Organosilicon pesticide booster and preparing method thereof

A synergist and organosilicon technology, which is applied in the fields of botanical equipment and methods, biocides, animal repellants, etc., can solve problems such as reduced yield, and achieve less side reactions, good physiological safety performance, and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

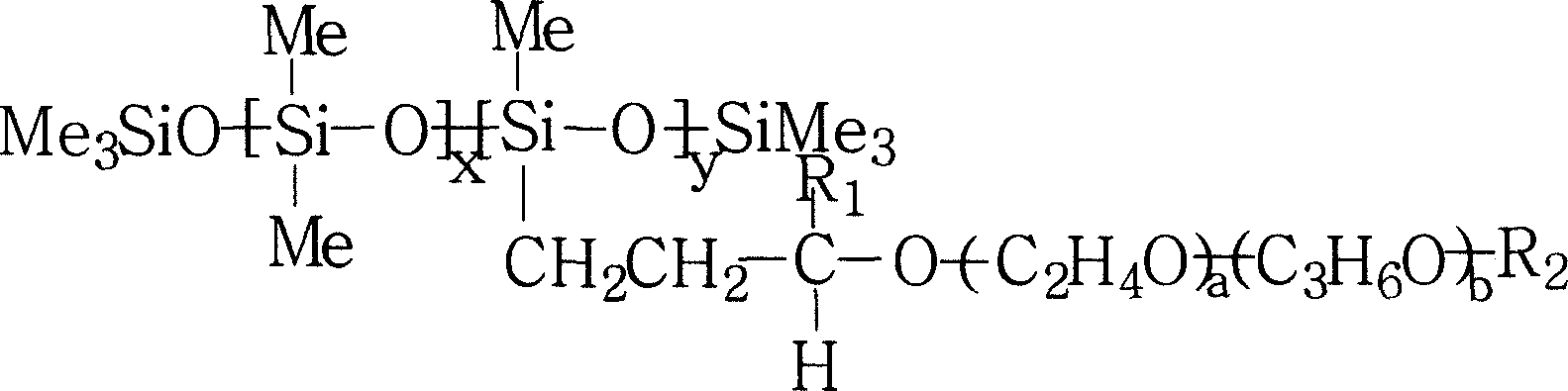

Method used

Image

Examples

Embodiment 1

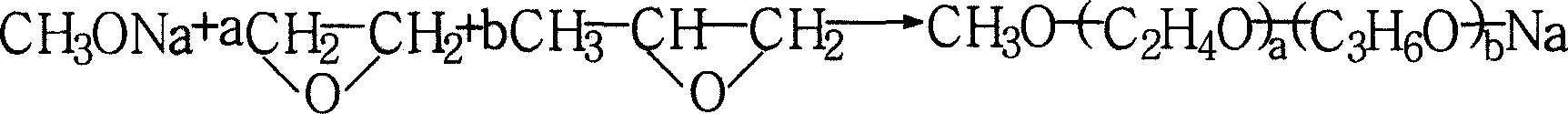

[0056] Put 162g of sodium methoxide and 324g of methanol into a 3L stainless steel autoclave to completely dissolve the sodium methoxide, then add 1100g of ethylene oxide, stir at high speed, raise the temperature to 98°C, and the pressure of the autoclave is 1-2.0 atm. As the reaction progressed, the pressure gradually decreased. When the pressure drop in the kettle was 1.3 atm, the temperature was lowered to normal temperature to obtain the polyoxyethylene ether sodium salt capped with methoxy group:

[0057] CH 3 O_C 2 h 4 O_ 6 Na

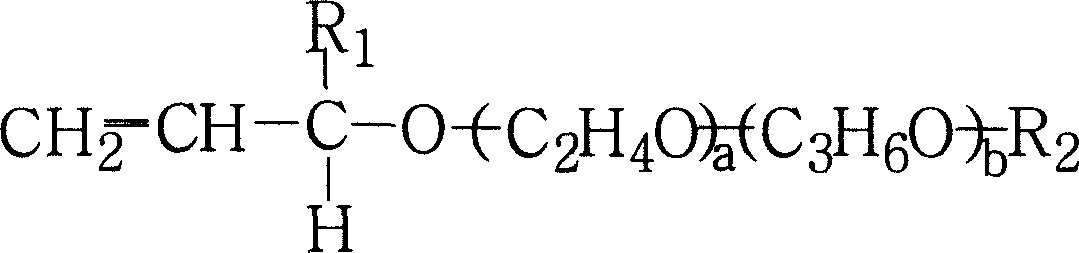

[0058] Transfer the obtained polyoxyethylene ether sodium salt to a normal-pressure reaction kettle, and after distilling off the methanol, add 280 g of 2-chlorobutene-1 into the kettle, stir at high speed, raise the temperature to reflux temperature, react for 2 hours, and distill out After unreacted 2-chlorobutene-1, decolorize and press filter to obtain terminal alkenyl polyether:

[0059]

Embodiment 2

[0061] Synthesis of terminal alkenyl copolyether

[0062] Add 54g of sodium methoxide into the autoclave, then add 120g of methanol and stir to fully dissolve it, add 420g of propylene oxide, stir at high speed, and raise the temperature to about 110°C. The pressure in the kettle rose to 1.7 atm. As the reaction proceeds, the pressure gradually decreases. When the pressure drops to 1.1-1.2 atm, drop to room temperature and then add 402 g of ethylene oxide, and raise the temperature to 105-110°C. The pressure inside the kettle is 1.8-2.0 atm. When the pressure in the kettle drops to 1.1-1.2atm, the temperature of the kettle is lowered to room temperature to obtain a methanol solution of epoxy polyether sodium salt with a methoxy head cap, and after distilling off the methanol, the following is obtained:

[0063] CH 3 O_C 3 h 6 O_ 3 _C 2 h 4 O_ 6 Na 780g.

[0064] Add 400 g of sodium salt of epoxy polyether with methoxy capped head into the reaction flask, then add 54 ...

Embodiment 3

[0067] Synthesis of Hydrosiloxane Ring Body:

[0068] Add 6000ml of petroleum ether (b·p60~90°C) and 920g of methyldichlorosilane into the reaction kettle equipped with high-efficiency reflux condenser, thermometer and stirrer. Start to stir, make the material in the kettle drop to 0°C, pass N 2 , add 500ml of distilled water dropwise, the dropping rate of distilled water is based on the control of the hydrolysis temperature not exceeding 10°C, it takes about 4 to 5 hours, and the released hydrogen chloride gas is absorbed into hydrochloric acid by falling film. 2 Speed to drive away the hydrogen chloride gas, then move the reactant to the separatory funnel, separate the aqueous solution, wash the organic phase twice with 2000ml distilled water, add 5% sodium carbonate solution to neutralize, add desiccant to dry, filter, Evaporate petroleum ether in vacuo to obtain hydrogen-containing cyclic siloxane (MeHSiO) n , where trimethylcyclotrisiloxane (D 3 -H )3.2%, tetramethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com