Heat-conduction heat-dissipation interface material and manufacturing method thereof

A technology of interface material and manufacturing method, which is applied in the processing and manufacturing of heat conduction and heat dissipation interface materials, and in the field of heat conduction and heat dissipation interface materials, can solve the problems of uncontrollable thermal conductivity, short service life, and large volume, and achieve light weight and improved service life , small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

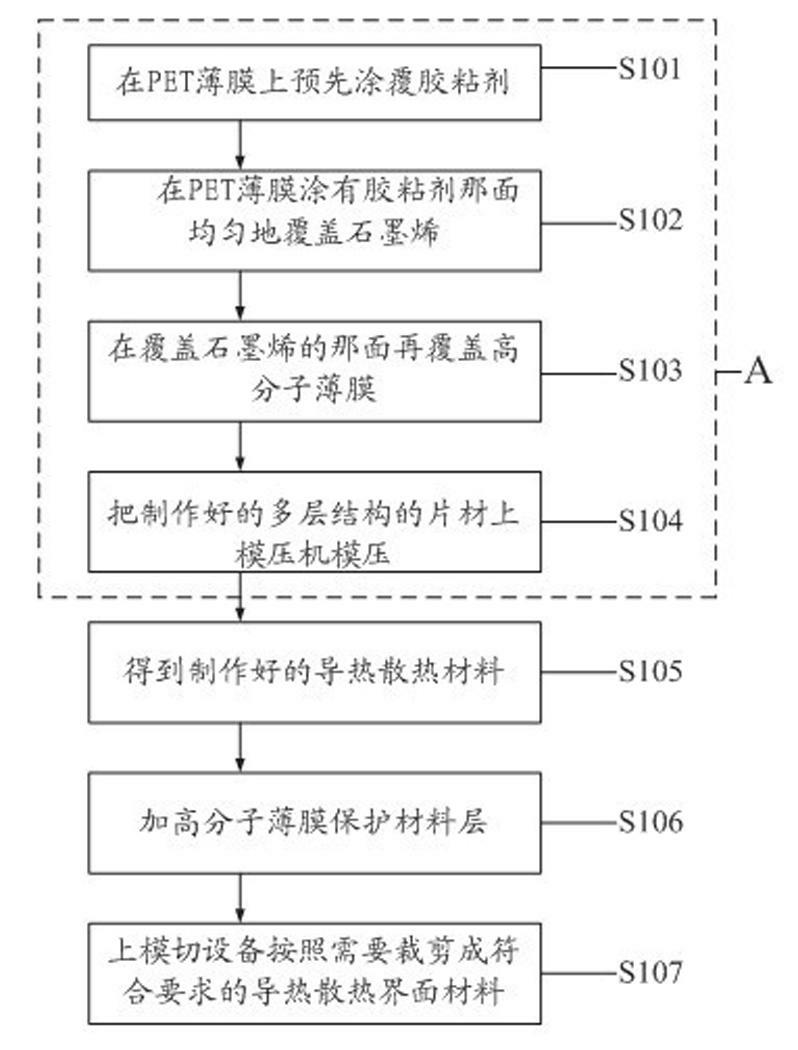

[0060] Please refer to image 3 , Is a flow chart of a matrix material of PET film, using graphene to make a thermal and heat dissipation interface material. It can be seen that it mainly includes the following steps:

[0061] S101: Pre-coated adhesive on PET film;

[0062] S102: Cover the surface of the PET film with adhesive evenly with graphene;

[0063] S103: Cover the side where the graphene is covered with a polymer film;

[0064] S104: Press the fabricated multilayer structure sheet on a molding machine;

[0065] S105: Obtain a manufactured heat and heat dissipation material;

[0066] S106: Add polymer film protective material layer;

[0067] S107: The upper die-cutting equipment is cut into thermal and heat dissipation interface materials that meet the requirements as required.

[0068] Please refer to image 3 , Step A: The production of thermal and heat dissipation materials includes step S101 to step S104.

[0069] Graphene has extraordinary electrical conductivity, the highest t...

Embodiment 2

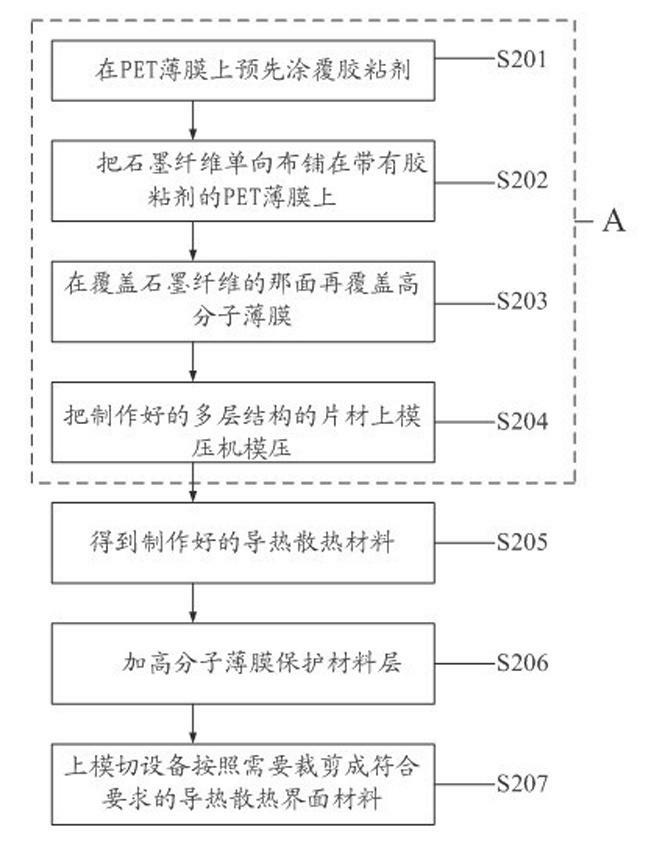

[0072] Please refer to Figure 4 , Is a flow chart of a matrix material of PET film, using graphite fiber to manufacture high thermal conductivity and heat dissipation interface material, it can be seen that it mainly includes the following steps:

[0073] S201: Pre-coated adhesive on PET film;

[0074] S202: Lay the graphite fiber unidirectional cloth on the PET film with adhesive;

[0075] S203: Cover the side covering the graphite fiber with a polymer film;

[0076] S204: Molding the manufactured multilayer structure sheet on a molding press;

[0077] S205: Obtain a manufactured heat and heat dissipation material;

[0078] S206: Add polymer film protective material layer or adhesive;

[0079] S207: The upper die-cutting equipment is cut into thermal and heat dissipation interface materials that meet the requirements as required.

[0080] Please refer to Figure 4 , Step A: The production of thermal and heat dissipation materials includes step S201 to step S204.

[0081] The above method ...

Embodiment 3

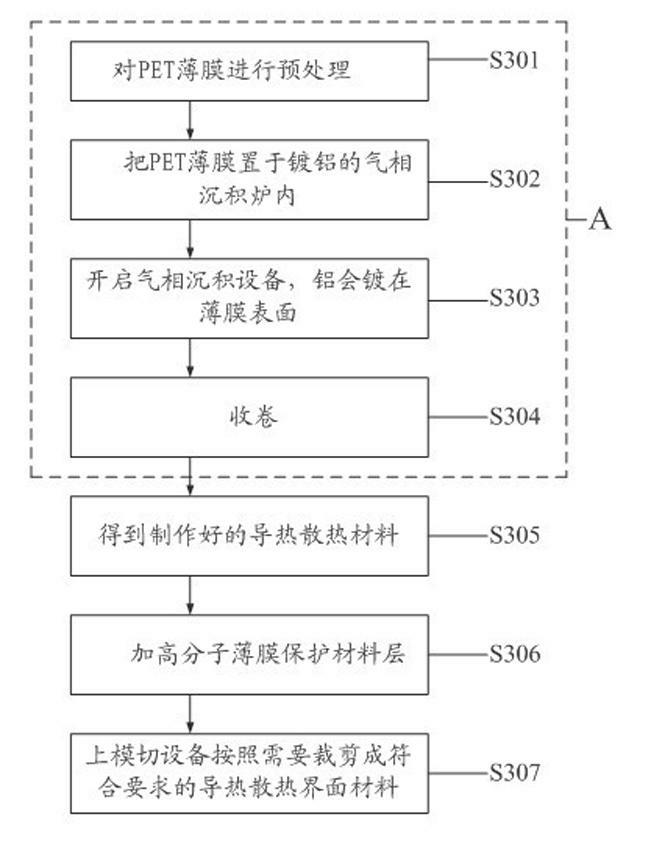

[0083] Please refer to Figure 5 , Is a flow chart of PET film, which uses aluminum powder to manufacture high thermal conductivity and heat dissipation interface material, as a matrix material. It can be seen that it mainly includes the following steps:

[0084] S301: Pretreatment of PET film;

[0085] S302: Put the PET film in the vapor deposition furnace for aluminum plating;

[0086] S303: Turn on the vapor deposition equipment, and aluminum will be plated on the surface of the film;

[0087] S304: Rewinding;

[0088] S305: Obtain a manufactured heat and heat dissipation material;

[0089] S306: Add a polymer film protective material layer;

[0090] S307: The upper die-cutting equipment is cut into thermal and heat dissipation interface materials that meet the requirements as required.

[0091] Please refer to Figure 5 , Step A: The production of heat and heat dissipation materials includes steps S301 to S304.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com