Manufacturing method of miniature and thin-walled composite ceramic wave-transparent antenna housing

A technology of composite ceramics and manufacturing methods, which is applied in the direction of antennas and radiation unit covers suitable for movable objects, can solve the problems of harsh re-entry environment and difficulty in meeting the use requirements, and achieve improved uniformity and strong operability , Realize the effect of real-time detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for manufacturing a miniature and thin-walled composite ceramic wave-transparent radome, comprising the following steps:

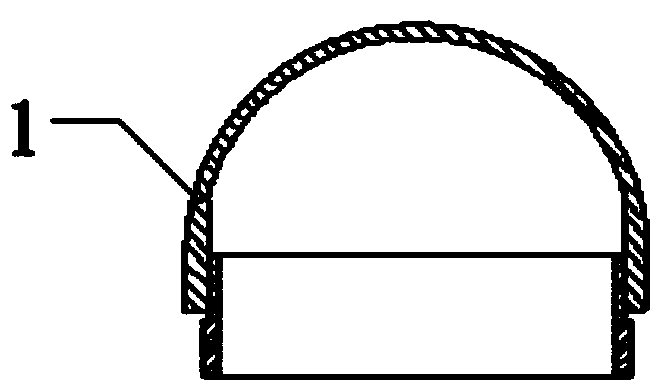

[0035] 1) if figure 1 Said, according to the size requirements of the cover body 1, its size is as follows

[0036] Table 1 Main Dimensions of Cover Body

[0037]

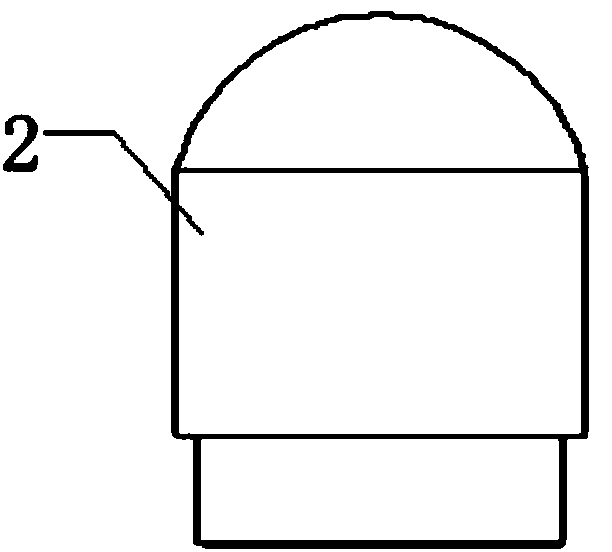

[0038] And design the corresponding braided mandrel 2 (such as figure 2 shown) and select the quartz glass fiber yarn, remove the organic epoxy sizing agent on the surface of the quartz glass fiber yarn, and then use the quartz fiber yarn as raw material to carry out mold-fitting weaving on the braiding mandrel 2 to obtain a cover braid that meets the requirements ;

[0039] 2) Boil the braided fabric in ultrapure water for 40 hours, bake it at 200°C for 48 hours, and bake it at 200°C with oxygen for 6 hours, then soak the fabric in acid solution for 10 hours, After soaking in the acid solution, boil the cover fabric in water for 20 hours, then soak the cover fabric in w...

Embodiment 2

[0050] A method for manufacturing a miniature and thin-walled composite ceramic wave-transparent radome, comprising the following steps:

[0051] 1) if figure 1 Said, according to the size requirements of the cover body 1, its size is as follows

[0052] Table 1 Main Dimensions of Cover Body

[0053]

[0054] And design the corresponding braided mandrel 2 (such as figure 2 shown) and select the quartz glass fiber yarn, remove the organic epoxy sizing agent on the surface of the quartz glass fiber yarn, and then use the quartz fiber yarn as raw material to carry out mold-fitting weaving on the braiding mandrel 2 to obtain a cover braid that meets the requirements ;

[0055] 2) Boil the braided fabric in ultrapure water for 60 hours, bake it at 300°C for 24 hours, and bake it at 400°C with oxygen for 3 hours, then soak the fabric in acid solution for 10 hours, After soaking in the acid solution, boil the cover fabric in water for 15 hours, then soak the cover fabric in w...

Embodiment 3

[0066] A method for manufacturing a miniature and thin-walled composite ceramic wave-transparent radome, comprising the following steps:

[0067] 1) if figure 1 Said, according to the size requirements of the cover body 1, its size is as follows

[0068] Table 1 Main Dimensions of Cover Body

[0069]

[0070] And design the corresponding braided mandrel (such as figure 2 shown) and select the quartz glass fiber yarn, remove the organic epoxy sizing agent on the surface of the quartz glass fiber yarn, and then use the quartz fiber yarn as raw material to carry out mold-fitting weaving on the braiding mandrel 2 to obtain a cover braid that meets the requirements ;

[0071] 2) Boil the braided fabric in ultrapure water for 50 hours, bake it at 400°C for 36 hours, and bake it at 300°C with oxygen for 4 hours, then soak the fabric in acid solution for 15 hours, After soaking in the acid solution, boil the cover fabric in water for 18 hours, and then soak the cover fabric in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com