Vegetable fiber-reinforced biomass resin-based foam plate and preparation method thereof

A plant fiber and biomass technology, applied in the field of plant fiber reinforced biomass resin-based foam board and its preparation, can solve the problems of shock absorption and noise reduction, sound absorption and sound insulation performance, etc., and achieve good heat insulation performance, thermal insulation Good insulation and heat preservation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Chopped ramie fibers are used to obtain a surface density of 400g / m by acupuncture equipment. 2 Ramie non-woven felt, spare.

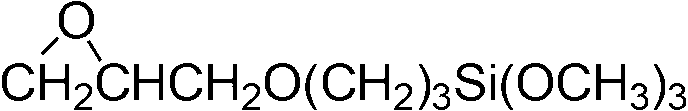

[0035] (2) Use 3% KH550 silane coupling agent aqueous solution to impregnate ramie non-woven felt, after the fabric is dried, impregnate non-woven felt with 10% nitrogen-phosphorus flame retardant aqueous solution, and dry it.

[0036] (3) Prepare a microcapsule foaming agent with a particle size of 10 μm, a capsule of degradable thermoplastic polylactic acid polymer PLA, and an initiation temperature of 120 °C.

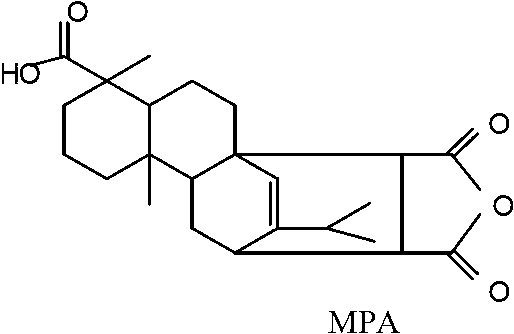

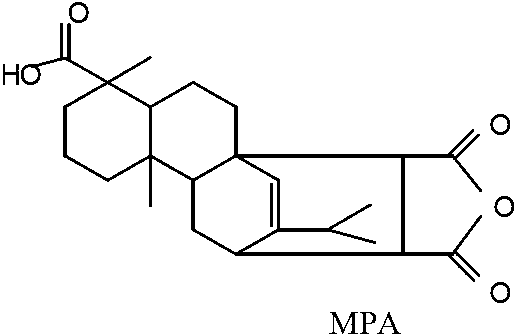

[0037] (4) Preparation of MPA type rosin-based epoxy resin curing agent

[0038]

[0039]And use it to replace the curing agent of 3233 epoxy resin of Beijing Aeronautical Materials Research Institute to obtain partially degradable 3233 epoxy resin. The partially bio-massified epoxy resin is prepared into a powder, and the particle size of the powder is between 10 μm and 20 μm.

[0040] (5) Add the microcapsule foaming agent ...

Embodiment 2

[0044] (1) Continuous sisal fibers are used and bonded to obtain a surface density of 100g / m 2 The sisal fiber non-woven felt, spare.

[0045] (2) Use 2% KH570 silane coupling agent aqueous solution to impregnate the ramie non-woven felt, after the fabric is dried, then impregnate the non-woven felt with 10% nitrogen-phosphorus flame retardant aqueous solution and dry it.

[0046] (3) Prepare a microcapsule foaming agent with a particle size of 10 μm, a capsule of degradable thermoplastic polylactic acid polymer PLA, and an initiation temperature of 120 °C.

[0047] (4) Preparation of MPA type rosin-based epoxy resin curing agent

[0048]

[0049] And use it to replace the curing agent of 3234 epoxy resin of Beijing Aeronautical Materials Research Institute to obtain partially degradable 3234 epoxy resin. The partially bio-massified epoxy resin is prepared into a powder, and the particle size of the powder is between 10 μm and 20 μm.

[0050] (5) Add the microcapsule foa...

Embodiment 3

[0054] (1) Continuous flax fibers are used and bonded to obtain a surface density of 80g / m 2 Flax fiber non-woven felt, spare.

[0055] (2) Use 2% KH570 silane coupling agent aqueous solution to impregnate the ramie non-woven felt, after the fabric is dried, impregnate the non-woven felt with 15% nitrogen-phosphorus flame retardant aqueous solution, and dry it.

[0056] (3) Prepare a microcapsule foaming agent with a particle size of 10 μm-20 μm. The capsule skin is polyacrylonitrile, the microcapsules are filled with alkane, and the initiation temperature is 150°C.

[0057] (4) Preparation of MPA type rosin-based epoxy resin curing agent

[0058]

[0059] And use it to replace the curing agent of 3234 epoxy resin of Beijing Aeronautical Materials Research Institute to obtain partially degradable 3234 epoxy resin. The partially bio-massified epoxy resin is prepared into a powder, and the particle size of the powder is between 10 μm and 20 μm.

[0060] (5) Add the microc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com