Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

841 results about "Specific discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Specific discharge. The rate of discharge of ground water per unit area of a porous medium measured at right angle to the direction of flow. Synonyms: Darcy velocity; seepage velocity.

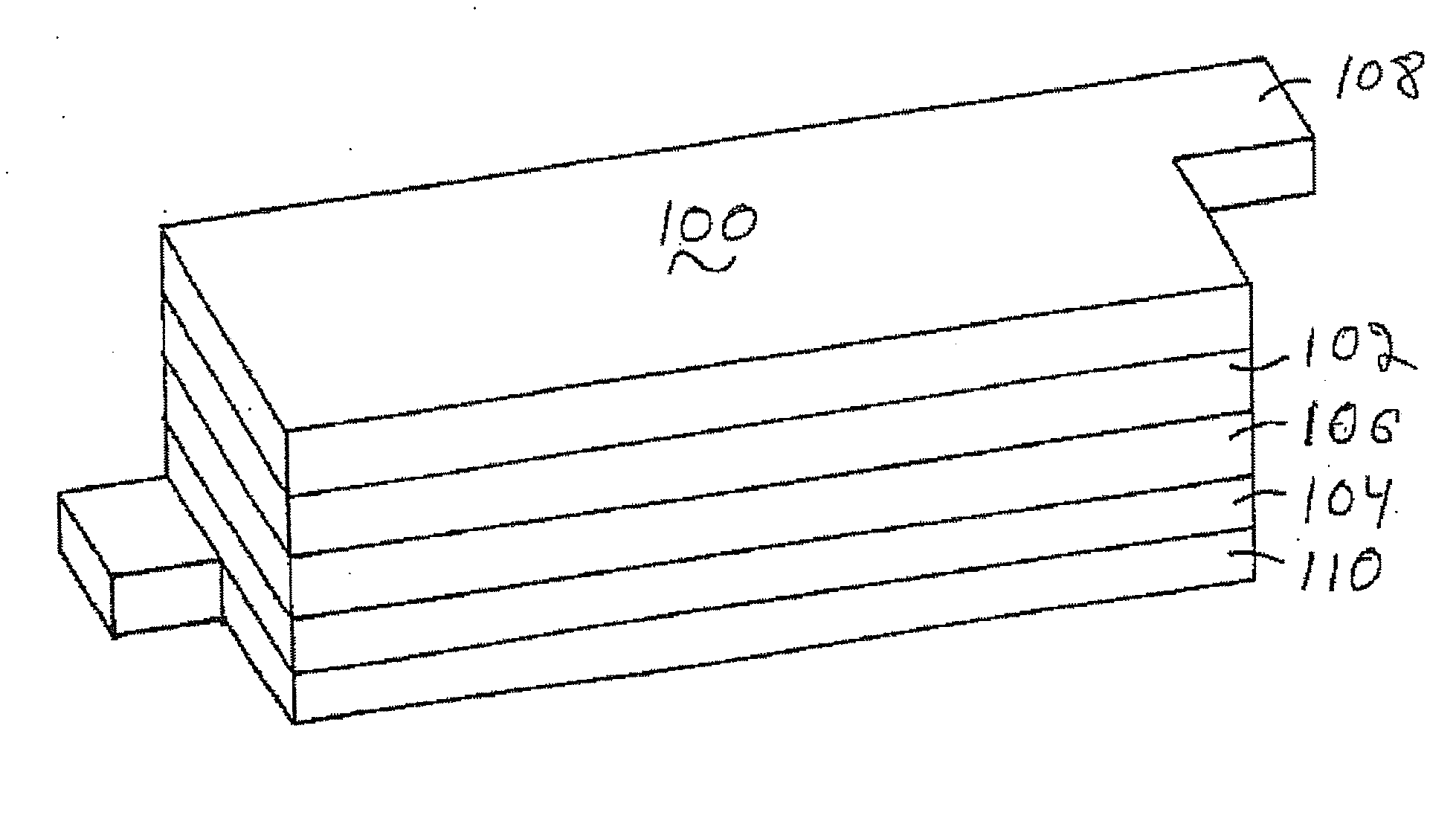

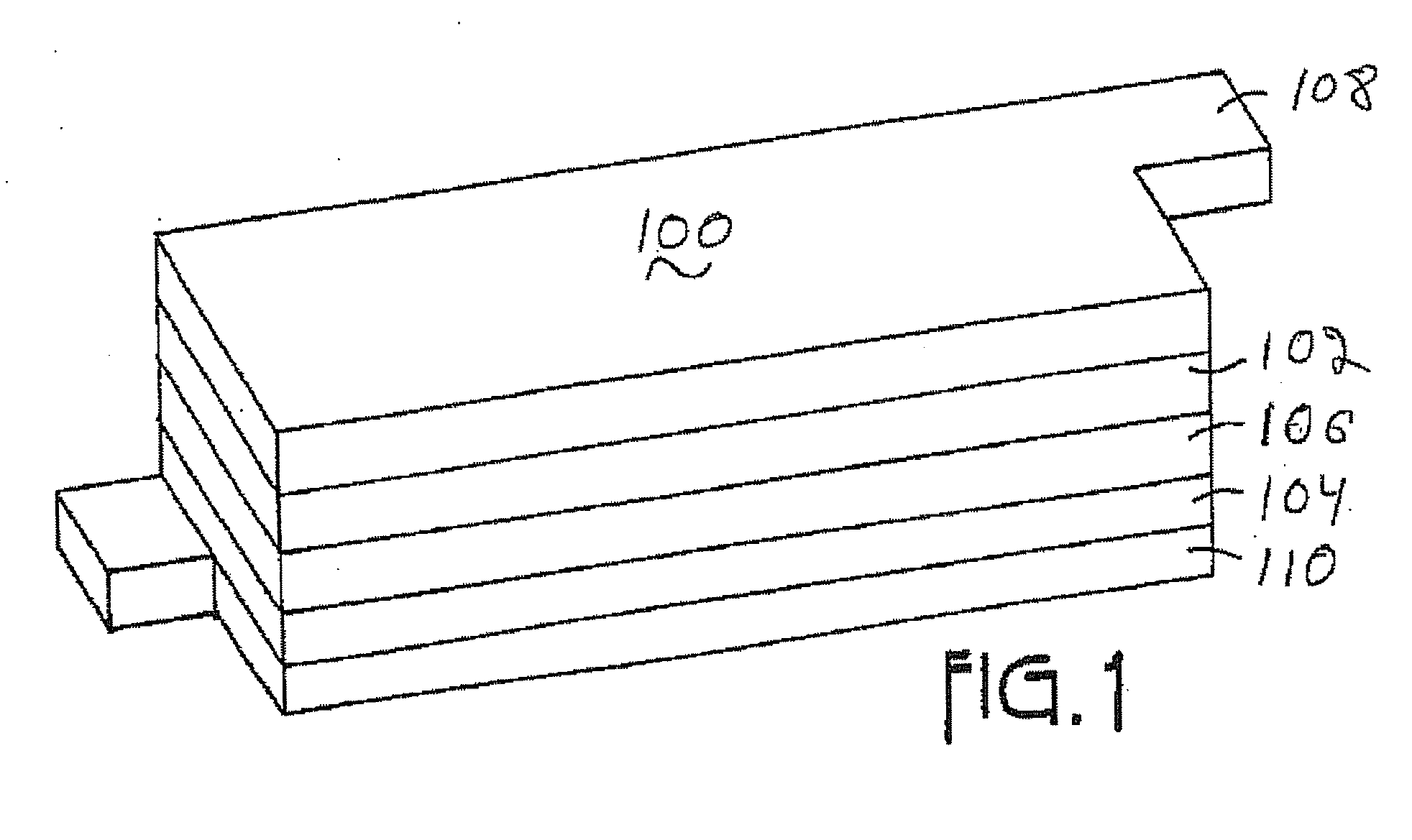

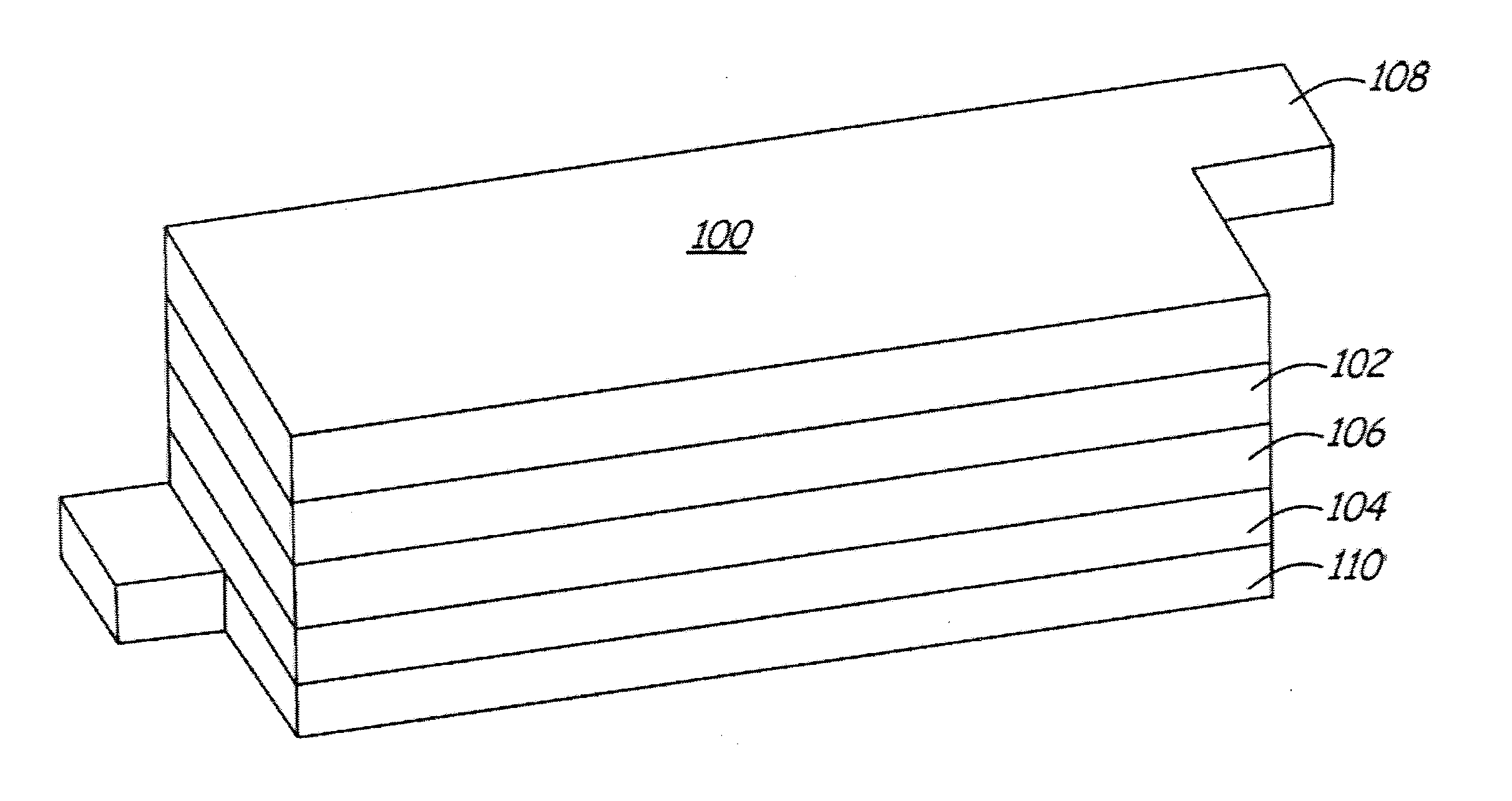

Positive electrode materials for lithium ion batteries having a high specific discharge capacity and processes for the synthesis of these materials

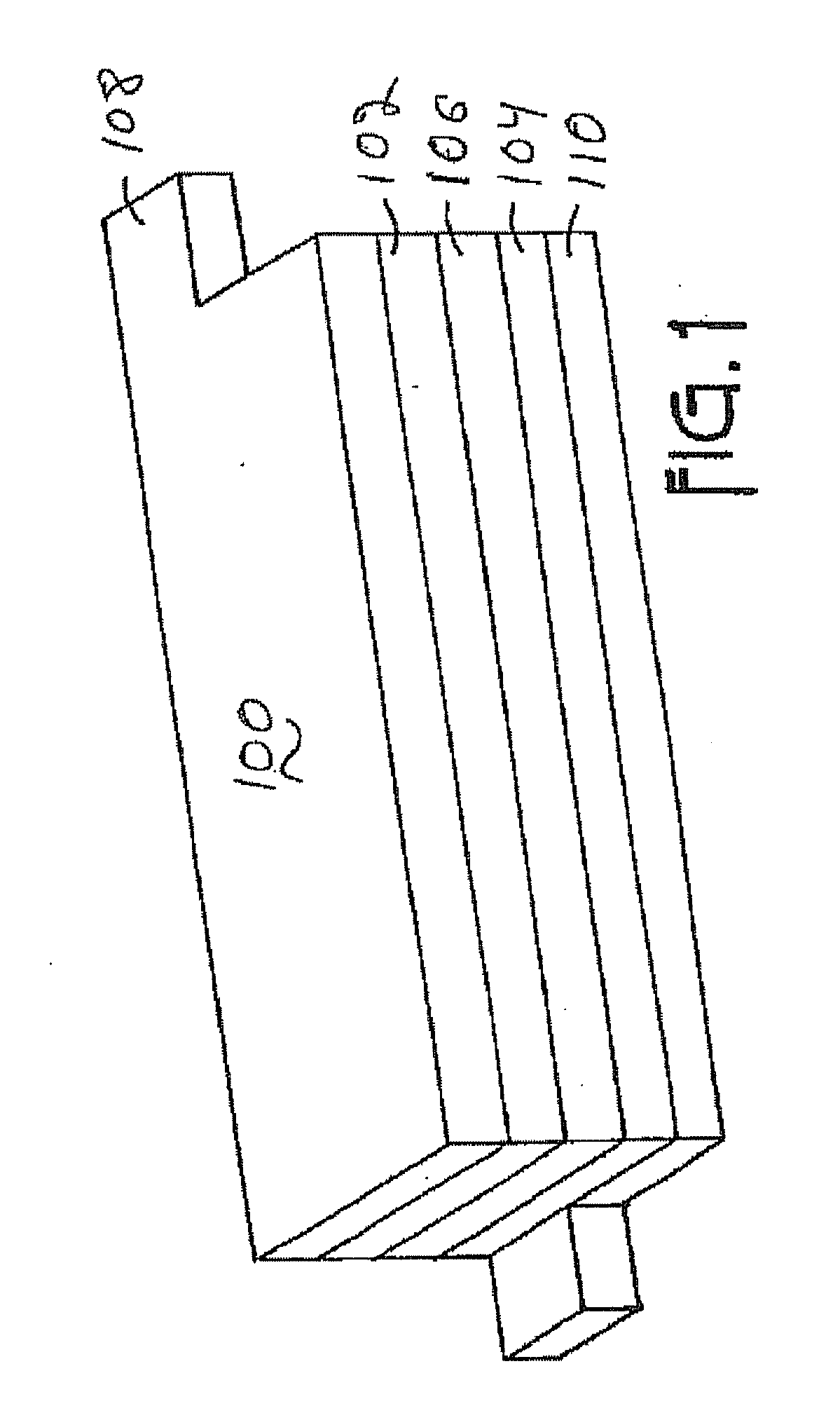

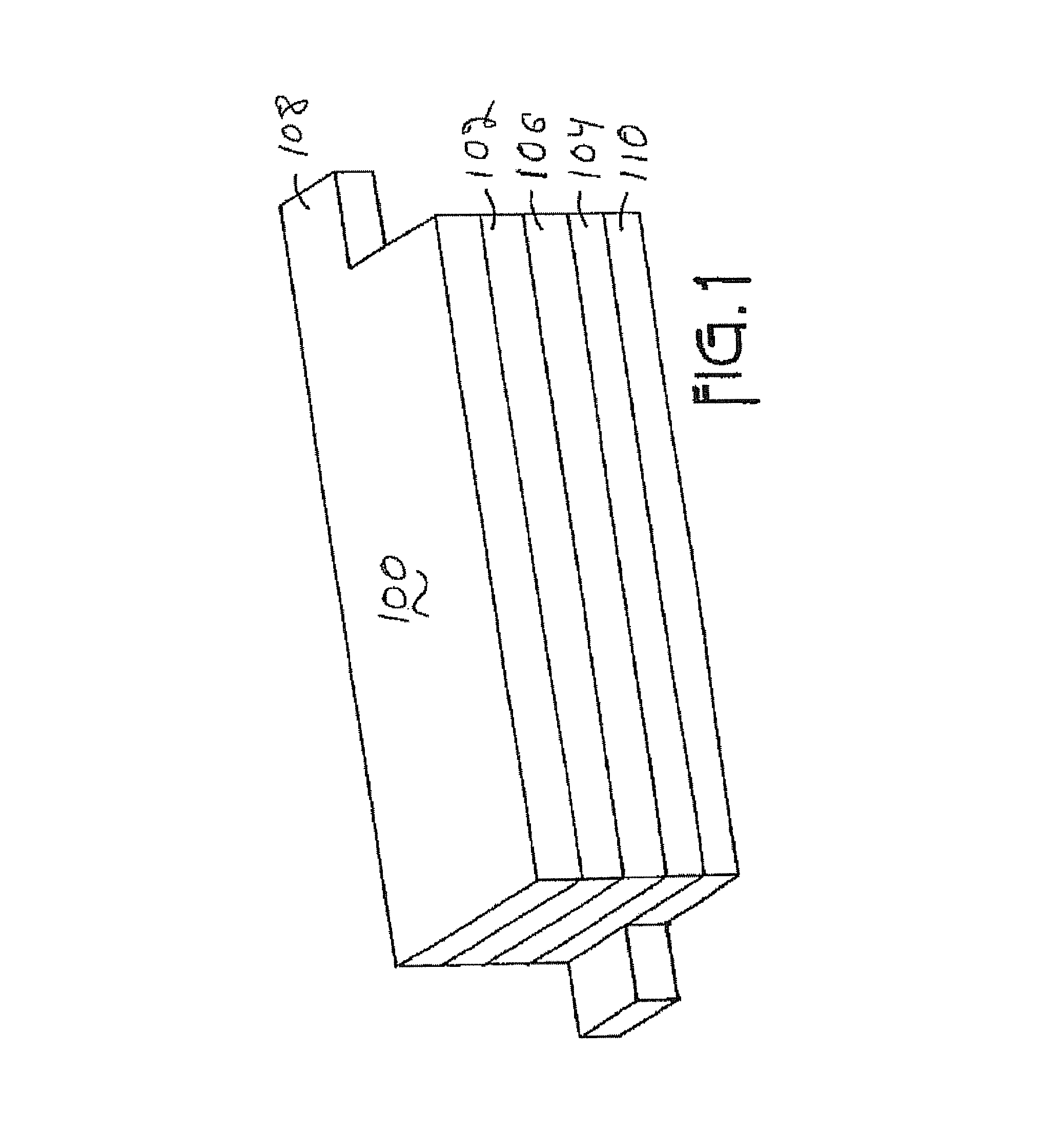

ActiveUS20100086853A1Electrode manufacturing processesAlkali metal oxidesDischarge rateLithium-ion battery

Owner:IONBLOX INC

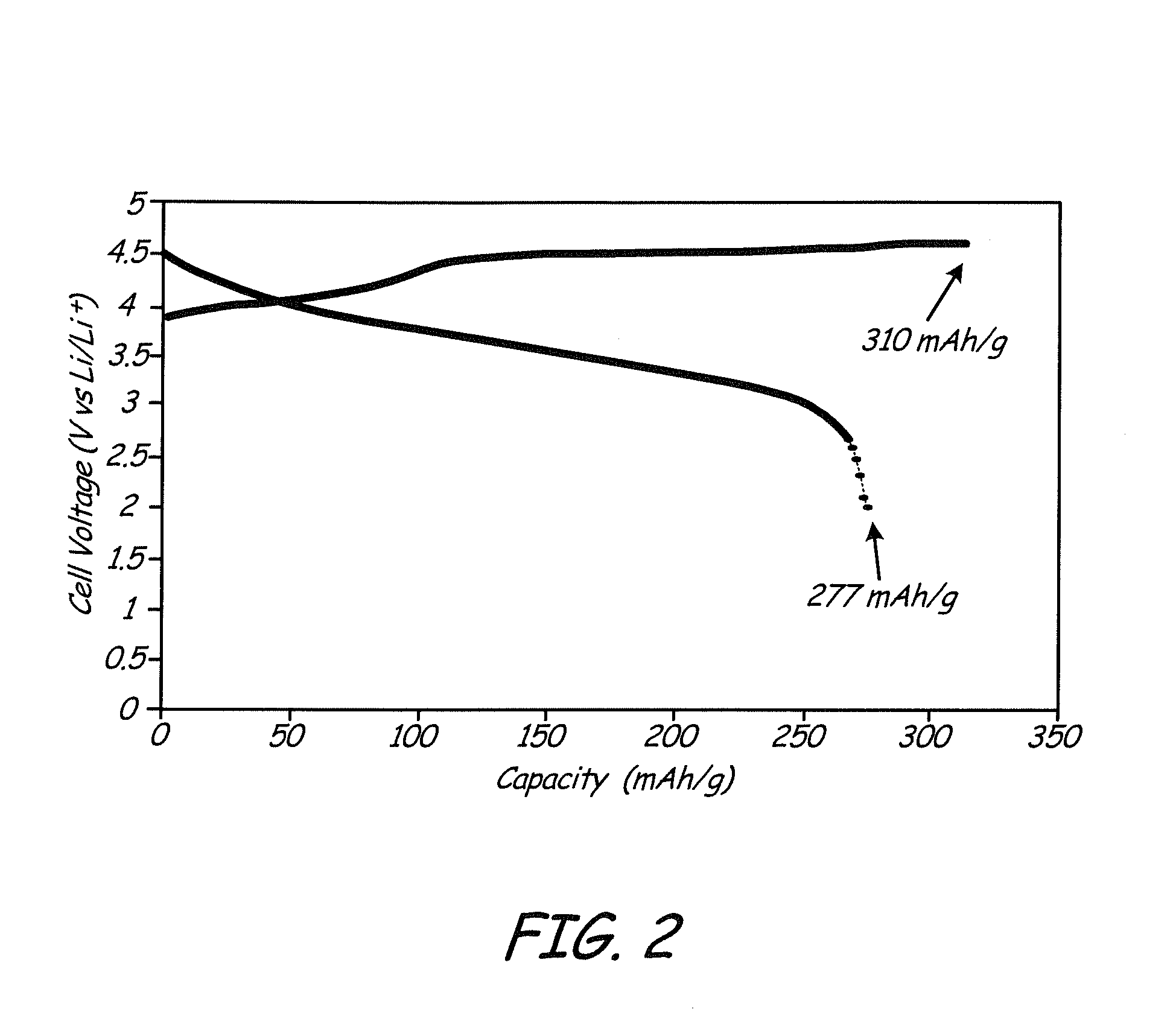

Positive electrode materials for high discharge capacity lithium ion batteries

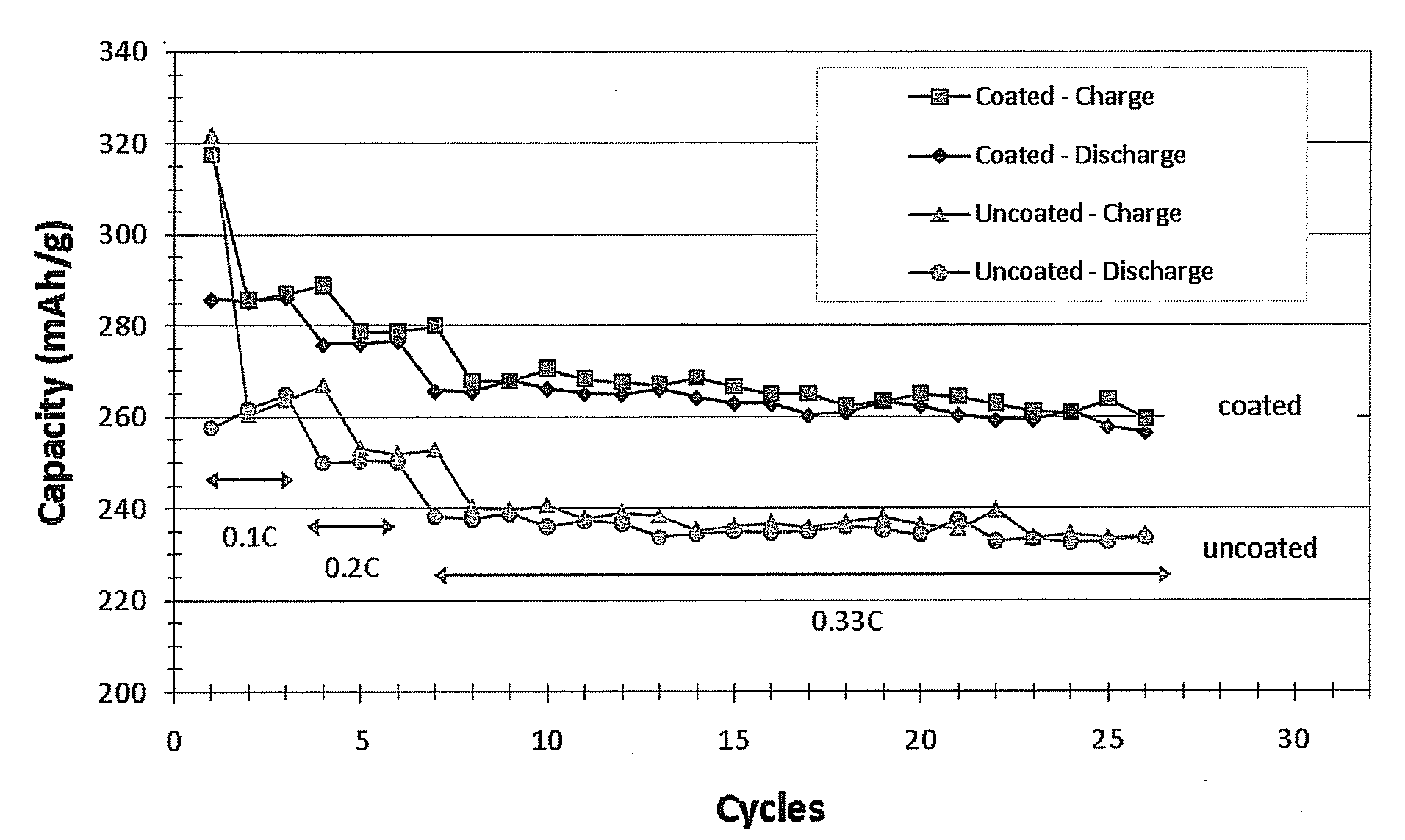

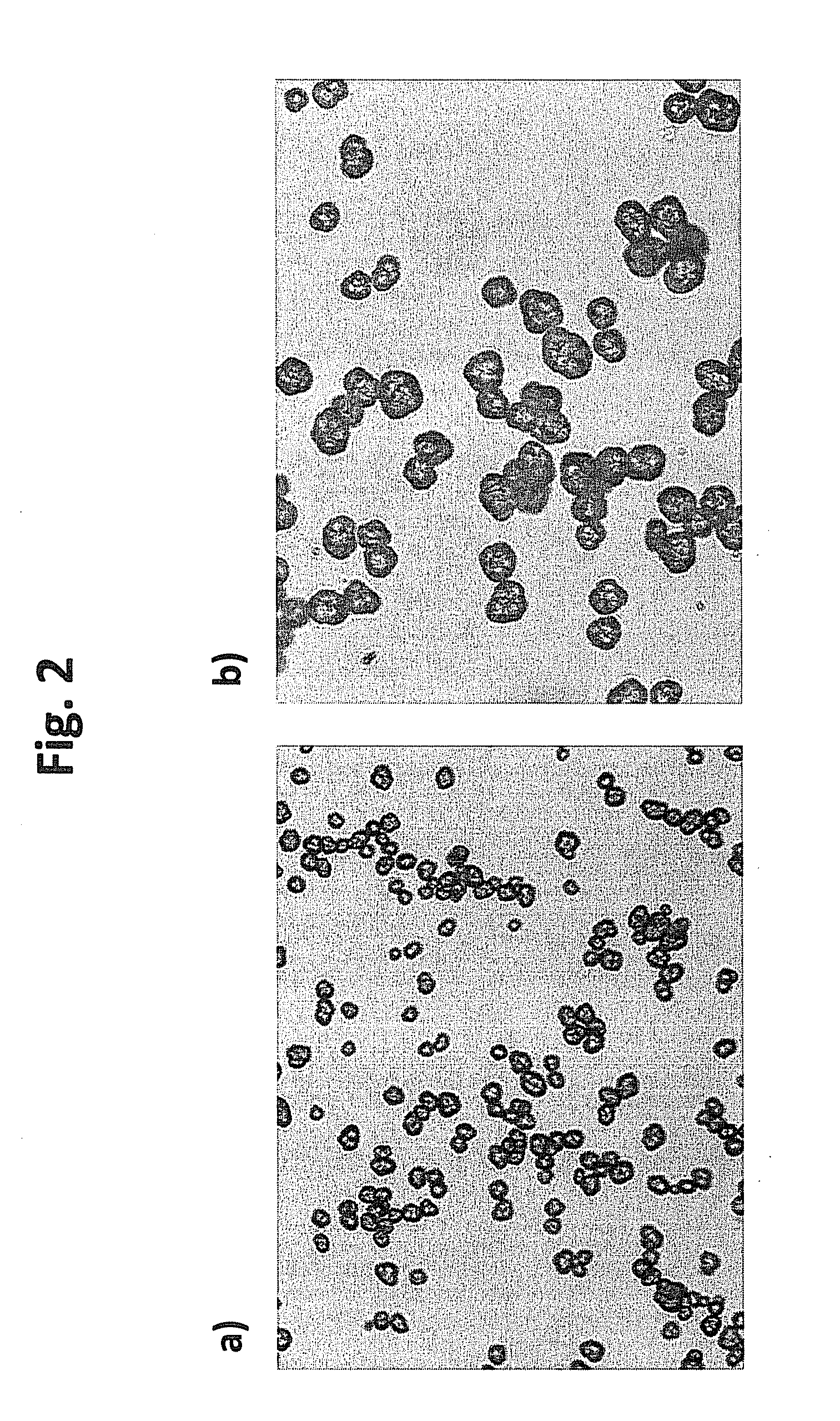

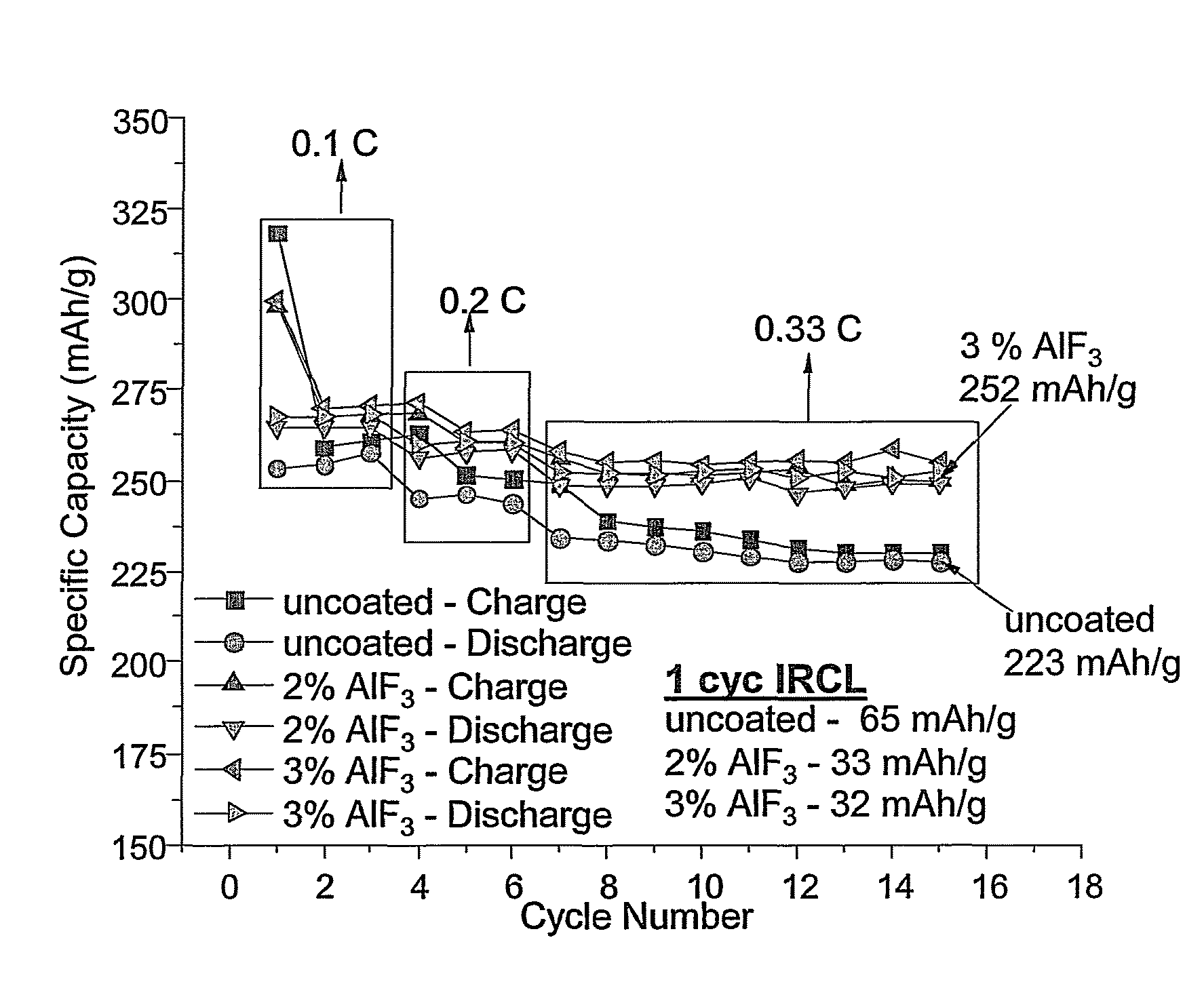

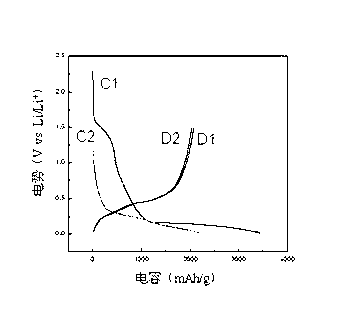

Positive electrode active materials are described that have a high tap density and high specific discharge capacity upon cycling at room temperature and at a moderate discharge rate. Some materials of interest have the formula Li1+xNiαMnβCoγO2, where x ranges from about 0.05 to about 0.25, α ranges from about 0.1 to about 0.4, β ranges from about 0.4 to about 0.65, and γ ranges from about 0.05 to about 0.3. The materials can be coated with a metal fluoride to improve the performance of the materials especially upon cycling. Also, the coated materials can exhibit a very significant decrease in the irreversible capacity lose upon the first charge and discharge of the battery.

Owner:IONBLOX INC

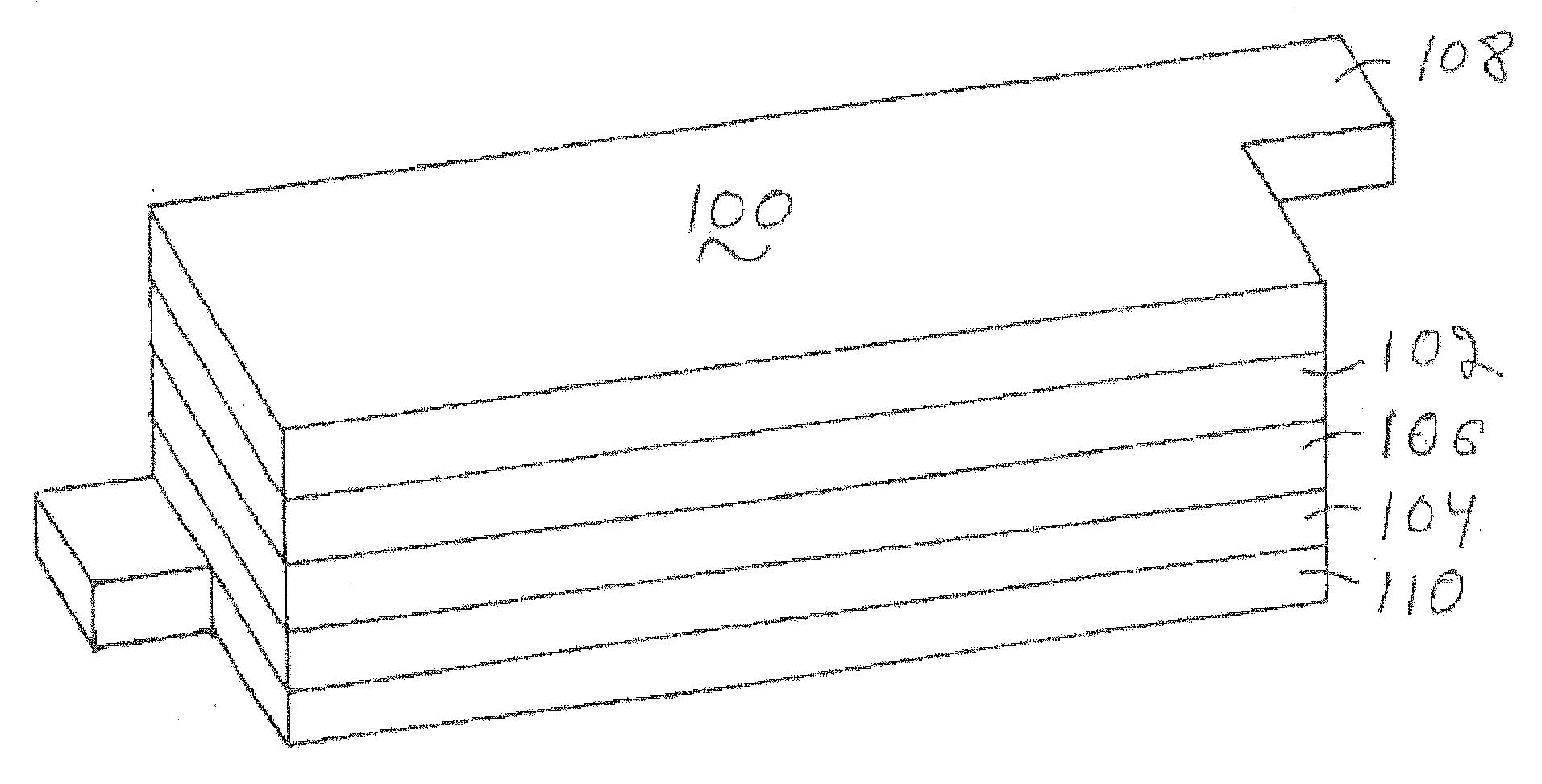

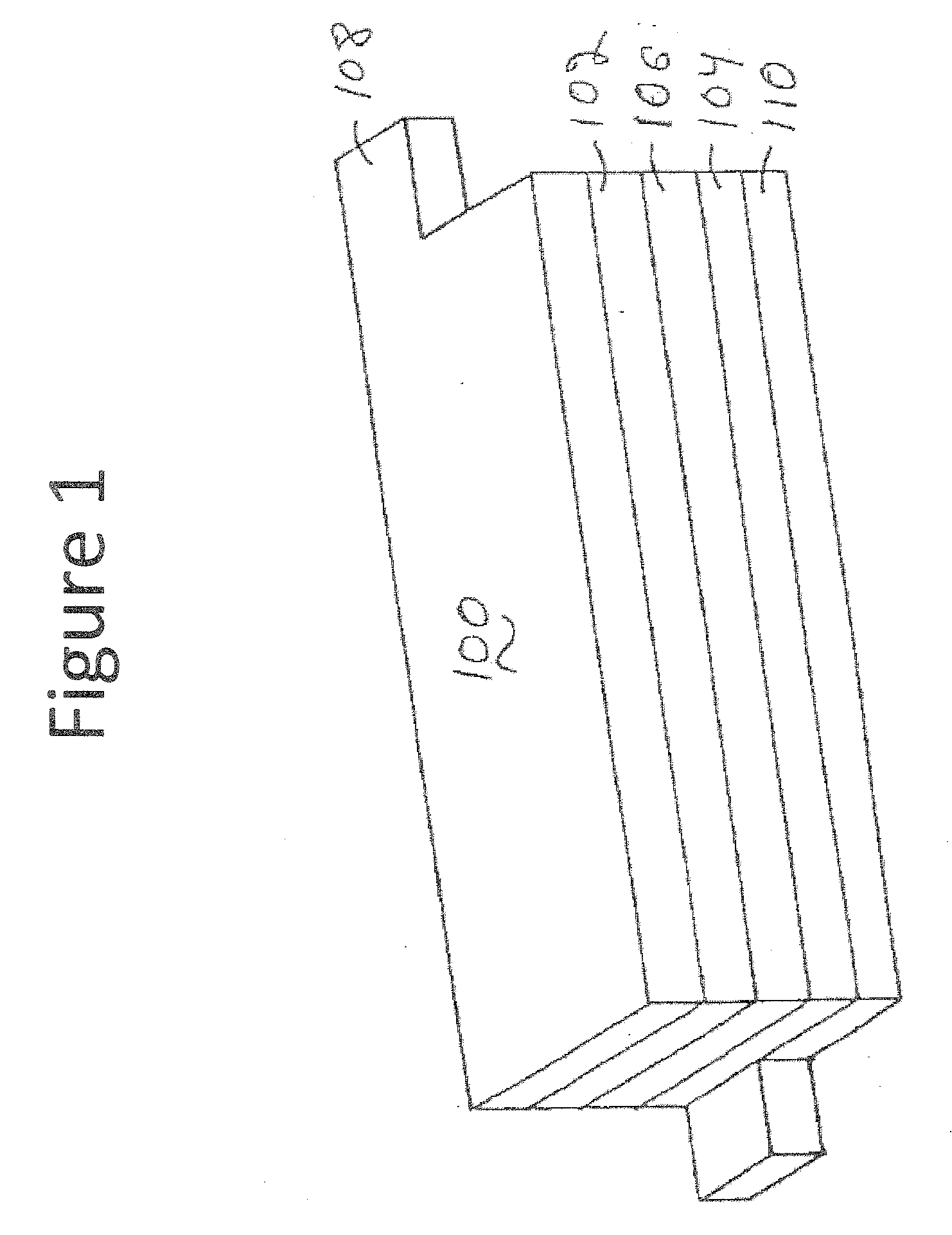

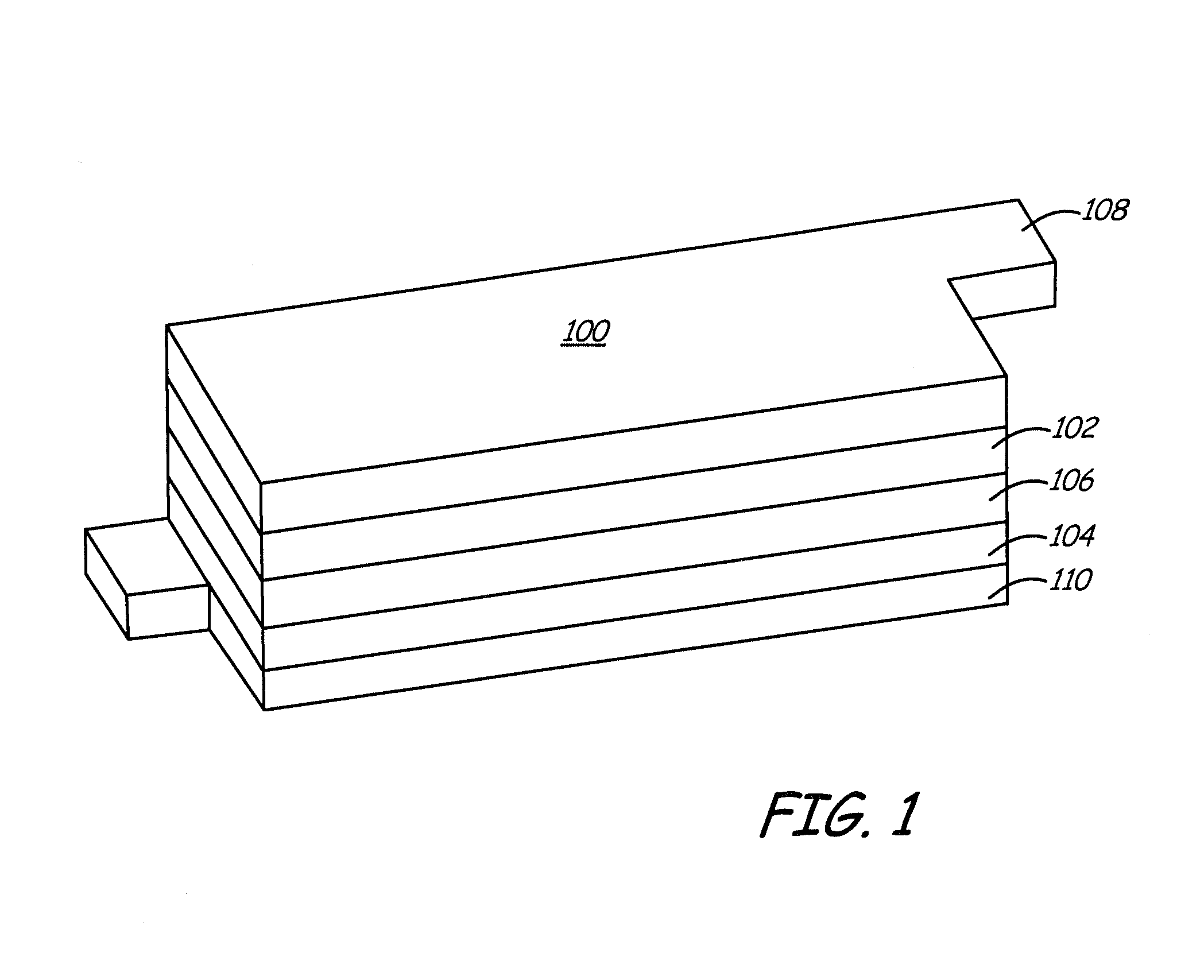

High Energy Lithium Ion Secondary Batteries

Lithium ion secondary batteries are described that have high total energy, energy density and specific discharge capacity upon cycling at room temperature and at a moderate discharge rate. The improved batteries are based on high loading of positive electrode materials with high energy capacity. This capability is accomplished through the development of positive electrode active materials with very high specific energy capacity that can be loaded at high density into electrodes without sacrificing performance. The high loading of the positive electrode materials in the batteries are facilitated through using a polymer binder that has an average molecular weight higher than 800,000 atomic mass unit.

Owner:IONBLOX INC

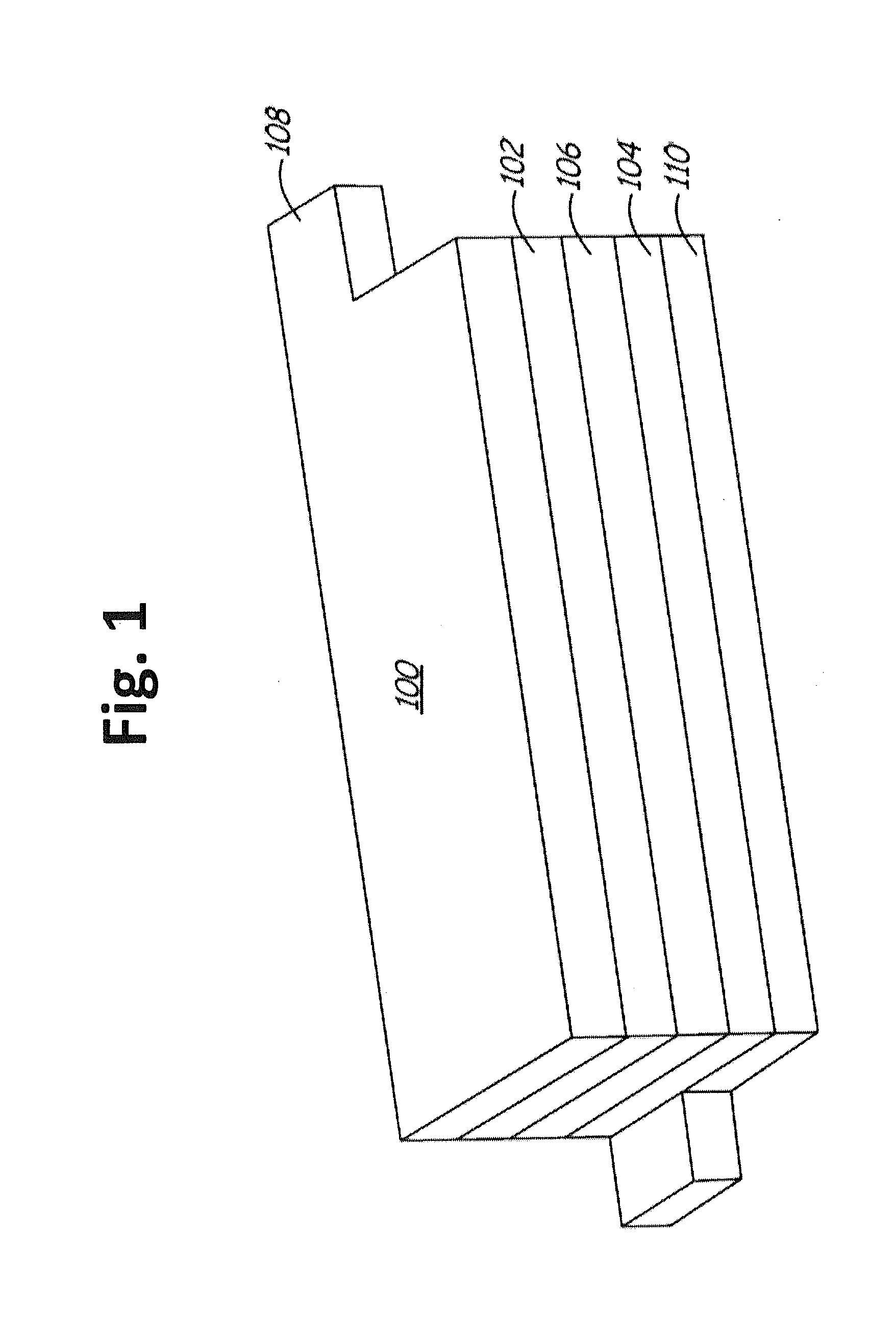

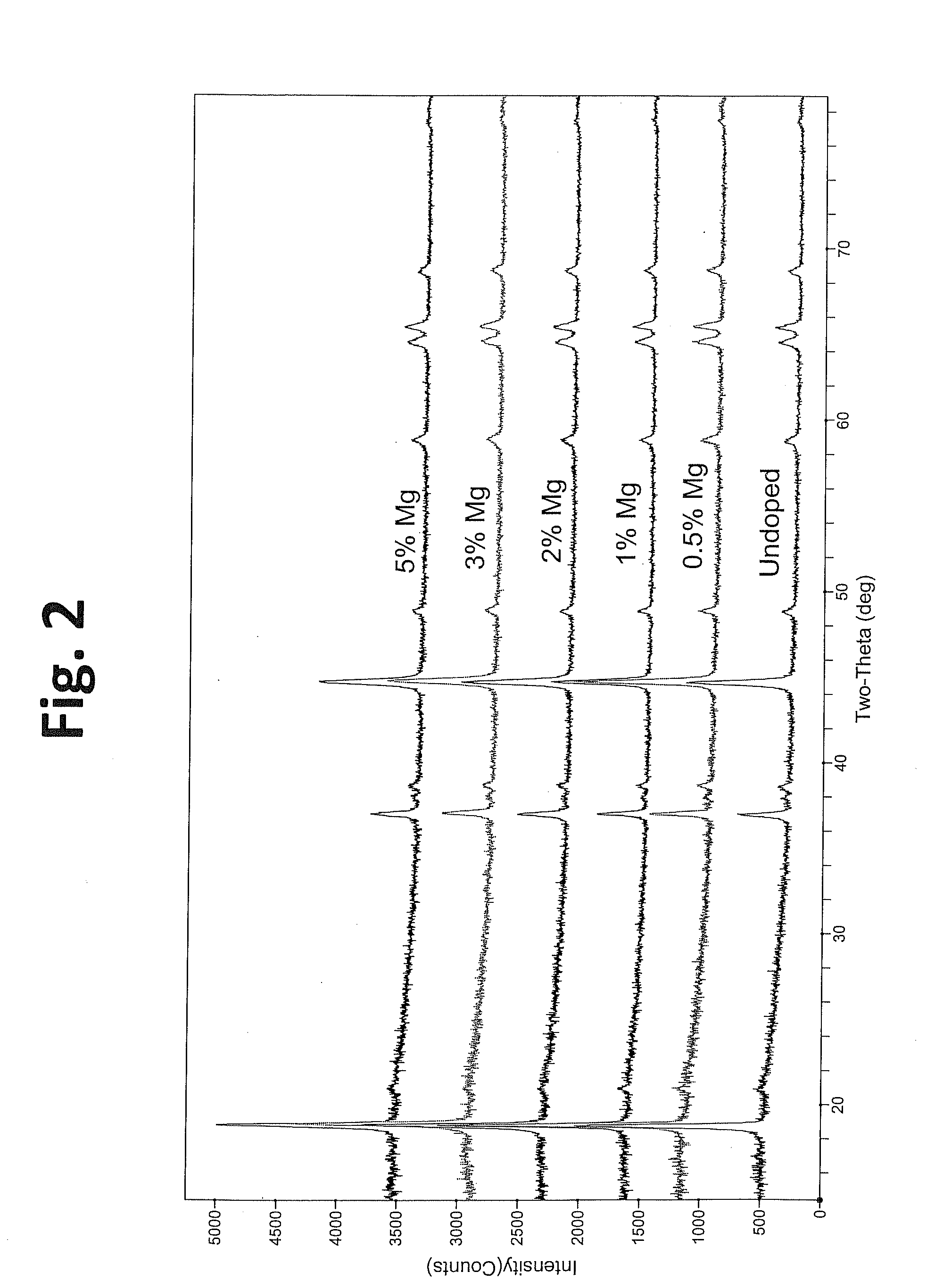

Doped positive electrode active materials and lithium ion secondary battery constructed therefrom

Positive electrode active materials comprising a dopant in an amount of 0.1 to 10 mole percent of Mg, Ca, Sr, Ba, Zn, Cd or a combination thereof are described that have high specific discharge capacity upon cycling at room temperature and at a moderate discharge rate. Some materials of interest have the formula Li1+xNiαMnβ-δCoγAδXμO2−zFz, where x ranges from about 0.01 to about 0.3, δ ranges from about 0.001 to about 0.15, and the sum x+α+β+γ+δ+μ can approximately equal 1.0. The materials can be coated with a metal fluoride to improve the performance of the materials especially upon cycling. The materials generally can have a tap density of at least 1.8 g / mL. Also, the materials can have an average discharge voltage of around 3.6 V.

Owner:IONBLOX INC

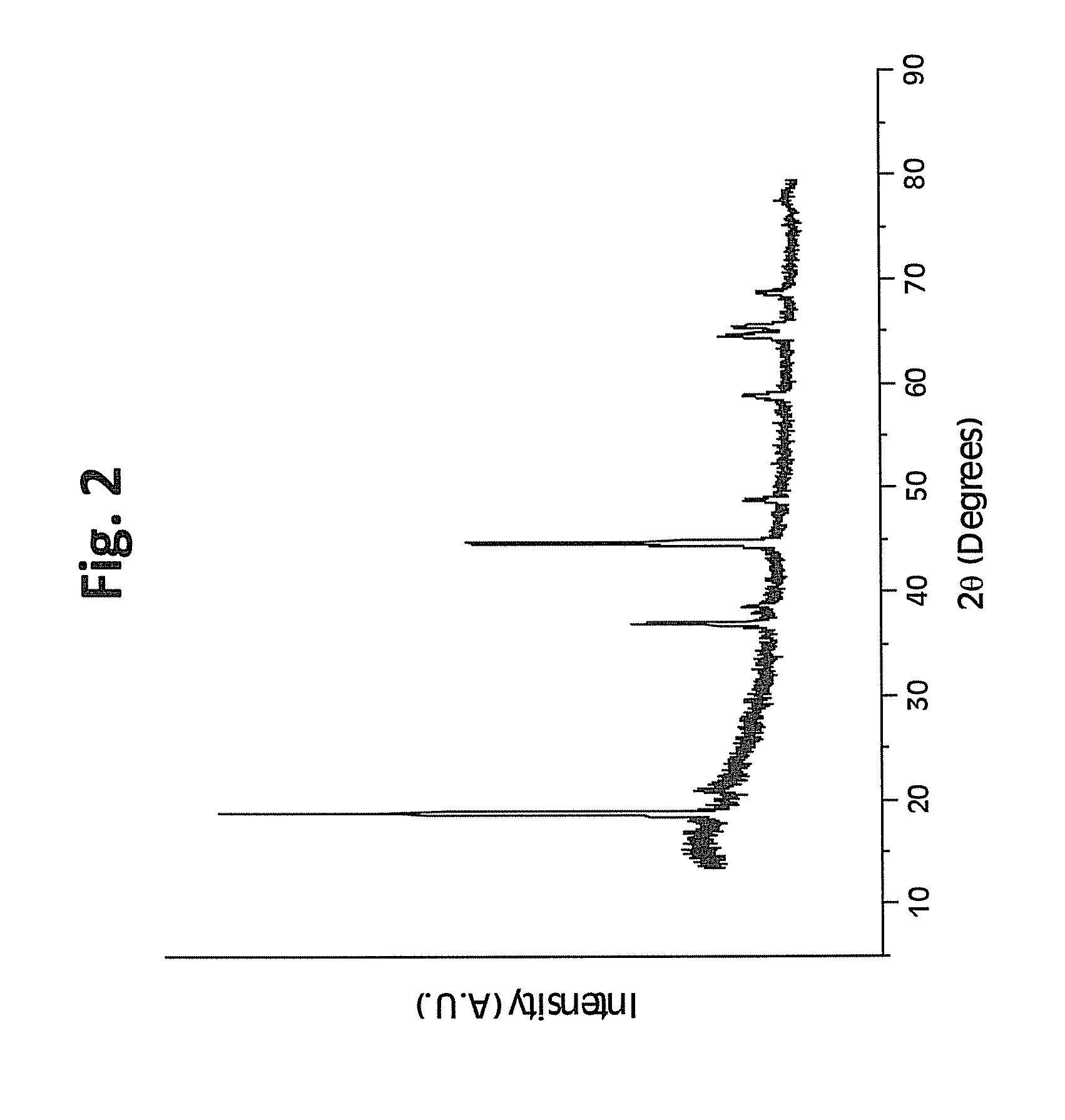

Positive electrode materials for lithium ion batteries having a high specific discharge capacity and processes for the synthesis of these materials

ActiveUS8389160B2Electrode manufacturing processesAlkali metal oxidesElectrical batteryDischarge rate

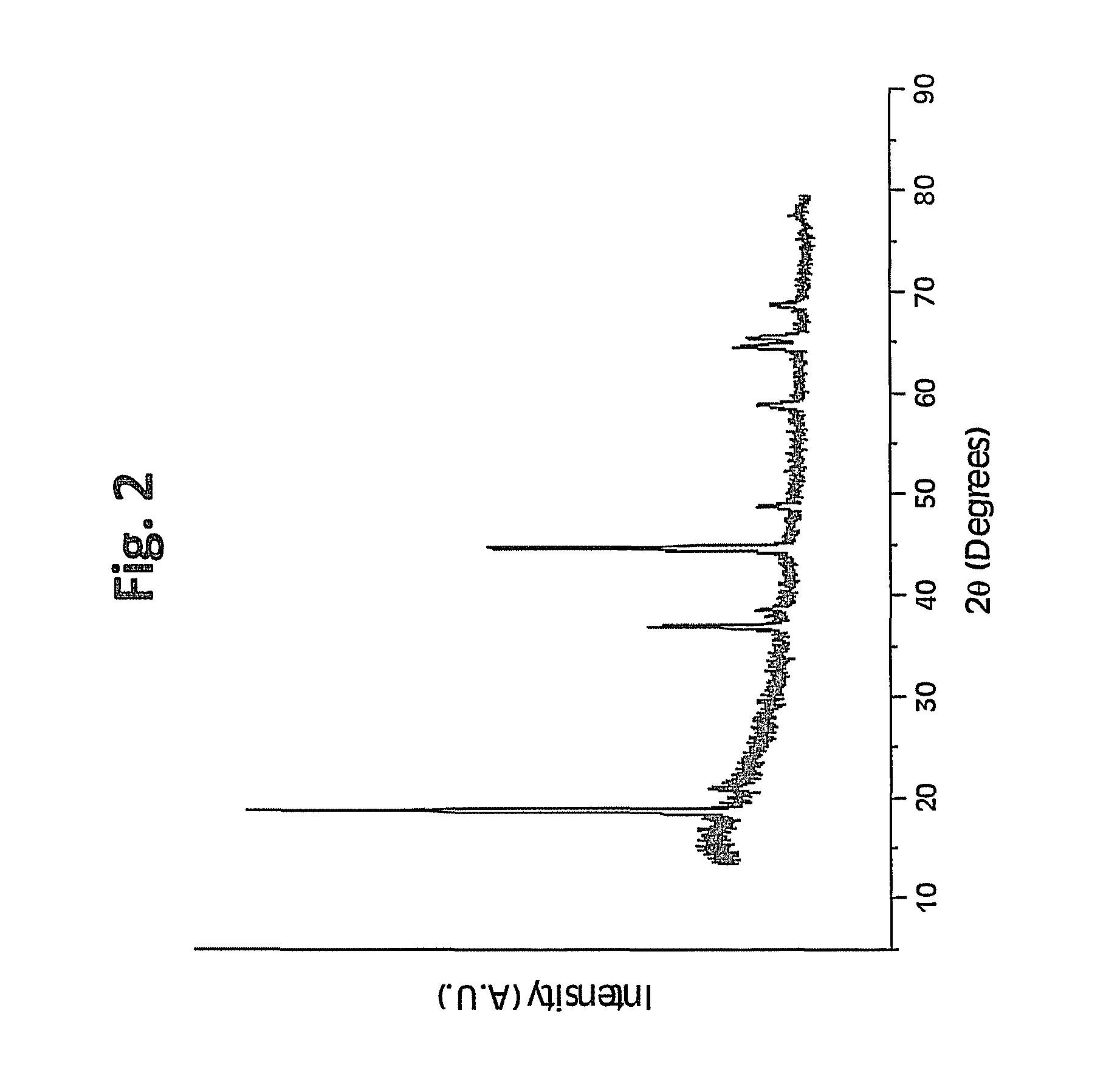

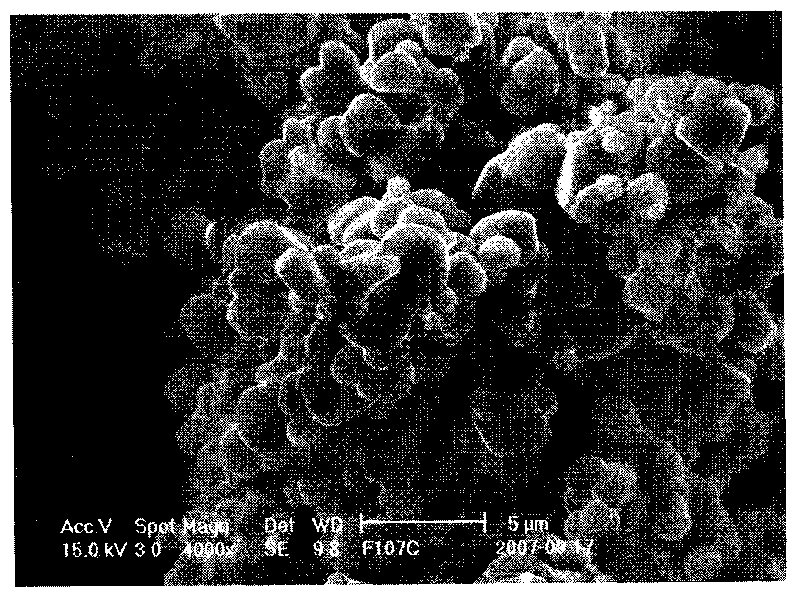

Positive electrode active materials are described that have a very high specific discharge capacity upon cycling at room temperature and at a moderate discharge rate. Some materials of interest have the formula Li1+xNiαMnβCOγO2, where x ranges from about 0.05 to about 0.25, α ranges from about 0.1 to about 0.4, β ranges from about 0.4 to about 0.65, and γ ranges from about 0.05 to about 0.3. The materials can be coated with a metal fluoride to improve the performance of the materials especially upon cycling. Also, the coated materials can exhibit a very significant decrease in the irreversible capacity lose upon the first charge and discharge of the cell. Methods for producing these materials include, for example, a co-precipitation approach involving metal hydroxides and sol-gel approaches.

Owner:IONBLOX INC

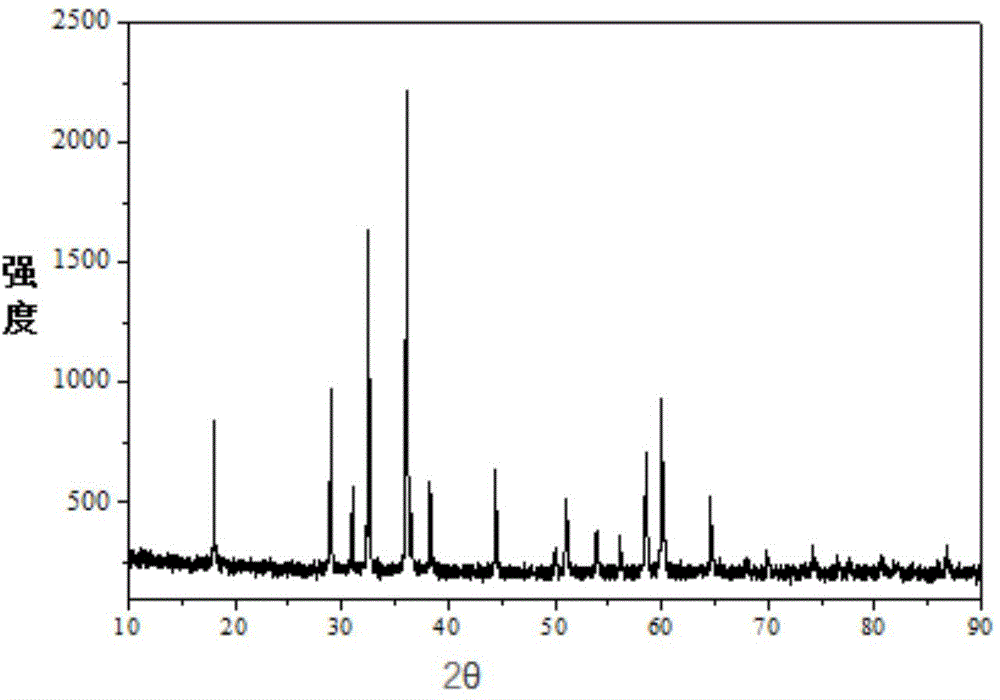

Lithium-rich manganese-based anode material and preparation method thereof

InactiveCN101694876AIncrease the charge cut-off voltageHigh specific capacityCell electrodesManganeseSpecific discharge

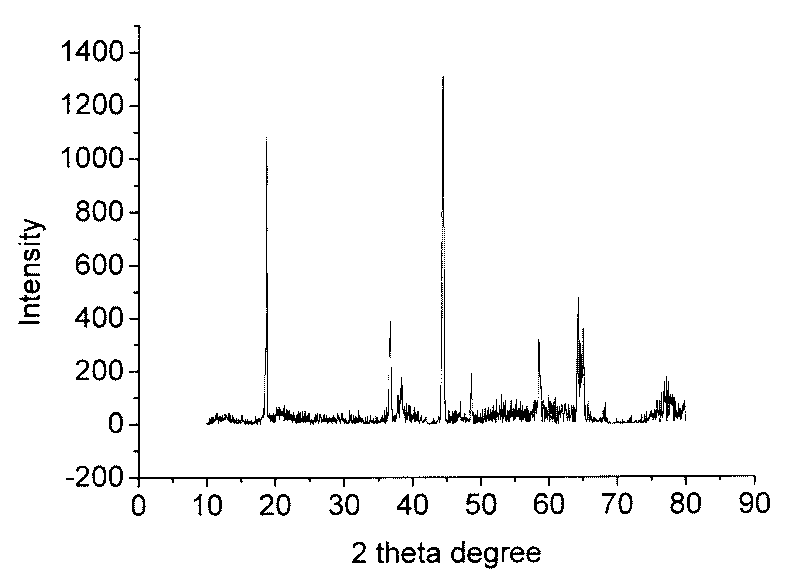

The invention relates to a lithium-ion secondary battery anode material technology, in particular to a lithium-rich manganese-based anode material Li(Li(1-2x) / 3Nix-aMyMn(2-x) / 3-b)O2 (M is Co, Al, Ti, Mg and Cu) and a preparation method thereof. A general formula of the lithium-rich manganese-based anode material is as follows: Li(Li(1-2x) / 3Nix-aMyMn(2-x) / 3-b)O2 (M is Co, Al, Ti, Mg and Cu), wherein x is more than 0 and less than or equal to 0.5, when M is Co and Al, y is more than 0 and less than 2x, a is equal to b, and b is equal to y / 2; when M is Ti, y is more than 0 and less than (2-x) / 3, a is equal to 0, and b is equal to y; and when M is Mg and Cu, y is more than 0 and less than x, a is equal to y, and b is equal to 0. The invention has high specific discharge capacity, excellent normal temperature and high temperature cycle performance, good safety, low raw material cost and production cost, and very high cost-performance ratio.

Owner:JIANGXI JIANGTE LITHIUM LON BATTERY MATERIAL +1

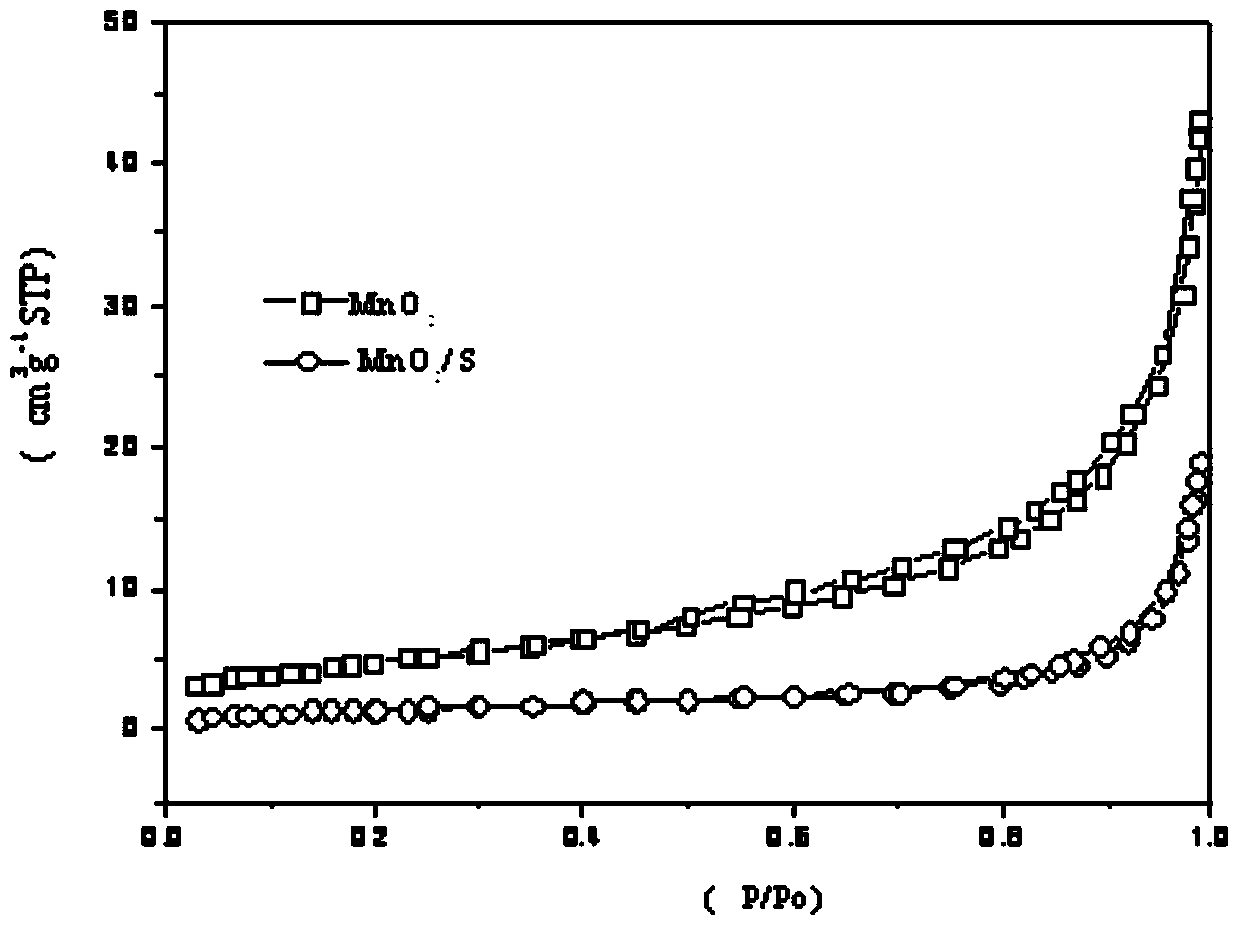

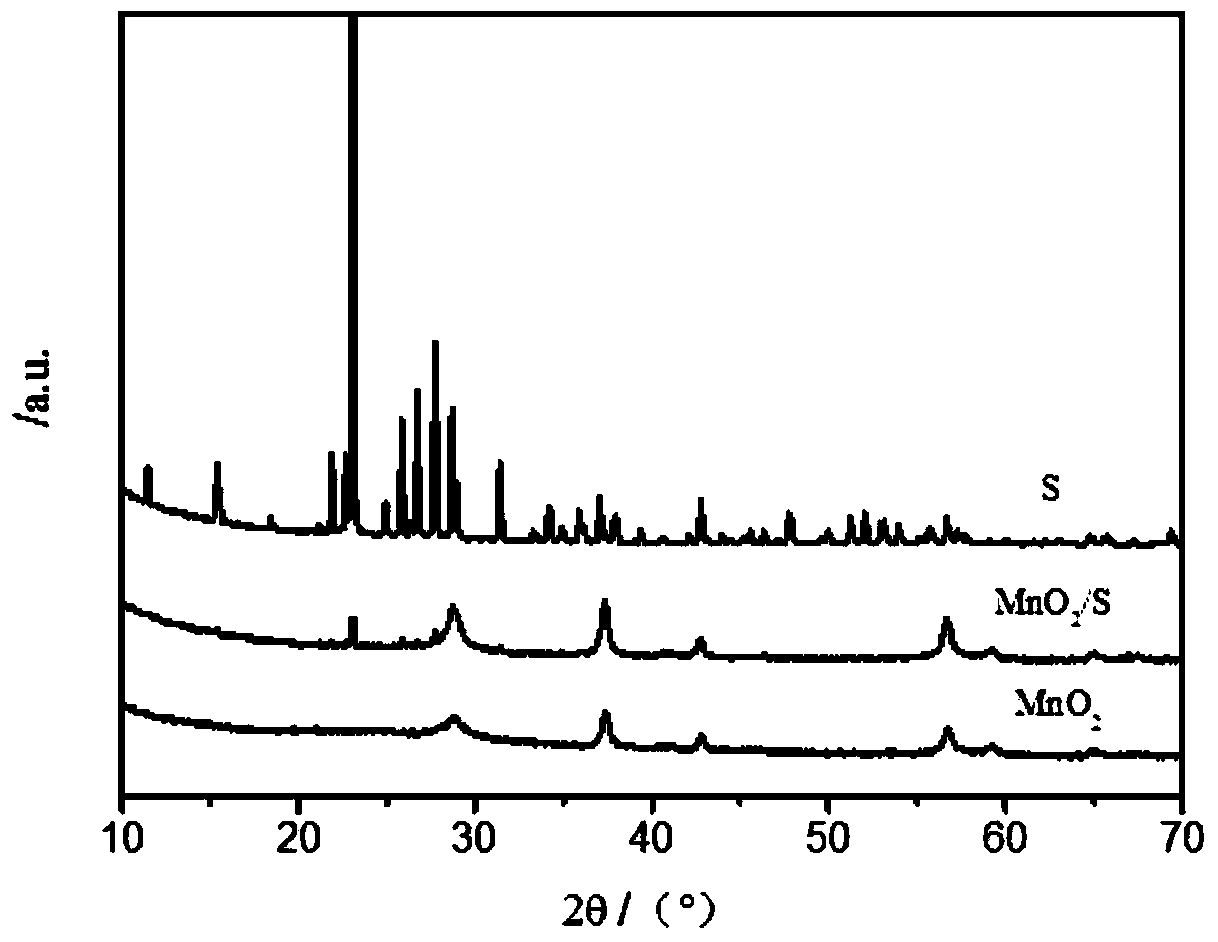

Functional composite membrane for lithium-sulfur battery and preparation method of functional composite membrane

InactiveCN105140447AImproved magnification performanceImprove ionic conductivityLi-accumulatorsCell component detailsLithium–sulfur batteryConductive materials

The invention relates to a functional composite membrane for a lithium-sulfur battery and a preparation method of the functional composite membrane. The composite membrane comprises a membrane for the lithium-sulfur battery and a functional modified layer, wherein the functional modified layer is located on the membrane for the lithium-sulfur battery, and comprises an electronic conductive material and / or inorganic oxides. Compared with the lithium-sulfur battery employing an ordinary battery membrane, the lithium-sulfur battery employing the functional composite membrane with the modified layer has a relatively high specific discharge capacity; the shuttle effect of the lithium-sulfur battery can be suppressed; the coulombic efficiency of the battery is improved; and the cycle performance of the battery is improved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

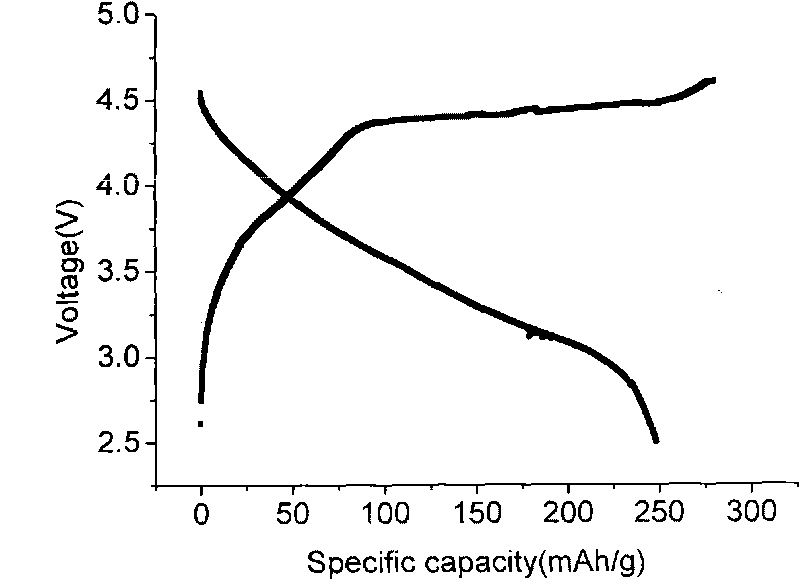

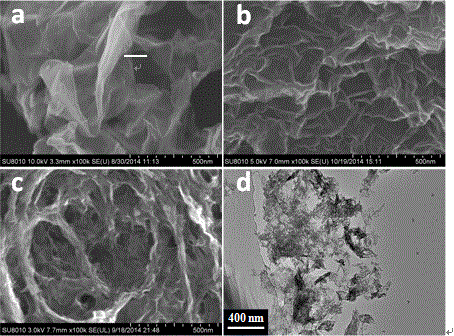

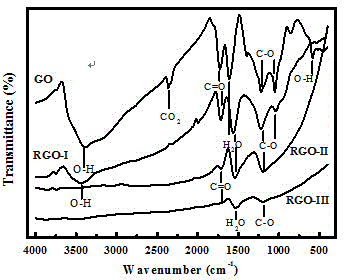

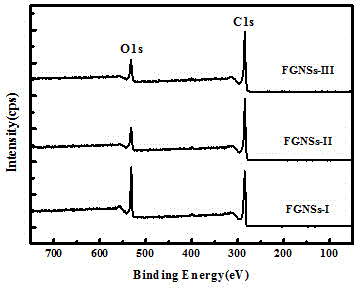

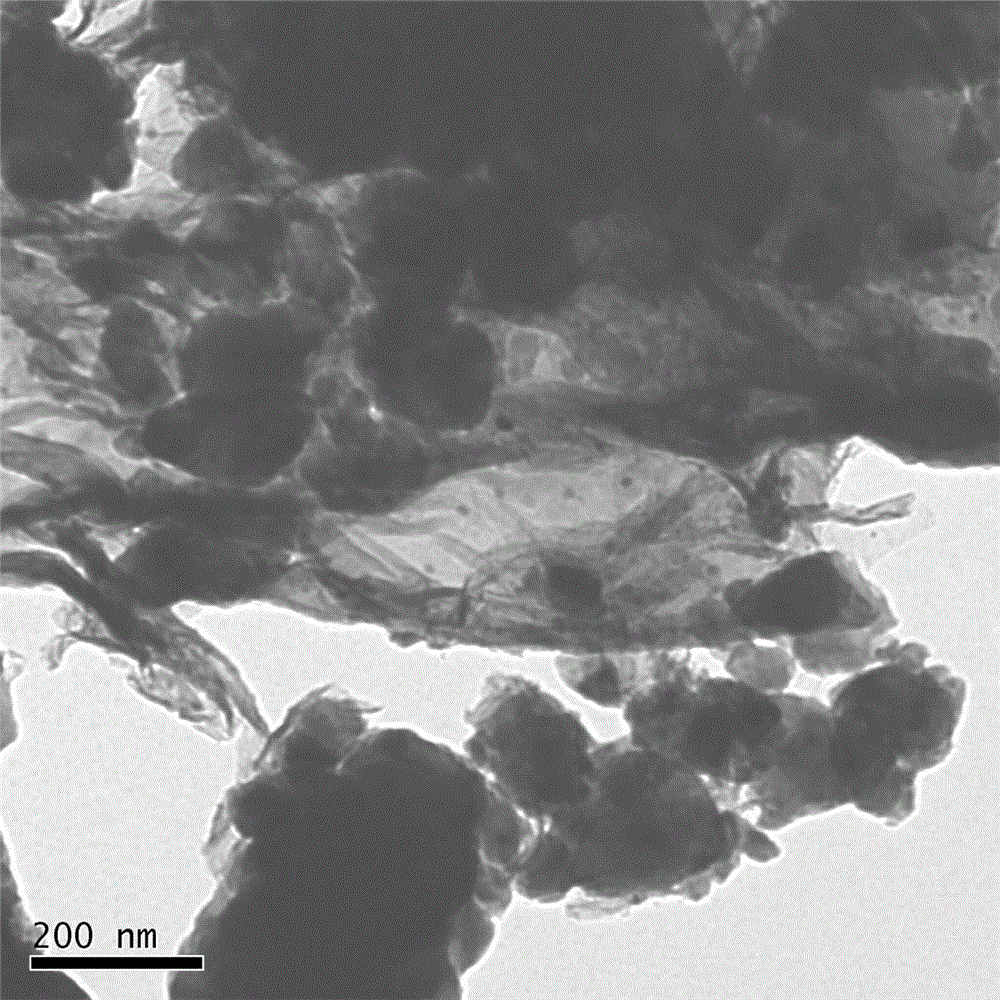

Method for preparing lithium ion battery anode/cathode material from reduced graphene oxide

The invention discloses a method for preparing a lithium ion battery anode / cathode material from reduced graphene oxide. The method comprises the following steps: performing ultrasonic dispersion on graphite oxide in an organic solvent, thereby obtaining a graphene oxide dispersion liquid; reducing by using an appropriate reducing agent or directly using a solvent, oxidizing graphene through oil bath backflow, a hydrothermal method or other reduction methods, thereby obtaining a reduced graphene oxide material containing part of oxygen-containing groups. When the prepared reduced graphene oxide material is used in a lithium ion battery anode material, a relatively high specific discharge capacity can be achieved, that is, is up to 280mAh / g, and good circulation stability and excellent rate performance are achieved. The prepared reduced graphene oxide material can be also used in a lithium ion battery cathode material, the specific discharge capacity can be kept being 900mAh / g and more than 900mAh / g after 100 rounds of charge / discharge circulation, and the circulation stability is relatively good. The method can be a significant study point of high-performance low-cost electrode materials of lithium ion batteries.

Owner:TIANJIN NORMAL UNIVERSITY

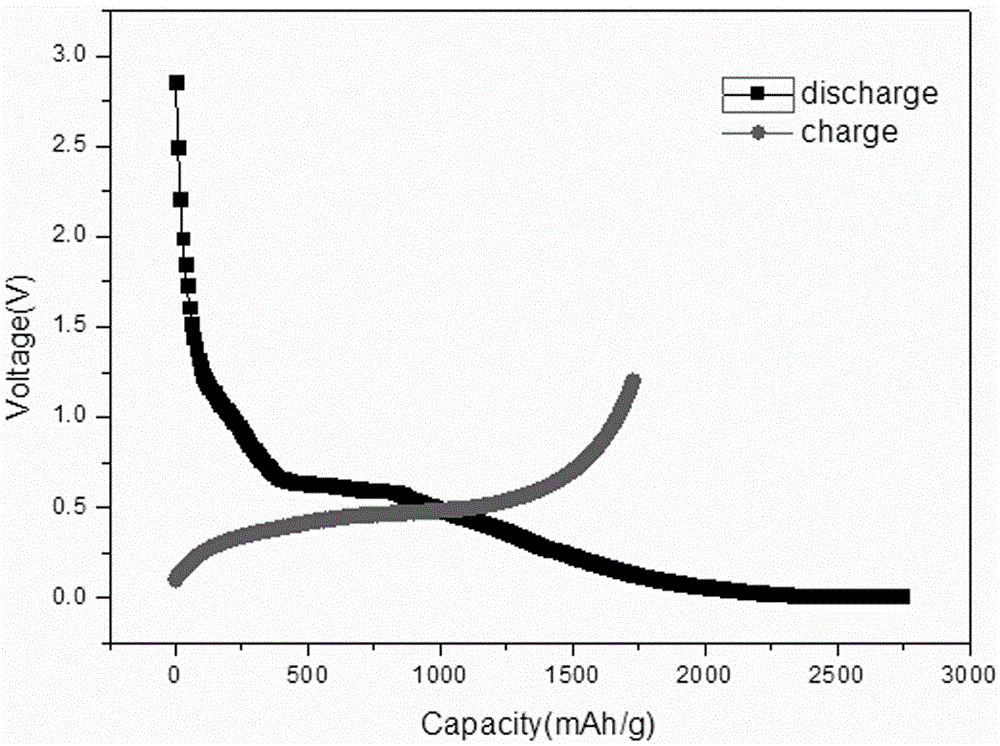

Silicon cathode material coated with graphene and preparation method thereof

InactiveCN104916826AWide variety of sourcesLow priceCell electrodesSecondary cellsOperabilitySilicon particle

The invention relates to the technical field of lithium-ion cathode material, in particular to silicon cathode material coated with graphene and a preparation method of the silicon cathode material coated with the grapheme. The preparation method comprises the following steps: A, preparing oxidized graphene suspension liquid; B, preparing nanometer silicon particle suspension liquid; and C, preparing silicon cathode material coated with grapheme. The preparation method adopts the electrostatic self-assembly synthetic technology and is wide in source of raw material, low in price, simple in synthetic method, easy for control of process conditions, strong in operability and good in repeatability. The silicon cathode material coated with grapheme is high in specific capacity and good in cycle performance and rate capability, wherein the specific discharge capacity for the first time under the electric current density of 0.01-1.2V, 200mA / g can reach 2746mAh / g, and the specific discharge capacity after 100 times of cycles can maintain 803.8mAh / g.

Owner:MCNAIR TECH +1

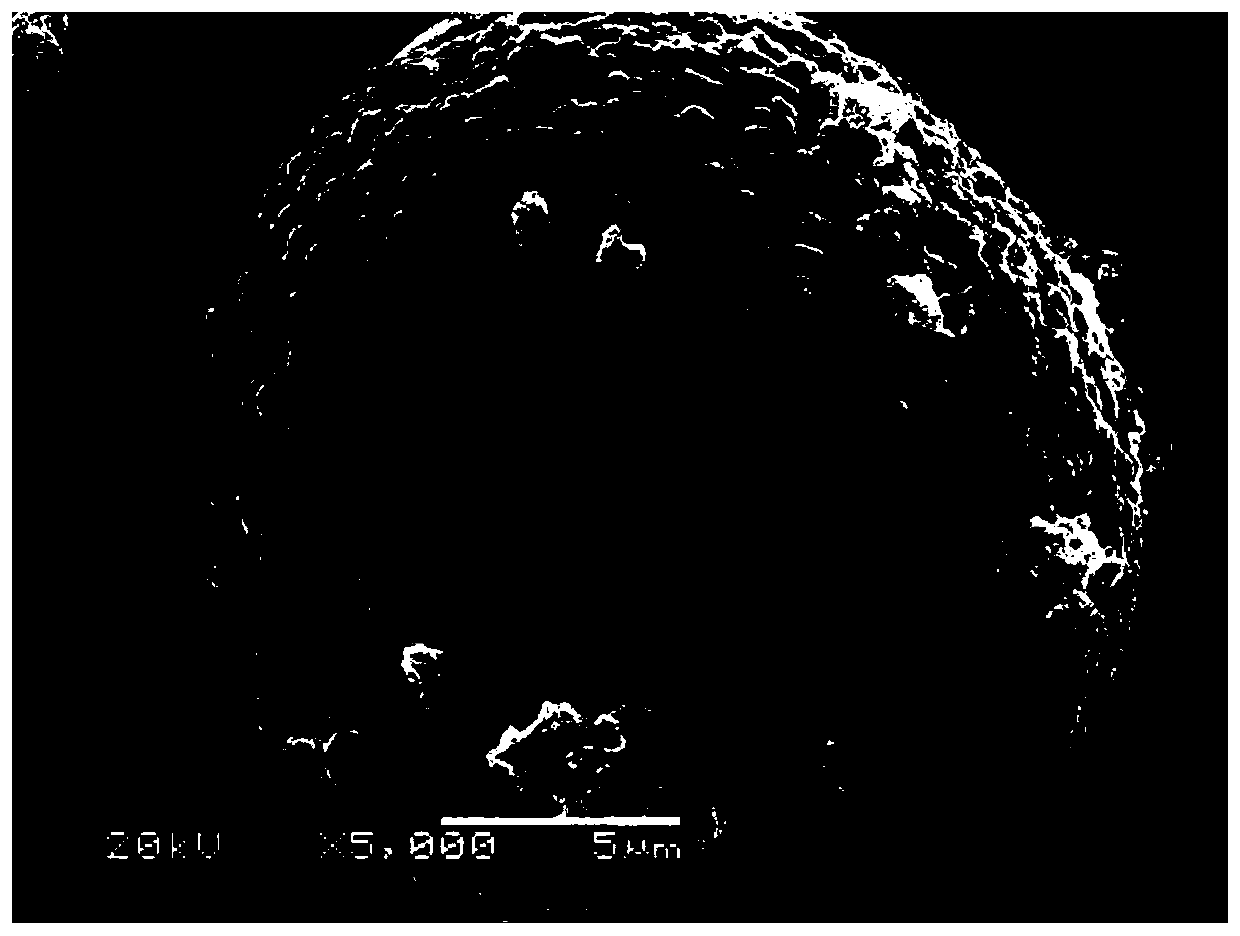

Porous silicon negative material of lithium ion battery and preparation method and application of material

The invention discloses a porous silicon negative material of a lithium ion battery, and a preparation method and application of the material. The method comprises the following steps of: reacting silicon alloy powder, which is taken as a raw material, with inorganic acid to generate porous silicon particles; and washing the porous silicon particles by an HF (Hydrogen Fluoride) acid solution to eliminate surface silicon oxide, and washing and drying the washed porous silicon particles so as to obtain the porous silicon material. The porous silicon material prepared by the method has a sponge-shaped structure which is formed by linking nano silicon particles; the particle sizes of the particles of the porous silicon negative material range from 0.01 micron to 50 microns; the specific surface area of the material is 30-600cm<2> / g; the porous silicon negative material can be taken as a negative material of a lithium ion battery; and in a lithium ion battery electrolyte, the porous silicon powder shows high specific discharge capacity and charge-discharge circulation stability. The porous silicon negative material has the advantages of low cost, simplicity and convenience in method and high electrochemical property, and can be applied to production of silicon negative materials of high-performance lithium ion batteries.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

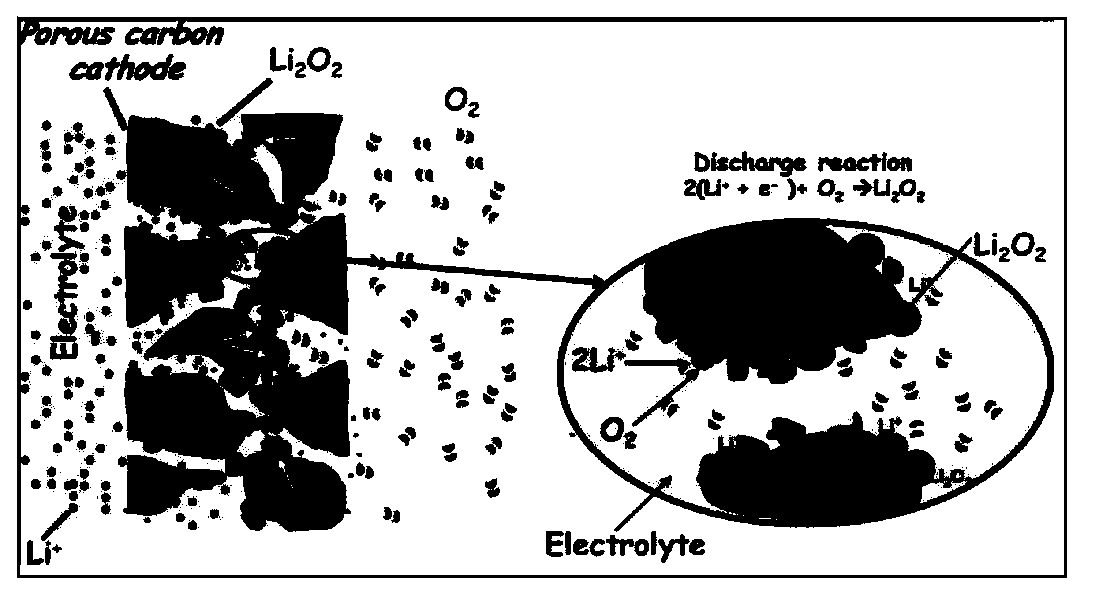

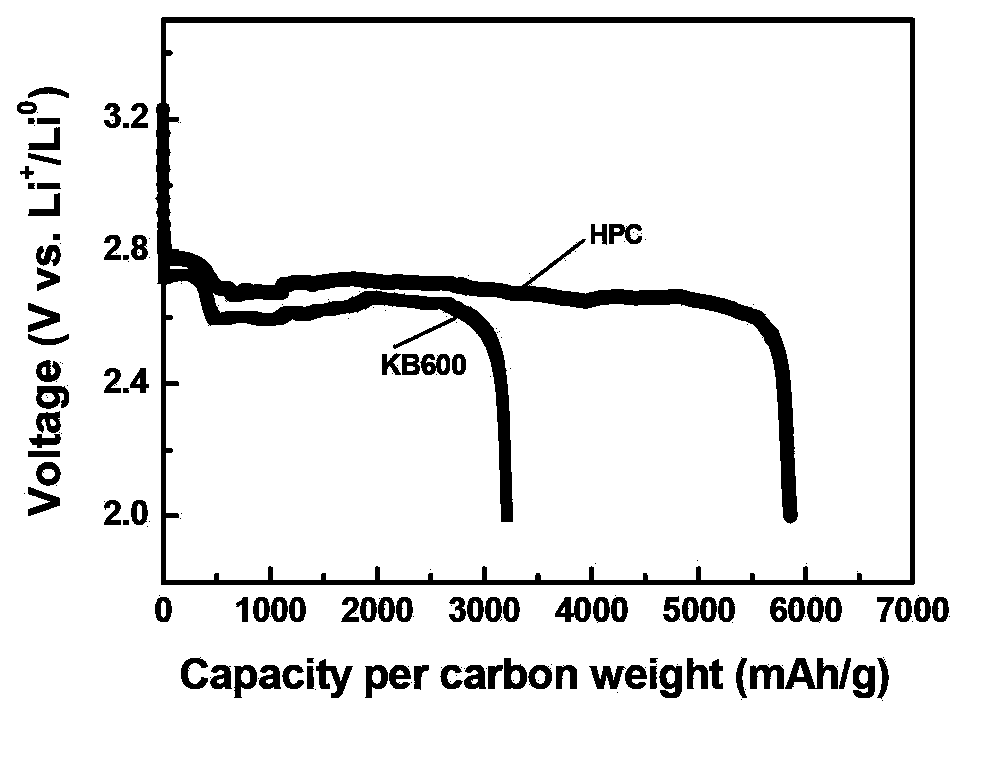

Porous carbon material used for lithium-air cell anode

ActiveCN103855413AShorten the diffusion distanceImprove space utilizationFuel and secondary cellsCell electrodesPorous carbonAir cell

The invention relates to an application of a porous carbon material with a grading pore structure in a lithium-air cell anode, and is characterized in that the carbon material has mutually communicated grading pore structure distribution which has a mesoporous structure for depositing the discharge products and a macroporous structure suitable for transmission of oxygen and an electrolyte. When the carbon material is taken as a material of the lithium-air cell anode, the space utilization rate of carbon material can be increased at maximum limitation during a charge and discharge process, specific discharge capacity, voltage platform and multiplying power discharge capability of the cell can be effectively increased, so that the energy density and power density of the lithium-air cell can be increased. The porous carbon material has the advantages that the preparation technology is simple, the material source is wide, the grading pore carbon material pore structure enables regulation and control, the regulation and control modes are various, and the doping of metal / metal oxide can be easily and simultaneously realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

High energy lithium ion secondary batteries

Lithium ion secondary batteries are described that have high total energy, energy density and specific discharge capacity upon cycling at room temperature and at a moderate discharge rate. The improved batteries are based on high loading of positive electrode materials with high energy capacity. This capability is accomplished through the development of positive electrode active materials with very high specific energy capacity that can be loaded at high density into electrodes without sacrificing performance. The high loading of the positive electrode materials in the batteries are facilitated through using a polymer binder that has an average molecular weight higher than 800,000 atomic mass unit.

Owner:IONBLOX INC

Preparation method for coating anode material of lithium battery

InactiveCN103579590AEasy and quick passImpede passingCell electrodesSecondary cellsSulfur electrodeLithium sulfur

The invention provides a preparation method for a coating anode material of a lithium battery. The preparation method comprises the following specific steps: (1) weighing a coating material and monomer sulfur; weighing the coating material and the monomer sulfur according to a mass ratio, wherein the mass ratio of the coating material to the monomer sulfur ranges from 1:1 to 1:100; (2) preparing a dispersion solution of the sulfur: dissolving the monomer sulfur into a sodium polyacrylate water solution with the mass percentage of 2%-10% at a room temperature to obtain the dispersion solution of the sulfur; (3) preparing a dispersion solution of the coating material: dissolving the coating material into a surfactant water solution at 20-45 DEG C to obtain the dispersion solution of the coating material; and (4) preparing the coating anode material of the lithium battery. According to the preparation method for the coating anode material of the lithium battery, self discharge of the battery is reduced effectively and the stability of the structure in a charging / discharging process of a sulfur electrode is kept; a sulfur active material prepared by the preparation method is used as a lithium-sulfur secondary battery anode material and the prepared lithium material has a high specific discharge capacity and a good circulating performance.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

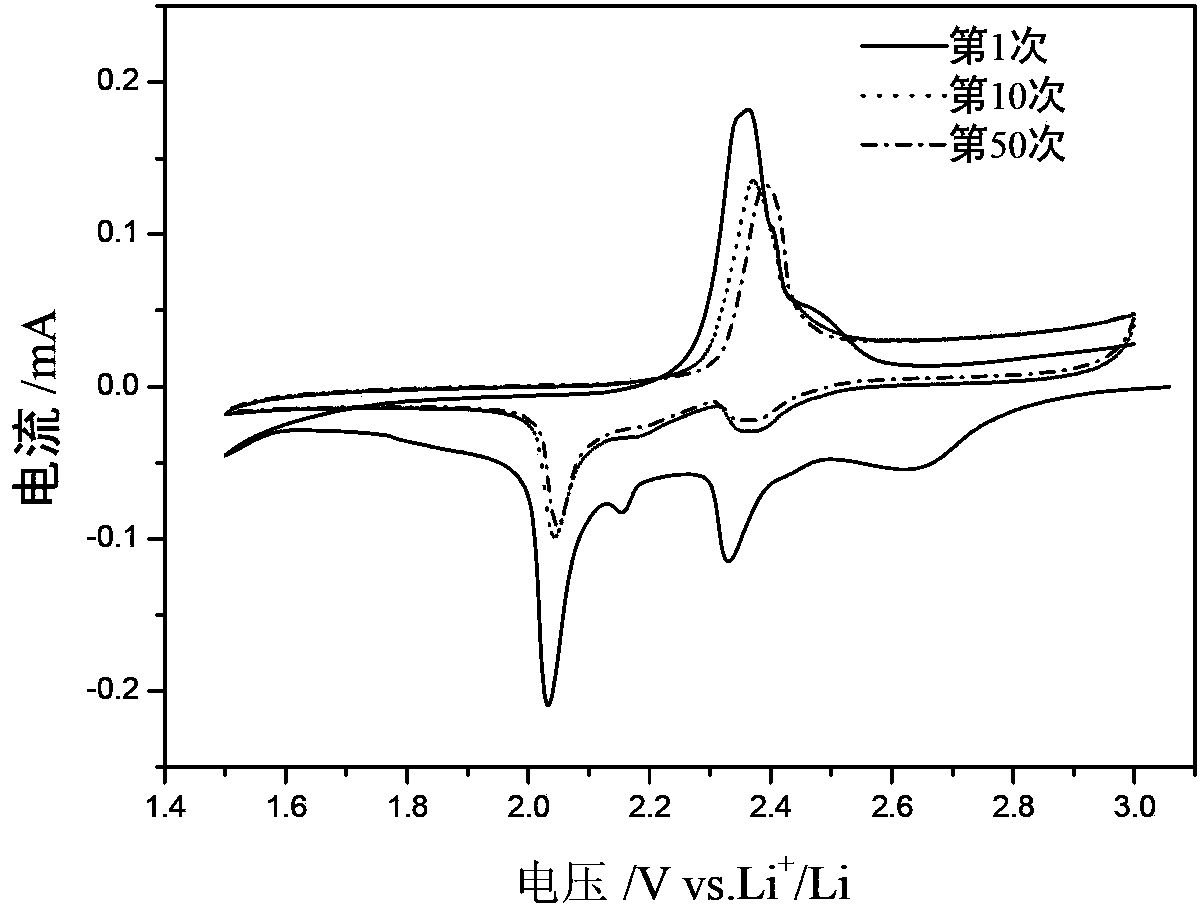

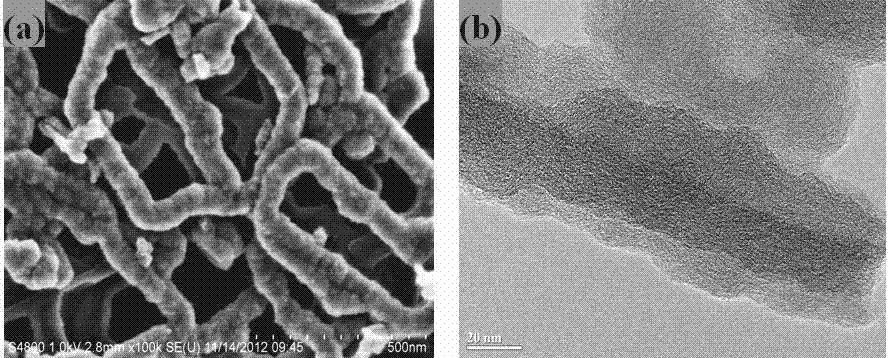

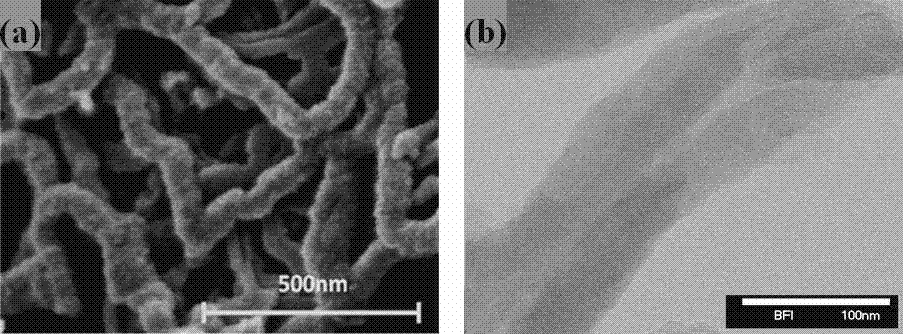

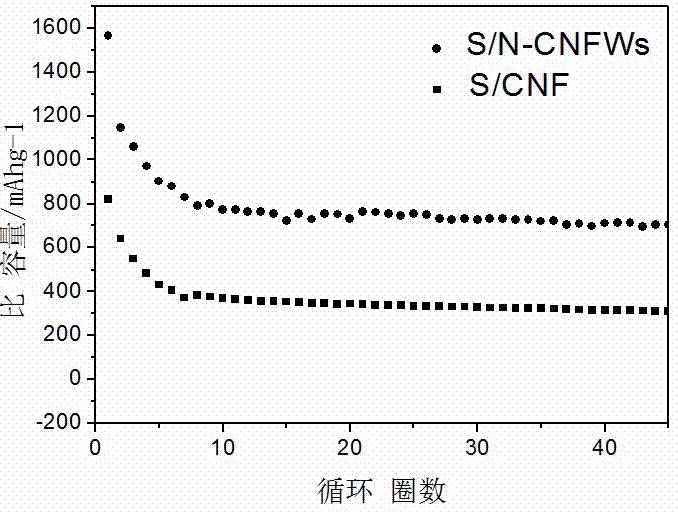

Sulfur-carbon composite material with nitrogen-doped porous carbon nanofiber net-shaped structure, as well as preparation method and application of composite material

InactiveCN103700818AEvenly distributedSimple processCell electrodesLi-accumulatorsCarbon compositesElectrolytic agent

The invention belongs to the technical field of lithium sulfur batteries, specifically relates to a sulfur-carbon composite material with a nitrogen-doped porous carbon nanofiber net-shaped structure, as well as a preparation method and an application of the composite material. By taking a polypyrrole net-shaped structure which is synthesized by virtue of a soft template method as a raw material, taking the potassium hydroxide as a pore forming agent, and taking the nitrogen-doped carbon nanofiber net-shaped structure which is synthesized through high-temperature carbonization under nitrogen atmosphere and is in a porous structure as a precursor, the sulphur-carbon composite material which can be used as the anode of the lithium sulfur battery can be prepared through heat treatment with elemental sulfur. The preparation method provided by the invention is simple, and good in reproducibility, and the prepared composite material is uniform in structure distribution, and can be used as the anode of the lithium sulfur battery. Due to the nitrogen doping and the tridimensional net-shaped structure, for the material, the conductivity can be improved, a transmission path of lithium ions is shortened, meanwhile, the dissolving of the sulfur and intermediate product in an electrolyte can be prevented, the electrochemistry performance of a positive material of the lithium sulfur battery is improved, good specific discharge capacity, cycle performance and rate performance can be achieved.

Owner:FUDAN UNIV

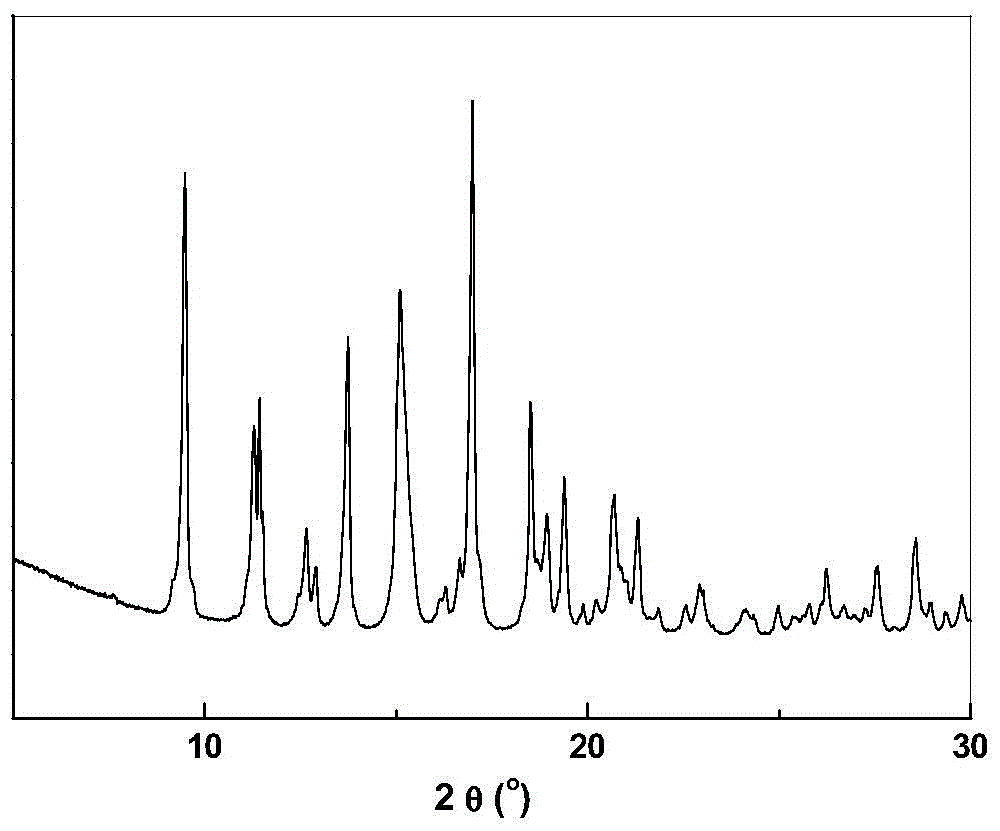

Binary metal organic framework material applied to super capacitor and preparation method for binary metal organic framework material

InactiveCN104992848ALarge specific surface areaAdjustable structureHybrid capacitor electrodesHybrid/EDL manufactureMetal-organic frameworkTerephthalic acid

The invention belongs to the field of super capacitors and particularly relates to a binary metal organic framework material applied to a super capacitor and a preparation method for the binary metal organic framework material. The binary metal organic framework material is formed of two types of metal ions and an organic ligand using a solvothermal method in a self assembly coordination manner. The two types of metal ions are Co-Ni, Co-Fe, Co-Mn, Ni-Mn or Ni-Cu. The organic ligand is trimesic acid, terephthalic acid, 2,6-naphthalene acid, 4,4'-biphenyl diacid or 2-methylimidazole. The binary metal organic framework material is advantaged by having multiple holes, large specific surface area and an adjustable structure, and being varied in structure. The cooperative effect between the two types of metal ions in the binary metal organic framework material (MOFs) is utilized, so that when the binary metal organic framework material is applied to the electrode material of a super capacitor, excellent cycling stability and high specific discharge capacity are achieved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

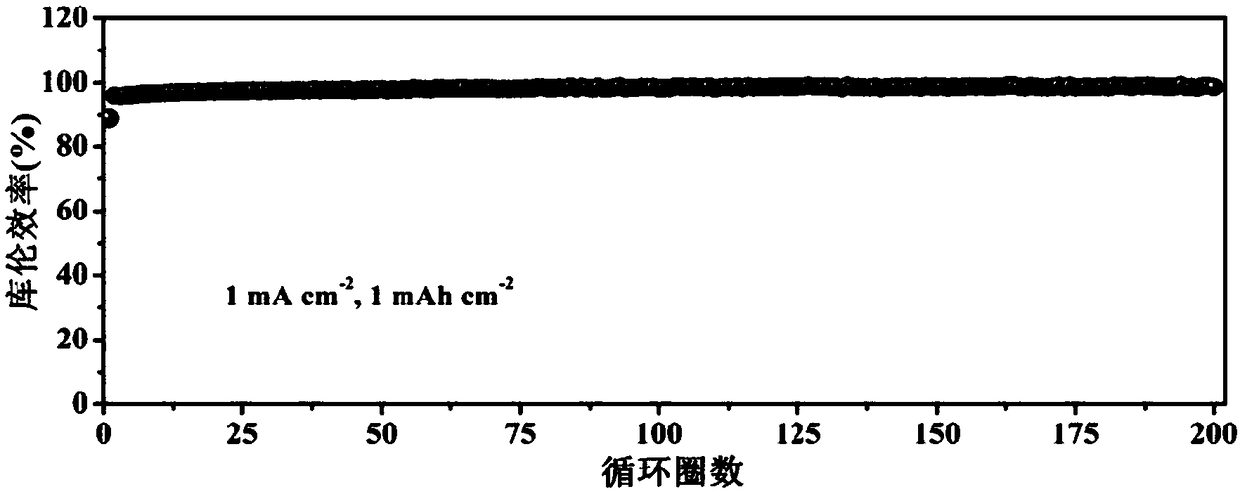

Lithium metal battery lithium negative electrode surface modification method, and lithium metal battery

ActiveCN108448058ASimple processEasy to operateElectrode manufacturing processesCell seperators/membranes/diaphragms/spacersHigh energyShielding gas

The invention discloses a lithium metal battery lithium negative electrode surface modification method, and a lithium metal battery. The modification method comprises the following steps: a lithium metal negative electrode is impregnated in or coated with a fluorine-containing ionic liquid in a dry protection gas atmosphere, is fluorinated, and is taken out to make a protection layer rich in lithium fluoride formed on the surface of the metal lithium negative electrode in order to obtain a lithium fluoride coated metal lithium negative electrode. The lithium fluoride protection layer obtainedby surface fluorination is very uniform and dense, and can reduce the consumption of lithium metal and an electrolyte and inhibit the formation of lithium dendrites in order to make the metal lithiumnegative electrode have a high specific discharge capacity, a long cycle life and a good safety, so the stability and the high efficiency of the lithium metal battery in a long cycle process are achieved, use requirements of a high-energy and high-power power battery are met, the industrialization process of the lithium metal battery is facilitated, and lithium metal battery has a wide applicationprospect.

Owner:SOUTH CHINA UNIV OF TECH

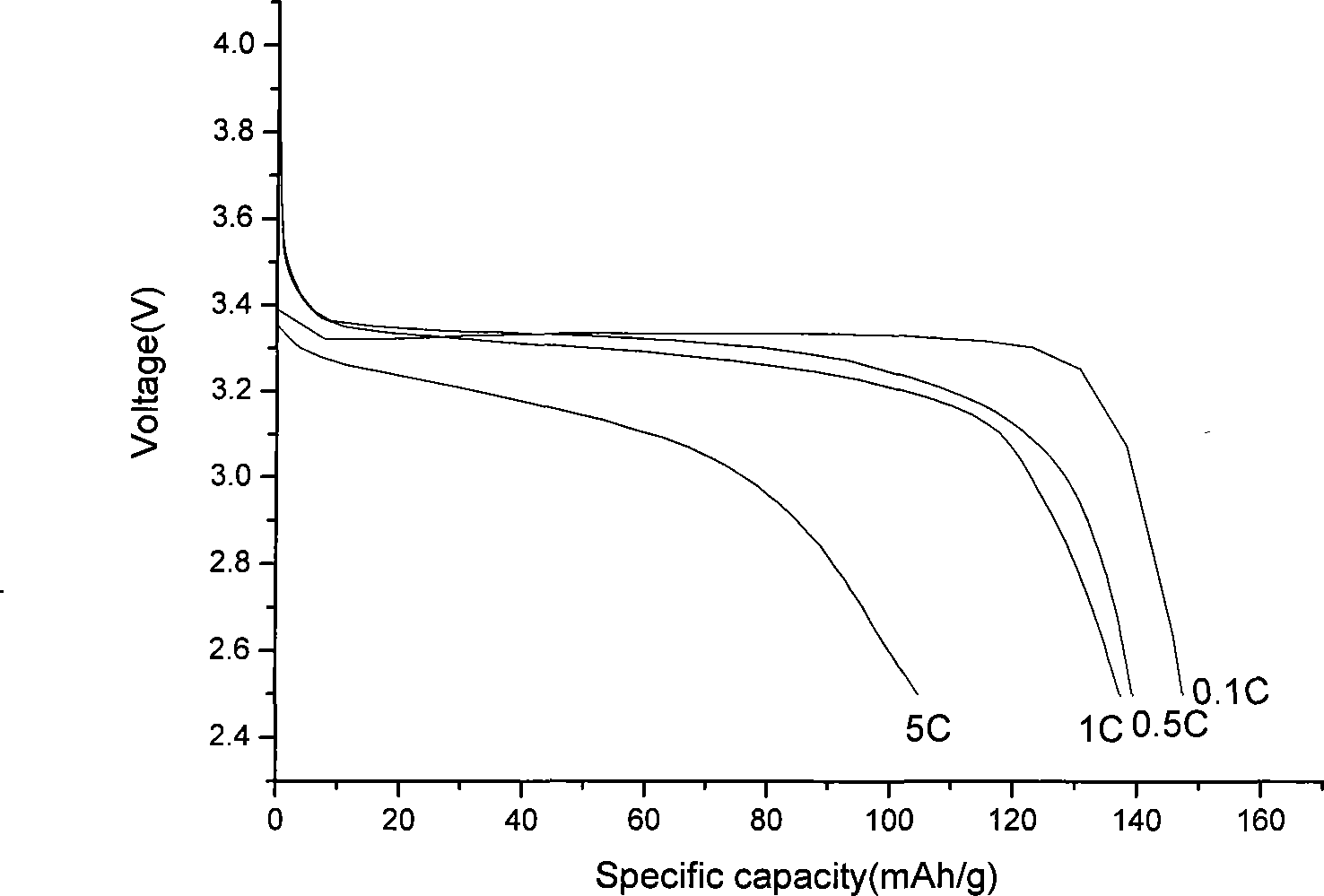

Method for making ferrous lithium phosphate/carbon compound material of high active disorderly ferric phosphate

InactiveCN101237043AHigh activitySmall particle sizeElectrode manufacturing processesPhosphorus compoundsCarbon compositesPhosphate

The present invention belongs to energy material, and in particular relates to a method of using high-activity disordered iron phosphate to prepare ferrous phosphate lithium / carbon composite material. A ferrous iron source is mixed with phosphorus source solution according to stoichiometric ratio, has hydrogen peroxide added in, has pH value controlled and is stirred so as to prepare high-activity disordered iron phosphate. iron phosphate, a lithium source and a carbon source are mixed pro rata, ball-milled uniformly, spray-dried and treated via high temperature under protective atmosphere, so as to obtain high specific capacity ferrous phosphate lithium / carbon composite material of which the average particle diameter is 200-500nm, 0.25C rate specific discharge capacity reaches 145-150mAh / g, 1C rate specific discharge capacity reaches 130-140mAh / g, and 5C rate specific discharge capacity reaches 105-110mAh / g. The method is low in cost and simple in process. Prepared material is good in electrochemical performance and especially excellent in rate performance, which is applicable to battery anode material of electric vehicles and other large-scale mobile devices.

Owner:NORTHEAST NORMAL UNIVERSITY

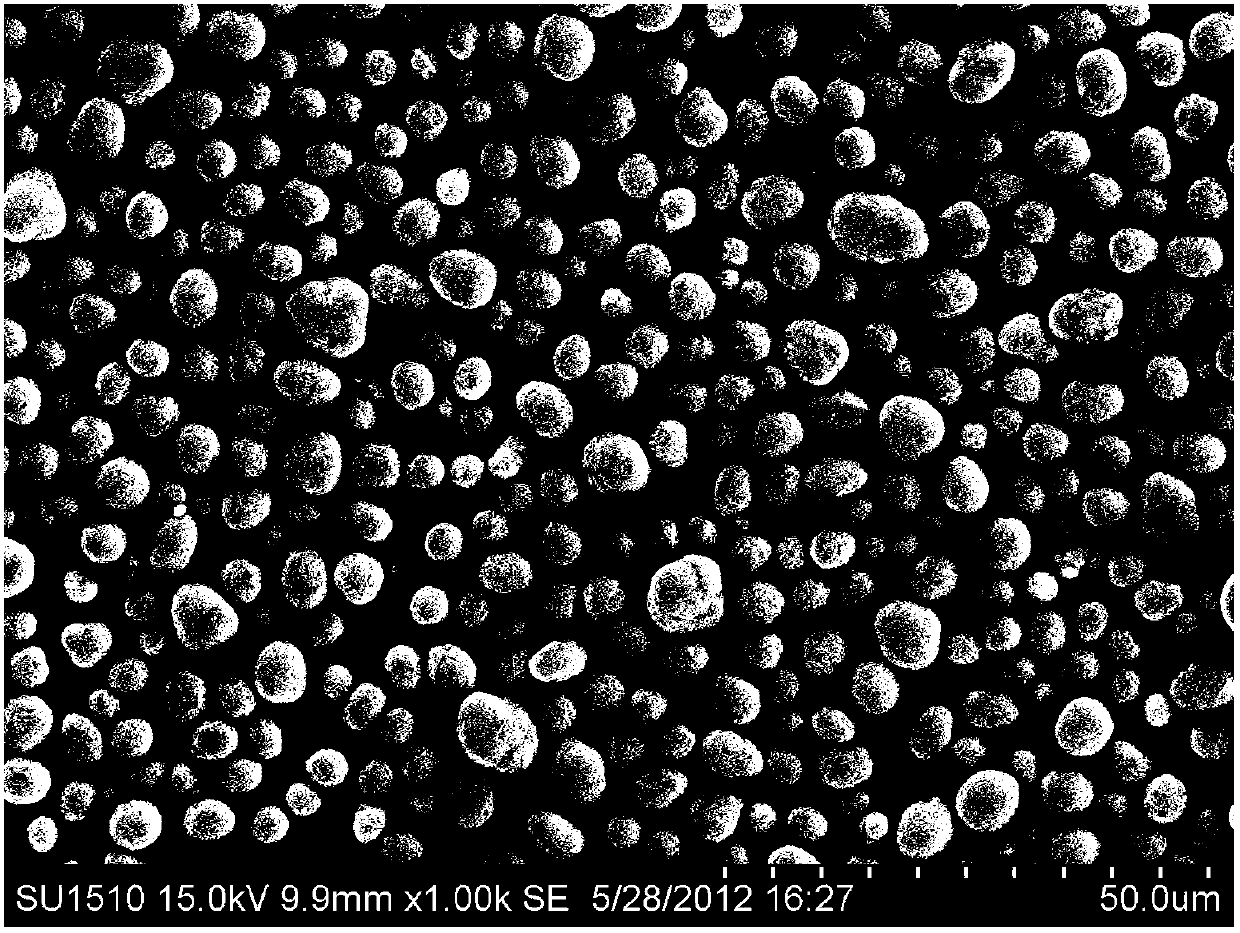

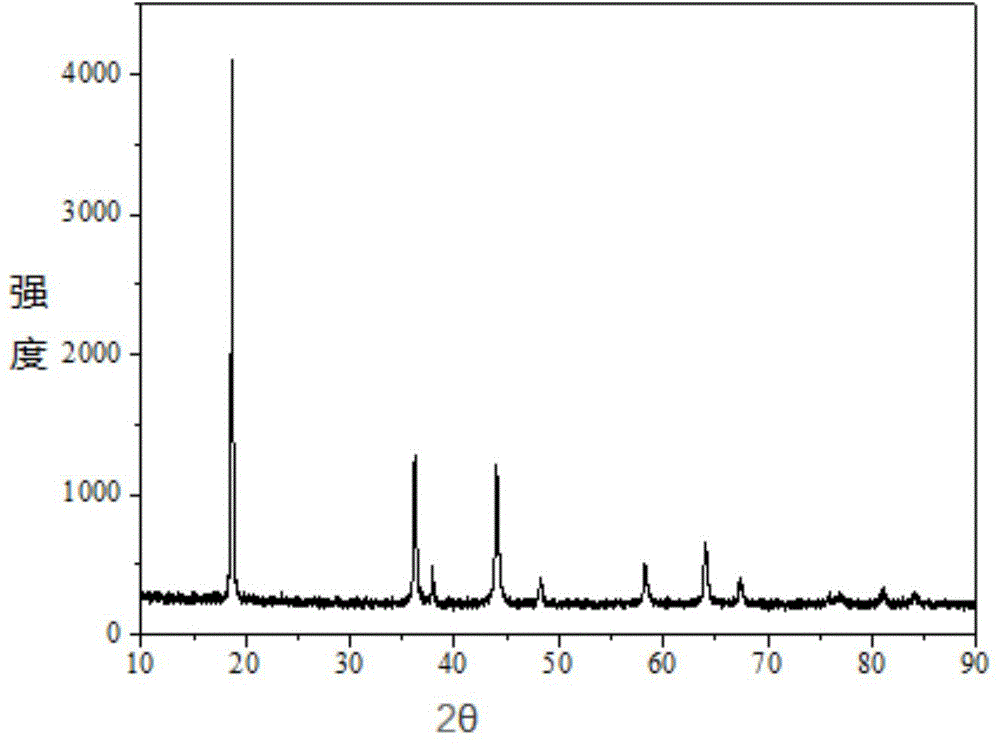

Preparation method of lithium-ion battery positive electrode material spherical nickel-cobalt-lithium aluminate

ActiveCN103296263AGuaranteed spherificationHigh tap densityCell electrodesNickel saltReaction temperature

The invention discloses a preparation method of lithium-ion battery positive electrode material spherical nickel-cobalt-lithium aluminate. The preparation method comprises the following steps of: firstly dissolving aluminum salt in deionized water, and preparing AlOOH aluminum sol by adding HNO3 or ammonium hydroxide and nitric acid; preparing nickel salt and cobalt salt into uniform aqueous solution according to a certain ratio; enabling the mixed salt solution to be collectively reacted with the aluminum sol and a mixed alkali solution, adjusting the pH value to be 9 to 12, controlling the reaction temperature, carrying out the solid-liquid separation after 20 to 30h of the reaction, and washing, filtering and drying the reaction product to obtain spherical nickel-cobalt-aluminum hydroxide precursor powder; then mixing the spherical nickel-cobalt-aluminum hydroxide precursor powder with lithium, sintering the mixture, and pulverizing and grading sintered material to obtain the lithium-ion battery positive electrode material spherical nickel-cobalt-lithium aluminate. The prepared spherical nickel-cobalt-lithium aluminate particles are controllable in shape and granularity, high in compacting density, high in specific discharge capacity, good in cycling stability and low in cost.

Owner:山东天骄新能源有限公司

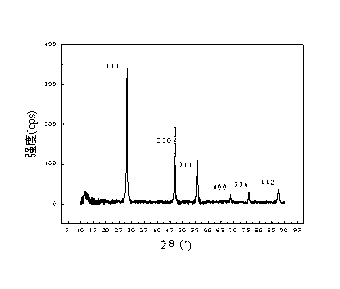

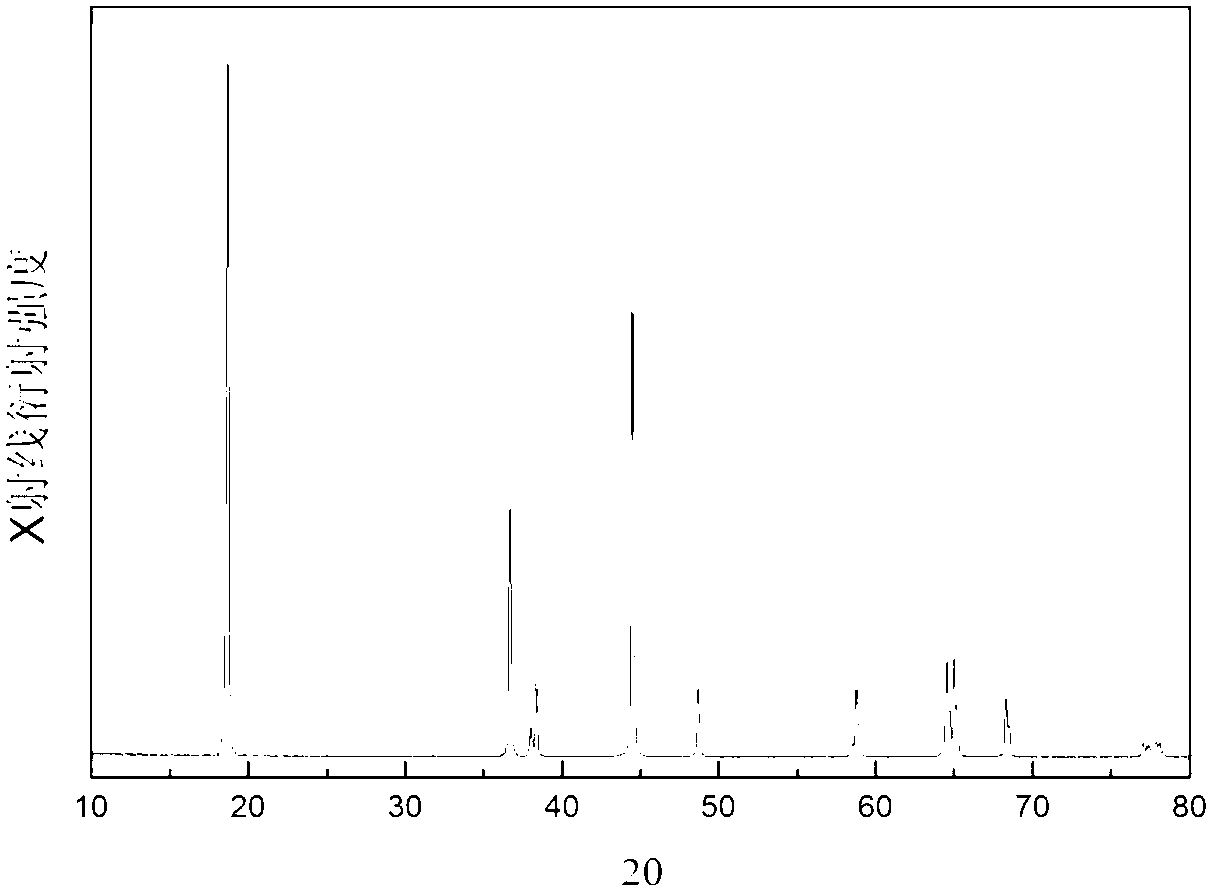

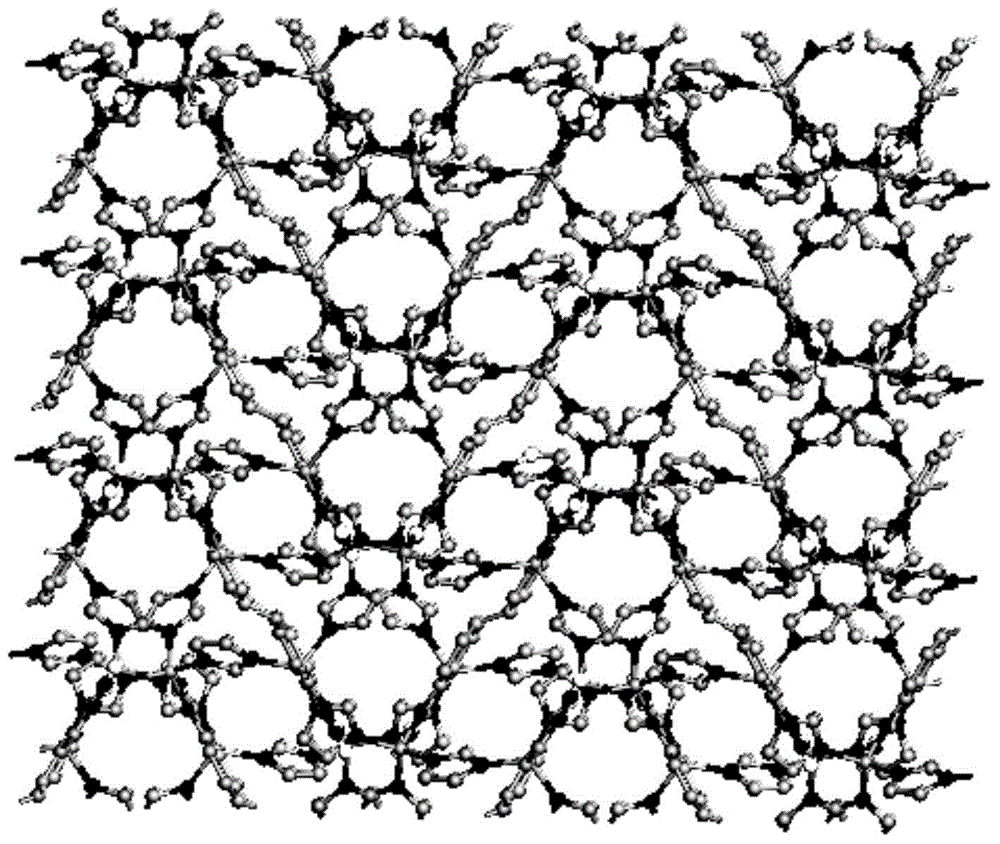

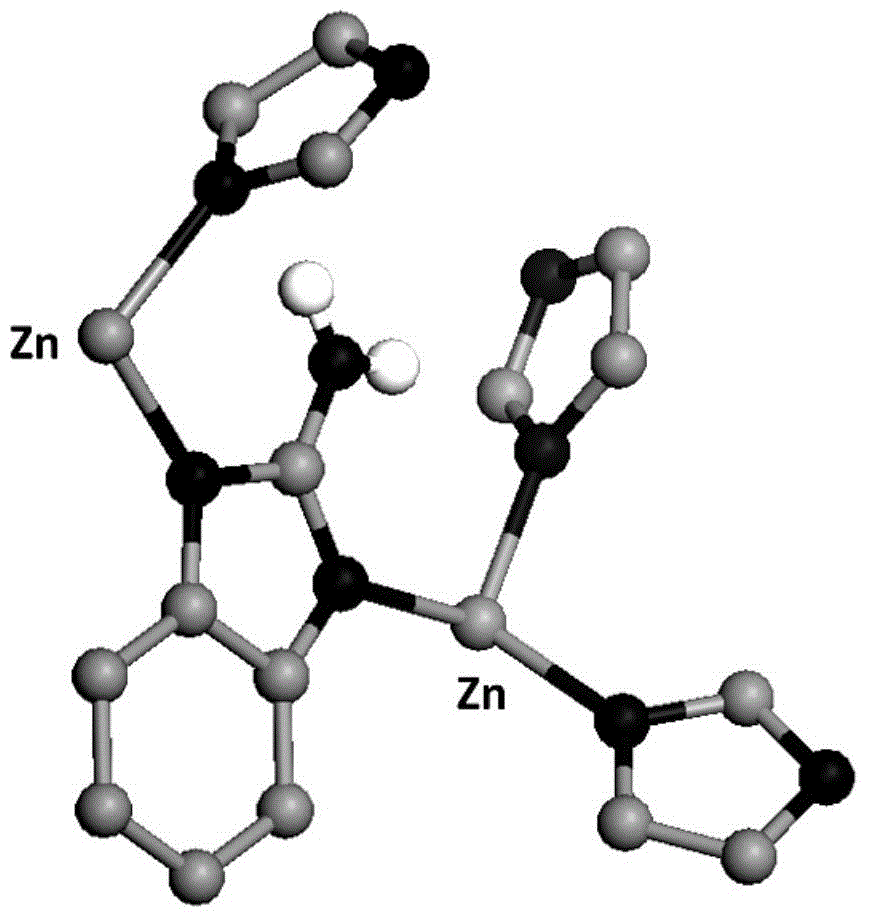

Functionalized ZIF type metal organic framework (MOF) porous material as well as preparation method and application of material

ActiveCN104307482AExcellent discharge specific capacityThe first discharge specific capacity is highOther chemical processesCell electrodesMetal-organic frameworkLithium-ion battery

The invention provides a functionalized ZIF type metal organic framework (MOF) porous material. A framework of the material comprises metal ions Zn<2+> or Co<2+> as well as imidazole and aminobenzimidazole. The material is excellent in physical and chemical stability and overcomes the defect that a traditional MOF porous material is sensitive to water; the material has a good CO2 adsorption property; besides, a lithium ion battery manufactured with the material as an electrode material has good electrochemical properties, and furthermore, after N cycles, the specific discharge capacity of the lithium ion battery tends to be stable, wherein N is greater than or equal to 10; as a result, the functionalized ZIF type MOF porous material has bright application prospect in the field of lithium ion batteries.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

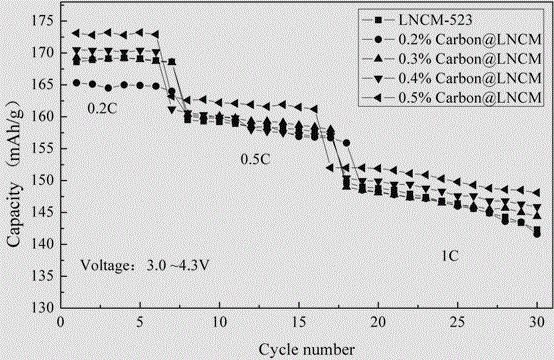

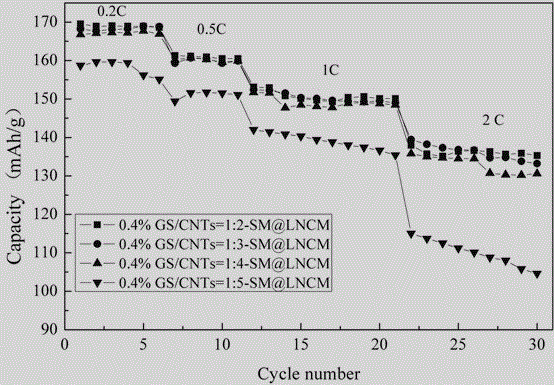

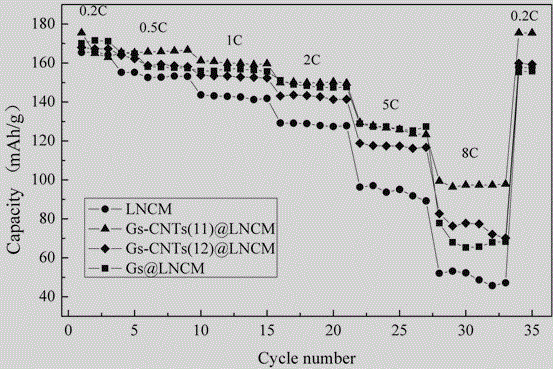

Coupled carbon nano tube-graphene composite three-dimensional network structure-coated ternary material and preparation method thereof

ActiveCN105070888AImprove conductivityIncrease the diffusion coefficientMaterial nanotechnologyCell electrodesManganeseCarbon nanotube

The invention relates to the technical field of battery materials, in particular to a coupled carbon nano tube-graphene composite three-dimensional network structure-coated ternary material and a preparation method thereof. According to the coupled carbon nano tube-graphene composite three-dimensional network structure-coated ternary material, a nickel-cobalt-manganese ternary material, carbon nano tubes and graphene are taken as raw materials; and the ternary material is characterized by being prepared by the following steps: with polyvinyl pyrrolidone as a dispersing agent, through a liquid-phase self-assembling method, simultaneously connecting the graphene and the carbon nano tubes with a silane coupling agent to form a three-dimensional network structure; and evenly dispersing the coupled carbon nano tube-graphene composite material and the nickel-cobalt-manganese ternary material through a physical method, coating the surface of the nickel-cobalt-manganese ternary material, and sintering the nickel-cobalt-manganese ternary material in an inert atmosphere, so as to obtain the evenly coated product. The product provided by the invention has the advantages of high specific discharge capacity, long cycle life and simplicity in preparation process; and large-scale production is easy to realize.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

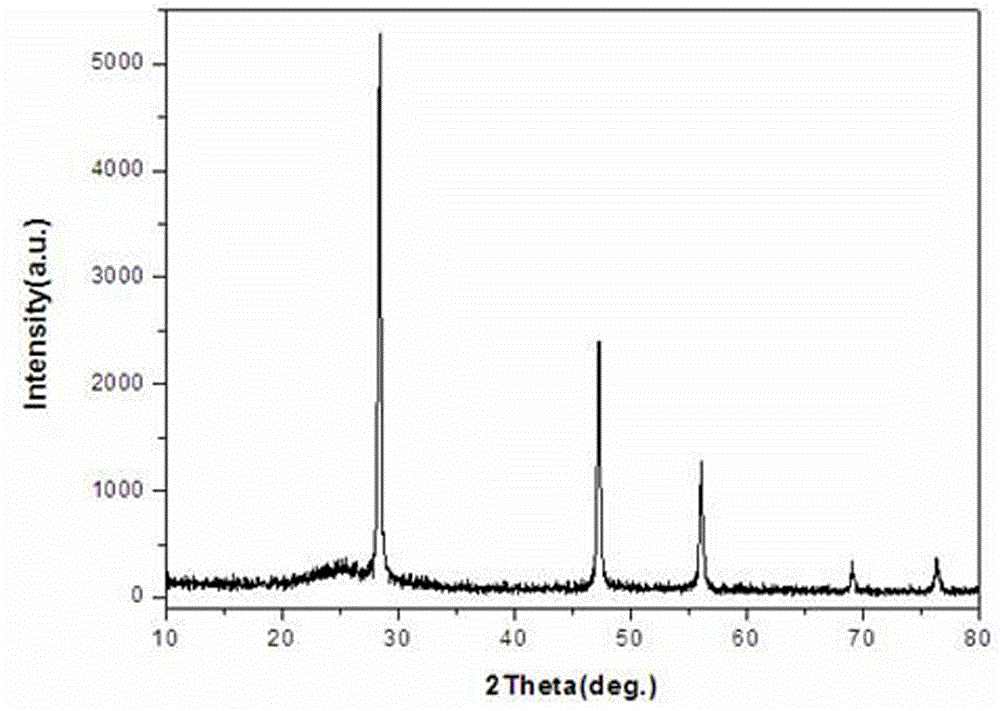

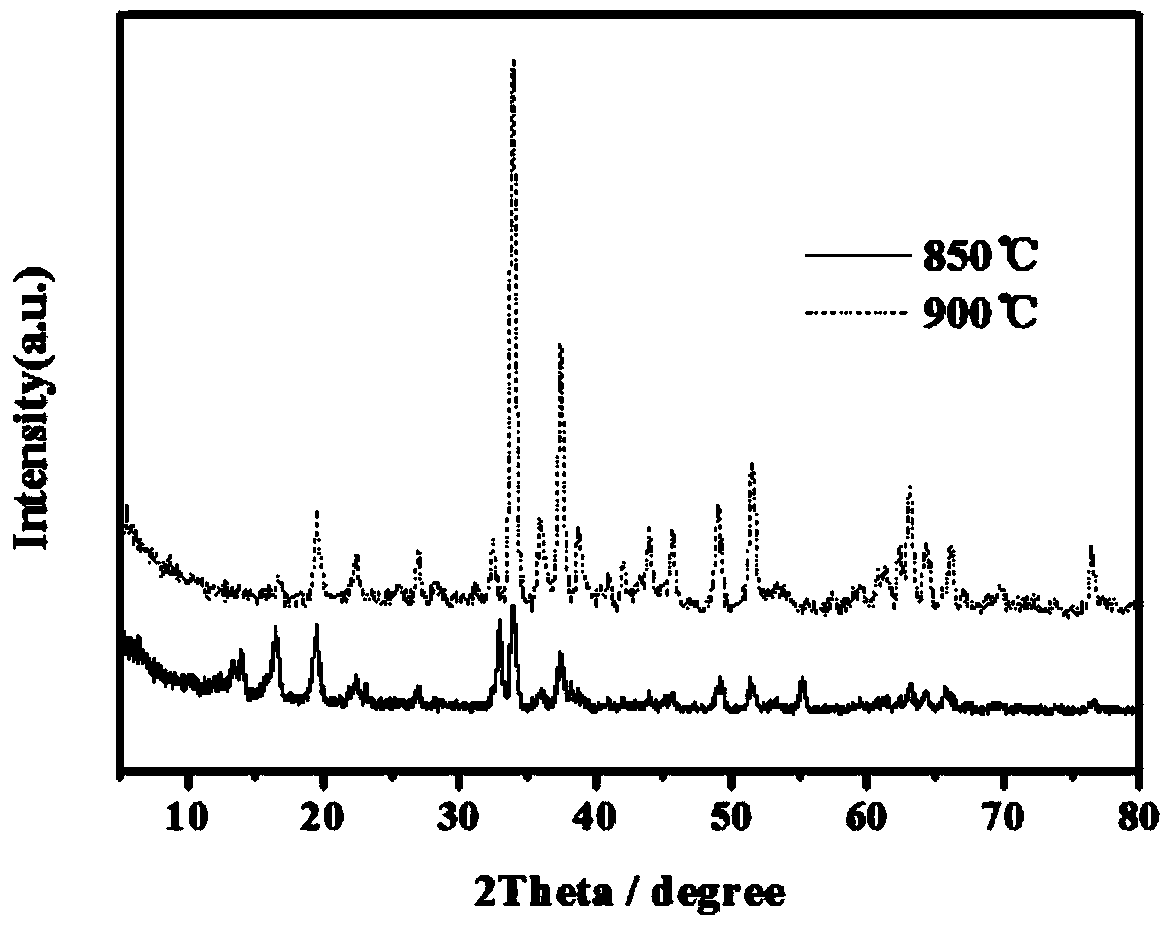

High-temperature solid-phase synthesis method of one-dimensional nano-sodion cell anode material NaxMnO2

InactiveCN103594707AUniform shapeEasy to shapeNon-aqueous electrolyte accumulatorsCell electrodesManganeseEvaporation

The invention discloses a high-temperature solid-phase synthesis method of a one-dimensional nano-sodion cell anode material NaxMnO2. The high-temperature solid-phase synthesis method comprises the following steps of 1, dissolving a sodium salt and a manganese salt in water according to a mole ratio of sodium to manganese of 0.44-0.56 to obtain a solution I, 2, dissolving citric acid in water to obtain a solution II, wherein a mole ratio of citric acid to the total metal ions is in a range 0.5-1, 3, dropwisely adding the solution I into the solution II and carrying out stirring for 10-60min, 4, carrying out heating evaporation on the mixed solution at a temperature of 60-90 DEG C to remove a solvent, heating the residues at a temperature of 120 DEG C for 6-24h, cooling the heated residues to a temperature of 10-30 DEG C, and grinding the cooled residues into powder, 5, heating the powder at a temperature of 350-500 DEG C for 3-10h, cooling the powder to a temperature of 10-30 DEG C, and grinding the cooled powder into fine powder, and 6, heating the fine powder at a temperature of 800-950 DEG C for 10-45h, and carrying out cooling to obtain the one-dimensional nano-sodion cell anode material NaxMnO2. The high-temperature solid-phase synthesis method has short synthesis time and a high yield in unit time. The one-dimensional nano-sodion cell anode material NaxMnO2 has uniform, dispersive, thin and long product morphology and good electrochemical properties (of a specific discharge capacity of 114mA.h / g at 0.1C charging-discharging multiplying power).

Owner:SOUTHWEST UNIVERSITY

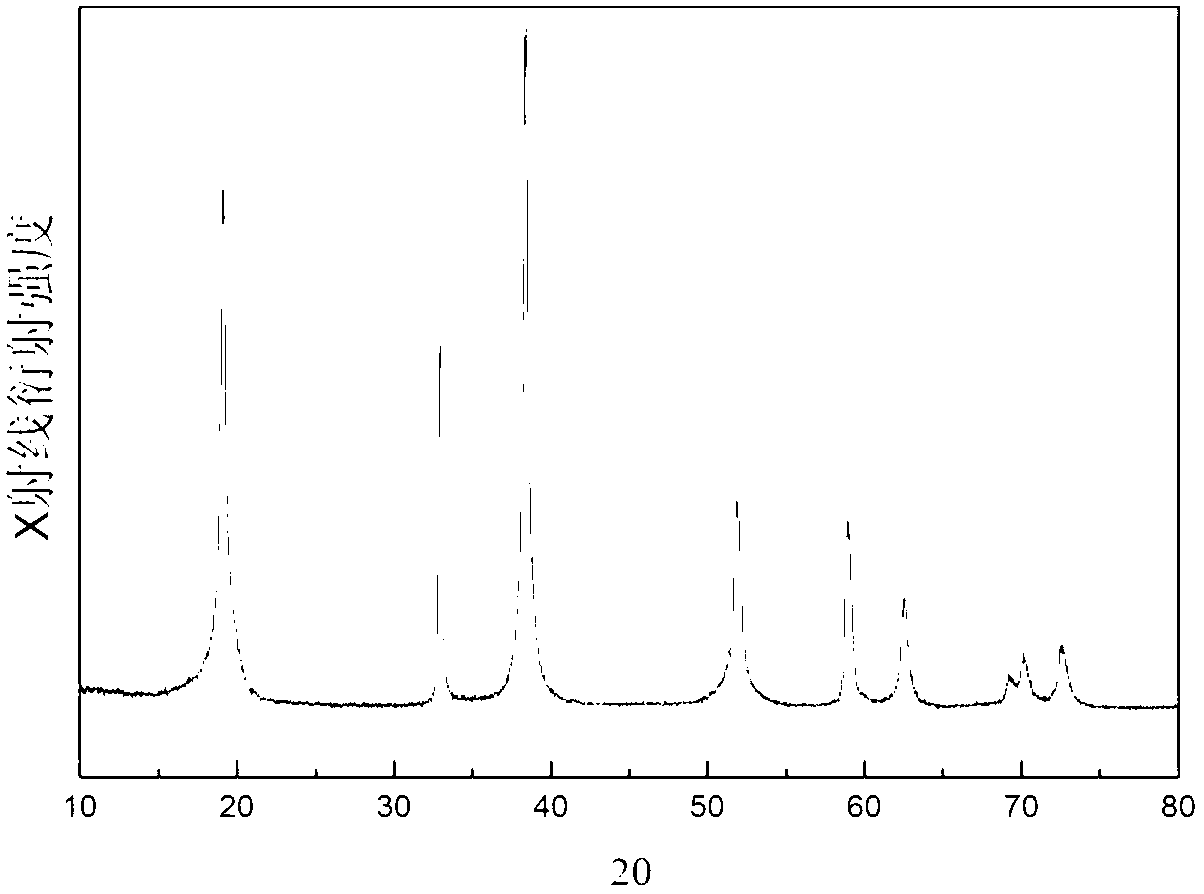

Process for preparing high density spherical lithium ferric phosphate

InactiveCN1821065AHigh yieldWide variety of sourcesCell electrodesPhosphorus compoundsFerrous ammonium phosphateEnergy source

The present invention is microwave synthesis process of high density spherical lithium ferric phosphate as the positive electrode material of lithium ion cell, and belongs to the field of energy source material preparing technology. Spherical lithium ferric phosphate is prepared through mixing ferrous sulfate and solid phosphorus in the required Fe / P ratio; adding in certain speed into deionized water; adding alkali matter to regulate pH value to form the precursor ammonium ferrous phosphate; drying the precursor, mixing with lithium acetate in the same ratio, adding proper amount of conducting agent, and high temperature treatment at 600-800 deg.c for 3-30 hr in the protecting atmosphere. Thus prepared spherical lithium ferric phosphate has average grain size of 5-10 microns, tap density 2.0-2.3 g / cu cm, and room temperature initial specific discharge capacity of 140-160 mA / g. The process is simple, low in cost, high in yield and suitable for industrial production.

Owner:TSINGHUA UNIV

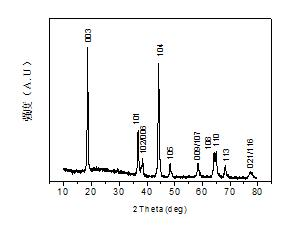

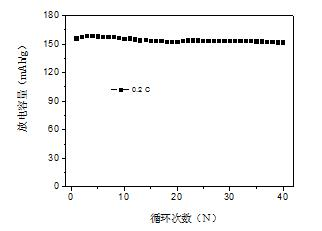

Method for preparing manganese lithium phosphate/carbon composite material by manganese phosphate

ActiveCN101673819ALow costThe synthesis process is simpleElectrode manufacturing processesCarbon compositesManganese

The invention discloses a method for preparing manganese lithium phosphate / carbon composite material by manganese phosphate, belonging to the technical field of energy material, comprising the following steps: firstly, preparing active manganese phosphate (MnPO4), secondly mixing the active manganese phosphate with lithium source and adding carbon source, ball milling and spray drying the materials, conducting heat treatment on the dried powder in the presence of protective atmosphere, heating to 300-850 DEG C and roasting for 2-12 hours and naturally cooling to obtain the manganese lithium phosphate / carbon composite material. The preparation method has low cost and simple synthesis technology, is applied to industrial production; the prepared manganese lithium phosphate / carbon composite material has a primary particle average diameter of 40-500 nm; the synthetic manganese lithium phosphate / carbon composite material has good electrochemical property when taken as the anode material ofthe lithium battery, high specific capacity and nice circulating performance at the conditions of room temperature and large current density; and the specific discharge capacity with 0.1 C multiplyingpower is more than 130 mAh / g.

Owner:TSINGHUA UNIV

Anode active substance for lithium ion battery and preparation method thereof

InactiveCN103928672AStable structureImprove electrochemical performanceCell electrodesSecondary cellsPower flowPhysical chemistry

The invention provides an anode active substance for a lithium ion battery and a preparation method thereof. The anode active substance is fluorine-doped Li2MnO3; the composition formula is Li2MnO3-xFx and x is more than or equal to 0.03 and less than or equal to 0.12. The preparation method is simple; according to the battery produced by the preparation method, the first-time specific discharge capacity is 172.4-209.1mAh / g when the current density is 5mA / g, and keeps 112.7-139.9mAh / g after 20 times of cycles; the retention rate is 58.6-66.9%.

Owner:WUHAN UNIV OF TECH

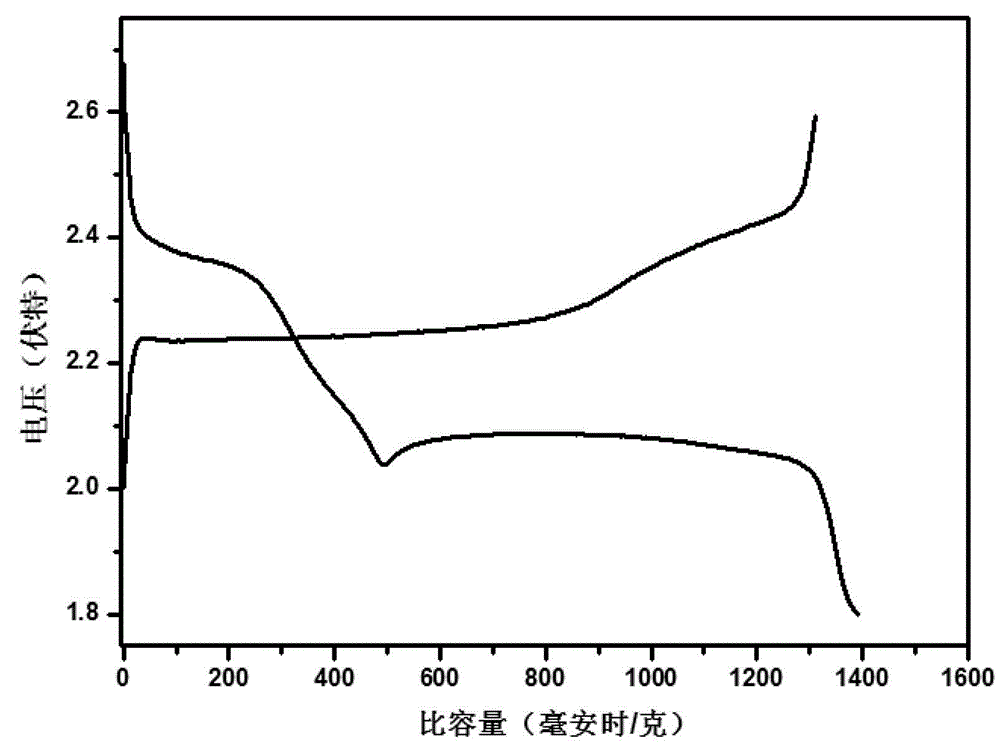

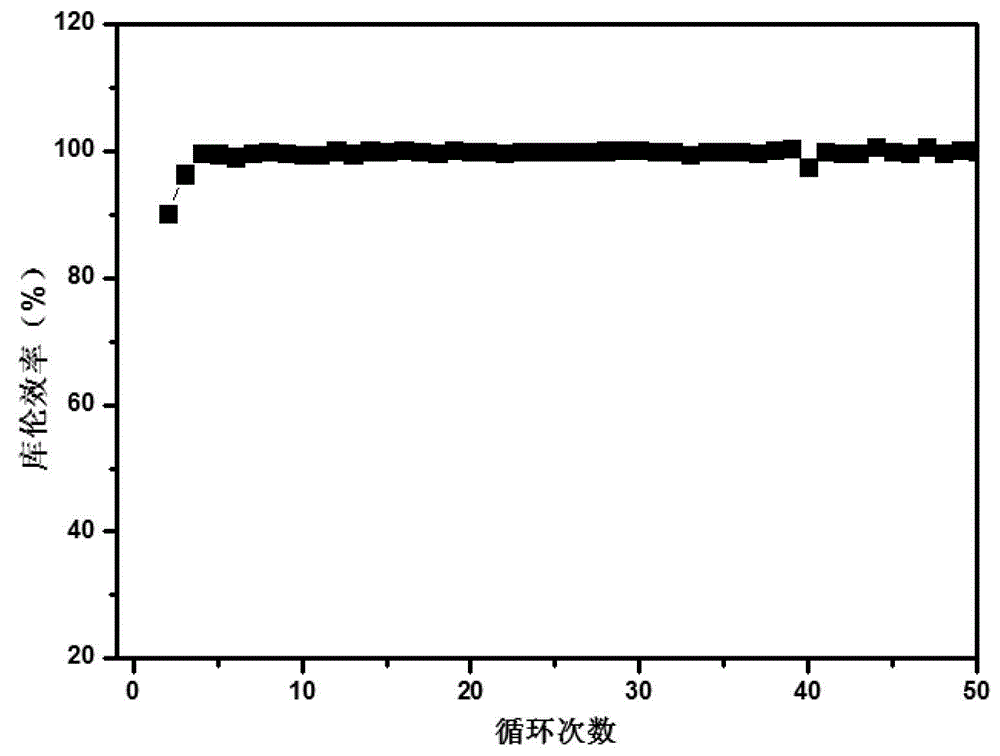

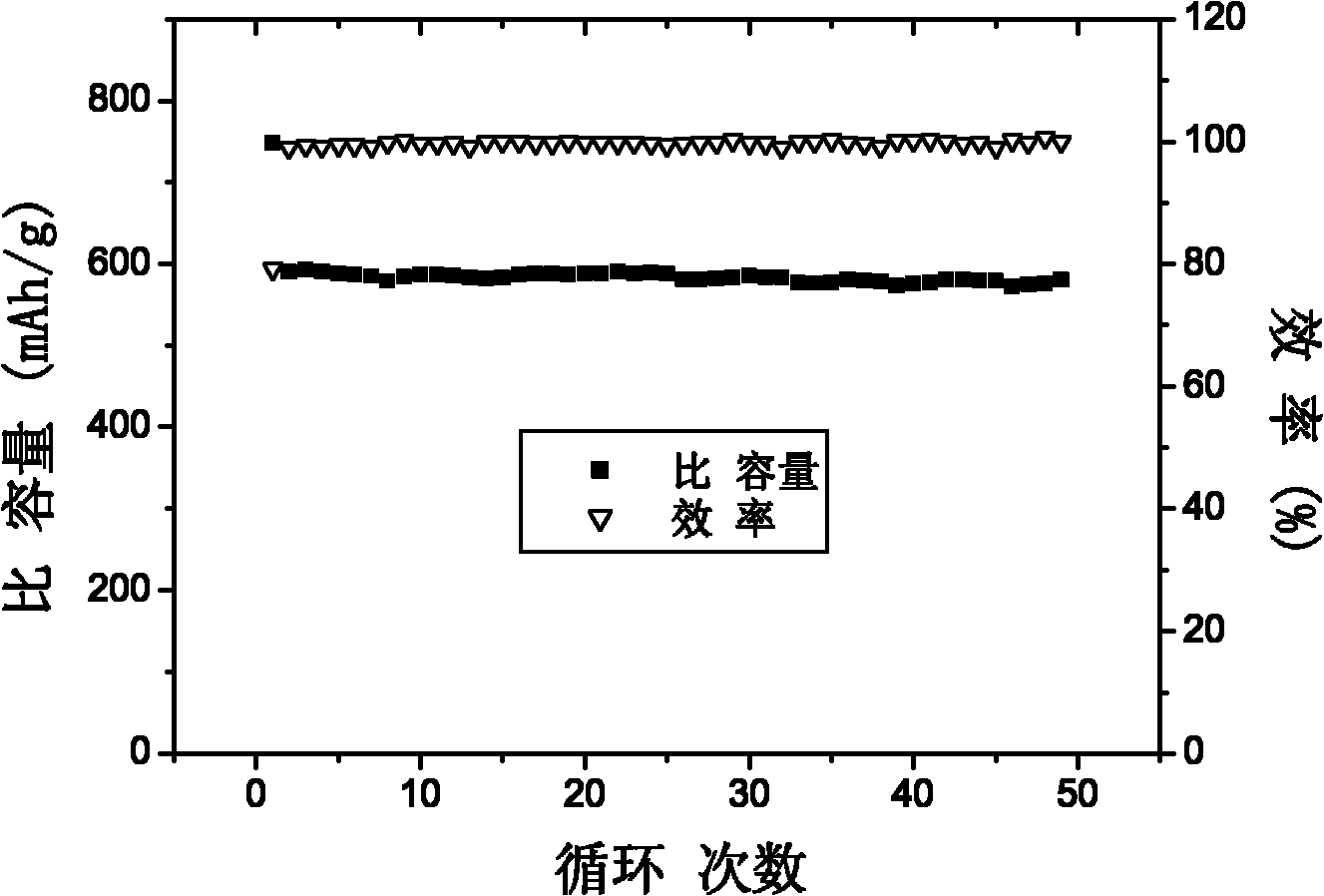

Preparation method of secondary lithium-sulfur battery anode adhesive

The invention discloses a preparation method of a secondary lithium-sulfur battery anode adhesive. Carbonylated beta-cyclodextrin is taken as an adhesive instead of beta-cyclodextrin, so that water dissolubility is enhanced. A secondary lithium-sulfur battery anode is obtained by the following steps of: uniformly dispersing the carbonylated beta-cyclodextrin, a sulfur-containing material and a conductive agent in water; coating the solution on current collecting fluid; drying; and tableting. A secondary lithium-sulfur battery consists of the anode and a metal lithium cathode. Charging and discharging are performed at the temperature of 0.1 DEG C. Primary specific discharge capacity is up to 822.2 mAh / g, secondary specific discharge capacity is 652.7 mAh / g and the capacity is kept at 627.5 mAh / g after 45 cycles. Therefore, capacity keeping rate is high, and the cycle performance of the battery is stable at the temperature of 55 DEG C.

Owner:SHANGHAI JIAO TONG UNIV

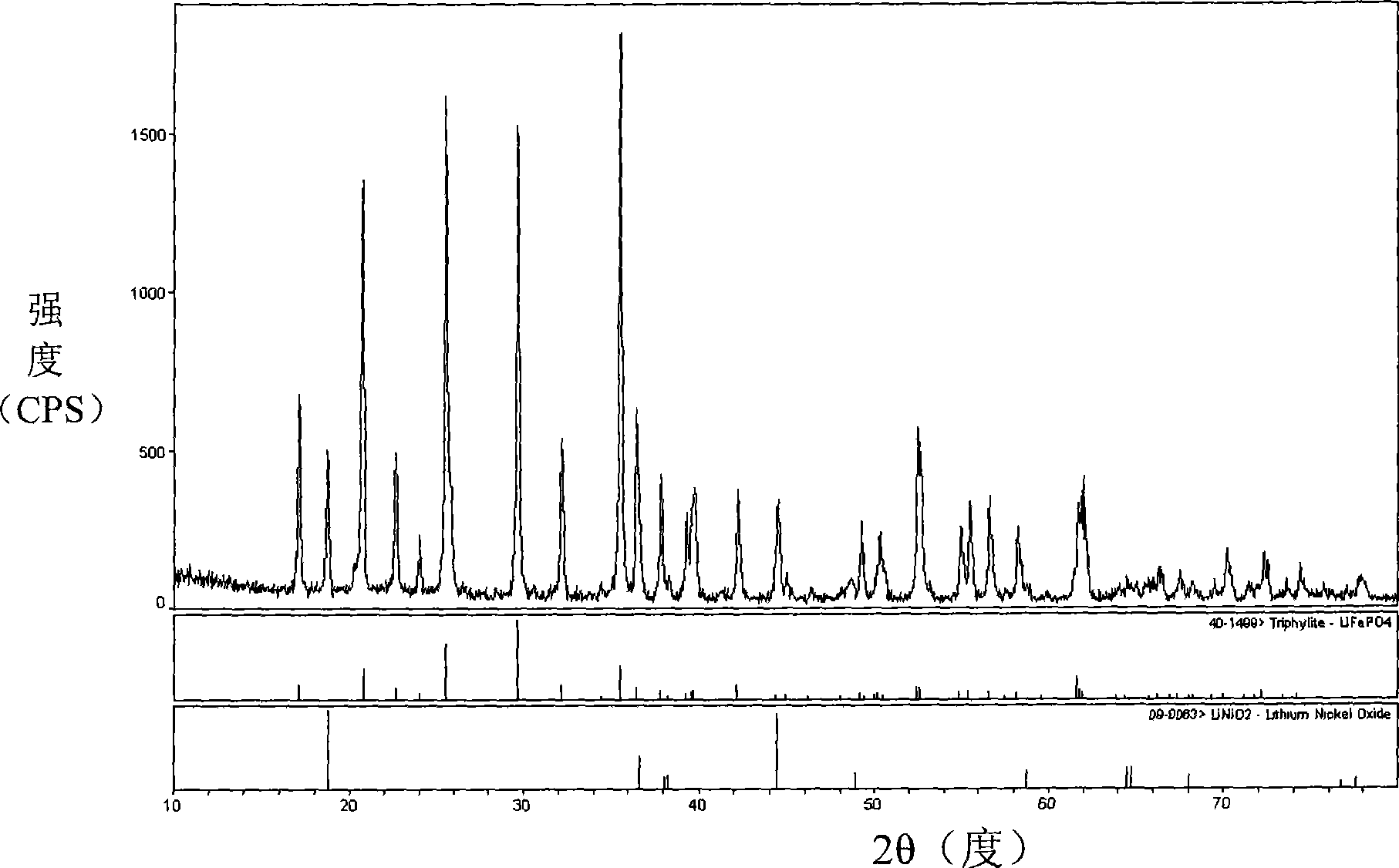

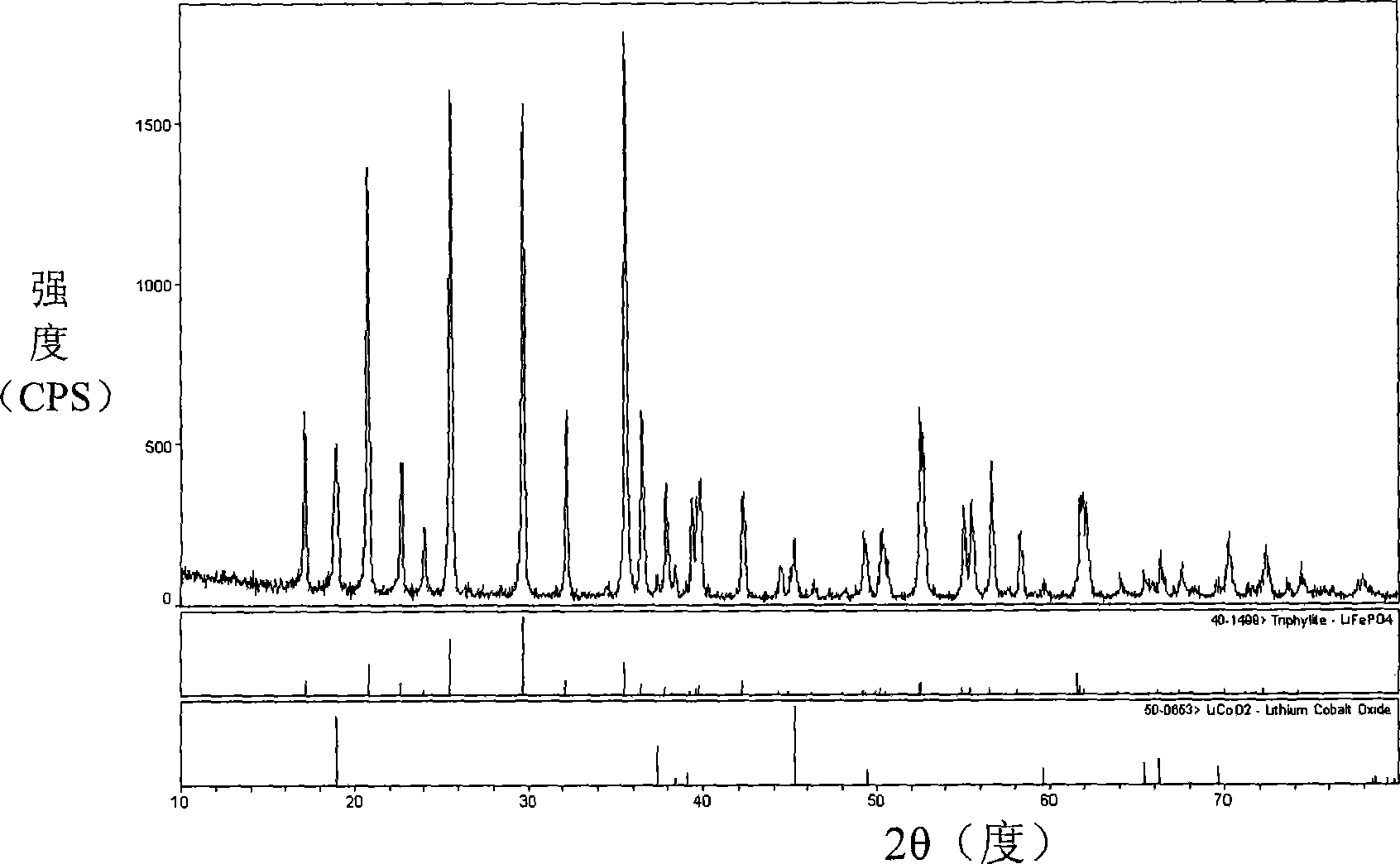

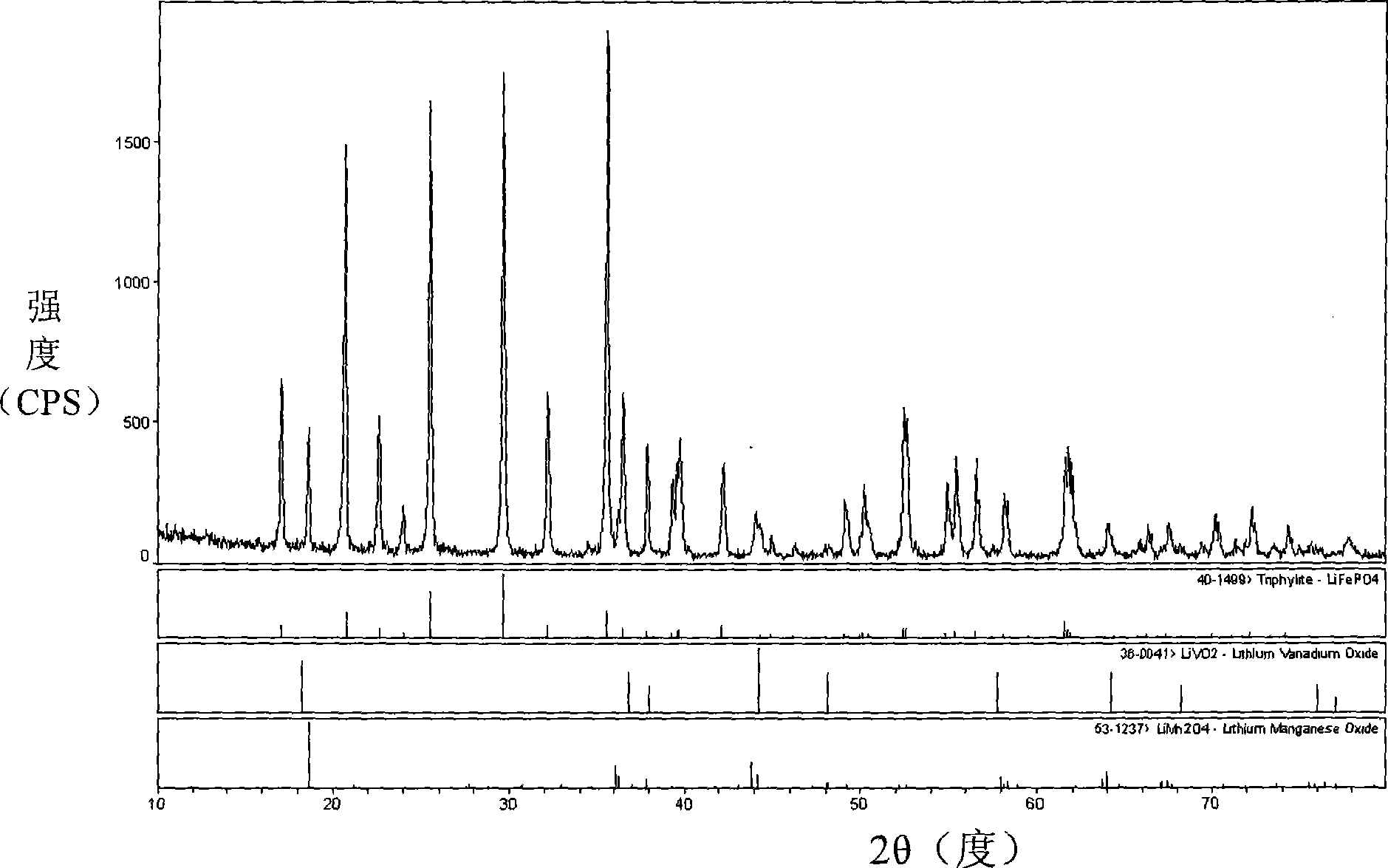

Positive pole active substance, positive pole and battery

ActiveCN101478042AQuality improvementImprove cycle performanceSecondary cellsActive material electrodesElectronElectrical resistivity and conductivity

The invention provides a positive electrode active substance, a positive electrode containing the positive electrode active substance and a battery including the positive electrode. The positive electrode active substance contains a crystal mixture including a first crystal and a second crystal, wherein the first crystal is selected from one or more of compounds represented by LixM'y (XO4) z, LiM'XO5, LiM'XO 6, and LiM'X2O7, where the ratio of x to z is larger than 0 and not larger than 1, the ratio of y to z is larger than 0 and not larger than 1.1, and M' is one or more selected from Na, Mn, Fe, Co, Ni, Ti, V, Y, Mg, Ca and Zn, and X is P, S, As, Mo or W; and the second crystal is selected from one or more of compounds represented by AaMbNcOd, where A, M and N are different from each others and are respectively metal elements of group IIA, IIIA, IVA, VA, IB, IIB, IIIB, IVB, VB, VIB, VIIB and VIII, a and b are not less than 0 and not larger than 6, c is larger than 0 and not larger than 6, d is larger than 0 and not less than 12, and the summation of a and b is not equal to zero. The positive electrode active substance has an electron conductivity of 0.01 to 10 S / cm at 25 DEG C, and can remarkably improve the specific discharge capacity and the cycle performance of the battery.

Owner:BYD CO LTD

High-temperature type lithium manganate anode material for power lithium ion battery and preparation method of high-temperature type lithium manganate anode material

ActiveCN104485452AImprove high temperature resistanceExcellent discharge specific capacityCell electrodesCobalt(II,III) oxideManganate

The invention discloses a high-temperature type lithium manganate anode material for a power lithium ion battery. The high-temperature type lithium manganate anode material consists of a core material as shown in a formula Li1+xMn2-y-zAyQzO4, and a coating layer on the surface of the core material, wherein the coating layer is one or more of cobaltosic oxide, aluminum oxide and nickel protoxide. The anode material is excellent in high-temperature property, and is good in specific discharge capacity, capacity retention ratio and electrochemical circulation property at high temperature. In addition, the preparation method of the anode material disclosed by the invention is simple in production process, easy to achieve and low in cost, and can be applied to large-scale industrialization production.

Owner:北京盟固利新材料科技有限公司

Positive pole active substance, positive pole and battery

ActiveCN101478041AQuality improvementImprove cycle performanceActive material electrodesSecondary cellsElectrical resistivity and conductivityElectron

The invention provides a positive electrode active substance, a positive electrode containing the positive active substance and a battery including the positive electrode. The positive active substance contains a crystal mixture containing a first crystal and a second crystal, wherein the first crystal is selected from one or more of compounds represented by LixxM'yy (XO4) zz, LiM'XO5, LiM'XO6, and LiM'X2O7, where the ratio of xx to zz is larger than 0 and not larger than 1, and the ratio of yy to zz is larger than 0 and not larger than 1.1; and the second crystal is one or more of compounds represented by LiDcO2, LiiNi(1-d-e)CodMneO2, LiNi(1-f-g) CofAlgO2, LixNi(1-y) CoO2 and LimMn(2-n)EnOj, where D is one element selected from B, Mg, Al, Ti, Cr, Fe, Cu, Zn, Ga, Y, La and V, c is larger than 0 and not larger than 3, i is not less than 0.9 and not larger than 1.2, d is not less than 0 and not larger than 0.5, e is larger than 0 and not larger than 0.3, f is not less than 0 and not larger than 0.5, g is not less than 0 and not larger than 0.3, x is not less than 0.9 and not larger than 1.1, y is not less than 0 and not larger than 1; E is one of B, Mg, Al, Ga and a transition metal except Mn, m is not less than 0.9 and not larger than 1.1, n is not less than 0 and not larger than 1, and j is larger than 1 and less than 6. The positive active substance has an electron conductivity of 0.001 to 10 S / cm at 25 DEG C, and can remarkably improve the specific discharge capacity and the cycle performance of the battery.

Owner:BYD CO LTD

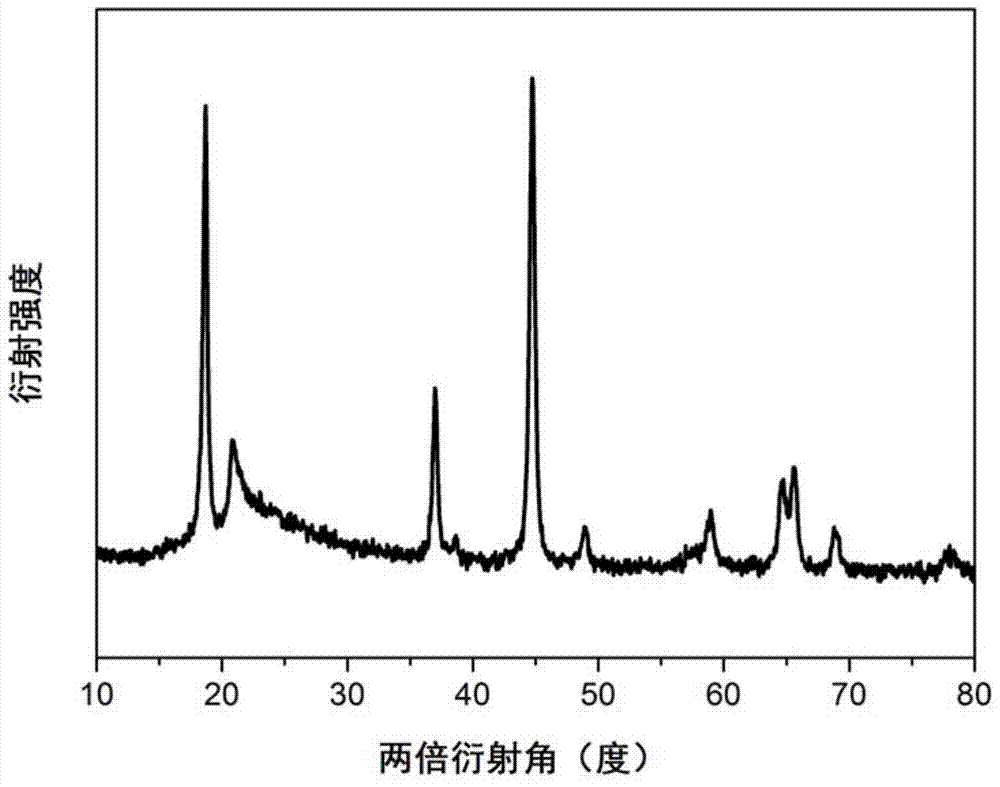

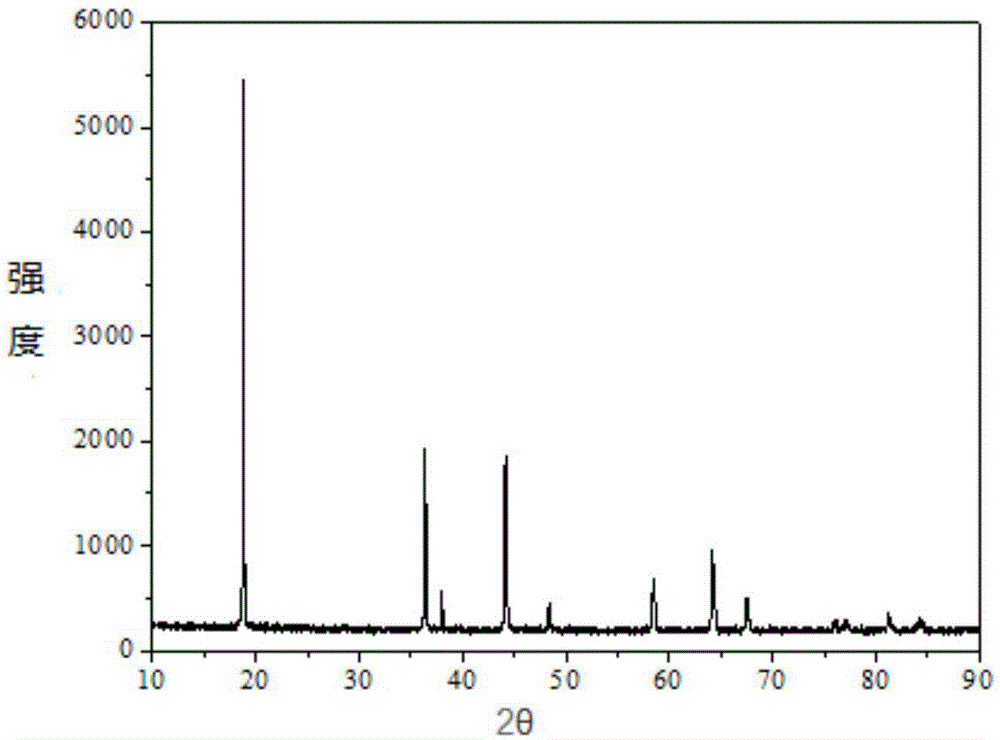

Preparation method of submicron level LiniO.5MnO.5O2 cathode material

InactiveCN101834291AEvenly dispersedImprove cycle stabilityCell electrodesManganese oxides/hydroxidesNickel saltLithium hydroxide

The invention discloses a preparation method of a submicron level LiniO.5MnO.5O2 cathode material, which comprises the steps of: taking soluble nickel salt and manganese salt to prepare a nickel salt water solution and a manganese salt water solution respectively, and mixing the two solutions; preparing a sodium hydroxide solution isometric to a metal ion solution, and adding ammonia as a precipitator solution; dropwise adding the metal ion solution and the precipitator solution into a water solution of surface active agents in parallel flow, and stirring the mixed solution evenly; controlling the temperature of the precipitation reaction to be 55 DEG C, and stirring at high speed, standing, vacuum filtrating, flushing, drying and grinding after the metal ion solution and the precipitator solution are completely added to obtain the powder; adding lithium hydroxide, and carrying out ball grinding to obtain a precursor. The heat treatment for the precursor comprises the following processes of: heating the precursor at 2 to 12 DEG C / min to 350 to 450 DEG C for 2 to 6 h for pre-treatment, and then continuing to heat the precursor at the speed of 2 to 12 DEG C / min to 700 to 1000 DEG C; calcinating the precursor for 8 to 20 DEG C, cooling the precursor at the speed of 2 to 12 DEG C / min down to 300 to 500 DEG C, and annealing the precursor for 2 to 4 h. In the invention, the submicron level uniformly distributed near-spherical LiniO.5MnO.5O2 material with no obvious glomeration by introducing the surface active agent into the LiniO.5MnO.5O2 cathode material prepared by the optimized coprecipitation method. The grains of the material are distributed uniformly, and the grain diameter is about 80 to 200nm; the material is in a near-spherical shape, and has higher specific discharge capacity and good cycling stability.

Owner:CENT SOUTH UNIV

High-nickel ternary cathode material coated with fast ion conductor and preparation method thereof

InactiveCN110690435AClose contactSolving lithium-ion transport problemsCell electrodesSecondary cellsElectrical conductorInternal resistance

The invention provides a high-nickel ternary cathode material coated with a fast ion conductor and a preparation method thereof. The high-nickel ternary cathode material is spherical or spheroidic secondary particles composed of primary particles, the diameter of the high-nickel ternary cathode material is 1-30 [mu]m, and the chemical formula of the high-nickel ternary cathode material is LiNi0.8Co0.1Mn0.1O2. The preparation method comprises the following steps of: weighing raw materials for synthesizing the fast ion conductor in proportion, and uniformly dispersing the raw materials in a solvent to obtain a mixed solution; adding the high-nickel ternary precursor into the mixed solution, and then performing stirring, drying and grinding to obtain high-nickel ternary precursor powder coated with the fast ion conductor; and uniformly mixing the obtained precursor powder with a lithium salt, and performing sintering to obtain the high-nickel ternary cathode material coated with the fastion conductor. The fast ion conductor material is used as a coating substance of the ternary cathode material and can provide a fast transmission channel for lithium ion transmission, so that the purpose of reducing the internal resistance of the battery is achieved; and after coating, the cycling stability of the battery is improved under the condition that the specific discharge capacity of thebattery is not reduced.

Owner:CENT SOUTH UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com