A preparation method and application of a lithium sulfide battery positive electrode

A lithium-sulfur battery and cathode technology, which is applied in the field of lithium-sulfur battery electrode materials and the preparation of lithium-sulfur battery cathodes, can solve problems such as excessive battery capacity decay, achieve broad industrial application prospects, reduce dissolution, and have strong operability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] ①Preparation of sulfur positive electrode: Preliminarily mix insoluble sulfur IS6005 (Henan Kailun Chemical Co., Ltd., sulfur content 94%; insoluble sulfur content 60%; oil content 4-6%) with Ketjen black at a mass ratio of 2:1 to obtain 5g After the mixture, add 0.05g of iodonitrobenzene and place it in a vibrating mill for 10 minutes of mixing to obtain mixture A; weigh 0.2g of binder polyvinylidene fluoride (PVDF) and add it to N-methylpyrrolidone (NMP), Stir in a homogenizer for 5 minutes to form a homogeneous solution; then add 1.8 g of mixture A, and stir in a homogenizer for 15 minutes at a speed of 15 kr / min to form a stable and uniform positive electrode slurry. The slurry was coated on a carbon-coated aluminum foil with a doctor blade, and dried in an oven at 80°C for 8 hours until the NMP was completely volatilized.

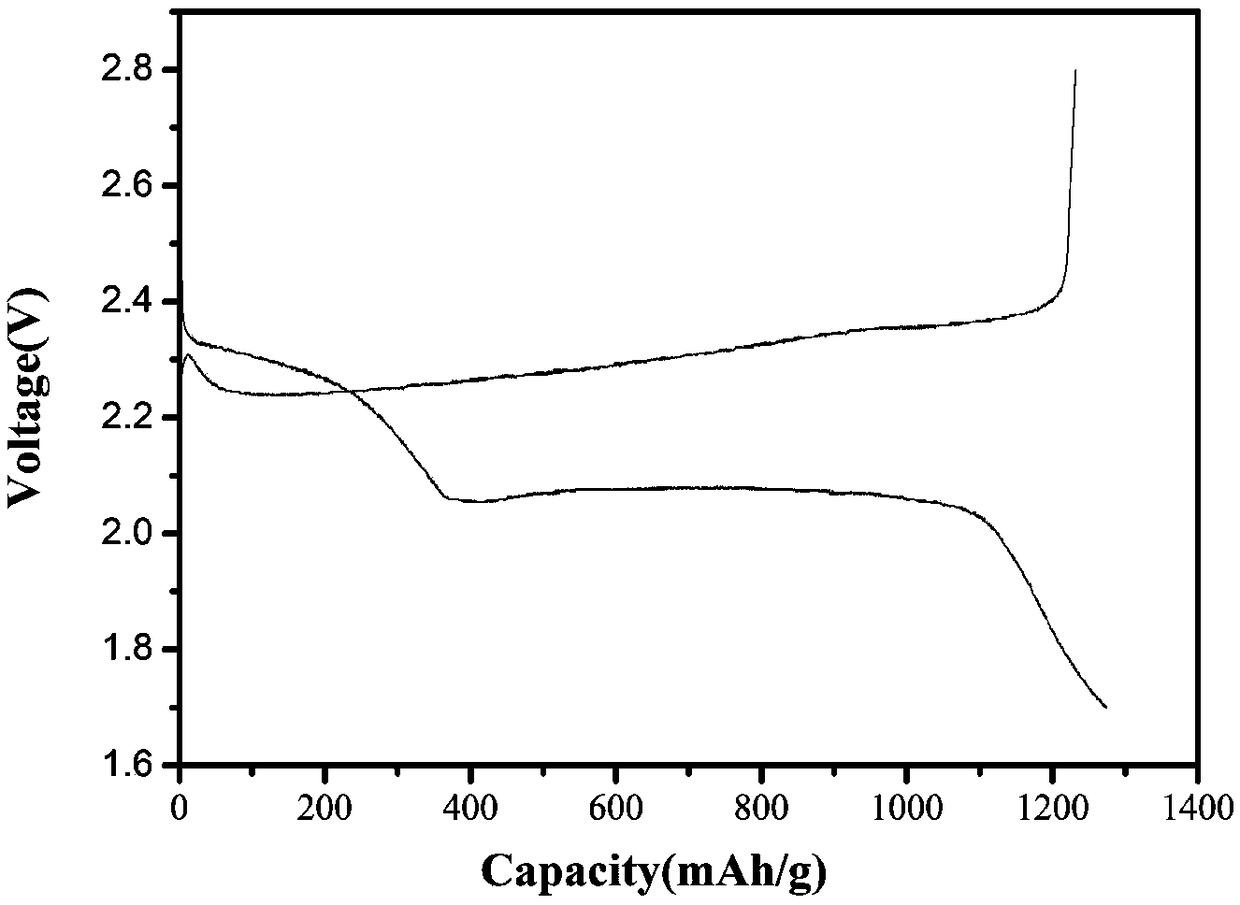

[0054] ②Lithium-sulfur button cell assembly test: punch the prepared sulfur pole piece into a Φ13mm circular pole piece, and bake it in an oven...

Embodiment 2

[0056] ①Preparation of sulfur cathode: Preliminarily mix insoluble sulfur IS8510 (Henan Kailun Chemical Co., Ltd., sulfur content 89%; insoluble sulfur content 85%; oil content 9-11%) with acetylene at a mass ratio of 2:1 to obtain 5 g of the mixture , then add 0.025g of dibenzothiazole disulfide and place it in a vibrating mill for mixing and grinding for 10min to obtain mixture A; weigh 0.2g of binder polyvinylidene fluoride (PVDF) and add it to N-methylpyrrolidone (NMP). Stir in a homogenizer for 5 minutes to form a homogeneous solution; then add 1.8 g of mixture A, and stir in a homogenizer for 15 minutes at a speed of 15 kr / min to form a stable and uniform positive electrode slurry. The slurry was coated on a carbon-coated aluminum foil with a doctor blade, and dried in an oven at 80°C for 8 hours until the NMP was completely volatilized.

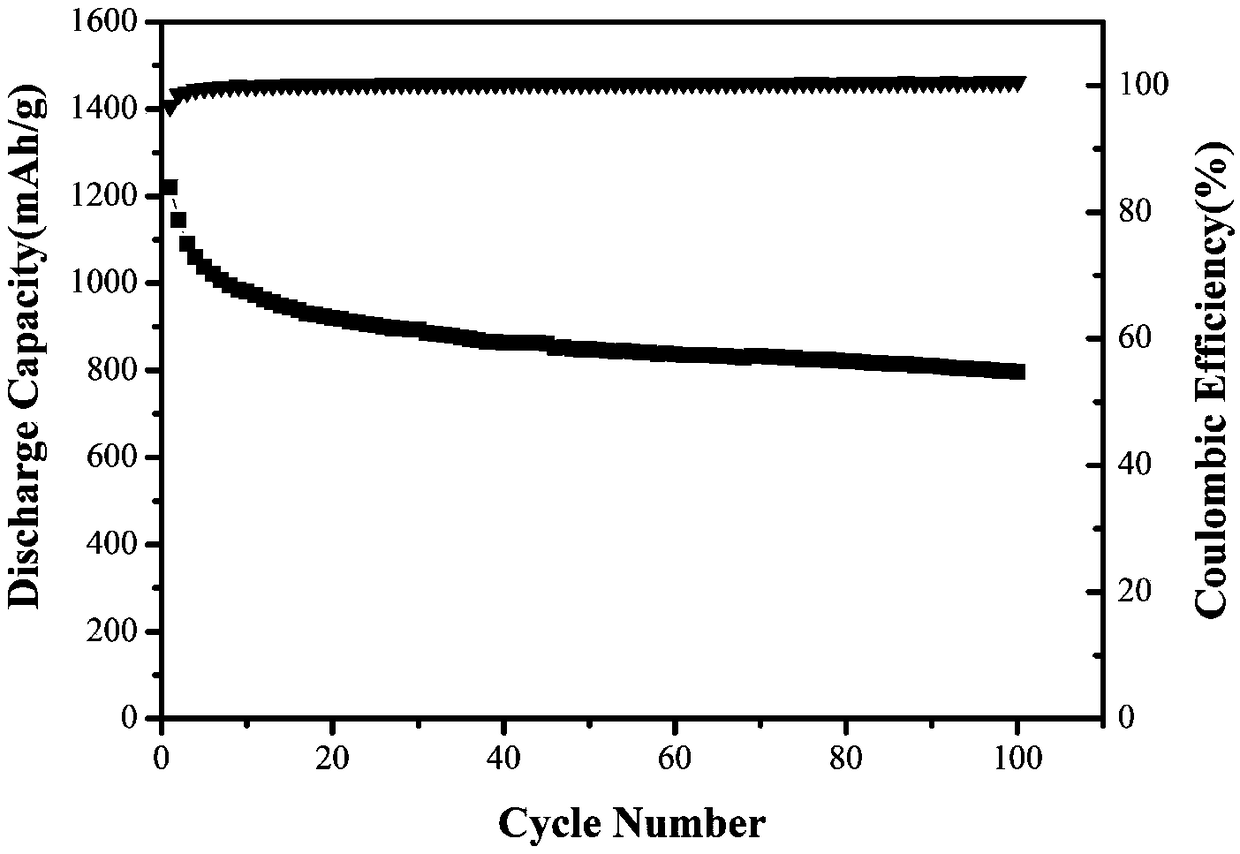

[0057] ②Lithium-sulfur button cell assembly test: punch the prepared sulfur pole piece into a Φ13mm circular pole piece, and bake it ...

Embodiment 3

[0059] ①Preparation of sulfur positive electrode: Preliminarily mix insoluble sulfur IS90 (Henan Kailun Chemical Co., Ltd., sulfur content 99.5%; insoluble sulfur content 90%; oil content 0.5-1%) with acetylene black at a mass ratio of 2:1 to obtain 5g Add 0.025g of dibenzothiazole disulfide to the mixture and place it in a vibrating mill for 10 minutes of mixing to obtain mixture A; weigh 0.2g of binder polyvinylidene fluoride (PVDF) and add it to N-methylpyrrolidone (NMP), Stir in a homogenizer for 5 minutes to form a homogeneous solution; then add 1.8 g of mixture A, and stir in a homogenizer for 15 minutes at a speed of 15 kr / min to form a stable and uniform positive electrode slurry. The slurry was coated on a carbon-coated aluminum foil with a doctor blade, and dried in an oven at 80°C for 8 hours until the NMP was completely volatilized.

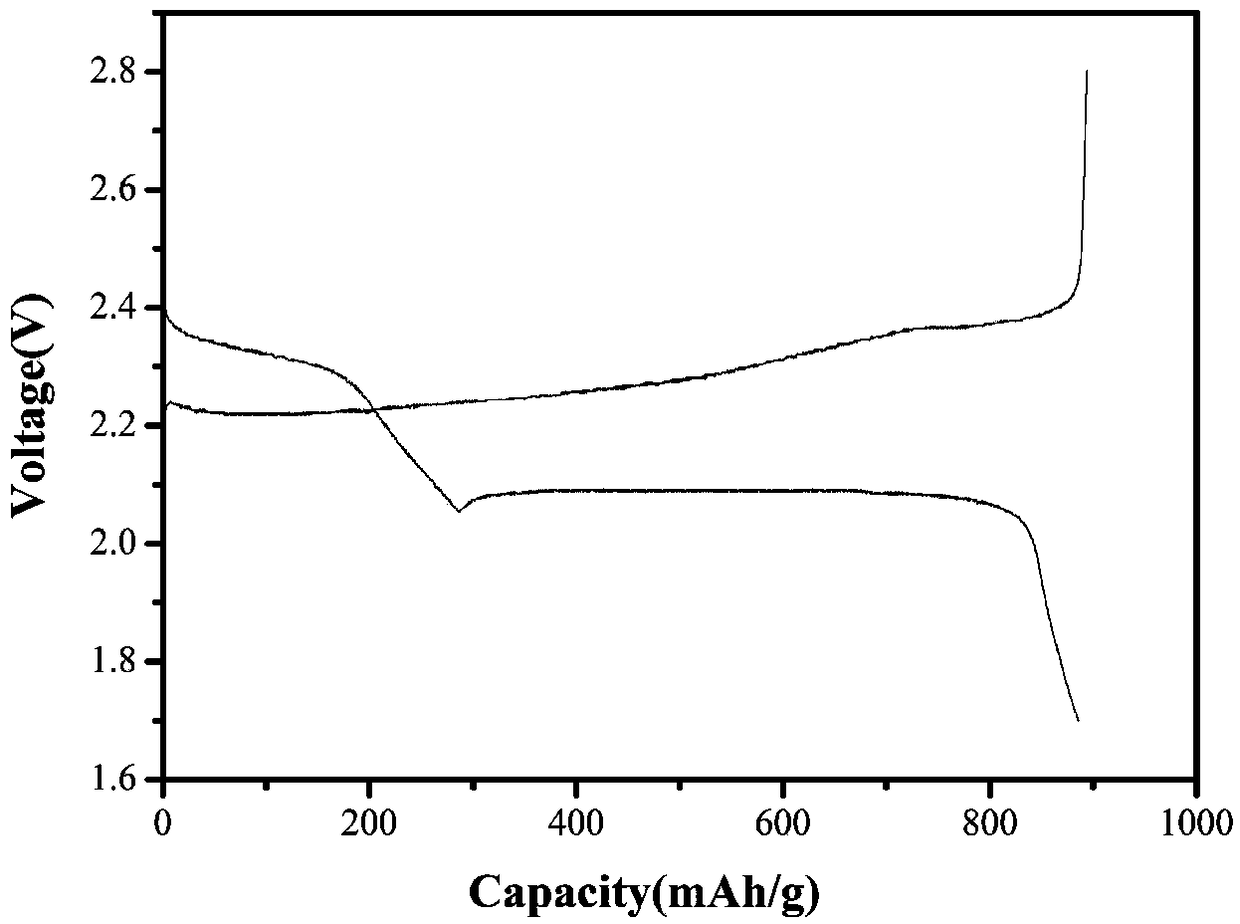

[0060] ②Lithium-sulfur button cell assembly test: punch the prepared sulfur pole piece into a Φ13mm circular pole piece, and bake it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com