Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Gel time controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

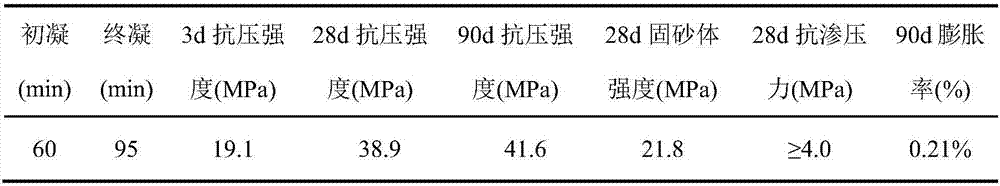

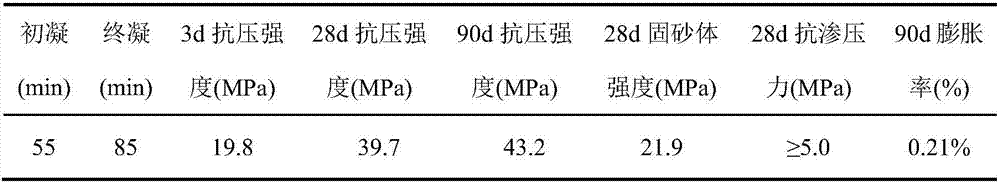

Efficient superfine cement based composite grouting material for grouting treatment of water-rich sand layer, preparation process and application

ActiveCN107572994AEasy to operateImprove applicabilityDrilling compositionSealing/packingMicrofine cementAluminate

The invention discloses an efficient superfine cement based composite grouting material for grouting treatment of a water-rich sand layer, a preparation process and application. The efficient superfine cement based composite grouting material is prepared from the following components in parts by weight: 40 to 80 parts of portland cement clinker, 10 to 45 parts of coal ash, 5 to 30 parts of superfine slag micro powder, 2 to 6.5 parts of desulphurization gypsum, 1 to 10 parts of silica fume, 0.51 to 2.10 parts of first mixed composite modifier, 0.4 to 2.4 parts of second mixed composite modifierand 5.5 to 8.9 parts of third mixed composite modifier; the coal ash is prepared from the following components in parts by weight: 50 to 100 parts of high-calcium coal ash and 0 to 50 parts of low-calcium coal ash; the first mixed composite modifier is prepared from the following components in parts by weight: 96 to 99 parts of super plasticizer and 1 to 4 parts of hydroxypropyl methyl cellulose;the second mixed composite modifier is prepared from the following components in parts by weight: 20 to 32 parts of sodium hydroxide, 21 to 28 parts of sodium carbonate, 18 to 32 parts of sodium sulfate and 18 to 36 parts of sodium metaaluminate; the third mixed composite modifier is prepared from the following components in parts by weight: 12 to 25 parts of calcium chloride, 8 to 21 parts of lithium chloride, 10 to 23 parts of triethanolamine and 32 to 68 parts of sulphoaluminate cement clinker.

Owner:SHANDONG UNIV

Preparation method of hydrophobic nano-aerogel composite material

The invention provides a preparation method of a hydrophobic nano-aerogel composite material. The preparation method comprises the following steps of mixing, aging, impurity removing, solvation, drying and hydrophobic modification. By the preparation method, the yield can be relatively high, the utilization rate of raw materials is higher, the cost is reduced, filtration and precipitation are not required, and the process is simpler; the hydrophobic nano-aerogel composite material prepared according to the preparation method can achieve a better hydrophobic effect, is uniform in microstructure, and has a wide application prospect.

Owner:河北金纳低碳材料有限公司

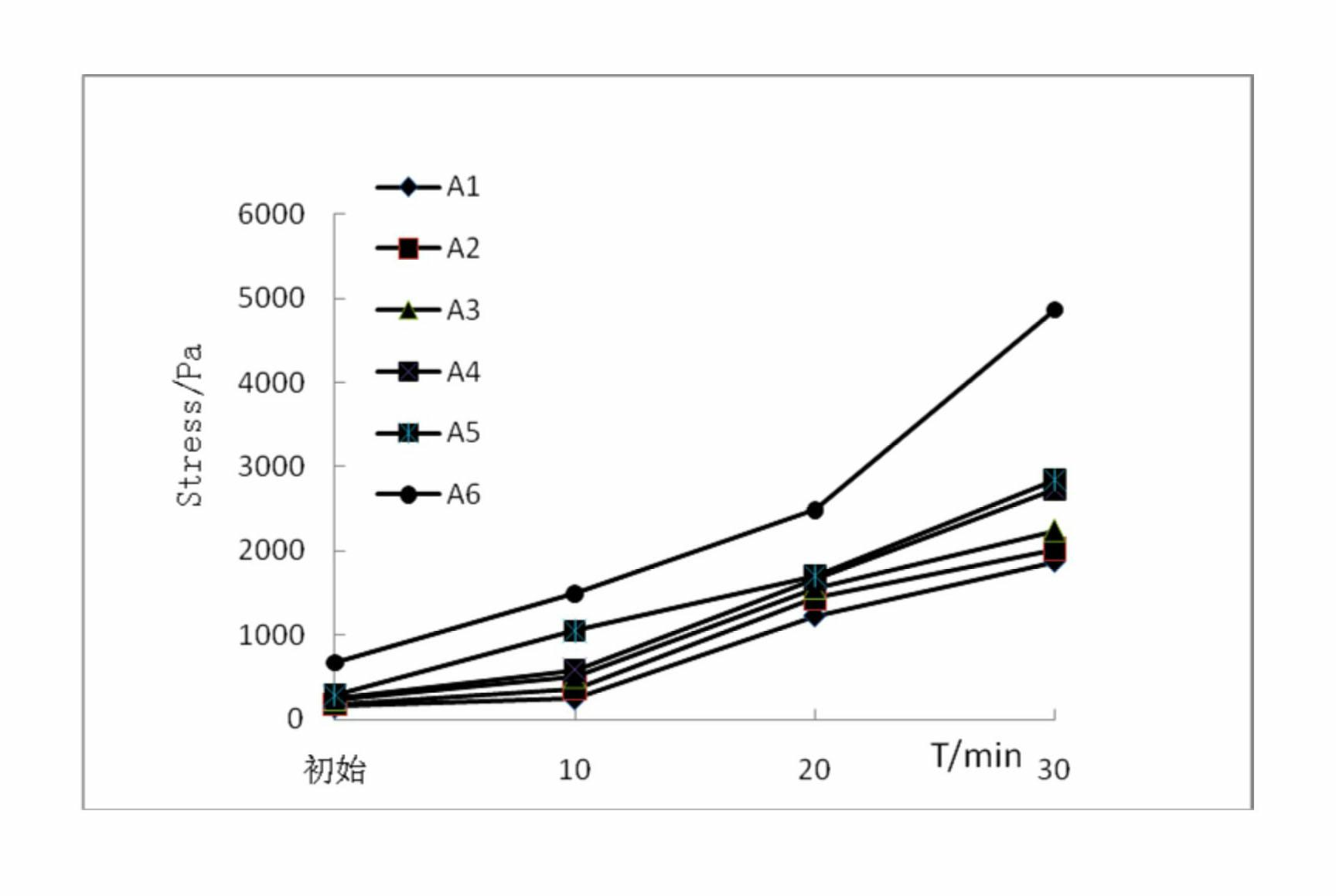

Controllable clay and cement seepage-proof reinforcement paste

The invention discloses controllable clay and cement seepage-proof reinforcement paste. The controllable clay and cement seepage-proof reinforcement paste is mainly prepared from clay raw stock, cement and water, wherein the clay raw stock is mainly obtained by stirring clay and water. A modifier is added in the controllable clay and cement seepage-proof reinforcement paste; the doping amount of the modifier is 1 to 3 percent; the modifier mainly comprises mineral additives, sulfate and bentonite in a mass ratio of a:b:c; and a:b:c is 5:(5-0):(0-5). The product has the advantages of high stability and water flow dilution resistance, controllable setting time, adjustable strength, high antiseepage performance, low cost, environment friendliness and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Environment-friendly acrylate grouting material as well as preparation method and application thereof

InactiveCN104177554AImprove water resistanceImprove aging resistancePolymer science(Hydroxyethyl)methacrylate

The invention provides an environment-friendly acrylate grouting material, as well as a preparation method and an application thereof. The material mainly comprises the following components in parts by weight: a main agent, namely 100 parts of methacrylic acid-beta-hydroxyethyl ester, a crosslinking agent which includes 5-30 parts of hydrophilic compound containing a diallyl ether functional group, 1-5 parts of initiator and 0.5-3 parts of accelerant, 0-20 parts of an adjuvant, and a solvent, namely 2-1,000 parts of water. The method comprises the following steps: firstly, mixing the main agent, the crosslinking agent, the accelerant, the adjuvant and a part of solvent evenly to form a solution A in use; then dissolving the initiator into a residual solvent to form a solution B; and finally mixing the solution A with the solution B evenly, and solidifying at room temperature. According to the grouting material disclosed by the invention, the technical problem that the existing organic grouting material cannot be grouted once after being mixed with an inorganic grouting material, and the technical problem that the existing grouting material has poor durability, low strength, poor water solubility, low water expansion rate and high toxicity are solved.

Owner:湖南博旺水电建设有限公司

Formula of organic silicon rubber for light-emitting diode (LED) chip packaging

InactiveCN102391651AMeet packaging requirementsRich sourcesSemiconductor devicesVulcanizationHazardous substance

The invention discloses a formula of organic silicon rubber for light-emitting diode (LED) chip packaging. According to the formula, the organic silicon rubber mainly comprises 45 to 85 percent of vinyl silicon oil, 35 to 65 percent of methyl hydrogen-containing silicon oil, 0.3 to 0.7 percent of platinum catalyst, 0.2 to 0.45 percent of catalysis inhibitor, and 1.2 to 1.8 percent of functional filler. The invention discloses the formula of the organic silicon rubber for LED packaging; the components in the formula are reasonable, the sources of the raw materials are rich, and the prepared organic silicon rubber can fully meet the packaging requirements of LED chips with different power, and has high hardness, light transmission, cold and heat resistance, and toughness; meanwhile, a vulcanization process in the process for preparing the organic silicon rubber is smooth, gelling time is easy to control, harmful substances are not breeded, and the organic silicon rubber is a more environment-friendly organic material.

Owner:常熟市广大电器有限公司

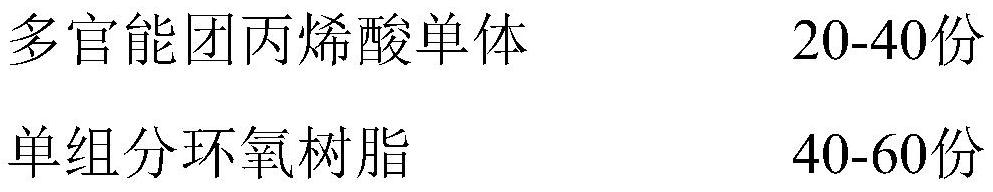

Synthesis method for low-viscosity high-temperature-resistant modified epoxy resin

The invention relates to a synthesis method for low-viscosity high-temperature-resistant modified high-performance epoxy resin. The method comprises the following steps: (1) adding multifunctional epoxy resin into a three-neck flask provided with a thermometer, a stirrer, a nitrogen lead-in pipe and a condenser and gradually heating and stirring; (2) when the temperature is raised to 80 DEG C, dropwise adding unsaturated monocarboxylic acid, adding a catalyst and a polymerization inhibitor, controlling the reaction temperature to be 80-120 DEG C and performing a partial polymerization reaction; (3) measuring the acid value every one hour and reaching a reaction endpoint until the acid value is reduced to 15 mgKOH / g; and (4) cooling a reaction product and adding a cross-linking agent, and controlling the temperature to be 60-80 DEG C and uniformly stirring to obtain the low-viscosity high-temperature-resistant modified epoxy resin. Compared with the multifunctional epoxy resin system, the modified epoxy resin system has the advantages of low viscosity, high activity, high temperature resistance, low cost and the like, is suitable for a resin transfer molding process and is mainly used as matrix resin of an advanced composite material.

Owner:EAST CHINA UNIV OF SCI & TECH +1

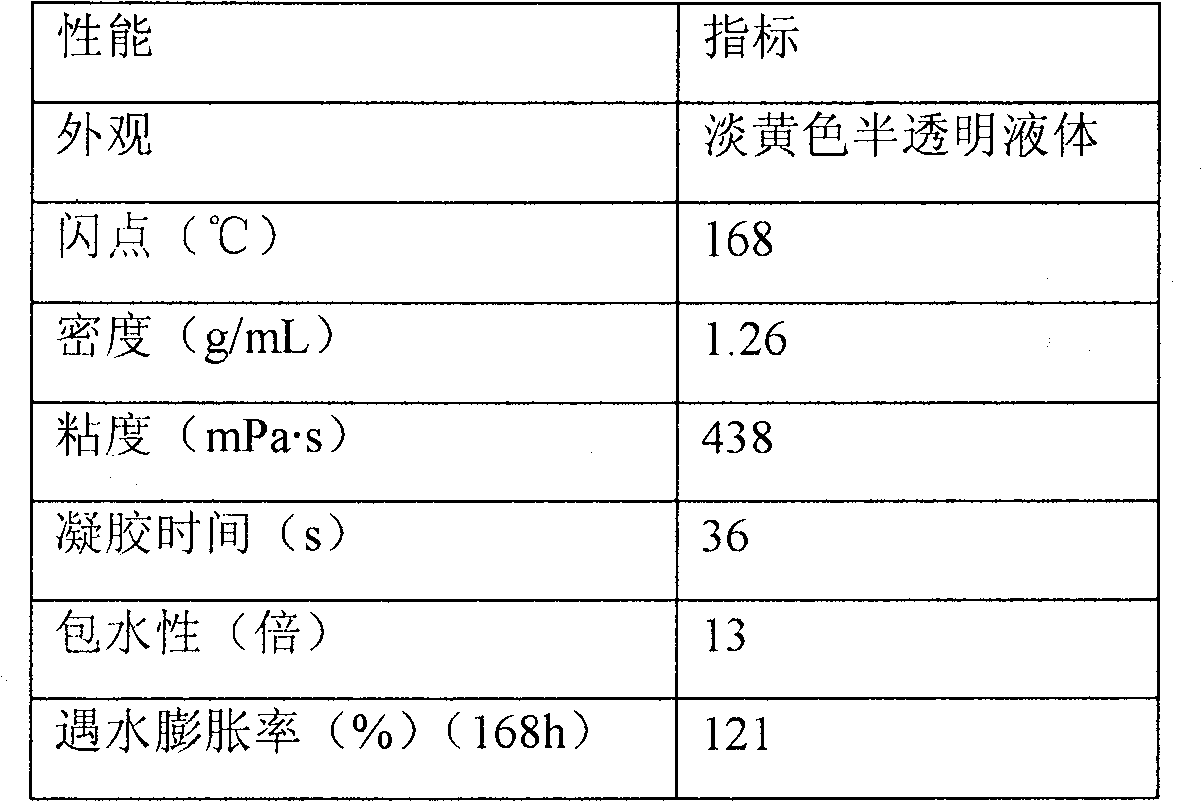

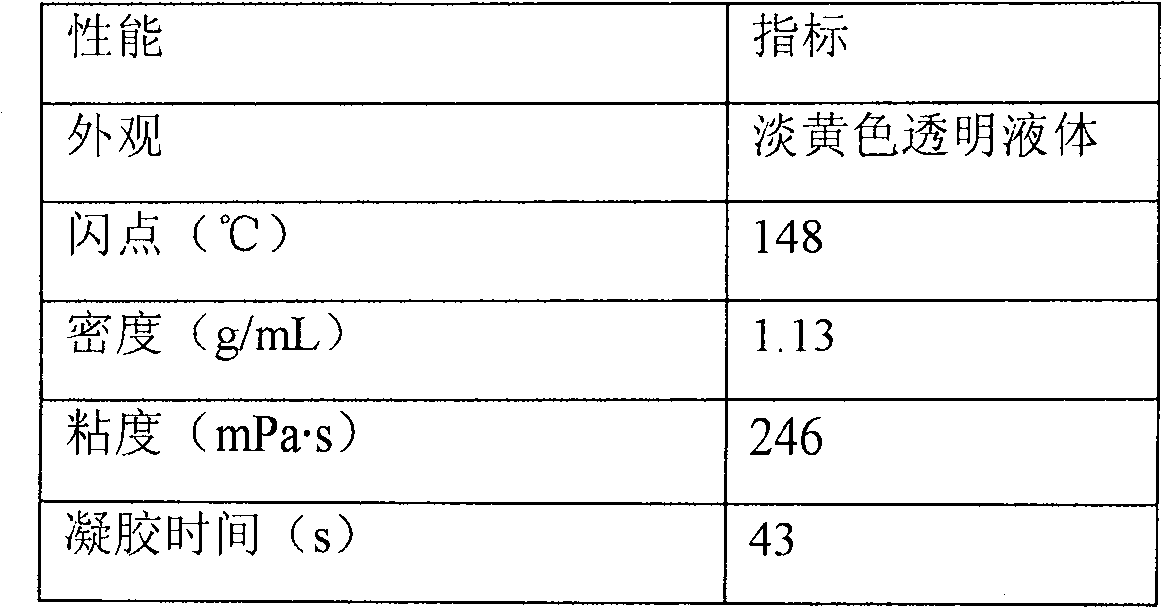

Low-viscosity high-flash-point waterborne polyurethane water shutoff material and preparation method thereof

The invention discloses a low-viscosity high-flash-point waterborne polyurethane water shutoff material and a preparation method thereof. The polyurethane water shutoff material comprises the following materials in parts by weight: 80 to 120 parts of waterborne polyether polyol, 20 to 30 parts of isocyanate, 0.05 to 0.5 part of catalyst, 25 to 35 parts of inert diluents, and 1.0 to 1.5 parts of cross-linking agent. The preparation method comprises the following steps of: dehydrating the waterborne polyether polyol, performing hybrid reaction on the dehydrated waterborne polyether polyol, the isocyanate and the catalyst till that the content of the NCO in a detection system is not reduced any more, adding the inert diluents into the mixture, uniformly mixing, and adding the chain-extension cross-linking agent into a certain quantity of water to form another component when the water shutoff material is used. The waterborne polyurethane water shutoff material has the characteristics of high water absorption capability, high flash point, no combustion, low viscosity, environment friendliness and the like; and the preparation method is simple and facilitates construction. The waterborne polyurethane water shutoff material is applicable to treatment on flowing water and gushing water as well as prevention and treatment on water seepage of underground works such as mine roadways, shafts, tunnels, subsea tunnels and subways.

Owner:HEFEI UNIV OF TECH

Environment-friendly high-performance furfural-free epoxy chemical grouting material, preparation method and application

InactiveCN102617983AAdjustable initial viscosityGel time controllableOther chemical processesSoil preservationEpoxyAdhesion force

The invention discloses an environment-friendly high-performance furfural-free epoxy chemical grouting material, which is prepared with 100 parts of epoxy resin, 100-150 parts of diluent, 8-20 parts of curing agents, 0.5 part of accelerators and 18 parts of other auxiliaries. Acetone is mixed with catalysts, benzaldehyde is dropped in at the room temperature, the reaction temperature is controlled to range from 20 DEG C to 40 DEG C, and reaction is performed for 0.5-5 hours, so that the diluent is obtained. The molar ratio of the benzaldehyde to the acetone is (0.8-2.5):1. The environment-friendly high-performance furfural-free epoxy chemical grouting material abandons toxic furfural and has an excellent mechanical performance and high surface adhesion force, the initial viscosity of slurry can be adjusted, and gelation time can be controlled. Moreover, the jet-grouted solid of the prepared grouting material is light in color, and the grouting material is capable of meeting the special requirements of a plurality of places on colors and can be widely used as building decoration materials and used for reservation of cultural relics and projects such as water plugging, water proofing, foundation reinforcement and the like.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

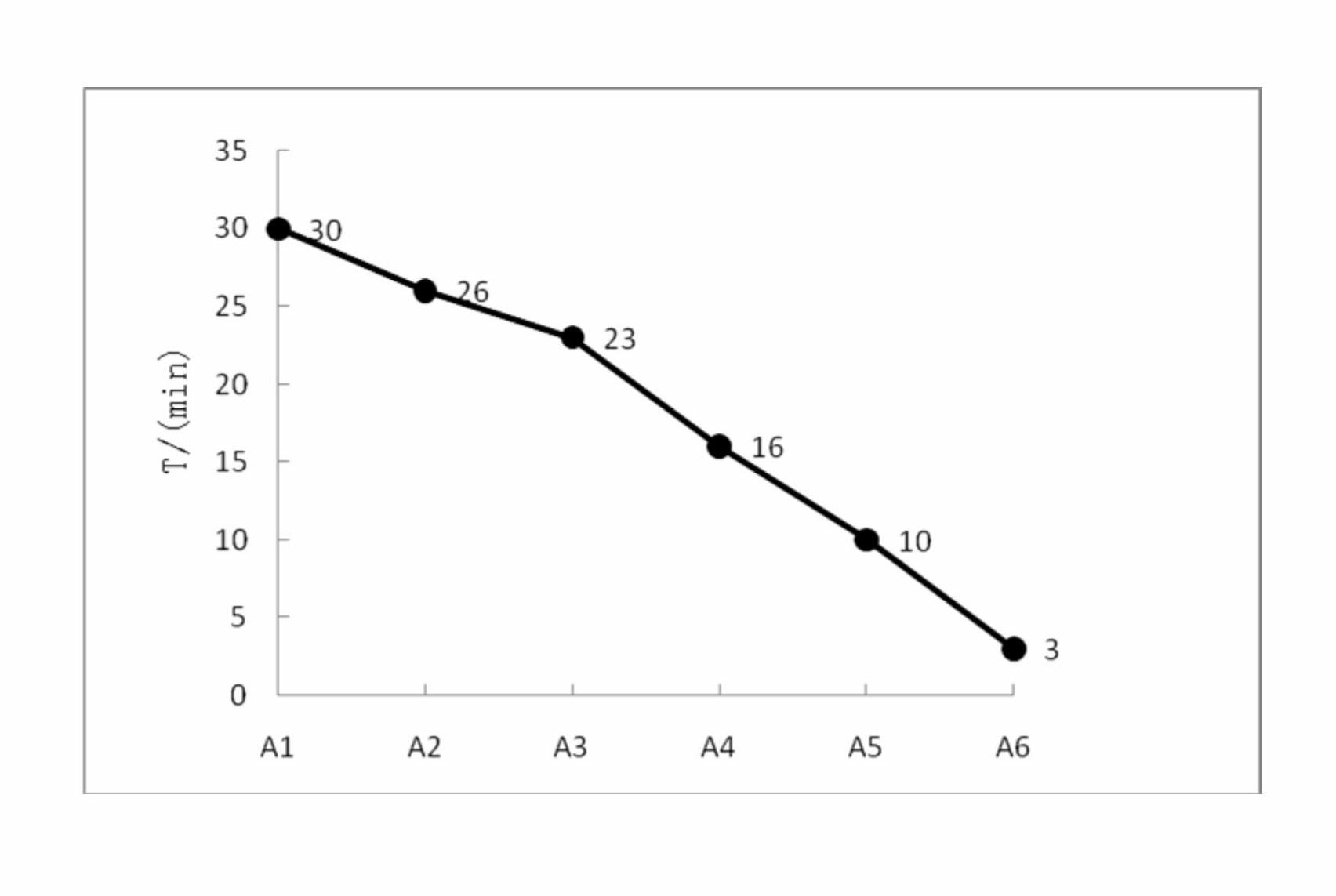

PS [PAM-Ca-LS (polyacrylamide-calcium lignin sulfonate)] lignin gel type profile control agent and method for preparing same

InactiveCN106811185ALow viscosityGel time controllableDrilling compositionCross-linkCalcium lignin sulfonate

The invention relates to a PS [PAM-Ca-LS (polyacrylamide-calcium lignin sulfonate)] lignin gel type profile control agent. By the aid of the PS lignin gel type profile control agent, the problem of poor profile control effects due to high initial viscosity, short profile control valid periods and low plugging efficiency of existing profile control agents mainly can be solved. The PS lignin gel type profile control agent is characterized by comprising, by weight, 0.5-1.5% of macromolecular polymers, 1-10% of gel, 0.2-2.0% of colloid stabilizers, 0.2-2.0% of reducing agents, 0.2-0.6% of chelating agents, 0-1.0% of retarders, 0.5-1.5% of cross-linking agents and the balance water. A method for preparing the PS lignin gel type profile control agent includes adding the corresponding water into a container, then sequentially adding the gel, the colloid stabilizers, the reducing agents and the chelating agents into the container, circularly stirring the corresponding water, the gel, the colloid stabilizers, the reducing agents and the chelating agents at the normal temperature under the normal pressure for half an hour to obtain first mixtures, then spreading the macromolecular polymers into the first mixtures, stirring the macromolecular polymers and the first mixtures for 2 hours to obtain second mixtures and allowing the second mixtures to stand still for 8 hours to obtain agents A; completely dissolving the cross-linking agents and the corresponding water according to a proportion of 1:1 to obtain agents B; adding the retarders into the agents A before the agents B are injected, adding the agents B into the agents A and uniformly stirring the agents A, the retarders and the agents B to obtain the PS lignin gel type profile control agent. The PS lignin gel type profile control agent and the method have the advantages of long profile control valid period, high plugging efficiency and good profile control effect.

Owner:大庆市杰森钻采助剂厂

Gel casting method and preparation method of ceramic

ActiveCN102452125AHigh tensile strengthHigh hardnessCeramic shaping apparatusHydrogenPlatinum complex

The invention provides a gel casting method, comprising the following steps of: firstly degassing and pre-polymerizing suspensoid containing ceramic powder and organic system to obtain ceramic size; pouring the ceramic size into a mould, drying and then curing in situ, and demoulding to obtain gel-cast wet blank, the organic system contains 100 parts by weight of vinyl-terminated polyorganosiloxane, 2-10 parts by weight of hydrogen-containing silicone oil, 1-10 parts by weight of vinyl silicone oil, 0.2-0.8 part by weight of platinum complex catalyst, 0.02-0.1 part by weight of crosslinking inhibitor, 0.02-0.1 part by weight of viscosifier and 100-1000 parts by weight of organic solvent. The invention also provides a method for preparing ceramic by adopting the gel casting method. The gel casting method provided by the invention has wide application fields, and the ceramic obtained by adopting the gel casting method provided by the invention has higher mechanical properties.

Owner:BYD CO LTD

Environment-friendly high-performance furfural-free epoxy chemical grouting material, preparation method and application

InactiveCN102617983BAdjustable initial viscosityGel time controllableOther chemical processesSoil preservationEpoxyBenzaldehyde

The invention discloses an environment-friendly high-performance furfural-free epoxy chemical grouting material, which is prepared with 100 parts of epoxy resin, 100-150 parts of diluent, 8-20 parts of curing agents, 0.5 part of accelerators and 18 parts of other auxiliaries. Acetone is mixed with catalysts, benzaldehyde is dropped in at the room temperature, the reaction temperature is controlled to range from 20 DEG C to 40 DEG C, and reaction is performed for 0.5-5 hours, so that the diluent is obtained. The molar ratio of the benzaldehyde to the acetone is (0.8-2.5):1. The environment-friendly high-performance furfural-free epoxy chemical grouting material abandons toxic furfural and has an excellent mechanical performance and high surface adhesion force, the initial viscosity of slurry can be adjusted, and gelation time can be controlled. Moreover, the jet-grouted solid of the prepared grouting material is light in color, and the grouting material is capable of meeting the special requirements of a plurality of places on colors and can be widely used as building decoration materials and used for reservation of cultural relics and projects such as water plugging, water proofing, foundation reinforcement and the like.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

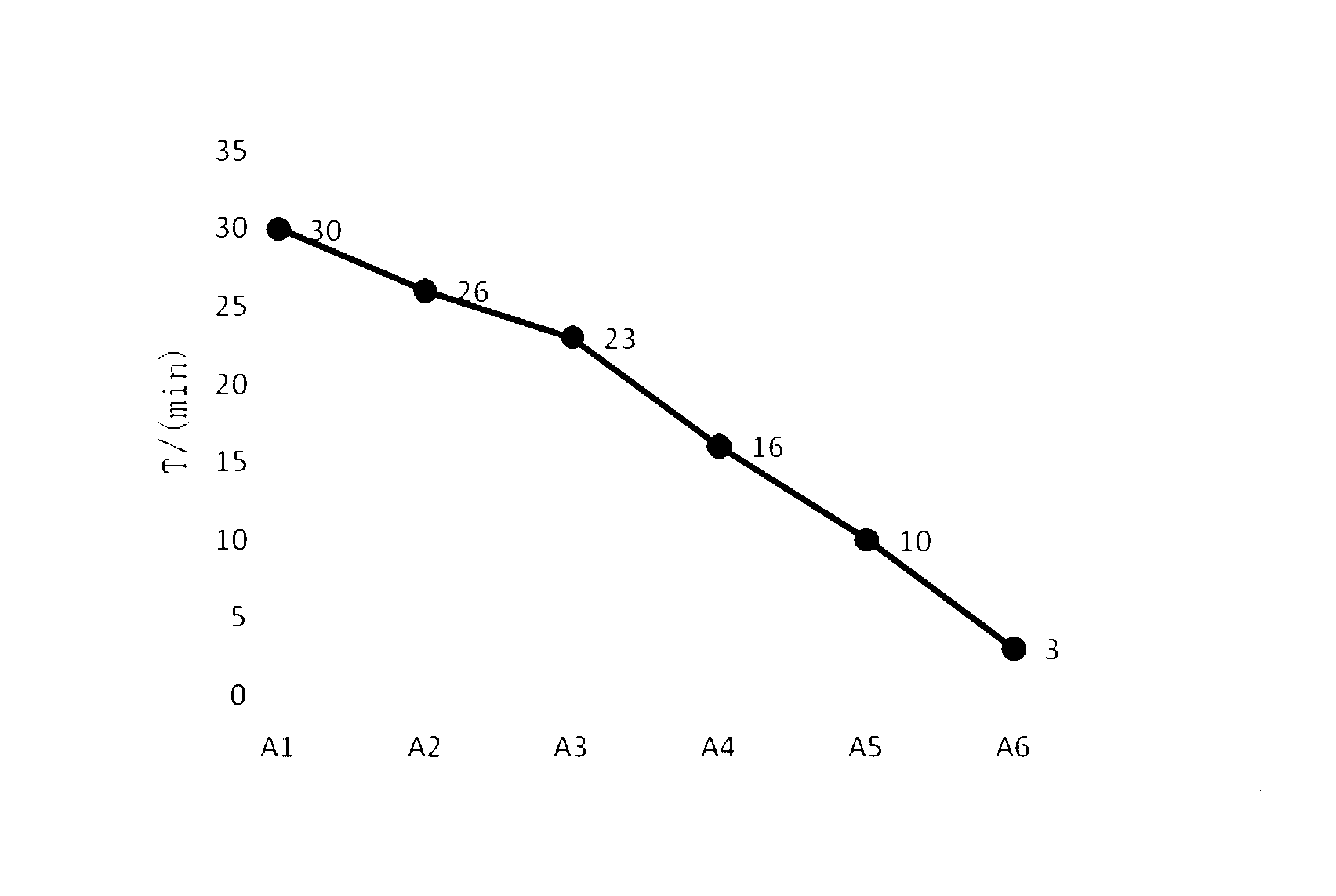

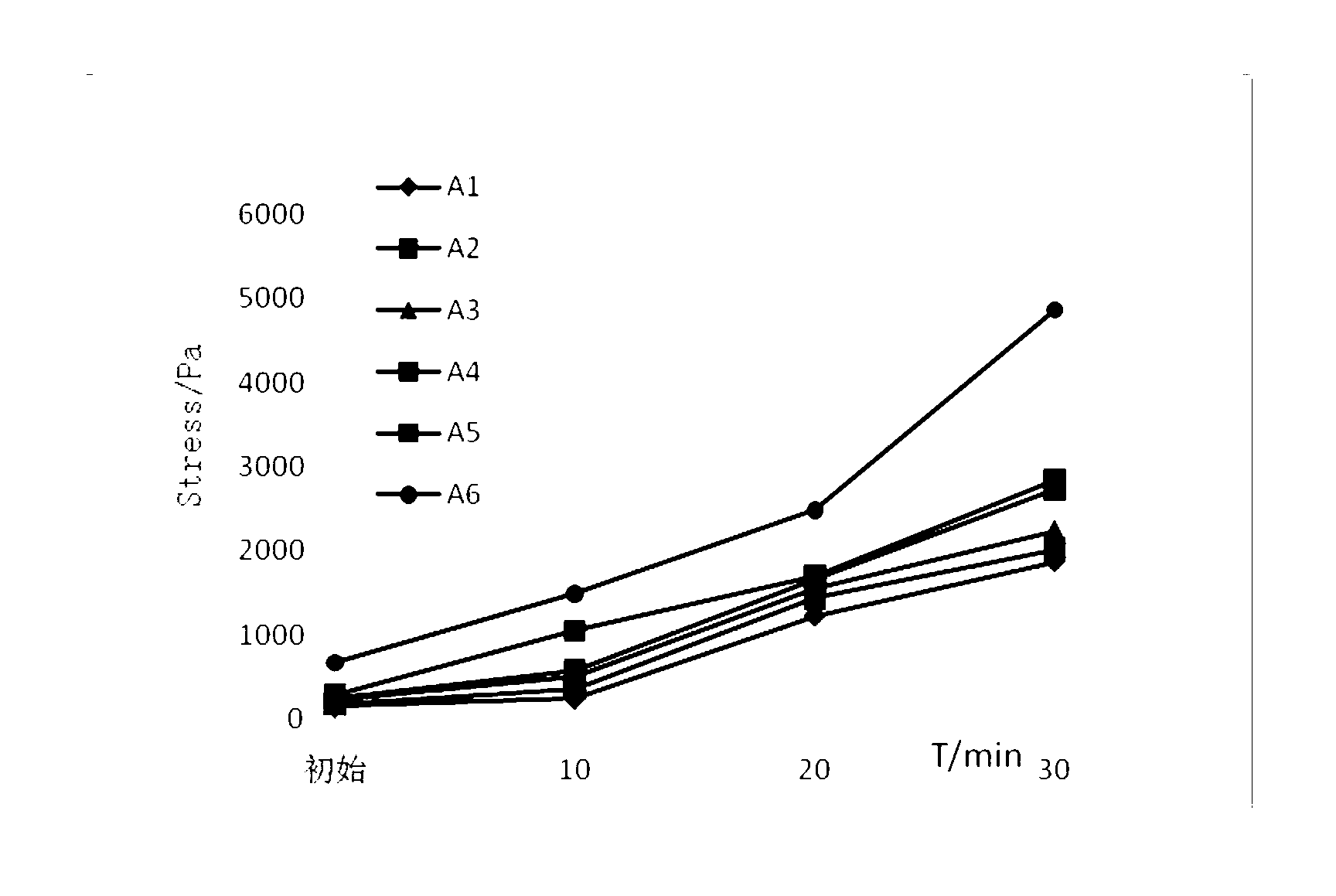

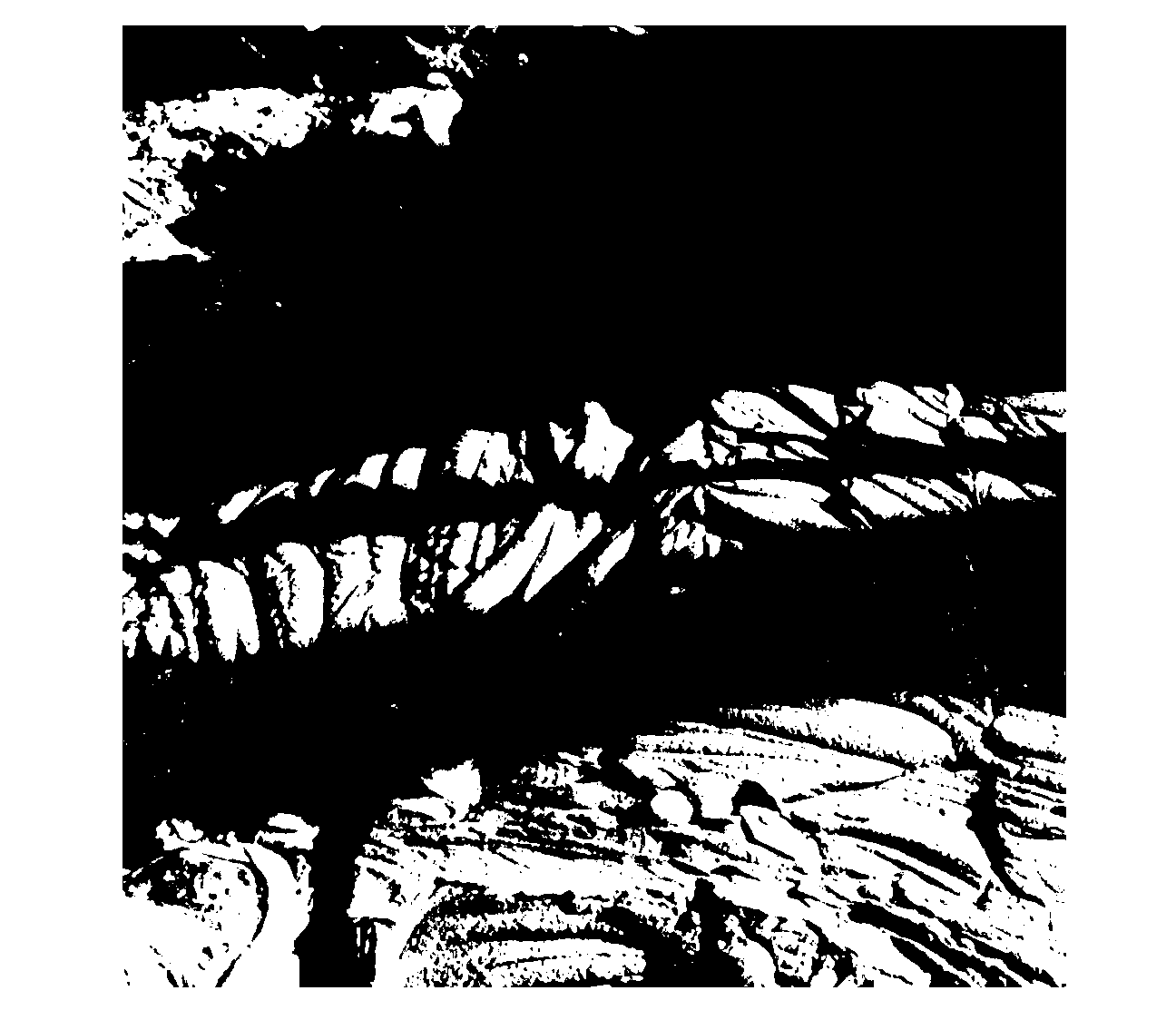

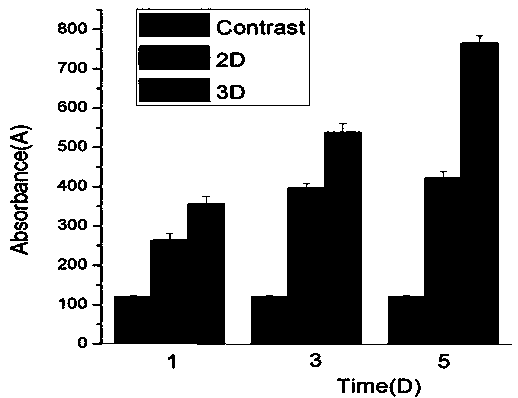

Self-assembly collagen template tissue engineering material as well as preparation method and application thereof

ActiveCN105802251AImprove mechanical propertiesGel time controllableProsthesisBiocompatibilityDrug biological activity

The invention discloses a self-assembly collagen template tissue engineering material as well as a preparation method and application thereof, and belongs to the field of biomedical materials. The self-assembly collagen template tissue engineering material is prepared from collagen and polyhydroxy alcohol by cross-linking and solidification through glutamine transaminase. The preparation method is simple, and is convenient to operate, controllable in process parameter and low in cost. The cross-linking by adopting a microbial enzyme is superior to that by adopting other cross-linking agents; the toxic and side effects of, for example, methacrylic anhydride (MA), a photoinitiator and the like to a cell are avoided; the obtained material has better biological activity, biocompatibility and mechanical properties, can be used for constructing a better three-dimensional scaffold system for the growth of the cell, and can be also used for loading a medicine. The material can be used for the generation of new tissue and the repair of injured tissue, and is clinically used for the fields of tissue engineering of cartilage, bones, skin, blood vessels and the like.

Owner:CHENGDU UNIV

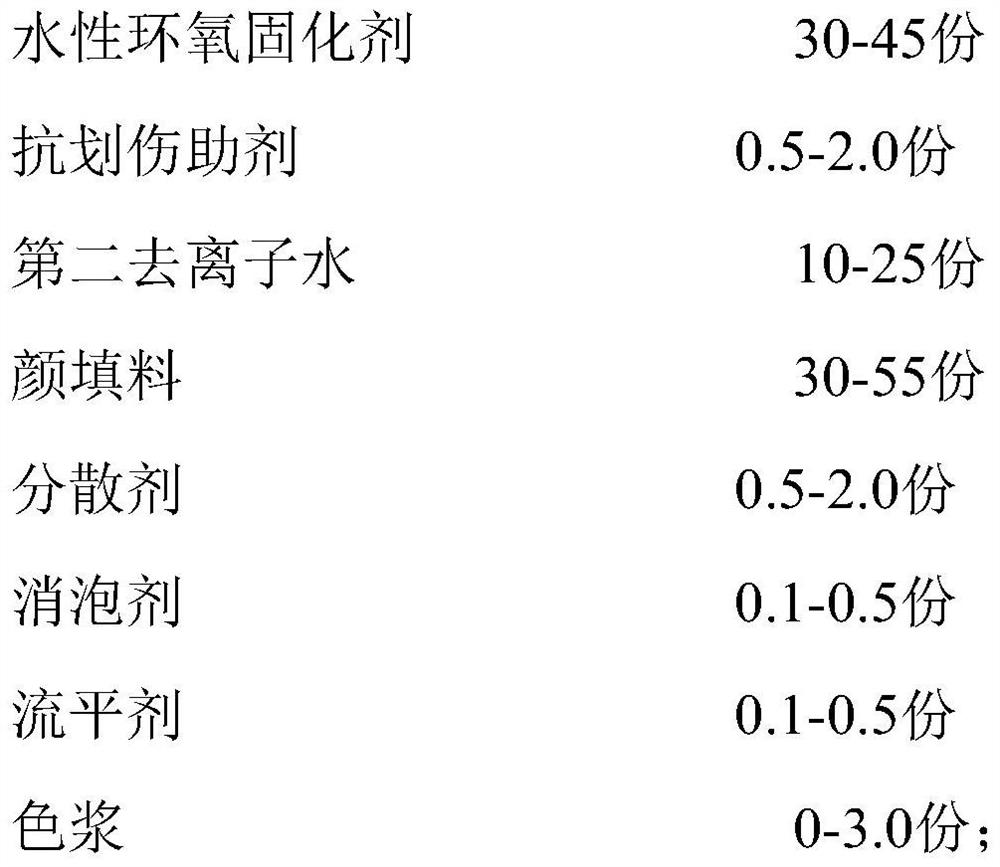

High-gloss high-hardness water-based epoxy floor coating and preparation method thereof

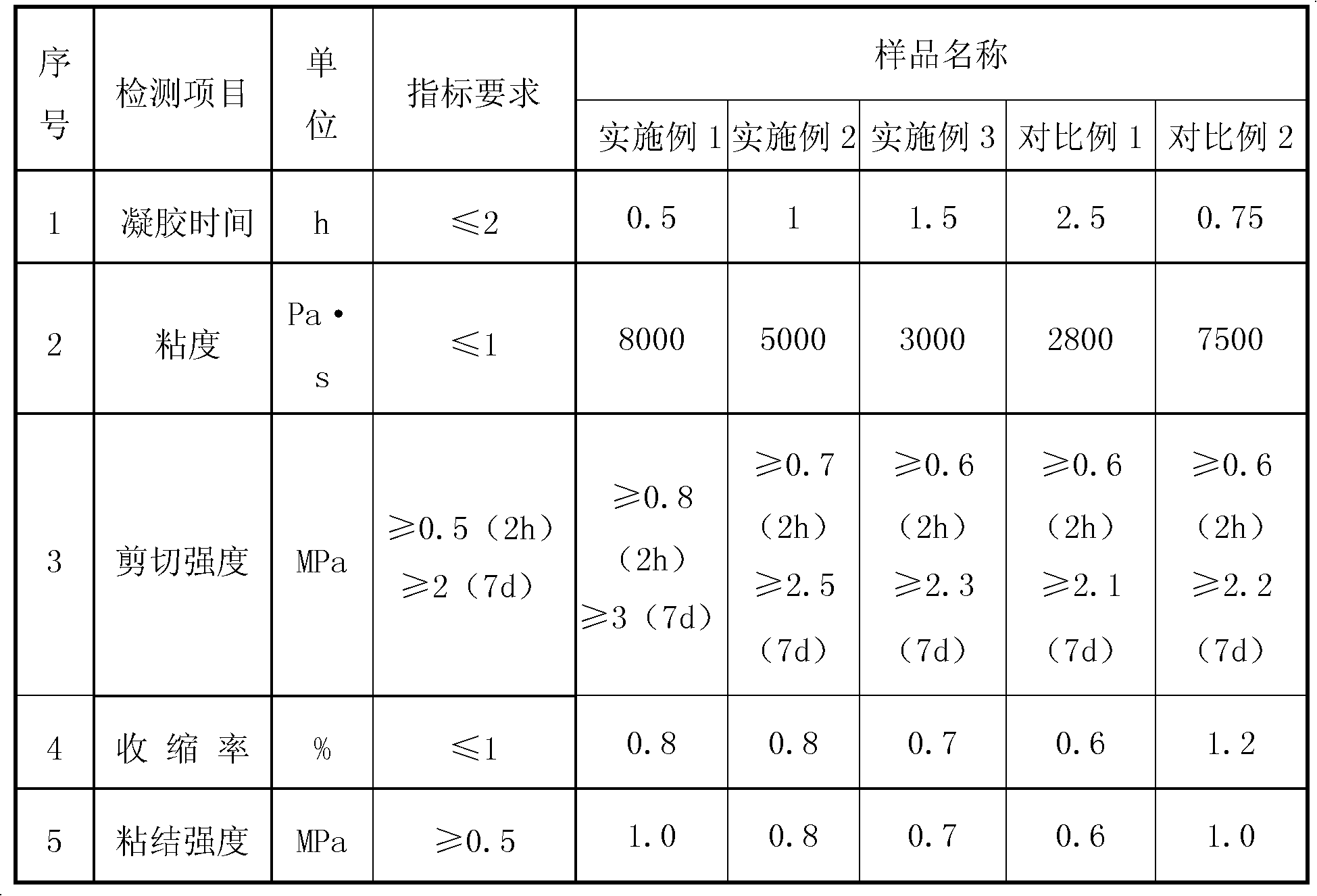

InactiveCN111763458AImprove the level ofReduce pollutionEpoxy resin coatingsPolymer scienceShrinkage rate

The invention belongs to the technical field of coatings and relates to a high-gloss high-hardness water-based epoxy floor coating and a preparation method thereof. The coating comprises a component Aand a component B. The component A is a water-based emulsion prepared from liquid epoxy resin, polyfunctional epoxy resin, hydrophilic modified polyfunctional epoxy resin and first deionized water; the component B is prepared from a water-based epoxy curing agent, second deionized water, a pigment filler, a dispersing agent, an antifoaming agent, a leveling agent, a scratch-resistant auxiliary agent and color paste. By compounding the modified polyfunctional epoxy resin, the scratch-resistant assistant and the pigment filler, the prepared floor coating has the advantages of favorable levelingproperty, high curing speed, high film crosslinking density, high bonding strength, low shrinkage rate during hardening and low tendency to flooding during construction. When coating film formation is performed, the hardness and gloss of a coating layer are high; the whole coating layer is seamless and flat, not prone to cracking and easy to clean; the probability of bubbles appearing on a water-resistant surface is low; and the environmental protection requirements are met.

Owner:英德市黑马涂料有限公司

Preparation method of special high-elasticity high-impregnation room temperature curing two-component interpentration polyurethane patching material for ballastless track boss resin patching

The invention discloses a preparation method of special high-elasticity high-impregnation room temperature curing two-component interpentration polyurethane patching material for ballastless track boss resin patching, which comprises the following three steps: preparing a modified interpentration polyether elastomer, synthesizing linear block MDI (diphenylmethane diisocyanate) prepolymer and curing two-component interpentration polyurethane. The patching material prepared using the method disclosed by the invention has the characteristics of proper viscosity, good permeability with boss resin, good compatibility, completely controllable curing time and strong interface adhesiveness, and has wide application prospects.

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD

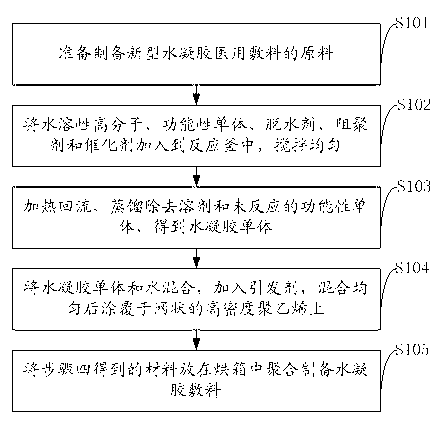

Preparation method of novel medical hydrogel dressing

InactiveCN103232611AGel time controllableGood water swelling and transparencyAbsorbent padsCoatingsFunctional monomerPolyethylene glycol

The invention discloses a preparation method of a novel medical hydrogel dressing. The method comprises the following steps of: preparing a material for preparing the novel medical hydrogel dressing; adding a water-soluble polymer, a functional monomer, a dehydrating agent, a polymerization inhibitor and a catalyst to a reaction kettle to evenly agitate; heating and refluxing, distilling to remove a solvent and unreacted functional monomer to obtain a hydrogel monomer; mixing the hydrogel monomer with water; adding an initiator, coating on net high-density polyethylene after evenly mixing; and putting the material prepared from the step 4 into an oven to polymerize and prepare the hydrogel dressing. According to the method disclosed by the invention, polyethylene glycol (PEG) and the functional monomer are taken as materials; crosslinking polymerized PEG monomer is prepared by alkyd reaction; and the crosslinking polymerized PEG is taken as the monomer; water is taken as medium. Thus, the synthetic novel medical hydrogel dressing is high in transparency, short in gelation time, excellent in swelling behavior, wide in material source, simple in process, safe and nontoxic, and has good development and application prospects.

Owner:NANJING 3H MEDICAL PROD CO LTD

Preparation method of gel additives with controllable slow release

ActiveCN102775815AGood sustained release effectGel time controllablePigment treatment with macromolecular organic compoundsPolymer scienceMicrowave

The invention discloses a preparation method of gel additives with controllable slow release. The preparation method comprises the steps of adding water in seaweed glue and gel additives to boil until the seaweed glue and the gel additives are completely dissolved, treating through high-pressure or super-pressure plants, atomizing and drying for prilling to obtain end products or treating through the high-pressure or super-pressure plants, quickly freezing through a single freezing machine, quickly thawing through microwave, conducting filter pressing on freeze thawing mixed liquor to be dewatered through a plate-and-frame filter press, extruding films obtained by filter pressing through a twin-screw extruder, conducting microwave drying on extrusive colloid, airing or stoving, smashing and sieving to obtain the end products. The preparation method has the advantages that prepared gel additives of alginate have good slow release effects, achieve controllable time and speed of gel and greatly expand application field and production process of the alginate.

Owner:青岛德慧海洋生物科技有限公司

Alkali-activated-carbonate/slag compound gel material and preparation method thereof

InactiveCN100340517CExpand raw material resourcesReduce energy consumptionSolid waste managementAlkali activatedSilicon oxide

The invention relates to an alkali-activated-carbonate / slag compound gel material and preparation method which comprises, calculated by mass portions, diluting 0.5-2 parts of additive with 10-25 parts of water, charging 30-50 parts of slag powder into the prepared additive solution, agitating homogeneously, then charging 30-65 parts of natron sodium oxide having a modulus of 1.4-1.8 and exciting agent with the sum of mass concentration 45-55% with the silicon oxide, charging 50-70 parts of marginal carbonate powdered ore, agitating homogeneously, thus obtaining the end product.

Owner:SOUTH CHINA UNIV OF TECH

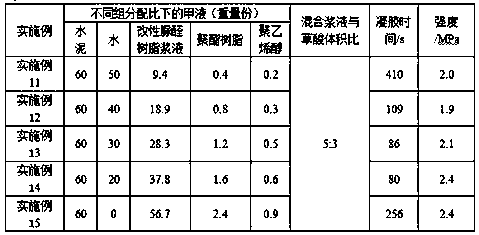

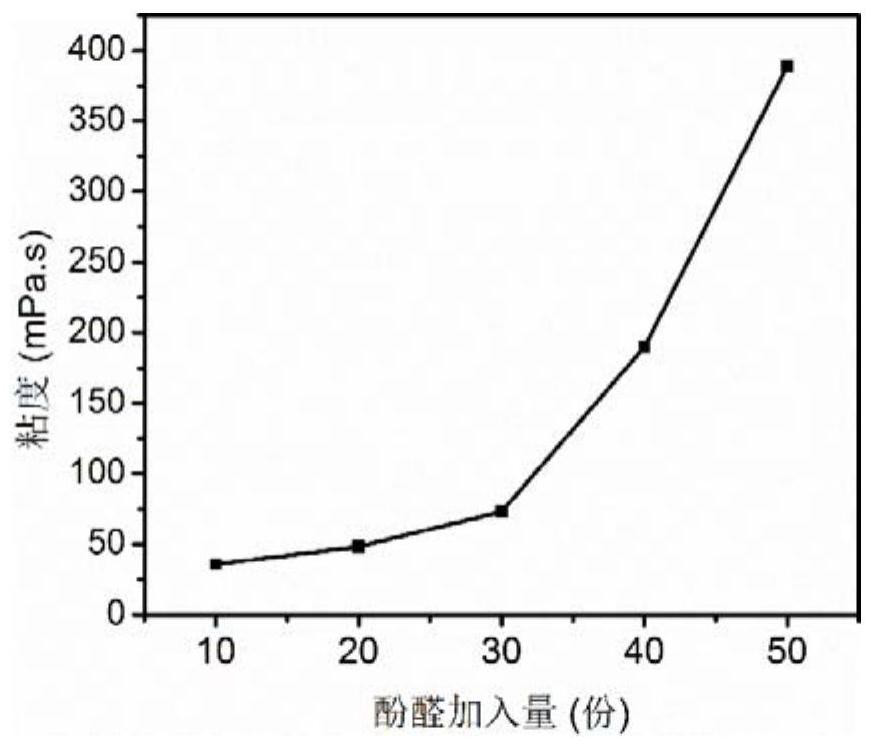

Cement-modified urea formaldehyde resin composite slurry material and preparation method thereof

The invention provides a cement-modified urea formaldehyde resin composite slurry material and a preparation method thereof. The material comprises, by weight, 0-50 parts of water, 60 parts of cement,9.4-56.7 parts of a modified urea formaldehyde resin slurry, 0.4-2.4 parts of a polyester resin and 0.2-0.9 part of polyvinyl alcohol. The material has the characteristics of good groutability, shortgelation time, adjustable gelation time, high induration strength and the like, and can be used in the fields of linear engineering karst disease (disaster) regulation, broken stratum reinforcement and the like.

Owner:KUNMING SURVEY DESIGN & RES INST OF CREEC

Sealing composition and its use

InactiveUS20030161692A1Reduce penetrationHigh S-valueArtificial islandsMixing methodsSilicon dioxideChemistry

The present invention relates to a method for sealing rock or soil comprising inserting a sealing composition obtained by mixing a silica sol and at least one gelling agent, wherein the silica sol has an S-value higher than about 72%, a method for preparing the sealing composition and the composition obtained from the method.

Owner:AKZO NOBEL CHEM INT BV

Controllable clay and cement seepage-proof reinforcement paste

The invention discloses controllable clay and cement seepage-proof reinforcement paste. The controllable clay and cement seepage-proof reinforcement paste is mainly prepared from clay raw stock, cement and water, wherein the clay raw stock is mainly obtained by stirring clay and water. A modifier is added in the controllable clay and cement seepage-proof reinforcement paste; the doping amount of the modifier is 1 to 3 percent; the modifier mainly comprises mineral additives, sulfate and bentonite in a mass ratio of a:b:c; and a:b:c is 5:(5-0):(0-5). The product has the advantages of high stability and water flow dilution resistance, controllable setting time, adjustable strength, high antiseepage performance, low cost, environment friendliness and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing wave-transmission SiO2 aerogel heat-insulation composite material by using normal-pressure drying equipment

The invention discloses a method for preparing a wave-transmission SiO2 aerogel heat-insulation composite material by using normal-pressure drying equipment. According to the method, tetraethoxysilane used as a precursor and absolute ethanol used as a solvent are subjected to acid-alkaline two-step reaction under the action of a catalyst so as to obtain SiO2 sol; and the SiO2 sol is mixed with quartz fiber, and the wave-transmission SiO2 aerogel heat-insulation composite material is prepared by the steps of performing gelling on the mixture of the SiO2 sol and the quartz fiber, aging, performing solvent replacement and surface modification, and performing gradient heating under normal pressure. The method for preparing the wave-transmission SiO2 aerogel heat-insulation composite material by using the normal-pressure drying equipment is easy to operate; equipment is simple; compared with a supercritical drying method, the method for preparing the wave-transmission SiO2 aerogel heat-insulation composite material by using the normal-pressure drying equipment has the advantage that the cost is reduced greatly; by the method, the composite material can be produced on a large scale conveniently; and a product has good wave transmission performance, heat insulation performance and the like, and has extremely obvious application value in military industry of long-endurance and high-mach aviation aerospacecrafts and the like.

Owner:湖北三江航天江北机械工程有限公司

A kind of self-assembled collagen template tissue engineering material and preparation method and application thereof

The invention discloses a self-assembly collagen template tissue engineering material as well as a preparation method and application thereof, and belongs to the field of biomedical materials. The self-assembly collagen template tissue engineering material is prepared from collagen and polyhydroxy alcohol by cross-linking and solidification through glutamine transaminase. The preparation method is simple, and is convenient to operate, controllable in process parameter and low in cost. The cross-linking by adopting a microbial enzyme is superior to that by adopting other cross-linking agents; the toxic and side effects of, for example, methacrylic anhydride (MA), a photoinitiator and the like to a cell are avoided; the obtained material has better biological activity, biocompatibility and mechanical properties, can be used for constructing a better three-dimensional scaffold system for the growth of the cell, and can be also used for loading a medicine. The material can be used for the generation of new tissue and the repair of injured tissue, and is clinically used for the fields of tissue engineering of cartilage, bones, skin, blood vessels and the like.

Owner:CHENGDU UNIV

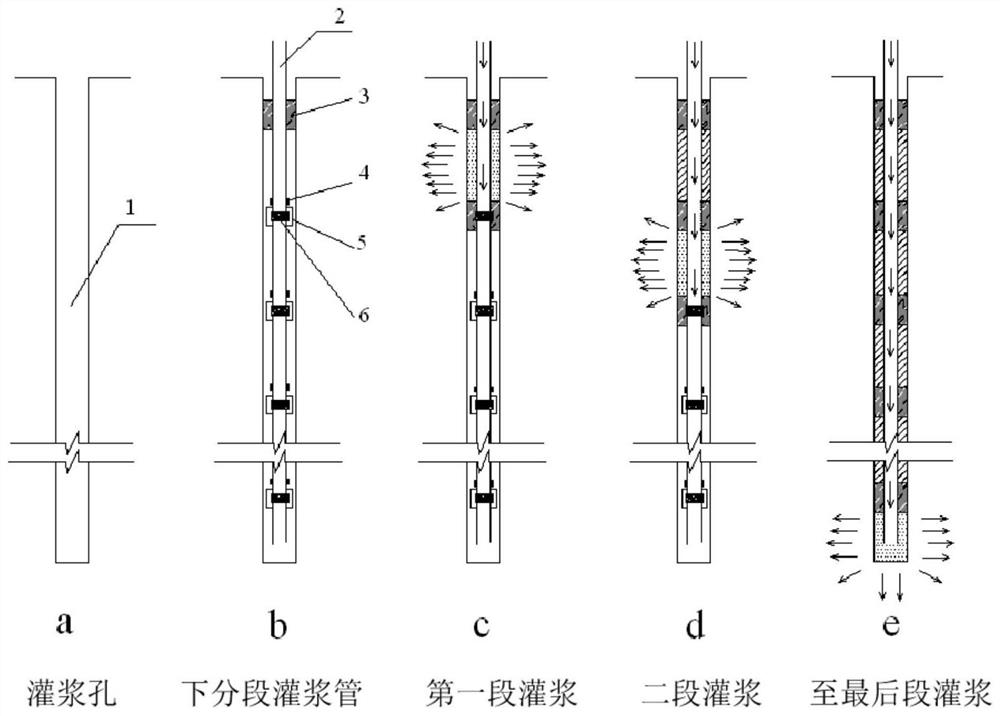

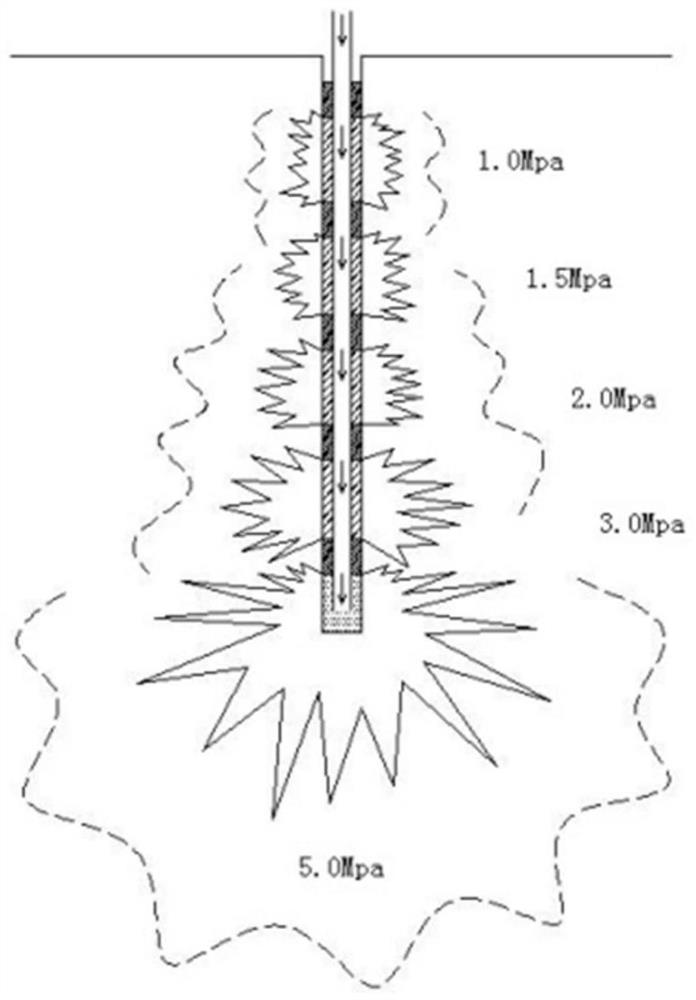

Systematic grouting process for dynamic water foundation pit cofferdam

PendingCN114232631AImprove the sealing pressure bearing capacityGood sealingFoundation engineeringEmergency rescueCofferdam

The invention discloses a systematic grouting process for a dynamic water foundation pit cofferdam, and belongs to the technical field of coating detection. The method comprises the following steps that drilling equipment is positioned; grouting holes are divided into rows, sequences and sections; drilling and grouting according to rows, sequences and sections; grouting is finished; according to the method, the process of repeated drilling, grouting and hole sweeping is avoided, drilling and grouting can be conducted in parallel, the construction efficiency is greatly improved, the construction time is saved, and the method is suitable for cofferdam grouting and emergency rescue construction; in addition, the sealing effect of a pouring orifice is improved, grouting and sealing are performed section by section from top to bottom, the sealing and pressure-bearing capacity of the orifice is greatly improved, a foundation is laid for improving the pouring pressure, and the filling effect is finally achieved. And meanwhile, a controllable plastic cement plastomer grouting process is adopted, the paste slurry forming process is improved, the viscosity of the poured slurry in the initial stage is low and similar to that of pure cement slurry, and therefore in the injection process, the requirements for equipment and the process are greatly lowered, and the application range is wider.

Owner:福建省天硕建设发展有限公司

A kind of environment-friendly acrylate grouting material and its preparation method and application

The invention provides an environment-friendly acrylate grouting material, as well as a preparation method and an application thereof. The material mainly comprises the following components in parts by weight: a main agent, namely 100 parts of methacrylic acid-beta-hydroxyethyl ester, a crosslinking agent which includes 5-30 parts of hydrophilic compound containing a diallyl ether functional group, 1-5 parts of initiator and 0.5-3 parts of accelerant, 0-20 parts of an adjuvant, and a solvent, namely 2-1,000 parts of water. The method comprises the following steps: firstly, mixing the main agent, the crosslinking agent, the accelerant, the adjuvant and a part of solvent evenly to form a solution A in use; then dissolving the initiator into a residual solvent to form a solution B; and finally mixing the solution A with the solution B evenly, and solidifying at room temperature. According to the grouting material disclosed by the invention, the technical problem that the existing organic grouting material cannot be grouted once after being mixed with an inorganic grouting material, and the technical problem that the existing grouting material has poor durability, low strength, poor water solubility, low water expansion rate and high toxicity are solved.

Owner:湖南博旺水电建设有限公司

A plugging agent system suitable for low-temperature oil reservoirs and its preparation method

ActiveCN104140796BGood sealingStrong anti-agingDrilling compositionTetramethylammonium hydroxideProton

Belonging to the technical field of oilfield chemistry and petroleum engineering, the invention discloses a plugging agent system suitable for low temperature oil reservoirs and a preparation method thereof. The plugging agent system consists of the following components by weight percent: 3-20% of water glass with a modulus of 4.4-12, 0.01-1% a proton source donor, and the balance water. Specifically, the water glass with a modulus of 4.4-12 is prepared by reaction of low modulus water glass and nano-silicon dioxide under the action of tetramethylammonium hydroxide. According to the invention, high modulus water glass and the proton source donor are compounded to form the plugging agent system, which can undergo gel reaction in the temperature range of 10-50DEG C and have adjustable gel time and high gel strength. The system also has strong temperature resistant, aging resistant and erosion resistant abilities, and can meet the technological requirements of low temperature oil reservoir profile control and water shutoff. The method for preparation of the high modulus water glass and the plugging agent system is simple and easy to operate, and is suitable for industrial production application.

Owner:CHINA PETROLEUM & CHEM CORP +1

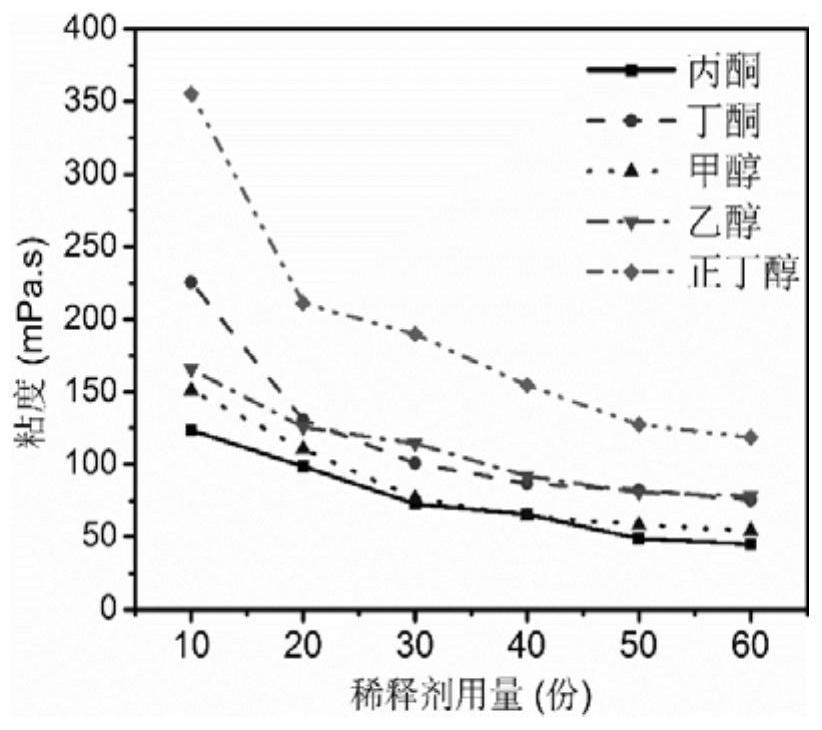

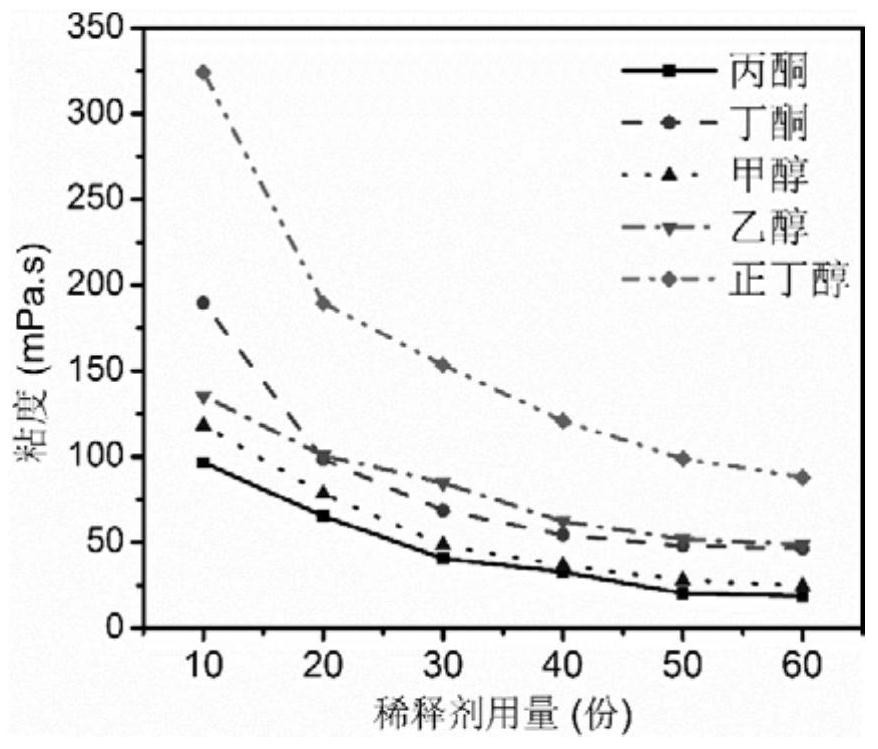

An epoxy-phenolic system water blocking agent used in oil and gas field exploitation

The invention discloses an epoxy-phenolic system water plugging agent used in oil and gas field exploitation. The epoxy-phenolic system water plugging agent is a novel water plugging agent formed by using epoxy resin as a resin matrix, novolac resin as a curing agent, imidazole as an accelerator and an alcohol or a ketone as a migratory diluent. The migratory diluent can greatly reduce the viscosity of the water plugging agent and ensure the transportability of the water plugging agent; and the migration diluent migrates into a water phase after meeting stratum water, and other components in the system settle to the bottom of a water layer in order to achieve effective curing. The addition of the migratory diluent reduces the adverse influences of the diluent on the curing process and theproperties of a cured product in order to achieve an adjustable curing time and ensure the mechanical strength of the cured product. The water plugging agent has the characteristics of low viscosity,good perfusion fluidity, wide application temperature range, adjustable curing speed and high strength after curing, and still has an excellent plugging property in high-temperature, high-salt, acidicand alkaline environments.

Owner:SICHUAN UNIV +1

A kind of mixed diluent and environment-friendly high-penetration epoxy grouting material prepared by using the same and preparation method thereof

ActiveCN113308209BGuaranteed to be friendlyEnsure safetySolid waste managementMacromolecular adhesive additivesPolymer scienceFirming agent

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +1

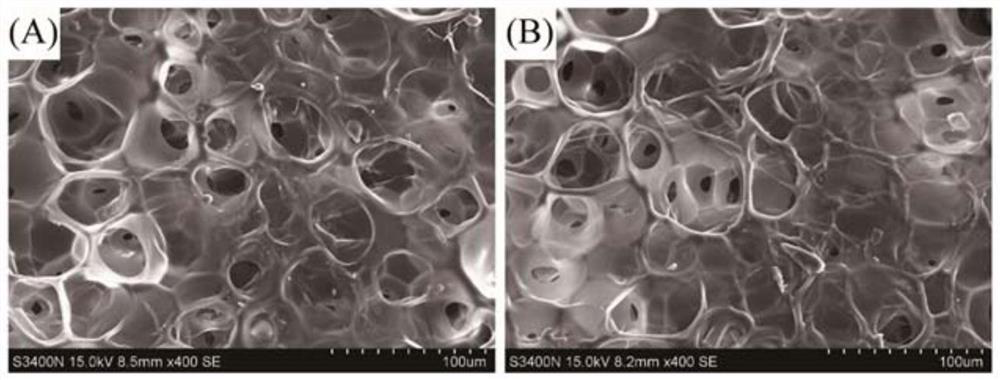

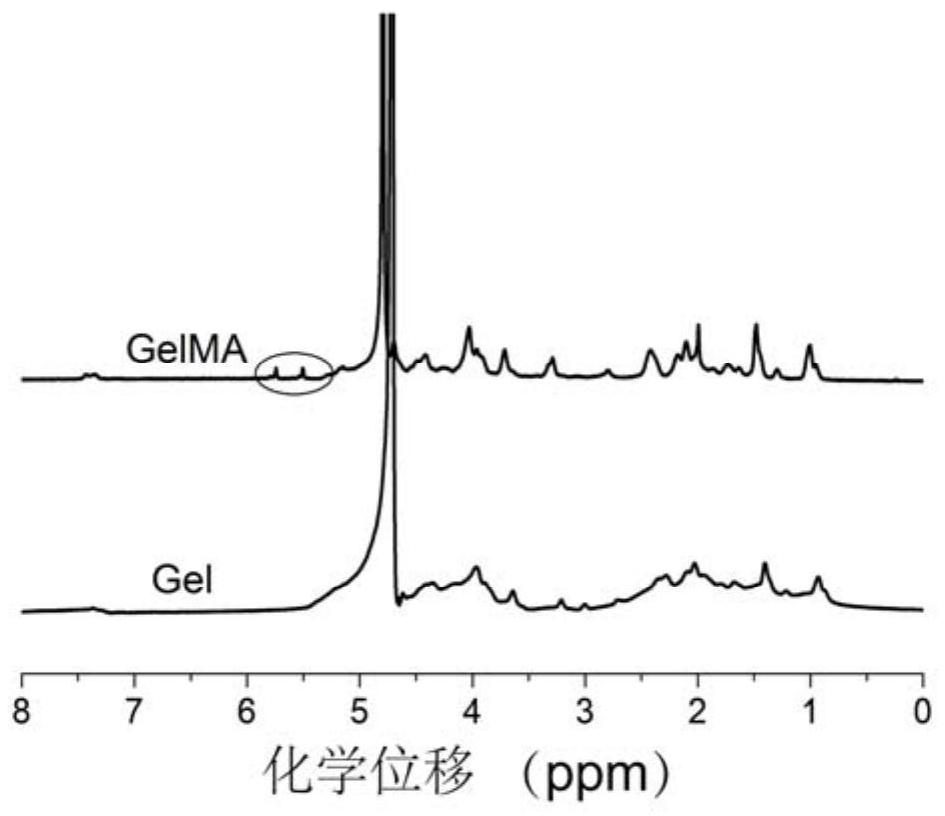

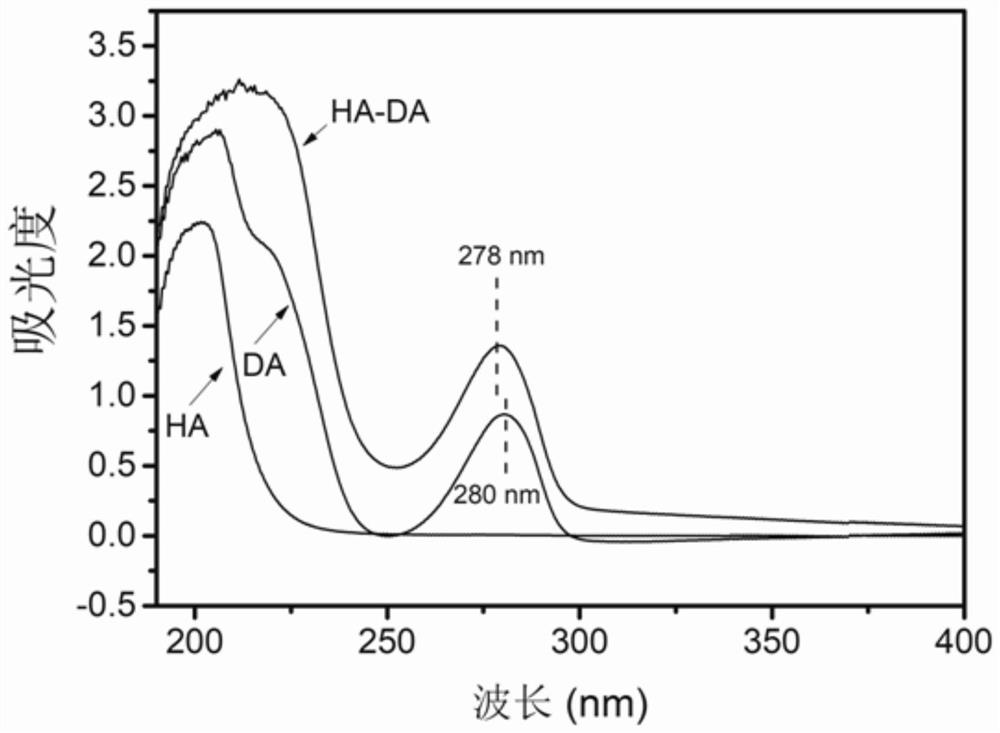

Adhesive hemostatic antibacterial hydrogel and preparation method thereof

ActiveCN110917392BWith drug sustained release abilityImprove mechanical propertiesBandagesTissue repairAntimicrobial peptides

The invention relates to an adhesive hemostatic and antibacterial hydrogel, the hydrogel comprises the following components in mass percentage: 0.5%-4% of hyaluronic acid modified dopamine, 1%-20% of methacrylated gelatin %, 0.005% to 0.05% of antibacterial peptide, 0.01% to 0.5% of photoinitiator, and the balance is deionized water. The invention utilizes the unique functions of methacrylated gelatin, hyaluronic acid-modified dopamine and antibacterial peptide, and synthesizes an adhesive hemostatic and antibacterial hydrogel based on methacrylic acid gelatin. The hydrogel of the present invention realizes the dual functions of antibacterial and promoting tissue repair and regeneration, and exhibits adjustable gel time, suitable swelling in vitro, appropriate degradation, good tissue adhesion, and adjustable fluid flow Denaturation performance and excellent compression and stretching performance; the hydrogel of the present invention has drug sustained-release capability, and has good hemocompatibility and cell compatibility.

Owner:BEOGENE BIOTECH GUANGZHOU

Preparation method of special high-elasticity high-impregnation room temperature curing two-component interpentration polyurethane patching material for ballastless track boss resin patching

The invention discloses a preparation method of special high-elasticity high-impregnation room temperature curing two-component interpentration polyurethane patching material for ballastless track boss resin patching, which comprises the following three steps: preparing a modified interpentration polyether elastomer, synthesizing linear block MDI (diphenylmethane diisocyanate) prepolymer and curing two-component interpentration polyurethane. The patching material prepared using the method disclosed by the invention has the characteristics of proper viscosity, good permeability with boss resin, good compatibility, completely controllable curing time and strong interface adhesiveness, and has wide application prospects.

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD

Low-viscosity high-flash-point waterborne polyurethane water shutoff material and preparation method thereof

The invention discloses a low-viscosity high-flash-point waterborne polyurethane water shutoff material and a preparation method thereof. The polyurethane water shutoff material comprises the following materials in parts by weight: 80 to 120 parts of waterborne polyether polyol, 20 to 30 parts of isocyanate, 0.05 to 0.5 part of catalyst, 25 to 35 parts of inert diluents, and 1.0 to 1.5 parts of cross-linking agent. The preparation method comprises the following steps of: dehydrating the waterborne polyether polyol, performing hybrid reaction on the dehydrated waterborne polyether polyol, the isocyanate and the catalyst till that the content of the NCO in a detection system is not reduced any more, adding the inert diluents into the mixture, uniformly mixing, and adding the chain-extension cross-linking agent into a certain quantity of water to form another component when the water shutoff material is used. The waterborne polyurethane water shutoff material has the characteristics of high water absorption capability, high flash point, no combustion, low viscosity, environment friendliness and the like; and the preparation method is simple and facilitates construction. The waterborne polyurethane water shutoff material is applicable to treatment on flowing water and gushing water as well as prevention and treatment on water seepage of underground works such as mine roadways, shafts, tunnels, subsea tunnels and subways.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com