Preparation method of polycarbonate microporous material with bimodal distribution

A technology of polycarbonate and microporous materials, which is applied in the field of preparation of polycarbonate microporous materials, can solve the problems of single-peak distribution of thermoplastic foam and easy pollution of the environment, and achieve improved storage modulus, excellent dielectric properties, Effect of Tensile Modulus Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

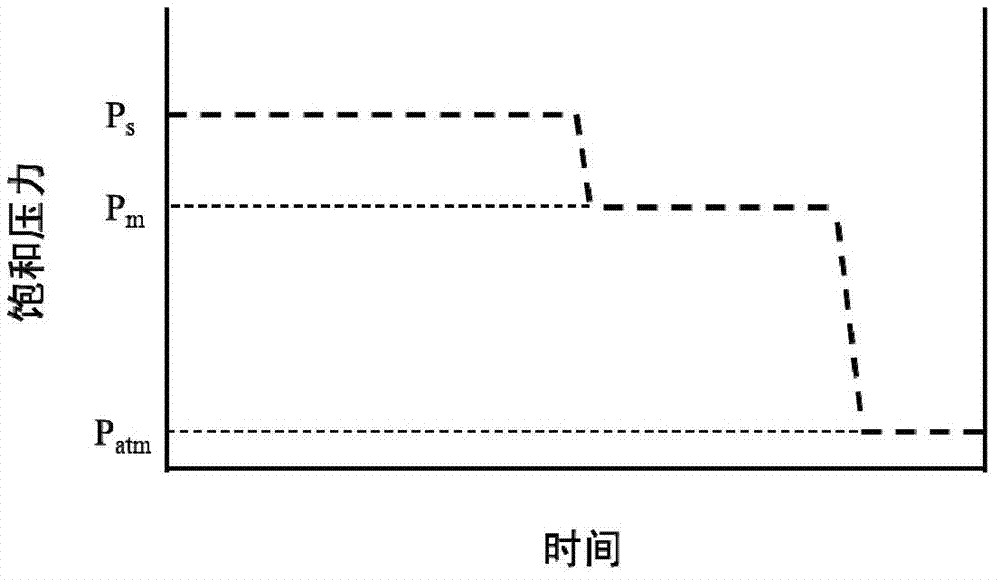

Method used

Image

Examples

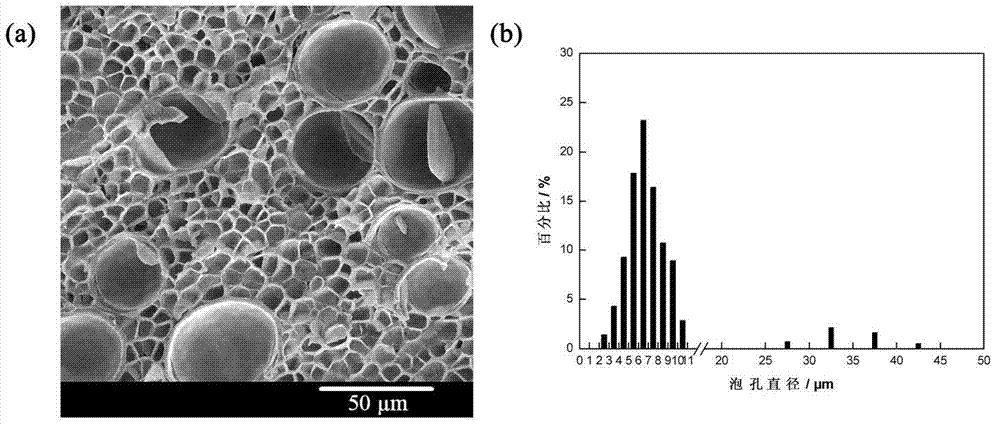

Embodiment 1

[0021] Embodiment 1: polycarbonate sheet is placed in autoclave, passes into supercritical CO 2 fluid to make polycarbonate sheets in supercritical CO 2 Carry out saturation in the fluid, the saturation pressure is 35MPa, the saturation temperature is 60°C, and the saturation time is 6h. After complete saturation, a uniform PC / CO 2 Mixture; depressurization for the first time in 20s, so that the saturation pressure in the autoclave is reduced to an intermediate pressure of 20MPa, the temperature remains constant, and the first nucleation occurs in the polycarbonate matrix and forms nuclei; After maintaining the constant temperature and pressure for 3 hours in this state, the pressure was released for the second time within 20 seconds to lower the pressure to atmospheric pressure to initiate the second nucleation; the polycarbonate sheet was quickly transferred to a constant temperature glycerin bath for nucleation Foaming, the foaming temperature is 100 ° C, and the foaming t...

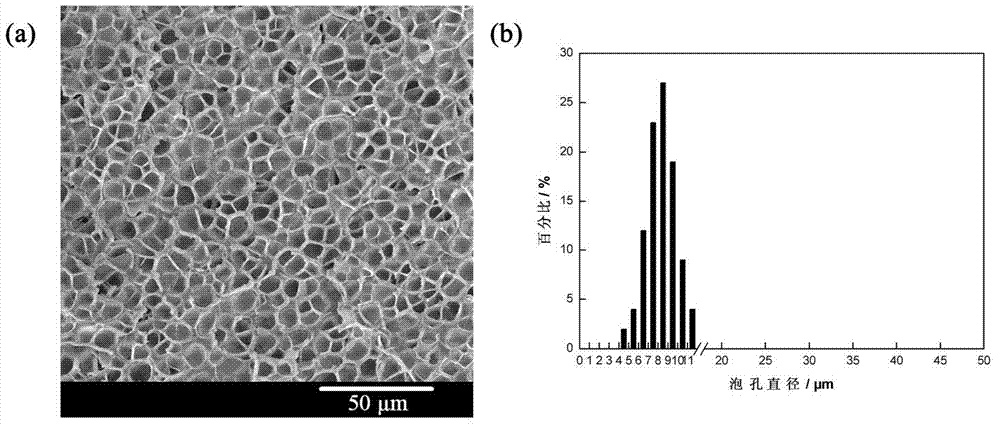

Embodiment 2

[0022]Embodiment 2: polycarbonate sheet is placed in autoclave, passes into supercritical CO 2 fluid to make polycarbonate sheets in supercritical CO 2 Saturation in the fluid, the saturation pressure is 25MPa, the saturation temperature is 25°C, and the saturation time is 3h. After complete saturation, a uniform PC / CO 2 Mixture; depressurize for the first time in 30s, so that the saturation pressure in the autoclave is reduced to an intermediate pressure of 20MPa, the temperature remains constant, and the first nucleation occurs in the polycarbonate matrix and forms nuclei; After maintaining the constant temperature and pressure in this state for 0.5h, the second pressure relief is carried out within 30s to reduce the pressure to atmospheric pressure to initiate the second nucleation; the polycarbonate sheet is quickly transferred to a constant temperature glycerin bath for Foaming, the foaming temperature is 160 ° C, and the foaming time is 5s, then the foamed material is p...

Embodiment 3

[0023] Embodiment 3: polycarbonate sheet is placed in autoclave, feeds supercritical CO 2 fluid to make polycarbonate sheets in supercritical CO 2 Carry out saturation in the fluid, the saturation pressure is 20MPa, the saturation temperature is 60°C, and the saturation time is 6h. After complete saturation, a uniform PC / CO 2 Mixture; within 10s, the pressure is relieved for the first time, so that the saturation pressure in the autoclave is reduced to an intermediate pressure of 14MPa, and the temperature is kept constant, and the first nucleation occurs in the polycarbonate matrix and forms nuclei; After maintaining constant temperature and pressure in this state for 1 hour, release the pressure for the second time within 10 seconds to reduce the pressure to atmospheric pressure to initiate the second nucleation; quickly transfer the polycarbonate sheet to a constant temperature glycerin bath for nucleation Foaming, the foaming temperature is 150 ° C, and the foaming time i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com