Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

916 results about "Cast films" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A film cast, movie cast, or just cast is the general term used for the collective talent appearing in a film, television or theatre project etc. A cast may be comprised of actors, actresses, singers, dancers, musicians, models, or any number of talent used on screen.

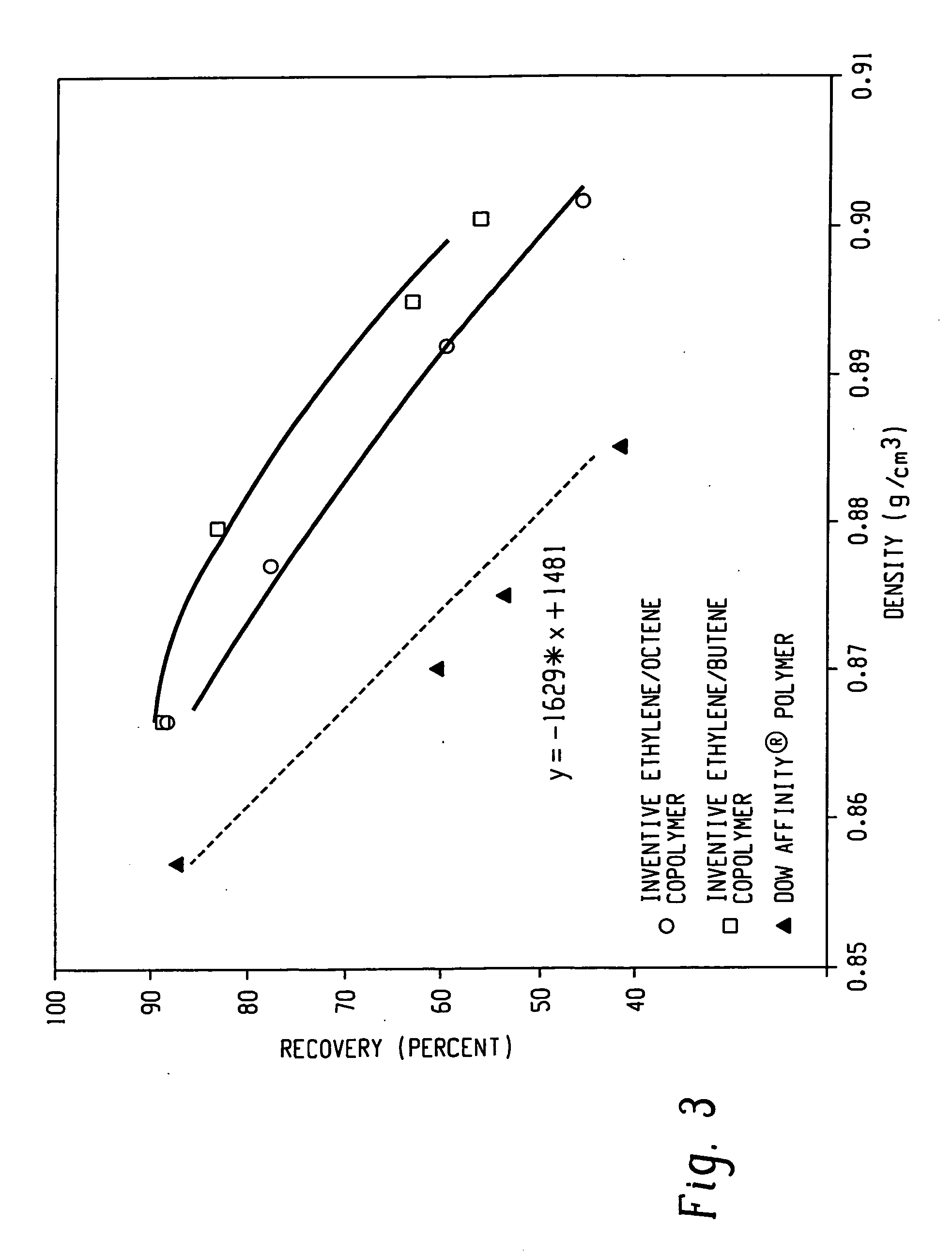

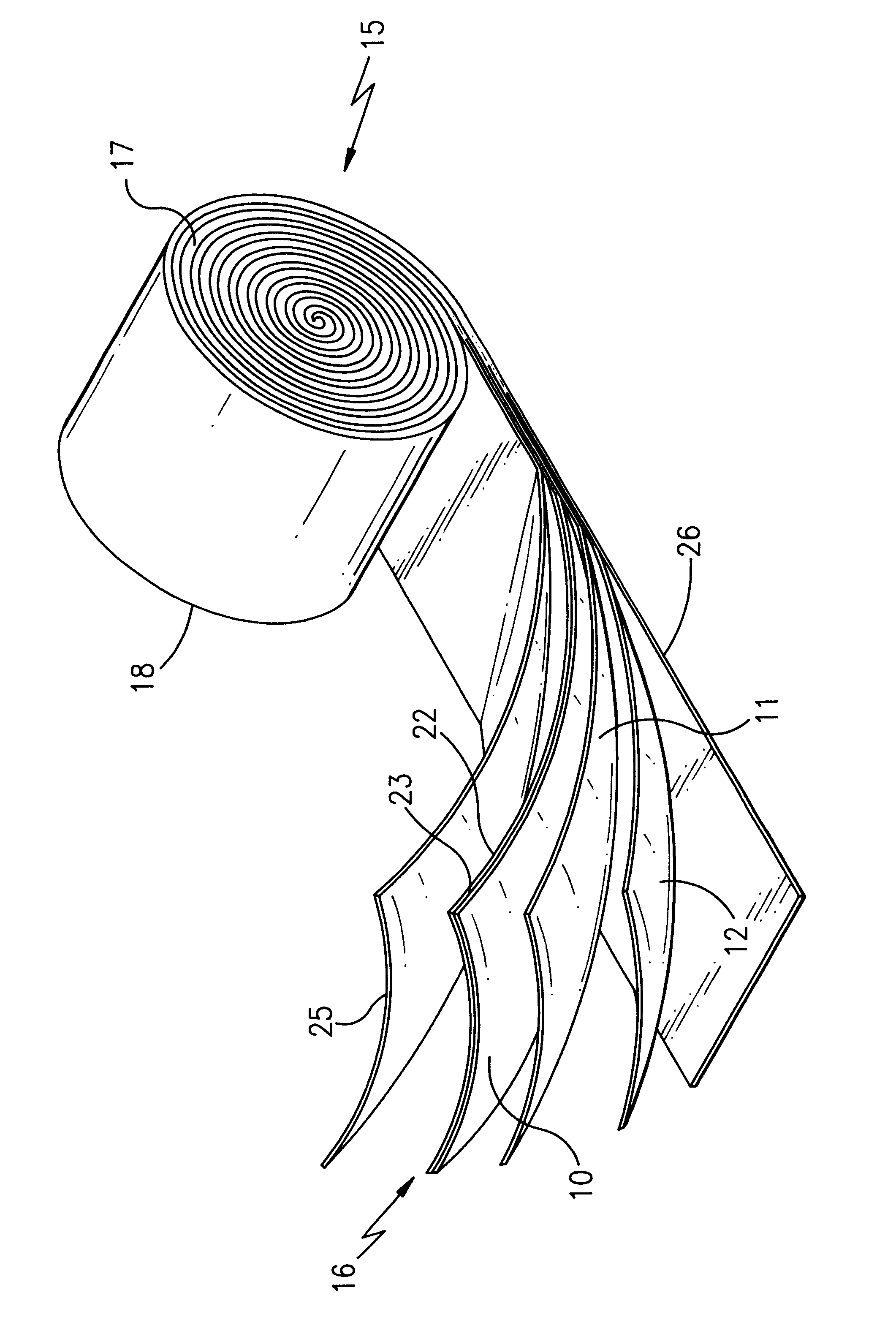

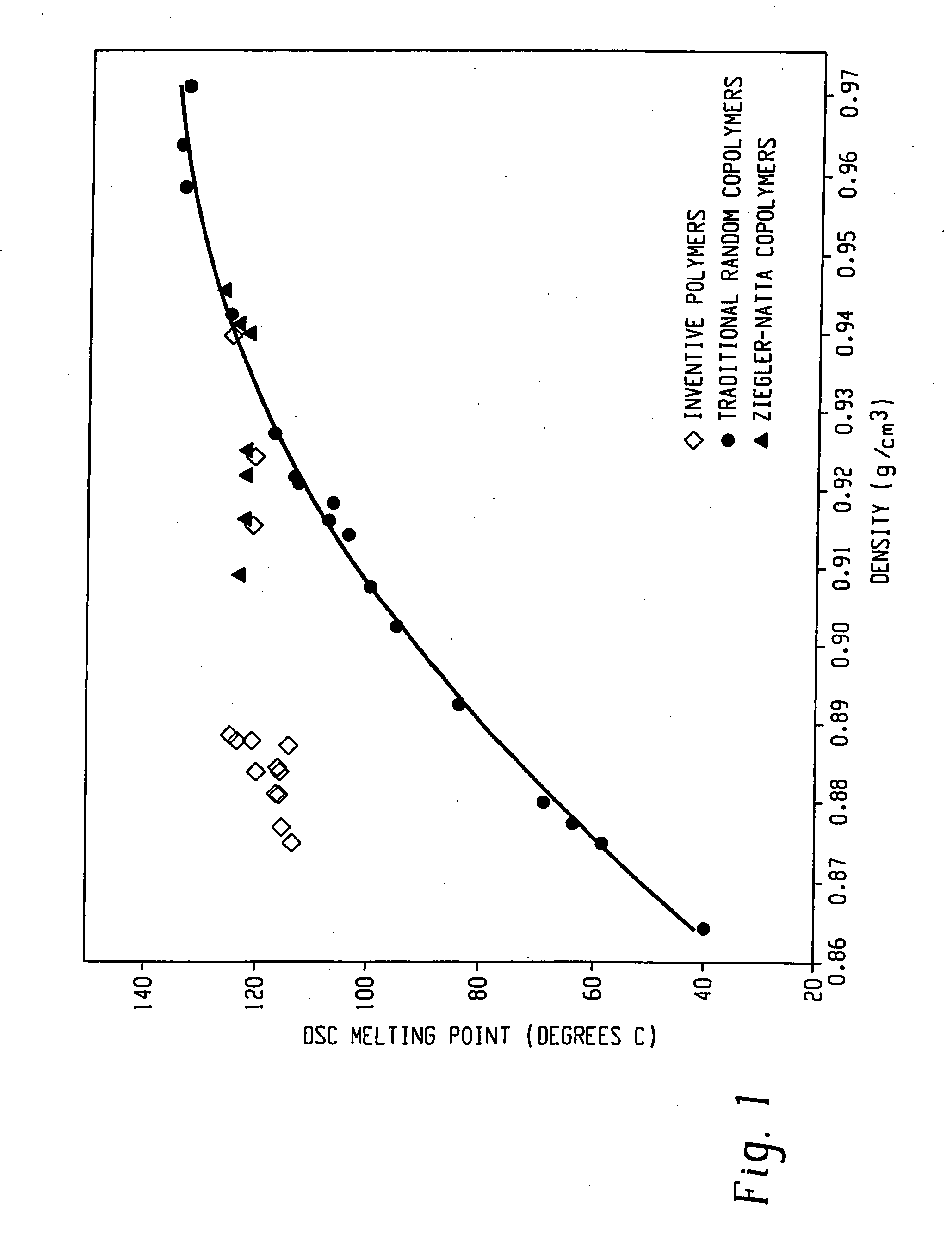

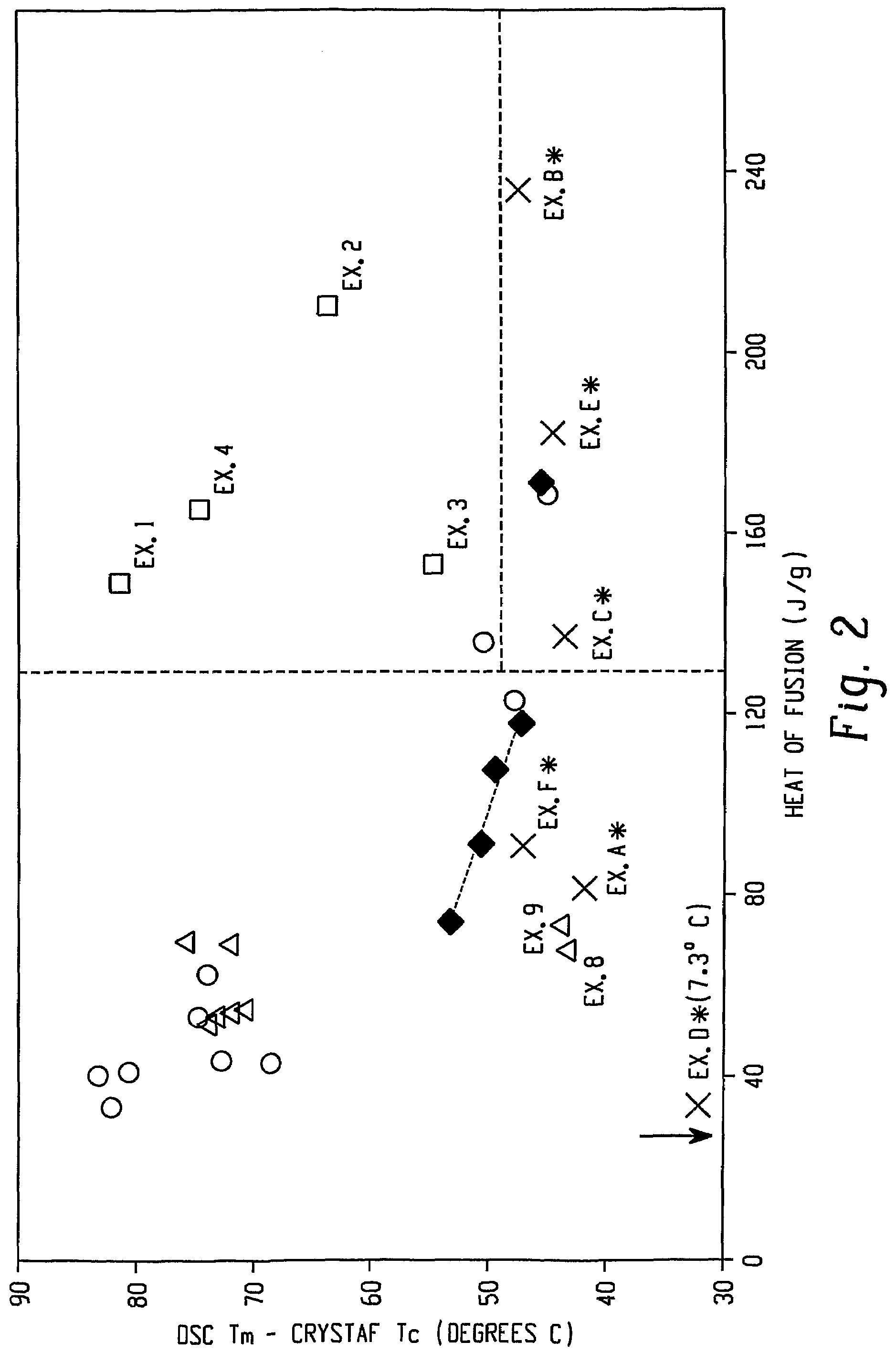

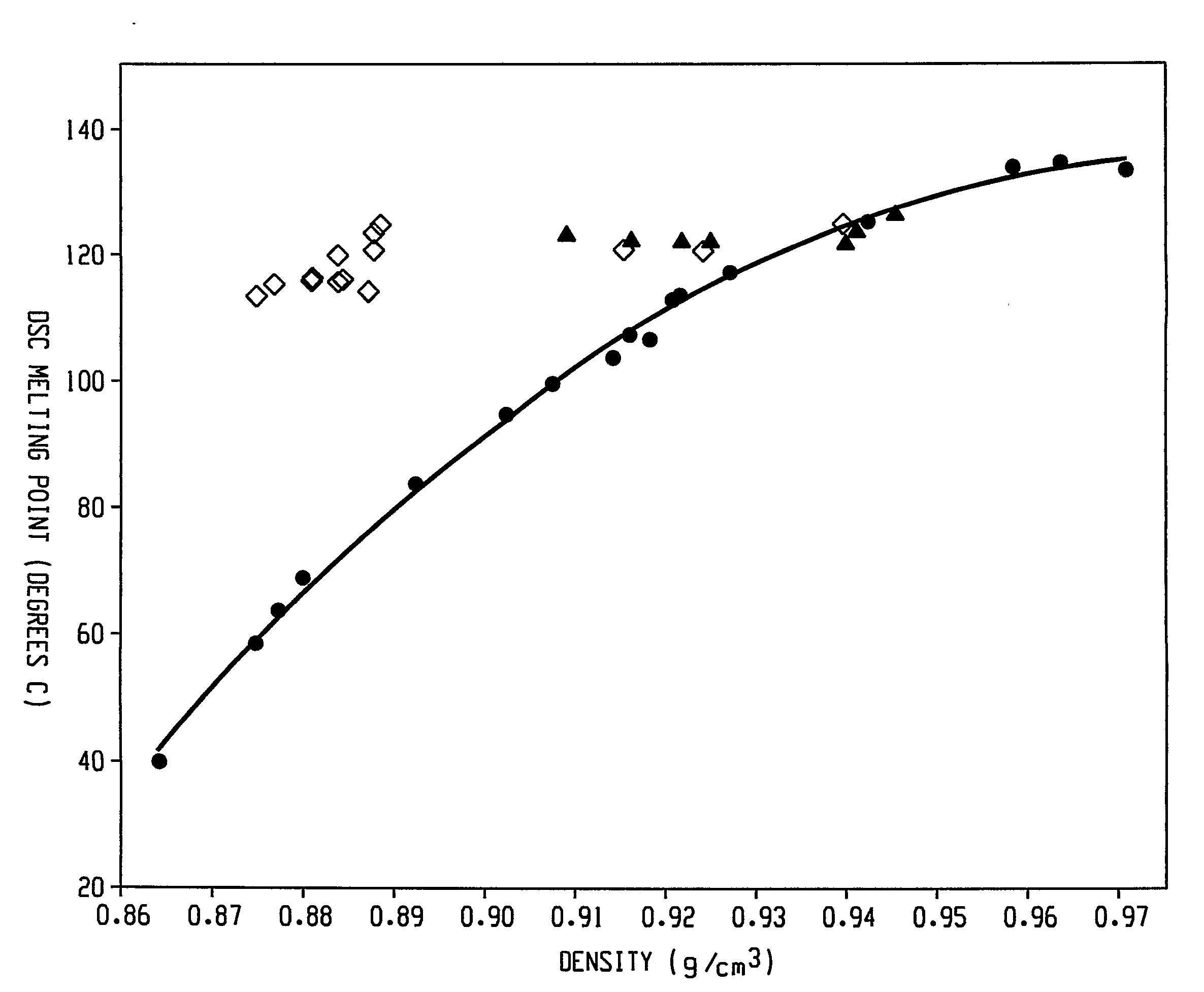

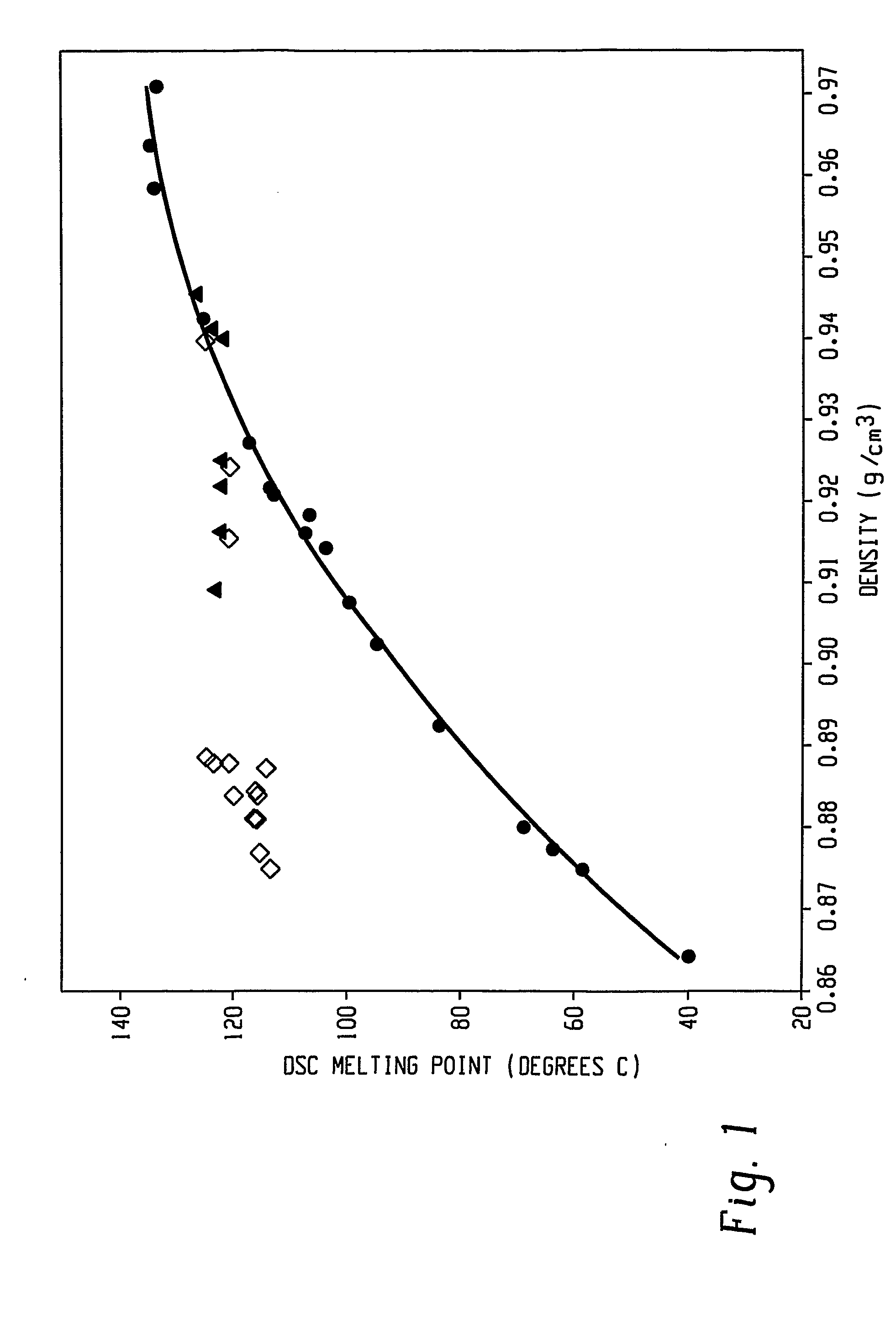

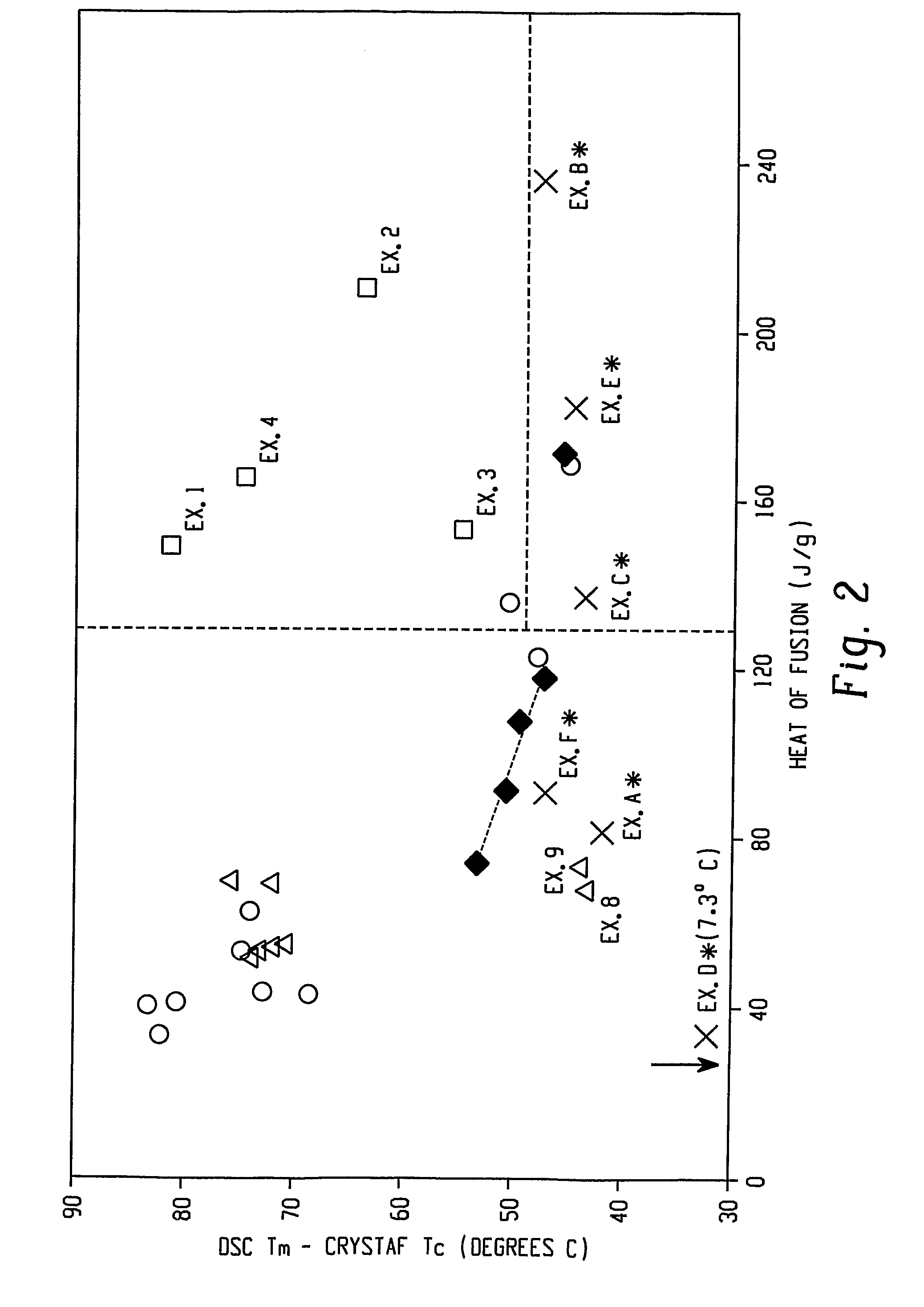

Compositions of ethylene/alpha-olefin multi-block interpolymer for elastic films and laminates

Owner:DOW GLOBAL TECH LLC

Compositions of ethylene/alpha-olefin multi-block interpolymer for elastic films and laminates

This invention relates to polyolefin compositions. In particular, the invention pertains to elastic polymer compositions that can be more easily processed on cast film lines, extrusion lamination or coating lines due to improved resistance to draw resonance. The compositions of the present invention preferably comprise an elastomeric polyolefin resin and a high pressure low density type resin.

Owner:DOW GLOBAL TECH LLC

Compositions of ethylene/alpha-olefin multi-block interpolymer for elastic films and laminates

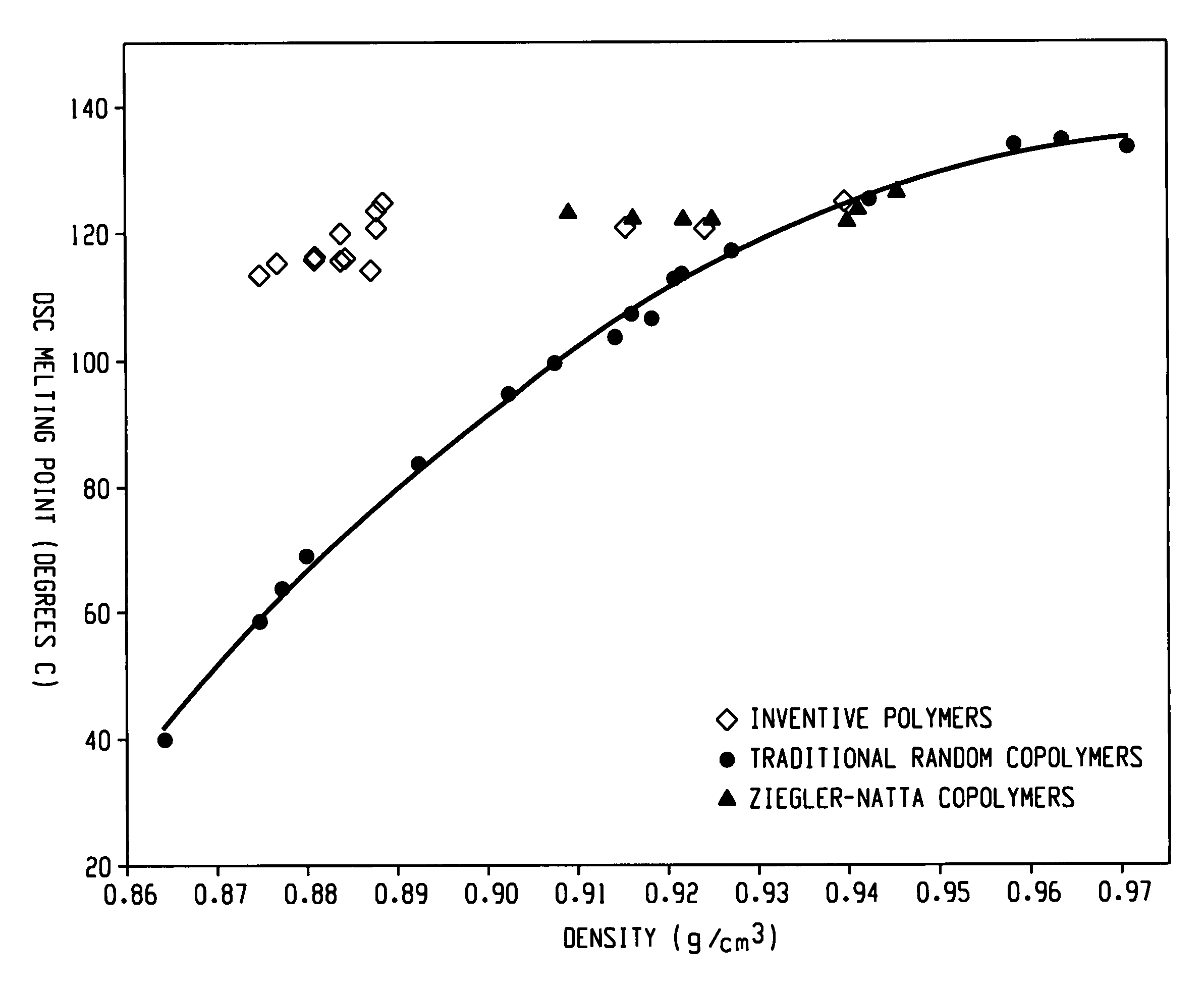

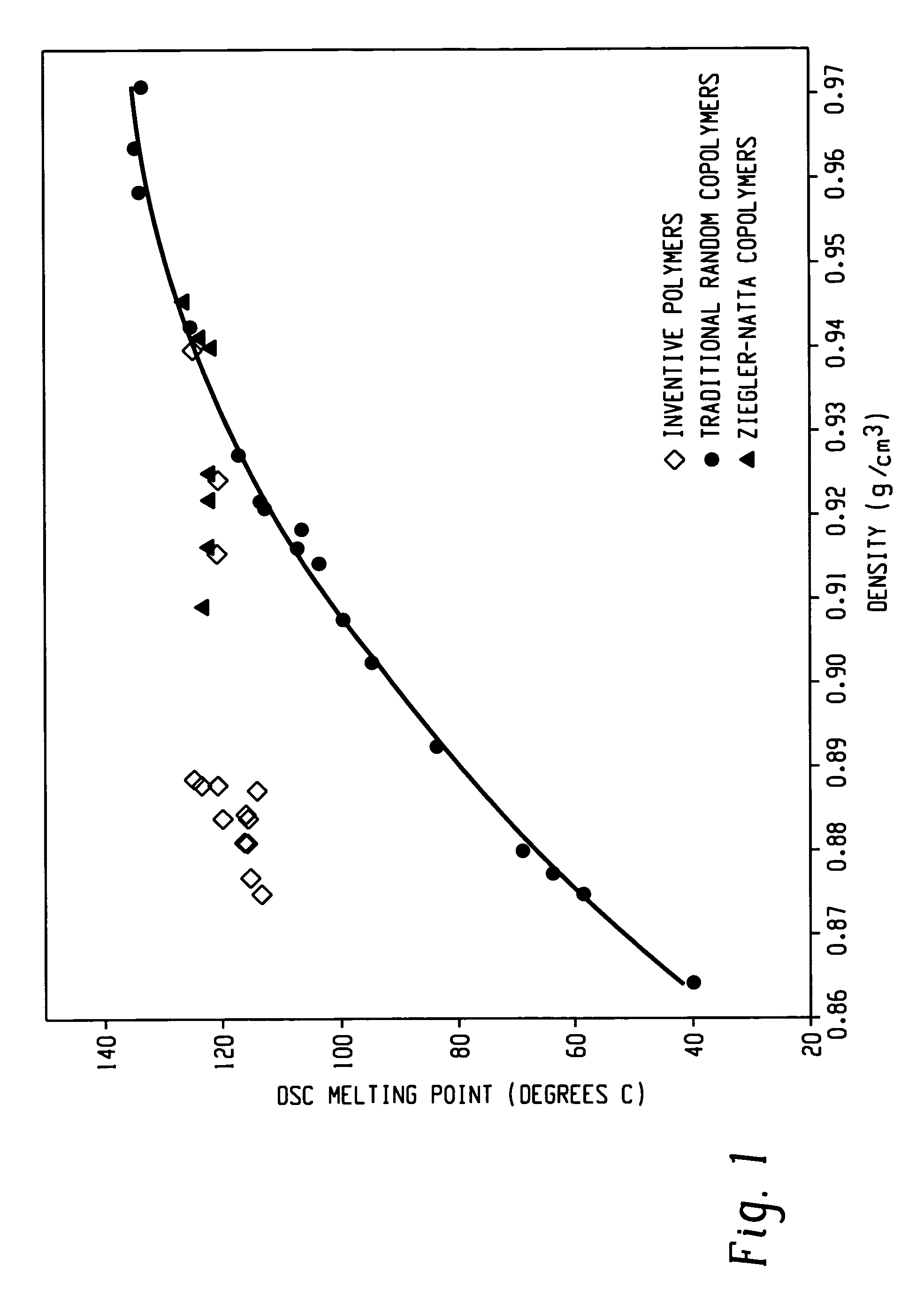

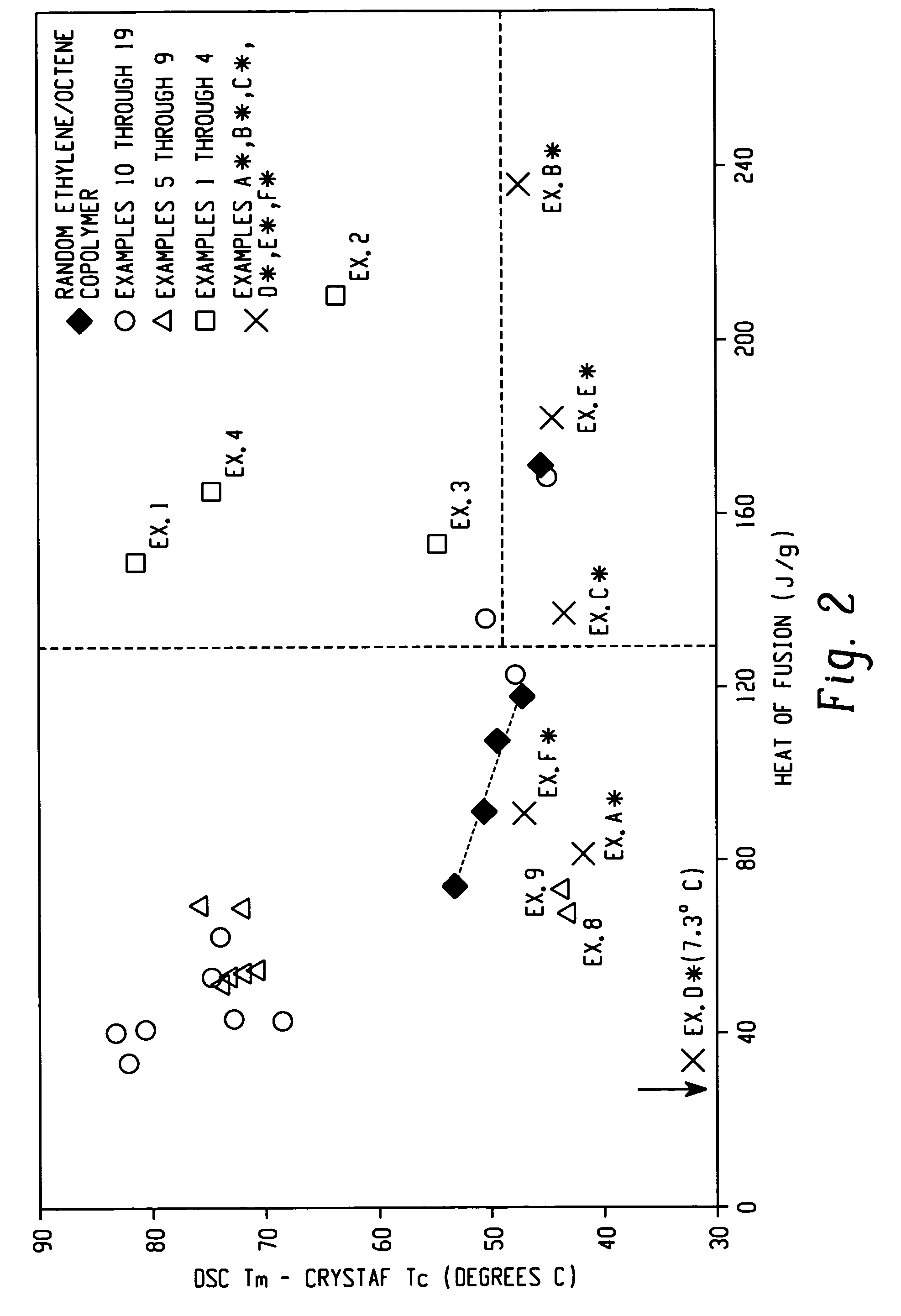

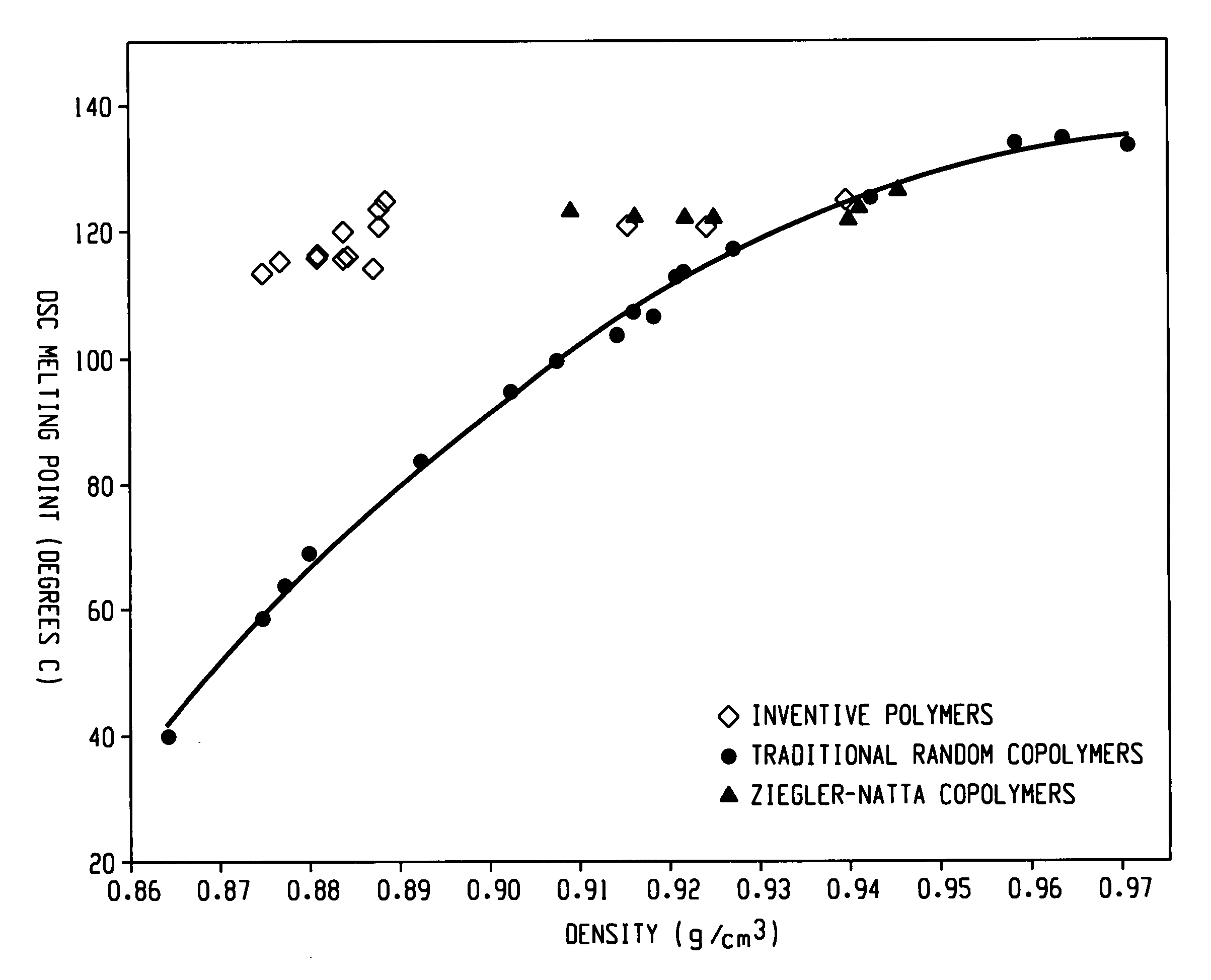

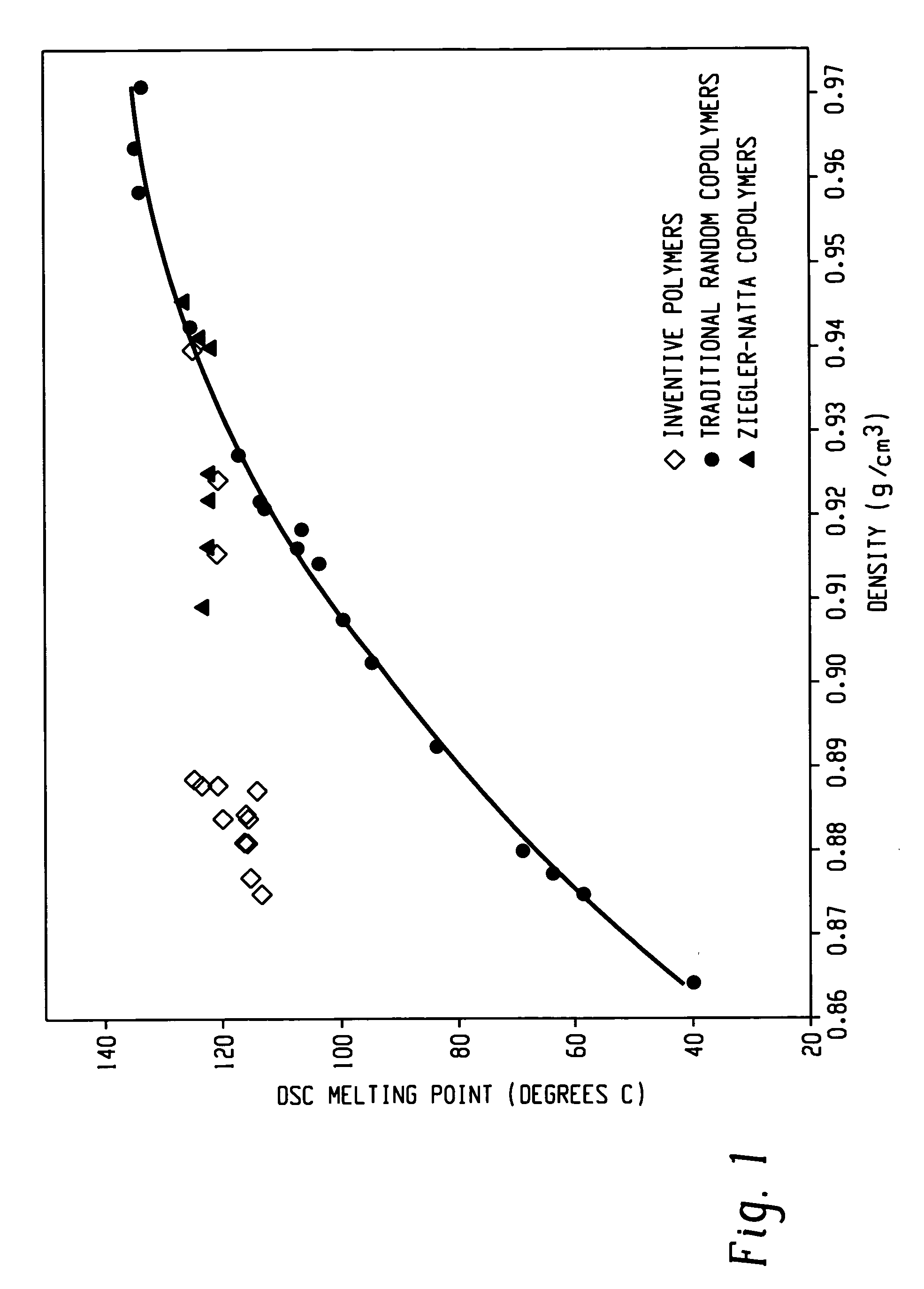

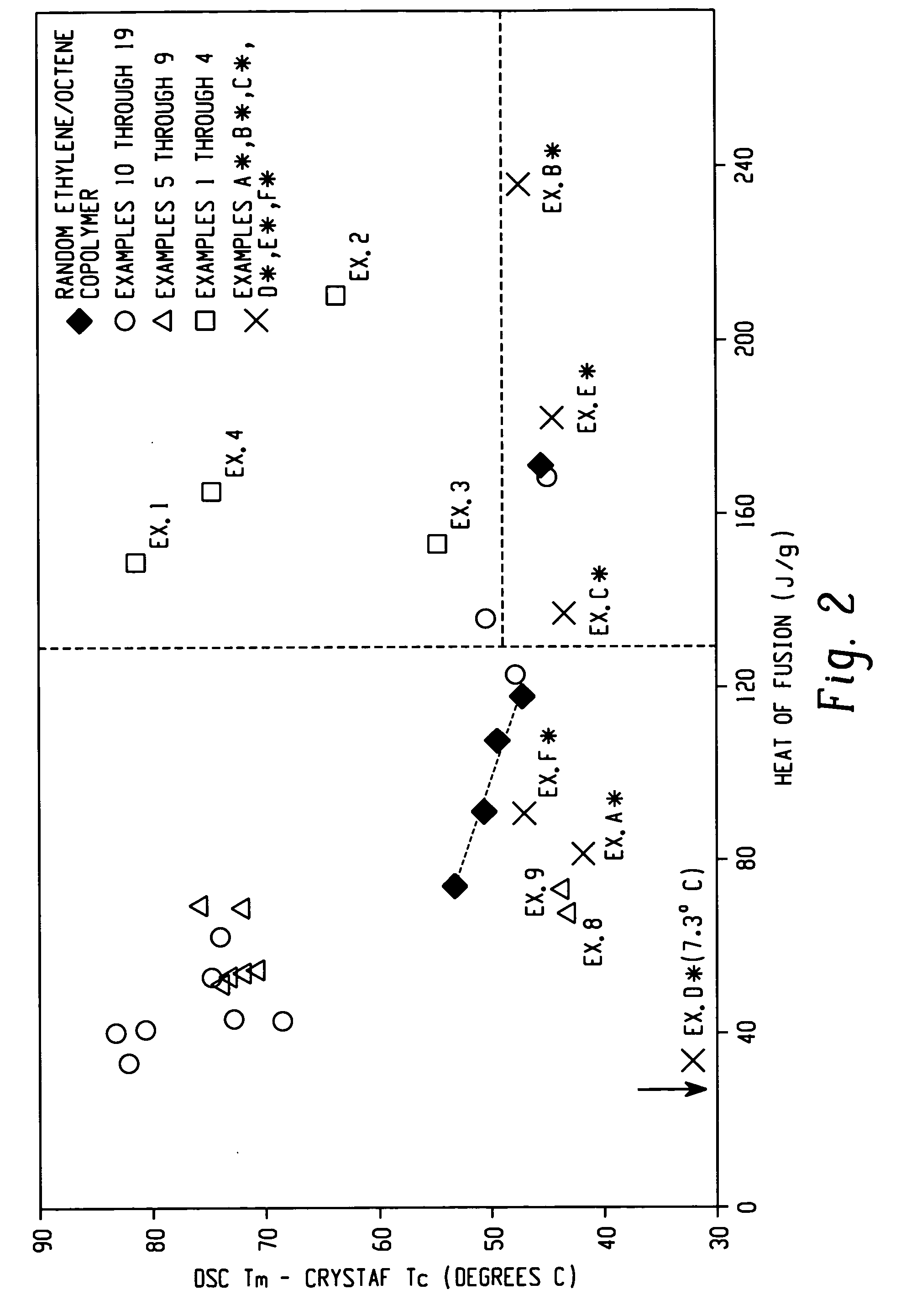

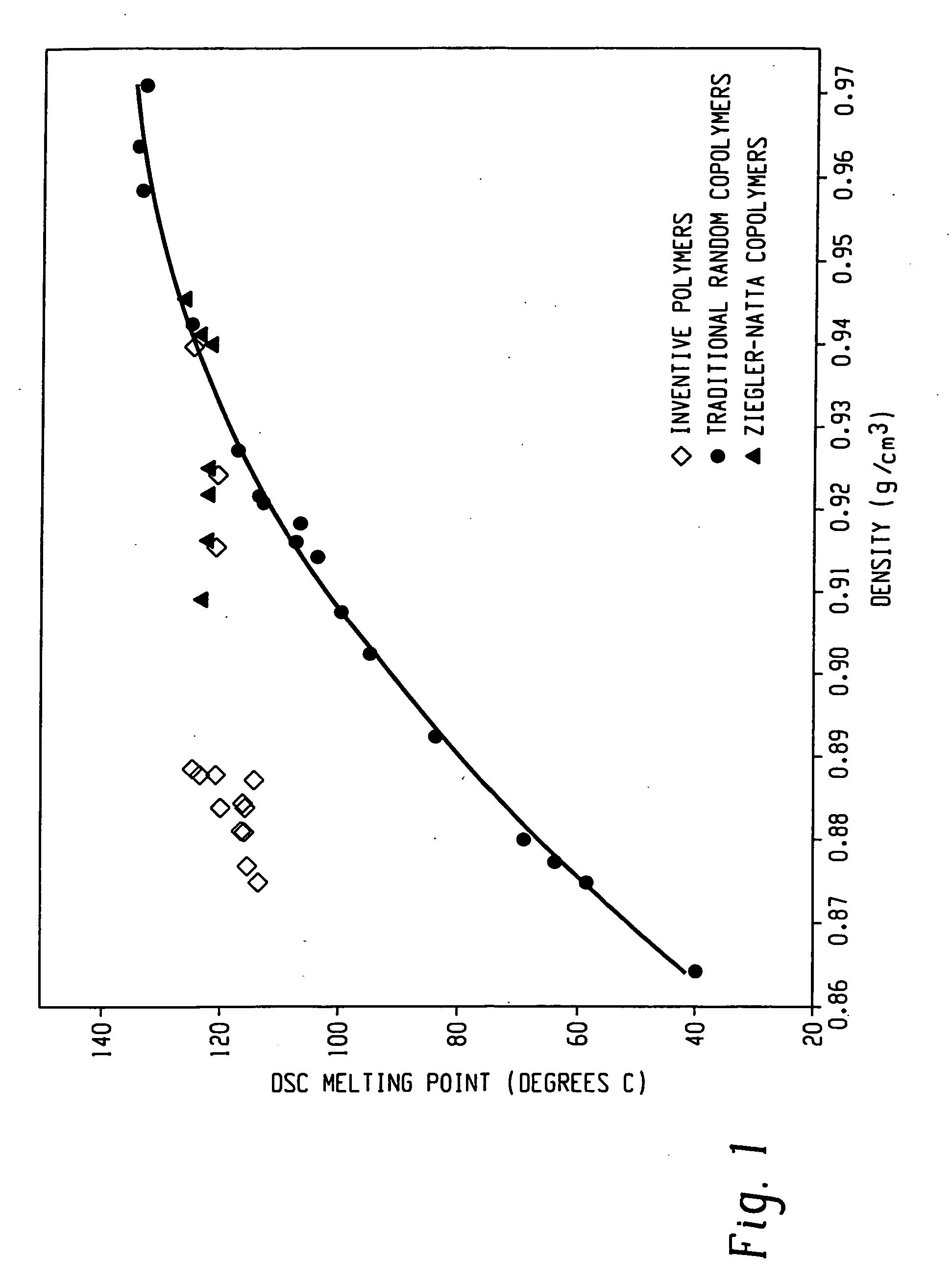

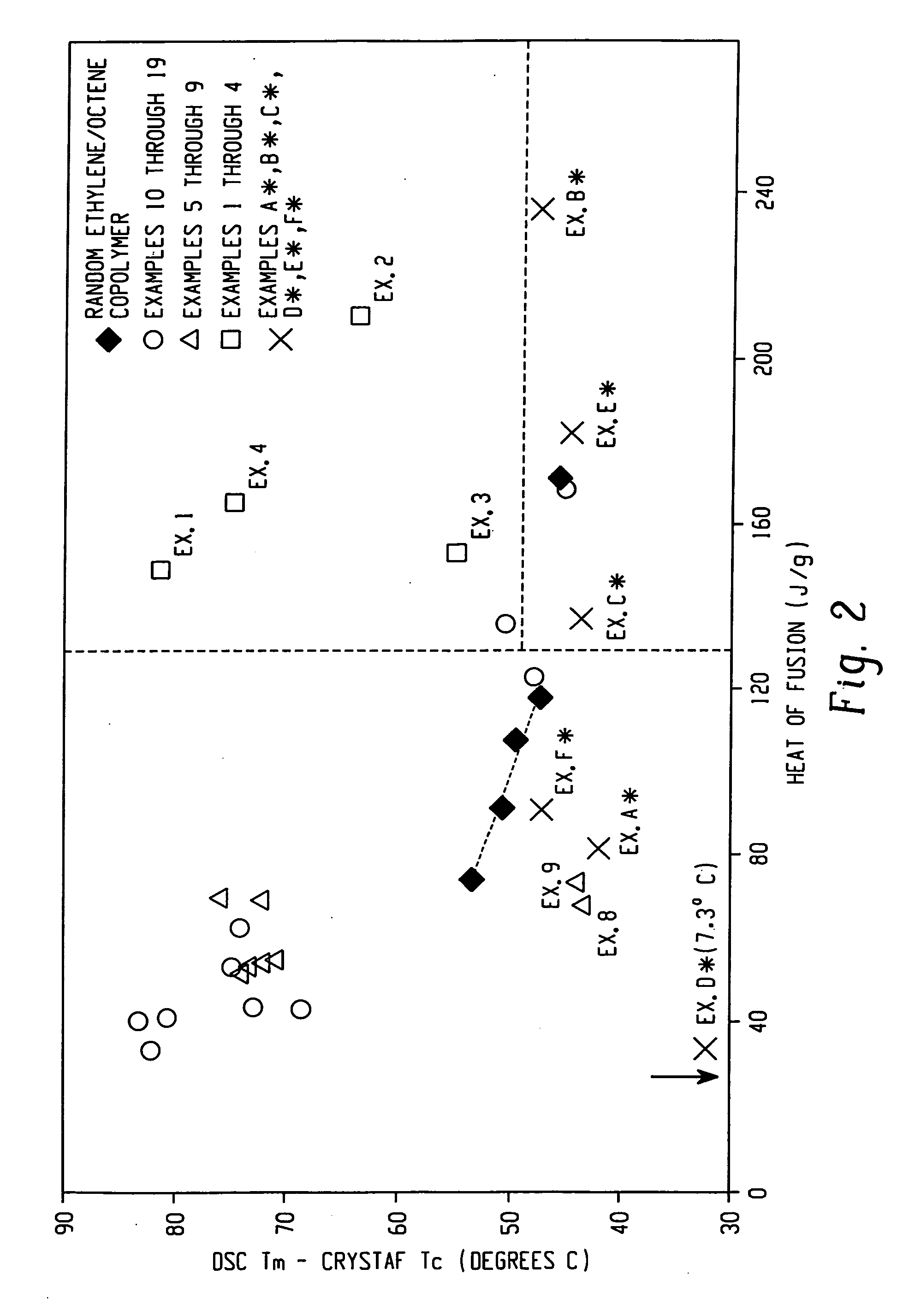

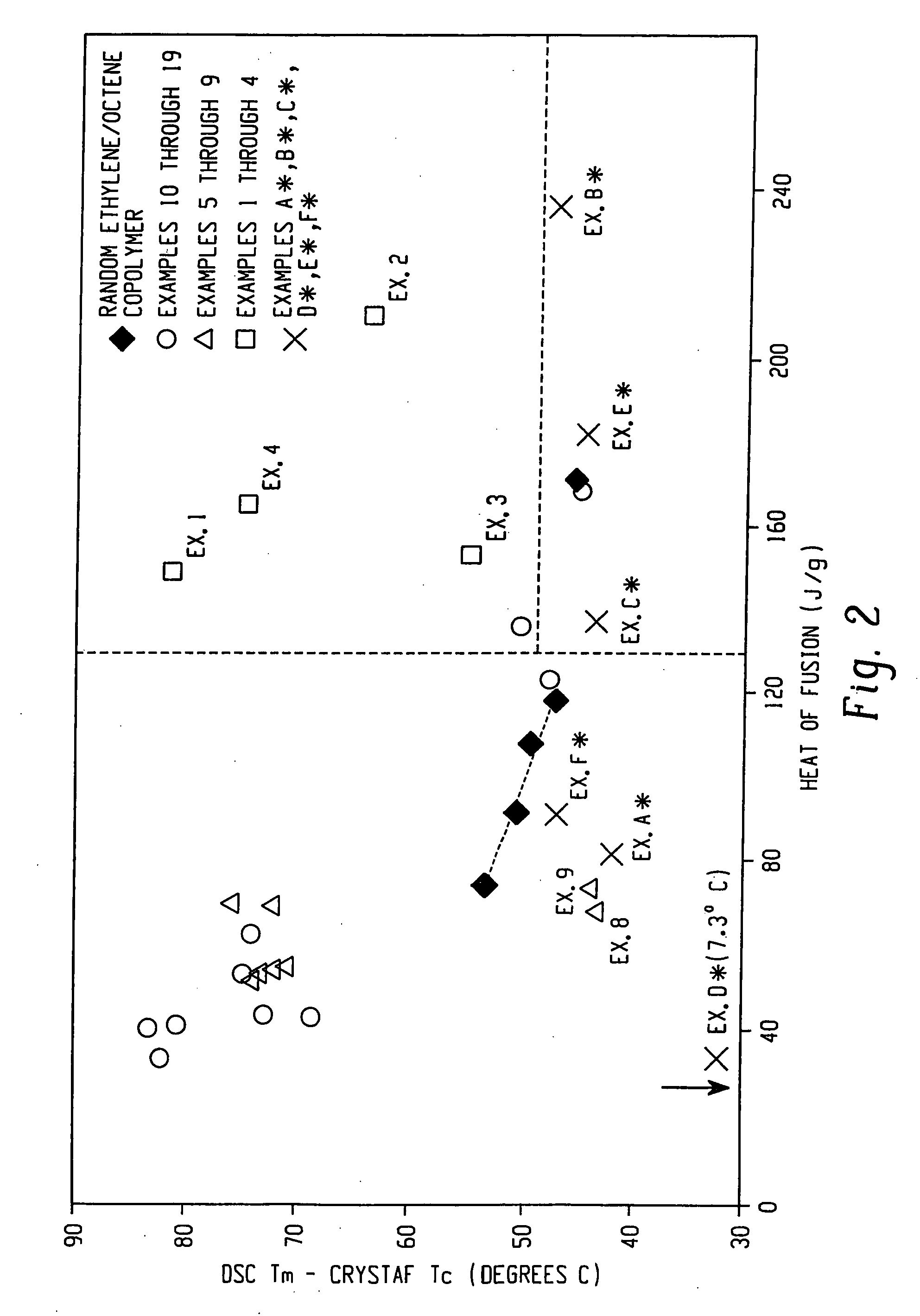

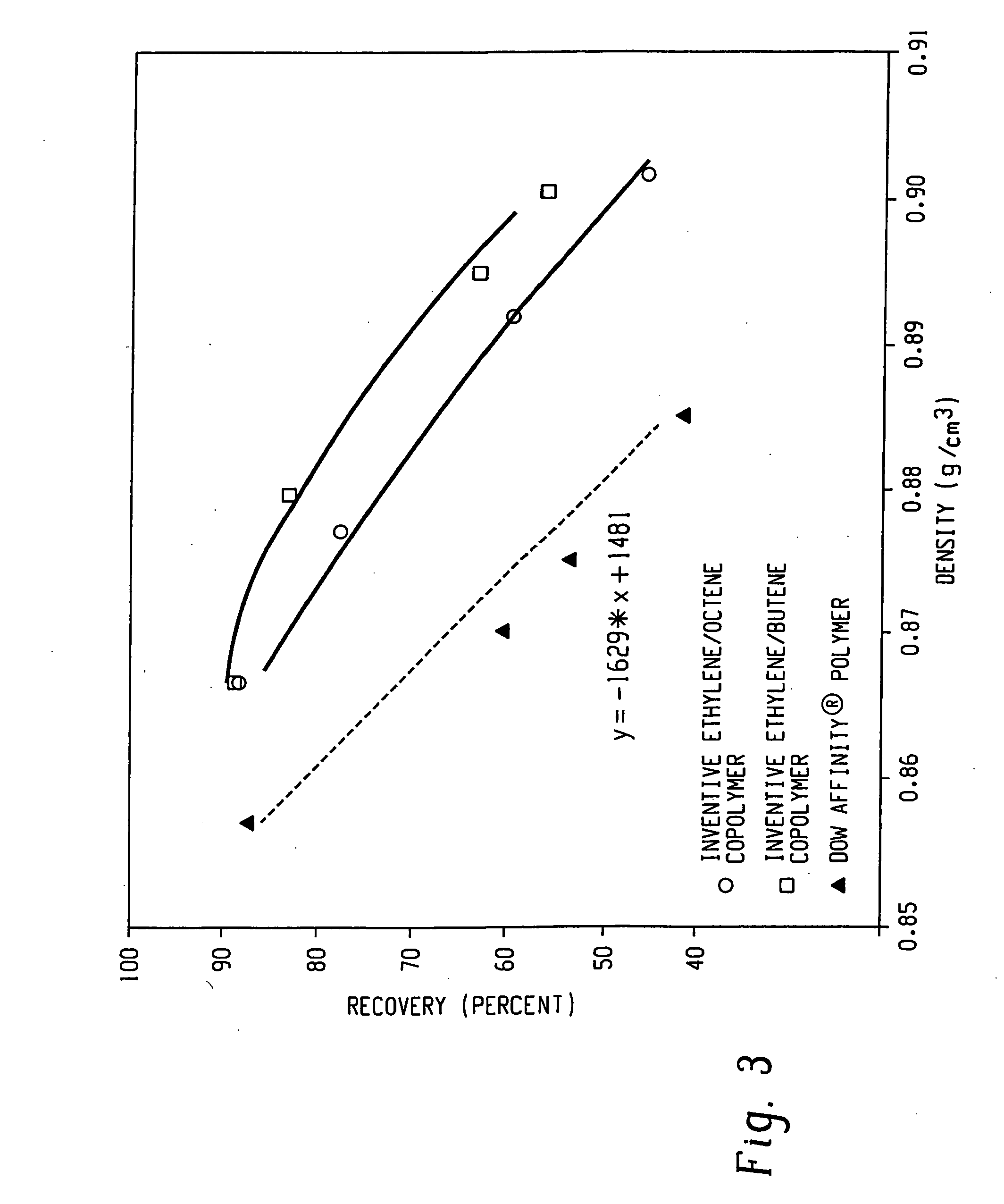

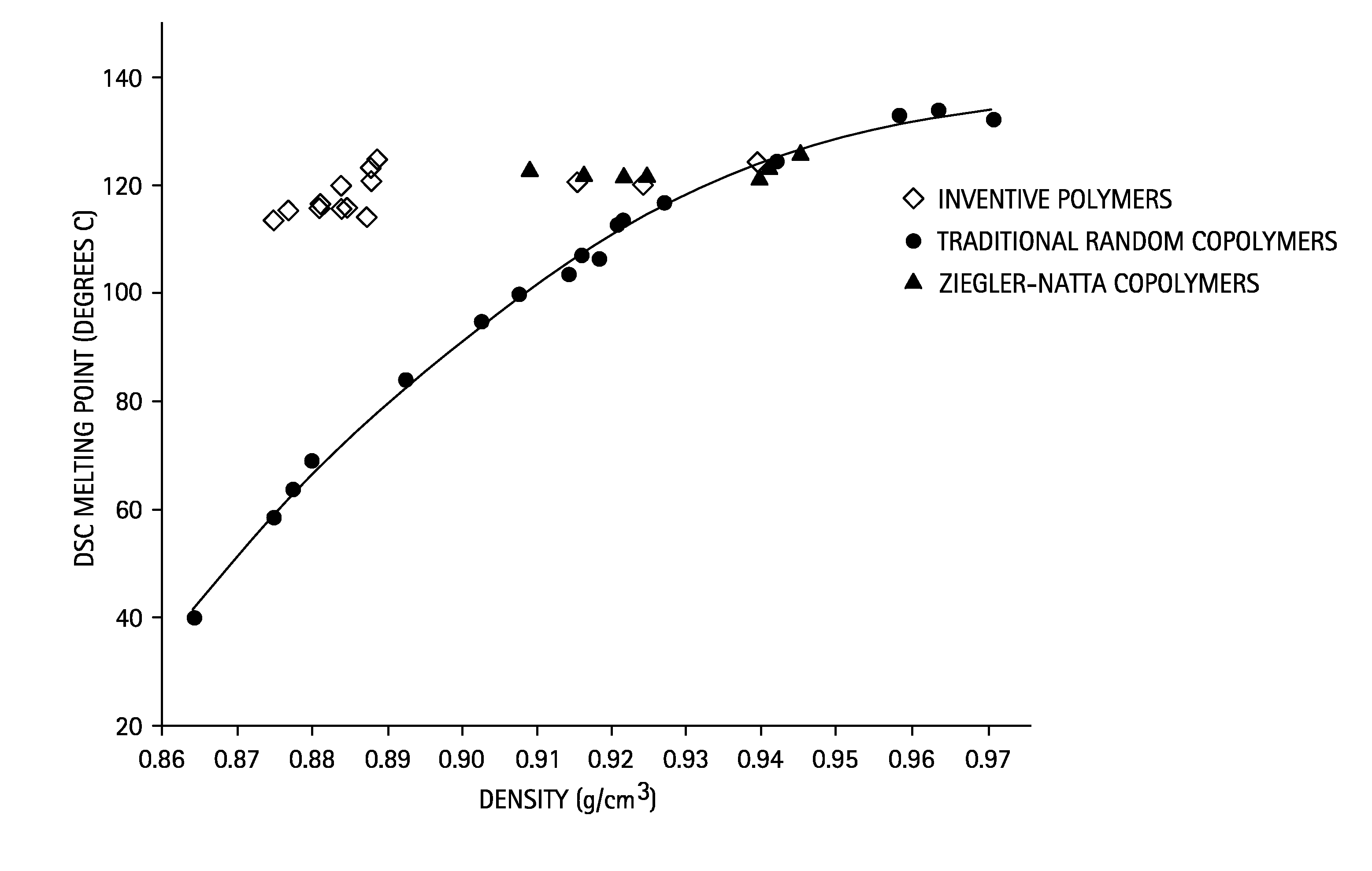

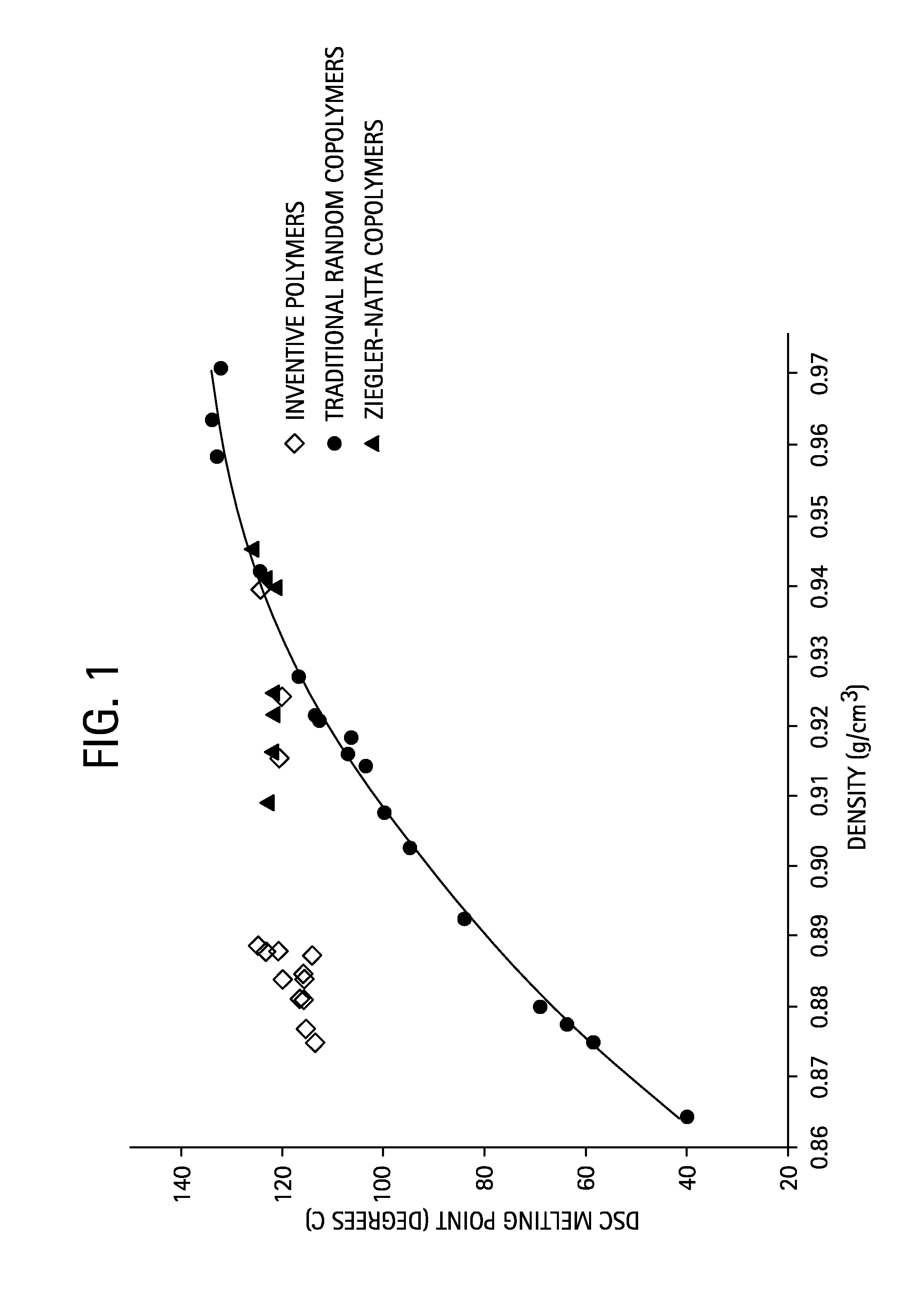

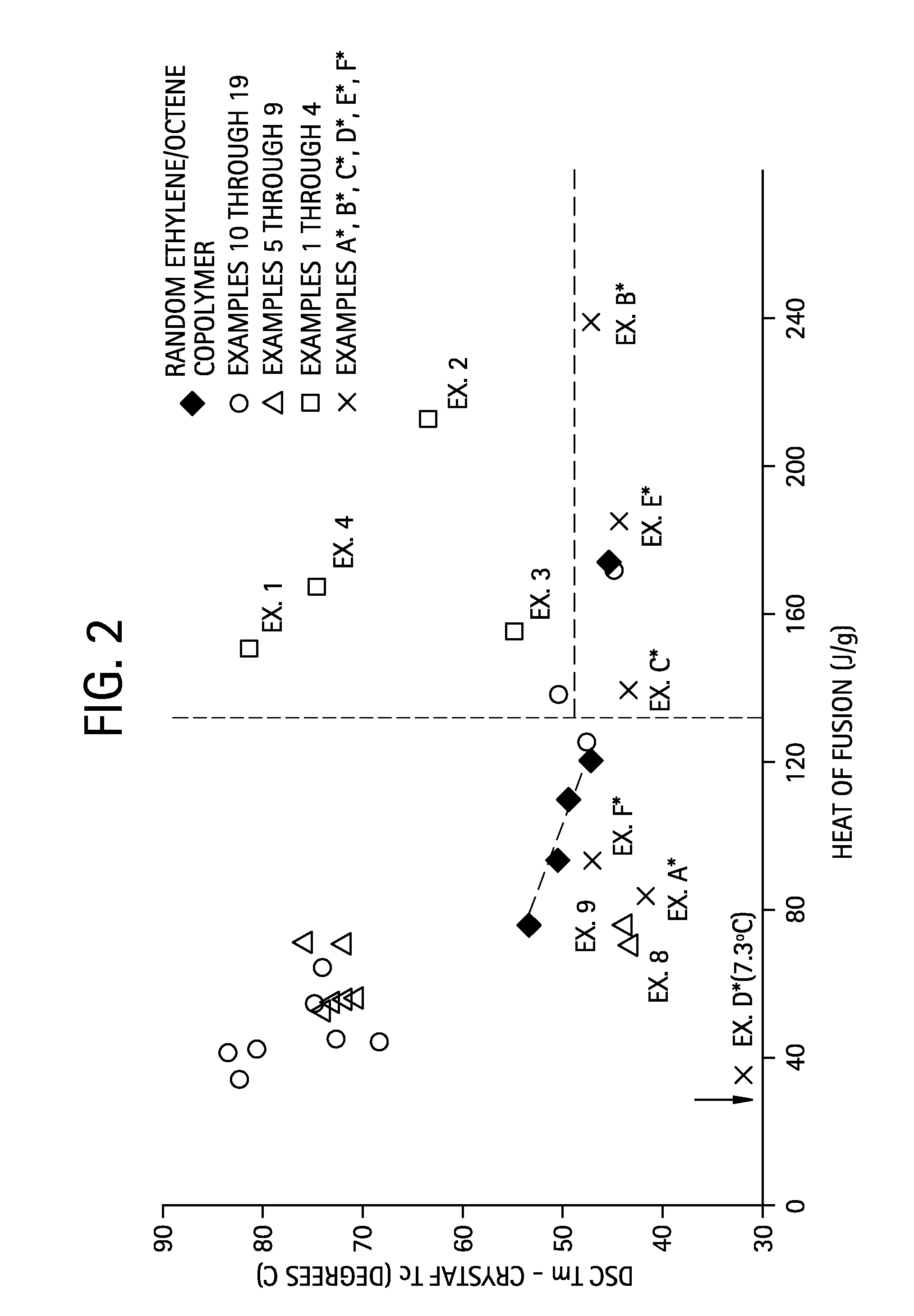

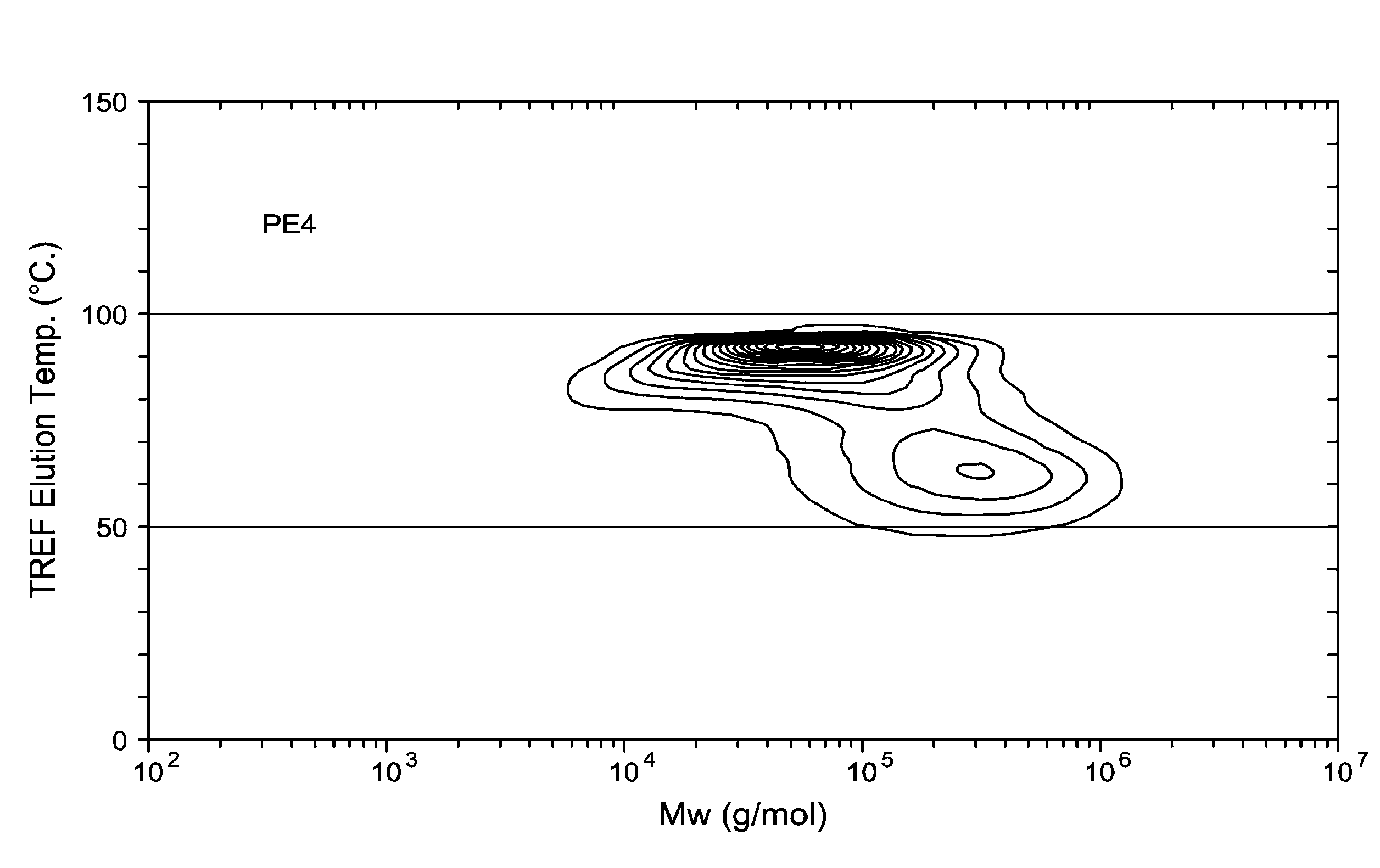

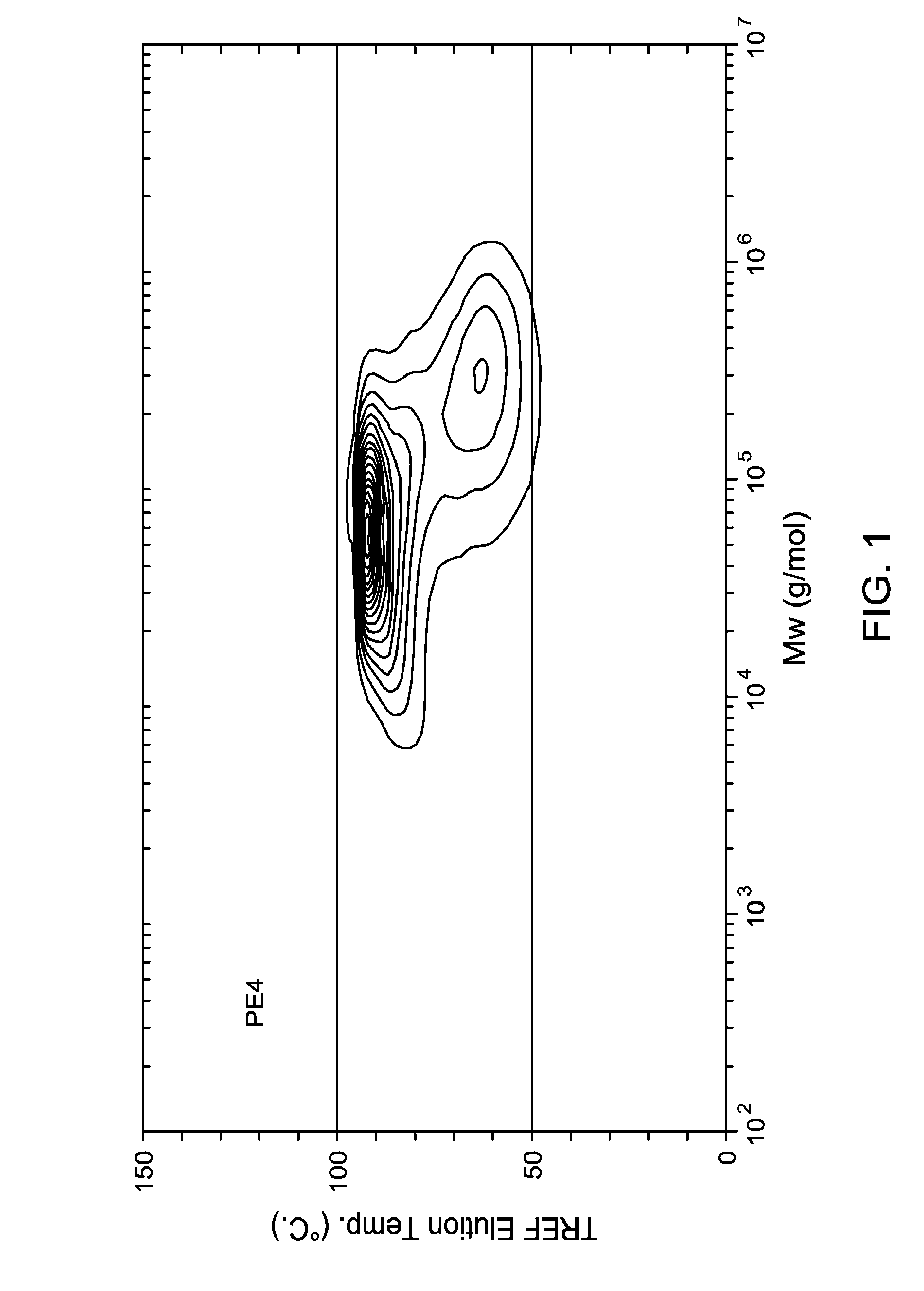

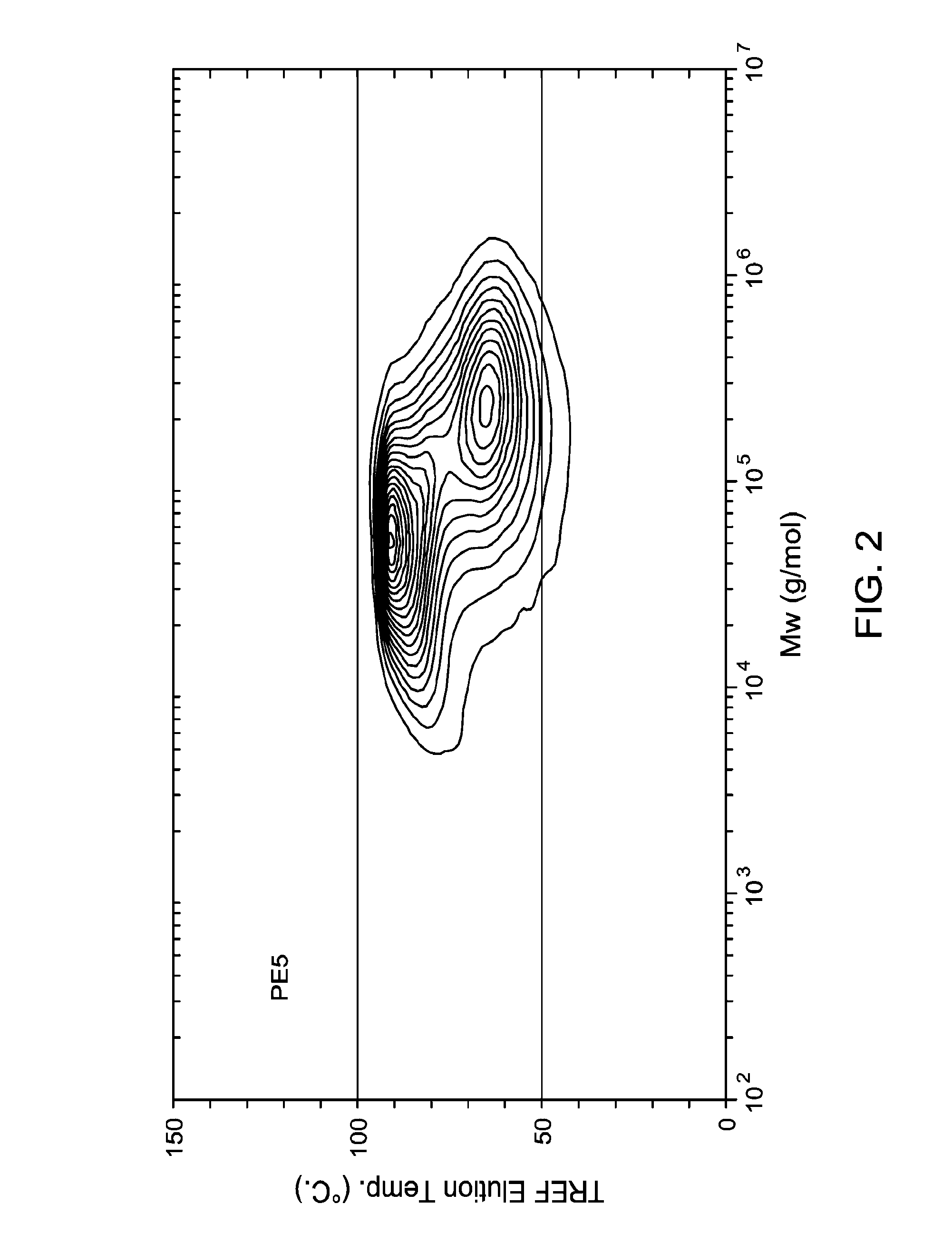

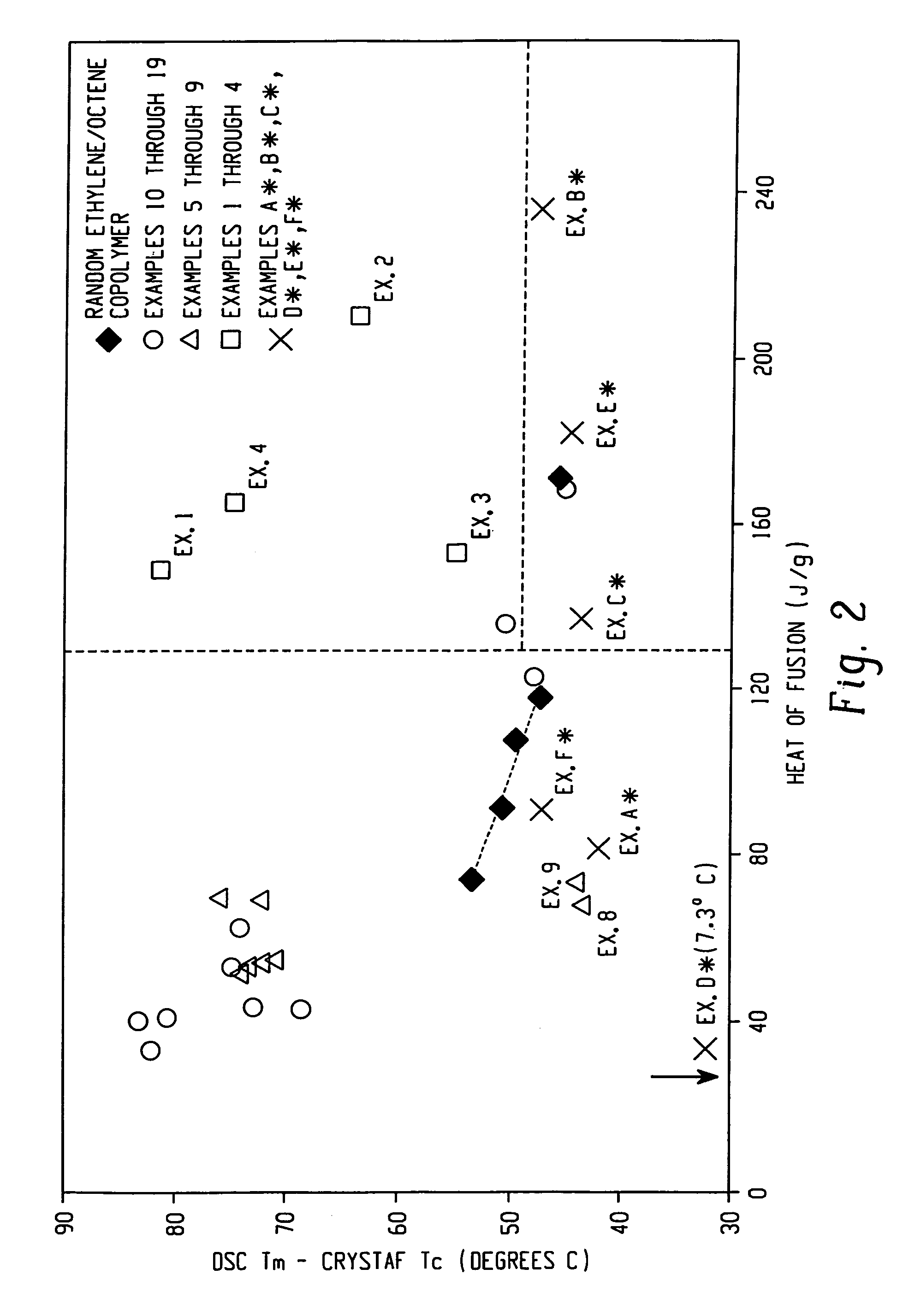

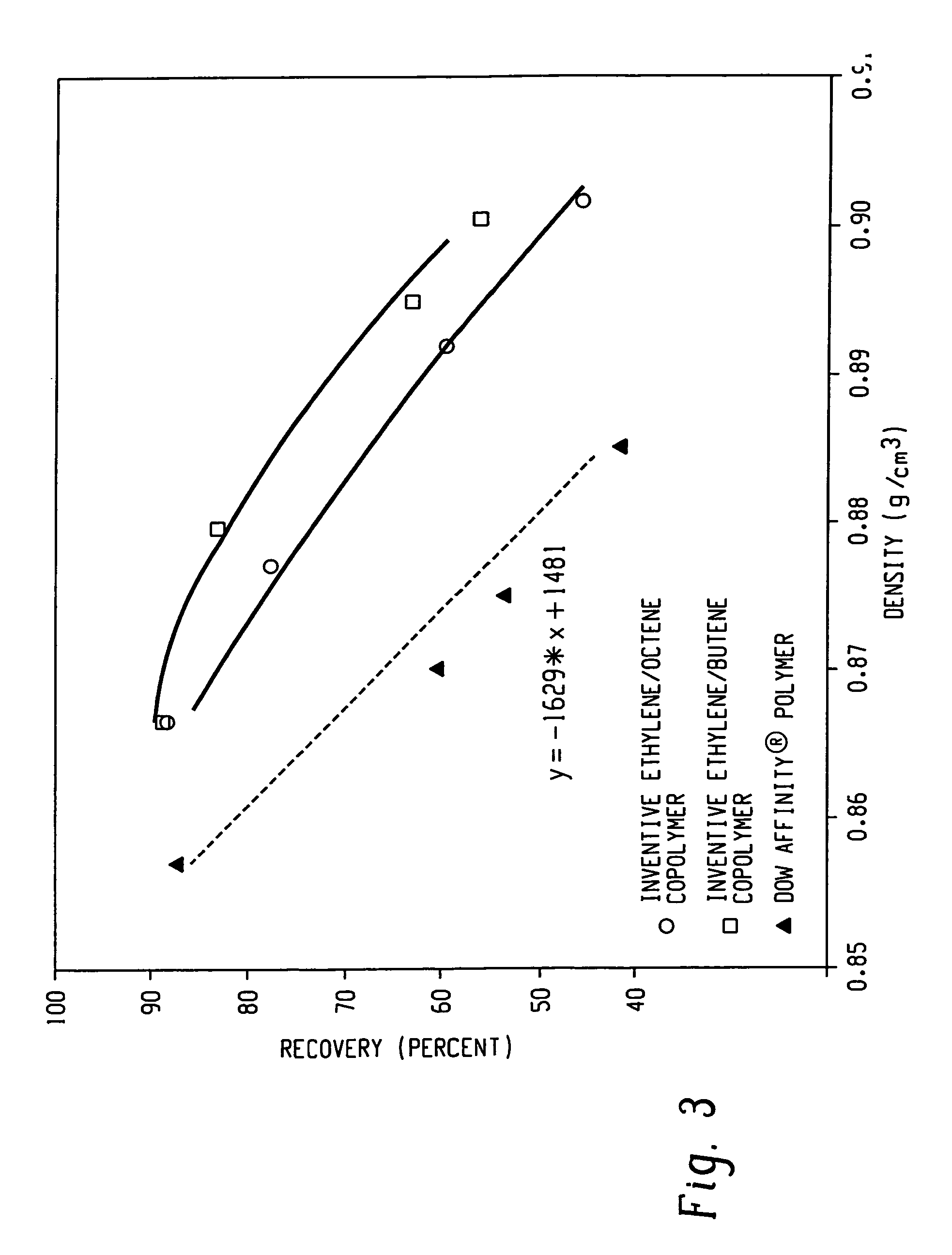

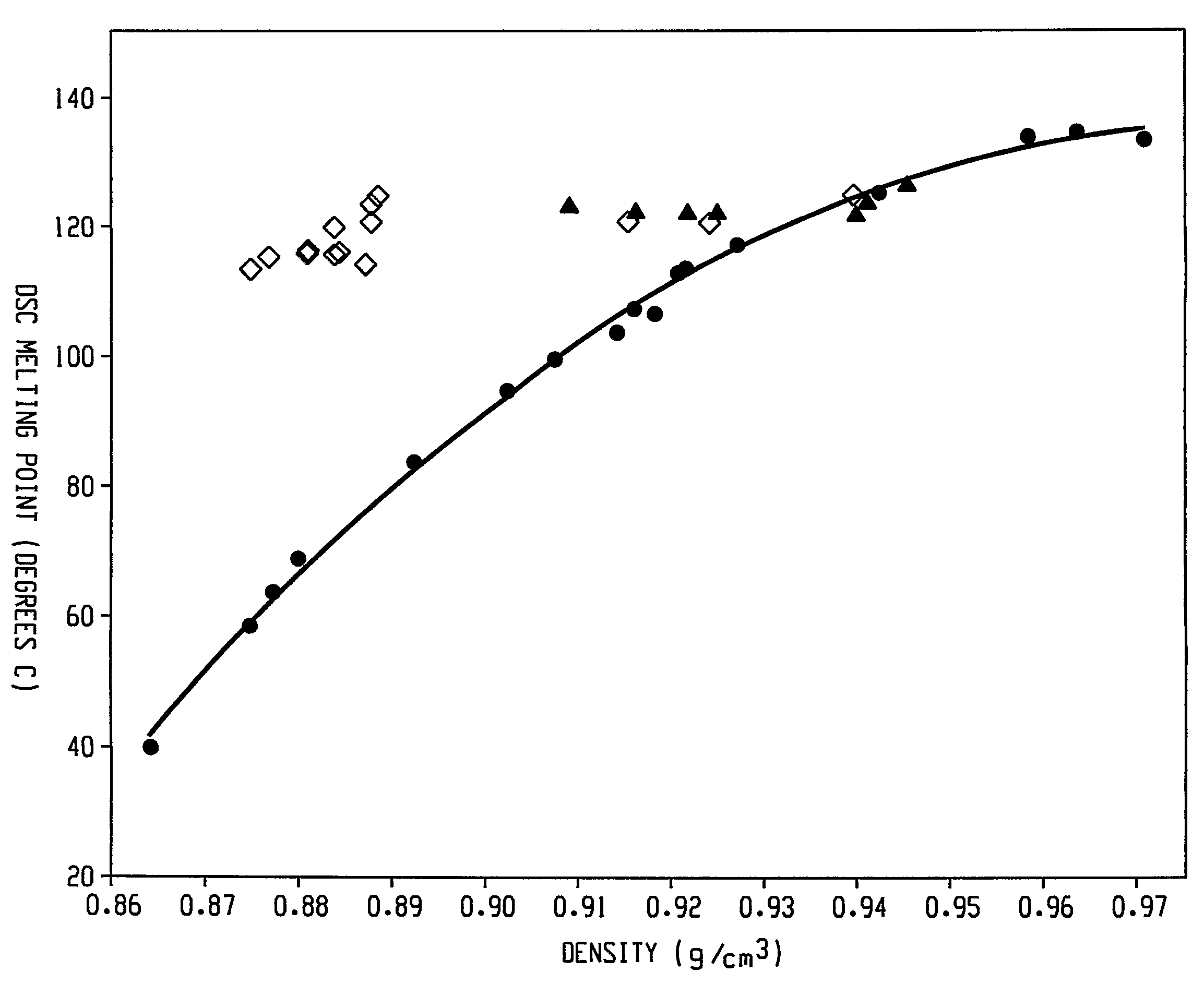

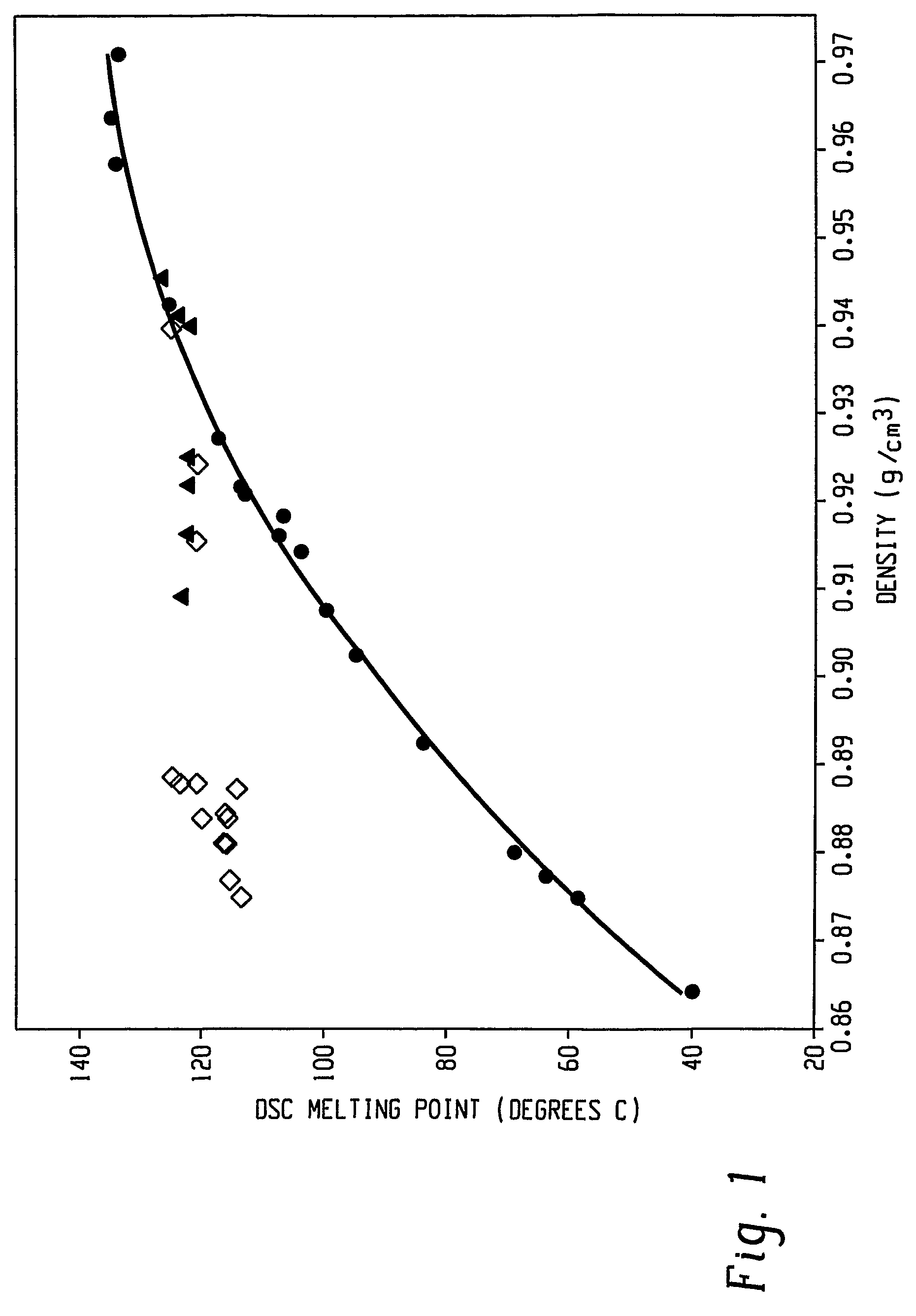

ActiveUS20070078222A1Easy to processHigh tensile strengthPersonal careSynthetic resin layered productsPolyolefinHigh pressure

This invention relates to polyolefin compositions. In particular, the invention pertains to elastic polymer compositions that can be more easily processed on cast film lines, extrusion lamination or coating lines. The compositions of the present invention preferably comprise an elastomeric polyolefin resin and a high pressure low density type resin.

Owner:DOW GLOBAL TECH LLC

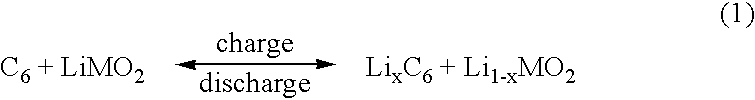

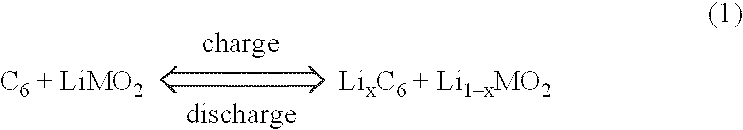

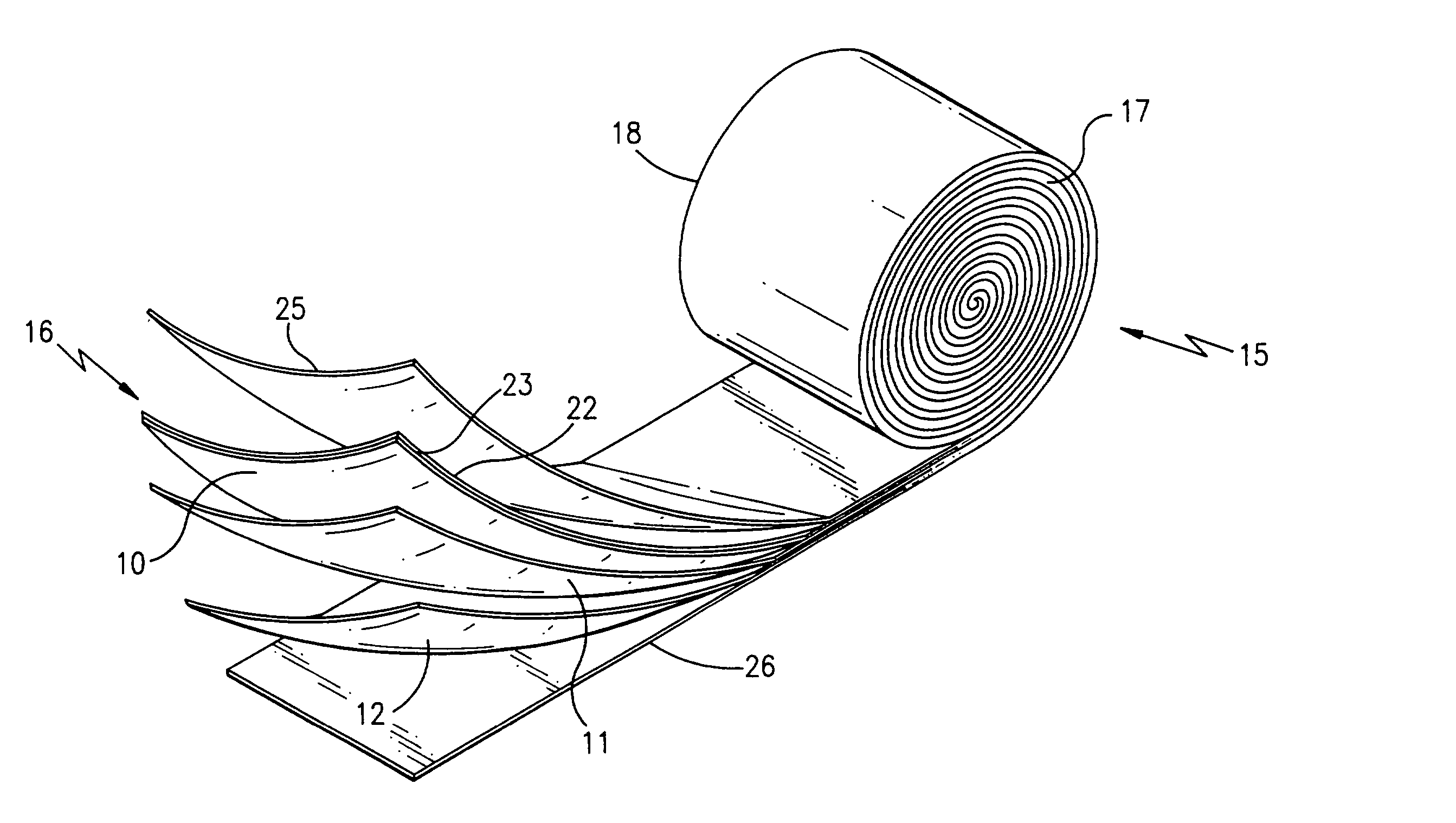

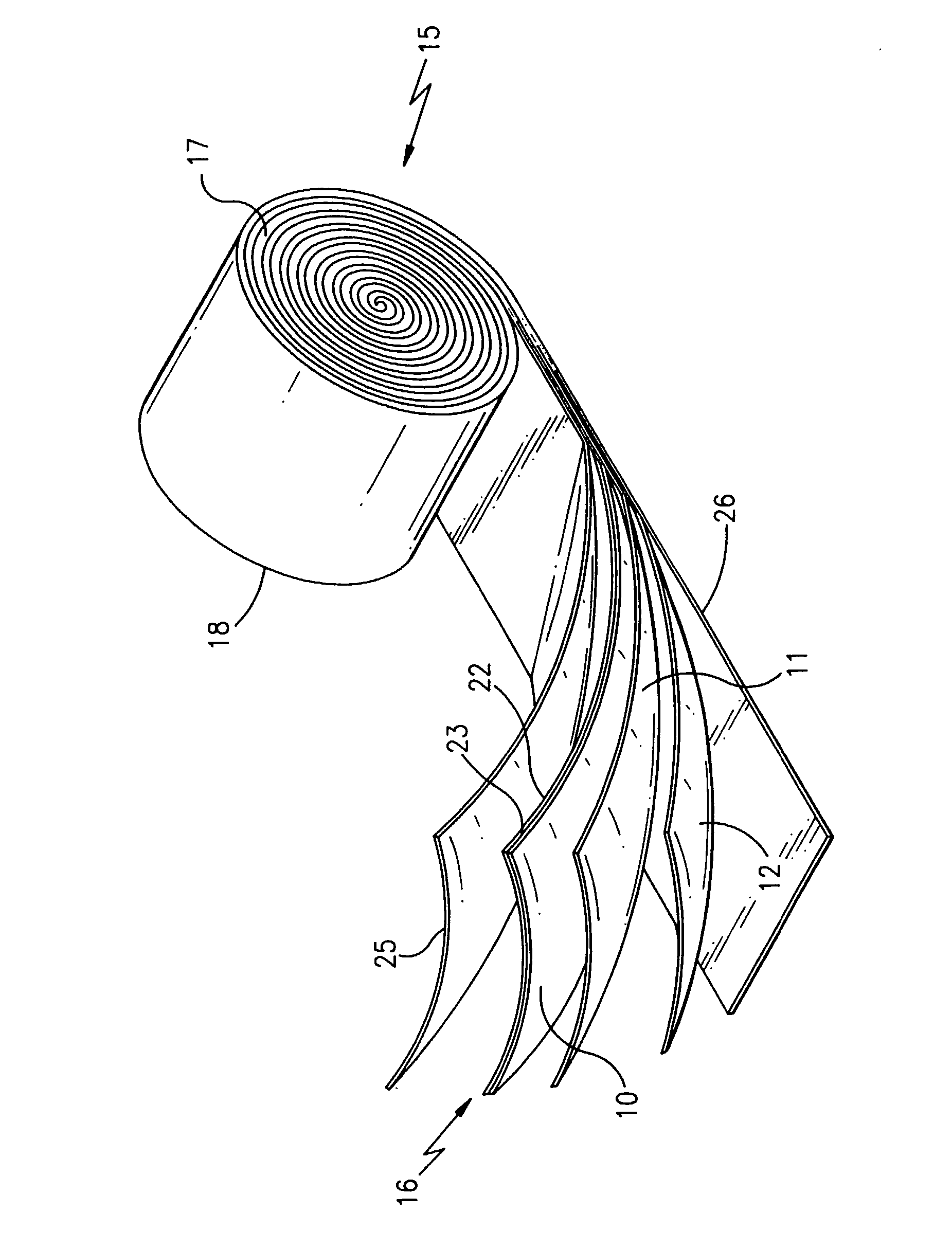

Lithium ion polymer electrolytes

InactiveUS6413676B1Prevent kinkingAvoid deformationElectrode manufacturing processesFinal product manufacturePorosityCross-link

A dimensionally stable, highly resilient, hybrid copolymer solid-solution electrolyte-retention film for use in a lithium ion battery in one preferred embodiment has a predominantly amorphous structure and mechanical strength despite contact with liquid solvent electrolyte. The film is a thinned (stretched), cast film of a homogeneous blend of two or more polymers, one of which is selected for its pronounced solvent retention properties. A very high surface area inorganic filler dispersed in the blend during formation thereof serves to increase the porosity of the film and thereby enhance electrolyte retention. The film is soaked in a solution of liquid polymer with liquid organic solvent electrolyte and lithium salt, for absorption thereof. Use of a cross-linked liquid polymer enhances trapping of molecules of the electrolyte into pores of the film. The electrolyte film is sandwiched between flexible active anode and cathode layers to form the lithium ion battery. Novel methods are provided for forming the electrodes, the polymer substrate, and other elements of the battery.

Owner:LITHIUM POWER TECH

Compositions of ethylene/alpha-olefin multi-block interpolymer for elastic films and laminates

ActiveUS20070155900A1Easy to processHigh tensile strengthPersonal careLayered product treatmentProduction linePolyolefin

This invention relates to polyolefin compositions. In particular, the invention pertains to elastic polymer compositions that can be more easily processed on cast film lines, extrusion lamination or coating lines. The compositions of the present invention preferably comprise an elastomeric polyolefin resin and a high pressure low density type resin.

Owner:DOW GLOBAL TECH LLC

Compositions of ethylene/alpha-olefin multi-block interpolymer for elastic films and laminates

ActiveUS20080177242A1Good physical propertiesElasticityCosmetic preparationsToilet preparationsElastomerPolyolefin

This invention relates to polyolefin compositions. In particular, the invention pertains to elastic polymer compositions that can be more easily processed on cast film lines, extrusion lamination or coating lines. The compositions of the present invention preferably comprise an elastomeric polyolefin resin and a high pressure low density type resin.

Owner:DOW GLOBAL TECH LLC

Films Comprising Ethylene-Based Polymers and Methods of Making Same

Films including a Layer A comprising 50.0 to 100.0 wt. %, based on the weight of the Layer A, of an ethylene-based polymer composition having therein a hafnium:zirconium (ppm / ppm) ratio>1.0, a CDBI less than 50%, and a g′vis≧0.98; wherein the Layer A is substantially free of polyethylene having 0.50≦g′vis≦0.85 are described. Particular films are suitable as cast films for TD shrink and draw tape bag applications.

Owner:EXXONMOBIL CHEM PAT INC

Liquid composition, process for its production and process for producing membrane-electrode assembly for polymer electrolyte fuel cells

ActiveUS20060019140A1Improve the immunityIncreased durabilityIon-exchanger regenerationFinal product manufacturePolymer scienceHigh energy

An electrolyte membrane is prepared from a liquid composition comprising at least one member selected from the group consisting of trivalent cerium, tetravalent cerium, bivalent manganese and trivalent manganese; and a polymer with a cation-exchange group. The liquid composition is preferably one containing water, a carbonate of cerium or manganese, and a polymer with a cation-exchange group, and a cast film thereof is used as an electrolyte membrane to prepare a membrane-electrode assembly. The present invention successfully provides a membrane-electrode assembly for polymer electrolyte fuel cells being capable of generating the electric power in high energy efficiency, having high power generation performance regardless of the dew point of the feed gas, and being capable of stably generating the electric power over a long period of time.

Owner:ASAHI GLASS CO LTD

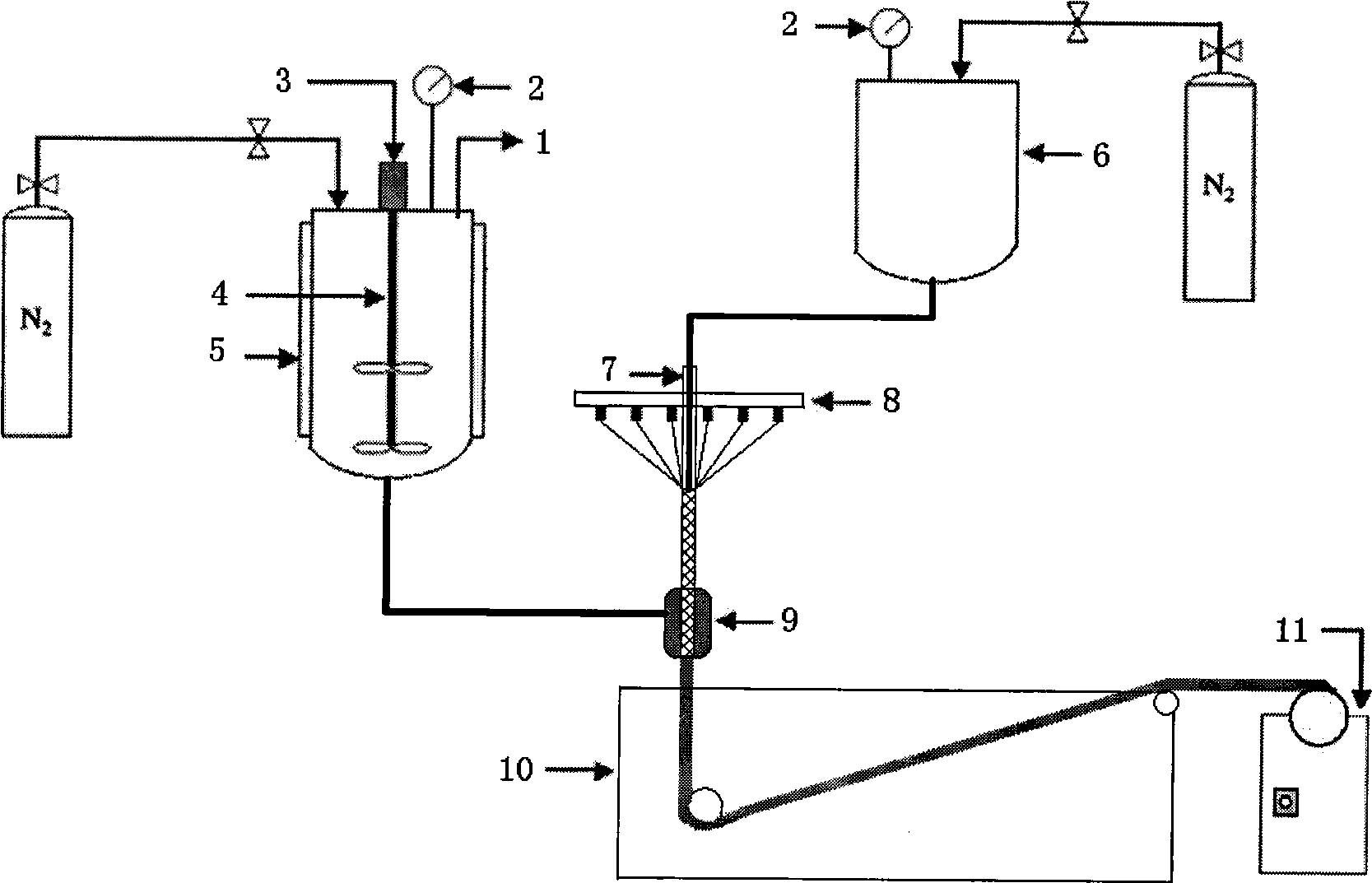

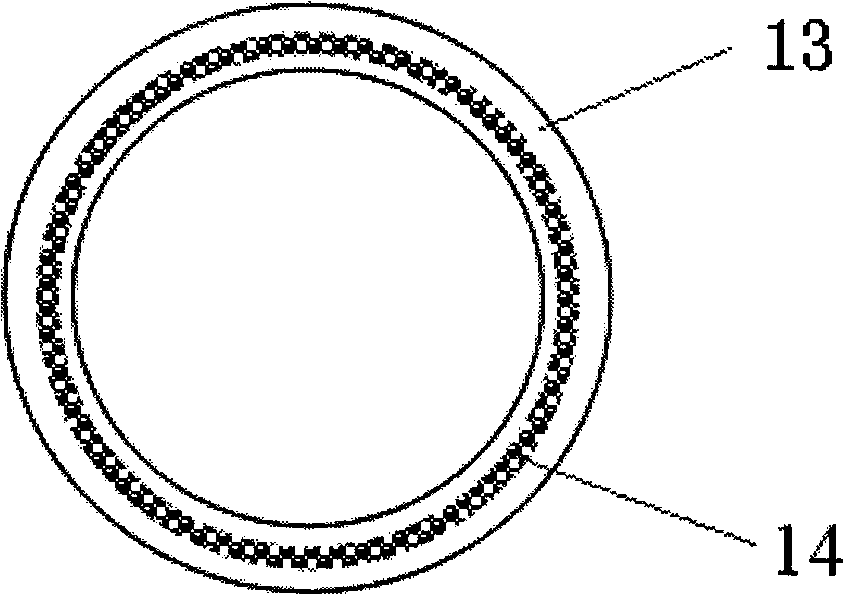

Method for preparing fiber braided tube embedded enhanced type polymer hollow fiber microporous membrane

ActiveCN101543731AControl the amount of infiltrationSolve technical problems that are easy to blockSemi-permeable membranesFiberHollow fibre membrane

The invention discloses a method for preparing a fiber braided tube embedded enhanced type polymer hollow fiber microporous membrane, which is characterized by adopting a fiber-braiding and coextrusion integrative membrane forming process, namely a core liquid tube is fixed in the middle of the braded tube, a fibrous bundle is braided into a fiber braided tube along the core liquid tube, then casting film liquid, core liquid and the fiber braided tube are co-extruded by an extrusion die, and the fiber braided tube embedded enhanced type polymer hollow fiber microporous membrane is prepared bya phase transformation method. The method successfully embeds the fiber braided tube into the body of the hollow fiber microporous membrane and introduces the core liquid into the inner cavity of thebraided tube, and effectively controls the inside diameter of the hollow fiber microporous membrane, so that the technical problems that in the prior coating process of preparing a fiber braided tubeenhanced type hollow fiber membrane, a polymer layer is easy to break away from the fiber braided tube, the hollow fiber inner cavity is easy to be blocked, and the like are solved, thus the polymer hollow fiber microporous membrane with high backwashing pressure, high mechanical strength, high flux, high retention performance and hydrophilic property is obtained.

Owner:TONGXIANG JIANMIN FILTER MATERIALS

Method of preparing a cellulose acylate, cellulose acylate film, polarizing plate, and liquid crystal display device

A method of preparing a cellulose acylate of a specific substitution degree, which includes: adding at least one selected from the group consisting of water and a carboxylic acid having 2 to 7 carbon atoms, as an activating agent, to a cellulose; and applying at least one treatment selected from (a) maintaining the cellulose at a temperature of 40° C. or more, for one hour or more, (b) irradiating microwaves to the cellulose, and (c) placing the cellulose under a pressure in the range of from 1.5 atm (0.15 MPa) to 100 atm (10.13 MPa); a cellulose acylate film prepared by means of a solution-casting film formation method or melt-casting film formation method, using the cellulose acylate which is prepared by the preparation method; and a polarizing plate and a liquid crystal display device, each of which contains the cellulose acylate film.

Owner:FUJIFILM CORP

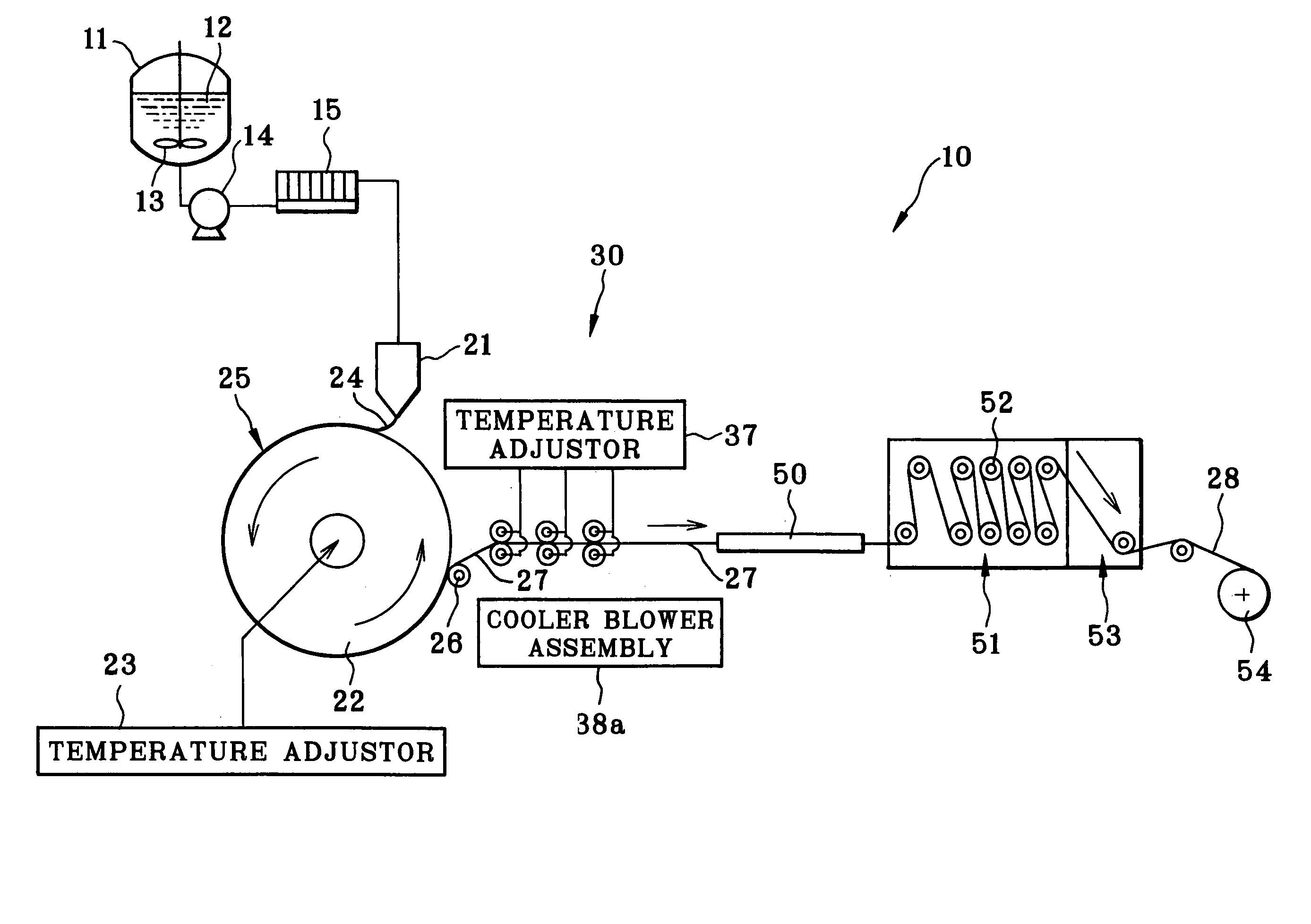

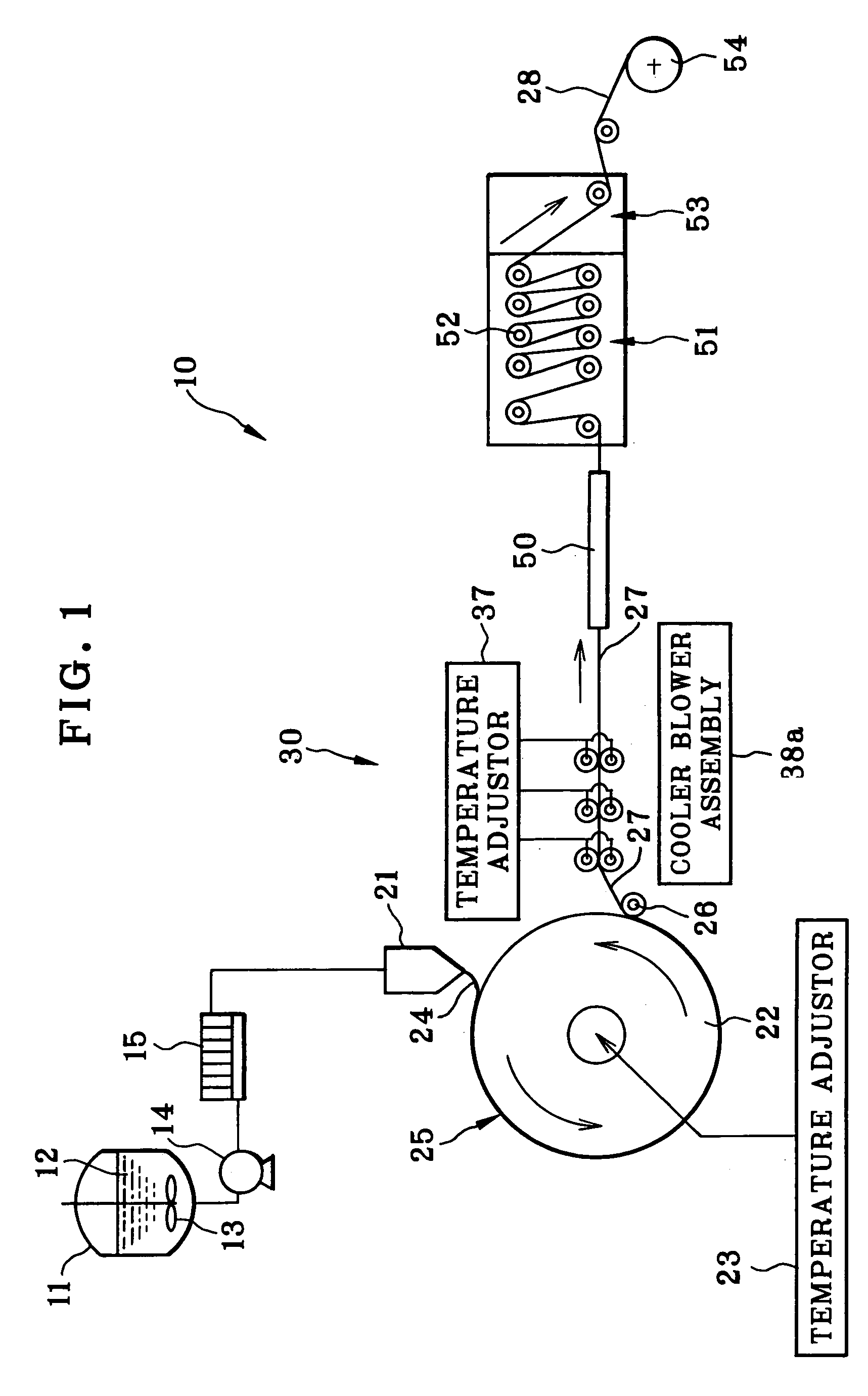

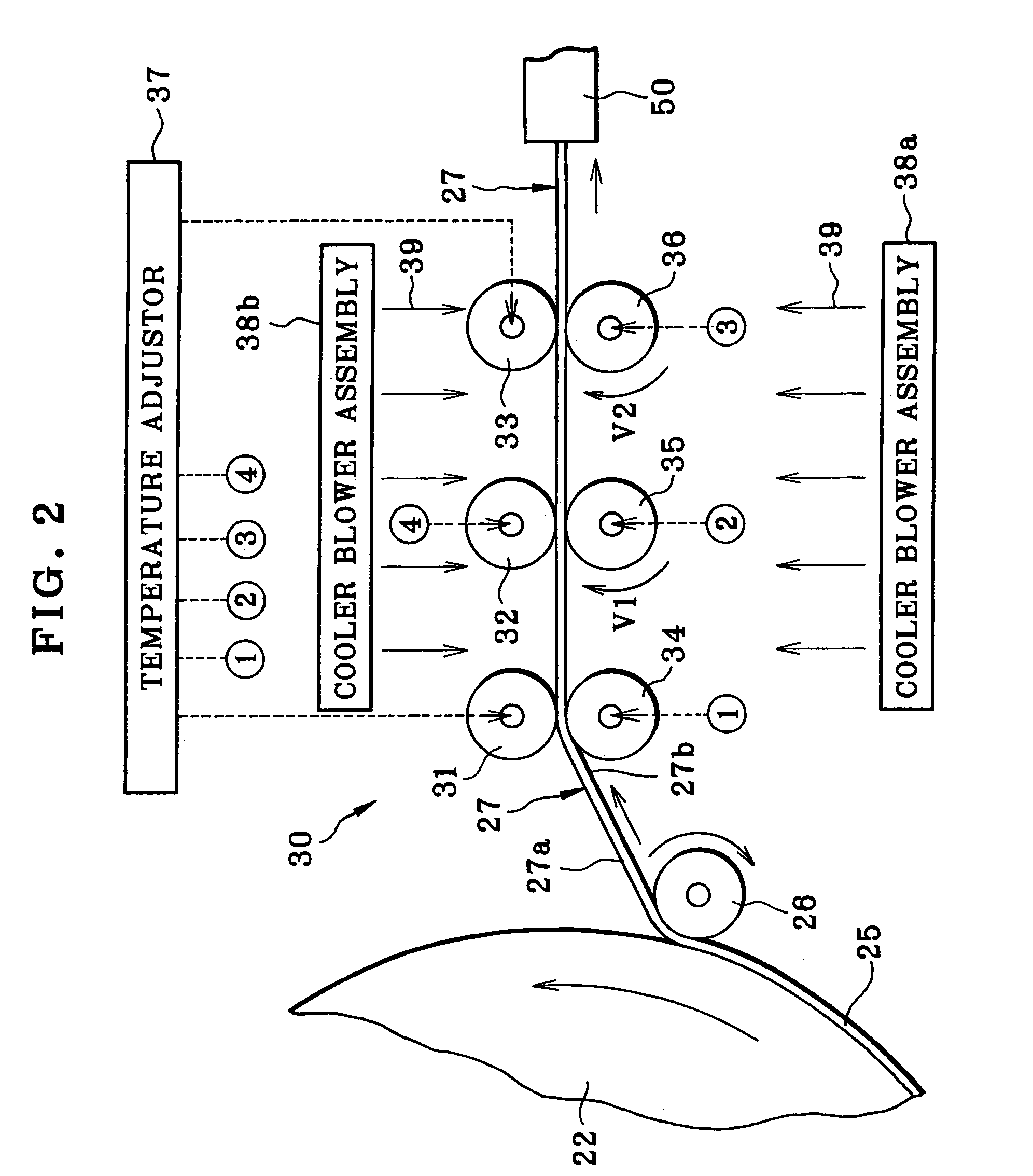

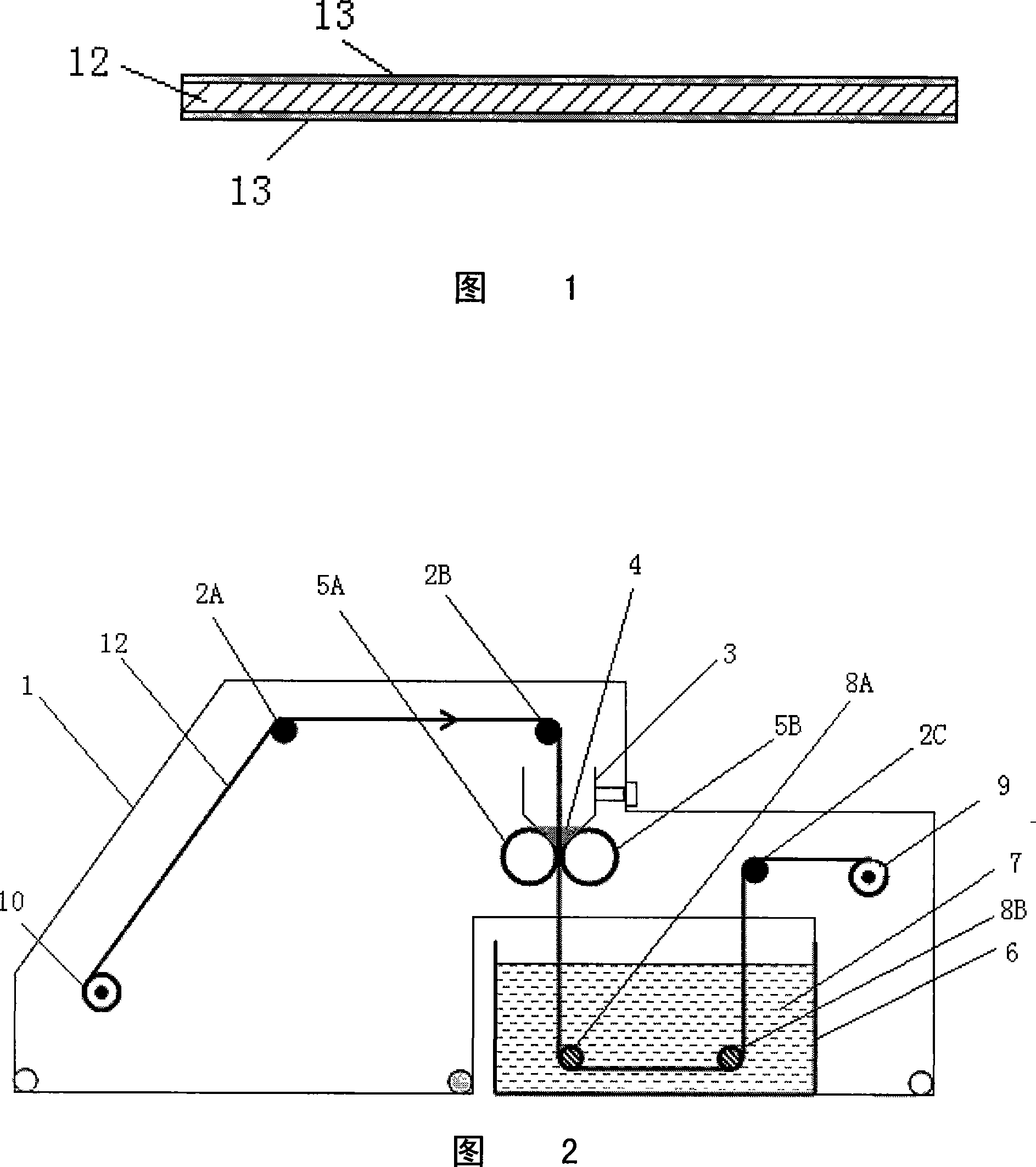

Solution casting process for producing polymer film

InactiveUS7172713B2Suppress wrinklesQuality improvementMovable spraying apparatusLaminationMetallurgyCast films

A solution casting process for producing cellulose triacetate (TAC) film is provided. Bead of dope, which includes cellulose triacetate and solvent, is cast on to a rotating supporting drum, to form self-supporting cast film. The self-supporting cast film is stripped from the supporting drum. The self-supporting cast film is dried while the self-supporting cast film being stripped is fed by feed rollers, to form the cellulose triacetate film. A surface temperature of the feed rollers is set equal to or lower than 0° C. The self-supporting cast film upon being stripped has modulus of longitudinal elasticity equal to or more than 450,000 Pa.

Owner:FUJIFILM HLDG CORP +1

Ionically conductive polymer electrolytes

InactiveUS20030091904A1Good flexibilityLower resistanceElectrode manufacturing processesFinal product manufacturePorosityCross-link

A dimensionally stable, highly resilient, hybrid copolymer solid-solution electrolyte-retention film for use in a lithium ion battery in one preferred embodiment has a predominantly amorphous structure and mechanical strength despite contact with liquid solvent electrolyte. The film is a thinned (stretched), cast film of a homogeneous blend of two or more polymers, one of which is selected for its pronounced solvent retention properties. A very high surface area inorganic filler dispersed in the blend during formation thereof serves to increase the porosity of the film and thereby enhance electrolyte retention. The film is soaked in a solution of liquid polymer with liquid organic solvent electrolyte and lithium salt, for absorption thereof. Use of a cross-linked liquid polymer enhances trapping of molecules of the electrolyte into pores of the film. The electrolyte film is sandwiched between flexible active anode and cathode layers to form the lithium ion battery. Novel methods are provided for forming the electrodes, the polymer substrate, and other elements of the battery.

Owner:LITHIUM POWER TECH

Fine cell foamed polyolefin film or sheet

InactiveUS20080281010A1Complete recyclabilityEasy to takeAbsorbent padsBaby linensPolymer sciencePolyolefin

Foamed film compositions using chemical blowing agents and produced by continuous blown film extrusion or cast film extrusion of polymer foams. The composition has small cell size and is suitable for the production of thin film articles. The articles may be monolayer or multilayered structures.

Owner:INGENIA POLYMERS CORP

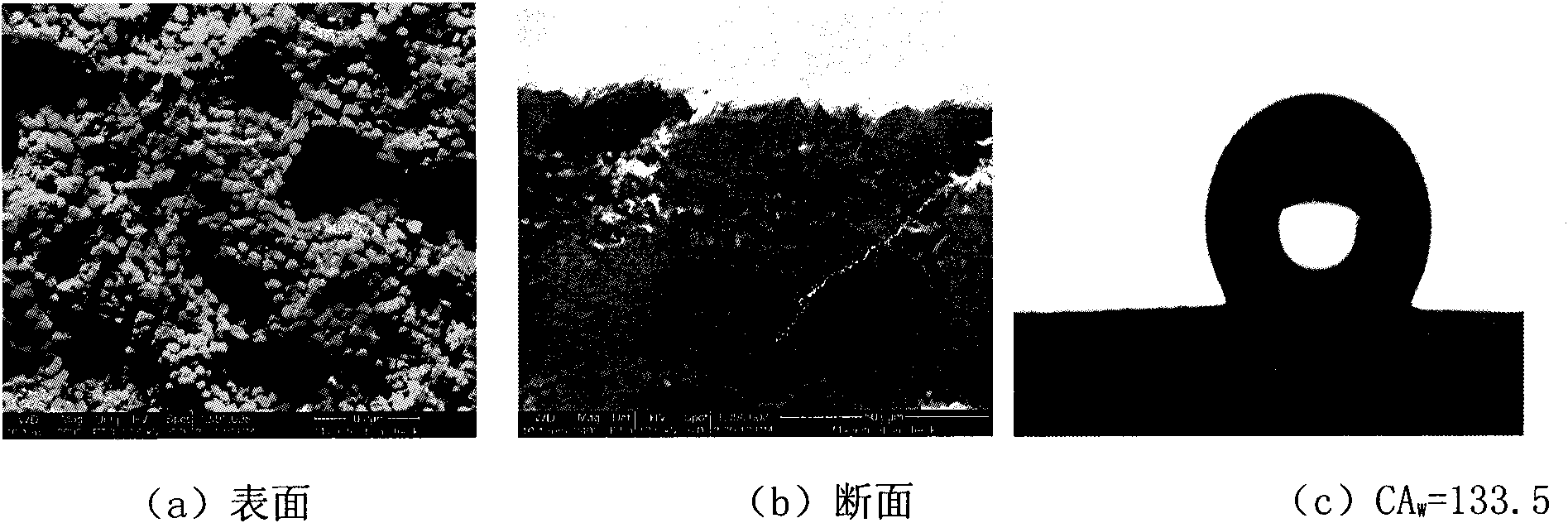

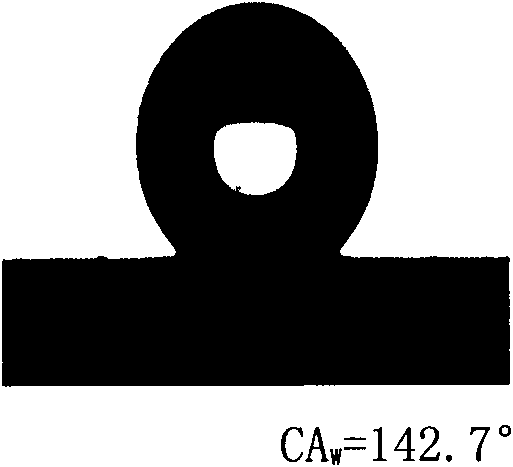

Polyvinylidene fluoride microporous film and preparation method

InactiveCN101632903AWith nanoscale dimensionsImprove hydrophobicitySemi-permeable membranesDistillationFatty alcohol

The invention provides a polyvinylidene fluoride microporous film and a preparation method; the polyvinylidene fluoride microporous film is prepared by using polyvinylidene fluoride, fatty alcohol (non solvent) and polar organic solvent as raw materials, the proportioning of which is as follows: the mass content of polyvinylidene fluoride is 10%-15%, and the content of non solvent is 6-12%; the specific steps are as follows: polyvinylidene fluoride, polar organic solvent and non solvent are mixed, dissolved and filtered, set aside and are deaerated to obtain clear casting film liquid which is struck on a coarse structure template substrate and placed in air; gel forms film in a coagulating bath, is processed by hot water, and then soaked in water and absolute ethyl alcohol to obtain high hydrophobic polyvinylidene fluoride microporous film; the contact angle between the surface of high hydrophobic polyvinylidene fluoride microporous film and water reaches 130 degrees to 140 degrees, air flux of the film reaches 6.0m<3> / (m<2>-h-kPa) under 60kPa, the maximum bore diameter is less than 0.5 mum, tensile strength reaches breaking strength which is larger than 5Mpa, and the elongation at break is larger than 50%. The invention is the polyvinylidene fluoride microporous film with high hydrophobicity, high flux and good mechanical strength and the preparation method, which is mainly applied to the film distillation and associated film process.

Owner:HEBEI UNIV OF TECH

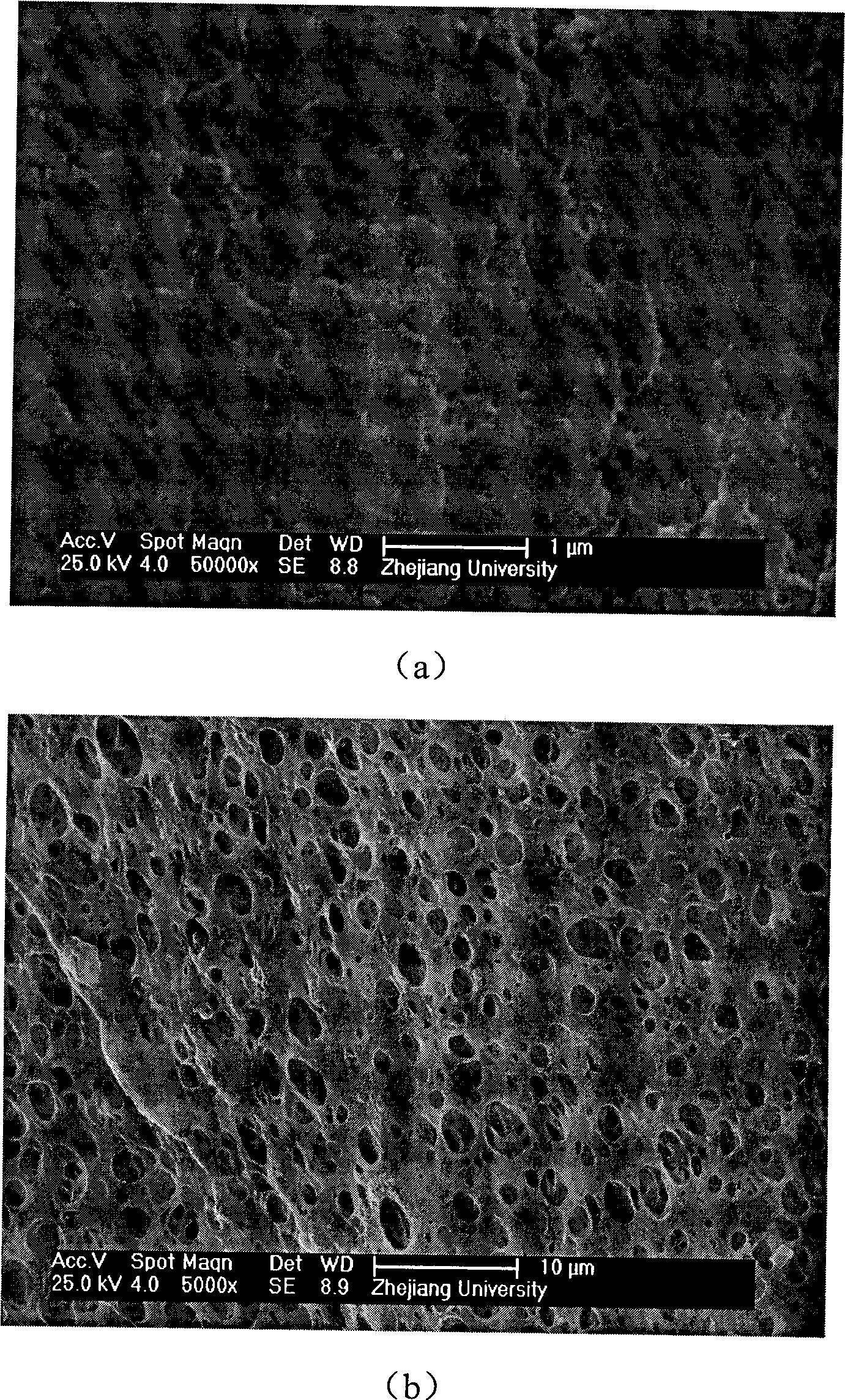

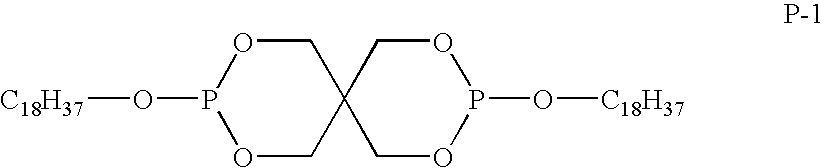

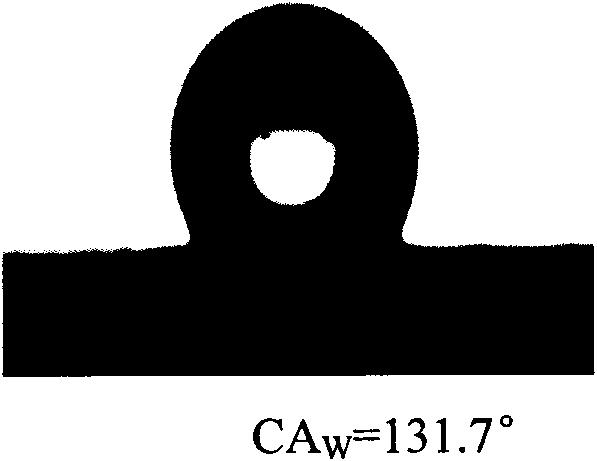

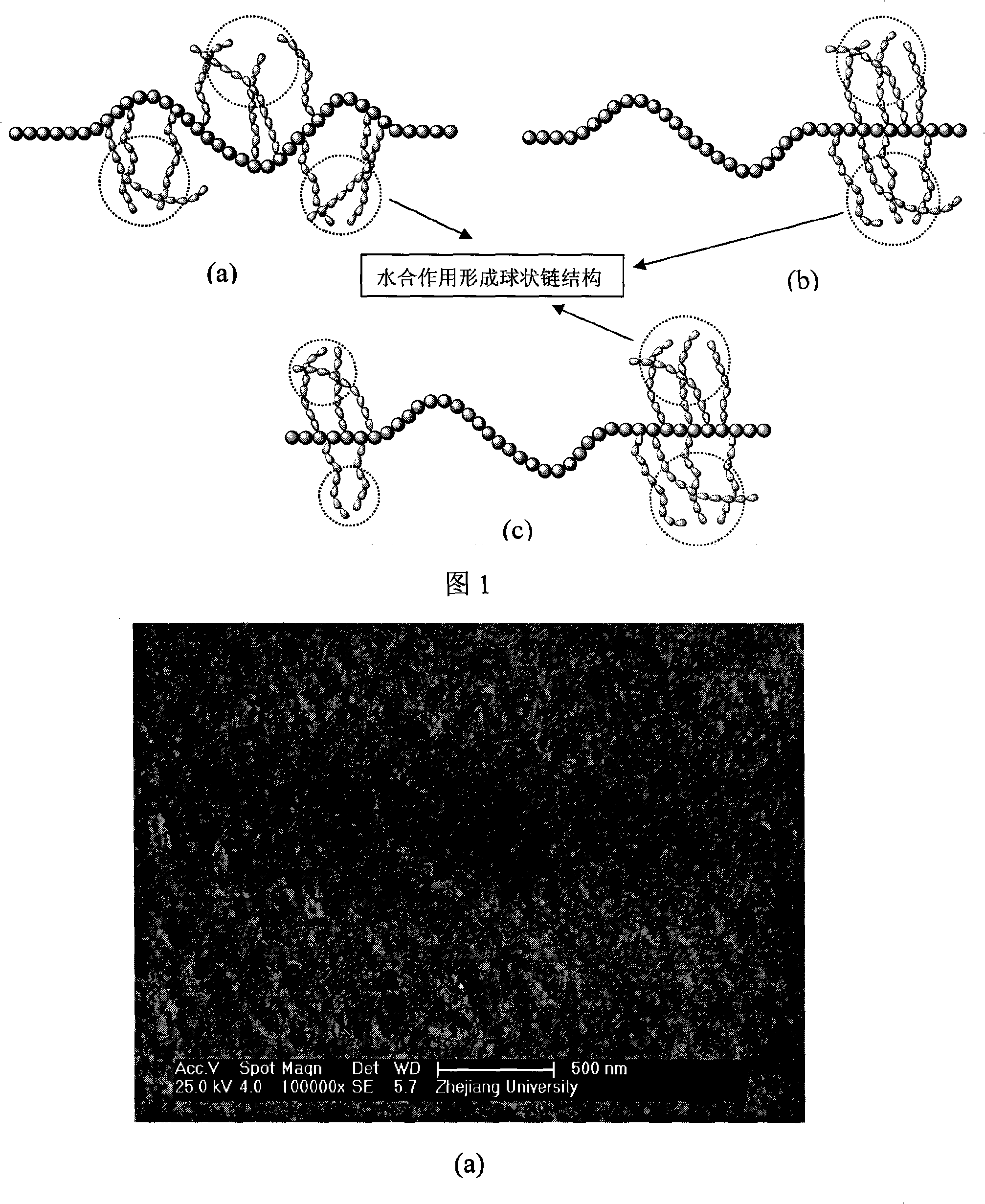

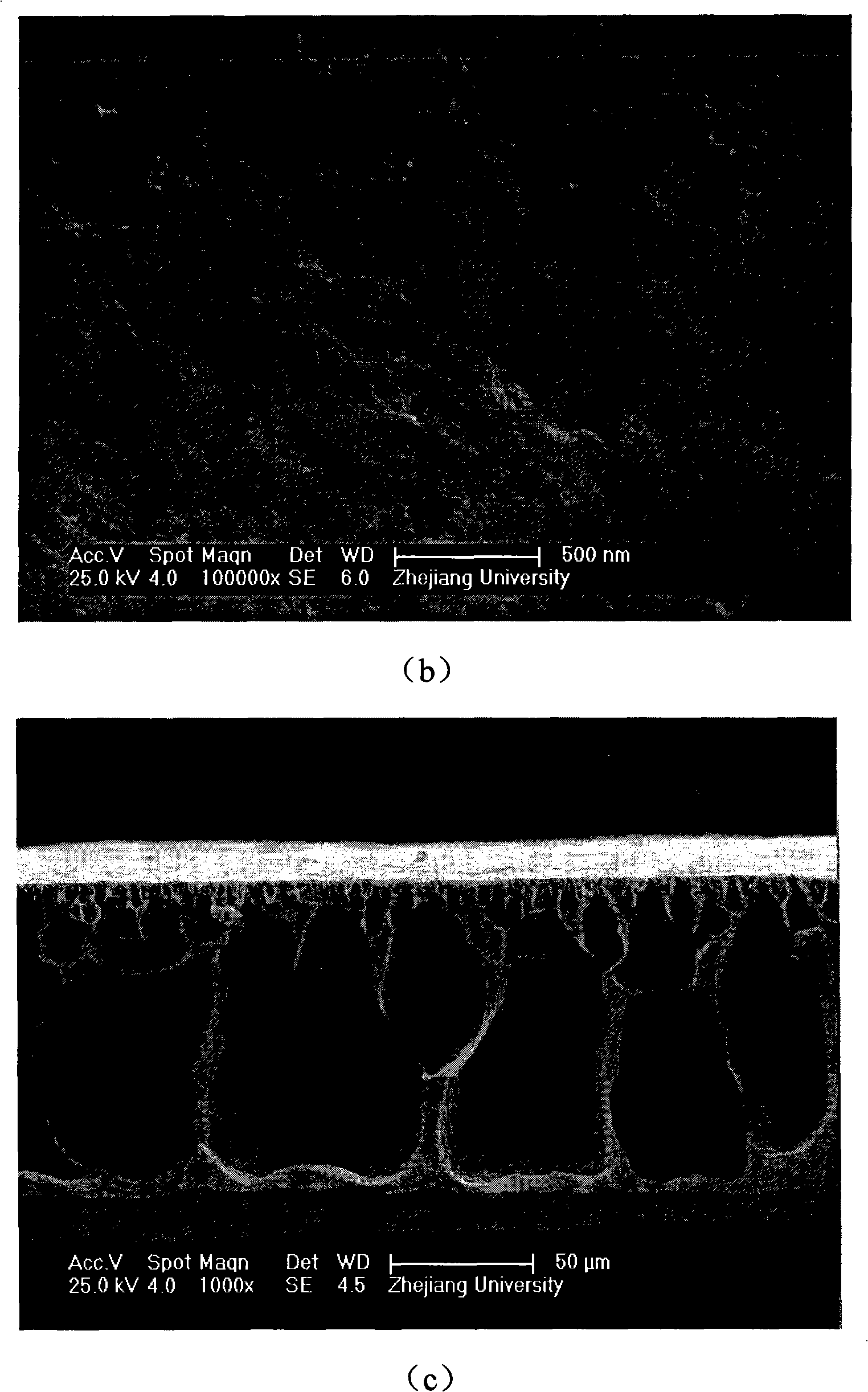

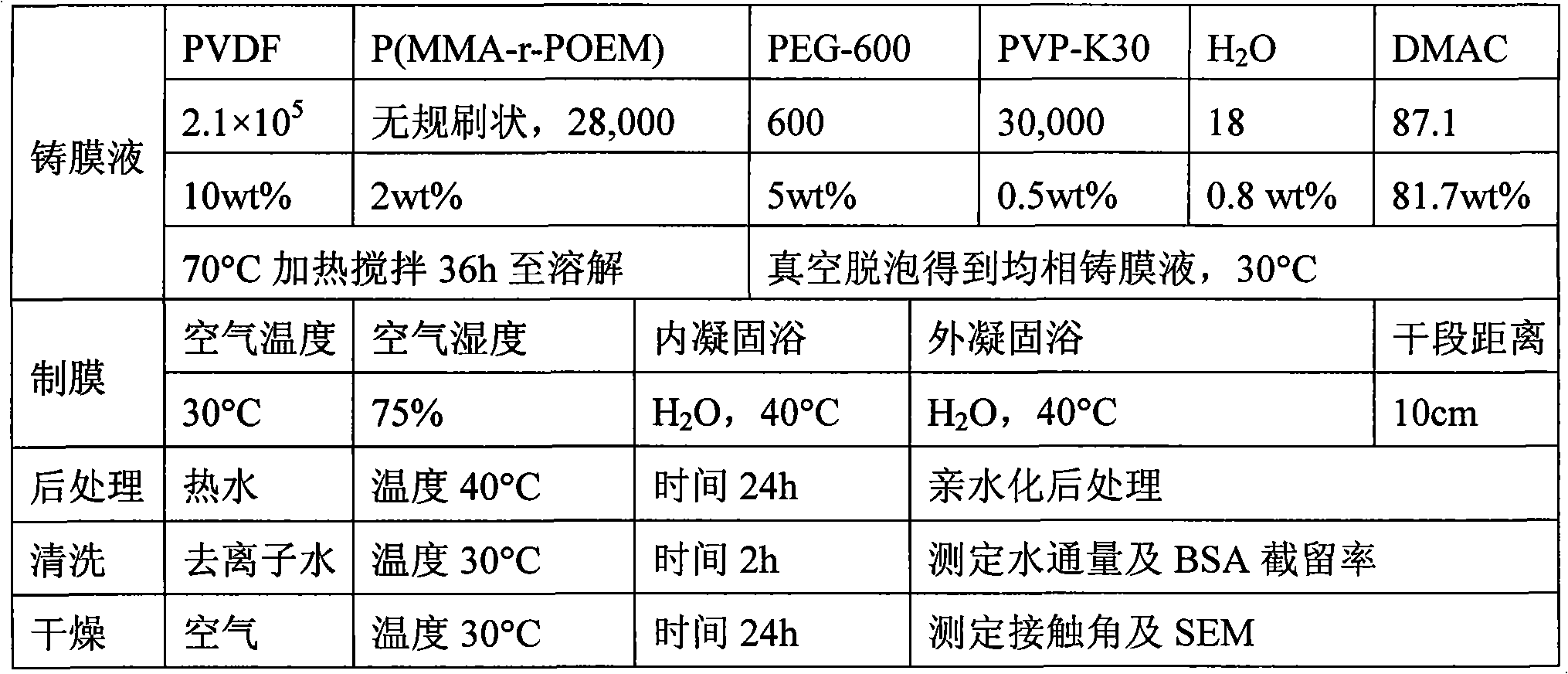

Method for modifying polyvinylidene fluoride ultrafiltration membrane by amphiphilic co-polymer

InactiveCN101264428AImprove hydrophilicityReduce energy consumptionSemi-permeable membranesUltrafiltrationDumbbell shaped

The invention discloses a method of producing the hyperfiltration membrane of amphiphilic copolymer modified polyvinylidene fluoride, comprising the following steps: 1) mixing polyvinylidene fluoride, poly (methyl methacrylate - monomethyl ether polyoxyethylene methyl methacrylate), additives, non-solvent and solvent to form the casting film solution; 2) making the casting film solution into the polyvinylidene fluoride membrane by using the film forming machine and then soaking in the coagulation bath; 3) conducting the posttreatment of hydrophilicity; 4)obtaining the hydrophilic polyvinylidene fluoride ultrafiltration membrane after cleaning and drying. The method is characterized in that the brush shape, chain ball shape or dumbbell shape amphiphilic copolymer are mixed with the polyvinylidene fluoride to produce the polyvinylidene fluoride hyperfiltration membrane with hydrophilicity, anti-pollution, large flux and high retention rate by adopting the solution phase conversion method. The method has the advantages that the obtained membrane is provided with dozens to hundreds nanometer of particular densified hydrogel surface layers, the contact angle of the membrane surface can be reduced below 60 degrees and can be lowered to 0 degree within tens of seconds, the water flux can reach 1000L / m<2> / h (0.1Mpa) or above, the retention rate of BSA can reach 90% or more and the recovery rate of water cleaning flux can reach 90% or higher.

Owner:ZHEJIANG UNIV

Compositions of ethylene/α-olefin multi-block interpolymer for elastic films and laminates

ActiveUS7737215B2Good physical propertiesElasticityPersonal careSynthetic resin layered productsPolyolefinLow density

This invention relates to polyolefin compositions. In particular, the invention pertains to elastic polymer compositions that can be more easily processed on cast film lines, extrusion lamination or coating lines. The compositions of the present invention preferably comprise an elastomeric polyolefin resin and a high pressure low density type resin.

Owner:DOW GLOBAL TECH LLC

Compositions of ethylene/alpha-olefin multi-block interpolymer for elastic films and laminates

This invention relates to polyolefin compositions. In particular, the invention pertains to elastic polymer compositions that can be more easily processed on cast film lines, extrusion lamination or coating lines due to improved resistance to draw resonance. The compositions of the present invention preferably comprise an elastomeric polyolefin resin and a high pressure low density type resin.

Owner:DOW GLOBAL TECH LLC

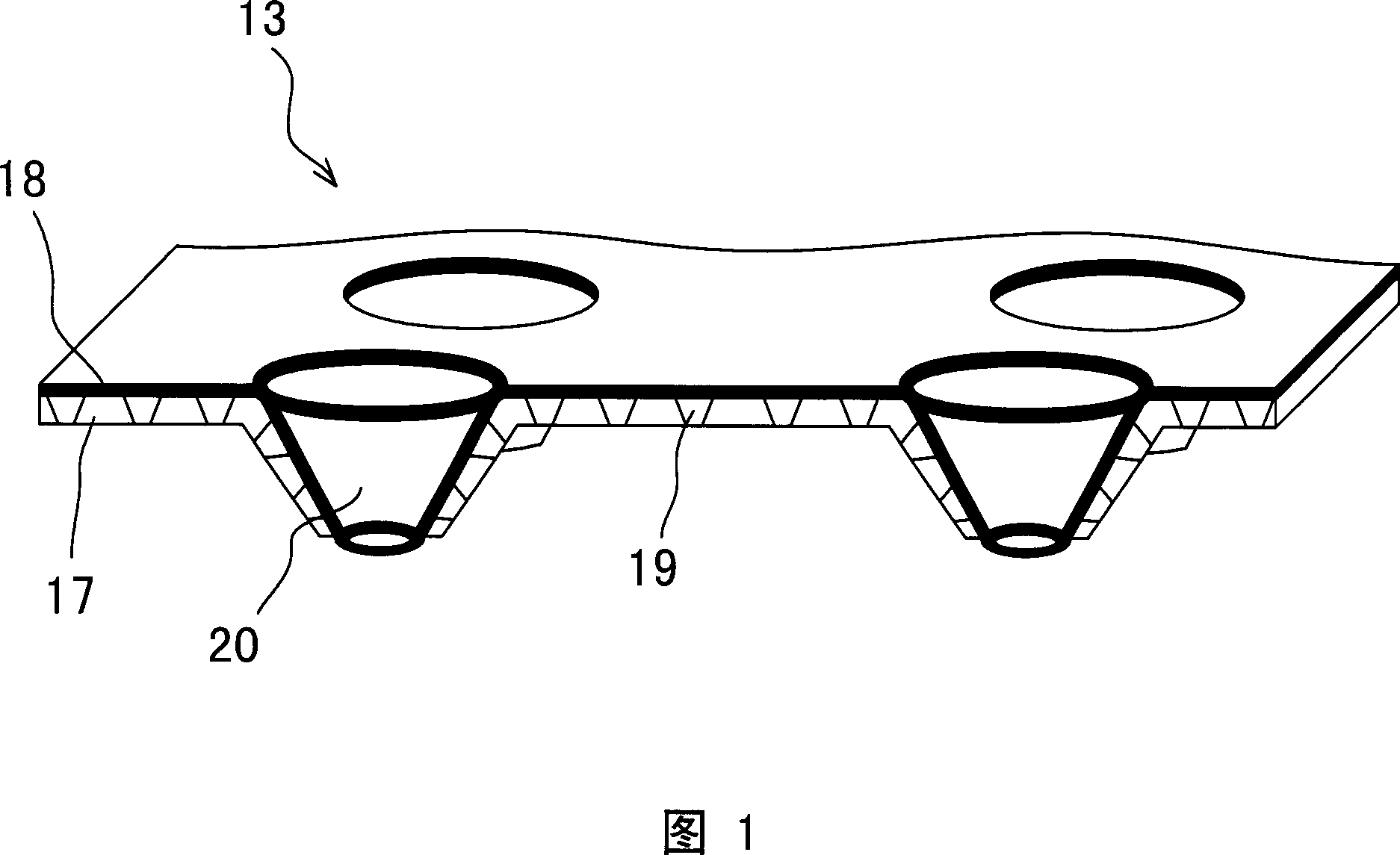

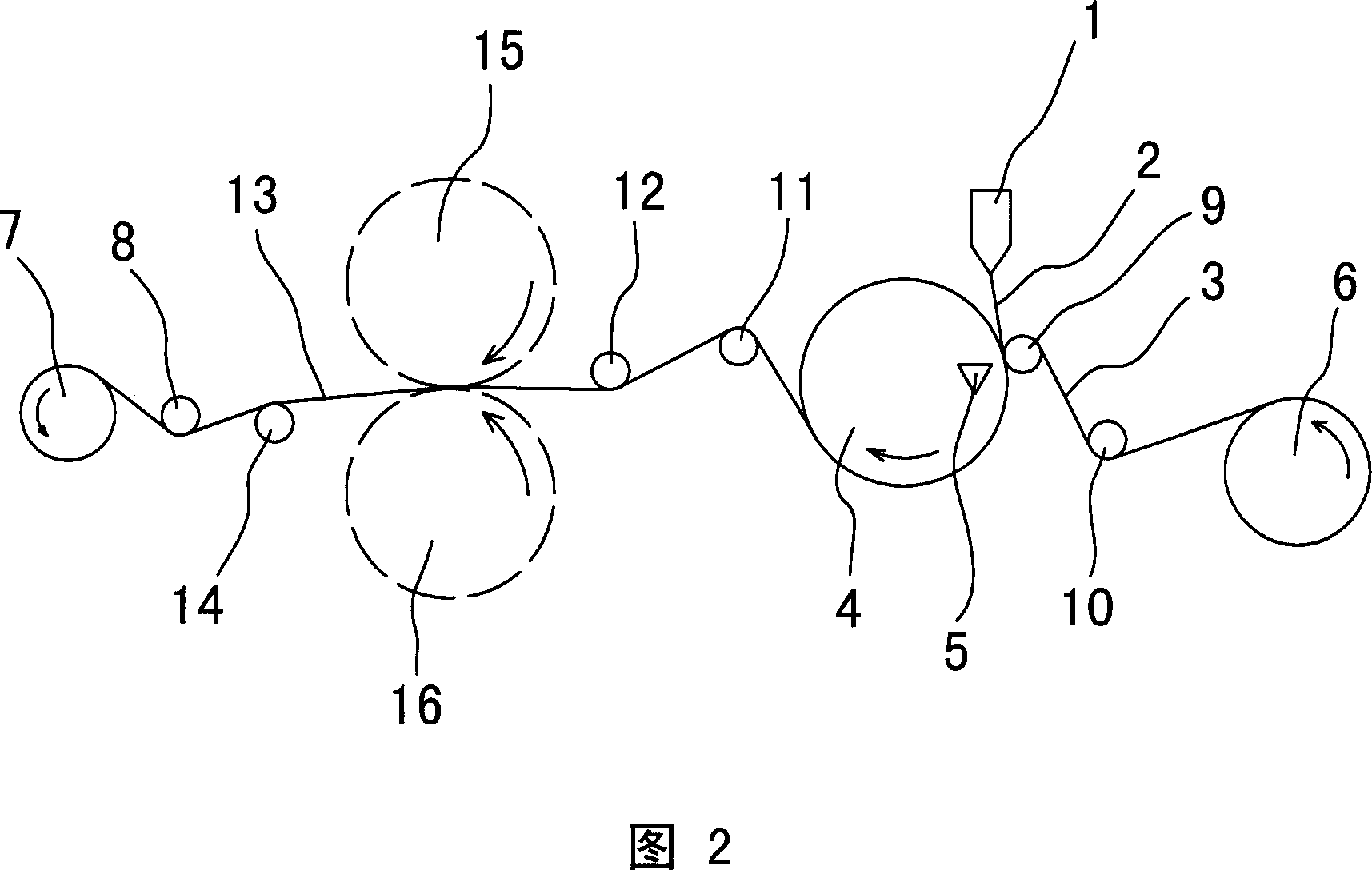

Composite punching film and its producing method

InactiveCN1943530AImprove breathabilityHigh porositySynthetic resin layered productsLaminationPunchingVolumetric Mass Density

A compound punching film and preparation thereof, said punching film consisting of a layer of plastic film and one or two side compound non-woven fabrics. On plastic film is of evenly spread tiny mesh, density thereof is 170-500 mesh / C sqm ,perforating rate is 10-35%. Said whole compound film is perforated of evenly big mesh , aperture thereof greater than that of tiny mesh two times, the shape of big mesh is of funnel, thereof protruding to one side and on the surface of awl is of tiny mesh. Said invention combines PE film technique and punching one, making compound of a layer of non-woven fabric and cast film with the help of high melting temp. of cast film, also making use of mesh cage through vacuum suction nozzle punching tiny mesh, thereafter punching big mesh by pressure roller machine, thus to prepare new compound punching film with good permeability, softness and strong third dimension.

Owner:蔡子辛 +1

Compositions of Ethylene/Alpha-Olefin Multi-Block Interpolymer for Elastic Films and Laminates

This invention relates to polyolefin compositions. In particular, the invention pertains to elastic polymer compositions that can be more easily processed on cast film lines, extrusion lamination or coating lines due to improved resistance to draw resonance. The compositions of the present invention preferably comprise an elastomeric polyolefin resin and a high pressure low density type resin.

Owner:DOW GLOBAL TECH LLC

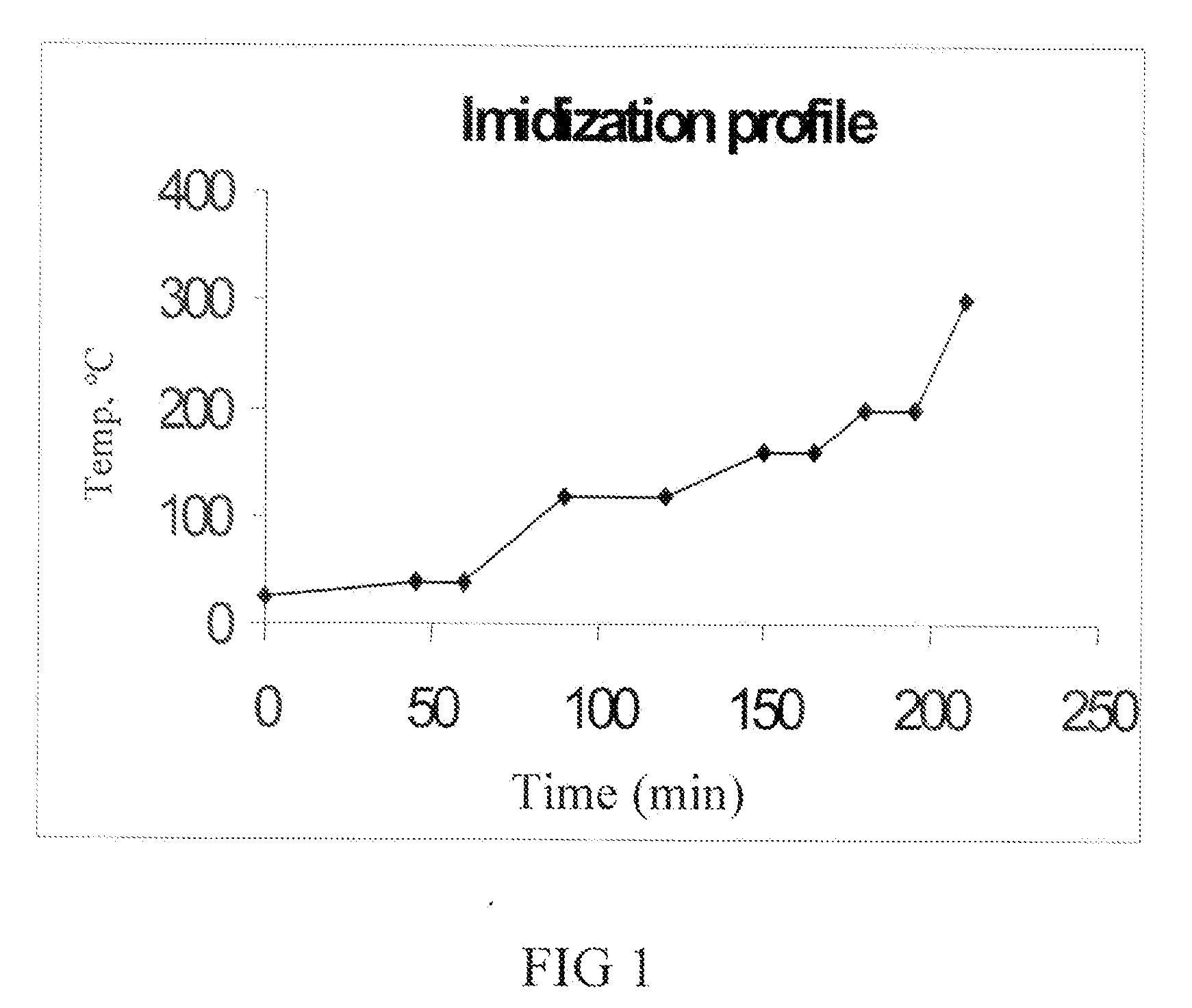

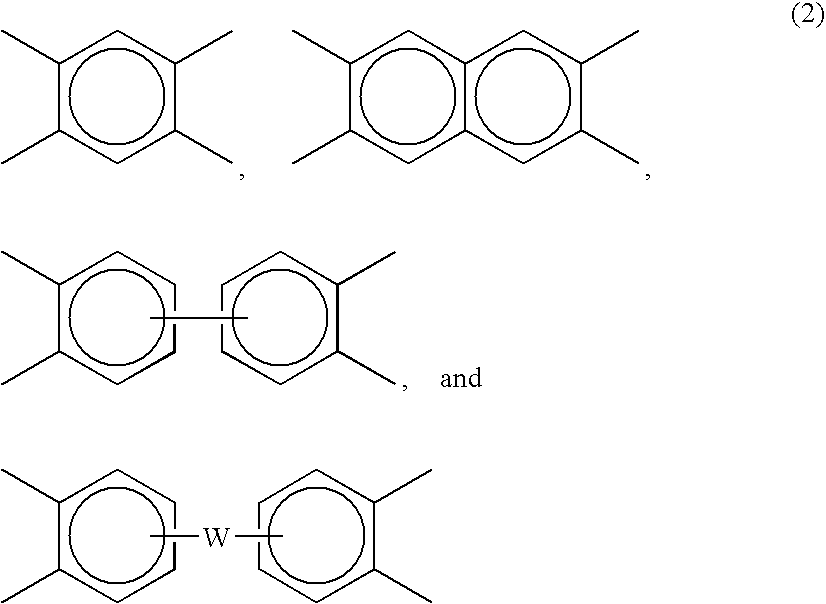

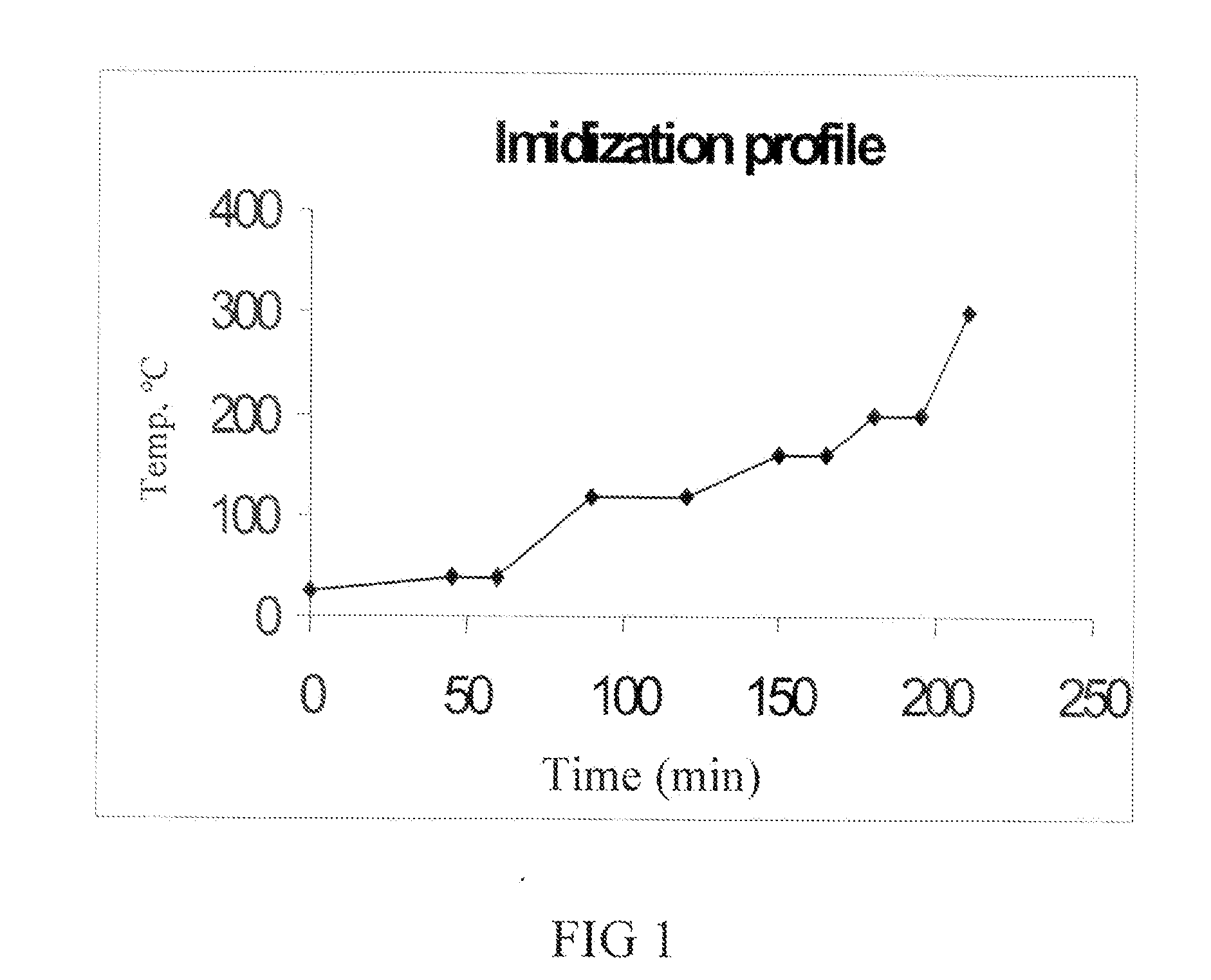

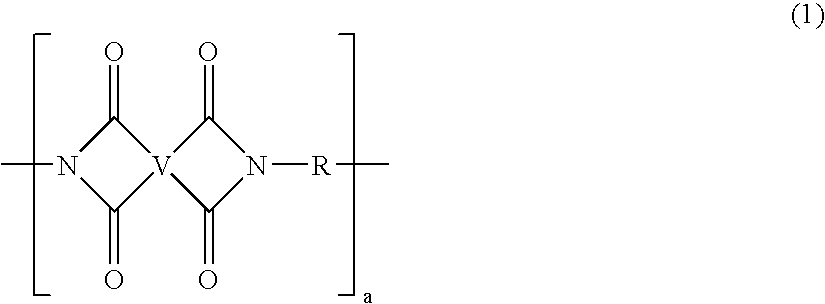

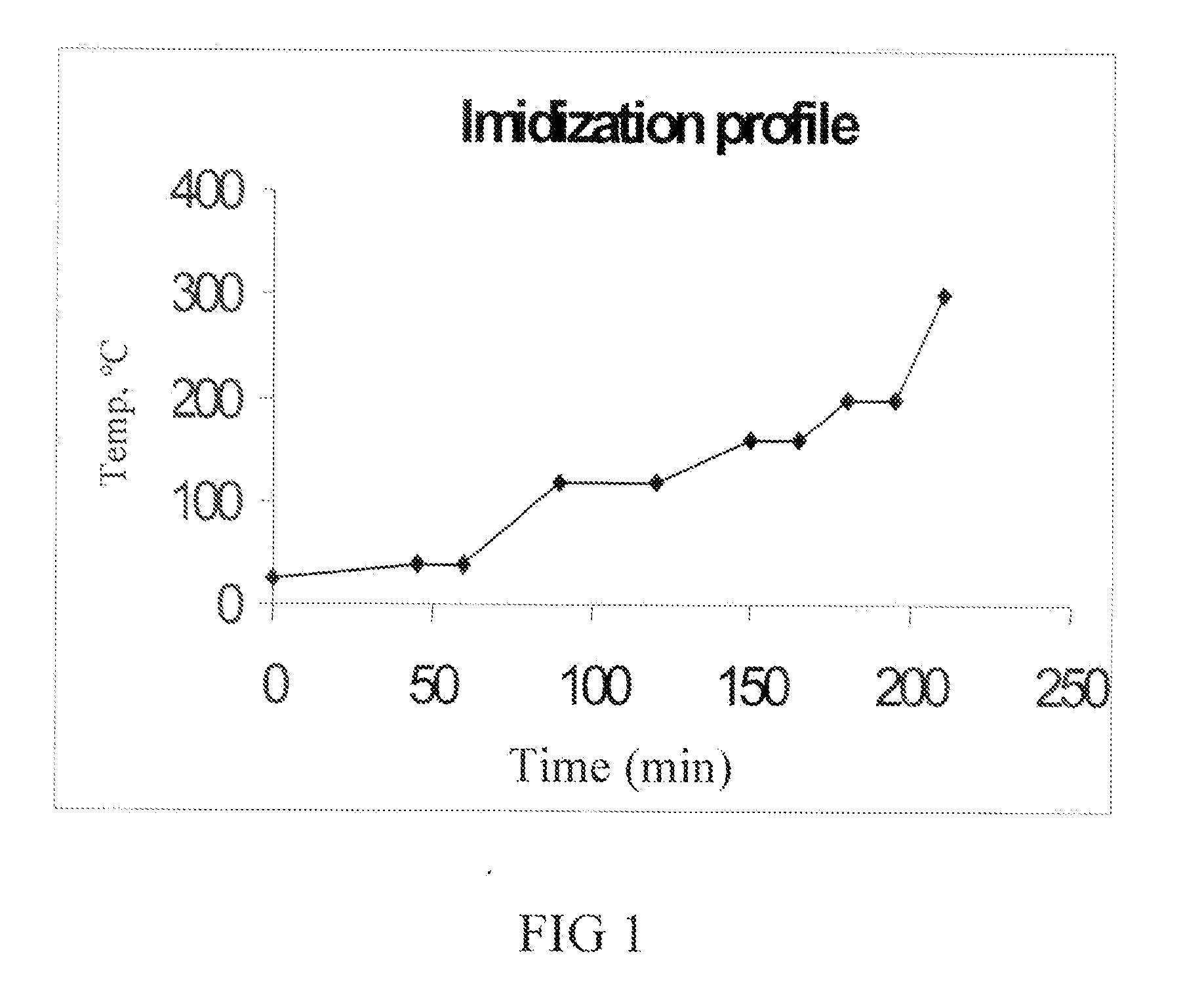

Polyimide solvent cast films having a low coefficient of thermal expansion and method of manufacture thereof

InactiveUS20080044639A1Material nanotechnologySynthetic resin layered productsPolymer scienceMicrometer

A solvent cast film comprises a polyimide comprising structural units derived from polymerization of a dianhydride component comprising a dianhydride selected from the group consisting of 3,4′-oxydiphthalic dianhydride, 3,3′-oxydiphthalic dianhydride, 4,4′-oxydiphthalic dianhydride, and combinations thereof, with a diamine component wherein the polyimide has a glass transition temperature of at least 190° C.; wherein the film has a coefficient of thermal expansion of less than 60 ppm / ° C., a thickness from 0.1 to 250 micrometers, and less than 5% residual solvent by weight; wherein the polyimide has less than 15 molar % of structural units derived from a member selected from the group consisting of biphenyltetracarboxylic acid, a dianhydride of biphenyltetracarboxylic acid, an ester of biphenyltetracarboxylic acid, and a combination thereof.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Method for preparing anti-pollution chitosan-nonwoven cloth composite porous filter membrane

InactiveCN101497002AImprove mechanical stabilityGood chemical stabilitySemi-permeable membranesWater bathsNonwoven fabric

The invention discloses a method for preparing an antipollution chitosan-nonwoven fabric composite porous filter membrane and belongs to the technical field of microfilter and ultrafilter composite membranes. The method is characterized in that the method adopts nonwoven fabric with nominal aperture of between 0.1 and 10 microns as a base membrane; a crosslinking agent is adopted to carry out pretreatment on the base membrane; 0.1 to 10 mass percent amylose is dissolved in an acetic acid solution; the crosslinking agent and a hole formation agent are added into the acetic acid solution; after the crosslinking reaction, a casting film liquid is obtained; at negative pressure, the casting film liquid is evenly coated on the surface and pores of the porous base membrane; and after treatment by a sodium hydroxide solution and a hot water bath, the antipollution chitosan-nonwoven fabric composite porous filter membrane is formed. The method has the advantages that the prepared composite membrane has good mechanical performance and chemical stability; and the surface of the membrane is levelled and smooth. The composite membrane has dual functions of hydrophile and antibiosis, can lighten adsorption of pollutants on the surface of the membrane, inhibit the growth and reproduction of thalli on the surface of the membrane, and keep the penetrating performance of the membrane and is widely applied to the water treatment process of various fields.

Owner:DALIAN UNIV OF TECH

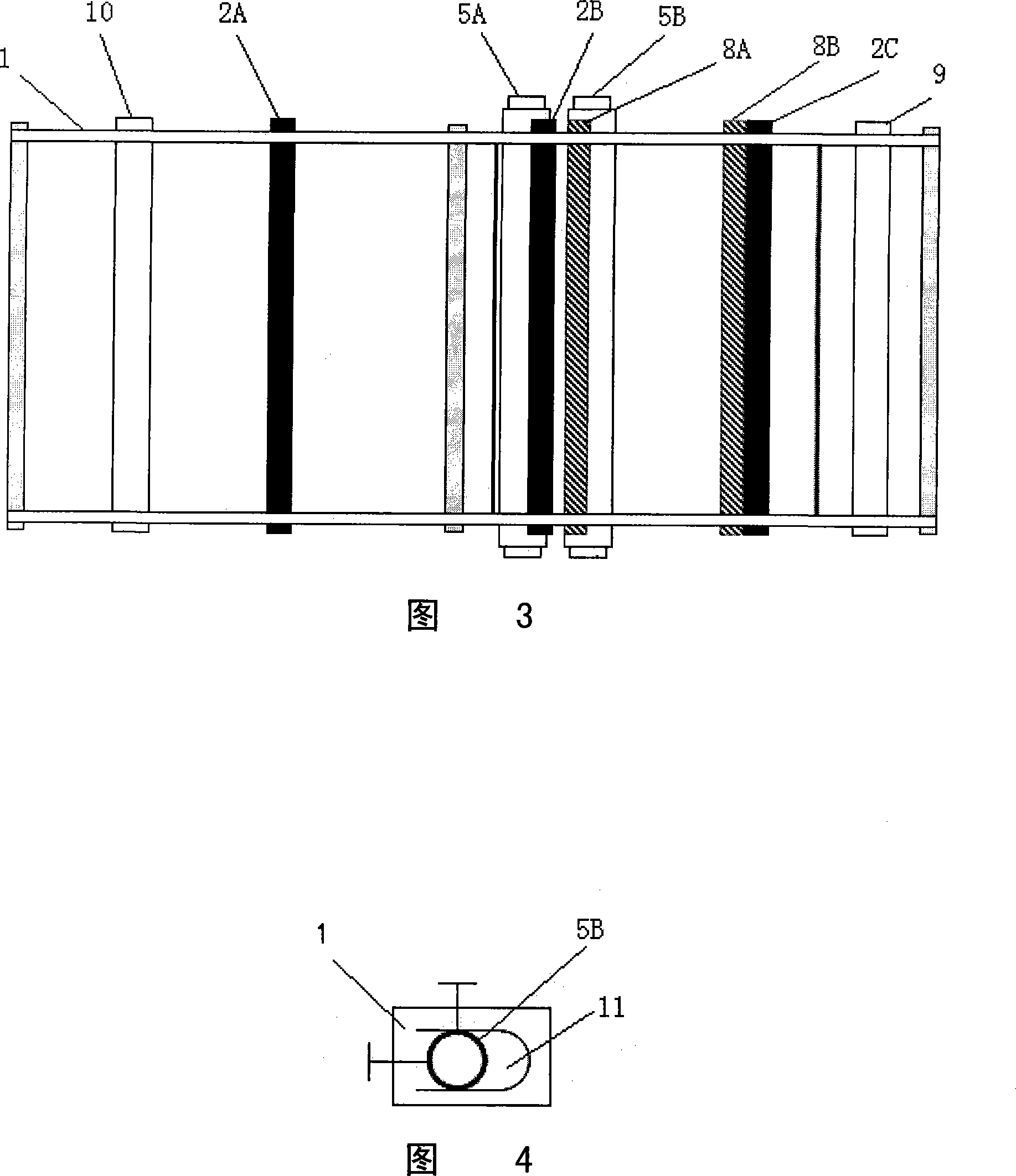

Reinforced microporous filter membrane and method and device for preparing the same

InactiveCN101239280AHigh strengthSmall filter resistanceSemi-permeable membranesPolymer resinOrganic solvent

The present invention provides an enhanced millipore filtering film and a method, device for preparing, the enhanced millipore filtering film includes a non-woven fabric as substrate, employing casting wipe way, casting film liquid is applied on the front and the back surfaces of the non-woven fabric, two layer film is formed by gelatin, characterized in that the thickness of the non-woven fabric is 30-120 micron, planar density of the non-woven fabric is 30-100g / m2, thickness of each film layer is 5-10 micron; casting film liquid in two film layer is composed by mixing a polymer resin, an organic solvent and an additive; parts by weight of the polymer resin in the casting film liquid, parts by weight of the organic solvent : parts by weight of the additive is 5-40:40-90: 0.5-50. The enhanced millipore filtering film of the invention is applied in the sampling monitor or filter of alpha radioaerosol under the high radon environment.

Owner:BEIJING RADIATION APPL RES CENT

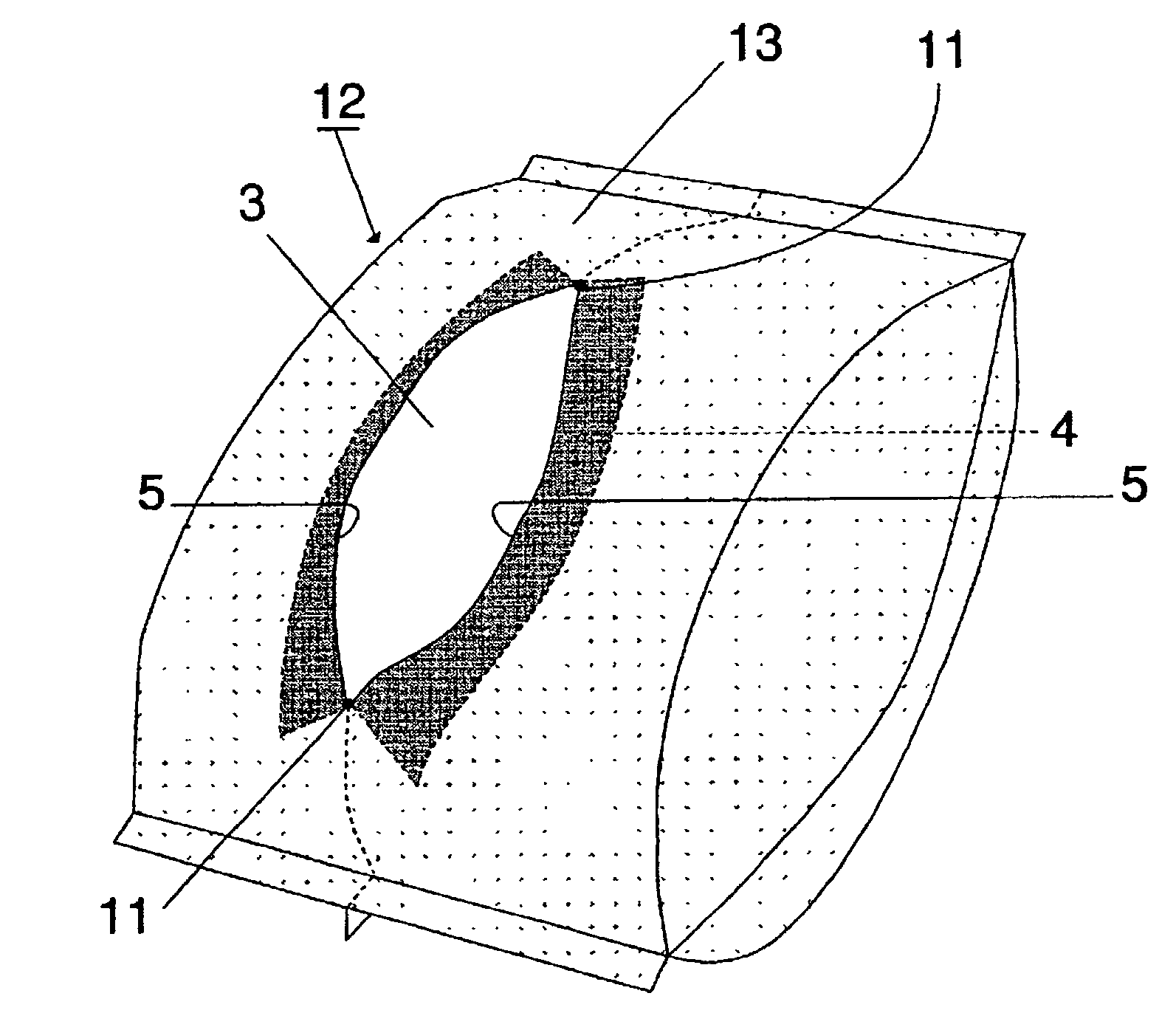

Packaging material and packaged product

A packaging material is provided that can provide a packaging bag or container cover in which the contents is shielded from the atmosphere and tightly sealed, a small hole is formed in the appropriate locations, without special processing of the heat seal portion, and the internal pressure is maintained with high stability at a level above the normal pressure. The packaging material is suitable, for example, for heating in a microwave oven. The packaging material uses a film in which a heat sealing agent (4) with a low melting point is applied to a prescribed zone of an oriented film (2) made of a synthetic resin, a cutting line (5) is cut in the oriented film (2) made of a synthetic resin in the form of a solid or broken line passing through the zone coated with the heat sealing agent (4), and a cast film (3) made of a synthetic resin and having heat sealing properties is affixed to the oriented film (2) made of a synthetic resin. Such film is used for a packaging bag (1) or a container cover.

Owner:CHOKOKU PLAST CORP +1

Ultra-low temperature heat sealing polypropylene casting film

InactiveCN101659141AReduce the initial heat sealing temperatureReduce scrap rateFlexible coversWrappersElastomerCompound a

The invention relates to an ultra-low temperature heat sealing polypropylene casting film which is formed by casting, co-extruding and compounding a heat-sealing layer, a polypropylene core layer and a polypropylene corona layer, wherein the heat-sealing layer is mainly prepared from the following components: 10-80 portions of polypropylene random copolymer, 20-90 portions of polyolefine elastomer, 0.1-0.5 portion of slipping agent and 0.1-0.5 portion of anti-blocking agent. By optimally designing the contents of various components of heat sealing material, the invention effectively reduces the initial heat sealing temperature of a packing film and widens the heat sealing temperature range. After being put into production, the ultra-low temperature heat sealing polypropylene casting film can improve the speed of packing and making bags, ensure the sealing performance of the bags and simultaneously reduce the scrape rate of making bags, thereby the production efficiency of application manufacturers can be greatly improved. The ultra-low temperature heat sealing polypropylene casting film can be widely applied to quick and automatic package of foods, medicines, textiles and other articles and particularly has advantages in the automatic packing filed with high requirement on air tightness.

Owner:湖北慧狮塑业股份有限公司

Articles comprising a polyimide solvent cast film having a low coefficient of thermal expansion and method of manufacture thereof

ActiveUS20080044682A1Printed circuit aspectsSynthetic resin layered productsPolymer sciencePolyetherimide

An article comprises a solvent cast film comprising a polyetherimide comprising structural units derived from a dianhydride component selected from the group consisting of 3,4′-oxydiphthalic anhydride, 3,3′-oxydiphthalic anhydride, 4,4′-oxydiphthalic anhydride, and combinations thereof, and a diamine component. The polyetherimide has a glass transition temperature that is at least 190° C. The film has a coefficient of thermal expansion of less than 60 ppm / ° C., a thickness from 0.1 to 250 micrometers, and less than 5% residual solvent by weight. The film has less than 15 molar % of a member selected from the group consisting of biphenyltetracarboxylic acid, dianhydrides of biphenyltetracarboxylic acid, esters of biphenyltetracarboxylic acid, and combinations thereof.

Owner:SHPP GLOBAL TECH BV

Articles comprising a polyimide solvent cast film having a low coefficient of thermal expansion and method of manufacture thereof

A solvent cast film comprises a polyimide comprising structural units derived from polymerization of a dianhydride component comprising a dianhydride selected from the group consisting of 3,4′-oxydiphthalic dianhydride, 3,3′-oxydiphthalic dianhydride, 4,4′-oxydiphthalic dianhydride, and combinations thereof, with a diamine component comprising 4,4′-diaminodiphenylsulfone; wherein the polyimide has a glass transition temperature from 190° C. to 400° C.; and wherein the film has a coefficient of thermal expansion of less than 60 ppm / ° C., a thickness from 0.1 to 250 micrometers, endless than 5% residual solvent by weight.

Owner:SHPP GLOBAL TECH BV

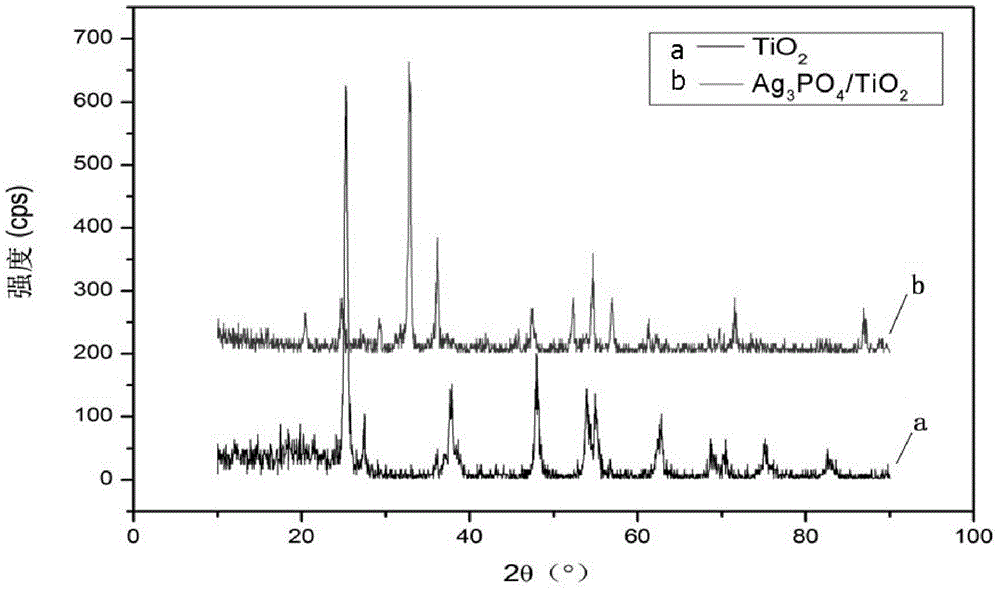

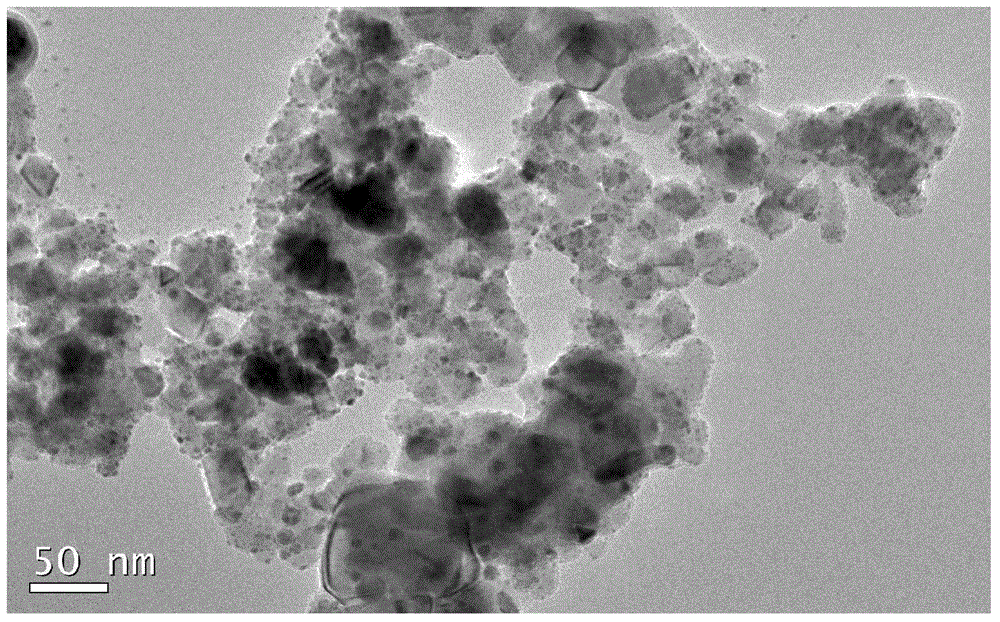

Visible-light-response antibacterial and antifouling polyvinylidene fluoride film and preparation method thereof

InactiveCN104383820AWith visible light catalytic antibacterial and antifouling propertiesEasy to manufactureSemi-permeable membranesOrganic-compounds/hydrides/coordination-complexes catalystsModified ultrafiltrationGlass sheet

The invention belongs to the technical field of modified ultrafiltration films, and discloses a visible-light-response antibacterial and antifouling polyvinylidene fluoride film and a preparation method thereof. The preparation method comprises the following steps: firstly depositing Ag3PO4 nanometer particles on the surface of TiO2 by using a in-situ deposition method to obtain an Ag3PO4 / TiO2 compound; then dissolving polyvinylidene fluoride powder, a pore-foaming agent and the Ag3PO4 / TiO2 compound in an organic solvent, mixing to enable the polyvinylidene fluoride powder, the pore-foaming agent and the Ag3PO4 / TiO2 compound to be uniformly dispersed, and then performing decompressing defoaming to obtain a casting film solution; and finally, scraping the film by using a scraper, tape-casting the casting film solution on a clean glass plate, and immersing in a coagulating bath after standing in air to obtain the visible-light-response antibacterial and antifouling polyvinylidene fluoride film. The visible-light-response antibacterial and antifouling polyvinylidene fluoride film has double performances of hydrophilcity and bacterium and fouling resistance, and can be used for lightening the situation that the surface of the polyvinylidene fluoride is polluted when water is treated, and effectively inhibiting the growth and the reproduction of bacteria and microorganisms on the surface of the film.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Hydrogel electrolyte thin film, and preparation method and application therefor

InactiveCN105161315ALower internal resistanceImproved magnification performanceHybrid capacitor electrolytesHybrid/EDL manufactureElectrolysisPhysical chemistry

A hydrogel electrolyte thin film is disclosed. The hydrogel electrolyte thin film comprises cross-linked macromolecular matrix materials and an electrolyte water solution; the macromolecular matrixes are mutually connected through chemical crosslinking to form space net structures; the electrolyte water solution is filled in the gaps of the space net structures; the macromolecular materials are poly (vinyl alcohol) or gelatin; and the electrolyte water solution is acid or salt electrolyte water solution. The hydrogel electrolyte thin film is prepared by a adopting a chemical crosslinking-casting film forming method or a chemical crosslinking-blade coating film forming method. The thin film is used for the gel electrolyte of flexible supercapacitors.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Polypropylene/polyethylene/polypropylene three-layer co-extruded lithium-ion battery separator and preparation method thereof

ActiveCN107331822AImprove integrityLow closed cell temperatureSecondary cellsCell component detailsSurface layerInter layer

The invention relates to a polypropylene / polyethylene / polypropylene three-layer co-extruded lithium-ion battery separator which adopts an A1 / B / A2 three-layer structure. Each of the surface layers A1 and A2 adopts a porous structure formed by co-polypropylene; the middle layer B adopts a porous structure formed by high-density polyethylene. The preparation method comprises steps as follow: high-density polyethylene and co-polypropylene are melted, plastified and then co-extruded synchronously from a three-layer composite casting die head with three cavities to be pulled into films, and a co-extruded cast film with an A1 / B / A2 three-layer structure is obtained; annealing treatment, longitudinal cold drawing and thermal stretching are performed, and the polypropylene / polyethylene / polypropylene three-layer co-extruded lithium-ion battery separator is obtained after thermal setting. According to the lithium battery separator, the cell closing temperature of the middle layer is relatively low, the melting temperature of the surface layers is relatively high, the melt completeness and the battery safety of the separator are improved under the condition that a lithium battery is in an extremely high temperature environment, besides, the middle layer has a low melt index, the surface layers have a high melt index, and accordingly, the strength of the middle layer and the plastification uniformity of the surface layers are good.

Owner:HUIQIANG WUHAN NEW ENERGY MATERIAL TECH

Preparation method of enhanced hollow polyvinylidene fluoride fiber membrane

ActiveCN103432916AImprove mechanical propertiesExtended service lifeSemi-permeable membranesEnhanceosomePolyvinylidene difluoride

The invention discloses a preparation method of an enhanced hollow polyvinylidene fluoride fiber membrane. The preparation method comprises the following steps: (1) preparation of an enhanceosome: braiding polyacrylonitrile fiber into a hollow braided pipe by adopting a two-dimensional braiding technology; (2) preparation of separation layer casting film liquor: respectively dissolving 5-25wt% polyvinylidene fluoride resin and 5-30wt% of additive into a solvent, stirring and dissolving under the condition of 70-90 DEG C, conducting vacuum defoaming to obtain the separation layer casting film liquor; (3) surface pretreatment of the enhanceosome: cleaning and drying the enhanceosome with a neutral detergent, and then infiltrating the enhanceosome with slight polar organic liquid; and (4) preparation of the enhanced hollow polyvinylidene fluoride fiber membrane: evenly coating the separation layer casting film liquor obtained from the step (2) on the surface of the enhanceosome treated in the step (3), and curing to obtain the enhanced hollow polyvinylidene fluoride fiber membrane. The binding strength of a separation layer on the surface of the enhanced hollow polyvinylidene fluoride fiber membrane prepared by adopting the method and the enhanceosome is high, and the separation layer and the enhanceosome are unlikely to strip, and high-pressure backflushing can be conducted.

Owner:TIANJIN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com