Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2918 results about "Cellulose acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellulose acetate is the acetate ester of cellulose. It was first prepared in 1865. Cellulose acetate is used as a film base in photography, as a component in some coatings, and as a frame material for eyeglasses; it is also used as a synthetic fiber in the manufacture of cigarette filters and playing cards. In photographic film, cellulose acetate replaced nitrate film in the 1950s, being far less flammable and cheaper to produce.

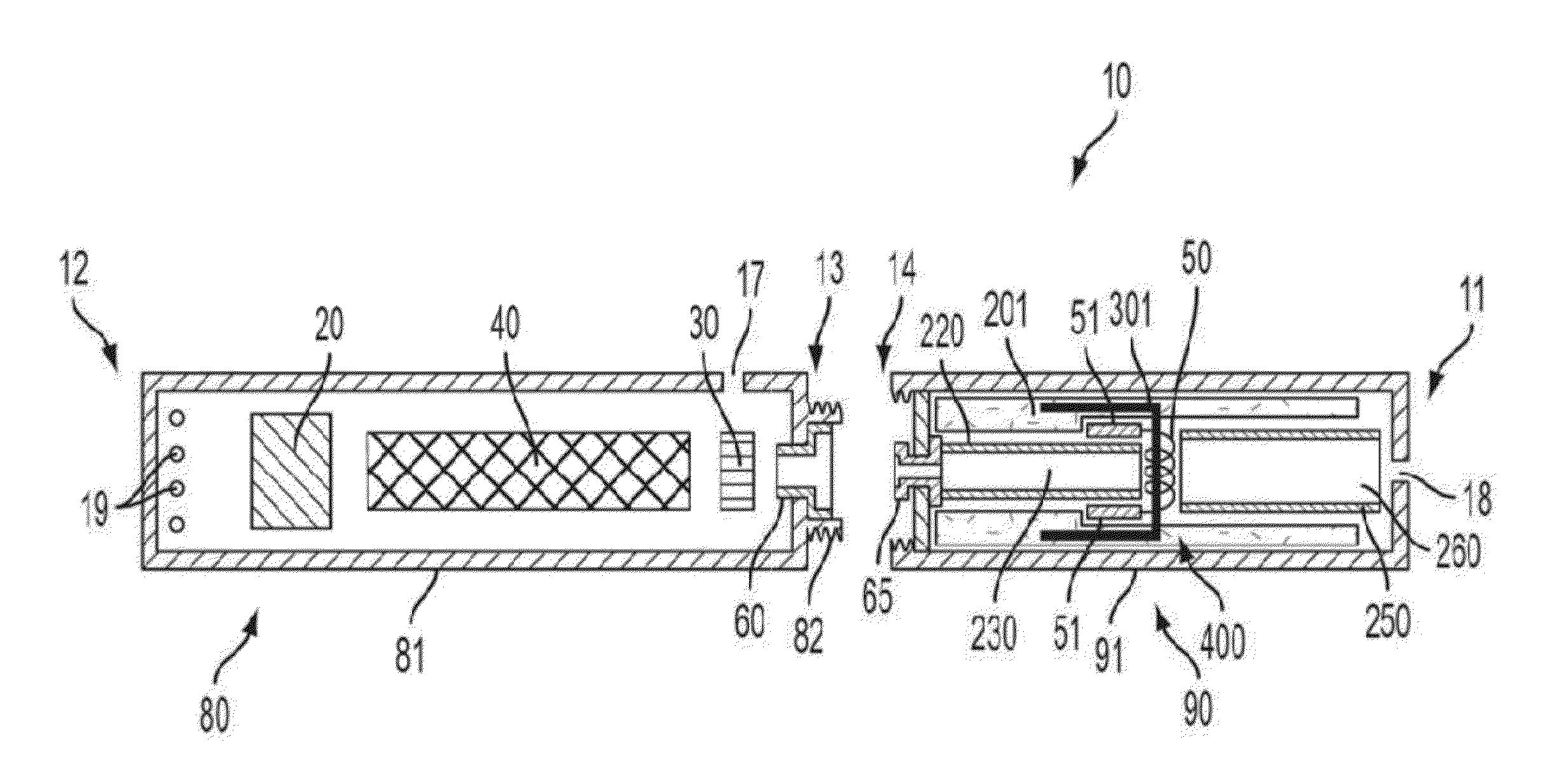

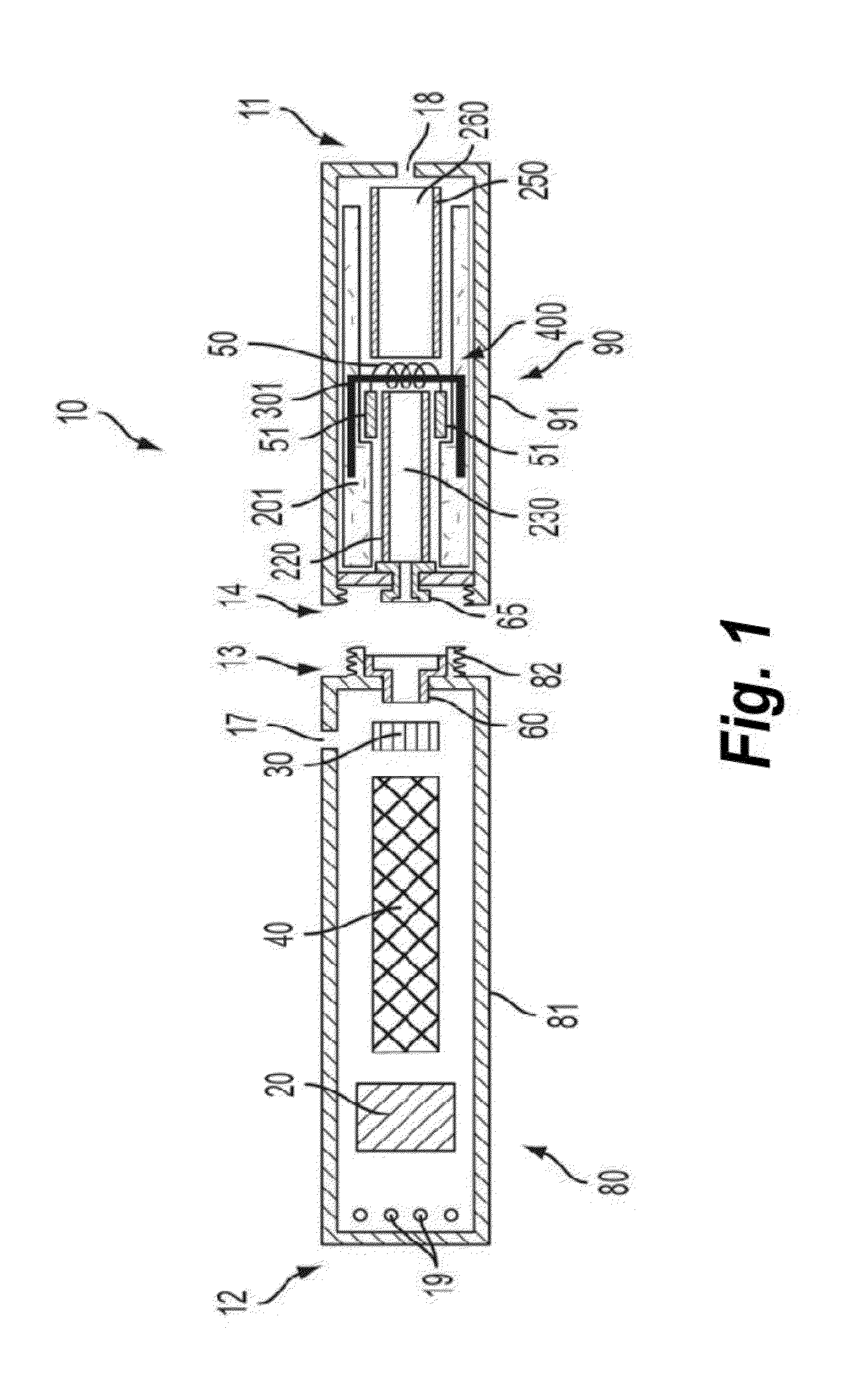

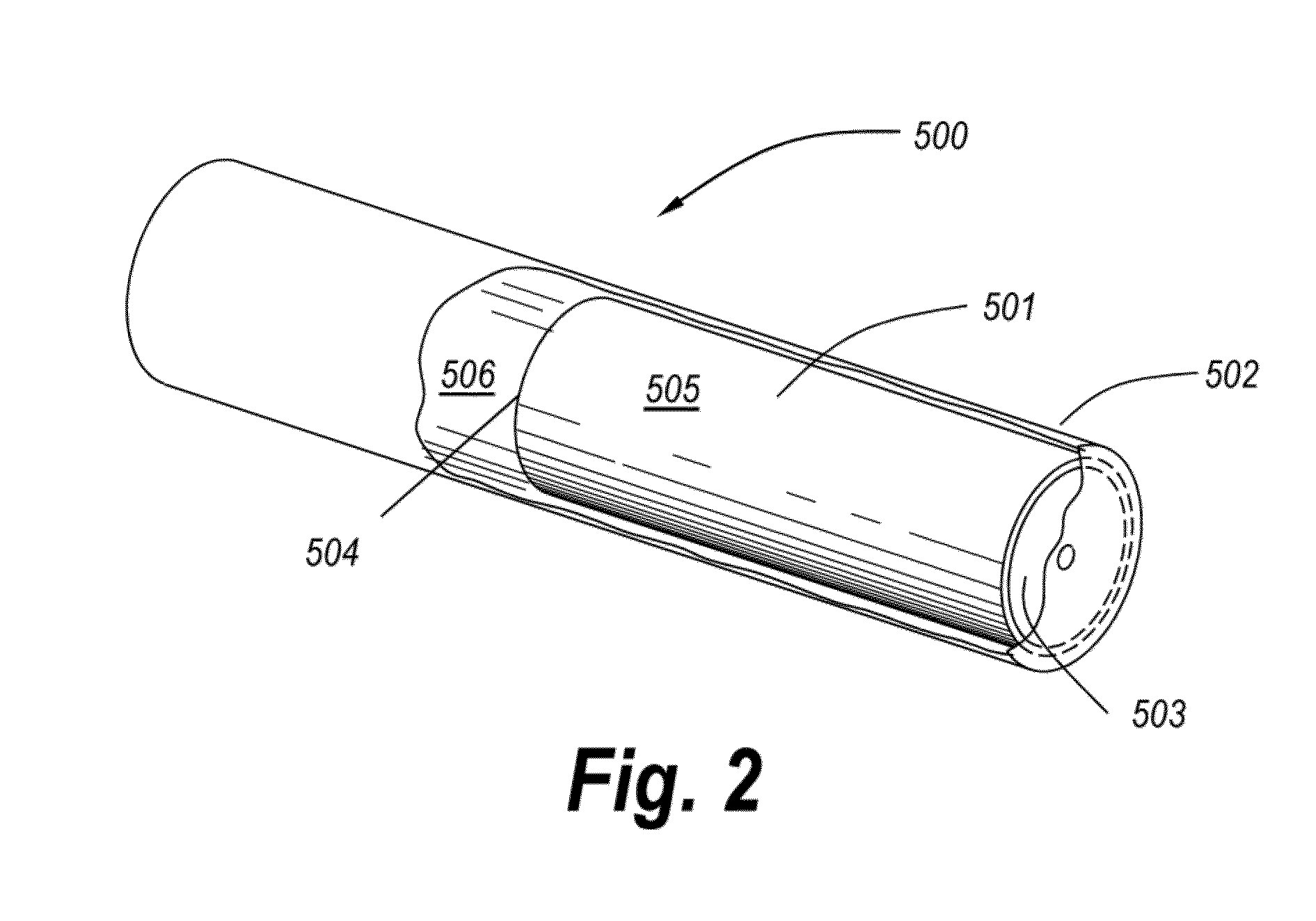

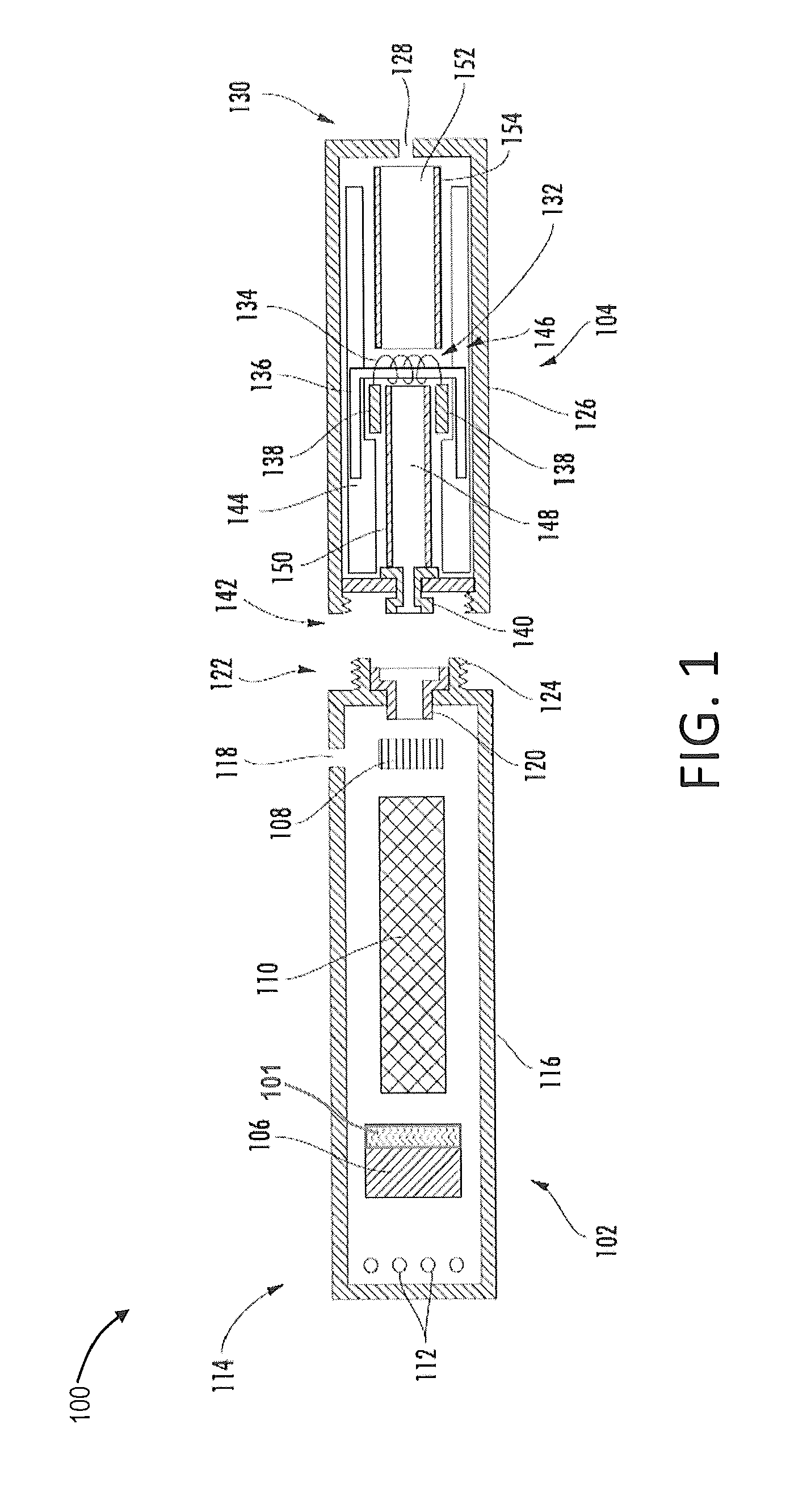

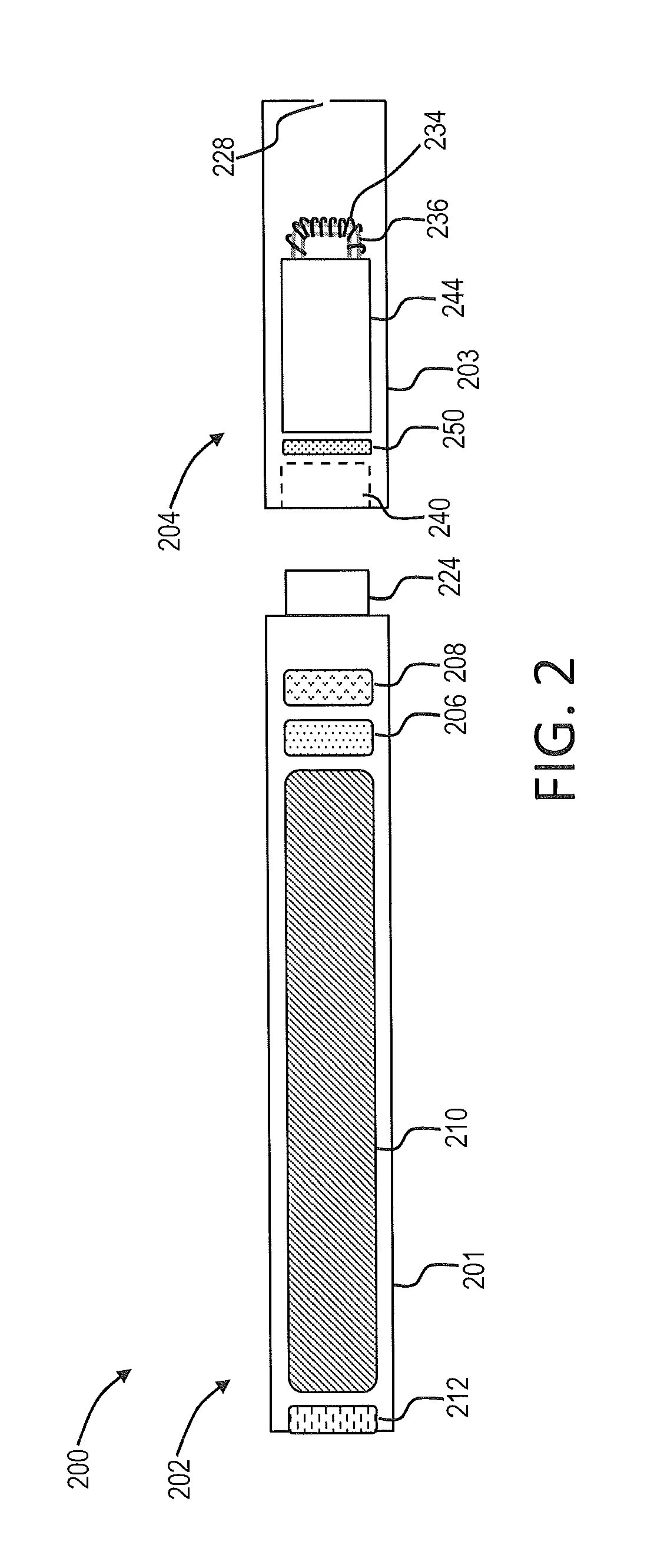

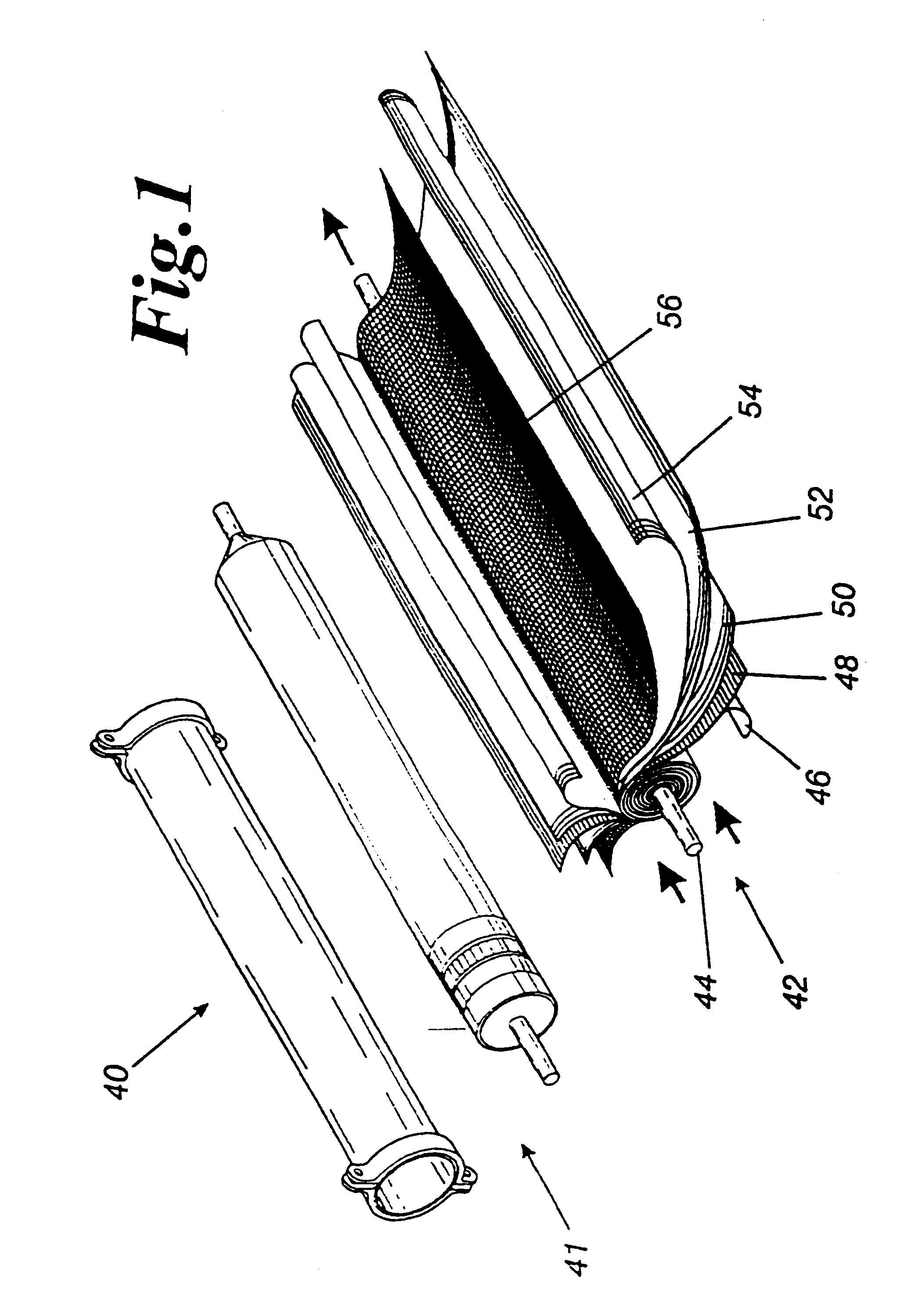

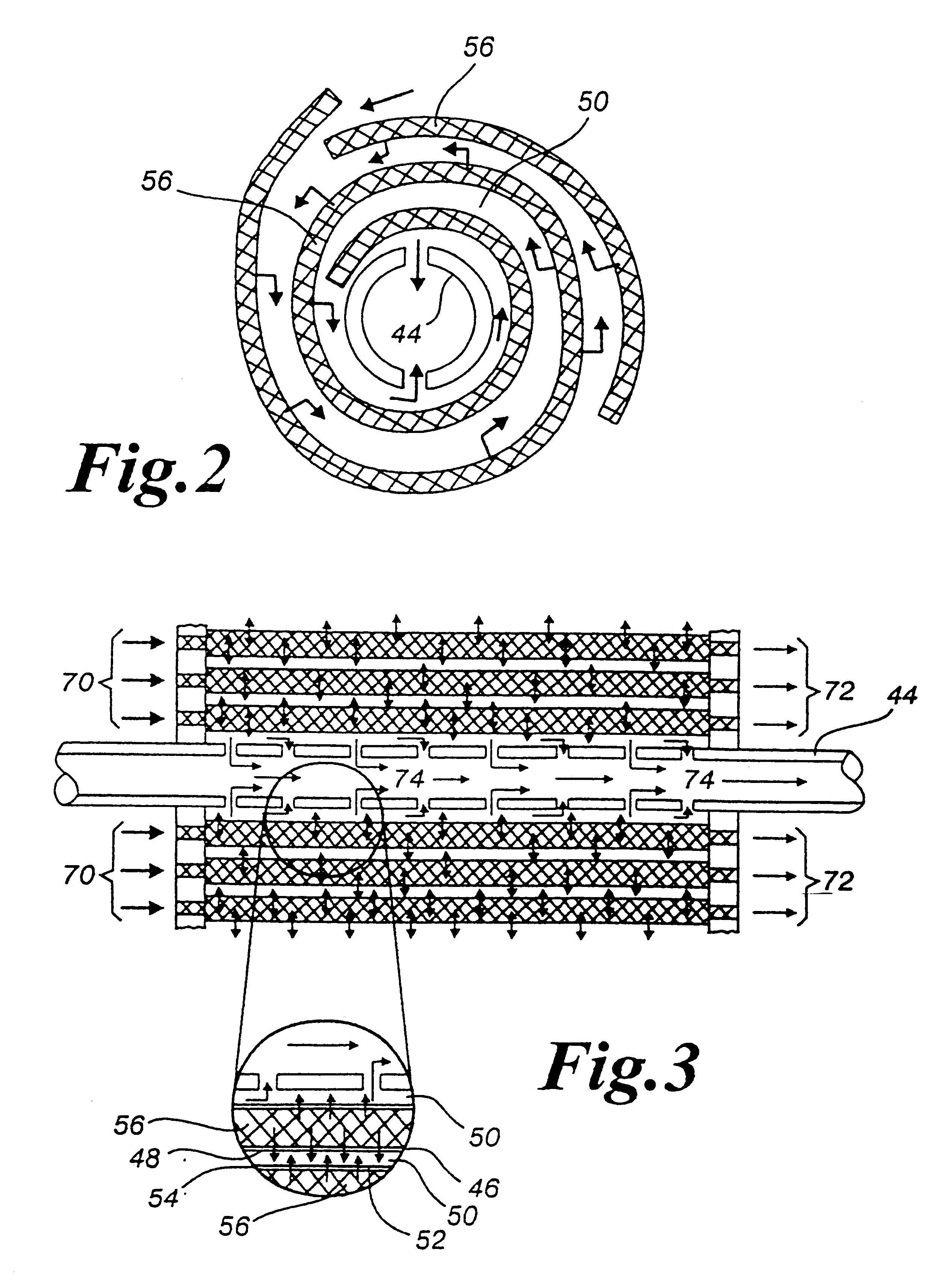

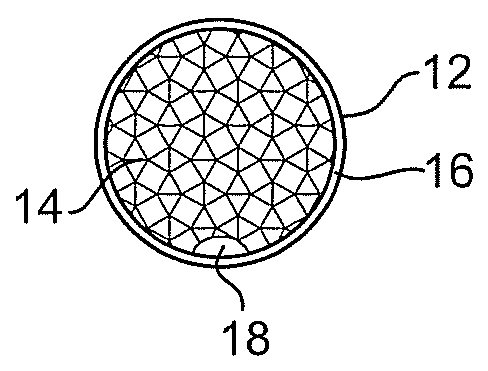

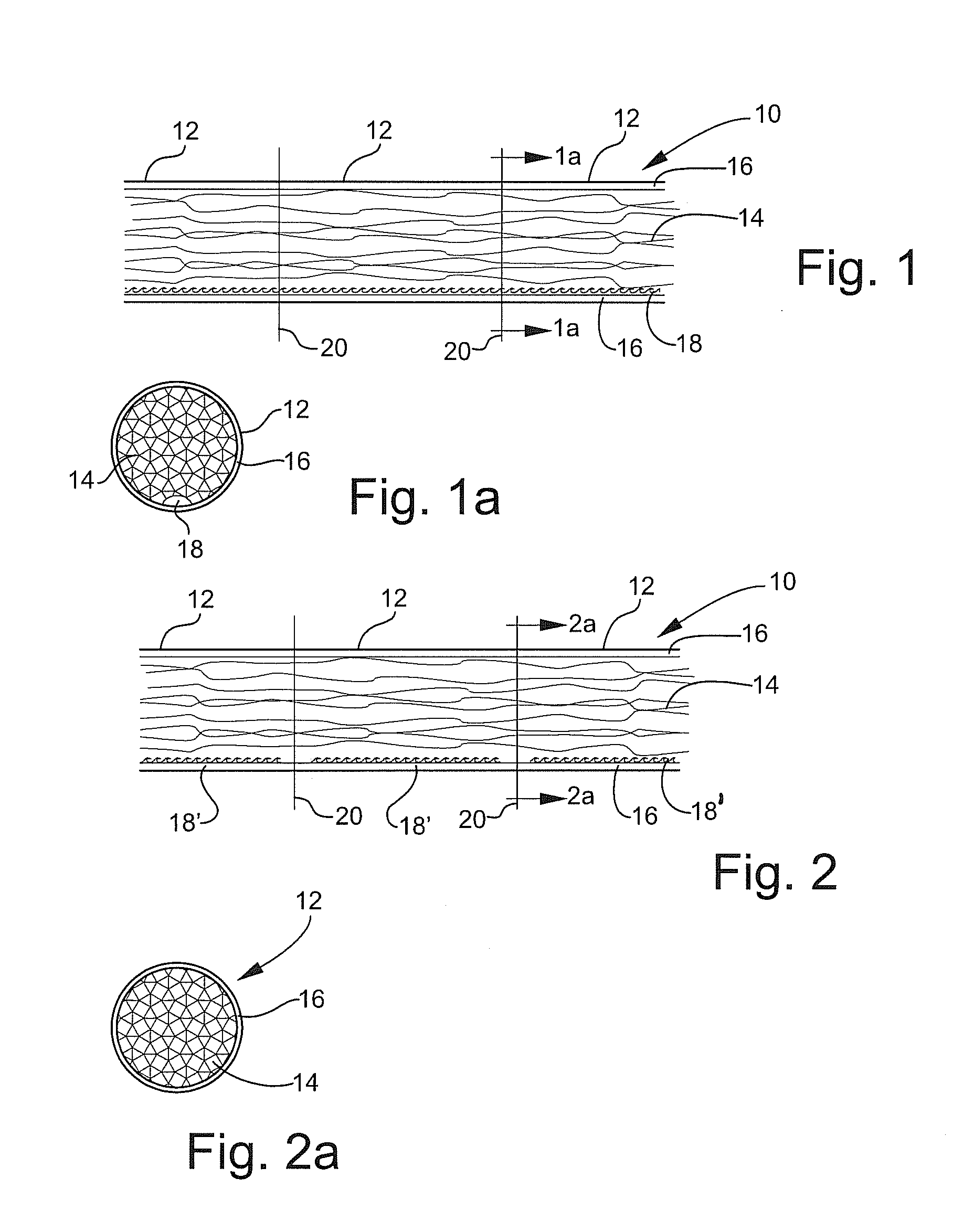

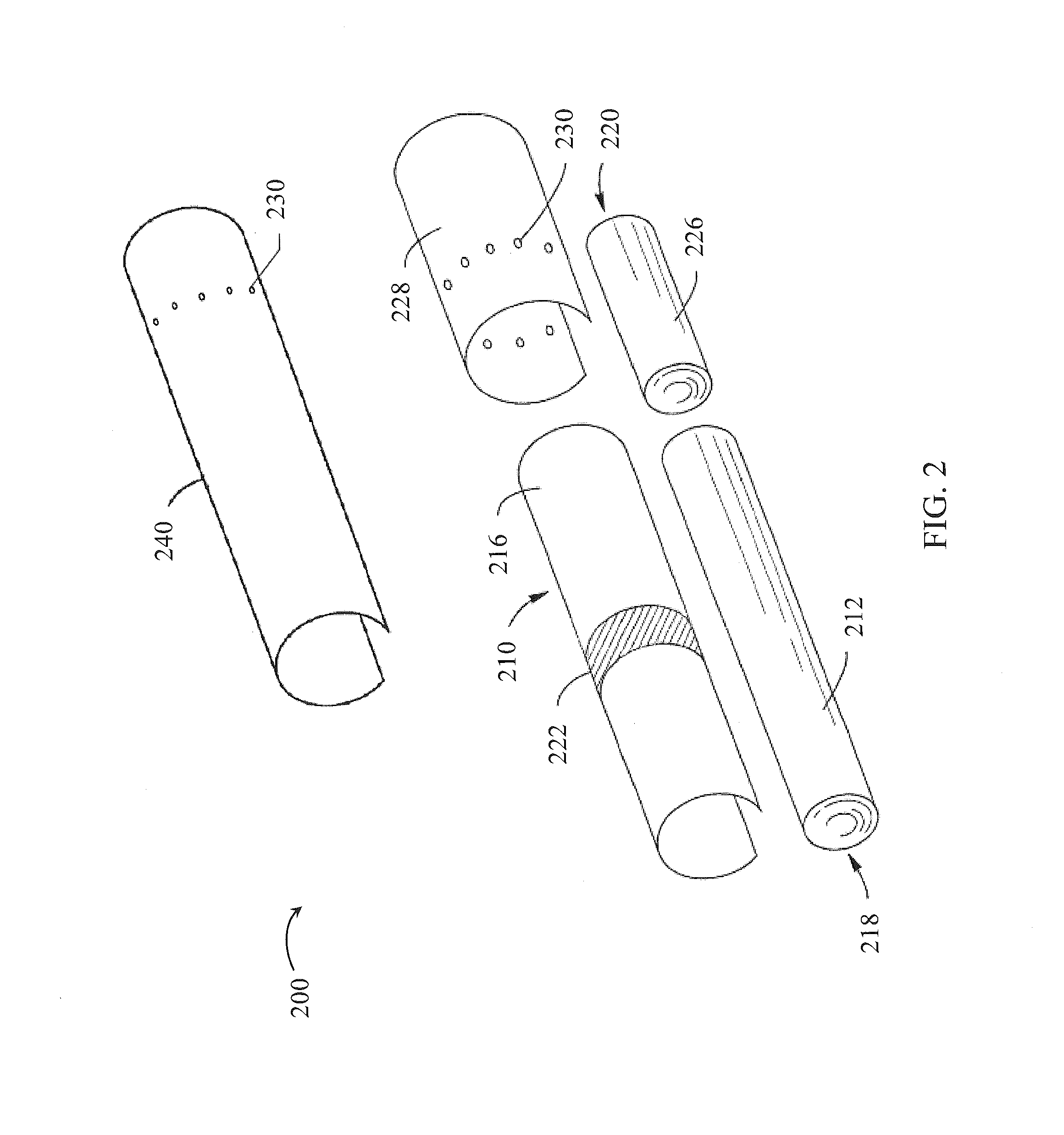

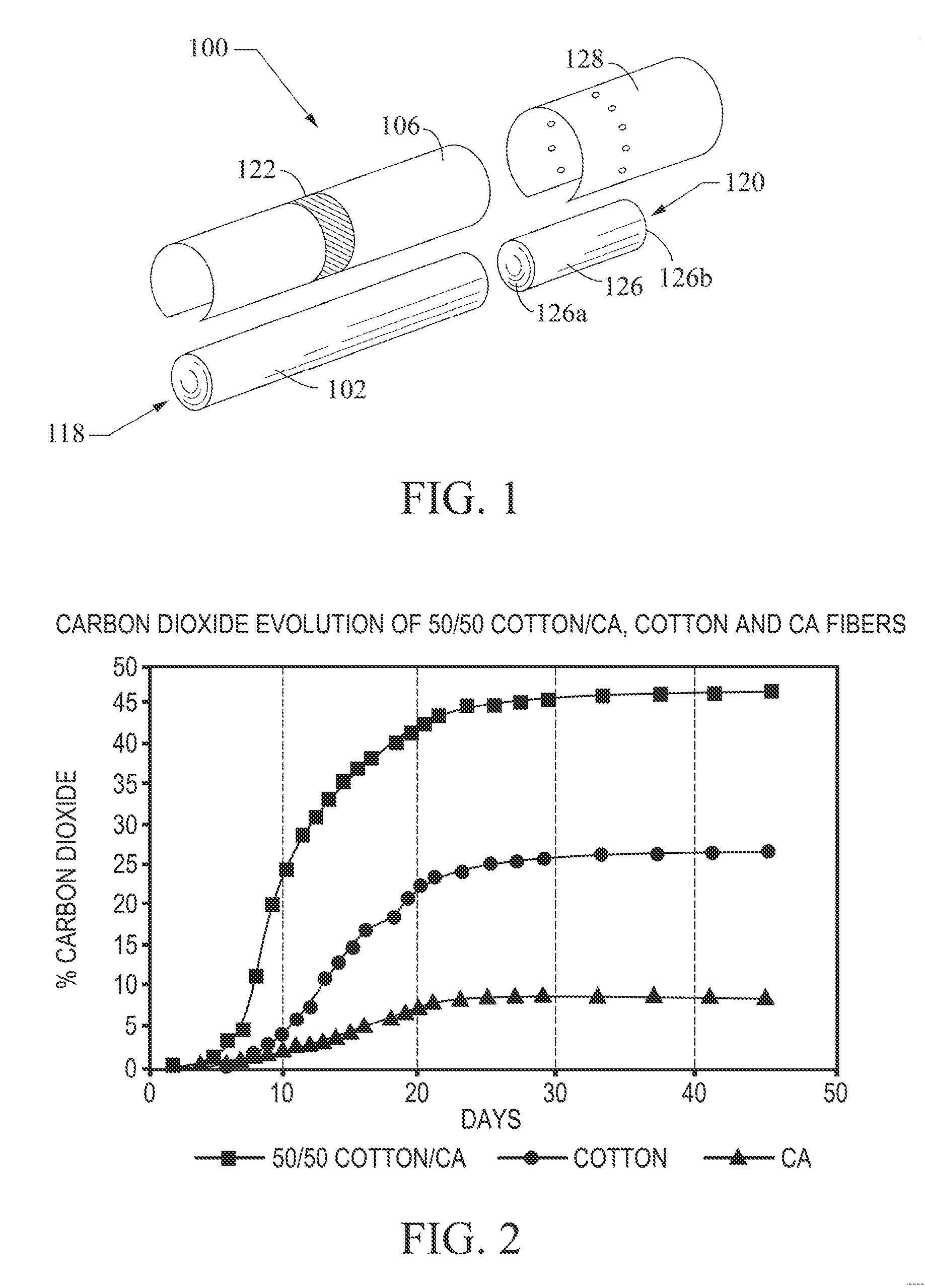

Electronic smoking article with improved storage and transport of aerosol precursor compositions

The present disclosure relates to reservoirs for storing products in electronic smoking articles. The reservoir is manufactured from cellulose acetate fiber, thermoplastic fiber, non-thermoplastic fiber, or a combination thereof. The reservoir is substantially tubular in shape and is adapted to accommodate internal components of the smoking article thereby increasing reservoir capacity. The internal components particularly can comprise an atomizer, which may include a braided wick.

Owner:RAI STRATEGIC HLDG INC

Electronic smoking article with improved storage of aerosol precursor compositions

The present disclosure relates to electronic smoking articles exhibiting improved moisture control of a reservoir contained therein. The reservoir can be formed of fibrous materials, such as cellulose acetate fiber, thermoplastic fiber, non-thermoplastic fiber, or a combination thereof. The disclosure further provides methods for forming electronic smoking articles and methods of packaging electronic smoking articles (including cartridges thereof) so as to improve moisture control of the reservoir.

Owner:RAI STRATEGIC HLDG INC

Melt-blown nonwoven fabric, process for producing same and the uses thereof

InactiveUS6207601B1Avoid undesirable oxidative processEliminate useLayered productsTobacco smoke filtersMean diameterPolymer science

The disclosure relates to a melt-blown non-woven fabric based on cellulose esters, with fibers of mean diameter less than about 10 microns. The fabric contains 0-10 wt. % extractable softener, has a reflection factor determined according to DIN 53 145 Part I (1992) of more than 60% and the cellulose ester has a degree of substitution DS of about 1.5-3.0. The softener is preferably water-extractable. A melt-blown non-woven fabric is produced with the cellulose ester as follows: a cellulose ester, cellulose acetate, with a DS of about 1.5-3.0, in particular 1.7-2.7, is mixed with softener in a weight ratio of about 2:1 to 1:4 and simultaneously heated and melted. The mixture of softener and cellulose ester has a melting index MFI (210 / 2.16) according to DIN 53 735 of about 400 to 5 g / 10 min., in particular 300 to 50 g / 10 min. The melt is worked in a melt-blown spinning device into a melt-blown non-woven fabric and the softener is then extracted with a softener solvent to leave a proportion of 0-10 wt. %. The melt-blown non-woven fabric is especially suitable as a filter material.

Owner:RHODIA ACETOW AG

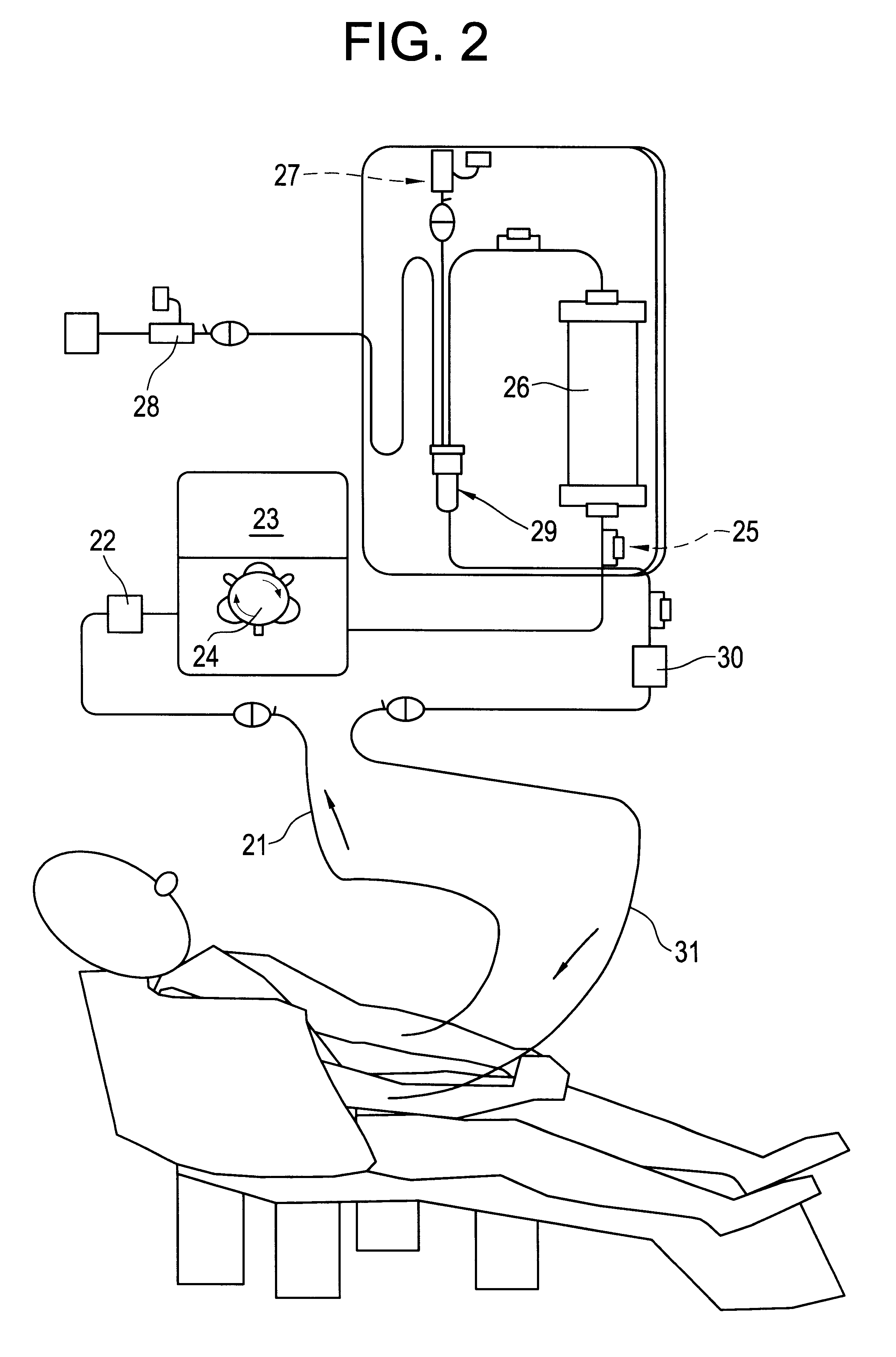

Methods of treatment of disease using adsorbent carriers

InactiveUS6498007B1Increase productionReduce in quantityAntibacterial agentsSolvent extractionDiseaseAcetic acid

The invention relates to a method for the removal of leucocytes from blood which comprises bringing blood that comprises infected leucocytes into contact with an adsorbent carrier that has a greater affinity for infected, activated and / or defective leucocytes than for uninfected leucocytes especially cellulose acetate. The method can be used in the apheresis treatment of diseases caused by pathogenic organisms, for example, HIV, HCV or malaria. It is especially useful for treatment of HIV.

Owner:JIMRO

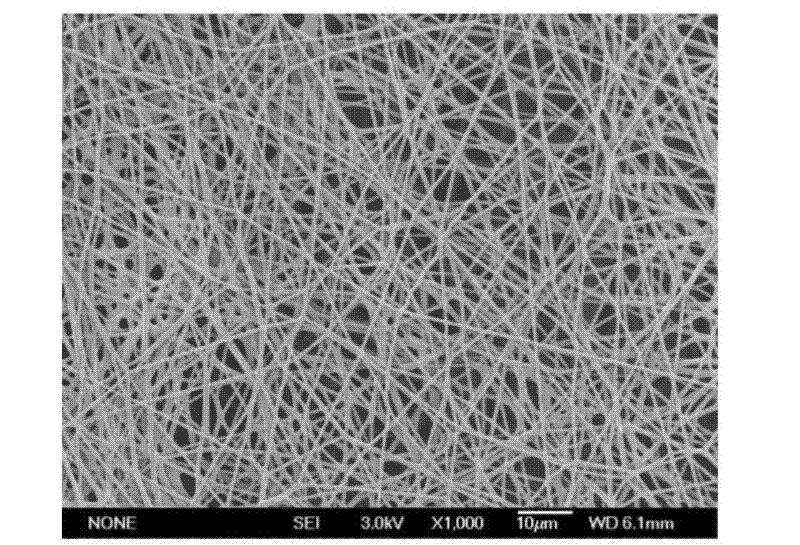

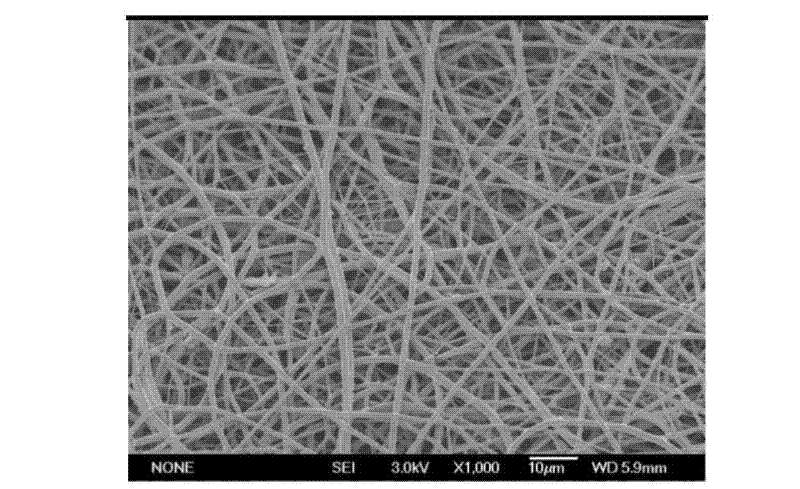

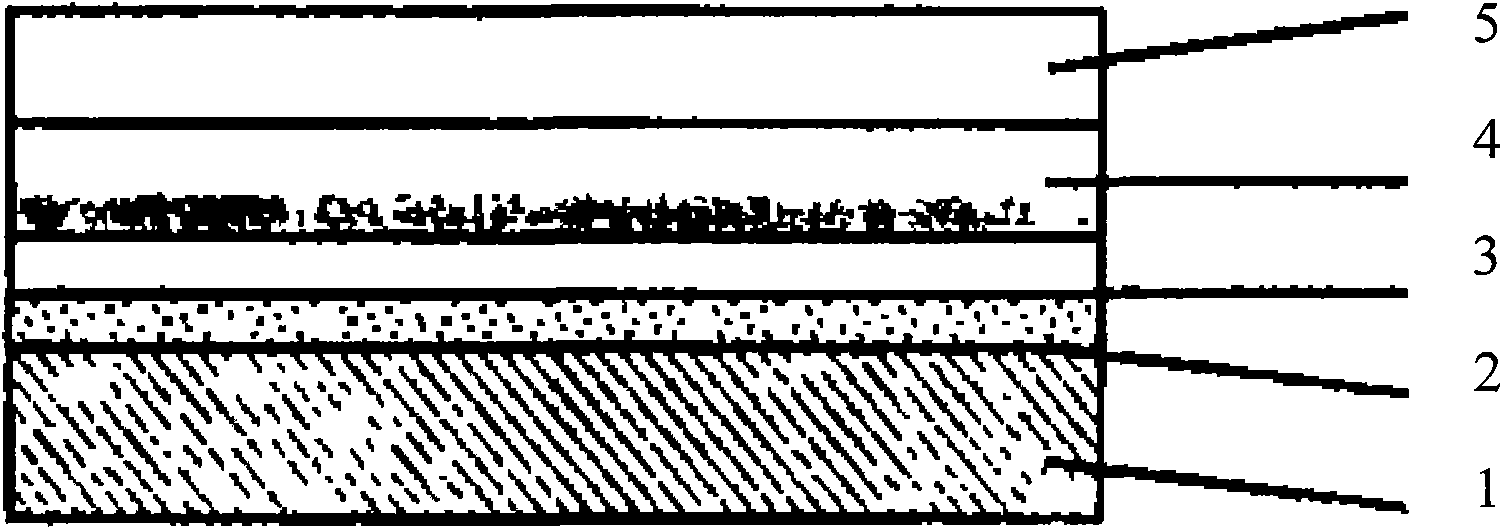

Composite fibre membrane with unidirectional water permeable performance and preparation method thereof

The invention discloses a composite fibre membrane with an unidirectional water permeable performance and a preparation method of the composite fibre membrane, belonging to the field of functional micron / nano composite fibre materials; the composite fibre membrane is composed of a two-layer structure; a hydrophile layer is a nano-scale fibre membrane composed of hydrophile polymers such as polyvinyl alcohol, cellulose acetate, polyacrylate and the like; fibre diameter is 100-800nm; thickness is 25-35 microns; a lyophobic layer is the micron-scale fibre membrane composed of lyophobic polymers such as polyurethane, polystyrene, polymethylmethacrylate or polycaprolactone and the like; thickness is 5-10 microns; and fibre diameter is1.0-3.0 microns. The composite fibre membrane can be controlled by regulating technical parameters and has hydrophile / lyophobic differences and an excellent directional water permeable performance; and the preparation method is characterized by simple operation, low energy consumption, high efficiency and is widely used for fields of perspiring-type waterproof dress materials, fuel cell electrolyte membranes, unidirectional liquid transmission and separation and the like.

Owner:BEIHANG UNIV

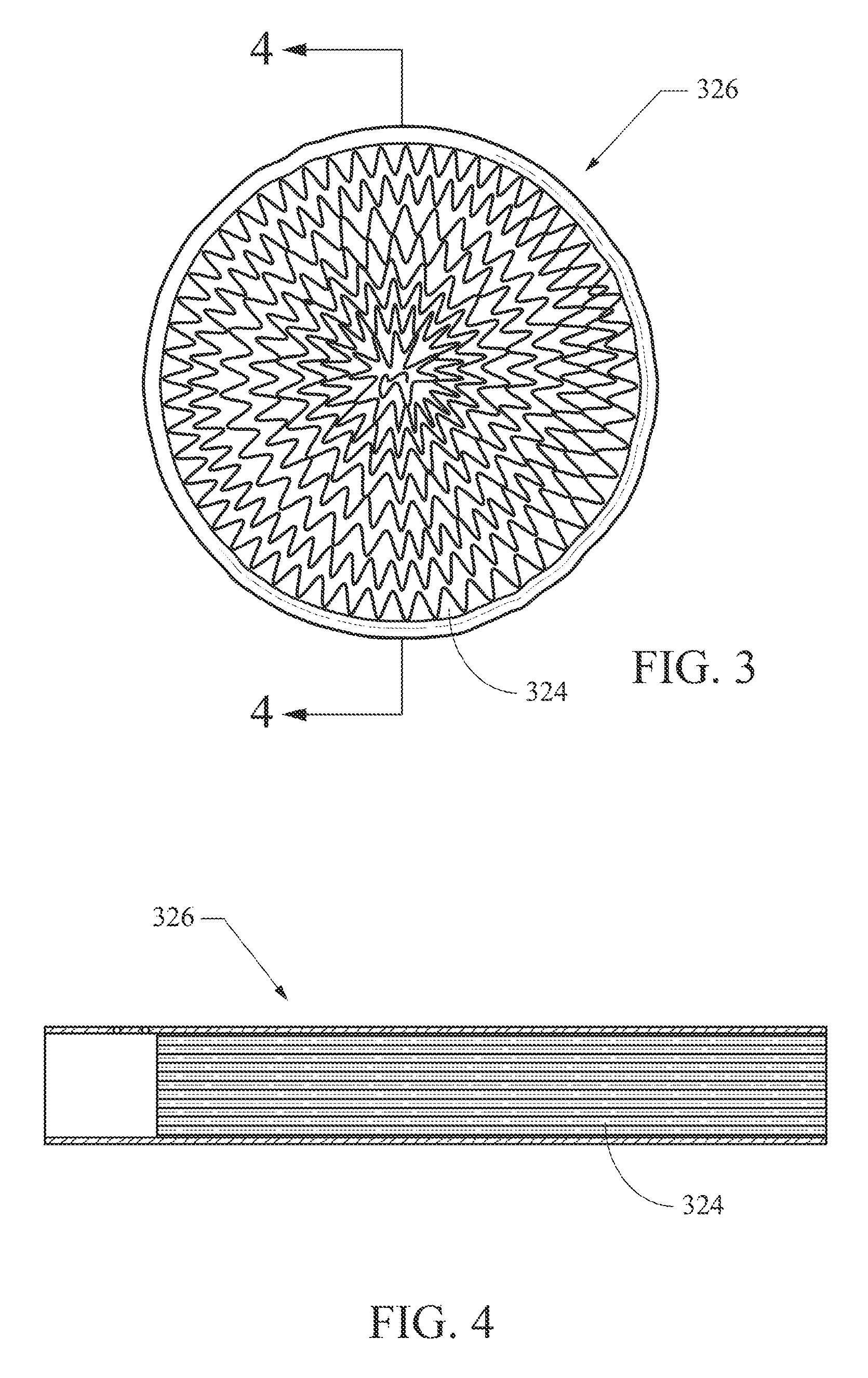

Biodegradable cigarette filter

InactiveUS20120000480A1Improve degradation rateIncrease usable surface areaTobacco treatmentTobacco smoke filtersFiberCellulose acetate

A biodegradable fiber (including fiber tow) and / or biodegradable paper substrate may be coated with cellulose acetate and / or plasticized cellulose acetate for use in a filter material configured for application in a filter of a smoking article. A filter made in accordance with this design may also include non-biodegradable material.

Owner:R J REYNOLDS TOBACCO COMPANY

A cigarette filter filament and preparation method thereof

InactiveCN1961765ANo pollutionReduce pollutionTobacco smoke filtersHeating/cooling textile fabricsPolyesterPolymer resin

The invention relates to a tobacco filter tip and relative preparation, wherein it is formed by spinning the lactic acid polymer resin, drawing, coiling and shaping, while the line density is 2-6dtex, the beam density is 3-6ktex, the coil number is 15-30n / 25mm. And it uses the adhesive method similar acetate fabric. Therefore, its polymer structure and large specific area can support the adsorption on organic, and filter the solid particle.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

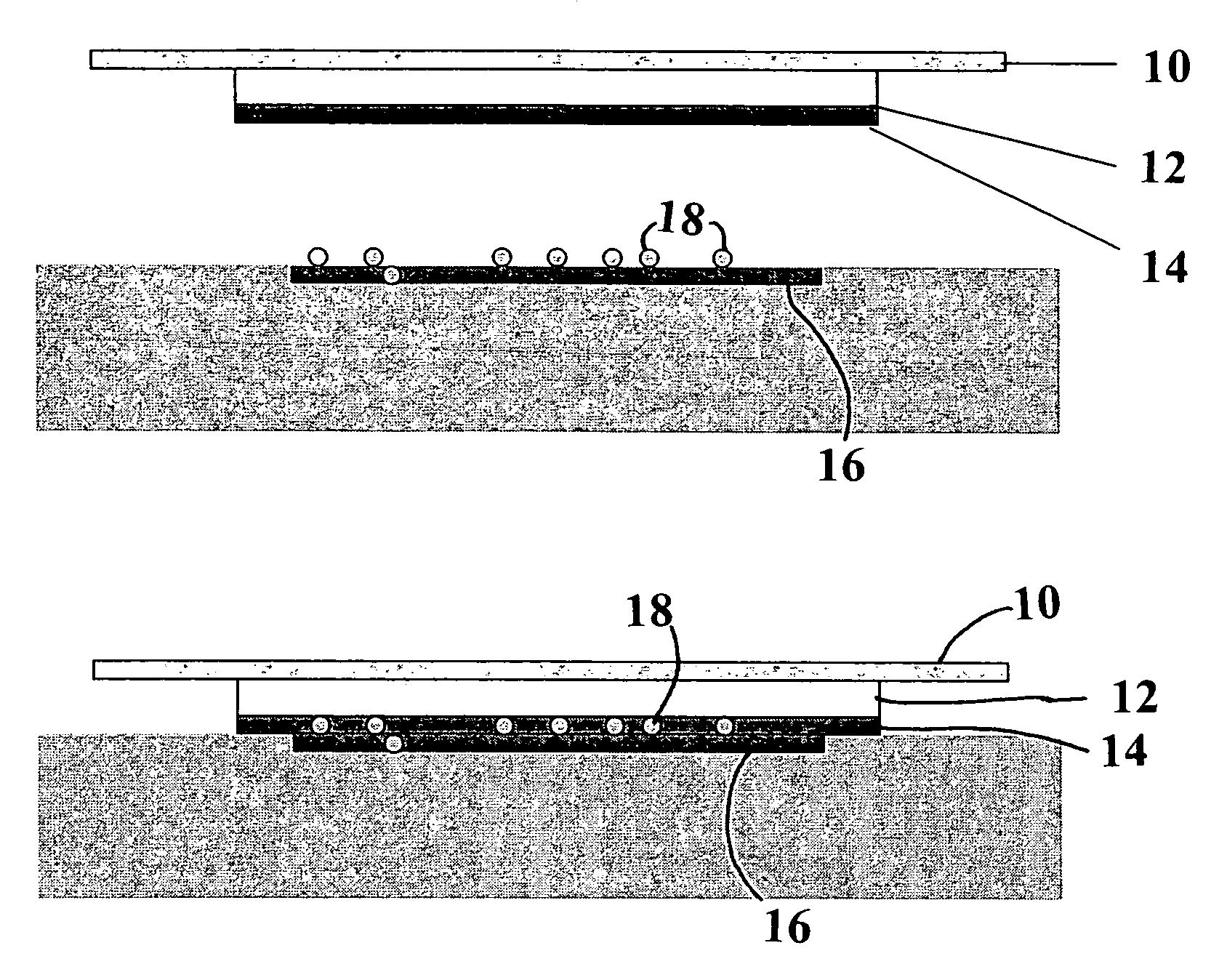

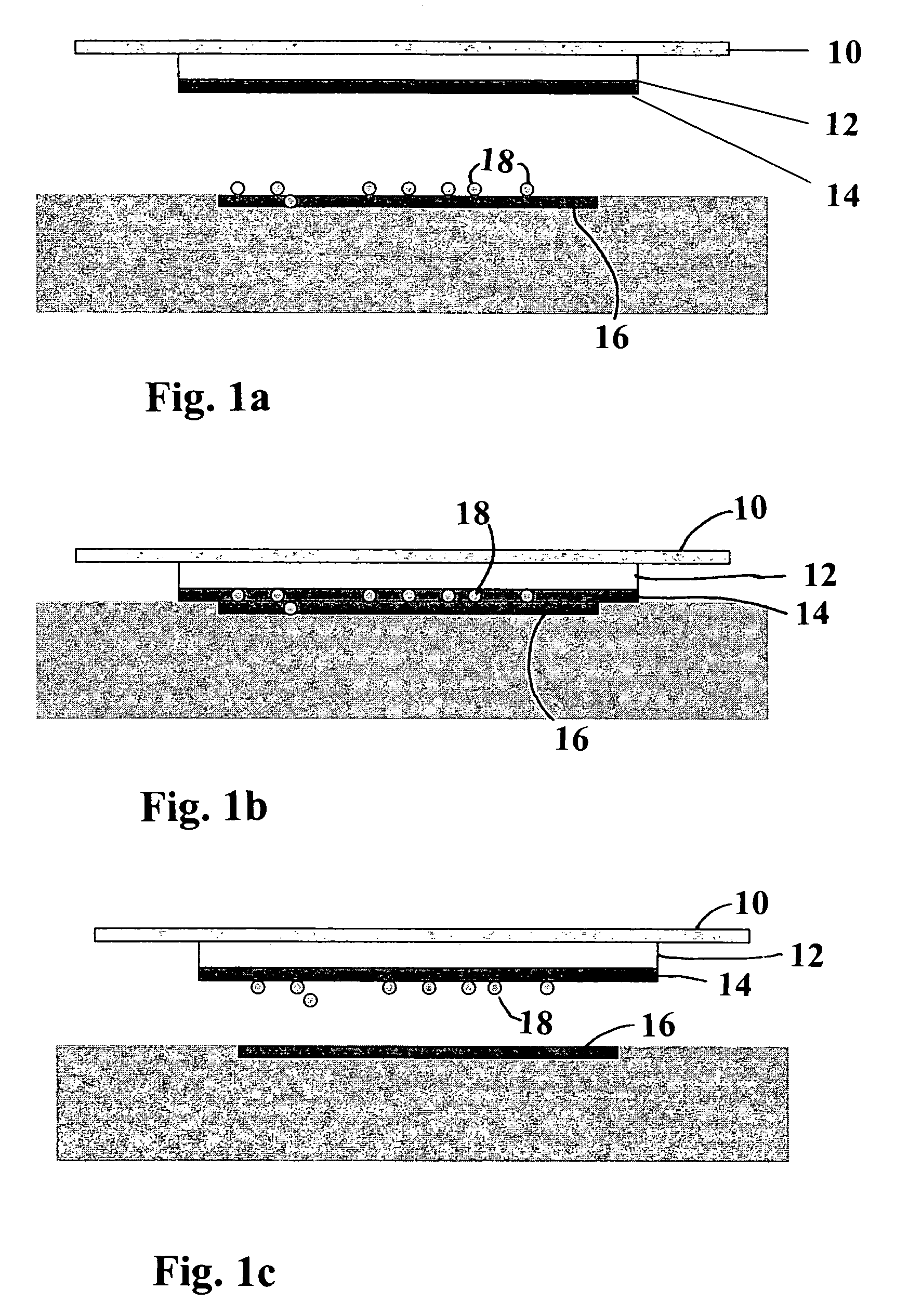

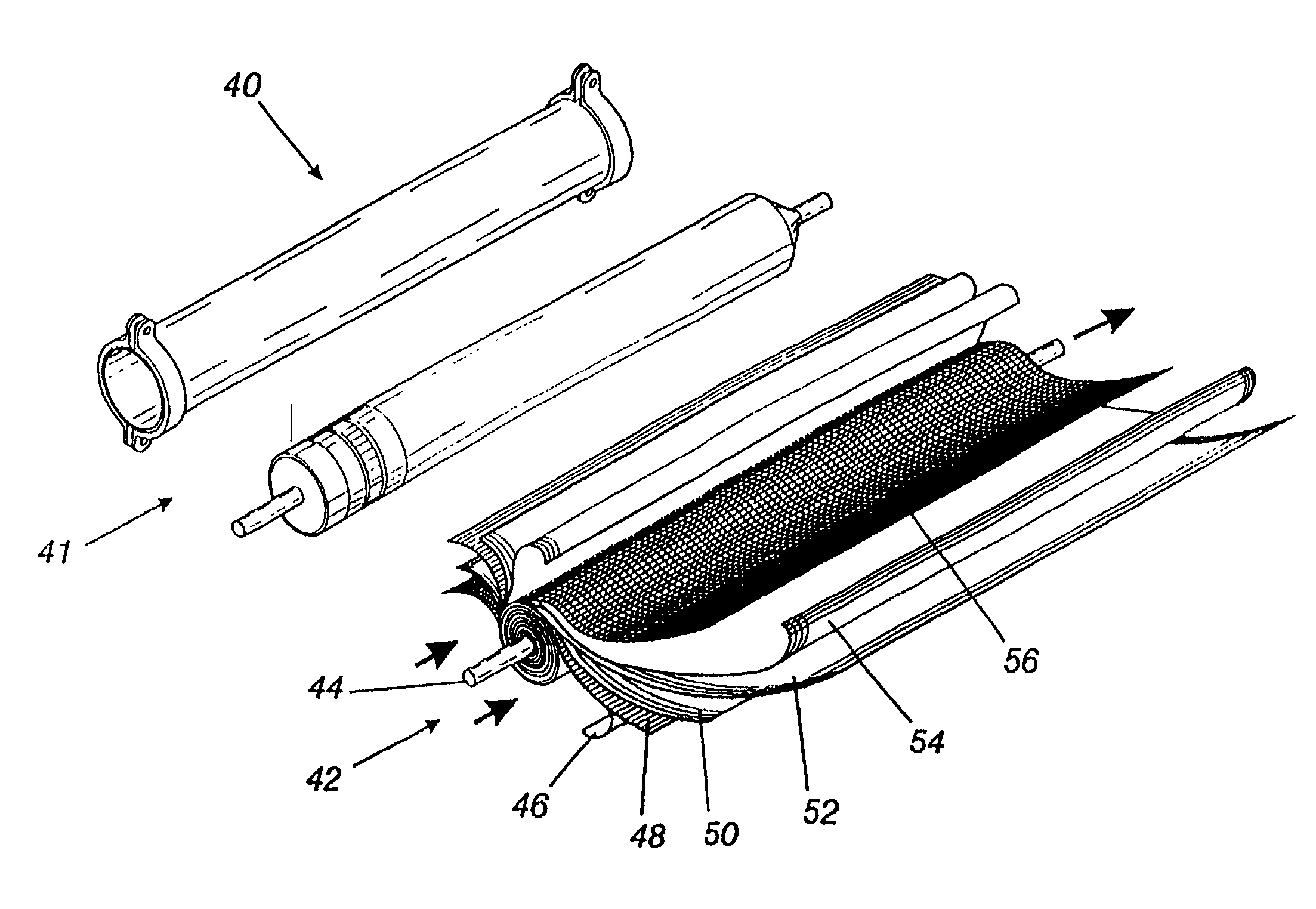

Antimicrobial semi-permeable membranes

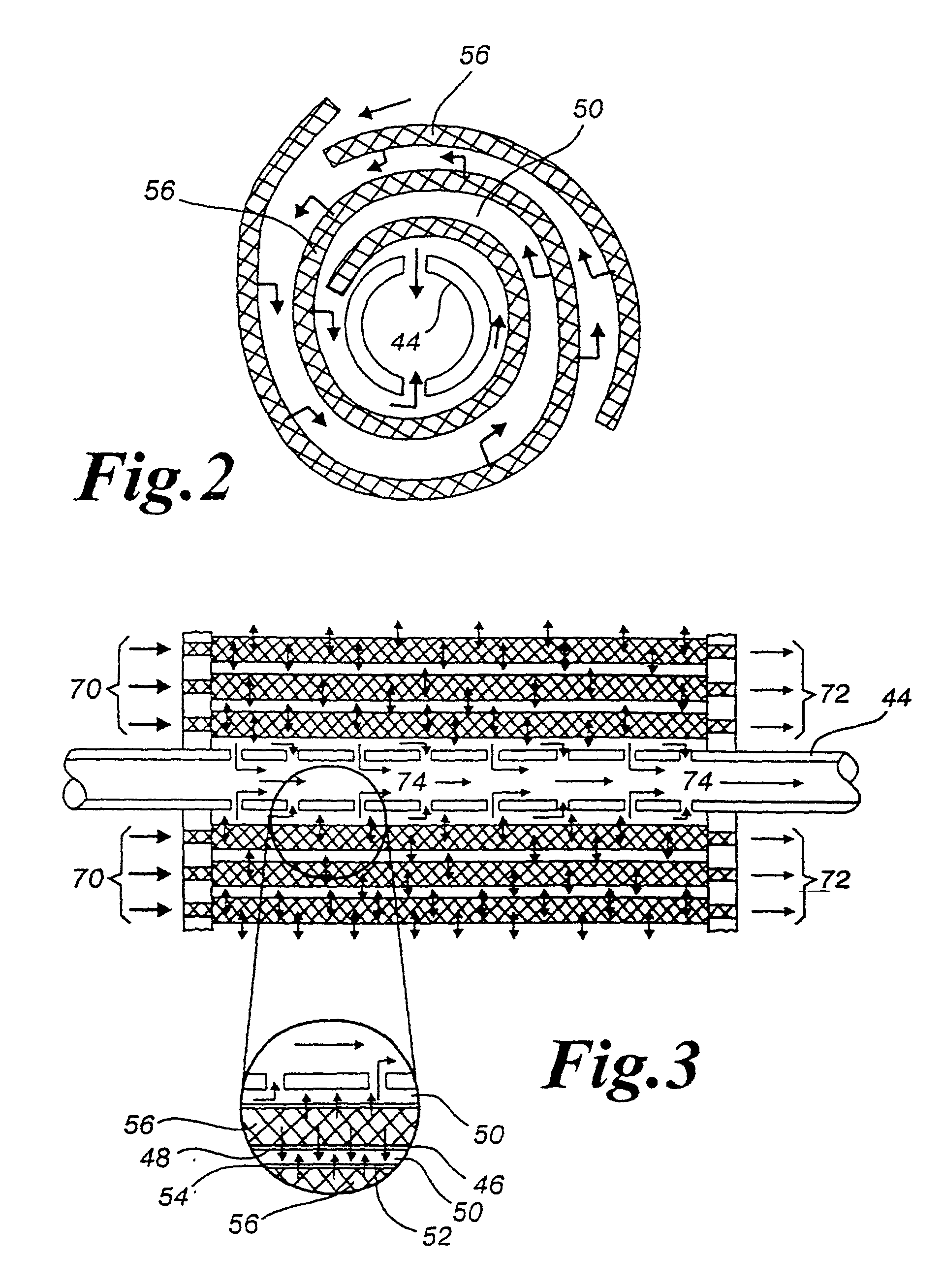

Cast semi-permeable membranes made from synthetic polymer used in reverse osmosis, ultrafiltration and microfiltration are treated with a non-leaching antimicrobial agent to prevent its bio-fouling and bacterial breakthrough. The semi-permeable membranes include a polymeric material and a non-leaching antimicrobial agent that is incorporated into and homogeneously distributed throughout the polymeric material. The polymeric material, in the case of one membrane, may be cellulose acetate. In the case of thin film composite polyamide membranes, the antimicrobial agent is incorporated in a microporous polysulfone layer that is sandwiched between a reinforcing fabric and an ultrathin polyamide material. The invention also includes a treatment of flat and hollow fiber semipermeable membranes made with polysulfones and polyvinylidene fluoride.

Owner:MICROBAN PROD CO INC

Wound dressing with a bacterial adsorbing composition

ActiveUS7576256B2Reduce in quantityNon-adhesive dressingsSurgical needlesMicroorganismWound dressing

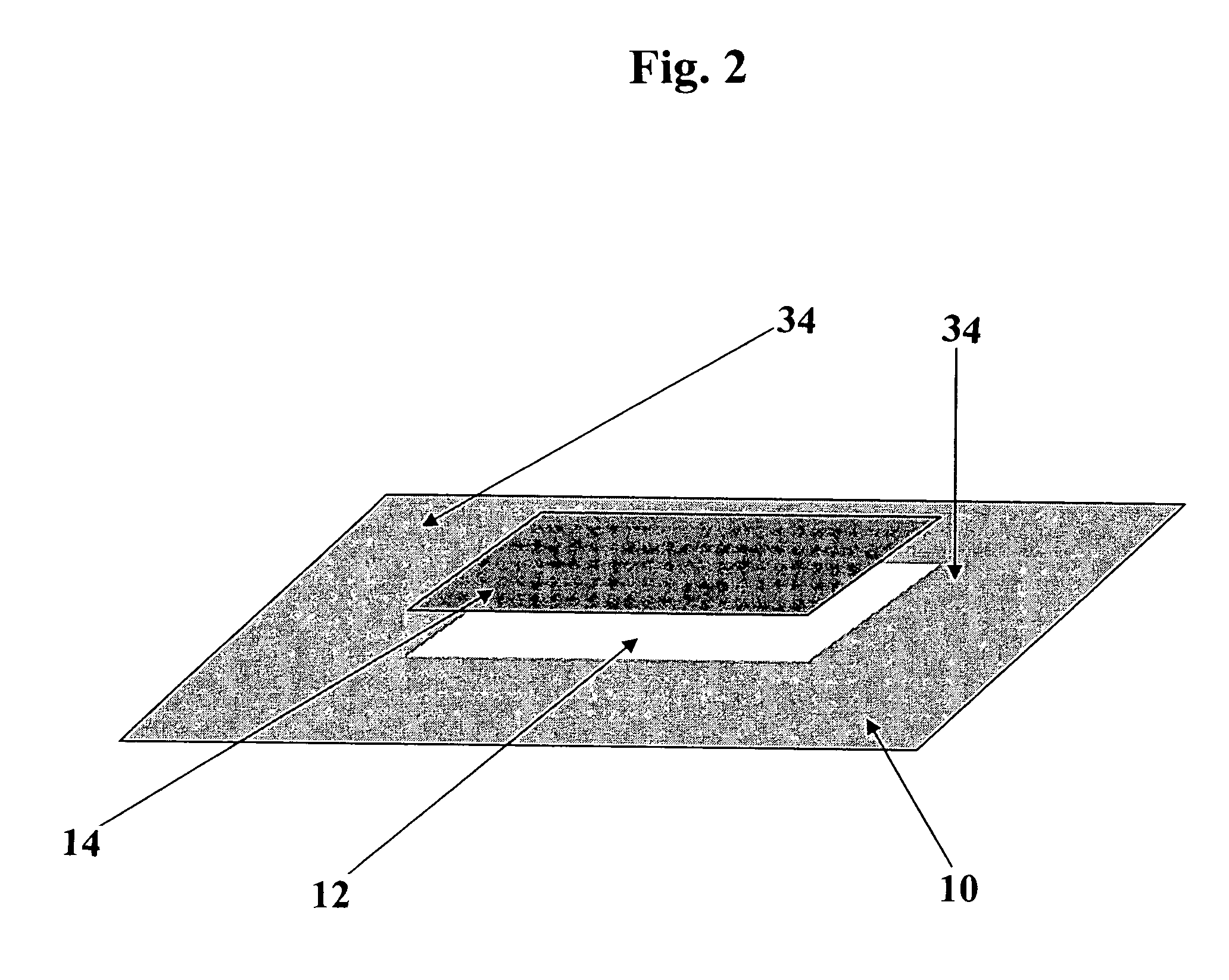

A wound dressing product, combining both a traditional dressing with a mounted absorbent material and a hydrophobic fabric attached thereto, which is to be placed towards the wound, and is capable of binding unwanted microorganisms. The wound dressing product protects the wound, absorbs exudate and reduces the number of pathogenic microorganisms, without using antimicrobial substances, and consists of three bonded layers: hydrophobic cellulose acetate fabric which binds microorganisms, an attached efficient absorbent material, and a backing (cover) which is preferably visually transparent, semi-permeable and self-adhesive.

Owner:ABIGO MEDICAL AB

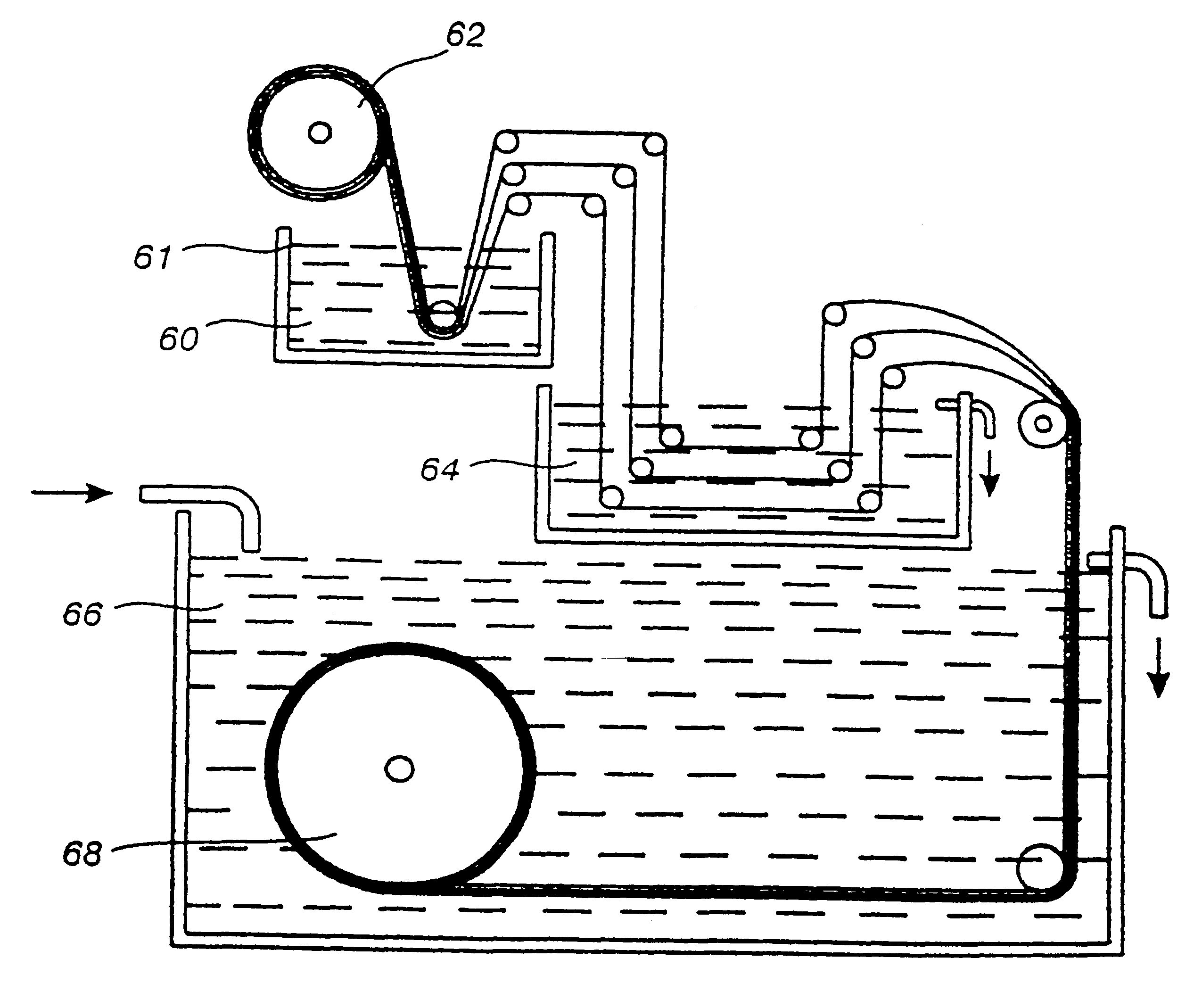

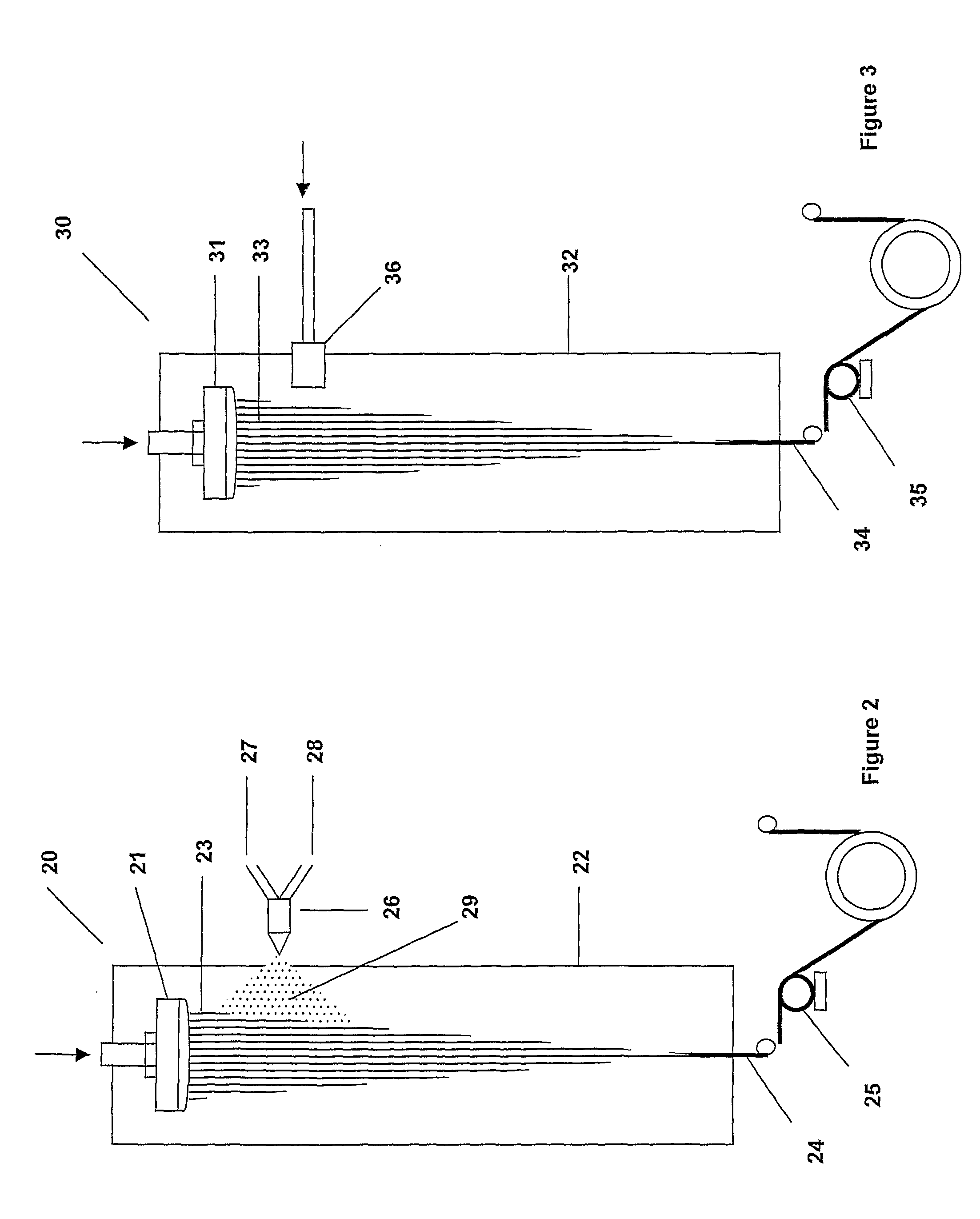

Process for making cellulose acetate tow

A process for making a cigarette tow comprising: spinning a dope; taking-up the as-spun cellulose acetate filaments; lubricating the filaments; forming a tow from the filaments; crimping the tow with a stuffer box crimper; drying the crimped tow; and baling the dried crimped tow. The process further comprises at least two of the following:A. crimping further comprising one roller of the pair of nip rollers being adapted to induce crimp into the tow;B. crimping further comprising one roller of the pair of nip rollers being made of a solid ceramic material;C. crimping further comprising a pair of tow edge lubricators;D. crimping further comprising a steam injector;E. further comprising plasticizing the tow;F. lubricating the filaments further comprises a finish consisting of a water emulsion.

Owner:DEUT BANK AG NEW YORK BRANCH AS COLLATERAL AGENT +1

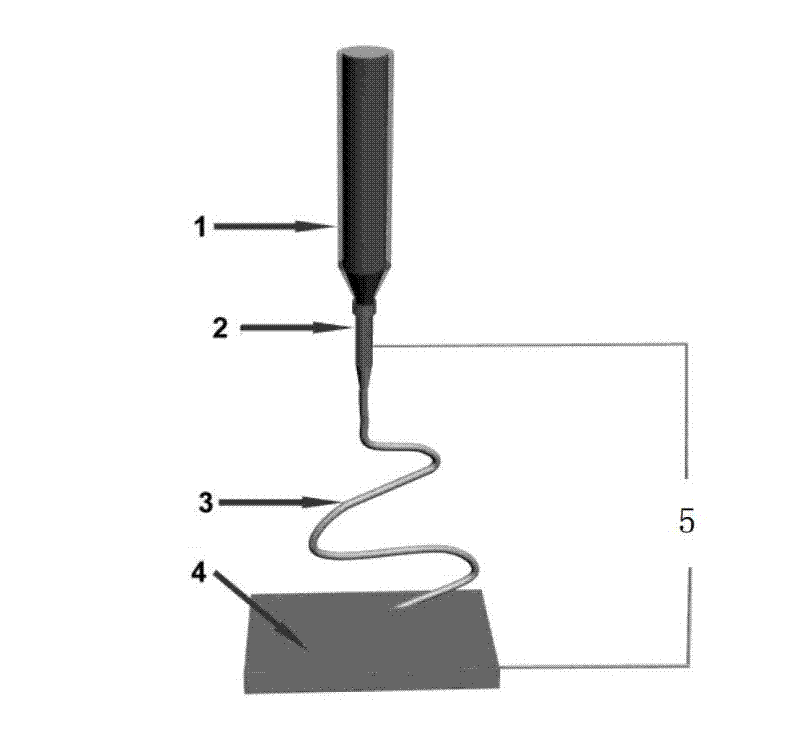

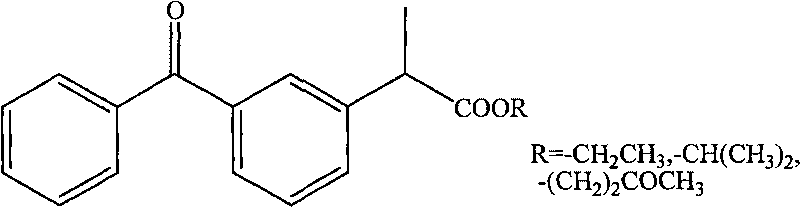

Medicinal fibre used for treating cutaneous inflammation and pain, preparation and application thereof

InactiveCN101724934AEasy to prepareLow costOrganic active ingredientsAntipyreticFiberOrganic solvent

The invention relates to medicinal fibre used for treating cutaneous inflammation and pain, which comprises the components of cellulose acetate nano fibre, a ketoprofen ester precursor medicine and a medicinal percutaneous sorbefacient, wherein the ketoprofen ester precursor medicine accounts for 0.1-30% of the total weight of the fibre, the medicinal percutaneous sorbefacient accounts for 0.1-10% of the total weight of the fibre, and the cellulose acetate nano fibre accounts for 1-99% of the total weight of the fibre; the preparation of the medicinal fibre comprises the following steps: dissolving the ketoprofen ester precursor medicine, the medicinal percutaneous sorbefacient and the cellulose acetate into an organic solvent to prepare spinning liquid and then spinning to prepare the required medicinal fibre. The medicinal fibre has the effect of treating cutaneous inflammation and pain, has simple preparation method, convenient source of the raw materials and low cost, is friendly to the environment and is suitable for industrialized production; the fibre can be prepared into medicine-carrying clothings or other fabrics which directly contact with the skin of a human body, and the percutaneous administration is safe and comfortable.

Owner:DONGHUA UNIV +1

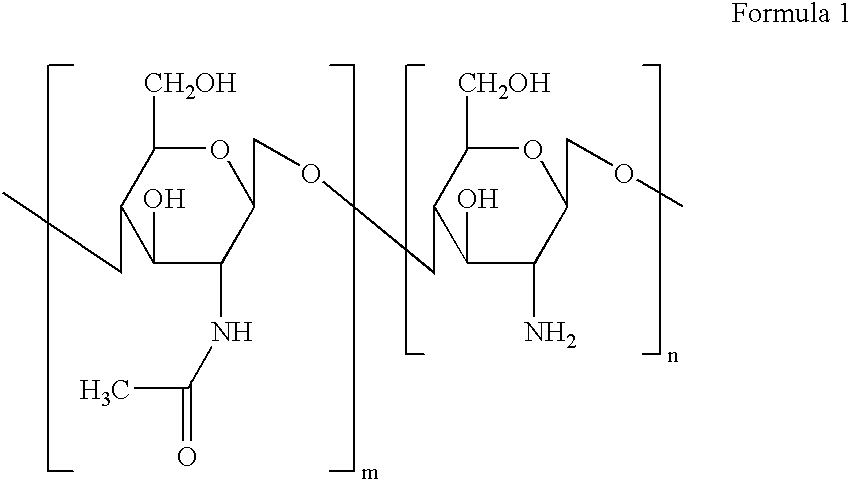

Polymer blends that swell in an acidic environment and deswell in a basic environment

InactiveUS6537584B1Improve propertiesControlling the swelling and/or deswelling behaviorBiocidePowder deliveryChemical structurePolymer dissolution

A polymer blend is prepared by dissolving chitosan and a second polymer in an acidic aqueous solution to form an aqueous polymer blend, dehydrating said aqueous polymer blend, and recovering said polymer blend. The second polymer may be selected from the group consisting of polyether glycols including polyethylene glycols; cellulose esters including cellulose acetate; poloxamers; polysaccharides including dextran and guar; polyvinylpyrrolidones; polyvinyl alcohols; and mixtures or copolymers thereof. These polymer blends swell in an acidic environment and deswell in a more neutral or basic environment. This technology is valuable for the dispensing of biologically active material or drugs into a surrounding environment, especially the environment as is found in the gastrointestinal tract. Since the various polymer blends of the present invention are not covalently or ionically crosslinked, but are physically combined, each polymer in the physical blend maintains its original chemical structure, and therefore, is safe for oral administration.

Owner:BTG INT LTD

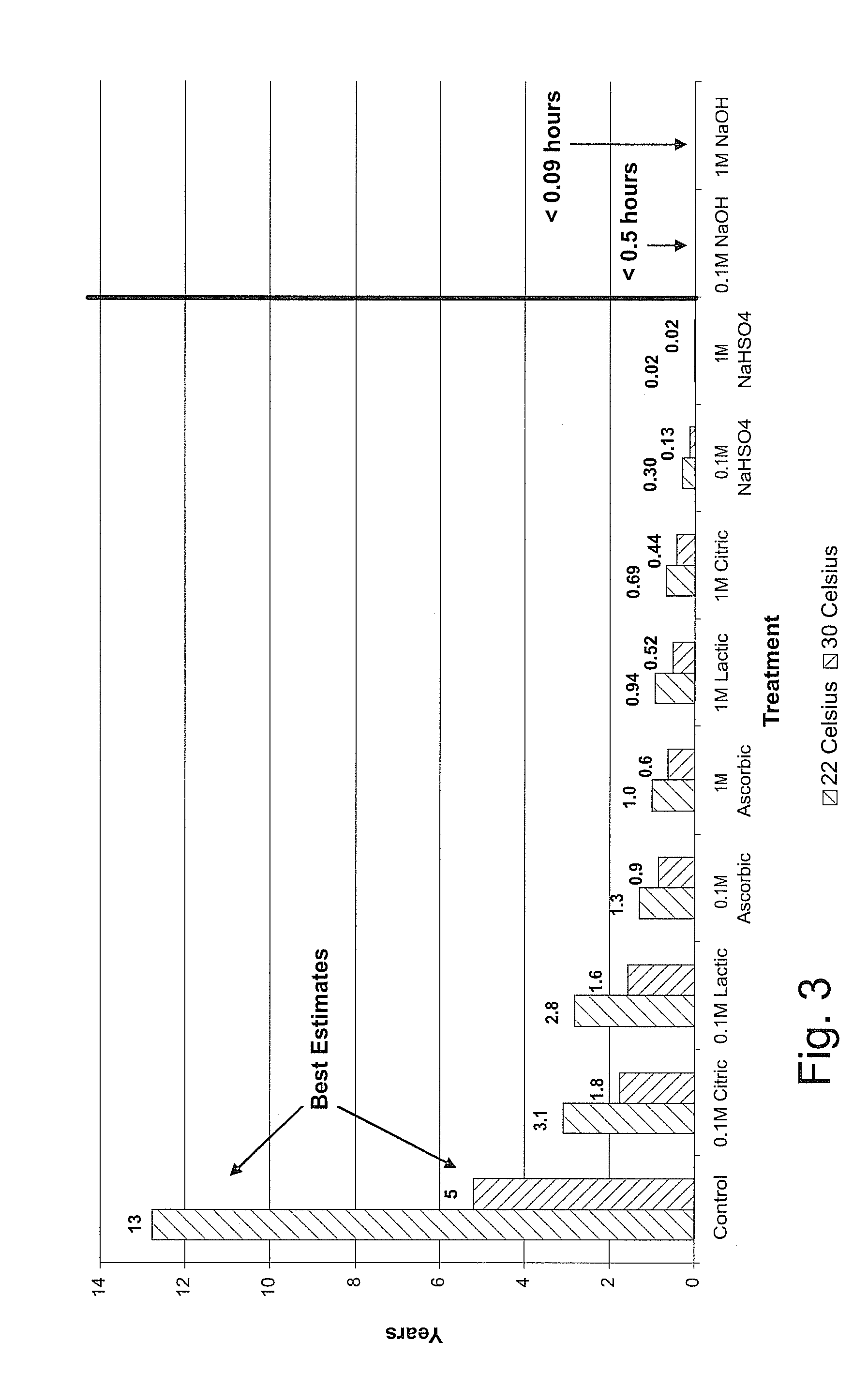

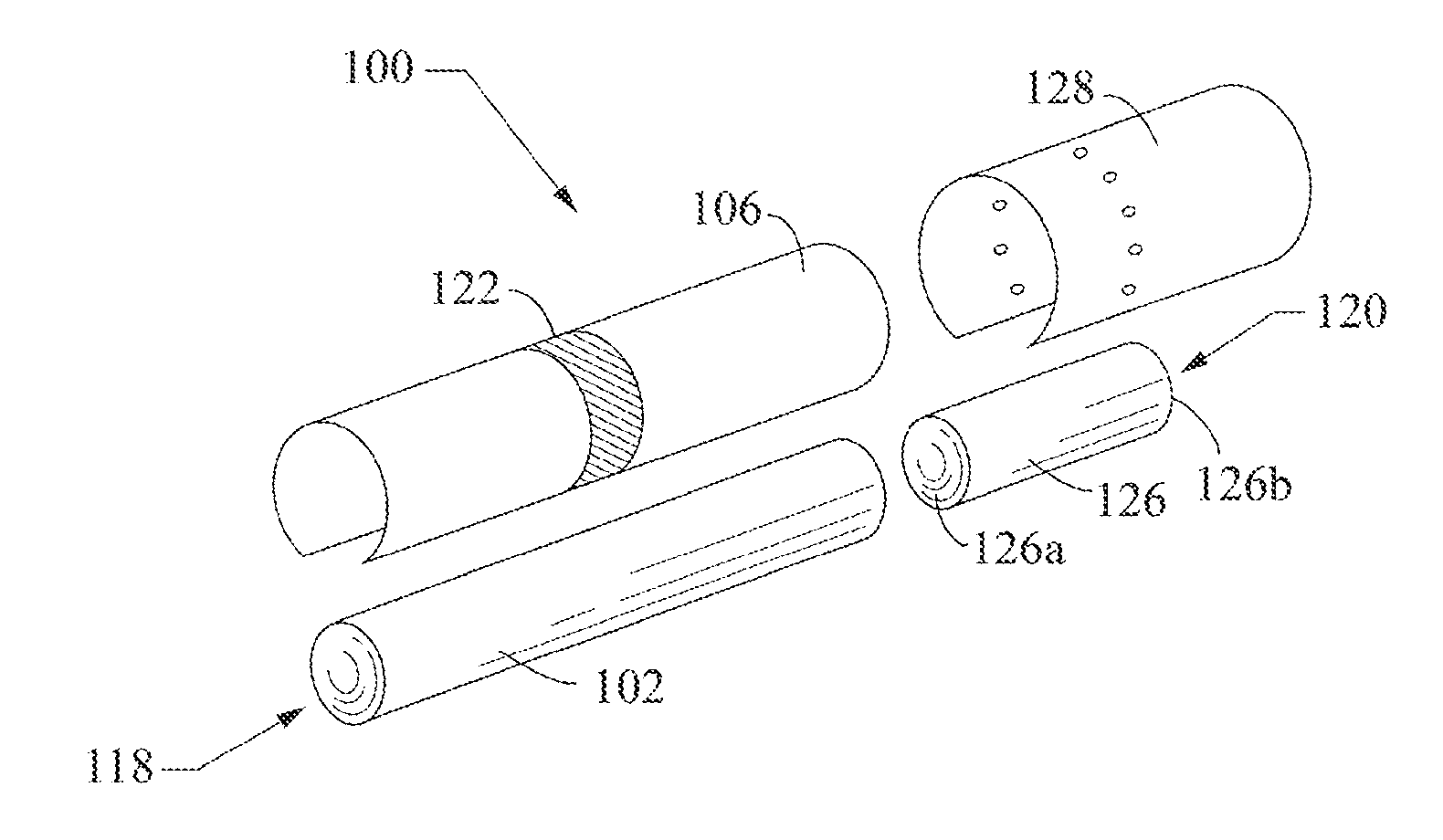

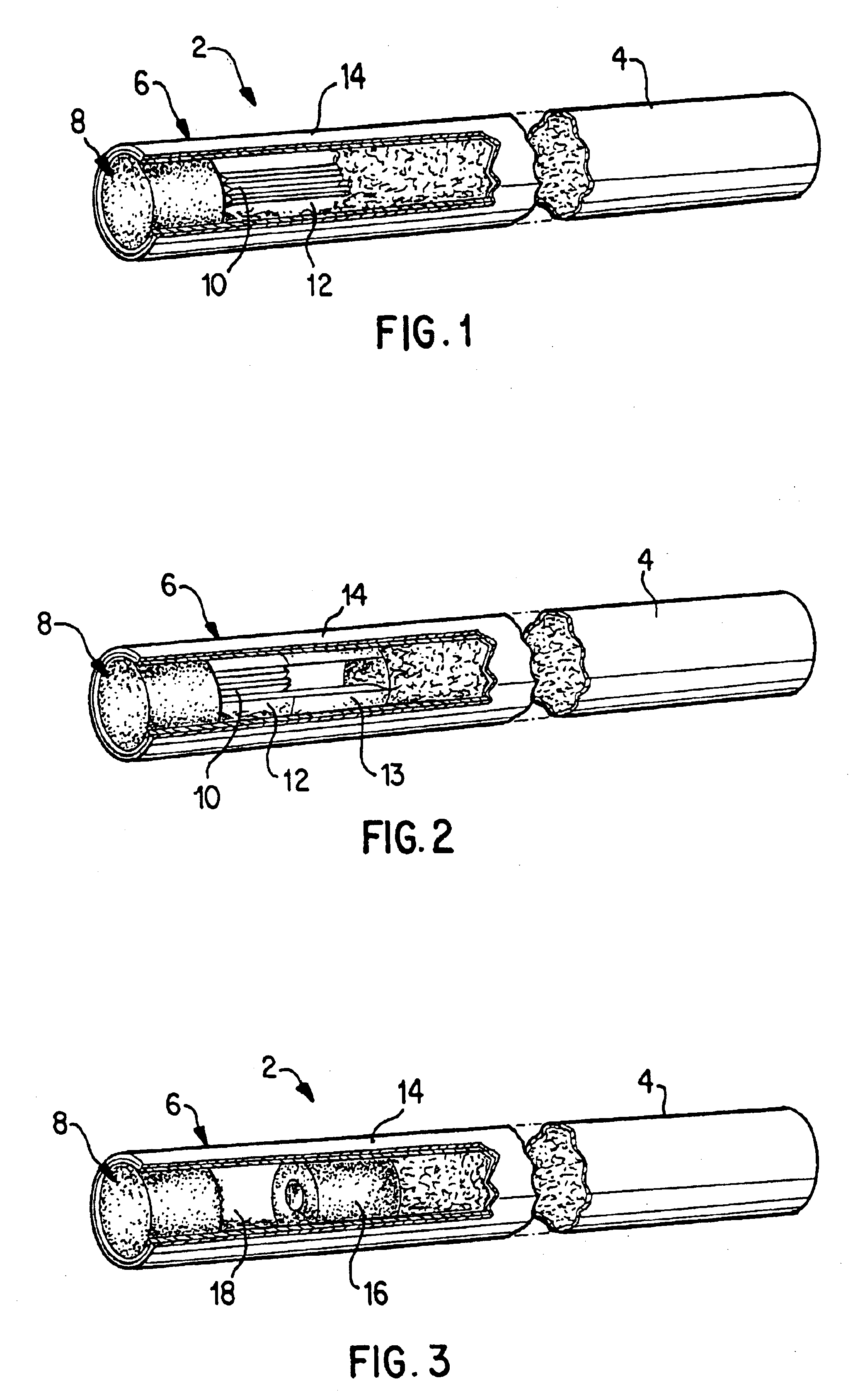

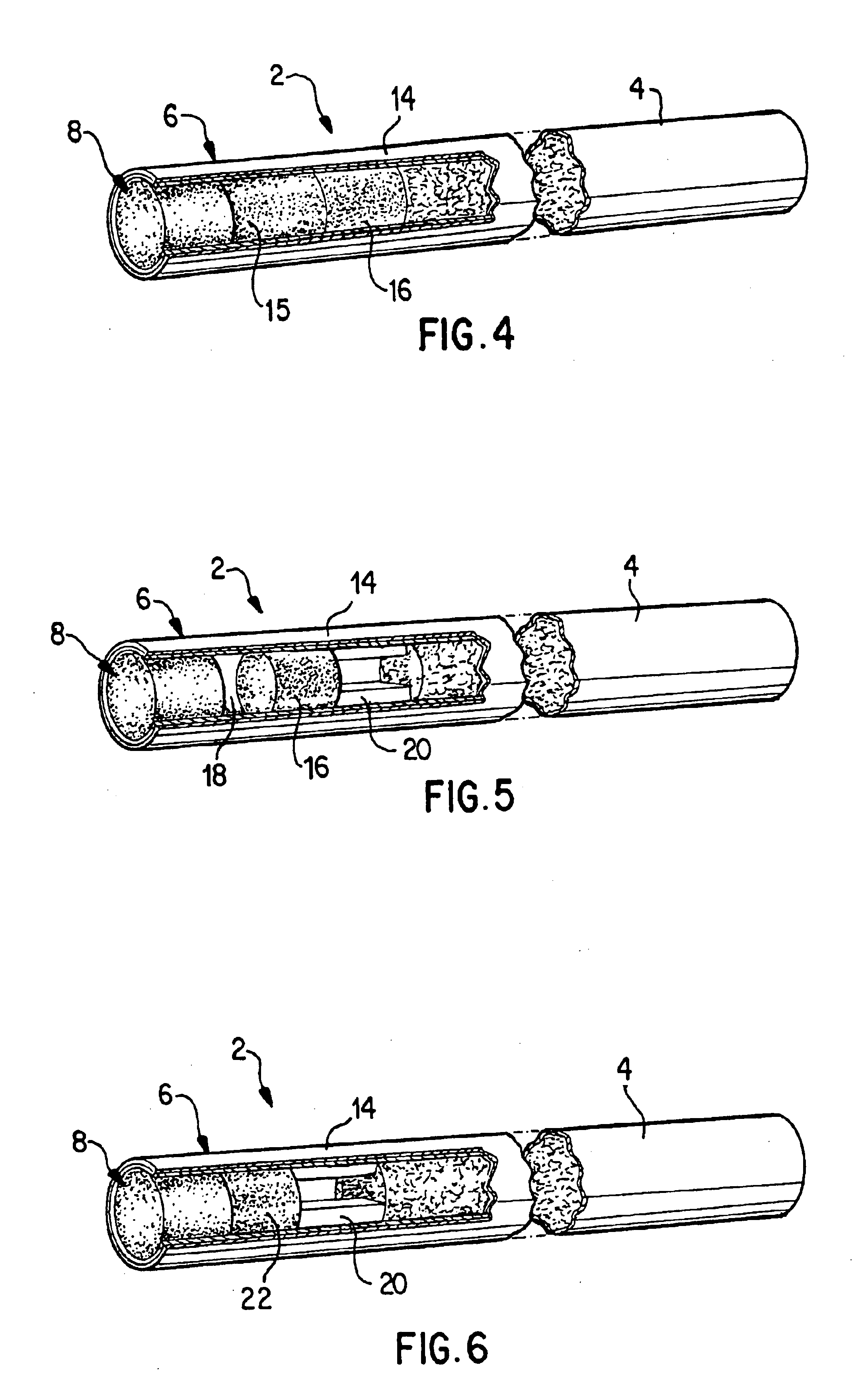

Degradable cigarette filter

A degradable cigarette filter includes a filter element of a bloomed cellulose acetate tow, a plug wrap surrounding the filter element, and either a coating or a pill in contact with the tow. The coating and / or pill may be composed of a material adapted to catalyze hydrolysis of the cellulose acetate tow and a water-soluble matrix material. The material may be an acid, an acid salt, a base, and / or a bacterium adapted to generate an acid. The coating may be applied to the tow, the plug wrap, or both. The pill may be placed in the filter element. When water contacts the water-soluble matrix material, the material adapted to catalyze hydrolysis is released and catalyzes the hydrolysis, and subsequent degradation, of the cellulose acetate tow. The foregoing is also applicable to articles made of cellulose esters.

Owner:ACETATE INT LLC

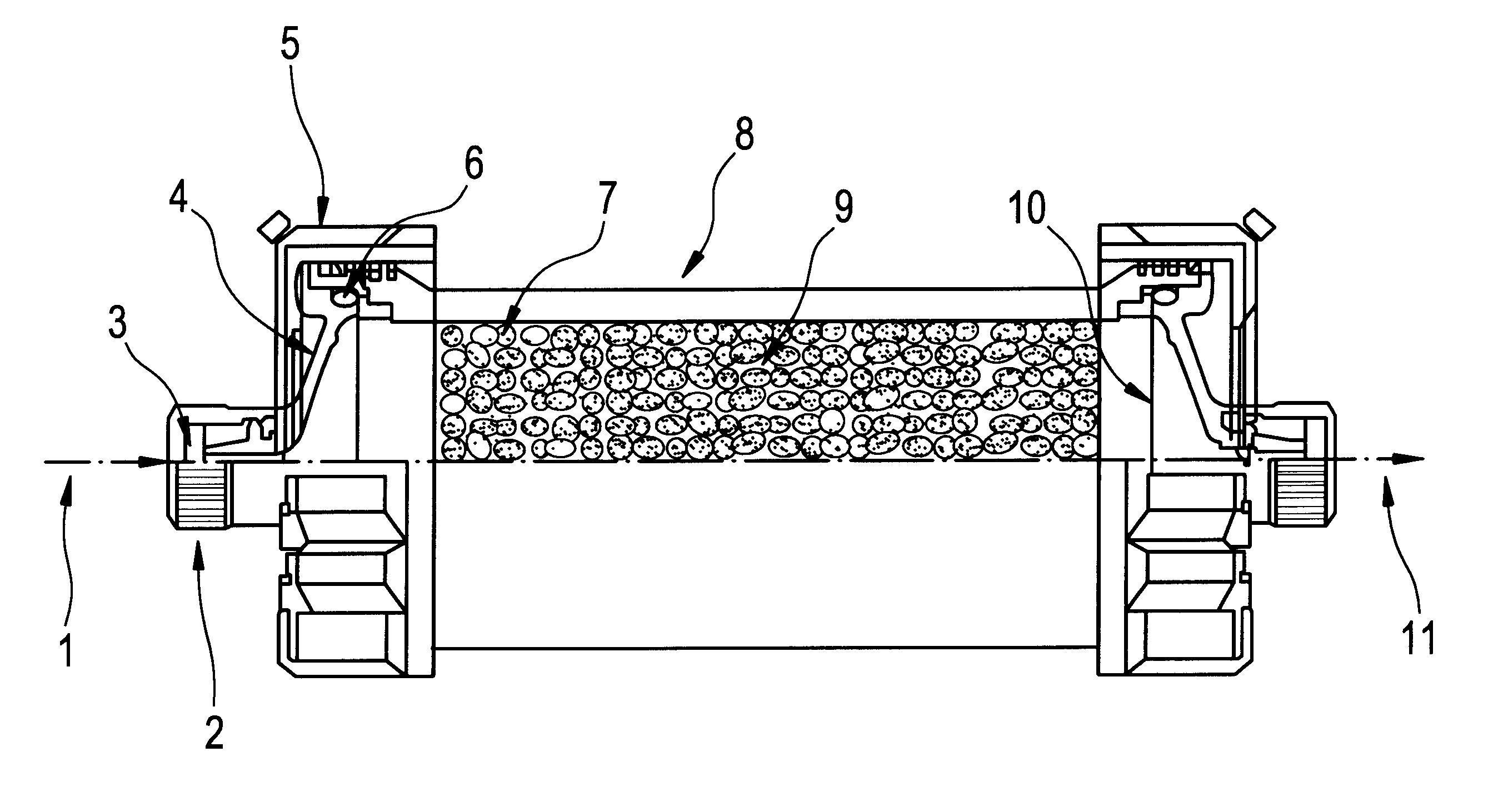

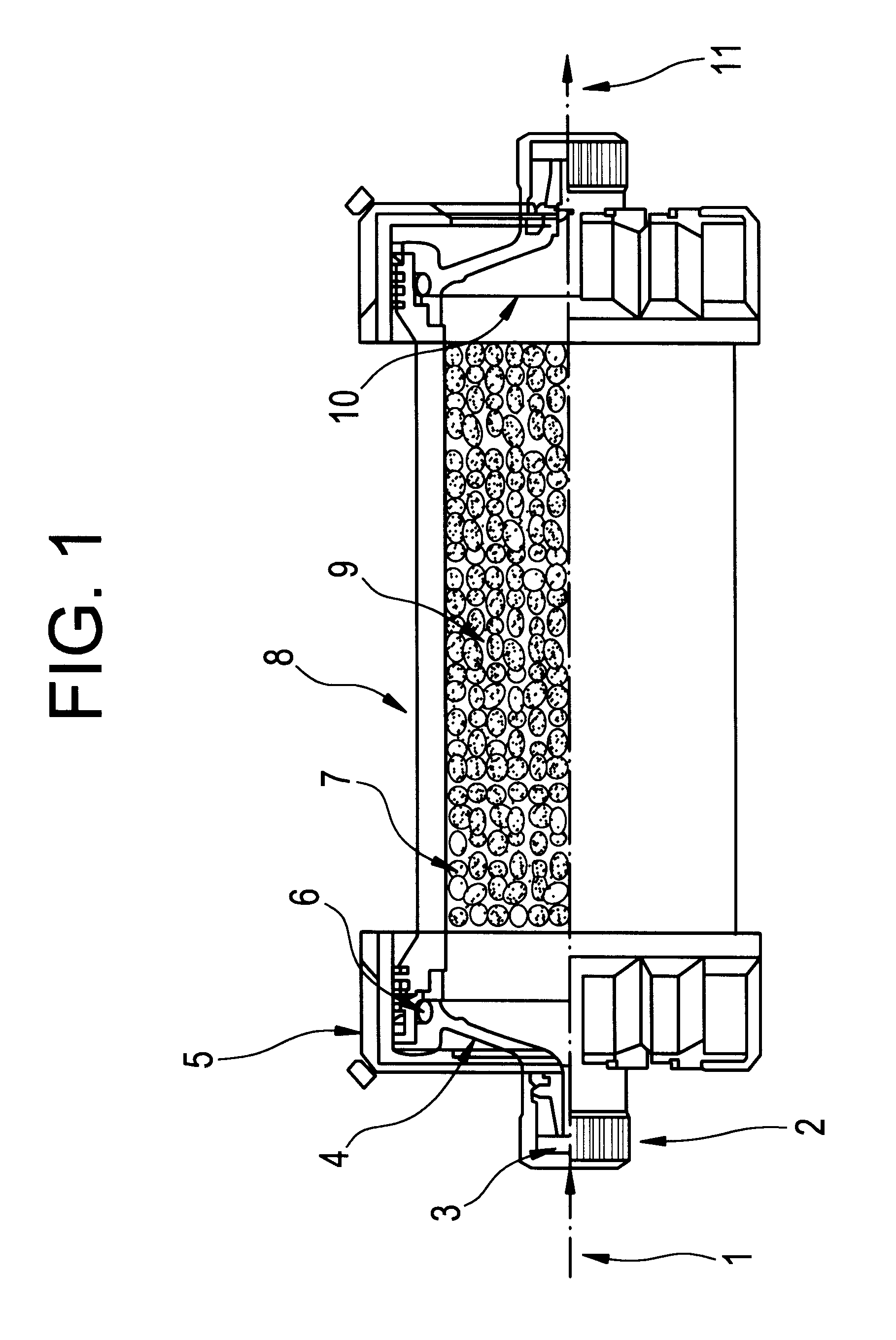

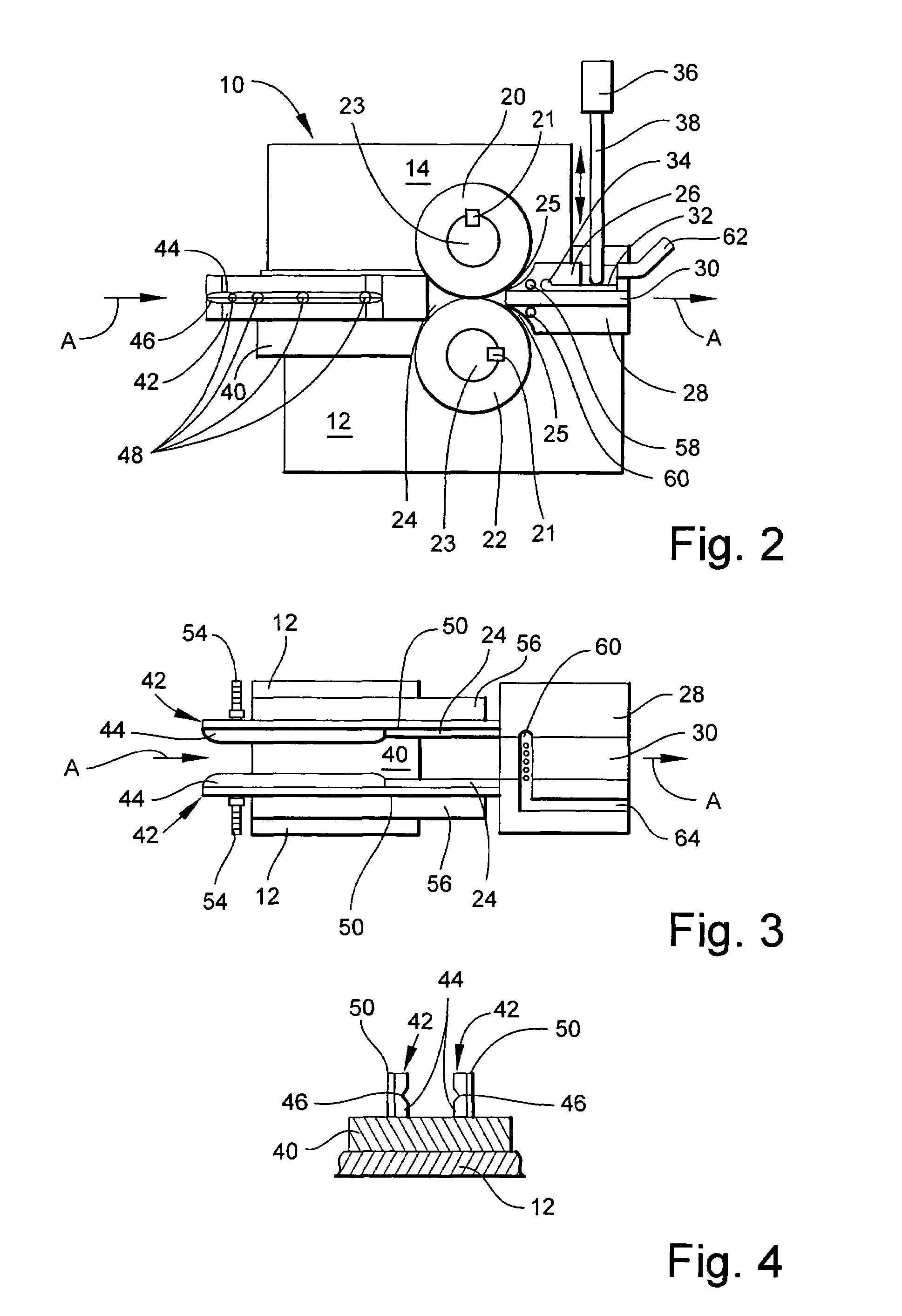

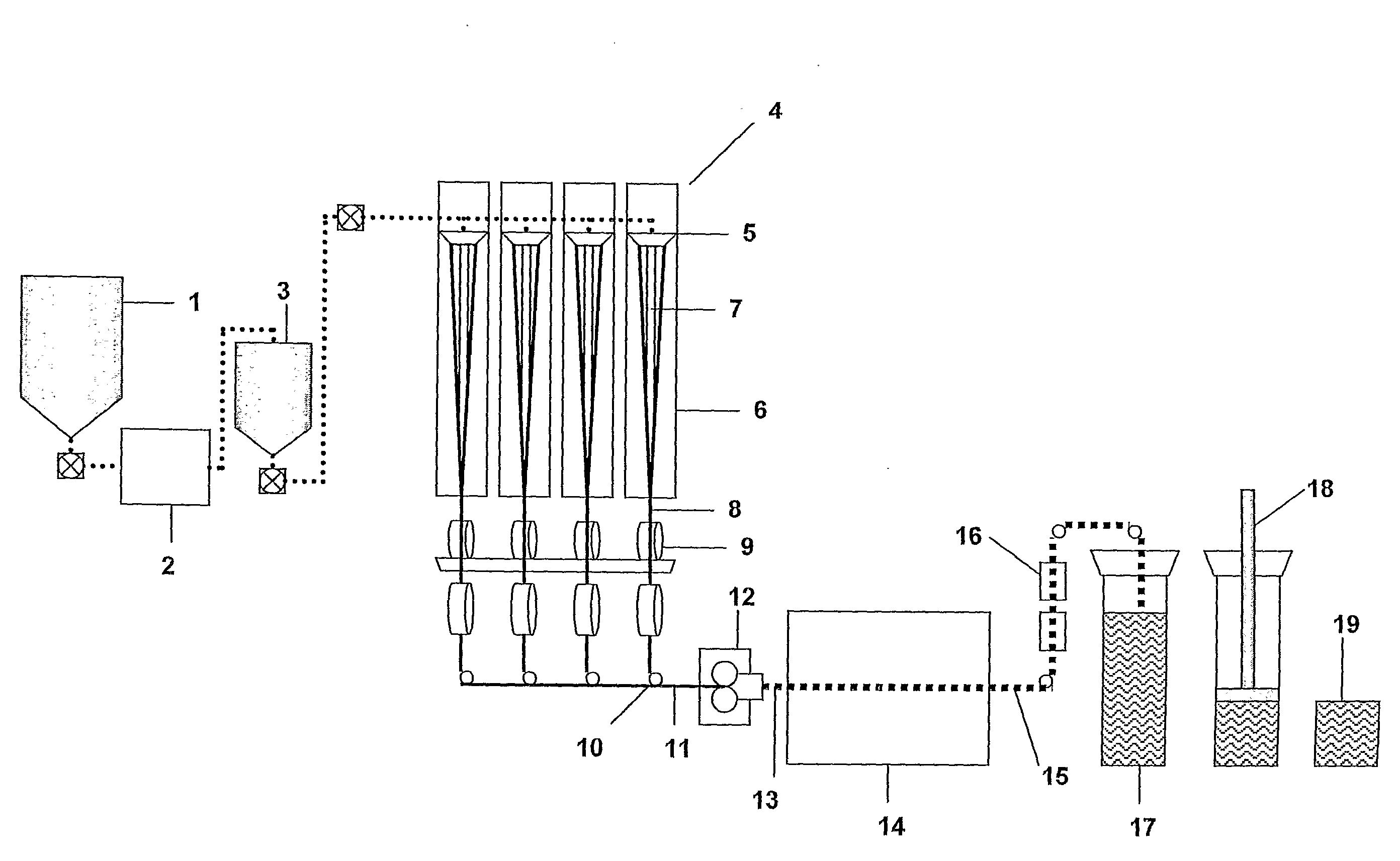

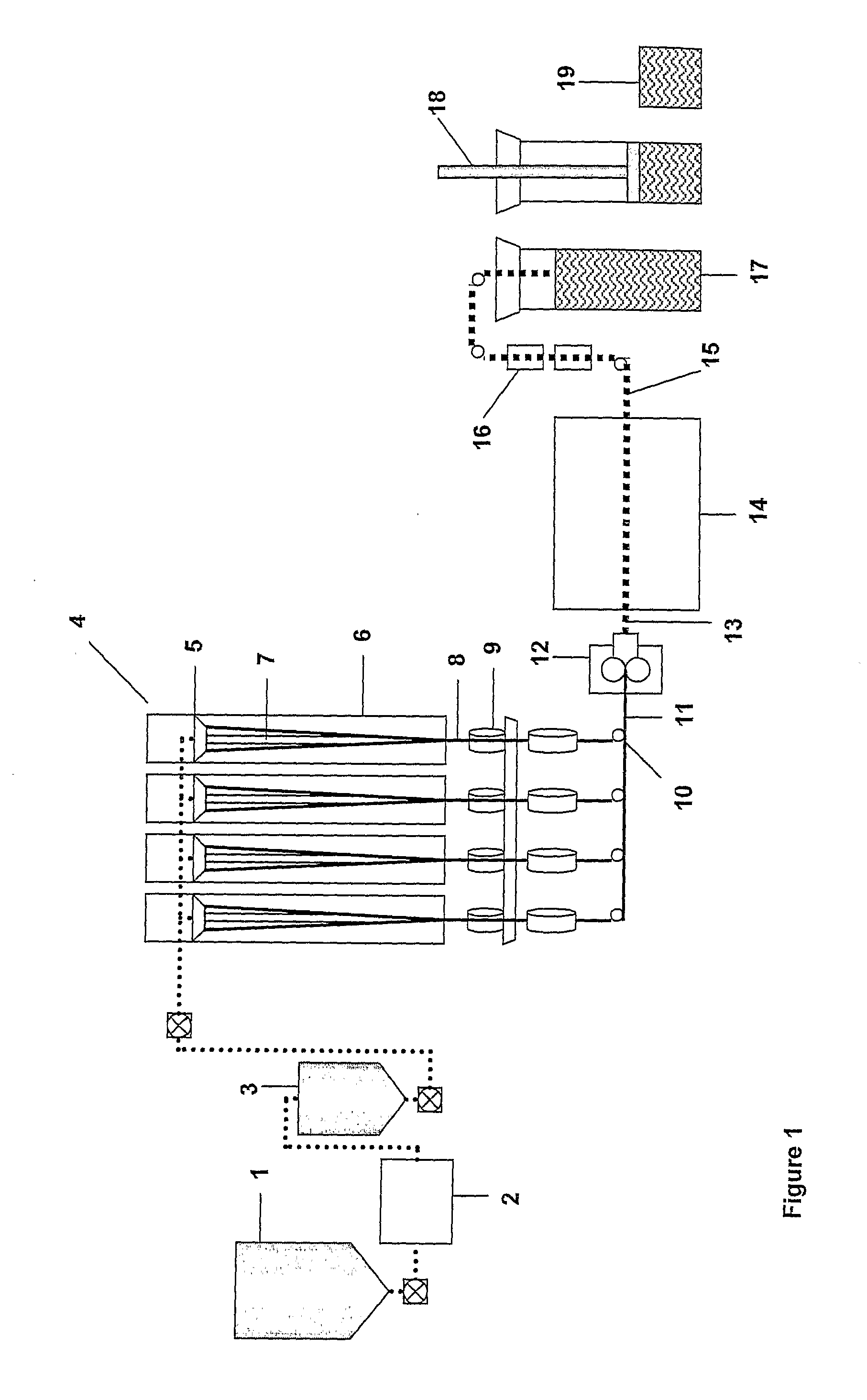

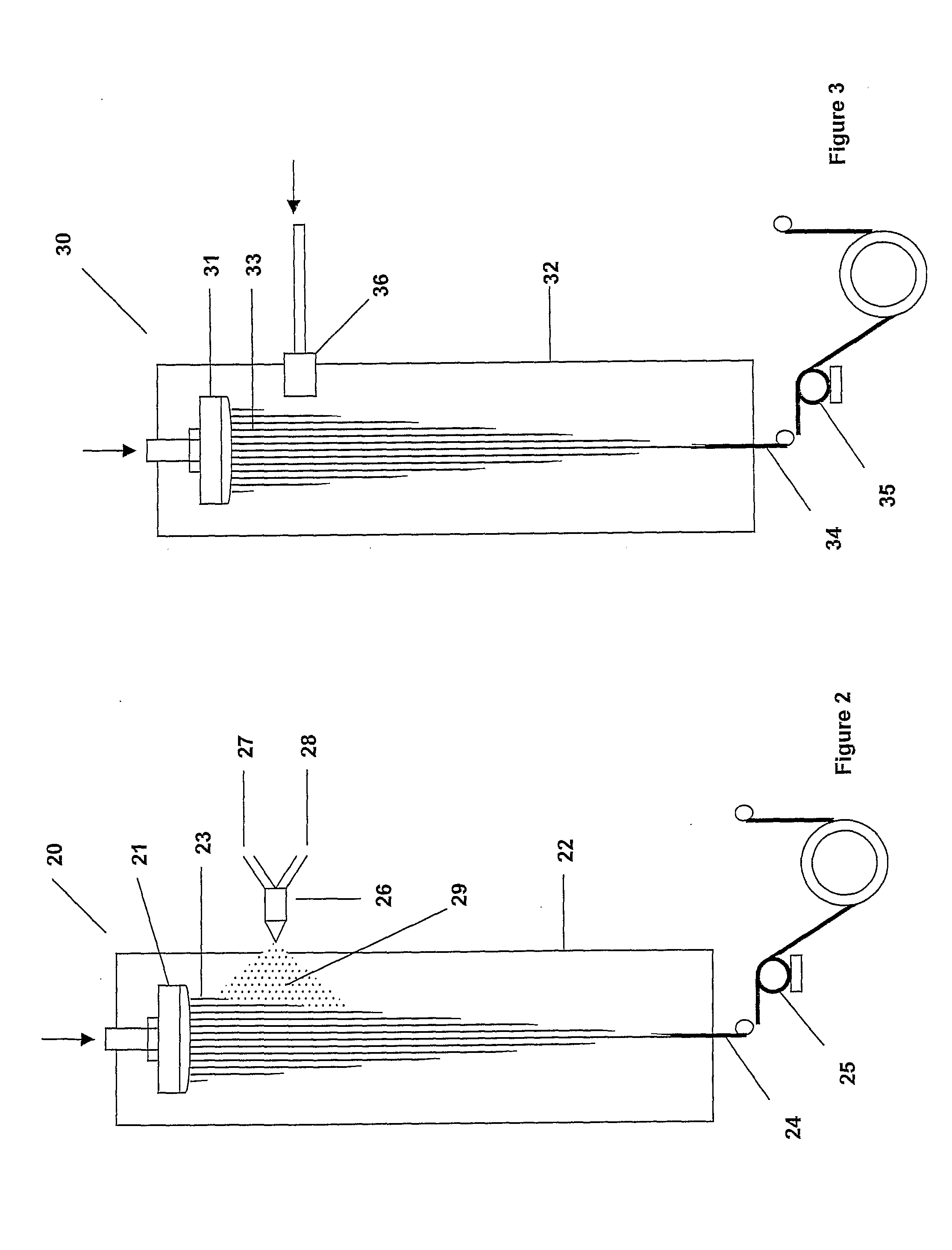

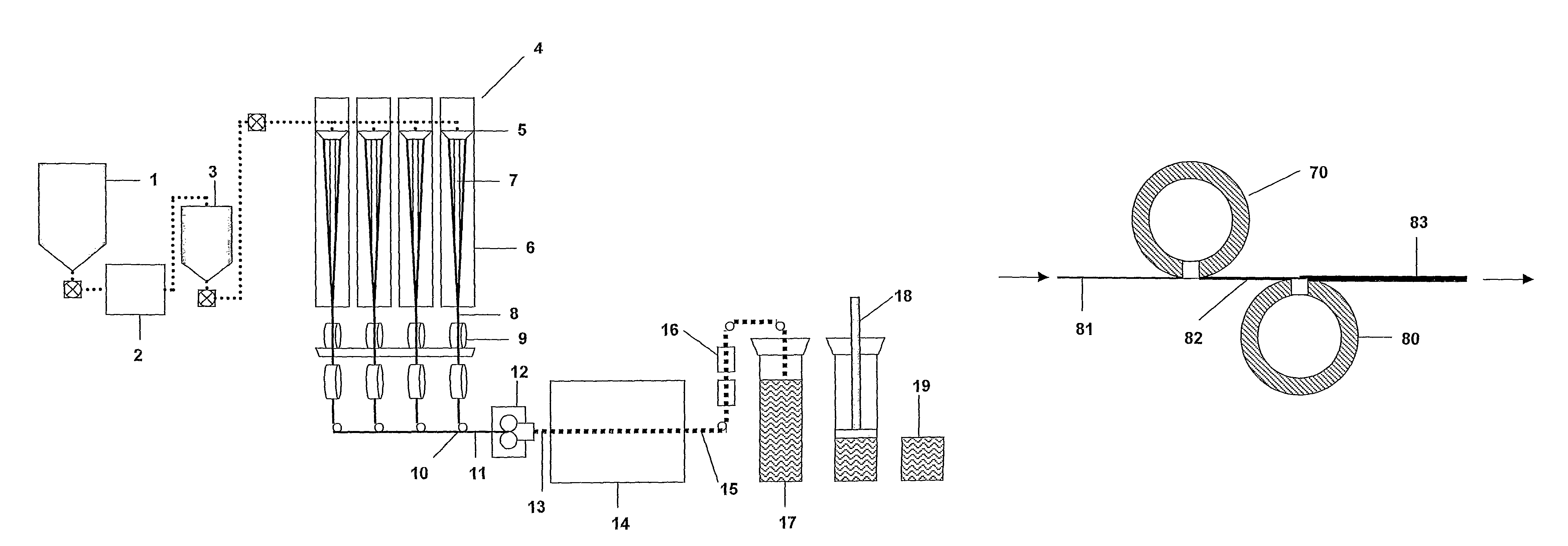

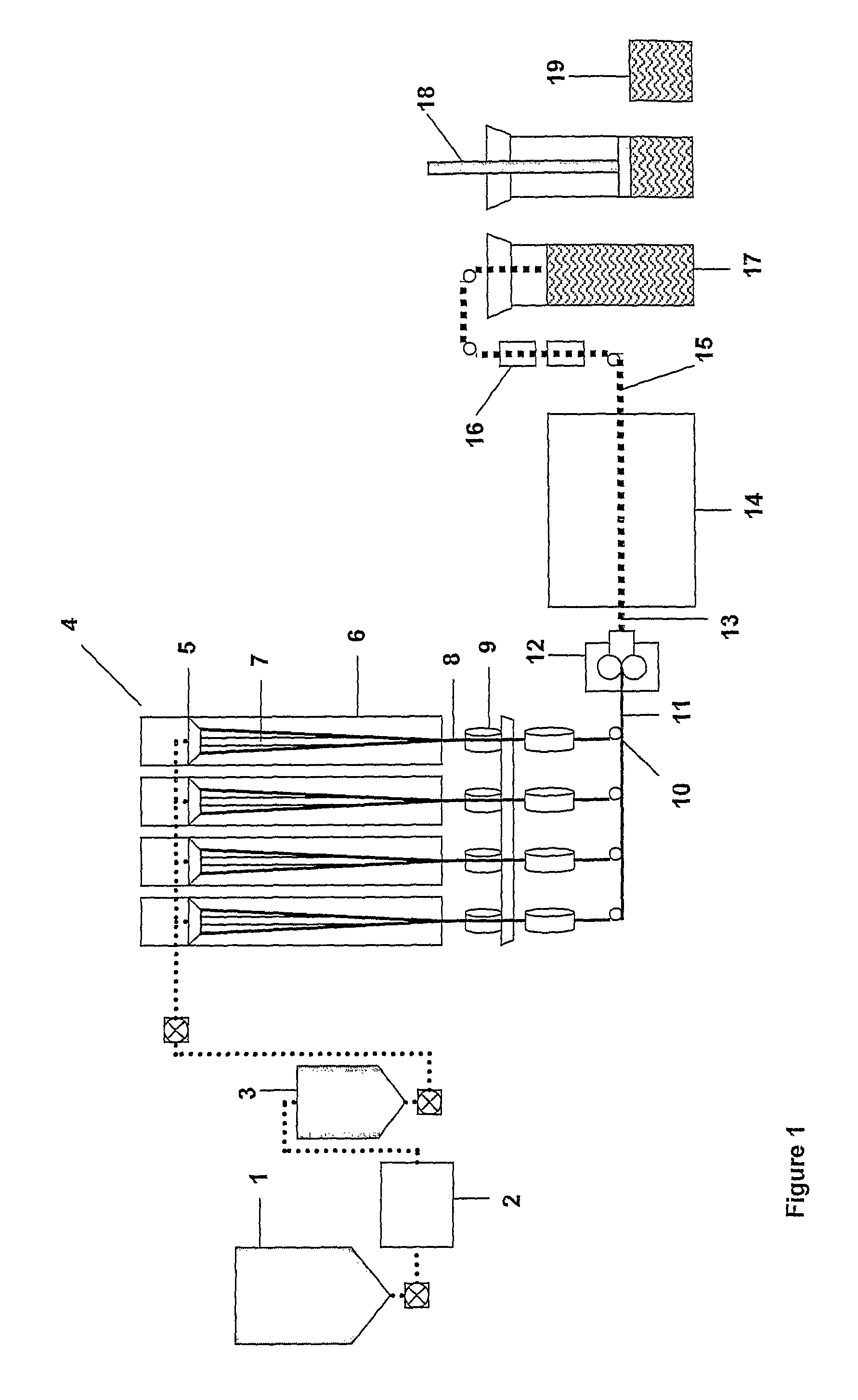

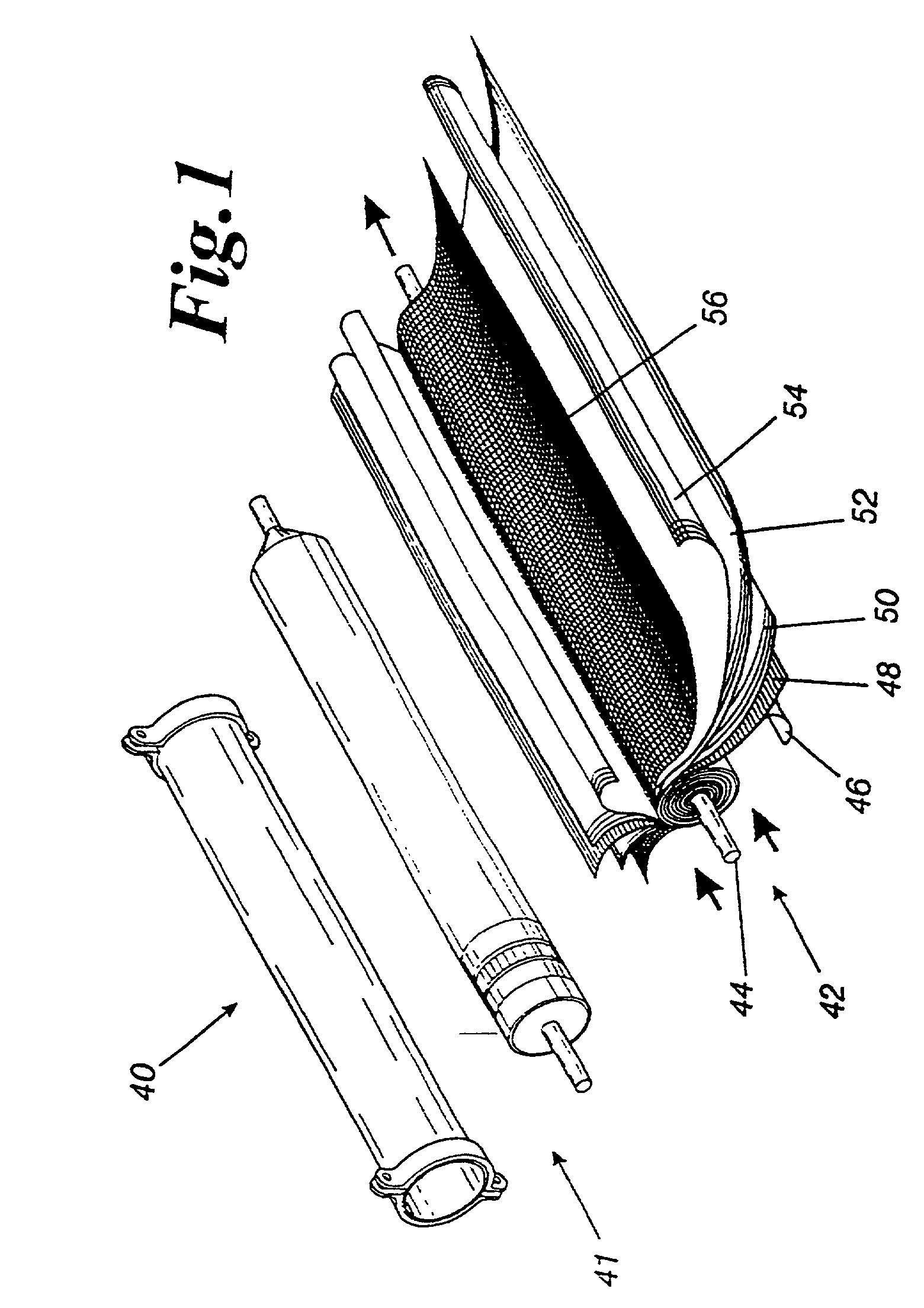

Process For Making Filter Tow

InactiveUS20080245376A1Consistent amountReduce concentrationCigar manufacturePaper/cardboard wound articlesCellulose acetateCyclodextrin

A method of preparing a crimped tow of cellulose acetate filaments comprising the steps of: a) providing cellulose acetate dope b) forming filaments (23) from the dope c) applying at least one additive to the filaments d) crimping the filaments to form a crimped tow wherein the at least one additive is capable of removing a component from cigarette smoke. Preferably, the component is a Hoffmann analyte. The additive may comprise a solution, liquid, emulsion or particulate material or combinations thereof. Preferably, the additive comprises an acidic compound or an alkaline compound. The additive may comprise malic acid, potassium carbonate, citric acid, tartaric acid, lactic acid, ascorbic acid, polyethyleneimine, cyclodextrin, sodium hydroxide, sulphamic acid, sodium sulphamate, polyvinyl acetate and carboxylated acrylate, carbon, silica, zeolite, clay, alumina, metal, molecular sieves or an ion exchange resin. The product tow can be processed on standard equipment to make efficient filter rods from which cigarette filter tips can be made which give significantly increased and selective retention of key smoke constituents.

Owner:CELANESE ACETATE LLC

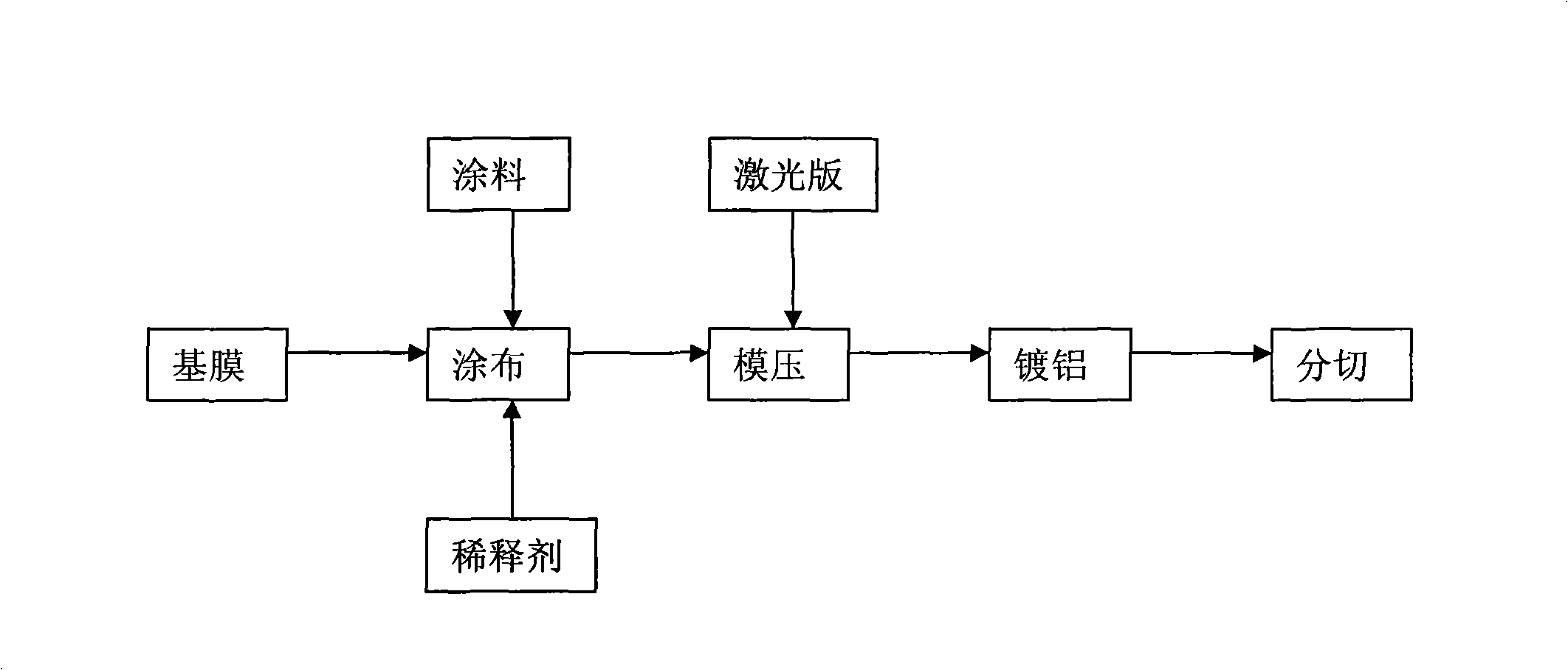

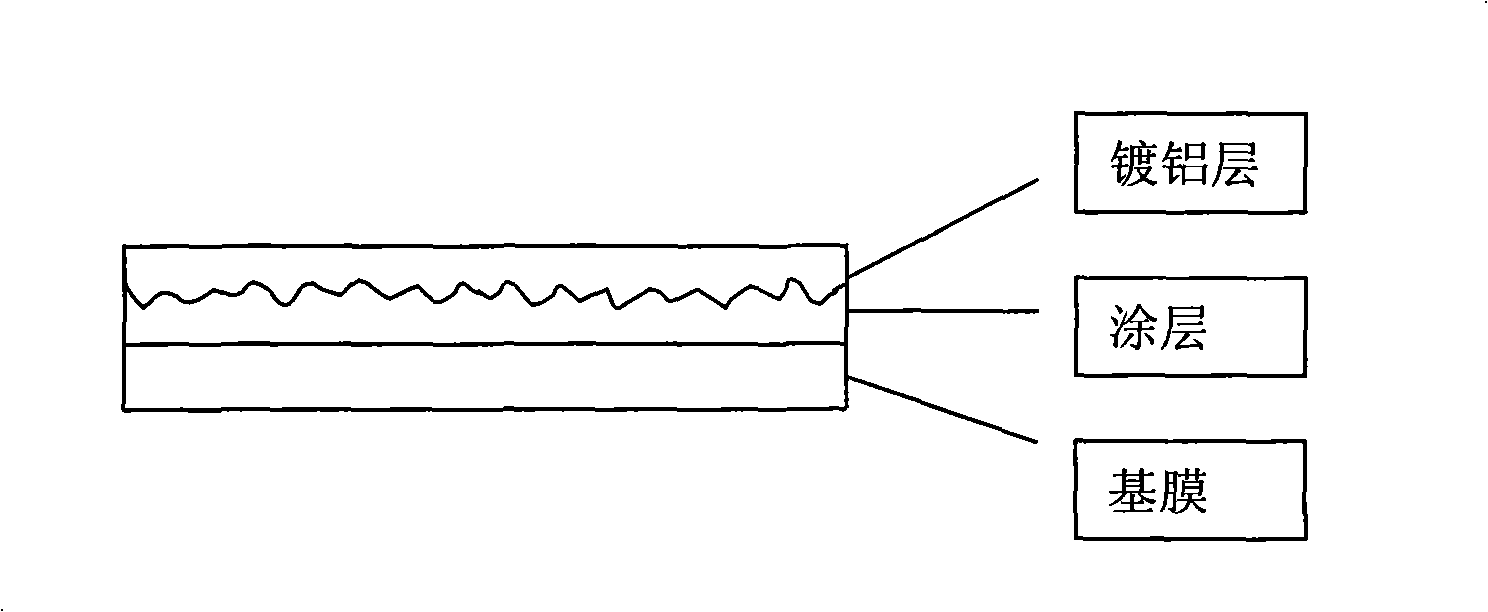

Process for producing PET laser transfer membrane

InactiveCN101537745ASimple processNovel processDecorative surface effectsPretreated surfacesBasementCoated membrane

The invention relates to a process for producing a PET laser transfer membrane. A PET membrane is used as a basement transfer membrane, and laser transfer pigment is coated and spread on the PET membrane. The method includes the following steps: a laser transfer pigment is coated and spread on the PET basement transfer membrane by an anilox roll at one step to form a coating layer, and a precoating membrane can be formed after the operation of drying is carried out; the precoating membrane is processed by the operation of laser mould pressing, and interference figures on a laser slab are printed on the coating layer of the precoating membrane by heat pressing so as to form a mould pressing membrane; and aluminum is coated on the mould pressing membrane, an aluminum layer is formed on an information layer, and the PET laser transfer membrane can be prepared, wherein the pigment includes thermoplastic acroid resin and cellulose acetate. The process has the advantages that the special singly coated laser transfer pigment and the unique manufacture process control are selected, and the entire process is simple, novel, stable and reliable. As the laser mould pressing transfer coating layer has the properties of easy mould pressing, favorable stripping, and the like, the operation of coating just needs to be carried out for one time, and therefore the production efficiency can be greatly improved. After being transferred and stripped, the aluminum coated membrane can be recycled to be repeatedly used for many times, and therefore cost can be greatly reduced; and the PET laser transfer membrane is the environmentally friendly anti-counterfeit laser material for packaging and printing.

Owner:上海宝绿包装材料科技有限公司

Process of making cellulose acetate tow

ActiveUS7585441B2Artificial filament physical treatmentArtificial filaments from cellulose derivativesFiberPlasticizer

In the manufacture of a fiber tow, particularly cellulose acetate tow, the tow is plasticized prior to entry into the crimper. The preferred plasticizer is water.

Owner:DEUT BANK AG NEW YORK BRANCH AS COLLATERAL AGENT +1

Process for making filter tow

InactiveUS8308624B2Consistent amountReduce concentrationCigar manufacturePaper/cardboard wound articlesCellulose acetateCyclodextrin

A method of preparing a crimped tow of cellulose acetate filaments comprising the steps of: a) providing cellulose acetate dope b) forming filaments (23) from the dope c) applying at least one additive to the filaments d) crimping the filaments to form a crimped tow wherein the at least one additive is capable of removing a component from cigarette smoke. Preferably, the component is a Hoffmann analyte. The additive may comprise a solution, liquid, emulsion or particulate material or combinations thereof. Preferably, the additive comprises an acidic compound or an alkaline compound. The additive may comprise malic acid, potassium carbonate, citric acid, tartaric acid, lactic acid, ascorbic acid, polyethyleneimine, cyclodextrin, sodium hydroxide, sulphamic acid, sodium sulphamate, polyvinyl acetate and carboxylated acrylate, carbon, silica, zeolite, clay, alumina, metal, molecular sieves or an ion exchange resin. The product tow can be processed on standard equipment to make efficient filter rods from which cigarette filter tips can be made which give significantly increased and selective retention of key smoke constituents.

Owner:CELANESE ACETATE LLC

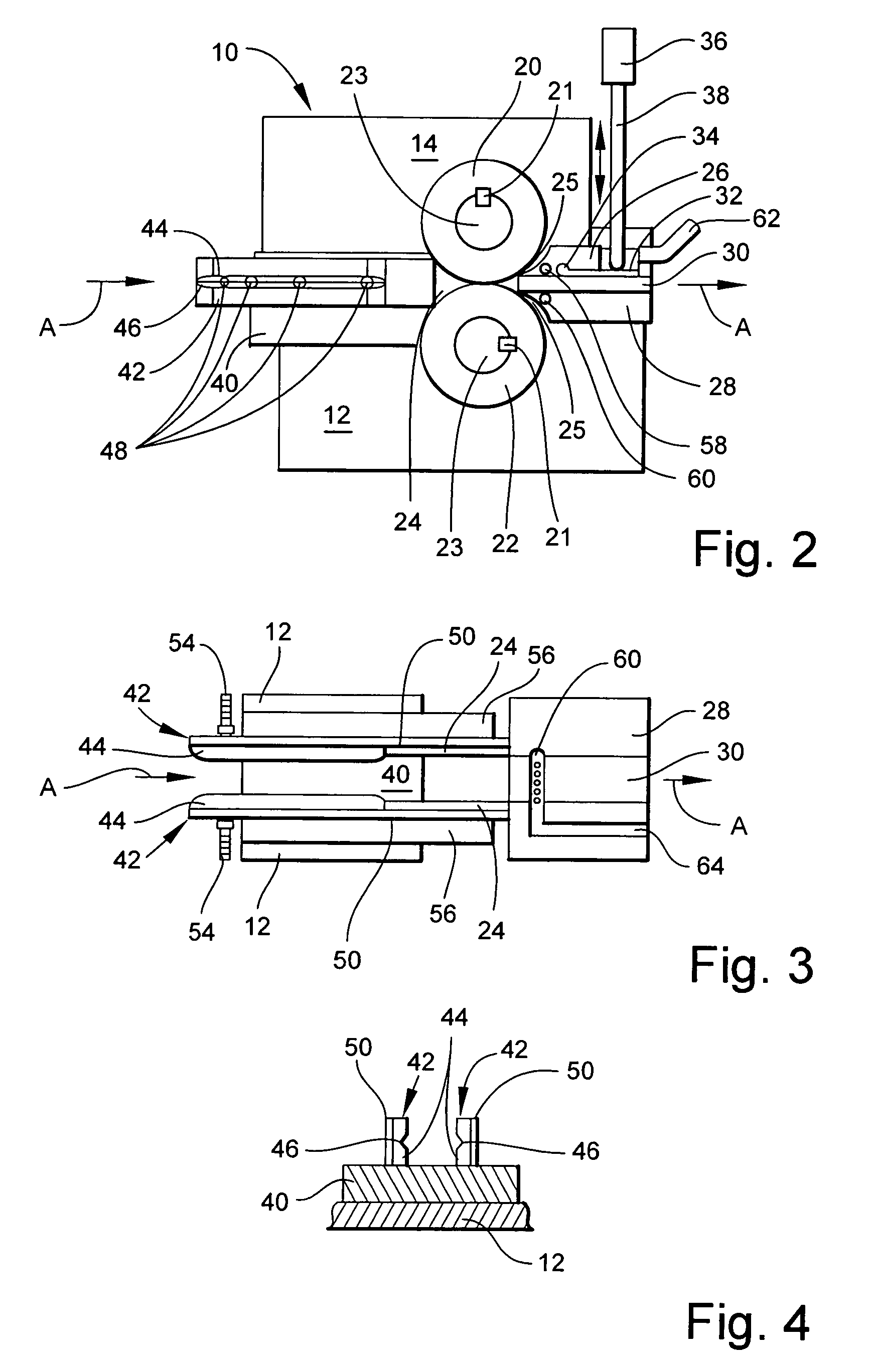

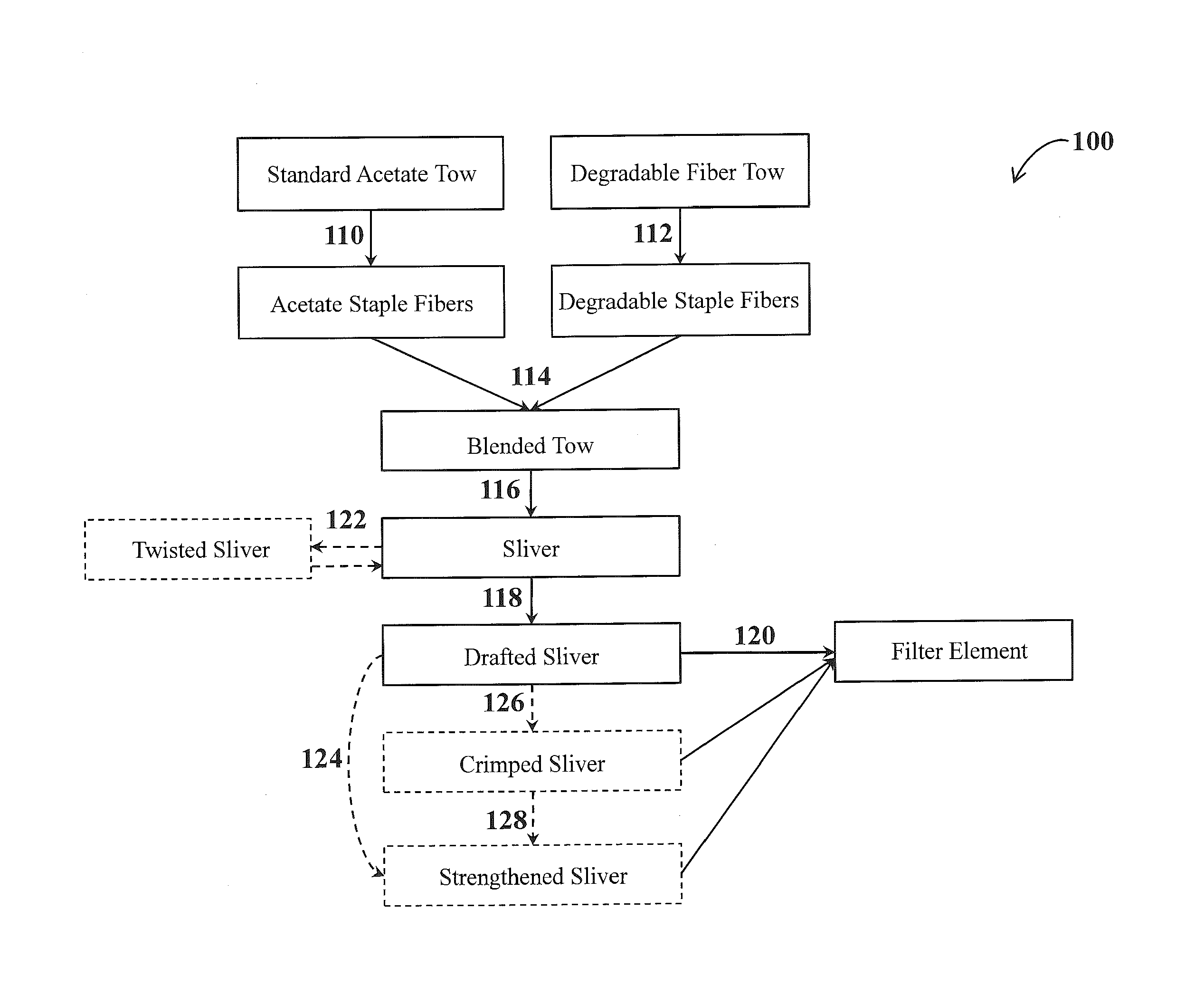

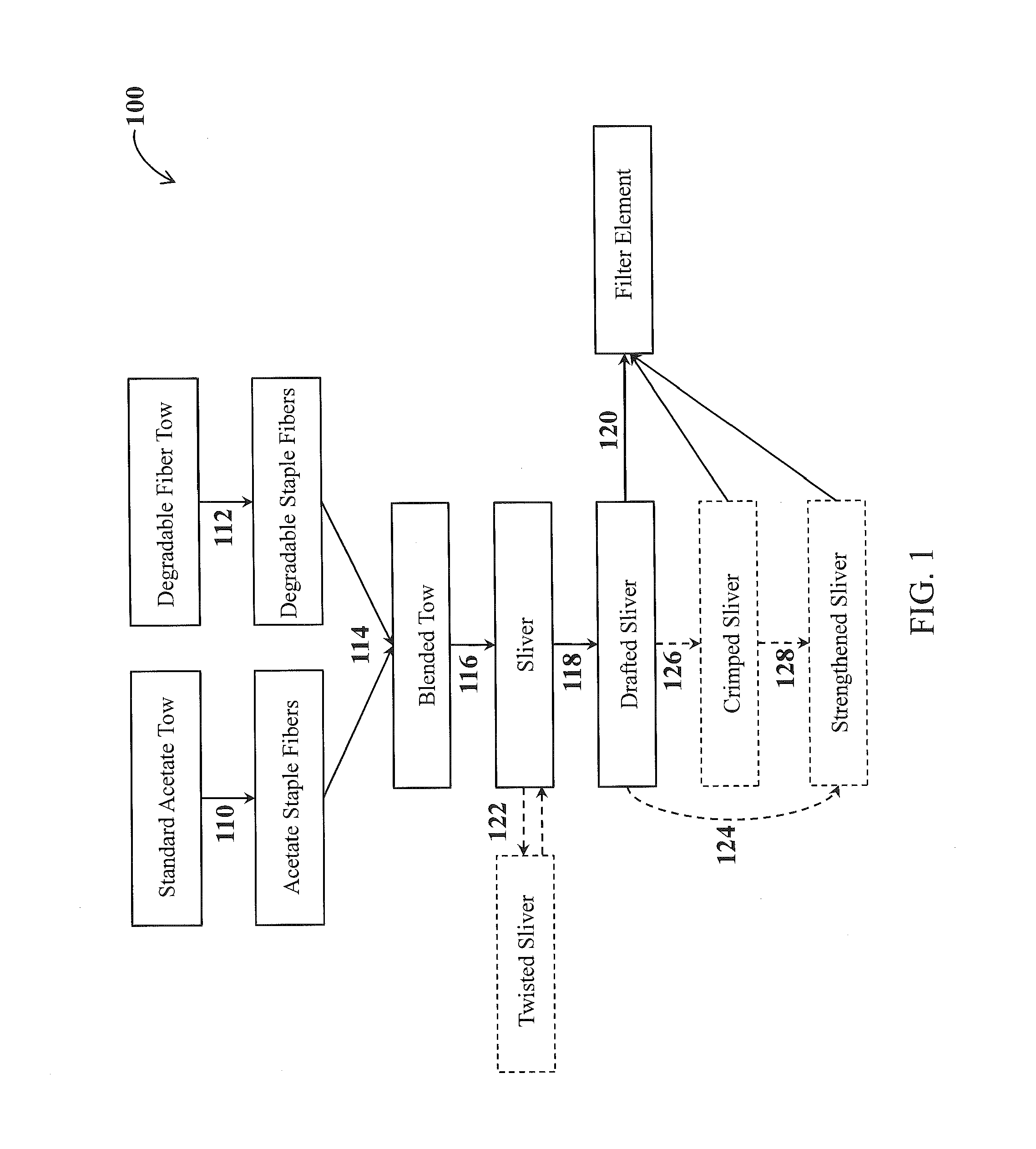

Mixed fiber sliver for use in the manufacture of cigarette filter elements

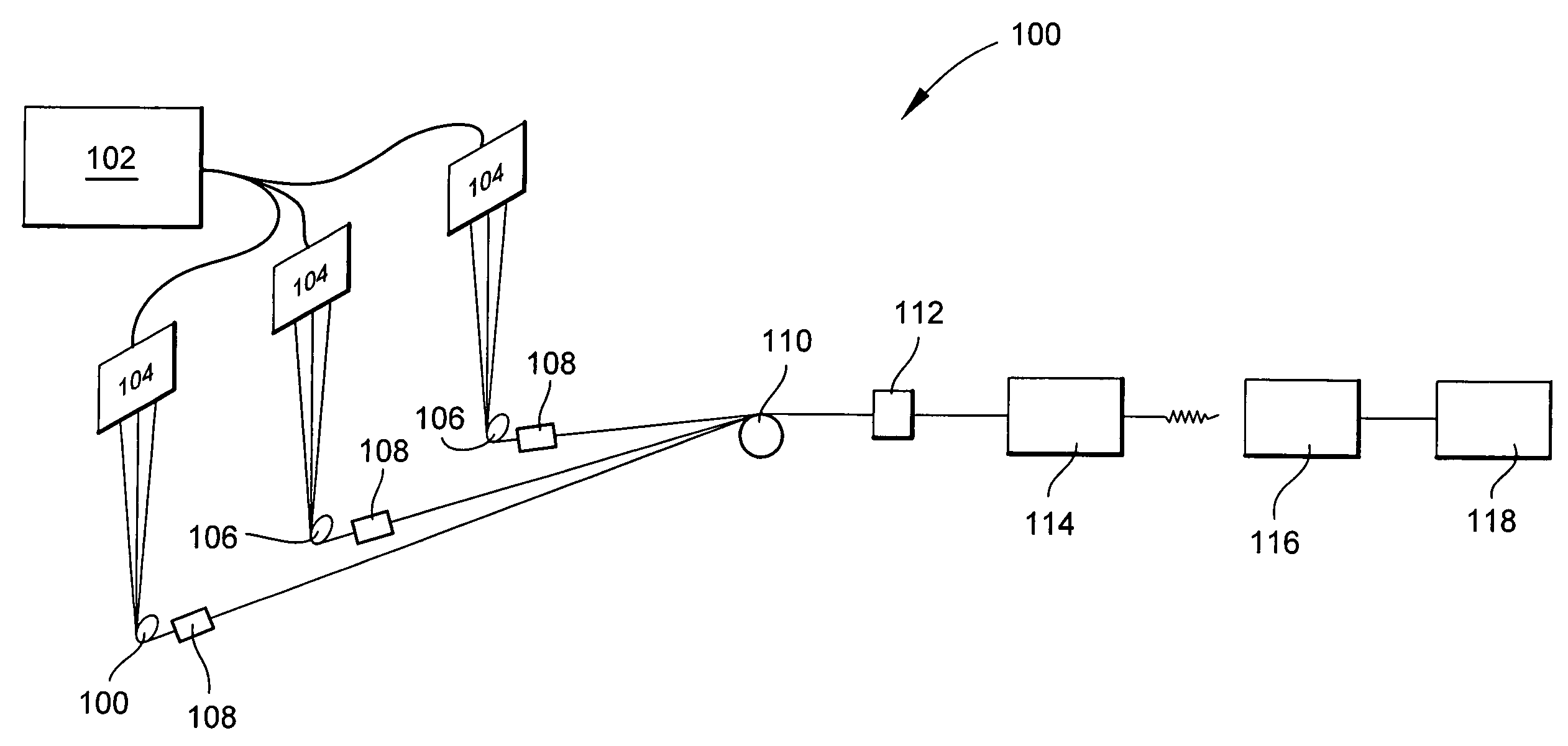

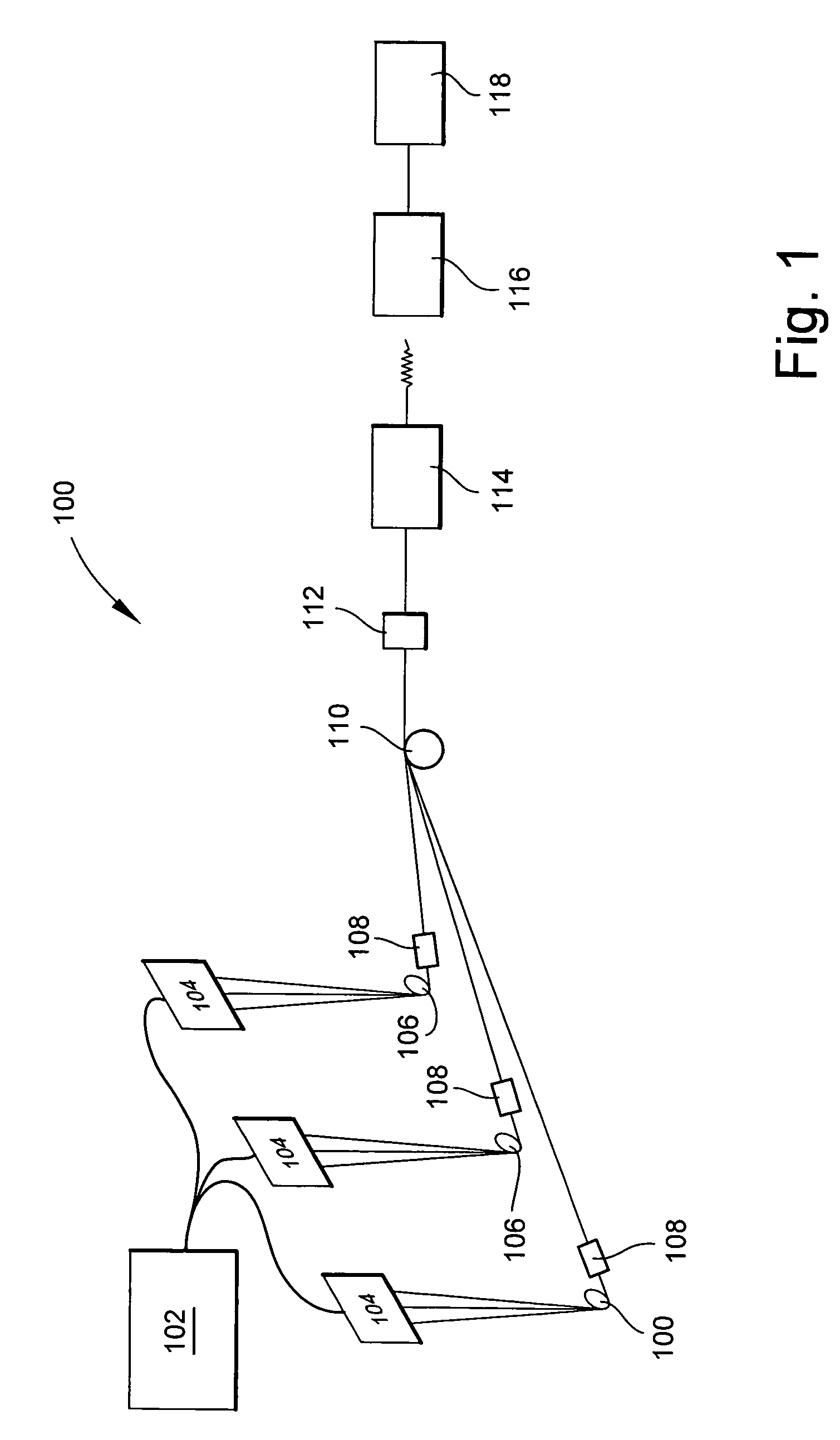

Smoking articles including filter elements formed from two or more fibrous inputs with different physical properties are provided. The two or more fibrous inputs are provided in the form of staple fibers, which are at least partially entangled with each other to form a mixed fiber sliver. The mixed fiber sliver includes a first plurality of cellulose acetate staple fibers blended with a second plurality of staple fibers comprising a polymeric material different from the first plurality of staple fibers, such as staple fibers of a degradable polymeric material. The entangled fibers of the mixed fiber sliver may be sufficiently separated from one another such that blooming operations typically required in filter element production may not be necessary prior to incorporating the mixed fiber sliver into a filter element. Related methods, apparatuses and mixed fiber products are also provided by the disclosure.

Owner:R J REYNOLDS TOBACCO COMPANY

Coated paper filter

InactiveUS20120305015A1Improve degradation rateIncrease speedTobacco treatmentTobacco smoke filtersFiberCellulose acetate

A biodegradable paper substrate and / or biodegradable fiber (including fiber tow) may be coated with cellulose acetate and / or plasticized cellulose acetate for use in a filter material configured for application in a filter of a smoking article. Flocking and / or fibrillation methods may be used to deposit and / or generate a plurality of fibers that may protrude beyond a surface of the biodegradable substrate material. A filter made in accordance with this design may also include non-biodegradable material.

Owner:R J REYNOLDS TOBACCO COMPANY

Antimicrobial semi-permeable membranes

Cast semi-permeable membranes made from synthetic polymer used in reverse osmosis, ultrafiltration and microfiltration are treated with a non-leaching antimicrobial agent to prevent its bio-fouling and bacterial breakthrough. The semi-permeable membranes include a polymeric material and a non-leaching antimicrobial agent that is incorporated into and homogeneously distributed throughout the polymeric material. The polymeric material, in the case of one membrane, may be cellulose acetate. In the case of thin film composite polyamide membranes, the antimicrobial agent is incorporated in a microporous polysulfone layer that is sandwiched between a reinforcing fabric and an ultrathin polyamide material. The invention also includes a treatment of flat and hollow fiber semipermeable membranes made with polysulfones and polyvinylidene fluoride.

Owner:MICROBAN PROD CO INC

High-performance flat-type cellulose acetate/graphene blend forward osmosis membrane

ActiveCN104474919APollution resistantImprove hydrophilicitySemi-permeable membranesCellulose acetateN-Methyl-2-pyrrolidone

The invention discloses a high-performance flat-type cellulose acetate / graphene blend forward osmosis membrane. 5 to 25 percent by weight of cellulose acetate, 1 to 15 percent by weight of additives, 0.01 to 2 percent by weight of graphene and mixed solvent of dimethylformamide, dimethylacetamide, or N-methylpyrrolidone and acetone are added into a dissolving tank according to a given sequence and are stirred and dissolved for 2 to 18 hours at the temperature of 5 to 75 DEG C to be uniformly mixed so as to prepare a forward osmosis membrane casting solution; the high-performance flat-type cellulose acetate / graphene blend forward osmosis membrane is prepared on a supporting material by adopting a phase inversion method. According to the forward osmosis membrane, 1M NaCl is used as a driving liquid, the deionized water is used as a raw material solution, the flux of pure water of the forward osmosis membrane is more than 21L / m<2> within the test time of one hour, and the salt flux in the reverse direction is less than 3.5g / m<2>.

Owner:UNIV OF JINAN

Production method of environment-friendly water-soluble gum electrochemical aluminothermic transfer printing film

InactiveCN101570090APromote environmental protectionThermographyInk transfer from master sheetPolyvinyl butyralAcrylic resin

The invention relates to a production method of an environment-friendly water-soluble gum electrochemical aluminothermic transfer printing film. The production method comprises the following steps: a PET film of 6 to 15 micron is adopted as a carrier film; the carrier film is sequentially provided with four coatings such as a releasing layer, a color layer, an aluminum layer and an adhesive layer; wherein the releasing layer, the color layer and the adhesive layer coat the coating materials on a PET basal membrane substrate by a smooth roll or an anilox roll in a forward coating mode or backward coating mode; the aluminum layer is spray-plated in a vacuum spray-plating mode; the invention adopts the environment-friendly material and the production technique to produce the aluminothermic transfer printing film product, and the key points are as follows: solvent based acrylic resin, ethylene-vinyl acetate resin, ketone resin and cellulosic resin hot melt adhesive are changed into cellulose acetate and products made by cellulose acetate; and vinyl cellulose, polyvinyl butyral and powdery silicon dioxide are synthesized by water and a mixed solvent in a mode of wetting and dispersing. The production method has the characteristics of having no solvent residue harmful to human body and being beneficial to environmental protection and the like.

Owner:莫国平

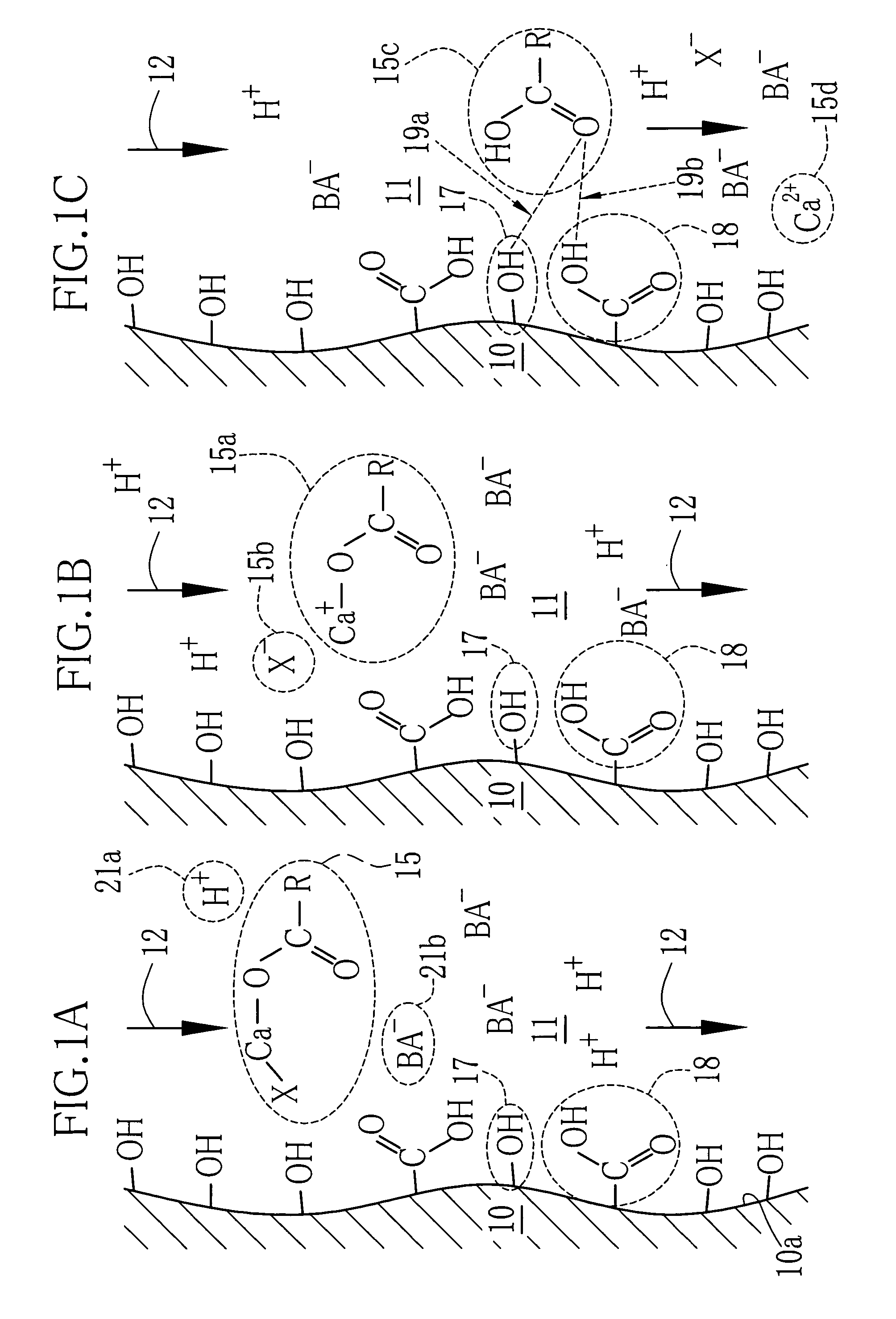

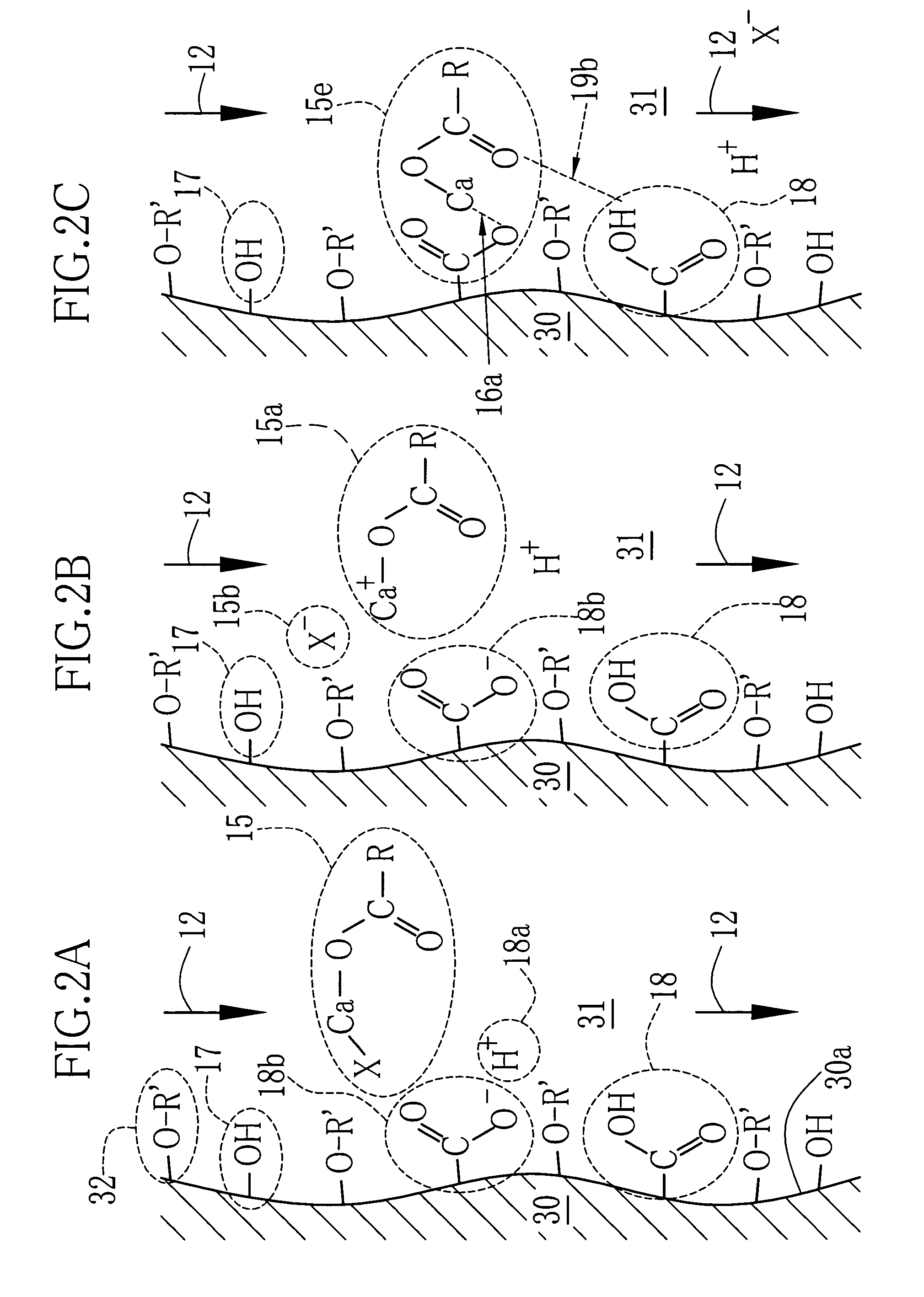

Cellulose acetate and dope containing the same

InactiveUS7122660B1Good release effectSatisfactory optical propertyArtificial filaments from cellulose derivativesCarboxyl radicalCellulose diacetate

Using the dope containing the following cellulose acetate (1), (2), or (3), a film is prepared by the casting process:(1) a cellulose acetate having carboxyl groups binding to at least one member selected from the group consisting of a cellulose acetate and a hemicellulose acetate, wherein at least a part of said carboxyl groups are in an acidic form;(2) a cellulose acetate containing at least one member selected from the group consisting of an acid having an acid dissociation exponent pKa of 1.93 to 4.50 in water, an alkali metal salt of said acid and an alkaline earth metal of said acid; or(3) a cellulose acetate containing an alkali metal or an alkaline earth metal wherein the total content of an alkaline metal and an alkaline earth metal in 1 gram of the cellulose acetate is from an effective amount to 5.5×10−6 equivalent (in terms of ion equivalent). The above cellulose acetate is also useful for spinning process. The cellulose acetate includes a cellulose diacetate and a cellulose triacetate. The cellulose acetate of the present invention has high film-releasability from a support and excellent optical characteristics.

Owner:DAICEL CHEM IND LTD

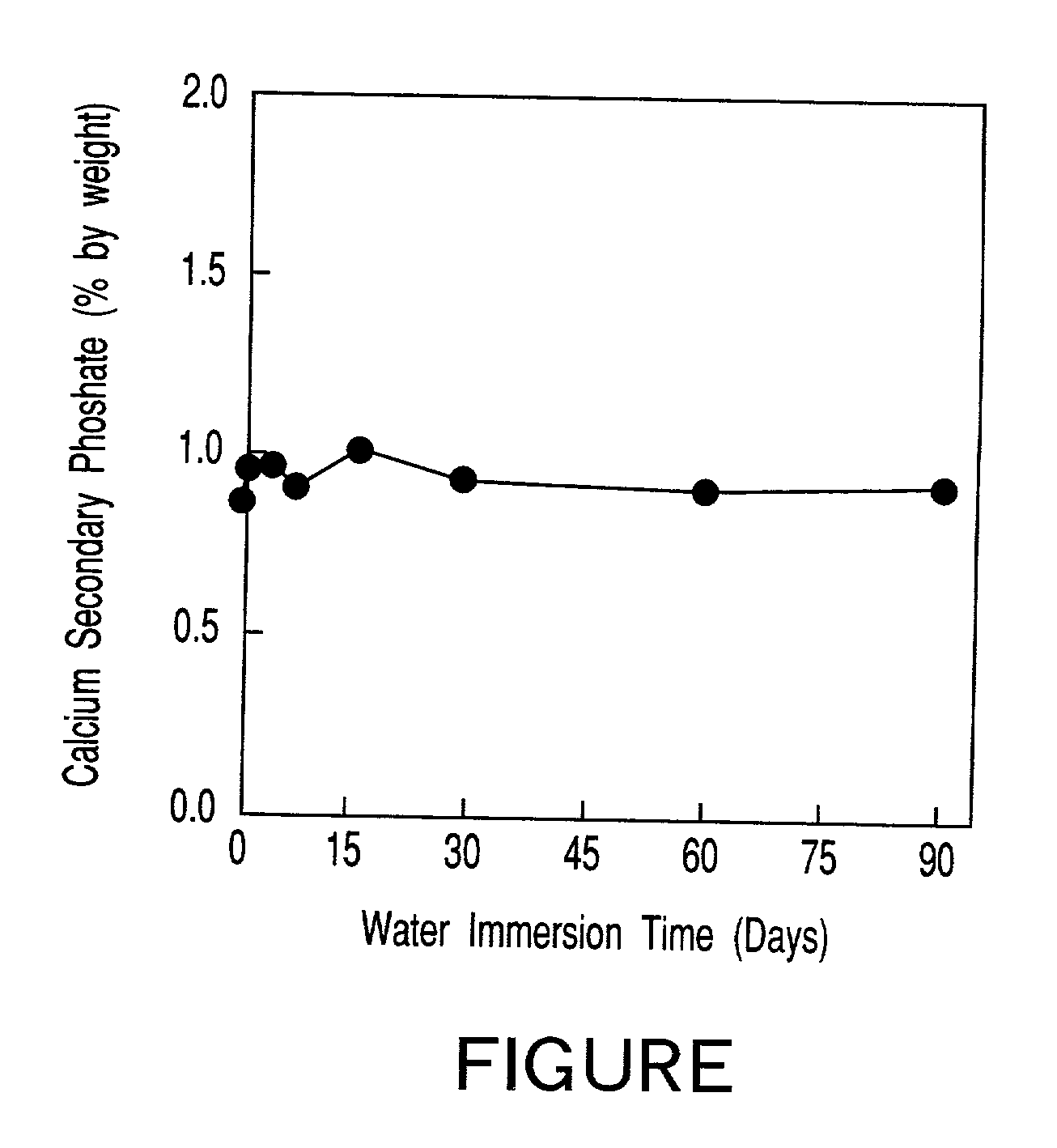

Biodegradable cellulose acetate structure and tobacco filter

A cellulose acetate structure excellent in its biodegradability. At least a surface region of the structure includes a biodegradable cellulose acetate composition containing a biodegradation promoting agent contained in cellulose acetate. The agent includes at least one compound selected from the group consisting of a salt of an oxygen acid of phosphorus, an ester of an oxygen acid of phosphorus or a salt thereof, carbonic acid and a salt thereof.

Owner:JAPAN TOBACCO INC

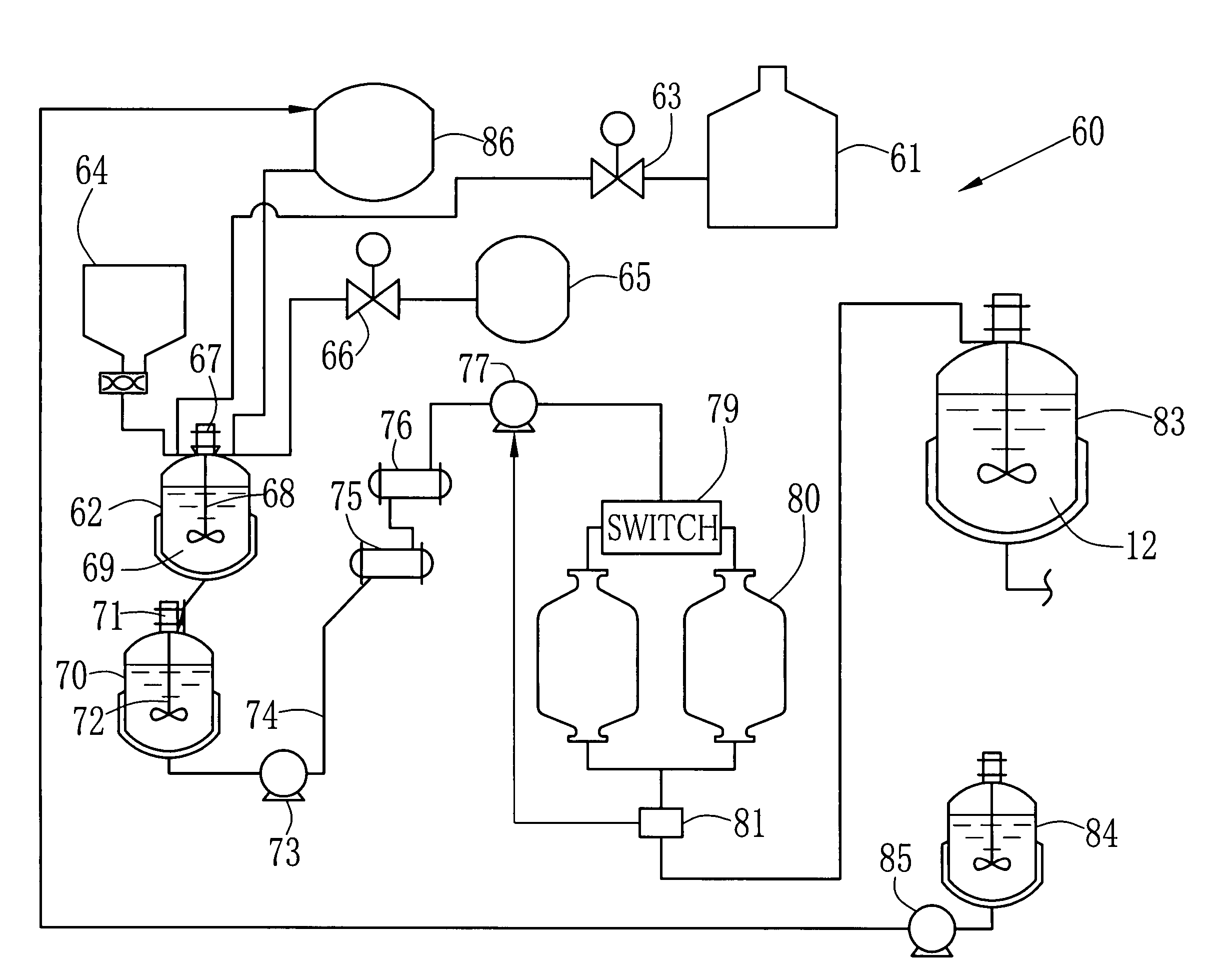

Methods for filtrating and producing polymer solution, and for preparing solvent

InactiveUS7347947B2Reduce generationGood estimateMembranesSugar derivativesCellulose acetateHydrogen-Ion Concentrations

A cellulose acetate solution is filtrated with a filter medium formed of cellulose fiber. Hydroxyl groups on the filter medium are substituted to other functional groups. An acidic material is added to the cellulose acetate solution, and the filtration is preformed. In order to estimate the hydrogen ion concentration of the organic solvent, a sample solvent of thereof is mixed with water so as to transport hydrogen ions from the sample solvent to the water of a predetermined volume. Then the water is separated from the sample solvent, and the pH value of the water is measured with a pH meter. The result of the measurement is regarded as the pH value of the organic solvent.

Owner:FUJIFILM CORP

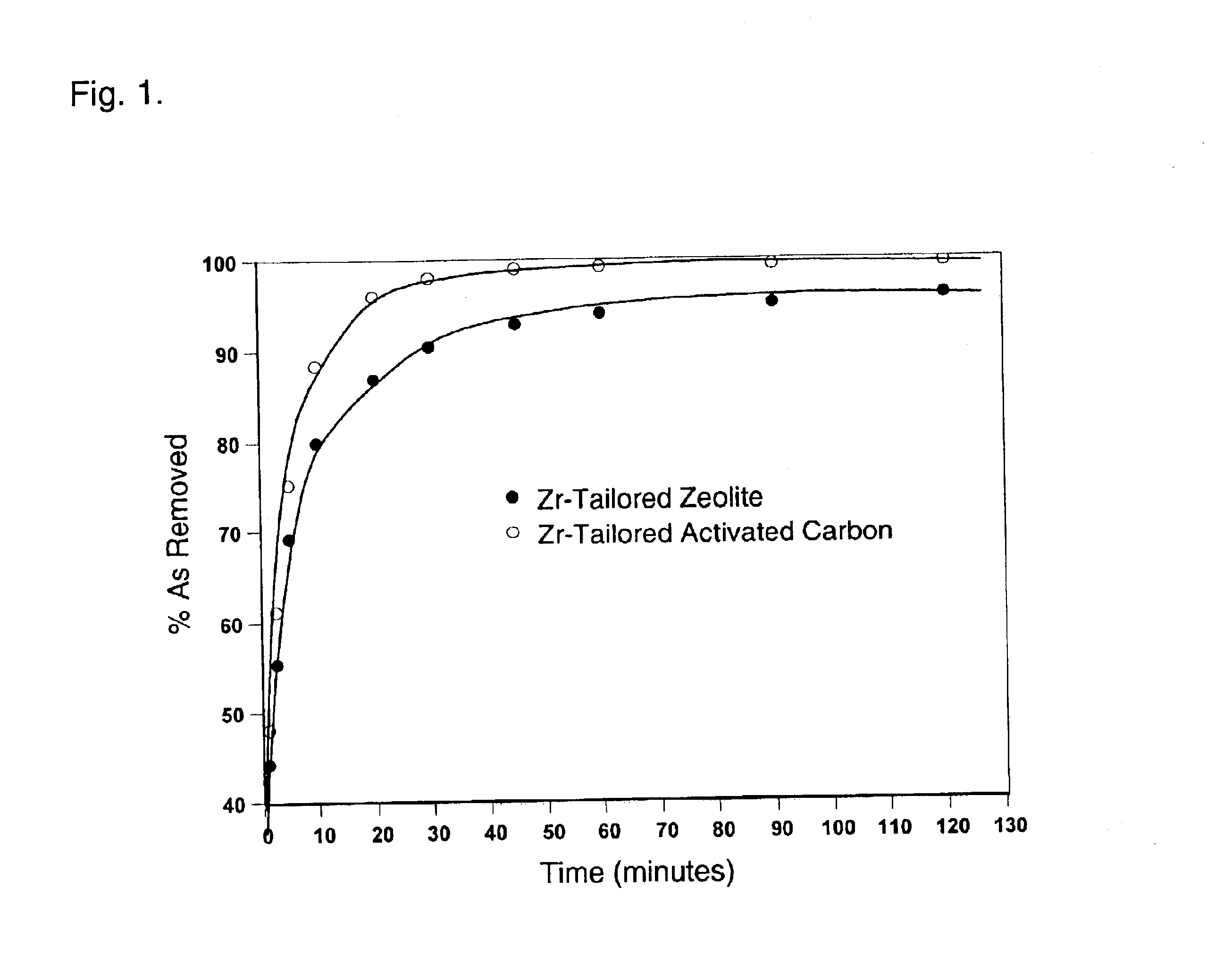

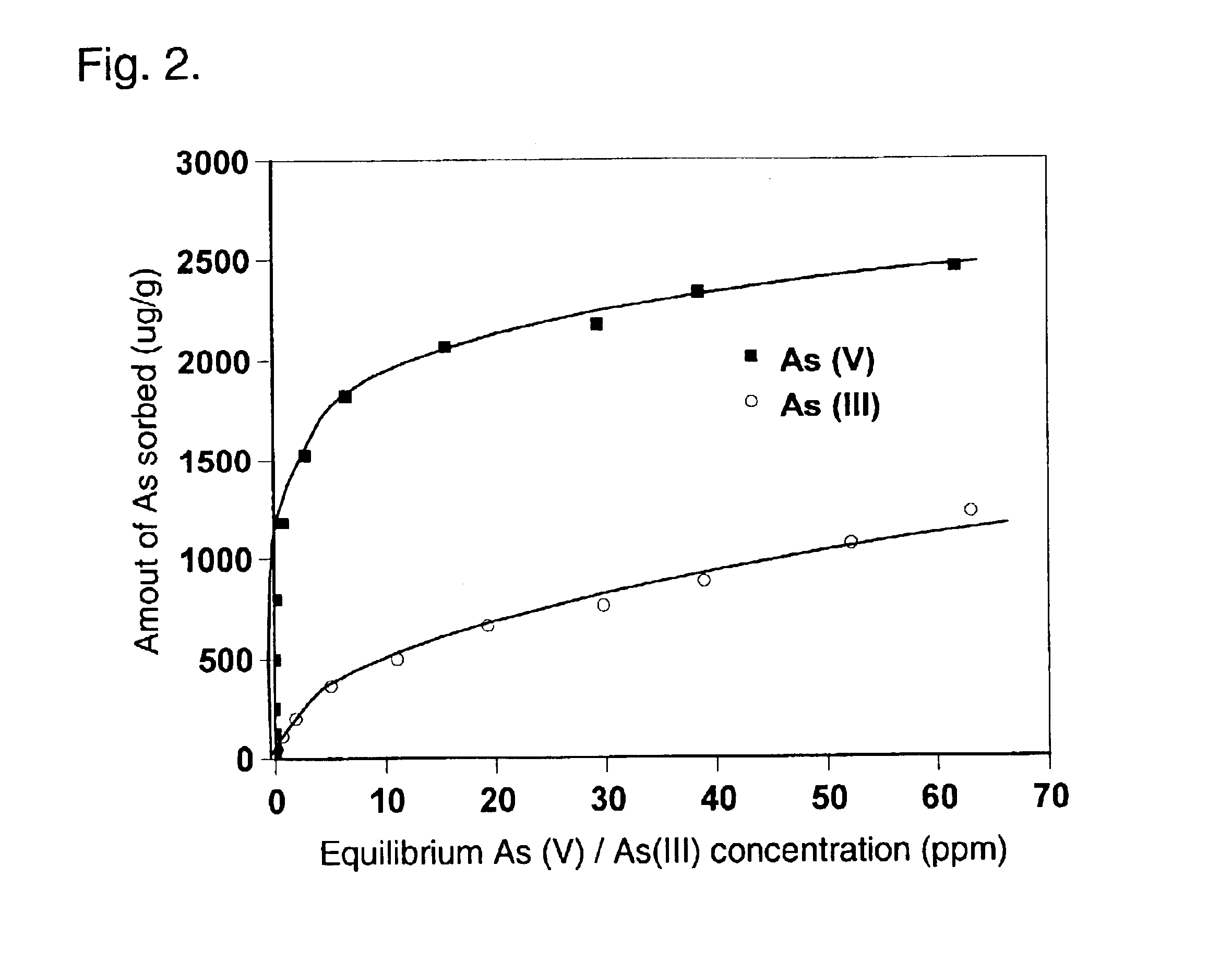

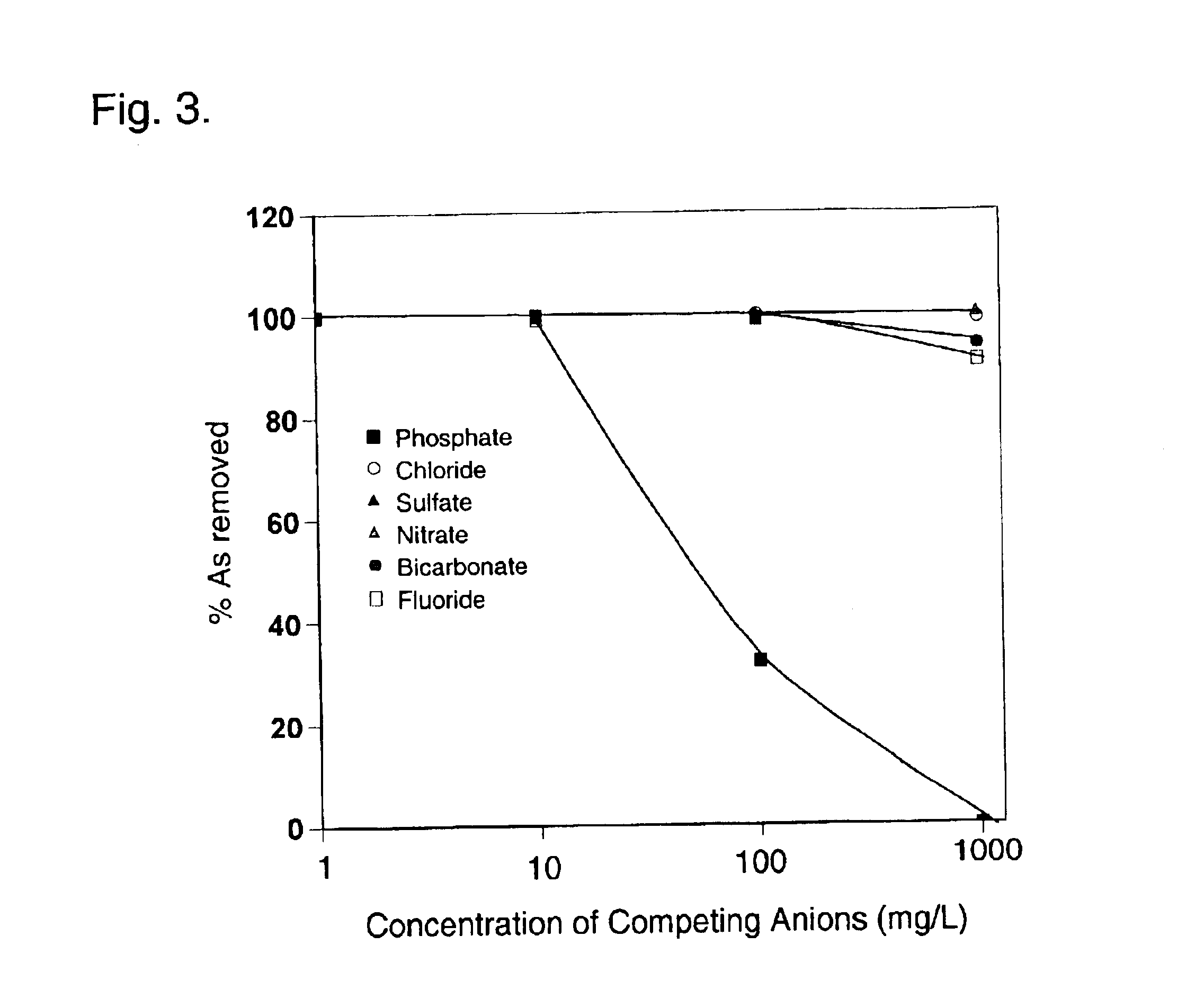

Zirconium-modified materials for selective adsorption and removal of aqueous arsenic

InactiveUS6824690B1Easy to manufactureLow costLiquid surface applicatorsLoose filtering material filtersFiberClay minerals

A method, composition, and apparatus for removing contaminant species from an aqueous medium comprising: providing a material to which zirconium has been added, the material selected from one or more of zeolites, cation-exchangeable clay minerals, fly ash, mesostructured materials, activated carbons, cellulose acetate, and like porous and / or fibrous materials; and contacting the aqueous medium with the material to which zirconium has been added. The invention operates on all arsenic species in the form of arsenate, arsenite and organometallic arsenic, with no pretreatment necessary (e.g., oxidative conversion of arsenite to arsenate).

Owner:SANDIA NAT LAB

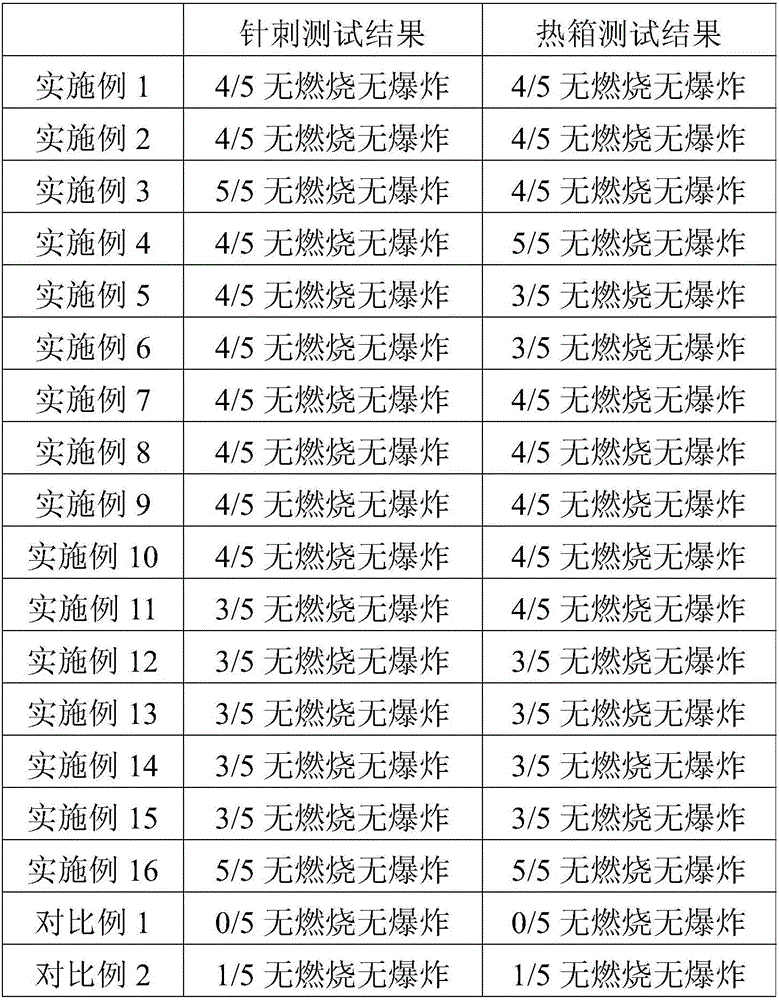

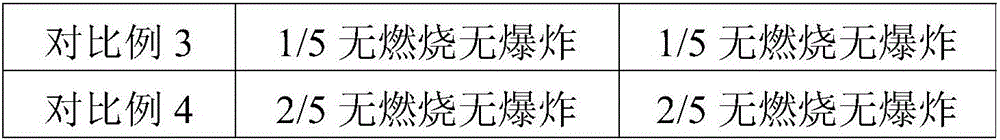

Electrode and preparation method therefor

ActiveCN107437622AImprove the high conductivity at room temperatureHigh strengthCell electrodesSecondary cellsLow-density polyethyleneEpoxy

The invention provides an electrode and a preparation method therefor. The electrode comprises a current collector and an active material layer arranged on the current collector; the electrode also comprises a coating layer arranged between the current collector and the active material layer; the coating layer comprises a polymer substrate and a conductive agent; the polymer substrate is selected from one or more of low-density polyethylene, high-density polyethylene, epoxy resin, polyvinylidene fluoride, an ethylene-ethyl acrylate copolymer, an ethylene-vinyl acetate copolymer, polybutylene, cellulose acetate and polyamide; and the conductive agent is selected from one or more of acanthosphere-shaped Ni powder, acanthosphere-shaped Cu powder, acanthosphere Al powder and acanthosphere-shaped tungsten carbide. The electrode has the advantages of low normal-temperature resistor and high PTC strength, so that improvement of safety performance of a lithium ion battery can be facilitated.

Owner:CONTEMPORARY AMPEREX TECH CO

Filter for selective removal of a gaseous component

A filter such as an air having a reagent which chemically reacts with and removes a gaseous component of an air stream. The reagent contains functional groups covalently bonded to a non-volatile inorganic substrate which is incorporated in the filter. The filter can remove gaseous components such as aldehydes. Preferred functional groups are 3-aminopropylsilyl groups covalently bonded to silica gel (APS silica gel). The reagent can be contained in a space in the filter or incorporated in one or more filter elements. The reagent can be part of or coated on paper such as filter paper or incorporated in non-paper filter elements formed from fibrous materials such as cellulose acetate or polypropylene fibers. Other preferred reagents include aminoethylaminopropylsilyl silica gel (AEAPS) and aminoethylaminoethylaminopropylsilyl silica gel (AEAEAPS).

Owner:FILIP MORRIS PRODAKTS INK

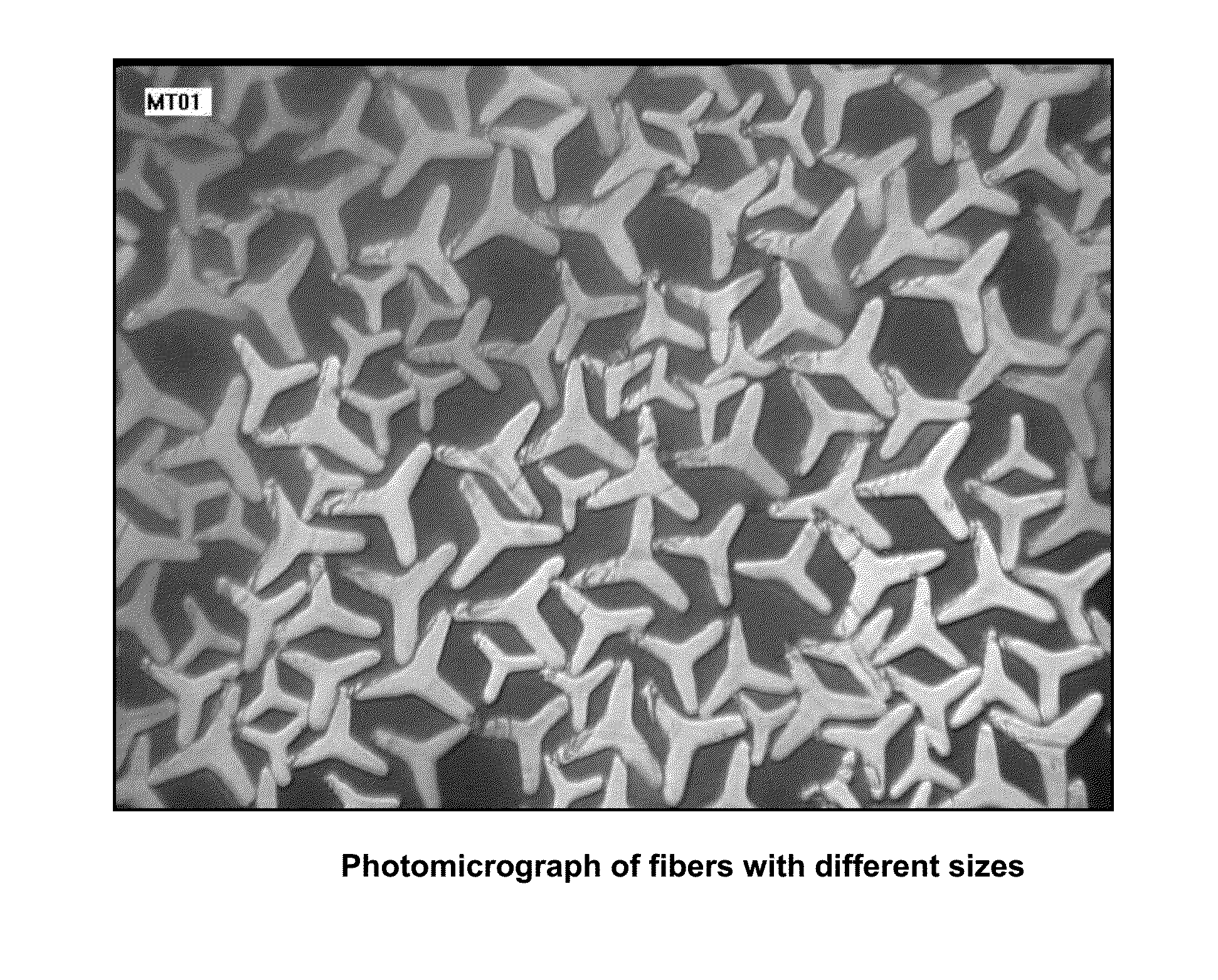

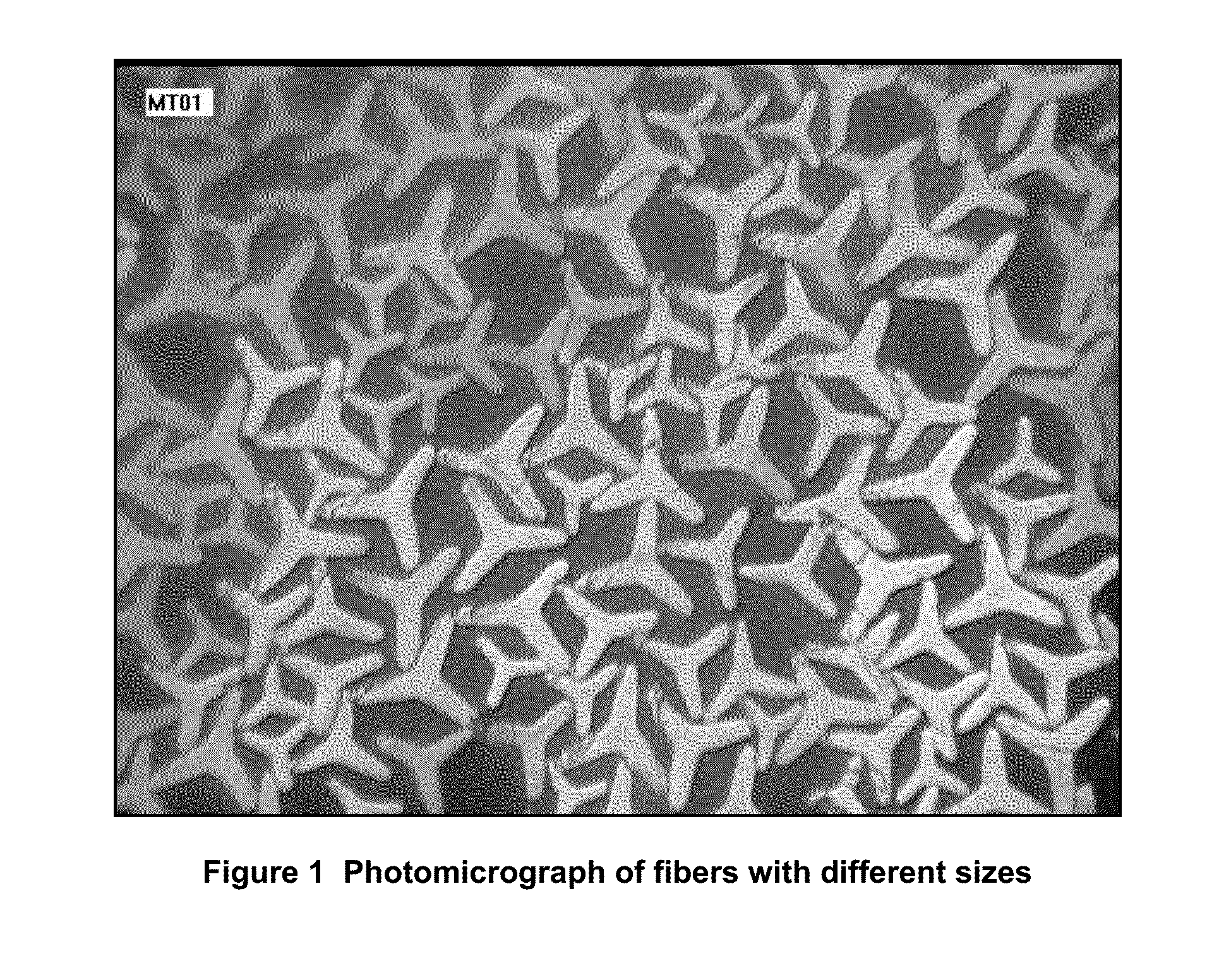

Method for making an acetate tow band with shape and size used for coding

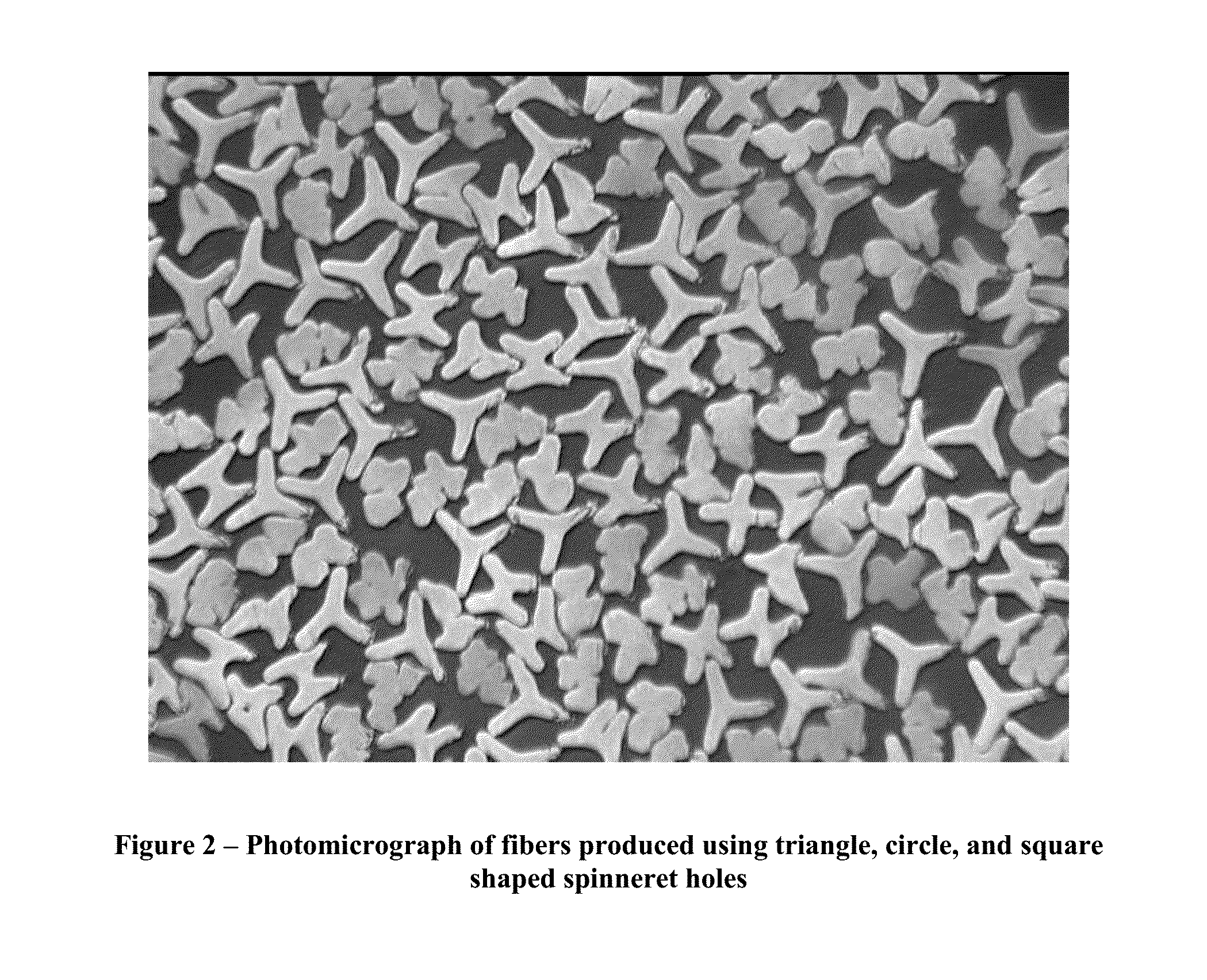

Disclosed is a method of making an acetate tow bands comprising identification fibers which can be used for tracking and tracing the acetate tow band through at least part of the supply chain. Each identification fiber exhibits at least one distinct feature. Each group of distinguishable identification fibers can exhibit a taggant cross-section shape, a taggant cross-section size, or combination of the same taggant cross-section shape and same taggant cross-section size. The distinct features and the number of fibers in each group of distinguishable identification fibers can represent at least one supply chain component of the acetate tow band, including the manufacturer of the acetate tow band and the customer of the acetate tow band. The identification fibers can be produced on a cellulose acetate tow line using one or more spinnerets with spinneret holes to produce the taggant cross-section shapes and / or taggant cross-section sizes.

Owner:EASTMAN CHEM CO

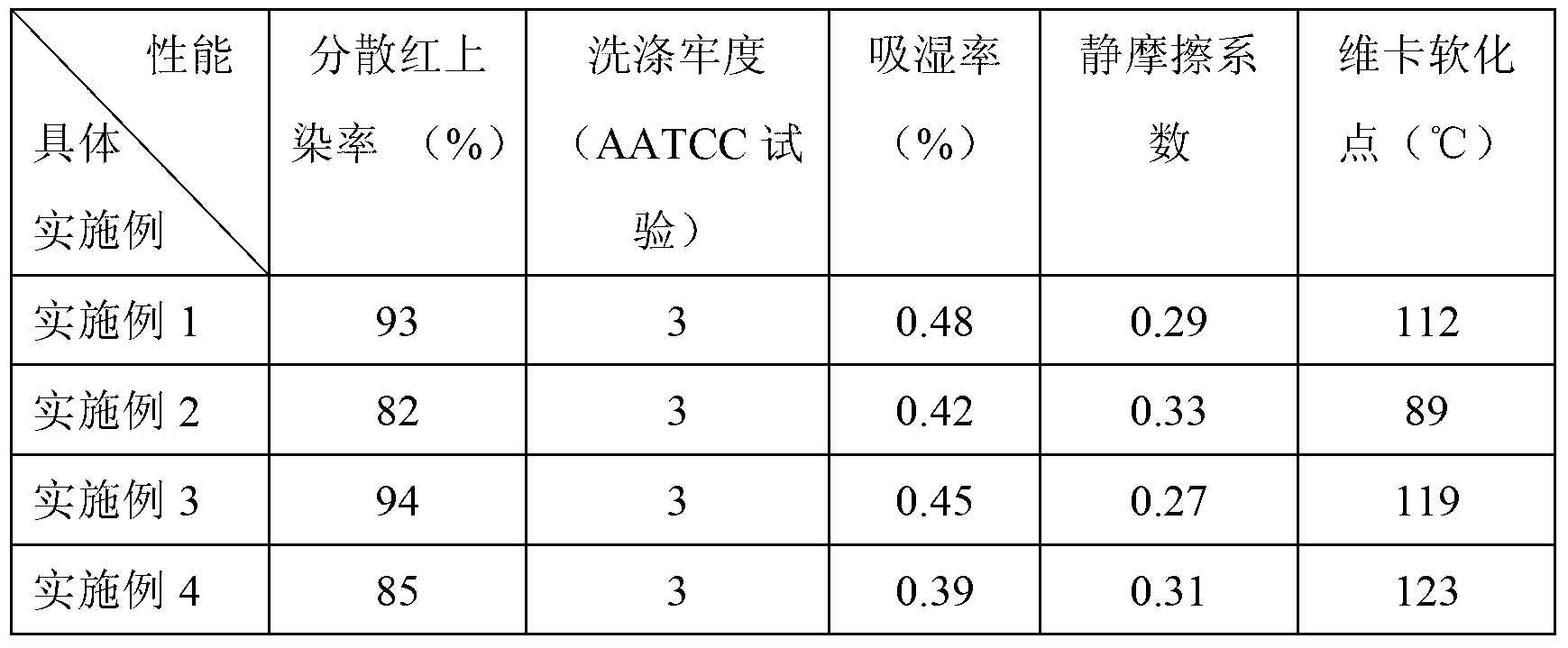

Modified polylactic acid fiber and preparation method thereof

ActiveCN103225125ASave raw materialsRich sourcesMelt spinning methodsMonocomponent polyesters artificial filamentEnvironmental resistanceCellulose diacetate

The invention discloses a modified polylactic acid fiber and a preparation method thereof. The modified polylactic acid fiber is prepared through blending polylactic acid, a cellulose derivative, a cellulose diacetate grafted polylactic acid copolymer, a lubricant, inorganic nanoparticles, a nucleating agent and an antioxidant. The preparation method comprises the following steps: adding partial polylactic acid slices and all other raw materials to a high speed mixer according to a mass component ratio, carrying out high speed dispersion, and carrying out melt blending and extrusion through a double screw extruder to obtain modified polylactic acid master batch slices; and carrying out dry mixing of the modified polylactic acid master batch slices and residual polylactic acid slices in the high speed mixer, carrying out melt spinning through a melt spinning machine, and stretching to obtain the modified polylactic acid fiber. The prepared polylactic acid fiber has the advantages of low cost, complete biodegradation, environmental protection, good spinning performance, stable filament bundle quality, excellent flexibility, excellent antifriction, excellent dyeing property and excellent comfortableness, and is a very good high-performance environmentally-friendly fiber material. The preparation method has the advantages of simplicity, low equipment requirement, and environmental protection in the production process, and is in favor of the industrialized production.

Owner:长沙乐远化工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com