Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

88results about How to "The first discharge specific capacity is high" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

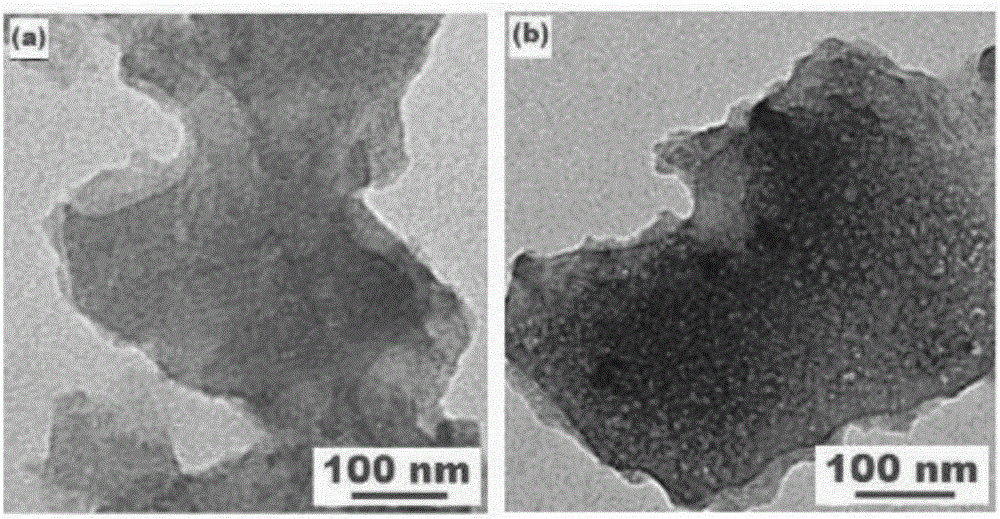

Carbon-silicon composite material, preparation method thereof, and lithium ion battery containing carbon-silicon composite material

InactiveCN102593418AEasy to makeControl silicon contentCell electrodesSecondary cellsPorous carbonLithium-ion battery

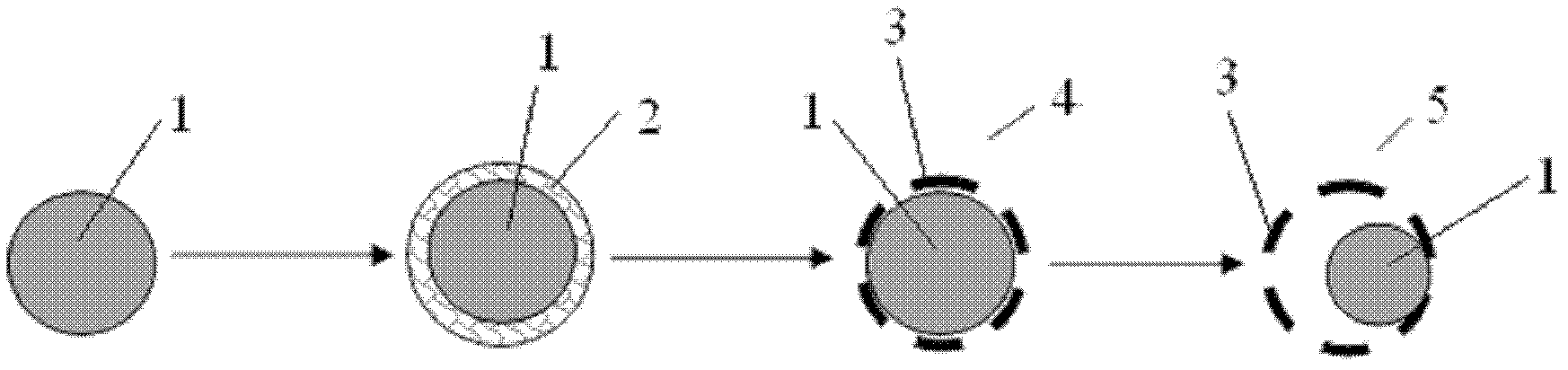

The invention discloses a carbon-silicon composite material, a preparation method of the carbon-silicon composite material and a lithium ion battery containing the carbon-silicon composite material. The preparation method comprises the steps of: directly selecting silicon powder as a raw material, wrapping the silicon powder with a precursor of organic carbon to obtain a porous carbon layer wrapping silicon composite material, and using corrosive liquid to remove partial silicon in the porous carbon layer wrapping silicon composite material by corrosion, so as to obtain the carbon-silicon composite material, wherein a gap exists between a carbon shell and the silicon arranged in the carbon shell. The preparation process is simple. The carbon-silicon composite material prepared by the preparation method disclosed by the invention is good in electrochemical property, and the battery prepared from the carbon-silicon composite material is good in cycling performance.

Owner:CHERY AUTOMOBILE CO LTD

Preparation method of nitrogen-rich multimode beehive carbon-sulfur composite anode material

ActiveCN103746098ALarge specific surface areaHigh nitrogen contentPositive electrodesLi-accumulatorsArgon atmosphereOxide composite

The invention relates to a preparation method of a lithium sulphur battery composite anode material. The preparation method is as follows: preparing a mixed solution of carbon tetrachloride, a nitrogen source and carbonate, heating and flowing back to obtain a nitrogen-rich polymerization / carbonic acid salt compound; high temperature pyrolyzing in a nitrogen or argon atmosphere after drying the compound, so as to form the nitrogen-rich carbon / oxide compound; adding dilute acid to remove vestigial oxide, so as to form the nitrogen-rich multimode beehive carbon material of a multilevel porthole structure; uniformly mixing the nitrogen-rich multimode beehive carbon and sublimed sulfur, heat preserving under vacuum condition, injecting sulfur gas to the nitrogen-rich multimode beehive carbon material, so that the lithium sulphur battery composite positive material can be obtained. The composite anode material provided by the invention is alveolate, and has the advantages that portholes are abundant, sulfur content is high, sulfur particle can be distributed uniformly in the nitrogen-rich multimode beehive carbon material of the multilevel porthole structure, and the carbon sulfur particles can be combined more tightly, the material mechanical stability is high, discharge specific capacity is high, cycle performance is excellent, and technological process is simple, pollution is avoided, cost is low, and the method is liable to large scale production and application.

Owner:CENT SOUTH UNIV

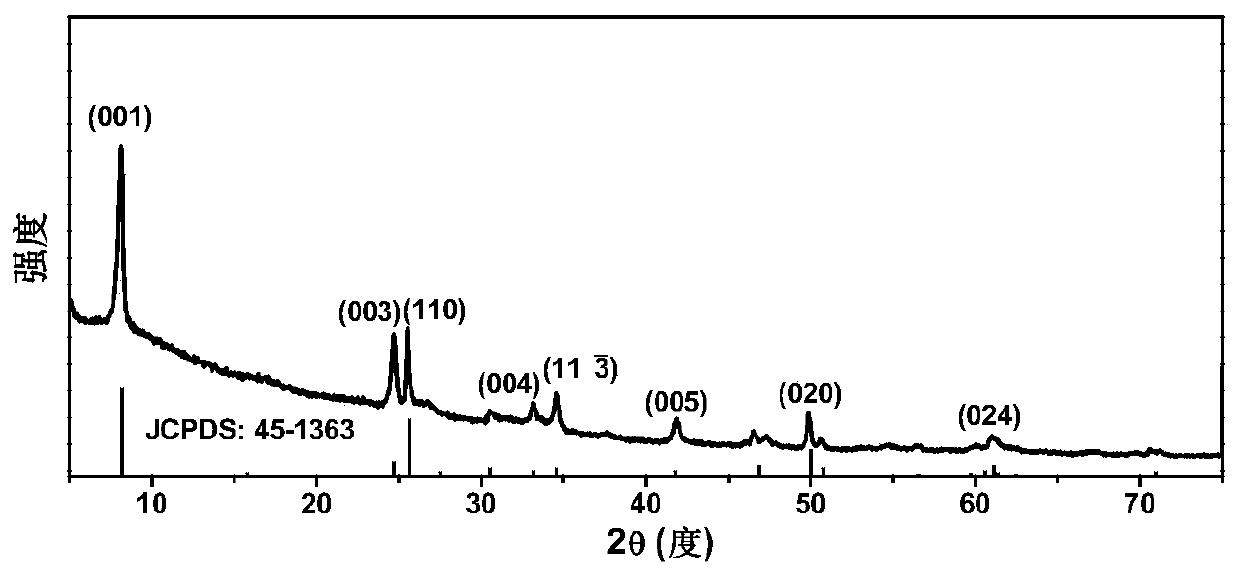

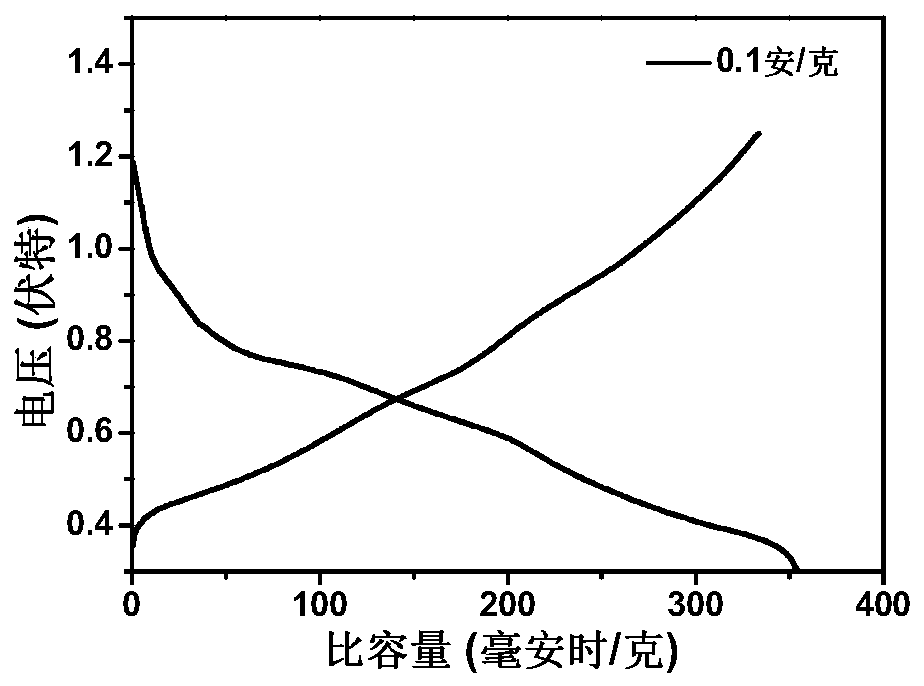

High-performance water system zinc ion battery anode material, manufacturing method and application thereof

ActiveCN110474044AEasy to prepareLow equipment requirementsFinal product manufactureSecondary cellsSpecific dischargeNanotechnology

The invention provides a high-performance water system zinc ion battery anode material, a manufacturing method and an application thereof. The anode material has the following general formula: (N,M) sigma=1V8O20 nH2O, wherein the N is one of Li, Na, K, Zn, Cu, Mg or Ca, the M is one of Mn, Fe, Co or Ni, and the n is 0.01-4. The anode material can be manufactured through one-step hydrothermal method, a reaction condition is mild, a manufacturing process is simple, and a requirement to equipment is low. A microscopic morphology of the obtained anode material is a nanobelt. The obtained anode material is firstly applied to a water system zinc ion battery, and has electrochemical performance such as a higher specific discharge capacity, a higher cycle stability and the like.

Owner:SHANDONG UNIV

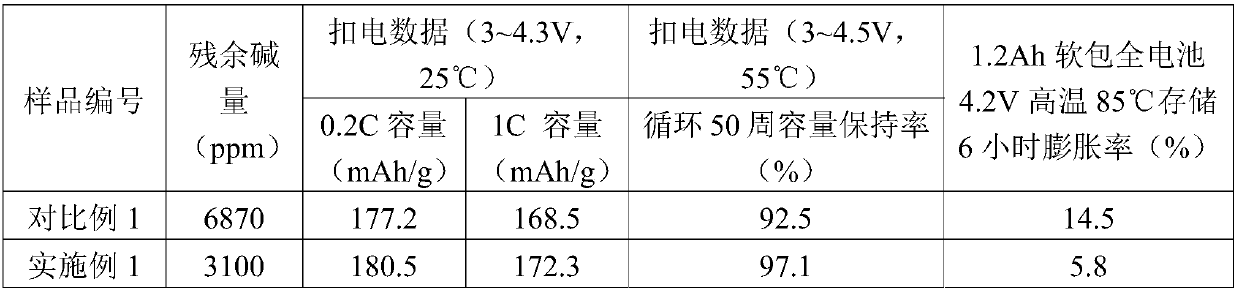

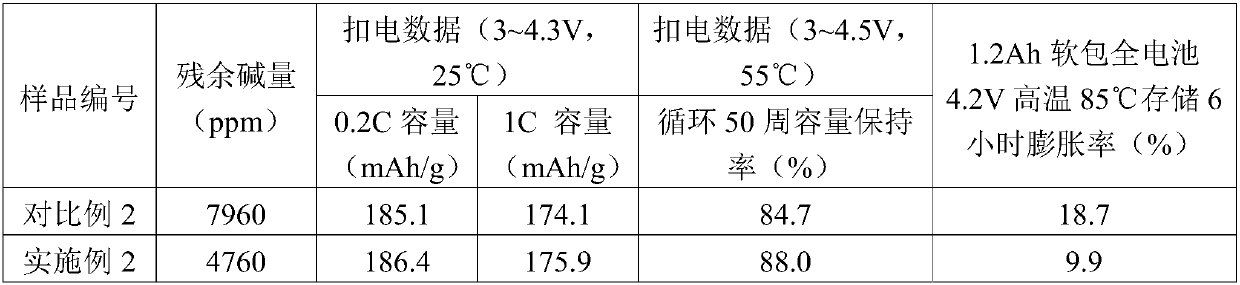

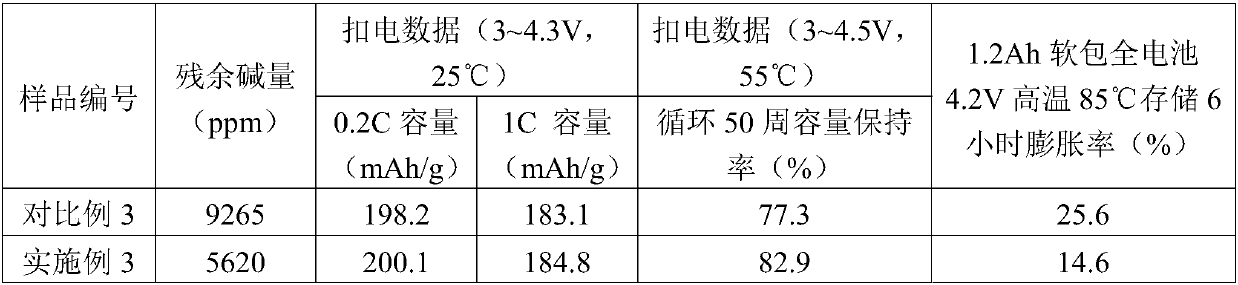

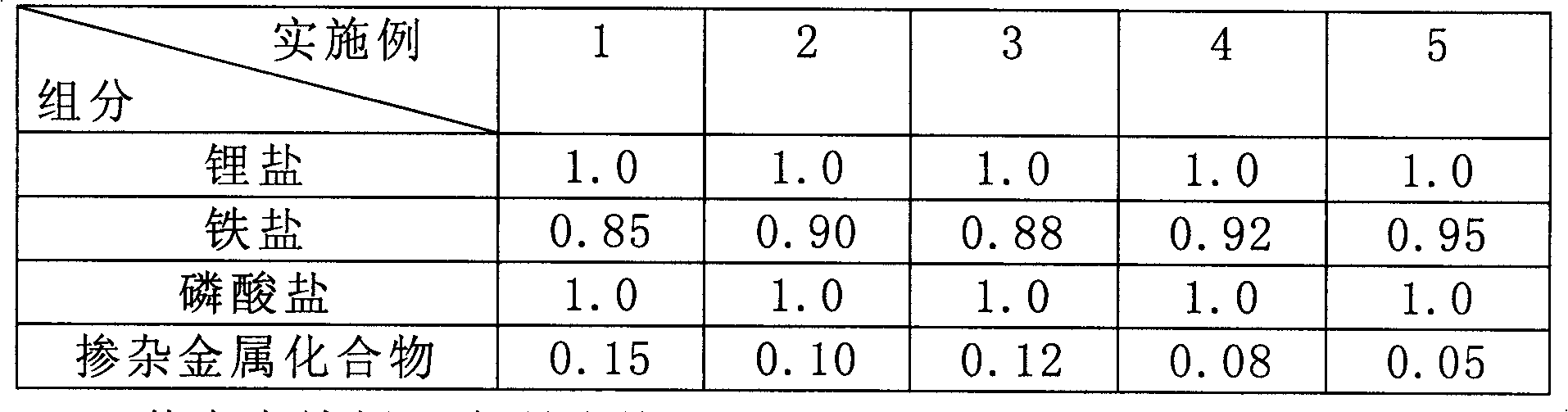

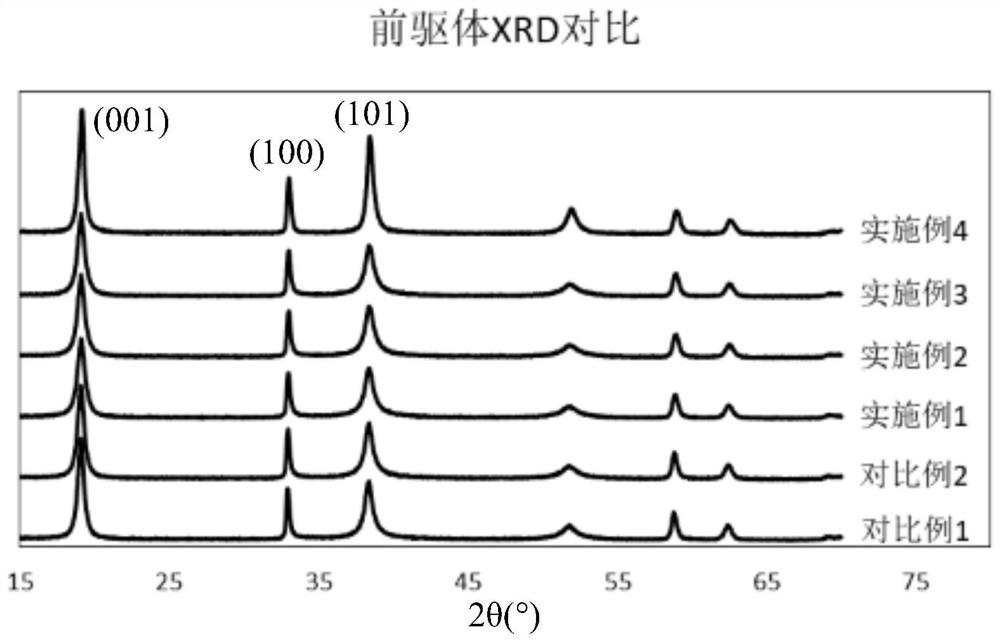

Two-layer coated modified ternary cathode high-nickel material and preparation method thereof

ActiveCN109830651AThe first discharge specific capacity is highImprove Coulombic efficiencyCell electrodesHigh temperature storageManganate

The invention provides a two-layer coated modified ternary cathode high-nickel material and a preparation method thereof. The double-layer coated modified ternary cathode high-nickel material has a double-layer coated structure which is composed of a Ni-Co lithium manganate substrate, a manganese oxide layer coating layer and a metal oxide outer layer coating layer. The preparation method comprises coating the ternary cathode material precursor NixCoyMn1-x-y(OH)2 as a precursor with the manganese oxide and the metal oxide. The method not only reduces the residual alkali on the surface of the material, but also stabilizes the Ni4+ generated by the material when fully charged, improves the high temperature storage performance and the safety performance. Further, the coated nano metal oxide at the outer layer effectively prevents the electrolyte from reacting with the material, improves the cycle performance of the material, increases the material capacity retention rate, and reduces thecost.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

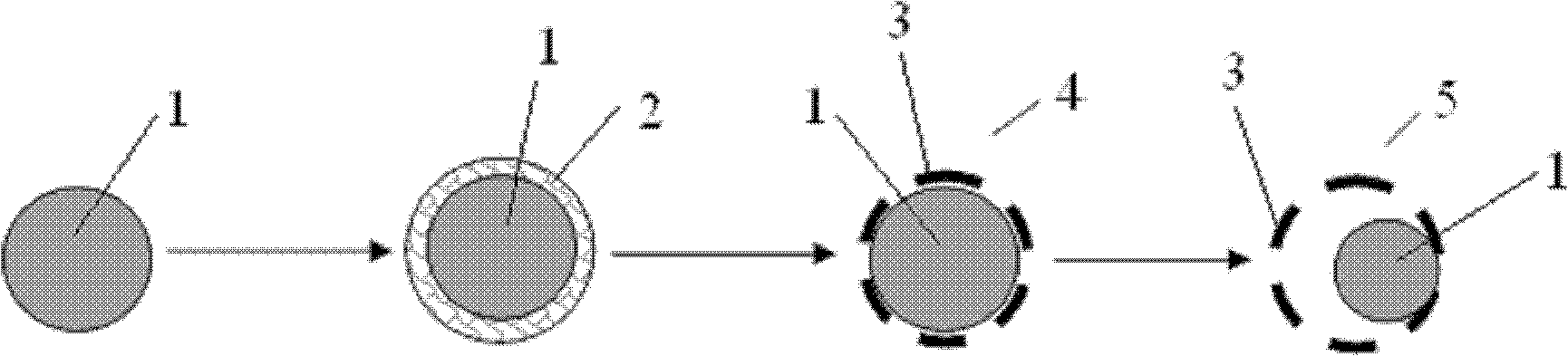

Nitrogen-rich eggshell type lithium sulfur battery anode material and preparation method and application thereof

InactiveCN105449209AImprove adsorption capacityThe first discharge specific capacity is highCell electrodesLi-accumulatorsChemical adsorptionMelamine formaldehyde resin

The invention discloses a lithium sulfur battery anode material and preparation method thereof, melamine formaldehyde resin rich in nitrogen is taken as a carbon source and nitrogen source, a nitrogen-rich hollow eggshell with the diameter of 100-300 nm is prepared with a nanometer SiO2 casting method, the interfacial adsorption of polysulfide is enhanced by the aid of the combined effect of physical adsorption and chemical adsorption, migration and shuttle effects of the polysulfide are effectively restrained, and charge and discharge stability of a lithium sulfur battery is enhanced. At the same time, an eggshell structure is formed after the hollow eggshell is filled with sulfur, and an interior gap exists between a sulfur inner core and a polymer shell so as to accommodate volume expansion in a sulfur atom lithiation process. The lithium sulfur battery anode material is applied to preparation of a lithium sulfur battery anode and the lithium sulfur battery. The lithium sulfur battery has excellent cycle performance and capacity retention ratio.

Owner:DALIAN UNIV OF TECH

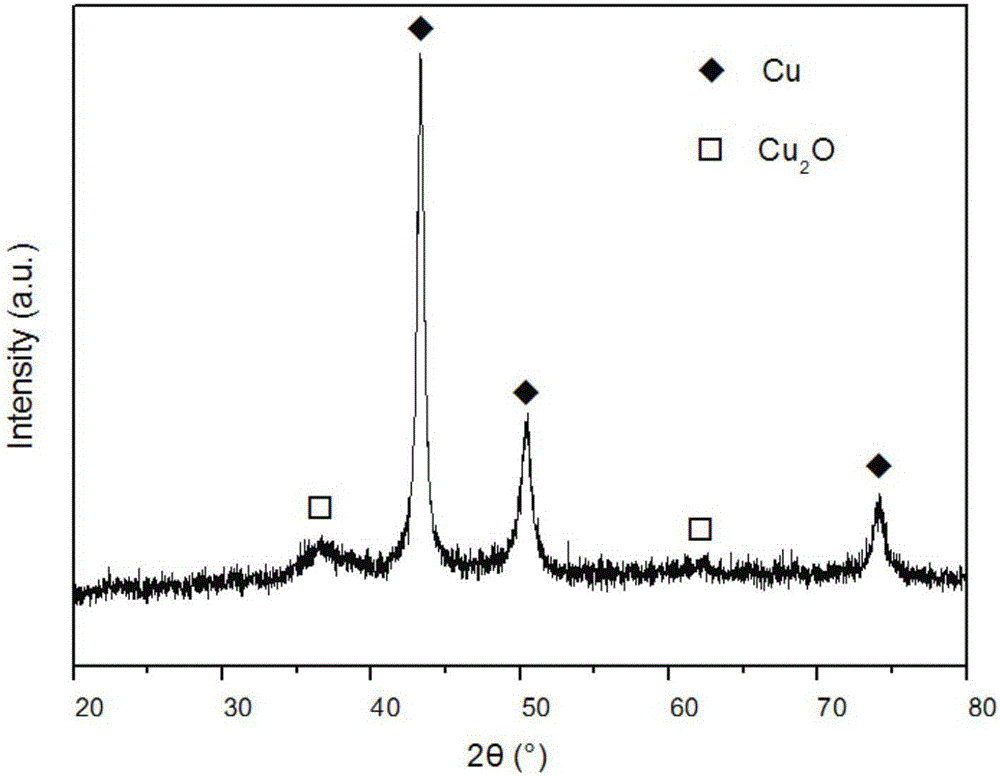

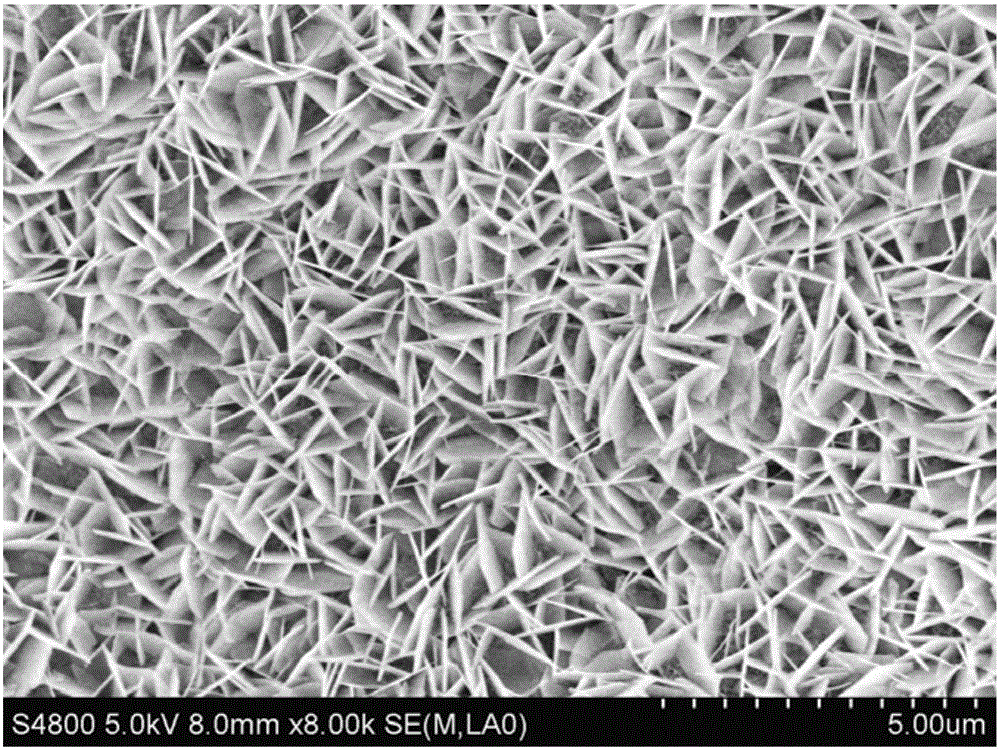

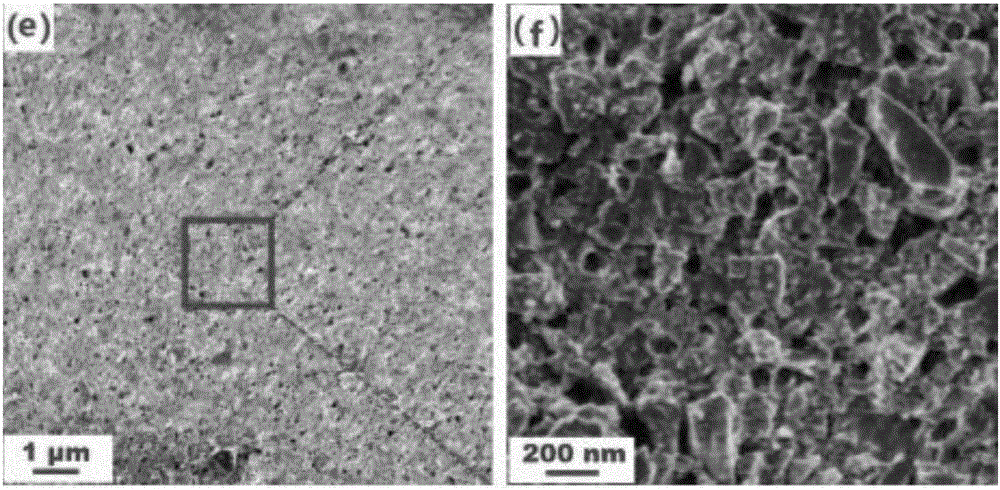

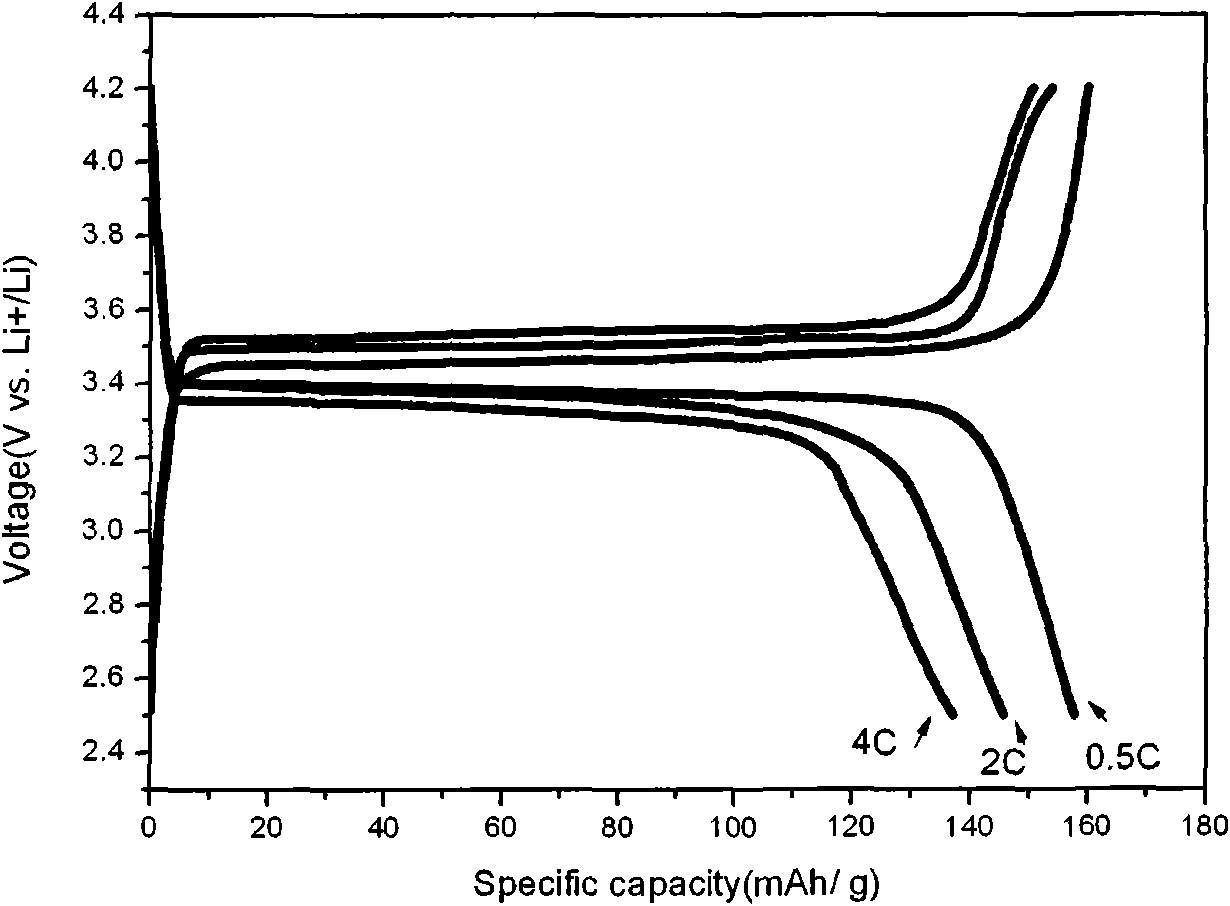

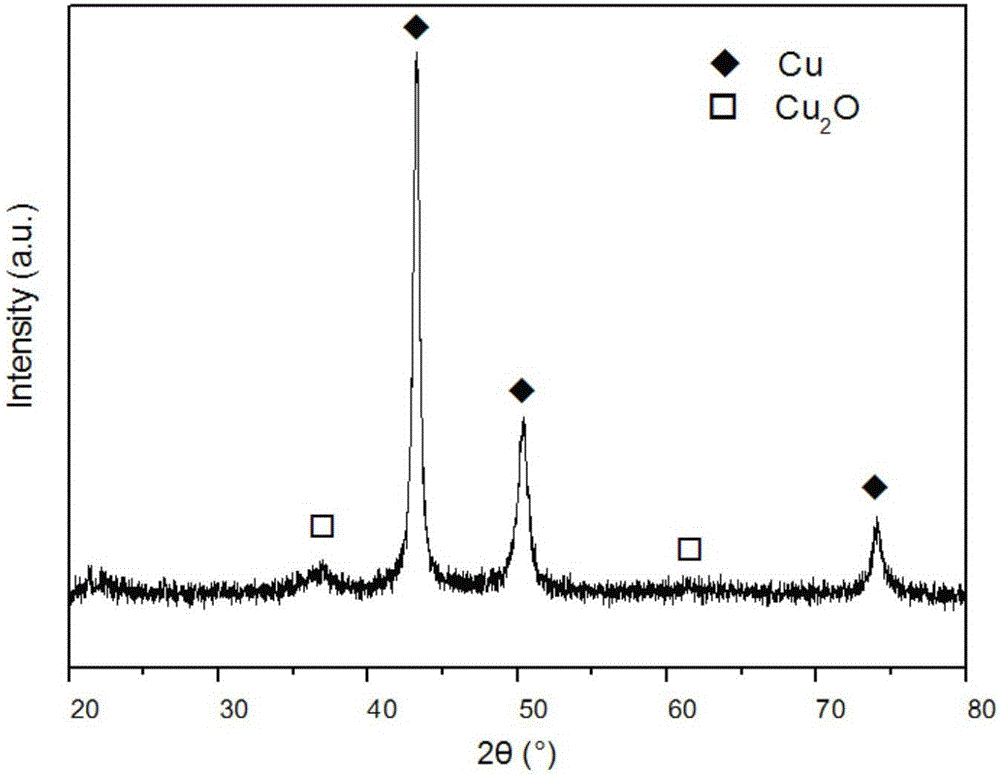

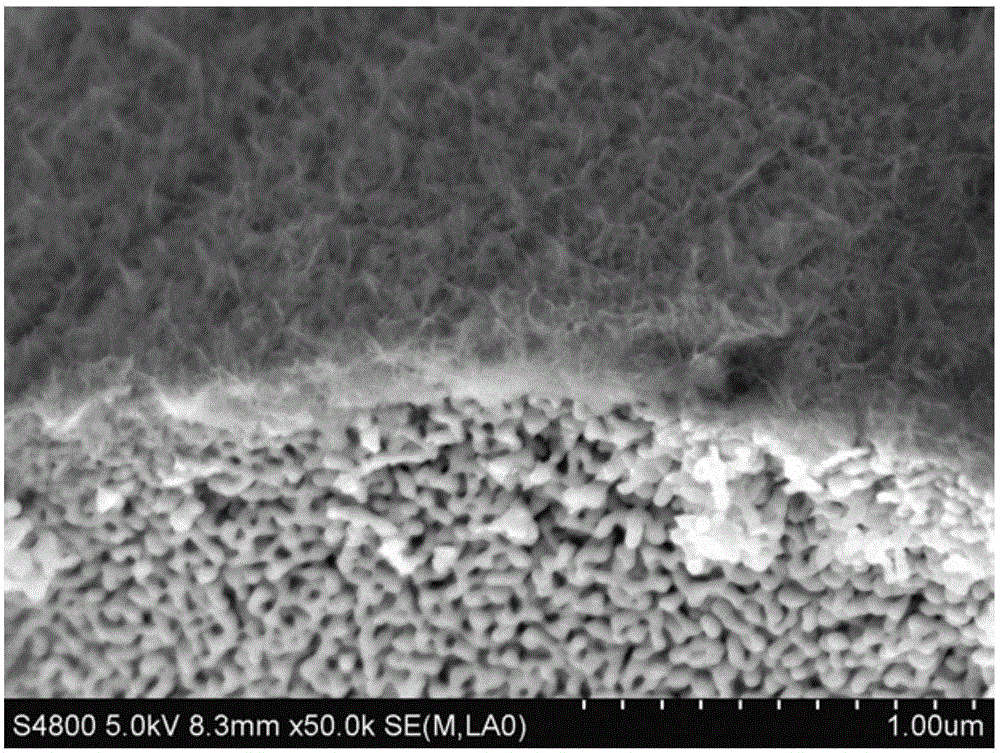

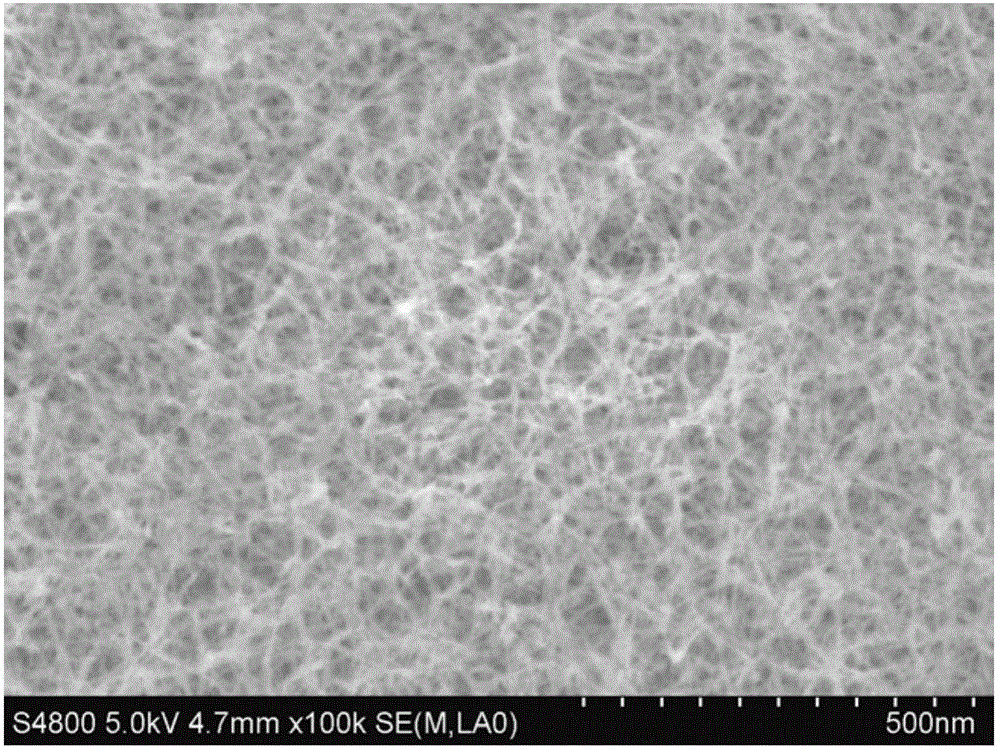

Three-dimensional nanometer porous copper/two-dimensional cuprous oxide nanosheet array type lithium ion battery negative electrode and one-step preparation method thereof

ActiveCN106229462AImprove liquidityFast formingMaterial nanotechnologyCell electrodesNanotechnologyLithium electrode

The invention provides a three-dimensional nanometer porous copper / two-dimensional cuprous oxide nanosheet array type lithium ion battery negative electrode. The lithium ion battery negative electrode comprises a three-dimensional nanometer porous copper substrate and a cuprous oxide nanosheet array layer, the three-dimensional nanometer porous copper substrate is used as a current collector, the cuprous oxide nanosheet array layer is used as an active lithium storage layer, the cuprous oxide nanosheet array is arranged on a surface of the substrate and is integrated with the substrate, and the cuprous oxide nanosheet array layer comprises cuprous oxide nanosheets formed on the substrate through in-situ growth, and the cuprous oxide nanosheets are perpendicular to the three-dimensional nanometer porous copper substrate and are arranged in a staggered manner to form an array structure. By the lithium ion battery negative electrode, the cycle performance and the specific capacity of the lithium ion battery can be improved. The invention also provides a one-step preparation method of the abovementioned lithium ion battery negative electrode. By the method, the production process of the lithium ion battery negative electrode can be effectively simplified.

Owner:SICHUAN UNIV

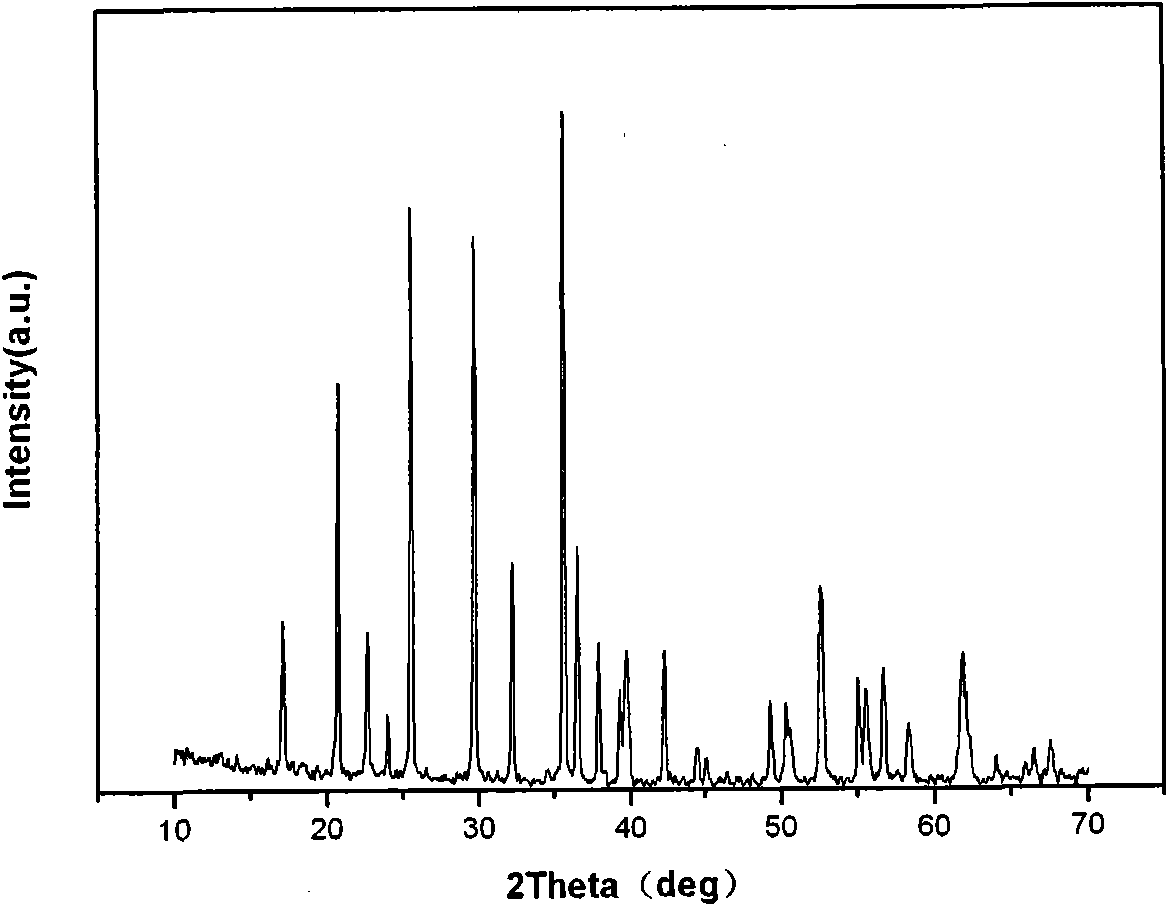

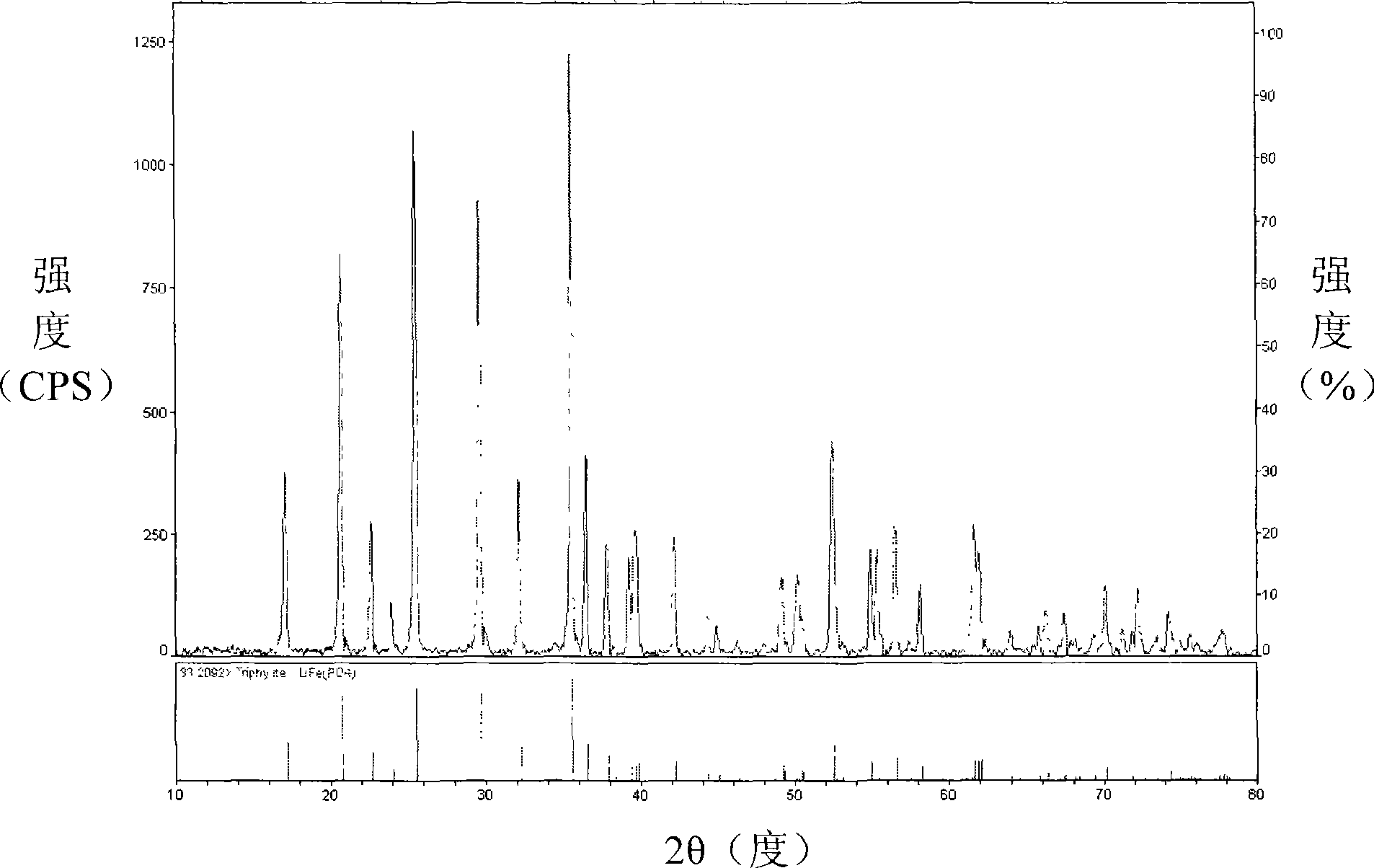

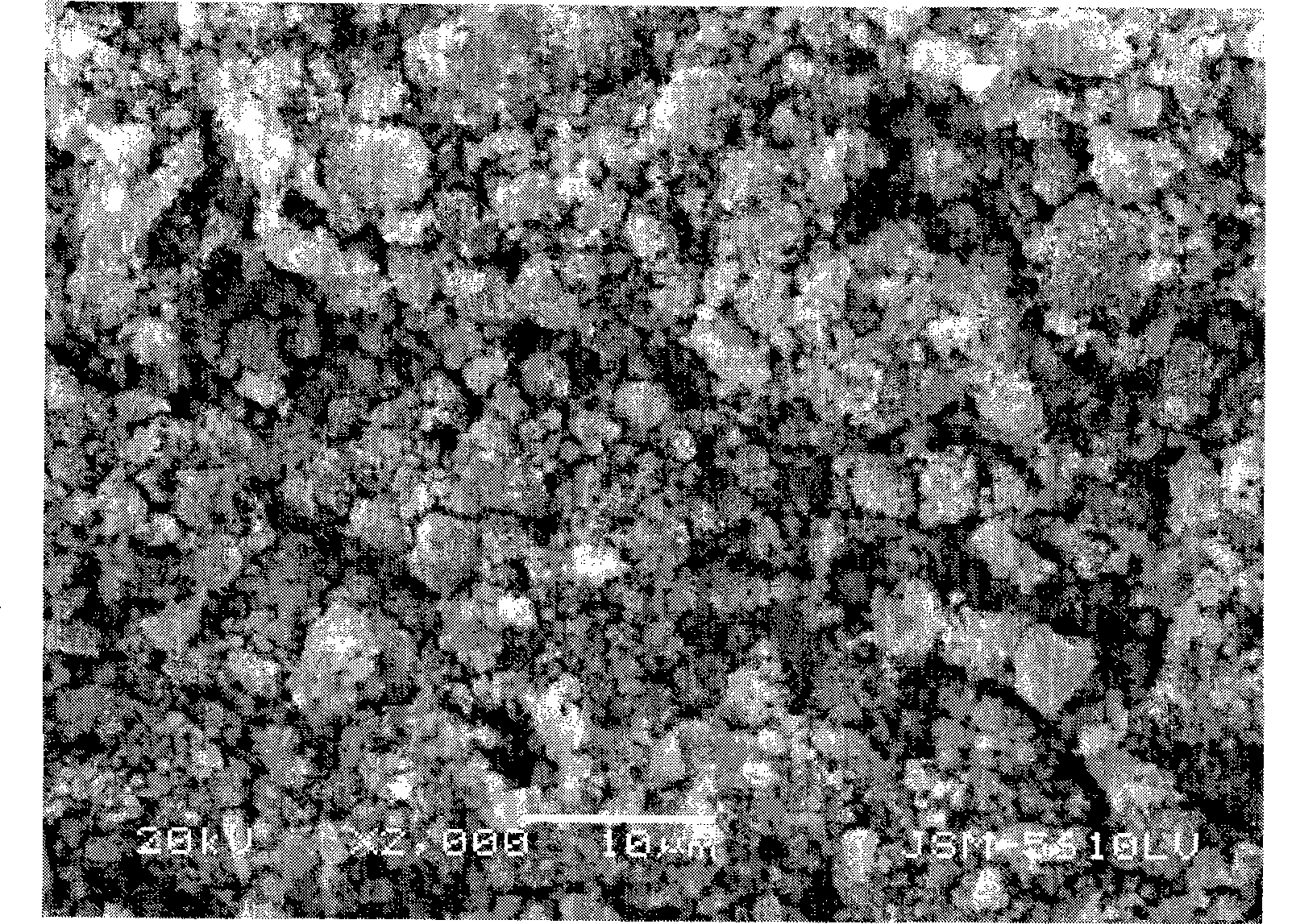

Method for preparing lithium iron phosphate

InactiveCN101209819AThe first discharge specific capacity is highImprove the problem of poor shape and granularityCell electrodesPhosphorus compoundsState of artLithium iron phosphate

The invention relates to a method for preparing lithium iron phosphate; wherein, the method includes mixing the water solutions of a ferric salt, a phosphoric acid and / or a phosphate, and an ammonia and / or an organic amine with the carbon atom number of 1 to 4 to acquire a mixture; drying the spray of the mixture to acquire a solid powder body; roasting the solid powder body with a temperature of 300- 900 DEG C and a time of 2- 24 hours to acquire an iron phosphate powder body; mixing the acquired iron phosphate powder body with a lithium salt and a carbon source uniformly and sintering thereof under an inert gas and / or a reducing gas. The first discharging capacity of a battery made by adopting the lithium iron phosphate prepared by the invention is remarkably higher than that of a battery made by the lithium iron phosphate prepared by the prior art.

Owner:海宁市盐官工业投资有限公司

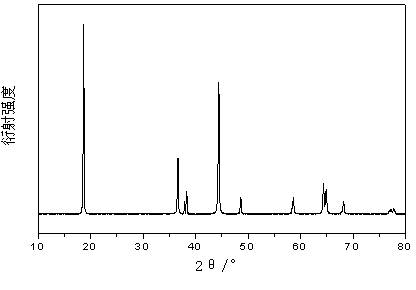

Lithium titanate composite material and preparation method thereof

InactiveCN101759227AThe first discharge specific capacity is highImprove rate discharge performanceMaterial nanotechnologyAlkali titanatesElectrochemistryImpurity

Owner:BYD CO LTD

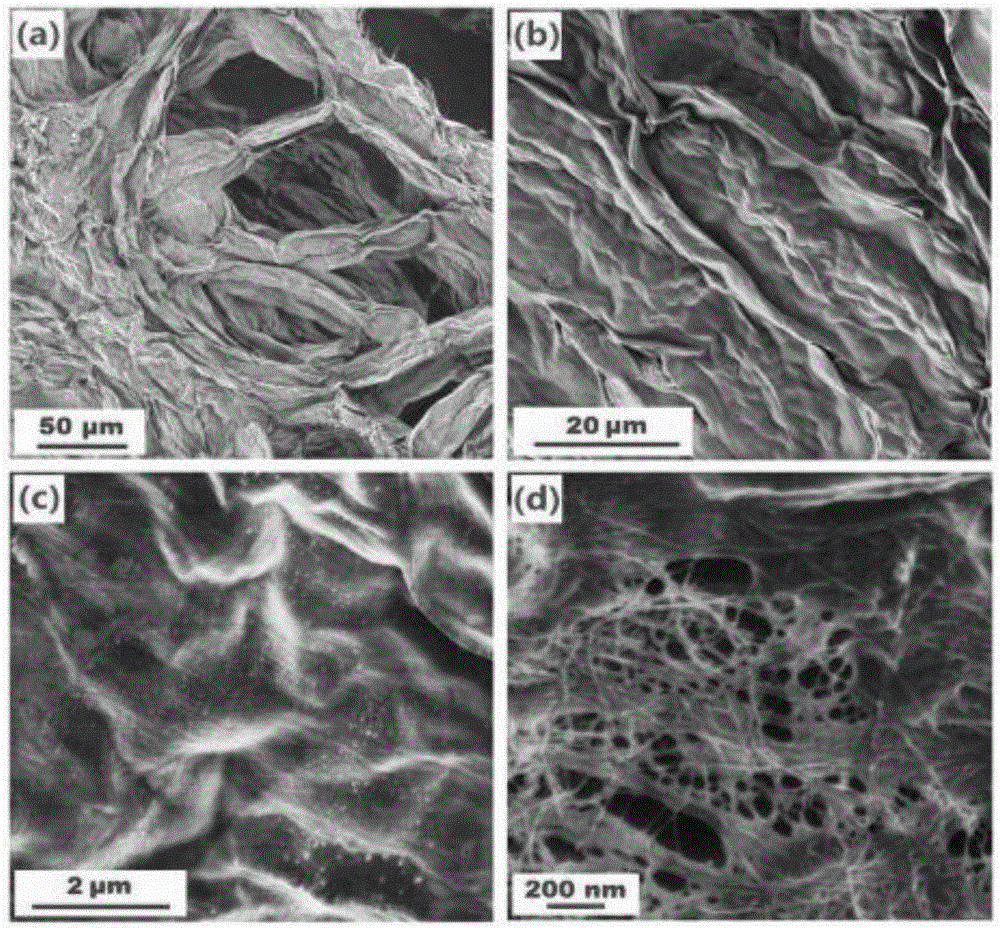

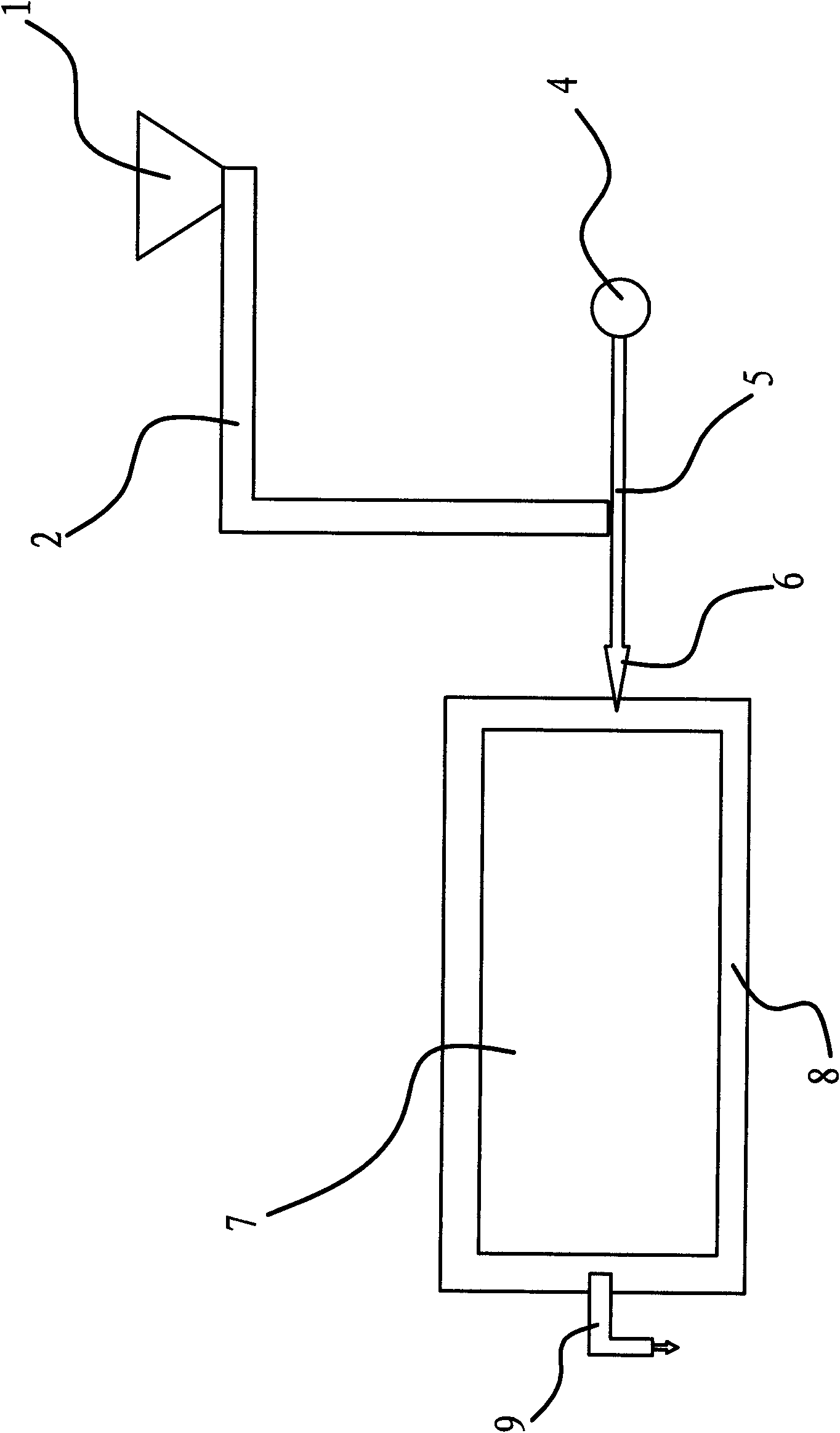

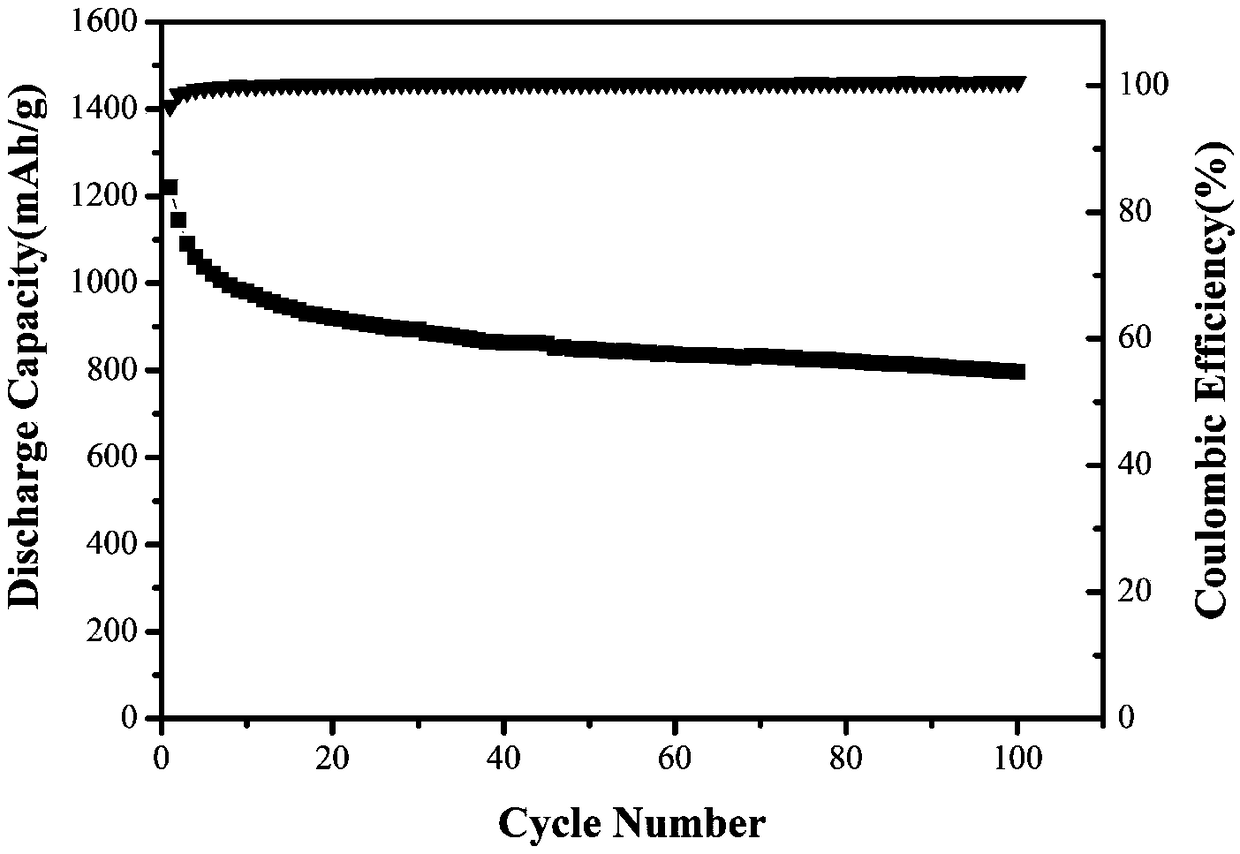

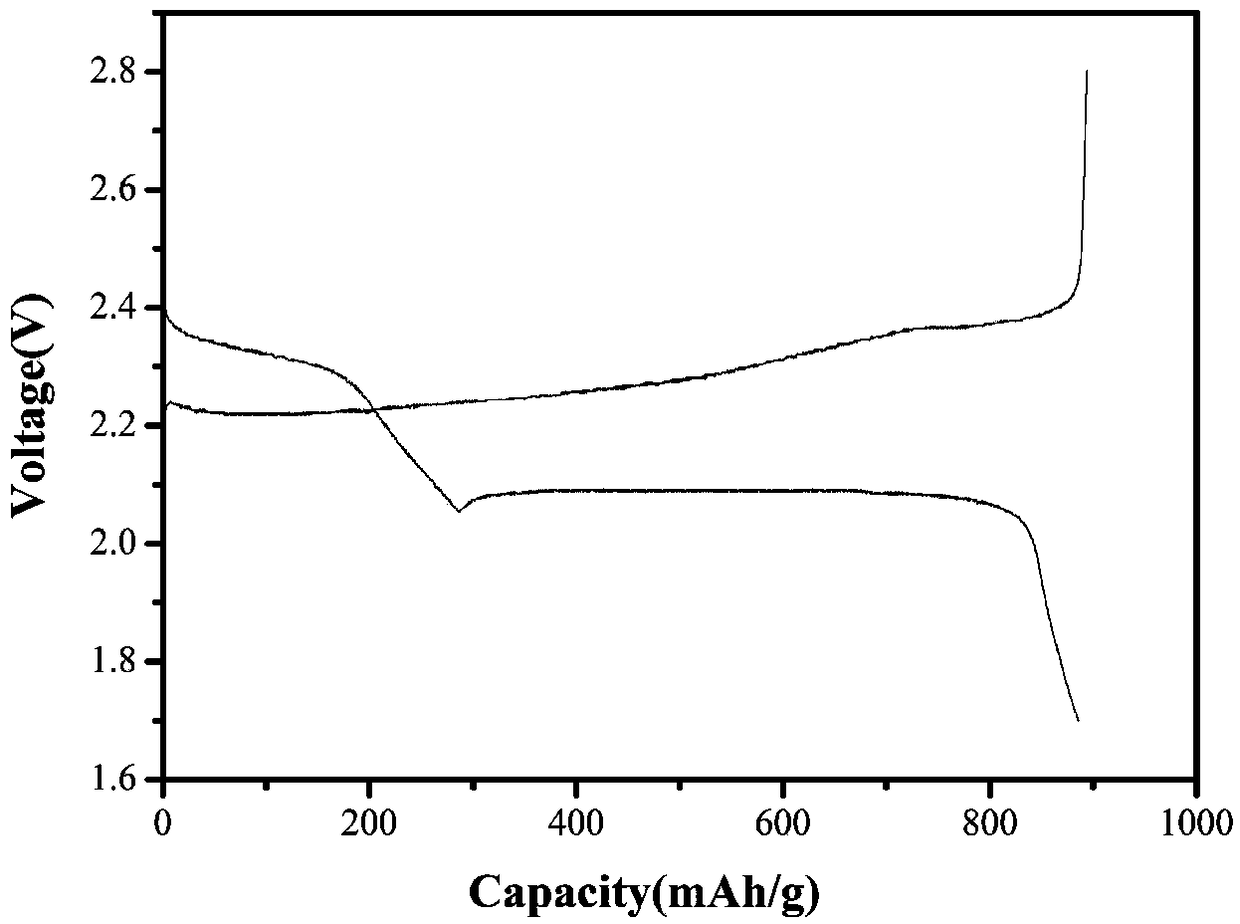

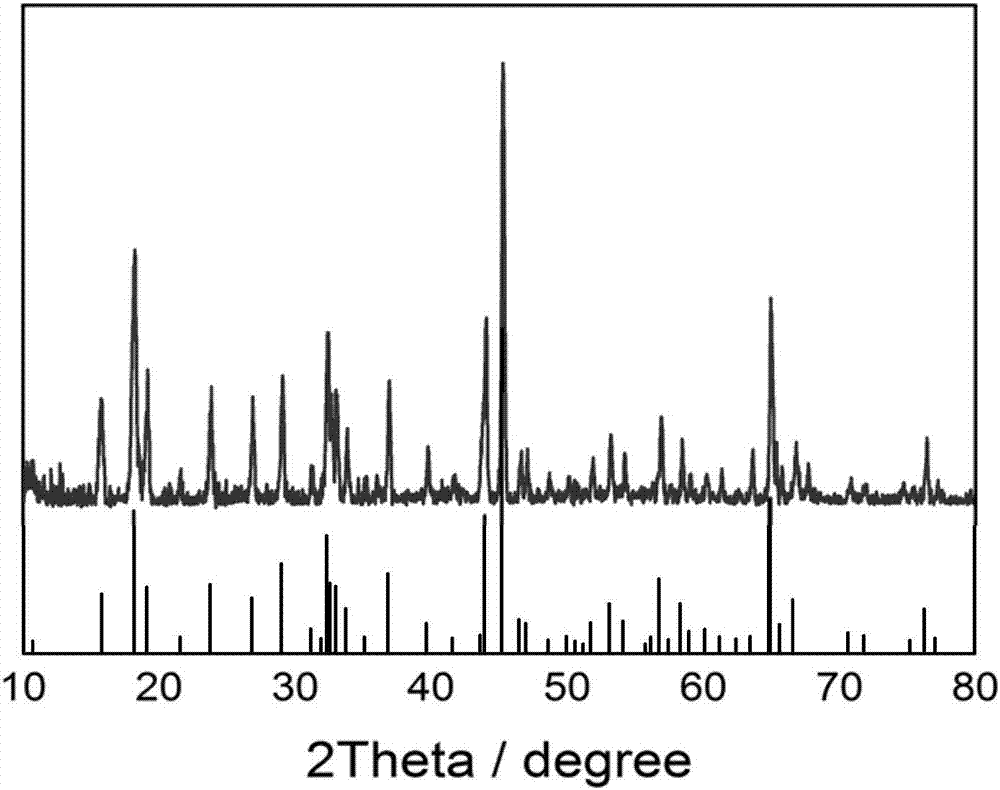

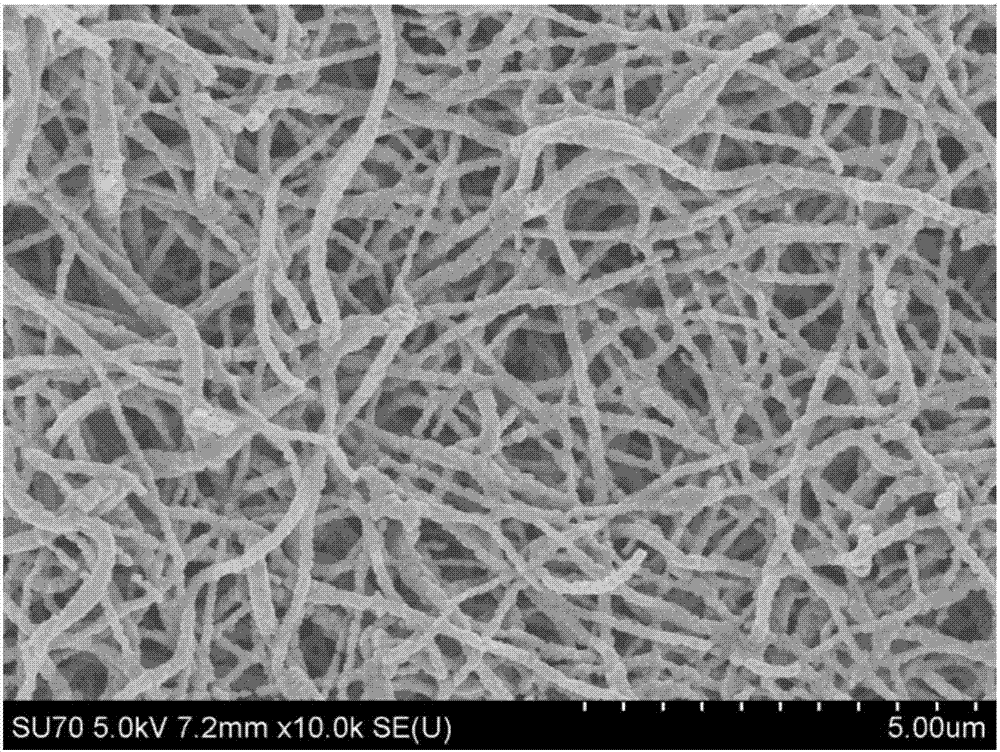

Preparation method for spirogyra-based biomass carbon material/nanometer sulfur composite material

The invention relates to a preparation method for a spirogyra-based biomass carbon material / nanometer sulfur composite material. The method comprises the following steps of washing and drying spirogyra, heating the washed and dried spirogyra in a vacuum tubular furnace, carrying out heat preservation and carbonization at 500-900 DEG C, mixing the carbonized spirogyra with nanometer sulfur with ultrasound, carrying out ball milling, drying the ball-milled mixture by an air blow drying box, heating the dried mixture in the vacuum tubular furnace, carrying out heat preservation for 3-6 hours at 100-200 DEG C, and afterwards cooling the mixture subjected to heat preservation to a room temperature with the furnace to obtain the target product, namely the spirogyra-based biomass carbon / nanometer sulfur composite material. According to the preparation method, the spirogyra is taken as a precursor for the first time, and a biomass carbon material with a continuous sheet-shaped structure similar to graphene and with nanoscale thickness is synthesized; the biomass carbon material comprises the sheet-shaped structure composed of continuous fibers, also is provided with nanoscale pores and is high in uniformity and continuity, the loading of sulfur particles is facilitated, and the obtained composite material has favorably electrochemical performance.

Owner:HEBEI UNIV OF TECH +1

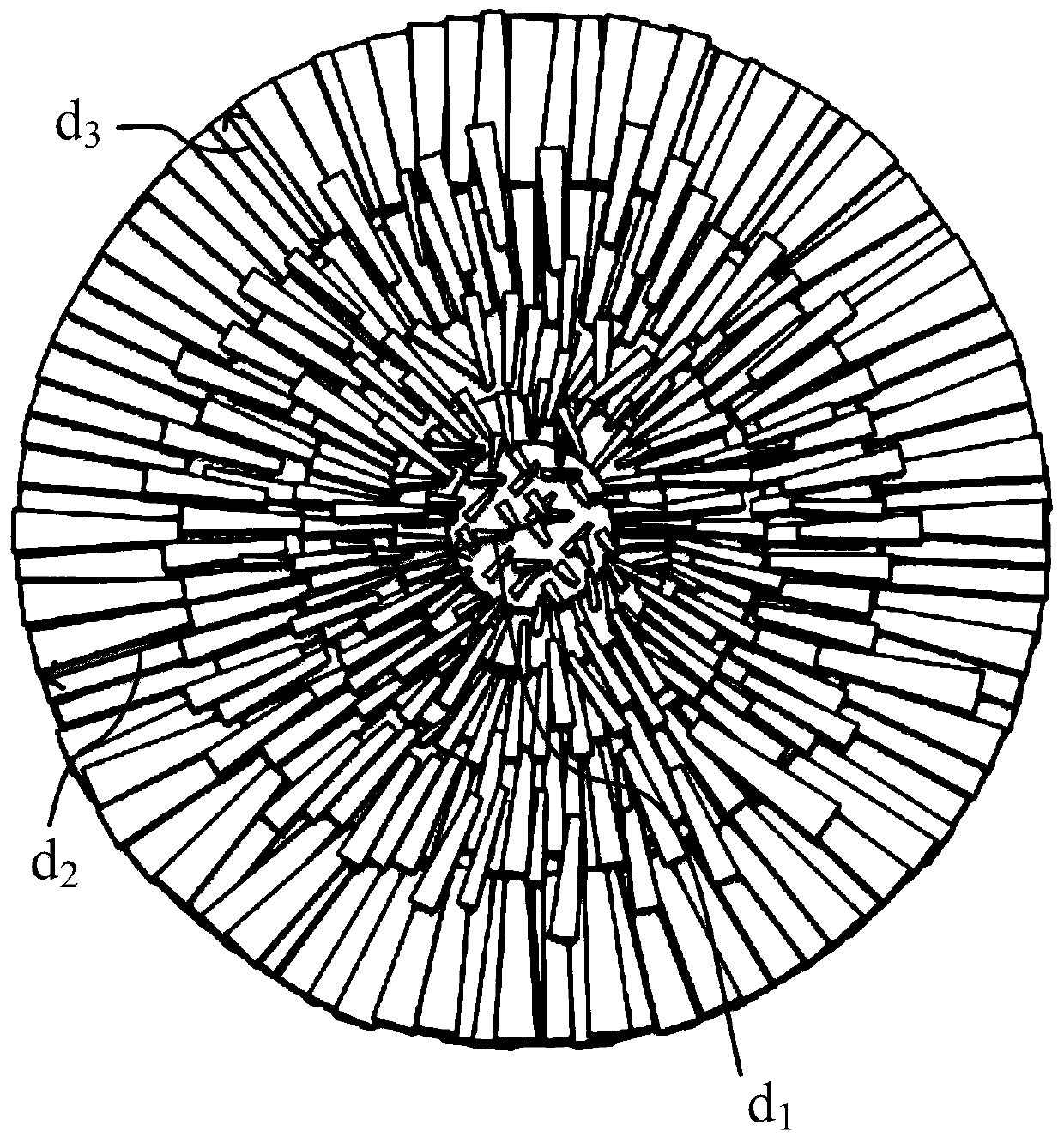

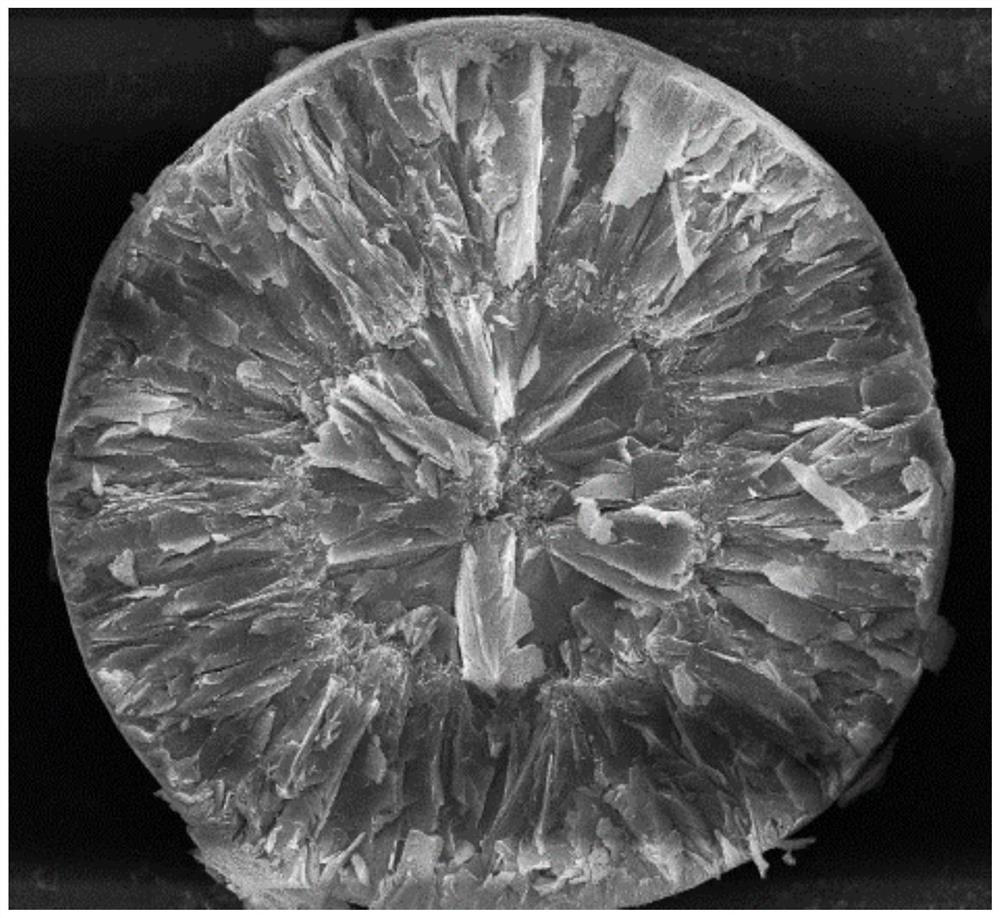

Positive electrode active material precursor and preparation method thereof, and positive electrode active material

InactiveCN111370679AHigh densityImprove cycle performanceCell electrodesSecondary cellsChemical engineeringBattery cell

The invention discloses a positive electrode active material precursor and a preparation method thereof, and a positive electrode active material. The positive electrode active material precursor comprises secondary particles formed by aggregation of a plurality of primary particles, each secondary particle comprises an internal area and an external area coating the external side of the internal area, the density of the internal area is smaller than that of the external area, and the density of the external area is gradually increased from inside to outside. According to the positive electrodeactive material precursor of the invention, the positive electrode active material adopting the positive electrode active material precursor has high initial charge specific capacity, initial discharge specific capacity, initial coulombic efficiency and cycle performance, so that the lithium ion secondary battery can have high initial charge specific capacity, initial discharge specific capacity,initial coulombic efficiency and cycle performance at the same time.

Owner:CONTEMPORARY AMPEREX TECH CO

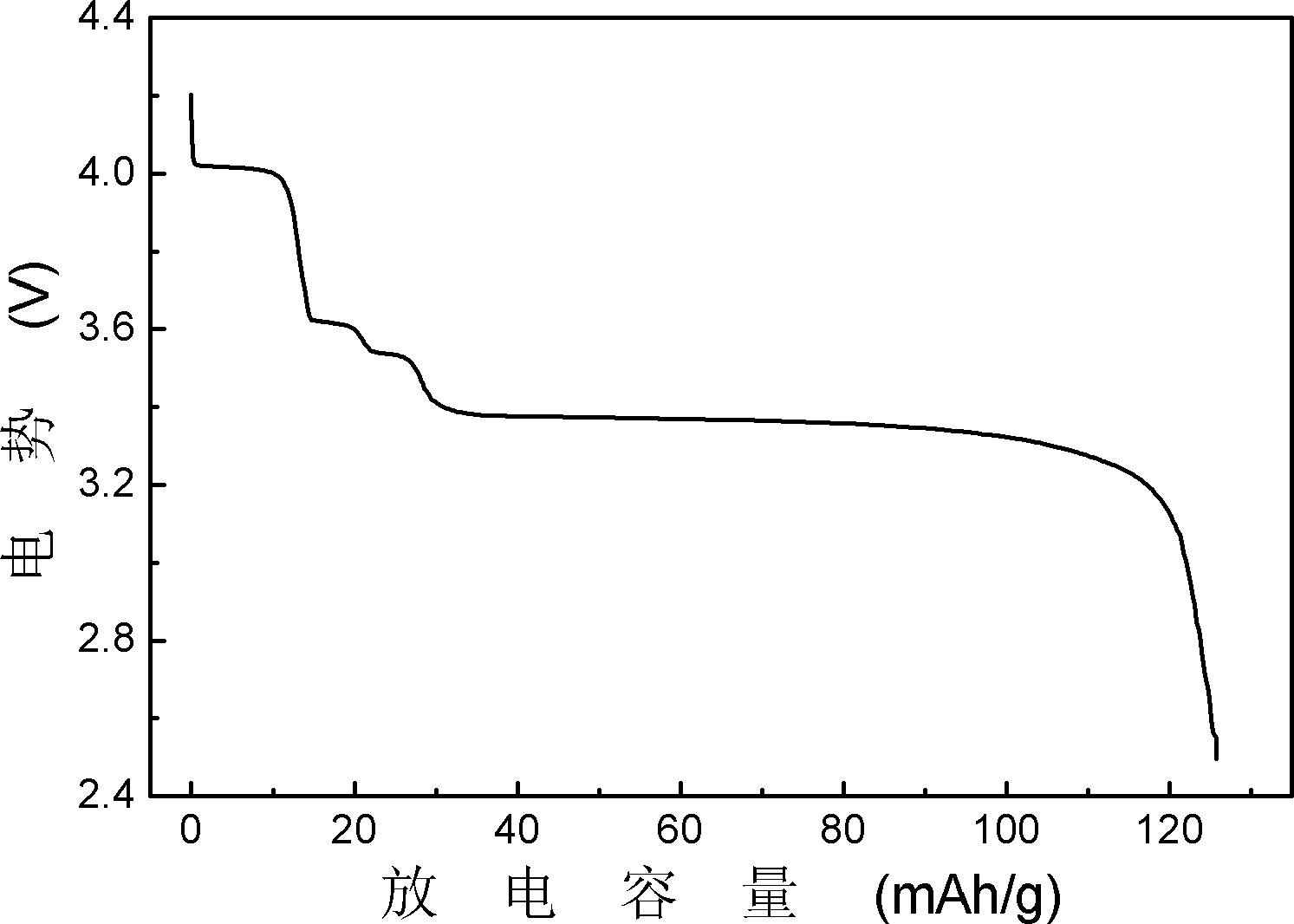

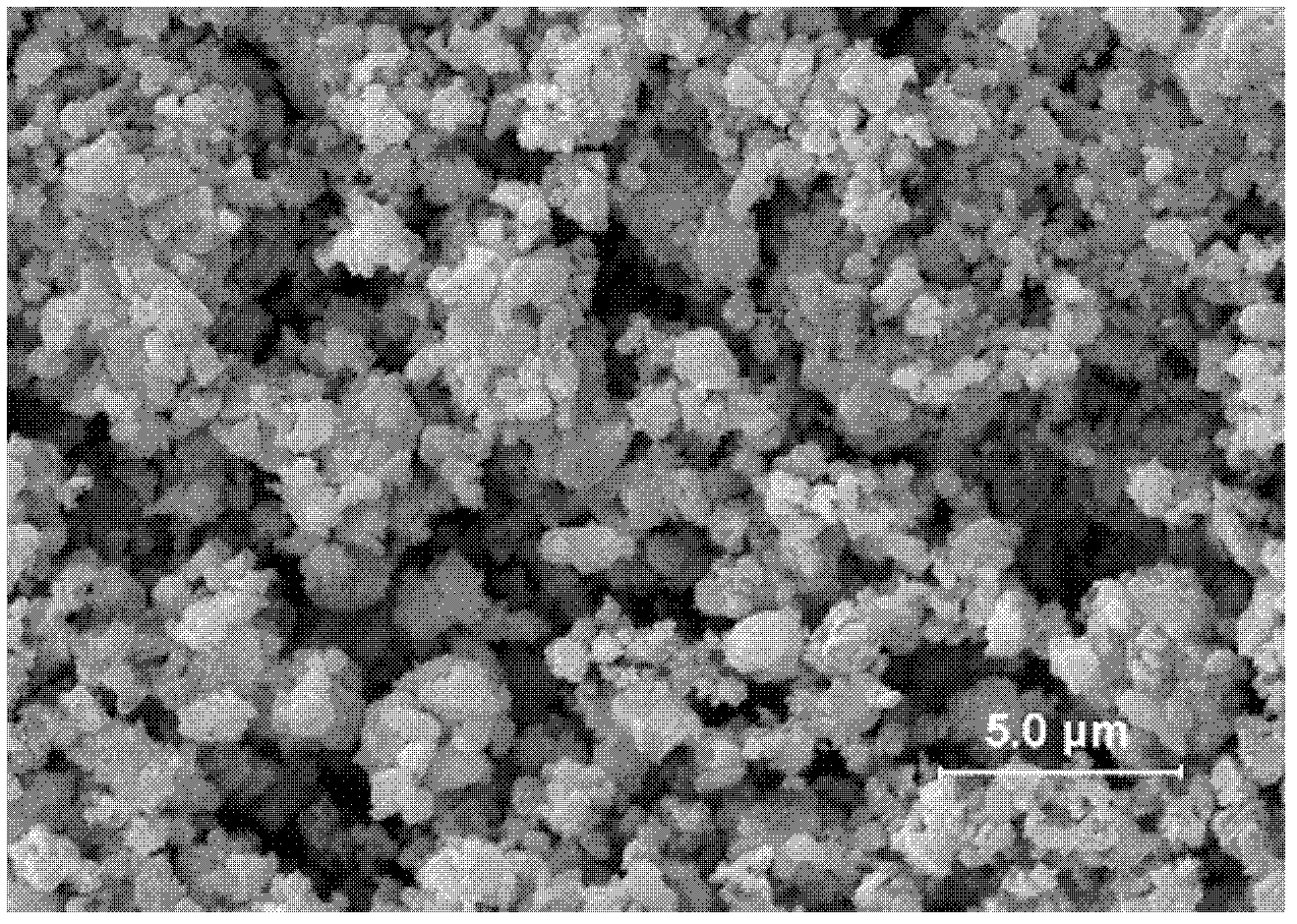

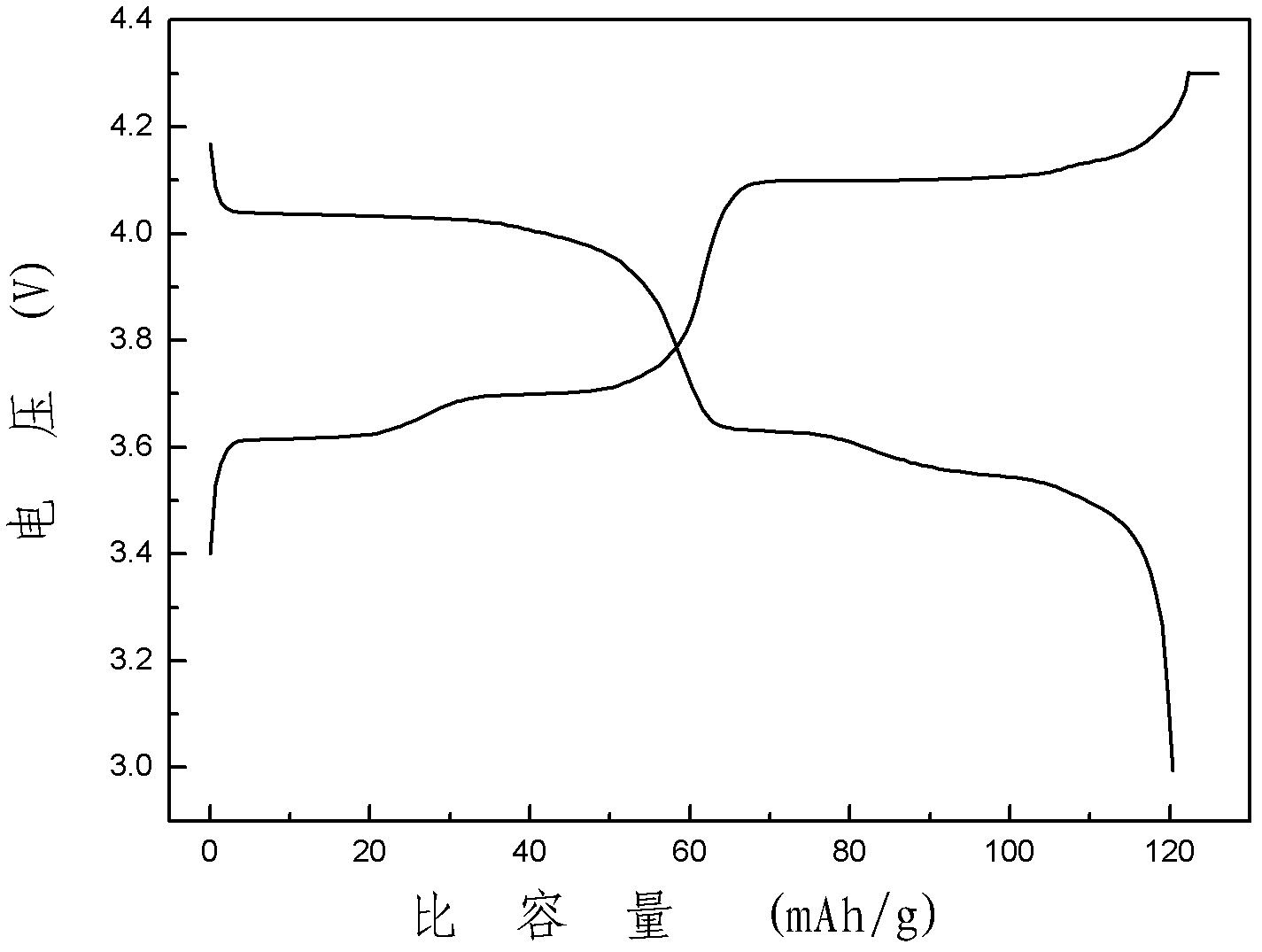

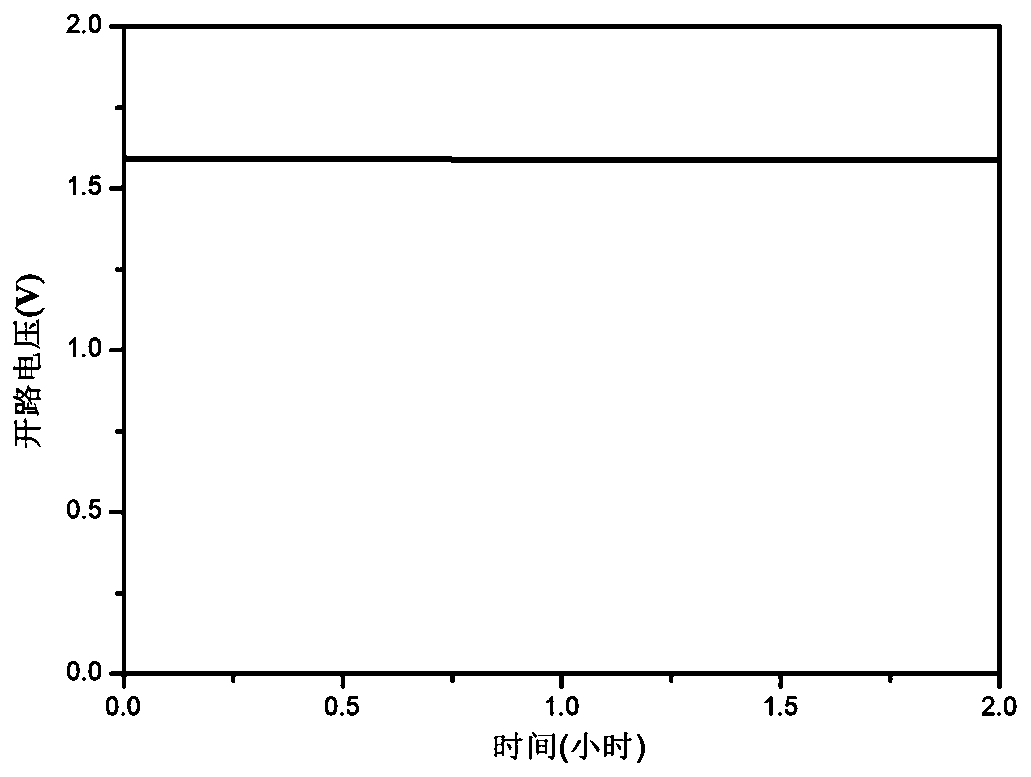

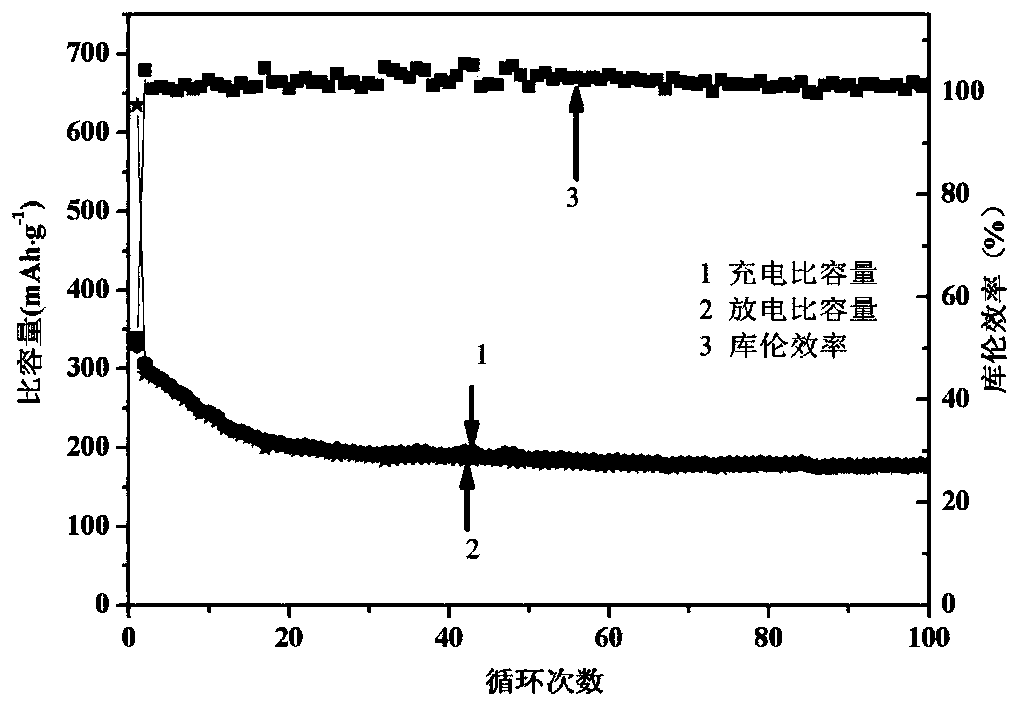

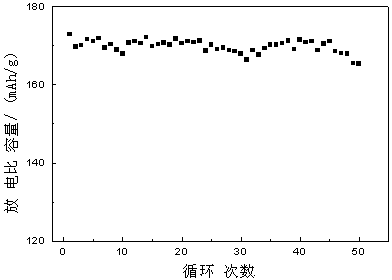

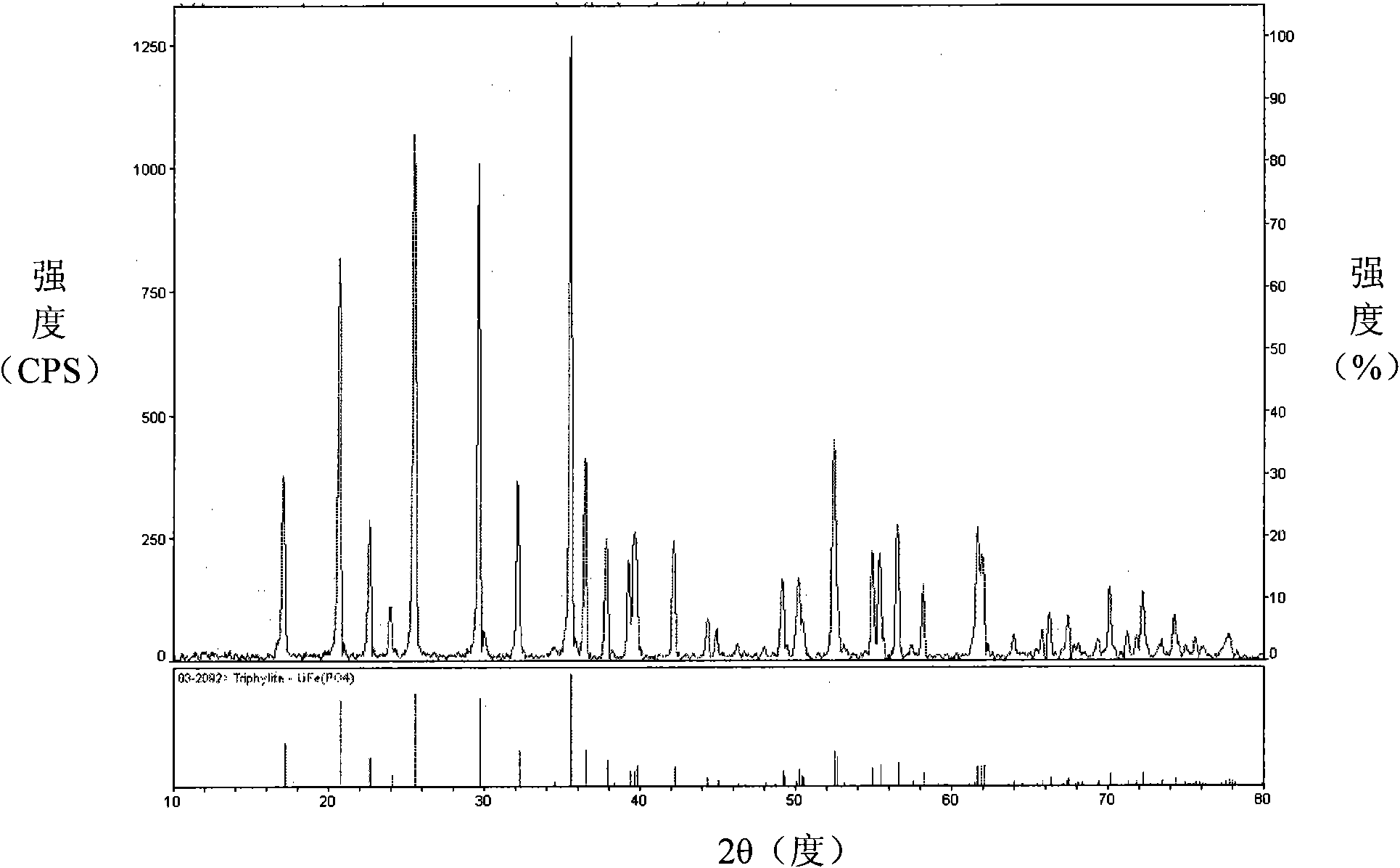

Method for preparing composite anode material LiFePO4/C for lithium ion battery

InactiveCN101937987AStable structureThe first discharge specific capacity is highCell electrodesPhosphorus compoundsPhosphatePolyethylene glycol

The invention relates to a method for preparing a composite anode material LiFePO4 / C for a lithium ion battery. The method comprises the steps of mixing, reacting, drying, calcining and cooling and is characterized in that: lithium salt, ferric salt and phosphate are mixed with a chemical substance, namely, formaldehyde capable of forming an ideal carbon gel pre-condensed substance and a resorcinol composition so as to form a complex rheological phase reaction system for preparing an LiFePO4 / C high molecular polymer; and reaction substances for preparing the LiFePO4 are uniformly distributed in the carbon gel pre-condensed substance. Simultaneously, polyethylene glycol (PEG) is added, pH is controlled and a reaction system is adjusted so as to adjust the structure of the carbon gel pre-condensed substance, a netlike porous structural material which is distributed uniformly can be obtained by calcining and carbon is uniformly coated on the surface of the LiFePO4. Under the condition of10C multiplying power, discharge specific capacity is up to 120.56mAh / g and circulating performance is high. The prepared anode material has a stable structure and high cyclical stability, does not contain any heavy metal and is an environmentally-friendly material.

Owner:HEFEI UNIV OF TECH

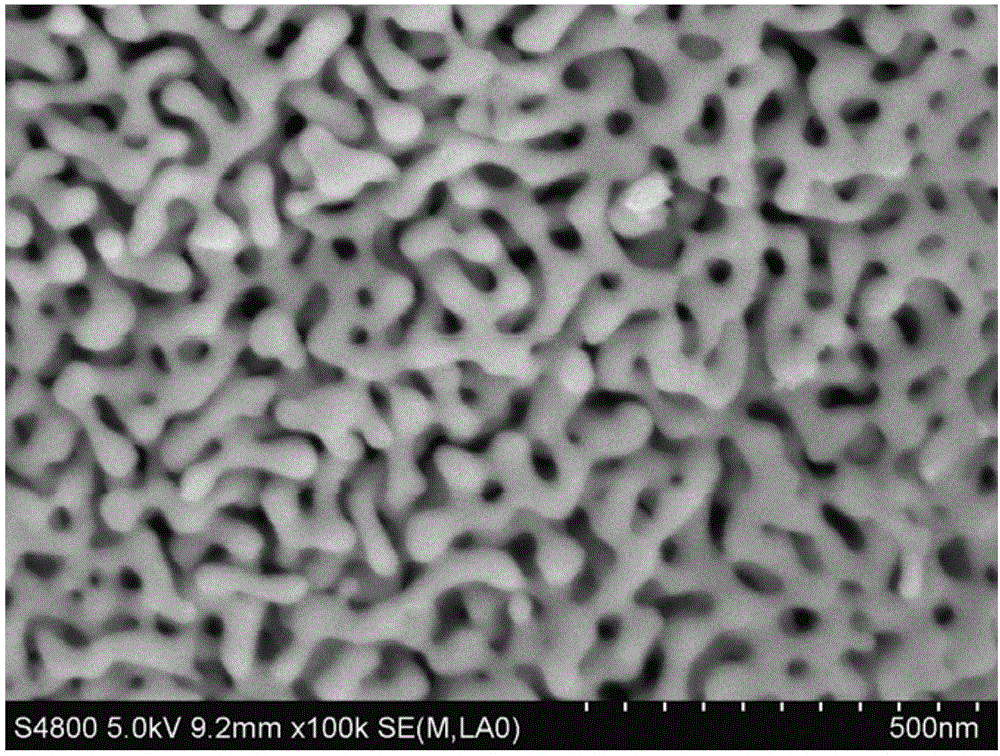

Three-dimensional nano porous copper/one-dimensional cuprous oxide nanowire network type lithium ion battery cathode and one-step preparation method thereof

ActiveCN106207090AImprove cycle performanceAlleviate volume changesMaterial nanotechnologyCell electrodesNanowireNetwork structure

The invention provides a three-dimensional nano porous copper / one-dimensional cuprous oxide nanowire network type lithium ion battery cathode. The lithium ion battery cathode is composed of a three-dimensional nano porous copper substrate and a cuprous oxide nanowire layer; the substrate is taken as a current collector, and the cuprous oxide nanowire layer is taken as an active lithium storage layer; the cuprous oxide nanowire layer is located on the surface of the substrate and combined with the substrate as a whole; the cuprous oxide nanowire layer is formed by cuprous oxide nanowires which are in-situ grown on the substrate and are mutually interweaved and stacked, and the cuprous oxide nanowire layer is of a network structure; and the lithium ion battery cathode can improve the cycle performance and specific capacity of a lithium ion battery. The invention further provides a one-step preparation method of the lithium ion battery cathode, and the method can effectively simplify the production technology of the lithium ion battery cathode.

Owner:SICHUAN UNIV

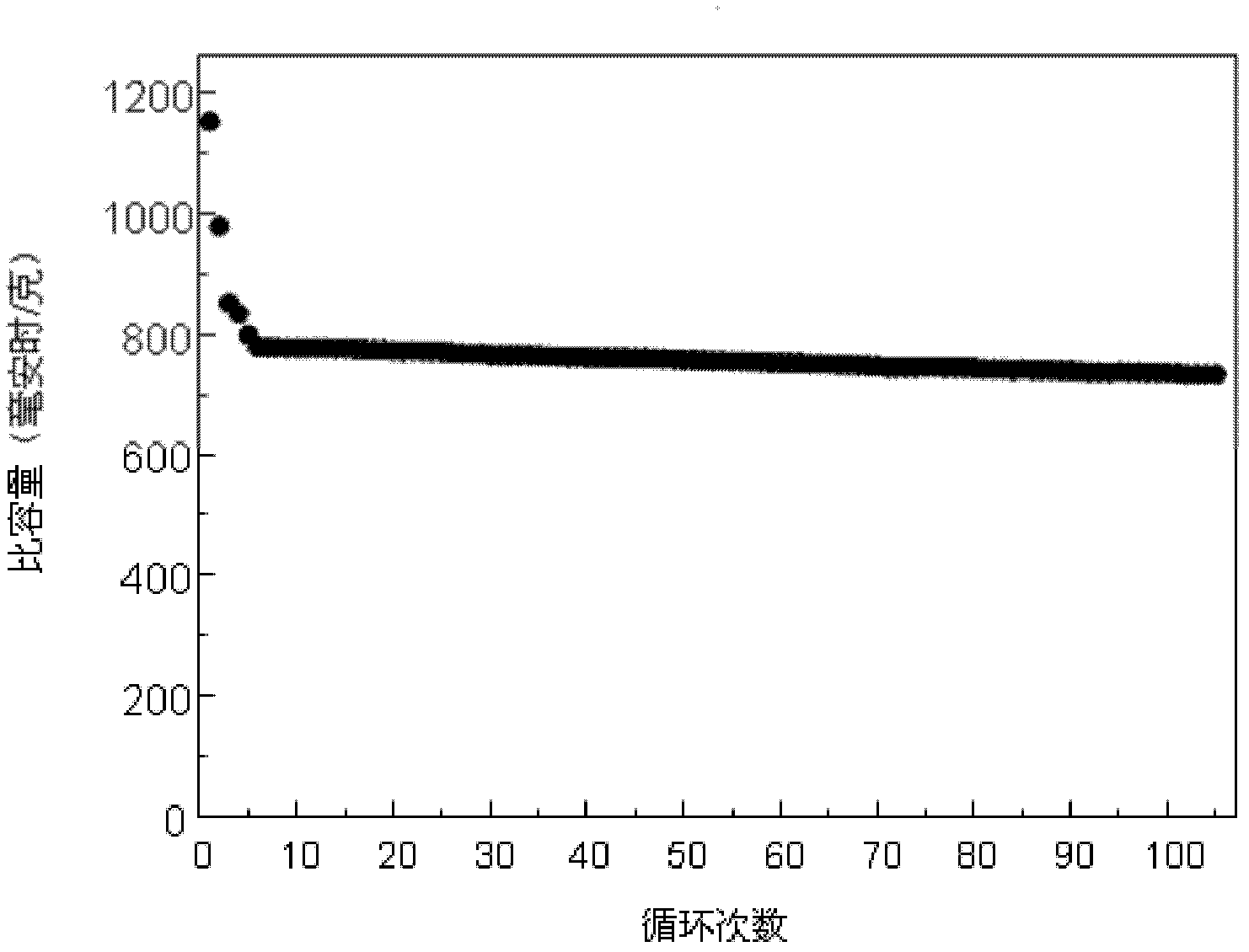

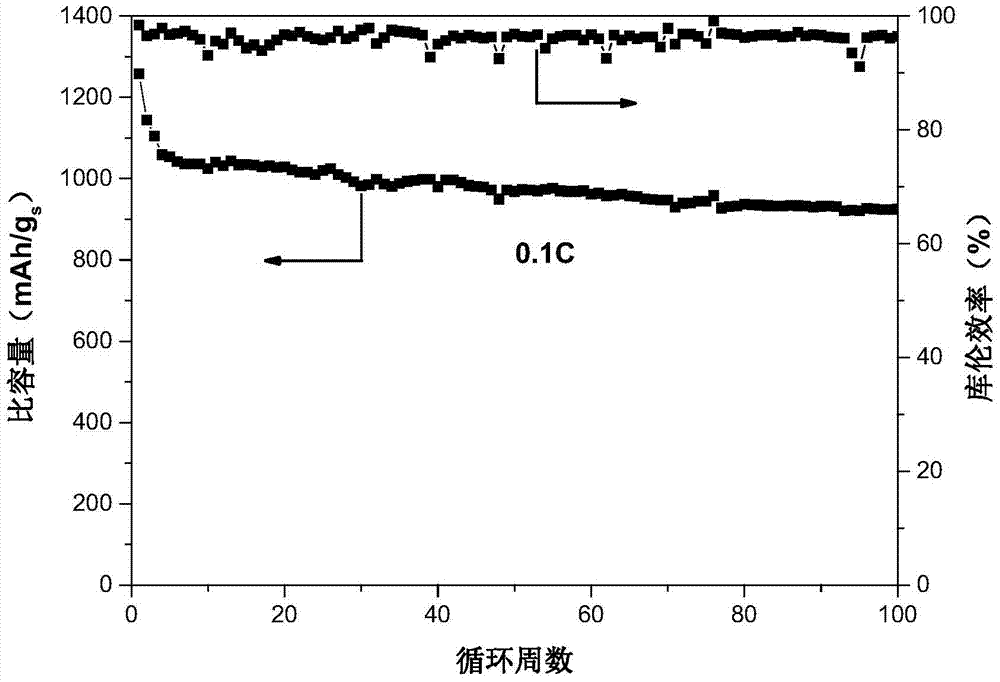

Lithium ion battery electrode material and its application in lithium ion batteries

ActiveCN104393300AExcellent discharge specific capacityThe first discharge specific capacity is highSecondary cellsNon-aqueous electrolyte accumulator electrodesMetal-organic frameworkEngineering

The invention provides a lithium ion battery electrode material. The electrode material comprises a metal-organic framework, and the metal-organic framework includes at least one diazole and at least one metal ion. Experiments confirm that the above lithium ion battery electrode has good charge and discharge cycle stability, and after multi-time cycle, the metal-organic framework still has a good structure, and the discharge specific capacity of the battery tends to stability, maintains at a high valve and has a small change amplitude, so the lithium ion battery electrode material is an electrode material with a good application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

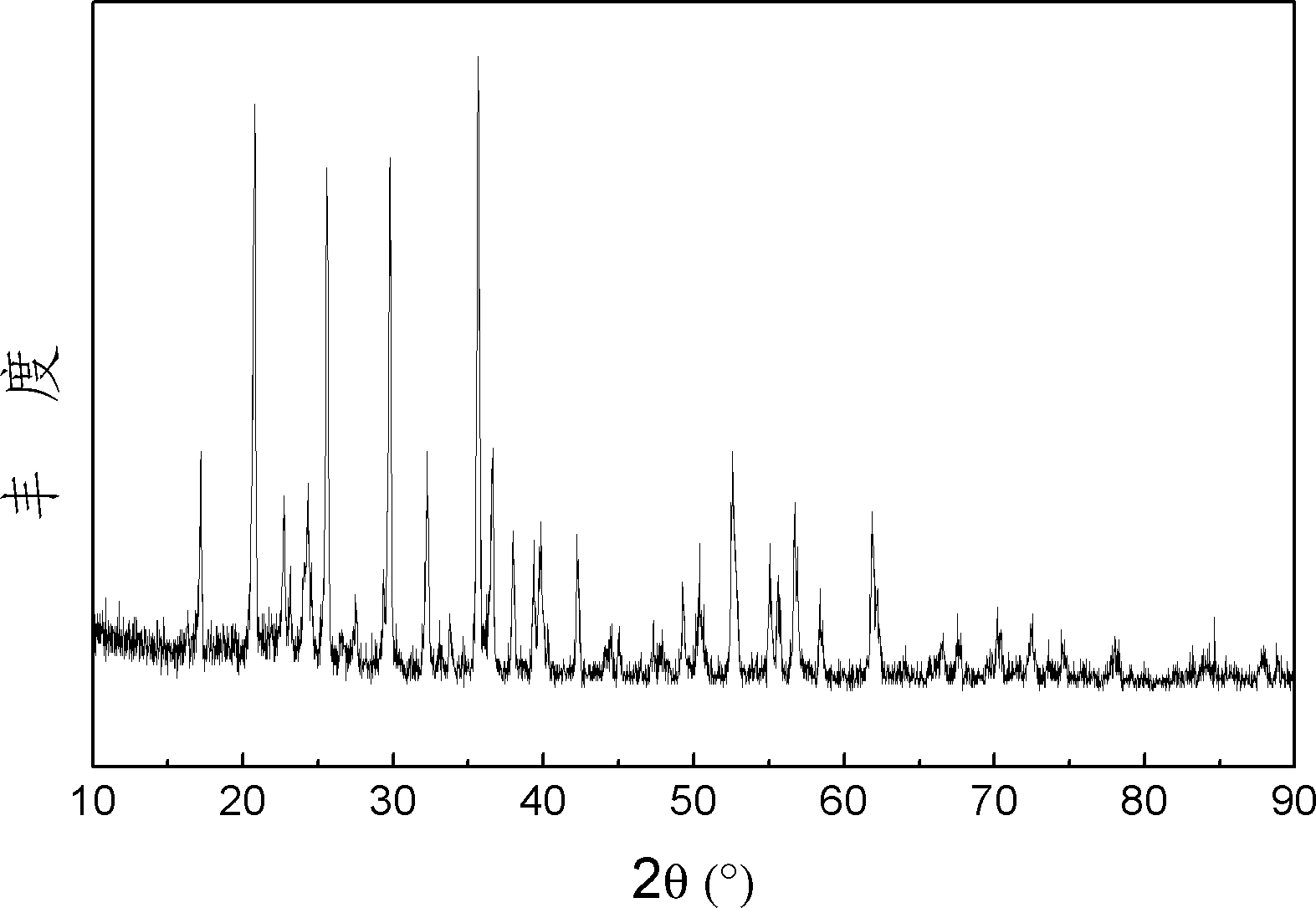

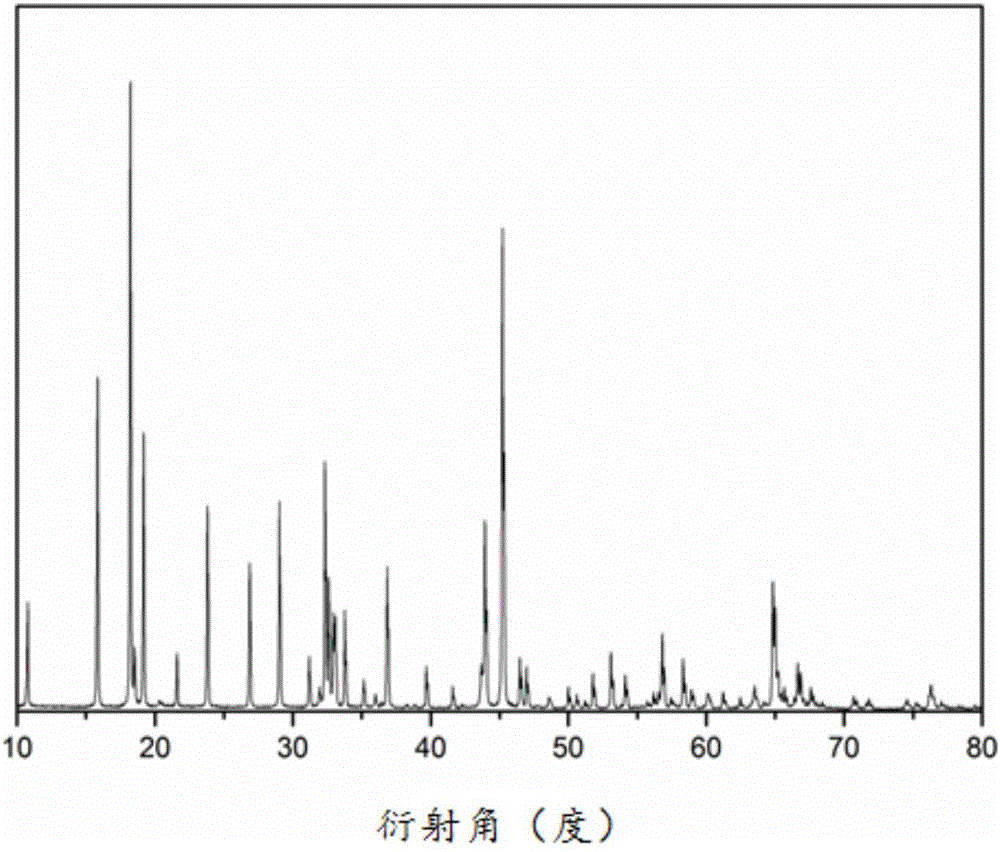

Method for preparing lithium ion battery anode material xLiFePO4.yLi3V2(PO4)3

InactiveCN102208620AImprove rate discharge performanceThe synthesis process is simpleCell electrodesLithiumPhosphate

The invention discloses a method for preparing a lithium ion battery anode material xLiFePO4.yLi3V2(PO4)3, and relates to a method for preparing a lithium ion battery anode material. The method solves the technical problems of poor magnification performance and complex synthesis process in the conventional method for synthesizing the xLiFePO4.yLi3V2(PO4)3. The method comprises the following steps of: weighing lithium source, iron source, vanadium salt, phosphate and carbon source, mixing, and performing wet milling, pre-sintering and calcination to obtain the xLiFePO4.yLi3V2(PO4)3. The process is simple, and environmental pollution easily caused in a liquid phase method is not caused. The anode material prepared by the method has good magnification discharge performance; and during 10C discharge, the discharge specific capacity is 90mAh / g, and the capacity is nearly not attenuated after 20 times of cycles.

Owner:HARBIN INST OF TECH

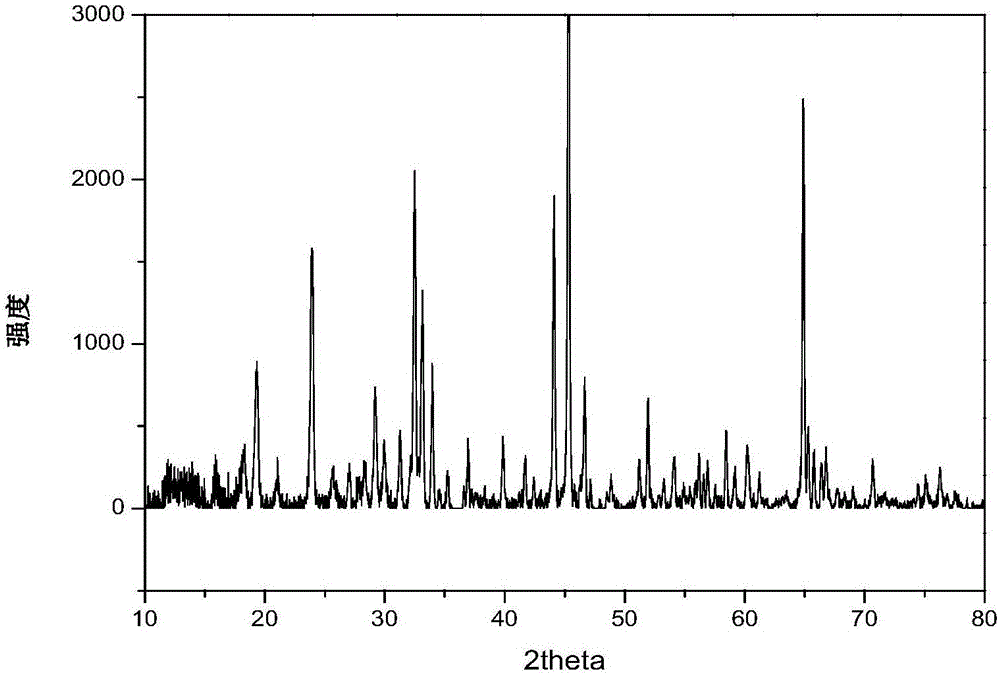

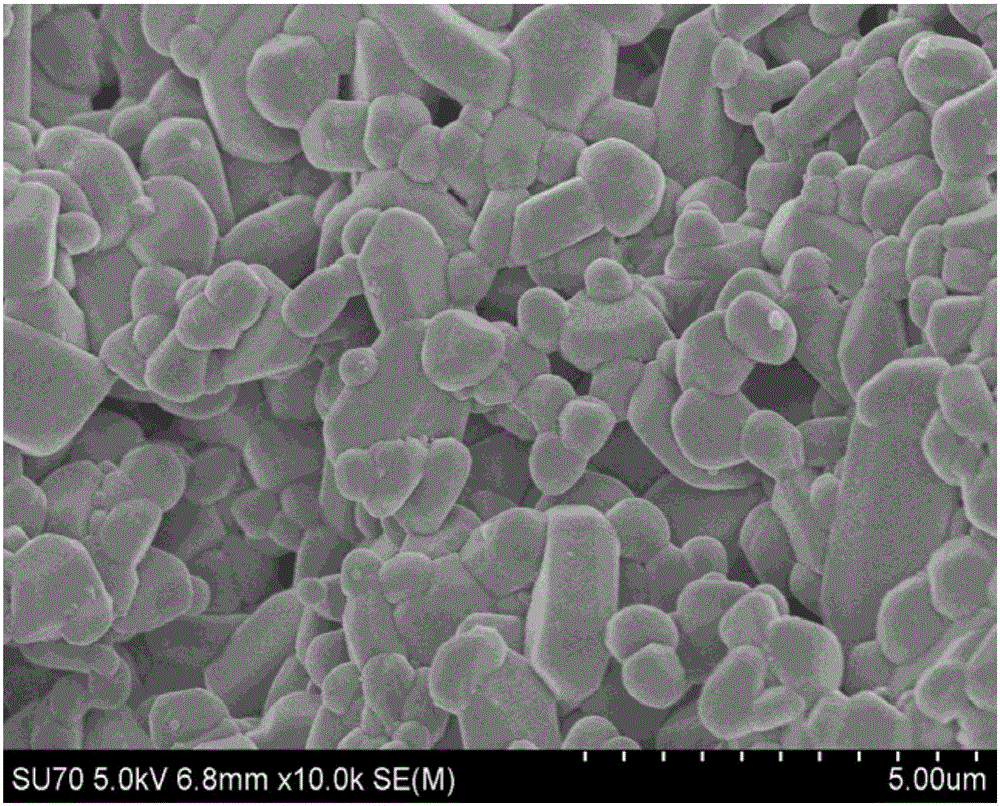

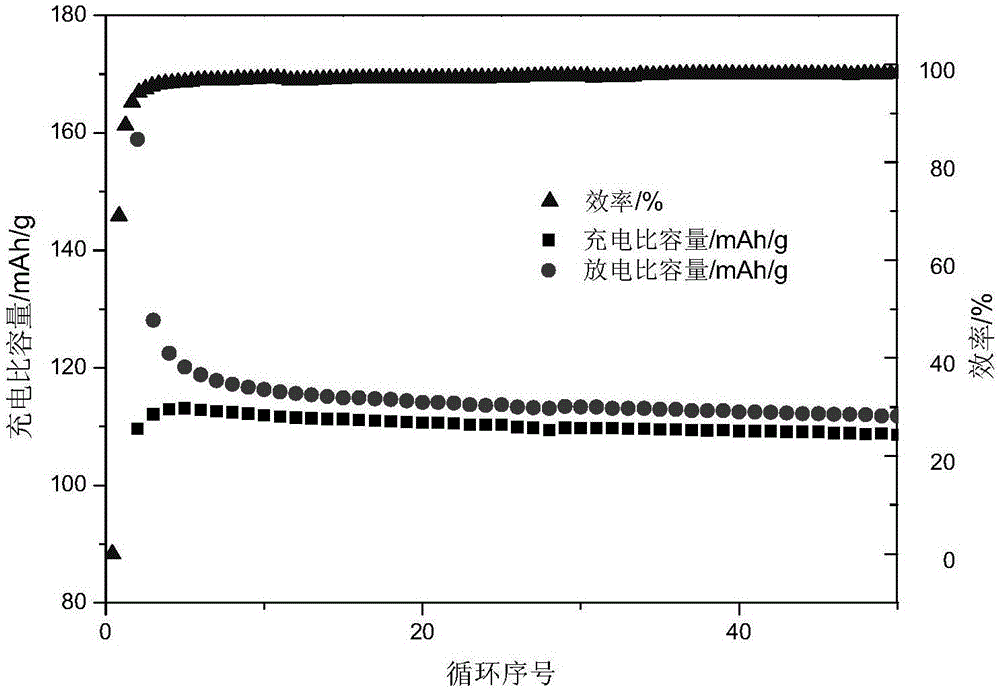

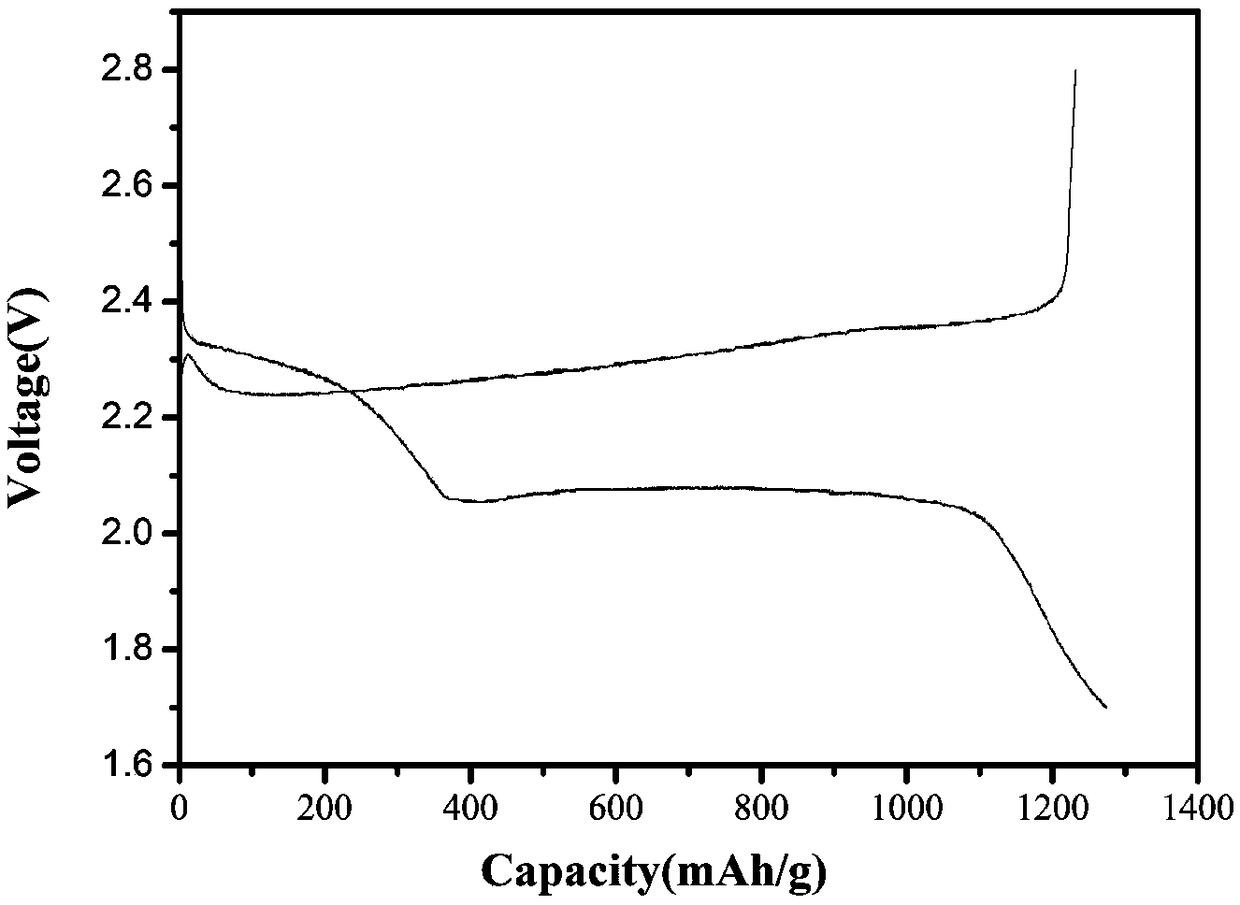

Preparation method of lithium ion battery anode material Li3V2(PO4)3

The invention discloses a preparation method of a lithium ion battery anode material Li3V2(PO4)3. The preparation method provided by the invention mainly solves the problem that the existing high-temperature solid-phase method and the existing carbon-thermal reduction method for preparation of lithium vanadium phosphate have the defects that a sintering temperature is high; sintering time is long; a volatile organic solvent is utilized as a ball milling dispersant so that a cost is high; spray and drying processes are unsafe; and a sol-gel technology is complex. The preparation method comprises the following steps of weighing one or more lithium sources, V2O5, a carbon source and a phosphorus source, adding the one or more lithium sources, V2O5, the carbon source and the phosphorus source into a hydrogen peroxide aqueous solution, carrying out wet ball milling, and carrying out calcination at a temperature of 550 to 650 DEG C in a protective atmosphere to obtain the lithium ion battery anode material Li3V2(PO4)3. The preparation method provided by the invention has simple processes, a low synthesis temperature, short sintering time and high production safety. The lithium ion battery anode material Li3V2(PO4)3 obtained by the preparation method has an initial discharge specific capacity of 104mAh / g under multiplying power of 10C and a capacity retention ratio great than or equal to 96.4% after 50 cycles. The preparation method provided by the invention is utilized for preparation of battery anode materials.

Owner:HARBIN INST OF TECH

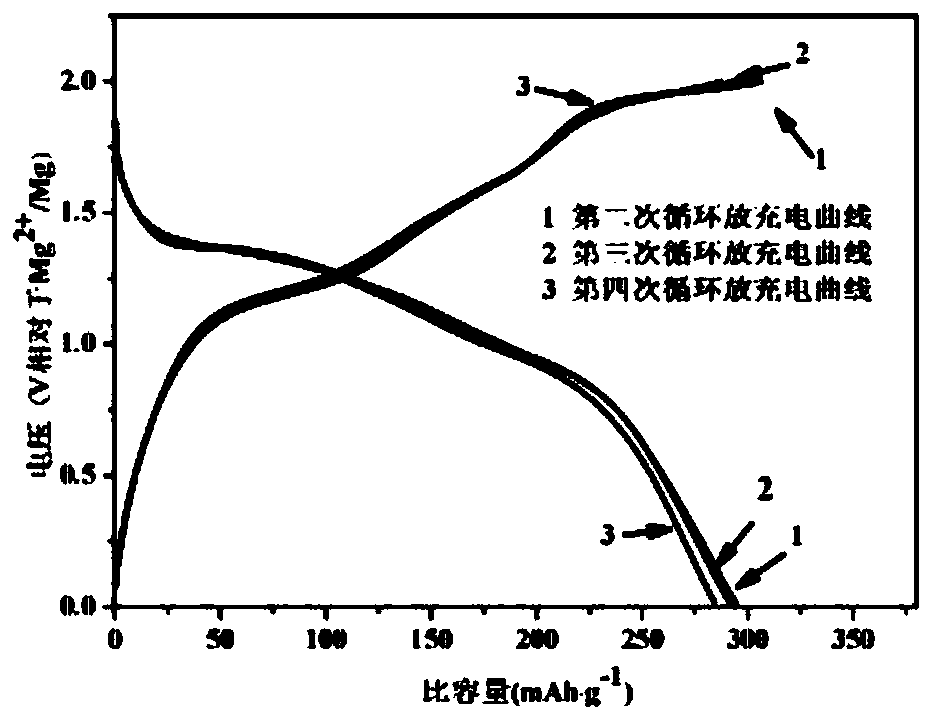

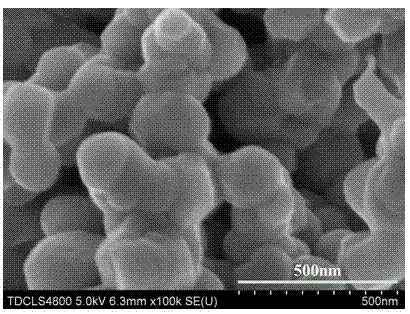

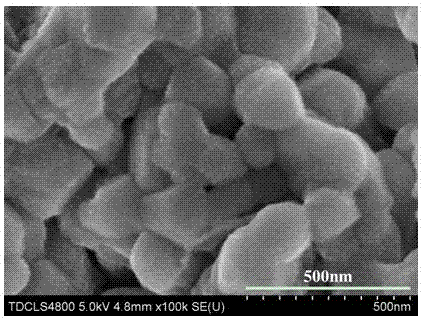

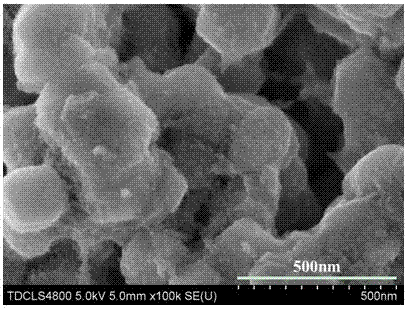

Magnesium-lithium double-ion battery composite cathode material, preparation method and application thereof, and battery system

ActiveCN109755553ASimple structureComplete structureMaterial nanotechnologyCell electrodesElectrochemical responseHigh current density

The invention provides a magnesium-lithium double-ion battery composite cathode material, a preparation method and application thereof, and a battery system, and belongs to the field of magnesium ionbatteries. In the magnesium-lithium double-ion battery composite cathode material, a polyaniline layer has a protective effect on the composite cathode material, and PANI-coated VS4 / rGO is higher in conductivity and of a more complete structure, which is favorable for achieving charging and discharging under a large current density; a PANI conductive layer does not participate in electrochemical reaction, and coats the surface of VS4 to improve the conductivity of VS4, and can well adapt to the charging and discharging process under the high current density; meanwhile, the PANI layer reduces the loss of active substances in the core VS4 during charging and discharging, thus maintaining the structural integrity; and the PANI layer allows VS4 to better adapt to the volume change caused by the intercalation and deintercalation of Mg<2+> and Li<+>, and reduces the loss of the active substances on a current collector, thereby significantly increasing the stable cycle capacity of the cathodematerial.

Owner:BEIHANG UNIV

Method for modifying ZrO2-coated lithium-rich laminar cathode material of lithium ion battery

InactiveCN103094577AThe first discharge specific capacity is highPromote circulationCell electrodesMass ratioZirconate

The invention discloses a method for modifying a ZrO2-coated lithium-rich laminar cathode material of a lithium ion battery. The method comprises the steps as follows: dissolving zirconium isopropoxide, zirconium propoxide or tetrabutyl zirconate in a solvent to prepare 0.001-1 mol / L of zirconate solution; dispersing the lithium-rich laminar cathode material in the prepared zirconate solution according to the mass ratio of ZrO2 to the lithium-rich laminar cathode material, ultrasonically mixing, sealing and stirring to obtain sol; evaporating the solvent of the prepared sol to dryness and drying to obtain a solid matter; and sintering the obtained solid matter for 1-10 h at the temperature of 350-600 DEG C to prepare the ZrO2-coated lithium-rich laminar cathode material. The ZrO2-coated lithium-rich laminar cathode material prepared with the method has the characteristics of high electrochemical capacity, good cycle stability, excellent rate performance and the like; and the preparation method is simple, easy, low in cost and good in reproducibility.

Owner:TIANJIN UNIV

Fabrication method of soft package lithium-sulfur battery

InactiveCN107910584AFast transferInhibition of dissolutionFinal product manufactureCell electrodesLithium–sulfur batterySulfur

The invention discloses a fabrication method of a soft package lithium-sulfur battery. The fabrication method comprises the following steps of 1, combining a lithium negative electrode and a negativecurrent collector to obtain a negative pole plate; 2, obtaining a separator or a separator coated with a conductive agent and a binding agent in a mixed way; 3, mixing the conductive agent, a sulfur positive active material and the binding agent, performing coating on a positive current collector, and then drying and cutting to obtain a positive pole plate; and 4, assembling the negative pole plate, the separator and the positive pole plate of the steps 1-3, obtaining a battery cell after a tab is welded, assembling the battery cell into a package shell, and performing liquid injection, package and aging to obtain the soft package lithium-sulfur battery. According to the fabrication method of the soft package lithium-sulfur battery, and the initial discharging specific capacity, the coulombic efficiency and the cycle stability of the battery all can be effectively improved under a synergistic effect of the whole battery structure.

Owner:XIAN UNIV OF TECH

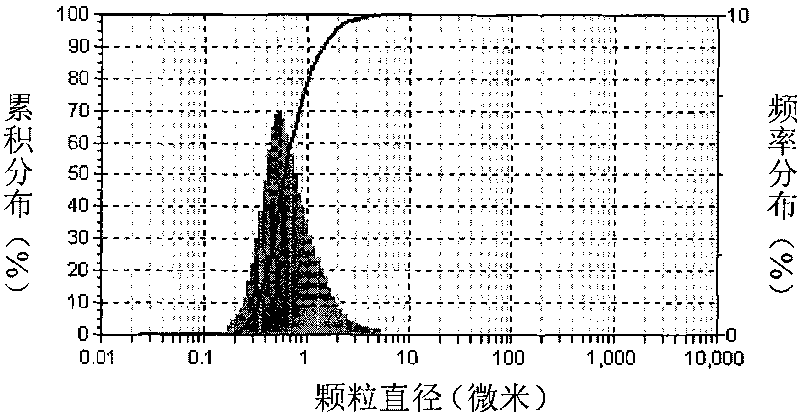

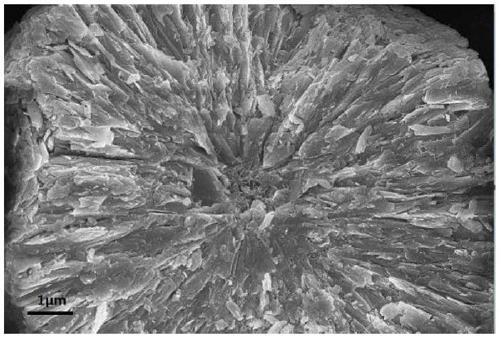

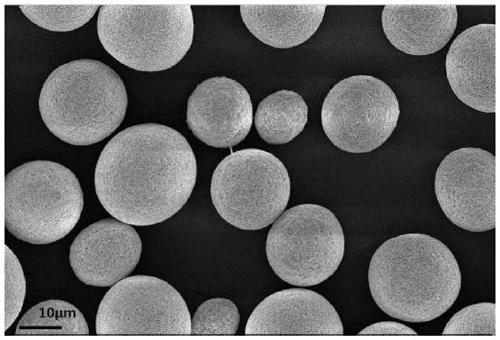

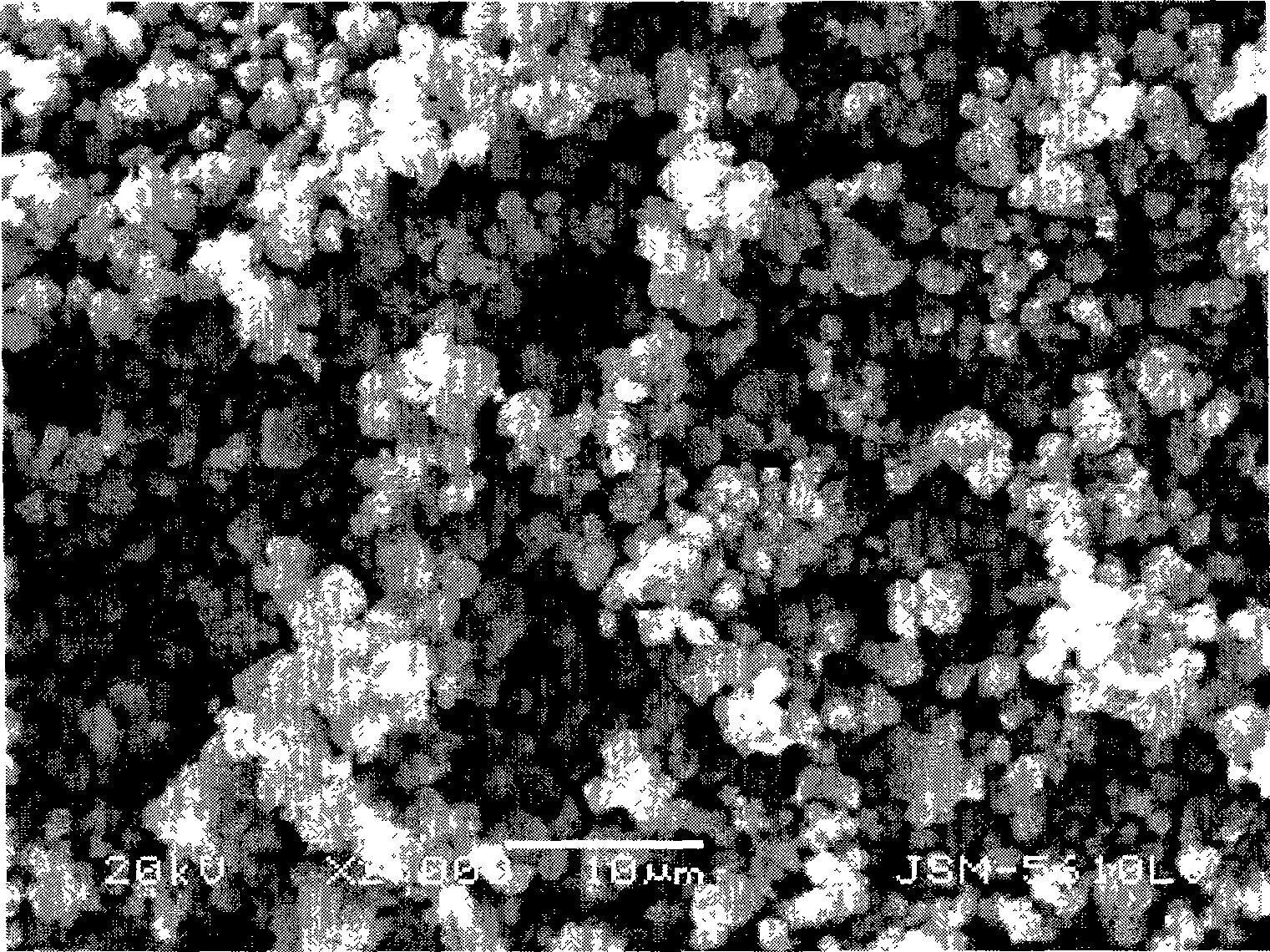

Preparation method of spherical lithium iron phosphate

InactiveCN101638226ASmall particle sizeAvoid crackingMaterial granulationPhosphorus compoundsLithium iron phosphateRoom temperature

The invention provides a preparation method of spherical lithium iron phosphate, which belongs to the technical field of lithium battery anode materials and solves the problems of low tap density, lowconductivity, irregular shape, unstable performance, poor post-processing affinity, and the like of lithium iron phosphate prepared by the preparation method of the prior lithium iron phosphate. Thepreparation method of spherical lithium iron phosphate comprises the following steps: A, preparing lithium iron phosphate powder; and B, preparing the spherical lithium iron phosphate. The preparationmethod of the spherical lithium iron phosphate has simple technical process and low production cost and is suitable for large-scale production. The prepared spherical lithium iron phosphate has smallgranularity, large tap density and high first discharging specific capacity at room temperature.

Owner:台州市杰南投资有限公司

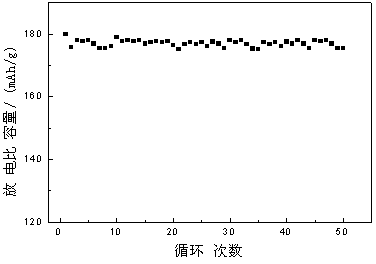

Preparation method of high-capacity lithium nickel cobalt aluminate

ActiveCN104795556AHomogeneous material phaseMorphological rulesCell electrodesSecondary cellsAluminiumLithium electrode

The invention relates to a preparation method of a high-capacity lithium ion battery cathode material of lithium nickel cobalt aluminate. The preparation method comprises: adding a nickel-containing compound, a cobalt-containing compound, a lithium-containing compound, and an aluminium-containing compound into a high temperature-resistant ball-milling tank and performing uniform mixing; putting the tank into a mechanical device capable of heating and rotating; performing ball milling at a room temperature; performing mixing for 5-20h; sintering the reactants in the ball-milling tank in the presence of air flow or oxygen flow at two temperature segments while keeping ball milling, wherein firstly, elevating the temperature to 400-600 DEG C in the presence of air flow or oxygen flow and performing sintering for 2-10h, and elevating the temperature to 700-900 DEG C in the presence of air flow or oxygen flow and performing sintering for 5-30h; performing cooling while performing ball milling till the temperature is relatively low; and opening the device to obtain cathode material powder of lithium nickel cobalt aluminate. The method is simple in technology, and raw materials can be completely mixed through high-temperature ball milling to obtain the cathode material of lithium nickel cobalt aluminate. In a voltage range of 3.0-4.2V and under a rate of 0.2C, the cathode material has an initial discharge specific capacity higher than 180mAH / g and has excellent cycle performance.

Owner:湖南秒冲新能源科技有限责任公司

CNT (Carbon Nano Tube)/SnO2 coaxial composite array lithium ion battery negative electrode material

InactiveCN103647047AImprove bindingGood electrical propertiesCell electrodesSecondary cellsCarbon nanotubeEvaporation

The invention discloses a preparation method of a CNT (Carbon Nano Tube) / SnO2 coaxial composite array lithium ion battery negative electrode material. The method comprises the following steps: firstly pre-depositing an aluminium oxide buffer layer and an iron catalyst layer on a tinsel current collector by utilizing an electron beam evaporation method, growing a CNT array in situ on the current collector by utilizing a hot CVD (Chemical Vapor Deposition) method, and then depositing an atomic layer on the generated CNT array, so as to obtain the CNT / SnO2 coaxial composite array. Microlitic SnO2 nano tubes are uniformly coated at the outside surface of CNTs, and are firmly combined with the CNTs, and the CNT / SnO2 coaxial material is directly and firmly combined with a metal base. The CNT / SnO2 coaxial composite array lithium ion battery negative electrode material provided by the invention shows excellent electrical property.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for preparing active substance lithium iron phosphate for lithium ion secondary battery anode

InactiveCN101378125AEvenly distributedSmall granularityElectrode manufacturing processesVehicular energy storageLithium iron phosphatePhosphate

The invention discloses a preparation method of lithium ferrous phosphate which is an active material of the anode of a lithium-ion secondary battery; the method comprises the following steps: lithium source, iron source, phosphorus source and carbon source are mixed in water, then dried and sintered; wherein, the iron source is ferric oxide and the phosphorus source is phosphoric acid. The lithium ferrous phosphate obtained by adopting the method has less crystal particle size, uniform distribution of particle size and lower production cost, and the battery prepared by the lithium ferrous phosphate has high specific capacity of charging for the first time and good cycle performance.

Owner:BYD CO LTD

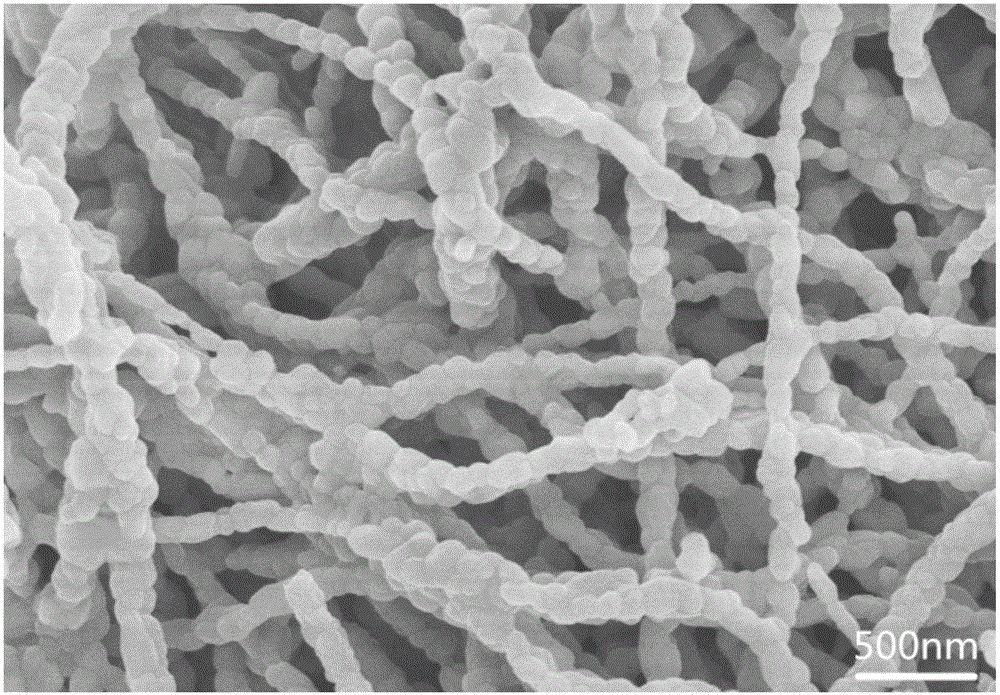

Sodium lithium titanate nanowire and preparation method thereof

ActiveCN105948108AImprove performanceThe first discharge specific capacity is highMaterial nanotechnologyAlkali titanatesNanowireSodium salt

The invention discloses a preparation method for preparing a sodium lithium titanate nanowire. According to the invention, a certain amount of lithium salt, sodium salt and titanium salt is dissolved in a mixed solution of dimethylformamide and ethanol. Meanwhile, glacial acetic acid and a polymer are added to form a clear solution. The clear solution is subjected to electrostatic spinning under a certain voltage and at a certain volumetric flow rate. The product of the electrostatic spinning is dried at a constant temperature, and then is sintered at a high temperature to obtain the corresponding NaLiTiO3 sodium lithium titanate nanowire. According to the technical scheme of the invention, the electrochemical performance and the lithium storage performance of the sodium lithium titanate nanowire are studied. Meanwhile, the NaLiTiO3 sodium lithium titanate nanowire as lithium ion battery cathode materials is successively prepared. The nanowire is excellent in physical and chemical properties. Electrochemical experiments prove that, the prepared NaLiTiO3 sodium lithium titanate nanowire as lithium ion battery cathode materials is wide in application prospect. The entire preparation process is simple in operation, low in raw material cost, small in equipment investment, and suitable for batch production.

Owner:滨州市科创孵化器有限公司

Method for preparing lithium iron phosphate as a positive electrode active material for a lithium ion secondary battery

ActiveCN101568489ASmall granularityEvenly distributedCell electrodesSecondary cellsElectrical batteryPhosphoric acid

Disclosed herein is a method for preparing lithium iron phosphate as a positive electrode active material for a lithium ion secondary battery comprising drying and sintering a mixture containing a lithium source, ferric oxide, phosphoric acid, a carbon source, and a solvent, in which the solvent is water and / or water soluble organic solvent. The lithium iron phosphate prepared by the inventive method has small particle size and uniform particle size distribution, and the battery prepared from the lithium iron phosphate has high initial discharge specific capacity, and good large-current discharge property and cycle performance.

Owner:BYD CO LTD

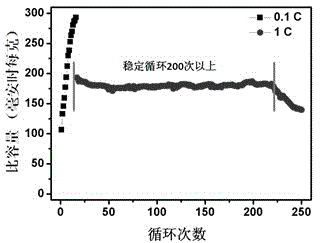

Spinel phase coated lithium-rich material Li1.87Mn0.94Ni0.19O3, preparation method and application therefor

InactiveCN105609718AReduce direct contactImprove cycle stabilityMaterial nanotechnologyCell electrodesHigh rateSpinel

The invention discloses a spinel phase coated lithium-rich material Li1.87Mn0.94Ni0.19O3, a preparation method and an application therefor, and belongs to the electrochemical technical field. The invention discloses a new material used as a lithium ion battery positive electrode, namely the spinel phase coated lithium-rich material Li1.87Mn0.94Ni0.19O3, and the preparation method is simple. When the material is used as the positive electrode material of a button lithium battery, the cycling stability of the button lithium battery under a high rate of 1C (250 mA / g) can be improved, and a relatively high specific capacity can be ensured as well; at present, the stable cycling performance of the button lithium battery under the rate of 1C is improved to be more than 200 circles; and meanwhile, the capacity is kept at about 180mA / g.

Owner:SHANDONG BAOLI BIOMASS ENERGY +1

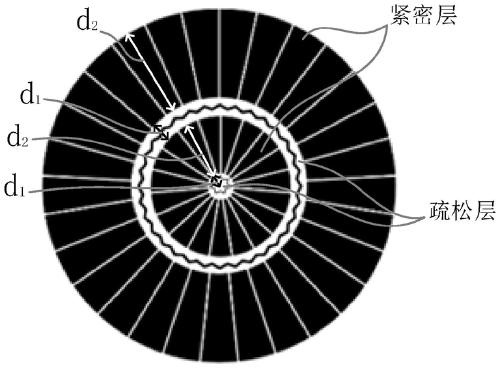

Positive electrode active material precursor, preparation method thereof, and positive electrode active material

ActiveCN111653756AImprove cycle performanceImprove capacity playCell electrodesSecondary cellsBattery cellChemical engineering

The invention discloses a positive electrode active material precursor, a preparation method thereof and a positive electrode active material. The positive electrode active material precursor comprises secondary particles formed by aggregation of a plurality of primary particles. Each secondary particle comprises a loose layer and a compact layer which are alternately distributed in the directionfrom the core to the outer surface of the secondary particle, the innermost part of each secondary particle is the loose layer, and the outermost part of each secondary particle is the compact layer.According to the positive electrode active material precursor, the positive electrode active material adopting the positive electrode active material has relatively high initial charge specific capacity, initial discharge specific capacity, initial coulombic efficiency and cycle performance, so that the lithium ion secondary battery can have relatively high initial charge specific capacity, initial discharge specific capacity, initial coulombic efficiency and cycle performance at the same time.

Owner:PINGNAN CONTEMPORARY ADVANCED MATERIALS TECH CO LTD

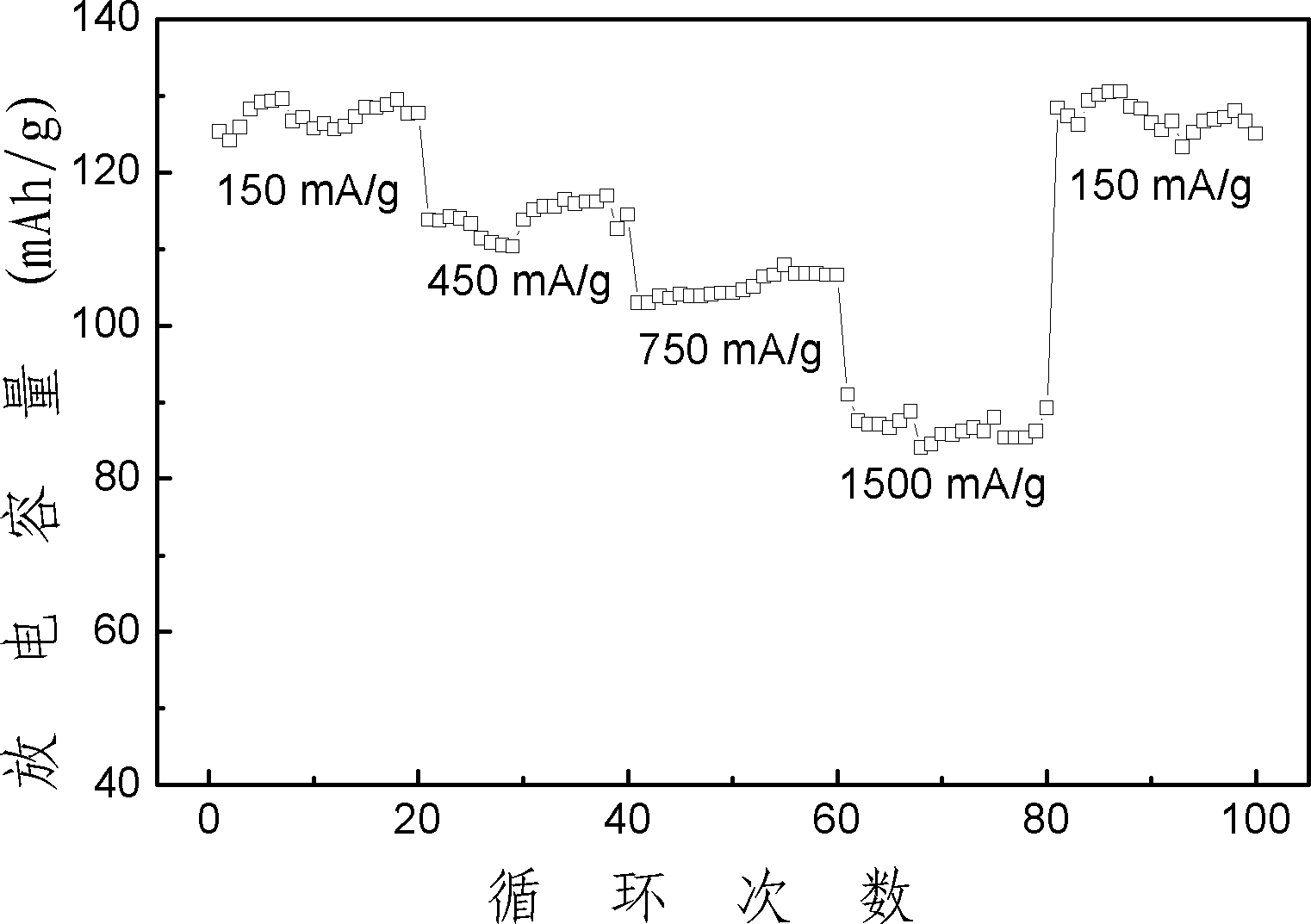

Anode material for lithium ion batteries and preparation method thereof

ActiveCN106602052AThe first discharge specific capacity is highGood capacity retentionCell electrodesSecondary cellsElectrical batteryBarium salt

The invention discloses an anode material for lithium ion batteries and a preparation method of the anode material. A sodium salt, a barium salt, a strontium salt, a lithium salt and a titanium salt are mixed in proportion, and the novel material for the lithium ion batteries is prepared through ball-milling, drying, grinding and sintering synthesis; the chemical formula of the anode material is Na0.5Ba0.25Sr0.5Li2Ti6O14, and the electrochemical performance and lithium storage performance of the cathode material are researched. Electrochemical experiments prove that the composite material prepared through the method has excellent physical and chemical properties, and has wide application prospect as the anode material for the lithium ion batteries. In the whole preparation process, the synthetic method is simple and easy to operate, the material preparation cost is low, the equipment investment is low, and the anode material is applicable for volume production.

Owner:NINGBO UNIV

A preparation method and application of a lithium sulfide battery positive electrode

ActiveCN109192967ASolve the shuttle problemImprove electrical performanceNon-aqueous electrolyte accumulator electrodesLi-accumulatorsThiazoleLithium–sulfur battery

The invention belongs to the field of lithium sulfide battery positive electrode material and specifically relates to a preparation method and application of a lithium sulfide battery positive electrode. The lithium sulfide battery positive electrode comprise a positive electrode active material, a stabilizer, a conductive agent and a bind, wherein that positive electrode active material is insoluble sulfur. The stabilizer is a compound capable of forming a common electron pair with sulfur atoms at both ends of the positive electrode active material, preferably at least one of a halogen, an organic halide and a thiazole compound. The positive electrode active material of the invention greatly reduces the dissolution of the polysulfide, and the insoluble sulfur stabilizer used together caneffectively restrain the generation of dead sulfur and the shuttle effect in the electrode reaction process. The positive electrode assembled lithium sulfide battery provided by the invention has highfirst discharge specific capacity and good cycle performance. In addition, the preparation method of the sulfide positive electrode provided by the invention is low in cost, simple in operation and easy to realize large-scale commercial manufacture.

Owner:CENT SOUTH UNIV

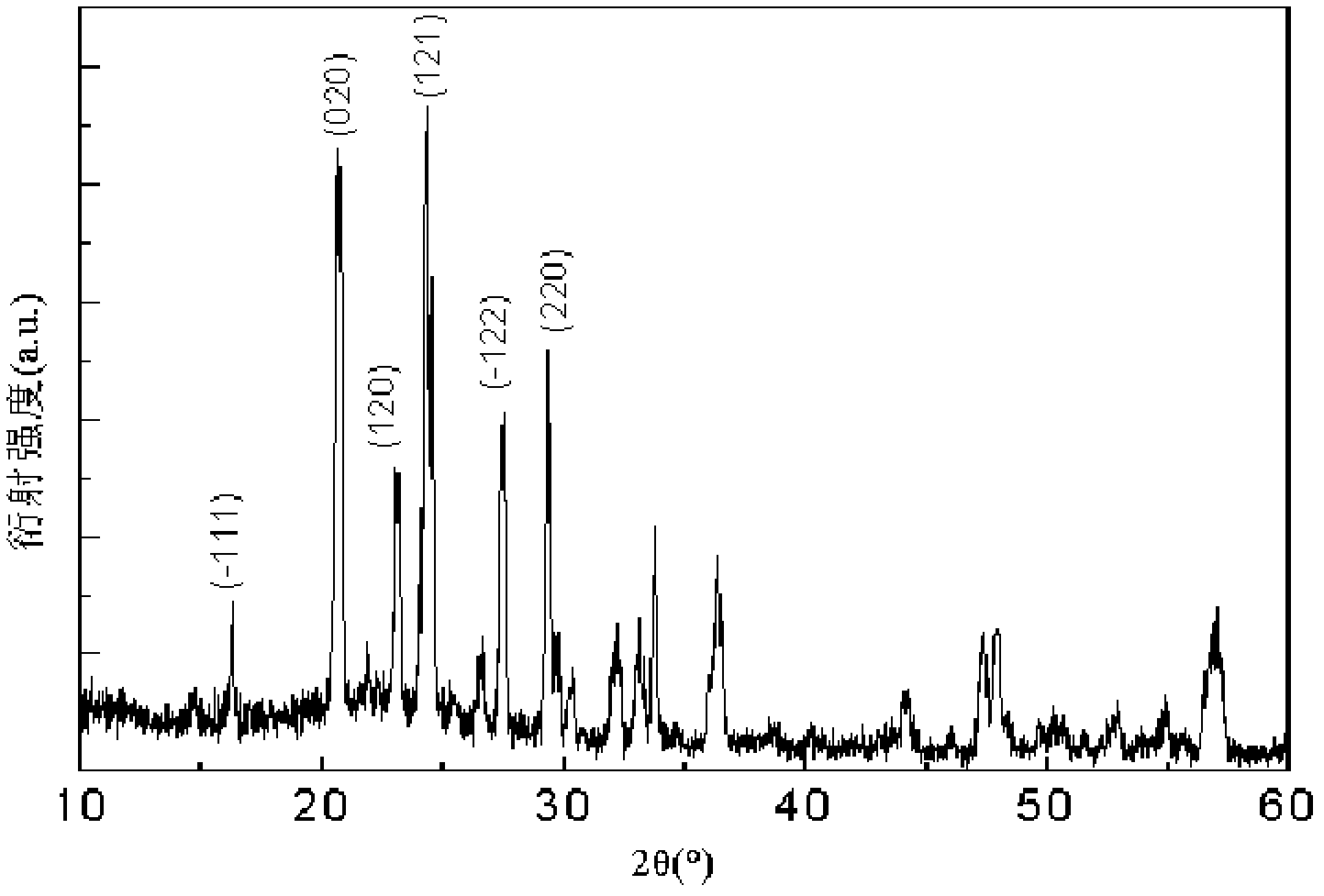

Carbon-coated Na2Li2Ti6O14 nanofiber and preparation method thereof

ActiveCN107119349AImprove performanceThe first discharge specific capacity is highMaterial nanotechnologySecondary cellsN dimethylformamideSolvent

The invention discloses carbon-coated Na2Li2Ti6O14 nanofiber and a preparation method thereof. Sodium salt and titanium salt are dissolved in N,N-dimethylformamide; lithium salt is dissolved in a mixed solvent of ethyl alcohol and glacial acetic acid; then, two solutions are mixed; macromolecule polyvinylpyrrolidone is added; stirring is performed so that a clear solution is formed; the clear solution is subjected to electrostatic spinning under certain voltage, certain volume flow rate and certain relative humidity; an electrostatic spinning product is dried at constant temperature; then, high-temperature sintering is performed and corresponding Na2Li2Ti6O14 nanofiber is obtained; then, carbon coating is performed. The preparation of the carbon-coated Na2Li2Ti6O14 nanofiber is successfully realized; when the prepared nanofiber is used as a lithium ion battery negative electrode material to perform performance test representation, a result shows that the nanofiber has excellent physical and chemical properties, and has wide application prospects when being used as the lithium ion battery negative electrode material. In the whole preparation process, the operation is simple; the raw material cost is low; the equipment investment is low; the nanofiber is suitable for batch production.

Owner:NINGBO UNIV

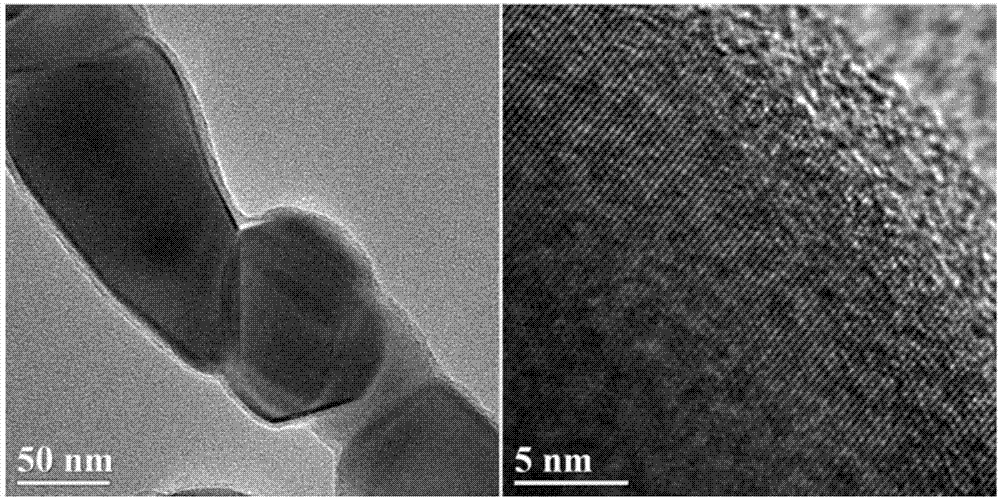

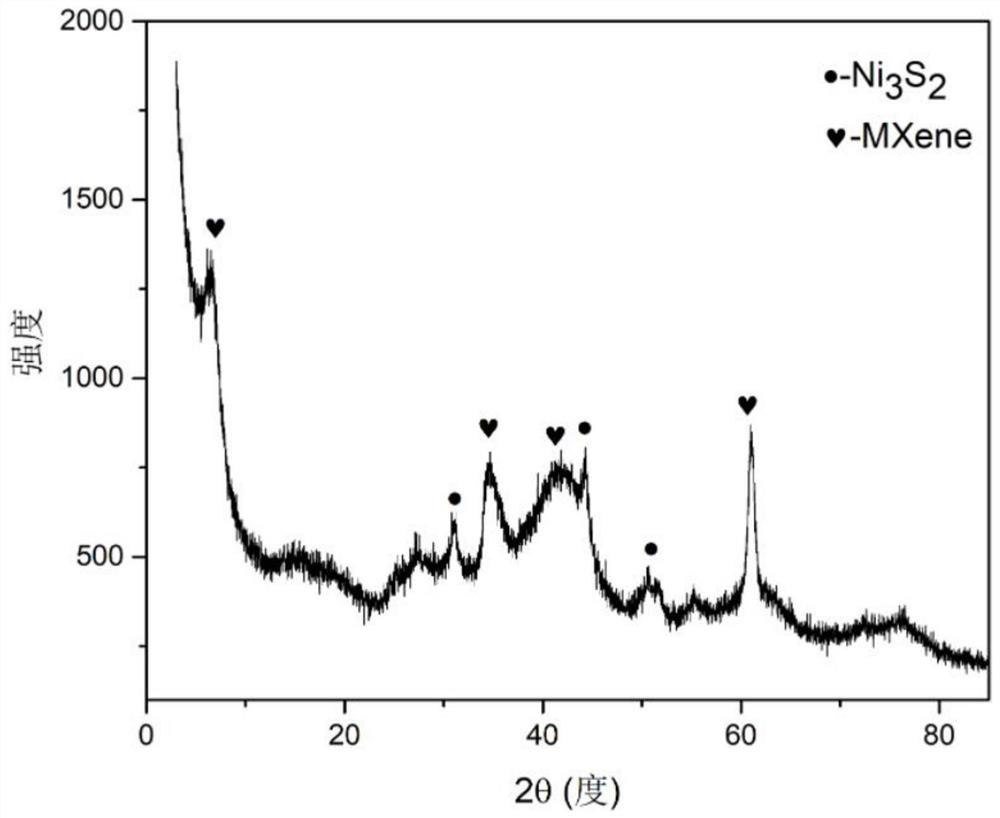

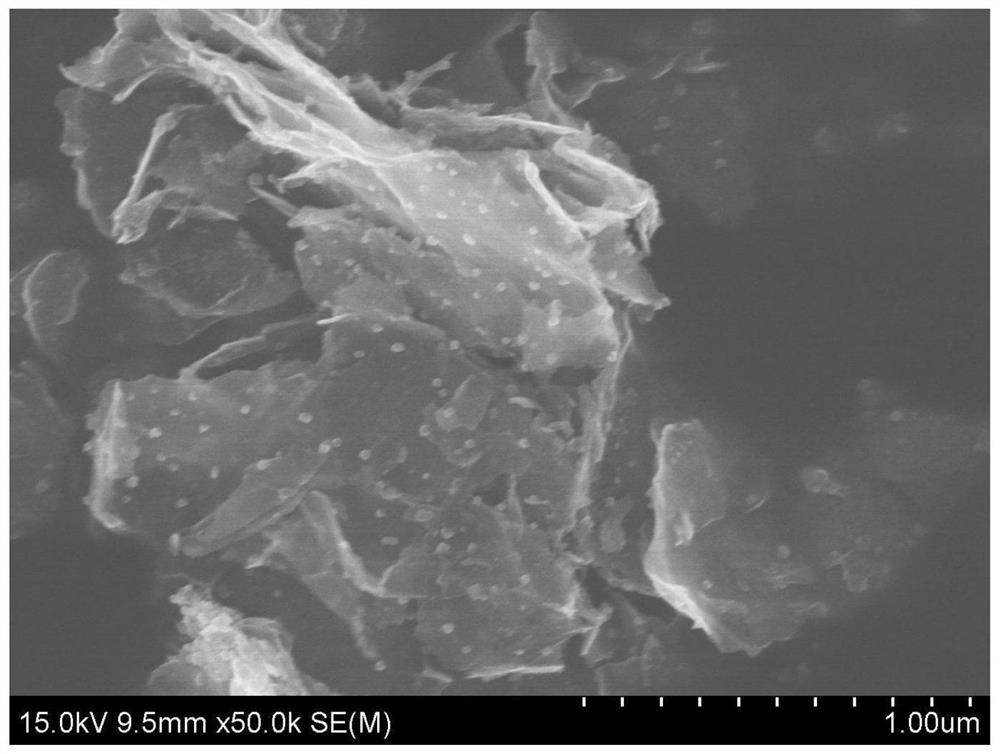

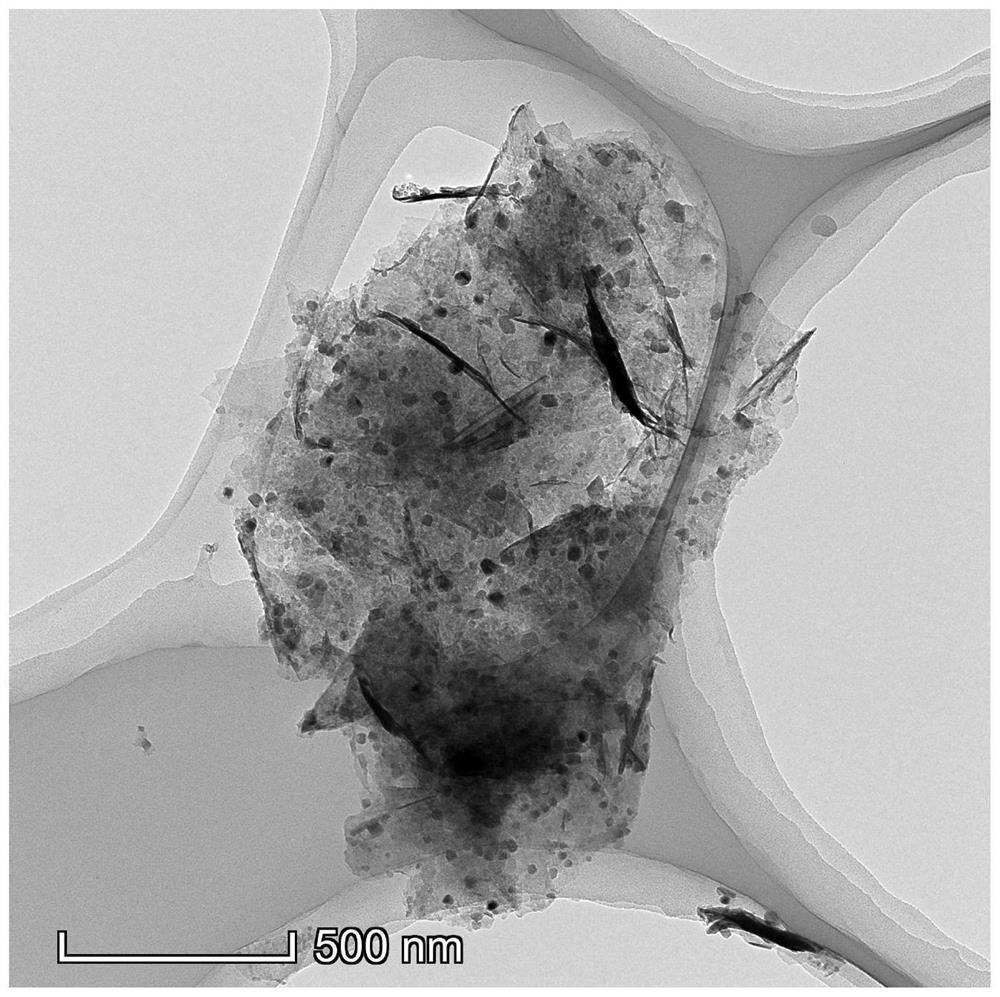

Battery negative electrode material and preparation method and application thereof

InactiveCN112467068AHigh specific capacityThe first discharge specific capacity is highElectrode thermal treatmentSecondary cellsNickel saltElectrical battery

The invention relates to the technical field of electrode materials, in particular to a battery negative electrode material and a preparation method and application thereof. The preparation method provided by the invention comprises the following steps: mixing MXene, nickel salt, weak base and water, and performing hydrothermal reaction to obtain a composite material of nickel hydroxide and MXene;and mixing the nickel hydroxide and MXene composite material with amidinothiourea, and carrying out heat treatment to obtain the battery negative electrode material. The preparation method disclosedby the invention is simple in process, safe to operate and low in cost. Meanwhile, according to the record of the embodiment, the battery negative electrode material prepared by the preparation methoddisclosed by the invention has relatively high first-time specific discharge capacity and relatively good cycling stability and rate capability.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com