Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6276 results about "Polymer composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Many common classes of polymers are composed of hydrocarbons, compounds of carbon and hydrogen. These polymers are specifically made of carbon atoms bonded together, one to the next, into long chains that are called the backbone of the polymer.

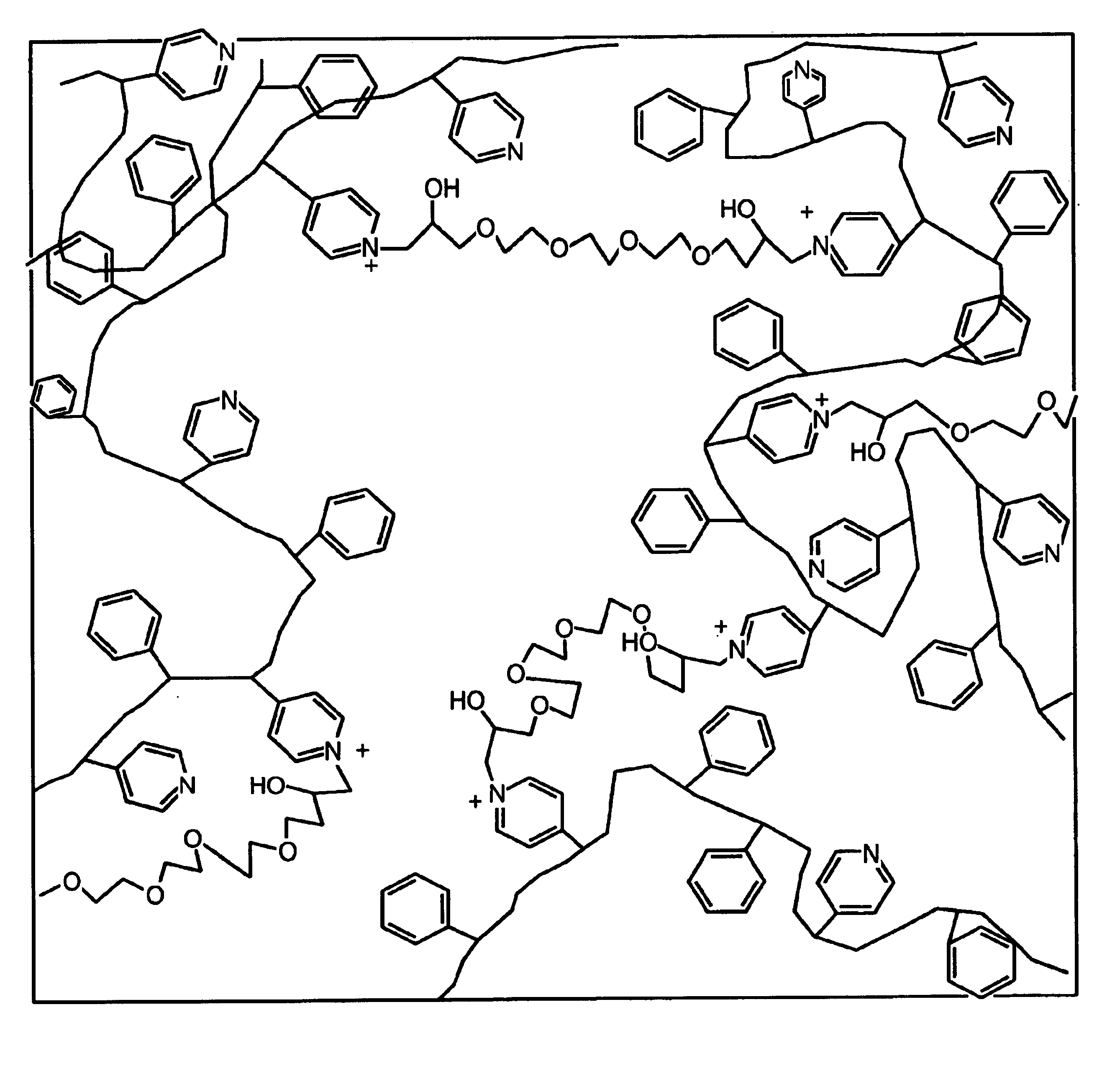

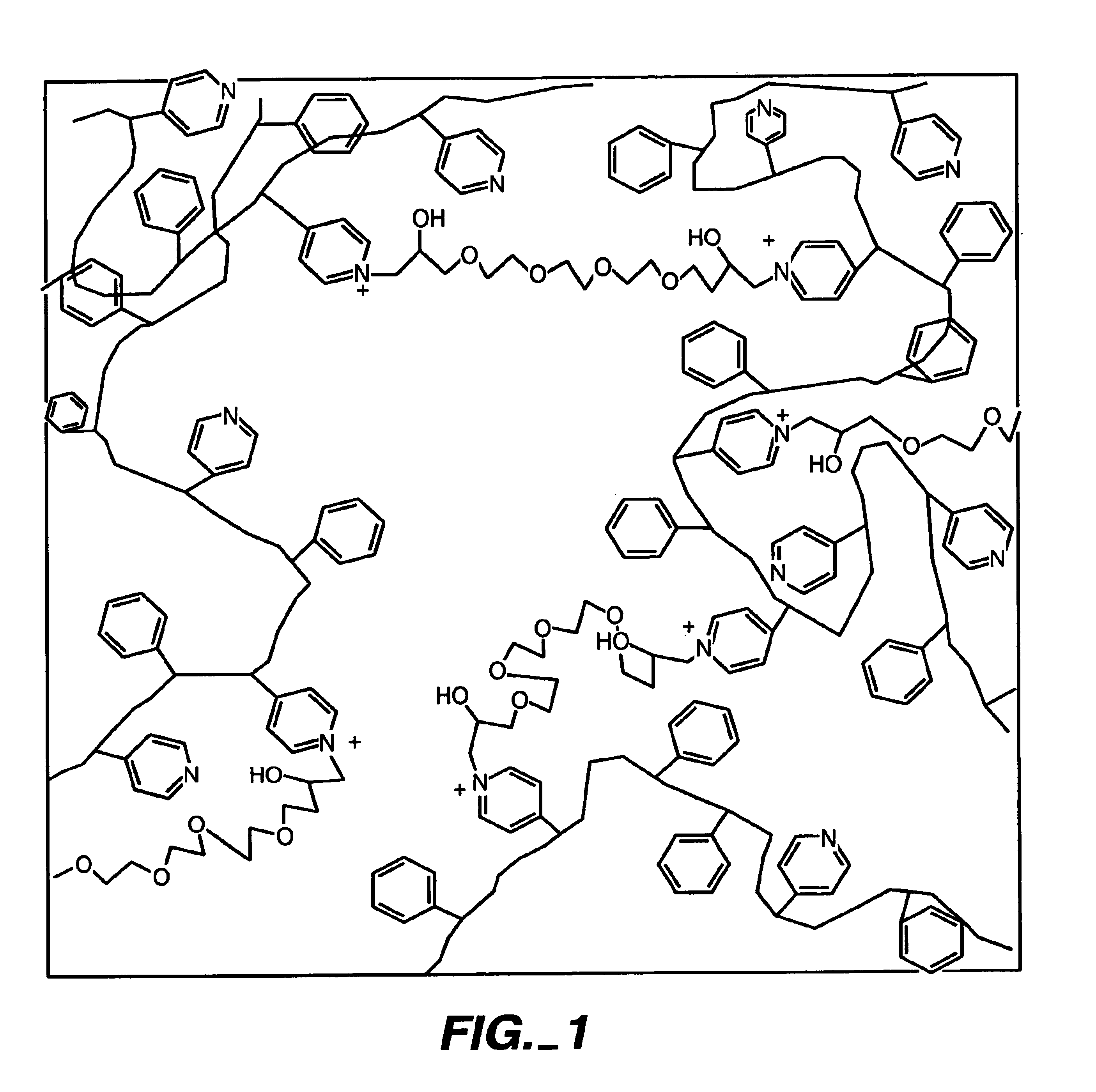

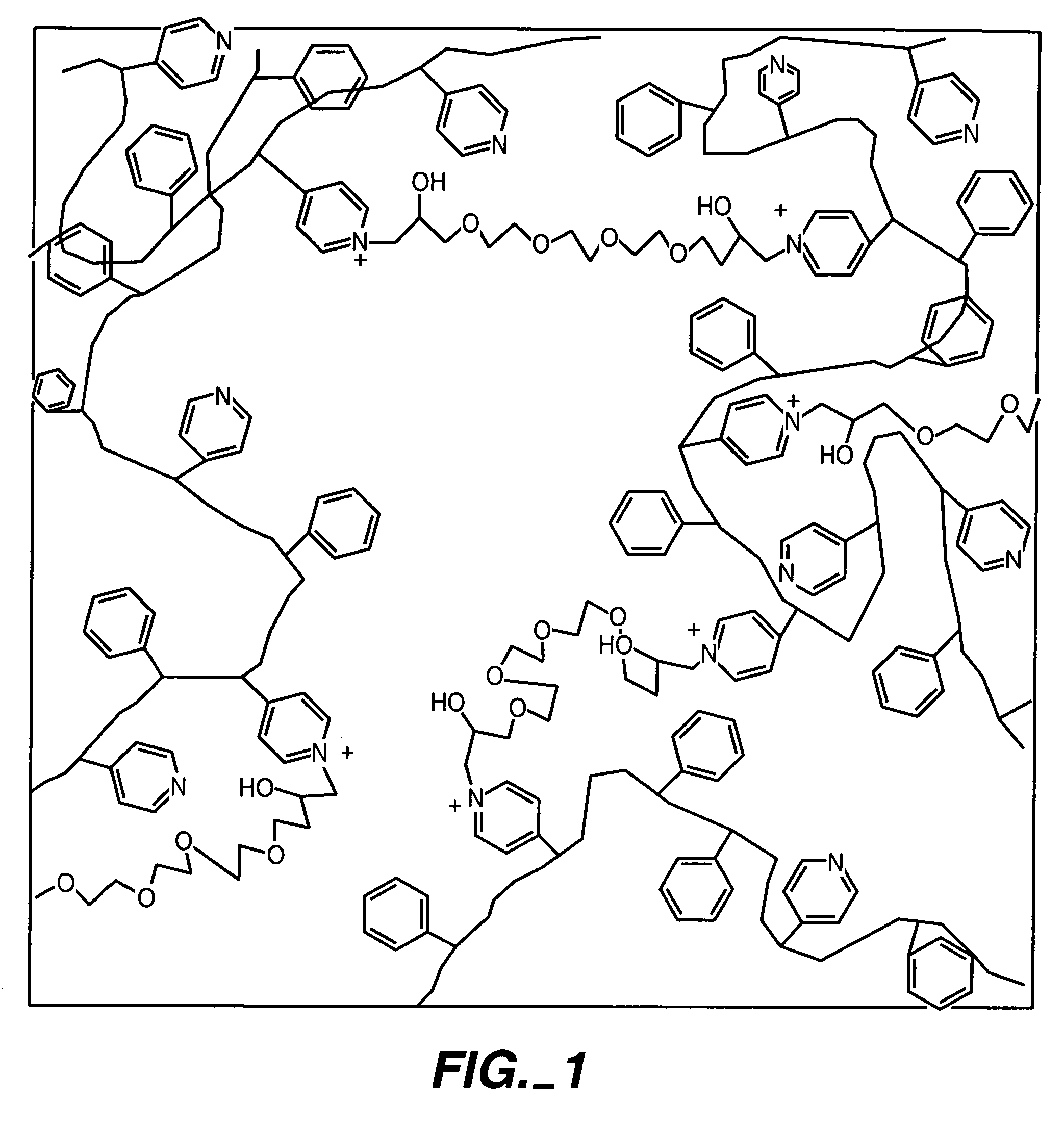

Biosensor membranes composed of polymers containing heterocyclic nitrogens

InactiveUS6932894B2Easy CalibrationConsider sensitivityImmobilised enzymesBioreactor/fermenter combinationsAnalyteNitrogen

Owner:ABBOTT DIABETES CARE INC

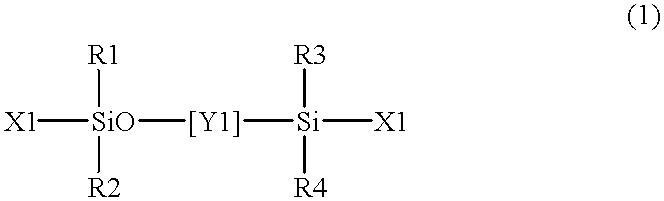

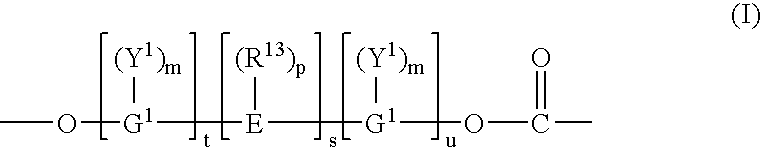

Long wearable soft contact lens

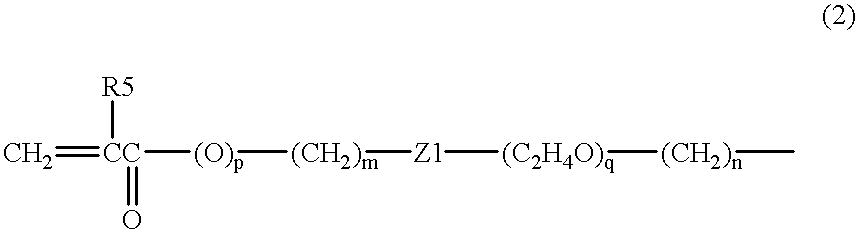

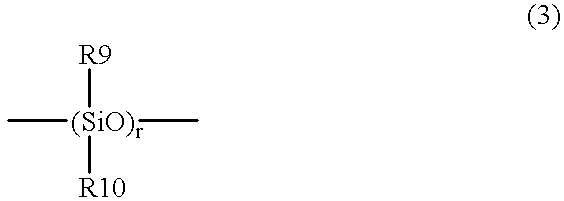

The present invention relates to a soft contact lens, and provides a contact lens which shows small and stable contact angle to water at its surface in water as well as in air, little deposition in wearing, high oxygen permeability, no adhesion of lens to a cornea and superior extended-wearing characteristics. The present invention provides a hydrogel soft contact lens which has contact angle at a lens surface in a range of 10-50° by the captive bubble method in water and 30-90° by the sessile drop method in air, oxygen permeability of not less than 30 and water content of not less than 5%, and also a hydrogel soft contact lens consisting of a polymer comprising a hydrophilic siloxanyl monomer shown by a specified general formula.

Owner:COOPERVISION INT LTD

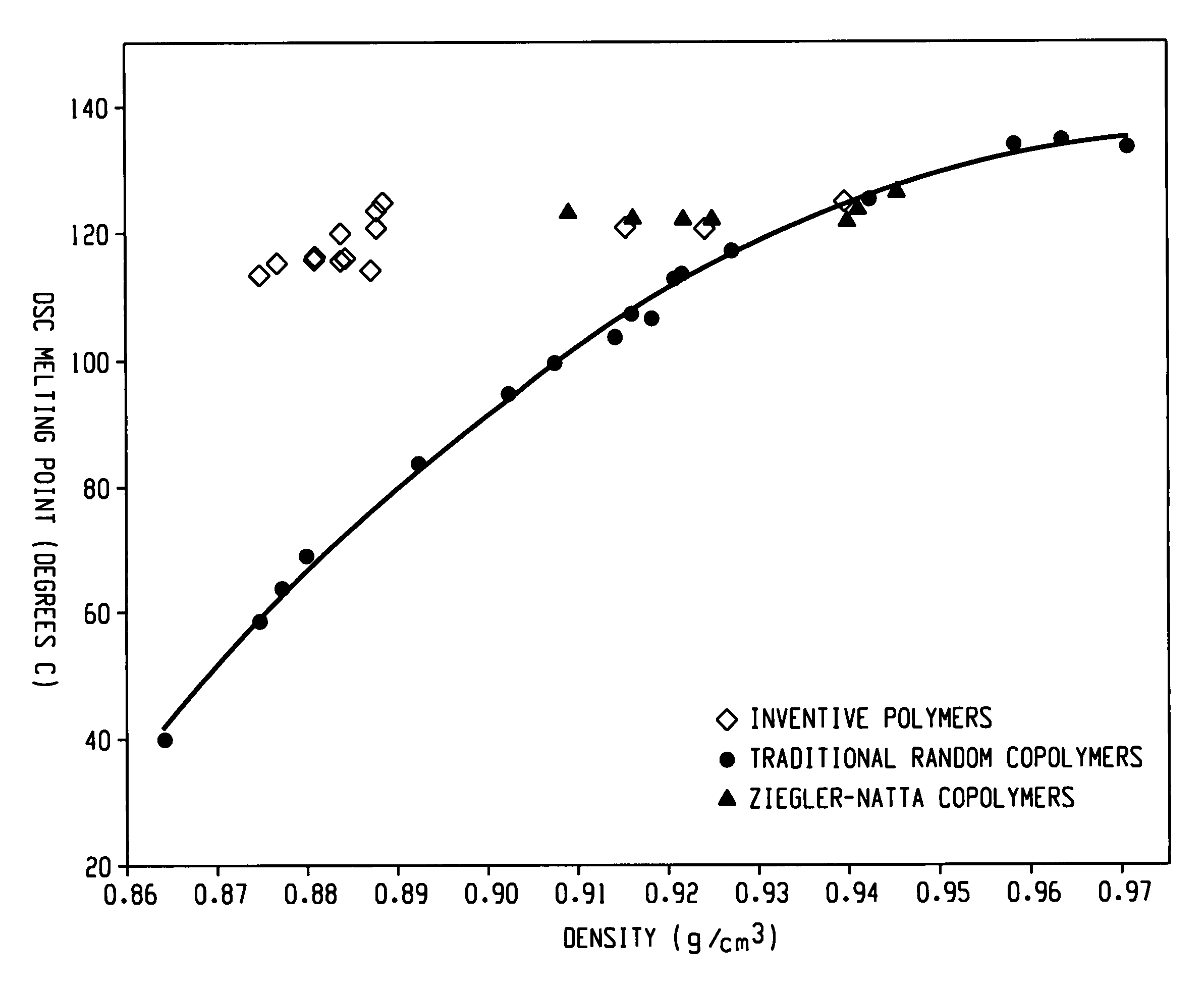

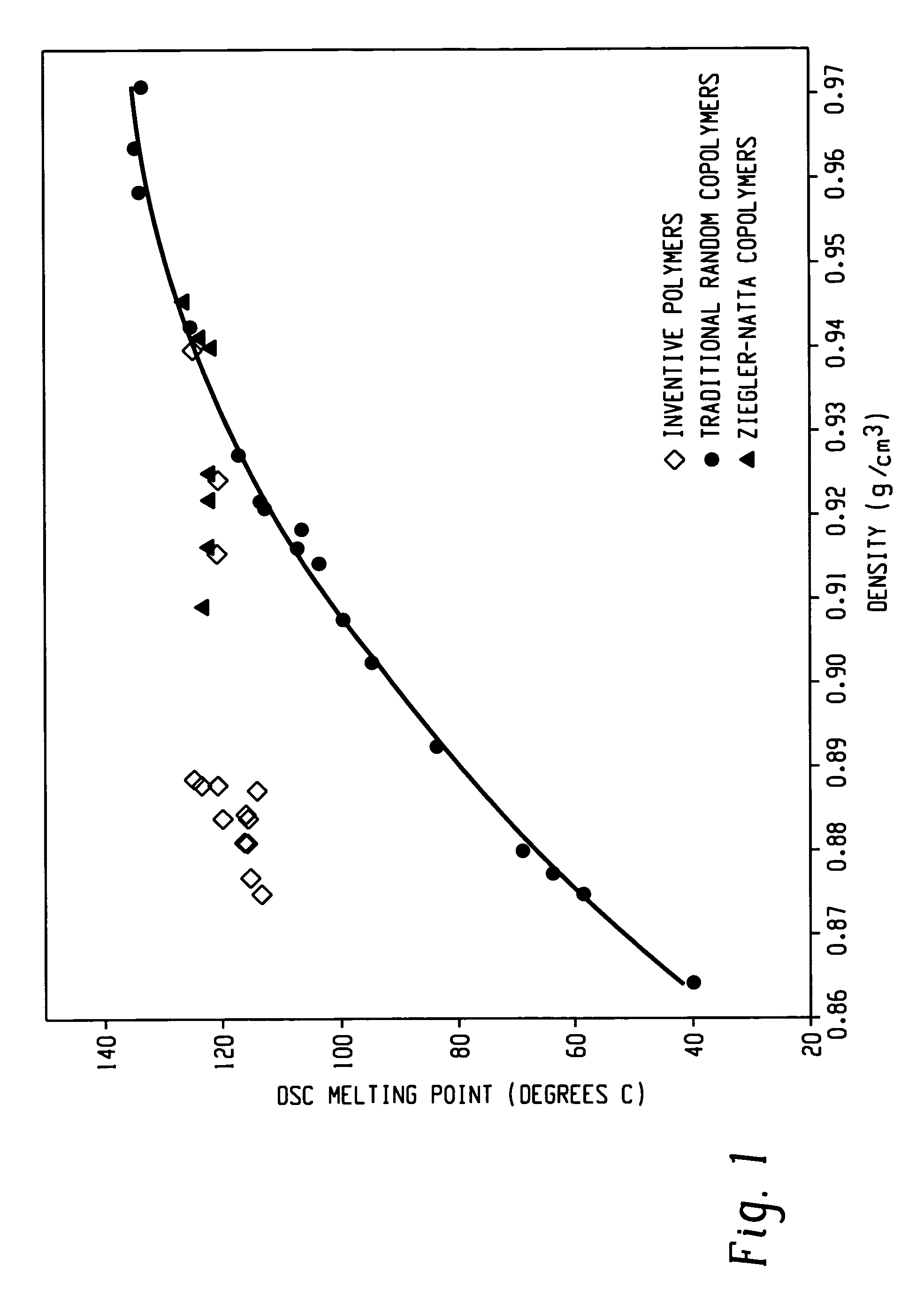

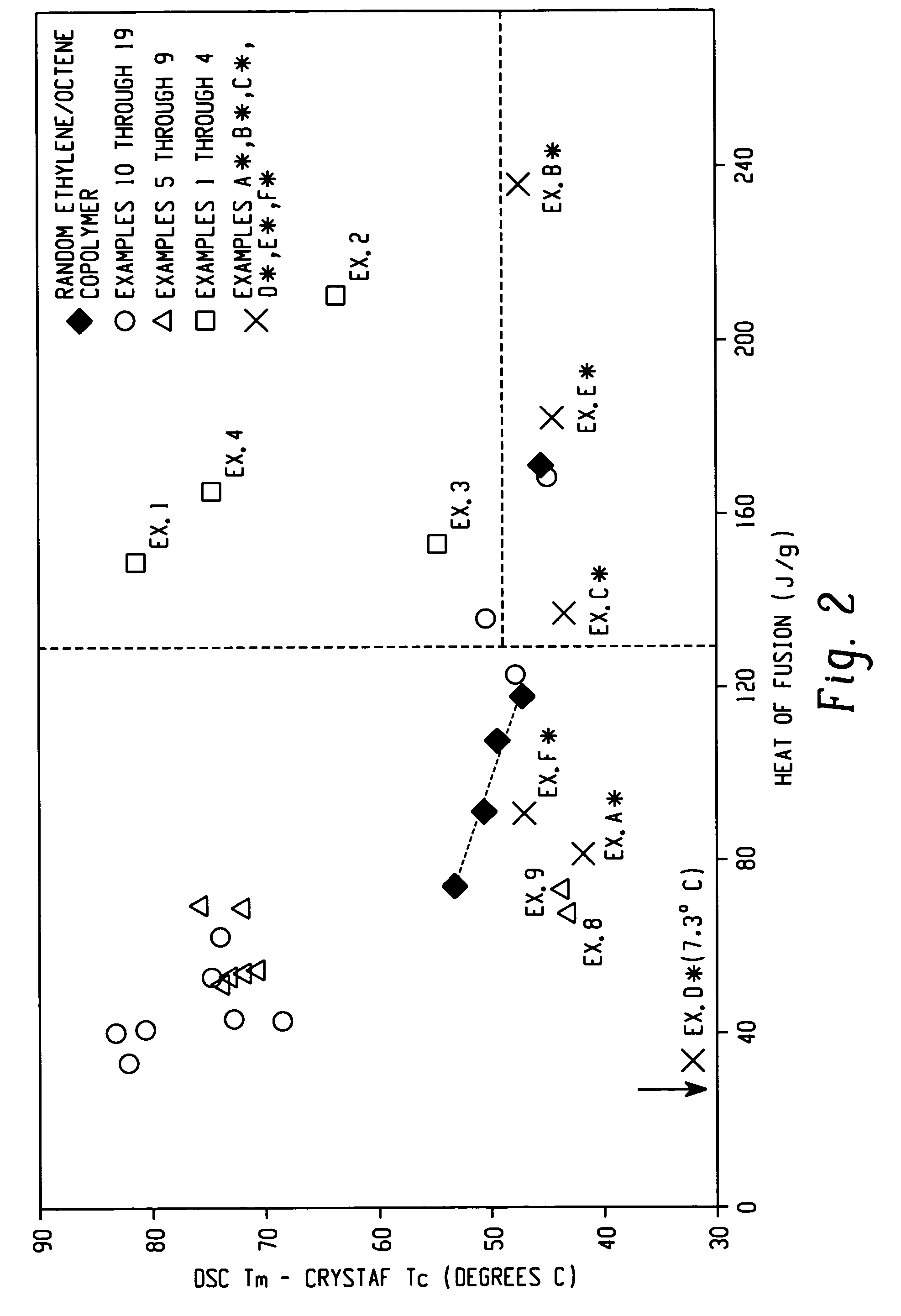

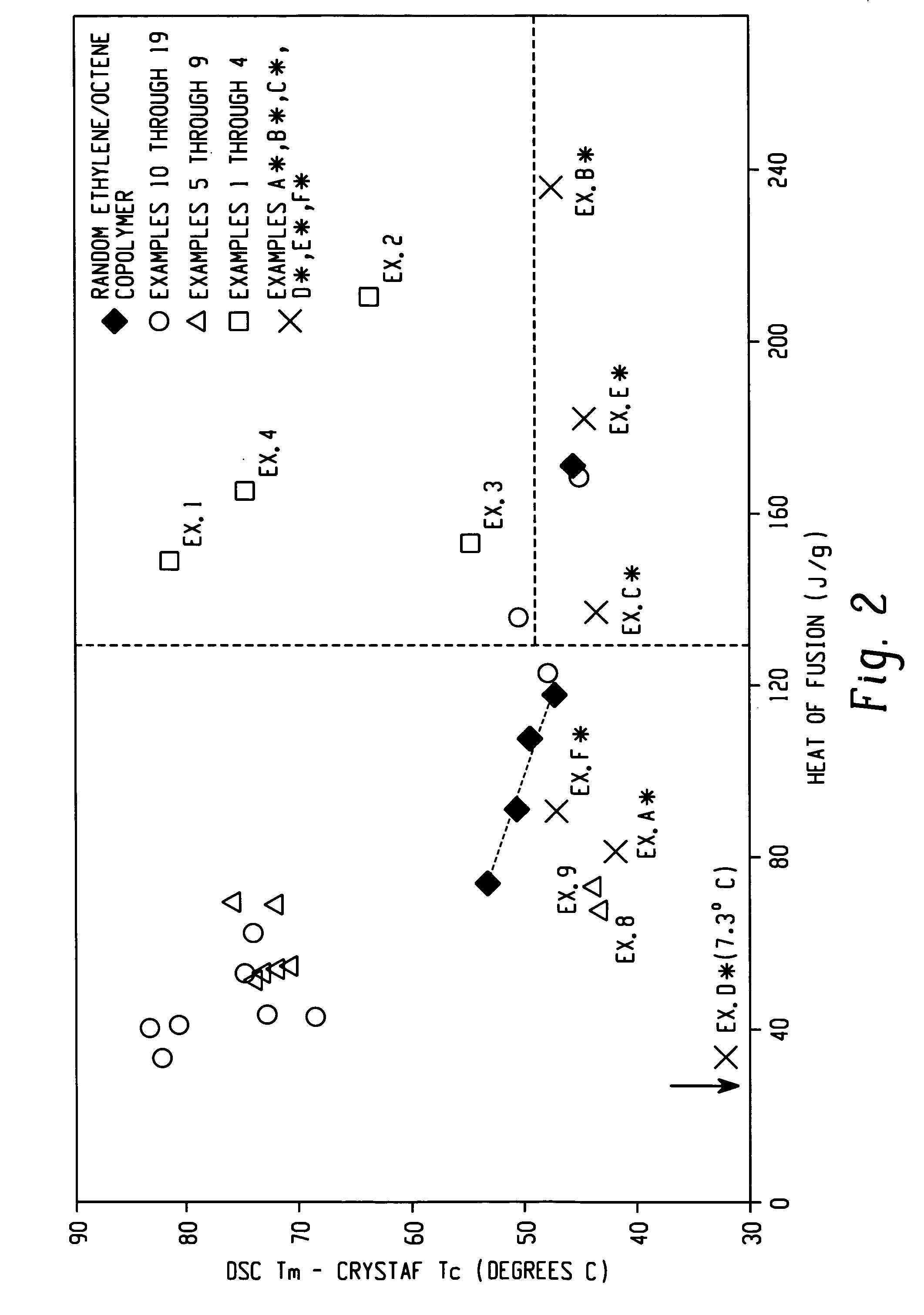

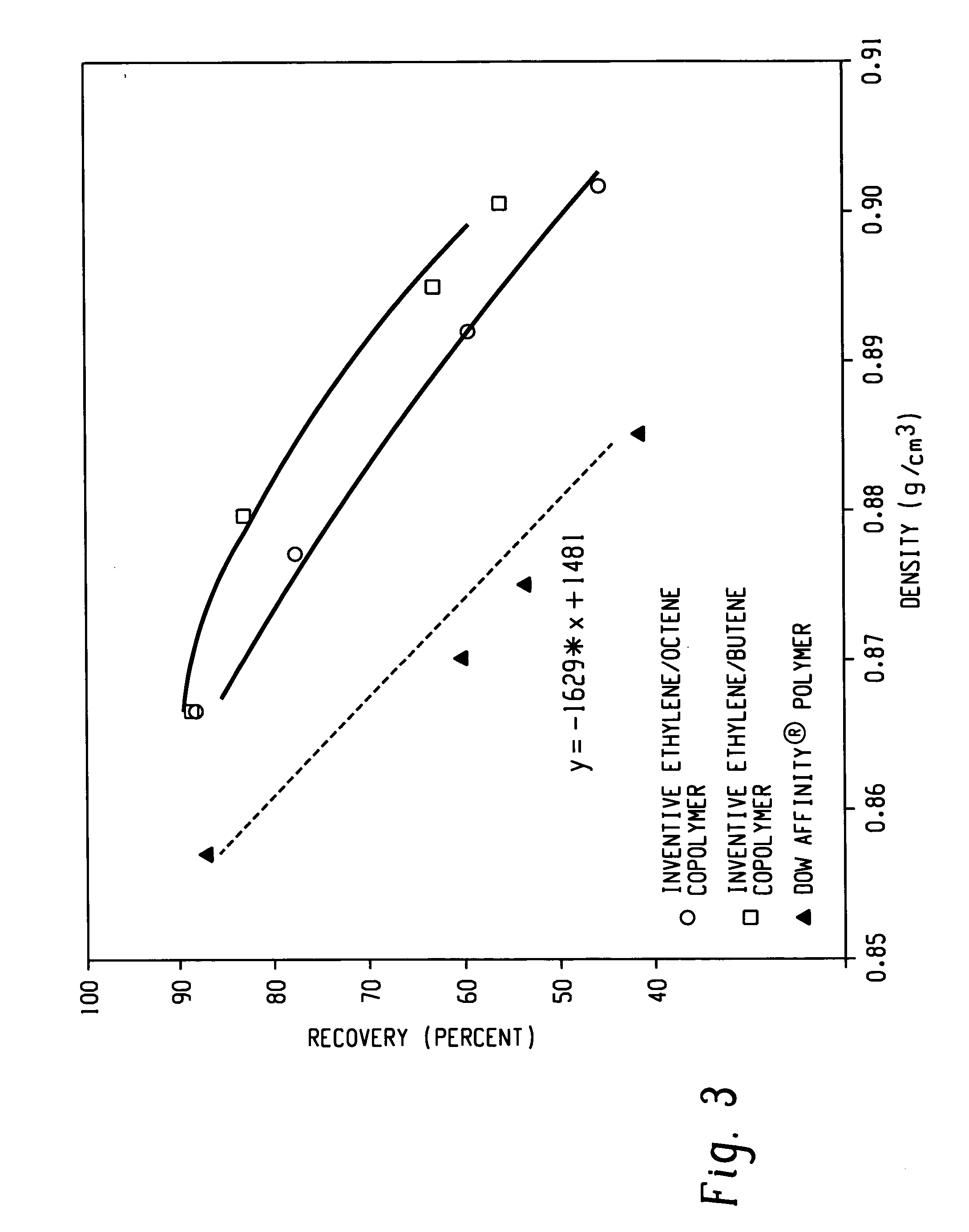

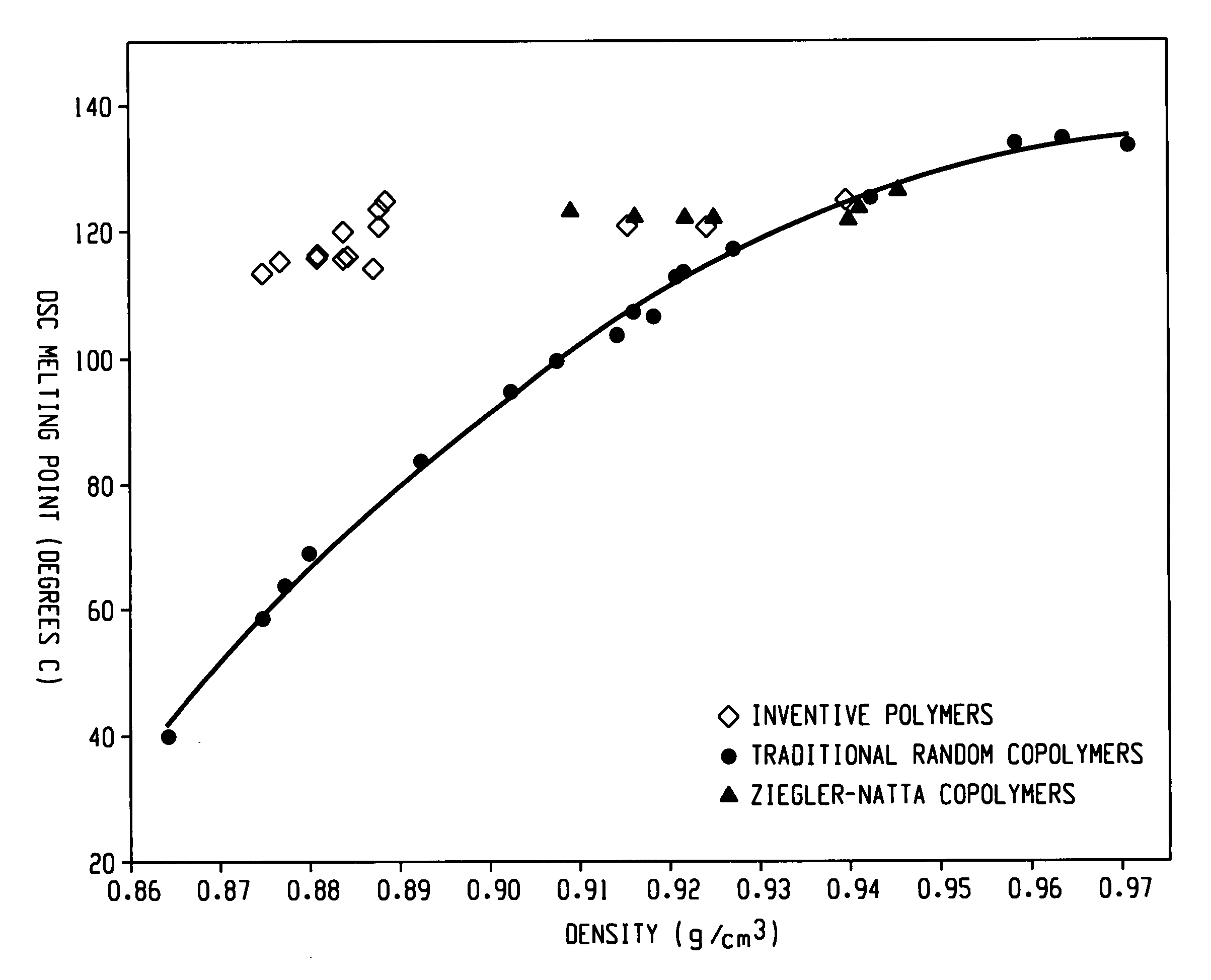

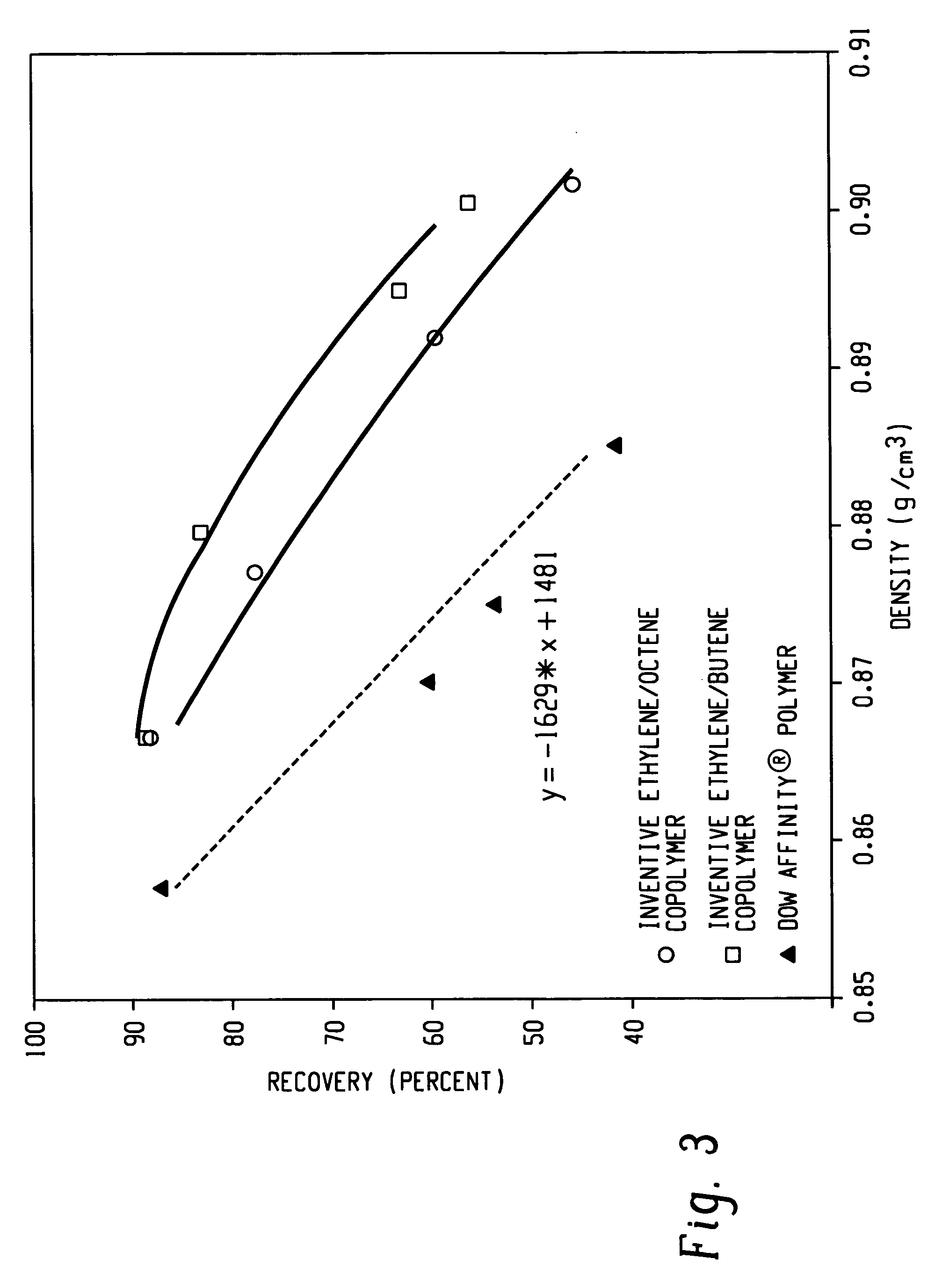

Compositions of ethylene/alpha-olefin multi-block interpolymer for elastic films and laminates

Owner:DOW GLOBAL TECH LLC

Biosensor membranes composed of polymers containing heterocyclic nitrogens

InactiveUS20050241957A1Easy CalibrationConsider sensitivityMicrobiological testing/measurementVolume/mass flow measurementAnalyteNitrogen

Owner:ABBOTT DIABETES CARE INC

Electrically conductive polymer composition

InactiveUS6184280B1Sufficient electrical conductivityImprove polymer propertiesOther chemical processesConductive materialPolymer scienceCarbon fibers

An electrically conductive polymer composition comprises a moldable organic polymer having hollow carbon microfibers and an electrically conductive white powder uniformly dispersed therein, the carbon fibers being present in an amount of 0.01 wt. % to less than 2 wt. % and the electrically conductive white powder being present in an amount of 2.5-40 wt. %, each percent range based on the total weight of the composition, the amounts of carbon microfibers and white powder being sufficient to simultaneously impart the desired electrical conductivity to the composition and white pigmentation to the composition.

Owner:MITSUBISHI MATERIALS CORP +1

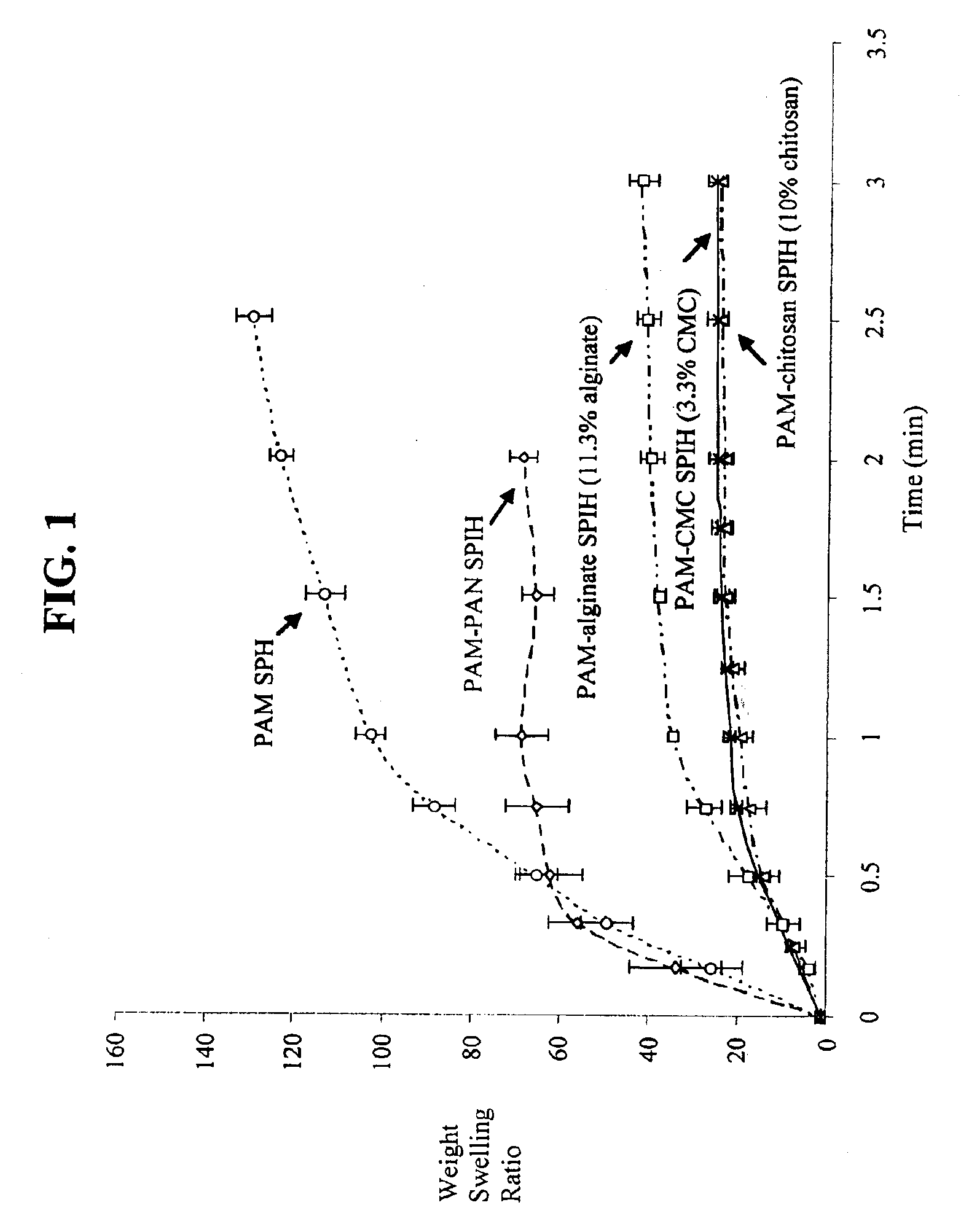

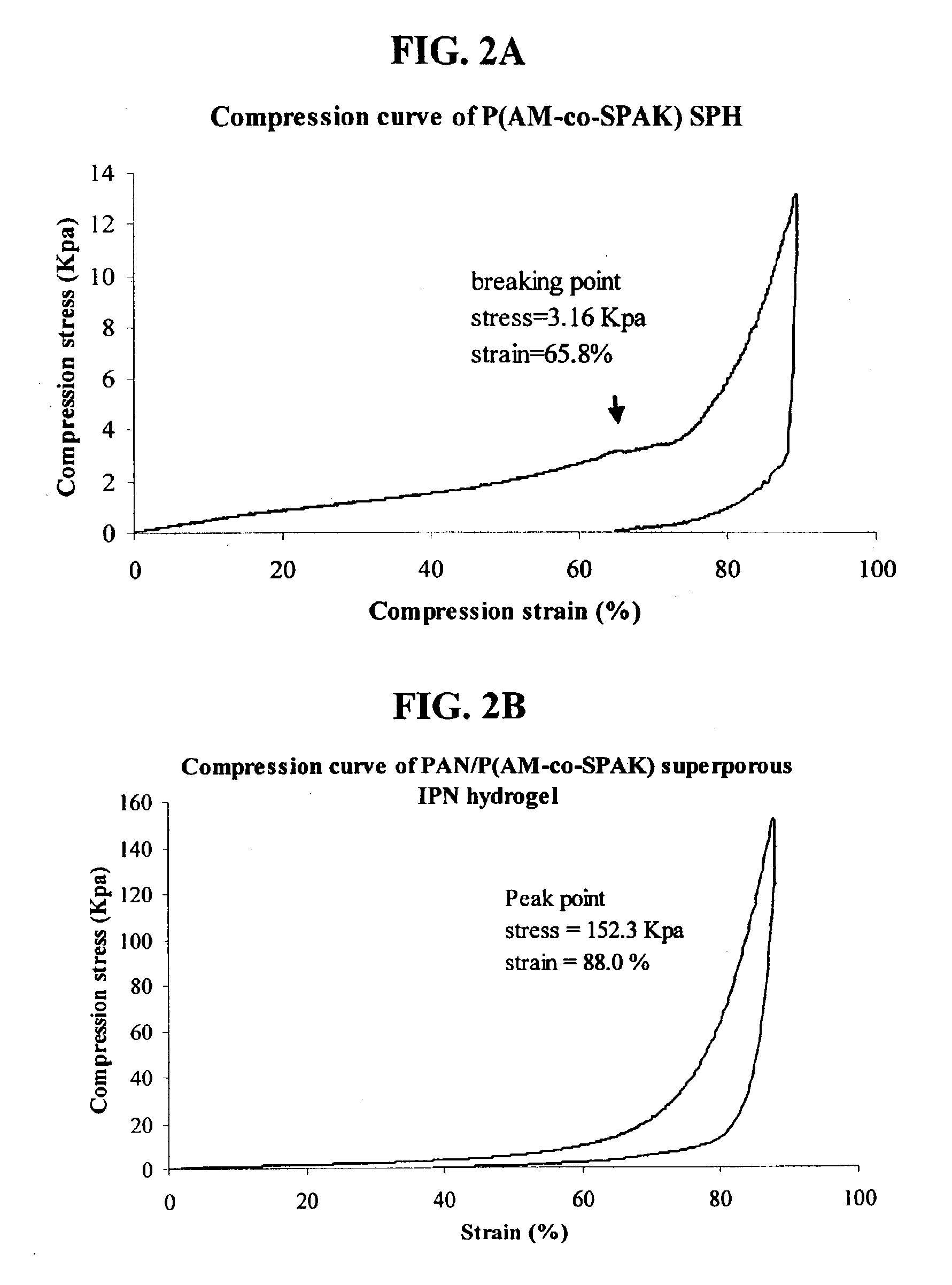

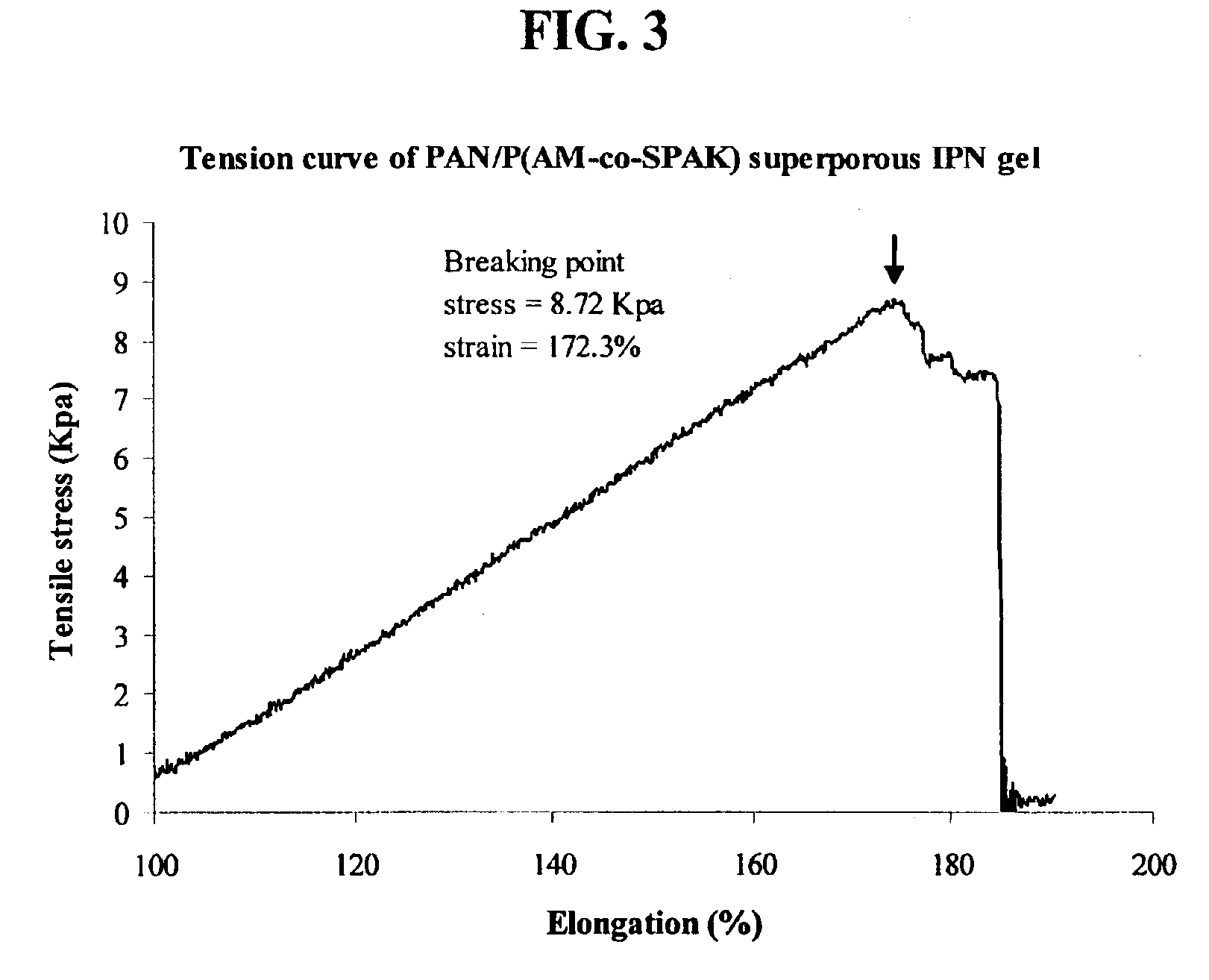

Hydrogels having enhanced elasticity and mechanical strength properties

InactiveUS6960617B2Great compression modulusEnhanced water absorbencePharmaceutical delivery mechanismAbsorbent padsPolyelectrolytePolymer science

Hydrogels having improved elasticity and mechanical strength properties are obtained by subjecting a hydrogel formulation containing a strengthening agent to chemical or physical crosslinking conditions subsequent to initial gel formation. Superporous hydrogels having improved elasticity and mechanical strength properties are similarly obtained whenever the hydrogel formulation is provided with a foaming agent. Interpenetrating networks of polymer chains comprised of primary polymer(s) and strengthening polymer(s) are thereby formed. The primary polymer affords capillary-based water sorption properties while the strengthening polymer imparts significantly enhanced mechanical strength and elasticity to the hydrogel or superporous hydrogel. Suitable strengthening agents can be natural or synthetic polymers, polyelectrolytes, or neutral, hydrophilic polymers.

Owner:PURDUE RES FOUND INC

Cap liners, closures and gaskets from multi-block polymers

A polymer composition comprises at least an ethylene / α-olefin interpolymer and at least one other polymer. The other polymer can be selected from a second ethylene / α-olefin interpolymer, an elastomer, a polyolefin, a polar polymer, and an ethylene / carboxylic acid interpolymer or ionomer thereof. The ethylene / α-olefin interpolymer is a block copolymer having at least a hard block and at least a soft block. The soft block comprises a higher amount of comonomers than the hard block. The block interpolymer has a number of unique characteristics disclosed here. Also provided are gaskets, bottle cap liners, and closures that comprise or obtained from a compositon comprising at least one ethylene / α-olefin interpolymer and at least one polyolefin. The gaskets are capable of compression sealing various containers, without contaminating the contents. Liquid containers particularly benefit from the use of the novel gasket materials disclosed herein.

Owner:DOW GLOBAL TECH LLC

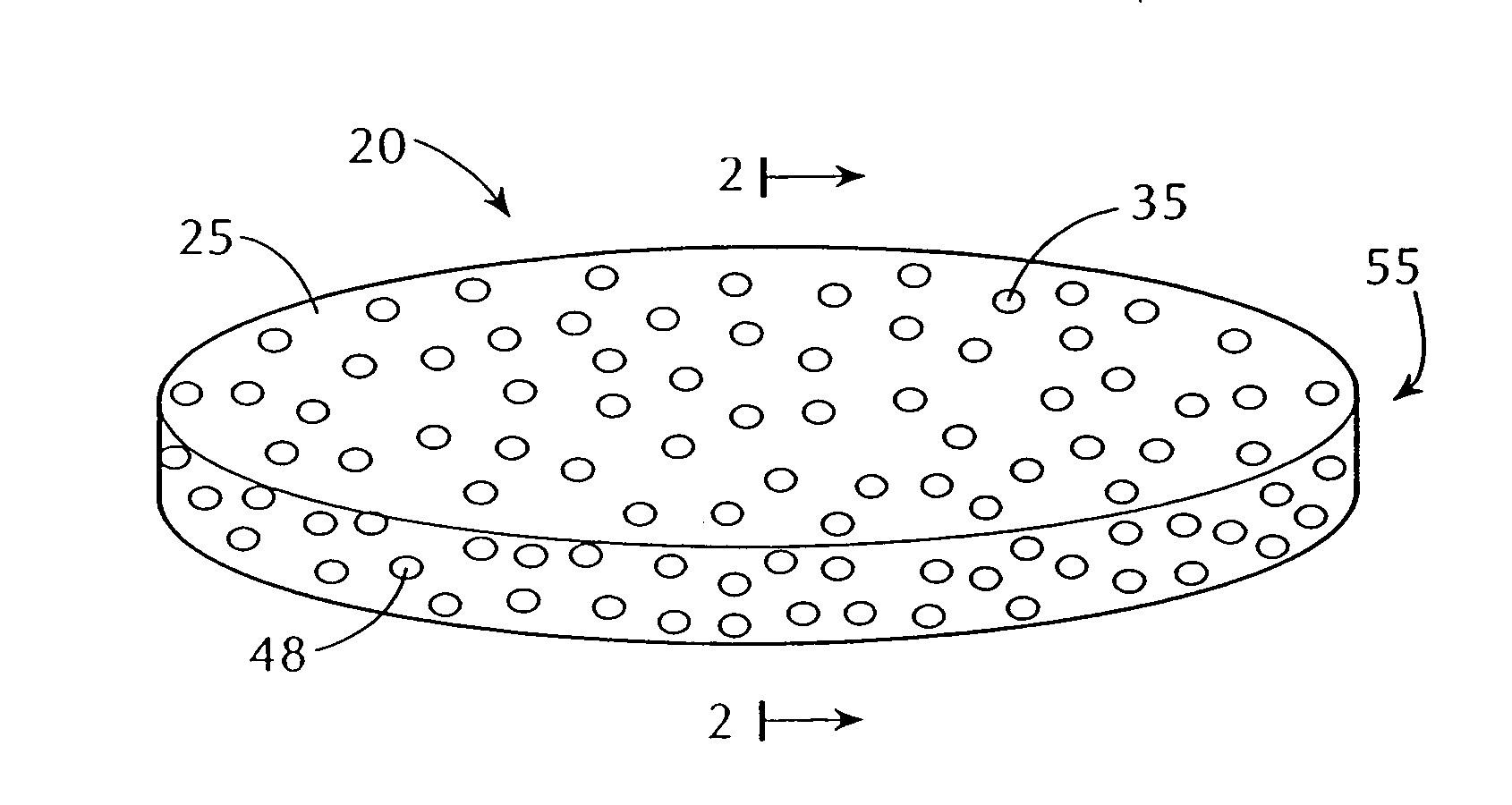

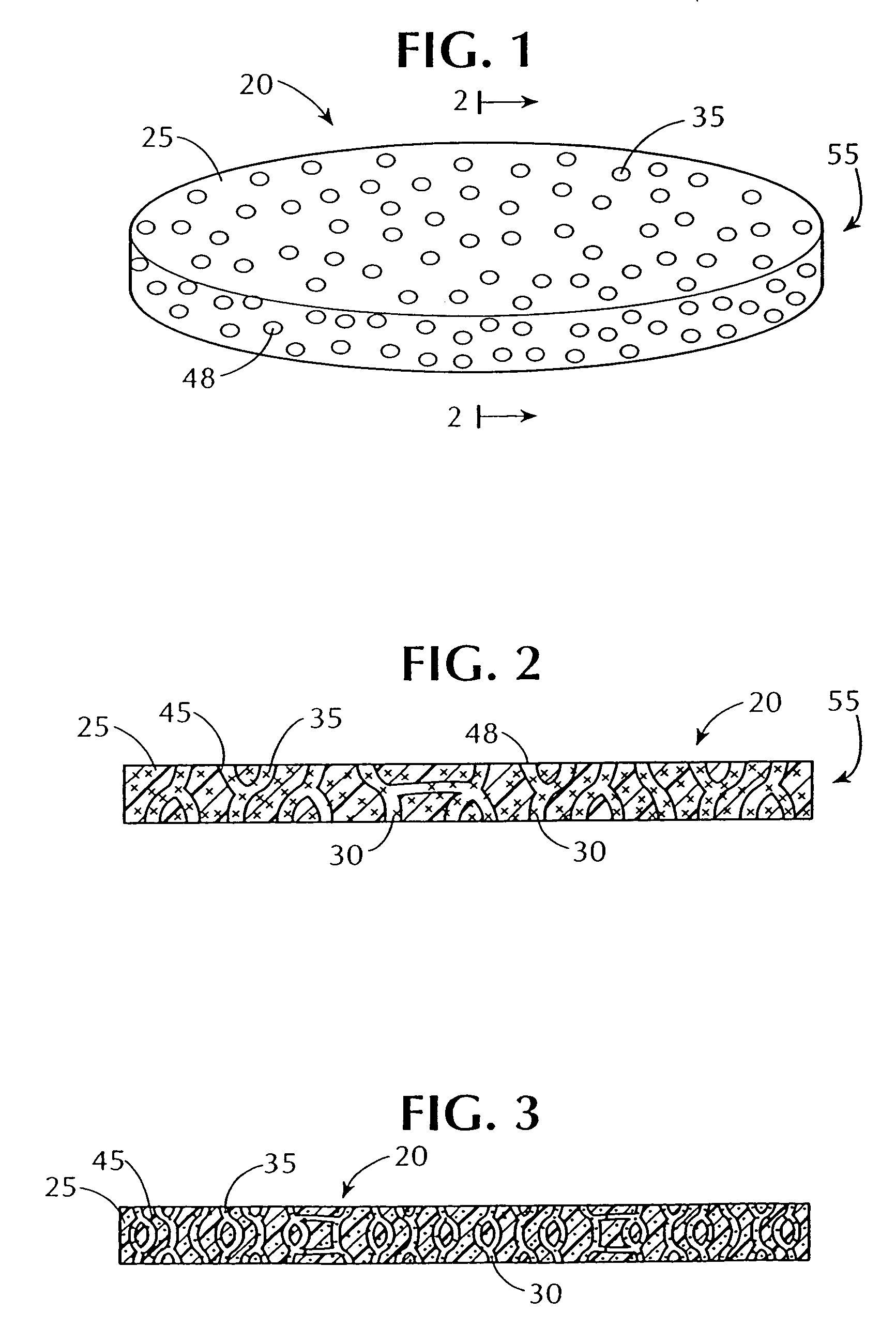

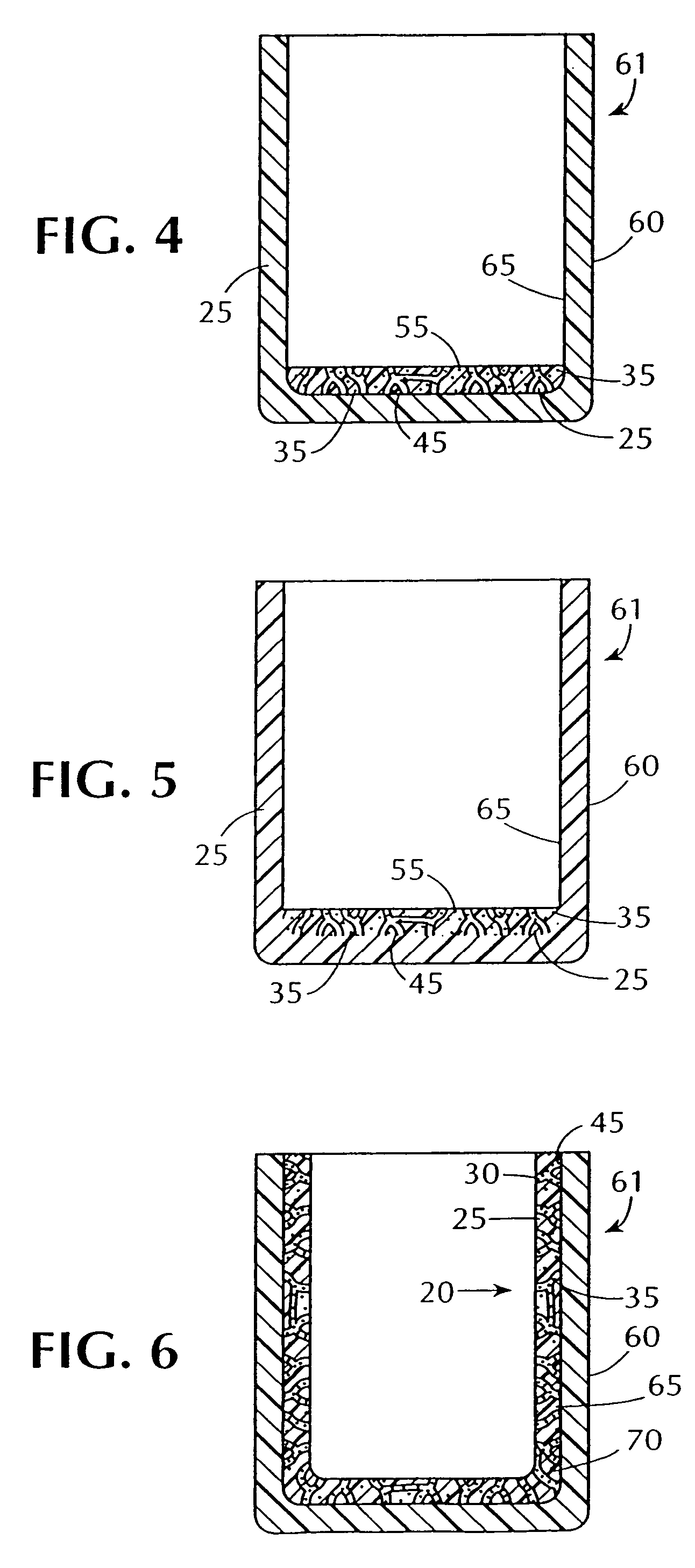

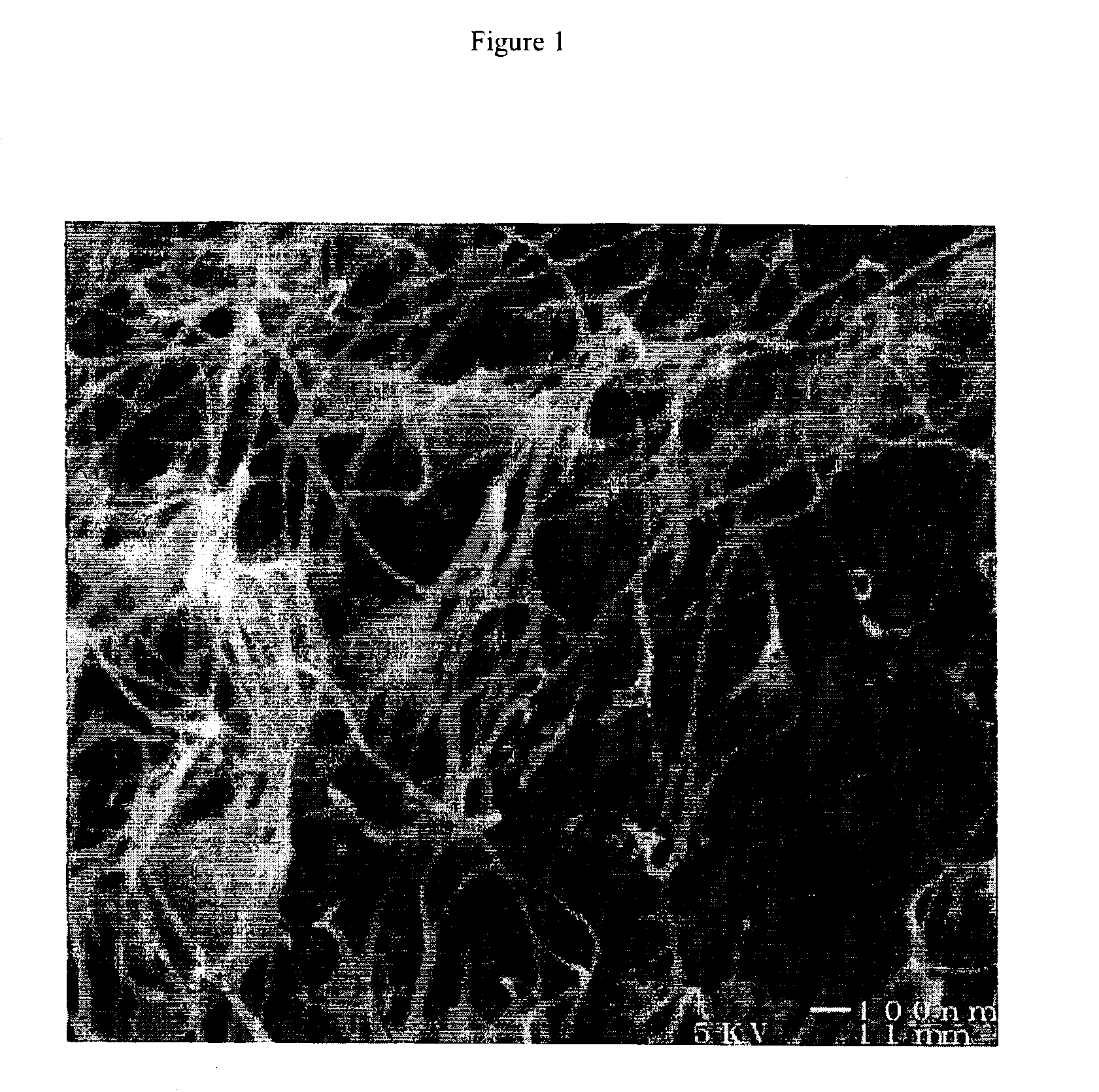

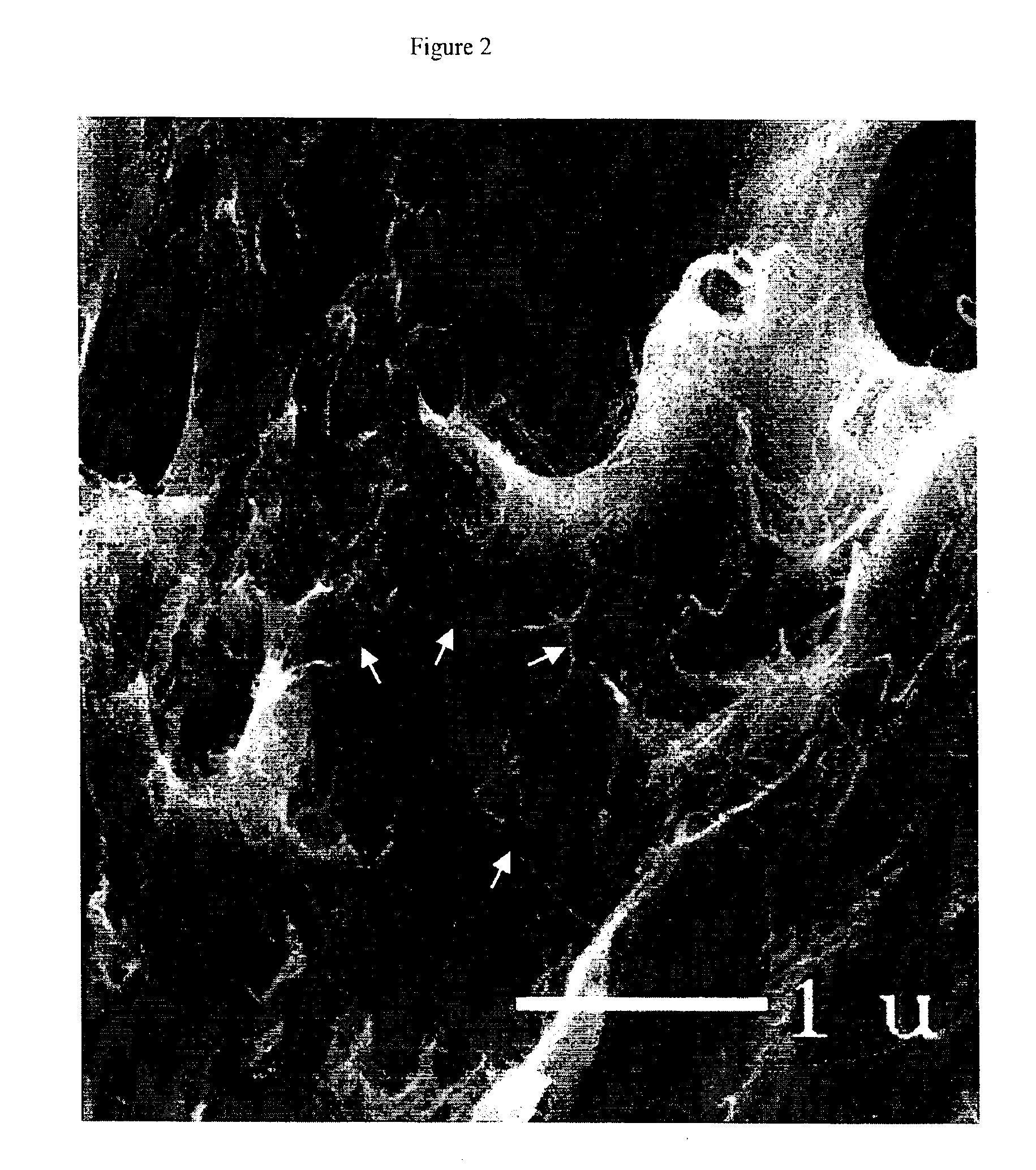

Desiccant entrained polymer

The present invention includes a composition having a co-continuous interconnecting channel morphology. These co-continuous interconnecting channels are predominately occupied with a polymer and particles that control the percolation through the composition. The particles are composed of a material such as an absorbing agent, releasing agent and / or activation agent. The polymer composition may be used to form a desired shaped article such as plug type inserts and liners for closed containers, or it may be formed into a film, sheet, bead or pellet.

Owner:CSP TECH NORTH AMERICA

Biocompatible crosslinked coating and crosslinkable coating polymer composition for forming such a coating

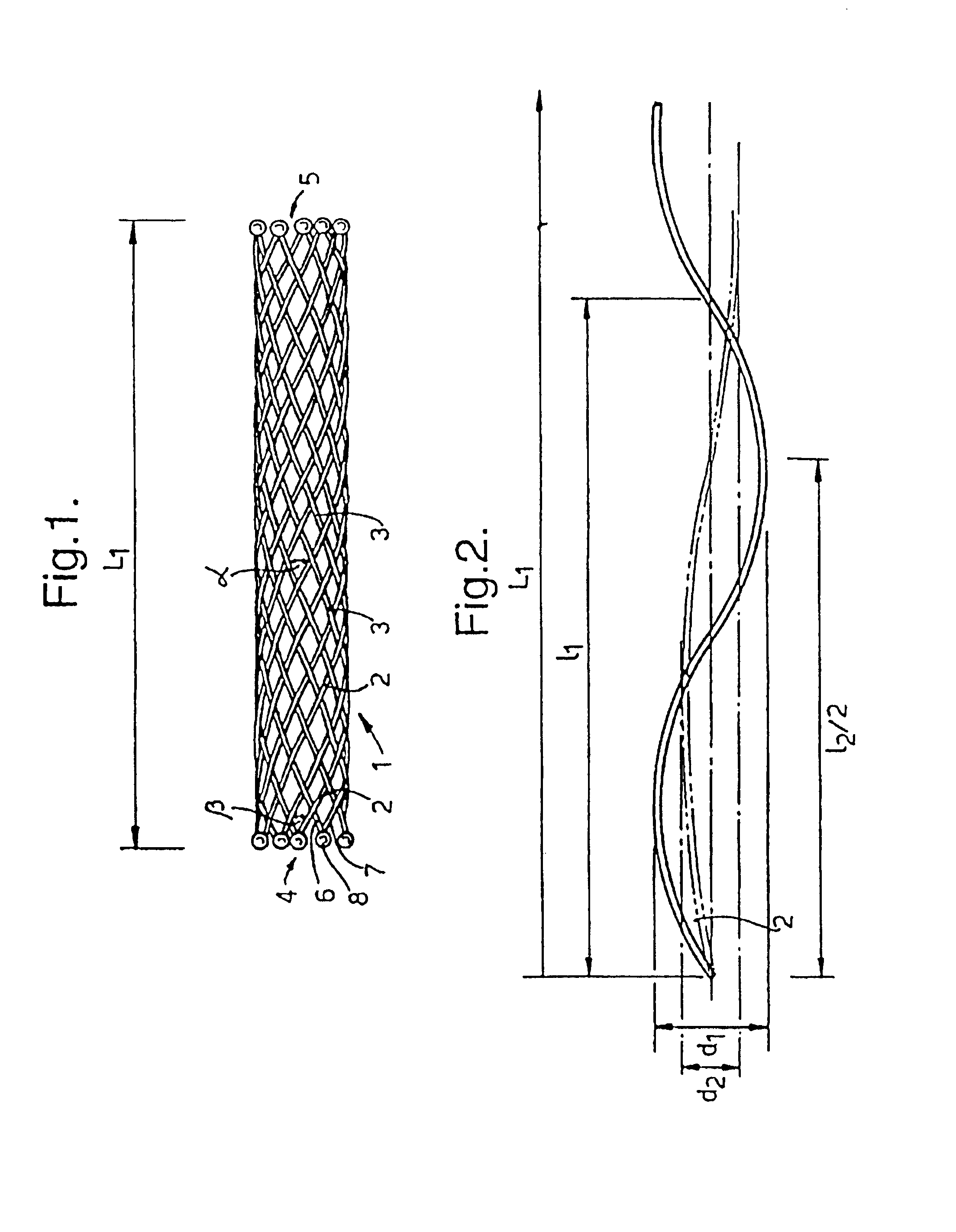

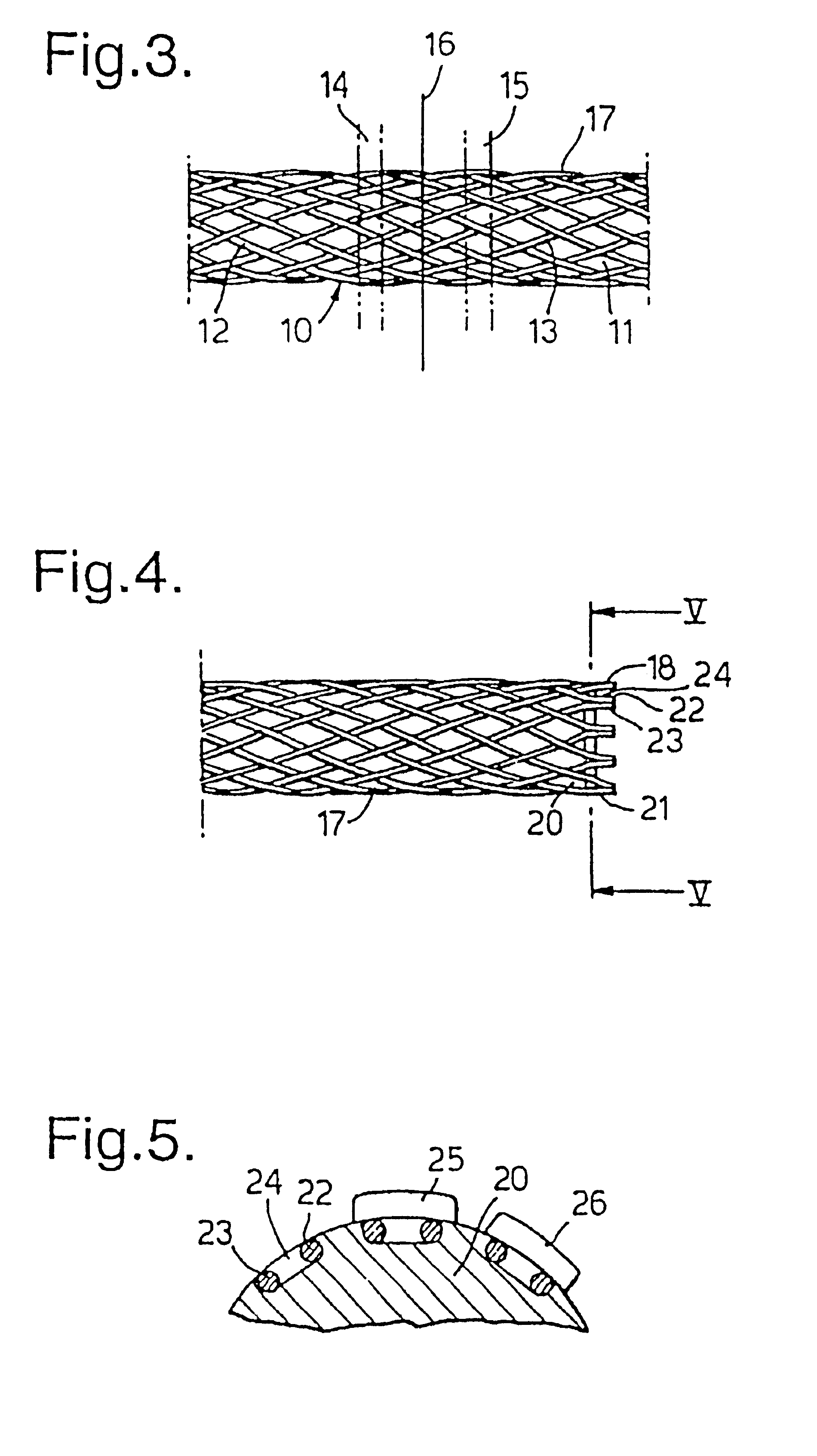

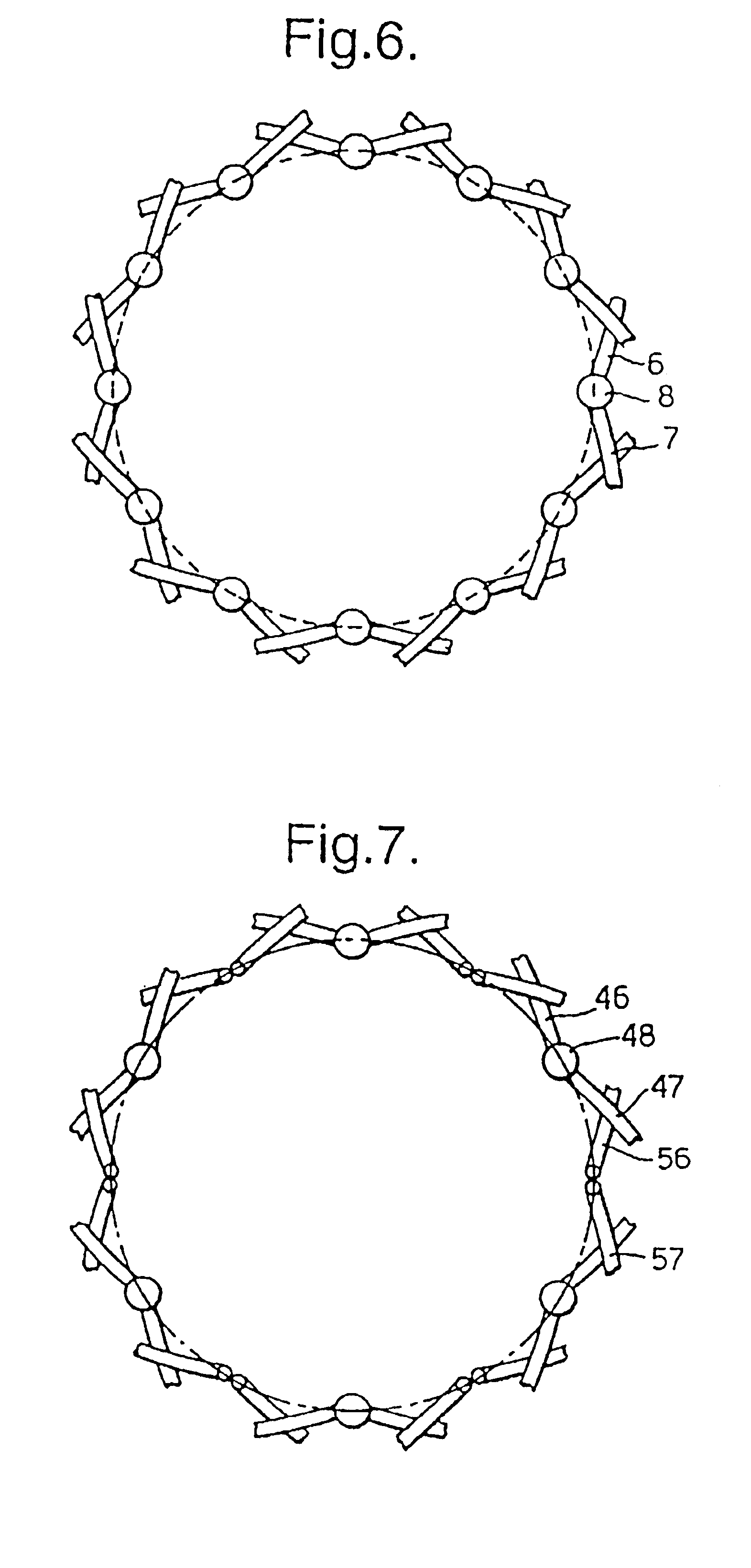

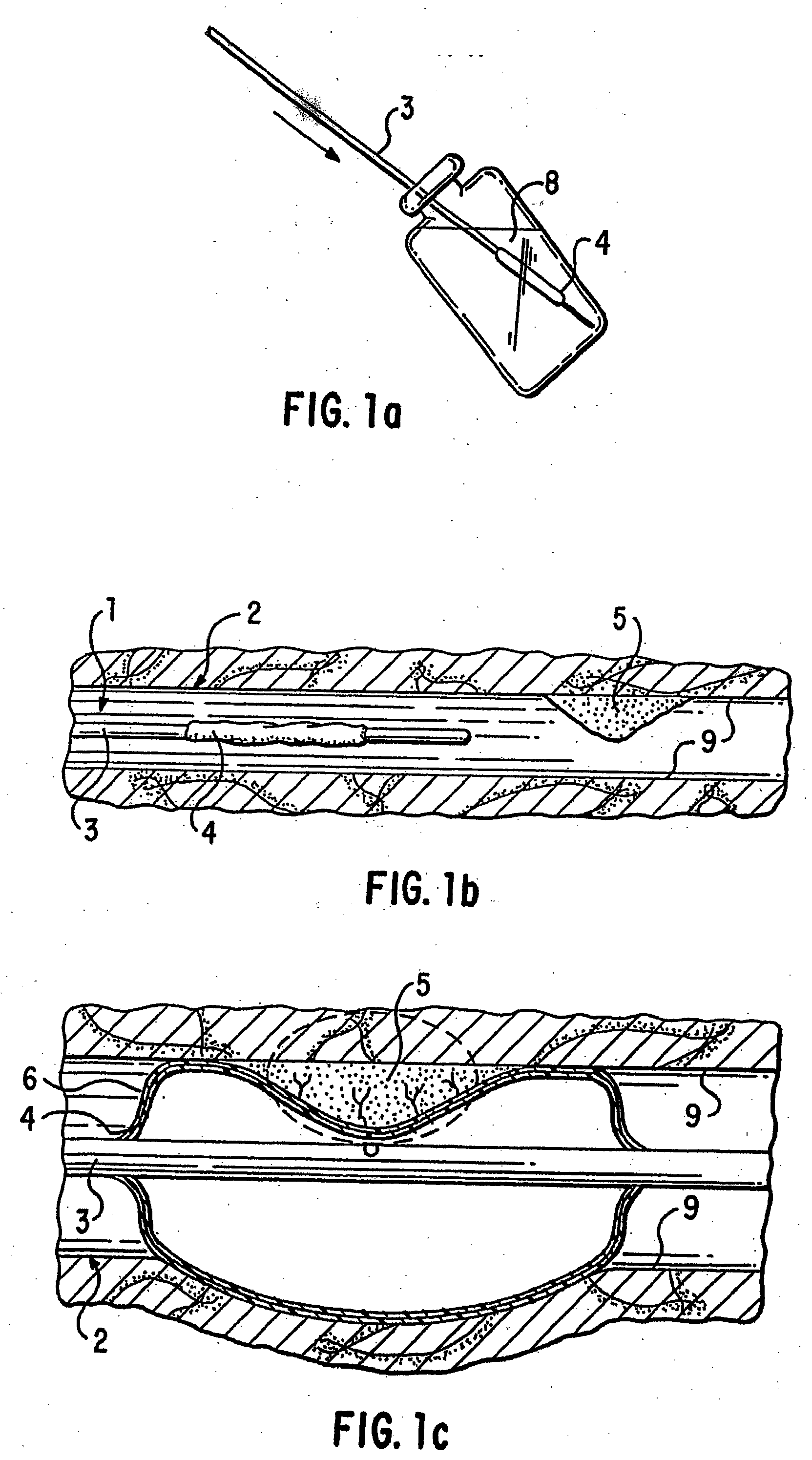

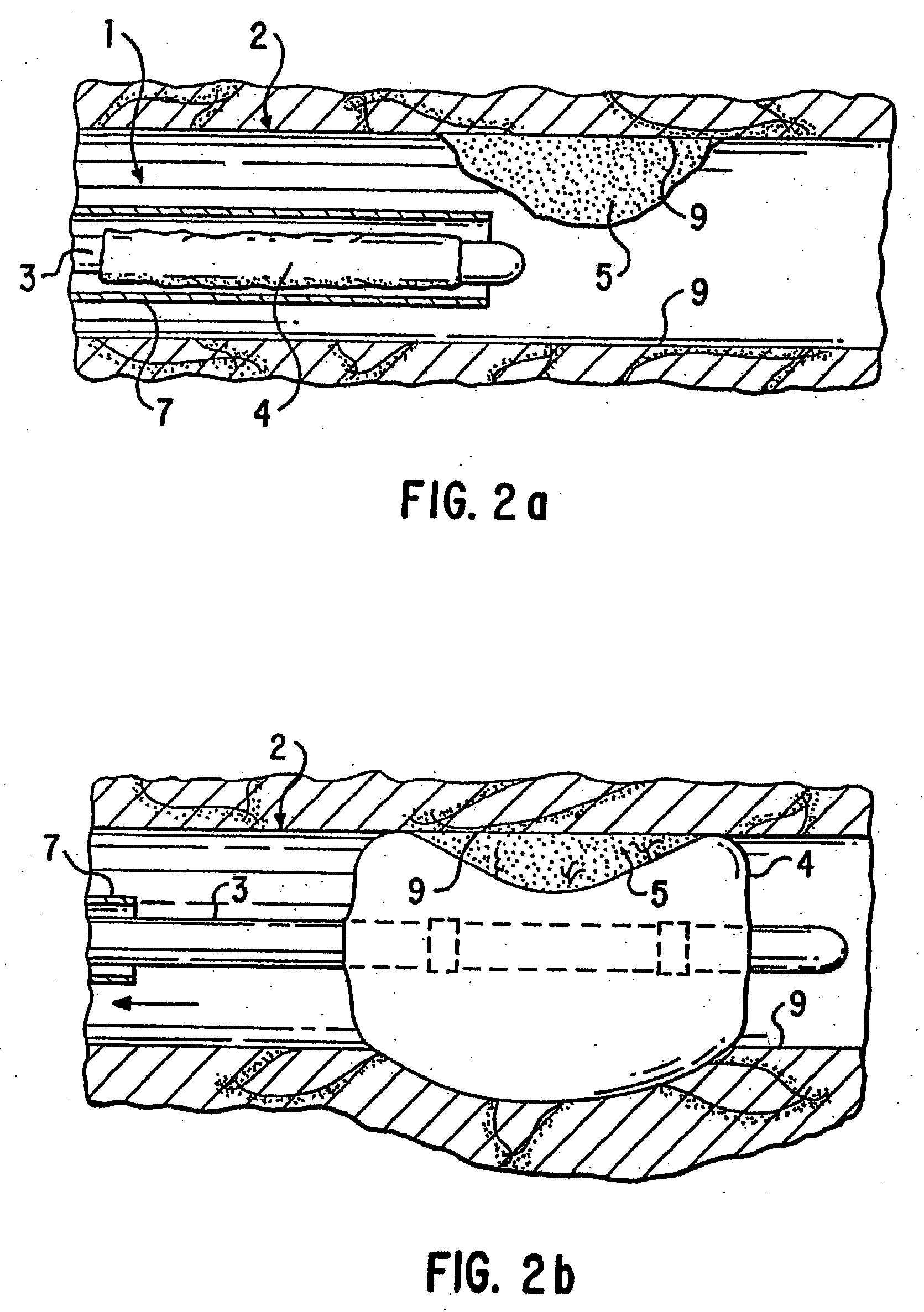

A braided stent (1) for transluminal implantation in body lumens is self-expanding and has a radial expanded configuration in which the angle α between filaments is acute. Some or all of filaments (6,7) are welded together in pairs at each end (4,5) of the stent to provide beads (8), thereby strengthening the stent and assisting its deployment from a delivery device. The stent is preferably completely coated using a biocompatible polymeric coating, said polymer preferably having pendant phosphoryl choline groups. A method of making the stent by braiding and welding is described as well as a delivery device for deploying the device.The present invention provides a biocompatible crosslinked coating and a crosslinkable coating polymer composition for forming such a coating. The biocompatible crosslinked coating may be formed by curing a polymer of 23 mole % (methacryloyloxy ethyl)-2-(trimethylammonium ethyl) phosphate inner salt, 47 mole % lauryl methacrylate, 5 mole % γtrimethoxysilyl propyl methacrylate and 25 mole % of hydroxy propyl methacrylate. The crosslinkable coating polymer may include 23 mole % (methacryloyloxy ethyl)-2-(trimethylammonium ethyl) phosphate inner salt, 47 mole % lauryl methacrylate, 5 mole % γtrimethoxysilyl propyl methacrylate and 25 mole % of hydroxy propyl methacrylate.<?insert-end id="INS-S-00001" ?>

Owner:BIOCOMPATIBLES UK LTD

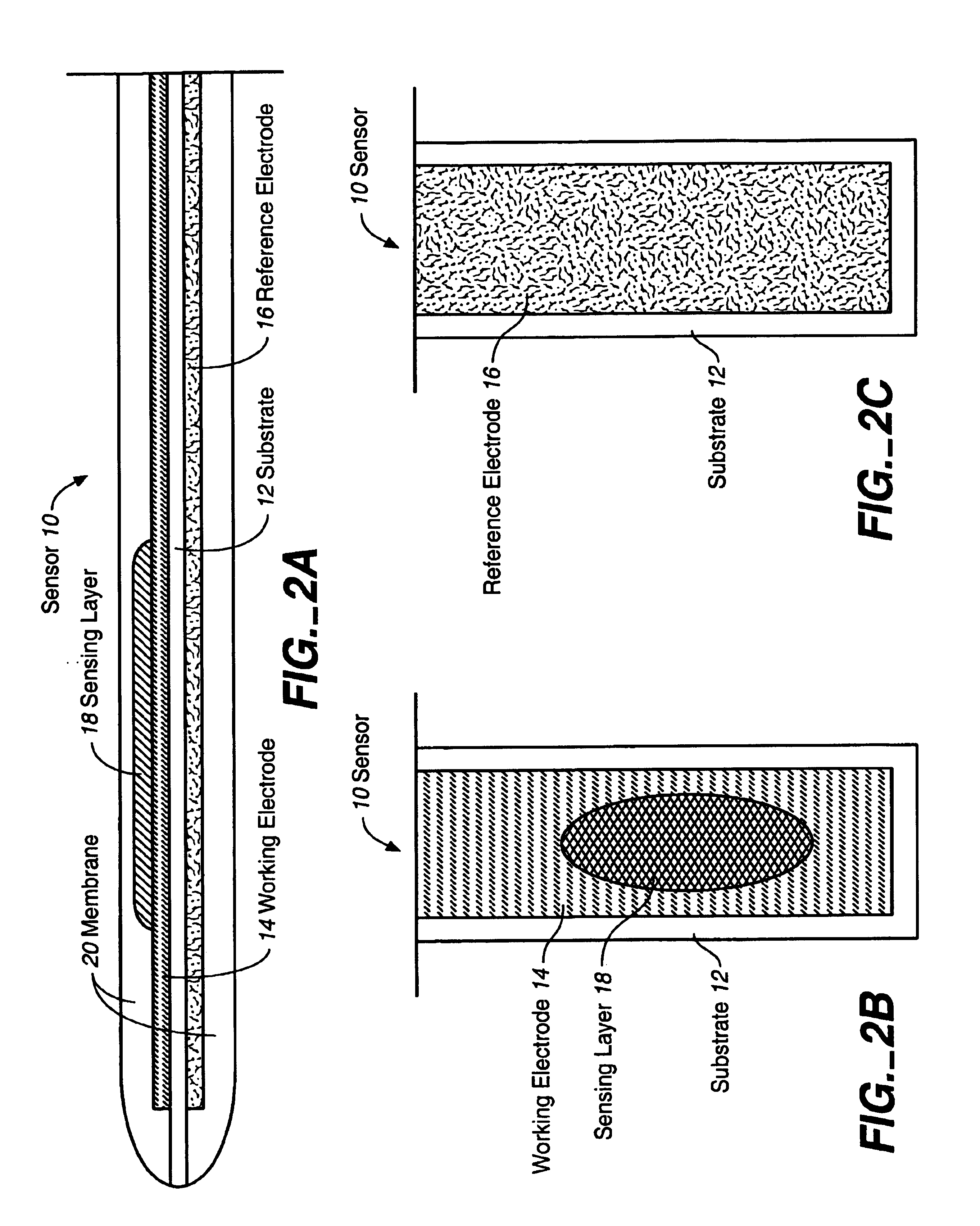

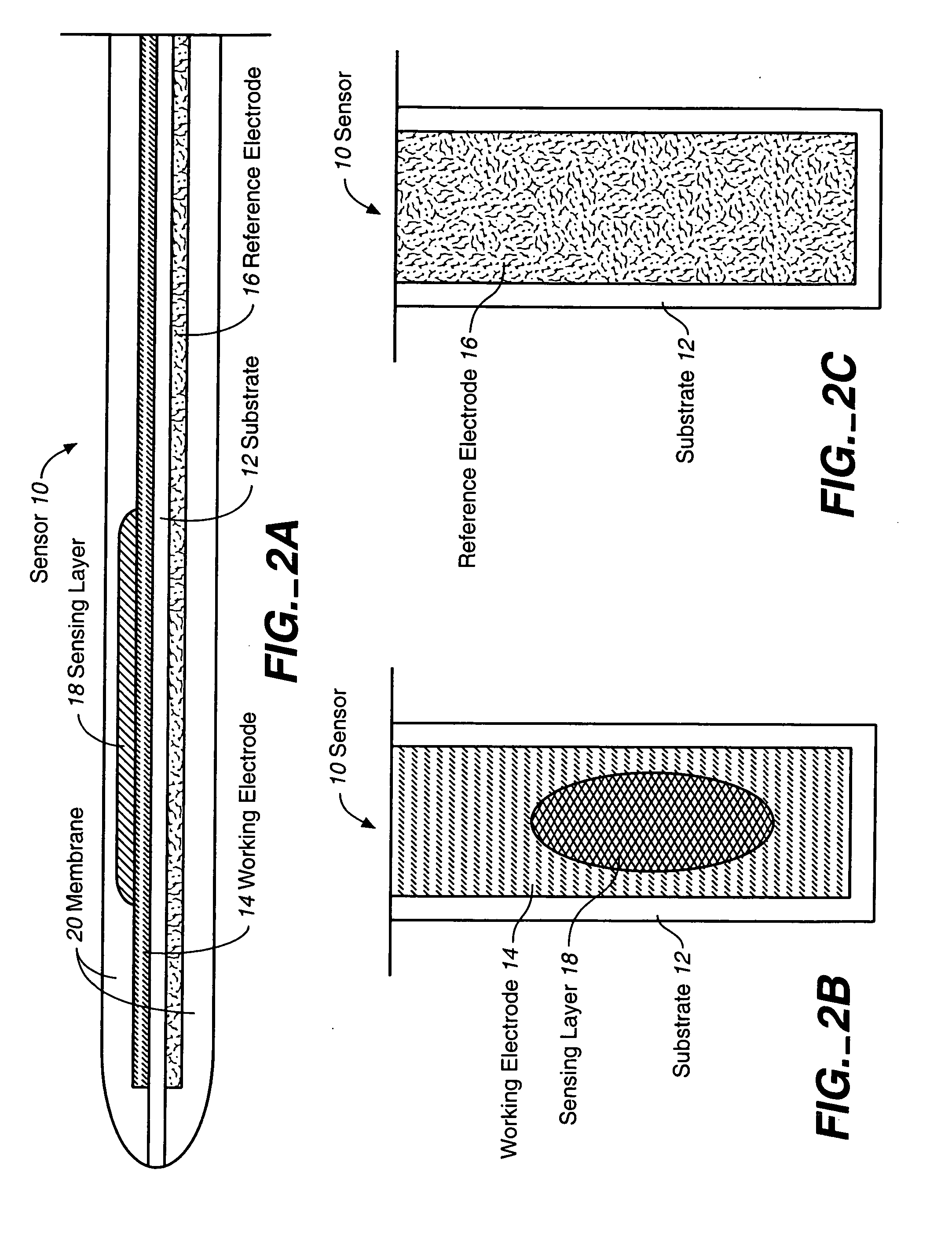

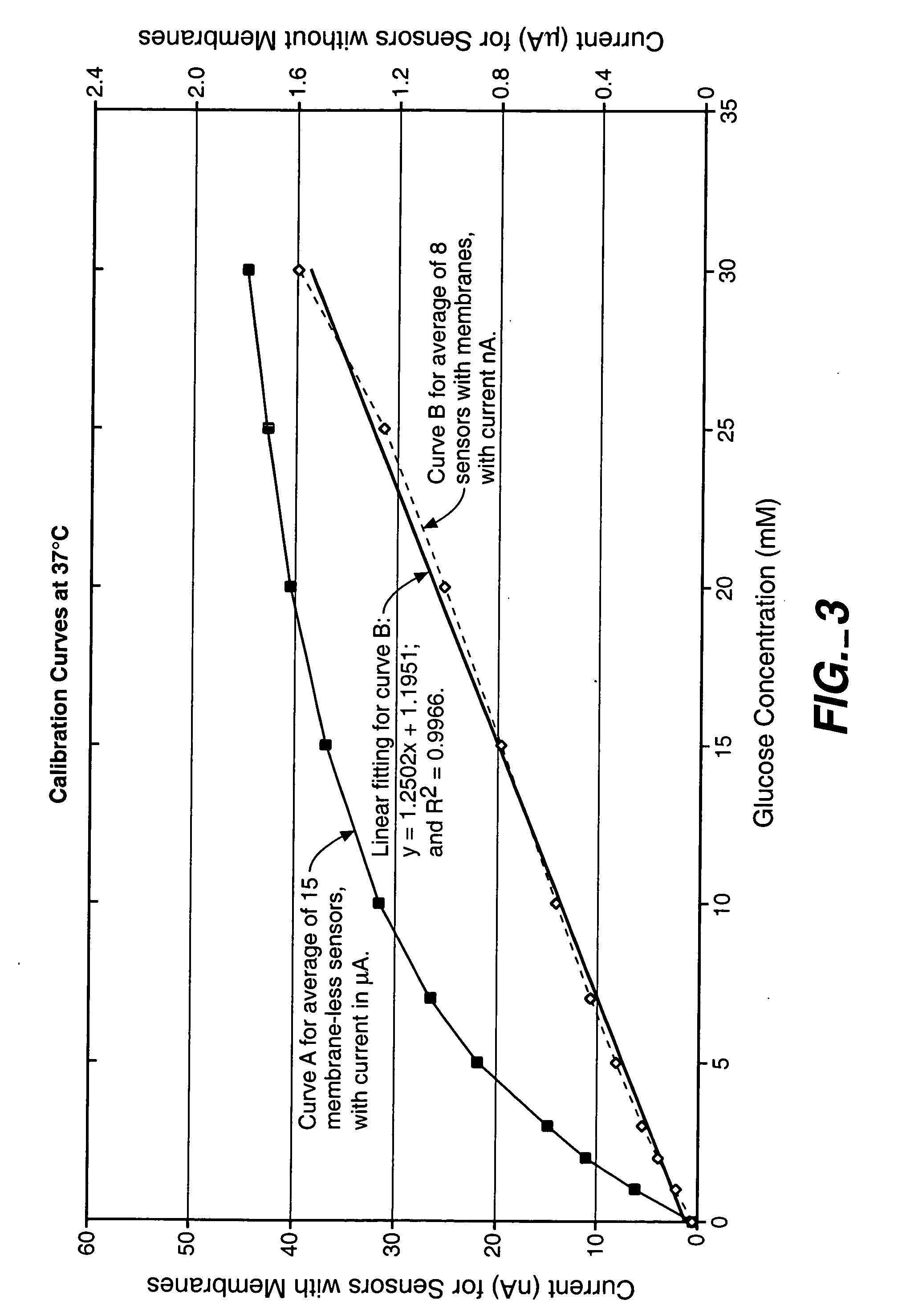

Membrane suitable for use in an analyte sensor, analyte sensor, and associated method

ActiveUS7699964B2Facilitate linear responsiveness and calibration and stabilityPreserve and improve performance of sensorImmobilised enzymesBioreactor/fermenter combinationsMetaboliteAmperometric biosensor

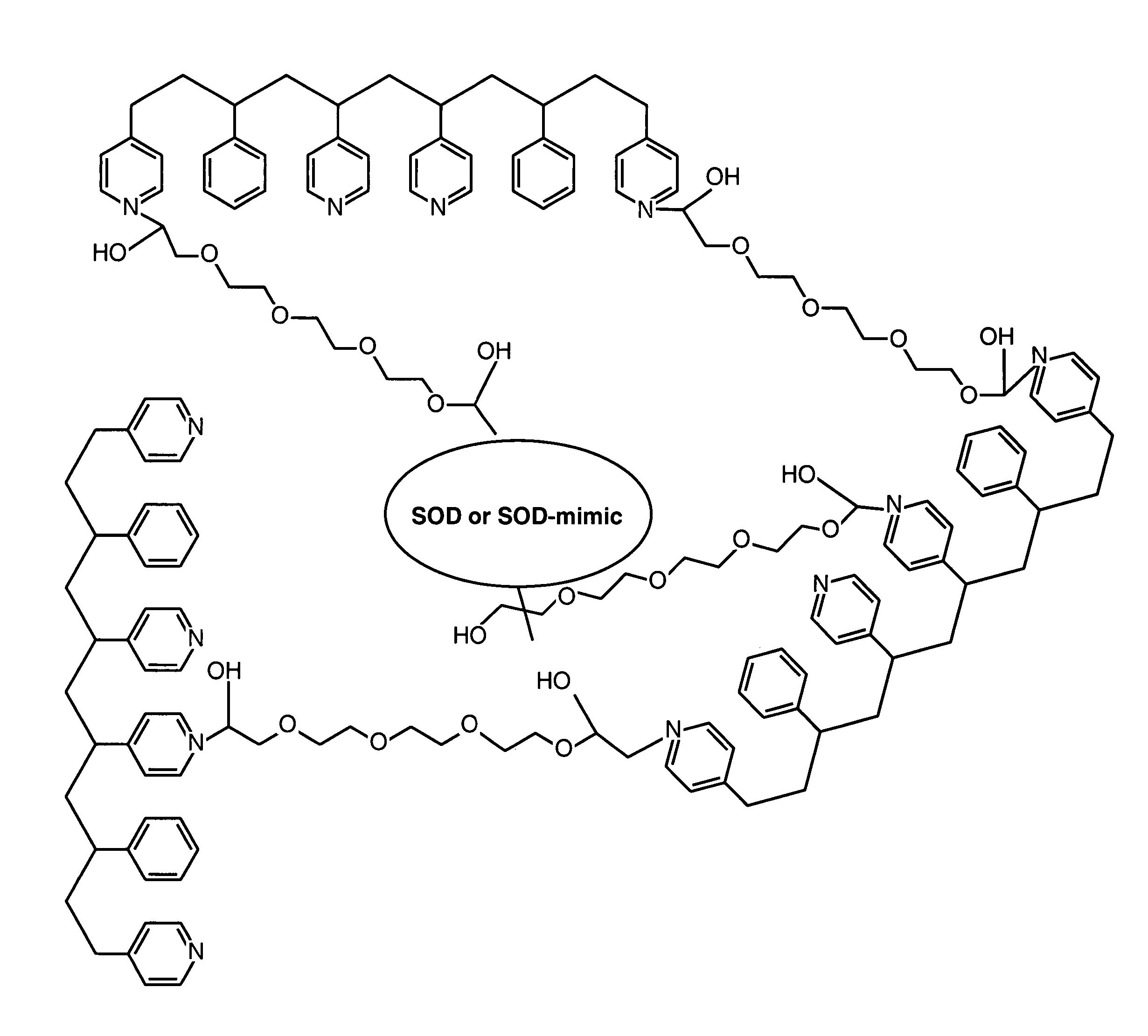

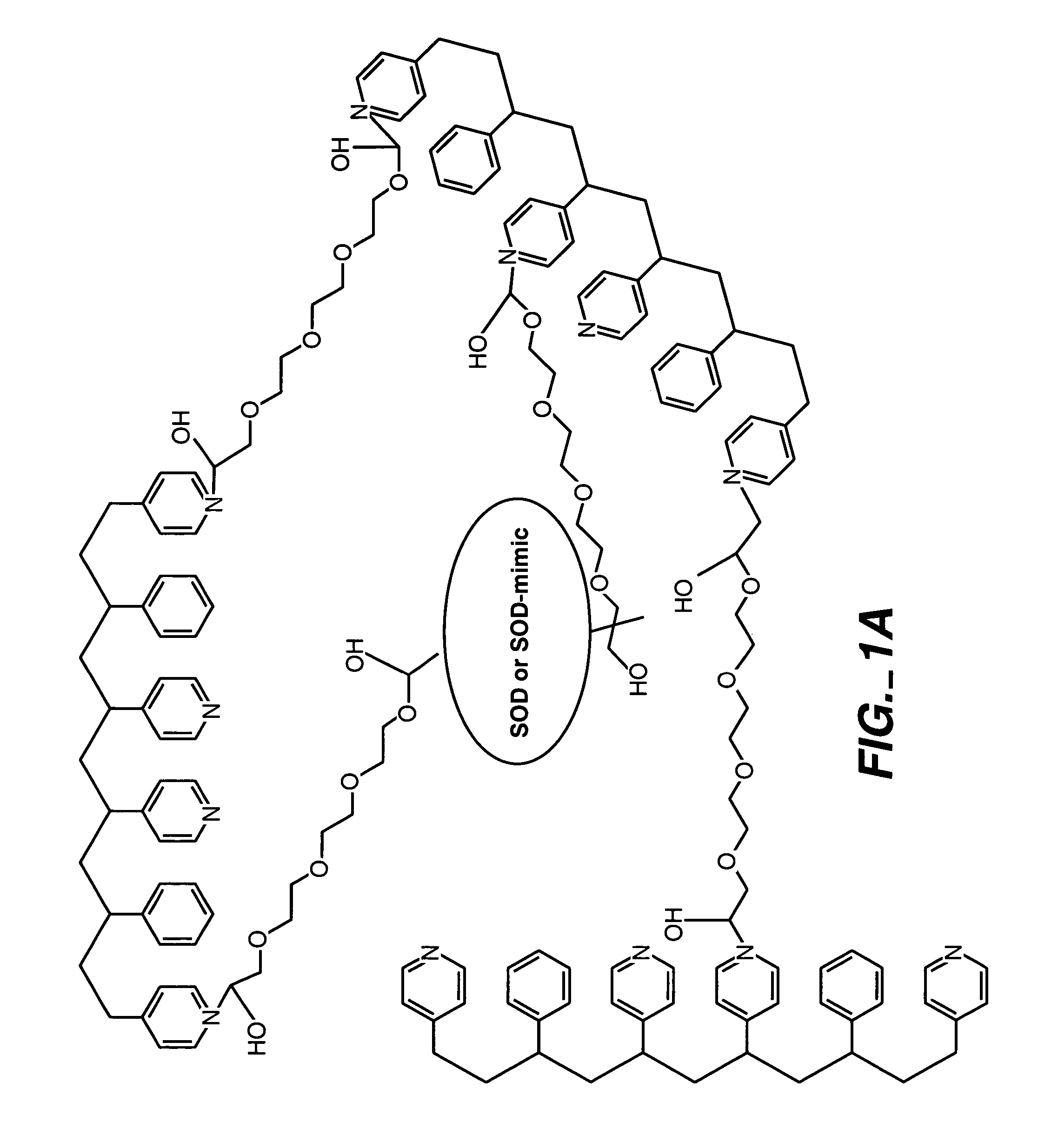

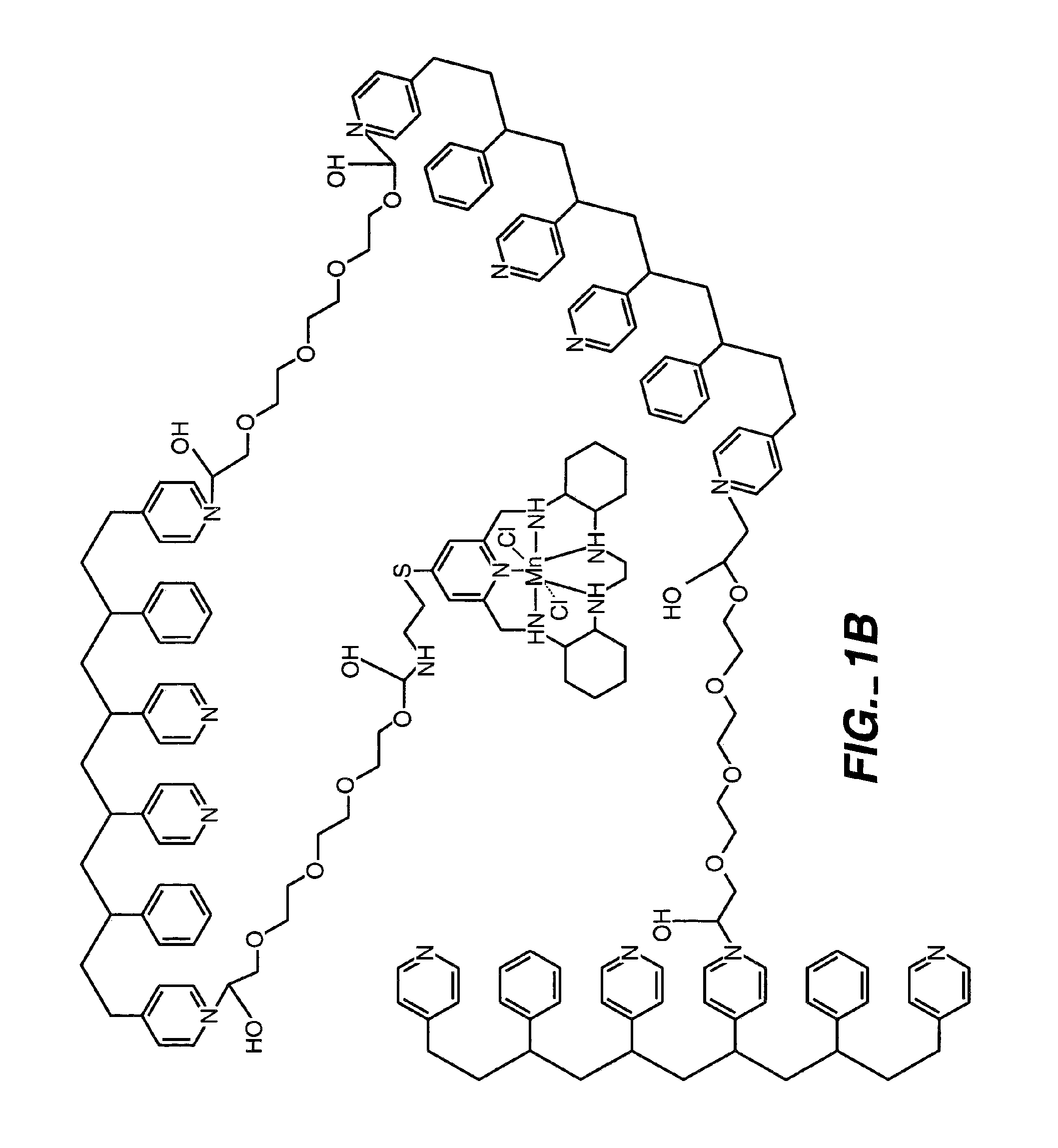

A multifunctional membrane is provided. The multifunctional membrane is suitable for use in an analyte sensor. In a particular application, the multifunctional membrane may be used in connection with an amperometric biosensor, such as a transcutaneous amperometric biosensor. Some functions of the membrane are associated with properties of membrane itself, which is comprised of crosslinked polymers containing heterocyclic nitrogen groups. For example, the membrane, by virtue of its polymeric composition, may regulate the flux of an analyte to a sensor. Such regulation generally improves the kinetic performance of the sensor over a broad range of analyte concentration. Other functions of the membrane are associated with functional components, such as a superoxide-dismutating / catalase catalyst, either in the form of an enzyme or an enzyme mimic, that can be bound to the scaffold provided by the membrane. The effect of any such enzyme or enzyme mimic is to lower the concentration of a metabolite, such as superoxide and / or hydrogen peroxide, in the immediate vicinity of the sensing layer of the biosensor. Lowering the concentrations of such metabolites, which are generally deleterious to the function of the sensor, generally protects or enhances biosensor integrity and performance. The membrane is thus an important tool for use in connection with analyte sensors, amperometric sensors, biosensors, and particularly, transcutaneous biosensors. A membrane-covered sensor and a method for making same are also provided.

Owner:ABBOTT DIABETES CARE INC

Filled polymer compositions made from interpolymers of ethylene/a-olefins and uses thereof

A filled polymer composition comprises (i) an ethylene / α-olefin interpolymer, and (ii) a filler. The ethylene / α-olefin interpolymer is a block copolymer having at least a hard block and at least a soft block. The soft block comprises a higher amount of comonomers than the hard block. The block interpolymer has a number of unique characteristics disclosed here. The filled polymer compositions provided herein, in certain embodiments, have relatively higher heat resistance and improved noise, vibration and harshness properties and can be used in automotive floorings, roofings, wire and cable coating applications.

Owner:DOW GLOBAL TECH LLC

Anti-blocking compositions comprising interpolymers of ethylene/alpha-olefins

Owner:DOW GLOBAL TECH LLC

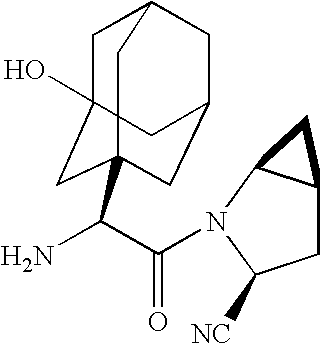

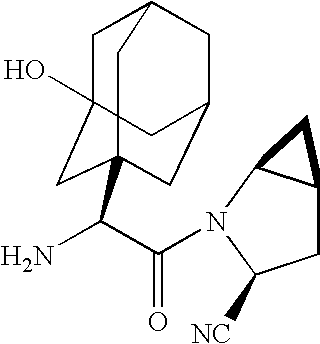

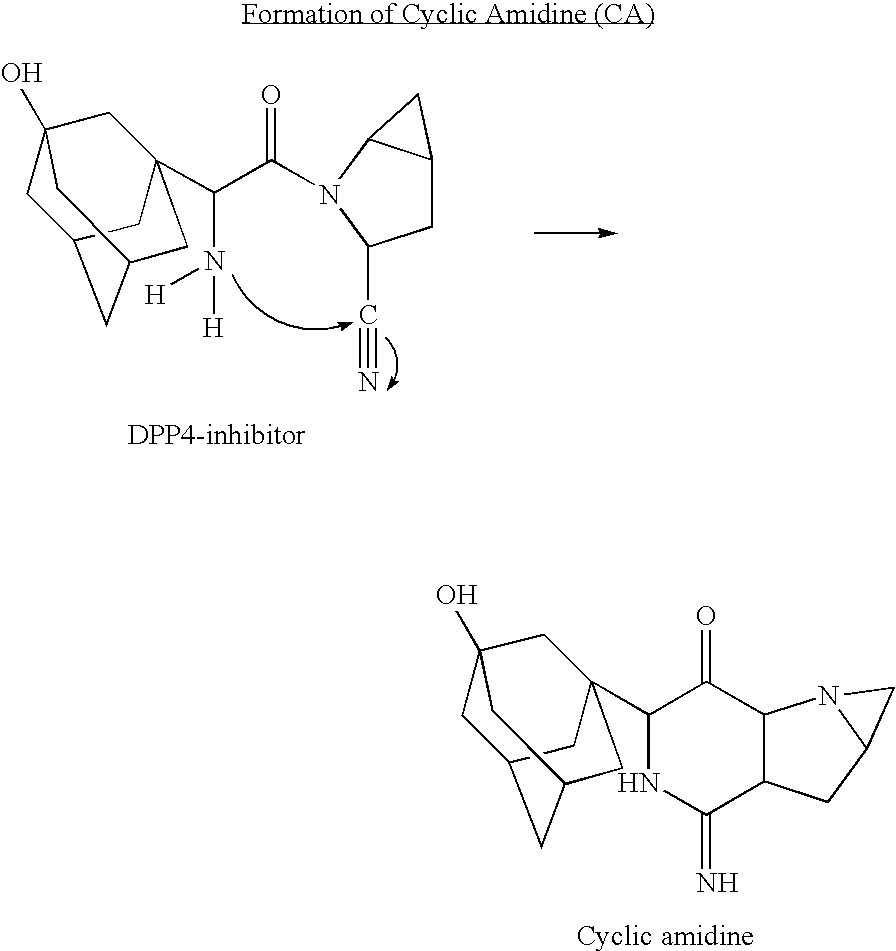

Coated tablet formulation and method

ActiveUS20050266080A1Good chemical stabilityEasy to prepareBiocideMetabolism disorderCoated tabletsExcipient

A coated tablet formulation is provided which includes a medicament such as the DPP4-inhibitor, saxaglipitin or its HCl salt, which is subject to intra-molecular cyclization, which formulation includes a tablet core containing one or more fillers, and other conventional excipients, which tablet core includes a coating thereon which may include two or more layers, at least one layer of which is an inner seal coat layer which is formed of one or more coating polymers, a second layer of which is formed of medicament which is the DPP4-inhibitor and one or more coating polymers, and an optional, but preferable third outer protective layer which is formed of one or more coating polymers. A method for forming the coated tablet is also provided.

Owner:ASTRAZENECA AB

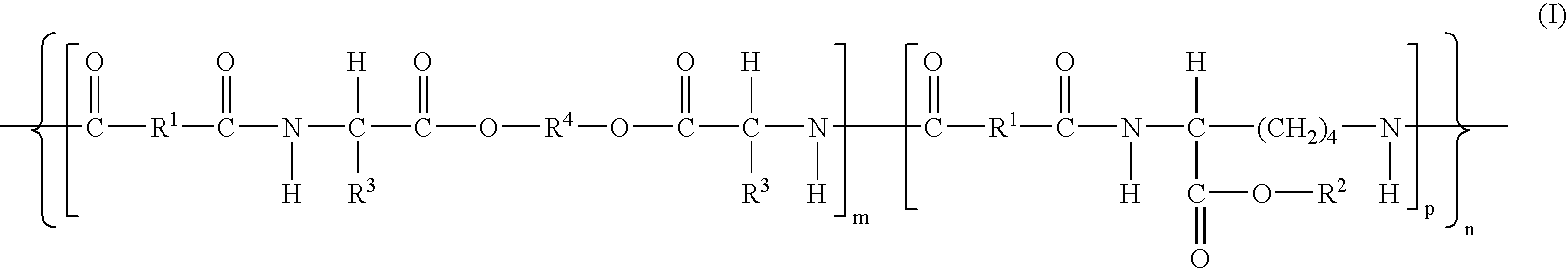

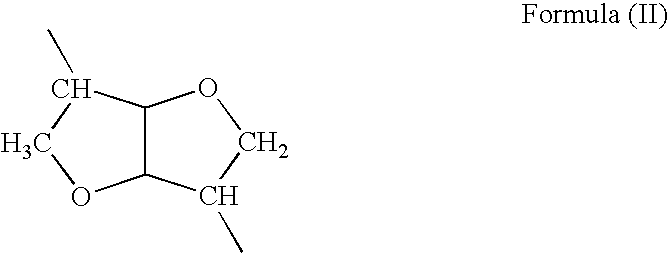

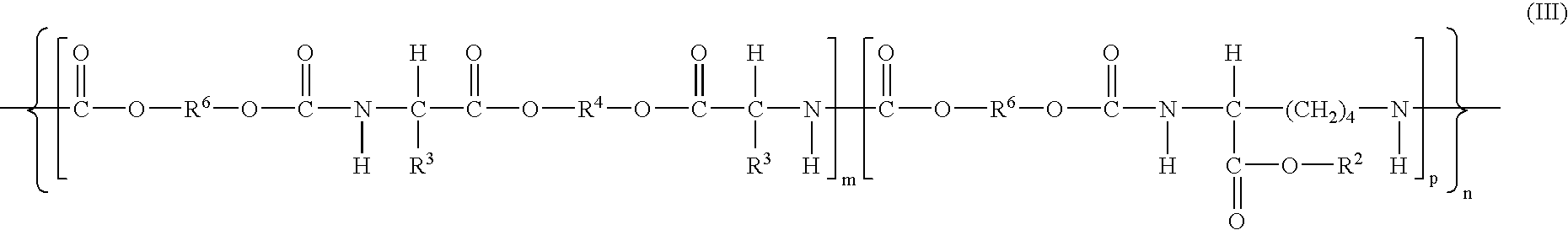

Wound healing polymer compositions and methods for use thereof

The present invention provides bioactive polymer compositions that can be formulated to release a wound healing agent at a controlled rate by adjusting the various components of the composition. The composition can be used in an external wound dressing, as a polymer implant for delivery of the wound healing agent to an internal body site, or as a coating on the surface of an implantable surgical device to deliver wound healing agents that are covalently attached to a biocompatible, biodegradable polymer and / or embedded within a hydrogel. Methods of using the invention bioactive polymer compositions to promote natural healing of wounds, especially chronic wounds, are also provided. Examples of biodegradable copolymer polyesters useful in forming the blood-compatible, hydrophilic layer or coating include copolyester amides, copolyester urethanes, glycolide-lactide copolymers, glycolide-caprolactone copolymers, poly-3-hydroxy butyrate-valerate copolymers, and copolymers of the cyclic diester monomer, 3-(S)[(alkyloxycarbonyl)methyl]-1,4-dioxane-2,5-dione, with L-lactide. The glycolide-lactide copolymers include poly(glycolide-L-lactide) copolymers formed utilizing a monomer mole ratio of glycolic acid to L-lactic acid ranging from 5:95 to 95:5 and preferably a monomer mole ratio of glycolic acid to L-lactic acid ranging from 45:65 to 95:5. The glycolide-caprolactone copolymers include glycolide and ε-caprolactone block copolymer, e.g., Monocryl or Poliglecaprone.

Owner:MEDIVAS LLC

Polymer compositions, method of manufacture, and articles formed therefrom

ActiveUS20060142455A1High tensile modulusImprove ductilityPigmenting treatmentMaterial nanotechnologyPolymer scienceFluoropolymer

A polymer composition is disclosed, which comprises a matrix polymer, a fluoropolymer that may be at least partially encapsulated by an encapsulating polymer, and a filler. Methods for making the polymer compositions and articles made of such compositions are also disclosed. The compositions and article can have improved tensile modulus, ductility, and / or impact properties.

Owner:SABIC INNOVATIVE PLASTICS IP BV

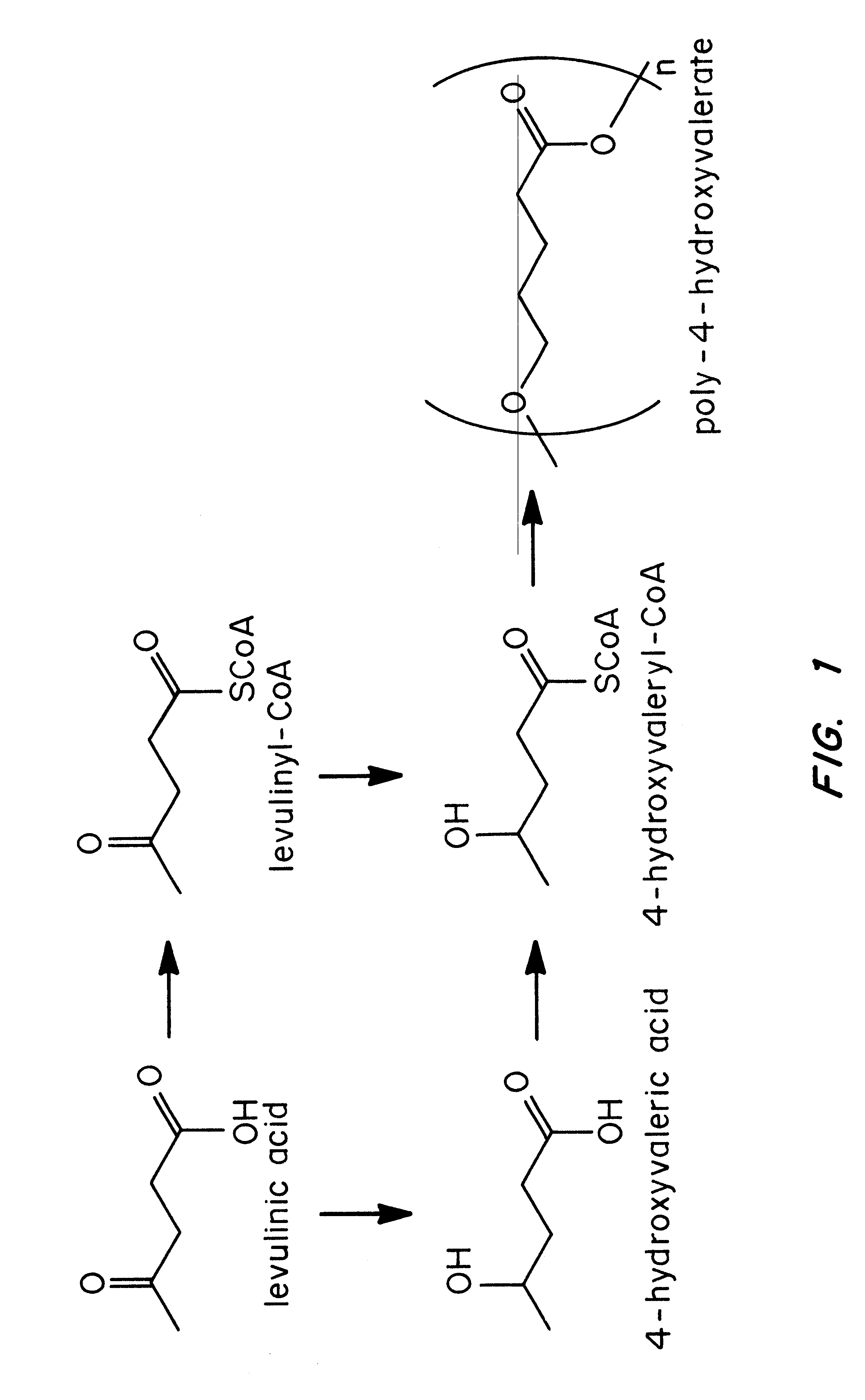

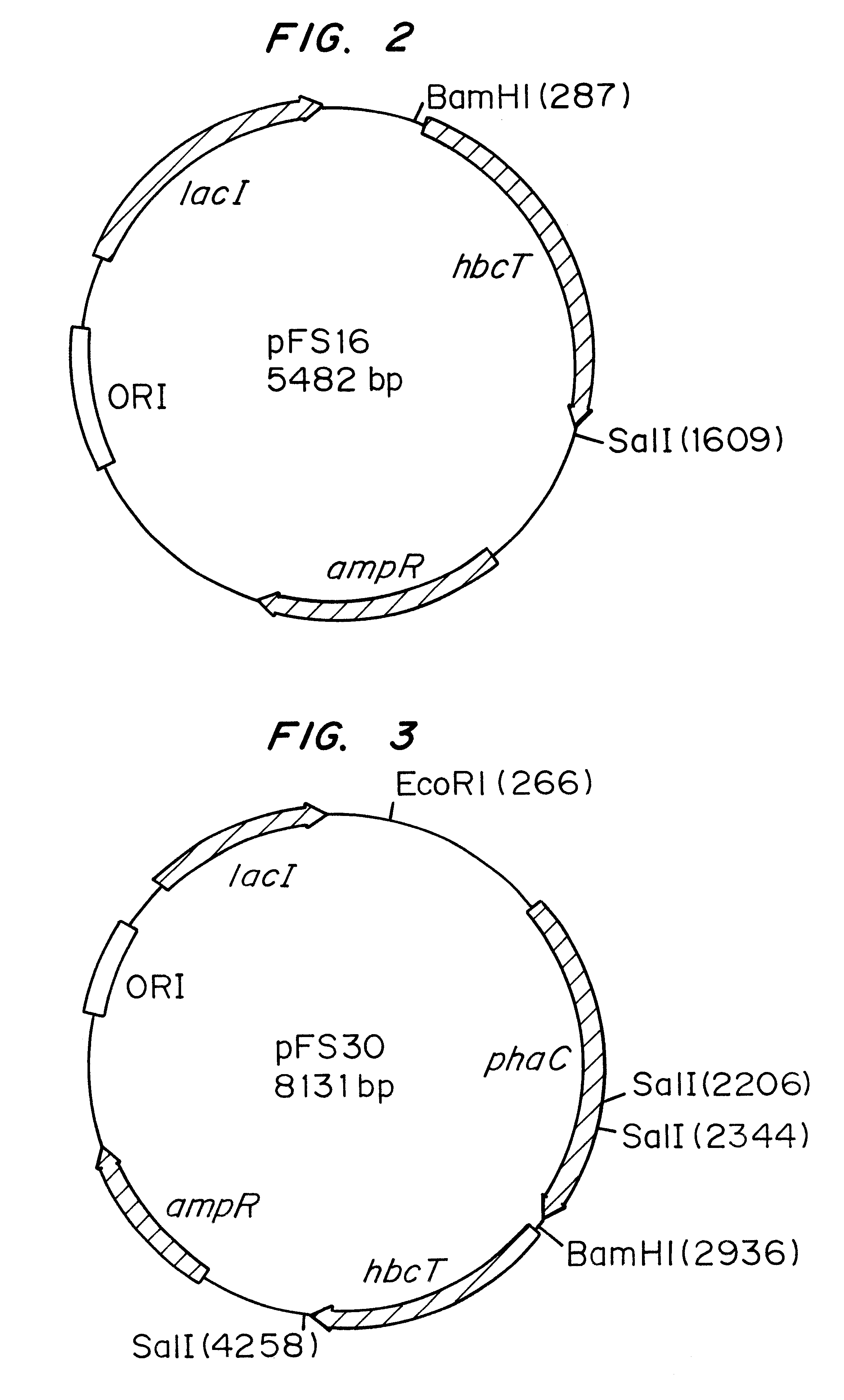

Polyhydroxyalkanoate biopolymer compositions

Several novel PHA polymer compositions produced using biological systems include monomers such as 3-hydroxybutyrate, 3-hydroxypropionate, 2-hydroxybutyrate, 3-hydroxyvalerate, 4-hydroxybutyrate, 4-hydroxyvalerate and 5-hydroxyvalerate. These PHA compositions can readily be extended to incorporate additional monomers including, for example, 3-hydroxyhexanoate, 4-hydroxyhexanoate, 6-hydroxyhexanoate or other longer chain 3-hydroxyacids containing seven or more carbons. This can be accomplished by taking natural PHA producers and mutating through chemical or transposon mutagenesis to delete or inactivate genes encoding undesirable activities. Alternatively, the strains can be genetically engineered to express only those enzymes required for the production of the desired polymer composition. Methods for genetically engineering PHA producing microbes are widely known in the art (Huisman and Madison, 1998, Microbiology and Molecular Biology Reviews, 63: 21-53). These polymers have a variety of uses in medical, industrial and other commercial areas.

Owner:METABOLIX

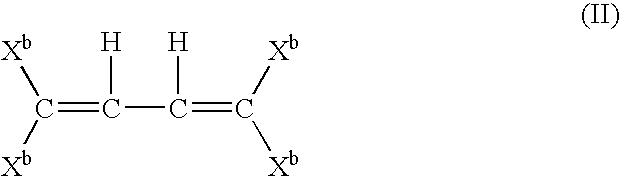

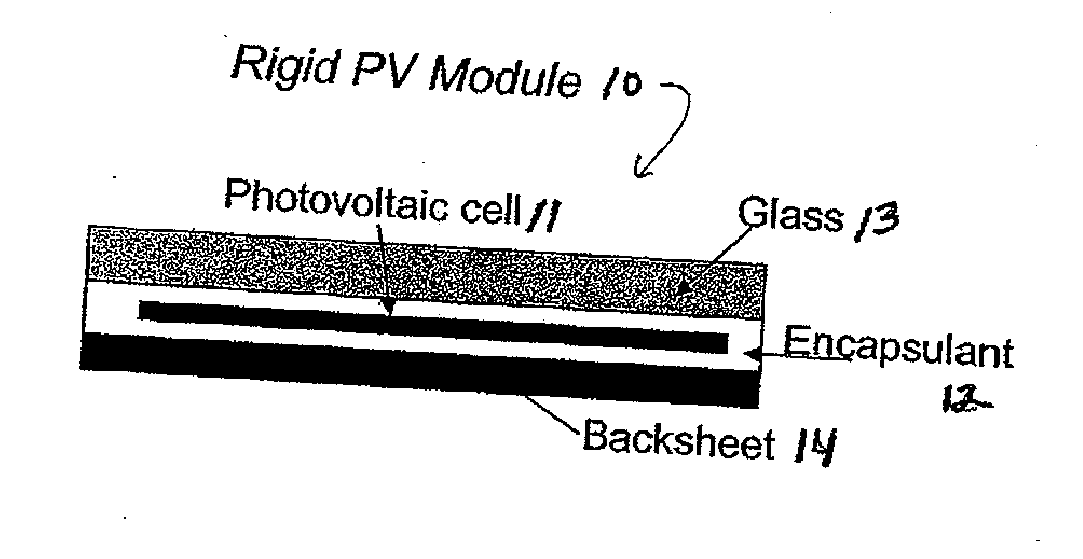

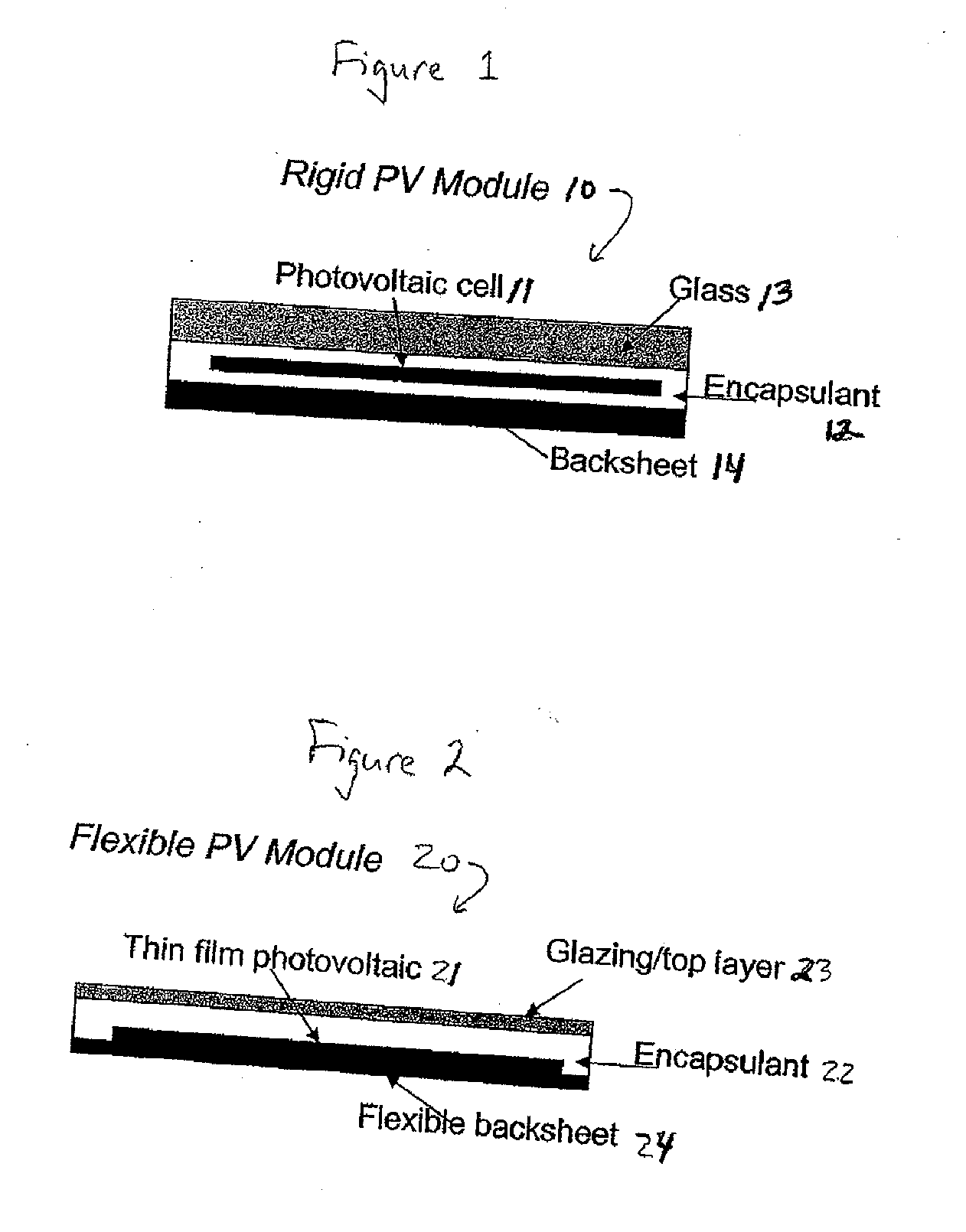

Electronic device module comprising polyolefin copolymer with low unsaturation and optional vinyl silane

InactiveUS20110290317A1Improve adhesionHigh processing temperatureGlass/slag layered productsPhotovoltaic energy generationPolymer sciencePolyolefin

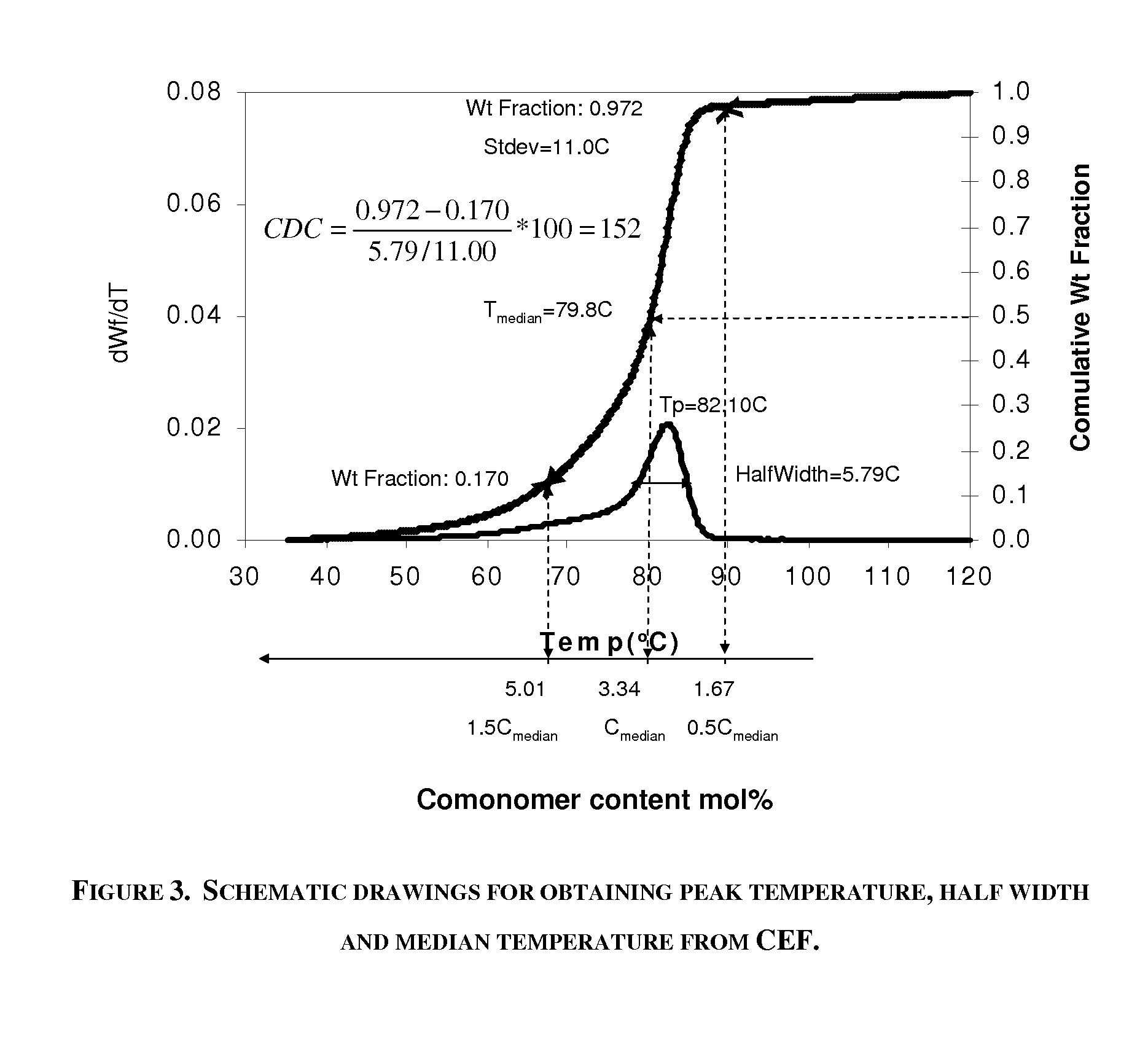

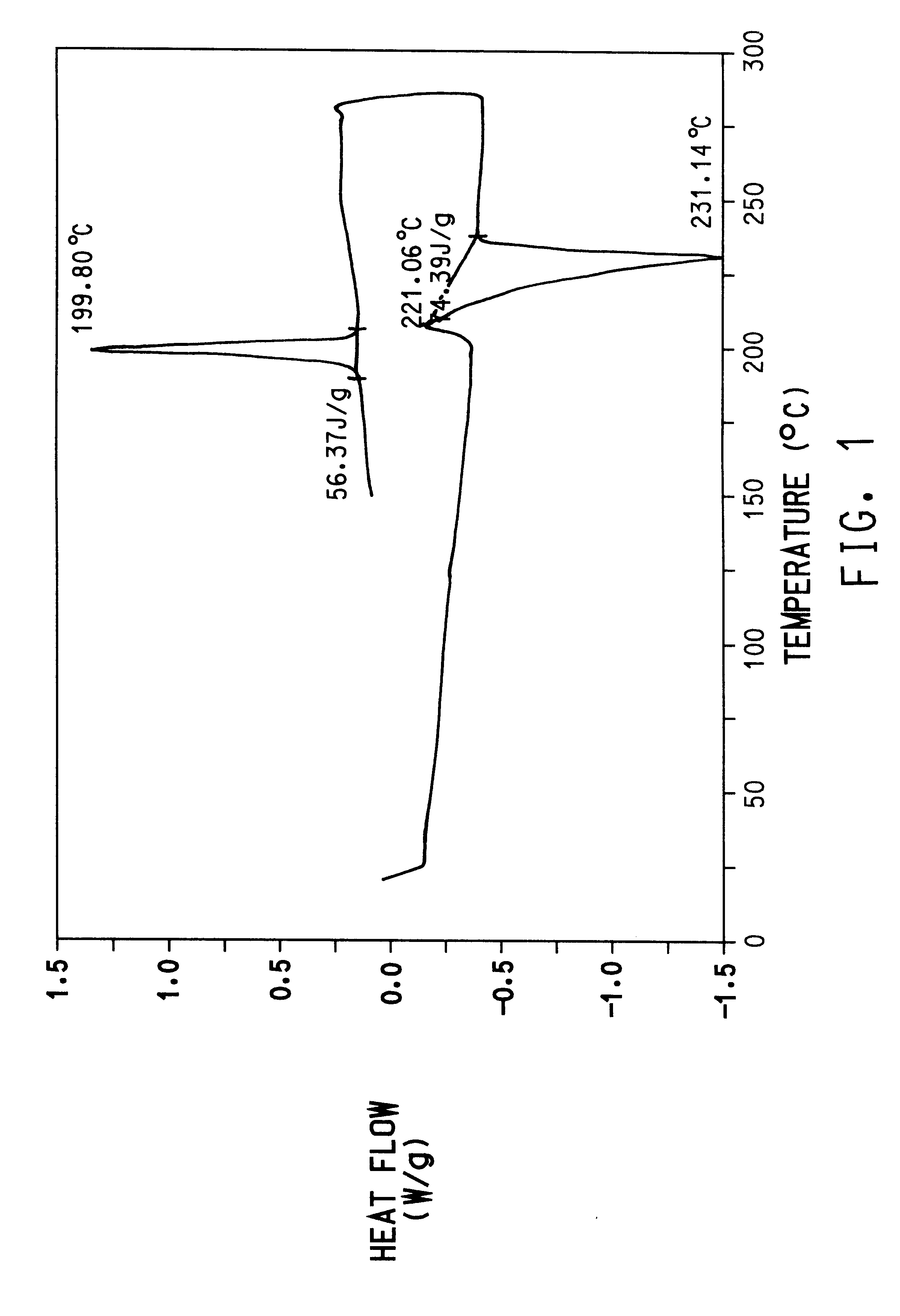

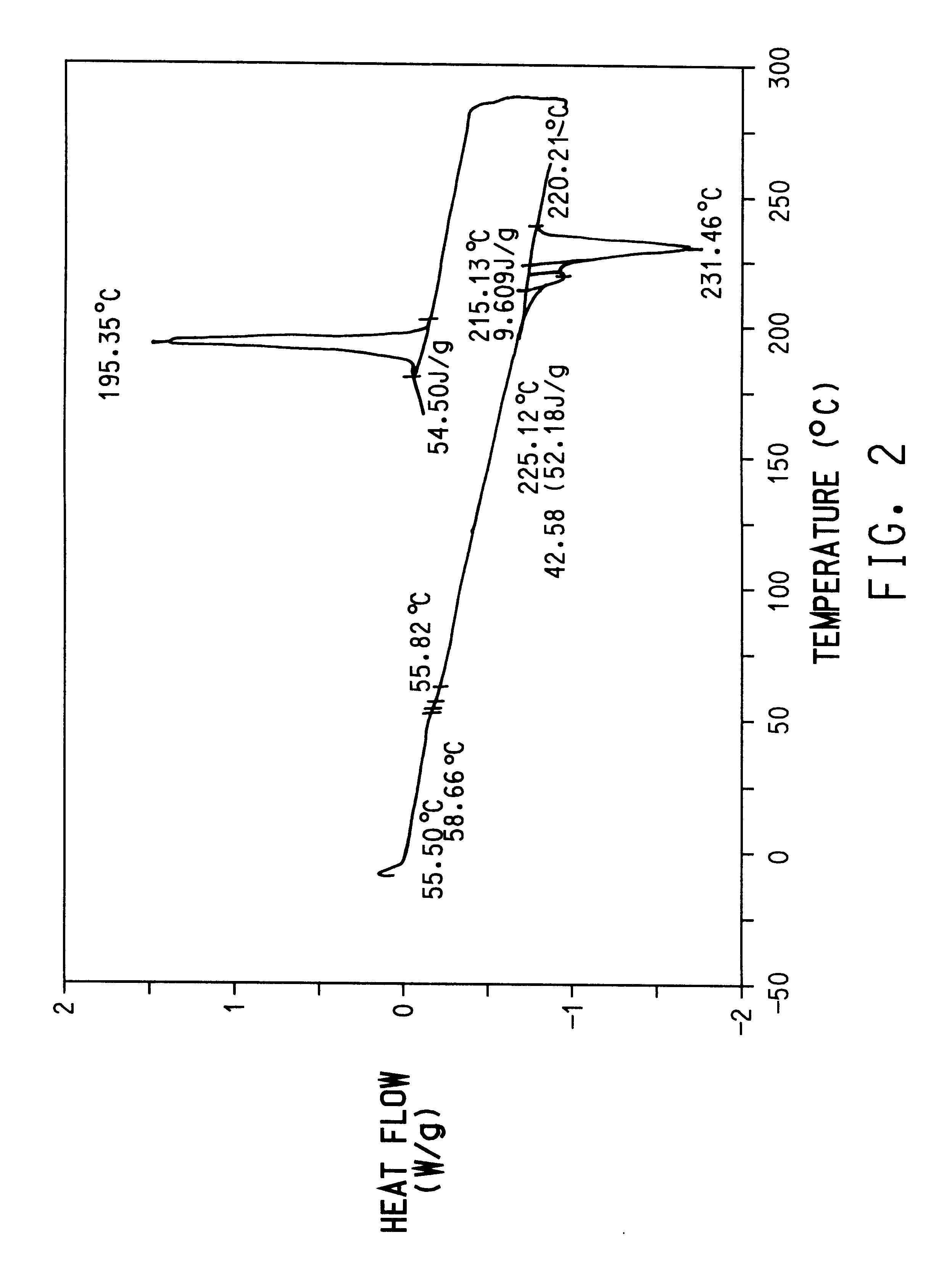

An electronic device module comprising:A. At least one electronic device, e.g., a solar cell, andB. A polymeric material in intimate contact with at least one surface of the electronic device, the polymeric material comprising (1) an ethylene-based polymer composition characterized by a Comonomer Distribution Constant greater than about 45, more preferably greater than 50, most preferably greater than 95, and as high as 400, preferably as high as 200, wherein the composition has less than 120 total unsaturation unit / 1,000,000C, preferably the ethylene-based polymer compositions comprise up to about 3 long chain branches / 1000 carbons, more preferably from about 0.01 to about 3 long chain branches / 1000 carbons; the ethylene-based polymer composition can have a ZSVR of at least 2; the ethylene-based polymer compositions can be further characterized by comprising less than 20 vinylidene unsaturation unit / 1,000,000C; the ethylene-based polymer compositions can have a bimodal molecular weight distribution (MWD) or a multi-modal MWD; the ethylene-based polymer compositions can have a comonomer distribution profile comprising a mono or bimodal distribution from 35° C. to 120° C., excluding purge; the ethylene-based polymer compositions can comprise a single DSC melting peak; the ethylene-based polymer compositions can comprise a weight average molecular weight (Mw) from about 17,000 to about 220,000, (2) optionally, a vinyl silane, (3) optionally, a free radical initiator, e.g., a peroxide or azo compound, or a photoinitiator, e.g., benzophenone, and (4) optionally, a co-agent.

Owner:NAUMOVITZ JOHN +3

Highly filled polymer composition with improved properties

InactiveUS6362252B1Reduce manufacturing costHigh tensile strengthConductive materialPlastic recyclingPolymer sciencePlasticizer

A highly filled polymer composition with improved properties comprising: a continuous matrix material; a filler material in an amount of 10 to 80 wt. % of said composition; a polymer plasticizer dispersed in said continuous matrix material in an amount of 0.5 to 15 wt. % of said filler; a filler coating material which coats said filler particles in the form of a continuous coating layer thus forming coated filler particles; a diffusion zone around said coated filler particles where said filler coating and said continuous matrix material are mutually diffused into one another wherein said filler coating material is distributed with concentration decreasing in the direction outward from said continuous coating layer. Provided also is a method of preparing the aforementioned composition which guarantees that during extrusion or similar treatment the filler particles are coated with a continuous layer of the filler coating material and that the aforementioned diffusion zone is formed around the coated filler particles. In the manufacture of various products such as pipes, sheets, profiles, etc., the composition of the invention combines high deformation capacity with sufficient strength. Furthermore, the composition of the invention possesses high anticorrosive properties, has low shrinkage, and has high adhesion to metals, wood, plastics, etc.

Owner:NEXT GENERATIONS TECH

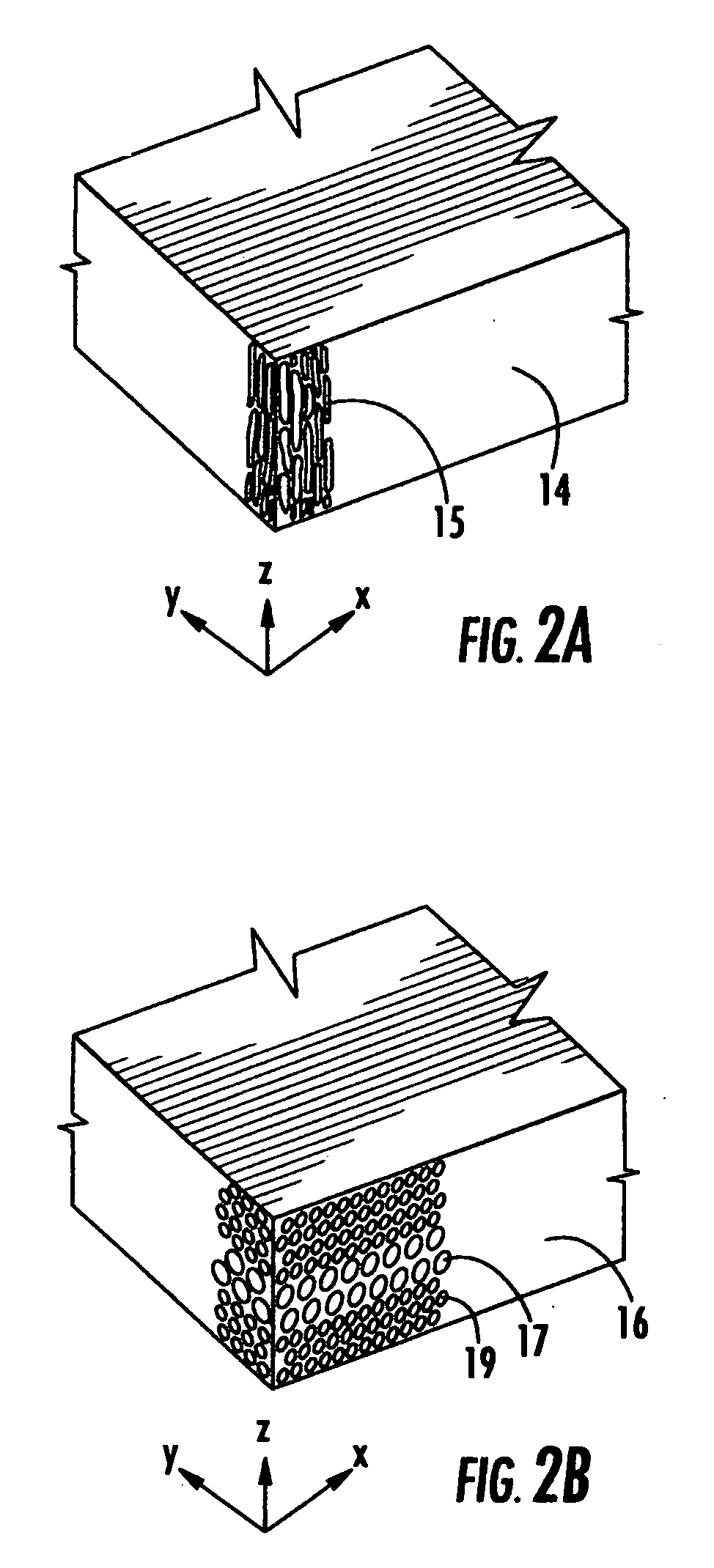

Composite panels

A composite panel consisting of outer skins and an inner core consisting of a foamed polymer, wherein the structure or properties of the inner core are anisotropic. The composite panel can be made by applying external heat and pressure to melt a skin of thermoplastic composite and an initial thickness of a thermoplastic core which has anisotropic properties causing the skin and core to fuse together followed by cooling the fused structure. The composite panel can be made by applying external heat and pressure to melt layers of a thermoplastic adhesive positioned between the outer skins and an inner core consisting of a foamed polymer, wherein the structure or properties of the inner core are anisotropic, so that the skins are bonded to the core by the melted layers of the thermoplastic adhesive followed by cooling the bonded structure.

Owner:EDWARDS CHRISTOPHER M

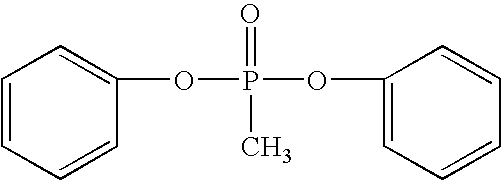

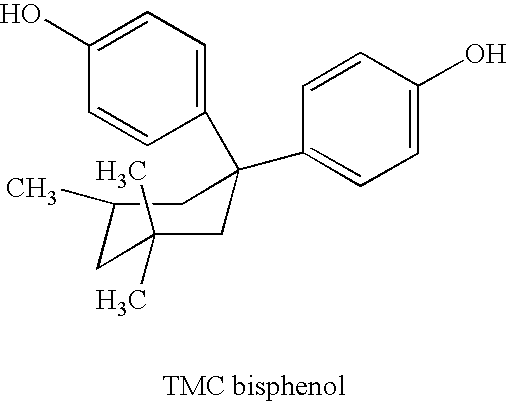

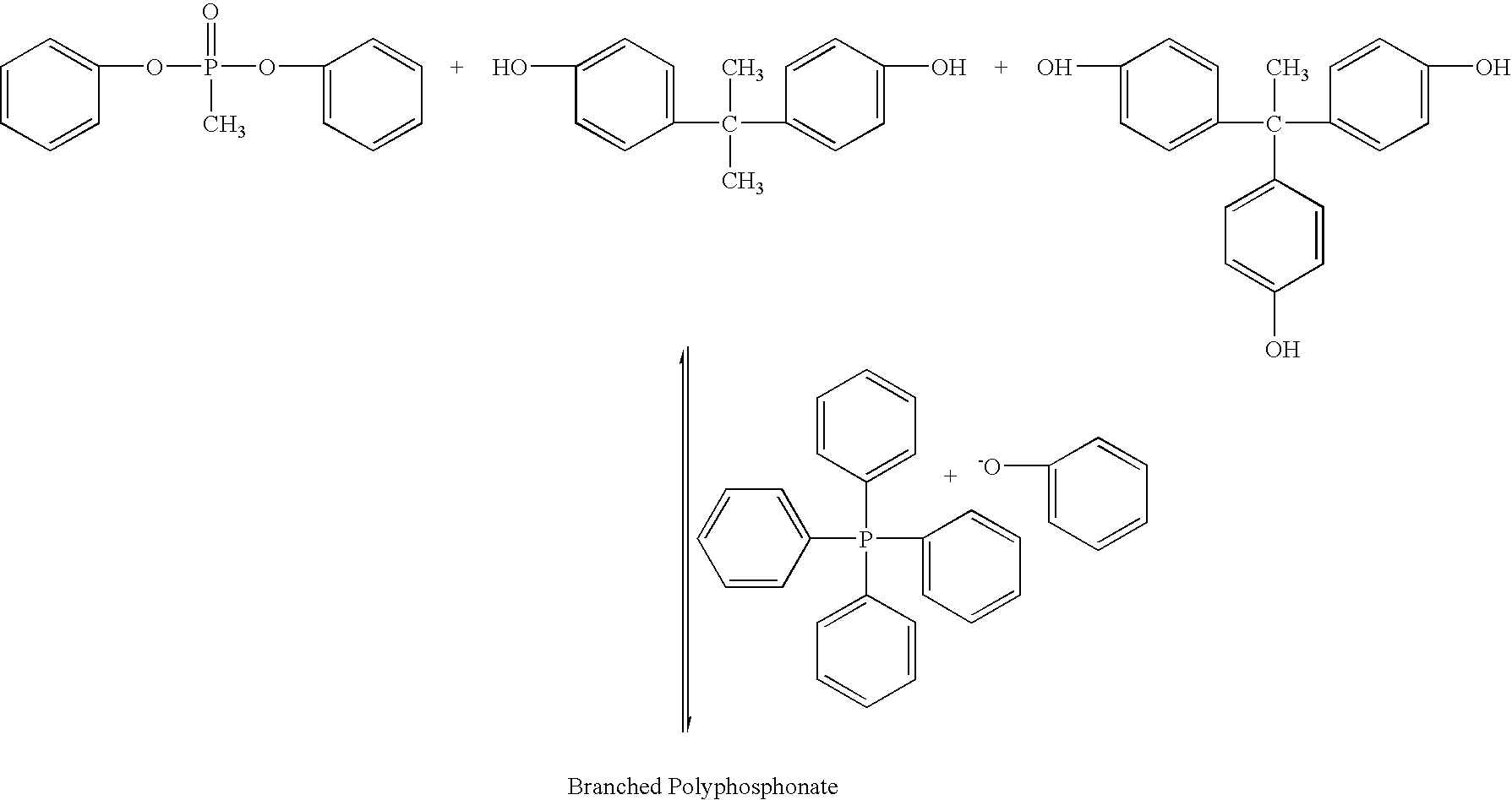

Branched polyphosphonates that exhibit an advantageous combination of properties, and methods related thereto

Disclosed are branched polyphosphonates produced via a superior transesterification process, and methods related thereto. These branched polyphosphonates exhibit a unique and advantageous combination of properties, such as outstanding fire resistance, improved heat stability, improved toughness, and superior processing characteristics. Also disclosed are polymer compositions that comprise these branched polyphosphonates and at least one other polymer, wherein the resulting polymer compositions exhibit flame retardant properties. Further disclosed are articles of manufacture produced from these polymers, such as fibers, films, coated substrates, moldings, foams, fiber-reinforced articles, or any combination thereof; these articles may be coated with a moisture barrier to enhance their moisture resistance properties.

Owner:FRX POLYMERS LLC

Antimicrobial compositions containing colloids of oligodynamic metals

InactiveUS7179849B2Reduced settlingReduce agglomerationOrganic active ingredientsPretreated surfacesSolubilityCatheter

Owner:CR BARD INC

Antimicrobial compositions

InactiveUS20100135949A1Reduce complicationsAvoid difficultyBiocidePretreated surfacesCetrimideO-Phthalaldehyde

Antimicrobial compositions and methods are disclosed. The antimicrobial compositions are particularly useful in providing antimicrobial capability to a wide-range of medical devices. In one aspect the invention relates a UV curable antimicrobial coating comprising a UV curable composition comprising an oligomer, a momoner, and a photoinitiator which are together capable of forming a UV curable polymer composition. The compositions include rheology modifiers as necessary. The compositions also include antimicrobial agents, which may be selected from a wide array of agents. Representative antimicrobial agents include cetyl pyridium chloride, cetrimide, alexidine, chlorexidine diacetate, benzalkonium chloride, and o-phthalaldehyde.

Owner:BECTON DICKINSON & CO

Loading and release of water-insoluble drugs

Owner:BOSTON SCI SCIMED INC

Low emission polymer compositions

InactiveUS6331264B1Improve stabilityEmission reductionCeramic shaping apparatusMelt spinning methodsMolten stateMolten salt

The invention comprises polymer compositions containing 3-hydroxypropanoxy terminated polymer that exhibit reduced levels of degradation product emissions during processing, by contacting the polymer in the molten state with a melt stable, organic nitrogen-containing stabilizing compound, such as polyamide.

Owner:DUPONT IND BIOSCIENCES USA LLC

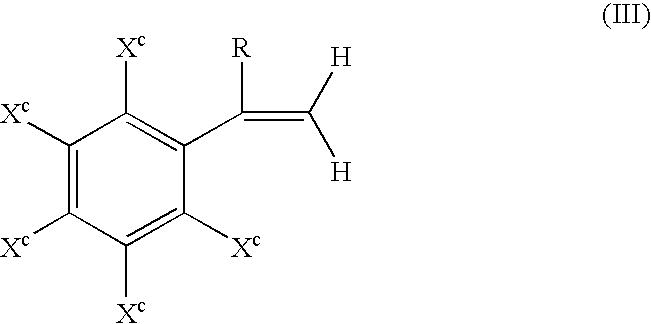

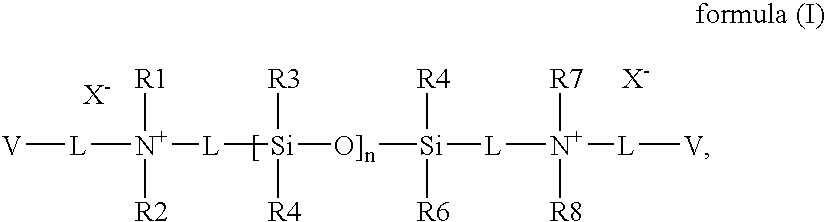

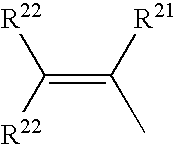

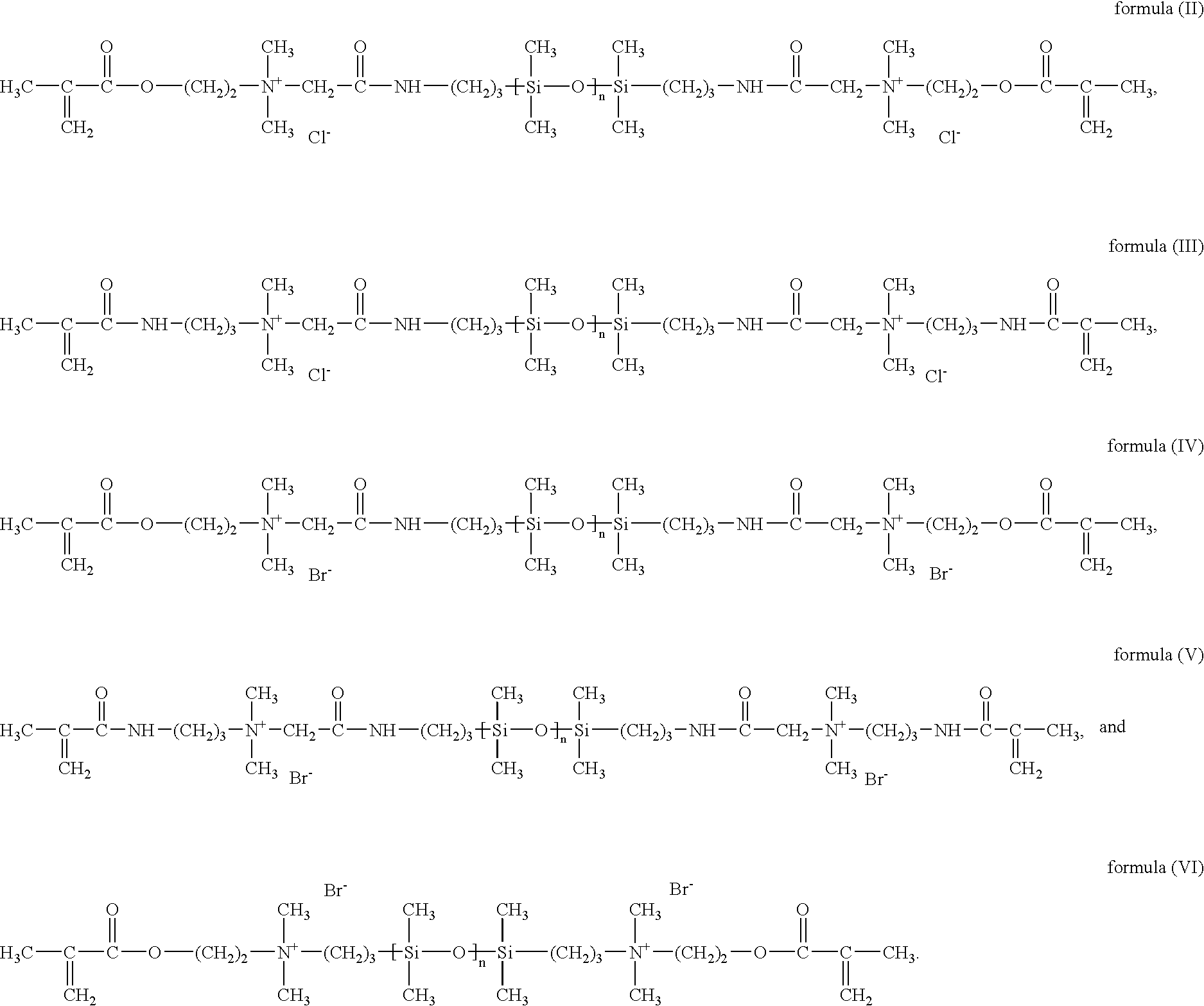

Silicon-containing monomers end-capped with polymerizable cationic hydrophilic groups

InactiveUS20070142584A1High oxygen permeabilityDesirable biocompatibilitySilicon organic compoundsIntraocular lensEndcappingOrganic solvent

The present invention relates to polymeric compositions useful in the manufacture of biocompatible medical devices. More particularly, the present invention relates to certain cationic monomers capable of polymerization to form polymeric compositions having desirable physical characteristics useful in the manufacture of ophthalmic devices. Such properties include the ability to extract the polymerized medical devices with water. This avoids the use of organic solvents as is typical in the art. The polymer compositions comprise polymerized silicon-containing monomers end-capped with polymerizable cationic hydrophilic groups.

Owner:BAUSCH & LOMB INC

Vapor deposition routes to nanoporous silica

InactiveUS6022812APretreated surfacesSemiconductor/solid-state device manufacturingPorosityPolymer science

A process for the manufacture of nanoporous silica dielectric films by vapor deposition of silica precursors on a substrate. The process provides for vaporizing at least one alkoxysilane composition; depositing the vaporized alkoxysilane composition onto a substrate; exposing the deposited alkoxysilane composition to a water vapor, and either an acid or a base vapor; and drying the exposed alkoxysilane composition, thereby forming a relatively high porosity, low dielectric constant, silicon containing polymer composition on the substrate.

Owner:ALLIED SIGNAL INC

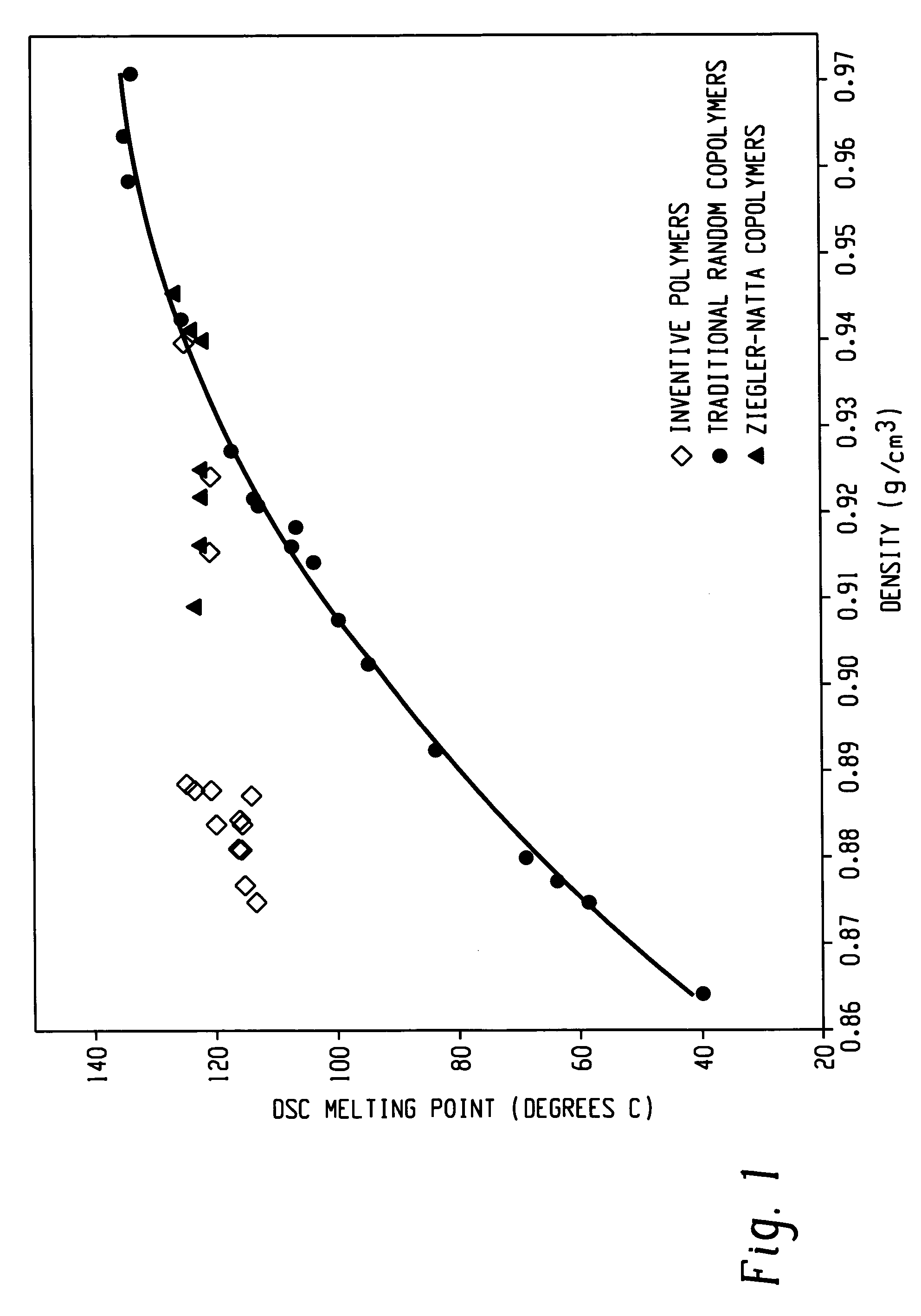

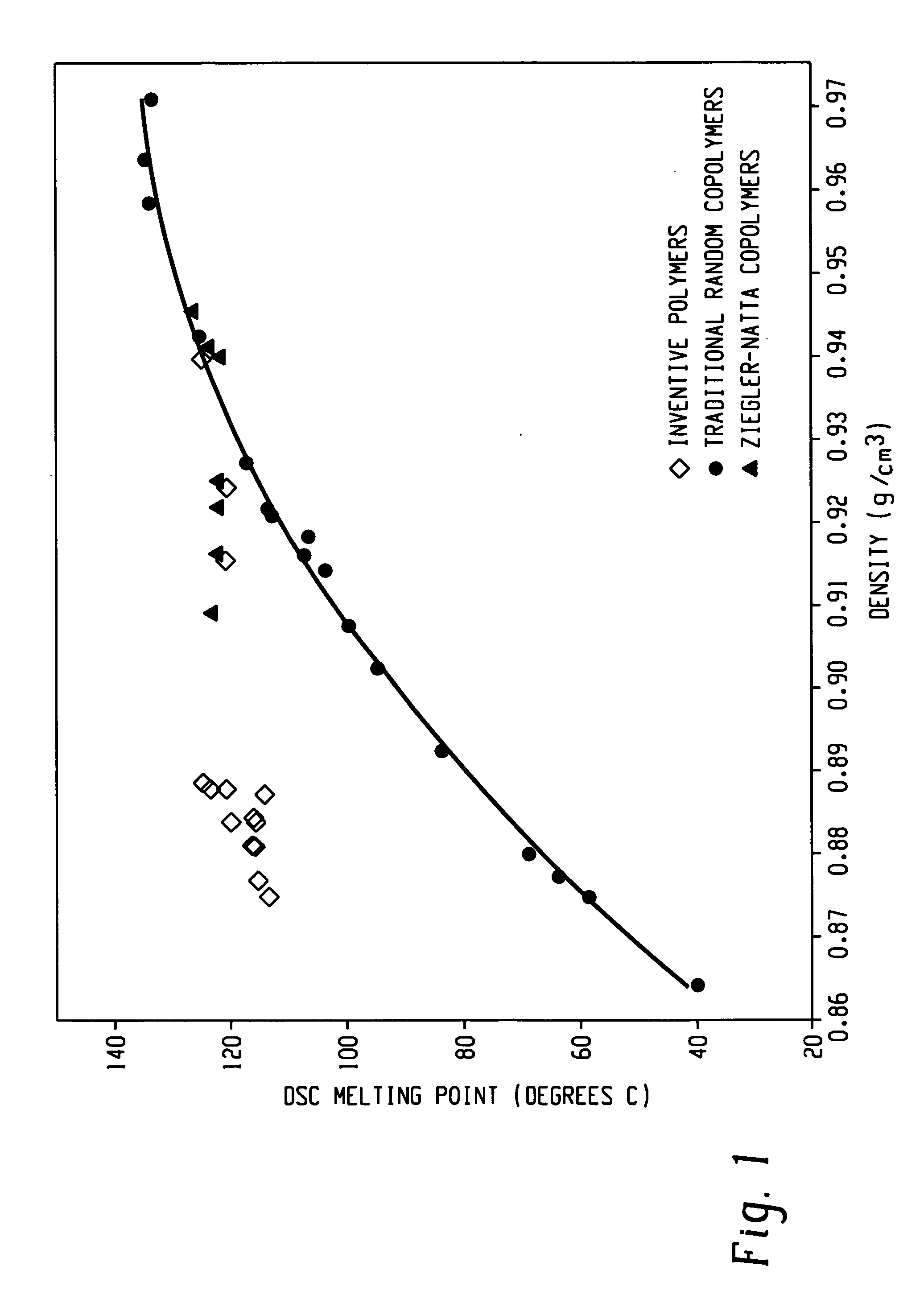

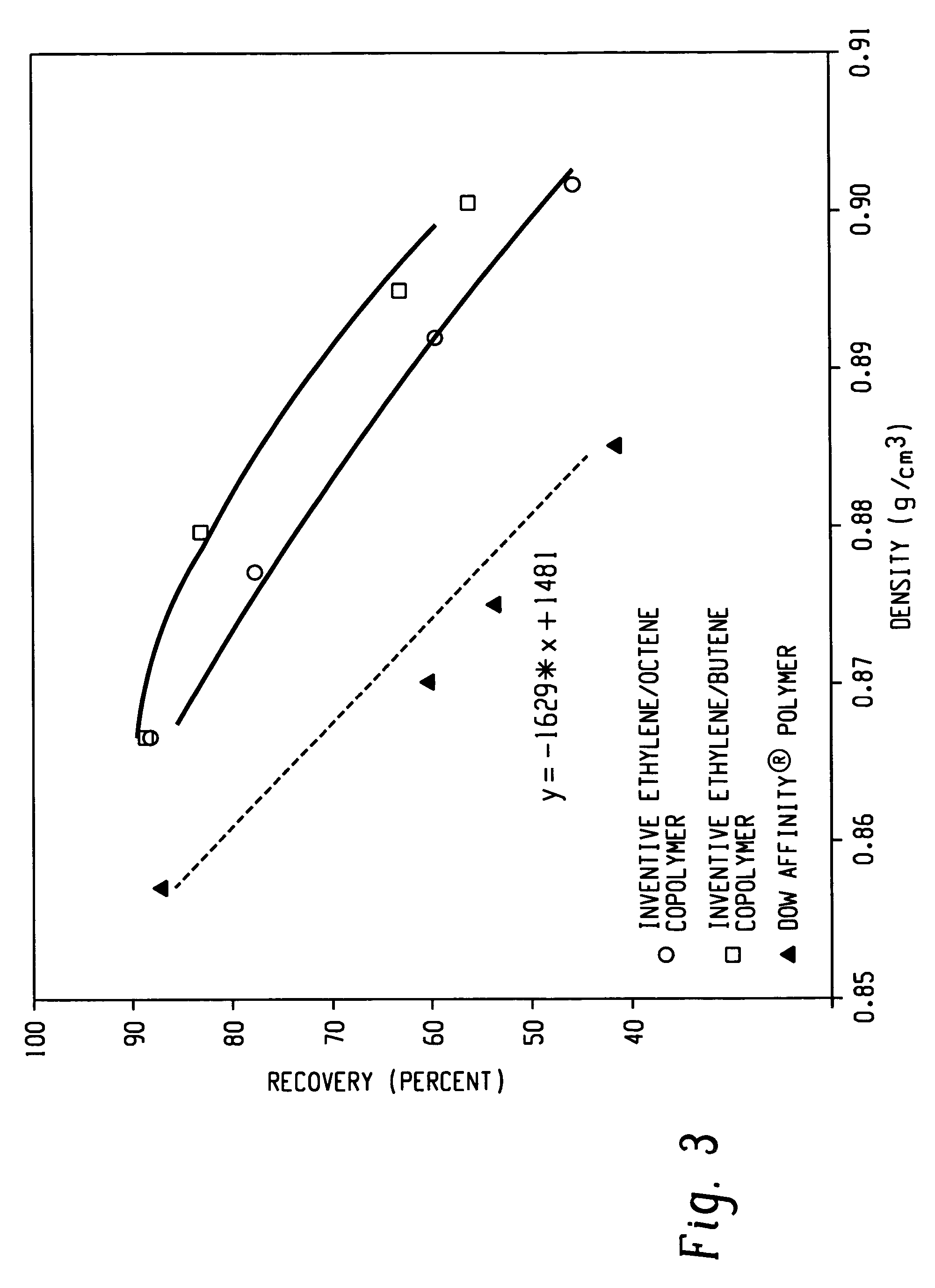

Compositions of ethylene/alpha-olefin multi-block interpolymer for elastic films and laminates

This invention relates to polyolefin compositions. In particular, the invention pertains to elastic polymer compositions that can be more easily processed on cast film lines, extrusion lamination or coating lines due to improved resistance to draw resonance. The compositions of the present invention preferably comprise an elastomeric polyolefin resin and a high pressure low density type resin.

Owner:DOW GLOBAL TECH LLC

Anti-blocking compositions comprising interpolymers of ethylene/alpha-olefins

Owner:DOW GLOBAL TECH LLC

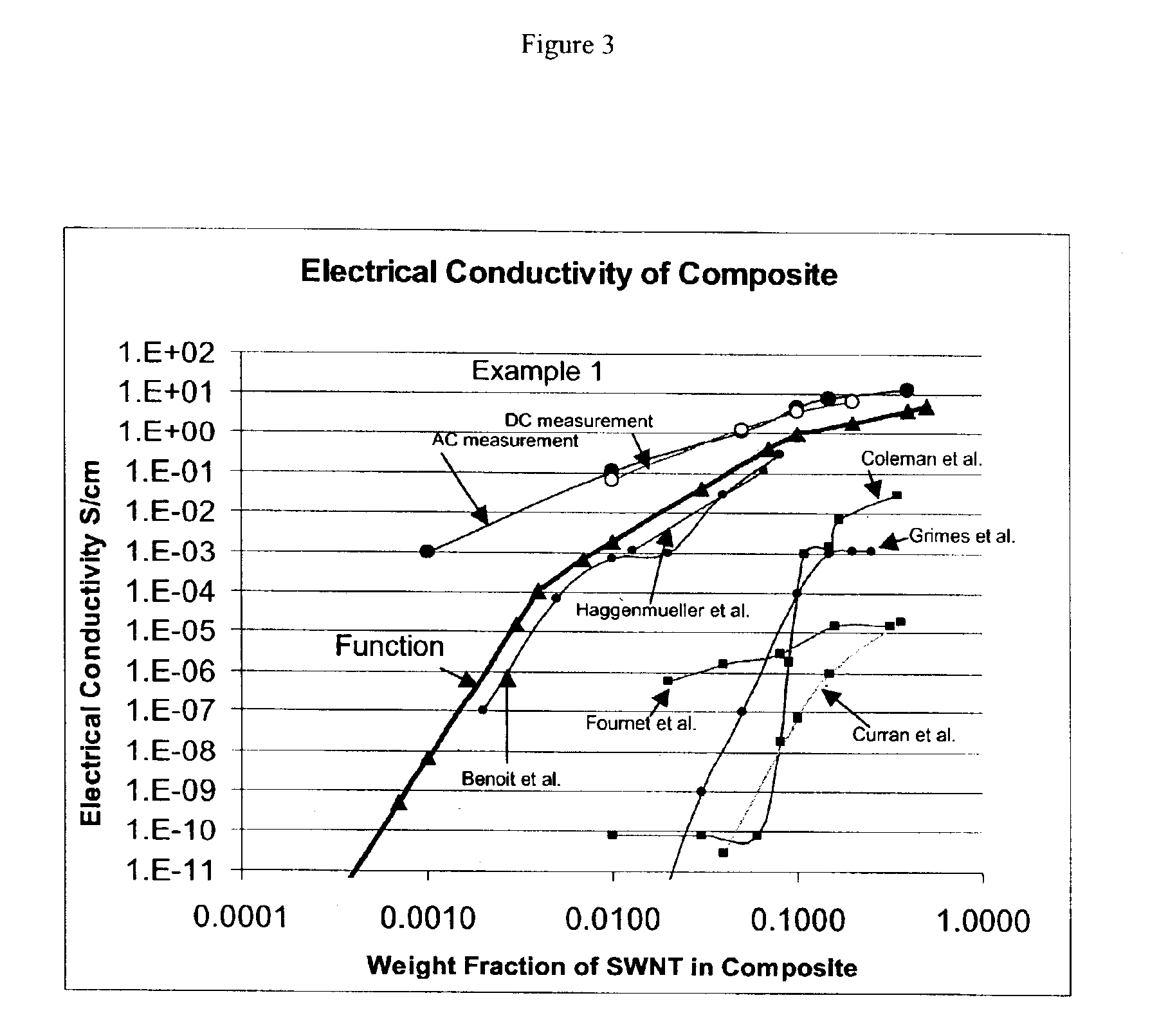

Composite materials comprising polar polymers and single-wall carbon nanotubes

InactiveUS6936653B2Improve conductivityMaterial nanotechnologyIndividual molecule manipulationPolyesterPolymer science

The invention relates to a composite comprising a weight fraction of single-wall carbon nanotubes and at least one polar polymer wherein the composite has an electrical and / or thermal conductivity enhanced over that of the polymer alone. The invention also comprises a method for making this polymer composition. The present application provides composite compositions that, over a wide range of single-wall carbon nanotube loading, have electrical conductivities exceeding those known in the art by more than one order of magnitude. The electrical conductivity enhancement depends on the weight fraction (F) of the single-wall carbon nanotubes in the composite. The electrical conductivity of the composite of this invention is at least 5 Siemens per centimeter (S / cm) at (F) of 0.5 (i.e. where single-wall carbon nanotube loading weight represents half of the total composite weight), at least 1 S / cm at a F of 0.1, at least 1×10−4 S / cm at (F) of 0.004, at least 6×10−9 S / cm at (F) of 0.001 and at least 3×10−16 S / cm (F) plus the intrinsic conductivity of the polymer matrix material at of 0.0001. The thermal conductivity enhancement is in excess of 1 Watt / m-° K. The polar polymer can be polycarbonate, poly(acrylic acid), poly(acrylic acid), poly(methacrylic acid), polyoxide, polysulfide, polysulfone, polyamides, polyester, polyurethane, polyimide, poly(vinyl acetate), poly(vinyl alcohol), poly(vinyl chloride), poly(vinyl pyridine), poly(vinyl pyrrolidone), copolymers thereof and combinations thereof. The composite can further comprise a nonpolar polymer, such as, a polyolefin polymer, polyethylene, polypropylene, polybutene, polyisobutene, polyisoprene, polystyrene, copolymers thereof and combinations thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com