Waterborne polyurethane-epoxy interpenetrating network superfine cement compound grouting material, preparation method thereof and application of grouting material

A technology of waterborne polyurethane and interpenetrating network, which is applied in the field of waterborne polyurethane-epoxy interpenetrating network ultrafine cement composite grouting material and its preparation, can solve the problem of low compressive strength and bonding strength of waterborne epoxy resin and cement-based grouting materials. Poor permeability of grouting materials, high toxicity of solvent-based epoxy resin, etc., to achieve the effect of increasing environmental protection, storage stability and water resistance, and increasing storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

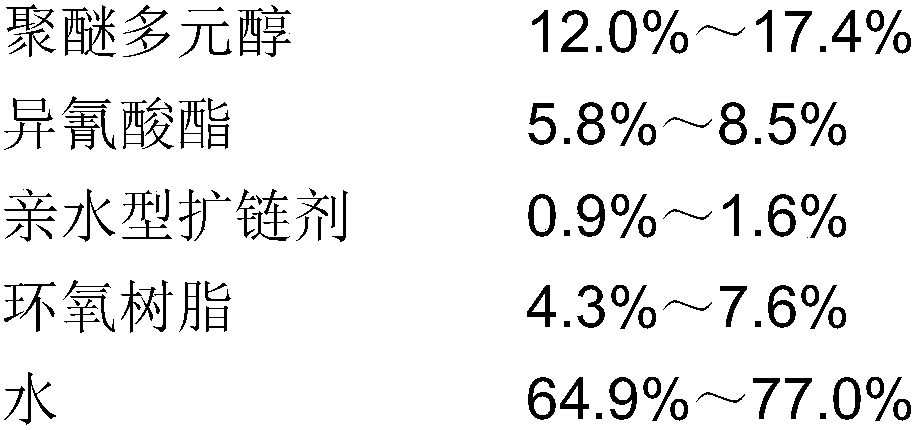

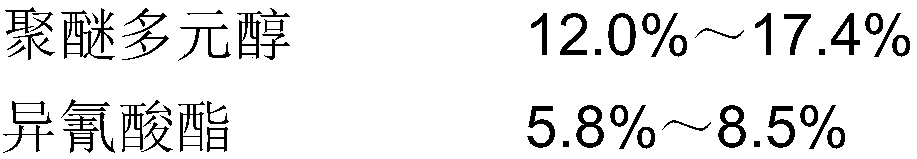

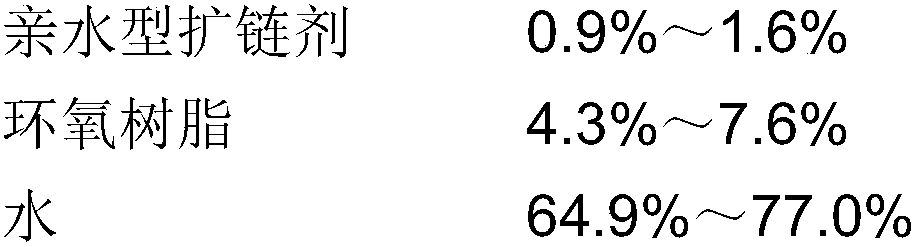

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of A component

[0032] In a closed reactor, add 90.0 g of polyether diol (GE-210), dehydrate for 2 hours at a temperature of 105 °C and a vacuum of -0.080 MPa, cool down to 50 °C, add 2,6-toluene di Isocyanate (TDI) 43.9g, heat up to 85°C, add catalyst dibutyltin dilaurate (DBTDL) 0.1g, react for 3h, then add 6.7g of dihydroxymethylpropionic acid at 80°C, react for 3h, gradually add polymerization To obtain a hydrophilic polyurethane prepolymer, cool down to 75°C, add 32.1g of unopened epoxy resin (E-51), and react for 4h to obtain a polyurethane-epoxy resin interpenetrating network polymer; continue to cool down to 50°C , add ring opener diethanolamine 8.6g, stir and react for 8h. After that, continue to cool down to 30°C, add 5.1g of triethylamine for neutralization reaction for 30min, add an appropriate amount of deionized water 345.4g under high-speed stirring, and obtain 520.0g of component A after shearing and dispersing for 45min.

[0033] (2) ...

Embodiment 2

[0037] (1) Preparation of A component

[0038] In a closed reactor, add 90.0g of polyether diol (GE-210), dehydrate at a temperature of 110°C and a vacuum of -0.083MPa for 2.5h, cool down to 52°C, and add 2,6-toluene Diisocyanate (TDI) 47.0g, heat up to 80°C, add catalyst dibutyltin dilaurate (DBTDL) 0.2g, react for 3.5h, then at 75°C, add 7.0g of dihydroxymethylpropionic acid, react for 3.5h, gradually Addition polymerization to obtain a hydrophilic polyurethane prepolymer, lower the temperature to 70 ° C, add 35.1 g of unopened epoxy resin (E-51), and react for 4.5 hours to obtain a polyurethane-epoxy resin interpenetrating network polymer; continue The temperature was lowered to 55°C, 9.4 g of a ring-opening agent diethanolamine was added, and the reaction was stirred for 8.5 hours. After that, continue to cool down to 35°C, add 5.3g of triethylamine to neutralize the reaction for 40 minutes, add an appropriate amount of deionized water 537.3g under high-speed stirring, an...

Embodiment 3

[0043] (1) Preparation of A component

[0044] In a closed reactor, add 90.0 g of polyether diol (GE-210), dehydrate for 3 hours at a temperature of 115 °C and a vacuum of -0.086 MPa, cool down to 55 °C, add 2,6-toluene di Isocyanate (TDI) 50.2g, heat up to 85°C, add catalyst dibutyltin dilaurate (DBTDL) 0.3g, react for 4h, then add 8.4g of dihydroxymethylpropionic acid at 75°C, react for 4h, gradually add polymerization To obtain a hydrophilic polyurethane prepolymer, cool down to 70°C, add 39.2g of unopened epoxy resin (E-51), and react for 5h to obtain a polyurethane-epoxy resin interpenetrating network polymer; continue to cool down to 50°C , Add ring opener diethanolamine 10.5g, stir and react for 9h. Afterwards, continue to lower the temperature to 40°C, add 6.4g of triethylamine for neutralization reaction for 45min, add an appropriate amount of deionized water 563.4g under high-speed stirring, and obtain 760.0g of component A after shearing and dispersing for 60min. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com