Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

181results about How to "Not easy to crack and deform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low cost and high efficient soundproof material and manufacturing method thereof

InactiveCN103897262AImprove heat and aging resistanceExcellent ozone resistanceSound producing devicesRelaxation effectFilling materials

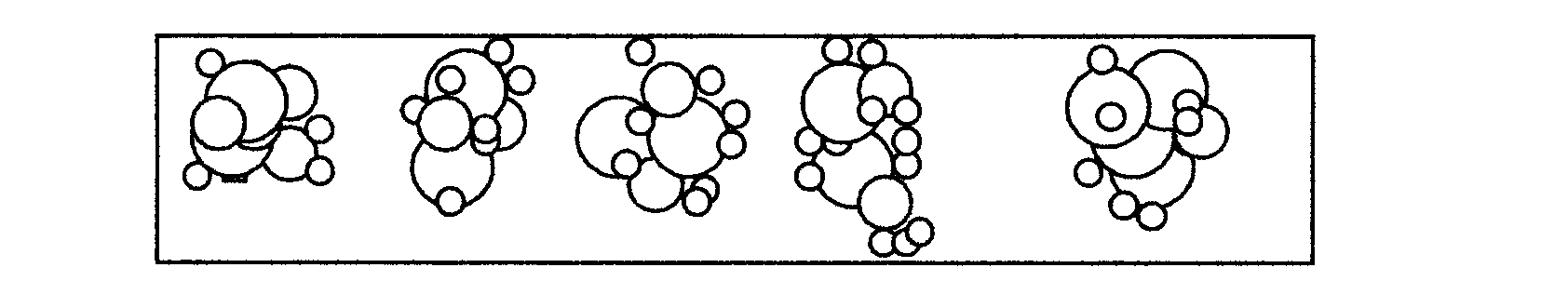

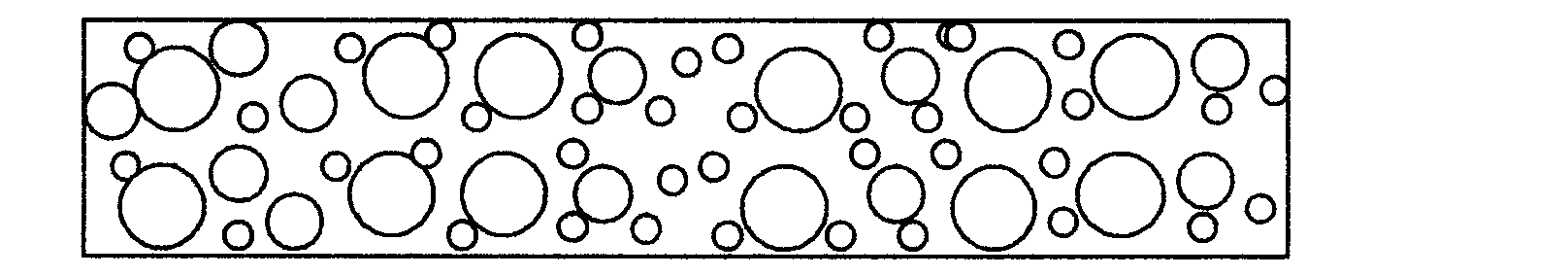

The invention relates to a low cost and high efficient soundproof material and a manufacturing method thereof, relates to the field of soundproof materials, solves the problems that in the prior art, soundproof materials do not have a prominent soundproofing effect, generate harmful gas, which can harm the human health, and have a high cost; and provides a low cost and high efficient soundproof material. The soundproof material comprises thermoplastic resin and an inorganic filling material, wherein the surface of the inorganic filling material has been processed by a coupling agent processing liquid, the inorganic filling material accounts for 15 to 80 wt% of the total weight of the soundproof material, and the balance being thermoplastic resin. In the soundproof material, the connections among the particles are abnormal, thus the internal friction of the incident sound waves is increased by the structure of the soundproof material, and a relaxation effect is generated to absorb the sound waves. Filling materials with different particle sizes are corresponding to waves in different wavelengths or frequencies, so the soundproof material can reduce sounds in different frequencies. Moreover the soundproof material has a good soundproof effect and is suitable for being promoted and used.

Owner:浙江艾迪雅科技有限责任公司

Polyurethane composite insulation board and preparation method thereof

InactiveCN101570987ALight weightHigh strengthSynthetic resin layered productsHeat proofingFiberGlass fiber

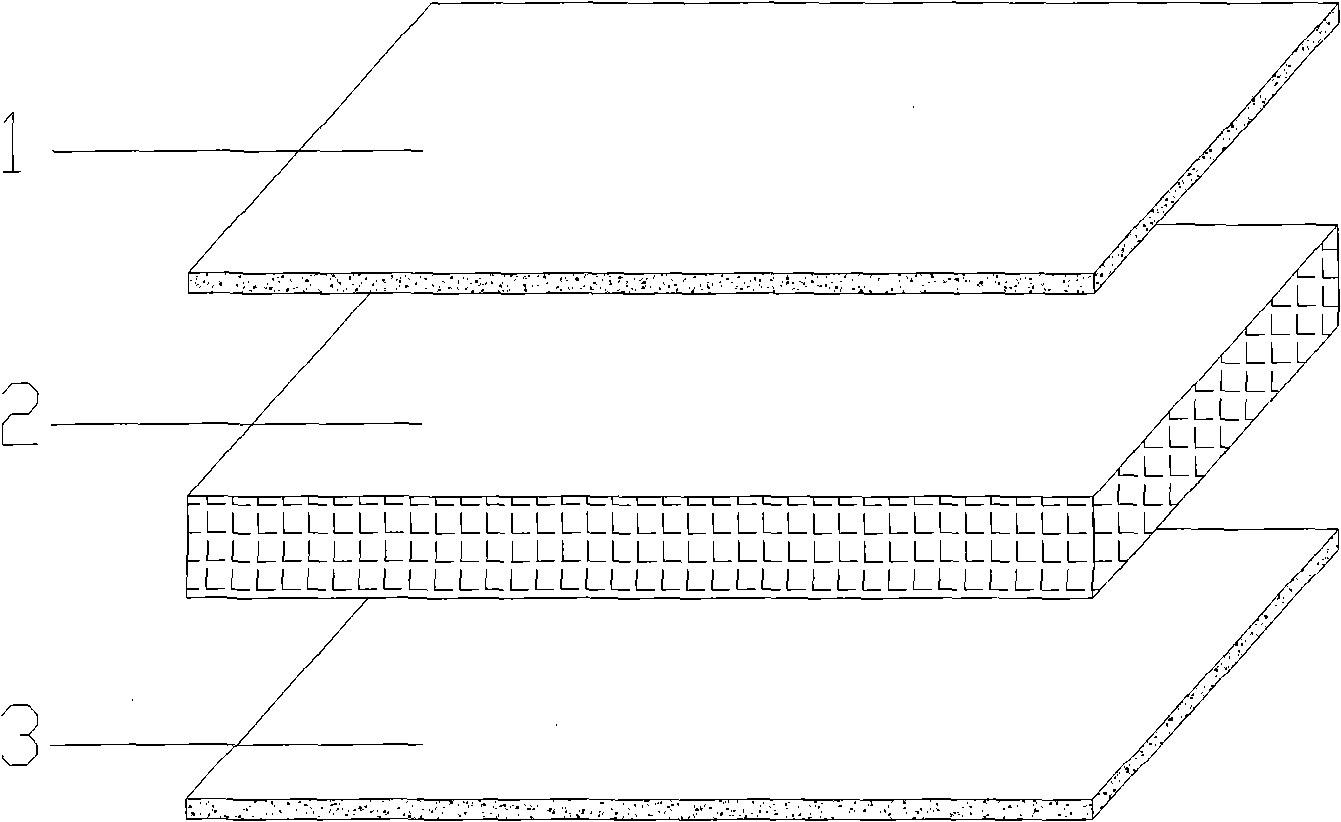

The invention discloses a polyurethane composite insulation board, which consists of a surface layer and an insulating layer, wherein the surface layer is fiber reinforced polyurethane, the density range of the surface layer is between 0.1 and 1.2 g / cm, and the surface layer contains 5 to 50 percent of reinforcing fiber; and the insulating layer is low-density polyurethane, the density range of the insulating layer is between 0.01 and 0.4 g / cm, and the insulating layer contains 5 to 50 percent of reinforcing fiber. A preparation method comprises the following steps: (1) opening an upper mold and a lower mold, evenly laying the polyurethane and glass fiber in a female mold, closing the molds and foaming to manufacture the surface layer; (2) spraying and laying the low-density polyurethane or the fully-mixed reinforcing fiber or the low-density polyurethane of structural polyurethane on the surface layer by adopting special spraying equipment, forming and molding, and manufacturing the insulating layer to form the composite insulation board; and (3) taking out the insulation board. The insulation board has light dead weight, good effect of heat insulation, high strength, difficult deformation, simple manufacturing process and low cost.

Owner:董升顺

Degreasing and desugaring method of sympodial bamboo

Owner:中宇创业联合控股有限公司

Soil solidifier and soil solidification method

InactiveCN103013526ALarge specific surface areaThere will be no "secondary mudification" phenomenonBuilding constructionsOrganic fertilisersSoil scienceSodium silicate

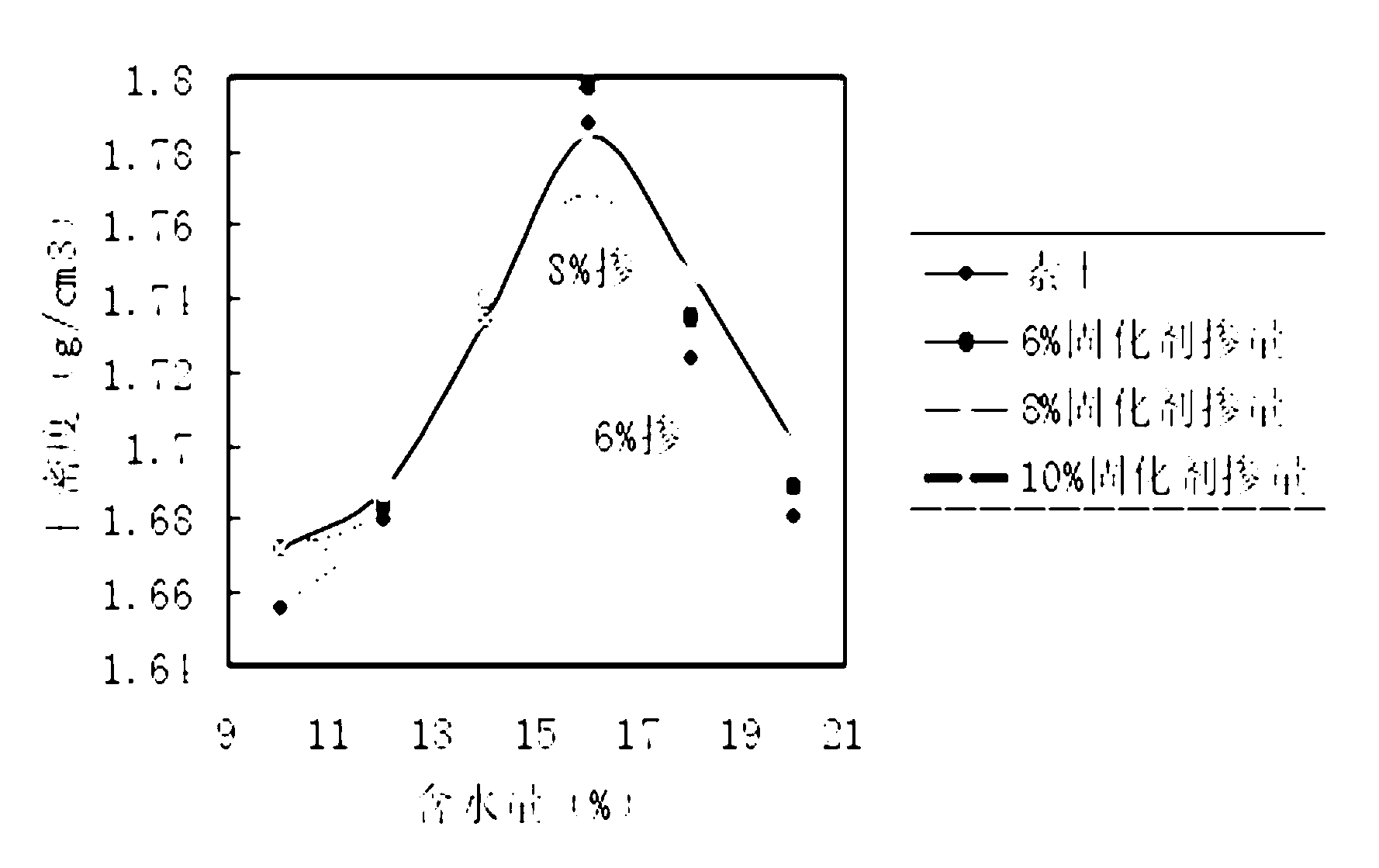

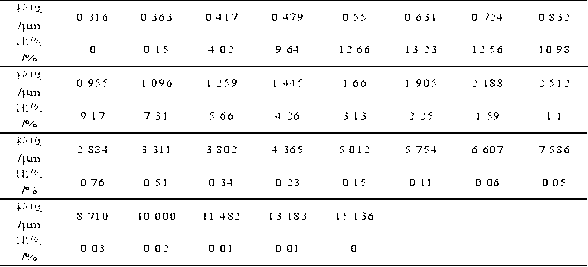

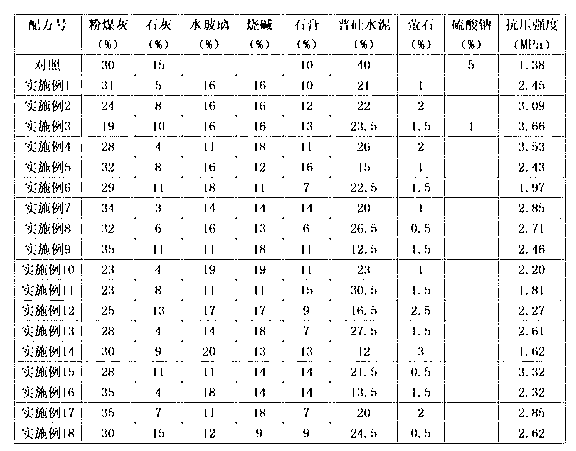

The invention relates to a soil solidifier and a soil solidification method. The soil solidifier comprises 15 to 30 percent of fly ash, 4 to 15 percent of lime, 10 to 20 percent of sodium silicate, 8 to 20 percent of caustic soda, 5 to 16 percent of gypsum, 10 to 32 percent of common silicate cement, 0.5 to 3.5 percent of fluorite and 0 to 1.5 percent of sodium sulfate. During solidification of soil, the soil solidifier is tight, relatively low in contraction and swelling coefficient and extremely small in solidified soil body contraction amount; deformation and cracks which are caused by expansion with heat and contraction with cold because of temperature change are avoided; therefore, the solidified soil body is high in seepage resistance, freezing resistance and cracking resistance; the problems of low water stability, high dry cracking performance and simplicity in cracking during solidification of the soil by the conventional solidification material are well solved; and the solidified soil body has a relatively good heat isolation function. The soil solidification method is easy to construct, time-saving and labor-saving; the solidifier cannot be influenced by the temperature; the solidification time is short; the working efficiency is high; the working period can be greatly shortened; and the cost is reduced.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

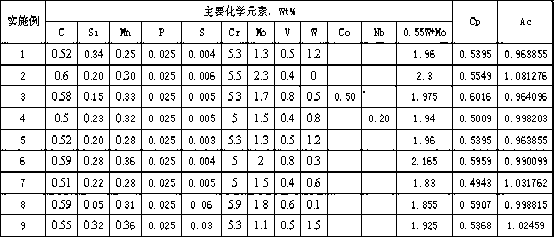

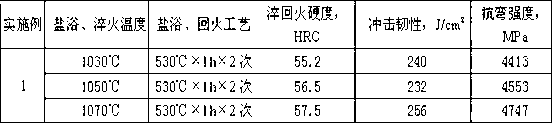

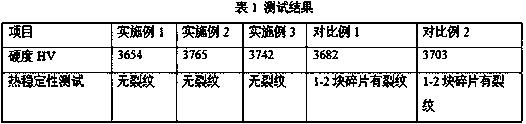

High-hardness high-tenacity cold and hot work die steel and production method thereof

The invention relates to die steel, in particular to high-hardness high-tenacity cold and hot work die steel which comprises the components in percentage by weight as follows: 0.50-0.65% of C, 0-0.35% of Si, 0.20-0.50% of Mn, 5.00-6.00% of Cr; 1.00-2.30% of Mo; 0-1.50% of W, 0.40-1.00% of V, no more than 0.25% of Nb, no more than 1.00% of Co, no more than 0.01% of S, no more than 0.025% of P and the balance of Fe and impurities. At the same time, the weight percentage which meets the requirement of Mo plus 0.55 W accounts for 1.80-2.30%, and the carbon saturation Ac is 0.90-1.10. The invention further provides a production method of the high-hardness high-tenacity cold and hot work die steel. Compared with conventional hot work die steel, the high-hardness high-tenacity cold and hot work die steel has the advantages that the steel has a wider application hardness range (54-58 HRC), higher strength (4000-4700 MPa), high tenacity (no less than 200J / cm <2>), temper-resistant stability and higher overall performance.

Owner:HEYE SPECIAL STEEL

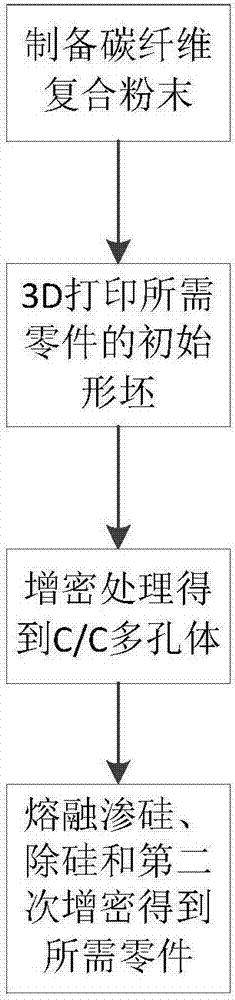

Method for preparing C/C-SiC composite part and product prepared through method

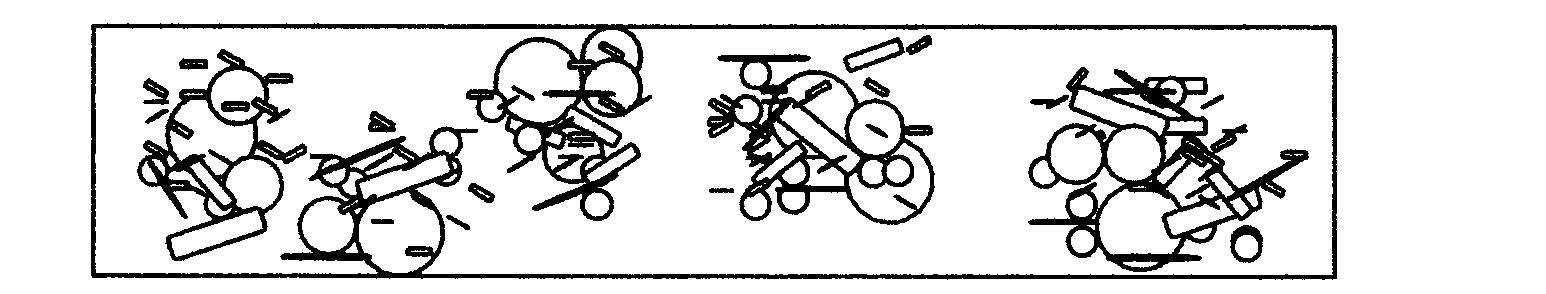

ActiveCN106927846AEvenly distributedAvoid damageAdditive manufacturing apparatusFiberSolvent evaporation

The invention belongs to the field of composites, and discloses a method for preparing a C / C-SiC composite part and a product prepared through the method. The method comprises the following steps that firstly, carbon fiber / phenolic resin composite powder is prepared by using a solvent evaporation method; secondly, according to a three-dimensional model of the part, the carbon fiber composite powder is molded into an initial molded blank by means of the 3D printing technology; thirdly, the initial molded blank is subjected primary densification and a C / C porous body is obtained; fourthly, the C / C porous body is subjected to a molten silicon infiltration reaction, high-temperature desilication and secondary densificaiton, and the final C / C-SiC part is obtained. By means of the method, the C / C-SiC composite part with a complex structure can be shaped in a near-net mode, the method is short in production period and low in cost, and the C / C-SiC composite part obtained through the method is low in residual silicon content and has excellent performance.

Owner:HUAZHONG UNIV OF SCI & TECH

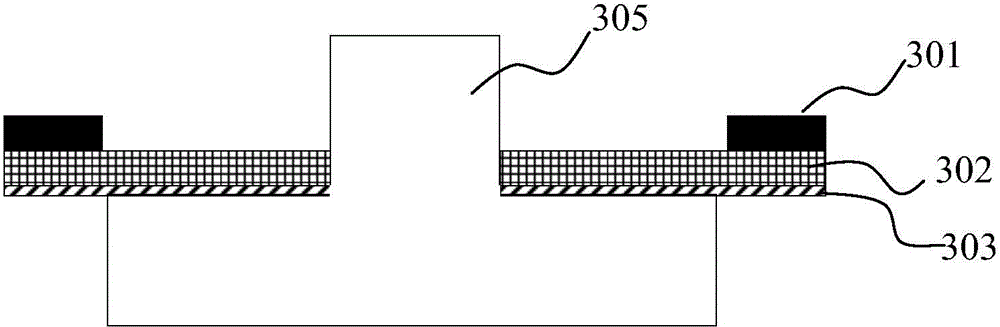

Wavelength conversion device, relevant fluorescent color wheel and relevant projection device

ActiveCN105737103AImprove output light efficiencyNot easy to crack and deformProjectorsSpectral modifiersFluorescenceSpecular reflection

The invention discloses a wavelength conversion device, a relevant fluorescent color wheel and a relevant projection device. The wavelength conversion device comprises a light-emitting layer, a sapphire layer and a specular reflection film which are stacked in sequence. The sapphire layer is used for supporting the light-emitting layer and the specular reflection film. The sapphire layer has the beneficial effects of being high in hardness, good in surface flatness and high in heat conductivity, so that plating of the specular reflection film is facilitated, heat can be evenly spread to the surface of the specular reflection film, the specular reflection film is not liable to crack or deform in the plating and using process, high reflectivity can be maintained during long-time work, and the light-emitting efficiency of the wavelength conversion device is high.

Owner:APPOTRONICS CORP LTD

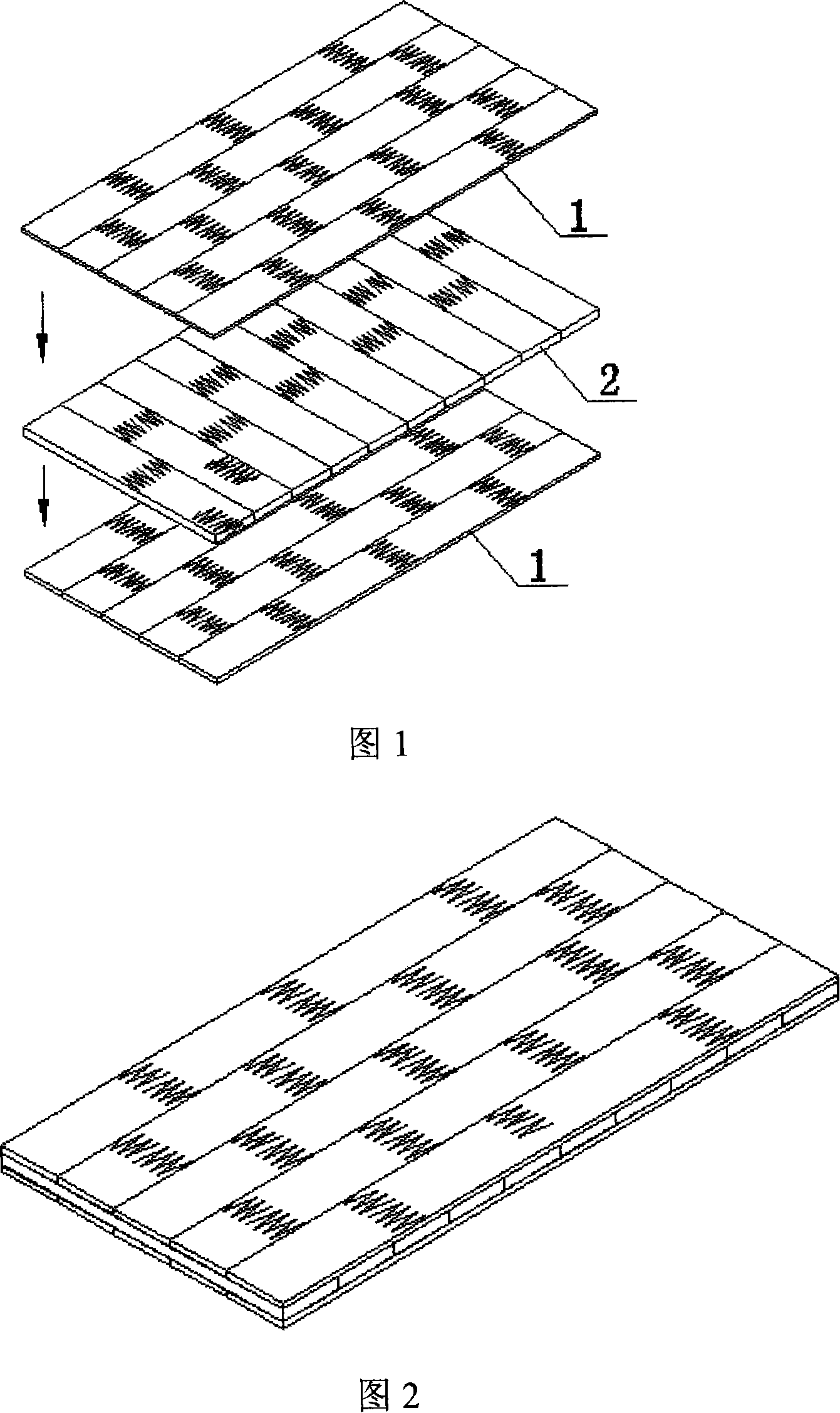

Pure china-fir three-layer real-wood integrated material and making method

The invention provides three-layer solid wood materials of pure Chinese fir and its preparation method. It is characterized in that: after planed and thickness defining, complete tenon process and finger joint of the Chinese fir square stocks. Then, dissect them into slice strips along their length direction and put the slice strips with the same lengths together to form plates. Based on the wood texture, press them to 18mm three-layer solid wood plates through vertically crossed by sizing layer-by-layer. The products have compact structure and light texture, eliminate the wood internal stress, have characteristics of large intensity, good flexibility, corrosion resistance and are moisture proof and uneasy to distort and crack.

Owner:林文信

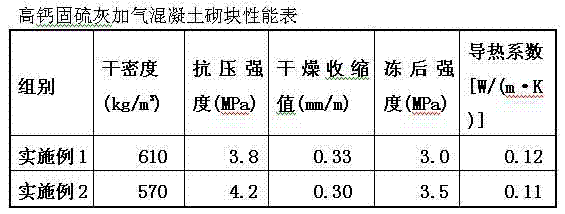

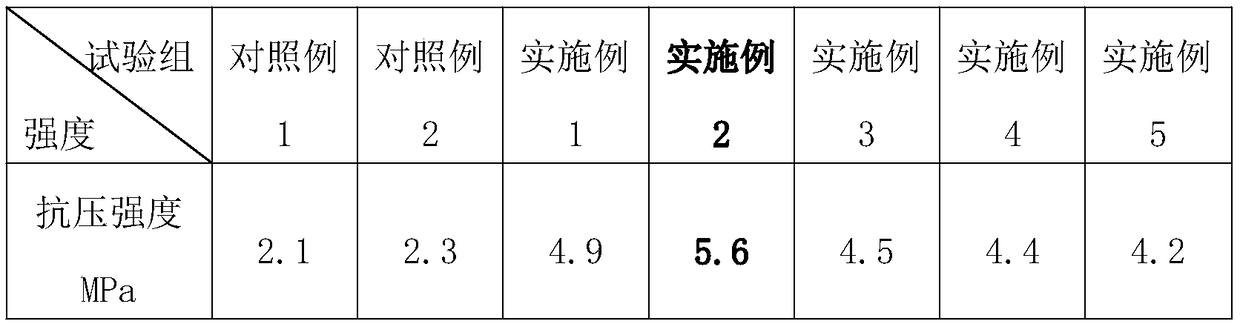

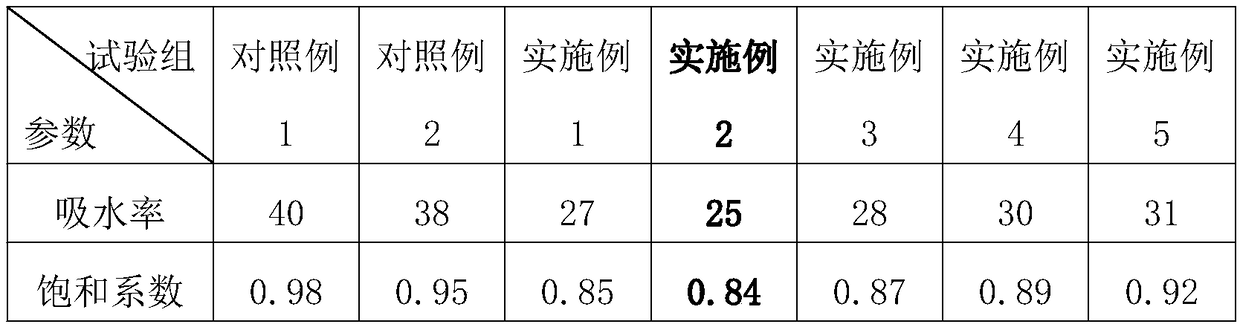

Manufacturing method of high-calcium solid sulfur ash aerated concrete building blocks

The invention discloses a manufacturing method of high-calcium solid sulfur ash aerated concrete building blocks. According to the invention, 40-70 parts of high-calcium solid sulfur ash, 20-40 parts of fly ash, 5-12 parts of cement, 0.1-15 parts of a silicon material, 10-20 parts of lime, 0.1-2 parts of gypsum, and 0.06-0.1 parts of aluminum powder are adopted as raw materials; high-calcium solid sulfur ash, fly ash, the silicon material, and gypsum are added into a mixer; water is added to the mixer, and stirring is carried out, such that a slurry is obtained; aluminum powder, lime, and cement are added to the slurry, and the mixture is well mixed by stirring, such that a casting slurry is obtained; the casting slurry is cast into a mold, and standing and preventive maintenance are carried out; when preventive maintenance is finished, building blocks are obtained by cutting; and the building blocks are subjected to autoclaved maintenance in an autoclave, such that finished products are obtained. With the method provided by the invention, the manufactured product can hardly crack and deform, and has advantages of high compressive strength and after-freeze strength. The method provided by the invention has the advantages of simple technical process, high high-calcium solid sulfur ash utilization amount, low manufacturing cost, convenient construction, and the like.

Owner:贵州省建筑材料科学研究设计院有限责任公司

Porous ceramic and manufacturing process thereof

The invention discloses porous ceramic with good drainage performance and a manufacturing process. The porous ceramic employs silicon carbide, pottery clay, mullite, and iolite as aggregates; wollastonite and spodumene are used as auxiliary materials, and low temperature ceramic glaze powder is used as a fluxing agent; bamboo charcoal and wood chip are used as pore forming agents; the raw materials are prepared according to a certain proportion, paraffin is used as a binder for preparing a slurry, a hot pressure casting and forming machine is used for preparing green compacts, and one-time wax discharging and sintering are carried out by a kiln in order to obtain finished products. Compared with prior art, the product has the functions of common porous ceramics, such as filtering, heat insulation, noise abatement and the like, and the product is characterized in that the product has liquid drainage, penetration, adsorption and fine filtering and other excellent functions, and at the same time, the product has high temperature resistance, quenching and quick heating resistance, and good thermal conductivity; in addition, the common ceramic raw materials are selected, and the porous ceramic has the advantages of low energy consumption, environmental protection without secondary pollution, low cost, and simple technology, and the ceramic is suitable for large scale production. The porous ceramic has wide applications and extremely good development prospects.

Owner:李安成

Rattan processing method for willow artworks

InactiveCN104441120AEasy to makeImprove insect repellencyWood treatment detailsReed/straw treatmentWater contentChemistry

The invention relates to a rattan processing method for willow artworks. The rattan processing method comprises the following steps: (1) preparing medicine liquid; (2) reducing the temperature of the medicine liquid to normal temperature, adding paraffin oil, glycerine and salicylic acid into the medicine liquid, and uniformly mixing to obtain a processing agent; and (3) air-drying rattan with dry hot air at the temperature of 35-50 DEG C till the water content of 25-30%, then soaking in the processing agent for 1-3 days, and then drying at the temperature of 60-65 DEG C till the water content of 25-38%. The rattan processing agent provided by the invention is simple in manufacturing method, anti-corrosion and anti-insect capabilities of the rattan processed by the processing agent are greatly upgraded, and the rattan processing time is shortened.

Owner:FUNAN NATURE ARTS & CRAFTS

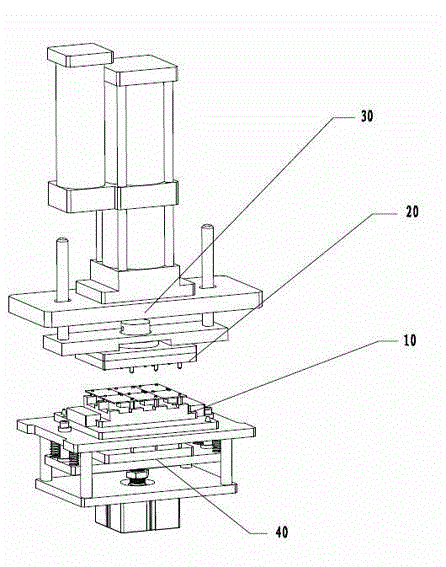

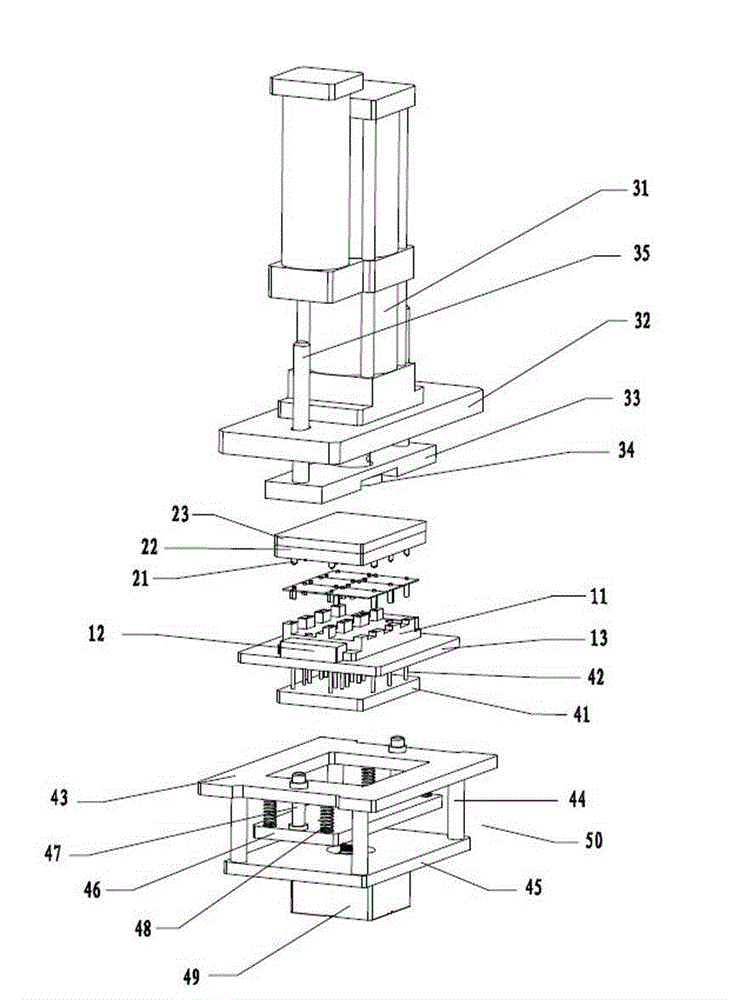

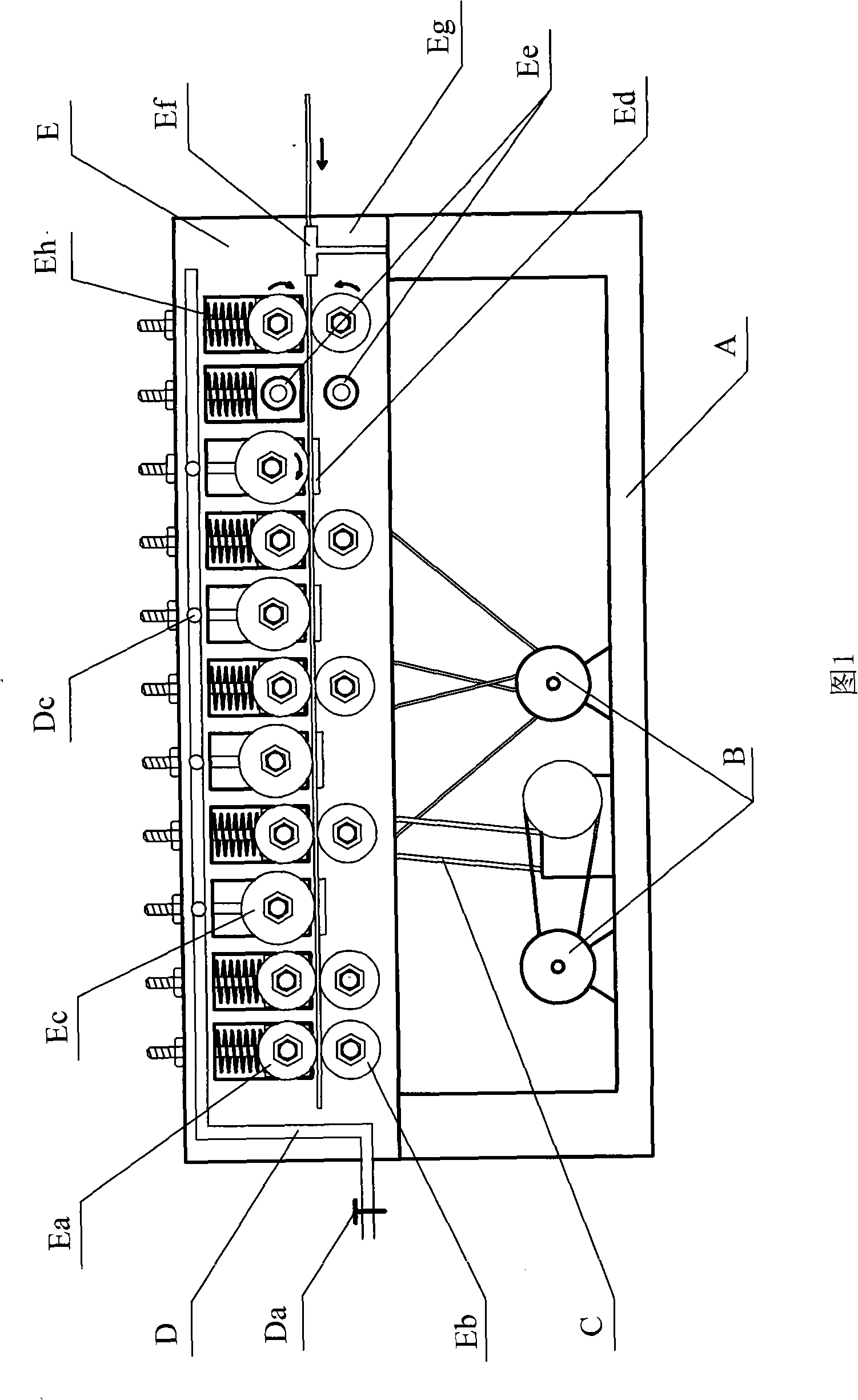

Riveting machine

InactiveCN103331379AGuaranteed to be riveted in placeNot easy to crack and deformShaping toolsEjection devicesMechanical engineeringPiston

The invention relates to a riveting machine. The riveting machine comprises a progressive pressure unit, wherein an upper die unit is arranged on a corresponding position below the progressive pressure unit, a movable part in the progressive pressure unit is fixedly connected with the upper die unit, a lower die unit is arranged on a corresponding position below the upper die unit, a jacking unit is arranged on the corresponding position below the lower die unit, the progressive pressure unit comprises a gas-liquid supercharging cylinder, the upper die unit comprises a plurality of forming heads, the upper die unit also comprises a forming head fixing plate, the forming heads are fixedly arranged on the lower surface of the forming head fixing plate, the lower die unit comprises a lower die, the lower die unit also comprises a lower die liner plate and a limiting block, the limiting block is fixedly arranged on the surface of the lower die liner plate, the jacking unit comprises an air cylinder and a discharging ejector pin liner plate, and the discharging ejector pin liner plate is arranged above a piston of the air cylinder. By adopting the structure, the riveting can be automatically carried out, the production efficiency is high, the workpiece after being machined is unlikely to fracture, and the workpiece after being riveted can be automatically ejected from the riveting machine.

Owner:SIMON ELECTRIC CHINA

Sympodial bamboo integration profile manufacturing method

ActiveCN103737692AHigh densityImprove the bactericidal effectPressure wood treatmentWood treatment detailsCarbonizationHigh pressure

The invention discloses a sympodial bamboo integration profile manufacturing method. The method is characterized by including the following steps: S1, soaking bamboo filaments of sympodial bamboo which are subjected to green planing and yellow removing in water for high-temperature stewing at temperature of 100-120 DEG C for at leat four hours, wherein the water contains, by mass, 5-10% of hydrogen peroxide and 0.5-1% of sodium hydroxide; S2, disposing wet bamboo filaments in a carbonization furnace for carbonizing at temperature of 130-15o DEG C and at pressure of 3-4 MPa for 4-6 hours; S3, drying for the first time, dipping in glue, and drying for the second time after glue dipping; S4, performing high-pressure forming at pressure of being not less than 1.2 t / cm2; S5, performing thermosetting for more than 10 hours at temperature of 80-150 DEG C under the condition that the pressure of being not less than 1.2 t / cm2 is maintained. By the sympodial bamboo integration profile manufacturing method, sympodial bamboo integration profiles meeting structural profile requirements can be manufactured.

Owner:SHENZHEN KANGER BAMBOO & WOOD

Firework outer cylinder with bottoms and method for making same

Disclosed is an outer tube of fireworks with bottom, whose characteristics is that its main component are haulm fiber, glass fiber, calcium sulfate, light filler, cement of high level and bond. It is formed by once overall stamp by special machine and natural drying, the product has U-typed bottom, a layer of kraft paper enclosing the outer wall of tube, and its appearance, size and length can be ordered by the size needs of different fireworks products. The invention has the advantages of abundant raw material, advanced technology, excellent chemical and physical stability, stable shape, resistance to humidity, high intension and notable safety, which can be widely used in outer tube of various fireworks products.

Owner:黄焱生

Ceramic product with high cold resistance and high heat resistance and preparation process thereof

The invention relates to the technical field of ceramic preparation, in particular to a ceramic product with high cold resistance and high heat resistance and a preparation process thereof. The ceramic product comprises a blank body, a heat insulation layer and a glaze material, wherein the blank body is prepared from 42 parts of olivinite, 8 parts of sodium lignin sulfonate, 13 parts of quartz, 15 parts of clay, 26 parts of molybdenite, 15 parts of melting aids, 20 parts of spodumene, 13 parts of mullite, 11 parts of sodium feldspar and 9 parts of calcium metasilicate; the heat insulation layer is prepared from 22 parts of glass fiber powder, 15 parts of rock wool powder, 9 parts of sodium silicate and 3 parts of sodium hexametaphosphate; the glaze material is prepared from 23 parts of mullite, 35 parts of Kaolin, 15 parts of spodumene, 17 parts of potash feldspar and 7 parts of clay. The preparation process comprises the following steps of proportioning, blank pulling, biscuiting, heat insulation layer coating, glazing and firing. The ceramic product produced by the process has the advantages of high mechanical intensity and strong thermal shock resistant performance.

Owner:福建省德化县嘉威陶瓷有限公司

Method for manufacturing bamboo ware and bamboo strip

InactiveCN101402214ANot easy to crack and deformImprove processing utilizationWood treatment detailsVeneer manufactureFiberEngineering

The invention relates to a method for manufacturing a bamboo product, namely bamboo sticks, and belongs to a bamboo stick processing method. Cut surface green bamboo chips and shiraia bambusicola chips are subjected to fiber forming, water milling, bleaching and drying to obtain the bamboo sticks. The water milling treatment can effectively remove burrs and stains on the surfaces of the bamboo sticks, so that the produced bamboo sticks have smooth surfaces without the burrs, and high product quality, save the steps of scraping surface green and stewing, simplify process flow, and save raw materials and processing cost; and the waste materials obtained after the water milling can be directly used for paper making, so that no pollution is caused. The processed bamboo sticks can be widely used in bamboo products such as bamboo mats, bamboo curtains, bamboo carpets, bamboo-splint woven handicraft articles and so on.

Owner:JIANGXI NANFENG ZHENYU IND GRP

Technique of preparing microcrystalline glass-ceramic composite board by one-step firing process

The invention relates to a method for preparing an architectural decoration used nucleated glass-ceramic composite board. The method is a preparation process of single firing of the nucleated glass-ceramic composite board, which is characterized in that the method comprises the steps of: (1) preparing ceramic powder; (2) preparing dry ceramic powder; (3) preparing master glass granule; (4) pretreating the master glass granule: the master glass granule and sodium cellulose glycolate solution are mixed according to the mass ratio of 1:0.02 to 1:0.1 before the dry ceramic powder and the master glass granule are mixed according to the mass ratio 1:4 to 1:8; (5) distribution and compaction: the master glass granule covered with ceramic is uniformly distributed at the bottom of the die cavity of a brick press at 1.2 to 4kg per m<2> before the ceramic powder is filled in the die cavity of the brick press, thus extruding the green compact of the composite board; (6) drying and burning; (7) polishing and treating. The method has the advantages of low consumption of productive energy, few pore defects of the products, high content of nucleated glass phase in the surface of the composite board, and good ornamental effect.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Aluminium electrolysis prebaked anode raw block preparation composition

InactiveCN1580331AShorten roasting timeReduce manufacturing costAluminium electrolysisCompressive strength

The invention has solve a technological problem: with the method the receipt to produce aluminum electrolyzing prebaked anode adopts petroleum coke of which the max particle size 6mm.Compared with the old method producing prebaked anode, the finish producing rate is higher and electrical resistivity compressive strength is great and the product less probably chink or deform.. The roasting time is shorter and the cost is less. The key point: prepare prebaked anode and petroleum coke and then temper in the constant proportion, until the temperature is up to 90-110 deg.C, add 16-17% draining, and follows at 140-160deg.C profiling and roasting. The invention can be applied to aluminum electrolyzing prebaked anode producing.

Owner:姬军伟

Open caisson support structure and open caisson construction method

ActiveCN106988334AEasy to assembleEasy to assemble and disassembleFoundation engineeringKeelWood plank

The invention discloses an open caisson support structure and an open caisson construction method. The open caisson support structure comprises a sleeper arranged on a sand cushion layer, a formwork is erected on the sleeper, and the formwork is composed of a plank and a blade foot die plate. A flat portion is arranged at the bottom of the blade foot die plate. Angle iron is fixedly arranged on the inner side of the flat portion. The plank is arranged on the outer side of the blade foot die plate. The plank is laid in the circumferential direction of the blade foot die plate. A cushion frame is arranged between the blade foot die plate and the plank. An iron plate frame is mounted outside the plank. The bottom of the iron plate frame and the sleeper are assembled together. The iron plate frame is connected with the plank through a split bolt in the radial direction. Multiple keels are arranged between the iron plate frame and the plank for isolation. The iron plate frame is configured in a split manner and formed by inserting multiple iron plate frame units. The split bolt is formed by connecting multiple bolt single joints. The open caisson construction method adopts the open caisson support structure for supporting. According to the open caisson support structure and the open caisson construction method, the split mounting type open caisson foundation is adopted, assembly is easy, and the reuse can be achieved.

Owner:杭州广赢建设工程有限公司

Environment-friendly casting coated sand and method for preparing the coated sand

The invention discloses an environment-friendly casting coated sand, which is prepared by the following raw materials in parts by weight: 70-75 parts of quartz sand, 0.2-0.3 part of calcium stearate, 4-6 parts of corncob powder, 13-15 parts of magnesium olivine sands, 2-3 parts of water, 0.7-1 part of urotropine, 4-6 parts of a thermoplastic phenolic resin, 3-5 parts of isopropanol, 5-7 parts of Portland cement, 2.5-4 parts of boric acid, and 5-7 parts of a synergistic agent. An inorganic silicate binder is added into the environment-friendly casting coated sand, so that the use amount of the phenolic resin is reduced and the environment-friendly casting coated sand is still good in cohesiveness and strength; the boric acid is added so that the heat resisting property of the product is improved; the synergistic agent prepared by a special process is added into the environment-friendly casting coated sand, so that liquidity, breathability, heat dispersion and strength of the coated sand are enhanced, and the surface of the environment-friendly casting coated sand isn't easy to crack and deform. By adopting the prepared product, the environmental pollution can be alleviated and the production cost is reduced, the amount of generated gas is low, the casting quality is high and the casting surface is smooth.

Owner:FANCHANG COUNTY JINKE CASTING

Floor board with environment-friendly, waterproof and flame-retardant functions and preparation method thereof

ActiveCN105885302AImprove flame retardant performanceImprove waterproof performanceCovering/liningsFlooring insulationsAgricultural engineeringLubricant

The invention relates to a floor board with environment-friendly, waterproof and flame-retardant functions and a preparation method thereof, and the floor board solves the technical problems that the current floor board is poor in flame resistance, poor in water resistance, easy to deform and crack, and not environmentally-friendly. The floor board comprises the following components in parts by weight: 30-35 parts of CPE, 10-20 parts of EVA, 40-50 parts of PVC, 12-20 parts of activated calcium carbonate powder, 0-2 parts of a lubricant and 0-1 part of OA6. The floor board with environment-friendly, waterproof and flame-retardant functions and the preparation method thereof are widely used for floor boards and preparation methods thereof.

Owner:WEIHAI HEGUANG FLOOR CO LTD

Novel color rammed earth wall and preparation method thereof

InactiveCN109138226AImprove compactionGood weather resistanceWallsCompressive strengthMaterials science

The invention relates to the technical field of building materials, and provides a novel color rammed earth wall. According to the technical scheme, the novel color rammed earth wall includes a main body material and bamboo ribs arranged at intervals, and further includes refractory cement, toner, soil curing agent, slaked lime, main body The material includes soil, coarse sand, stone, a soil stabilizer and slaked lime. The main body material includes clay, coarse sand and gravel, and the weight ratio of the clay to the coarse sand to the gravel is 6:2:2. The refractory cement accounts for 6%-8% of the weight of the main body material, the soil stabilizer accounts for 0.02-0.04% of the weight of the main body material, the slaked lime accounts for 2%-4% of the weight of the main body material, and the use amount of the toner is 38%-42% of the use amount of the refractory cement. The width of the bamboo ribs is 2-4cm, and the bamboo ribs are laid every 30-60cm of height for a layer; and2-3 bamboo ribs are longitudinally laid on each layer, and the horizontal spacing is 80cm-120cm. The prepared novel color rammed earth wall has high compressive strength, attractive appearance and great ornamental value.

Owner:重庆美索新乡土旅游开发有限公司

Soil compaction assistant and preparation method thereof

ActiveCN104762088AIncreased unconfined strengthMeet road buildingBuilding constructionsOrganic fertilisersCelluloseCrack resistance

Owner:NANJING HYDRAULIC RES INST

Supporting hanger for grooved cable bridge and preparation process of supporting hanger

ActiveCN104862608AHigh elastic limitIncrease yield pointSolid state diffusion coatingCable trayElectric cables

The invention discloses a supporting hanger for a grooved cable bridge. The supporting hanger comprises the following constituents: C, Cr, B, Ni, N, Mo, Cu, Al, V, W, Si, Mn, Nb, Ti, S, P, and the balance of Fe and inevitable impurities. The invention further provides a preparation process of the supporting hanger for the grooved cable bridge. The preparation process is simple and feasible, low in manufacture cost and pollution-free in the manufacture process, and the prepared supporting hanger is abrasion-proof, corrosion resistant, high in strength and long in service life.

Owner:KINGSHORE NEW RESOURCES ELECTRIC JIANGSU

Soft embedding section specimen and production method thereof

ActiveCN109523873AEasy to storeEasy to useDead animal preservationEducational modelsResin embeddingPre treatment

The invention relates to a soft embedding section specimen and a production method thereof, and belongs to the technical field of biological resin embedding section. The method comprises the steps that a biological specimen is frozen and sawed into slice section specimens, and pre-processed section specimens are obtained after dehydrating and defatting are conducted on the section specimens; the pre-processed section specimens are embedded in molds, a soft embedding agent fills the molds under a non-inducing temperature, wherein the embedding agent is an embedding agent which has flexibility after curing; curing is conducted at the inducing temperature after filling is completed, and the producing is completed. The specimen has the advantages that the flexibility after curing is better, cracking and deforming do not easily take place, and the storage and use are convenient.

Owner:河南中博科技有限公司

Pre-coated sand added with graphene and having rapid heat radiation effect and preparation method thereof

The invention discloses pre-coated sand added with graphene and having rapid heat radiation effect. The pre-coated sand is characterized by being prepared from the following raw materials in parts by weight: 80-90 parts of quartz sand, 8-10 parts of electric smelting ceramsite, 3-5 parts of graphene, 0.6-0.8 part of urotropin, 2-3 parts of water, 0.3-0.35 part of calcium stearate, 5-6 parts of thermoplastic phenolic resin, 2-4 parts of mullite fibers, 1-2 parts of a silane coupling agent KH-550 and 5-7 parts of a synergist. According to the pre-coated sand, the synergist is added on the basis of a traditional pre-coated sand formula and is prepared by a special process, so that the flowability, the air permeability, the heat radiation and the strength of the pre-coated sand are enhanced; the surface is dense and is not easy to crack and deform; proper amount of the electric smelting ceramsite is matched with the quartz sand so that the flowability and the air permeabilityof the product are enhanced; the mullite fibers are added so that the fire resistance is enhanced; and the pre-coated sand has the advantages of rapid heat radiation, high temperature resistance, high size precision of a produced casting, smooth surface, convenience for storage and the like, and is widely applied in recent years day by day.

Owner:FANCHANG COUNTY JINKE CASTING

Method for preparing hot pressed sintered high-density magnesium oxide target

The invention discloses a method for preparing a hot pressed sintered high-density magnesium oxide target and mainly solves the technical problems of easiness in transformation, low rate of finished products, higher cost and low purity of the target in the prior art. The method comprises the following steps of: a, weighing nano-sized magnesia powder with a certain amount and high purity, and selecting a mould which has the same diameter as the target prepared according to the requirement; b, placing the mould into a hot-pressing sintering furnace body, charging by a vibration funnel method, measuring and ensuring that the stack heights of the powders in the mould are the same; and c, vacuumizing, heating and pressurizing, and maintaining pressure until the sintered size of the magnesium oxide target is a design value. The method has a simple preparation process and can quickly enable the product to be densified; the prepared product has the advantages of high density, fine grain and the like; other impurities cannot be introduced; the product is difficult to deform and crack during sintering; the rate of finished products is high; and the high-density high-purity magnesium oxide target can be prepared by the method.

Owner:沈阳临德陶瓷研发有限公司

Precoated sand for high-strength crack-resistant hot method and preparation method thereof

The invention discloses precoated sand for a high-strength crack-resistant hot method, which is characterized by being produced by the following raw materials in parts by weight: 5-7 parts of plastic property phenolic resin, 80-88 parts of silica sand, 8-10 parts of iron sand, 0.5-0.6 part of lignocelluloses, 3-5 parts of saw dust, 1-2 parts of carbon fibers, 3-5 parts of boron nitride, 0.8-1.2 parts of urotropine, 2.5-3 parts of water, 0.28-0.3 part of calcium stearate and 5-7 parts of synergist. According to the invention, one kind of synergist is added on the basis of the traditional formula, and common precoated sand is modified; the precoated sand is manufactured by a special technology, so the mobility, the air permeability, the thermal dissipation and the intensity of the precoated sand are enhanced; the surface is compact and does not easily crack and deform; the iron sand is added, so that the intensity is increased; since the saw dust and the carbon fibers are added, the tenacity is improved; the precoated sand produced by the invention has the advantages that the intensity is high; the crack resistance is good; the curing speed is rapid; and the production requirements can be met.

Owner:MAANSHAN HENGYI MACHINERY MFG

Wood softening treatment fluid for polyglutamic acid-aloe vera gel artworks and preparation method of wood softening treatment fluid

InactiveCN106313245AImprove toughnessImprove rigidityWood treatment detailsWood impregnation detailsPolyvinyl alcoholPolyethylene glycol

The invention discloses wood softening treatment fluid for polyglutamic acid-aloe vera gel artworks. The wood softening treatment fluid is prepared from the following raw materials of, by weight, 0.5-1 part of aloe vera gel, 0.1-0.15 part of polyglutamic acid, 0.3-0.5 part of lanonol polyoxyethylene ether, 5-10 parts of polyethylene glycol, 4-6 parts of glacial acetic acid, 0.5-1 part of alum, 2-4 parts of hydrogen peroxide with the mass fraction of 20-30%, 1-2 parts of polyvinyl alcohol, 0.05-0.1 part of benzyl cinnamate, 0.01 part of ethylparaben, 0.1-0.15 part of sodium benzoate and 50-60 parts of water. The wood softening treatment fluid has the beneficial effects that the softening and processing performance is good, the strength and toughness of wood are high, bounce is not likely to happen, follow-up treatment is not influenced, a dried finished product is high in size stability, not likely to crack and deform and not likely to mildew and rot, the hand feeling is smooth and fine, the application range is wide, and energy saving and environment protection are achieved.

Owner:FUNAN YONGXING ARTS & CRAFTS

Motherboard of holographic concave blazed grating and manufacturing method of motherboard

InactiveCN103941319AGood flexibilityNot easy to crack and deformDiffraction gratingsPhotomechanical exposure apparatusEtchingBlazed grating

The invention discloses a motherboard of a holographic concave blazed grating and a manufacturing method of the motherboard. The manufacturing method comprises the steps that (1) a holographic concave grating mask is manufactured; (2) a metal layer is deposited on the holographic concave grating mask; (3) the meal layer is coated with an adhesion agent; (4) the metal layer connected with a male die is separated from the holographic concave grating mask and cleaned, and a convex metal grating mask is obtained; (5) a grating tooth structure of the convex metal grating mask is measured, and grating tooth duty ratio information is obtained, and the duty ratio of grating teeth is adjusted through an electroforming or film coating method and a chemical etching or ion etching method; (6) the convex metal grating mask is etched through ion beams to be converted into a triangular blazed structure, and the motherboard of the holographic concave blazed grating is obtained. According to the motherboard of the holographic concave blazed grating and the manufacturing method of the motherboard, the concave grating mask structure is transferred to the convex metal layer, the metal layer is good in flexibility, the transfer precision of the grating groove type structure is high, cracking and deformation are not prone to occurrence, and durability is good.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com