Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

16660 results about "Prepolymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The term pre-polymer refers to a monomer or system of monomers that have been reacted to an intermediate molecular mass state. This material is capable of further polymerization by reactive groups to a fully cured high molecular weight state. As such, mixtures of reactive polymers with un-reacted monomers may also be referred to as pre-polymers. The term “pre-polymer” and “polymer precursor” may be interchanged.

Fast curing compositions

Fast curing surgical adhesives and sealants contain an NCO-terminated hydrophilic urethane prepolymer derived from an aromatic diisocyanate and a polyol. Substantially all the aromatic diisocyanate used to prepare the NCO-terminated hydrophilic urethane prepolymer is in the para form. Optionally, the aromatic diisocyanate is substituted with at least one electron withdrawing group, such as, for example, a fluorine group.

Owner:TYCO HEALTHCARE GRP LP

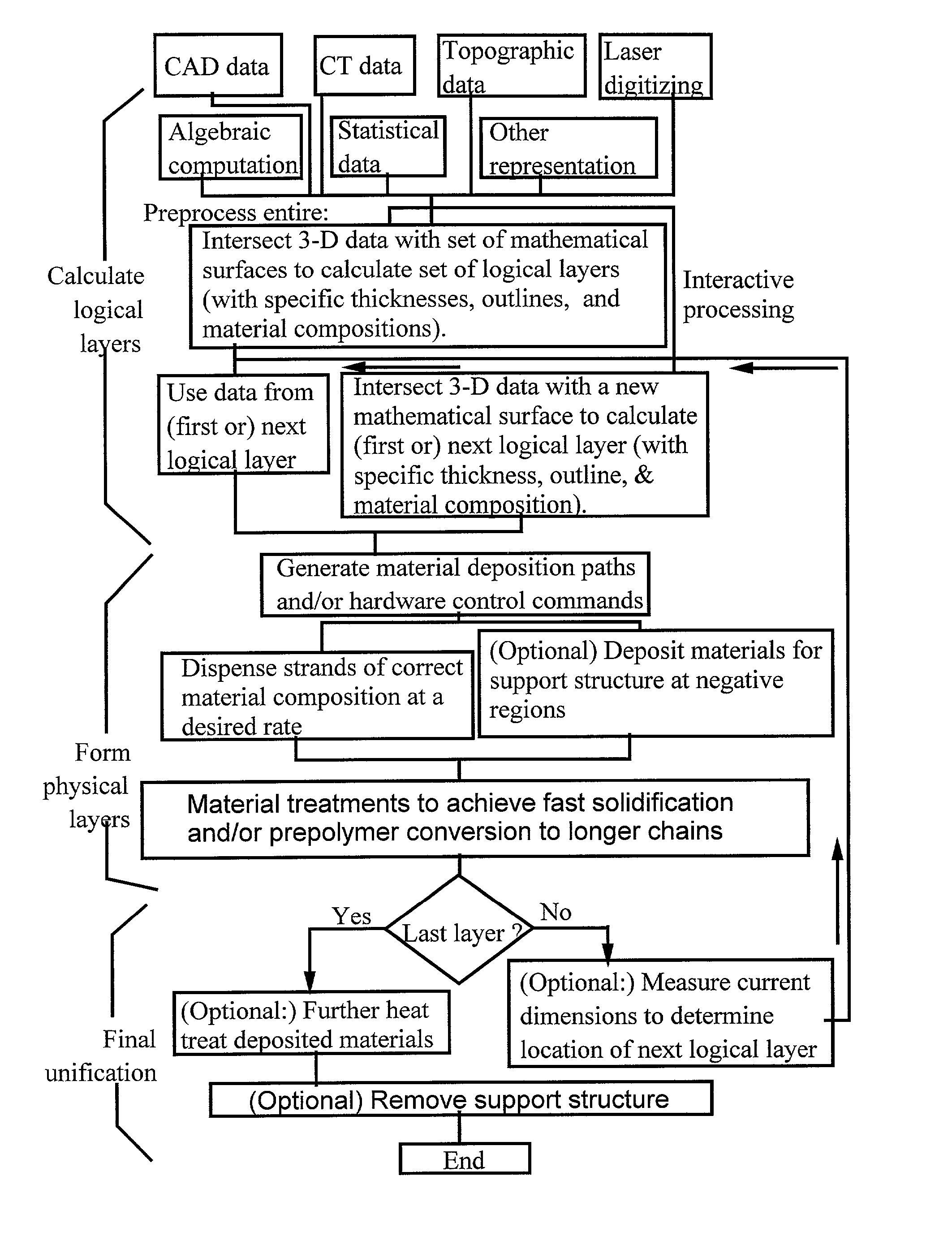

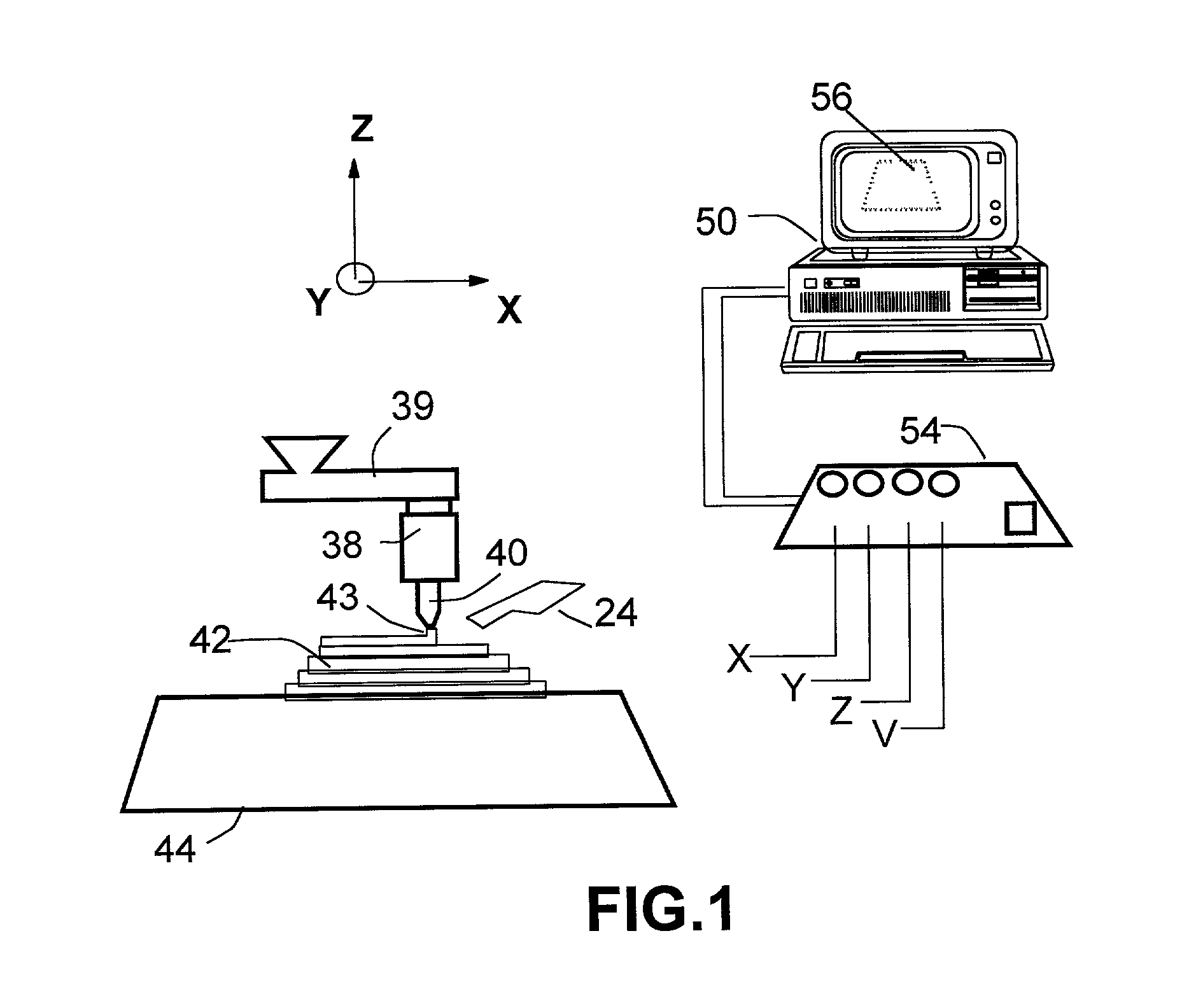

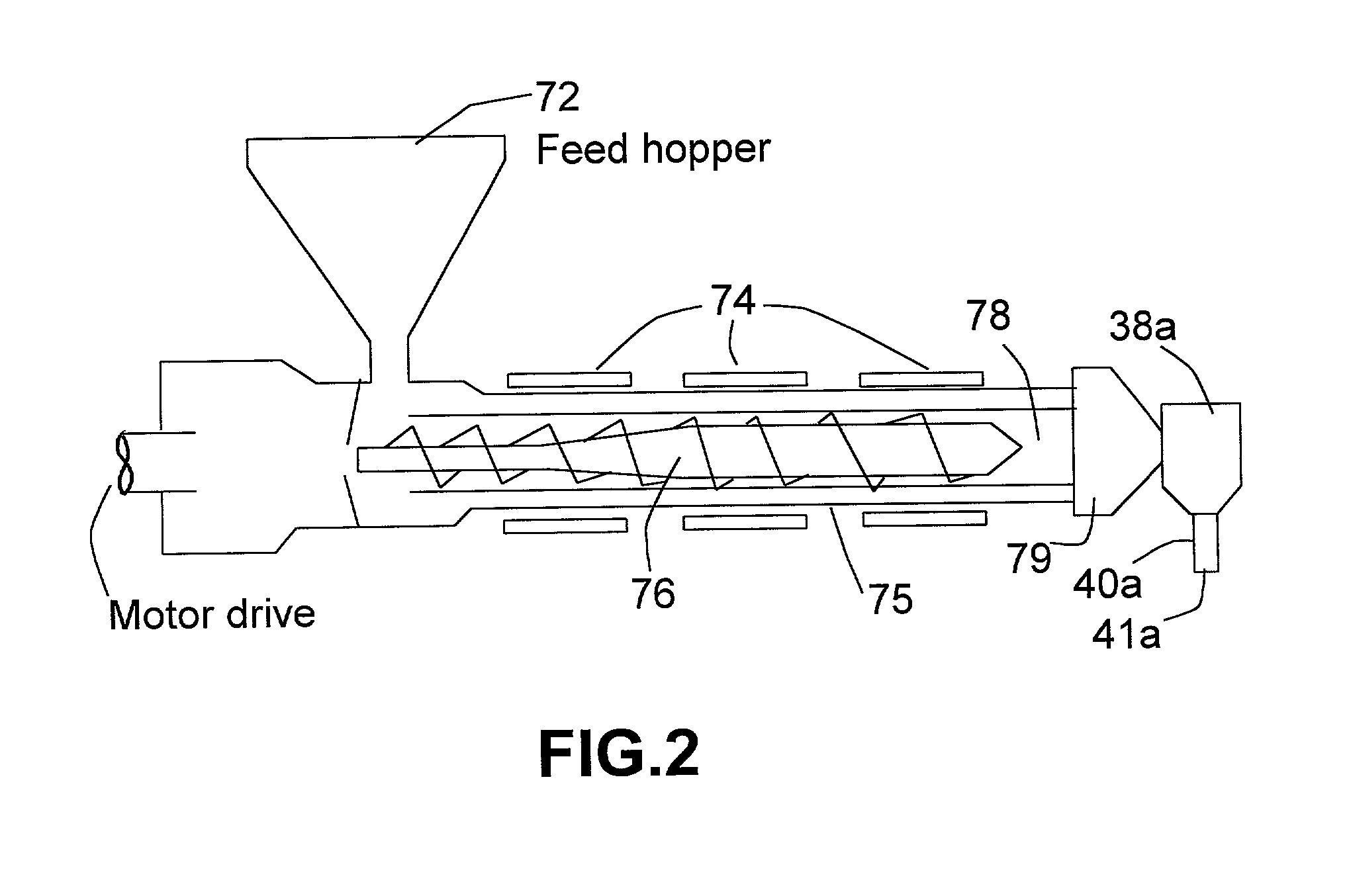

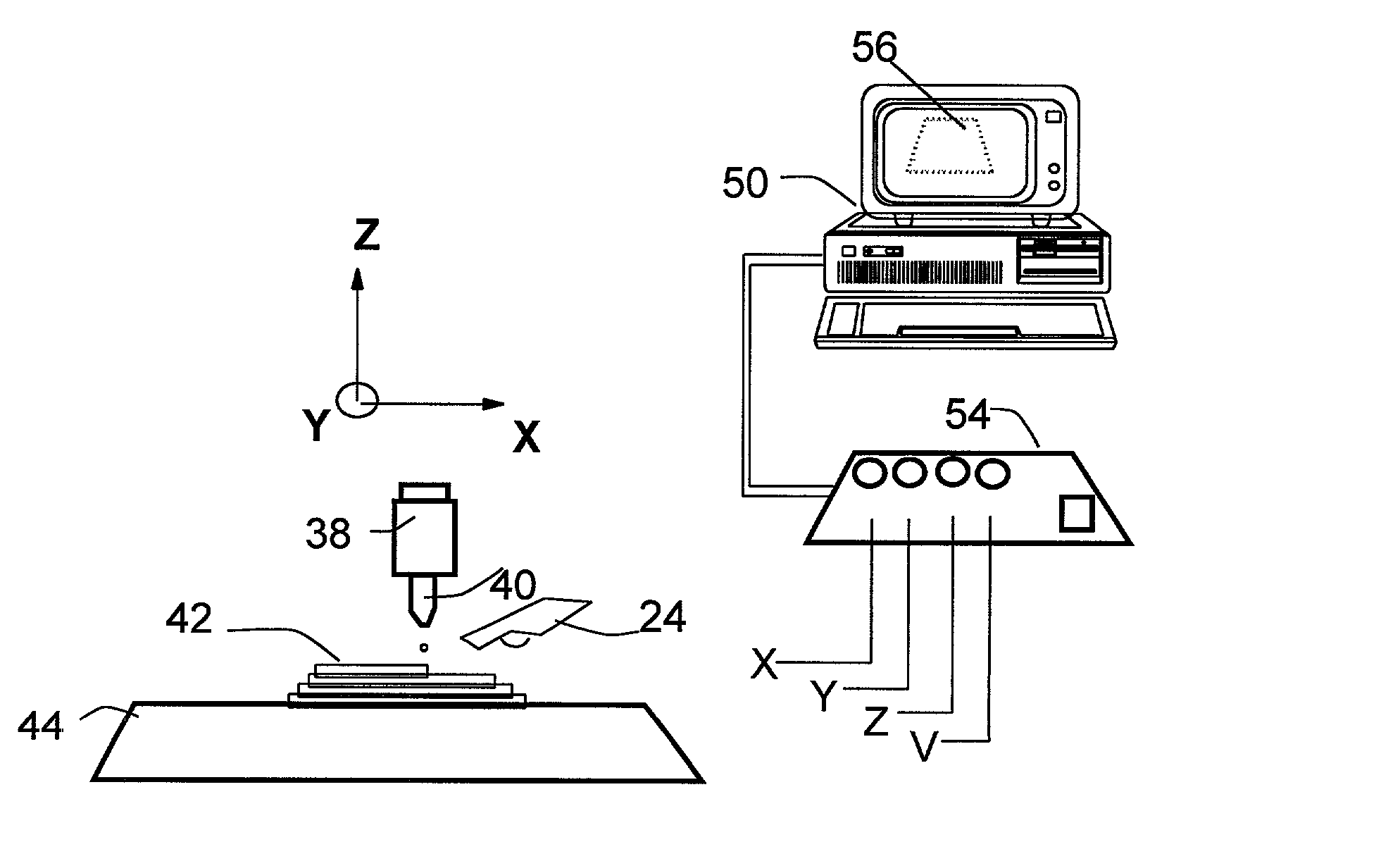

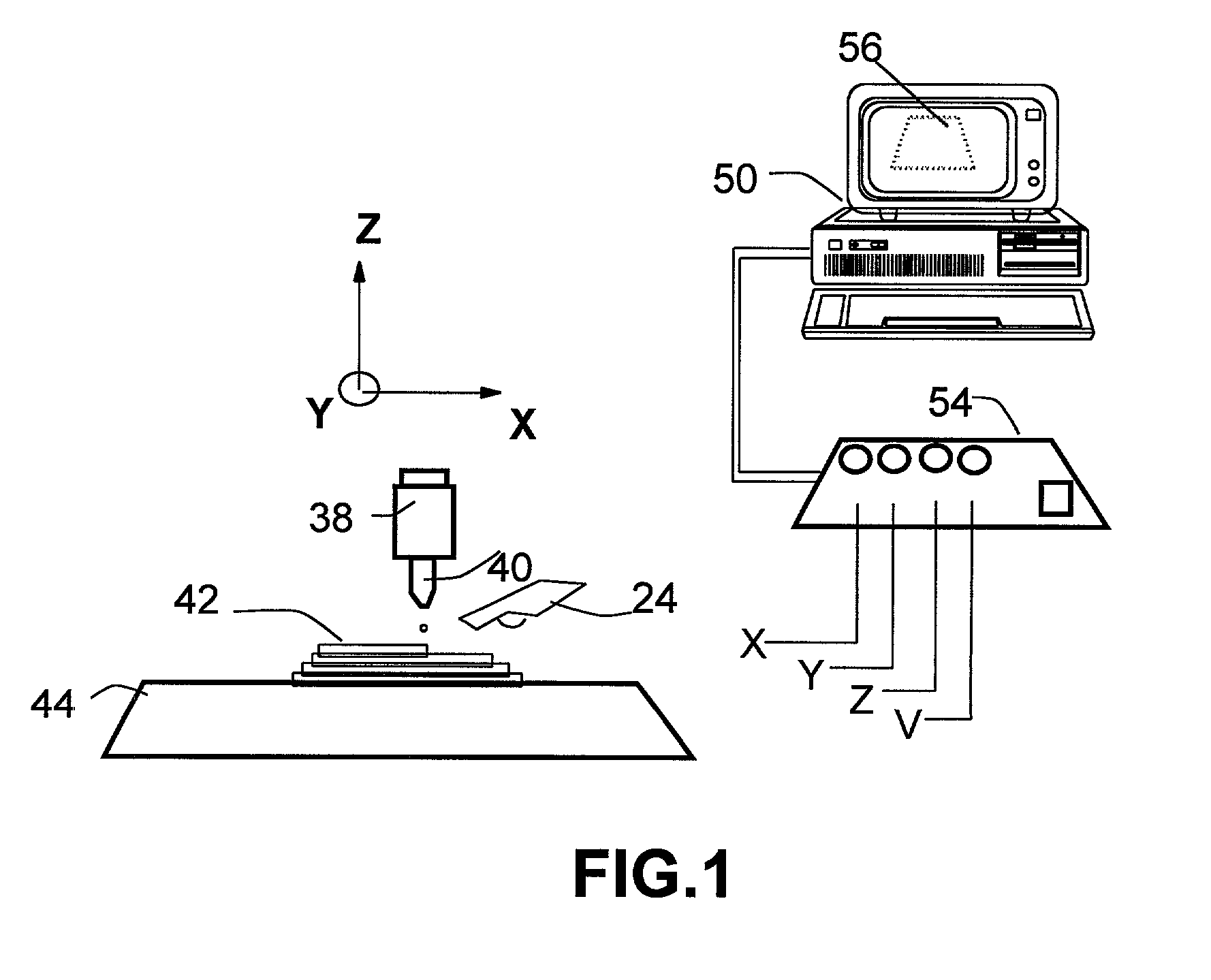

Freeform fabrication method using extrusion of non-cross-linking reactive prepolymers

InactiveUS20020113331A1Fast formingDifficult to prepareProgramme controlComputer controlCross-linkThermoplastic

An extrusion-based freeform fabrication method for making a three-dimensional object from a design created on a computer, including (a) providing a support member; (b) operating a dispensing head having at least one dispensing nozzle with a discharge orifice for dispensing continuous strands of a material composition in a fluent state at a first temperature onto the support member, the material composition including a reactive prepolymer with a melting point above 23° C. and the first temperature being greater than the prepolymer melting point; (c) operating material treatment devices for causing the dispensed strands of material composition to rapidly achieve a rigid state in which the material composition is substantially solidified to build up the 3-D object, the material treatment devices also working to convert the reactive prepolymer to a higher molecular weight thermoplastic resin; and (d) operating control devices for generating control signals in response to coordinates of the object design to control the movement of the dispensing nozzle relative to the support member and for controlling the strand dispensing of the material composition to construct the 3-D object.

Owner:ZHANG TAN +3

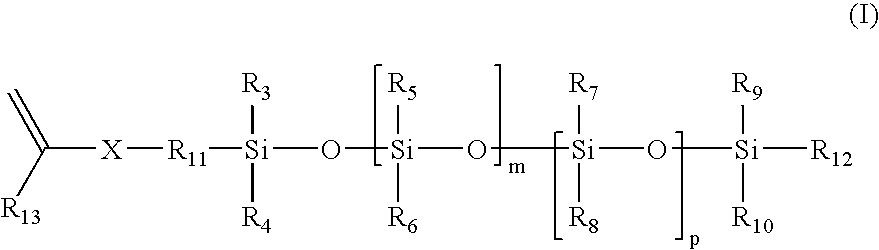

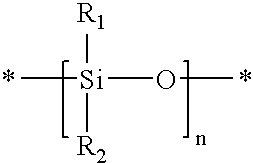

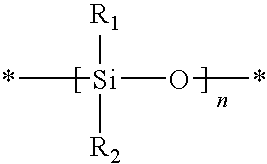

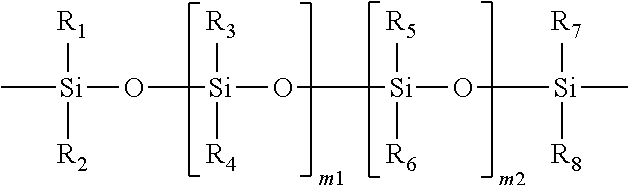

Prepolymers with dangling polysiloxane-containing polymer chains

The invention provide a new class of silicone-containing prepolymers containing dangling polysiloxane-containing polymer chains. This class of silicone-containing prepolymer is capable of being actinically crosslinked to form a silicone hydrogel material with a relatively high oxygen permeability, a reduced elastic modulus, and a relatively high ion permeability. The present invention is also related to silicone hydrogel contact lenses made from this class of silicone-containing prepolymers and to methods for making the silicone hydrogel contact lenses.

Owner:ALCON INC

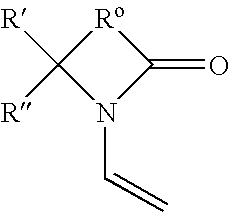

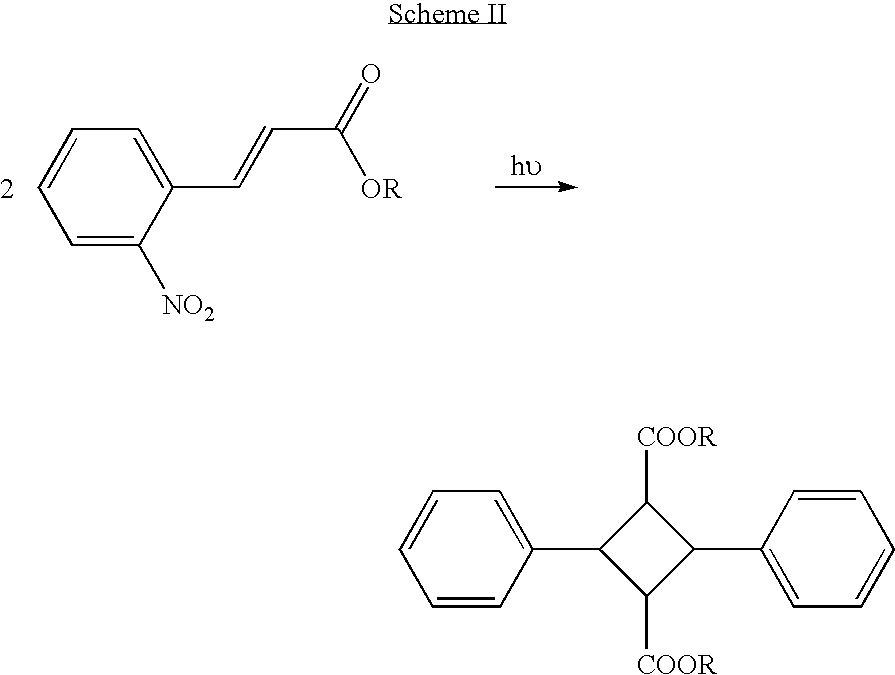

Production of ophthalmic devices based on photo-induced step growth polymerization

The invention provide a new lens curing method for making hydrogel contact lenses. The new lens curing method is based on actinically-induced step-growth polymerization. The invention also provides hydrogel contact lenses prepared from the method of the invention and fluid compositions for making hydrogel contact lenses based on the new lens curing method. In addition, the invention provide prepolymers capable of undergoing actinically-induced step-growth polymerization to form hydrogel contact lenses.

Owner:ALCON INC

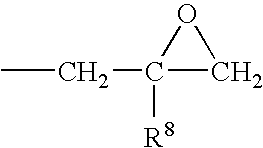

Process for applying a streamable epoxy adhesive

InactiveUS20050070634A1Low viscosityHigh strength bondAdhesive processes with adhesive heatingEpoxy resin adhesivesBENZYL ALCOHOL/WATERViscosity

The invention is a composition comprising applying to a substrate a stream of an adhesive comprising: one or more epoxy resins; one or more rubber modified epoxy resins; one or more toughening compositions comprising the reaction product of one or more isocyanate terminated prepolymers and one or more capping compounds having one or more phenolic, benzyl alcohol, aminophenyl, or, benzylamino groups wherein the reaction product is terminated with the capping compounds; one or more curing agents for epoxy resins and one or more catalysts which initiate cure at a temperature of about 100° C. or greater; and optionally; fillers adhesion promoters, wetting agents or rheological additives useful in epoxy adhesive compositions; wherein the adhesive composition has a viscosity at 45° C. of about 20 Pa.s to about 400 Pa.s. The composition can be used as an adhesive and applied as a stream using a high speed streaming process.

Owner:DOW GLOBAL TECH LLC

Silicone-containing prepolymers with dangling hydrophilic polymer chains

ActiveUS20080234457A1Reduce molecular weightHigh molecular weightOptical articlesProsthesisPolymer scienceHydrophilic polymers

The invention provide a new class of silicone-containing prepolymers containing dangling hydrophilic polymer chains. This class of silicone-containing prepolymer is capable of being actinically crosslinked to form a silicone hydrogel material with a hydrophilic surface without post curing surface treatment. The present invention is also related to silicone hydrogel contact lenses made from this class of silicone-containing prepolymers and to methods for making the silicone hydrogel contact lenses.

Owner:ALCON INC

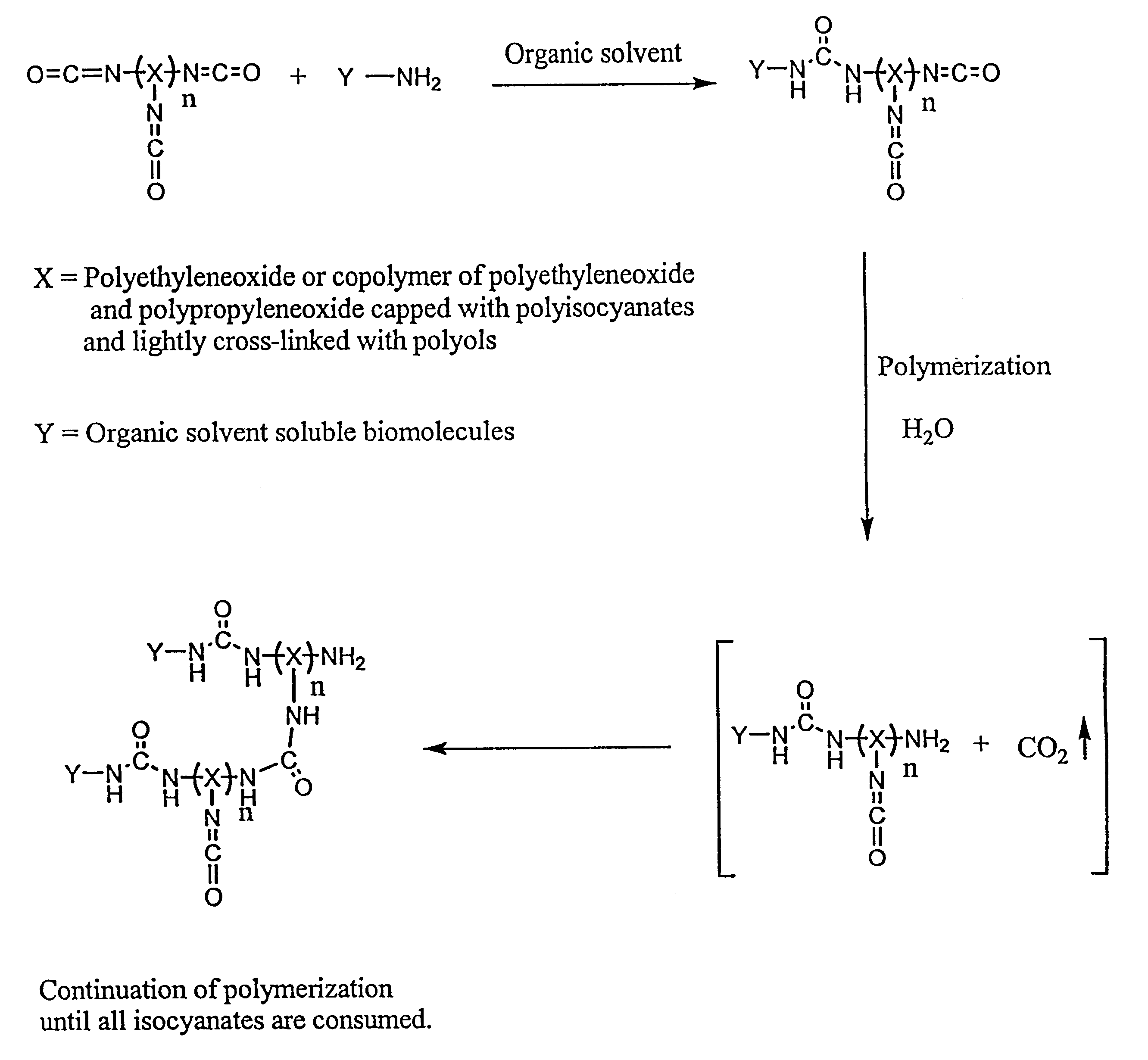

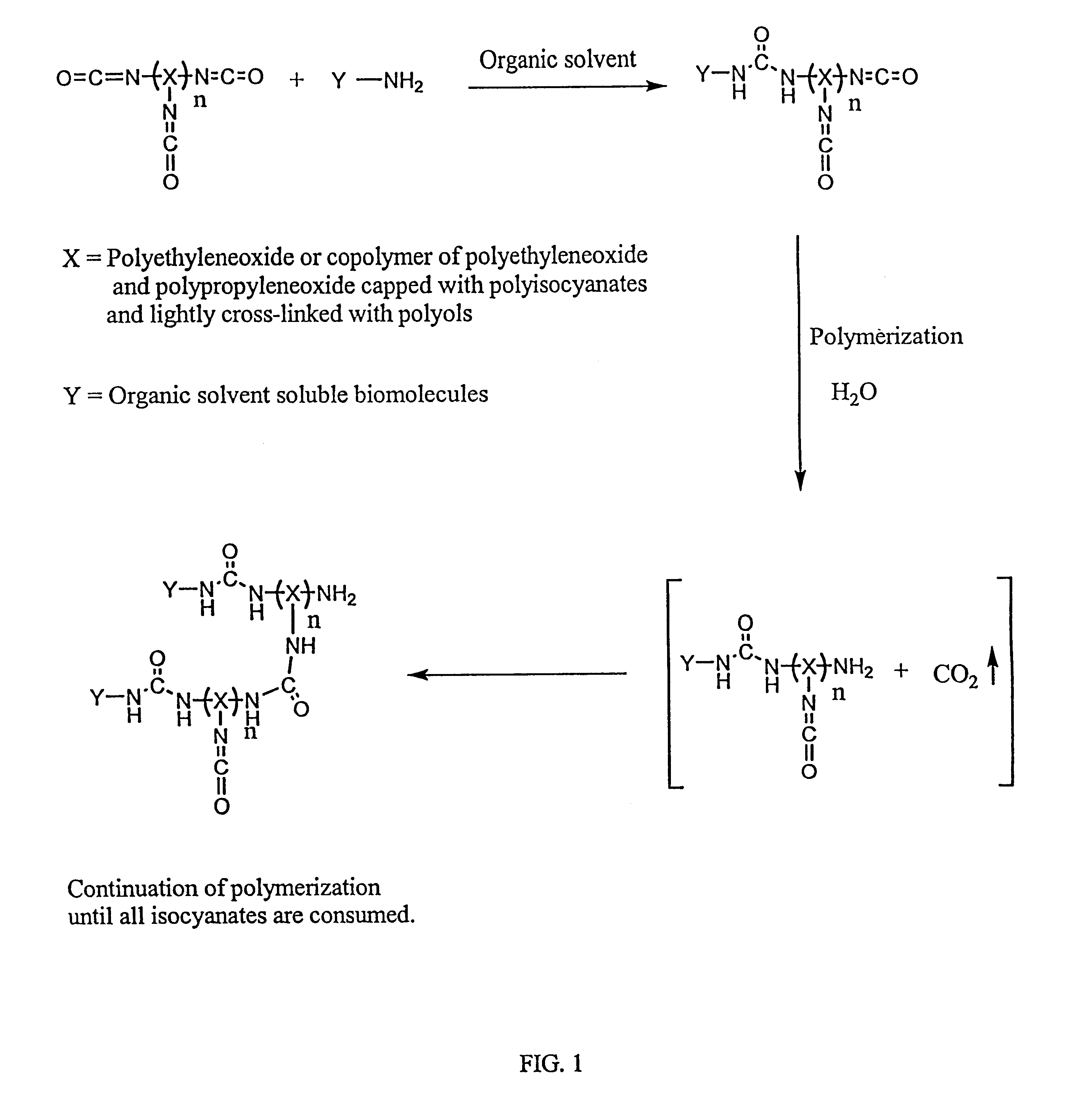

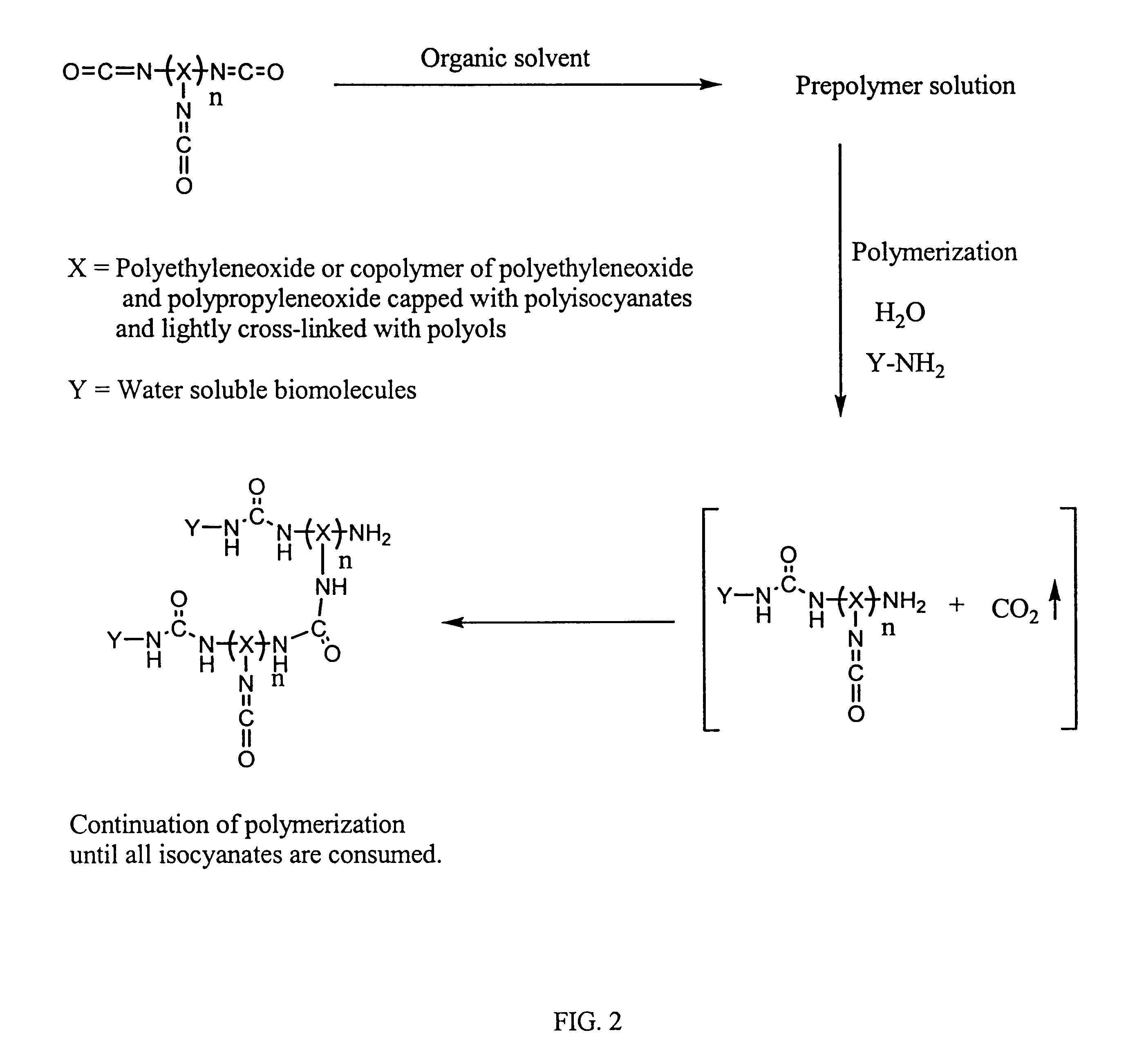

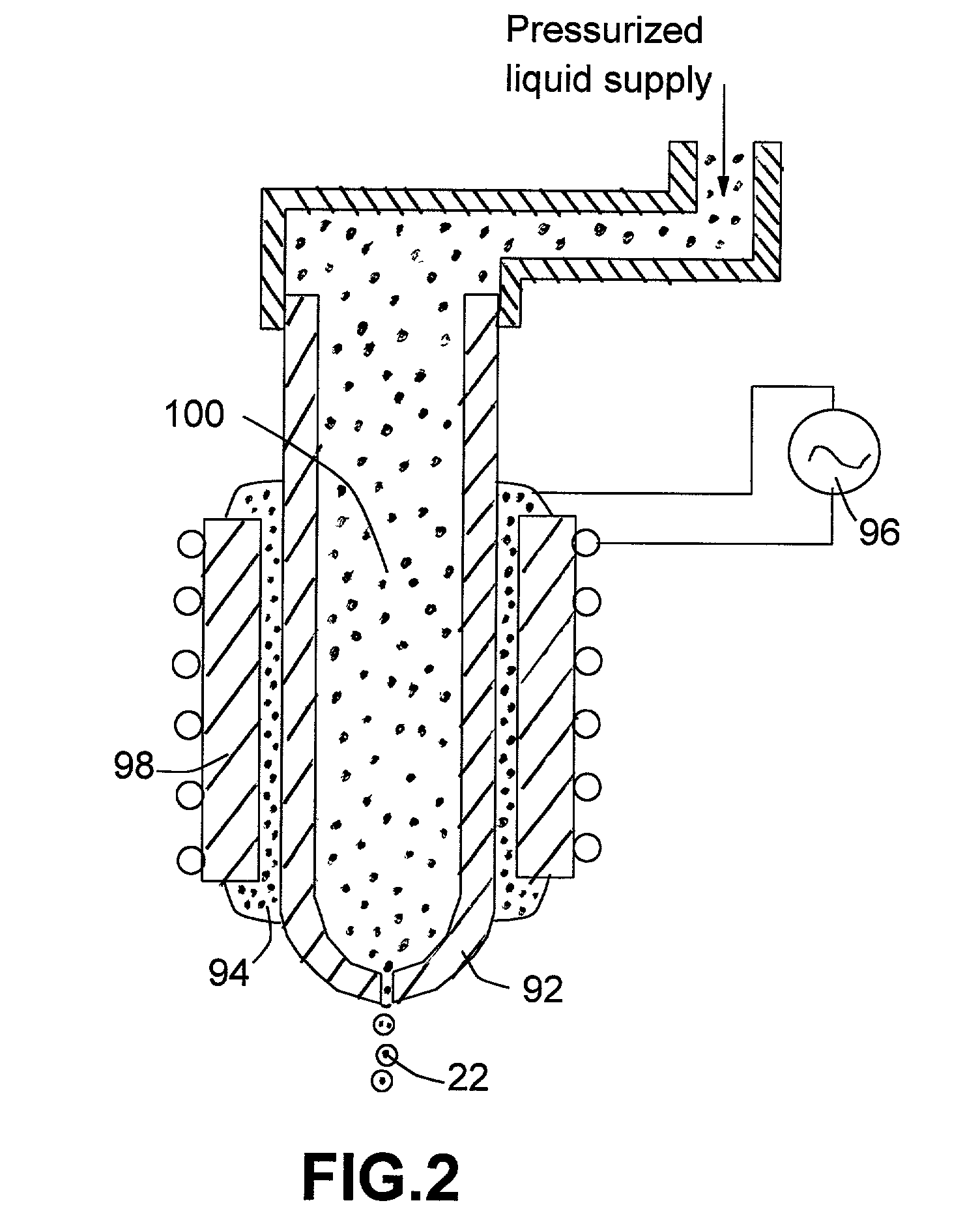

Method of making biochips and the biochips resulting therefrom

InactiveUS6174683B1Rapid and simple and cost-effective methodHigh sensitivityBioreactor/fermenter combinationsBiological substance pretreatmentsSodium bicarbonateSolid substrate

Methods for preparing a biochip are provided herein wherein the biomolecular probe to be used with the biochip is alternatively bound to a hydrogel prepolymer prior to or simultaneously with polymerization of the prepolymer. In particularly preferred embodiments, a polyurethane-based hydrogel prepolymer is derivatized with an organic solvent soluble biomolecule, such as a peptide nucleic acid probe in aprotic, organic solvent. Following derivatization of the prepolymer, an aqueous solution, for example sodium bicarbonate, preferably buffered to a pH of about 7.2 to about 9.5, is added to the derivatized prepolymer solution to initiate polymerization of the hydrogel. Alternatively, a water soluble biomolecule, such as DNA or other oligonucleotide, is prepared in an aqueous solution and added to the polyurethane-based hydrogel prepolymer such that derivatization and polymerization occur, essentially, simultaneously. While the hydrogel is polymerizing, it is microspotted onto a solid substrate, preferably a silanated glass substrate, to which the hydrogel microdroplet becomes covalently bound. Most preferably the hydrogel microdroplets are at least about 30 mum thick, for example about 50 mum to about 100 mum thick. The resulting biochips are particularly useful for gene discovery, gene characterization, functional gene analysis and related studies.

Owner:BIOCEPT INC

Process for preparing a polymer having a 2,5-furandicarboxylate moiety within the polymer backbone and such (CO)polymers

A process for preparing a polymer having a 2,5-furandicarboxylate moiety within the polymer backbone and having a number average molecular weight of at least 10,000 (as determined by GPC based on polystyrene standards) includes a first step where a prepolymer is made having the 2,5-furandicarboxylate moiety within the polymer backbone, followed in a second step by a polycondensation reaction. In the first step a 2,5-furandicarboxylate ester is transesterified with a compound or mixture of compounds containing two or more hydroxyl groups, in the presence of a tin(IV) based transesterification catalyst. In the second step at reduced pressure and under melt conditions the prepolymer prepared in the first step is polycondensed in the presence of a tin (II) based polycondensation catalyst until the polymer is obtained. This polymer may then be subjected to Solid State Polycondensation. Polymers so produced may have a 2,5-furandicarboxylate moiety within the polymer backbone, and having a number average molecular weight of at least 20,000 (as determined by GPC based on styrene standards), and an absorbance as a 5 mg / mL solution in a dichloromethane:hexafluoroisopropanol 8:2 at 400 nm of below 0.05.

Owner:FURANIX TECH BV

Production of polytrimethylene ether glycol and copolymers thereof

A process for the manufacture of polytrimethylene ether glycol comprising the steps of: (a) providing (1) 1,3-propanediol reactant selected from the group consisting of 1,3-propanediol and / or oligomers or prepolymers of 1,3-propanediol having a degree of polymerization of 2-9 and mixtures thereof, and (2) a polycondensation catalyst; and (b) polycondensing the 1,3-propanediol reactant to form a polytrimethylene ether glycol at less than one atmosphere pressure, and the product of the process. In addition, polytrimethylene ether glycol has a number average molecular weight greater than 1,500, an APHA color of less than 120, an unsaturation of less than 20 meq / kg, and a content of cyclic ether oligomers of less than 2%.

Owner:DUPONT IND BIOSCIENCES USA LLC

Droplet deposition method for rapid formation of 3-D objects from non-cross-linking reactive polymers

InactiveUS20020111707A13D object support structuresSpecial data processing applicationsThermoplasticControl signal

A droplet deposition-based freeform fabrication method for making a three-dimensional object from a design created on a computer, including (a) providing a support member; (b) operating a droplet dispensing head for dispensing droplets of a material composition in a fluent state at a first temperature onto the support member, the material composition including a reactive prepolymer with a melting point above 23° C. and the first temperature being greater than the prepolymer melting point; (c) operating material treatment devices for causing the material composition to rapidly achieve a rigid state in which the material composition is substantially solidified to build up the 3-D object, the material treatment devices also working to convert the reactive prepolymer to a higher molecular weight thermoplastic resin; and (d) operating control devices for generating control signals in response to coordinates of the object design to control the movement of the dispensing head relative to the support member and for controlling the droplet dispensing of the material composition to construct the 3-D object.

Owner:LI ZHIMIN +3

Toughened epoxy adhesive composition

ActiveUS20060276601A1Improved lap shear and impact peel strengthGood storage stabilityPolyureas/polyurethane adhesivesSynthetic resin layered productsElastomerEnd-group

The invention is an epoxy resin based adhesive composition comprising an epoxy resin and a compound comprising an elastomeric prepolymer residue selected from the group of a polyurethane, a polyurea and a polyurea polyurethane having isocyanate end groups, the isocyanate end groups of said prepolymer residue being capped by a capping compound selected from the group consisting of a primary aliphatic, cycloaliphatic, heteroaromatic and araliphatic amine, a secondary aliphatic, cycloaliphatic, aromatic, heteroaromatic and araliphatic amine, a thiol and an alkyl amide, said capping compound being bound to the end of the polymer chain of the elastomeric prepolymer in a manner such that the end to which it is bonded no longer has a reactive group. In addition to the capping compound defined above above, a capping compound selected from the group consisting of a phenol and a polyphenol can be used for capping the isocyanate end groups of the prepolymer residue

Owner:DOW GLOBAL TECH LLC

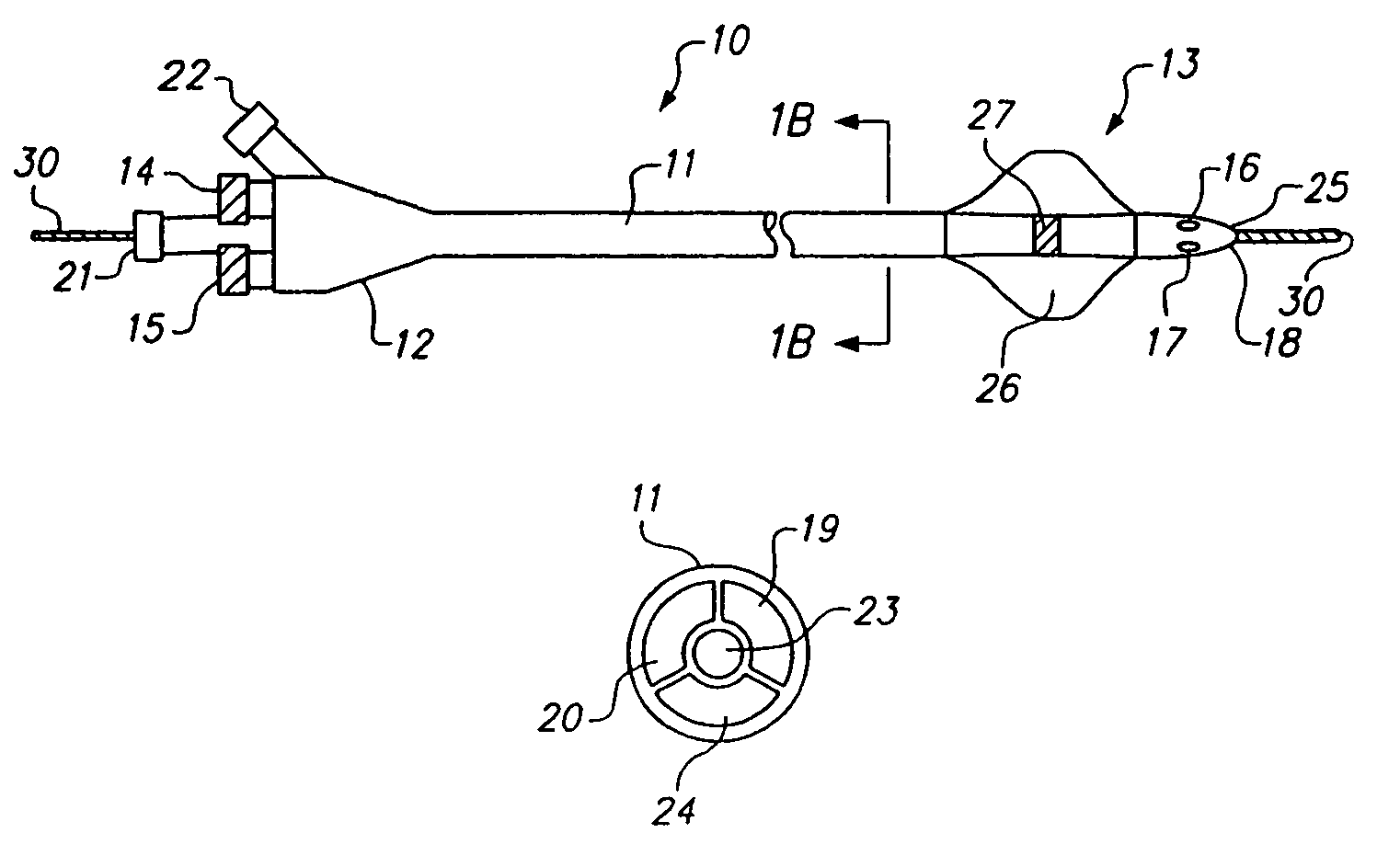

Methods and apparatus for intraluminal deposition of hydrogels

Owner:INCEPT LLC

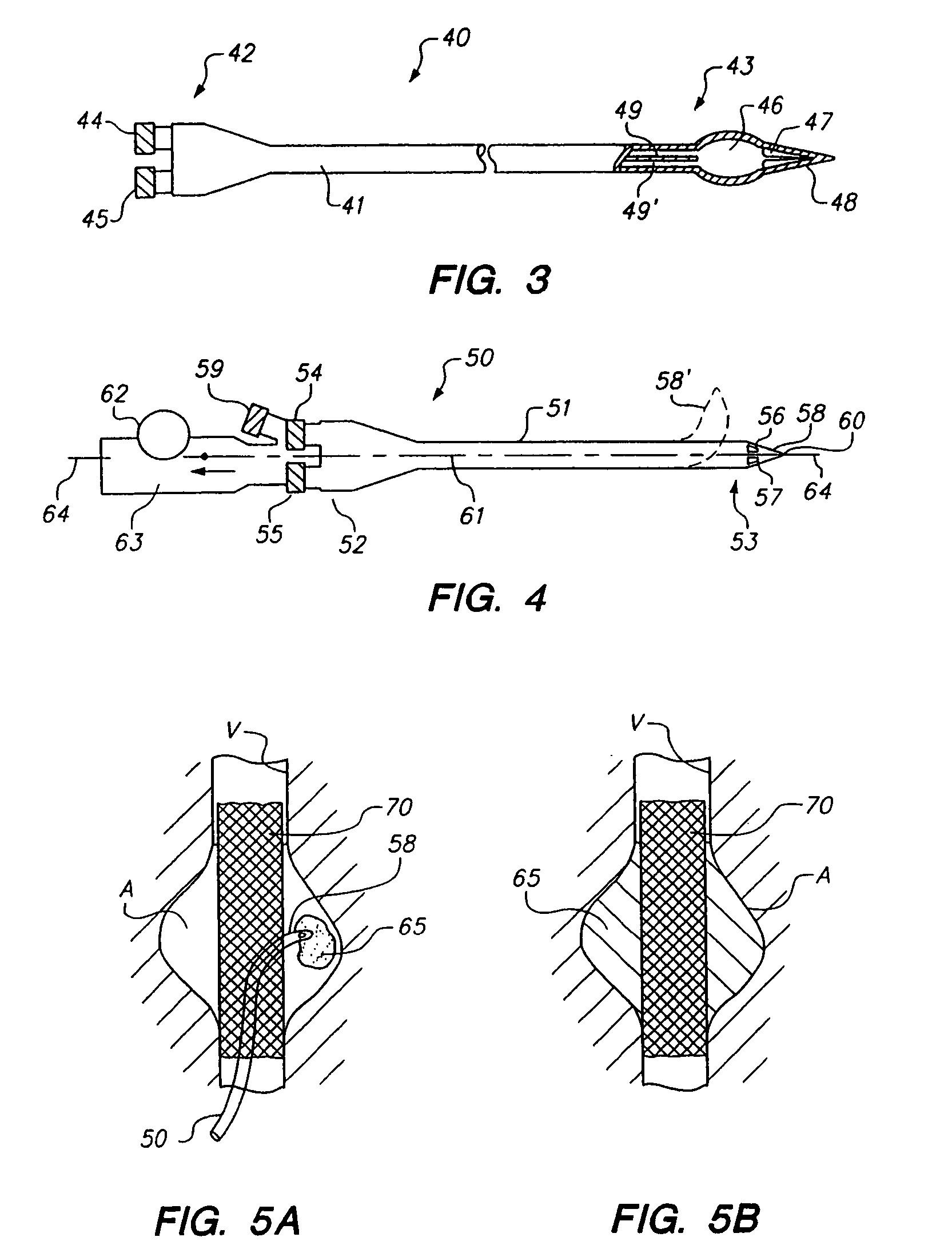

Methods for embolizing blood vessels

InactiveUS6335384B1Reduce molecular weightEasy to adjustHeavy metal active ingredientsOrganic active ingredientsParticulatesMedicine

Disclosed are methods useful for treating vascular lesions wherein a non-particulate agent such as a metal coil is introduced into a vascular site (e.g., an aneurysm cavity) in conjunction with an embolizing composition comprising a biocompatible polymer and a biocompatible solvent.The biocompatible solvent is miscible or soluble in blood and also solubilizes the polymer during delivery. The biocompatible polymer is selected to be soluble in the biocompatible solvent but insoluble in blood. Upon contact with the blood, the biocompatible solvent dissipates from the embolic composition whereupon the biocompatible polymer precipitates. Precipitation of the polymer in the presence of the non-particular agent permits the agent to act as a structural lattice for the growing polymer precipitate.In another embodiment, the biocompatible polymer composition can be replaced with a biocompatible prepolymer composition containing a biocompatible prepolymer.

Owner:MICRO THEREPEUTICS INC

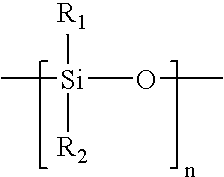

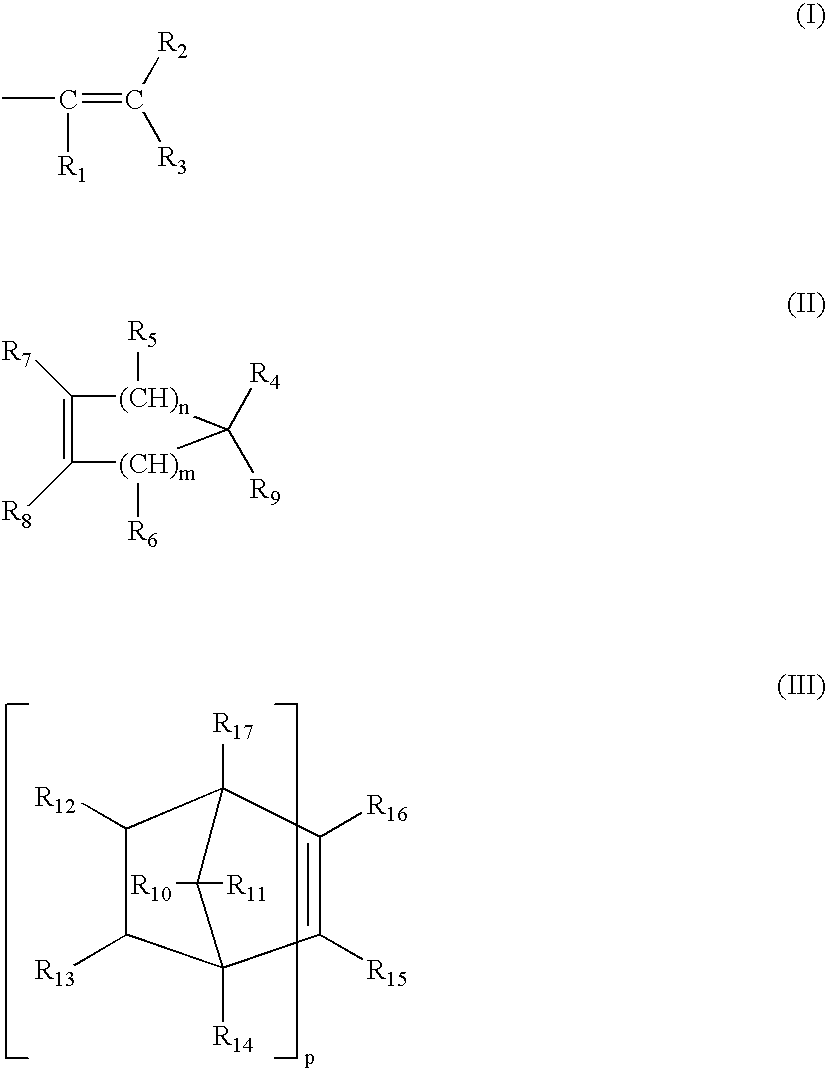

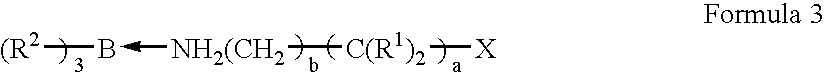

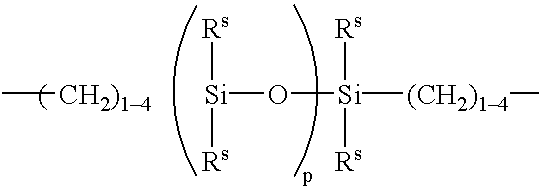

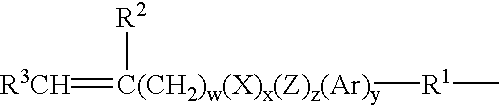

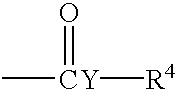

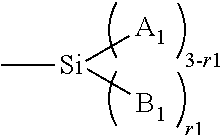

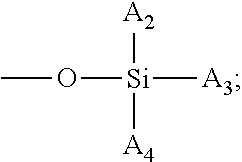

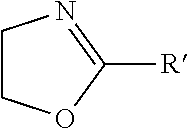

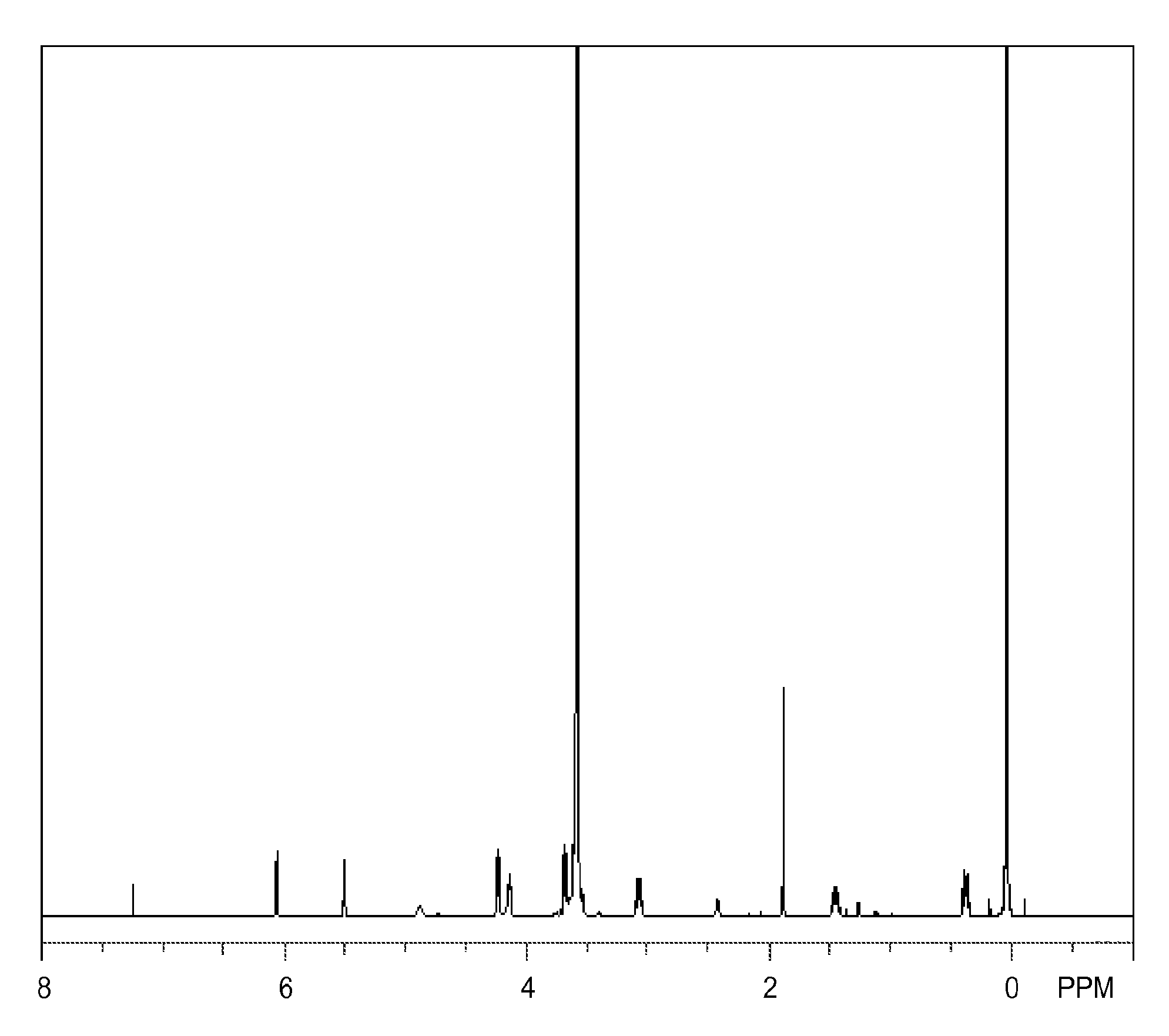

Amine organoborane complex initiated polymerizable compositions containing siloxane polymerizable components

InactiveUS6777512B1Easy to useBroaden applicationOrganic-compounds/hydrides/coordination-complexes catalystsGroup 3/13 element organic compoundsAminosilochromeOligomer

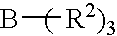

In one embodiment the invention is a polymerizable composition comprising a) an organoborane amine complex; b) one or more of monomers, oligomers or polymers having olefinic unsaturation which is capable of polymerization by free radical polymerization; c) one or more compounds, oligomers or prepolymers having a siloxane backbone and reactive moieties capable of polymerization; and d) a catalyst for the polymerization of the one or more compounds, oligomers or prepolymers having a siloxane backbone and reactive moieties capable of polymerization. This composition may further comprise a compound which causes the organoborane amine complex to disassociate. In a preferred embodiment, the two part composition further comprises a compound which is reactive with both the b) one or more of monomers, oligomers or polymers having olefinic unsaturation which is capable of polymerization by free radical polymerization; and the c) one or more compounds, oligomers or prepolymers having a siloxane backbone and reactive moieties capable of polymerization. This composition can be polymerized by contacting the two parts of the composition. In another embodiment the invention is an organoborane amine complex comprising an alkyl borane having ligands which are alkyl, cycloalkyl or both and an amino siloxane.

Owner:DOW GLOBAL TECH LLC

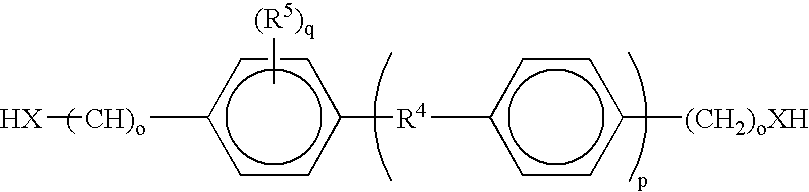

Hydrogel from polysiloxane-containing urethane prepolymer, tris (trimethylsiloxy) silylpropyl methacrylate, and a hydrophilic comonomer

A polyurethane based prepolymer is provided and useful in biomedical devices which provides high oxygen permeability and superior physical properties. A hydrogel is produced from a comonomer mixture containing a polysiloxane-containing urethane prepolymer, tris(trimethylsiloxy)-silylpropyl methacrylate and a hydrophilic comonomer. The hydrogel is especially useful for biomedical materials such as contact lenses and implants.

Owner:BAUSCH & LOMB INC

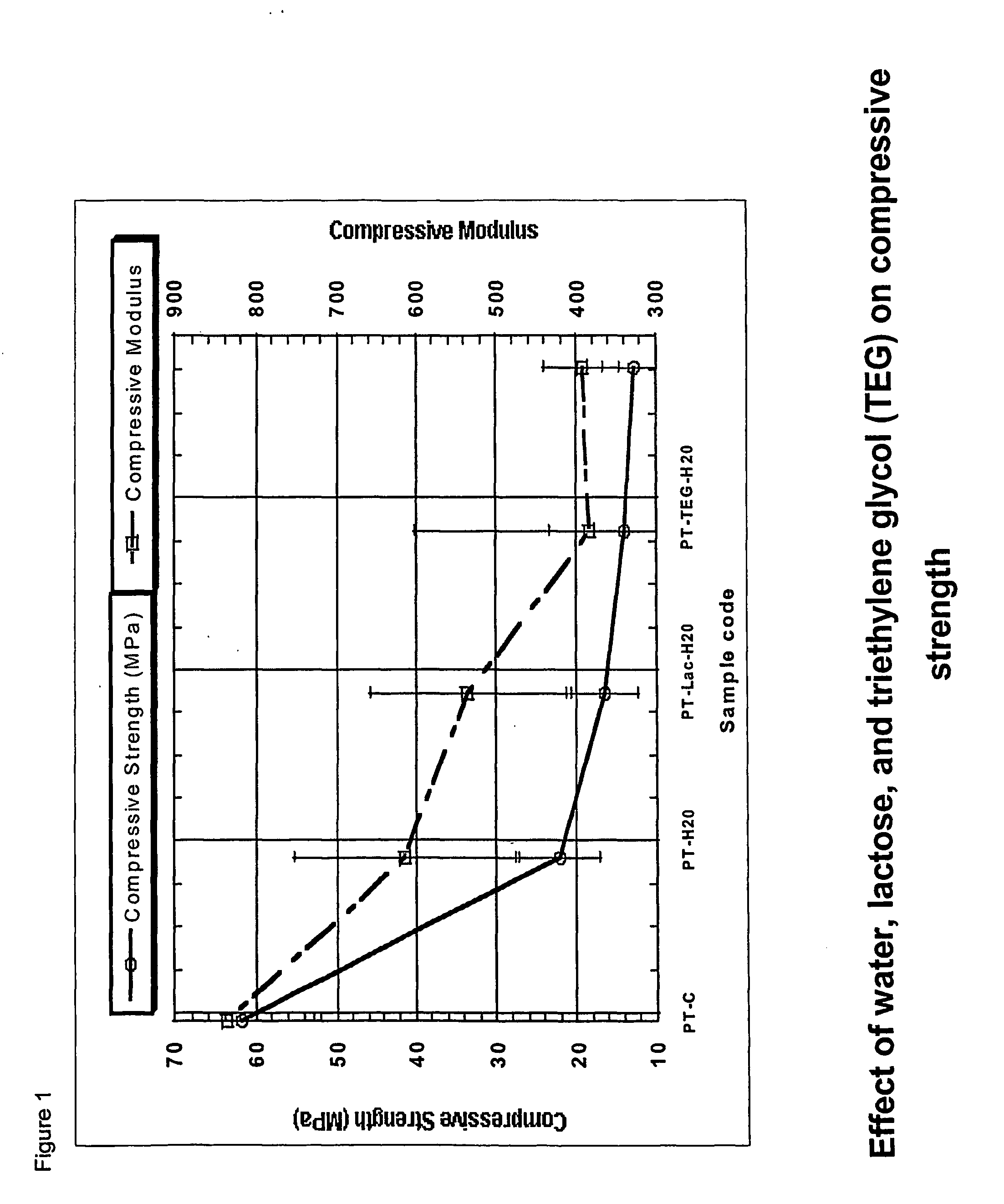

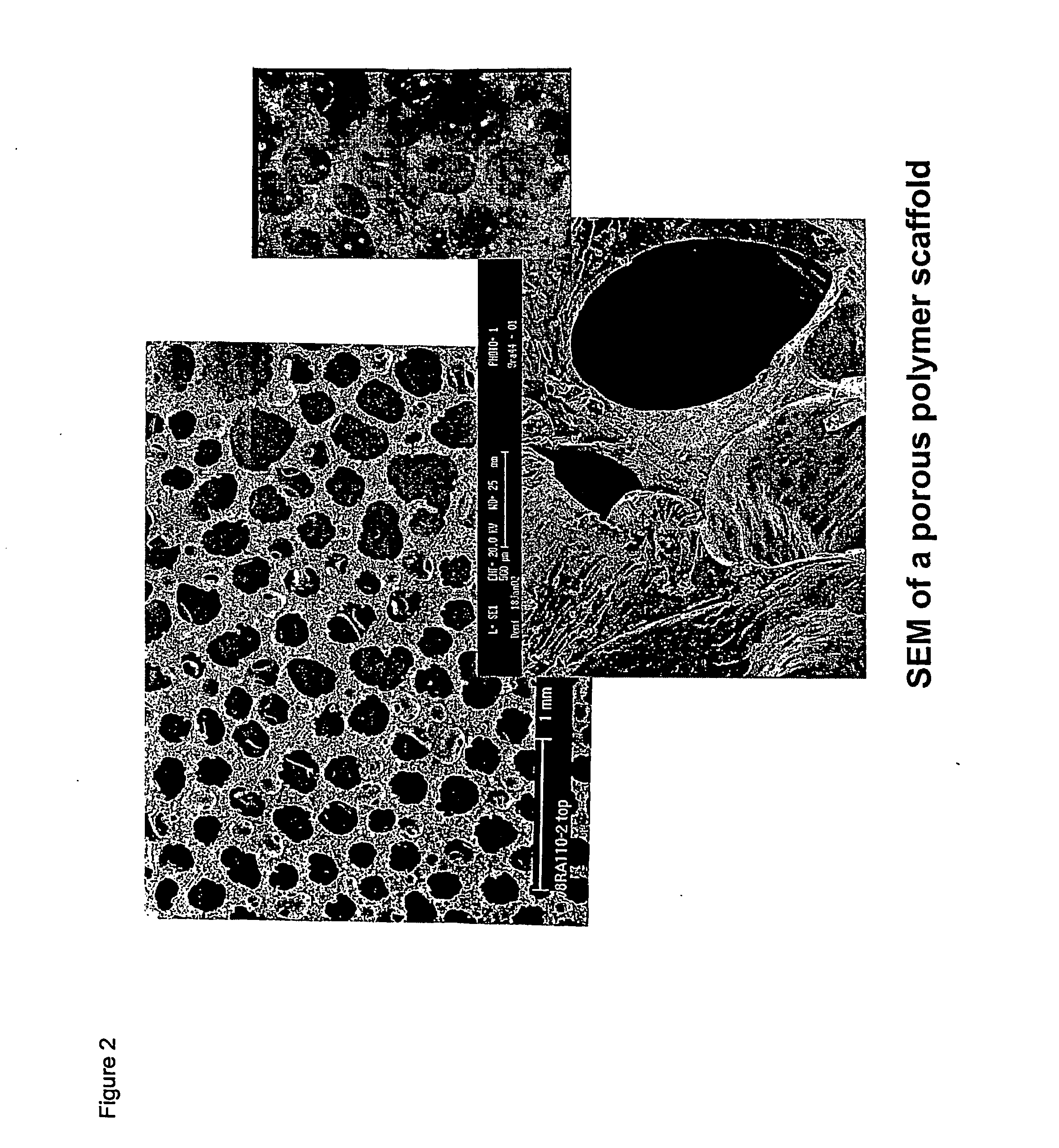

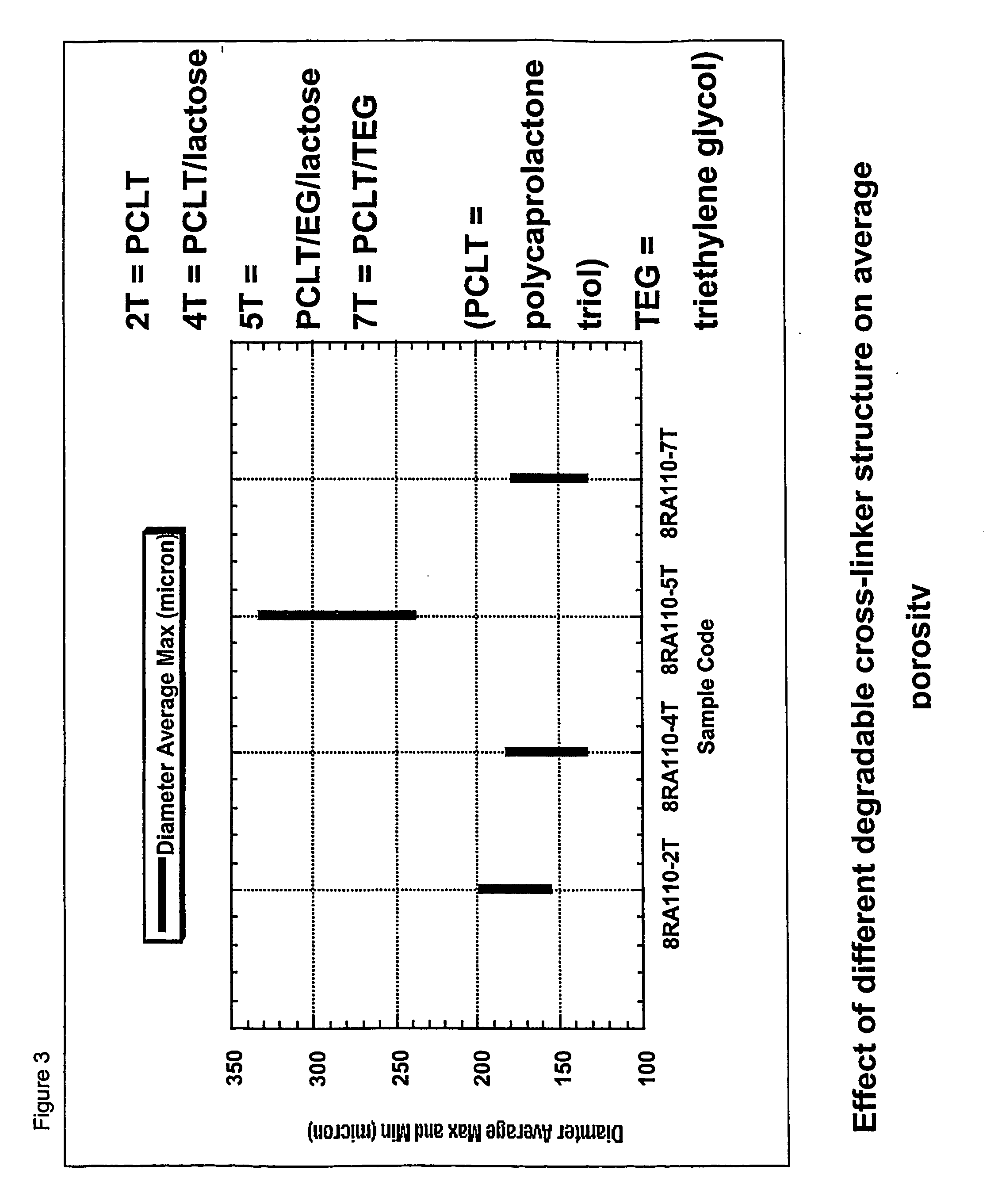

Biodegradable polyurethane/urea compositions

The present invention relates to biocompatible, biodegradable polyurethane / urea polymeric compositions that are capable of in-vivo curing with low heat generation to form materials suitable for use in scaffolds in tissue engineering applications such as bone and cartilage repair. The polymers are desirably flowable and injectable and can support living biological components to aid in the healing process. They may be cured ex-vivo for invasive surgical repair methods, or alternatively utilized for relatively non-invasive surgical repair methods such as by arthroscope. The invention also relates to prepolymers useful in the preparation of the polymeric compositions, and to methods of treatment of damaged tissue using the polymers of the invention.

Owner:POLYNOVO BIOMATERIALS PTY LTD

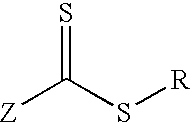

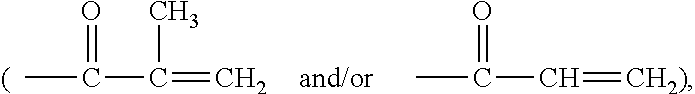

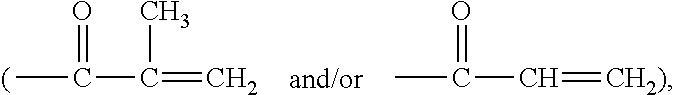

Actinically-crosslinkable siloxane-containing copolymers

The invention provide a class of actinically-crosslinkable silicone-containing prepolymers which comprise dangling polysiloxane chains each having a terminal ethylenically-unsaturated group and are obtained in a one-step of RAFT polymerization of a reactive mixture comprising a polysiloxane crosslinker, a hydrophilic vinylic monomer, a RAFT agent, and a free-radical initiator. The present invention is also related to silicone hydrogel contact lenses made from a prepolymer of the invention and methods for making the contact lenses in a cost-effective way and with high consistency and high fidelity to the original lens design.

Owner:ALCON INC

Production of polytrimethylene ether glycol and copolymers thereof

A process for the manufacture of polytrimethylene ether glycol comprising the steps of: (a) providing (1) 1,3-propanediol reactant selected from the group consisting of 1,3-propanediol and / or oligomers or prepolymers of 1,3-propanediol having a degree of polymerization of 2-9 and mixtures thereof, and (2) a polycondensation catalyst; and (b) polycondensing the 1,3-propanediol reactant to form a polytrimethylene ether glycol at less than one atmosphere pressure, and the product of the process. In addition, polytrimethylene ether glycol has a number average molecular weight greater than 1,500, an APHA color of less than 120, an unsaturation of less than 20 meq / kg, and a content of cyclic ether oligomers of less than 2%.

Owner:DUPONT IND BIOSCIENCES USA LLC

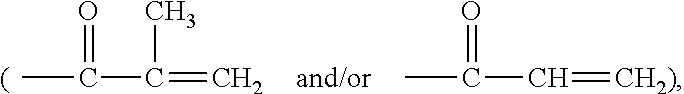

Amphiphilic siloxane-containing (meth)acrylamides and uses thereof

The invention provides an amphiphilic siloxane-containing (meth)acrylamide which comprises one sole (meth)acrylamido group, one sole tris(trimethylsiloxy)silyl group, and one polyethylene glycol segment which is either dangling polymer chain or a hydrophilic linker between the (meth)acrylamido group and the tris(trimethylsiloxy)silyl group. The present invention is also related to a polymer, an actinically-crosslinkable silicone-containing prepolymer, a silicone hydrogel polymeric material, or a silicone hydrogel contact lens, which comprises monomeric units derived from an amphiphilic siloxane-containing (meth)acrylamido group, one tris(trimethylsiloxy)silyl group of the invention. In addition, the invention provides a method for making silicone hydrogel contact lenses using a water-based lens-forming formulation comprising an amphiphilic siloxane-containing (meth)acrylamido group, one tris(trimethylsiloxy)silyl group of the invention and / or an actinically-crosslinkable silicone-containing prepolymer of the invention.

Owner:ALCON INC

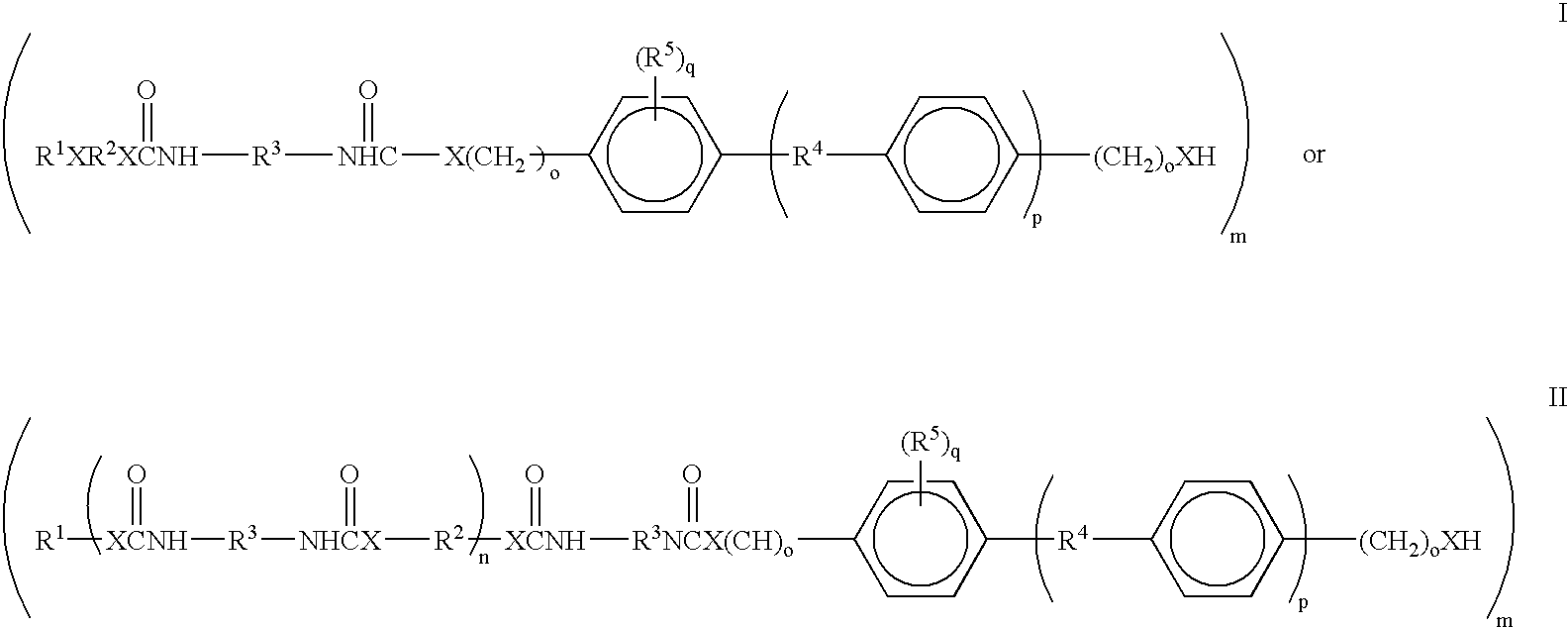

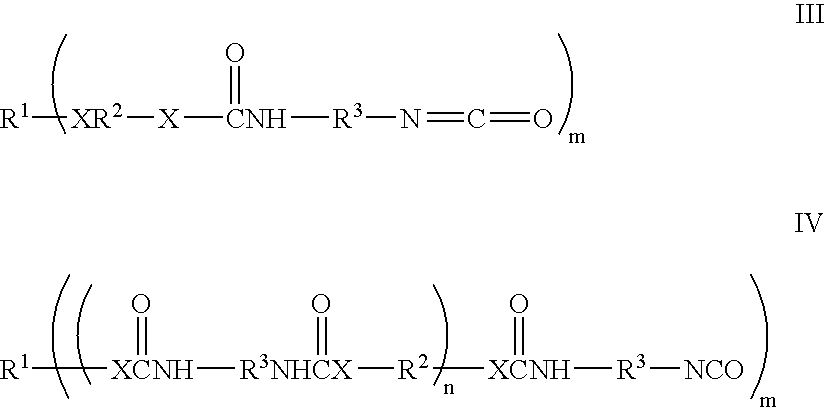

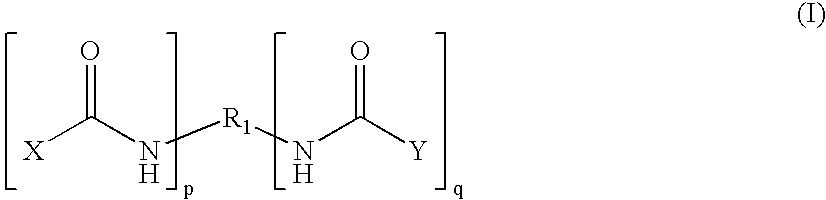

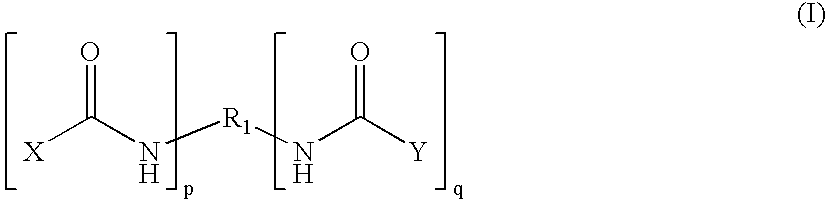

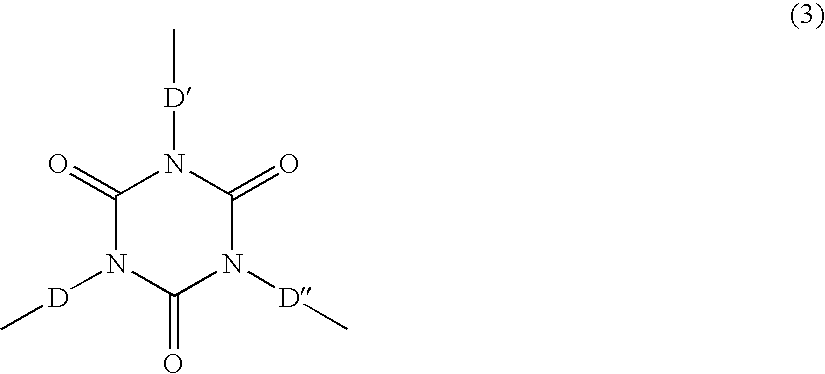

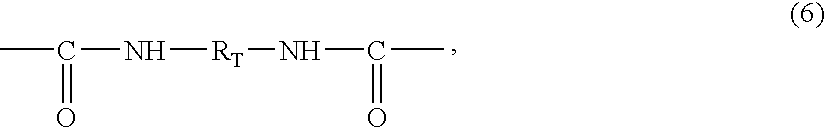

Crosslinkable polyurea prepolymers

The present invention provides a water-soluble crosslinkable polyurea prepolymer. The crosslinkable polyurea prepolymer of the invention is prepared by reacting an amine- or isocyanate-capped polyurea with a multifunctional compound having at least one one ethylenically unsaturated group and a function group coreactive with the capping amine or isocyanate groups of the amine- or isocyanate-capped polyurea. The amine- or isocyanate-capped polyurea is a copolymerization production of: (a) at least one poly(oxyalkylene)diamine, (b) optionally at least one organic di- or poly-amine, (c) optionally at least one diisocyanate, and (d) at least one polyisocyanate. The crosslinkable polyurea prepolymer of the invention can find use in economically producing contact lenses which have durable, highly elastic soft contact lenses with desired physical properties. In addition, the present invention provides method for making a medical device, preferably an ophthalmic device, more preferably a contact lens.

Owner:ALCON INC

Amphiphilic siloxane-containing vinylic monomers and uses thereof

The invention provides an amphiphilic siloxane-containing vinylic monomer which comprises one sole ethylenically unsaturated group and a siloxane-containing group covalently linked to the ethylenically-unsaturated group through a hydrophilic linker. The present invention is also related to a polymer, an actinically-crosslinkable silicone-containing prepolymer, a silicone hydrogel polymeric material, or a silicone hydrogel contact lens, which comprises monomeric units derived from an amphiphilic siloxane-containing vinylic monomer of the invention. In addition, the invention provides a method for making silicone hydrogel contact lenses using a water-based lens-forming formulation comprising an amphiphilic siloxane-containing vinylic monomer of the invention and / or an actinically-crosslinkable silicone-containing prepolymer of the invention.

Owner:ALCON INC

Tris(trimethyl siloxyl)silane vinylic monomers and uses thereof

The invention provides a TRIS-containing vinylic monomer which comprises one sole (meth)acryloyloxy group and a tris(trimethylsiloxy)silyl group covalently linked to the ethylenically-unsaturated group through a polyoxyethylene linker. The present invention is also related to a polymer, an actinically-crosslinkable silicone-containing prepolymer, a silicone hydrogel polymeric material, or a silicone hydrogel contact lens, which comprises monomeric units derived from a TRIS-containing vinylic monomer of the invention. In addition, the invention provides a method for making a TRIS-containing vinylic monomer of the invention.

Owner:SHIN ETSU CHEM IND CO LTD +1

Method for making isosorbide containing polyesters

This invention relates to a process for producing a polyester comprising the steps of:(g) obtaining an aqueous homogenous solution of isosorbide;(h) feeding the aqueous homogenous solution of step (a) into a reactor;(i) feeding one or more glycols and one or more dicarboxylic acids either into the aqueous solution of step (a) or into the reactor of step (b) either prior to, during and / or subsequent to step (b);(j) esterifying the reactor contents at sufficient temperatures and pressures, and optionally in the presence of suitable catalysts, to effect esterification;(k) forming a prepolymer; and(l) polycondensing the prepolymer at sufficient temperatures and pressures in the presence of a suitable catalyst to effect polycondensation to form a polyester.

Owner:EASTMAN CHEM CO

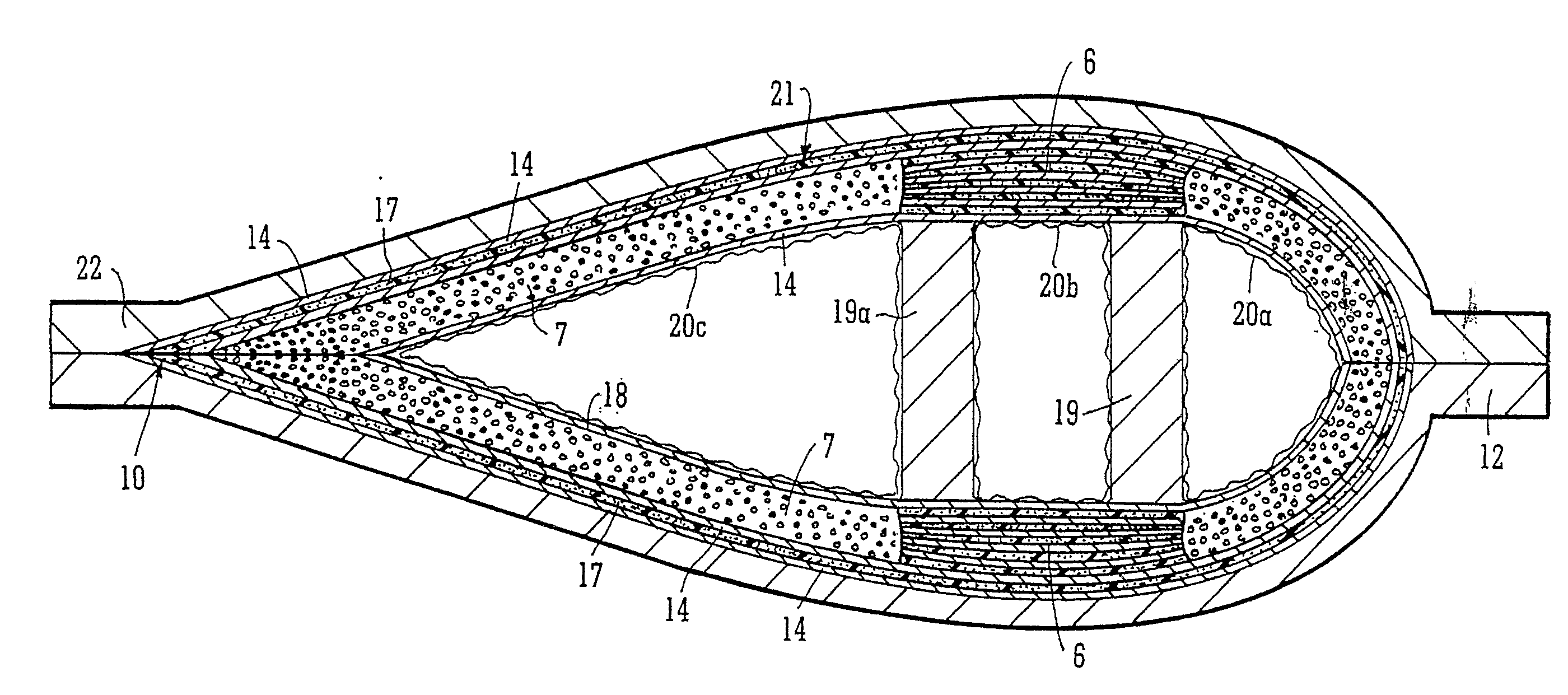

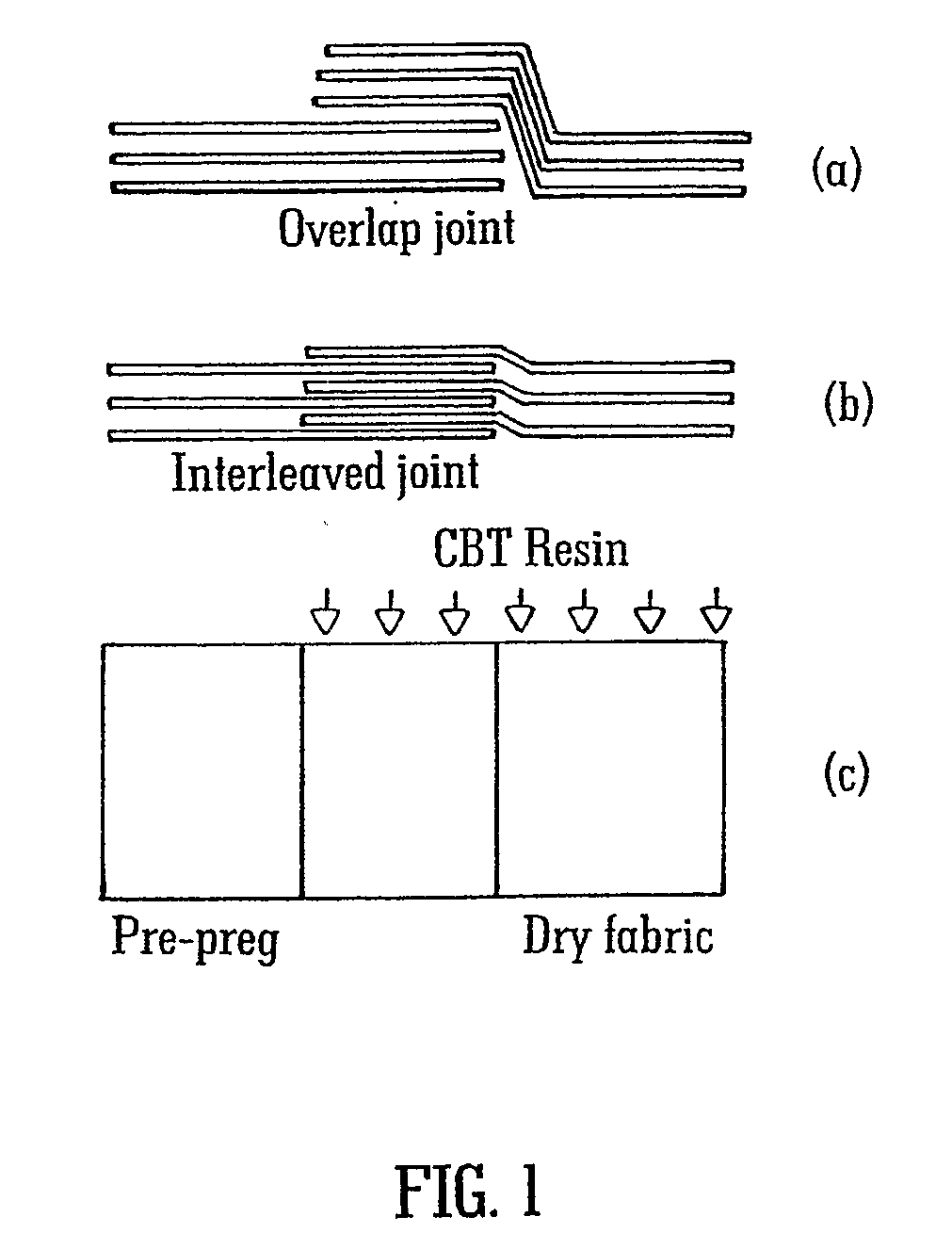

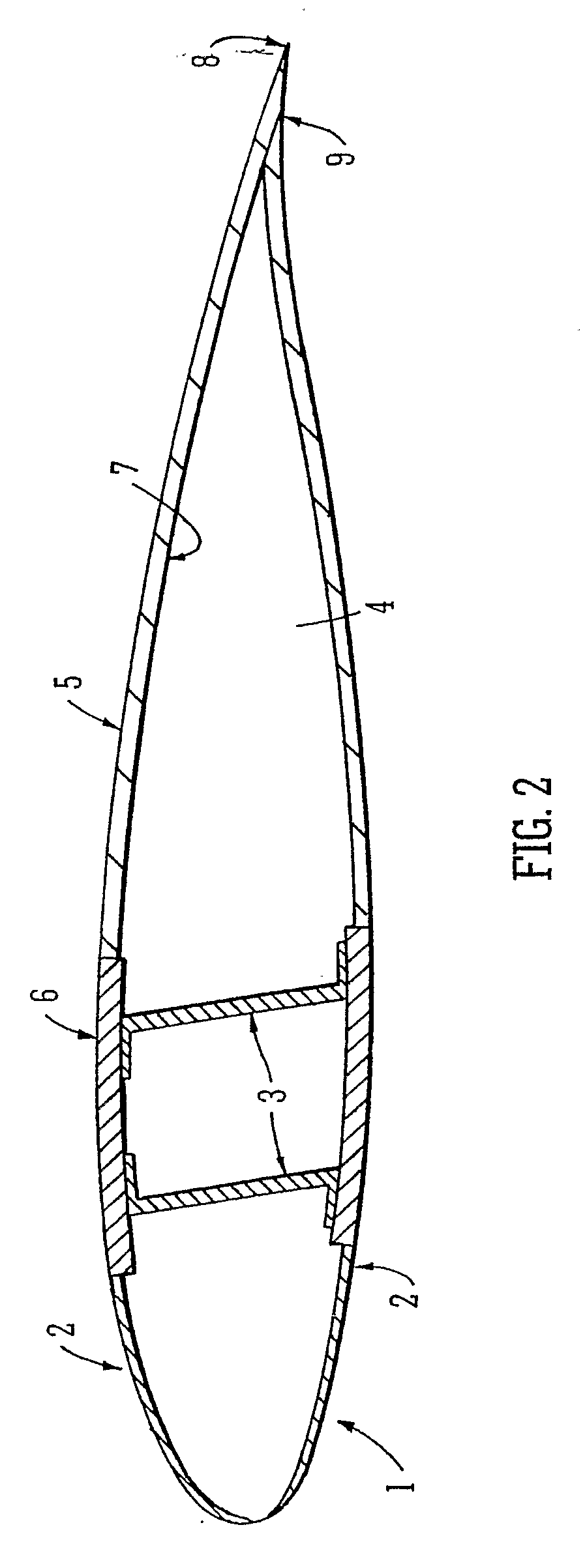

Composite Articles Comprising In-Situ-Polymerisable Thermoplastic Material and Processes for their Construction

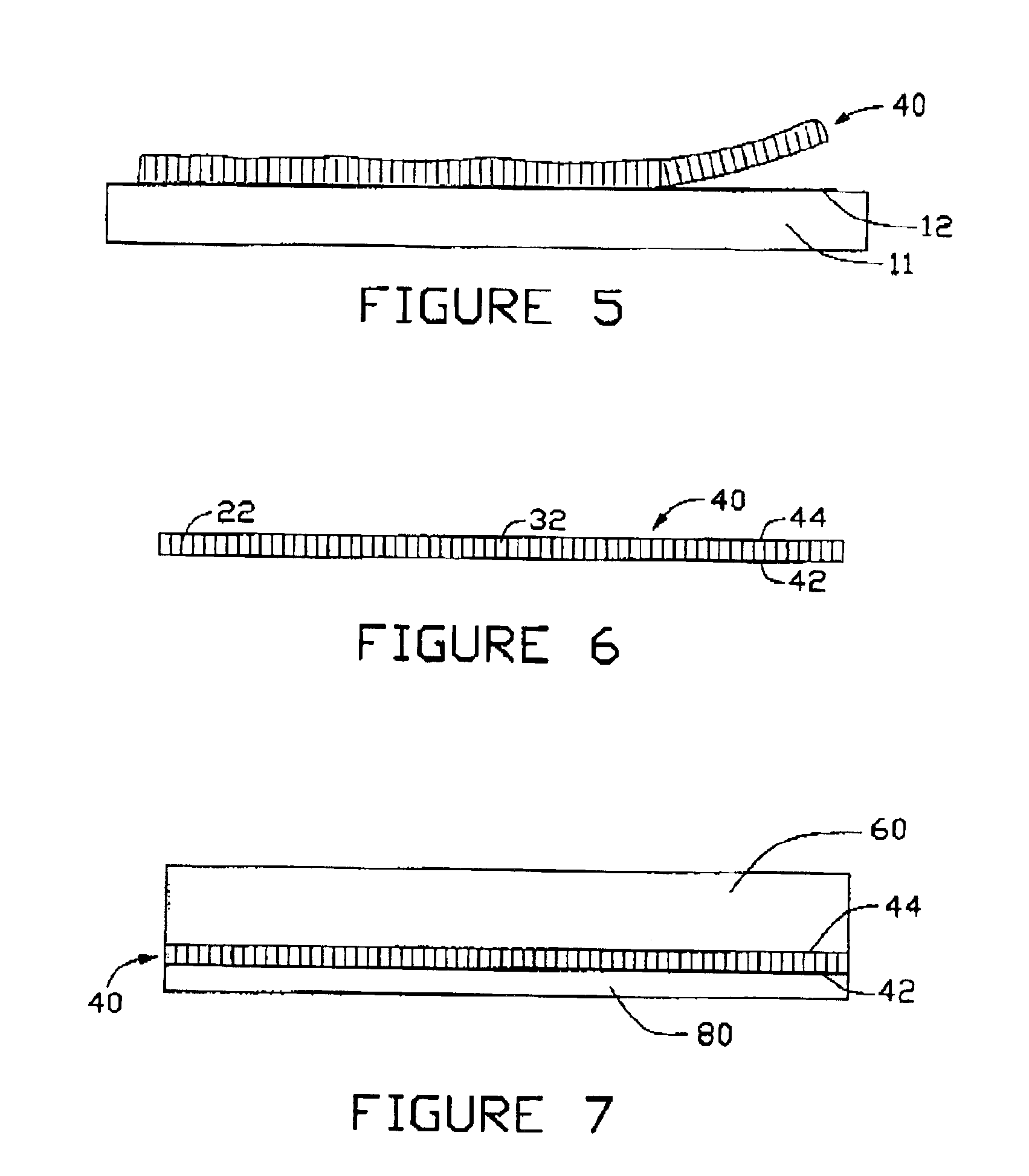

InactiveUS20100062238A1Reliable constructionLow costFinal product manufacturePretreated surfacesTurbine bladeIn situ polymerization

A process for the manufacture of a composite article is described wherein the process comprises the steps of (i) providing on a tool (22) a fibrous material (14) having associated therewith in at least one region thereof an in-situ polymerisable non-fibrous form of a thermoplastic material; (ii) applying heat and a vacuum to said material; and additionally (iii) drawing into the fibrous material, from a source external to the tool, additional thermoplastic pre-polymer material. The process described is particularly useful for the manufacture of a large composite structure such as thermoplastic composite wind turbine blade, for example.

Owner:UNIVERSITY OF LIMERICK +2

Biodegradable in-situ forming implants and methods of producing the same

A biodegradable polymer is provided for use in providing syringeable, in-situ forming, solid biodegradable implants for animals. The polymer is placed into the animal in liquid form and cures to form the implant in-situ. A thermoplastic system to form said implant comprises the steps of dissolving a non-reactive polymer in biocompatible solvent to form a liquid, placing the liquid within the animal, and allowing the solvent to dissipate to produce the implant. An alternative, thermosetting system comprises mixing together effective amounts of a liquid acrylic ester terminated, biodegradable prepolymer and a curing agent, placing the liquid mixture within an animal and allowing the prepolymer to cure to form the implant. Both systems provide a syringeable, solid biodegradable delivery system by the addition of an effective level of biologically active agent to the liquid before injection into the body.

Owner:ATRIX LAB

Microcapsules having improved printing and efficiency

InactiveUS6544926B1Efficient use ofSharpness of image printing qualitiesPretreated surfacesGlass/slag layered productsChromogenicColloid

Dual shell microcapsule aggregate particles and copy materials coated therewith, such aggregate particles having inner shells surrounding chromogenic nucleus material, and outer shells encompassing multiple such inner shells to form aggregate particles thereof. The inner shells are derived from polar pre-polymer compositions. The outer shells are derived from complex colloids such as gelatin and gelatin derivatives. The outer shell material causes agglomeration of the inner shells into aggregate particles, thus increasing the sizes of the particles without increasing the sizes of the respective inner-shell microcapsules which contain the chromogenic material.

Owner:ENCAPSYS LLC

Immobilized microorganism preparation method

ActiveCN101629173AIncrease biomassHigh activityOn/in organic carrierMicroorganismPolyethylene glycol

The invention relates to an immobilized microorganism preparation method in biochemical technical field, comprising the following steps: step 1, preparing a solution of which preparation method per 100ml comprises the following steps: (1) dissolving 12-18g of polyethylene glycol prepolymer in water to obtain a solution A; (2) adding microorganism in the solution A, then adding 0.5-1g of N,N-dimethylbisacrylamide and 0.05-0.1g of silicon dioxide, then adding 0.05-0.2g of diethoxyacetophenone and obtaining a solution B; (3) adding water in the solution B to ensure the volume of the obtained solution is 100ml, mixing evenly and obtaining the desired solution; step 2, placing the solution obtained in the step 1 under a ultraviolet lamp for curing, cutting, and washing to obtain the immobilized microorganism. The method of the invention can be performed at room temperature, the reaction process is easy to control and the prepared embedded bacteria particles have longer service life.

Owner:山东青素环保材料有限责任公司

Thermal interface material and method for making same

InactiveUS6924335B2Uniform and high thermoconductivityImprove thermal conductivityMaterial nanotechnologySemiconductor/solid-state device detailsCarbon nanotubePrepolymer

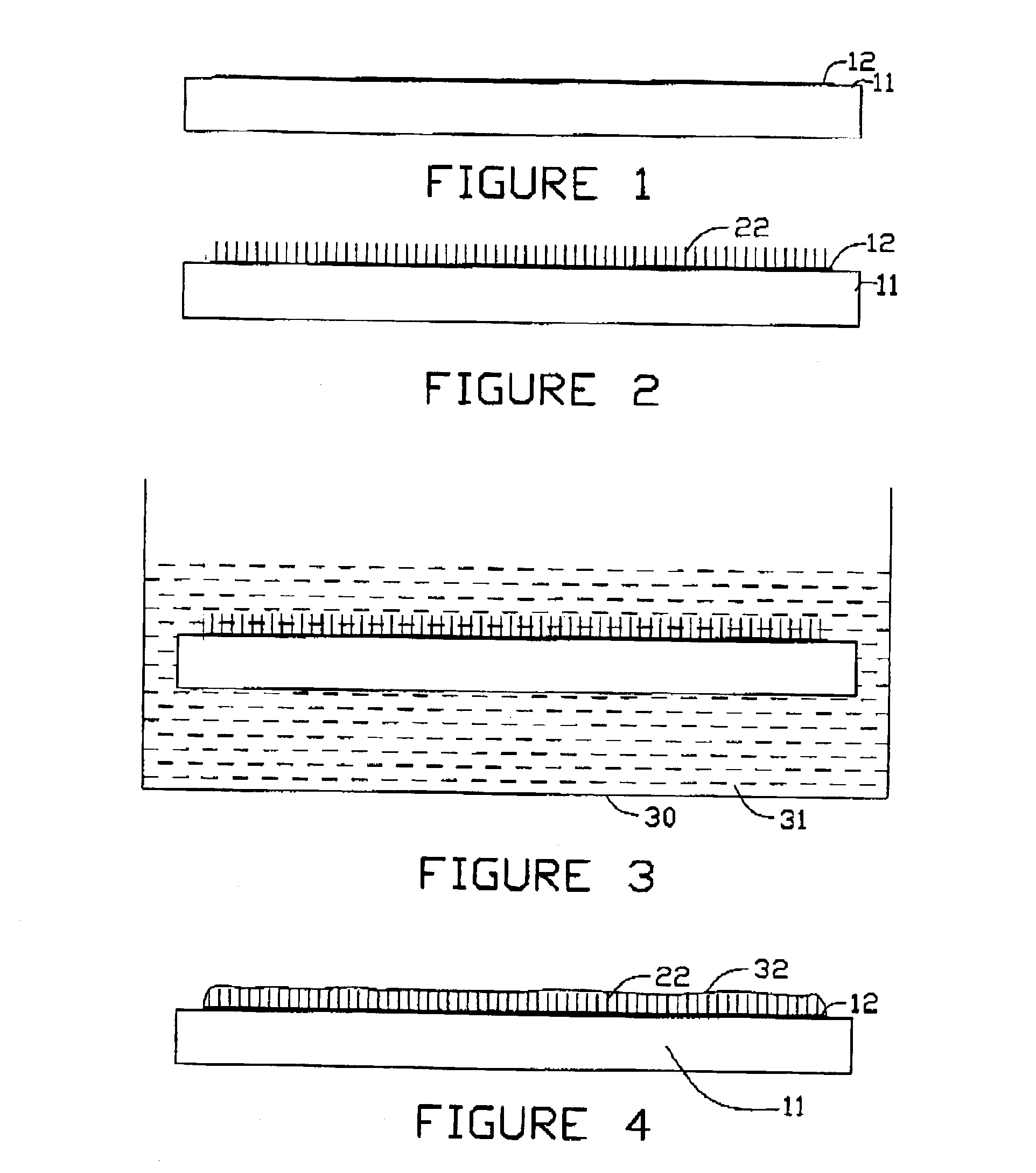

A thermal interface material (40) includes a polymer matrix (32) and an array of carbon nanotubes (22) incorporated in the polymer matrix. The polymer matrix has a thermally conductive first face (42) and an opposite thermally conductive second face (44). The carbon nanotubes are substantially parallel to each other, and extend between the first and the second faces. A preferred method for making the thermal interface material includes the steps of: (a) forming the array of carbon nanotubes on a substrate (11); (b) immersing the carbon nanotubes in a liquid prepolymer (31) such that the liquid prepolymer infuses into the array of carbon nanotubes; (c) polymerizing the liquid prepolymer to obtain the polymer matrix having the carbon nanotubes secured therein; and (d) peeling the polymer matrix having the carbon nanotubes off from the substrate to obtain the thermal interface material.

Owner:TSINGHUA UNIV +1

Polyurethane adhesive for windshield applications

InactiveUS20030070741A1Sufficient developmentSufficient working timeWindowsWindscreensPrepolymerIsocyanate

A polyurethane adhesive which is useful in bonding porous and non-porous surfaces is provided. The adhesive is especially useful in bonding windshield glass into automotive frames under a variety of environmental conditions, particularly in after market windshield replacement applications. The polyurethane includes at least one urethane prepolymer which is based on at least one thermoplastic polyol. In one embodiment, the urethane prepolymer may be formed from one or more polyisocyanates, one or more polyetherpolyols and one or more thermoplastic polyesterpolyols, wherein the prepolymer has a free isocyanate content of from about 0.6 to about 3.5 % by weight, based on the weight of the polyurethane. In another embodiment, a one-part adhesive composition is provided which includes an isocyanate-functional and thermoplastic polyurethane prepolymer having a free isocyanate content of from about 0.6 to about 3.5 % by weight, based on the weight of the polyurethane, and a combination of several catalysts which are capable of catalyzing the reaction of isocyanate moieties with isocyanate-reactive moieties while providing less temperature dependent catalyzing of the reaction between isocyanate moieties and water. Also provided is a process for bonding two or more substrates together utilizing the polyurethane adhesive. In automotive windshield replacement applications, the polyurethane adhesive allows for a sufficient working time and development of green strength to provide a safe drive-away time within 1 hour at a temperature from about 0 to about 100° C.

Owner:SIKA TECH AG

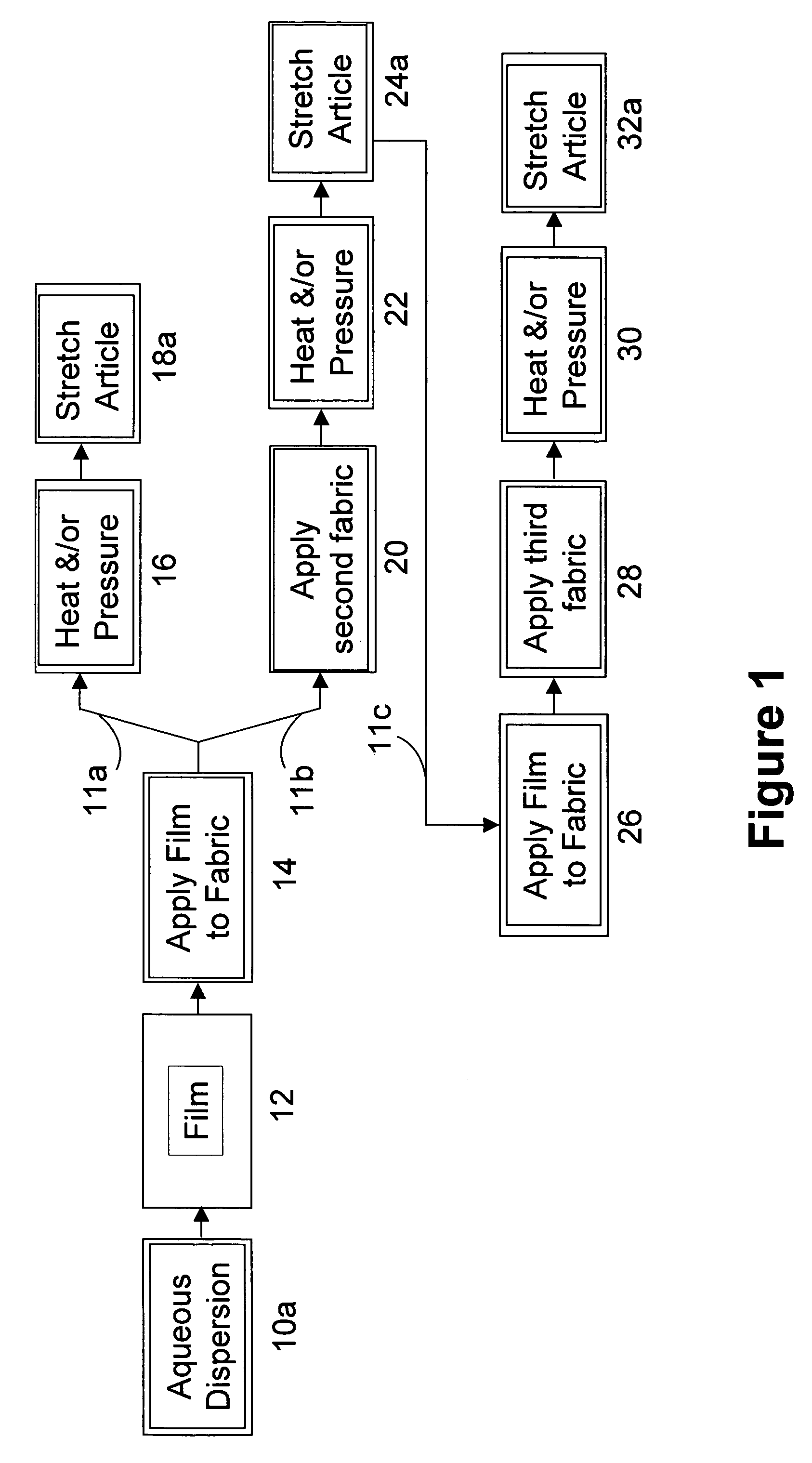

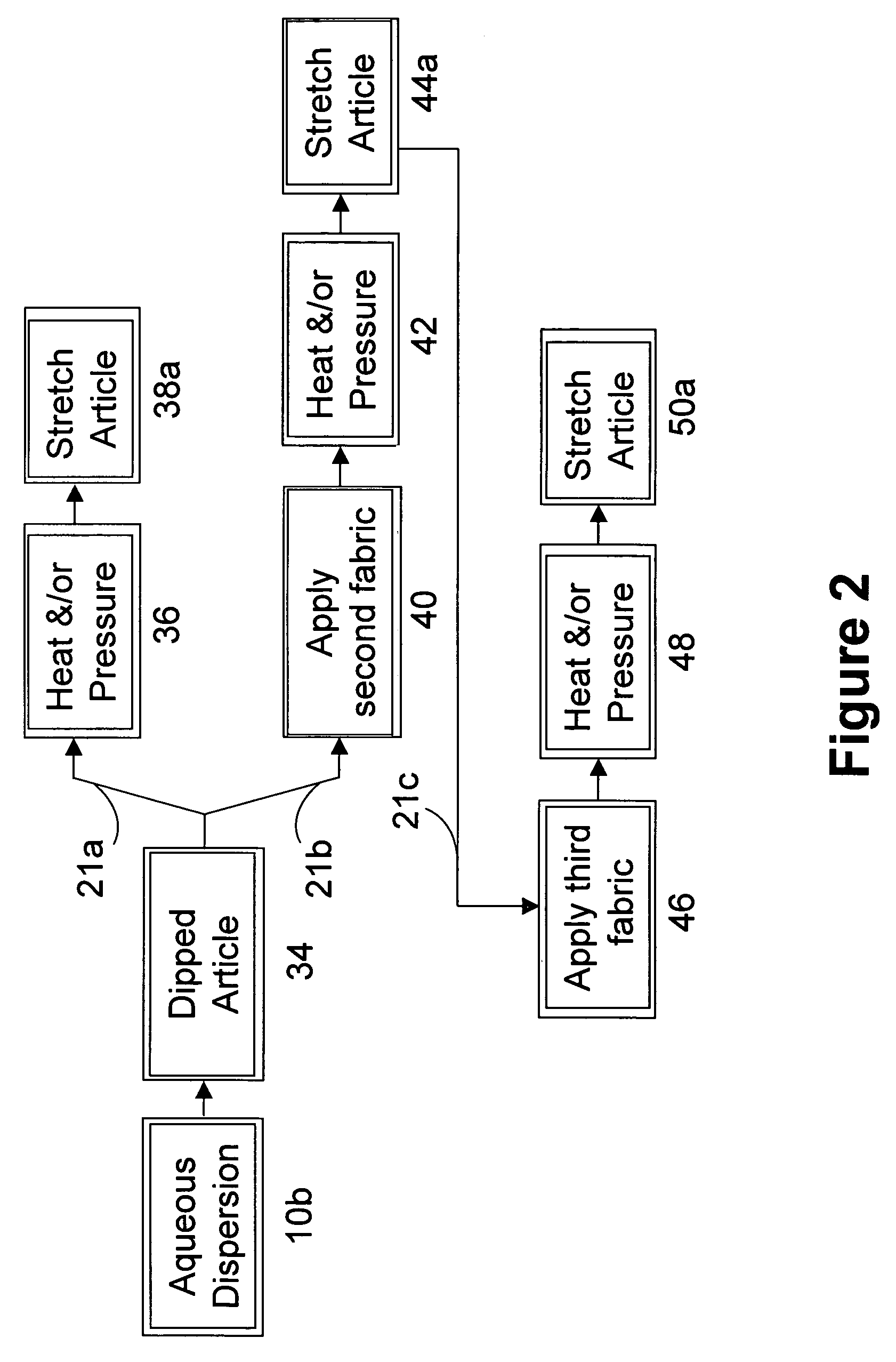

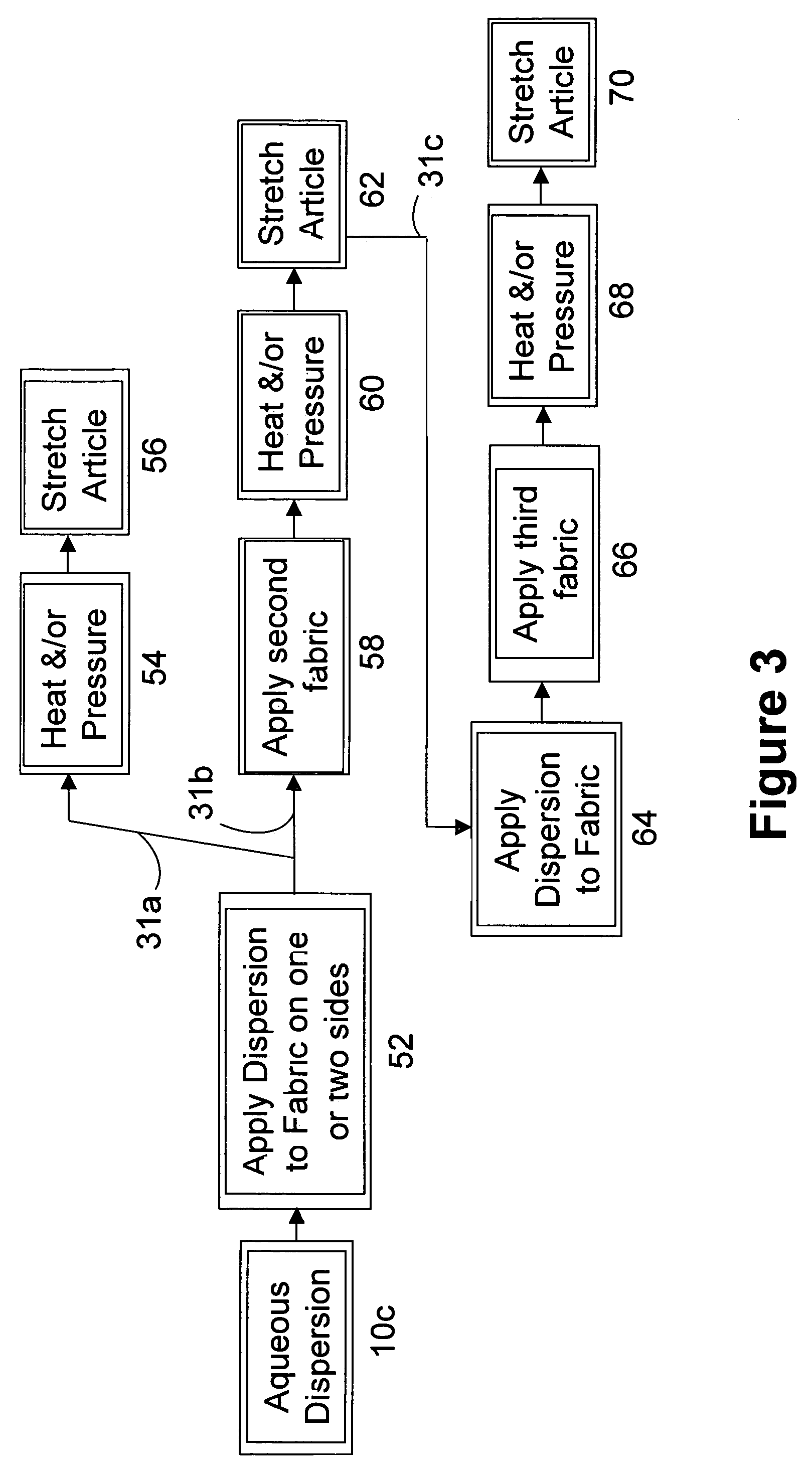

Solvent free aqueous polyurethane dispersions and adhesive films therefrom for stretch fabrics

Novel aqueous polyurethane dispersions and adhesive films formed therefrom are provided. The aqueous polyurethane dispersions are provided in solvent-free systems of a prepolymer comprising at least one polyether or polyester polyol, a mixture of MDI isomers, and a diol. The adhesive films from such dispersions can be heat-activated for bonding, lamination, and adhesion of textile fabrics, including stretch fabrics.

Owner:THE LYCRA CO LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com