Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

300results about How to "High tensile modulus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer compositions, method of manufacture, and articles formed therefrom

ActiveUS20060142455A1High tensile modulusImprove ductilityPigmenting treatmentMaterial nanotechnologyPolymer scienceFluoropolymer

A polymer composition is disclosed, which comprises a matrix polymer, a fluoropolymer that may be at least partially encapsulated by an encapsulating polymer, and a filler. Methods for making the polymer compositions and articles made of such compositions are also disclosed. The compositions and article can have improved tensile modulus, ductility, and / or impact properties.

Owner:SABIC INNOVATIVE PLASTICS IP BV

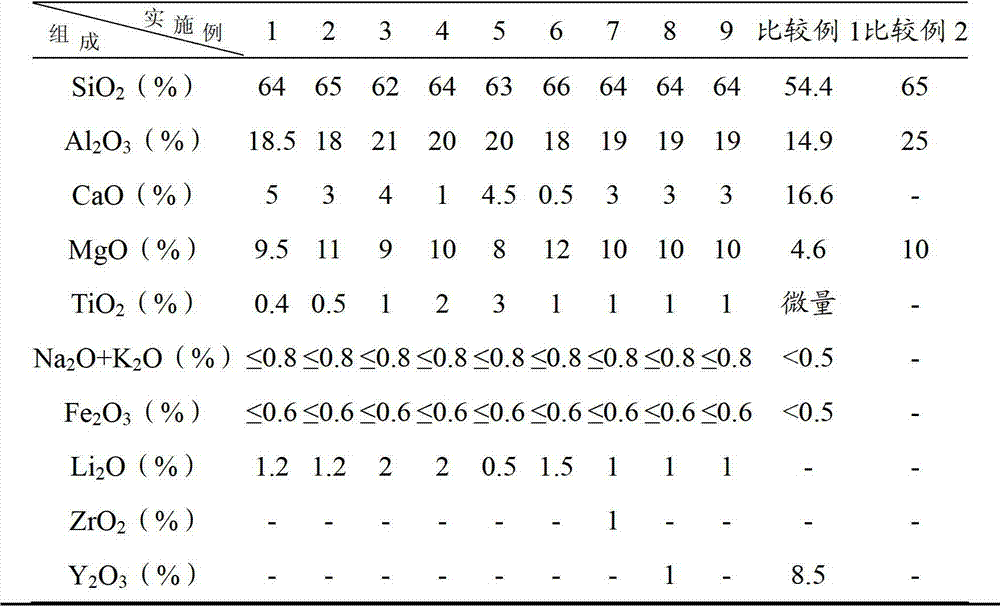

Glass fiber

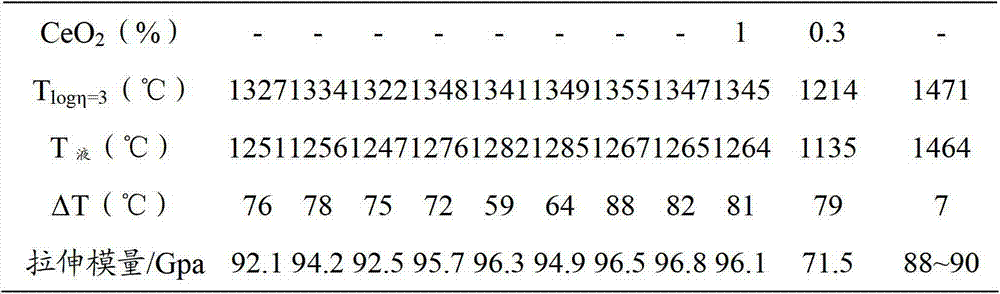

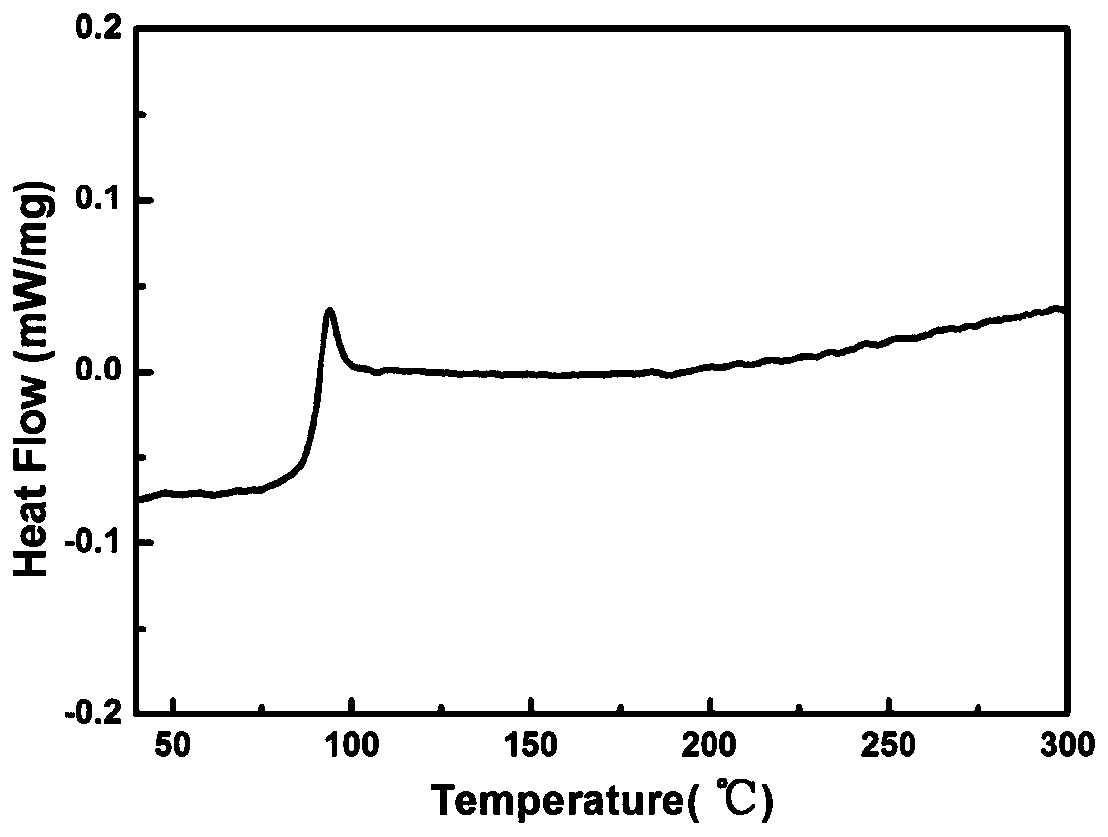

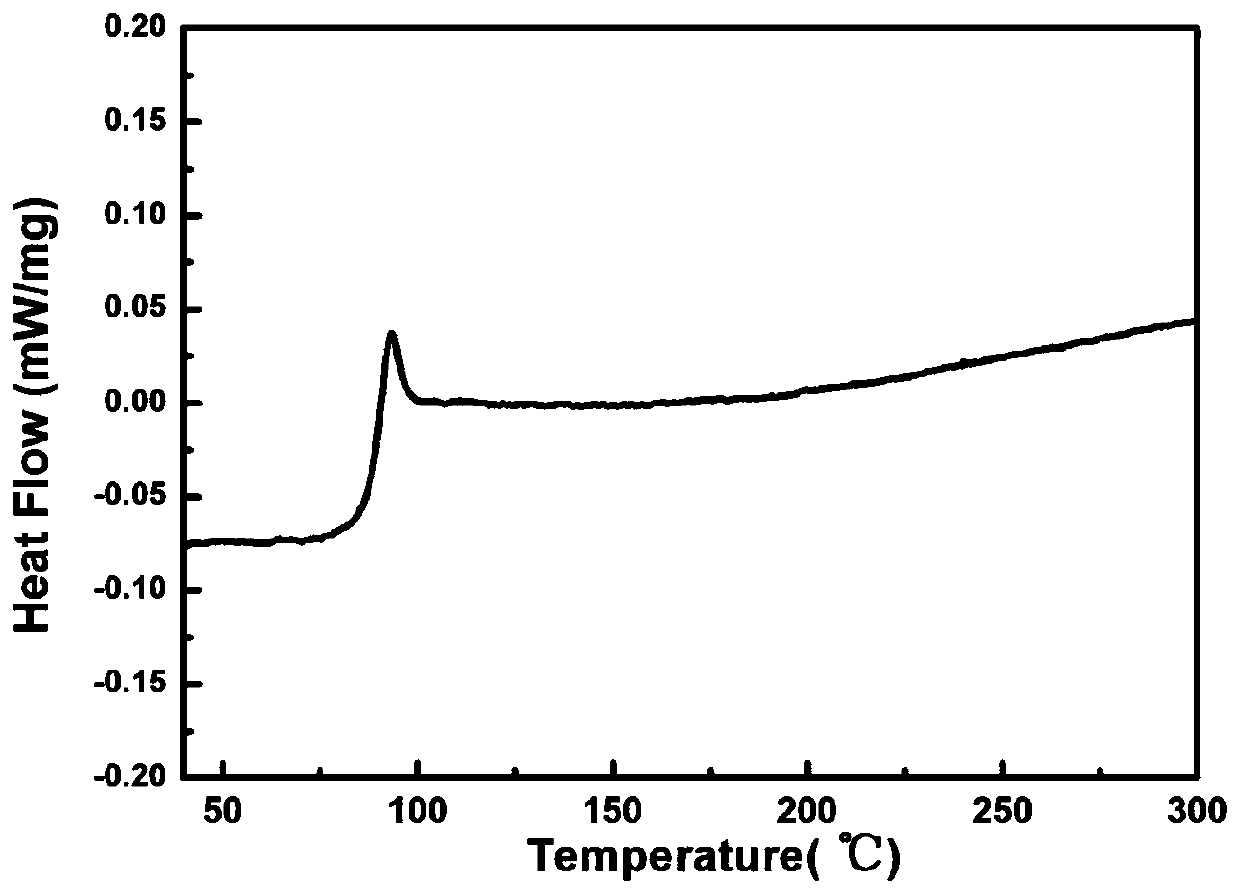

InactiveCN103086605AHigh tensile modulusLow molding temperatureGlass fiberCrystallization temperature

The invention provides a glass fiber which comprises 62-66 wt% of SiO2, 18-21 wt% of Al2O3, 0.5-5 wt% of CaO, 8-12 wt% of MgO, 0.5-2 wt% of Li2O, 0.4-3 wt% of TiO2, 0.1-0.6 wt% of Fe2O3 and 0.1-0.8 wt% of Na2O and K2O. The total mass content of the Na2O, K2O and Li2O is 0.5-3 wt%. Therefore, the glass fiber provided by the invention has low forming temperature and upper limit crystallization temperature on the premise of having high tensile modulus, so that the glass fiber is applicable to large-scale industrial production.

Owner:CHONGQING POLYCOMP INT

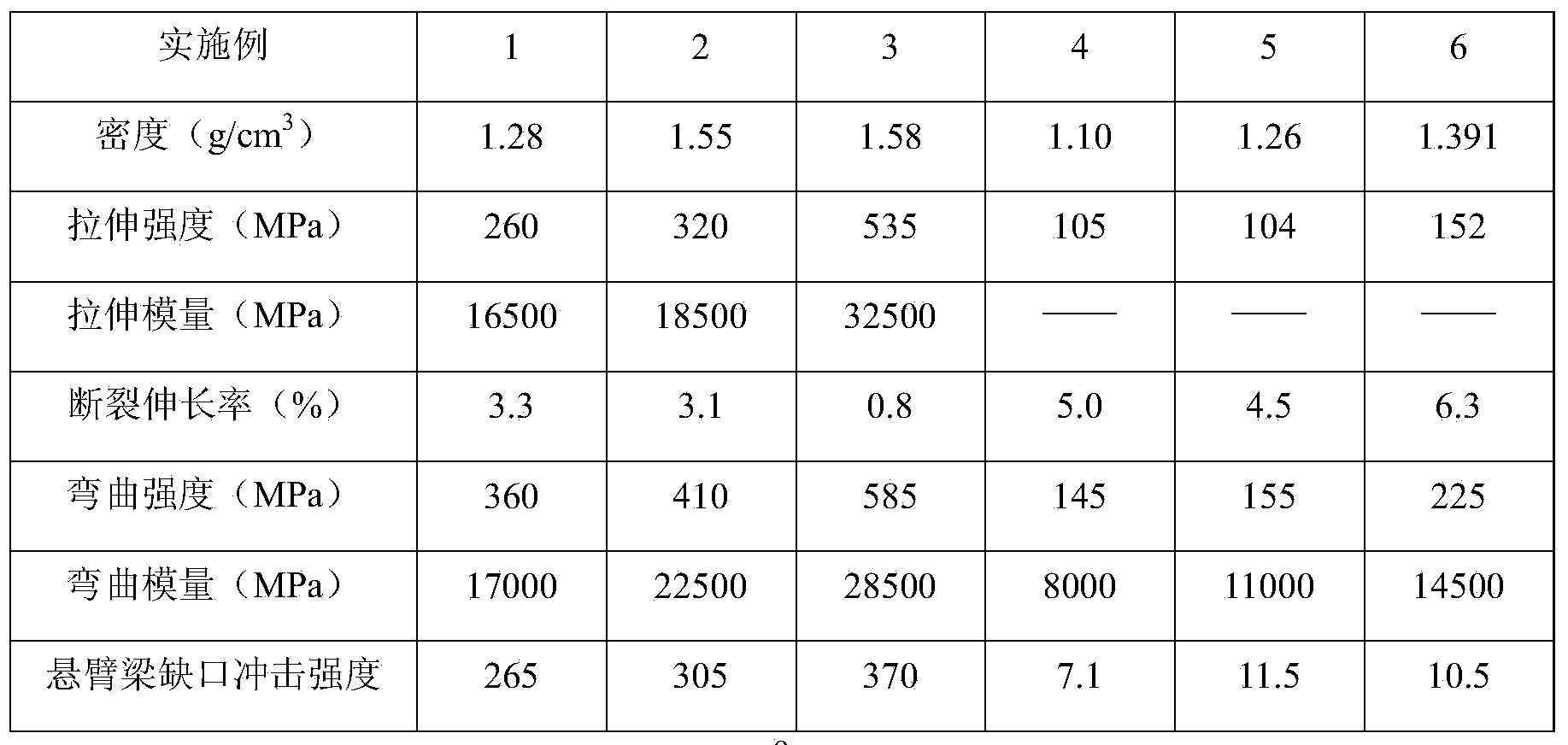

Fiber-reinforced thermoplastic composite and preparation method thereof

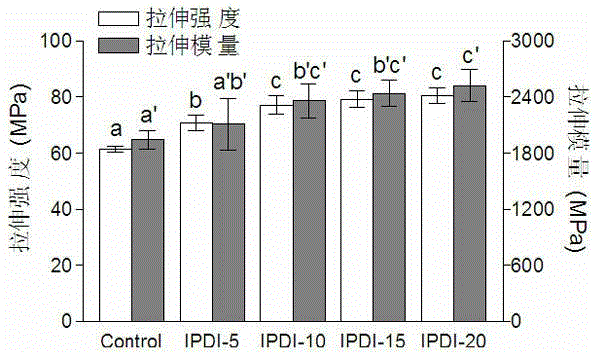

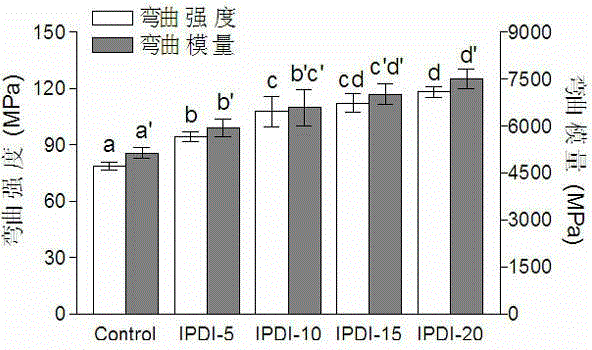

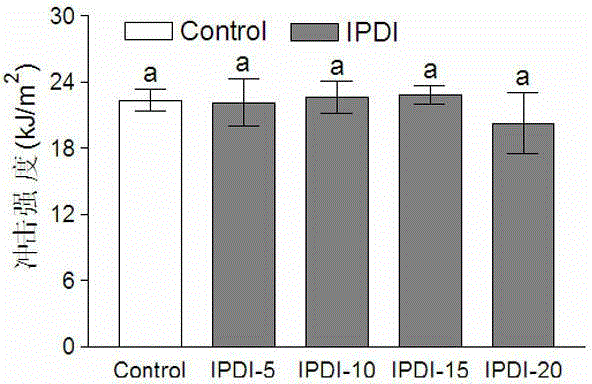

The invention discloses a fiber-reinforced thermoplastic composite and a preparation method of the fiber-reinforced thermoplastic composite. The preparation method comprises the following steps that firstly, fibers are treated through a modified surface treating agent; secondly, the treated fibers in the first step are soaked in thermoplastic resin in the molten state; thirdly, the fibers which are soaked in the thermoplastic resin in the second step are cooled and solidified, so that the fiber-reinforced thermoplastic composite is obtained. The modified surface treating agent comprises, by mass, 0.5-15% of thermoplastic resin powder. The mechanical properties such as the tensile strength, the tensile modulus, the bending strength, the bending modulus and the cantilever beam notch impact strength of the fiber-reinforced thermoplastic composite prepared through the preparation method are greatly improved, and particularly the properties such as the bending strength, the bending modulus and the cantilever beam notch impact strength are improved by about 15% to the maximum degree.

Owner:KINGFA SCI & TECH CO LTD

Graphene oxide-based curing agent as well as preparation and use thereof

InactiveCN104262588AImprove thermal stabilityLow resistivityNon-macromolecular adhesive additivesEpoxy resin adhesivesArray data structureGlycidyl ethers

The invention discloses a preparation method of a graphene oxide-based curing agent and application of the graphene oxide-based curing agent in epoxy resin conductive glue. The conductive glue consists of the following components in parts by weight: 1-2 parts of a graphene oxide-based curing agent, 3-10 parts of a conventional curing agent, 10-20 parts of E-51 epoxy resin, 10-20 parts of AG-80 epoxy resin, 15-25 parts of carbon black, 15-25 parts of silver precipitate powder, 1-8 parts of amine accelerants, 1-5 parts of a liquid imidazole defoaming agent and 1-20 parts of glycidyl ether diluents. The preparation method of the graphene oxide-based curing agent comprises the following steps: firstly, preparing graphene oxide and then modifying the graphene oxide to obtain a graphene oxide-based curing agent capable of conducting and toughening; and then, blending according to a formula of the conductive glue and curing to obtain a graphene oxide-based epoxy resin composite material. The graphene oxide-based curing agent with capacity of conducting and toughening is obtained by the preparation method; and an epoxy-based composite adhesive material prepared by taking the graphene oxide as the curing agent has good conducting capacity, acid and alkaline resistance, thermal stability and mechanical performance; and the adhesive is suitable for adhering electronic elements.

Owner:HUNAN UNIV

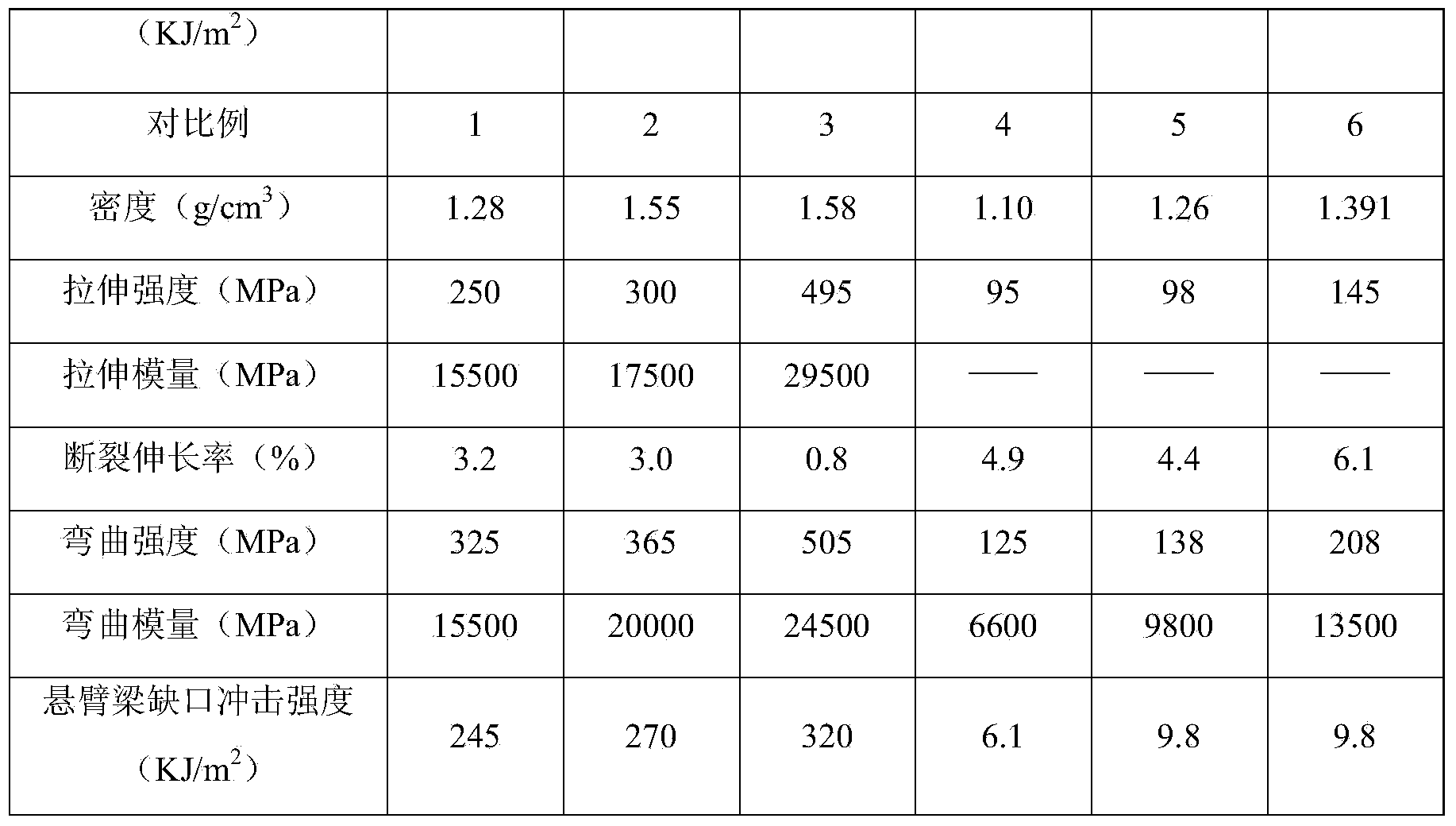

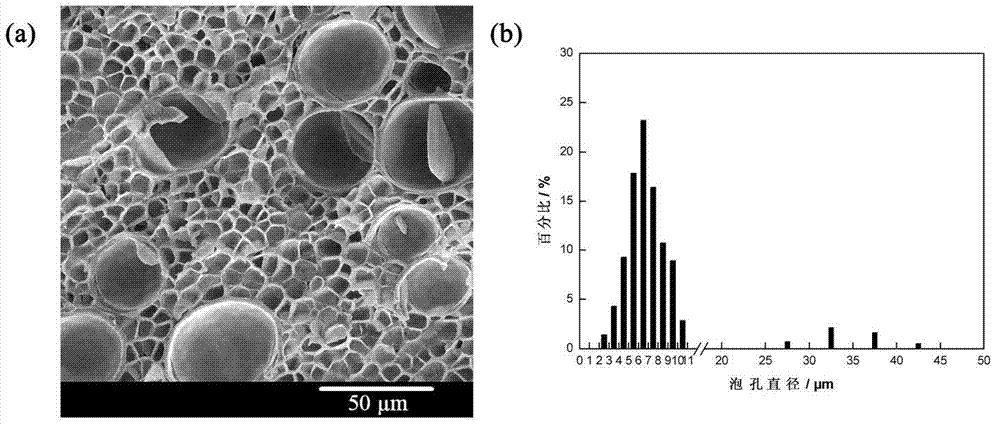

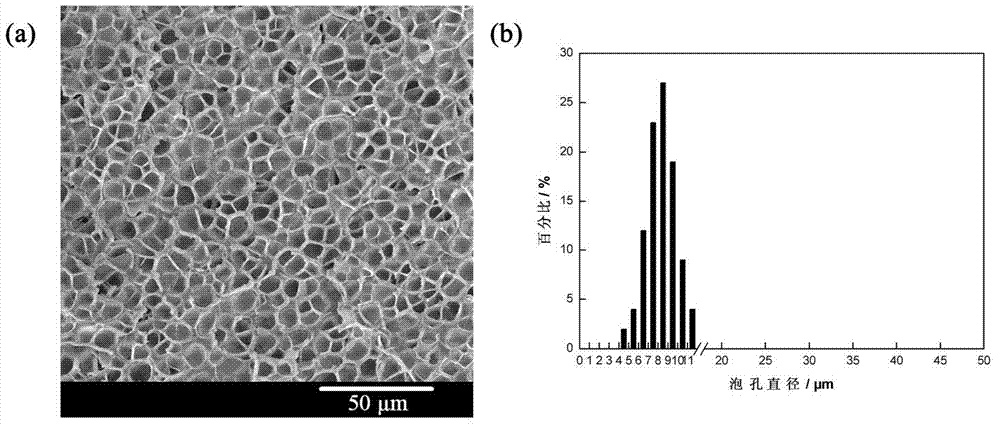

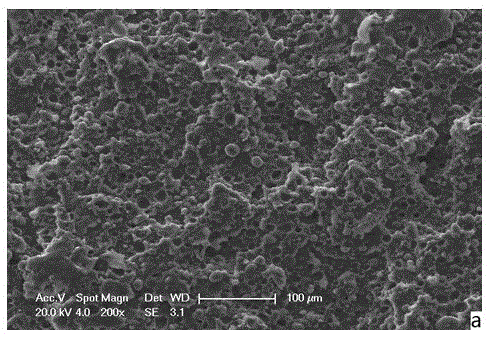

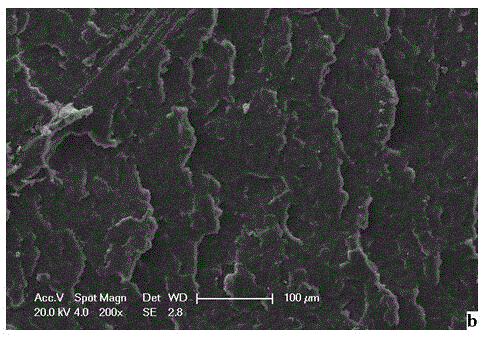

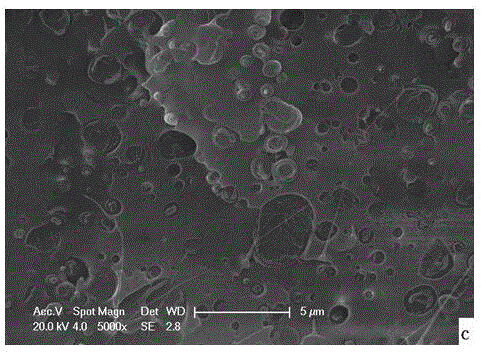

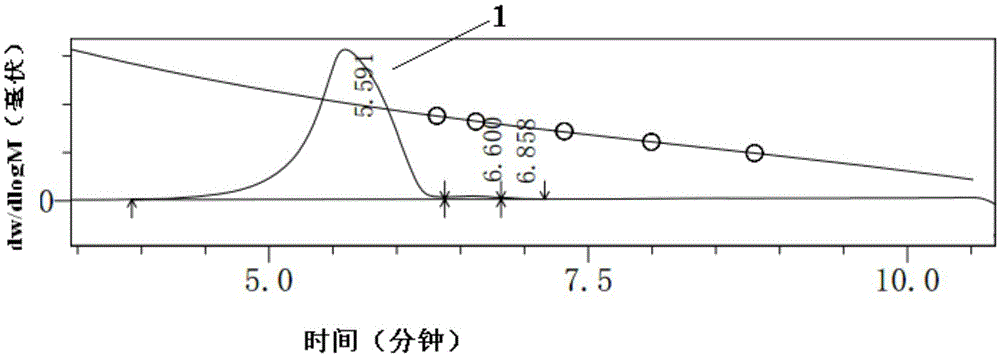

Preparation method of polycarbonate microporous material with bimodal distribution

The invention discloses a preparation method of a polycarbonate microporous material with bimodal distribution, aiming at solving the technical problem that the thermoplastic foam prepared by adopting the existing preparation method only has unimodal distribution or easily pollutes the environment. According to the technical scheme, the preparation method disclosed by the invention comprises the steps of: placing a polycarbonate sheet in CO2 fluid under a super-critical state to carry out saturation to obtain an even PC (polycarbonate) / CO2 mixture after being entirely saturated; carrying out first-time fast pressure relief within the time of 4-30 seconds, and keeping for 0.5-3 hours under the constant-temperature and constant-pressure state; carrying out second-time fast pressure relief within the time of 4-30 seconds, thus relieving the pressure in an autoclave to the atmospheric pressure; fast taking out the CO2 gas-containing polycarbonate sheet, transferring to a constant-temperature glycerol bath to carry out foaming; and finally, shaping the foamed polycarbonate sheet in an ice-water bath for 30 minutes to obtain the polycarbonate microporous material with bimodal distribution. The supercritical CO2 fluid used in the preparation method is low-cost, non-toxic and non-inflammable, and has no pollution to the atmosphere and water body, as well as no damage role to ozone sphere, thus being an environment-friendly physical foaming agent.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

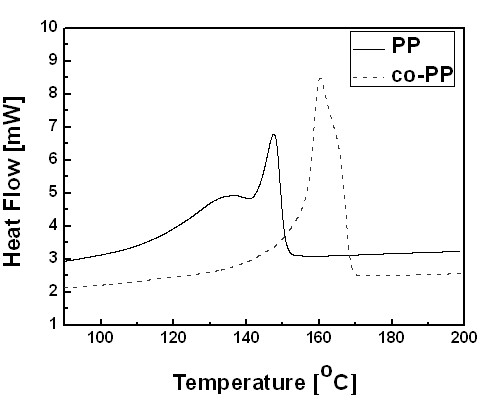

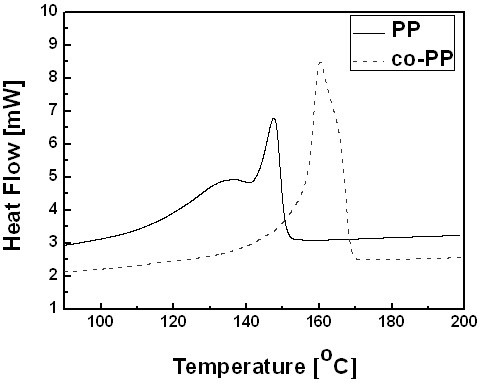

Method for preparing high-strength polymer composite material

The invention discloses a method for preparing a high-strength polymer composite material. The method comprises the following steps of: S1: modifying a monomer into nano inorganic particles by chemical graft polymerization, and melting, blending and extruding the modified nano particles and a thermoplastic polymer to manufacture a rod-like preformed blank, or melting, blending and stamping the modified nano particles and the thermoplastic polymer to manufacture a flaky preformed blank, wherein the molar amount of the monomer is same as that of nano inorganic particles, the consumption of the nano inorganic particles is 1 to 3 weight percent of the thermoplastic polymer; S2: stretching the preformed blank at a temperature of between 130 and 150 DEG C and at a speed of 10 to 50 millimeters per minute, and cooling to obtain a fiber-like or flaky reinforced phase; and S3: preparing a film from a copolymer with melting point of 140 to 150 DEG C by a film blowing method, and preparing the composite material from the oriented reinforced phase and a matrix phase with low melting point through a tensile force self-adjusting die by a thin layer bedding-hot pressing method. By combining a self-reinforcing technology and an inorganic particle filling modified polymer composite material, the polymer composite material with remarkably improved tensile strength and tensile modulus can be obtained.

Owner:SUN YAT SEN UNIV +3

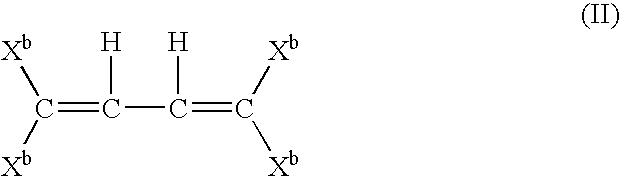

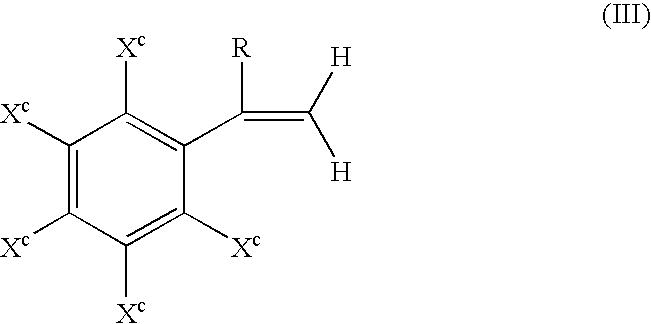

Product prepared by light-curing rapid prototyping process and preparation method thereof

InactiveCN109280395AImprove mechanical propertiesHigh tensile strengthAdditive manufacturing apparatusLiquid lineDouble bond

The invention discloses a product and a preparation method thereof. The product is prepared by a light-curing rapid prototyping process, and a raw material used in the light-curing rapid prototyping process is a liquid photosensitive resin material. The product has an excellent mechanical property, and is high in tensile strength and tensile modulus, smooth and clean on surface, small in cure shrinkage, stable in size and good in mechanical property. The liquid photosensitive resin material contains liquid polycarbosilane having a line-ring structure and containing unsaturated double bond andis good in stability and easy to store, and the synthetic route of the material is green and environmentally friendly without corrosion; and a liquid line-ring polycarbosilane active group is large indensity, fast in curing speed, high in cured product strength, low in molecular weight and viscosity, good in fluidity and printable performance, and especially suitable for a 3D printing technologyof light-curing rapid prototyping.

Owner:BEIJING HENGCHUANG ADVANCED MATERIALS & ADDITIVE MFG INST CO LTD

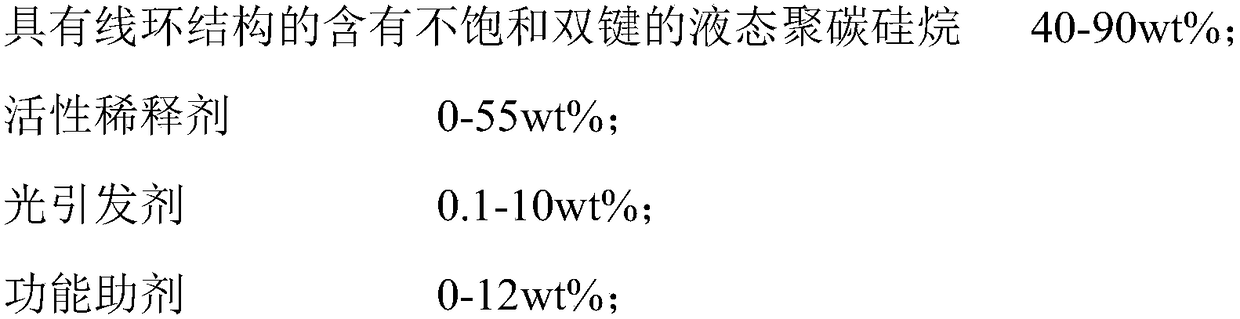

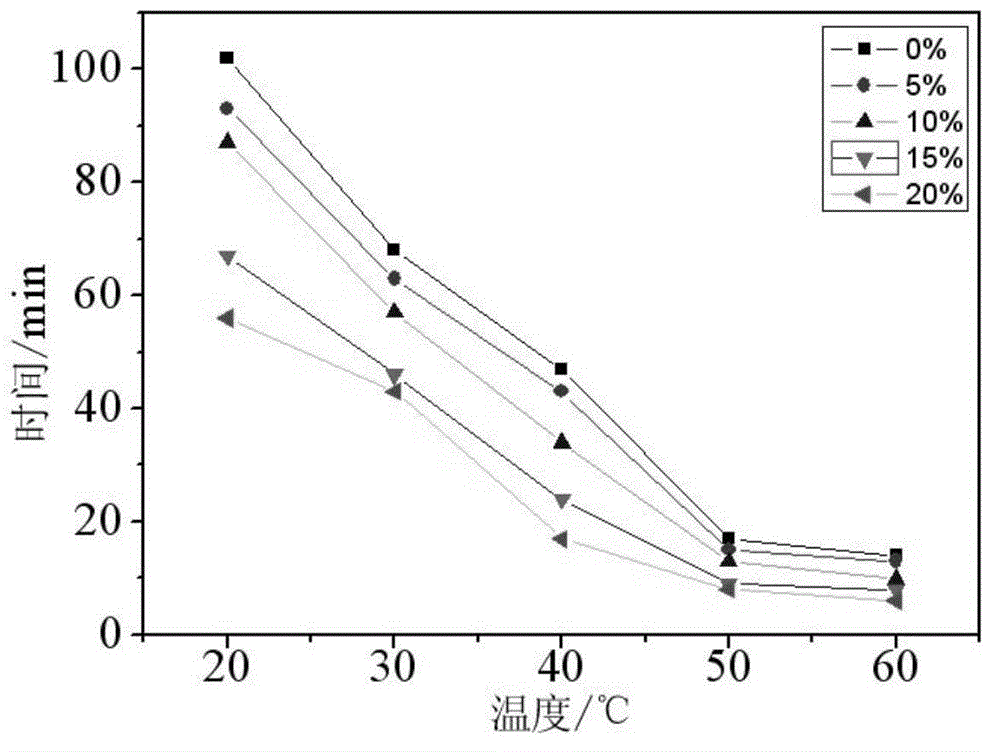

Low dielectric constant polyhedral oligomeric silsesquioxane (POSS)/ epoxy resin hybrid material and preparation method

The invention relates to a low dielectric constant polyhedral oligomeric silsesquioxane (POSS) / epoxy resin hybrid material and a preparation method. Epoxy resin and eight epoxy group polyhedral oligomeric silsesquioxane (G-POSS) are evenly mixed in a 80 DEG C breaker according to a certain proportion, an equivalent amount of curing agent triethylene tetramine (TETA) (an amino group in the TETA and an epoxy group in the G-POSS, epoxy resin (EP) are measured according to a 1:1 molar rate) is added and fully stirred, after vacuum defoamation is conducted for 20-30 minutes, the mixture is slowly poured into a preheating mold, conducted solidification in a stove 50 DEG C / 2 hours, 70 DEG C / 3 hours and 80DEG C / 1 hour, cooled to room temperature along with the stove and processed for 4-6 hours after demolding. The low dielectric constant POSS / epoxy resin hybrid material is small in average grain size and excellent in transparent performance, mechanical property and dielectric property.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Macrofiber-reinforced long carbon chain nylon and preparation method thereof

The invention discloses macrofiber-reinforced long carbon chain nylon and a preparation method of the macrofiber-reinforced long carbon chain nylon. The macrofiber-reinforced long carbon chain nylon comprises the following components in parts by weight: 30-65 percent of nylon 1010, 0-30 percent of nylon 6, 0-30 percent of nylon 66, 30-60 percent of long glass fiber, 0.3-1 percent of an antioxidant and 0.5-2 percent of a lubricating agent. According to the macrofiber-reinforced long carbon chain nylon and the preparation method of the macrofiber-reinforced long carbon chain nylon, the problem that strength, modulus and the like cannot reach those of the traditional staple fiber reinforced nylon product is effectively solved; and meanwhile, the macrofiber-reinforced long carbon chain nylon has more excellent low moisture absorption property, size stability and low-temperature impact property and simultaneously meets the requirements of low-carbon emission and environment-friendly materials.

Owner:安特普工程塑料(苏州)有限公司

Polymeric material for 3D printing and preparation method of polymeric material

The invention relates to a polymeric material for 3D printing. The raw materials of the polymeric material comprise the following components in parts by weight: 20-100 parts of polybuthylenesuccinate and 0.1-80 parts of a modifying agent, wherein the modifying agent is selected from one kind or more than two kinds of polylactic acid, a reinforcing filler and a nucleator. Polymer resins which can be used for 3D printing, disclosed by the invention, not only have high toughness, but also have high mechanical strength and high heat resistance, so that the polymeric resins have a wide application prospect in 3D printing materials.

Owner:TSINGHUA UNIV

High-dipping-degree long glass fiber reinforced polypropylene composite material and preparation method thereof

InactiveCN109251413AHigh degree of impregnationHigh tensile strengthPolypropylene compositesGlass fiber

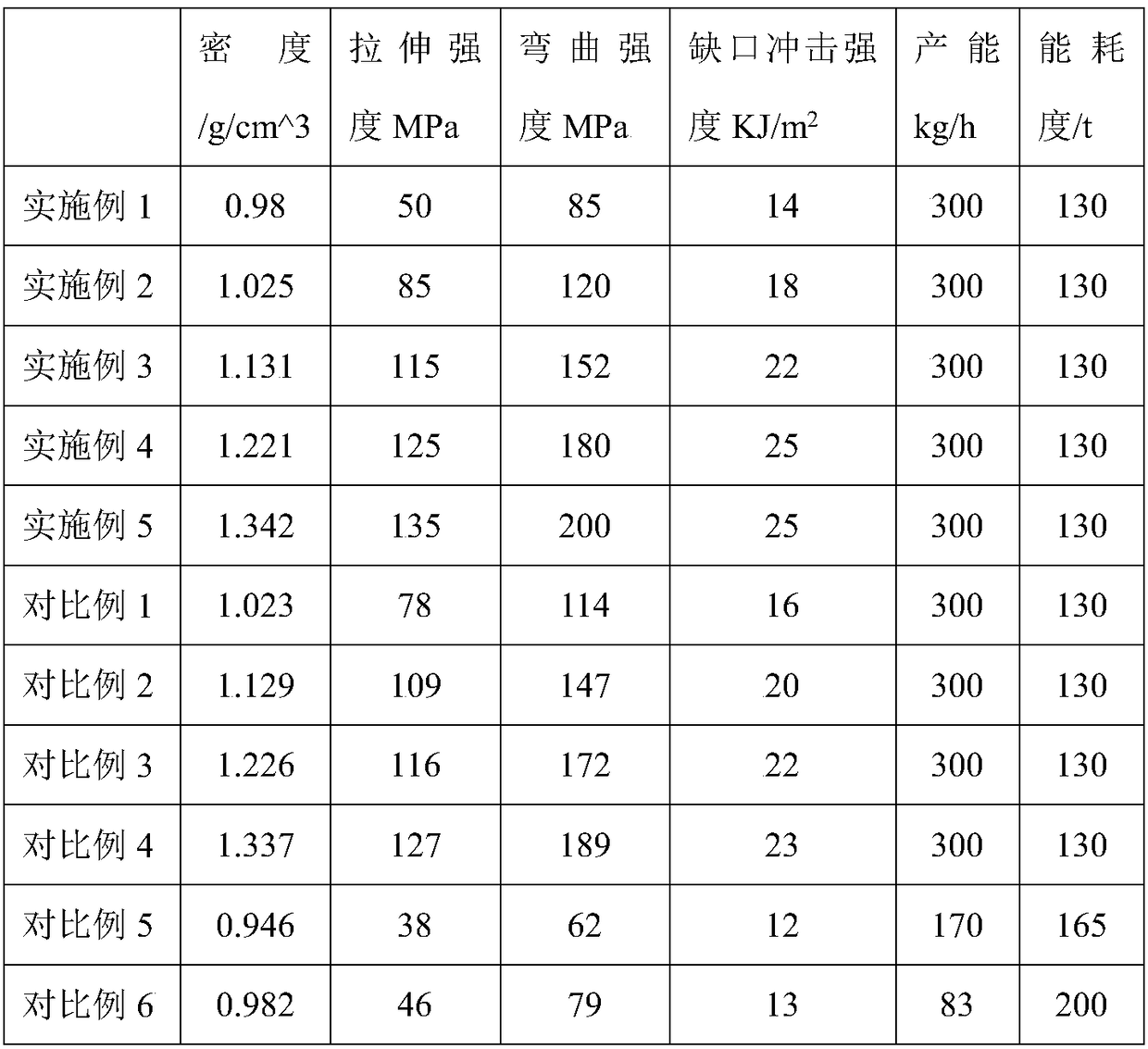

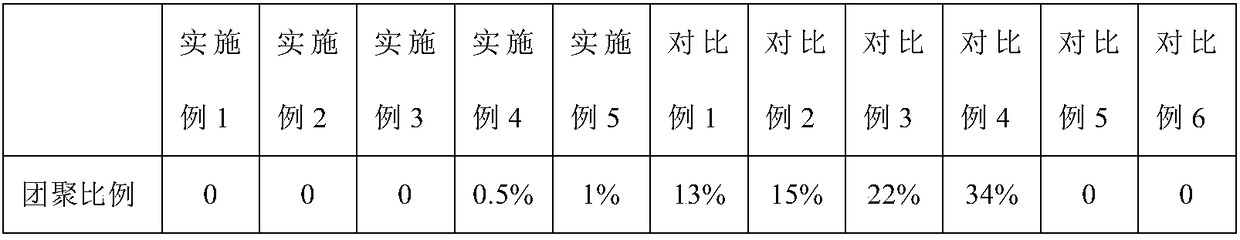

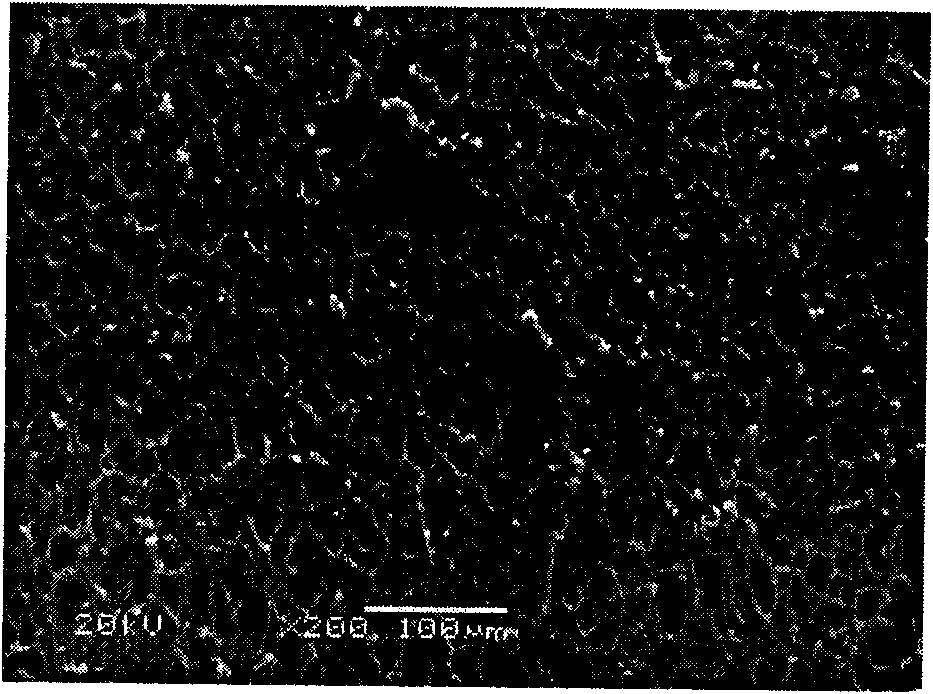

The invention discloses a high-dipping-degree long glass fiber reinforced polypropylene composite material and a preparation method thereof, and the high-dipping-degree long glass fiber reinforced polypropylene composite material is prepared from the following raw materials in parts by weight: 30-90 parts of polypropylene resin, 10-60 parts of glass fiber, 1-10 parts of a compatilizer, 1-10 partsof a flexibilizer, 0.1-1 part of an antioxidant and 0.2-2 parts of a lubricant. The glass fiber directly enters an impregnation tank for production after being treated by a treatment liquid on line. Compared with a common long glass fiber reinforced polypropylene composite material in the current market, the high-dipping-degree long glass fiber reinforced polypropylene composite material disclosedby the invention is greatly improved in tensile strength, tensile modulus, impact strength and the like, the glass fiber is high in dipping degree in polypropylene, the glass fiber is completely dispersed, and the occurrence ratio of the agglomeration defects of the glass fiber on the surface of the finished product is greatly reduced. In addition, the glass fiber is added in an online continuousmode, so that the energy consumption is greatly reduced, and the productivity is improved.

Owner:ZHEJIANG PRET NEW MATERIALS

Modified EVA microporous elastomer composite material and preparation method thereof

The invention provides a modified EVA microporous elastomer composite material and a preparation method thereof. In the prior art, the properties of the EVA microporous elastomer composite material are modified mainly by mixing fillings in the EVA, which cannot satisfy the use of the composite material in special fields. The formula includes EVA material, organic montmorillonite, polyurethane, styrene-butadiene rubber, foaming agent, zinc oxide, zinc stearate and stearic acid; and the preparation method comprises the steps of: adding the montmorillonite in the EVA for melting, shearing and dispersion treatment; mixing with the polyurethane and the styrene-butadiene rubber on a double-roller mixing machine after cooling; and adding auxiliary agent, thin-passing for more than ten times, taking off sheets and cutting; coating parting agent on the inner wall of a metal mould, heating, drying, adding the cut mixture to the mould, sealing, heating for 20 minutes, cooling and demoulding. By adopting a nano-intercalation technology, the invention greatly improves the tensile modulus of the modified EVA microporous elastomer material on the premise of basically not decreasing the toughness.

Owner:SHAANXI UNIV OF SCI & TECH

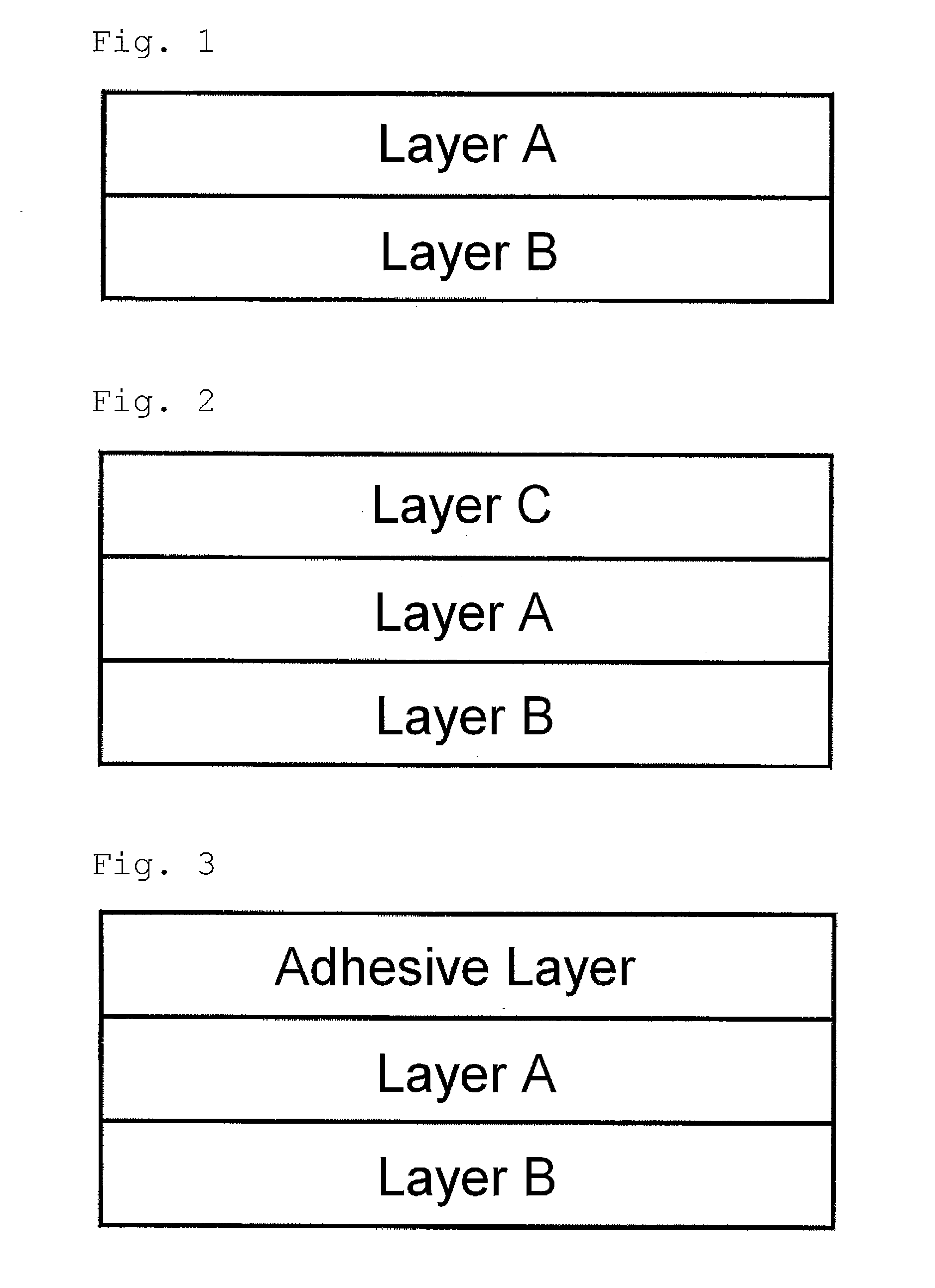

Method for producing laminated film, polarizing plate, liquid crystal display device, and optical film

InactiveUS20140293201A1Reduce thicknessHigh tensile modulusLamination ancillary operationsSynthetic resin layered productsLiquid-crystal displaySolvent

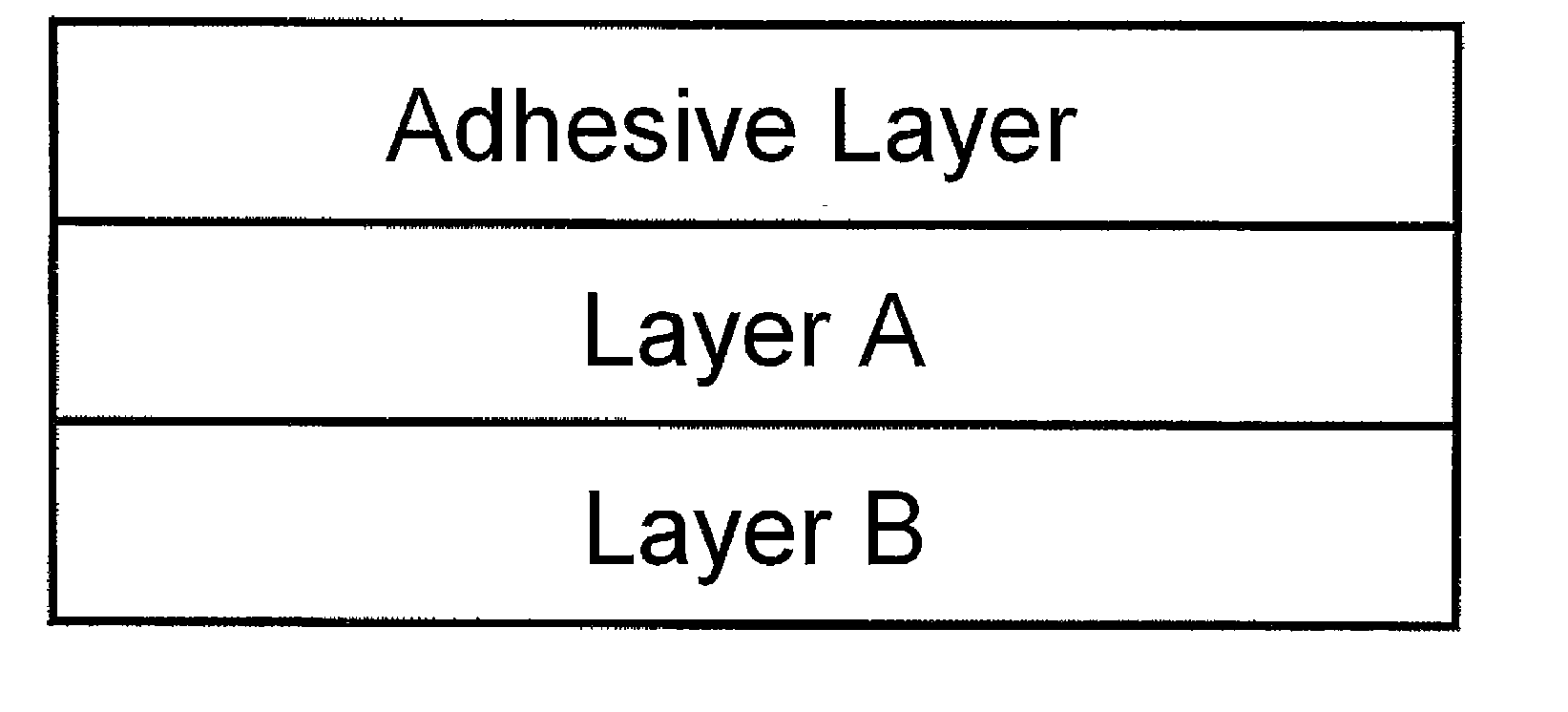

A laminated film having a retardation layer A and a layer B that are formed through solvent co-casting is provided. The layer A has a thickness of 5 to 30 μm. The layer B has a higher tensile modulus compared to the layer A. An interlayer peeling force between the layer A and the layer B is 0.05 to 5 N / cm. The laminated film overcomes the deterioration of handling property generally occurring with the reduction of film thickness in solvent casting method.

Owner:FUJIFILM CORP

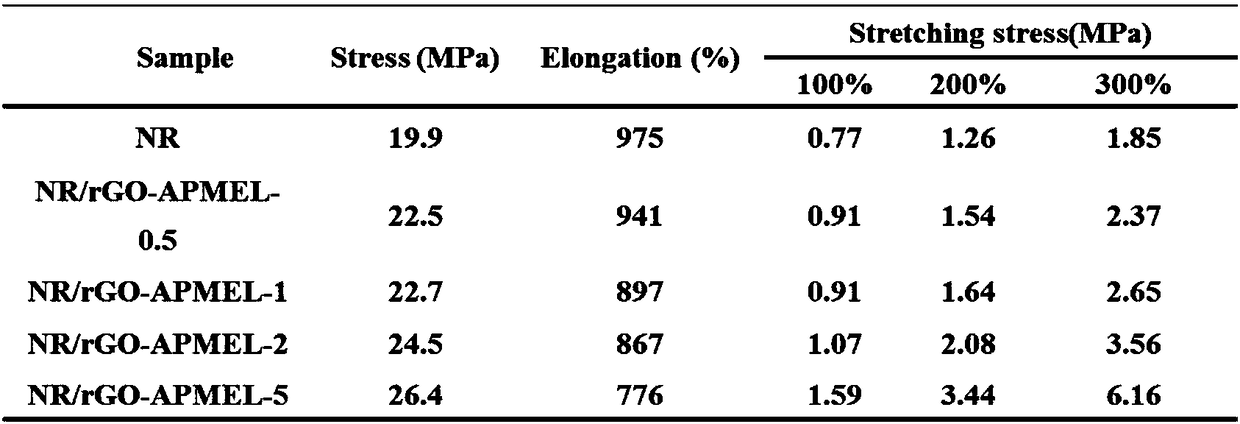

Preparation method of polymer modified graphene composite material

The invention discloses a preparation method of a polymer modified graphene composite material. The preparation method includes the steps: firstly, preparing graphite oxide in an ultrasonic radiationreactor into modified graphene by modifiers; secondly, dispersing the modified graphene into polymer emulsion to prepare stable polymer / modified graphene composite emulsion; thirdly, adding emulsion breakers into the composite emulsion to obtain polymer / modified graphene composite master batches; finally, adding the master batches, polymers and various auxiliary materials into an extruder, meltingthe materials at a certain temperature and extruding the materials to obtain the polymer / modified graphene composite material. Performances such as the tensile strength and the tensile modulus of thecomposite material are good, the preparation method is simple in preparation process, low in reaction temperature, easy to control and low in energy consumption, waste gas and waste liquid are avoided in the production process, and the preparation method is environmentally friendly.

Owner:SICHUAN UNIV

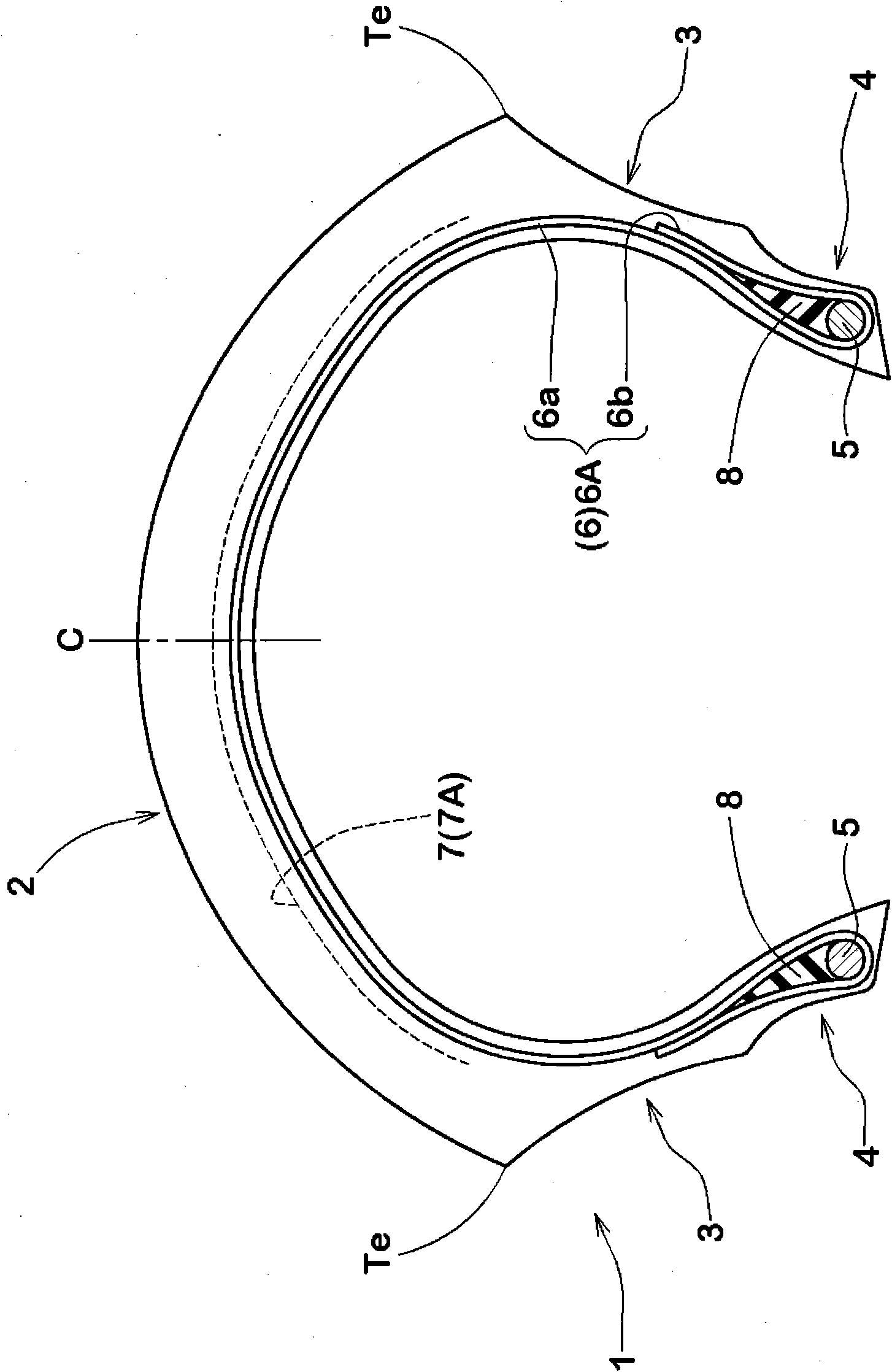

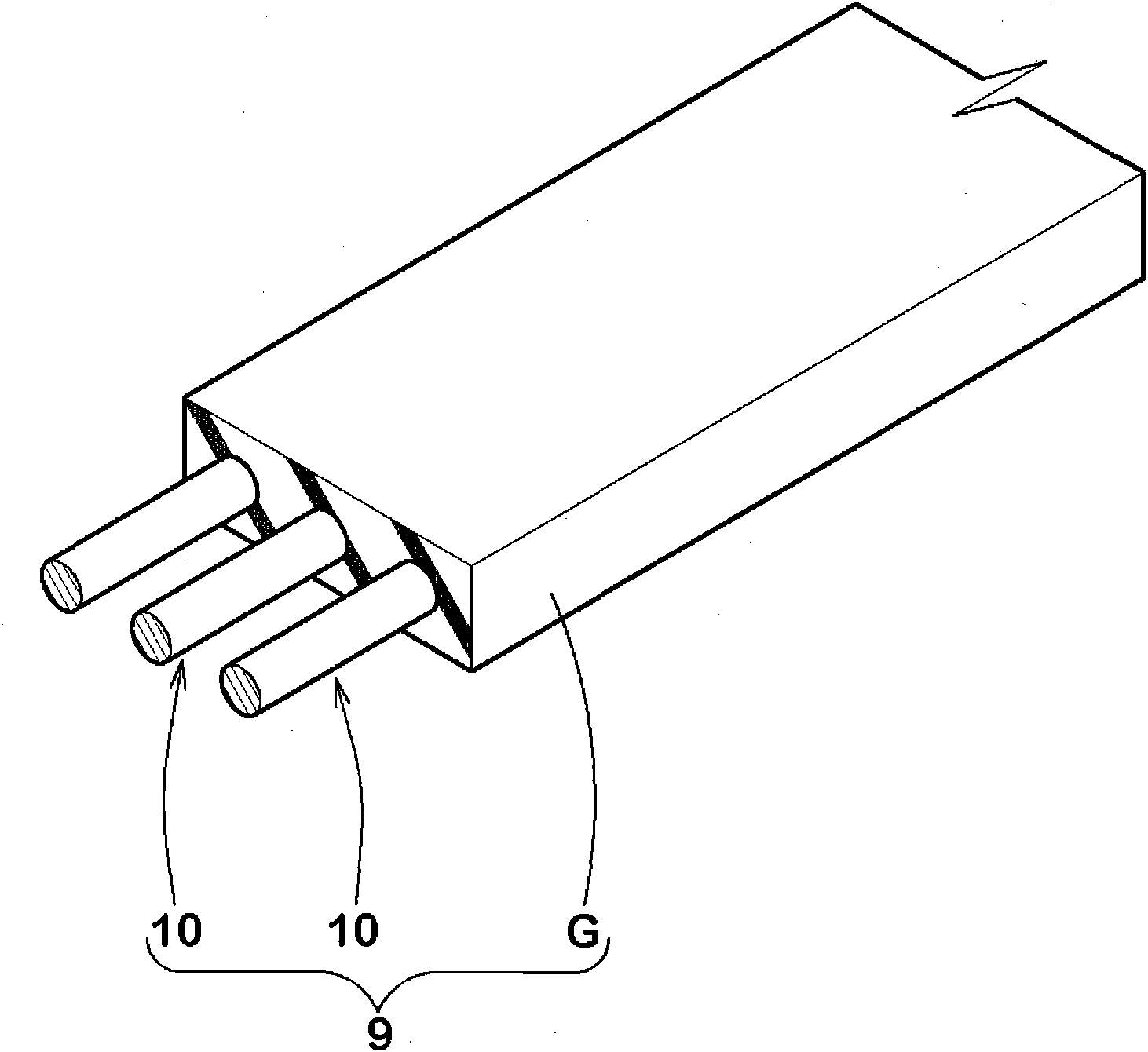

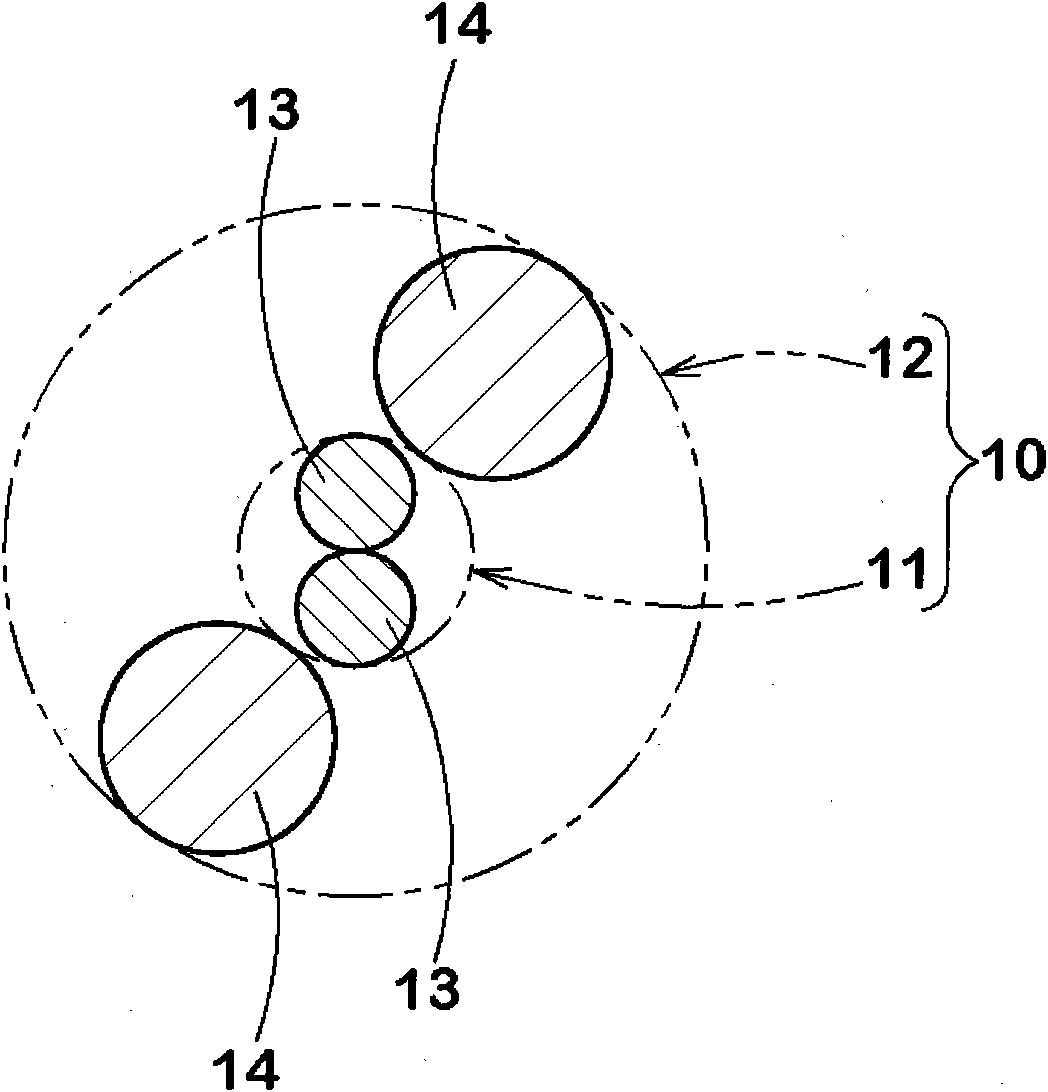

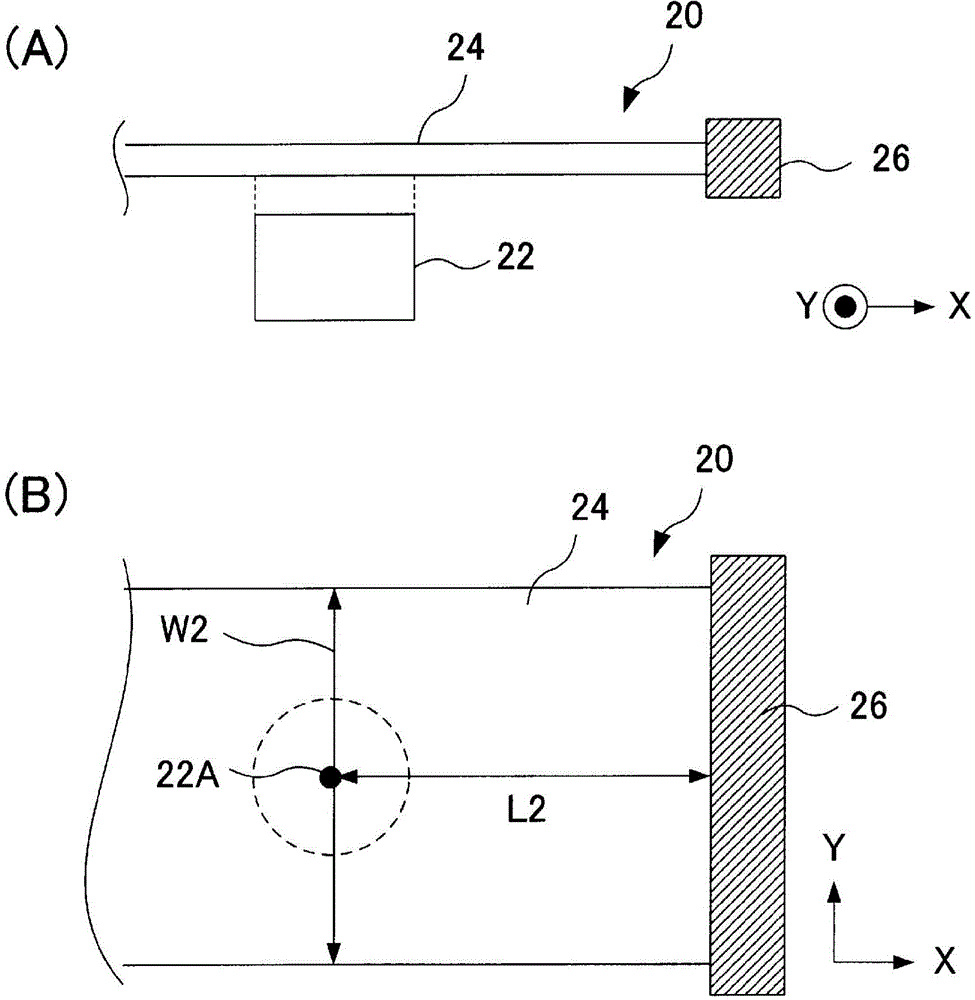

Tire cord and pneumatic tire including the same

InactiveCN101922071AGood molding precisionTensile modulus changeMotorcycle tyresPneumatic tyre reinforcementsAramidesEngineering

Owner:SUMITOMO RUBBER IND LTD

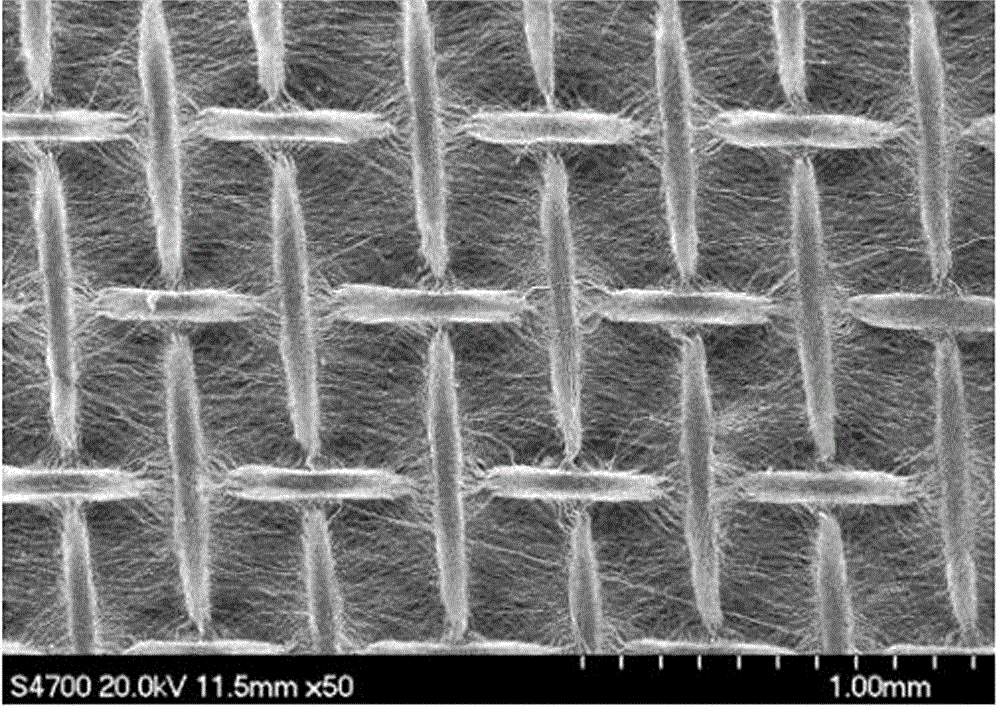

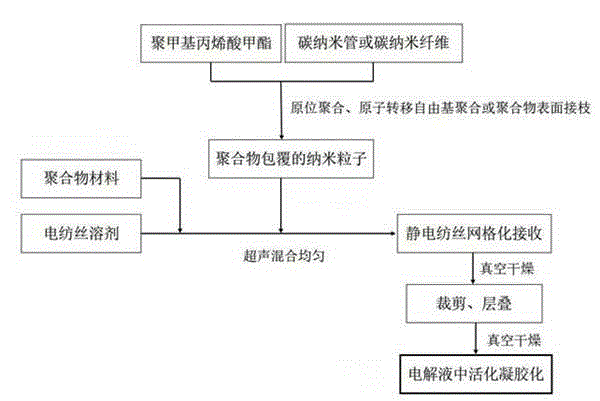

Preparation method of nano-doped grid patterning gel polymer electrolyte

ActiveCN104638294AIncrease capacityImprove electrochemical performanceMaterial nanotechnologyFinal product manufactureElectrolytic agentFiber

The invention relates to a porous polymer electrolyte skeleton material having a grid patterning structure and doped by nanoparticles, and a method for preparing a gel polymer electrolyte through using the skeleton material, and belongs to the field of polymer lithium ion batteries. The method comprises the following steps: 1, dispersing the nanoparticles in a polymer electrostatic spinning liquid, and making a nanoparticle doped polymer nanometer fiber film through an electrostatic spinning technology by using a grid patterning receiving device; 2, drying the nanometer fiber film, cutting the nanometer fiber film, and carrying out laminating compaction to make the polymer gel electrolyte skeleton; and 3, putting the skeleton material in an electrolyte solution in a glove box, and carrying out activation and gelating. The gel polymer electrolyte maintains good electrochemical performances, has greatly improved mechanical performances, makes up the mechanical-electrochemical performance unbalance defect of the gel polymer electrolyte, meets assembling needs of button batteries, and can be used in secondary lithium ion batteries.

Owner:BEIJING UNIV OF CHEM TECH

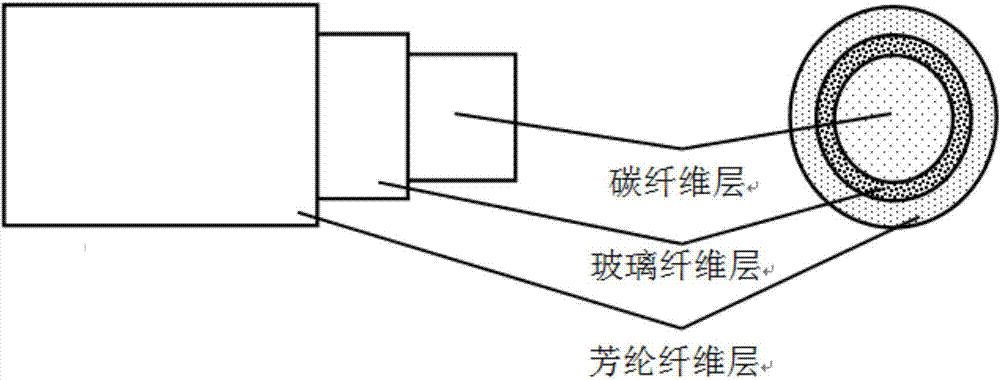

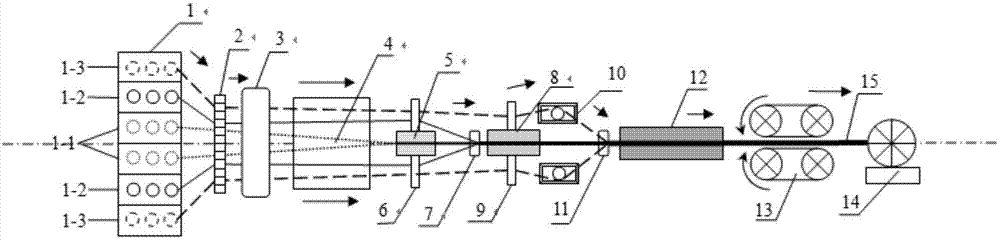

Three-layer concentric high-performance fiber composite material cable core rod and manufacturing method thereof

InactiveCN104851497AHigh strengthImprove toughnessInsulated cablesPower cablesGlass fiberLow density

The invention discloses a three-layer concentric high-performance fiber composite material cable core rod and a manufacturing method thereof. The internal layer of the core rod is made of carbon fiber composite material, the intermediate layer is made of glass fiber composite material, and the external layer is made of aramid fiber composite material so that a concentric structure is formed by the three layers. The invention also discloses a manufacturing method of the core rod. Carbon fiber, glass fiber and aramid fiber are infiltrated in liquid resin in an open glue tank; carbon fiber composite material preformed core rod is firstly formed by the impregnated carbon fiber; the impregnated glass fiber evenly wraps the carbon fiber composite material preformed core rod so that a two-layer concentric structured carbon fiber / glass fiber composite material preformed core rod is formed; and aramid fiber through impregnation and online ultrasound processing evenly wraps the carbon fiber / glass fiber composite material preformed core rod so that a three-layer concentric structured carbon fiber / glass fiber / aramid fiber composite material core rod is obtained, and thus the core rod is enabled to possess the characteristics of high strength, high toughness, high insulation, low density and high tensile modulus.

Owner:SHANDONG UNIV

Polylactic acid and polystyrene compatibilization blending material and preparation method thereof

Owner:HUBEI UNIV OF TECH

Plant fiber reinforced modified soy-based resin composite material

ActiveCN104448793AImprove impact strengthImprove mechanical propertiesSynthetic resin layered productsLaminationChemistryResin composite

The invention discloses a plant fiber reinforced modified soy-based resin composite material and a preparation method thereof. Cross-linking agents and epoxidized soybean oil acrylate are blended to prepare soy-based resin, the soy-based resin is modified by modifiers to obtain modified soy-based resin, and plant fibers, the modified soy-based resin and initiators are hot-pressed to obtain the plant fiber reinforced modified soy-based resin composite material. The plant fiber reinforced modified soy-based resin composite material has excellent tensile strength, tensile modulus, bending strength, bending modulus and impact strength.

Owner:FUJIAN AGRI & FORESTRY UNIV

Environment-friendly stable polyamide acid solution and preparation method thereof

ActiveCN105461926AImprove thermo-oxidative stabilityHigh glass transition temperaturePolyamidePolyamic acid

The invention relates to a polyamide acid solution and a preparation method thereof, in particular to an environment-friendly stable polyamide acid solution and a preparation method thereof. The environment-friendly stable polyamide acid solution and the preparation method thereof aim at solving the problems of difficultly of large-scale preparation of a polyamide acid aqueous solution, wide molecular weight distribution and poor batch stability in the prior art. The environment-friendly stable polyamide acid solution is prepared from tertiary amine, aromatic primary amine, aromatic dianhydride, aromatic diamine and water, wherein repetitive units of polyamide acid in the polyamide acid aqueous solution are shown in the specification. The preparation method includes the steps that tertiary amine, aromatic primary amine, aromatic dianhydride, aromatic diamine and water are taken, and weighed tertiary amine is divided into tertiary amine A and tertiary amine B; water and aromatic primary amine are added into a three-necked bottle under certain conditions for a reaction; weighed tertiary amine A and weighed aromatic diamine are added into the three-necked bottle for a reaction, reaction liquid is heated, then weighed aromatic dianhydride is added into the three-necked bottle and stirred for a reaction, then the reaction liquid is cooled, weighed tertiary amine B is added and stirred for a reaction, and the reaction liquid is cooled and subjected to standing.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

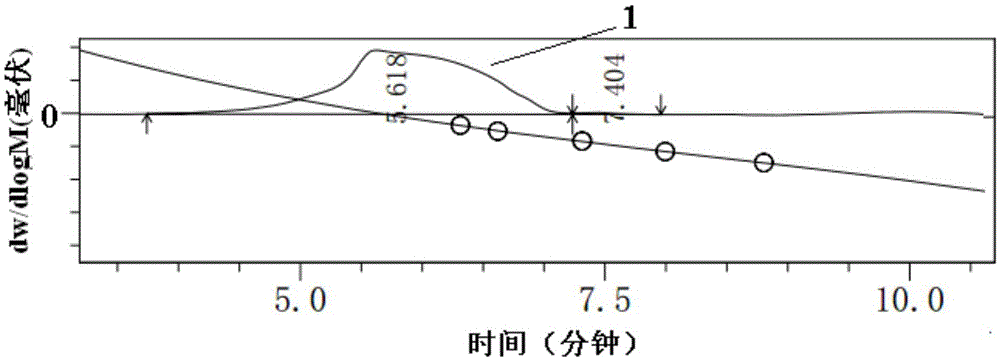

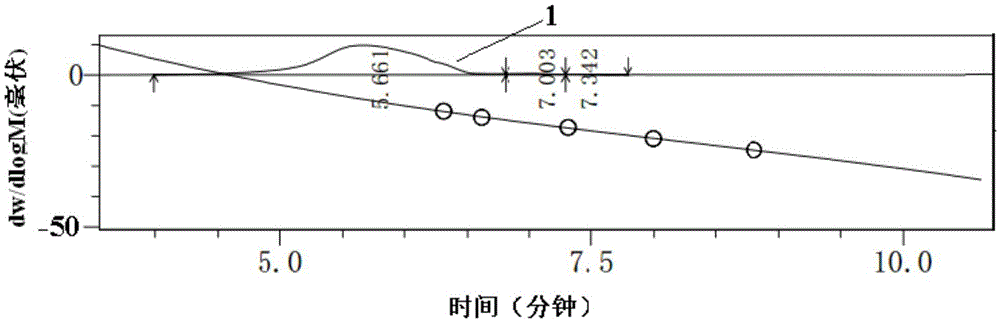

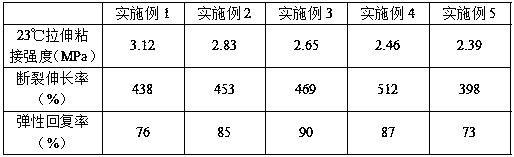

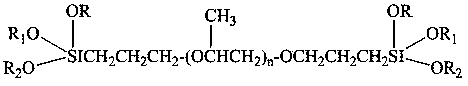

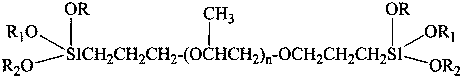

High-adhesion silane-modified polyether sealant for prefabricated building and preparation method of sealant

ActiveCN110256994AHigh tensile modulusImprove adhesionNon-macromolecular adhesive additivesEpoxy resin adhesivesChemistryCalcium carbonate

The invention discloses a high-adhesion silane-modified polyether sealant for a prefabricated building and a preparation method of the sealant. The method comprises the following steps: adding nano calcium carbonate, heavy calcium carbonate and amino-terminated polyether into a reaction kettle, blending for 1-2 hours in a vacuum condition, then adding a silane-modified polyether polymer, a coupling agent I, a thixotropic agent, an antiaging agent and a water-removing agent, and blending for 0.5-1 hour in the vacuum condition to obtain an ingredient A; adding epoxy resin, a flexible diluent, a coupling agent II and a catalyst into the reaction kettle, and blending for 1-2 hours in the vacuum condition to obtain a modified polyether sealant ingredient B for a base coat-free prefabricated building; and the ingredient A and the ingredient B are mixed in proportion to obtain the sealant.

Owner:山西省建筑科学研究院有限公司

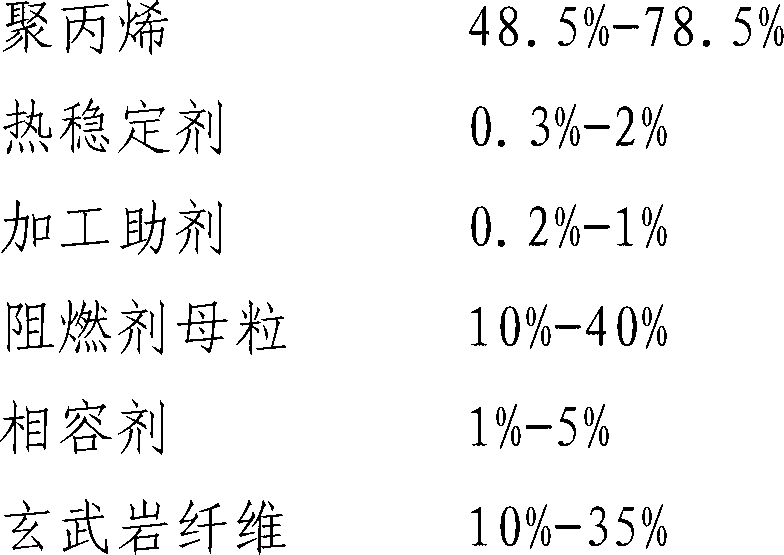

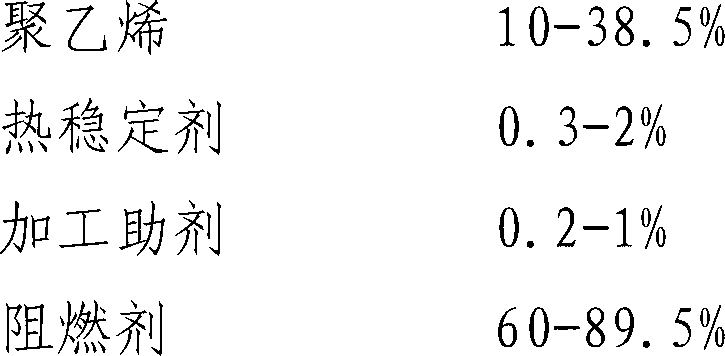

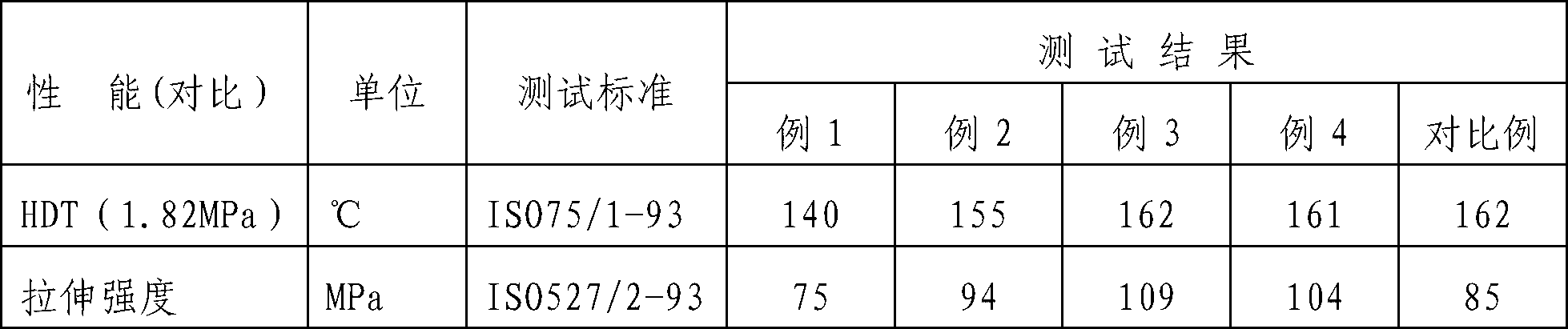

Basalt fiber polypropylene composite material enhanced by expansion flame retardants and method for preparing same

InactiveCN102936373AImprove mechanical propertiesImprove bending strengthChemical industryPolypropylene composites

The invention belongs to the field of novel composite materials and particularly relates to a basalt fiber polypropylene composite material enhanced by expansion flame retardants and a method for preparing the same. The polypropylene composite material comprises, by weight, 48.5% to 78.5% of polypropylene, 0.3% to 2% of heat stabilizers, 0.2% to 1% of processing agents, 10% to 40% of flame retardant master batches, 1% to 5% of compatilizers and 10% to 35% of basalt fibers. Mechanical properties of the polypropylene composite material are improved, for example, bending strength, tensile strength and tensile modulus, and particularly the bending strength is improved by 39%, the excellent mechanical properties enable the polypropylene composite material can be used in certain special occasions, such as fields of aerospace, metallurgy and chemical industry, auto parts and the like. As expansion flame retardants are added, the flame retardant effect of the polypropylene composite material is good, and poisonous gas and smog cannot be emitted during combustion to pollute the environment.

Owner:SHANGHAI KINGFA SCI & TECH +1

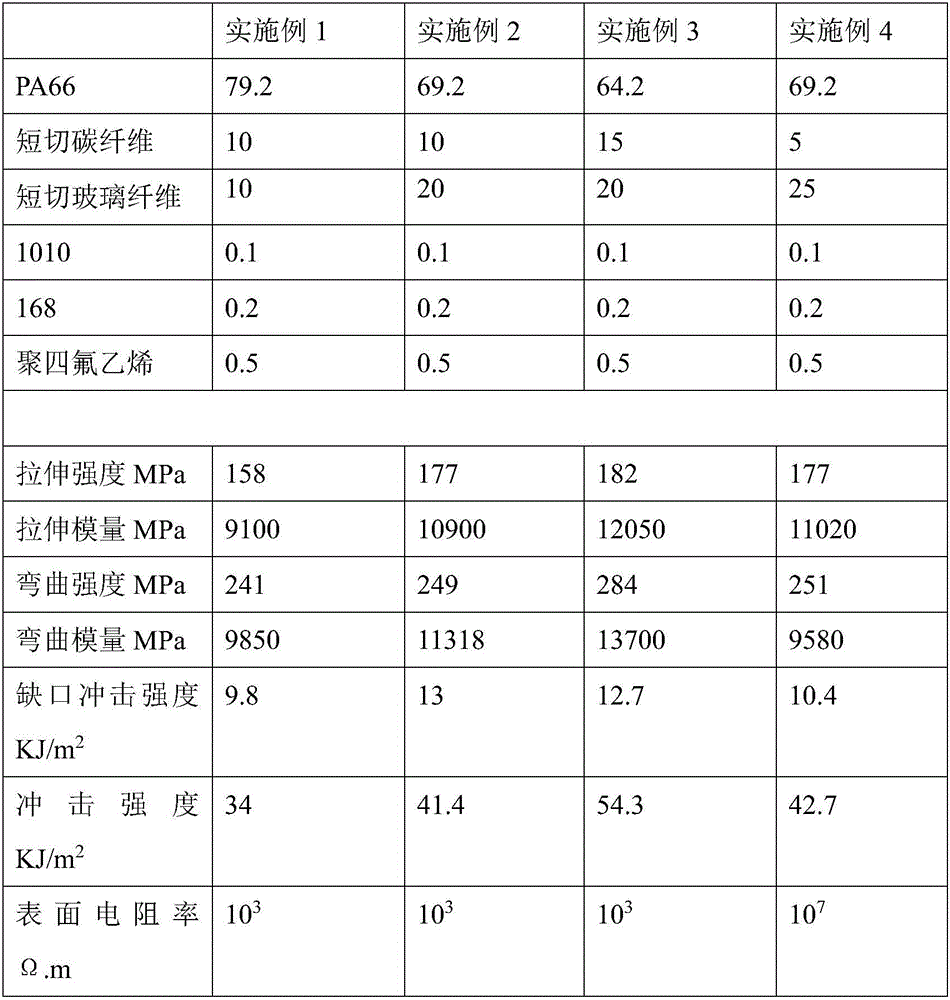

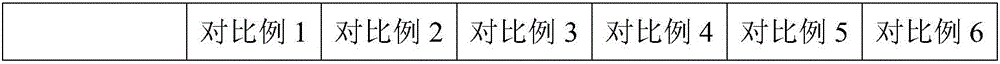

Fiber blend reinforced nylon composite material and preparation method thereof

The invention discloses a fiber blend reinforced nylon composite material and a preparation method thereof. The composite material comprises, by weight, 30-90 parts of nylon resin, 5-30 parts of short glass fibers, 5-30 parts of short carbon fibers, 0-10 parts of a flexibilizer, 0.1-1 part of an antioxidant and 0.2-2 parts of a lubricant. Compared with common glass fiber reinforced nylon composite materials in the present market, the fiber blend composite material disclosed in the invention has the advantages of greatly improved tensile strength, greatly improved tensile modulus, greatly improved impact strength, and electricity conducting performance; and the preparation method has the advantages of simplicity in operation, very low price, and suitableness for industrial production and application.

Owner:SHANGHAI PRET COMPOSITES +4

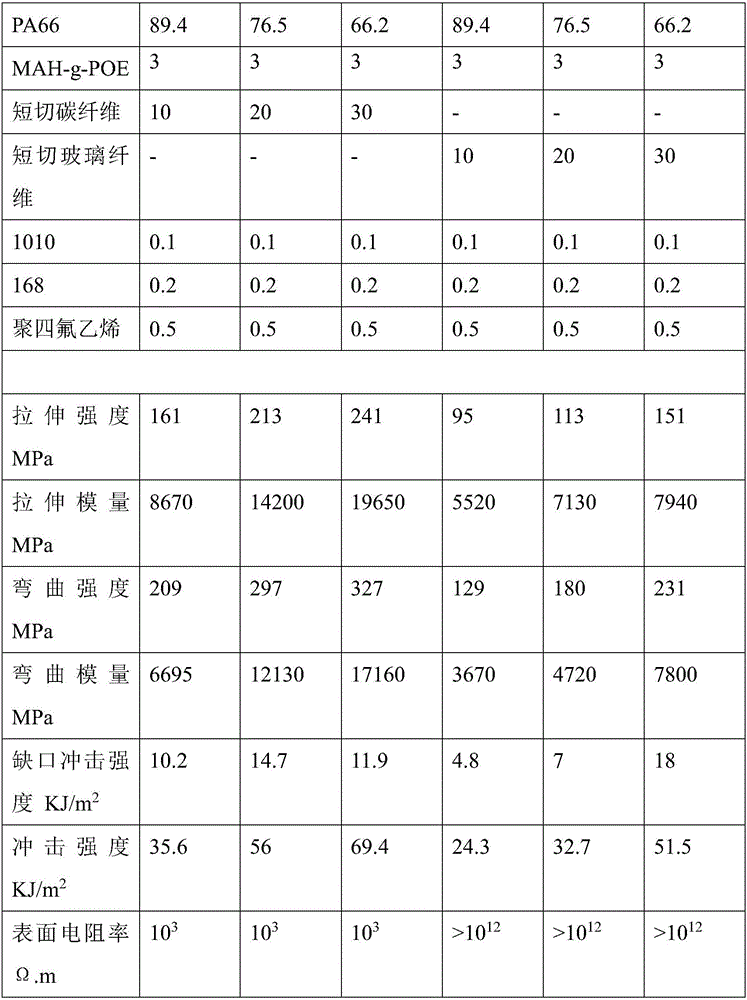

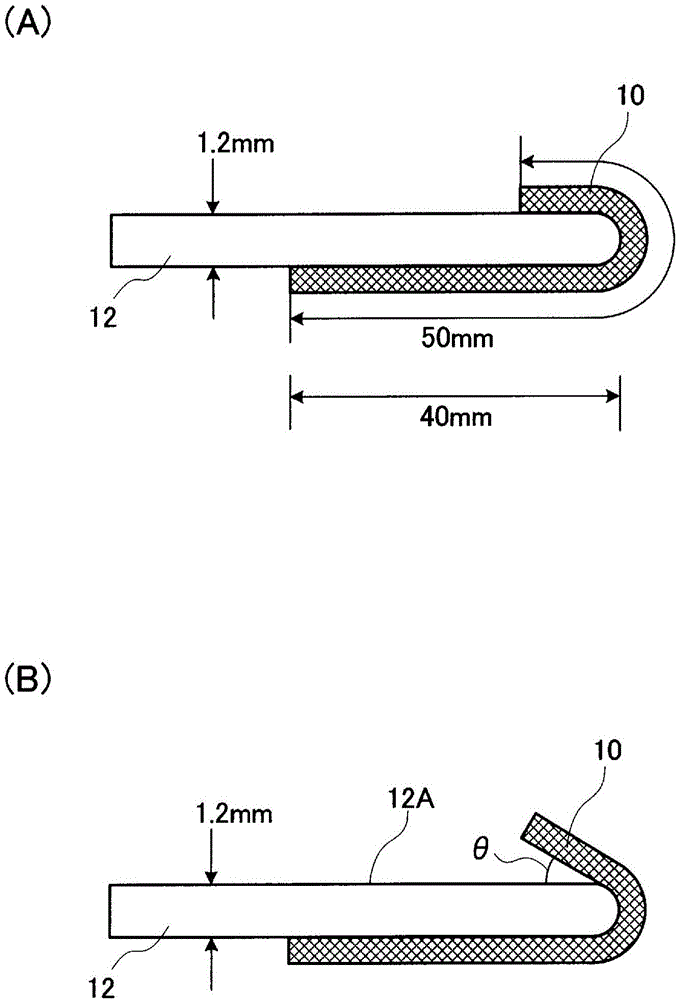

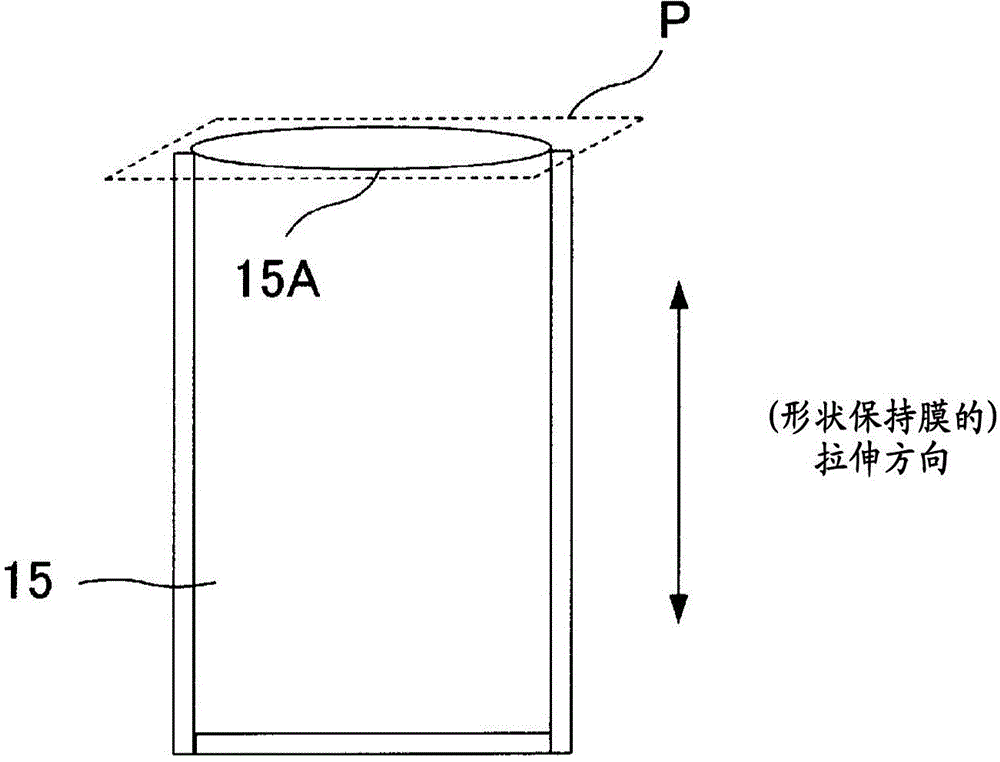

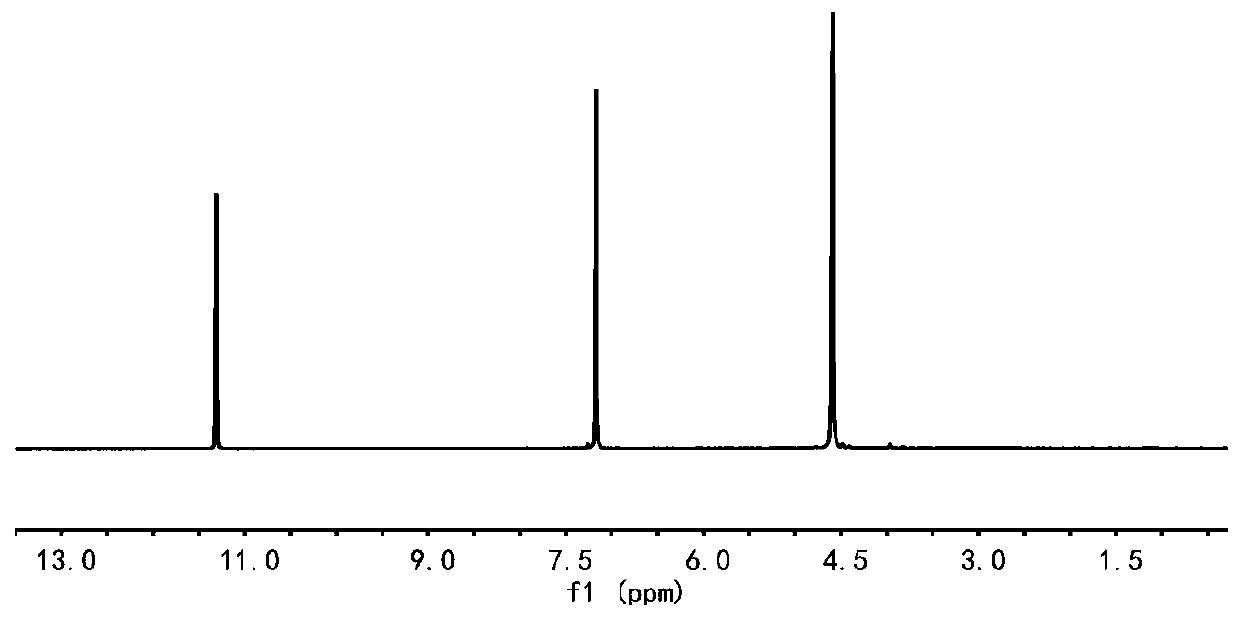

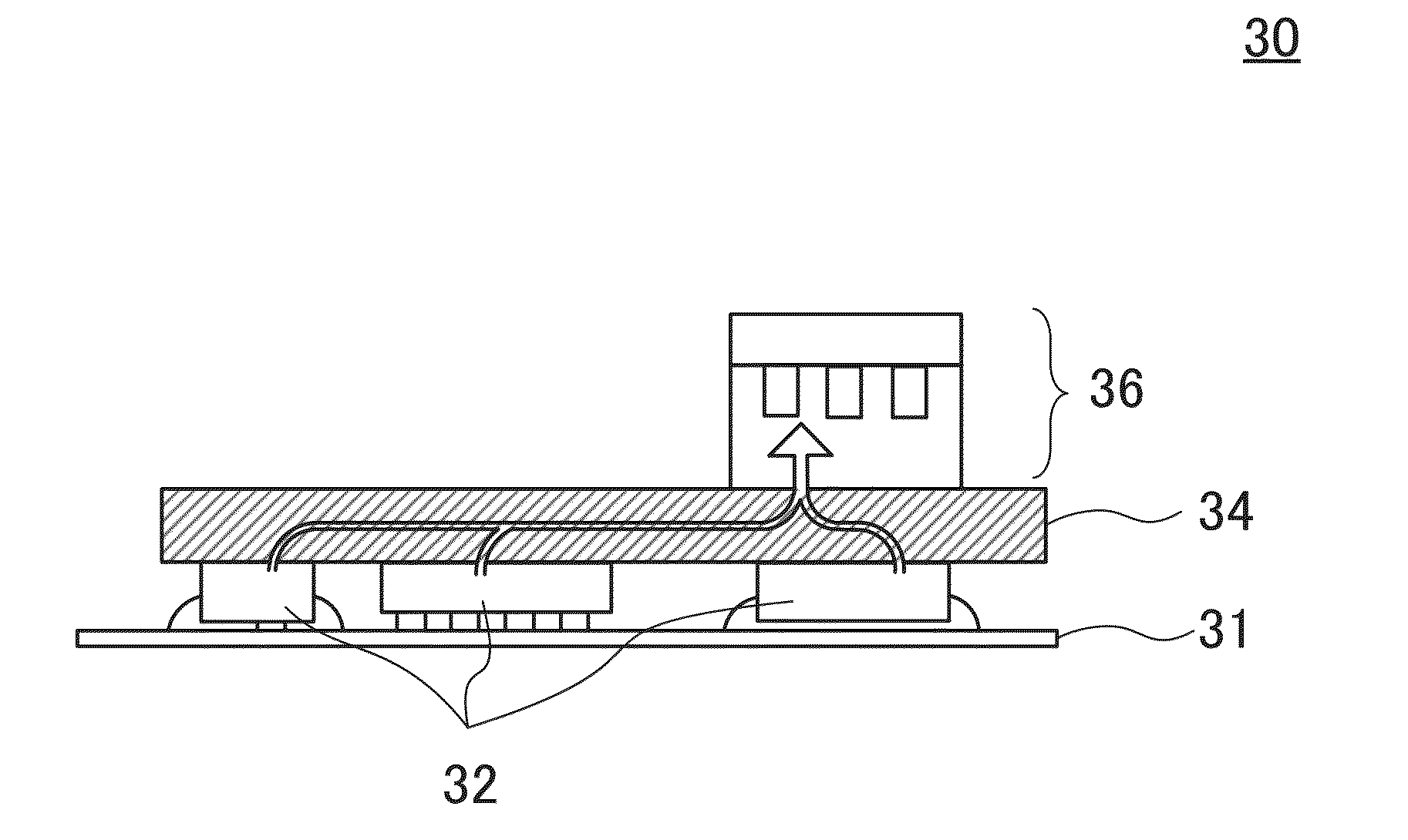

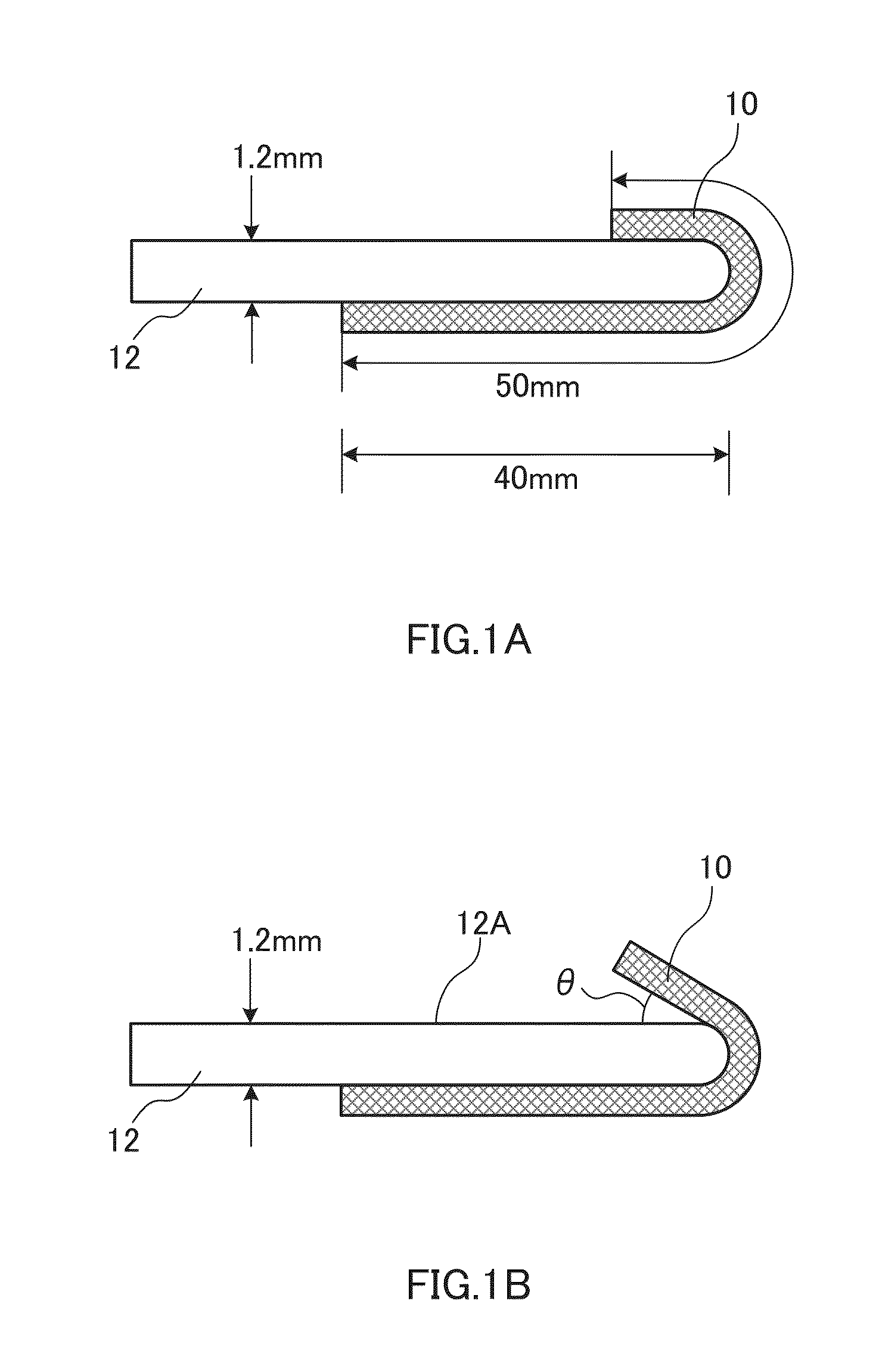

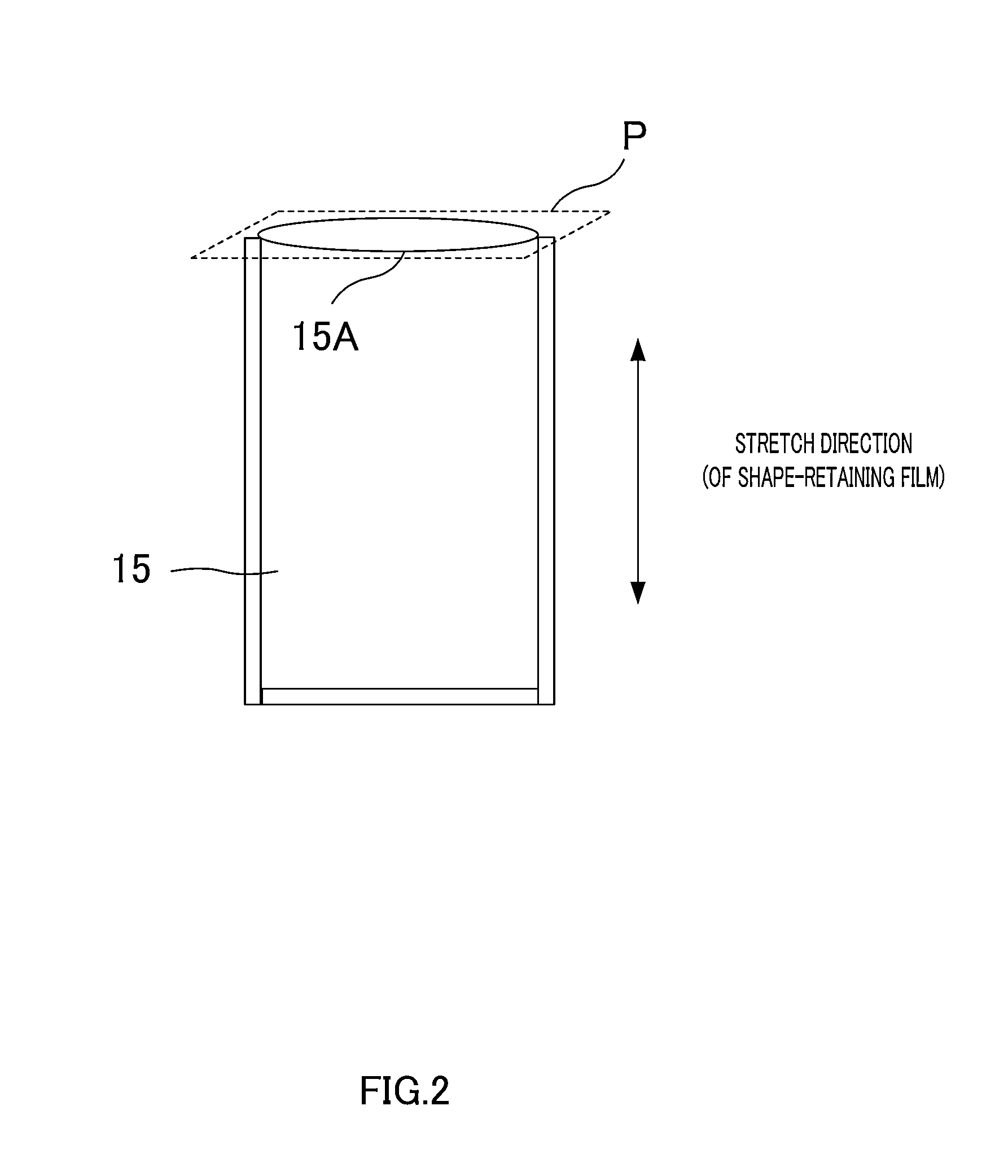

Shape retaining film and production method therefor, laminated filmtape, self-adhesive filmtape, anisotropic thermal conductive film, and shape retaining fiber

InactiveCN103068576AGood shape retentionHigh tensile modulusSemiconductor/solid-state device detailsSynthetic resin layered productsFiberTear resistance

The purpose of the present invention is to provide a shape retaining film excellent in shape retention, and further having high tensile elasticity and good longitudinal tear resistance. The shape retaining film is composed of at least one base material layer containing an ethylene polymer that has the density of 900 kg / m3 or more, and the weight-average molecular weight (Mw) / number-average molecular weight (Mn) of 5 to 20, and at least one soft layer containing a high polymer material. The ethylene polymer is an ethylene homopolymer or an ethylene-a-olefin copolymer in which the content of a-olefin unit having 3 to 6 carbon atoms is less than 2% by weight. The high polymer material has the melting point (Tm2) lower than the melting point (Tm1) of the ethylene polymer, the tensile elasticity of 10 to 50 GPa, and the recovery angle of 65 or less as a result of 180 bending test.

Owner:MITSUI CHEM INC

Furan dicarboxylic acid copolyester and preparation method thereof

ActiveCN109810248AHigh tensile modulusHigh tensile strengthMonocomponent copolyesters artificial filamentFuranMechanical property

The invention relates to furan dicarboxylic acid copolyester and a preparation method thereof. The preparation method comprises the following steps: mixing a first component, a second component and athird component with the mole ratio of 1 to (1.1 to 2.0) to (0.0001 to 0.02) with an esterification catalyst to obtain a first intermediate product, wherein the first component comprises at least oneof furan dicarboxylic acid and a furan dicarboxylic acid ester compound, the second component comprises at least one of aromatic diol and aliphatic diol, and the third component comprises polyhydric alcohol with hydroxyl number being greater than or equal to 3; performing prepolymerization reaction and polycondensation on the first intermediate product to obtain the furan dicarboxylic acid copolyester. In the preparation method, the polyhydric alcohol with hydroxyl number being greater than or equal to 3 serves as a connection point of chain segments, so that the chain segment structure of thefuran dicarboxylic acid copolyester is expanded to a network structure, thereby obtaining the colorless or lightcolor furan dicarboxylic acid copolyester with excellent mechanical property and air barrier property and high molecular weight.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

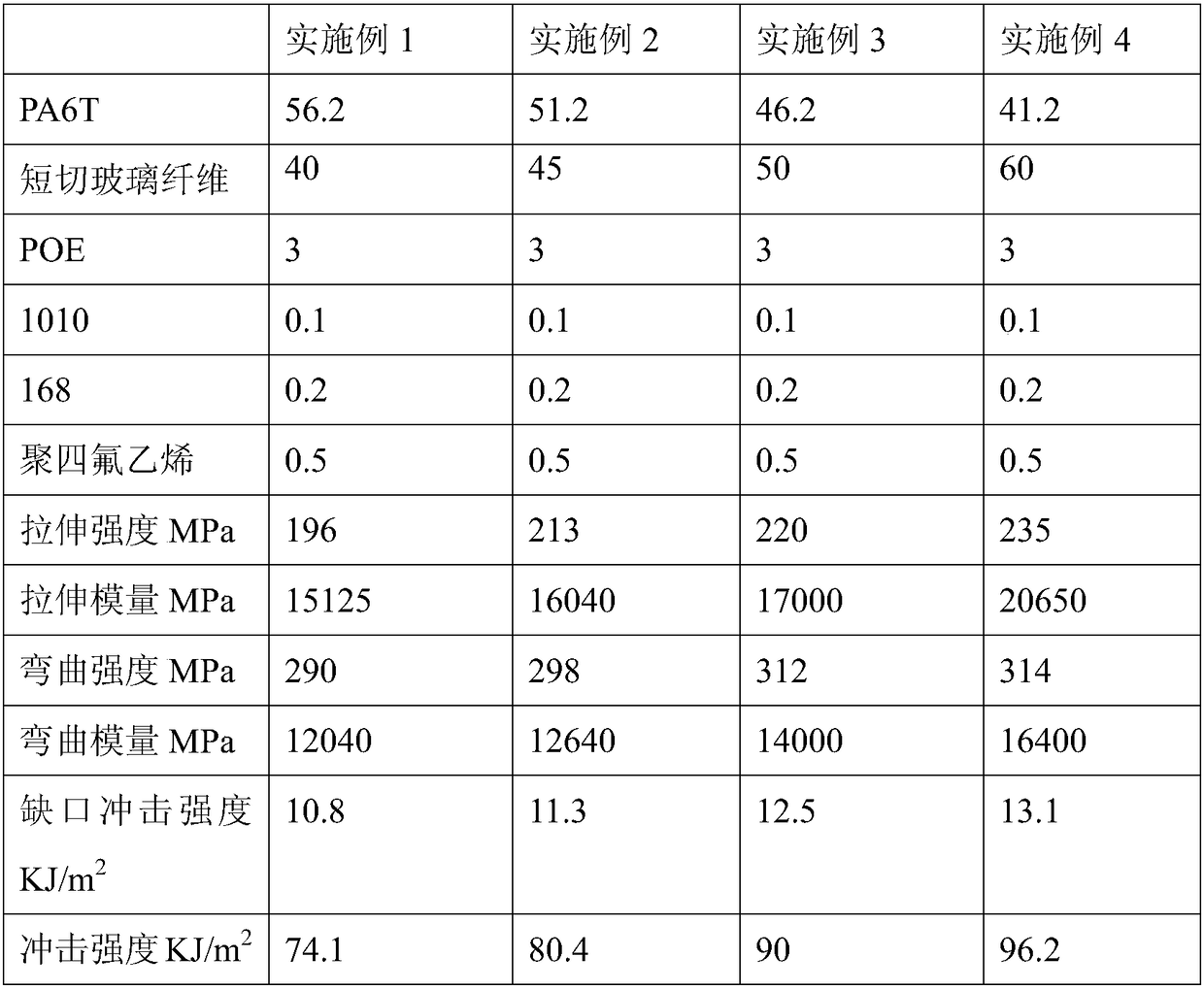

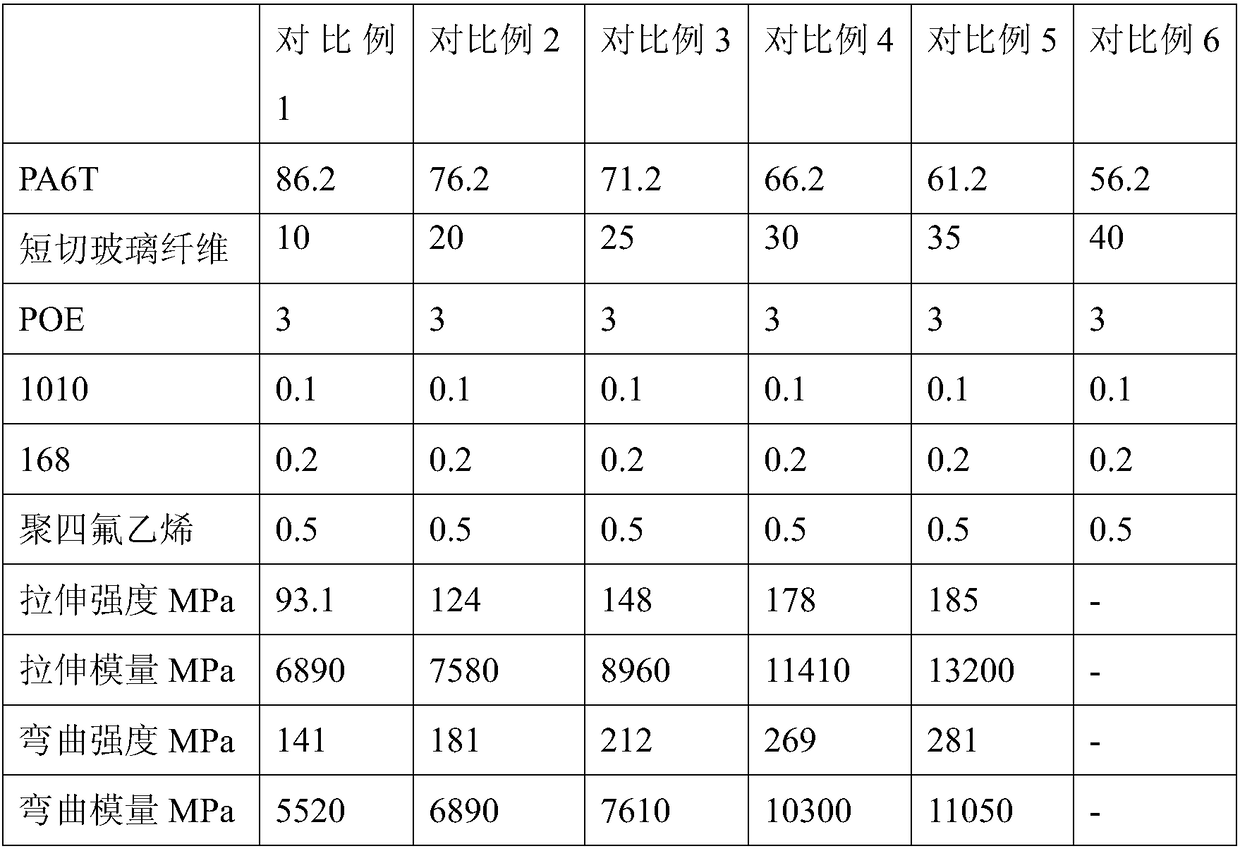

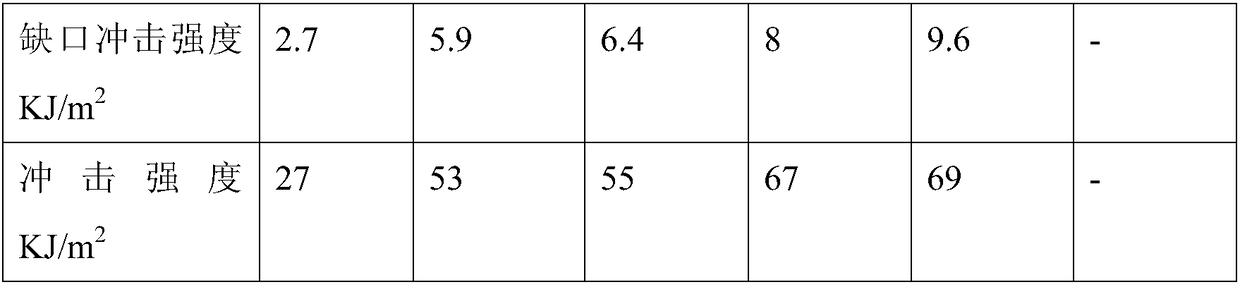

High glass fiber content enhanced high-temperature nylon composite material and preparation method thereof

The invention discloses a high glass fiber content enhanced high-temperature nylon composite material and a preparation method thereof. The high glass fiber content enhanced high-temperature nylon composite material is composed of five components by weight: 30-90 parts of high temperature nylon resin, 20-60 parts of chopped glass fiber, 1-10 parts of a flexibilizer, 0.1-1 part of an anti-oxidant and 0.2-2 parts of a lubricant, Compared with the commonly used glass fiber reinforcement high-temperature nylon composite material on market, the tensile strength, the tensile modulus, and the impactintensity of the high glass fiber content enhanced high-temperature nylon composite material are greatly increased.

Owner:CHONGQNG PRET NEW MATERIAL +4

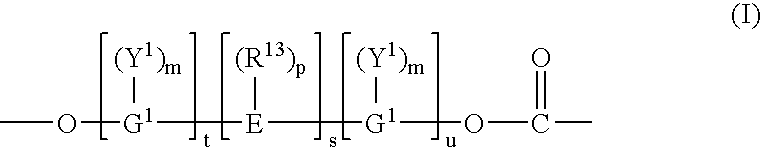

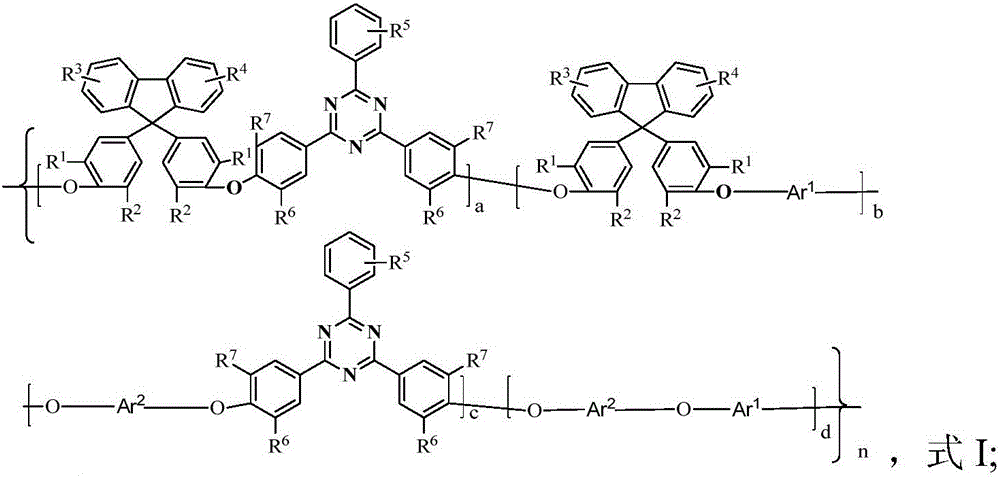

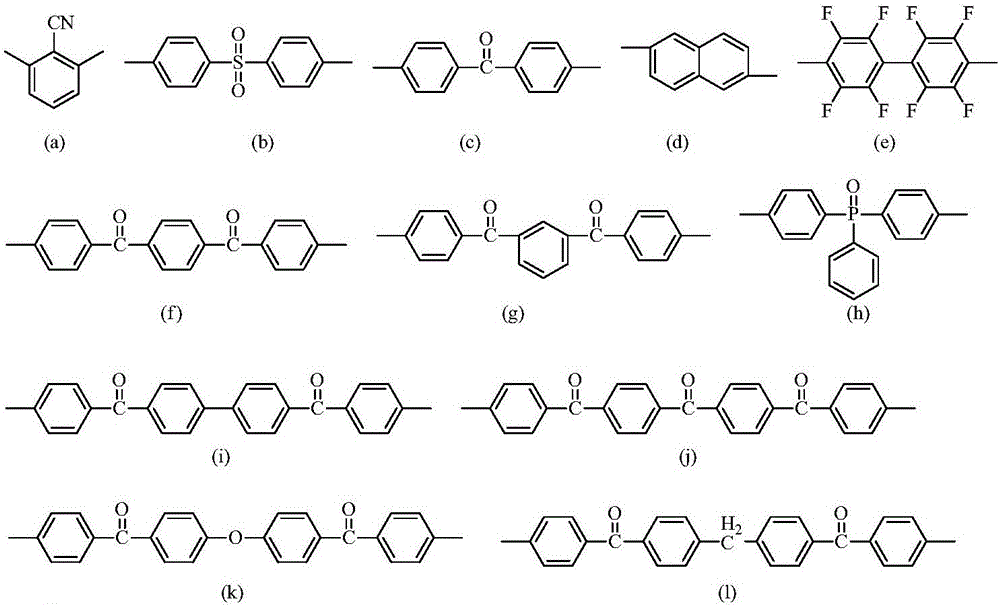

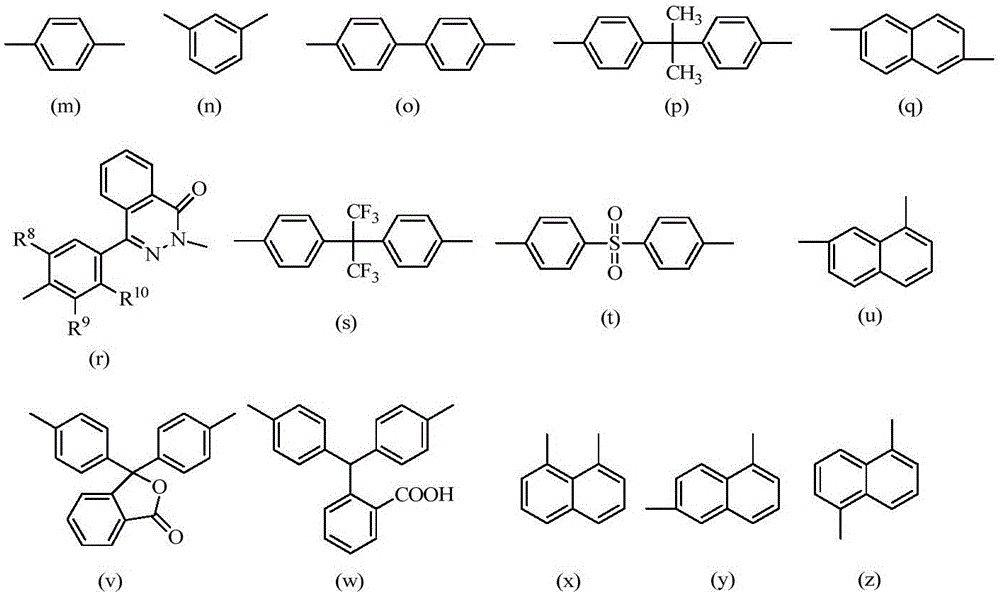

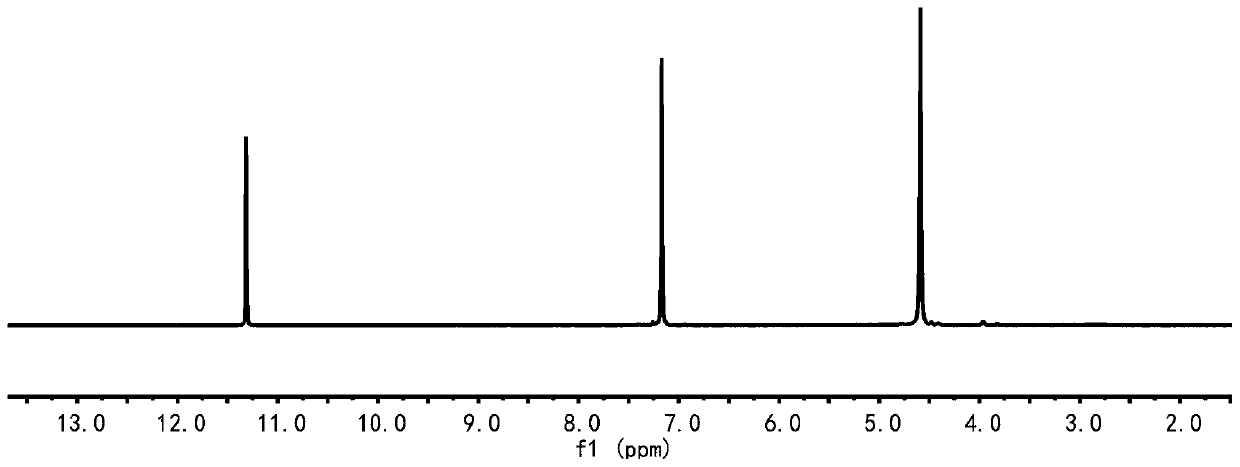

Polyarylether with main chain containing bisbenzofiurene and triaryl-s-triazine structure and preparation method of polyarylether

ActiveCN106589348AHigh glass transition temperatureHigh thermal decomposition temperatureSolubilityBackbone chain

The invention discloses a polyarylether with the main chain containing a bisbenzofiurene and triaryl-s-triazine structure and a preparation method of the polyarylether and belongs to the field of the synthesis of polymer materials. The structure of the polyarylether contains a bisbenzofiurene group and a triaryl-s-triazine group and has a structural formula shown in the formula I. The preparation method includes the steps that a bisbenzofiurene-containing bisphenol monomer, a triaryl-s-triazine-containing bishalogen monomer, a bisbenzofiurene-free bisphenol monomer and a triaryl-s-triazine-free bishalogen monomer as raw materials are subjected to a nucleophilic substitution in the presence of a base catalyst, a solvent and a dehydrating agent to obtain the polyarylether. The polyarylether has better solubility in common organic solvents, at the same time, has a higher glass transition temperature (more than 290 DEG C) and a higher thermal decomposition temperature (the 5% weight loss temperature is more than 500 DEG C), is suitable for use as a high performance structural material, and also can serve as composite matrix resin or a functional membrane material and the like.

Owner:DALIAN UNIV OF TECH

Furyl copolyester and preparation method thereof

ActiveCN109810247AHigh tensile modulusHigh tensile strengthMonocomponent copolyesters artificial filamentFiberEngineering plastic

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Shape retaining film and production method therefor, laminated film-tape, self-adhesive film-tape, anisotropic thermal conductive film, and shape retaining fiber

InactiveUS20130143014A1Good shape retentionHigh tensile modulusSemiconductor/solid-state device detailsSynthetic resin layered productsFiberSoft layer

The purpose of the present invention is to provide a shape retaining film excellent in shape retention, and further having high tensile elasticity and good longitudinal tear resistance. The shape retaining film is composed of at least one base material layer containing an ethylene polymer that has the density of 900 kg / m3 or more, and the weight-average molecular weight (Mw) / number-average molecular weight (Mn) of 5 to 20, and at least one soft layer containing a high polymer material. The ethylene polymer is an ethylene homopolymer or an ethylene-α-olefin copolymer in which the content of a-olefin unit having 3 to 6 carbon atoms is less than 2% by weight, The high polymer material has the melting point (Tm2) lower than the melting point (Tm1) of the ethylene polymer, the tensile elasticity of 10 to 50 GPa, and the recovery angle of 65° or less as a result of 180° bending, test.

Owner:MITSUI CHEM INC

Application of hyperbranched polyester in PA6 (polyamide 6)

The invention relates to a hyperbranched polyester, particularly application of a hyperbranched polyester in PA6 (polyamide 6). The application comprises the following steps: (1) drying hydroxyl-terminated hyperbranched polyester; (2) drying pure PA6; (3) uniformly mixing the hydroxyl-terminated hyperbranched polyester obtained in the step (1) with the pure PA6 obtained in the step (2); and (4) granulating the uniformly mixed hydroxyl-terminated hyperbranched polyester and pure PA6 obtained in the step (3) by using a double screw extruder, and drying to obtain the modified PA6 product. The application can obviously lower the melt viscosity of PA6 and improve the physical properties.

Owner:WEIHAI CY DENDRIMER TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com