Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6597 results about "Nano tube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

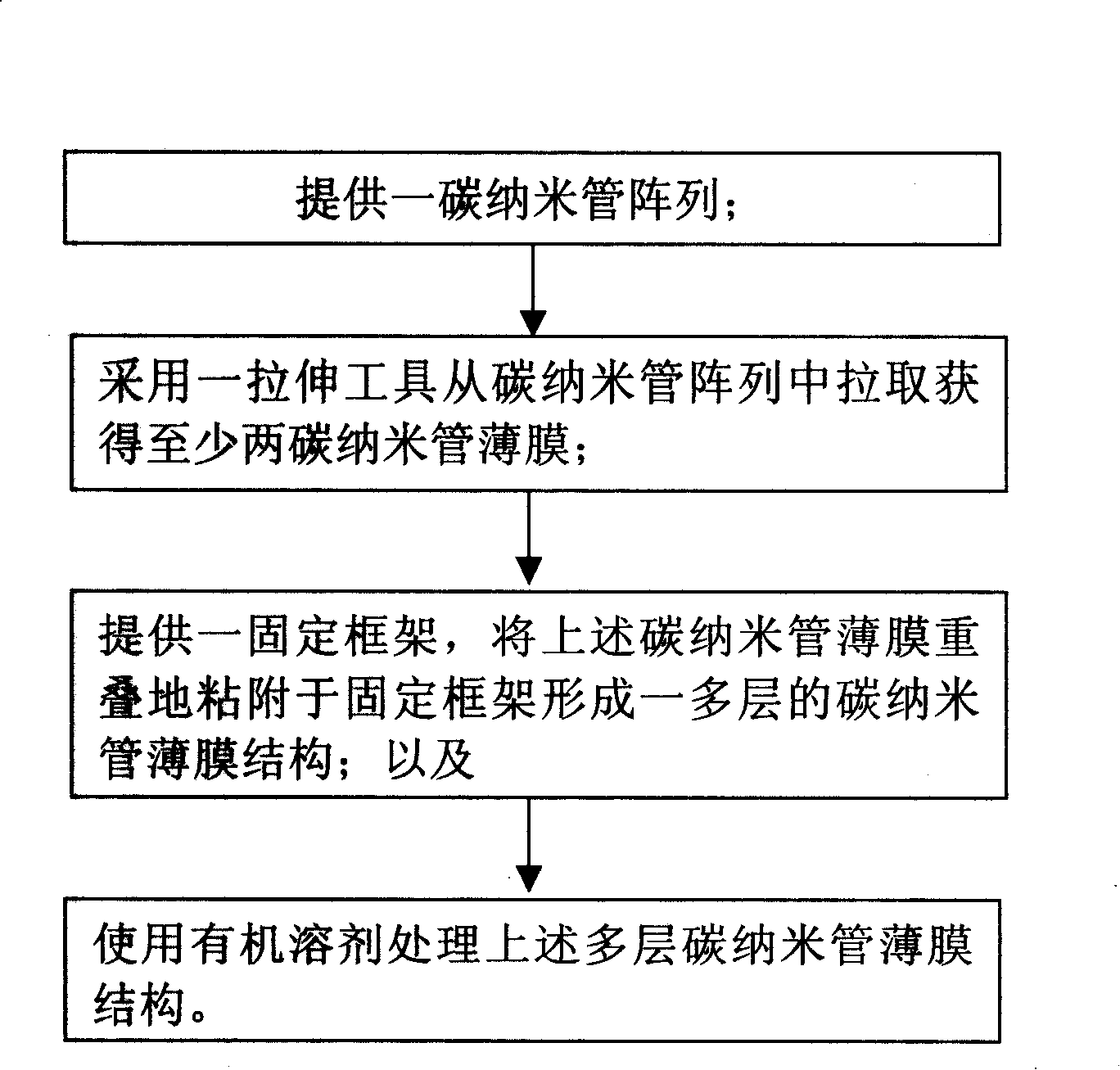

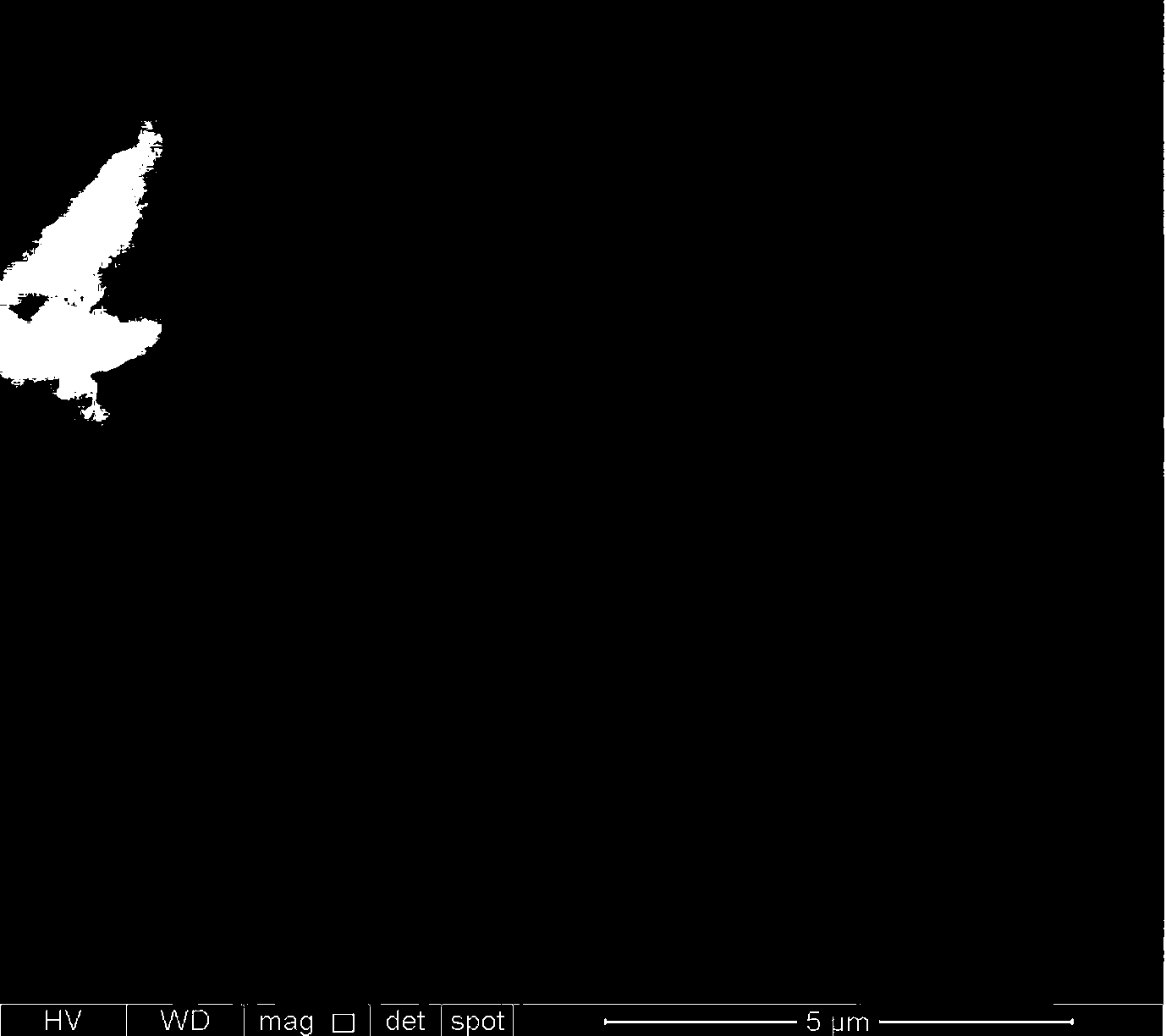

Carbon nano-tube thin film structure and preparation method thereof

ActiveCN101239712ASmall surface to volume ratioNon stickyMaterial nanotechnologyLamination ancillary operationsOrganic solventFixed frame

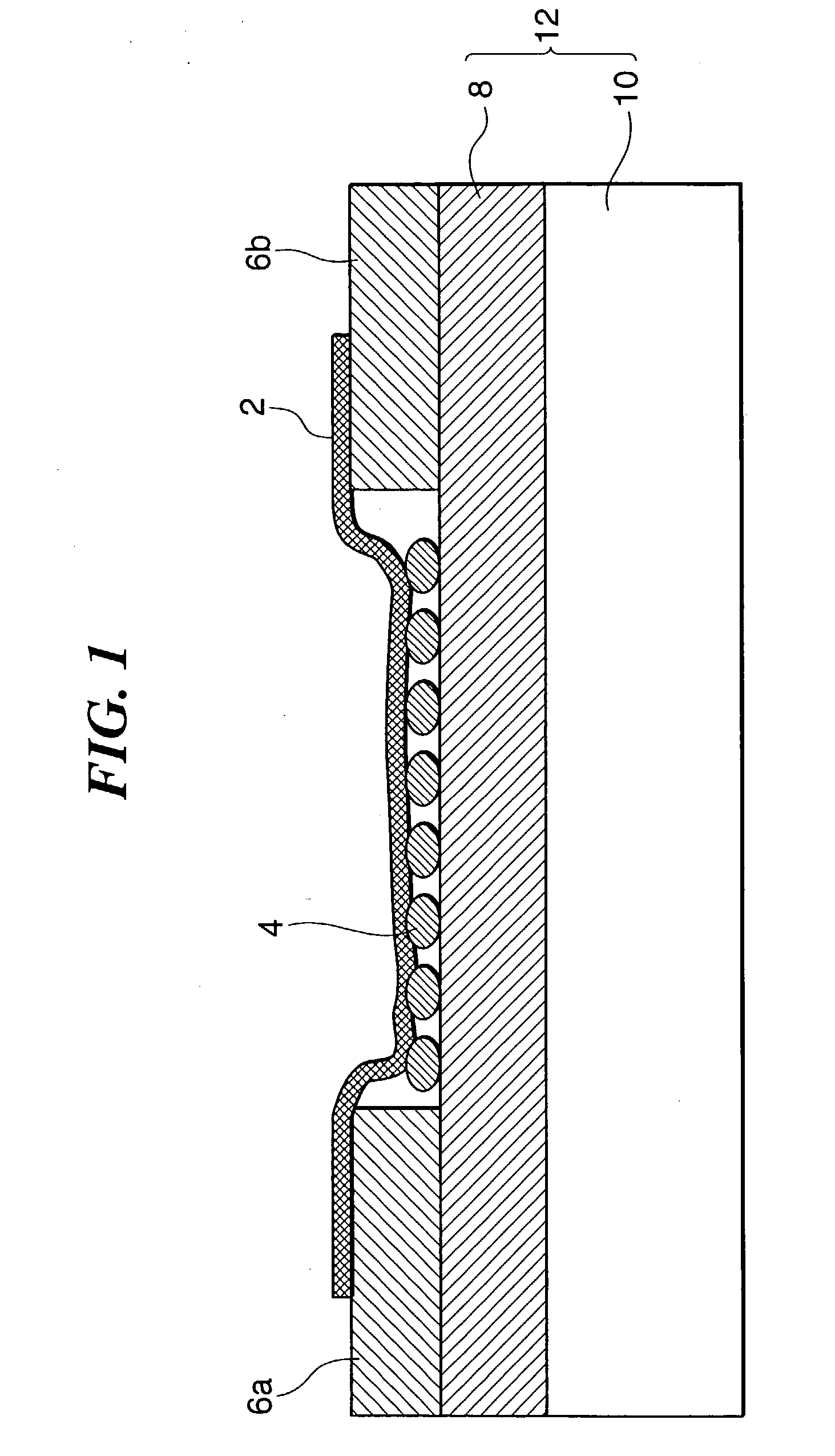

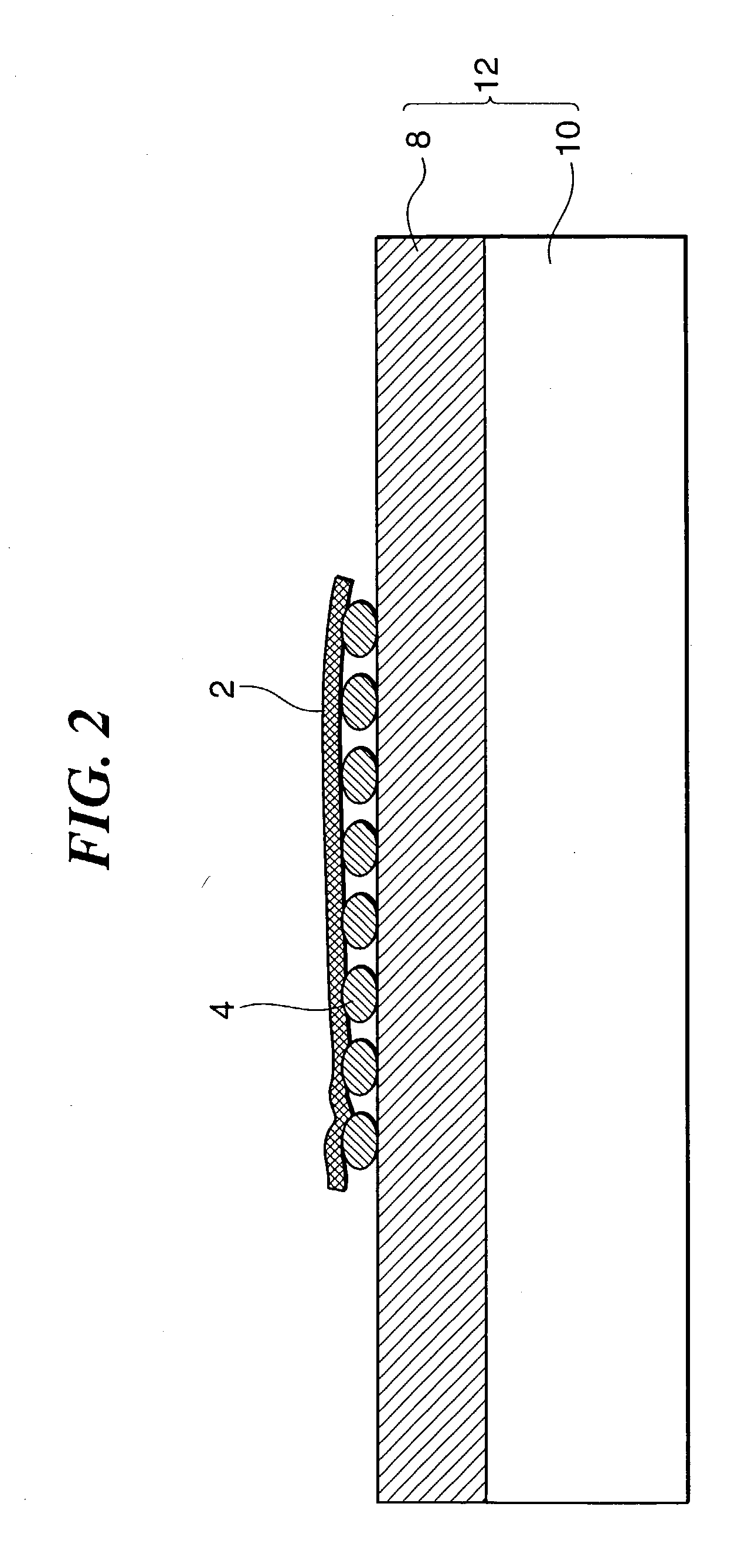

The present invention provides a preparing method of carbon nanotube film structure, including following steps: providing a carbon nanotube array; adopting a pulling tool to acquire at least two carbon nanotube films from the carbon nanotube array; providing a fixed frame, forming a multiple-layer carbon nanotube film structure by overlap adhereing the carbon nanotube film in the fixed frame; and treating the multiple-layer carbon nanotube film by an organic solvent. The carbon nanotube film structure prepared by the method includes at least two layers overlapped and cross-over installed carbon nanotube film, which includes multiple carbon nanotube bundle end to end and arranged in the direction, the multiple-layer carbon nanotube film further includes millipore crosswise formed by multiple carbon nanotube bundles.

Owner:TSINGHUA UNIV +1

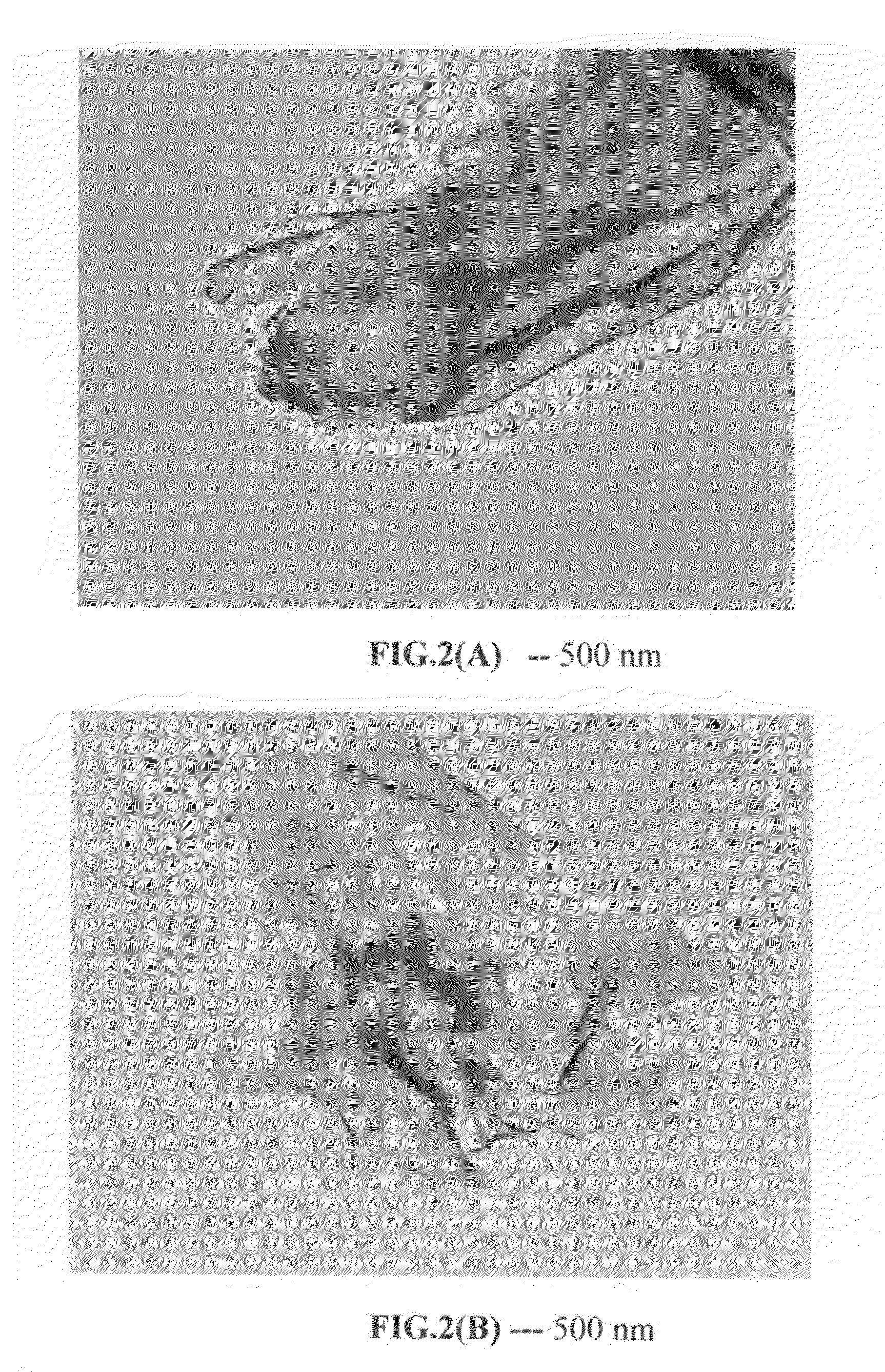

Method of producing exfoliated graphite, flexible graphite, and nano-scaled graphene platelets

ActiveUS20080279756A1Good dispersionImprove conductivityCarbon compoundsFibre chemical featuresFiberLiquid medium

The present invention provides a method of exfoliating a layered material (e.g., graphite and graphite oxide) to produce nano-scaled platelets having a thickness smaller than 100 nm, typically smaller than 10 nm. The method comprises (a) dispersing particles of graphite, graphite oxide, or a non-graphite laminar compound in a liquid medium containing therein a surfactant or dispersing agent to obtain a stable suspension or slurry; and (b) exposing the suspension or slurry to ultrasonic waves at an energy level for a sufficient length of time to produce separated nano-scaled platelets. The nano-scaled platelets are candidate reinforcement fillers for polymer nanocomposites. Nano-scaled graphene platelets are much lower-cost alternatives to carbon nano-tubes or carbon nano-fibers.

Owner:GLOBAL GRAPHENE GRP INC

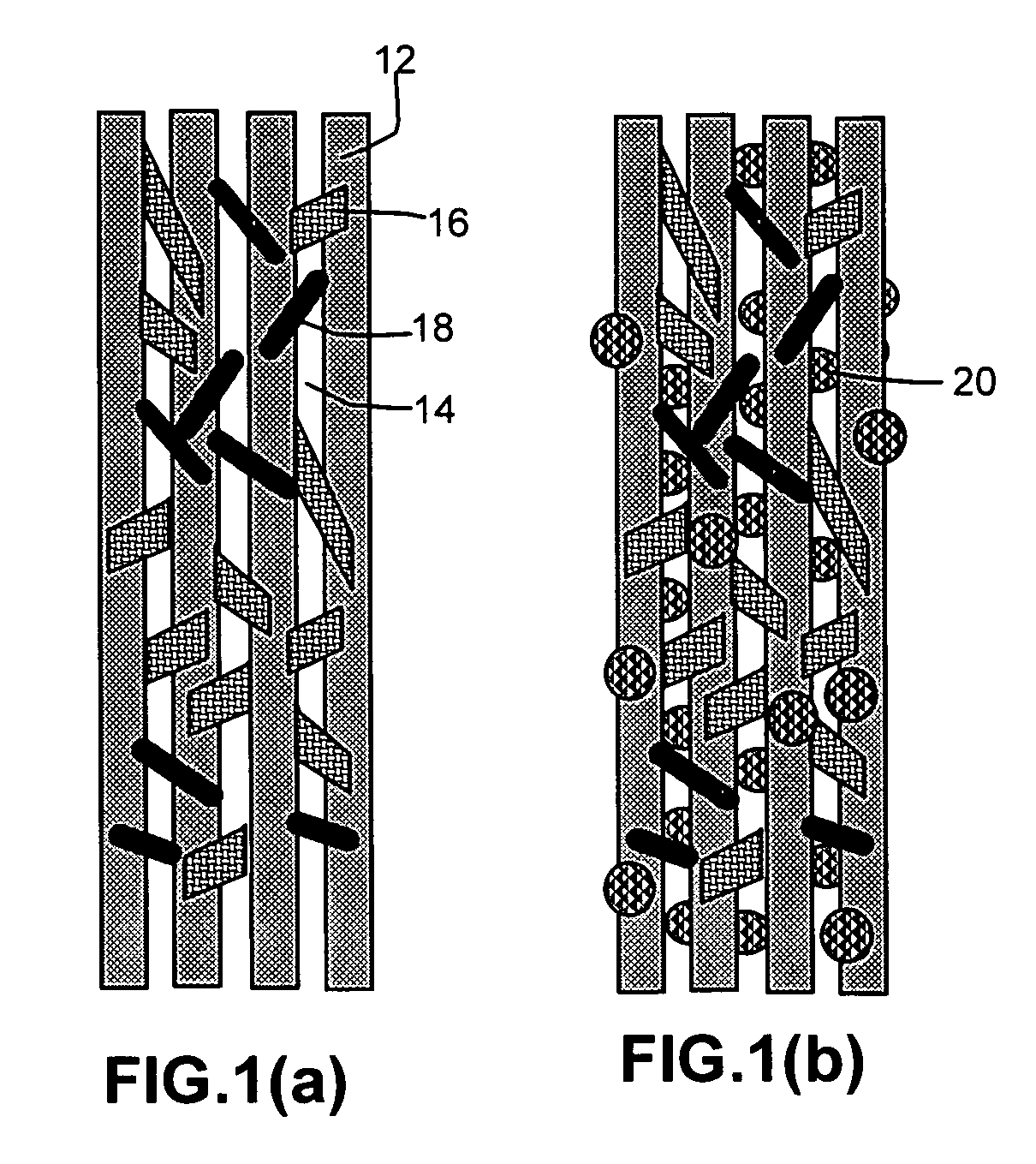

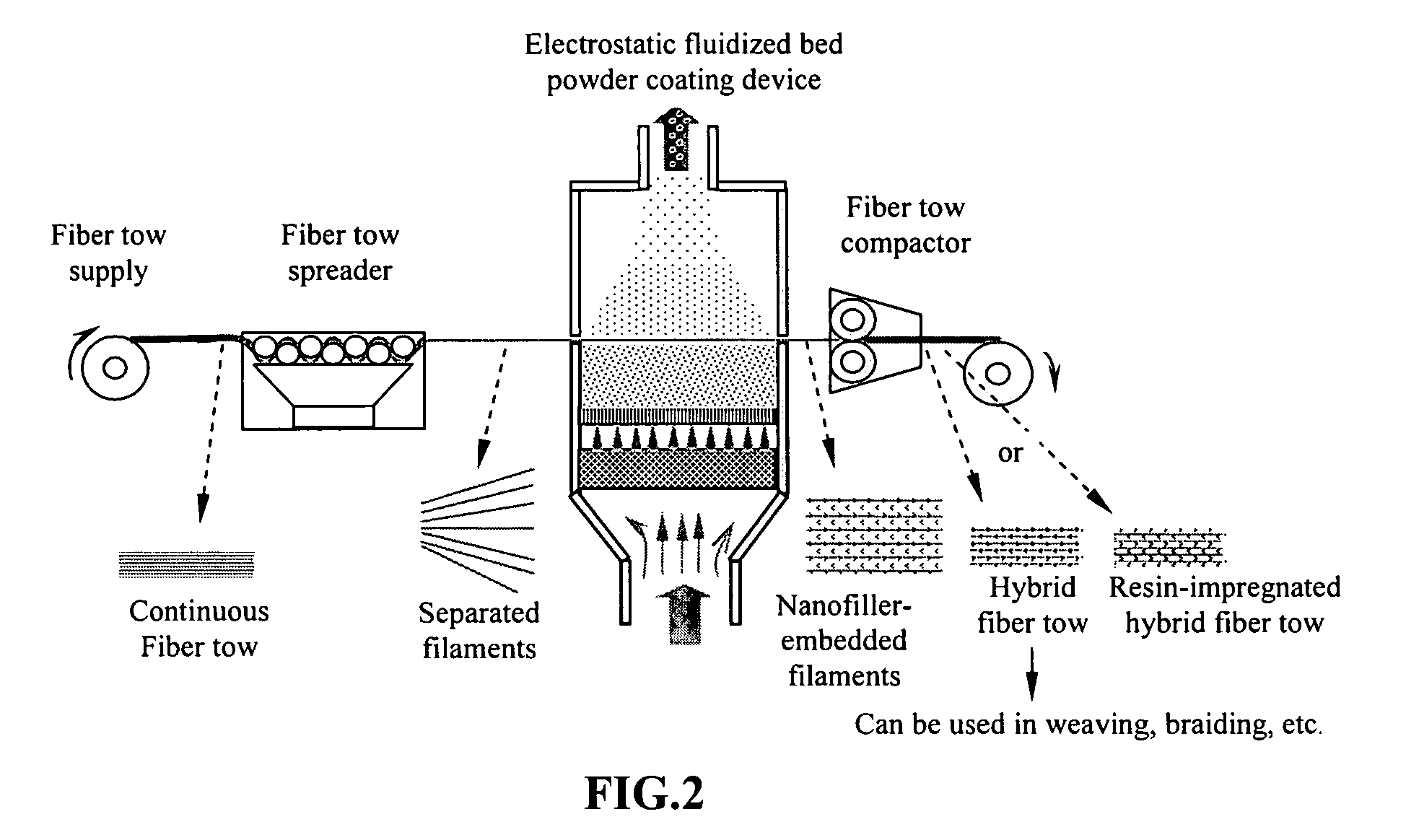

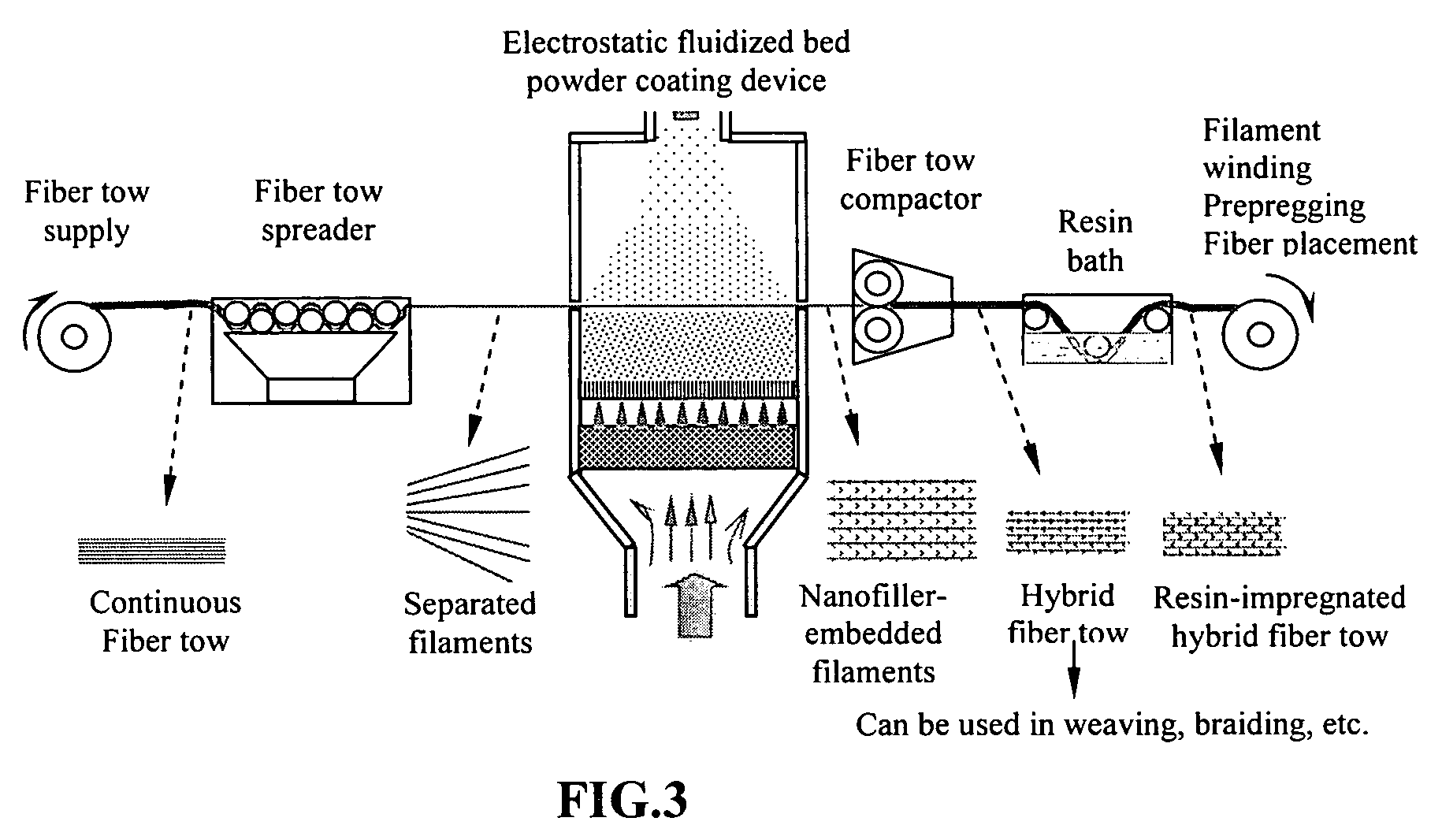

Hybrid fiber tows containning both nano-fillers and continuous fibers, hybrid composites, and their production processes

Disclosed is a hybrid fiber tow that comprises multiple continuous filaments and nanoscale fillers embedded in the interstitial spaces between continuous filaments. Nanoscale fillers may be selected from a nanoscale graphene plate, non-graphite platelet, carbon nano-tube, nano-rod, carbon nano-fiber, non-carbon nano-fiber, or a combination thereof. Also disclosed are a hybrid fiber tow impregnated with a matrix material and a composite structure fabricated from a hybrid fiber tow. The composite exhibits improved physical properties (e.g., thermal conductivity) in a direction transverse to the continuous fiber axis. A roll-to-roll process for producing a continuous fiber tow or matrix-impregnated fiber tow and an automated process for producing composite structures containing both continuous filaments and nanoscale fillers are also provided.

Owner:NANOTEK INSTR

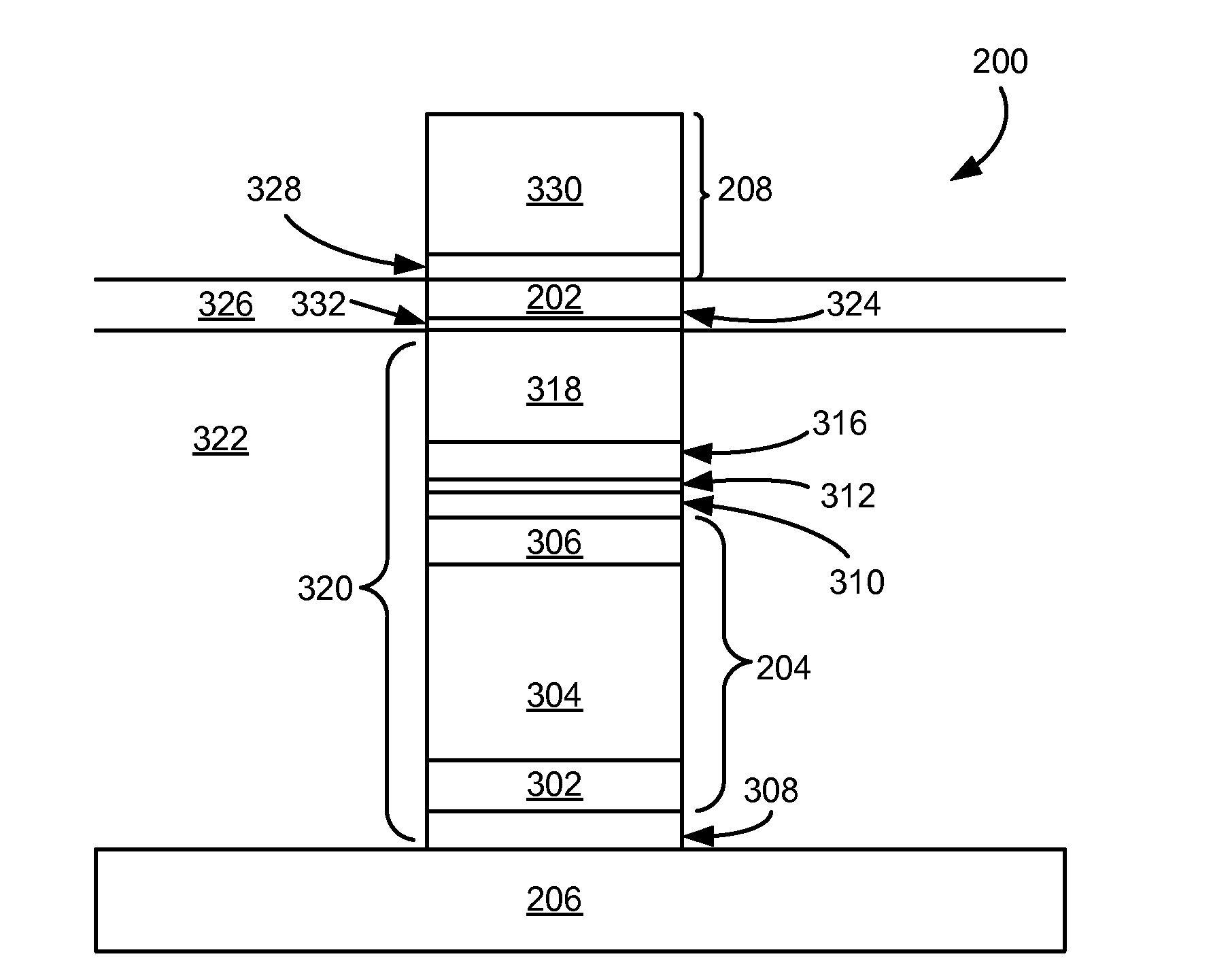

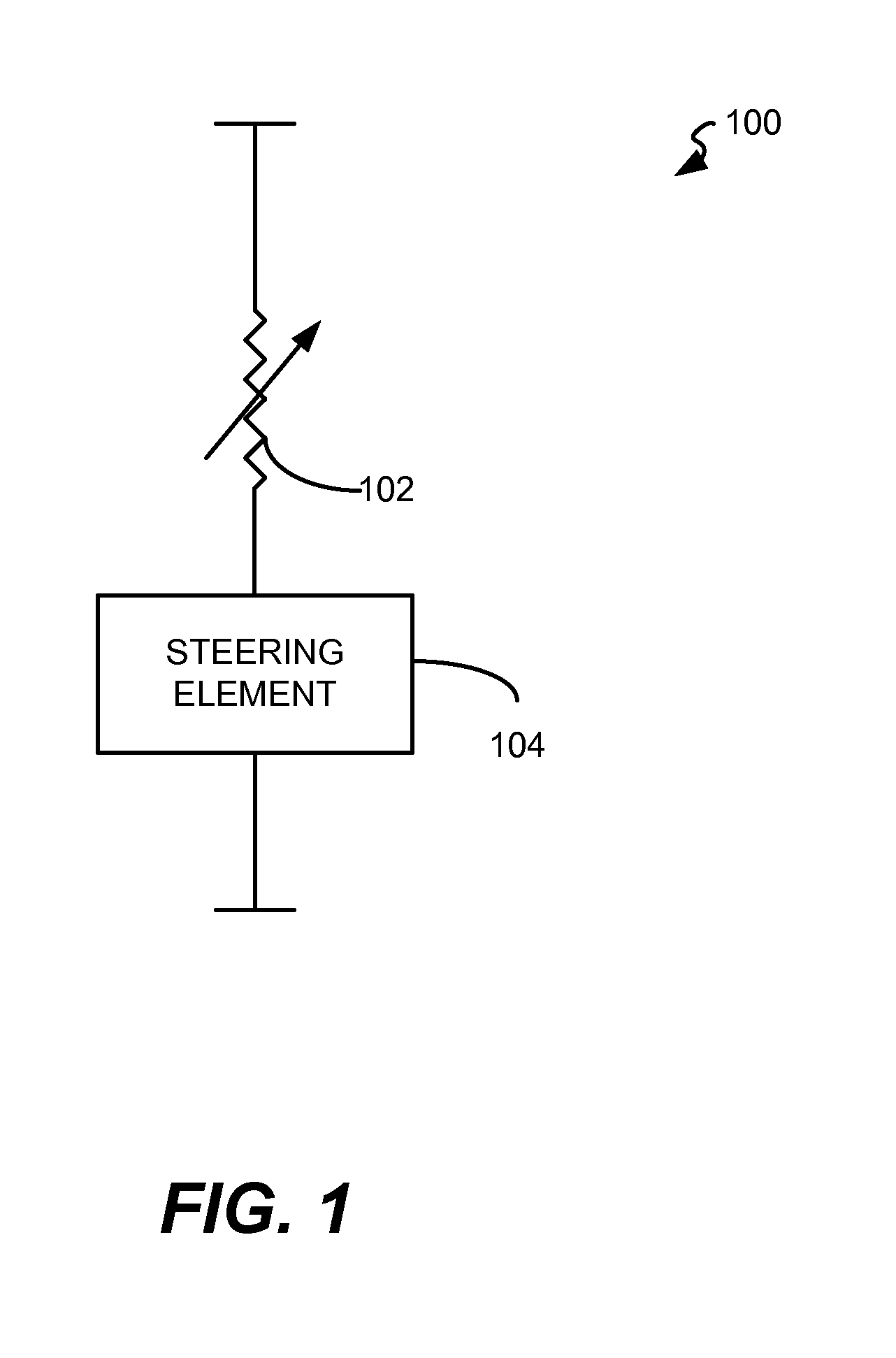

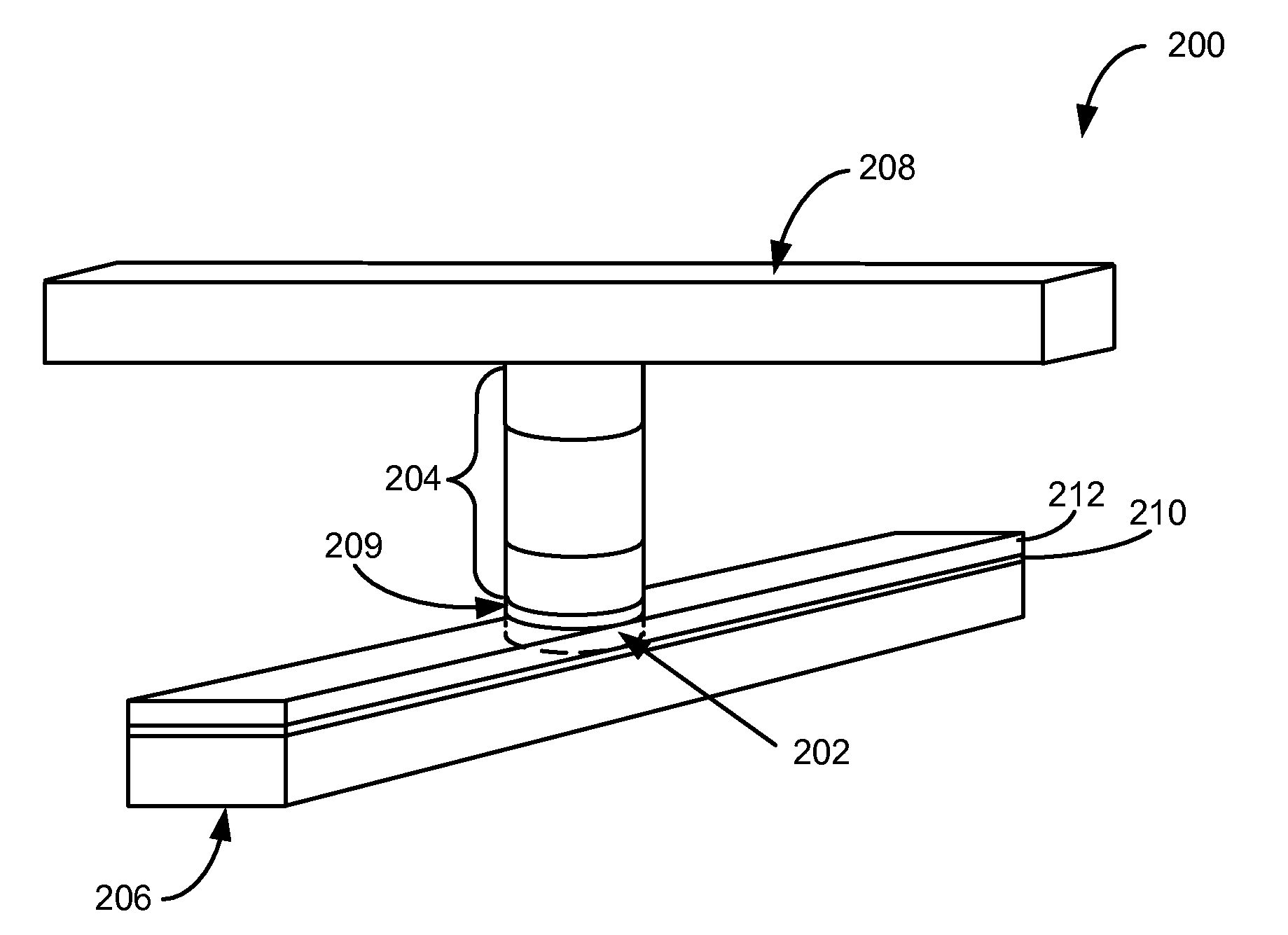

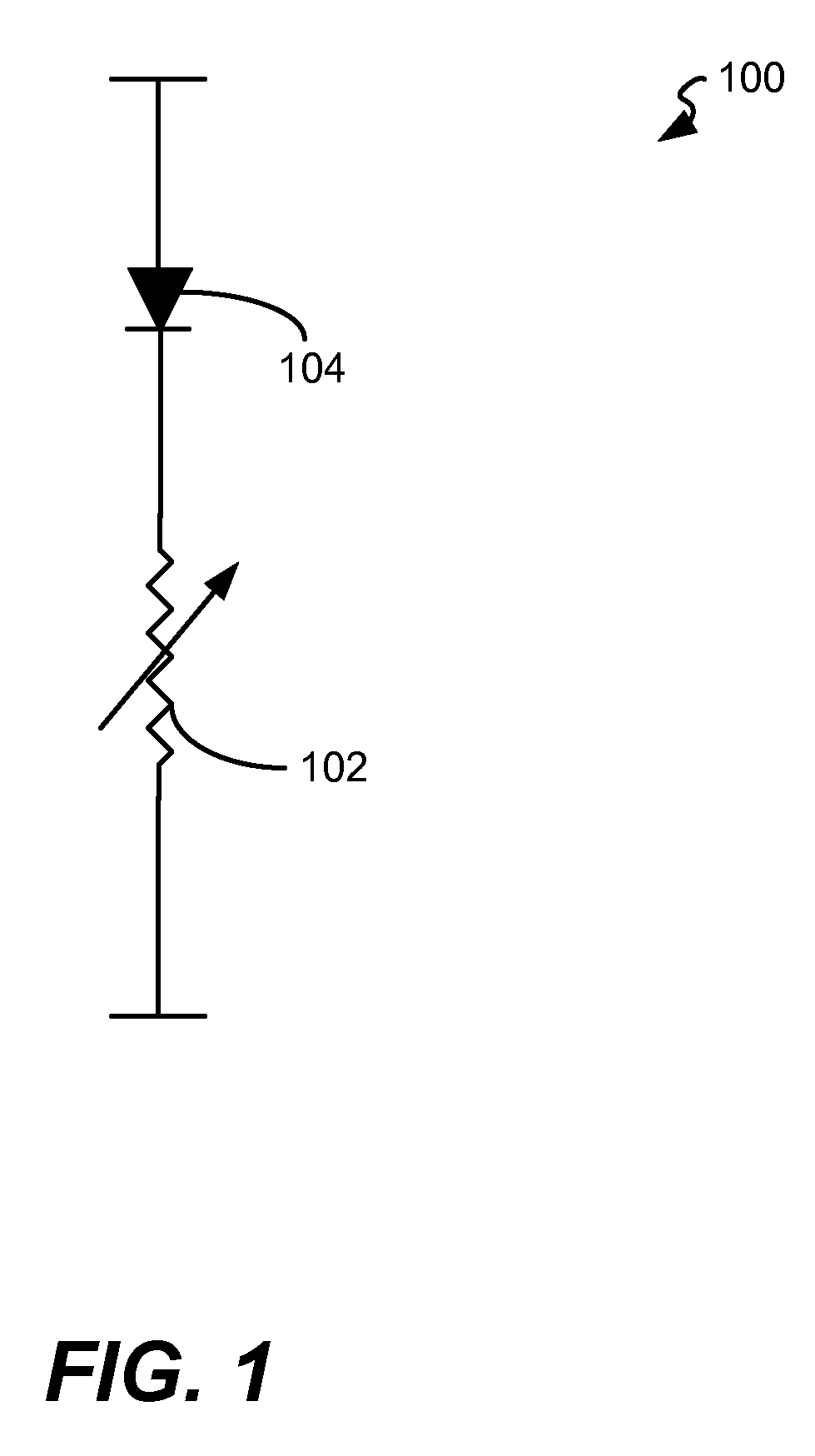

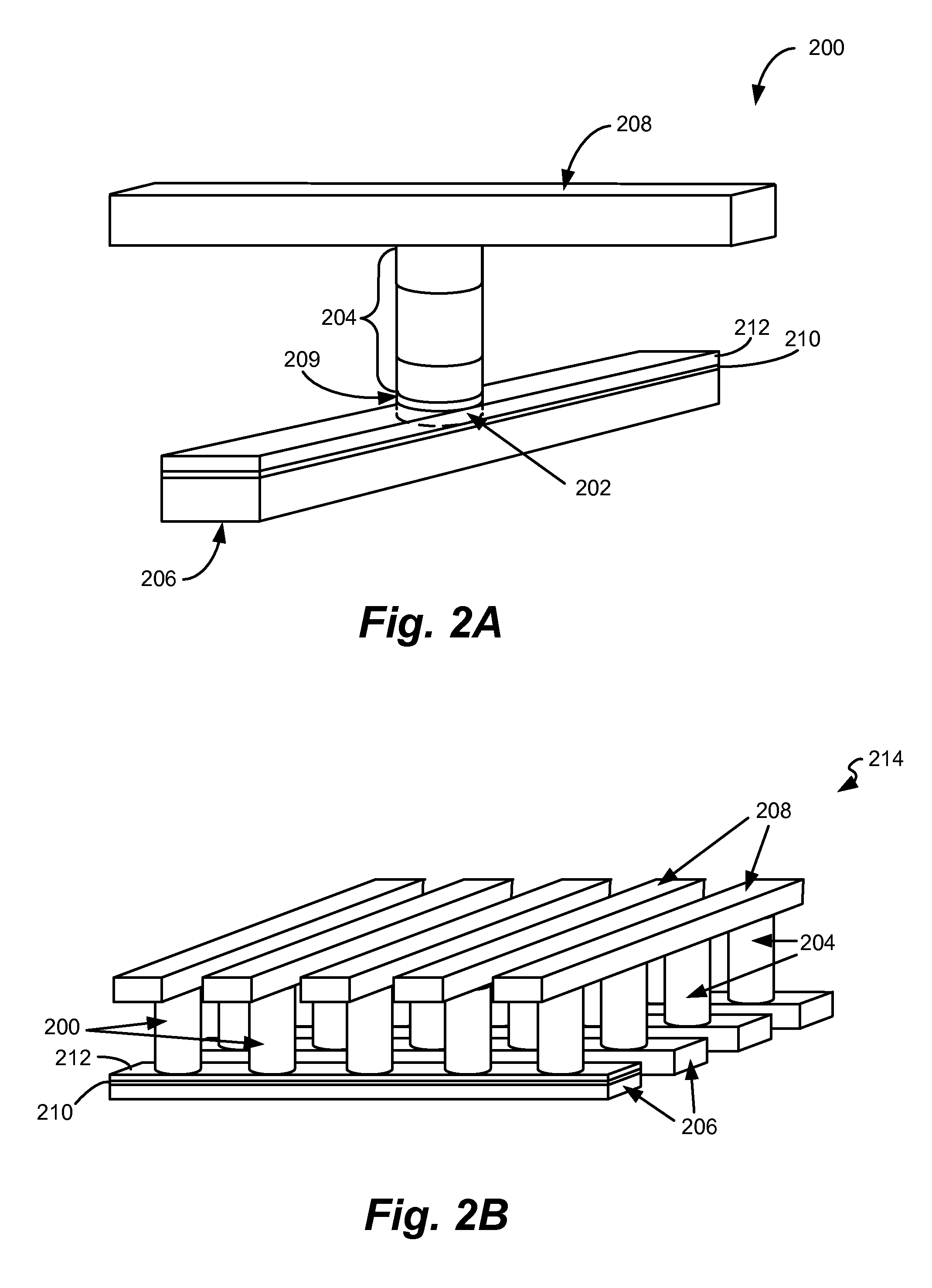

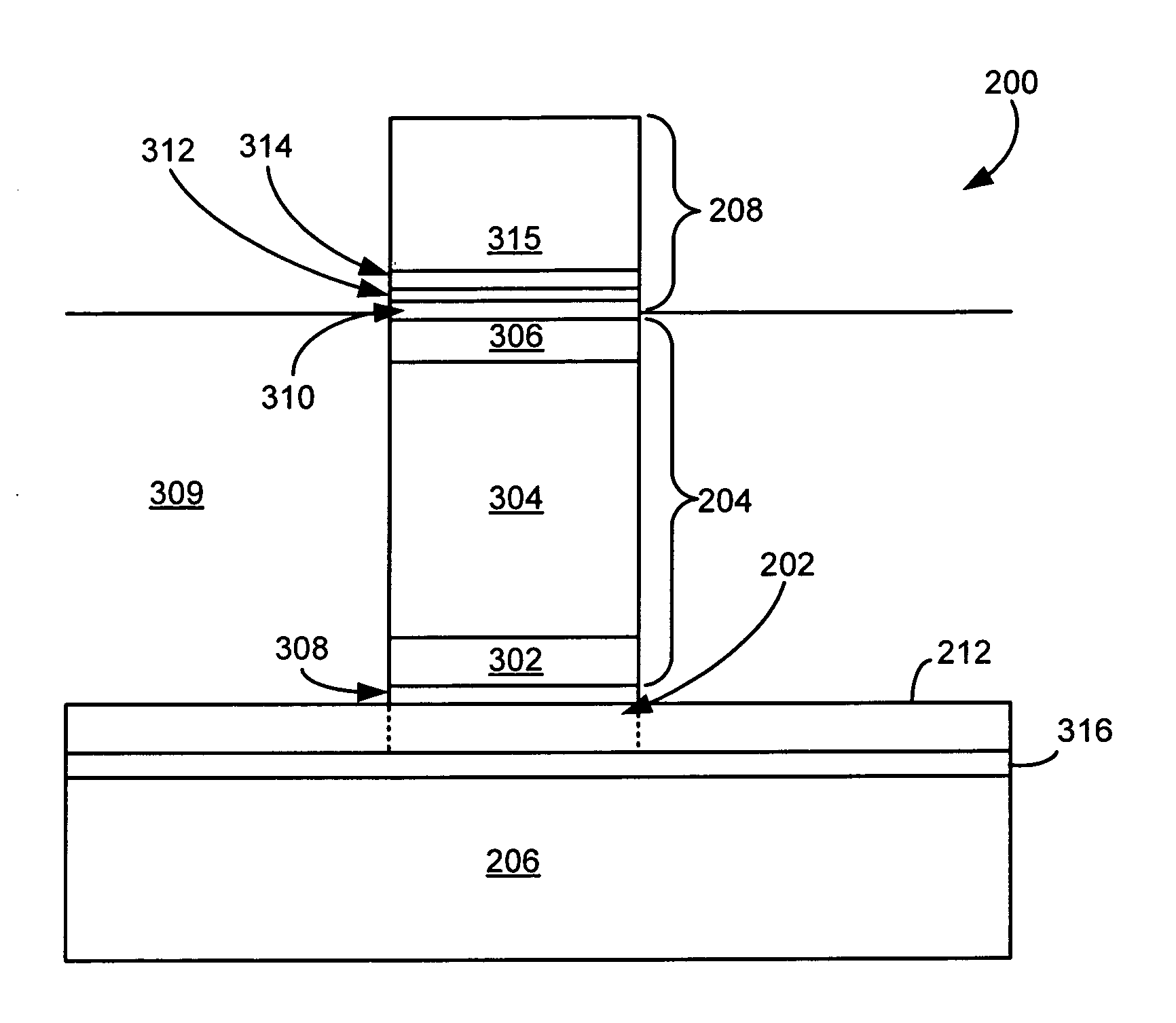

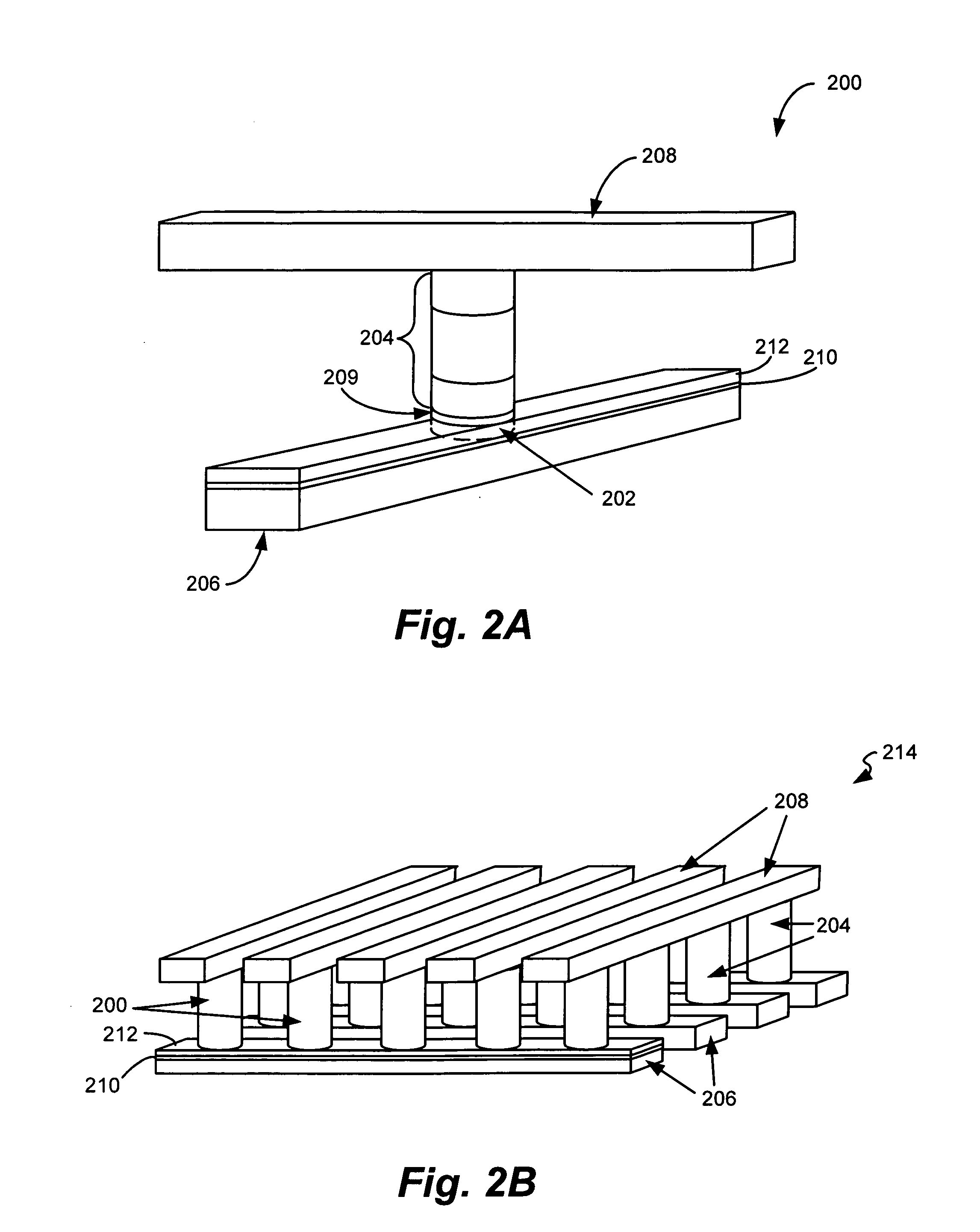

Memory cell that employs a selectively fabricated carbon nano-tube reversible resistance-switching element and methods of forming the same

In some aspects, a method of fabricating a memory cell is provided that includes (1) fabricating a steering element above a substrate; and (2) fabricating a reversible-resistance switching element coupled to the steering element by selectively fabricating carbon nano-tube (CNT) material above the substrate. Numerous other aspects are provided.

Owner:SANDISK TECH LLC

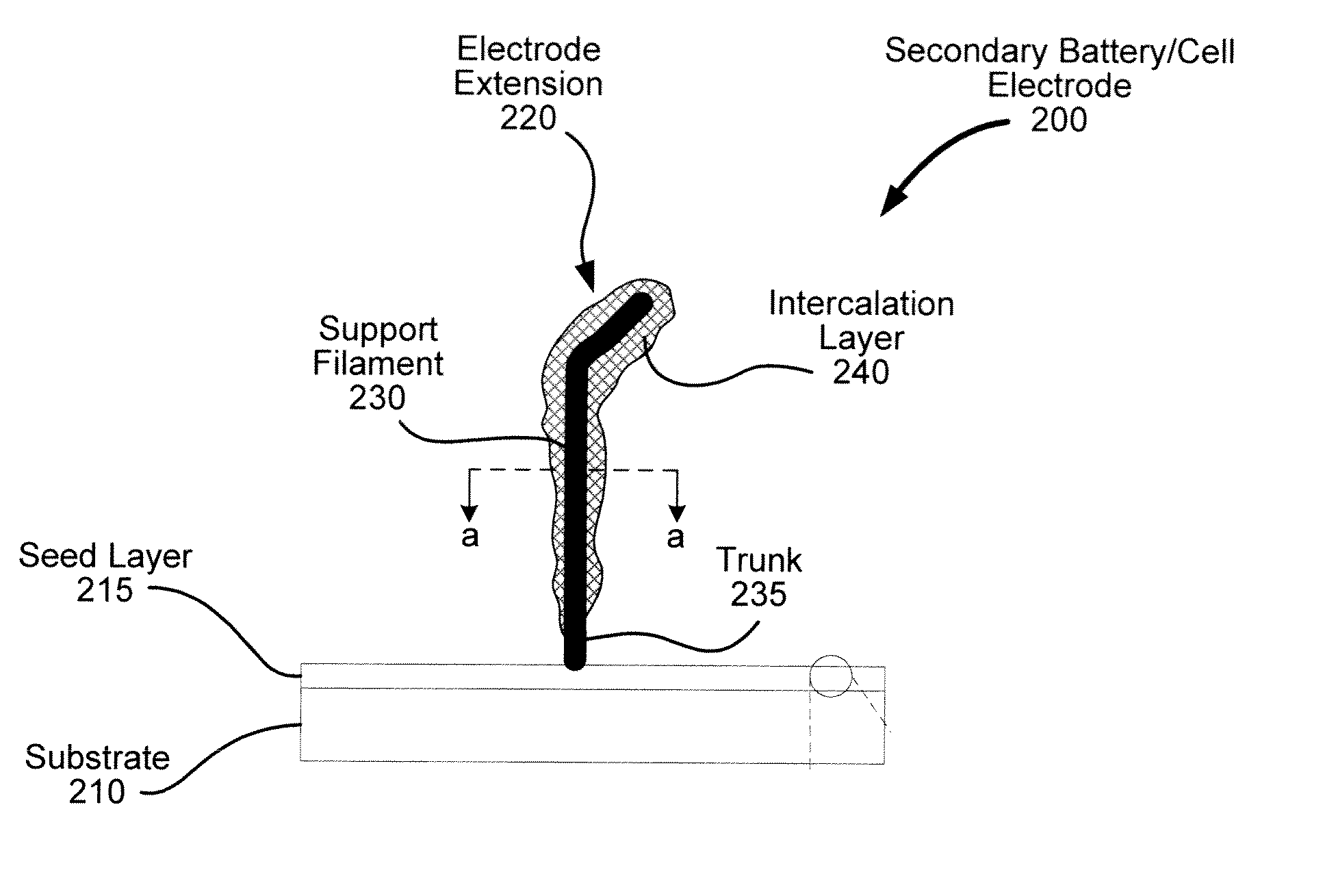

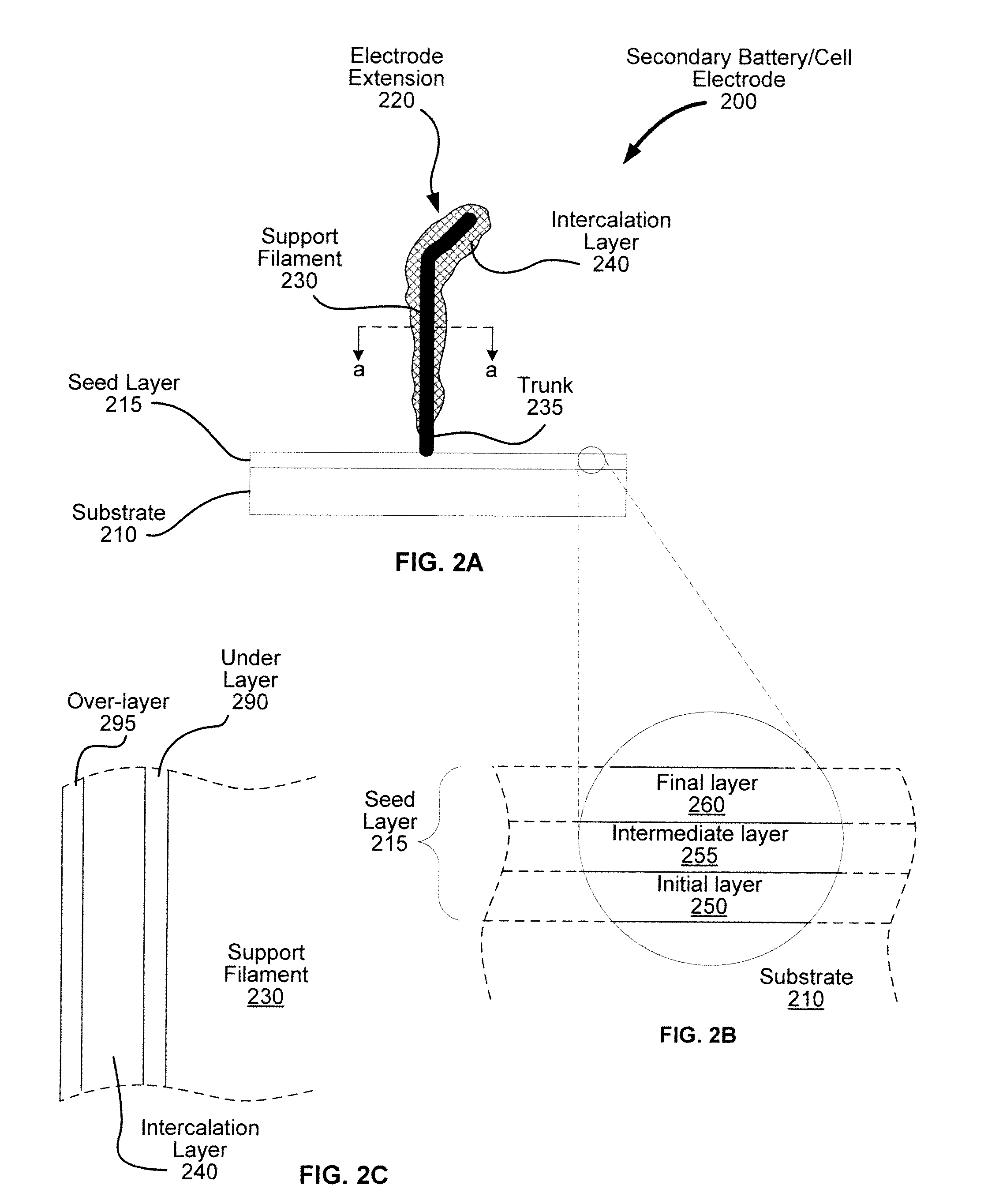

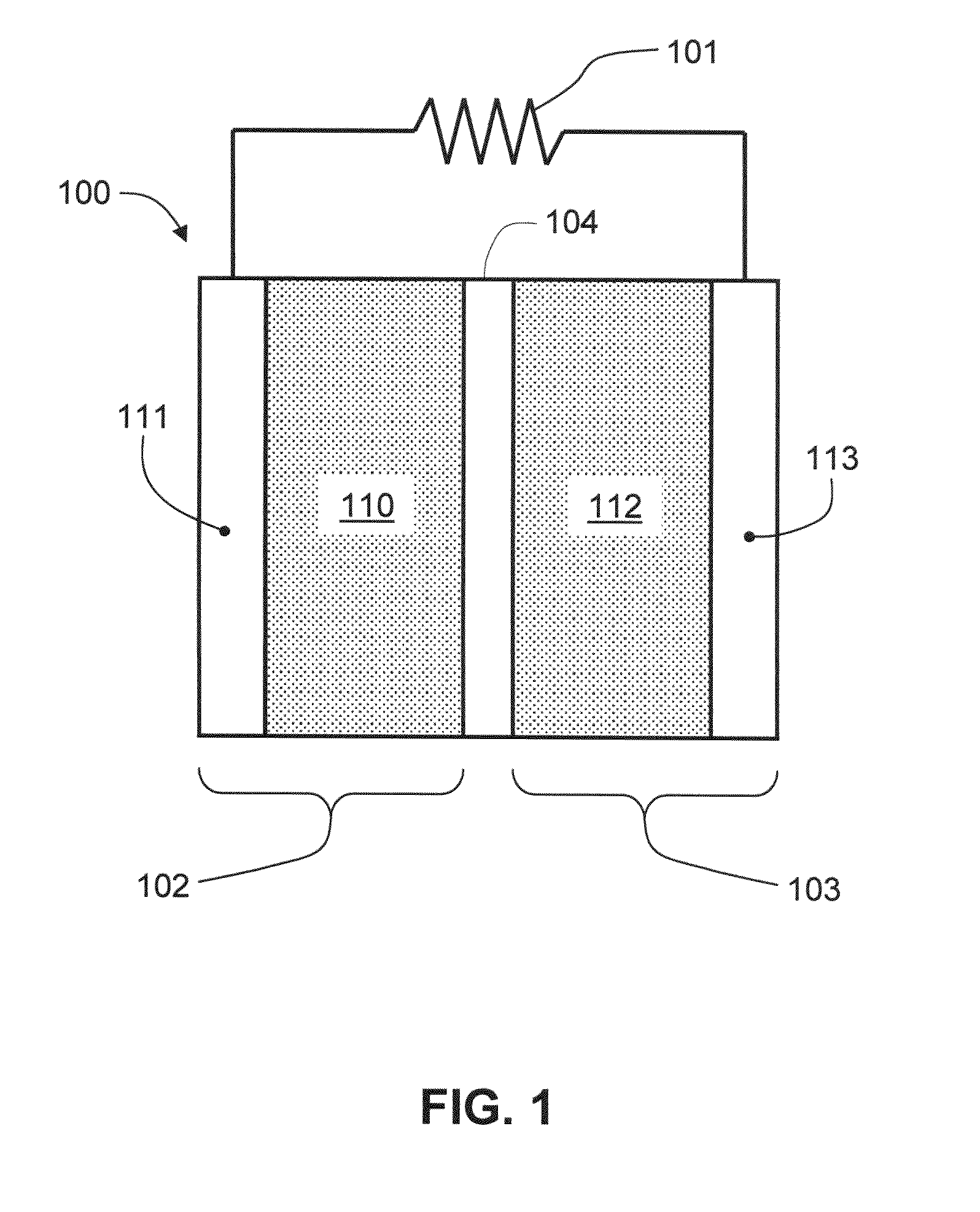

High Capacity Electrodes

A high capacity electrode includes a conducting substrate on which a plurality of support filaments are disposed. Each of the support filaments have a length substantially greater than their width and may include, for example, a carbon nano-tube (CNT), a carbon nano-fiber (CNF), and / or a nano-wire (NW). The support filaments are coated with a material, such as silicon, having a greater ion absorbing capacity greater than the neat support filaments. A trunk region of the support filaments proximate to the substrate is optionally kept free of ion absorbing material. This trunk region allows for the expansion of the ion absorbing material without detaching the support filaments form the substrate.

Owner:CF TRAVERSE LLC

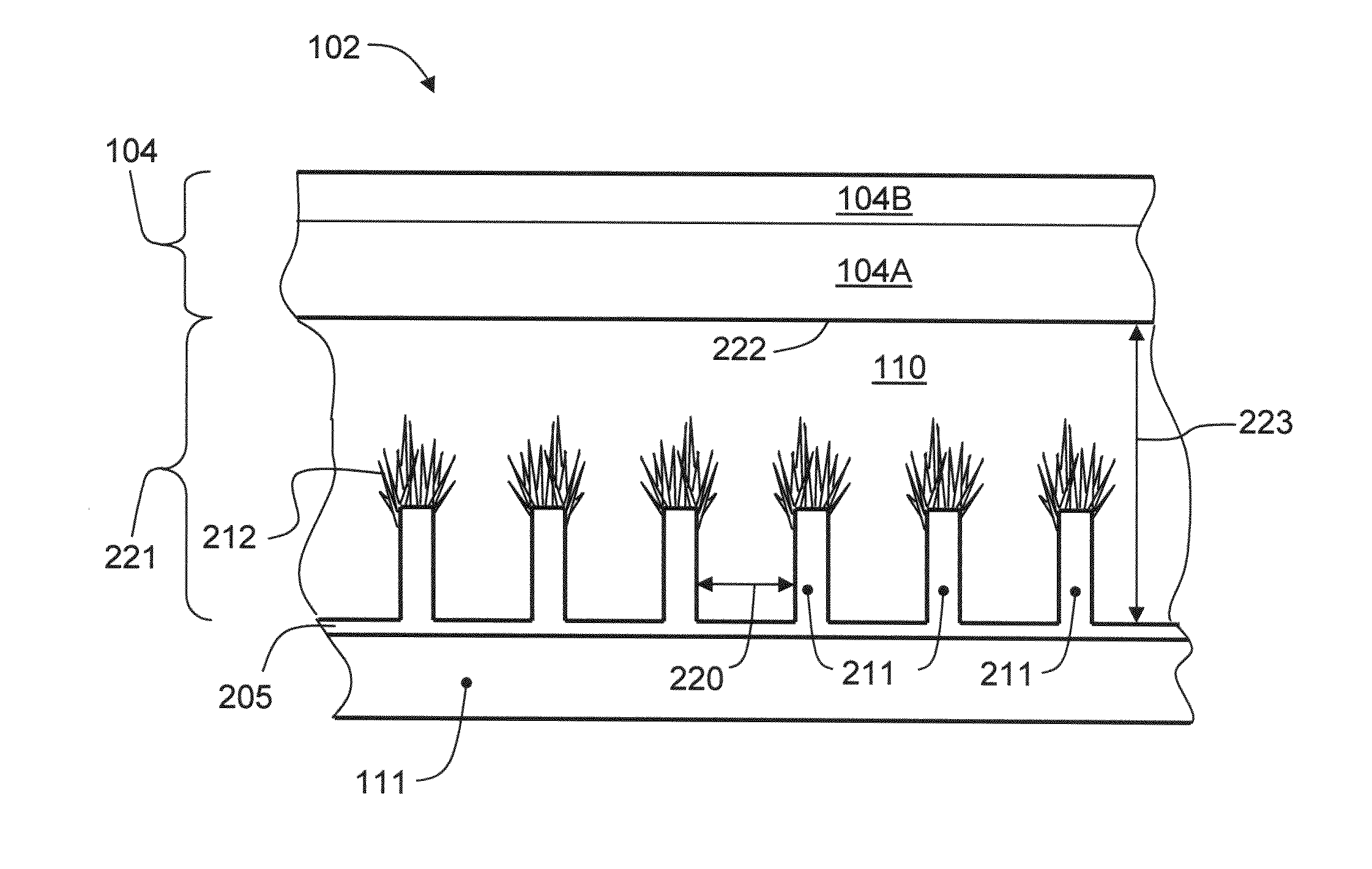

Heat conductive silicone grease composition

ActiveCN102634212AImprove thermal conductivityExtended service lifeHeat-exchange elementsCarbon nanotubeGraphite

The invention discloses a heat conductive silicone grease composition which mainly contains a carbon nano tube, graphite, phase-change capsule particles and silicone oil, wherein the carbon nano tube can speed up the conduction of heat further; the phase-change capsule particles are used for improving the initial temperature absorption velocity of a heat end; the phase-change capsule particles, the carbon nano tube and graphite in a fluid form full-three-dimensional network distribution of particles (phase-change capsule), a line ( the carbon nano tube) and a plane (graphite) in the fluid finally. The heat conductive silicone grease composition provided by the invention has high heat conduction rate and low heat resistivity, the heat radiation efficiency of the heat conductive silicone grease is improved greatly, the service life of the heat conductive silicone grease is prolonged greatly, and the heat conductive silicone grease composition has high practical value.

Owner:HUZHOU MINGSHUO OPTOELECTRONICS TECH CO LTD

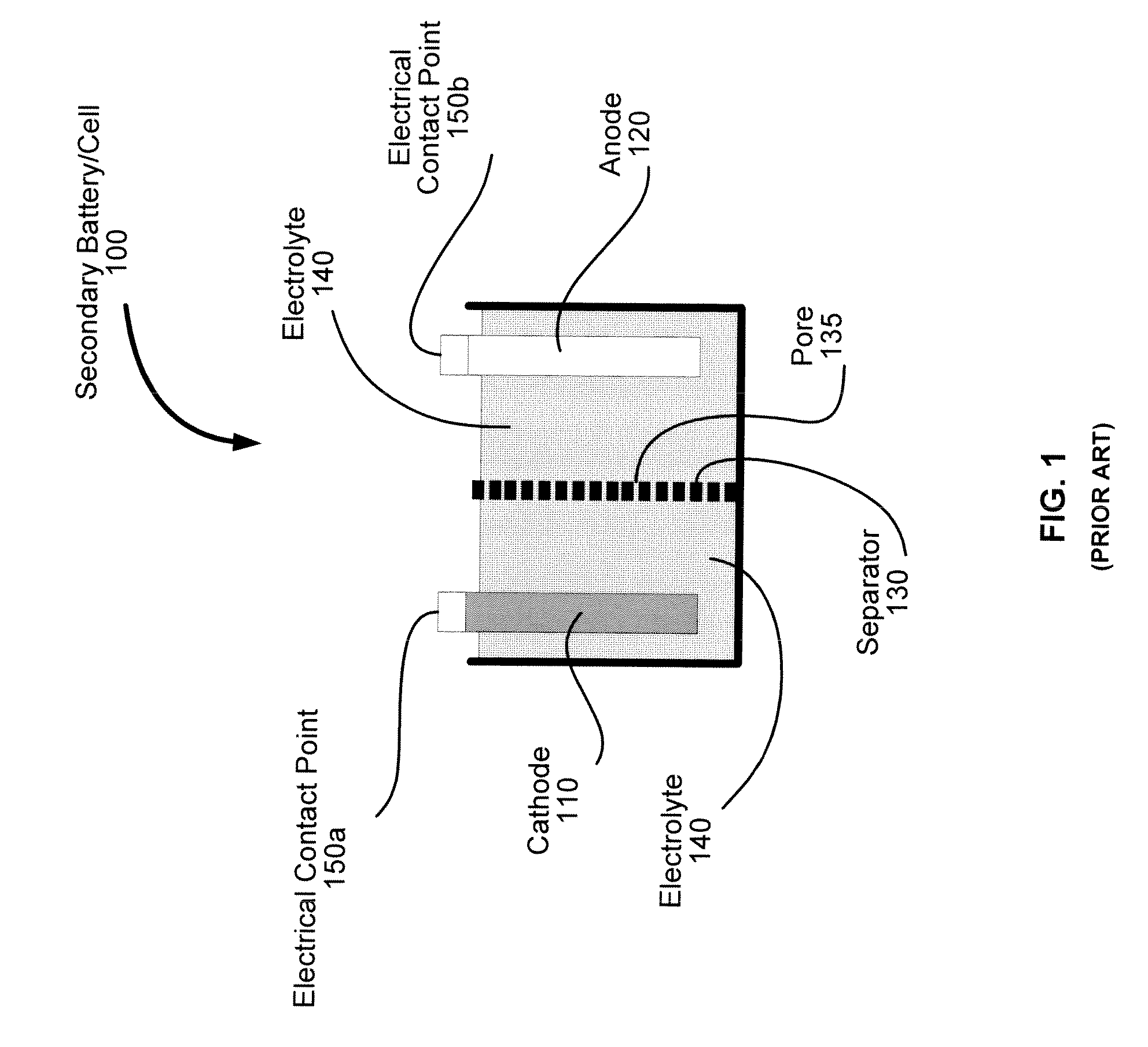

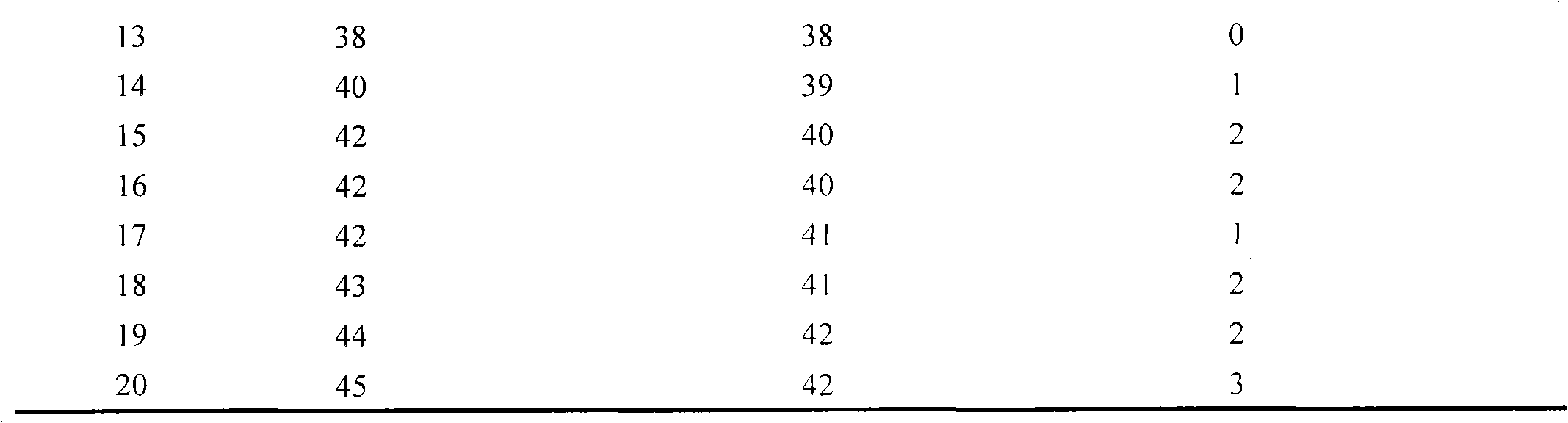

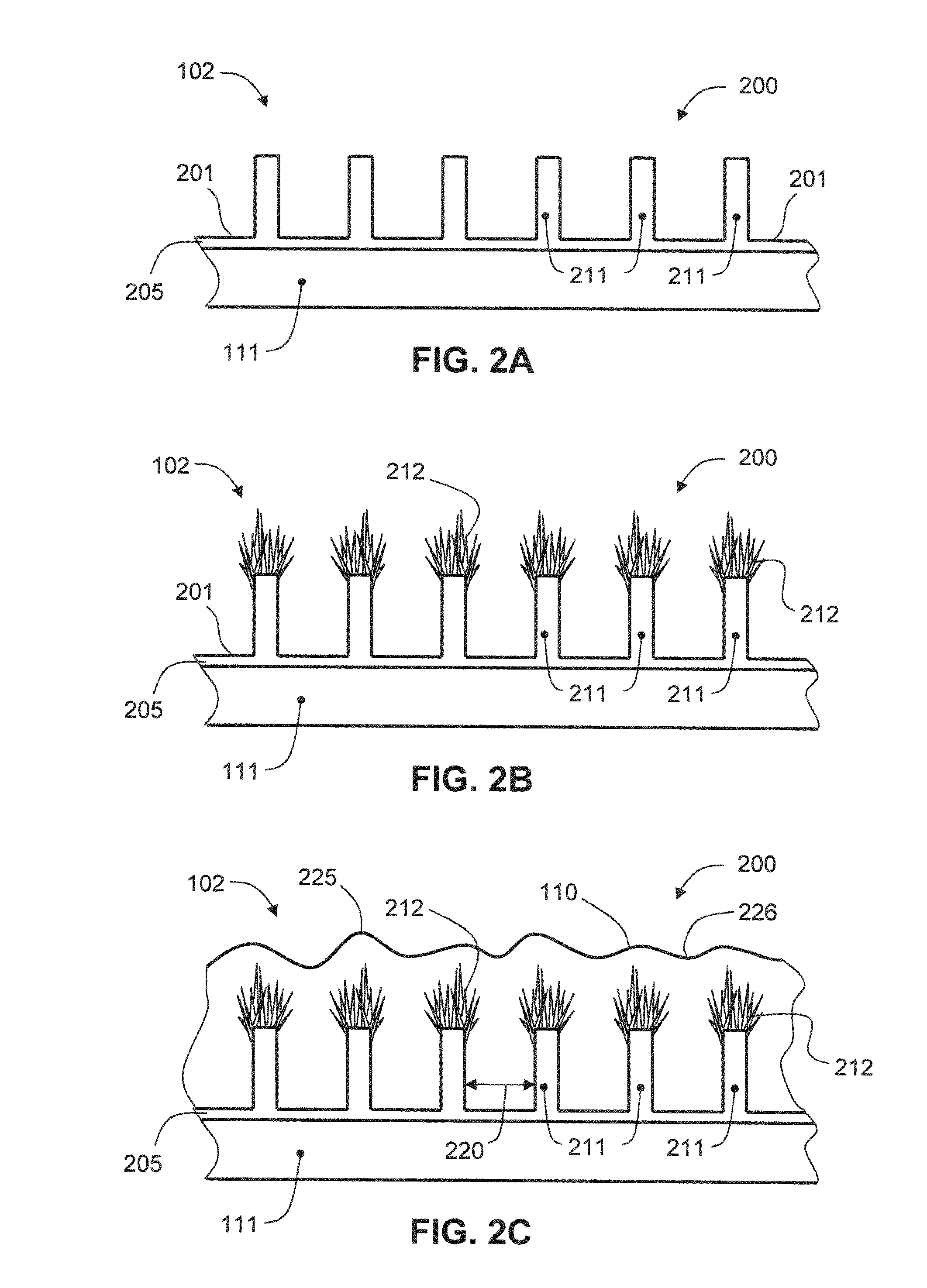

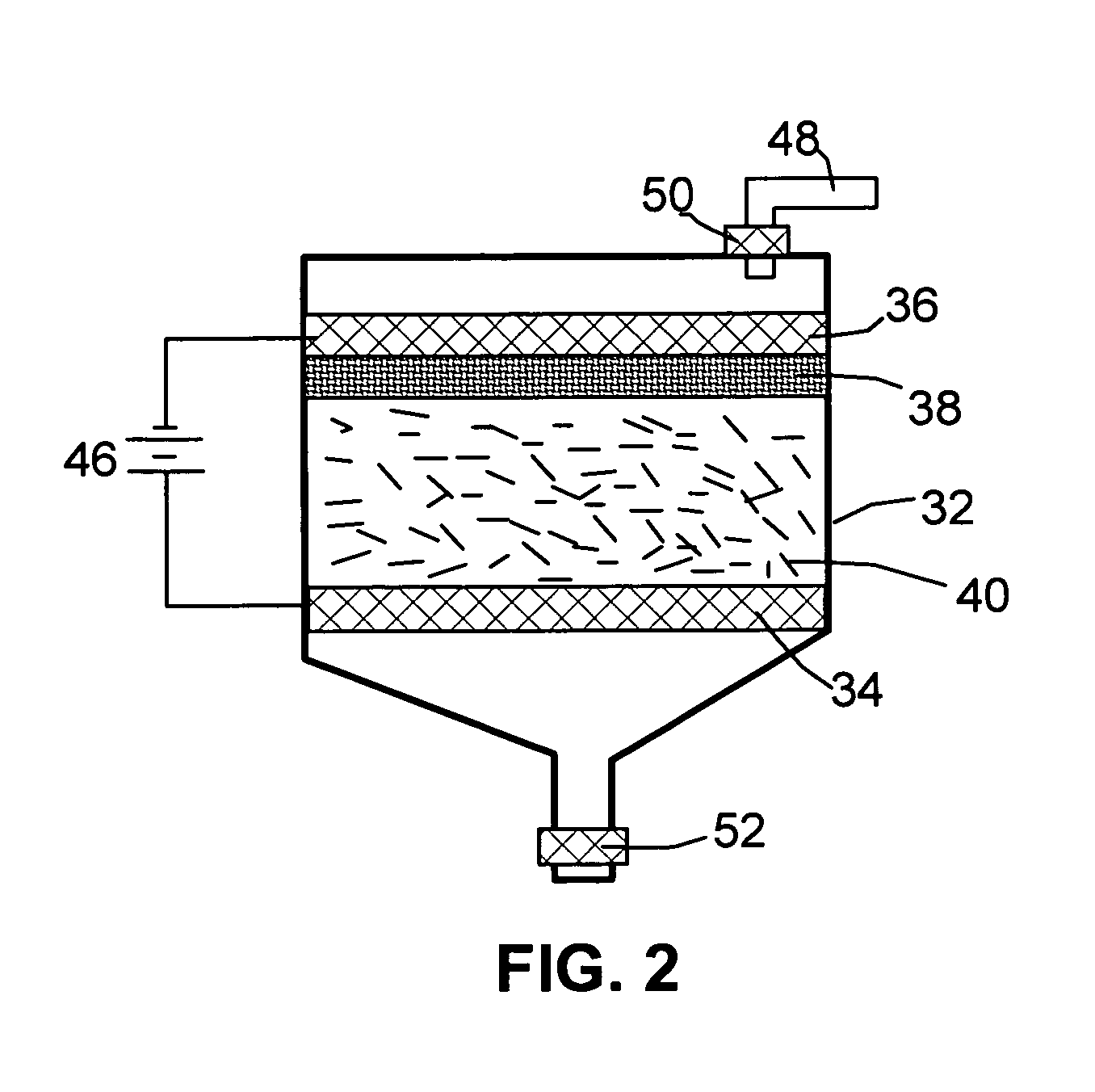

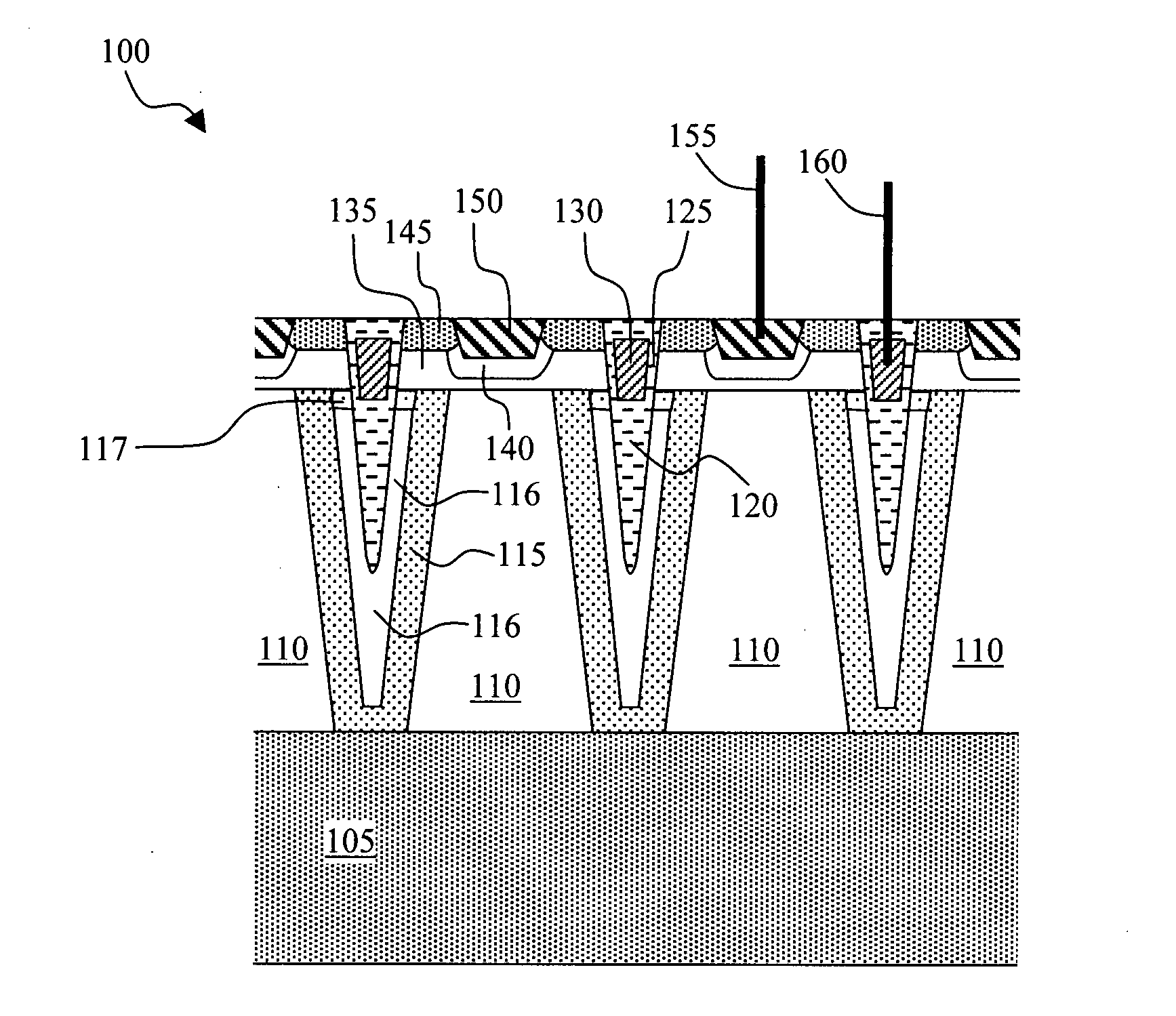

Thin film electrochemical energy storage device with three-dimensional anodic structure

InactiveUS20100216026A1Final product manufactureElectrode carriers/collectorsPorosityMicro structure

A method for forming a battery from via thin-film deposition processes is disclosed. A mesoporous carbon material is deposited onto a surface of a conductive substrate that has high surface area, conductive micro-structures formed thereon. A porous, dielectric separator layer is then deposited on the layer of mesoporous carbon material to form a half cell of an energy storage device. The mesoporous carbon material is made up of CVD-deposited carbon fullerene “onions” and carbon nano-tubes, and has a high porosity capable of retaining lithium ions in concentrations useful for storing significant quantities of electrical energy. Embodiments of the invention further provide for the formation of an electrode having a high surface area conductive region that is useful in a battery structure. In one configuration the electrode has a high surface area conductive region comprising a porous dendritic structure that can be formed by electroplating, physical vapor deposition, chemical vapor deposition, thermal spraying, and / or electroless plating techniques.

Owner:APPLIED MATERIALS INC

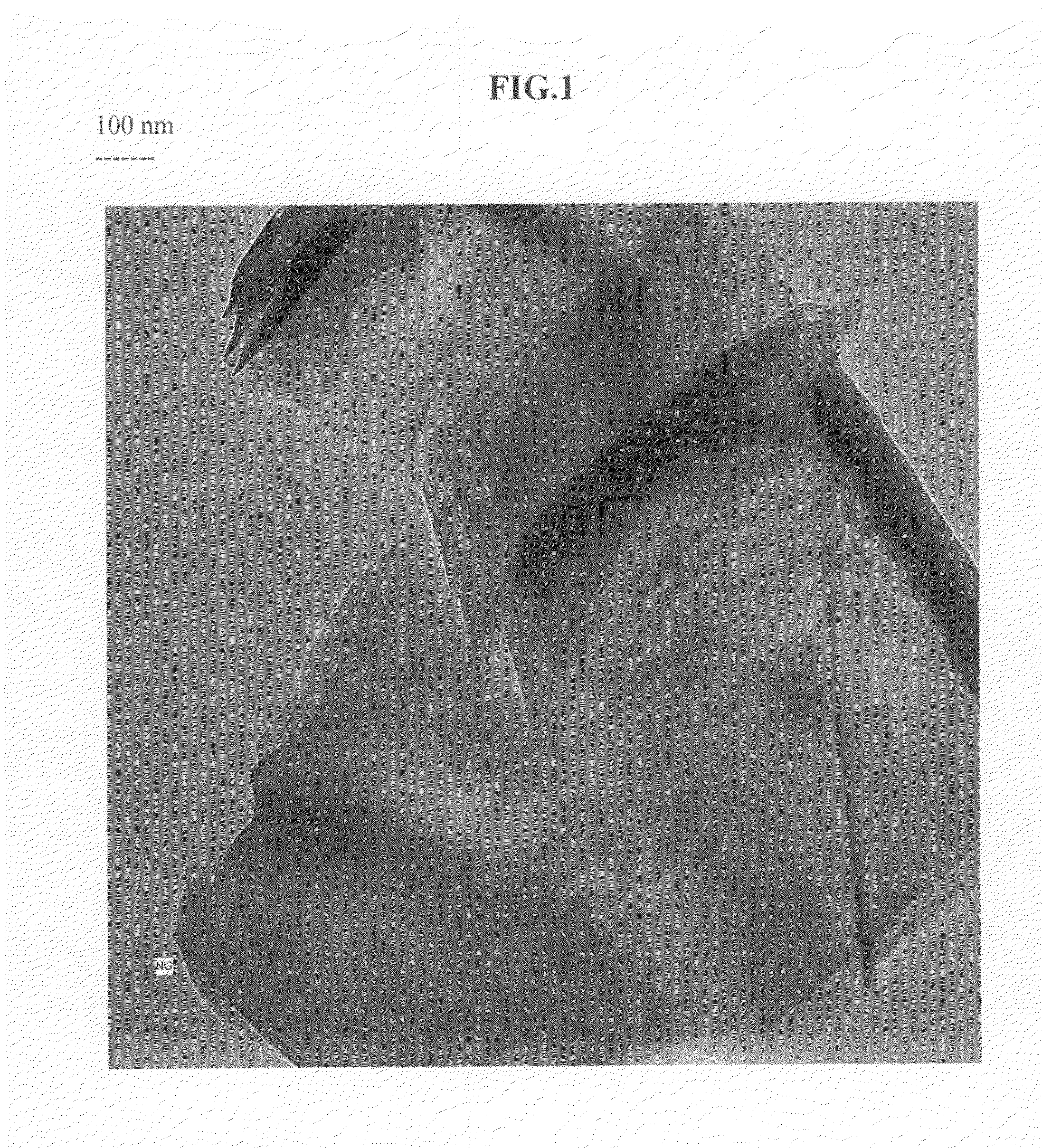

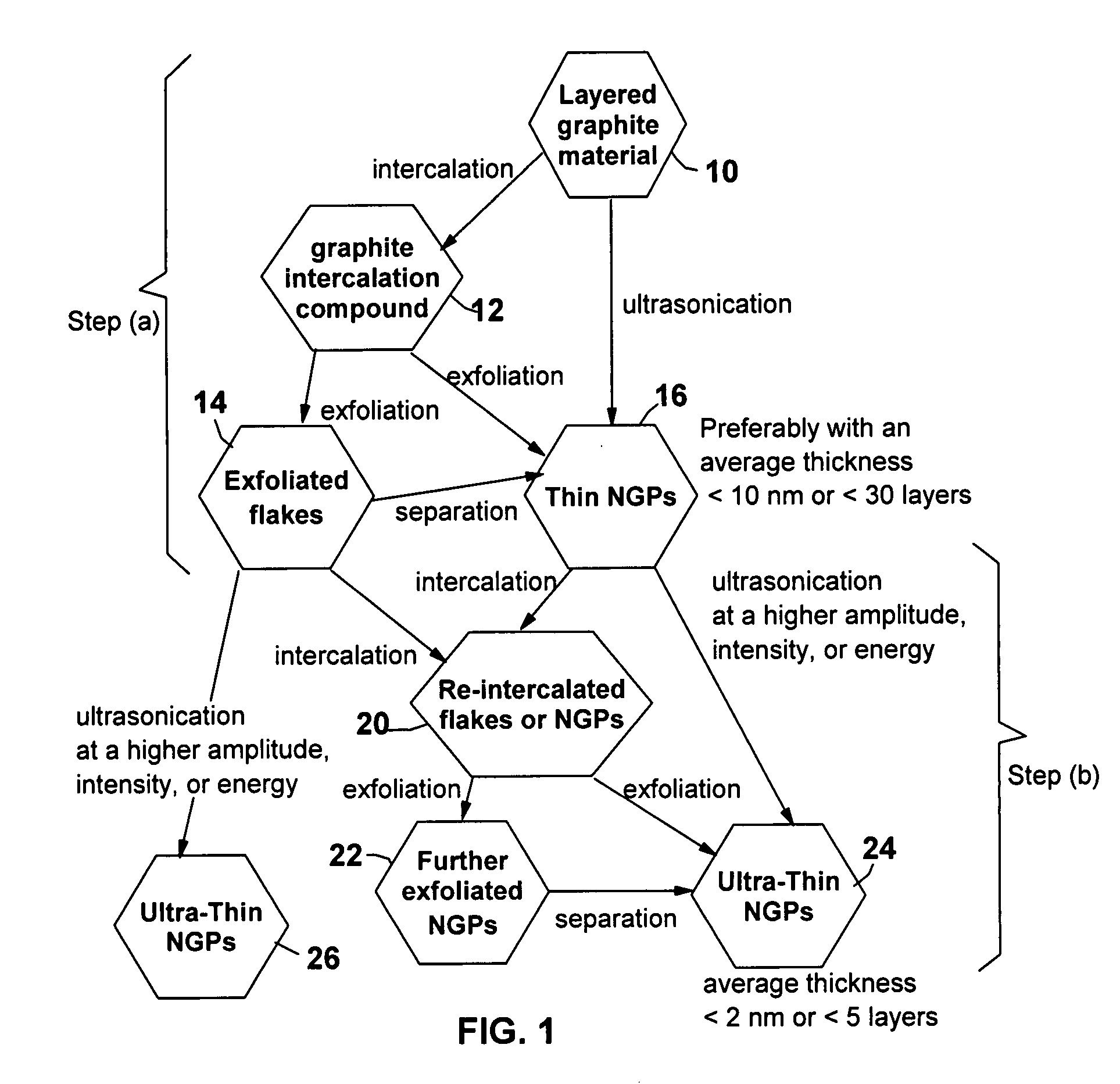

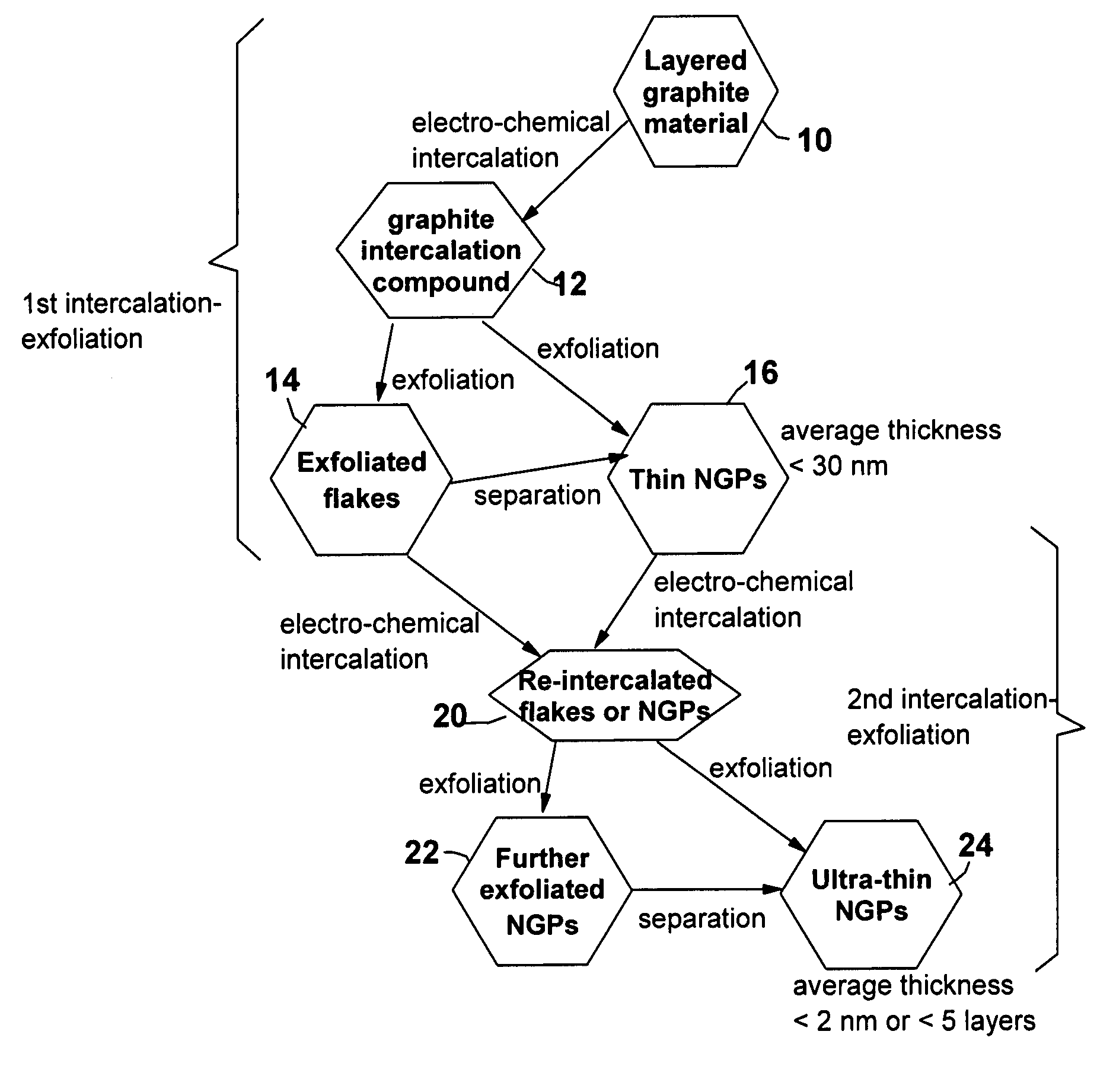

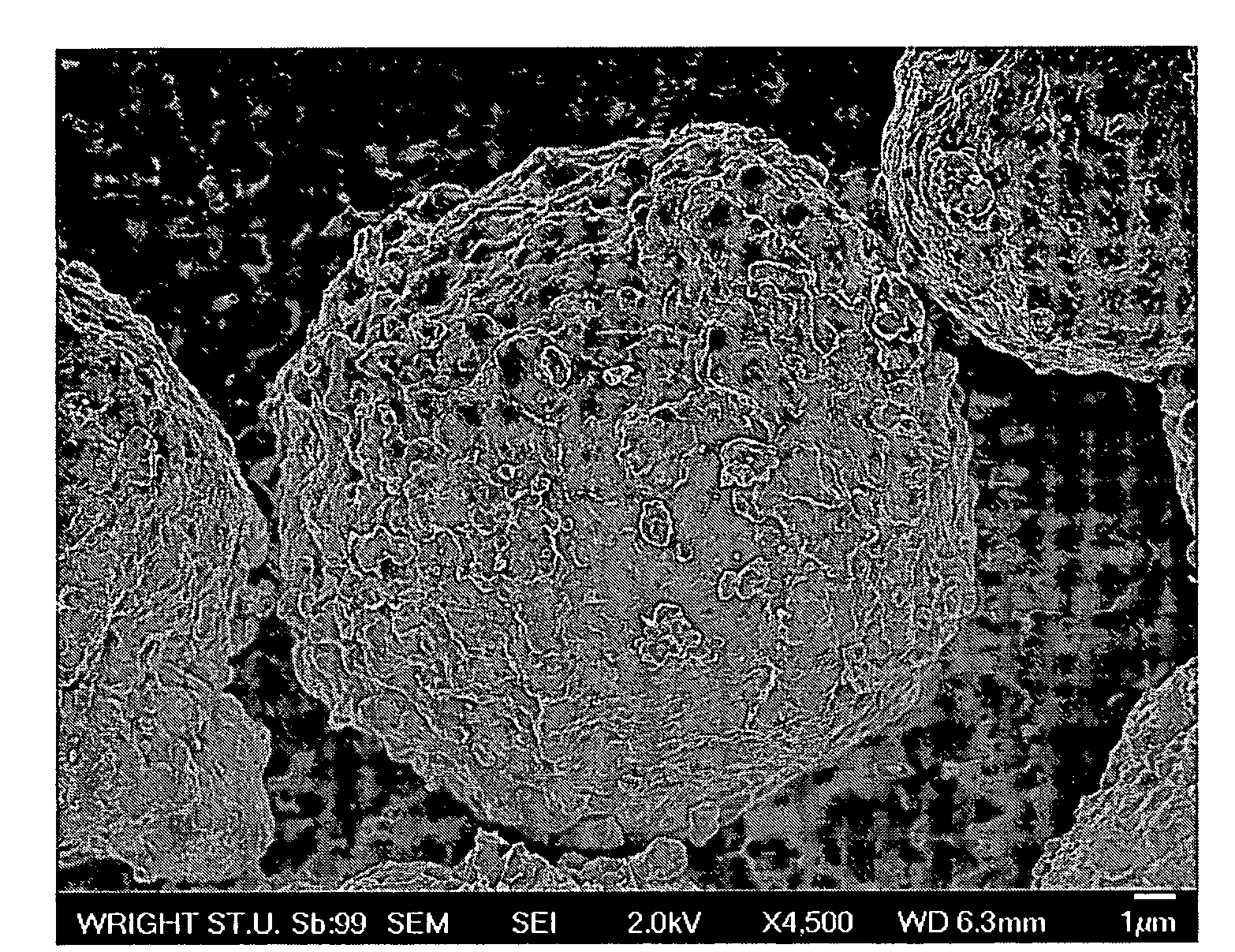

Method for producing ultra-thin nano-scaled graphene platelets

InactiveUS20090022649A1Good dispersionImprove conductivityMaterial nanotechnologyGraphiteFiberCarbon nanotube

A method of producing ultra-thin, separated nano-scaled platelets having an average thickness no greater than 2 nm or comprising, on average, no more than 5 layers per platelet from a layered graphite material. The method comprises: (a) providing a supply of nano-scaled platelets with an average thickness of no more than 10 nm or having, on average, no more than 30 layers per platelet; and (b) intercalating the supply of nano-scaled platelets to produce intercalated nano platelets and exfoliating the intercalated nano platelets at a temperature and a pressure for a sufficient period of time to produce the ultra-thin nano-scaled platelets. The nano-scaled platelets are candidate reinforcement fillers for polymer nanocomposites. Nano-scaled graphene platelets are much lower-cost alternatives to carbon nano-tubes or carbon nano-fibers.

Owner:NANOTEK INSTR

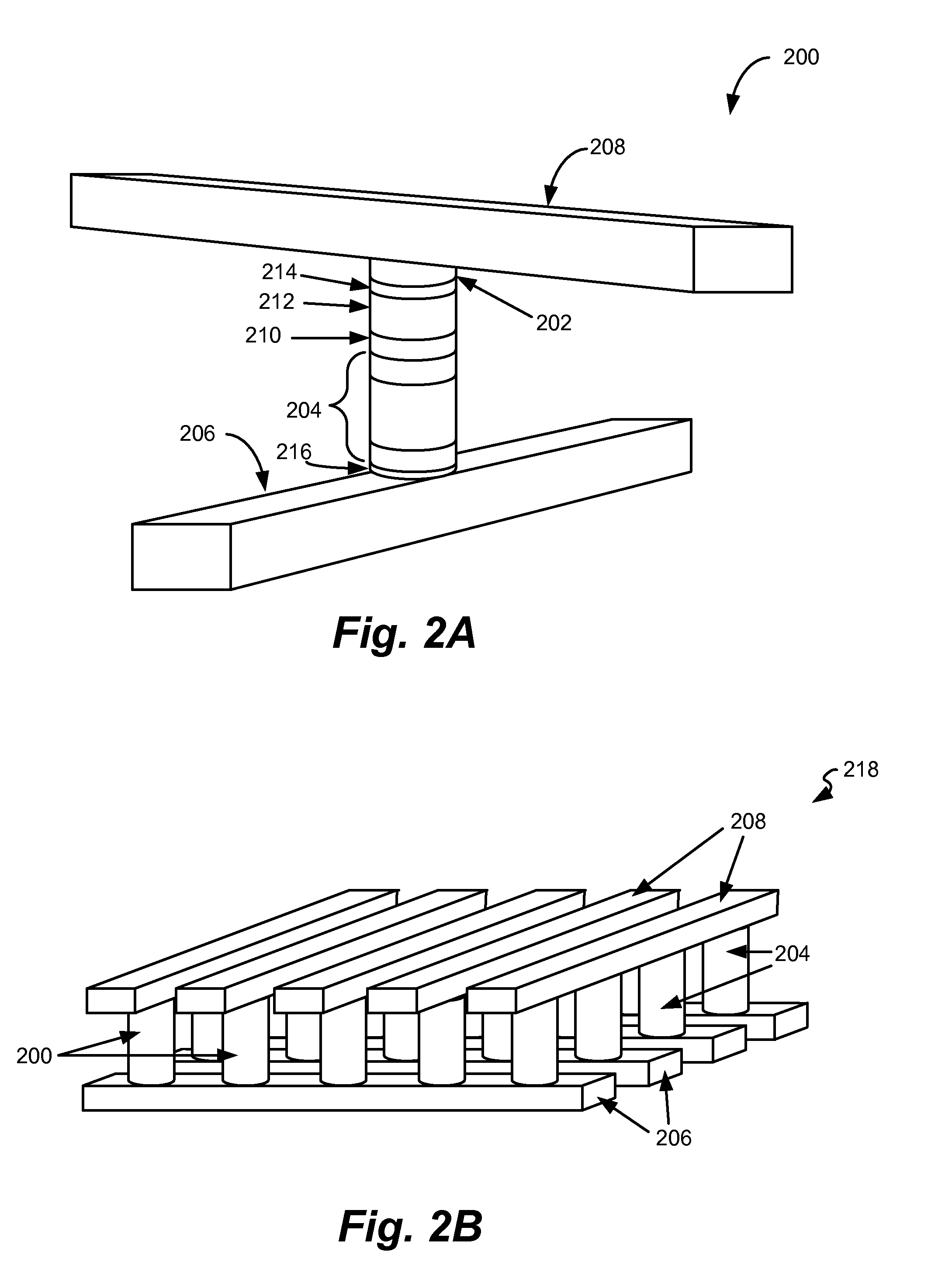

Memory cell that employs a selectively fabricated carbon nano-tube reversible resistance-switching element formed over a bottom conductor and methods of forming the same

In some aspects, a method of fabricating a memory cell is provided that includes (1) fabricating a first conductor above a substrate; (2) selectively fabricating a carbon nano-tube (CNT) material above the first conductor; (3) fabricating a diode above the CNT material; and (4) fabricating a second conductor above the diode. Numerous other aspects are provided.

Owner:SANDISK TECH LLC

Photoelectric conversion element and photoelectric conversion device

InactiveUS20030189235A1Response speed to lightFinal product manufactureNanoinformaticsCarbon nanotubePhotoelectric conversion

A photoelectric conversion element comprising a substrate and a light sensor disposed on a surface of the substrate and receiving high speed optical pulse signals and converting them into high frequency waves in which the light sensor comprises at least carbon nano-tubes, as well as a photoelectric conversion device having the element, for directly converting high speed optical pulses signals in a communication band into signals of high frequency waves or electromagnetic waves.

Owner:FUJIFILM BUSINESS INNOVATION CORP

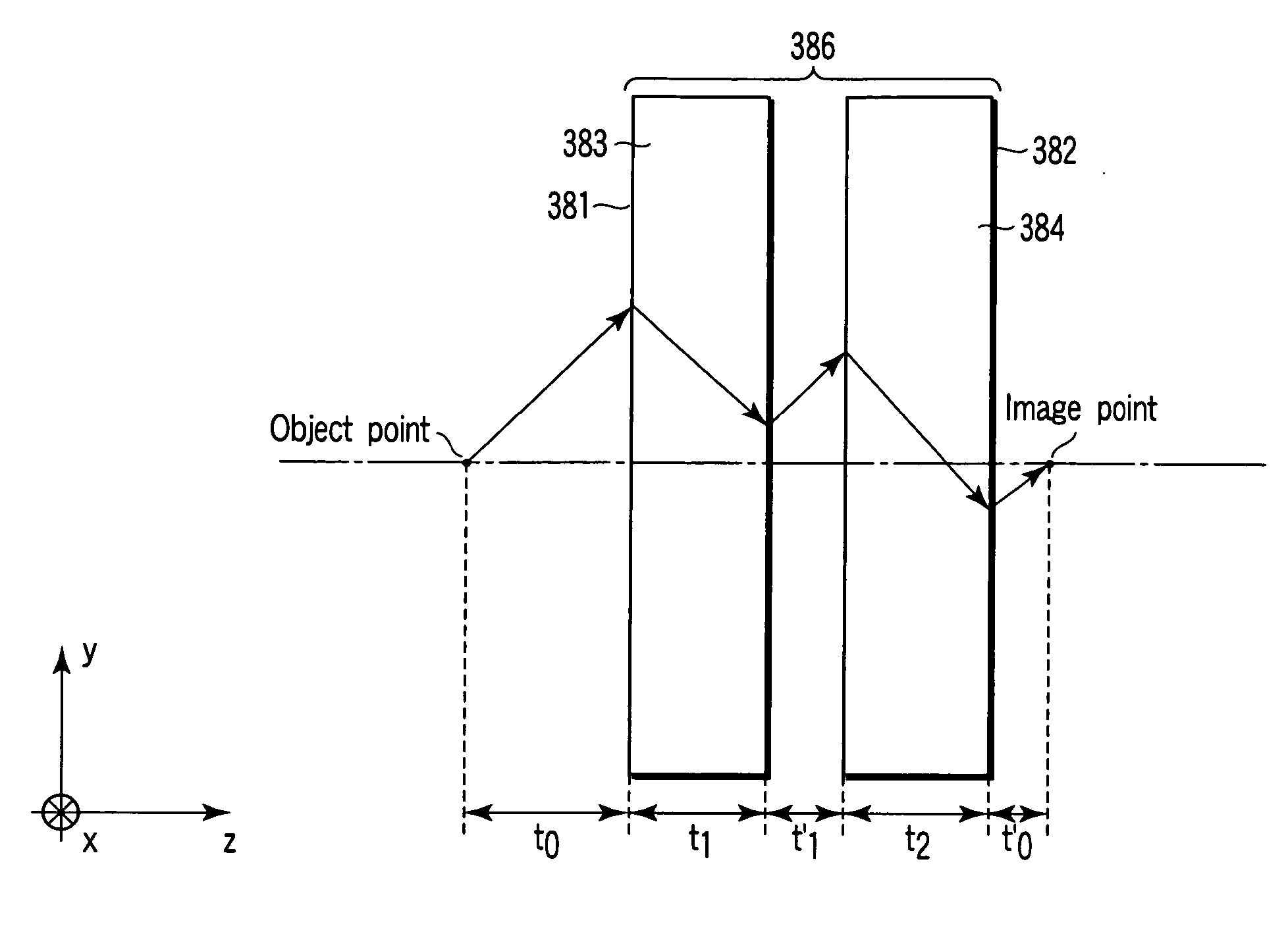

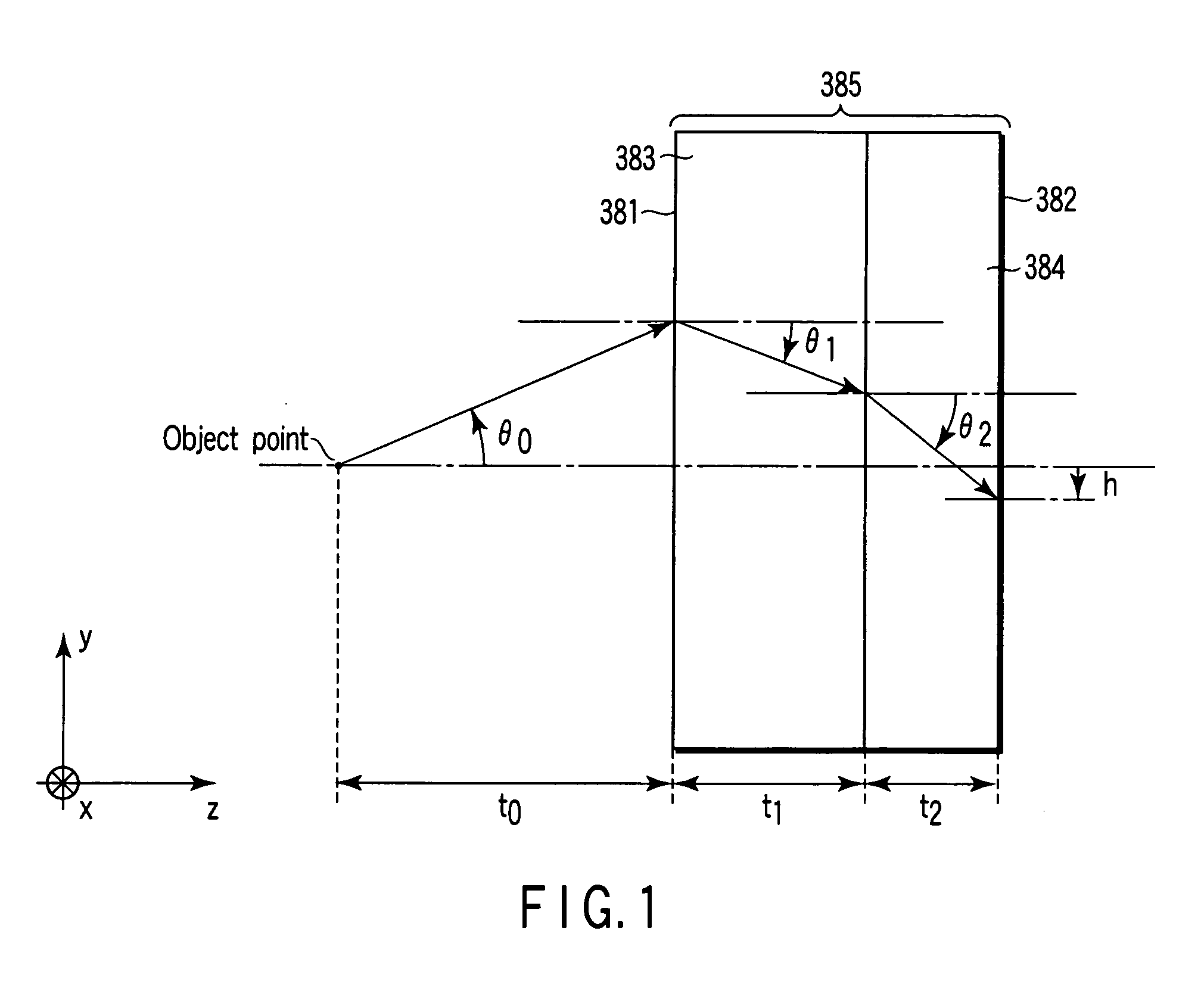

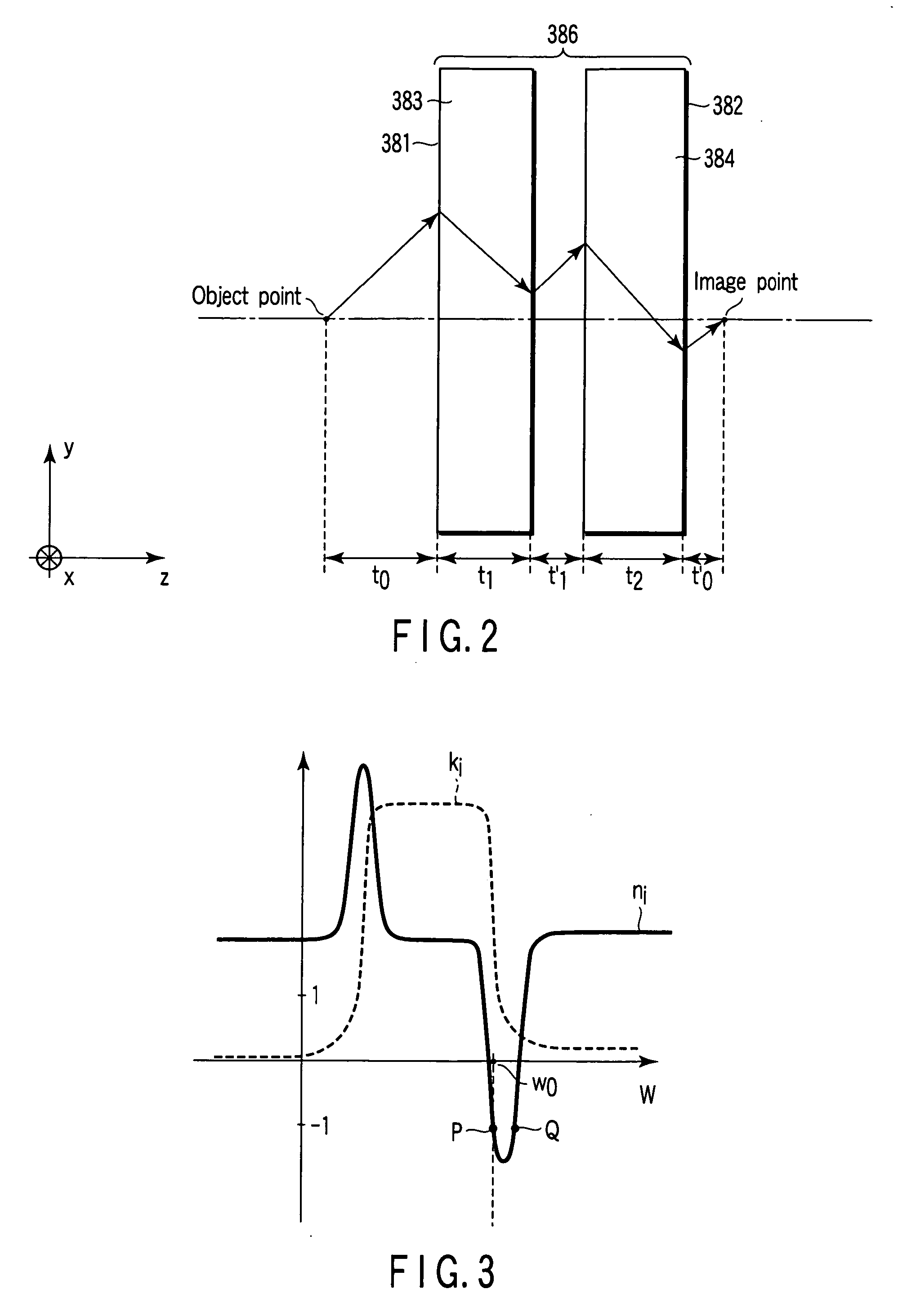

Medium exhibiting negative refraction, optical element, and optical system

InactiveUS20060171032A1Small thicknessPhotomechanical apparatusNanoopticsNegative refractionCarbon nanotube

An optical element using a medium exhibiting negative refraction, a carbon nano tube being used for the medium exhibiting negative refraction, is disclosed. There is also disclosed an optical system having a plurality of optical elements each formed of a medium exhibiting negative refraction, wherein the plurality of optical elements includes optical elements having different chromatic dispersions.

Owner:OLYMPUS CORP

Memory cell with planarized carbon nanotube layer and methods of forming the same

In some aspects, a method of fabricating a memory cell is provided that includes (1) fabricating a first conductor above a substrate; (2) fabricating a carbon nano-tube (CNT) material above the first conductor; (3) depositing a dielectric material onto a top surface of the CNT material; (4) planarizing the dielectric material to expose at least a portion of the CNT material; (5) fabricating a diode above the first conductor; and (6) fabricating a second conductor above the CNT material and the diode. Numerous other aspects are provided.

Owner:SANDISK TECH LLC

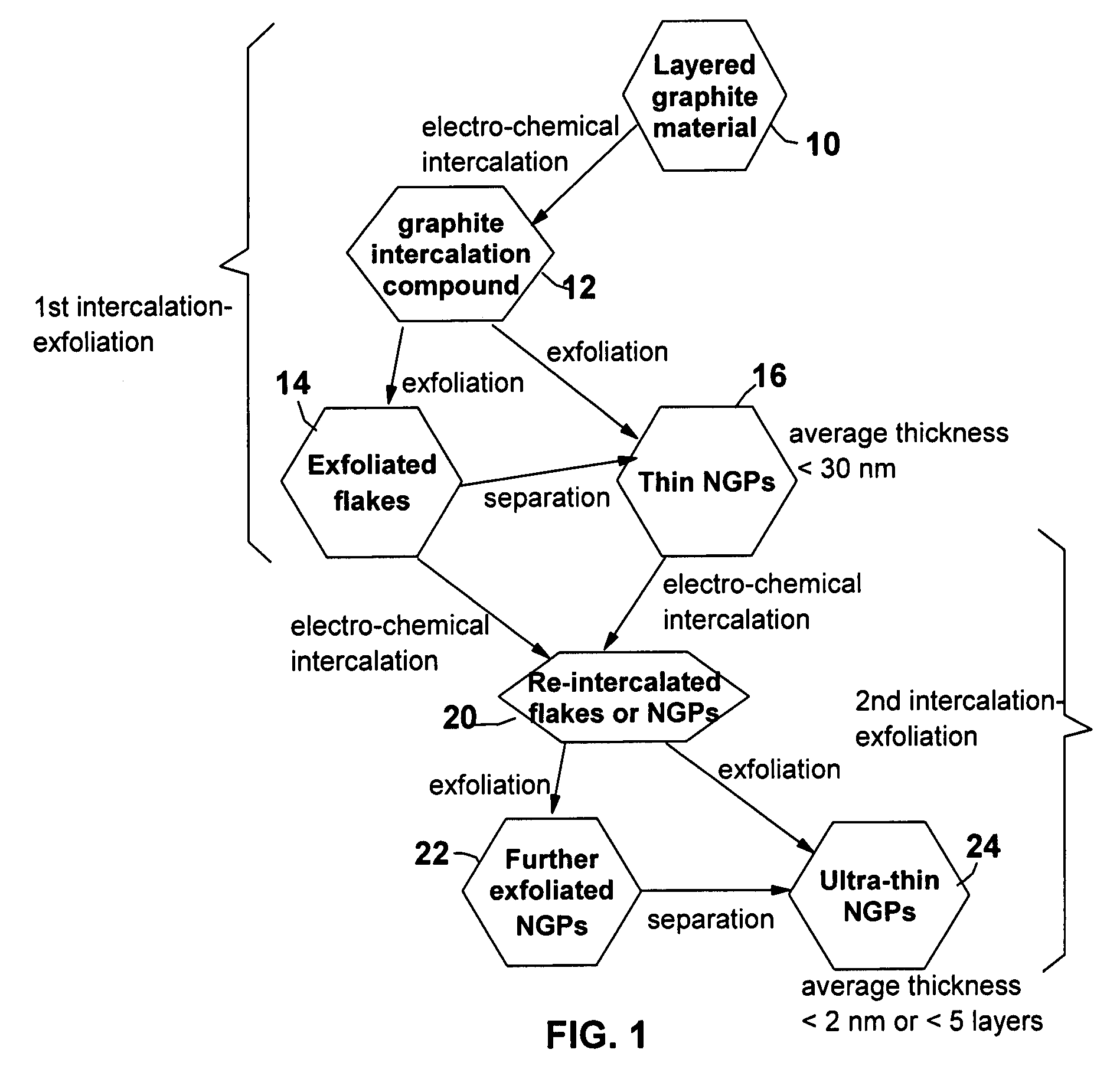

Electrochemical method of producing nano-scaled graphene platelets

A method of producing nano-scaled graphene platelets with an average thickness smaller than 30 nm from a layered graphite material. The method comprises (a) forming a carboxylic acid-intercalated graphite compound by an electrochemical reaction which uses a carboxylic acid as both an electrolyte and an intercalate source, the layered graphite material as an anode material, and a metal or graphite as a cathode material, and wherein a current is imposed upon the cathode and the anode at a current density for a duration of time sufficient for effecting the electrochemical reaction; (b) exposing the intercalated graphite compound to a thermal shock to produce exfoliated graphite; and (c) subjecting the exfoliated graphite to a mechanical shearing treatment to produce the nano-scaled graphene platelets. Preferred carboxylic acids are formic acid and acetic acid. The exfoliation step in the instant invention does not involve the evolution of undesirable species, such as NOx and SOx, which are common by-products of exfoliating conventional sulfuric or nitric acid-intercalated graphite compounds. The nano-scaled platelets are candidate reinforcement fillers for polymer nanocomposites. Nano-scaled graphene platelets are much lower-cost alternatives to carbon nano-tubes or carbon nano-fibers.

Owner:GLOBAL GRAPHENE GRP INC

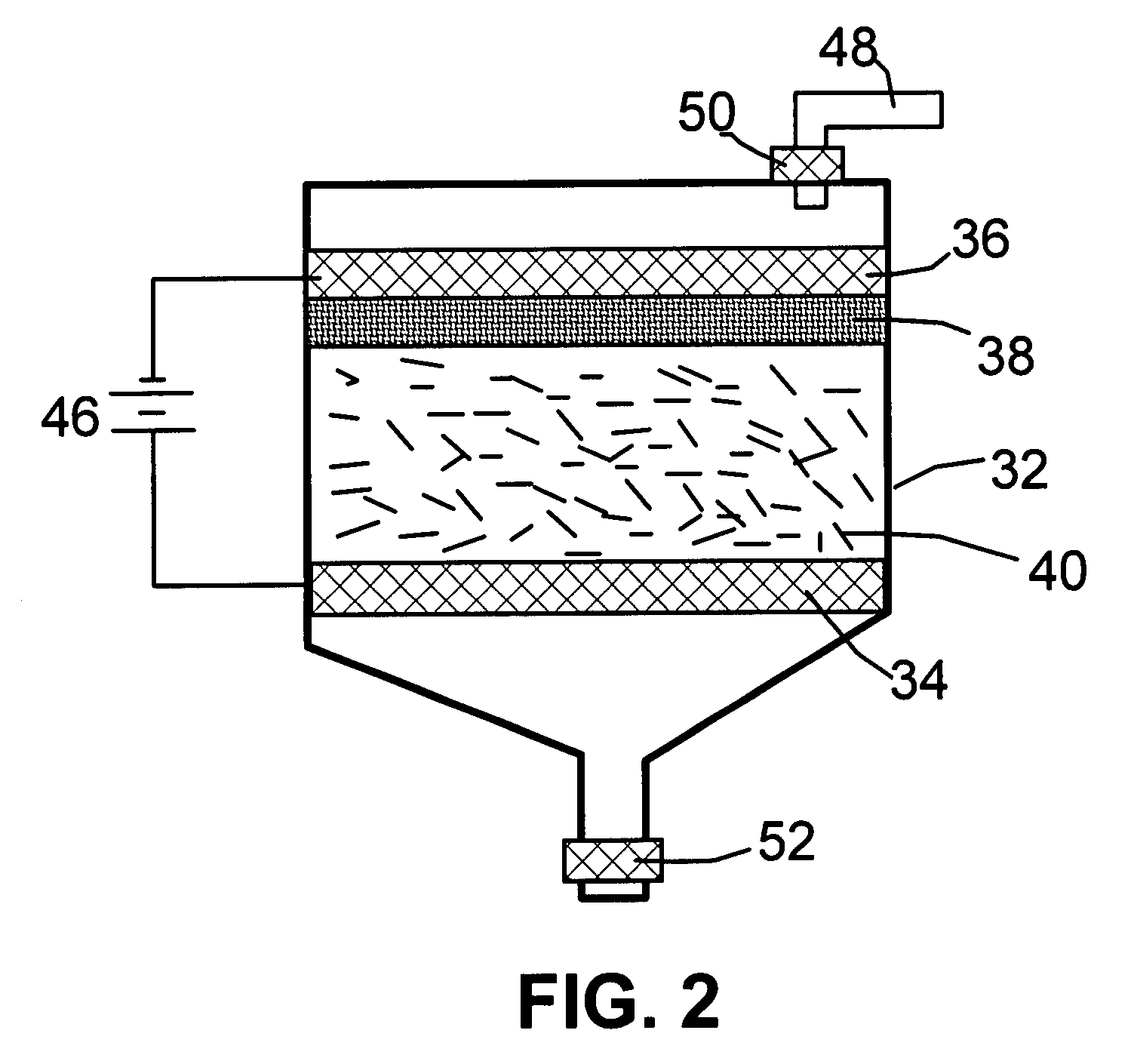

Production of ultra-thin nano-scaled graphene platelets from meso-carbon micro-beads

ActiveUS20090169467A1Improve permeabilityPromote quick completionMaterial nanotechnologyPigmenting treatmentFiberMetallurgy

A method of producing nano-scaled graphene platelets (NGPs) having an average thickness no greater than 50 nm, typically less than 2 nm, and, in many cases, no greater than 1 nm. The method comprises (a) intercalating a supply of meso-carbon microbeads (MCMBs) to produce intercalated MCMBs; and (b) exfoliating the intercalated MCMBs at a temperature and a pressure for a sufficient period of time to produce the desired NGPs. Optionally, the exfoliated product may be subjected to a mechanical shearing treatment, such as air milling, air jet milling, ball milling, pressurized fluid milling, rotating-blade grinding, or ultrasonicating. The NGPs are excellent reinforcement fillers for a range of matrix materials to produce nanocomposites. Nano-scaled graphene platelets are much lower-cost alternatives to carbon nano-tubes or carbon nano-fibers.

Owner:GLOBAL GRAPHENE GRP INC

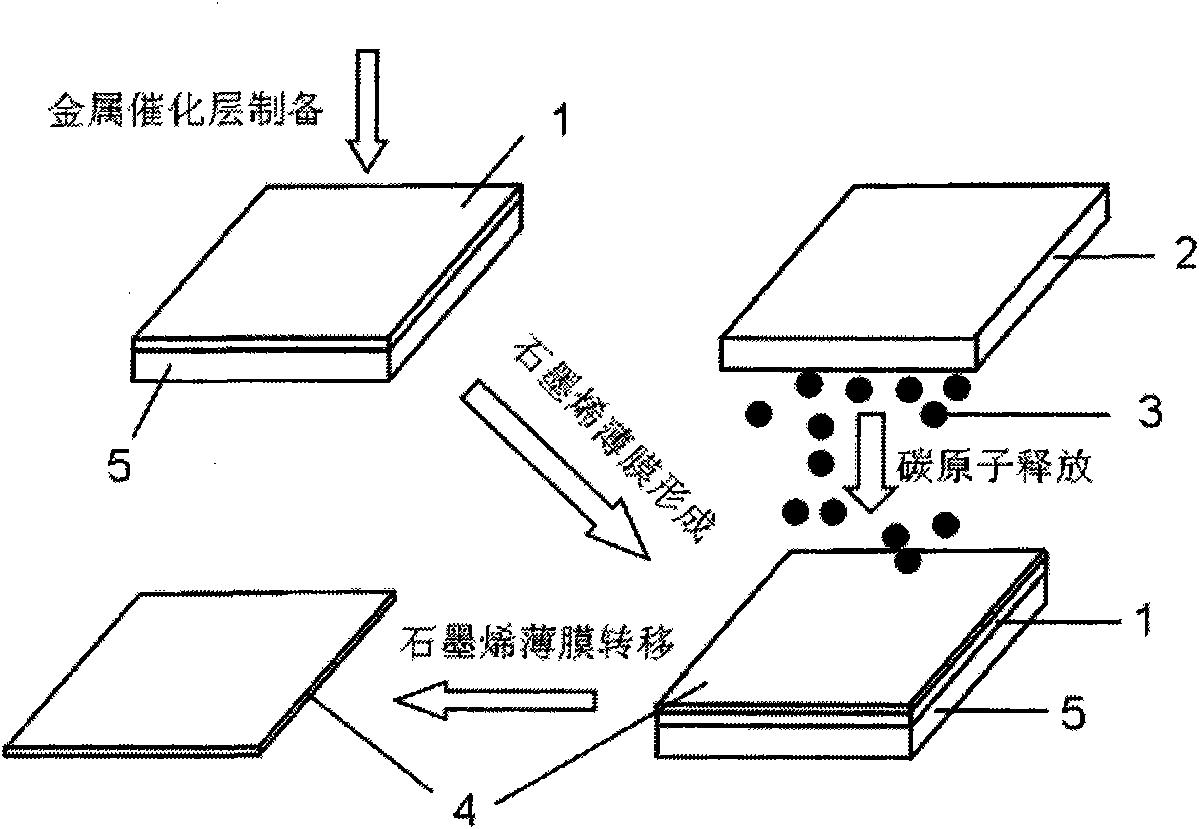

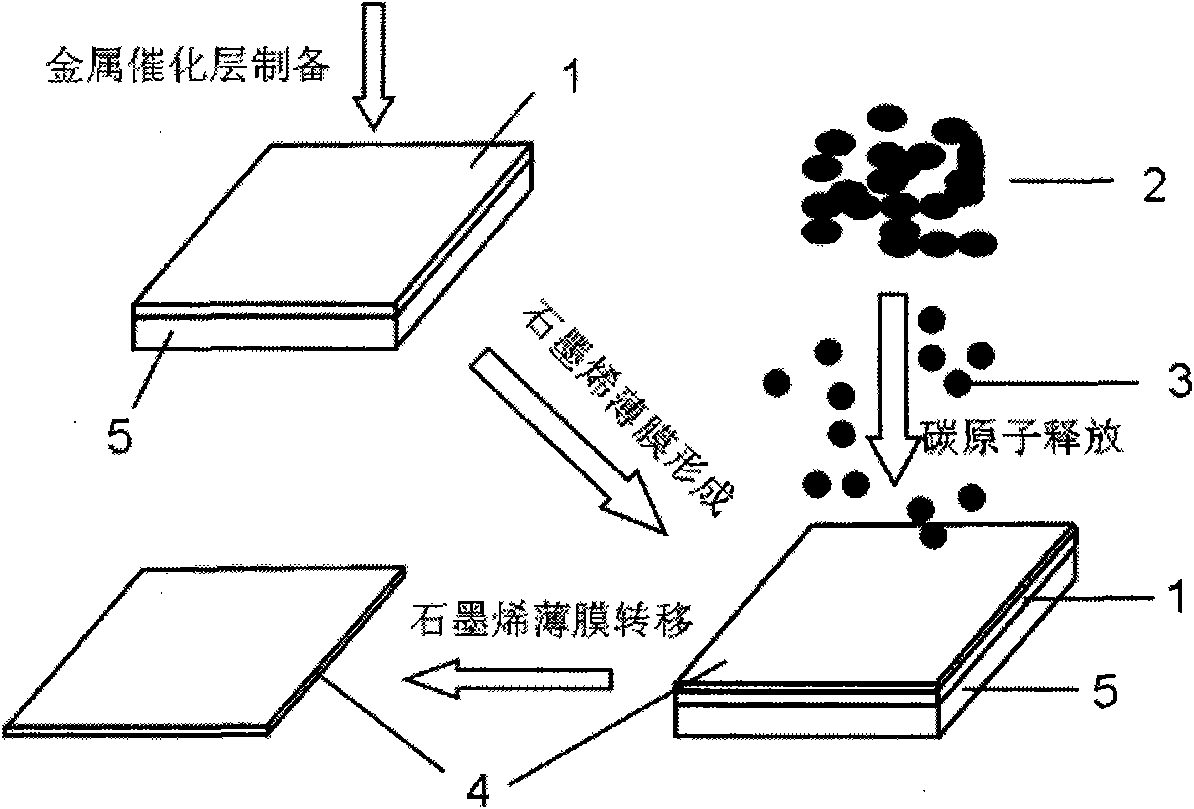

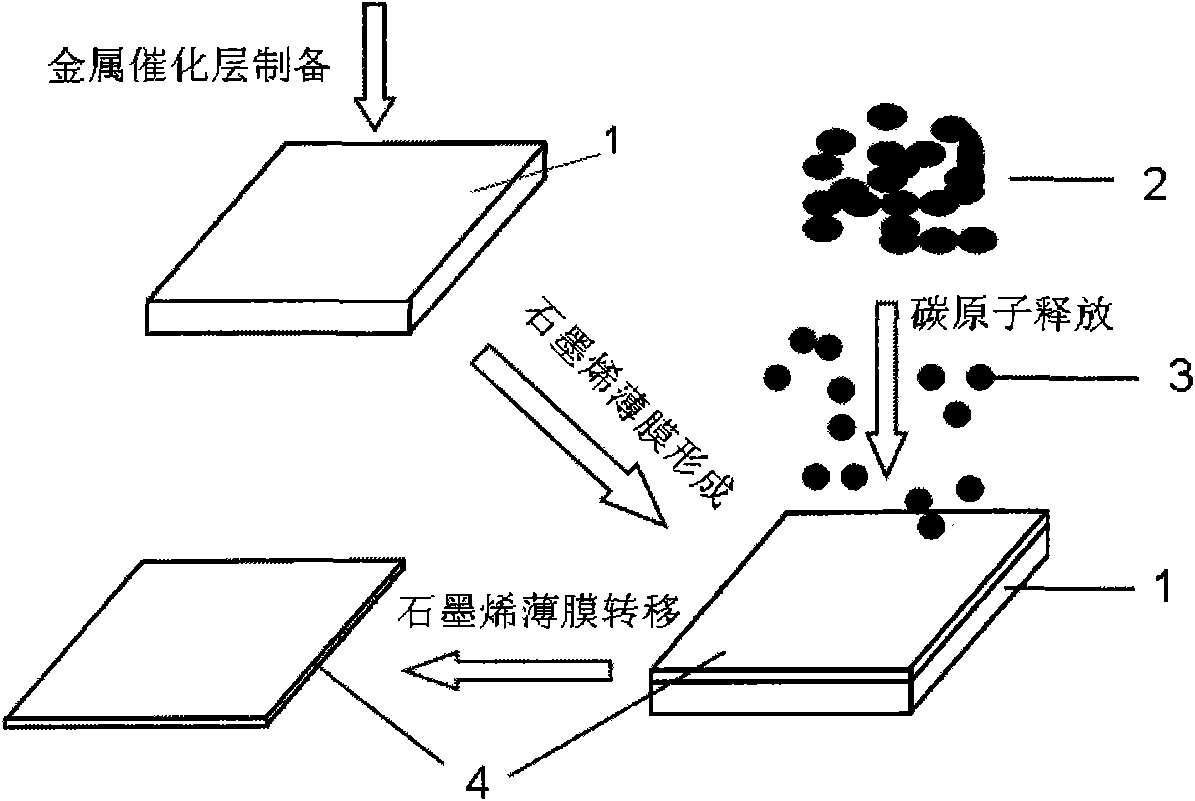

Method for preparing graphene membrane

The invention discloses a method for preparing a graphene membrane. Carbon atoms are released from a solid carbon source by a method such as heat treatment, heat evaporation, sputtering, electron beam deposition, laser deposition or plasma deposition to form the graphene membrane on a catalytic layer or a substrate, wherein the solid carbon source is graphite, amorphous carbon, diamond, fullerene or carbon nano tubes. In the method for preparing the graphene membrane, the solid carbon source is used, the method is simple; and the prepared graphene membrane is easy to control in terms of thickness, structure and size, has excellent photoelectric characteristics and is suitable for preparing high-performance photoelectronic devices on a large scale.

Owner:ZHEJIANG UNIV

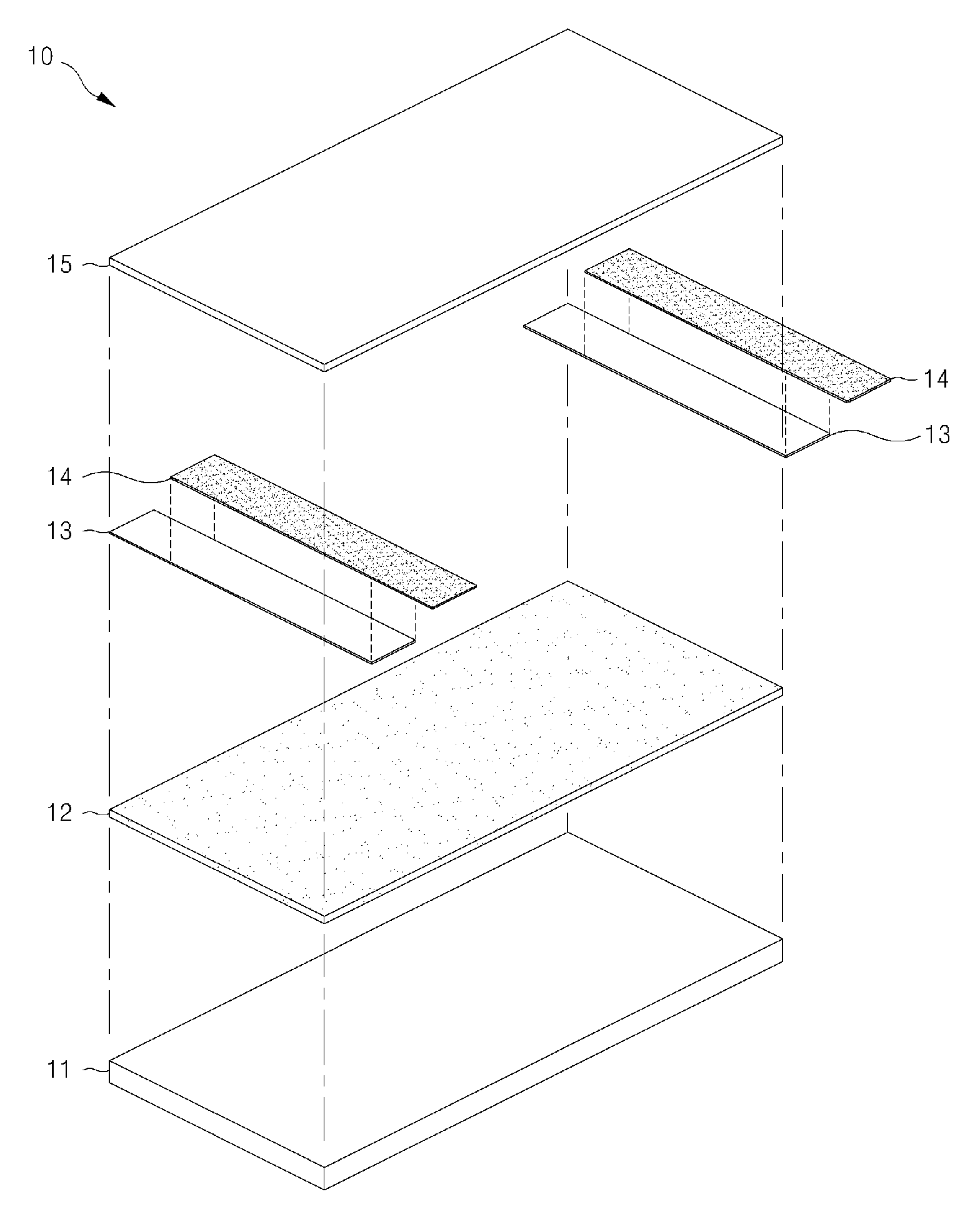

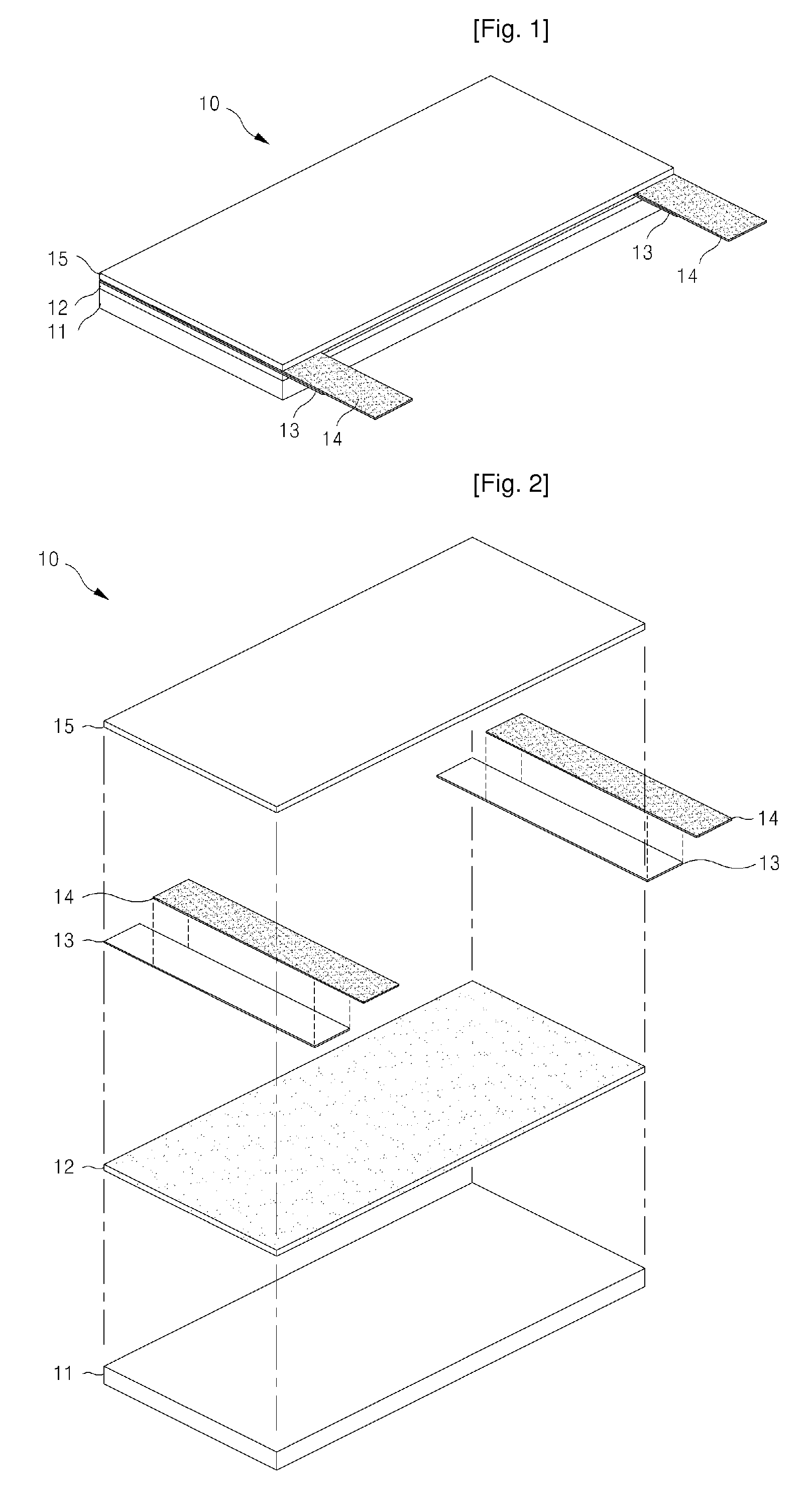

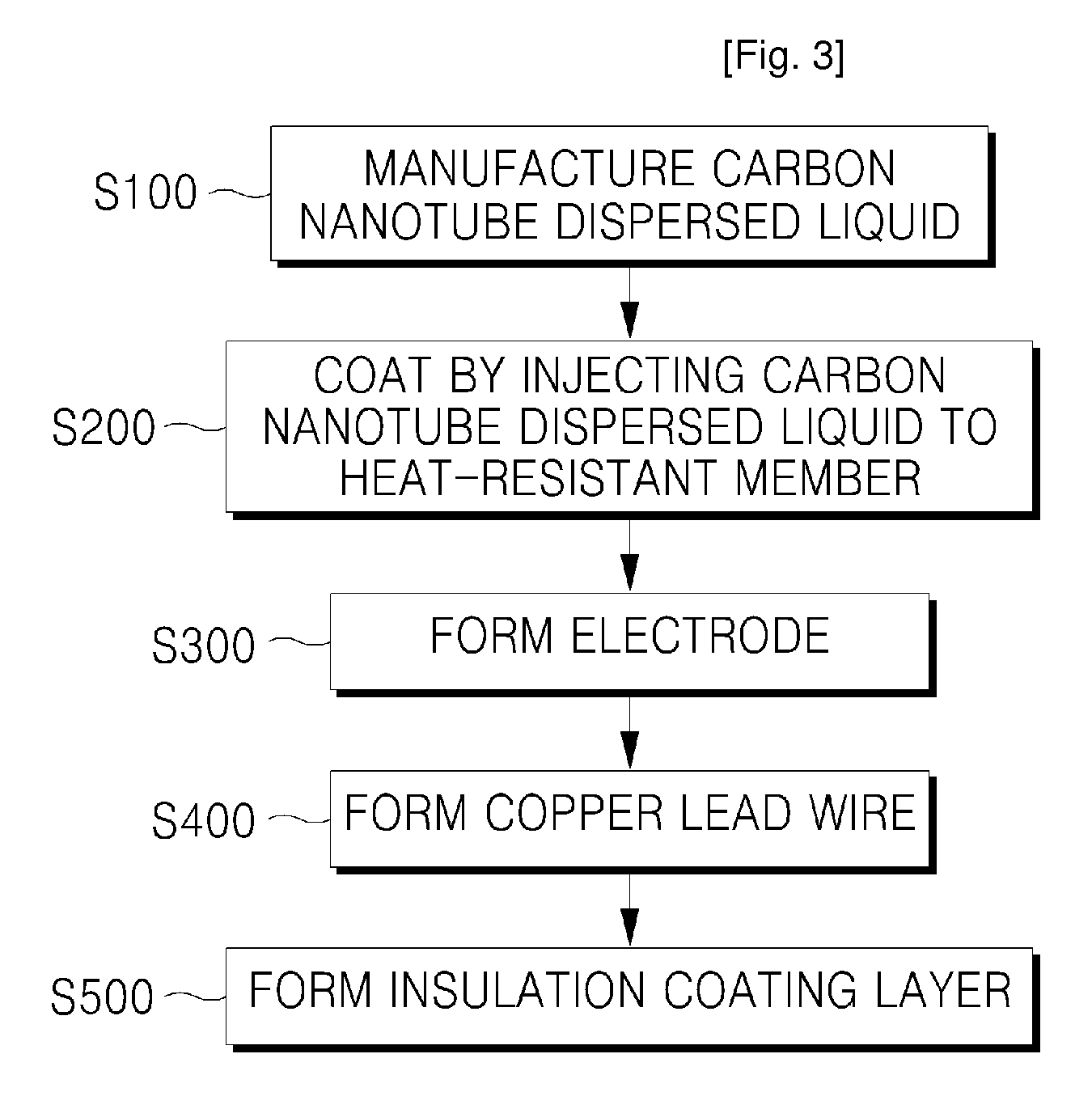

Heating element using carbon NANO tube

InactiveUS20090194525A1Easy to changeQuality improvementHeating element materialsCarbon nanotubesCarbon nanotubeCoating

Provided is a heating element using carbon nanotube including a heat-resistant member having a heat-resistant characteristic, a carbon nanotube coating layer formed on at least one surface of the heat-resistant member, and a pair of electrodes electrically connected to the carbon nanotube coating layer and inducing heating of the carbon nanotube coating layer when connected to power. The manufactured in a simple process of coating a heat-resistant member with carbon nanotube, relatively reduce the overall manufacturing time, easily change the shape and specifications, and have a heating efficiency higher than that of a heating element having a different shape and material.

Owner:EXAENC CORP

High-strength and high-toughness reactive powder concrete of carbon doped nano-tube and preparation method of high-strength and high-toughness reactive powder concrete

The invention provides high-strength and high-toughness reactive powder concrete of a carbon doped nano-tube. The high-strength and high-toughness reactive powder concrete is prepared by taking cement, a carbon nano-tube, silica fume, a water reducing agent, silica sand, coal ash, quartz powder, steel fiber and water as raw materials, wherein all the components in the mixture are calculated in parts by mass: 1000-1200 parts of cement, 250-350 parts of silica fume, 250-350 parts of slag powder, 40-50 parts of water reducing agent, 1200-1400 parts of silica sand, 180-230 parts of water, 190-230 parts of steel fiber, 180-250 parts of coal ash, 80-120 parts of quartz powder, 0.1-5 parts of carbon-nano-tube dispersing agent and 1-10 parts of carbon nano-tube powder. The invention also provides a preparation method of the high-strength and high-toughness reactive powder concrete. The reactive powder concrete obtained by the invention has the high compression strength of 250-300MPa and breaking strength of 45-60MPa, which are higher than the 200-level related performances of the traditional RPC (Reactive Powder Concrete). Meanwhile, the initial cracking strength of the reactive powder concrete material prepared by using the carbon nano-tube is greatly improved and is up to 10MPa in a direct stretching state, and the tensile strain corresponding to peak stress is up to more than 0.5%, so that the toughness and strength of the traditional RPC material are greatly improved.

Owner:浙江固邦新材料有限公司

Method for preparing graphene-carbon nano tube hybrid composite

InactiveCN101734650ALow costIncrease stiffnessNanostructure manufactureChemical industryCarbon nanotube

The invention provides a method for preparing a graphene-carbon nano tube hybrid composite and relates to a method for preparing a functional high molecular material and a device thereof. The method comprises the following steps of: carrying out the stirring and sonic oscillation treatment on graphene and carbon nano tubes to preform an entangled network structure, thoroughly mixing the entangled network structure and polymer particles, and thus obtaining an uniformly-mixed system in which the graphene-carbon nano tube network is coated on the surfaces of the polymer particles after removing the solvent; and putting the uniformly-mixed system in a mould, hot-compacting, and obtaining the graphene-carbon nano tube hybrid composite after cooling and demoulding. By mingling the graphene and the carbon nano tubes in advance to form the communicated network structure, the method realizes the advantage complementation of the graphene and carbon nano tube structures and enables the hybrid composite to have favorable electric conduction and heat conduction properties. The method can be widely used in the fields such as aviation, transportation and communication, electronic industry, civil facilities, construction, chemical industry and the like, can be produced in the industrial scale, and has the advantages of low cost and environmental friendliness.

Owner:SHENYANG JIANZHU UNIVERSITY

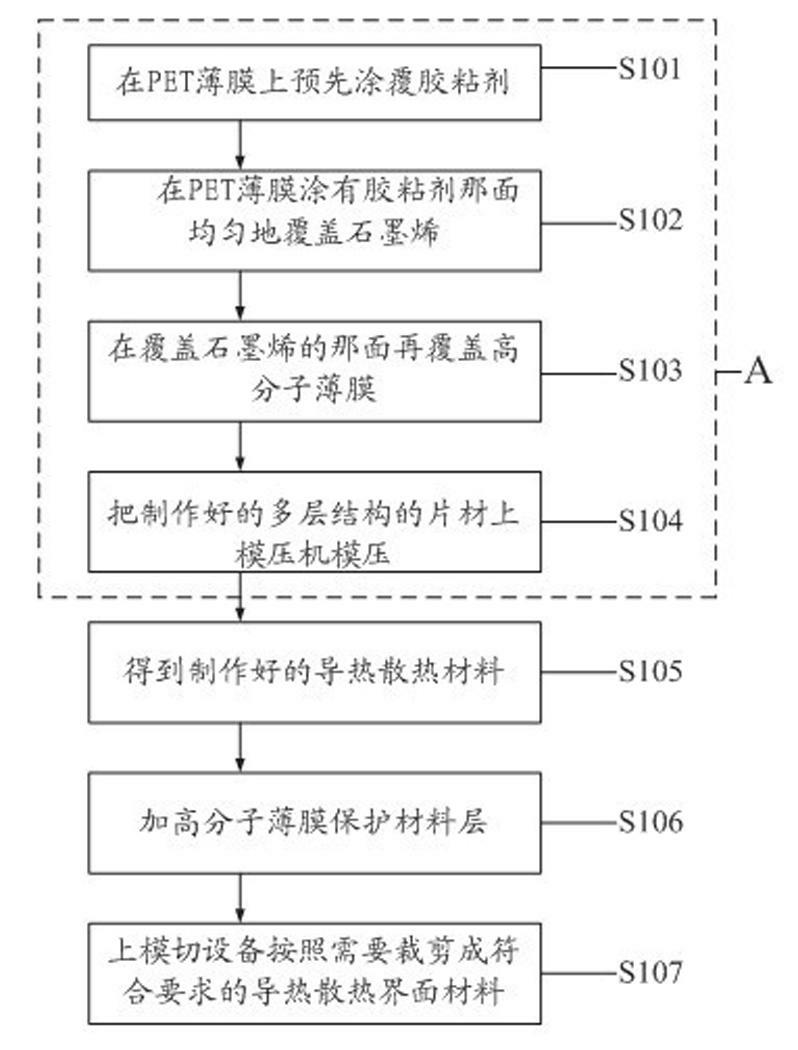

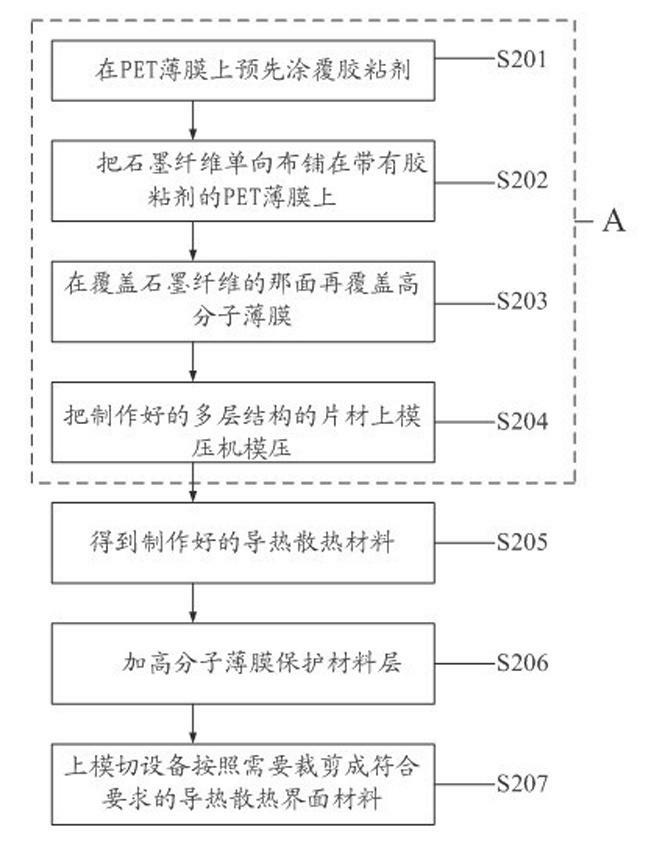

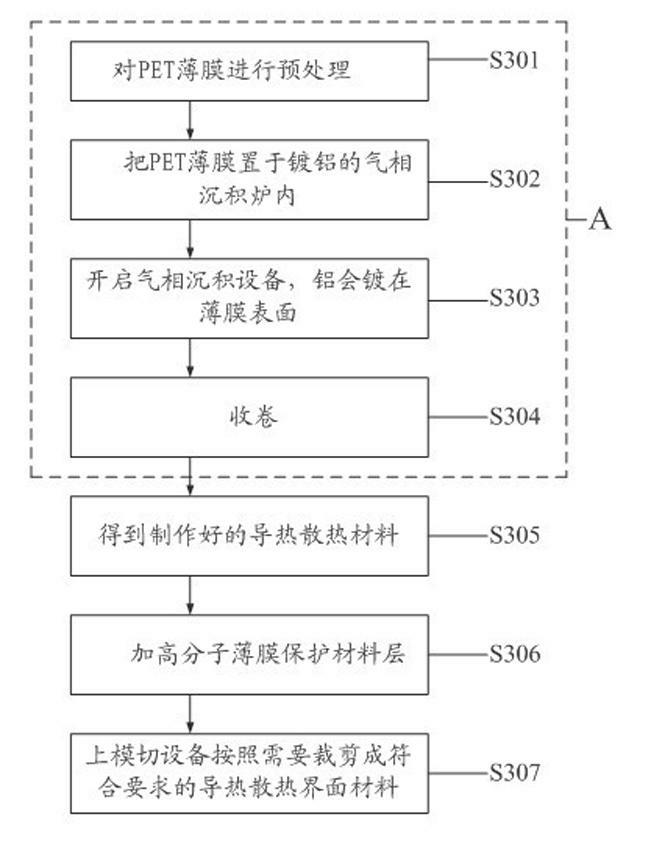

Heat-conduction heat-dissipation interface material and manufacturing method thereof

ActiveCN102651961AReduce volumeThe overall thickness is thinLayered productsCooling/ventilation/heating modificationsMetal fiberCalcium silicate

The invention provides a heat-conduction heat-dissipation interface material and a manufacturing method thereof, wherein the heat-conduction heat-dissipation interface material is applied to the field of heat dissipation of electronic products. The heat-conduction heat-dissipation interface material comprises a heat-conduction heat-dissipation layer and a surface protective material layer, wherein the heat-conduction heat-dissipation layer consists of one or more of graphite, nano graphite, crystalline flake graphite, graphene, pyrolytic carbon, pyrolytic graphite, graphite powder, carbon nano tubes, carbon fibers, graphite fibers, resin, ceramic fibers, quartz fibers, metal fibers, zirconia, boron nitride, silicon nitride, boron carbide, silicon carbide, magnesia powder, metasillicio acid fibers, calcium silicate aluminum fibers, aluminium oxide fibres, copper power, aluminium power, silver power, tungsten power and molybdenum power; and the surface protective material layer is a polymeric membrane. The heat-conduction heat-dissipation interface material manufactured according to the materials and the method provided by the invention has the advantages of effectively improved heat-dissipation performance, small volume, light weight and small thickness, can be used for prolonging the service life of an electronic component, and simultaneously is easy to produce and process.

Owner:SHANGHAI QI JIE CARBON MATERIALS

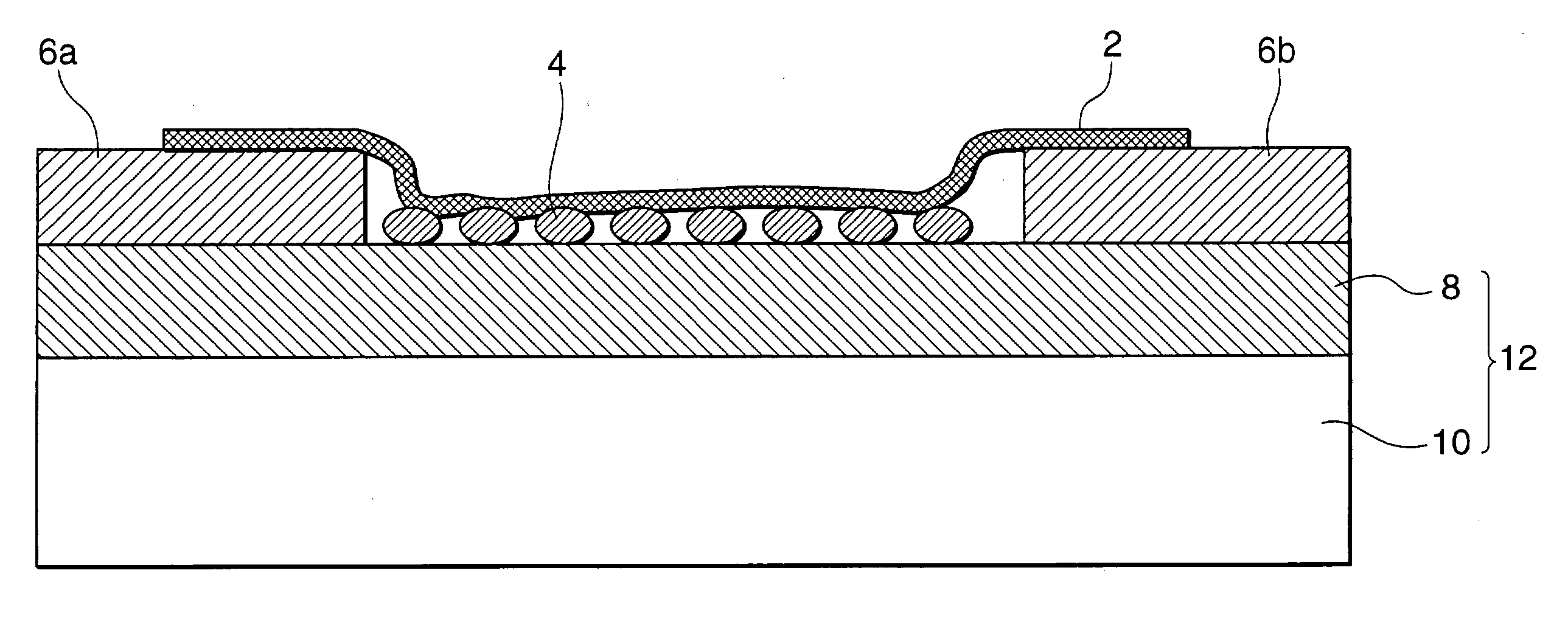

Strip electrode with conductive nano tube printing

InactiveUS20050186333A1Accurate electronic readoutMinimizing strip to strip variationImmobilised enzymesBioreactor/fermenter combinationsSilver inkCarbon nanotube

A sensor system that detects a current representative of a compound in a liquid mixture features a multi or three electrode strip adapted for releasable attachment to signal readout circuitry. The strip comprises an elongated support which is preferably flat adapted for releasable attachment to the readout circuitry; a first conductor and a second and a third conductor each extend along the support and comprise means for connection to the circuitry. The circuit is formed with single-walled or multi walled nanotubes conductive traces and may be formed from multiple layers or dispersions containing, carbon nanotubes, carbon nanotubes / antimony tin oxide, carbon nanotubes / platinum, or carbon nanotubes / silver or carbon nanotubes / silver-cloride. An active electrode formed from a separate conductive carbon nanotubes layer or suitable dispersion, positioned to contact the liquid mixture and the first conductor, comprises a deposit of an enzyme capable of catalyzing a reaction involving the compound and preferably an electron mediator, capable of transferring electrons between the enzyme-catalyzed reaction and the first conductor. A reference electrode also formed from a conductive carbon nanotube layer or suitable dispersion is positioned to contact the mixture and the second conductor. The system includes circuitry adapted to provide an electrical signal representative of the current which is formed from printing conductive inks made with nano size particles such as conductive carbon or carbon / platinum or carbon / silver, or carbon nanotubes / antimony tin oxide to form a conductive carbon nanotube layers. The multiple-electrode strip is manufactured, by then applying the enzyme and preferably the mediator onto the electrode. Alternatively the electrode can have a carbon nanotubes / antimony tin oxide, carbon nanotubes / platinum, or carbon nanotubes / silver or carbon nanotubes / silver-cloride surface and or a conductive carbon or silver ink surface connecting leg. The carbon nanotube solution is first coated and patterned into electro shapes and the conductive carbon nanotubes, carbon or silver ink can be attached by printing the ink to interface with the carbon nanotube electro surface. A platinum electrode test strip is also disclosed that is formed from either nano platinum distributed in the carbon nanotube layer or by application or incorporation of platinum to the carbon nanotube conductive ink.

Owner:DOUGLAS JOEL S MR

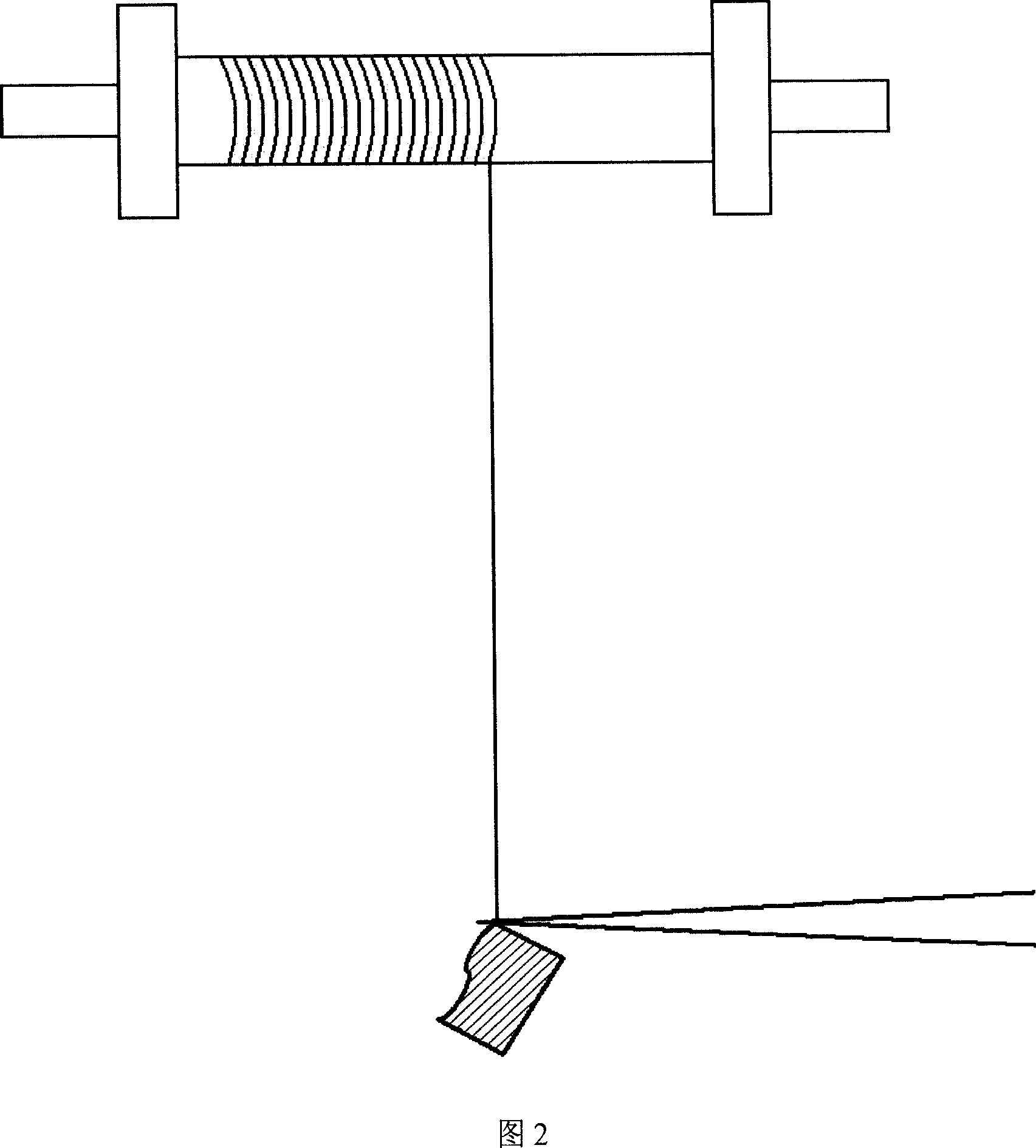

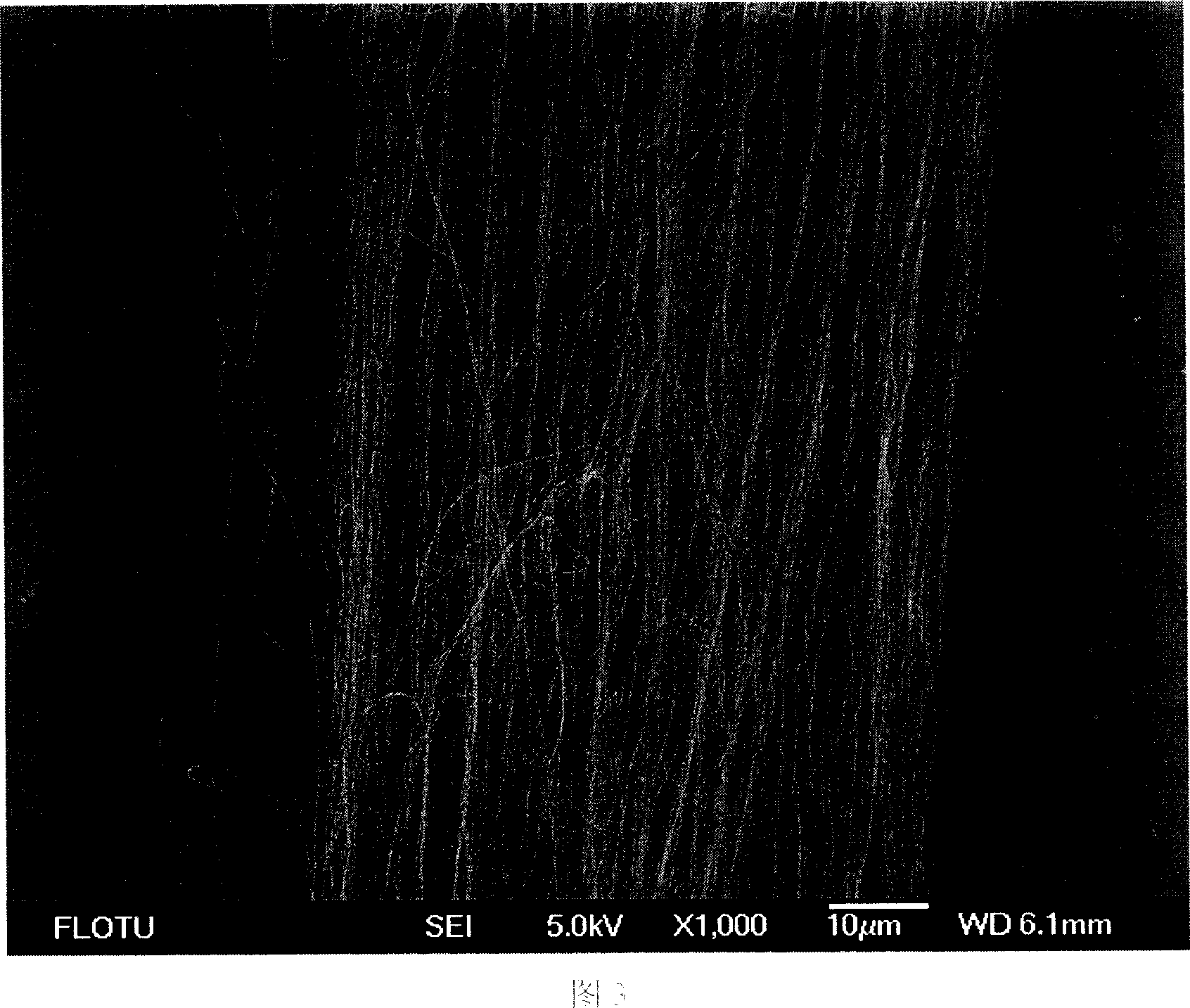

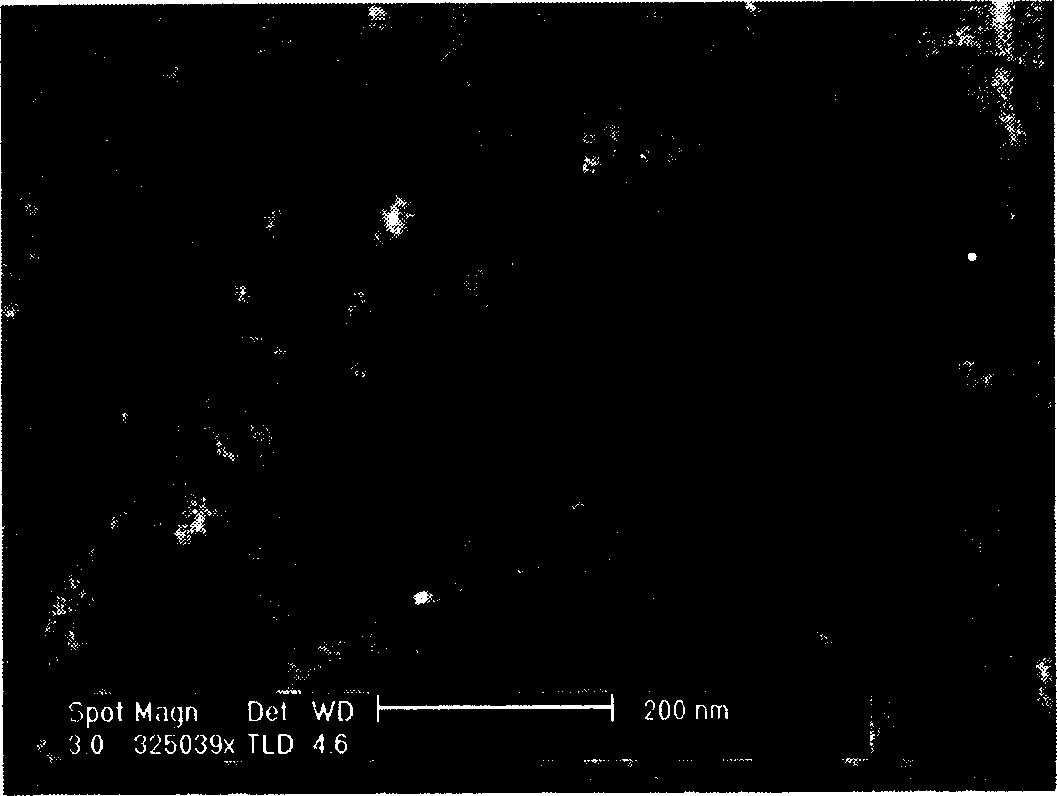

Ultralong orientational carbon nano-tube filament/film and its preparation method

ActiveCN1948144ASolve the problem of high-volume preparationMaterial nanotechnologyIndividual molecule manipulationMicrometerCarbon nanotube

Owner:TSINGHUA UNIV

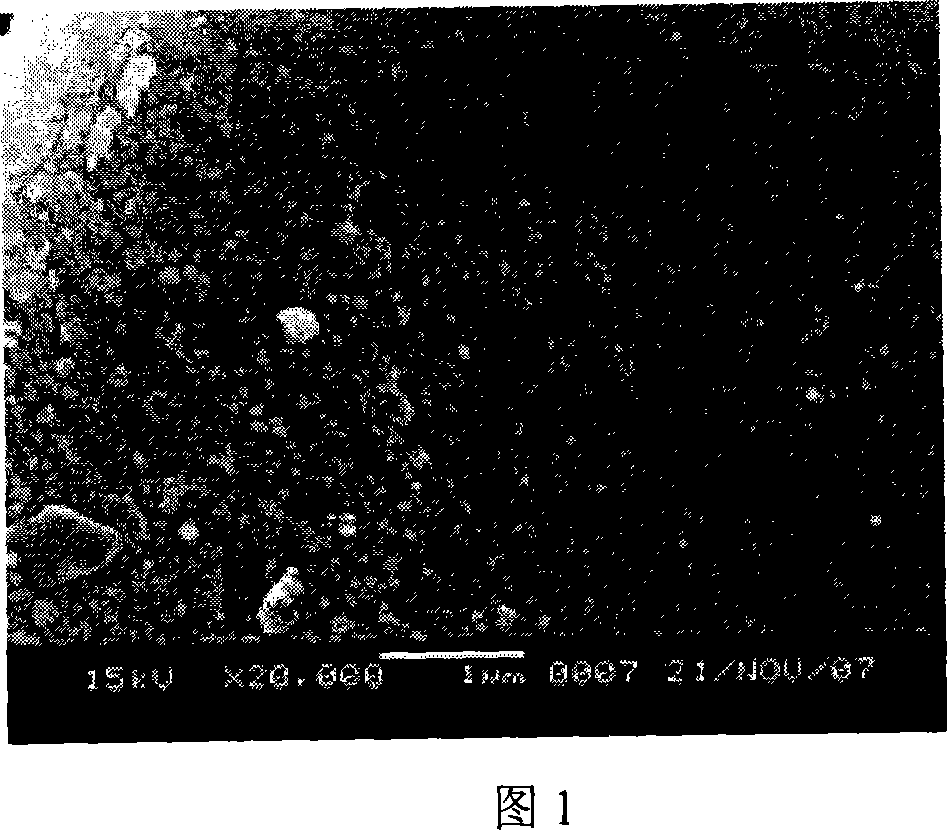

Carbon silicon composite material, its preparation method and use

InactiveCN1903793AStable structureLarge specific surface areaElectrode manufacturing processesFuel cellsSilicon matrixCarbon fibers

The present invention relates to a carbon-silicon composite material. It includes silicon matrix and carbon nano tube or nano carbon fibre grown on the matrix. The average grain size of the described silicon matrix is 100 nm-100 micrometer, the diameter of the described carbon nano tube or nano carbon fibre is 1-200 nm and its length is 1 nm-100 micrometer. The described carbon nano tube is single-wall, double-wall or multiwall. Said invention also provides its preparation method and concrete steps.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

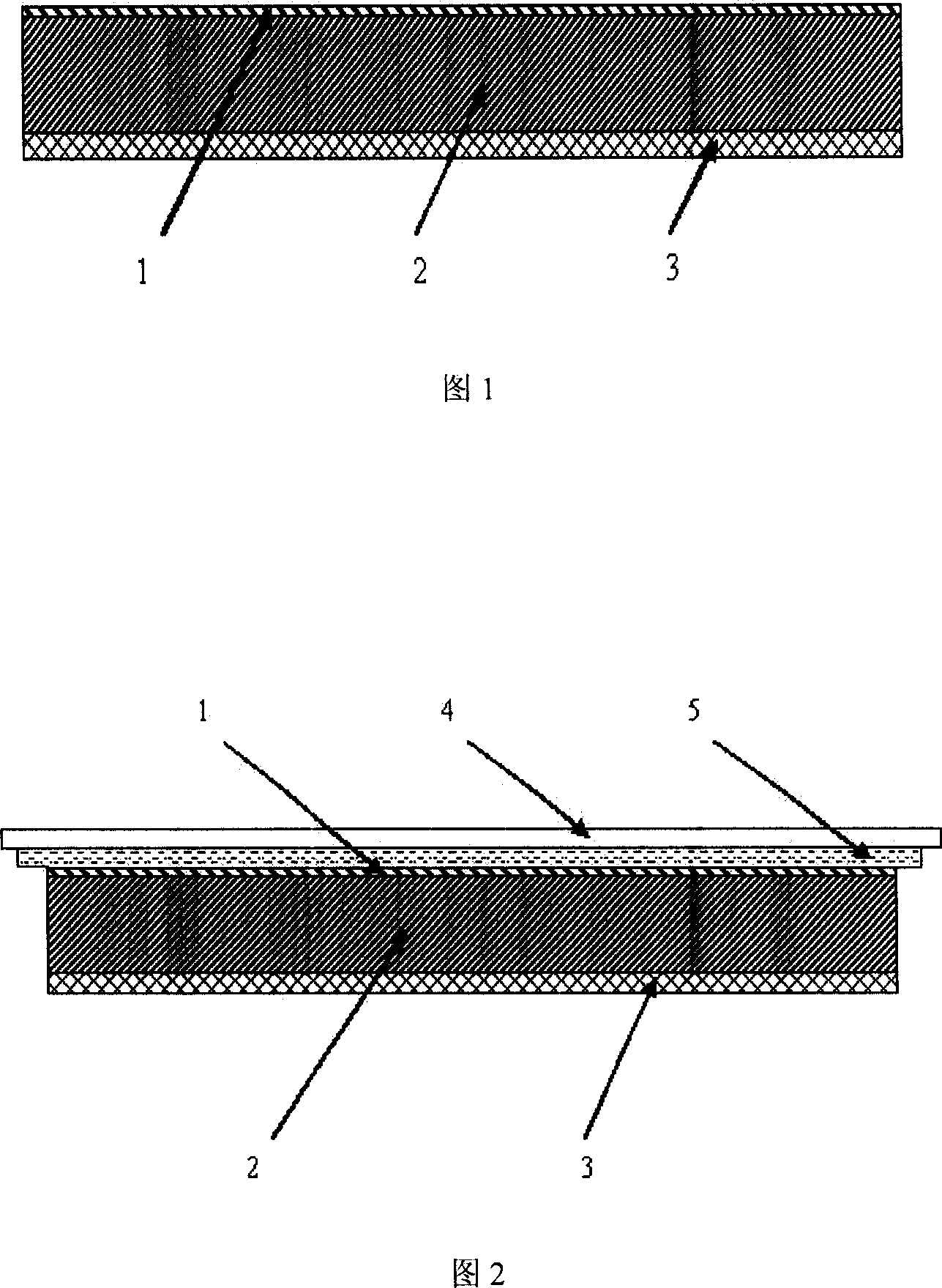

Carbon nano tube film-based solar energy battery and its preparing method

ActiveCN1996620AEasy to prepareImprove conversion efficiencyFinal product manufactureNanoinformaticsElectricityFilm base

This invention relates to solar energy battery of carbon nanometer tube film and its process method in solar battery and nanometer material application technique field, which comprises the following technique: adopting carbon nanometer tube film as photo electricity conversion materials with carbon nanometer film as upper electrode; the film is set with transparent conductive film as conversion materials; the film is used as upper electrode.

Owner:TSINGHUA UNIV

Method for manufacturing polyacrylonitrile-based carbon fiber with enganced carbon nano-tube

InactiveCN101250770ASimple preparation processEasy to controlArtifical filament manufactureCarbon fibersHeat conducting

The invention relates to a method for preparing polyacrylonitrile-based carbon fiber with reinforced carbon nanometer tubes, which comprises the following steps: respectively dispersing and dissolving carbon nanometer tubes (CNT) and polyacrylonitrile (PAN) in dissolvent, obtaining PAN / CNT spinning solution through mixing the solution, obtaining PAN / CNT fiber through carrying out the wet-spinning method to the solution, then carrying out pre-oxidation and carbonization to the wet-spinning fiber to prepare the carbon fiber with reinforced carbon nanometer tubes. The mechanical property of the carbon fiber which is prepared by the method of the invention is obviously improved, and the prepared carbon fiber can be applied to the fields of reinforcing materials, conducting, electrostatic resistance, heat conducting and the like.

Owner:DONGHUA UNIV

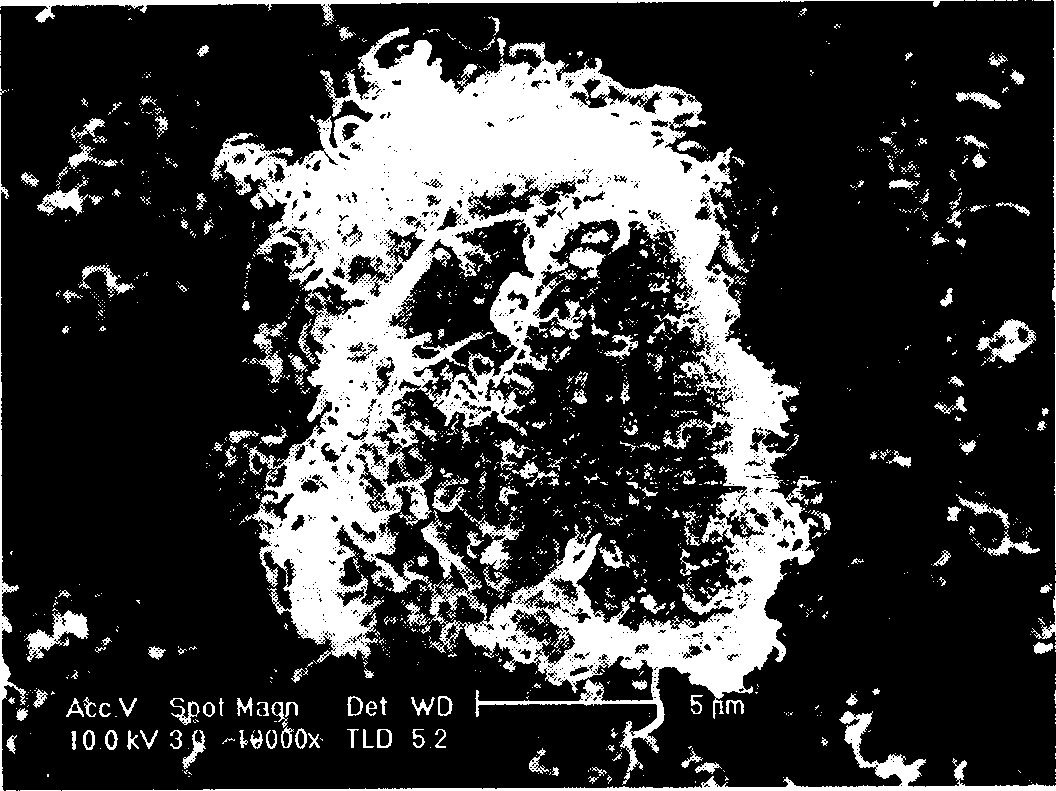

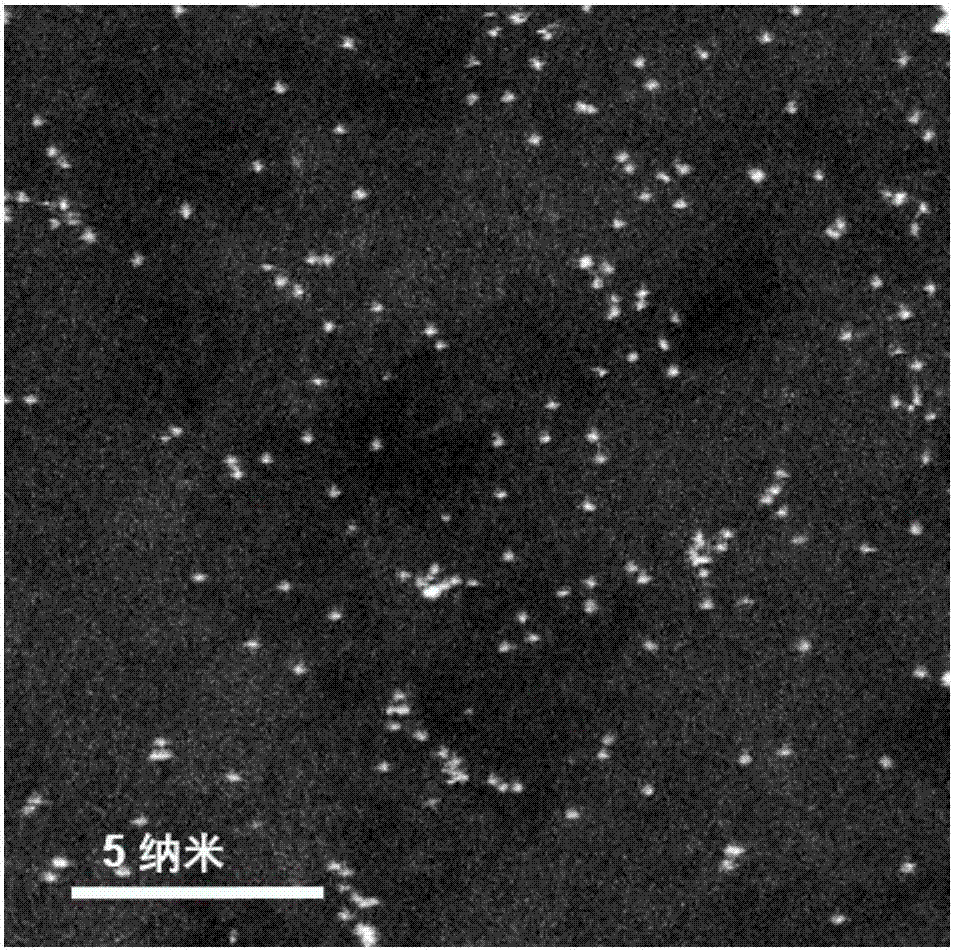

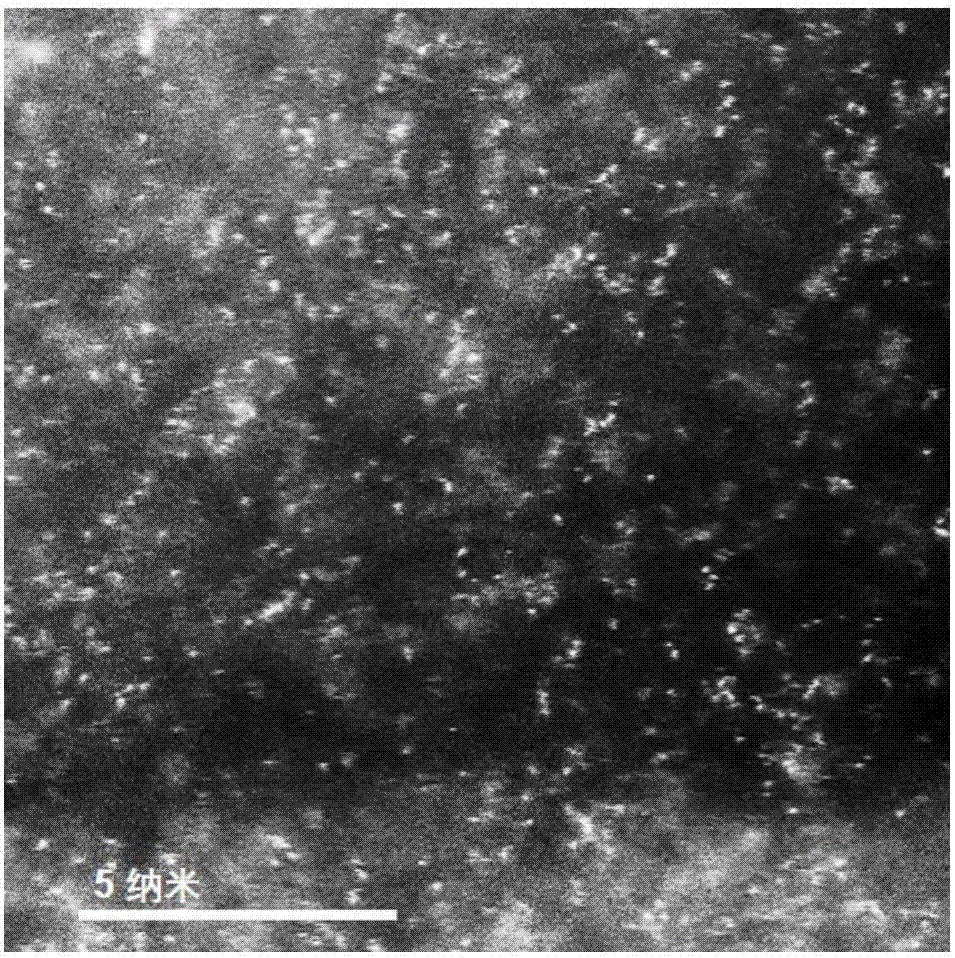

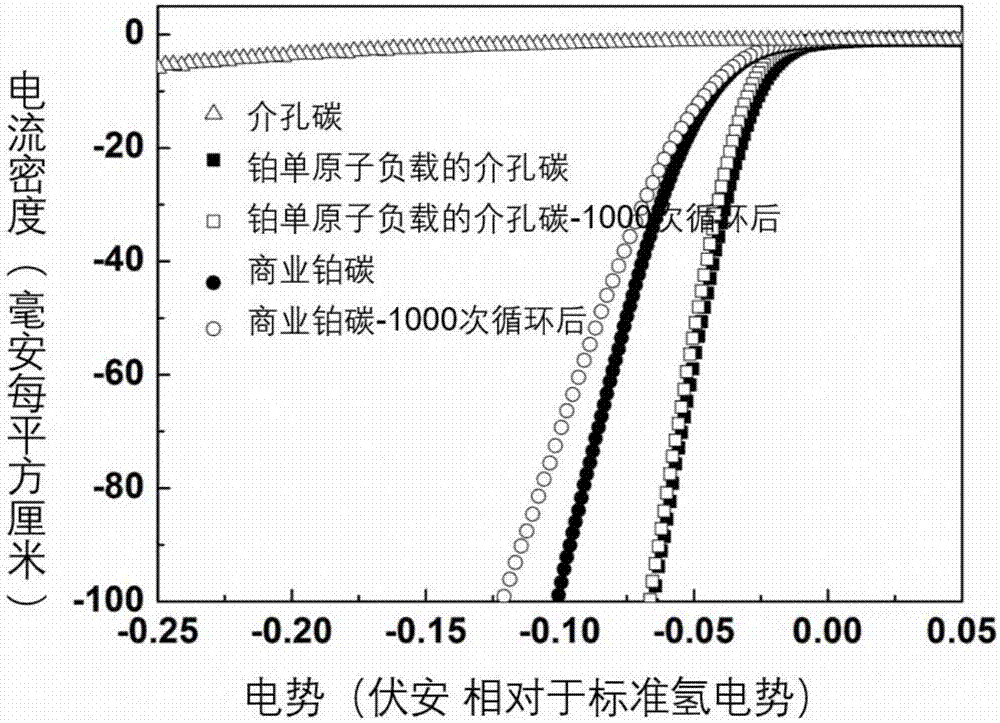

Preparation method of metal mono-atoms

ActiveCN106914237AImprove performanceLow costMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsCarbon filmFiltration

The invention relates to a preparation method of metal mono-atoms and belongs to the technical field of materials science and engineering. The metal mono-atoms prepared through the method may include: Pt, Ag, Au, Pd, Rh, Ir, Ru, Co, Ni and Cu, and metal mono-atoms supported on TiO2, zinc oxide, cerium oxide, aluminum oxide, silicon oxide, ferric oxide, manganese oxide, C3N4, mesoporous carbon, ultrathin carbon films, graphene, carbon nano tubes or molecular sieve materials, etc. The method includes the steps of: preparing a precursor solution in a certain concentration, and freezing the solution; and under an ice phase, processing ice cubes by means of external field or reaction between reactants in the ice cubes, and when the ice cubes are molten, a mono-atom solution is finally produced; mixing the mono-atom solution with different materials, performing ultrasonic treatment, filtration, cleaning and drying to finally obtain the mono-atoms supported on various materials. The preparation method is quick, has high product density, allows mass production, is high in efficiency and has wide application range, and compared with a co-precipitation method and an impregnation method, the method has significant advantages.

Owner:TSINGHUA UNIV

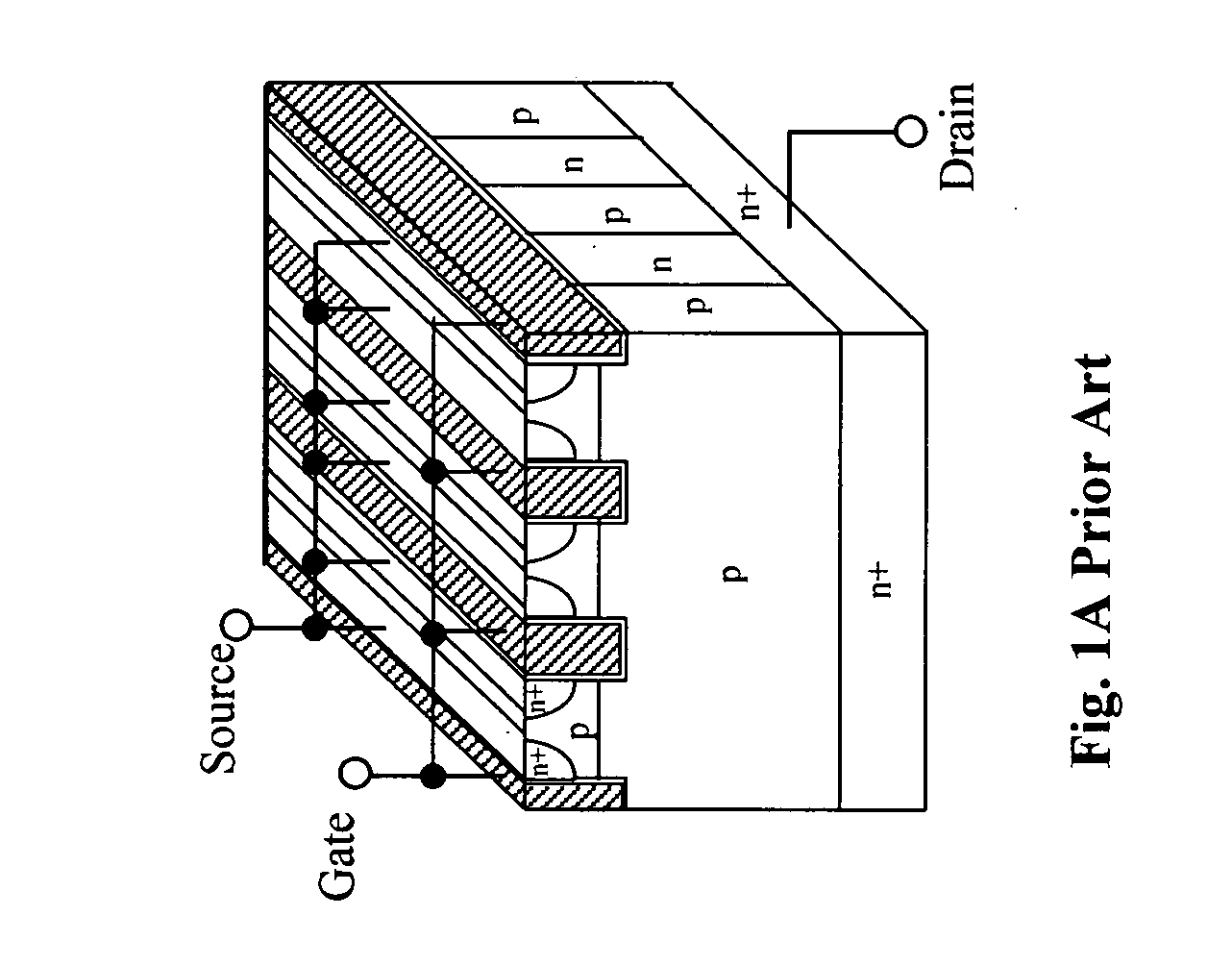

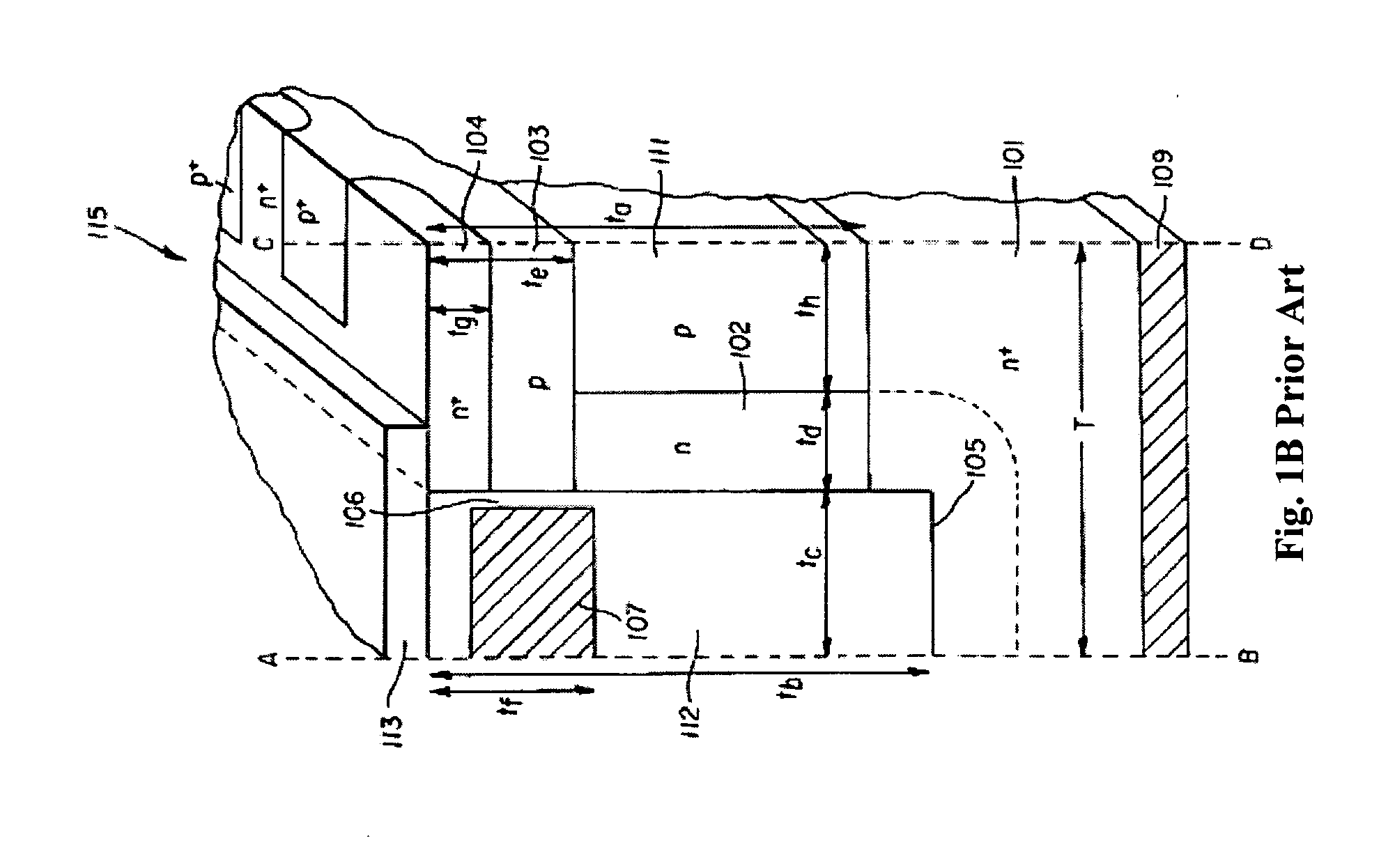

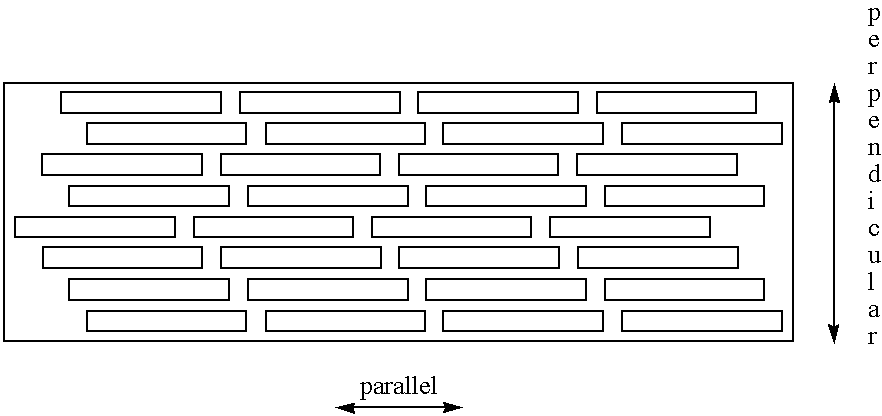

Configurations and methods for manufacturing devices with trench-oxide-nano-tube super-junctions

ActiveUS20100314682A1High production costEasy to fillSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringNon doped

This invention discloses semiconductor power device disposed on a semiconductor substrate of a first conductivity type. The semiconductor substrate supports an epitaxial layer of a second conductivity type thereon wherein the semiconductor power device is supported on a super-junction structure. The super-junction structure comprises a plurality of trenches opened from a top surface in the epitaxial layer; wherein each of the trenches having trench sidewalls covered with a first epitaxial layer of the first conductivity type to counter charge the epitaxial layer of the second conductivity type. A second epitaxial layer may be grown over the first epitaxial layer. Each of the trenches is filled with a non-doped dielectric material in a remaining trench gap space. Each of the trench sidewalls is opened with a tilted angle to form converging U-shaped trenches.

Owner:ALPHA & OMEGA SEMICON INC

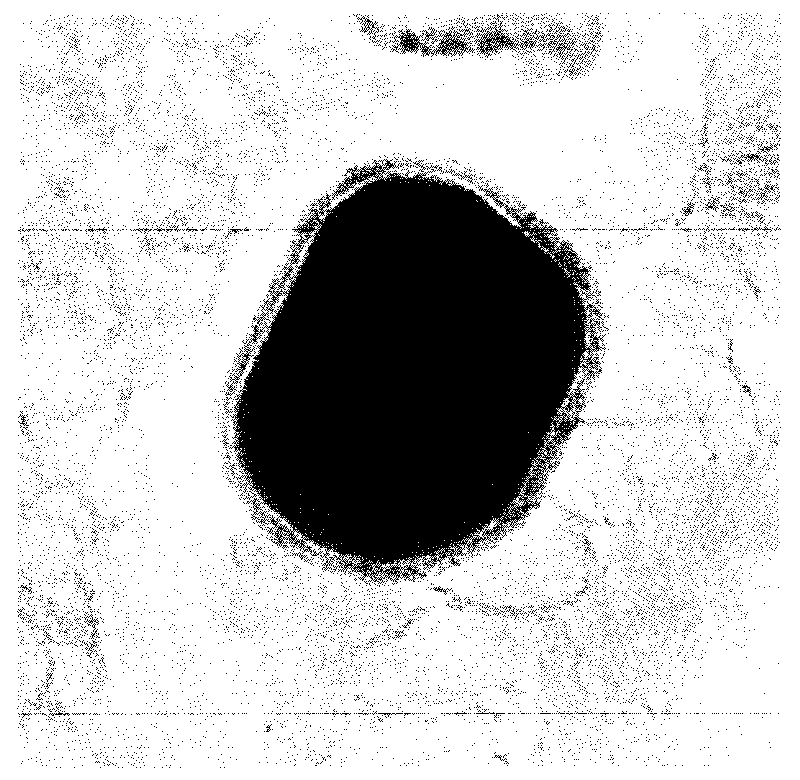

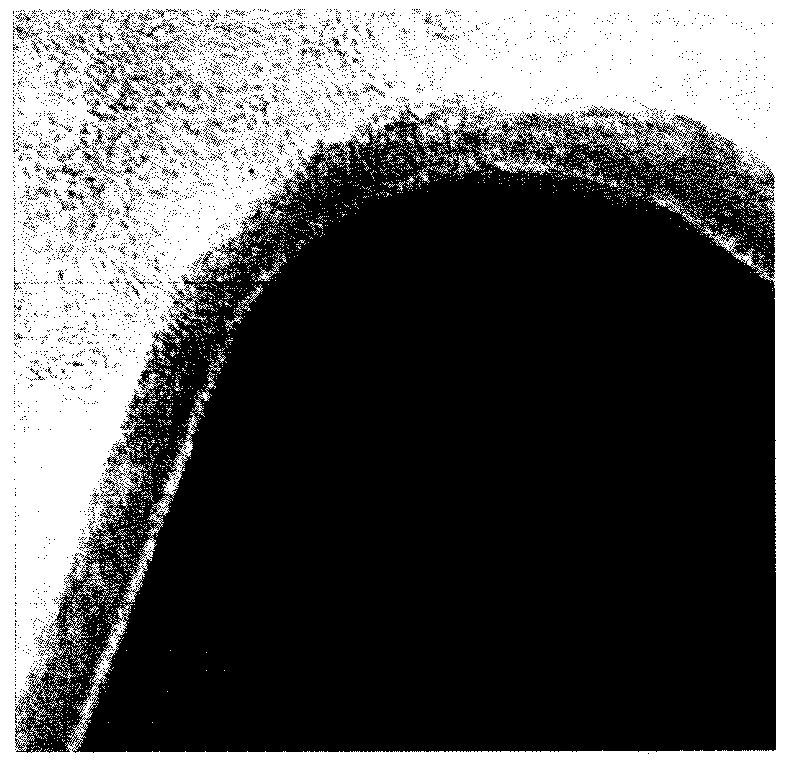

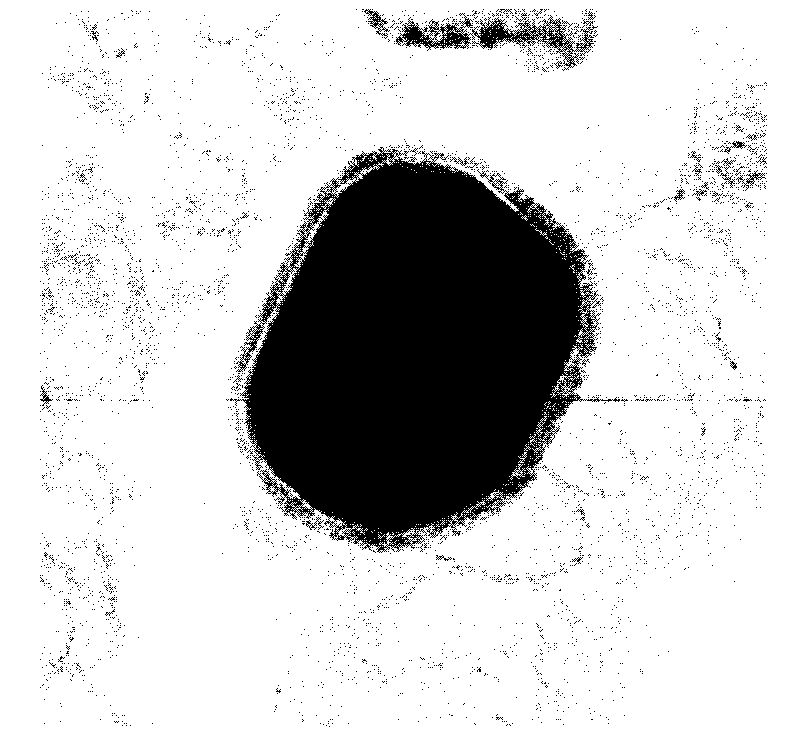

Angioplasty super balloon fabrication with composite materials

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

Integral supported carbon molecular sieve catalyst, preparing method and applications thereof

InactiveCN101224432AReduce the number of growthSave raw materialsMolecular sieve catalystsEther preparation by compound dehydrationGas phaseCarbon nanotube

A catalyst for an integrated supported carbon modular sieve comprises an integrated beehive cordierite, a carbon-nano tube and an HZSM-5 modular sieve, wherein the carbon-nano tube takes 7-20 proportions, HZSM-5 takes 10-30 proportions, and cordierite tales 60-80 proportions. The preparation method is that: carbon-nano tube is produced in situ on the integrated beehive cordierite by using chemical vapor deposition firstly, and the carbon-nano tube is taken as carrier, then the ZSM-5 modular sieve is developed on the carrier by using a secondary growth method. The catalyst for an integrated supported carbon-modular sieve can be used for the gas-phase synthesis of dimethyl ether DME by the dehydration of methanol.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

Core-shell composite anode material for lithium ion battery and preparation method thereof

ActiveCN101740752AImprove conductivityHigh specific capacitySecondary cellsIron compoundsLithium iron phosphateElectrical battery

The invention discloses a core-shell composite anode material for a lithium ion battery. The composite anode material has a core-shell structure; the core-shell structure consists of a core-layer active material and a shell-layer active material; the core-layer active material is LiFePO4 or lithium manganate; the shell-layer active material is carbon-containing LiFePO4; the LiFePO4 has an Li1-XMXFePO4 or LiFe1-yMyPO4 structure; the lithium manganate has a LiMnO2 or LiMn2O4 structure; the carbon is selected from one or more of carbon nano tubes, superfine conductive black and an agraphitic carbon material; and the composite anode material comprises 65 to 99 mass percent of core-layer active material and 1 to 35 mass percent of shell-layer active material. The composite anode material of the invention has stable performance and excellent electrochemical properties; and the lithium ion battery manufactured by using the material has relatively high charge-discharge capacity and excellent cycle performance, can perform quick charging and large multiplying-factor discharging, can adapt to an ultra-low temperature working environment and is safe and stable.

Owner:SHENZHEN DYNANONIC

Sidewall-functionalized carbon nanotubes, and methods for making the same

ActiveUS20050147553A1Broaden applicationPigmenting treatmentMaterial nanotechnologyCarbon nanotubeOxygen mixture

The invention provides a method of functionalizing the sidewalls of a plurality of carbon nanotubes with oxygen moieties, the method comprising: exposing a carbon nanotube dispersion to an ozone / oxygen mixture to form a plurality of ozonized carbon nanotubes; and contacting the plurality of ozonized carbon nanotubes with a cleaving agent to form a plurality of sidewall-functionalized carbon nanotubes.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com