Ultralong orientational carbon nano-tube filament/film and its preparation method

A technology of carbon nanotube film and carbon nanotube, which is applied in the direction of oriented carbon nanotube, carbon nanotube, nanostructure manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1. This embodiment investigates the preparation of carbon nanotube arrays by the flotation method, adopting a silicon dioxide sheet with an infinite radius of curvature of 1 mm in thickness and 25 mm in length and width of 25 mm as a substrate, and then putting the ball particles into a fixed bed for reaction In the reactor, the temperature was raised to the reaction temperature of 900° C. under the atmosphere of hydrogen and argon. Then, a cyclohexane solution of ferrocene is introduced, the carbon nanotube catalyst precursor ferrocene decomposes in situ to form an iron catalyst, and the carbon source is catalyzed and cracked to form a carbon nanotube array. After 2.5 hours, an array with a length of 5.4 mm can be obtained on the surface of the silicon dioxide wafer (Fig. 1).

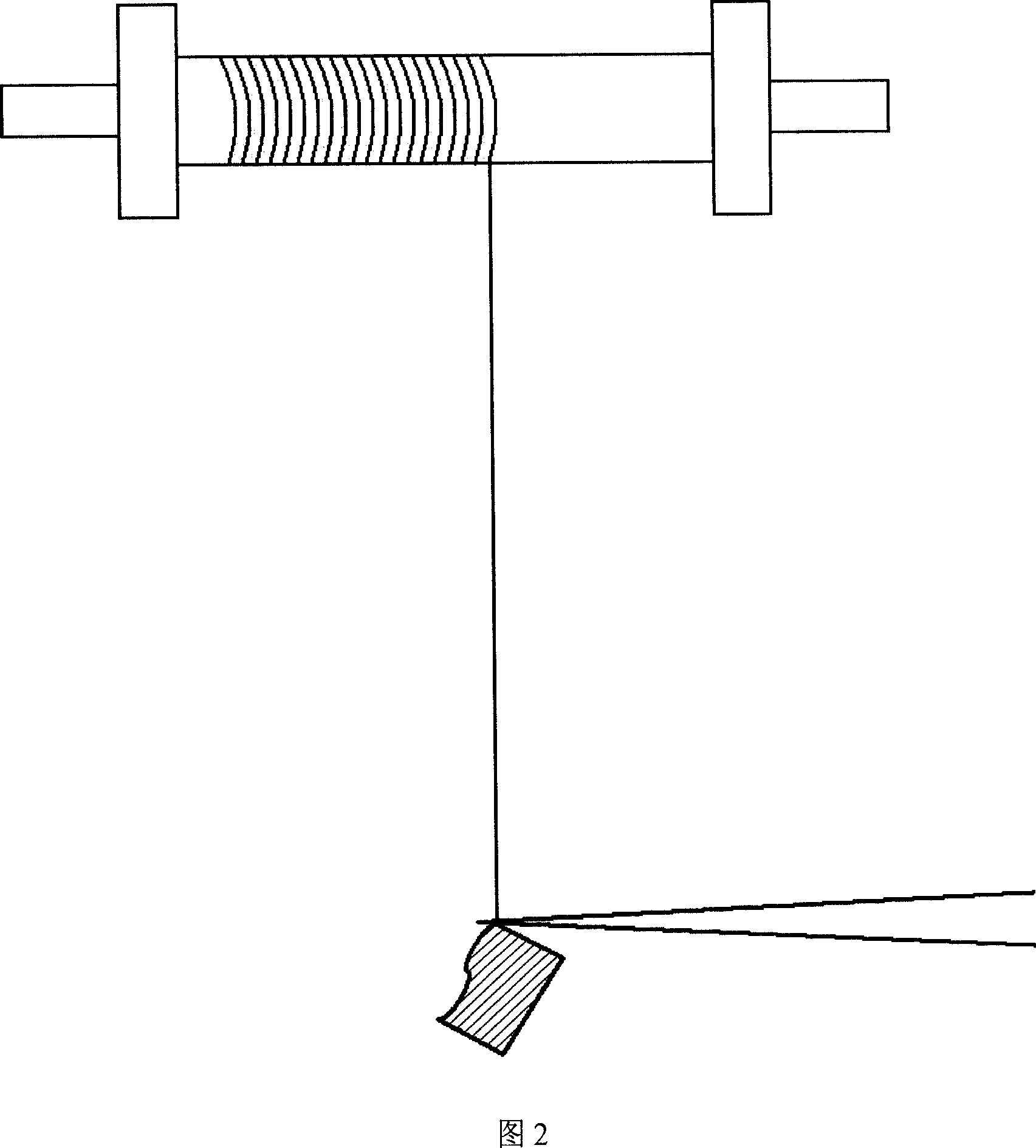

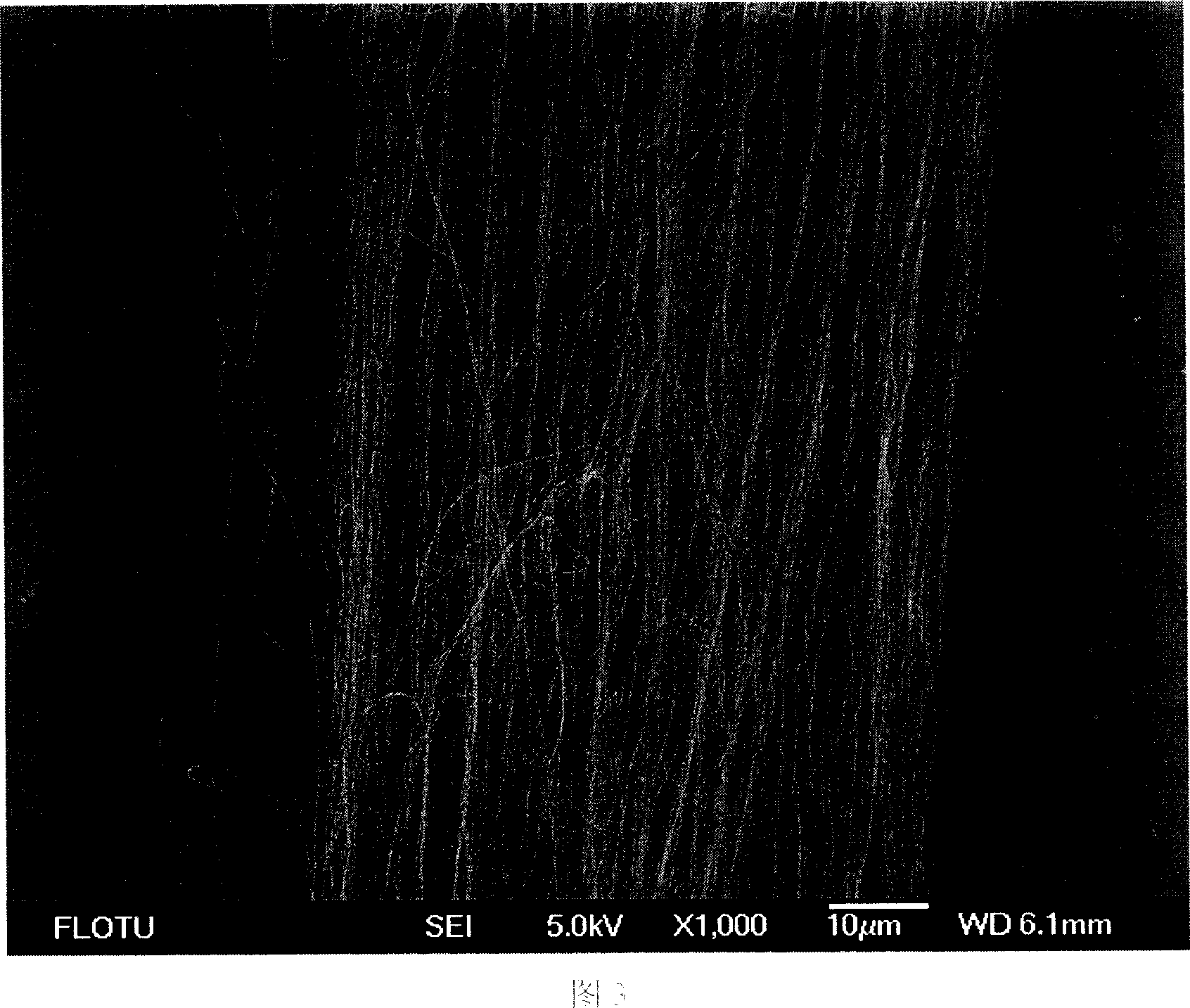

[0030] Take out the silicon dioxide substrate, keep the array on its surface, and directly use the stretching tool tweezers to pull a selected section of the carbon nanotube array inc...

Embodiment 2

[0033] Example 2. A silica / zirconia composite ball with a radius of curvature of 1 mm was used as a substrate, and the ball was placed in a moving bed reactor, and the temperature was raised to a reaction temperature of 750° C. under an atmosphere of hydrogen and nitrogen. Then a xylene solution containing 1:1 nickelocene and ferrocene is introduced, the catalyst precursor is decomposed in situ to form a carbon nanotube catalyst, and the carbon source is catalytically cracked to form a carbon nanotube array. An array with a length of 0.5 mm can be obtained on the surface of the ball after 1 hr.

[0034] Peel off the carbon nanotube array obtained above from the surface of the silica sphere, and then use a fixed stretching die to draw a selected section of the carbon nanotube array including one end of a plurality of carbon nanotube bundles to extract a carbon nanotube with a diameter of about 100 μm. The nanotube bundle is continuously stretched at a speed of 0.01m / s, and afte...

Embodiment 3

[0035]Example 3. Quartz fibers with a radius of curvature of 10 μm were used as substrates, and then the fibers were placed in a moving bed reactor, and the temperature was raised to a reaction temperature of 800° C. under an atmosphere of hydrogen and argon. Then a benzene solution of cobalt carbonyl is passed through, the cobalt carbonyl is decomposed in situ to form a nickel catalyst, and the carbon source is catalytically cracked to form a carbon nanotube array. After 0.8hr, an array with a length of 0.3mm can be obtained on the surface of the quartz fiber.

[0036] Take out the quartz fiber covered with the array, keep the array on its surface, directly use the stretching tool tweezers to pull a selected section of the carbon nanotube array including one end of a plurality of carbon nanotube bundles to extract the carbon nanotube bundle with a diameter of 0.8 μm, and pass through Stretching at a speed of 0.1 cm / s is continued, and after 10 minutes of stretching, the carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com