Novel color rammed earth wall and preparation method thereof

A rammed earth wall and colored technology, applied to walls, building components, buildings, etc., can solve the problems of poor waterproof and anti-seepage performance of the wall, difficult to control the color, and the wall base is easy to be damp and rotted, so as to achieve good viewing and decoration properties, changing thermal and mechanical properties, and increasing the effective area of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

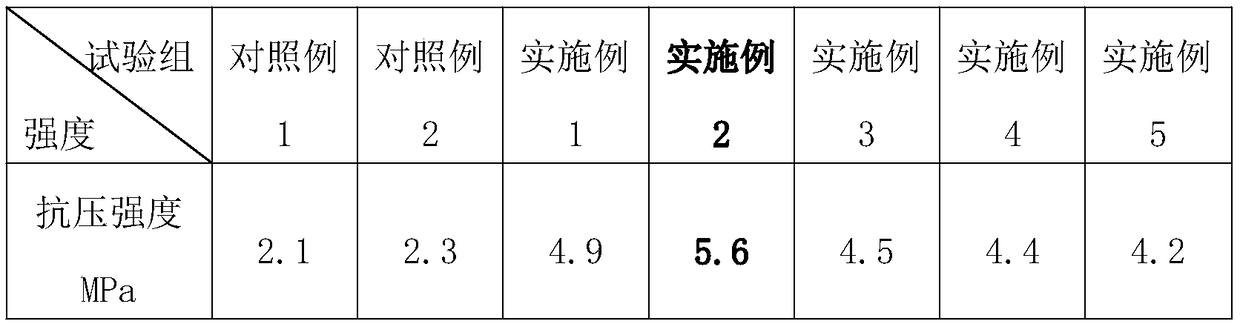

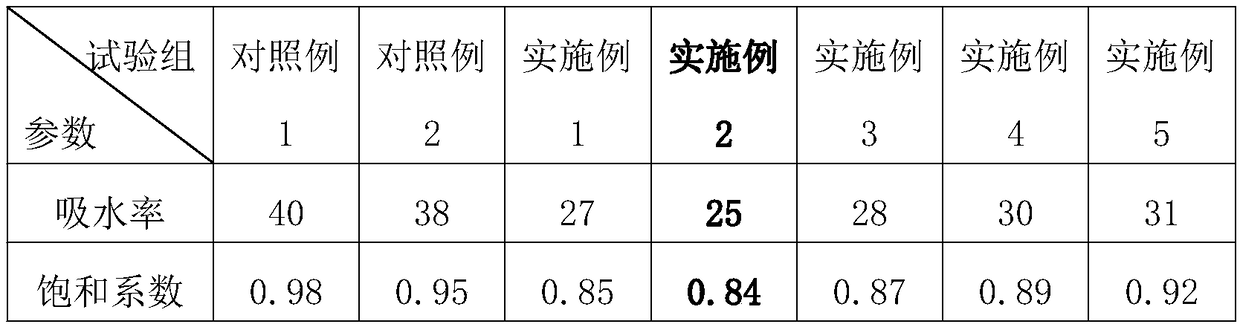

Examples

Embodiment 1

[0025] Prepare novel colored rammed earth wall by following steps and formula:

[0026] S1. Raw material selection and processing: drying and screening soil, selecting coarse sand, and screening stones; specifically, after drying the soil, use a sieve with an aperture of 5 mm to obtain soil with a size ≤ 5 mm; the selected color is yellow or close to yellow coarse sand for later use; then use a sampling sieve or use sieves with sieve holes of 5mm and 10mm respectively to screen out stones with a size of 5-10mm, and choose colored stones to make the appearance of the rammed earth wall more colorful and improve Ornamental. Therefore, the solid phase of the rammed earth wall is stone and coarse sand, that is to say, the aggregate of the rammed earth wall is stone and coarse sand, which ensures the strength of the rammed earth wall.

[0027] S2. Raw material ratio: Prepare raw materials according to the proportion of the color rammed earth wall; specifically, the weight ratio of ...

Embodiment 2

[0034] Prepare novel colored rammed earth wall by following steps and formula:

[0035] S1. Raw material selection and processing: drying and screening soil, selecting coarse sand, and screening stones; specifically, after drying the soil, use a sieve with an aperture of 5 mm to obtain soil with a size ≤ 5 mm; the selected color is yellow or close to yellow Coarse sand for use; then use a sampling sieve or use a sieve with a mesh size of 5mm and 10mm respectively to screen out stones with a size of 5-10mm.

[0036] S2. Raw material ratio: Prepare raw materials according to the proportion of the color rammed earth wall; specifically, the weight ratio of soil, coarse sand and stones in the main material is soil: coarse sand: stone = 6:2:2; refractory cement accounts for The proportion is 8% of the weight of the main material, the proportion of the soil curing agent is 0.03% of the weight of the main material, the proportion of slaked lime is 4% of the weight of the main material...

Embodiment 3

[0043] Prepare novel colored rammed earth wall by following steps and formula:

[0044] S1. Raw material selection and processing: drying and screening soil, selecting coarse sand, and screening stones; specifically, after drying the soil, use a sieve with an aperture of 5 mm to obtain soil with a size ≤ 5 mm; the selected color is yellow or close to yellow Coarse sand for use; then use a sampling sieve or use a sieve with a mesh size of 5mm and 10mm respectively to screen out stones with a size of 5-10mm.

[0045] S2. Raw material ratio: Prepare raw materials according to the proportion of the color rammed earth wall; specifically, the weight ratio of soil, coarse sand and stones in the main material is soil: coarse sand: stone = 6:2:2; refractory cement accounts for The proportion is 8% of the weight of the main material, the proportion of the soil curing agent is 0.03% of the weight of the main material, the proportion of slaked lime is 4% of the weight of the main material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com