Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11116results about How to "Improved magnification performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

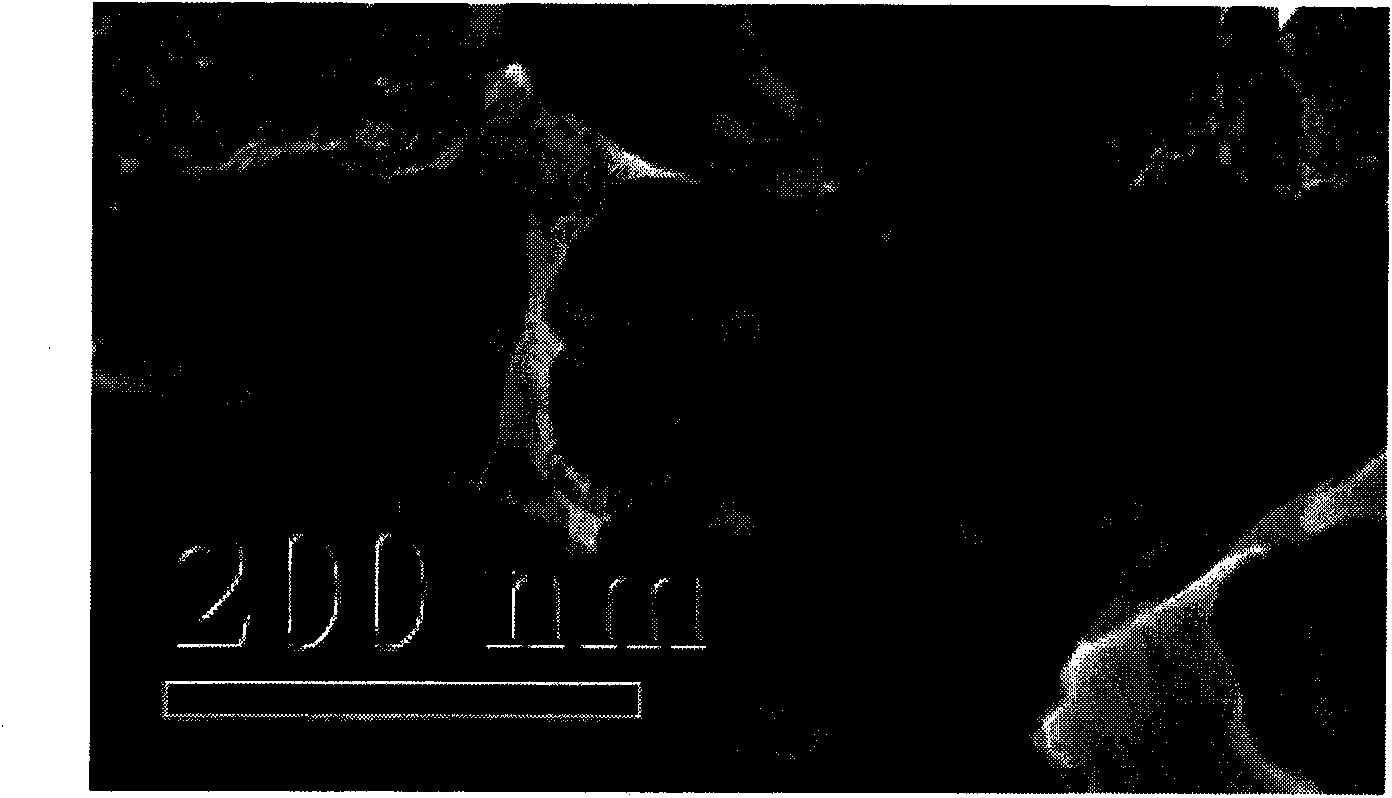

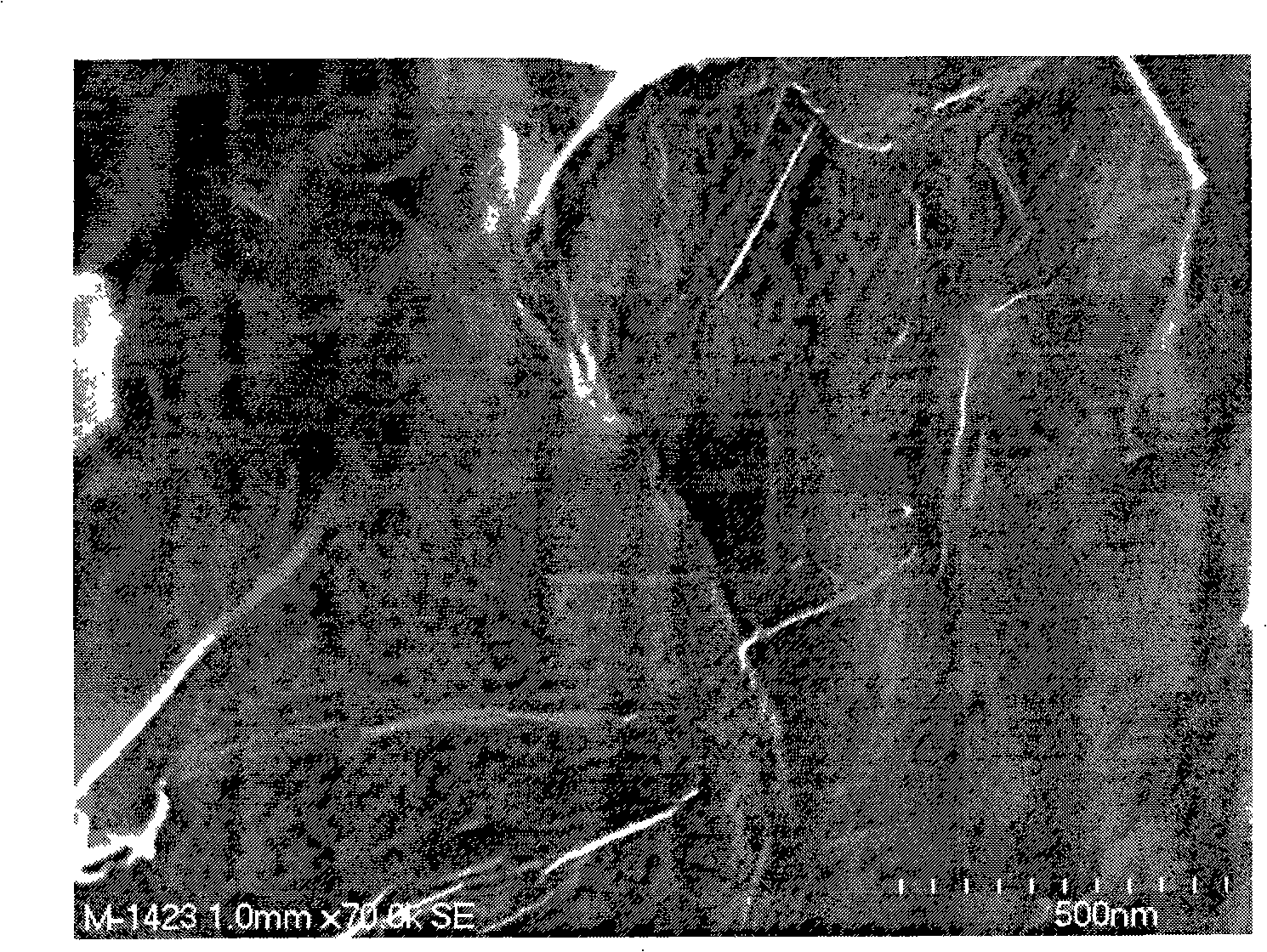

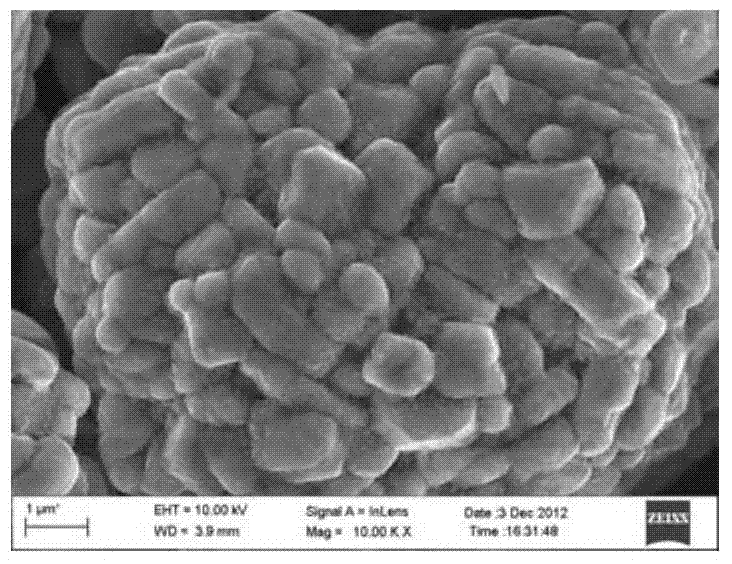

Graphene/metal oxide composite cathode material for lithium ion battery and preparation

InactiveCN102646817APromote circulationExcellent rate performanceCell electrodesHigh energyIn situ polymerization

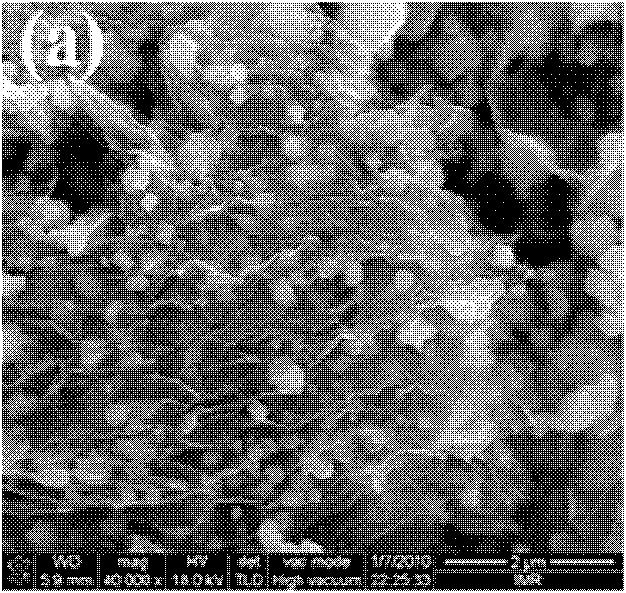

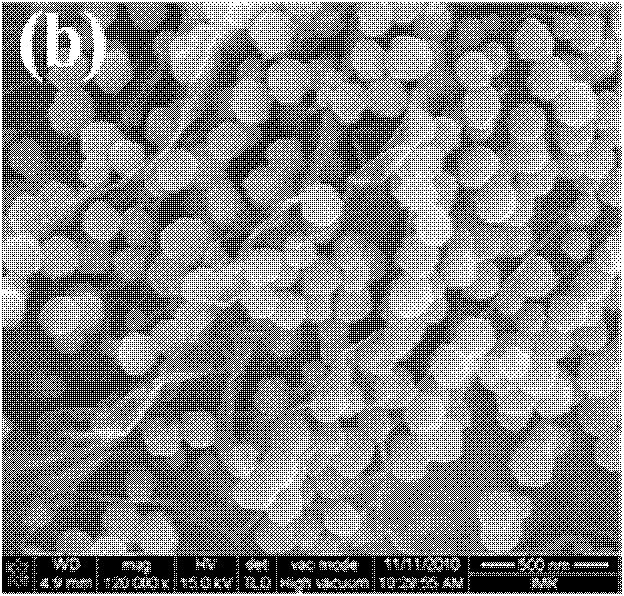

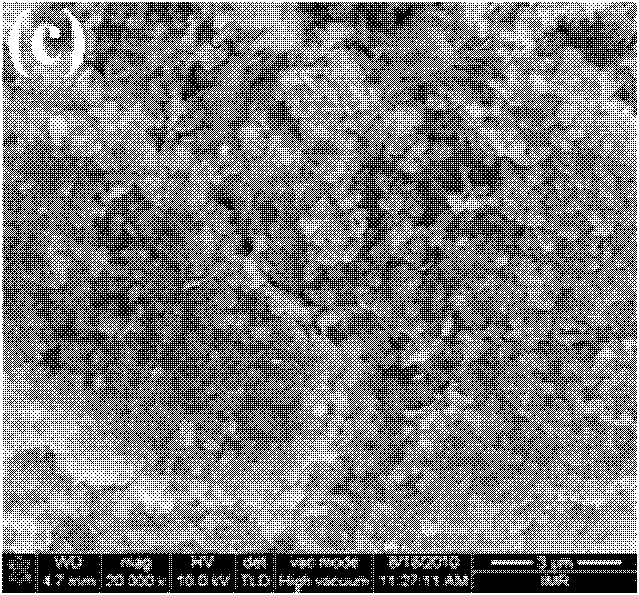

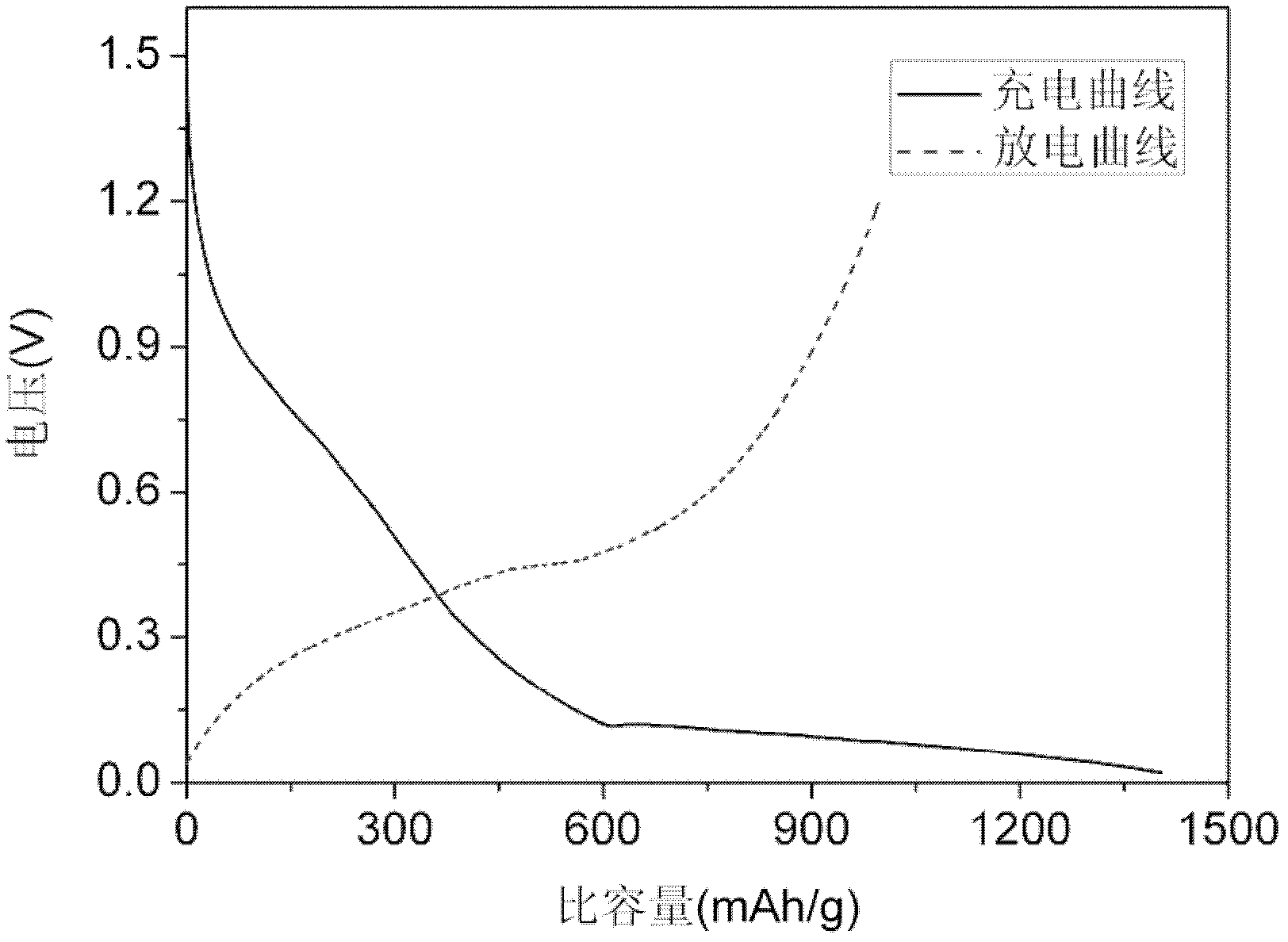

The invention belongs to the fields of material synthesis and energy technology, and especially relates to a graphene / metal oxide composite cathode material for lithium ion batteries and a preparation method thereof. Grapheme is dispersed into various metal oxide precursor salt solutions; a graphene / metal oxide compound is obtained directly by a hydrothermal method, or an graphene / metal oxide compound is obtained by a liquid in-situ polymerization method or a coprecipitation process; and the graphene / metal oxide compound is obtained by heat treatment or hydrothermal treatment. In the invention, the novel three-dimensional composite cathode material of graphene-coated metal oxide or graphene-anchored metal oxide is prepared by carrying metal oxide particles with graphene as a carrier. The obtained composite material can be used as a lithium ion battery cathode, which has a high specific capacity, excellent cycle stability and rate capability, and is expected to be used as a lithium ion battery cathode material with a high energy density and a high power density.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

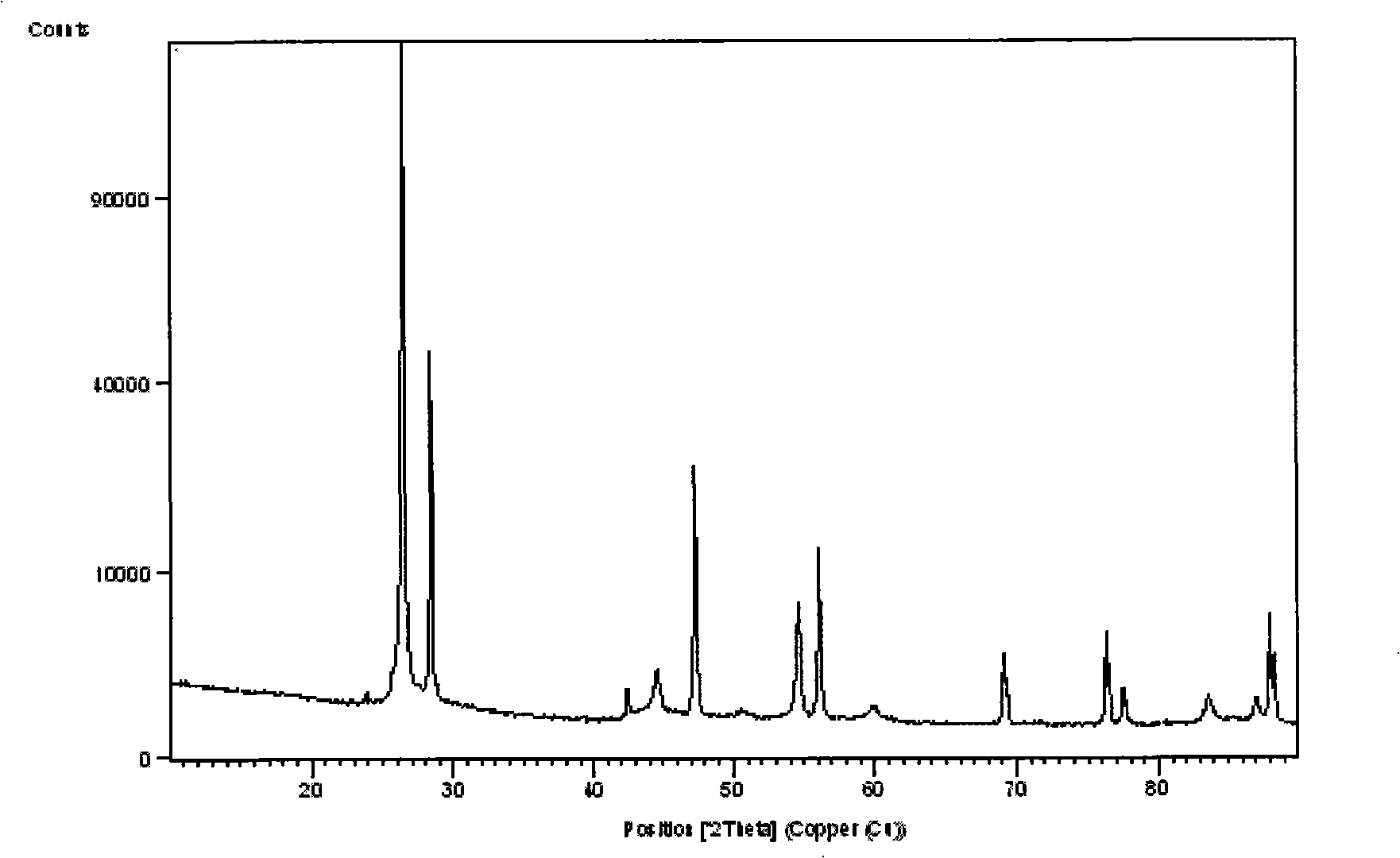

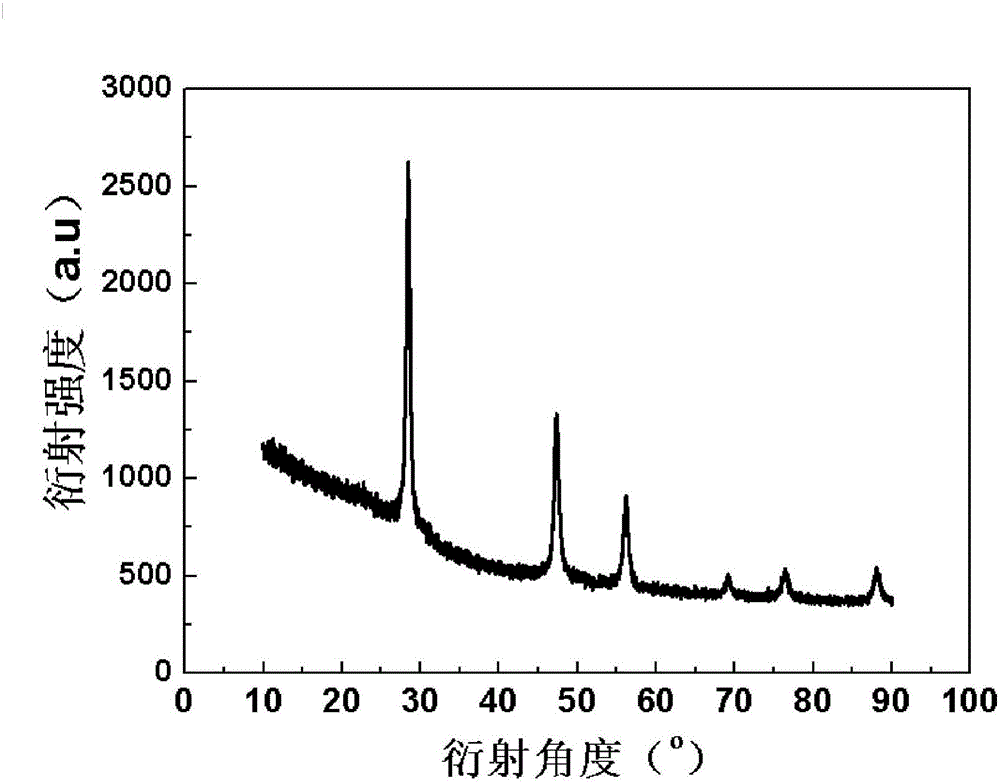

Graphite composite lithium ion battery anode material lithium iron phosphate and preparation method thereof

ActiveCN101562248AImprove electronic conductivityImprove tap densityElectrode manufacturing processesPower batteryChemical Linkage

The invention relates to a graphene composite lithium ion battery anode material lithium iron phosphate and a preparation method thereof. The composite material of lithium iron phosphate and graphene is connected by interface of chemical bonding. The invention also provides the method for preparing the graphene composite lithium ion battery anode material lithium iron phosphate in an in-situ symbiosis reaction mode, and the obtained anode material has high tap density and good magnifying performance, and is suitable to be used as a anode material of a lithium ion power battery.

Owner:龚思源

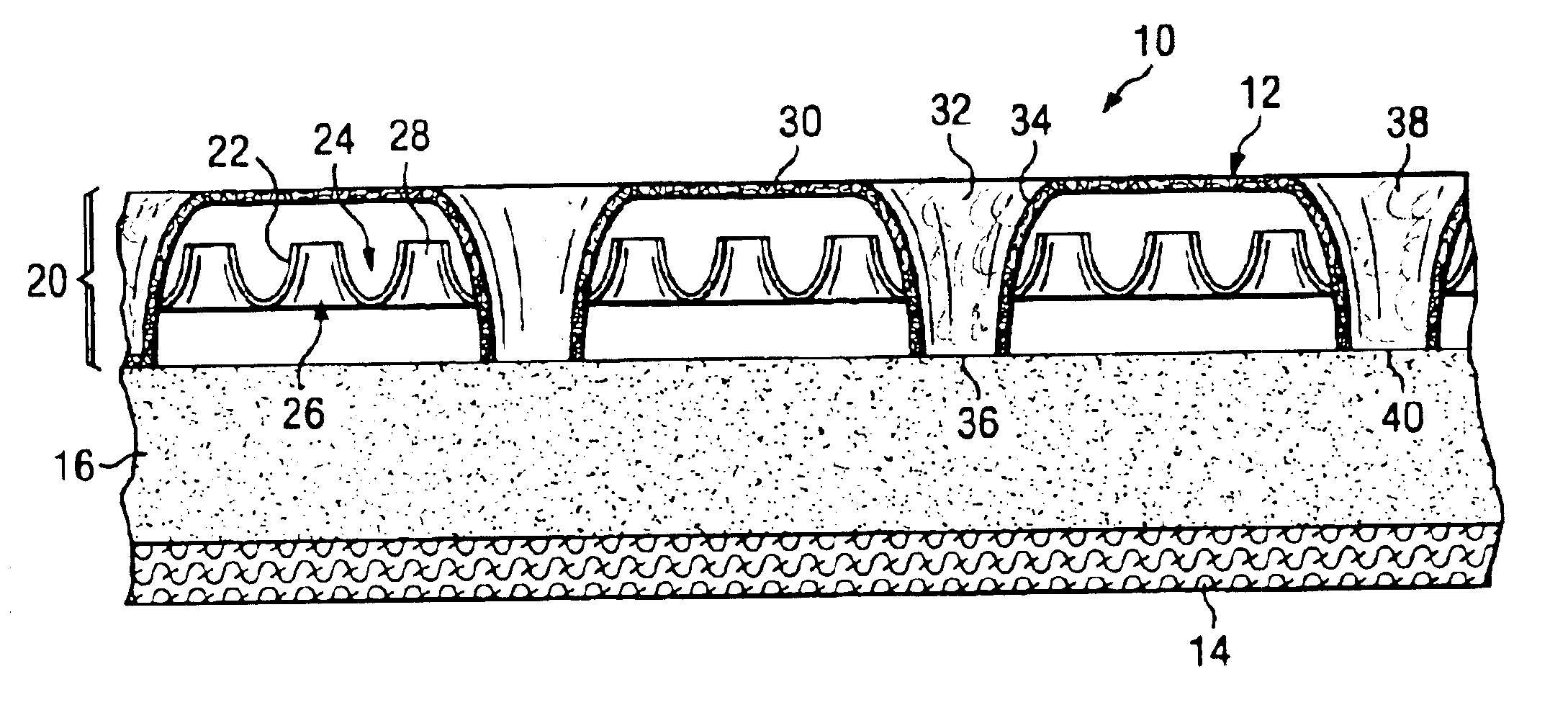

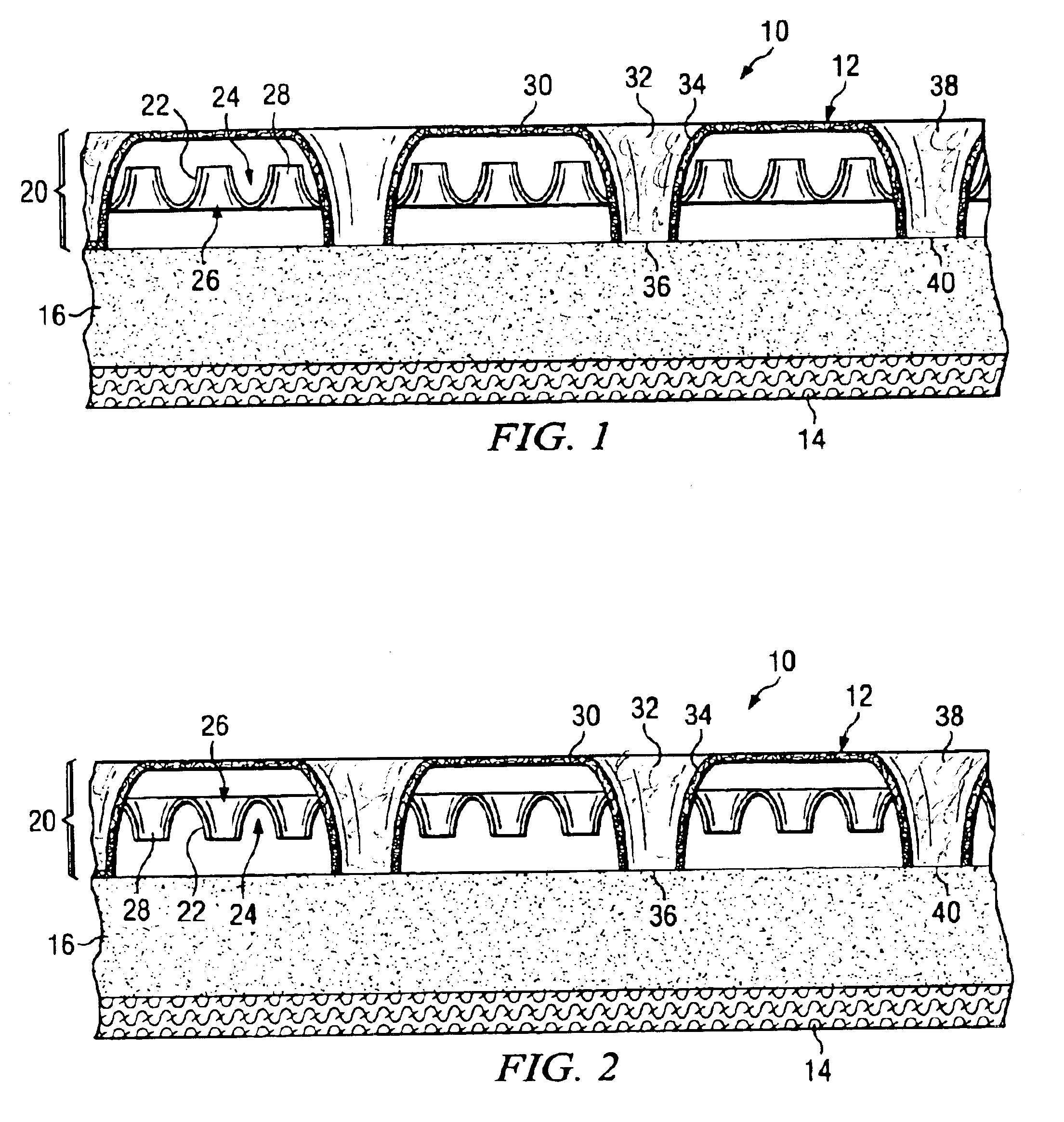

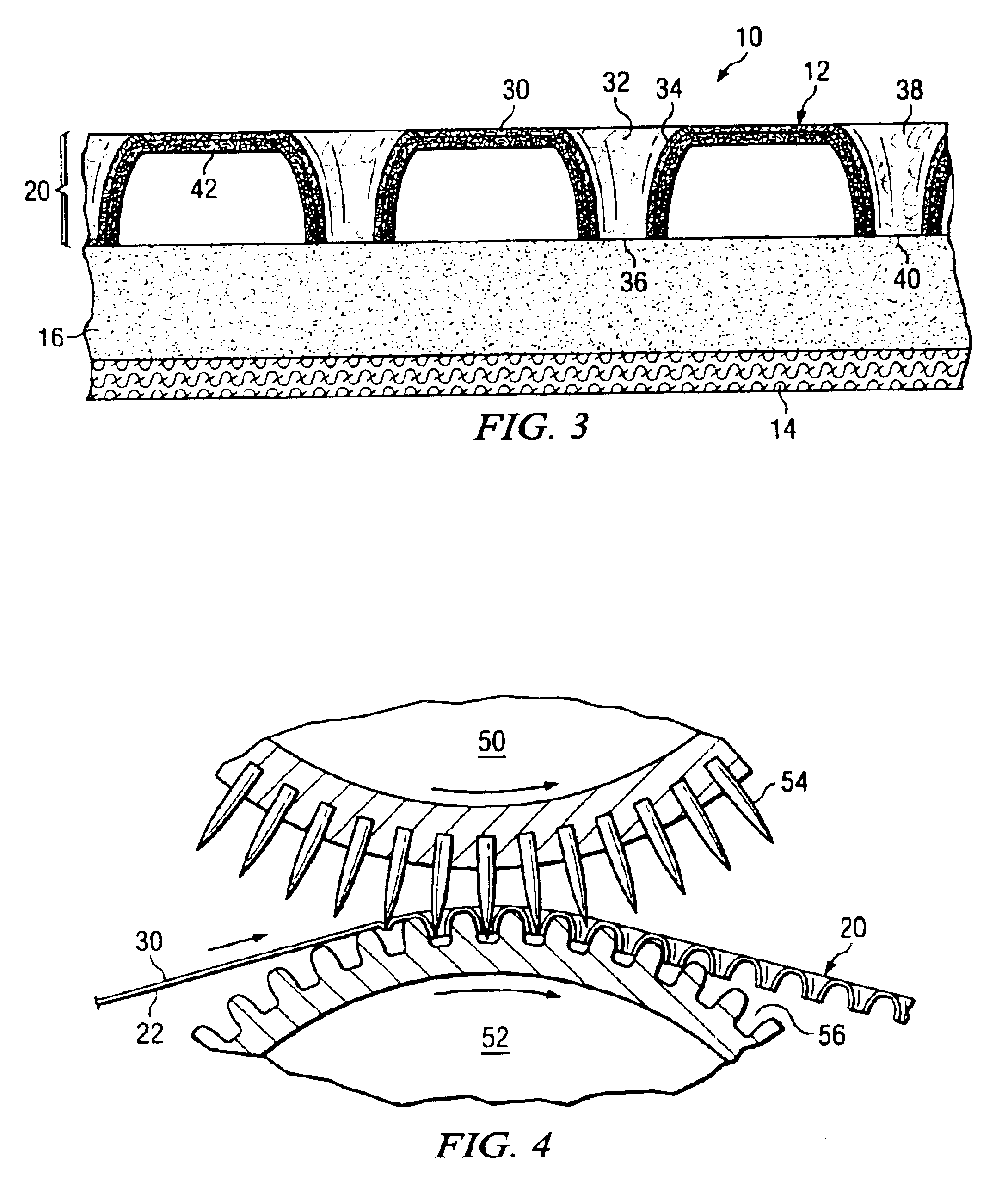

Apertured nonwoven composites and method for making

InactiveUS6849319B2Improved magnification performanceLow absorption rateLamination ancillary operationsLaminationFiberEngineering

Owner:TREDEGAR FILM PROD CORP

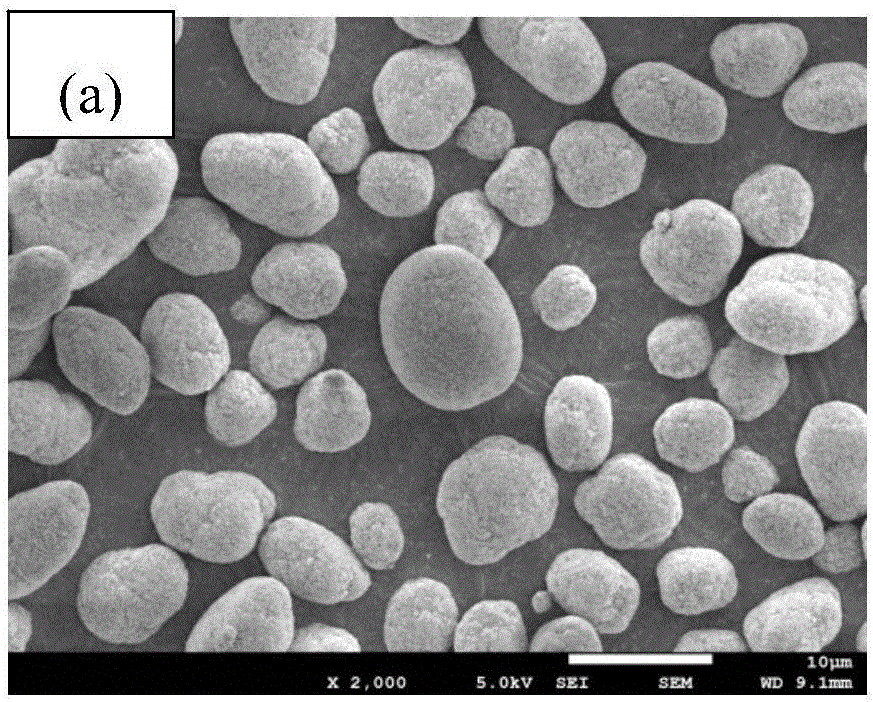

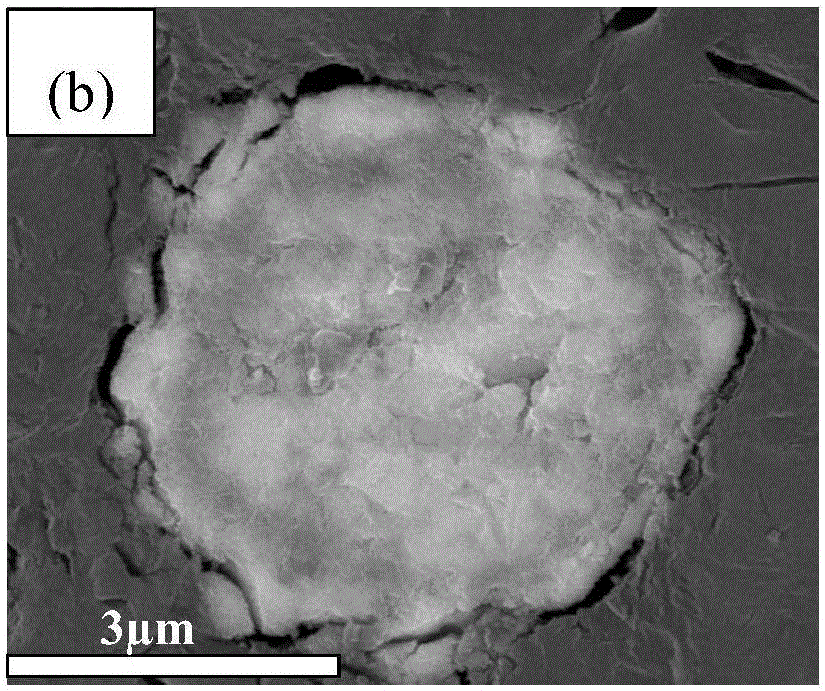

Graphite powder of lithium ionic cell cathode and preparation thereof

ActiveCN101323447AHigh purityImprove liquid absorption capacityCell electrodesSpherical shapedGraphite

The invention discloses a graphite powder of the cathode of a lithium ion battery, and a preparation method thereof; the technical problem to be solved is that the transmission speed of a lithium ion and an electrolyte to the inside of the electrode needs to be increased. The graphite powder of the cathode of the lithium ion battery of the invention has the microscopic feature of massive, spherical and near-spherical shapes and has the characteristics of nano-porous. The preparation method thereof comprises the following steps of: grinding, adding coating modifiers or / and catalysts, mixing, dissolving, and carrying out preheating treatment and heat treatment. Compared with the prior art, the invention carries out modifying treatment to graphite material and realizes the characteristic of nano-porous by adding pore-forming agents, thus being beneficial to the transmission of the lithium ion, improving the liquid-absorbing performance of a pole piece after compaction, reducing the content of impurity in the graphite, improving the liquid-absorbing performance and the magnification performance of the graphite material, meeting the requirements of the lithium ion dynamic battery for the compatibility and the charging and discharging performance with large magnification of the electrolyte of the graphite material and having the advantages of lower production cost, simple technique and easy industrialization.

Owner:BTR NEW MATERIAL GRP CO LTD

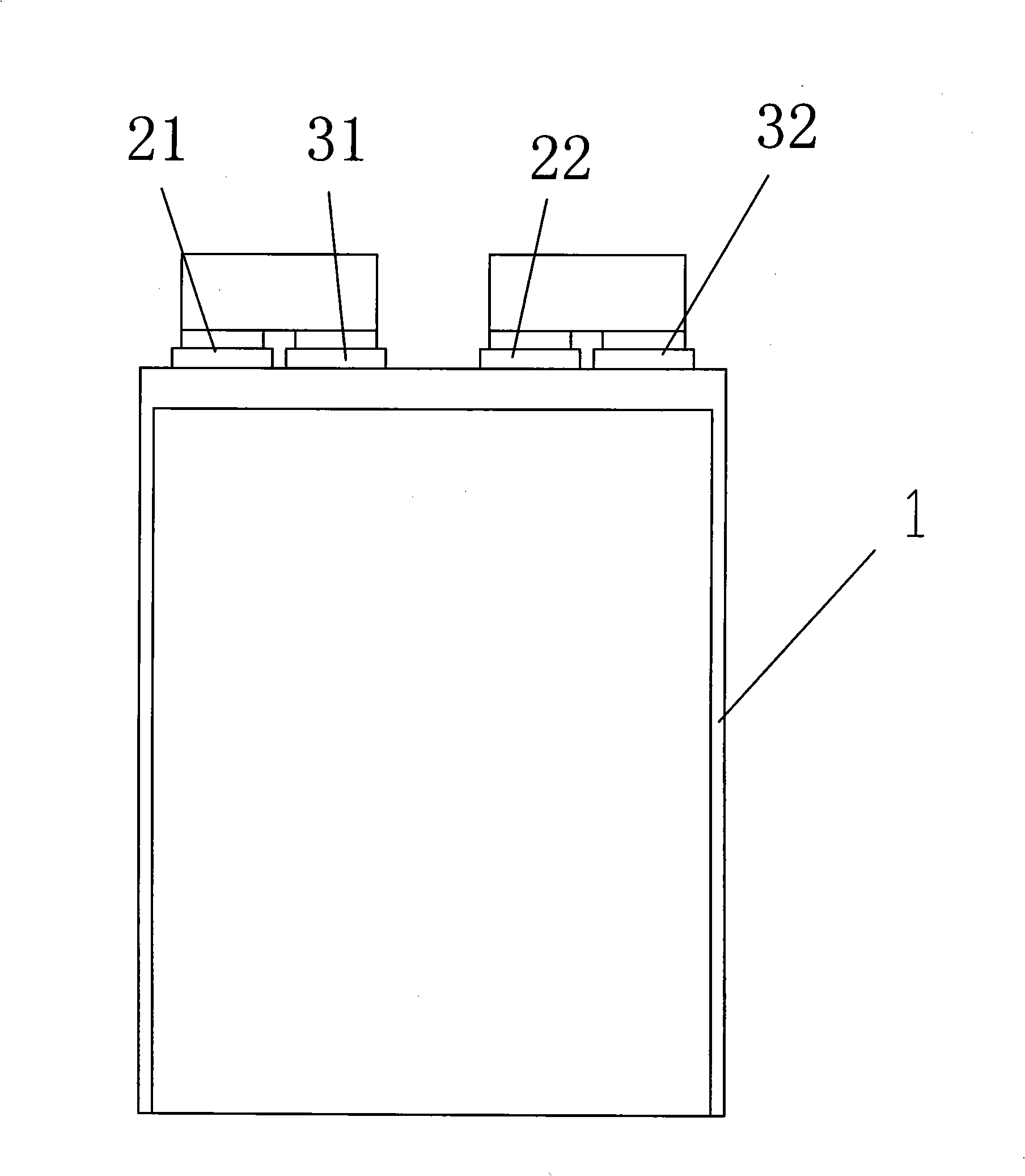

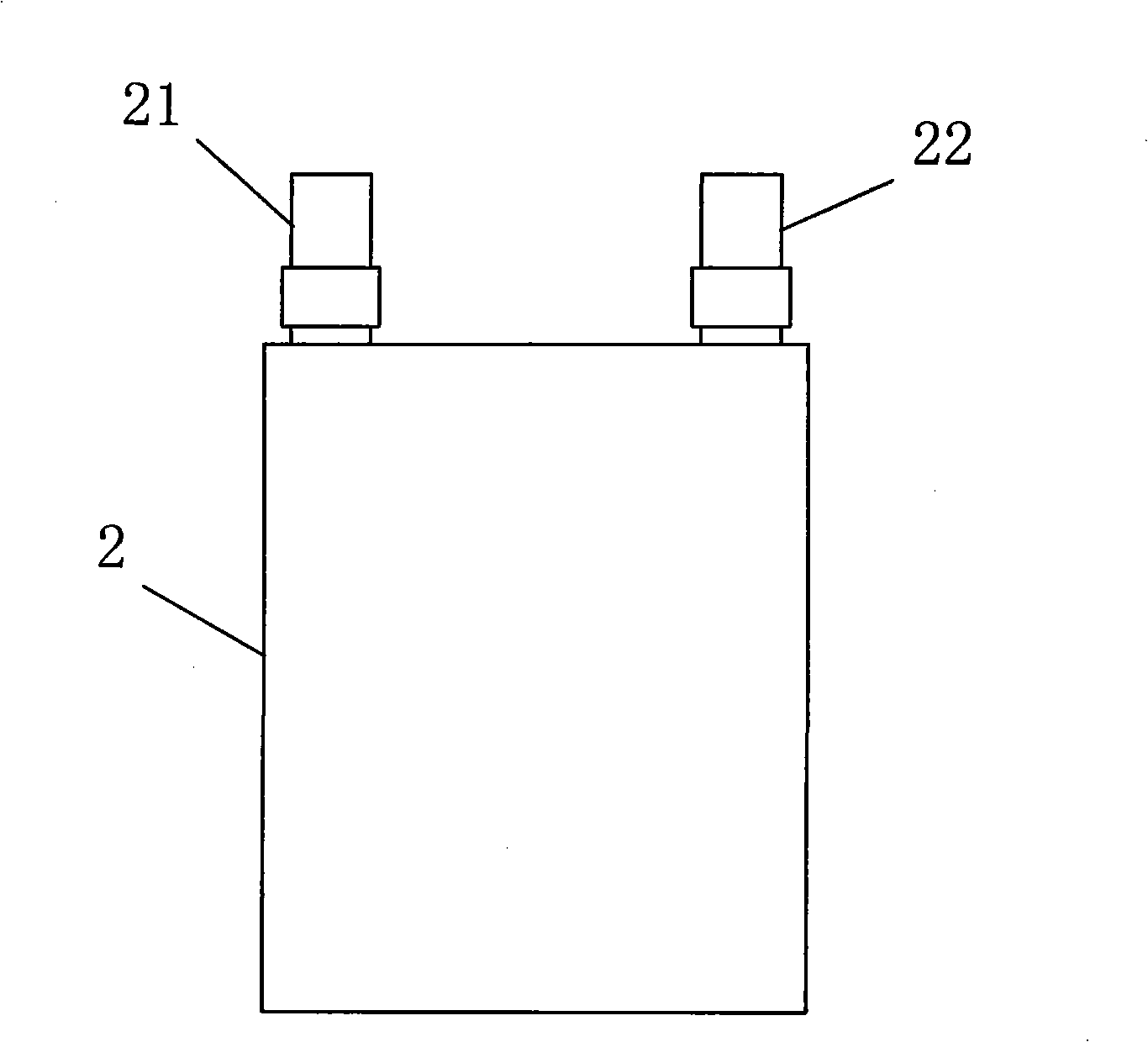

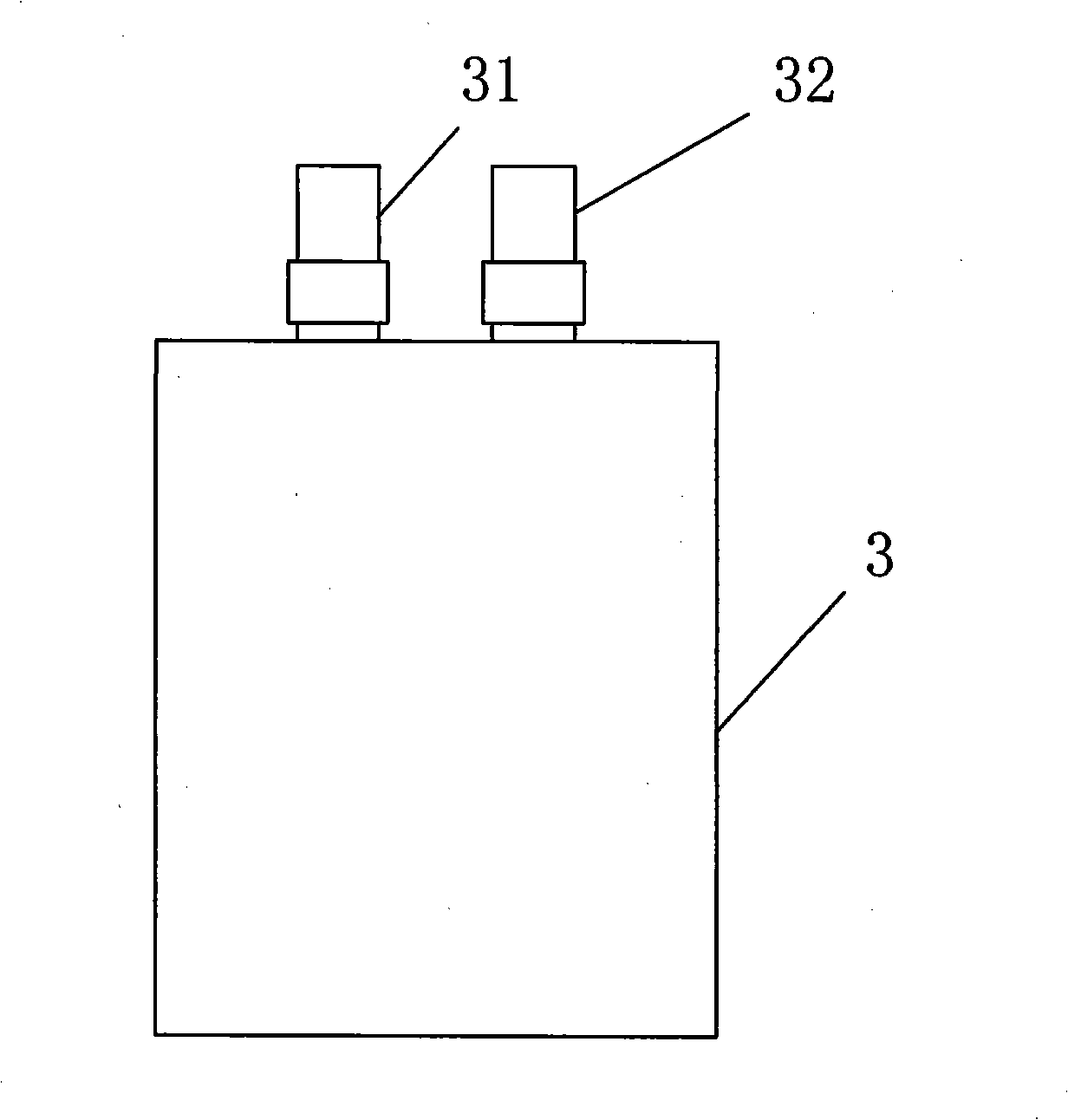

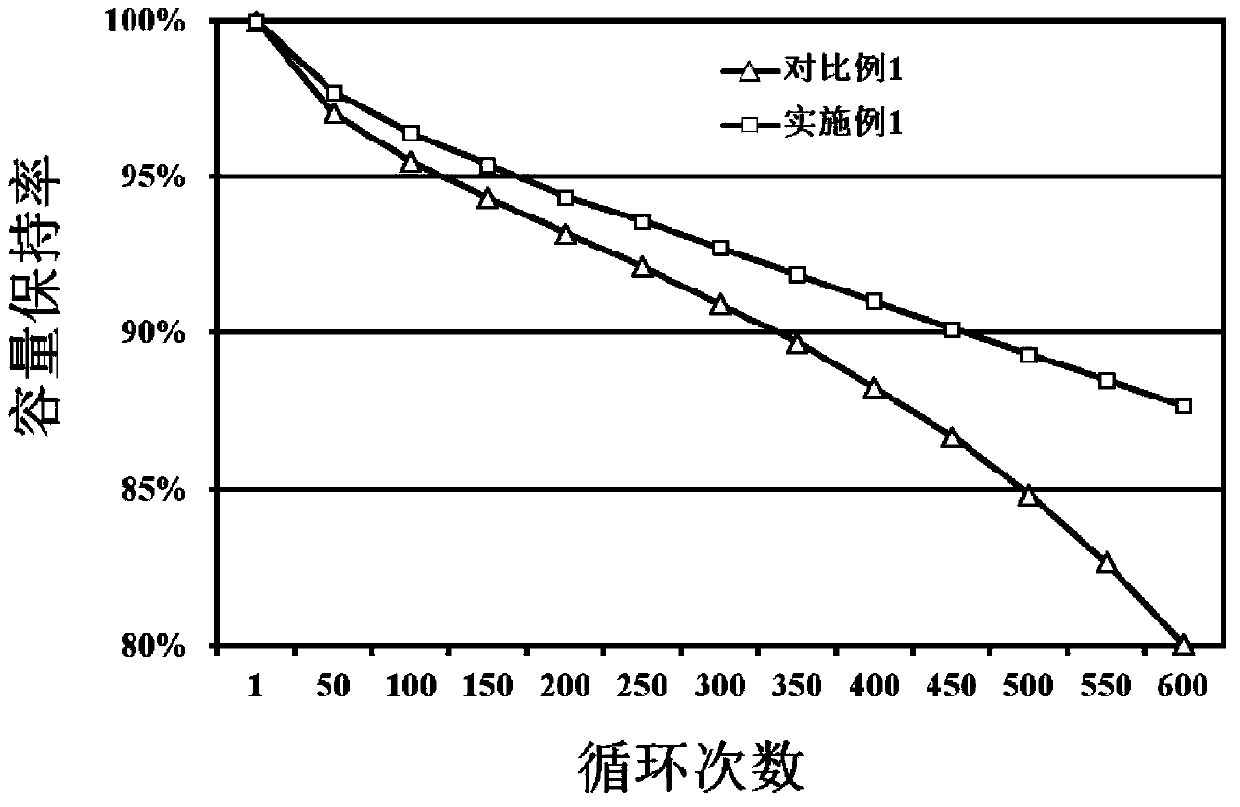

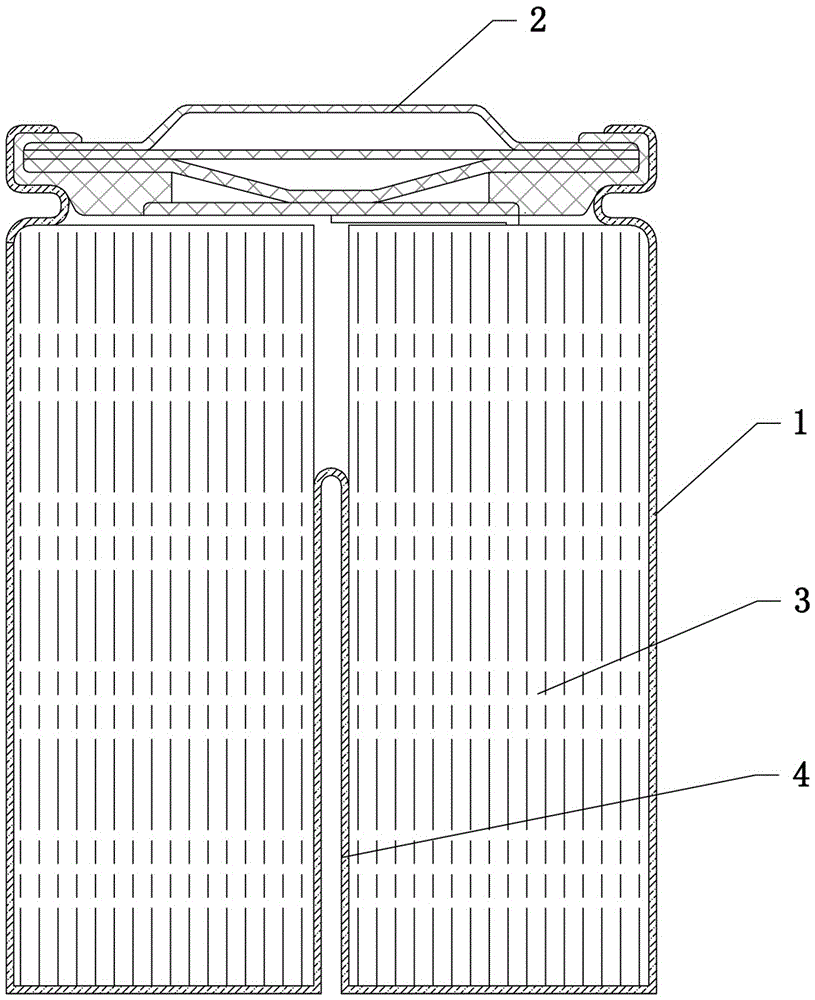

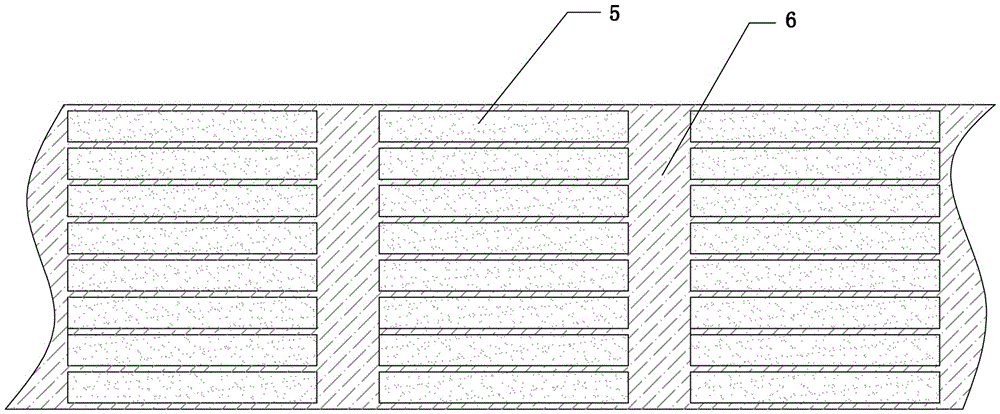

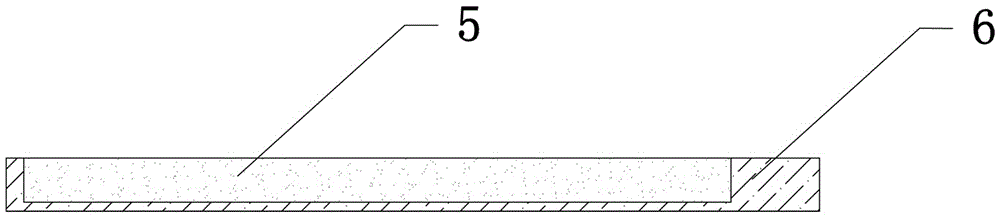

Large-capacity high power polymer ferric lithium phosphate power cell and preparation method thereof

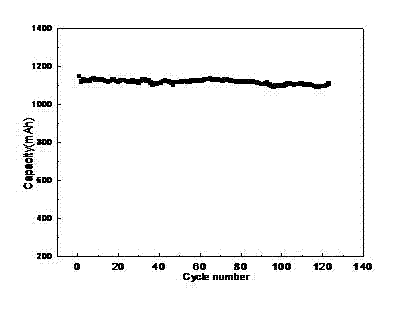

InactiveCN101409369AImprove securityIncrease capacityElectrode manufacturing processesFinal product manufactureSlurryElectric vehicle

The invention discloses a large-capacity high-power polymer lithium iron phosphate power battery. The weight ratio of anode slurry is as follows: 81 to 85 percent of lithium iron phosphate, 1 to 5.5 percent of superconduction carbon, 0 to 2.5 percent of conductive carbon soot, 0 to 4 percent of conductive black lead, 0 to 2.5 percent of crystalline flake graphite, 0 to 2 percent of carbon nanometer tube as well as 6 to 7.5 percent of polyvinylidene fluoride; the weight ratio of cathode slurry is as follows: 89 to 91 percent of cathode material, 1 to 3.5 percent of superconduction carbon, 0 to 2 percent of conductive carbon soot, 0 to 4 percent of conductive black lead, 2.5 to 3.5 percent of styrene-butadiene rubber as well as 1.5 to 2 percent of sodium carboxymethyl cellulose; the steps for preparing the battery are as follows: preparing slurry, coating the anode and the cathode, rolling and pressing a polar plate, transversely and separately cutting the polar plate, baking the polar plate, welding the polar ears of the anode and the cathode, preparing a battery cell, putting the electric core into a shell and sealing, baking the electric core, injecting liquid into the battery as well as forming the battery and dividing the volume of the battery. The invention relates to a lithium-ion secondary battery which can provide drive energies for electric tools, electric bicycles, motor cars and electric vehicles.

Owner:MCNAIR TECH

All-solid state lithium ion battery composite positive electrode material and preparation method thereof, and all-solid state lithium ion battery

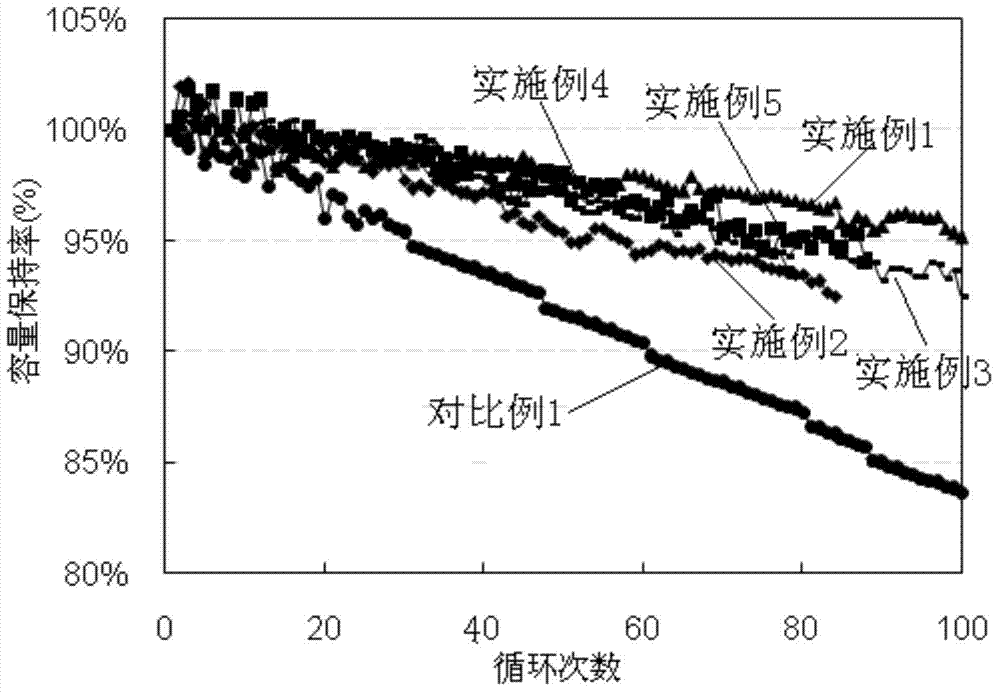

ActiveCN103633329AImprove cycle lifeImprove discharge capacityCell electrodesSecondary cellsSolid state electrolyteTitanium disulfide

Embodiments of the present invention provide an all-solid state lithium ion battery composite positive electrode material, which comprises a positive electrode active material and a cladding layer arranged on the surface of the positive electrode active material, the positive electrode active material is one or a plurality of materials selected from a lithium cobalt oxide, lithium nickelate, lithium manganate, lithium iron phosphate, lithium nickel cobalt manganese, vanadium pentoxide, molybdenum trioxide and titanium disulfide, and the cladding layer material is one or a plurality of lithium-containing transition metal oxides. According to the present invention, with the cladding layer, formation of the space charge layer can be effectively inhibited, the electrode / inorganic solid state electrolyte interface can be improved, and the interface resistance of the all-solid state lithium ion battery can be easily reduced so as to improve cycle stability and durability of the all-solid state lithium ion battery. Embodiments of the present invention further provide a preparation method for the all-solid state lithium ion battery composite positive electrode material, and an all-solid state lithium ion battery containing the all-solid state lithium ion battery composite positive electrode material.

Owner:泰州市海通资产管理有限公司

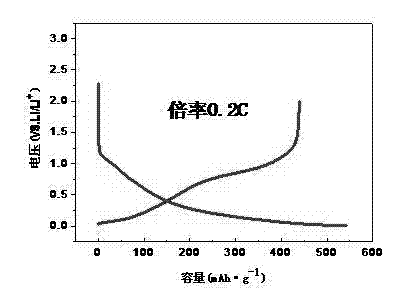

Hard carbon cathode material for lithium ion power and energy storage battery and preparation method of hard carbon cathode material

ActiveCN103094528ALow costImprove cycle performanceCell electrodesCarbon preparation/purificationElectrical batteryEnergy storage

The invention relates to a preparation method of a hard carbon cathode material. The preparation method comprises the step of preparing the hard carbon cathode material by using thermosetting resin or pyrolysis products of a mixture of thermosetting resin and thermoplastic resin as a hard carbon matrix and adopting a carbon material as a coating. In the preparation process of the hard carbon cathode material, a curing agent and a doping matter can be added. The hard carbon cathode material prepared by adopting the preparation method has the characteristics of high capacity, high first-time coulombic efficiency, excellent rate performance, low cost and the like, and is suitable for industrialized production.

Owner:JIXI BTR GRAPHITE IND PARK CO LTD +2

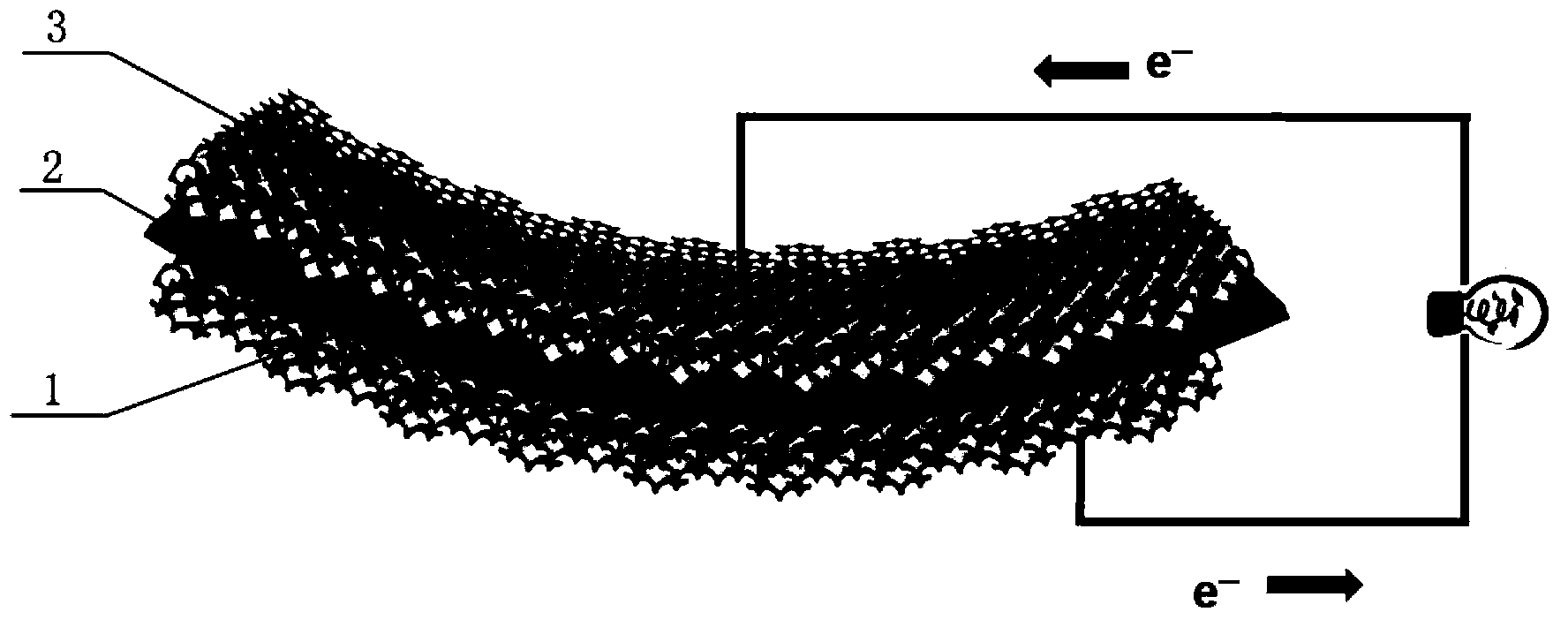

Rapidly charged flexible lithium ion battery and preparation method of electrodes of rapidly charged flexible lithium ion battery

InactiveCN103682368AReduce electrode massImproved magnification performanceElectrode carriers/collectorsSecondary cellsElectrical batteryGraphene foam

The invention discloses a rapidly charged flexible lithium ion battery and a preparation method of electrodes of the rapidly charged flexible lithium ion battery, belonging to the technical field of lithium ion batteries. The electrodes of the lithium ion battery are integrally designed by a current collector and active substances. An ultralight and flexible three-dimensional graphene communicating network structure (short for graphene foams) is used as a current collector, the active substances are embedded on the surface of the three-dimensional graphene foams, the integrated active substances and the current collector can be obtained through hydrothermal, pulp filling and impregnation processes, and the content of the active substances can be regulated as required. The electrodes of the battery are not required for a metal current collector, a binder and a conductive agent, the ultrahigh conductivity and porous structure of the three-dimensional graphene network provide rapid diffusion channels for lithium ions and electrons. The lithium ion battery consisting of a positive electrode and a negative electrode can be rapidly charged, is bendable and has no capacity loss. The method disclosed by the invention is low in product production cost, ultralight and ultrathin, and capable of realizing large-batch production, and has high practical application values.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

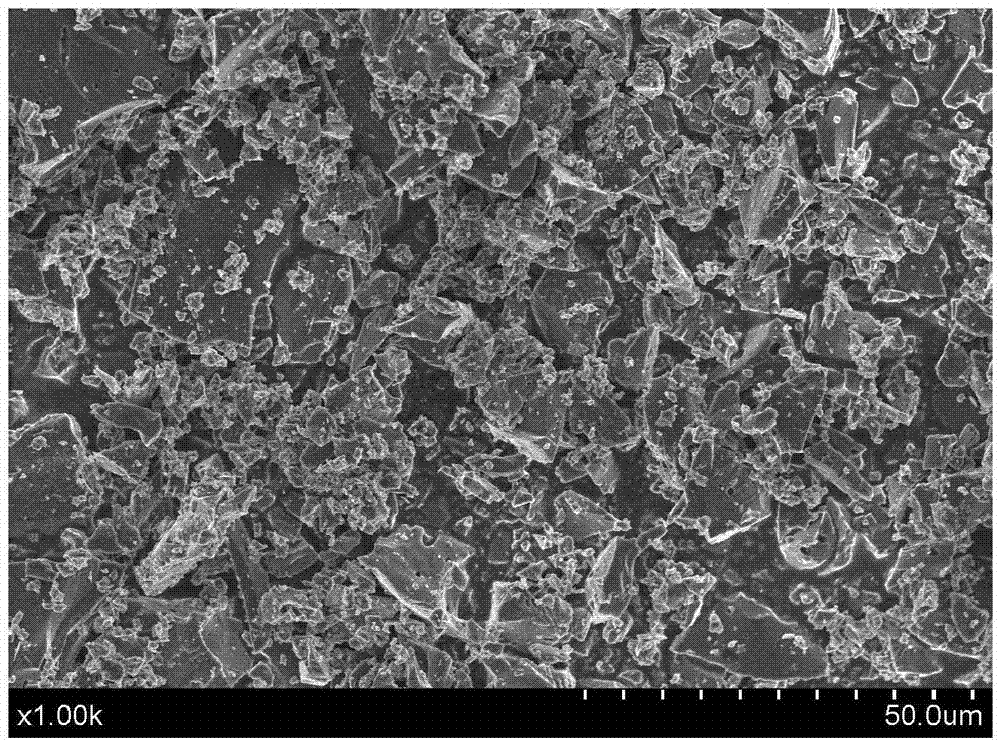

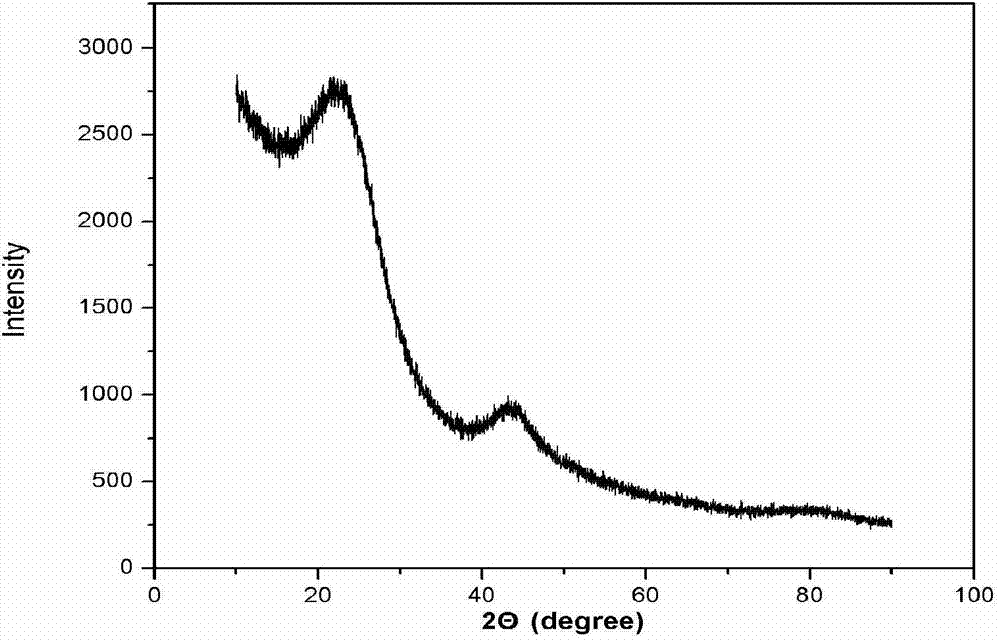

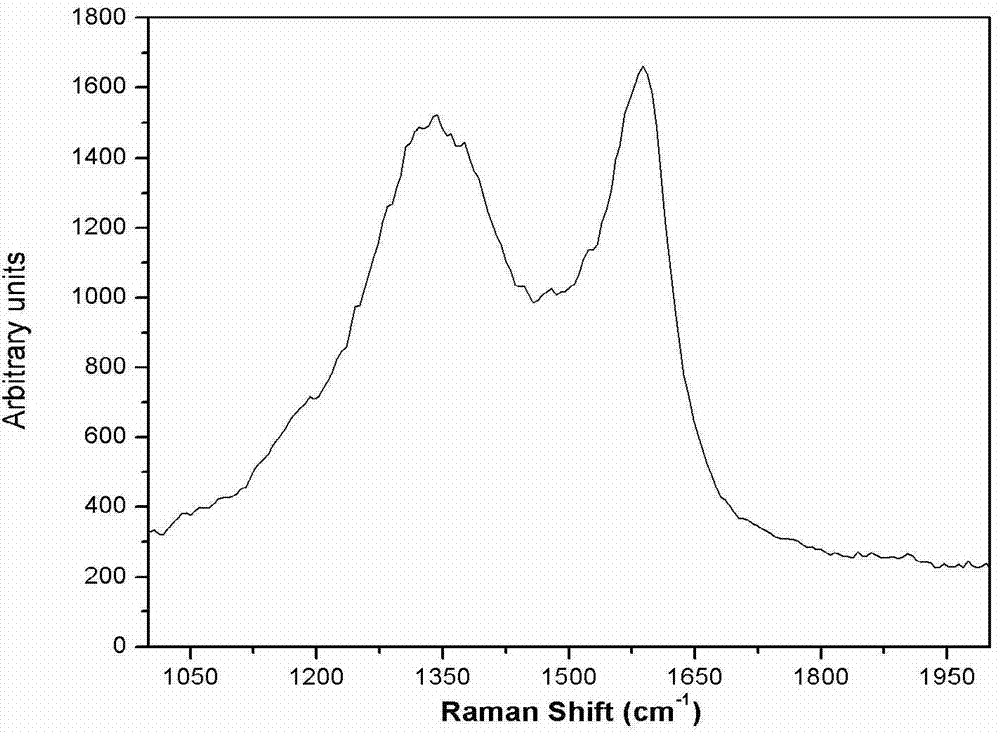

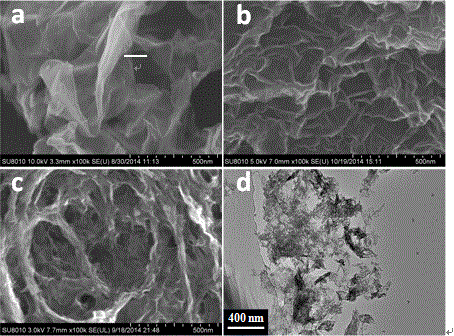

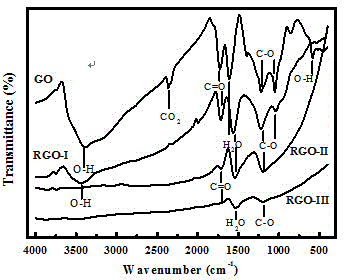

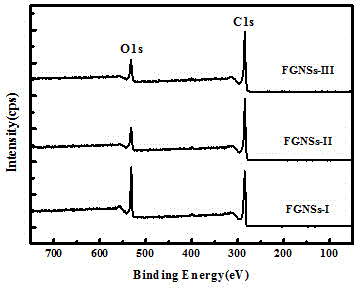

Method for preparing lithium ion battery anode/cathode material from reduced graphene oxide

The invention discloses a method for preparing a lithium ion battery anode / cathode material from reduced graphene oxide. The method comprises the following steps: performing ultrasonic dispersion on graphite oxide in an organic solvent, thereby obtaining a graphene oxide dispersion liquid; reducing by using an appropriate reducing agent or directly using a solvent, oxidizing graphene through oil bath backflow, a hydrothermal method or other reduction methods, thereby obtaining a reduced graphene oxide material containing part of oxygen-containing groups. When the prepared reduced graphene oxide material is used in a lithium ion battery anode material, a relatively high specific discharge capacity can be achieved, that is, is up to 280mAh / g, and good circulation stability and excellent rate performance are achieved. The prepared reduced graphene oxide material can be also used in a lithium ion battery cathode material, the specific discharge capacity can be kept being 900mAh / g and more than 900mAh / g after 100 rounds of charge / discharge circulation, and the circulation stability is relatively good. The method can be a significant study point of high-performance low-cost electrode materials of lithium ion batteries.

Owner:TIANJIN NORMAL UNIVERSITY

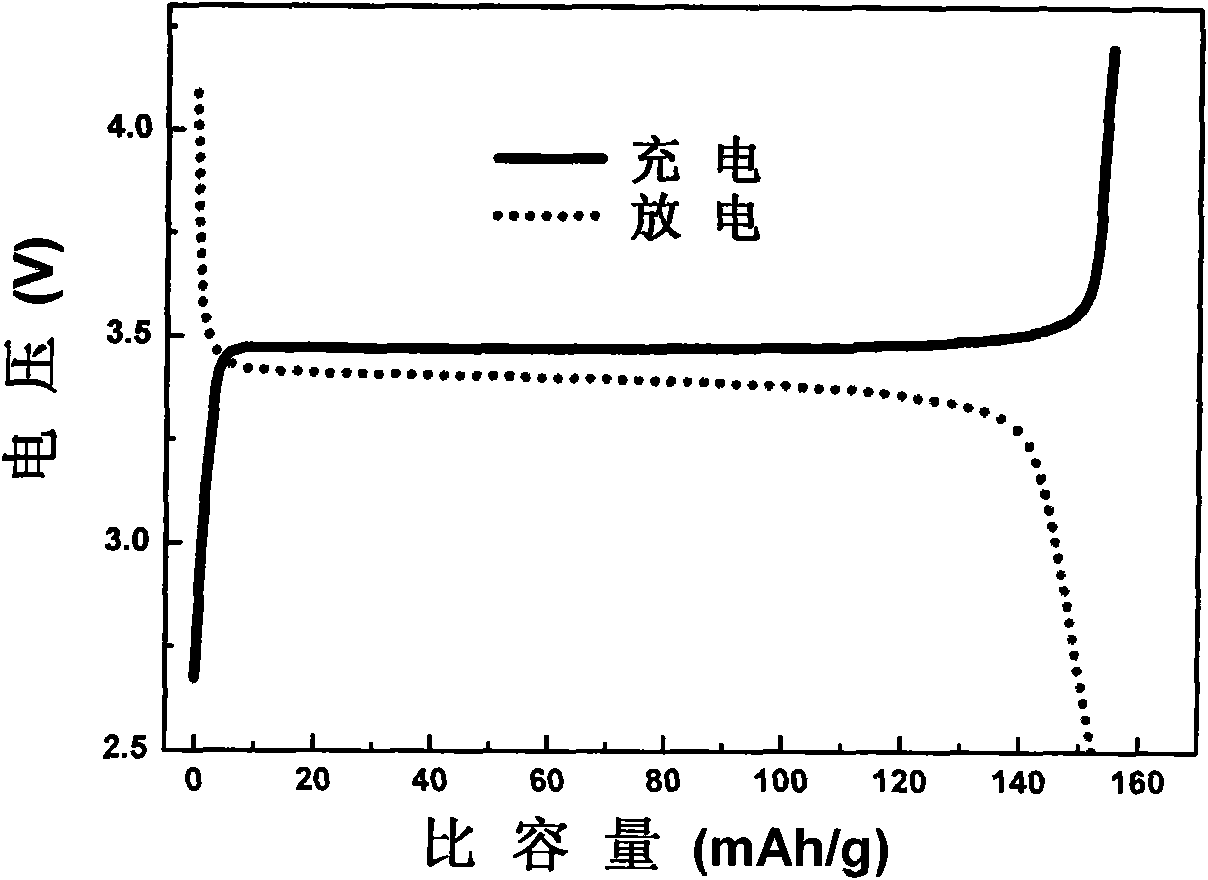

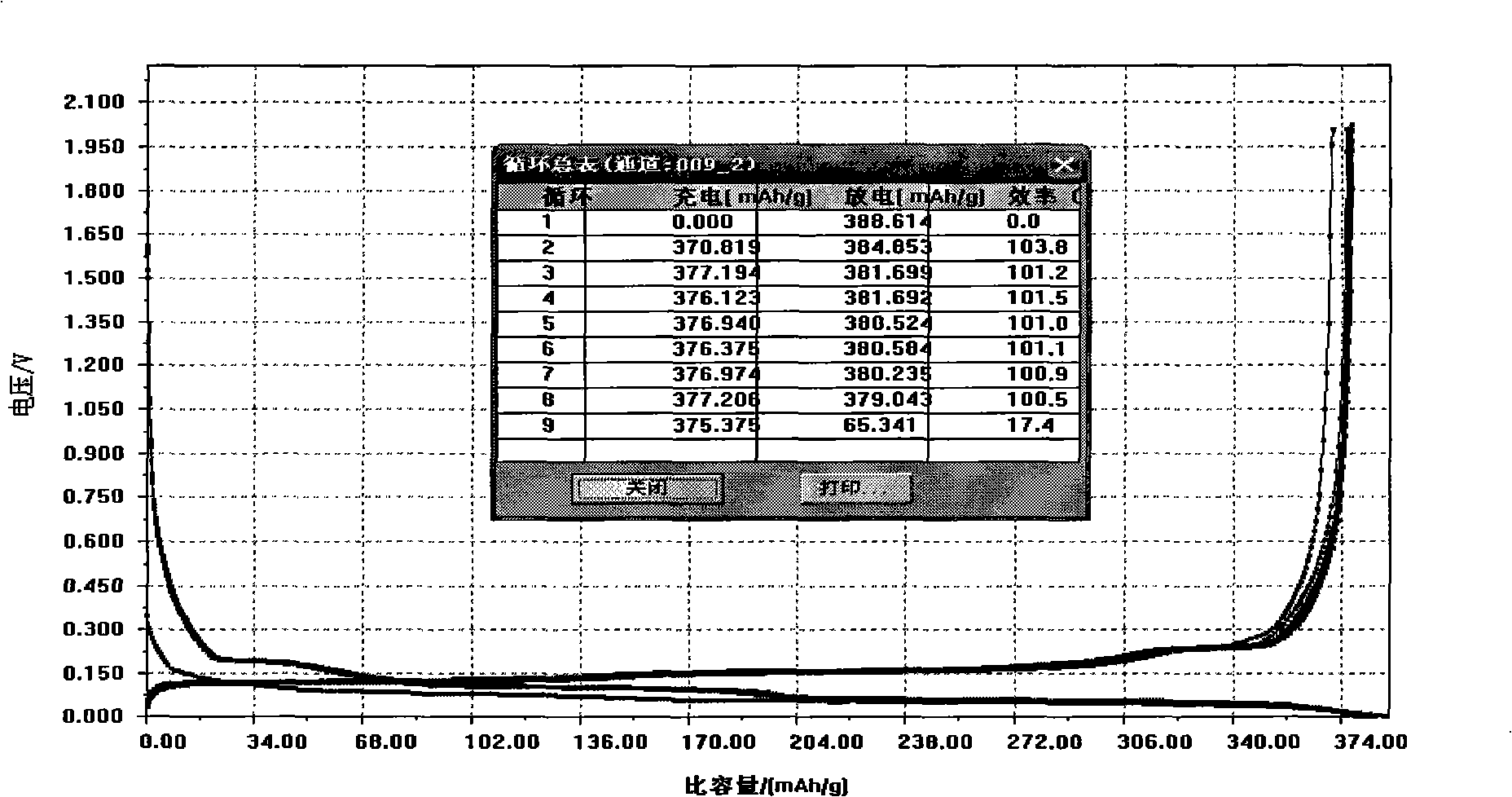

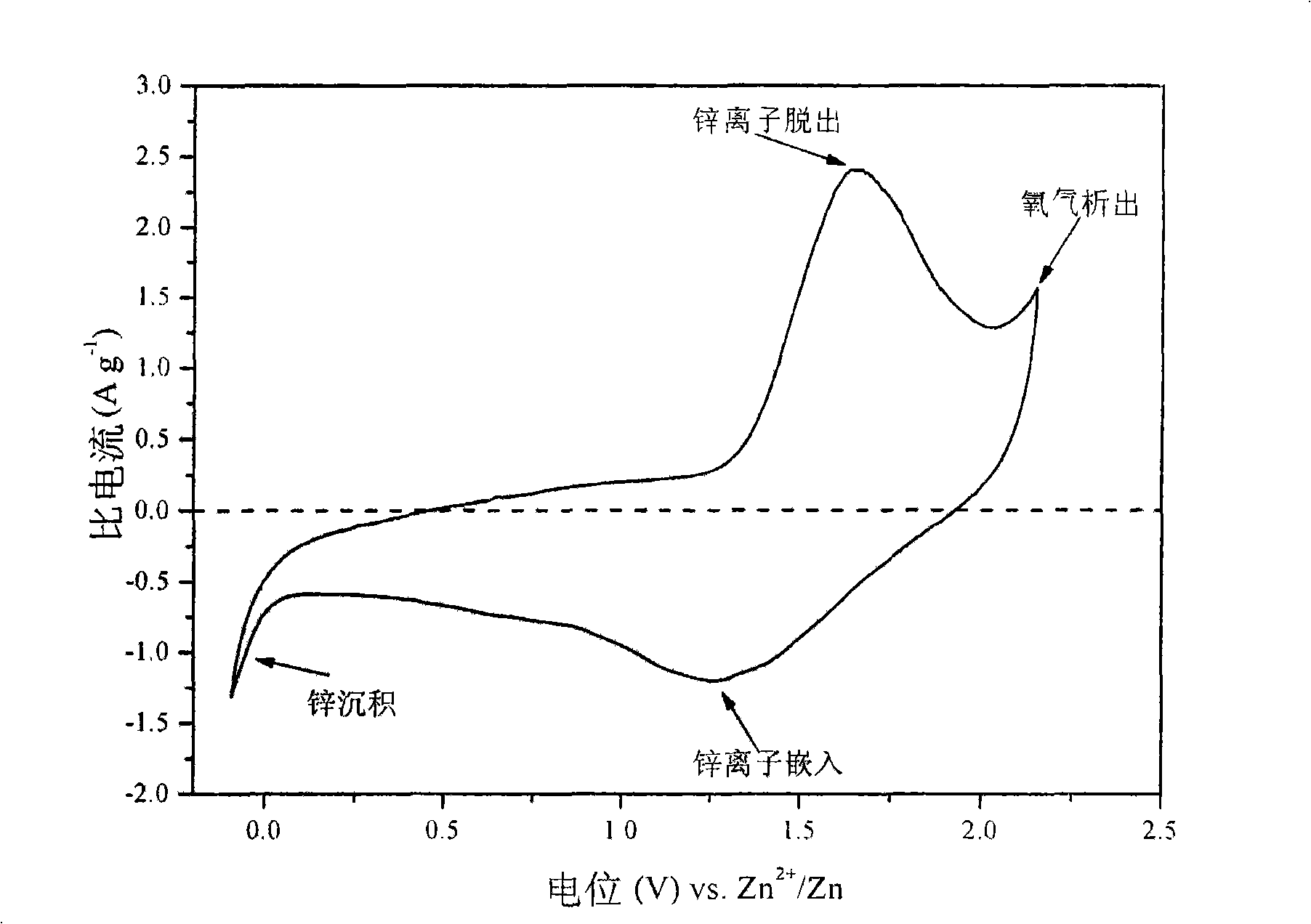

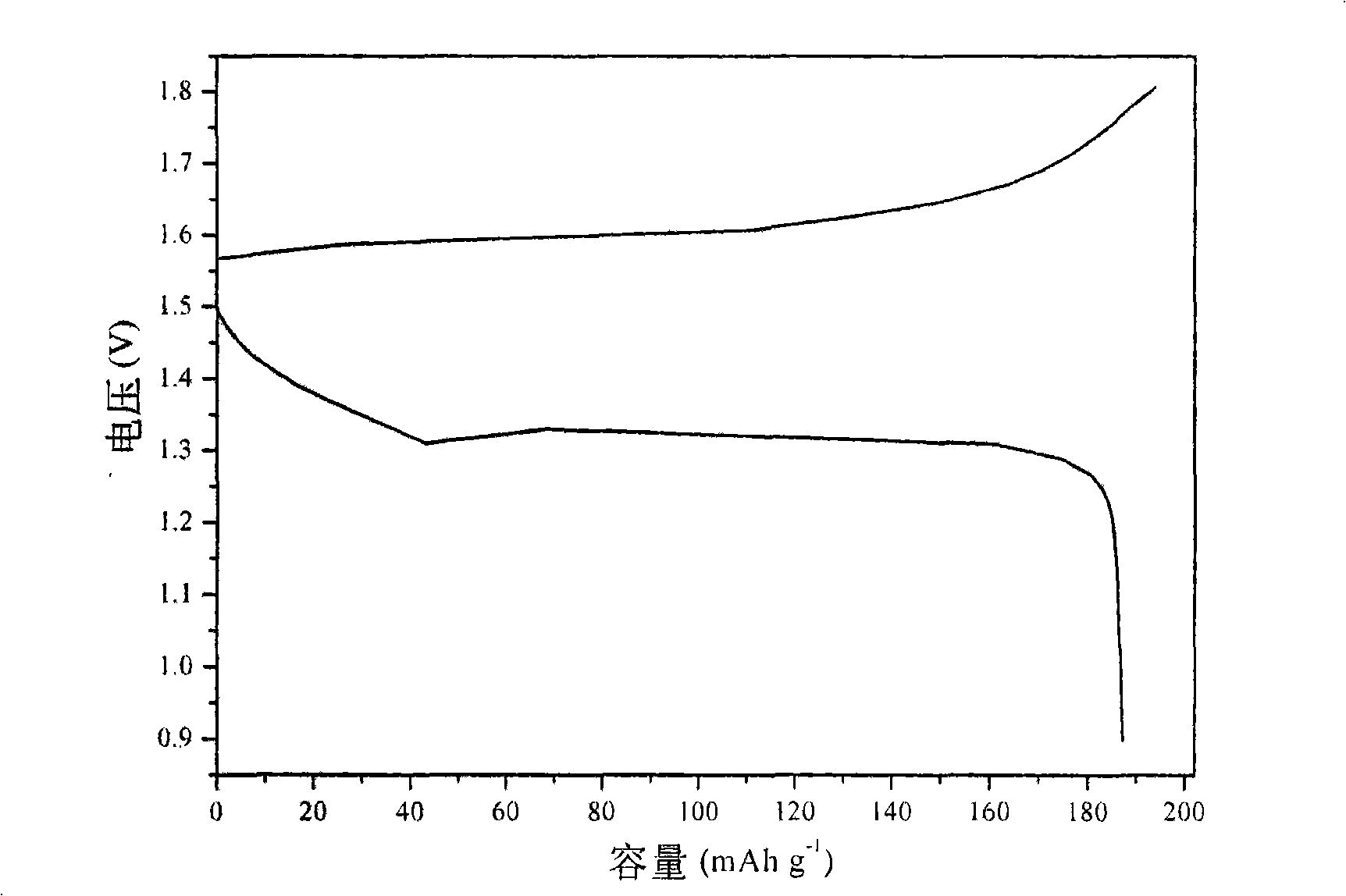

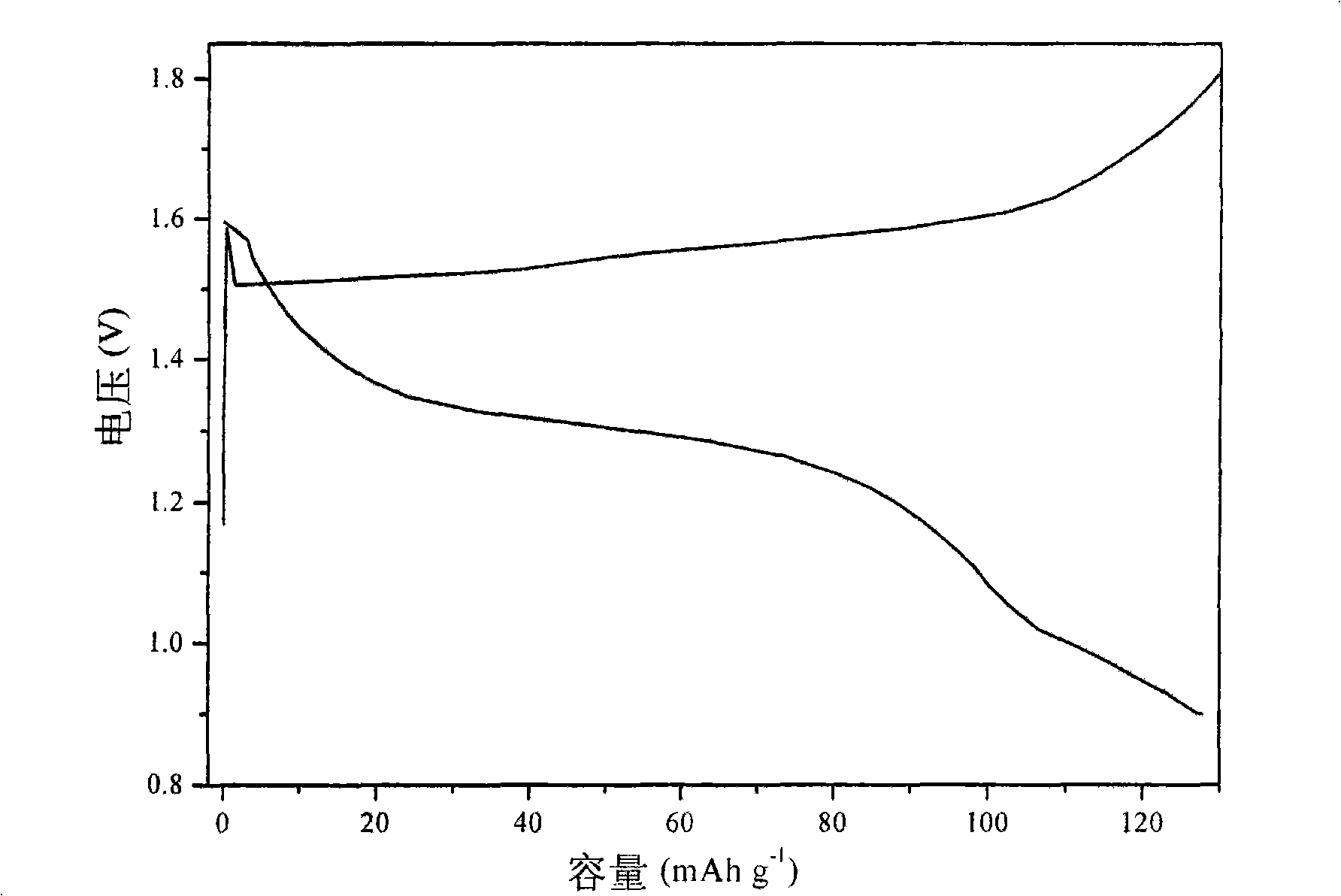

Chargeable zinc ion battery

ActiveCN101540417AImproved magnification performanceGood reversibilityAlkaline accumulatorsActive material electrodesZinc ionManganese

The invention discloses a chargeable zinc ion battery, which comprises an anode, a cathode, isolating membrane arranged between the anode and the cathode, and electrolyte which contains the anion and the cation and has ionicconductivity, wherein the cathode adopts active materials which are mainly zinc elements, the active materials of the anode are oxide materials of manganese which can occlude and release zinc ions, the electrolyte is liquid or gel materials with ionicconductivity which adopts the soluble salt of zinc as solute and water as solvent, and the pH value of the electrolyte lies between 3 and 7. The battery has the characteristics of high capacity, chargeable property, long cycle life and the like. Proven by experiments, the chargeable zinc ion battery has excellent rate performance, reversible performance and cycle performance.

Owner:SHENZHEN CITY THROUGH SCI & TECH OF NEW ENERGY CO LTD

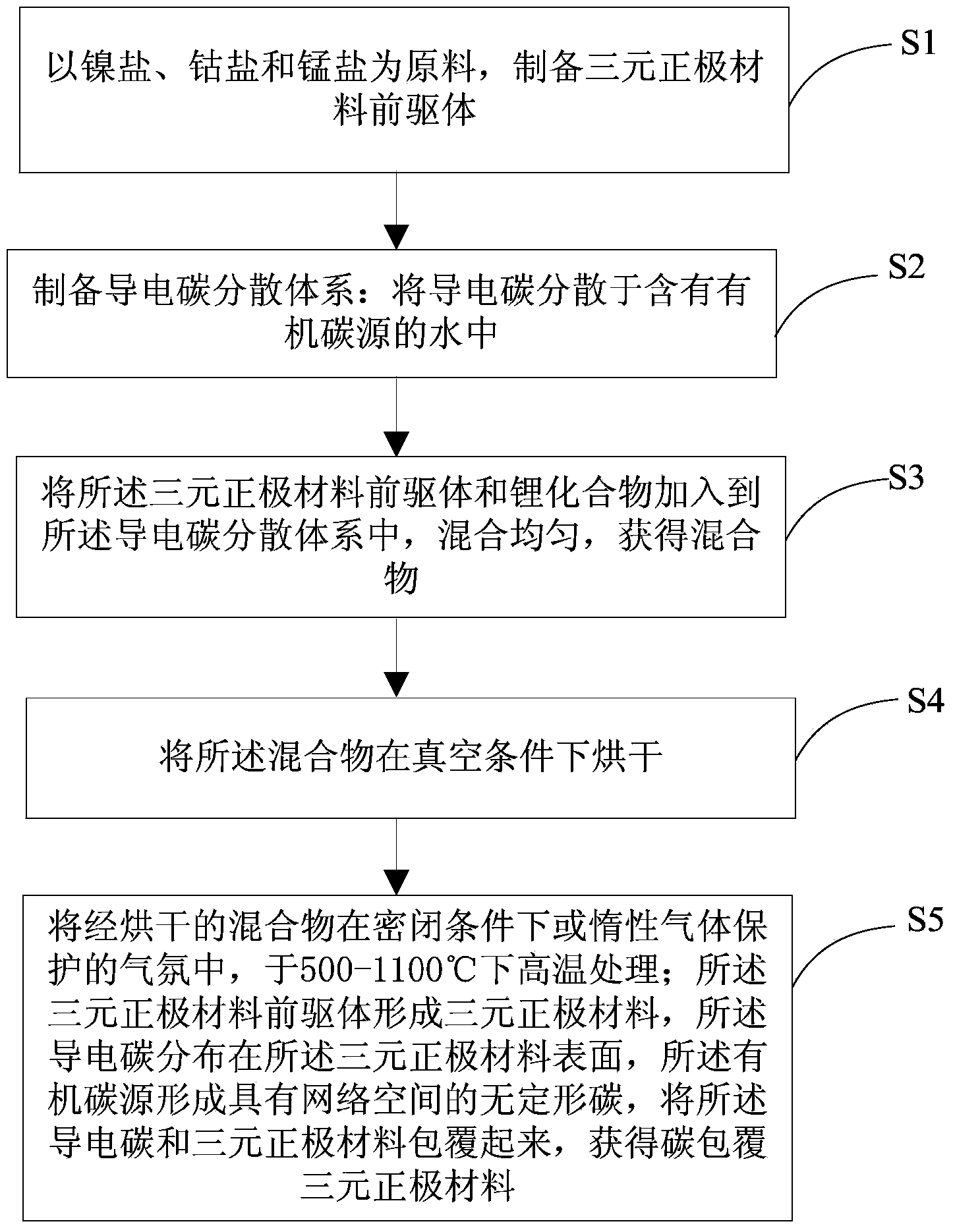

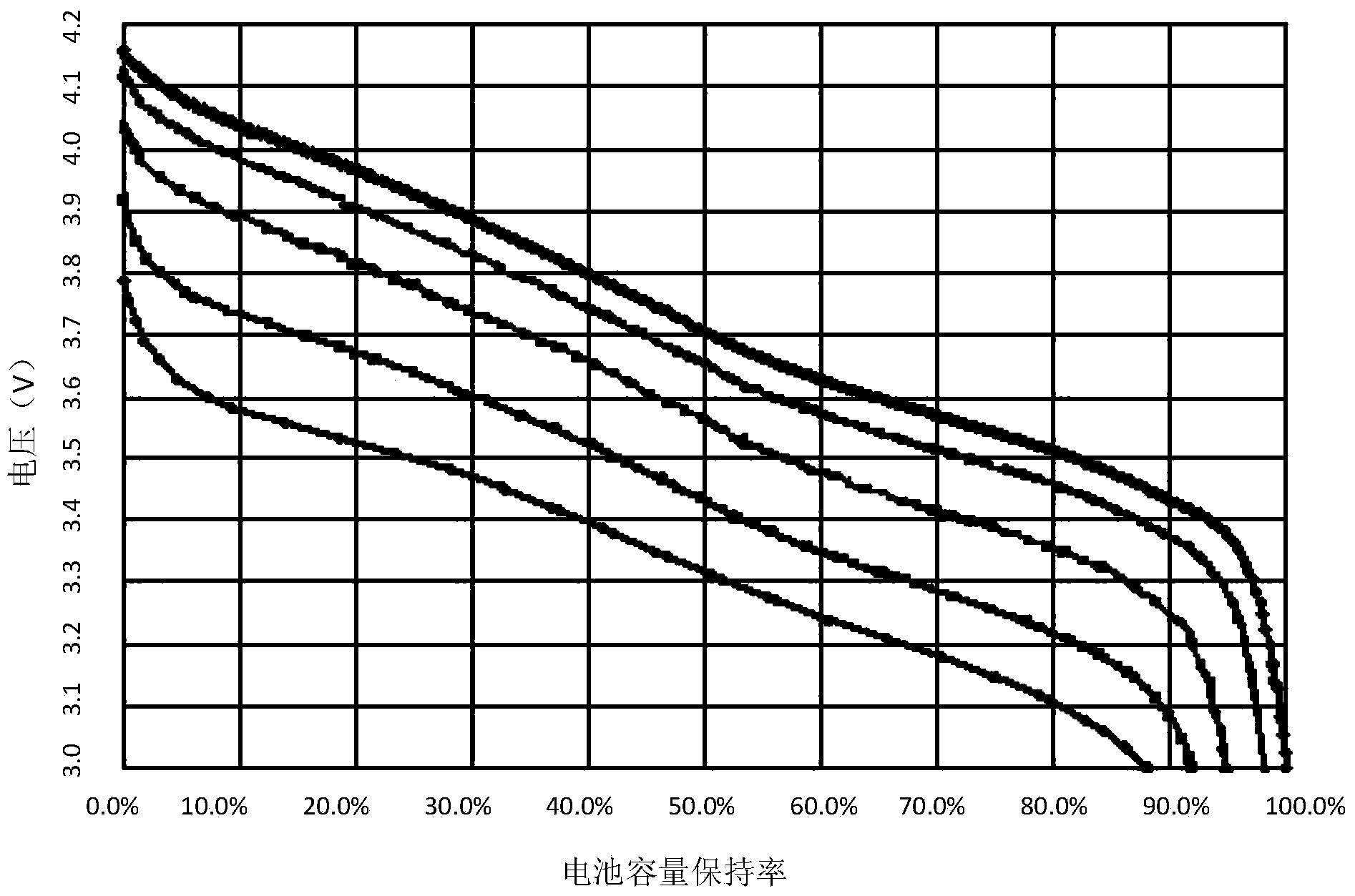

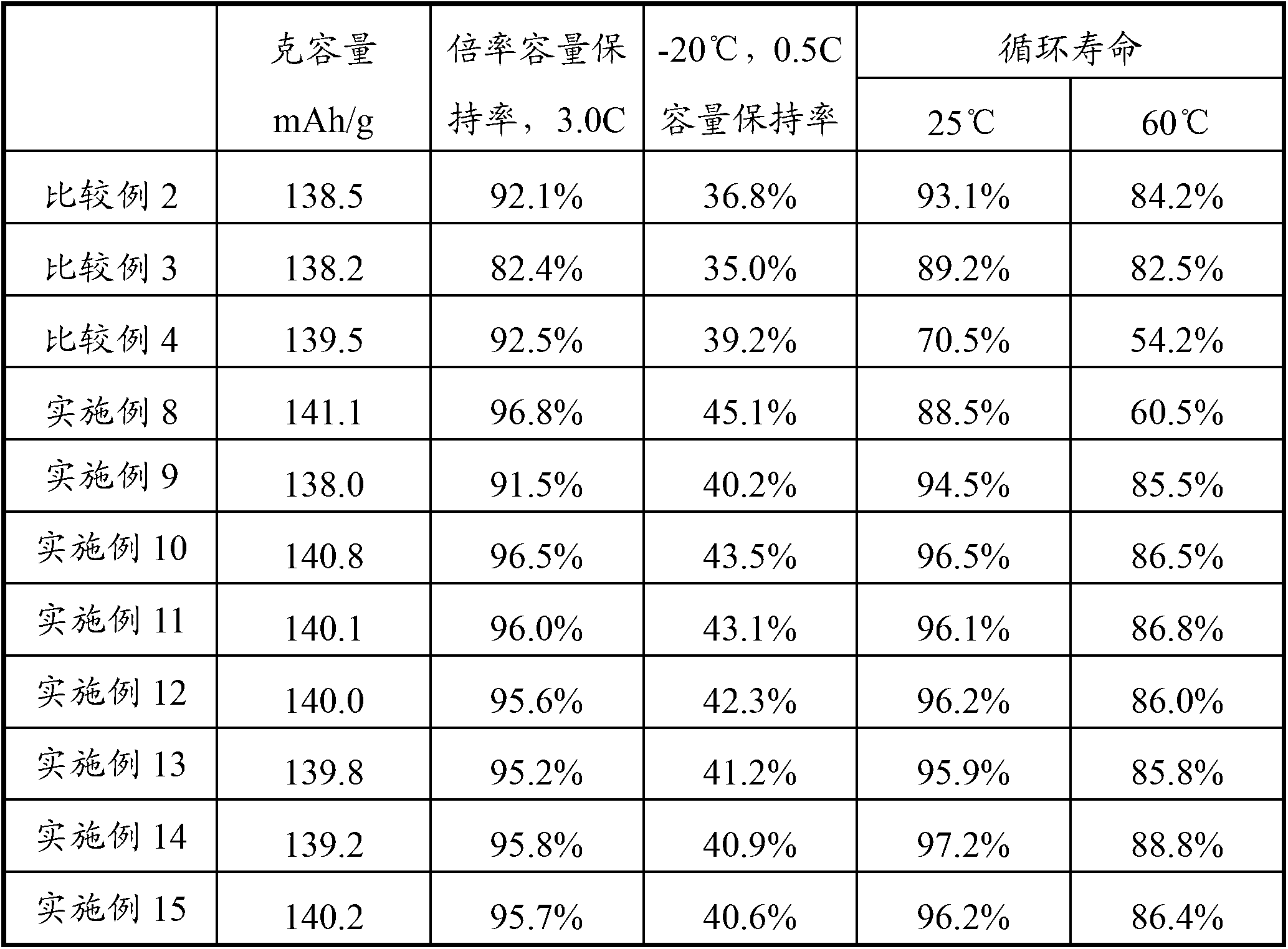

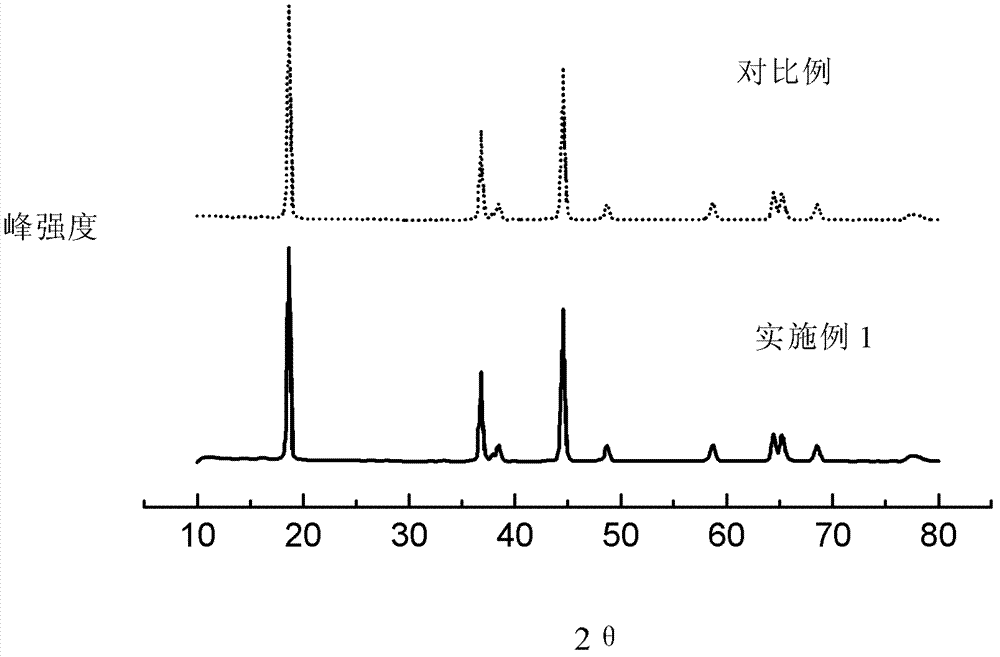

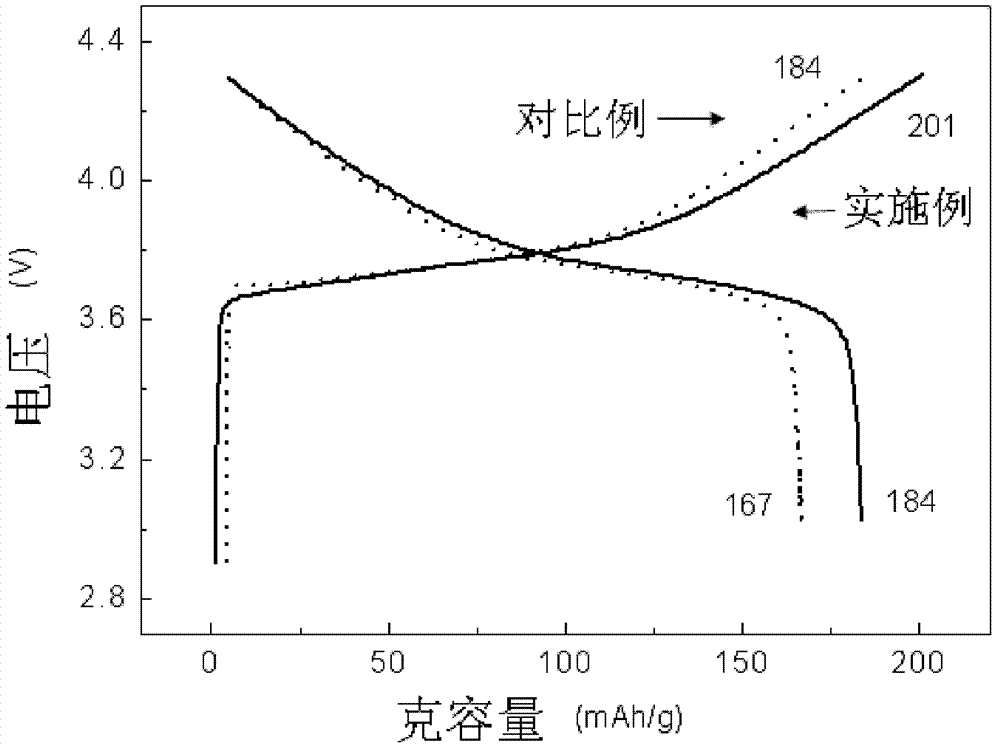

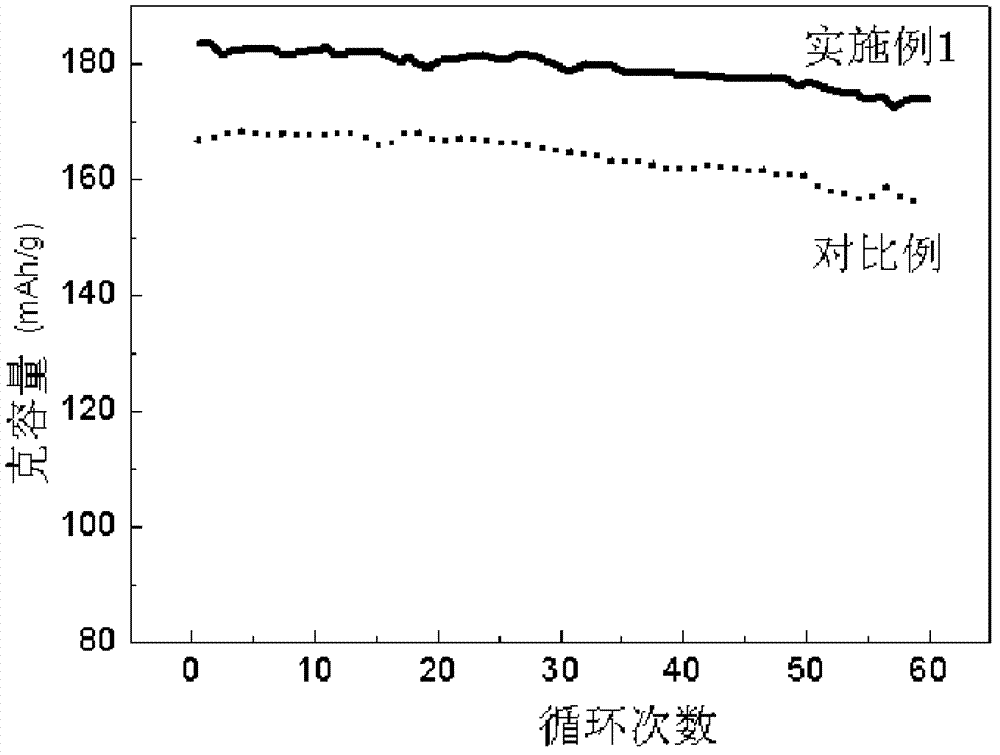

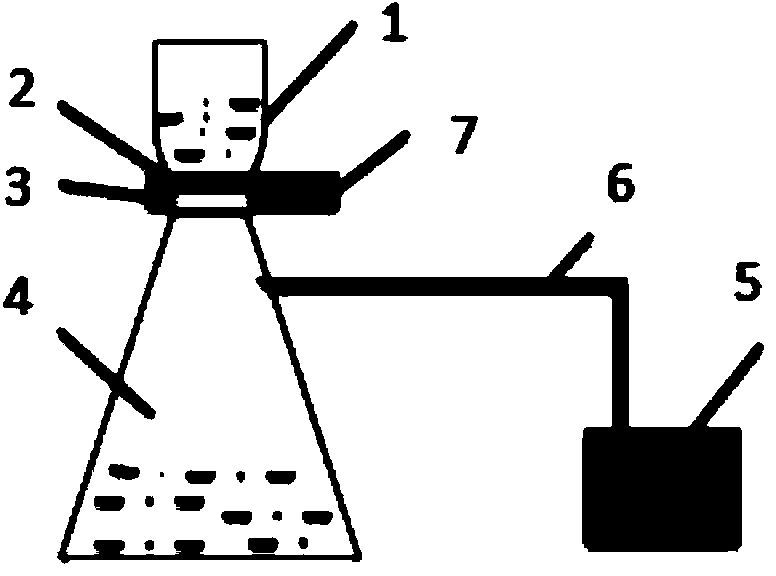

Carbon-coated ternary positive electrode material and preparation method thereof

ActiveCN103474628AImproved magnification performanceImprove conductivityCell electrodesNickel saltManganese

The invention discloses a carbon-coated ternary positive electrode material and a preparation method thereof. The preparation method comprises the following steps: S1, preparing a ternary positive electrode material precursor by taking nickel salt, cobalt salt and manganese salt as raw materials; S2, preparing a conductive carbon dispersion system, wherein conductive carbon is dispersed in water containing an organic carbon source; S3, adding the ternary positive electrode material precursor and a lithium compound into the conductive carbon dispersion system, and mixing uniformly to obtain a mixture; S4, drying the mixture under a vacuum condition; S5, carrying out high temperature treatment on the dried mixture under a closed condition or in an inert gas protection atmosphere so as to obtain the carbon-coated ternary positive electrode material. The carbon-coated ternary positive electrode material is uniform in coating, simple to operate, low in cost and high in efficiency; the conductive carbon and the ternary positive electrode material are simultaneously coated with network-shaped amorphous carbon which serves as a conductive medium or a channel of the conductive carbon and the ternary positive electrode material, thereby greatly improving the rate performance of the ternary positive electrode material.

Owner:SHENZHEN BETTERPOWER BATTERY

Lithium-ion secondary battery and electrolyte thereof

InactiveCN103078141AFacilitated DiffusionImproved magnification performanceSecondary cellsNon-aqueous electrolyte accumulator electrodesMethyl carbonateCarbonate

The invention discloses a lithium-ion secondary battery and an electrolyte thereof. The electrolyte comprises a solvent, lithium salt and a film forming additive, wherein the solvent comprises a first solvent and a second solvent; the first solvent comprises linear carboxylic ester and ethylene carbonate; the second solvent is one or more of ethyl methyl carbonate, diethyl carbonate, dimethyl carbonate and propylene carbonate; and the film forming additive is one or more of fluoroethylene carbonate, vinylene carbonate, 1,3-propane suhone, succinonitrile, adiponitrile, lithium bis(oxalato)borate, and lithium oxalyldifluoroborate. Due to the collocation of linear carboxylic ester and ethylene carbonate, a solvent system with a higher dielectric constant and low viscosity is obtained; the film forming additive improves poor compatibility between linear carboxylic ester and graphite; and finally the lithium-ion secondary battery adopting the electrolyte presents high-power discharge capacity, excellent high-temperature cycling stability and low-temperature charge and discharge properties.

Owner:NINGDE AMPEREX TECH

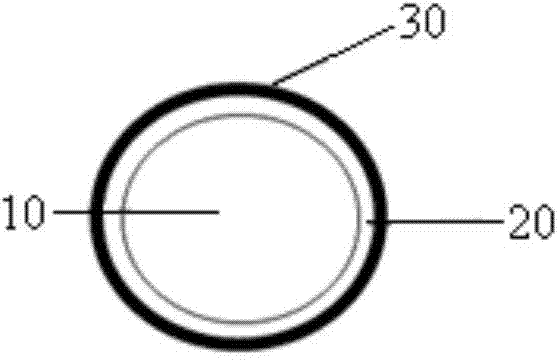

Cylindrical lithium ion battery and manufacturing method therefor

ActiveCN105470558AAvoid deformationImprove securityFinal product manufactureSecondary cellsElectrical polarityEngineering

The invention belongs to the technical field of lithium batteries and discloses a steel shell type cylindrical lithium ion battery and a manufacturing method therefor. The technical scheme adopted by the invention is as follow: the cylindrical lithium ion battery comprises a cylindrical steel shell, a positive plate, a negative plate and a diaphragm, wherein two sides of each of the positive plate and the negative plate are coated with active substances with corresponding activities; the positive plate, the negative plate and the diaphragm are arranged at intervals and wound into a battery cell; the battery is characterized in that a negative current collector is further arranged on an outer layer of the positive plate, the negative plate and the diaphragm arranged at intervals and is wound into the battery cell together with the positive plate, the negative plate and the diaphragm; a tube body is arranged in the middle of the steel shell; the upper part of the tube body is sealed; the periphery of the lower part of the tube body is hermetically connected with the bottom surface of the steel shell; a lower opening of the tube body is communicated with the outside; two short edges and a long edge of the negative plate are left as uncoated regions; the positive plate is provided with a tab; the diaphragm is longer than a coated region on the negative plate at the starting end of winding and wider than the coated region on the negative plate; the center of the battery cell is inserted in the tube body; and the tab of the positive electrode is opposite to the uncoated region of the negative plate in direction.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

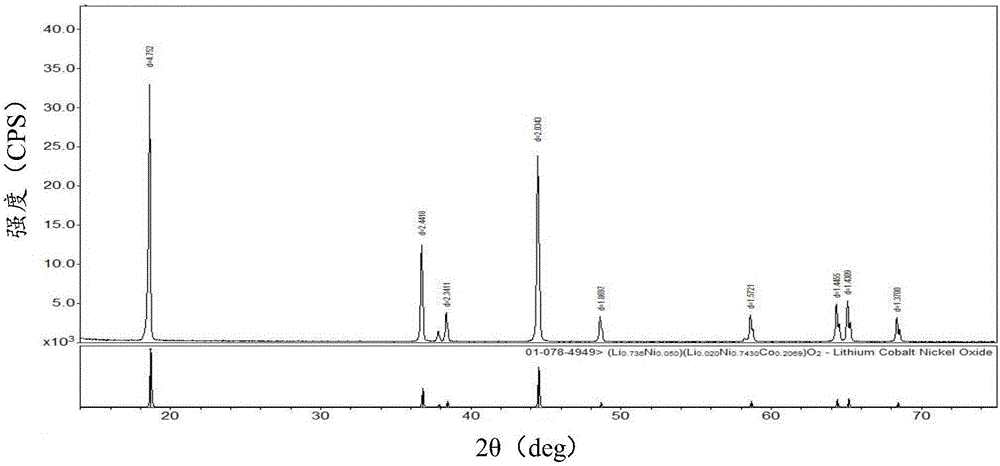

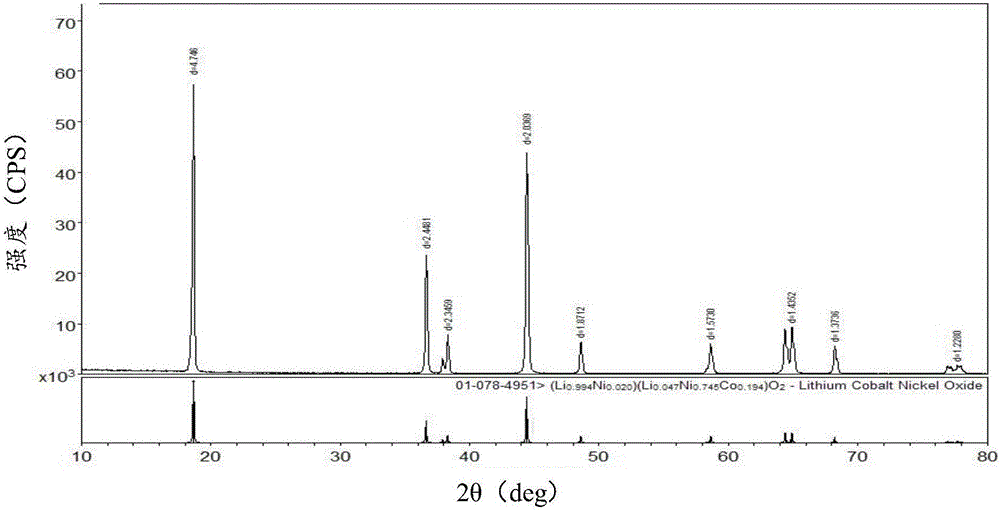

Lithium nickel cobalt manganese positive electrode material and preparation method thereof

InactiveCN103490060AReasonable structureGood ability to withstand high voltageCell electrodesSecondary cellsRare-earth elementLithium

The invention discloses a lithium nickel cobalt manganese positive electrode material. The lithium nickel cobalt manganese positive electrode material comprises a lithium nickel cobalt manganese oxide contained core pure phase layer having a thickness of 5-8mum, a surface coat containing oxides, phosphates or fluorides of coating elements comprising Li, Al, Mg, Ti and Zr and having a thickness of 50-100nm, and a superficial doped transition layer positioned between the core pure phase layer and the surface coat, containing doping elements comprising Al, Mg, Ti and Zr or one of rare earth elements and having a thickness of 1-2mum. The lithium nickel cobalt manganese positive electrode material can inhibit the material dissolving in a cycle process without reducing a specific capacity, and has the characteristics of high capability excellent cycle and rate performances, and excellent thermal stability.

Owner:NINGDE AMPEREX TECH

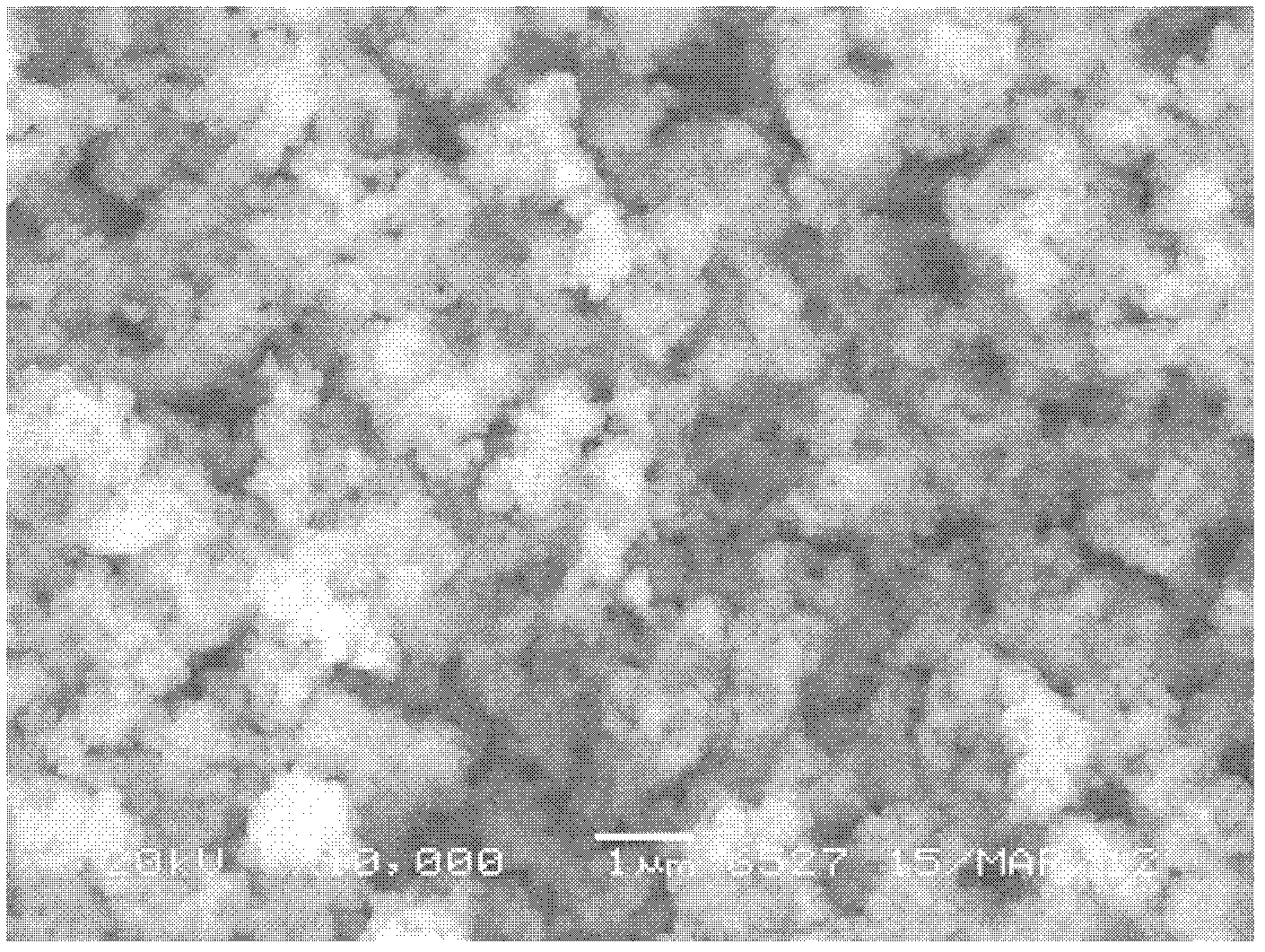

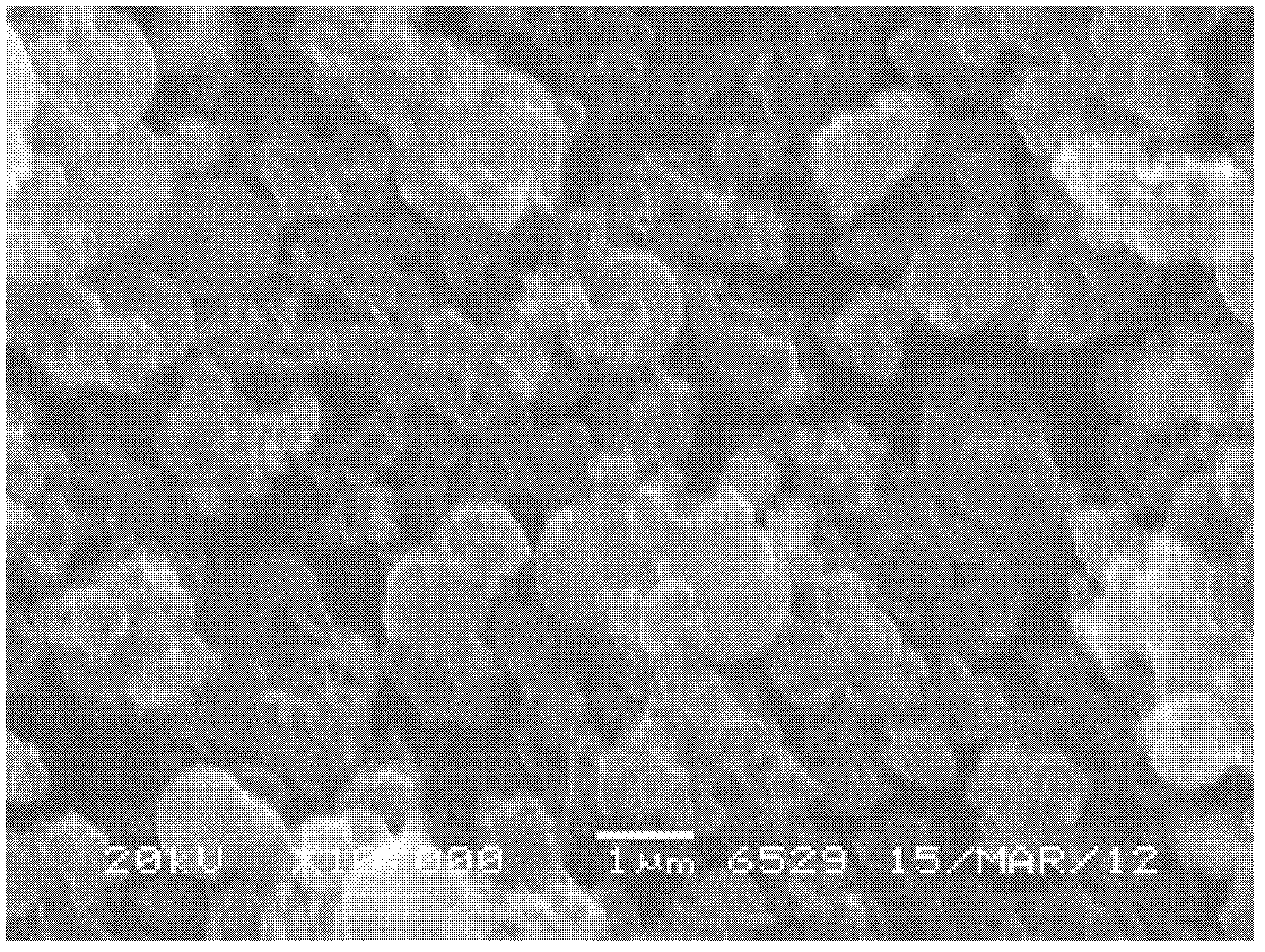

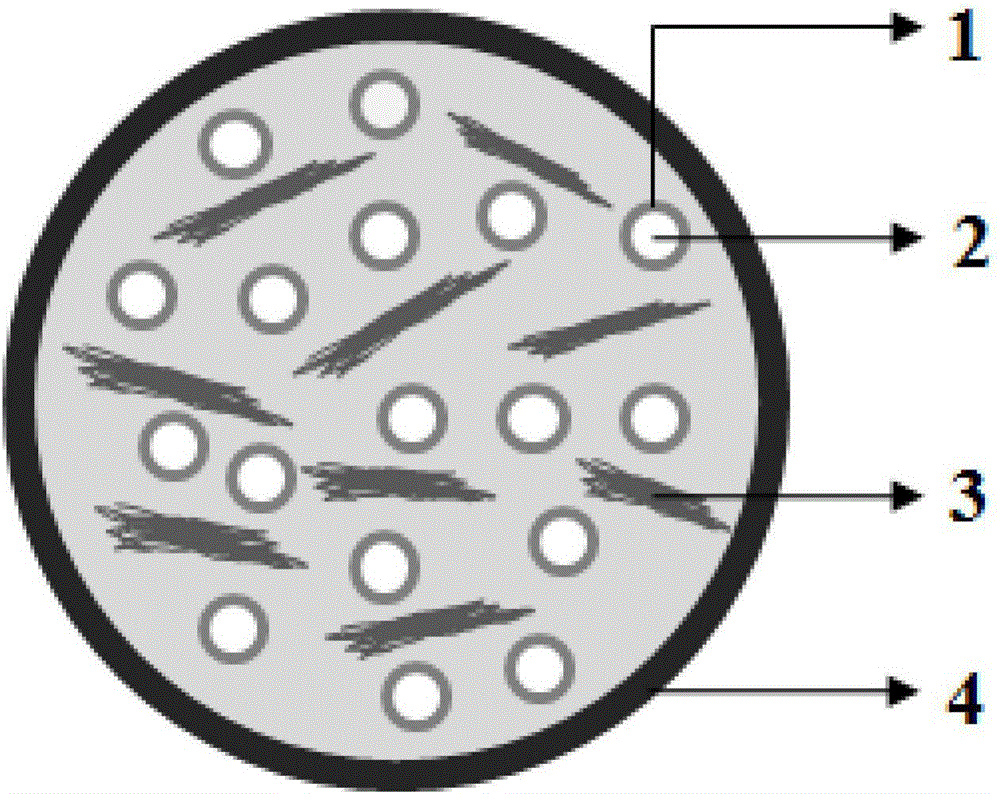

Silicon-carbon composite cathode material with three-dimensional preformed hole structure and preparation method thereof

ActiveCN102623680ALow tap densityReduce volume specific capacityCell electrodesCarbon compositesCarbonization

The invention discloses a silicon-carbon composite cathode material with a three-dimensional preformed hole structure and a preparation method thereof. According to the composite cathode material, a carbon material having high electric conductivity and a stable structure is used as a matrix for dispersedly containing high-volume silicon particles, and proper three-dimensional expansion spaces are reserved around one or several silicon particles. The preparation method comprises the following steps of: carrying out surface modification on the silicon particles; coating the silicon particles by silicon dioxide; coating the silicon dioxide / silicon composite particles by carbon source precursors; carrying out high-temperature carbonization treatment; and removing a silicon dioxide template, and the like. When the composite material prepared by the preparation method is used for a lithium ion battery, the reversible specific capacity is high, and the cycle performance is excellent. The silicon-carbon composite cathode material has the advantages of simple preparation process and wide raw material resource and is suitable for industrial production.

Owner:湖南宸宇富基新能源科技有限公司

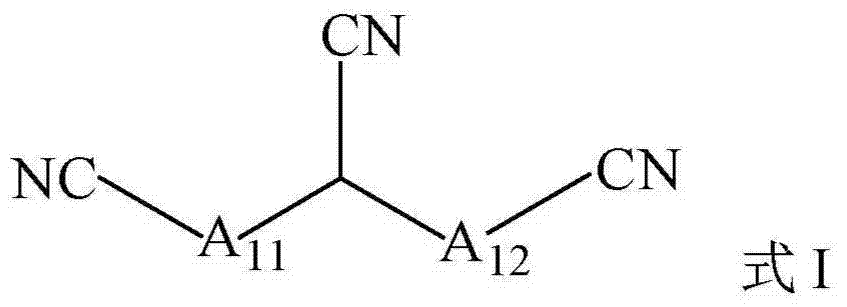

Electrolyte additive and application thereof in lithium ion battery

ActiveCN104766995AImprove cycle lifeImprove featuresLi-accumulatorsOrganic electrolytesHigh temperature storageSulfur

The invention discloses an electrolyte additive and an application thereof in a lithium ion battery. The electrolyte additive comprises a polynitrile-based compound and a compound comprising a sulfur bond and an oxygen bond. When the electrolyte additive is applied to the lithium ion battery, good cycle life, good low-temperature discharging property and good high-temperature storage property of the lithium ion battery under the high voltage still can be maintained.

Owner:CONTEMPORARY AMPEREX TECH CO

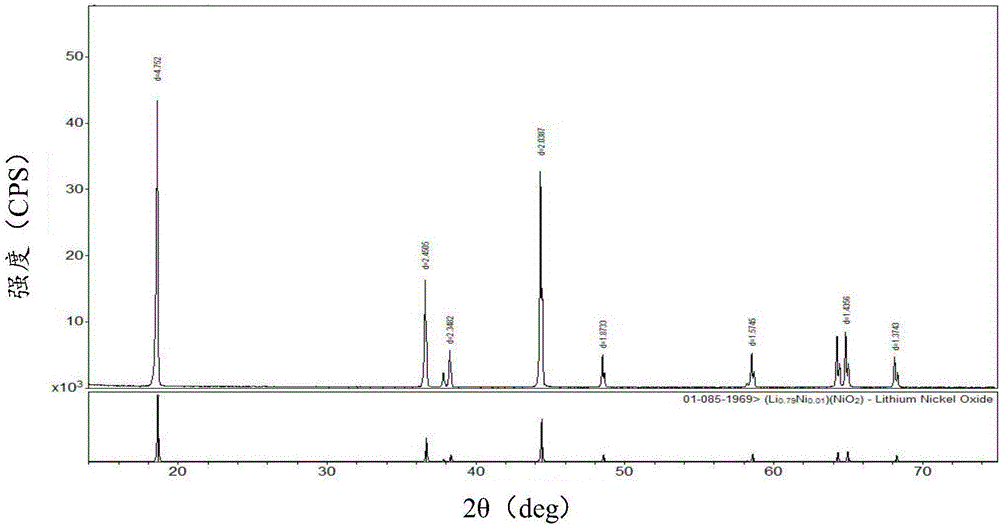

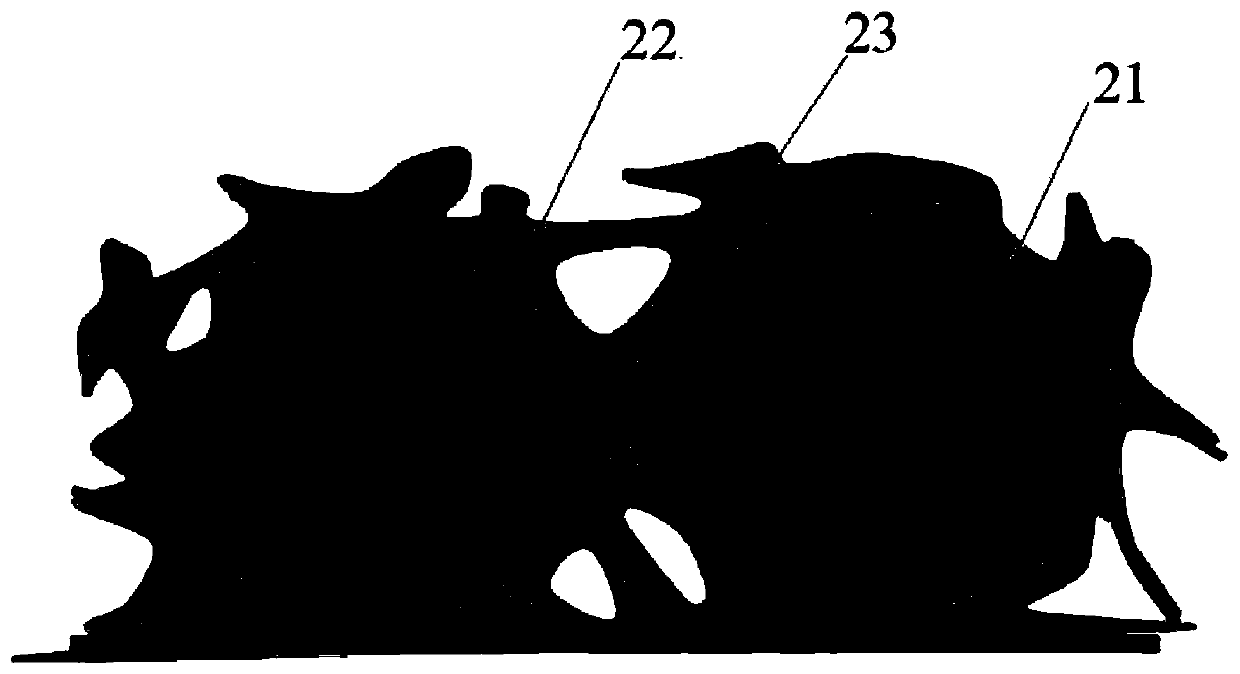

Lithium ion battery gradient core shell cathode material and synthetic method thereof

ActiveCN103236537AGuaranteed cycle performanceGuaranteed rate performanceCell electrodesNickel compoundsElectrical batteryPhysical chemistry

The invention provides a lithium ion battery gradient core shell cathode material and synthetic method thereof, and relates to a lithium ion battery cathode material and synthetic method thereof. The lithium ion battery gradient core shell cathode material provided by the present invention may have two kinds of core shell structures as follows: a two-layer structure: a ternary material is used as a core material, and a binary material or a unitary material is casing material, and the ternary material external layer is covered by the binary material or the unitary material; three-layer structure: the ternary material is used as a core material, and the binary material and the unitary material are casing materials, and the ternary material external layer is covered with the binary material, and the binary material is covered with the unitary material. The synthetic method includes: employing a coprecipitation method for obtaining a precursor, and then adding lithium source, calcining and coating to obtain the ternary gradient core shell material. Under the prerequisite that the structure stability of the material is kept, the cost is reduced, and the gram capacity of the material is improved, and the material circulating performance and rate capability of the material are improved, and the safety performance and low temperature performance of the ternary cathode material are increased, and the preparation technology is optimized and improved.

Owner:HARBIN INST OF TECH

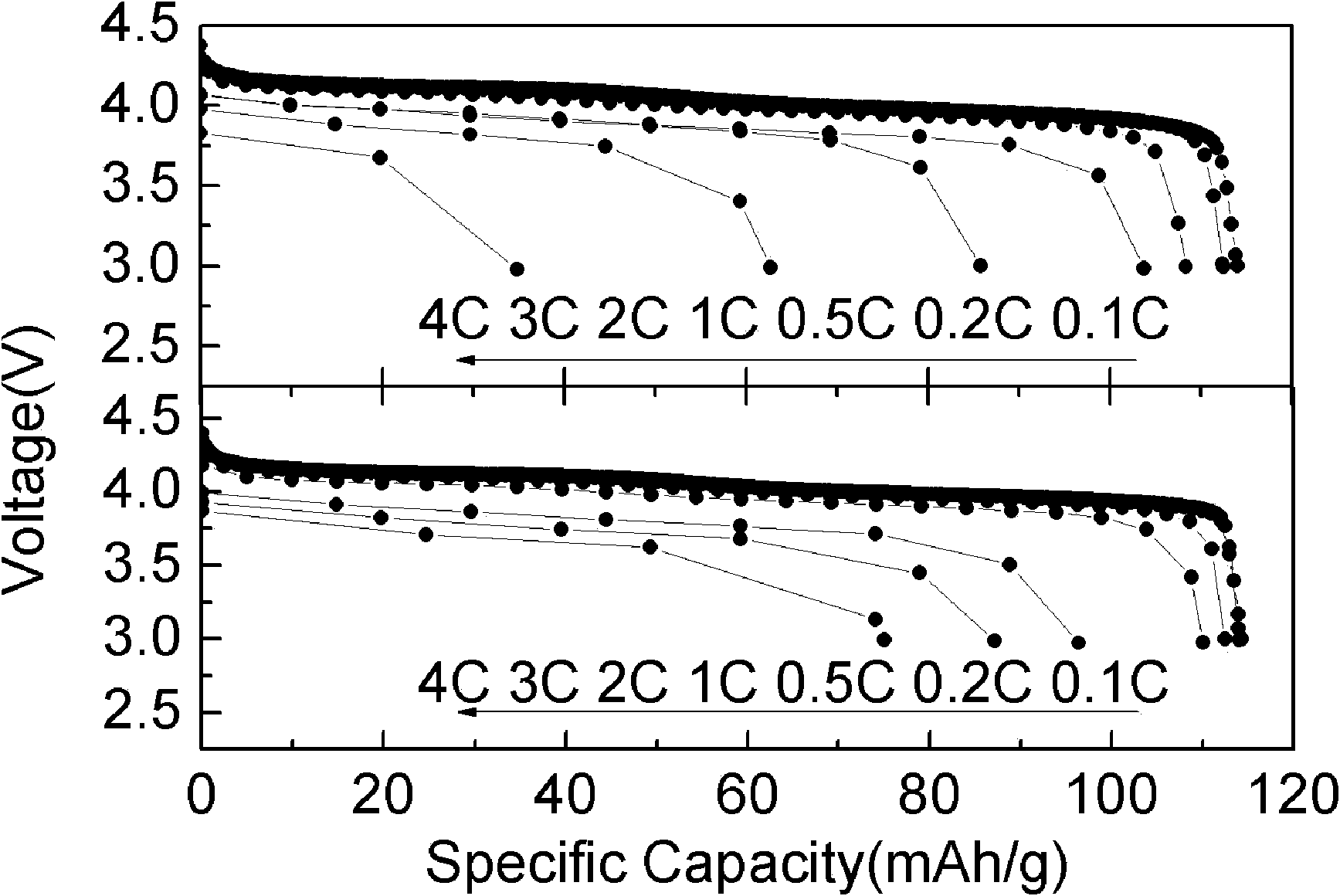

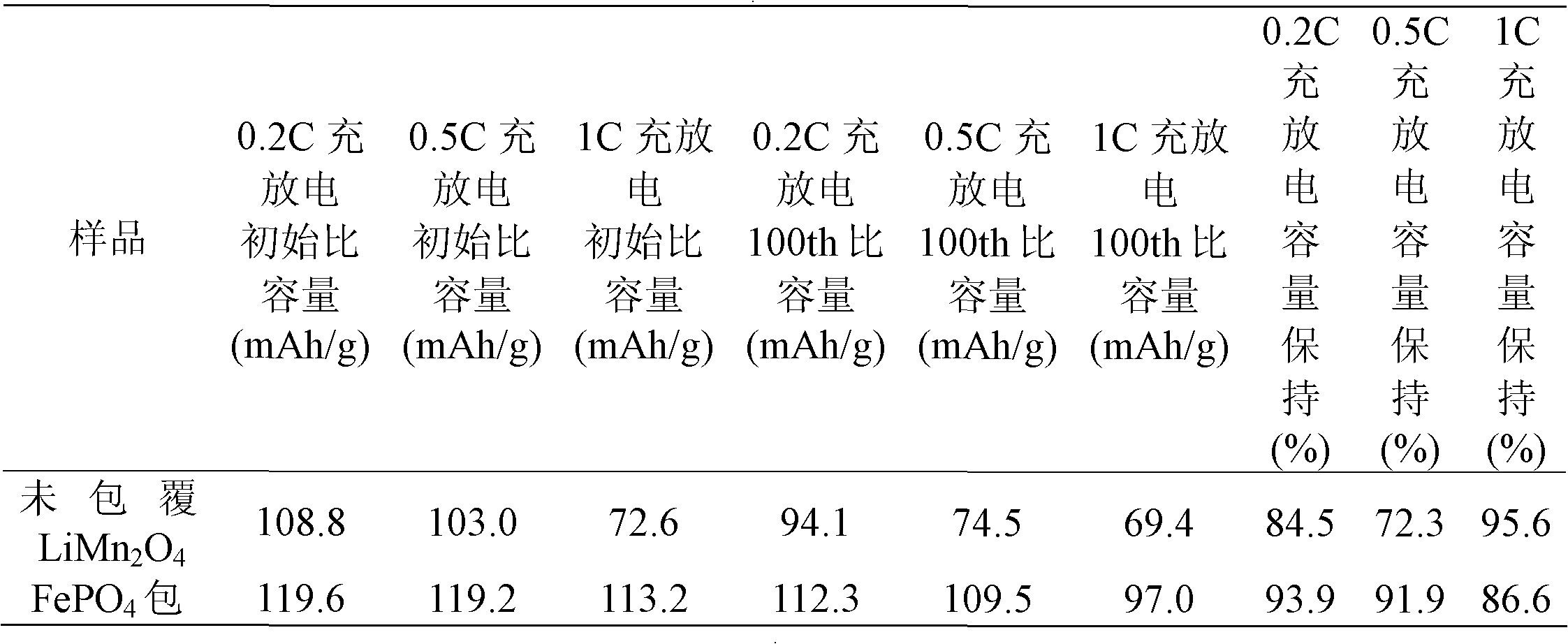

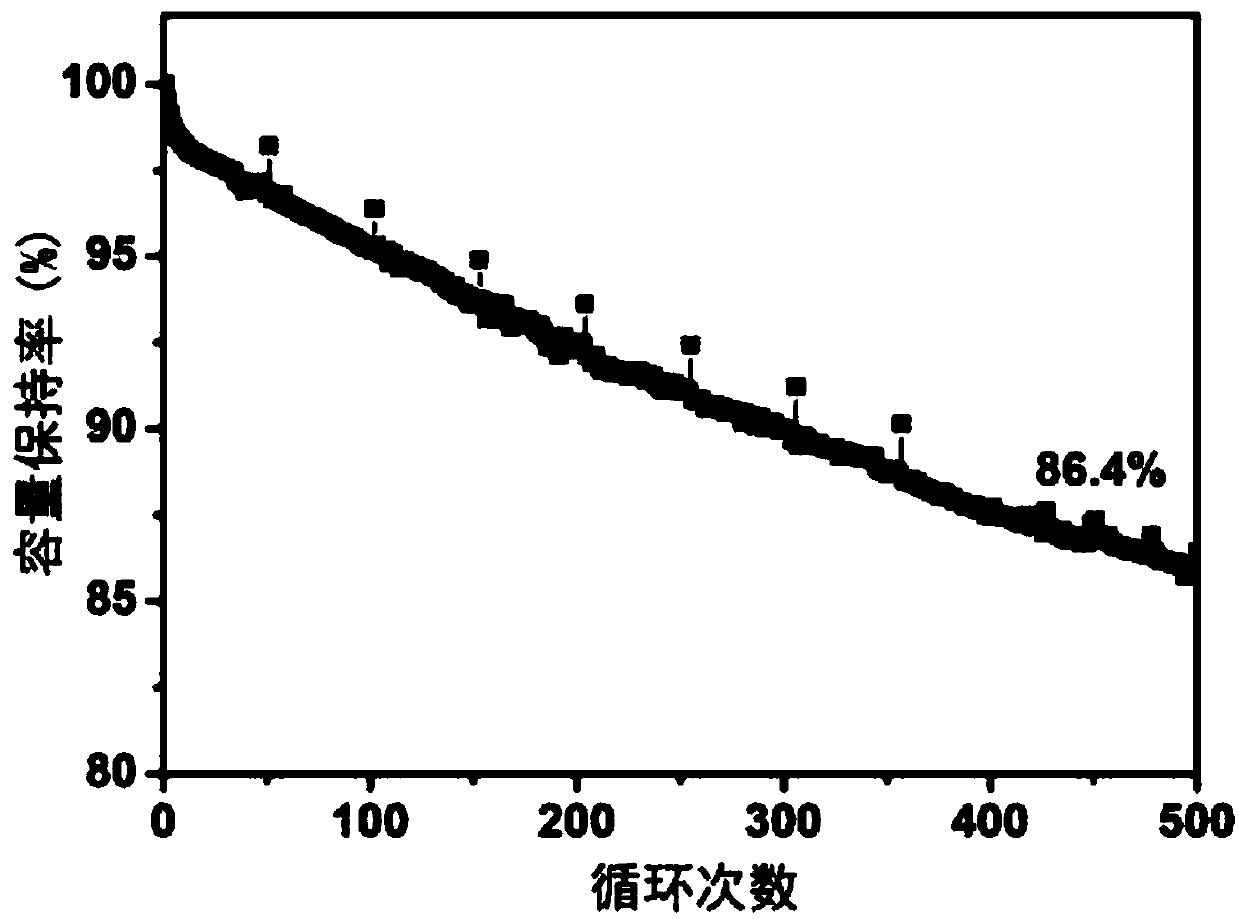

Transition metal phosphate-clad composite lithium ion battery anode material

InactiveCN101859887AReduce erosionImprove cycle performanceNon-aqueous electrolyte accumulator electrodesLithiumElectrochemical response

The invention discloses a transition metal phosphate-clad composite lithium ion battery anode material with lithium-storing active material as a main core and electrochemically active transition metal phosphate as a cladding layer. The active material core mainly carries out electrochemical reaction, and provides battery capacity; and the cladding layer not only can protect the lithium-storing active material and reduce the dissolution and erosion of the active material by electrolyte, but also can increase the battery capacity and improve the rate capability of the active material.

Owner:HUAZHONG UNIV OF SCI & TECH

Doped multi-layer core-shell silicon-based composite material for lithium ion battery and preparation method thereof

ActiveCN109599551AInhibits and buffers swellingPrevent partial failureMaterial nanotechnologySecondary cellsCarbon filmComposite film

The present invention relates to a doped multi-layer core-shell silicon-based composite material for a lithium ion battery, and a preparation method thereof. Other than being doped with a necessary lithium element, the material is also doped with at least a non-metallic element and a metal element; the material has a structure in which a silicon oxide particle doped with elements is taken as a core, and a multilayer composite film which is tightly coated on the surface of the core particle is taken as a shell; the core particle contains uniformly dispersed monoplasmatic silicon nanoparticles,the content of doping elements gradually decreases from the outside to the inside without a clear interface, and a dense lithium silicate compound is formed on the surface of the core particle by embedding and doping the lithium element; and the multilayer composite film is a carbon film layer and a doped composite film layer composed of the carbon film layer and other elemental components. The doped multi-layer core-shell silicon-based composite material provided by the present invention has a high capacity, good rate performance, high coulombic efficiency, good cycle performance, a low expansion rate, and other electrochemical characteristics when the material is used for the negative electrode of lithium ion battery.

Owner:BERZELIUS (NANJING) CO LTD +1

Anode active material, preparation method of anode active material, high-performance anode slurry containing anode active material, and all-solid-state lithium ion battery

ActiveCN106784798AImprove mobilityImprove electrochemical performanceCell electrodesSecondary cellsInorganic compoundSulfide

The invention relates to an anode active material, a preparation method of the anode active material, high-performance anode slurry containing the anode active material, and an all-solid-state lithium ion battery. The anode active material is a nickel-rich type core-shell structure particle or a nickel-rich type core-shell structure particle coated with an inorganic compound coating layer at the surface; an inner core of the nickel-rich type core-shell structure particle is LiNixCoyMn1-x-yO2; the shell is nickel cobalt lithium aluminate. The invention also provides the high-performance anode slurry, which comprises the anode active material, a composite conductive agent, a composite bonding agent, an additive and an organic solvent, wherein the additive is sulfide solid electrolyte; the anode slurry is used for preparing an anode plate consisting of an anode current collector, an anode slurry layer and a modification layer; the anode plate, the sulfide solid electrolyte and a cathode plate are assembled into the all-solid-state lithium ion battery. The all-solid-state lithium ion battery has the prominent advantages of high mass specific energy, high volumetric specific energy, good rate capability, good cycle performance, high safety and the like, and has wide application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

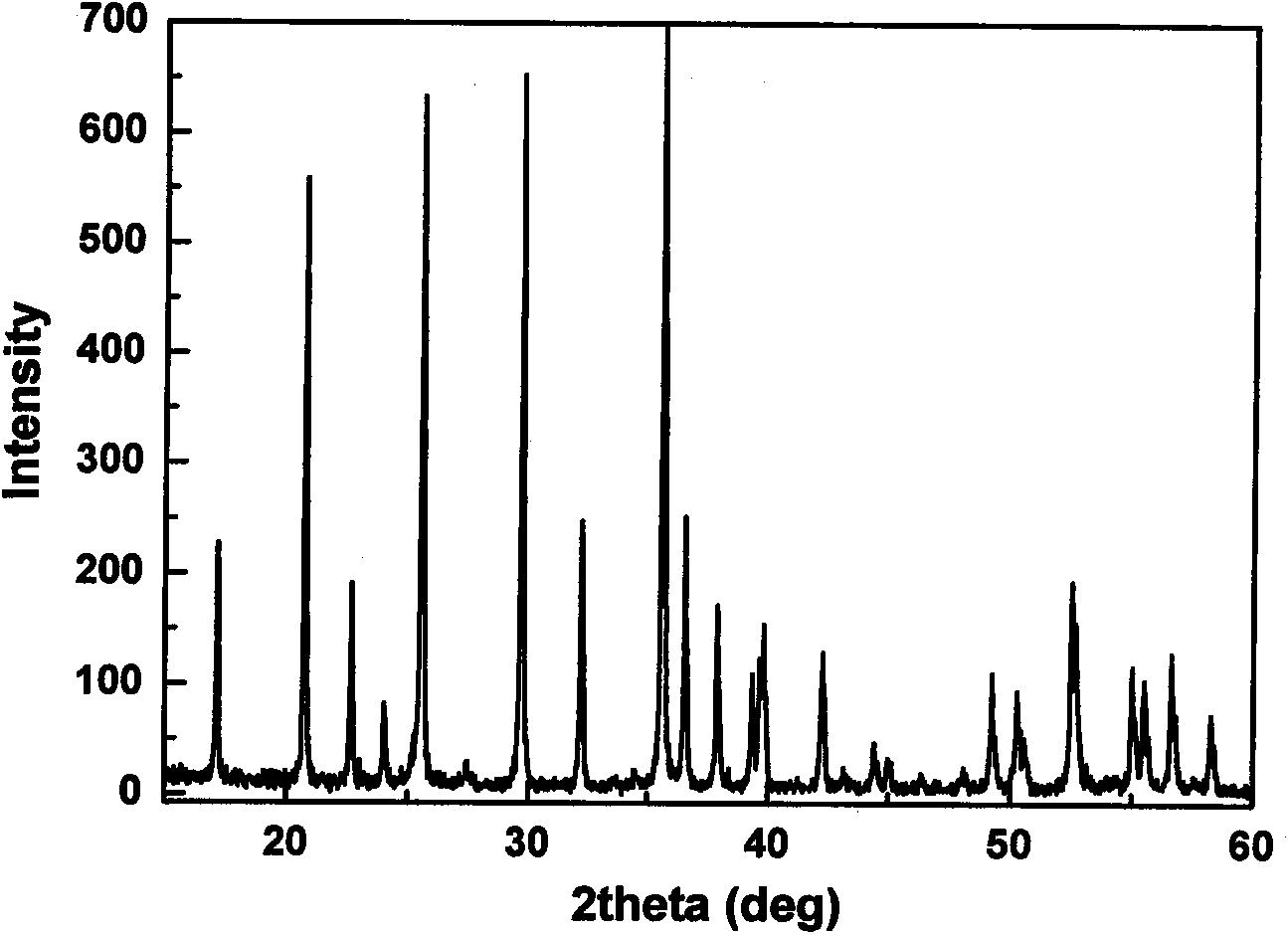

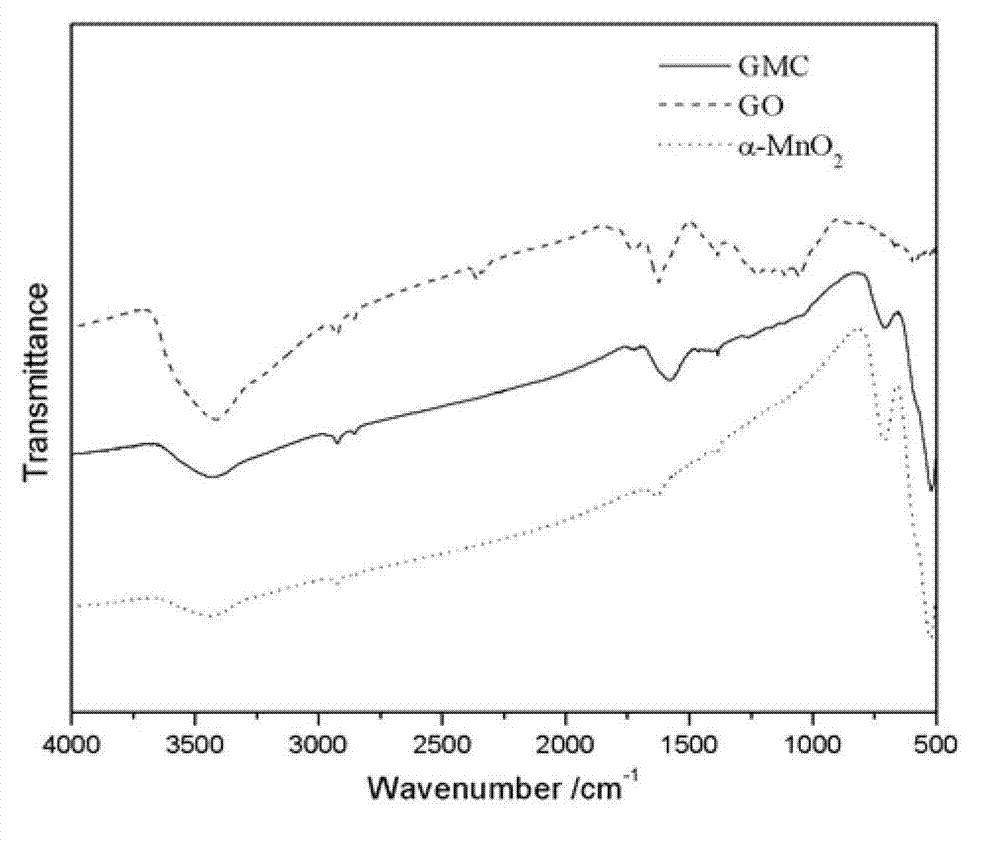

Method for compounding graphene and metallic oxide/metallic compound and composite material thereof

ActiveCN103094540AImprove cycle performanceImproved magnification performanceMaterial nanotechnologyCell electrodesSolubilityGram

The invention discloses a method for compounding graphene and a metallic oxide / metallic compound. The method comprises the following steps: a, dissolving graphene oxide in a dispersing agent, regulating the PH value of the solution to be 5-9, and preparing a graphene oxide solution; and b, adding the oxide / metallic compound into the graphene oxide solution, ultrasonically mixing, reacting at the temperature of 70-120 DEG C for 32-40 hours. According to the method for compounding graphene and the metallic oxide / metallic compound, a reducing agent is not used, the composite material is reduced by utilizing the reducing property of graphene oxide in a hydrothermal environment, and the final product forms the uniformly dispersed graphene and oxide / metallic compound composite material by utilizing the high water solubility of the graphene oxide; and moreover, according to the material, the cycle performance, rate capability and gram volume of the oxide which serves as an electrode of a lithium ion battery can be effectively improved, and the impendence is reduced.

Owner:CHENGDU SCI & TECH DEV CENT CHINA ACAD OF ENG PHYSICS

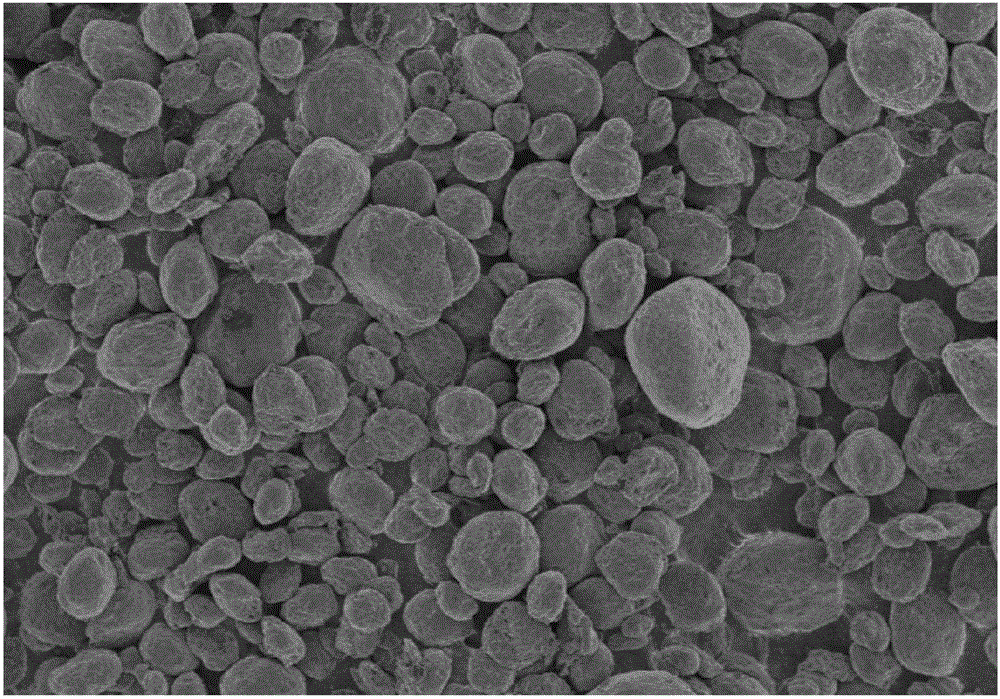

Particle appearance regulatory lithium iron phosphate preparation method

ActiveCN101007630AGood for solid phase diffusionUniform size distributionCell electrodesPhosphorus compoundsLithium iron phosphatePhosphate ion

The invention discloses a modulating method of LiFePO4 particle shape, which comprises the following steps: blending one or more composition with lithium ion, ferric ion and phosphate radical ion; adding solvent and certain quantity of crystal growing inhibitor; proceeding solvent heat reaction under certain temperature; washing; filtering; drying; sintering to improve crystallizing property; obtaining the product with regular shape and size.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

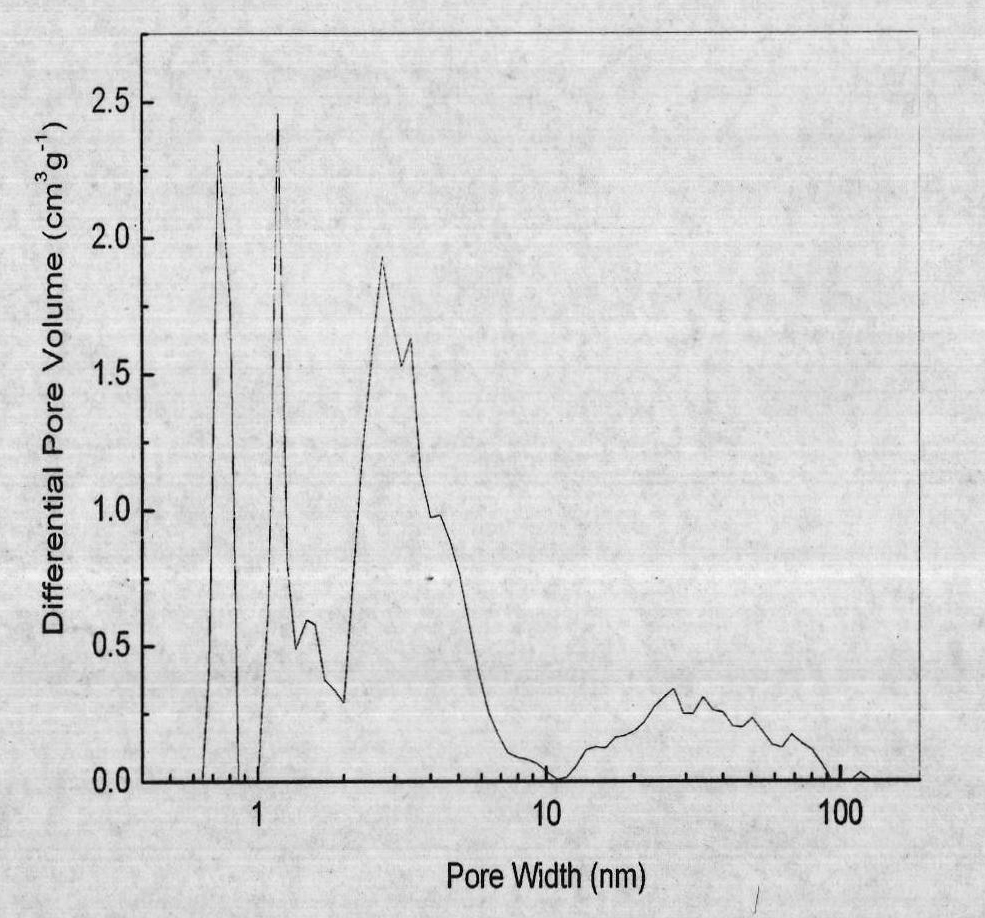

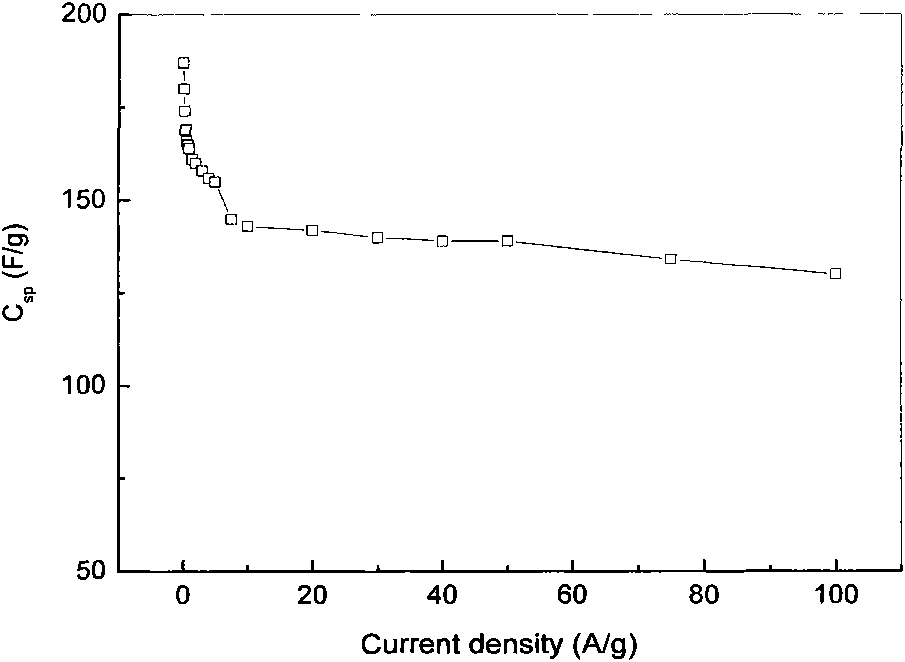

Preparation method of porous structured active carbon

The invention provides a preparation method of porous structured active carbon. The preparation method comprises the following steps of: drying animal bones serving as raw materials; pre-carbonizing at the temperature of 400 to 500 DEG C under the protection of an inert gas; crushing into powder; adding an activating agent into the powder; performing chemical activation under the protection of the inert gas; cooling and taking a product out; and performing aftertreatment process such as acid-washing, water-washing and drying to obtain the porous structured active carbon, wherein the product prepared at 850 DEG C has the specific surface area of 2,157 square meters per gram and the pore volume of 2.26 cubic centimeters per gram; the pores are in a three-dimensional distribution of micropores, mesopores and macropores. By taking organic substances and inorganic substances in the animal bones as a carbon source and a natural template with a special pore structure, the preparation method overcomes the defects of requirement on a template and difficulty in immersing pores in a template by using a carbon precursor, prepares the porous active carbon, and is low in cost and simple in process.

Owner:BEIJING UNIV OF CHEM TECH

Carbon-coated nano silicon/graphene/cracked carbon layer composition material, preparation method, and lithium ion battery including the composition material

InactiveCN106067547AAchieve perfect compoundSimple processMaterial nanotechnologyCell electrodesNano siliconCarbon layer

The invention relates to a carbon-coated nano silicon / graphene / cracked carbon layer composition material, a preparation method thereof, and a lithium ion battery including the composition material. The composite material comprises spherical particles formed by uniformly dispersing carbon-coated nano silicon in graphene sheets, and a cracked carbon layer which coats the surfaces of the spherical particles. The carbon-coated nano silicon comprises nano silicon and carbon coating layer which coats the surface of the nano silicon. The method is simple, has excellent process performance and is environment-friendly. The carbon-coated nano silicon / graphene / cracked carbon layer composition material has stable structure and high compact density, has excellent performance when being used as an anode material of the lithium ion battery, has high anode capacity, excellent rate capability and cyclic performance, is more than 1500 mAh / g in first-time reversible capacity, is more than 90% in first-time coulomb efficiency and is more than 90% in 500-time cyclic capacity retention ratio and has low expansion.

Owner:BTR NEW MATERIAL GRP CO LTD

Gradient distribution multivariate composite material precursor as well as preparation method and application thereof

ActiveCN103367704AImproved thermal stability and safety performanceHigh discharge specific capacityCell electrodesIonTemperature cycling

The invention relates to a gradient distribution multivariate composite material precursor as well as a preparation method of the gradient distribution multivariate composite material precursor and an application in preparation of a lithium ion battery anode material. The precursor is prepared from the following molecular formula: NixCoyMnzM1-x-y-z(OH)2, wherein x is more than 0.2 and less than 0.8, y is more than 0.1 and less than 0.5, z is more than 0 and less than 0.6, and M is a doped metal ion and comprises one or more of Mg, Ca, Zn, Al, Cr, Zr and Ti; the precursor comprises a core part and an outer layer shell part in which multiple layers are sequentially covered in the core; a molecular formula composition of the core part is NikConMnmM1-k-n-m(OH)2, wherein k is more than 0.5 and less than 1, n is more than 0.05 and less than 0.5, and m is more than 0 and less than 0.6; and the outer layer shell part is used for controlling the proportion of the raw material components and a preparation process to ensure that the material composition of the outer layer shell part is distributed in a gradient mode. Compared with a ternary material with a uniform internal structure, the lithium ion battery anode material has the advantages that the high specific discharge capacity is developed; and meanwhile, the cycling stability, the high-temperature cycling stability and the rate capability of the materials also can be greatly improved.

Owner:SUZHOU GCL ENERGY TECH DEV CO LTD

Ceramic diaphragm for lithium ion battery and preparation method of ceramic diaphragm

InactiveCN105514328AImproved cycle life and rate performanceImprove bindingCell component detailsSolventCeramic particle

The invention discloses a ceramic diaphragm for a lithium ion battery. The ceramic diaphragm comprises a diaphragm base material and a ceramic coating on the surface of the diaphragm base material, wherein ceramic particles having a porous structure and a high specific surface area are selected for the ceramic coating. A preparation method includes the following steps of firstly, evenly mixing ceramic particles, binder and solvent to obtain coating slurry; secondly, evenly coating the surface of the diaphragm base material with the coating slurry, and conducting drying to form the ceramic diaphragm. Quite strong binding force exists between the porous ceramic powder and the binder, and the powder falling phenomenon is effectively avoided; meanwhile, the ceramic diaphragm has high electrolyte wettability and quite strong liquid absorption capacity, the cycle life and rate capability of the lithium ion battery are increased, and excellent electrochemical performance is achieved; in addition, under the same thickness, the mass of the porous ceramic coating is far lower than that of an ordinary ceramic coating, and the energy density of the battery is improved.

Owner:TIANNENG SAFT ENERGY JOINT CO

Hard carbon negative electrode material of lithium ion battery, preparation method and application of hard carbon negative electrode material

InactiveCN102820455AIncrease capacityImprove the first Coulombic efficiencyCell electrodesDischarge efficiencyPhysical chemistry

The invention relates to a hard carbon negative electrode material of a lithium ion battery, and a preparation method and application of the hard carbon negative electrode material. The hard carbon negative electrode material is doped with silicon and phosphorus, wherein the mass ratio of silicon precursor, phosphorus precursor and hard carbon precursor is 1:(0.1 to 5):(5 to 30). Due to the addition of silicon / phosphorus, the hard carbon negative electrode material provided by the invention is remarkably improved in the first discharge capacity (up to 550.8mAh / g), the first charge / discharge efficiency (up to 80.9%) and the first coulombic efficiency by doping, is remarkably reduced in the irreversible capacity, and has the advantages of excellent cycle performance and rate capability, good PC (poly carbonate) consistency and high PC resistance, wherein the capacity retention ratio is above 95% after discharge cycle for 100 weeks at a high discharge rate of 10C.

Owner:天津市贝特瑞新能源科技有限公司

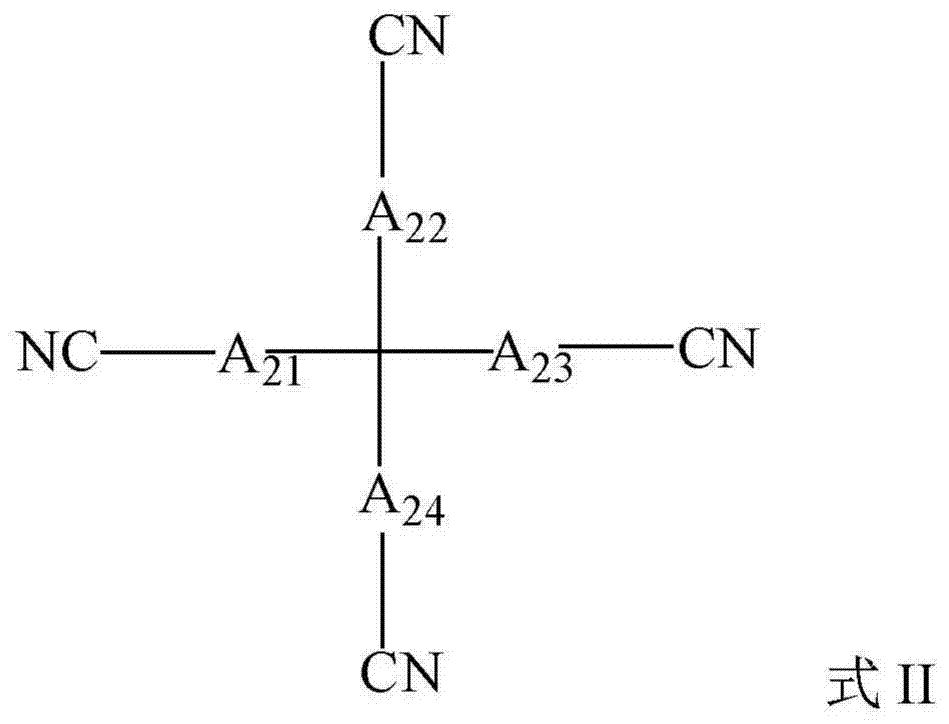

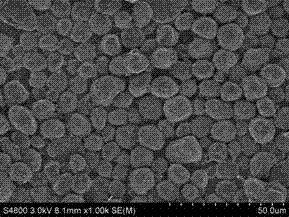

Single-crystal lithium nickel manganese cobalt positive electrode material, preparation method thereof and lithium ion battery

ActiveCN106505193AImproved magnification performanceIncrease gram capacityCell electrodesSecondary cellsElectrical conductorInternal resistance

The invention provides a single-crystal lithium nickel manganese cobalt positive electrode material. The single-crystal lithium nickel manganese cobalt positive electrode material comprises a substrate, wherein the substrate is a compound shown as a formula I of LiNi<x>Co<y>Mn<1-x-y>M<z>O<2>, x is more than or equal to 0.3 but less than or equal to 0.75, y is more than or equal to 0.2 but less than or equal to 0.3, z is more than or equal to 0 but less than or equal to 0.1, and a coating layer is coated on a surface of the substrate and is one or more of Li2ZrO3, Li2SnO3, LiNbO3, Li4Ti5O12 and LiAlO2. Compared with the prior art, a fast ion conductor is coated on the surface, thus, the rate performance of a single-crystal material is improved, the gram capacity of the single-crystal material is improved, the cycle performance of the material is further improved, the internal resistance can also be reduced, the polarization loss is reduced, and the cycle lifetime of a battery is prolonged; and meanwhile, the advantage of large compaction of a single-crystal ternary material is maintained, a particle broken phenomenon caused by rolling particles similar to secondary particles during battery fabrication can be prevented due to relatively high compaction, and the cycle performance is improved.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

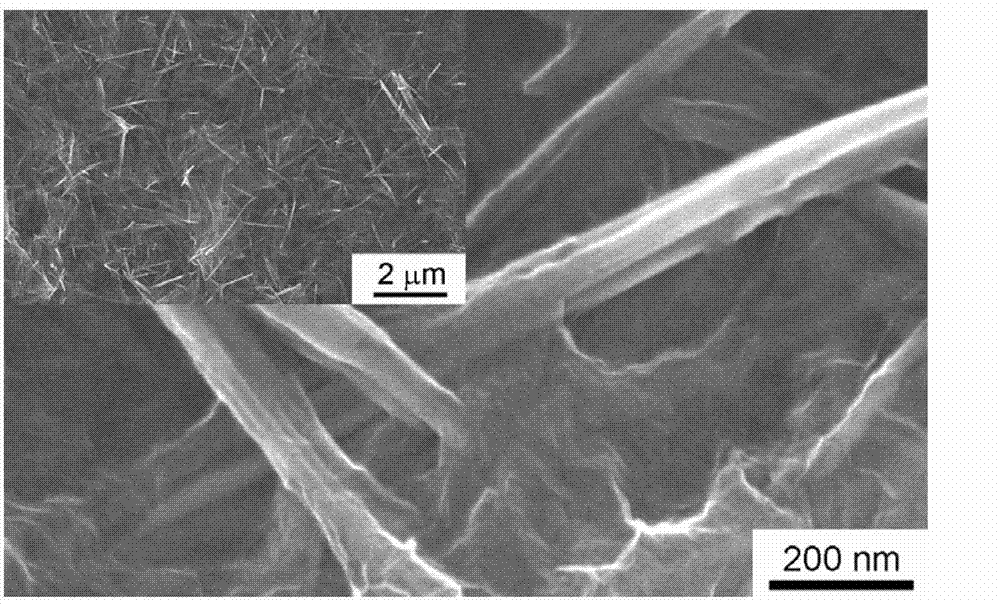

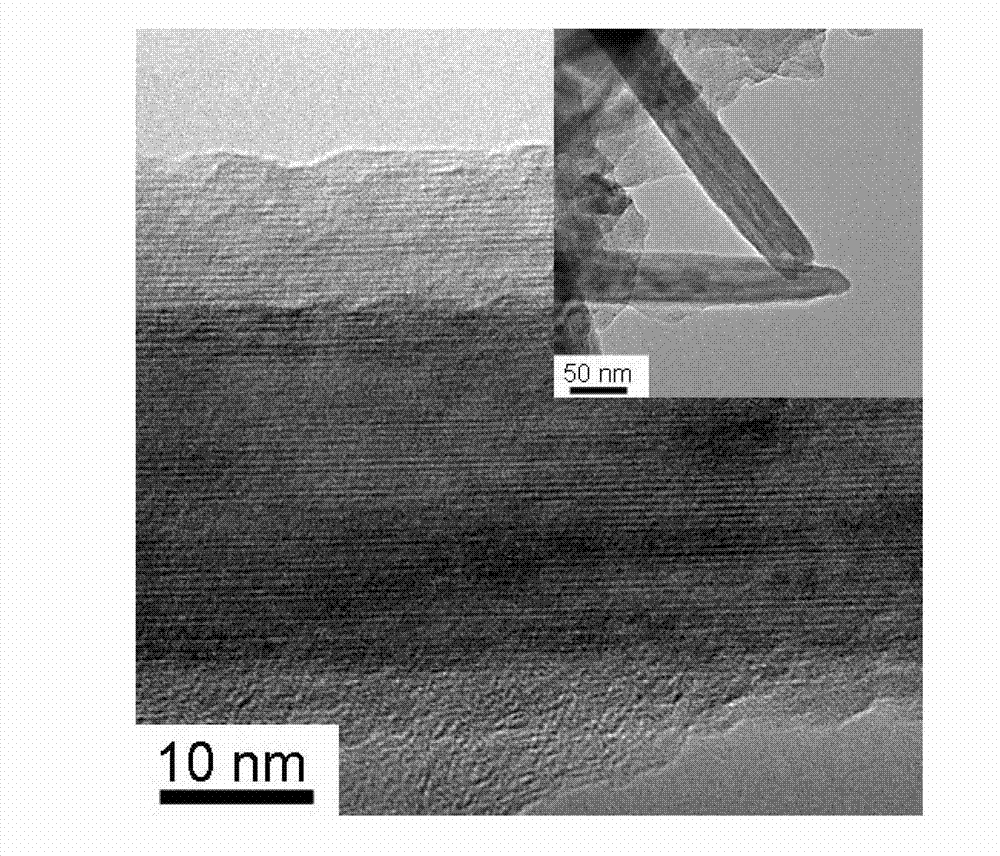

Combined electrode of battery and preparation method thereof

InactiveCN103730630AImprove electronic conductivityImprove ionic conductivityActive material electrodesElectrolyte layer coatingSolid state electrolyteElectrical battery

The application relates to the field of energy storage materials, and discloses a combined electrode with ultrahigh electron and ionic conductivity and a preparation method thereof. The combined electrode is formed in a manner that a battery active material is uniformly tied in a three-dimensional multi-hole network formed by carbon nano tubes which are connected in a crossing manner, and meshes and the surface of the active material are filled or coated with a solid electrolyte material. According to the combined electrode, the carbon nano tubes, which are communicated with one another, can form an ultrahigh electrical transmission network, on the one hand, a solid electrolyte can provide the ultrahigh lithium-ion transmission capacity while not influencing the connection of the carbon nano tubes and the conductive capacity of the electrode; on the other hand, the three-dimensional network formed by the carbon nano tubes is also fixed by virtue of the solid electrolyte, the formation of a solid electrolyte interface is controlled, and an active material is protected under the high charge-discharge voltage. The combined electrode has the high reversible capacity and the enhanced rate capability, and can meet the requirement of a power automobile or a mixed power automobile.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

Titanium dioxide/graphene nanocomposite material and preparation method and application thereof

InactiveCN102569761AShape is easy to controlControllable surface structureCell electrodesGraphene nanocompositesHigh energy

The invention relates to a titanium dioxide / graphene nanocomposite material, a preparation method of the nanocomposite material and application of the nanocomposite material in the field of energy source and cleaning environment. The graphene accounts for 1-25wt% and the balance is titanium dioxide. Morphology of the titanium dioxide is a mesoporous structure or a structure with a dominant high energy surface, and titanium dioxide is scattered uniformly on the surface of graphene. According to the invention, by adopting a titanium source and graphene as initial materials, and water or organic solvents as reaction solvents, the nanocomposite material with titanium dioxide with the mesoporous structure or a titanium dioxide nano sheet with the dominant high energy surface compounded with graphene can be obtained through hydrothermal synthesis or a hydrolysis reaction. The invention can be carried out in an aqueous solution system and the crystallinity of the product is high. The composite material can be applied to a cathode material of a power ion battery, has a higher charge-discharge capacity, is excellent in high current charge and discharge, stable in circulating performance, has very good photocatalytic performance and can be used to light degradation of organic pollutants and water photolysis for preparing hydrogen.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com