A stain-resistant real stone paint

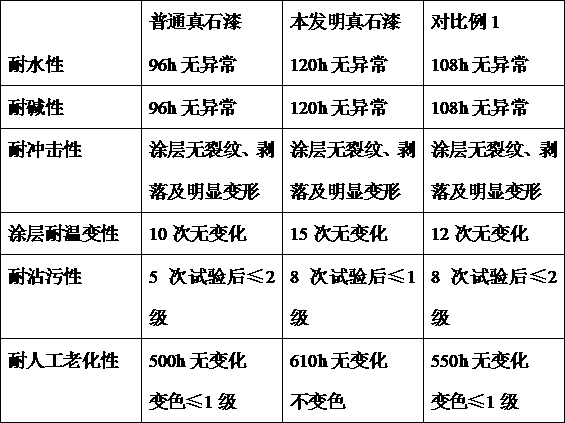

A real stone paint and anti-fouling technology, applied in the field of decorative materials, can solve the problems of poor adhesion of real stone paint, pollution of real stone paint walls, etc., and achieve the effects of good anti-fouling, increased coverage and easy construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A stain-resistant real stone paint, which is made of the following ingredients in parts by weight: pure acrylic emulsion 30-32, ethyl silicate 0.1-0.2, modified wood fiber 0.6-0.8, castor oil 0.8-1.2, active silica fume powder 0.8-1.2, dispersant 0.5-0.8, sodium dodecyl sulfonate 0.9-1.3, cellulose acetate 1.2-1.4, polyurethane thickener 0.2-0.4, film-forming aid 1.3-1.6, ethylene glycol 1-2 , defoamer 0.1-0.2, water 22-28, natural colored sand 58-62; the preparation method of described modified wood fiber is: add its 10 times of quality deionized water to wood fiber, with 120r / min rotating speed Stir and heat up to 78°C, add ascorbic acid with 0.2% lignocellulosic mass, stir at 90r / min for 10min, continue heating to 86°C, then add 1.2% lignofibrous sodium hydroxide, stir at 120r / min After 20 minutes, keep warm at 80-82°C, add acrylic acid with 1.8% wood fiber quality dropwise in 1h, and stir at 250r / min for 15min, then lower the temperature to 72-74°C, keep warm for 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com