Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

677 results about "Quartz fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quartz fiber is a fiber created from high purity natural quartz crystals. It is made by first softening quartz rods (in an oxyhydrogen flame) and then creating filaments from the rods. Since natural quartz crystals of high purity are rare, quartz fiber is more expensive than alternatives (glass fiber and high silica fiber) and has limited applications.

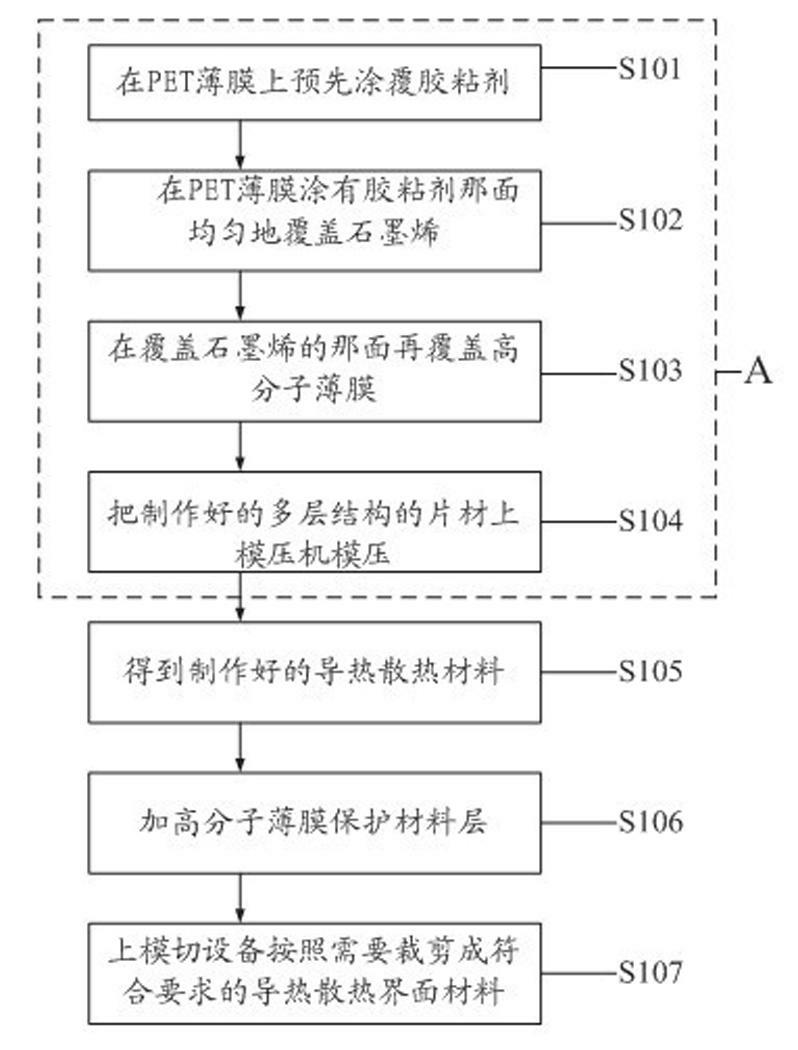

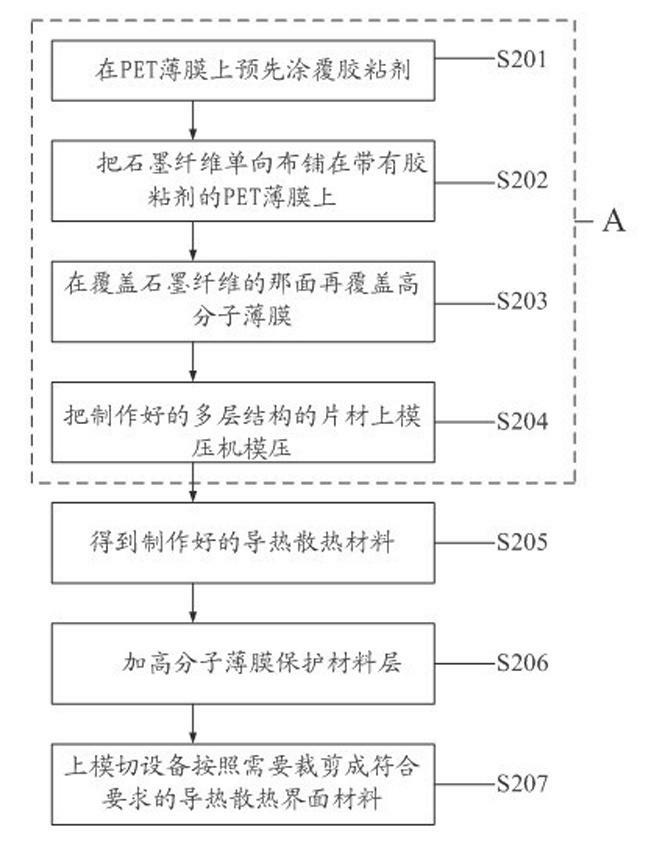

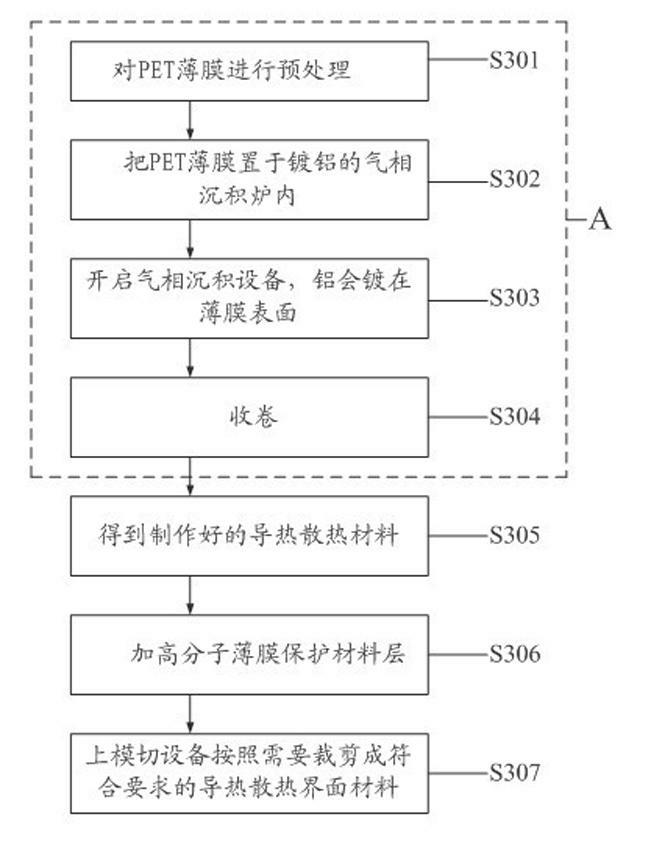

Heat-conduction heat-dissipation interface material and manufacturing method thereof

ActiveCN102651961AReduce volumeThe overall thickness is thinLayered productsCooling/ventilation/heating modificationsMetal fiberCalcium silicate

The invention provides a heat-conduction heat-dissipation interface material and a manufacturing method thereof, wherein the heat-conduction heat-dissipation interface material is applied to the field of heat dissipation of electronic products. The heat-conduction heat-dissipation interface material comprises a heat-conduction heat-dissipation layer and a surface protective material layer, wherein the heat-conduction heat-dissipation layer consists of one or more of graphite, nano graphite, crystalline flake graphite, graphene, pyrolytic carbon, pyrolytic graphite, graphite powder, carbon nano tubes, carbon fibers, graphite fibers, resin, ceramic fibers, quartz fibers, metal fibers, zirconia, boron nitride, silicon nitride, boron carbide, silicon carbide, magnesia powder, metasillicio acid fibers, calcium silicate aluminum fibers, aluminium oxide fibres, copper power, aluminium power, silver power, tungsten power and molybdenum power; and the surface protective material layer is a polymeric membrane. The heat-conduction heat-dissipation interface material manufactured according to the materials and the method provided by the invention has the advantages of effectively improved heat-dissipation performance, small volume, light weight and small thickness, can be used for prolonging the service life of an electronic component, and simultaneously is easy to produce and process.

Owner:SHANGHAI QI JIE CARBON MATERIALS

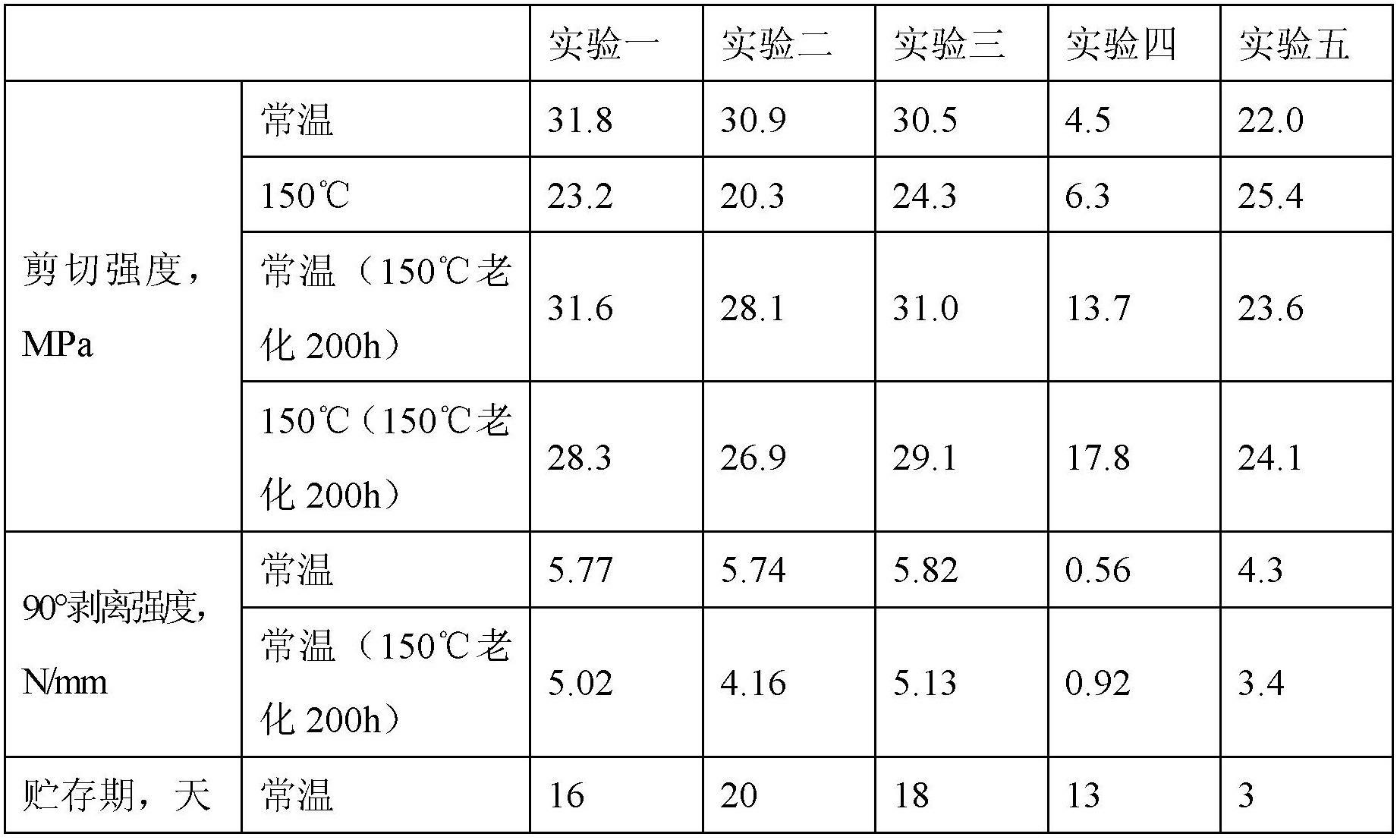

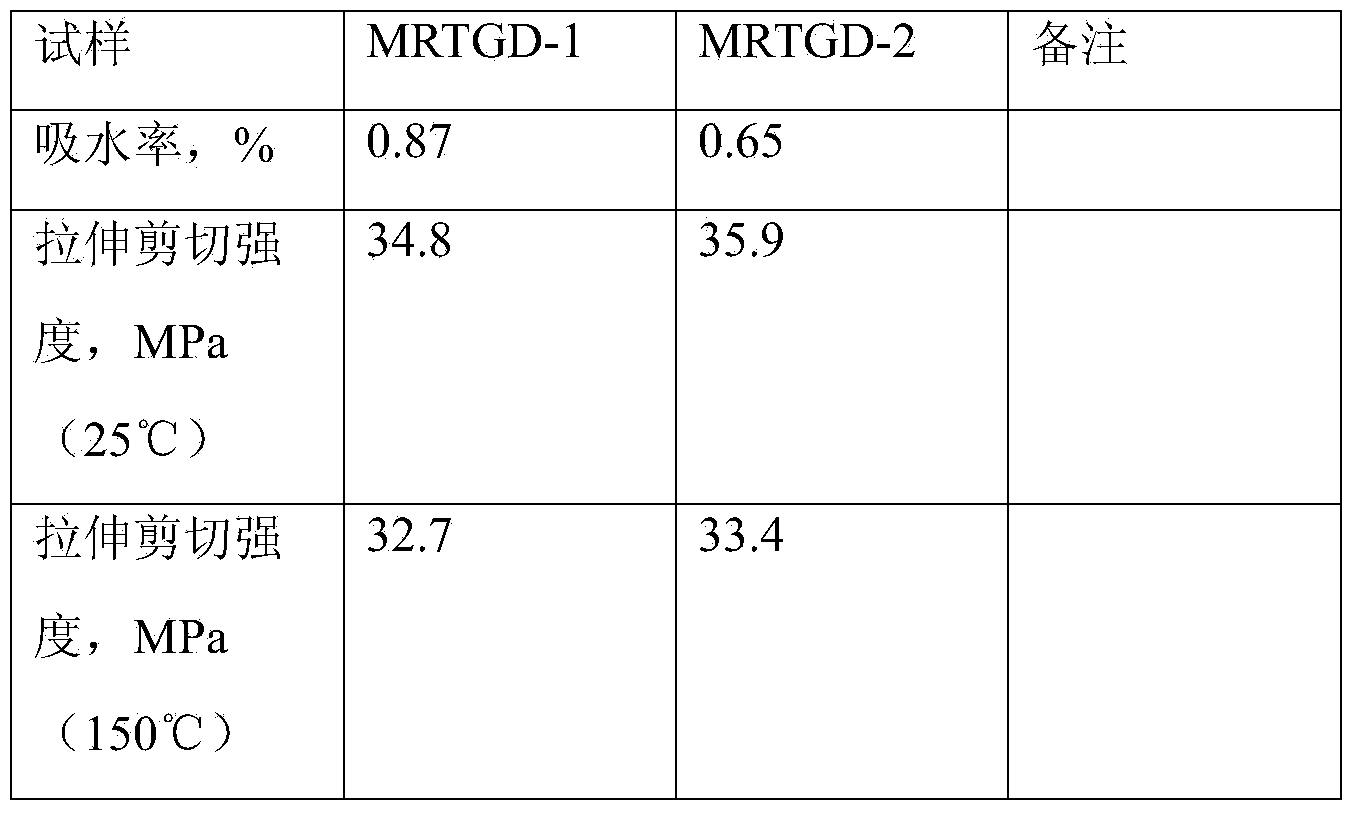

Low-temperature curing cyanate ester adhesive and preparation method thereof

InactiveCN102676112ALow curing temperatureHigh bonding strengthFilm/foil adhesivesEpoxy resin adhesivesPolymer scienceAdhesive

The invention discloses a low-temperature curing cyanate ester adhesive and a preparation method thereof, which relate to an adhesive and a preparation method thereof and solve the technical problems of high curing temperature and short room-temperature storage period of the existing cyanate ester adhesive. The adhesive disclosed by the invention is manufactured by adopting cyanate ester resin, a catalyst, modified resin, organic nano particles, inorganic nano particles, a thinning agent and a toughening agent. The preparation method comprises the following steps that: firstly, a mixture A is prepared; secondly, the toughening agent is added into the mixture A to obtain a mixture B; thirdly, the modified resin and the thinning agent are added into the mixture B and are stirred and mixed uniformly, the catalyst is added into the mixture to obtain a substrate, and then the substrate and quartz fiber fabric are subjected to hot melting to be combined into a low-temperature curing cyanate ester carrier adhesive film, so the low-temperature curing cyanate ester adhesive is obtained. The curing temperature of the low-temperature curing cyanate ester adhesive prepared by the preparation method provided by the invention is low, the low-temperature curing cyanate ester adhesive can be cured at a temperature of 120-140 DEG C, and the room-temperature storage period of the low-temperature curing cyanate ester adhesive is as long as 20 days, and meanwhile, the low-temperature curing cyanate ester adhesive has high bonding strength and excellent heat-resistant performance and is suitable for bonded materials which cannot resist to high temperature.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

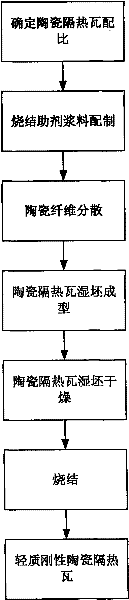

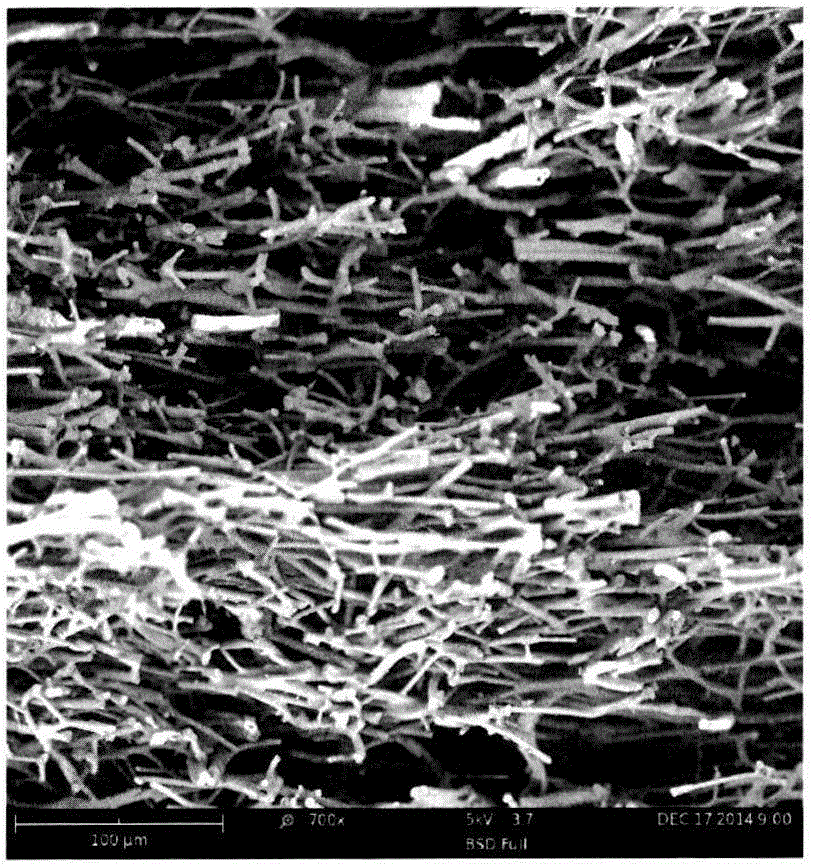

Lightweight rigid ceramic heat-insulation tile and manufacture method thereof

The invention relates to lightweight rigid ceramic heat-insulation tile and a manufacture method thereof. The lightweight rigid ceramic heat-insulation tile comprises the following components: ceramic fibers, starch accounting for 0.05-15wt% of the ceramic fibers, a sintering aid and a sunscreen, wherein the ceramic fibers are composed of 50-100wt% of quartz fibers and 0-50wt% of porzite fibers; the sintering aid is boron nitride accounting for 0.01-15wt% of the ceramic fibers; and the sunscreen is silicon carbide accounting for 0-20wt% of the ceramic fibers. According to the invention, the quartz fibers and porzite fibers are utilized as raw materials to manufacture the ceramic heat-insulation tile with good heat-insulation and mechanical properties through fiber dispersion, wet blank shaping, high-temperature sintering and like. The obtained ceramic heat-insulation tile has the advantages that the density is 0.15-0.80 g / cm<3>, the thermal conductivity at room temperature is 0.045W / m.K, and the plane tensile strength is larger than 0.4 MPa. According to the invention, the porzite fibers are utilized to substitute for aluminum oxide fibers and aluminum borosilicate fibers, and the performance of the ceramic heat-insulation tile is approximate to that of the ceramic heat-insulation tiles used by the space shuttles in America.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

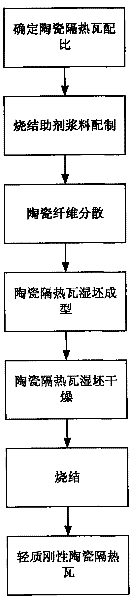

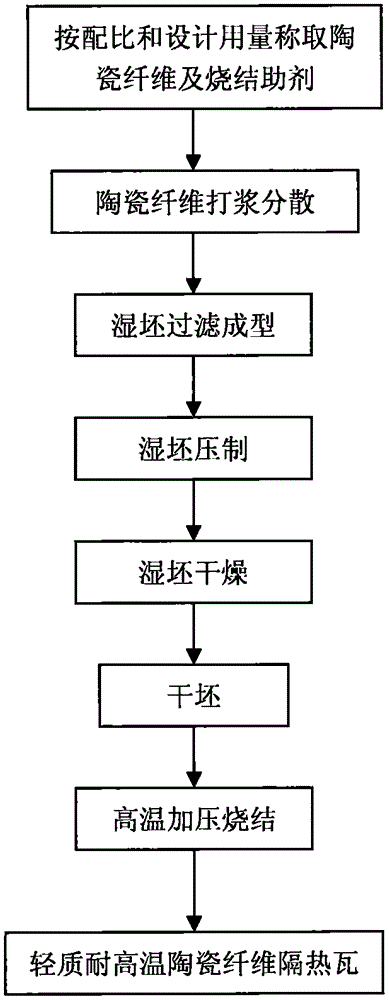

Light-weight, high temperature-resistance and heat-insulation ceramic fiber tile and making method thereof

ActiveCN105272322AOvercome the problem of uneven distributionImprove mechanical propertiesRoom temperatureSlurry

The invention relates to a light-weight, high temperature-resistance and heat-insulation ceramic fiber tile and a making method thereof. The heat insulation tile comprises ceramic fibers and boron oxide, wherein the ceramic fibers comprise quartz fibers, alumina fibers and yttrium oxide stabilized zirconia fibers. The making method of the light-weight, high temperature-resistance and heat-insulation ceramic fiber tile comprises the following steps: preparing a sintering aid suspension, preparing a ceramic fiber slurry, carrying out wet green body molding, drying the obtained wet green body, and carrying out pressurization sintering. The heat insulation tile has good heat insulation effect and mechanical performances, has light weight and resists high temperature; the density is controllable between 0.10g / cm<3> and 0.90g / cm<3>; the lowest apparent heat conduction coefficient at room temperature reaches 0.033W / (m.K); the compressive strength at room temperature is greater than 3.0Mpa; and the long-time use temperature can reach 1350DEG C.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Method for preparing wave-transmission SiO2 aerogel heat-insulation composite material by using normal-pressure drying equipment

InactiveCN102531521AUniform and stable structureGel time controllableSupercritical dryingPolymer science

The invention discloses a method for preparing a wave-transmission SiO2 aerogel heat-insulation composite material by using normal-pressure drying equipment. According to the method, tetraethoxysilane used as a precursor and absolute ethanol used as a solvent are subjected to acid-alkaline two-step reaction under the action of a catalyst so as to obtain SiO2 sol; and the SiO2 sol is mixed with quartz fiber, and the wave-transmission SiO2 aerogel heat-insulation composite material is prepared by the steps of performing gelling on the mixture of the SiO2 sol and the quartz fiber, aging, performing solvent replacement and surface modification, and performing gradient heating under normal pressure. The method for preparing the wave-transmission SiO2 aerogel heat-insulation composite material by using the normal-pressure drying equipment is easy to operate; equipment is simple; compared with a supercritical drying method, the method for preparing the wave-transmission SiO2 aerogel heat-insulation composite material by using the normal-pressure drying equipment has the advantage that the cost is reduced greatly; by the method, the composite material can be produced on a large scale conveniently; and a product has good wave transmission performance, heat insulation performance and the like, and has extremely obvious application value in military industry of long-endurance and high-mach aviation aerospacecrafts and the like.

Owner:湖北三江航天江北机械工程有限公司

High-temperature-resistant high-strength aluminum oxide fiber enhanced composite material and preparation method thereof

The invention relates to a high-temperature-resistant high-strength aluminum oxide fiber enhanced composite material and a preparation method thereof. The preparation method comprises the following steps of: by taking a two-dimensional cloth paving layer and 2.5D woven or orthogonally three-dimensional woven continuous aluminum oxide fiber preform as an enhancer, preparing a matrix through a double nano composite impregnation liquid where silicon dioxide and aluminum oxide are uniformly mixed; and finally obtaining the aluminum oxide fiber enhanced composite material through the process of vacuum pressure impregnation, micro-positive pressure medium and low temperature pre-curing, micro-positive pressure curing and atmosphere temperature programming sub-sectional thermal treatment, wherein the mass ratio of silicon dioxide to aluminum oxide in the composite material is (19:1)-(12:8), and the volume content of the aluminum oxide fibers is 30-60%. The prepared composite material has a high-temperature-resistant property and a high-temperature mechanical property, and is high in compactness; the room temperature tensile strength of the material reaches 310+ / -30MPa, the tensile strength at 1100 DEG C reaches 135+ / -20MPa, and the tensile strength at 1200 DEG C reaches 90+ / -10MPa; and compared with a similar quartz fiber enhanced silicon dioxide oxide / oxide composite material, the performance is improved by 4-5 times.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

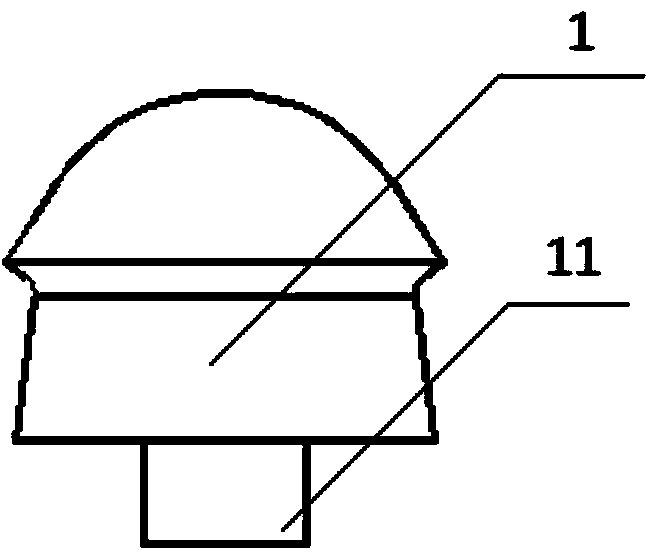

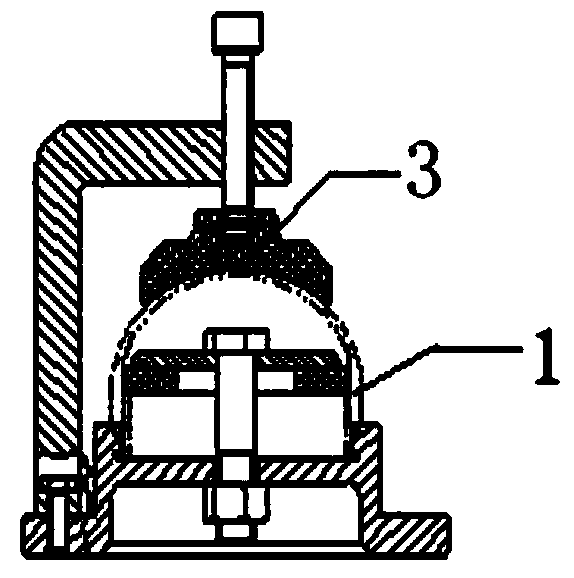

Preparation of solid-phase microextraction (SPME) fiber and extraction device assembled by same

InactiveCN102989432AOvercoming the problem of poor mechanical strengthUnique designComponent separationOther chemical processesSolid-phase microextractionMetal-organic framework

Disclosed is a preparation of an SPME fiber. A covalent bond method is adopted to prepare metal-organic frameworks (MOFs) as a coating for the extraction fiber. The fiber preparing method includes performing APTES amino-functionalization on a quartz fiber, namely, placing the fiber with amino on the surface into an MOF solution for reaction. An extraction device assembled by the prepared SPME coating comprises a device body, a microsyringe outer tube, a microsyringe needle, a push-pull rod and the extraction fiber with the coating, wherein the push-pull rod is arranged in the microsyringe outer tube and forms a sliding matching with the inner wall of the tube, the lower end of the push-pull rod is corroded by an aqua regia solution to obtain a corrosion end which is inserted into the extraction fiber with the coating, and a handle is arranged at the upper end of the push-pull rod. The preparation and the device have the advantages that an organic ligand of the extraction fiber coating and the MOFs is highly ordered and controllable, the extraction device has a novel structure, the coating fiber fixation is firm, and the stability and service life of the extraction fiber coating are improved.

Owner:NANKAI UNIV

TGDADPE type epoxy matrix resin for advanced composite material and preparation method thereof

InactiveCN103483553AConvenient sourceSimple preparation processSynthetic resin layered productsGlass fiberDiaminodiphenyl ether

The invention relates to a TGDADPE type epoxy matrix resin for an advanced composite material and a preparation method of the TGDADPE type epoxy matrix resin for the advanced composite material. The TGDADPE type epoxy matrix resin for the advanced composite material is prepared from N,N,N',N'-tetraglycidyl-4,4'-diaminodiphenyl ether epoxy resin, aromatic diamine, aromatic binary anhydride, a curing agent and organic solvent, wherein the mass ratio of the N,N,N',N'-tetraglycidyl-4,4'-diaminodiphenyl ether epoxy resin, the aromatic diamine, the aromatic binary anhydride, the curing agent and the organic solvent is 100:5-10:10-20:1-5:80-200. The preparation method of the TGDADPE type epoxy matrix resin is simple in operation technology, the prepared matrix resin is excellent in overall performance and good in wettability to glass fiber, carbon fiber, quartz fiber, basalt fiber and aramid fiber and can be used for preparing the advanced composite material good in overall performance, and the preparation method of the TGDADPE type epoxy matrix resin is suitable for industrial production and has broad application prospects.

Owner:DONGHUA UNIV +1

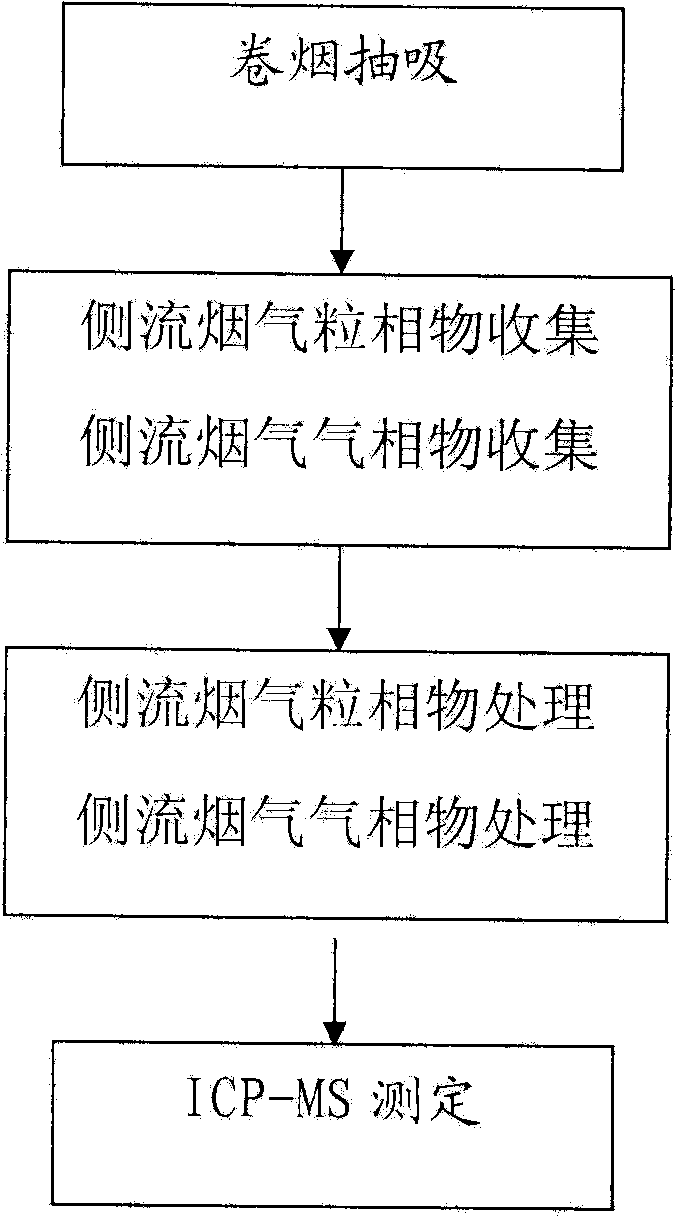

Method for detecting chromium, nickel, arsenic, selenium, cadmium and lead in cigarette side-stream smoke

InactiveCN103969324AAvoid cross contaminationImprove purification effectPreparing sample for investigationMaterial analysis by electric/magnetic meansInductively coupled plasmaInductively coupled plasma mass spectrometry

The invention relates to a method for detecting chromium, nickel, arsenic, selenium, cadmium and lead in cigarette side-stream smoke. The method is characterized in that a fishtail cover is connected with a quartz fiber filter disc in series to collect particulate matters in the cigarette side-stream smoke, a triple-tandem nitrite acid solution is used for collecting gas phase matters in the side-stream smoke, a microwave digestion method is used for digesting samples, and the contents of chromium, nickel, arsenic, selenium, cadmium and lead in the particulate matter and gas phase matter samples are detected through ICP-MS (Inductively Coupled Plasma Mass Spectrometry). The method overcomes the defects of sample collecting and processing methods and detecting techniques in the prior art and fills the blank of domestic detecting techniques for heavy metal in the side-stream smoke. The fishtail cover is connected with the purified quartz fiber filter disc in series to collect the particulate matters in the side-stream smoke, so that the background interference is effectively reduced. A three-stage absorption bottle collects the gas phase matters in the side-stream smoke, so that the gas phase matters can be completely collected. The microwave digestion method treats the samples, so that the digestion effect is good, and the element loss is few. The ICP-MS is adopted for determination, so that the method is fast and accurate, high in sensitivity, good in repeatability and high in recovery rate.

Owner:CHINA NAT TOBACCO QUALITY SUPERVISION & TEST CENT

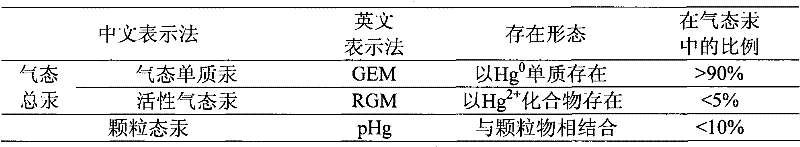

Method and device for combined collection of trace level mercury species in atmosphere

ActiveCN102221489ASmall and portableImprove experimental efficiencyWithdrawing sample devicesTest efficiencyDiffusion

The invention provides a method and a device for combined collection of trace level mercury species in atmosphere, belonging to the technical field of atmosphere environment monitoring. The method can control the sampling process by a program controller; the sampling airflow can sequentially pass by a diffusion pipe filled with a KCl coating, a filtration membrane pipe filled with quartz fibers, and a mercury capturing pipe filled with gold-plated quartz sands; and the trace level gas state divalent mercury (RGM), grain-state mercury (pHg) and gas-state elementary mercury (GEM) are respectively adsorbed or intercepted by the KCl saturated solution, the quartz fiber filtration membrane and the gold-plated quartz sands, thus realizing the combined sampling on three different mercury species. In the invention, the device has a simple system, the parameter can be adjusted accurately; the running is reliable, the test efficiency is high; synchronous series sampling is carried out on the trace level mercury in three different species in the atmosphere, a large amount of apparatuses required for field operation are reduced; the test efficiency is improved, and the function of twofold efficiency with half effort is achieved.

Owner:中科嘉辞(昆山)环保科技有限公司

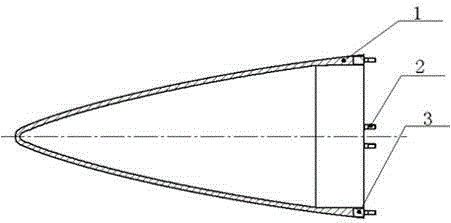

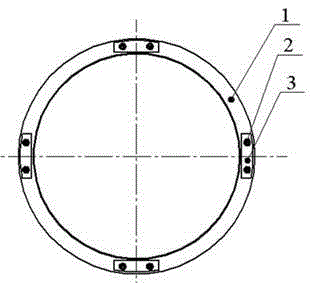

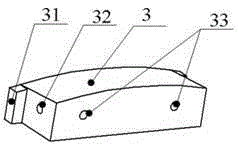

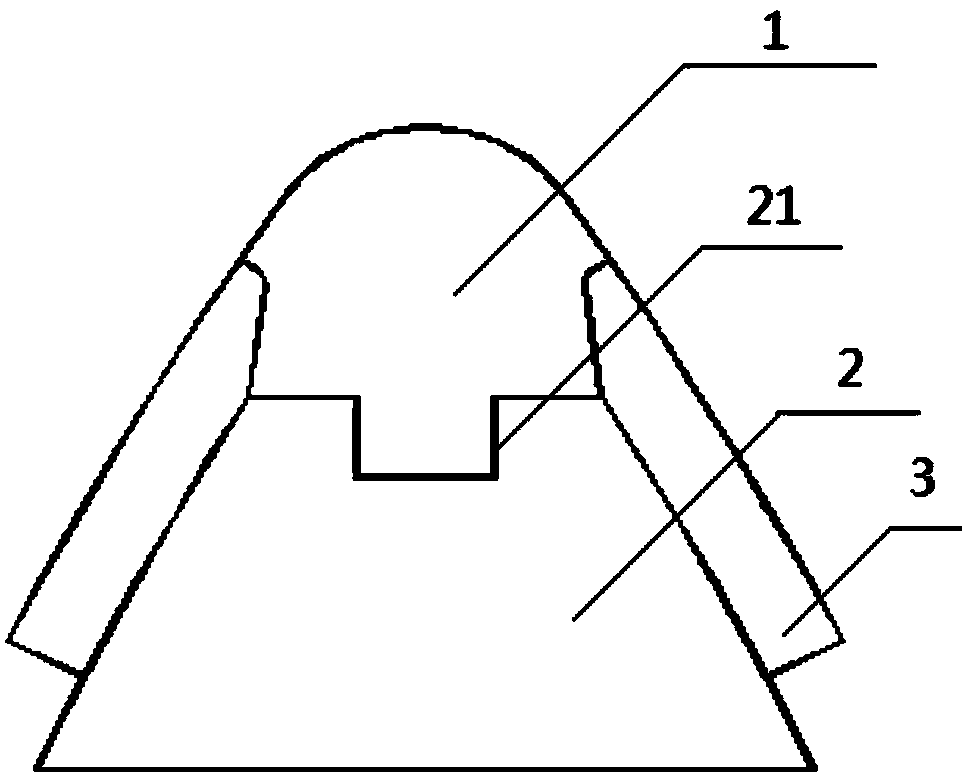

Antenna housing structure and forming method and die thereof

ActiveCN105415710ASolve the problem of transition connectionReduce structural weightRadiating element housingsTransfer moldingHigh intensity

An antenna housing structure comprises a housing body, a plurality of embedded inserts and a plurality of connection studs, wherein the housing body is made of silicon-contained quartz fiber reinforced aryne composite materials and prepared through a resin transfer molding technique; the multiple embedded inserts are made of low-expansion alloy steel materials and arranged at the root of the housing body, the embedded inserts are woven in a quartz fiber reinforcement body before being formed, the embedded inserts and the housing body are combined into a whole after the embedded inserts are formed, and a threaded hole is formed in the end face of each embedded insert; the multiple connection studs are made of high-strength steel materials, external threads are arranged at the two ends of each connecting stud, the external thread at one end of each connection stud is assembled in the threaded hole of the corresponding embedded insert of the housing body, and the external thread at the other end of each connection stud is connected with a cabin. The antenna housing structure and the forming method and the die thereof have the advantages that by the adoption of the resin transfer molding technique and the embedded inserts, the problem that transition connection between a traditional antenna housing and a cabin can only be achieved through low-expansion alloy steel connection rings is solved, the structural weight is reduced substantially, and the connection reliability is improved.

Owner:SHANGHAI RADIO EQUIP RES INST

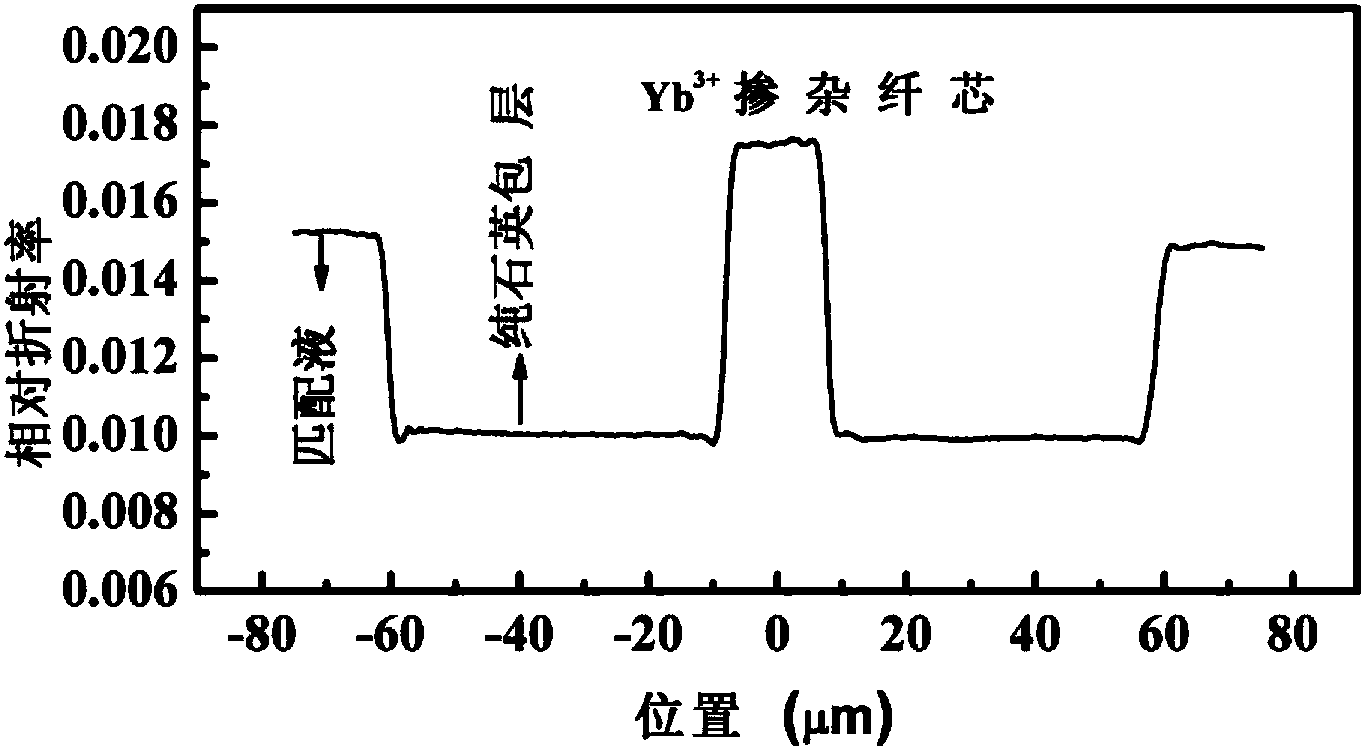

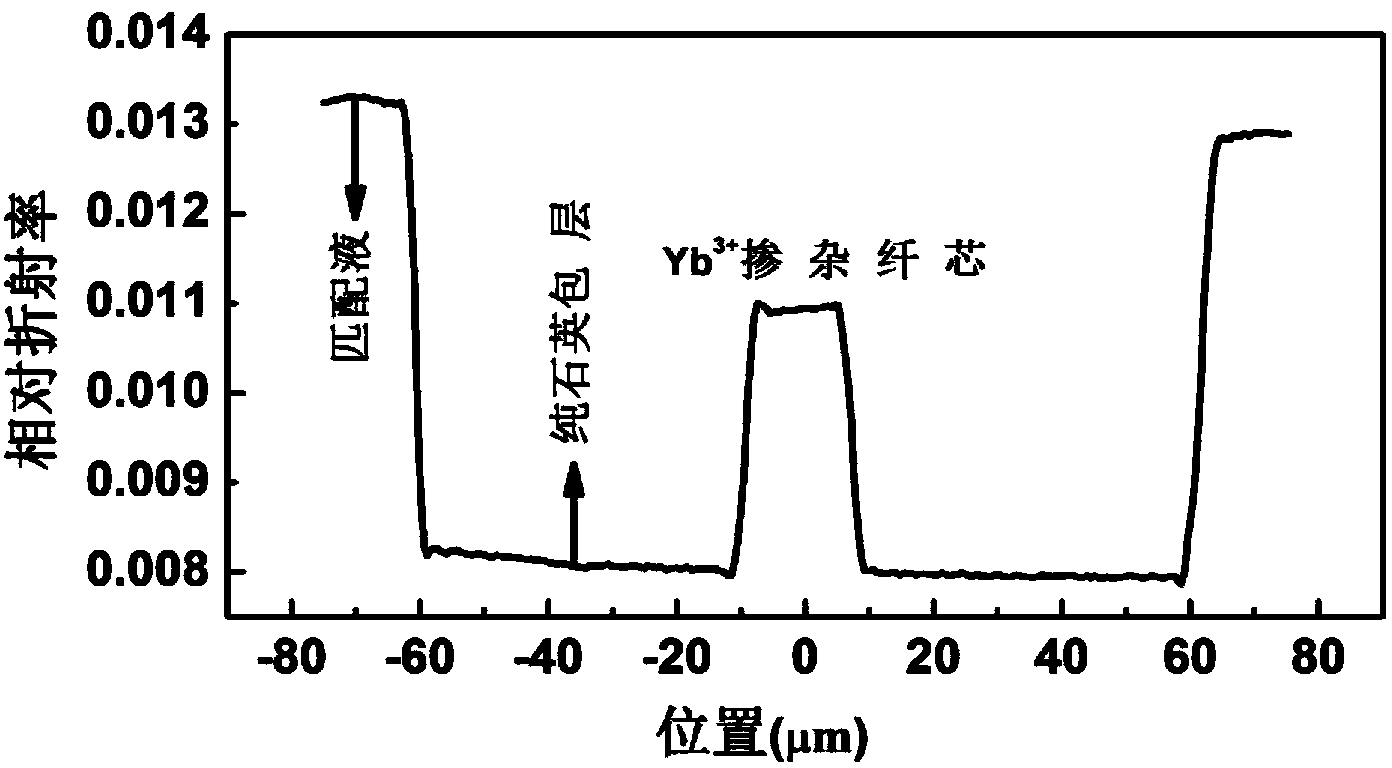

Preparation method of core rod of Yb doped quartz fiber preform

ActiveCN103373811AEvenly dopedReduce hydroxyl concentrationGlass making apparatusPhotonic crystalRare earth

A preparation method of a core rod of a Yb doped quartz fiber preform. Employing a sol gel method, the preparation method prepares a rare earth doped silicon oxide powder by starting from a solution; the powder is subjected to decarburization, dehydroxylation and ball milling; and the treated powder is sintered into glass, which is processed into the core rod. The core rod obtained by the method can be used in preparation of double cladding Yb doped quartz fiber with large size, high uniformity and large mode field, and photonic crystal with large mode field and doped with Yb quartz fiber, so as to realize high laser efficiency.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

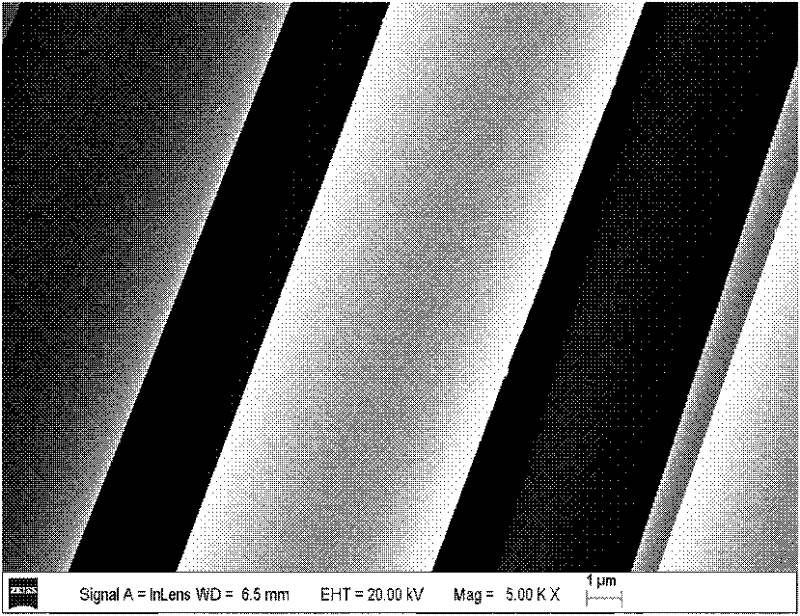

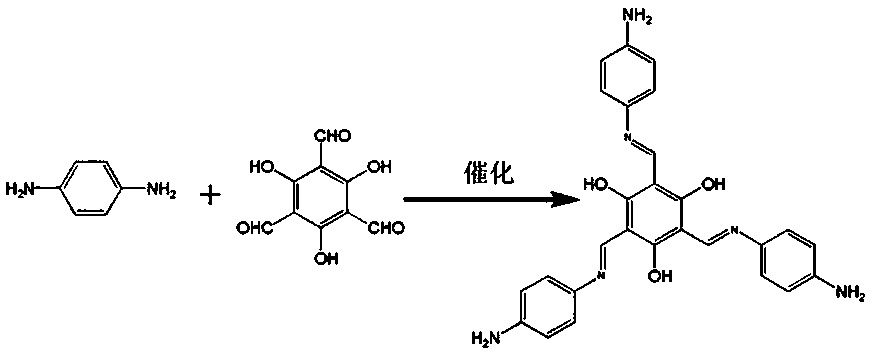

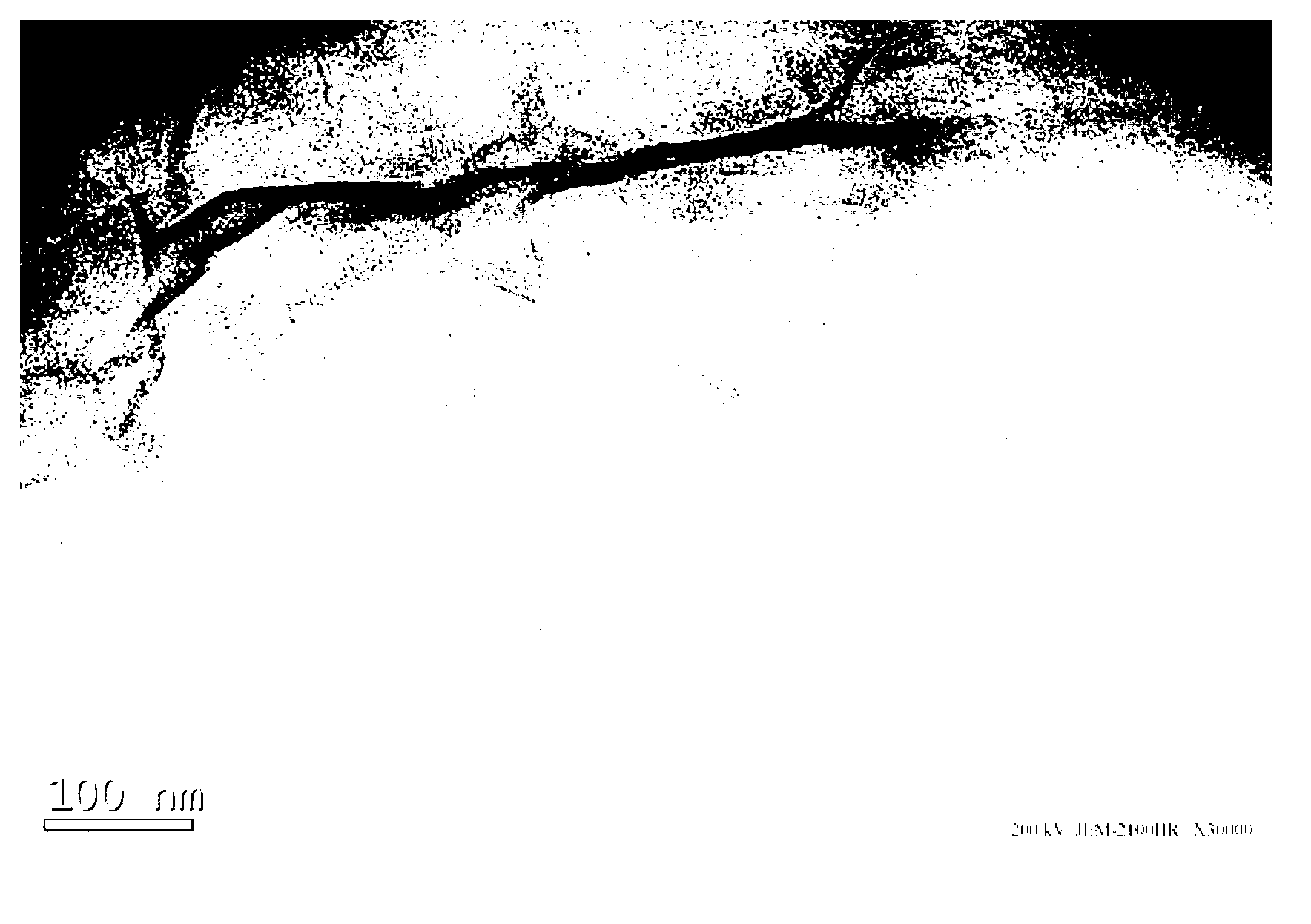

Surface modification method for quartz fibre

The invention discloses a surface modification method for quartz fibre, belonging to the technical field of quartz fibre composite material, and relating to a method for self-assembling silicon dioxide particles on the surface of the quartz fibre. The method comprises the following steps: preparing monodisperse SiO2 globules of which the grain diameter is 100-600 nm; ablating the quartz fibre, and carrying out infiltration surface treatment; dipping the quartz fibre subjected to surface treatment in collosol so that the surface of the quartz fibre is coated with one layer of metallic oxide film with positive charges; and dipping the quartz fibre with the positive charges in turbid liquid of silicon dioxide colloidal solid so as to finally obtain the product. In the invention, the quartz fibre is treated with alumina colloidal (or other colloidals) and silica colloidal, so that the surface of the quartz fibre is coated with two layers of inorganic substances, the mechanical property ofthe quartz fibre at high temperature is improved; the interface performance of a quartz fibre based composite material is improved; and the mechanical property of the composite material at high temperature is improved.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method for alumina coat on quartz fibre surface

The invention relates to a preparation method for an alumina coat on quartz fibre surfaces, and belongs to the technical field of special functional ceramics. The preparation method comprises the following steps: respectively adding aluminum ion, nitric acid and chelating agent in solvent according to the molar ratio of 1: (0.03-0.28): (0.5-1) till all the materials are hydrolyzed to generate sediments; then, adding peptizator to carry out peptization; carrying out reflux heating and stirring for 8 to 24h at a temperature of between 50 and 100 DEG C to obtain transparent and stable Al2O3 sol; putting quartz fibre into a steeping vat of Al2O3 sol for steeping and then heating up and gradually drying the quartz fibre at a temperature of between room temperature and 80 DEG C; and finally, carrying out heat treatment at a temperature of between 450 and 850 DEG C to obtain the quartz fibre coated with the alumina coat. The preparation method is scientific, reasonable and easy to implement; moreover, the Al2O3 coat coated on the surface of the quartz fibre increases material mechanical property and reduces material brittle fracture.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

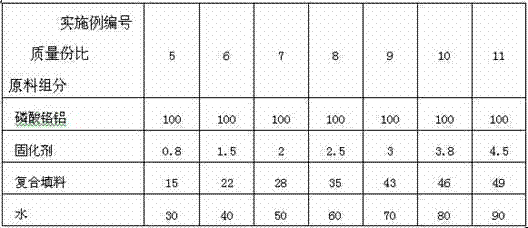

Preparation method of quartz fiber/chrome aluminum phosphate-based high temperature wave-transmitting material

InactiveCN102514346AImprove mechanical propertiesGood physical propertiesLamination ancillary operationsLaminationMoisture resistanceALUMINUM PHOSPHATE

The invention discloses a reparation method of quartz fiber / chrome aluminum phosphate-based high temperature wave-transmitting material, characterized by comprising the following steps of: heating quartz fiber cloth at a temperature of 200-800 DEG C, cooling the quartz fiber cloth, and coating a protection coating on the surface of the quartz fiber cloth; mixing the chrome aluminum phosphate, curing agent, composite stuffing and water to prepare a chrome aluminum phosphate binding material; coating the chrome aluminum phosphate binding material on the surface of the quartz fiber cloth having the protection coating, drying at a temperature of 80-100 DEG C, and flatly laying the quartz fiber cloth; and processing more than two pieces of flatly laid and overlapped high temperature wave-transmitting material monomers by a mould press forming technique to obtain the product, namely, quartz fiber / chrome aluminum phosphate-based high temperature wave-transmitting material. The preparation method of the invention has the advantages of simple technique, good availability of raw materials and convenience for operation; besides, the prepared quartz fiber reinforced chrome aluminum phosphate-based high temperature wave-transmitting material has excellent moisture resistance, heat-resisting stability, mechanical property and dielectric property, so that the material is suitable for the use as a high temperature resistant wave-transmitting material.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Manufacturing method of high-temperature-resistant ablation-resistant antenna housing body

The invention discloses a manufacturing method of a high-temperature-resistant ablation-resistant antenna housing body. The manufacturing method disclosed by the invention comprises the following steps: (1), preparing an end cap with a clamping column by adopting a high-temperature-resistant ablation-resistant material, wherein the clamping column is a prism with 5-7 lateral edges; (2), fixing the end cap on a woven core model with a clamping groove matched with the clamping column through the clamping column, and producing a quartz fibre woven body meeting the requirements to form an original billet; (3), poaching, roasting, acid-leaching, immersing and drying the original billet; (4), putting the dried original billet in silica sol, respectively immersing and compounding in vacuum and vibration states, and repeating the step for 4-8 times; and (5), sintering the immersed and compounded original billet, enabling the original billet to be ceramicized to form a crude billet, and machining to obtain the high-temperature-resistant ablation-resistant antenna housing body. The method disclosed by the invention is simple in process; the prepared high-temperature-resistant ablation-resistant antenna housing body can stand the tests of high-mach and long-endurance working conditions.

Owner:湖北三江航天江北机械工程有限公司

Heat-resistant wave-absorbing material and preparation method thereof

The invention discloses a heat-resistant wave-absorbing material, which is a composite material with quartz as matrix and a quartz fiber needled part as a reinforced phase. The composite material contains a short carbon fiber; the length of the short carbon fiber is 5-6mm; the volume content of the short carbon fiber in the composite material is 0.002-0.005g / cm<3>; the volume density of the quartz fiber needled part is 0.43-0.45g / cm<3>; and the preparation method disclosed by the invention comprises the following steps: selecting raw materials; preparing a fiber preformed part; dipping the fiber preformed part for a plurality of times; and carrying out gel and heat treatment until densification is finished. When the heat-resistant wave-absorbing material disclosed by the invention is 3.5mm in thickness, the reflectivity within a frequency range of 8-18GHz can be lower than -8dB; the heat-resistant wave-absorbing material has relatively good wave-absorbing property when the thickness is relatively small; and the preparation method disclosed by the invention is simple in processing step, free of a harmful and toxic pollutant in the technological process, and good in compatibility with the environment.

Owner:NAT UNIV OF DEFENSE TECH

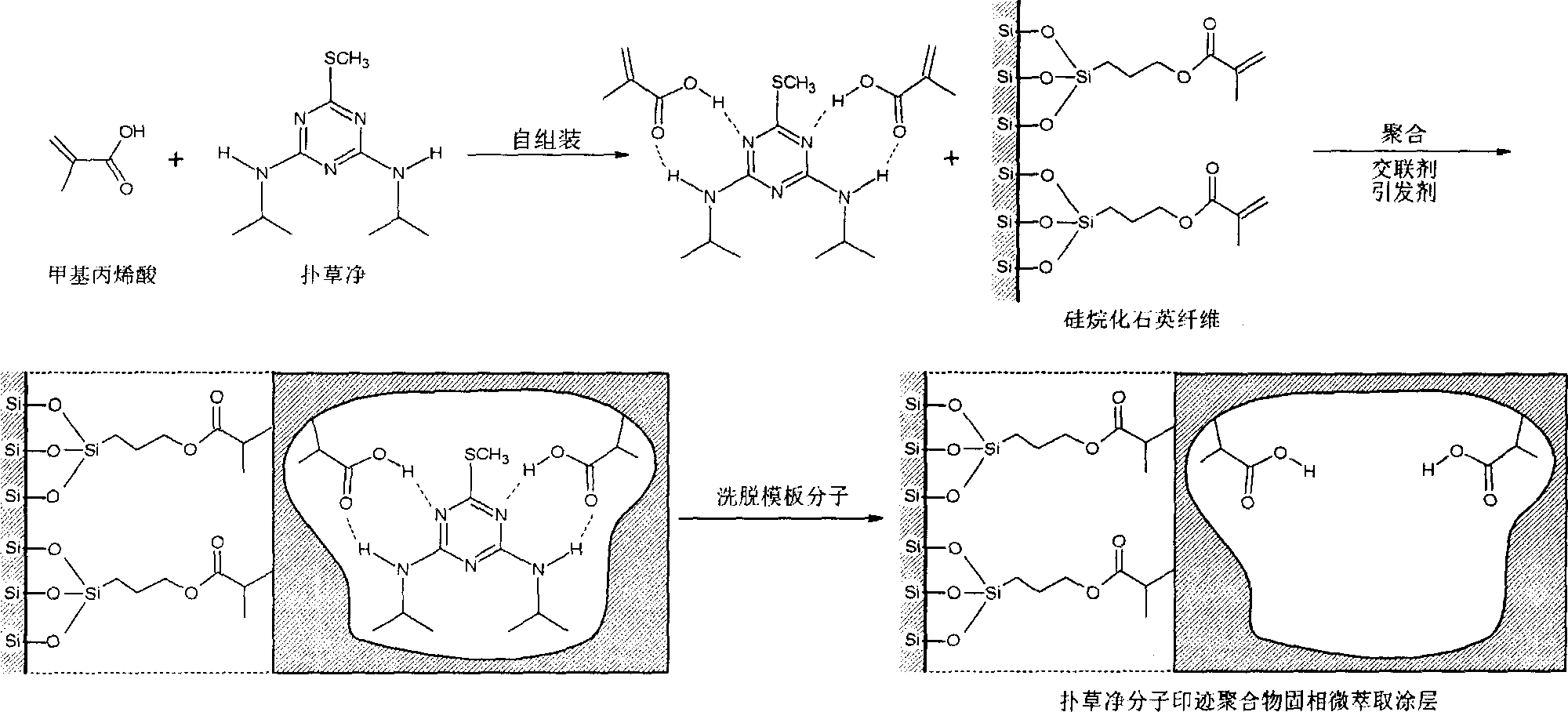

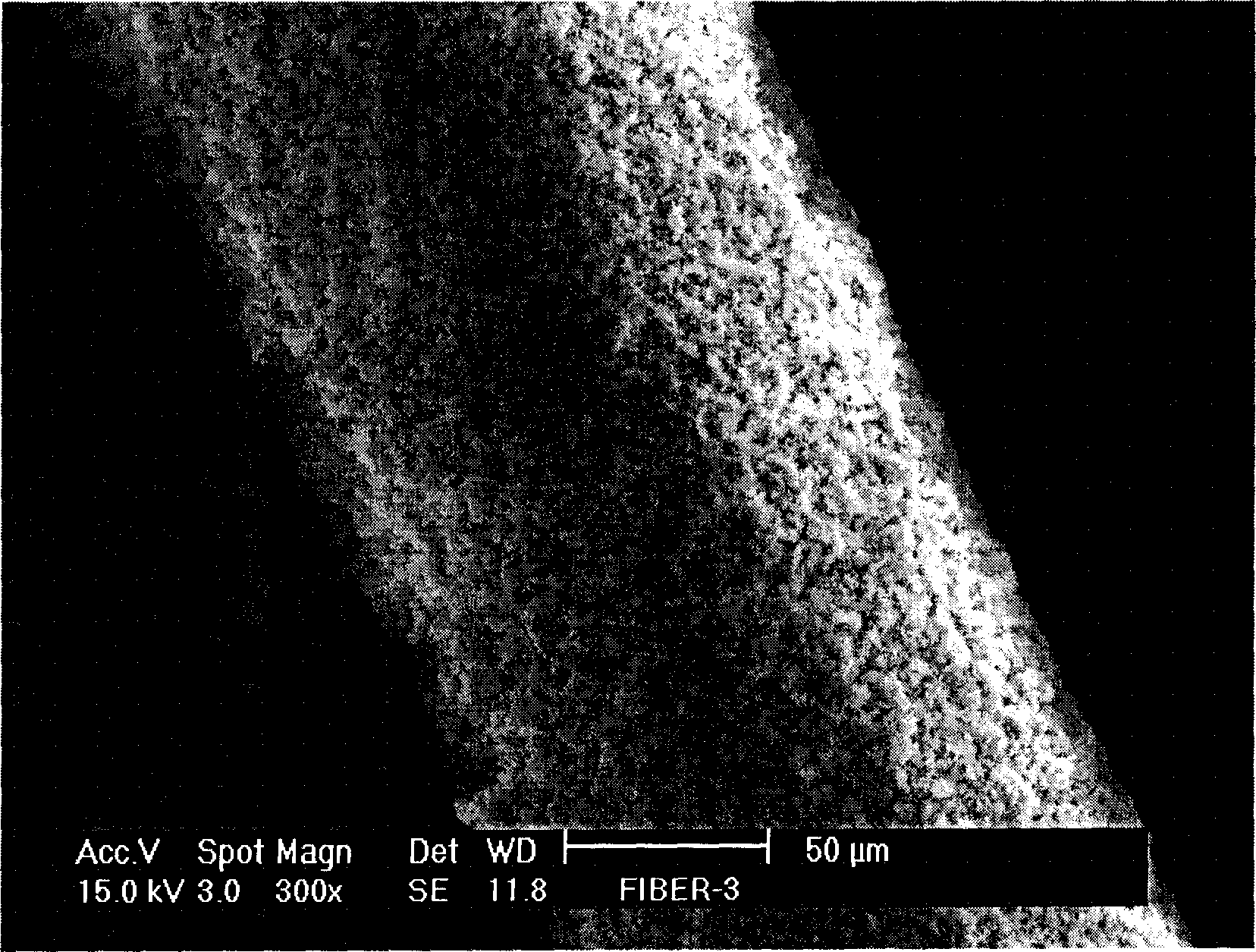

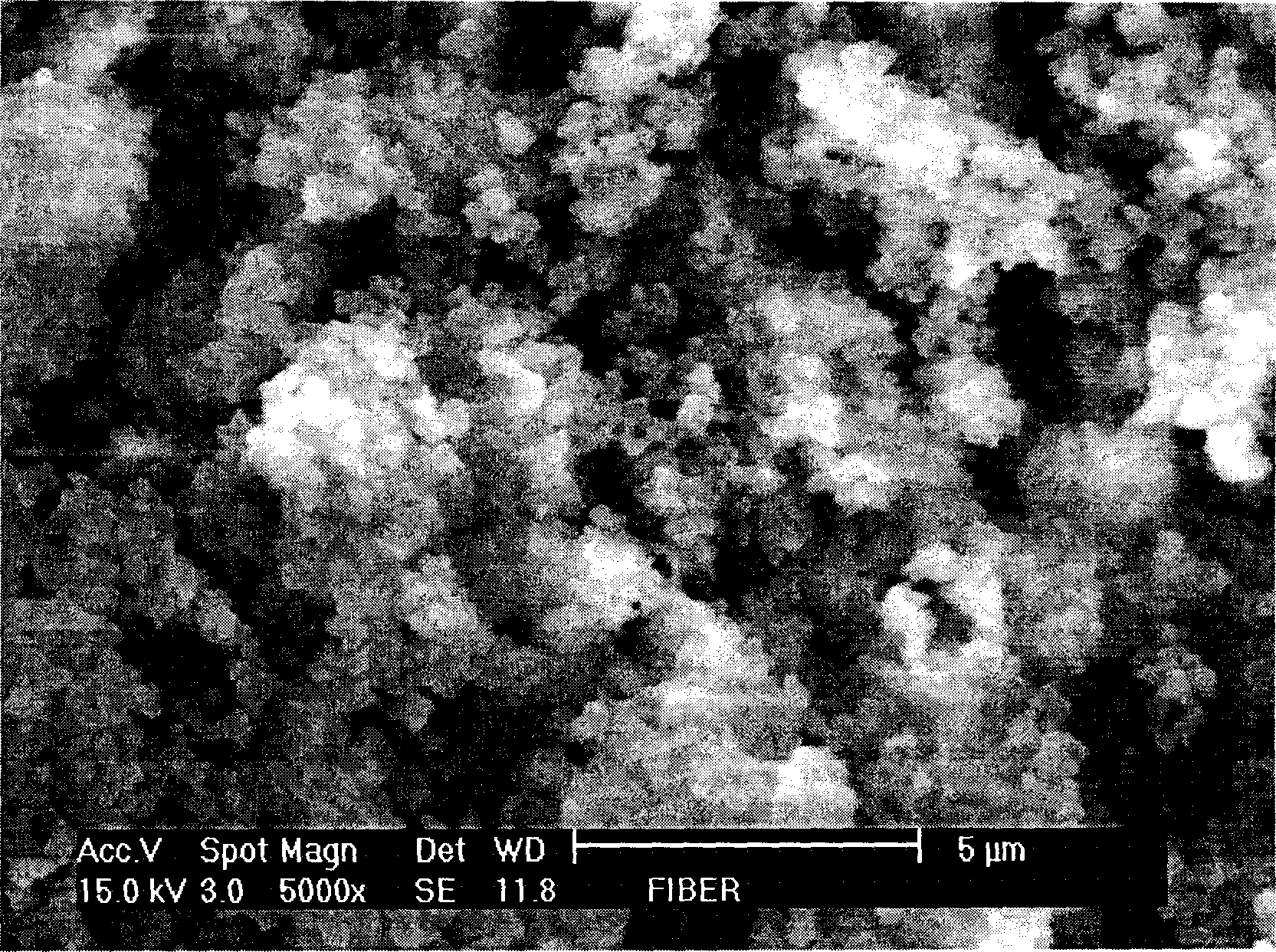

Molecular blotting solid phase microextraction coating preparation method

InactiveCN1843551ALarge specific surface areaImprove stabilityIon-exchange process apparatusComponent separationPrometryneSolid-phase microextraction

The invention discloses a method for preparing the molecular engram solid phase micro-extraction coat, which comprises following steps: alkali cleaning, acid cleaning, activating and silanizing quartz fiber; assembling the template molecular and functional nomomer; adding crosslinking agnet and initiator, inserting silanized quartz molecular and thermally initiating the polymerization; extracting out the fiber to be aged; repeating aforementioned steps to reach needed thickness of coat; washing and removing the template molecular. Compared with commercial coat, the Prometryne molecular engram solid phase micro-extraction coat prepared by said method has better molecular recognition function on the triazine herbicide, while said coat is in porous structure without broken in long service. And its thickness can be adjusted via the plating times with better repeating ability. The extracting head can be used with the liquid chromatography, to separated and collect the triazine herbicide in the complex base as environment sample and food.

Owner:SUN YAT SEN UNIV

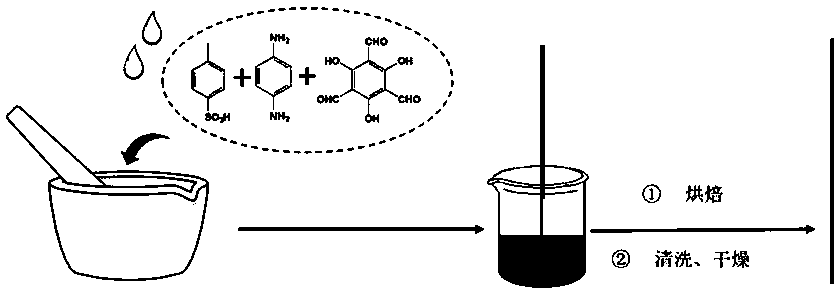

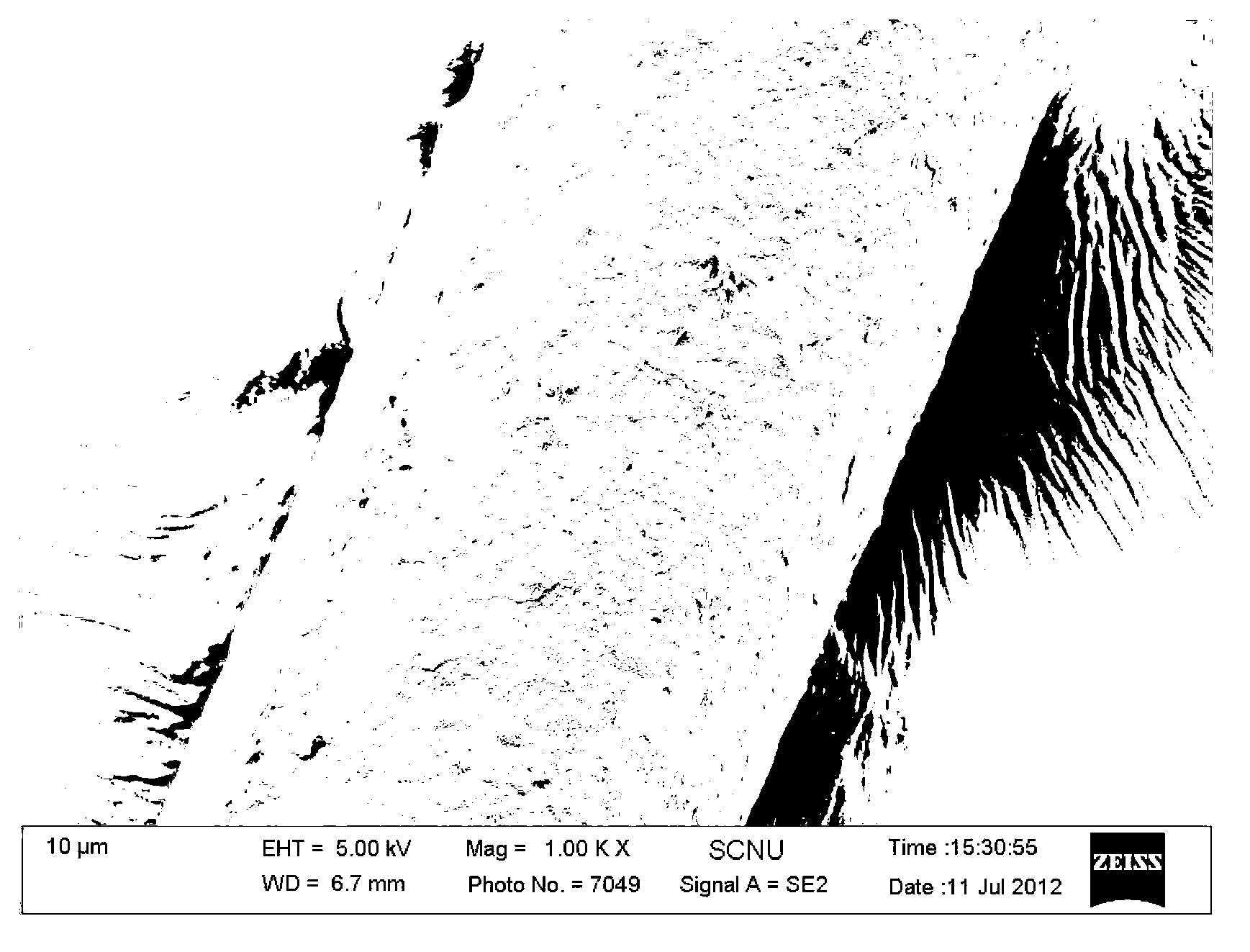

Simple and rapid preparation method and application of covalent-organic framework compound solid-phase microextraction coating

ActiveCN108543519AThickness is easy to controlShorten the timeComponent separationOther chemical processesOrganic solventSolid-phase microextraction

The invention provides a simple and rapid preparation method and application of a covalent-organic framework compound solid-phase microextraction coating. According to the preparation method, the covalent-organic framework compound coating is quickly formed on quartz fiber, a device needed for the entire synthesizing process is extremely easy, and the method comprises the steps of performing amino-functionalization on the quartz fiber, impregnating surface amino-functionalized quartz fiber in a ground material precursor, repeating performing impregnating for several times, performing simple baking and cleaning the coating, so that the covalent-organic framework compound solid-phase microextraction coating can be obtained. The synthesizing method of the invention is easy to operate, requires few devices, and does not need an organic solvent, and by using the method, the covalent-organic framework compound solid-phase microextraction coating with high-temperature resistance, solvent resistance, acid and alkali resistance, high specific surface area, controllable pore size, and controllable thickness can be quickly prepared. Then the extraction coating is used to enrich environmentalpollutants polychlorinated biphenyls in water and it is detected that the coating has good enriching effects by using gas chromatography-mass spectrometry, thereby showing that the coating has good application prospect in the environment and other fields.

Owner:FUZHOU UNIV

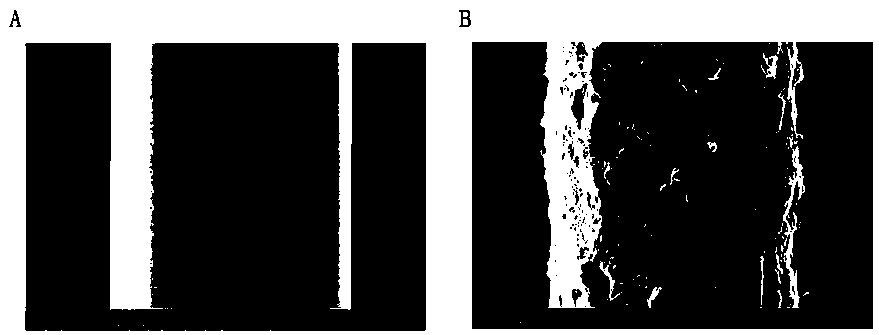

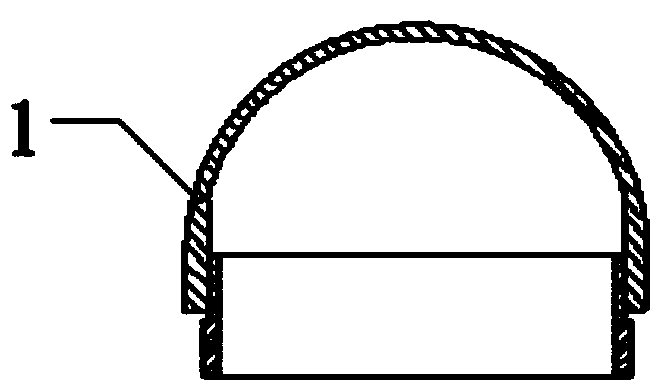

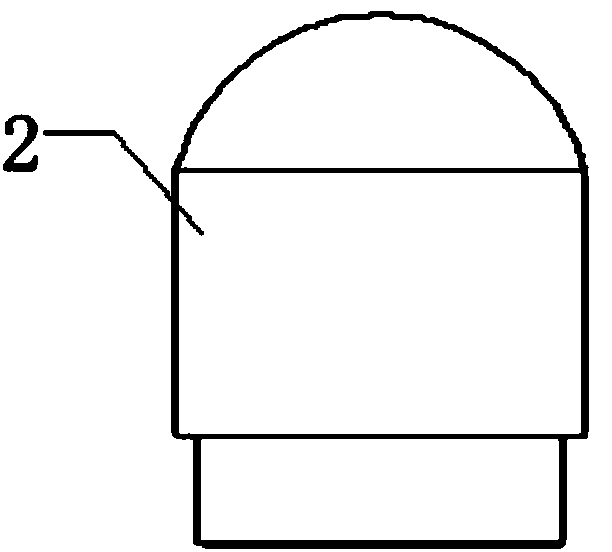

Bi/Er or Bi/Er/Al co-doped quartz fiber and preparation method thereof

ActiveCN105467511AImprove qualityImprove uniformityGlass optical fibreGlass making apparatusOptoelectronicsAtomic layer deposition

The invention relates to a Bi / Er or Bi / Er / Al co-doped silica fiber based on atomic layer deposition (ALD) technology and a preparation method thereof, and belongs to the fiber technology field. The quartz fiber comprises a fiber core, an inner cladding and a cladding, and is characterized in that the fiber core is made of GeO2; the inner cladding is made of a co-doped material of Bi / Er or Bi / Er / Al; and the cladding is made of pure quartz. The two fiber structures are shown in the following pictures: picture 1(a), wherein the fiber core diameter phi=5-20mum; the inner cladding diameter phi=8-50mum; and the cladding diameter phi=40-400mum; picture 1 (b), wherein the fiber core diameter phi=5-80mum; and the cladding diameter phi=60-400mum. Different ions are doped are deposited alternatively by using ALD technology, and the deposition concentration is 0.01-10mol%. The quartz fiber has the advantages of a simple and reasonable structure, a uniform distribution and a controllable doped concentration.

Owner:SHANGHAI UNIV

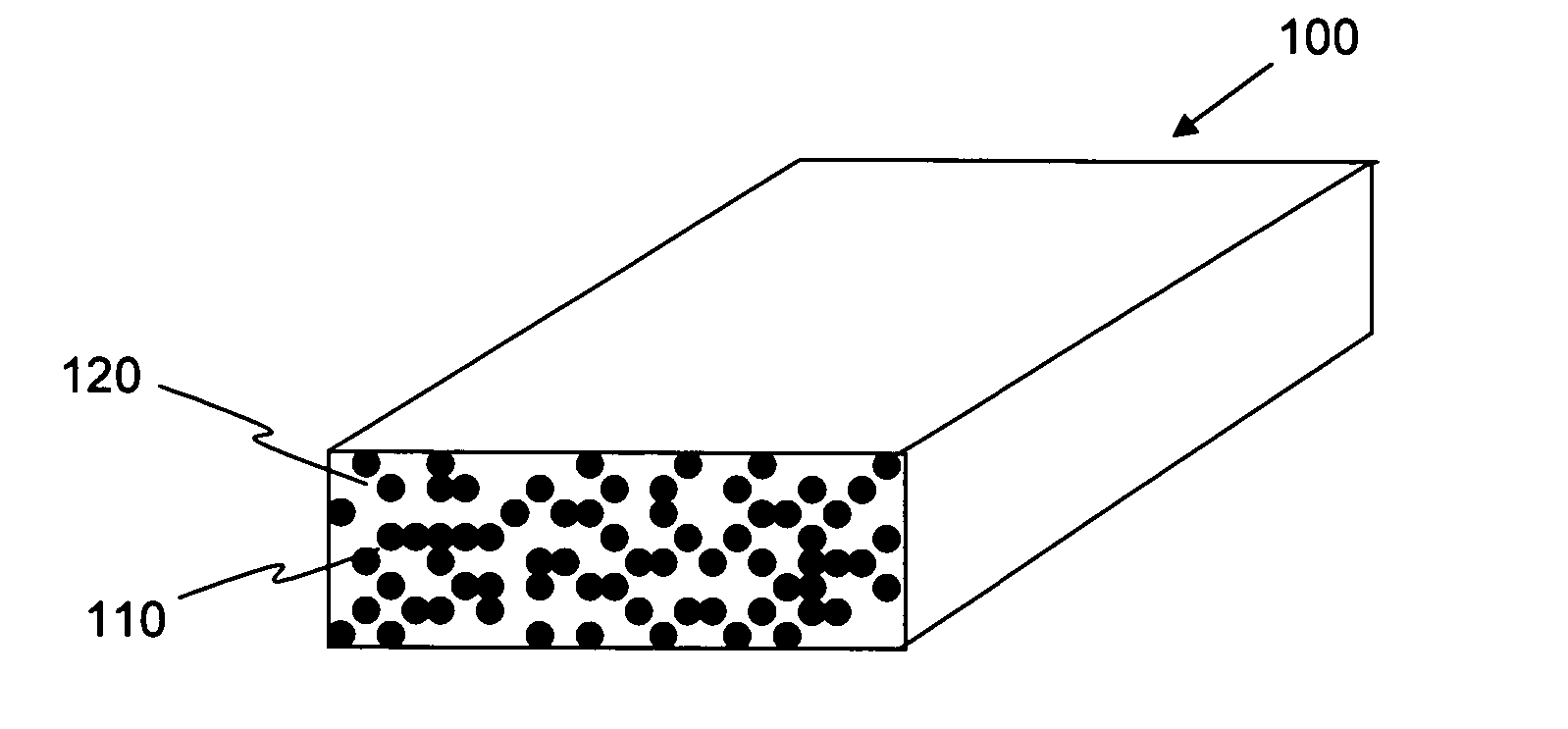

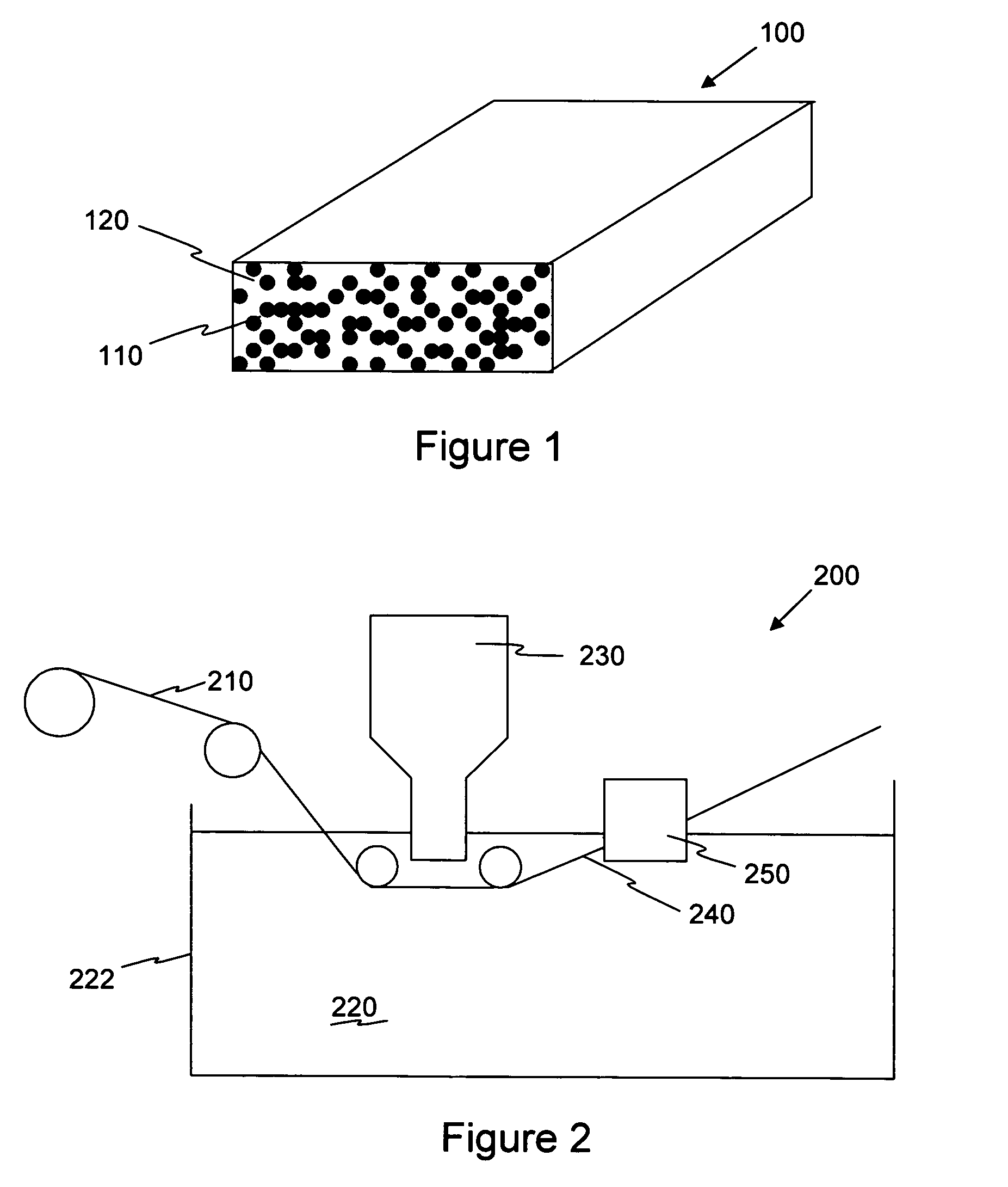

Glass fiber metal matrix composites

A glass fiber reinforced metal matrix composite is described. The composite includes glass fibers distributed in a metal matrix body. The fibers may be uniformly distributed in the metal matrix and may include continuous lengths of the glass fibers. The glass fibers may be glass fibers, S-glass, E-glass fibers, soda-lime-silica fibers, basalt fibers, quartz fibers, or other similar glassy fibers. The metal matrix may include aluminum or alloys of aluminum as well as other metals and alloys.

Owner:TOUCHSTONE RES LAB

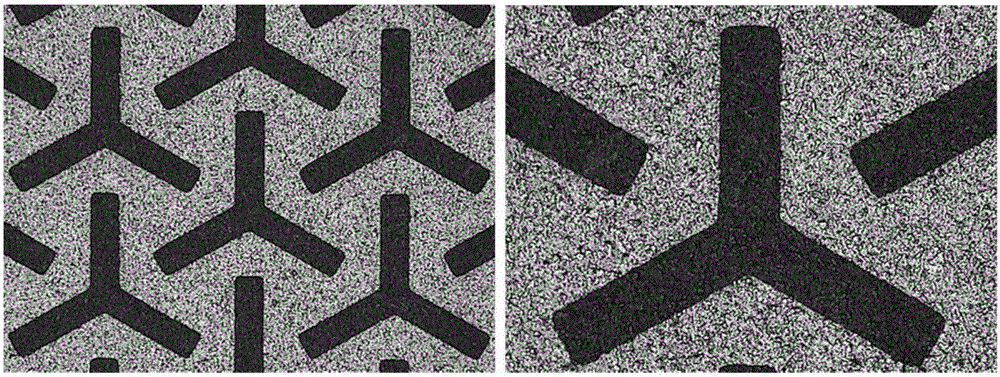

Medium temperature frequency selective surface material and preparation method thereof

ActiveCN106515140AHigh temperature resistanceImprove temperature resistanceLamination ancillary operationsSynthetic resin layered productsAdhesiveHeat resistance

The invention discloses a medium temperature frequency selective surface material. With a layered structure, the medium temperature frequency selective surface material comprises a base layer (quartz fiber reinforced polyimide resin matrix composite material), an intermediate medium layer (high temperature resistant polyimide film) and a metal frequency selective surface layer from the bottom up in order. The preparation method includes: coating a quartz fiber cloth with a polyimide solution to make a prepreg, and then making the prepreg into the base layer; preparing a layer of metal plating on the surface of a polyimide film, and then etching a frequency selective surface on the metal plating, thus obtaining the intermediate medium layer / metal frequency selective surface layer; and coating a polyimide adhesive to the base layer surface, then bonding the base layer and the intermediate medium layer / metal frequency selective surface layer into a whole by hot mould pressing technique, thus obtaining the medium temperature frequency selective surface material. The medium temperature frequency selective surface material provided by the invention has significantly improved temperature resistant grade, can tolerate 400DEG C-600DEG C in a short term, and has good heat resistance.

Owner:NAT UNIV OF DEFENSE TECH +1

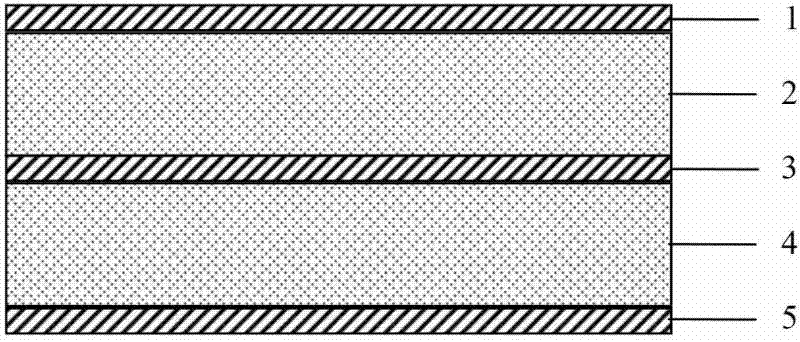

Wave-transmitting material with broadband resin matrix interlayer structure and preparation method of wave-transmitting material

ActiveCN102303441AImprove toughnessHigh strengthSynthetic resin layered productsPolymer scienceResin matrix

The invention discloses a wave-transmitting material with a broadband resin matrix interlayer structure and a preparation method of the wave-transmitting material. The wave-transmitting material comprises an outer skin layer, a first foam sandwich layer, a middle skin layer, a second foam sandwich layer and an inner skin layer which are sequentially overlapped and tightly combined, wherein the outer skin layer, the middle skin layer and the inner skin layer are made of continuous quartz fibre reinforced resin-base composite materials; the first foam sandwich layer and the second foam sandwich layer are made of polyurethane foams, the outer skin layer, the middle skin layer and the inner skin layer have dielectric constants of 3.1-3.2 and loss angle tangent values of 0.009-0.01; and the first foam sandwich layer and the second foam sandwich layer have dielectric constants of 1.10-1.15 and loss angle tangent values of 0.005-0.006. The preparation method comprises the steps of: preparing reinforced materials, and laying the reinforced materials according to the layering order and the thickness of each layer, pre-forming and curing to obtain the wave-transmitting material. The wave-transmitting material has the advantages of simple structure and high cost performance.

Owner:NAT UNIV OF DEFENSE TECH

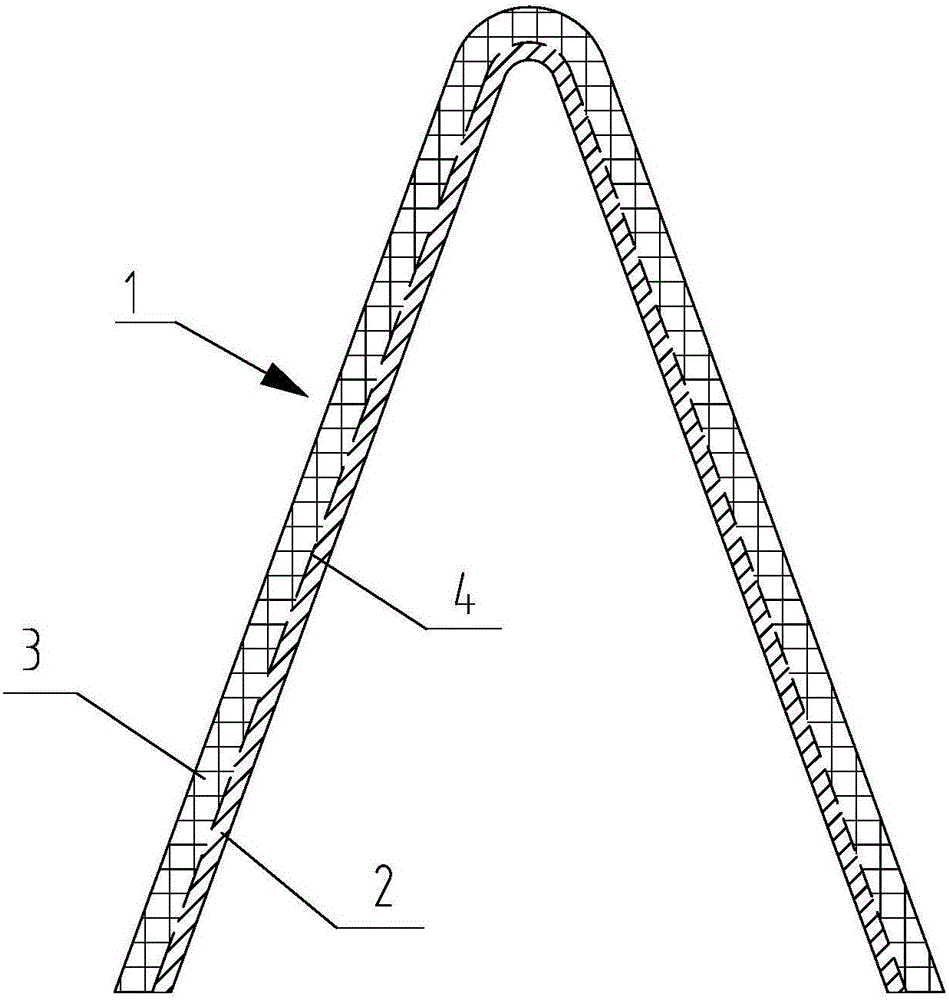

Cover body of broadband wave-transmitting dual-layer composite ceramic antenna cover and fabrication method for cover body

ActiveCN106129615AGuaranteed strength performanceGuaranteed electricityRadiating element housingsComposite ceramicBroadband

The invention discloses a cover body of a broadband wave-transmitting dual-layer composite ceramic antenna cover and a fabrication method for the cover body. The fabrication method for the cover body of the broadband wave-transmitting dual-layer composite ceramic antenna cover comprises the following steps of 1) weaving a shaped fabric; 2) pre-processing the shaped fabric; 3) impregnating an outer layer of the shaped fabric; 4) performing integral impregnation; 5) repeating to perform integral impregnation in the above step of 4) for two or three times; 6) sintering an intermediate blank; 7) roughly processing a cover body blank; 8) repeating to perform integral impregnation in the above step of 4) on the roughly-processed cover body blank for one time, and performing high-temperature sintering; and 9) finely processing an initial cover body. The shaped fabric of the cover body of the dual-substrate composite ceramic antenna cover is formed by laying and integratedly stitching a hollow quartz fiber fabric, a hollow quartz fiber felt and a solid quartz fiber fabric, the integral formation of the dual-layer composite ceramic antenna cover can be achieved, thus, the connection strength and the assembly accuracy of the cover body are improved, and the production cost is reduced.

Owner:湖北三江航天江北机械工程有限公司

High temperature-resistant quartz fiber reinforced silica-based composite material, and preparation method and application thereof

ActiveCN108911777ALow tensile strengthAvoid churnRadiating element housingsNano al2o3Temperature resistance

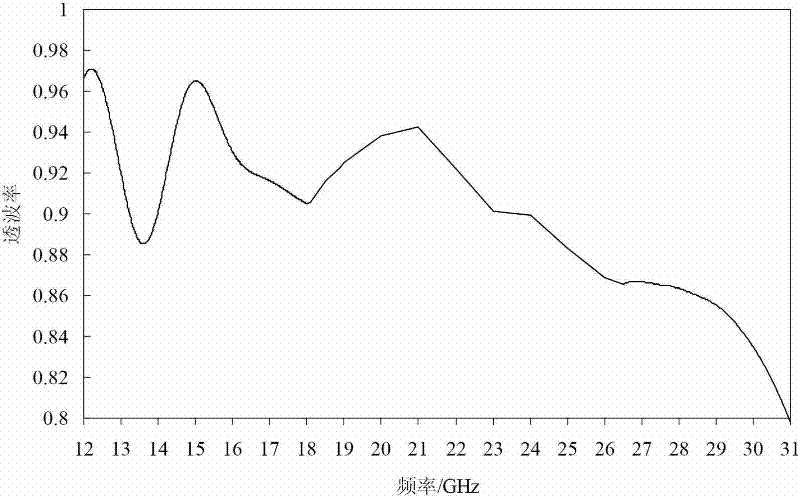

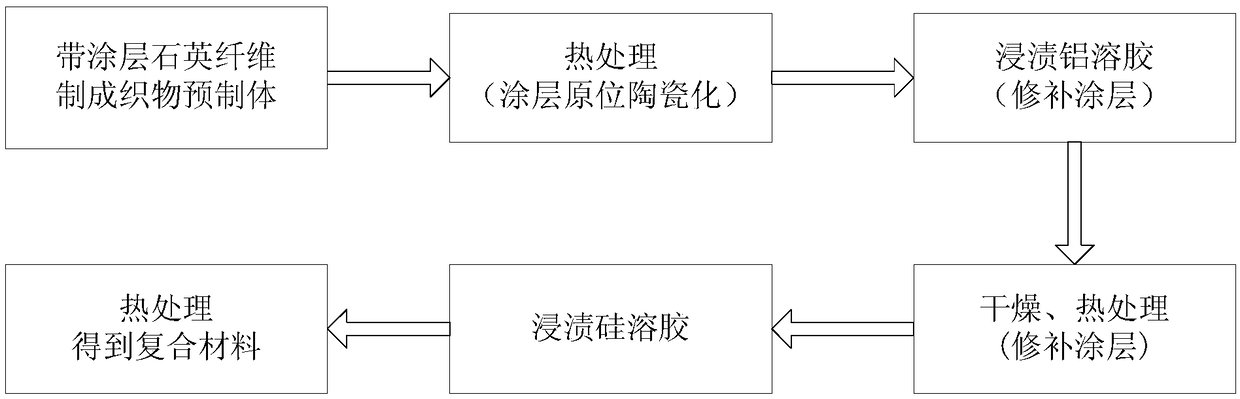

The invention relates to a high temperature-resistant quartz fiber reinforced silica-based composite material, and a preparation method and an application thereof. The method comprises the following steps: preparing a fabric preform from a quartz fiber having a coating layer on the surface of a monofilament, and carrying out heat treatment on the prepared fabric preform to obtain a fabric preformhaving a ceramized coating layer on the surface of the monofilament, wherein the coating layer contains water and alumina and / or nano-alumina particles; impregnating the fabric preform having the ceramized coating layer on the surface of the monofilament in an aluminum sol having a solid content of 5-10 wt%, and performing drying and heat treatment to obtain a fabric preform having the ceramized coating layer completely coating the monofilament fiber; and impregnating the obtained fabric perform in a silica sol, and then performing drying curing and heat treatment to obtain the high temperature-resistant quartz fiber reinforced silica-based composite material. The high temperature resistance of the quartz fiber reinforced silica composite material is greatly improved, the tensile strengthat 1200 DEG C is increased to 30 MPa or above from about 10 MPa, and the 1200 DEG C high temperature strength retention rate is increased to 80% or above from 50% or below.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

C/(SiC/BN)n compound interface phase coating, coating fiber and preparation method of coating fiber

The invention discloses a C / (SiC / BN)n compound interface phase coating which comprises a C layer and a periodic superposed layer, wherein the periodic superposed layer refers to alternative periodic superposition of SiC layers and BN layers. The coating fiber comprises a fiber base body and the C / (SiC / BN)n compound interface phase coating applied to the surface of the base body, wherein the fiber base body is selected from one of mullite fiber, carbon fiber, silicon carbide fiber and quartz fiber. The preparation method of the coating fiber comprises the following steps: preparing a fiber base body material, and depositing the C layer on the surface of the fiber base body with a chemical vapor deposition method at first; then alternatively depositing the SiC layers and the BN layers on the surface of the C layer with the chemical vapor deposition method, repeating the alternative depositing process 3-5 times, and obtaining the coating fiber. The coating fiber has the advantages of good physical and chemical compatibility, high temperature resistance, oxidation resistance, good toughening effect and the like.

Owner:NAT UNIV OF DEFENSE TECH

Quartz/quartz-boron nitride high-temperature wave-permeable material and preparation method thereof

ActiveCN102167609APreparation process operation safetyOperation process securityPhysical chemistryBoron nitride

The invention relates to a quartz / quartz-boron nitride high-temperature wave-permeable material and a preparation method thereof. The chemical formula of the quartz / quartz-boron nitride high-temperature wave-permeable material is SiO2f / SiO2-BN; and the wave-permeable material contains 40-65vol% of quartz fiber (SiO2f), 10-30vol% of SiO2 and 5-15vol% of BN. The preparation method comprises the following steps: firstly, preparing a green quartz / quartz ceramic body from quartz textile and SiO2 sol by a sol-gel process; and then, by using the green quartz / quartz ceramic body as well as boric acid, carbamide and ethanol as raw materials, carrying out vacuum impregnation and non-pressure sintering, thus obtaining the quartz / quartz-boron nitride high-temperature wave-permeable material. The quartz / quartz-boron nitride high-temperature wave-permeable material has favorable ablation resistance, mechanical properties and dielectric properties, and has the advantages of simple preparation process, low cost and fine molding and processing performance.

Owner:NAT UNIV OF DEFENSE TECH

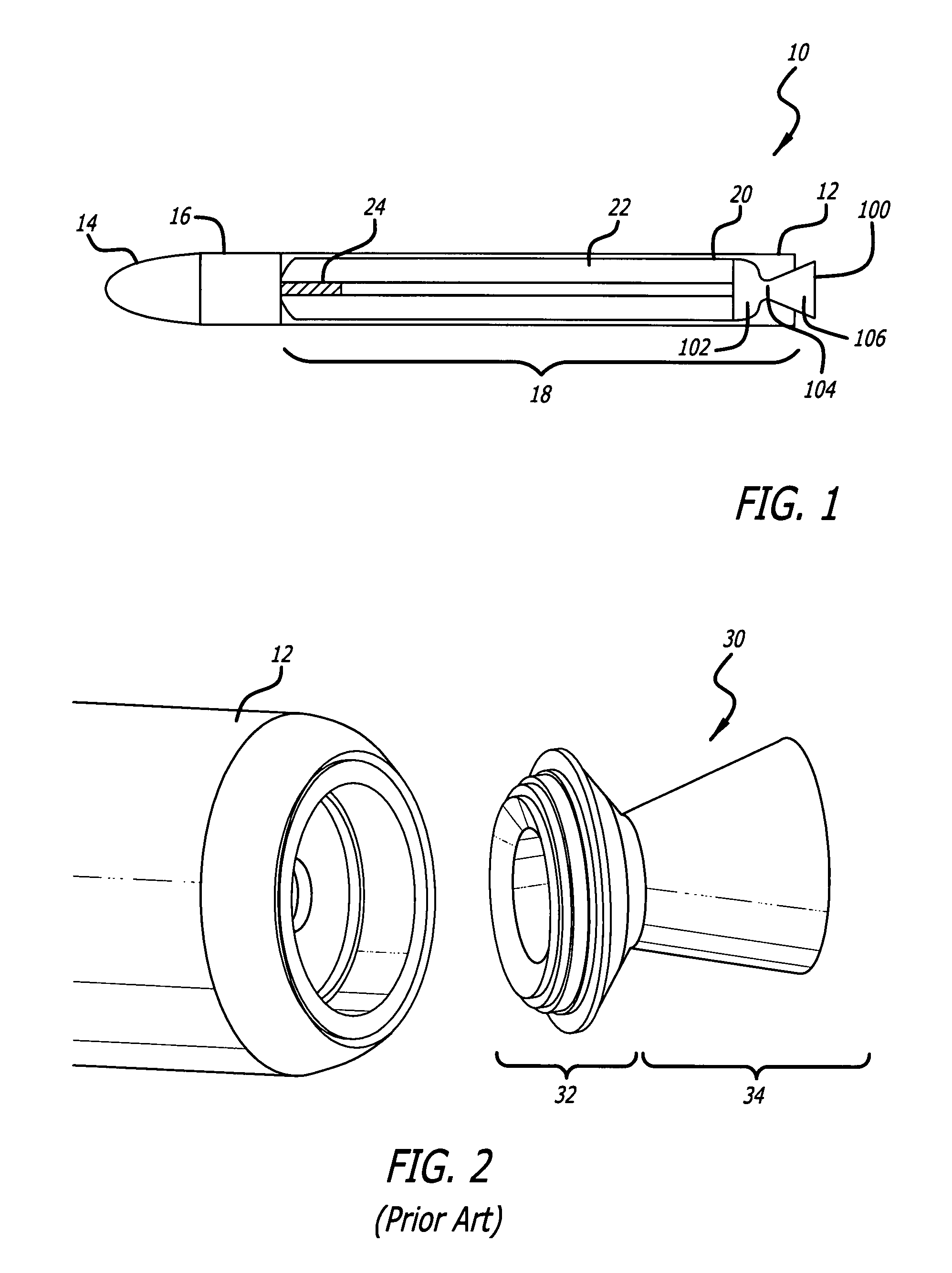

Integral composite rocket motor dome/nozzle structure

An integral composite rocket motor nozzle. The novel nozzle includes a first layer of a first reinforcement material, a second layer of a second reinforcement material, and a common matrix material surrounding the first and second reinforcement materials such that the reinforcement materials and matrix material form a single integral composite structure. In an illustrative embodiment, the first reinforcement material includes graphite fibers for providing structural support, and the second reinforcement material includes glass or quartz fibers for providing thermal insulation on a first side of the first layer. The nozzle may also include a third layer of a third reinforcement material for providing thermal insulation on a second side of the first layer. In a preferred embodiment, the first layer is shaped to form an integrated dome and nozzle structure.

Owner:RAYTHEON CO

Preparation method for solid-phase micro-extraction head based on single-stranded DNA aptamer modified graphene oxide coating

InactiveCN103055830AIncrease loading capacityHigh enrichment efficiencyComponent separationOther chemical processesInstabilityQuartz fiber

The invention discloses a preparation method for a novel solid-phase micro-extraction head based on a single-stranded DNA aptamer modified graphene oxide coating. The preparation method comprises the following steps: (1) subjecting a quartz fiber to silanization; (2) coating a porous polymer solution on the surface of the quartz fiber; (3) repeatedly coating a porous polymer coating; (4) carrying out silanization; (5) intercalating the silanized porous polymer coating quartz fiber into a mixed solution of a PBS buffer solution, a catalyst EDC solution, an NHS solution and an aqueous graphene oxide solution; (6) repeating step (4) and step (5) a plurality of times on the same quartz fiber; and (7) taking out the graphene oxide / porous polymer coating quartz fiber and intercalating the graphene oxide / porous polymer coating quartz fiber into a mixed solution of the PBS buffer solution, the EDC solution, the NHS solution and an aptamer solution. The preparation method provided by the invention overcomes the disadvantages of a low immobilization rate, easy shedding, instability and the like of conventional coating methods, substantially increases the immobilization rate of an aptamer and improves enrichment efficiency of SPME.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Manufacturing method of miniature and thin-walled composite ceramic wave-transparent antenna housing

ActiveCN104393402AGuarantee processing qualityReduce pittingAntenna adaptation in movable bodiesRadiating element housingsYarnComposite ceramic

The invention discloses a manufacturing method of a miniature and thin-walled composite ceramic wave-transparent antenna housing. The manufacturing method includes the following steps that: a corresponding braiding core model is designed according to size requirements of a housing body; quartz fiber yarns are adopted as raw materials so as to be attached to and braided on the braiding core model, so that required housing body braided fabric can be obtained; the housing body braided fabric is boiled in water, and then is socked in acid liquid, and finally is socked and composited in a container filled with a silica solution, and therefore, a housing body blank can be obtained; and a bonding part of a connecting ring and the housing body is processed, so that the miniature and thin-walled composite ceramic wave-transparent antenna housing can be obtained. According to the manufacturing method of the invention, mechanical processing is divided into coarse processing and fine processing, and therefore, processing quality of the surface of the housing body can be effectively ensured, and pits on the surface of the housing body are decreased significantly, and at the same time, the uniformity of the materials of the housing body can be improved; after mechanical processing every time, high temperature heat treatment is performed on the housing body blank, and therefore, organic impurities such as oil contamination by which the housing body blank is contaminated in a machining process can be effectively removed, and the performance of a product can be effectively ensured.

Owner:湖北三江航天江北机械工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com