Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5019results about "Flooring insulations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

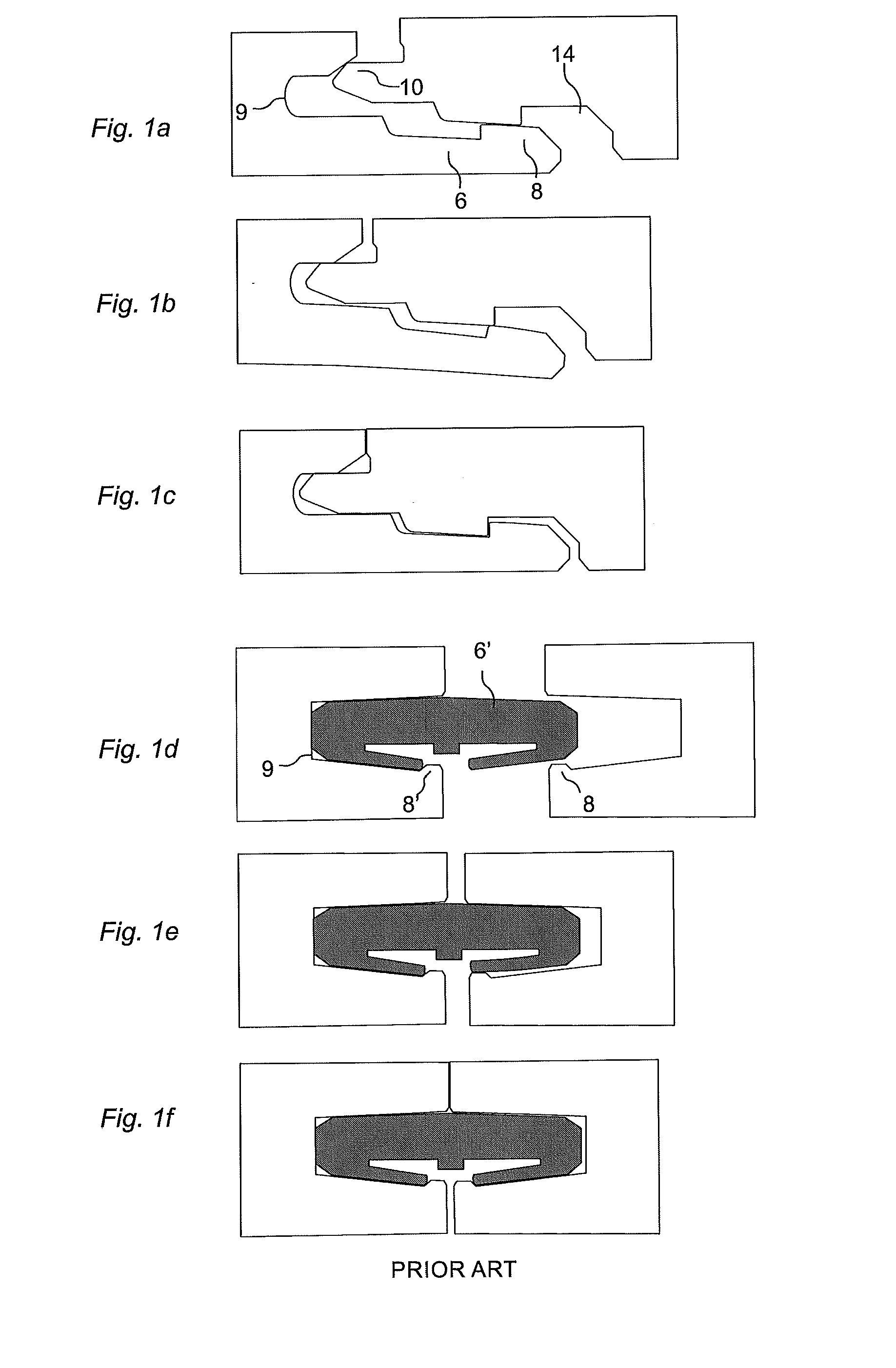

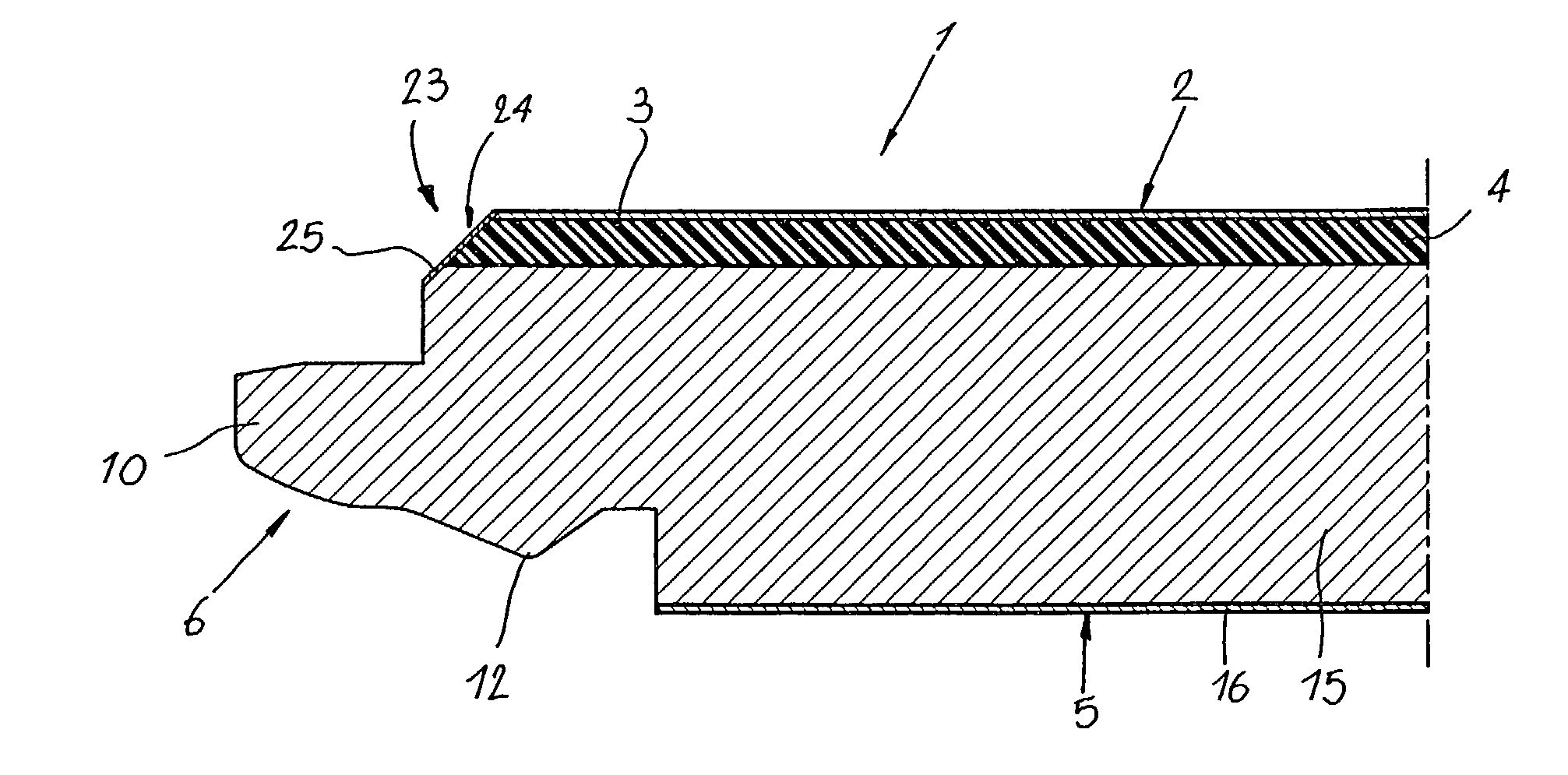

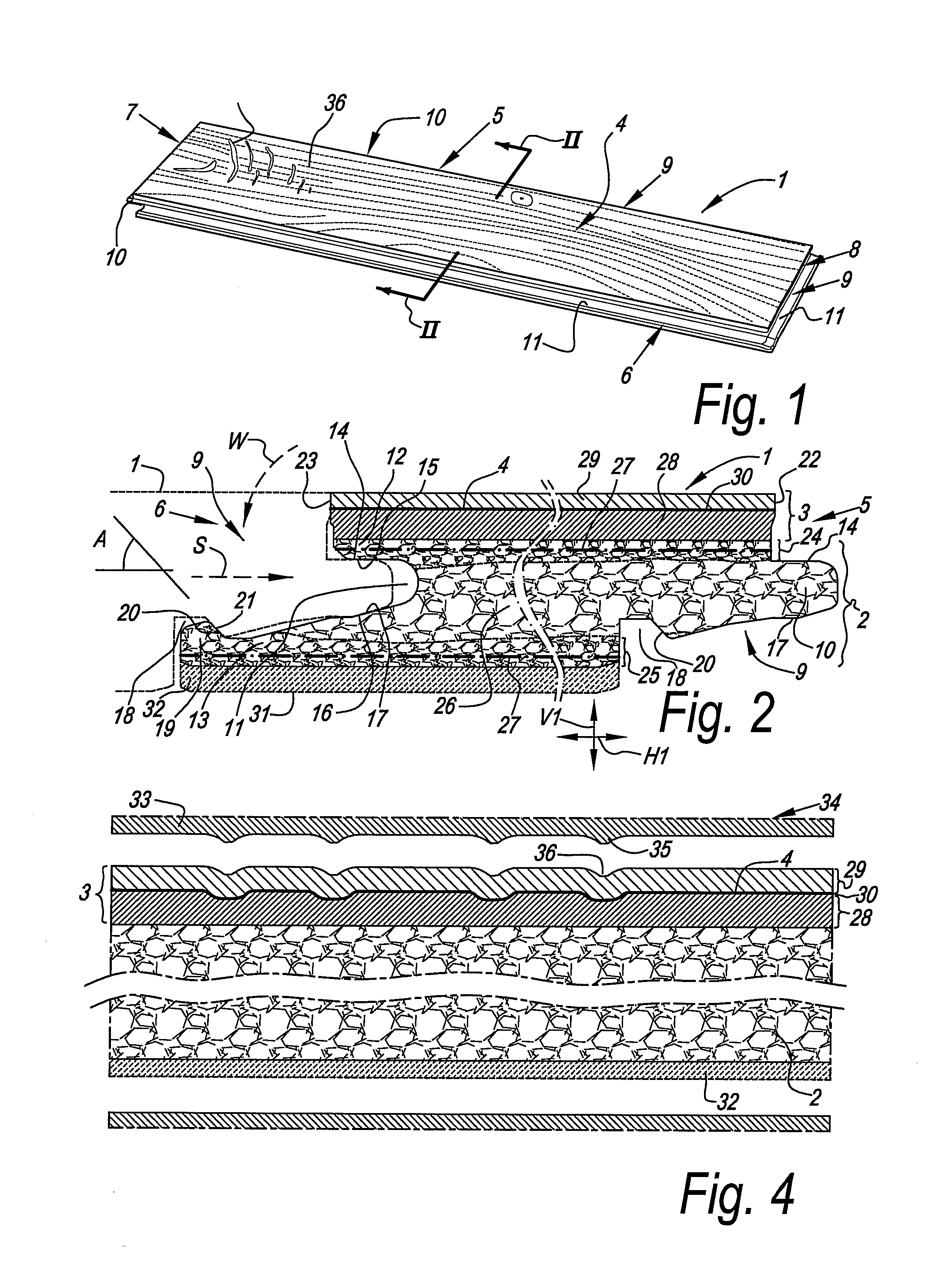

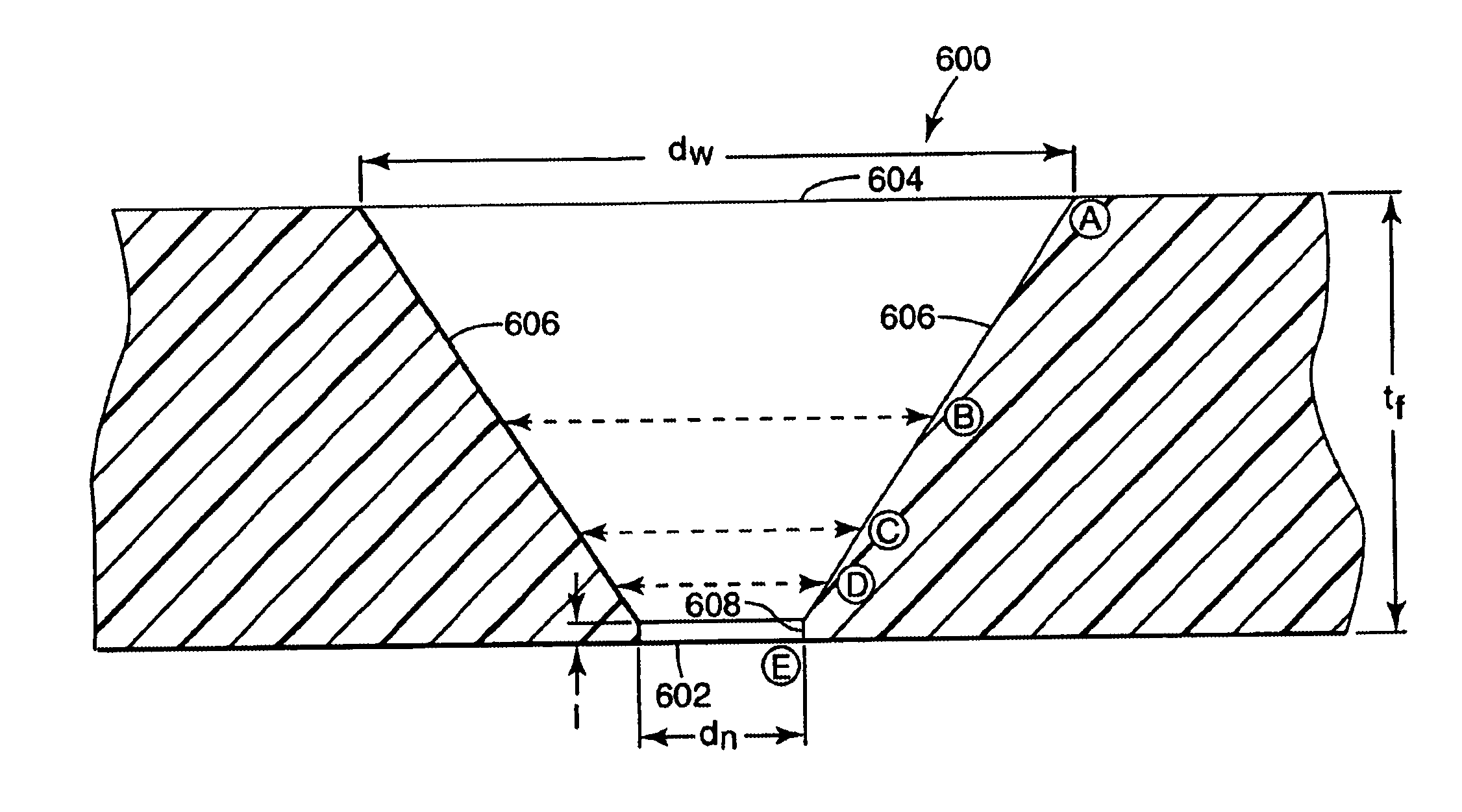

Mechanical locking system for panels and method of installing same

ActiveUS20080034708A1Simple horizontal displacementReduces snapping resistanceCovering/liningsWallsMechanical engineeringEngineering

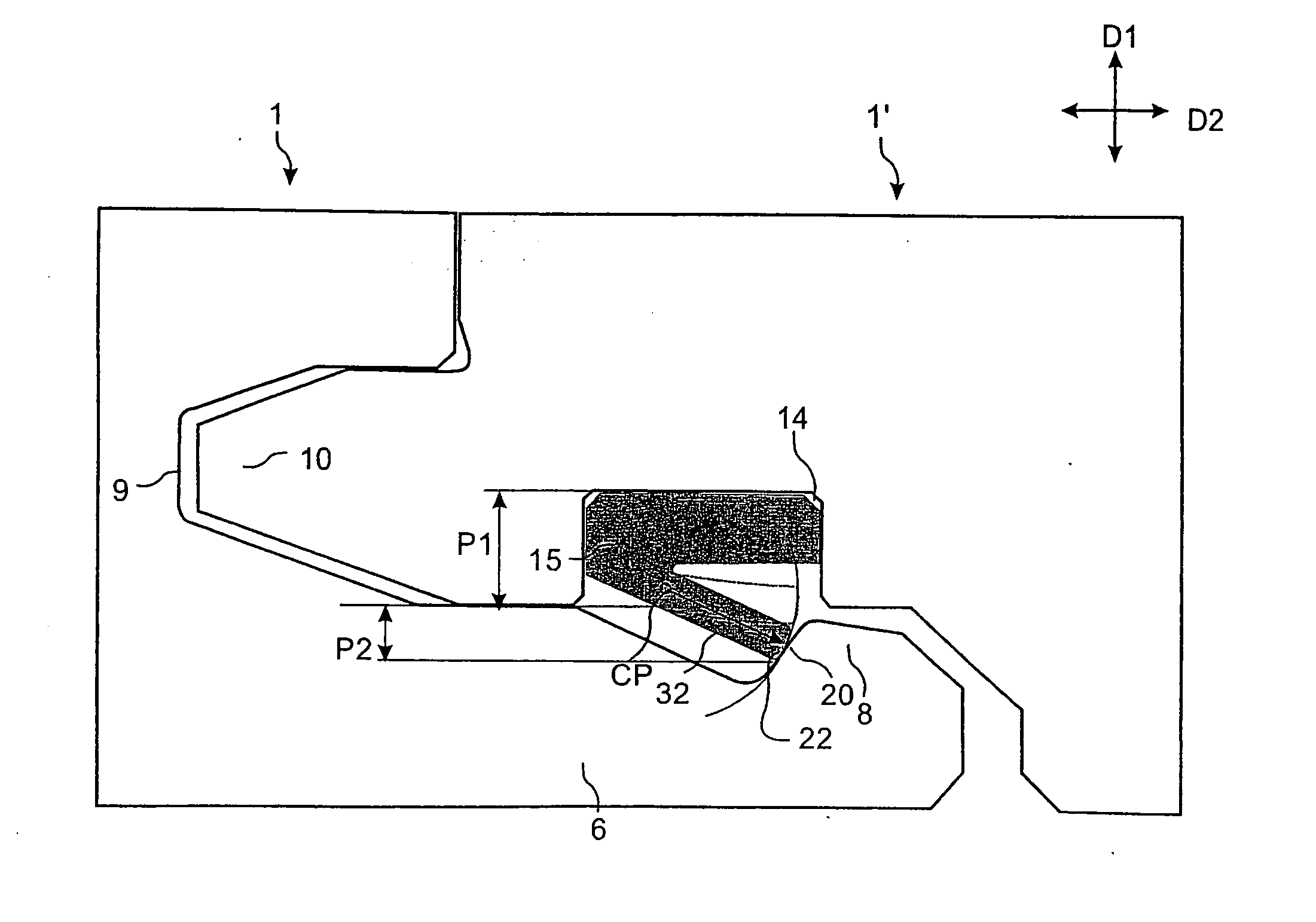

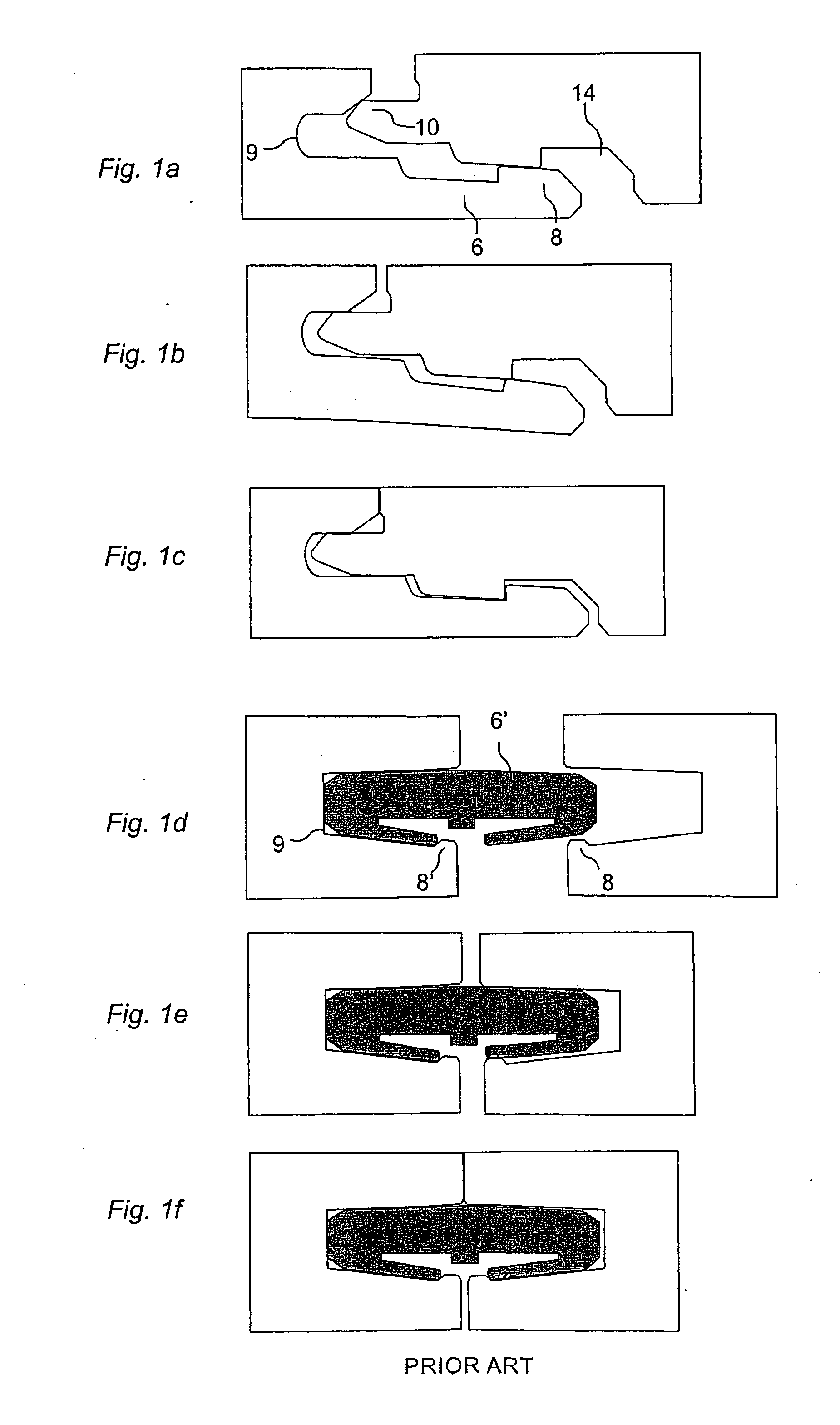

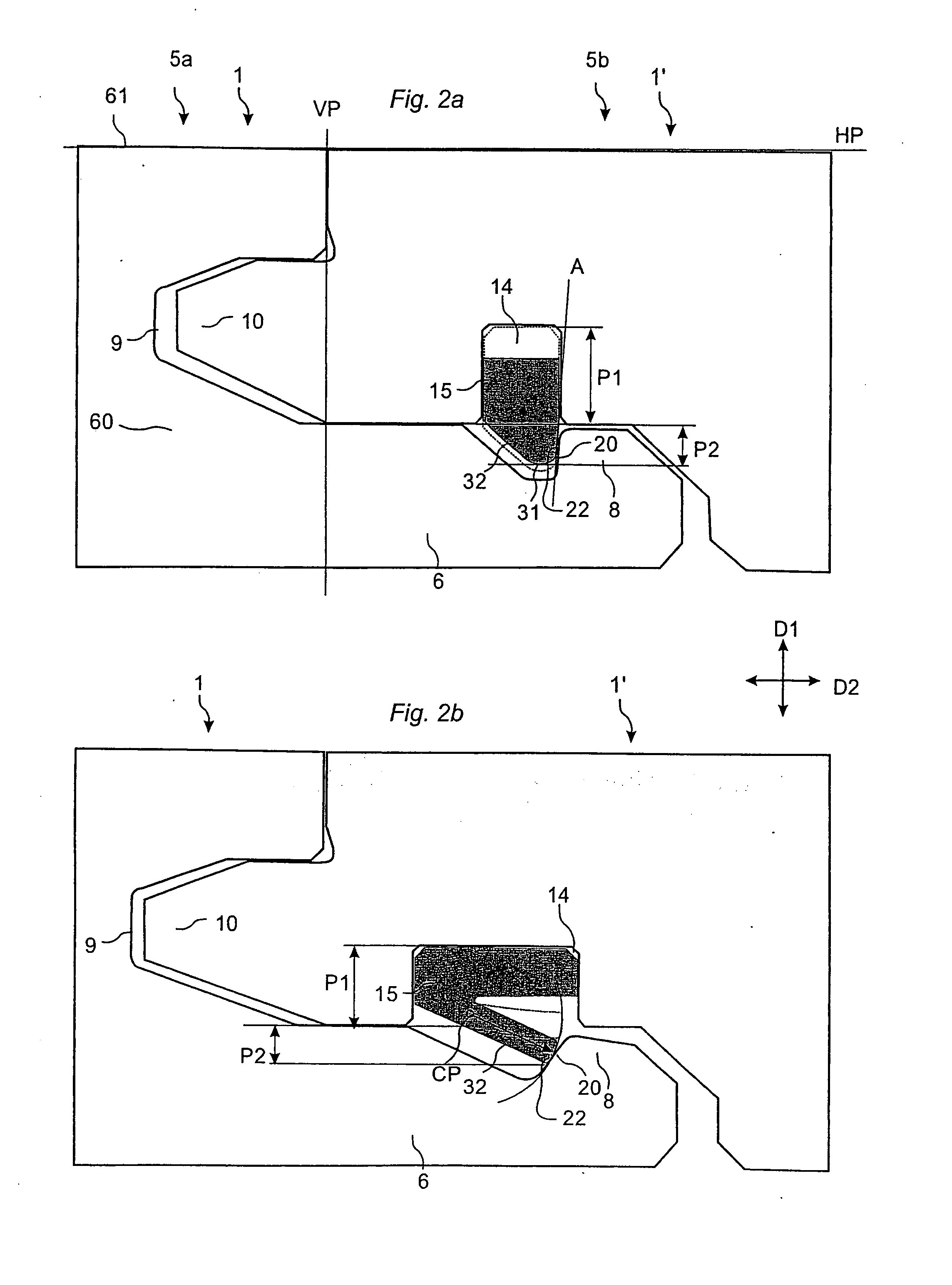

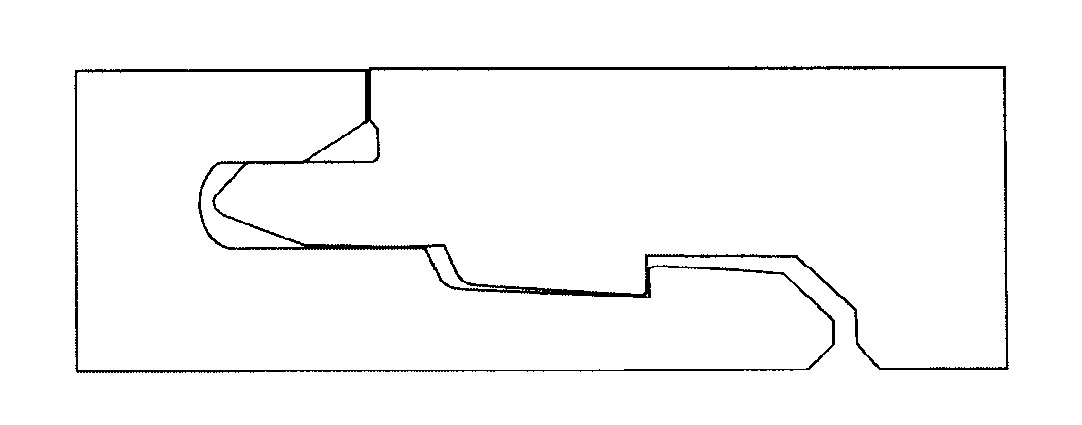

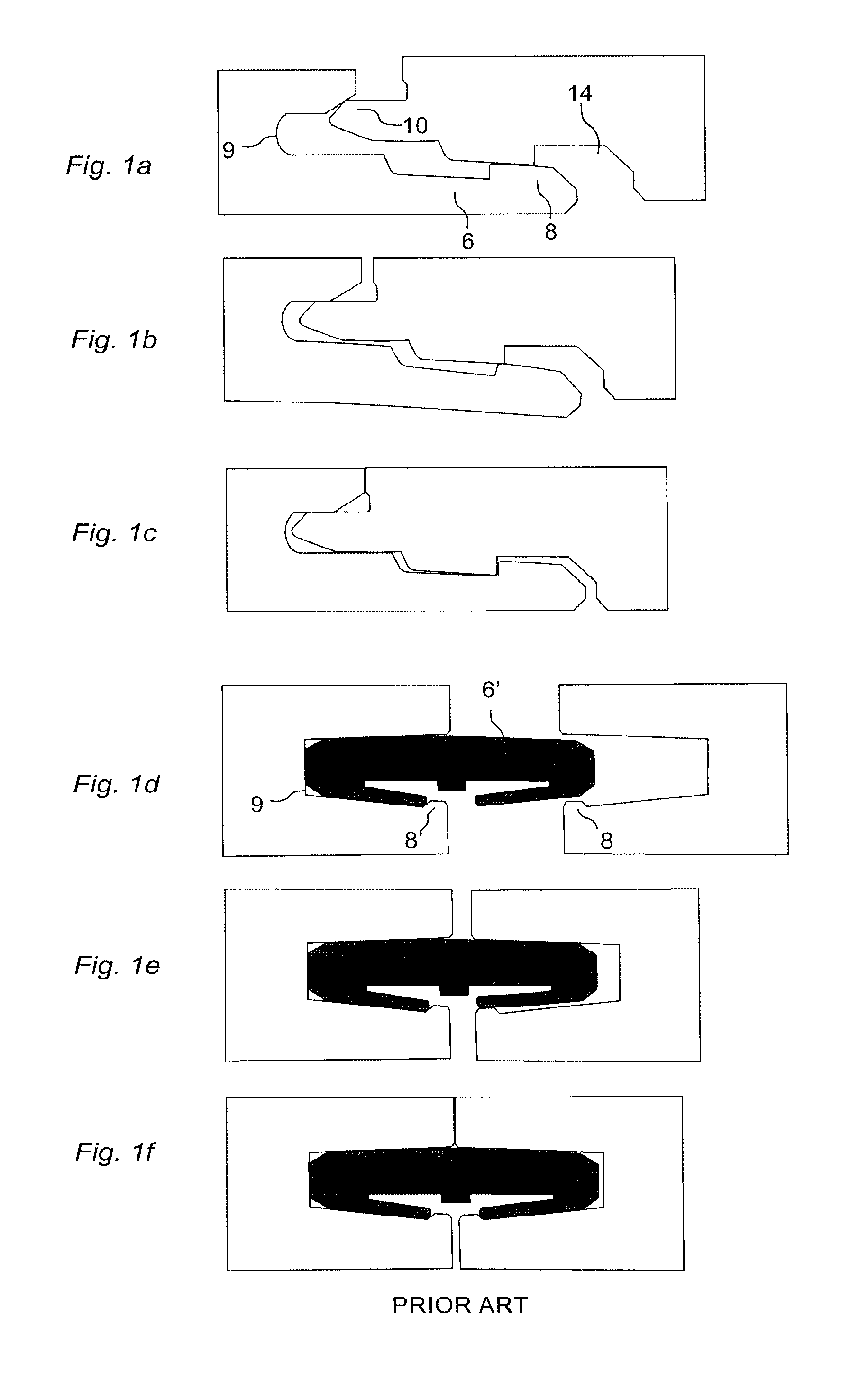

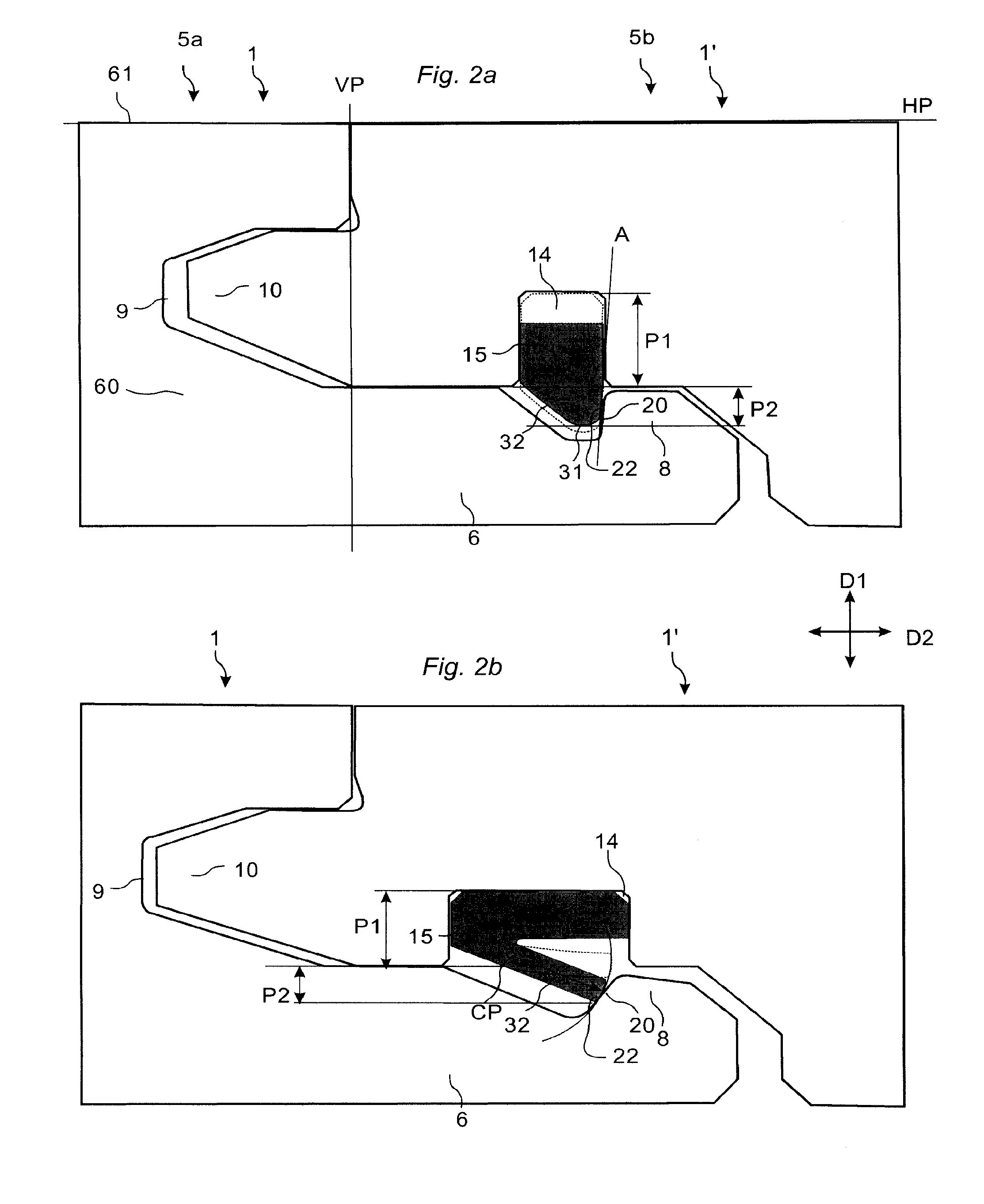

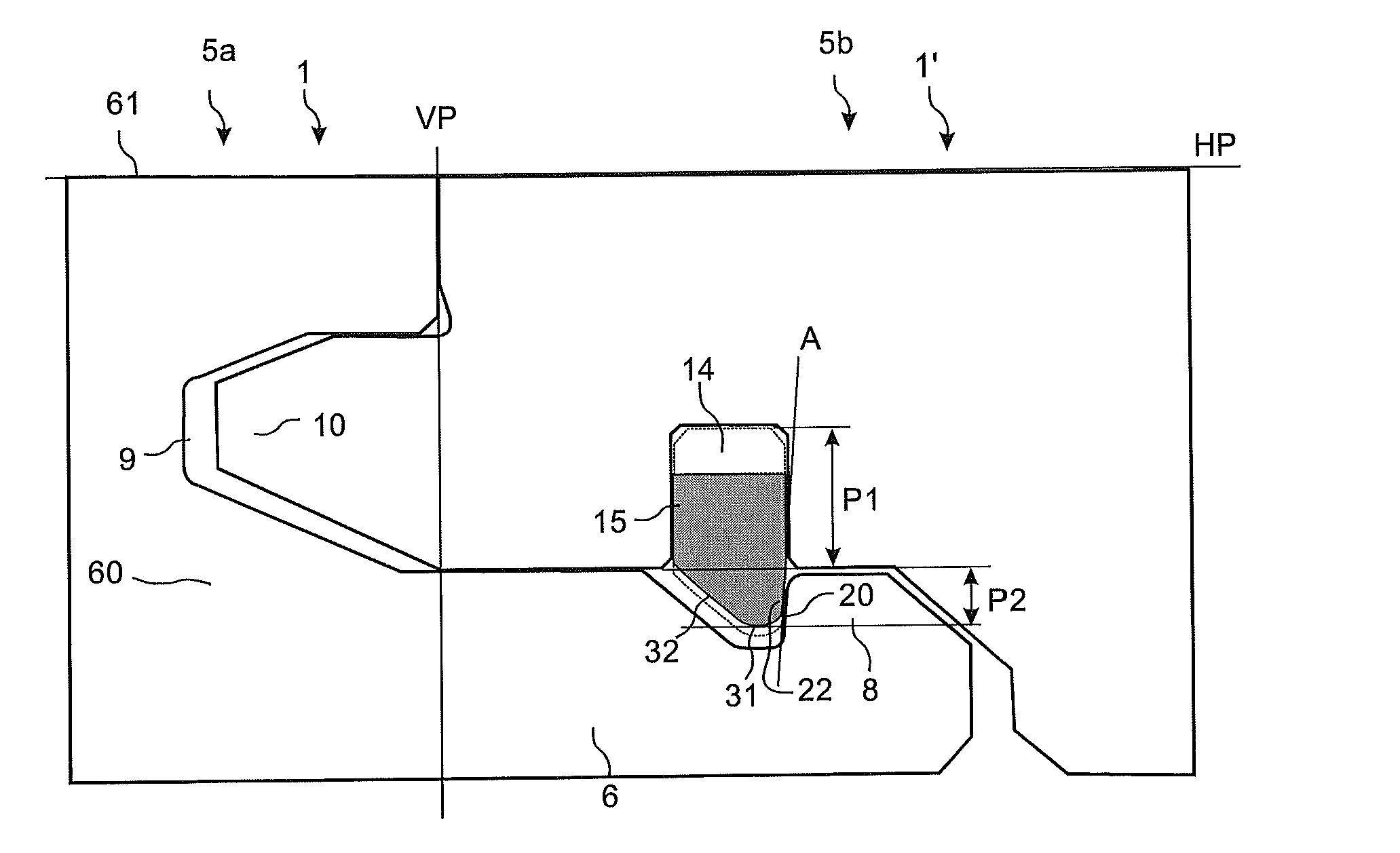

Floor panels ( 1, 1 ') are provided with a mechanical locking system including a flexible locking element 15 in a locking groove 14 which during a horizontal motion is displaced vertically.

Owner:VÄLINGE INNOVATION AB

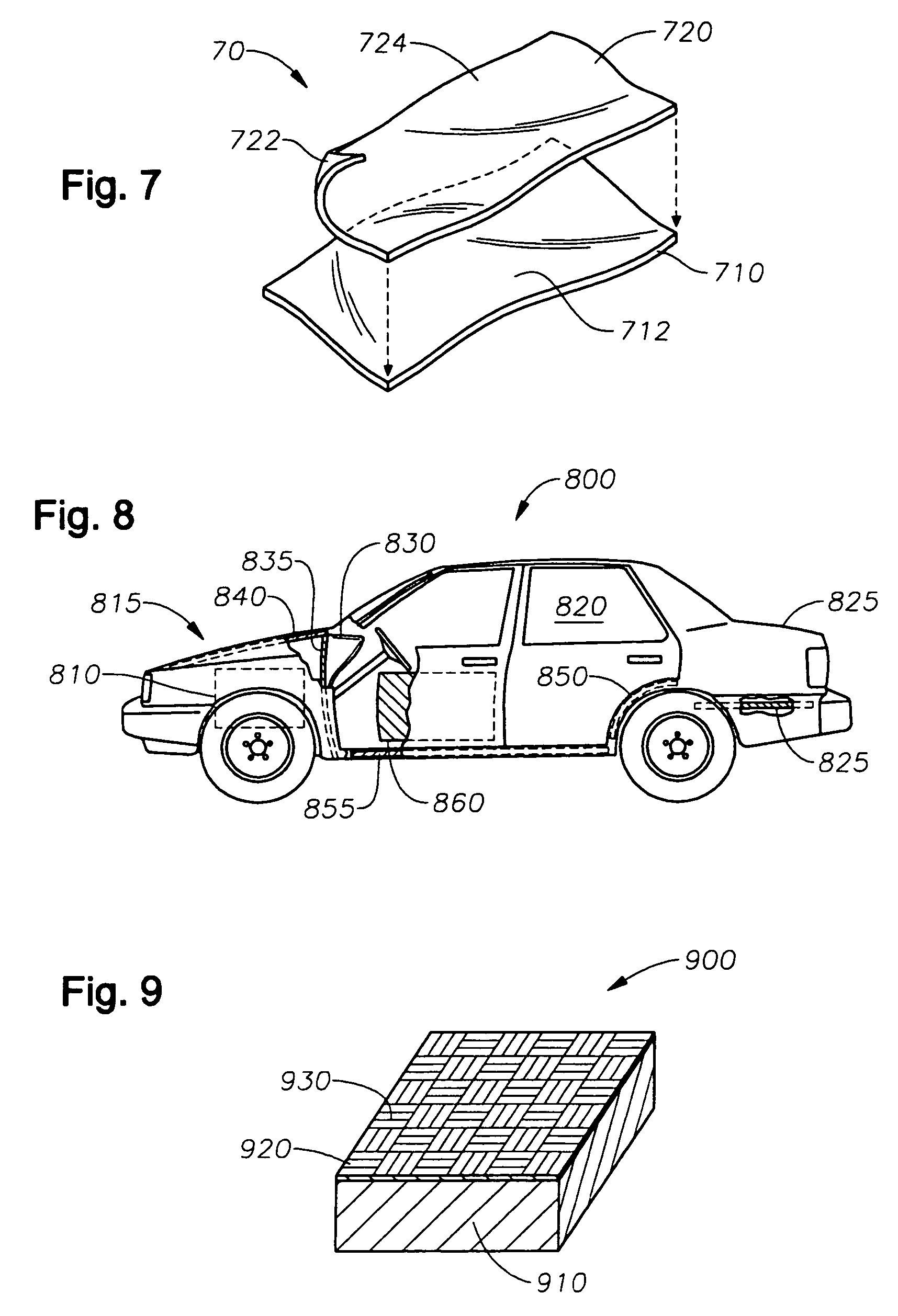

Glider bar for flooring system

A flooring system for use with floating floors is described which includes a glider bar having base portions including extending rails in the form of dovetail protrusions. The bases and rails are longitudinally moveable relative to anchoring plates, which anchoring plates are affixed to a subflooring. Flush finished floor moldings are slid longitudinally along the rails and are glued or mechanically fixed, at one side only, to the adjacent floating laminate flooring. By this assembly, smooth transitions between adjacent floating floors, or where floating floors meet another hard floor covering, or carpet, can be achieved. The system can also be used with flush stair nosing elements.

Owner:PERGO

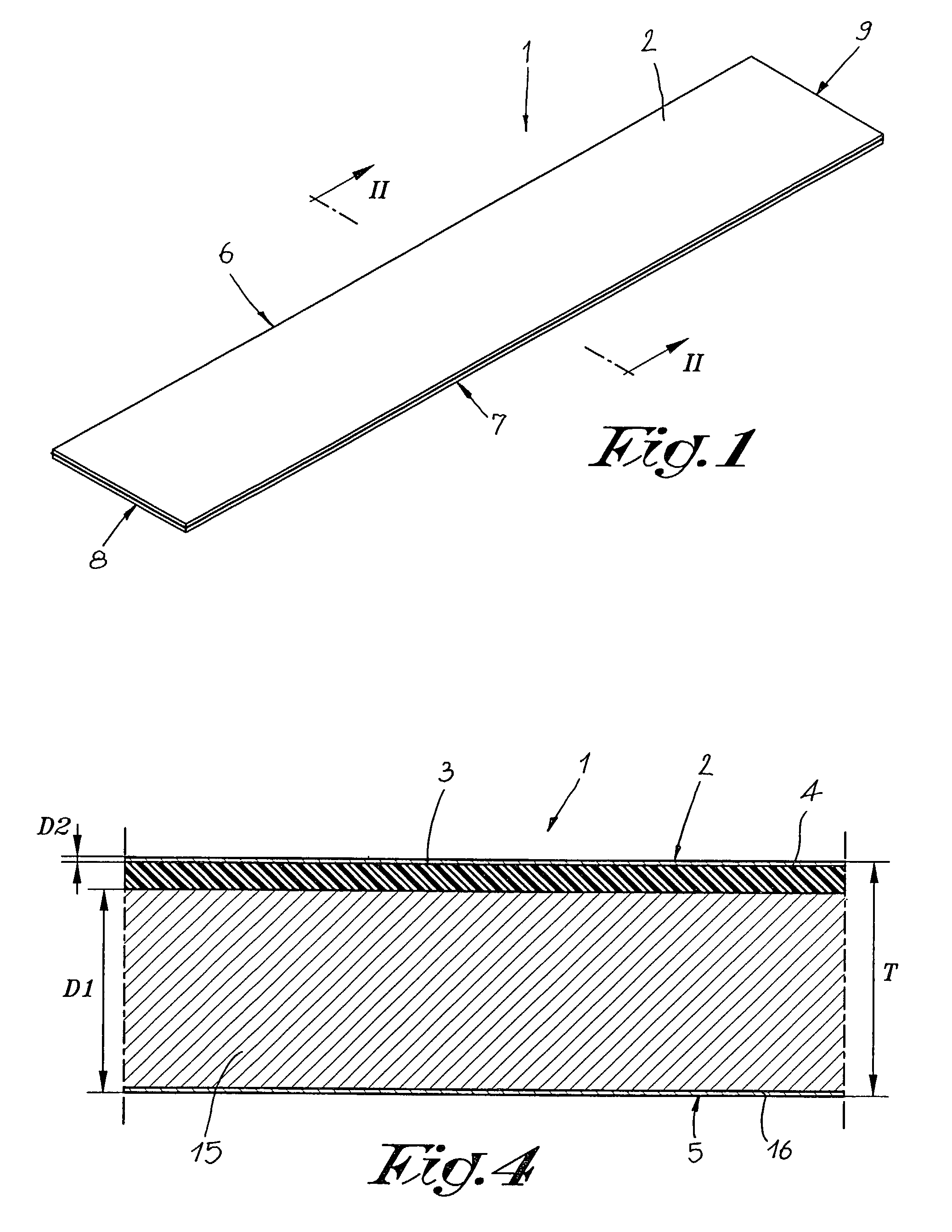

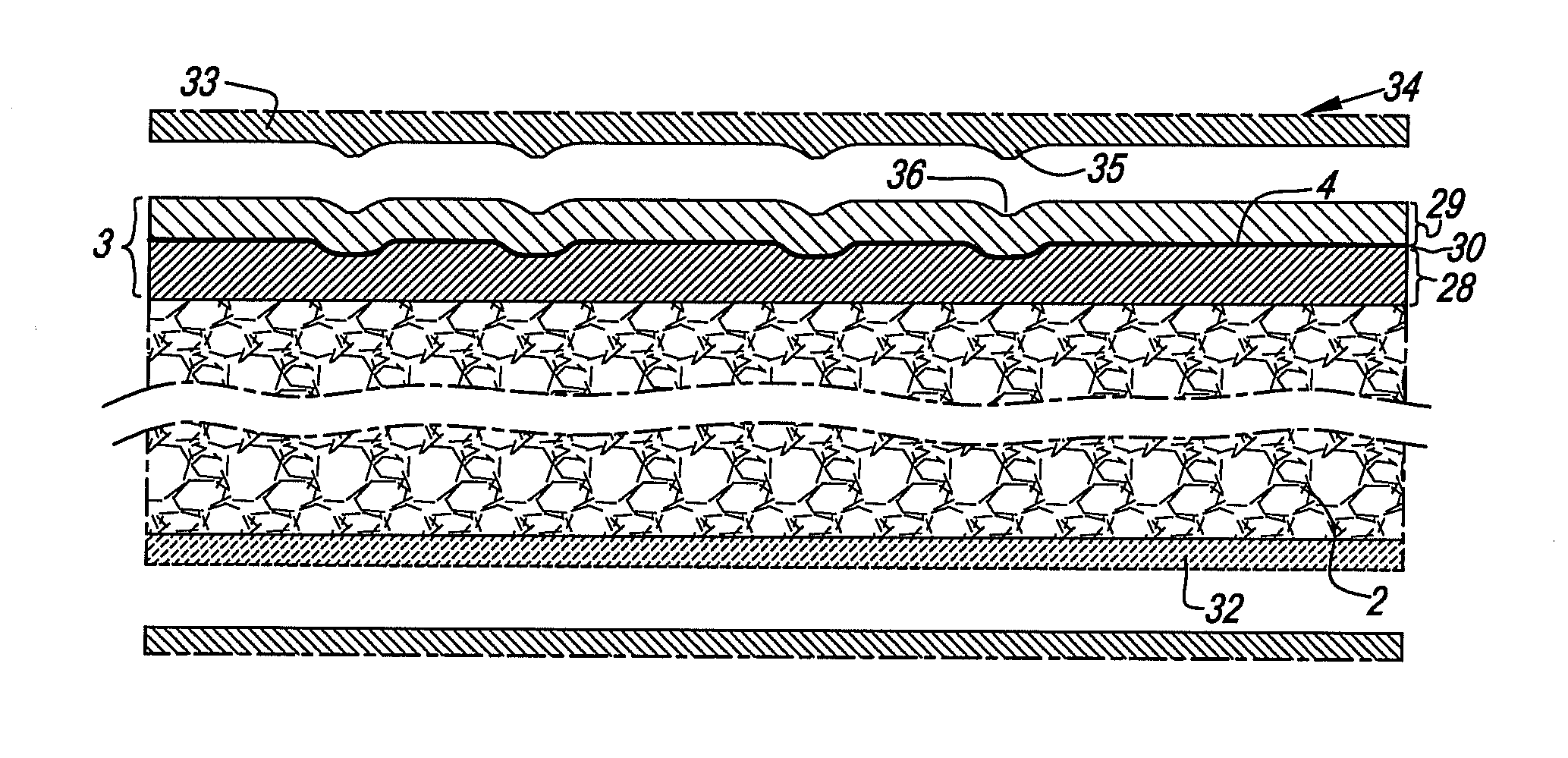

Floorboards for floorings

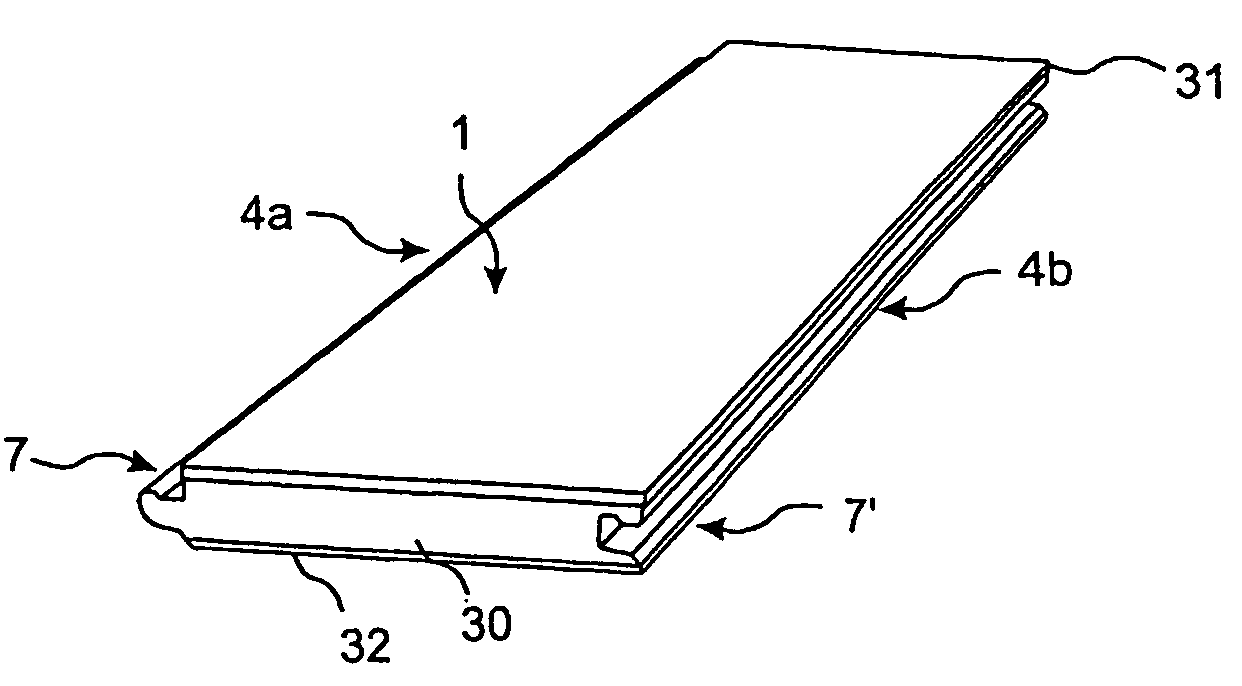

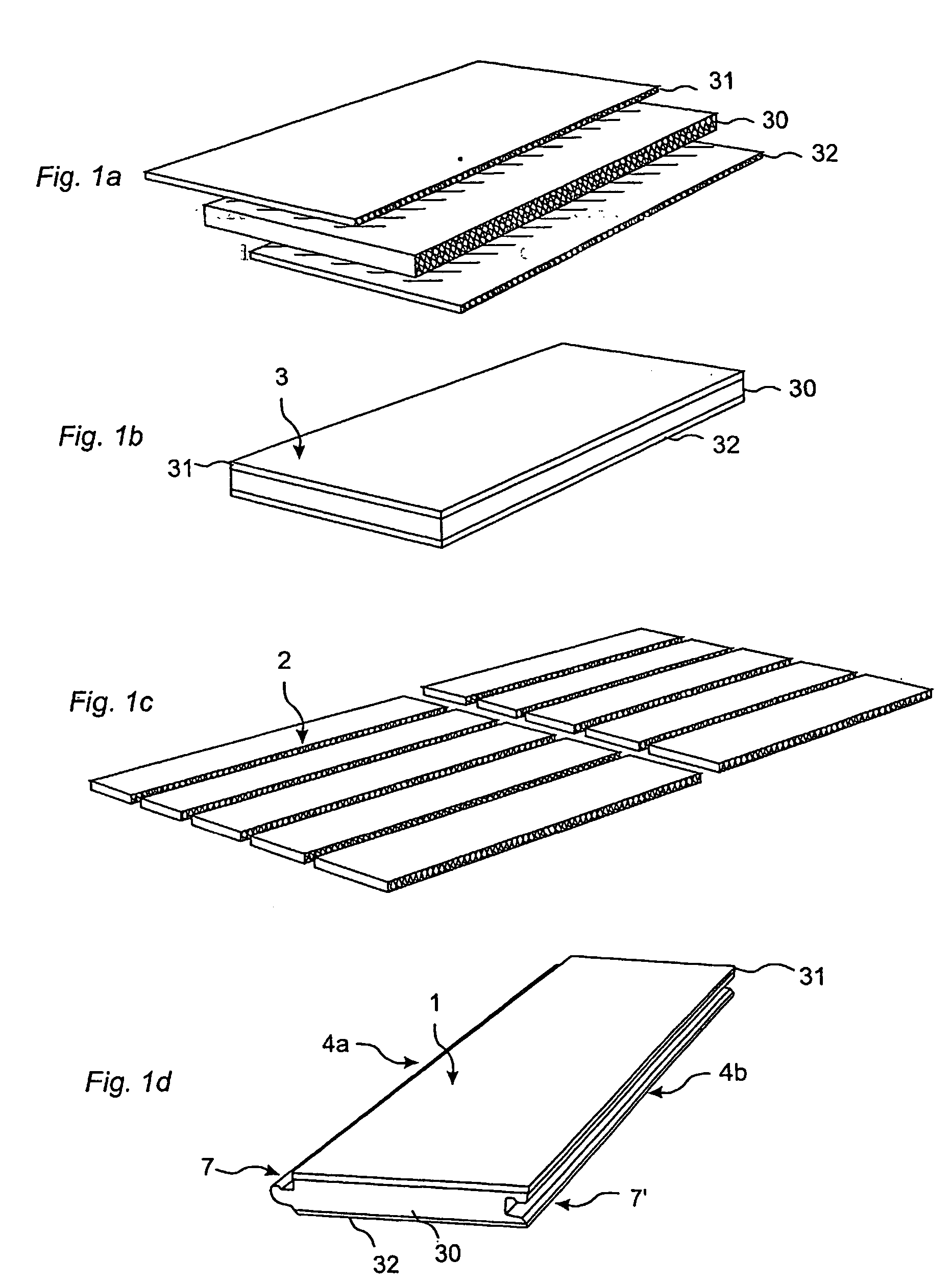

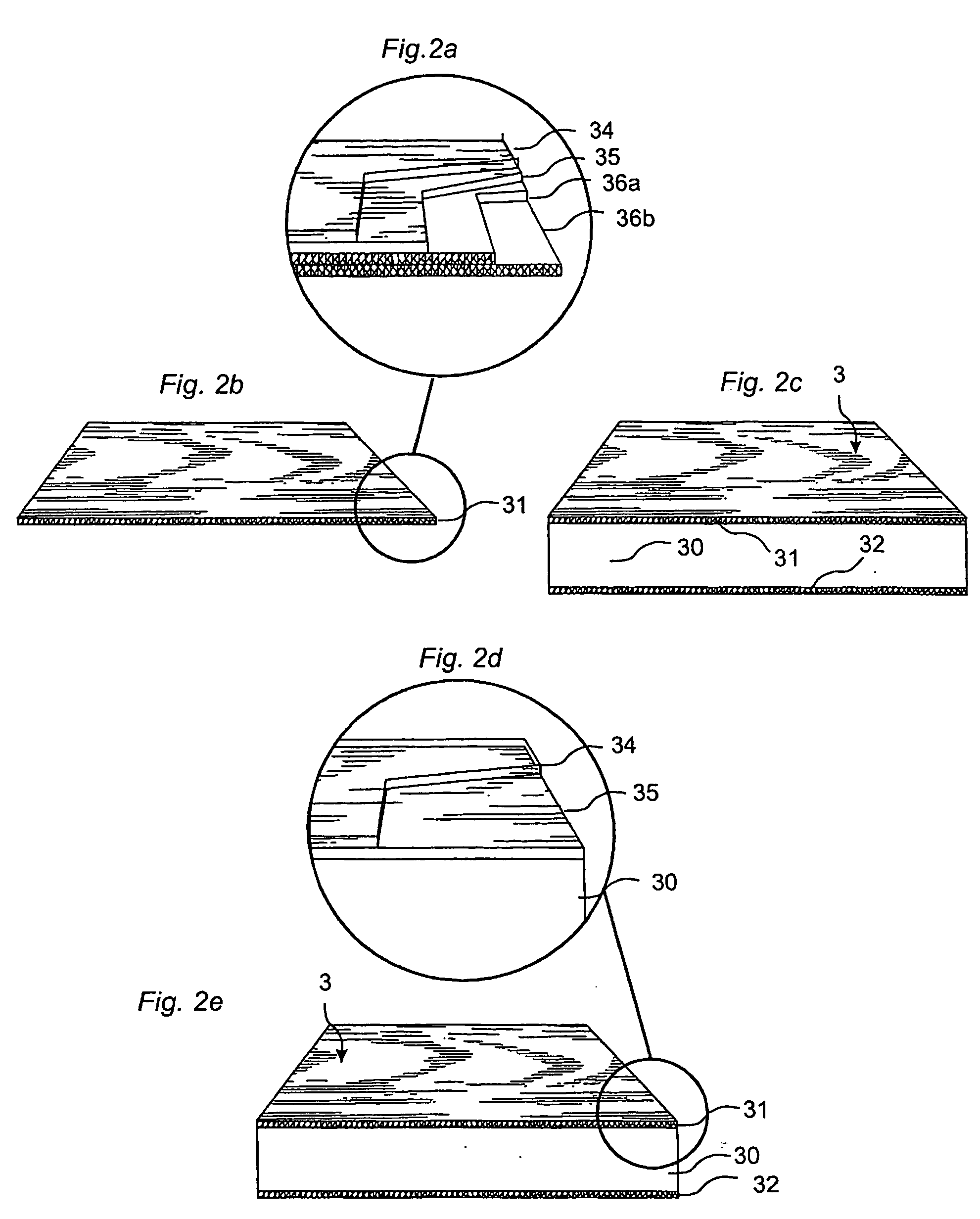

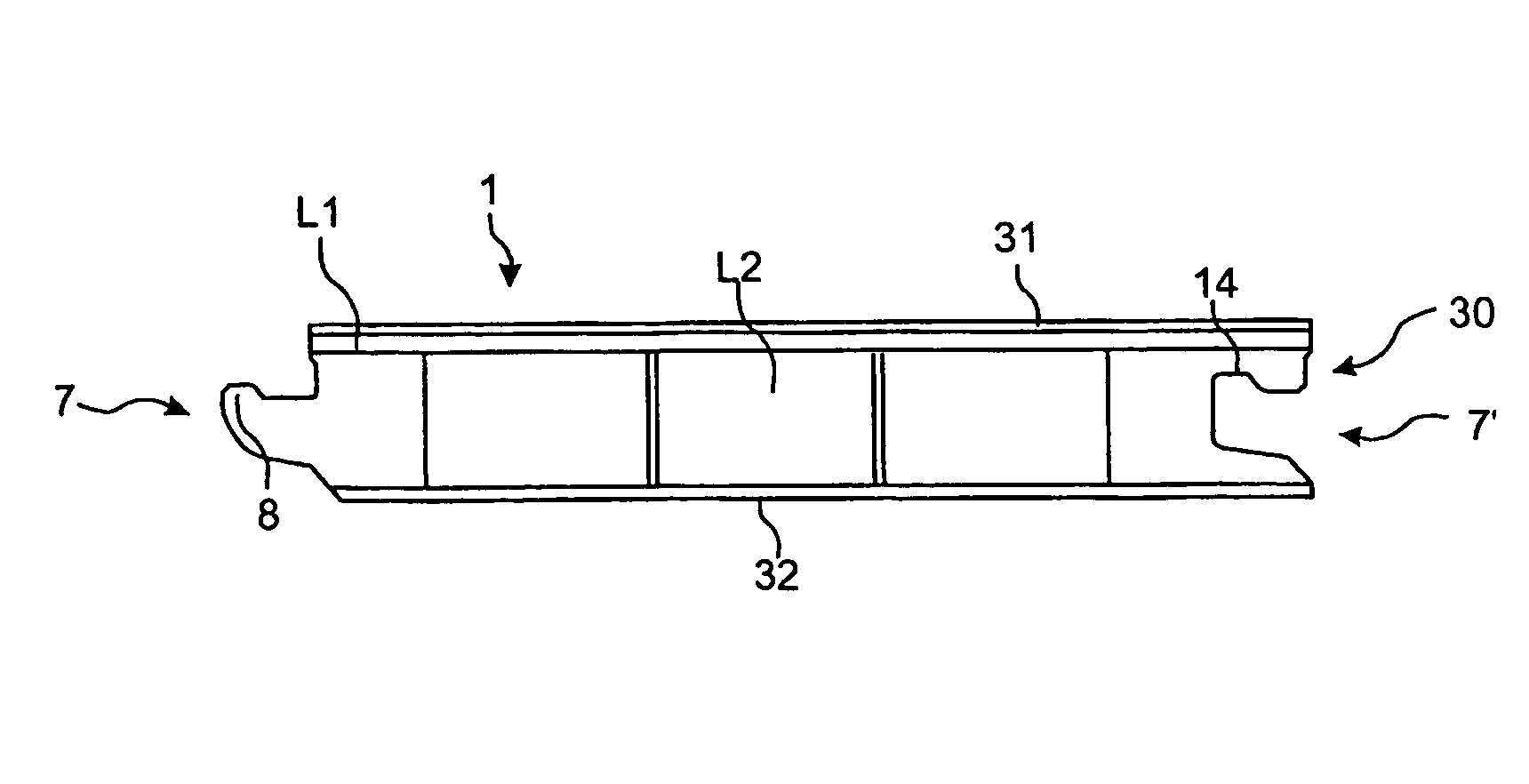

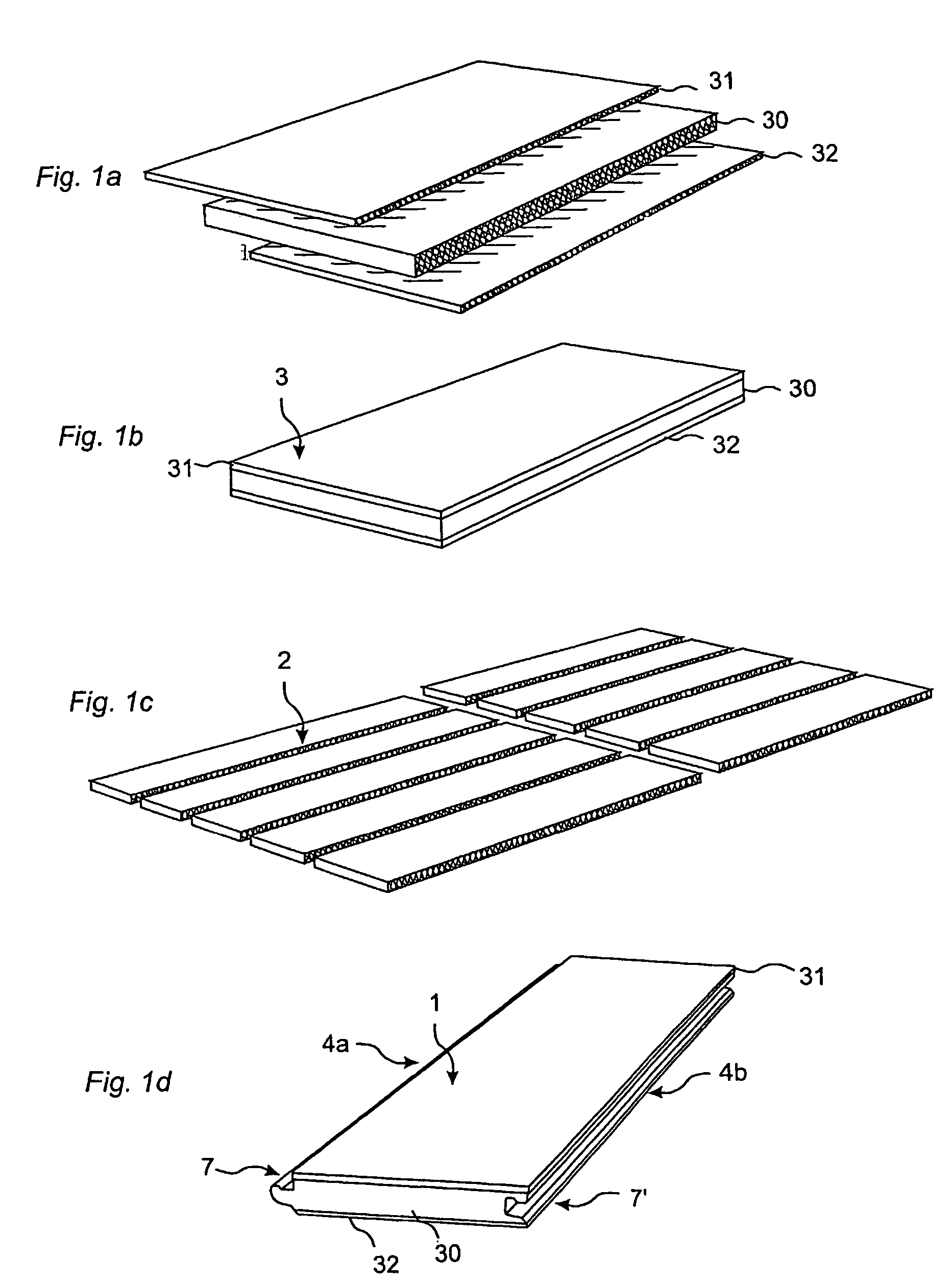

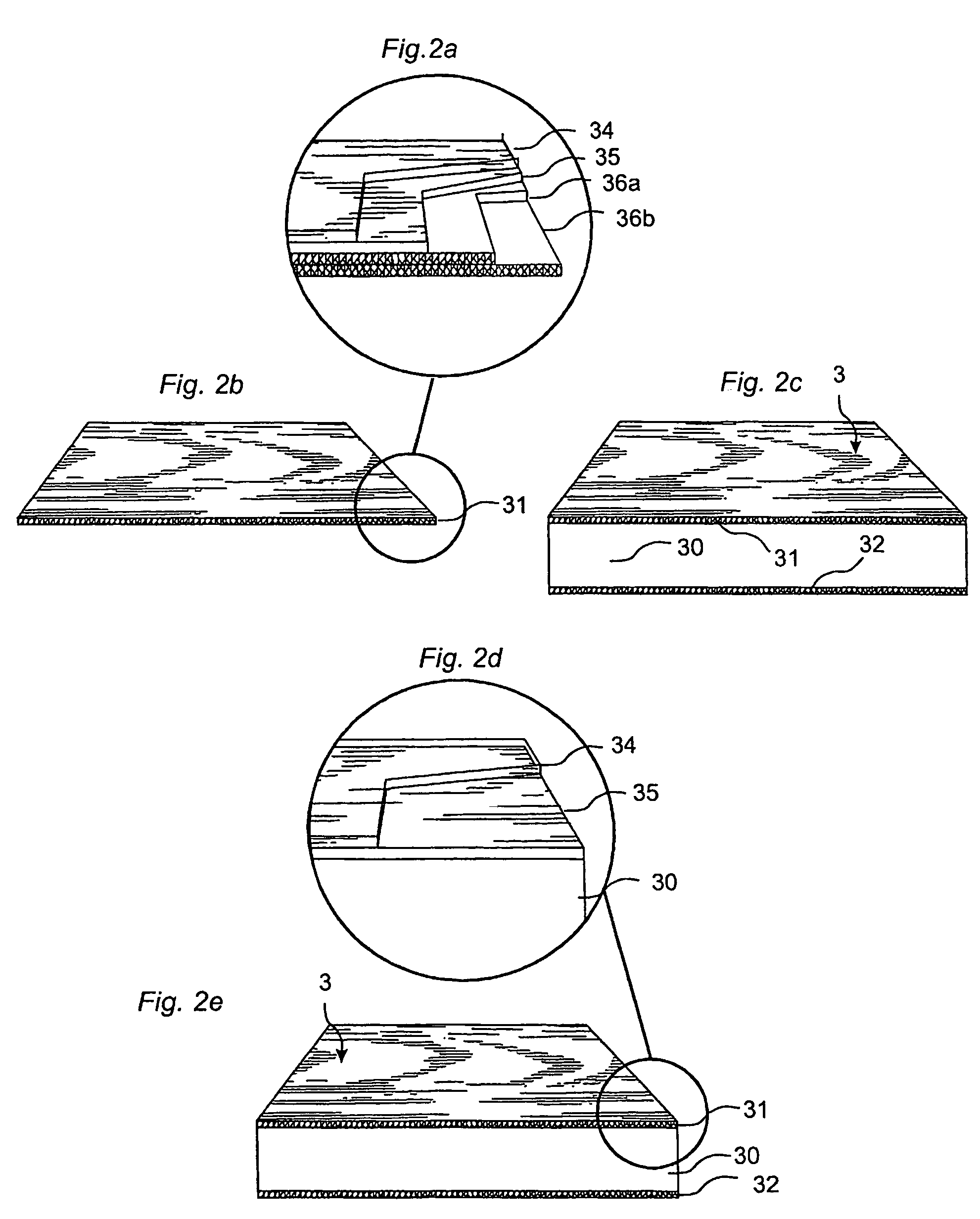

Floorboards for making a floating floor have a core ( 30 ) which comprises at least two layers of material (L 1, L 2 ), which are arranged at different distances from the surface layer ( 31 ), and which differ in respect of material properties or material composition. Semi manufactures for making such floorboards are also disclosed.

Owner:VÄLINGE INNOVATION AB

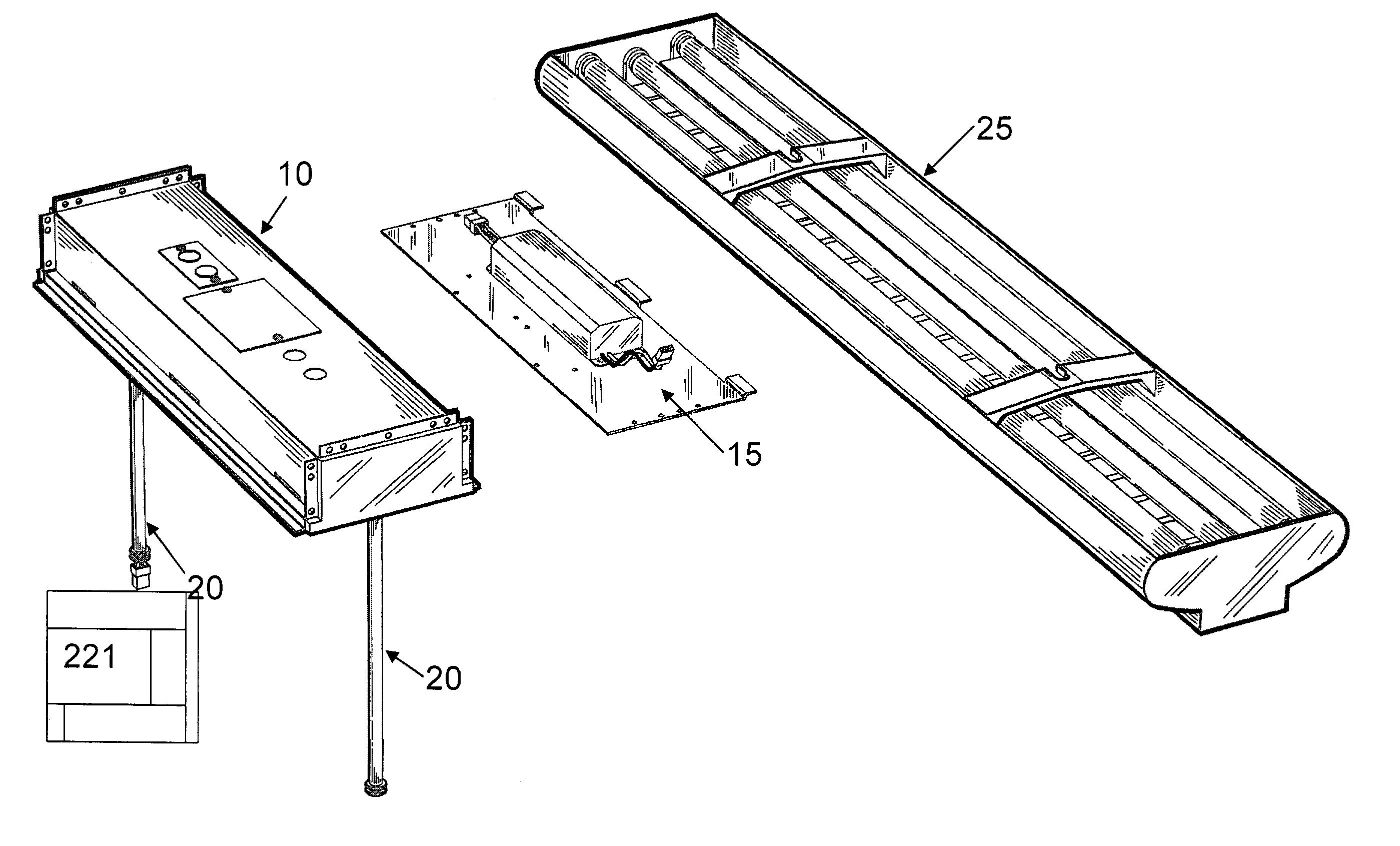

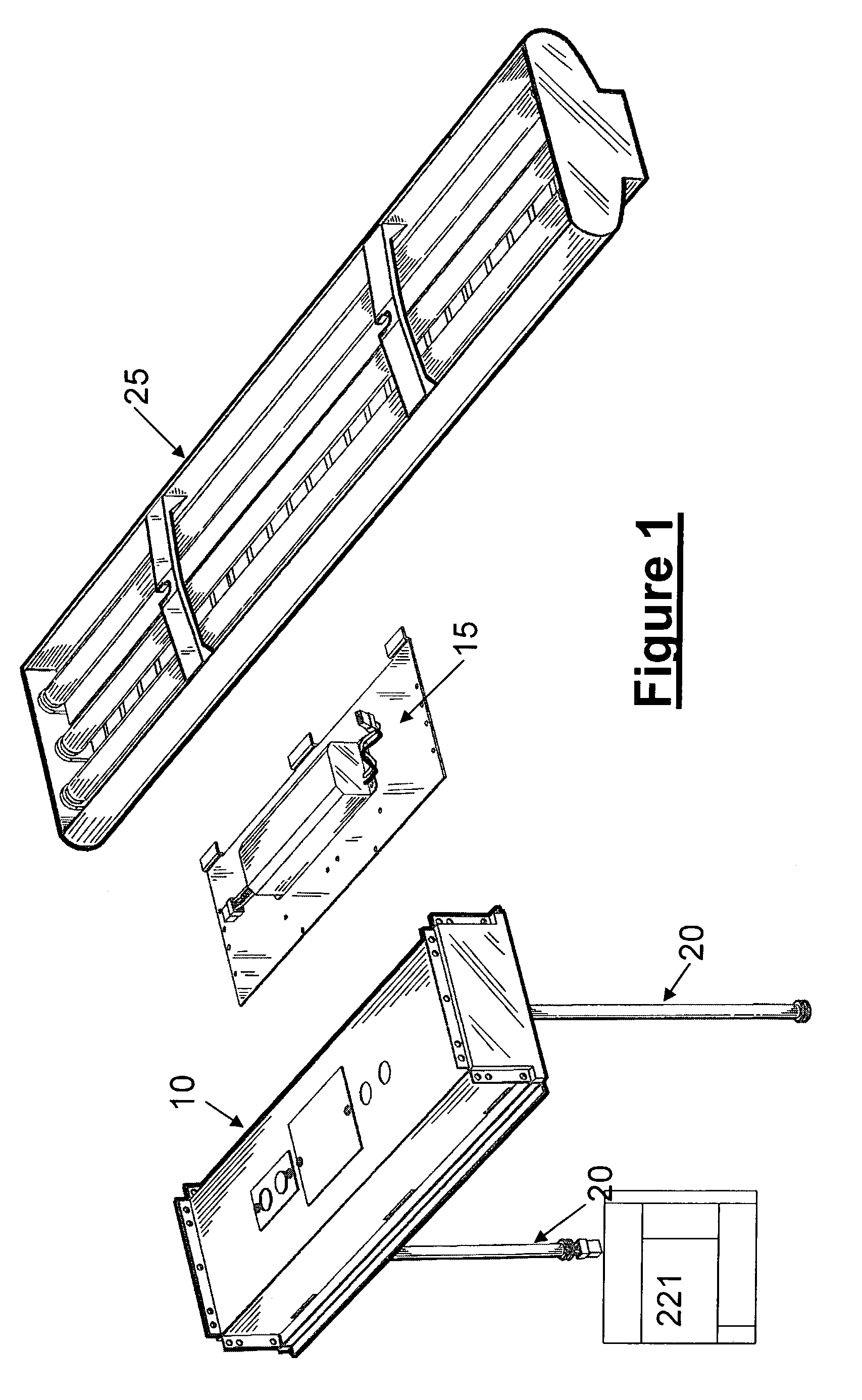

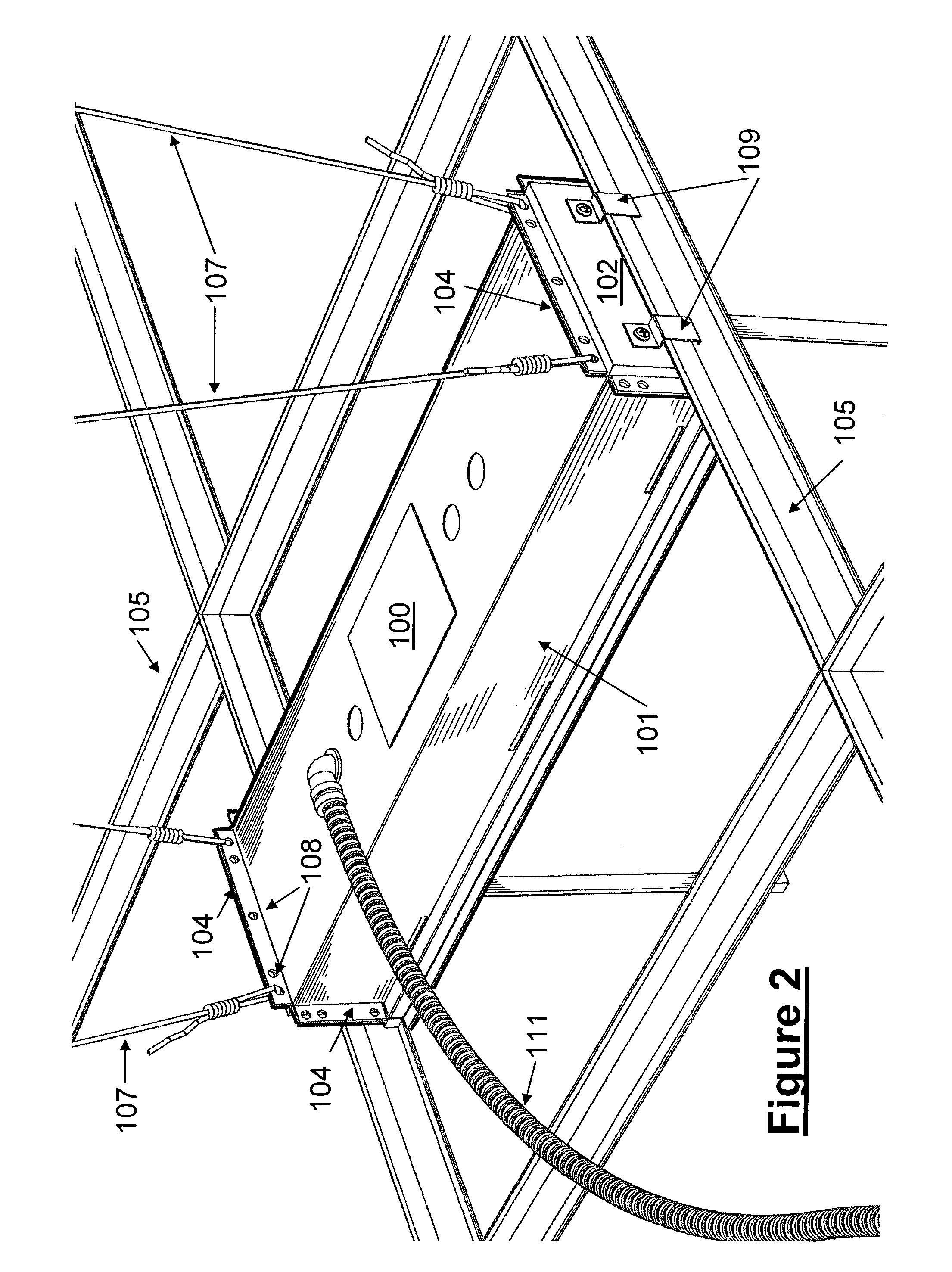

Modular ambient lighting system

InactiveUS6979097B2Support flexibilityEnabling changeCoupling device connectionsLight source combinationsTransformerElectrical connection

The invention is a modular ambient lighting system for providing lighting to the interior of the building. The system features three separate modules: (1) a support module, (2) a power module, and (3) a light fixture body module. The support module provides an electrical connection to the building and structural connection to the ceiling of the building. An interchangeable power module fits into a recess or “foot print” in the support module. The power module includes the electrical components of the lighting system (e.g. ballast, transformer, emergency batteries, etc). An interchangeable light fixture body module houses the lamp that can be configured to deliver direct, indirect, or direct / indirect illumination. The interchangeable features of the modules offers superior flexibility because of the ease to reconfigure the electrical operation of the light system, the type illumination delivered, or the aesthetics of the light system.

Owner:ELAM THOMAS E +1

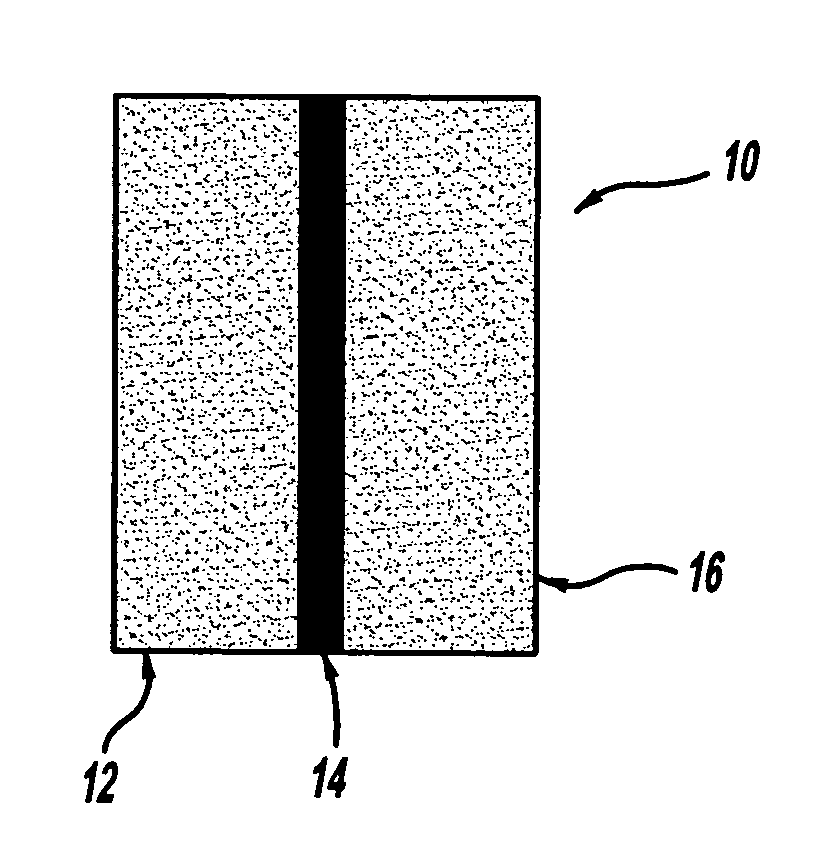

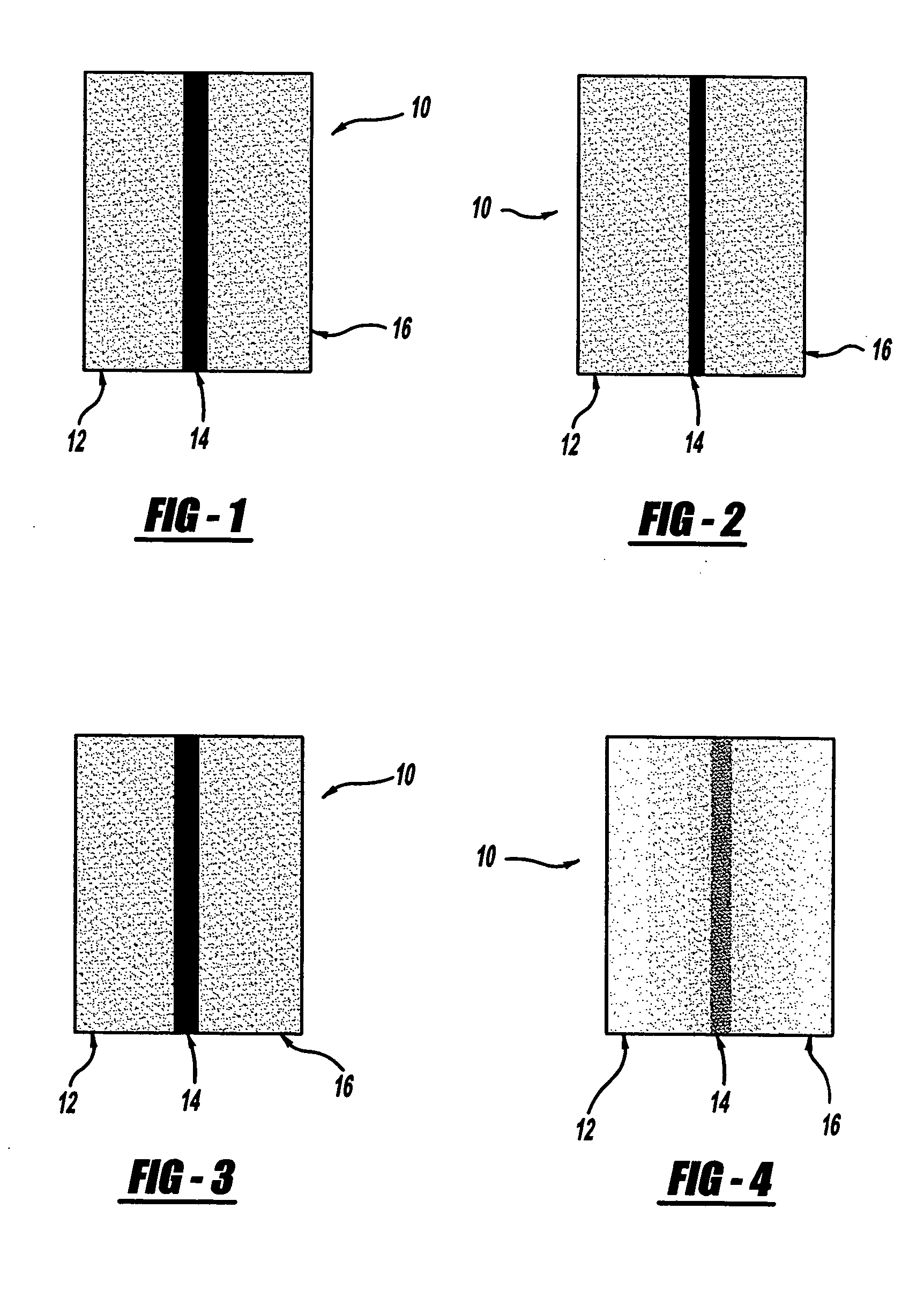

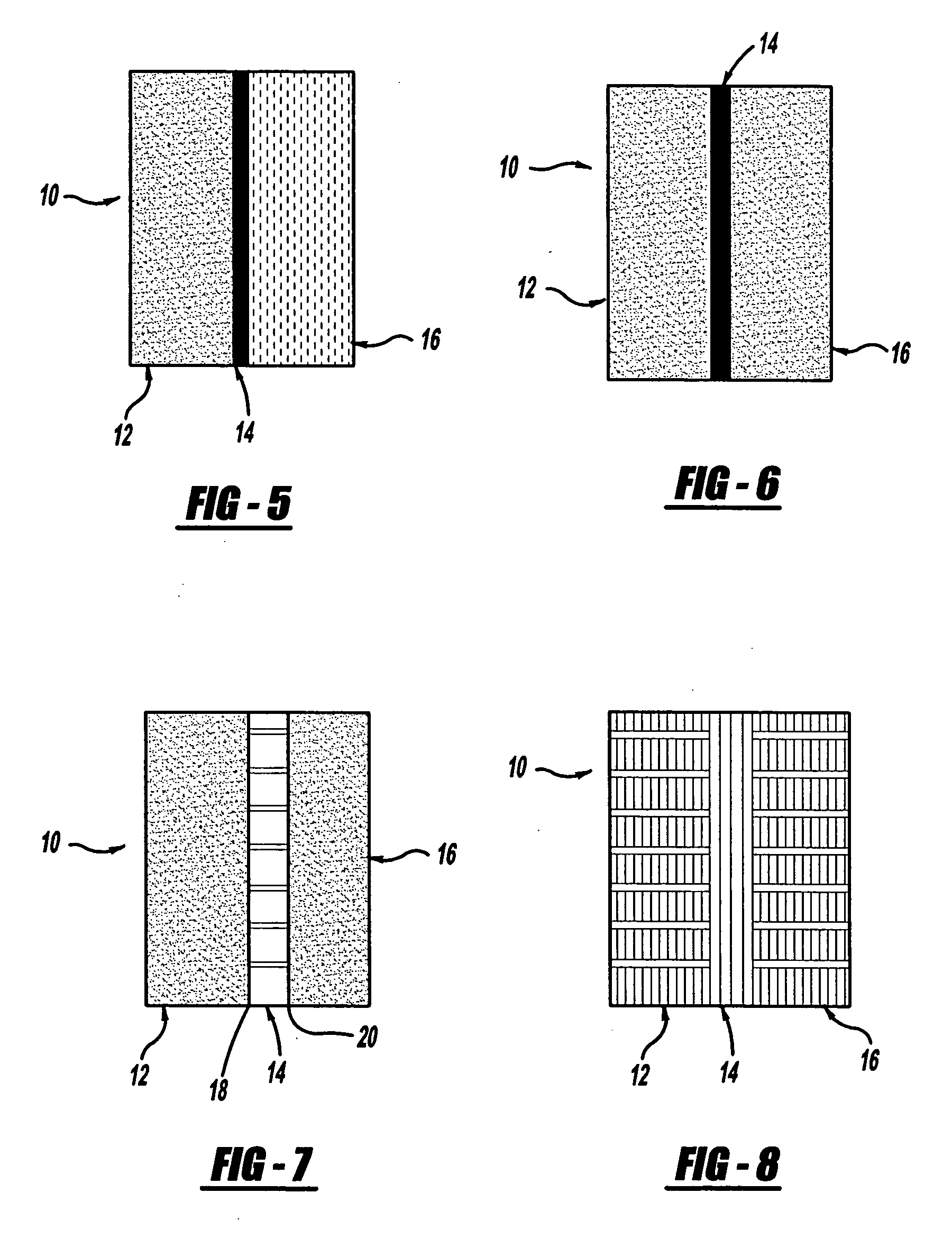

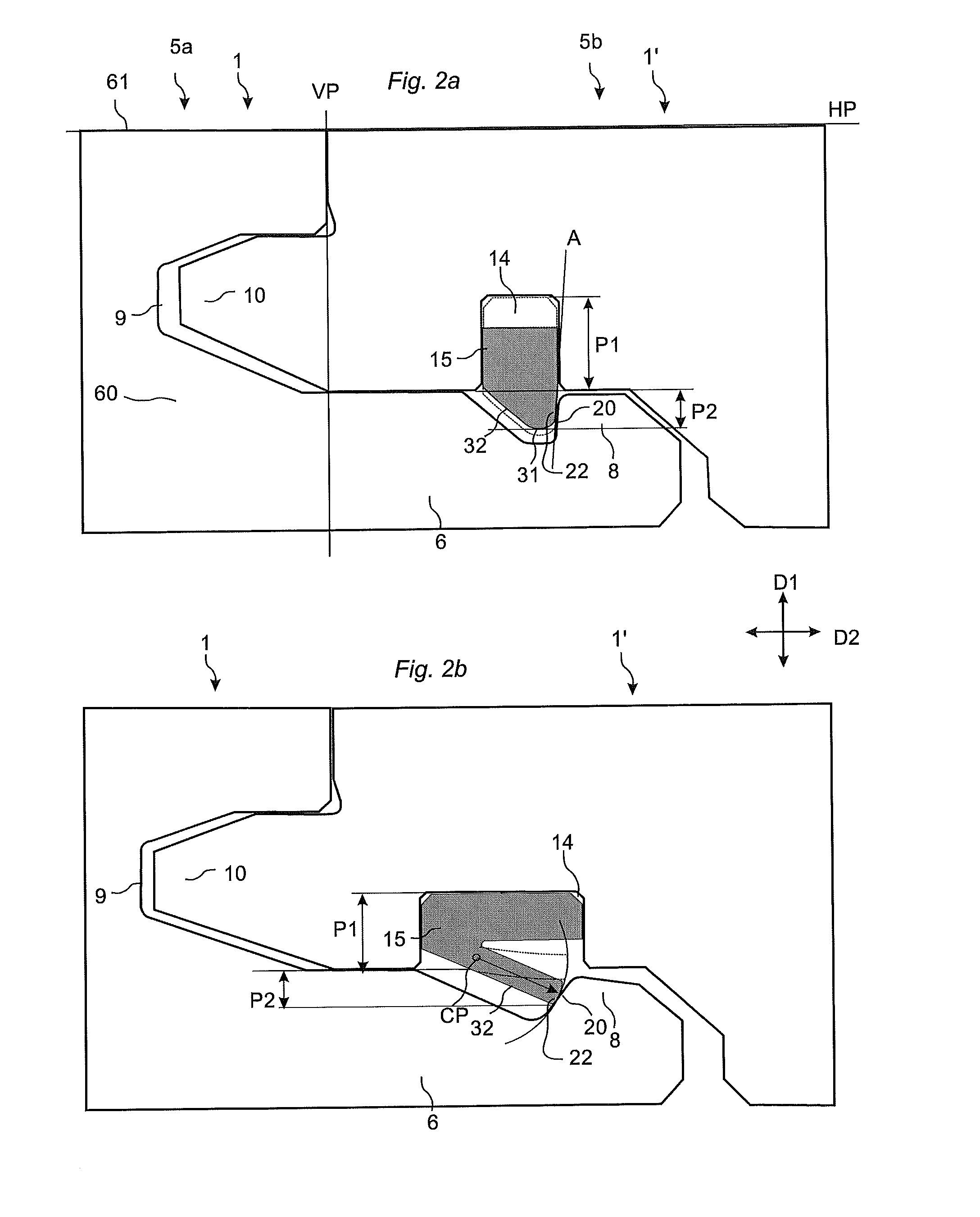

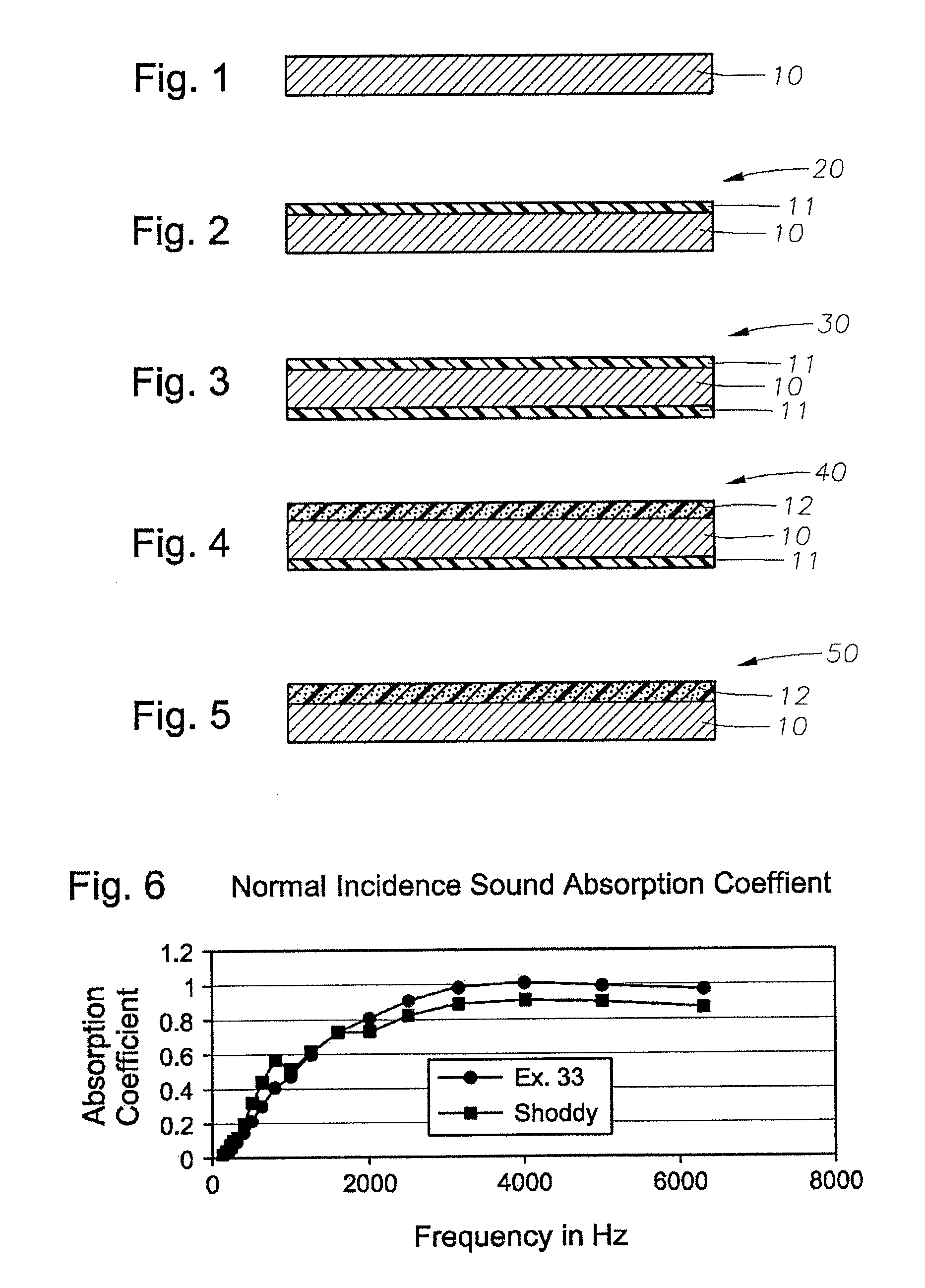

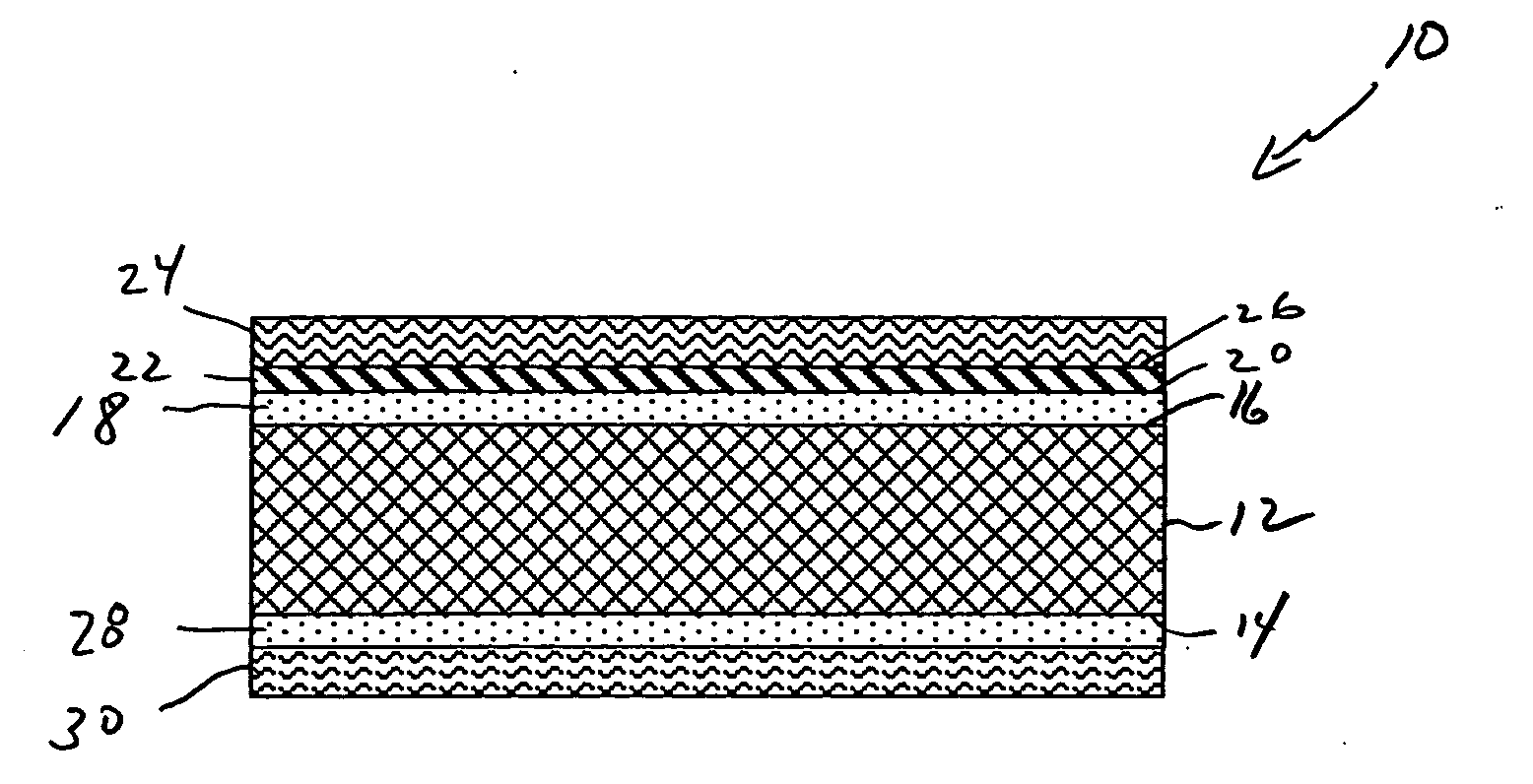

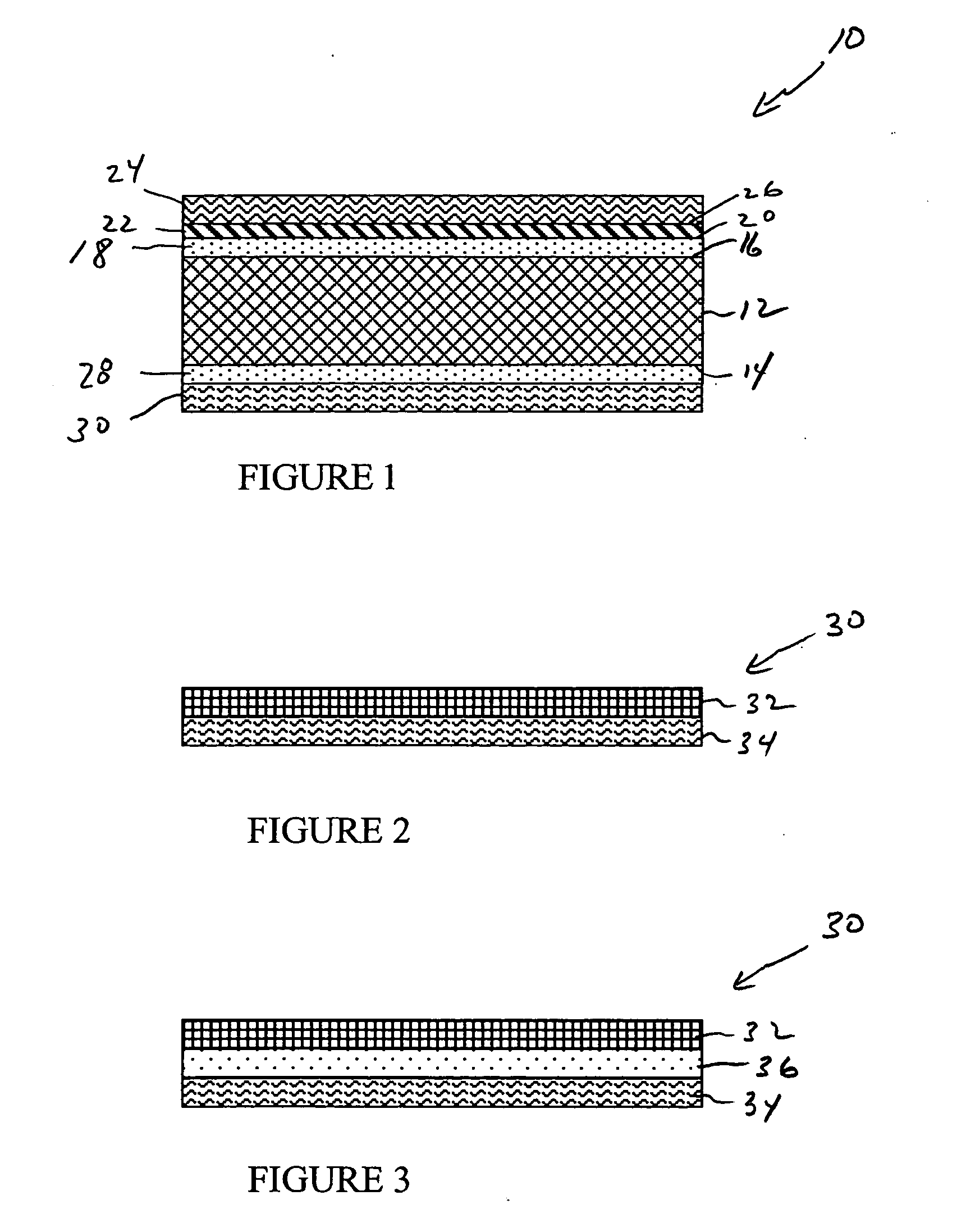

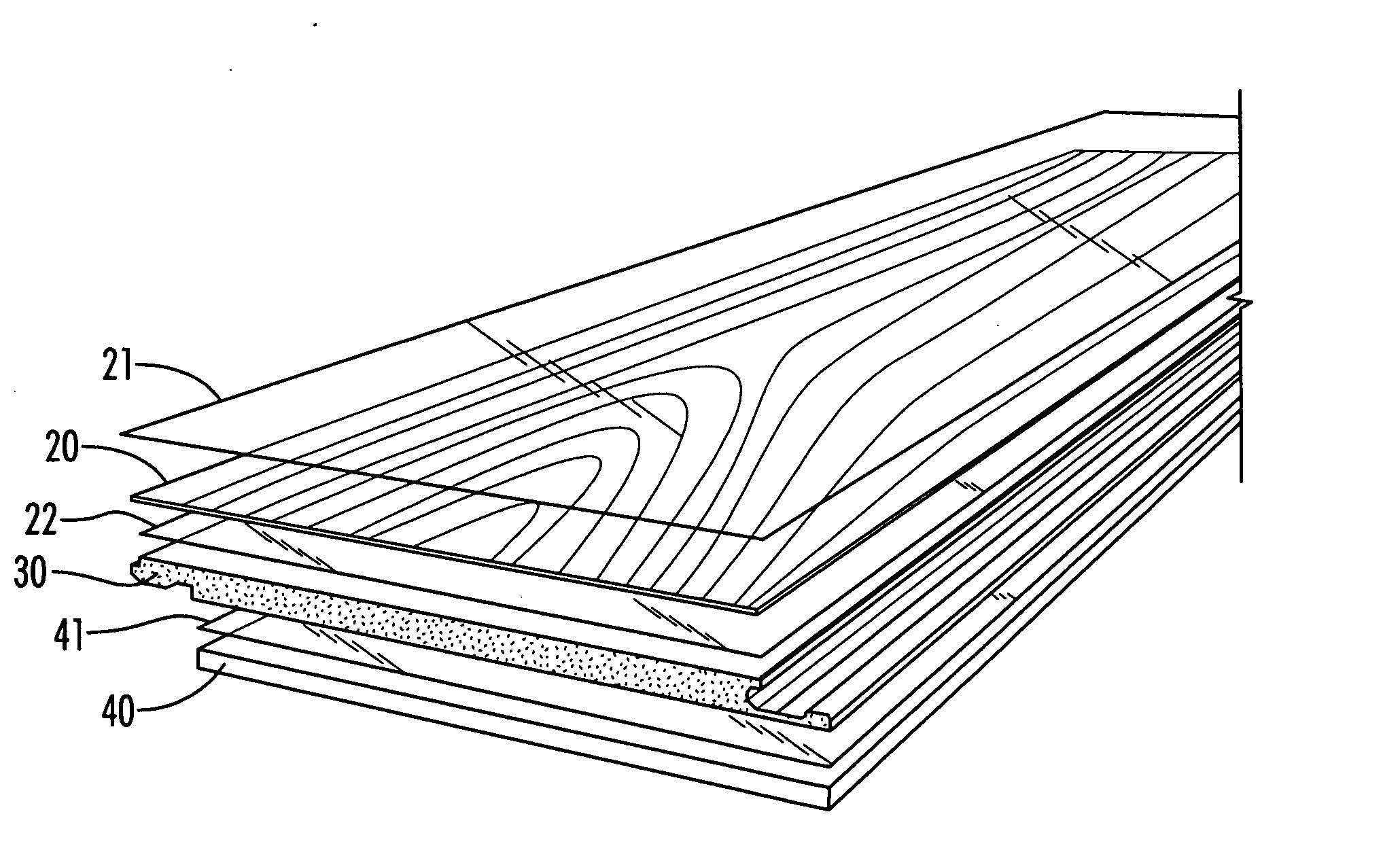

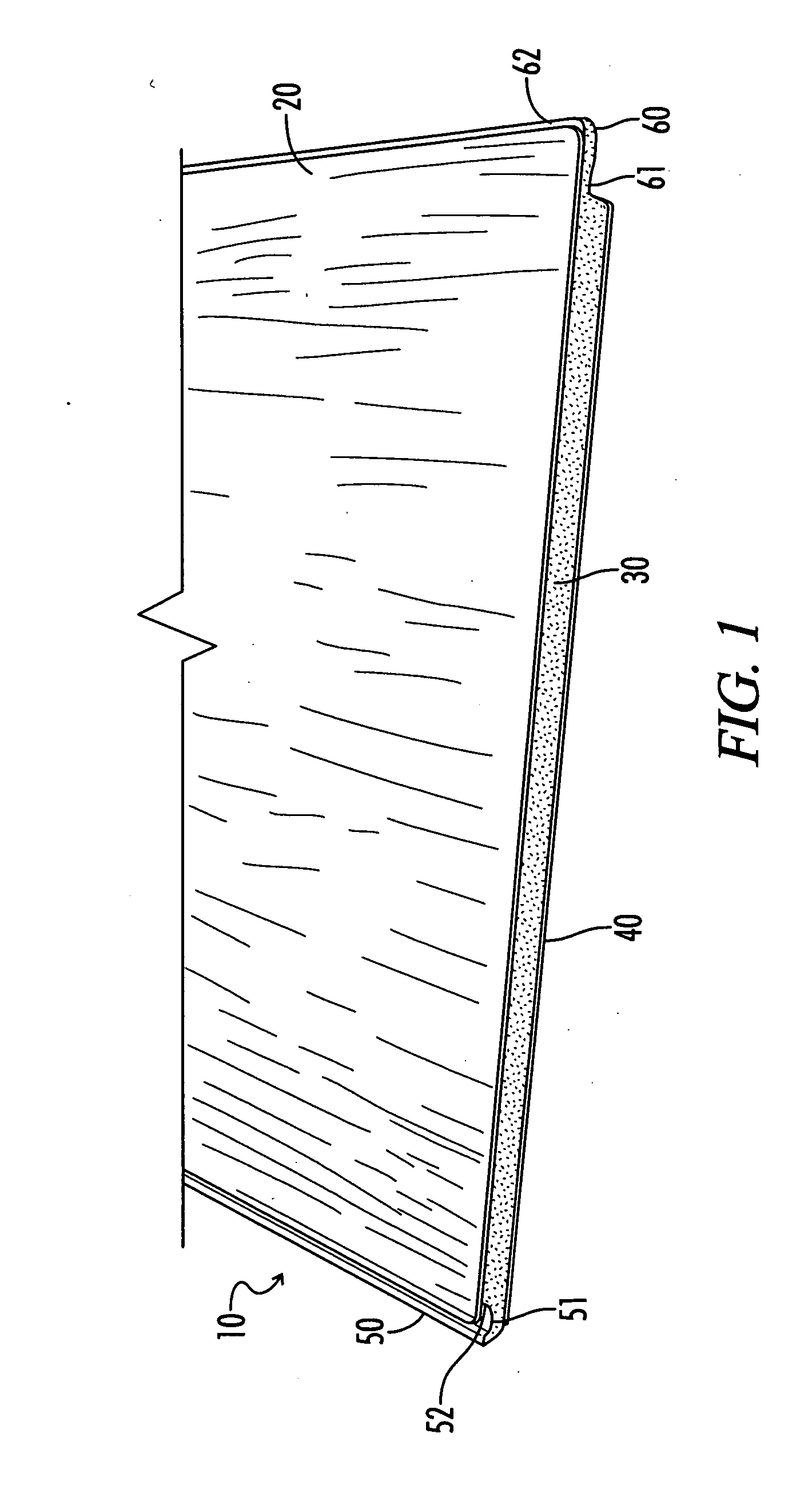

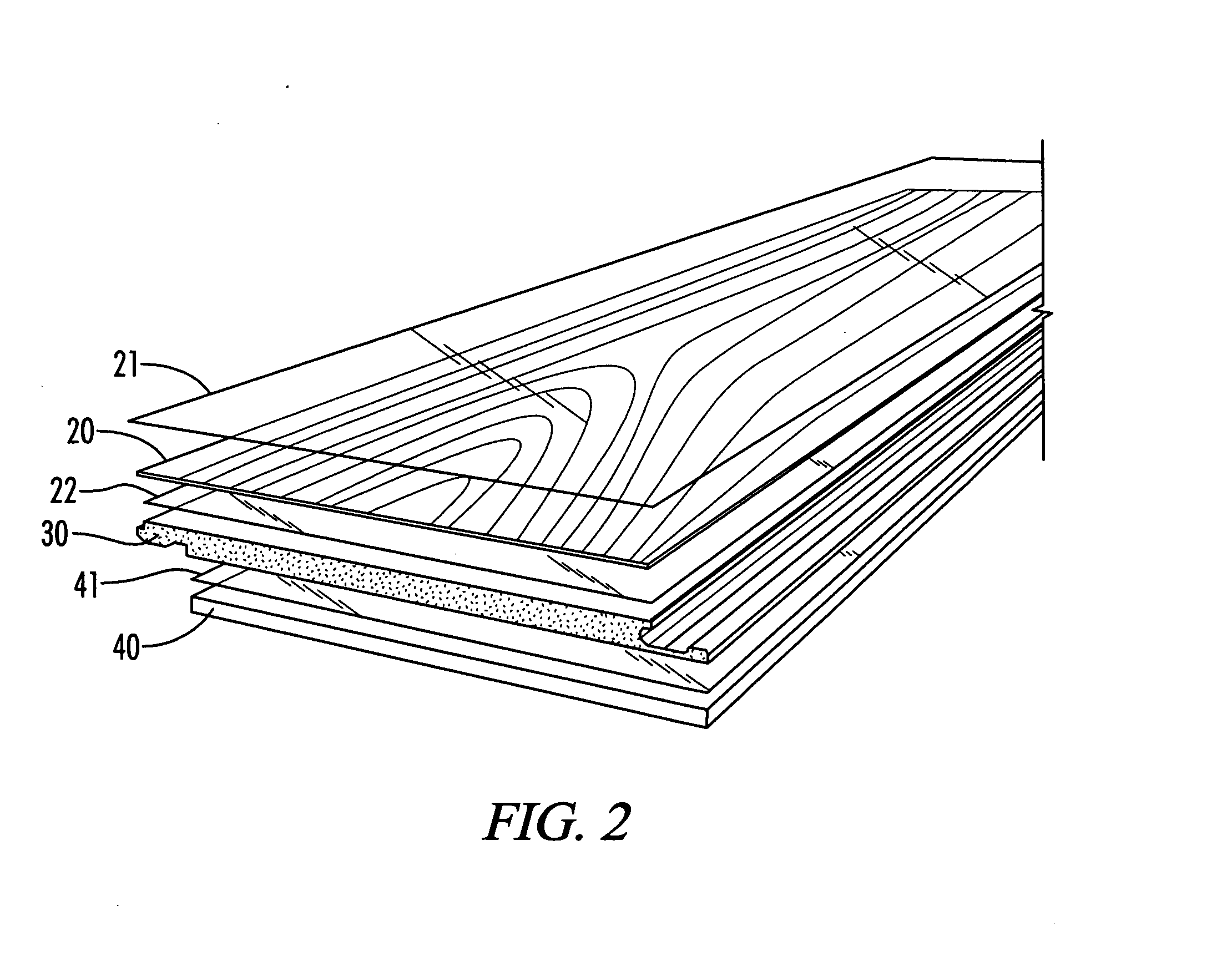

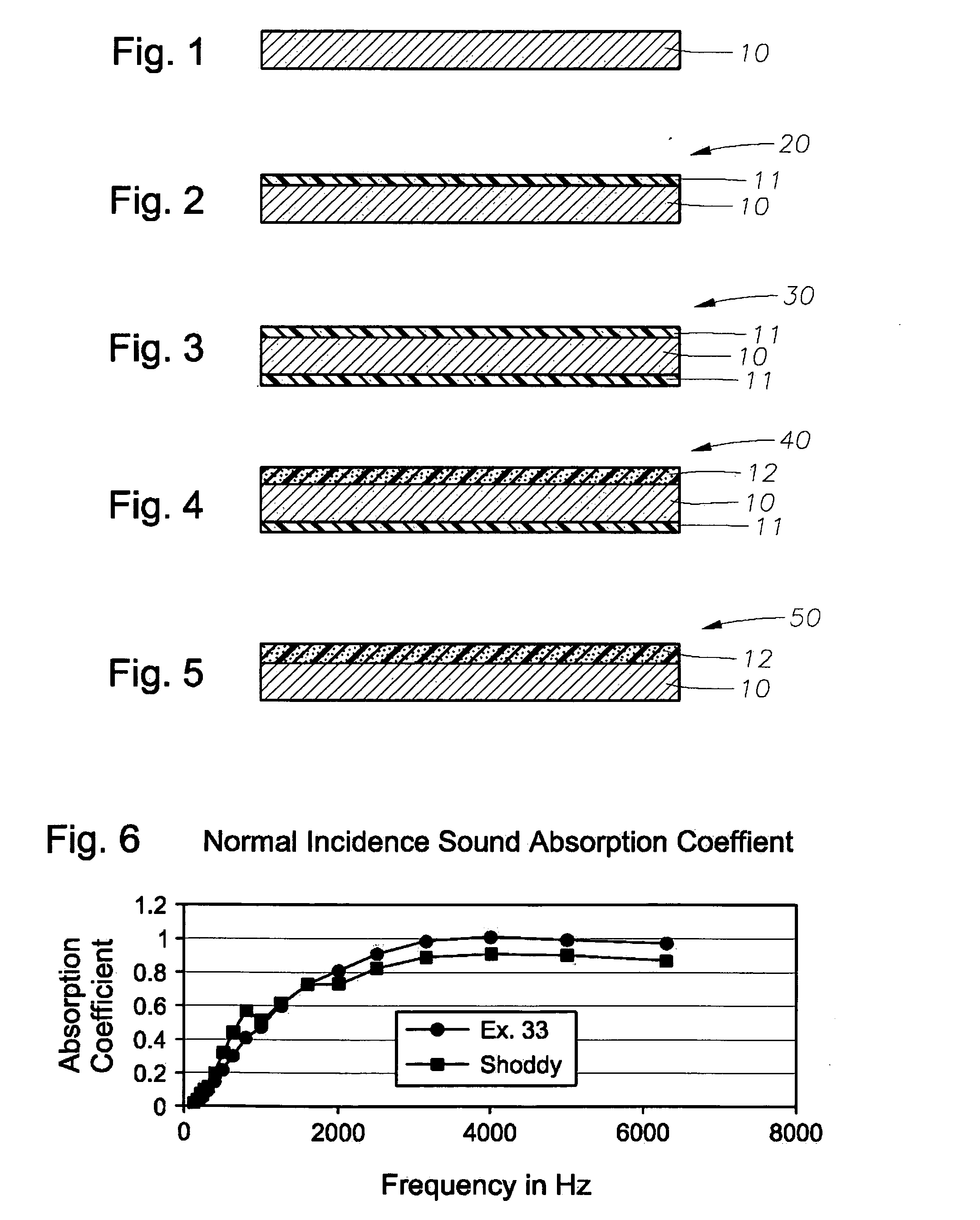

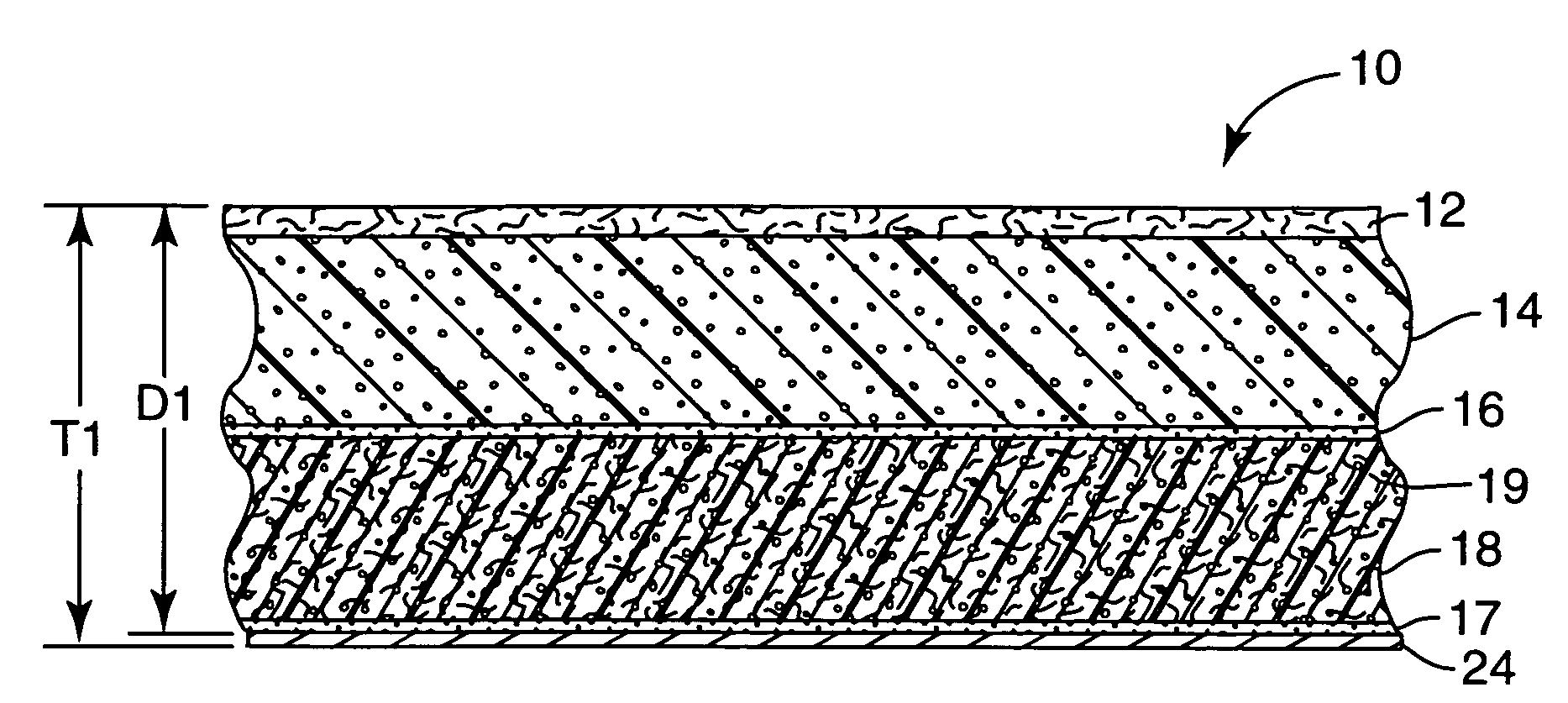

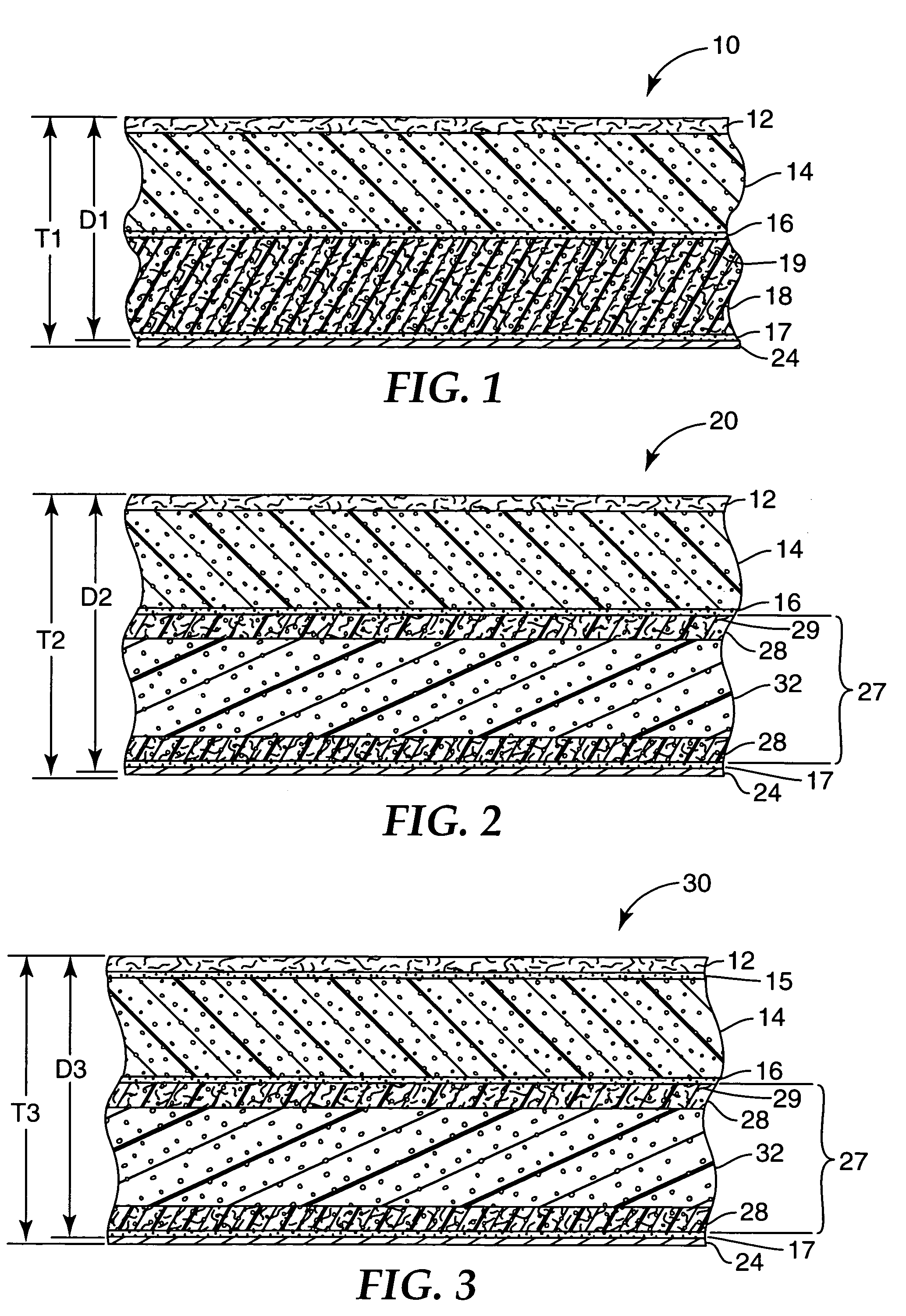

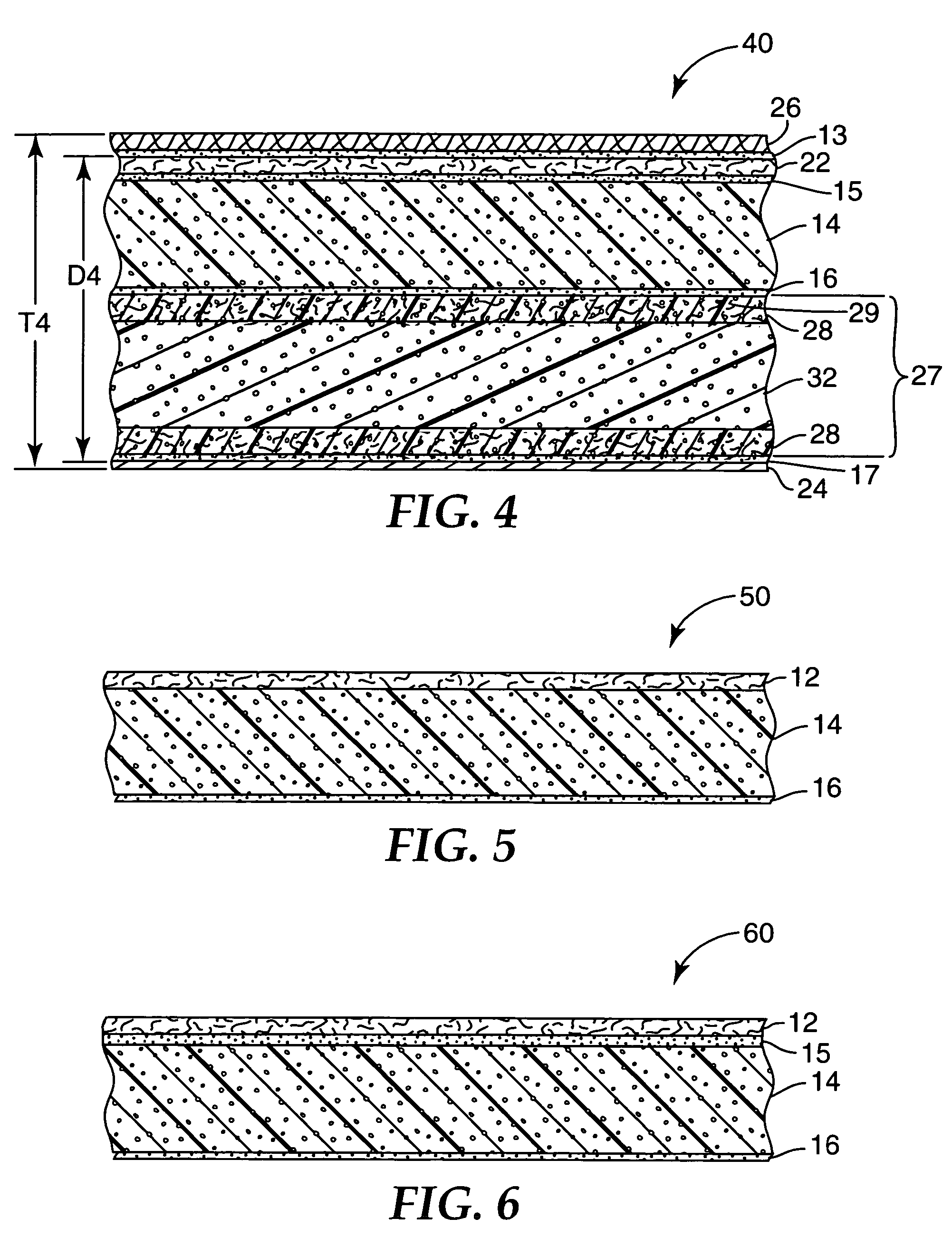

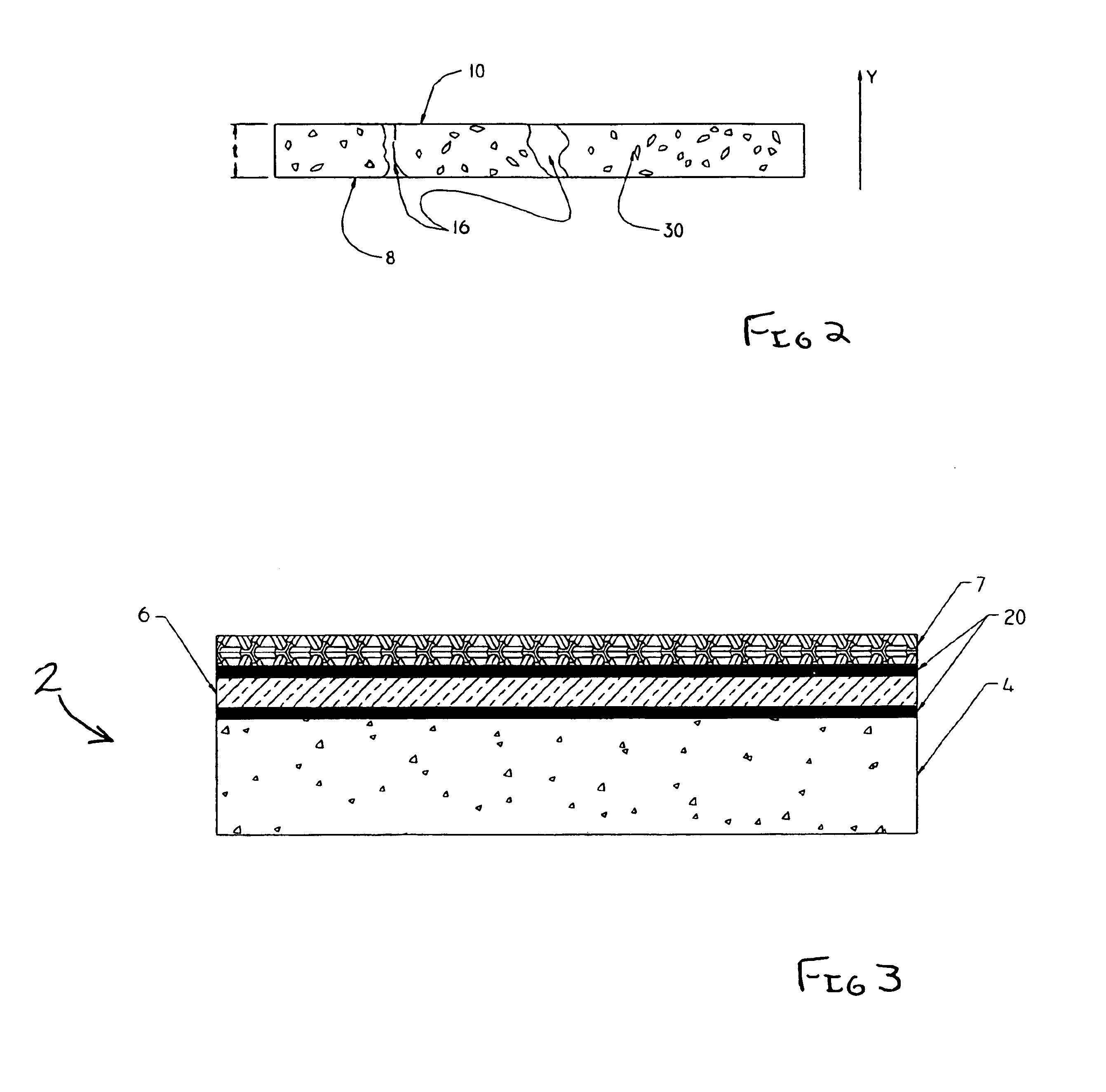

Sound insulating system

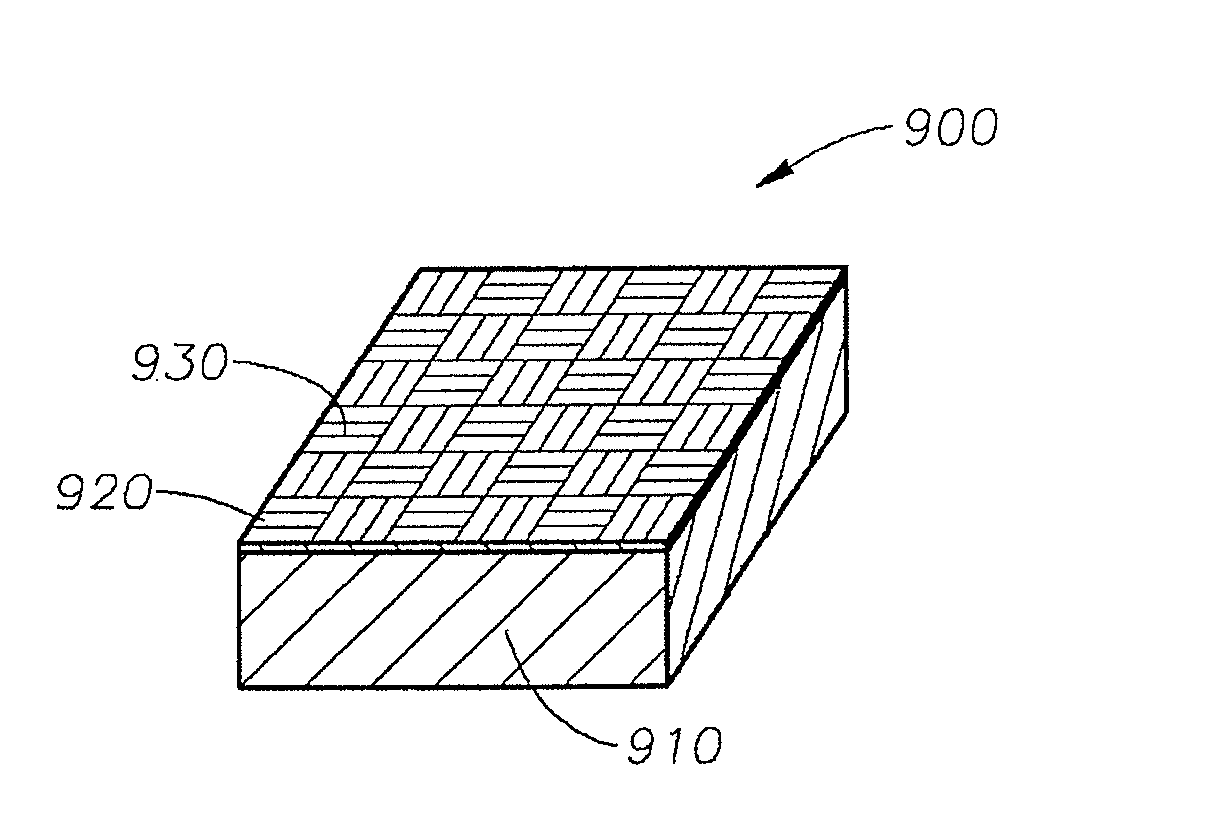

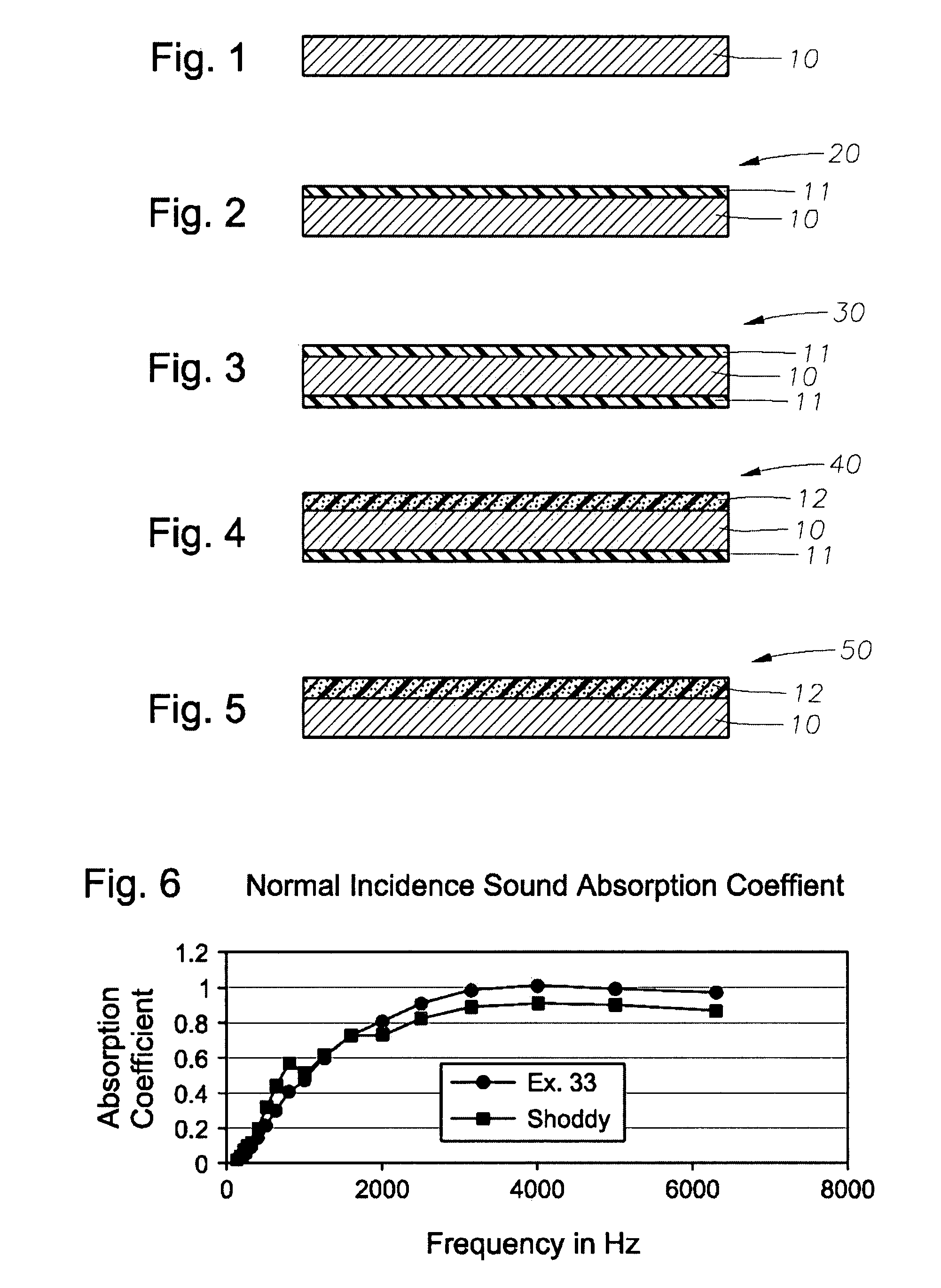

The present invention relates to a sound insulating system. The sound insulating system comprises a first sound absorbing layer. A barrier layer is positioned adjacent the first sound absorbing layer. A second absorbing layer is also provided and is adjacent the barrier layer.

Owner:DOW GLOBAL TECH LLC

Mechanical locking system for panels and method of installing same

ActiveUS20080155930A1Function increaseLower resistanceCovering/liningsFloorsEngineeringMechanical engineering

Floor panels are provided with a mechanical locking system including a flexible locking element in a locking groove, which during a horizontal motion is displaced vertically.

Owner:VÄLINGE INNOVATION AB

Mechanical locking system for floor panels

ActiveUS20120036804A1Function increaseLower resistanceConstruction materialCovering/liningsMechanical engineering

Floor panels (1, 1′) are shown, which are provided with a mechanical locking system consisting of a flexible locking element 15 in a locking groove 14 which during a horizontal motion is displaced vertically.

Owner:VÄLINGE INNOVATION AB

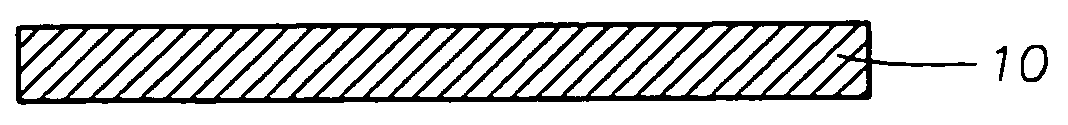

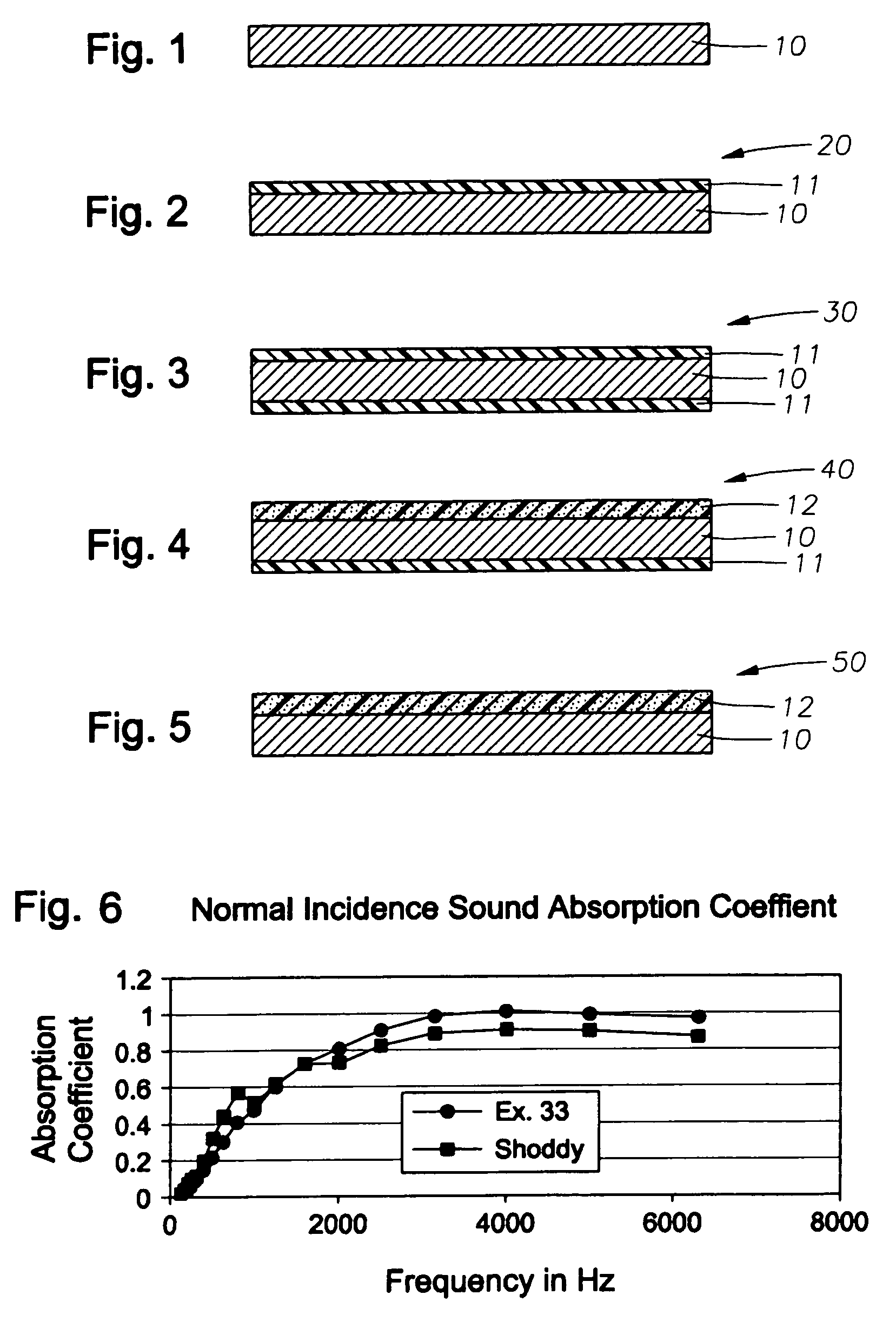

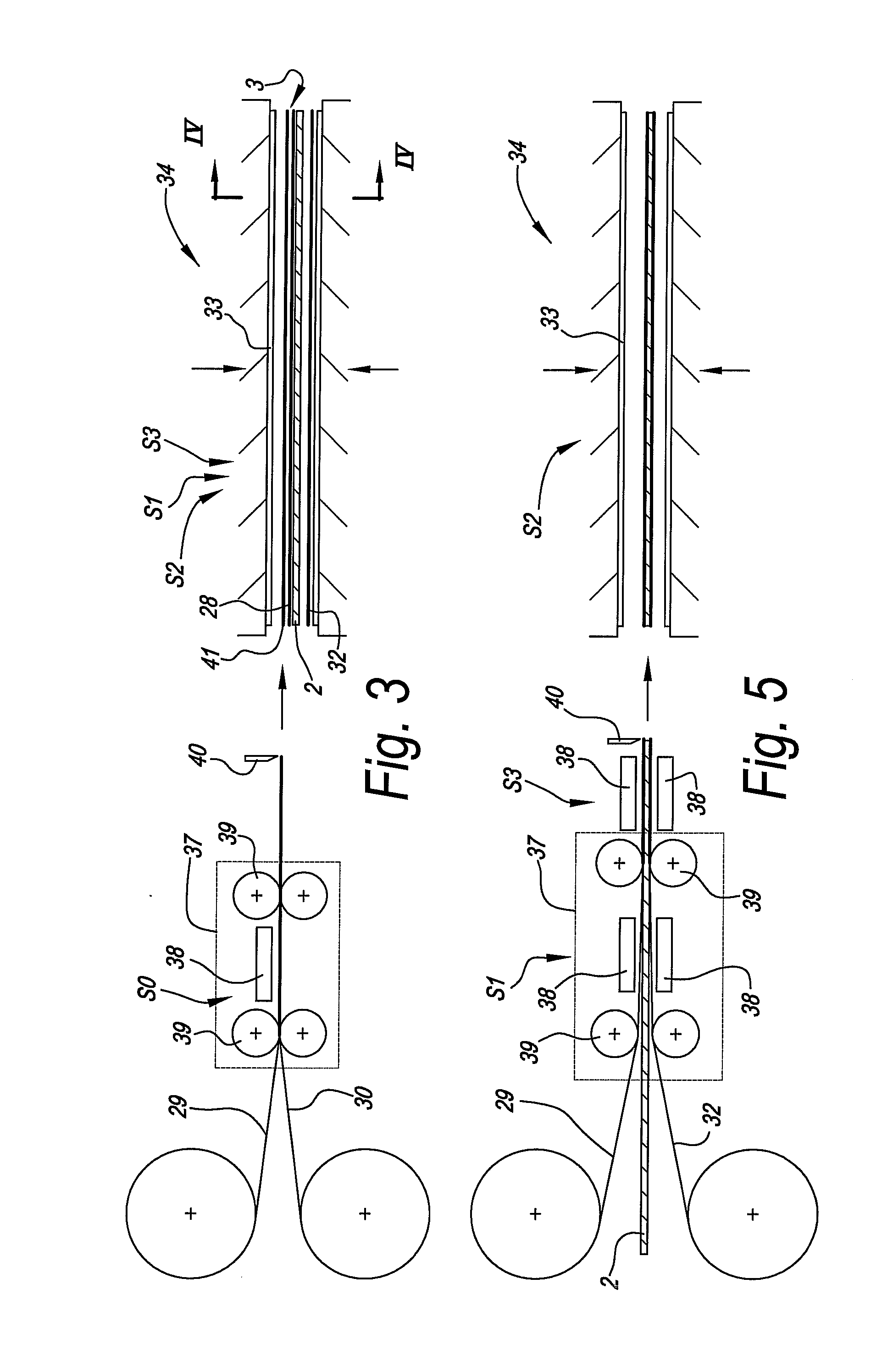

Nonwoven material for acoustic insulation, and process for manufacture

An improved acoustically and thermally insulating composite material suitable for use in structures such as buildings, appliances, and the interior passenger compartments and exterior components of automotive vehicles, comprising at least one airlaid fibrous layer of controlled density and composition and incorporating suitable binding agents and additives as needed to meet expectations for noise abatement, fire, and mildew resistance. Separately, an airlaid structure which provides a reduced, controlled airflow therethrough useful for acoustic insulation is provided, and which includes a woven or nonwoven scrim.

Owner:GLATFELTER CORP

Floor panel and method for the manufacture thereof

ActiveUS8196366B2Global structure of such floor panel still can be kept relatively thick and stableReduce thicknessCovering/liningsWallsFloor covering

Owner:FLOORING IND LTD

Panel and methods for manufacturing panels

InactiveUS20130062006A1Realized more smoothly and/or economicallyAcceptable soundCovering/liningsDecorative surface effectsSynthetic materialsEngineering

Owner:FLOORING IND LTD

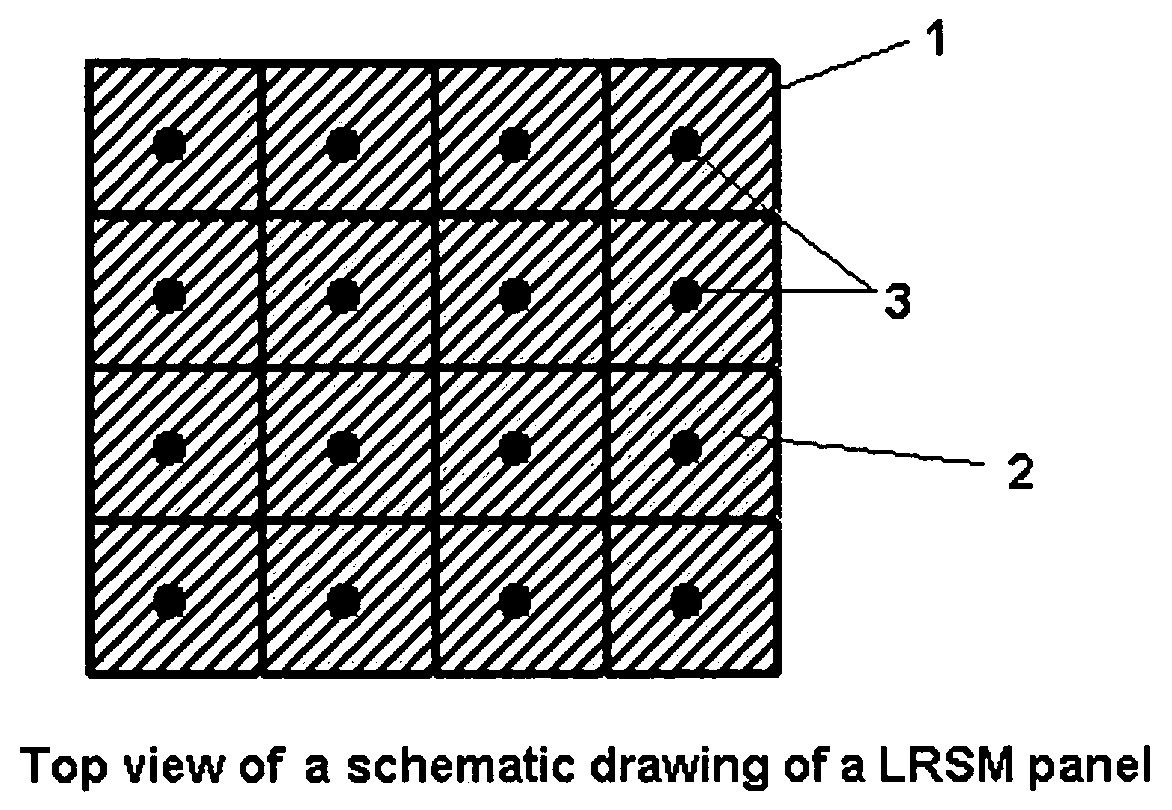

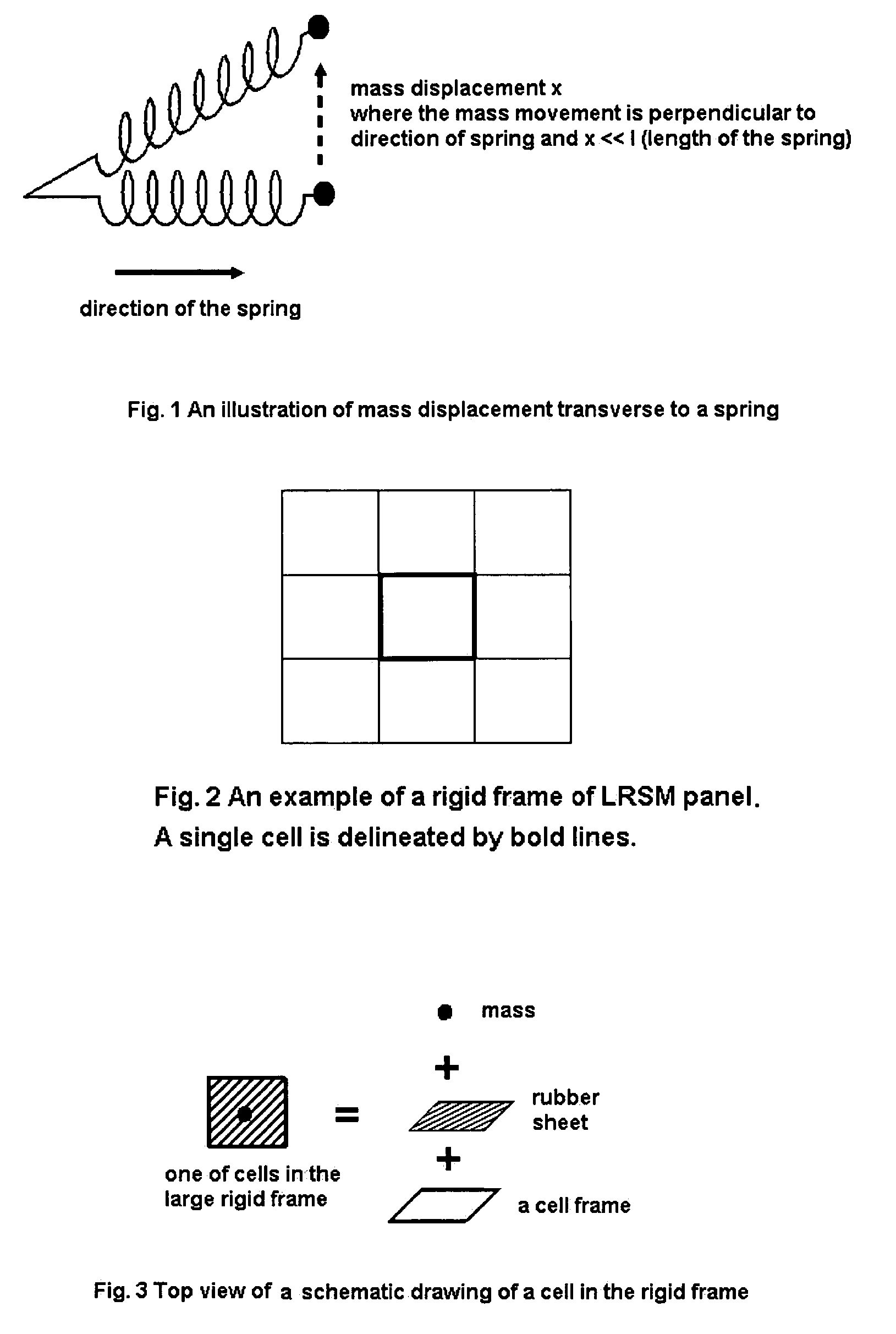

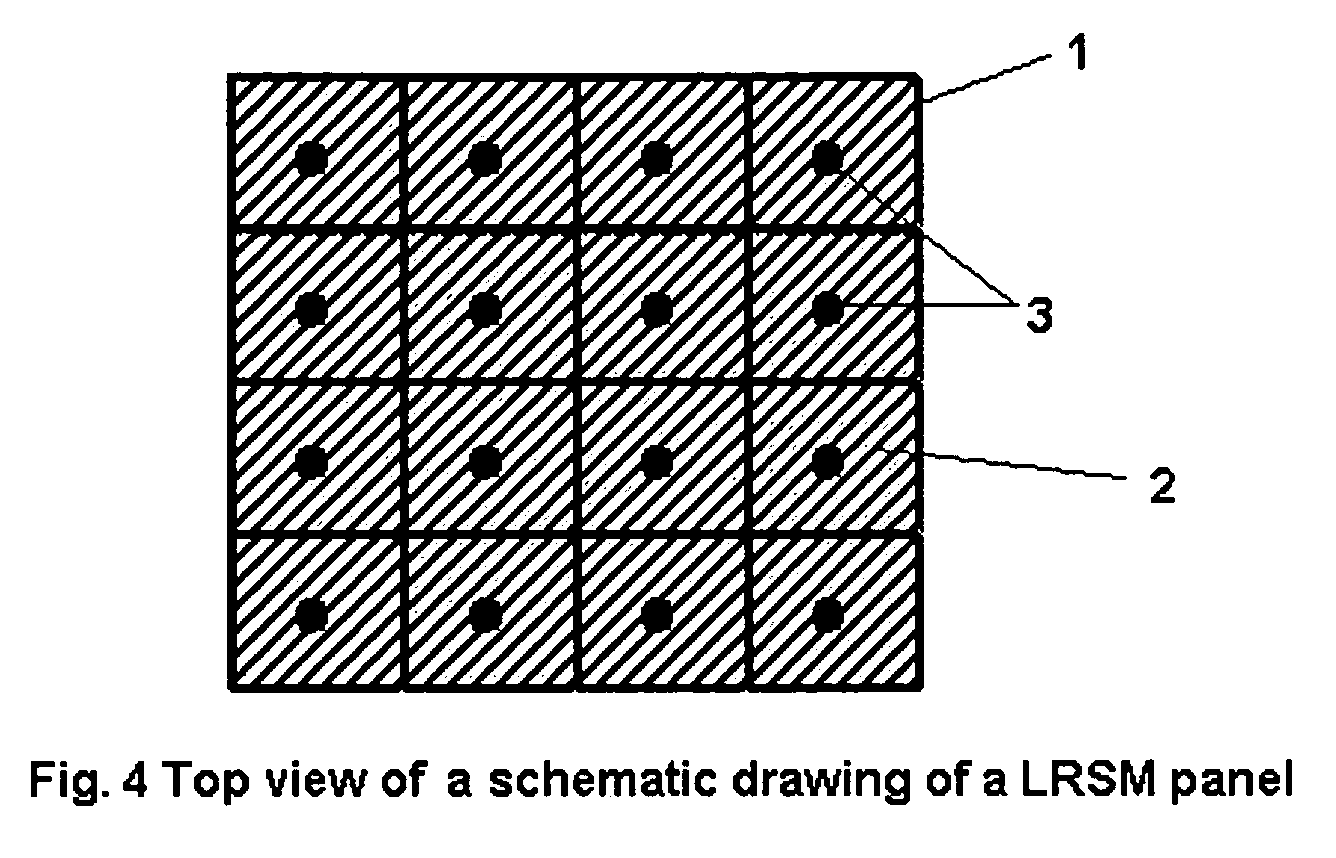

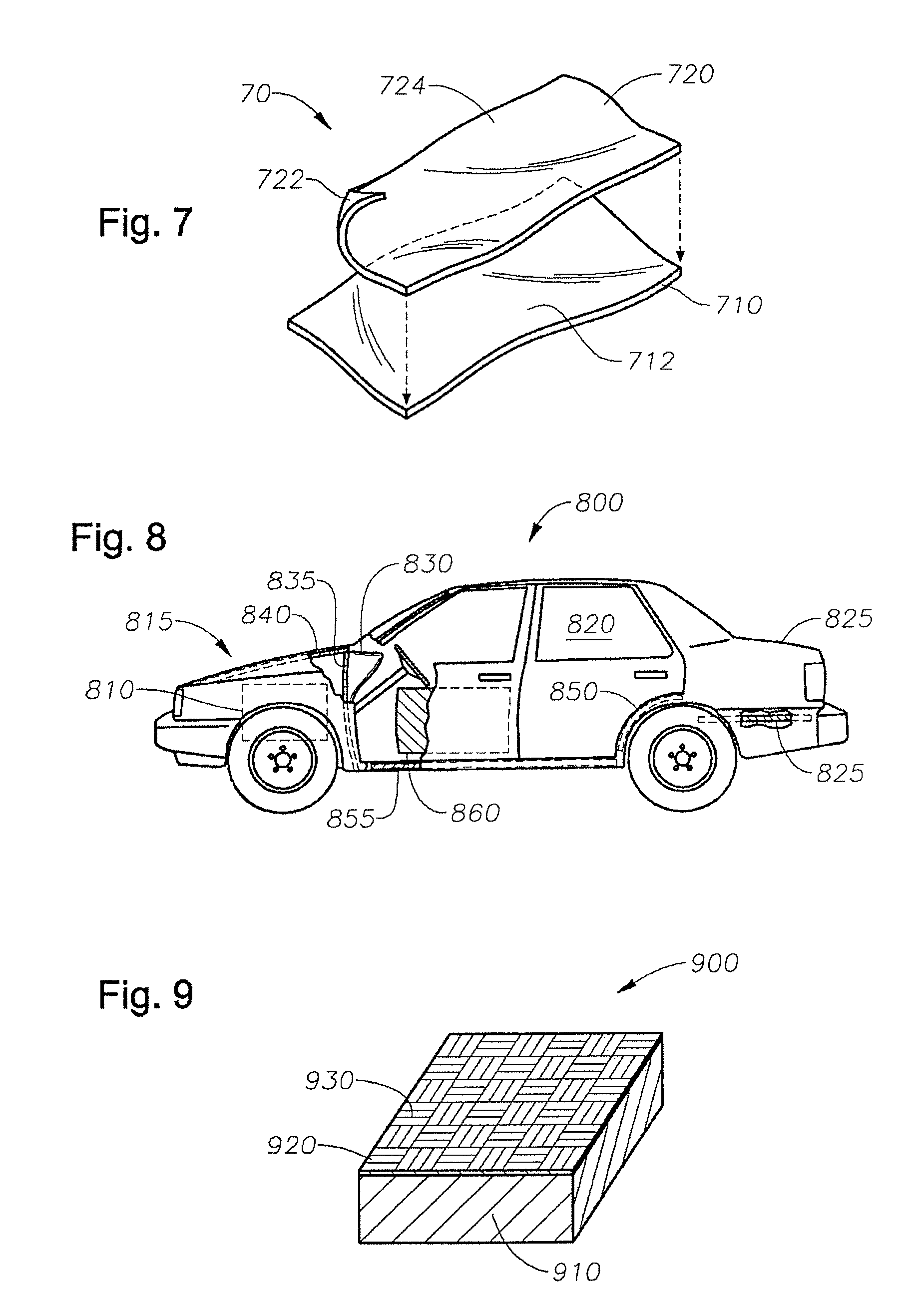

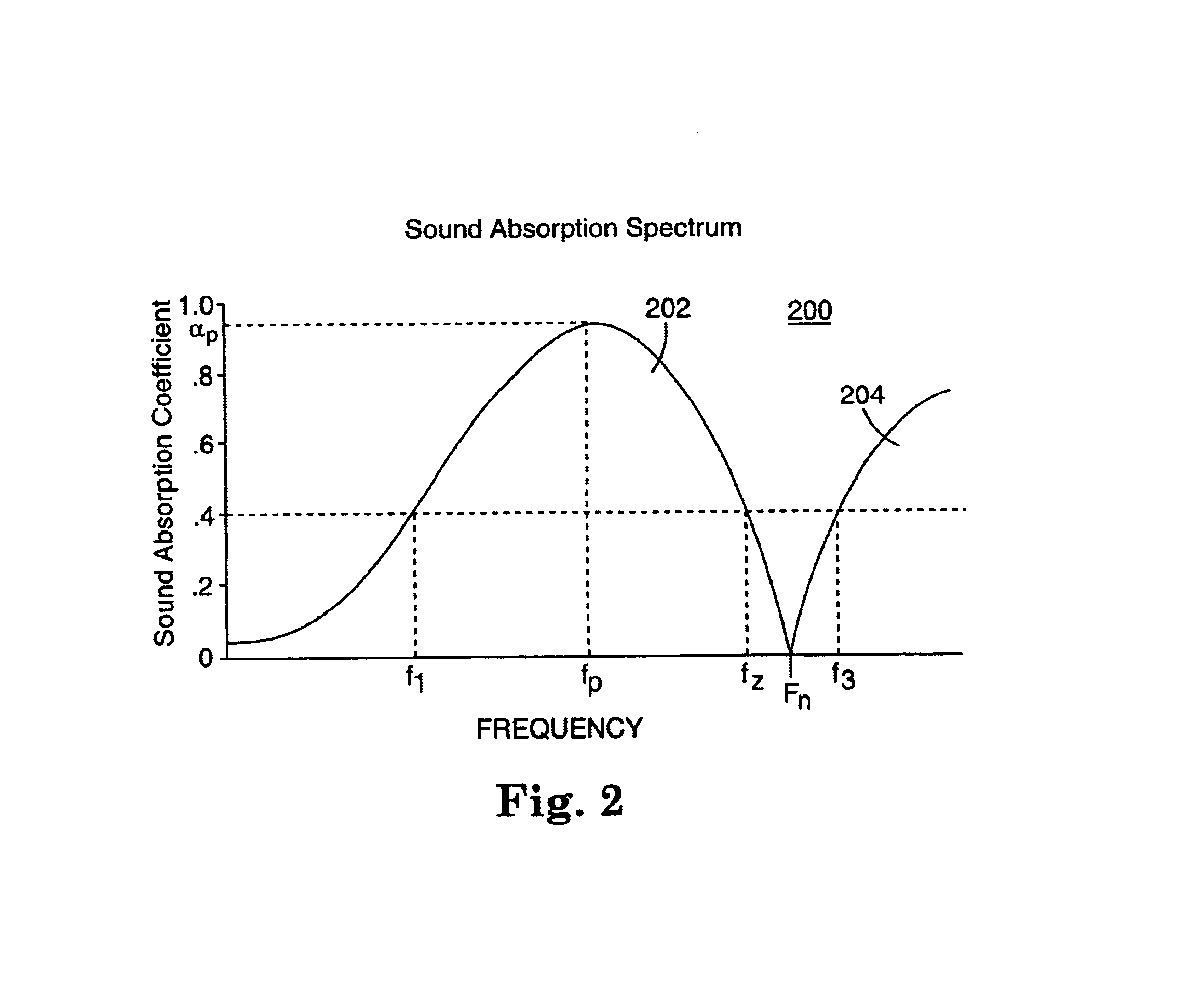

Sound attenuating structures

There is disclosed a sound attenuation panel comprising, a rigid frame divided into a plurality of individual cells, a sheet of a flexible material, and a plurality of weights. Each weight is fixed to the sheet of flexible material such that each cell is provided with a respective weight and the frequency of the sound attenuated can be controlled by suitable selecting the mass of the weight.

Owner:THE HONG KONG UNIV OF SCI & TECH

Nonwoven material for acoustic insulation, and process for manufacture

InactiveUS7837009B2Improve acoustic propertiesReduce weightLiquid surface applicatorsWallsMildewEngineering

An improved acoustically and thermally insulating fire-retardant composite material suitable for use in structures such as buildings, appliances, and the interior passenger compartments and exterior components of automotive vehicles is provided. The material is comprised of at least one airlaid fibrous layer of controlled density and composition and incorporating suitable binding agents and additives as needed to meet expectations for noise abatement, fire-retardancy, and mildew resistance. Separately, an airlaid structure which provides a reduced, controlled airflow therethrough useful for acoustic insulation is provided, and which includes a woven or nonwoven scrim. A process for the production of the fire retardant nonwoven material is also provided.

Owner:GEORGIA PACIFIC NONWOVENS LLC

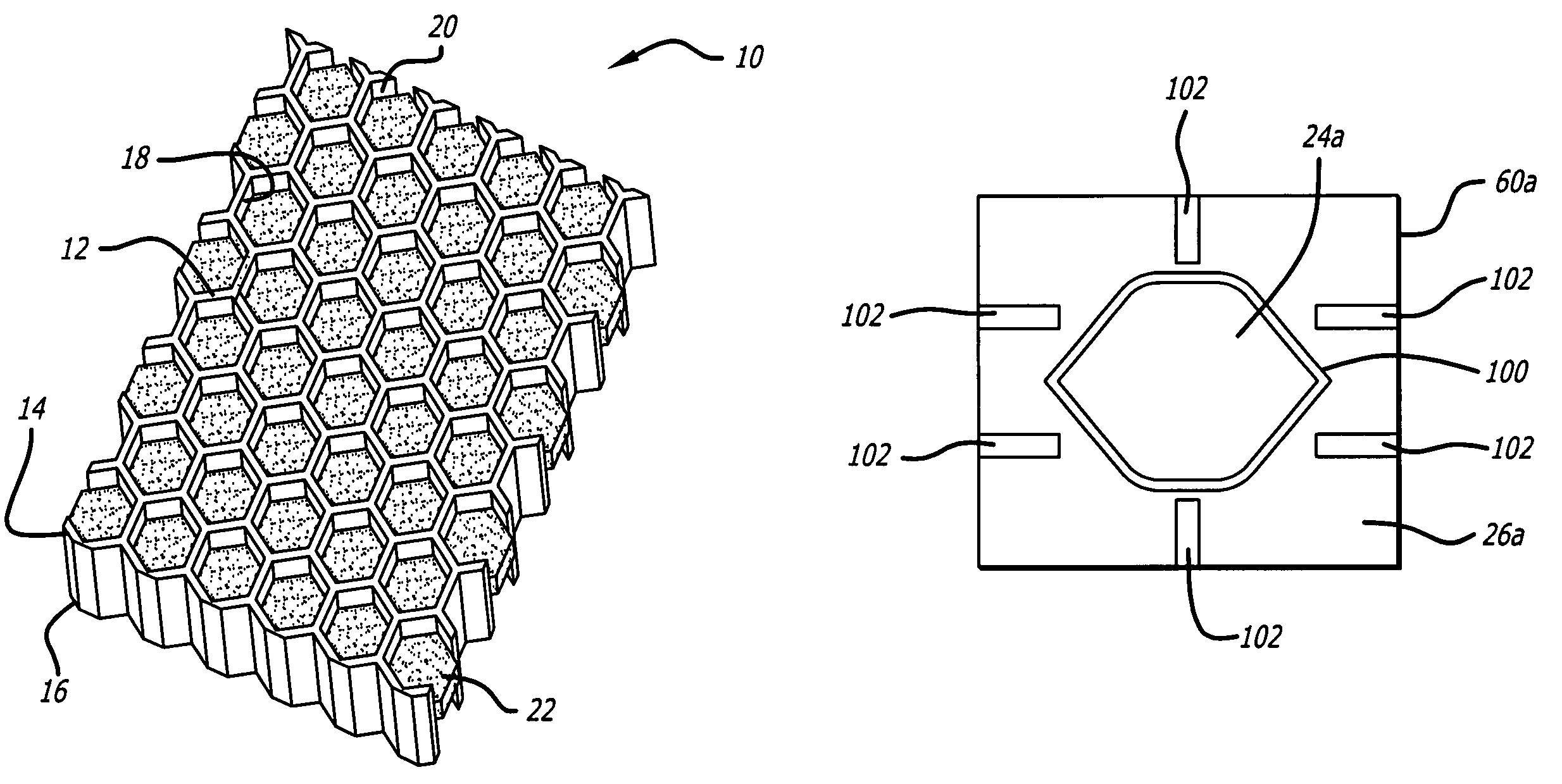

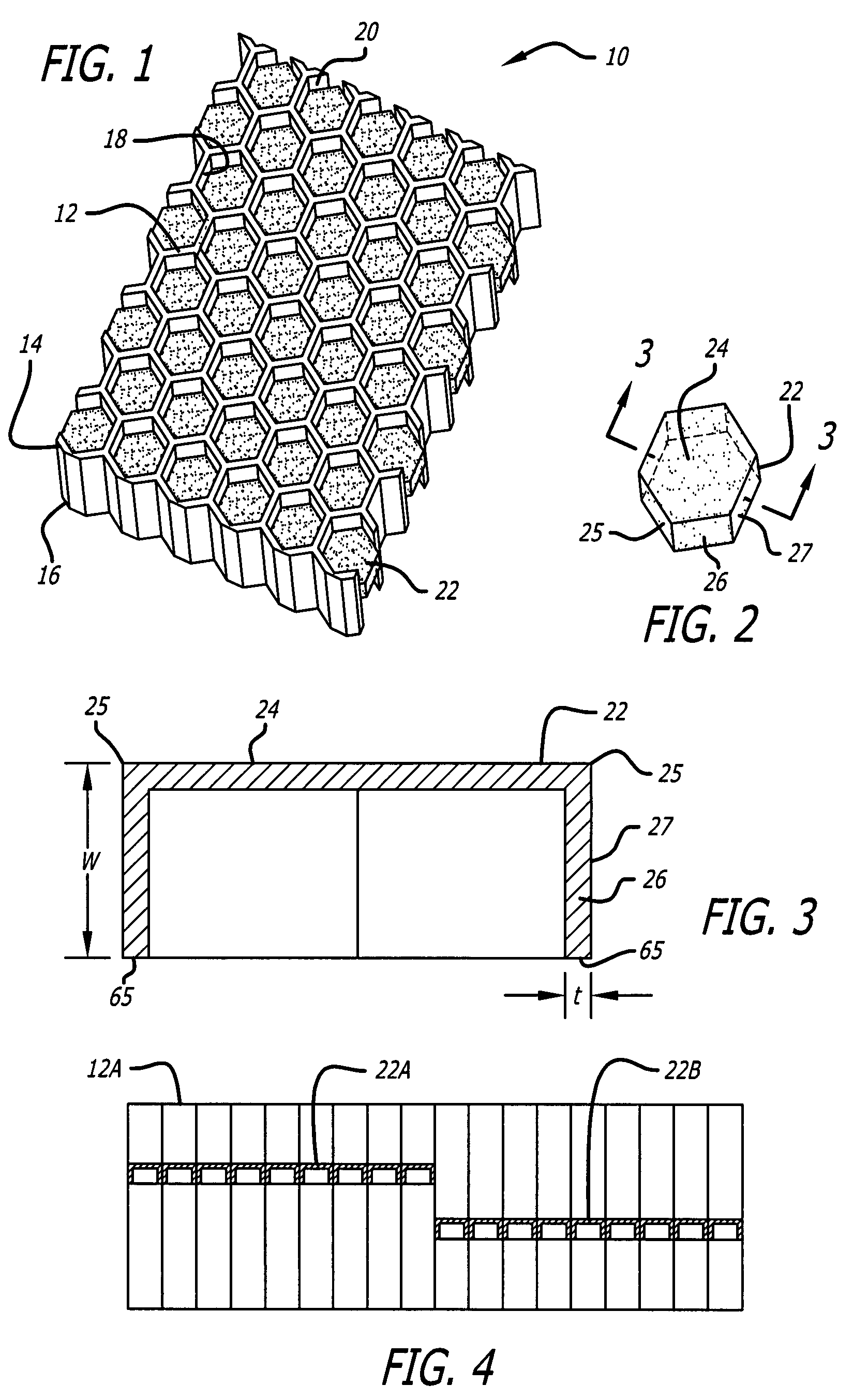

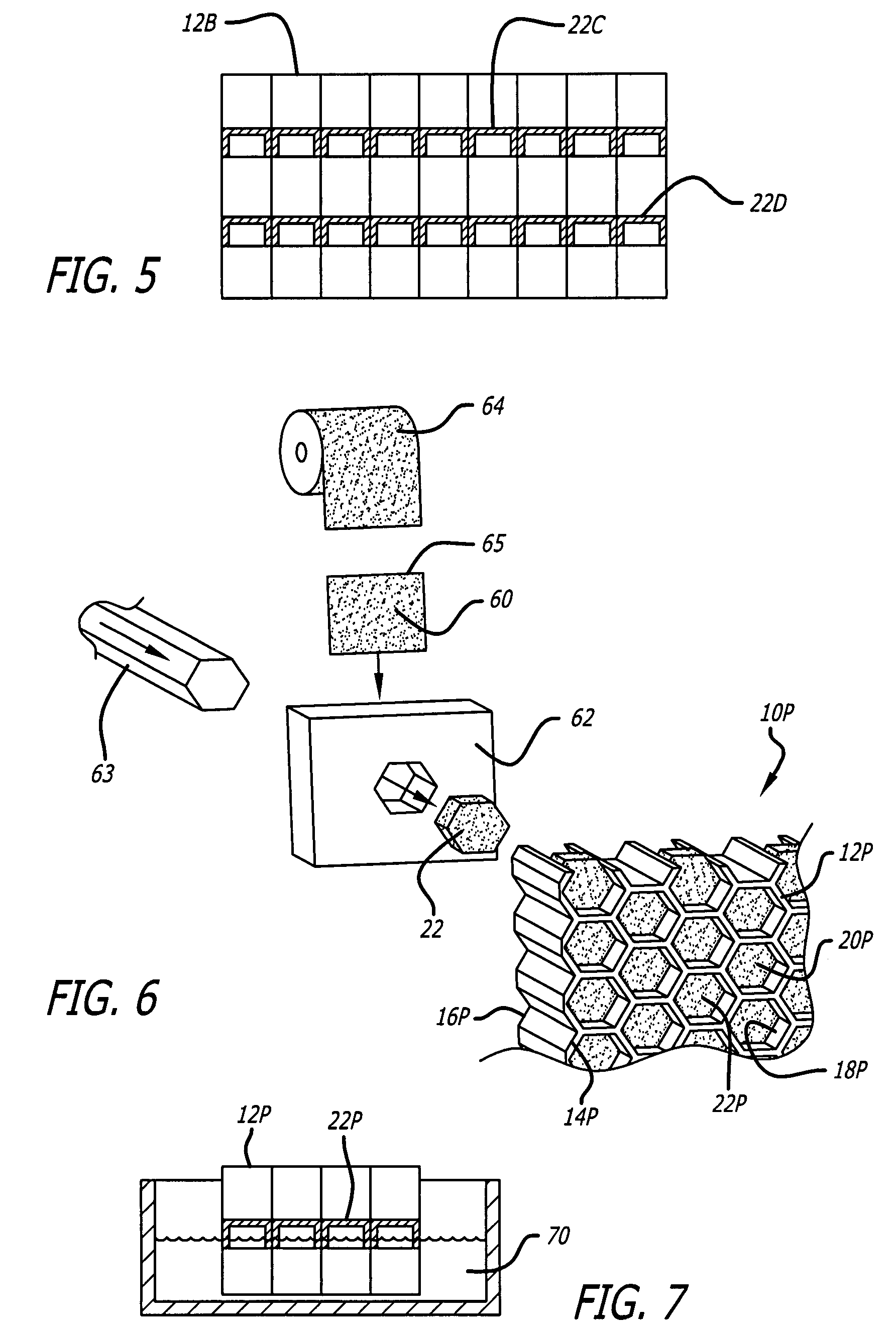

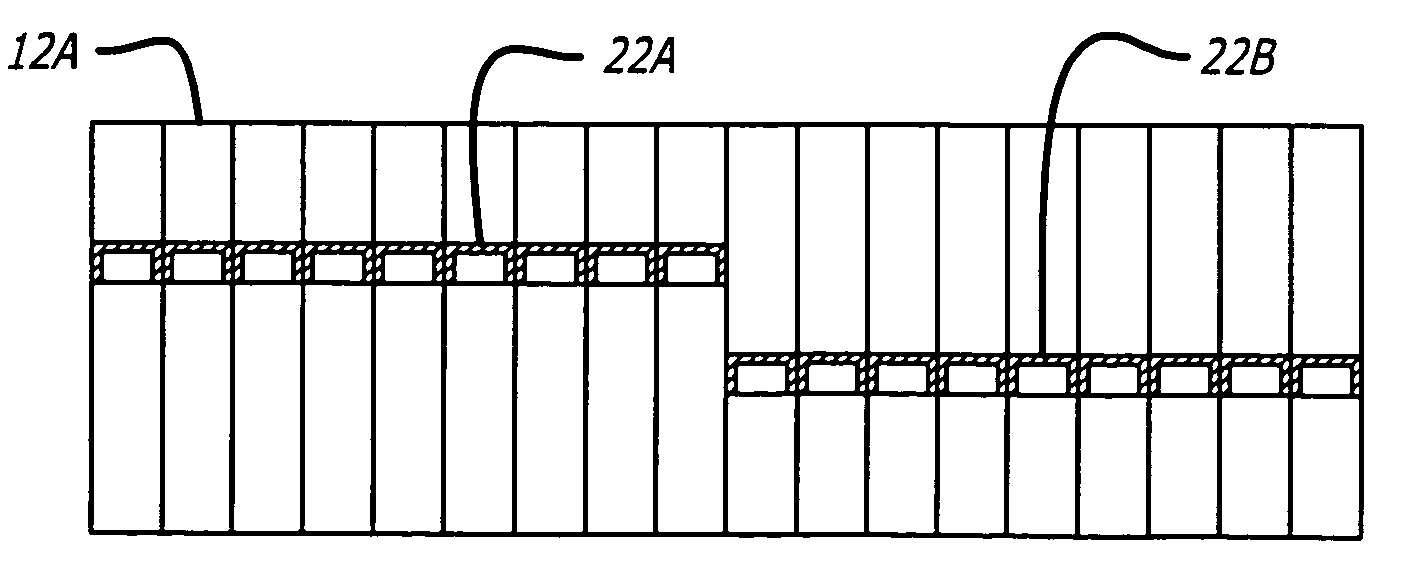

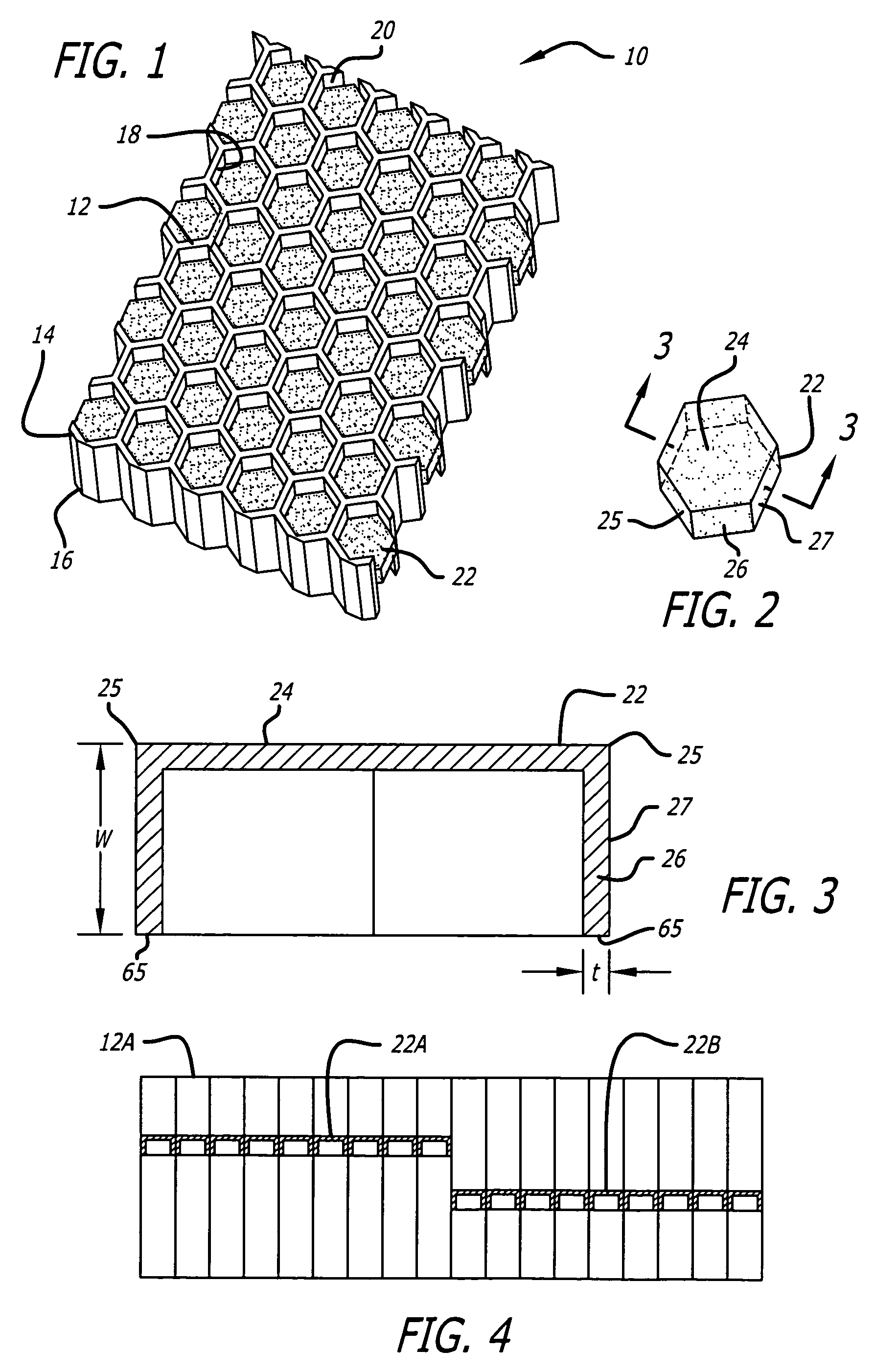

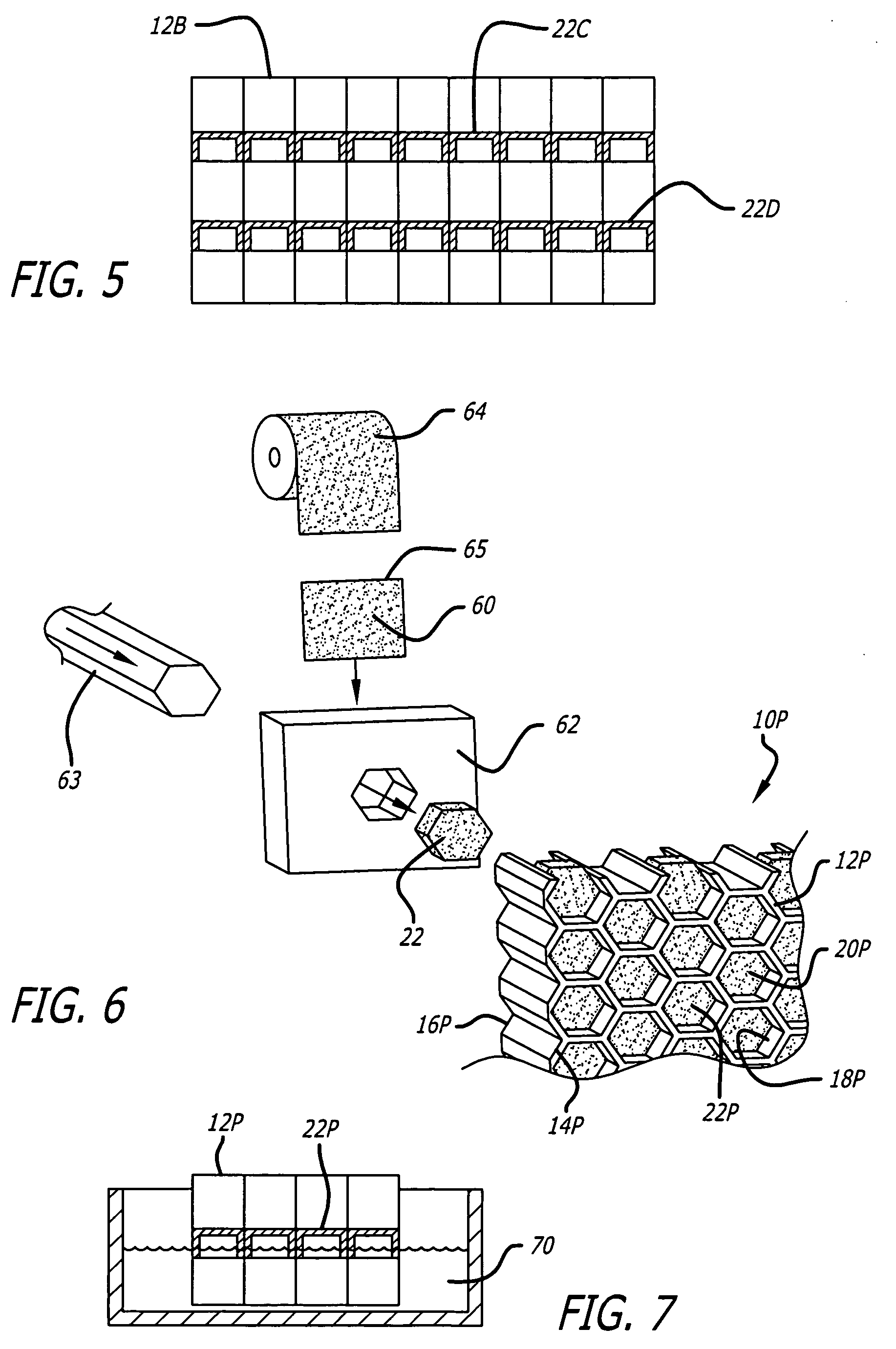

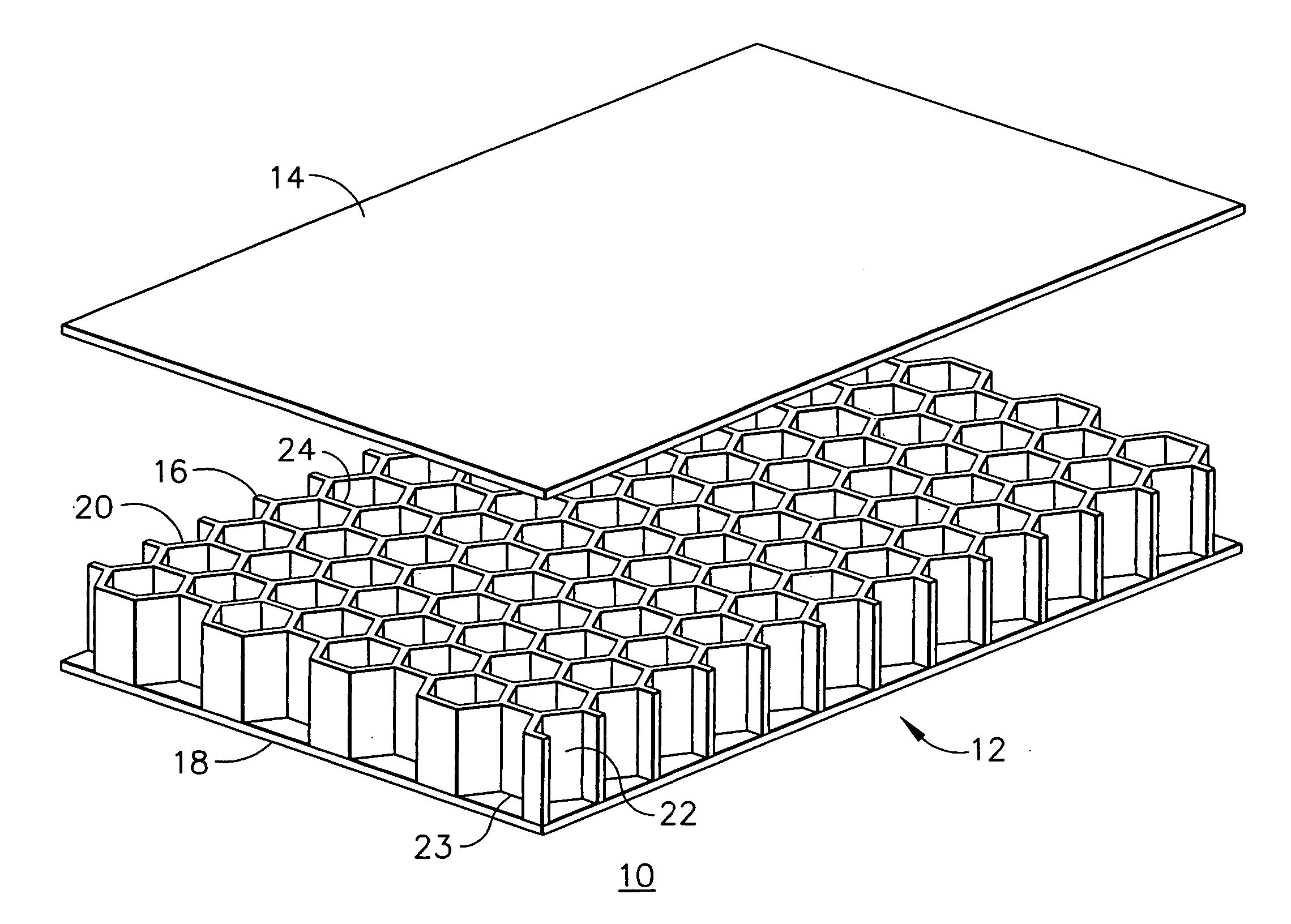

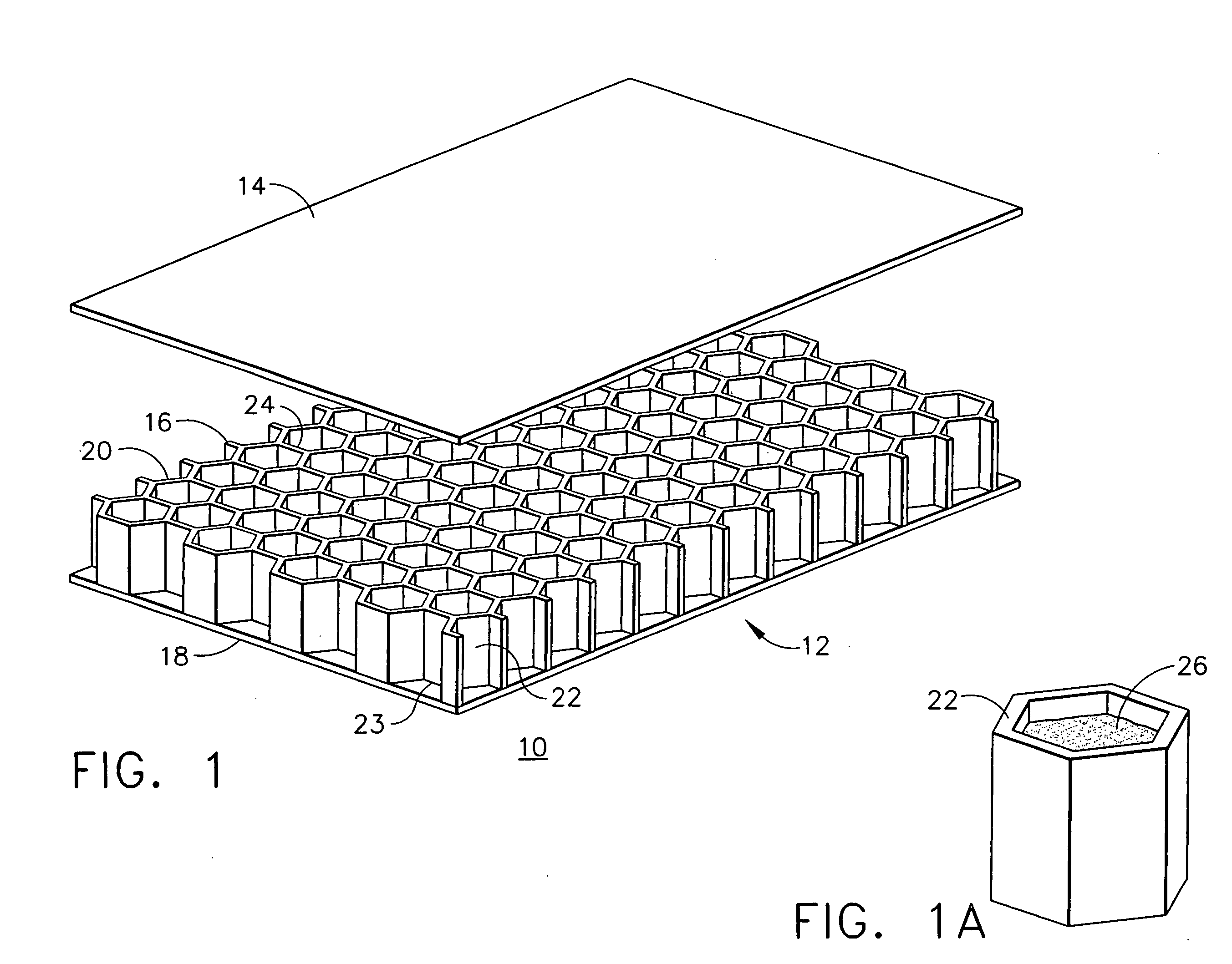

Acoustic septum cap honeycomb

Owner:HEXCEL

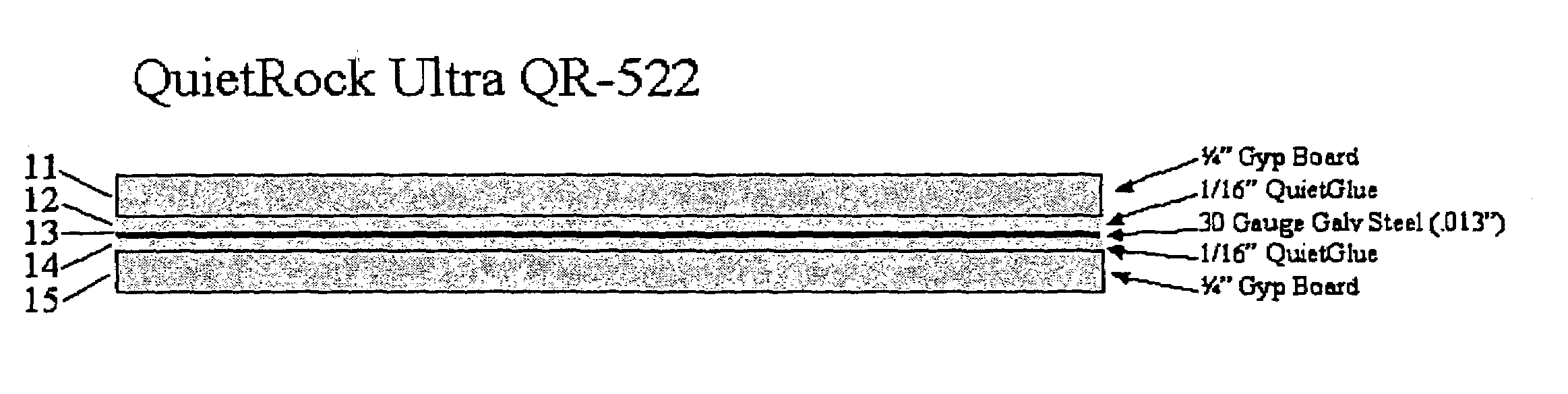

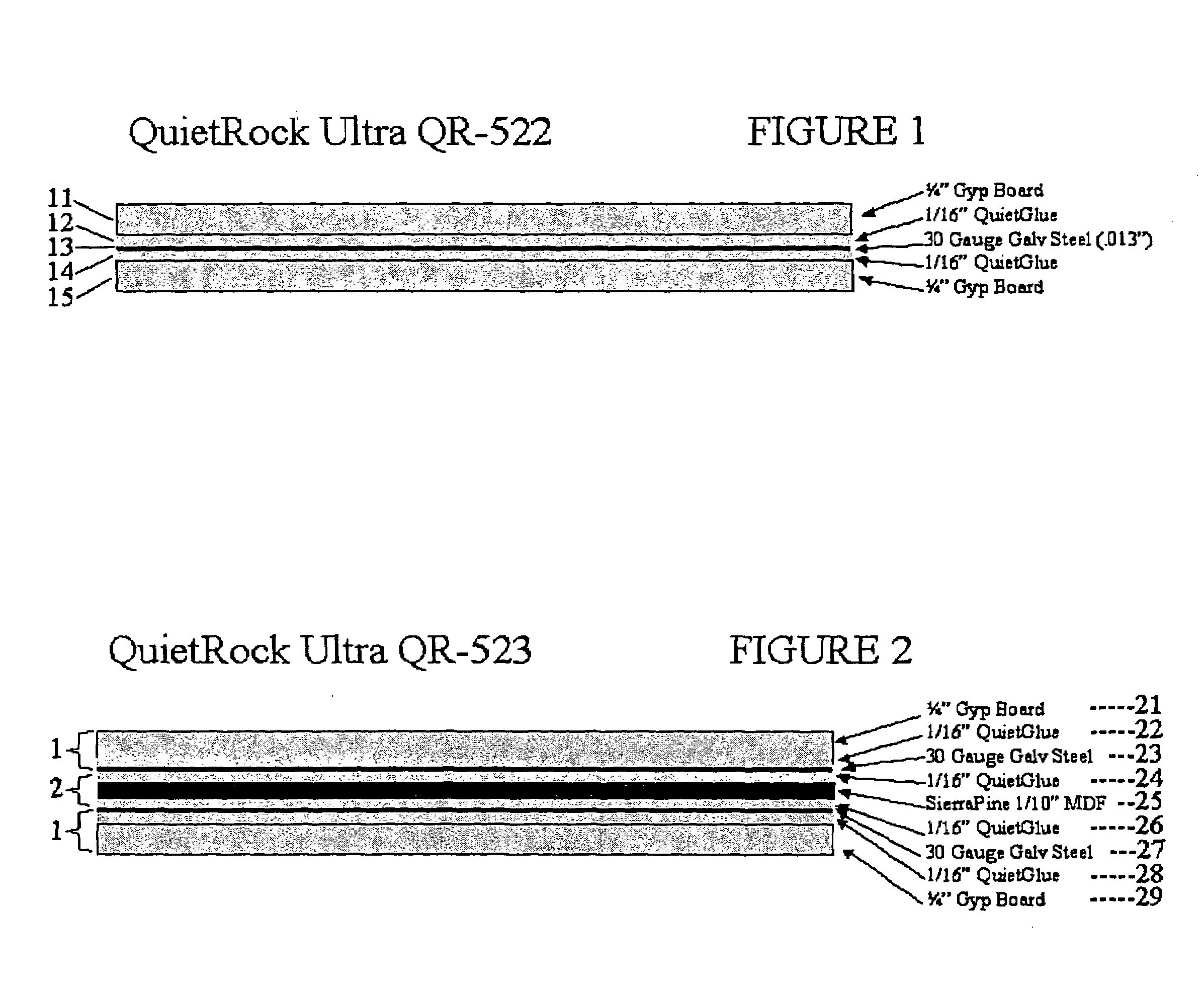

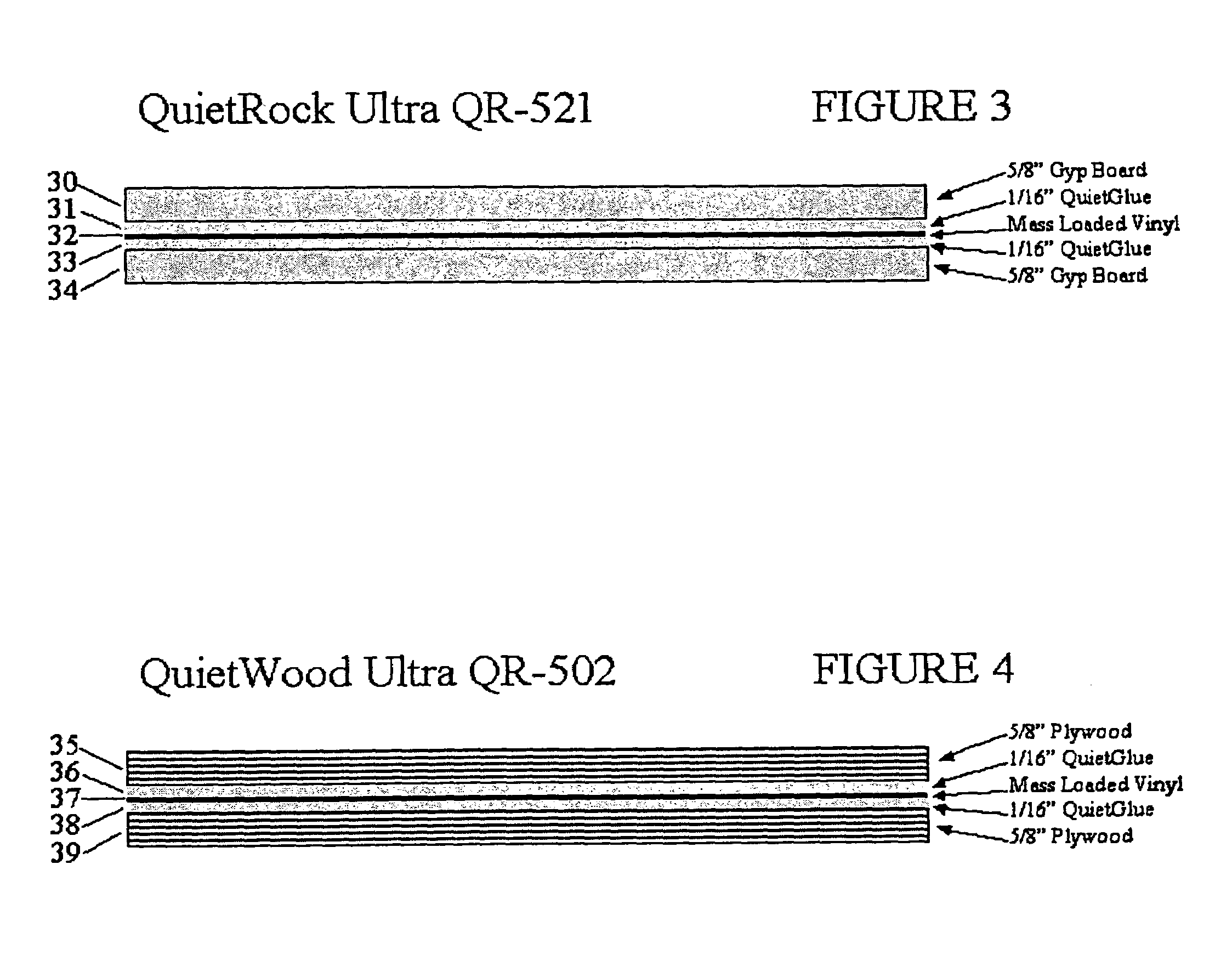

Acoustical sound proofing material and methods for manufacturing same

ActiveUS7181891B2Improve abilitiesReduce sound transmissionBuilding roofsCeilingsUltrasound attenuationCellulose

An improved acoustical damping wall (ceiling or floor) or door material comprises a laminar structure having as an integral part thereof one or more layers of viscoelastic material which also functions as a glue and one or more constraining layers, such as metal, cellulose, wood, or petroleum-based products such as plastic, vinyl, plastic or rubber. In one embodiment, standard wallboard, typically gypsum, comprises the external surfaces of the laminar structure; and one or more constraining layers are fabricated between the gypsum exterior. The resulting structure improves the attenuation of sound transmitted through the structure.

Owner:PACIFIC COAST BUILDING PRODS

Decorative interior sound absorbing panel

A multi-layered fiber reinforced thermoplastic sound absorbing panel includes a porous fiber reinforced thermoplastic core layer having a first surface and a second surface, and includes a thermoplastic material and from about 20 weight percent to about 80 weight percent fibers, a tie layer covering the second surface of the core layer and including a thermoplastic material, and a barrier layer covering the tie layer. The barrier layer includes a thermoplastic material having a melting temperature higher than the melting temperature of the core layer thermoplastic material. The tie layer bonds the barrier layer to the core layer. The panel also includes a non-woven layer including a fabric bonded to the barrier layer. The non-woven layer forms an outer surface of the panel.

Owner:HANWA AZDEL INC

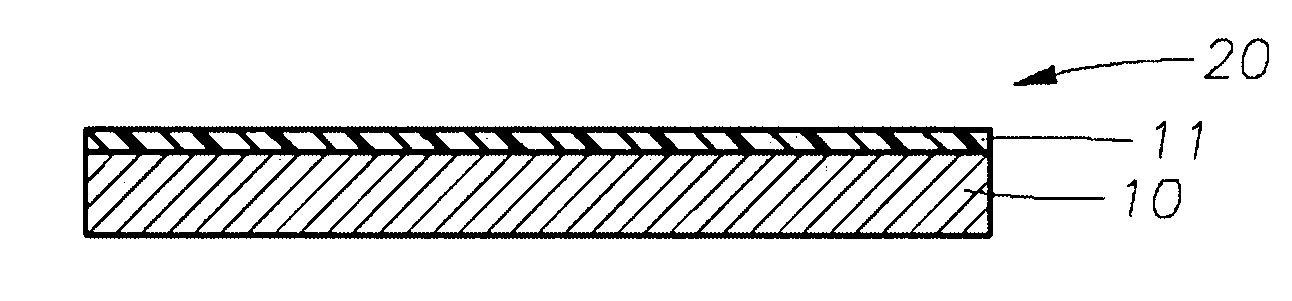

Vibration dampening laminate

The present invention provides a vibration dampening laminate that is lightweight and has superior sound insulation and vibration dampening properties. The vibration dampening laminate comprises a constraining layer, a viscoelastic adhesive layer, a foam spacing layer and a pressure sensitive adhesive layer including a release layer. The pressure sensitive adhesive layer and release layer are contoured to fit a profile of the article being soundproofed and vibration dampened.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

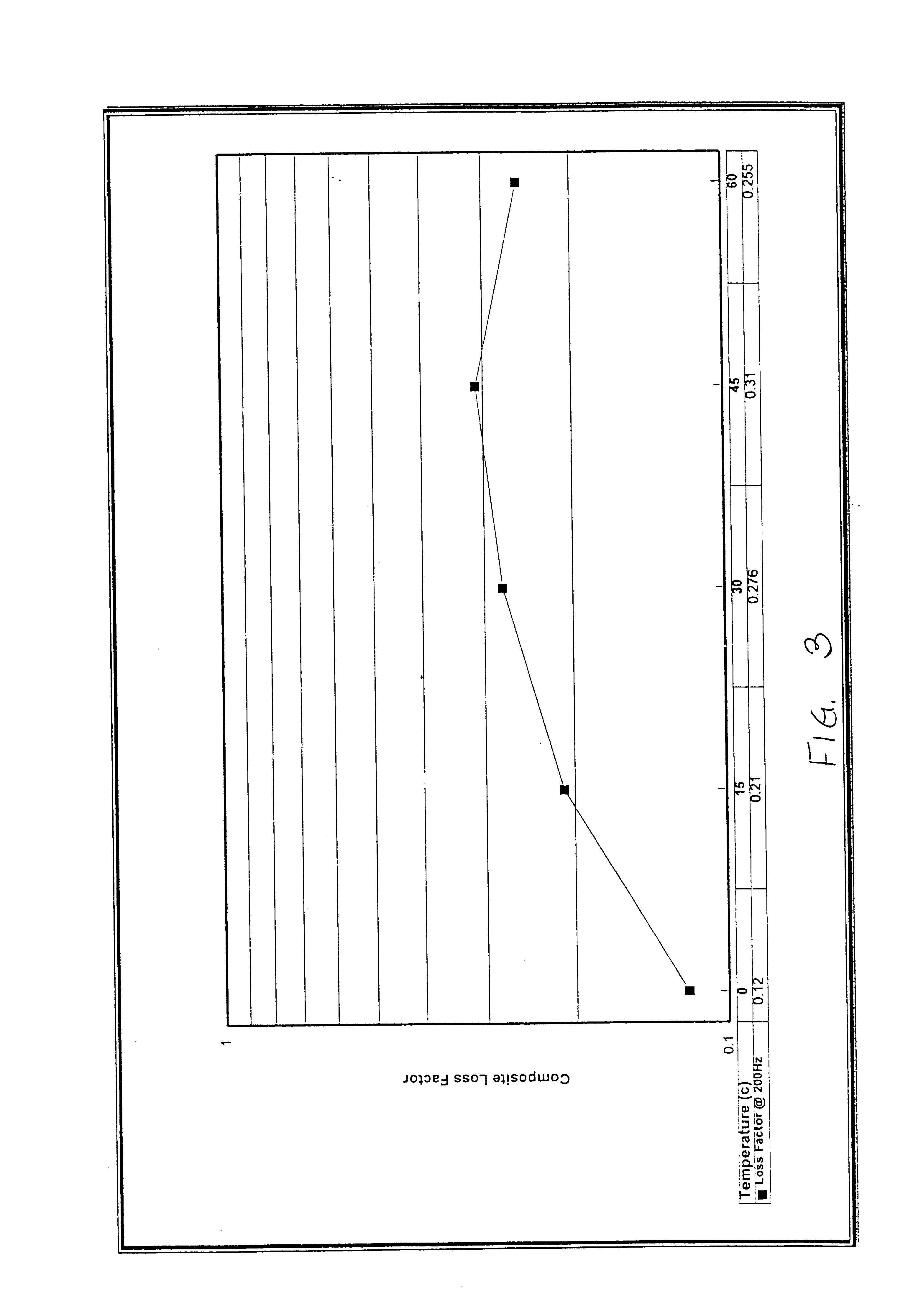

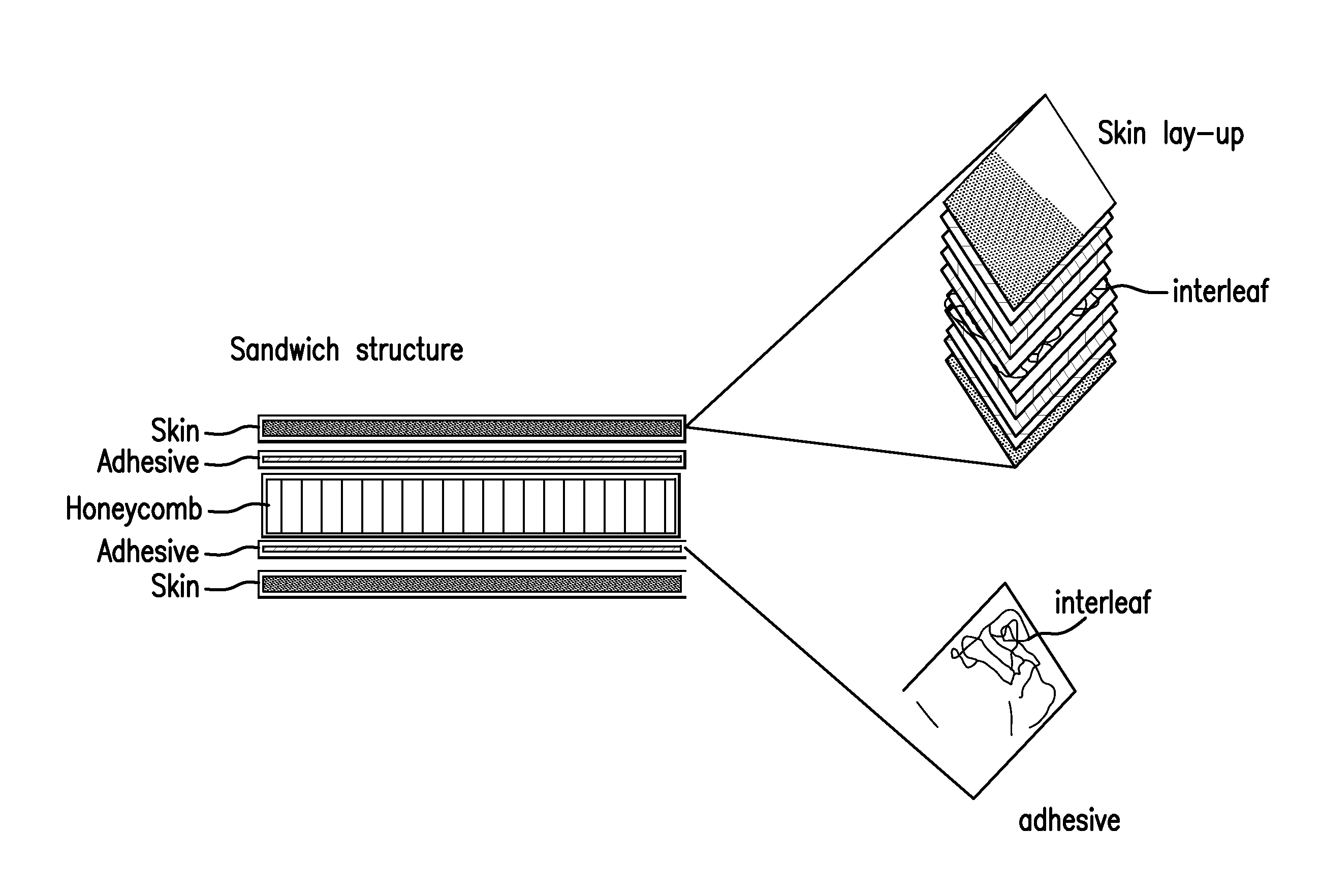

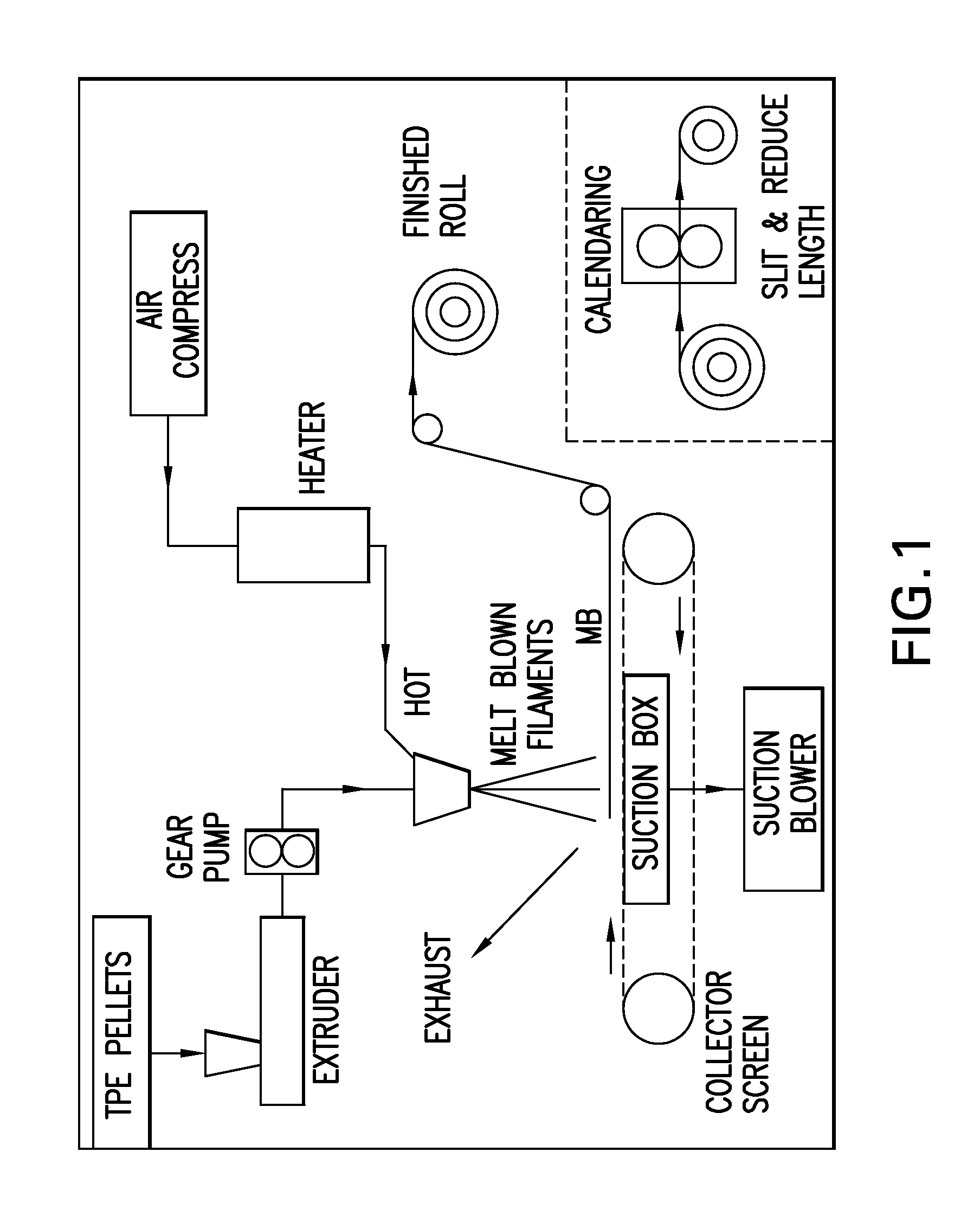

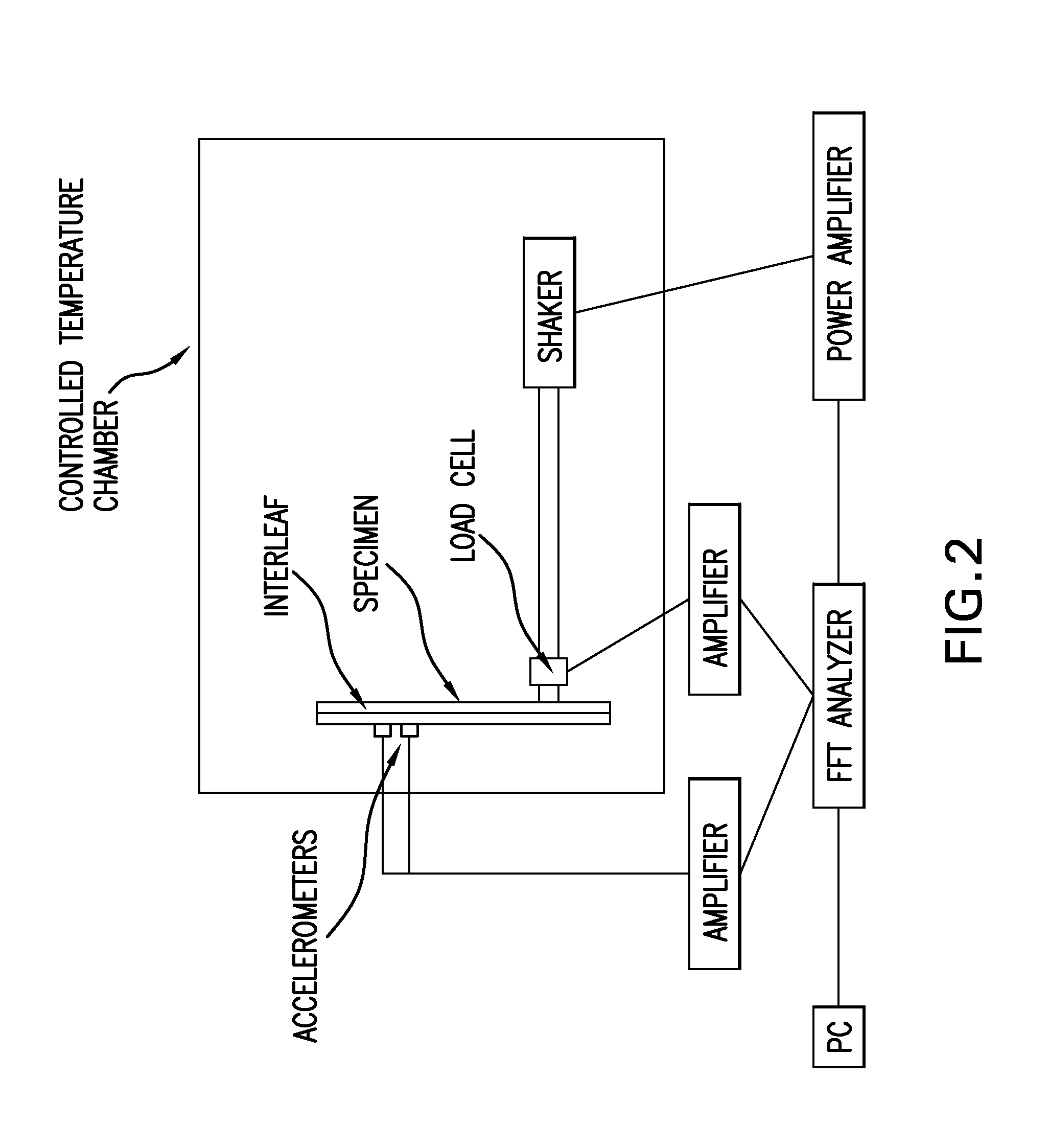

Structural composite material with improved acoustic and vibrational damping properties

A composite material comprises a nonwoven layer having a viscoelastic interleaf, which may be positioned mid-ply therein.

Owner:CYTEC TECH CORP

Acoustic septum cap honeycomb

An acoustic structure that includes a honeycomb having cells in which septum caps are located. The septum caps are formed from sheets of acoustic material and include a resonator portion and a flange portion. The flange portion has an anchoring surface that provides frictional engagement of the septum caps to the honeycomb cells when the caps are inserted into the honeycomb during fabrication of the acoustic structure. An adhesive is applied to the anchoring surface of the septum caps after the caps have been inserted into the honeycomb cells to provide a permanent bond.

Owner:HEXEL CORP

Fire retardant nonwoven material and process for manufacture

An improved acoustically and thermally insulating fire-retardant composite material suitable for use in structures such as buildings, appliances, and the interior passenger compartments and exterior components of automotive vehicles is provided. The material is comprised of at least one airlaid fibrous layer of controlled density and composition and incorporating suitable binding agents and additives as needed to meet expectations for noise abatement, fire-retardancy, and mildew resistance. Separately, an airlaid structure which provides a reduced, controlled airflow therethrough useful for acoustic insulation is provided, and which includes a woven or nonwoven scrim. A process for the production of the fire retardant nonwoven material is also provided.

Owner:GLATFELTER CORP

Floor panel and methods for manufacturing floor panels

ActiveUS20130067842A1High densityHigh sensitivityCovering/liningsDecorative surface effectsPanellingEngineering

In a method for manufacturing floor panels that have at least a substrate and a top layer provided on the substrate, the top layer including a thermoplastic layer that is translucent or transparent, the method may involve providing the top layer, including the thermoplastic layer, on the substrate. The method may also involve heating at least the thermoplastic layer, and structuring the thermoplastic layer using a mechanical press element.

Owner:FLOORING IND LTD

Acoustical gypsum board for ceiling panel

Low density acoustical gypsum boards having a perforated cover sheet that have good sound absorption properties and are generally clear of falling gypsum dust. The invention optionally provides a cover sheet having a pattern producing a textured visual effect particularly when viewed from a distance. The acoustical gypsum boards can be produced on modified existing gypsum board lines.

Owner:USG INTERIORS INC

Engineered Waterproof Flooring and Wall Covering Planks

Owner:SHAW INDS GROUP

Nonwoven material for acoustic insulation, and process for manufacture

InactiveUS20080121461A1Improve acoustic propertiesReduce weightLiquid surface applicatorsWallsVolumetric Mass DensityEngineering

An improved acoustically and thermally insulating fire-retardant composite material suitable for use in structures such as buildings, appliances, and the interior passenger compartments and exterior components of automotive vehicles is provided. The material is comprised of at least one airlaid fibrous layer of controlled density and composition and incorporating suitable binding agents and additives as needed to meet expectations for noise abatement, fire-retardancy, and mildew resistance. Separately, an airlaid structure which provides a reduced, controlled airflow therethrough useful for acoustic insulation is provided, and which includes a woven or nonwoven scrim. A process for the production of the fire retardant nonwoven material is also provided.

Owner:GEORGIA PACIFIC NONWOVENS LLC

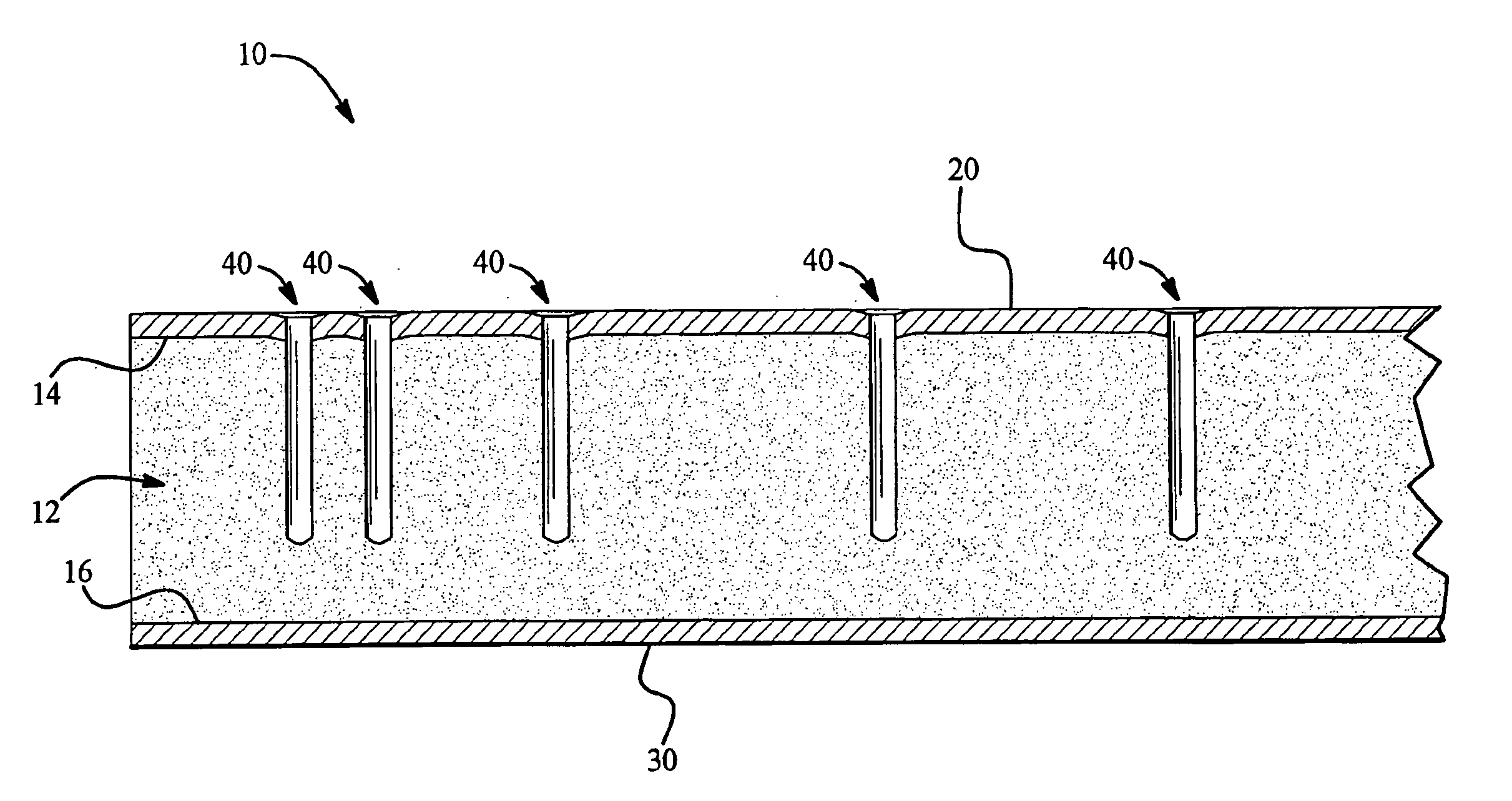

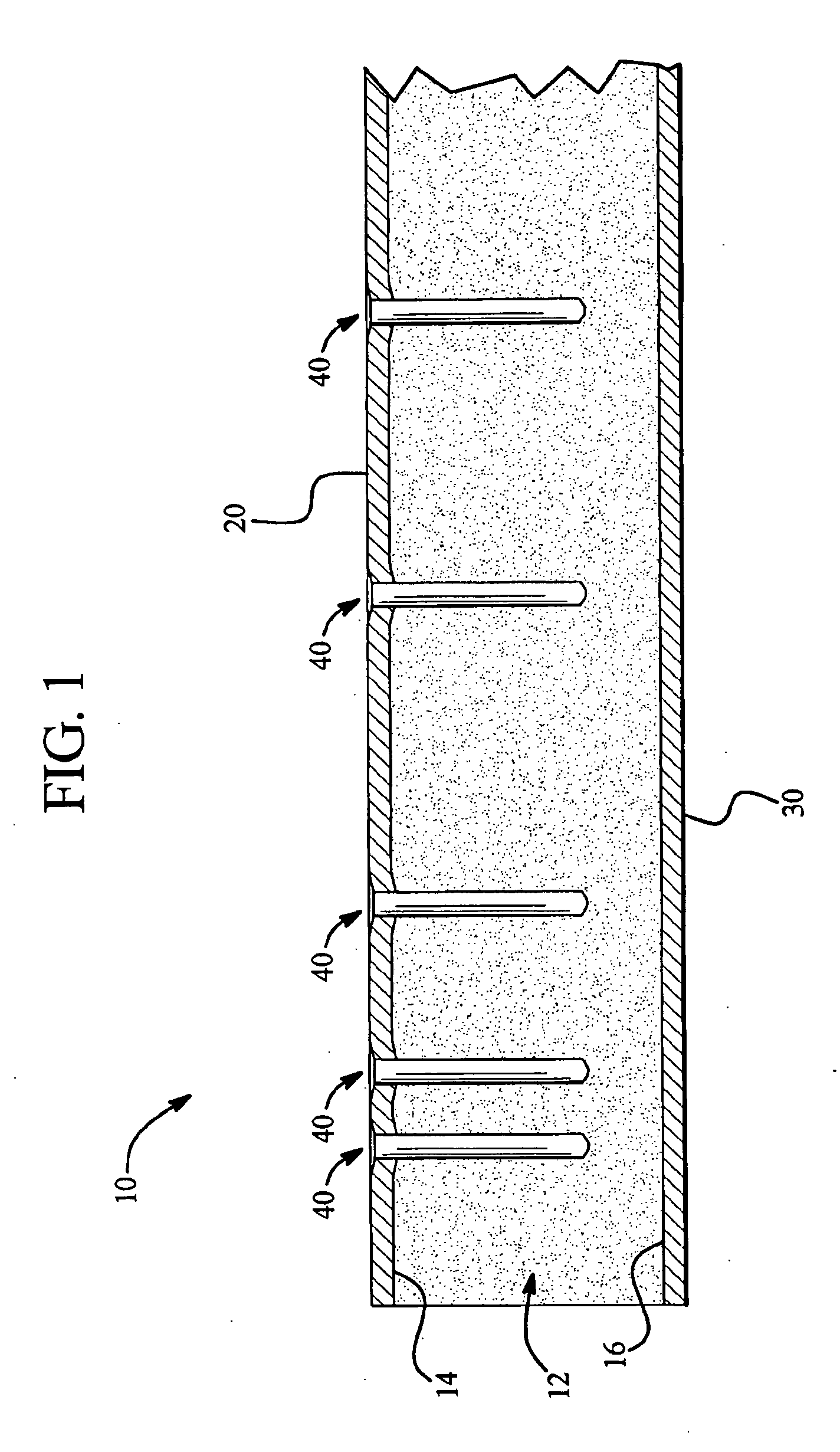

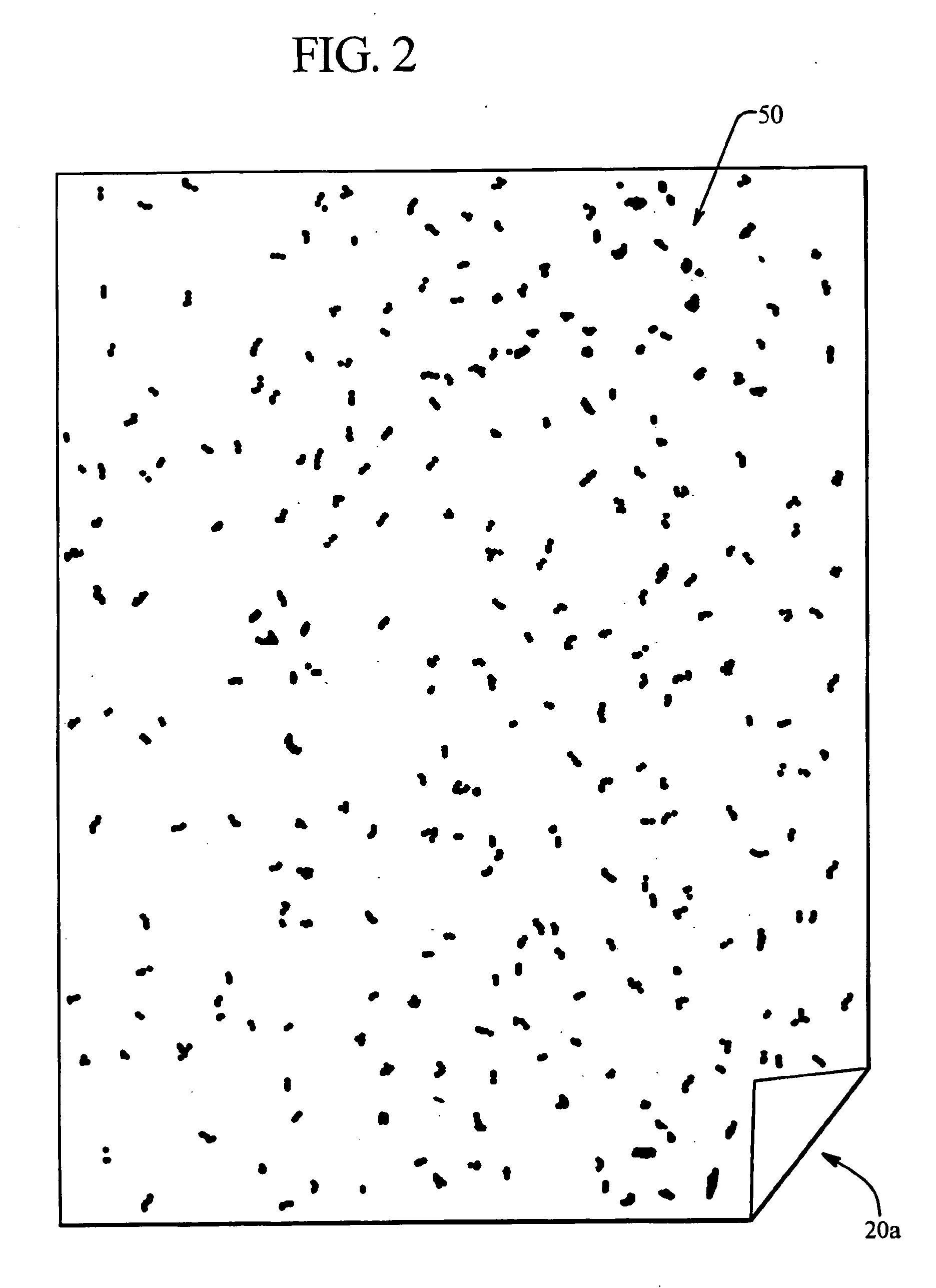

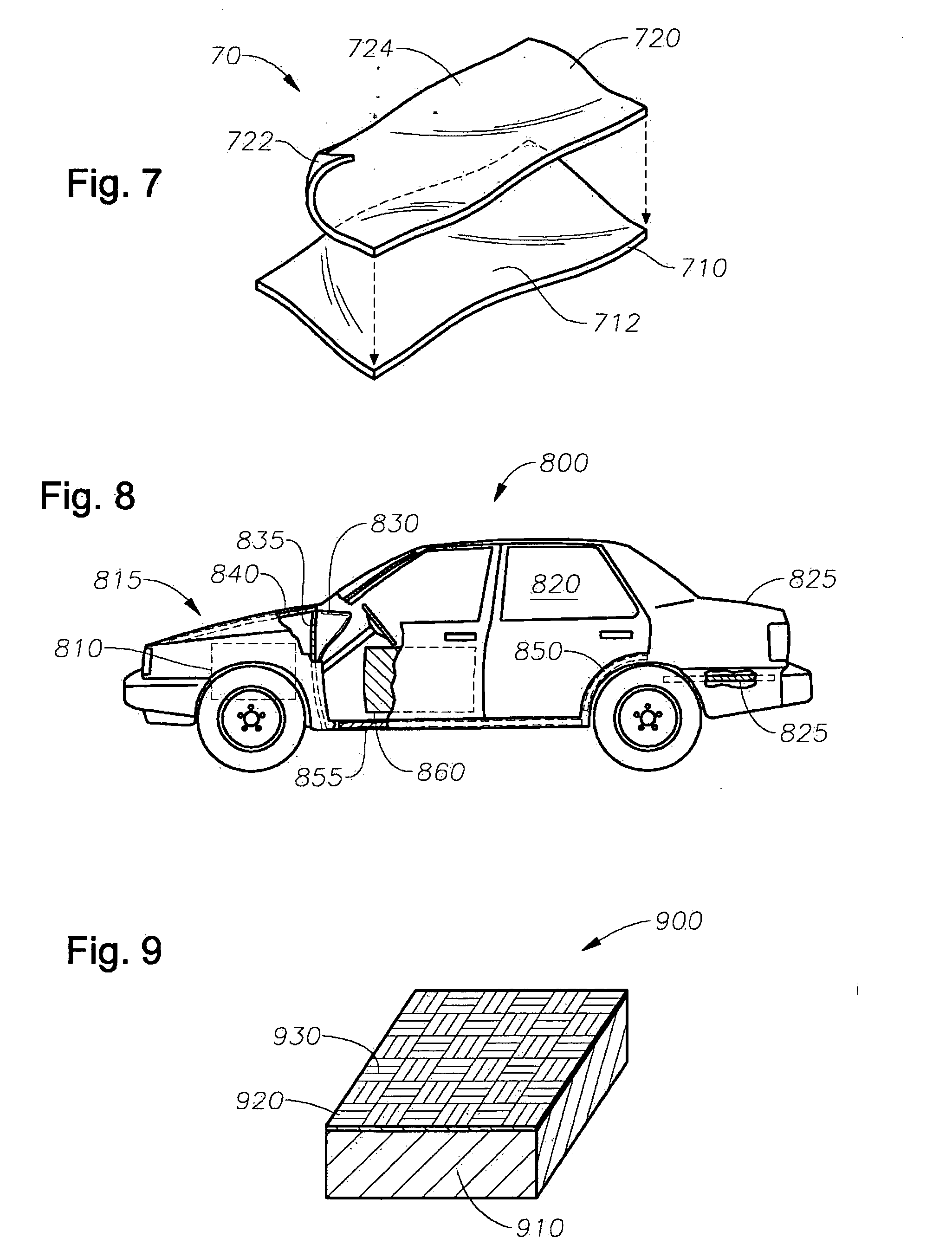

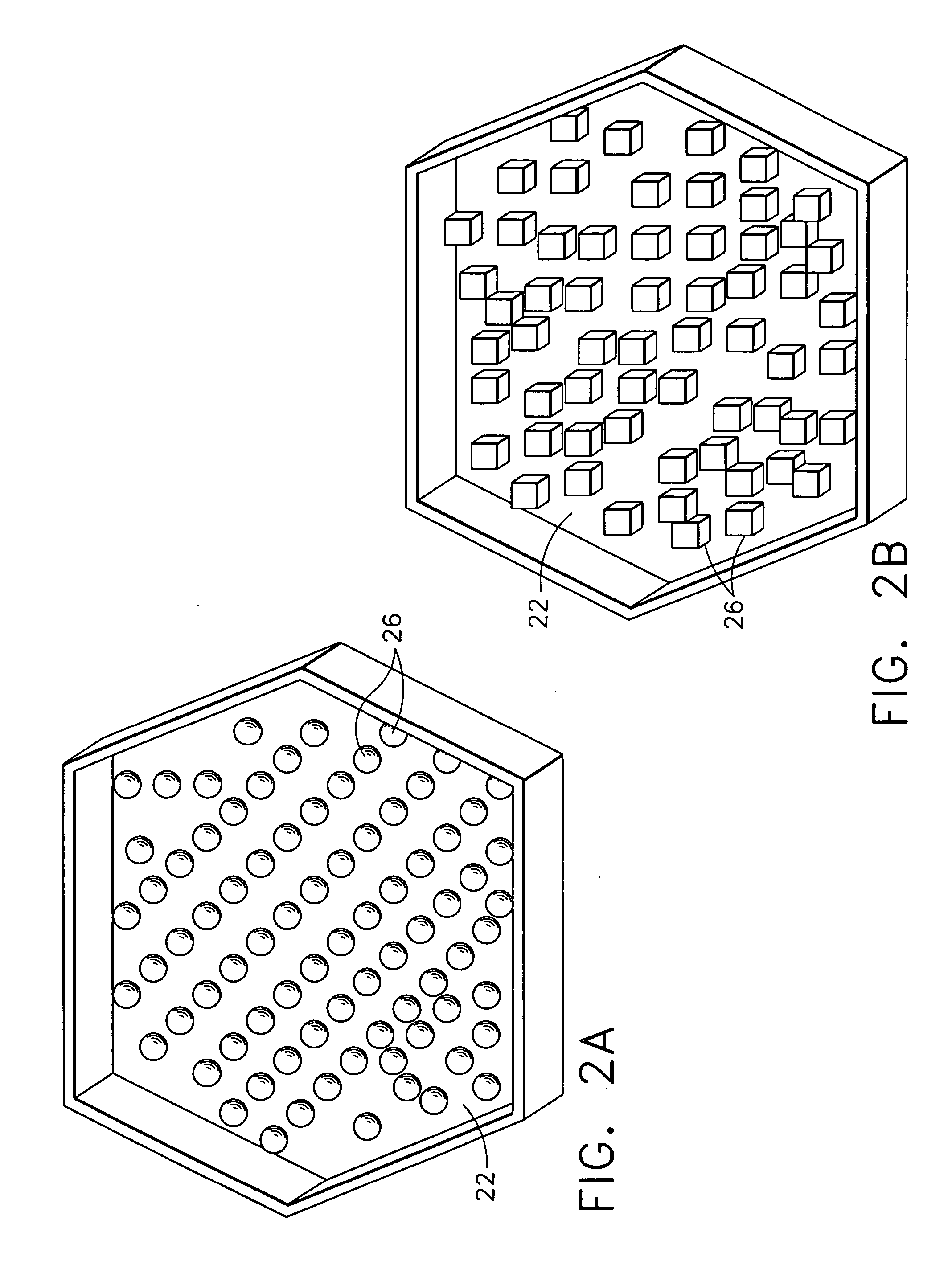

Apparatus and method for aircraft cabin noise attenuation via non-obstructive particle damping

InactiveUS20050194210A1Increase dampingIncreased durabilityLayered productsFuselage insulationFilling materialsEngineering

An apparatus for reducing noise in an aircraft cabin is disclosed. The apparatus comprises a structure portion and filler material. The structure portion further comprises an internal member having at least one cavity disposed therein. Each of the at least one cavity of the structure portion are filled with the filler material.

Owner:THE BOEING CO

Floorboards for floorings

Floorboards for making a floating floor have a core (30) which comprises at least two layers of material (L1, L2), which are arranged at different distances from the surface layer (31), and which differ in respect of material properties or material composition. Semi manufactures for making such floorboards are also disclosed.

Owner:VÄLINGE INNOVATION AB

Sound absorbing material

InactiveUS20060225952A1Improve sound absorptionLow costSound proofingWoven fabricsMaterials scienceBulk density

A sound-absorbing material, wherein a non-woven fabric with a mass per unit area of 150 to 800 g / m2 and a bulk density of 0.01 to 0.2 g / cm3 and a surface material with an air permeability of not more than 50 cc / cm2 / sec measured according to JIS L-1096 are layered.

Owner:TAKAYASU CO LTD +2

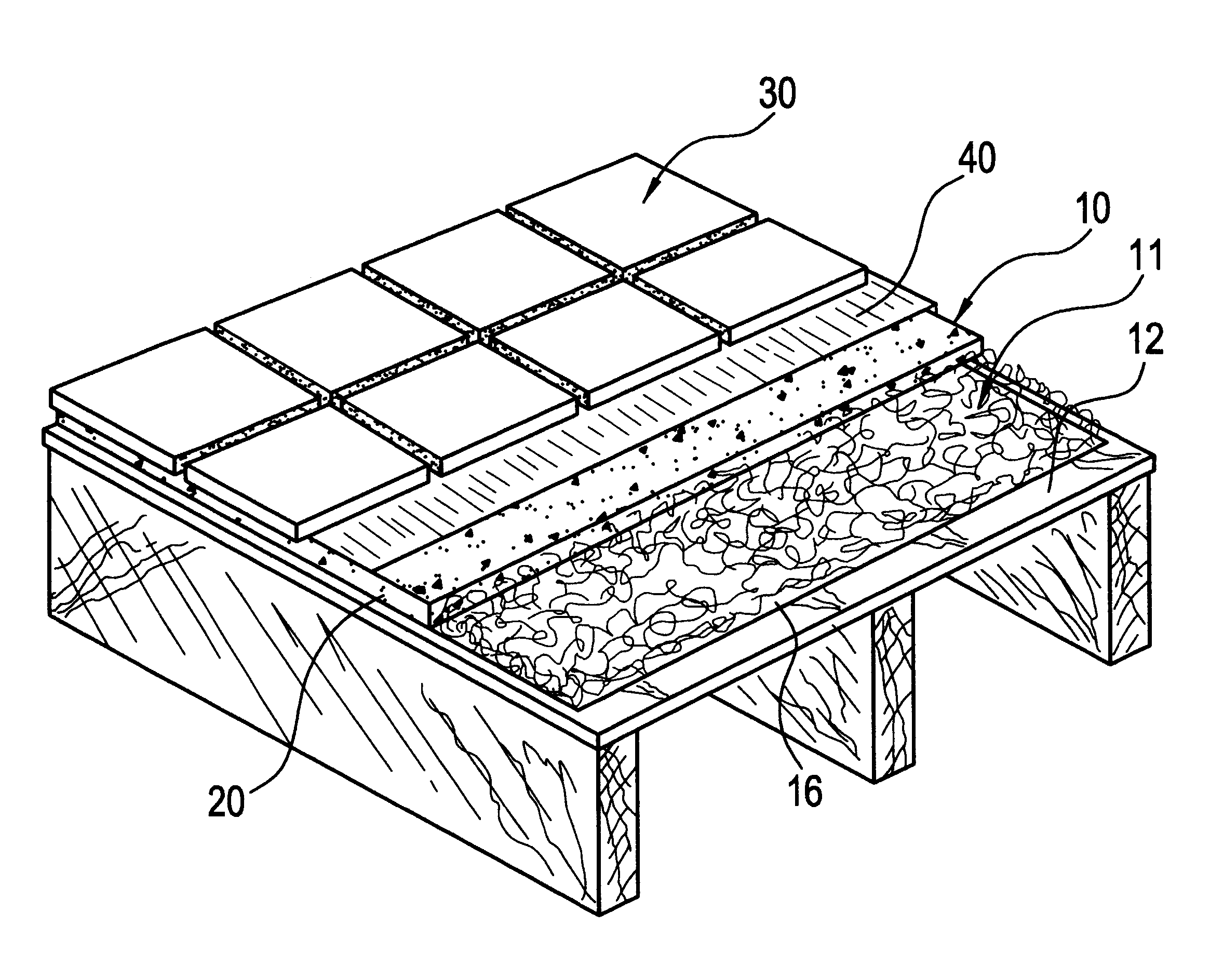

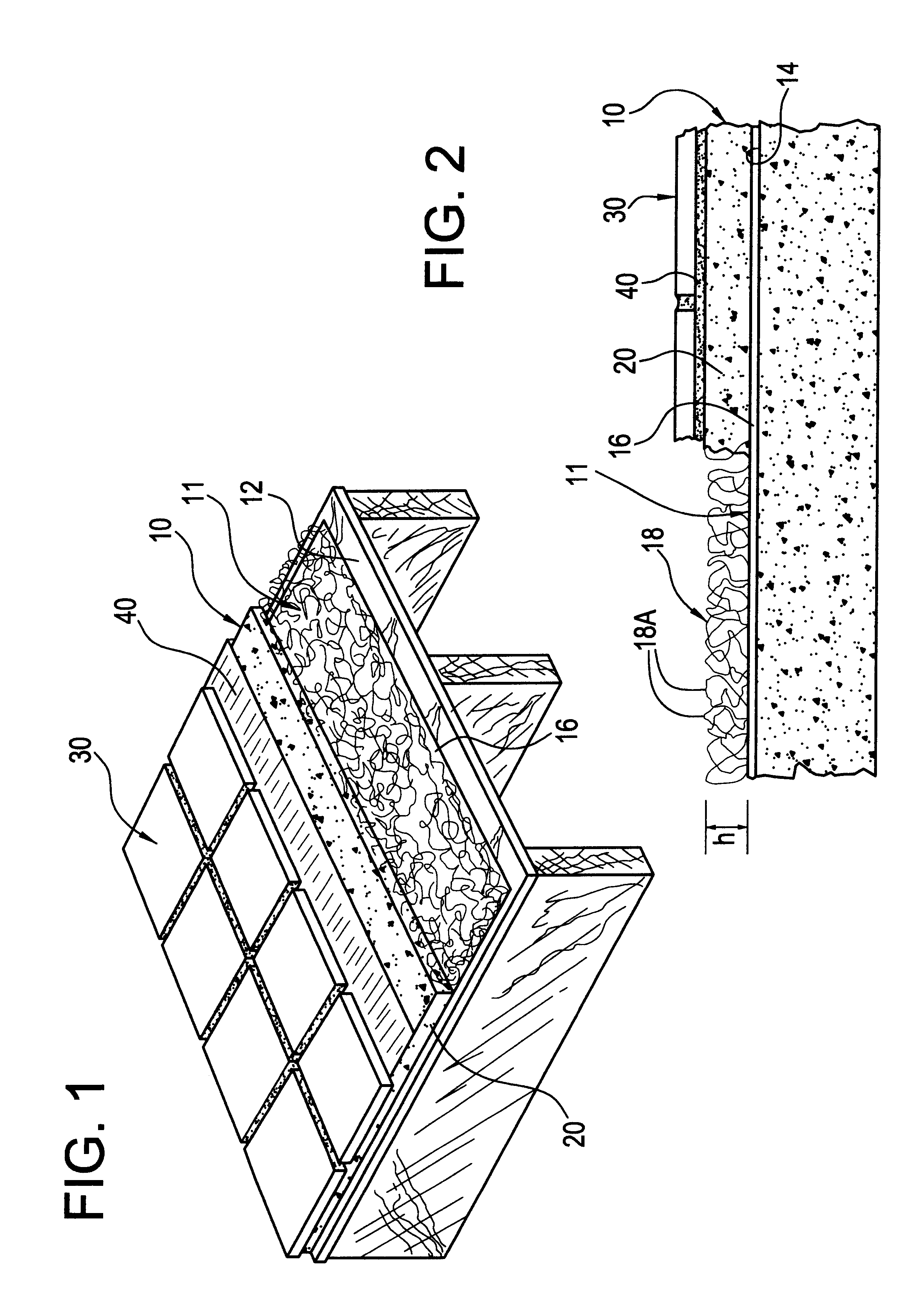

Finished flooring underlayment and method of making same

InactiveUS6167668B1Laborious and expensiveQuick installationFloorsBuilding repairsMembrane surfaceMaterials science

A finished flooring underlayment is disclosed including a flexible membrane which is resistant to water, mold and deterioration under wet or dry conditions, and which has intertwined filaments bonded to the membrane surface that act as mortar reinforcement and as gauges to provide a uniform thickness of application for cementicious mortar. The mortar is provided separately and is mixed to a suitable consistency with either water or latex additive, then poured or placed on the mat, utilizing the gauges provided by the filaments to effect a uniform thickness of application. This mortar hardens to a strong, load bearing surface or slab suitable for application of finished flooring.

Owner:CITIZENS BANK OF CONNECTICUT

Microperforated polymeric film for sound absorption and sound absorber using same

Microperforated polymeric films and sound absorbers using such films are provided. The microperforated polymeric films may be relatively thin and flexible and may further include holes having a narrowest diameter less than the film thickness and a widest diameter greater than the narrowest diameter. The microperforated polymeric films of a sound absorber may also have relatively large free span portions, which, in certain embodiments, may vibrate in response to incident sound waves.

Owner:3M INNOVATIVE PROPERTIES CO

Sound absorptive multilayer composite

ActiveUS7320739B2Improve acoustic performanceIncreasing the thicknessMembranesSemi-permeable membranesOpen cellAirflow

A sound absorptive multilayer composite having an air-impermeable barrier, an air-permeable reinforcing core having an airflow resistance of at least about 100 mks Rayls and a thickness at least about ⅓ the final composite thickness, an air-permeable open cell foam or fibrous pad having an airflow resistance less than about 2000 mks Rayls and a thickness at least about 1 / 10 the final composite thickness and a semipermeable airflow-resistive membrane having an airflow resistance of about 500 to about 4000 mks Rayls can provide improved acoustic performance. For example, existing vehicular headliner designs may be improved by adding a properly chosen and properly positioned semipermeable airflow-resistive membrane, a properly chosen and properly positioned air-impermeable barrier, or a properly chosen and properly positioned open cell foam layer.

Owner:3M INNOVATIVE PROPERTIES CO

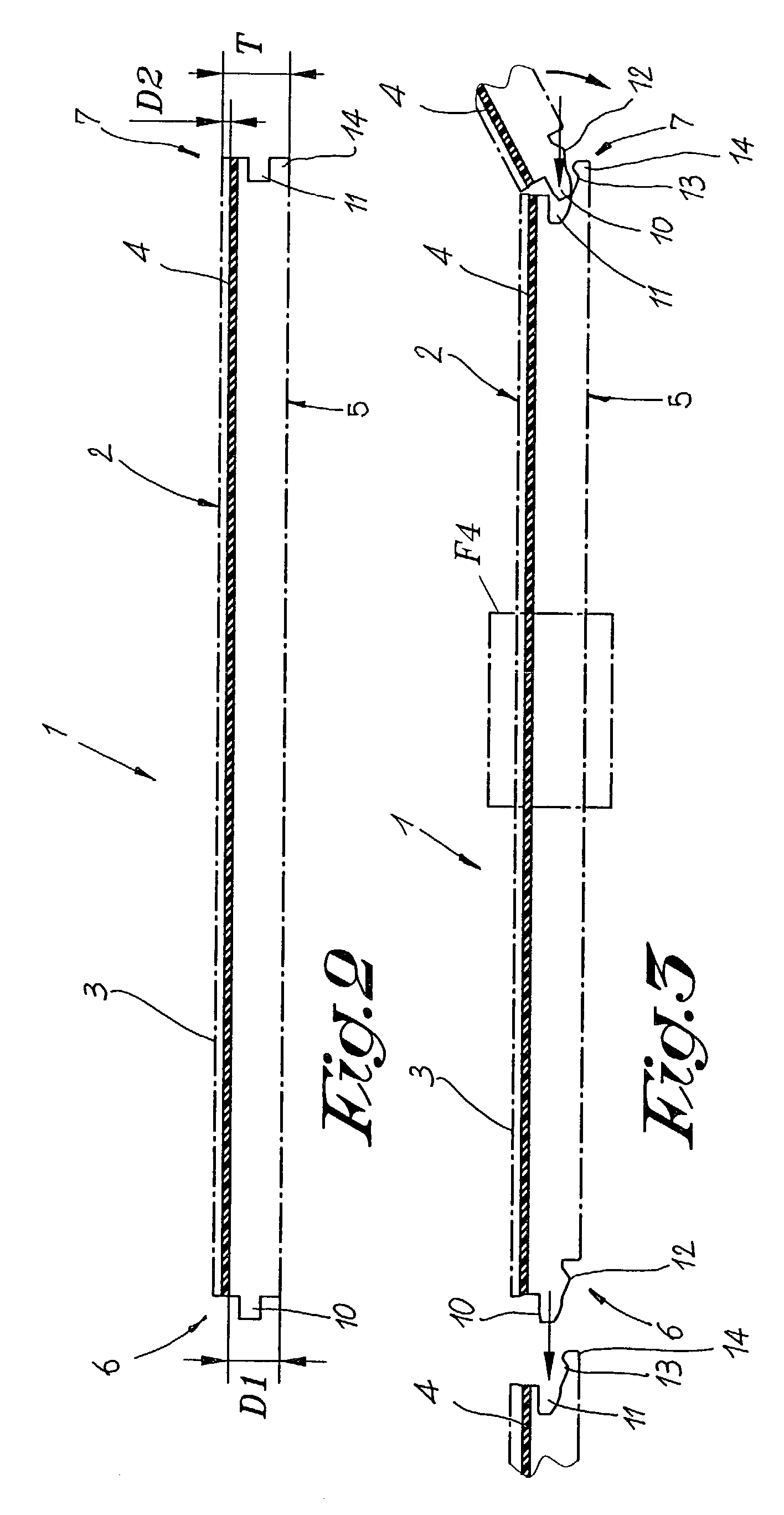

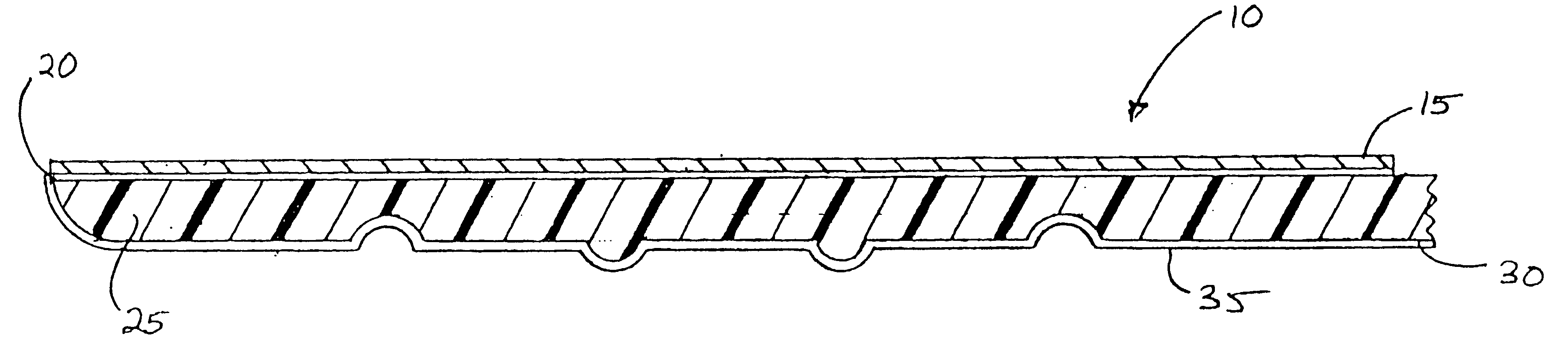

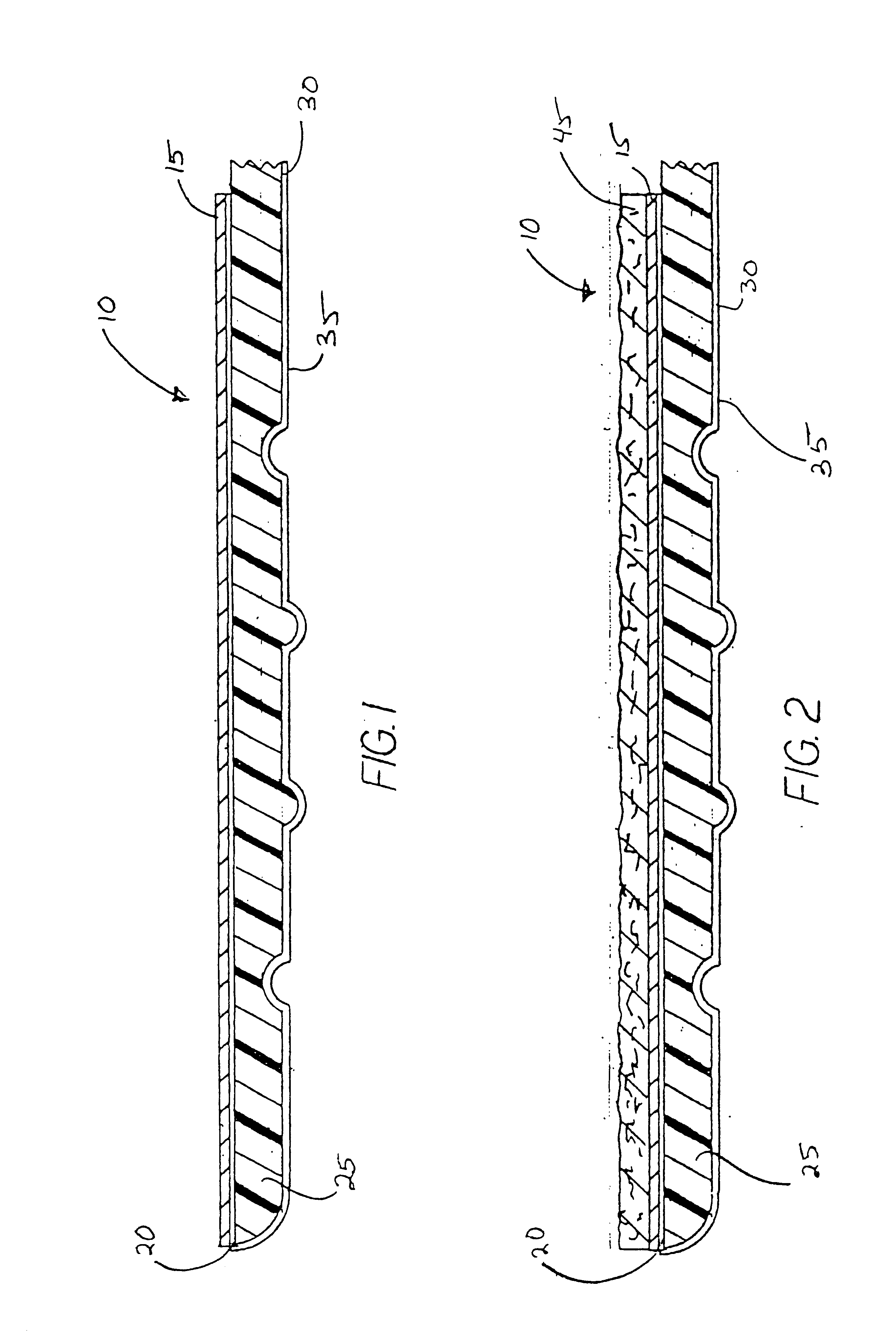

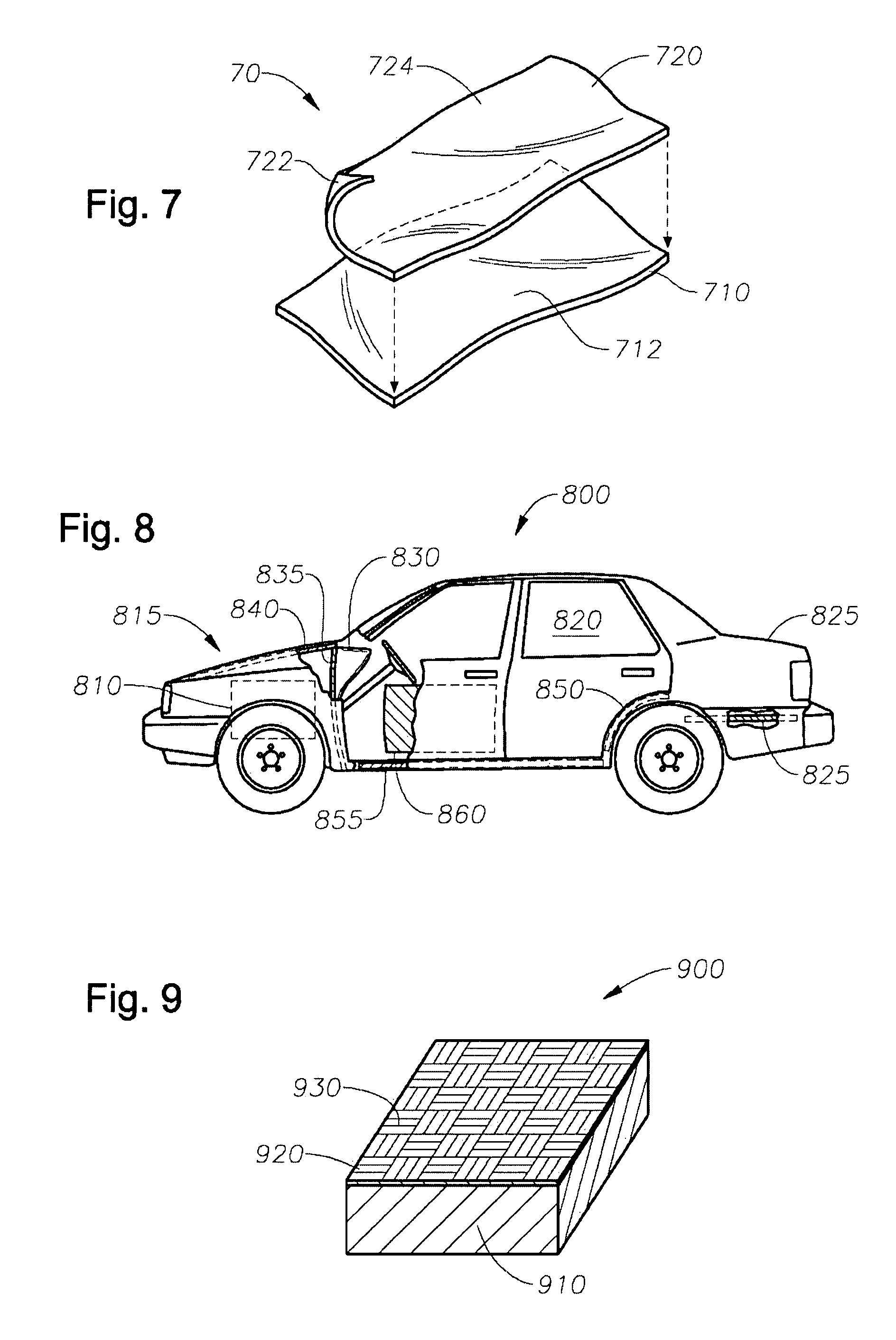

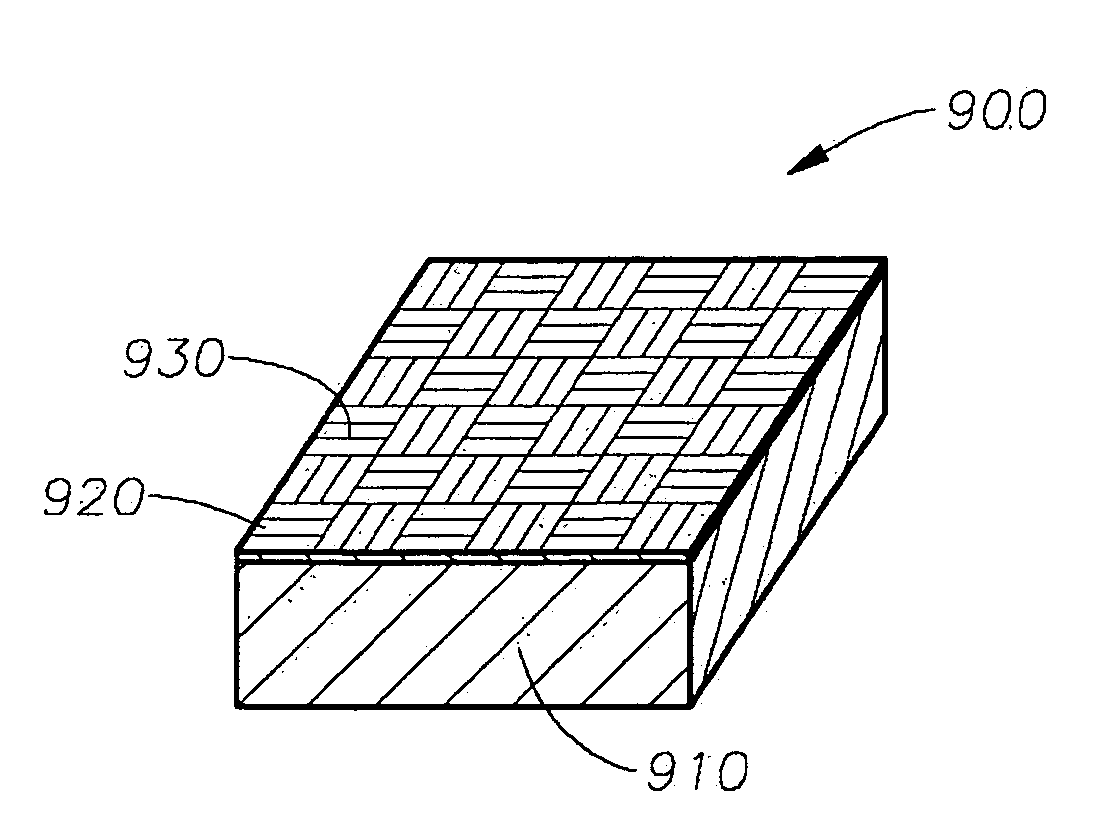

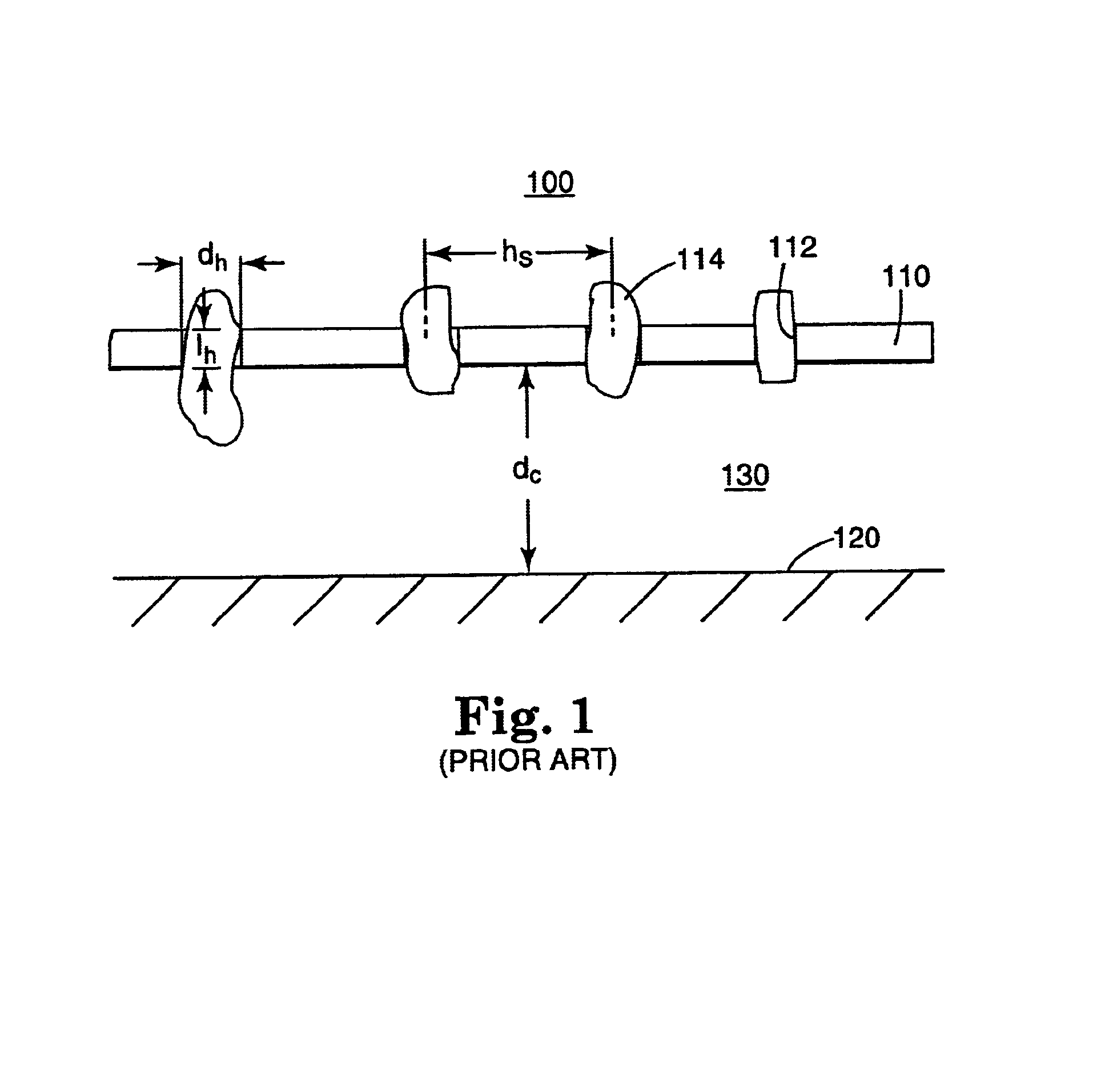

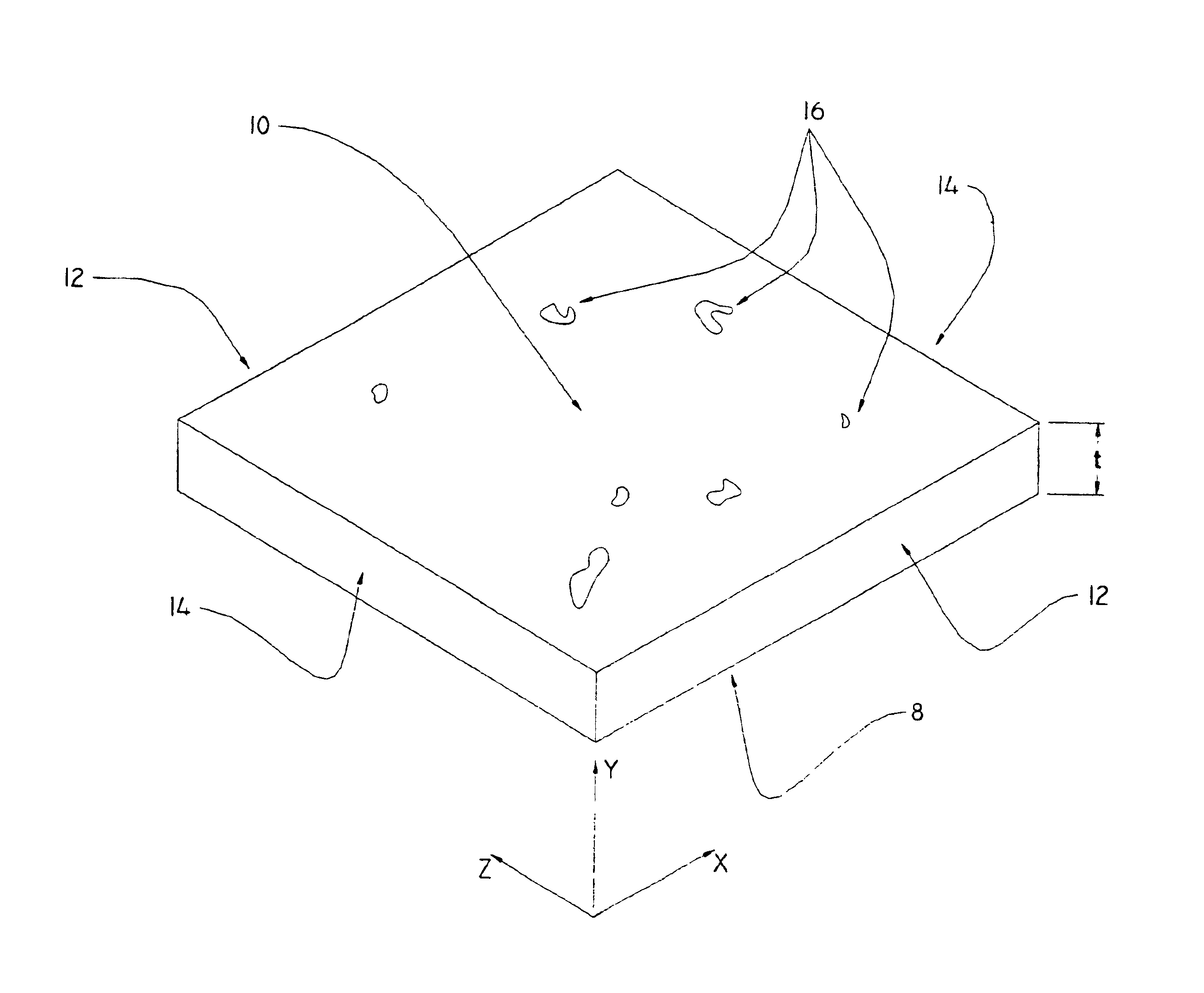

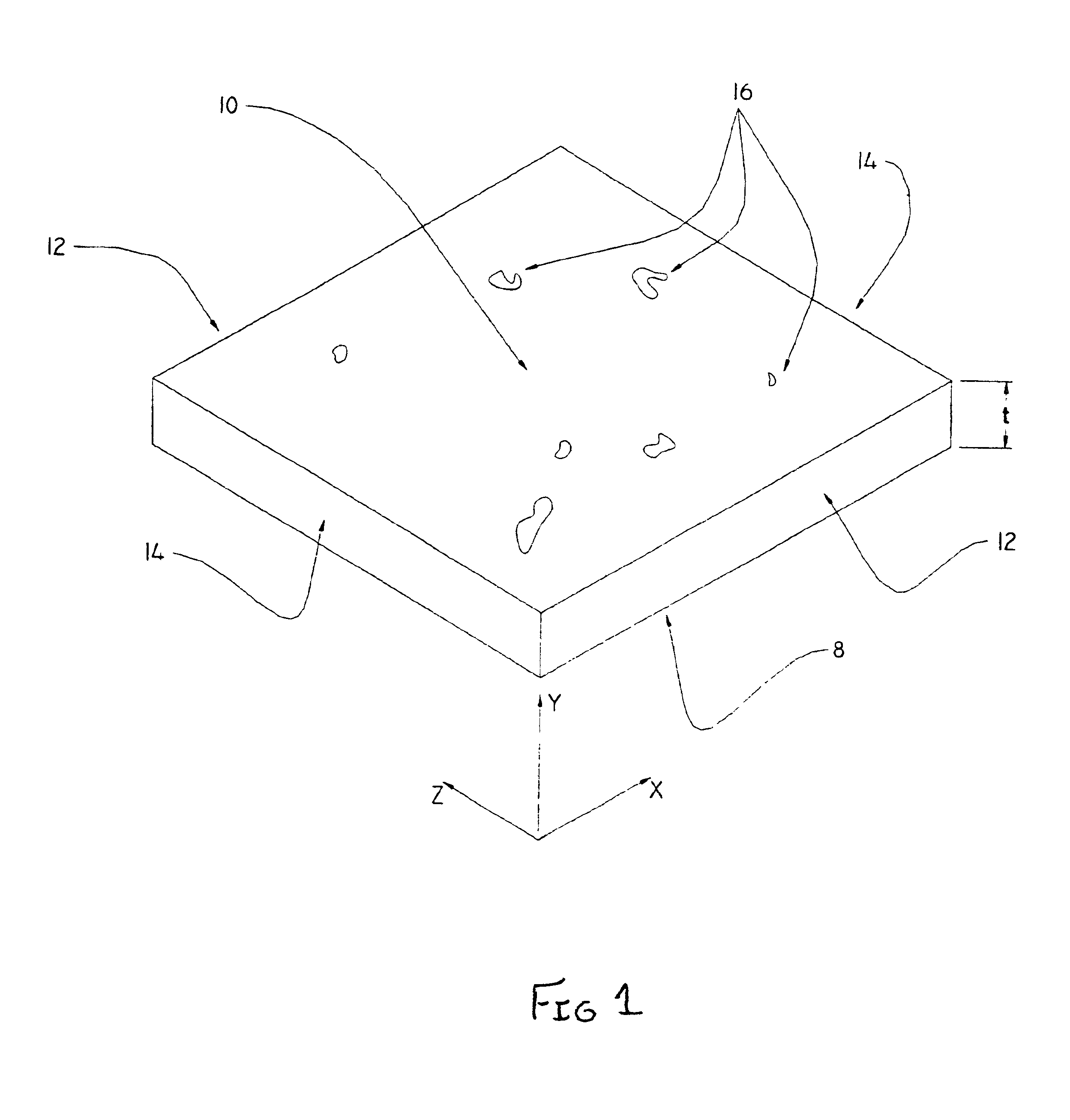

Impact sound insulation

InactiveUS6920723B2Minimizes height requirementAvoid damageSki bindingsCeilingsEngineeringUltimate tensile strength

A substrate for use in a flooring system which has a subfloor and a decorative upper layer. The substrate is made in a continuous sheet which has a bottom surface, a top surface, side surfaces and end surfaces. The top surface and the oppositely facing bottom surface are essentially parallel to each other and are spaced apart by the thickness of the substrate. Voids are provided in the substrate, the voids are provided between particles of rubber or other similar material. When the substrate is positioned between the subfloor and the decorative top layer, the particles of rubber provide the strength required to prevent deformation of the substrate in the direction of the thickness and the voids contribute to the sound dampening characteristics required to provide decibel reduction across the thickness of the substrate.

Owner:ECORE INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com