CNT (Carbon Nano Tube)/SnO2 coaxial composite array lithium ion battery negative electrode material

A technology for carbon nanotube arrays and lithium-ion batteries, which can be applied to battery electrodes, secondary batteries, circuits, etc., and can solve the problems of complex manufacturing processes of button batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

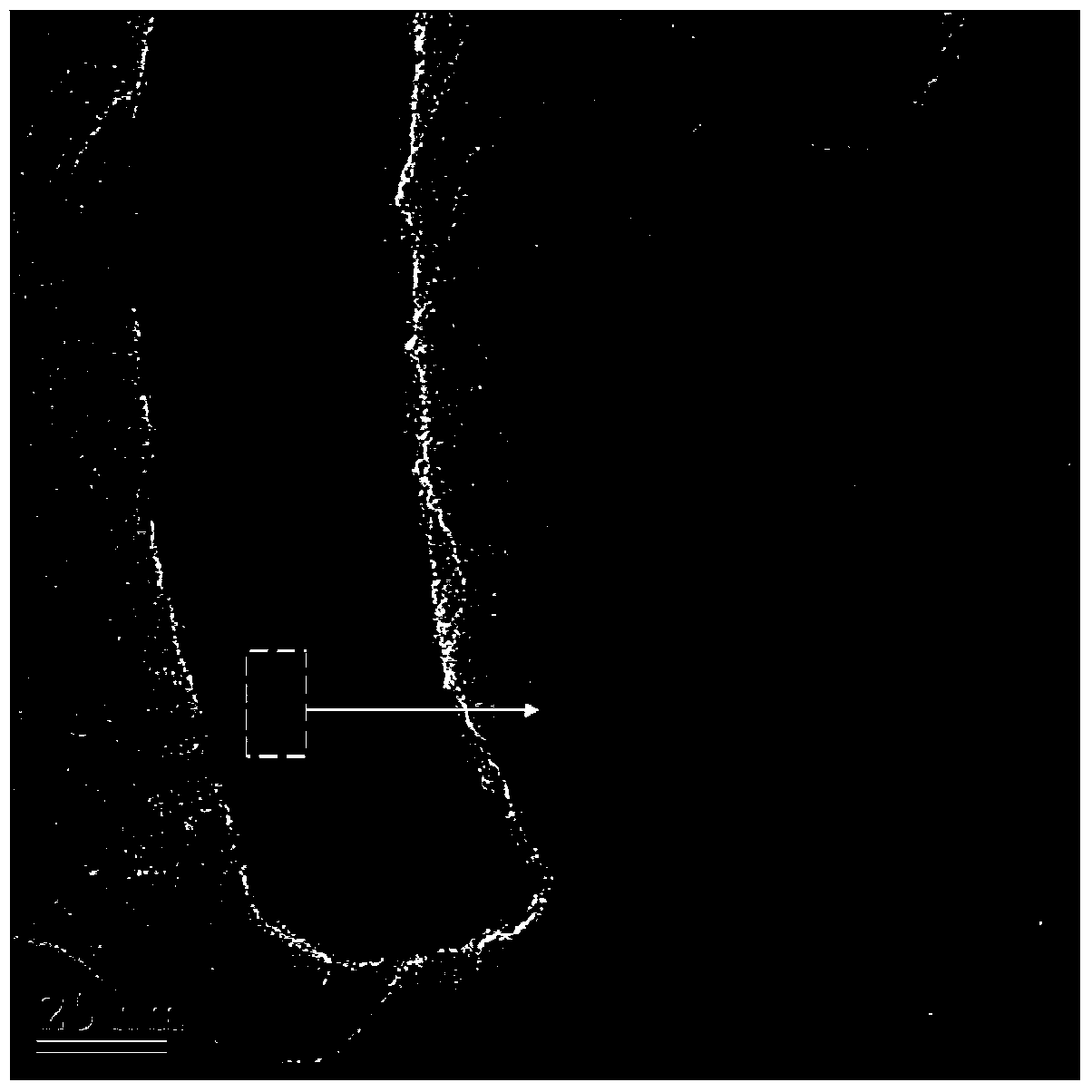

Image

Examples

Embodiment 1

[0025] Using tantalum foil with a thickness of 30 μm and a purity of 99.90% as the substrate, the ultra-high vacuum electron beam evaporation system (model: UMS500P) was used at 4.0×10 -8 Under the pressure of mbar, 11nm thick alumina and 0.8nm thick iron were sequentially deposited at room temperature at the rate of 0.02nm / s and 0.05nm / s to obtain a three-layer structure of iron catalyst layer / alumina buffer layer / metal tantalum foil.

[0026] The obtained three-layer structure was placed in the central heating zone of a thermal CVD furnace (model: OTF-1200X), and the temperature was raised to 650 °C under the protection of argon, then the argon was turned off, hydrogen was introduced and pretreated for 20 minutes. Feed the mixed gas of acetylene, hydrogen and argon with the flow rate of 8sccm, 60sccm and 140sccm respectively again until the pressure in the furnace rises to 1.2×10 4 Pa, keep warm for 30 minutes and then cool down to obtain carbon nanotube arrays grown in situ...

Embodiment 2

[0037] Preparation of carbon nanotubes / SnO according to the process shown in Example 1 2 Coaxial composite array lithium-ion battery anode material, the difference is only in the atomic layer deposition of SnO 2 The temperature is 400°C.

[0038] The test results show that the first discharge specific capacity of the prepared negative electrode material is 1168.2mAh / g, the first charge specific capacity is 693.3mAh / g, and the highest reversible discharge specific capacity and the highest reversible charge specific capacity are 735.1mAh / g and 669.7mAh respectively. / g, and its Coulombic efficiency has remained at a high level of around 95%.

Embodiment 3

[0040] Preparation of carbon nanotubes / SnO according to the process shown in Example 1 2 Coaxial composite array lithium-ion battery anode material, the difference is only in the atomic layer deposition of SnO 2 The temperature is 200°C.

[0041] The test results show that the first discharge specific capacity of the prepared negative electrode material is 1521.9mAh / g, the first charge specific capacity is 716.7mAh / g, and the highest reversible discharge specific capacity and the highest reversible charge specific capacity are 752.8mAh / g and 680.1mAh respectively. / g, its Coulombic efficiency has been maintained at a high level of around 91%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com