane will automatically modulate and spatially localize ohmic heating within the engaged tissue from Rf energy application—across micron-scale portions of the engagement surface.

Owner:ETHICON ENDO SURGERY INC

Electrosurgical instrument and method of use

InactiveUS7311709B2Reduce conductancePrevent any substantial dehydrationSurgical instruments for heatingCoatingsMicron scaleSpatial positioning

An electrosurgical medical device and method for creating thermal welds in engaged tissue. In one embodiment, at least one jaw of the instrument defines a tissue engagement plane carrying a variable resistive body of a positive temperature coefficient material that has a selected decreased electrical conductance at each selected increased temperature thereof over a targeted treatment range. The variable resistive body can be engineered to bracket a targeted thermal treatment range, for example about 60° C. to 80° C., at which tissue welding can be accomplished. In one mode of operation, the engagement plane will automatically modulate and spatially localize ohmic heating within the engaged tissue from Rf energy application across micron-scale portions of the engagement surface. In another mode of operation, a variable resistive body will focus conductive heating in a selected portion of the engagement surface.

Owner:ETHICON ENDO SURGERY INC

Electrosurgical instrument and method of use

InactiveUS7112201B2Reduce conductancePrevent any substantial dehydrationSurgical instruments for heatingCoatingsMicron scaleElastomer

An electrosurgical medical device and method for creating thermal welds in engaged tissue. In one embodiment, at least one jaw of the instrument defines a tissue engagement plane carrying a conductive-resistive matrix of a conductively-doped non-conductive elastomer. The engagement surface portions thus can be described as a positive temperature coefficient material that has a unique selected decreased electrical conductance at each selected increased temperature thereof over a targeted treatment range. The conductive-resistive matrix can be engineered to bracket a targeted thermal treatment range, for example about 60° C. to 80° C., at which tissue welding can be accomplished. In one mode of operation, the engagement plane will automatically modulate and spatially localize ohmic heating within the engaged tissue from Rf energy application—across micron-scale portions of the engagement surface. In another mode of operation, a conductive-resistive matrix can induce a “wave” of Rf energy density to sweep across the tissue to thereby weld tissue.

Owner:ETHICON ENDO SURGERY INC

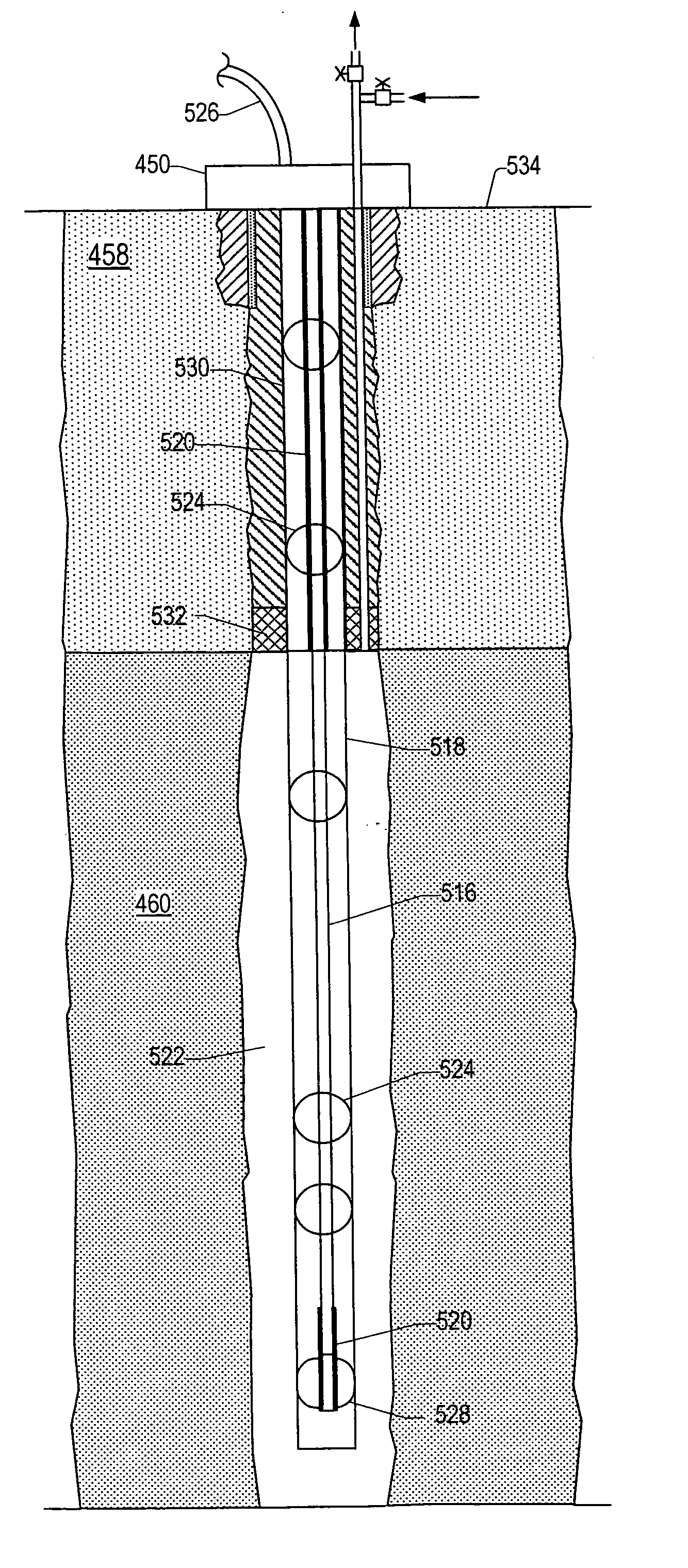

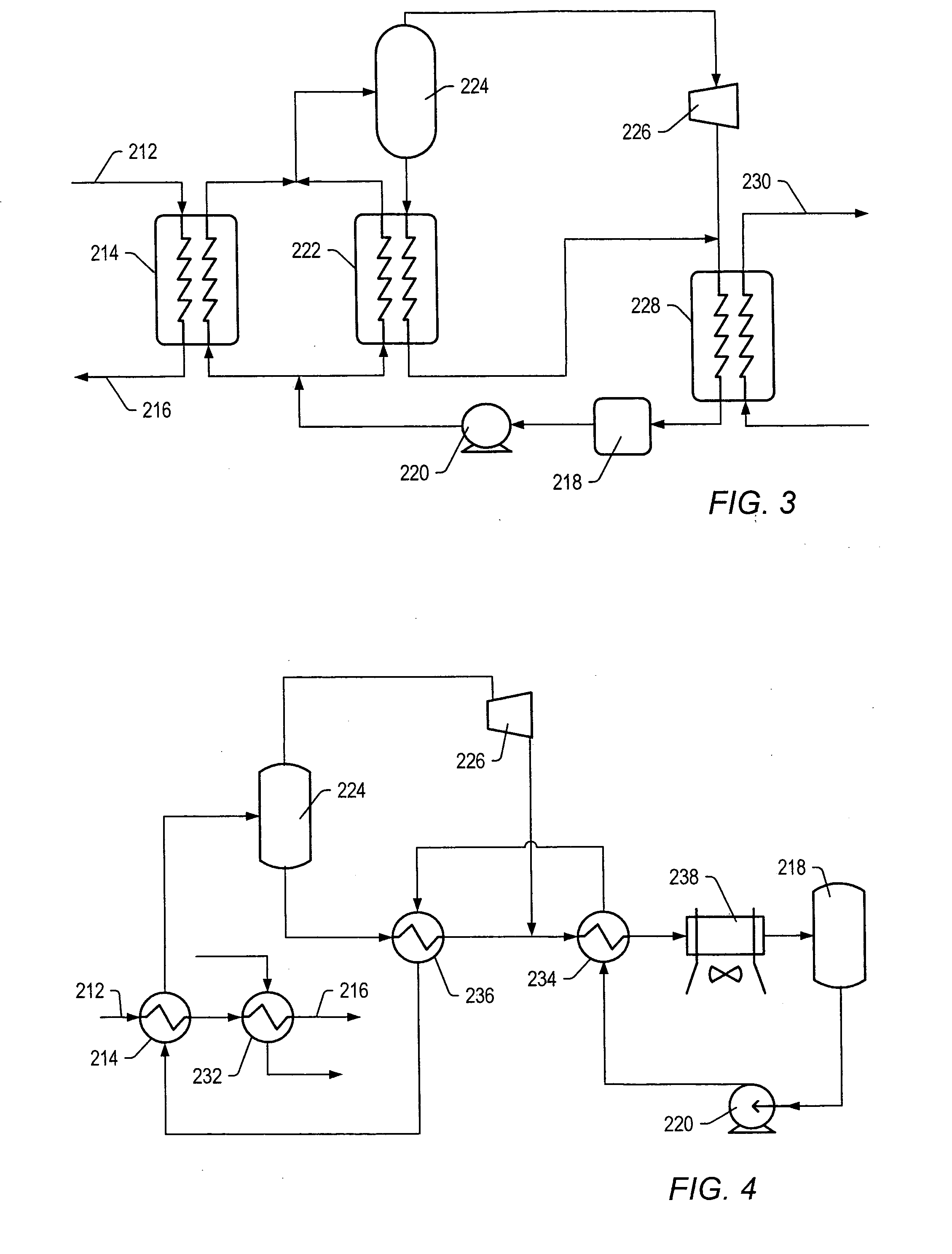

Subsurface heaters with low sulfidation rates

Owner:SHELL OIL CO

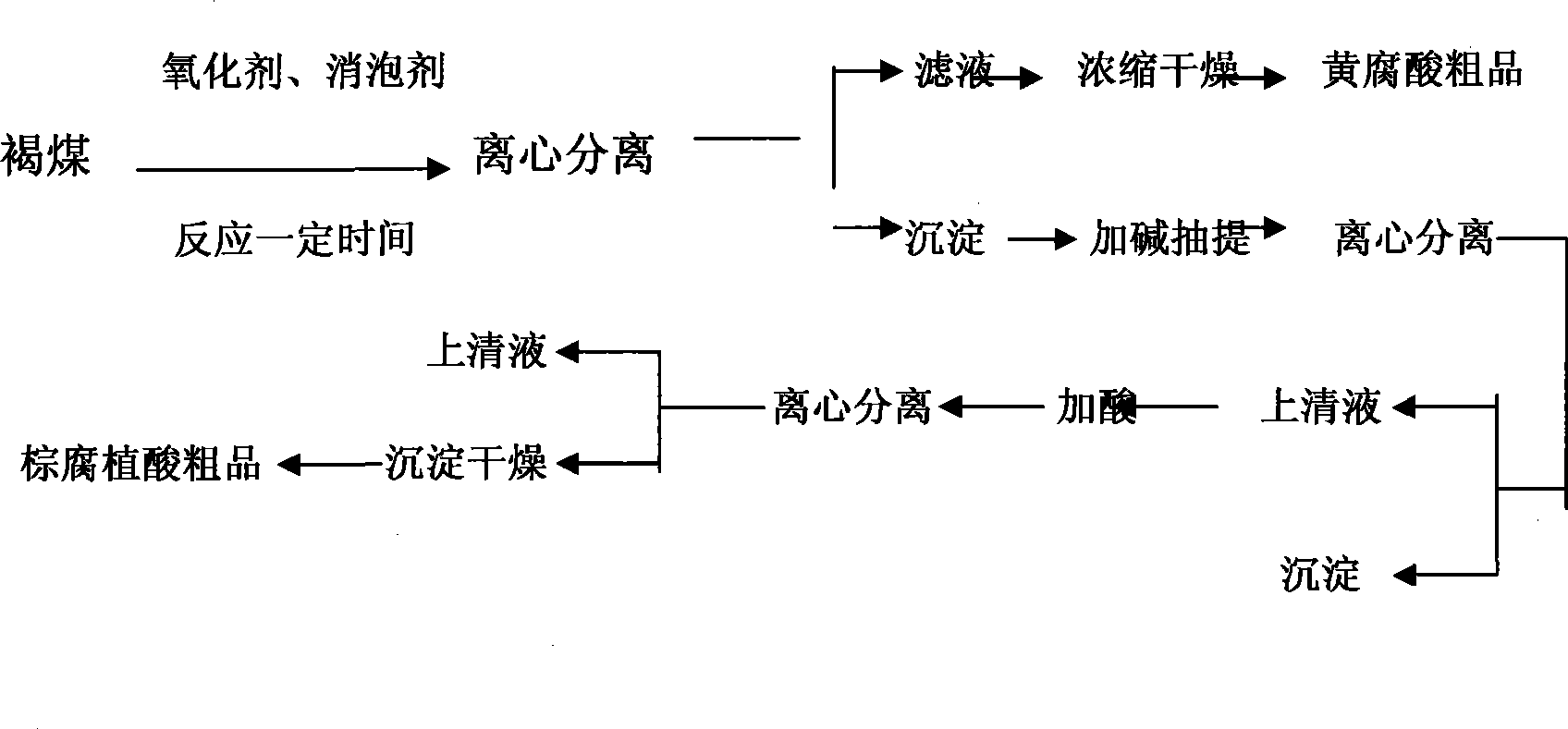

Method for preparing humic acid and salt thereof by oxidation and degradation of brown coal

The invention discloses a method for producing humic acid and salt thereof through the oxidative degradation of young lignite. The method comprises the following steps: carrying out the oxidation reaction of the lignite containing the humic acid and aqueous hydrogen peroxide solution; after the reaction, obtaining water soluble fulvic acid through centrifugal separation, supernatant filtration, concentration and drying; adding alkali into the fulvic acid to prepare a fulvic acid salt product; carrying out the alkaline extraction and centrifugal separation of the residue deposit of the production of the fulvic acid, adding acid into the supernatant till the pH value is 1 to 2, carrying out a reaction at an increased temperature or room temperature, carrying out centrifugal separation after the reaction is finished, and obtaining purified ulmic acid after precipitation and drying; and directly concentrating and drying the supernatant in the previous step to obtain the humate. The method can improve the yield of the fulvic acid and total humic acid in the young lignite, and simultaneously increase the active group in the humic acid. The method can be used for producing fulvic acid, fulvic acid salt, ulmic acid and ulmic acid salt products. In particular, the method puts an end to the environmental pollution caused by the nitric acid which is taken as an oxidation degradation agent. In addition, the method has a short technological line, low cost, simple requirements on equipment, and moderate conditions. The method which can be applied to the industrialized production has good application prospect.

Owner:KUNMING UNIV OF SCI & TECH +4

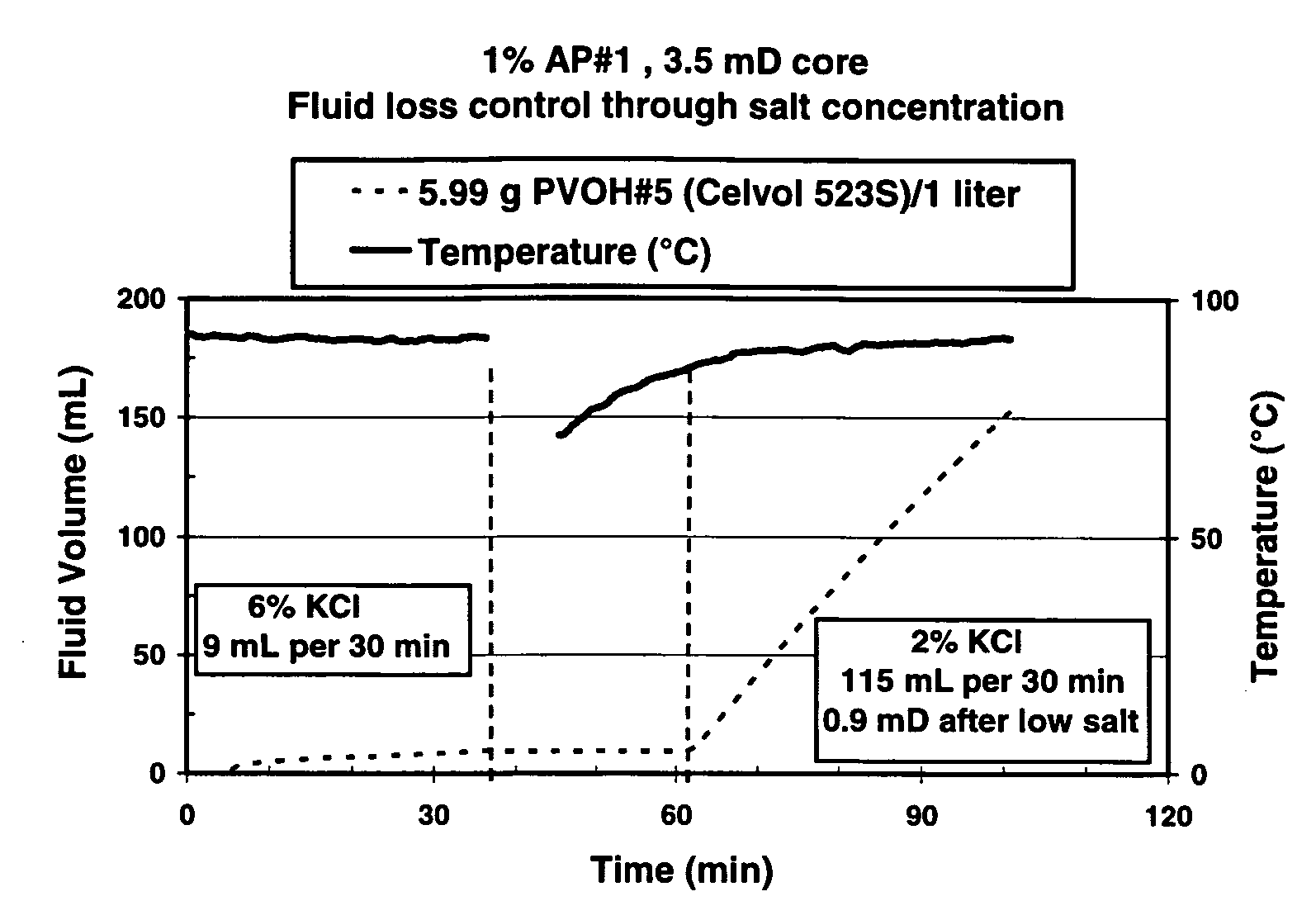

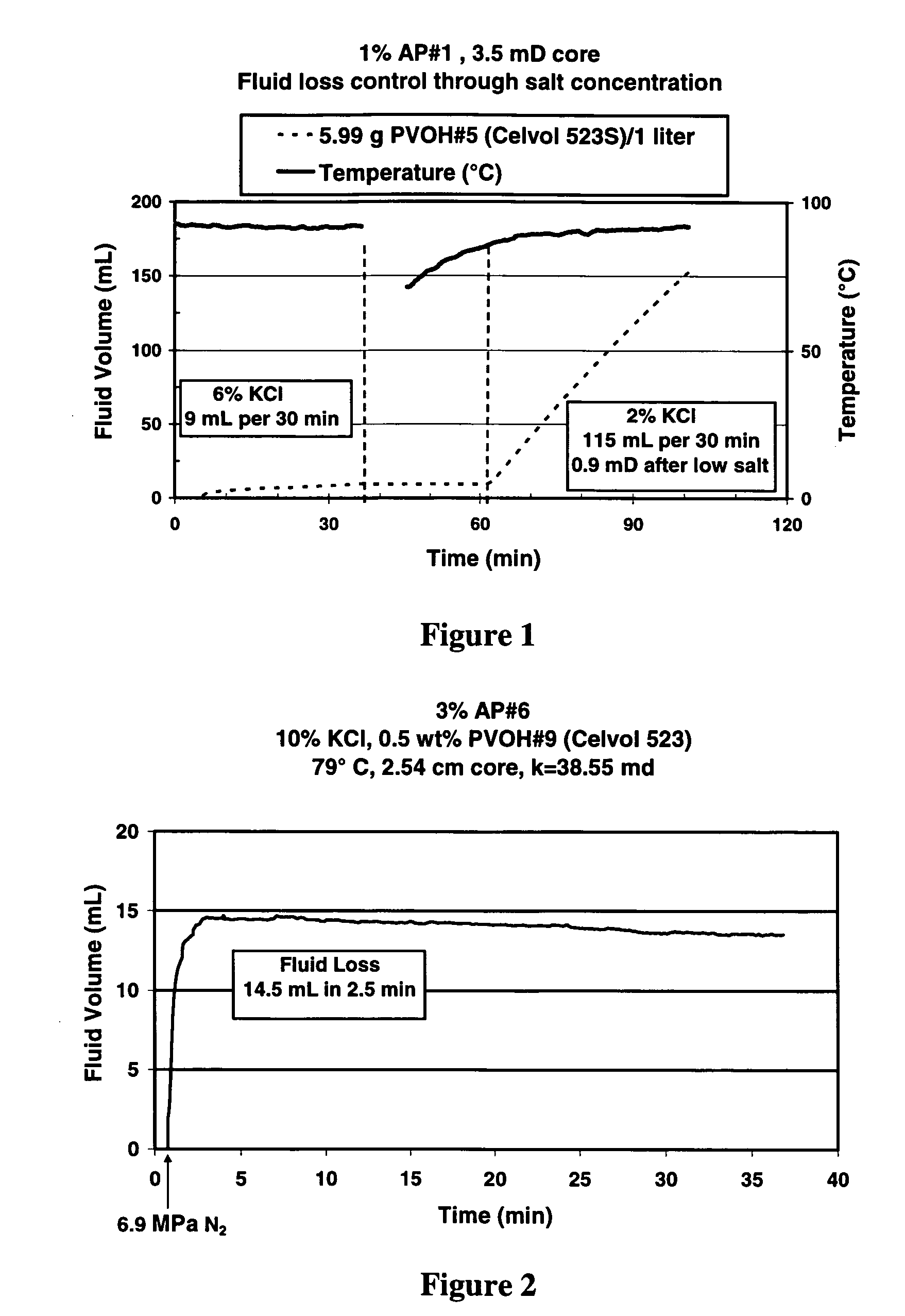

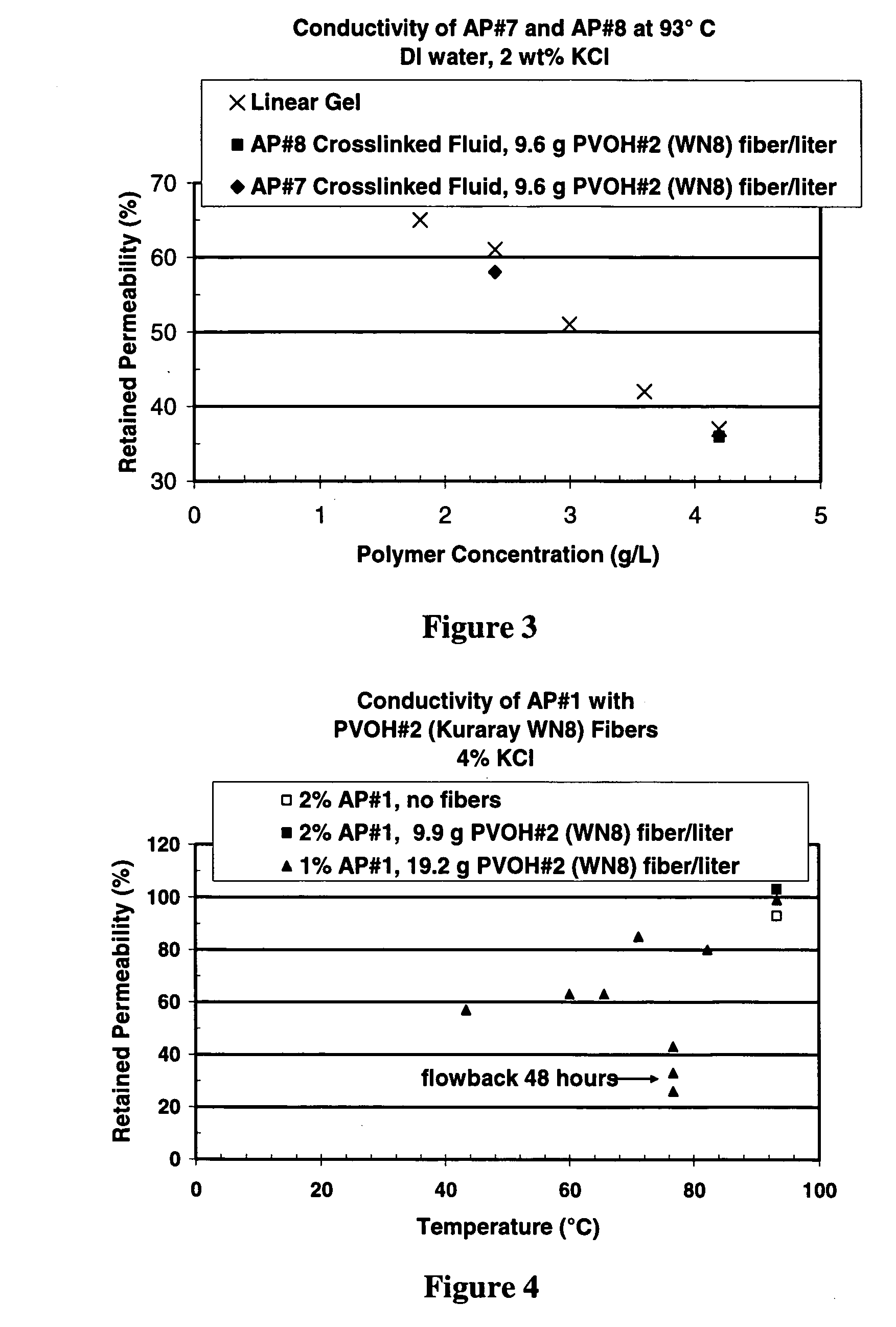

Well treatment with dissolvable polymer

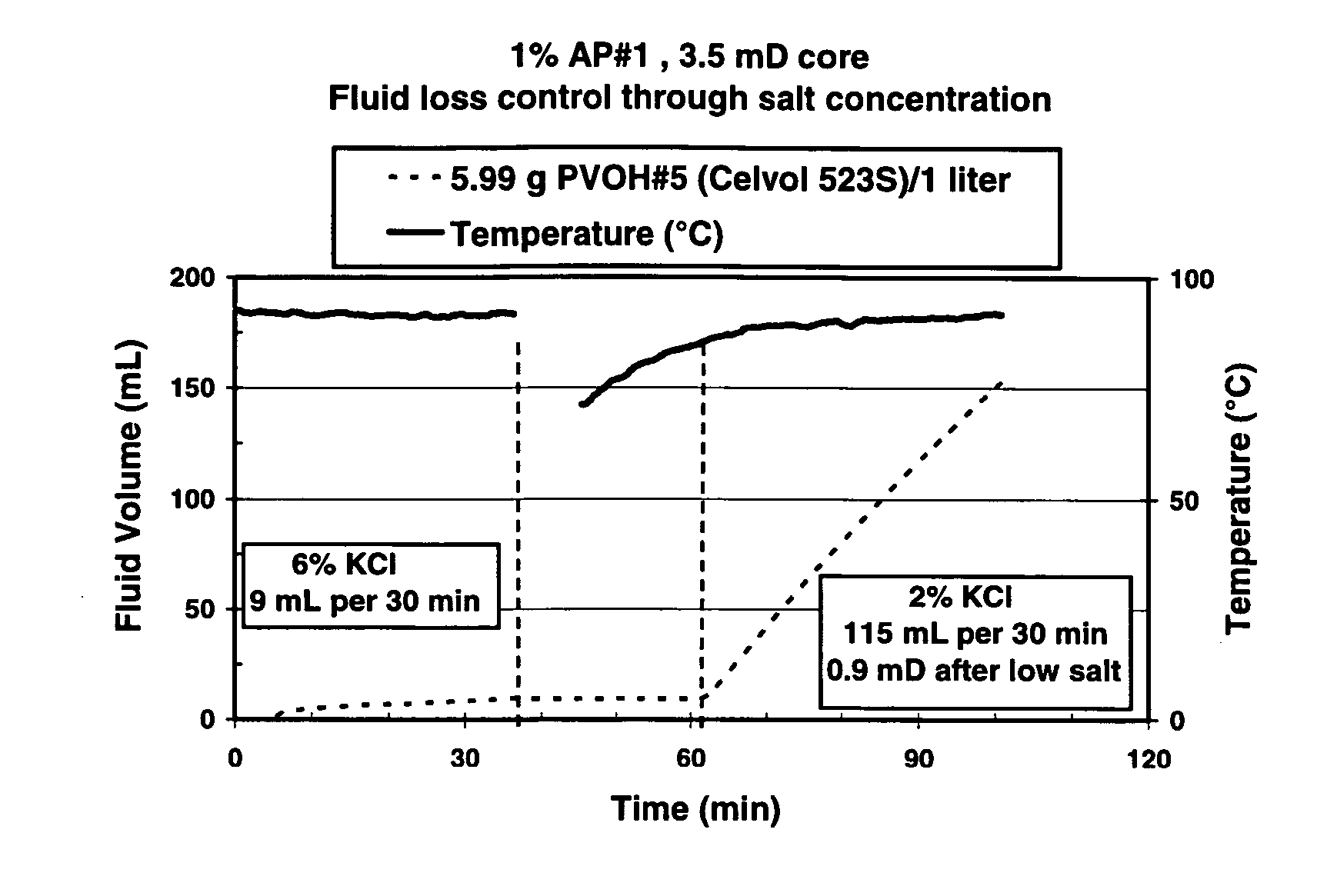

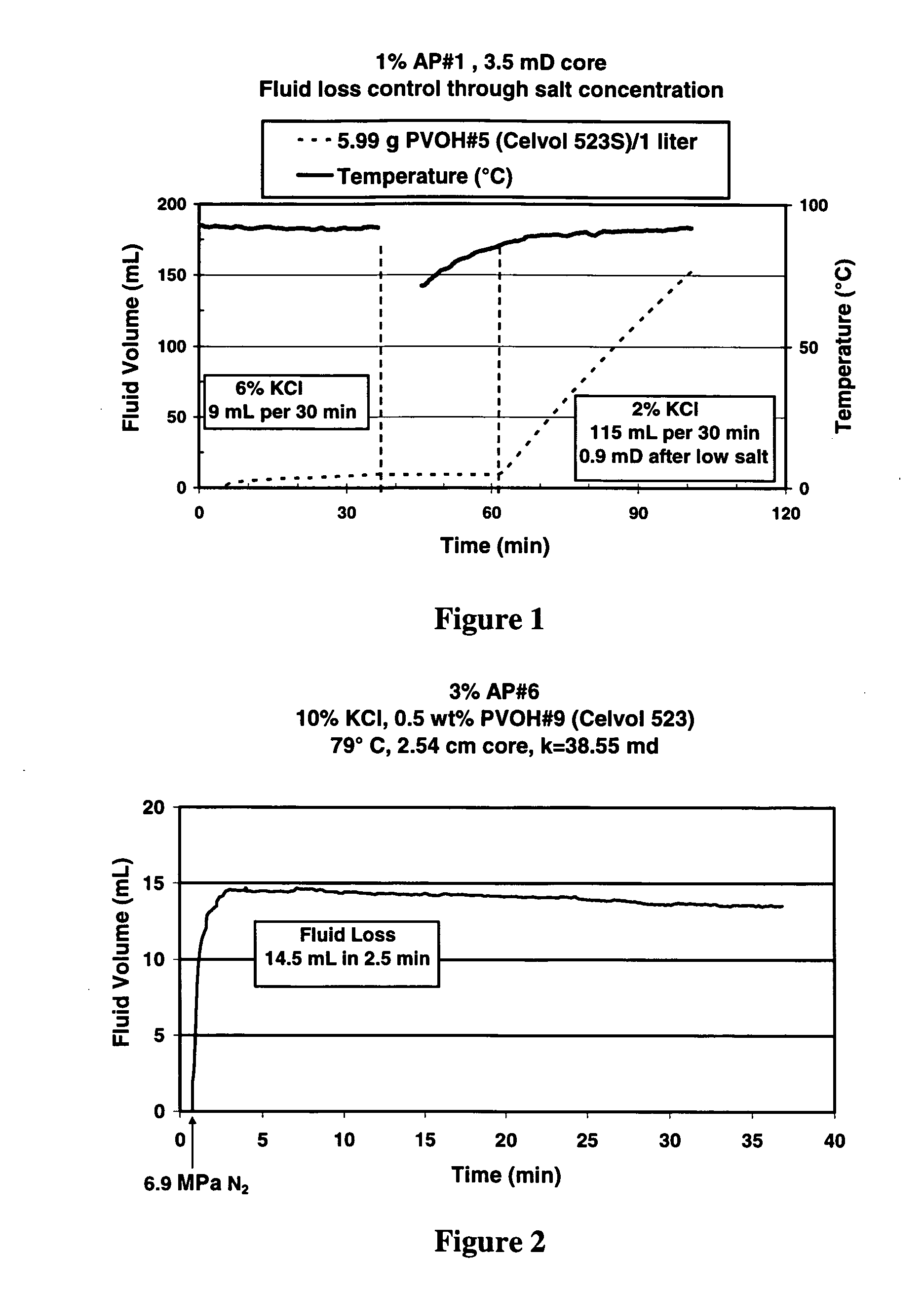

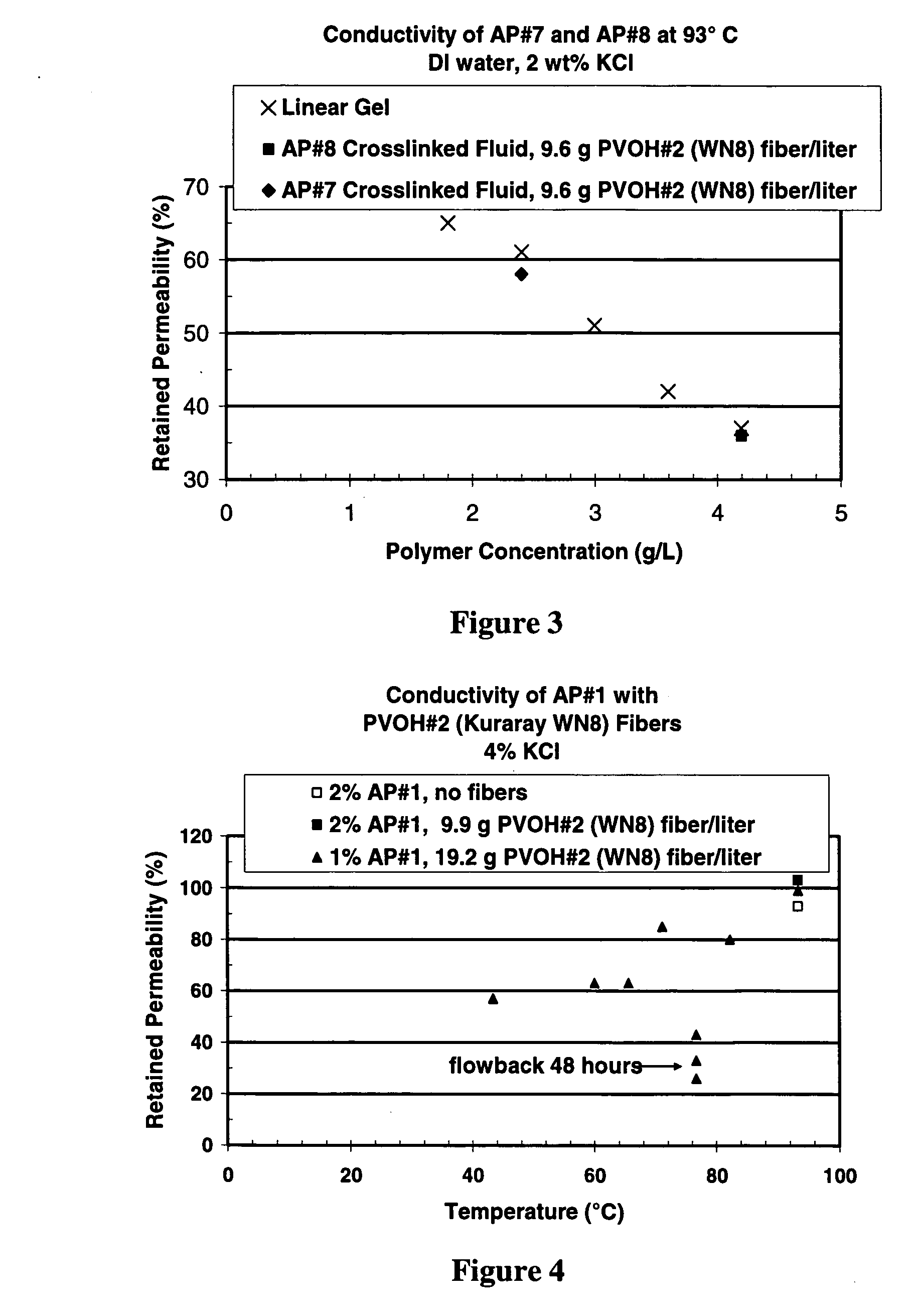

InactiveUS20060157248A1Ease and flexibility for subsequent completion processEasy to processInsulationLiquid/gas jet drillingPolyvinyl alcoholDissolution

Well treatment is disclosed that includes injecting a well treatment fluid with insoluble polyol polymer such as polyvinyl alcohol (PVOH) dispersed therein, depositing the insoluble polymer in the wellbore or an adjacent formation, and thereafter dissolving the polymer by reducing salinity and / or increasing temperature conditions in the environment of the polymer deposit. The method is disclosed for filter cake formation, fluid loss control, drilling, hydraulic fracturing and fiber assisted transport, where removal of the polyol at the end of treatment or after treatment is desired. The method is also disclosed for providing dissolved polyol as a delayed breaker in crosslinked polymer viscosified systems and viscoelastic surfactant systems. Also disclosed are well treatment fluids containing insoluble amorphous or at least partially crystalline polyol, and a PVOH fiber composition wherein the fibers are stabilized from dissolution by salinity.

Owner:SCHLUMBERGER TECH CORP

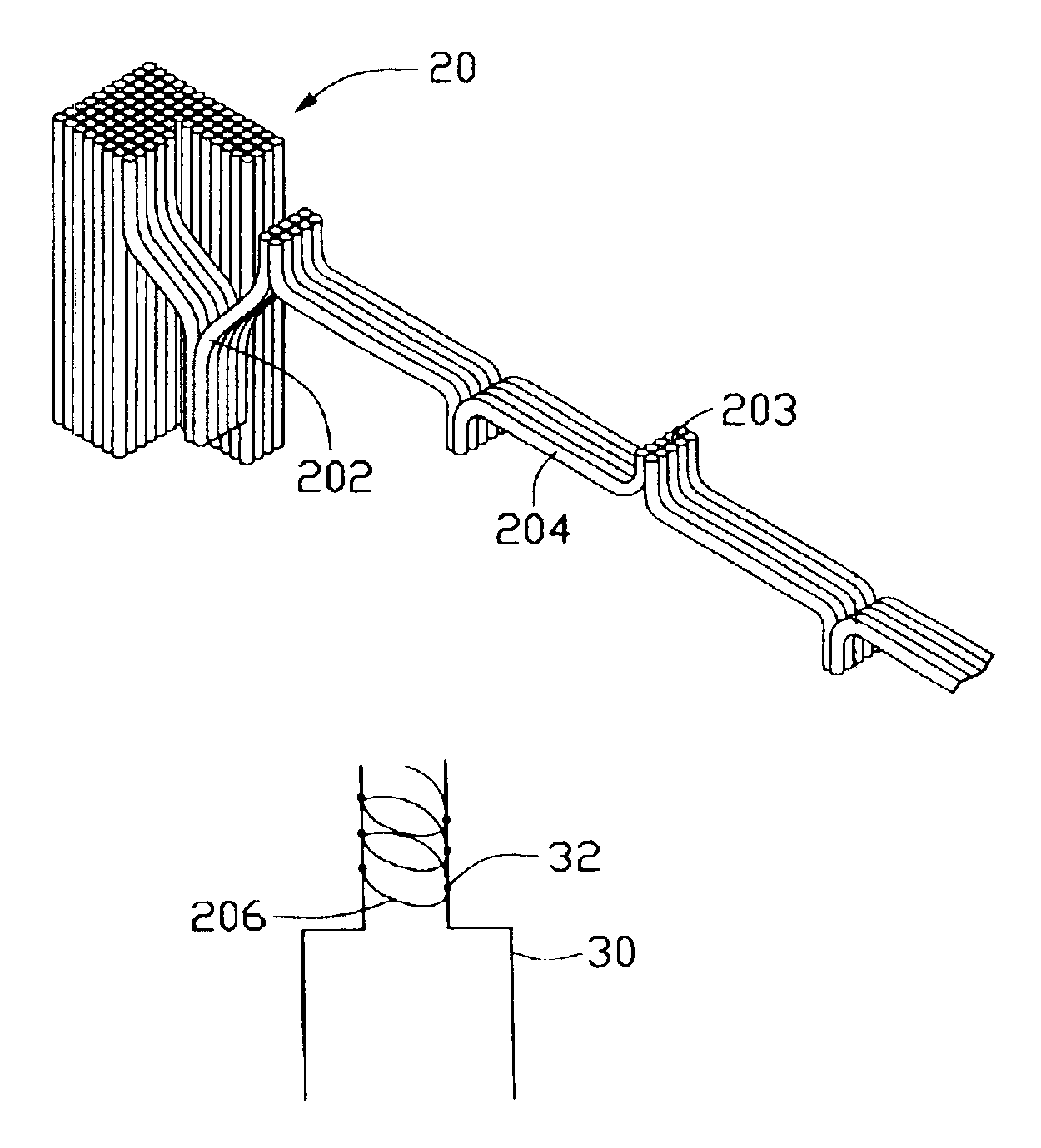

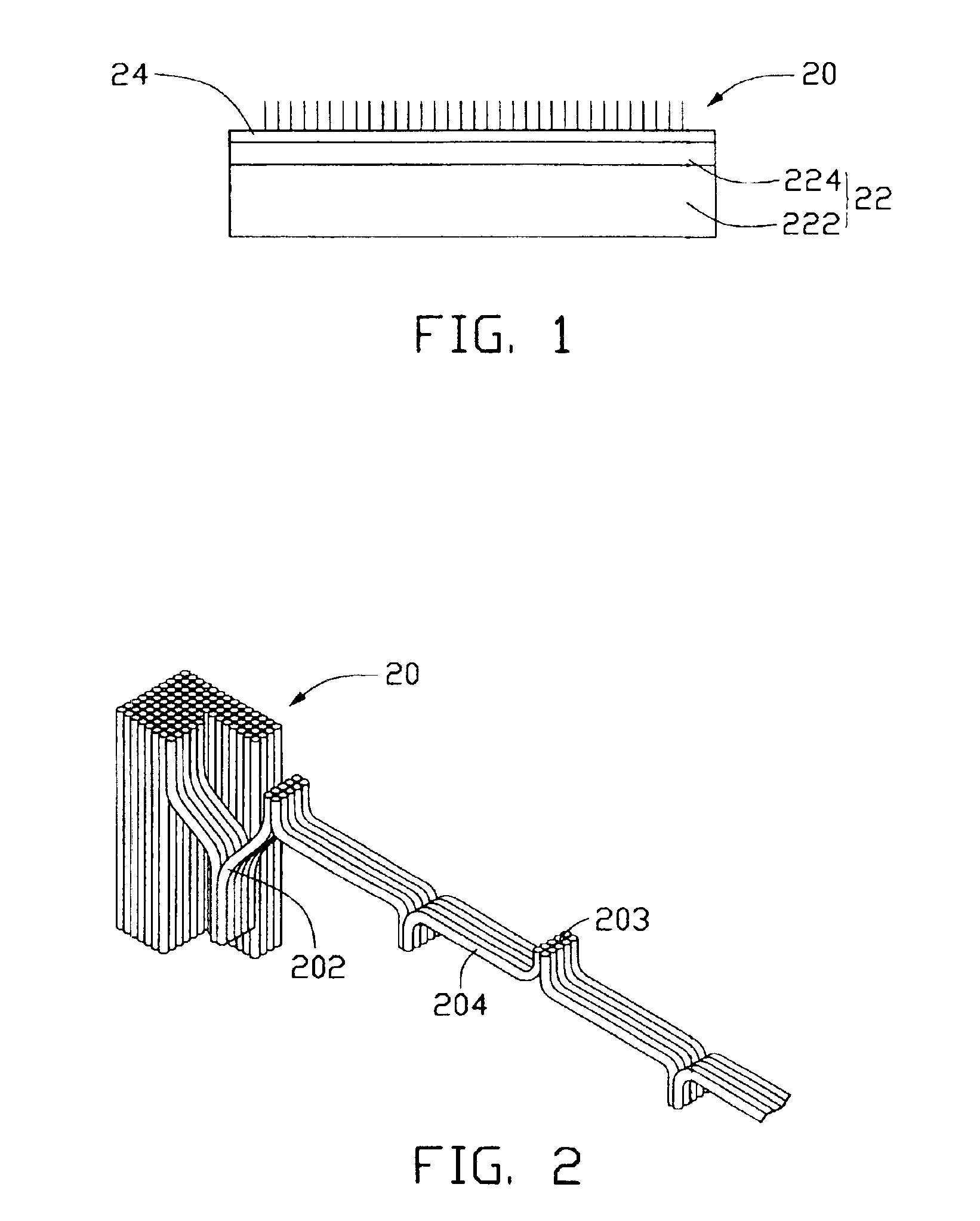

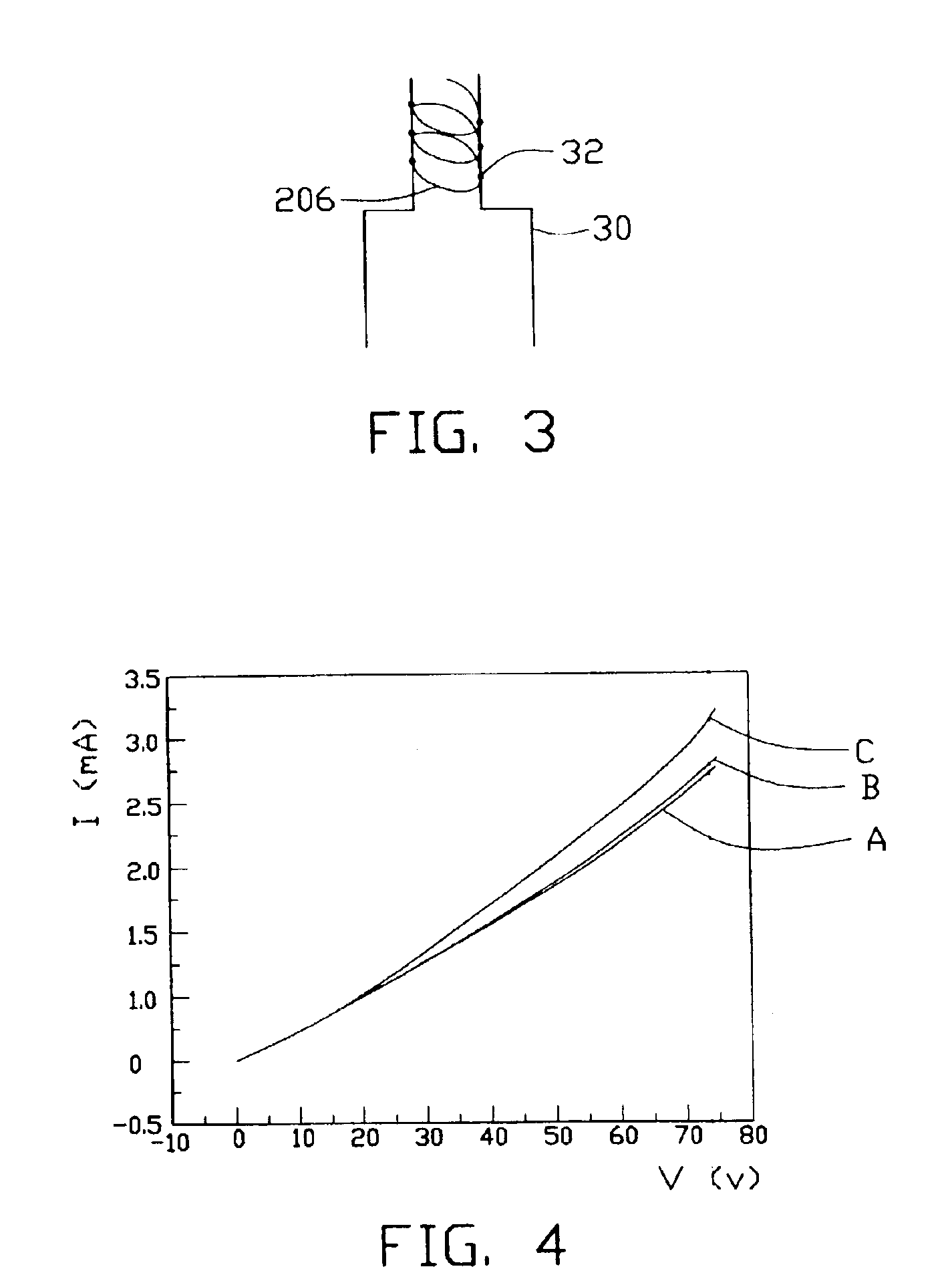

Method of manufacturing a light filament from carbon nanotubes

InactiveUS6957993B2Large specific surface areaIncreased durabilityMaterial nanotechnologyNanoinformaticsCarbon nanotube yarnCarbon nanotube fet

A light filament (206) formed from carbon nanotubes is characterized by high mechanical strength and durability at elevated temperatures, a high surface area to volume ratio, and high emissivity. Additionally, electrical resistance of the light filament does not increase with increasing temperature as much as electrical resistance of metallic light filaments. Accordingly, power consumption of the light filament is low at incandescent operating temperatures. A method for making a light filament made of carbon nanotubes includes the steps of: forming an array of carbon nanotubes (20); pulling out carbon nanotube yarn (204) from the carbon nanotube array; and winding the yarn between two leads (30) functioning as electrodes to form the light filament.

Owner:HON HAI PRECISION IND CO LTD +1

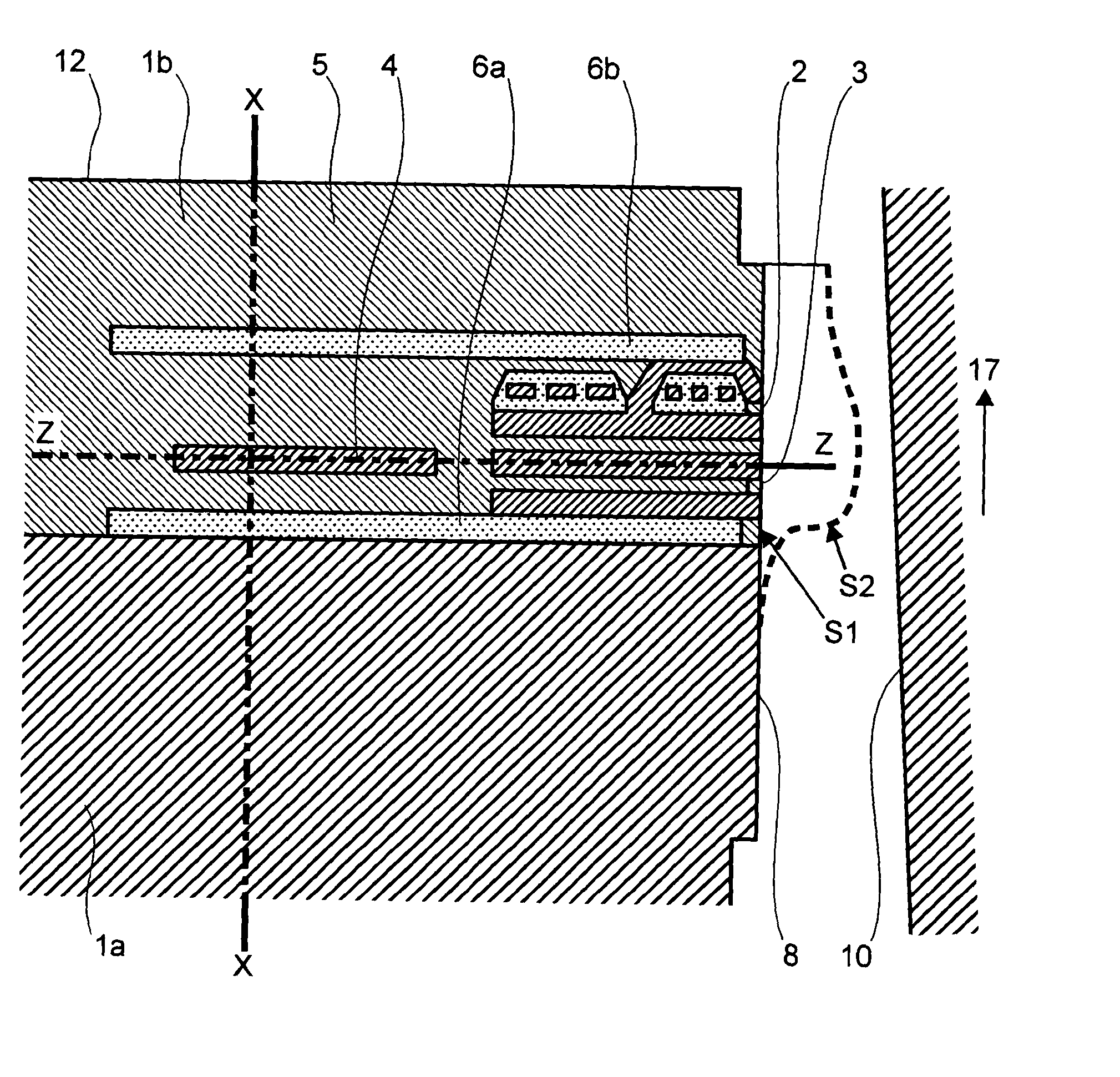

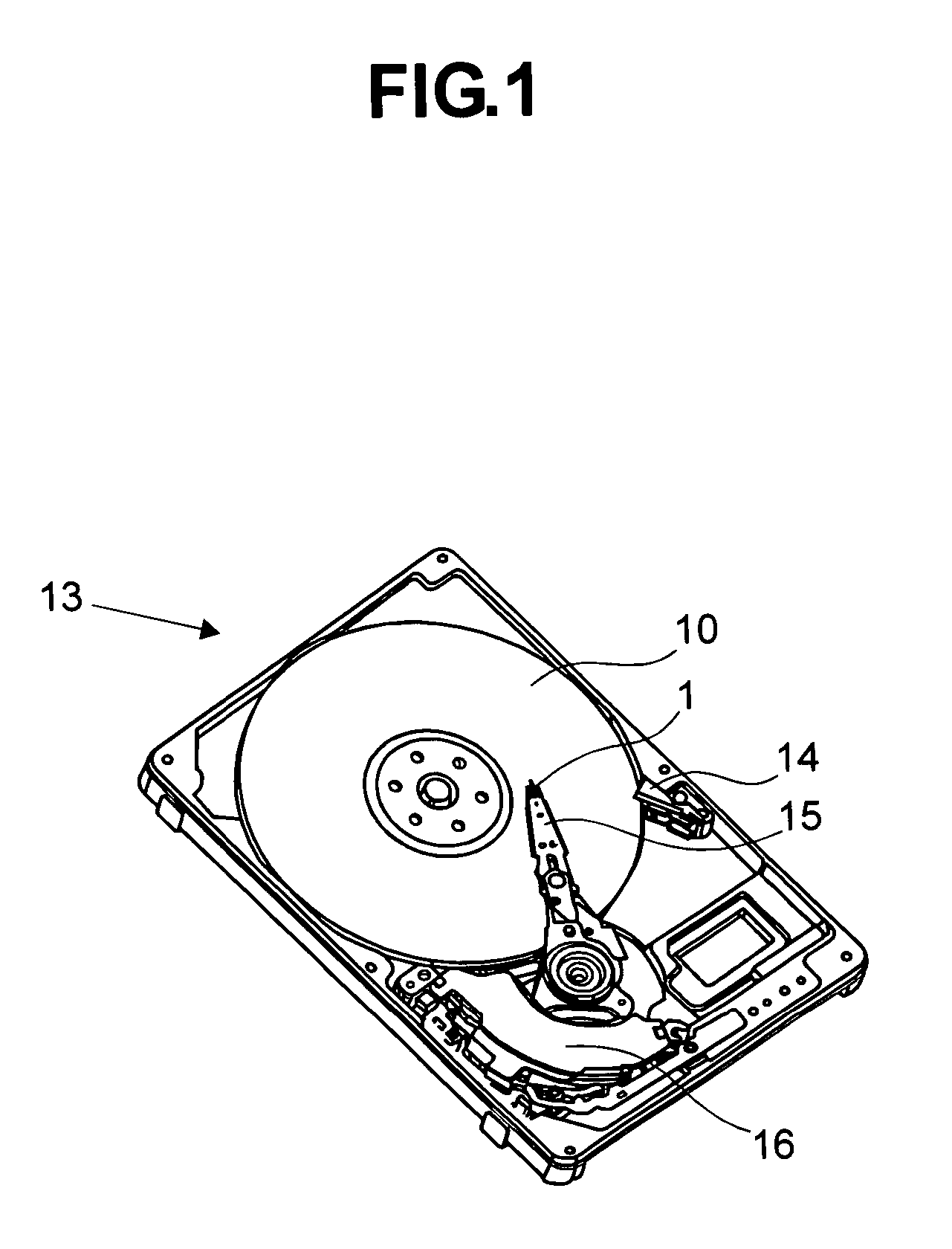

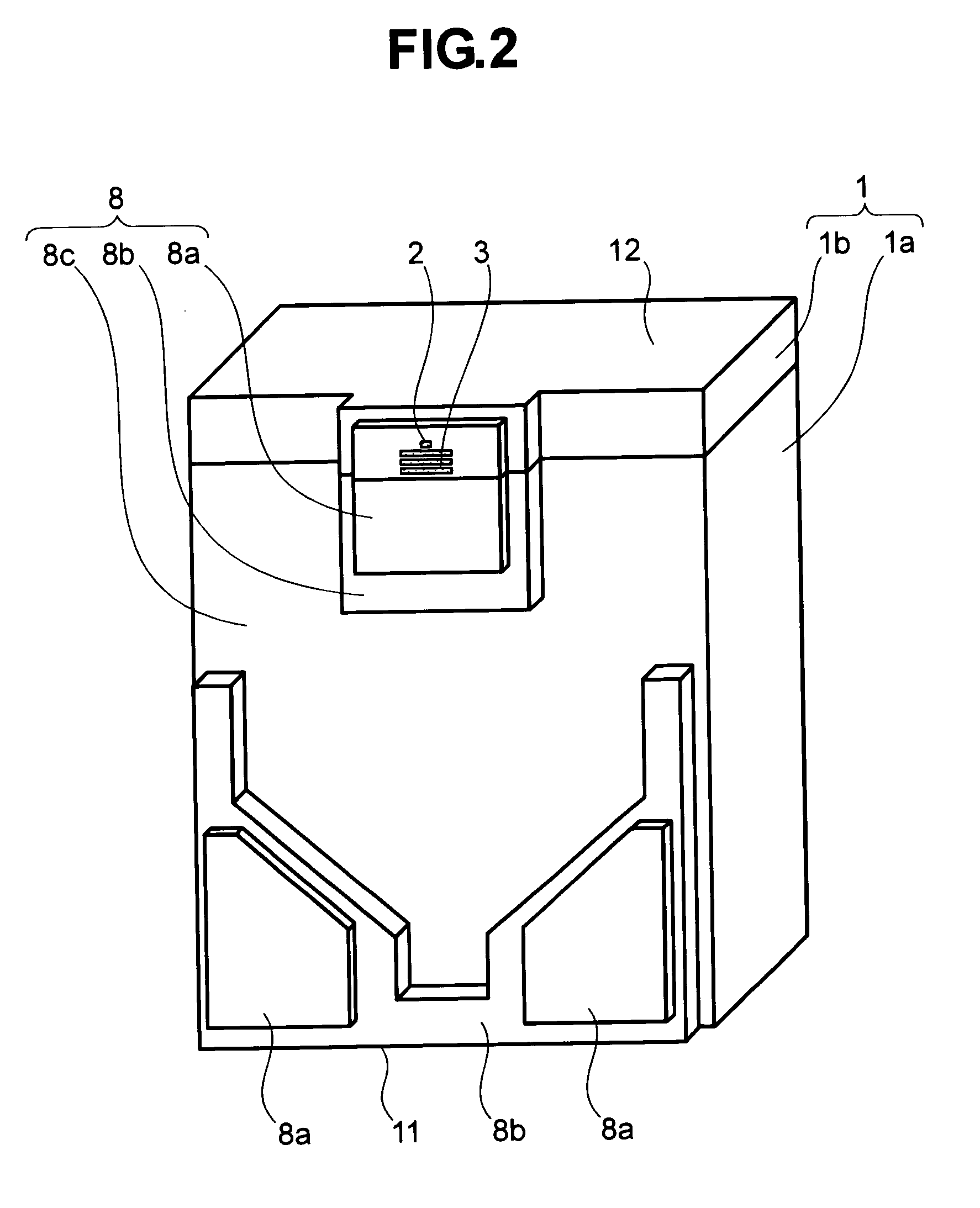

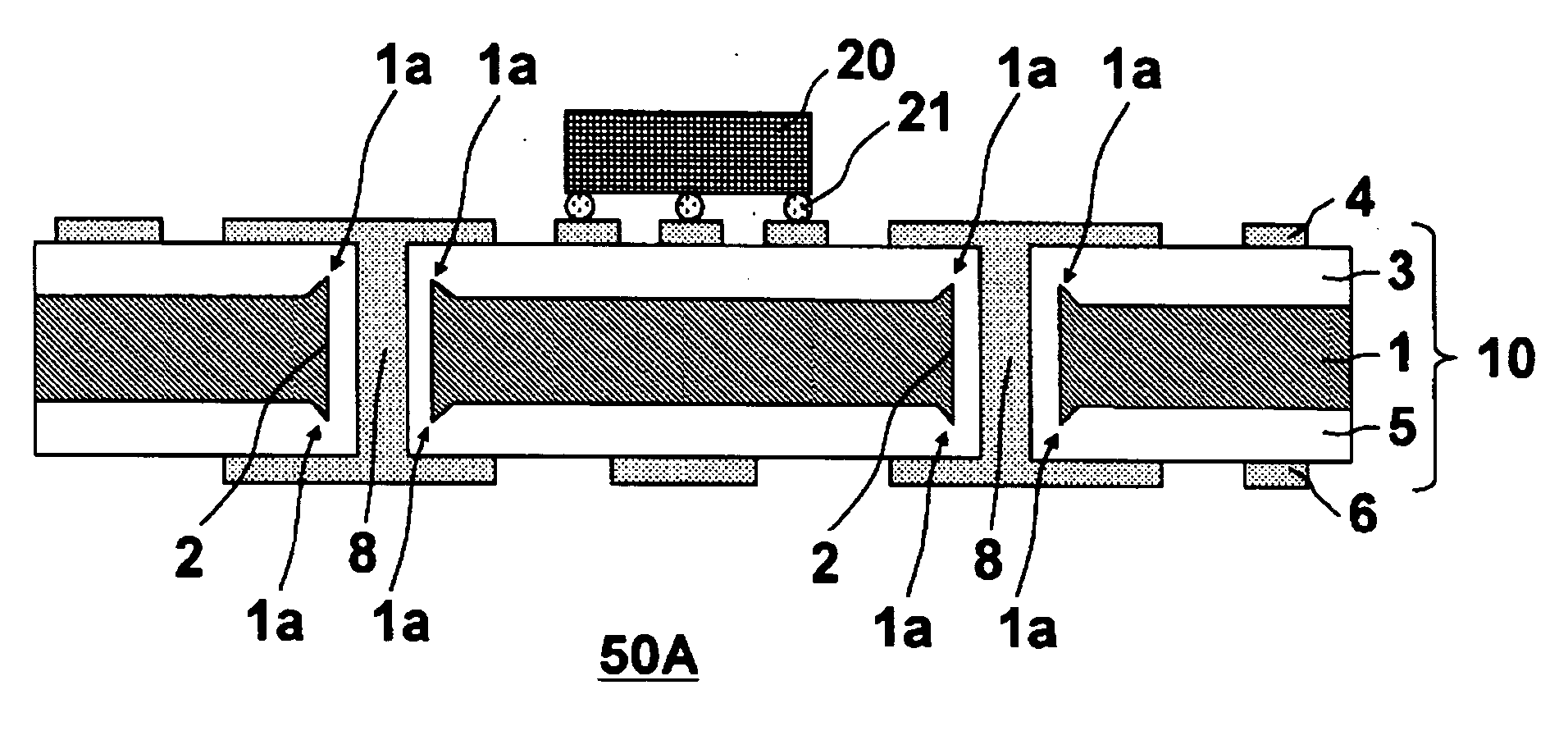

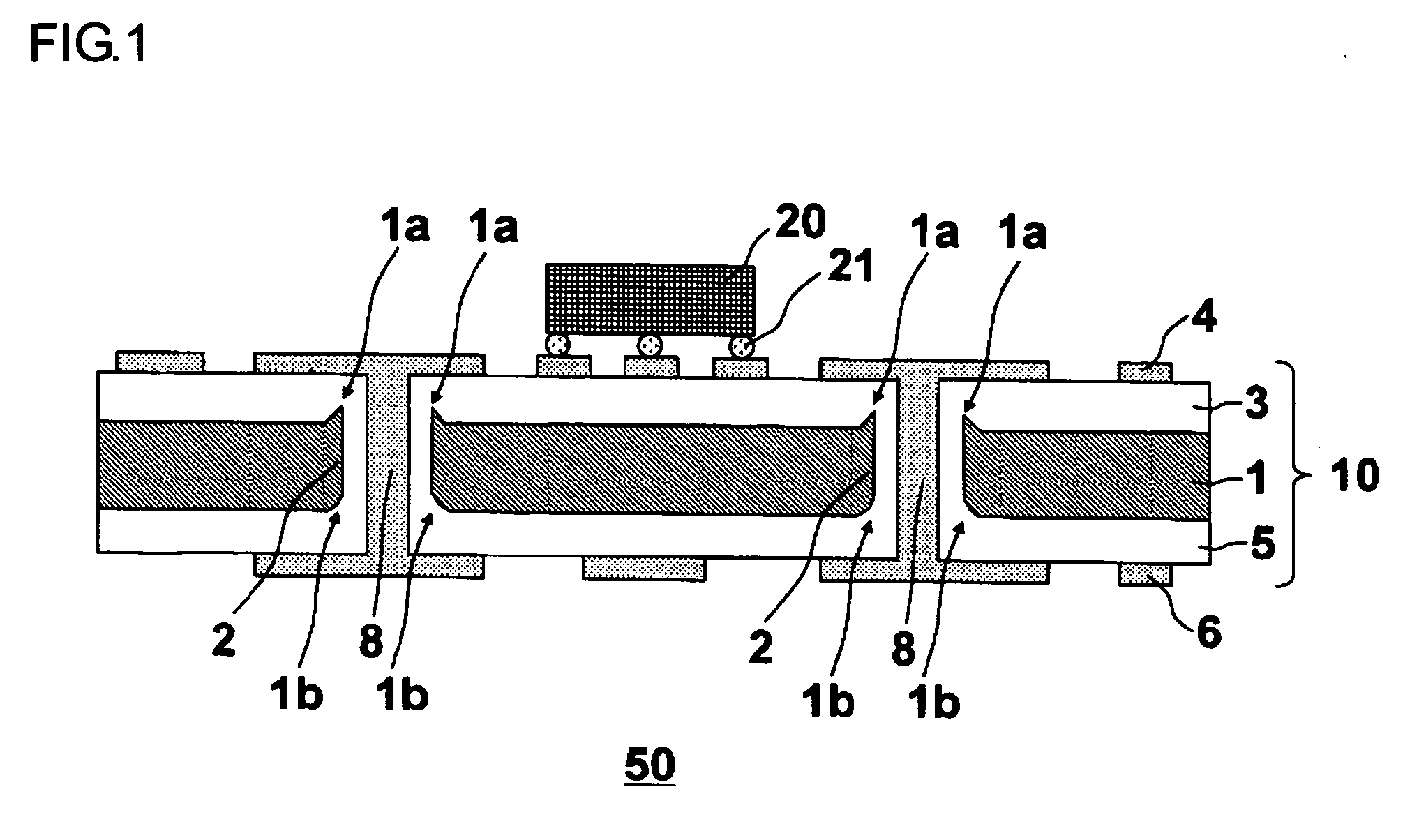

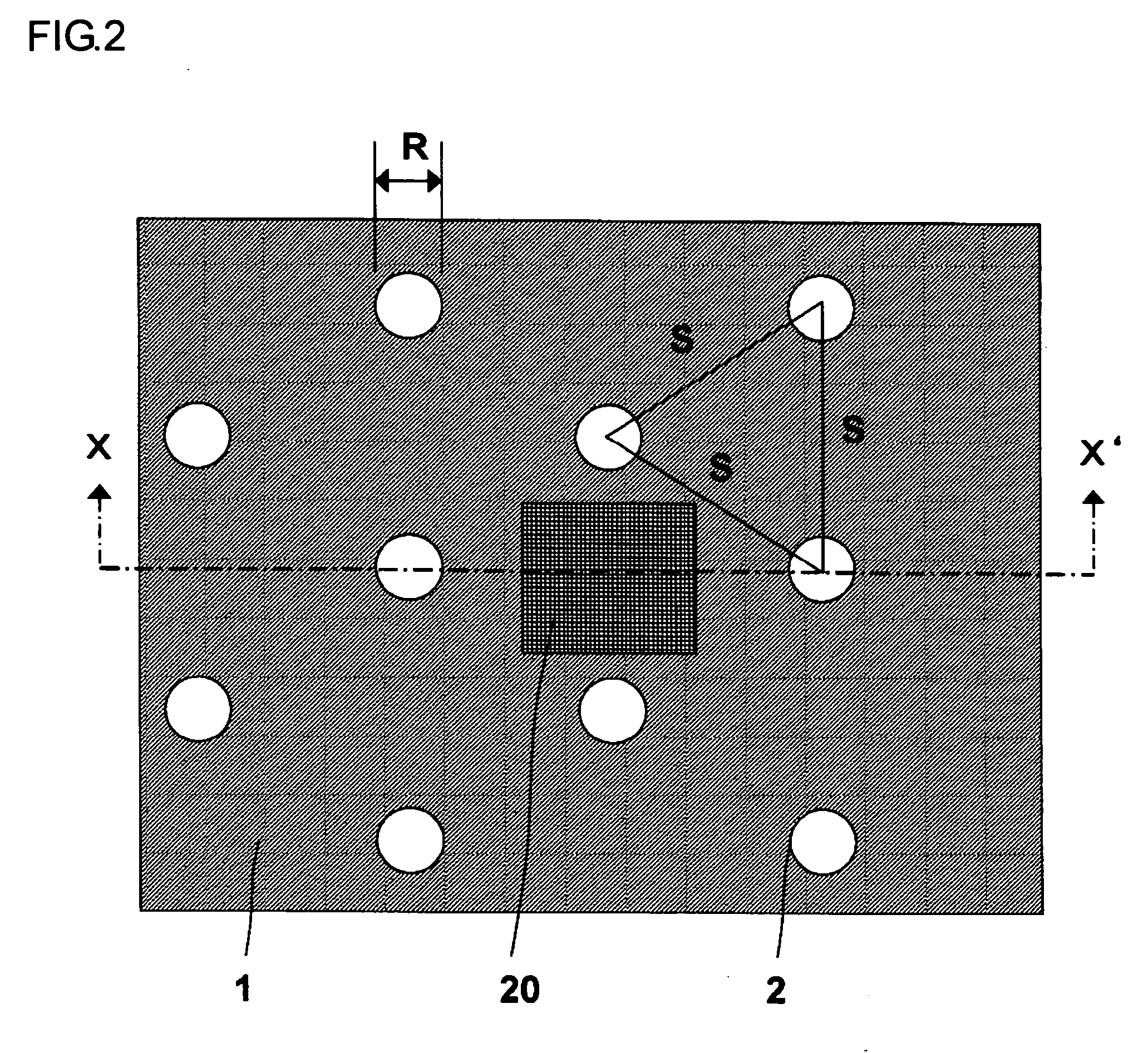

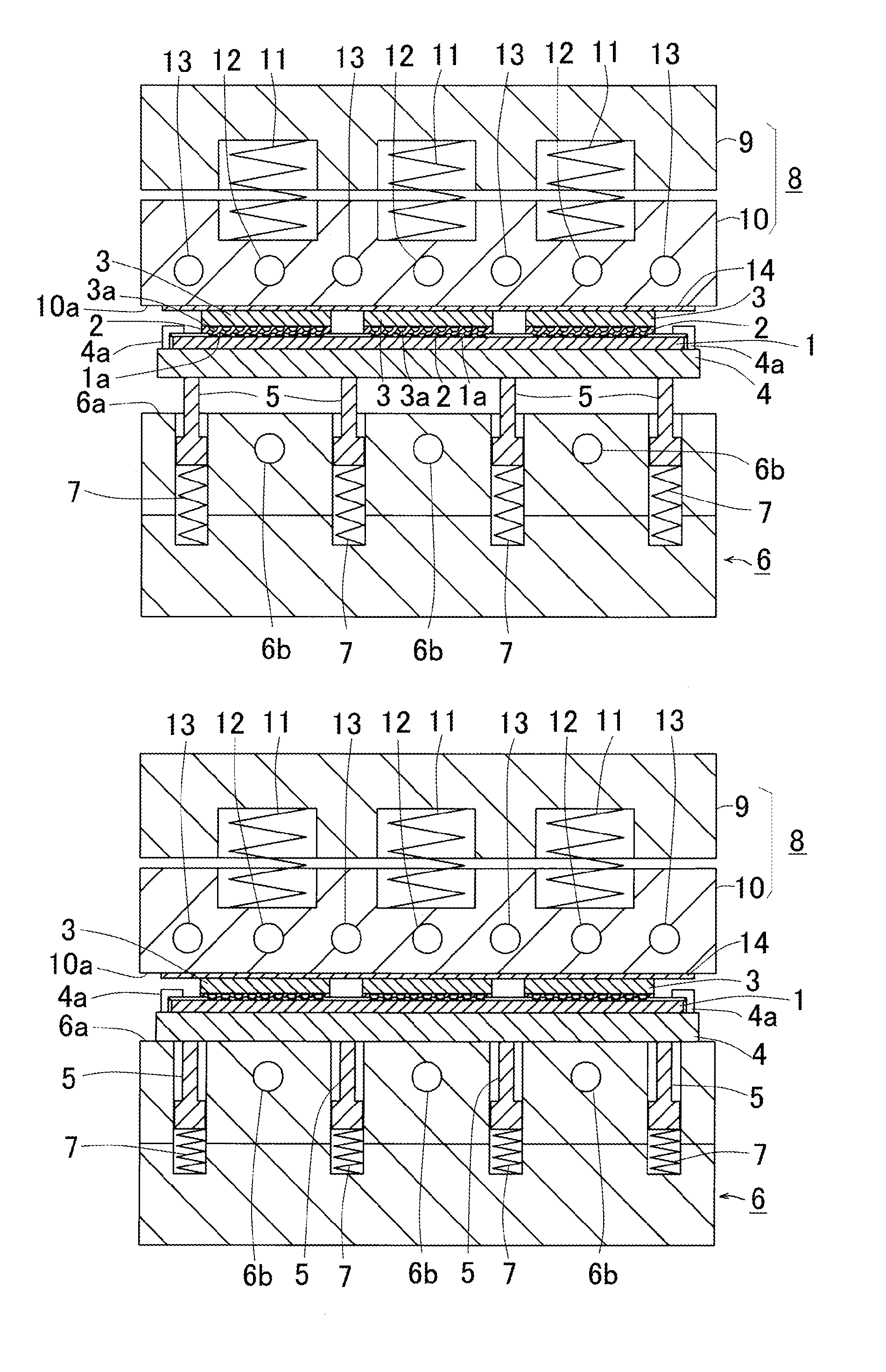

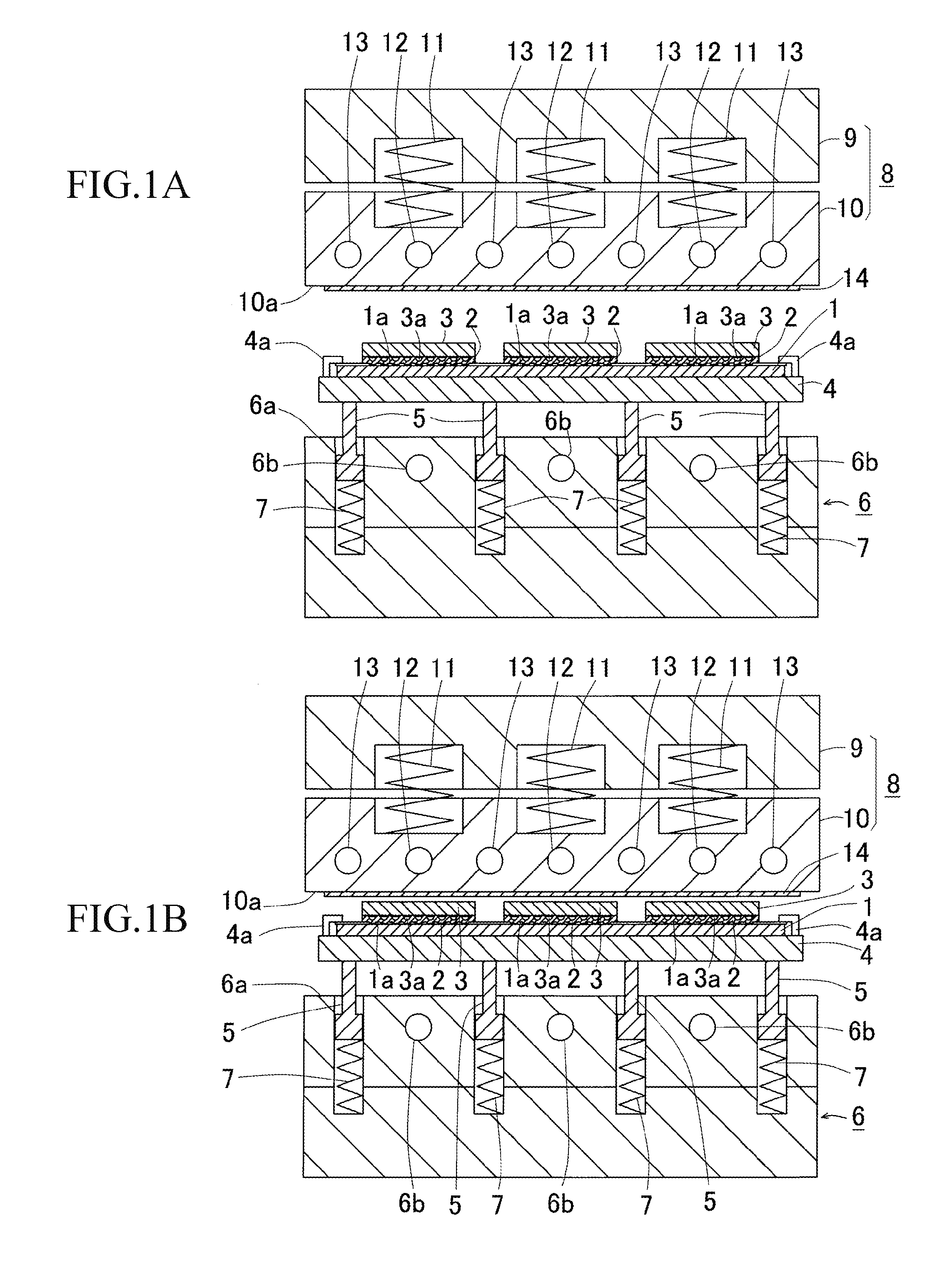

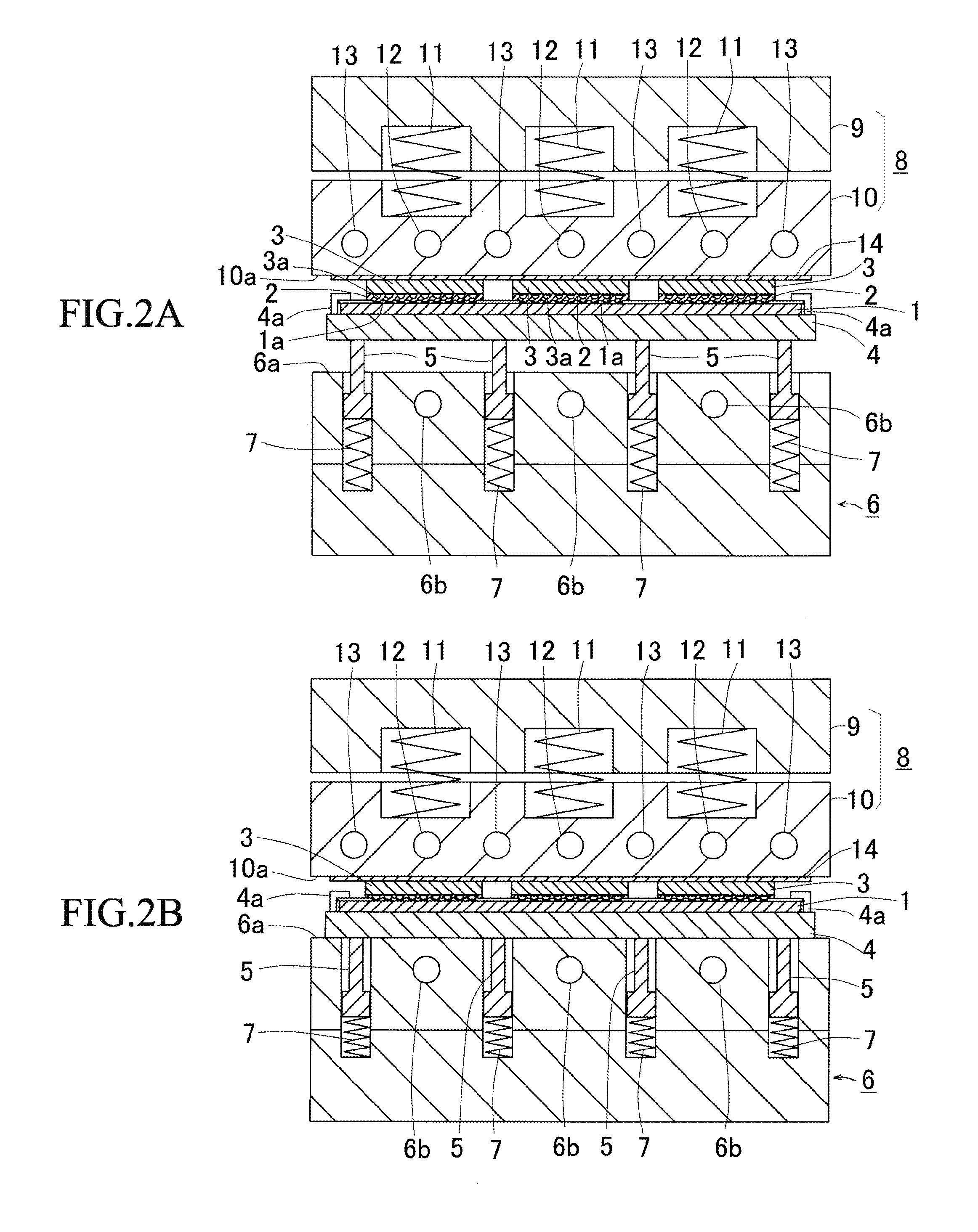

Magnetic head slider and magnet disk apparatus

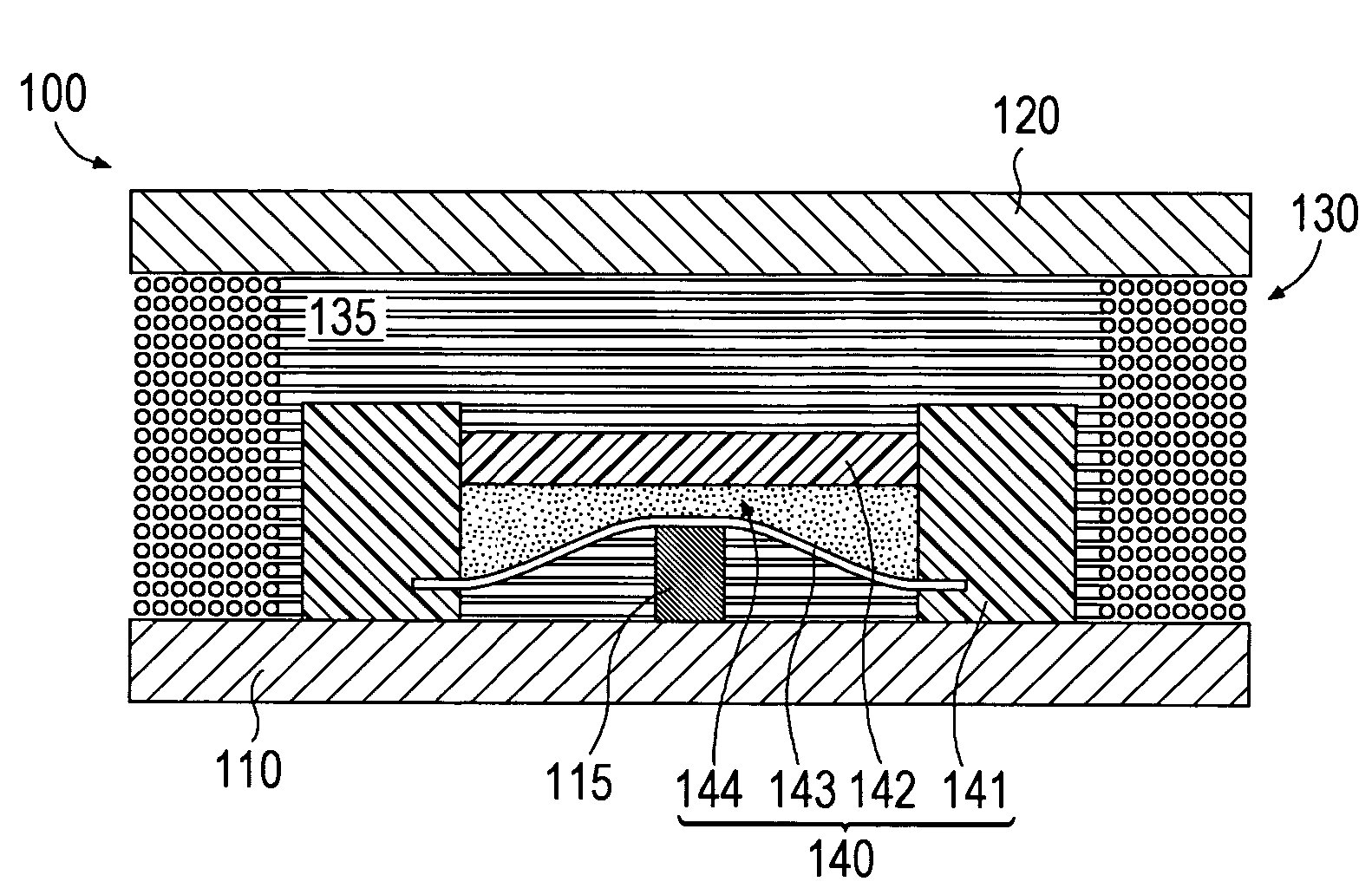

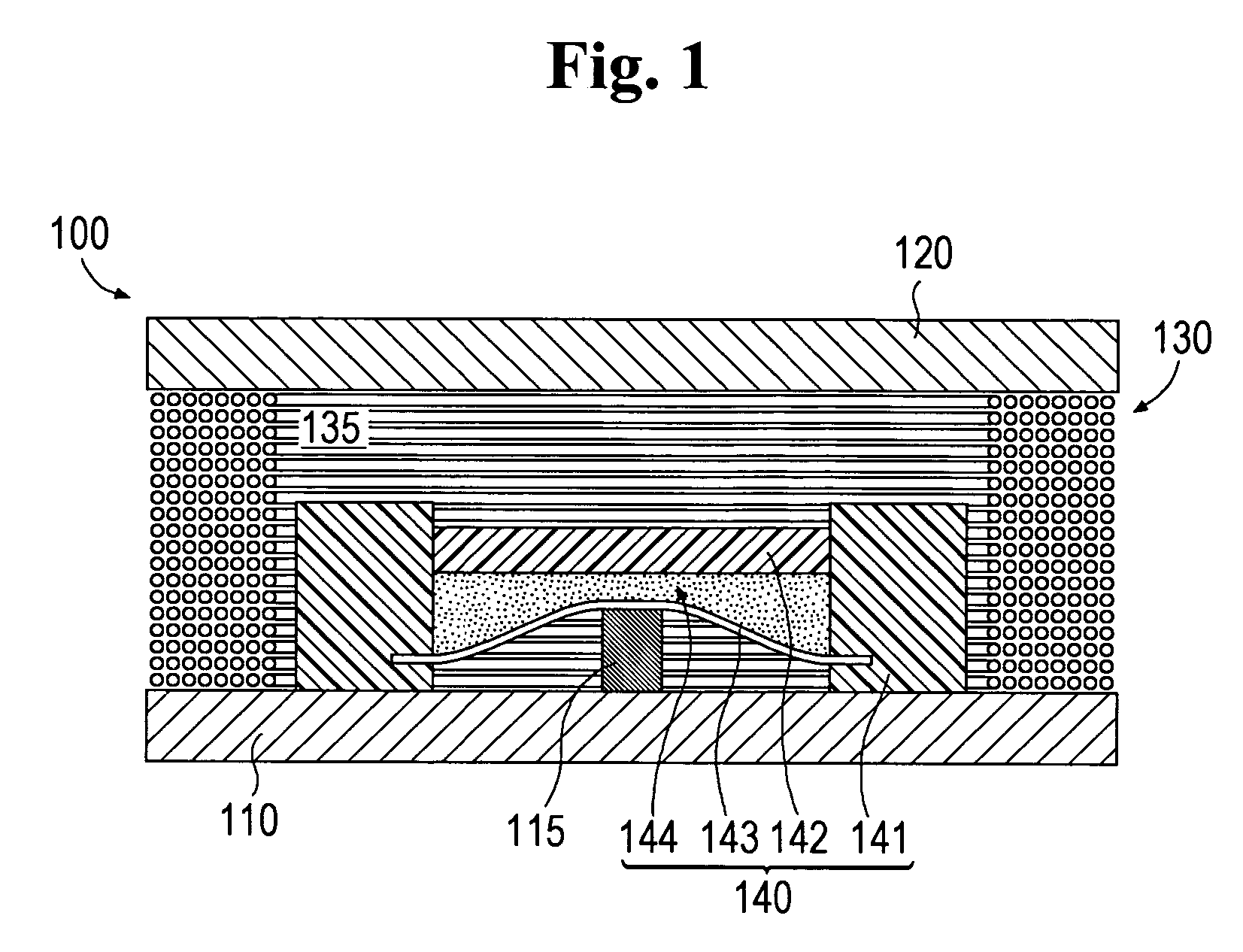

ActiveUS20050024775A1Improve efficiencySmall loadHeads using thin filmsFluid-dynamic spacing of headsElectric forceThermal expansion

In a slider using thermal expansion type, being adjustable on a flying height thereof, having problems to be solved, i.e., to reduce the electric power consumption, and to lesson the heat load upon a reproducing element thereof, wherein a heating device 4 is located separating from tip portions of the recording and reproducing elements 2 and 3. Also, for deforming only the vicinity of the heating device 4 and the recording and reproducing elements 2 and 3, so as to protrude from, the heating device 4 and the recording and reproducing elements 2 and 3 are surrounded by a resin film 6 of small rigidity, thereby increasing an amount of protrusion of the recording and reproducing elements 2 and 3 per a unit of electric power, but without increasing temperature of the reproducing element 3, with an aim of the structure of cutting off the force from materials of circumferences against the deformation.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD +1

Well treatment with dissolvable polymer

InactiveUS7398826B2Easy to processRestore permeabilityInsulationLiquid/gas jet drillingPolyvinyl alcoholDissolution

Well treatment is disclosed that includes injecting a well treatment fluid with insoluble polyol polymer such as polyvinyl alcohol (PVOH) dispersed therein, depositing the insoluble polymer in the wellbore or an adjacent formation, and thereafter dissolving the polymer by reducing salinity and / or increasing temperature conditions in the environment of the polymer deposit. The method is disclosed for filter cake formation, fluid loss control, drilling, hydraulic fracturing and fiber assisted transport, where removal of the polyol at the end of treatment or after treatment is desired. The method is also disclosed for providing dissolved polyol as a delayed breaker in crosslinked polymer viscosified systems and viscoelastic surfactant systems. Also disclosed are well treatment fluids containing insoluble amorphous or at least partially crystalline polyol, and a PVOH fiber composition wherein the fibers are stabilized from dissolution by salinity.

Owner:SCHLUMBERGER TECH CORP

Heat-curable eproxy resin composition

InactiveUS20050159511A1Other chemical processesPolyureas/polyurethane adhesivesAdhesiveReactive diluent

The invention relates to compositions containing at least one epoxy resin A with on average more than one epoxy group per molecule; at least one epoxy adduct B with on average one epoxy group per molecule; at least one thixotropic agent C, based on a urea derivative in a non-diffusing support material; and at least one curing agent D for epoxy resins, which is activated by an increased temperature. According to preferred embodiments, the invention also relates to compositions containing at least one core-shell polymer E and / or filler F and / or reactive diluent G. The invention also relates to the use of said compositions as a single-component adhesive and to a method for producing the compositions. The invention further relates to the use of the thixotropic agent C, based on a urea derivative in a non-diffusing support material as an agent for increasing the impact resistance.

Owner:SIKA SCHWEIZ AG

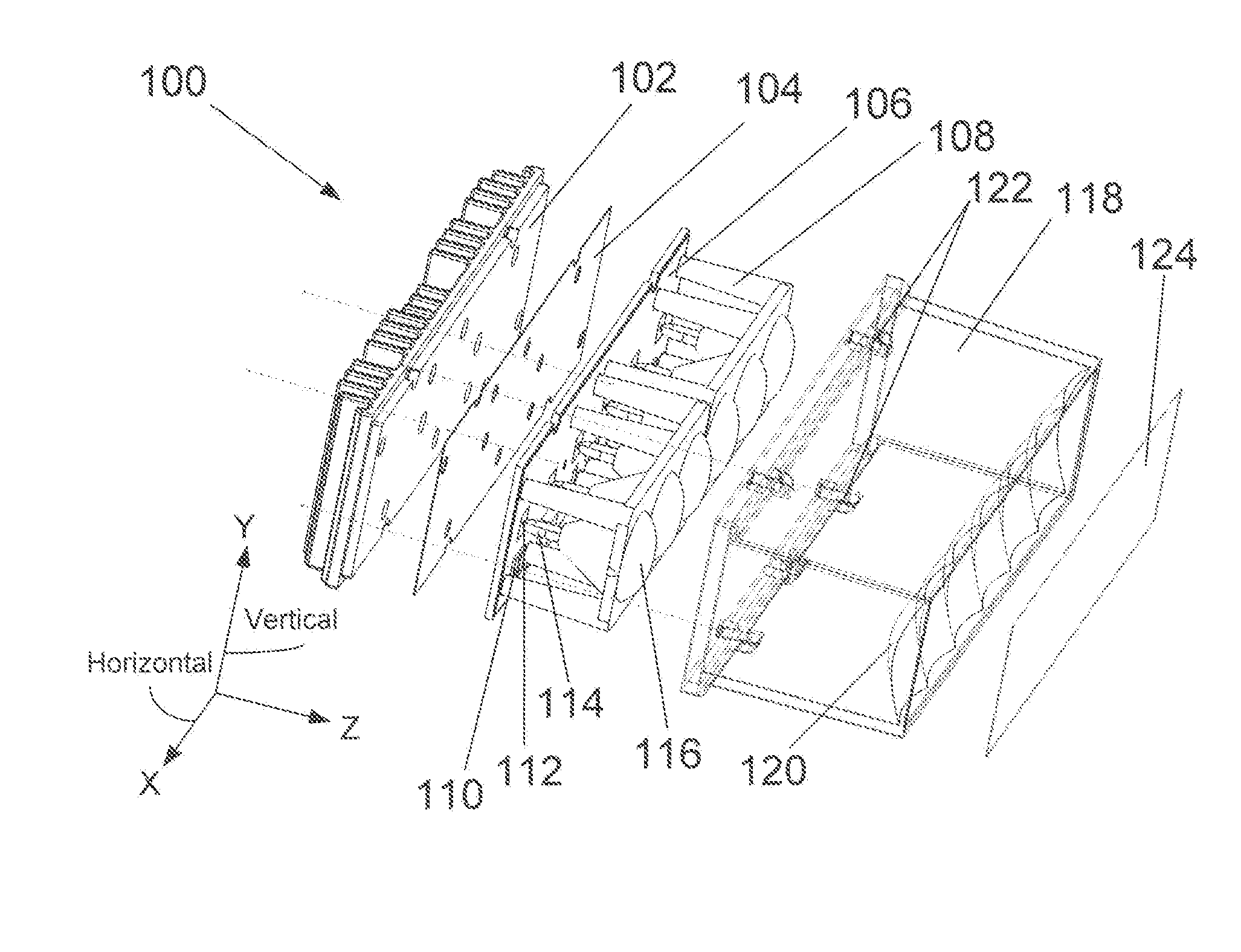

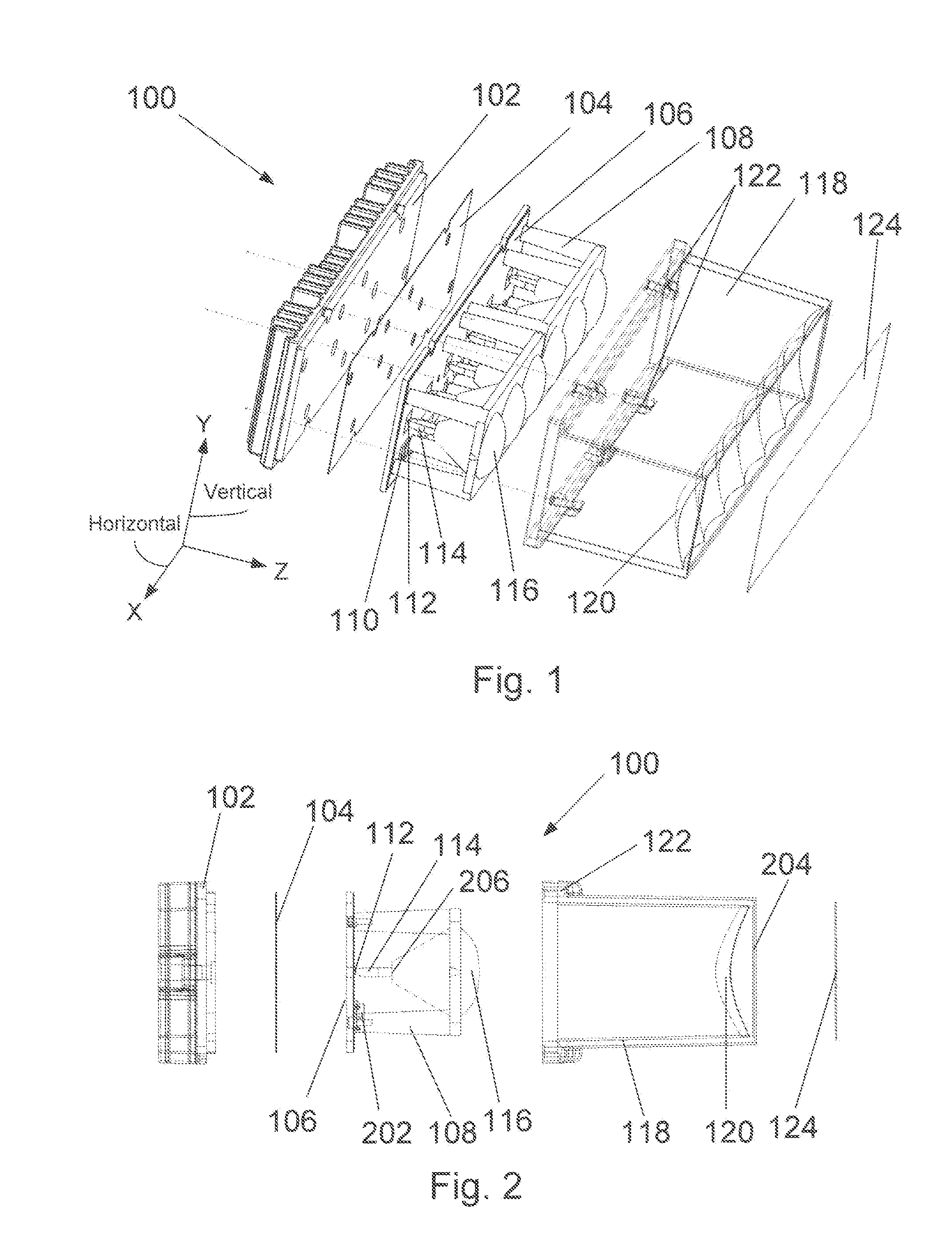

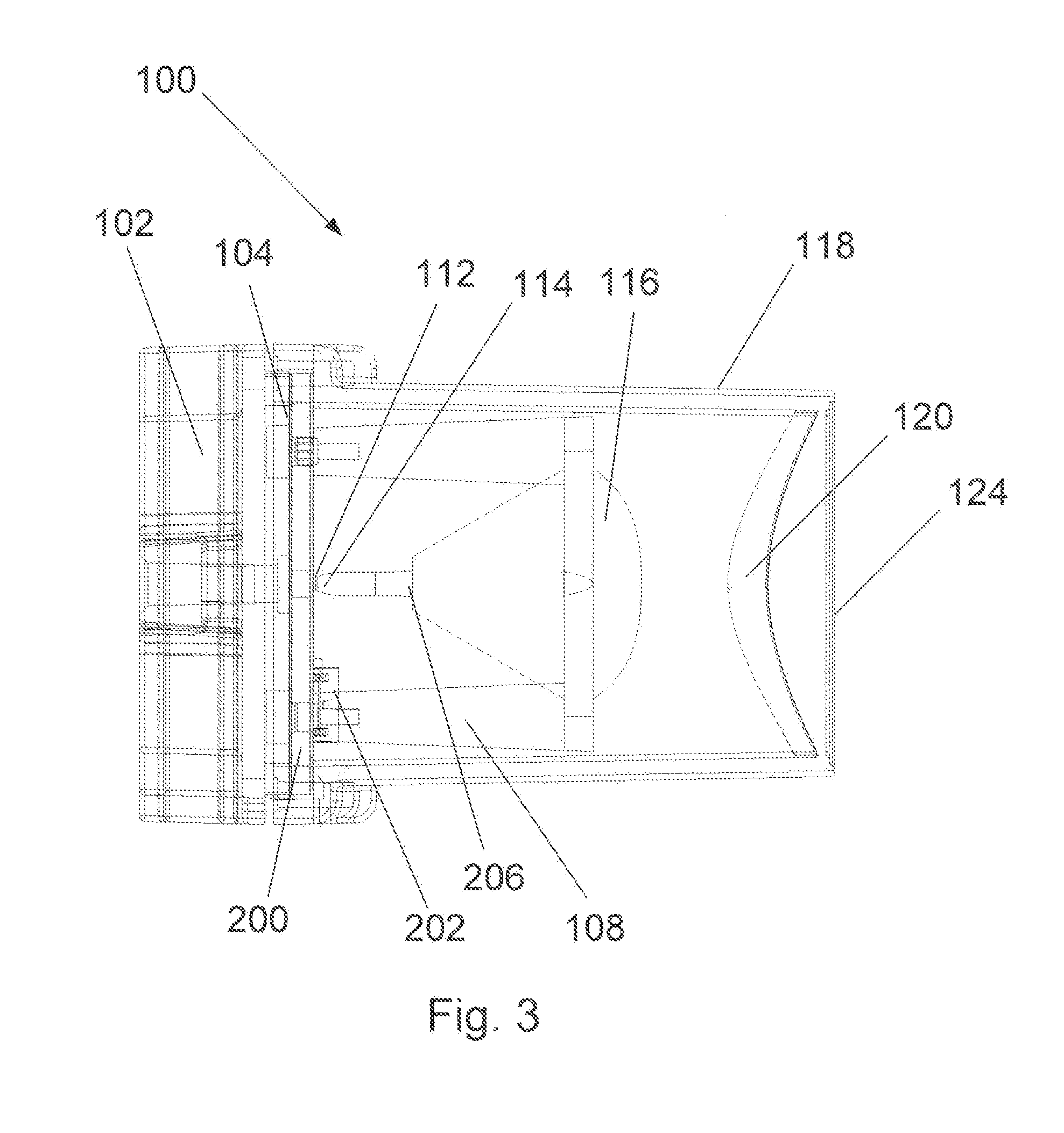

Light emitting diode emergency lighting module

InactiveUS20100110660A1Good competitive advantageEasy to spreadPoint-like light sourceElongate light sourcesOn boardEffect light

The present invention uses “Chip-on-Board” (COB) metal core printed circuit board (PCB) technology in conjunction with high efficiency compact imaging and non-imaging optics to provide an emergency light that is more compact, offers higher performance with respect to luminance levels (higher brightness), longer life, and lower cost relative to systems incorporating pre-packaged LED devices. The thermal impedance between the LED junction and the heat sink is significantly reduced for COB technology by placing the LED die directly on a metal core (or other high thermal conductivity material substrate), thereby increasing temperature dependant life and thermally dependant output power. Additionally, because there is no encapsulant or domed optic over the LED die initially, it is possible to get a much more compact and efficient substantially Etendue (area, solid angle, index squared product) preserving collection optic directly over the die. Cost is significantly reduced for COB configurations due to elimination of the expense of additional components attached to the LED die for the case of pre-packaged LED devices.

Owner:INNOVATIONS & OPTICS

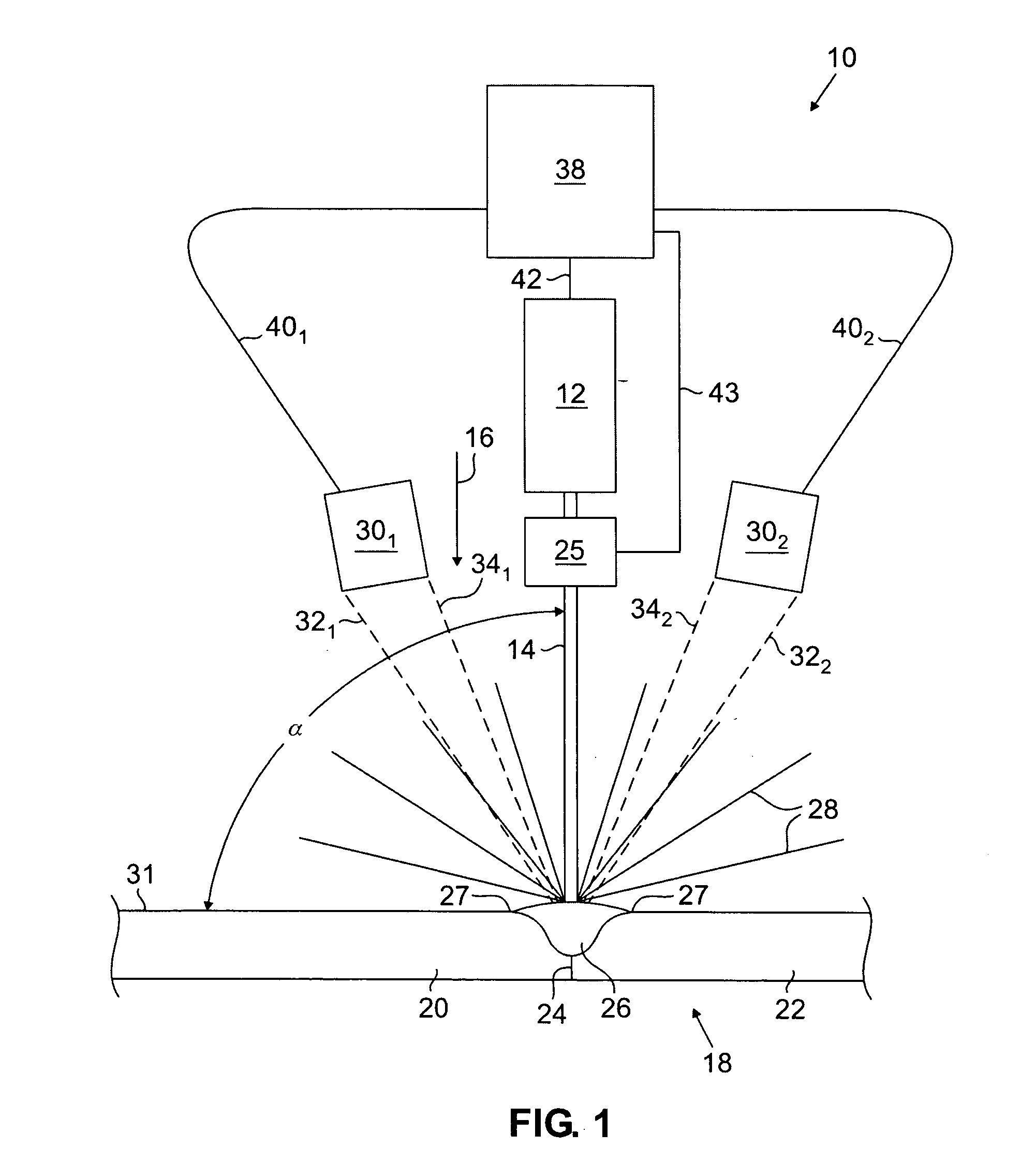

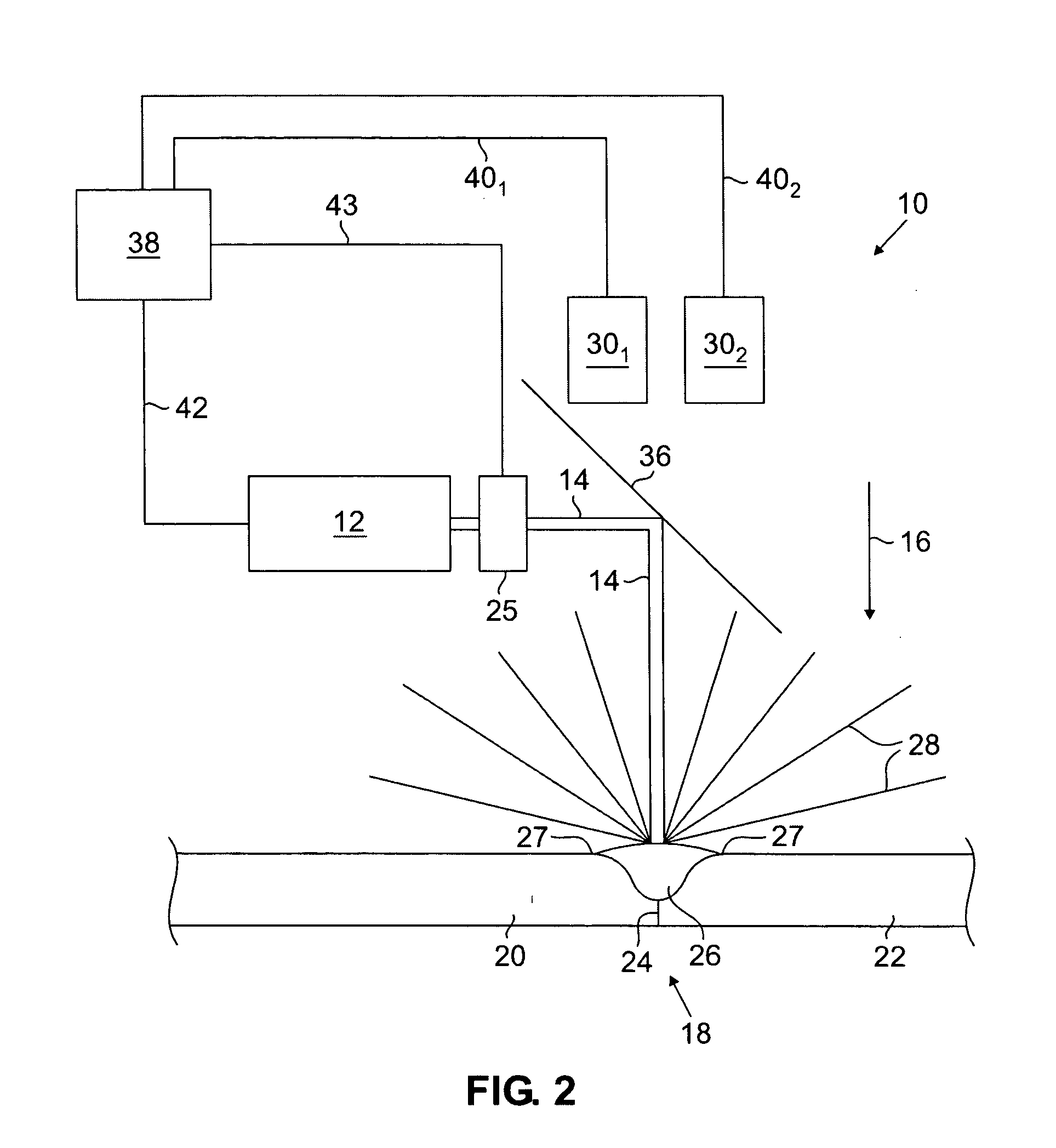

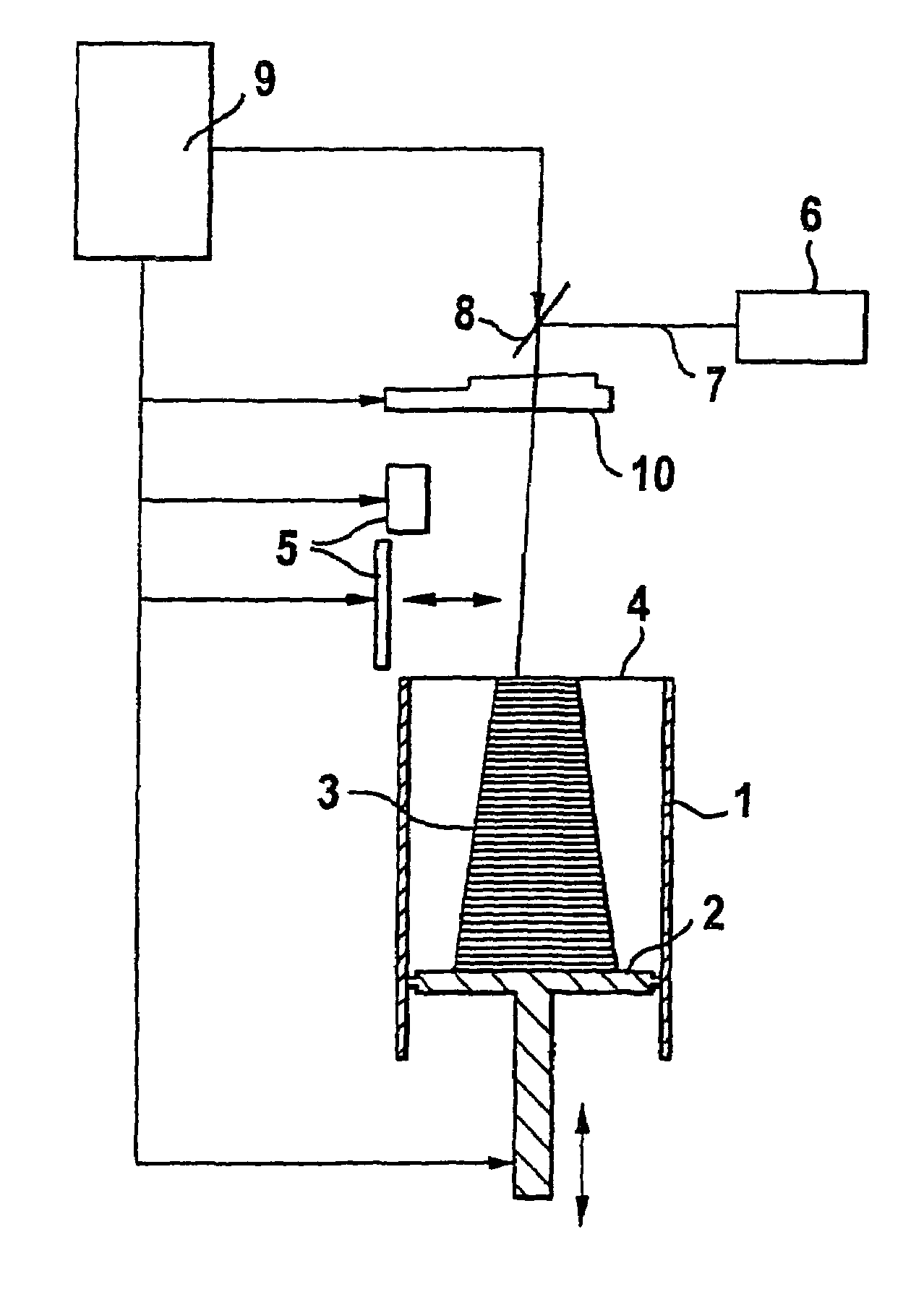

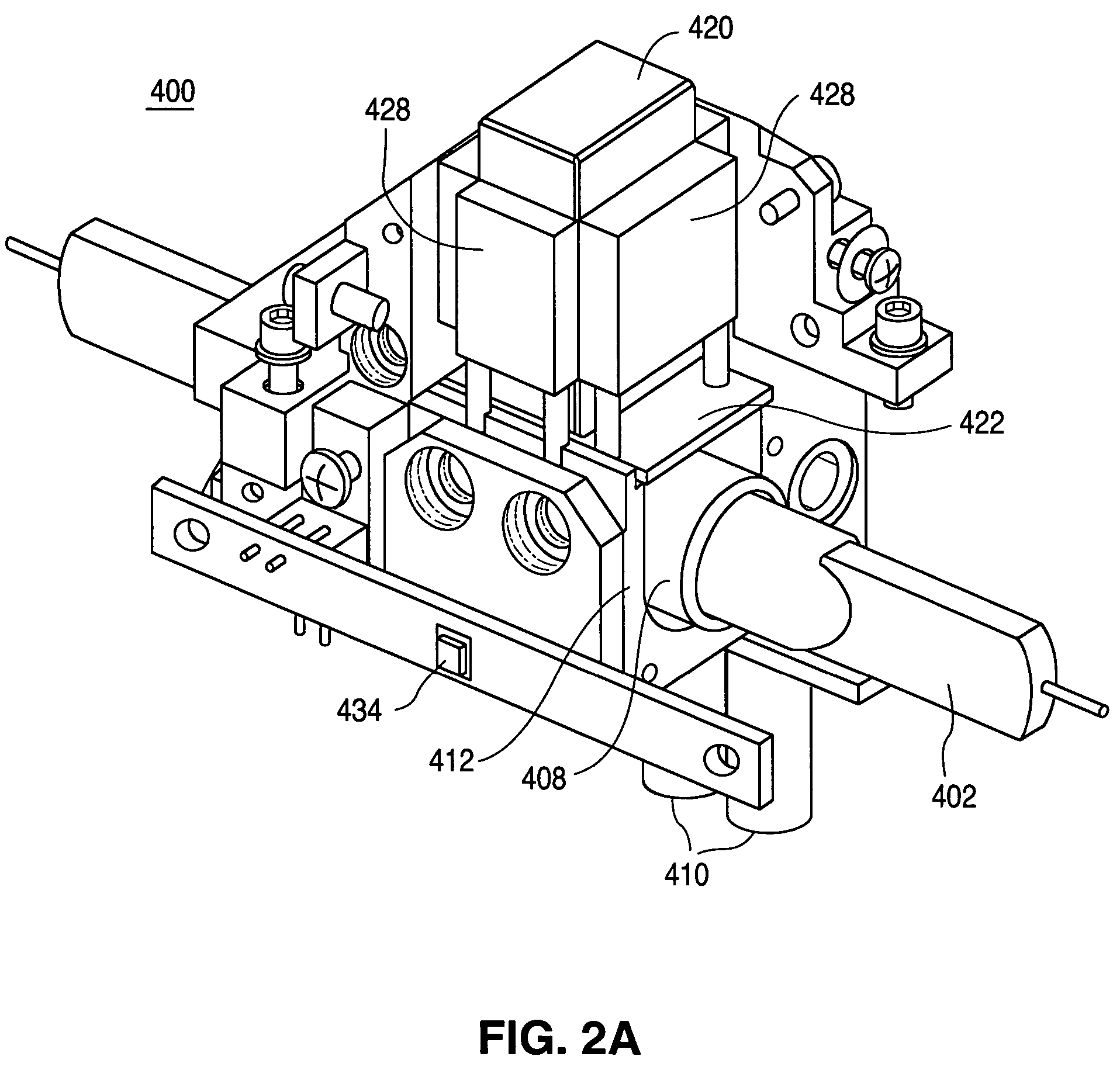

Method and apparatus for controlling and adjusting the intensity profile of a laser beam employed in a laser welder for welding polymeric and metallic components

InactiveUS20060000812A1Enhanced signalImprove signal-to-noise ratioMechanical working/deformationLamination ancillary operationsLight beamOptoelectronics

A method and apparatus is provided for forming a fusion bond between two materials such as two components of a catheter. The method begins by forming a bond site by positioning a portion of a first body with respect to a portion of a second body so that a fusion bond site is formed. A laser beam is generated that has an intensity profile across its width. The laser beam is directed onto at least a portion of the first and second bodies within the bond site so that a fusion zone having an increased temperature is formed. After the laser beam is generated, the intensity profile of the laser beam that is directed onto the bond site is controllably adjusted by an optical element such as a dynamically-adjustable beam shaping element

Owner:BOSTON SCI SCIMED INC

Separator for electrochemical device, electrode for electrochemical device, and electrochemical device

ActiveUS20100015530A1Improve reliabilityImprove load characteristicsHybrid capacitor separatorsHybrid capacitor electrodesPhysical chemistryPolyresin

A separator for an electrochemical device of the present invention includes a porous film including: a filler; an organic binder; and at least one resin selected from resin A that has a melting point of 80 to 140° C. and resin B that absorbs a non-aqueous electrolyte and swells upon heating and whose swelling degree increases with increasing temperature, and the filler contains boehmite having a secondary particle structure in which primary particles are connected.

Owner:MAXELL HLDG LTD

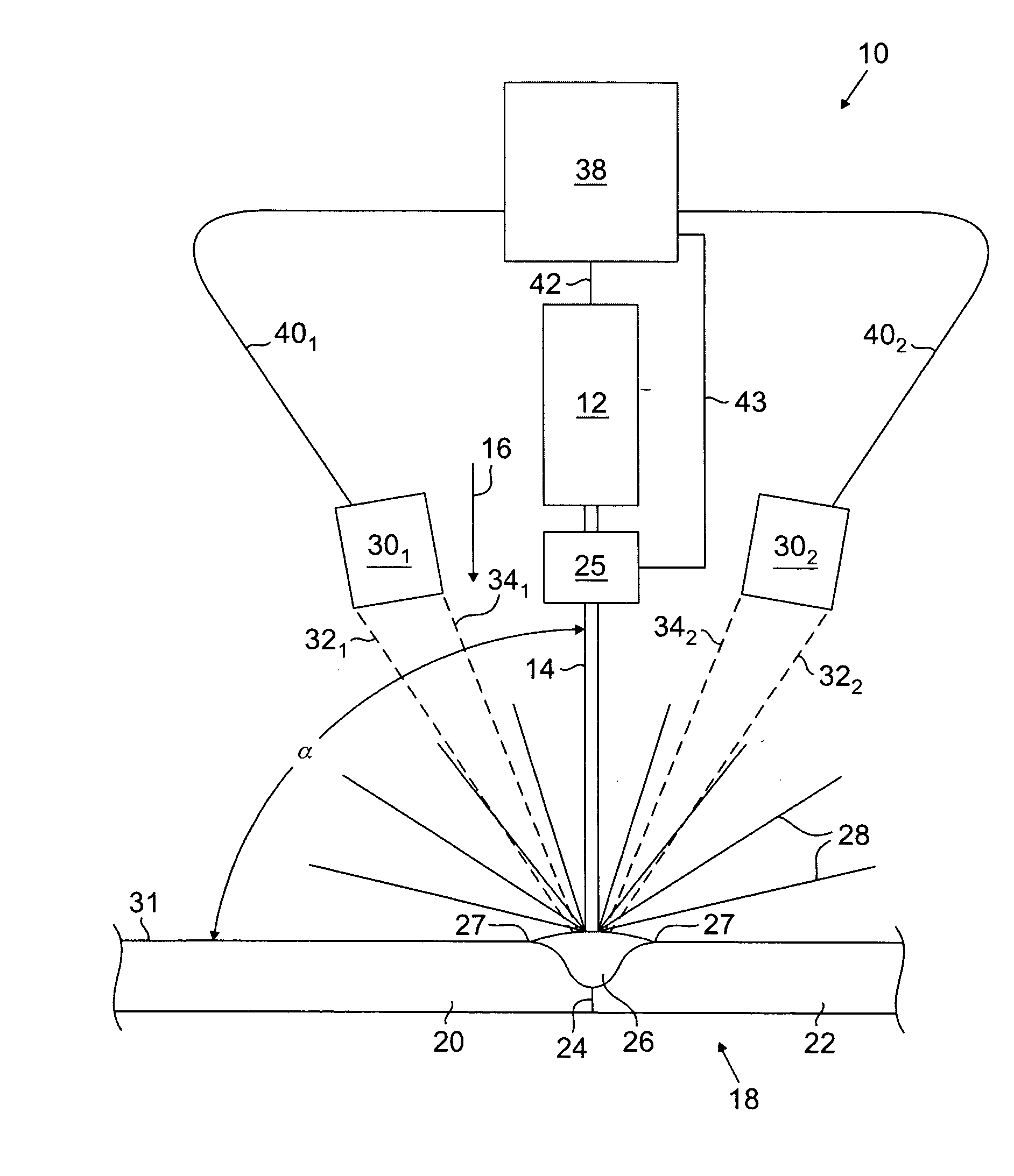

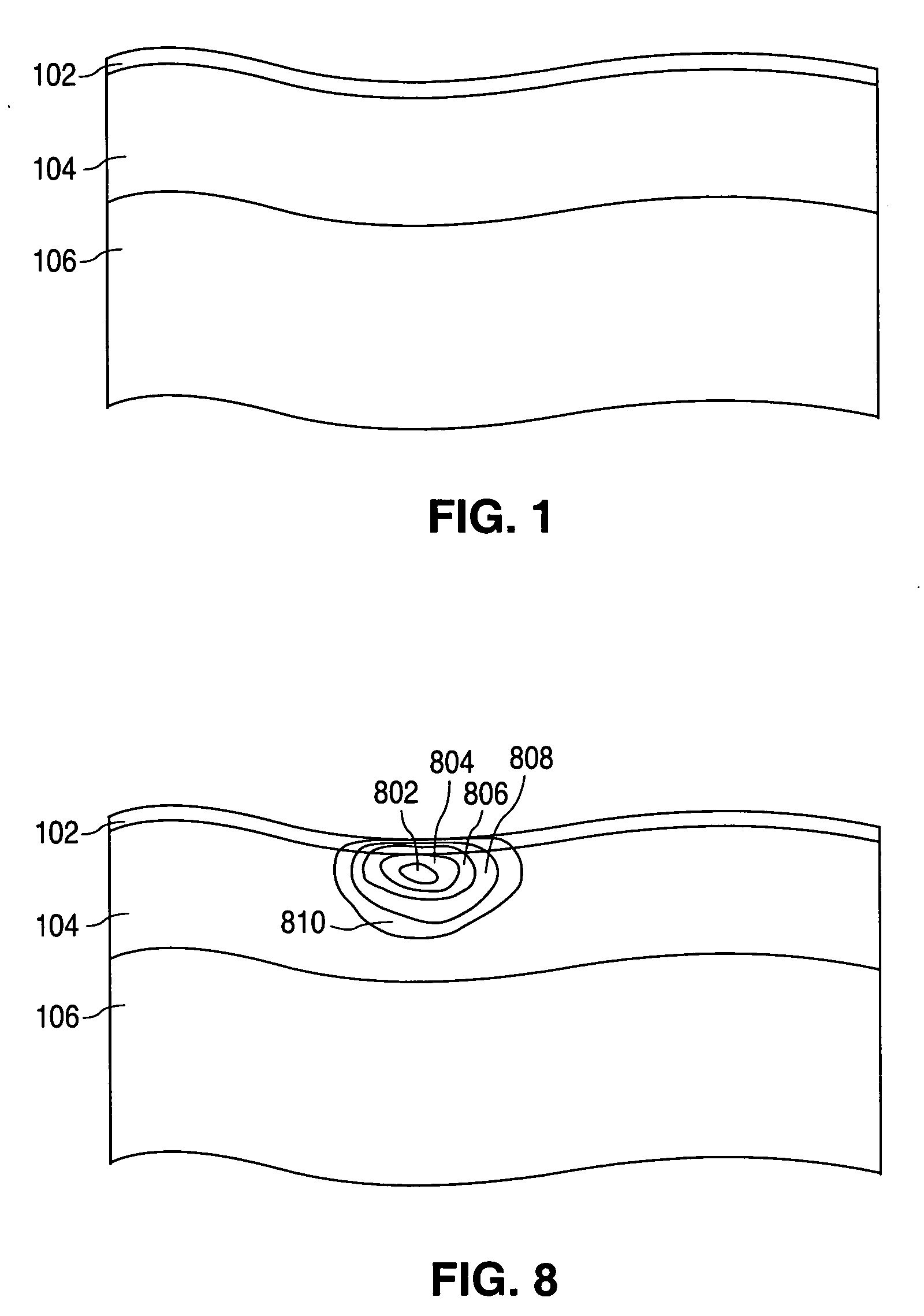

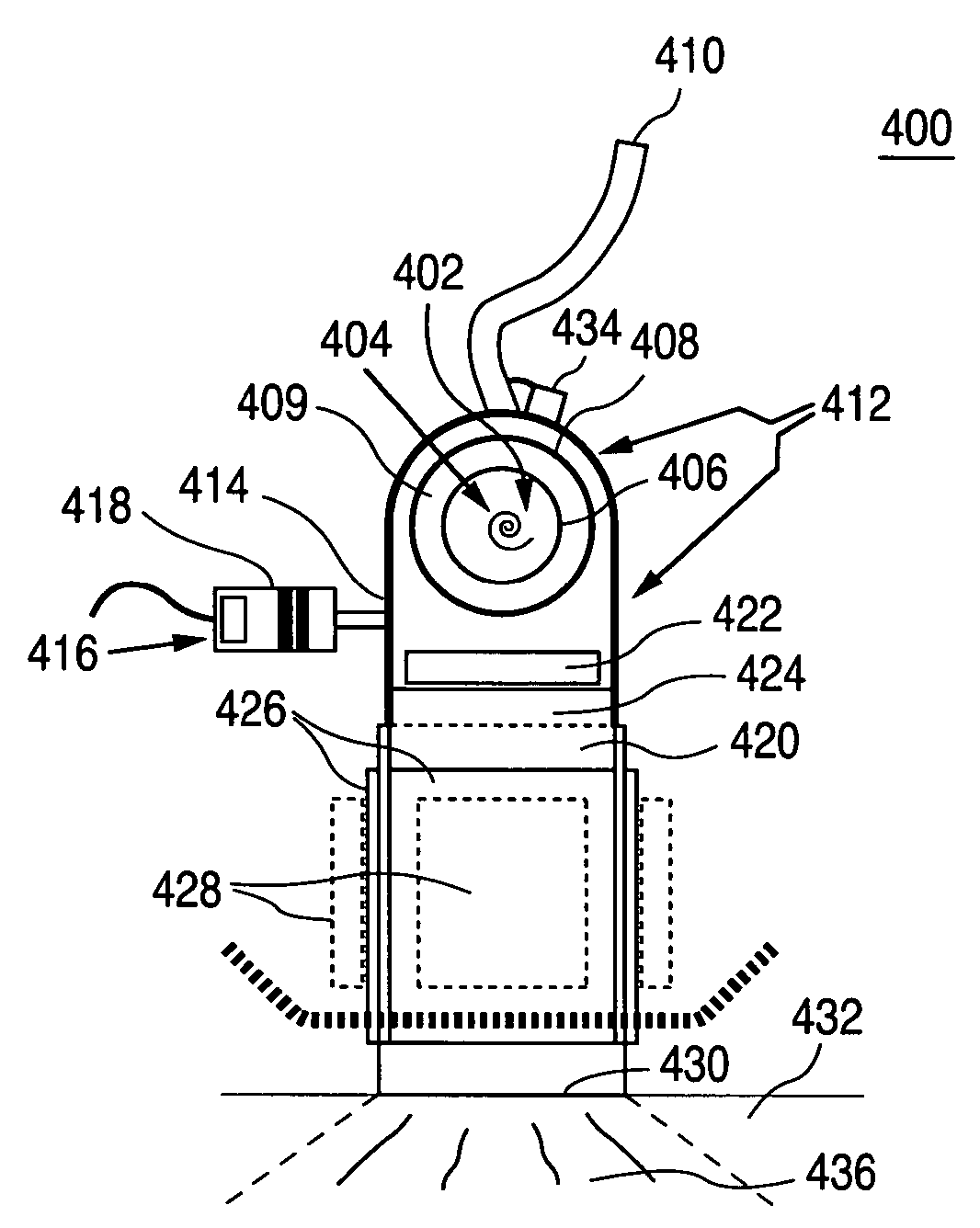

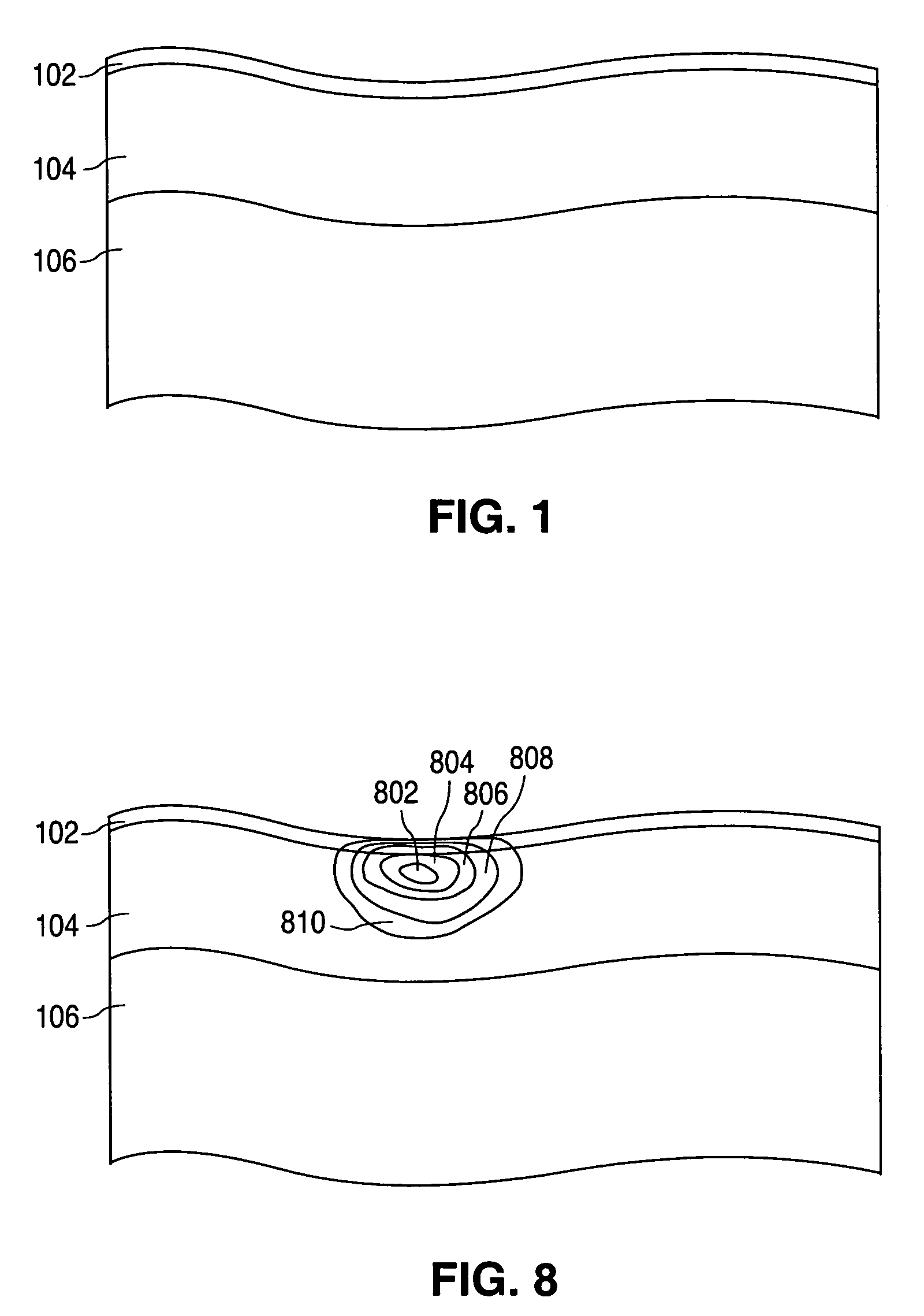

System and method for heating skin using light to provide tissue treatment

A system and method for using a light source to treat tissue with NIR light. The operation provides for generating higher temperatures in deeper layers of tissue relative to shallower layers of tissue. The increased temperature in dermal layers can operate to induce collagen shrinkage, or remodeling. One of the light sources for providing a broad spectrum of NIR light is a filament light. The light from the filament lamp can be selectively filtered, and after filtering this light is applied to the skin, where the selective filtering can enhance the ability to elevate the temperature of deeper layers of tissue, relative to layers of tissue which are closer to the surface of the skin.

Owner:CUTERA

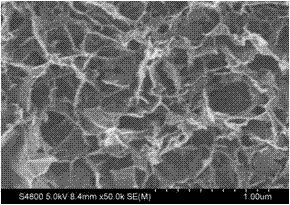

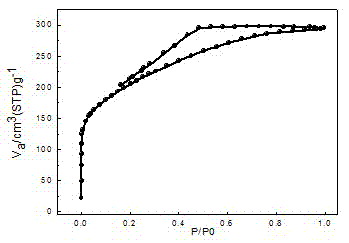

High-density high-rigidity graphene porous carbon material as well as preparation method and applications thereof

ActiveCN102730680AHigh densityHigh hardnessCell electrodesGrapheneMaterials preparationGel preparation

The invention discloses a high-density high-rigidity graphene porous carbon material as well as a preparation method and applications thereof. The method comprises the following steps: 1. original colloidal sol preparation: adding graphene-based component or a mixture of graphene-based component and auxiliary components into a solvent for dispersion to obtain the original colloidal for preparing the graphene porous carbon material; 2. graphene-based gel preparation: placing the original colloidal sol prepared in the step 1 into a reaction container, reacting for 0.1-100 hours at the temperature of 20-500 DEG C to obtain the graphene-based gel; and 3. high-density high-rigidity graphene porous carbon material preparation: drying the graphene-based gel at the temperature of 0-200 DEG C, increasing temperature to 100-3600 DEG C at anoxic atmosphere for conducting thermal treatment for 0.1-100 hours, or / and reacting for 0.1-50 hours at the temperature of 200-2000 DEG C by adopting an activation reaction method. Compared with the prior art, the prepared graphene-based material has the advantages of high density, high rigidity, abundant pores, large specific surface area and stable pore structure.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

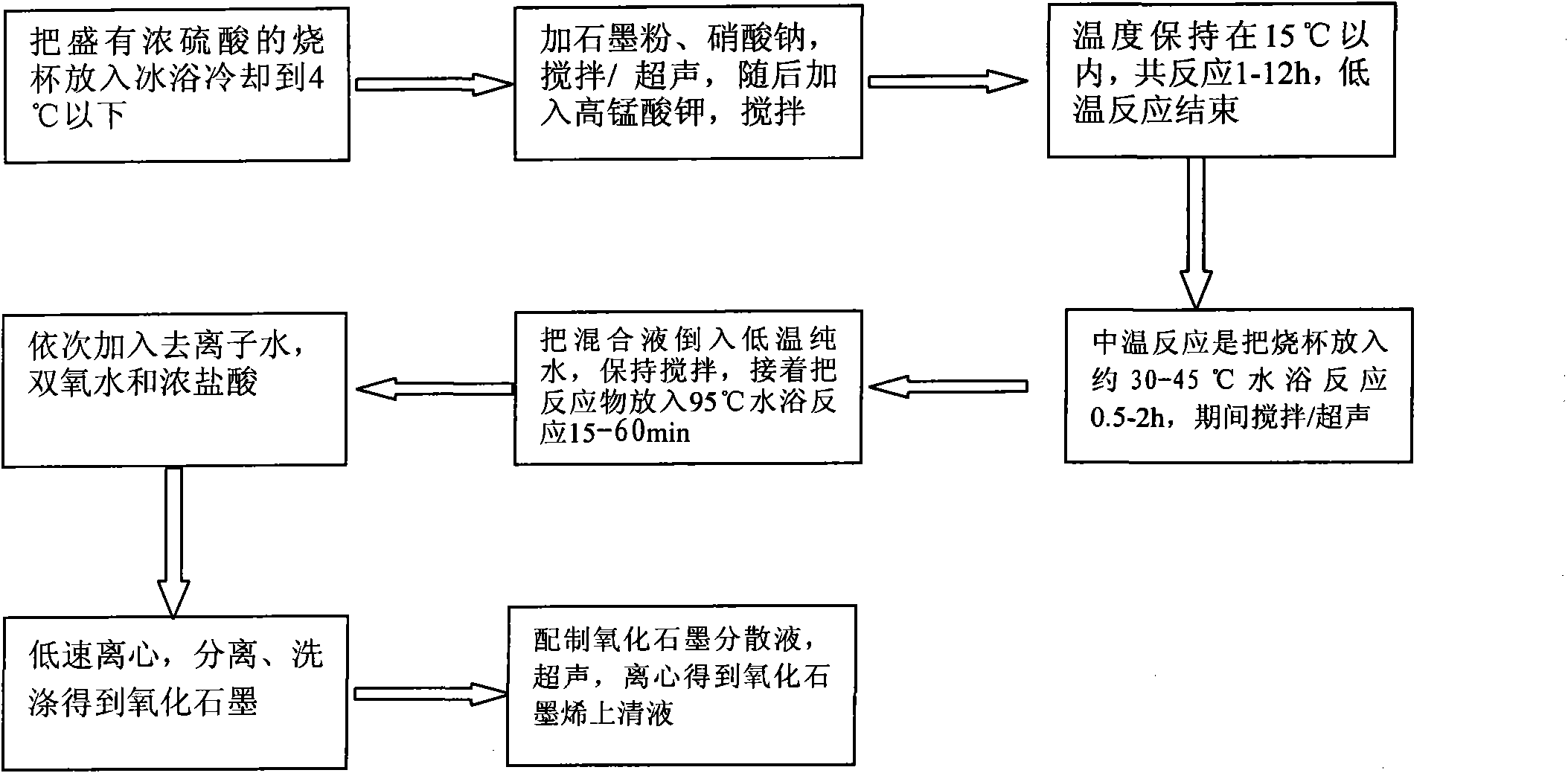

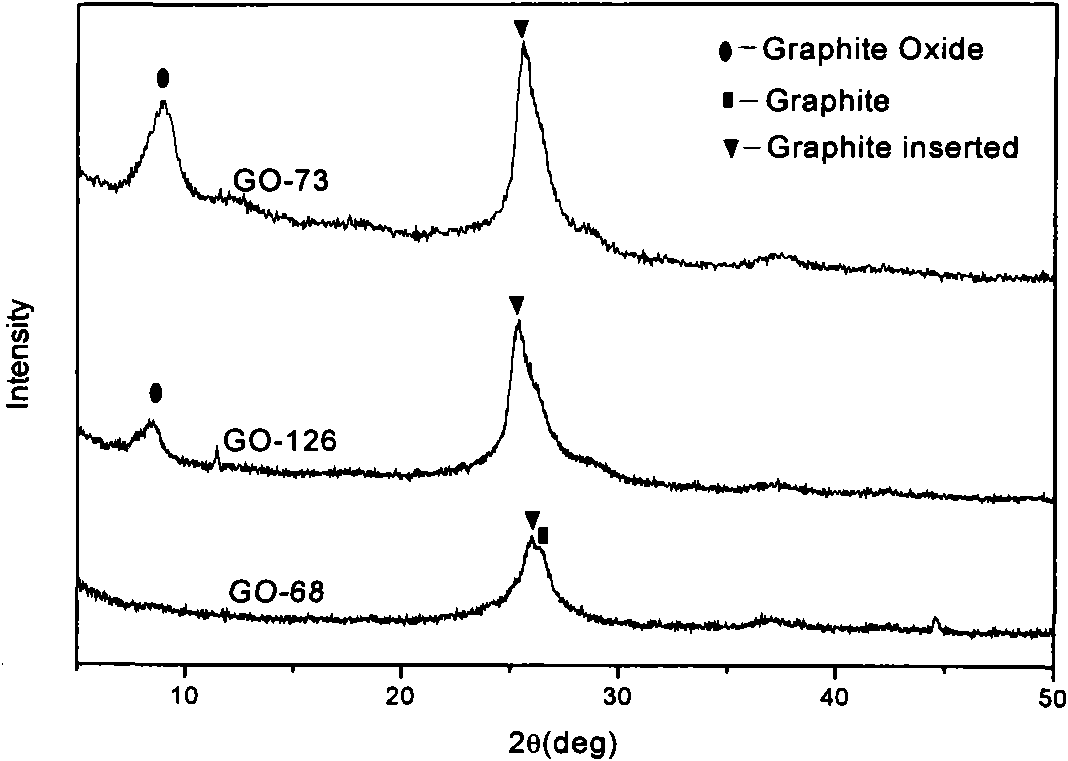

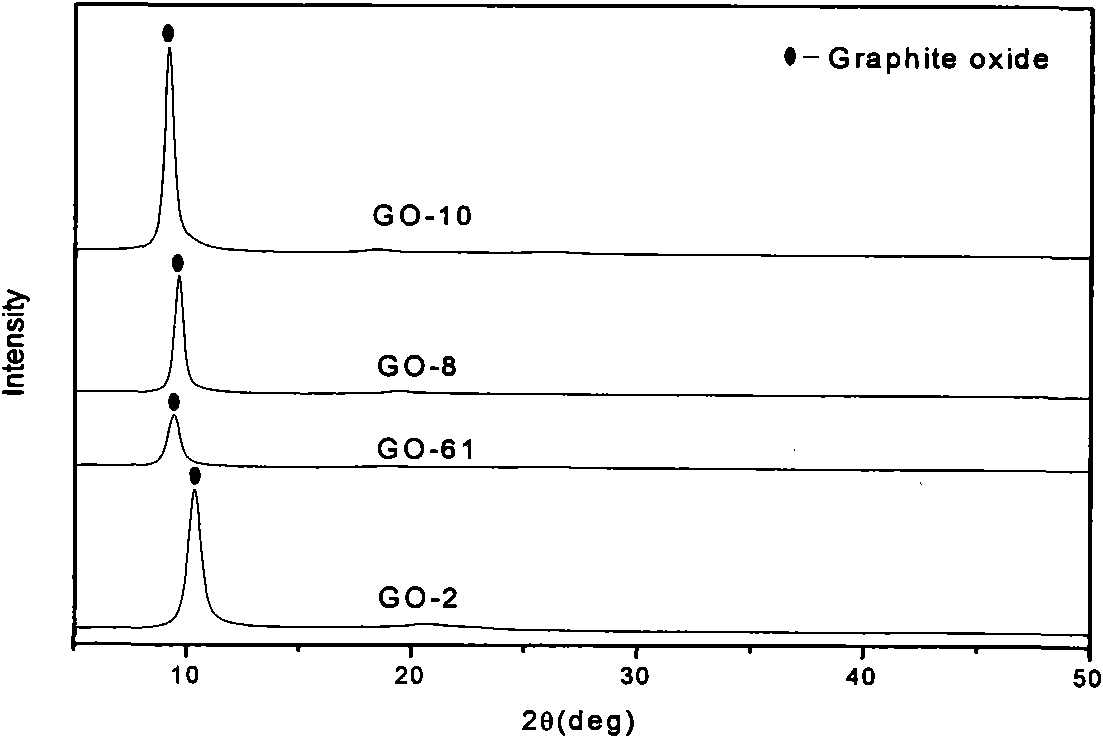

Method for synthesizing graphene oxide by ultrasonic assistance Hummers method

InactiveCN102153075AImprove efficiencyHigh degree of oxidationUltrasonic oscillationMechanical property

The invention relates to a method for synthesizing graphene oxide by an ultrasonic assistance Hummers method. The method for synthesizing the graphene oxide includes the steps as follows: firstly adding ultrasonic oscillation in low-temperature and middle-temperature reaction stages of the Hummers method to improve the intercalation efficiency and the oxidation degree of graphite oxide; secondly slowly dropping mixed liquor containing concentrated sulphuric acid into low-temperature deionized water to increase temperature when high-temperature reaction begins, thus effectively preventing intercalated materials such as sulphuric acid molecules and the like from rapidly escaping from graphite layers due to overhigh local temperature; and finally obtaining the graphite oxide through low-speed centrifugation. The method for synthesizing the graphene oxide by using the ultrasonic assistance Hummers method is convenient and fast, saves resources, and can effectively increase spacings of graphite oxide layers. The prepared graphene oxide can serve as a wild phase of a composite material and papyraceous laminated graphite oxide based composite material with high mechanical property and the like can be prepared. The reduction product graphene can be used for preparing graphene-based composite materials such as transparent electrodes, super capacitors, hydrogen storage materials, chemical / biological sensors, thin film transistors and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

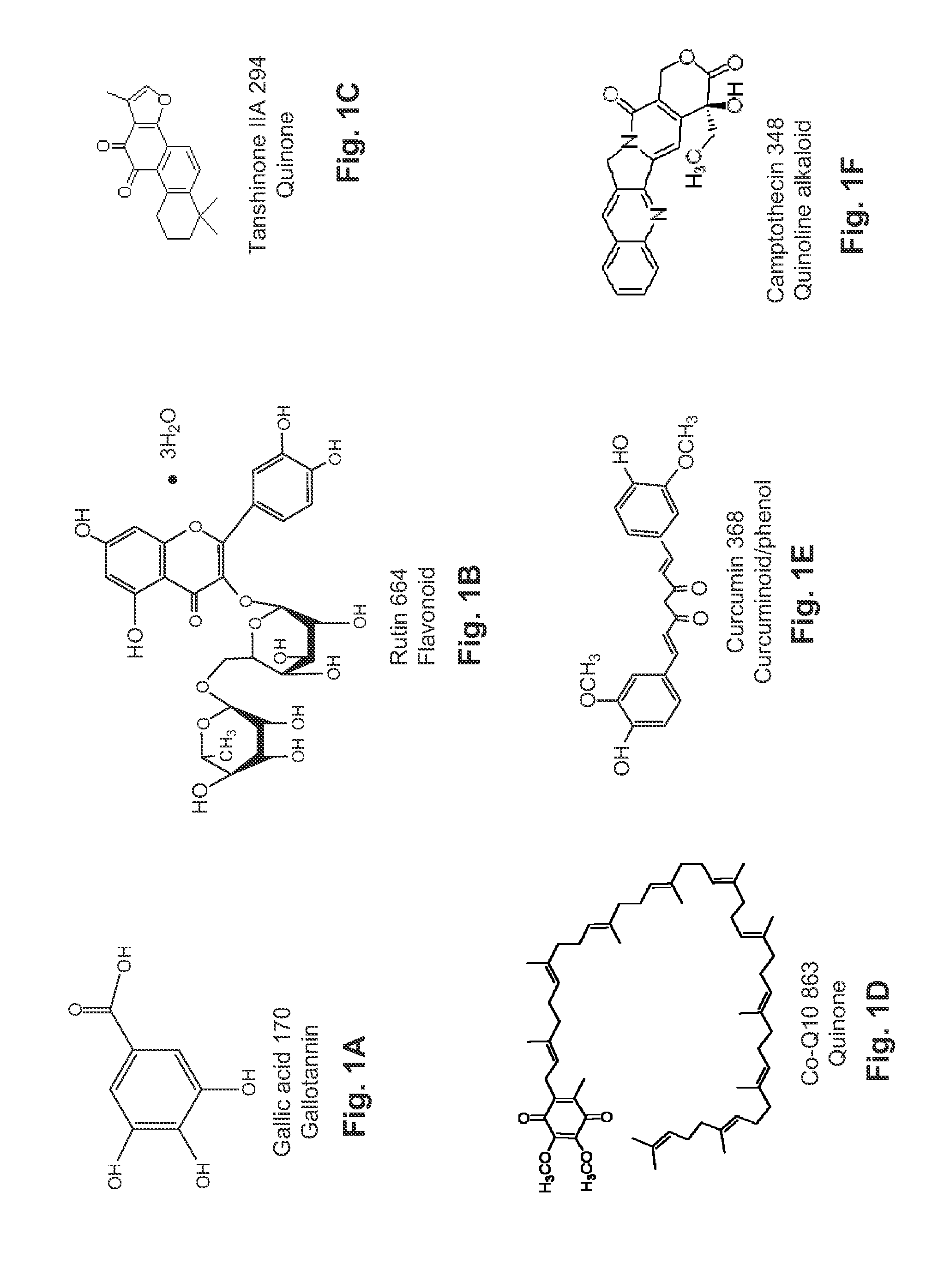

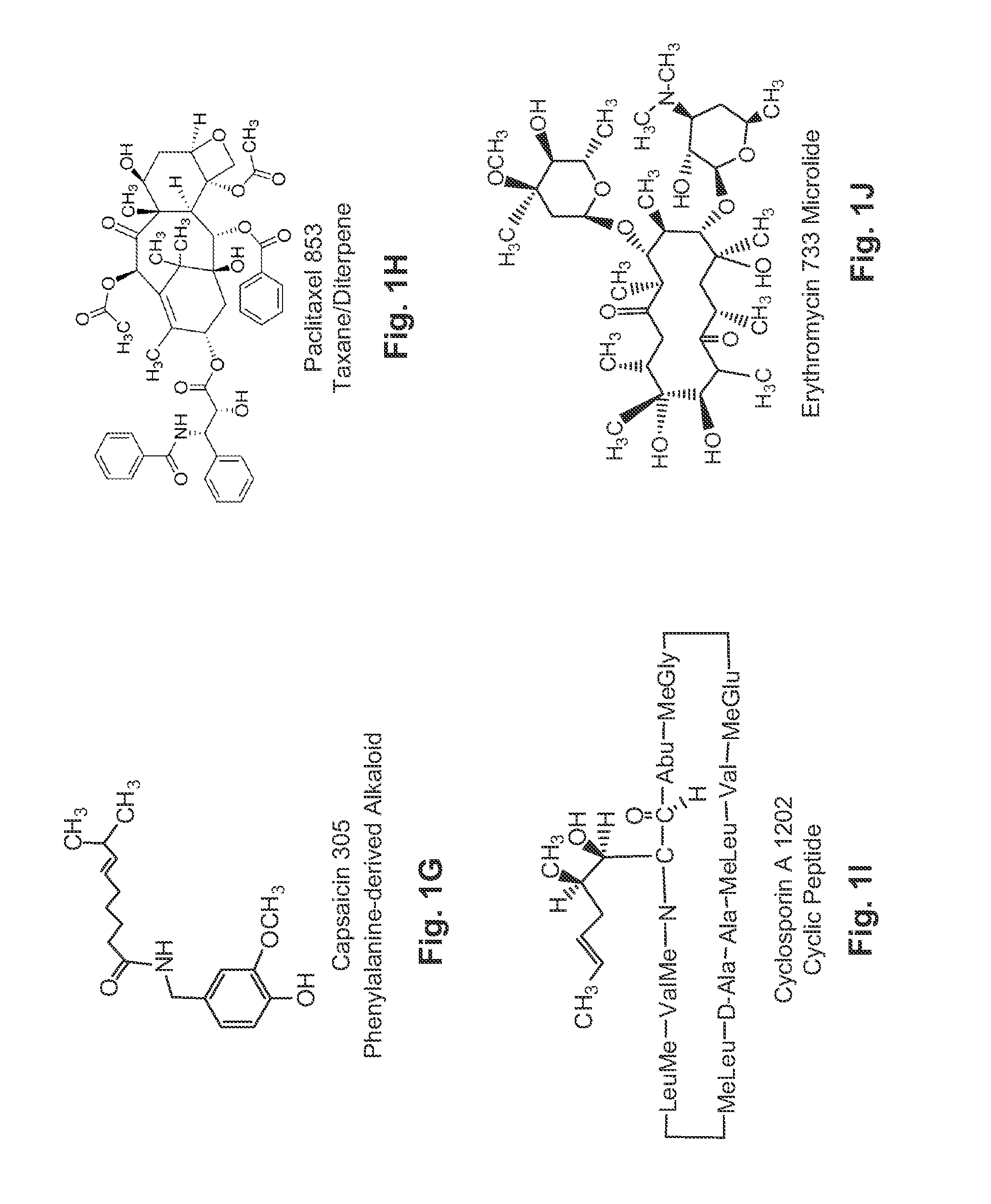

Water Soluble Drug-Solubilizer Powders and Their Uses

InactiveUS20120329738A1Improve gastrointestinal absorptionEfficient processingBiocideCarbohydrate active ingredientsWater soluble drugGastrointestinal absorption

Enhanced methods have been discovered, using either sonication or homogenization followed by increased temperature and pressure, to solubilize compounds using diterpene glycosides and to produce a powder form of the compound-solubilizer complex than can be reconstituted in water. Without the diterpene glycoside, the compounds were insoluble or sparingly soluble in water, including some fat-insoluble vitamins. Water solutions of these compounds were made using a diterpene glycoside solubilizer, for example, rubusoside. The compound-solubilizer complex was then dehydrated to a stable powder that could then be reconstituted with water. A reconstituted drug-solubilizer complex (curcumin-rubusoside) was shown to be effective on reconstitution. In addition, the diterpene glycoside, rubusoside, was shown to be an inhibitor of permeability glycoprotein (P-gp), and will thus increase gastrointestinal absorption of certain drugs administered with rubusoside.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

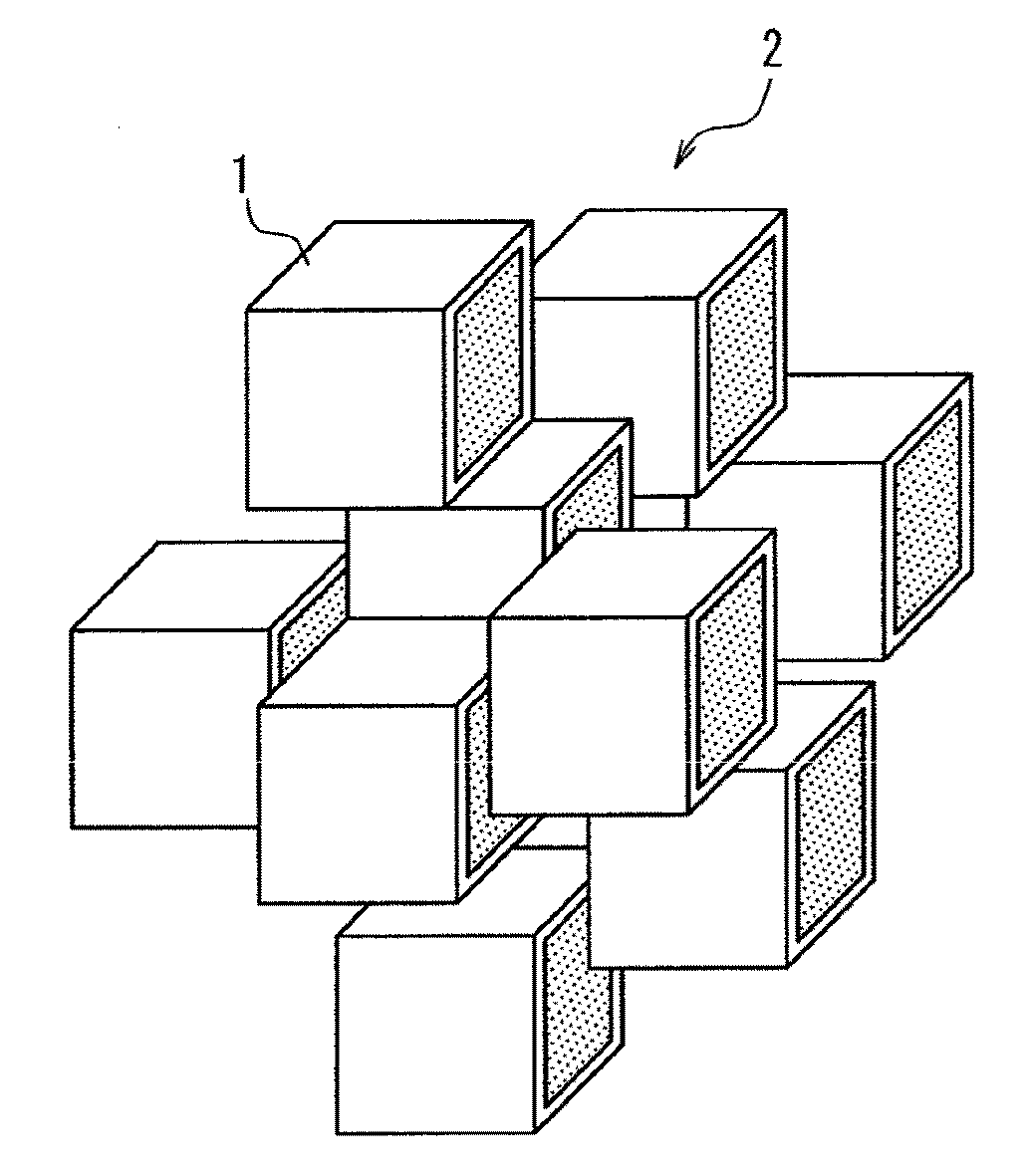

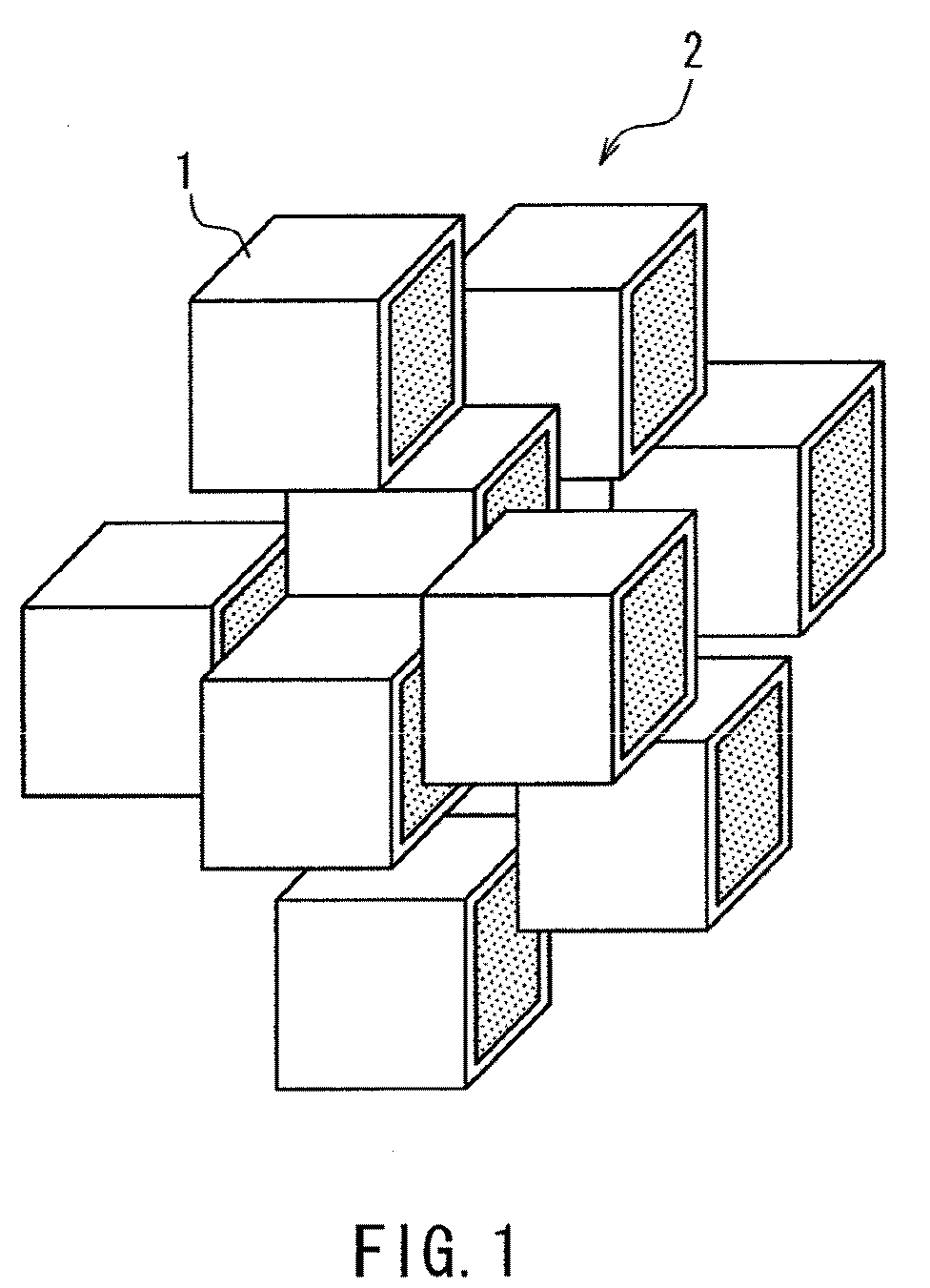

Circuit board and circuit apparatus using the same

InactiveUS20070023202A1Suppress drop in reliabilityIncrease temperaturePrinted electric component incorporationPrinted circuit aspectsElectrical conductorSolder ball

Owner:SANYO ELECTRIC CO LTD

High temperature treated media

ActiveUS20120234748A1Reduce and eliminate in filtrationImprove filtering effectNon-fibrous pulp additionNatural cellulose pulp/paperParticulatesFiber

A thermally bonded filtration media that can be used in high temperature conditions in the absence of any loss of fiber through thermal effects or mechanical impact on the fiber components is disclosed. The filter media can be manufactured and used in a filter unit or structure, can be placed in a stream of removable fluid, and can remove a particulate load from the mobile stream at an increased temperature range. The combination of bi-component fiber, other filter media fiber, and other filtration additives provides an improved filtration media having unique properties in high temperature, high performance applications.

Owner:DONALDSON CO INC

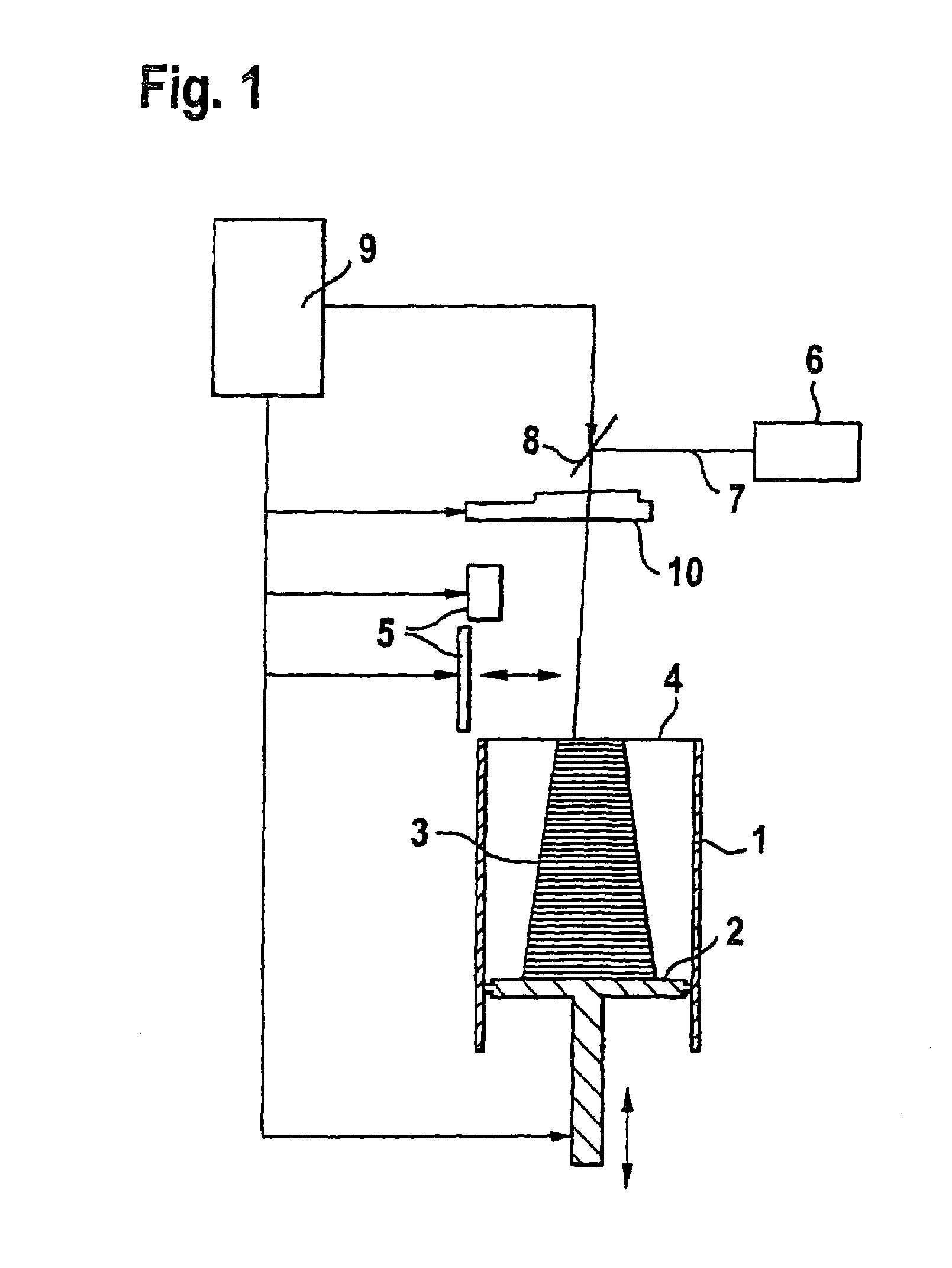

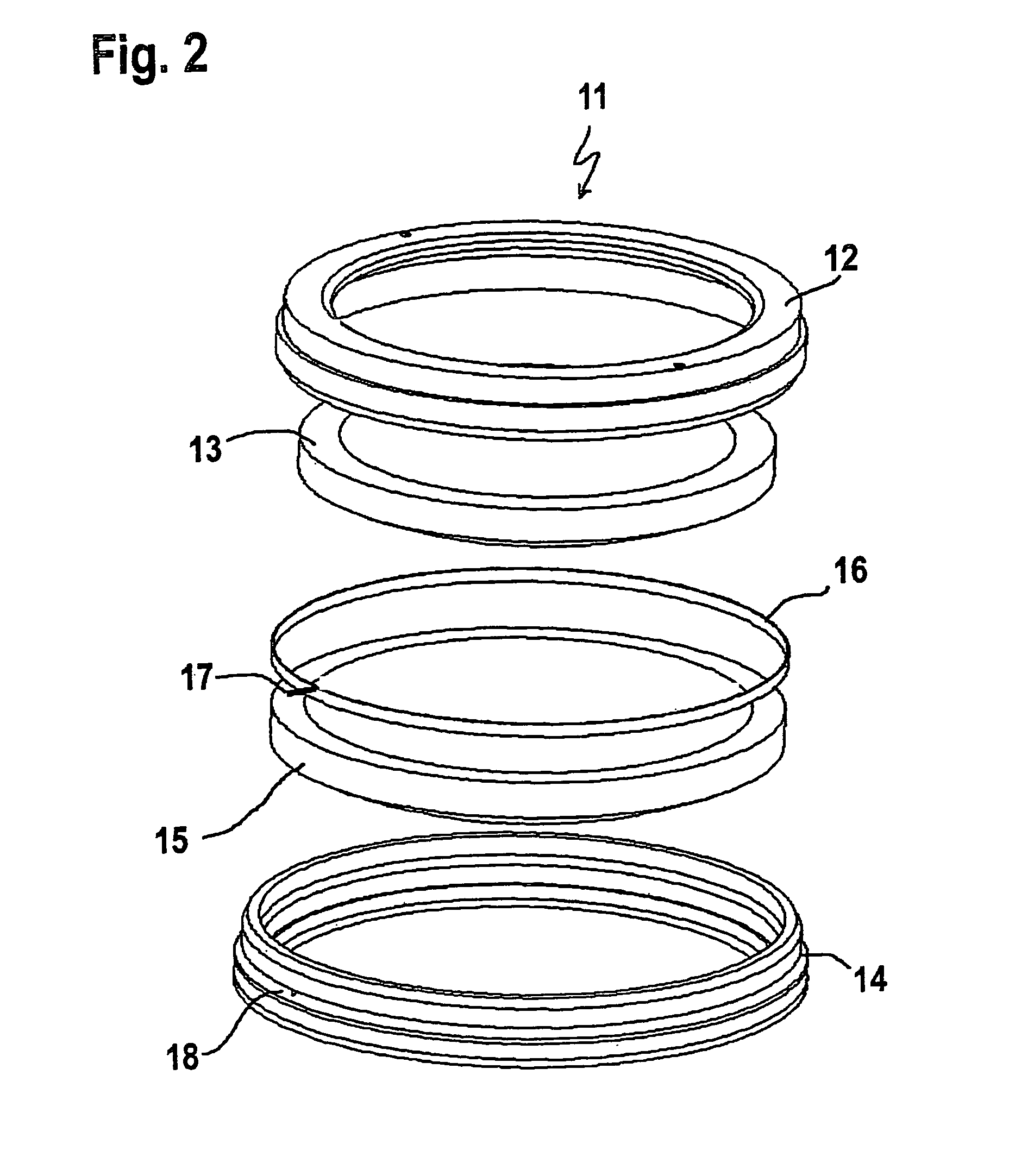

Device for layerwise manufacturing of a three-dimensional object

ActiveUS8075814B2Avoid pollutionEnhanced couplingMouldsConfectioneryEngineeringElectromagnetic radiation

An apparatus for layerwise manufacturing of a three-dimensional object by solidification of a material, which can be solidified via electromagnetic radiation, includes a source for the electromagnetic radiation, a building space for manufacturing the three-dimensional object, a coupling window, for transmitting the electromagnetic radiation into the building space and a heating element for heating the coupling window. By the heating element the temperature of the lens is increased during the building of the three-dimensional object. By the increased temperature the accumulation of contamination on the coupling window is prevented.

Owner:EOS ELECTRO OPTICAL SYST

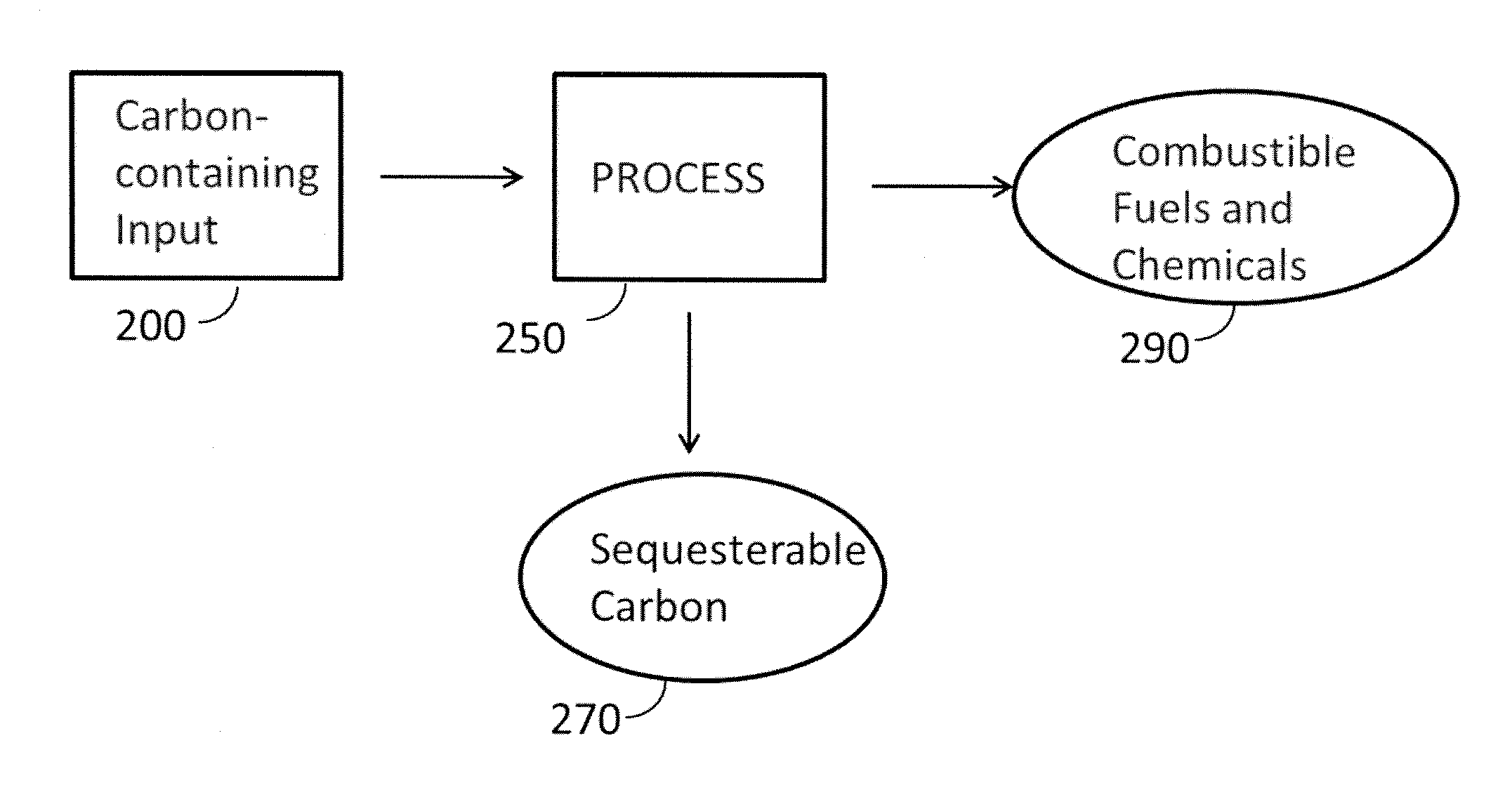

Method for producing negative carbon fuel

ActiveUS20130025190A1Improve thermal conductivityBio-organic fraction processingCarbon compoundsCarbon creditCarbon offset

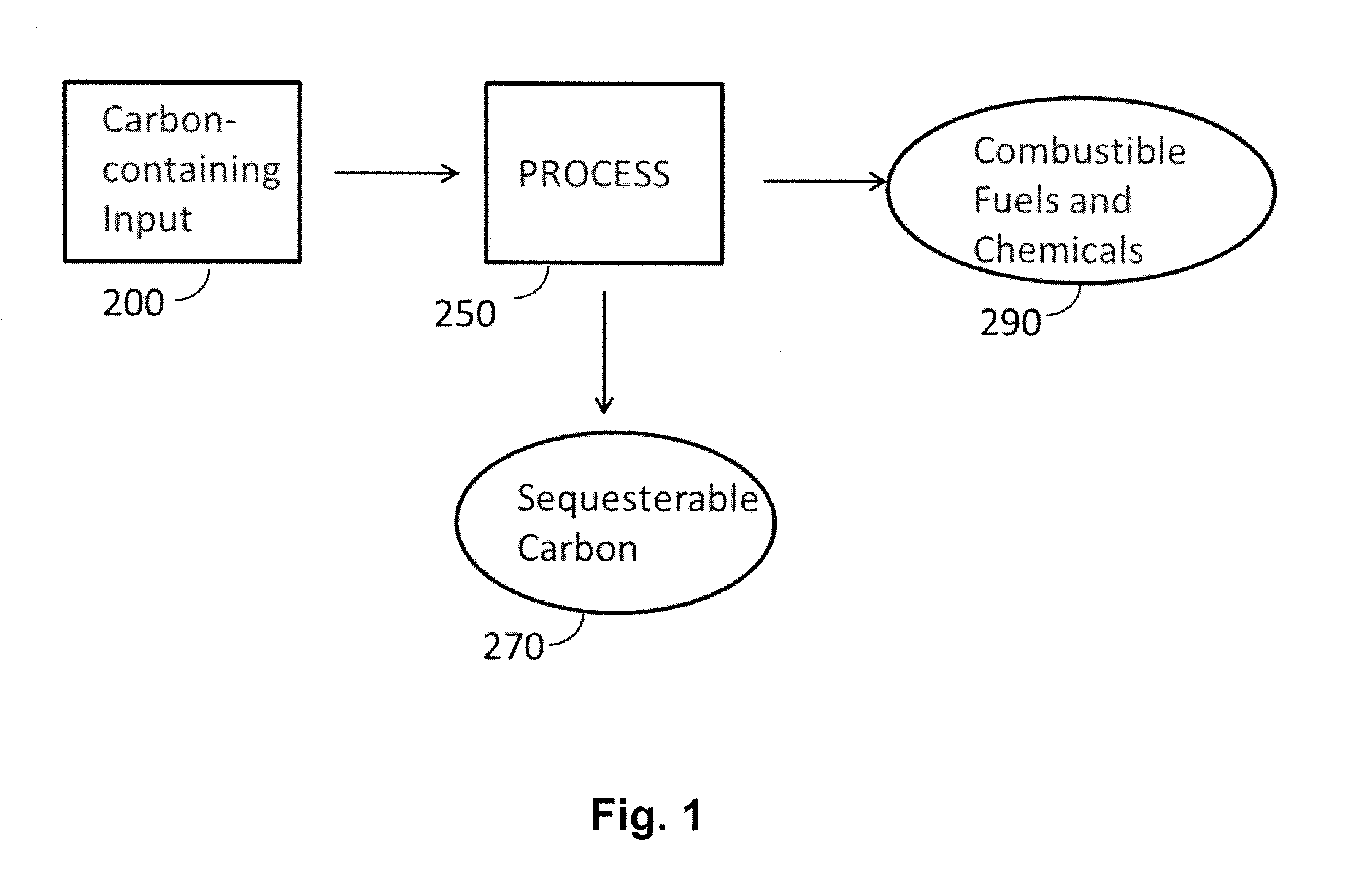

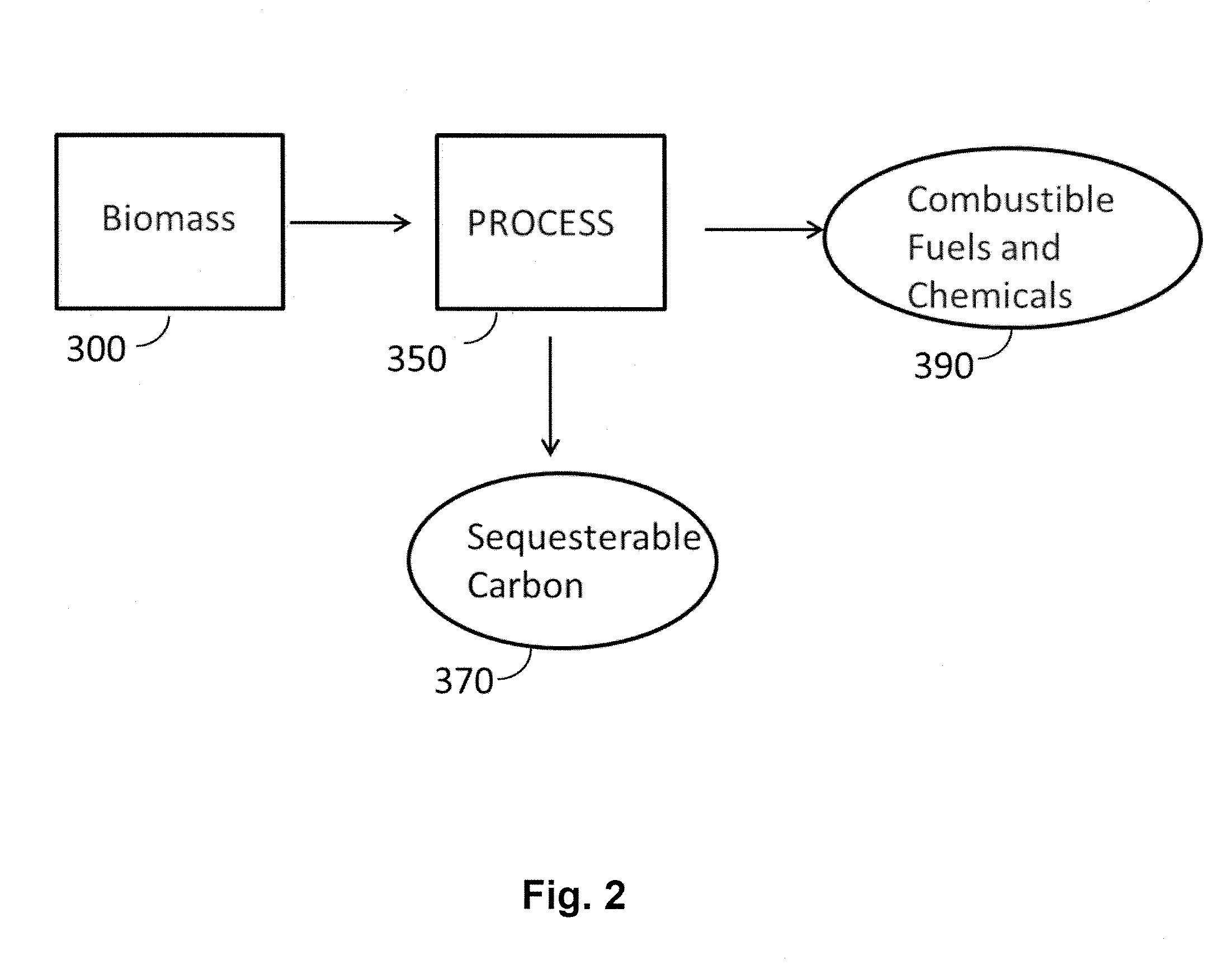

A method and process is described for producing negative carbon fuel. In its broadest form, a carbon-containing input is converted to combustible fuels, refinery feedstock, or chemicals and a carbonaceous solid concurrently in separate and substantially uncontaminated form. In an embodiment of the invention, biomass is converted via discrete increasing temperatures under pressure to blendable combustible fuels and a carbonaceous solid. The carbonaceous solid may be reacted to synthesis gas, sold as charcoal product, carbon credits, used for carbon offsets, or sequestered.

Owner:COOL PLANET ENERGY SYST

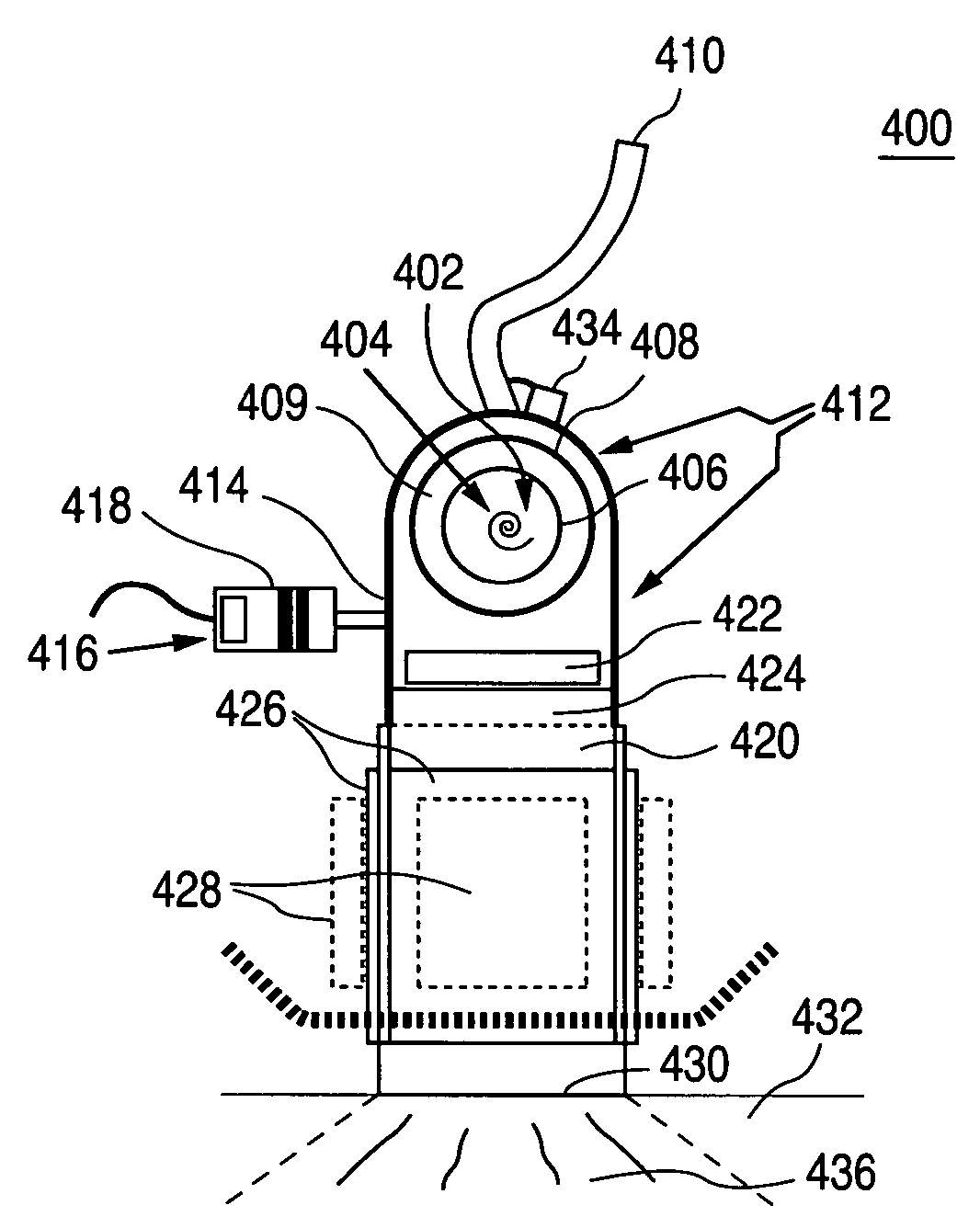

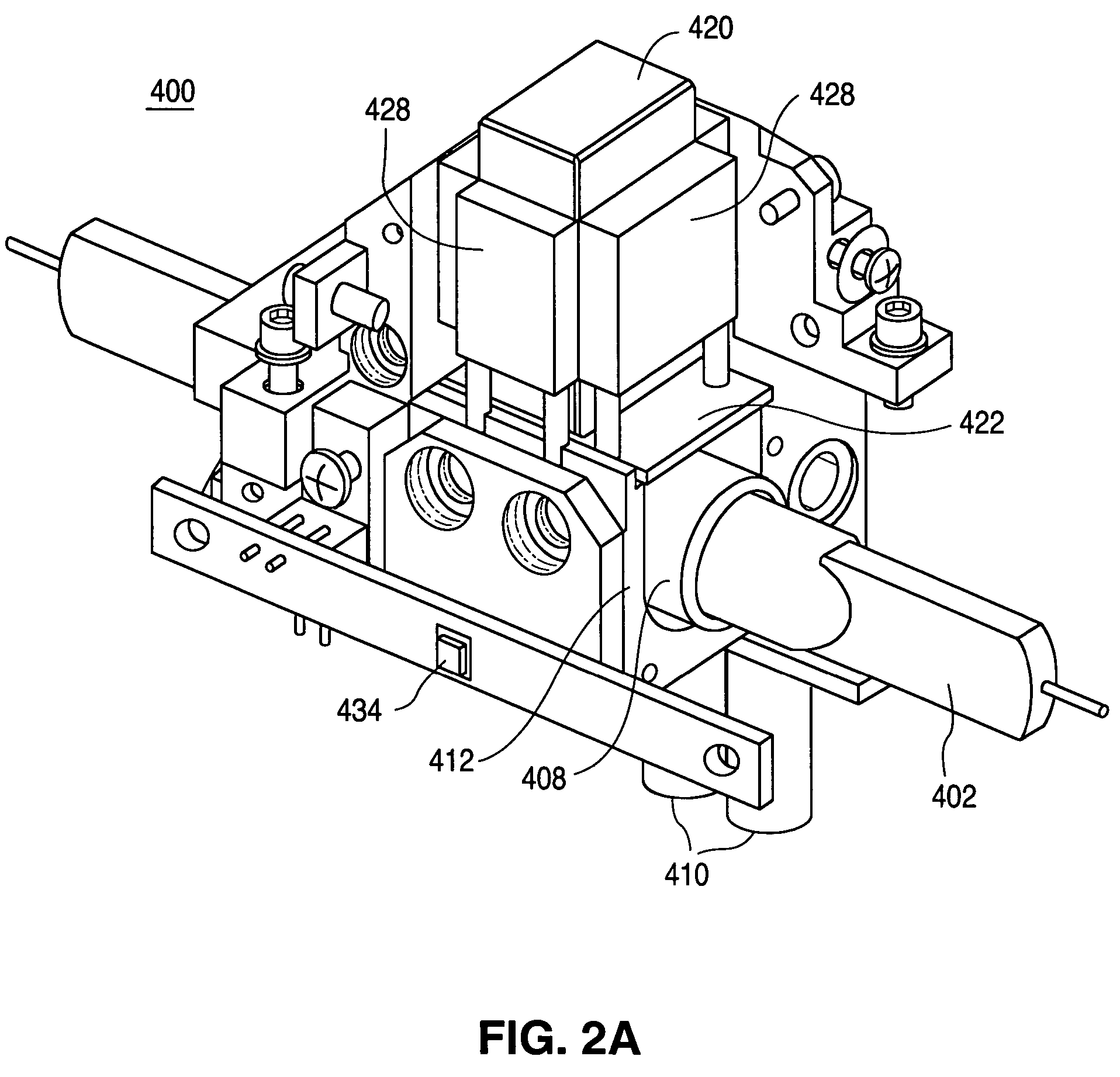

Micro power generator and apparatus for producing reciprocating movement

InactiveUS7329959B2Improve output and efficiencyExtended temperature rangeSteam useGas turbine plantsReciprocating motionEngineering

There is provided a micro power generator enhanced in efficiency and power generation output, and having an increased temperature range for operation. The micro power generator comprises: a high-temperature heat source; a low-temperature heat source; an enclosed body containing a working substance therein, the enclosed body being deformable by means of a phase change of the working substance between a first shape wherein heat can be transferred from the high-temperature heat source and a second shape wherein heat can be transferred to the low-temperature heat source; a permanent magnet constituting the enclosed body, the permanent magnet being maintained in a first position when the enclosed body has the first shape and in a second position when the enclosed body has the second shape; and a wire in which an electric current is induced by a movement of the permanent magnet. Further, the present invention provides an apparatus for producing a reciprocating movement between two heat sources having a temperature difference therebetween.

Owner:KOREA INST OF SCI & TECH

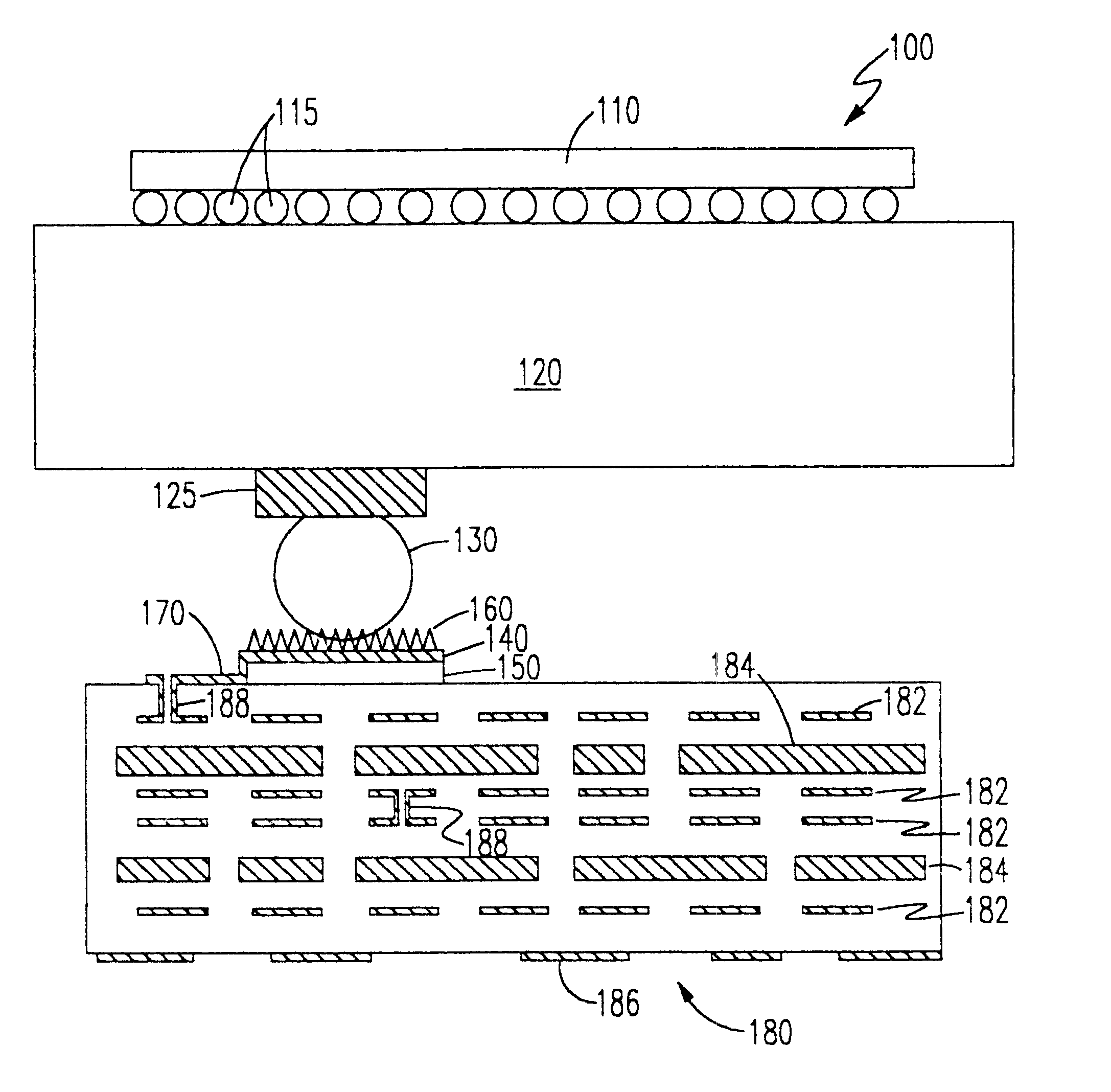

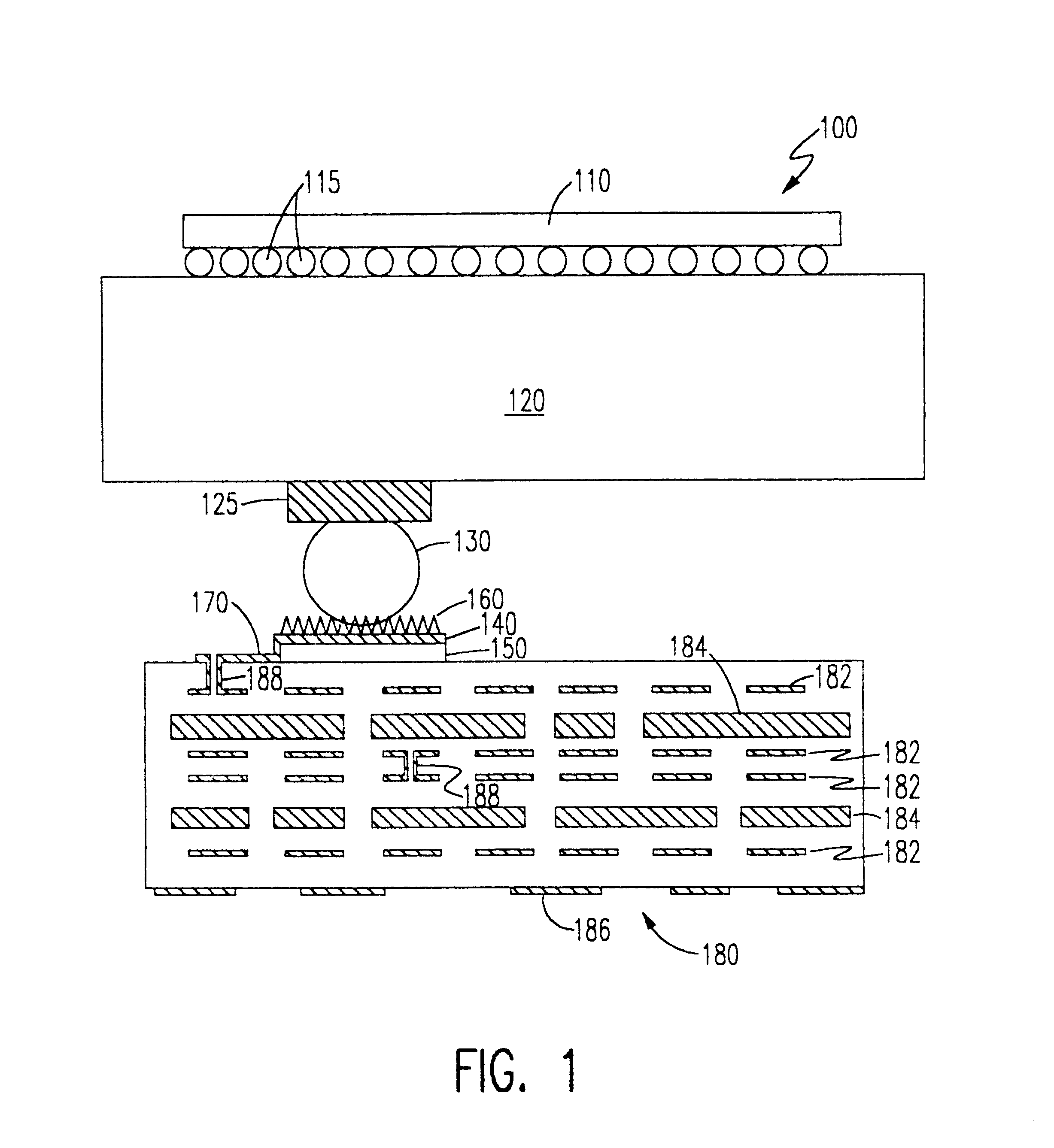

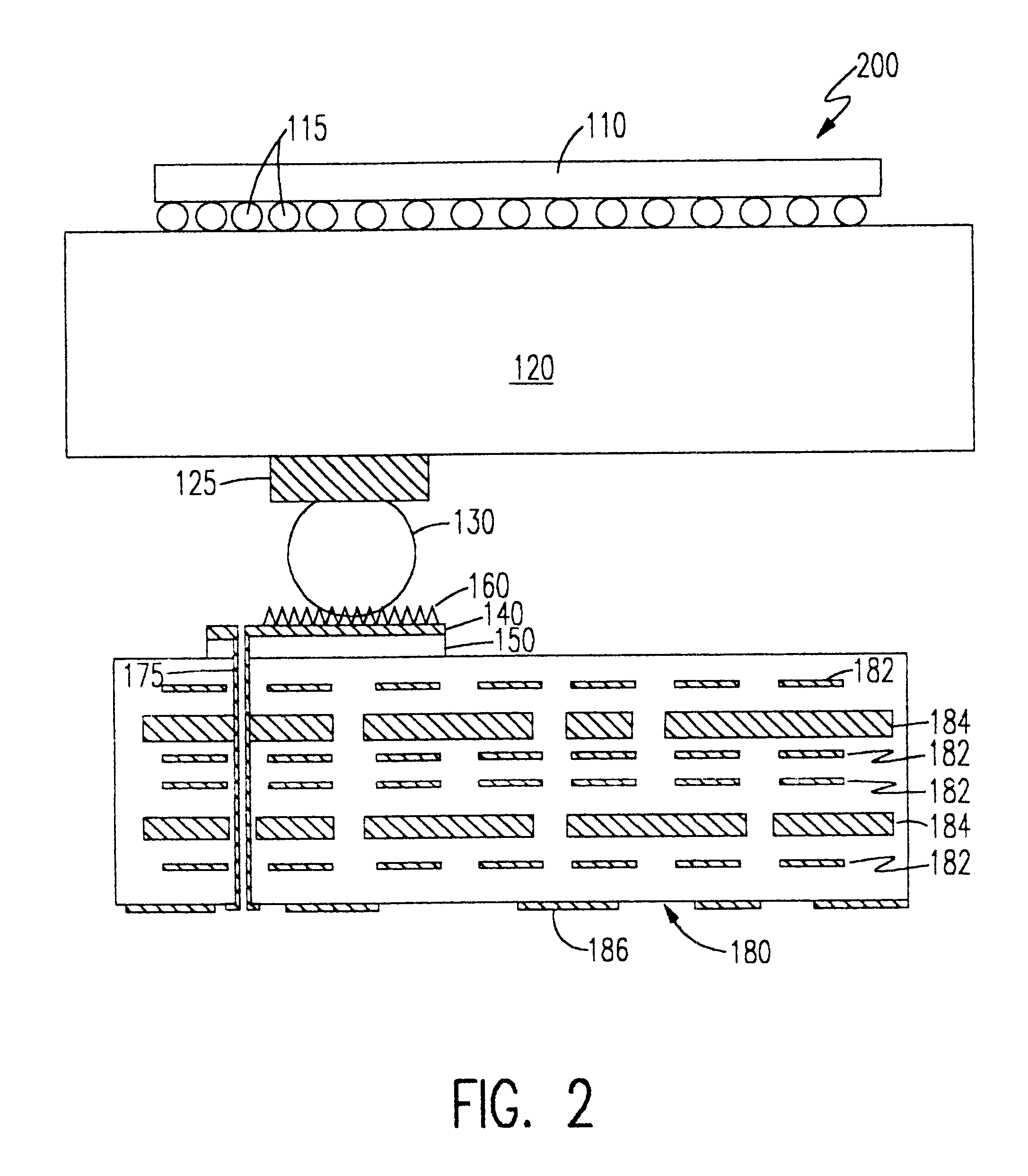

Circuit package having low modulus, conformal mounting pads

InactiveUS6399896B1Increase in number and sizeClosely matchedSemiconductor/solid-state device detailsSolid-state devicesElastomerThermal expansion

Reliability of circuit packaging while accommodating larger chips and increased temperature excursions is achieved by use of compliant pads only at the locations of connections between packaging levels, preferably between a laminated chip carrier and a printed circuit board. The invention allows the coefficient of thermal expansion of the chip carrier to be economically well-matched to the CTE of the chip and accommodation of significant differences in CTEs of package materials to be accommodated at a single packaging level. The compliant pads are preferably of low aspect ratio which are not significantly deflected by accelerations and can be formed on a surface or recessed into it. Connections can be made through surface connections and / or plated through holes. Connection enhancements such as solder wettable surfaces or dendritic textures are provided in a conductive metal or alloy layer over a compliant rubber or elastomer layer which may be conductive or non-conductive.

Owner:IBM CORP

Bonding apparatus and bonding method

InactiveUS20120247664A1Improve reliabilityReduce gapSolid-state devicesLaminationAdhesiveIncrease temperature

The bonding apparatus is capable of effectively increasing temperature of a substrate and reducing occurrence of position gaps and poor connection in a process of flip-chip-bonding semiconductor devices to the substrate. The bonding apparatus comprises: a supporting unit for supporting the substrate, on which the semiconductor devices have been adhered by a non-conductive; and a heating / pressing unit for heating and pressing the substrate, the heating / pressing unit having a built-in heat source and a clamping face, onto which the substrate supported by the supporting unit is pressed. The substrate supported by the supporting unit is moved toward the clamping face of the heating / pressing unit so as to preheat the substrate and the semiconductor devices by radiation heat. Then, the semiconductor devices are pressed onto the clamping face of the heating / pressing unit so as to cure the non-conductive adhesive and bond bumps of the semiconductor devices to terminal sections of the substrate.

Owner:APIC YAMADA CORP

System and method for heating skin using light to provide tissue treatment

A system and method for using a light source to treat tissue with NIR light. The operation provides for generating higher temperatures in deeper layers of tissue relative to shallower layers of tissue. The increased temperature in dermal layers can operate to induce collagen shrinkage, or remodeling. One of the light sources for providing a broad spectrum of NIR light is a filament light. The light from the filament lamp can be selectively filtered, and after filtering this light is applied to the skin, where the selective filtering can enhance the ability to elevate the temperature of deeper layers of tissue, relative to layers of tissue which are closer to the surface of the skin.

Owner:CUTERA

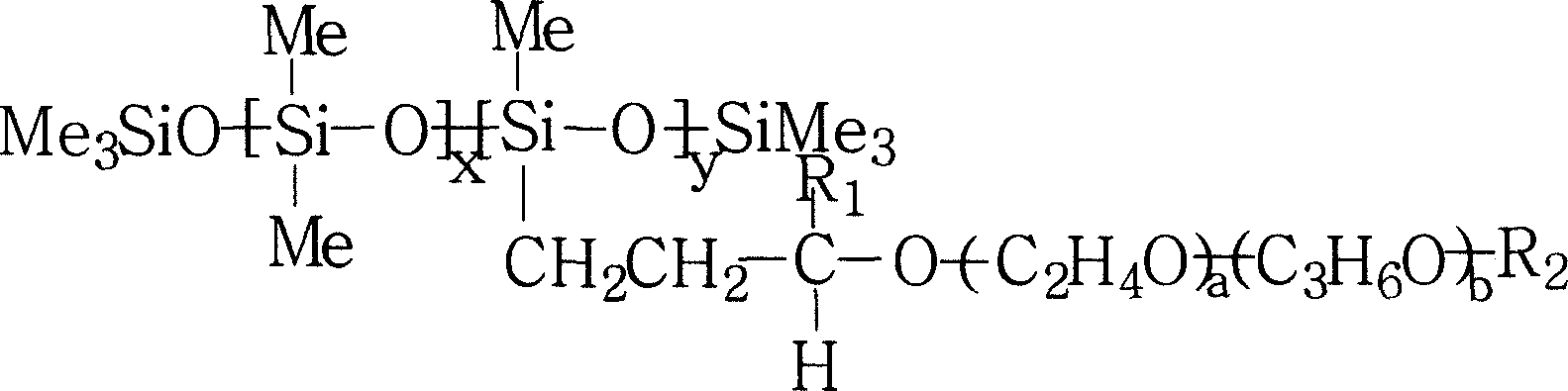

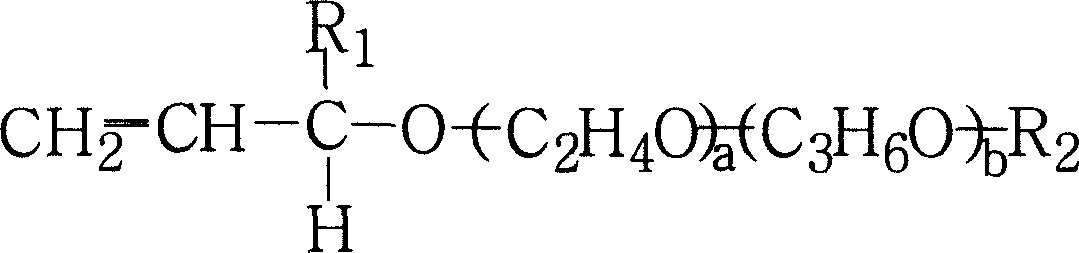

Organosilicon pesticide booster and preparing method thereof

InactiveCN101011062ALower the surface tension of the liquidGood physiological safety performanceBiocideAnimal repellantsSodium bicarbonatePlatinum

The invention relates to an organic silicon pesticide booster with low surface tension, less side effect and high yield. The chemical formula of invention is as following one, wherein, Me=CH3, R1=CH3, R2=H, CH3, C4H9, -O(O)CCH3, x=0-10, y=1-20, a=5-25, b=0-15. And the preparation comprises that putting the hydrogen siloxane and polyalkenylethers into reaction kettle, protected by N2, to increase temperature and be mixed quickly; then adding some platinum-1.3-divinyl tetramethyl disilyloxy-acetylacetone as catalyst, naturally increasing temperature to 110Deg. C, making solution transparent, adding baking soda, compressing and filtering, to obtain needed organic silicon pesticide booster. The invention has wide application in variable pesticides.

Owner:ZHANGJIAGANG JUNBO NEW MATERIAL

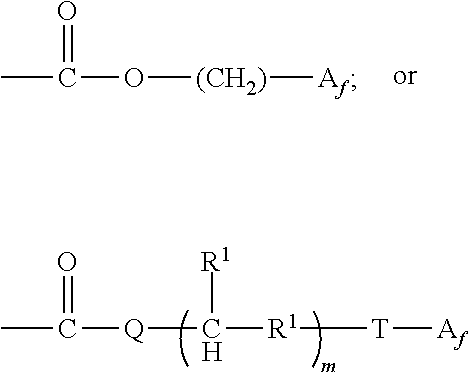

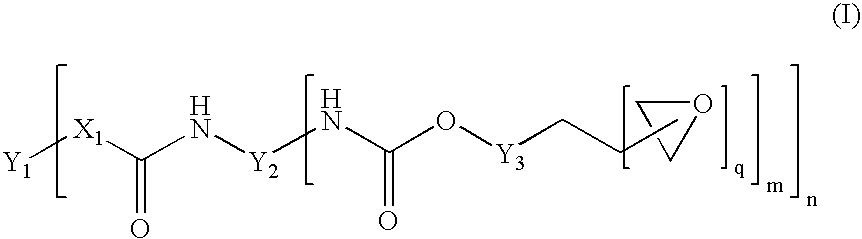

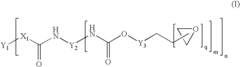

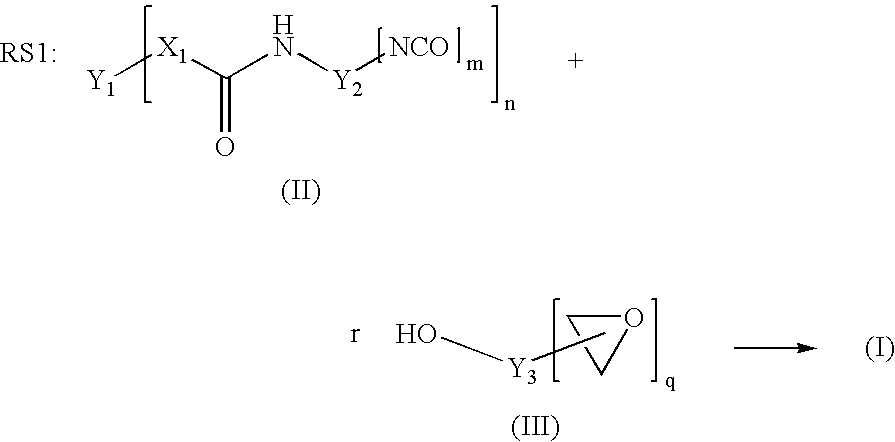

Thermally hardenable epoxy resin composition having an improved impact resistance at low temperatures

The invention relates to compositions containing at least one epoxide adduct A that comprises an average of more than one epoxide group per molecule, at least one polymer B of formula (I), at least one thixotropic agent C based on a urea derivative in a non-diffusing carrier material, and at least one hardener D for epoxy resins, which is activated at an increased temperature. Said composition is used especially as an adhesive and is provided with an extraordinarily high impact peel working value, especially at low temperatures. The invention further relates to epoxide group-terminal impact strength modifiers of formula (I), which significantly increase the impact resistance in epoxy resin compositions, particularly two-component epoxy resin compositions.

Owner:SIKA TECH AG

Coupling photovoltaic and concentrated solar power technologies for desalination

ActiveUS10065868B2Eliminate needSolar heating energyGeneral water supply conservationWater sourceEngineering

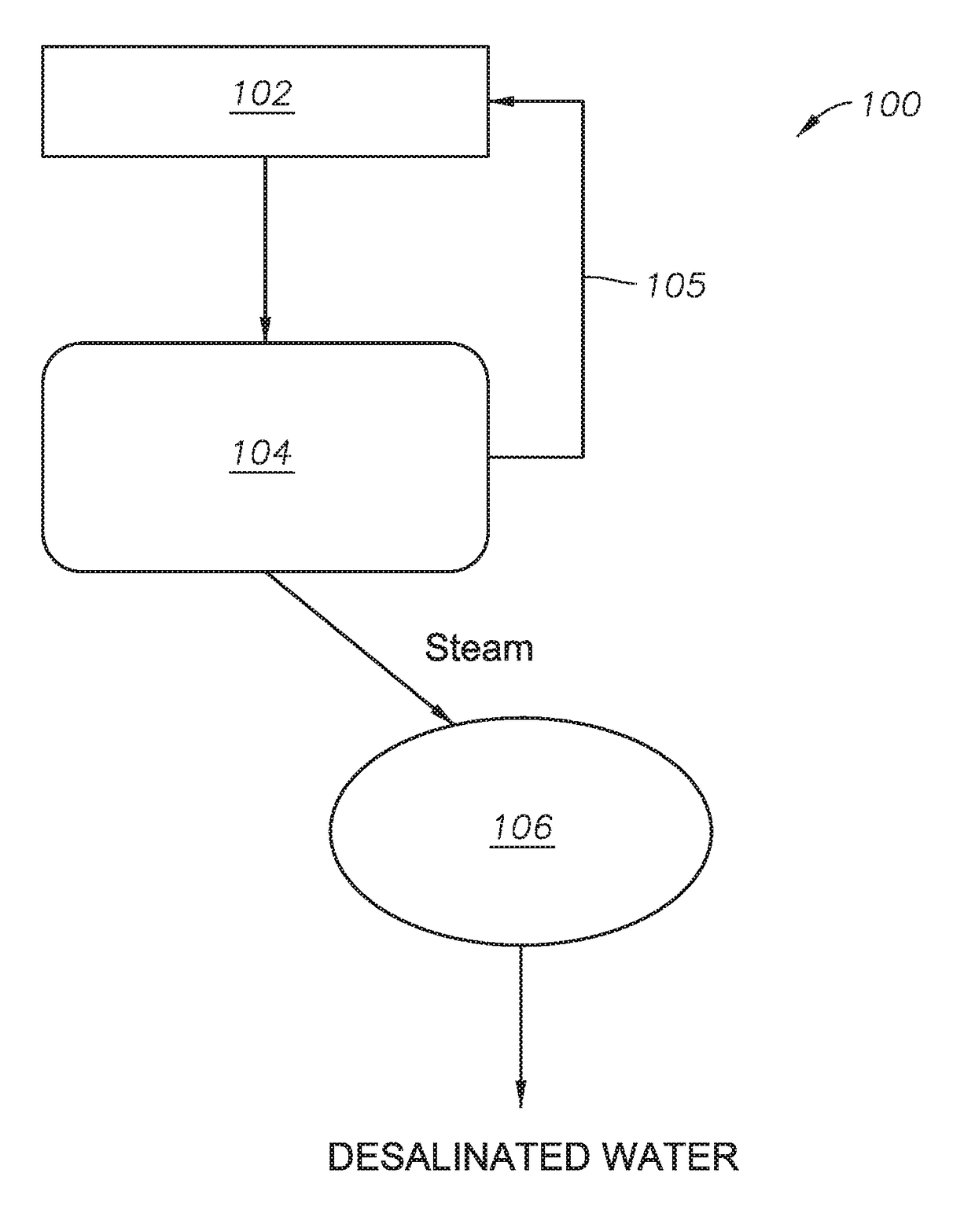

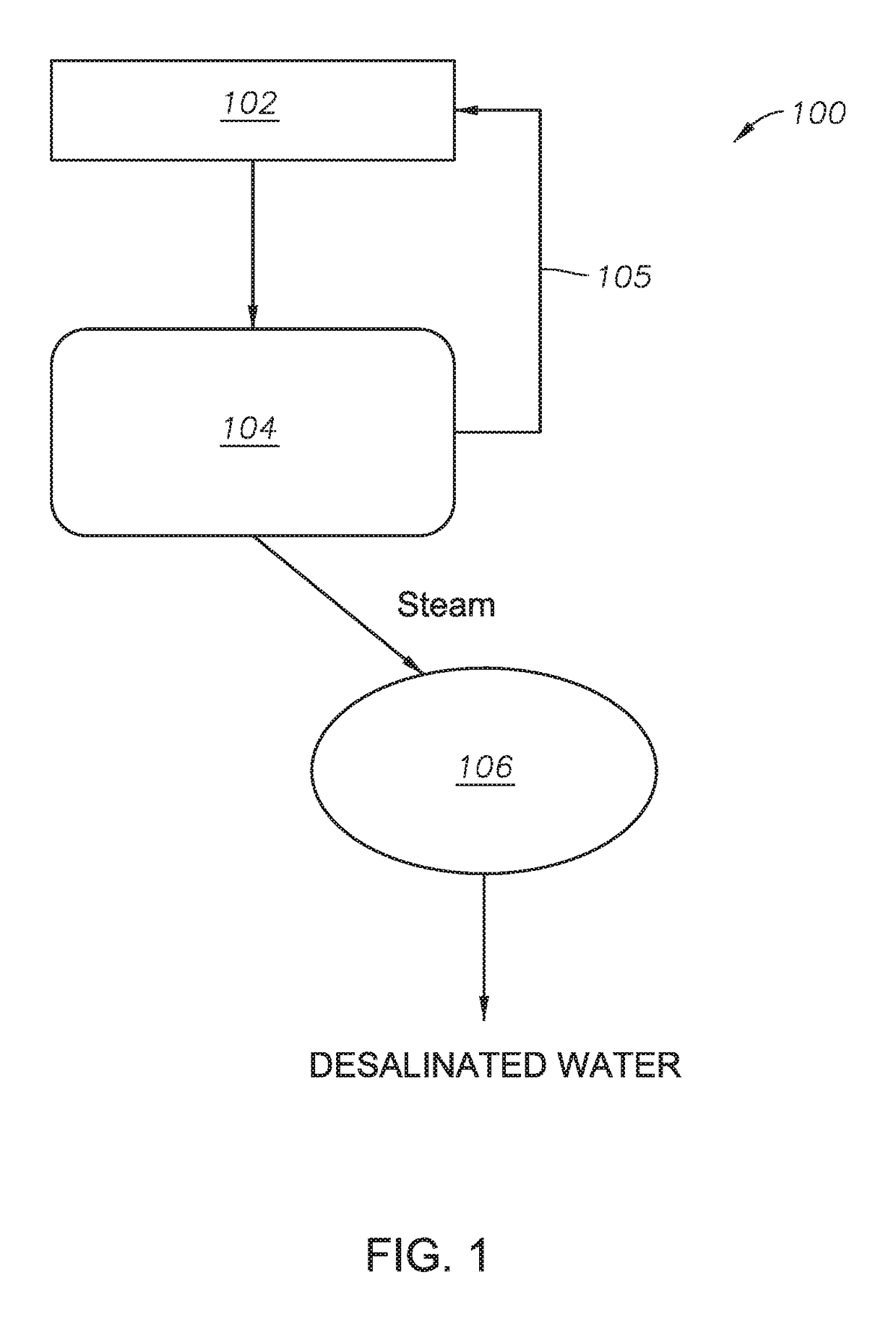

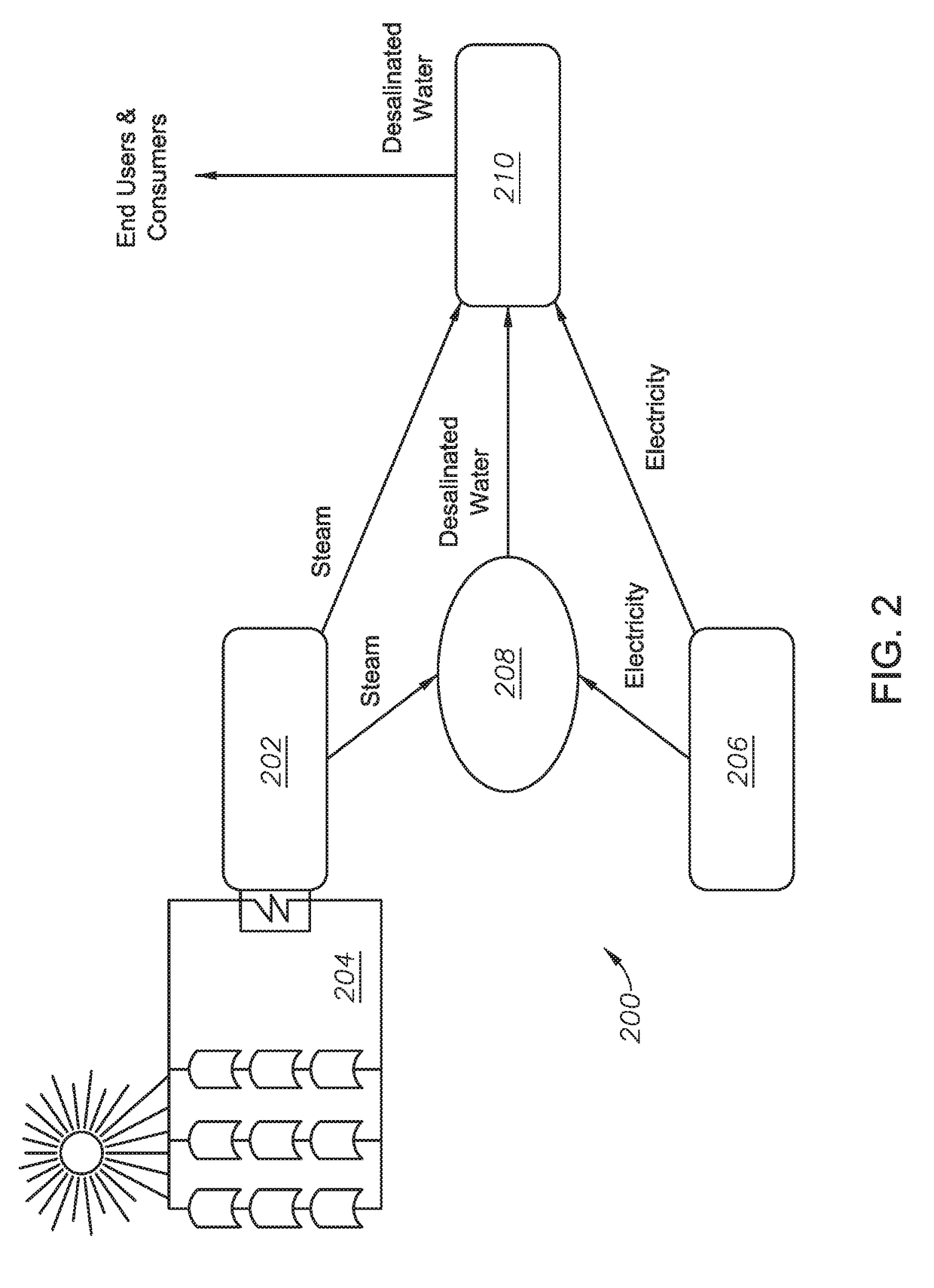

Systems and methods for the desalination of water are disclosed. A system includes a concentrated solar power (CSP) system, the CSP system operable to concentrate solar energy to increase temperature and pressure of a heat transfer fluid and operable to produce steam utilizing heat from the heat transfer fluid; a photovoltaic (PV) system, the PV system operable to collect solar energy to produce electricity; a desalination system in fluid communication with the CSP system and in electrical communication with the PV system, the desalination system operable to produce desalinated water from a salt water source utilizing the steam from the CSP system and electricity from the PV system; and a pump station in fluid communication with the CSP system and the desalination system, and in electrical communication with the PV system, the pump station operable to transmit the desalinated water to consumers for use.

Owner:SAUDI ARABIAN OIL CO

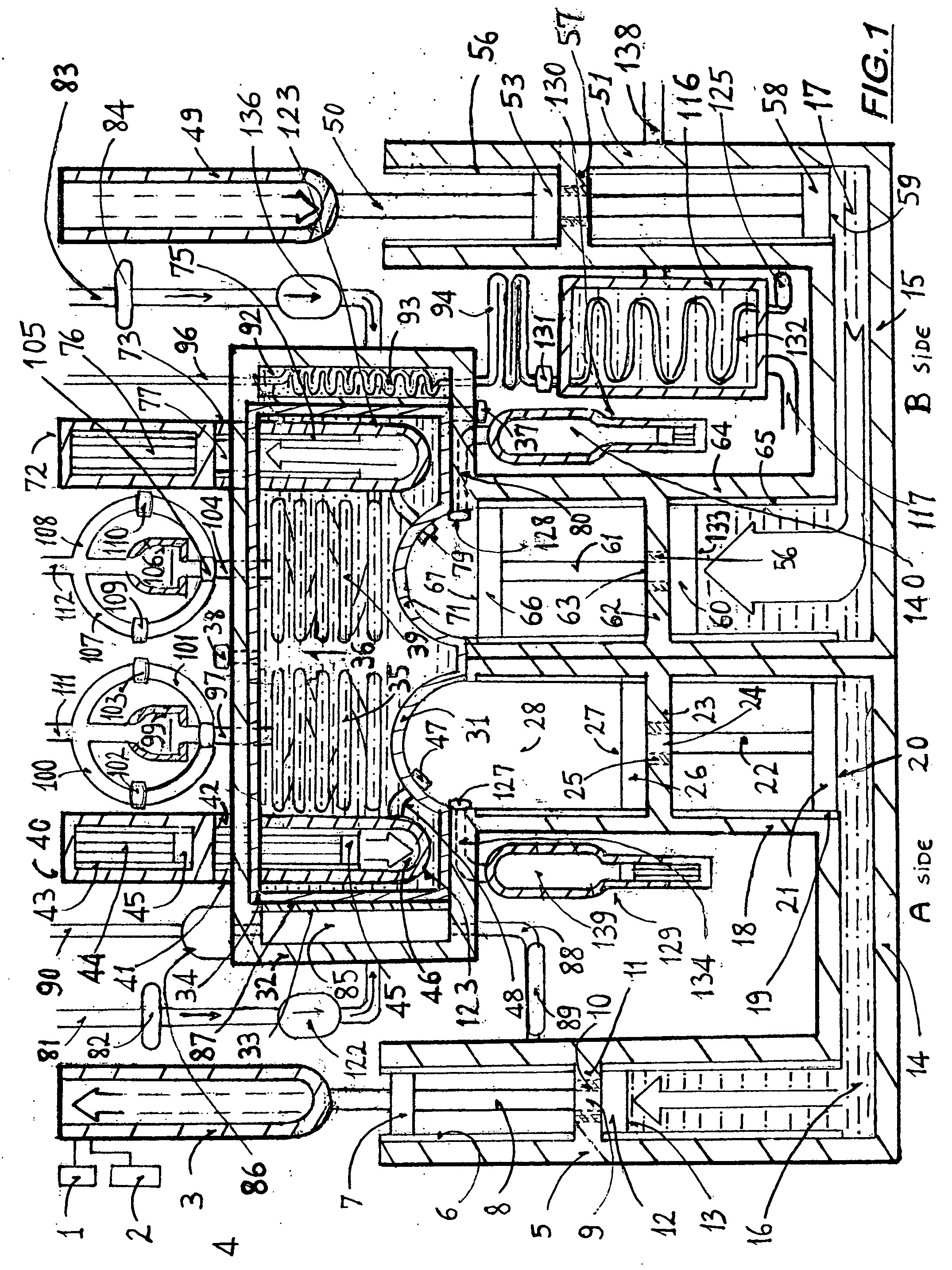

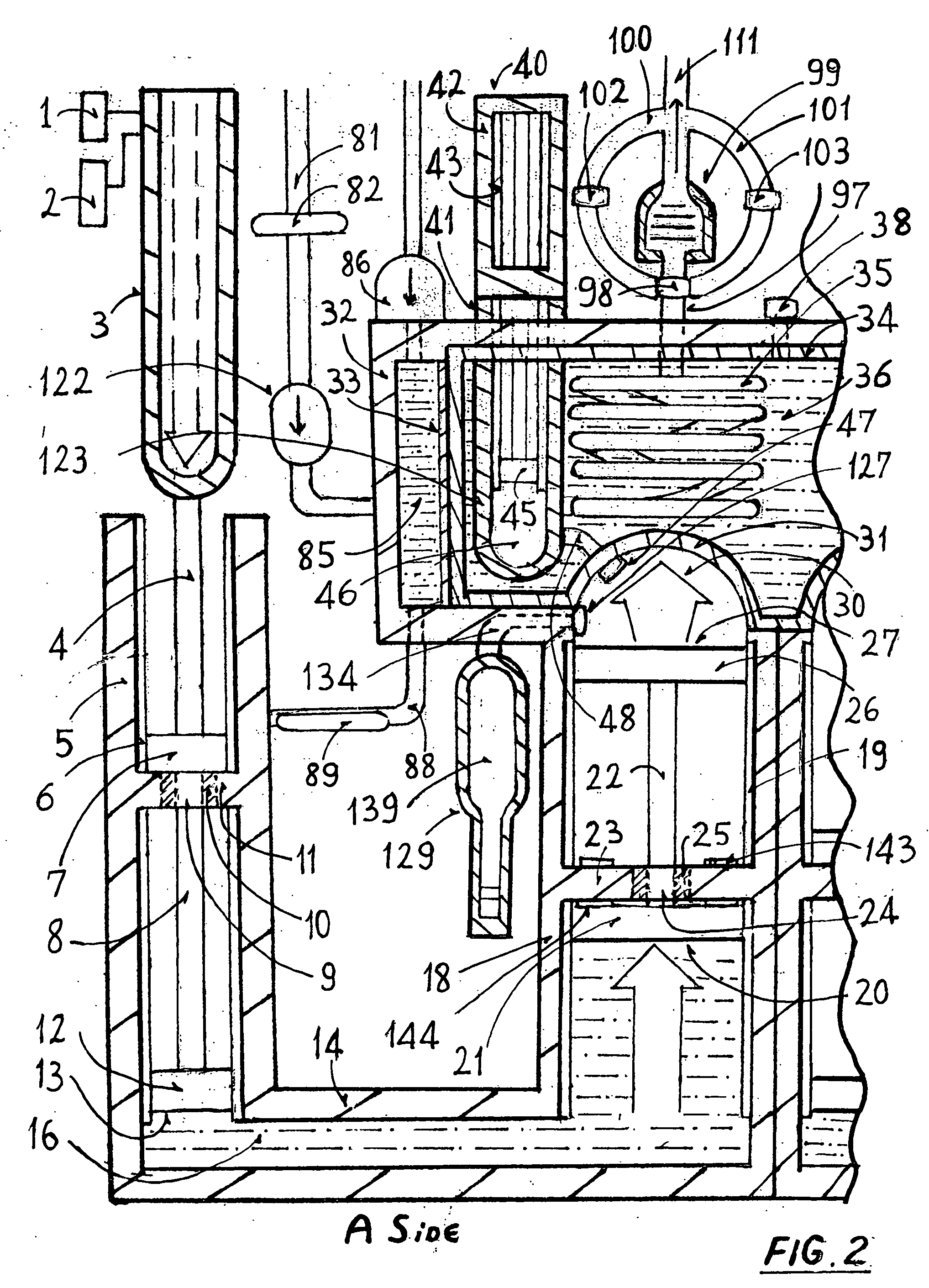

Hydraulic-compression power cogeneration system and method

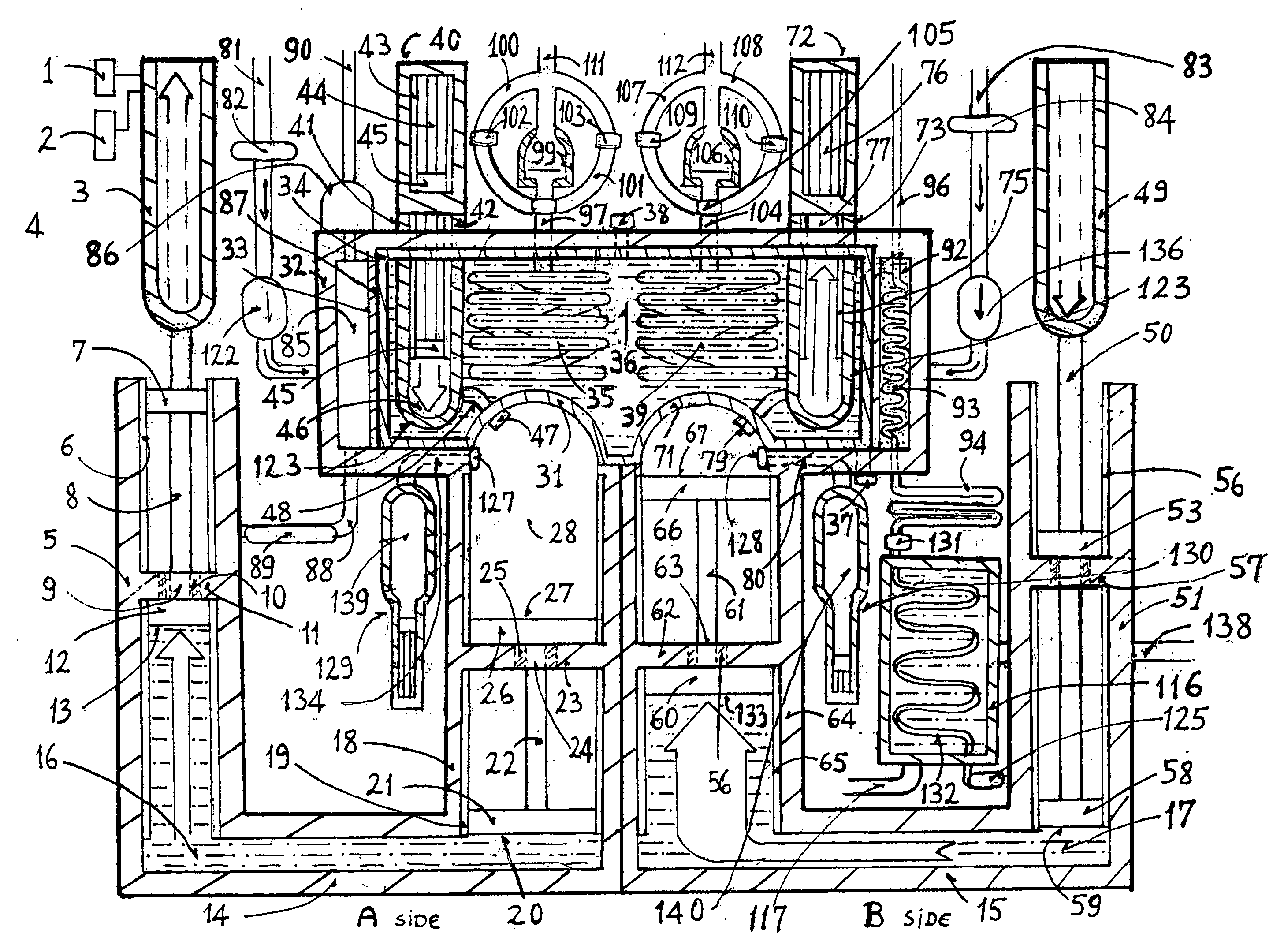

A system and method for converting kinetic energy into useable thermal energy by means of a gas compression based cogeneration. Kinetic forces applied, that are coupled to kinetic components of electro-mechanic thrusters 3, 49-input side, and upper small area pistons 7, 53-receiving side transmitted by shafts 4 and 50 get multiplied through Pascal hydraulic oil links 16 and 17, that are between the lower side small area pistons 12, 58 and lower side large area pistons 21, 60. At least two compression chambers are used to compress gas therein repeatedly to increase the pressure and temperature of the same. Auxiliary compressors 41, 73 help to increase temperature of compressed gas further. Said heat generated is conducted into a single liquid sodium thermal storage volume 36 that facilitates a highly stable thermal storage volume and contains working gas spiral sections 35, 39 circulating within. Steam 113 generated within spiral sections 35, 39 generates power in turbines 99, 106 and then heat residential and / or commercial buildings 115. Service hot-water is provided utilizing a water tank 85 and refrigerant coil circulation oil volume 92, both utilize thermal storage volume 36 waste heat by conduction for a triple integrated system. The system may also be combined with other power generation systems. In second embodiment 121 with more than two units of compression chambers and higher capacity, low cost electric power generated enables efficient hydrogen mass production. A thermo-physical cogeneration system with central heating means, and a cogeneration power plant 121 with hydrogen mass production and hydrogen storage capabilities; are presented as what are new in the art.

Owner:ZABTCIOGLU FIKRET M

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com