Method for modifying ZrO2-coated lithium-rich laminar cathode material of lithium ion battery

A lithium-ion battery, cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as affecting the electrochemical performance and cycle stability of materials, destroying the surface film of electrode materials, and deteriorating battery cycle performance. Good cycle performance, good electrochemical performance, and good environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

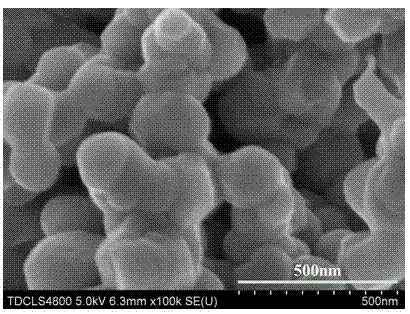

Embodiment 1

[0024] 1) Lithium-rich cathode material Li 1.2 mn 0.54 Ni 0.13co 0.13 o 2 Preparation: NiSO 4 ·6H 2 O, CoSO 4 ·7H 2 O, MnCl 2 4H 2 O is raw material, takes nickel sulfate 2.623kg according to the ratio in molecular formula, cobalt sulfate 2.805kg and manganese chloride 7.99kg are made into the 30L solution A that metal element concentration is 2mol / L. Weigh Na 2 CO 3 6.372kg was prepared into 40L of 1.5mol / L solution, wherein 510.9g of ammonia water was added, mixed evenly and recorded as solution B. Add 20L of deionized water into the reaction kettle as the bottom liquid, and slowly add solutions A and B into the reaction kettle at a feeding speed of 30ml / min at the same time, and control the pH value of the reaction process by adjusting the pH value to 8, the temperature at 60°C, and the stirring speed at 500°C RPM / min, age for 2 hours after the reaction is complete, filter with suction, wash, and dry to obtain the nickel-cobalt-manganese carbonate precursor. T...

Embodiment 2

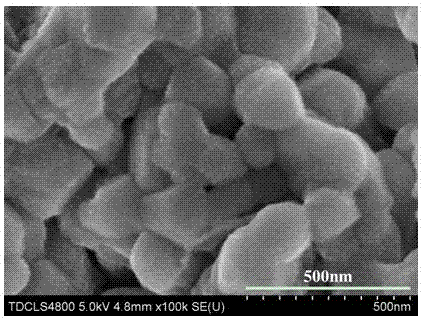

[0032] 1), preparation of lithium-rich cathode material Li 1.2 mn 0.54 Ni 0.13 co 0.13 o 2 , the steps are the same as step 1) in Example 1).

[0033] 2), in 40ml n-propanol solution, drop 0.2279g Zr(OC 3 h 7 ) 4 , quickly covered with plastic wrap, and stirred at room temperature for 15 minutes. After 15min, quickly add 2.94g Li to the above solution 1.2 mn 0.54 Ni 0.13 co 0.13 o 2 Cover the positive electrode material with plastic wrap and stir for 4 hours at room temperature; after stirring for 3 hours, punch some small holes in the plastic wrap.

[0034] 3) Transfer the solution obtained in step 2) to a constant temperature water bath at 80°C, remove the plastic wrap after 30 minutes, and stir until the n-propanol evaporates to dryness.

[0035] 4) The experimental materials obtained in step 3) were placed in a watch glass and dried in a drying oven at 80°C for 12 hours.

[0036] 5) The experimental material obtained in step 4) is heat-treated, raised to 450°...

Embodiment 3

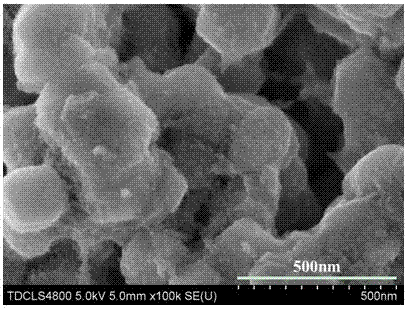

[0038] 1), preparation of lithium-rich cathode material Li 1.2 mn 0.54 Ni 0.13 co 0.13 o 2 , the steps are the same as step 1) in Example 1).

[0039] 2) Add 0.5997g Zr(OC 3 h 7 ) 4 , quickly covered with plastic wrap, and stirred at room temperature for 15 minutes. After 15 minutes, quickly add 2.91g of positive electrode material to the above solution, cover with plastic wrap, and stir at room temperature for 4 hours; after stirring for 3 hours, make some small holes in the plastic wrap.

[0040] 3) Transfer the solution obtained in step 2) to a constant temperature water bath at 80°C, remove the plastic wrap after 30 minutes, and stir until the n-propanol evaporates to dryness.

[0041] 4) The experimental materials obtained in step 3) were placed in a watch glass and dried in a drying oven at a temperature of 80°C.

[0042] 5) The experimental material obtained in step 4) is heat-treated, raised to 450°C at 2-3°C / min, sintered at 450°C for 4 hours, and cooled to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com