Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

308 results about "Cellulose triacetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellulose triacetate, (triacetate, CTA or TAC) is a chemical compound produced from cellulose and a source of acetate esters, typically acetic anhydride. Triacetate is commonly used for the creation of fibres and film base. It is chemically similar to cellulose acetate. Its distinguishing characteristic is that in triacetate, at least "92 percent of the hydroxyl groups are acetylated." During the manufacture of triacetate, the cellulose is completely acetylated; whereas in normal cellulose acetate or cellulose diacetate, it is only partially acetylated. Triacetate is significantly more heat resistant than cellulose acetate.

Asymmetric Gas Separation Membranes with Superior Capabilities for Gas Separation

InactiveUS20080143014A1Excellent permeation fluxHigh selectivityMembranesSemi-permeable membranesCellulose diacetatePolymer science

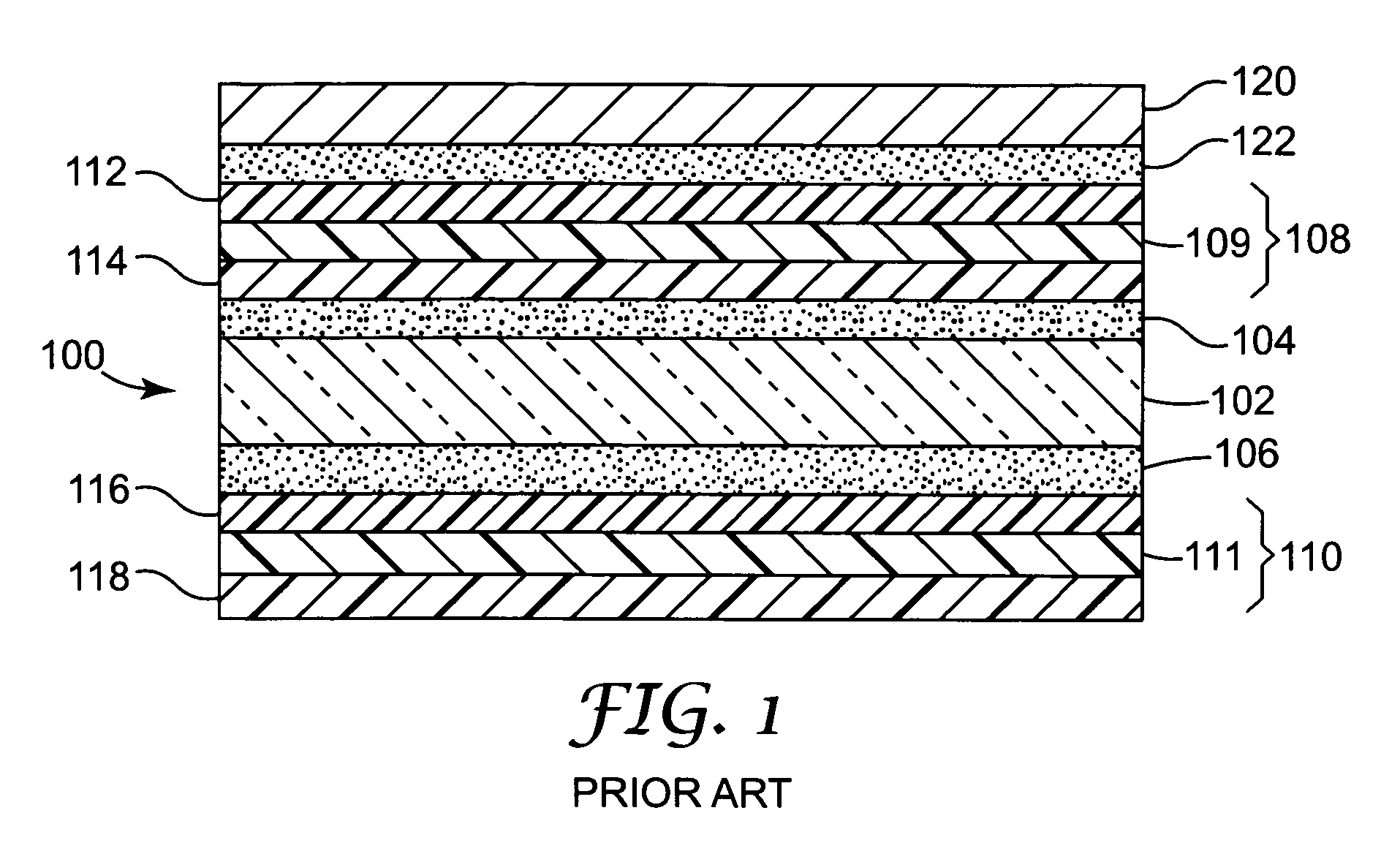

This invention relates to a method of making flat sheet asymmetric membranes, including cellulose diacetate / cellulose triacetate blended membranes, polyimide membranes, and polyimide / polyethersulfone blended membranes by formulating the polymer or the blended polymers dopes in a dual solvent mixture containing 1,3 dioxolane and a second solvent, such as N,N′-methylpyrrolidinone (NMP). The dopes are tailored to be closed to the point of phase separation with or without suitable non-solvent additives such as methanol, acetone, decane or a mixture of these non-solvents. The flat sheet asymmetric membranes are cast by the phase inversion processes using water as the coagulation bath and annealing bath. The dried membranes are coated with UV curable silicone rubber. The resulting asymmetric membranes exhibit excellent permeability and selectivity compared to the intrinsic dense film performances.

Owner:UOP LLC

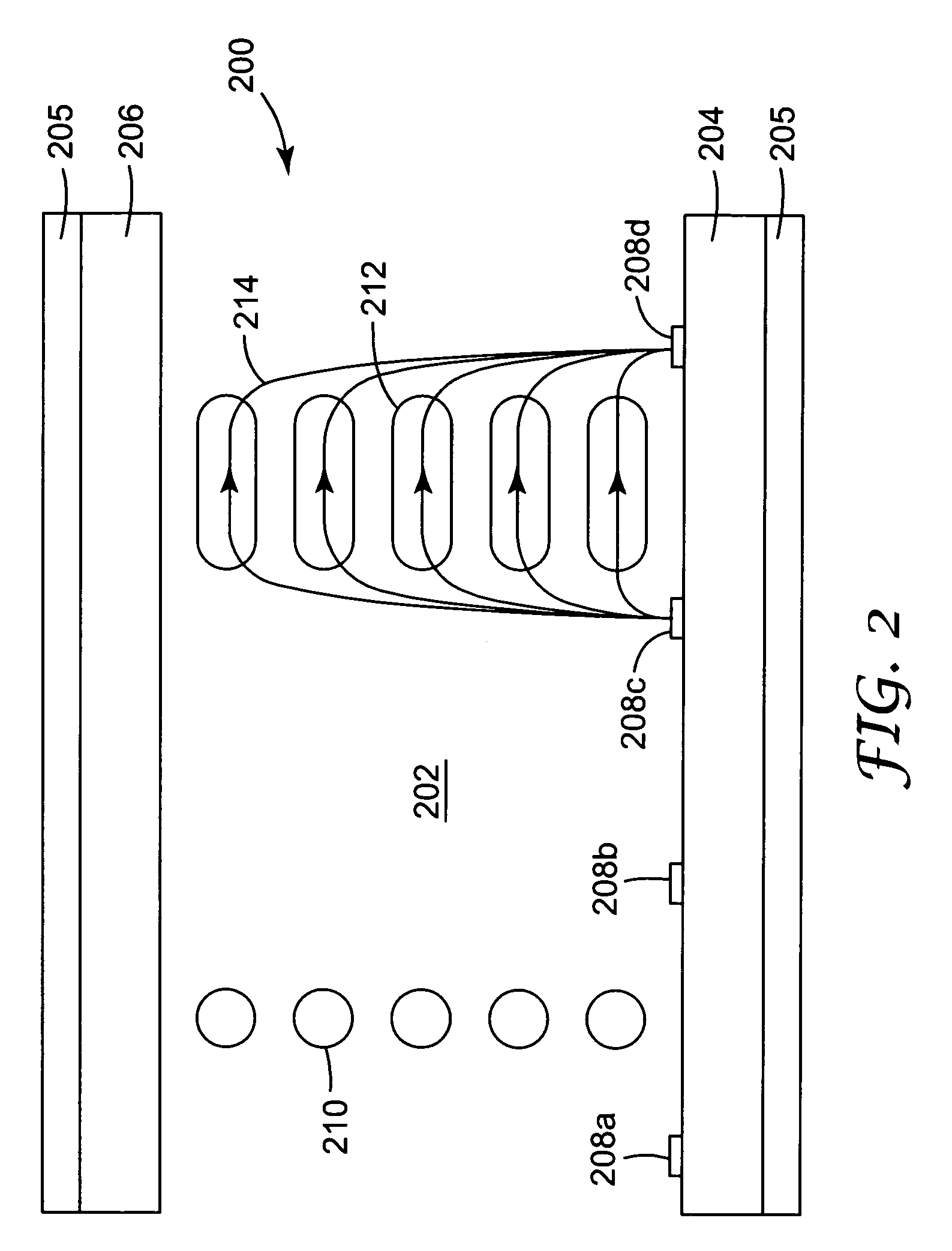

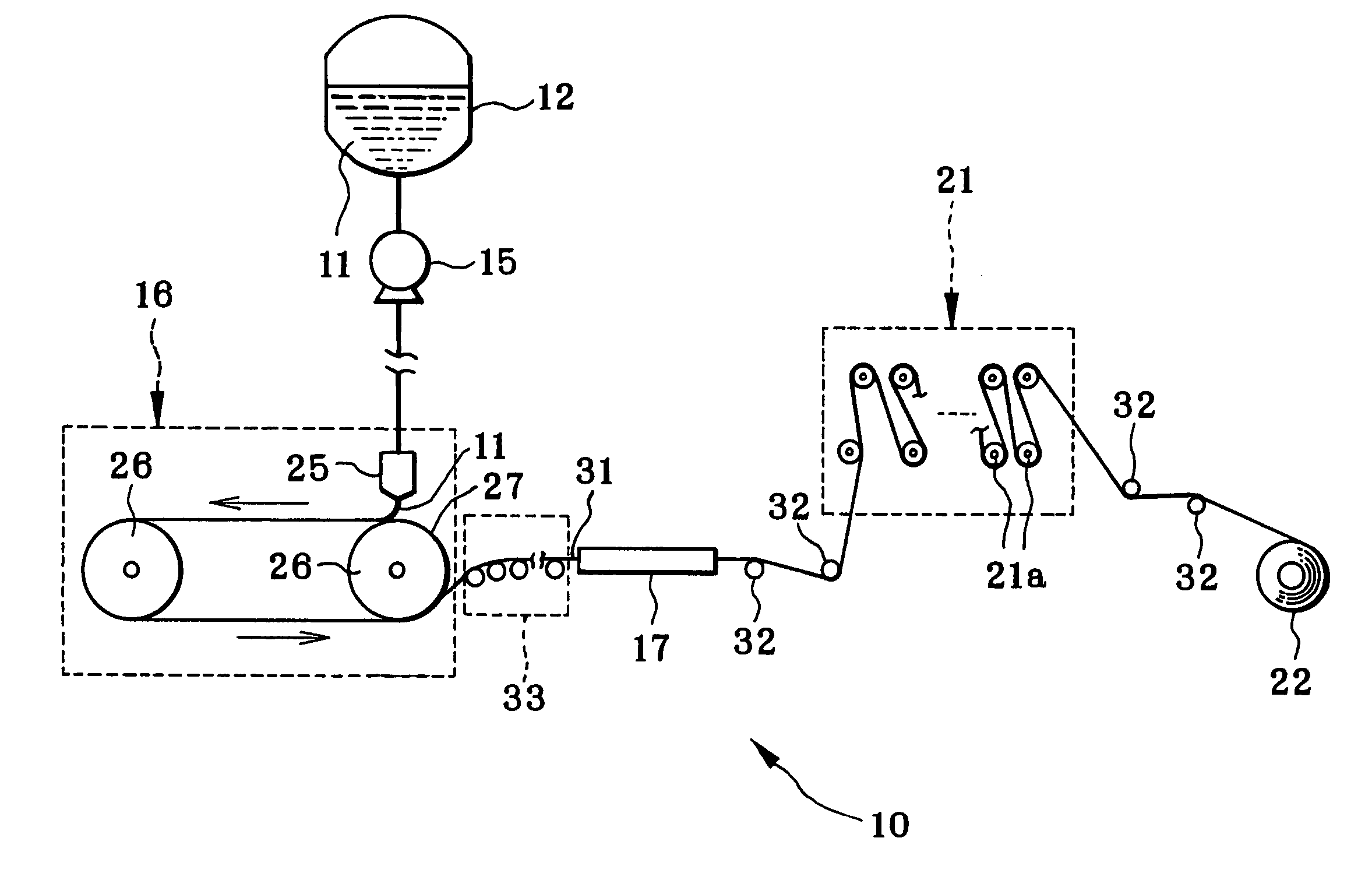

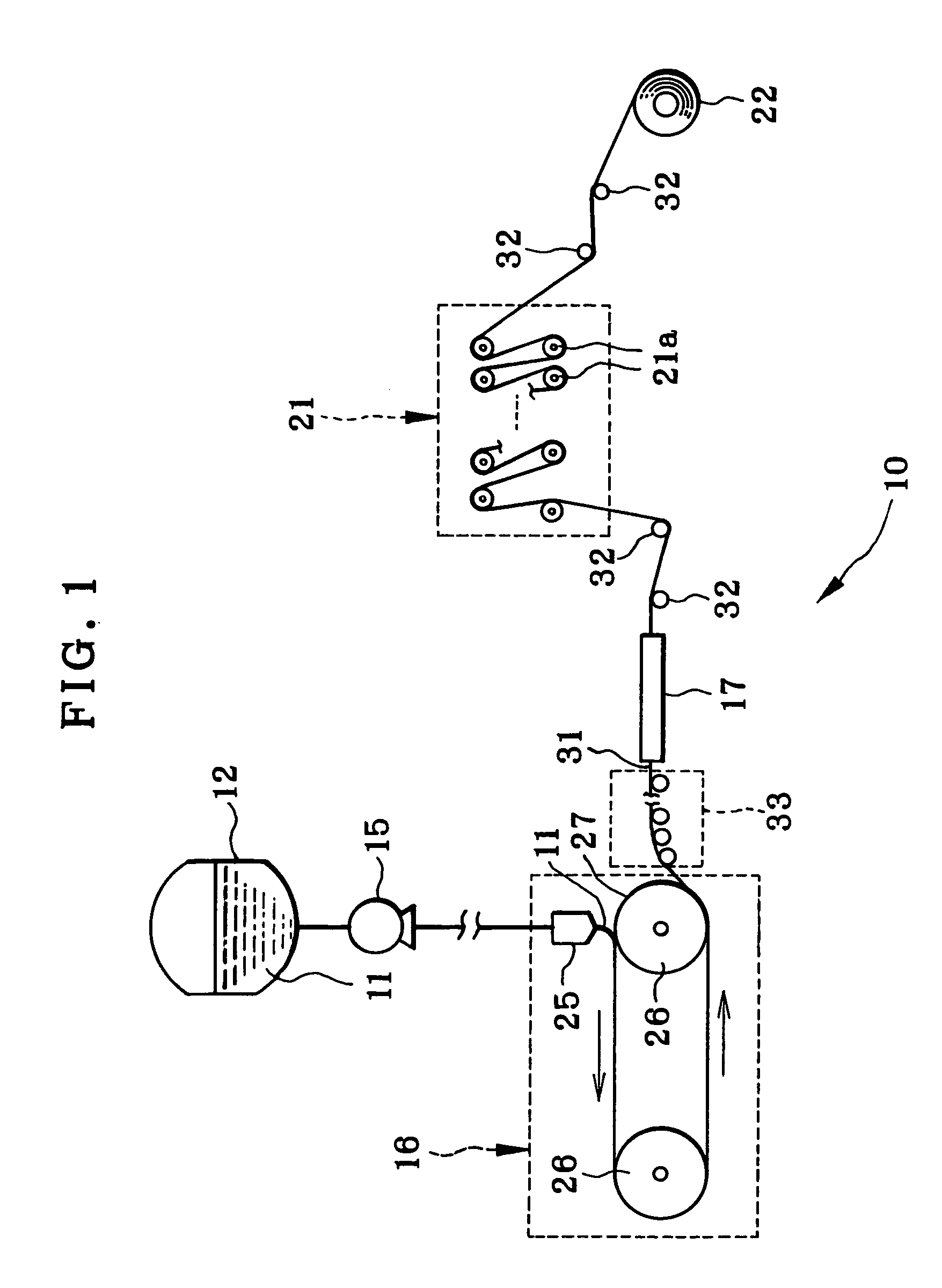

Solution casting process for producing polymer film

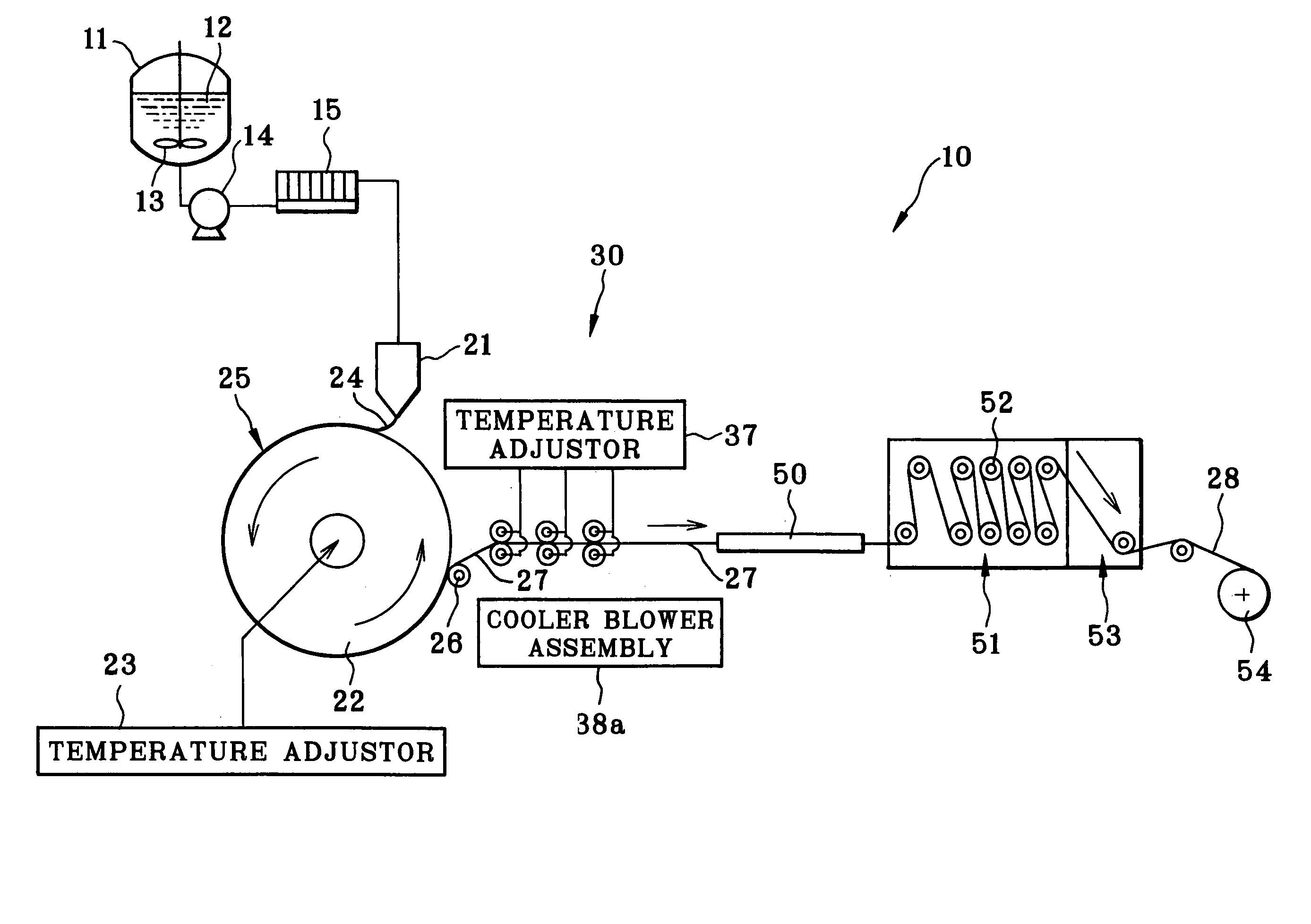

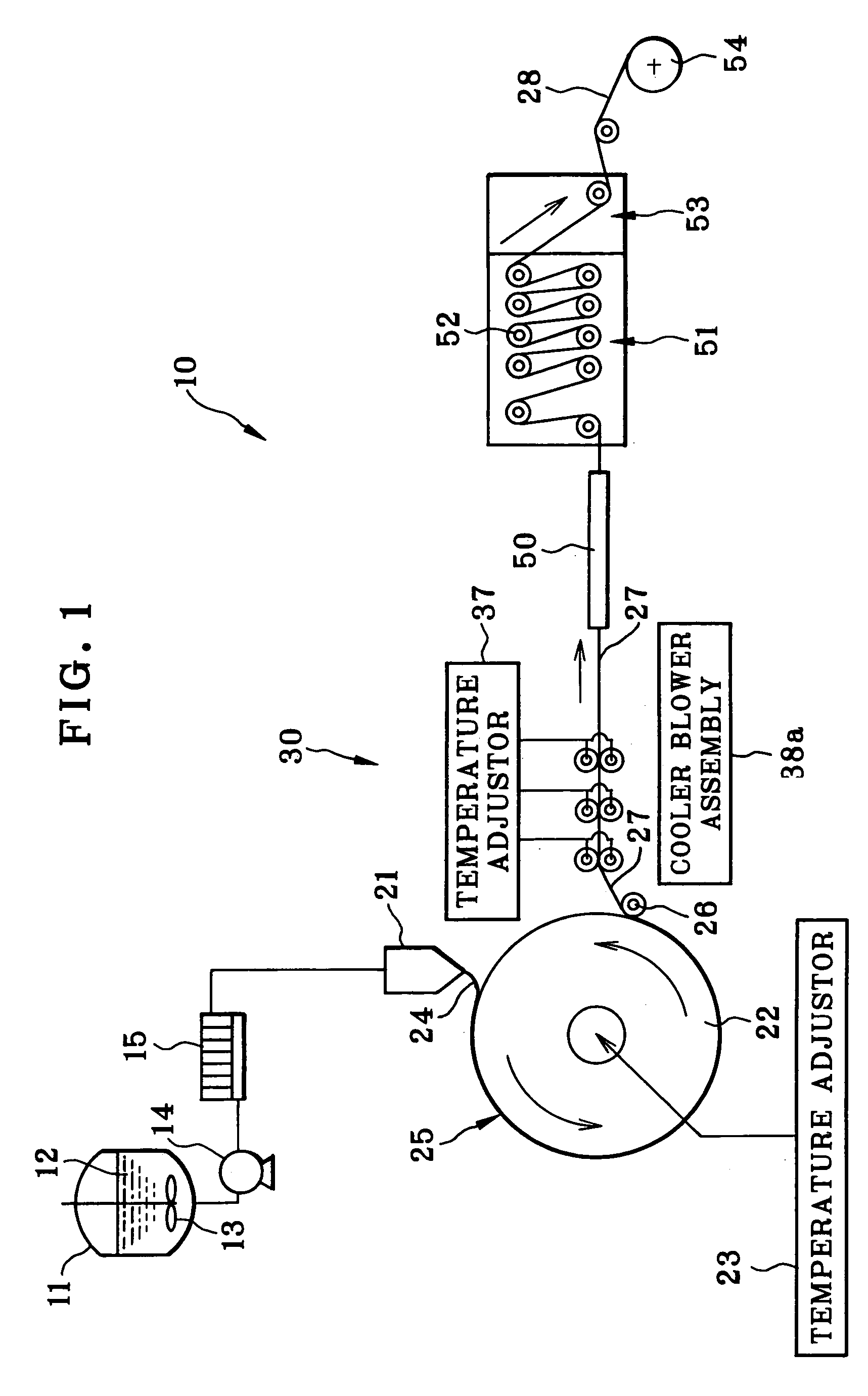

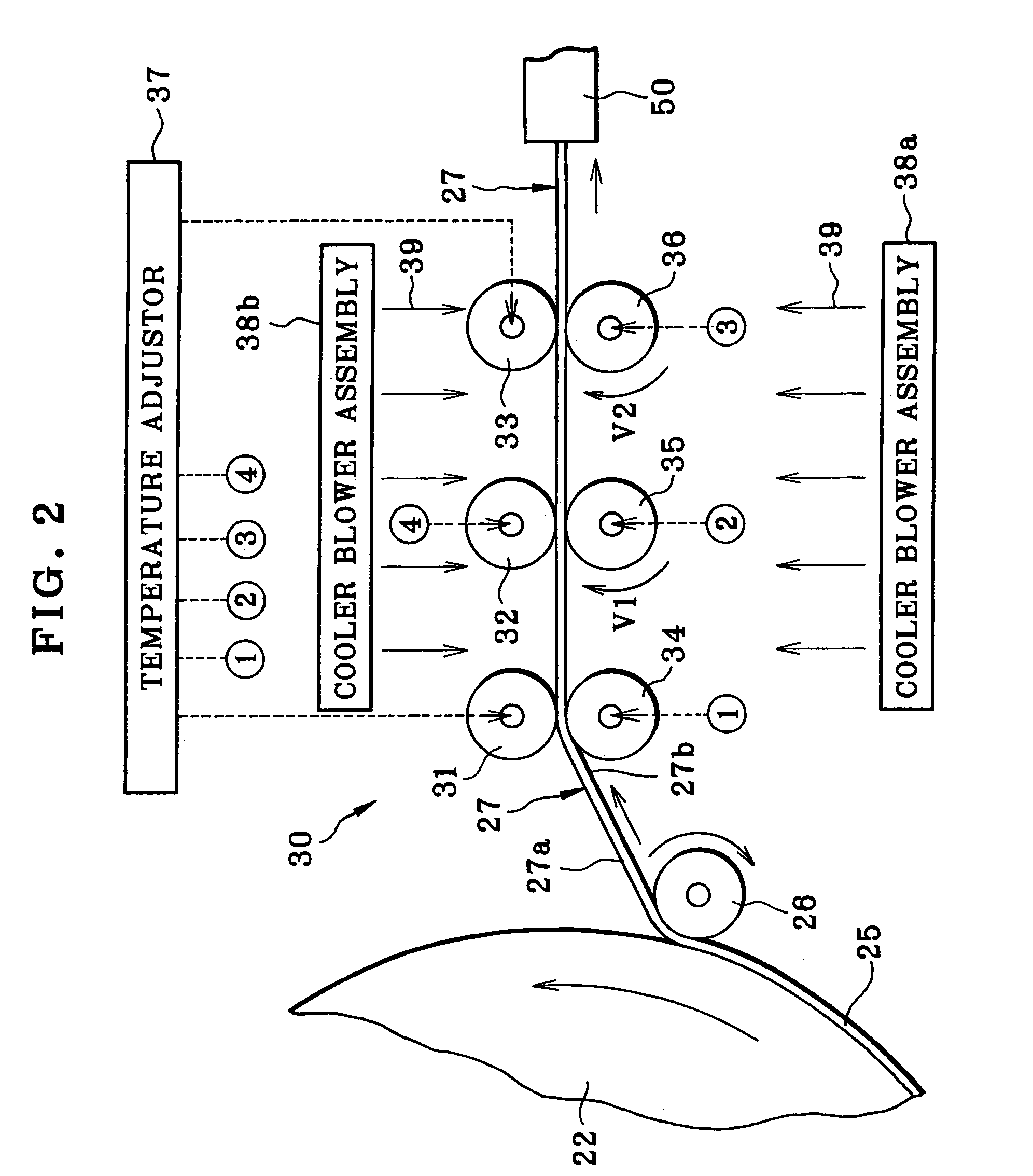

InactiveUS7172713B2Suppress wrinklesQuality improvementMovable spraying apparatusLaminationMetallurgyCast films

A solution casting process for producing cellulose triacetate (TAC) film is provided. Bead of dope, which includes cellulose triacetate and solvent, is cast on to a rotating supporting drum, to form self-supporting cast film. The self-supporting cast film is stripped from the supporting drum. The self-supporting cast film is dried while the self-supporting cast film being stripped is fed by feed rollers, to form the cellulose triacetate film. A surface temperature of the feed rollers is set equal to or lower than 0° C. The self-supporting cast film upon being stripped has modulus of longitudinal elasticity equal to or more than 450,000 Pa.

Owner:FUJIFILM HLDG CORP +1

Cellulose acetate and dope containing the same

InactiveUS7122660B1Good release effectSatisfactory optical propertyArtificial filaments from cellulose derivativesCarboxyl radicalCellulose diacetate

Using the dope containing the following cellulose acetate (1), (2), or (3), a film is prepared by the casting process:(1) a cellulose acetate having carboxyl groups binding to at least one member selected from the group consisting of a cellulose acetate and a hemicellulose acetate, wherein at least a part of said carboxyl groups are in an acidic form;(2) a cellulose acetate containing at least one member selected from the group consisting of an acid having an acid dissociation exponent pKa of 1.93 to 4.50 in water, an alkali metal salt of said acid and an alkaline earth metal of said acid; or(3) a cellulose acetate containing an alkali metal or an alkaline earth metal wherein the total content of an alkaline metal and an alkaline earth metal in 1 gram of the cellulose acetate is from an effective amount to 5.5×10−6 equivalent (in terms of ion equivalent). The above cellulose acetate is also useful for spinning process. The cellulose acetate includes a cellulose diacetate and a cellulose triacetate. The cellulose acetate of the present invention has high film-releasability from a support and excellent optical characteristics.

Owner:DAICEL CHEM IND LTD

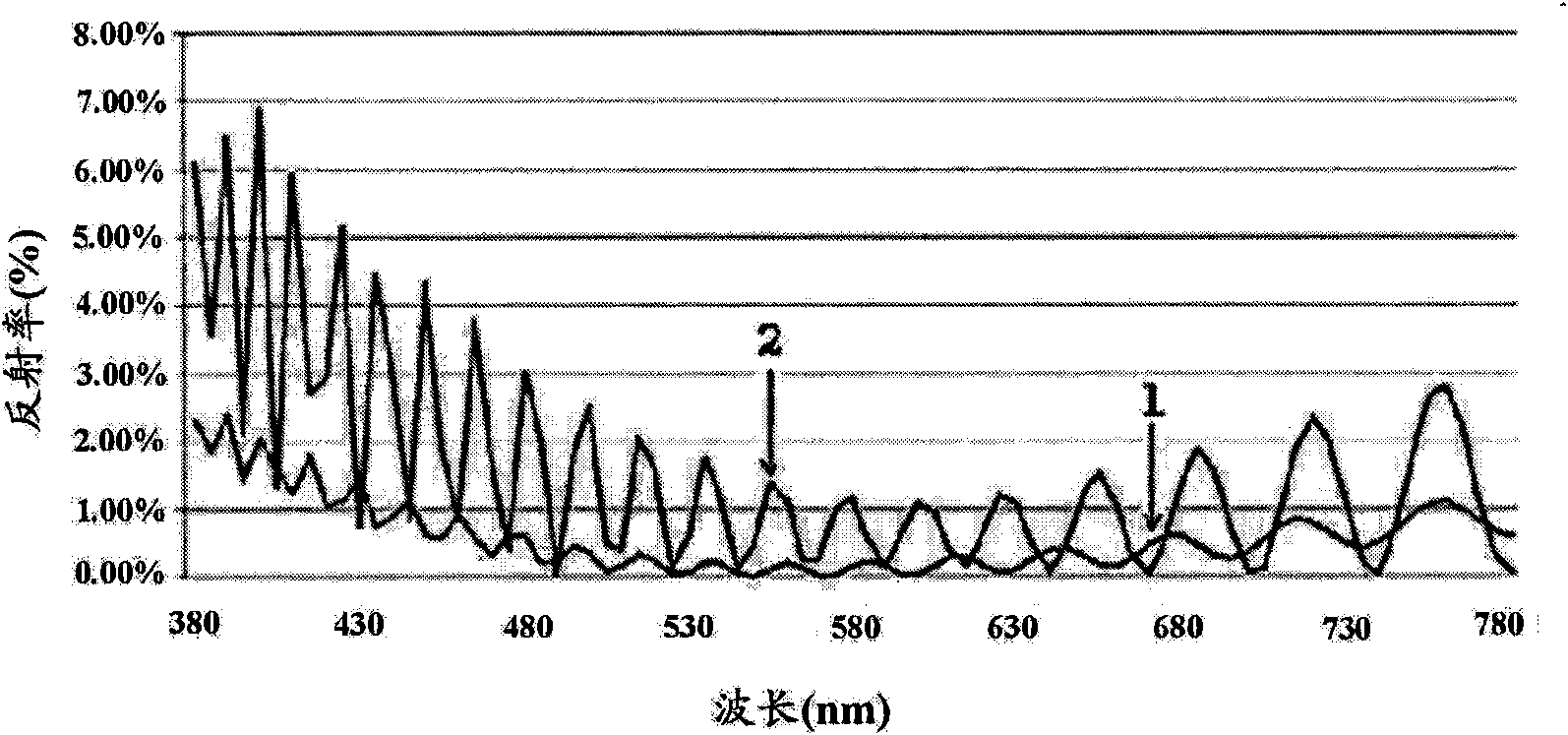

Anti-reflection film and polarization plate containing the same

InactiveCN101900841AExcellent rainbow effectReduce reflectivityCellulosic plastic layered productsPolarising elementsAngle of incidencePolyvinyl alcohol

The present invention generally relate to an anti-reflection film and a polarization plate containing the same, particularly relate to the anti-reflection film having an excellent rainbow effect and low reflectivity by reducing amplitude of reflection spectrum, and the polarization plate containing the anti-reflection film. The anti-reflection film includes a cellulose triacetate (TAC) transparent base for protecting a polyvinyl alcohol (PVA) polaroid sheet; a high-hardness layer coated on the transparent base and having a high refractivity of 1.50-1.60 as well as antistatic function; and a low refractivity layer coated on the high-hardness layer by a wet method and having a refractivity of 1.31-1.40, wherein the anti-reflection film has an average specular reflectance of 0.1-1.40% in a wavelength range from 480-680nm at an incidence angle of 5 DEG.

Owner:TORAY ADVANCED MATERIALS KOREA

Plasticization resistant membranes

InactiveUS20100270234A1Increase heightGood chemical stabilitySemi-permeable membranesProductsParaffin waxCross-link

This invention discloses a composition of, a method of making, and an application of high plasticization-resistant chemically cross-linked organic-inorganic hybrid membranes such as cross-linked cellulose acetate-cellulose triacetate-polyurethanepropylsilsesquioxane membranes. These cross-linked membranes with covalently interpolymer-chain-connected hybrid networks were prepared via a sol-gel condensation polymerization of cross-linkable organic polymer-organosilicon alkoxide precursor membrane materials. CO2 plasticization tests on these cross-linked membranes demonstrate extremely high CO2 plasticization resistance under CO2 pressure up to 5516 kPa (800 psig). These new cross-linked membranes can be used not only for gas separations such as CO2 / CH4 and CO2 / N2 separations, O2 / N2 separation, olefin / paraffin separations (e.g. propylene / propane separation), iso / normal paraffins separations, but also for liquid separations such as desalination.

Owner:UOP LLC

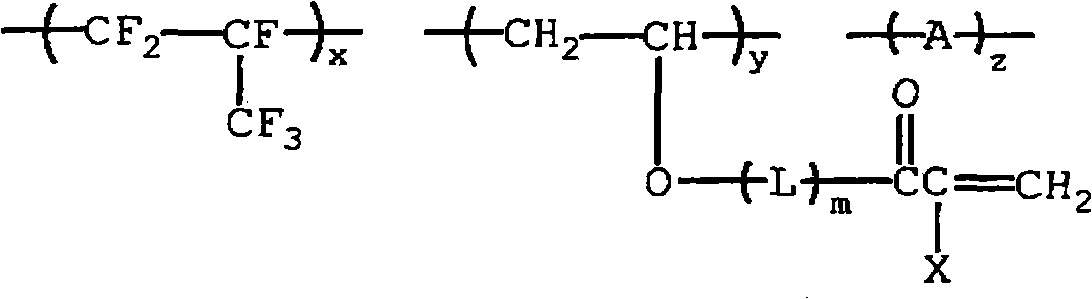

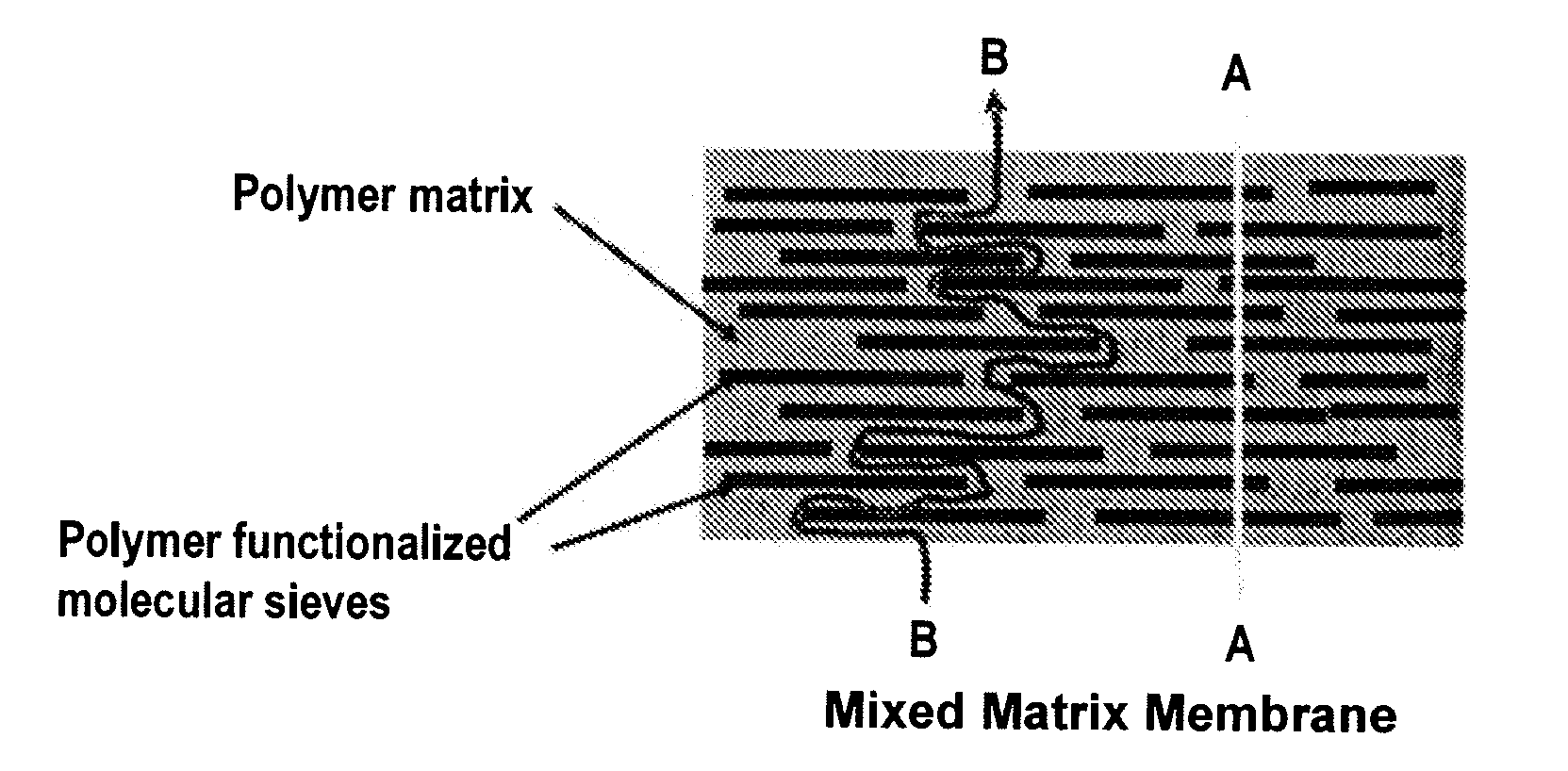

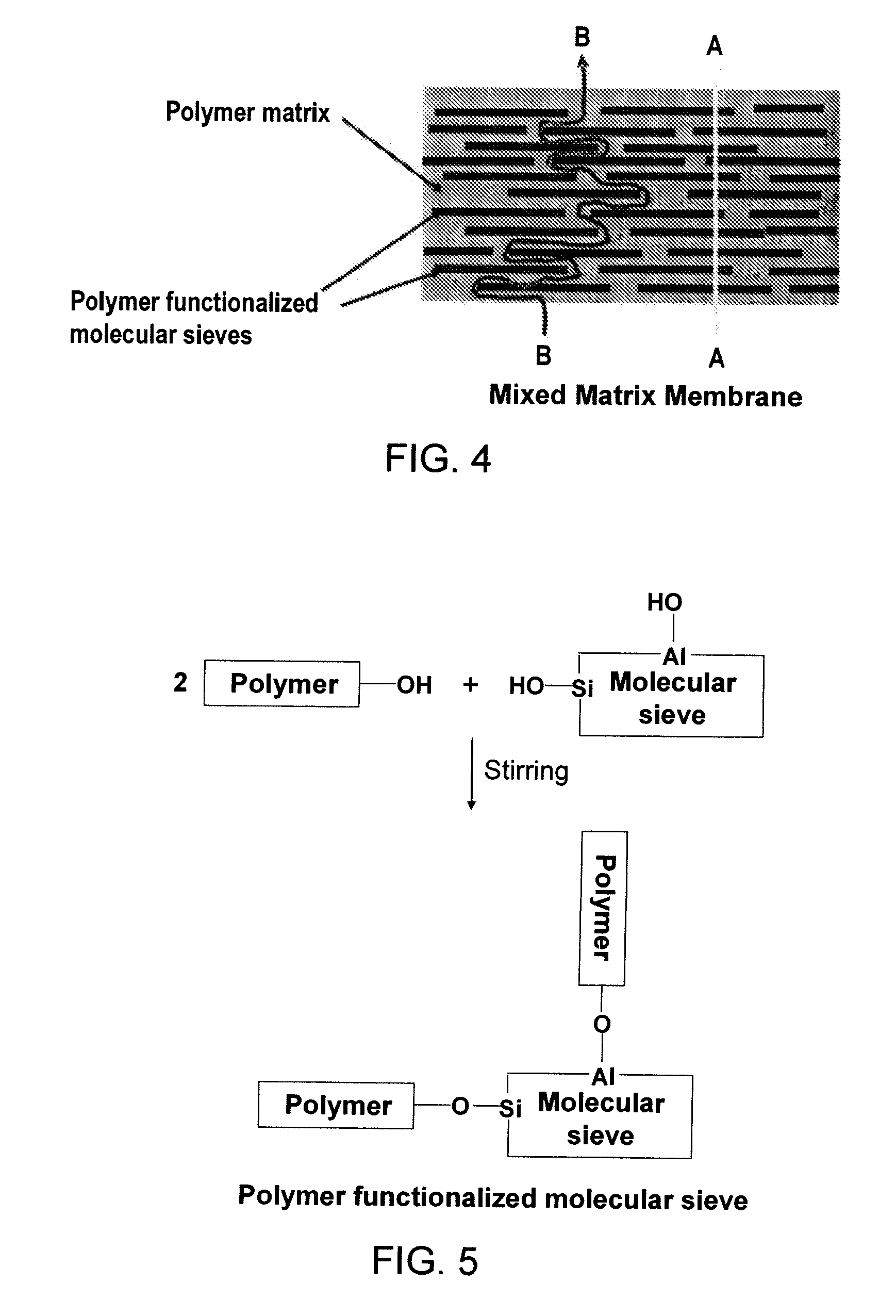

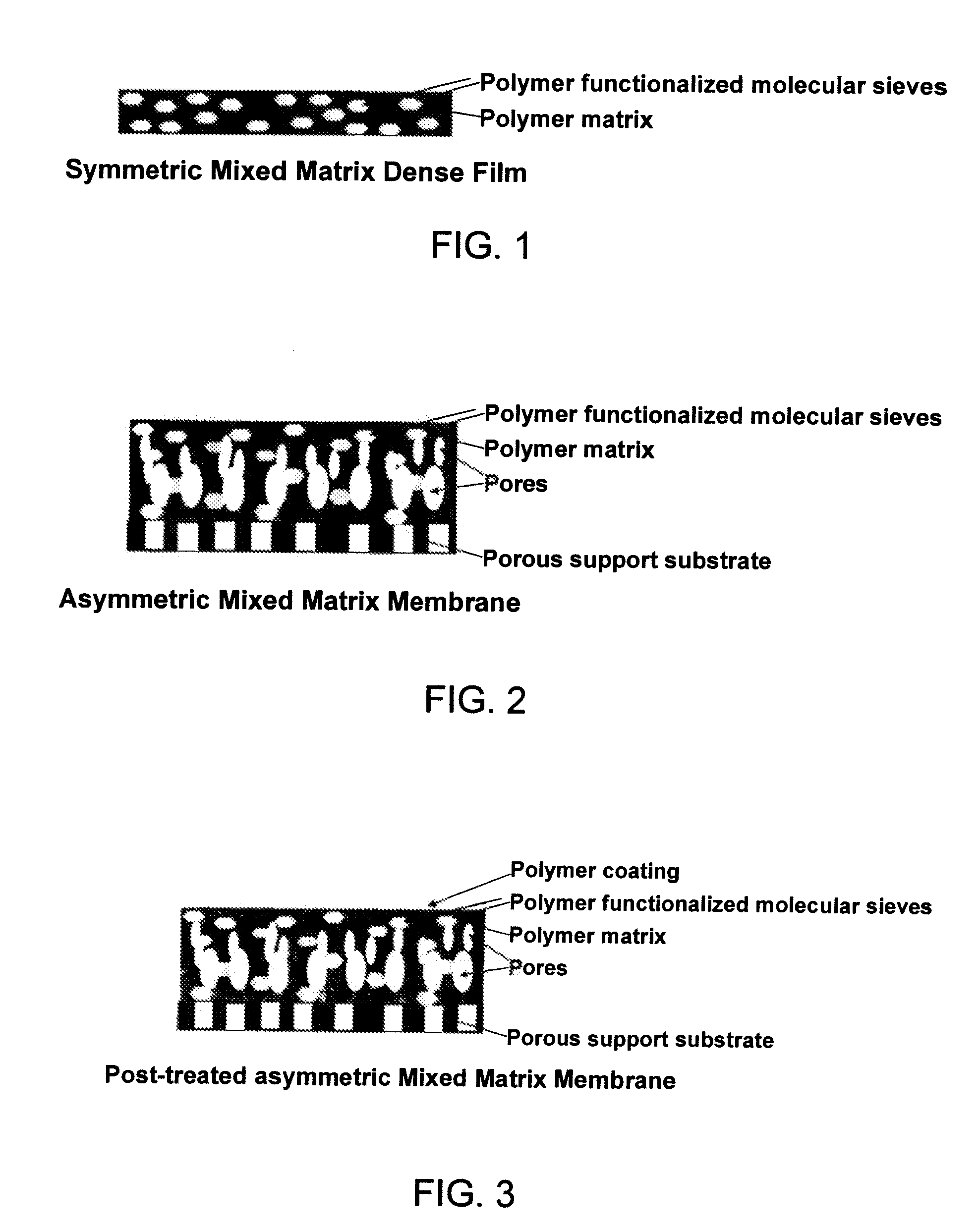

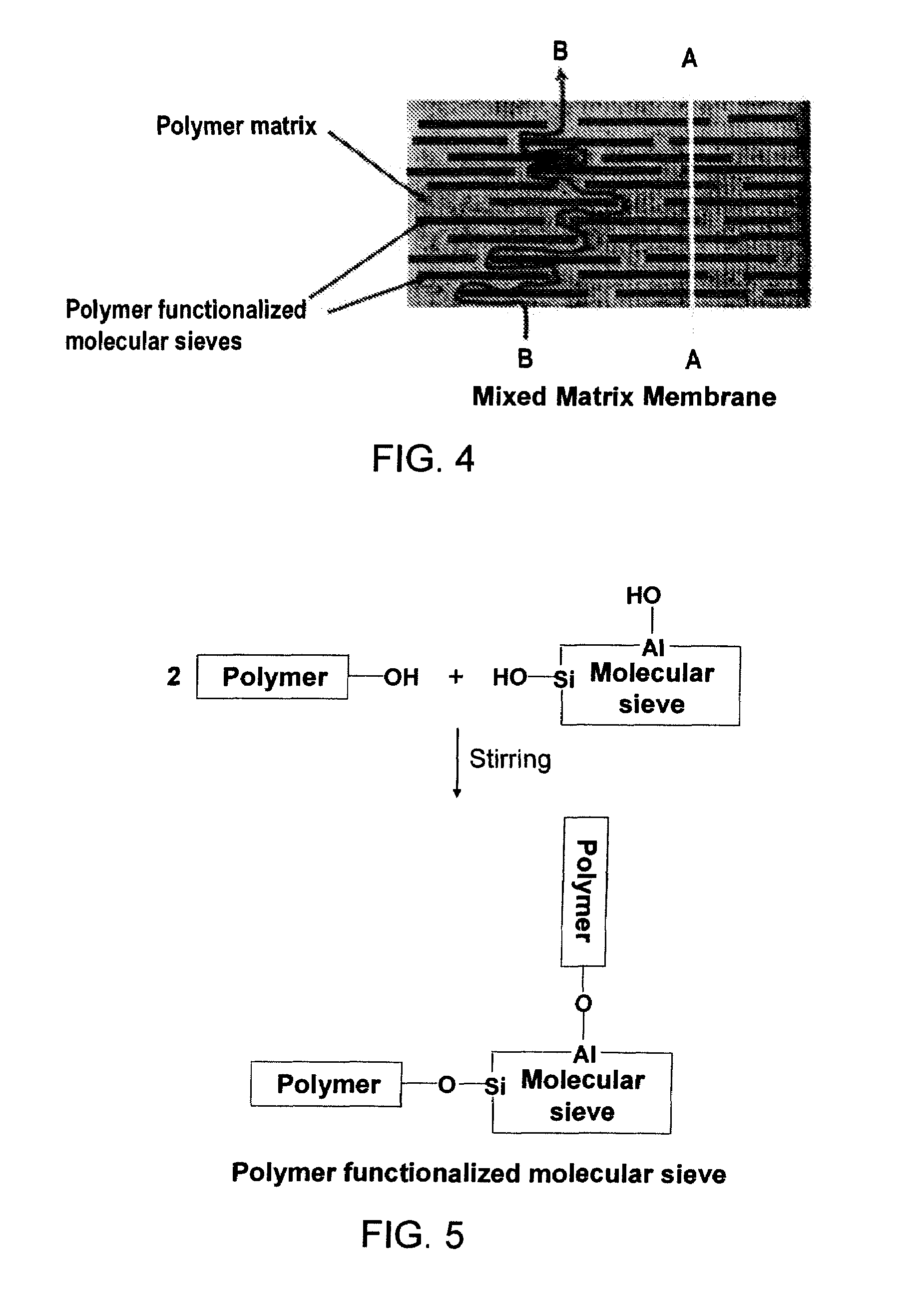

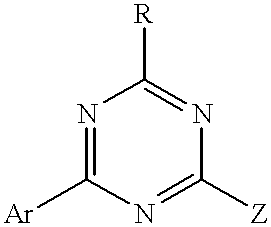

Method of Making Polymer Functionalized Molecular Sieve/Polymer Mixed Matrix Membranes

InactiveUS20090131242A1Easy to separateAverage permeabilitySemi-permeable membranesGas treatmentPolymer scienceCellulose acetate

The present invention discloses a method of making polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs) with either no macrovoids or voids of less than several Angstroms at the interface of the polymer matrix and the molecular sieves by incorporating polyethersulfone (PES) or cellulose triacetate (CTA) functionalized molecular sieves into a continuous polyimide or cellulose acetate polymer matrix. The MMMs, particularly PES functionalized AlPO-14 / polyimide MMMs and CTA functionalized AlPO-14 / CA MMMs have good flexibility and high mechanical strength, and exhibit significantly enhanced selectivity and / or permeability over the polymer membranes made from the corresponding continuous polymer matrices for carbon dioxide / methane (CO2 / CH4), hydrogen / methane (H2 / CH4), and propylene / propane separations. The MMMs are suitable for a variety of liquid, gas, and vapor separations such as deep desulphurization of gasoline and diesel fuels, ethanol / water separations, pervaporation dehydration of aqueous / organic mixtures, CO2 / CH4, CO2 / N2, H2 / CH4, O2 / N2, olefin / paraffin, iso / normal paraffins separations, and other light gas mixture separations.

Owner:UOP LLC

Cellulose composites comprising hydrophobic particles and their use in paper products

InactiveUS20080041542A1Non-fibrous pulp additionNatural cellulose pulp/paperSolventAlkaline hydrolysis

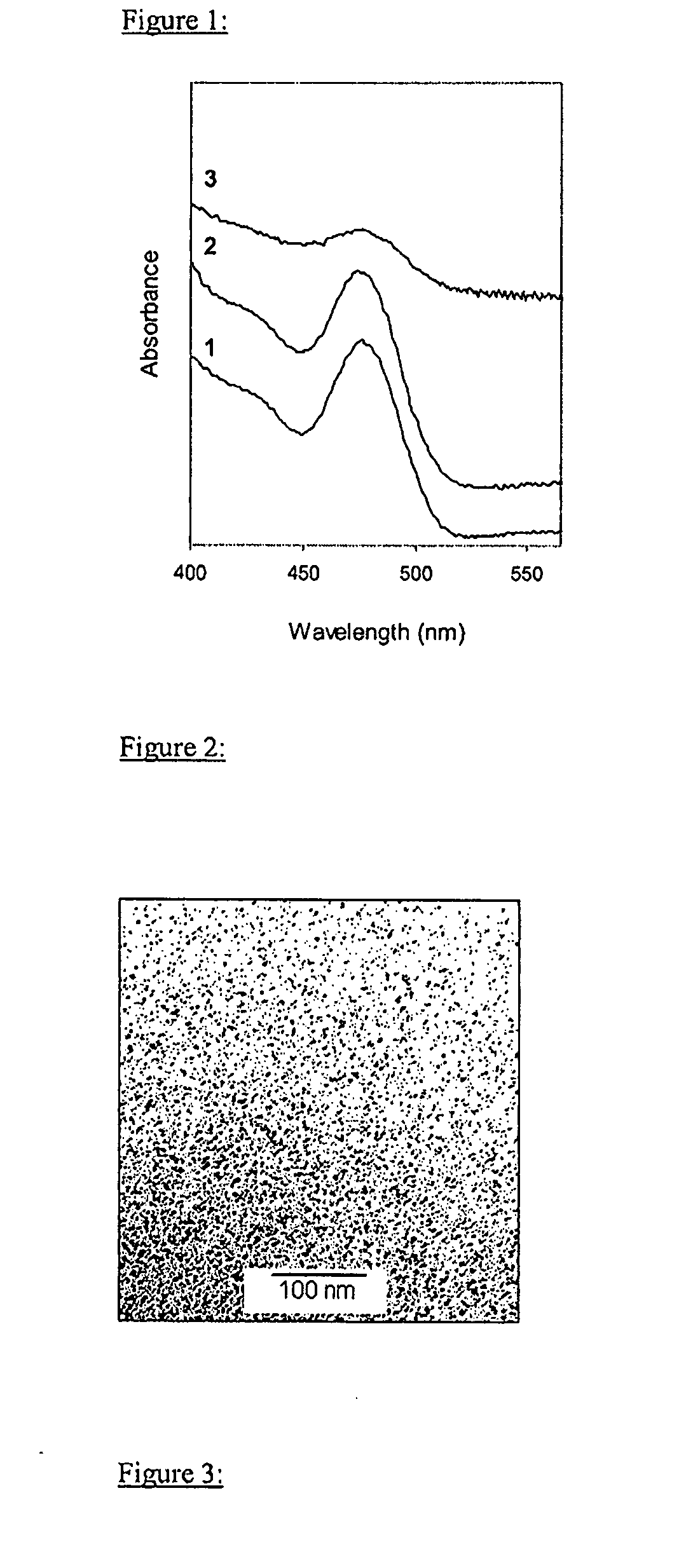

Polymer composite films were prepared by solvent casting suspensions of quantum dots (QDs) in cellulose triacetate (CTA) solution. The films were robust and possessed the optical properties characteristic of QDs. Transmission electron microscopy (TEM) images of the films revealed that the QDs were well dispersed within the CTA film matrix. The selective alkaline hydrolysis of QD / CTA films in 0.1N NaOH over 24 hours resulted in the surface conversion of CTA to regenerated cellulose. Optical properties of the films were probed both before and after the hydrolysis reaction using fluorescence spectroscopy, and were found generally unaltered. The cellulose surfaces of the alkaline treated films allow for facile incorporation of the films into paper sheets.

Owner:ABITBOL TIFFANY +1

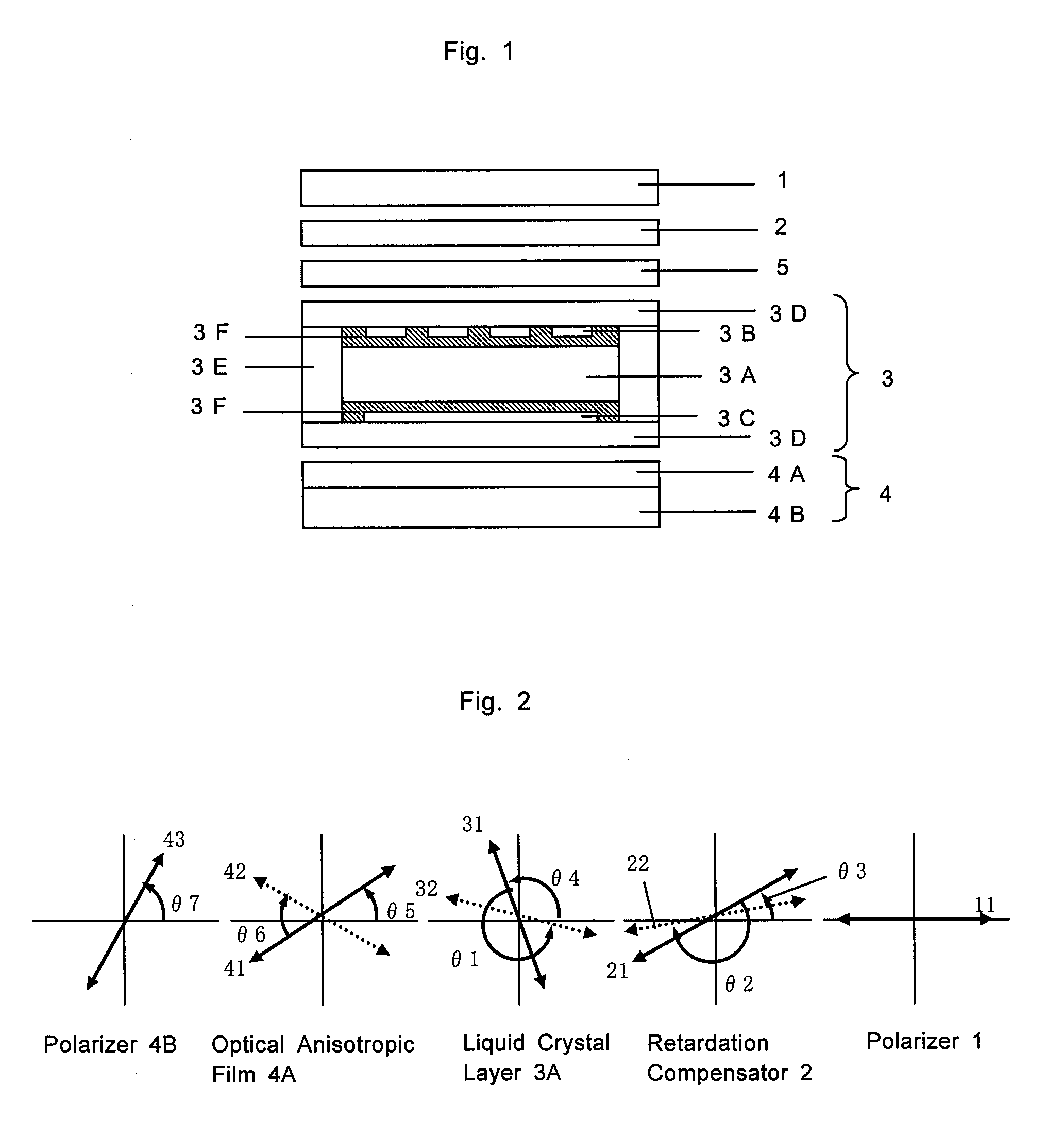

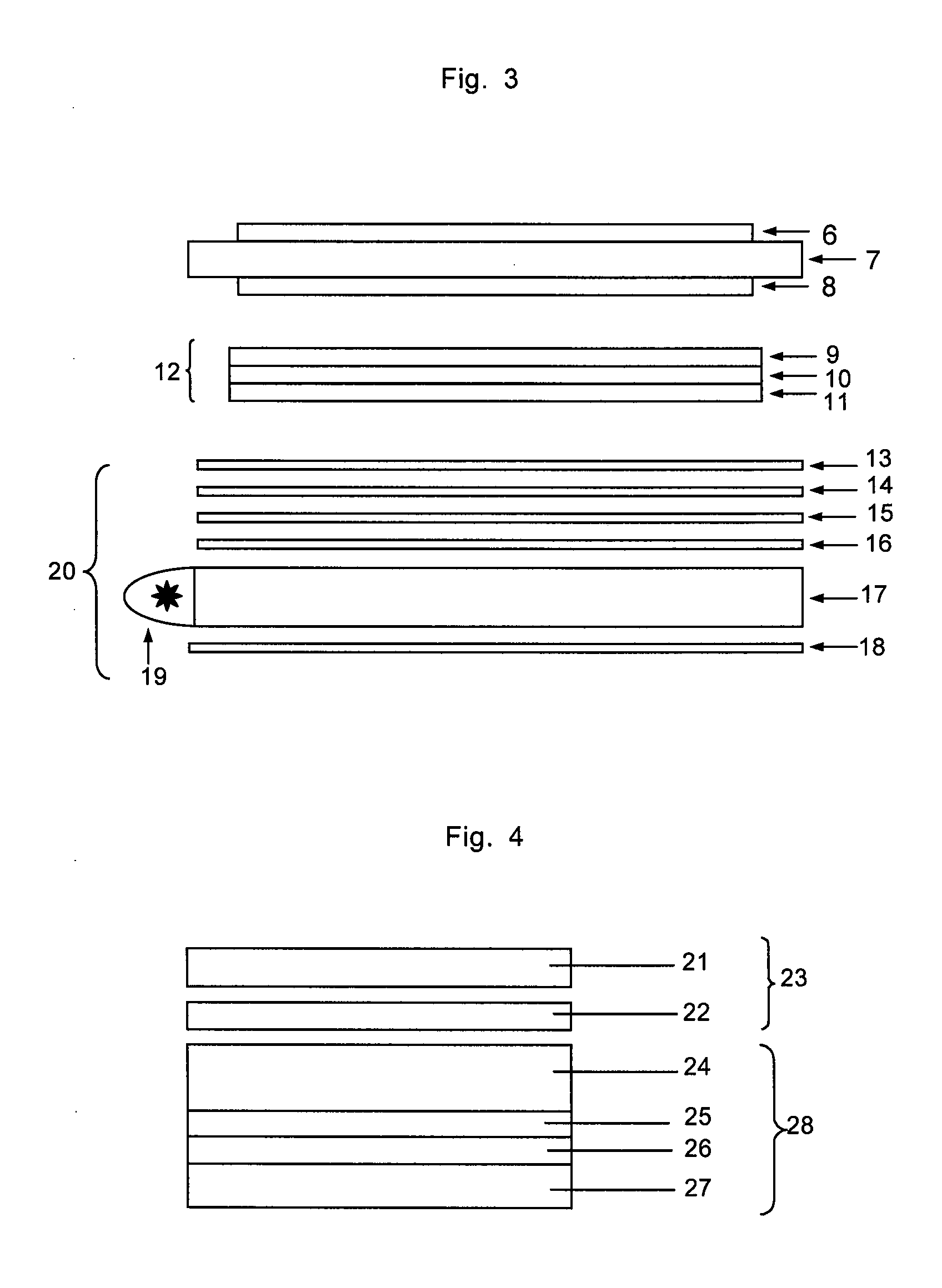

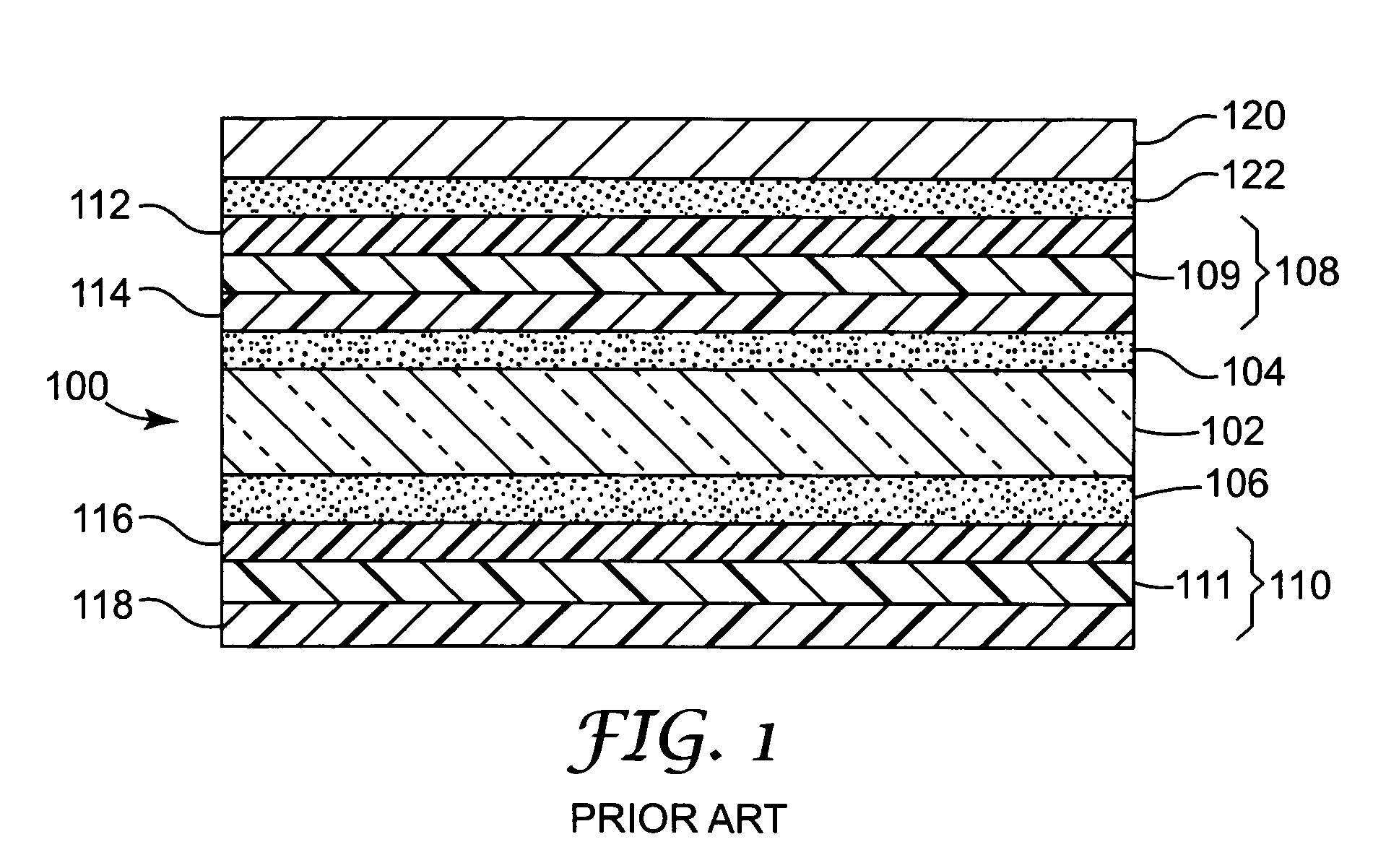

Liquid crystal display with neutral dark state

InactiveUS7057682B2Reduction of useful viewing angle of displayIncrease typePolarising elementsNon-linear opticsColor shiftImage contrast

A polarizer is used with a liquid crystal display (LCD) cell whose liquid crystal molecules are switched in the plane of the cell. The LCD has birefringent properties that are different from other types of LCD cell and, unlike other types of LCD, the image contrast is maintained and there is little color shift in the dark state when a low birefringence polarizer is used with the SIP LCD cell. In one embodiment, the x-z retardation of the layers between the polarization-sensitive absorbing layer and the LCD is less than 20 nm. In another embodiment, the x-z birefringence is less than 0.0005. The low levels of retardation and birefringence may be achieved by omitting the commonly used cellulose triacetate layer between the polarization-sensitive absorbing layer and the LCD.

Owner:SEIKO EPSON CORP

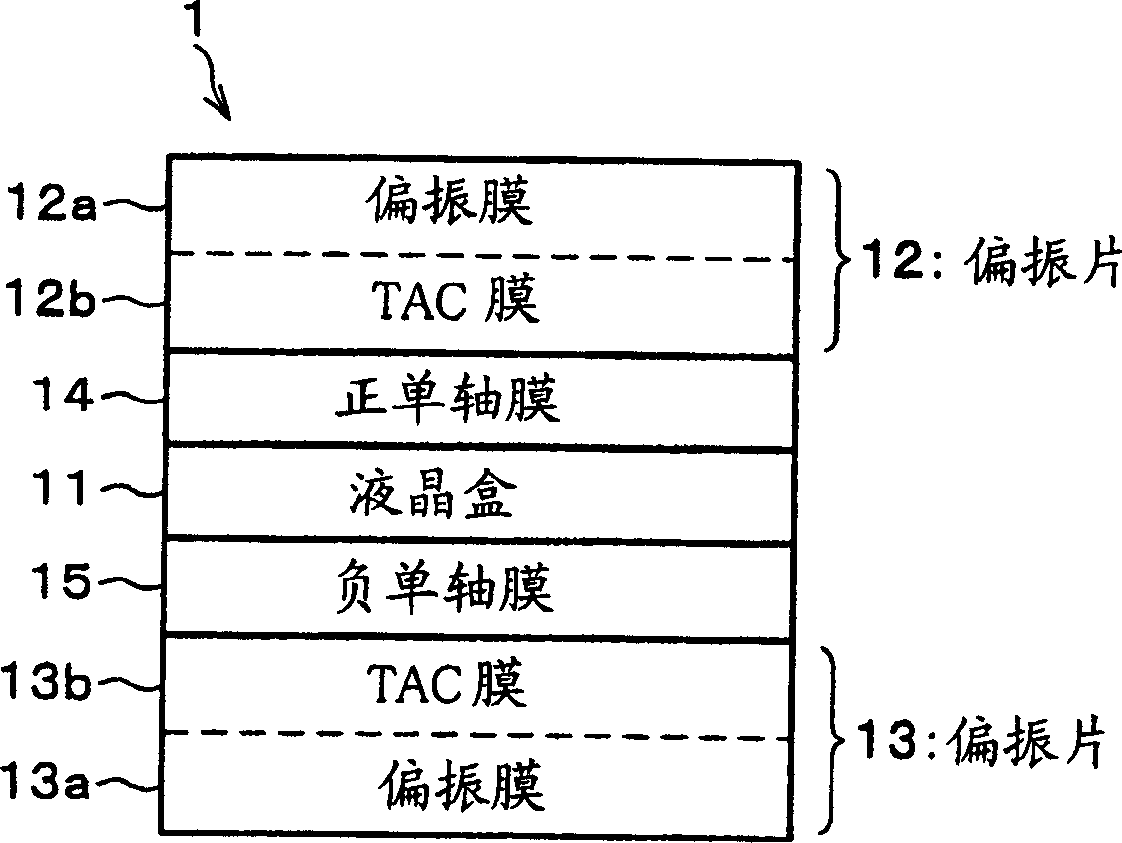

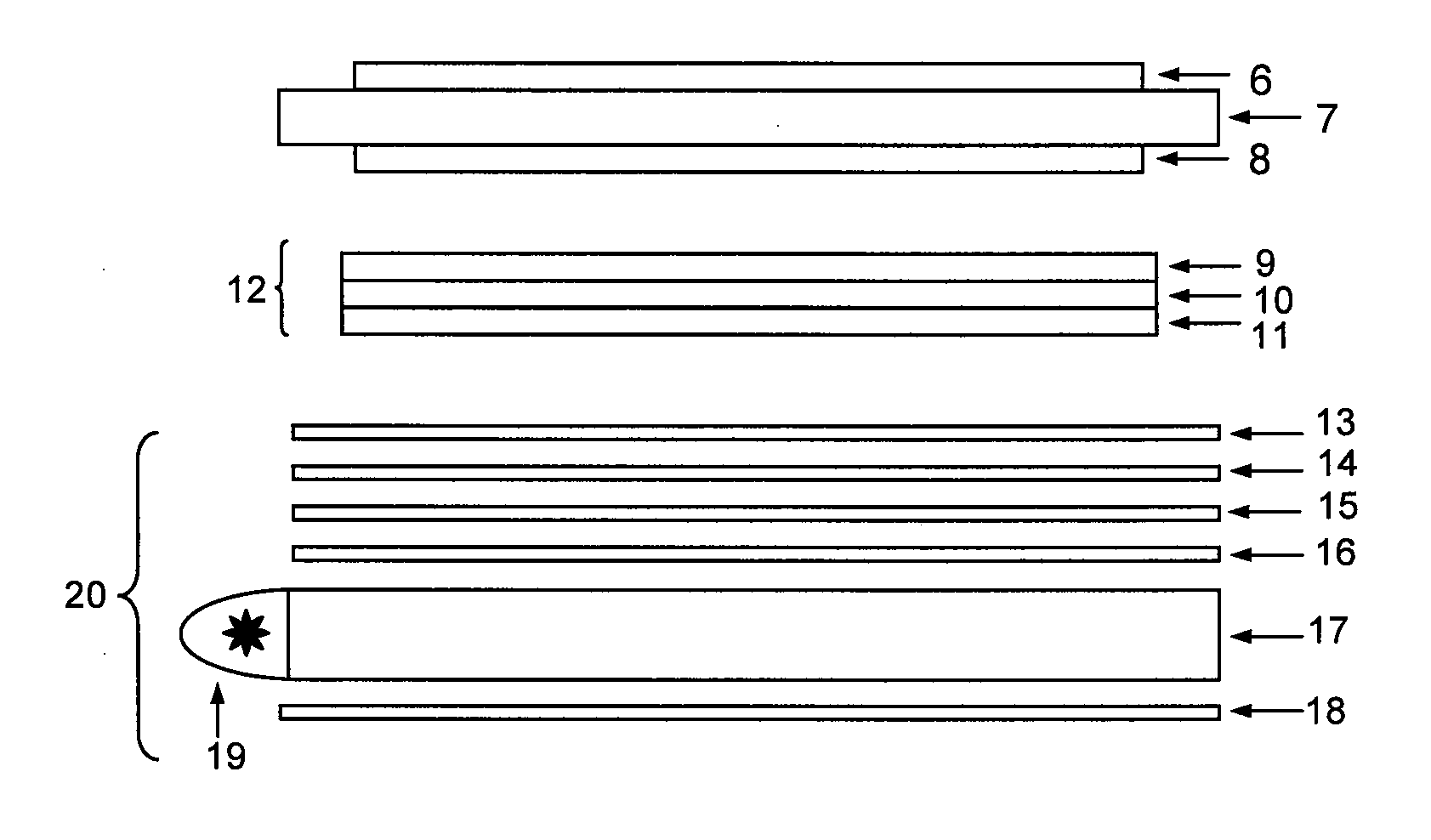

Liquid crystal display device

A positive uniaxial film (14) with a retardation of Rp [nm] in an in-plane direction is provided between a vertical alignment mode liquid crystal cell (11) and a polarizing plate (12), and a negative uniaxial film (15) with a retardation of Rn [nm] in a thickness direction is provided between the liquid crystal cell (11) and a polarizing plate (13). Further, when a parameter alpha1 [nm] relative to Rp is: alpha1=135-0.7xRtac; and a parameter beta1 [nm] relative to Rn is: beta1=Rlc-65-1.4xRtac, where Rtac [nm] is a retardation in a thickness direction of the respective triacetyl cellulose films (12b and 13b) of polarizing plates (12 and 13), the retardations Rp and Rn are set to be values greater than 90% but smaller than 110% with reference to the parameters alpha1 and beta1, respectively. This makes it possible to surely provide a vertical alignment mode liquid crystal display device which can maintain a high contrast when viewed from an oblique direction.

Owner:SHARP KK

Double layered forward osmosis membrane and preparation method thereof

InactiveCN103055713AIncrease effective water fluxAvoid enteringSemi-permeable membranesPolyesterPolymer science

The invention discloses a double layered forward osmosis membrane which is characterized by comprising an intermediate porous support layer and ultrathin layers at both sides. A support material such as screen cloth or nonwoven is further embedded in the middle of the porous support layer. The material of the porous support layer and the ultrathin layers is cellulose triacetate fiber, cellulose diacetate fiber or a mixture thereof; and the support material is cotton, polyester or nylon. The preparation method of the double layered forward osmosis membrane includes immersing the processed support material in the film casting solution of cellulose triacetate fiber, cellulose diacetate fiber or the mixture thereof, pulling out from the middle of both sides of a blade, and forming the double layered forward osmosis membrane via a phase inversion method. The advantage of the present invention is that the forward osmosis membrane having two layers can effectively prevent a solute entering into the porous support layer, and reduce the concentration polarization within the support layer, thereby significantly improving the effective water flux of the forward osmosis membrane.

Owner:XIAN HHJ WATER TREATMENT TECH

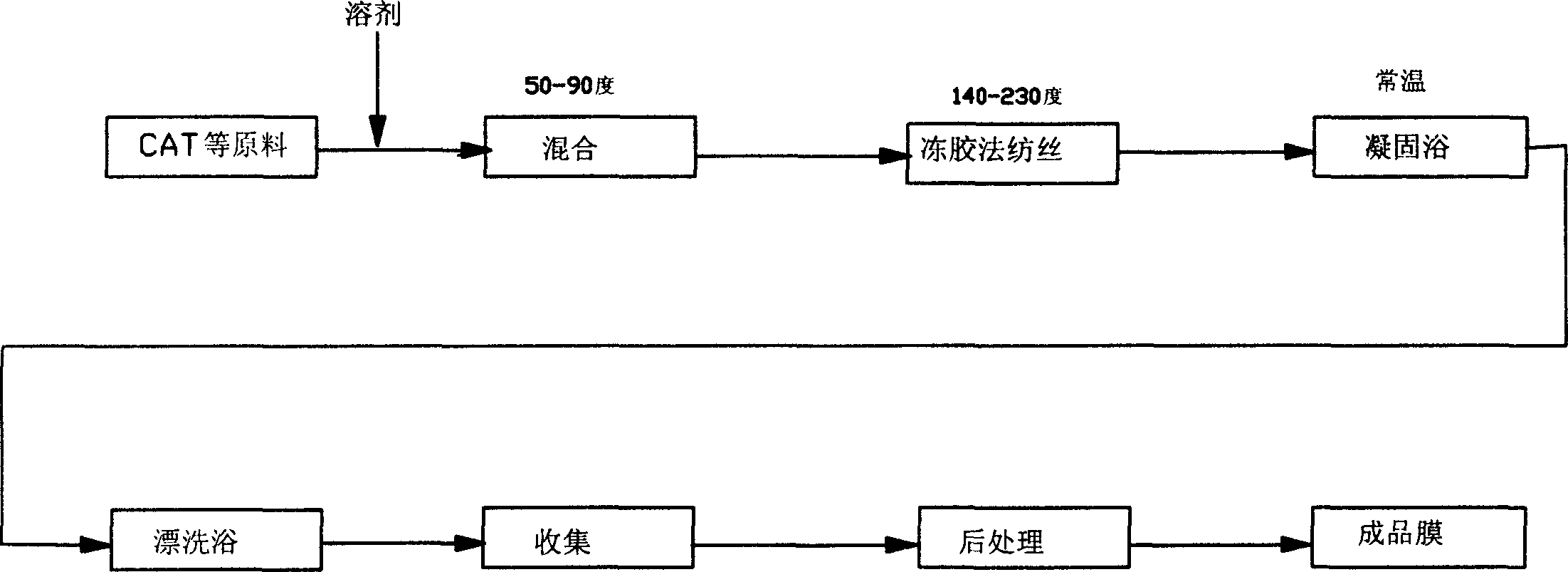

Antibiotic cellulose acetate nanofiltration membrane and its preparation method

ActiveCN101053782AGood sterilization functionGood antibacterial functionSemi-permeable membranesWater desalinationCellulose acetate

The invention discloses an antibacterial cellulose acetate nanofiltration membrane and a preparation method thereof. The casting film liquid, composed of 5-14% by weight of secondary cellulose acetate, 3-9% by weight of cellulose triacetated, 15-24% by weight of acetone, 1-5% by weight of maleic acid, 50-55% by weight of dioxane, 5-12% by weight of porogens that is methanol or ethanol and chemical modified nano-particle, is treated to obtain the antibacterial cellulose acetate natrium filter film after filtrating, debubbling, film flotation on the base cloth, solidifying in the gel baith and post processing. The invention brings the plasm chemical modified antibacterial nano-particle into the cellulose acetate nanofiltration membrane to make the nanofiltration membrane have a strong bacteriostasis and sterilization function, and the surface of the nanofiltration membrane is hard to absorb alga and animalcule to raise the use life and the service efficiency of the nanofiltration membrane remarkably. The antibacterial cellulose acetate nanofiltration membrane prepared based on the invention has the advantage of a steady structural properties, a strong erosion-resisting vharacteristics by animalcule and a high water flux of the film. The invention can be broadly used in the field of treatment of ground drinking water, biological pharmacy and the pretreatment of sea water desalination.

Owner:SHIJIAZHUANG NO 4 PHARMA

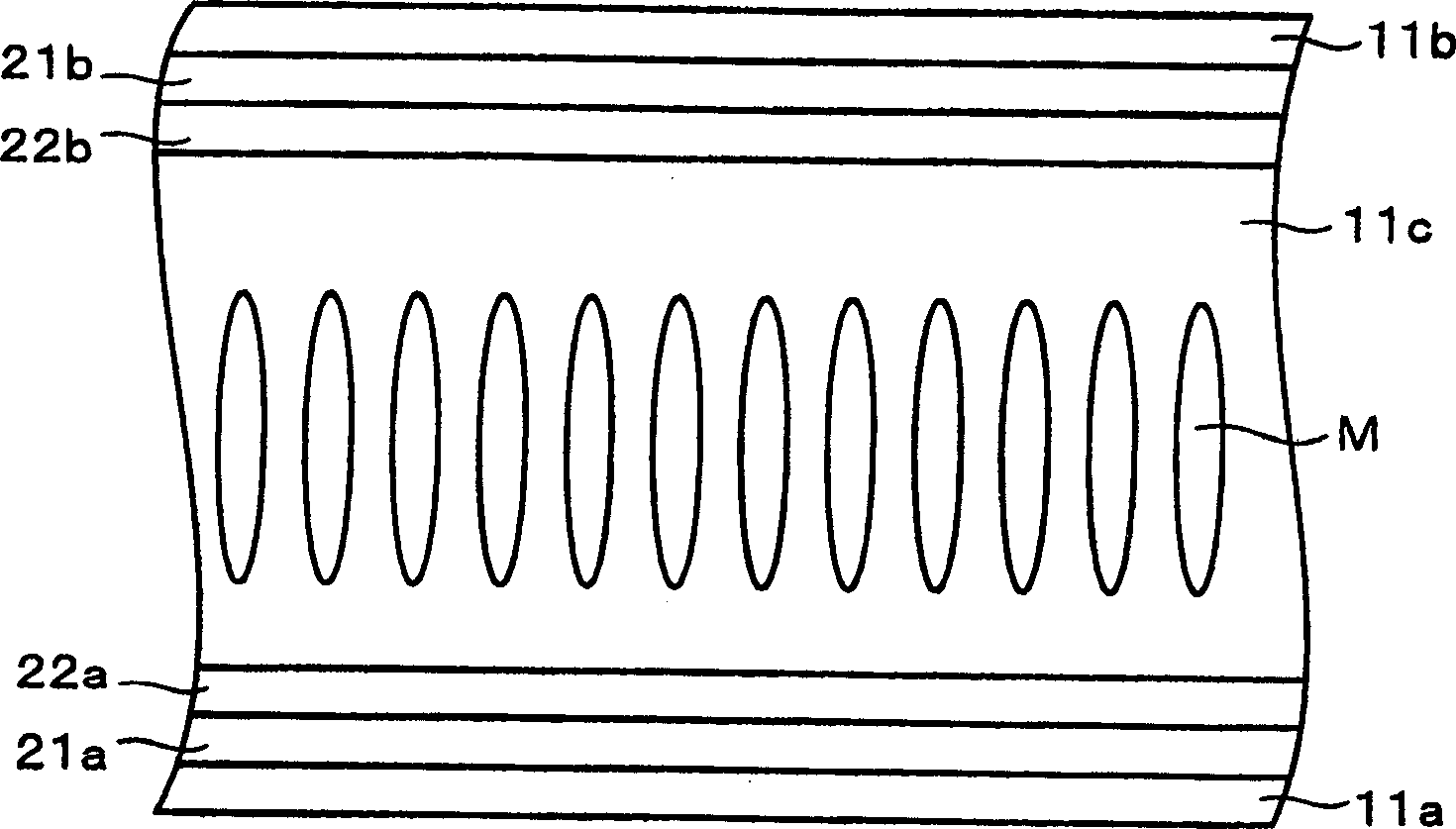

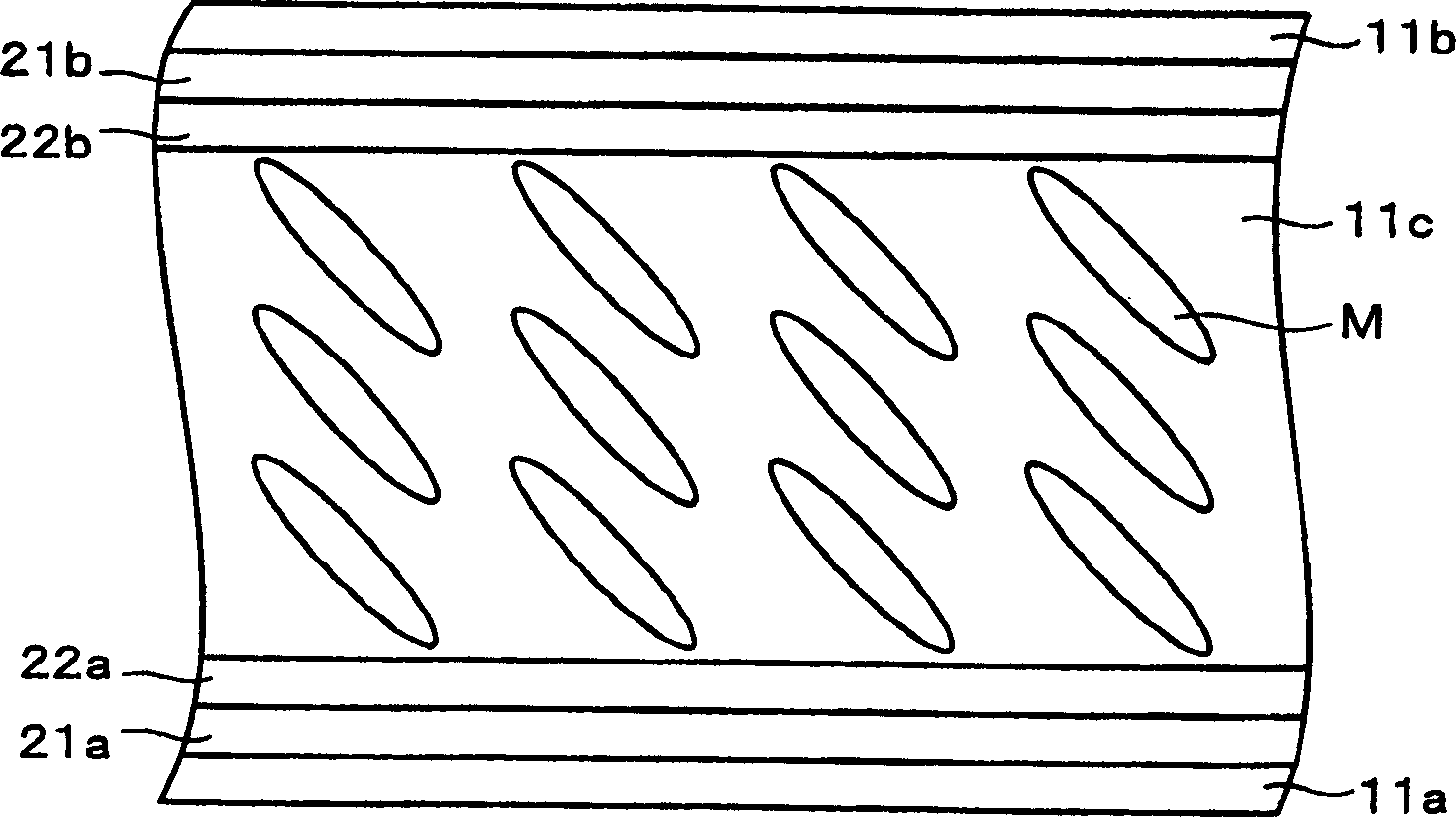

Circular Polarizer, Process for Producing the Same, Optical Film, Liquid Crystal Display Device and Electroluminescence Device

InactiveUS20080106675A1Less strainRemove defectLiquid crystal compositionsSolid-state devicesLiquid-crystal displayPolarizer

A circular polarizer includes at least an optically anisotropic element, a transmissive protection film and a polarizing element sandwiched therebetween. The optically anisotropic element has a liquid crystal layer aligned on a cellulose triacetate film and a retardation of approximately ¼ wavelength in the visible light region. The liquid crystal layer includes a liquid crystal film with a fixed twisted nematic alignment. The circular polarizer is suppressed in thickness by simplifying the layer structure without causing defects, such as peeling off the layers, even under elevated temperature and humidity condition and makes it possible to set arbitrarily the angle of the alignment axis direction of the optically anisotropic element including a liquid crystal layer with a fixed twisted alignment with respect to the absorption axis of the polarizing element, so that the optically anisotropic element and polarizing element both in the form of an elongate film can be laminated continuously to one another.

Owner:NIPPON OIL CORP

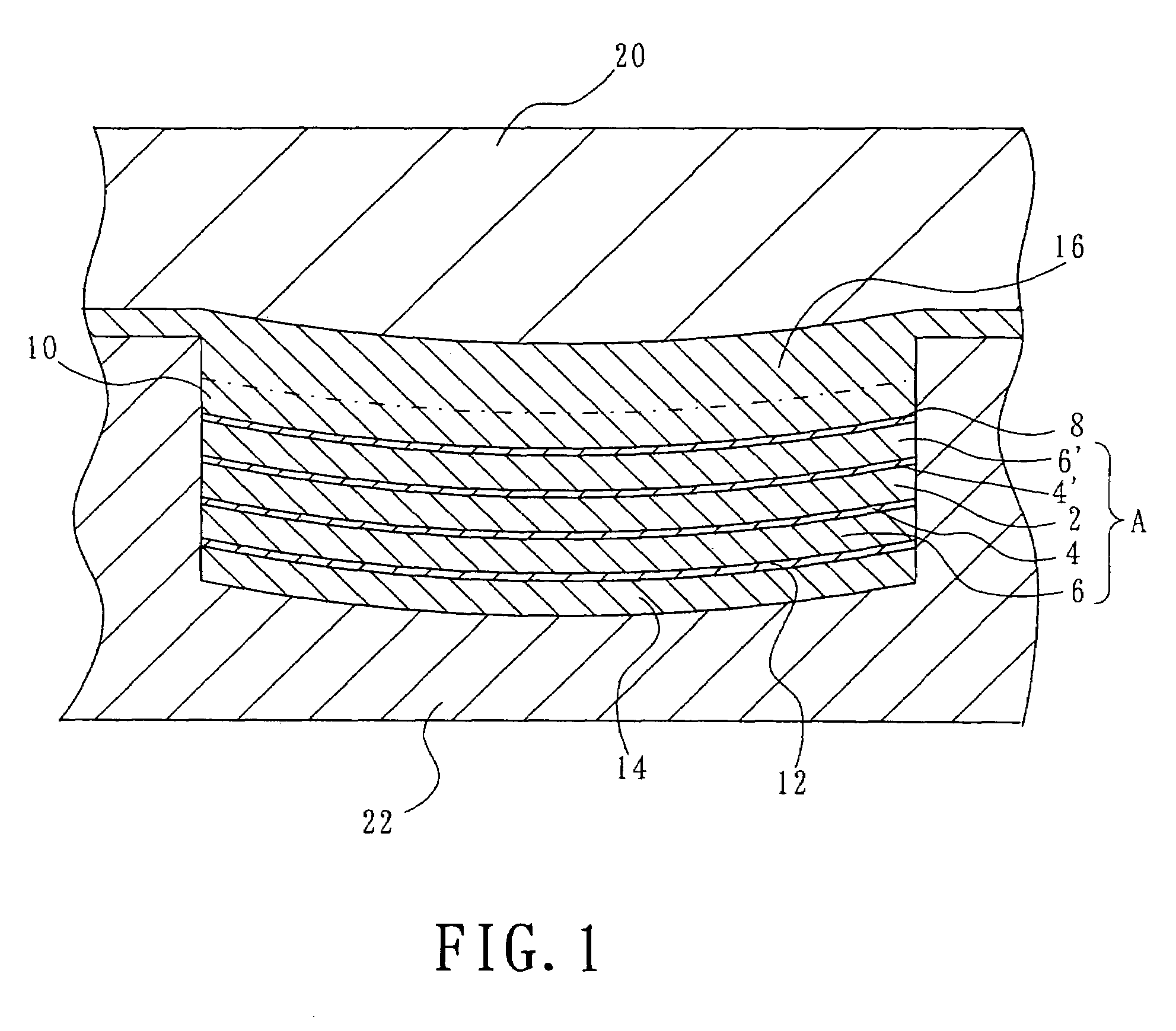

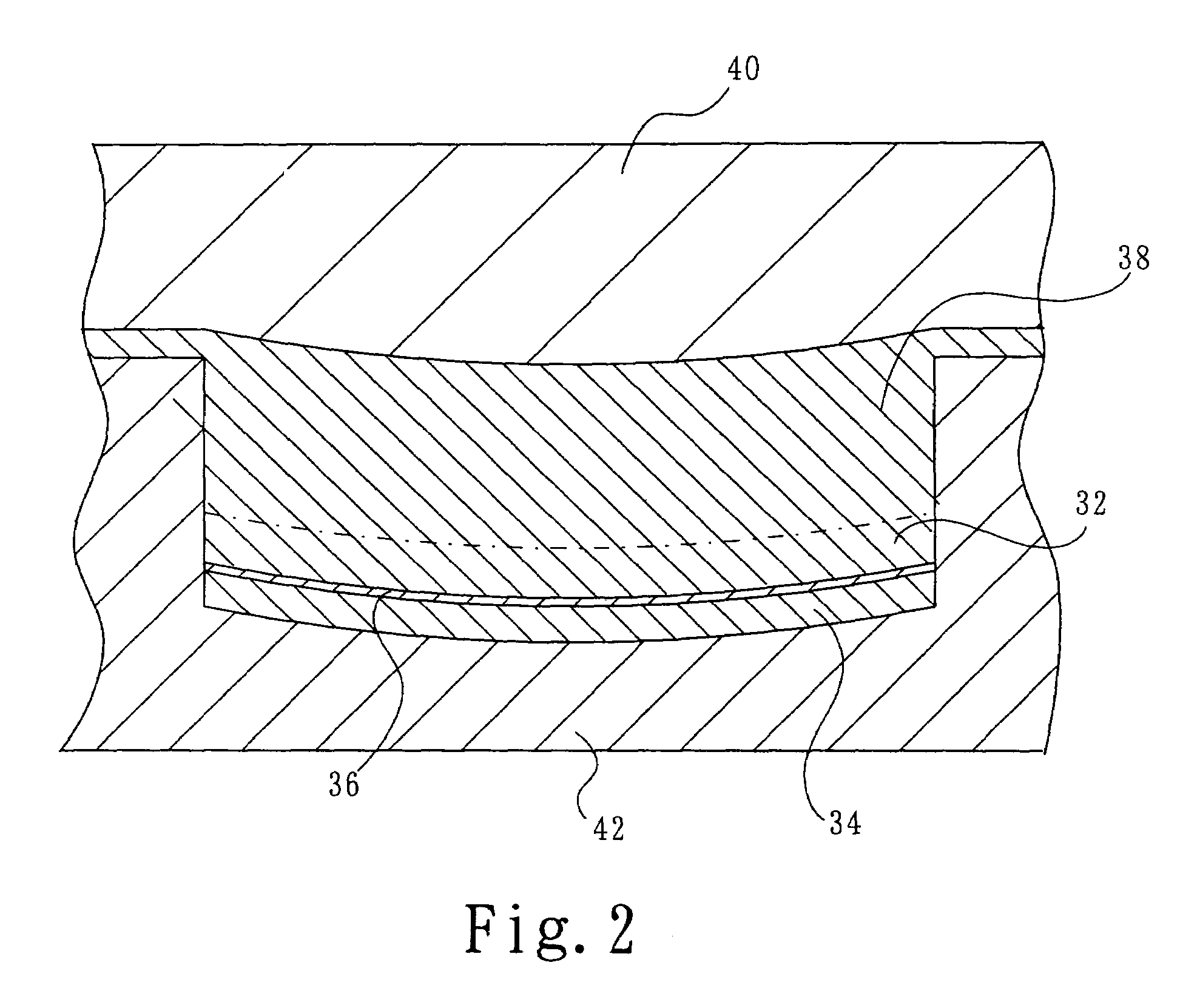

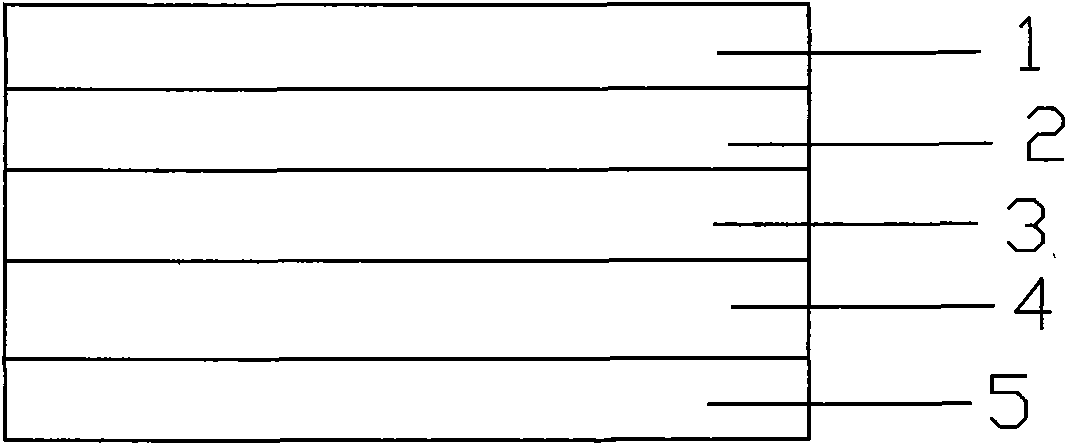

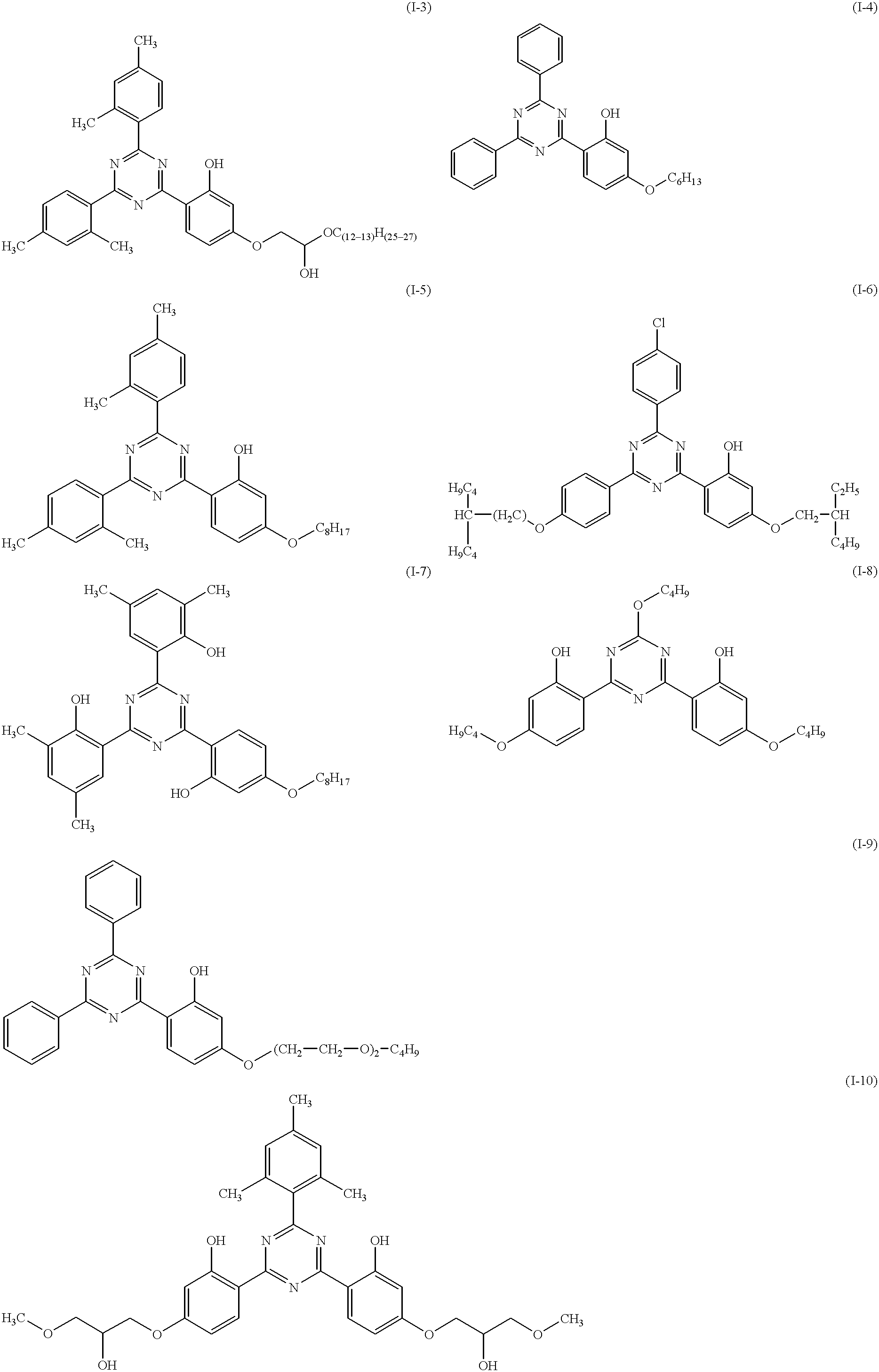

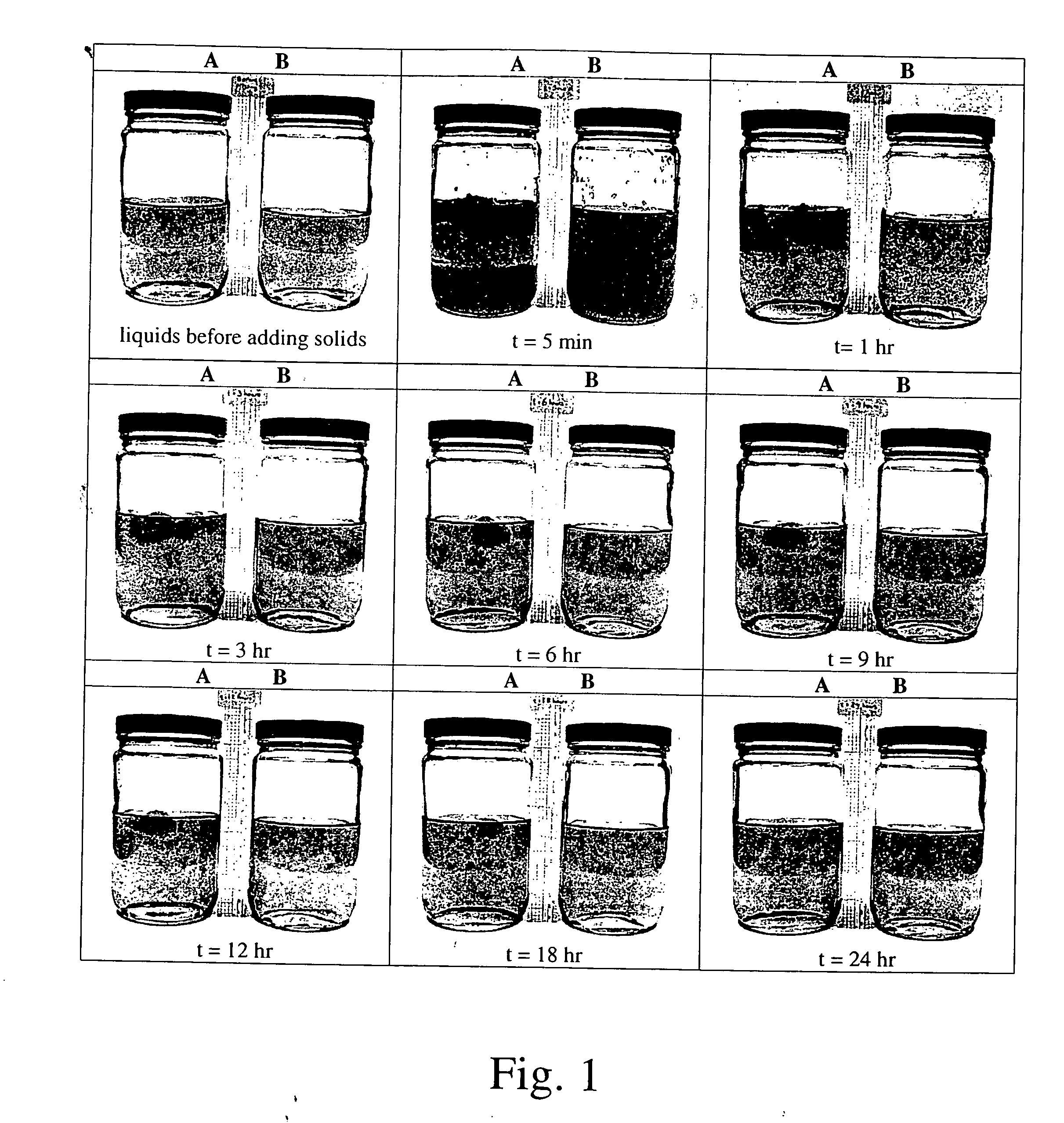

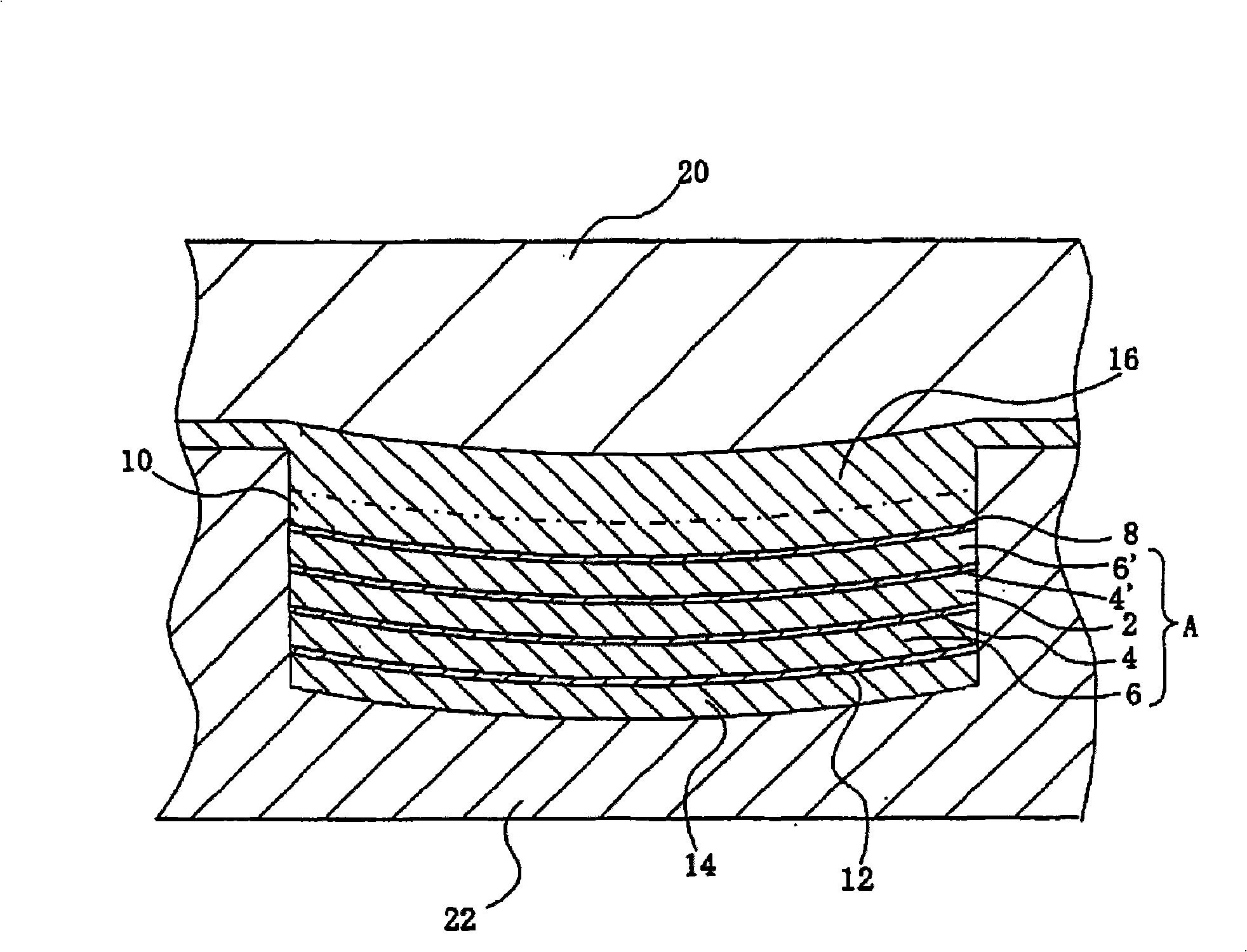

Molded laminate for optical use

InactiveUS7289257B1Improve polarizationEconomically manufacturedOptical articlesNon-linear opticsAdhesiveUv absorber

A polarizing sheet (A) includes a polarizing film (2) and cellulose triacetate films (6, 6′) bonded to opposing surfaces of the polarizing film (2) with adhesive layers (4, 4′) interposed, respectively. A thermoplastic film (10) is stacked on the exposed surface of one (6′) of the cellulose triacetate films. Another cellulose triacetate film (14) free of an ultraviolet absorber is bonded to the exposed surface of the other cellulose triacetate film (6) of the polarizing sheet with an adhesive (12) containing an organic photochromic compound, to thereby form a laminate sheet. The laminate sheet is placed in an injection mold, and a molding resin material fusible with the thermoplastic film (10) is injected over the thermoplastic film.

Owner:NAKAGOSHI YASUNOBU

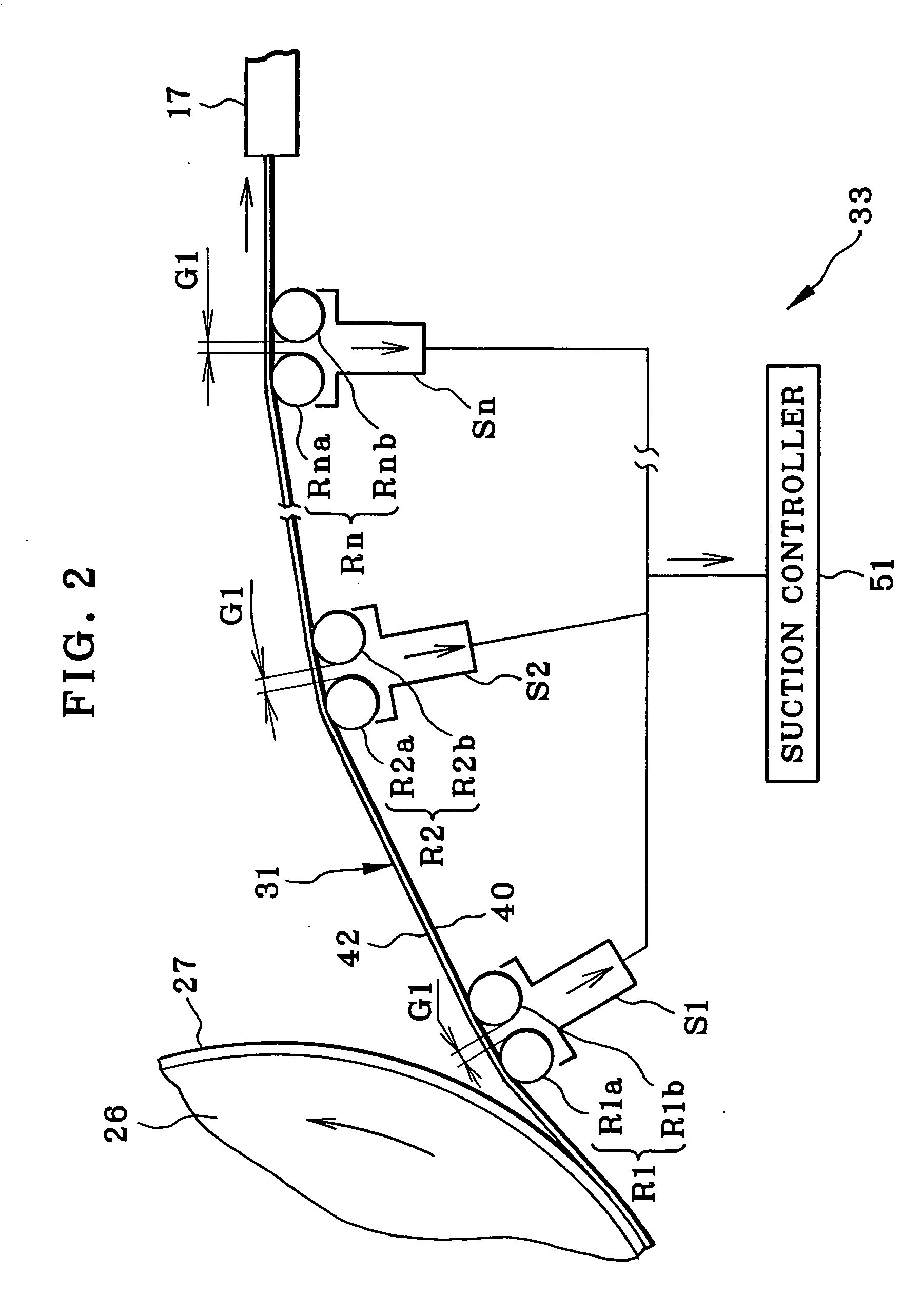

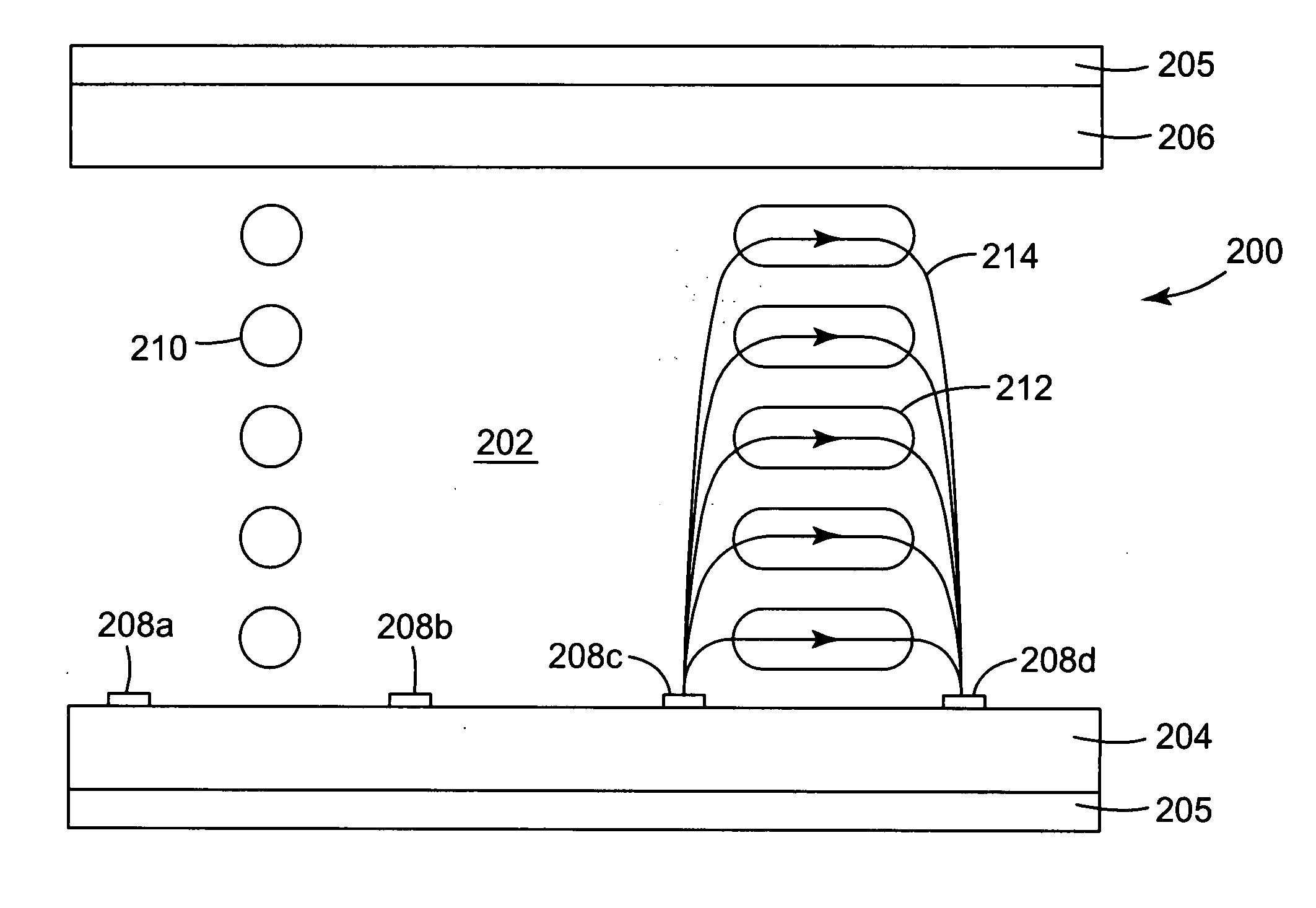

Solution casting apparatus and process, cellulose acylate film, polarizing plate, and image display device

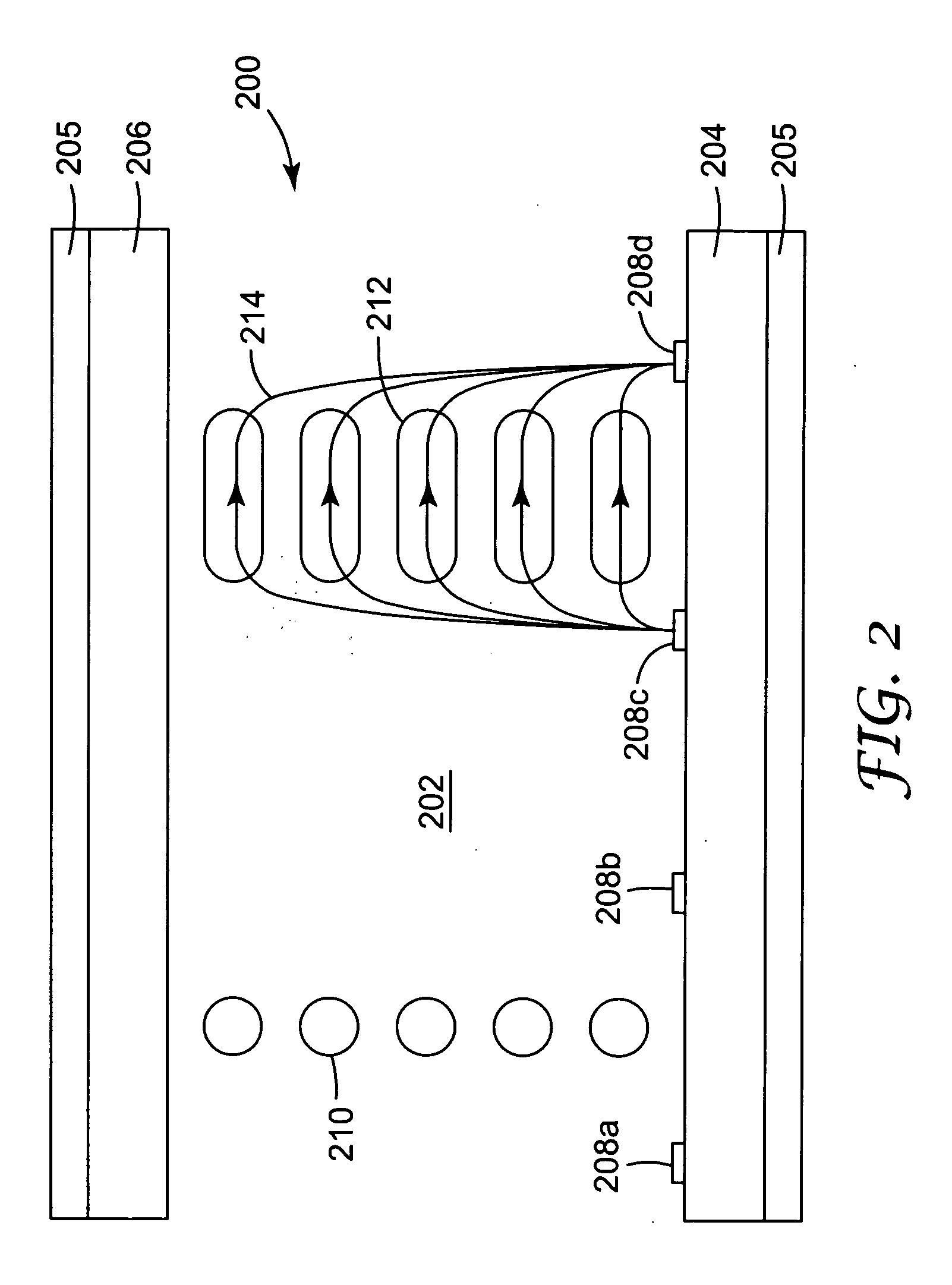

A solution casting apparatus includes a band-shaped support for casting of dope containing cellulose triacetate thereon. So polymer film of cellulose triacetate is formed. Plural rotatable transport rollers support the polymer film stripped from the band-shaped support. A tentering device stretches the polymer film. The transport rollers are provided with a suction device for drawing nearer the polymer film by suction.

Owner:FUJIFILM CORP +1

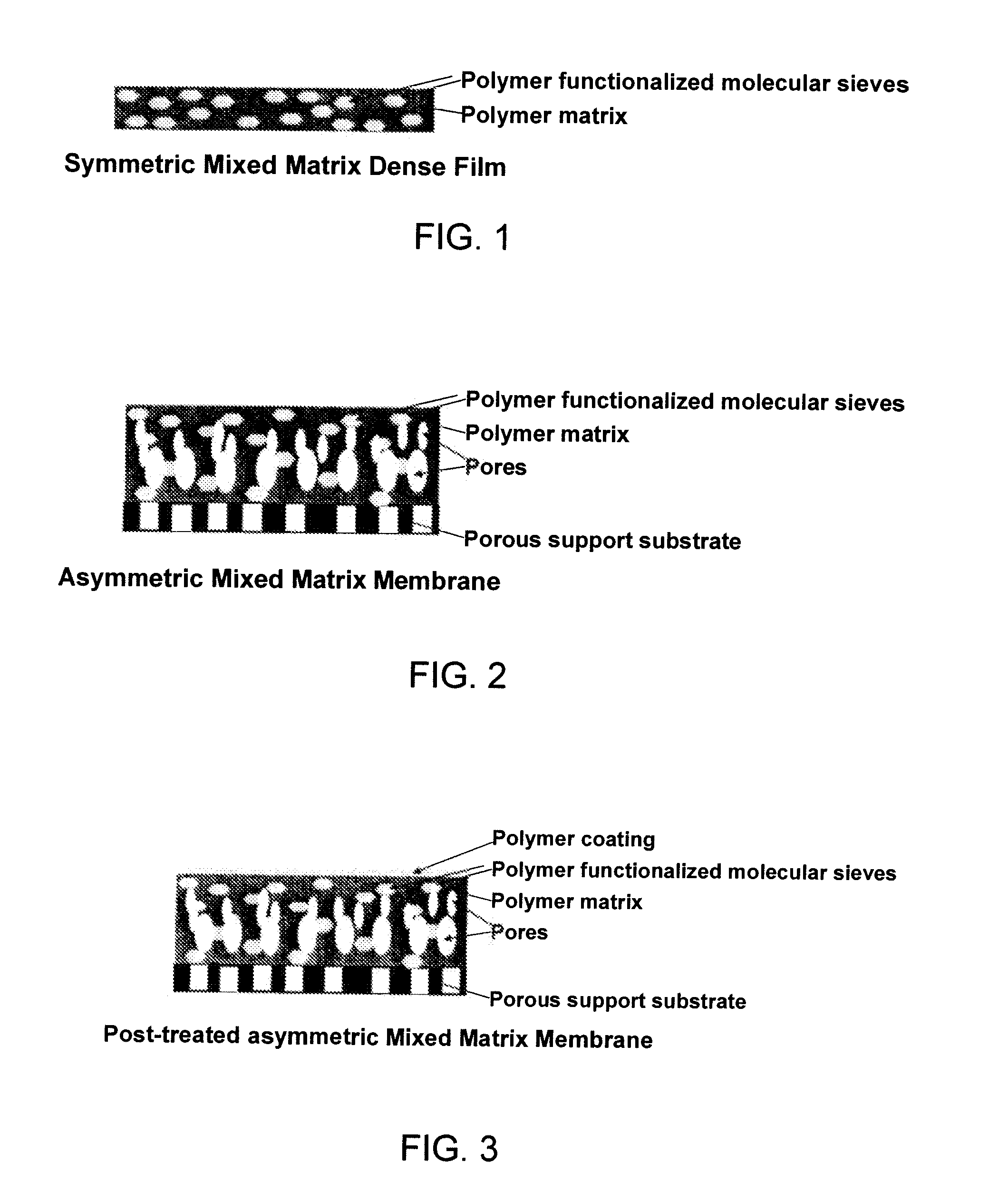

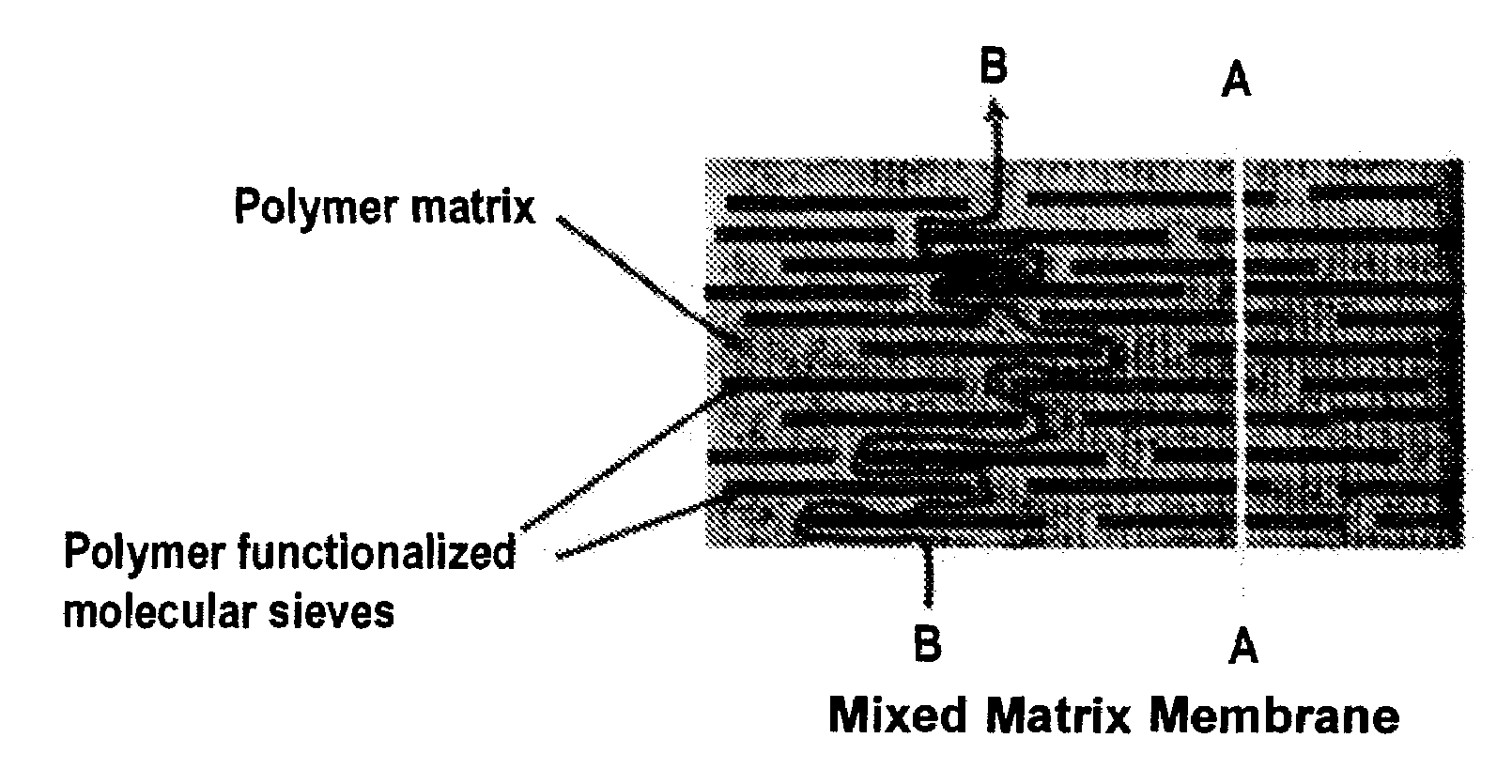

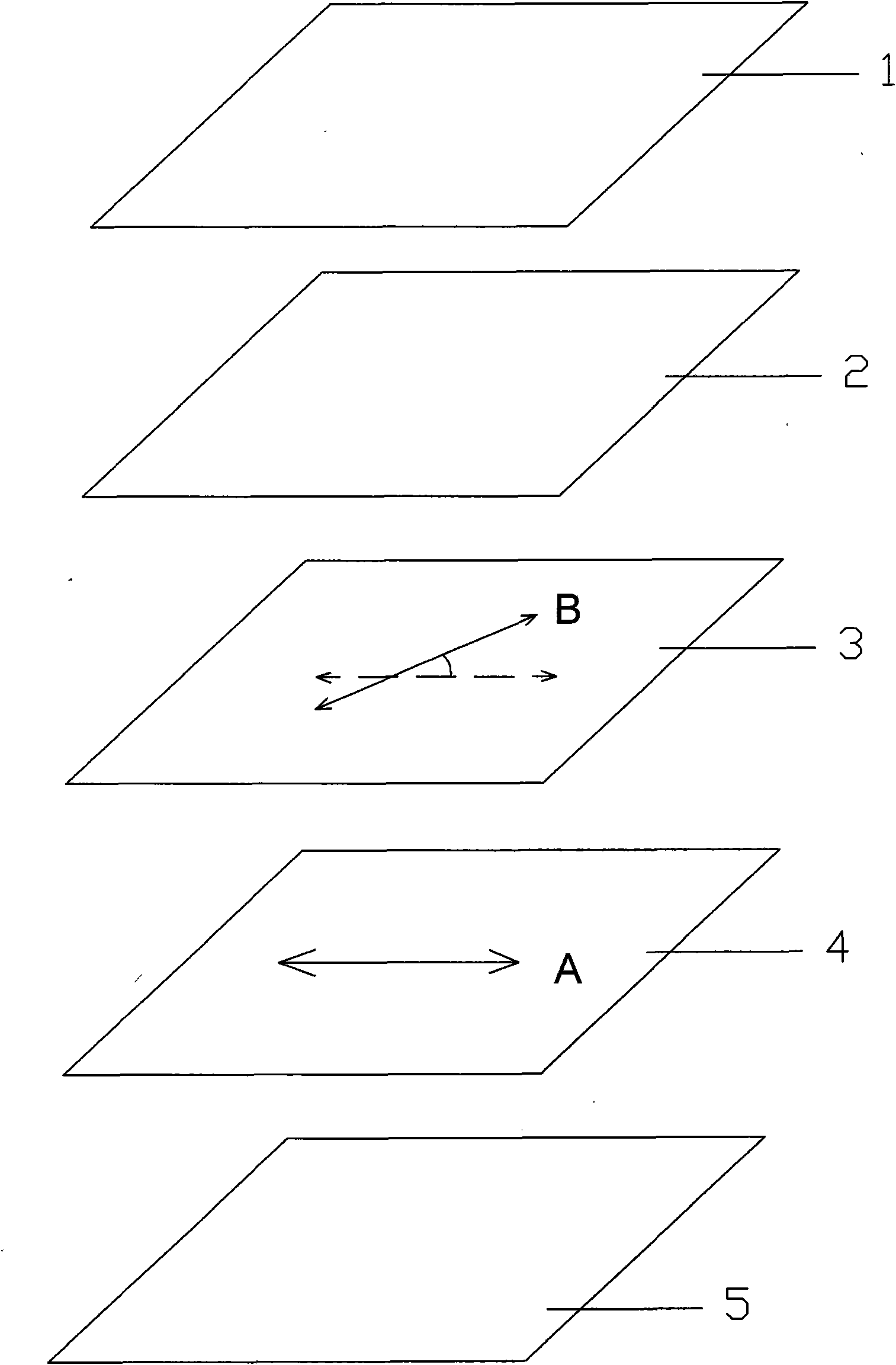

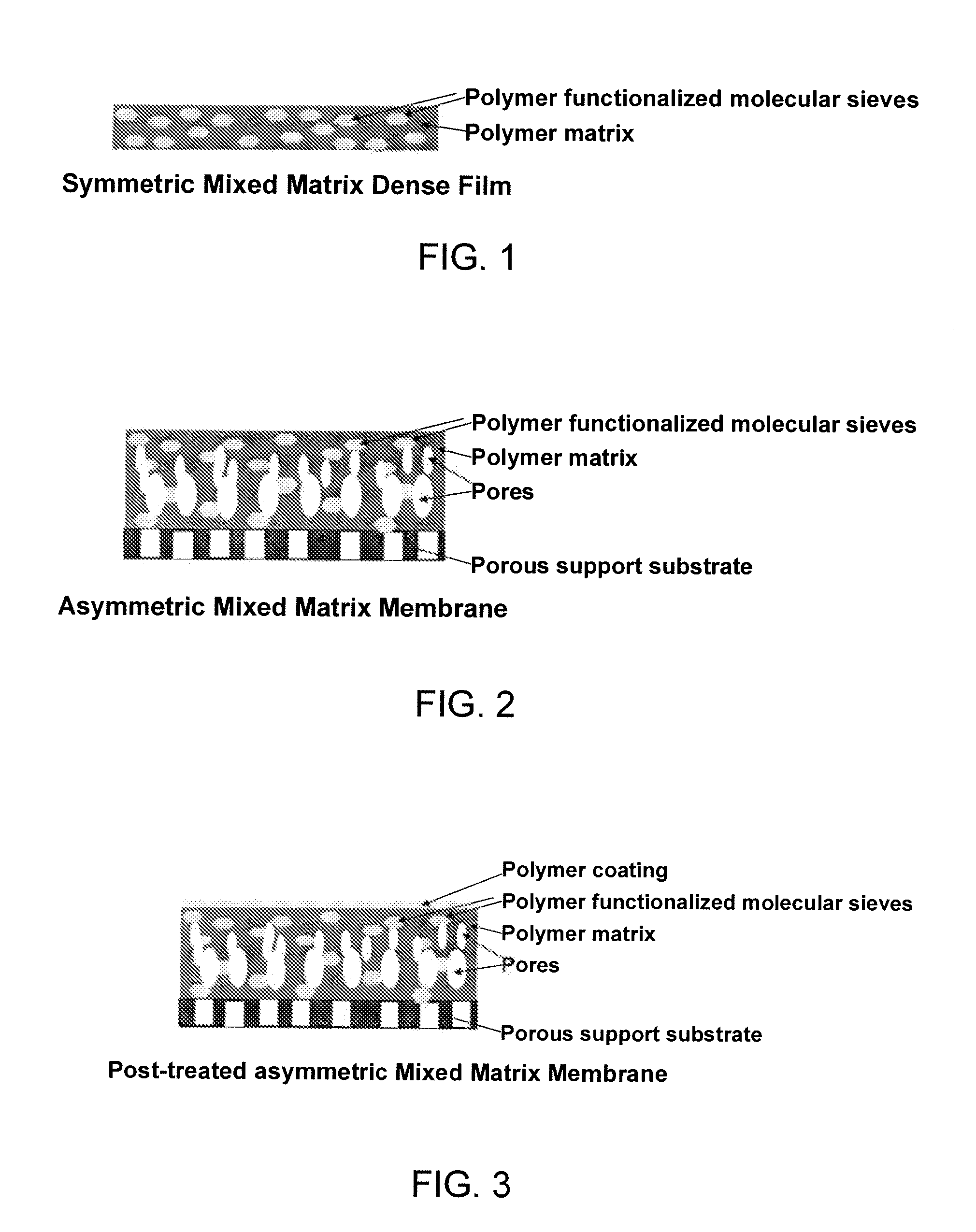

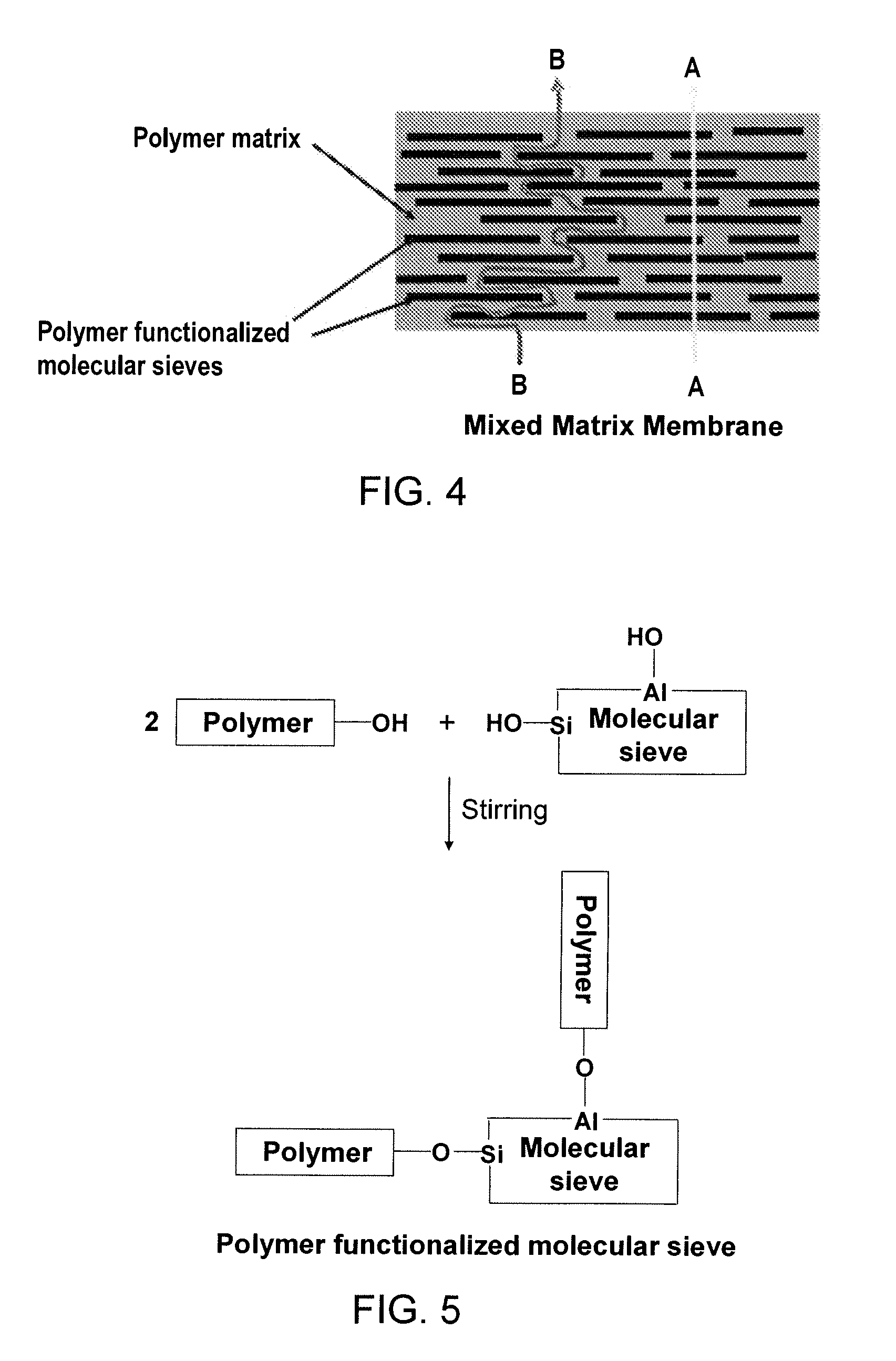

Polymer Functionalized Molecular Sieve/Polymer Mixed Matrix Membranes

InactiveUS20090126570A1Easy to separateAverage permeabilitySemi-permeable membranesIsotope separationFiberHollow fibre

The present invention discloses polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs) with either no macrovoids or voids of less than several Angstroms at the interface of the polymer matrix and the molecular sieves by incorporating polyethersulfone (PES) or cellulose triacetate (CTA) functionalized molecular sieves into a continuous polyimide or cellulose acetate (CA) polymer matrix. The MMMs, in the form of symmetric dense film, asymmetric flat sheet membrane, or asymmetric hollow fiber have good flexibility and high mechanical strength, and exhibit significantly enhanced selectivity and / or permeability over the polymer membranes made from the corresponding continuous polymer matrices for carbon dioxide / methane (CO2 / CH4) and hydrogen / methane (H2 / CH4) separations. The MMMs are suitable for a variety of liquid, gas, and vapor separations such as deep desulfurization of gasoline and diesel fuels, ethanol / water separations, pervaporation dehydration of aqueous / organic mixtures, CO2 / CH4, CO2 / N2, H2 / CH4, O2 / N2, olefin / paraffin, iso / normal paraffins separations, and other light gas mixture separations.

Owner:UOP LLC

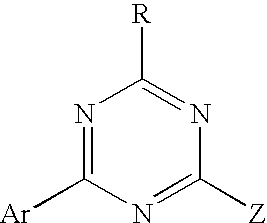

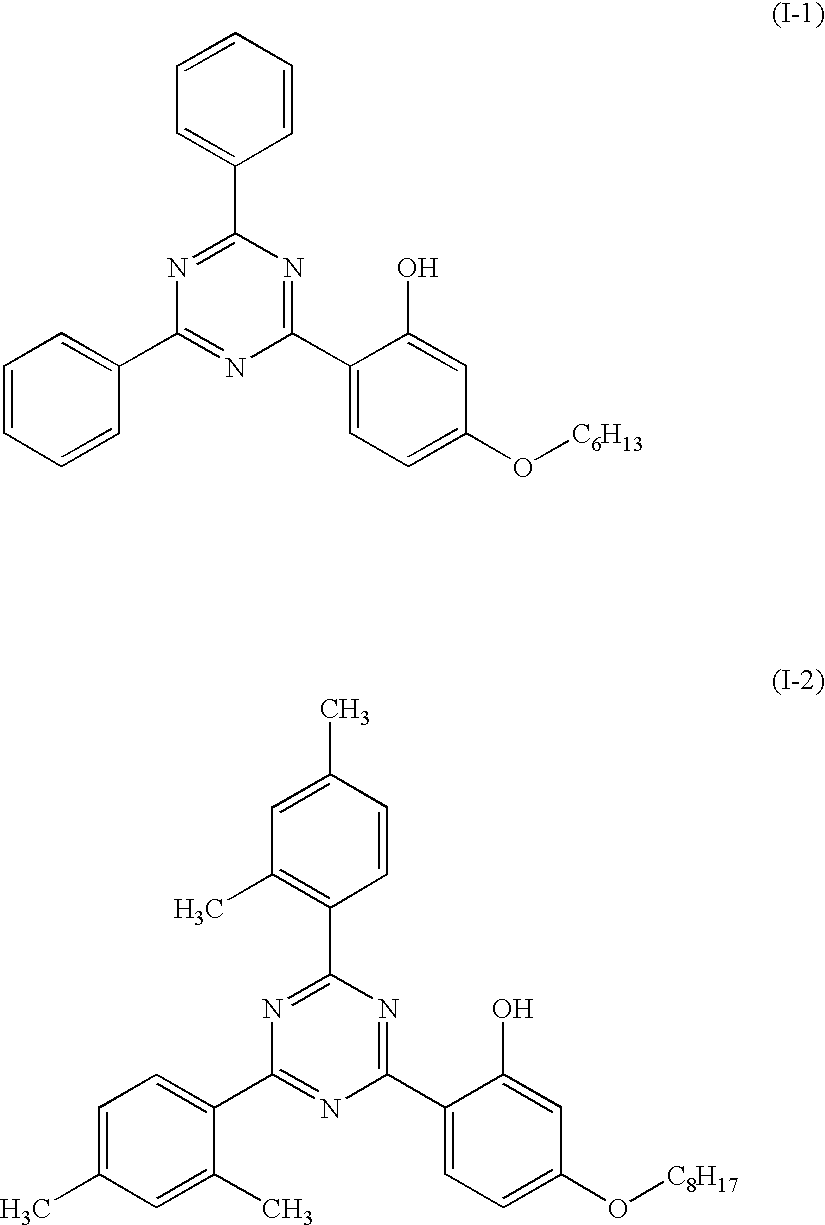

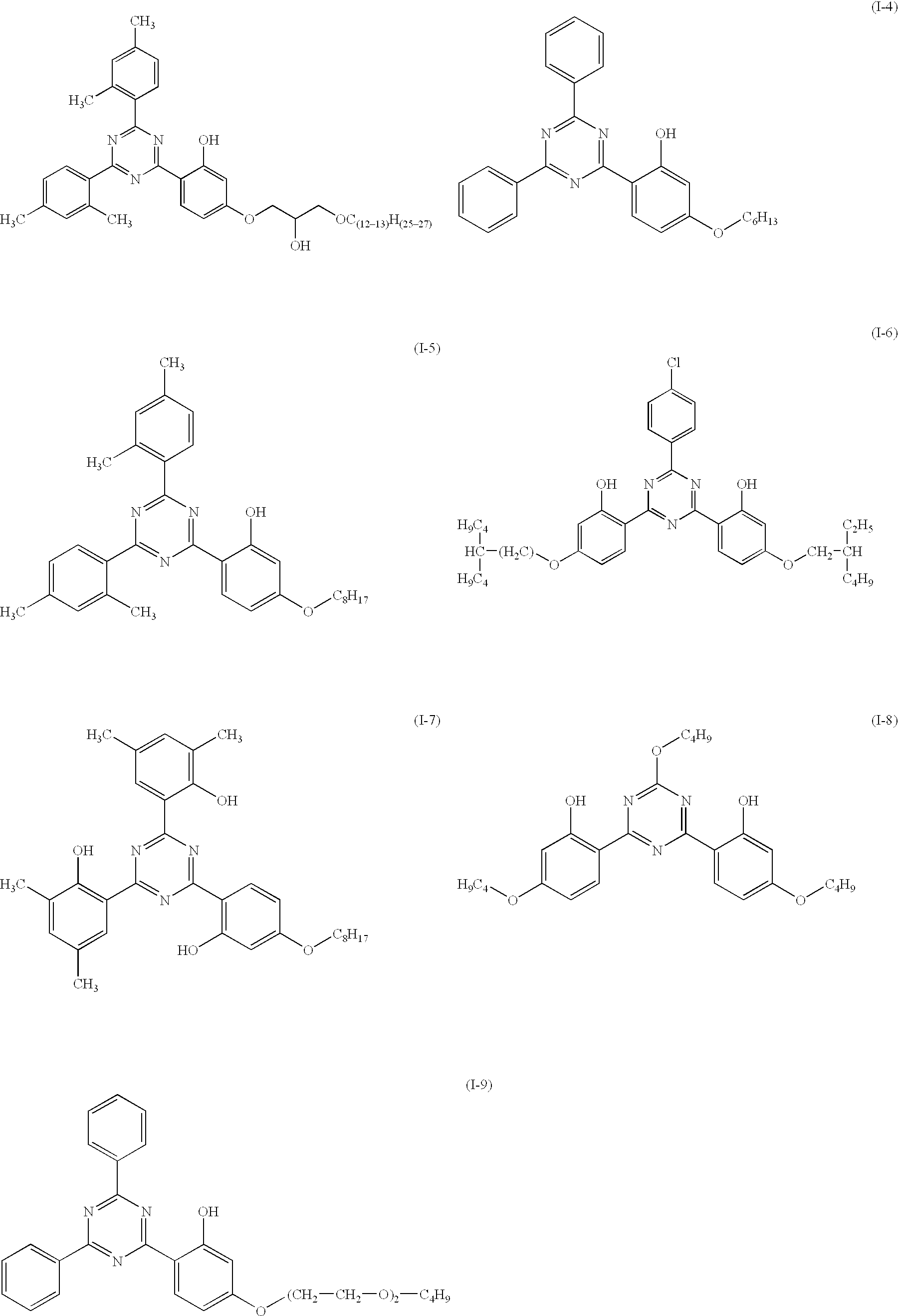

UV-absorbing film and its use as protective sheet

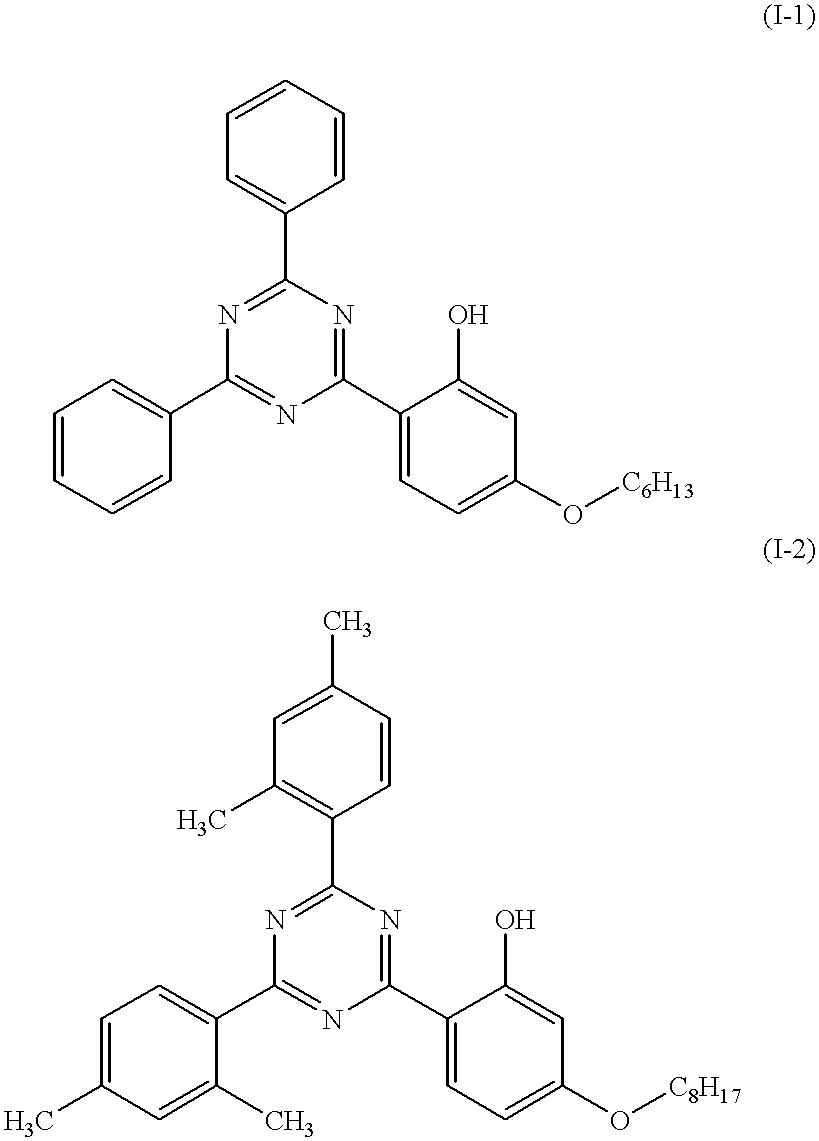

InactiveUS6468609B2Effective protectionInhibit deteriorationLiquid crystal compositionsCellulosic plastic layered productsLiquid-crystal displayAlkoxy group

UV-absorbers of the 4-alkoxy-2-hydroxyphenyl-s-triazine type are incorporated in a cellulose triacetate film. Such an UV-cut off film can be used advantageously, amongst others, as protective sheet for a polarizer in a Liquid Crystal Display.

Owner:INNOLUX CORP

Reusable three-dimensional polarized glass polarizer and glasses using same

ActiveCN101598830AExtended service lifeAvoid scratchesSynthetic resin layered productsPolarising elementsTectorial membraneCellulose acetate

The invention provides a reusable three-dimensional (3D) polarized glass polarizer and glasses using the same. The polarizer comprises a protective film, a scratch resistant cellulose triacetate (TAC) film, a retardation film, a scratch resistant polarizing film and a protective film in turn. An absorption axis of the scratch resistant polarizing film and a slow axis of the retardation film form an angle between 40 and 50 degrees or an angle between 130 and 140 degrees. The reusable three-dimensional (3D) polarized glass polarizer can effectively be prevented from scratching, and the hardness effect of the scratch resistance can reach more than 2H to prolong the service life of a product.

Owner:SHENZHEN SUNNYPOL OPTOELECTRONICS

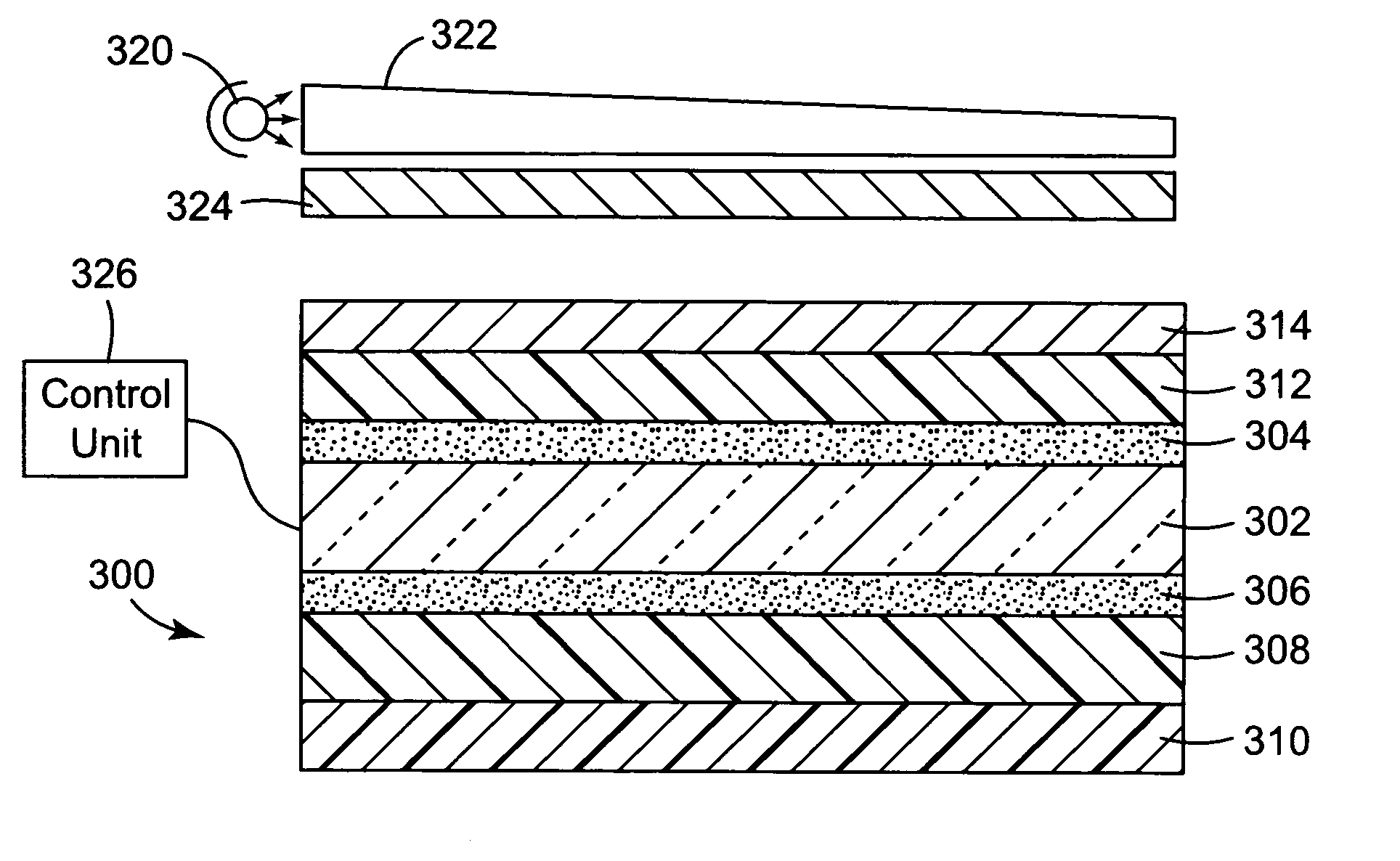

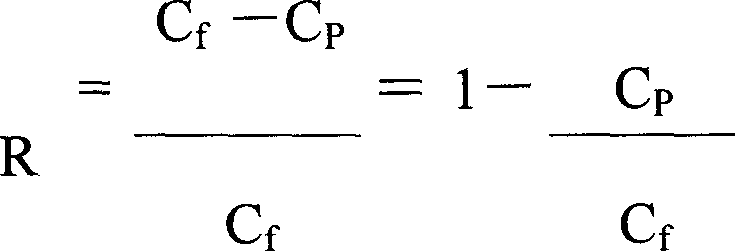

Method for preparing polyvinylidene fluoride composite cellulose acetate forward osmosis membrane

ActiveCN102580562AHigh water fluxHigh Salt RejectionSemi-permeable membranesConcentration polarizationFiltration

The invention relates to a method for preparing a polyvinylidene fluoride composite cellulose acetate forward osmosis membrane. The conventional product has a serious inside concentration polarization phenomenon and low actual flux. The method comprises the following steps of: preparing a polyvinylidene fluoride cast membrane solution from polyvinylidene fluoride and additive; preparing a cellulose acetate cast membrane solution from cellulose acetate, cellulose triacetate and molecular sieve; and uniformly coating the polyvinylidene fluoride cast membrane solution on a non-woven fabric to obtain a hydrophilic polyvinylidene fluoride micro-filtration base membrane, drying or naturally drying in air to form a dry hydrophilic polyvinylidene fluoride membrane, uniformly coating the cellulose acetate cast membrane solution on the dry hydrophilic polyvinylidene fluoride membrane, and thus obtaining the composite forward osmosis membrane. The forward osmosis membrane prepared by the method has high mechanical strength and solvent tolerance, high water flux and high salt intercepting rate, and can be applied in the fields of desalting of seawater and brine, softening of hard water, first-aid water bags and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Production process of bamboo charcoal fiber

InactiveCN102051701AFunction increaseHygroscopicArtificial filaments from cellulose derivativesDry spinning methodsSpinningCellulose acetate

The invention relates to a production process of bamboo charcoal fiber, comprising the following steps: pulverizing bamboo charcoal powder until the particle size is below the micron order, dispersing evenly; preparing cellulose triacetate from refined cotton linters as a raw material, dissolving the cellulose triacetate in dichloromethane to form a 10-50wt% spinning solution, adding bamboo charcoal micro powder to the spinning solution, wherein the weight ratio of the bamboo charcoal micro powder to the cellulose triacetate is 1:(50-100), and preparing bamboo charcoal acetate fiber by a dry spinning method. The invention has high performances of both bamboo charcoal fiber and acetate fiber, the manufactured fabric has the functions of moisture absorption, permeability, antibiosis, bacteriostasis, deodorization, high adsorption, temperature and humidity adjustment, far infrared radiation, electromagnetic radiation prevention and the like, and the fabric is soft, delicate, nonirritating and hypo-allergenic to skin, washable, sunfast, heat resistant, easy to wash, vermin-proof and moisture-proof.

Owner:ZHEJIANG MINXIN ECO TECH

Polymer Functionalized Molecular Sieve/Polymer Mixed Matrix Membranes

InactiveUS20090126566A1Easy to separateAverage permeabilitySemi-permeable membranesMembranesFiberHollow fibre

The invention discloses the use of polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs) with either no macrovoids or voids of less than several Angstroms at the interface of the polymer matrix and the molecular sieves by incorporating polyethersulfone (PES) or cellulose triacetate (CTA) functionalized molecular sieves into a continuous polyimide or cellulose acetate (CA) polymer matrix. The MMMs, particularly PES functionalized AlPO-14 / polyimide MMMs and CTA functionalized AlPO-14 / CA MMMs, in the form of symmetric dense film, asymmetric flat sheet membrane, or asymmetric hollow fiber have good flexibility and high mechanical strength, and exhibit significantly enhanced selectivity and / or permeability over the polymer membranes made from the corresponding continuous polymer matrices for carbon dioxide / methane (CO2 / CH4), hydrogen / methane (H2 / CH4), propylene / propane separations and a variety of liquid, gas, and vapor separations.

Owner:UOP LLC

UV-absorbing film and its use as protective sheet

InactiveUS20010003363A1Effective protectionInhibit deteriorationLiquid crystal compositionsCellulose adhesivesLiquid-crystal displayAlkoxy group

UV-absorbers of the 4-alkoxy-2-hydroxyphenyl-s-triazine type are incorporated in a cellulose triacetate film. Such an UV-cut off film can be used advantageously, amongst others, as protective sheet for a polarizer in a Liquid Crystal Display.

Owner:INNOLUX CORP

Preparation method of composite forward osmosis membrane

ActiveCN103962015AImprove salt interception rateHigh water fluxSemi-permeable membranesWater channelCellulose acetate

The invention provides a preparation method of a composite forward osmosis membrane. A nanotube and cellulose triacetate are combined, the nanotube has a good water channel, the transferring speed of water molecules in the forward osmosis membrane is increased, the water flux in a forward osmosis process is greatly improved, the saline ion interception capability is improved, and the salt intercepting rate of the forward osmosis membrane is improved due to the special cavity structure of the nanotube. The invention also provides the composite forward osmosis membrane prepared by the method. The composite forward osmosis membrane has high water flux and high salt intercepting rate.

Owner:ETERNAL GUANGDONG TECH ELECTRIC CO LTD

Liquid crystal display with neutral dark state

InactiveUS20050140895A1Reduction of useful viewing angle of displayIncrease typePolarising elementsNon-linear opticsColor shiftImage contrast

A polarizer is used with a liquid crystal display (LCD) cell whose liquid crystal molecules are switched in the plane of the cell. The LCD has birefringent properties that are different from other types of LCD cell and, unlike other types of LCD, the image contrast is maintained and there is little color shift in the dark state when a low birefringence polarizer is used with the SIP LCD cell. In one embodiment, the x-z retardation of the layers between the polarization-sensitive absorbing layer and the LCD is less than 20 nm. In another embodiment, the x-z birefringence is less than 0.0005. The low levels of retardation and birefringence may be achieved by omitting the commonly used cellulose triacetate layer between the polarization-sensitive absorbing layer and the LCD.

Owner:SEIKO EPSON CORP

Production process of cotton pulp for cellulose triacetate

ActiveCN101597870AEmission reductionReduce pollutionPulp bleachingPulping with inorganic basesCellulose acetateWastewater

The invention relates to a production process of cotton pulp for cellulose triacetate, in particular to a simple production process of cotton pulp using cotton linter as a raw material; in the whole pulping process, the wastewater COD discharge is as low as 20250-25050mg / l, so that the environmental pollution and sewage treatment pressure can be reduced; on the conditions of stable polymerization, high whiteness and alpha cellulose content, uniform fiber length and proper compactness, the product has low content of methylene dichloride extract and metallic ions, low ash content and low dust, thus being applicable to the industry for producing cellulose triacetate.

Owner:山东银鹰化纤有限公司

Asymmetric gas separation membranes with superior capabilities for gas separation

InactiveUS20100244306A1Excellent permeation fluxHigh selectivityProductsSemi-permeable membranesCellulose diacetatePolyimide membrane

This invention relates to a method of making flat sheet asymmetric membranes, including cellulose diacetate / cellulose triacetate blended membranes, polyimide membranes, and polyimide / polyethersulfone blended membranes by formulating the polymer or the blended polymers dopes in a dual solvent mixture containing 1,3 dioxolane and a second solvent, such as N,N′-methylpyrrolidinone (NMP). The dopes are tailored to be closed to the point of phase separation with or without suitable non-solvent additives such as methanol, acetone, decane or a mixture of these non-solvents. The flat sheet asymmetric membranes are cast by the phase inversion processes using water as the coagulation bath and annealing bath. The dried membranes are coated with UV curable silicone rubber. The resulting asymmetric membranes having a skin thickness of less than 100 nm, exhibit excellent permeability and selectivity compared to the intrinsic dense film performances.

Owner:UOP LLC

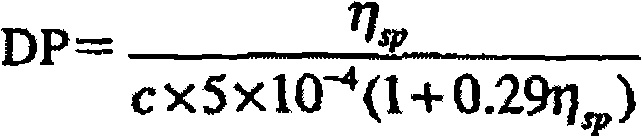

Hollow fiber alloy nano filtering membrane of cellulose triacetate and its production method

InactiveCN1698941AImprove performanceGood biocompatibilitySemi-permeable membranesFiberWater softening

This invention relates to a new cellulose triacetate hollow fiber alloy film, in addition to a preparing method. It mixes the cellulose triacetate and acid, alkali resistance high molecular material to modify, which can decrease the sensitivity of the cellulose triacetate to acid and alkali, and increase the bioavailability and permeable quantity of the film. The film is manufactured with 45-85% cellulose triacetate, 5-25% disperse component, 10-30% pore former. The invention can be widely used in water softening and sea water desalting.

Owner:HANGZHOU WATER TREATMENT TECH RES & DEV CENT NAT BUREAU OF OCEANGRAPHY

Cellulose pulp and production method thereof

InactiveCN101691407AChemical/chemomechanical pulpNon-woody plant/crop pulpCellulose diacetateCellulose acetate

The invention discloses cellulose pulp and a production method thereof, mainly used for producing cellulose diacetate and cellulose triacetate. In the invention, category II cotton linter, or category III cotton linter with ripeness being 60-70%, or a mixture of category II cotton linter and category III cotton linter are used as the raw material, I type cellulose crystallity of cellulose pulp is within the range of 60-74%, the acetifying reaction has good performance and low cost, and the invention is suitable for commercialized production of cellulose diacetate.

Owner:NANTONG CELLULOSE FIBERS CO LTD +1

Preparation method of cellulose acetate

The invention belongs to the field of high polymer chemistry, and relates to a preparation method of cellulose acetate. The product obtained by the method provided by the invention has the advantages of high degree of substitution and high viscosity. The method comprises the following steps: A. soaking 1 part by weight of cellulose with 8-20 parts by weight of glacial acetic acid at 20-60 DEG C; B. esterifying at 20-58 DEG C for 3-8 hours by adding 4-6 parts by weight of acetic anhydride and 0.005-0.05 part by weight of catalyst; C. adding 0.5-1.5 parts by weight of 60-80% acetic acid at 15-25 DEG C, and reacting until the content of acetic acid in the cellulose acetate reaches 60.5-62.5%; D. adding 1.1-1.5 parts by weight of 5-15% acetate water solution, and reacting at 20-50 DEG C for 1-3 hours; and E. filtering, settling and granulating. The product obtained according to the invention has the advantages of high degree of substitution (the content of acetic acid in the product is higher than or equal to 60.0%) and high viscosity (the falling ball viscosity is higher than or equal to 70 seconds). The method provided by the invention increases the consumption of acetates for neutralization, effectively removes sulfates and enhances the heat resistance of the cellulose triacetate film.

Owner:LUZHOU NORTH CHEM IND

Method for compounding polymer pellets with functional additives

New methods of forming compounded cellulose esters are provided. The methods comprise mixing a cellulose ester, functional additive, and a swelling agent and subsequently removing at least a portion of the swelling agent. The swelling agent is one that assists in causing the functional additive to penetrate into the cellulose ester, while not acting significantly as a solvent for the cellulose ester. Preferred cellulose esters include, but are not limited to, cellulose acetates, cellulose triacetates, cellulose acetate phthalates, and cellulose acetate butyrates. The functional additive can be a plasticizer, stabilizer, or other additive selected to modify a particular property of the cellulose.

Owner:EASTMAN CHEM CO

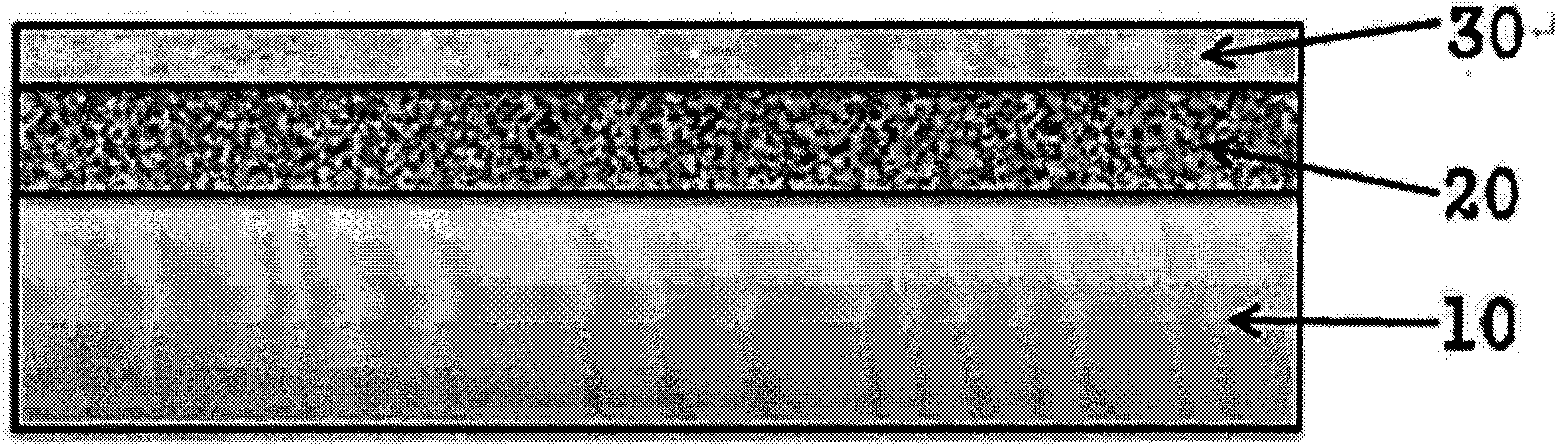

Molded laminate for optical use

A polarizing sheet (A) includes a polarizing film ( 2 ) and cellulose triacetate films ( 6, 6 ') bonded to opposing surfaces of the polarizing film ( 2 ) with adhesive layers ( 4, 4 ') interposed, respectively. A thermoplastic film ( 10 ) is stacked on the exposed surface of one ( 6 ') of the cellulose triacetate films. Another cellulose triacetate film ( 14 ) free of an ultraviolet absorber is bonded to the exposed surface of the other cellulose triacetate film ( 6 ) of the polarizing sheet with an adhesive ( 12 ) containing an organic photochromic compound, to thereby form a laminate sheet. The laminate sheet is placed in an injection mold, and a molding resin material fusible with the thermoplastic film ( 10 ) is injected over the thermoplastic film.

Owner:中越 康亘 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com