Hydrogel electrolyte thin film, and preparation method and application therefor

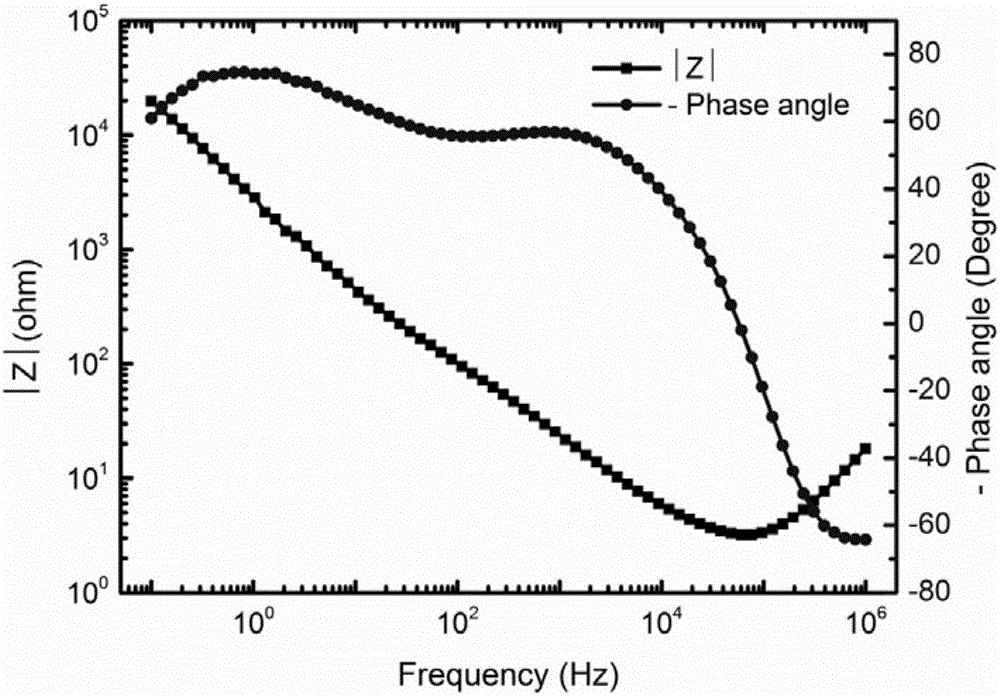

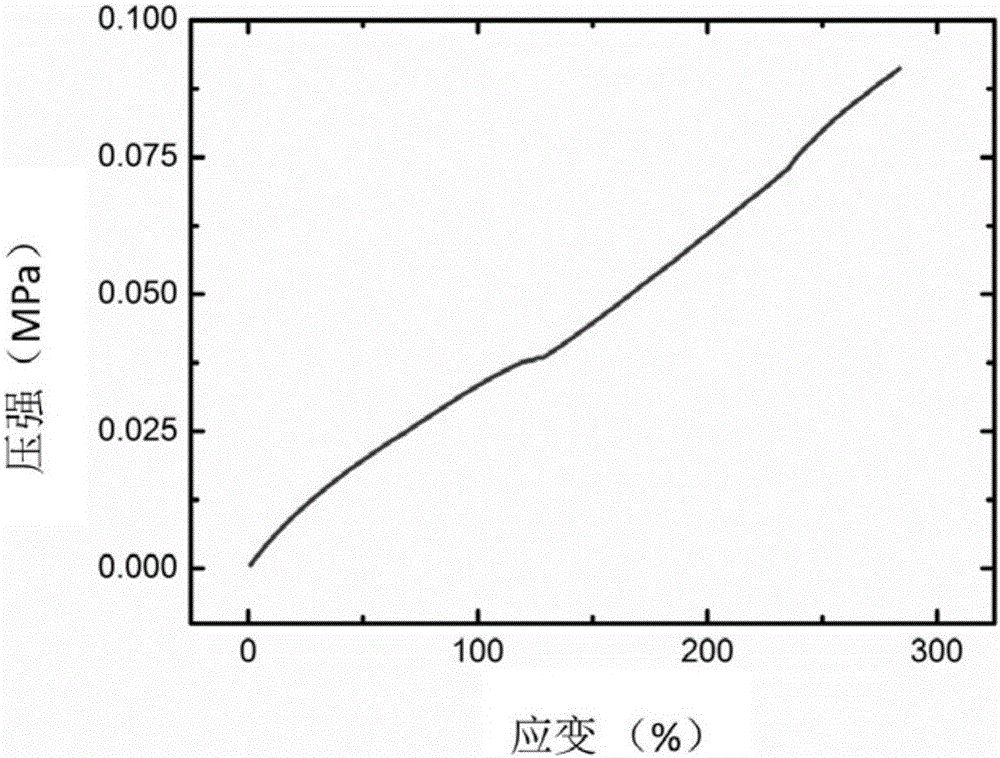

A technology of electrolyte film and hydrogel, which is applied in the manufacture of hybrid capacitor electrolytes and hybrid/electric double layer capacitors. Effect of bending resistance and improvement of magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] First add 1g of polyvinyl alcohol to 10mL containing 0.5molL -1 In the aqueous solution of sulfuric acid, make the content of polyvinyl alcohol 0.1gmL -1 , heated to 95° C. for 1 hour under electromagnetic stirring until the solution became clear, and a mixed solution of the polymer matrix and the aqueous electrolyte solution was obtained. Then, the mixed solution was cooled to 5 degrees Celsius. Add 2ml glutaraldehyde aqueous solution into the mixed solution, the volume ratio of the glutaraldehyde aqueous solution is 5%, stir for 20s, and quickly pour the mixed solution into a Φ90mm plastic round watch glass, and the mixed solution loses fluidity after about 10s , to complete gelation. The film was peeled off to obtain a hydrogel electrolyte film, and the thickness of the film was measured to be 1 mm by a thickness gauge. The self-supporting film as Figure 4 shown. Based on the total amount of the hydrogel electrolyte film, the content of the polymer matrix is ...

Embodiment 2

[0043] First add 0.3g polyvinyl alcohol to 10mL containing 2molL -1 In the aqueous solution of sulfuric acid, make the content of polyvinyl alcohol be 0.03gmL -1 , heated to 95° C. under electromagnetic stirring, and kept for 1 hour until the solution became clear, and a mixed solution of the polymer matrix and the aqueous electrolyte solution was obtained. Then, the mixed solution was cooled to 1°C. Add 2ml of glutaraldehyde aqueous solution into the mixed solution, the volume percentage of the glutaraldehyde aqueous solution and the mixed solution is 5%, stir for 60s, and quickly pour the mixed solution into a Φ90mm glass round watch glass for about 10s After the mixed solution loses fluidity, gelation is complete. The film is peeled off to form a hydrogel electrolyte film. A thickness gauge measures the thickness of the film to be 1 mm. Based on the total amount of the hydrogel electrolyte film, the content of the polymer matrix is 2% by weight, and the content of the...

Embodiment 3

[0045] First add 2g polyvinyl alcohol to 4mL containing 0.01molL -1 In the aqueous solution of sulfuric acid, make the content of polyvinyl alcohol be 0.5gmL -1 , heated to 95° C. under electromagnetic stirring, and kept for 1 hour until the solution became clear, and a mixed solution of the polymer matrix and the aqueous electrolyte solution was obtained. Then, the above mixed solution was cooled to 1°C. Add 2ml of glutaraldehyde aqueous solution into the above mixed solution, the volume ratio of glutaraldehyde aqueous solution is 0.4%, stir for 5s, and quickly pour the mixed solution into a Φ90mm plastic round watch glass, after about 10s, the mixed solution loses fluidity, Gelation is complete. The film was peeled off to form a hydrogel electrolyte film, and the film thickness measured by a thickness gauge was 500 μm. Based on the total amount of the hydrogel electrolyte film, the content of the polymer matrix is 20% by weight, and the content of the aqueous electrolyt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com