Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1014results about How to "Improve acoustic performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

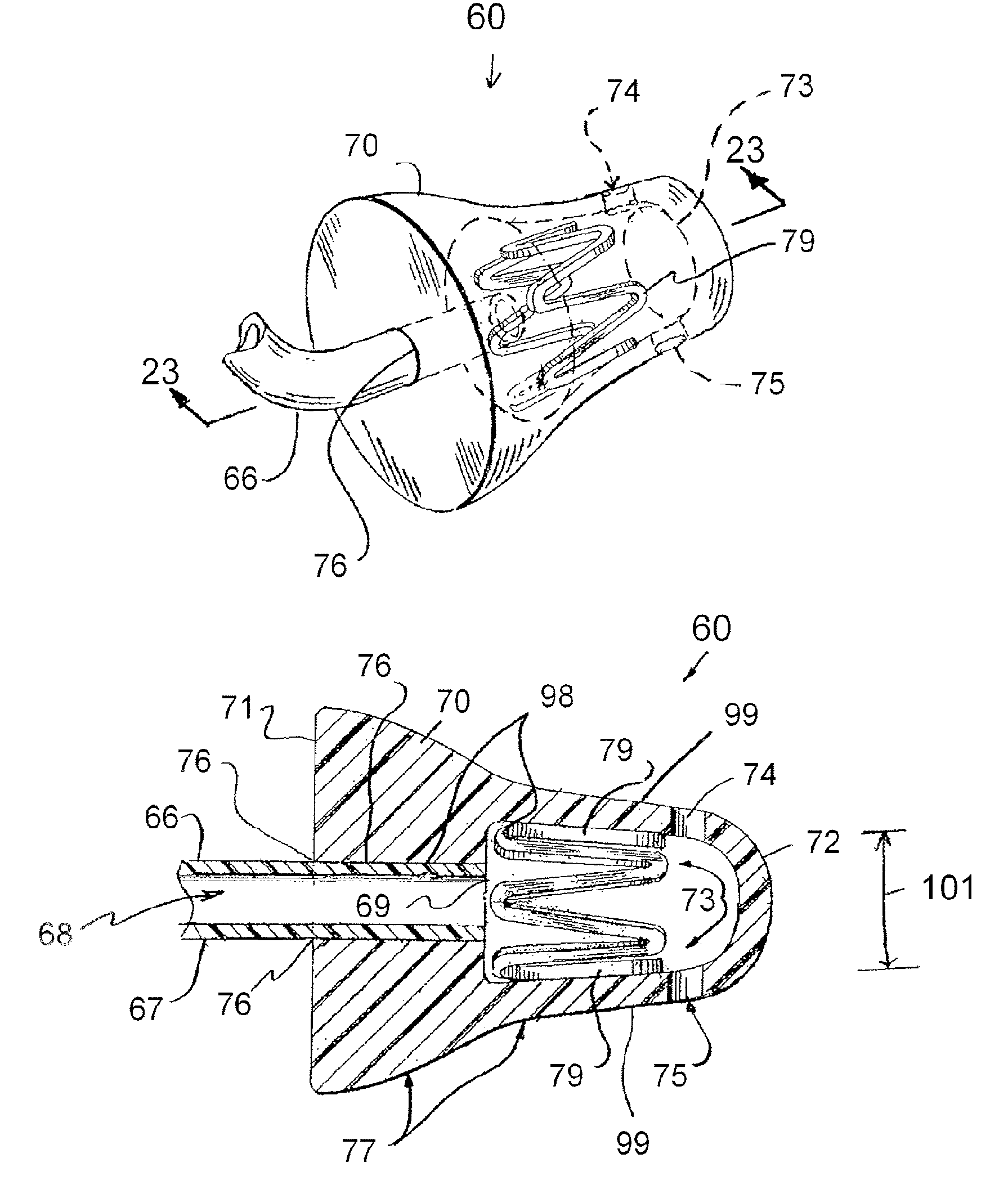

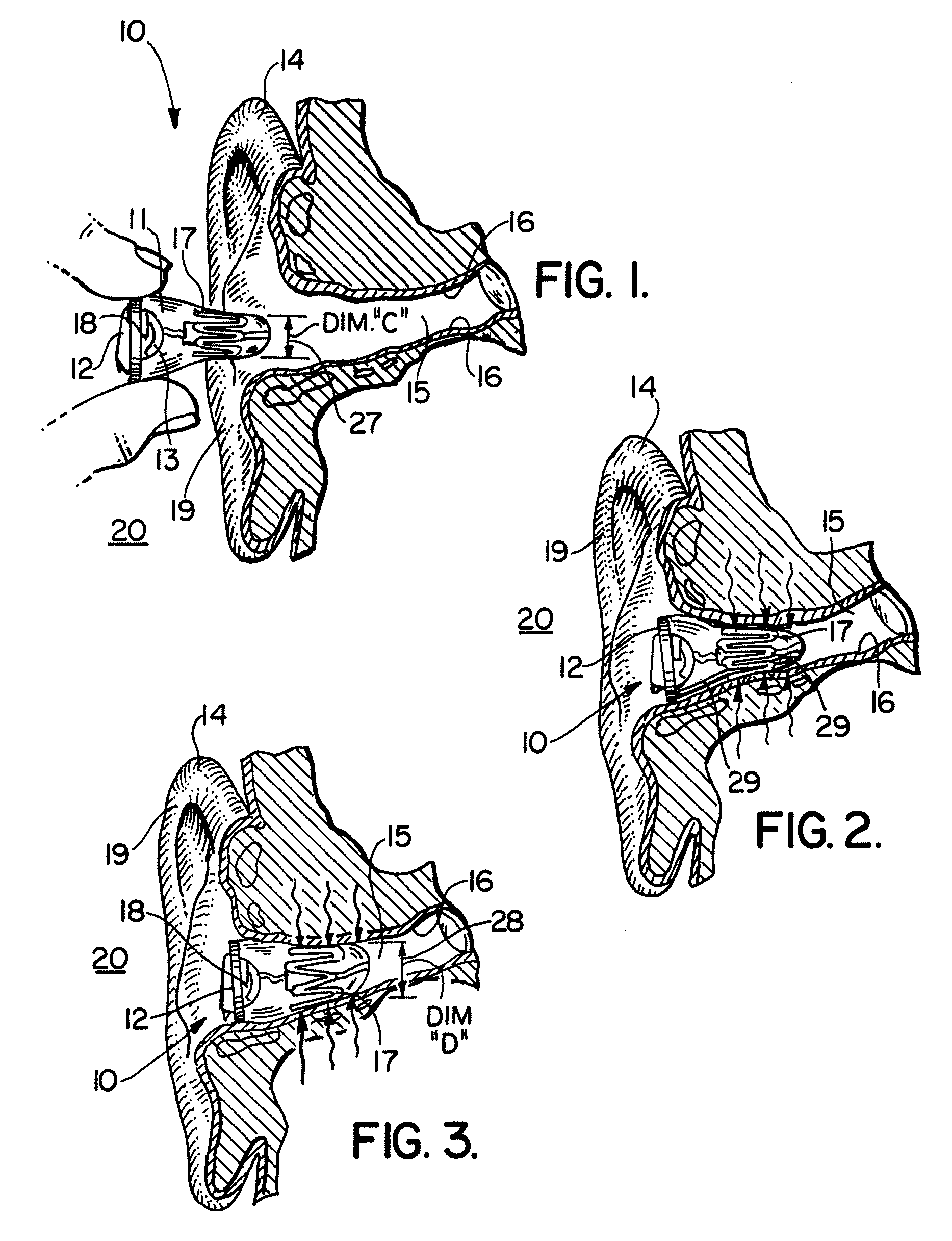

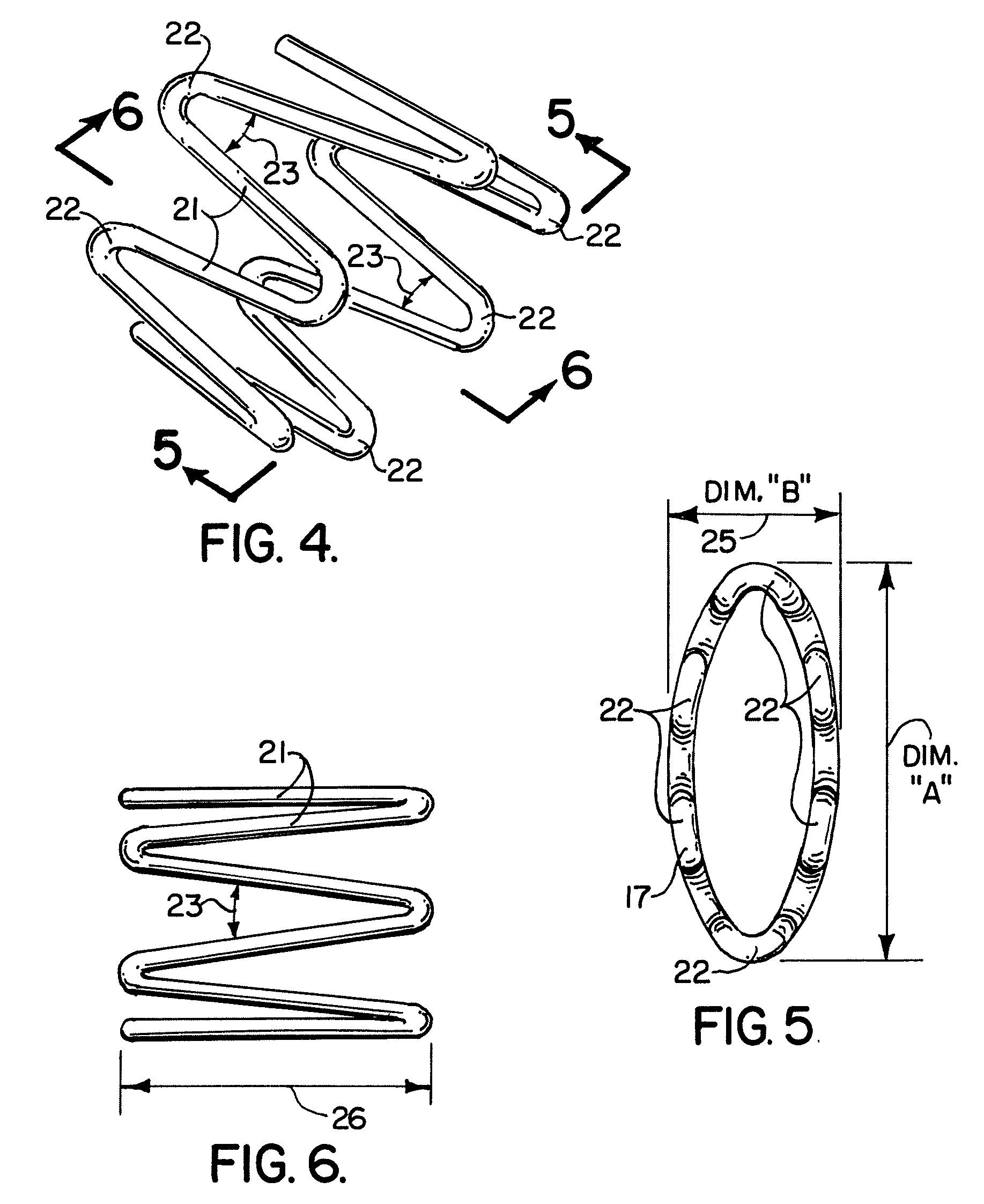

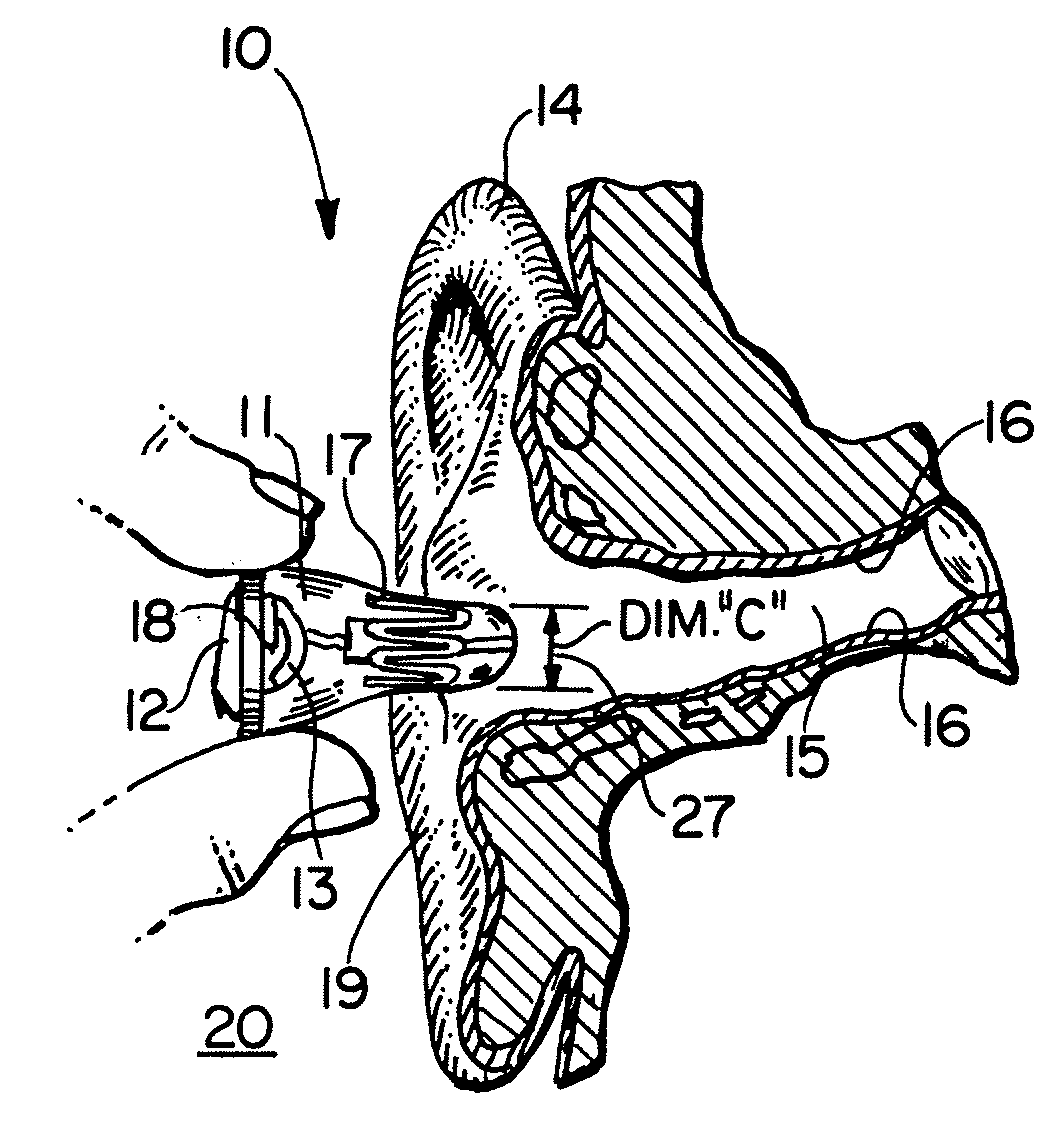

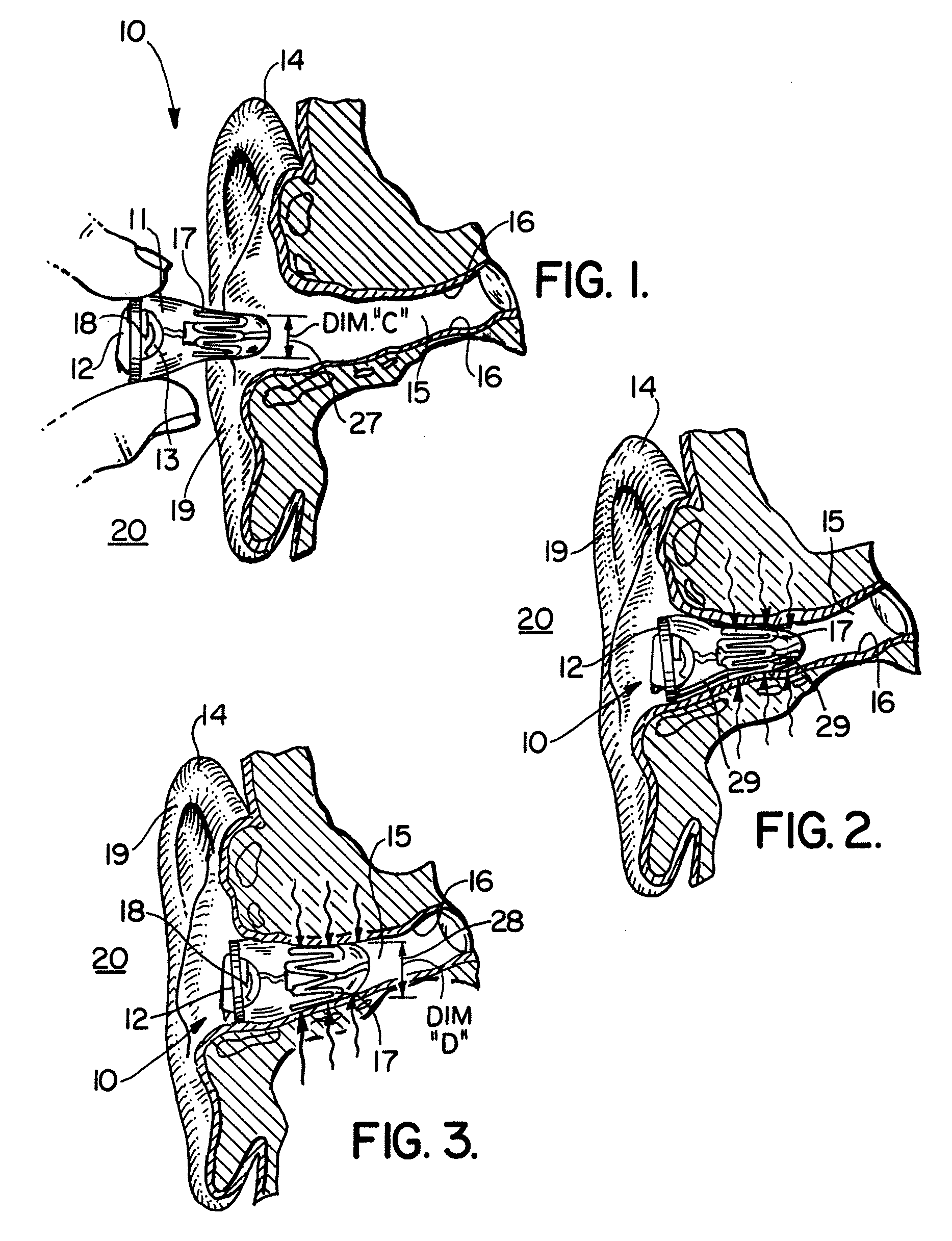

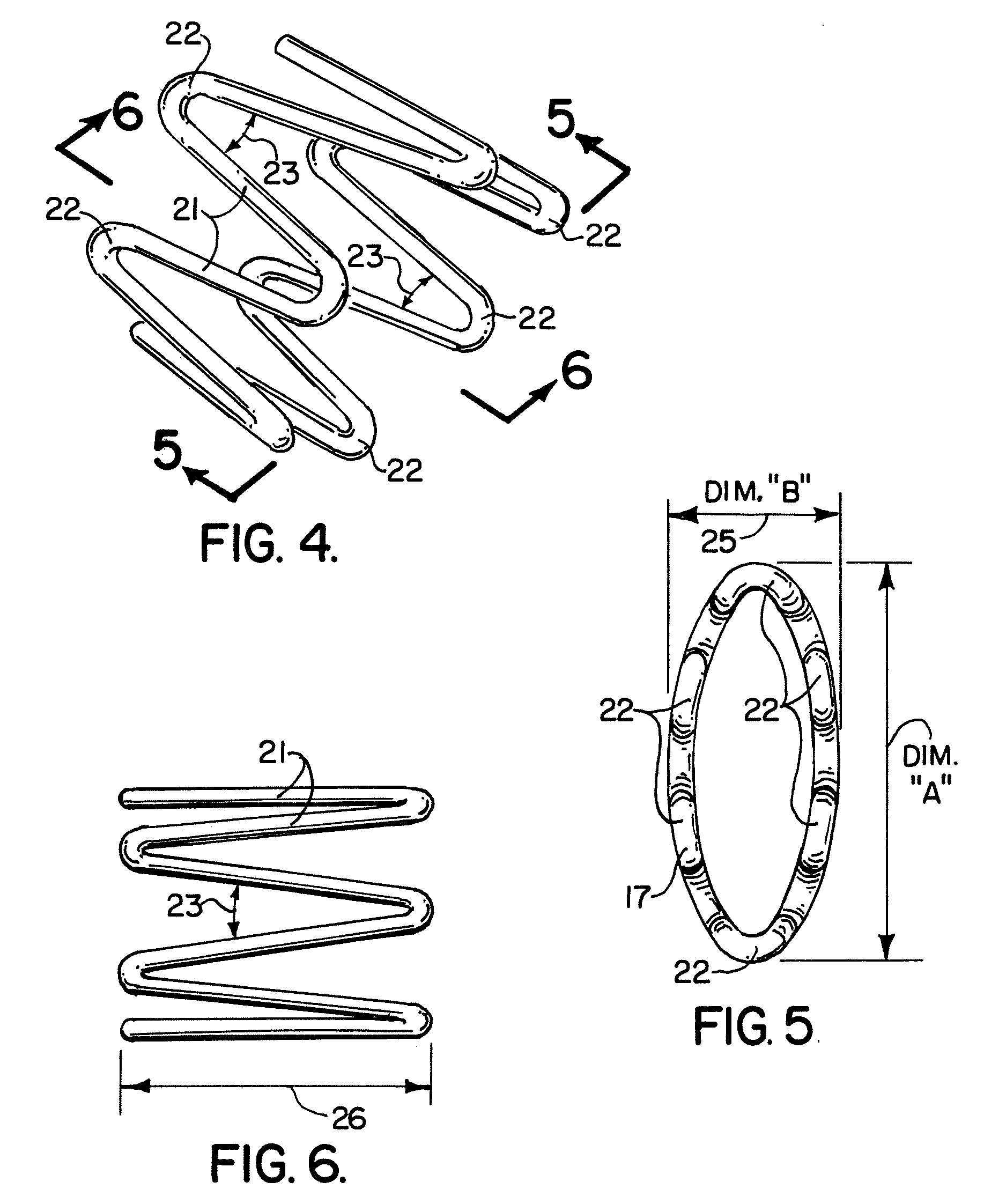

Self forming in-the-ear hearing aid with conical stent

InactiveUS7778434B2Maintain good propertiesReduce leakageEar moulds/tips acoustic sealsEarplugsInsertion stentSelf forming

A hearing aid body is provided that contains electronic hearing aid components and that is attachable to the user's body outside the ear canal. A conduit connects the hearing aid body to the flexible plug. The conduit enables sound emitted by the hearing aid to travel via the conduit to the flexible plug so that the user's able to hear a sound that is amplified by the hearing aid and received by the plug via the conduit. The conduit can be a flexible hollow tube or an electronic conduit that transmit electrical signals between the hearing aid and the plug. A stent embedded in the plug is provided, the stent having a first smaller diameter at a temperature below body temperature and being expandable to a second greater diameter when subjected to the user's body temperature, such as the temperature in the ear canal of a user.

Owner:GENERAL HEARING INSTR

Self forming in-the-ear hearing aid with conical stent

InactiveUS20070183613A1Enhance fitCost-effectiveEar moulds/tips acoustic sealsEarplugsEar canalSelf forming

A hearing aid body is provided that contains electronic hearing aid components and that is attachable to the user's body outside the ear canal. A conduit connects the hearing aid body to the flexible plug. The conduit enables sound emitted by the hearing aid to travel via the conduit to the flexible plug so that the user's able to hear a sound that is amplified by the hearing aid and received by the plug via the conduit. The conduit can be a flexible hollow tube or an electronic conduit that transmit electrical signals between the hearing aid and the plug. A stent embedded in the plug is provided, the stent having a first smaller diameter at a temperature below body temperature and being expandable to a second greater diameter when subjected to the user's body temperature, such as the temperature in the ear canal of a user.

Owner:GENERAL HEARING INSTR

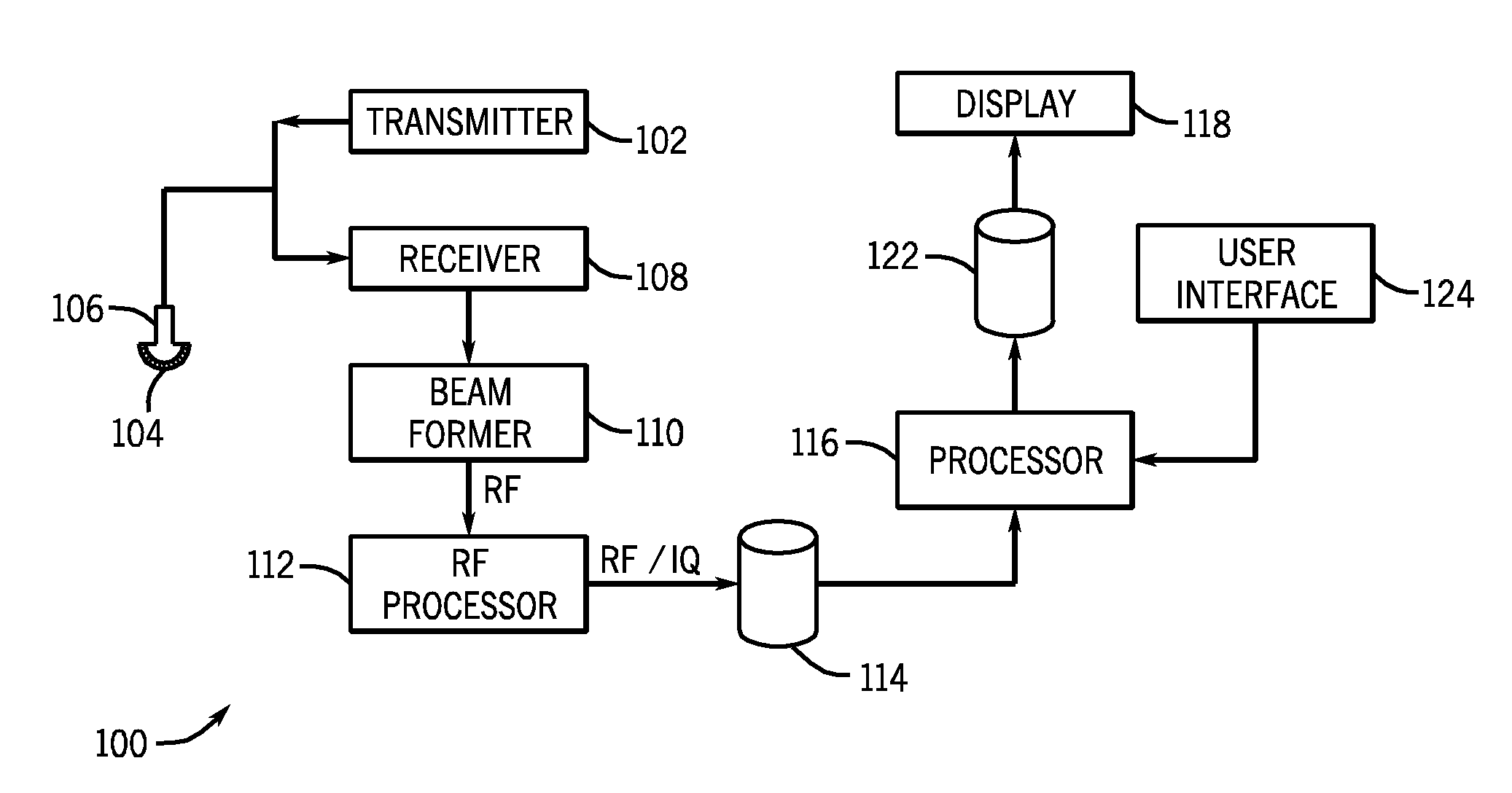

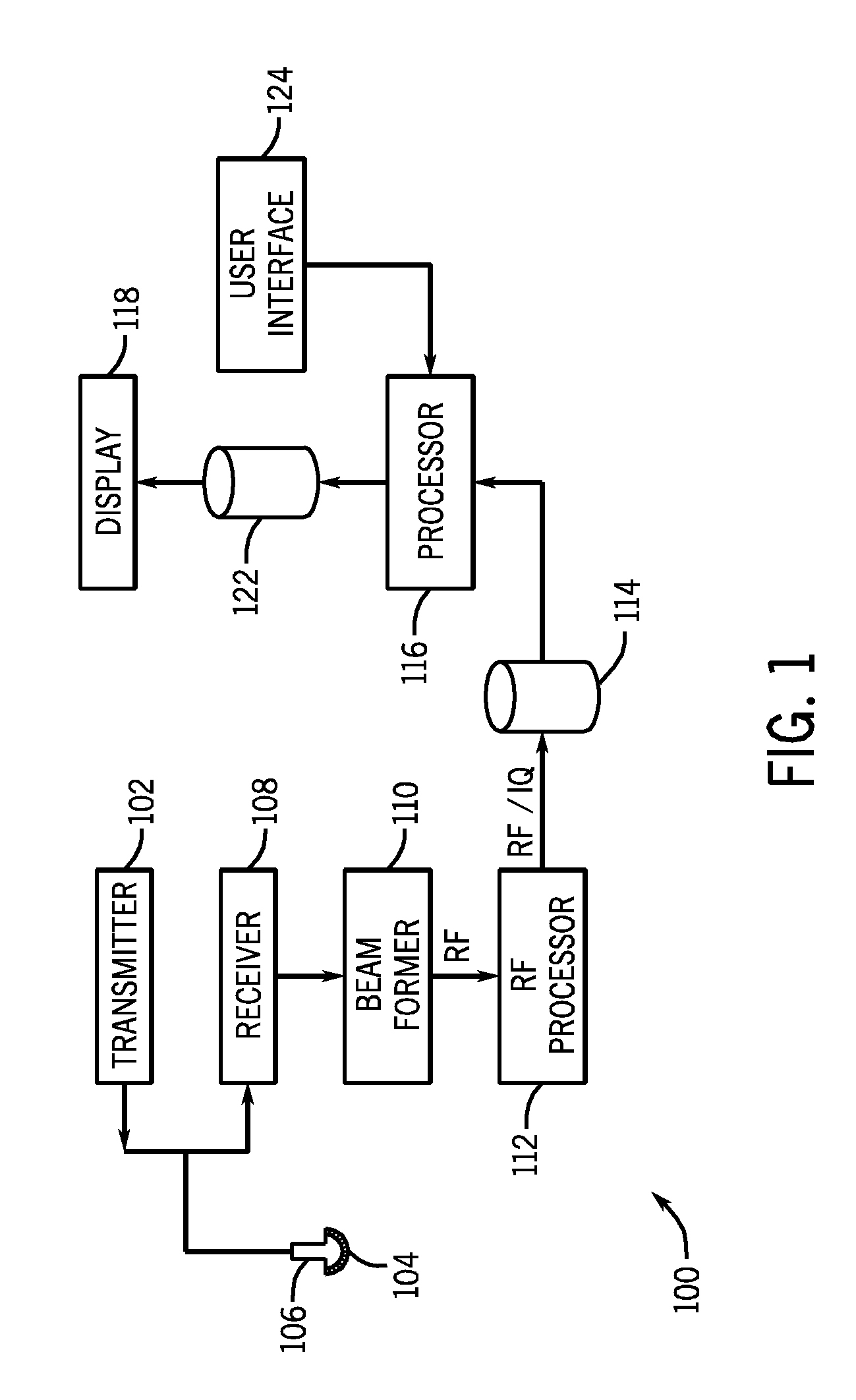

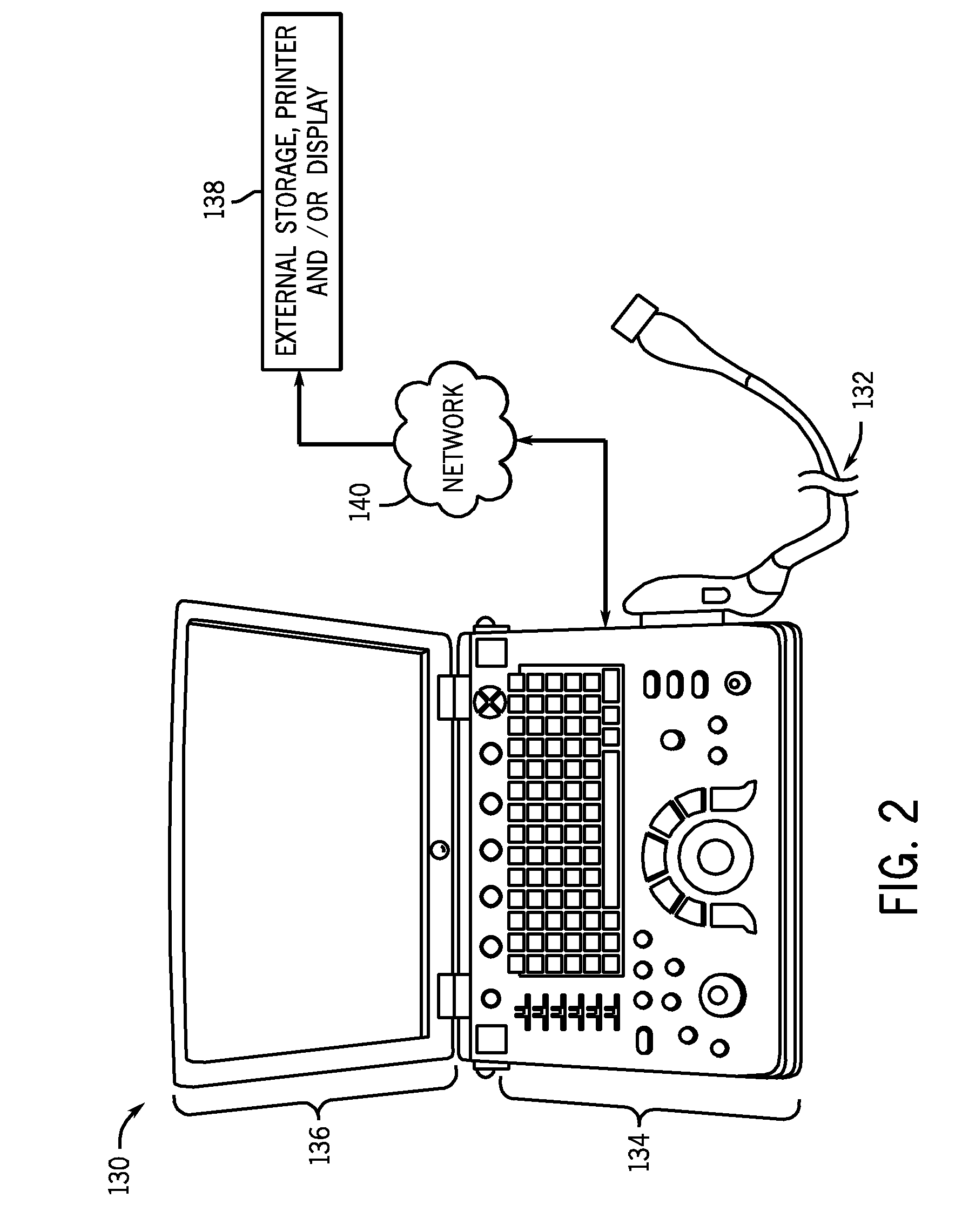

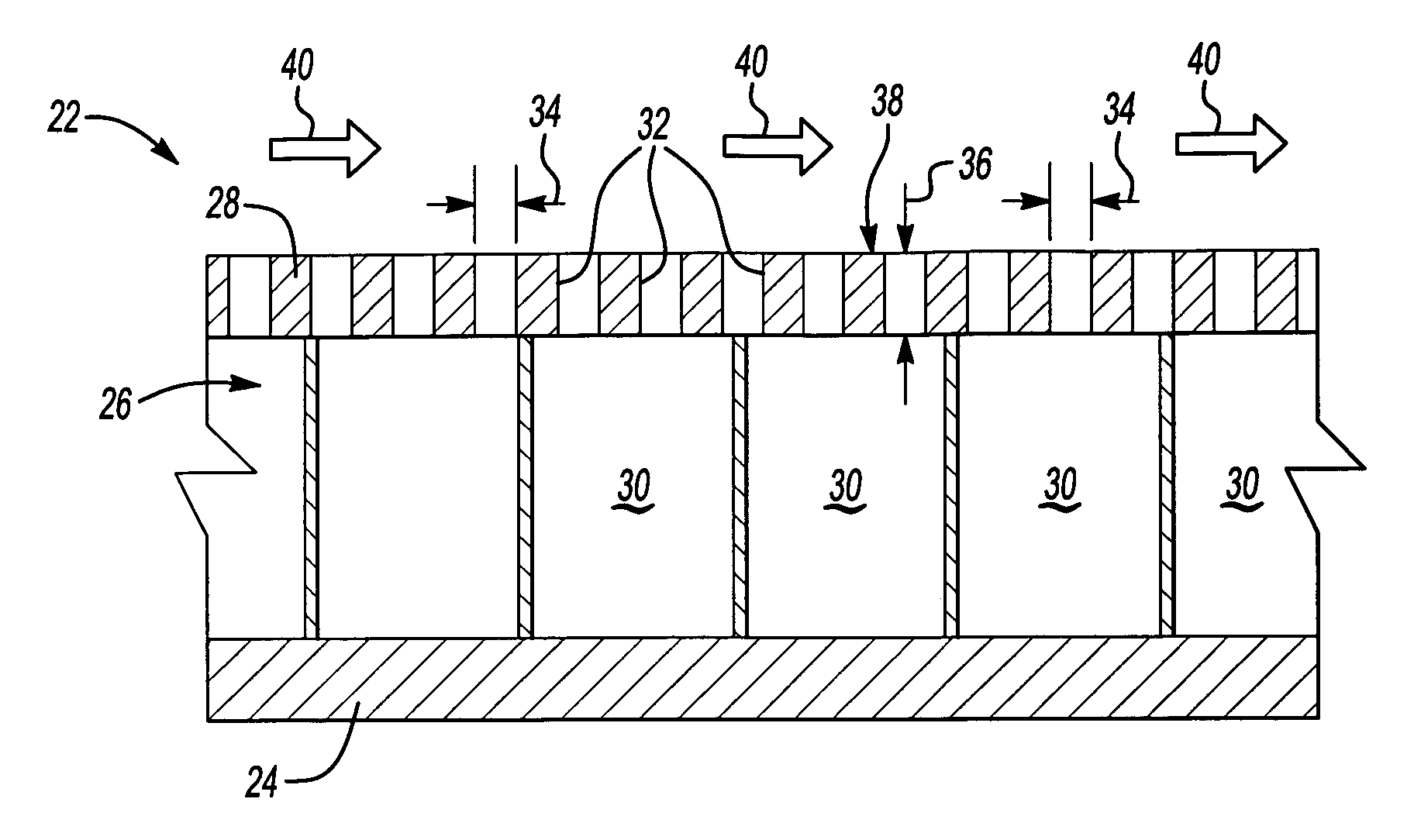

Ultrasound transducer with improved acoustic performance

ActiveUS20100317972A1Improve acoustic performanceReduce artifactsUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostriction/magnetostriction machinesTransducerAcoustic impedance

A system for improving the acoustic performance of an ultrasound transducer by reducing artifacts within the acoustic spectrum is disclosed. The system includes an acoustic layer having an array of acoustic elements, a dematching layer coupled to the acoustic layer and having an acoustic impedance greater than an acoustic impedance of the acoustic layer, and an interposer layer coupled to the dematching layer and comprising a substrate and a plurality of conductive element. The interposer layer is formed to have an acoustic impedance lower than the acoustic impedance of the dematching layer. The ultrasound transducer also includes an integrated circuit coupled to the interposer layer and electrically connected to the array of acoustic elements through the dematching layer and the interposer layer.

Owner:GENERAL ELECTRIC CO

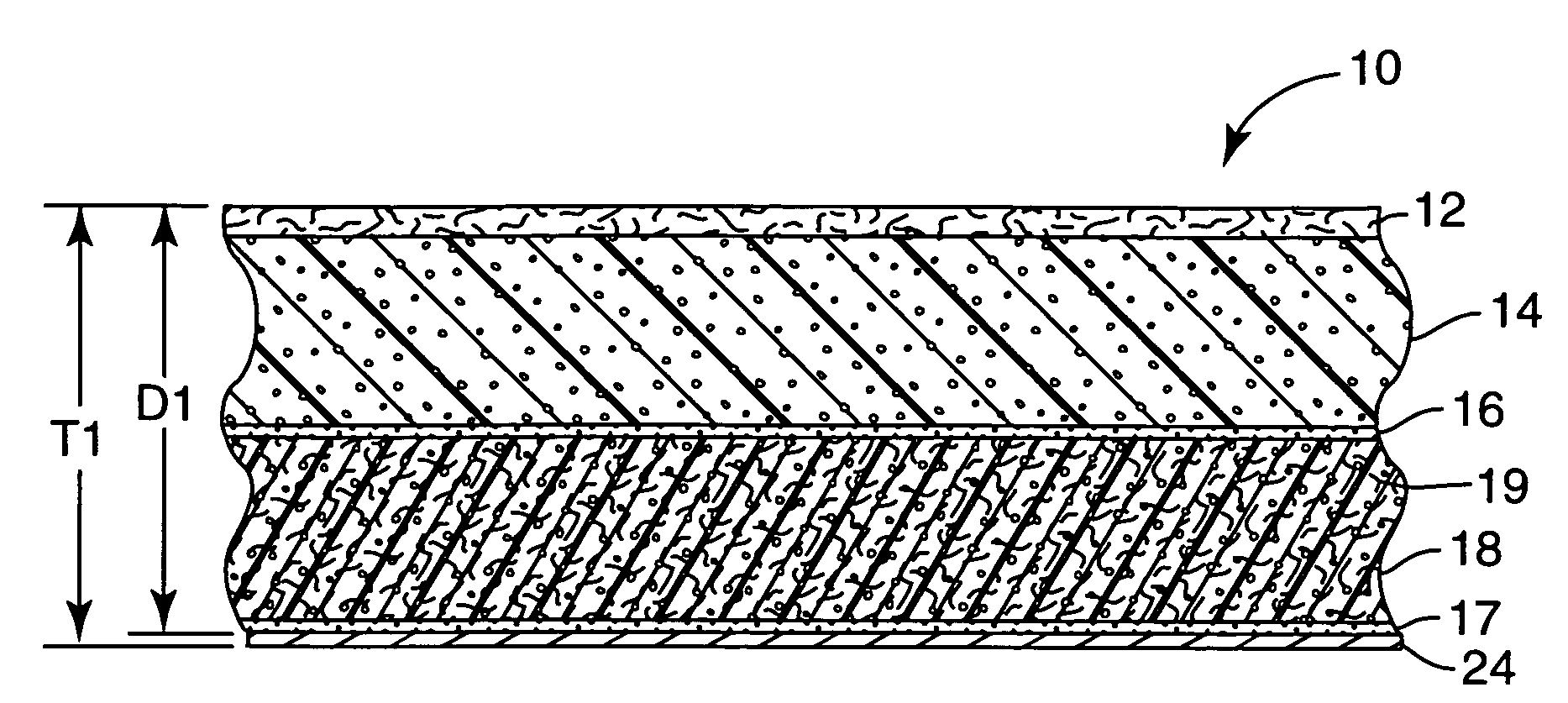

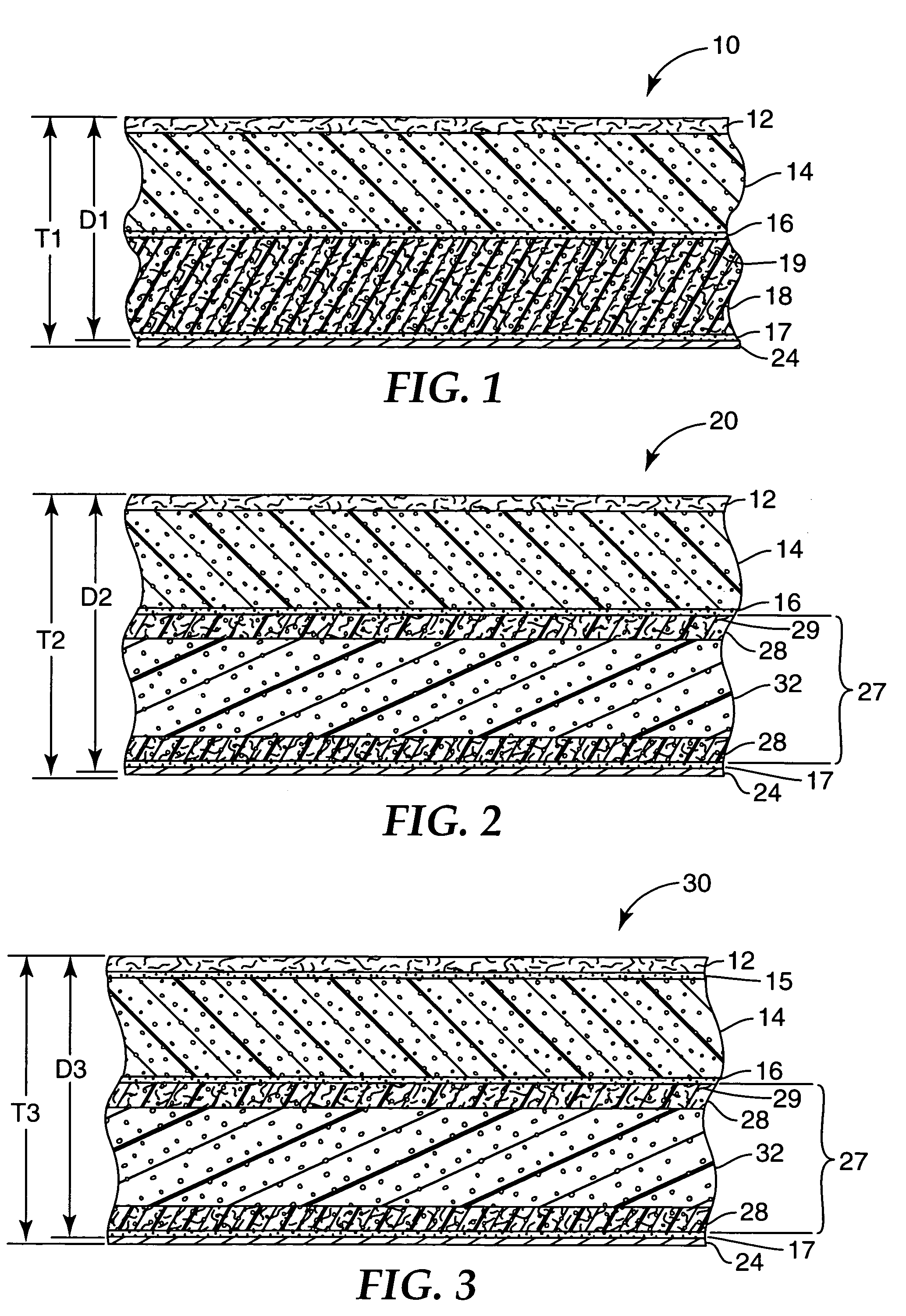

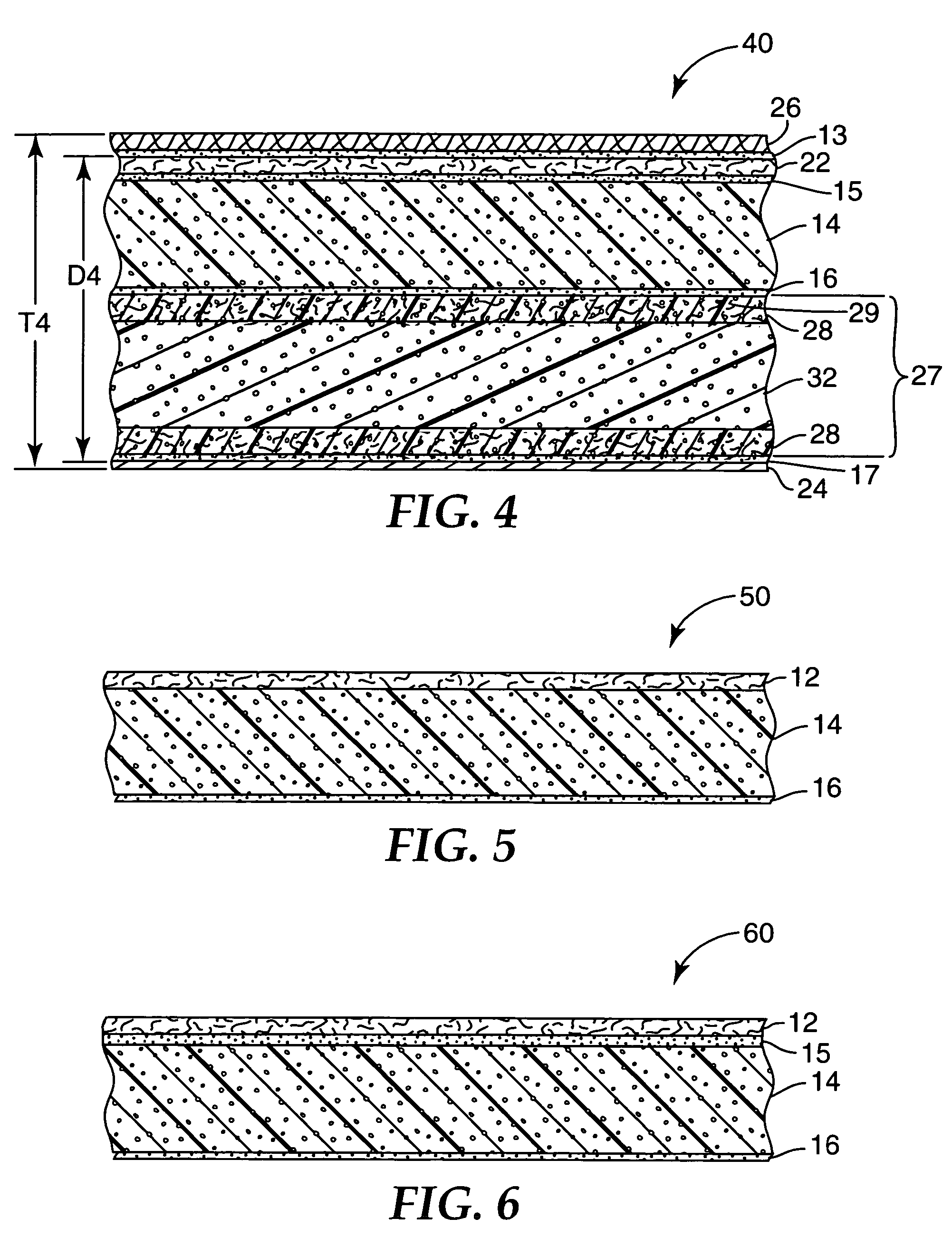

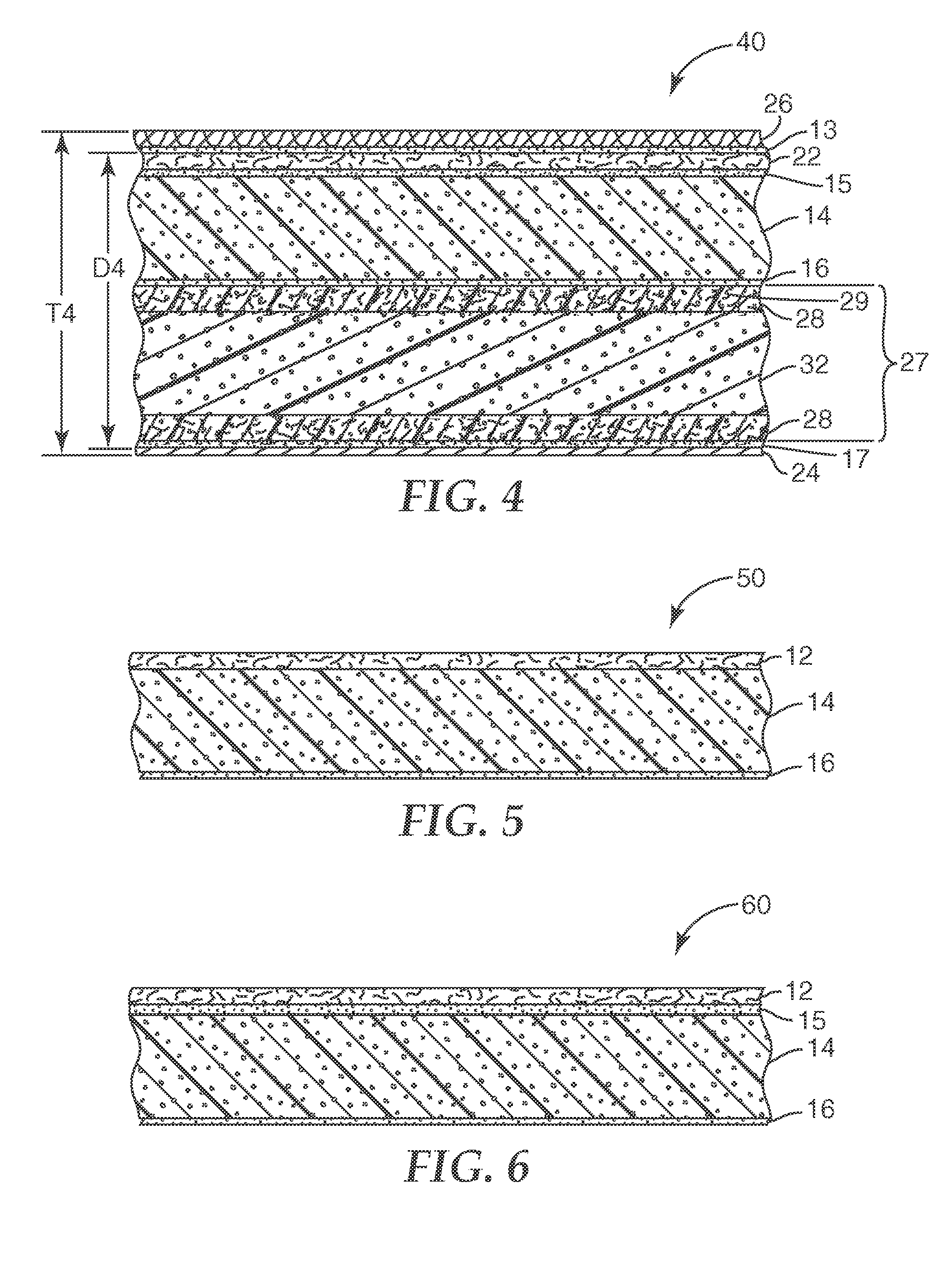

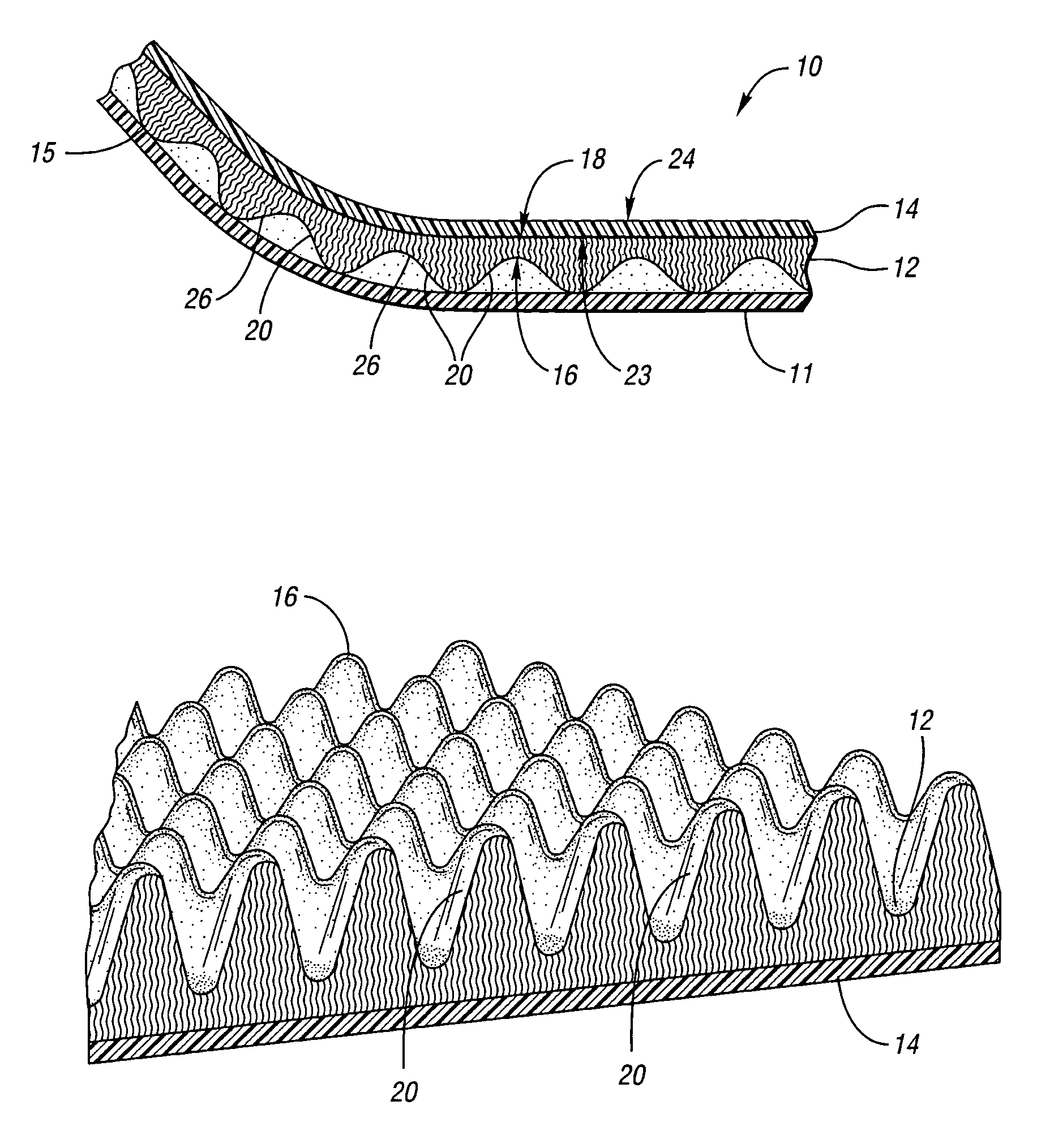

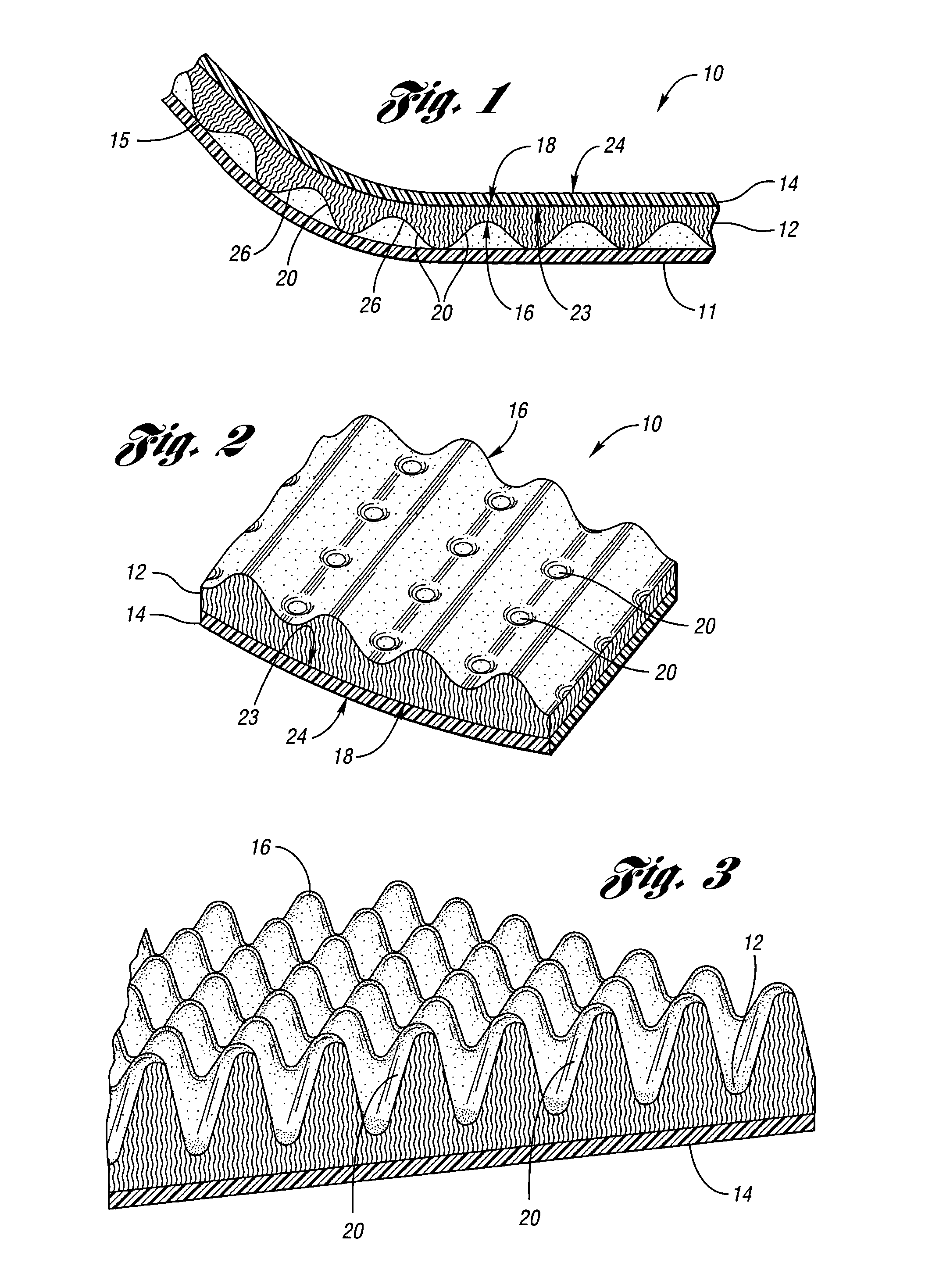

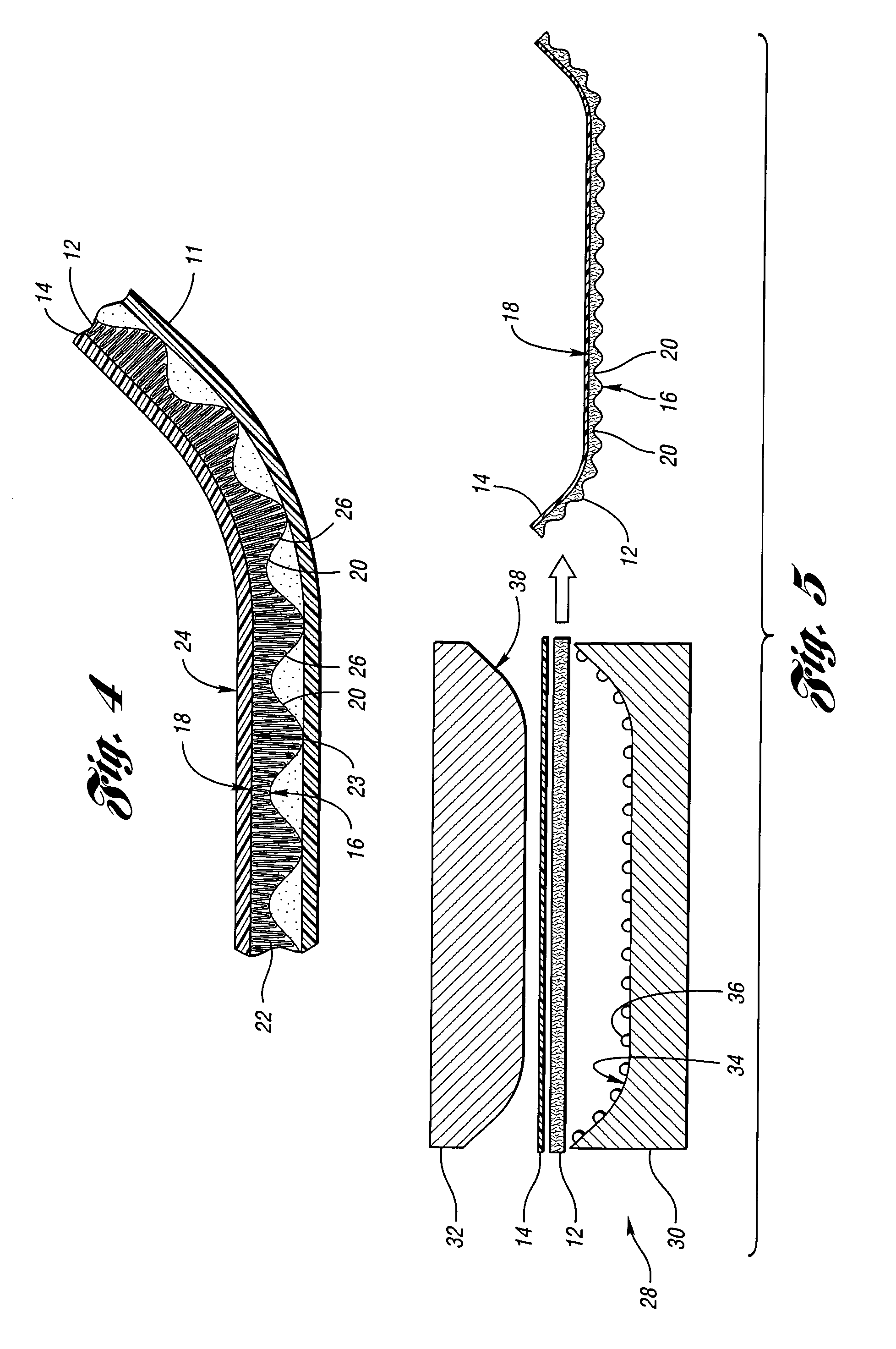

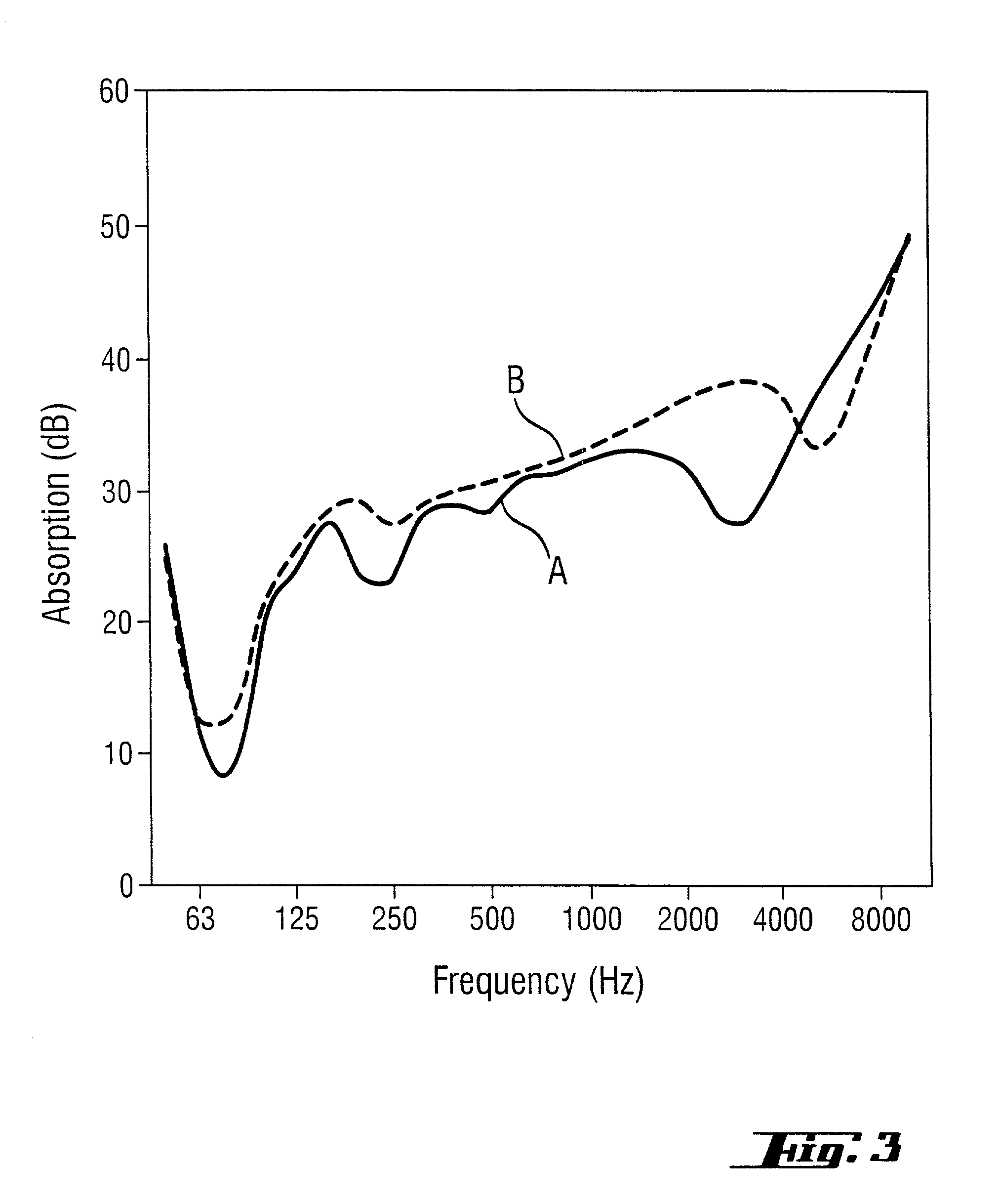

Sound absorptive multilayer composite

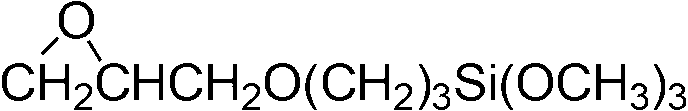

ActiveUS7320739B2Improve acoustic performanceIncreasing the thicknessMembranesSemi-permeable membranesOpen cellAirflow

A sound absorptive multilayer composite having an air-impermeable barrier, an air-permeable reinforcing core having an airflow resistance of at least about 100 mks Rayls and a thickness at least about ⅓ the final composite thickness, an air-permeable open cell foam or fibrous pad having an airflow resistance less than about 2000 mks Rayls and a thickness at least about 1 / 10 the final composite thickness and a semipermeable airflow-resistive membrane having an airflow resistance of about 500 to about 4000 mks Rayls can provide improved acoustic performance. For example, existing vehicular headliner designs may be improved by adding a properly chosen and properly positioned semipermeable airflow-resistive membrane, a properly chosen and properly positioned air-impermeable barrier, or a properly chosen and properly positioned open cell foam layer.

Owner:3M INNOVATIVE PROPERTIES CO

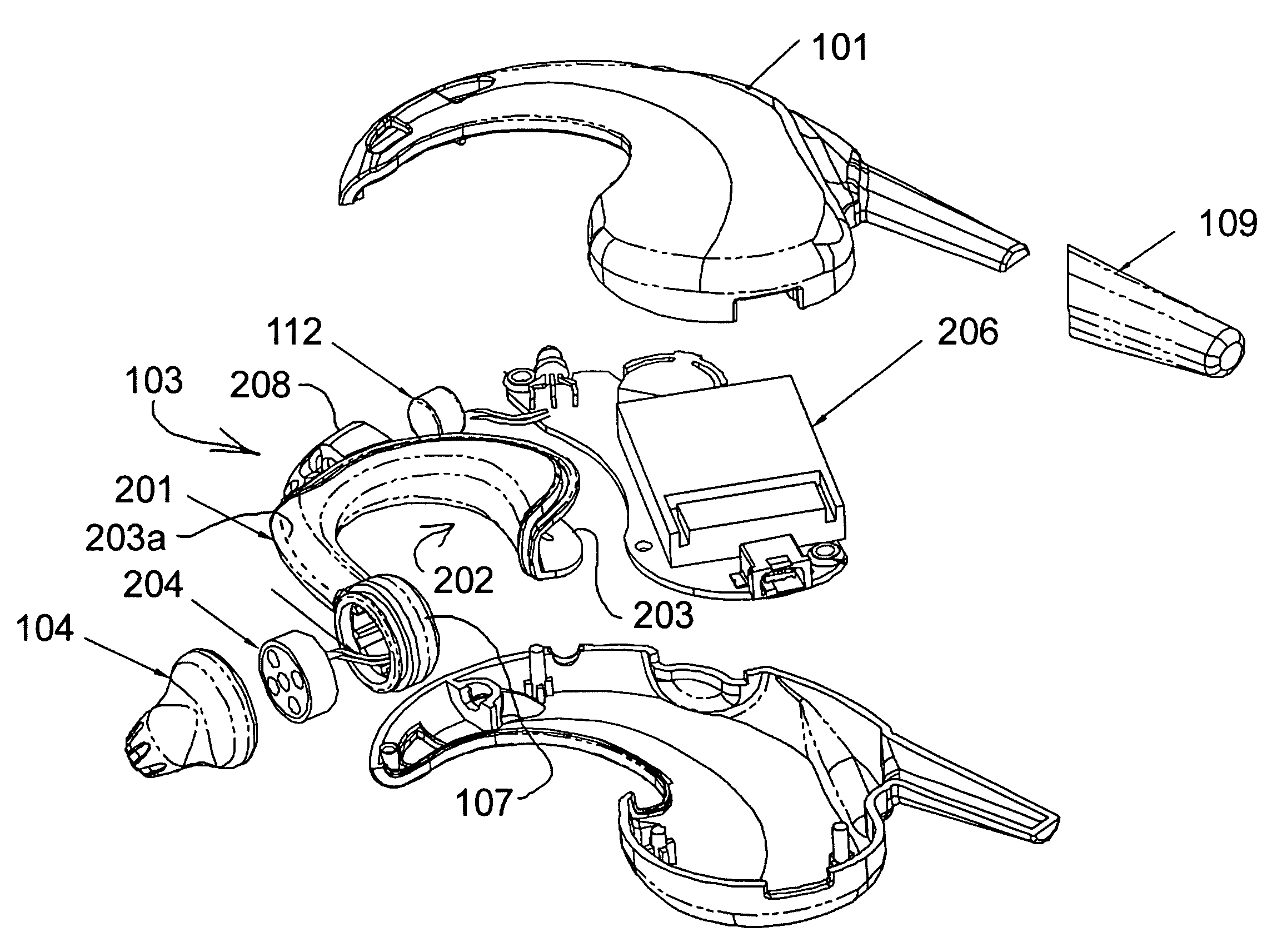

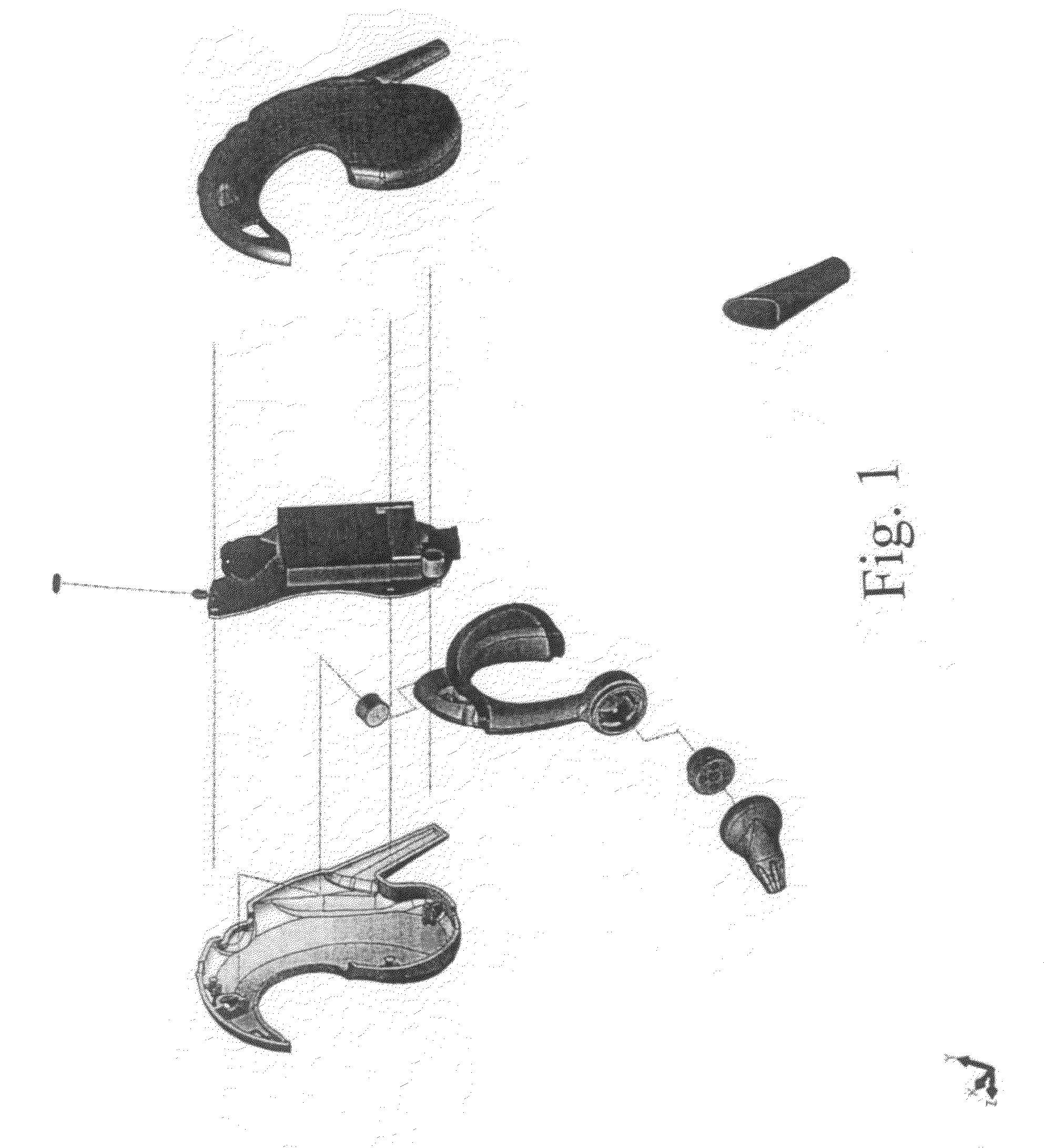

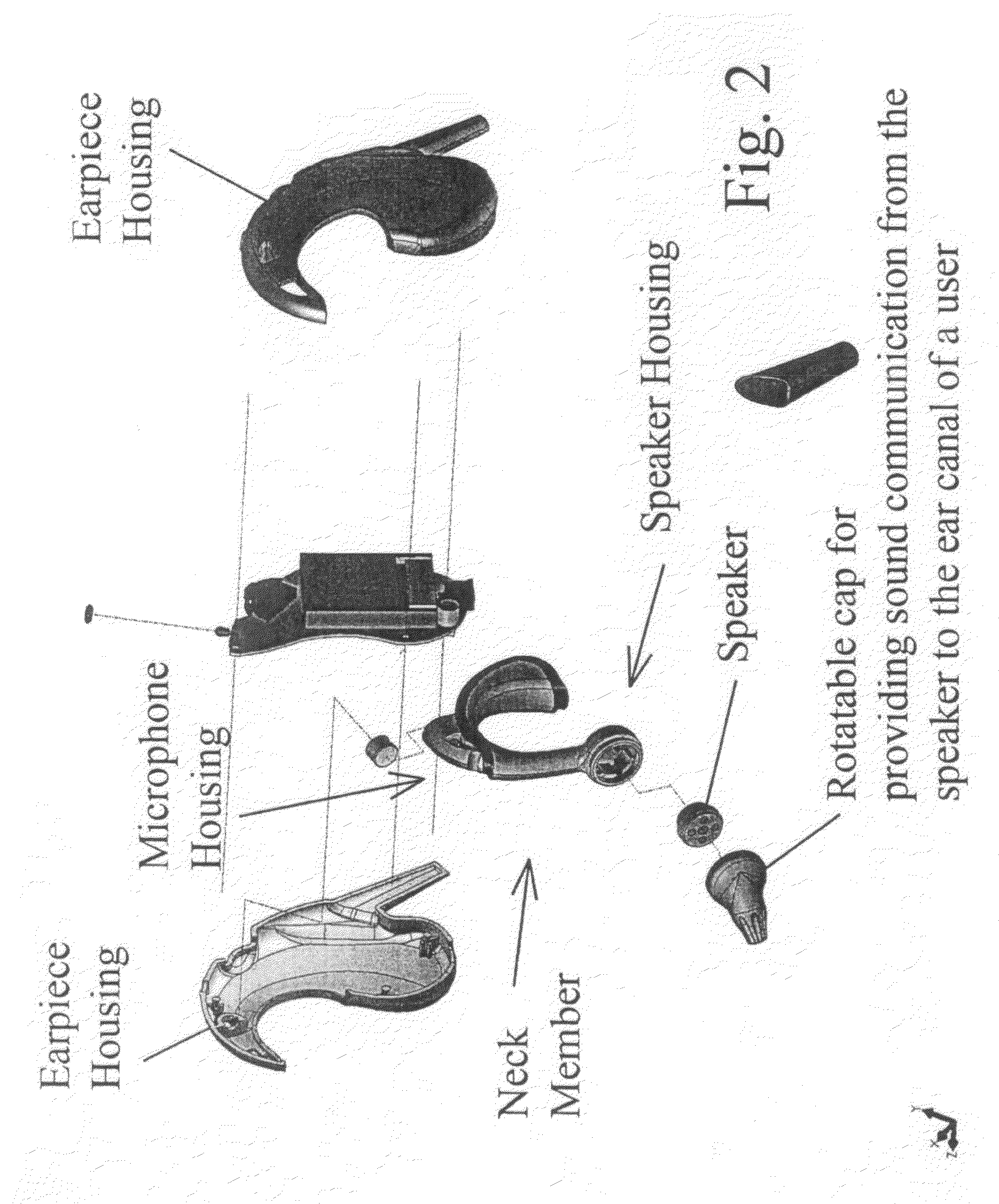

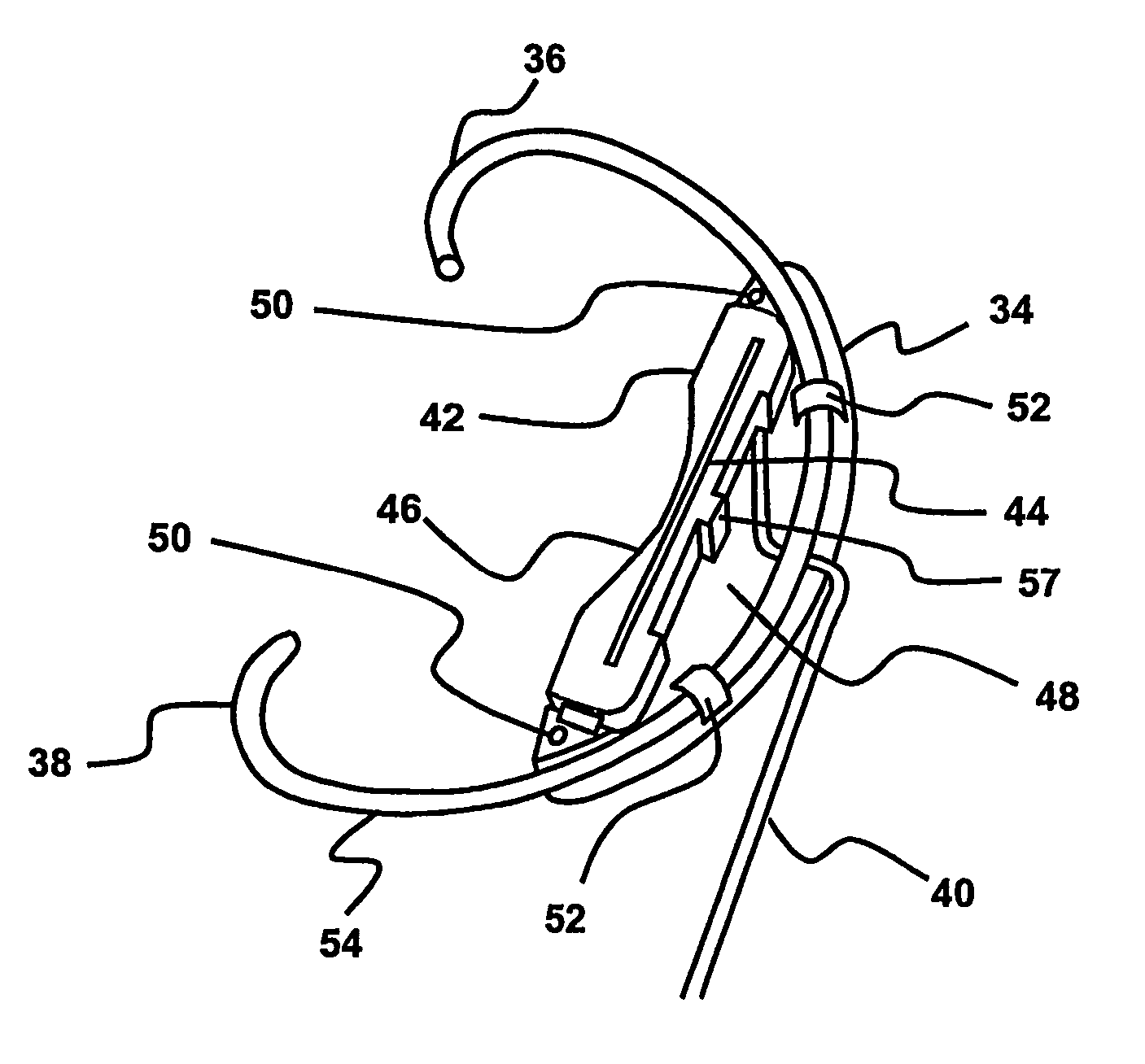

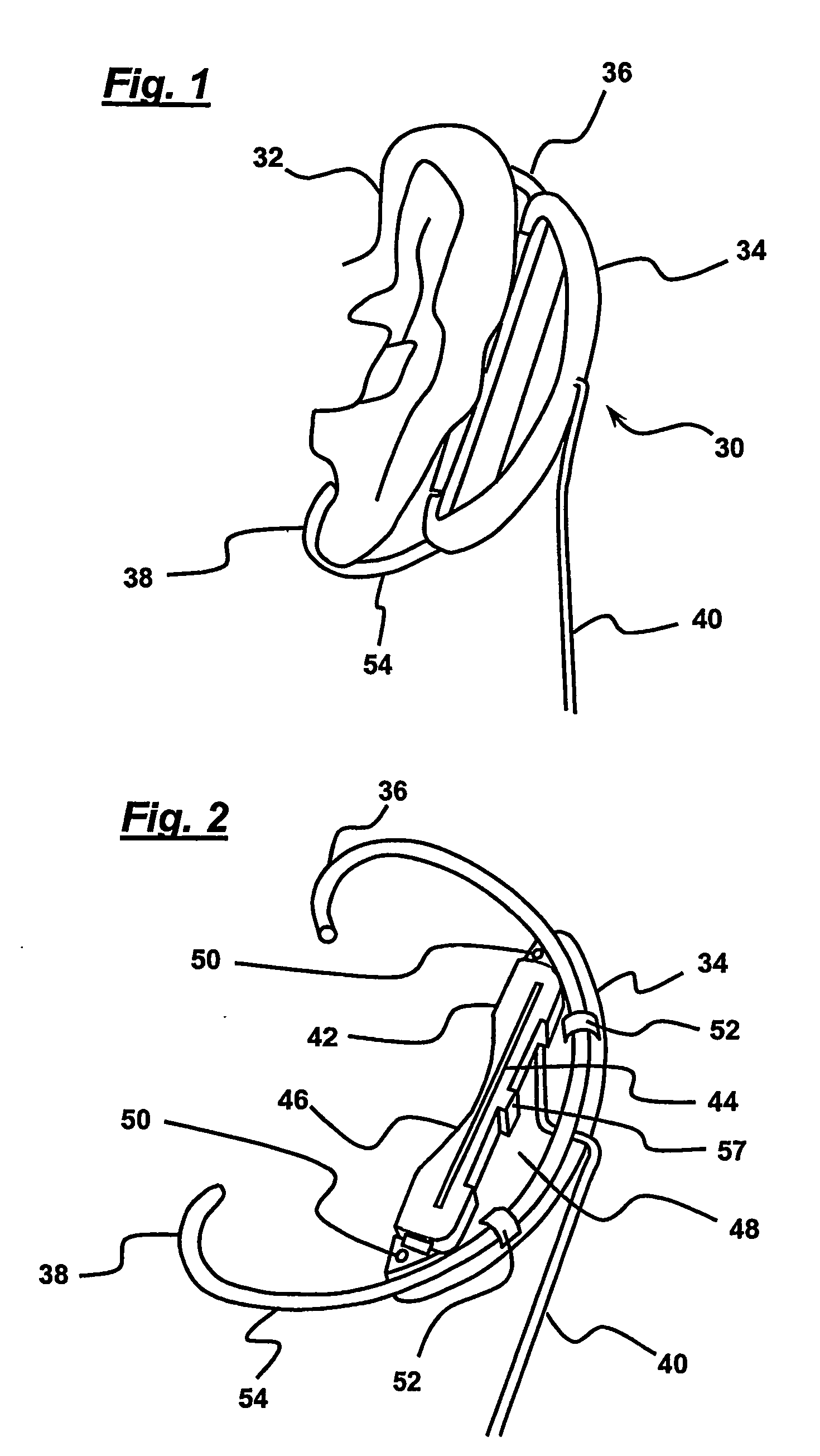

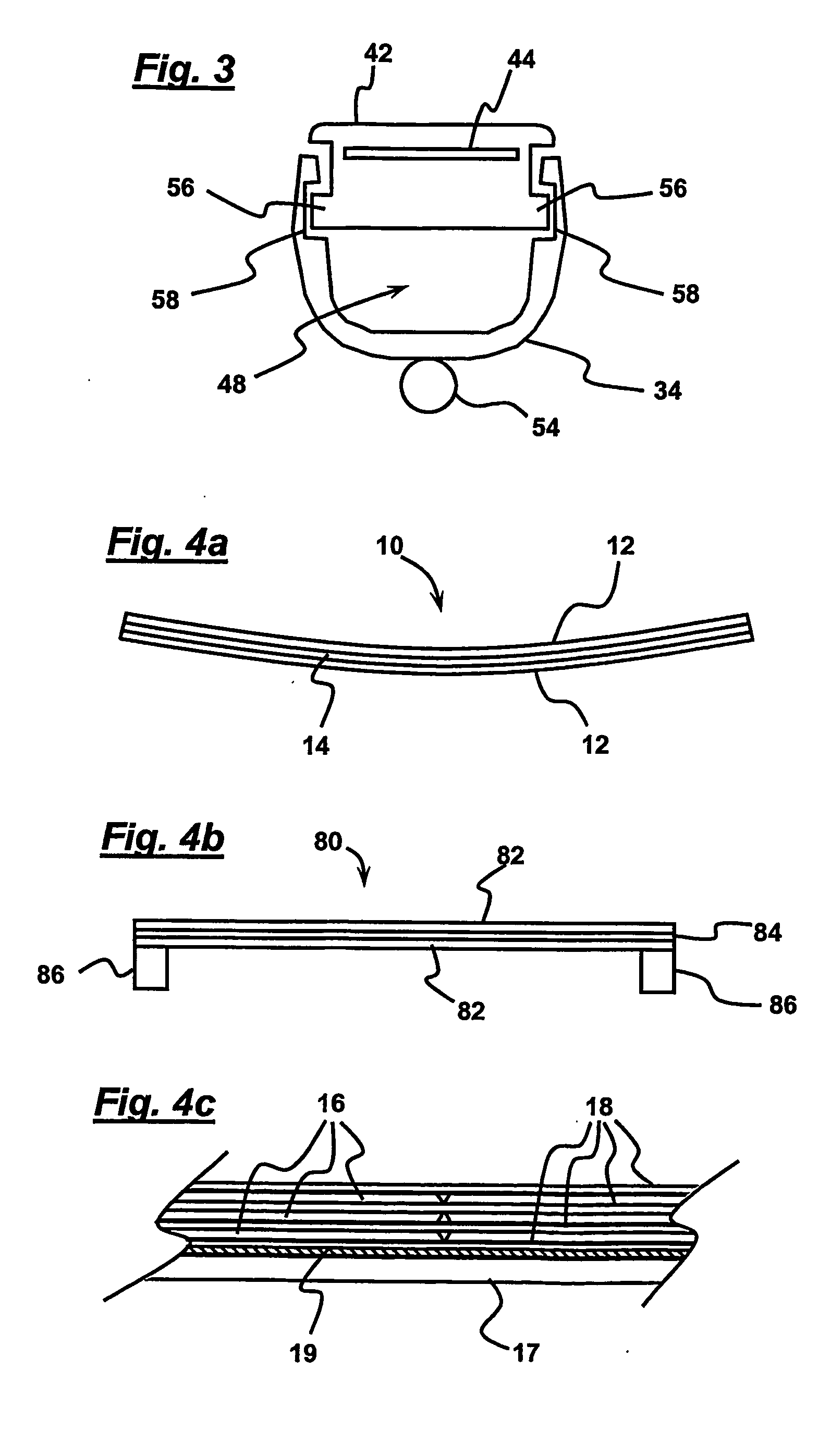

Earset assembly

ActiveUS7570777B1Not uncomfortable tension and pressureHigh quality acoustic performanceDeaf-aid setsLoudspeakerEngineering

A wired or wireless earset assembly includes an earset housing having a curved portion configured to fit to the top of an ear, a speaker driver contained in a speaker housing, a flexible tube having a first extension so as to be coupled with at least a part of the curved portion of the earset housing and a second extension coupled with the speaker housing, a rotatable cap containing a bud coupled with the speaker driver, a sound delivery port in the bud, a circuitry for processing an input signal in the case, and a wire in the flexible tube connecting the circuitry and the speaker driver.

Owner:DOLBY LAB LICENSING CORP

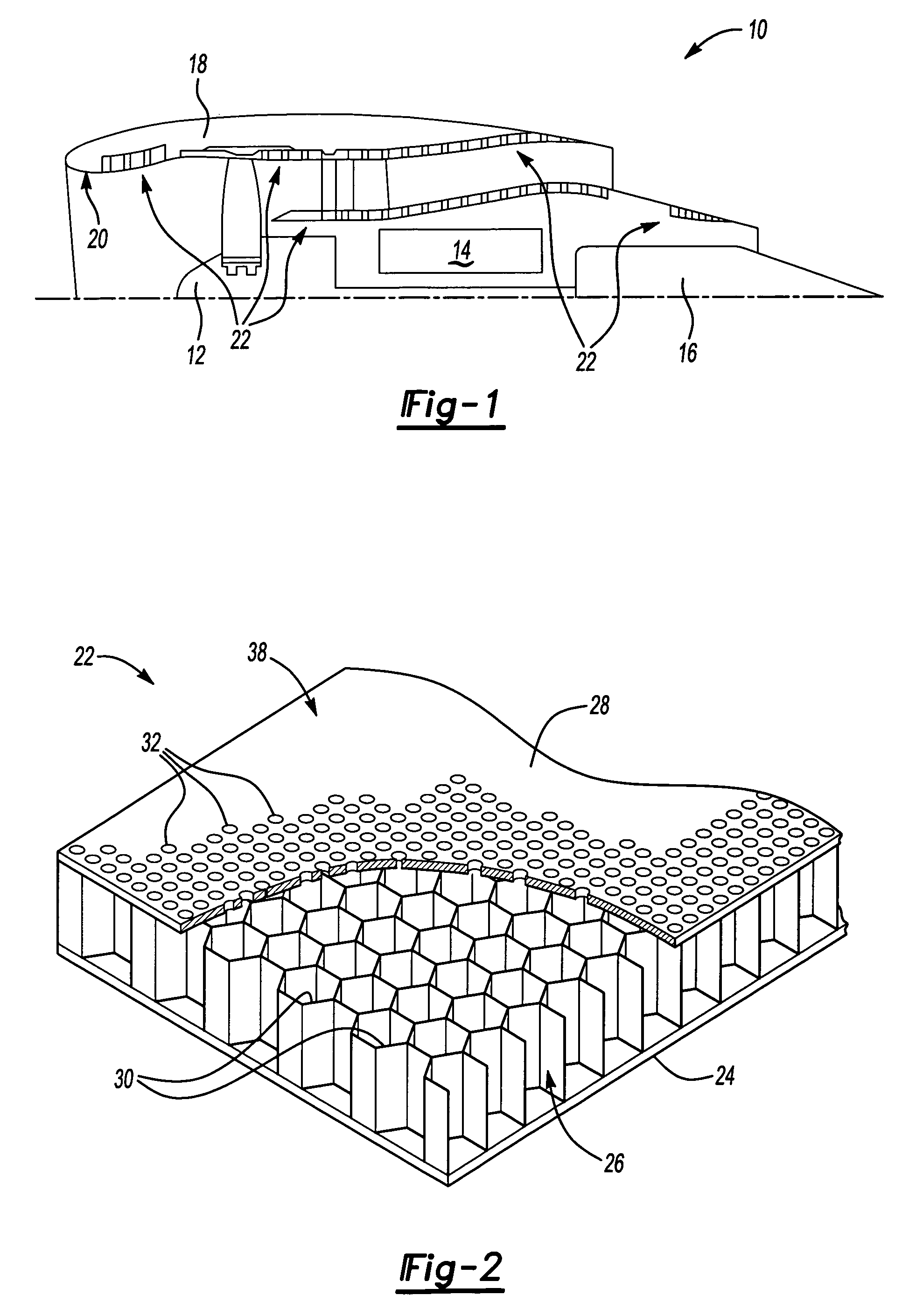

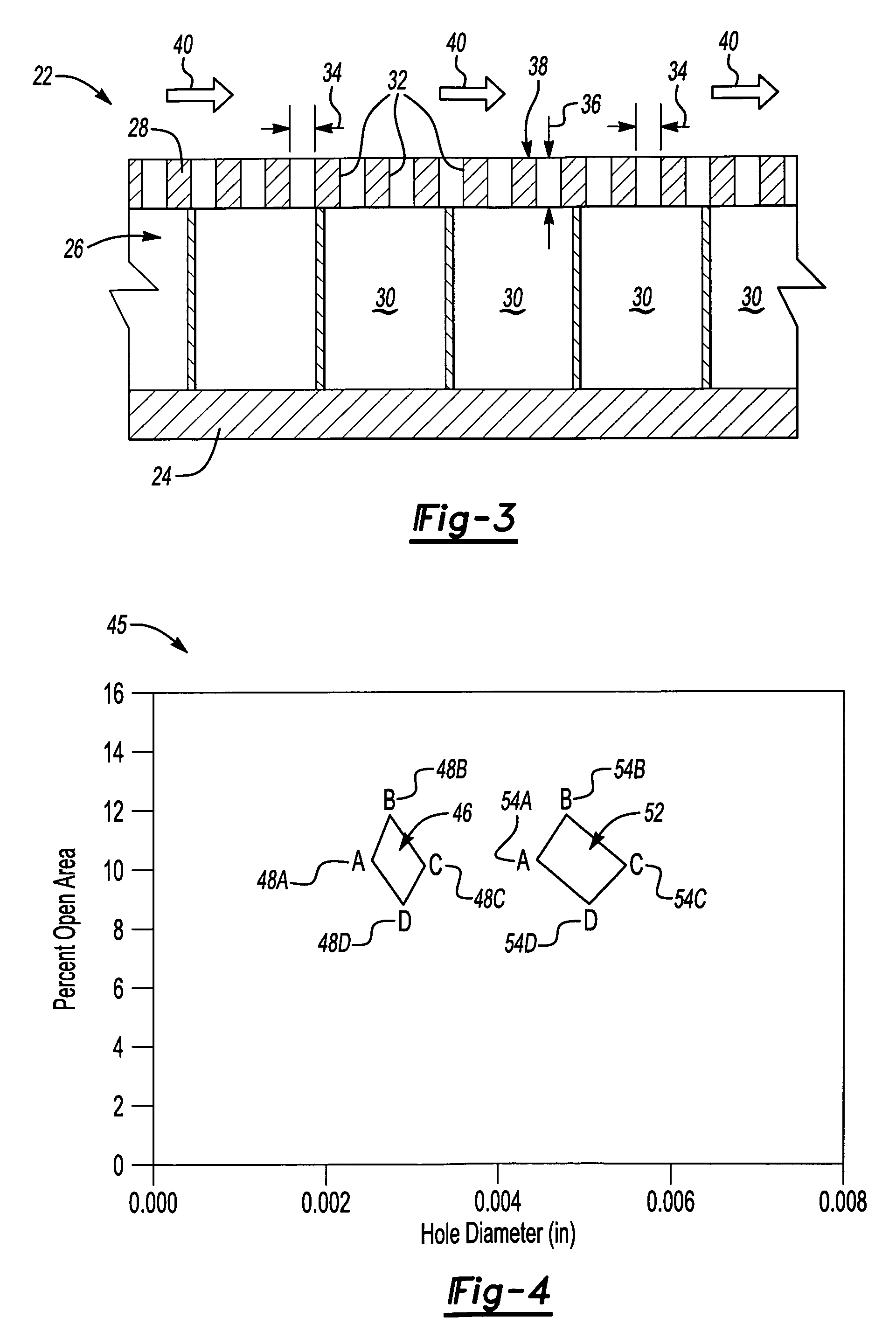

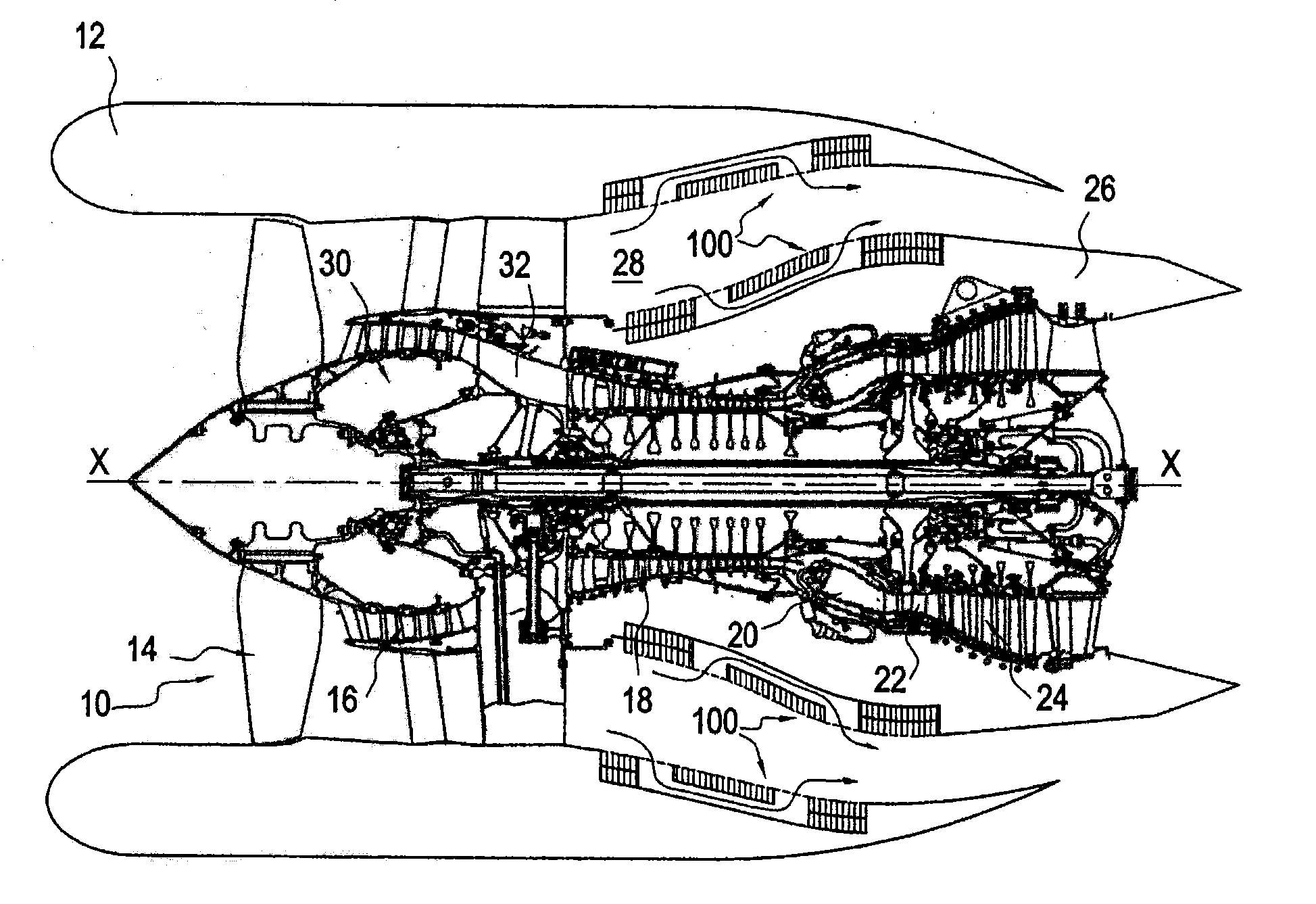

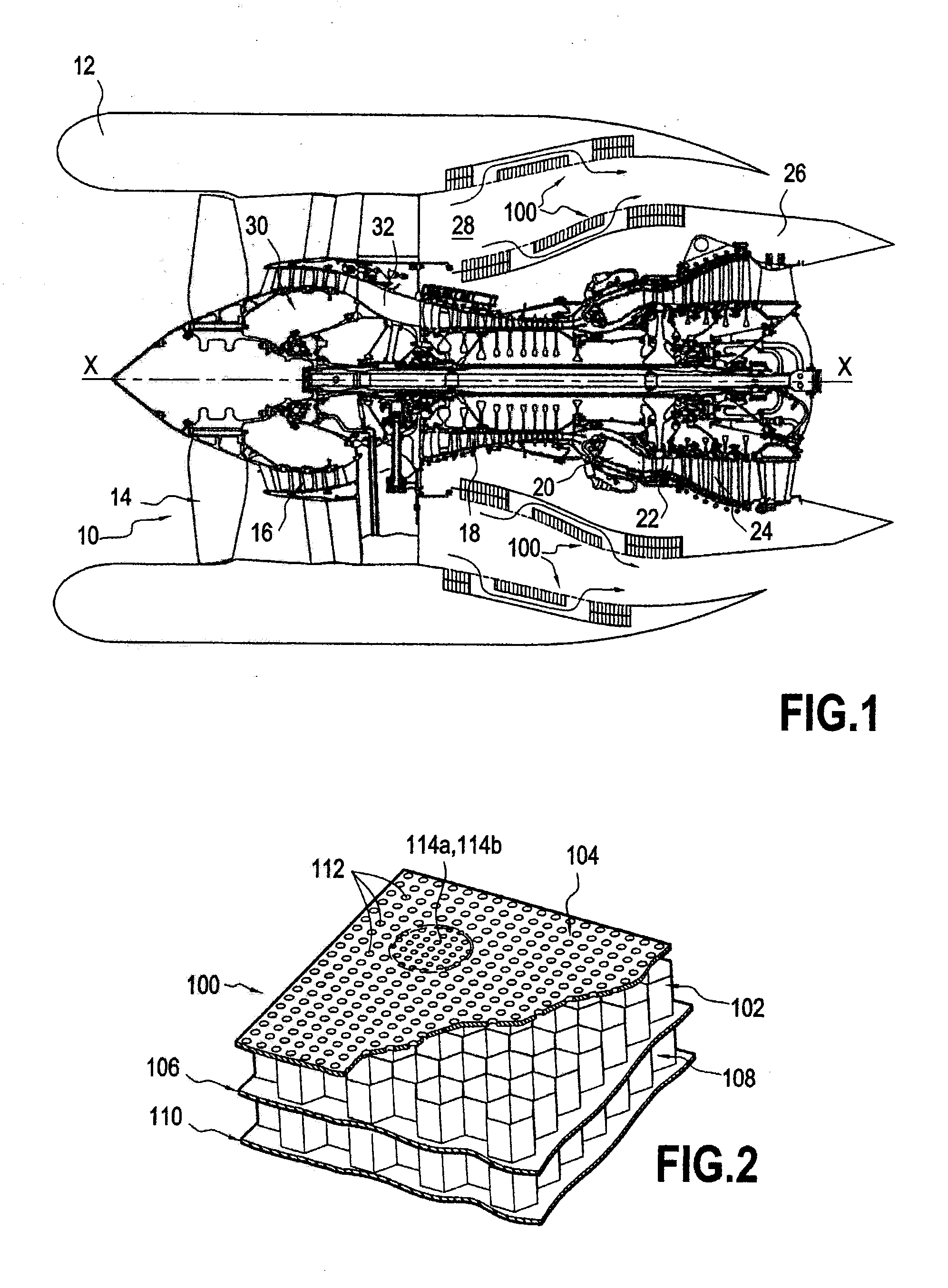

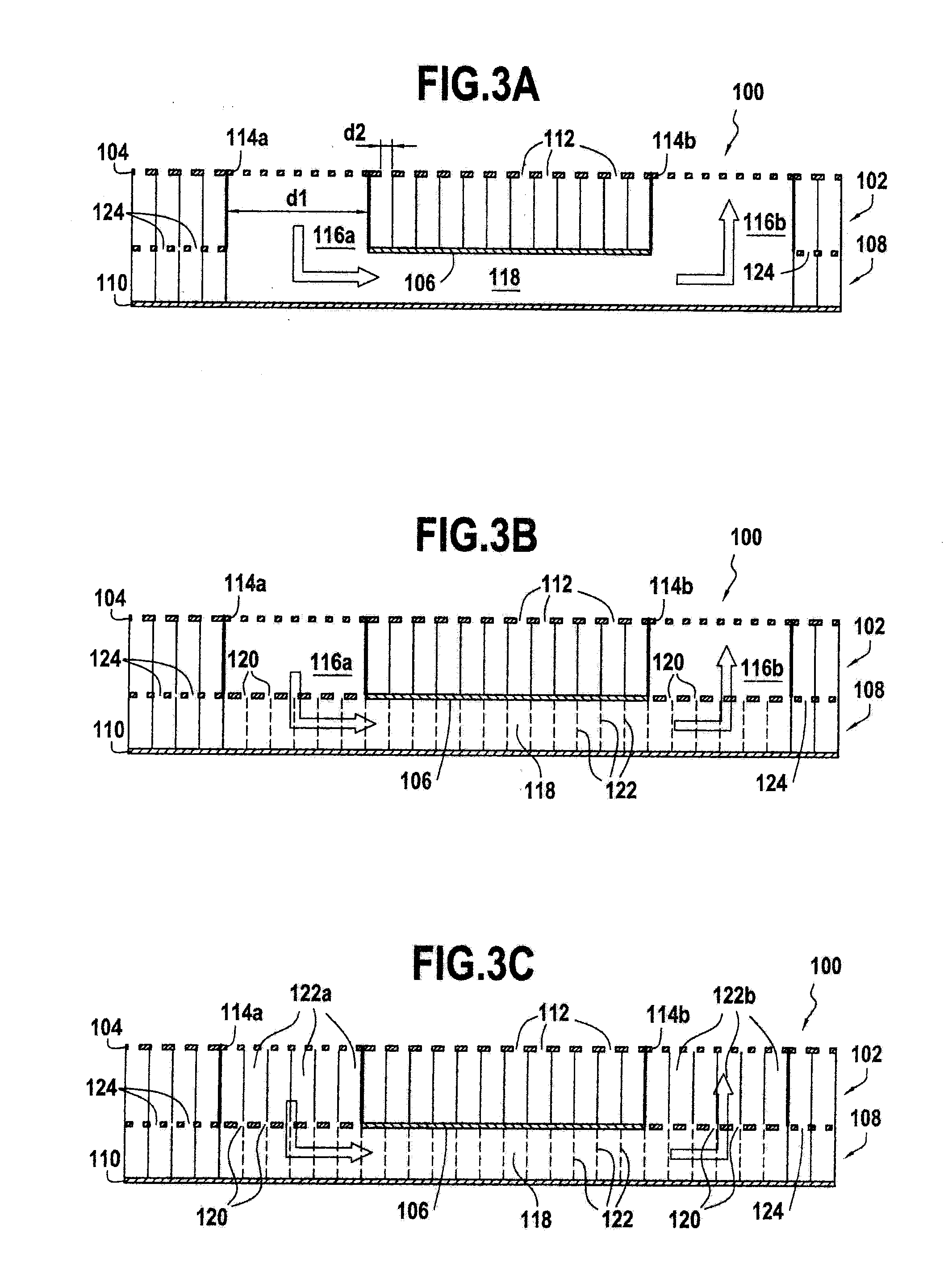

Micro-perforated acoustic liner

ActiveUS7540354B2Drag minimizationPerformance maximizationEngine manufactureLayered productsEngineeringFace sheet

An example liner assembly includes a backing plate that supports a cellular structure covered by a perforated face sheet including a plurality of openings. Each of the plurality of openings is of a size determined to provide desired acoustic performance.

Owner:RTX CORP

Sound absorptive multilayer composite

InactiveUS20080073146A1Improve acoustic performanceIncreasing the thicknessSemi-permeable membranesMembranesMechanical engineeringOpen cell

A sound absorptive multilayer composite having an air-impermeable barrier, an air-permeable reinforcing core having an airflow resistance of at least about 100 mks Rayls and a thickness at least about ⅓ the final composite thickness, an air-permeable open cell foam or fibrous pad having an airflow resistance less than about 2000 mks Rayls and a thickness at least about 1 / 10 the final composite thickness and a semipermeable airflow-resistive membrane having an airflow resistance of about 500 to about 4000 mks Rayls can provide improved acoustic performance. For example, existing vehicular headliner designs may be improved by adding a properly chosen and properly positioned semipermeable airflow-resistive membrane, a properly chosen and properly positioned air-impermeable barrier, or a properly chosen and properly positioned open cell foam layer.

Owner:3M INNOVATIVE PROPERTIES CO

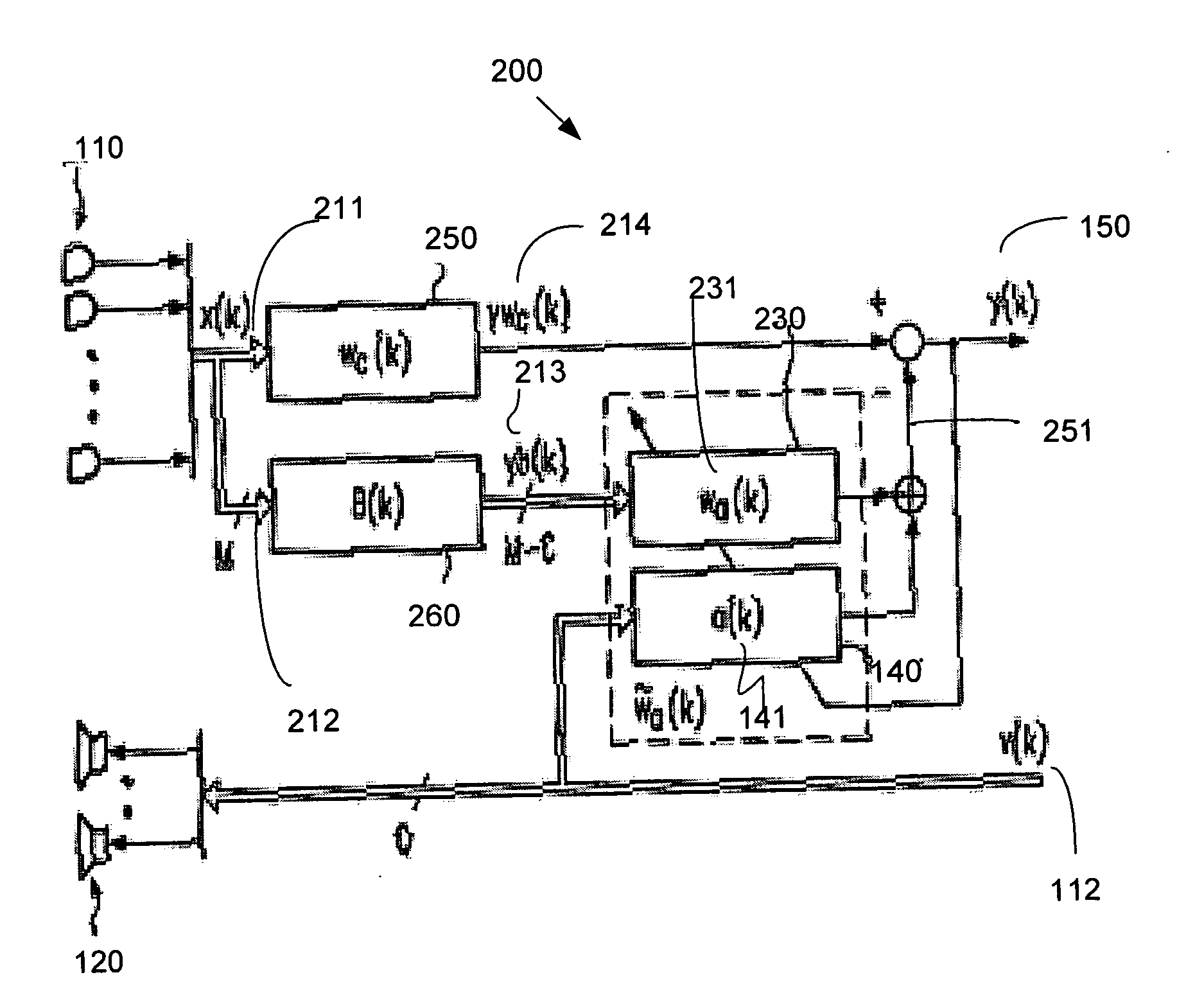

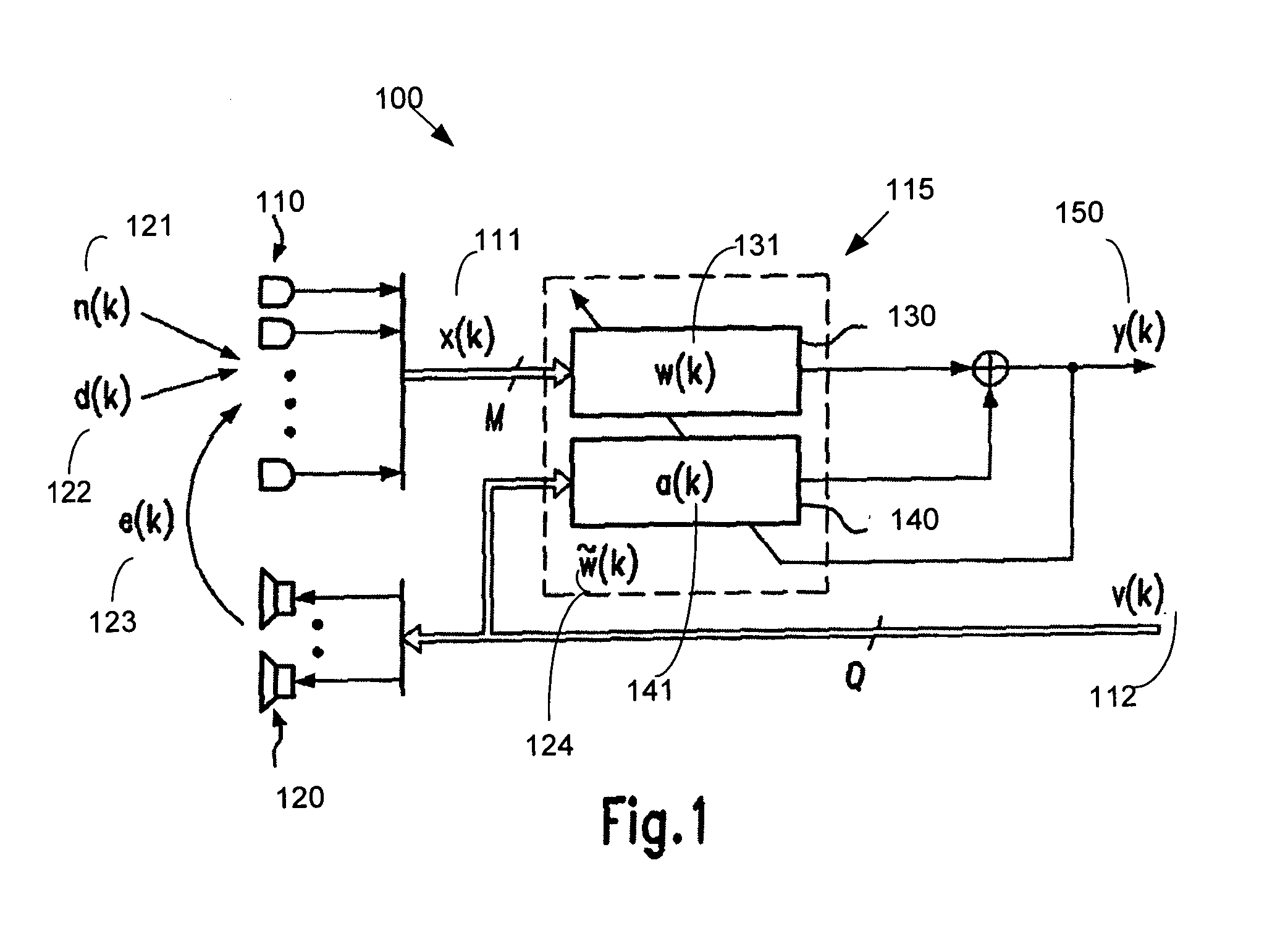

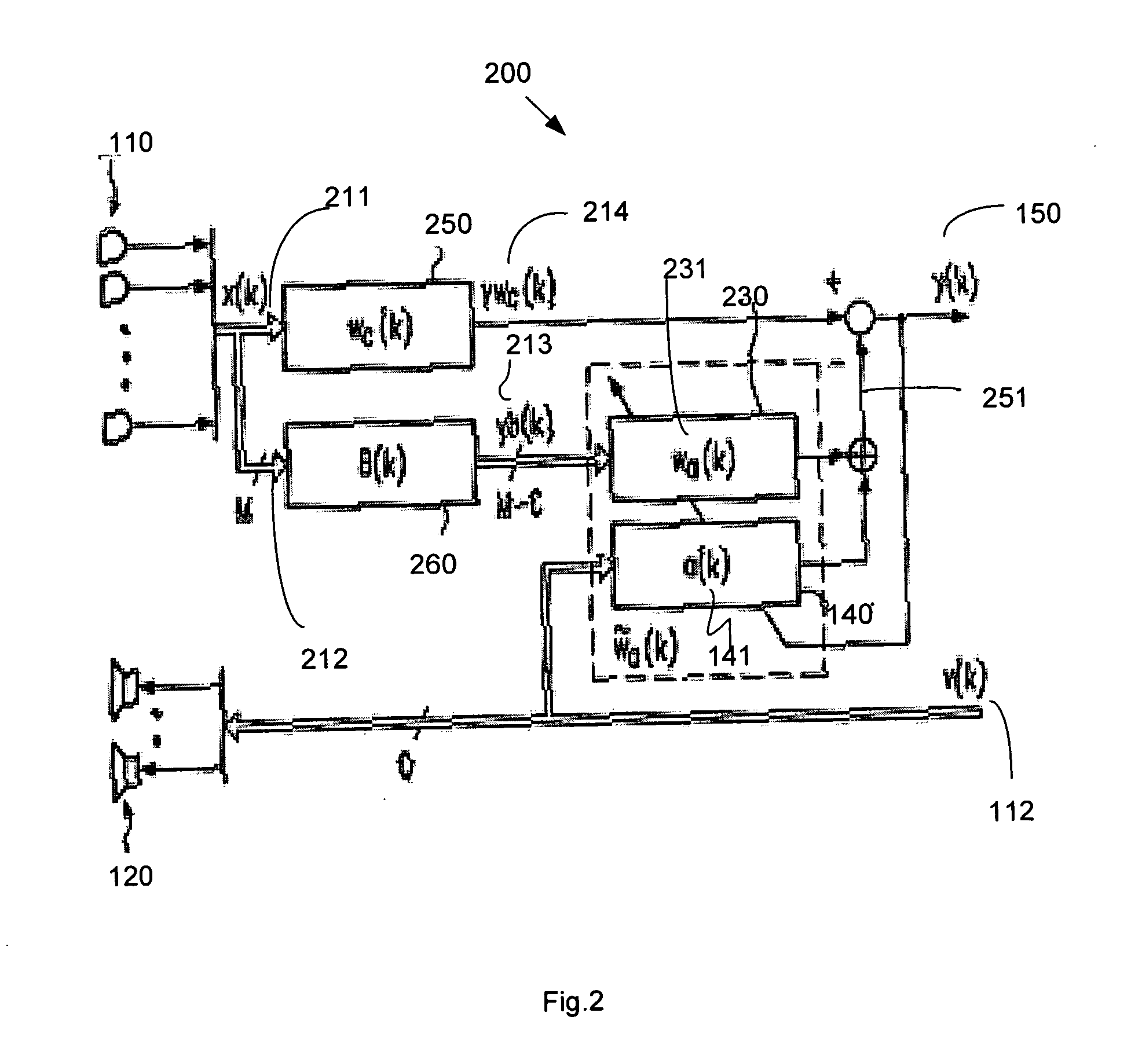

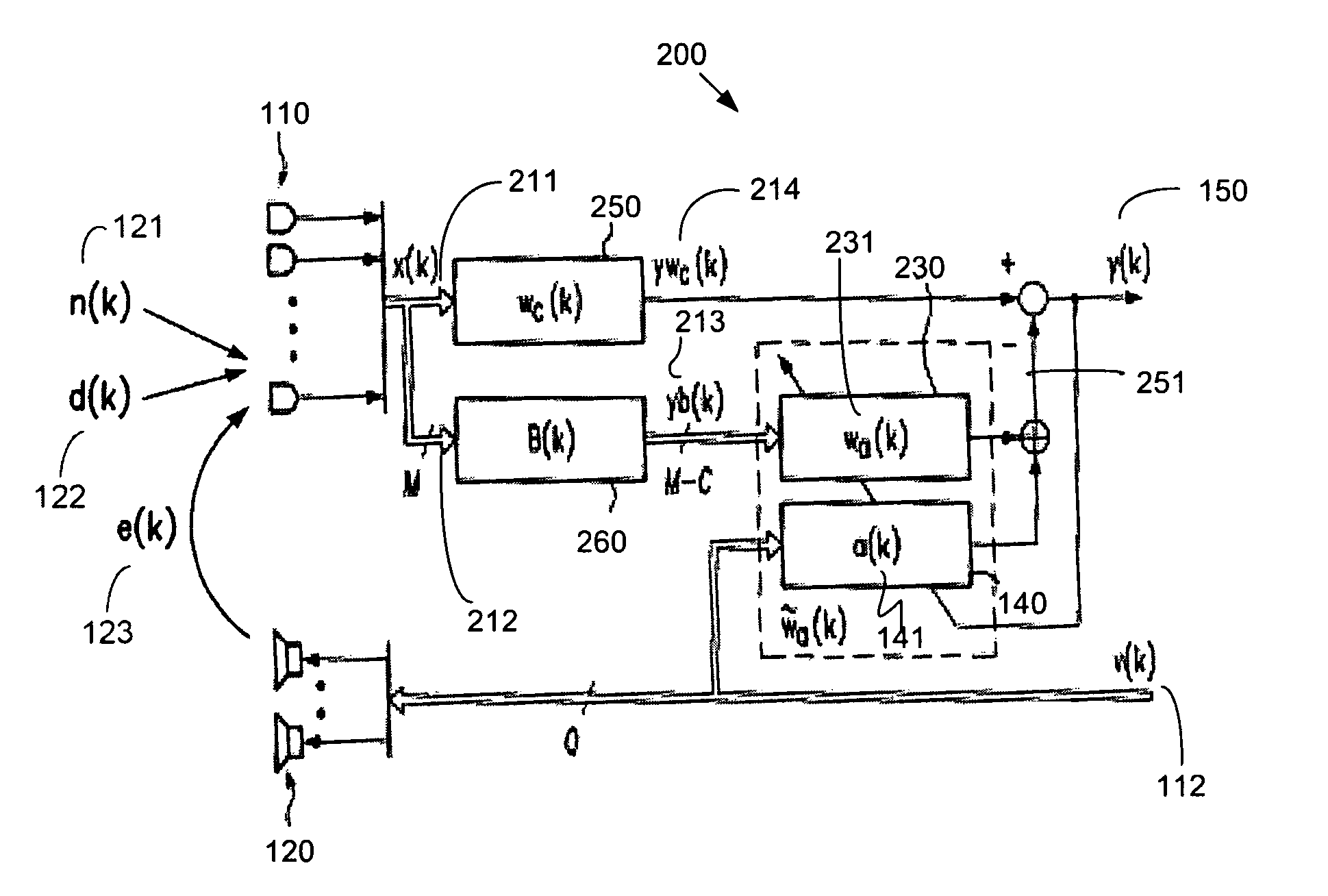

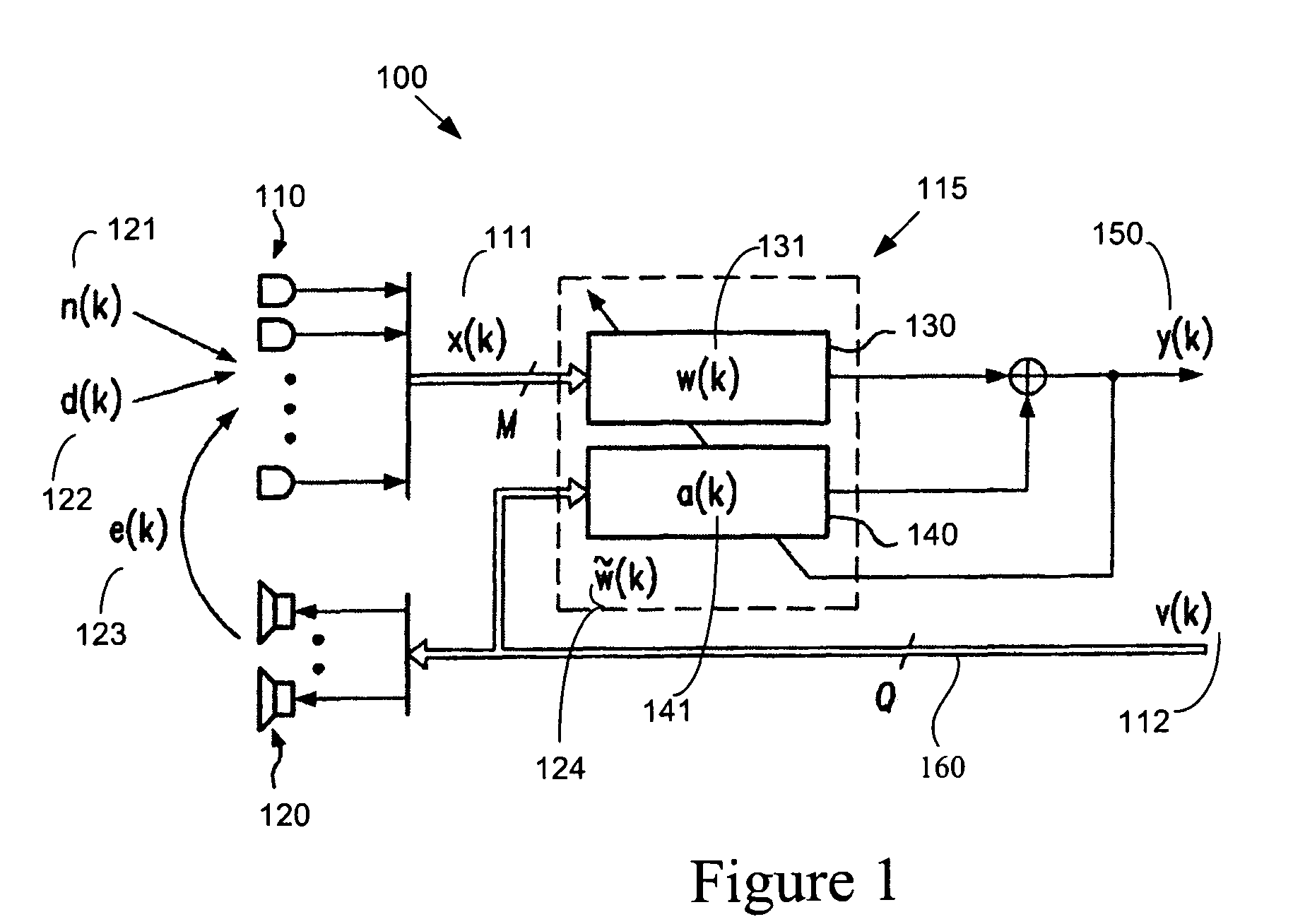

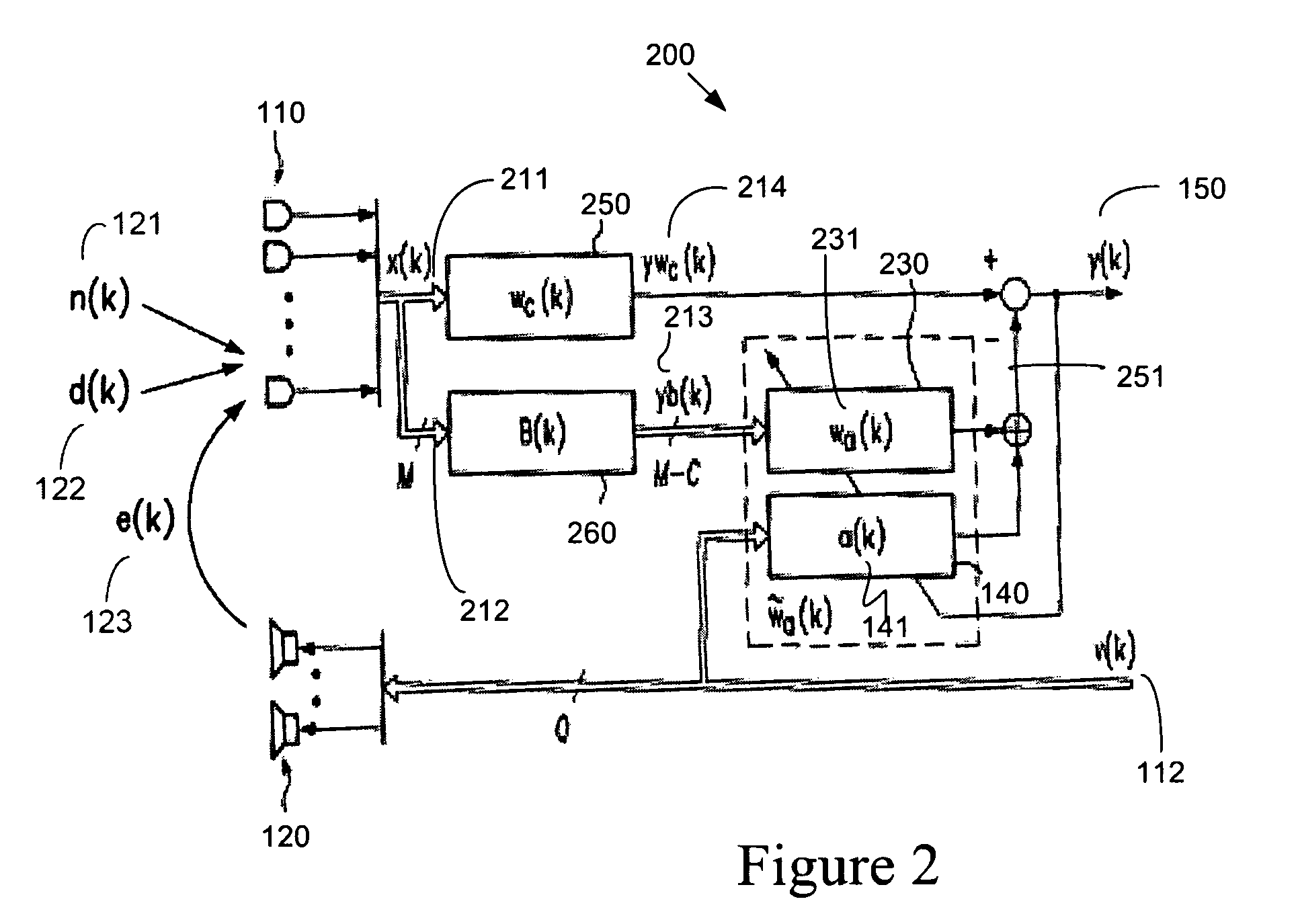

Speech signal processing with combined noise reduction and echo compensation

ActiveUS20060153360A1Improve acoustic performanceReduce echoTwo-way loud-speaking telephone systemsSpeech recognitionAcoustic noise reductionIn vehicle

A speech signal processing system combines acoustic noise reduction and echo cancellation to enhance acoustic performance. The speech signal processing system may be used in vehicles or other environments where noise-suppressed communication is desirable. The system includes an adaptive beamforming signal processing unit, an adaptive echo compensating unit to reduce acoustic echoes, and an adaptation unit to combine noise reduction and adaptive echo compensating.

Owner:NUANCE COMM INC

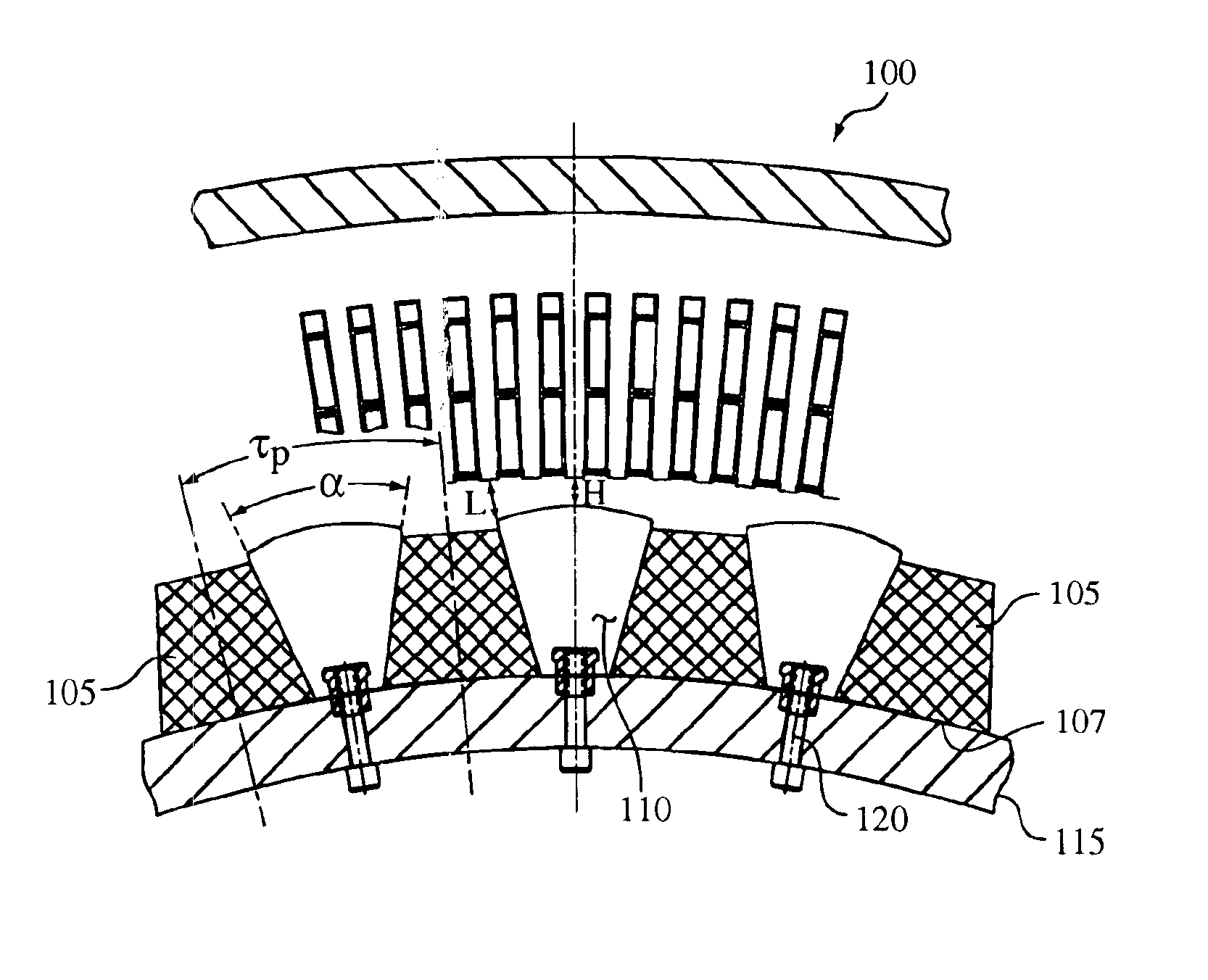

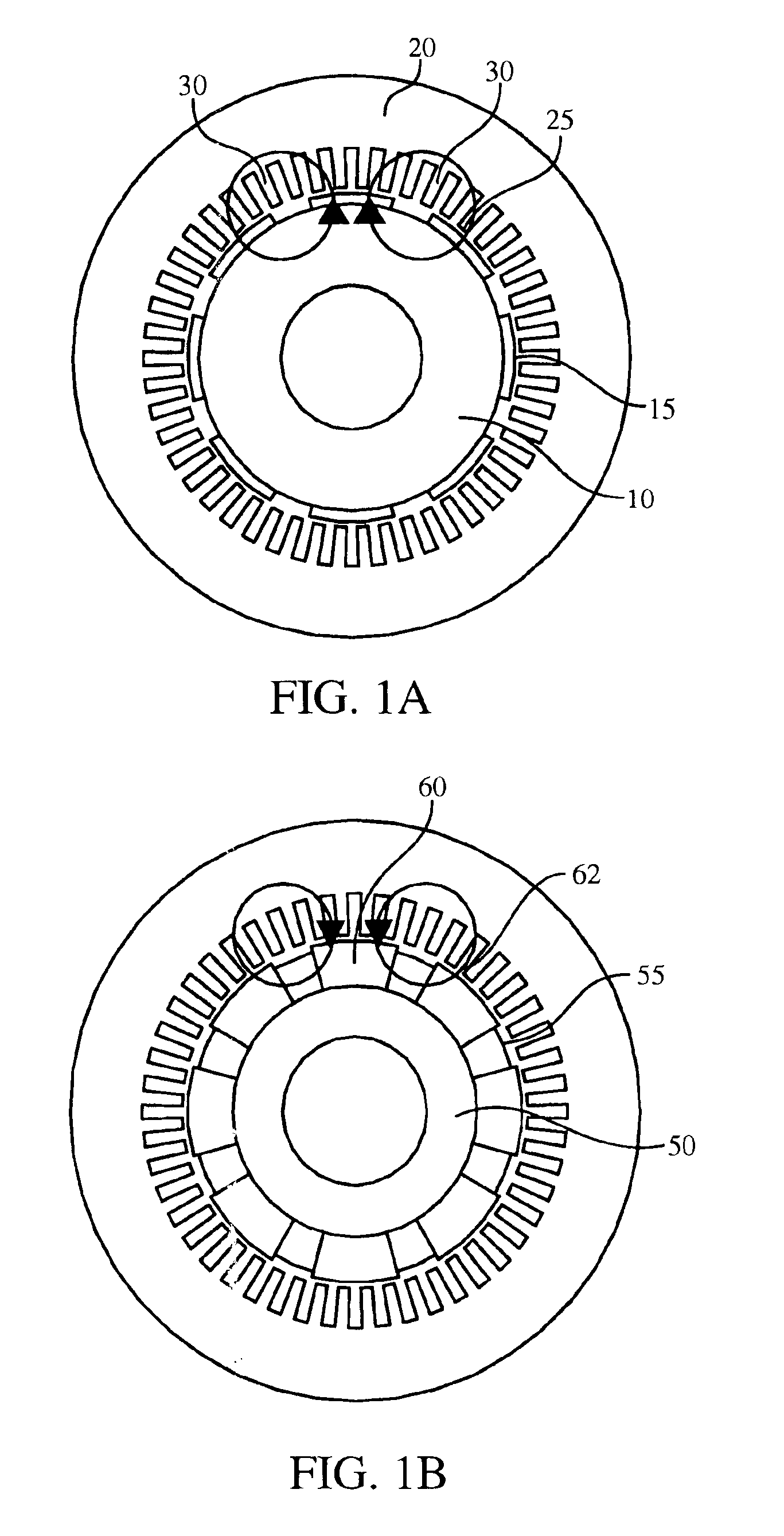

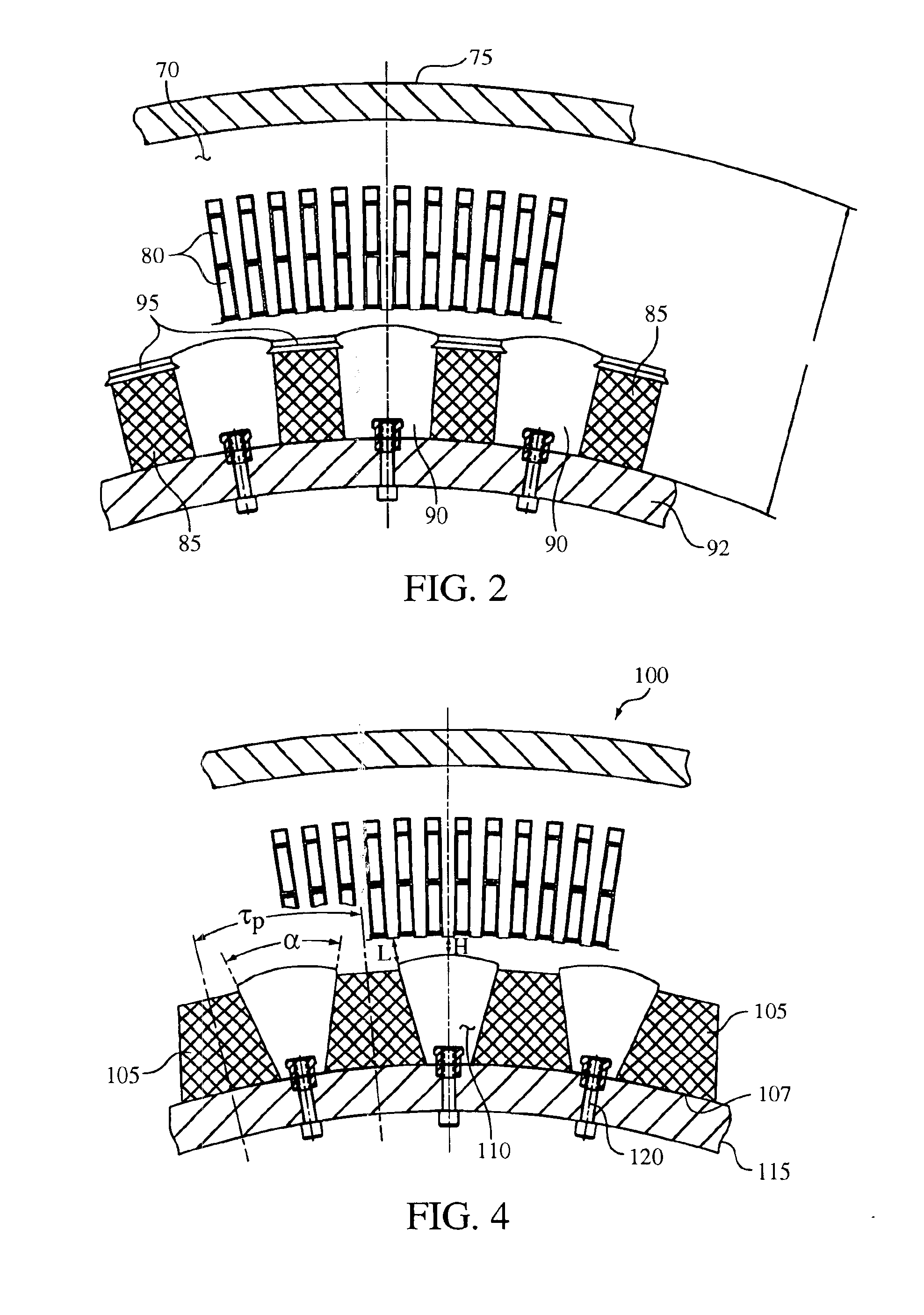

Trapezoidal shaped magnet flux intensifier motor pole arrangement for improved motor torque density

InactiveUS6879075B2Increase torqueImprove power characteristicsSynchronous generatorsWindingsPermanent magnet synchronous machineElectric machine

A permanent magnet synchronous machine with improved torque and power characteristics. A circumferential-oriented rotor assembly is provided with alternating permanent magnets and magnetic pole pieces. In order to reduce the amount of leakage flux in the rotor and increase the effective length of the permanent magnet, a trapezoidal or otherwise tapered permanent magnet structure is used. By alternating trapezoidal permanent magnet, and magnetic pole pieces, a higher intensity magnetic field is created in the air gap utilizing the same radial space in the motor without altering the weight or volume of the motor compared to conventional machines.

Owner:CURTISS WRIGHT ELECTRO MECHANICAL

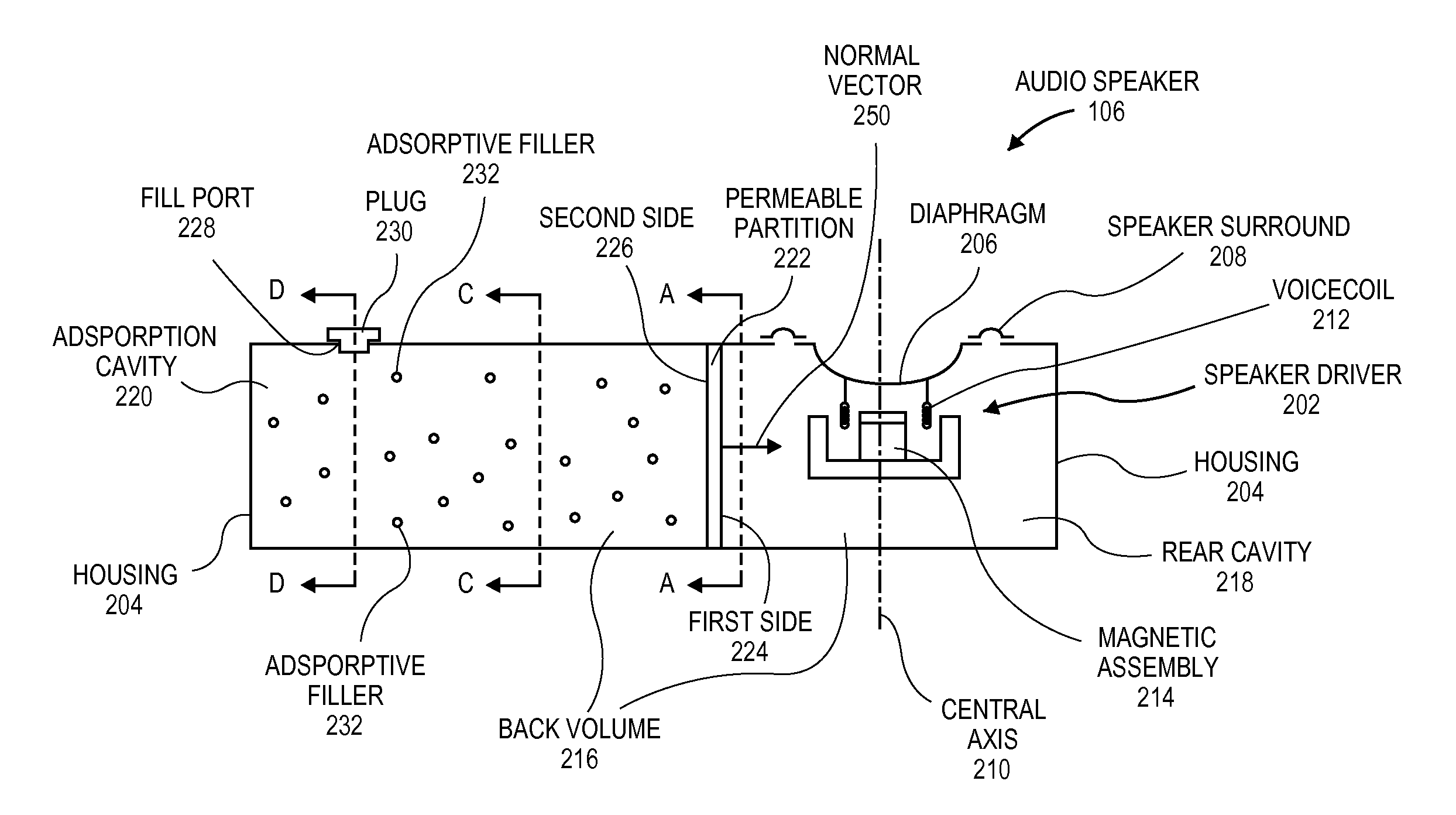

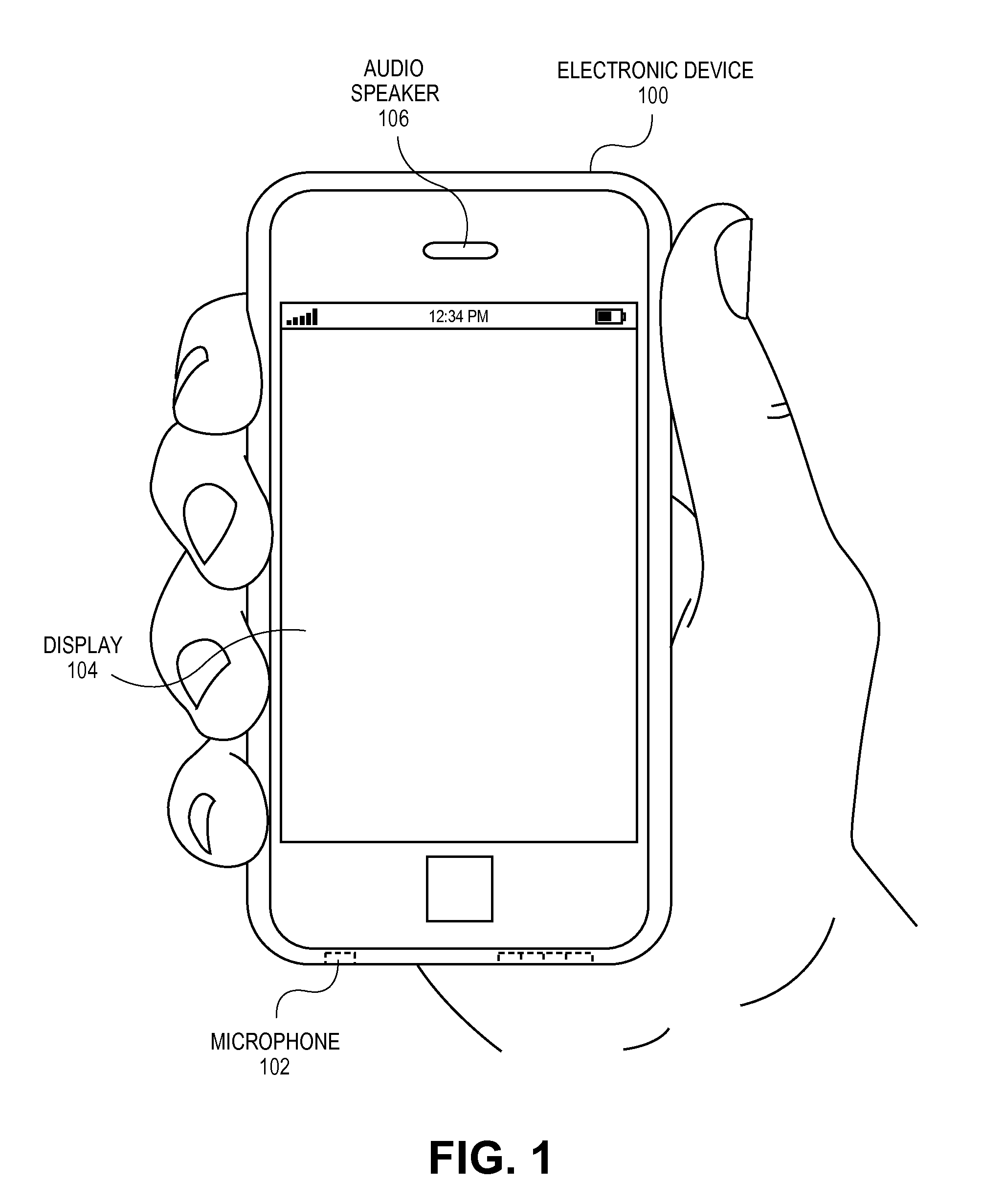

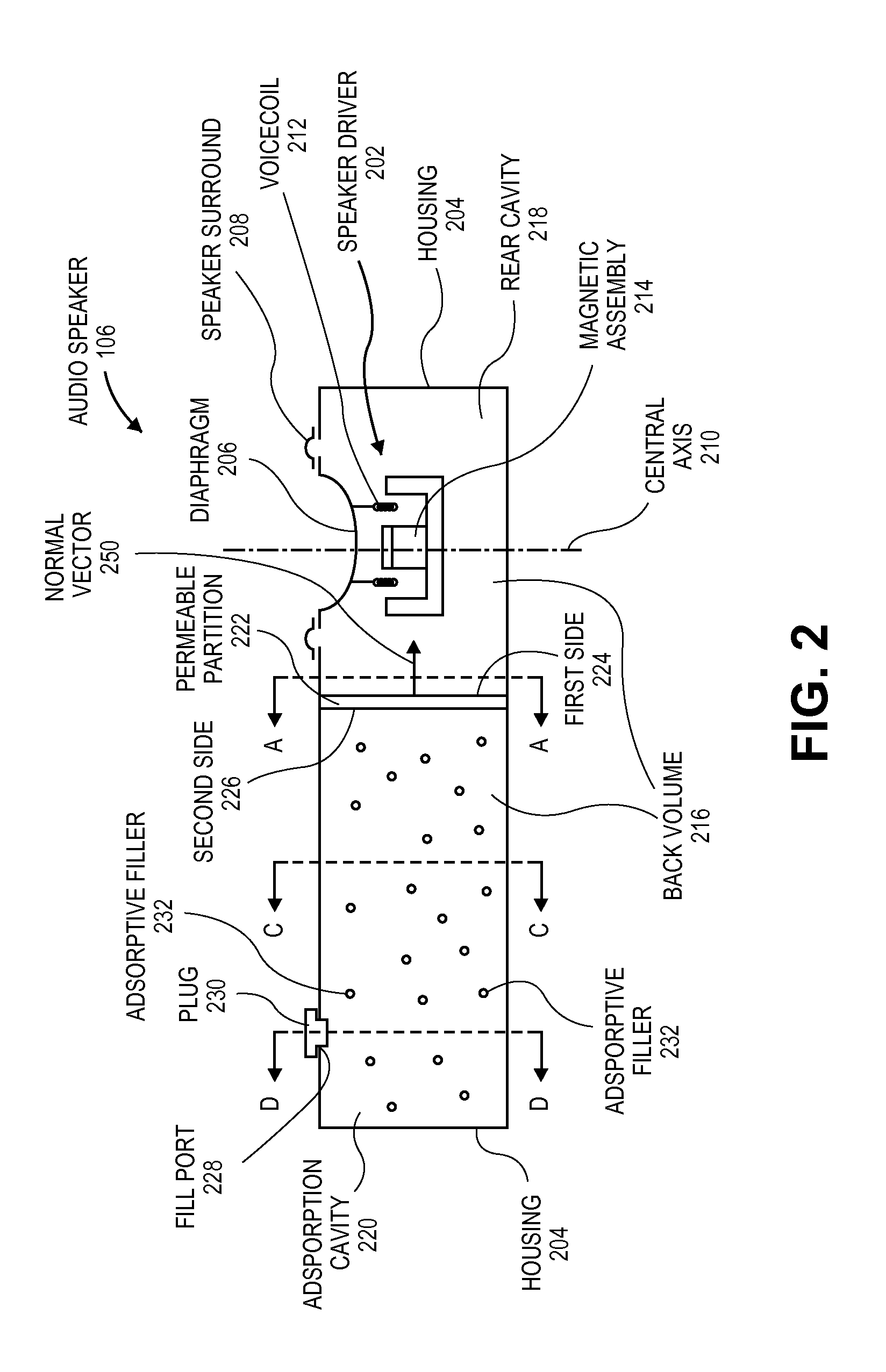

Audio speaker with back volume containing adsorptive material

ActiveUS20160345090A1Reduce spacingEffective back volume can be increasedGas treatmentDispersed particle separationEngineeringSound production

An audio speaker having a speaker housing surrounding a back volume that is divided into a rear cavity behind a speaker driver and an adsorption cavity separated from the rear cavity by a permeable partition, is disclosed. More particularly, the adsorption cavity may be defined between the speaker housing and the permeable partition, and may be directly filled with adsorptive particles to adsorb gas during sound generation. The permeable partition may allow the gas to flow between the rear cavity and the adsorption cavity, and may retain the adsorptive particles within the adsorption cavity. Other embodiments are also described and claimed.

Owner:APPLE INC

Sound production device

InactiveCN103347235AImprove acoustic performanceAdjustable sound qualityElectrical transducersLoudspeakerEngineering

The invention discloses a sound production device which comprises a loudspeaker monomer and a peripheral shell used for containing and fixing the loudspeaker monomer. The loudspeaker monomer comprises a vibrating diaphragm. Spaces on the rear side of the vibrating diaphragm form rear vocal cavities and the rear vocal cavities are composed of the loudspeaker monomer and the peripheral shell together. Moreover, the rear vocal cavities are of sealed structures. A leakage hole is formed in the vibrating diaphragm and communicated with the two sides of the vibrating diaphragm. A leakage hole is of a hole-shaped structure or a slit-shaped structure. Due to the structure, air flows in the rear vocal cavities are balanced, and tone quality is adjusted, so that acoustic performance of the sound production device with the completely sealed rear vocal cavities is improved.

Owner:GOERTEK INC

Speech signal processing with combined noise reduction and echo compensation

ActiveUS7747001B2Improve acoustic performanceReduce echoTwo-way loud-speaking telephone systemsSpeech recognitionAcoustic noise reductionIn vehicle

A speech signal processing system combines acoustic noise reduction and echo cancellation to enhance acoustic performance. The speech signal processing system may be used in vehicles or other environments where noise-suppressed communication is desirable. The system includes an adaptive beamforming signal processing unit, an adaptive echo compensating unit to reduce acoustic echoes, and an adaptation unit to combine noise reduction and adaptive echo compensating.

Owner:NUANCE COMM INC

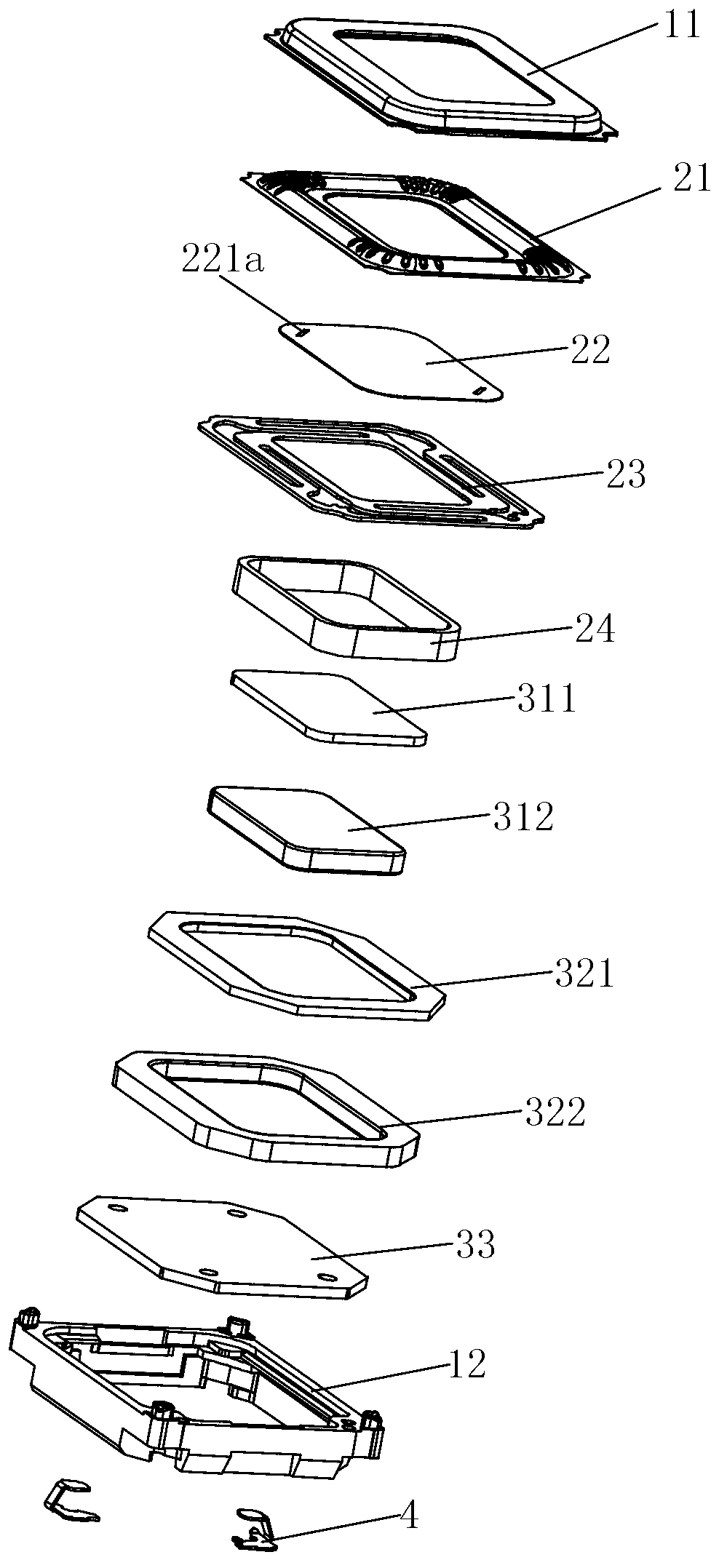

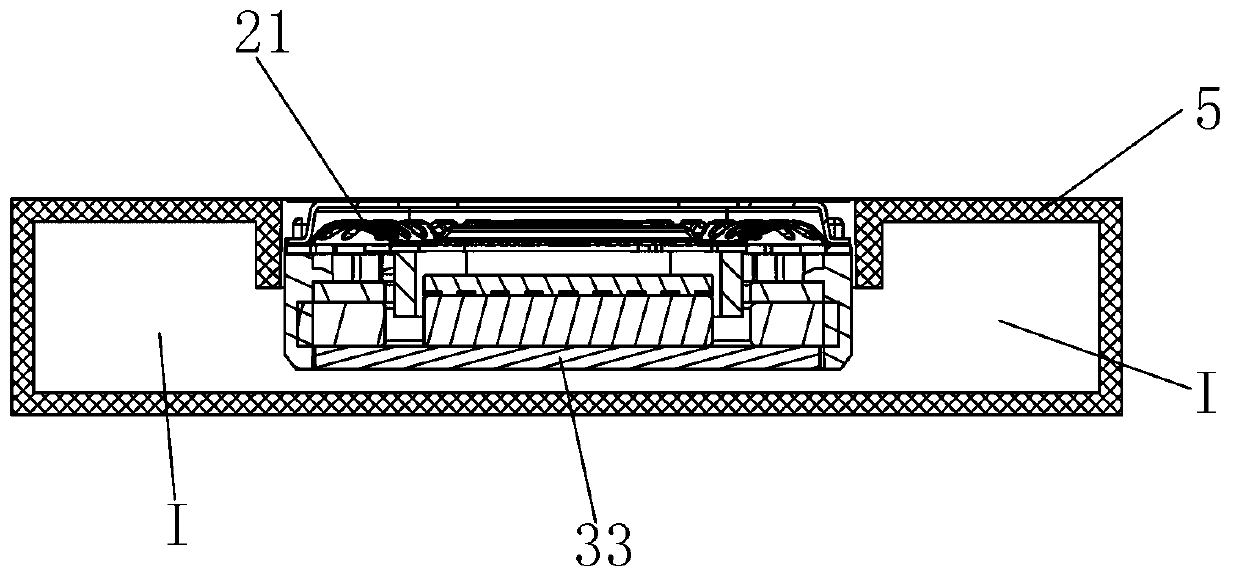

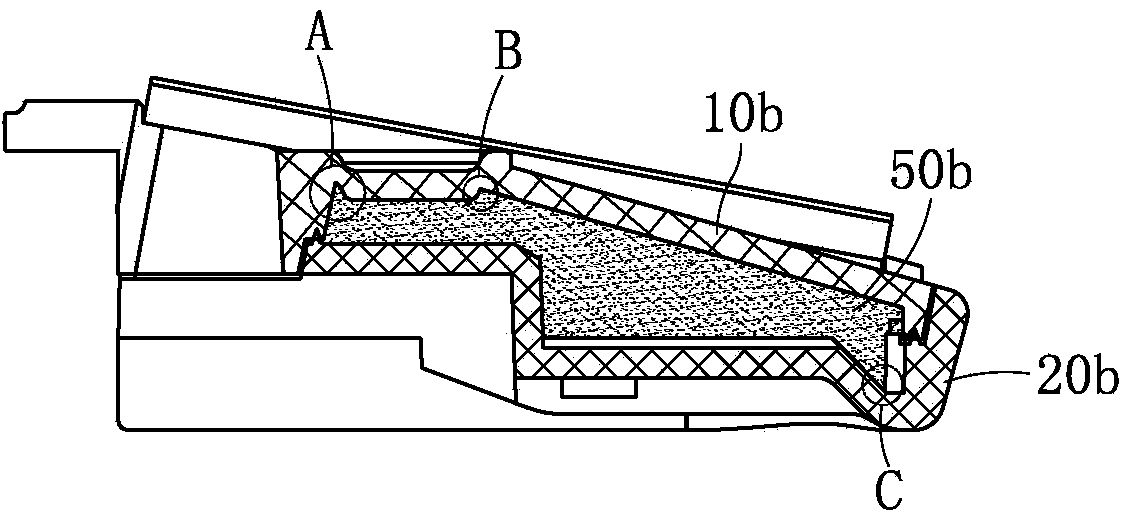

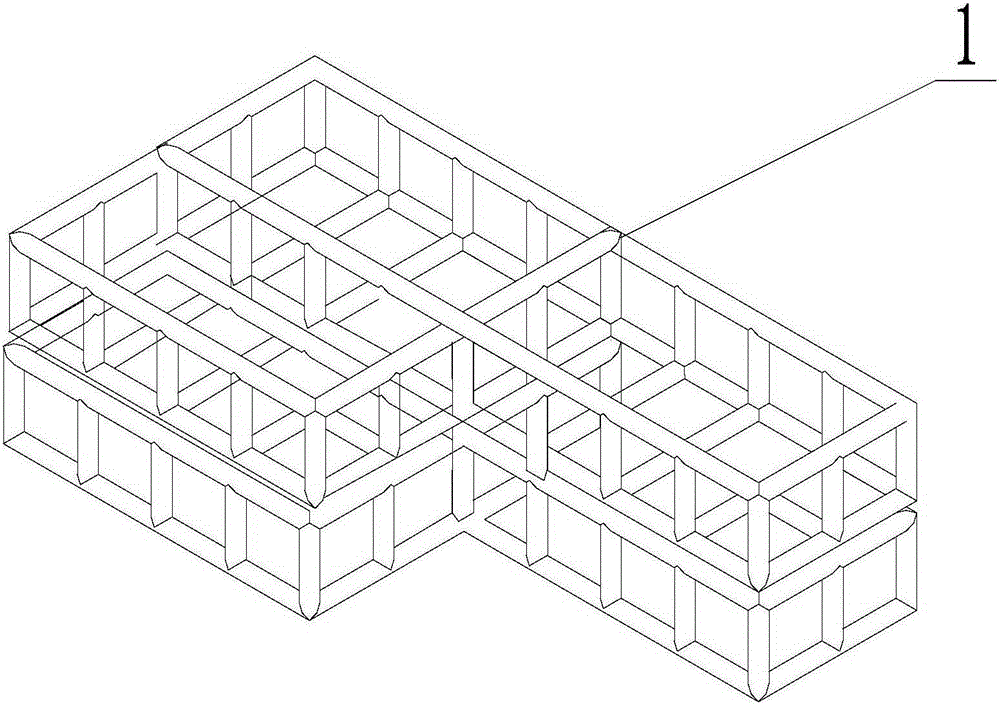

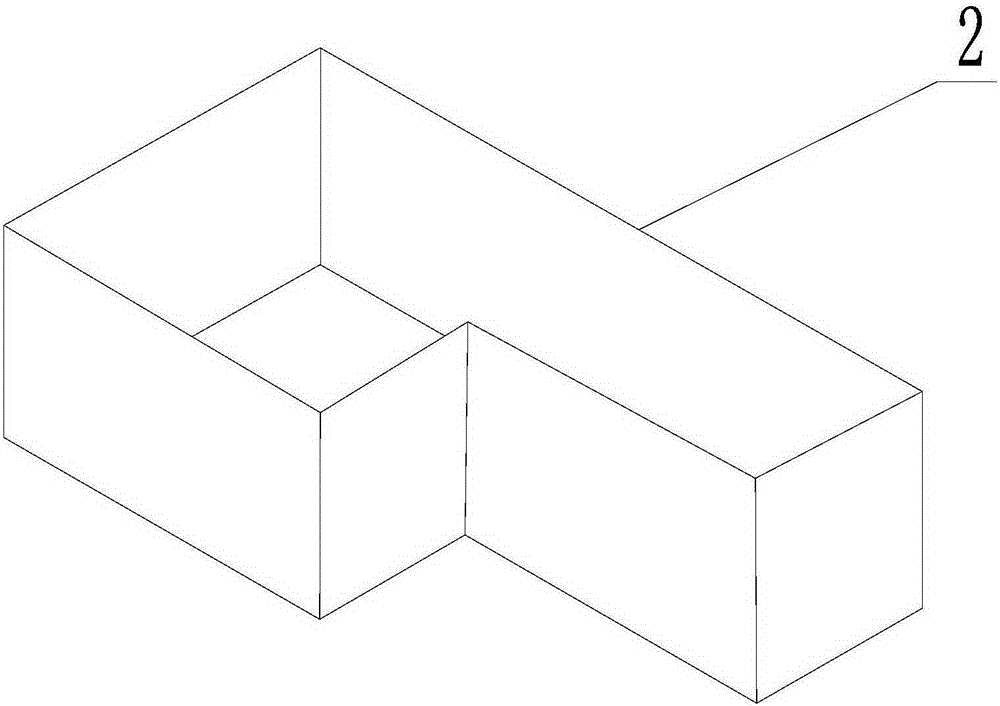

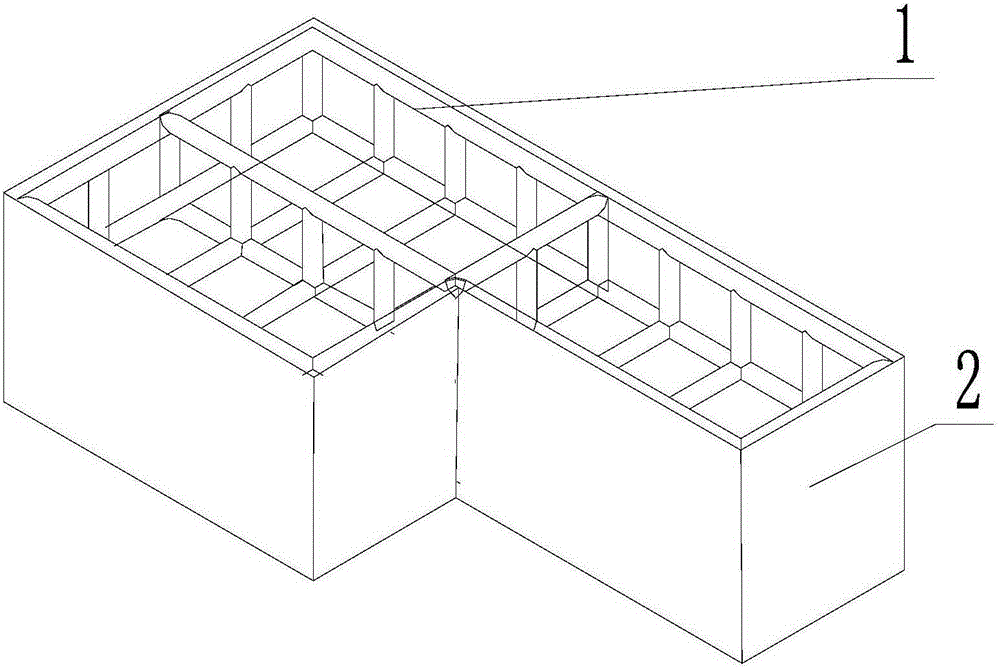

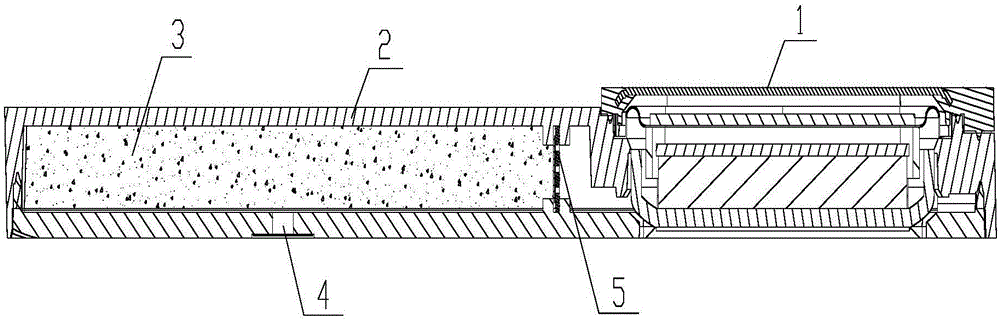

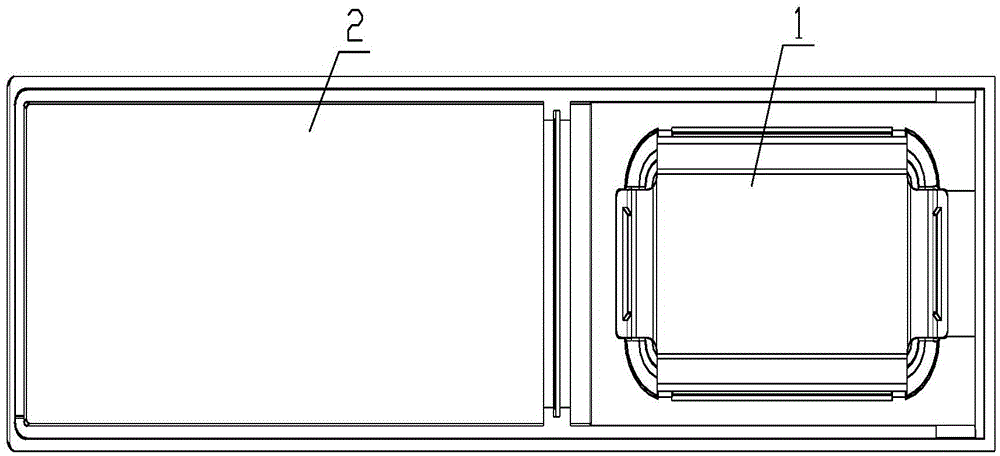

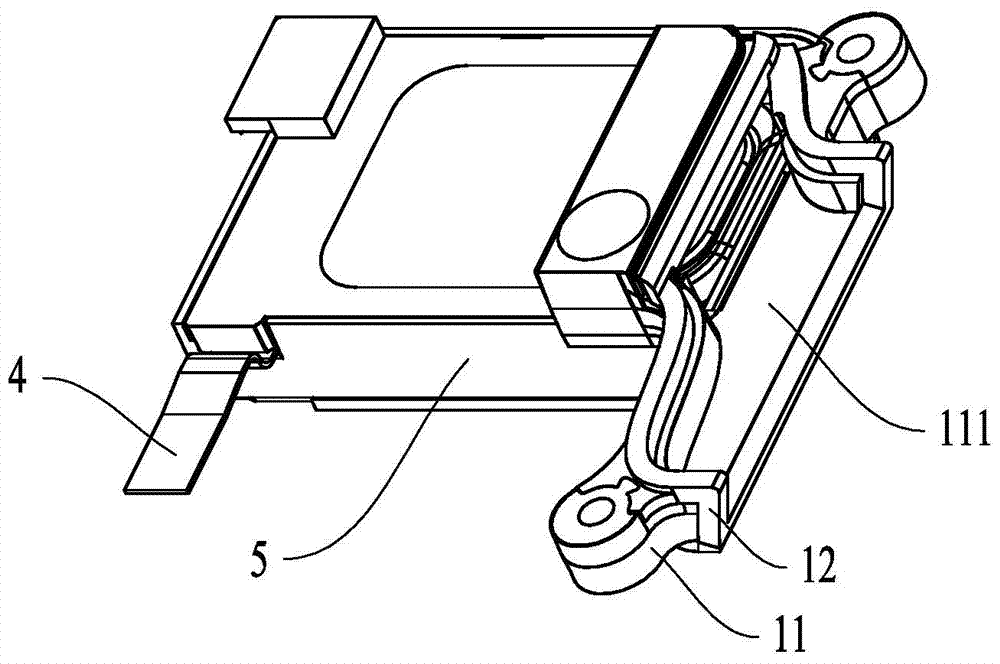

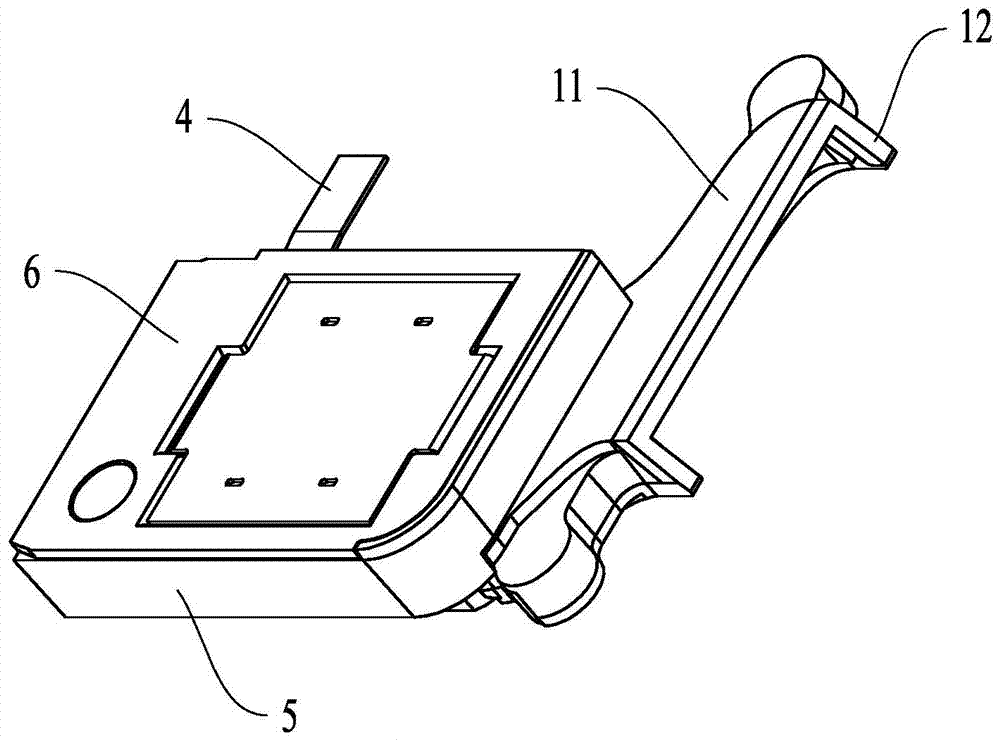

Loudspeaker die set

ActiveCN104202703ABandwidthSmooth IF CurveLoudspeaker transducer fixingFrequency/directions obtaining arrangementsState of artEngineering

The invention discloses loudspeaker die set, and relates to the technical field of electroacoustic products. The loudspeaker die set comprises a housing in which a single loudspeaker body is contained; the single loudspeaker body comprises a vibrating system and a magnetic circuit system; an inner cavity of the whole die set is divided into two cavities, namely, a front vocal cavity and a rear vocal cavity, through the single loudspeaker body; a sound absorbing material is positioned in the rear vocal cavity; a separating structure for separating the sound absorbing material and the single loudspeaker body is also arranged in the rear vocal cavity; the whole rear vocal cavity is divided into a filling area and a non-filling area through the separating structure; the sound absorbing material which is foaming material is positioned in the filling area; the sound absorbing material is filled by foaming the foaming material and fully filled in the filling area. With the adoption of the loudspeaker die set, the technical problems of poor consistency and high production cost of the loudspeaker die set product in the prior art can be solved; the loudspeaker die set is high in acoustic performance, high in production efficiency, small in production cost, and high in product consistency.

Owner:GOERTEK INC

Audio apparatus

ActiveUS20070025574A1Improve acoustic performanceImprove securityPiezoelectric/electrostrictive transducersBone conduction transducer hearing devicesCouplingTransducer

Audio apparatus (30) comprising a piezoelectric transducer (44) and coupling means (54) for coupling the transducer to a user's pinna (32) whereby the transducer excites vibration in the pinna (32) to cause it to transmit an acoustic signal from the transducer (44) to a user's inner ear, characterised in that the transducer is embedded in a casing (42) of relatively soft material and the casing (42) is mounted to a housing (34) of relatively hard material such that a cavity (48) is defined between the casing (42) and housing (34). A method of designing audio apparatus comprising mechanically coupling a piezoelectric transducer to a user's pinna and driving the transducer so that the transducer excites vibration in the pinna to cause it to transmit an acoustic signal from the transducer to a user's inner ear, characterised by embedding the transducer in a casing of relatively soft material and by mounting the casing to protective housing of relatively hard material such that a cavity is defined between the casing and housing.

Owner:GOOGLE LLC

Preparation method of sound absorbing material, the sound absorbing material and filling method of same

ActiveCN105237033ARich microscopic pore structureImprove mass transfer efficiencyTransducer detailsSound producing devicesMetallurgySlurry

Owner:GOERTEK INC

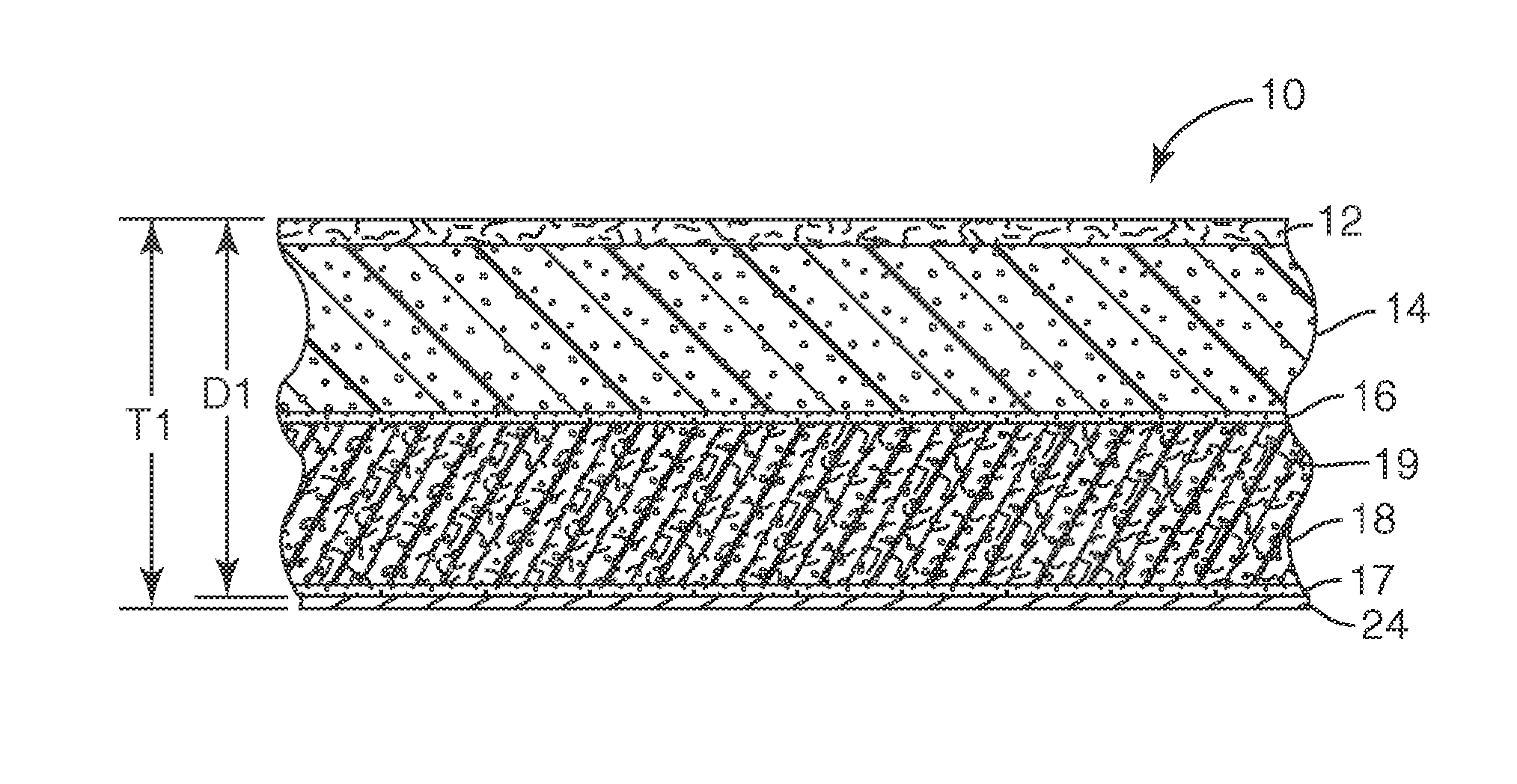

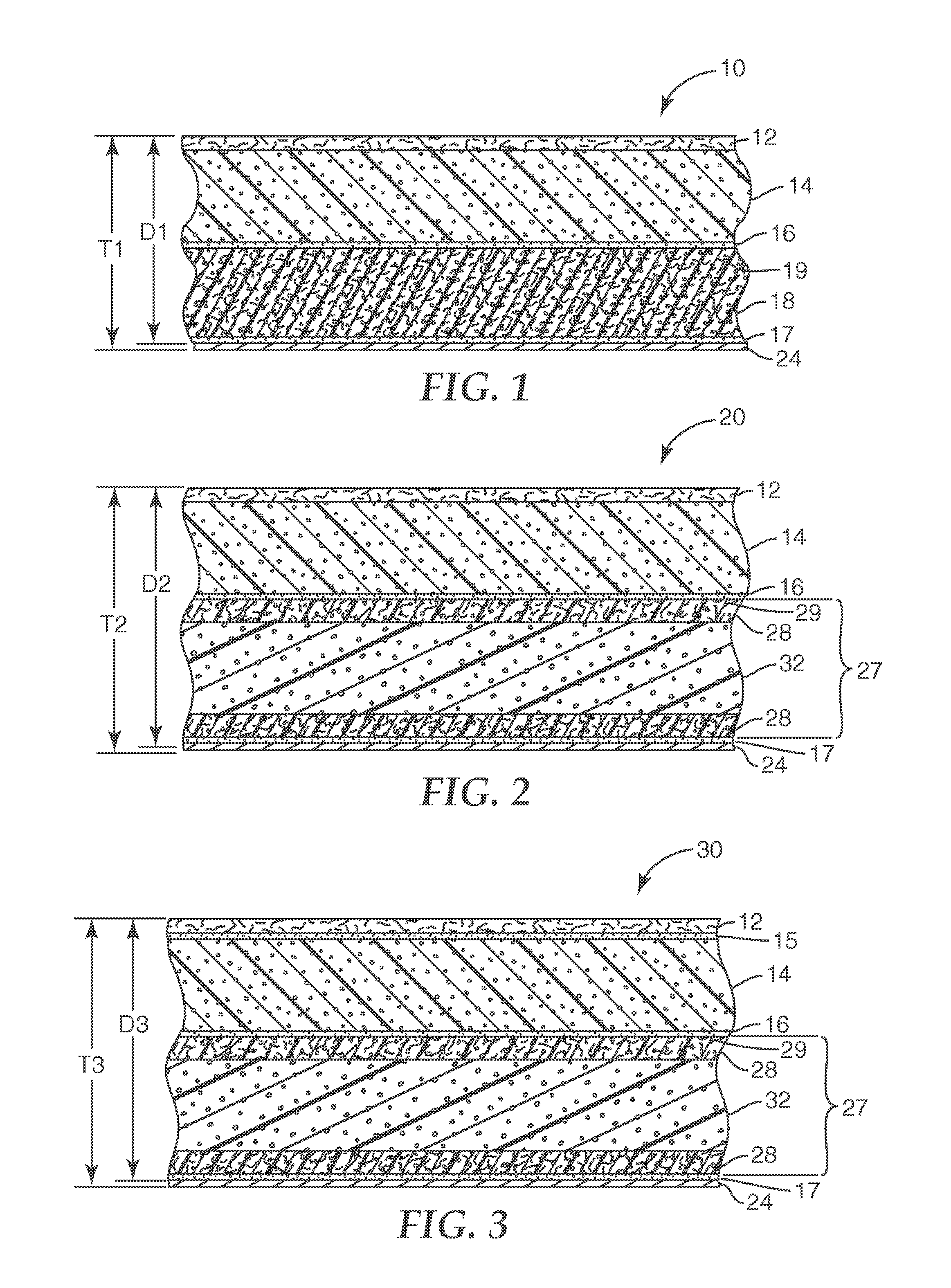

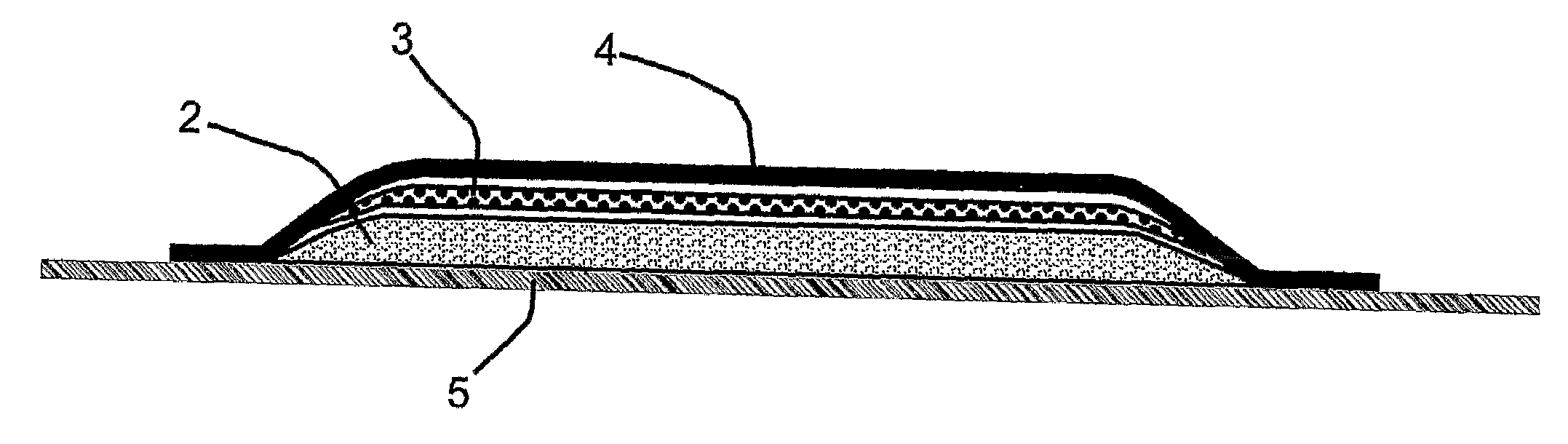

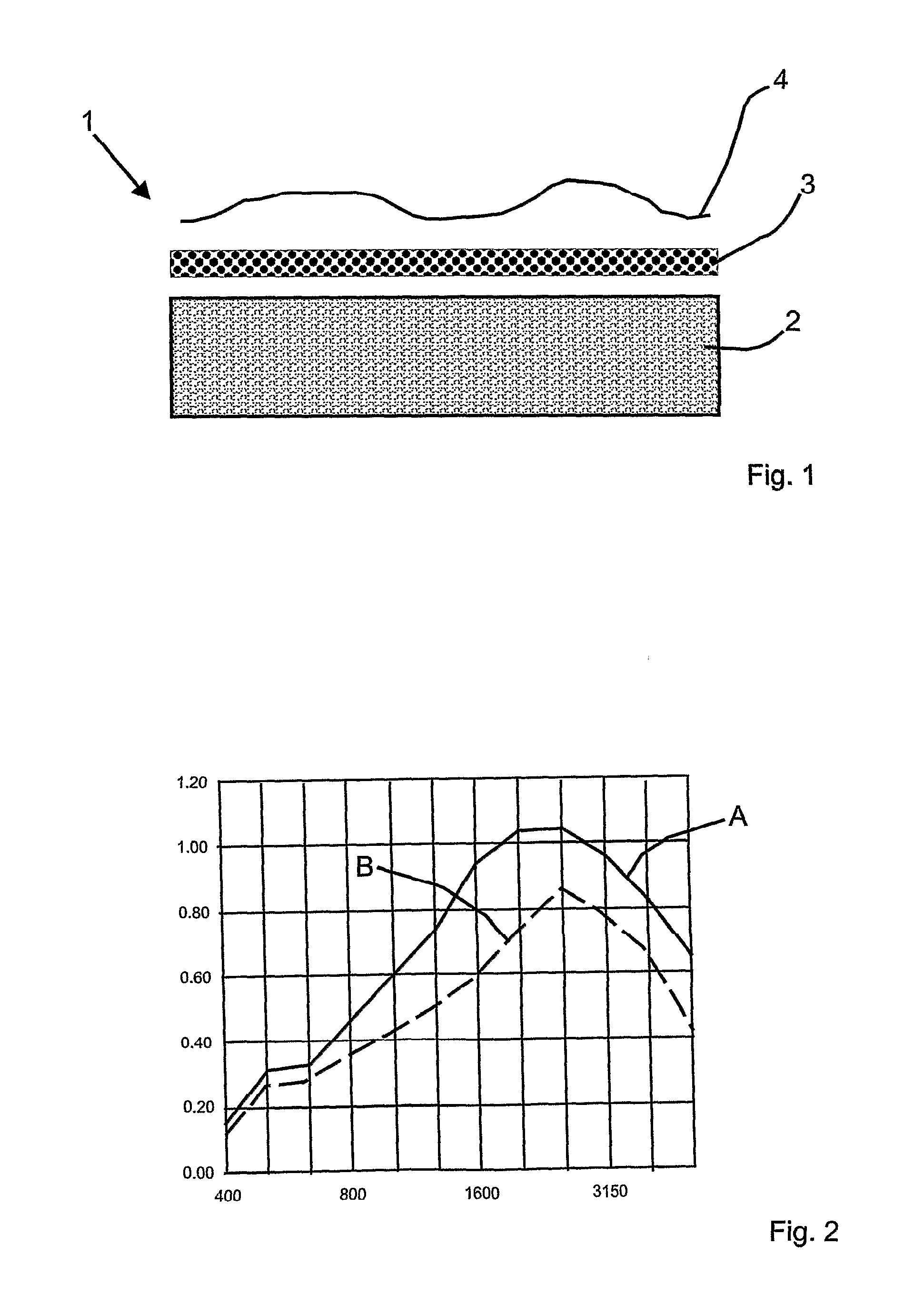

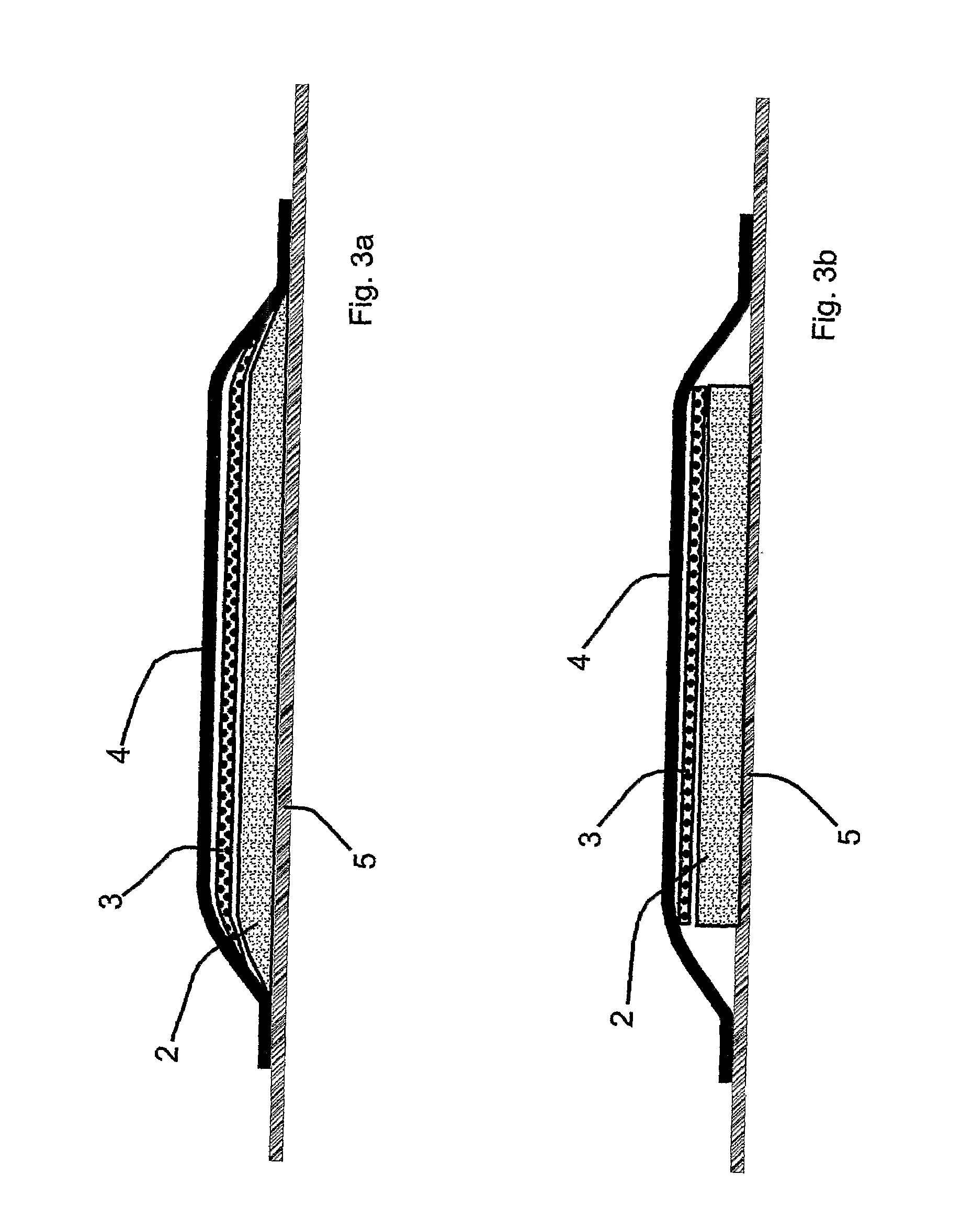

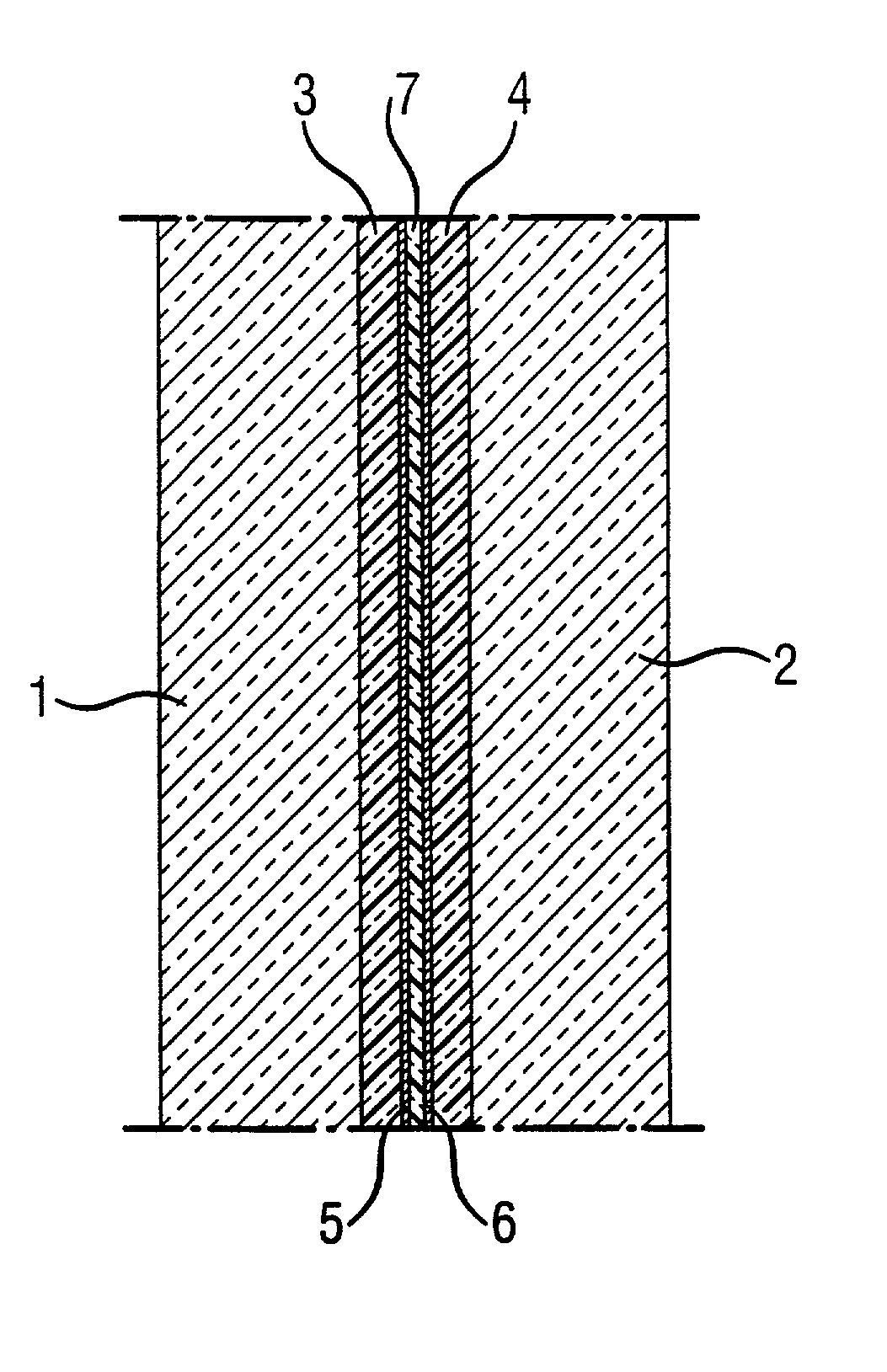

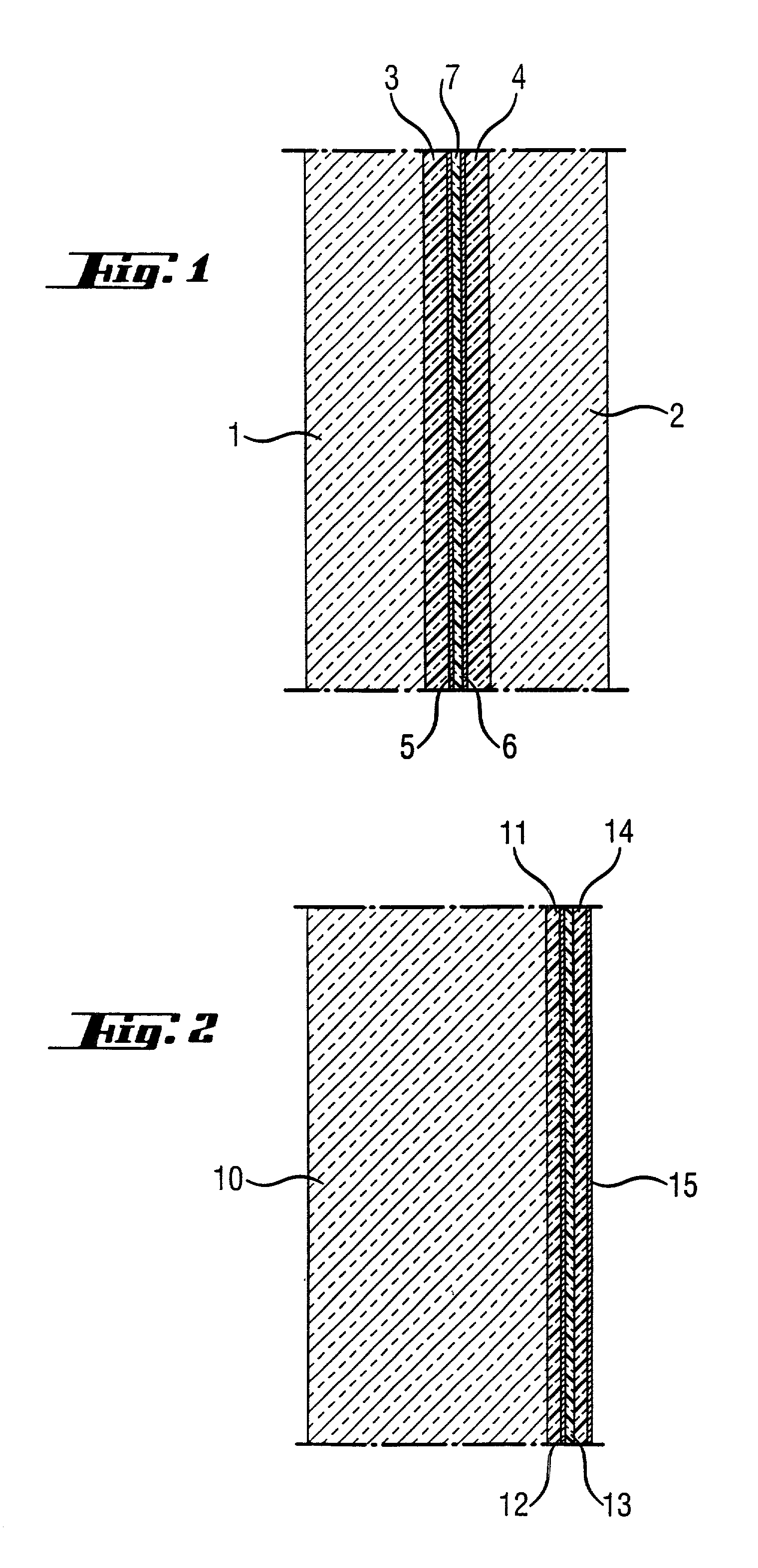

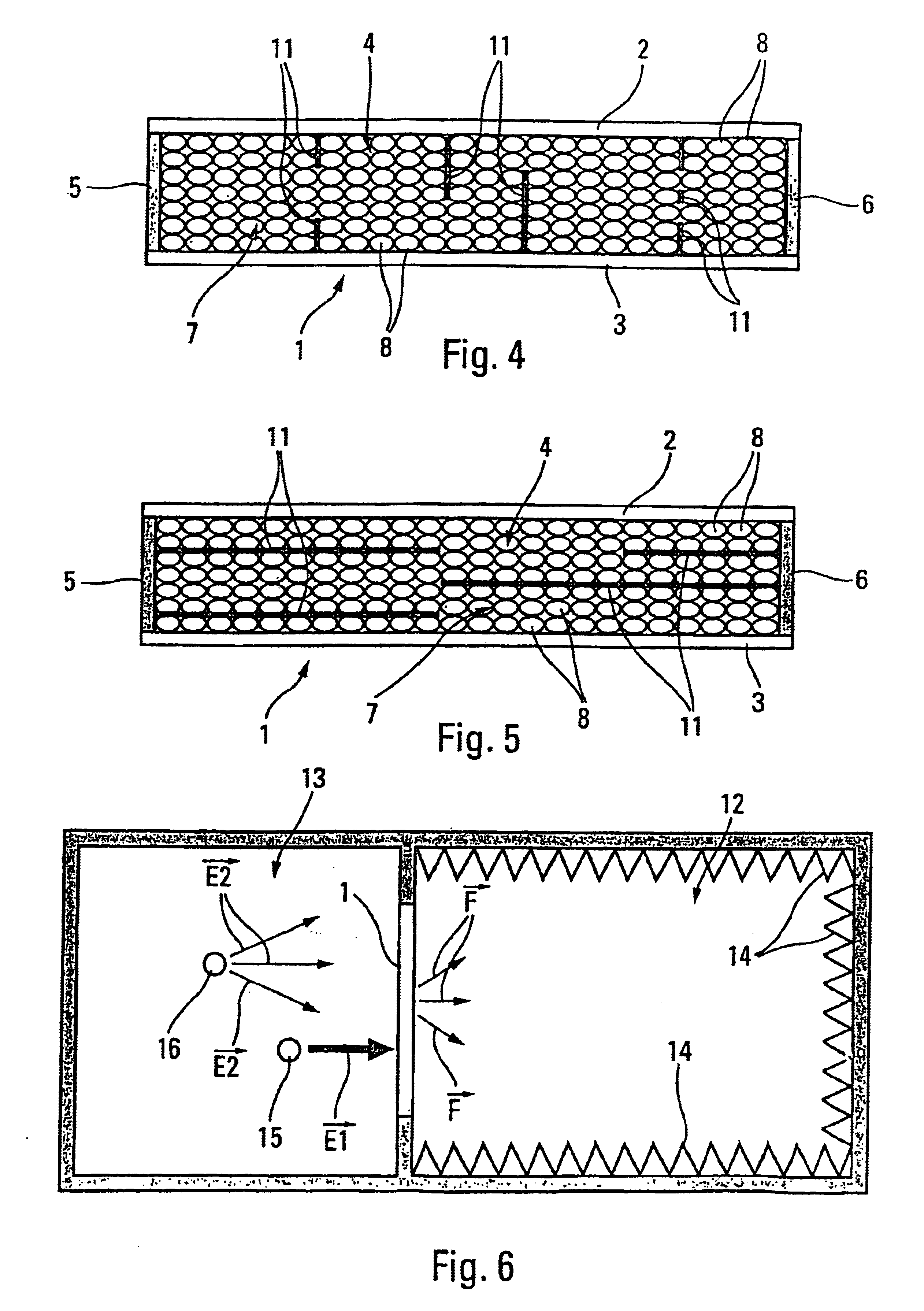

Sealed thin-multi-layer sound absorber

InactiveUS7677358B2Improve acoustic performanceWide frequency bandwidthWallsMachines/enginesEngineeringSound Absorber

The invention relates to a thin sound absorbing multi-layer assembly, which is intended, in particular, to reduce interior or exterior noise of a motor vehicle. The assembly according to the invention comprises at least three stacked layers consisting respectively of: a first layer (4) being impervious and having an area weight of between (20) to (100 g / m2); a second layer (3) having an air flow resistance of between (250) to (2500 Ns / m3) and an area weight of between (15) to (250 g / m2); a third layer (2) being an open pored, acoustic spring type layer having a thickness of between (2) to (30 mm) and an area weight of between (50) to (1000 g / m2).

Owner:RIETER TECHNOLOGIE AG

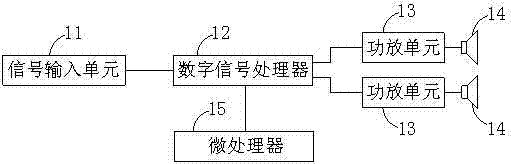

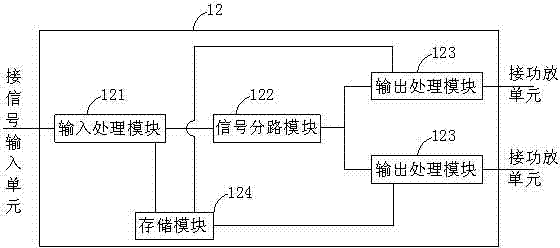

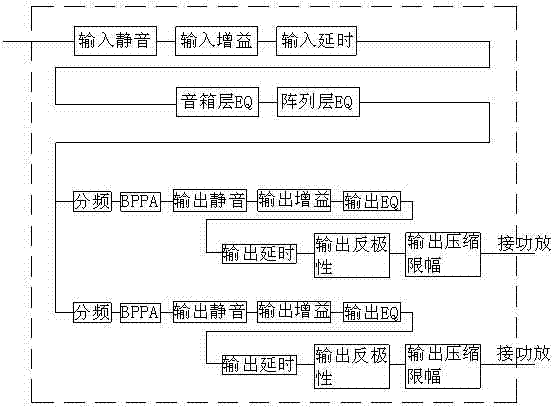

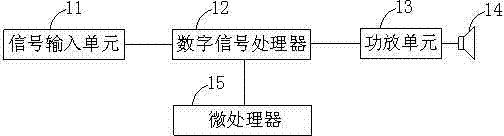

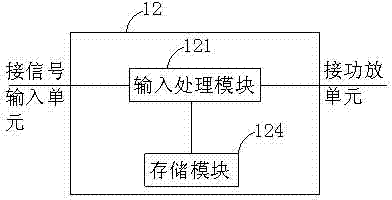

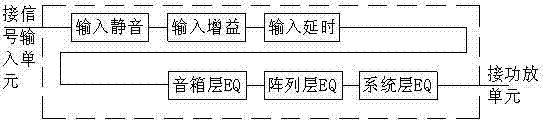

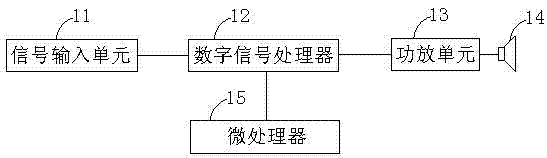

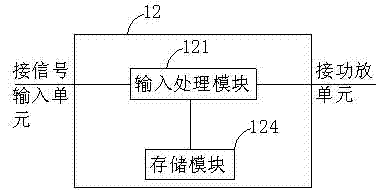

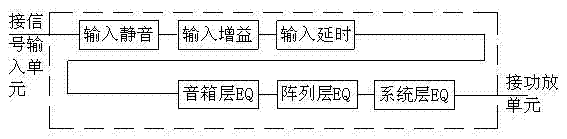

Method for correcting stage and video professional sound system

ActiveCN102780965AIncrease the difficultyIncreased complexityElectrical apparatusEngineeringComputer science

The invention relates to a sound box control technology, in particular to a method for correcting a stage and video professional sound system. According to the method, the multilayer adjustable problem of system layers is solved by adopting active speakers (in particular to two-or-more-way sound boxes) with array layer DSP (Digital Signal Processor) parameters and introducing sound box models to virtualize a plurality of layers of DSP parameters; and an array group model is also introduced to implement the synchronization adjustment on each sound box model of an array group. All in all, according to the technology, not only can the difficulty in debugging and correcting the sound system be simplified and the workload is reduced, but also the system debugging can be ensured to obtain a better sound effect.

Owner:GUANGZHOU LEAFUN CULTURE SCI & TECH

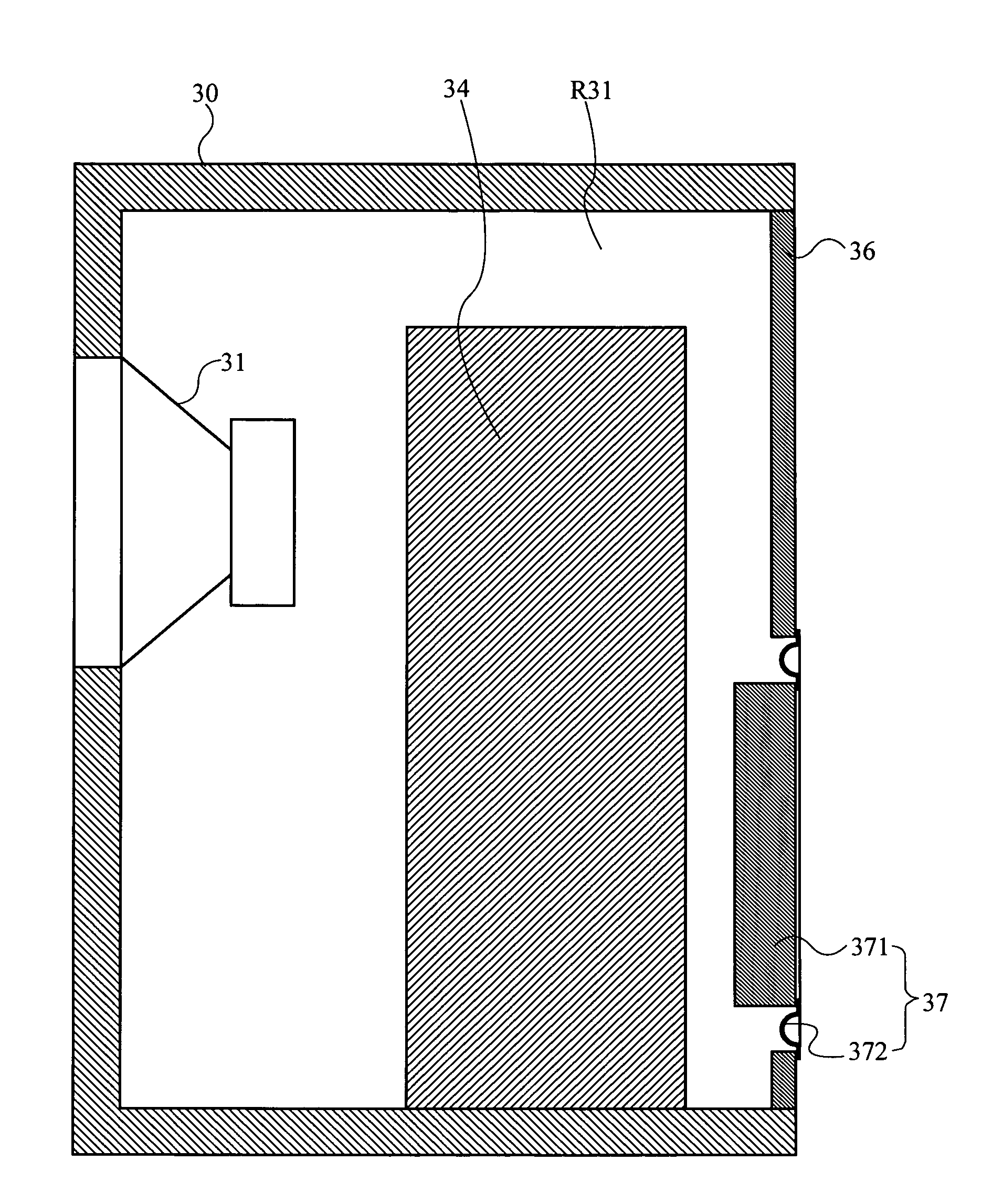

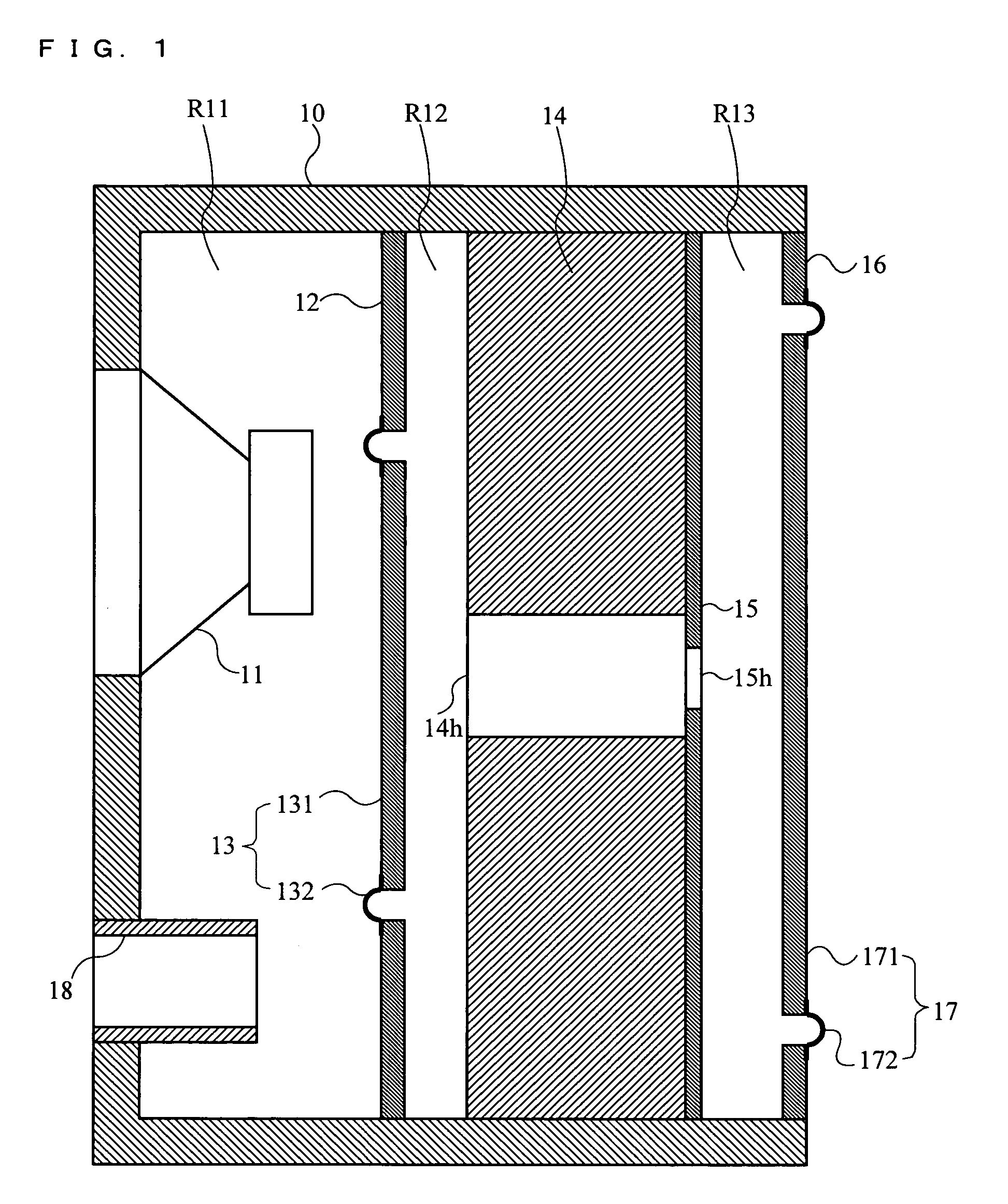

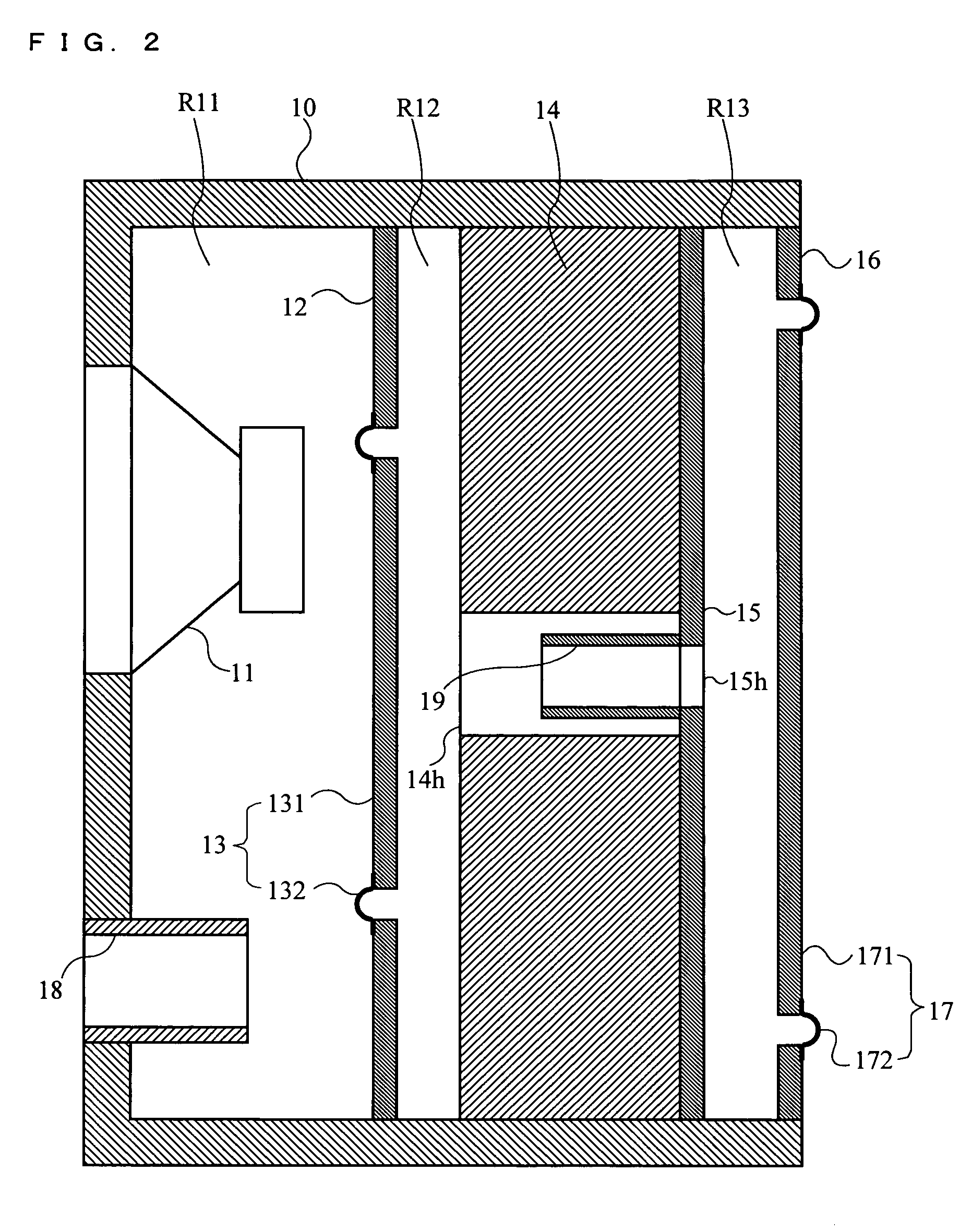

Speaker system

ActiveUS7477755B2Reduce pressure changesImprove acoustic performanceFrequency/directions obtaining arrangementsLoudspeaker spatial/constructional arrangementsEngineeringAtmospheric pressure

A speaker system according to the present invention comprises a cabinet (10), a speaker unit (11), a first parting board (12), a drone cone (13), an adsorption member (14), a second parting board (15), a backboard (16), a variable mechanism (17), and a port (18). A sound pressure generated by the speaker unit (11) causes a pressure variation in a second chamber (R12) via the drone cone (13). The adsorption member (14) with an effect of physical adsorption is operable to suppress the pressure variation. Furthermore, by displacing the diaphragm (171), the variable mechanism (17) is operable to reduce a pressure variation of a direct current component, which is caused by variations in ambient temperature or atmospheric pressure of the speaker system.

Owner:PANASONIC CORP

Method for correcting sound system

ActiveCN102780961AIncrease the difficultyIncreased complexityElectrical apparatusEngineeringComputer science

The invention relates to a sound box control technology, in particular to a method for correcting a sound system. According to the method, the multilayer adjustable problem of system layers is solved by adopting active speakers (in particular to two-or-more-way sound boxes) with array layer DSP (Digital Signal Processor) parameters and introducing sound box models to virtualize a plurality of layers of DSP parameters; and an array group model is also introduced to implement the synchronization adjustment on each sound box model of an array group. According to the technology, not only can the difficulty in debugging and correcting the sound system be simplified and the workload is reduced, but also a better system sound effect can be obtained.

Owner:GUANGZHOU LEAFUN CULTURE SCI & TECH

Multi-layer acoustic treatment panel

ActiveUS20130142624A1Improve efficiencyMitigate such drawbackEngine manufacturePump componentsPorosityAcoustic wave

A multilayer acoustic treatment panel including a first cellular-structure core sandwiched between a perforated skin and an intermediate skin; and a second cellular-structure core sandwiched between the intermediate skin and a continuous skin. The perforated skin includes at least one pair of high-porosity zones presenting a perforation ratio greater than a perforation ratio of a remainder of the perforated skin and including an inlet zone and an outlet zone longitudinally spaced apart from each other, the high-porosity zones of a given pair communicating through the first cellular-structure core and the intermediate skin with the two ends of a soundwave flow channel arranged in the second cellular-structure core.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A +2

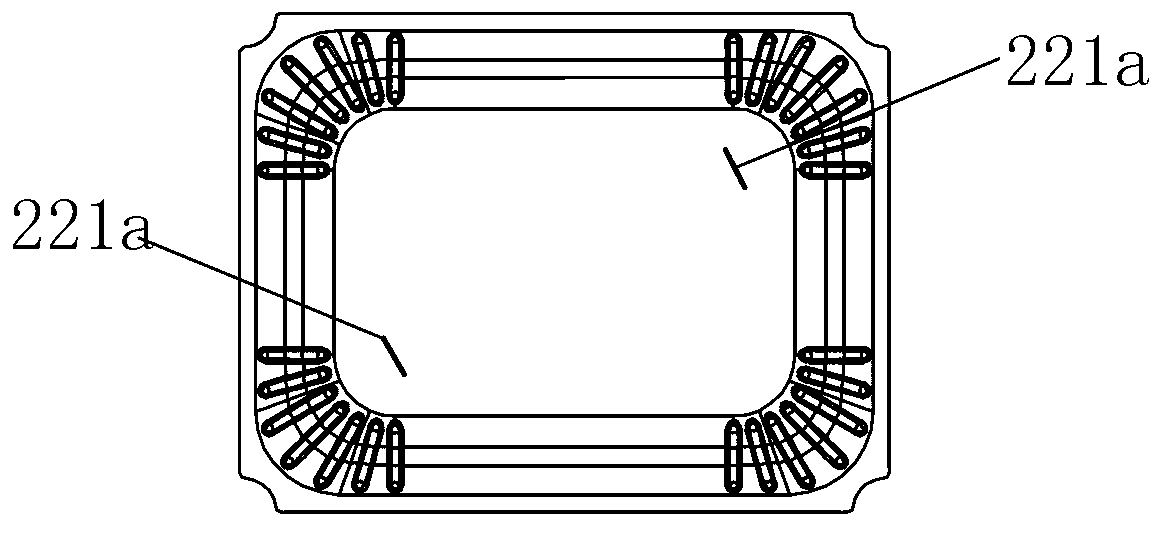

Loudspeaker module

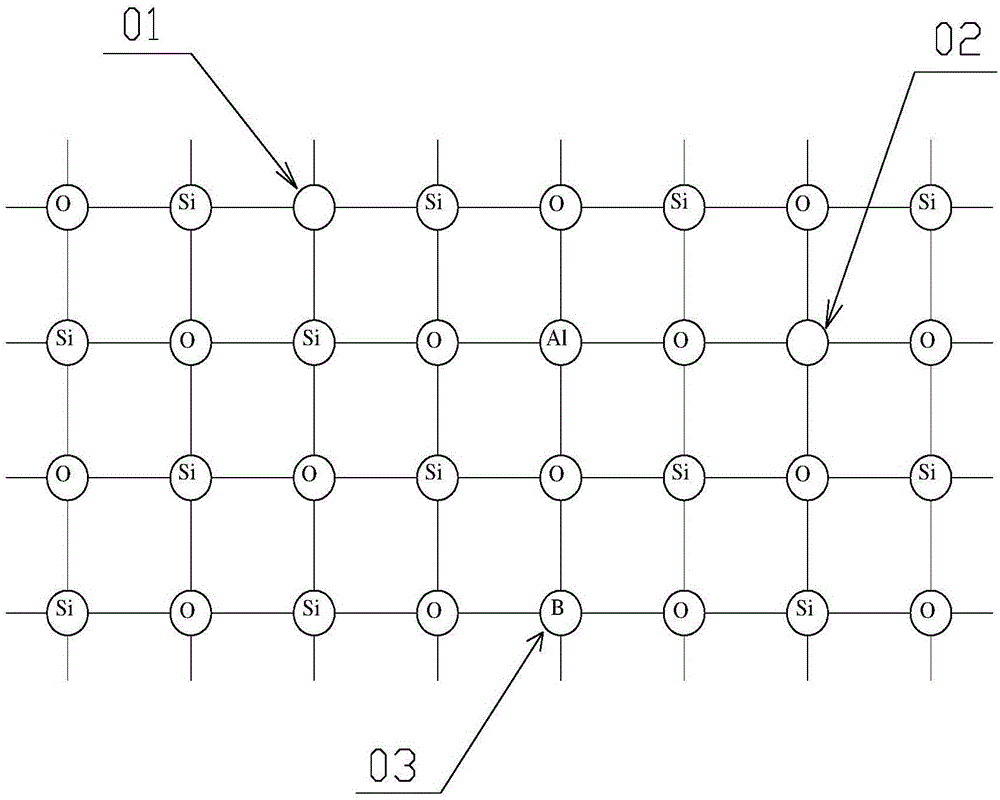

ActiveCN105142074AImprove acoustic performanceAvoid adsorptionSingle transducer incorporationLoudspeaker transducer fixingCrystal structureHeteroatom

The invention provides a loudspeaker module. The loudspeaker module comprises a shell and a loudspeaker monomer contained in the shell, wherein the loudspeaker monomer divides a cavity formed by the shell into a front vocal cavity and a rear vocal cavity; the rear vocal cavity is filled with acoustic materials; heteroatoms are doped in the crystal structures of the acoustic materials. The loudspeaker module provided by the invention can reduce the adsorption of acoustic materials inside the loudspeaker module to heterogeneous molecules, and even reject the heterogeneous molecules, so as to guarantee that the acoustic materials are long-term effective and improve the stability of the acoustical property of the loudspeaker module.

Owner:GOERTEK INC

Specialized speaker system regulation method

ActiveCN102811412AIncrease the difficultyIncreased complexityElectrical apparatusComputer scienceDigital signal processor

The invention relates to a sound box control technique, in particular to a speaker system regulation method. The method comprises a speaker system model establishing step and a virtual input process parameter correcting step, wherein a speaker system model comprises a plurality of sound box models. Each sound box model is corresponding to a hypostatic active sound box and includes a virtual input process parameter and a virtual output process parameter, the virtual input process parameter includes one or more virtual DSP (digital signal processor) data, each DSP data includes multilayers of DSP parameters in the same type. Thus, no matter how many layers of DSP parameters each hypostatic DSP of the hypostatic sound box includes, the technique can realize multilayer adjustability of the input process parameter in the system layer so as to simplify the operations of debugging and correcting of the speaker system, improve the debugging efficiency, and guarantee the debugging effect of the system.

Owner:GUANGZHOU LEAFUN CULTURE SCI & TECH

Sound insulation system

A sound insulation system for use with a vehicle includes a layer of fibrous padding material having a first surface and an opposite second surface. The first surface includes multiple spaced apart recesses. The second surface includes a substantially flat surface portion that extends over two adjacent recesses. The multiple recesses are configured to define multiple voids when the sound insulation system is mounted in the vehicle, thereby enhancing acoustical performance of the sound insulation system.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

Soundproofing laminated window for vehicles

InactiveUS20020068177A1Reduce noise radiationExcellent ease of useWindowsWindscreensEngineeringElectrical and Electronics engineering

The invention relates to a soundproofing window in which an intermediate film provides for damping of vibrations transmitted in particular by structure-borne conduction.

Owner:SAINT GOBAIN VITRAGE SA

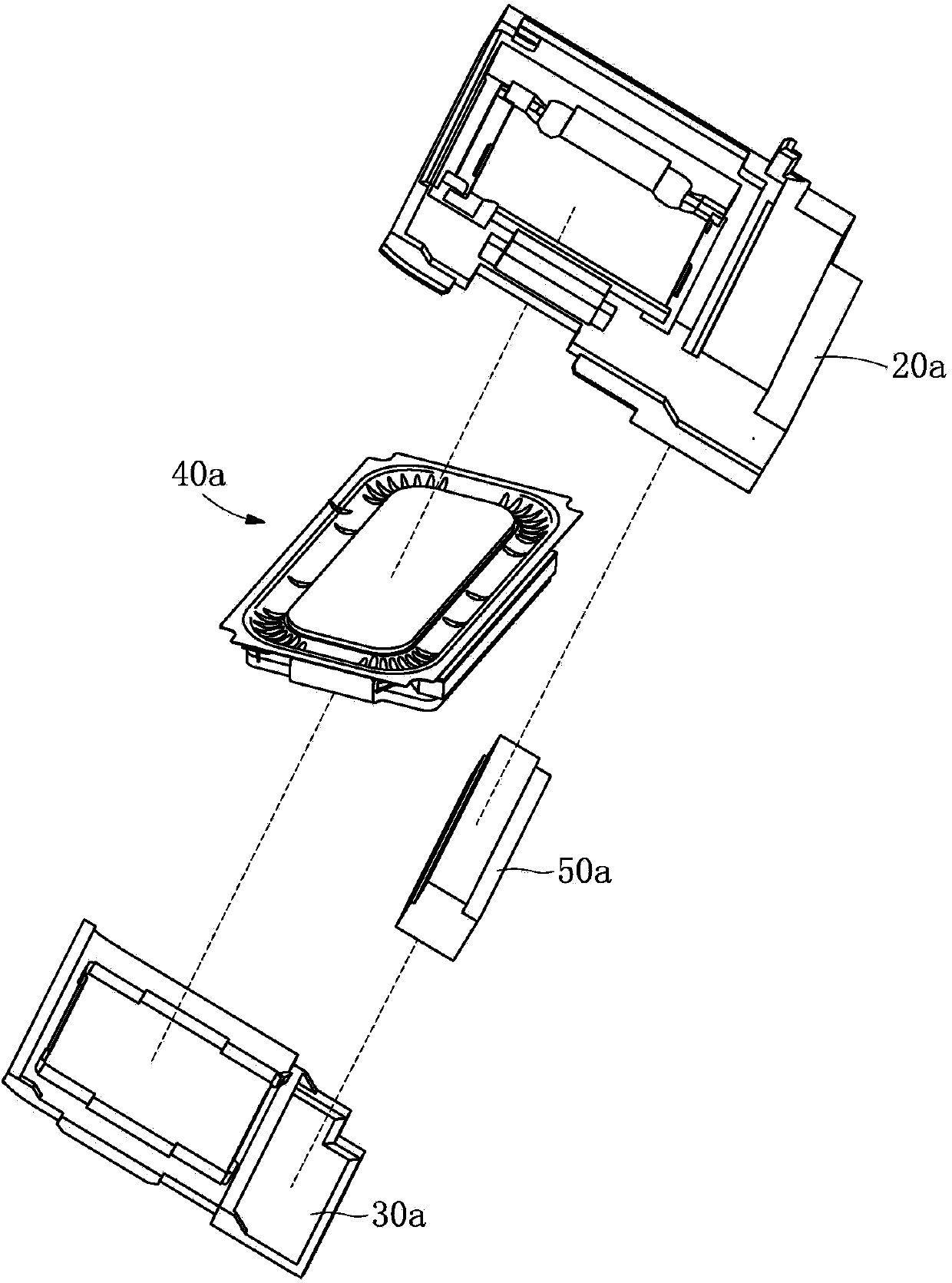

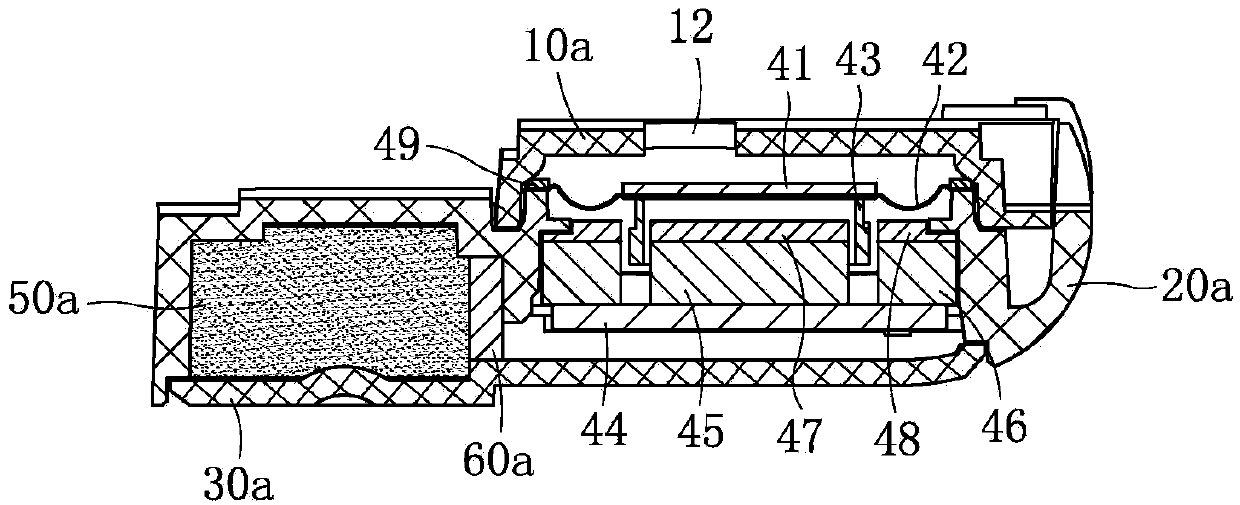

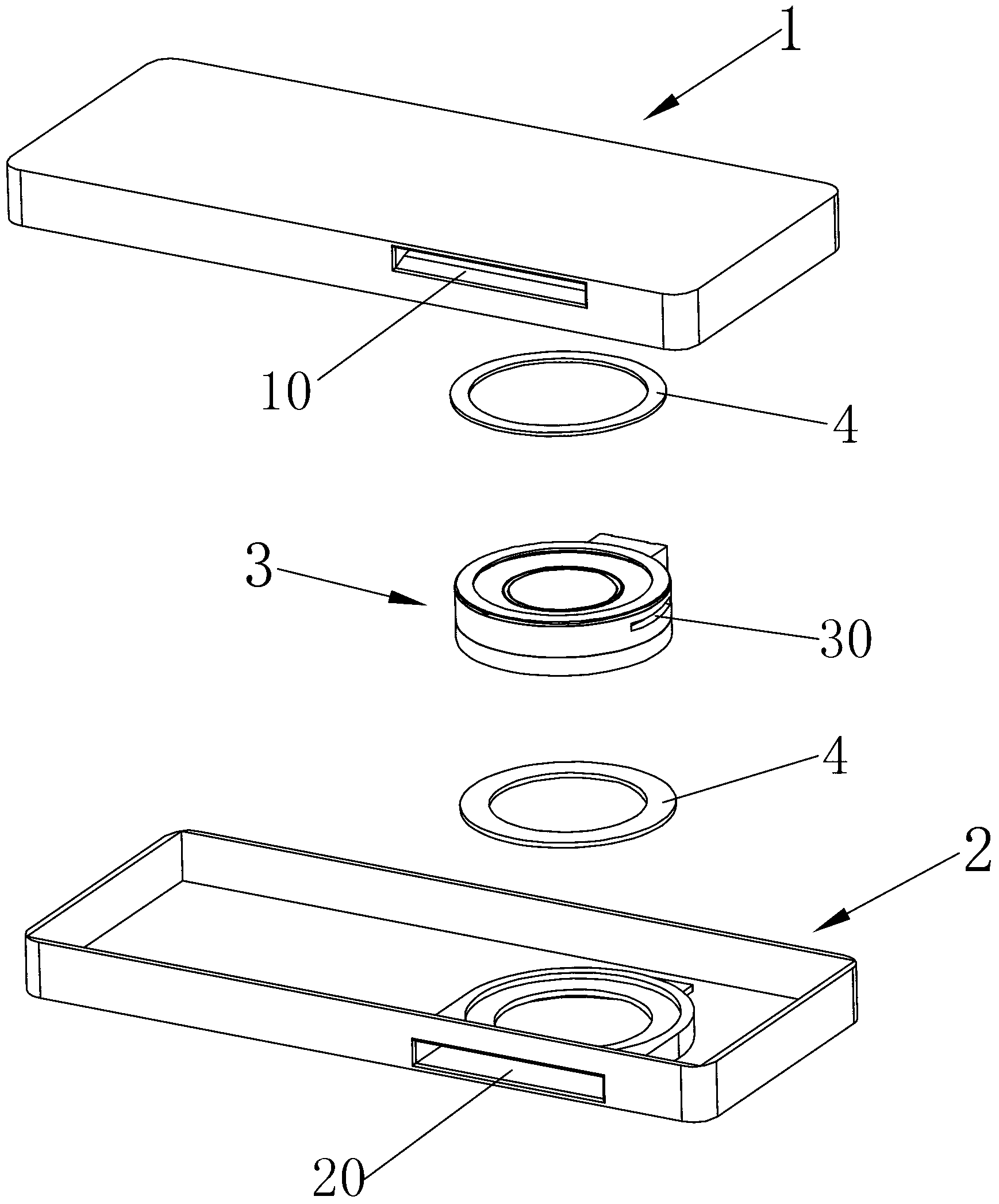

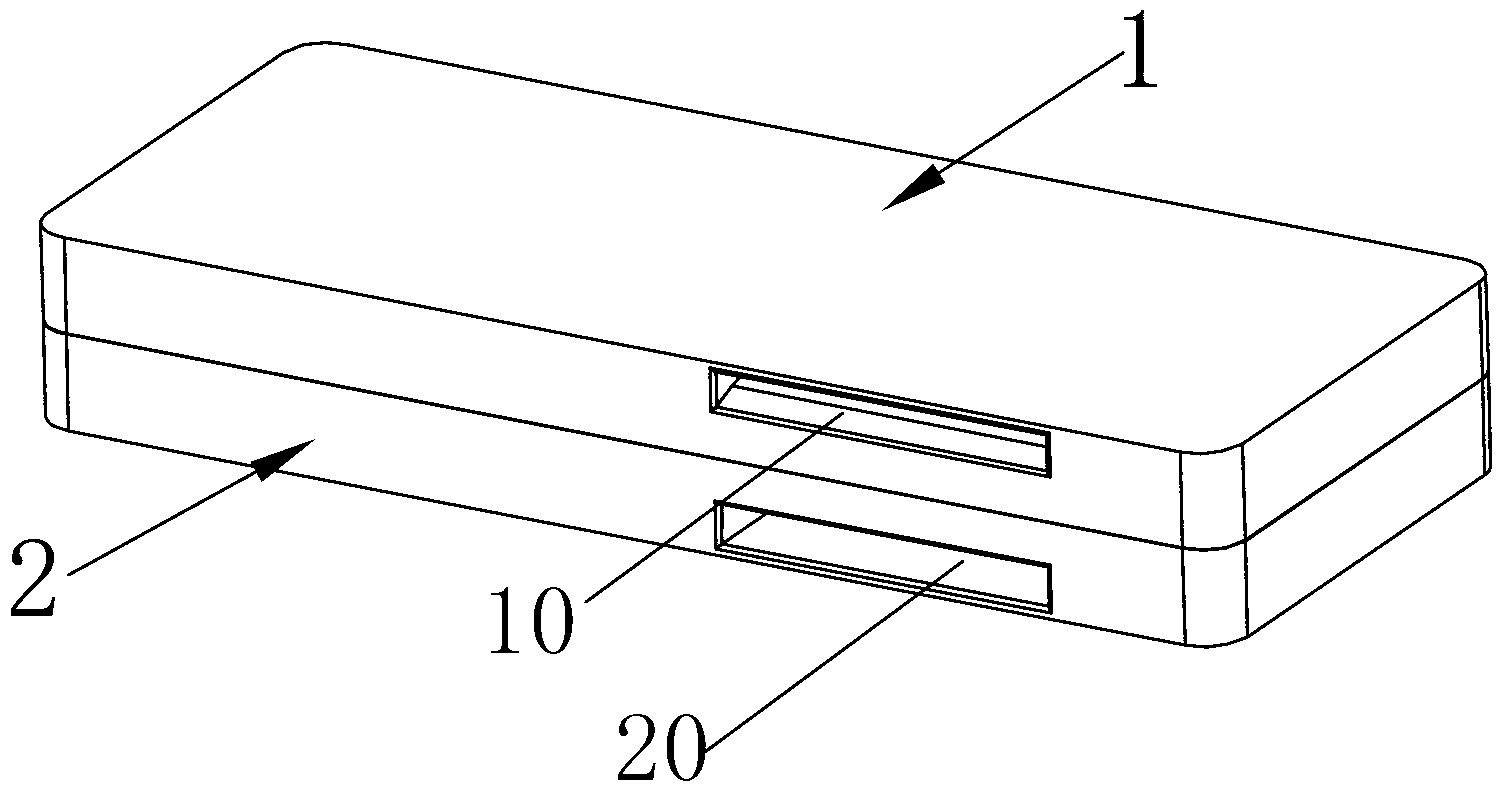

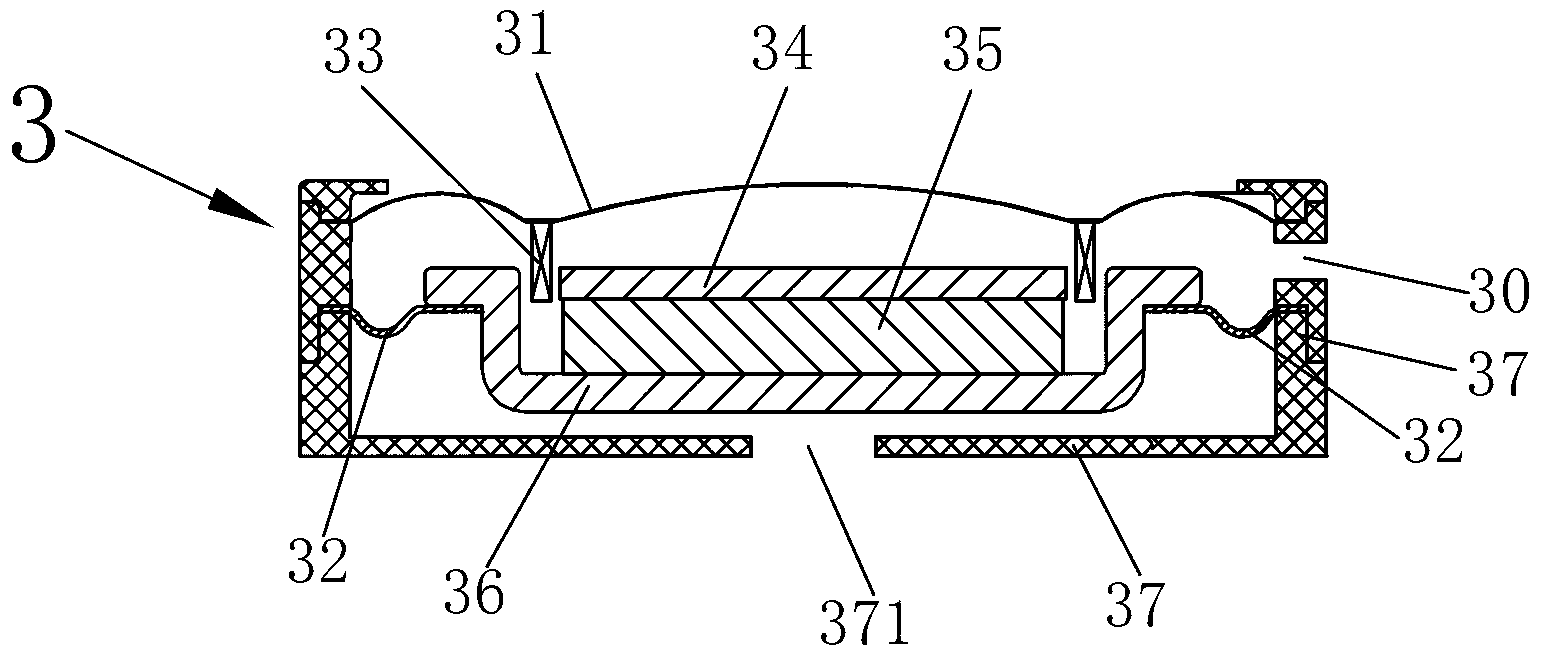

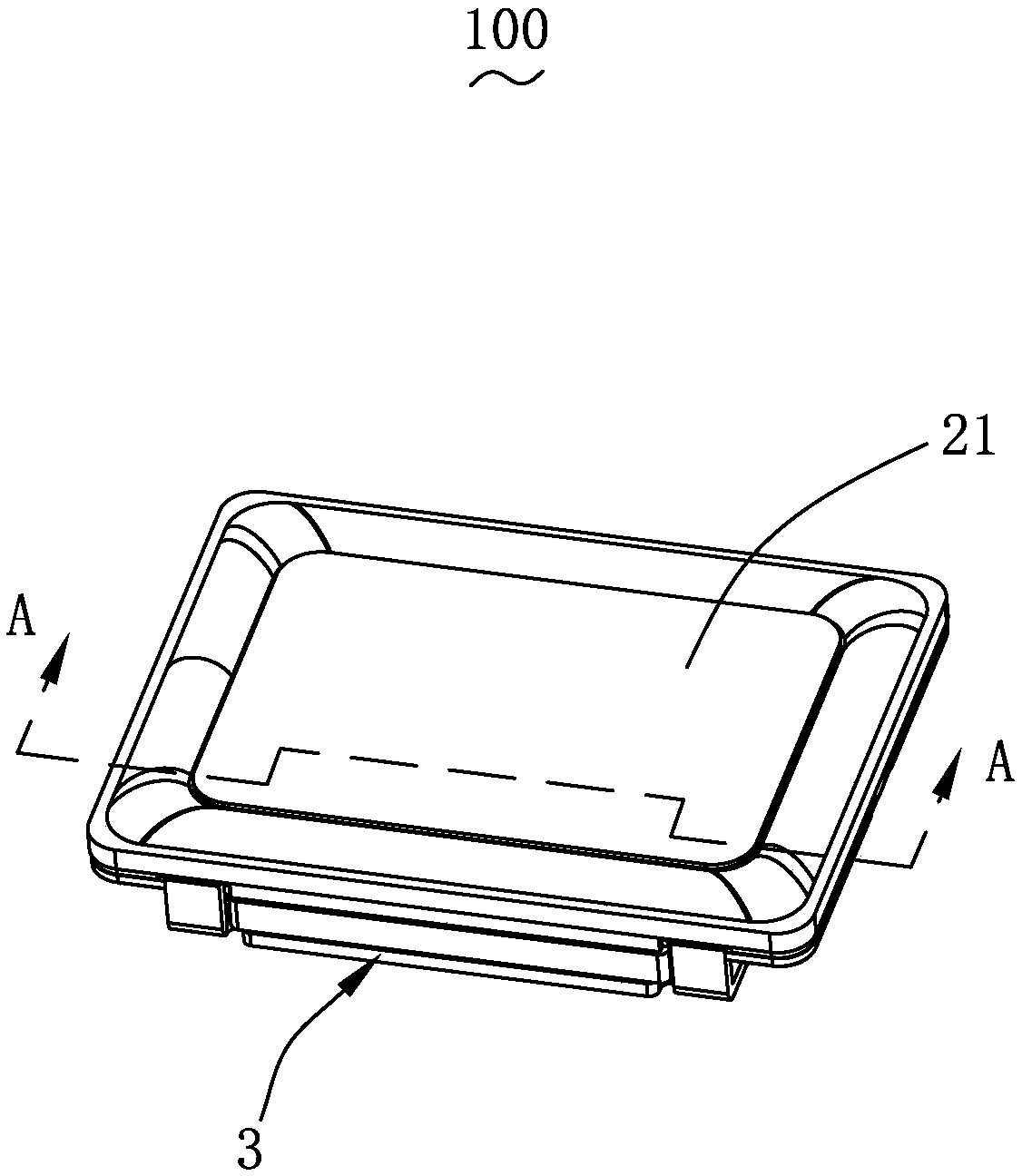

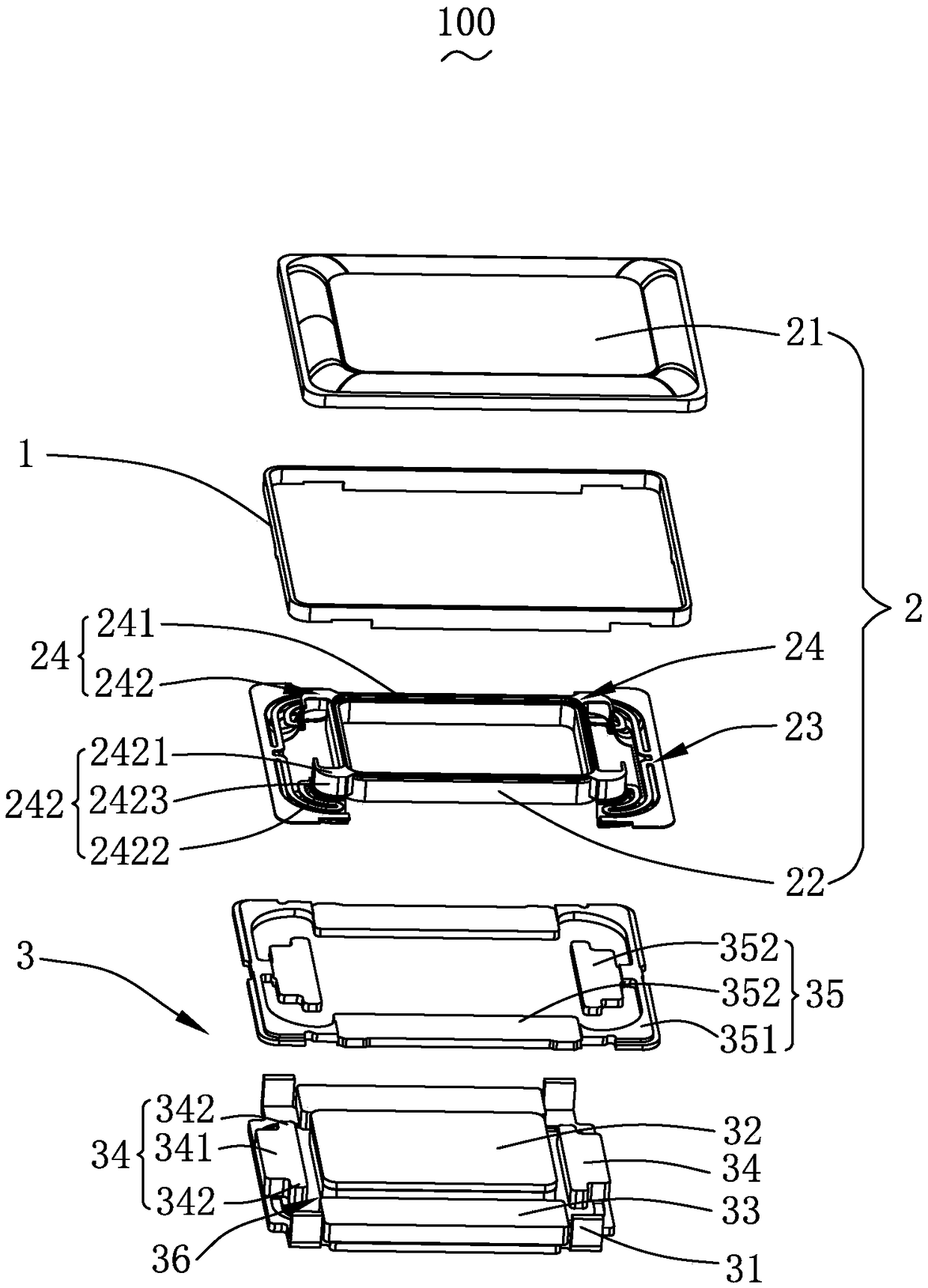

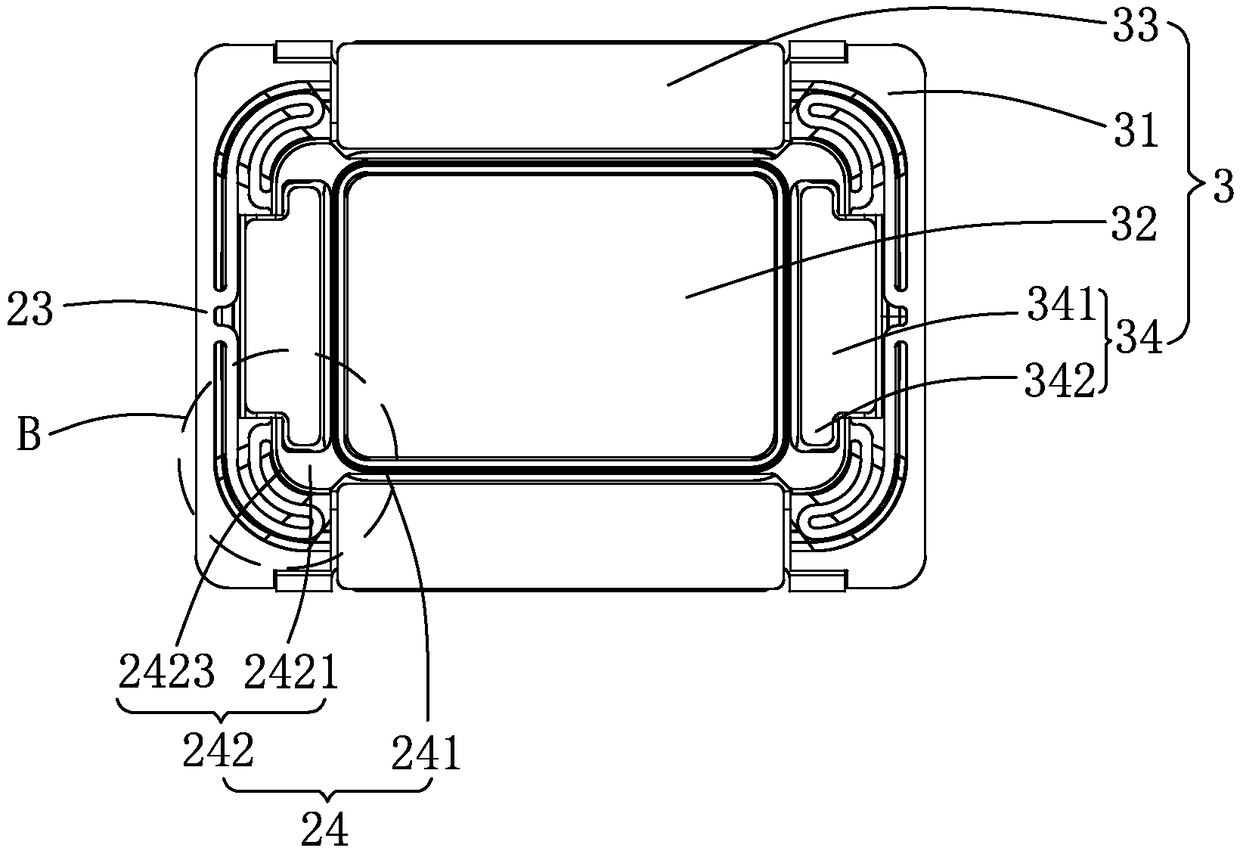

Loudspeaker module and manufacturing method thereof

ActiveCN103618984AReduce sheddingGuaranteed firmnessElectrical transducersDomestic articlesEngineeringSoft materials

The invention relates to the electroacoustic technical field, and provides a loudspeaker module and a manufacturing method thereof. The loudspeaker module comprises a case and a single loudspeaker body combined inside the case. The single loudspeaker body comprises a vibrating diaphragm assembly and a magnetic circuit assembly. A front sound cavity and a rear sound cavity are formed between the single loudspeaker body and the case. The case is provided with an elastic part, the elastic part is combined with the end surface of the opening end of the front sound cavity or the rear sound cavity, and the elastic part and the case are of an integrated structure formed in an injection molding mode. By adopting the structure in the loudspeaker module, the process of attaching the elastic part manually is eliminated, the accuracy and the stability of combination of the elastic part are guaranteed, the elastic part does not fall easily, the sealing property between a sound outlet hole of the loudspeaker module and a sound hole of a mobile phone after the loudspeaker module and a terminal electronic product are assembled can be effectively guaranteed, and the acoustic performance is improved. The manufacturing method for the loudspeaker module can solve the technical problems effectively and can be popularized to production for other structures with soft materials or hard materials needing to be injected into other materials.

Owner:GOERTEK INC

Double-vibrating-diaphragm speaker module

ActiveCN103297904ABoost low frequency soundImprove acoustic performanceLoudspeaker transducer fixingLoudspeakersLoudspeakerVoice coil

The invention discloses a double-vibrating-diaphragm speaker module which comprises a single speaker body and a peripheral shell for accommodating the single speaker body. The single speaker body comprises a first vibrating diaphragm, a voice coil, a magnetic circuit and a second vibrating diaphragm, a first sound outlet and a second sound outlet communicating with the outside are formed in the peripheral shell, a first sound cavity communicating with the first sound outlet is formed between the first vibrating diaphragm and the peripheral shell, a second front sound cavity communicating with the second sound outlet is formed between the second vibrating diaphragm and the peripheral shell, a space between the first vibrating diaphragm and the second diaphragm is communicated with a rear sound cavity. The double-vibrating-diaphragm speaker module of the structure can be used with a double-vibrating-diaphragm speaker, so that low-frequency sound effect of the speaker module is improved, and acoustic performance of the double-vibrating-diaphragm speaker module is improved.

Owner:GOERTEK INC

Sound production device

ActiveCN109348370AImprove acoustic performanceAchieve inhibitionDiaphragm mounting/tensioningEngineeringSound production

The invention discloses a sound production device. The sound production device comprises a frame, a vibrating system and a magnetic circuit system; the vibrating system comprises a vibrating diaphragm, a voice coil, elastic support assemblies and a support skeleton; the support skeleton comprises an annular skeleton main body and at least two skeleton connecting parts outwards extending from the skeleton main body; the skeleton main body is located between the vibrating diaphragm and the voice coil and at least enables the skeleton connecting parts to be connected in pairs; and each skeleton connecting part is provided with a top wall facing the vibrating diaphragm, a bottom wall facing the elastic support assembly and a side wall connecting the top wall with the bottom wall, wherein the top wall is connected with the bottom face of the vibrating diaphragm, the side wall is connected with the side face of the voice coil, and the bottom wall is connected with the corresponding elastic support assembly, so that the voice coil is elastically hung under the vibrating diaphragm. Compared with the prior art, the sound production device is good in stability and acoustic performance.

Owner:AAC TECH PTE LTD

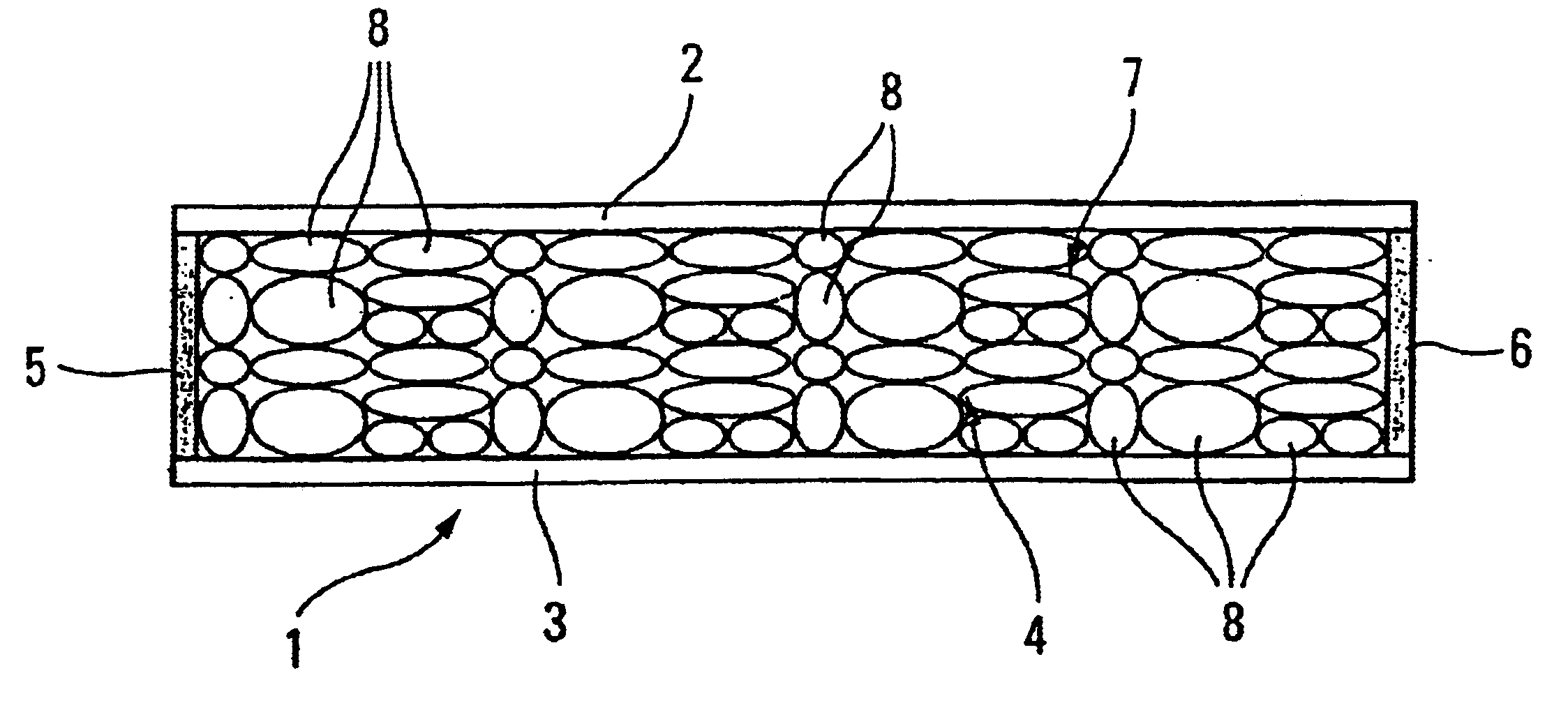

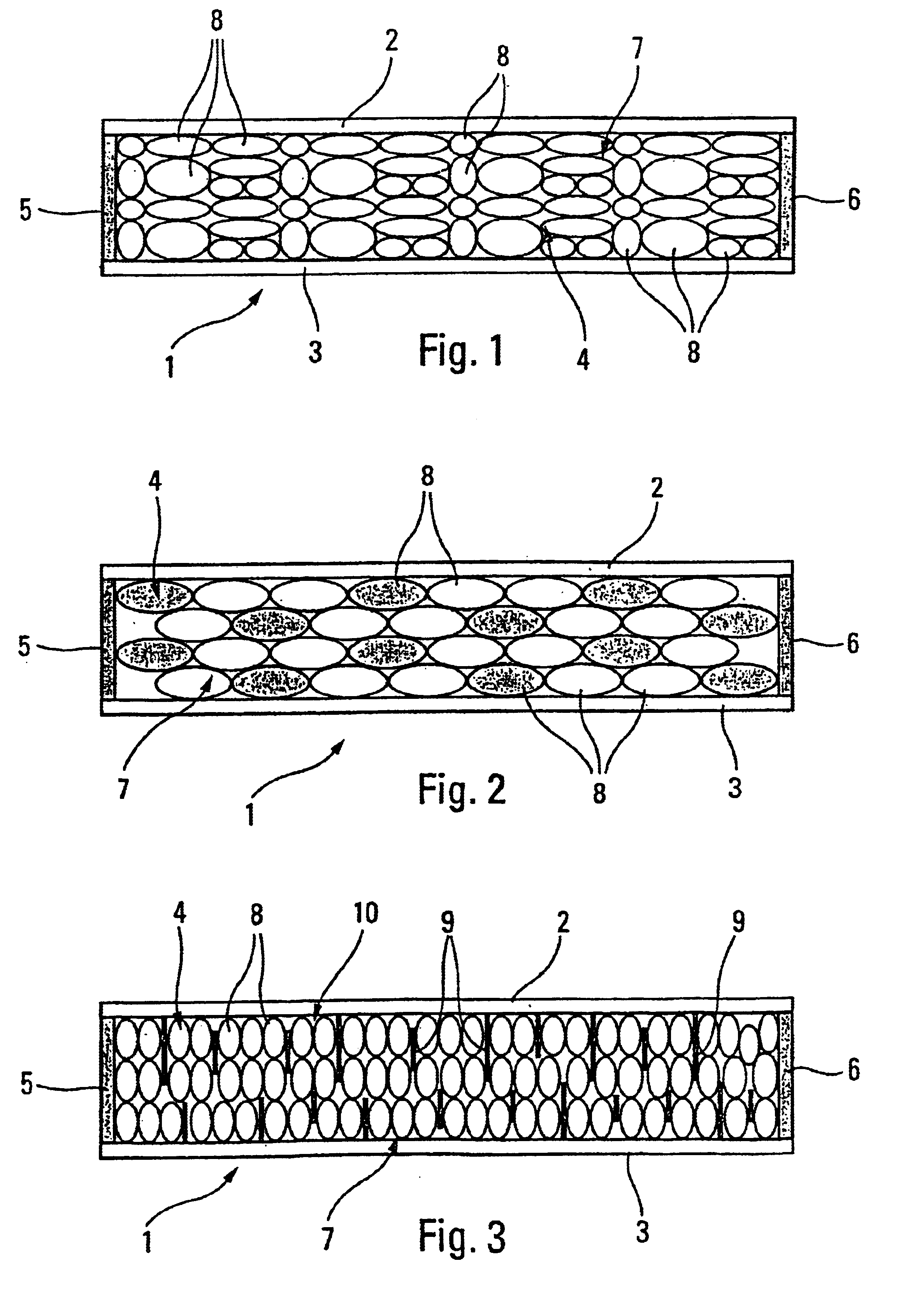

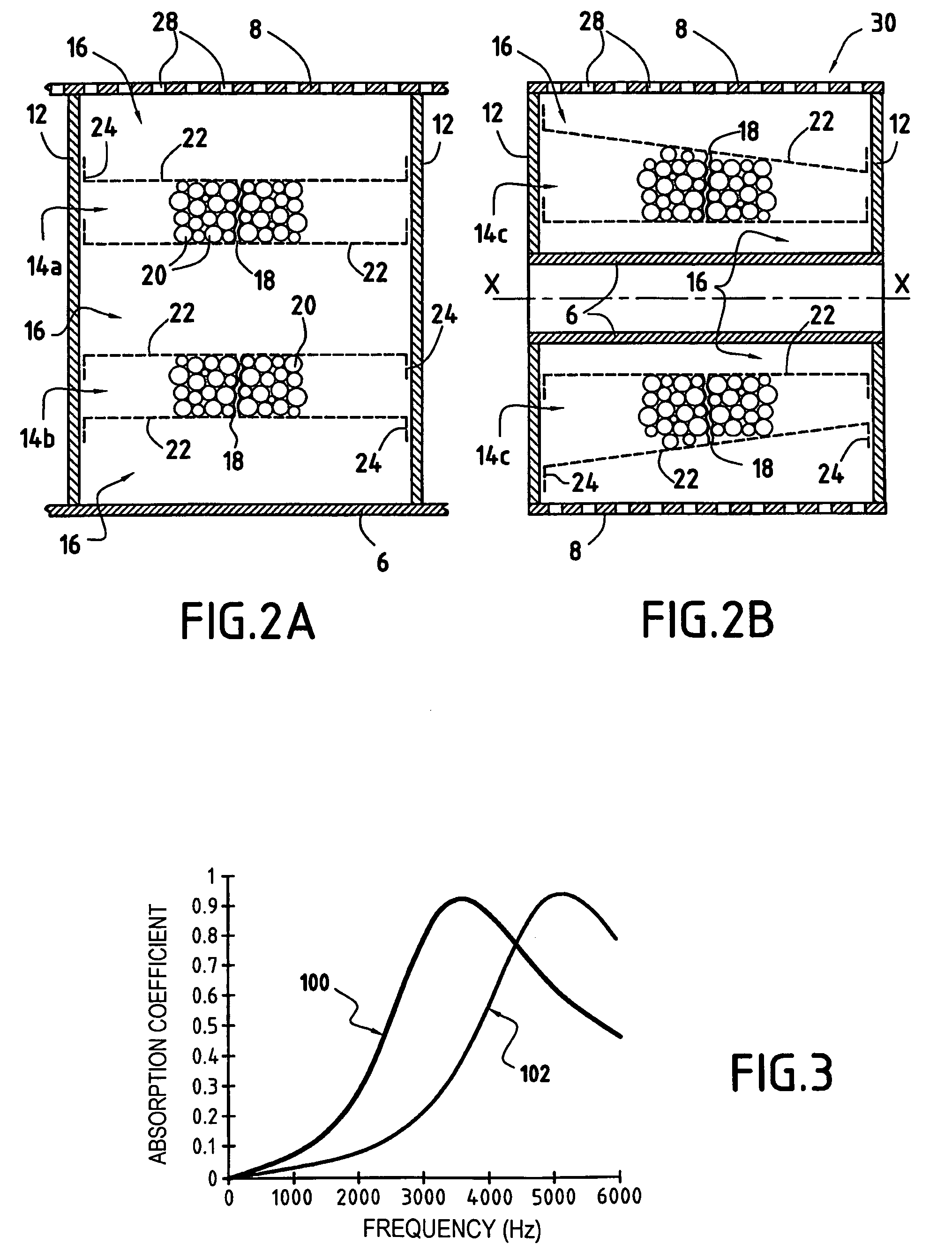

Soundproofing panel, in particular structural or lining panel for a rotorcraft

The invention concerns a sound-proofing panel, in particular a rotorcraft structural or lining panel: the sound-proofing panel (1) comprises at least two opposite plates (2, 3, 5, 6) forming between them a closed internal space (4), and an aggregate (7) including at least solid elements (8) in contact and which fills entirely said internal space (4).

Owner:ATECA +1

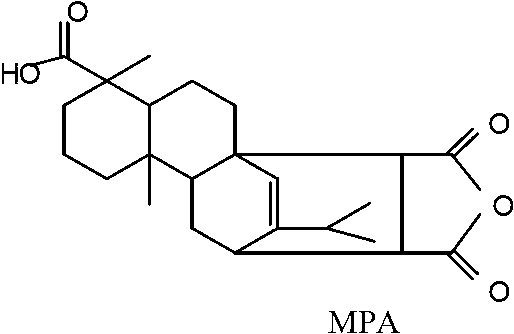

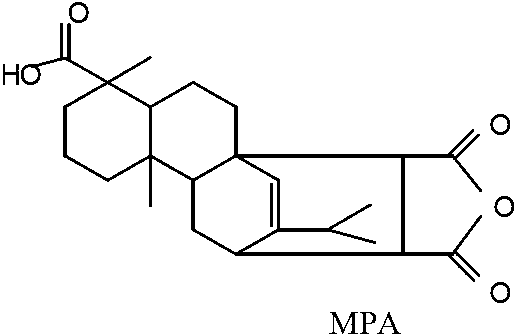

Vegetable fiber-reinforced biomass resin-based foam plate and preparation method thereof

ActiveCN102838844AGive full play to the mechanical propertiesMake full use of the acoustic characteristicsWater basedEpoxy

The invention belongs to the design and manufacturing technology of environment-friendly composite material foaming plate, referring to a vegetable fiber-reinforced biomass resin-based foam plate and a preparation method of the foam plate. A light and high-performance composite material foam plate is manufactured by using vegetable fibers such as ramee, flax, hemp and jute as reinforced body, and loading expansion biomass resin and biomass epoxy resin. The preparation method comprises the steps of manufacturing a fiber felt with a certain thickness by needling or by using adhesive; and carrying out fire retarding or / coupling treatment on the chopped fiber felt; preparing epoxy resin by a MPA (maleopimaric acid anhydride) rosin-based epoxy resin curing agent; preparing epoxy resin into water-based suspension; adding 5-15% (mass percentage) of a microcapsule foaming agent to the suspension; fully immersing the treated fiber felt in the resin suspension, and removing the excess resin; finally, heating the chopped fiber felt immersed by resin for 10-15min in an oven at a certain temperature; after the resin cures, obtaining the vegetable fiber-reinforced biomass resin-based foam plate.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

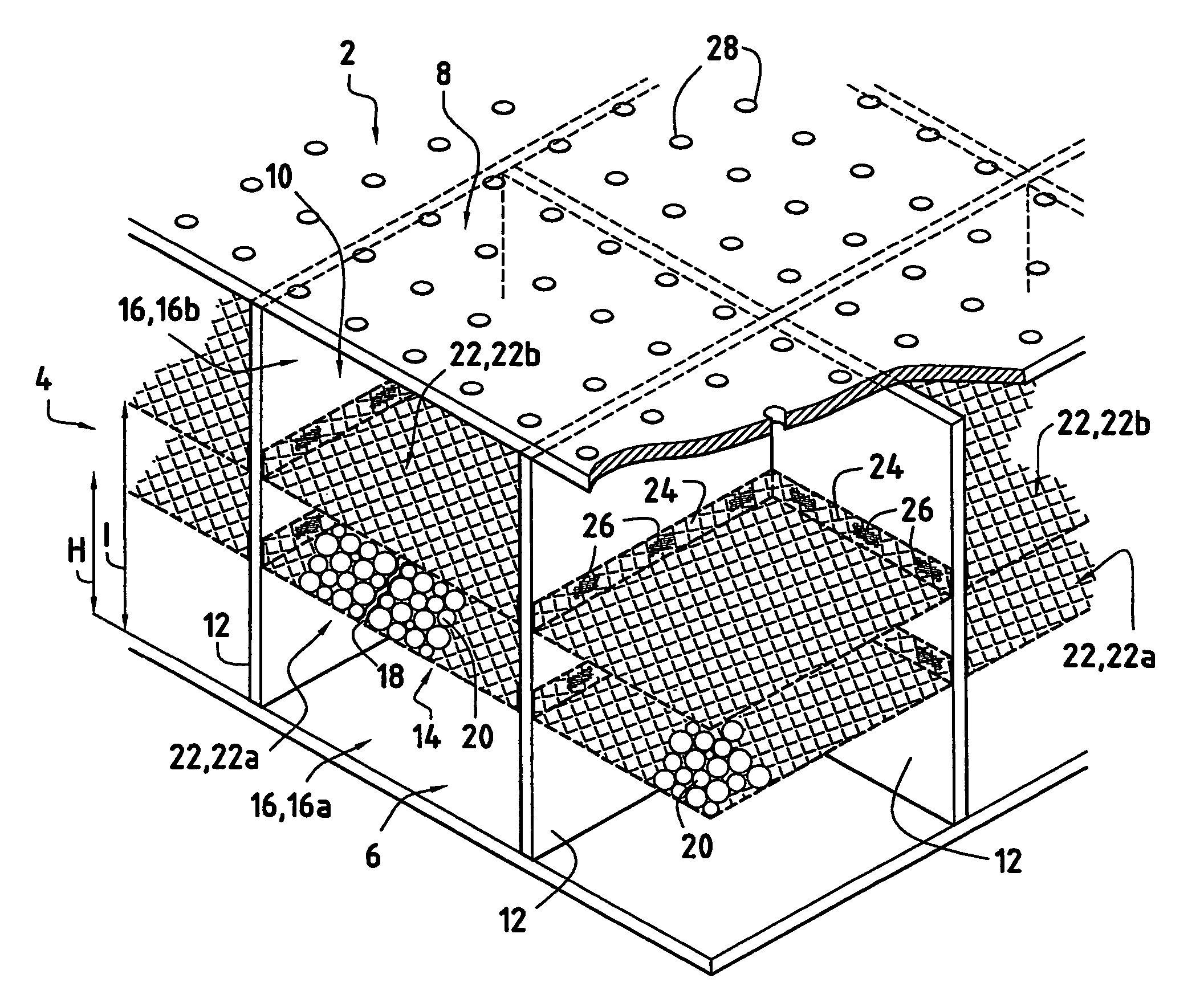

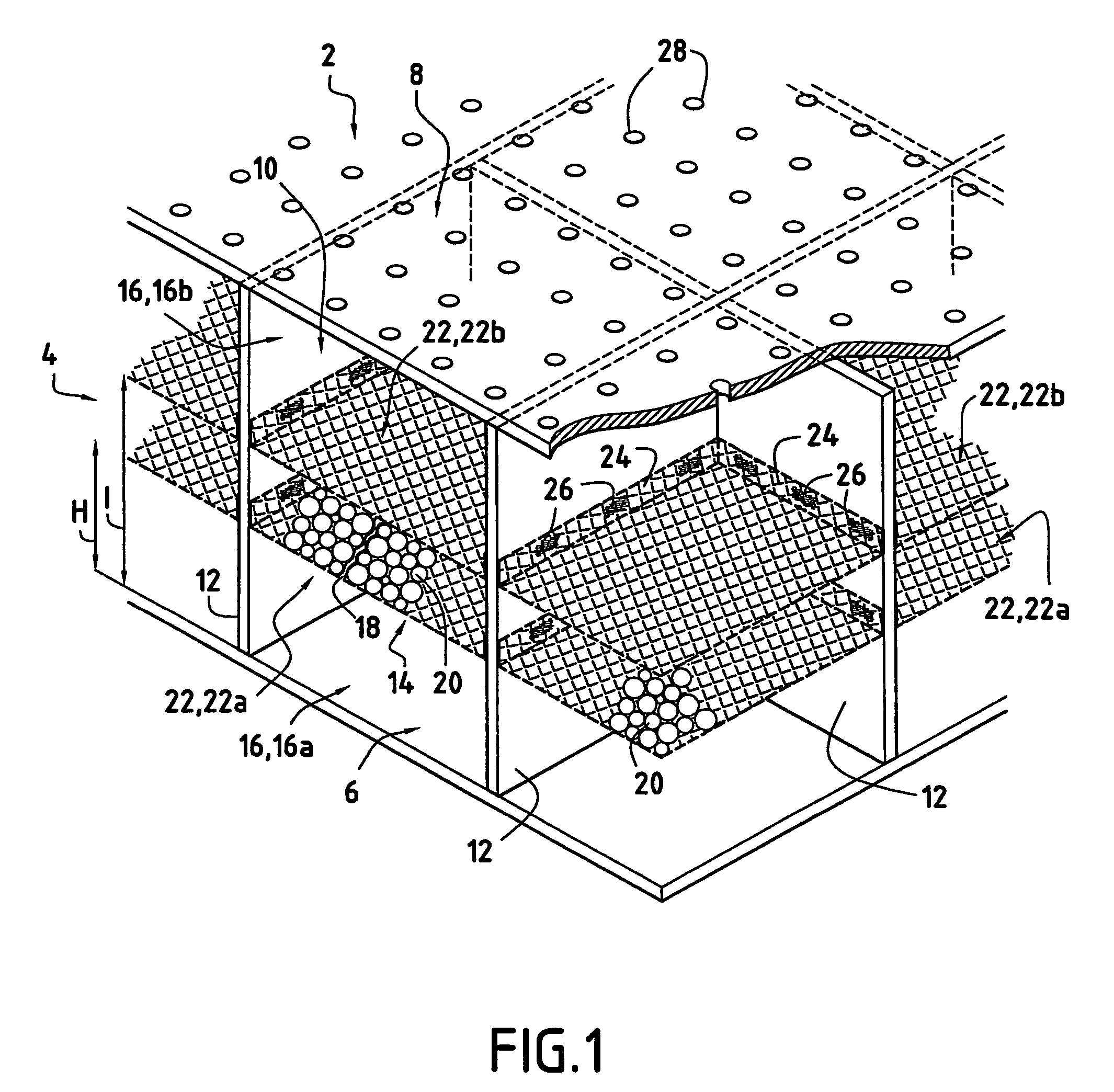

Soundproofing panel with beads, and a method of manufacture

ActiveUS7520369B2Mitigate such drawbackImprove acoustic performanceCeilingsWallsSound energySolid wall

A soundproofing panel having a core sandwiched between a solid wall and a porous wall. The core being connected to the walls and having partitions extending in the thickness direction between the two walls so as to form cells. Each cell containing at least one sound energy dissipating layer constituted by hollow spherical beads having mutually contacting walls that are porous and micro-perforated, and being held in position in the thickness direction between the two walls by nets that are secured to the partitions.

Owner:ATECA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com