Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

182 results about "Microfine cement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

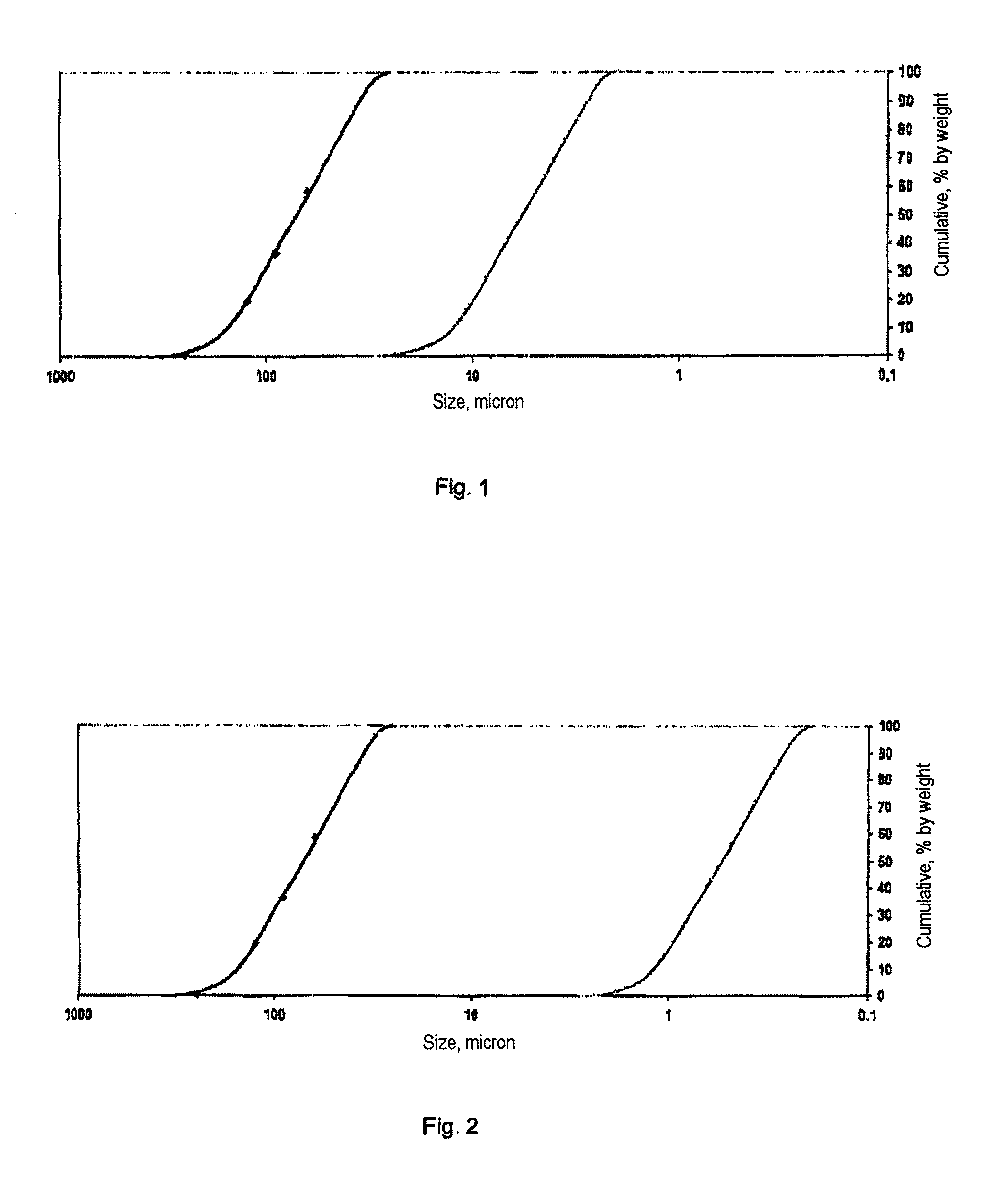

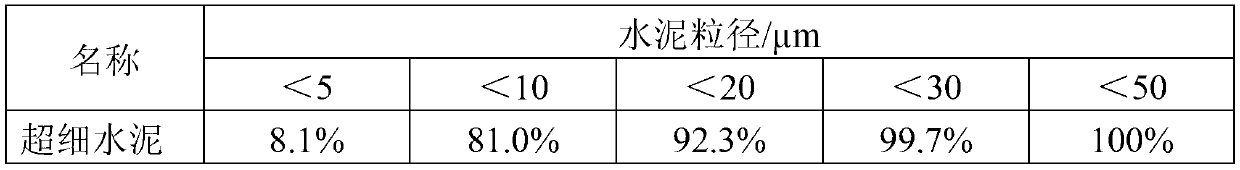

Microfine Cement for Injection of Rock and Soil. DESCRIPTION. MicroCem is a Portland cement based grouting material composed of microfine particles with a specific surface area of >800m²/kg. As a grout, it has excellent permeability, strength and durability properties.

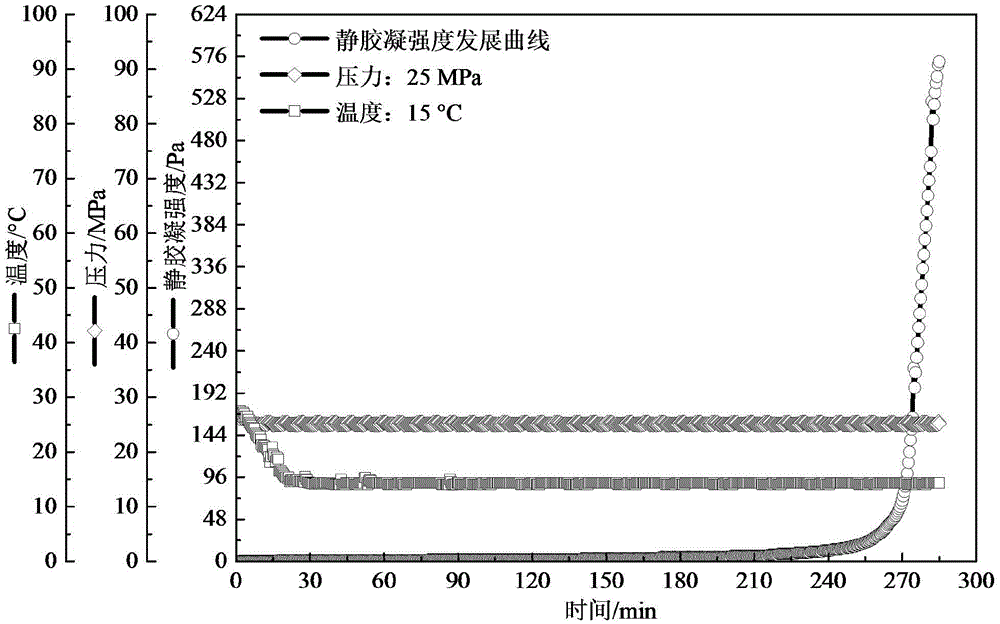

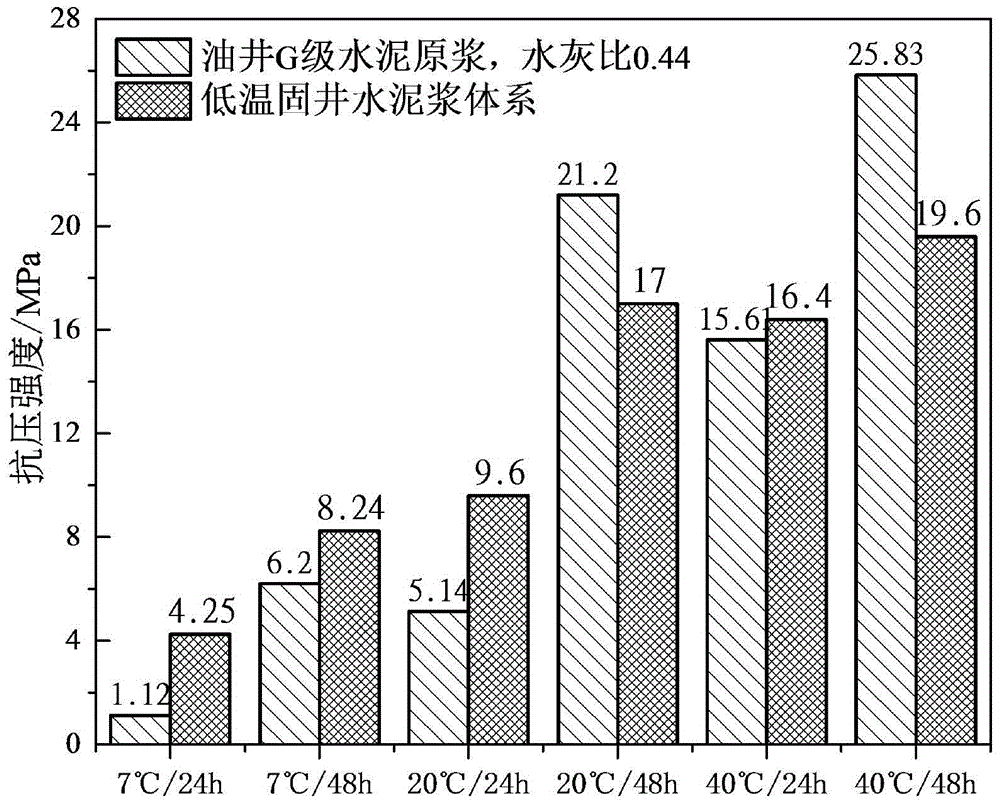

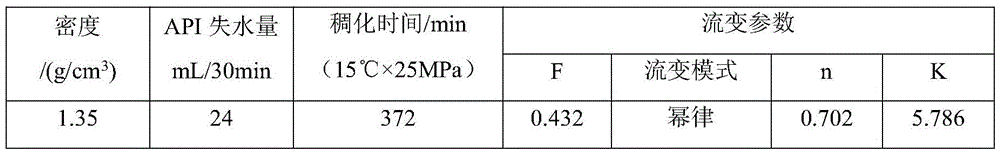

Low-temperature cementing slurry system and composition thereof

InactiveCN105462571AReduce intensityHigh strengthDrilling compositionMicrofine cementCalcium silicate

The present invention provides a low-temperature cementing slurry system. The slurry system has the characteristics of low density, low temperature early strength and low water loss, and has performances such as thickening time and compressive strength meeting the requirements of deepwater cementing construction site. The low-temperature cementing slurry system comprises the following components by weight: 100 parts of oil well cement, 62-175 parts oil well superfine cement, 7.3-23 parts of nano-silica, 10-32 parts active calcium silicate, 15-50 parts of hollow glass microballoon, 3.6-10 parts of an early strength agent, 3.2-8.6 parts of a fluid loss agent, 0.8-2.0 parts of a dispersing agent and 120-195 parts of water. The low-temperature cementing slurry system has density between 1.30-1.60 g / cm<3>, and is particularly suitable for cementing operations on a deepwater low-temperature surface casing segment. The invention has important significance in reducing the offshore cementing cost, and offshore oil and gas resource exploitation.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

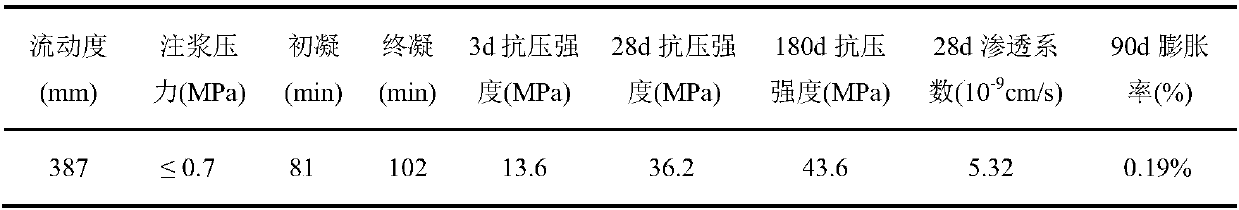

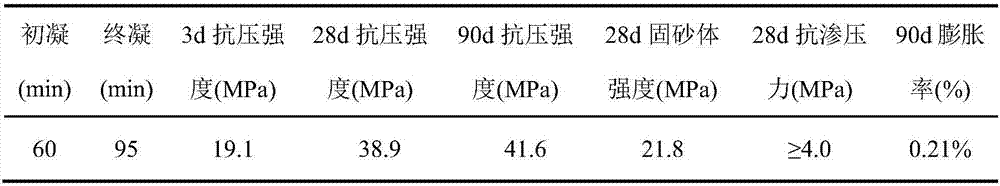

High-performance superfine cement based grouting material for microfissuring and silty fine sand soil grouting treatment and application of grouting material

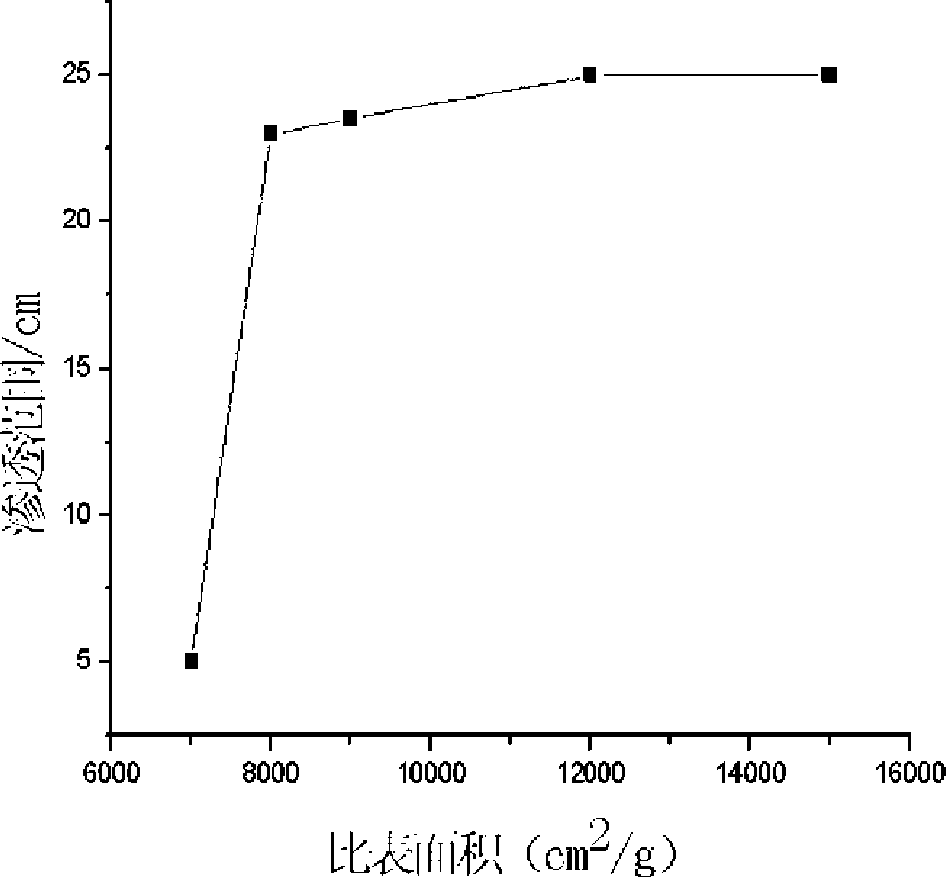

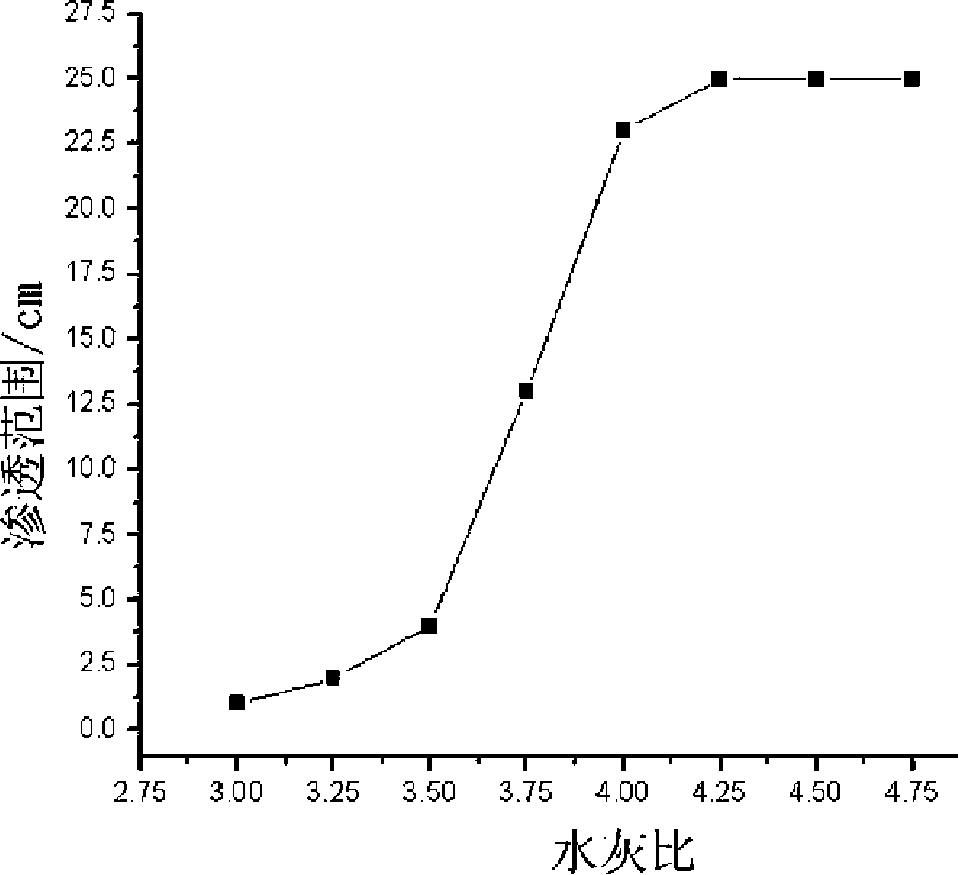

The invention discloses a high-performance superfine cement based grouting material for microfissuring and silty fine sand soil grouting treatment, and application of the grouting material. The grouting material comprises the following ingredients in parts by weight: 50-79 parts of Portland cement clinker, 19-48 parts of an auxiliary cementing material and 2-7 parts of desulfurized gypsum, whereinthe auxiliary cementing material comprises the following ingredients in parts by weight: 25-57 parts of mineral slag, 8-21 parts of steel slag, 18-36 parts of pulverized fuel ash, 6-12 parts of limestone flour, 1-8 parts of silica fume and 2.5-12.8 parts of a high-performance composite regulator; the high-performance composite regulator comprises the following ingredients in parts by weight: 5-16parts of sodium hydroxide, 4-12 parts of sodium silicate, 4-14 parts of potassium metaaluminate, 12-21 parts of calcium chloride, 11-18 parts of lithium chloride, 4-12 parts of triethanolamine, 21-27parts of alum, 18-29 parts of aluminum sulfate, 0.2-1.5 parts of hydroxypropyl methyl cellulose, 0.1-3.0 parts of viscous polymer, 0-0.8 parts of polypropylene fiber and 0.5-3.0 parts of a superplasticizer; and the viscous polymer is an acrylic ester polymer or an ethylene-vinyl acetate copolymer.

Owner:SHANDONG UNIV

Mine fracture grouting material and usage method thereof

The invention discloses a mine fracture grouting material and a usage method thereof. The mine fracture grouting material comprises raw materials of, by weight, 5.5-6.0kg of superfine cement, 0.5-1.0kg of silica powders, 2.5-3.0kg of coal ashes, 0.3-0.5kg of bentonite and 0.05-0.12kg of water reducing agents. According to the mine fracture grouting material, the superfine cement is used as a host material and supplemented by other materials, and the main fracture grouting material has the advantages of being high in concretion rate, tiny in expansibility, low in bleeding rate and good in stability; when the water cement ratio is 1: 1, the 28-day compression strength of the mine fracture grouting material can reach 15MPa; the mine fracture grouting material can be well injected and permeated into fine fractures of rock masses; the problem of ground water environmental pollution caused by chemical grouts is absent, and engineering requirements of reinforcement and impervious effects are satisfied; and grouts manufactured by the mine fracture grouting material can be applicable to mine water management and micropore fractured rock mass reinforcing engineering of hydraulic and hydro-power engineering rock masses.

Owner:NO 1 SURVEYING TEAM OF ANHUI CHARCOAL FIELD & GEOLOGY BUREAU

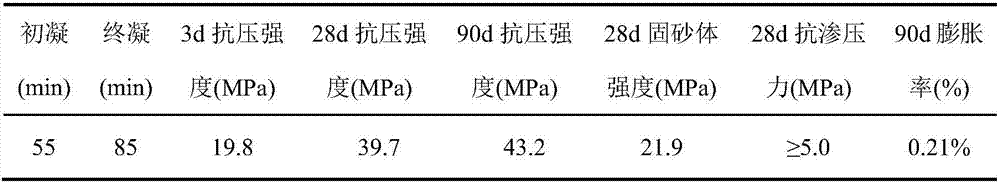

Efficient superfine cement based composite grouting material for grouting treatment of water-rich sand layer, preparation process and application

ActiveCN107572994AEasy to operateImprove applicabilityDrilling compositionSealing/packingMicrofine cementAluminate

The invention discloses an efficient superfine cement based composite grouting material for grouting treatment of a water-rich sand layer, a preparation process and application. The efficient superfine cement based composite grouting material is prepared from the following components in parts by weight: 40 to 80 parts of portland cement clinker, 10 to 45 parts of coal ash, 5 to 30 parts of superfine slag micro powder, 2 to 6.5 parts of desulphurization gypsum, 1 to 10 parts of silica fume, 0.51 to 2.10 parts of first mixed composite modifier, 0.4 to 2.4 parts of second mixed composite modifierand 5.5 to 8.9 parts of third mixed composite modifier; the coal ash is prepared from the following components in parts by weight: 50 to 100 parts of high-calcium coal ash and 0 to 50 parts of low-calcium coal ash; the first mixed composite modifier is prepared from the following components in parts by weight: 96 to 99 parts of super plasticizer and 1 to 4 parts of hydroxypropyl methyl cellulose;the second mixed composite modifier is prepared from the following components in parts by weight: 20 to 32 parts of sodium hydroxide, 21 to 28 parts of sodium carbonate, 18 to 32 parts of sodium sulfate and 18 to 36 parts of sodium metaaluminate; the third mixed composite modifier is prepared from the following components in parts by weight: 12 to 25 parts of calcium chloride, 8 to 21 parts of lithium chloride, 10 to 23 parts of triethanolamine and 32 to 68 parts of sulphoaluminate cement clinker.

Owner:SHANDONG UNIV

Non-floating bead low-density cement mortar

InactiveCN101475347AGood settlement stabilityMeet technical needsSolid waste managementMicrofine cementParticle density

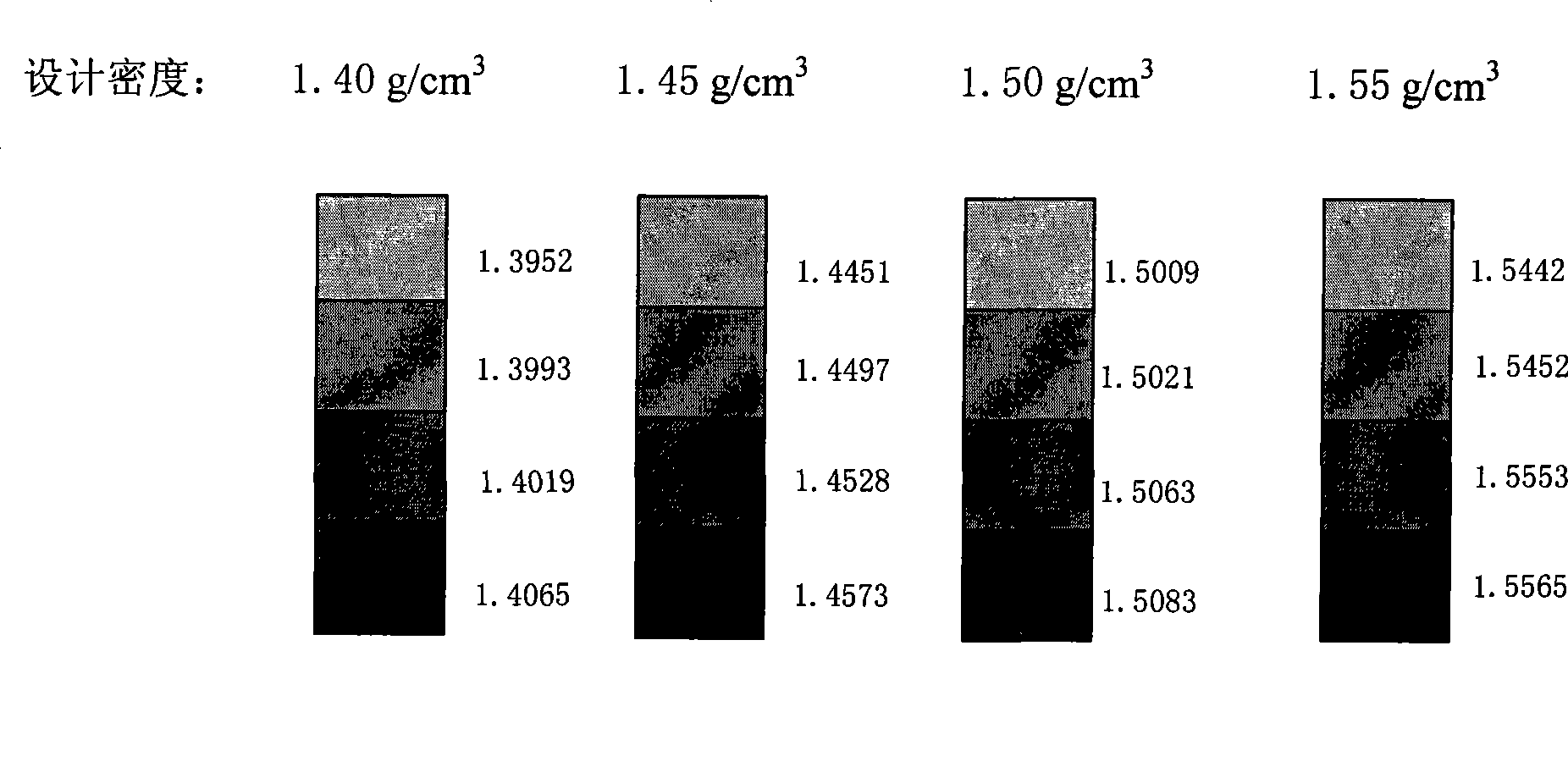

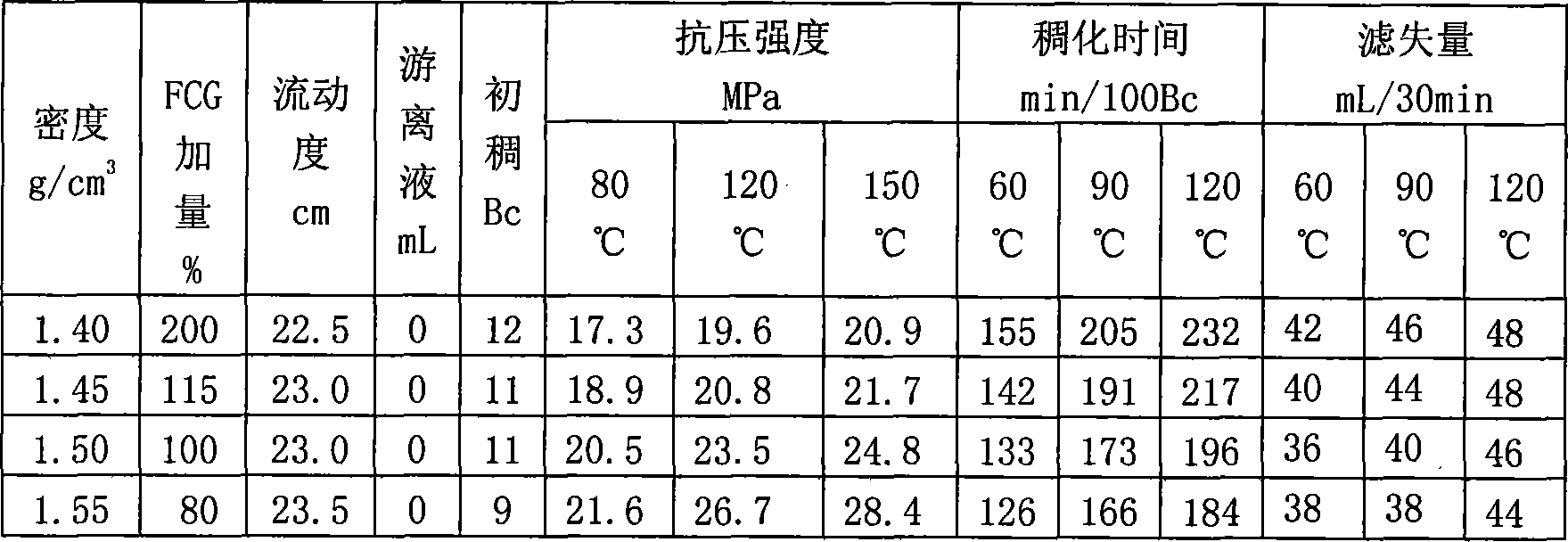

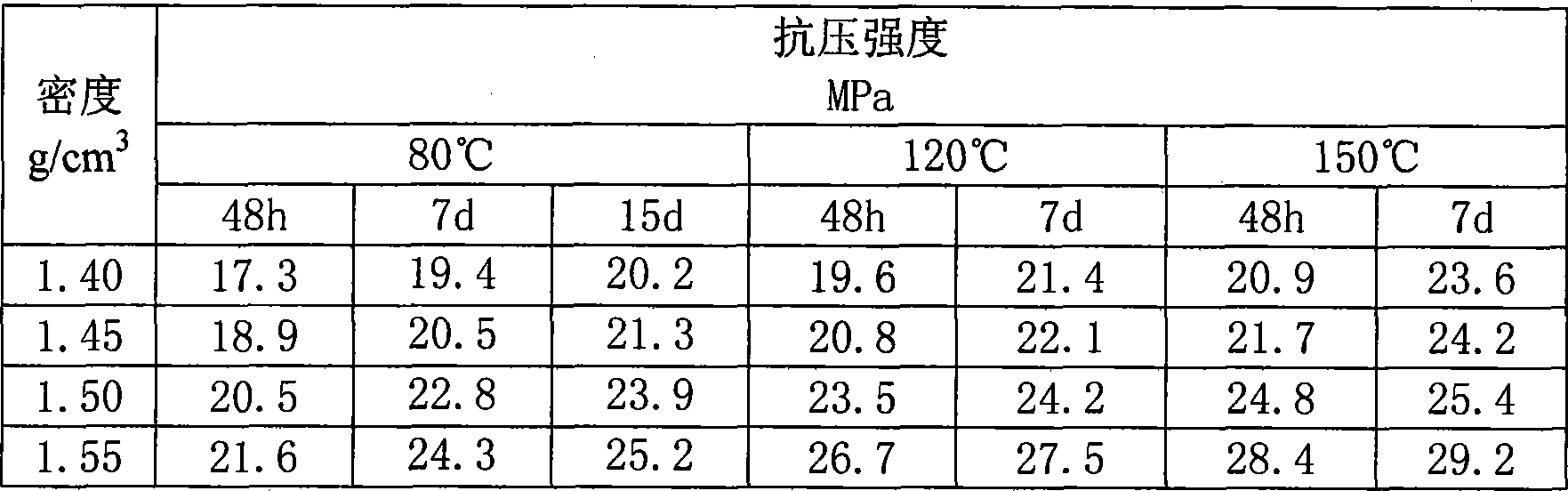

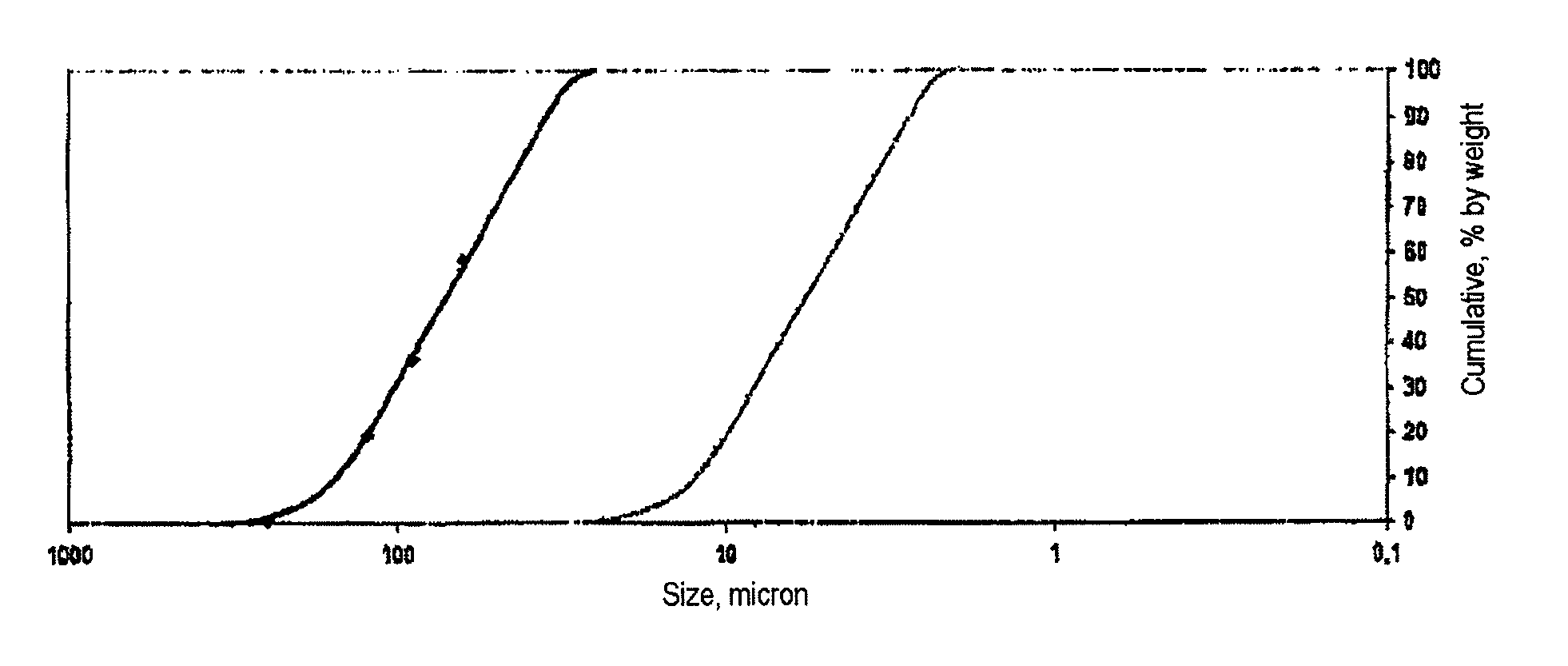

The invention relates to a non-cenosphere light weight cement slurry, which mainly solves the problem that the cement slurry cannot keep the density thereof under a high pressure condition. The non-cenosphere light weight cement slurry is characterized by comprising the following components in portion by weight: 100 portions of cement, 116 to 321 portions of water, 52 to 136 portions of fly ash, 14 to 38 portions of silica fume, 14 to 38 portions of superfine cement, and 6 to 11 portions of early strength agent, wherein the particle diameter of the silica fume (of which the SiO2 content is more than 90 percent) is more than 0 and less than 0.5 mu m, the particle density of the silica fume and the fly ash is 2.0 grams per cubic meter, and the particle diameter of the superfine cement is more than 0 and less than 2 mu m. The light weight cement slurry forms a set of incompressible light weight cement slurry system of which the density is between 1.40 and 1.55 grams per cubic meter through preferentially selecting external additives and applying a grain composition principle, wherein the flowability and the sedimentation stability of the cement slurry are good, the set cement strength is more than 15 MPa and cannot decline at a temperature of 150 DEG C so as to satisfy the technical requirements on oil field exploration and development.

Owner:DAQING OILFIELD CO LTD +1

Method of preparing low-density well cementation cement check block of oil well by utilizing silicon carbide ceramic microbeads

The invention provides a method of preparing a low-density well cementation cement check block of an oil well by utilizing silicon carbide ceramic microbeads. The method comprises the following steps: preparing silicon carbide closed-hole hollow ceramic microbeads; burdening; mixing; stirring and mixing; carrying out mould testing; carrying out a strength test. The method is characterized by specifically comprising the following steps: stirring and mixing 40-50wt% of G-grade well cementation cement, 10-15wt% of 13-micron superfine cement, 25-35wt% of closed-hole silicon carbide ceramic microbeads with the grain size of 5-50 microns, 5-7wt% of coal ash with the loss on ignition of 1.1%, 1.5-2wt% of calcium oxide with the purity of 99.9%, 0.5-1.0wt% of sodium sulfate and 1-3wt% of micro-silicon in a stirrer for 40 seconds in a micro-silicon of 0.5-0.6(W / C); pouring and carrying out mould testing; maintaining for 24 hours and 48 hours in a water bath maintaining box at a constant temperature of 52 DEG C; soaking for 1 hour in cold water after demoulding and carrying out performance test.

Owner:鑫领域智能科技(邳州)有限公司

Injecting paste material for underground structure water plugging and preparation method thereof

The invention provides an injecting paste material for underground structure water plugging and a preparation method thereof and belongs to the field of material science. The injecting paste material comprises the following raw materials in parts by weight: 200-600 parts of Portland cement, 600-900 parts of ultra-fine slag powder, 550-650 parts of water, 10-30 parts of sodium silicate, 5-10 parts of high efficiency slushing agent and 0.5-2 parts of cellulose ether. The water glass (sodium silicate) and Portland cement serve as an activator of the ultra-fine slag powder, the water amount of the injecting paste material is reduced by using the high efficiency slushing agent, the cellulose ether serves as a water-retaining agent, a thixotropic agent and a thickening agent of the injecting paste material, the superfine cement is replaced by employing the Portland cement and the ultra-fine slag powder, various materials can be mixed and stirred on site, the Portland cement, the ultra-fine slag powder and the cellulose ether are uniformly mixed and packaged in advance and are transported to the site and are uniformly mixed and stirred with water, water glass and high efficiency slushing agent, various requirements of the injecting paste are met, and the amount of the ultra-fine cement is reduced.

Owner:QINGDAO BAOJILI ENG TECH CONSULTINGCO +1

Hyper-fine cement

The invention relates to a process for producing a hyper-fine cement, in which cement is wet milled in a nonaqueous solvent, if appropriate in the presence of a grinding aid, as a result of which a hyper-fine cement having a particle size D50 of <1 μm is obtained.The hyper-fine cement is suitable for sealing or strengthening porous molded articles, rock or porous formations, in particular for the gastight sealing of natural gas reservoirs and also for making polymer materials or components composed of pressed textiles or natural fibers fire resistant.

Owner:EPG ENGINEERED NANOPROD GERMANY

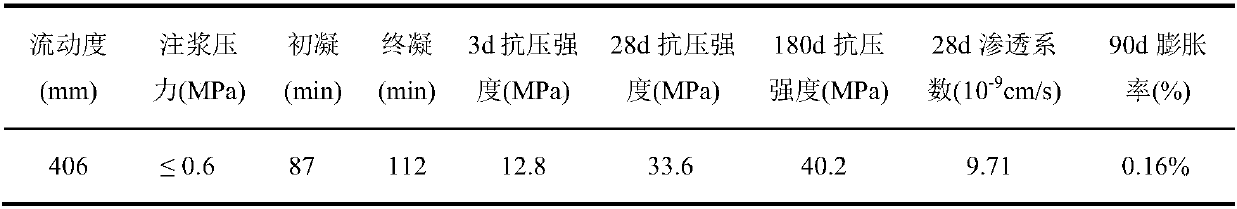

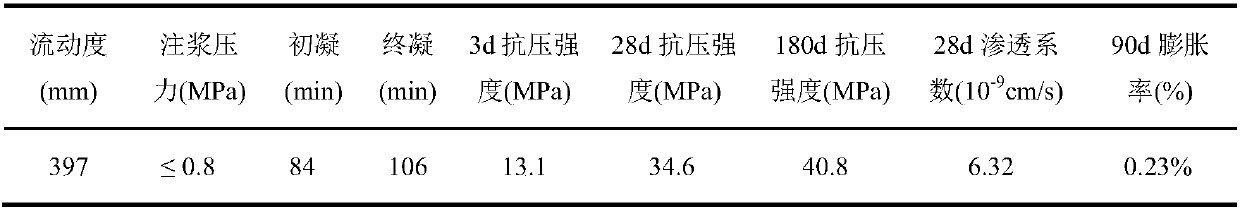

Composite superfine cement grout slurry and preparation method thereof

The invention provides a composite superfine cement grout slurry and a preparation method thereof. The slurry is prepared by conducting ball milling on a matrix component and an additive component to obtain an ultrafine composite grouting material and mixing the water and cement according to a ratio of 0.5-0.8. The matrix consists of ordinary silicate cement, fly ash, slag and water; and the additive component comprises a grinding agent, an activator, a composite superplasticizer, an expansive agent and a retarder. The composite superfine cement grout slurry contains the following components by weight: 10% of slag, 0.8%-1.2% of composite superplasticizer, 5%-10% of expansive agent and 0.1%-0.6 of the retarder. The composite superfine cement grouting slurry provided by the invention has high fluidity and high bonding strength, and good impermeability and volume stability, and can significantly improve groutability and reinforce performance of subtle fracture of rocks if applied.

Owner:CHINA UNIV OF MINING & TECH

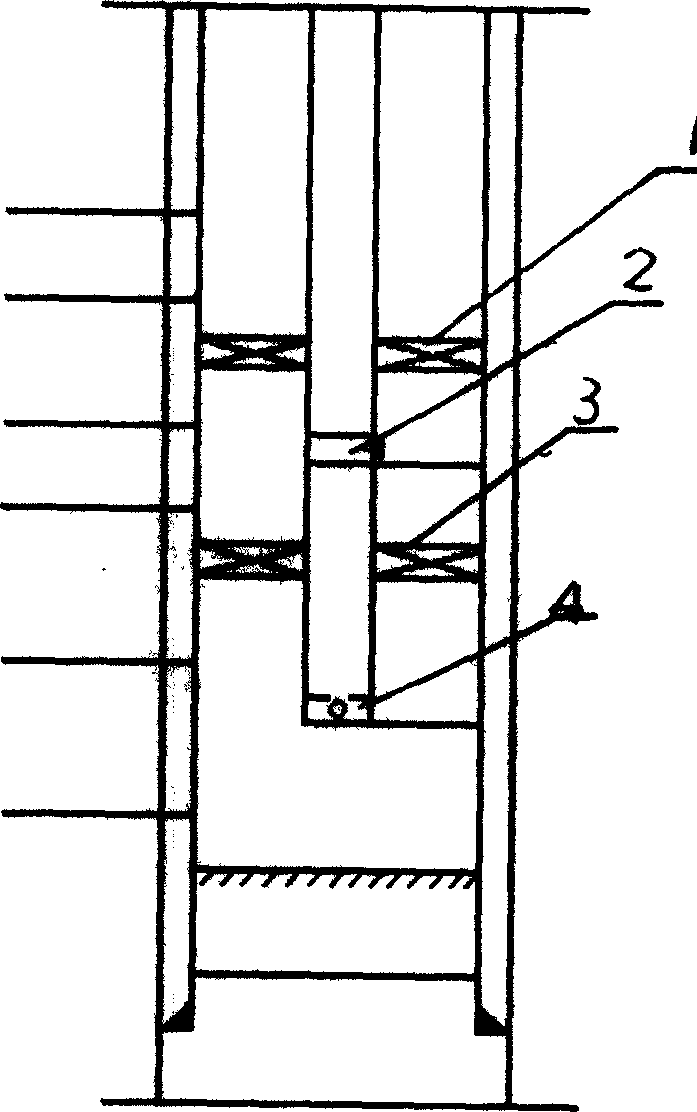

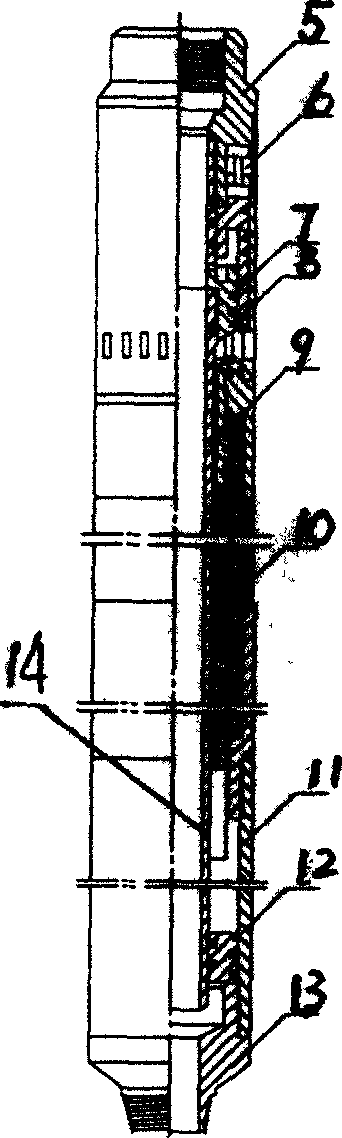

Technique for plugging high penetrative water-yielding stratum in oil well by using superfine cement

This is a sealing technology used to seal the high permeation water layer during the oil well recover procession. This technology use pipe-stake it is composed with the double hydraulic expanding separator and throttle. It use the separator seal the water layer to separate the oil-layer and water-layer. The super tiny cement powder is squeezed out of throttle into the underground, then close the oil well. To spread the pressure: During the cement slurry solidified time interval. Washing the well, wash out the surplus cement slurry to the oil well, hoist the pipe stake to safety segment and close the well, to wait for the cement slurry solidify.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

Low-self-shrinkage high-toughness cement-based composite material and preparation method thereof

InactiveCN110734255AIncrease late strengthReduce autogenous shrinkageMicrofine cementAggregate (composite)

The invention discloses a low -self-shrinkage high- toughness cement-based composite material which is prepared from the following raw materials in percentage by mass according to the Dinger-Funk powder close packing theory: 15-22% of ultrafine cement, 20-28% of a mineral admixture, 10-14% of steel slag powder, 2-6% of gypsum, 0-10% of silica fume, 0-5% of nano-powder, 0-5% of porous powder, 15-25% of a fine aggregate, 1-2.5% of fibers, 0.3-2% of an additive, 0-0.5% of a defoaming agent, 0-1% of a water retention component and 10-18% of water. By utilizing the water absorption characteristic of the porous powder, a base material has a self-curing effect, the later strength can be improved and the self-shrinkage of the high-toughness cement-based composite material can be reduced while thecost of the raw materials is reduced, and the cracking risk of the high-toughness cement-based composite material due to shrinkage is avoided.

Owner:CHINA WEST CONSTR ACAD OF BUILDING MATERIALS CO LTD +1

Method for preparing oil well cementation cement briquette through silica-alumina composite ceramic microbeads

InactiveCN103880359AThe density change rate is smallChange the dependence of floating beadsMicrofine cementComposite ceramic

The invention provides a method for preparing an oil well cementation cement briquette through silica-alumina composite ceramic microbeads. The method comprises the steps of preparing silica-alumina composite ceramic blind-hole hollow microbeads, burdening, mixing, stirring and pulping, pouring a test mold and carrying out a strength test, and concretely comprises the steps of evenly mixing 40-50wt% of G-class oil well cement, 10-15% of superfine cement with the particle size of 13mu m, 25-35wt% of composite ceramic blind-hole hollow microbeads with the particle size of 5-50mum, 5-7wt% of pulverized ash with ignition loss of 1.1%, 1.5-2wt% of calcium oxide with the purity of 99.9%, 0.5-1.0wt% of sodium sulfate and 1-3wt% of silica fume, stirring and pulping for 40 seconds in a stirrer in a water-cement ratio of 0.5-0.6(W / C), pouring the test mold, curing for 24 hours and 48 hours in a water-bath curing box with the constant temperature of 52DEG C, soaking for one hour in cold water after demolding, and performing a performance test.

Owner:广州信浚建材科技有限公司

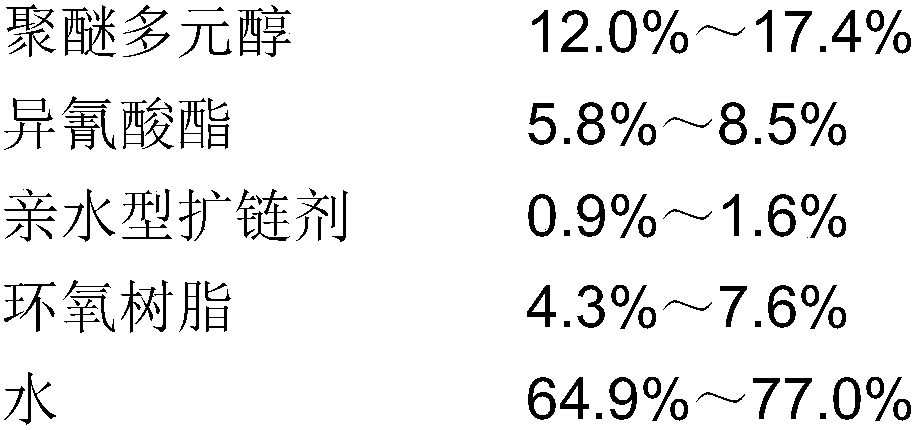

Waterborne polyurethane-epoxy interpenetrating network superfine cement compound grouting material, preparation method thereof and application of grouting material

The invention discloses a waterborne polyurethane-epoxy interpenetrating network superfine cement compound grouting material, a preparation method thereof and an application of the grouting material.The grouting material comprises a first component, a second component and superfine cement, and the weight ratio of the first component, the second component to the superfine cement is (0.5-0.7):0.01:1. By the aid of molecular structure design, epoxy resin is modified by waterborne polyurethane, a polyurethane structure is introduced into an epoxy resin molecular chain to form a waterborne polyurethane-epoxy interpenetrating network structure, the flexibility and the impact resistance of the epoxy resin are improved, the excellent adhesive property of the epoxy grouting material is kept, the prepared grouting material is free from any volatile solvents, and the environmental protection property of the grouting material is enhanced.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

Ultra-fine cement slurry for reinforcing powder fine sand and preparation method thereof

A superfine cement serum which is used by the reinforcing powder fine sand is mixed into the mixed serum according to the following weight parts ratio: water for 100 parts; superfine cement for 20-40 parts; suspension agent for 0.5-3 parts; thinning agent for 0.5-2 parts; high efficiency water reducing agent for 0.2-1 part, and the mixed serum can be mixed with surfactant for 0.5-1 part. Firstly the water is added into the mixing tank, along with the slow mixing the alta-mud, the thinning agent and the high efficiency water reducing agent are added in sequence, after mixing for two minutes the superfine cement is slowly added in the mixing state, then the mixture is mixed for five minutes at the rotary speed fro 500-1500 rounds / min. At the same time the second mixing tank can be added with water, sodium silicate and disodium hydrogen phosphate, and the accelerator serum is obtained after mixing for two minutes, the serum are abstracted from the two mixing tanks respectively with a double-liquid mud-injection pump, and the ratio of weight part of the two serum is 10:2-4. The serum of the invention settles the problem that the superfine cement serum is used for quickly reinforcing the powder fine sand earth.

Owner:BEIJING MUNICIPAL ENG RES INST +1

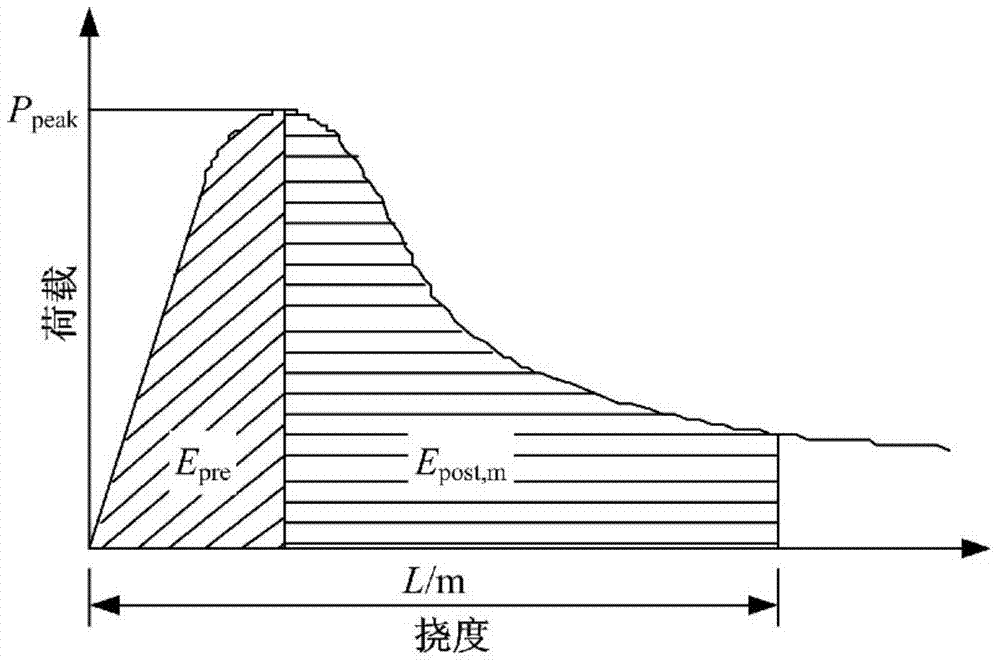

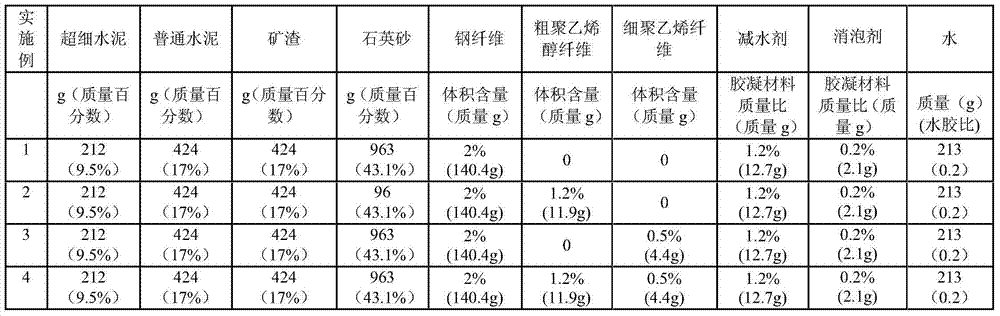

Steel fiber and high-performance synthetic fiber mixed toughened RPC (reactive powder concrete) and preparation method

The invention provides steel fiber and high-performance synthetic fiber mixed toughened RPC (reactive powder concrete) and a preparation method, belonging to the technical field of concrete. The toughened RPC is characterized in that raw materials include Portland cement, superfine cement, admixtures, additives, steel fibers, coarse polypropylene fibers, fine polyvinyl alcohol fibers and water; the water-binder ratio is 0.18-0.21; the Portland cement and the superfine cement respectively account for 17-20% and 8-9% of total concrete by mass; the steel fibers, the coarse polypropylene fibers and the fine polyvinyl alcohol fibers respectively account for 1-3%, 1.2-1.7% and 0.3-0.6% of the whole concrete by volume. The preparation method comprises the steps of pouring sand and powder into a stirrer to be stirred uniformly, then adding the additives and water, mixing the fibers and stirring the materials when the stirred materials are changed to colloids from granules, pouring after the fibers are dispersed uniformly, and carrying out vibratory compaction or vibration molding and curing. The toughened RPC and the preparation method have the beneficial effects that the mechanical toughness of the RPC can be improved, and the economical efficiency and wide applicability of the material can be improved.

Owner:江苏丹凤建筑集成化科技有限公司

Method for preparing oil well cement test block by utilizing silicon oxynitride ceramic composite microspheres

The invention provides a method for preparing an oil well cement test block by utilizing silicon oxynitride ceramic composite microspheres. The method comprises the following steps: preparing silicon oxynitride ceramic composite obturator hollow microspheres, compounding, mixing, performing stirring and size mixing, performing mold testing and performing strength testing; uniformly mixing and stirring 40 to 50 percent by weight of G-grade oil well cement, 10 to 15 percent by weight of 13-micrometer ultrafine cement, 25 to 35 percent by weight of silicon oxynitride ceramic composite obturator hollow microspheres with the granularity of 5 to 50 micrometers, 5 to 7 percent by weight of coal ash with the burning loss of 1.1 percent, 1.5 to 2 percent by weight of calcium oxide with the purity of 99.9 percent, 0.5 to 1.0 percent by weight of sodium sulfate and 1 to 3 percent by weight of silica fume, stirring and mixing the raw materials for 40 seconds inside a stirring machine with the water-ash ratio of 0.5 to 0.6 (W / C), then pouring the mixture into a test mold, conserving for 24-48 hours in a water-bath maintenance box at a constant temperature of 52 DEG C, immersing the demolded mixture in cold water for 1 hour, and finally performing the performance test on the mixture.

Owner:SHANDONG UNIV OF TECH

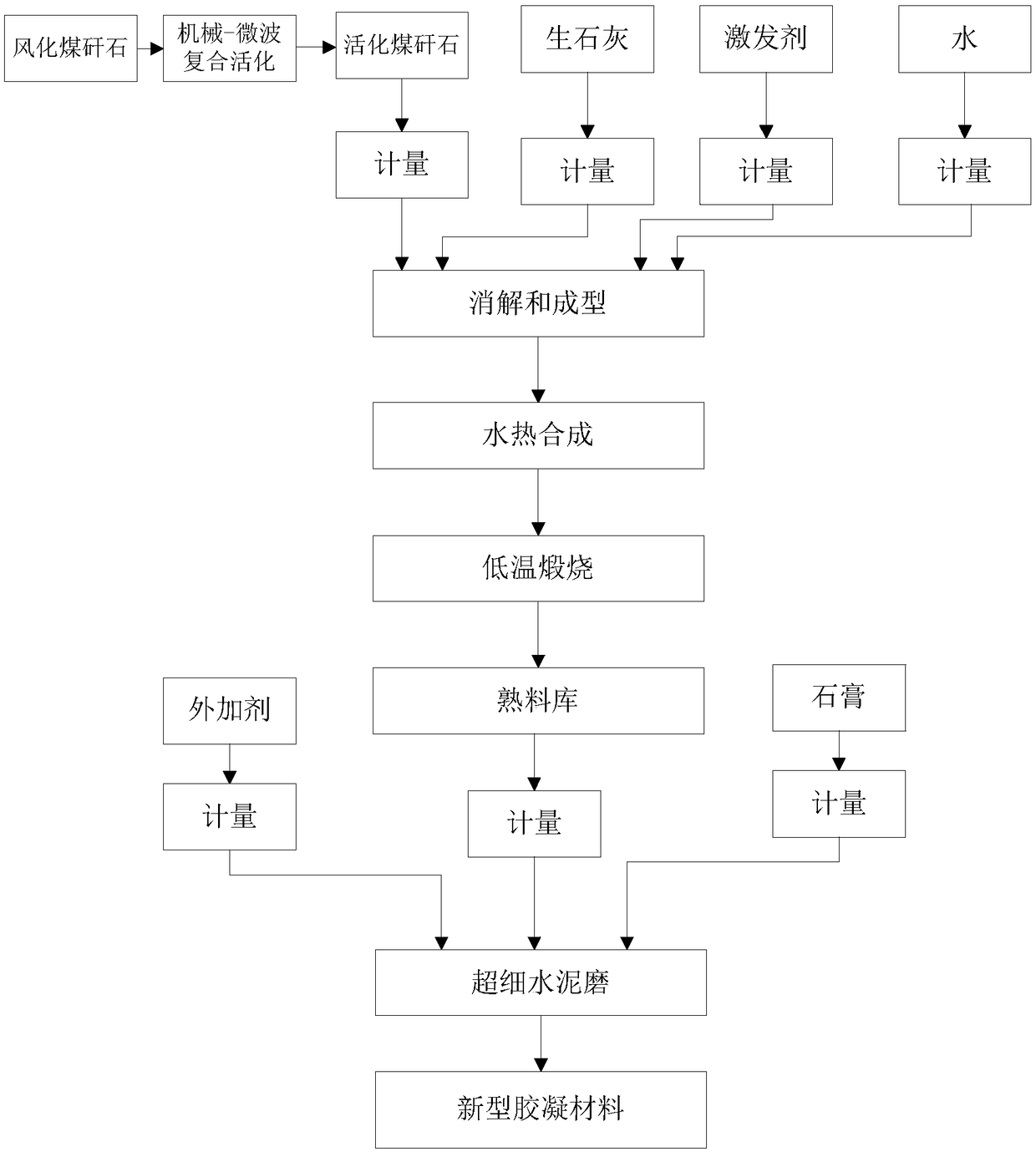

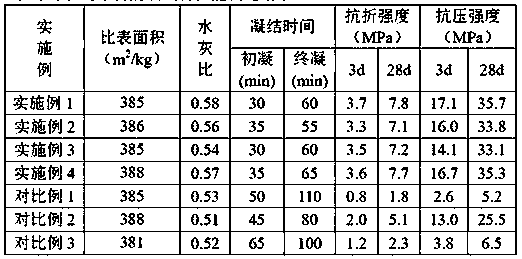

Cementing material with coal gangue as raw material and preparation method of cementing material

ActiveCN109485278ARealize the utilization of large quantities of resourcesReduce occupancyCement productionMicrofine cementEcological environment

The invention discloses a cementing material with coal gangue as a raw material and a preparation method of the cementing material. The cementing material contains the following components in parts bymass: 92-95 parts of clinker, 3-7 parts of gypsum and 0.5-1.5 parts of water reducer, wherein raw materials of the clinker include the following components in parts by mass: 60-75 parts of activatedcoal gangue powder, 25-40 parts of quick lime, 0.5-2 parts of exciting agent and 70-90 parts of water. The novel cementing material is prepared by carrying out mechanical-microwave combined activationon coal gangue, then, uniformly mixing coal gangue with the quick lime, and grinding the mixture by using a superfine cement grinding mill by using chemical strengthening, hydrothermal synthesis andlow-temperature calcination methods. A great deal of piled and stored coal gangue is utilized, so that the land occupied by the coal gangue is reduced; natural resources can be saved, and the deterioration of an ecological environment due to exploitation of cement raw materials is effectively solved; and the preparation method is simple, low in energy consumption, high in coagulation speed, high in strength and good in corrosion resistance, and the strength of the cementing material at each age meets a corresponding strength requirement of P.F 32.5 cement.

Owner:YANGZHOU UNIV

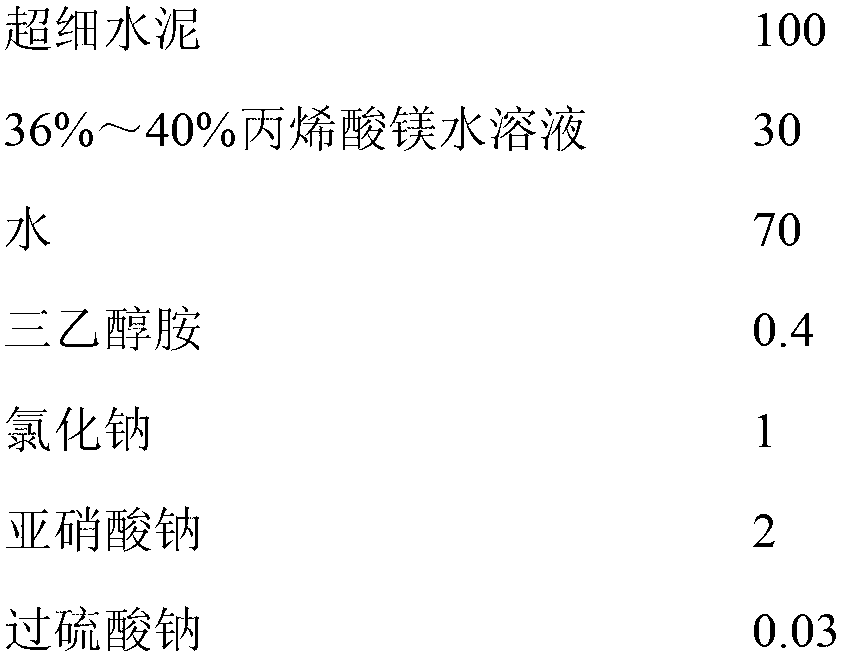

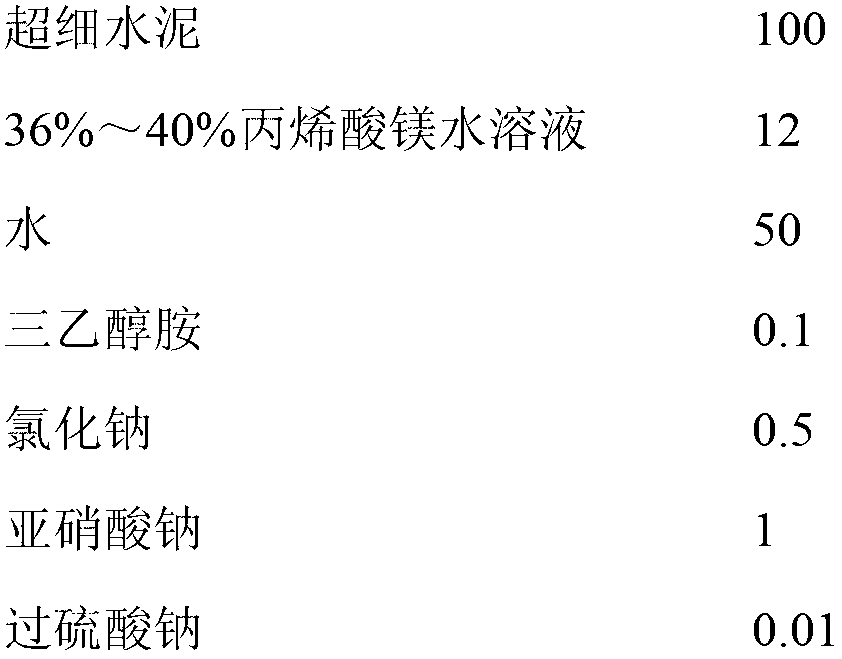

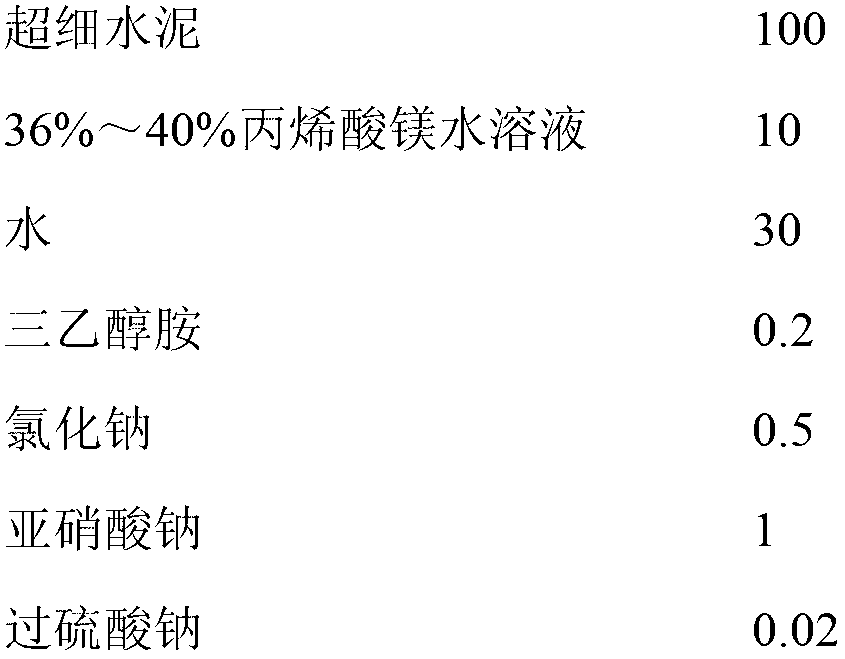

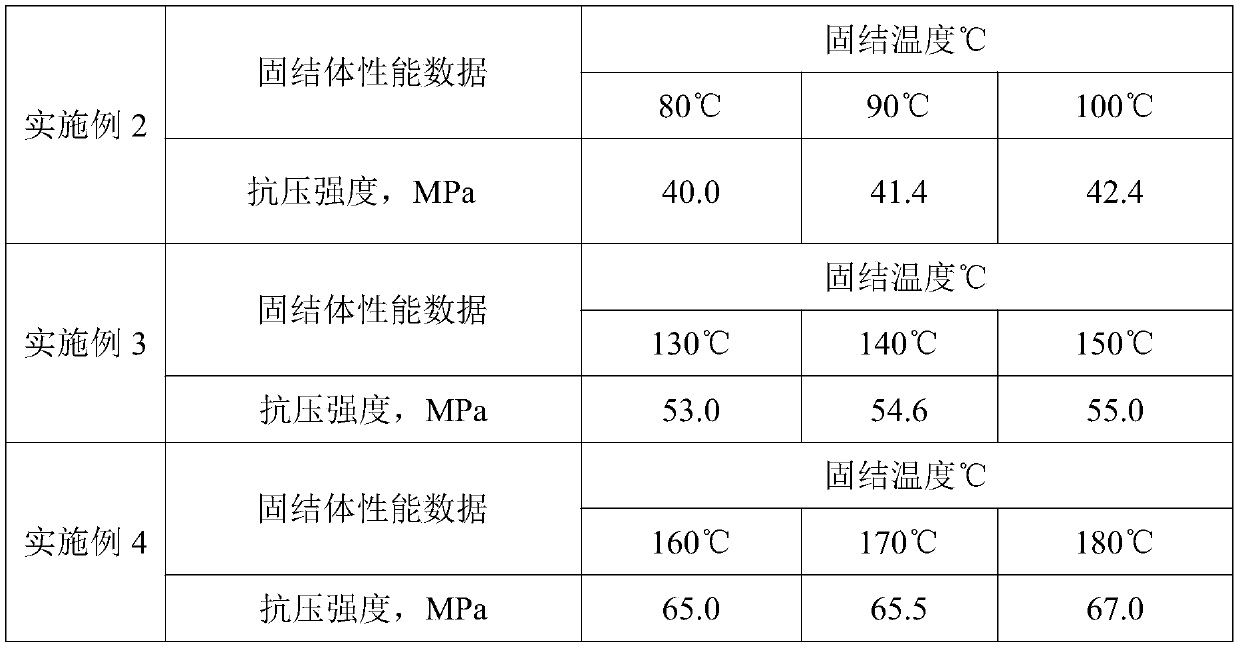

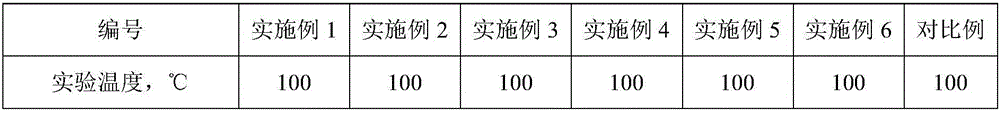

Magnesium acrylate-superfine cement compounded grouting material and preparation method thereof

Owner:SOUTHWEST JIAOTONG UNIV

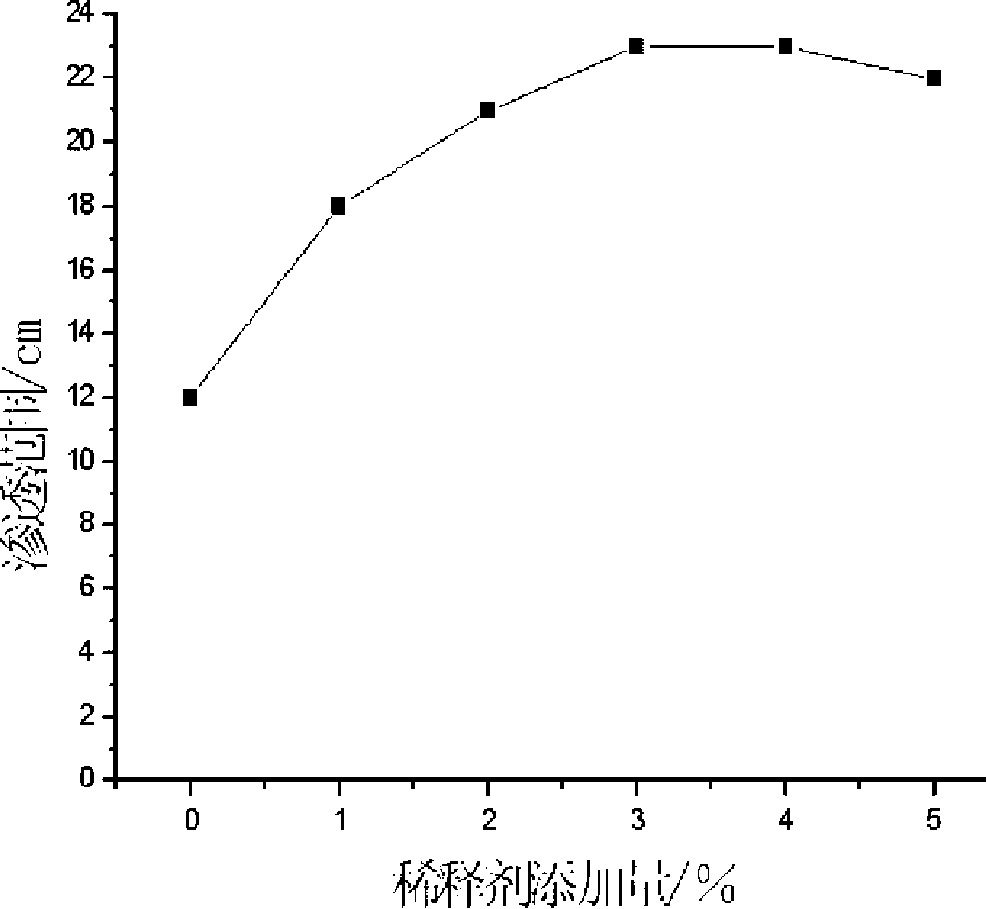

Novel green grouting superfine cement

InactiveCN102838332AConducive to turning waste into treasureReduce pollutionAluminateMicrofine cement

The invention discloses novel green grouting superfine cement. The superfine cement comprises the following minerals of superfine silicate cement, superfine aluminate cement, superfine mineral powder, superfine coal ash, a swelling agent, a water reducing agent, a retarding agent and a diluting agent. The temperature range of the superfine cement when in use is 5-60 DEG C; the compression strength of cement stone is more than 20 MPa within 24 hours, the compression strength within 3 days is more than 42 MPa, the compression strength within 7 days is more than 55 MPa, and the compression strength within 28 days is more than 65 MPa; the initial setting time of the cement is 23-208min, the final setting time is 45-223min, time is adjustable and controllable, and the cement is high in penetrating power and can penetrate through a narrow gap with a width of 15 mum; a cement slurry body with controllable setting time and controllable strength can be formed on the premise of a water-to-cement ratio ranging from (1 to 1) to (3 to 1); and the superfine cement can be applied to seepage prevention, leaking stoppage and reinforcement in excavation of projects such as water dams, mine roadways, tunnels and the like, and is a novel green blocking material.

Owner:SHANDONG JIANZHU UNIV

Light-weight high-strength foam concrete and preparation method thereof

The invention belongs to the technical field of building materials, and particularly relates to light-weight high-strength foam concrete and a preparation method thereof. The light-weight high-strength foam concrete is prepared by enabling superfine cement-based slurry to be uniformly mixed with a foam stabilizer, foam and a light-weight aggregate according to a mass ratio of (250-800):(0.05-5):(15-30):(2-6) and wet-milling, forming and maintaining, wherein the obtained light-weight high-strength foam concrete is 180-600 kg / m<3> in apparent density, 0.8-8.5 MPa in compressive strength, 0.055-0.12 W / m-k in heat conductivity coefficient, belongs to a A-stage incombustible material, and can be used as a light-weight high-strength composite wallboard.

Owner:郑州工大高新材料科技有限公司

Method of preparing oil well cement briquette from quartz ceramic closed-pore hollow microspheres

The invention provides a method of preparing oil well cement briquette from quartz ceramic closed-pore hollow microspheres. The method comprises the following steps of preparing quartz ceramic closed-pore hollow microspheres, preparing materials, mixing, stirring and size-mixing, mould testing and carrying out a strength test; the method is characterized in that 40wt%-50wt% of G-level oil well cement, 10wt%-15wt% of 13-mu m superfine cement, 25wt%-35wt% of quartz ceramic closed-pore hollow microspheres with particle diameter of 5 mum -50 mum, 5wt%-7wt% of coal ashes with loss on ignition of 1.1%, 1.5wt%-2wt% of calcium oxide with purity of 99.9%, 0.5wt%-1.0wt% of sodium sulfate and 1wt%-3wt% of micro-silicon are uniformly mixed, stirring and size-mixing are carried out for 40 seconds in a stirrer in a water-cement ratio (W / C)of 0.5-0.6, the materials are poured into mould testing, maintained for 24 hours and 48 hours in a water-bath maintenance box at a constant temperature of 52 DEG C, and de-molded and then soaked in cold water for 1 hour to carry out performance test.

Owner:广州市昊晶建筑材料有限公司

Method for preparing oil well cementing cement briquette with silicon carbide/boron carbide hollow ceramic microbeads

InactiveCN103803883AChange the dependence of floating beadsLow densityMicrofine cementComposite ceramic

The invention provides a method for preparing an oil well cementing cement briquette with silicon carbide / boron carbide hollow ceramic microbeads. The method comprises preparation of silicon carbide / boron carbide closed-pore hollow composite ceramic microbeads, burdening, mixing, stirring and size mixing, mold testing and strength testing. The method is characterized in that 40-50wt% of grade G oil well cement, 10-15wt% of 13-micron superfine cement, 25-35wt% of silicon carbide / boron carbide composite ceramic microbeads having the grain size ranging from 5 to 50 microns, 5-7wt% of fly ash having the loss on ignition of 1.1%, 1.5-2wt% of calcium oxide having the purity of 99.9%, 0.5-1.0wt% of sodium sulfate and 1-3wt% of micro-silicon are stirred in a stirrer in a water cement ratio ranging from 0.5 to 0.7 (W / C) for size mixing for 40 seconds, next, the mixture is poured into a test mold and maintained in a water-bath curing box at a constant temperature of 52 DEG C for 24 hours or 48 hours, and after being demolded, the obtained material is soaked in cold water for 1 hour, and then the properties of the obtained material are tested.

Owner:SHANDONG UNIV OF TECH

High-strength composite plugging system for plugging pipe flow channel and preparation method thereof

InactiveCN102911650AImprove performanceMeet the sealing strength needsDrilling compositionViscous liquidMicrofine cement

The invention discloses a high-strength composite plugging agent material for plugging a developed pipe flow channel of an oil-water well and a preparation method thereof. The method comprises the following steps: superfine cement, hydroxypropyl guar gum, floating beads, a hydrophobic water-swelling agent and modified latex are used as main materials; the main materials form gum viscous liquid by the hydroxypropyl guar gum, and superfine cement and hydrophobic water-swelling agent particles are suspended; a system enters into the depth of a plugging purpose formation, the superfine cement particles are settled, gathered and solidified, and the pipe flow channel space is shortened; and the hydrophobic water-swelling agent particles suck a lot of water to be swelled to fill the surplus channel space, and the binding and filling type plugging of the plugging agent and the pipe flow channel is realized. In addition, the supporting effect of the modified latex and the floating beads is utilized, the superfine cement and the hydroxypropyl guar gum are isolated, and the phenomenon that the superfine cement is easy to flocculate and non-condense in a hydroxypropyl guar gum basic solution is eliminated. The site configuration process is simple, the water cement ratio is high, the amount of formed slurry is large, the cost is low, the plugging strength of the solidified system is large, and the effective acting time is long.

Owner:PETROCHINA CO LTD

High-strength sealing plugging agent

ActiveCN110591673ALittle change in performanceImprove the consolidation effectDrilling compositionFiberMicrofine cement

The invention discloses a high-strength sealing plugging agent, which comprises, by mass, 15-20% of a fluorenyl epoxy resin, 10-12% of an epoxy resin, 10-12% of an alkaline phenol formaldehyde resin,20-30% of a solvent, 4-5% of a coupling agent, 15-20% of a filler, 4-5% of a degassing agent and 4-5% of a curing agent, wherein the degassing agent is a modified calcium-based degassing agent, the fluorenyl epoxy resin is 9,9-bis[(2,3-epoxypropoxy)phenyl]fluorene, the filler is a compounding agent prepared from superfine cement powder and PVA fibers according to a mass ratio of 4:1-3:1, and the curing agent is prepared by compounding benzophenone imine and 9,9-bis(4-aminophenyl)fluorene according to a mass ratio of 1:1. According to the invention, the plugging agent can effectively plug crackand micro-crack leakage layers of oil wells, gas wells and water wells, has characteristics of good sealing property, high compressive strength, strong scouring resistance, good operability and highplugging success rate, and particularly has outstanding effect in gas well micro-crack plugging treatment.

Owner:新疆艾瑞克石油技术有限公司

Well cementation material, well cementation material system and preparation method thereof

ActiveCN106497529AReduce surface tensionEliminate Bubble ProblemsDrilling compositionMicrofine cementFiber

The invention discloses a well cementation material, a well cementation material system and a preparation method thereof. The well cementation material comprises the following components by weight: 100 parts of a high temperature resistant well cementation matrix material, 5-9 parts of a high temperature microcrystalline reinforced material, 1-2 parts of a filtrate reducer, and 1-4 parts of silica fume. The high temperature resistant well cementation matrix material is obtained by firing MgO, Al2O3, SiO2, CaO, SO3 and Na2O, and the high temperature microcrystalline reinforced material consists of superfine cement and mineral fiber. The well cementation material slurry prepared from the well cementation material and water has the advantages of good system stability, low filtration water loss, long coagulation time, and fast strength development. The formed hardened body has high strength at low temperature, high strength at high temperature, low permeability and slight expansion performance, low strength retrogression rate and permeability at high temperature, has good application prospects in the heavy oil reservoir high temperature steam injection development field, and has good adaptability in shallow heavy oil thermal production well cementing engineering construction.

Owner:中石化石油工程技术服务有限公司 +1

Thickener and super high-density cement paste based on thickener

ActiveCN103773341ADensity meetsImprove performanceDrilling compositionMicrofine cementMining engineering

The invention discloses a thickener and a super high-density cement paste based on the thickener. The thickener comprises the following components in parts by weight: 80-90 parts of iron ore powder, 5-10 parts of manganese mineral powder, 5-10 parts of G-grade superfine cement and 5-10 parts of silica fume. The super high-density cement paste provided by the invention is stable in performance, and low in water loss, has certain anti-gas channeling ability and ideal thickening transition time, and can form strong set cement. A high-pressure hydrocarbon reservoir can be effectively controlled, jump-out of an oil gas is avoided, and the cementing quality can be better improved.

Owner:四川川庆井下科技有限公司

Grouting slurry for reinforcing tunnel face of jacking culvert of fine-sand layer and grouting method

ActiveCN105731978AImprove permeabilityNo pollution in the processUnderground chambersTunnel liningMicrofine cementSlurry

The invention provides grouting slurry for reinforcing the tunnel face of a jacking culvert of a fine-sand layer and a grouting method. When the jacking frame culvert is reinforced by a pipe curtain and the tunnel face needs to keep self-stabilization at certain slope ratio, the diluted water glass and prepared calcium chloride solution are sequentially adopted for horizontal grouting reinforcement by a modified perforated-pipe grouting technology; and the unconfined compressive strength of the reinforced soil body can reach 100-500kPa, and the slope ratio required by the blade feet of the jacking culvert can be realized. Compared with the reinforcement by chemical slurry and high-pressure jet grouting, the grouting method is safe and stable; compared with the reinforcement by superfine cement grouting, the spreading range is large, the strength after reinforcement can meet the requirement on slope ratio stability, the excavation is easy, the construction is convenient, and the construction cost is reduced by more than half; meanwhile, by adopting the grouting technology provided by the invention, sectional grouting can be realized, the pipeline is not blocked easily, and an aim of dominant permeation of slurry in the dense fine-sand layer is achieved; and a slurry plug is not arranged at the lower end but the upper part, the grouting range is expanded, and the grouting effect is relatively good.

Owner:中铁四院集团工程建设有限责任公司

Mine whole-tailing and composite superfine cement bond filling material

The invention discloses a mine whole-tailing and composite superfine cement bond filling material, which is formed by mixing the components such as composite superfine cement, whole tailings and water, and a mass ratio of the composite superfine cement to the whole tailings to the water is (30-100): (900-970): (150-350); and the composite superfine cement is formed by mixing a dispersing agent and superfine cement, and a mass ratio of the dispersing agent to the superfine cement is (0.1-0.5): 100. According to the invention, the bond filling material is formed by mixing the composite superfine cement, the whole tailings and water, the fineness of the superfine cement is 400-800 m<2> / kg (the fineness of general purpose portland cement is 300-400 m<2> / kg), the finer the cement particles, the greater the surface action (namely the cement particles are more likely to cluster), the superfine cement particles in the composite superfine cement are dispersed in the whole tailing particles through the dispersing agent, so that the composite superfine cement bond filling material can meet the requirements of filling material conveying and strength, therefore, the mixing amount of the composite superfine cement is reduced, and the filling material cost is lowered.

Owner:郑州工大建材有限公司

Method for preparing low-density cement briquette for oil well cementation by use of silicon nitride ceramic microbeads

InactiveCN103880362AThe density change rate is smallHigh compressive strengthMicrofine cementWell cementing

The invention provides a method for preparing a low-density cement briquette for oil well cementation by silicon nitride ceramic microbeads. The method comprises the steps of preparing silicon nitride ceramic closed-pore hollow microbeads, proportioning, mixing, stirring to form a slurry, testing a mold and carrying out a strength test; specifically, the method comprises the following steps: evenly mixing and stirring 40-50wt% of G-grade oil well cement, 10-15wt% of superfine cement having a grain size of 13 microns, 25-35wt% of silicon nitride ceramic closed-pore hollow microbeads having a grain size in the range from 5 to 50 microns, 5-7wt% of fly ash having the ignition loss of 1.1%, 1.5-2wt% of calcium oxide having the purity of 99.9%, 0.5-1.0wt% of sodium sulfate and 1-3wt% of micro-silicon together, stirring in a stirrer in a water-cement ratio of 0.5-0.6 (W / C) to form a slurry for 40 seconds, pouring the mixture in a mold to test the mold, curing for 24 hours and 48 hours in a water-batch curing box at a constant temperature of 52 DEG C, demolding and then soaking in cool water for 1 hour to carry out a performance test.

Owner:于海花

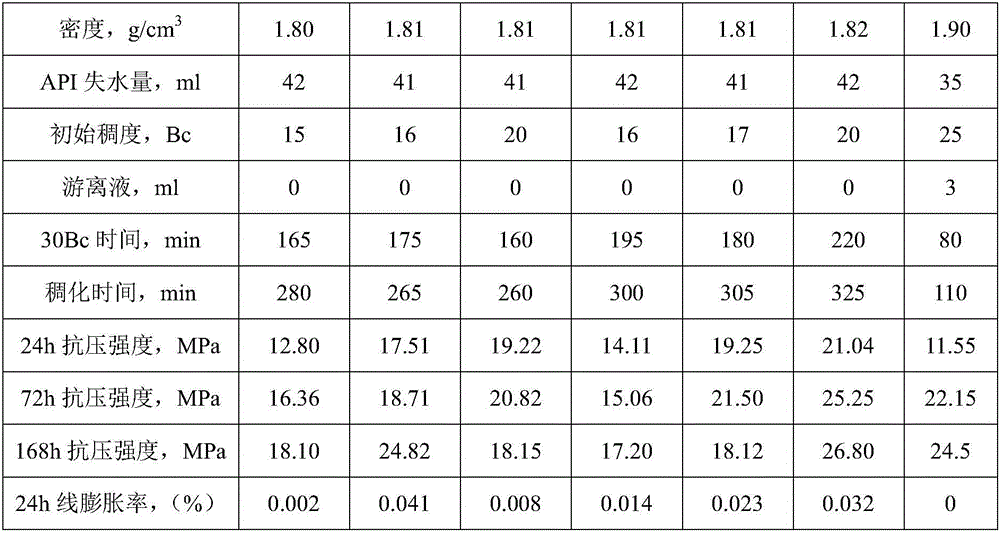

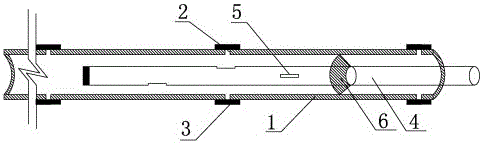

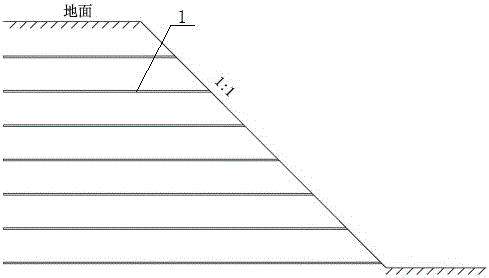

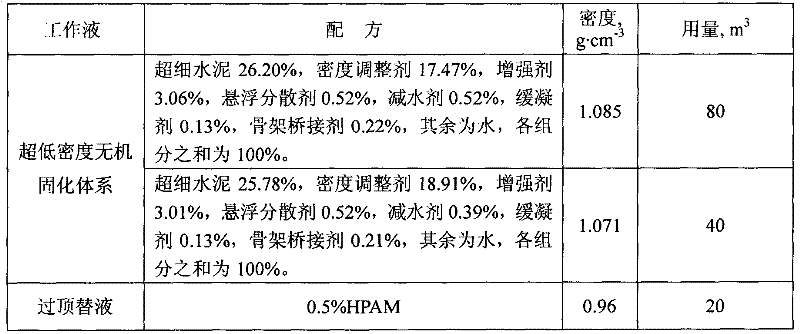

Inorganic solidifying system for controlling bottom water coning in fracture-cavity karst reservoir, and injection method thereof

ActiveCN102199418AChange the flow directionControl ConingFluid removalDrilling compositionMicrofine cementSaline water

The invention provides an inorganic solidifying system for controlling bottom water coning in a fracture-cavity karst reservoir, and an injection method of the inorganic solidifying system. The inorganic solidifying system comprises ultrafine cement, a density modifying agent, a reinforcing agent, a suspension dispersing agent, a frame bridging agent, a drag reducer, and a retarder. The density of the inorganic solidifying system is 1.06 to 1.09 g / m<3>. The initial setting time of the system under a temperature of 130 DEG C is 5 to 10 hours. The compressive strength of the system is 1.0 to 4.0 Mpa. The injection method is that: first, an inorganic solidification system with a relatively large density is prepared and is injected into a stratum, then an inorganic solidifying system with a relatively small density is prepared and is injected into the stratum, and finally a displacing liquid is injected into the stratum. Because the density of the inorganic solidifying system is between the density of oil in the oil reservoir and the density of salt water in the stratum, the inorganic solidifying system is positioned below the oil reservoir and above the salt water reservoir in the stratum. Therefore, the inorganic solidifying system can be solidified to form a separator near the separating surface between oil and water. Thus, the winding direction of the bottom water is efficiently changed, the bottom water coning is controlled, the oil flooding efficiency of the bottom water is improved, and the fracture-cavity karst reservoir exploitation effect is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com